Patents

Literature

588results about "Envelope/housing resistor manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

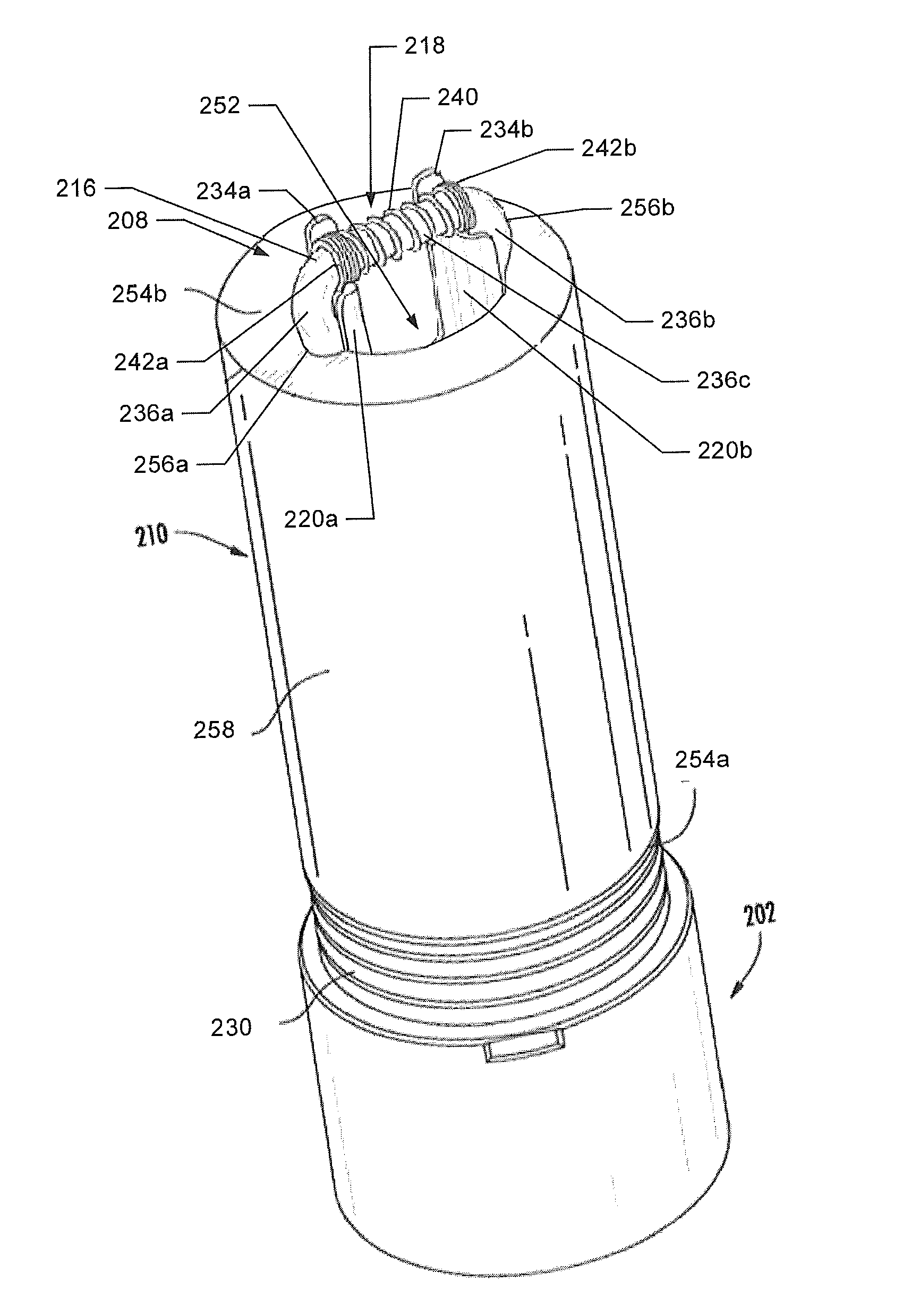

