Patents

Literature

50 results about "Longitudinal development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

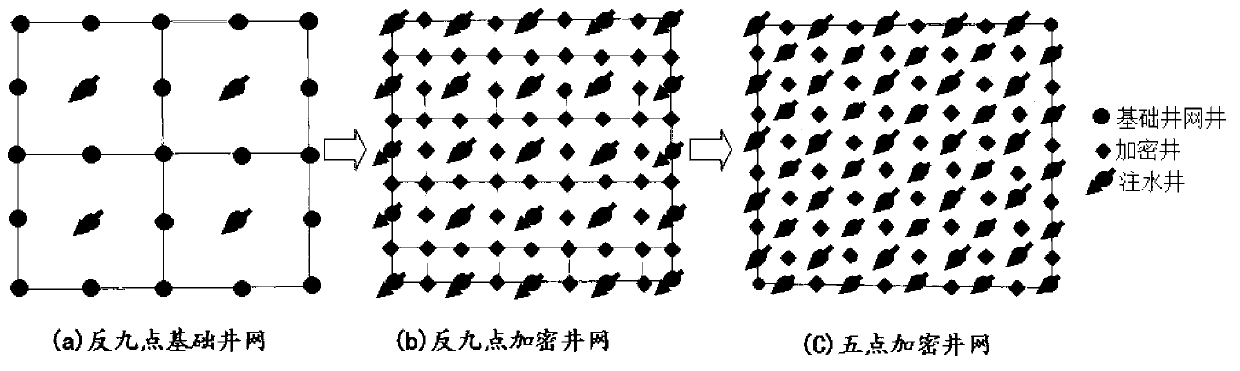

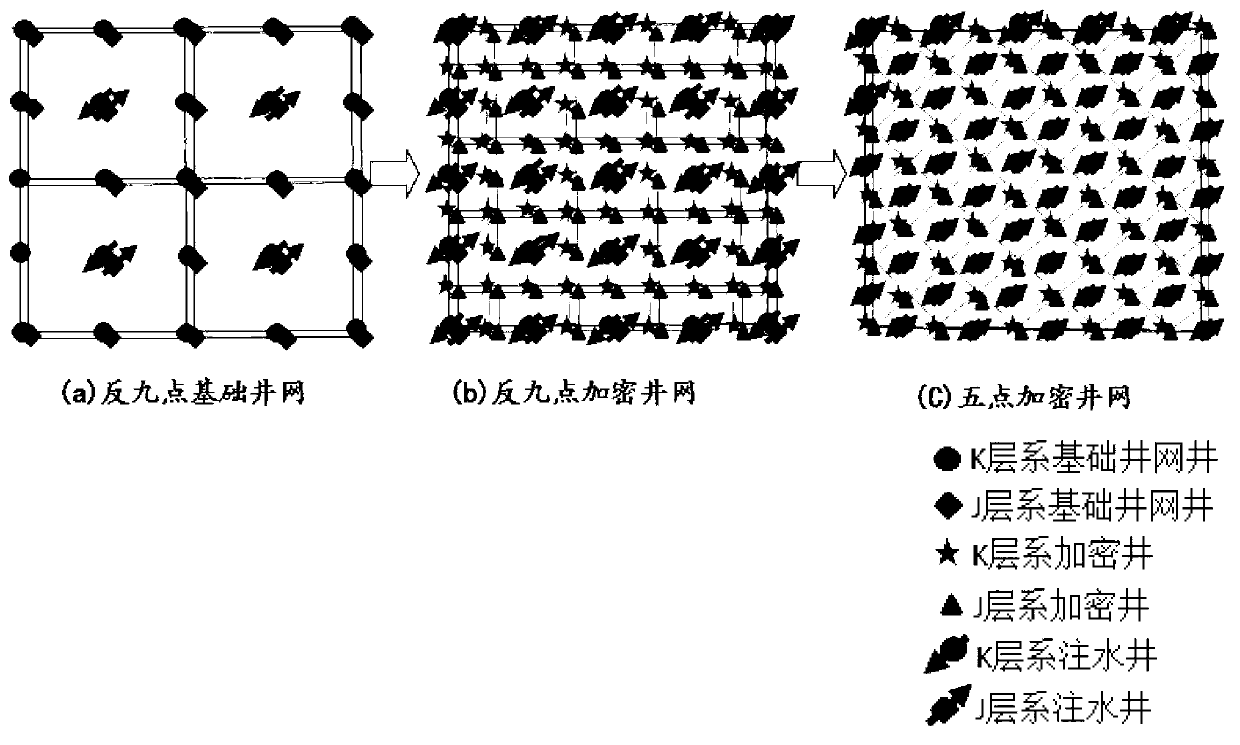

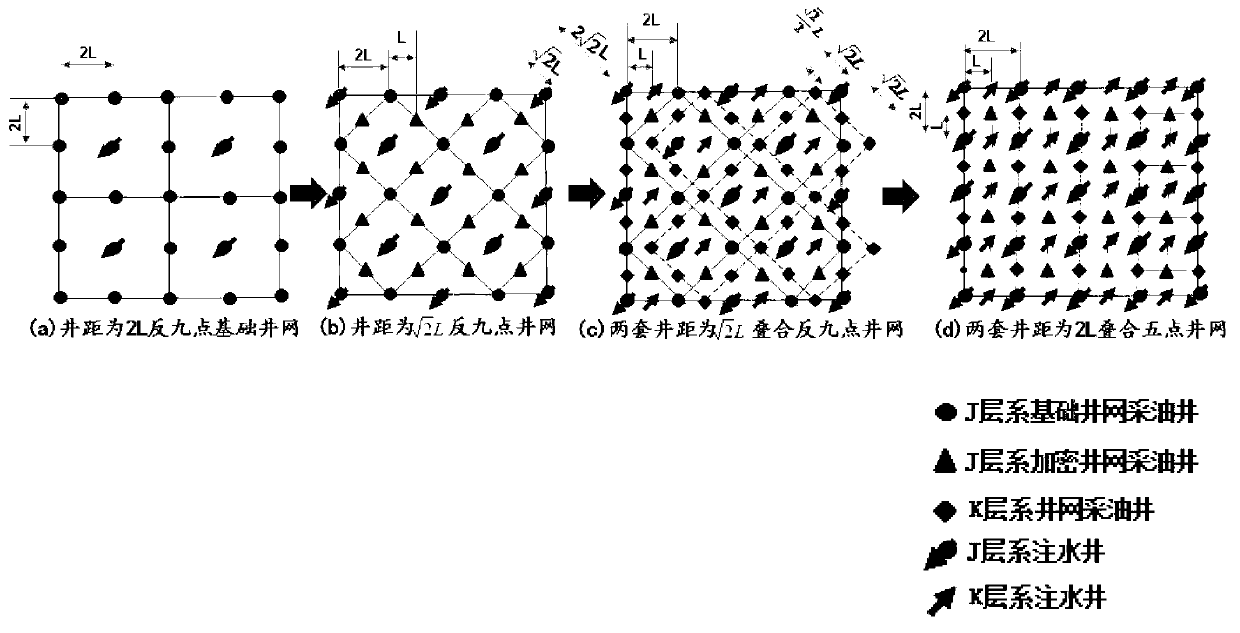

Longitudinally superposed developing two-strata oil reservoir well pattern, and arrangement method of two-strata oil reservoir well pattern

ActiveCN102839959AReduce developmentIncrease profitFluid removalWell drillingLongitudinal development

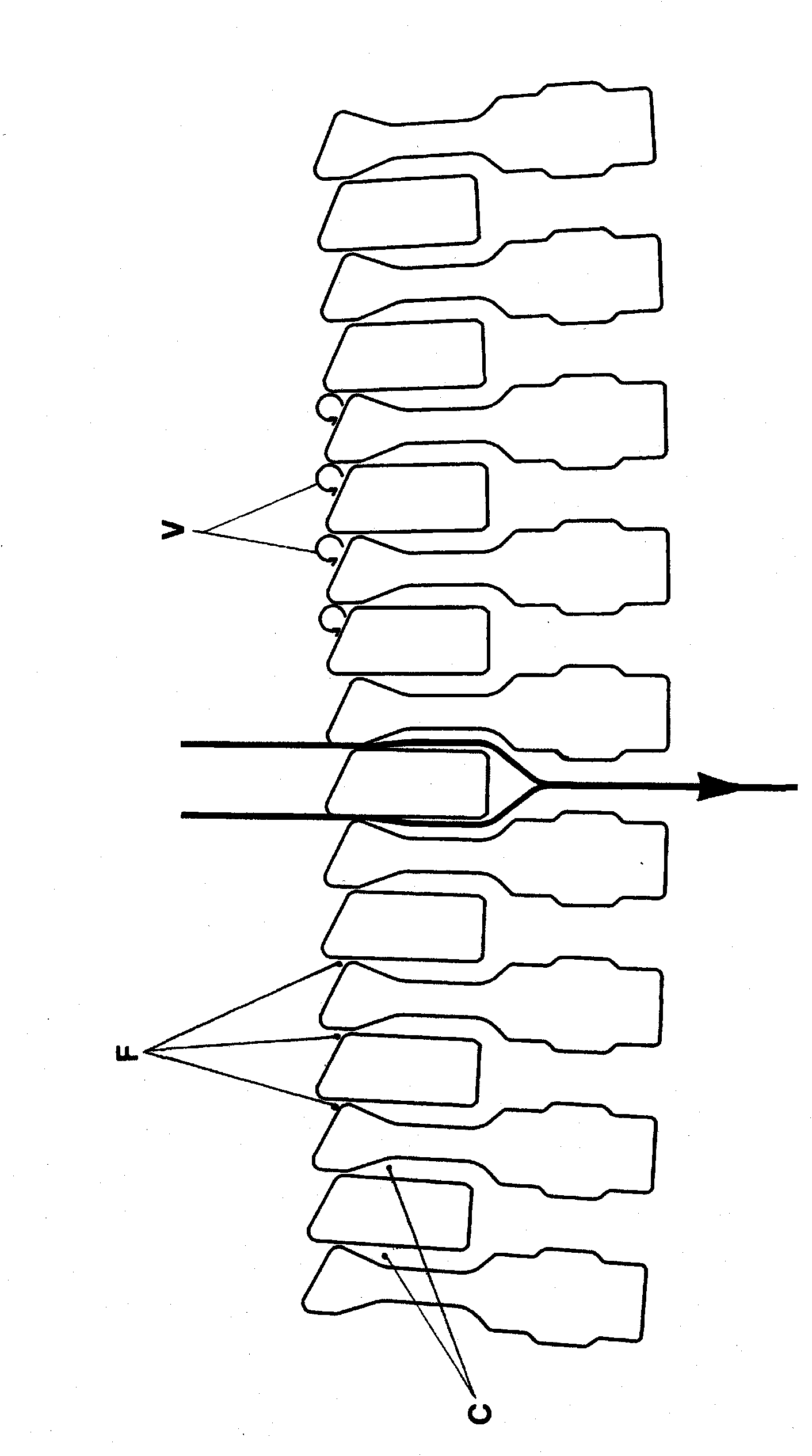

The embodiment of the invention discloses a longitudinally superposed developing two-strata oil reservoir well pattern, and an arrangement method of the two-strata oil reservoir well pattern. The method comprises the following steps: firstly determining the longitudinal development strata of the oil reservoir and the rational well distance, and determining the well spacing of a basic well pattern and the well spacing of a middle transitional well pattern according to the longitudinal development layer coefficient. According to the longitudinally superposed developing two-strata oil reservoir, the well spacing of the basic well pattern is 2L, after being encrypted once, the well spacing of a middle transitional well pattern is square root of 2 times L; after being encrypted twice, two superposed well patterns with a well spacing of square root of 2 times L are formed; the well spacing of the superposed well pattern after alternative strata development is L; the evolution process of the well spacing is as follows: 2L to 2 times square root of 2 L to L; the conversion middle process of a well pattern with a well spacing of square root of 2 times L; in the same drilling speed, well placement uniformity coefficient and reserve control speed are increased; the well spacing is encrypted in the alternation of well patterns; each well pattern can realize order development to each strata; the utilization ratio of the well patterns is improved; and meanwhile, the oil reservoir is uniformly used, so that the method is in favor of increasing accumulated oil production of an oil field and improving the recovery ratio; and interlayer interference generated by extracting oil in multiple oil layers of longitudinal series of strata is avoided.

Owner:PETROCHINA CO LTD

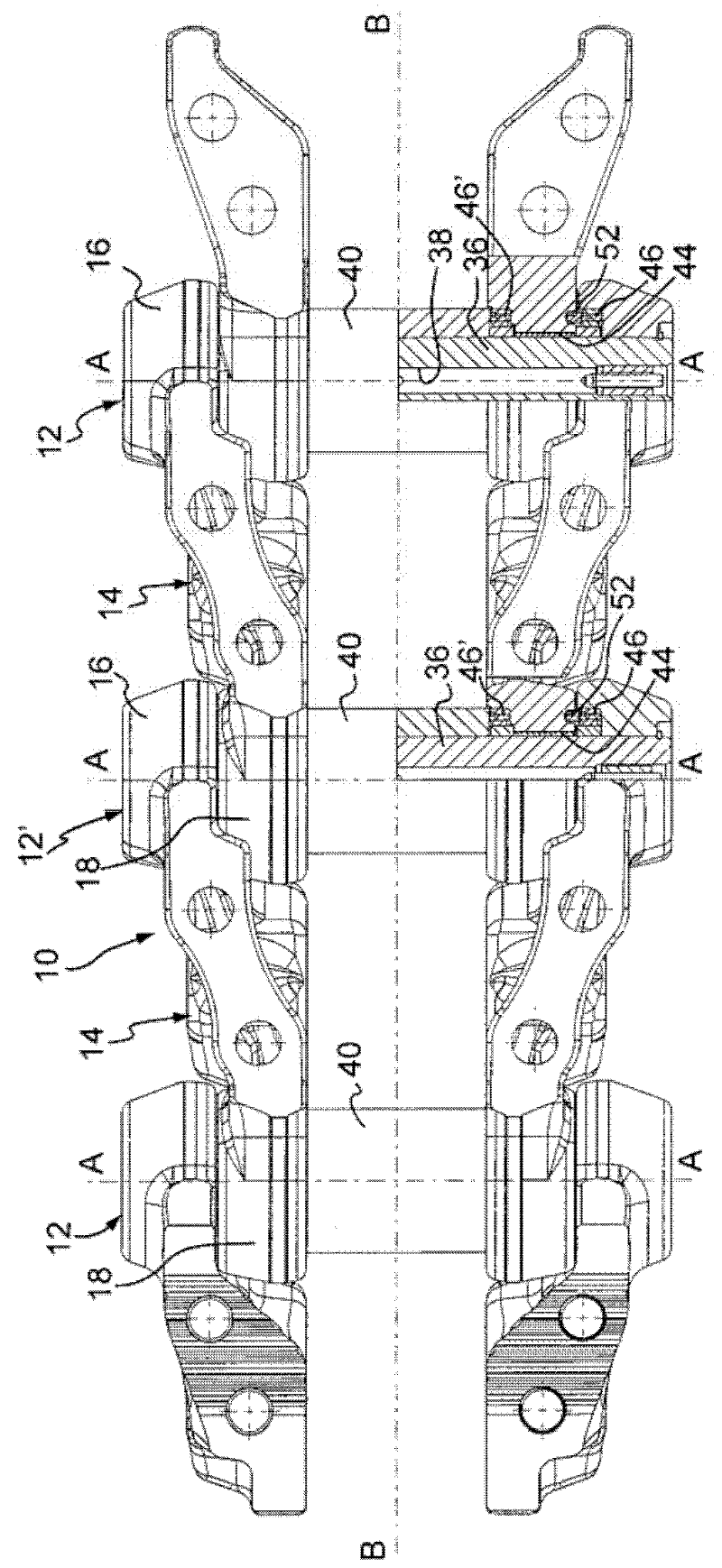

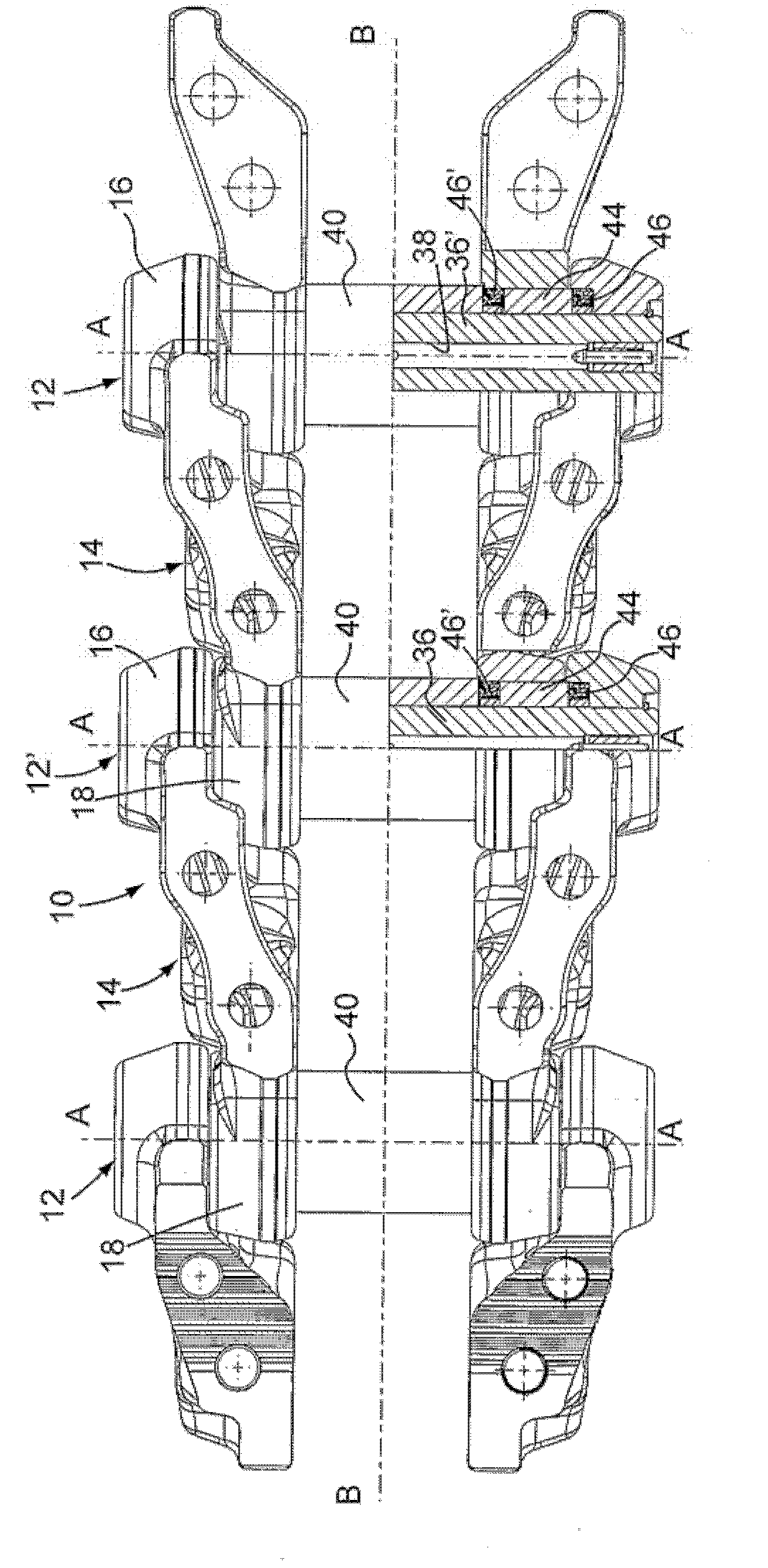

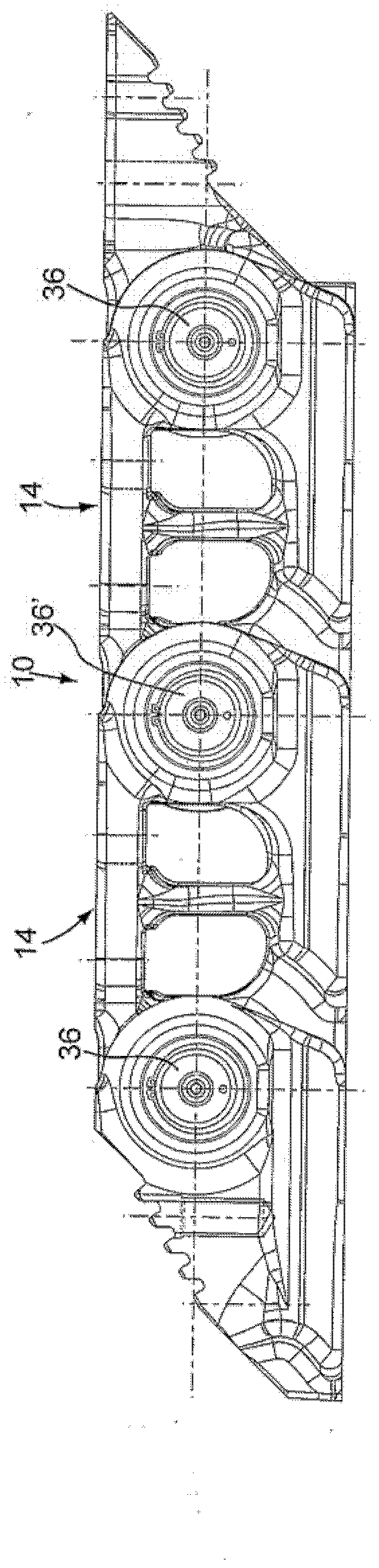

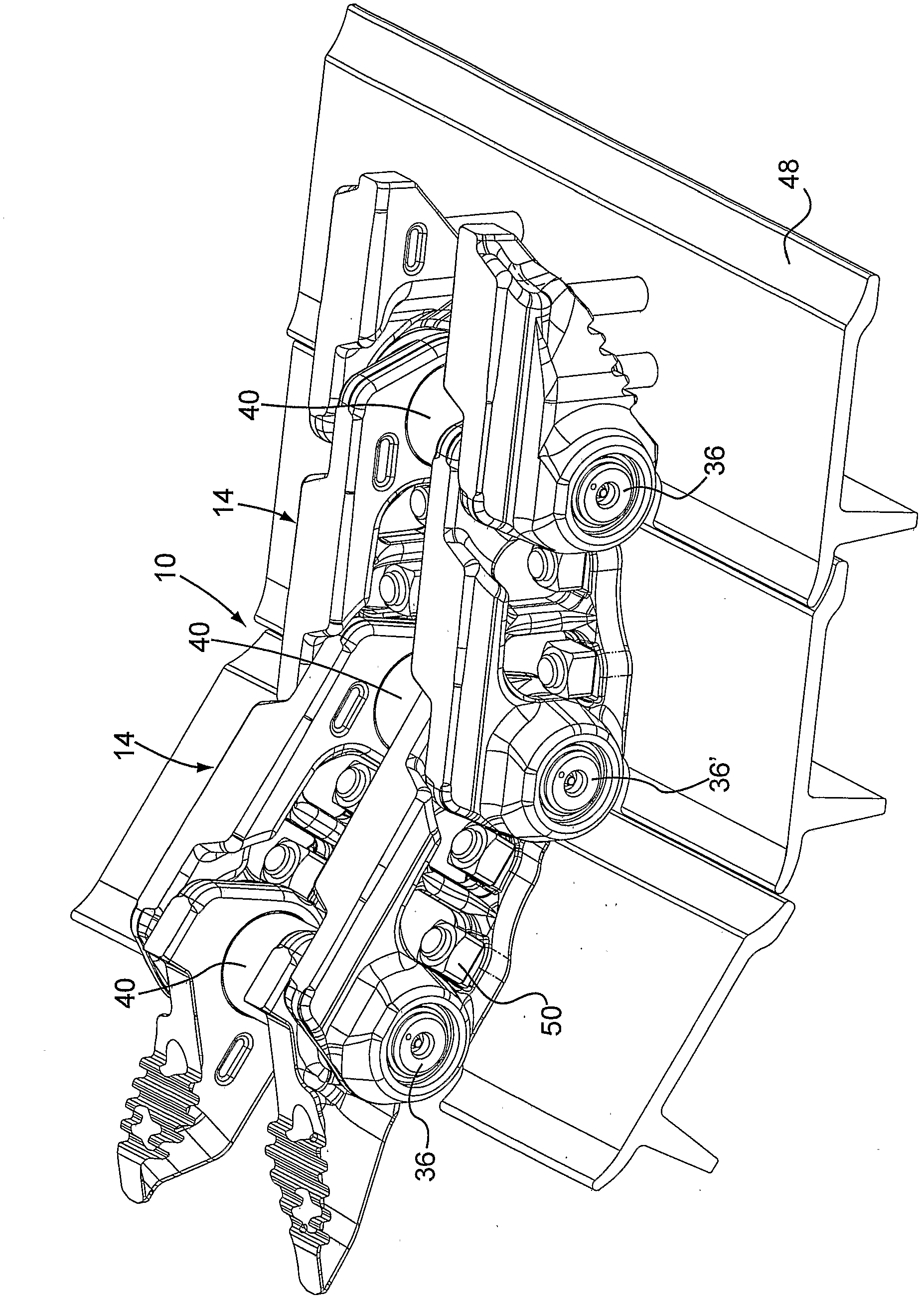

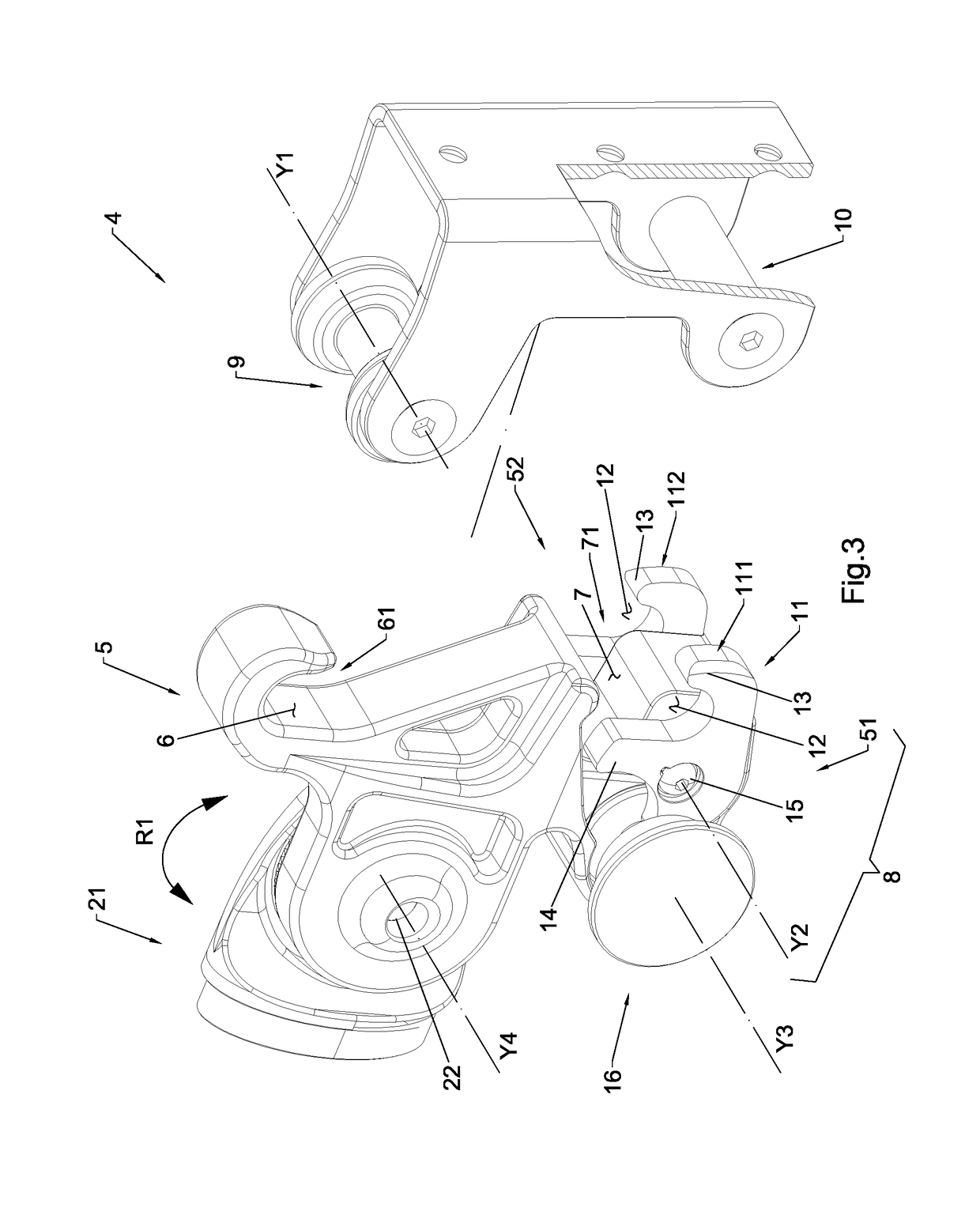

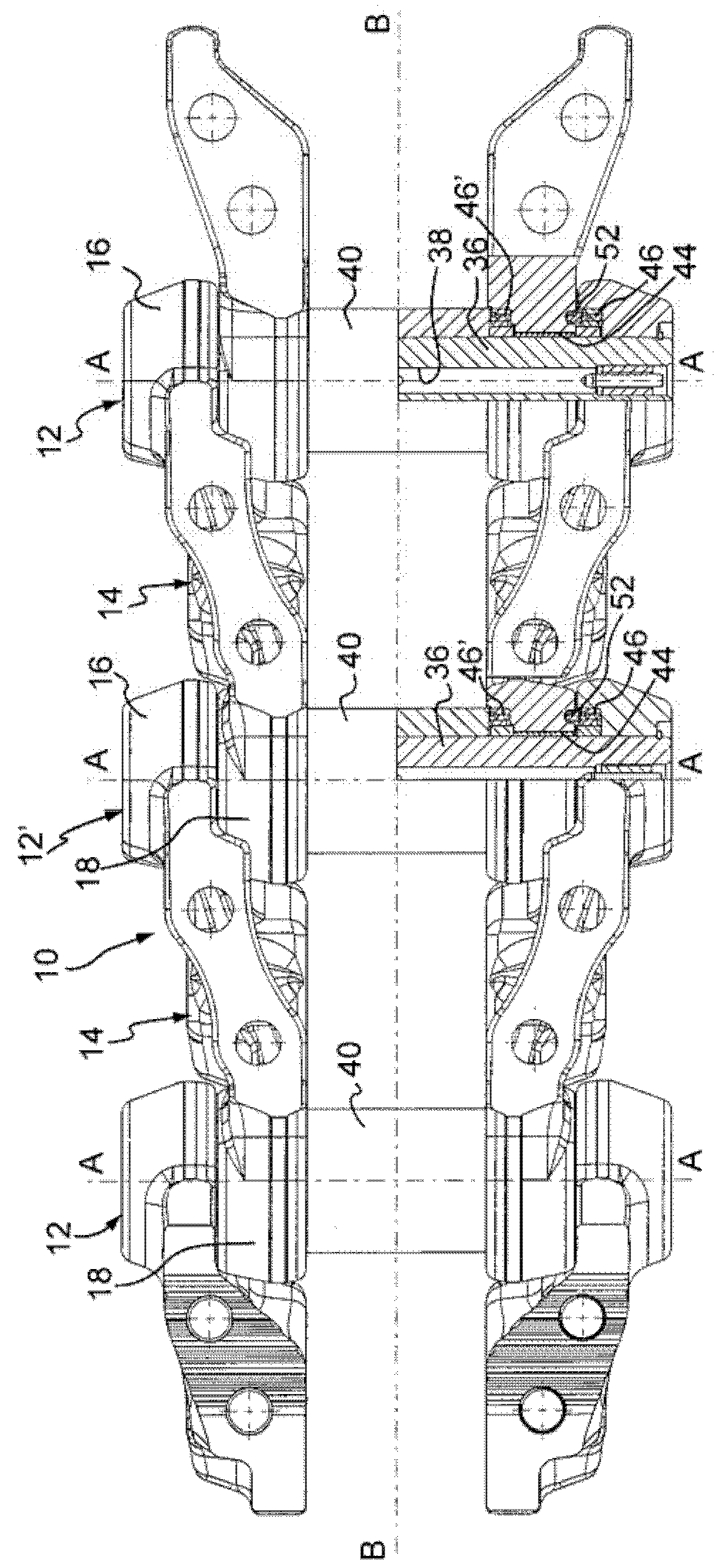

Track with rotating bushings for track-type vehicles with improved sliding bearing

