Improved filtering drum for fibre suspensions in water

A filter cartridge, suspension technology, applied in the field of cellulose fibers, which can solve the problems of limiting filtration speed and efficiency, slow downward movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

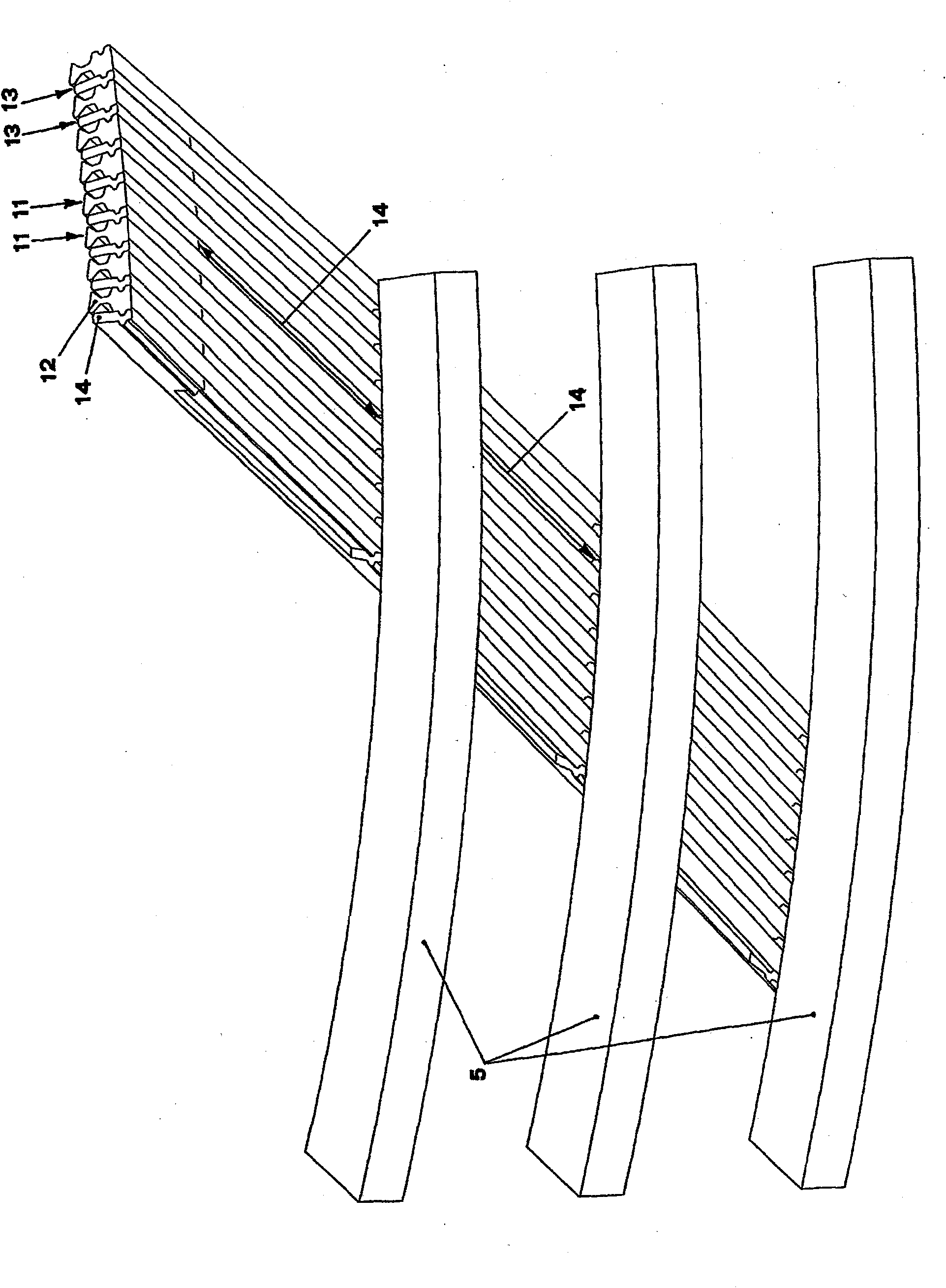

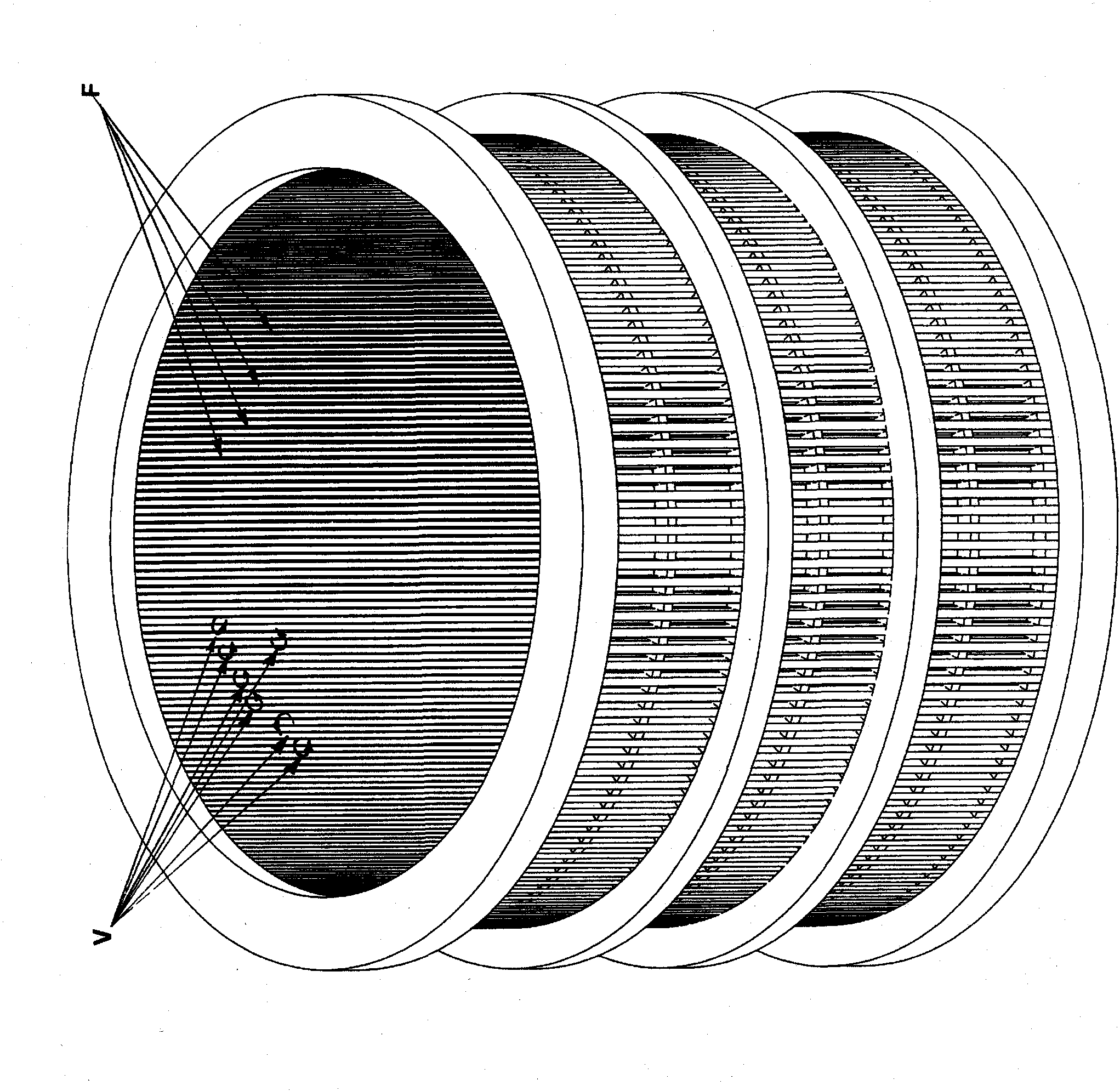

[0024] The filter cartridge which is the subject of the invention is shown in axonometric projection on image 3 , where the filter cartridge is indicated with 1 as a whole.