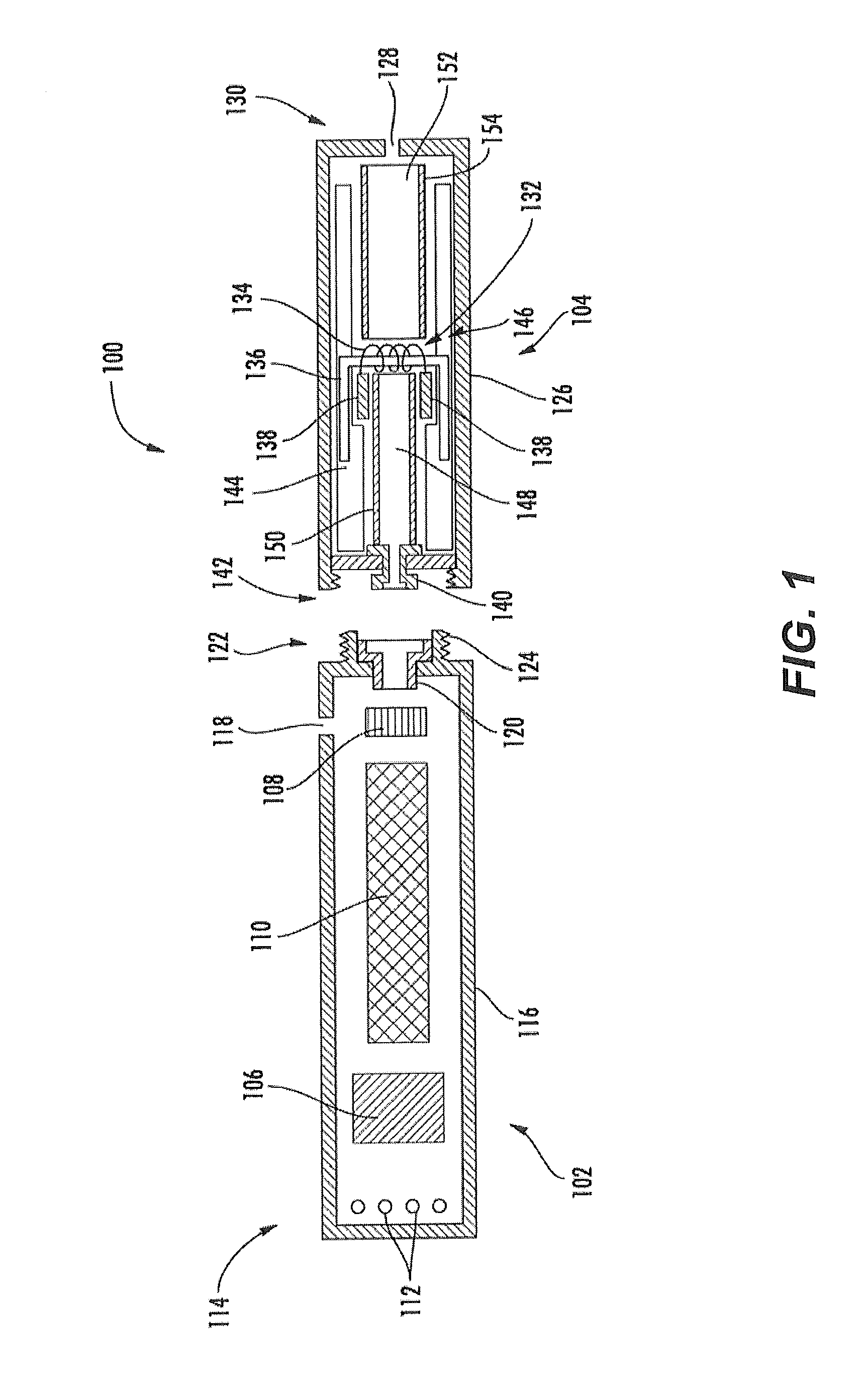

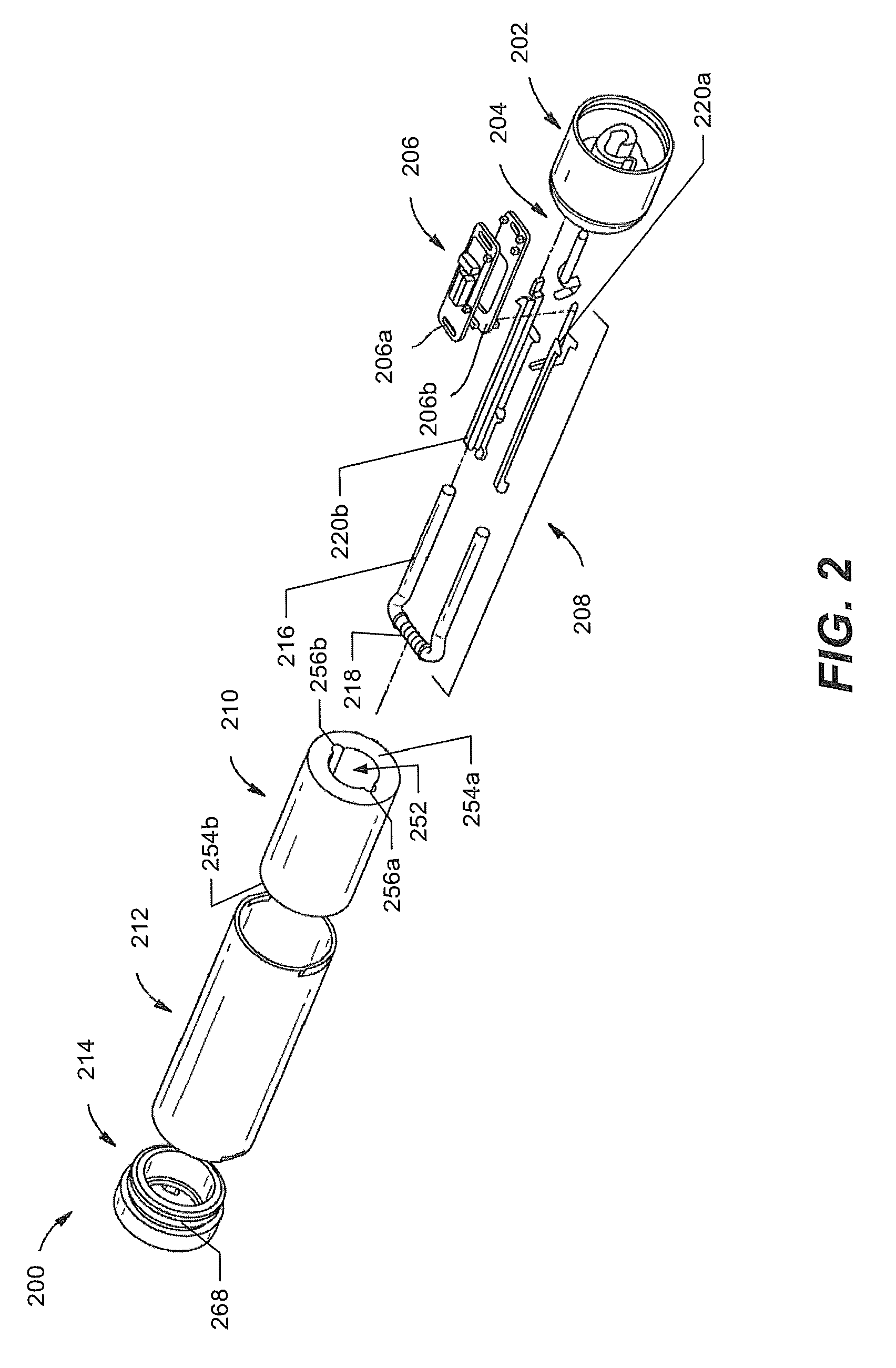

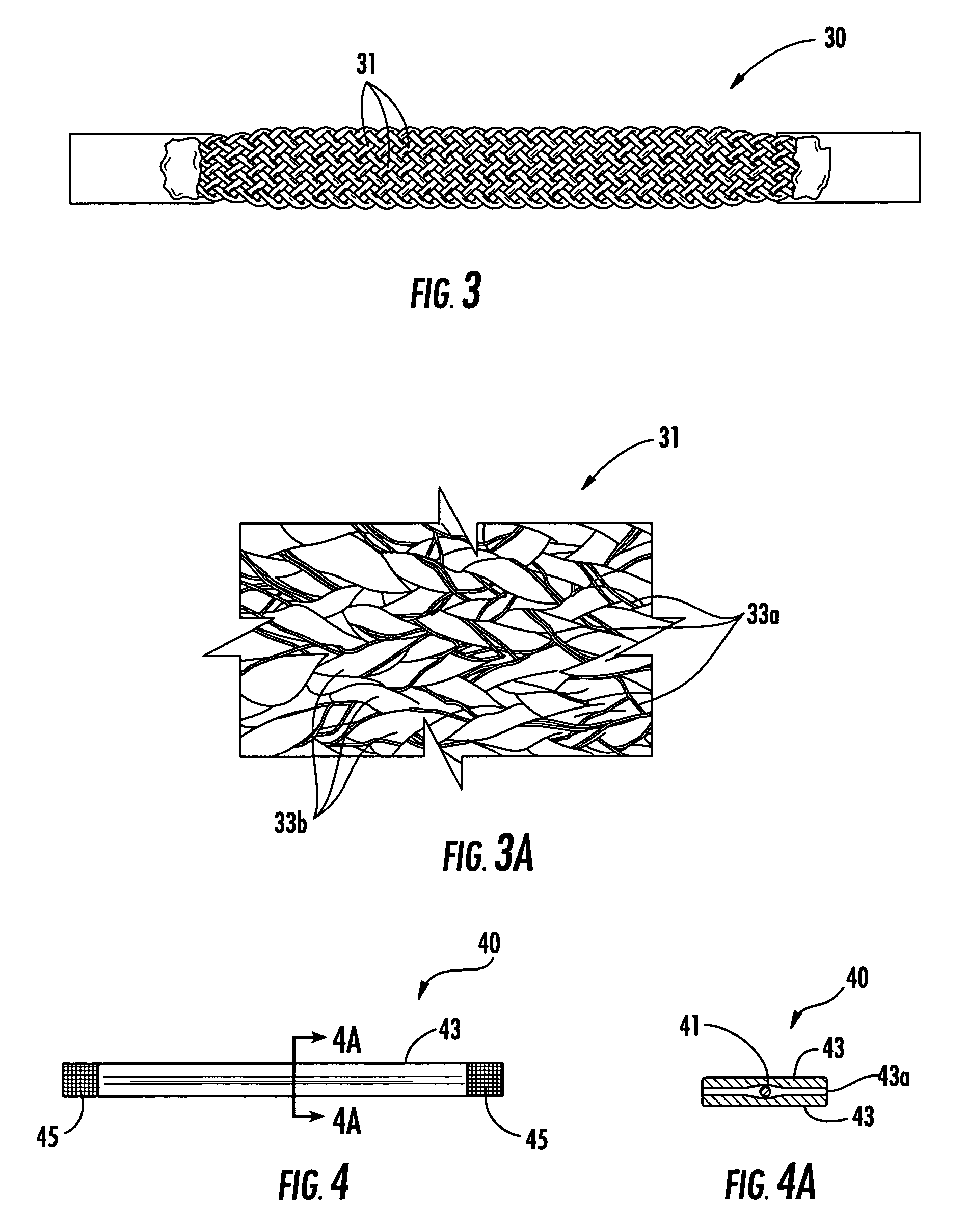