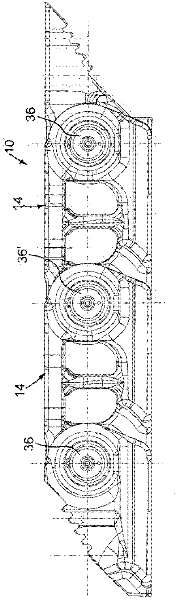

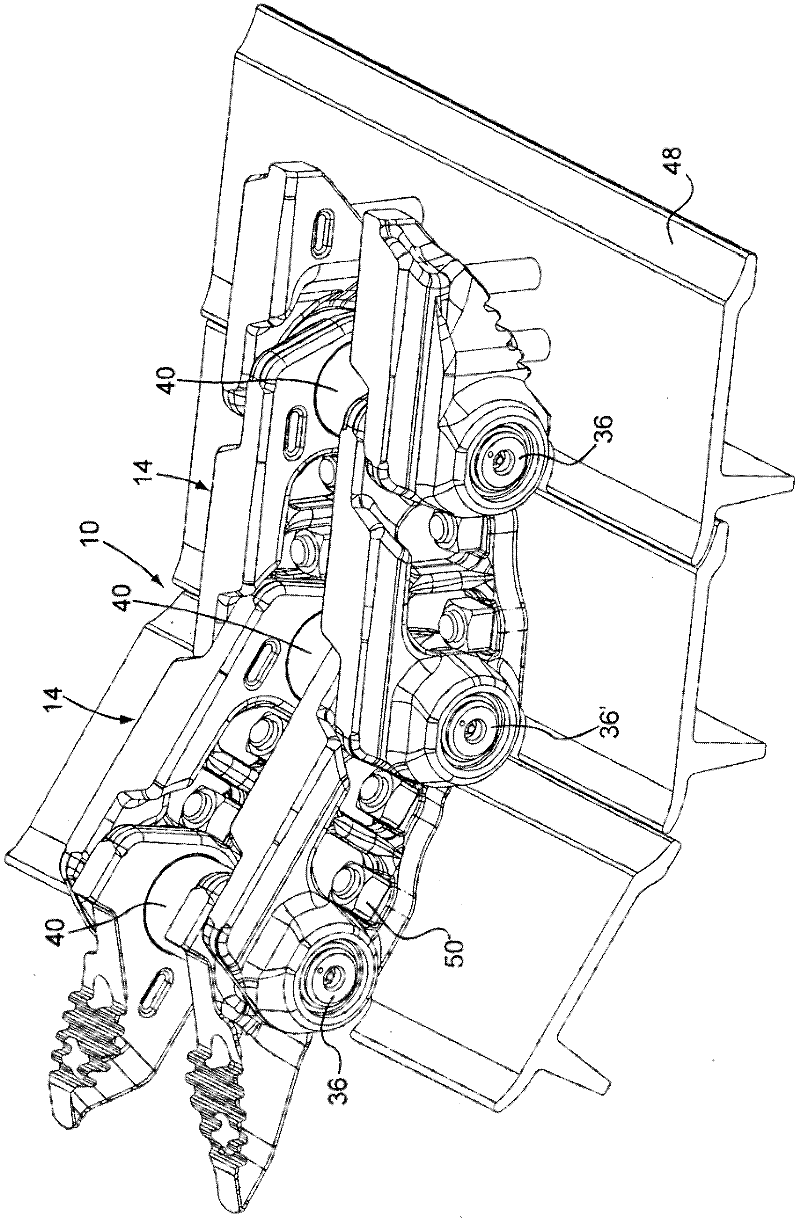

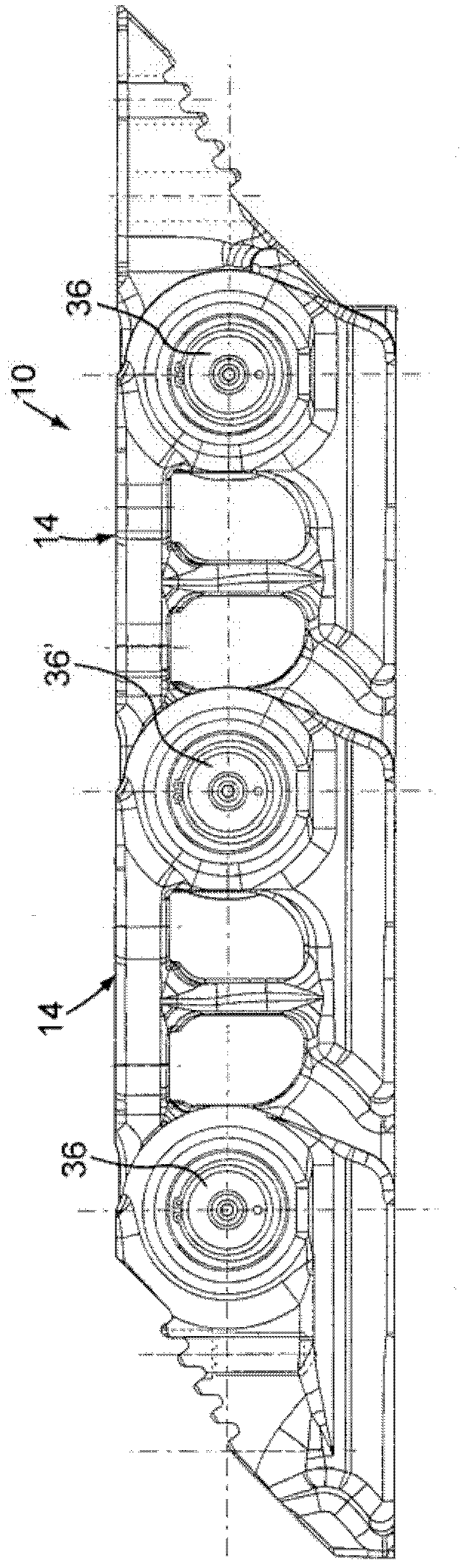

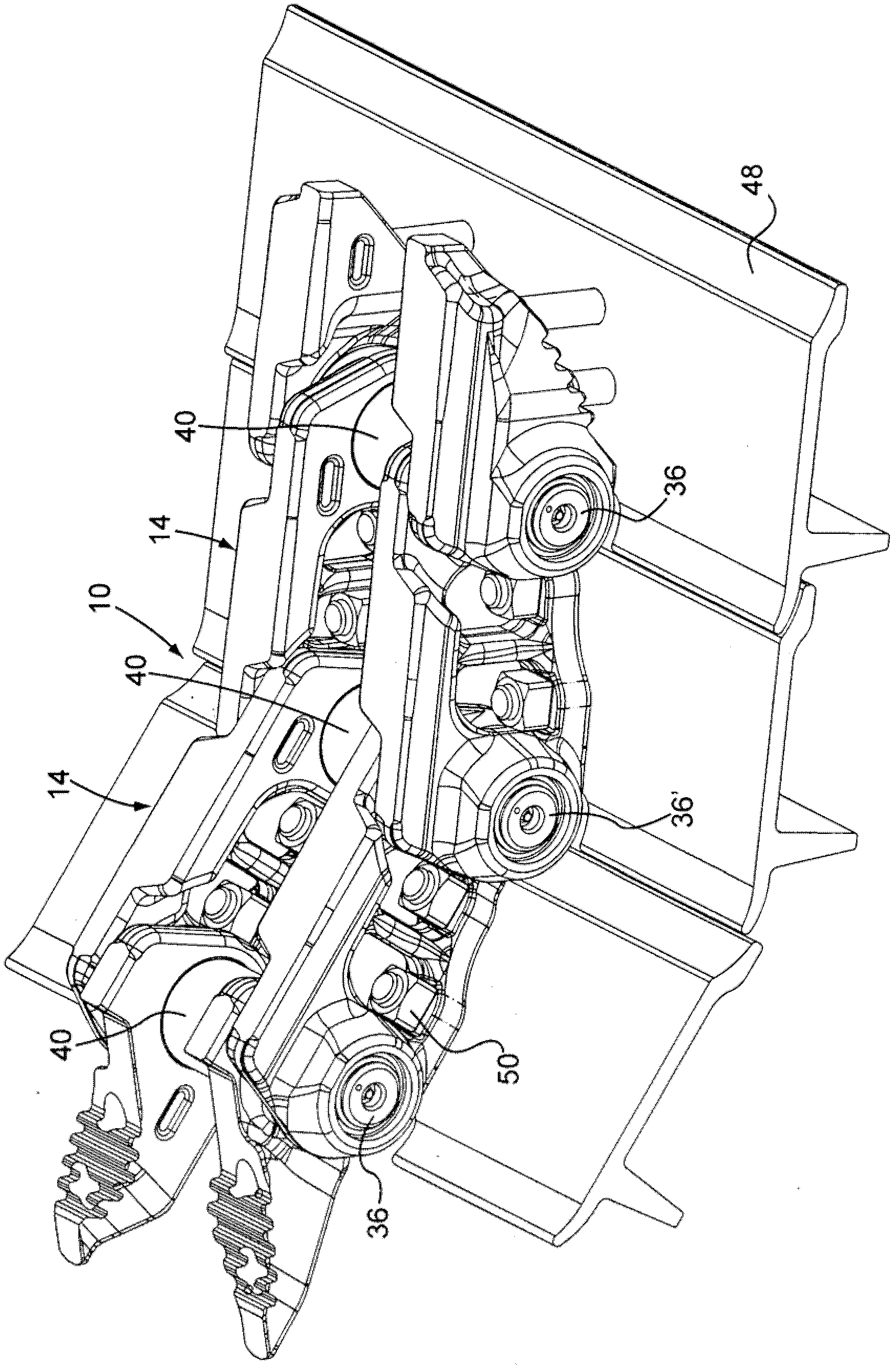

A track (10) for track- type vehicles is described, comprising a continuous sequence of articulated joints (12, 12') of the hinge type, oriented according to a first axis (A-A) substantially perpendicular to the central longitudinal development axis (B-B) of the track (10). The articulated joints (12, 12'), provided with pins (36, 36'), are connected to each other and maintained at a constant distance through pairs of links (14) having longitudinal development, arranged laterally and symmetrically with respect to the longitudinal central axis (B-B). Around each pin (36, 36') a bushing (40) is mounted free to rotate with respect to the pin (36, 36') itself and at least one sliding bearing (44) is press-fitted between each pin (36, 36') and the links (14). The presence of sliding bearings (44) made in composite material and having a small thickness and the geometrical / size characteristics of the links (14) and of the sliding bearings (44) themselves makes it possible to improve the stability and the fatigue and wearing resistance of the articulated joints (12, 12') of the track (10).

Owner:BELLCO SPA

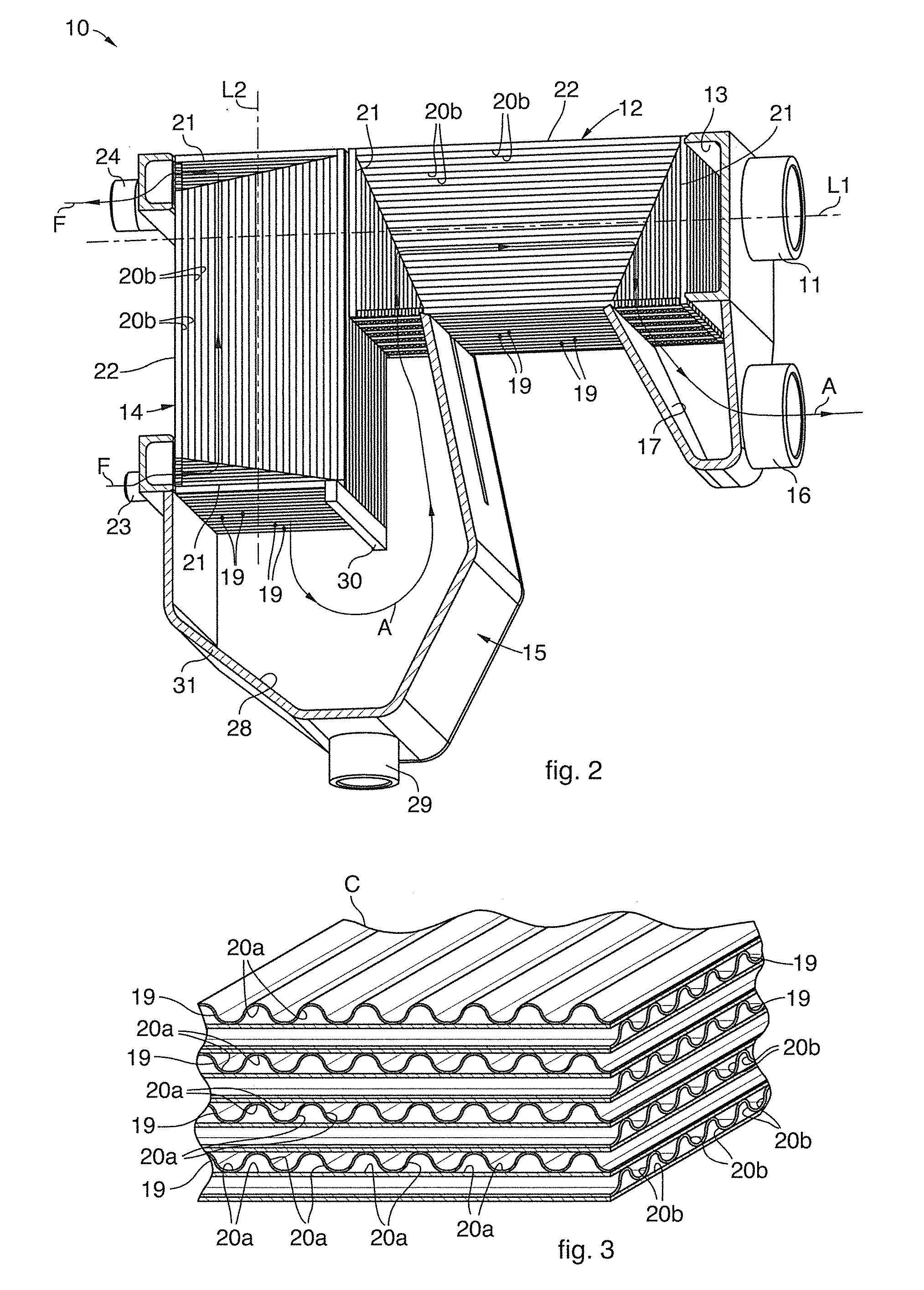

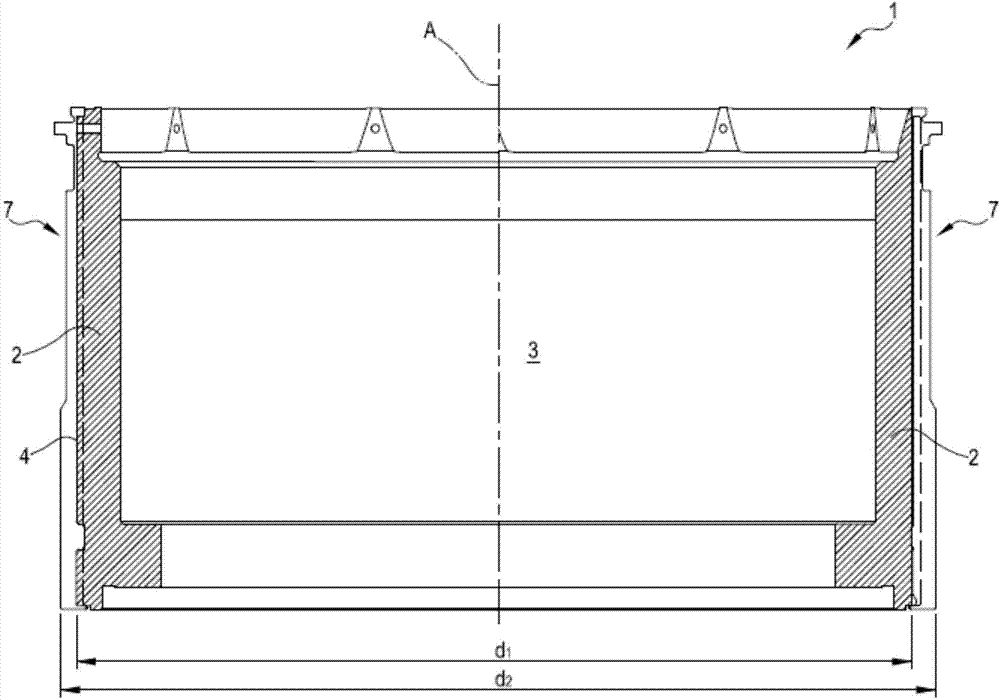

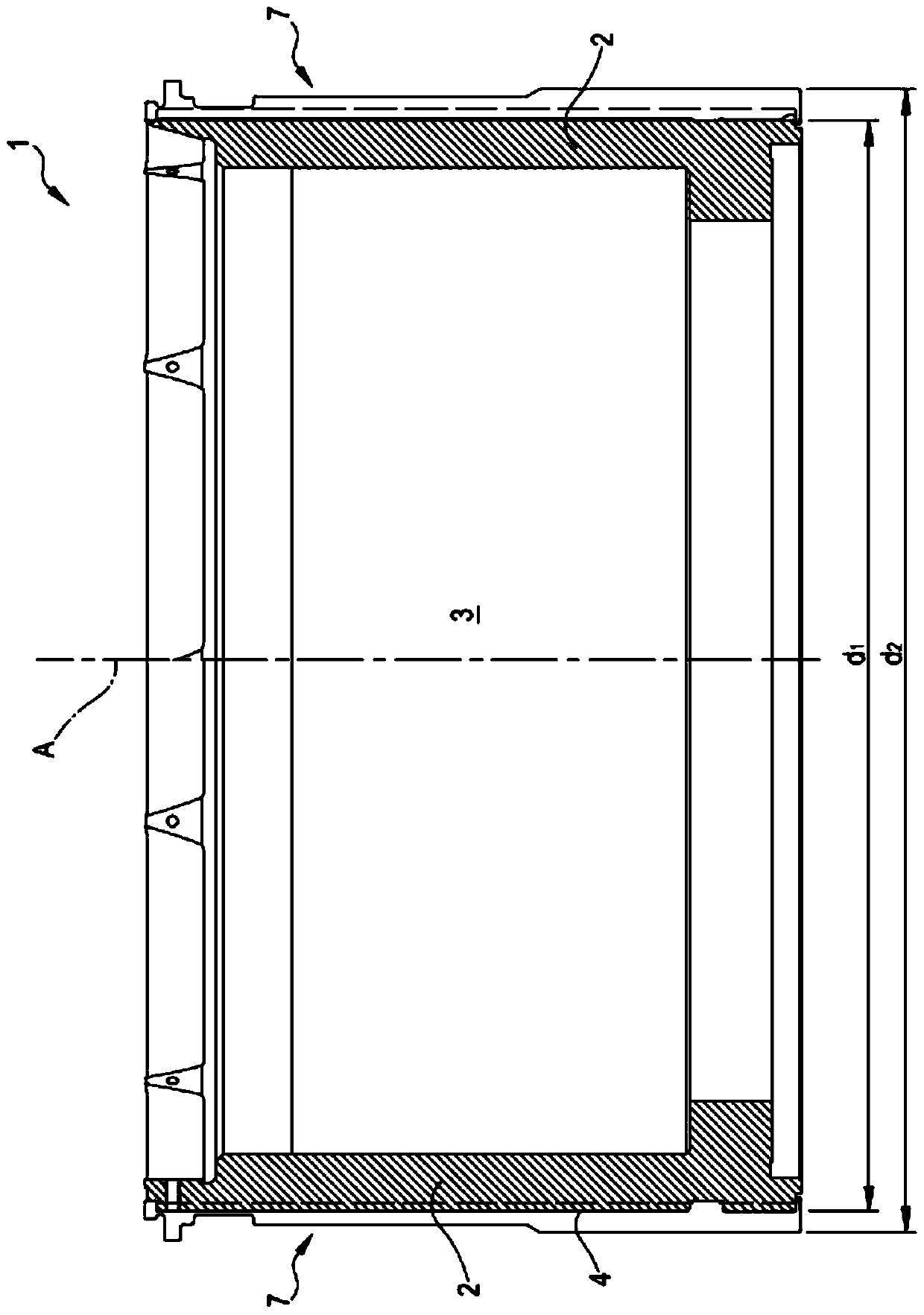

Heat exchanger

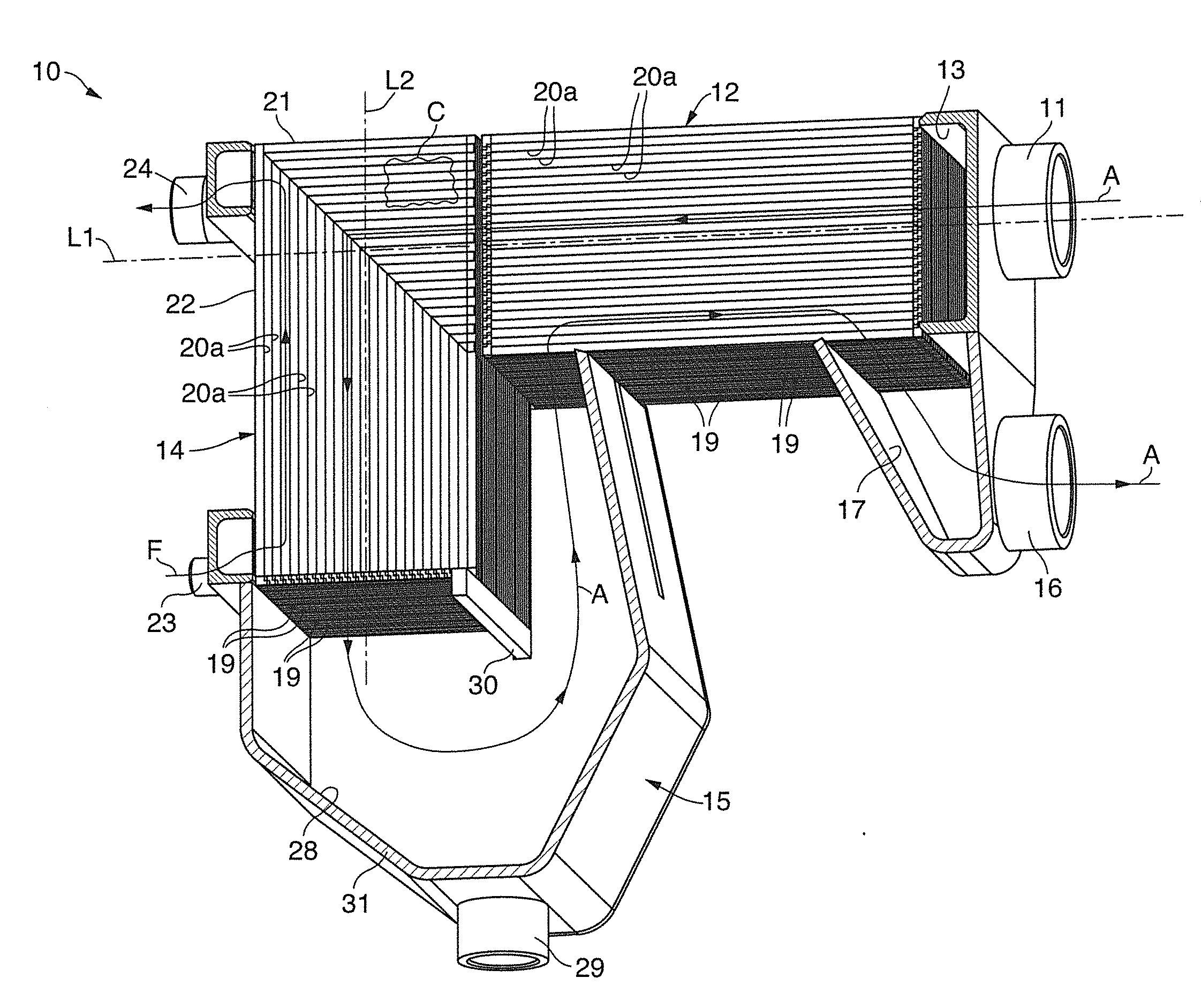

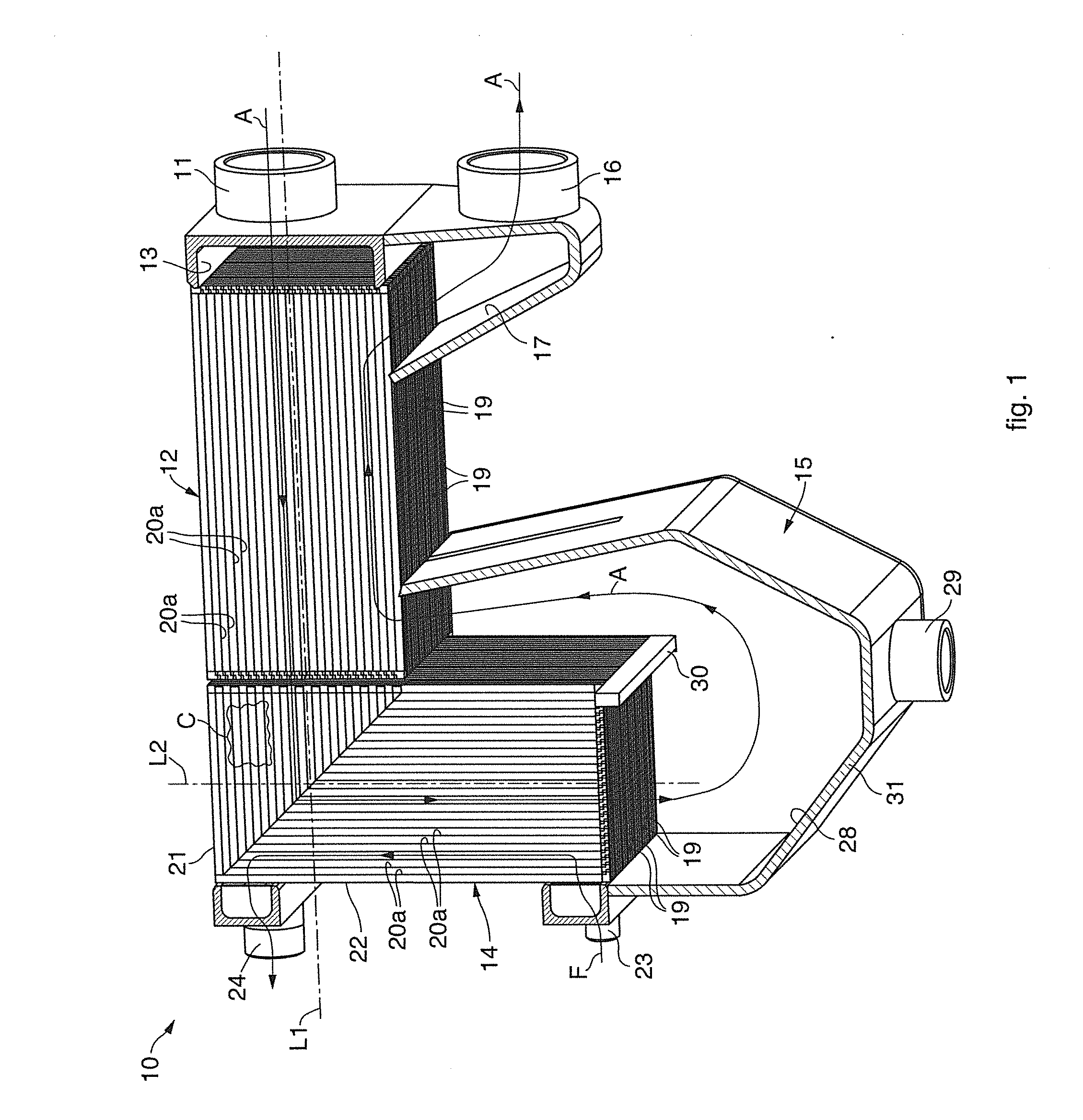

InactiveUS20130269910A1Reduce vertical volumeCompact configurationDispersed particle separationHeat exchanger casingsEngineeringLongitudinal development

A heat exchanger comprises at least a pre-cooling unit, or pre-exchanger, having a longitudinal development along at least a first longitudinal axis, and at least a cooling unit, or evaporator, having a longitudinal development along at least a second longitudinal axis and connected to the pre-exchanger in order to define a fluid-dynamic circuit for the circulation of a fluid, such as air, in said pre-exchanger and said evaporator. The first longitudinal axis and said second longitudinal axis are angled with respect to each other by an angle comprised between 45° and 135°.

