Oil tank fixed to the engine block

A technology of engine body and oil tank, which is applied in the direction of engine lubrication, engine components, machine/engine, etc., can solve problems such as engine failure, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

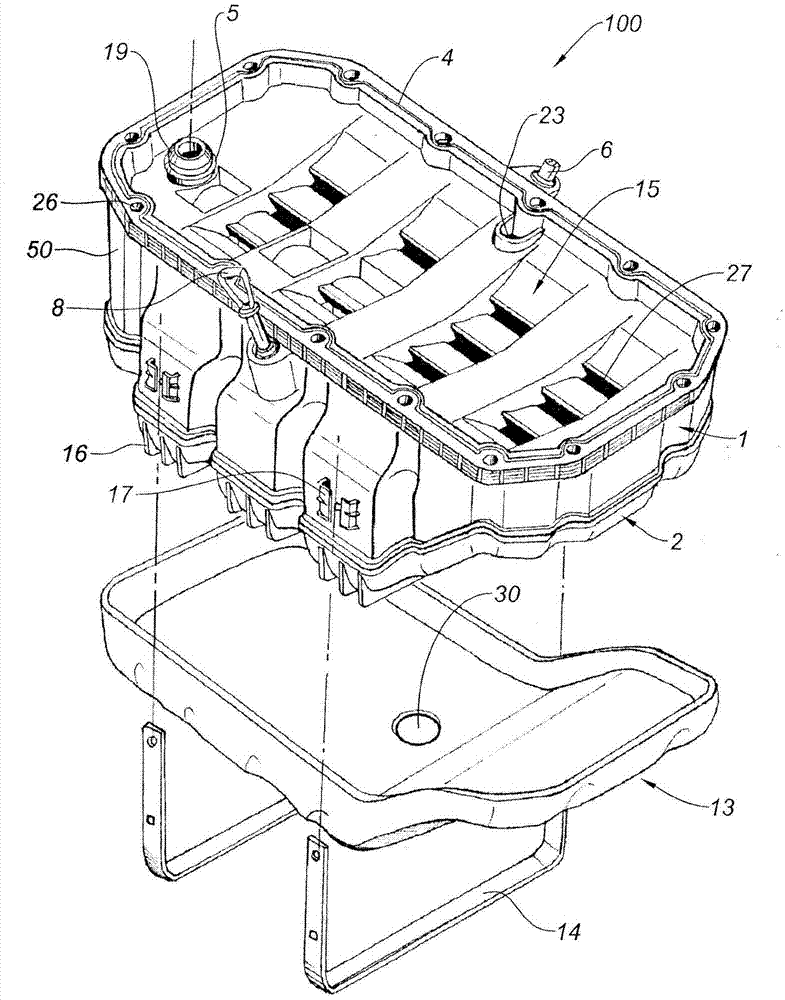

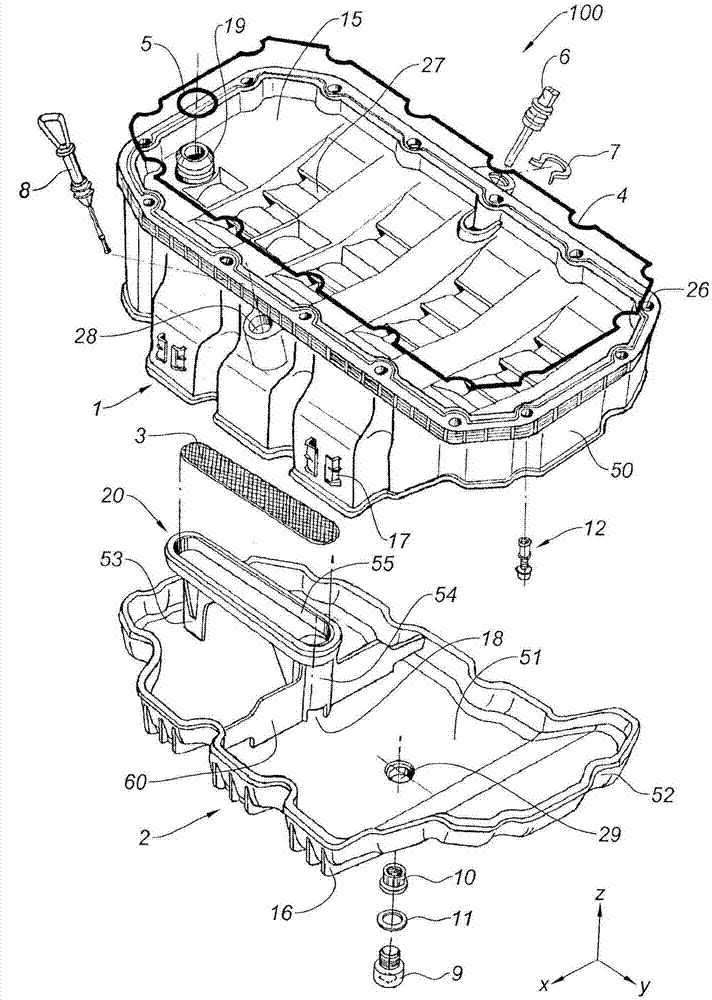

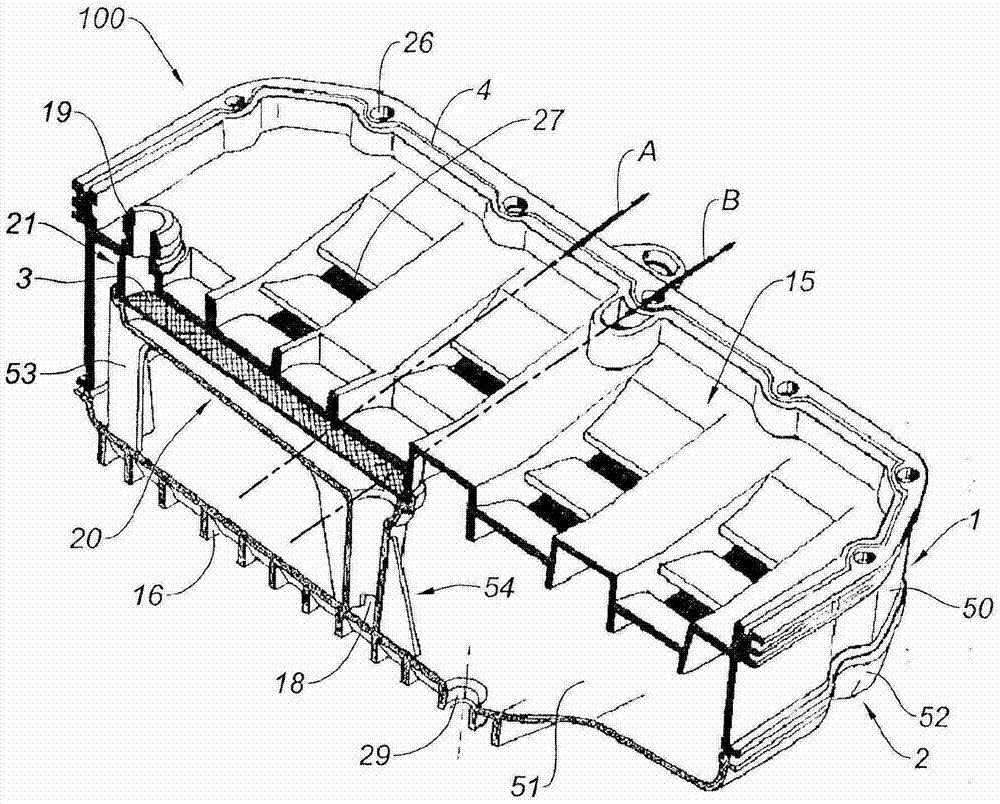

[0047] figure 1 The lower engine module or oil tank module 100 formed by the upper shell 1 and the lower shell 2 assembled together is shown without limitation. The oil tank 100 is designed to be fixed in the engine block 24 of an internal combustion engine, such as Image 6 Shown.

[0048] Such as figure 2 As shown, the axis Z is defined as a vertical axis, and the axis X and the axis Y define a horizontal plane. The terms "up", "down", "high", and "low" are used relative to the Z axis. The term "longitudinal" is used relative to axis Y, and the term "transverse" is used relative to axis X. The engine oil tank 100 is depicted in the figure in this case.

[0049] The upper shell 1 integrates multiple components to achieve normal operation of the device.

[0050] The upper shell 1 is molded as a single element. For example, it can be obtained by injecting plastic, molding a thermoplastic material, or molding aluminum. It includes an upper wall 15 forming an anti-emulsification p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com