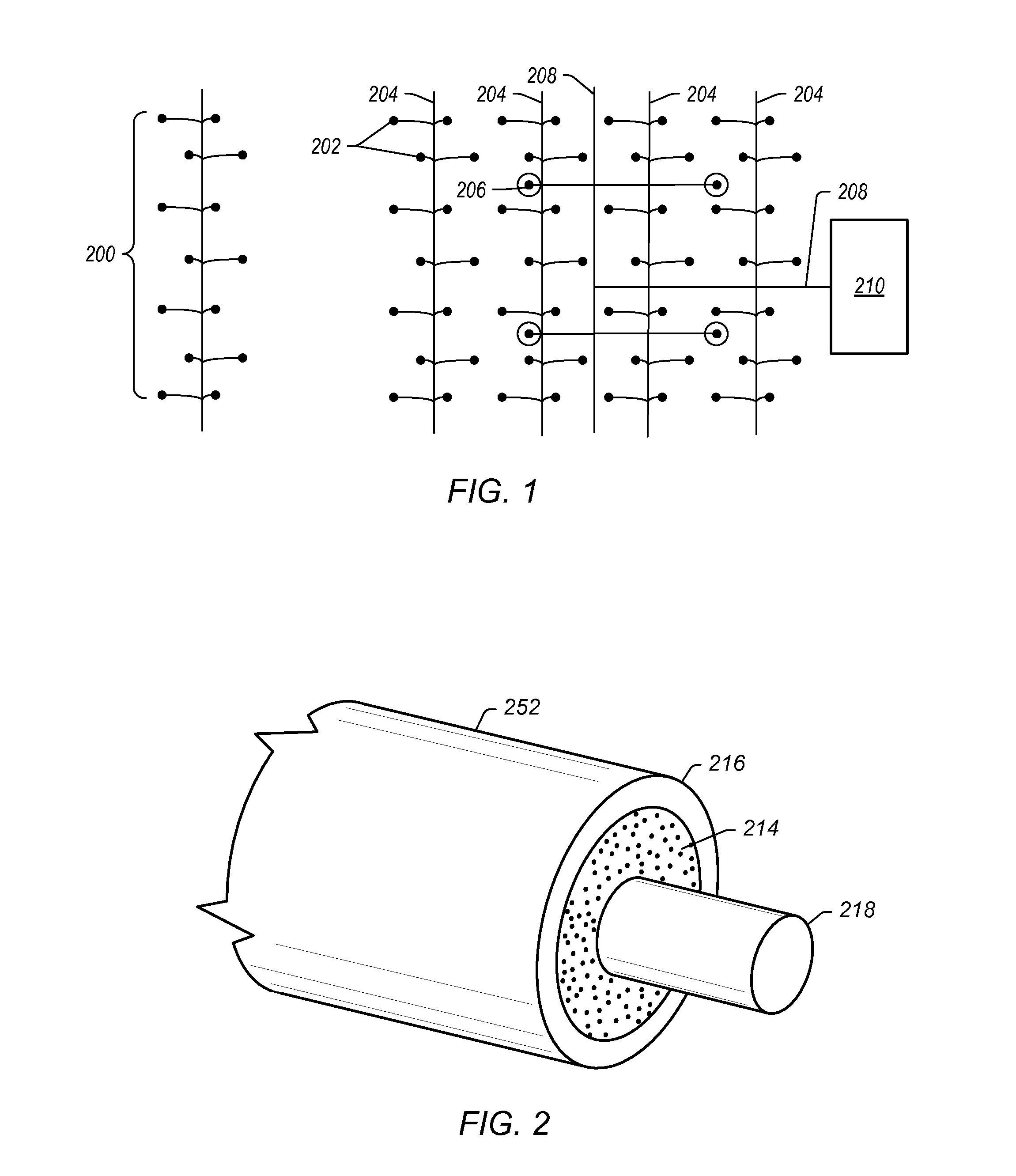

Atomizer for an aerosol delivery device and related input, aerosol production assembly, cartridge, and method