Owner:OFF MEC INDALI CON UNICO SOCIO

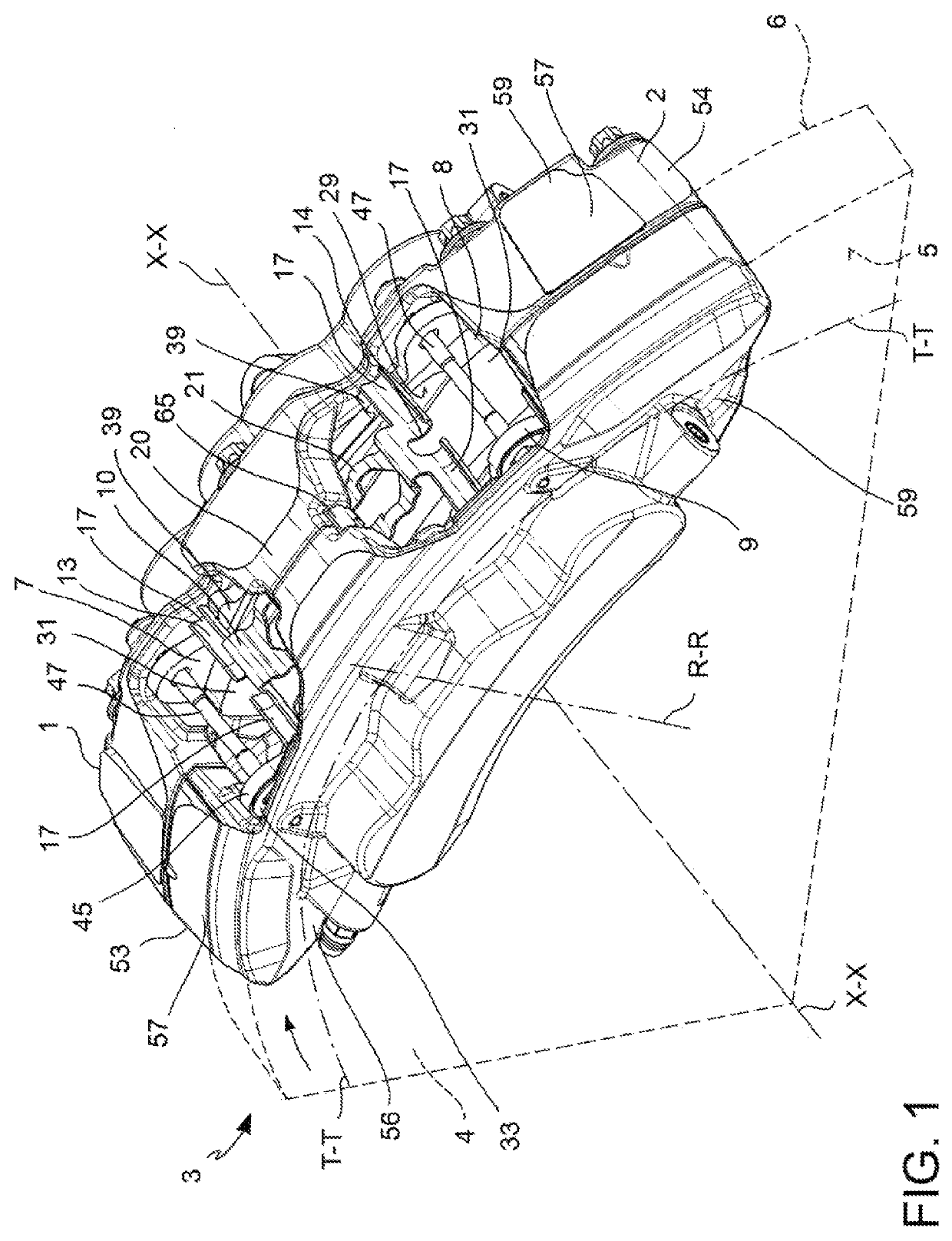

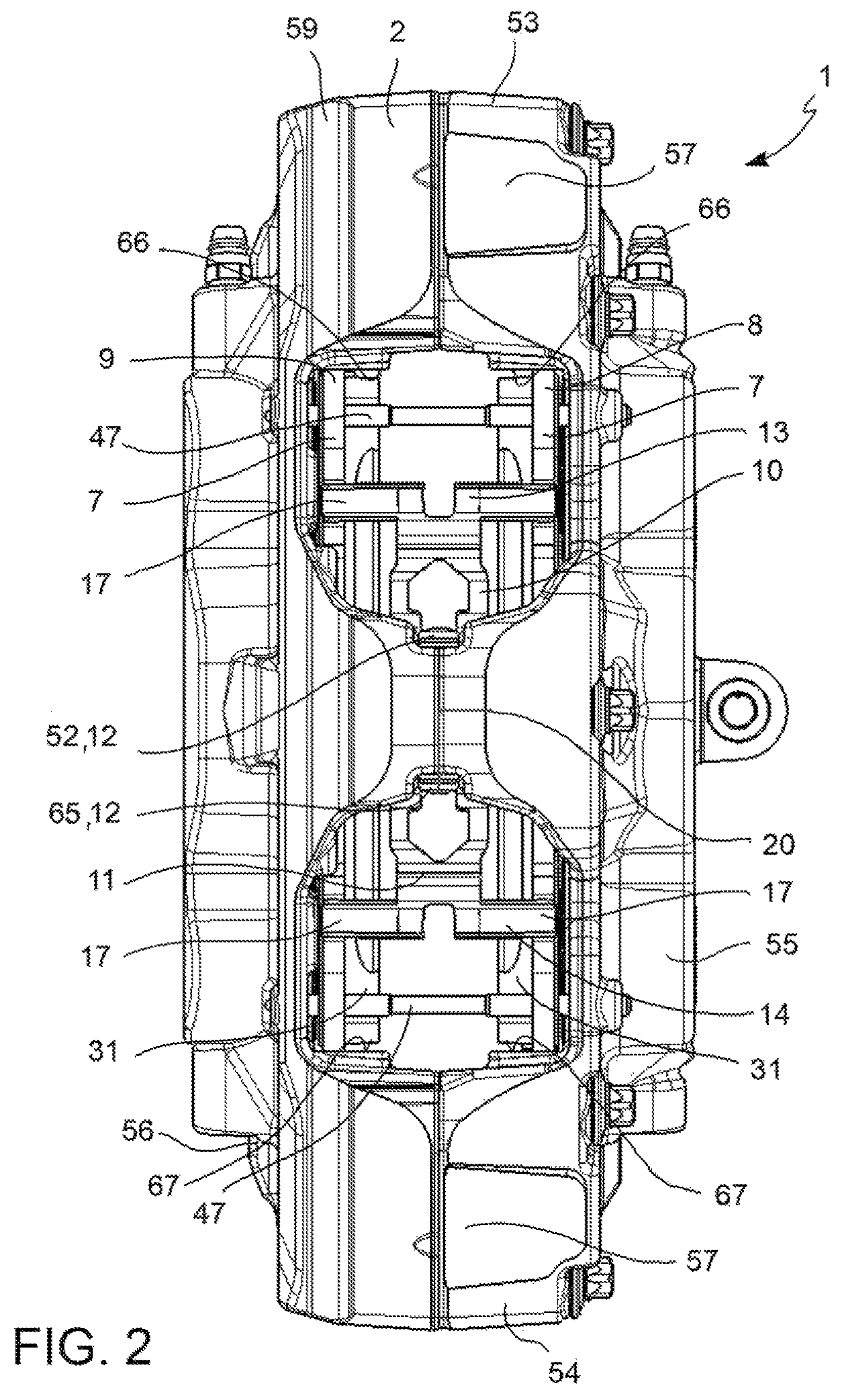

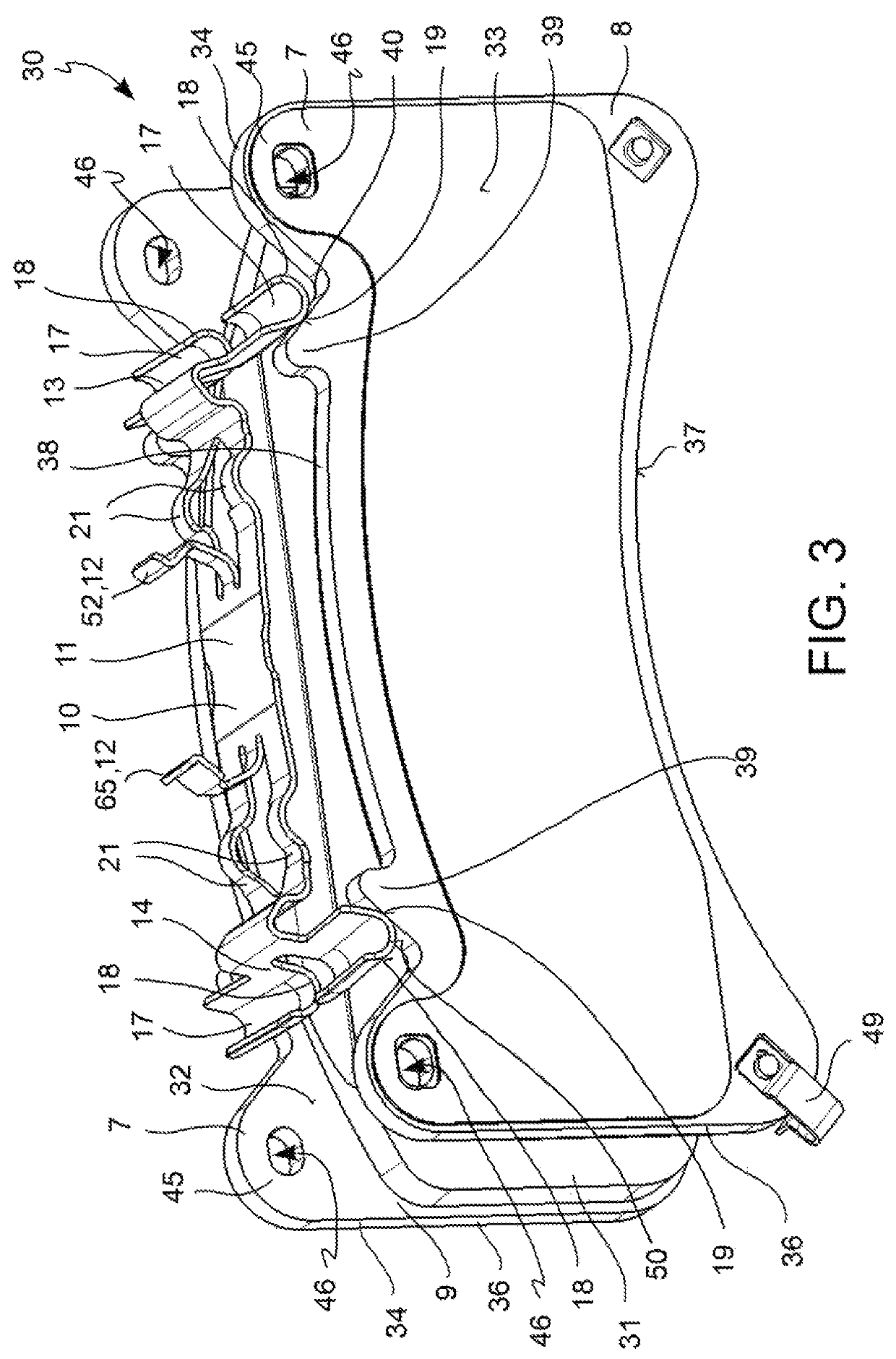

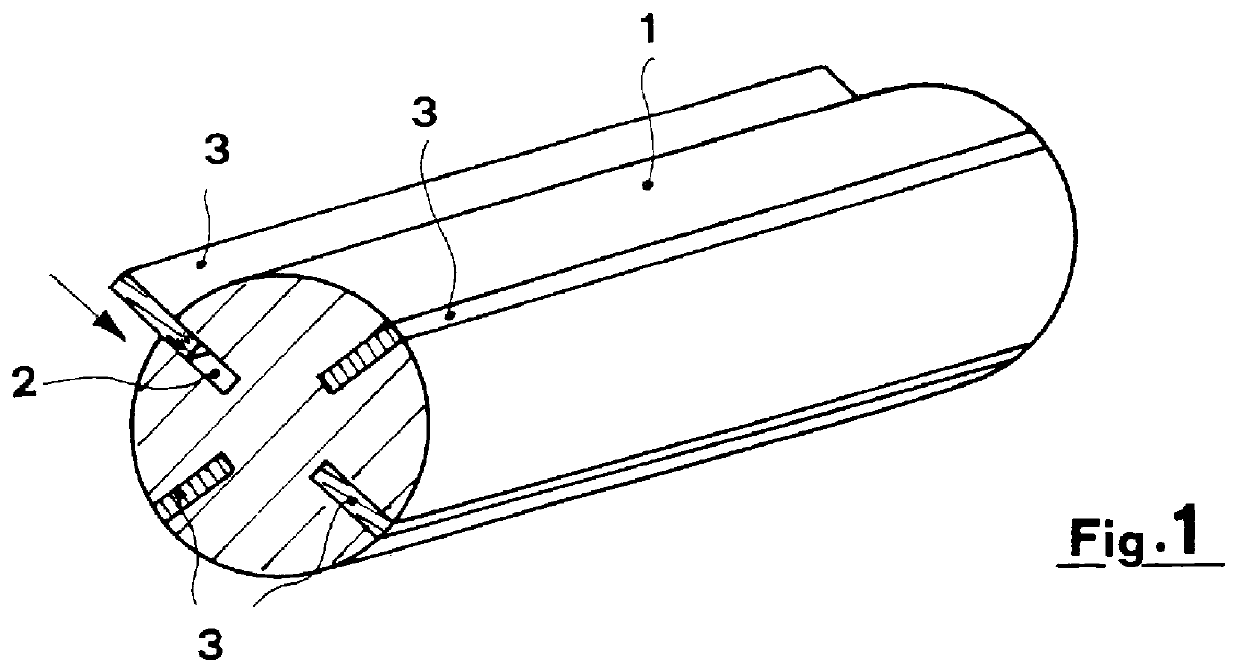

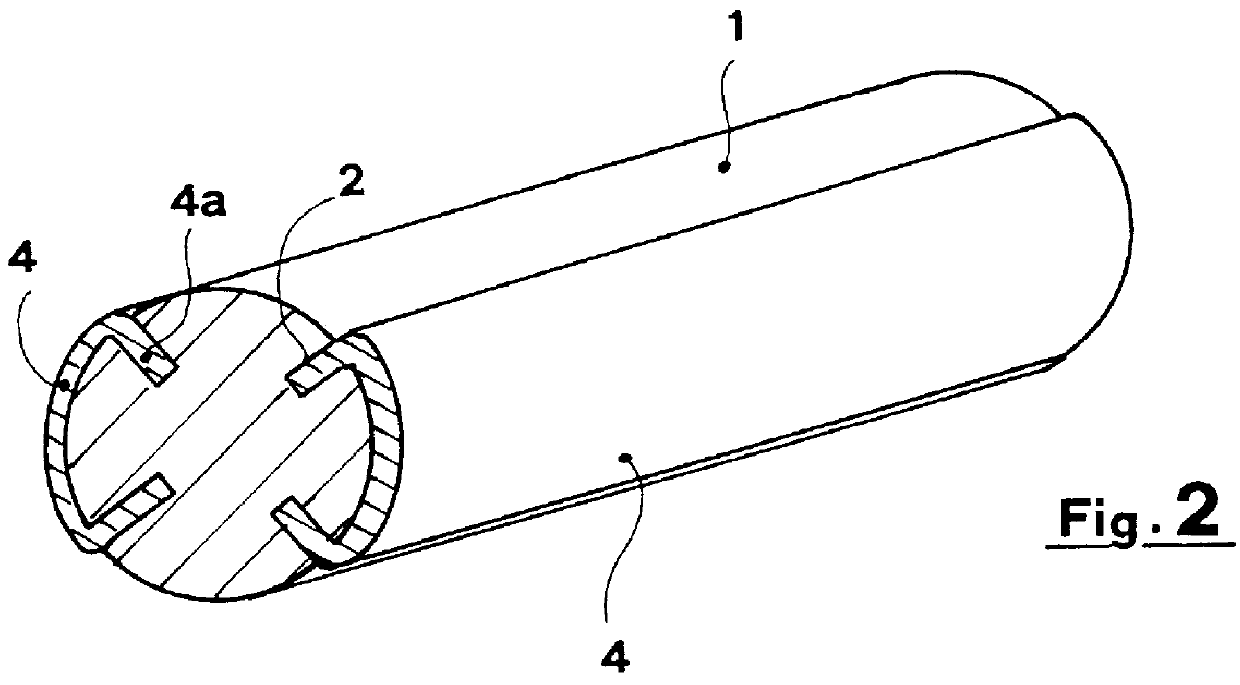

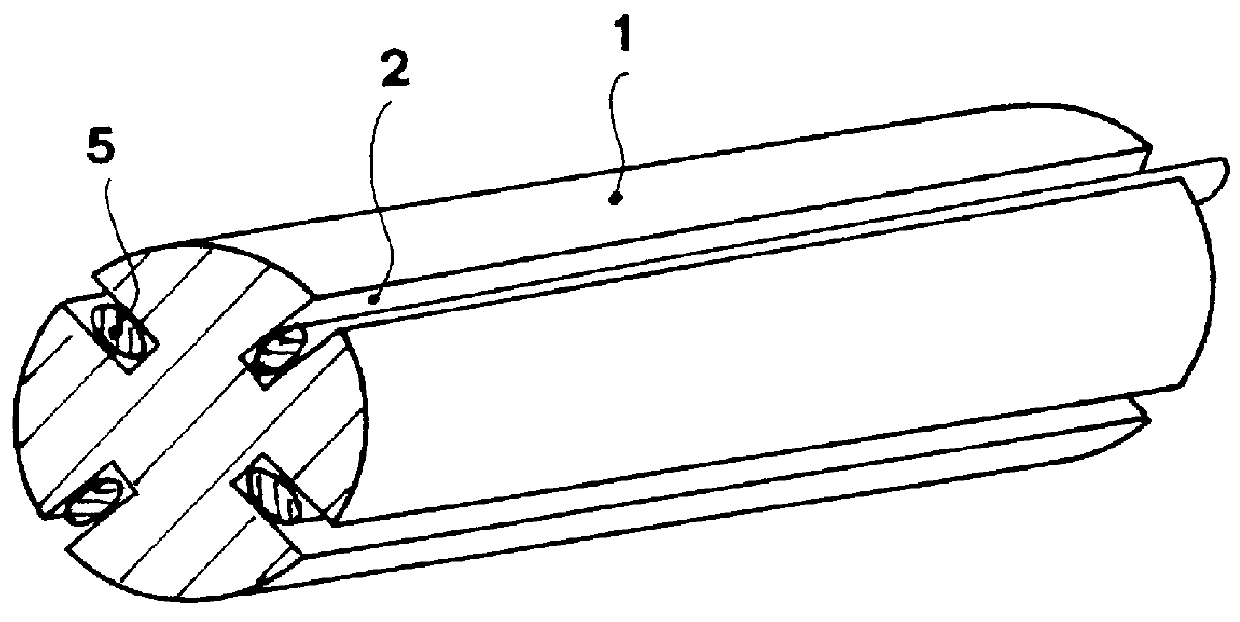

Track with rotating bushings for track-type vehicles

ActiveCN102421661ABalanced abrasion resistance levelSimple designEndless track vehiclesLongitudinal developmentMechanical engineering

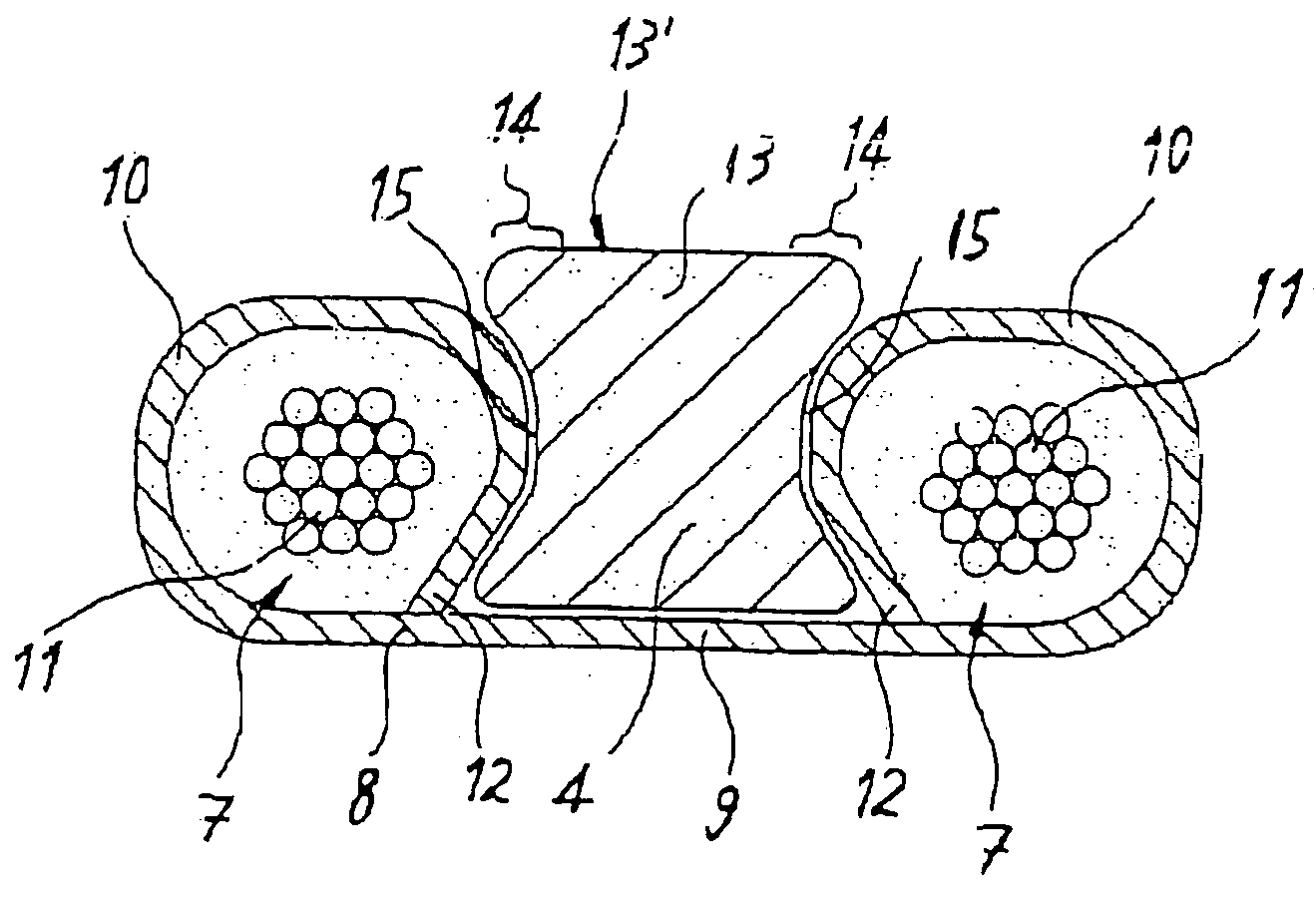

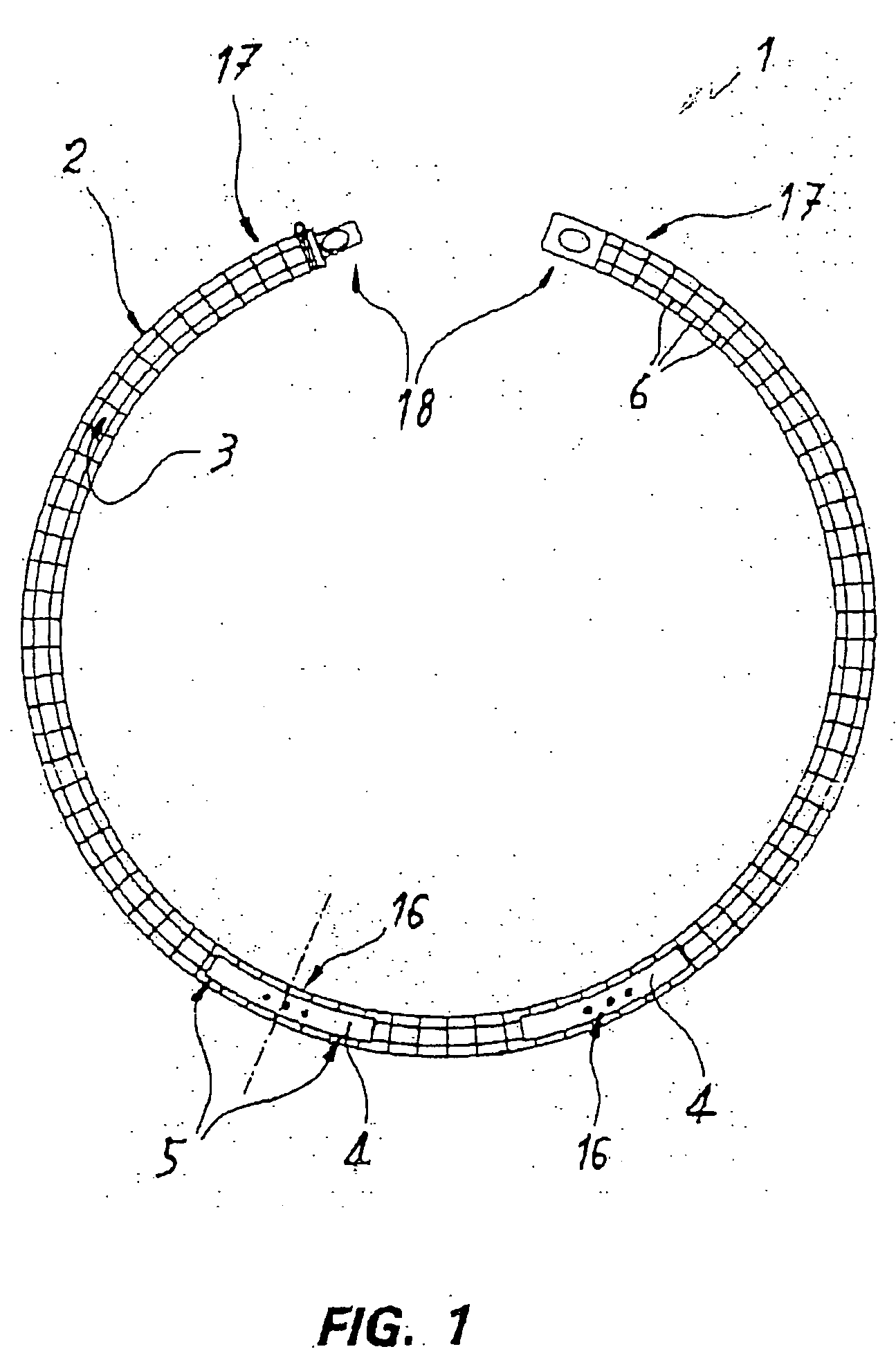

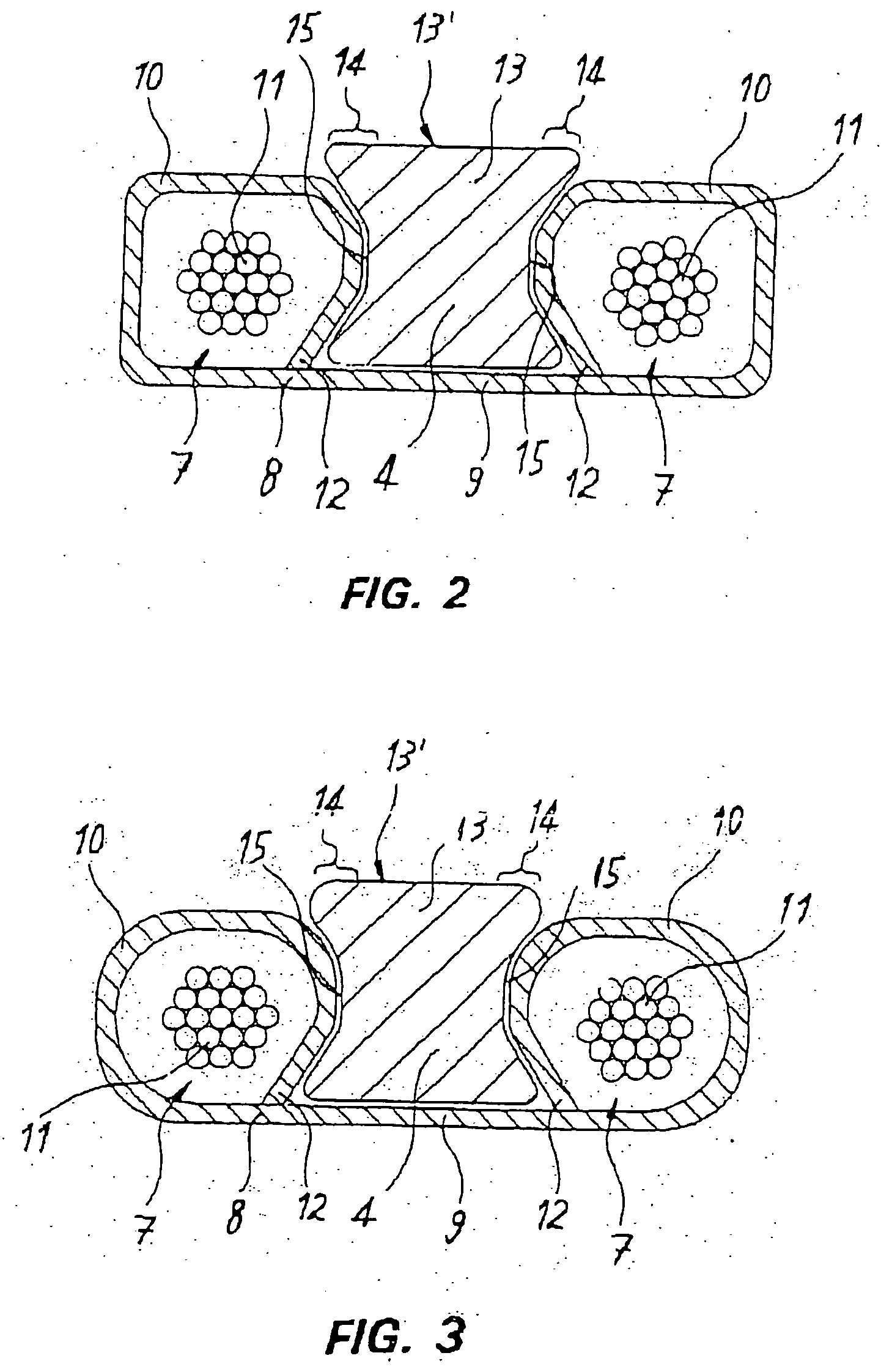

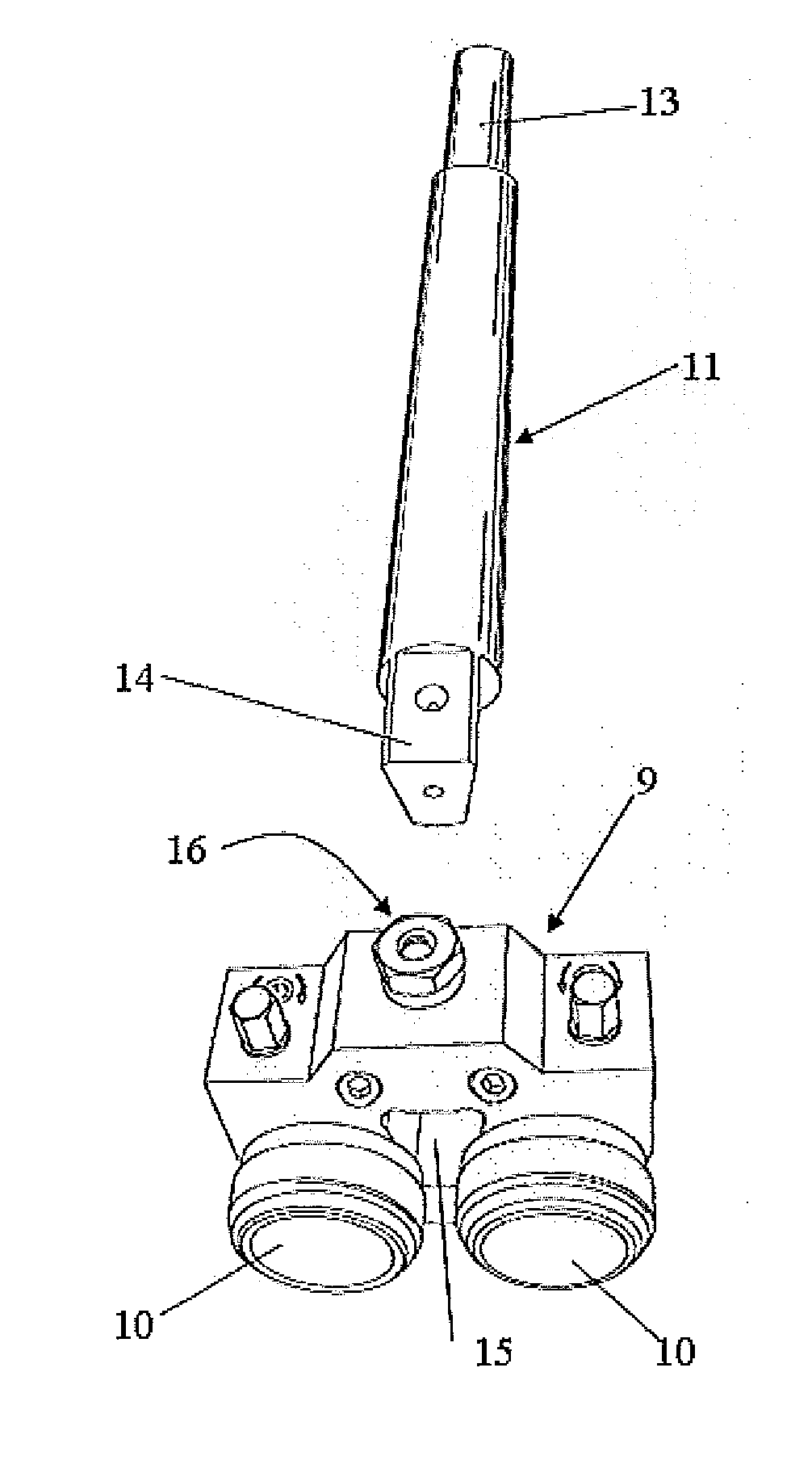

A track (10) for track-type vehicles is described, comprising a continuous sequence of articulated joints (12, 12') of the hinge type, oriented according to a first axis (A-A) substantially perpendicular to the central longitudinal development axis (B-B) of the track (10). The articulated joints (12, 12'), provided with pins (36, 36'), are connected to each other and maintained at a constant distance through pairs of links (14) having longitudinal development, arranged laterally and symmetrically with respect to the longitudinal central axis (B-B). Around each pin (36, 36') a bushing (40) is mounted free to rotate with respect to the pin (36, 36') itself and between each pin (36, 36') and the links (14) at least one sliding bearing (44) is press-fitted. The geometric / size characteristics of the links (14) and of the sliding bearings (44) make it possible to improve the stability and the resistance to fatigue and wearing of the articulated joints (12, 12') of the track (10).

Owner:BELLCO SPA

Cutting device for rolls of ribbon-like material, in particular a paper material

InactiveUS20120048088A1Cut commercializationReduce productionStock shearing machinesMetal working apparatusLongitudinal developmentBiomedical engineering

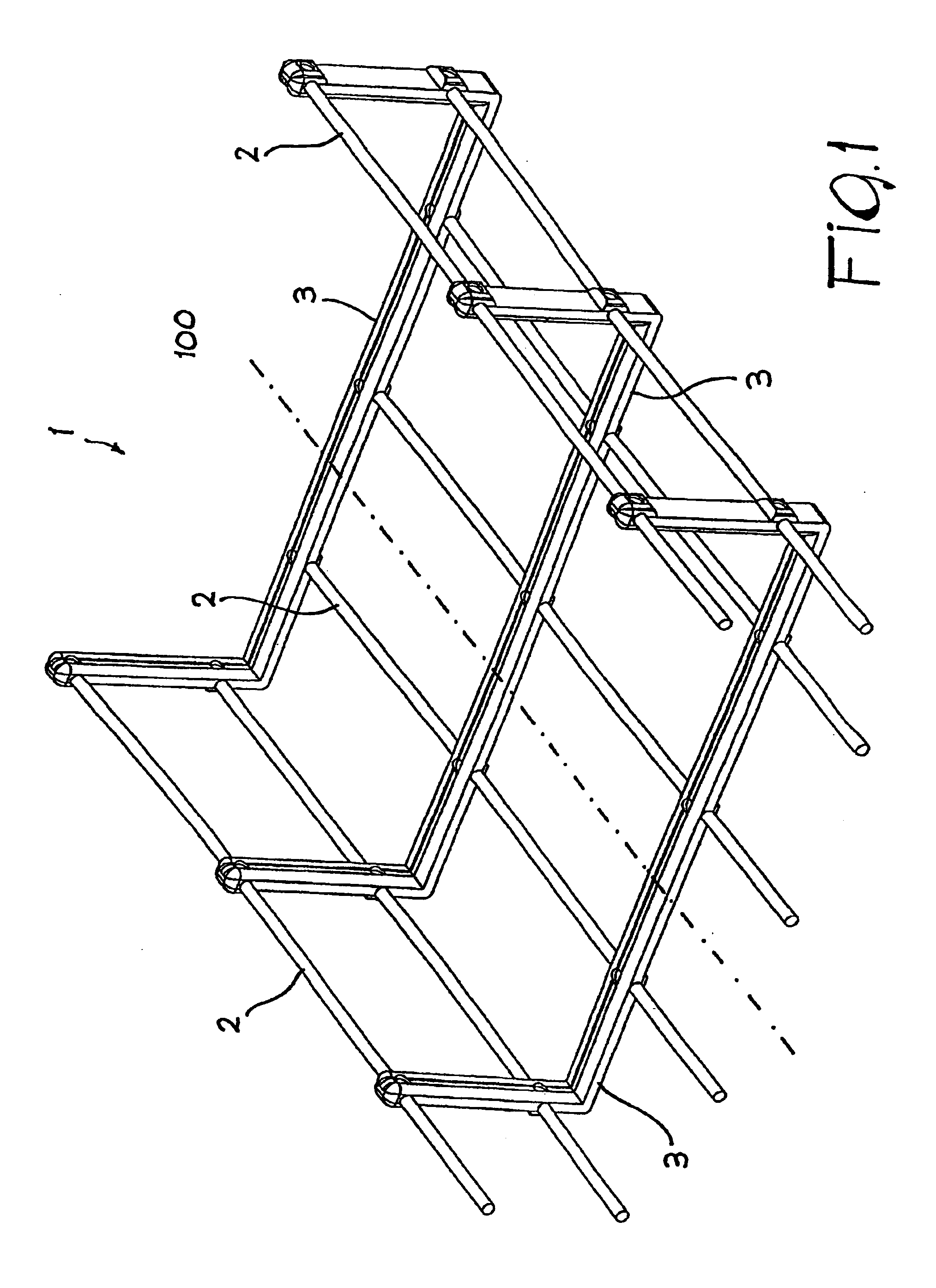

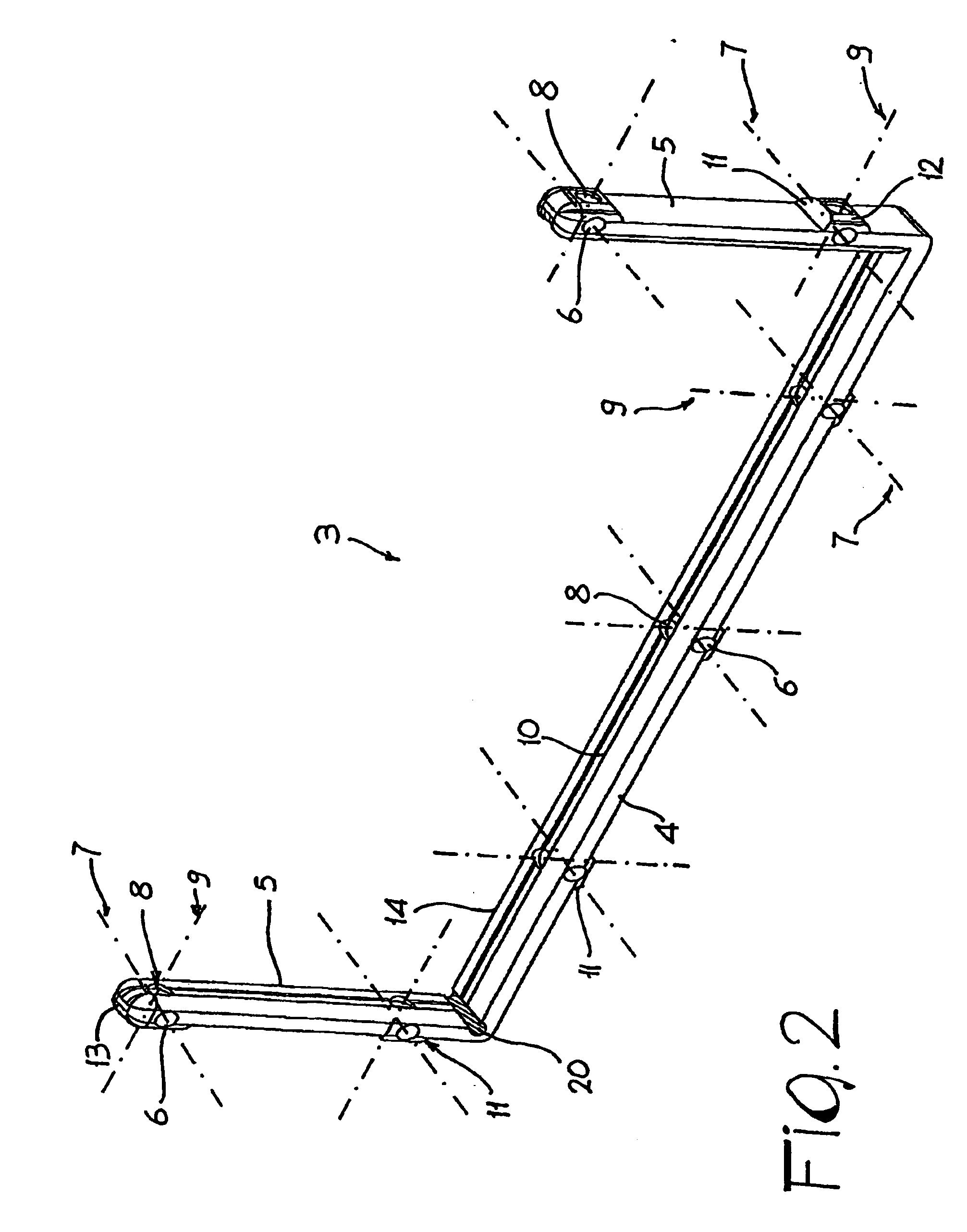

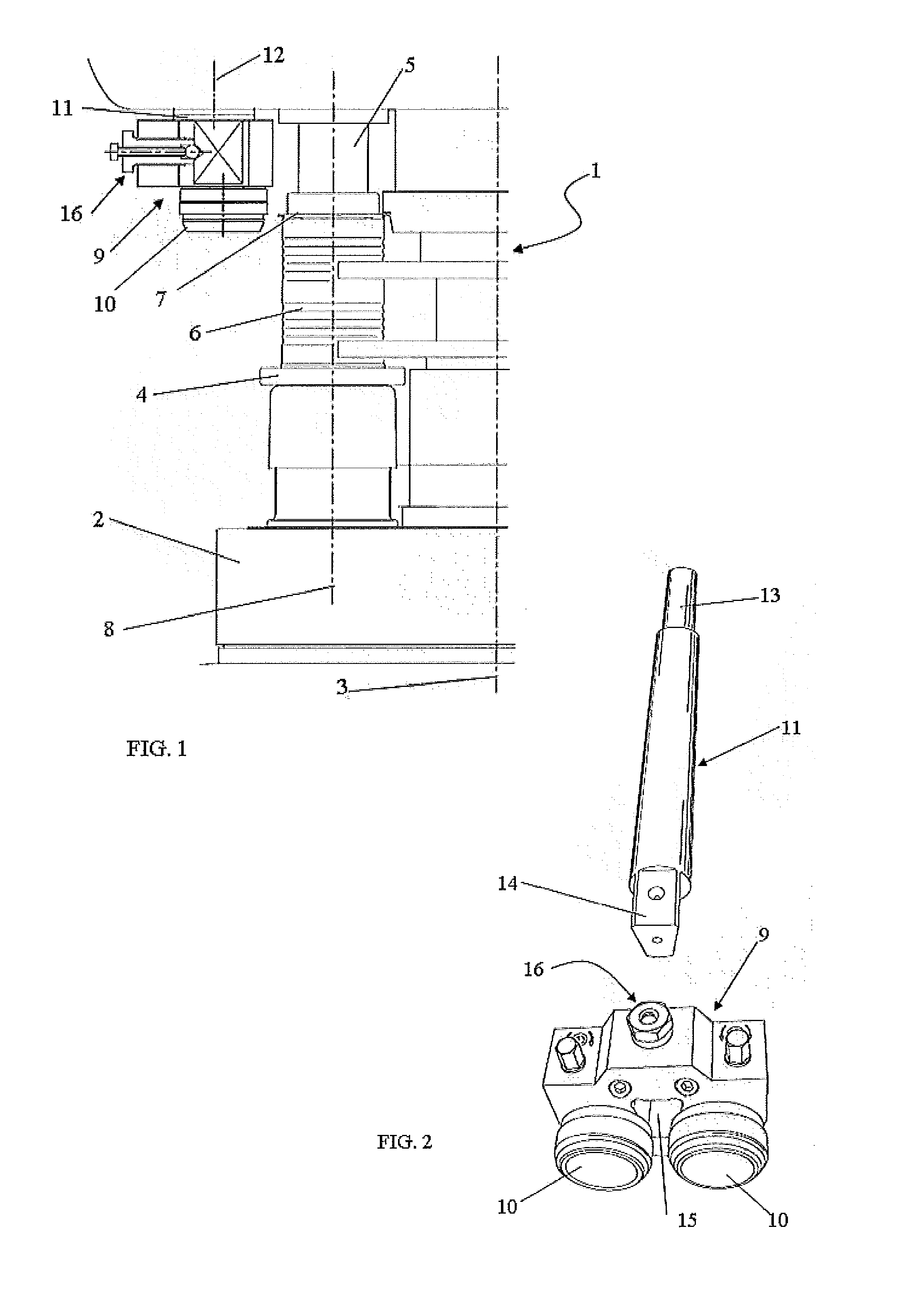

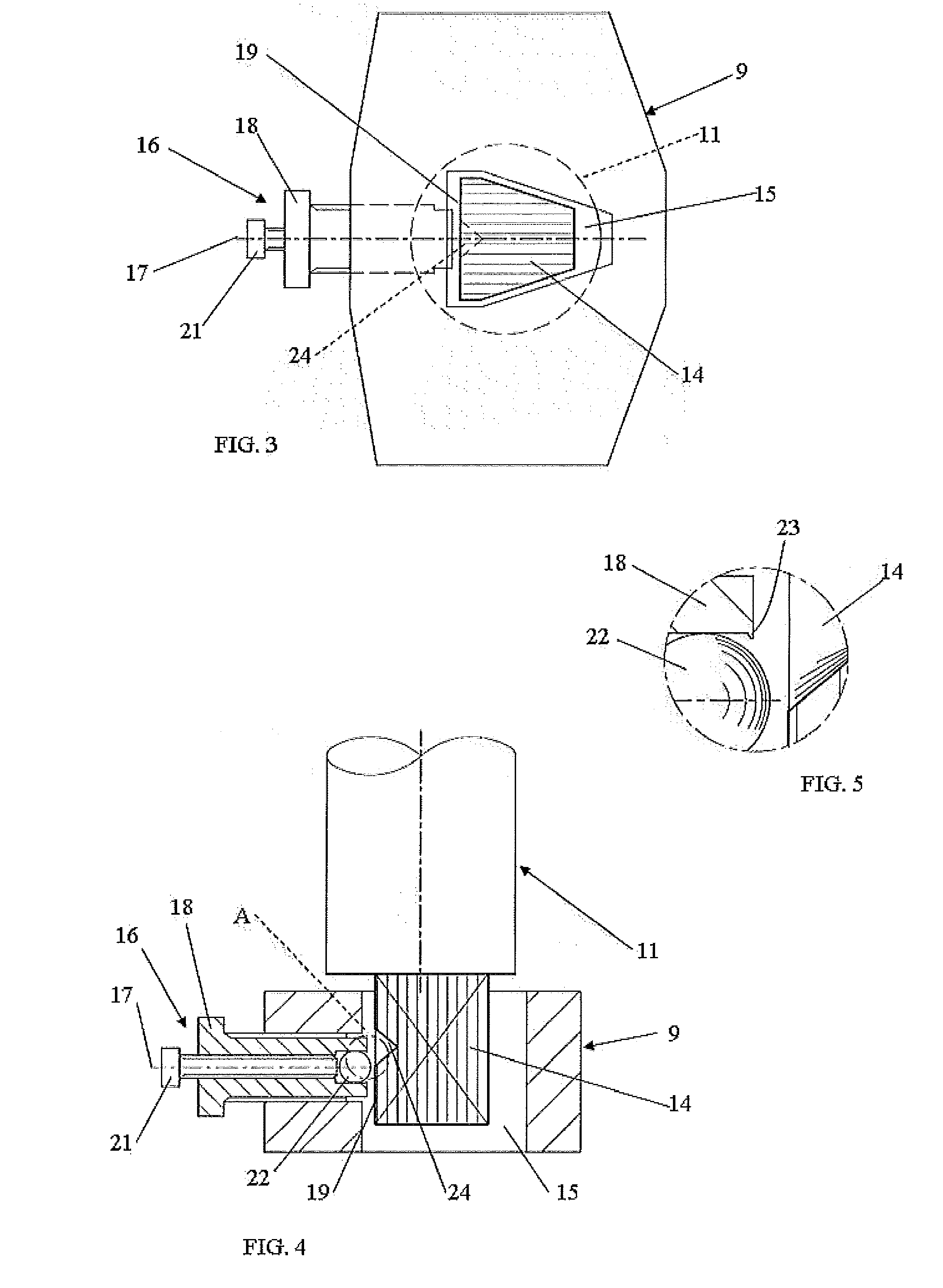

The present invention concerns a cutting device for rolls of ribbon-like material. The device 1 comprises cutting means active on at least one roll in order to divide this latter in two or more pieces. The cutting means are commutable between a non operative condition, in which they do not act on the roll, and an operative condition, in which they transversally cut the roll. The cutting means comprise a thread-like cutting element which develops transversally to the roll. The cutting thread is mobile along its longitudinal development so as to cut the roll. The cutting means comprise at least one handling member, preferably two pulleys operatively associated to the thread-like cutting element to move this latter along its longitudinal development.