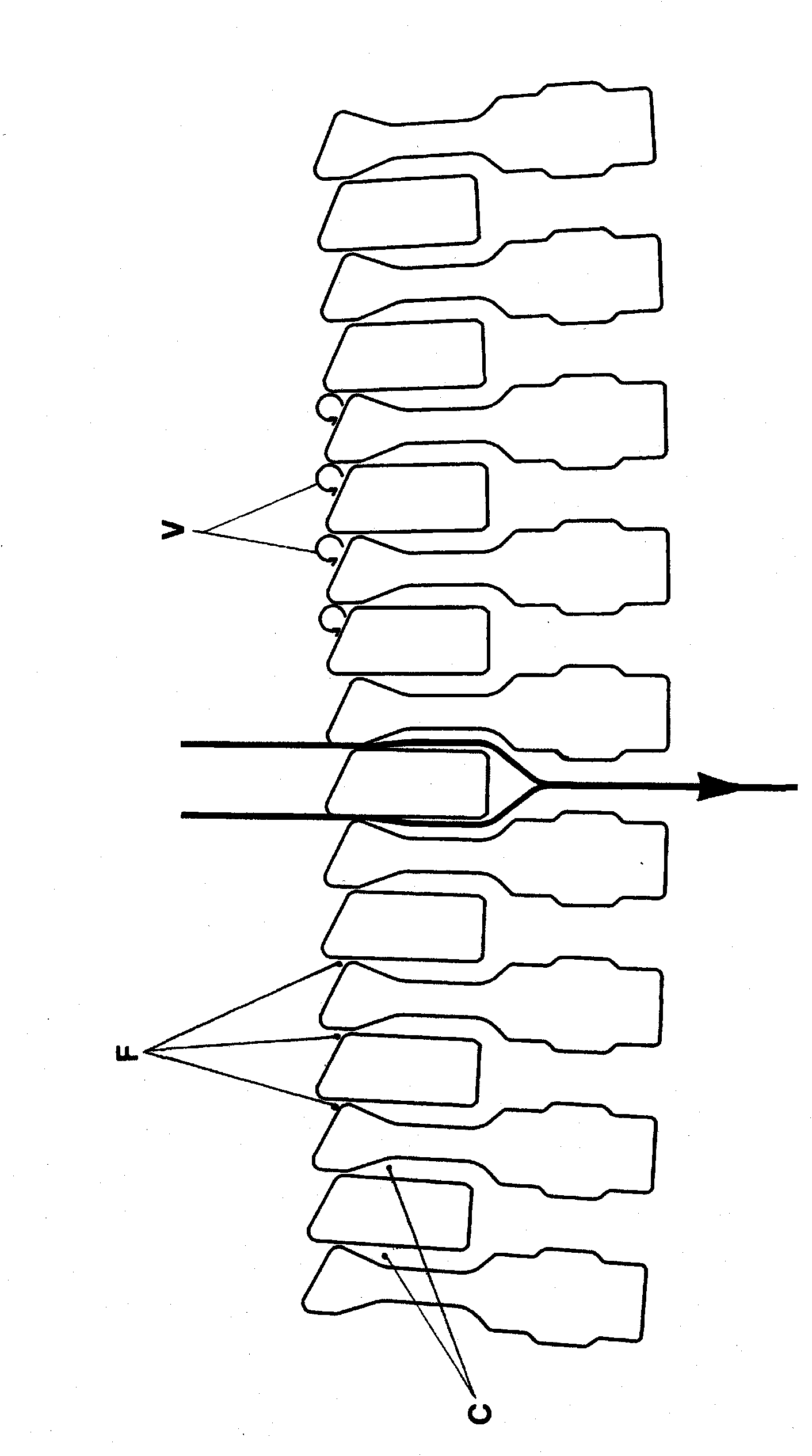

[0025] The filter cartridge for filtering fibers in an aqueous suspension comprises a plurality of mainly longitudinally extending profiled rods 2 arranged side by side next to each other in such a way as to form a plurality of slits 3 .

[0026] In this way, the profiled bar 2 defines a tubular structure of substantially circular cross-section, wherein the tubular structure defines a longitudinal axis X, wherein the inner surface 4 of the tubular structure is a filtering surface.

[0027] The profiled bar itself has an edge 5 towards the inside of the barrel 1, wherein the profiled bar is formed in sections with various geometries, but in any case forms a slit 3 with a constricted-expanded cross-section, wherein the slit The slots 3 can create a Venturi effect on fluid flowing radially through them.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com