Heat exchanger

a technology of heat exchanger and heat exchanger body, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, and separation processes, etc., can solve the problems of many known heat exchangers, affecting the efficiency affecting the operation of the heat exchanger itself, so as to reduce the weight, bulk and load loss, and reduce the effect of air path deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

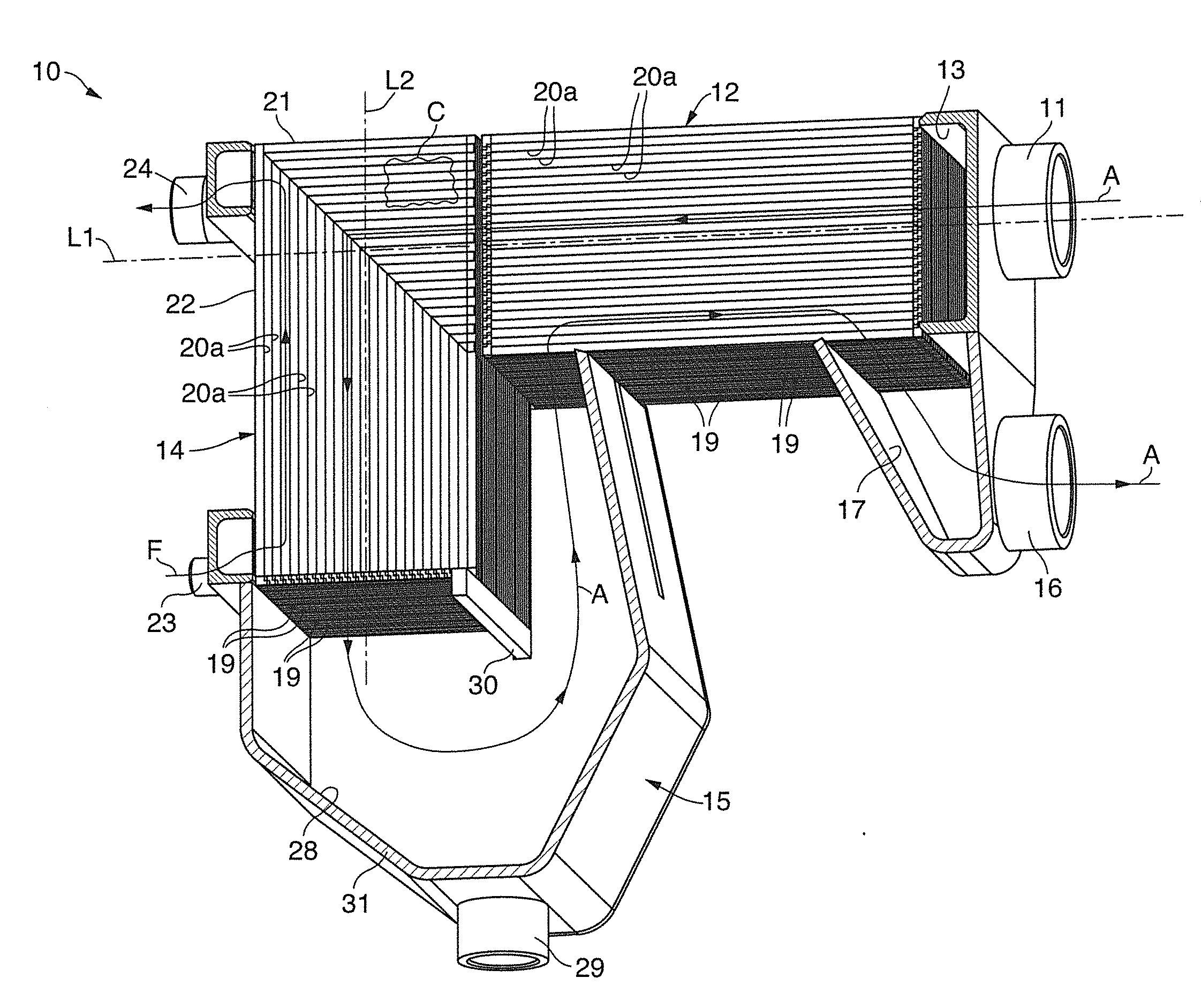

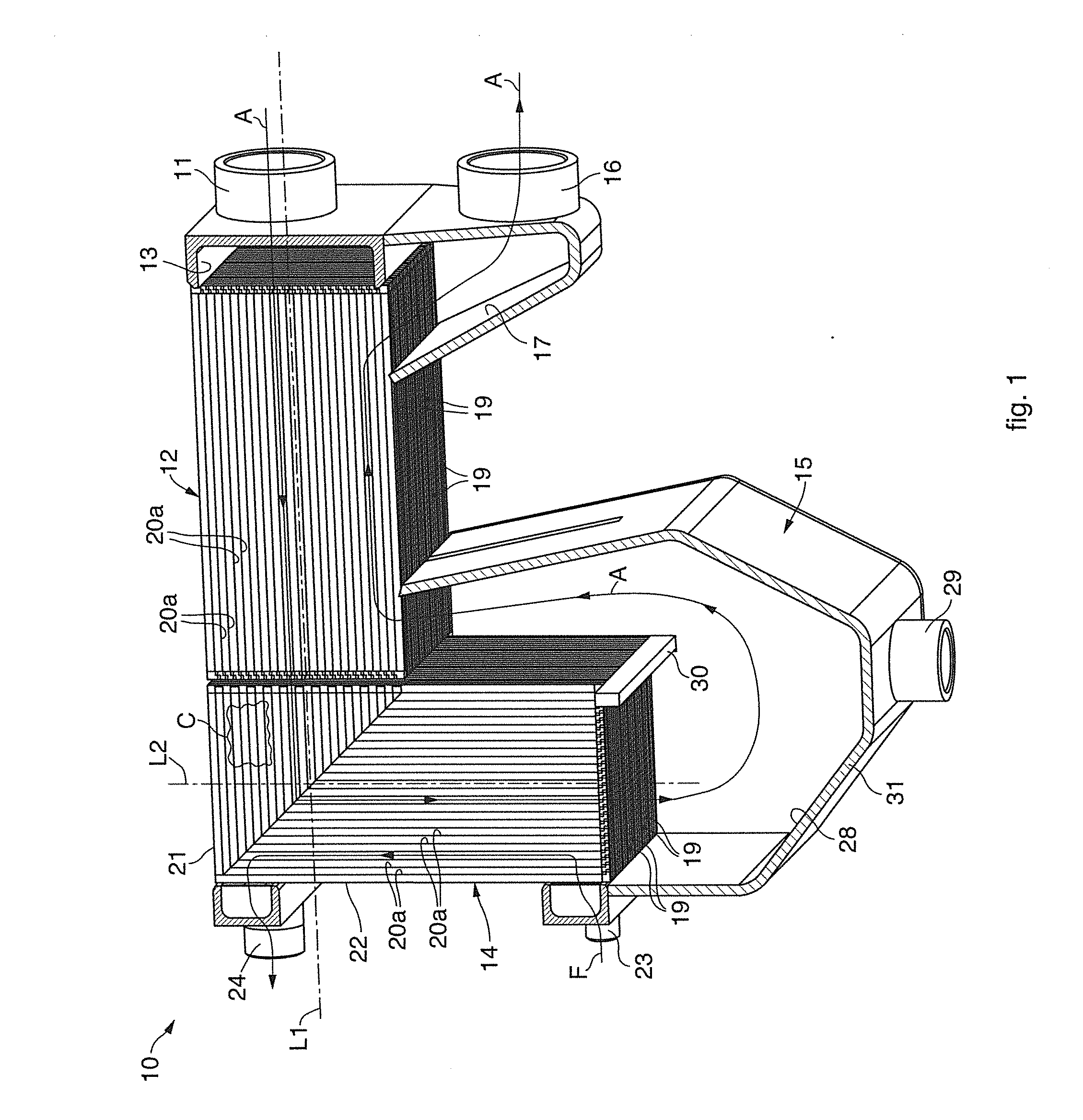

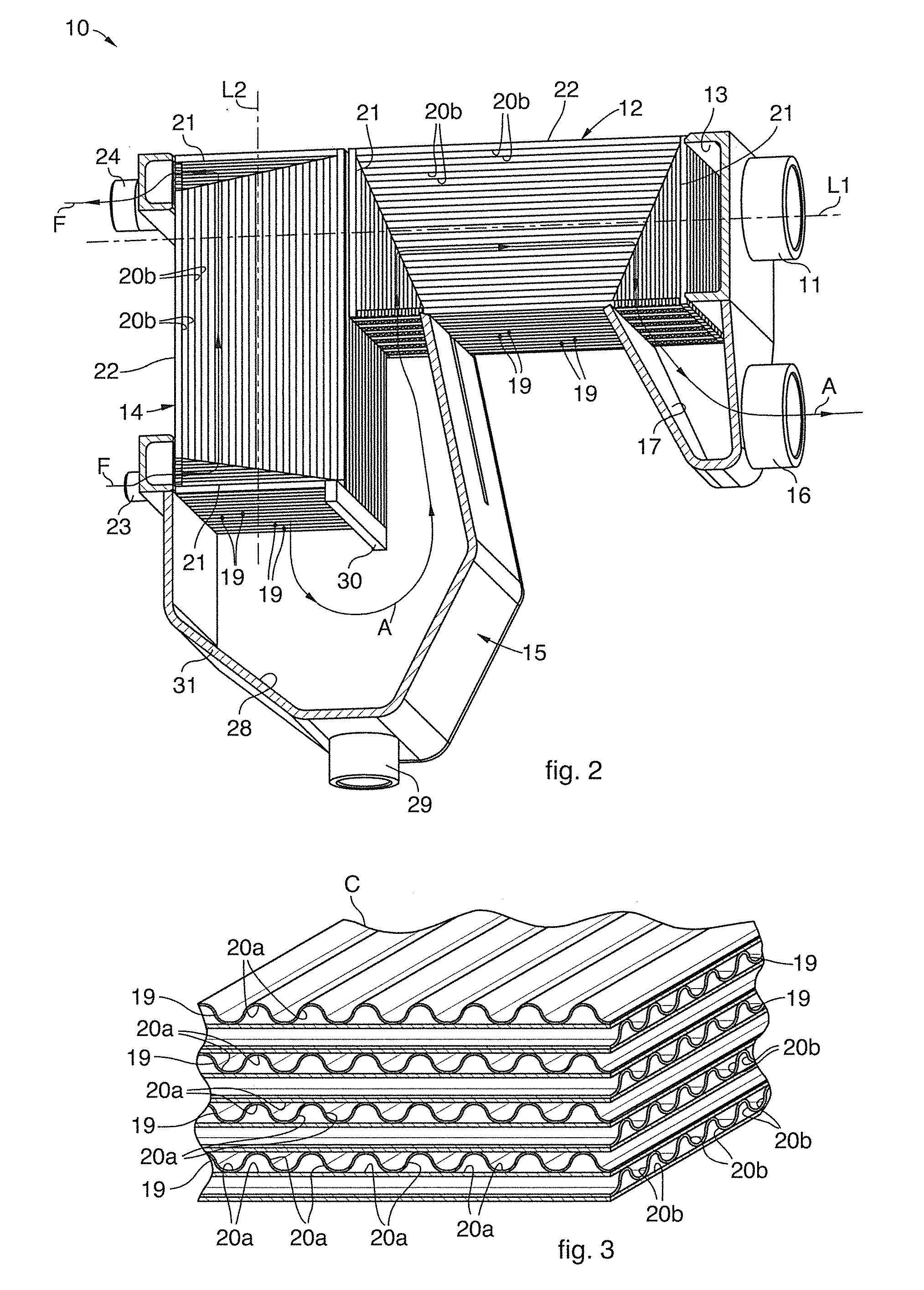

[0051]With reference to FIGS. 1 and 2, a heat exchanger 10 according to the present invention is suitable to allow the exchange of heat between a stream of hot fluid, in this case air A, to be cooled, and a stream of cooling fluid, in this case freon F.

[0052]The heat exchanger 10 comprises a pre-cooling unit, or pre-exchanger 12, a cooling unit or evaporator 14, and a unit to separate the condensation, or separator 15.

[0053]In use, the heat exchanger 10 is positioned so that the pre-exchanger 12 and the evaporator 14 are disposed above the separator 15 and that the air A and the freon F enter and exit laterally from the heat exchanger 10.

[0054]The path of air A inside the heat exchanger 10 is shown in FIGS. 1 and 2, and is articulated as described hereafter.

[0055]Hot air A enters the exchanger 10 from an entrance pipe 11 positioned at one end of the pre-exchanger 12, and is distributed uniformly over the whole height of the latter by an entrance collector 13, so that the largest hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com