Owner:GAMBINI INT

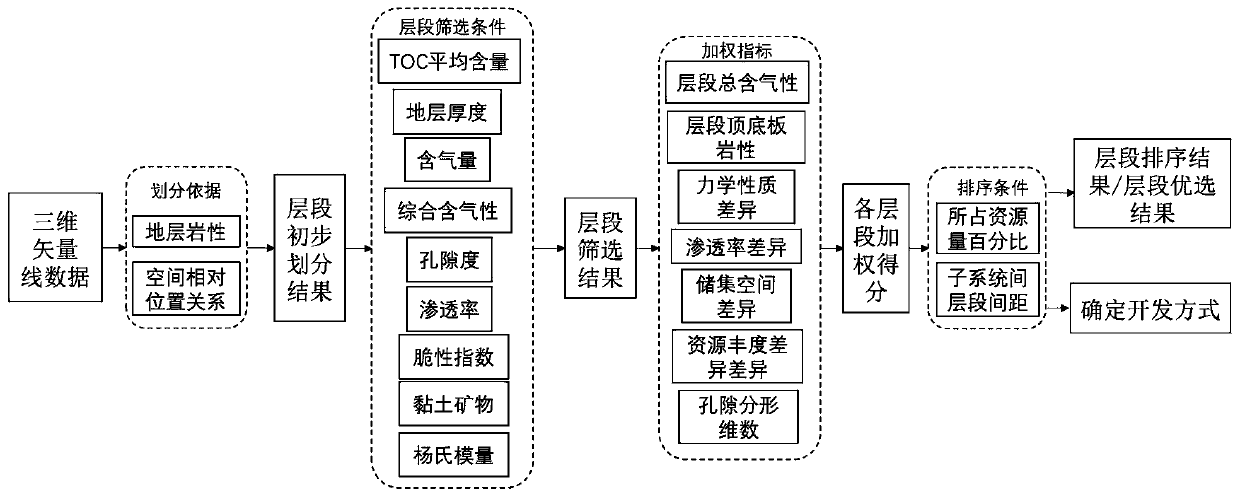

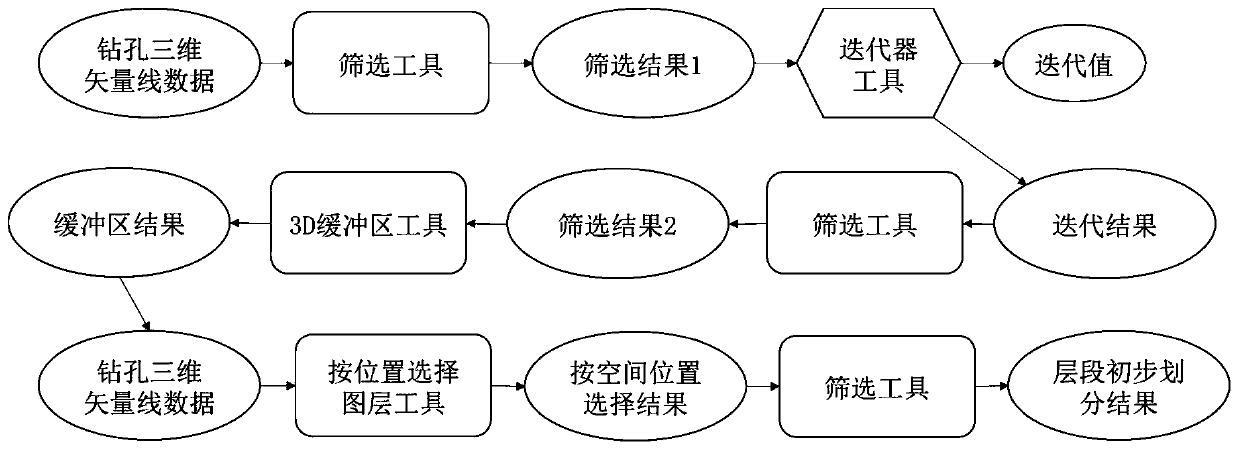

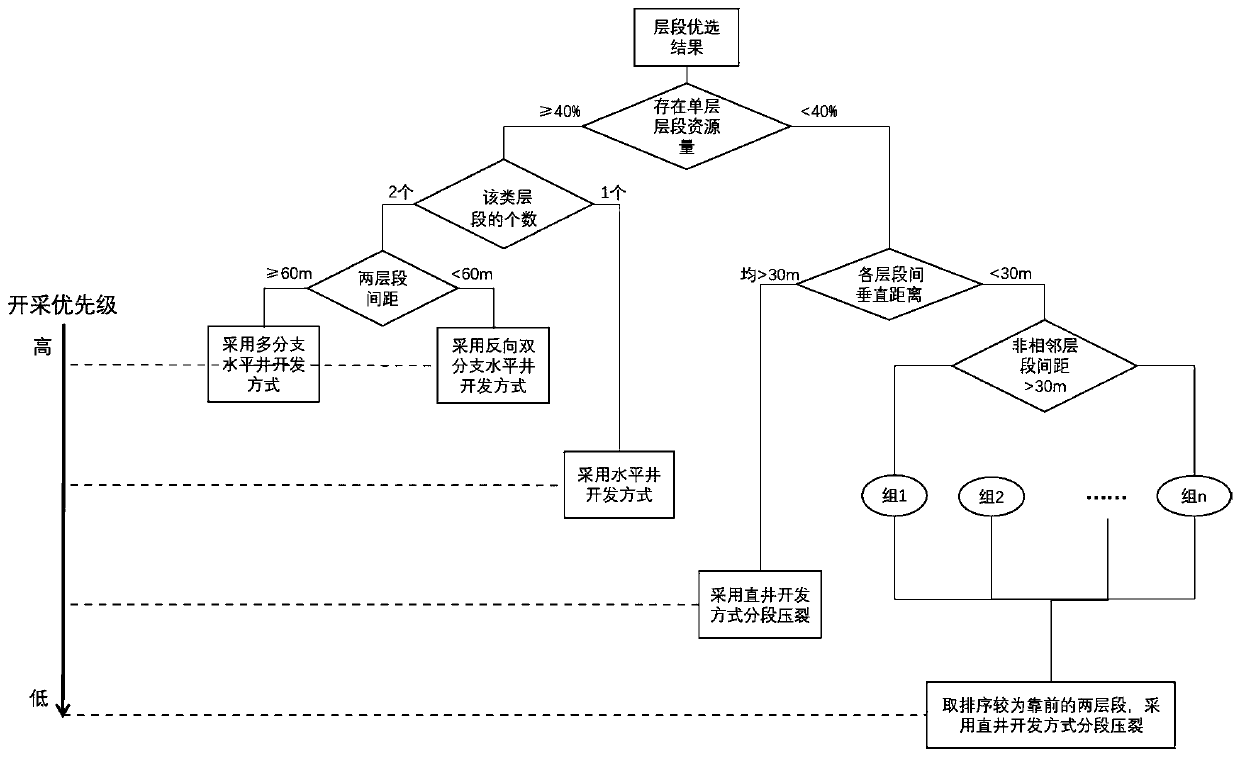

GIS technology-based coal-series gas longitudinal development interval optimization method

ActiveCN110516016ARealize visual displaySurveyClimate change adaptationProcess engineeringLongitudinal development

The invention discloses a GIS technology-based coal-series gas longitudinal development interval optimization method, including the steps: building a coal-series gas longitudinal development intervalbasic database, and preliminarily determining a coal-series gas longitudinal development interval according to a coal-series gas reservoir combination mode; constructing a coal-series gas interval optimal evaluation index system, and obtaining an interval screening result by utilizing an interval screening condition; selecting a weighting index, and determining the weight and score of each weighting index in the coal-series gas interval in an expert scoring mode; performing weighted calculation on the index score in each interval, calculating the proportion of the cumulative score of each interval in the cumulative scores of all the intervals, and sorting the intervals according to the proportion; and according to the score ratio of each interval and the distance between the intervals, determining the interval mining priority and the coal series gas development mode. The GIS technology-based coal-series gas longitudinal development interval optimization method is simple in step, reduces a large amount of repeated operation, achieves longitudinal coal-series gas interval optimization, has the advantages of being visual, vivid, rapid and efficient, and provides a more reliable basisfor coal-series gas exploration and development.

Owner:CHINA UNIV OF MINING & TECH

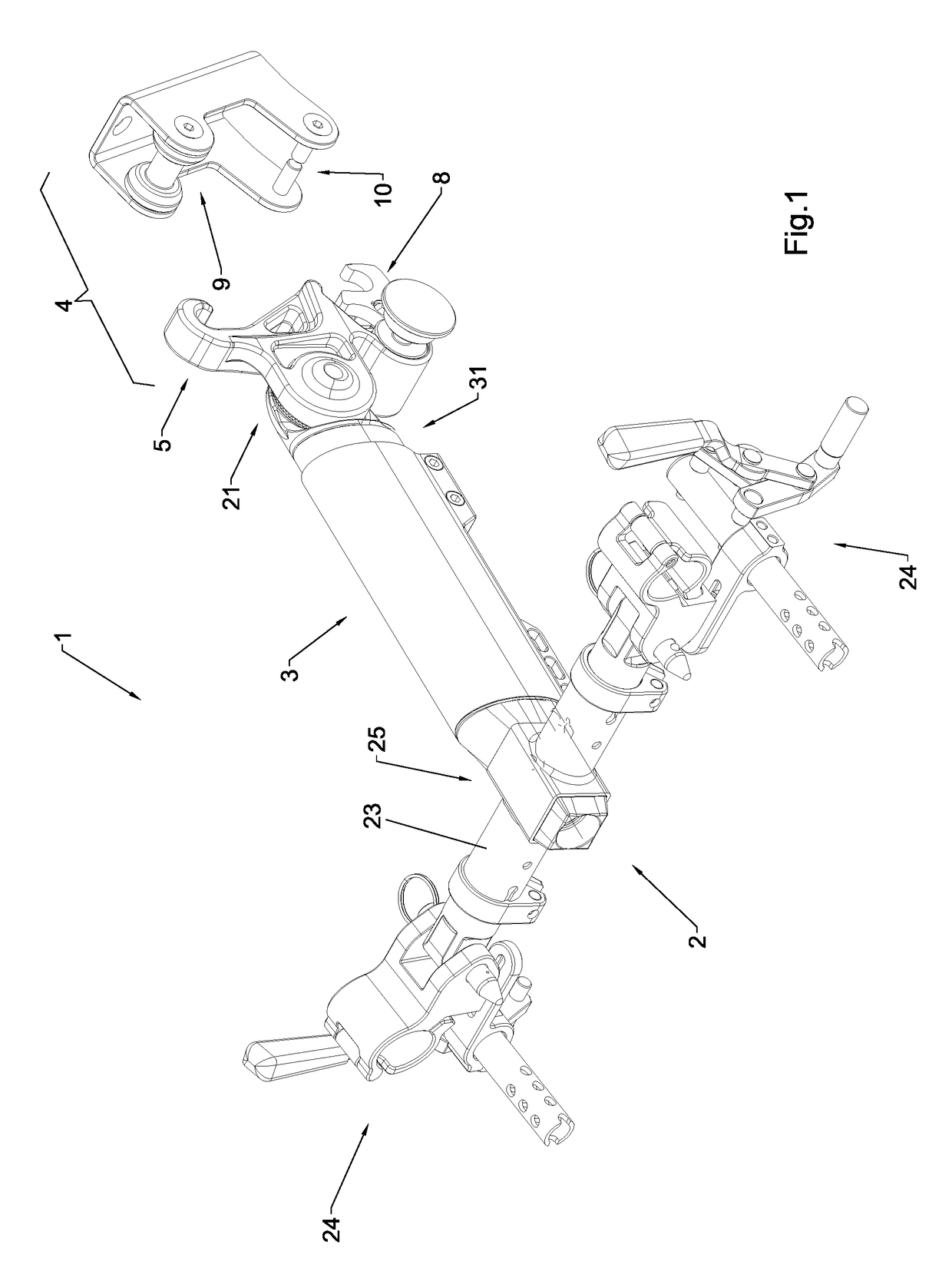

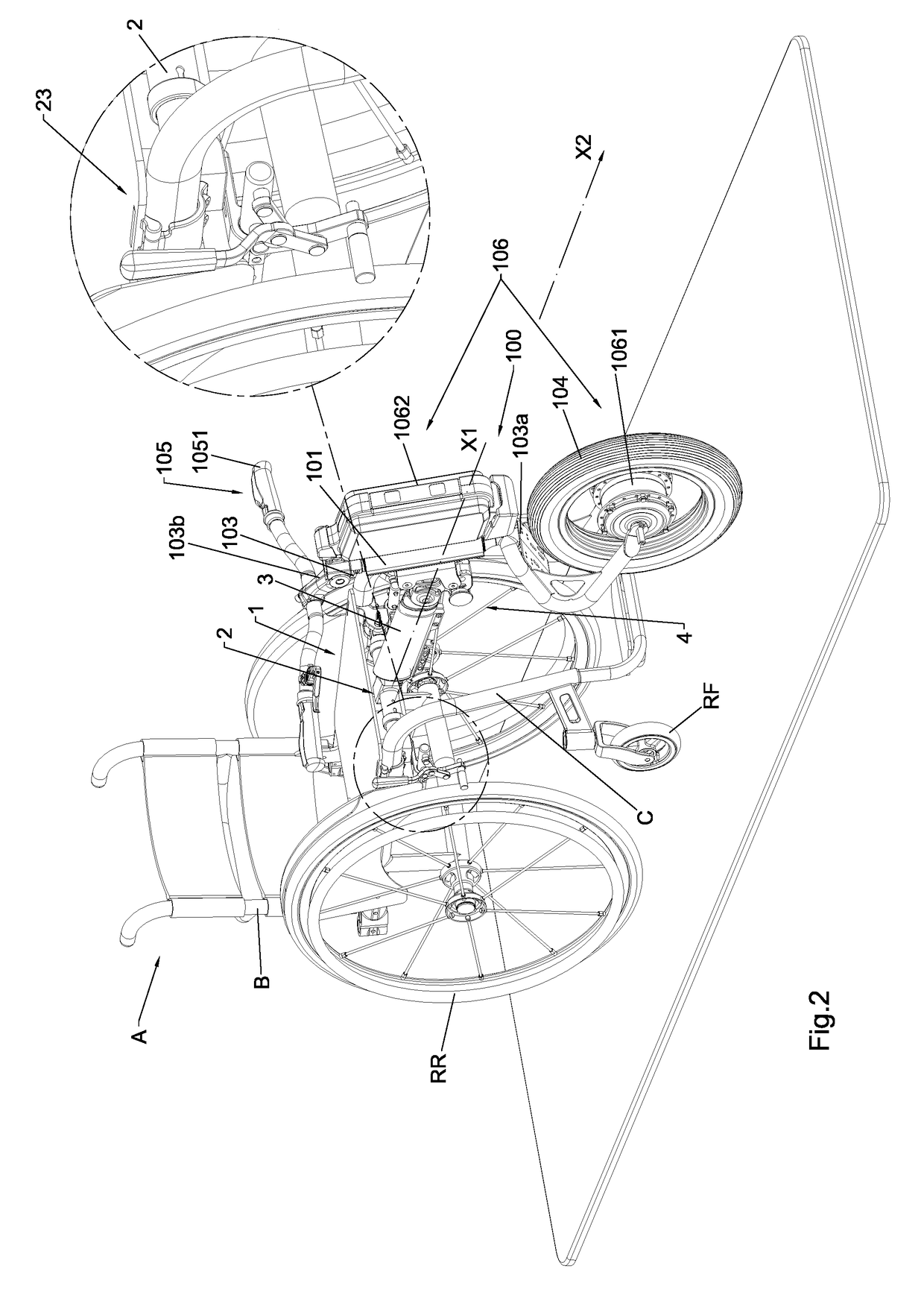

Connection assembly for coupling an auxiliary drive system to a wheelchair for disabled people

ActiveUS20190015272A1Easy to operateRobust and stable couplingWheelchairs/patient conveyanceWheelchairCoupling

A connection assembly for coupling an auxiliary drive system to a wheelchair for disabled people, of the type comprising a fixing structure adapted to be fixed to the framework of the wheelchair and a longitudinal member operatively connected to the fixing structure so that the longitudinal development axis of the longitudinal member is substantially parallel to the advancement direction of the wheelchair. The connection assembly comprises connection means associated with the free end of the longitudinal member and with the auxiliary drive system, such connection means are configured to allow rapid coupling and decoupling of the auxiliary drive system to / from the wheelchair.

Owner:KLAXON MOBILITY GMBH

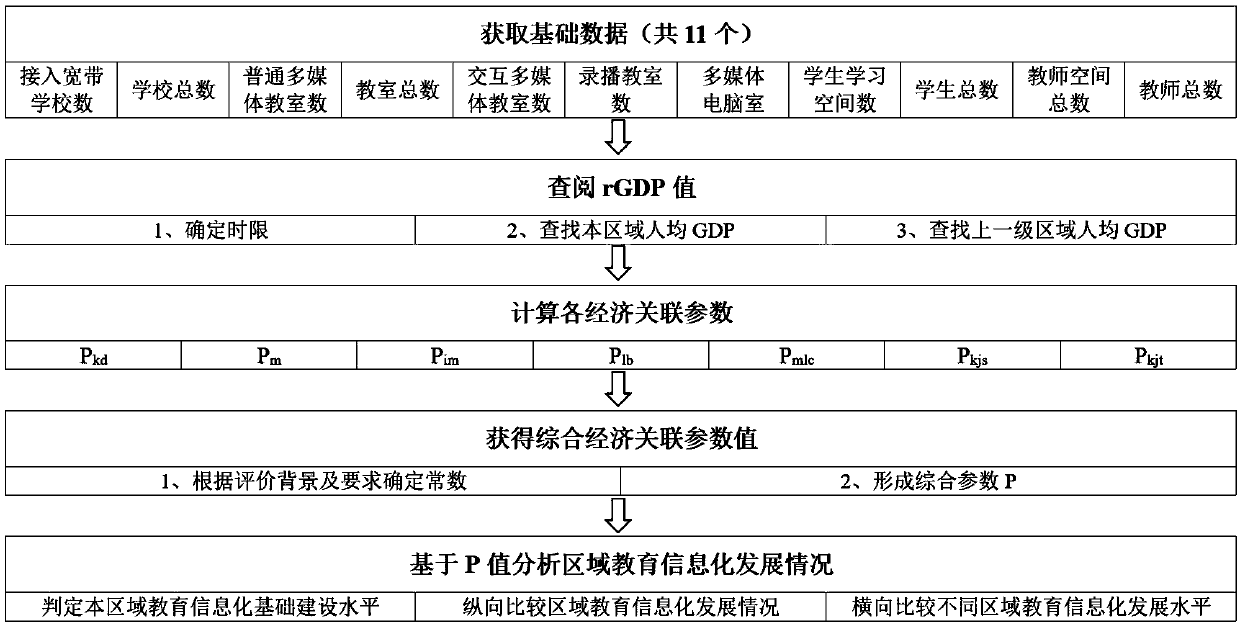

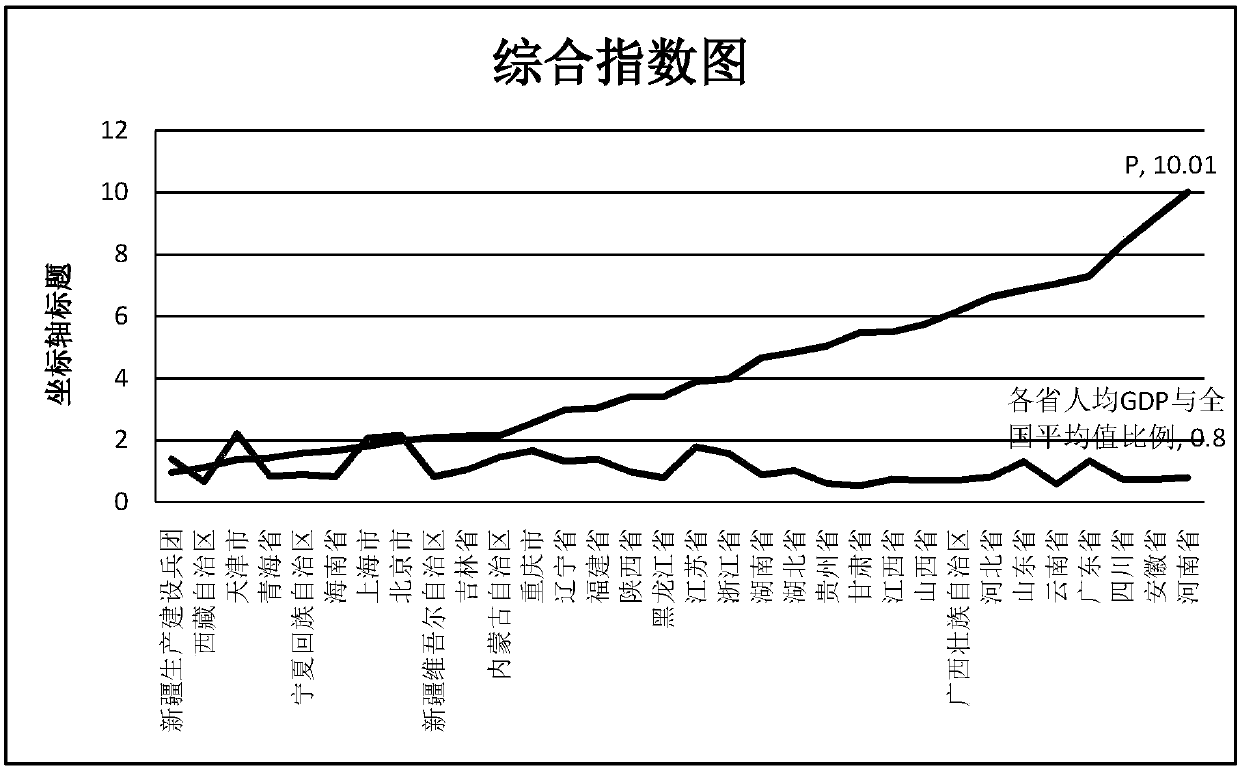

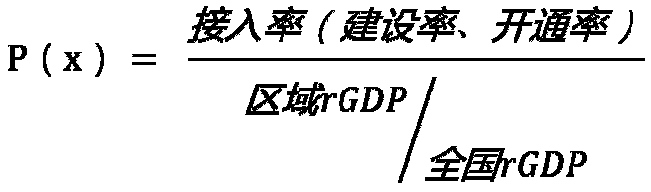

Method for analyzing level of education informatization construction based on economic correlation parameters

InactiveCN107679698AEnsure objectivityAvoid Data Collection EffortsResourcesInformatizationInformation technology education

The invention discloses a method for analyzing the level of education informationization construction based on economic correlation parameters, which includes the following steps: S1. Obtain 11 basic education data in relevant areas; S2. Determine the time limit according to needs, and consult the per capita domestic production Total value rGDP value; S3. Calculation of various economic correlation parameters, including seven parameters of Pkd, Pm, Pim, Plb, Pmlc, Pkjs and Pkjt; S4. According to the seven economic correlation parameters, P represents the basis of education informatization Build a comprehensive level; S5. Analyze the development of regional education informatization based on the P value, determine the level of education informatization infrastructure in the region, compare the development of regional education informatization vertically, and compare the development level of education informatization in different regions horizontally. The present invention judges the information construction situation under the education and teaching level, education management method and economic development level in different regions by comprehensive correlation parameters, which can realize the evaluation anytime and anywhere, and guarantee the objectivity and routine of the evaluation.

