Vertical-well double-layer partial-pressure commingling method and device for coalbed methane

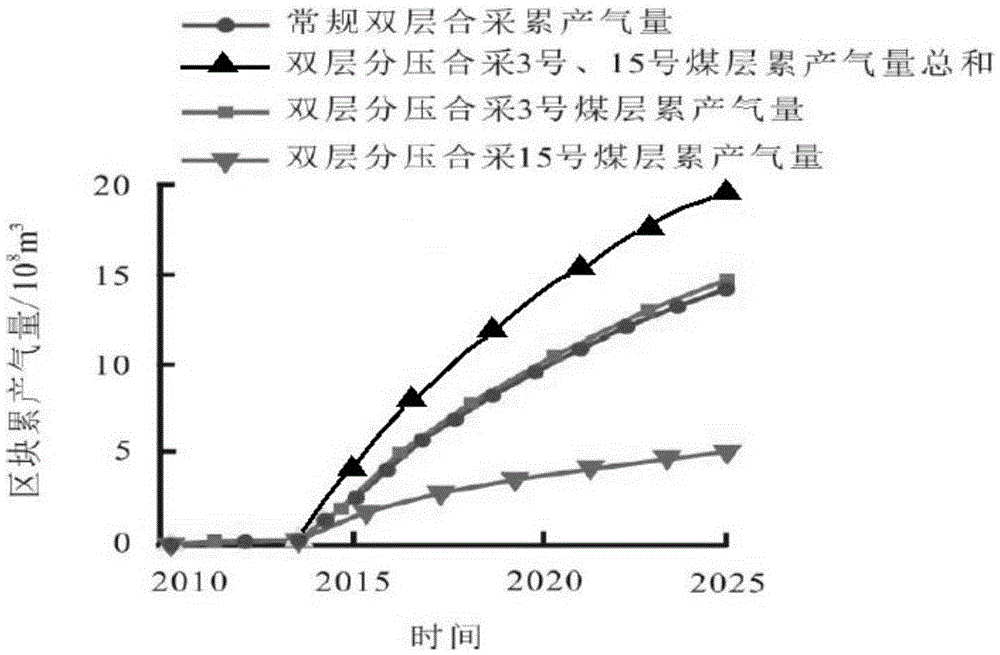

A coalbed methane, double-layer technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as poor reservoir stability, avoid interlayer interference, avoid wellbore fluid accumulation, and promote The effect of drainage pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

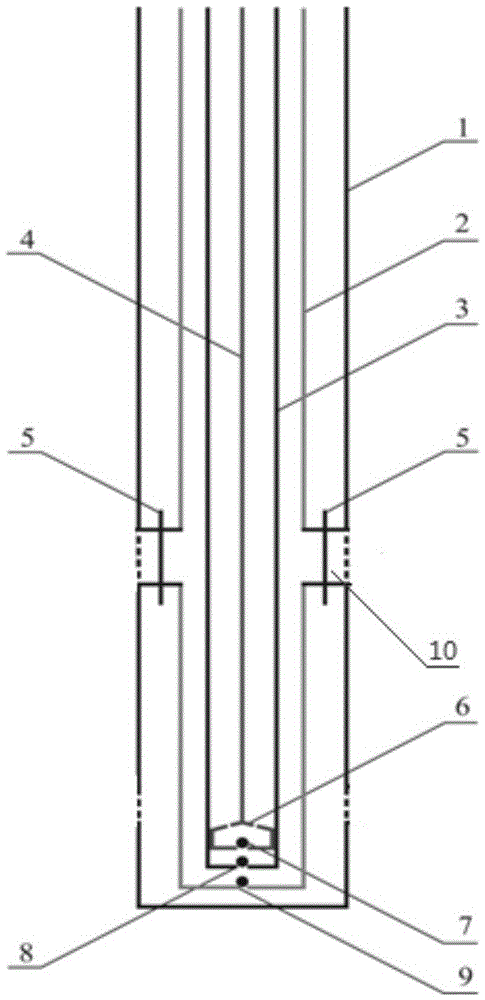

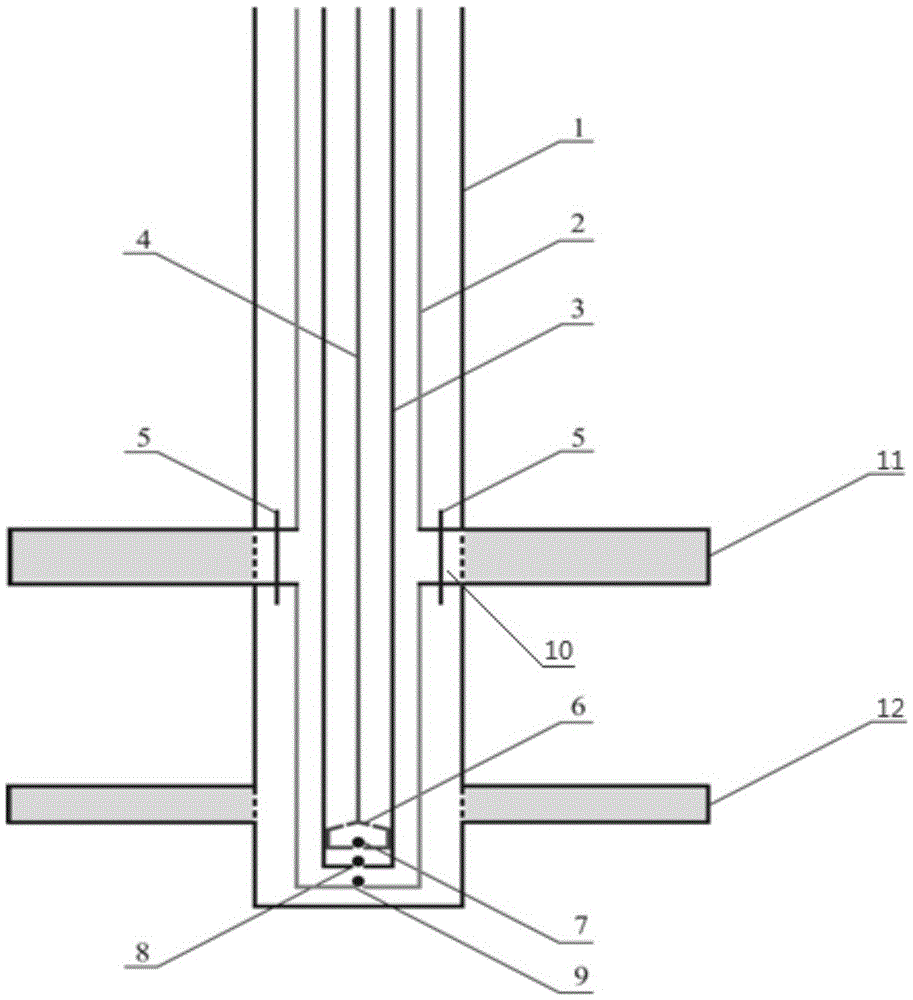

[0034] like figure 1 As shown, in the double-layer partial pressure combined production method of coalbed methane vertical well disclosed by the present invention, a pipeline is arranged in the well, and there are three channels isolated from each other in the pipeline: the first channel, the second channel and the third channel, and the first channel and the The side walls of the second channel are respectively connected with the two coal seams, so that the gas produced by the two coal seams is discharged to the wellhead through the first channel and the second channel respectively, and the liquid produced by the two coal beds flows into the first channel and the second channel respectively. At the bottom of the channel, gas-liquid separation is realized in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com