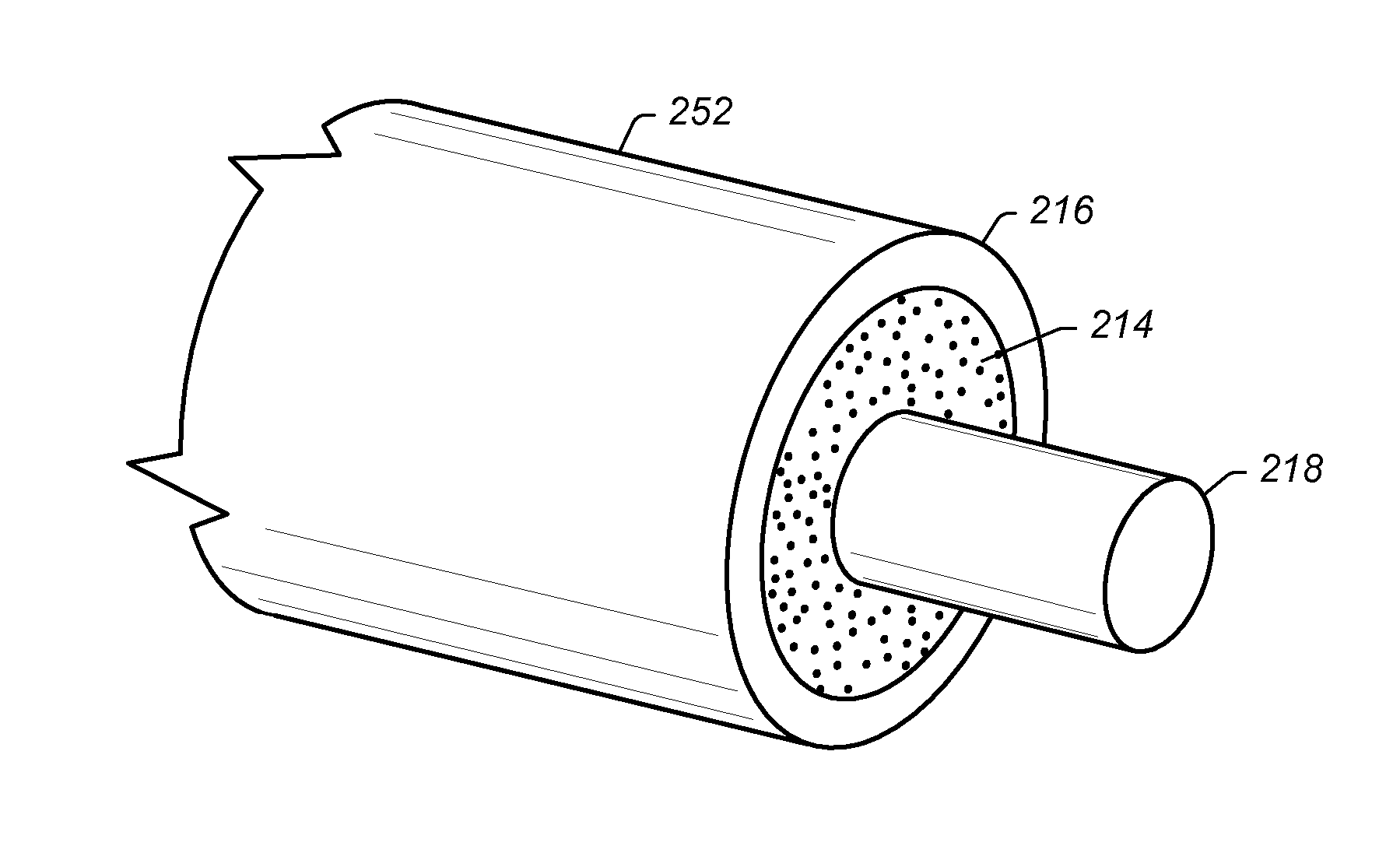

The present disclosure relates to atomizers for an aerosol delivery device such as a smoking article. The atomizer may include a liquid transport element and a wire extending along at least a portion of a longitudinal length thereof. The wire may define contact portions configured to engage heater terminals and a heating portion configured to produce heat. The heating portion may include a variable coil spacing. In other atomizers, the wire may extend at least partially through the liquid transport element proximate the contact portions. Related inputs, cartridges, aerosol production assemblies, and methods of forming atomizers are also provided.