Owner:SOUTH CHINA NORMAL UNIVERSITY

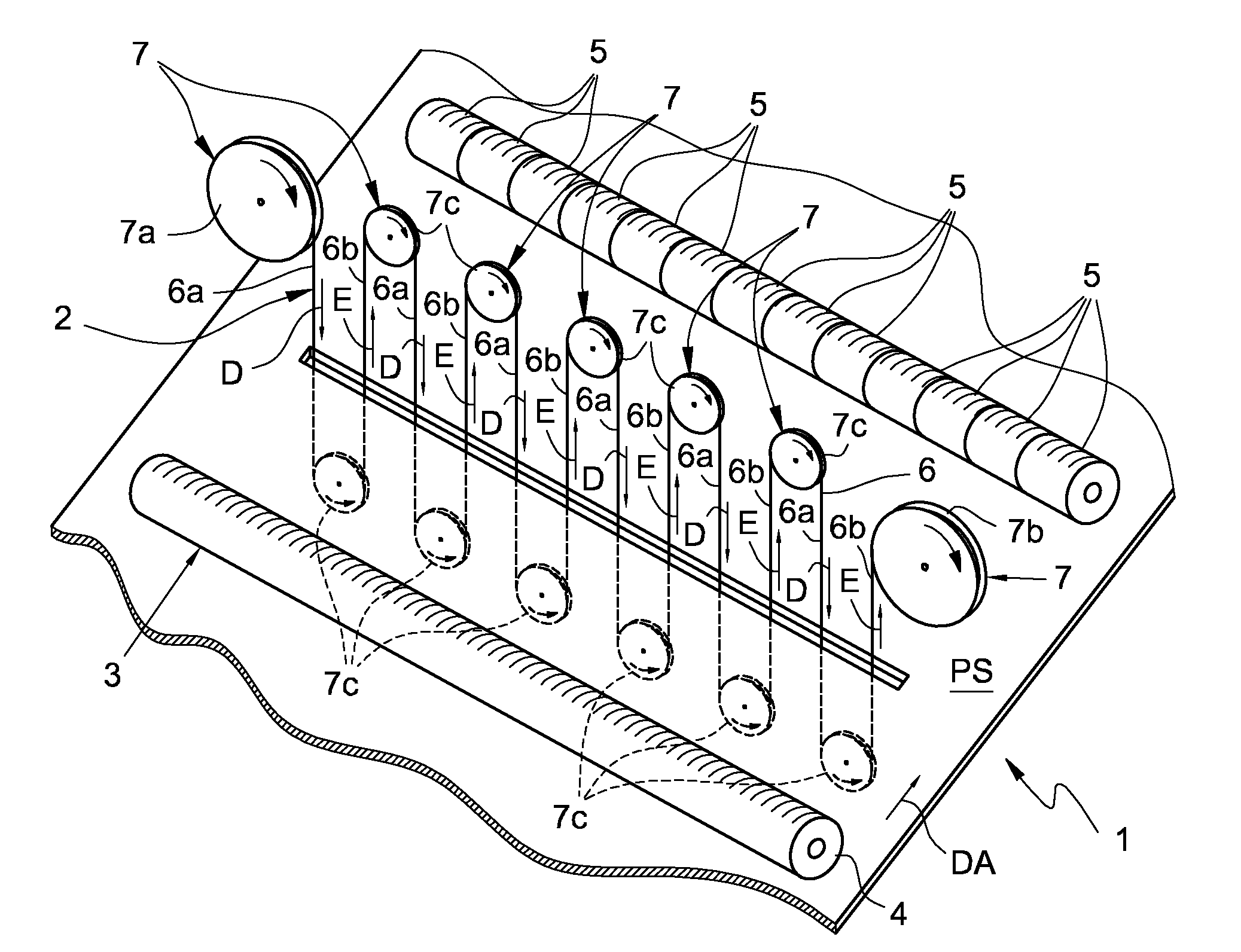

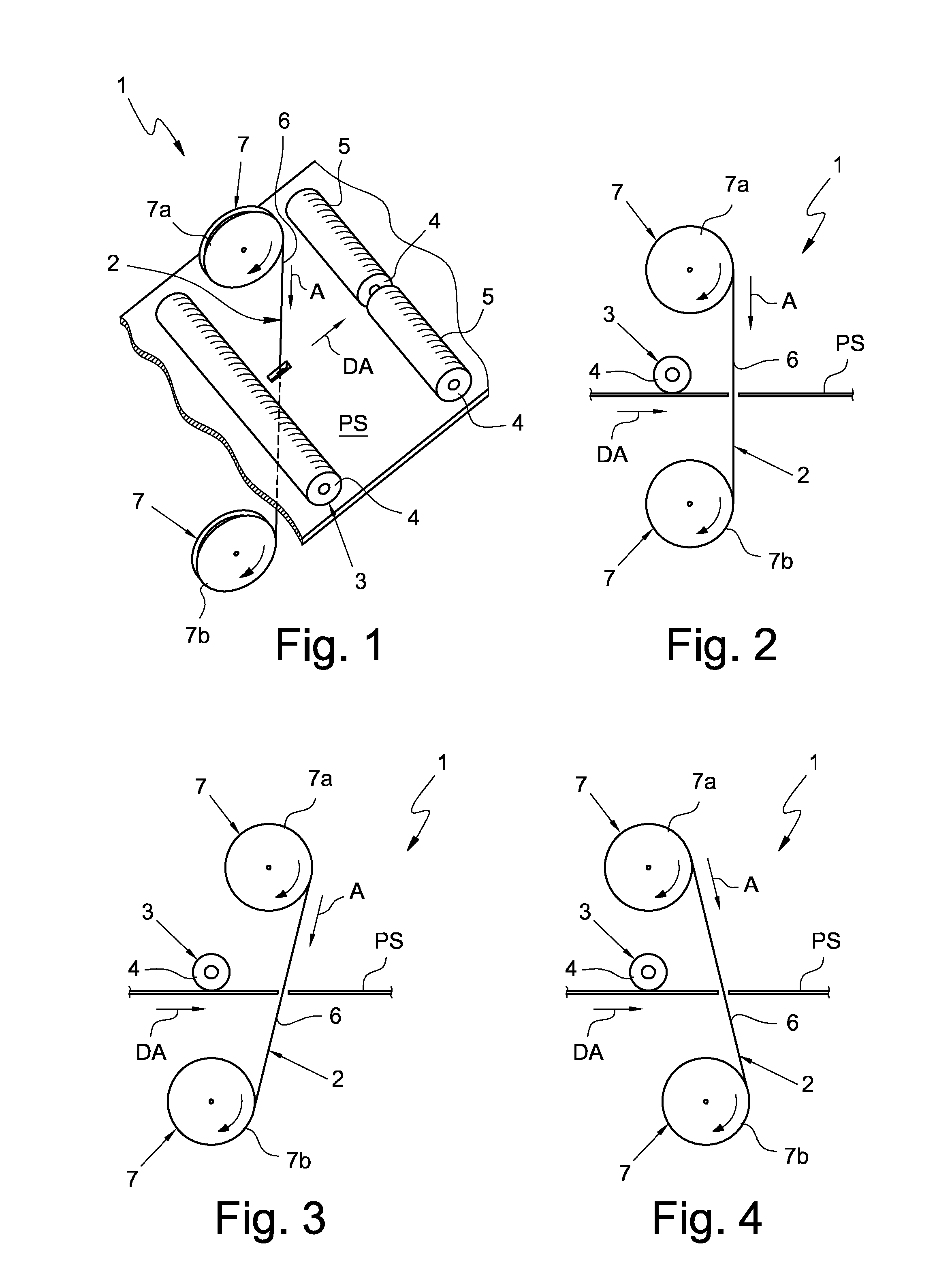

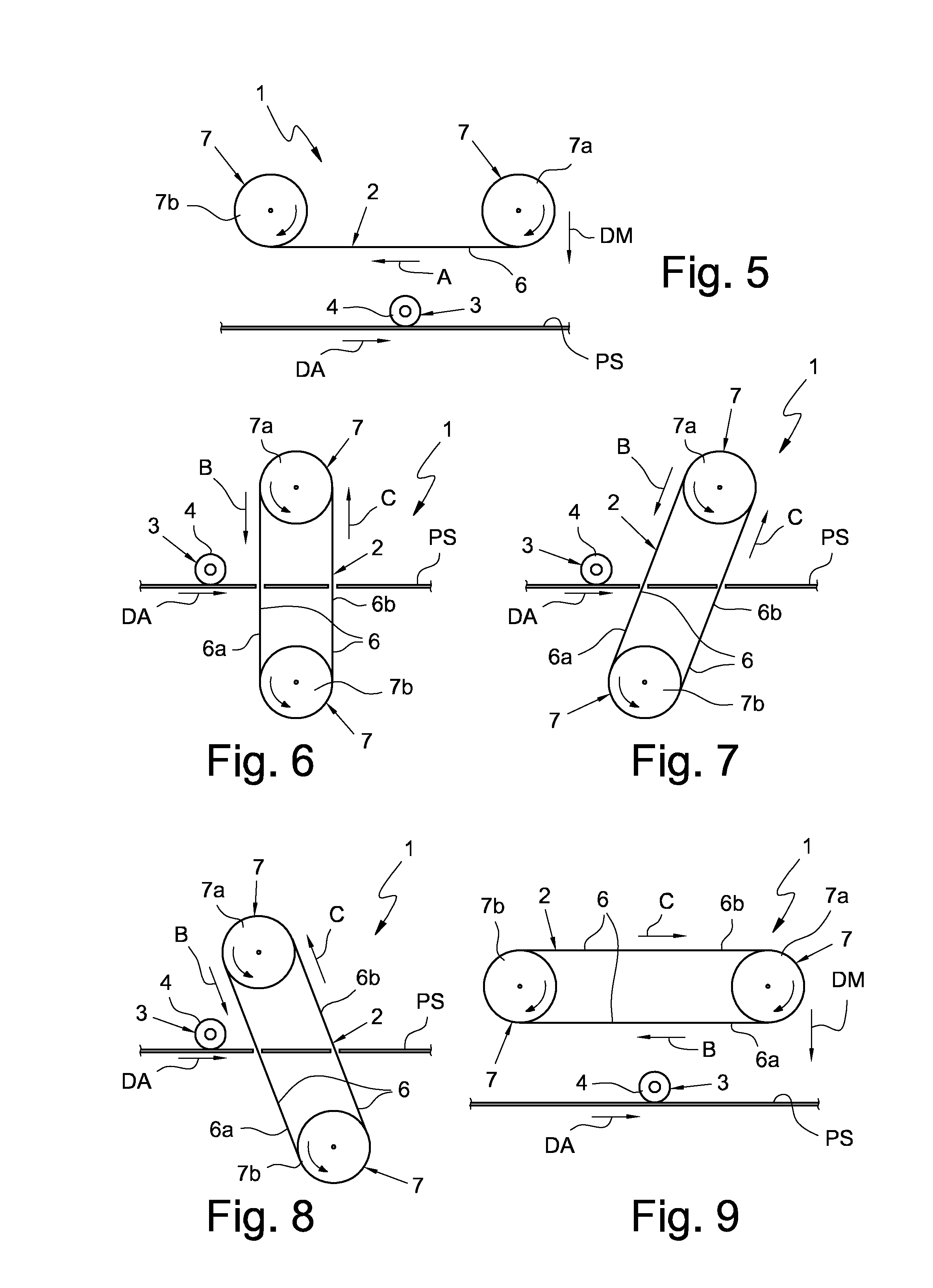

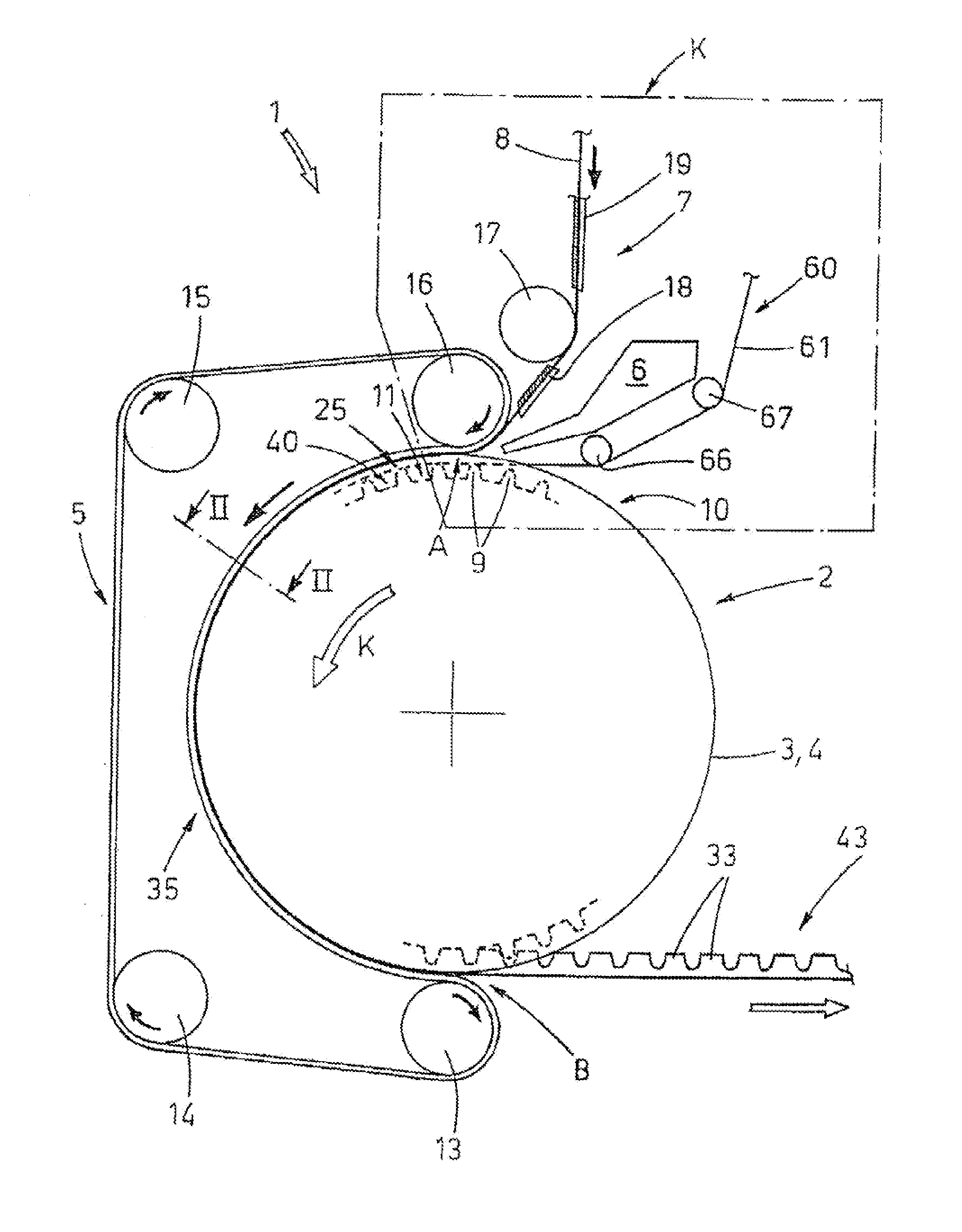

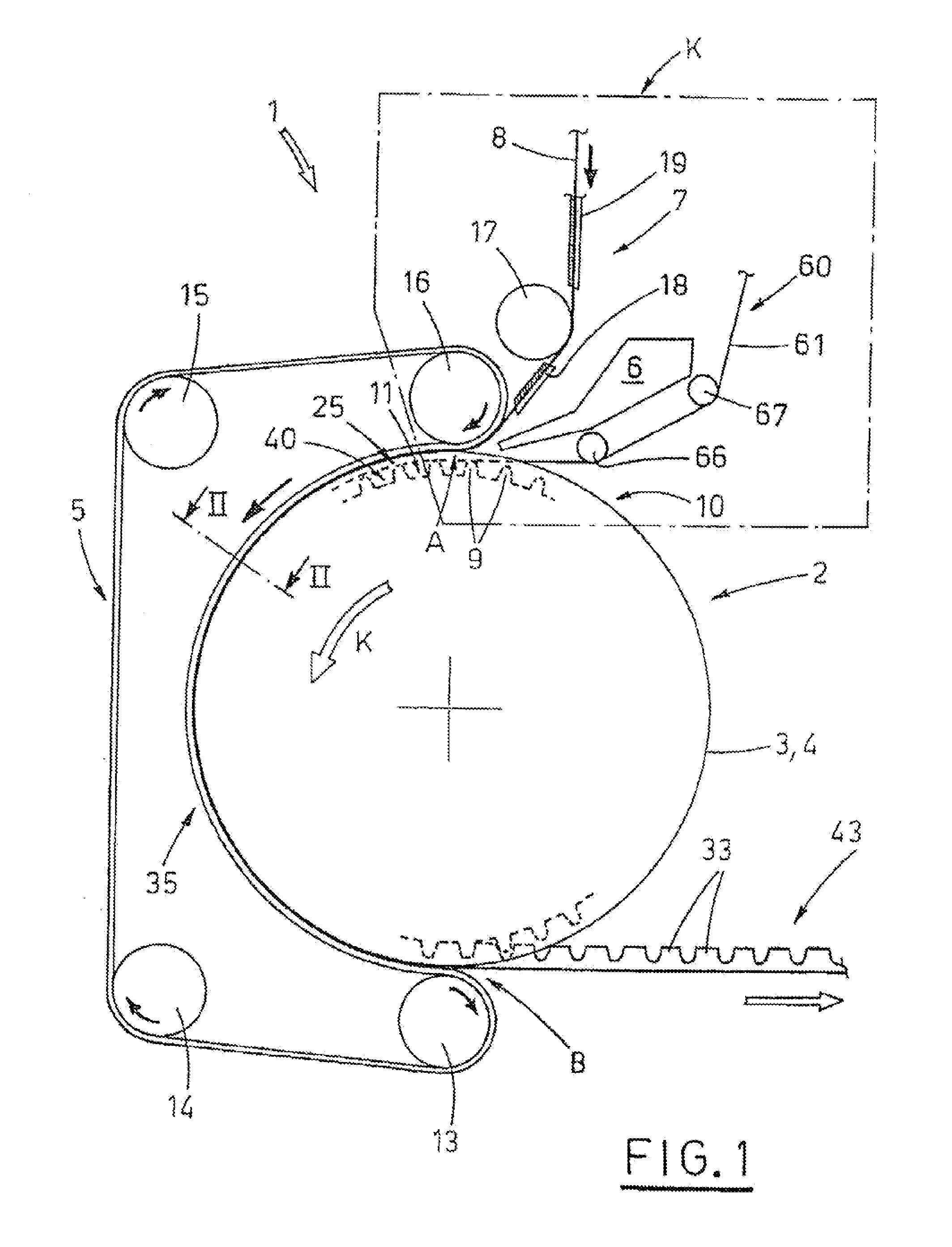

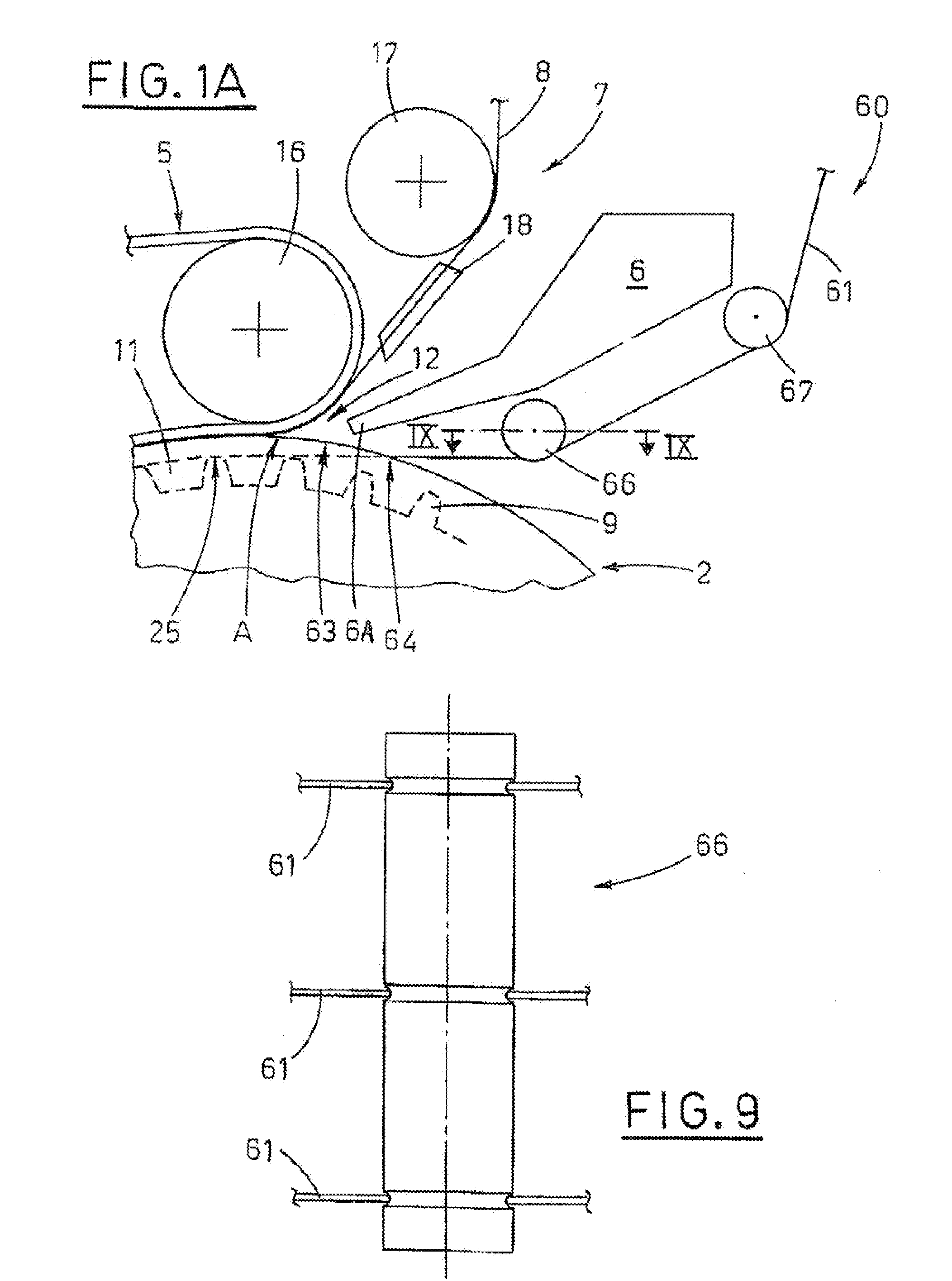

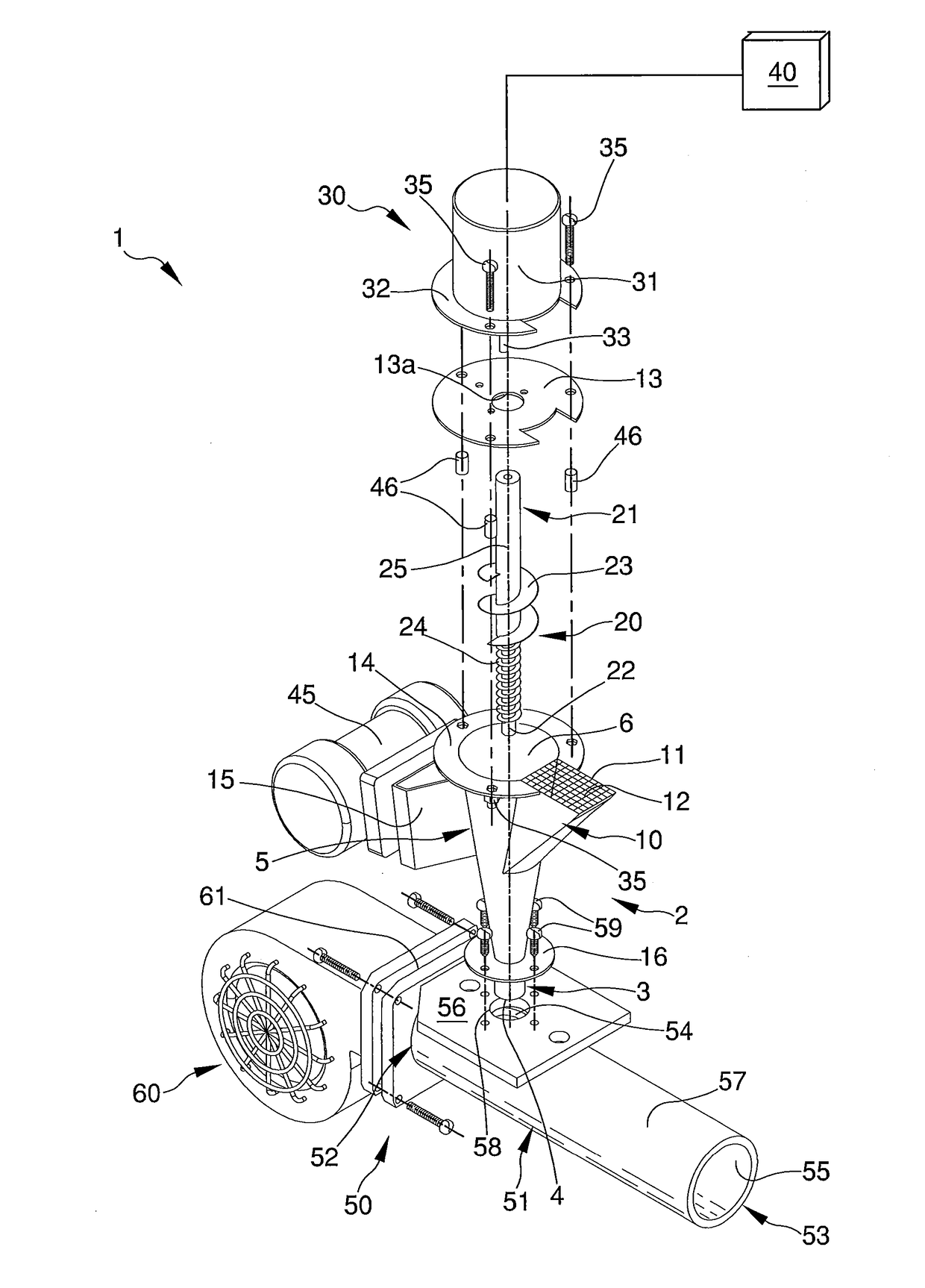

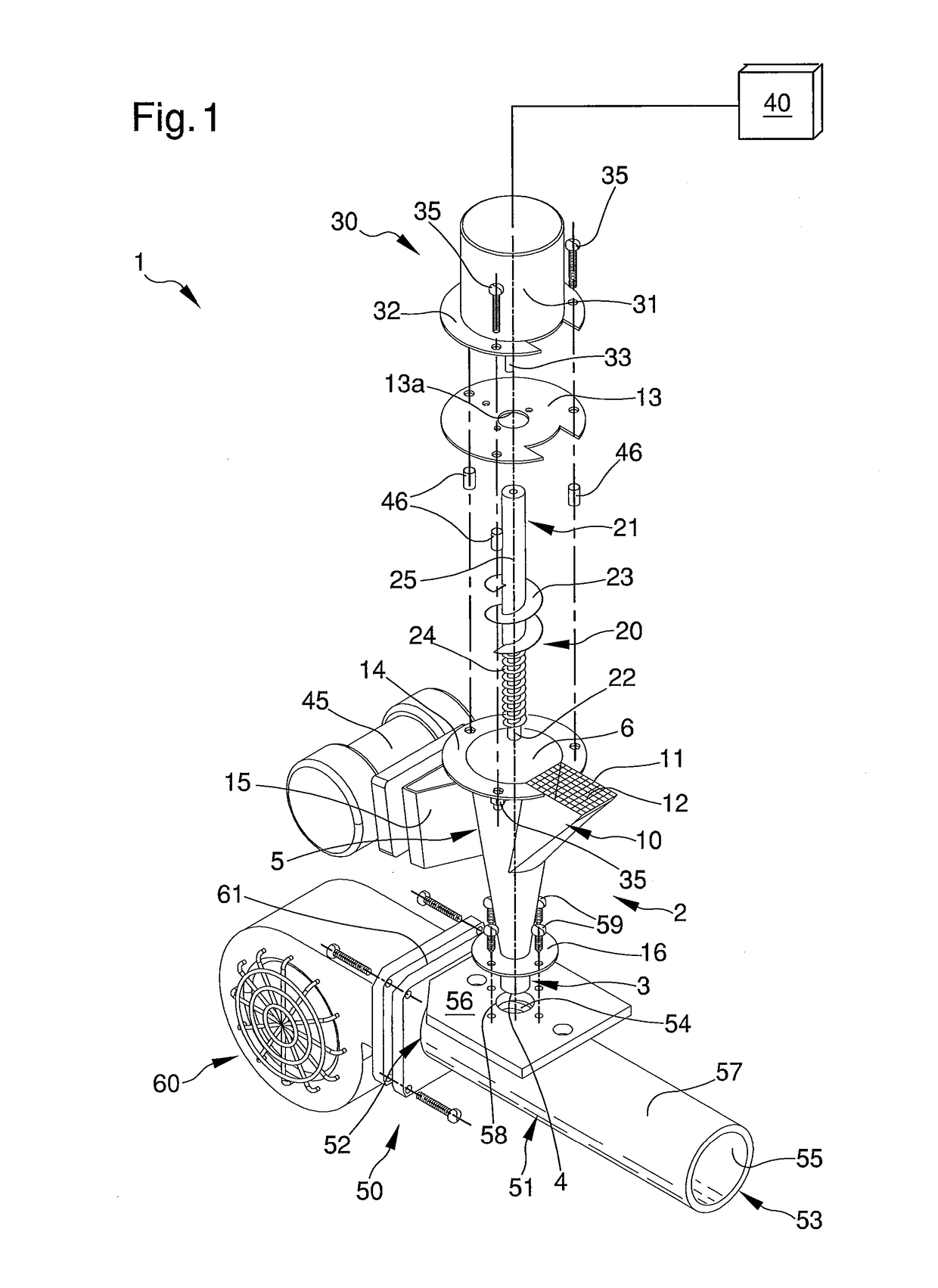

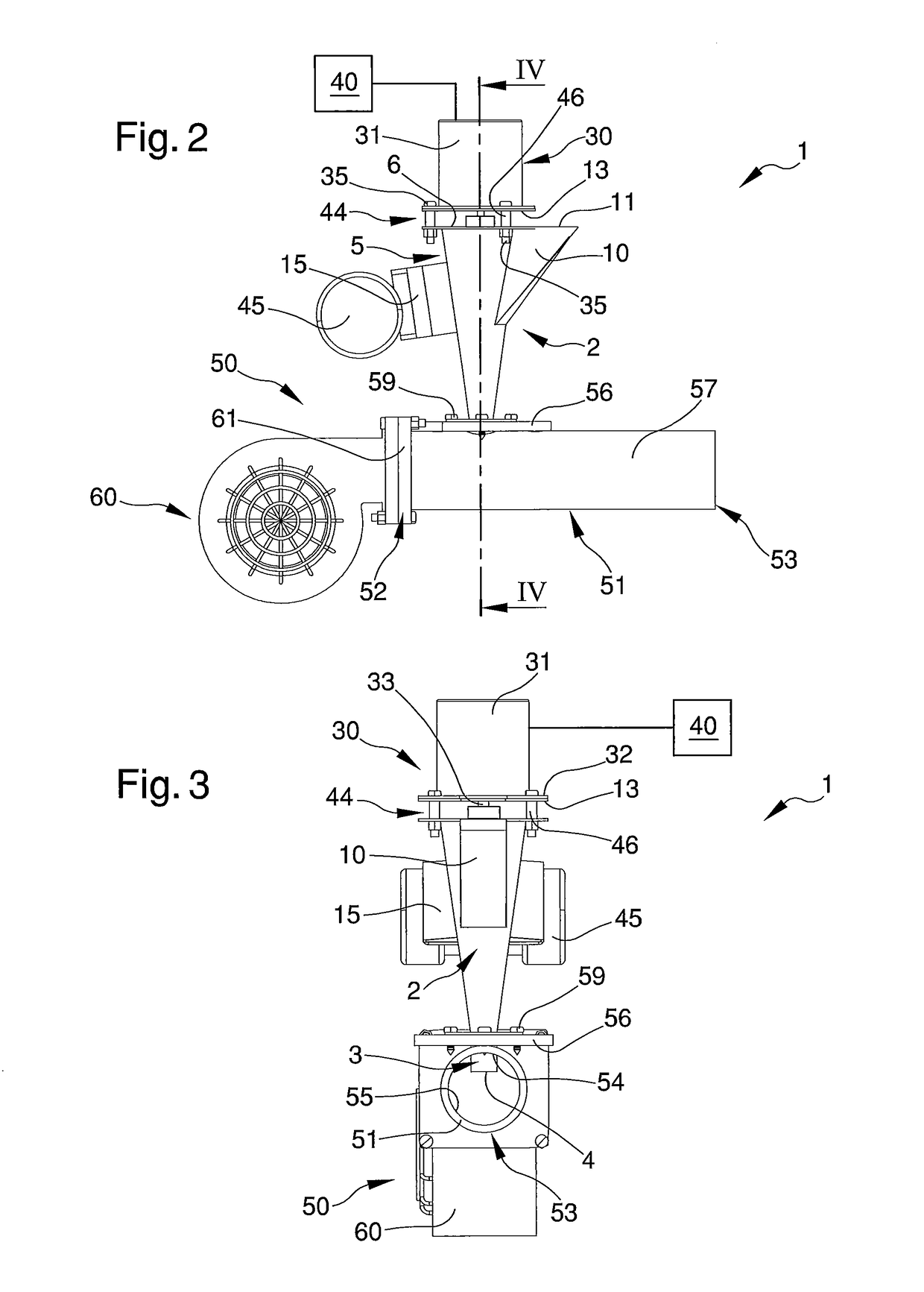

Cogged belt for conveying articles and/or for power transmission, and a method and an apparatus for realising the cogged belt

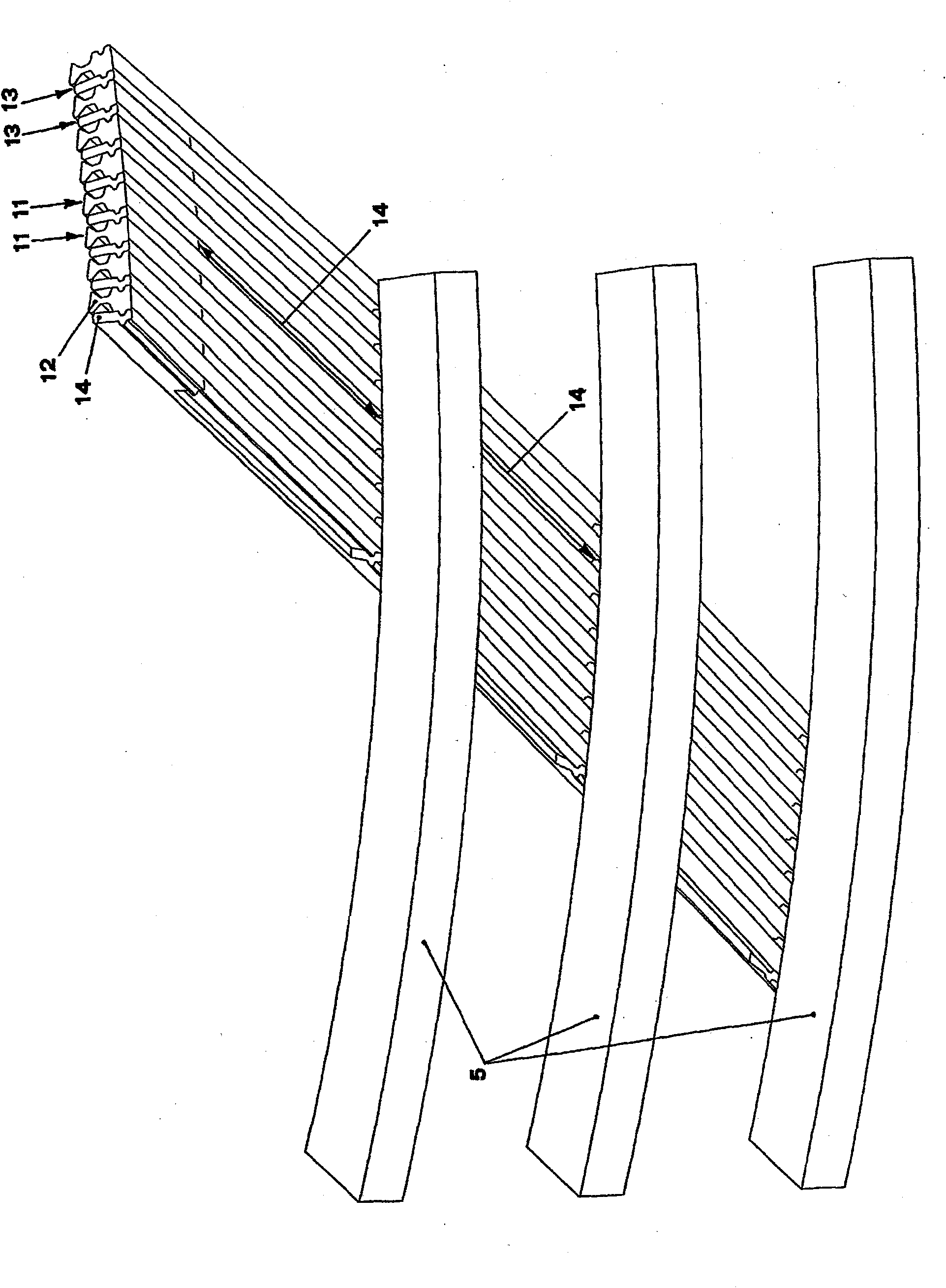

ActiveUS20110241251A1Improve the immunityLow traction resistanceV-beltsTailstocks/centresLongitudinal developmentEngineering

The invention relates to a cogged belt for conveying articles and / or for power transmission, and a method and an apparatus for realisation thereof. The cogged belt (30, 50) comprises: a prefabricated belt (8) comprising a textile or a meshed net; and a covering (26) made of a thermoplastic or heat-hardening material fixed in a single body by fusion to the prefabricated belt (8) and substantially entirely covering a side of the prefabricated belt (8), the covering (26) forming a cogged profile (43). The cogged belt (30, 50) can further comprise at least a cord-shaped reinforcing core (61) at least partially incorporated in the covering (26). The method includes use of a mould (10) which is: mobile, exhibits a longitudinal development and comprises a succession of spaces (11, 11A, 11B) for containment of molten thermoplastic or heat-hardening material, the method comprising stages of: supplying a prefabricated belt (8) which faces the spaces (11, 11A, 11B) and advances at a same velocity as the mobile mould (10), and supplies molten thermoplastic or heat-hardening material into the spaces (11, 11A, 11B) in order to enable formation of a single body (30, 50). An additional stage of the method further includes supplying at least a reinforcing core (61) to be incorporated in the single body (30, 50). The apparatus comprises: a cogged pulley (2) activated by actuator organs; two lateral sides (3, 4) fixed to heads of the pulley (2); a contrast belt (5) facing a circular sector of the pulley (2); a supply device (6) of molten thermoplastic or heat-hardening material; a first station (7) for supplying a prefabricated belt (8), and an additional second station (60) for supplying at least a reinforcing core (61).

Owner:VISION TECH SRL

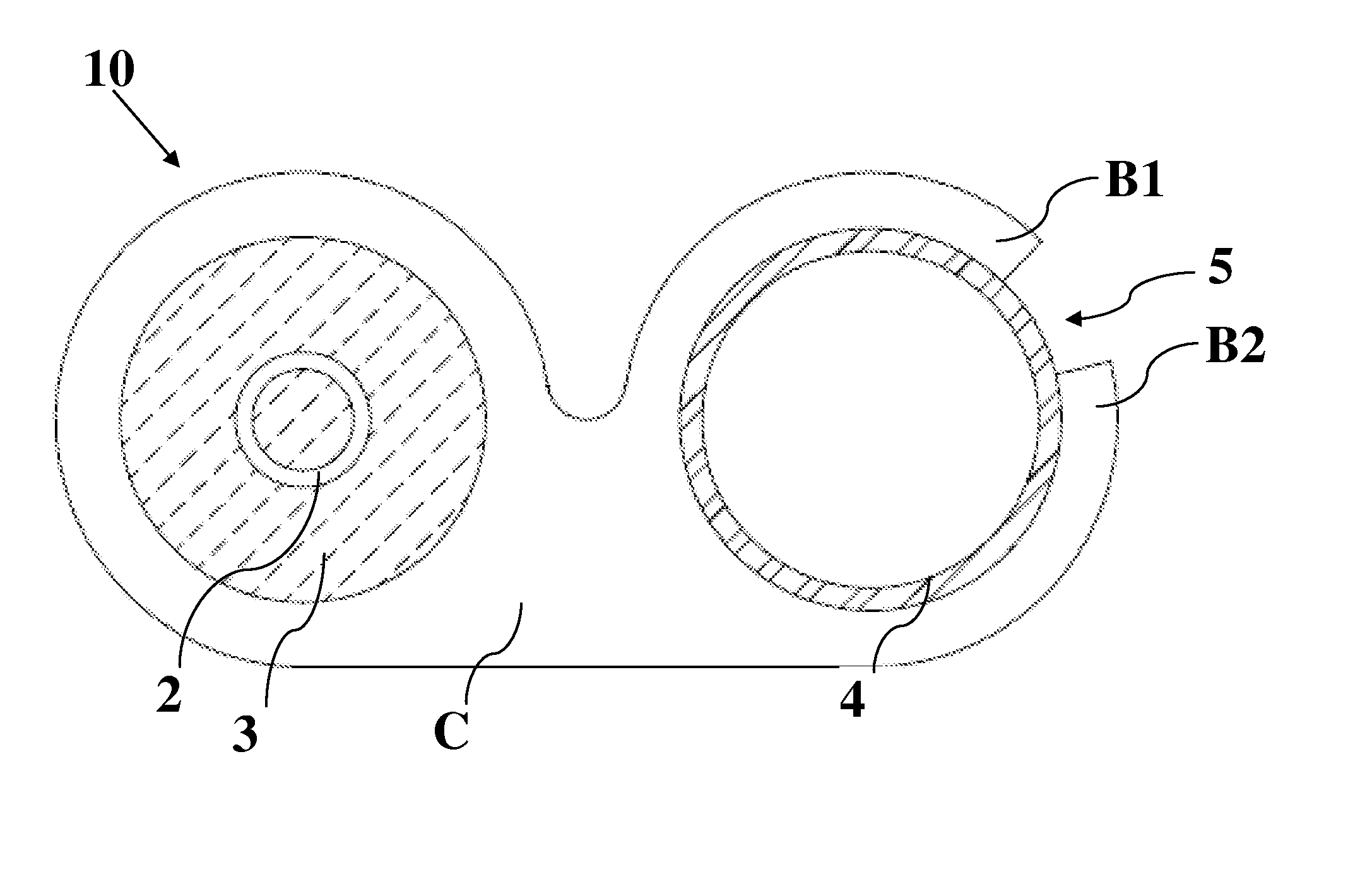

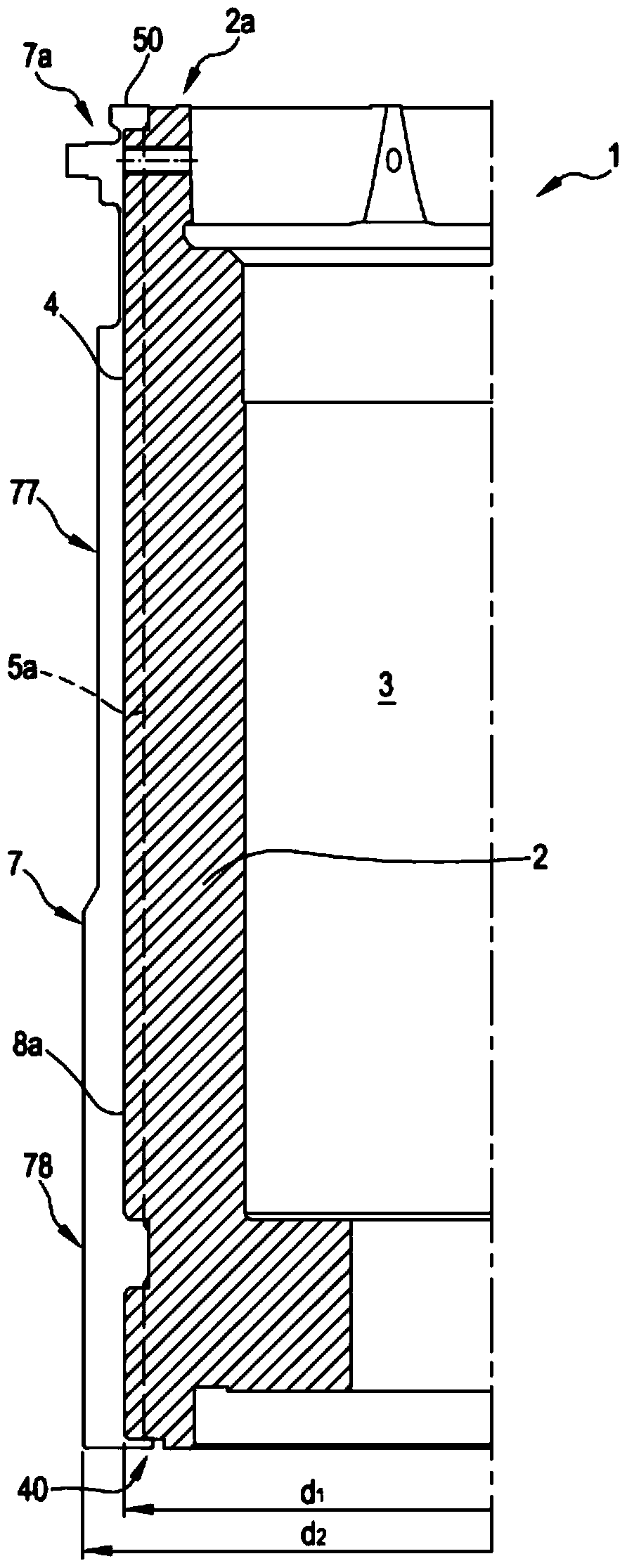

Section bar for a heater and fluid flow heater, in particular for coffee machines

ActiveUS20140233931A1Improve simplicityImprove versatilityEnvelope/housing resistor manufactureImmersion heating arrangementsLongitudinal developmentEngineering

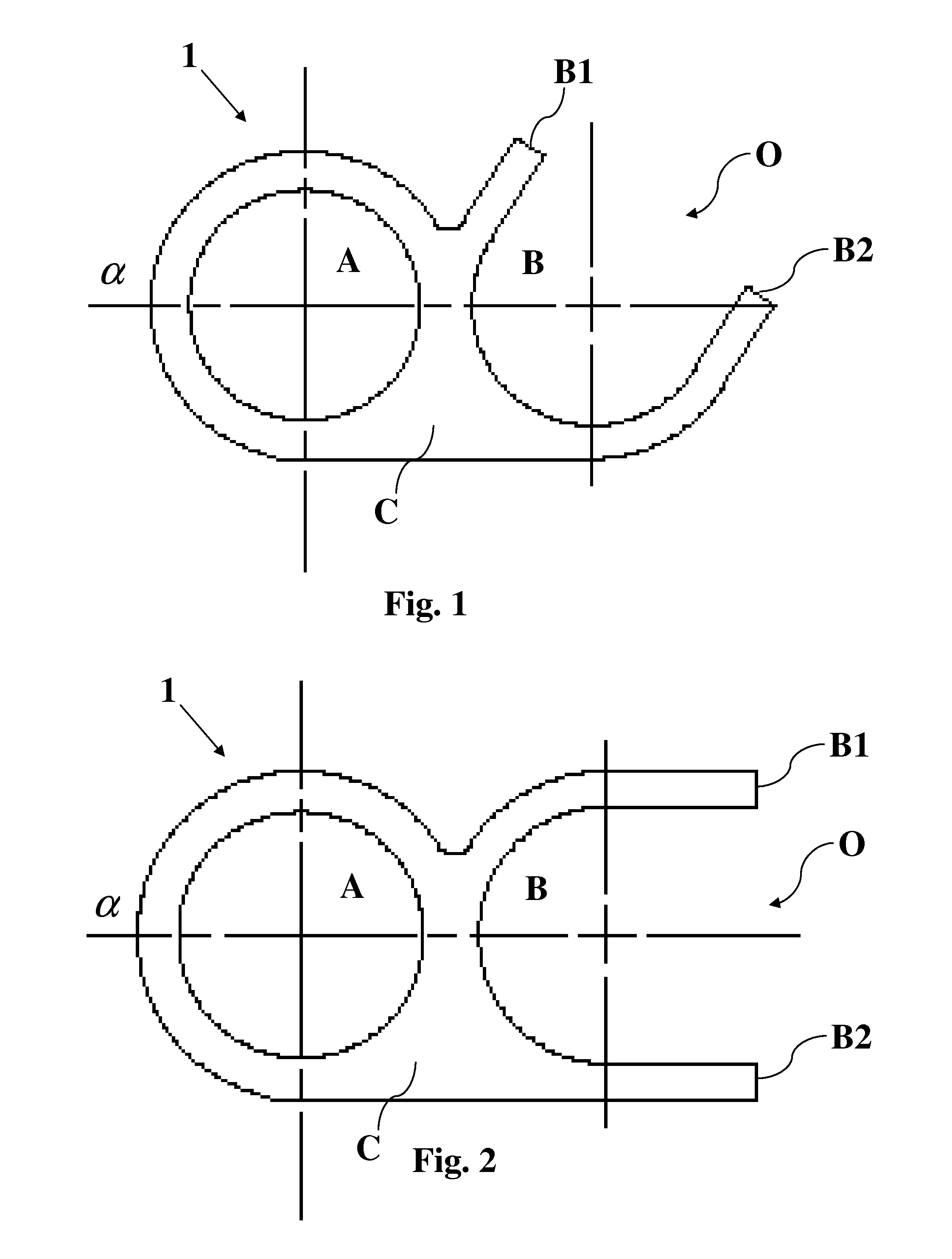

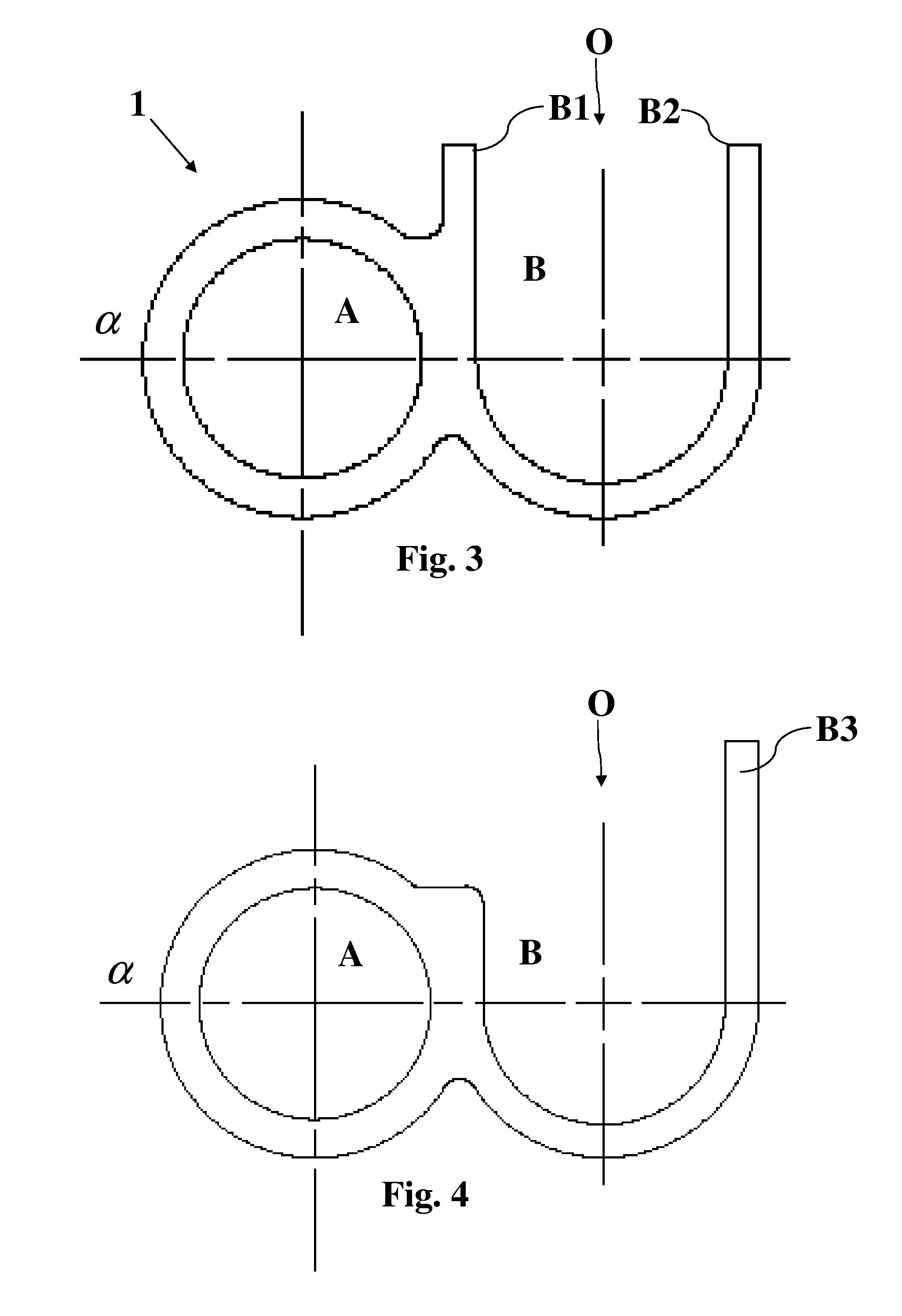

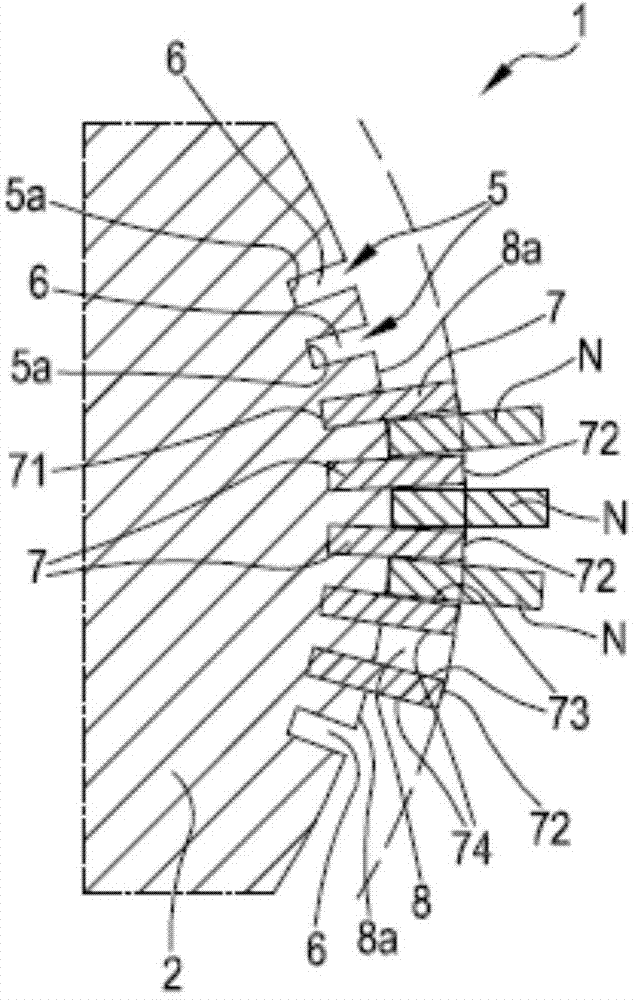

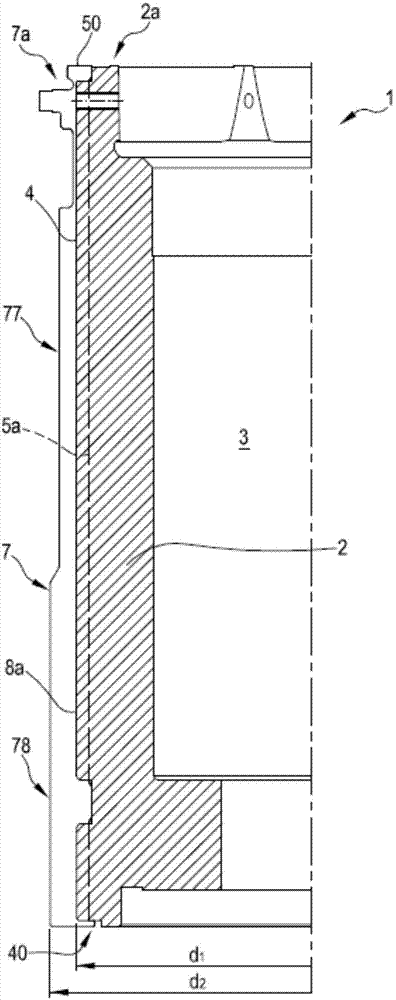

The section bar (1) for a fluid flow heater for coffee machines has a longitudinal development with two opposing ends and a first tubular cavity (A), that is accessible at the opposing ends of the section bar (1), and a second cavity (B) having an opening (O) that extends along the longitudinal development of the section bar (1). A heater (10) having an encased resistor (2, 3) integrated in the first cavity (A) of the section bar (1) and a tubular fluid circulation conduit (4) inserted into the second cavity (B) of the section bar (1) and fixed by means of bending at least one lug (B1, B2, B3) around the tubular fluid circulation conduit (4), so that the opposing ends of the tubular fluid circulation conduit (4) emerge with respect to the opposing ends of the section bar (1).

Owner:I R C A S P A IND RESISTENZE CORAZZATE E AFFINI

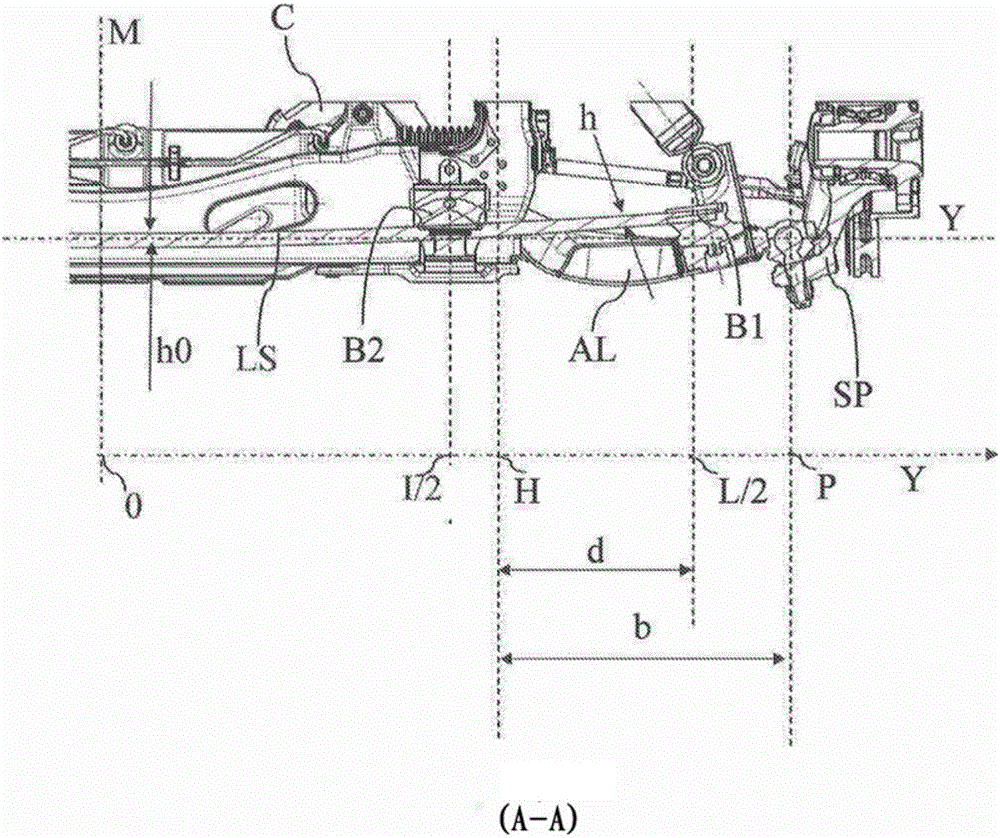

Double wishbone or mcpherson suspension with transverse leaf spring and dimensioning method thereof

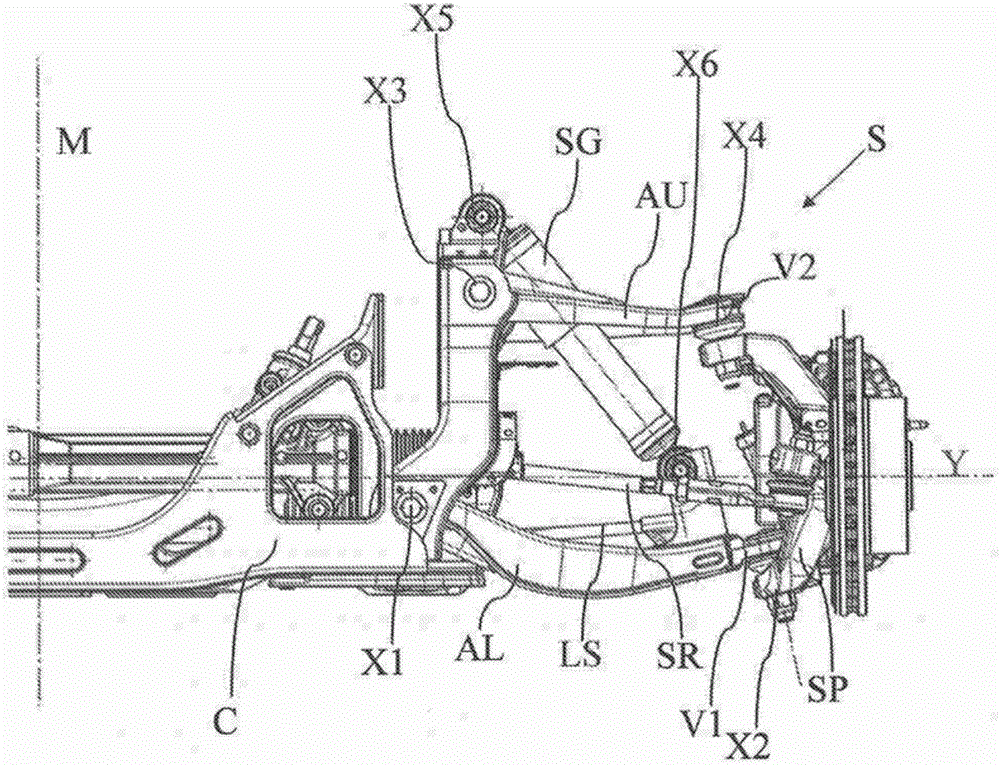

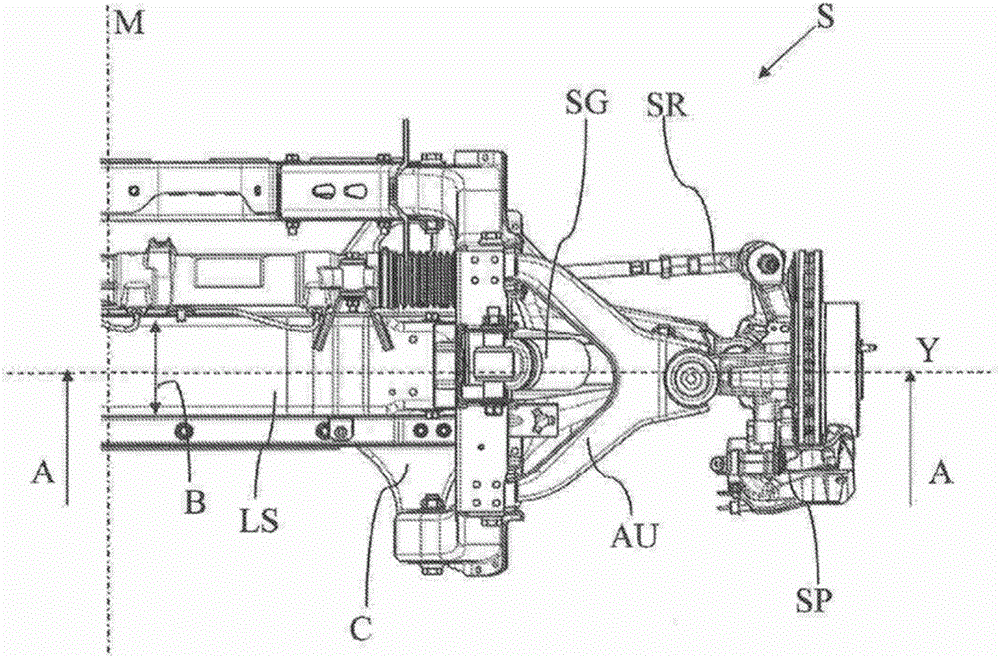

Method for dimensioning a quadrilateral or McPherson suspension (S) with cross leaf spring (LS) defining a longitudinal development (Y), arranged parallel to a symmetrical vehicle axle defined by the suspension (S), having an intermediate point of reference (M), an end point (L / 2) connected to a lower arm (AL) of the suspension and a constraint point (1 / 2), intermediate between the first two, constrained to a fixed part (C), said method comprising a step of defining the following distances measured along said longitudinal development (Y) starting from said intermediate point of reference (M) : - P = distance of the connection (X2) between lower arm (AL) and wheel hub (SP), - L / 2 = distance from said end point (L / 2) of the leaf spring (LS), - H = distance of the hinging between said first part of the lower arm and said fixed part (C), - 1 / 2 = distance of said intermediate constraint point (1 / 2); - a step of defining with d a difference / distance between H and L / 2 and with b a difference / distance between H and P, - a step of defining R = b / (b-d), - a step of defining ks = ksosp * R2 [eq.l], where ks is the stiffness of the leaf spring upon symmetrical vertical loads and ksosp is the stiffness of the suspension upon symmetrical vertical loads, - a step of defining a thickness h of said leaf spring (LS) according to the following equations: - h = hO between said reference intermediate point (M) and 1 / 2, - h(Y) = 2* ( (Y- (costi) ) / (cost2) )0-5 between 1 / 2 and L / 2 [eq. 2 ], where Y is an independent variable, costi = 1015.00942 and cost2 = -8.51224 and wherein the material of said leaf spring has a Young module comprised between 195 GPa and 210 GPa.

Owner:IVECO SPA

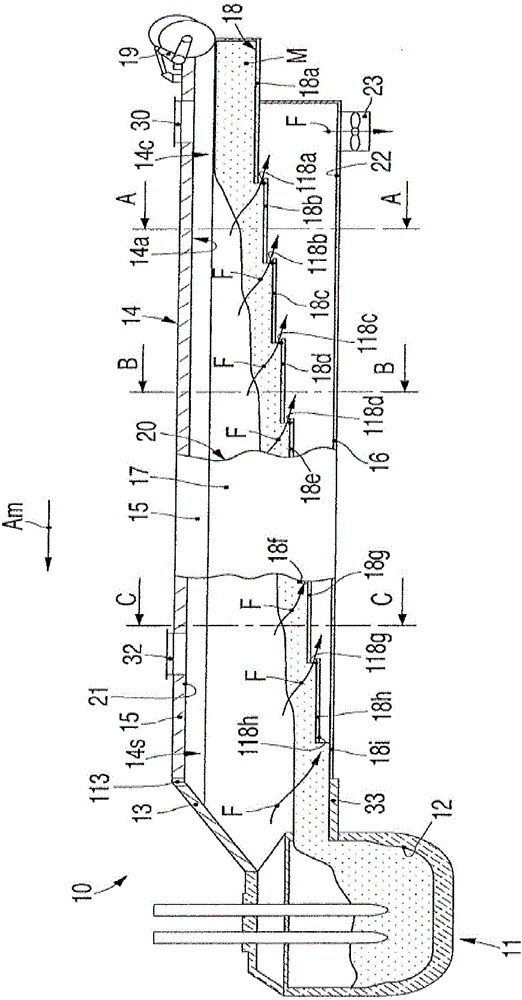

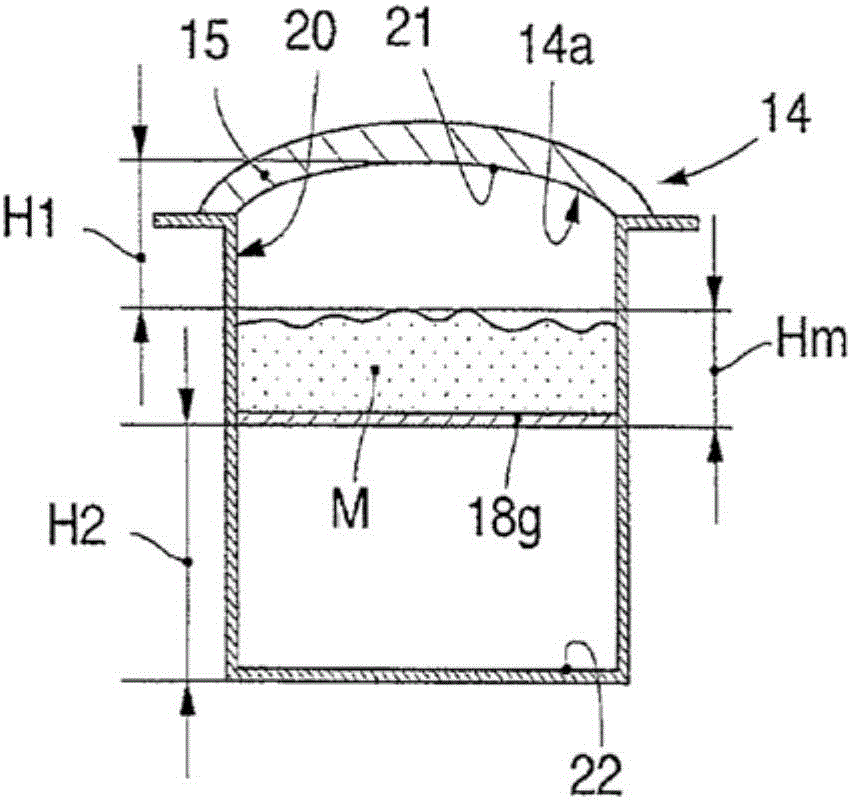

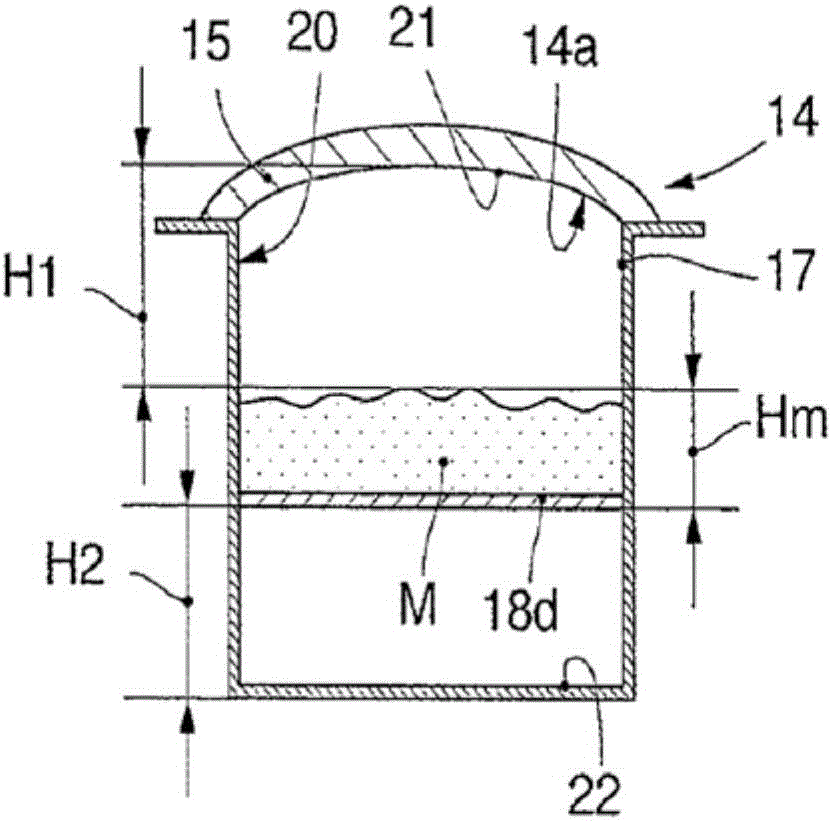

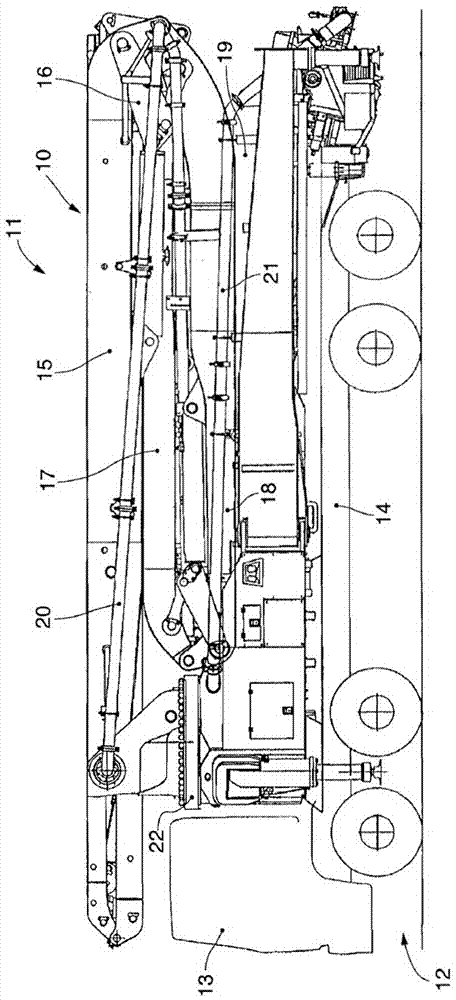

Apparatus to move and preheat metal material

ActiveCN106460076AReduce volumeImprove heat exchange conditionsMuffle furnacesRetort furnacesLongitudinal developmentMechanical engineering

An apparatus (10) to move and preheat metal material (M) to be fed to a container (12) comprises a containing structure (14), having an internal compartment (14a) and provided with a support wall (18), a conveyor (20) for the material (M), a fume transit section (21) whose volume reduces as it is distanced from said container (12) along the longitudinal development of said containing structure (14), and a collector (22) for hot fumes (F) whose volume increases in a manner correlated to said reduction in the fume transit section (21). The collector (22) is located below said conveyor (20) inside the internal compartment (14a) essentially along the entire longitudinal development of said containing structure (14). Moreover, one or more through apertures (1 18a- 1 18h) are made in said support wall (18) to put the conveyor (20) and the collector (22) into fluidic connection.

Owner:DANIELI & C OFF MEC SPA

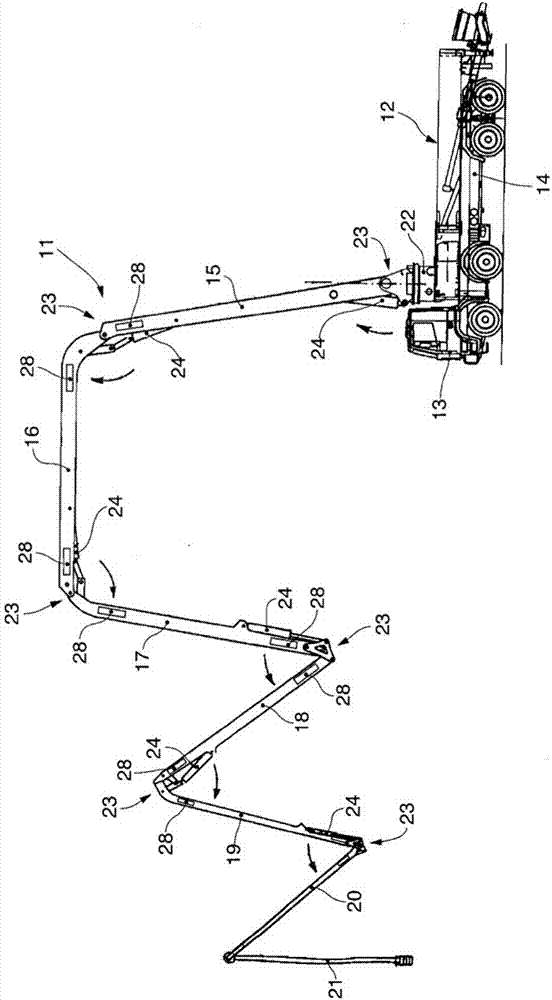

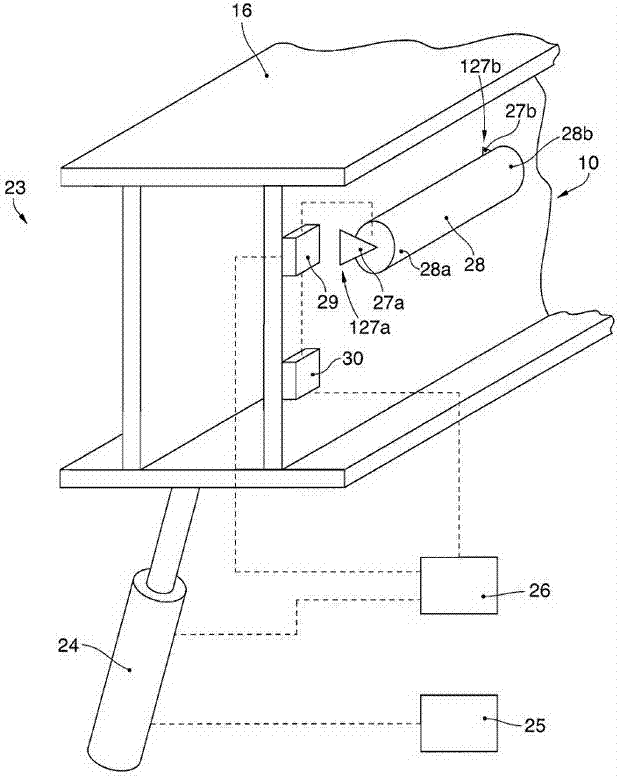

Apparatus and corresponding method to control the vibrations of an articulated arm

InactiveCN103807351ANon-rotating vibration suppressionBuilding material handlingVertical planeEngineering

Apparatus to actively control the vibrations of an articulated arm(11), for example for pumping concrete, consisting of a plurality of segments(15-20) pivoted to each other in correspondence to their own pivoting ends(23) and of drive actuators(24) each cooperating with two of said segments in order to extend and / or fold back the articulated arm. Each of the drive actuators(24) is connected to a drive circuit in order to act on a vertical plane substantially defined by the two segments of the articulated arm to which it is associated. Said apparatus also comprises at least one auxiliary actuator associated to at least one of said segments of the articulated arm in proximity to at least one of the pivoting ends(23), said auxiliary actuator being provided with at least two operative ends, each of said operative ends being connected to a corresponding support, said supports being provided on said segment distanced to each other along the longitudinal development of said corresponding segment and defining, on the segment(15-20), respective application zones, said auxiliary actuator(28) being selectively activable to induce, in said application zones, compensation forces acting on a damping plane which is different from said vertical plane.

Owner:CIFA

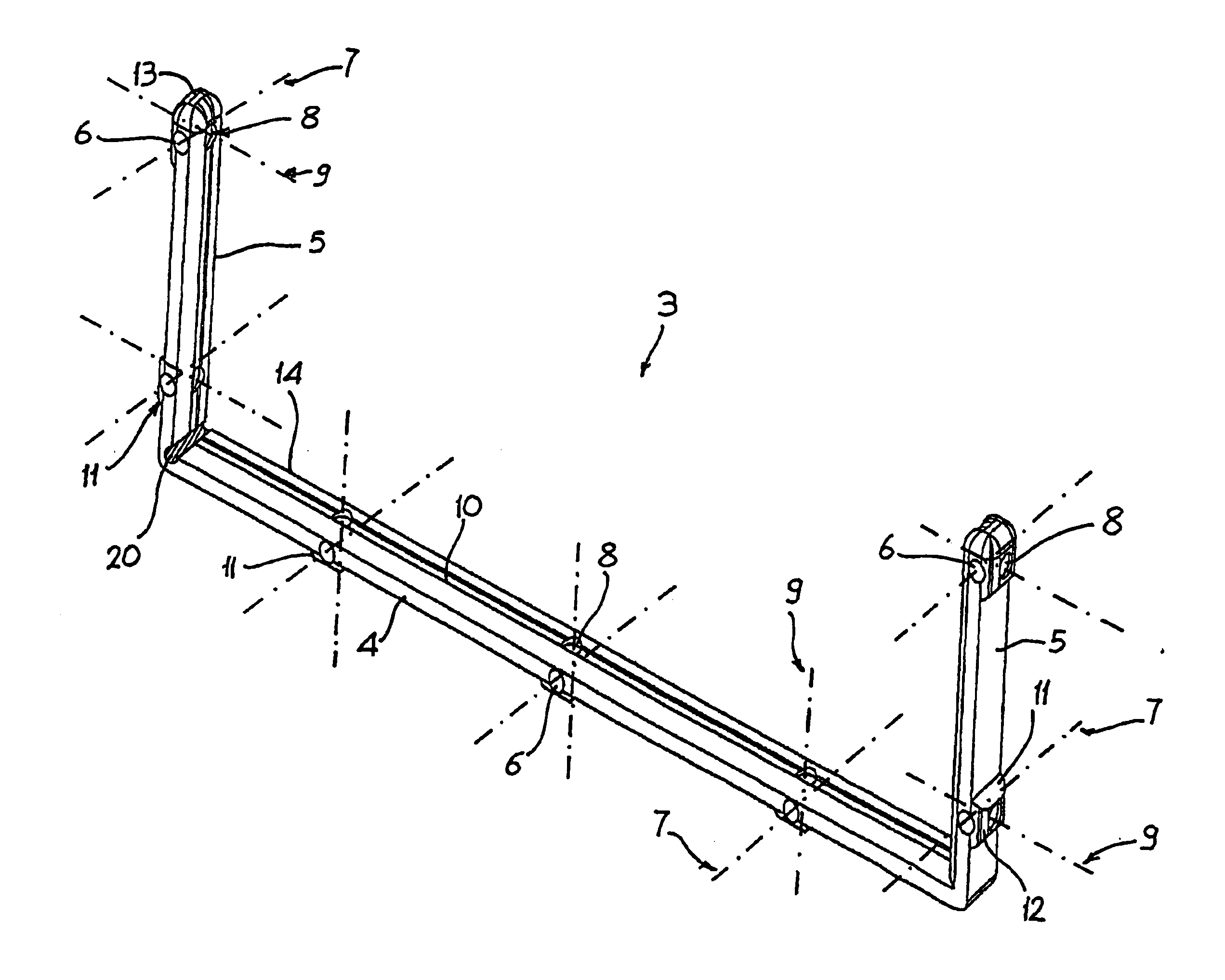

Duct for cables

InactiveUS6870102B2Improve mechanical propertiesImprove functionalityPipe supportsSubstation/switching arrangement detailsCouplingLongitudinal development

A duct for electrical cables comprises a plurality of filiform elements arranged substantially parallel to one another according to the longitudinal development of the duct. The duct of the invention includes, for at least a portion of its length, a plurality of structural modules, which are arranged in a transverse direction with respect to said filiform elements and are set at a distance from one another in succession according to the longitudinal development of the duct. The supporting modules have a basically U-shaped body that includes a central wall from which there project, on opposites sides with respect to one another, two side walls that are set substantially parallel to one another. On said shaped body coupling means, designed to enable connection with said filiform elements, are arranged.