Owner:RAI STRATEGIC HLDG INC

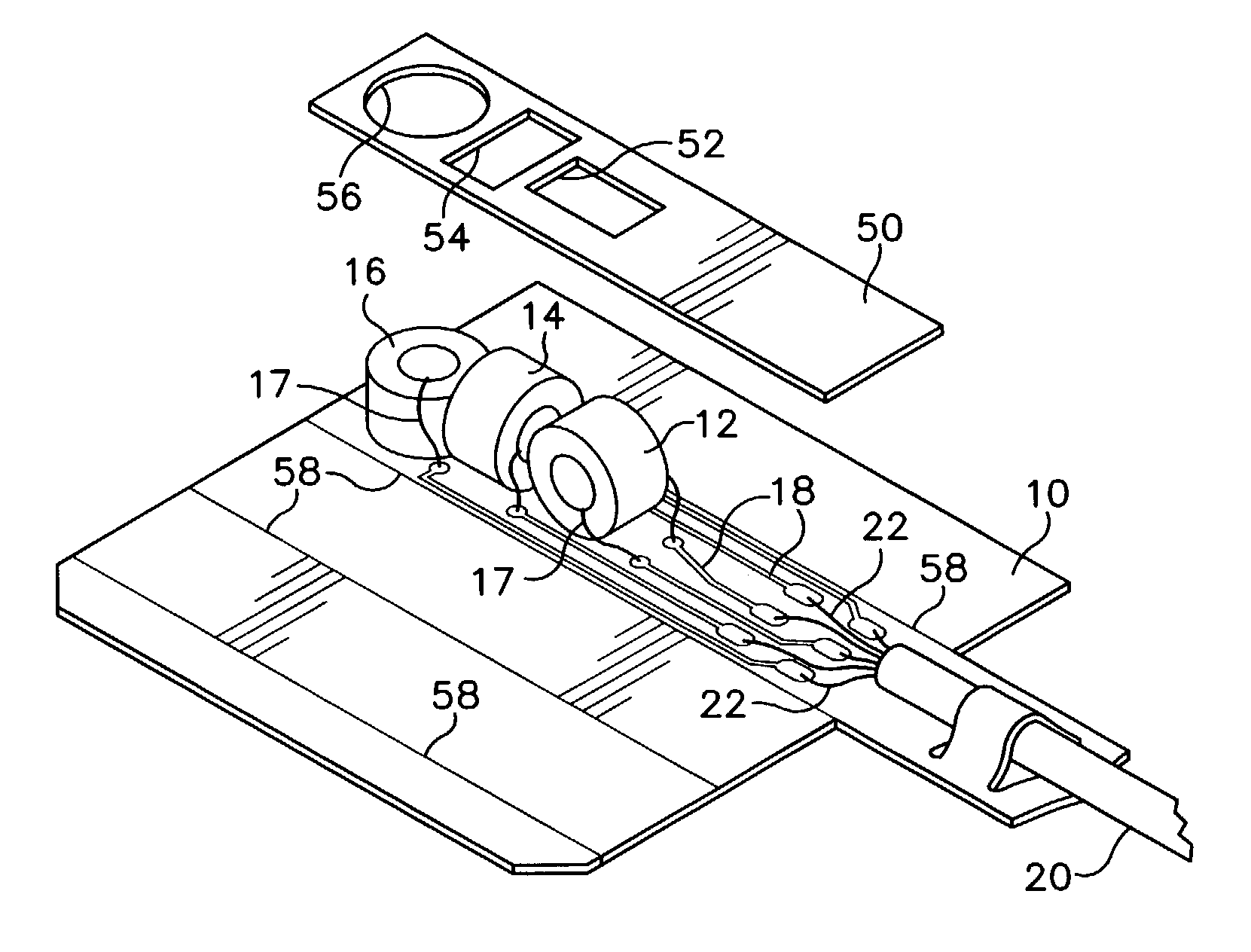

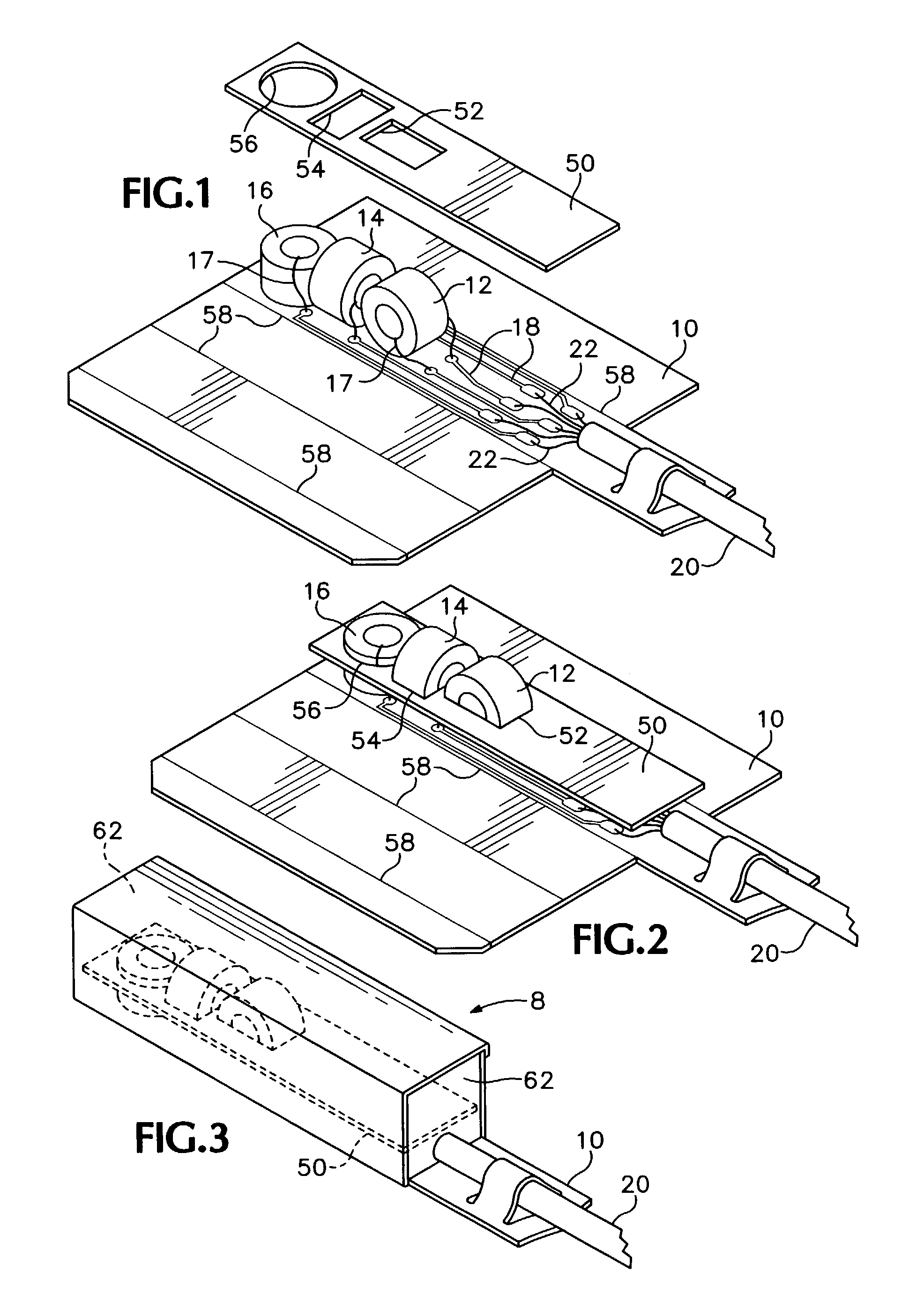