Owner:ABB SPA

Method and device for controlling a car, in particular a sport car

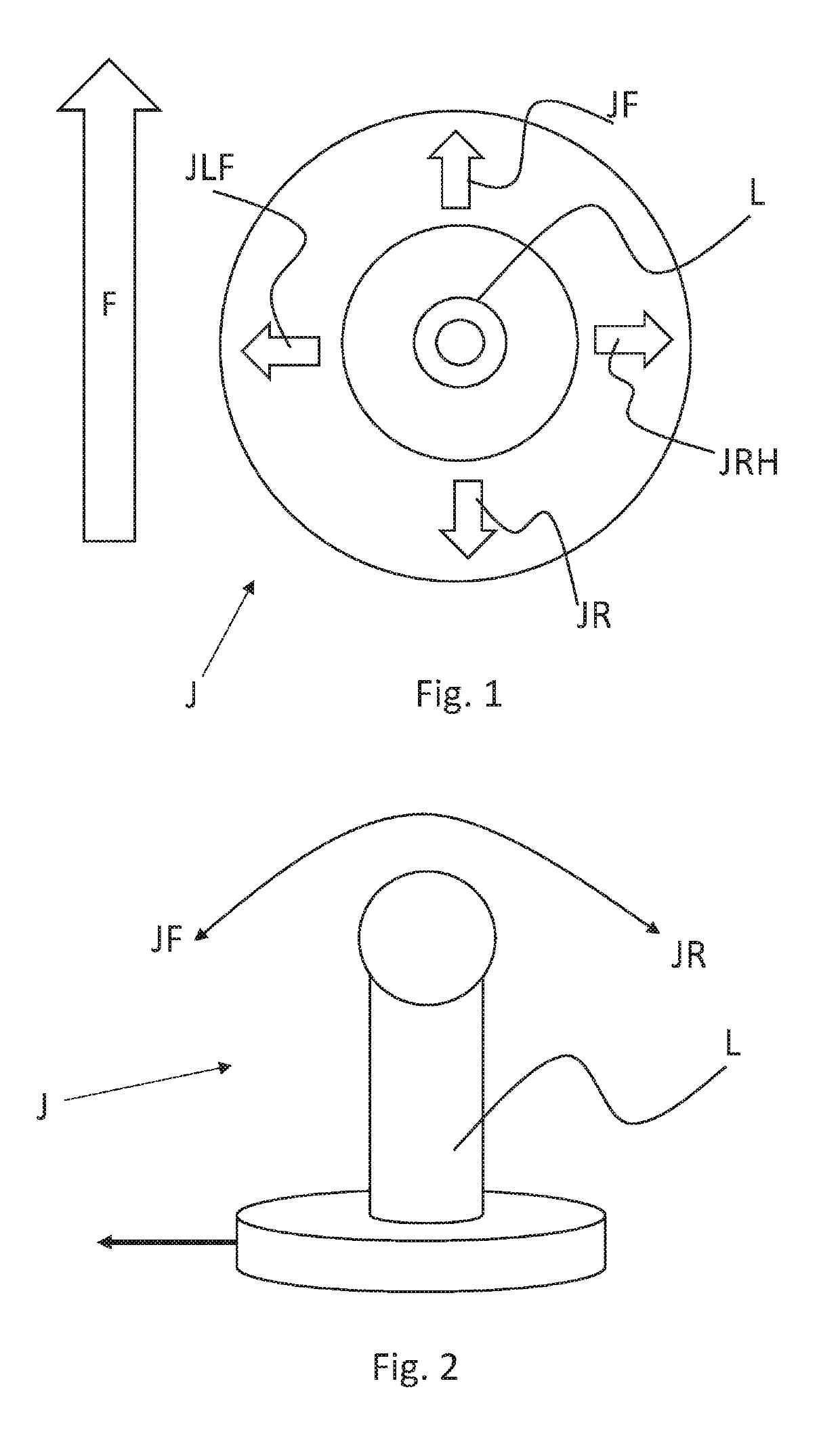

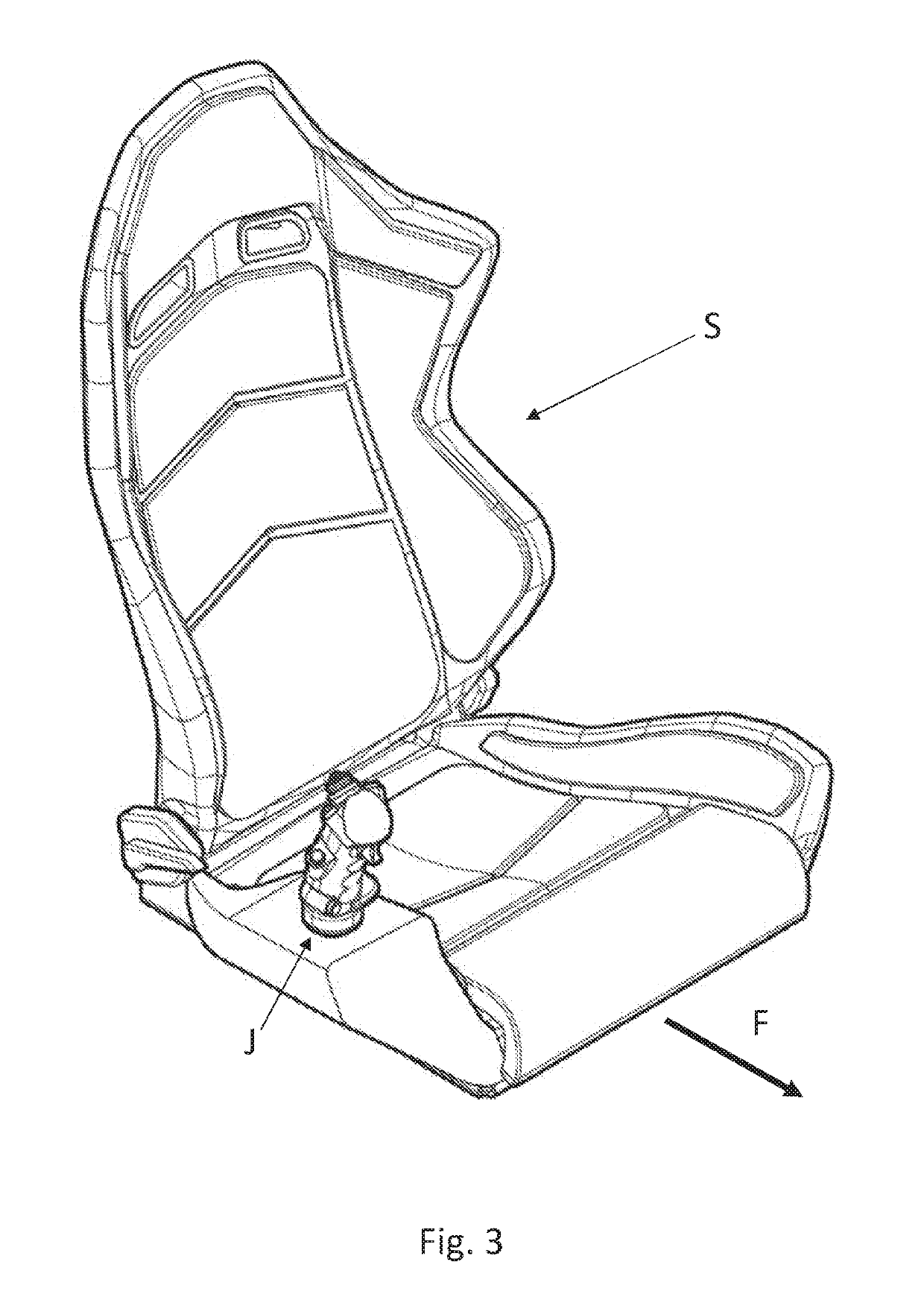

ActiveUS20190329651A1Simple and intuitiveEasy to driveVehicle sub-unit featuresHand leversJoystickLongitudinal development

Method for controlling a car, in particular a sports car, provided with a relative power train, relative braking devices and relative steering means, the method being based on a joystick comprising a lever, arranged in the car to identify a forward tilt and a backward tilt parallel to a longitudinal development of the car for interacting with said power train and with said braking devices, and two side tilts to the left and to the right for interacting with said steering means so as to determine a trajectory of the car, wherein the method, according to a first operating condition, comprises a first step of respectively associating said forward tilt and said backward tilt with a proportional forward and backward acceleration of the car.

Owner:SPAN FERRARI SPA

Spring device for disc brake, pad spring and disc brake assembly

A spring device for a disc brake, a pad and spring assembly for a disc brake, a brake caliper, and a disc brake is described. The spring device may have a spring body having prevalently longitudinal development, with at least one coupling portion, to couple in a snapping manner the spring device to a portion of an associable brake caliper in a removable manner. The spring pad assembly may have at least one brake pad having at least one ramp surface, inclined with respect to the radial direction and to the tangential direction, which forms an abutment reference for the at least one thrust surface of the spring device. The at least one ramp surface of the support plate puts in traction the spring device.

Owner:FRENI BREMBO SPA

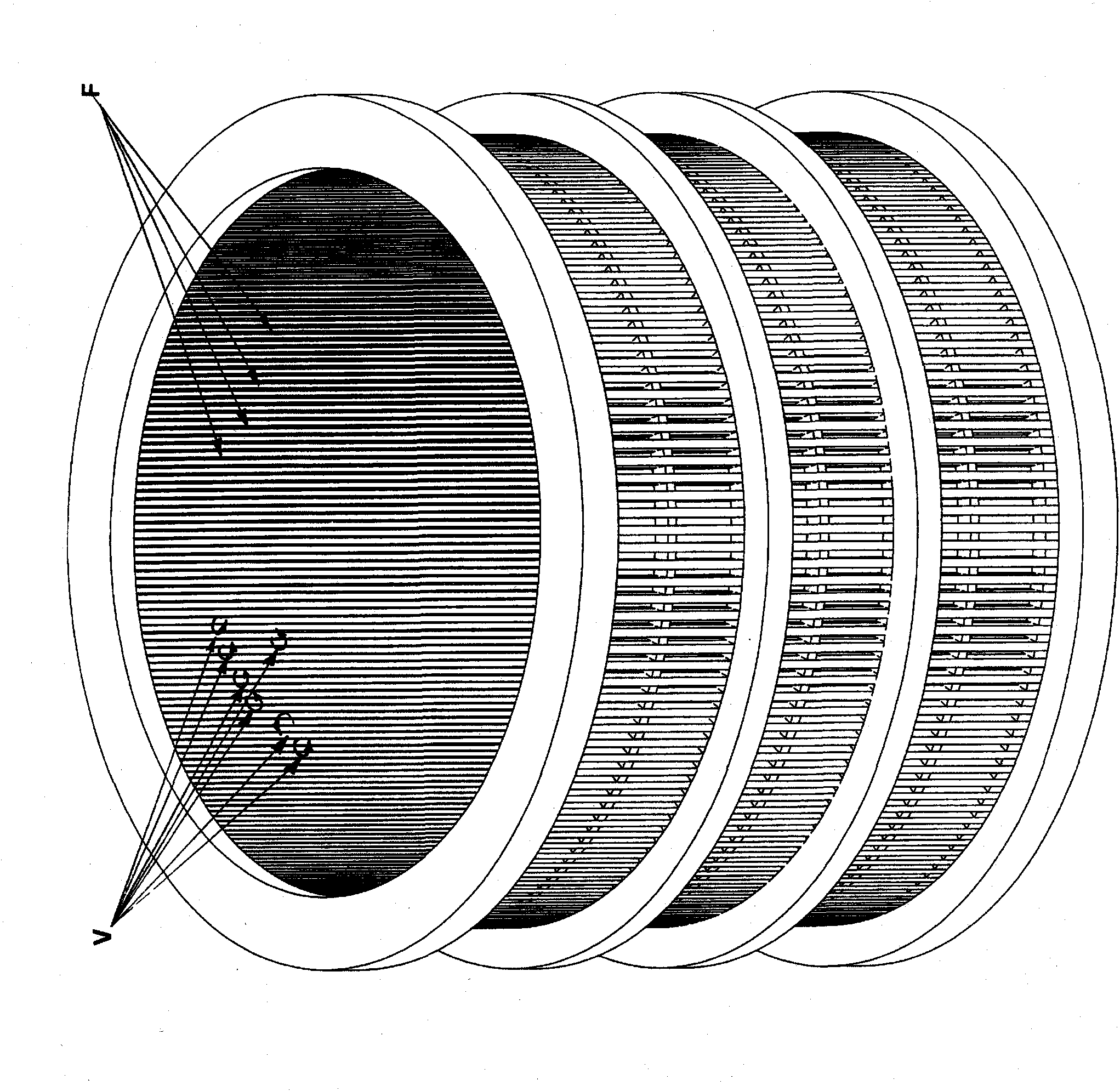

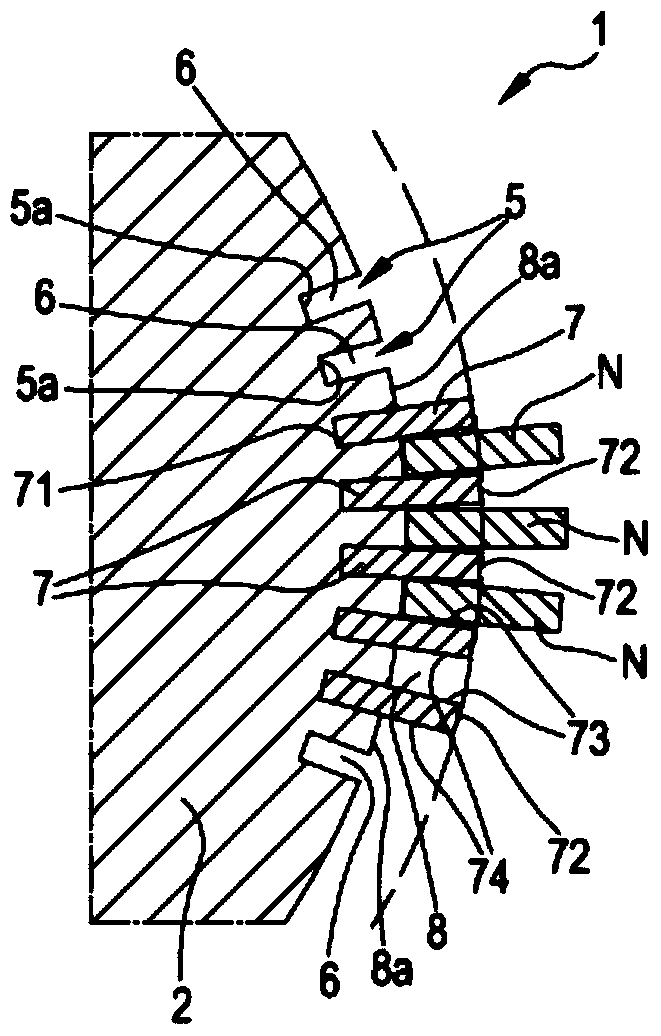

Needle cylinder for circular knitting machine

A needle cylinder (1) for a circular knitting machine for knitwear or hosiery, comprising a cylinder body (2) provided with an external surface (4) and with a plurality of vertical slots (5) made in the external surface, wherein the plurality of slots realize a corresponding plurality of seatings (6). The cylinder comprises a plurality of vertical beams, or walls (7), each wall having a prevalent longitudinal development and being positionable in a respective seating (6). Each pair of adjacent walls (7) defines a needle channel (8), corresponding to a vertical space comprised between the adjacent walls; the needle channel is configured for movably housing a respective needle. The body (2) is further provided with a first annular niche (10) extending in circular fashion about the external surface (4). At least one of the walls exhibits at least a respective first protuberance (11) configured to insert in a respective angular portion of the first niche (10).

Owner:SANTONI SPA

Improved filtering drum for fibre suspensions in water

The invention concerns a filtering drum (1) for fibre suspensions in water, comprising a plurality of shaped bars (2; 11, 13) with mainly longitudinal development, arranged side by side in order to define a tubular structure having substantially circular cross section, with the inner lateral surface (4) covered by a plurality of slits (3) that create a filtering surface, two or more annular elements (15) coaxial with one another and spaced according to the longitudinal axis (X) defined by the tubular structure, coupled through contact outside the shaped bars (2; 11, 13), wherein the shaped bars (2; 11, 13) are arranged according to a helical pattern.

Owner:COMER SPA

Catamaran boat

ActiveCN107107990AEasy to operateLow costTowing/pushing equipmentHulls from prefabricated subunitsCouplingLongitudinal development

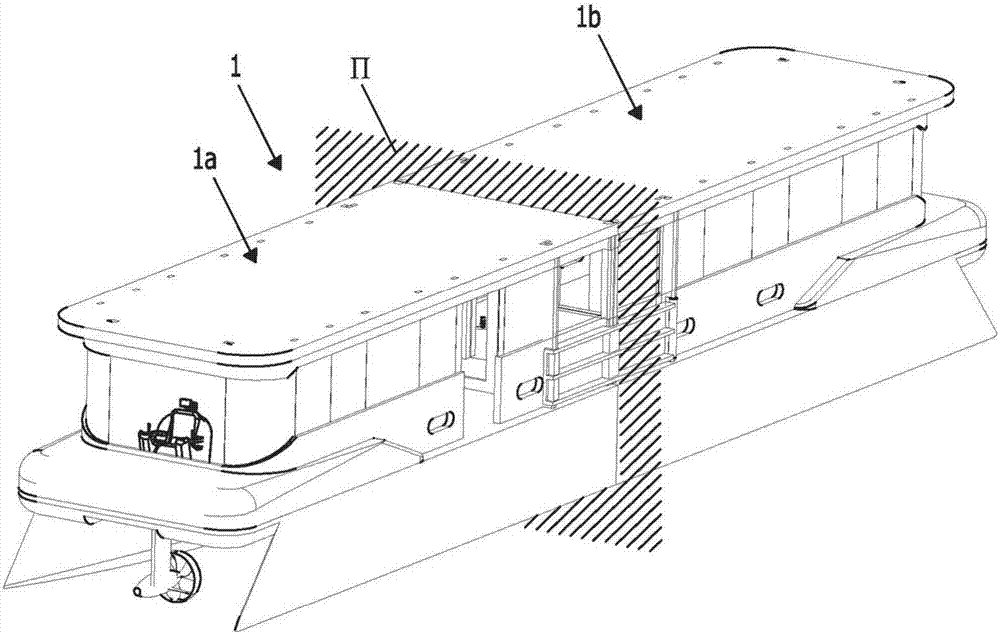

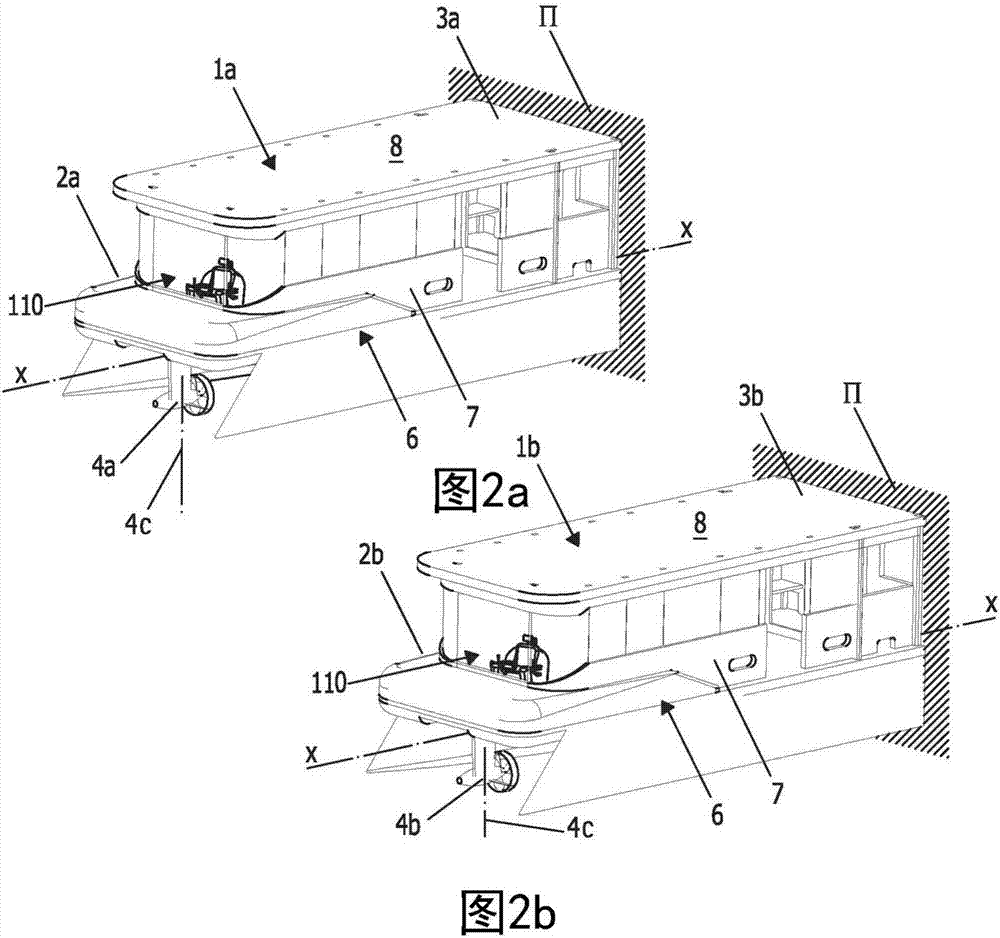

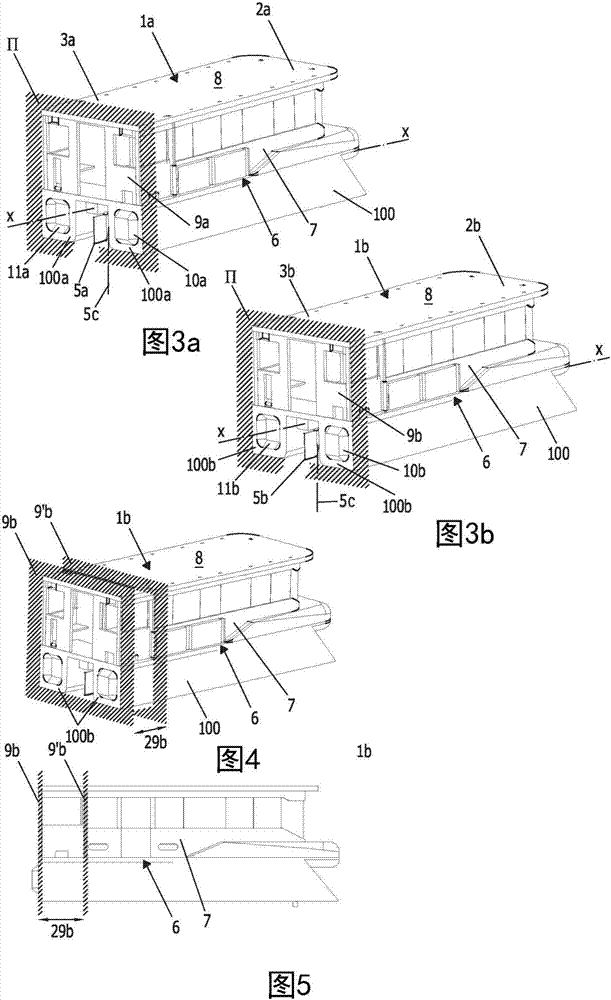

The invention relates to the nautical sector, and concerns in particular a catamaran boat (1) comprising: a first catamaran craft (1a) functioning independently, having a prevailing direction of longitudinal development along the median axis (x) and comprising a bow (2a), a stern (3a), motor means (4a) and directional means (5a); a second catamaran craft (1b) functioning independently, having a prevailing direction of longitudinal development along the median axis (x) and comprising a bow (2b), a stern (3b), motor means (4b) and directional means (5b), where said first catamaran craft (1a) and said second catamaran craft (1b) each comprise joining means for their mutual stable coupling, obtained matching the relative sterns (3a, 3b), on a transverse junction plane (pi), to carry out said catamaran boat (1) able to function as a single unit.

Owner:J 斯卡努 +1

Device for supplying micronized medical salt

ActiveUS9629968B2Easy to moveLarge diameterRespiratorsLiquid surface applicatorsControl mannerEngineering

The device (1) for supplying micronized medical salt comprises a container (2) for medical salt, having a vertical longitudinal development and a lower end portion (3) provided with a mouth of release (4) of the medical salt, a screw (20) inserted into the container and having an upper end (21) and a lower end (22) which is free, rotation members (30) of the screw mechanically connected thereto for rotating it with respect to the container, where the screw advances the medical salt downward so that the medical salt is released in a controlled manner from the mouth of release (4), the device further comprising a dispenser (50) which comprises a supply duct (51) and a ventilation member (60) which generates an air flow within the supply duct, where the mouth of release is in communication with the supply duct so as to release the medical salt directly in the air flow.

Owner:AEROTECHMED SA

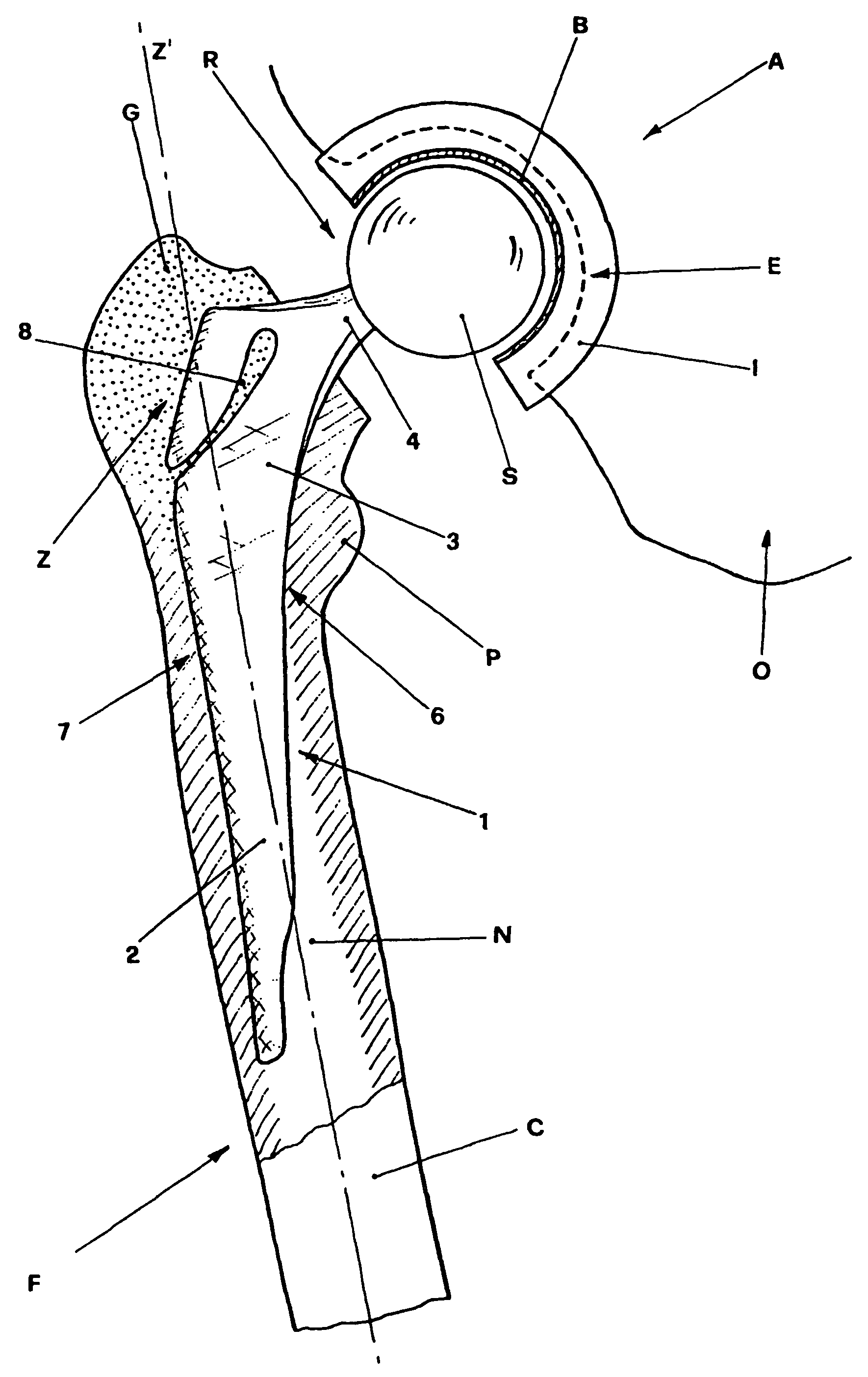

Femoral stem for hip prosthesis

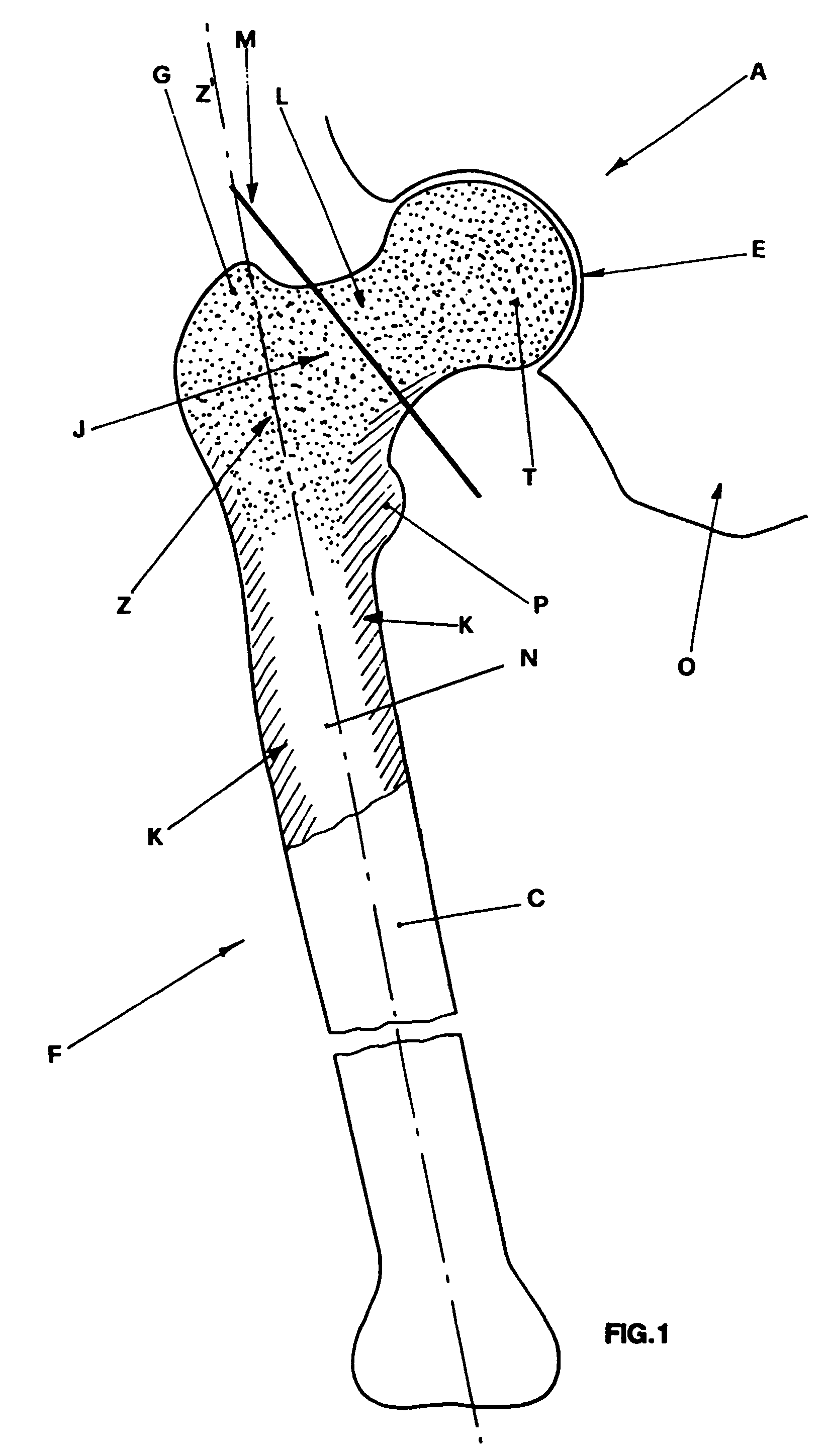

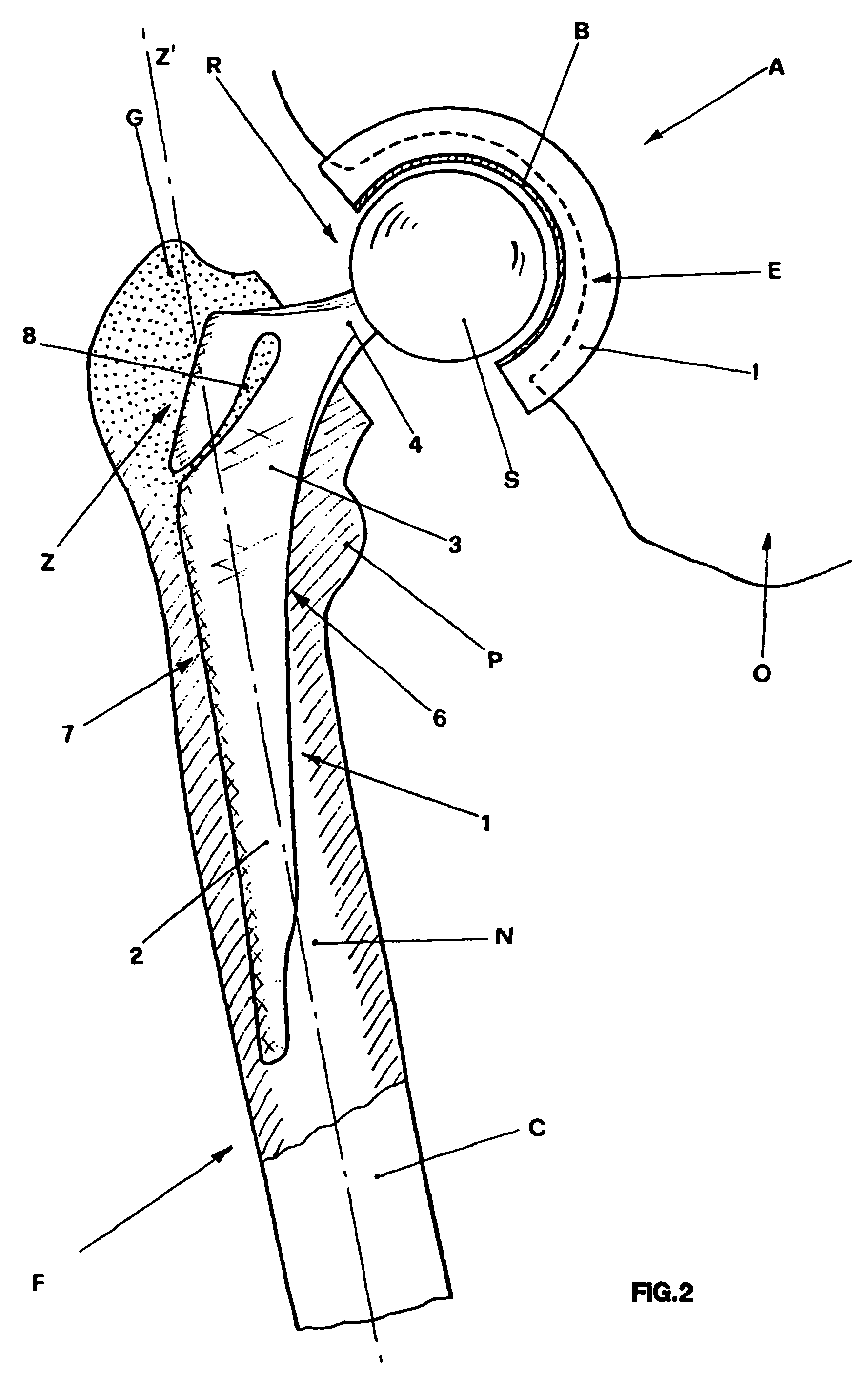

InactiveUS7374575B2Optimal secondary stabilityEffective stimulationAnkle jointsJoint implantsFemoral canalFemoral stem

A femoral stem for hip prosthesis is disclosed comprising: a main body with a mainly longitudinal development and a generally wedge shaped, which is inserted into the femoral canal present in the body of the femur; a central body of a generally trapezoidal shape integral with the main body, located in the proximal zone of the femur; an appendix projecting from the central body provided with a terminal pin receiving spherical head of joint into the cotyle belonging to the prosthesis and inserted into the acetubular zone of the pelvic bone. The main body and the central body are defined by a shaped surface on one side and a mixtilinear surface on the opposite side from which a shaped notch is starting involving the central body and extending up to the proximity of the projecting appendix.

Owner:CURRADINI GIORGIO E

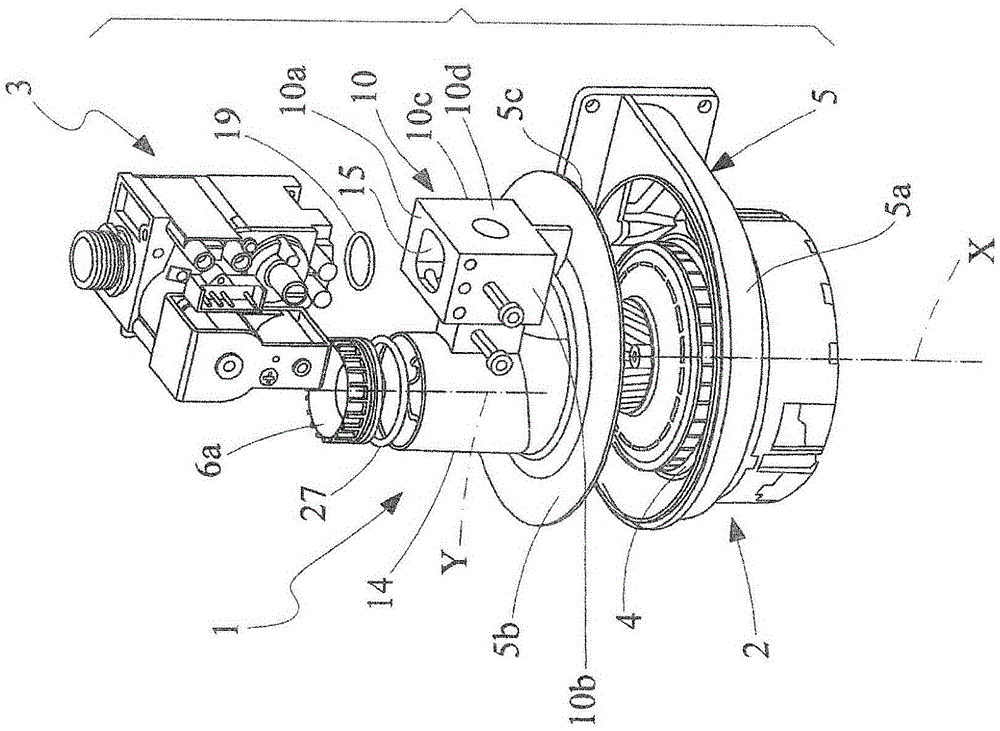

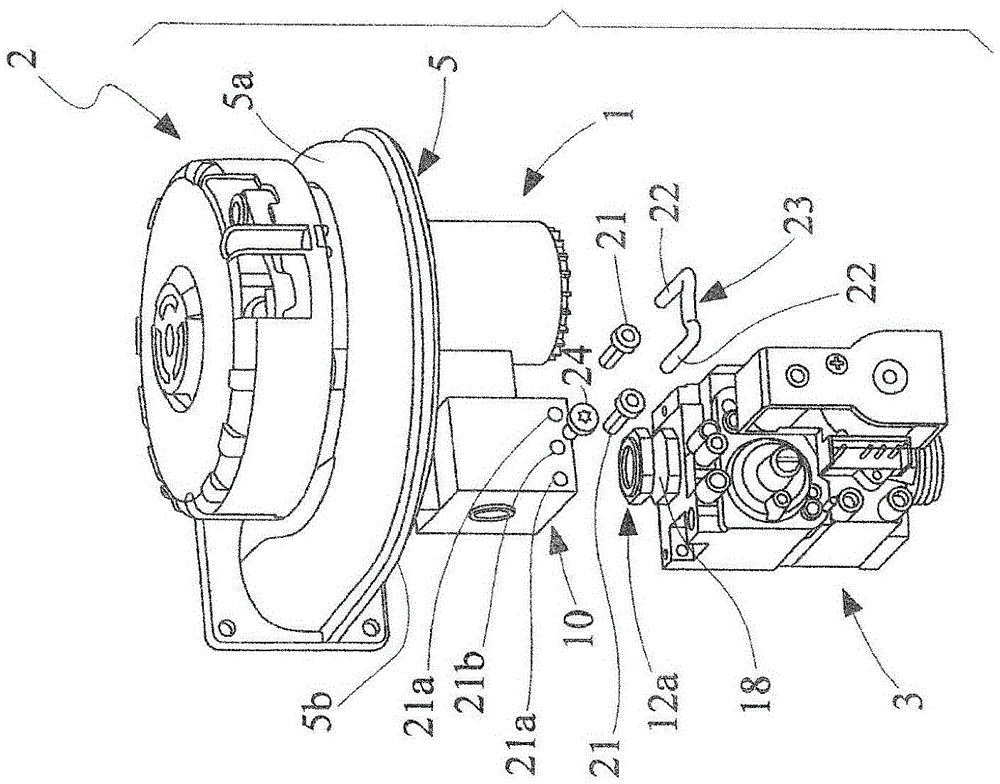

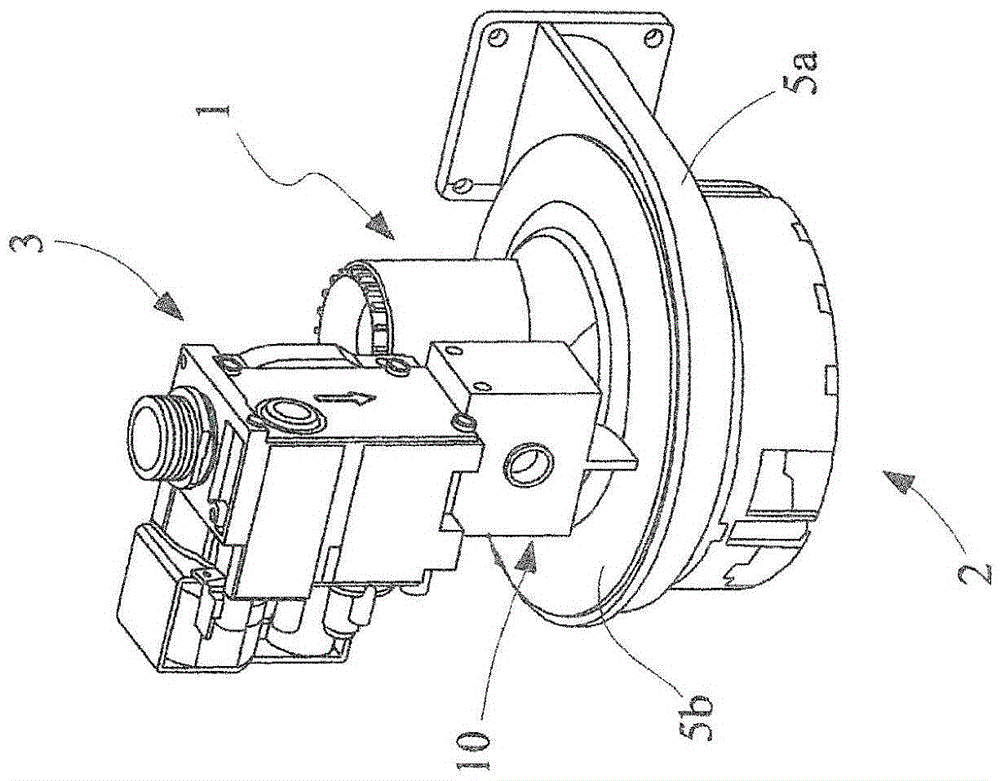

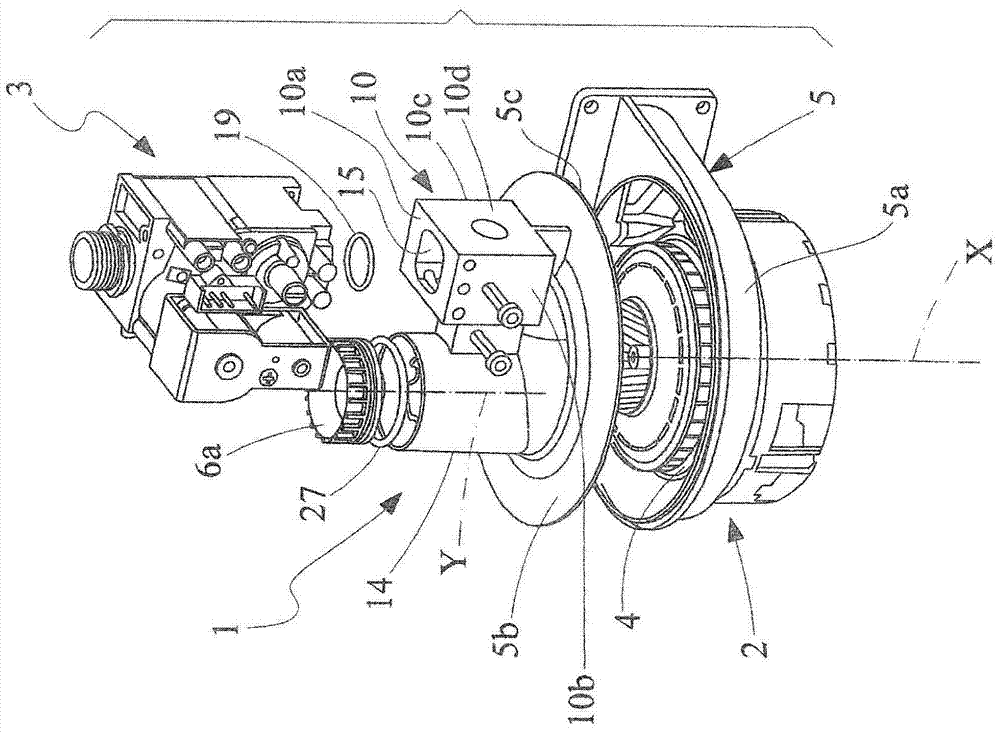

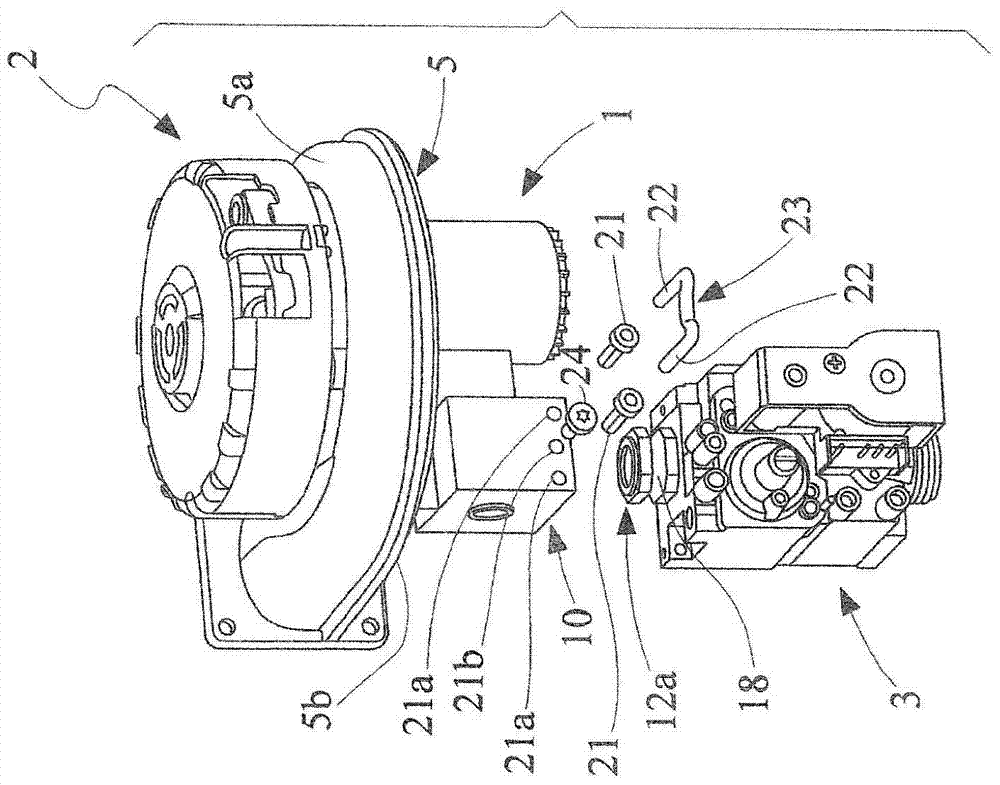

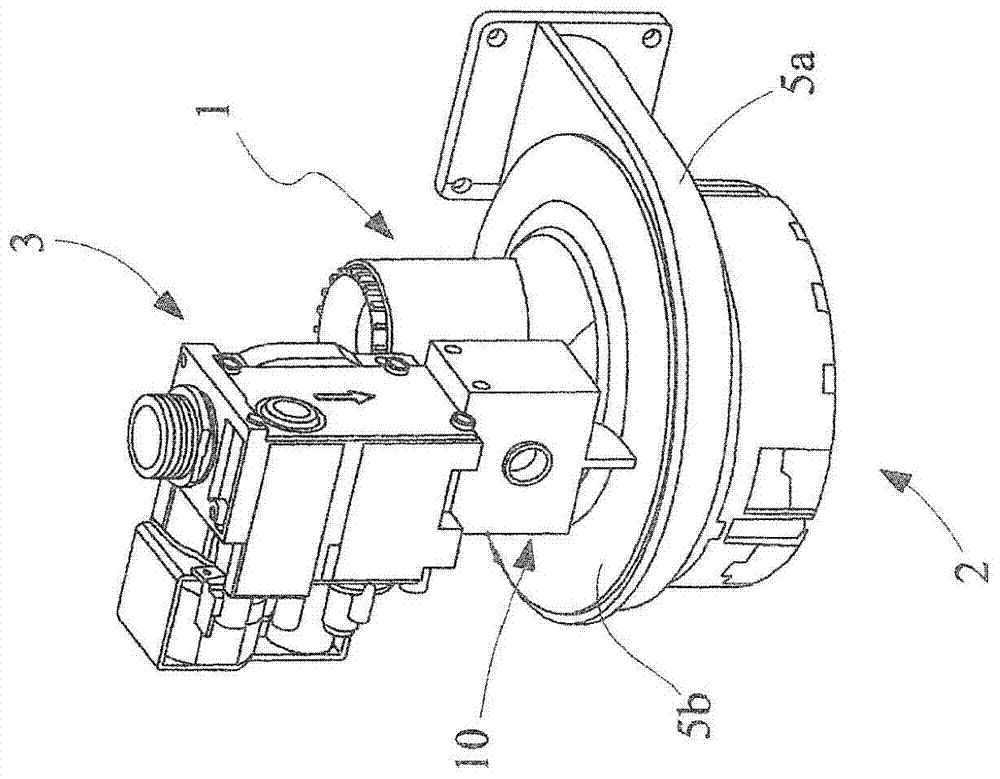

An air-gas mixer device for premix burner equipment

InactiveCN105612386AMaintain functional featuresSpecial fuel supply arrangementsBlast-producing apparatusImpellerEngineering

What is described is an air-gas mixer device for premix burner equipment of boilers, particularly of condensing boilers, comprising flow guide means for guiding an air-gas mixture to the intake section (2a) of a centrifugal fan (2) with an impeller (4) driven in rotation about a first axis (X), the guide means including a tubular Venturi effect conduit structure (6) with contiguous converging and diverging portions (6a, 6b) developed in an axially symmetric manner about a second axis (Y), a section being provided between the portions of conduit into which section the gas flow is delivered for mixing with the air flow supplied through the converging portion (6a) of the conduit. The conduit (6) is in communication with the intake section (2a) of the fan, downstream of the diverging portion (6b) with respect to the direction of the flow, and the impeller (4) of the fan is housed in a scroll manifold (5) including a housing (5a) for receiving the impeller (4) and a cover plate (5b) to close the housing (5a), a through aperture (7) being formed in the cover plate (5b) to put the Venturi effect conduit (6) into communication with the intake section (2a) of the fan. The axis of rotation (X) of the fan (2) does not coincide with the axis (Y) of longitudinal development of the Venturi effect conduit (6), the offset between the first and second axes (X, Y) being chosen so as to allow the mixer device to have a valve unit (3) mounted on it for supplying the gas flow into the Venturi effect conduit (6) with a configuration in which the projection of the overall dimensions of the Venturi effect conduit (6) and of the valve unit (3), in the direction of the axis of rotation (X), lies substantially and predominantly within the projection of the cover plate (5b) of the fan in the direction of the axis of rotation (X).

Owner:СІТ С П А

Composite wire for the manufacture of jewelry articles

InactiveUS6146772APig casting plantsSemiconductor/solid-state device detailsLongitudinal developmentWork in process

A composite wire for the manufacture of semifinished products to be subjected to an emptying process in the field of goldsmithery. The wire comprises a support core developing essentially along one of its longitudinal axes in a nonprecious metal that is removable by chemical or electrochemical means as well as a plurality of sections in precious metal having an essentially longitudinal development of which at least a portion of each one is radially engaged in the core.

Owner:CENTO GROUP

Ornamental item with variable configuration, and method for its manufacture

InactiveUS20050172669A1Reduce weightComfortable to wearBraceletsWrist-watch strapsLongitudinal developmentBiomedical engineering

An ornamental item with variable configuration, of the necklace or bracelet type, comprises an at least partially flexible elongated base element (2) made of precious or semi-precious, and it is characterized in that the elongated base element (2) has, on a first visible side, a slide and support guide (3). Moreover, one or more ornamental elements (4) are provided, able to be selectively inserted into said slide guide (3), as well as means (6) for locking each of the ornamental elements (4) in a predetermined position along the longitudinal development of said elongated base element (2).

Owner:LACCHETTI GIAN PAOLO

Rotary seamer

InactiveUS20100119335A1Strong and preciseQuick installationPackagingHollow articlesLongitudinal developmentEngineering

A rotary seamer (1) comprises a seaming turret (2), a seaming station pivotally associated to the seaming turret (2) to set in rotation around its own axis (8) a container (6) to be seamed, a shaft (11) having a first end (13) hinged in the seaming turret (2), a seaming block (9) also called lever, defining a cavity (15) with longitudinal development, shaped complementarily relative to a second end (14) of the shaft (11) in such a way that it can be coupled thereto by inserting the shaft (11) into the cavity (15), and means (16) for anchoring transversely the seaming block (9) to the shaft (11), acting in a predetermined transverse direction (17) in such a way as to create at least one contact surface (20) between shaft (11) and cavity (15), said second end (14) of the shaft (11) and said cavity (15) being so shaped that said contact surface (20) has at least one oblique portion relative to the direction (17) in which said means (16) act. Currently, there are mainly two types of shaft ends for mounting the seaming block on the related shaft: the bevel one with disc shaped tongue and the grooved one. Both solution entail complicated mountings, with poor precision.

Owner:CFT PACKAGING

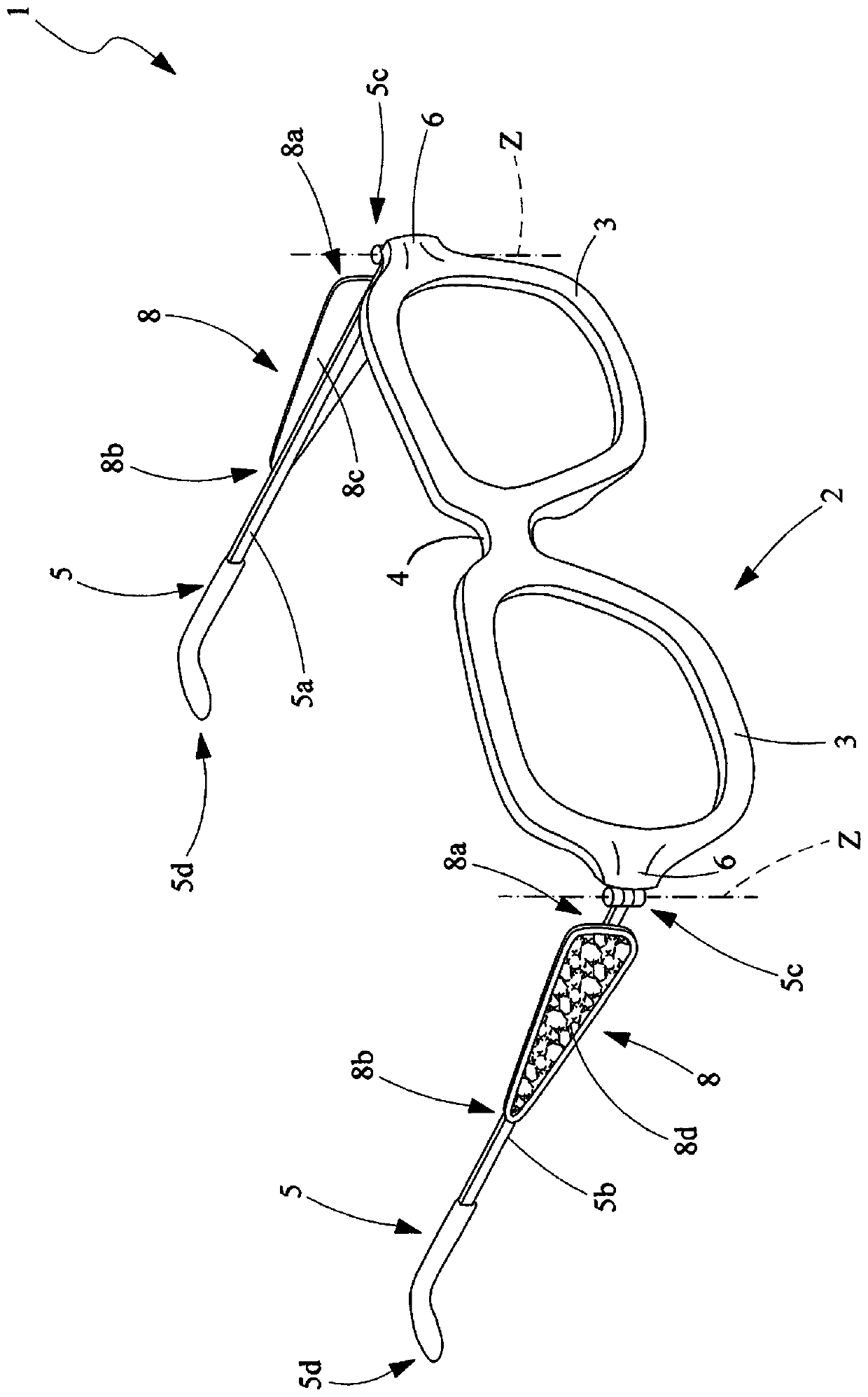

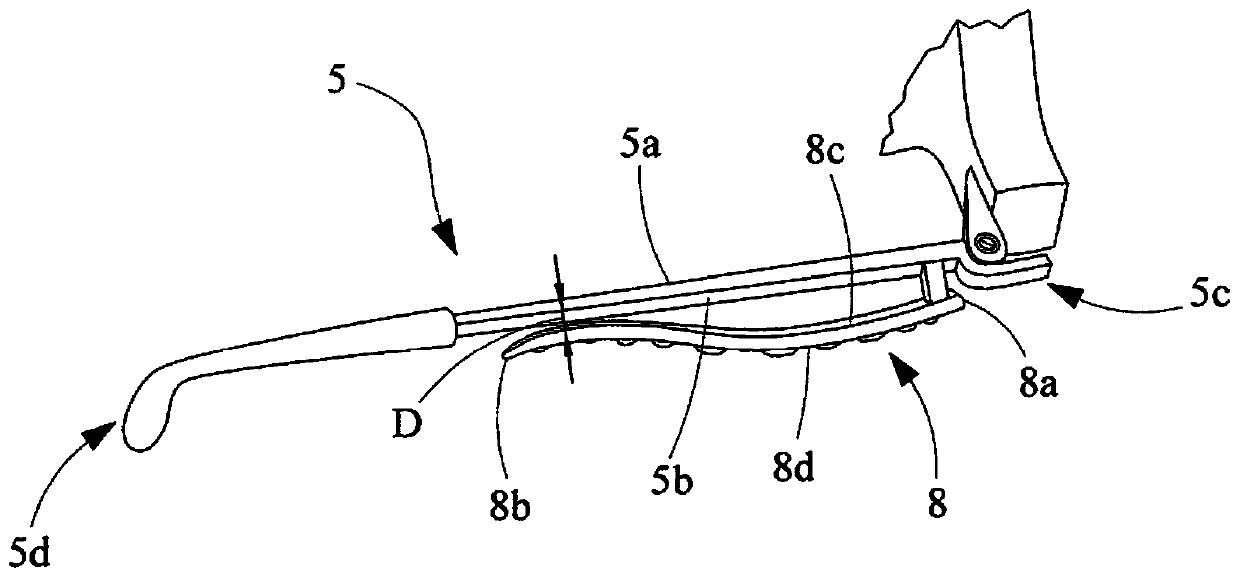

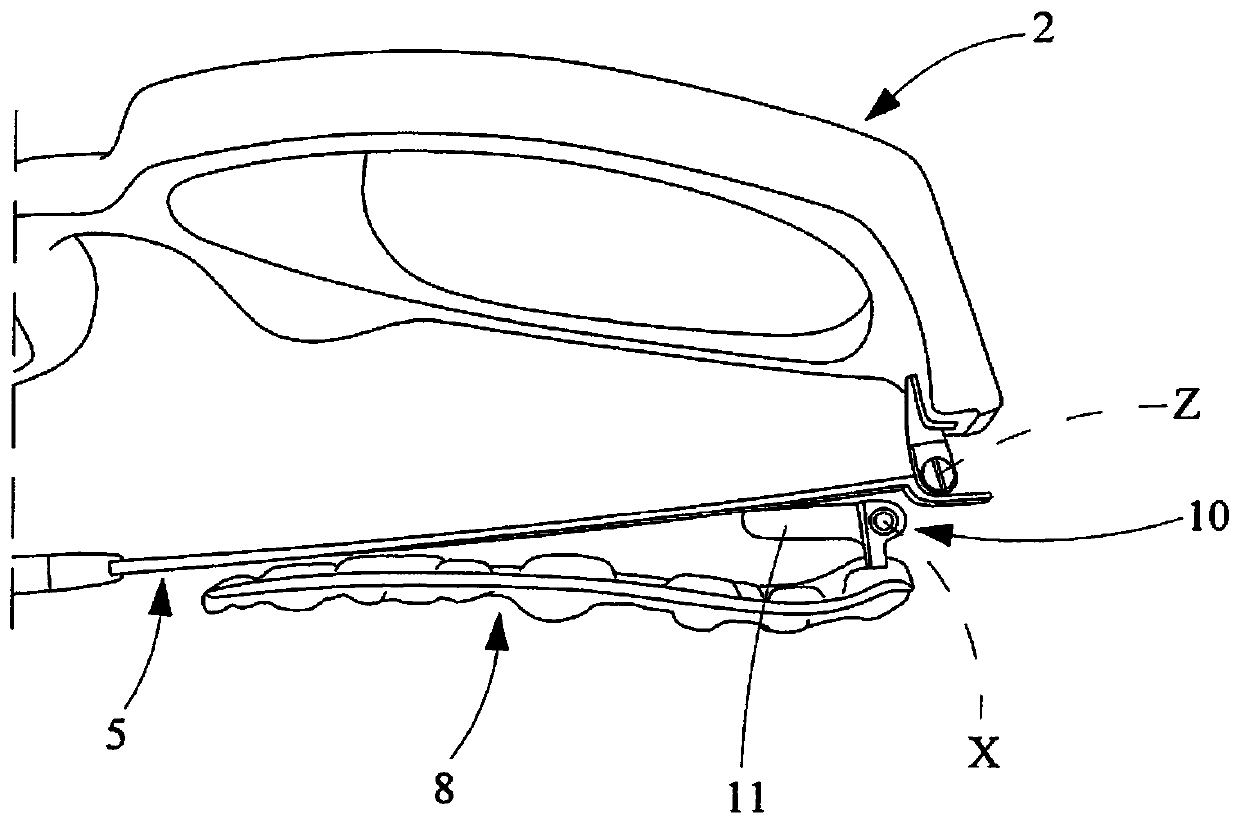

Spectacles

There are described a pair of spectacles comprising a front assembly mount (2) and a pair of arms (5) which extend from respective opposing lateral lugs (6) of the front mount, there being defined oneach arm an internal lateral flank (5a), which is directed towards the head with the spectacles being worn, and an opposing external lateral flank (5b). The pair of spectacles further comprises on atleast one of the arms (5) a respective support element (8), which is secured to the external flank (5b) of the arm in the region of a portion of the arm near the respective lug (6) for articulation tothe mount (2) and which extends in the direction of longitudinal development of the arm behind the external flank (5b) and with a predetermined spacing from the external flank of the arm, the support(8) carrying a surface (8d), which is visible from the outer side with the spectacles being worn, which is intended to be decorated or to support decorative patterns.

Owner:SAFILO SPA

Air-gas mixer units for premix burner installations

InactiveCN105612386BMaintain functional featuresSpecial fuel supply arrangementsBlast-producing apparatusRotational axisImpeller

Described here is an air-gas mixer arrangement for a premix burner installation of a boiler, in particular for a condensing boiler, which air-gas mixer arrangement comprises flow guiding means for bringing the air- The gas mixture is directed to the inlet section (2a) of a centrifugal fan (2) with an impeller (4) driven in rotation about a first axis (X), said guiding means comprising a tubular Venturi effect A duct structure (6) having successive converging and diverging sections (6a, 6b) extending axisymmetrically about a second axis (Y) with a section provided between the sections of the duct to which the gas flow is delivered In this section, to mix with the air flow supplied through the duct constriction (6a). The duct (6) communicates downstream of the diffuser portion (6b) with respect to the direction of flow with the inlet section (2a) of the fan whose impeller (4) is housed in a vortex header (5) comprising A housing (5a) for receiving the impeller (4) and a cover plate (5b) for closing the housing (5a), a through hole (7) is formed in the cover plate (5b) so that the Venturi effect conduit (6) It communicates with the inlet section (2a) of the fan. The axis of rotation (X) of the fan (2) does not coincide with the axis (Y) of the longitudinal extension of the Venturi effect duct (6), the offset between the first and second axes (X, Y) being chosen such that the mixer means has a valve unit (3) mounted thereon to supply gas flow into the venturi effect conduit (6) in such a configuration that the venturi effect conduit (6) and the valve unit ( The projection of the overall size of 3) in the direction of the rotation axis (X) is substantially and mainly located within the projection of the fan cover (5b) in the direction of the rotation axis (X).

Owner:СІТ С П А

Needle cylinders for circular knitting machines

A needle cylinder (1) for a circular knitting machine for knitwear or hosiery, comprising a cylinder body (2) provided with an external surface (4) and with a plurality of vertical slots (5) made in the external surface, wherein the plurality of slots realize a corresponding plurality of seatings (6). The cylinder comprises a plurality of vertical beams, or walls (7), each wall having a prevalent longitudinal development and being positionable in a respective seating (6). Each pair of adjacent walls (7) defines a needle channel (8), corresponding to a vertical space comprised between the adjacent walls; the needle channel is configured for movably housing a respective needle. The body (2) is further provided with a first annular niche (10) extending in circular fashion about the external surface (4). At least one of the walls exhibits at least a respective first protuberance (11) configured to insert in a respective angular portion of the first niche (10).

Owner:SANTONI SPA

Track with rotating bushings for track-type vehicles with improved sliding bearing

A track (10) for track-type vehicles is described, comprising a continuous sequence of articulated joints (12, 12′) of the hinge type, oriented according to a first axis (A-A) substantially perpendicular to the central longitudinal development axis (B-B) of the track (10). The articulated joints (12, 12′), provided with pins (36, 36′), are connected to each other and maintained at a constant distance through pairs of links (14) having longitudinal development, arranged laterally and symmetrically with respect to the longitudinal central axis (B-B). Around each pin (36, 36′) a bushing (40) is mounted free to rotate with respect to the pin (36, 36′) itself and at least one sliding bearing (44) is press-fitted between each pin (36, 36′) and the links (14). The presence of sliding bearings (44) made in composite material and having a small thickness and the geometrical / size characteristics of the links (14) and of the sliding bearings (44) themselves makes it possible to improve the stability and the fatigue and wearing resistance of the articulated joints (12, 12′) of the track (10).

Owner:BELLCO SPA

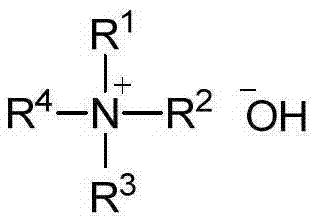

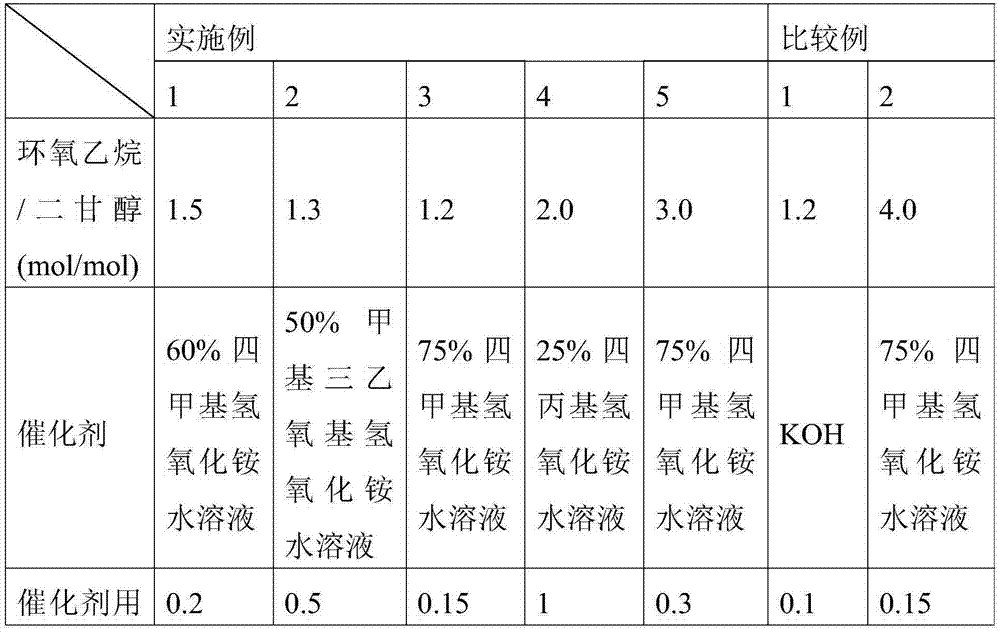

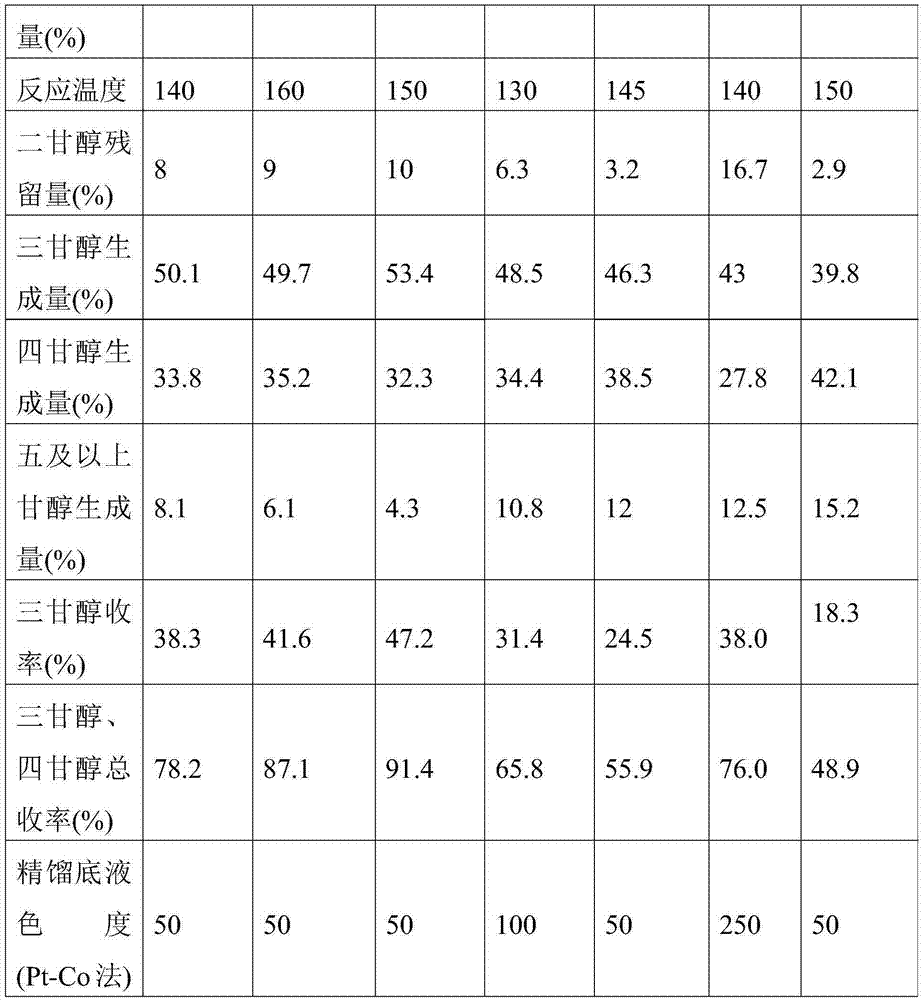

Method for polymerization of diglycol and ethylene oxide

The invention discloses a method for polymerizing diethylene glycol and ethylene oxide. The method comprises the following steps: under the protection of inert gas and / or nitrogen, and in the presence of a quaternary ammonium base, diethylene glycol It can be polymerized with ethylene oxide at a molar ratio of 1:1 to 1:3. The method of the present invention has high reaction activity and good selectivity, the catalyst can be easily removed, the neutralization process is reduced, and the rectification substrate has a light color, which can be directly used to produce products such as polyethylene glycol and polyethylene glycol dimethyl ether ; The method of the present invention can not only improve the production capacity of triethylene glycol and / or tetraethylene glycol, but also can co-produce other polymerized glycols, such as pentaethylene glycol; through the process of the present invention, not only the vertical development of products can be realized , to create higher economic benefits, but also reduce investment in environmental protection and reduce the impact on the environment.

Owner:SHANGHAI DONGDA CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com