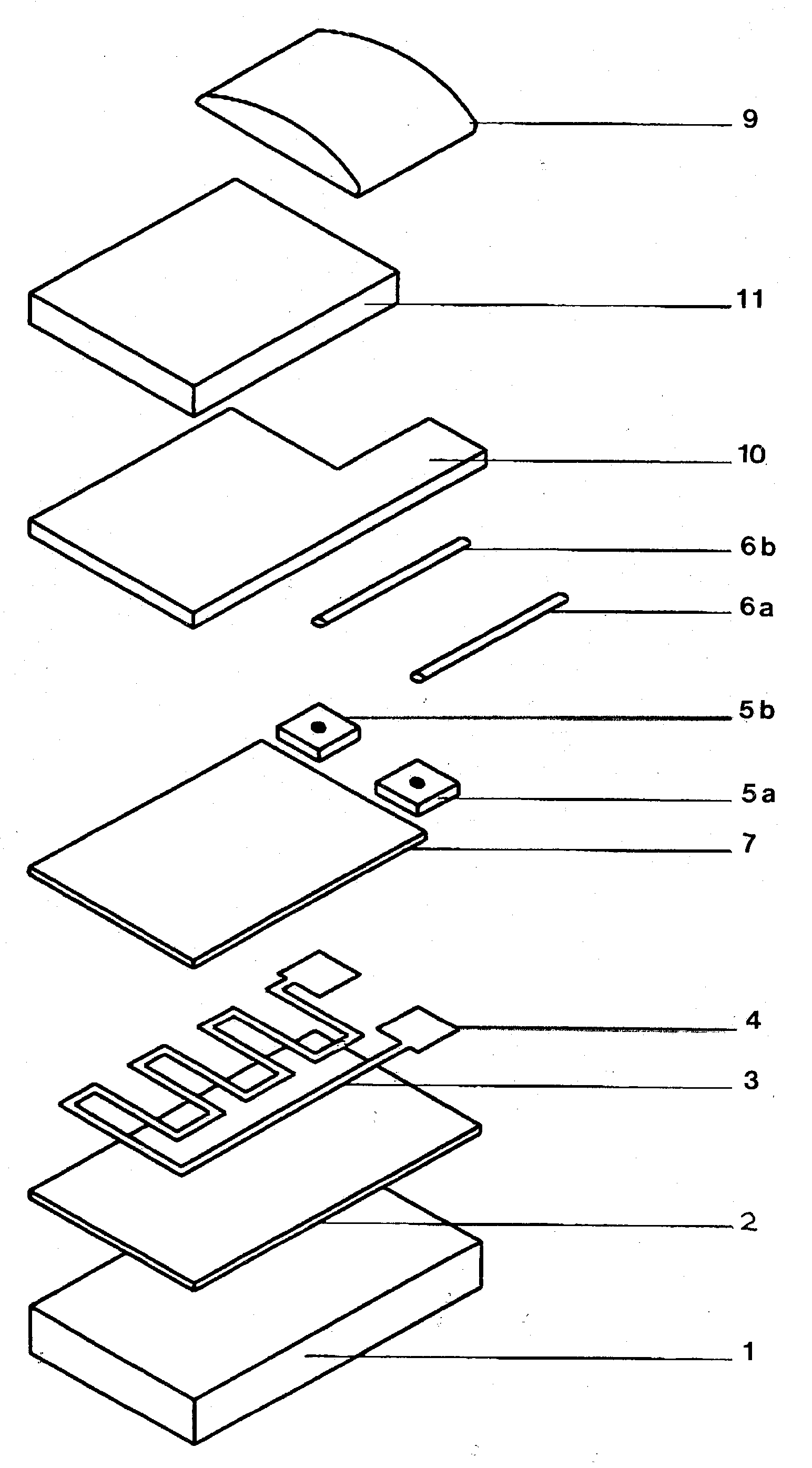

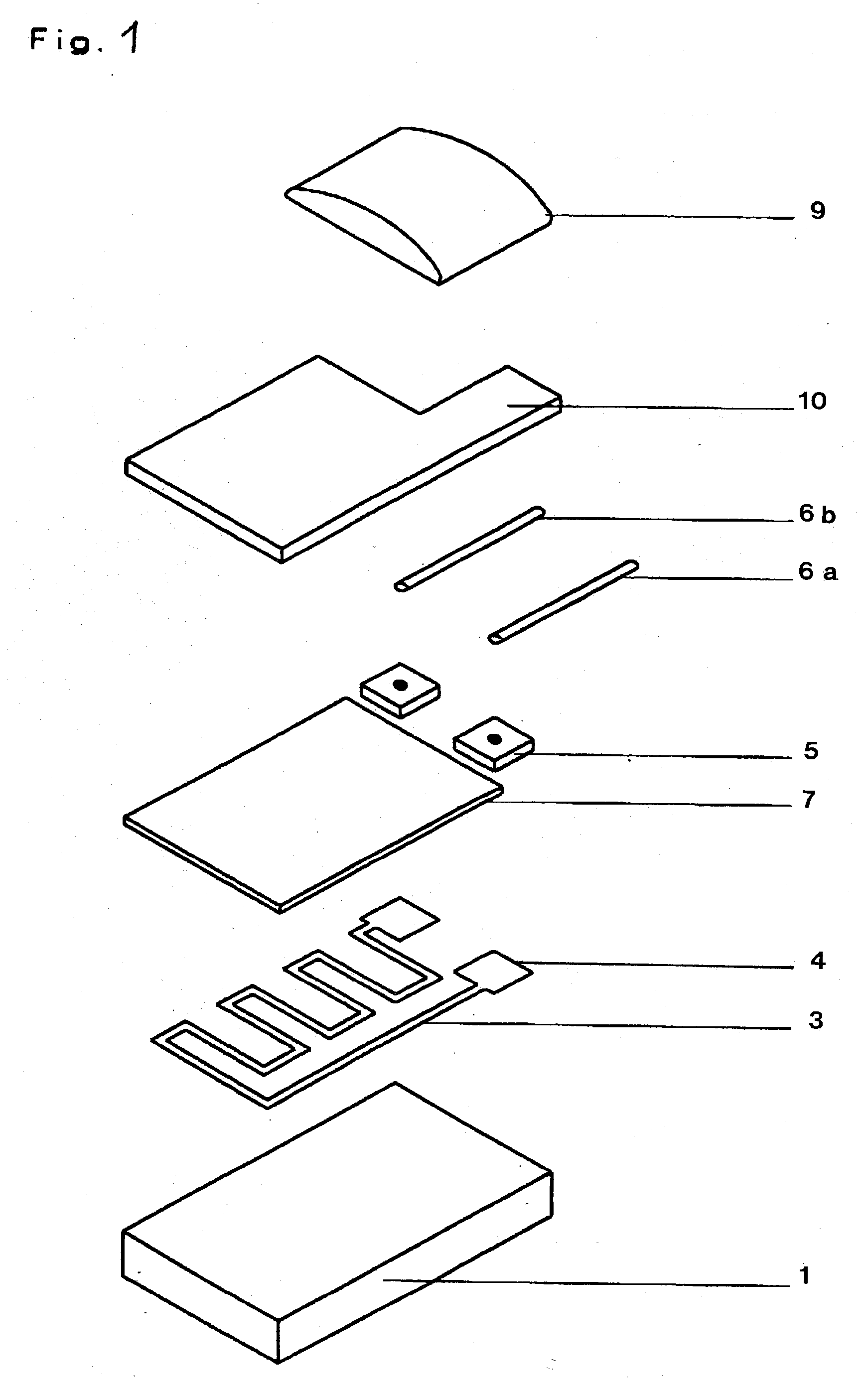

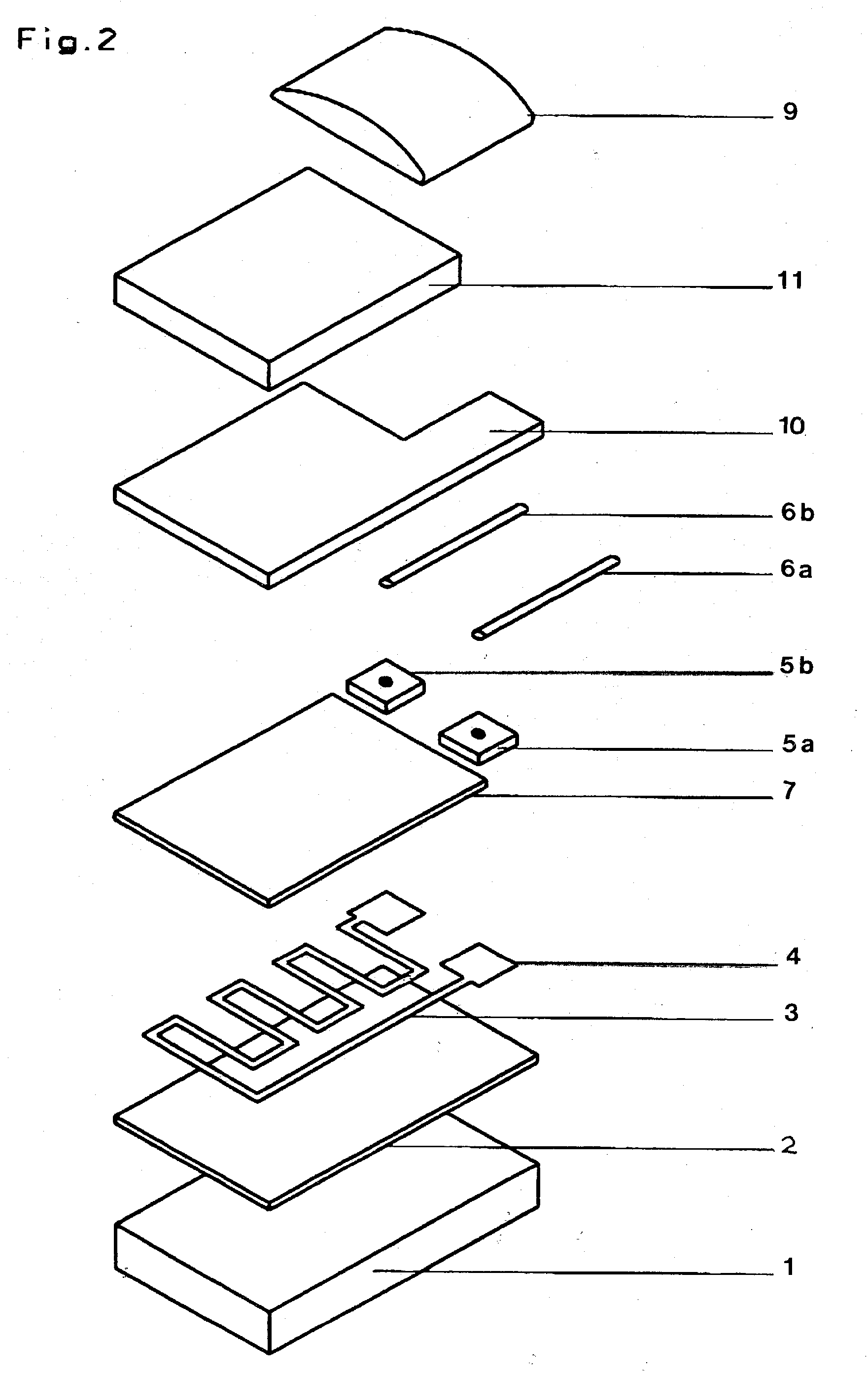

Method of making a miniaturized positional assembly

InactiveUS7028387B1ElectrocardiographyEnvelope/housing resistor manufactureEngineeringMechanical engineering

Owner:ADVANCED NEUROMODULATION SYST INC

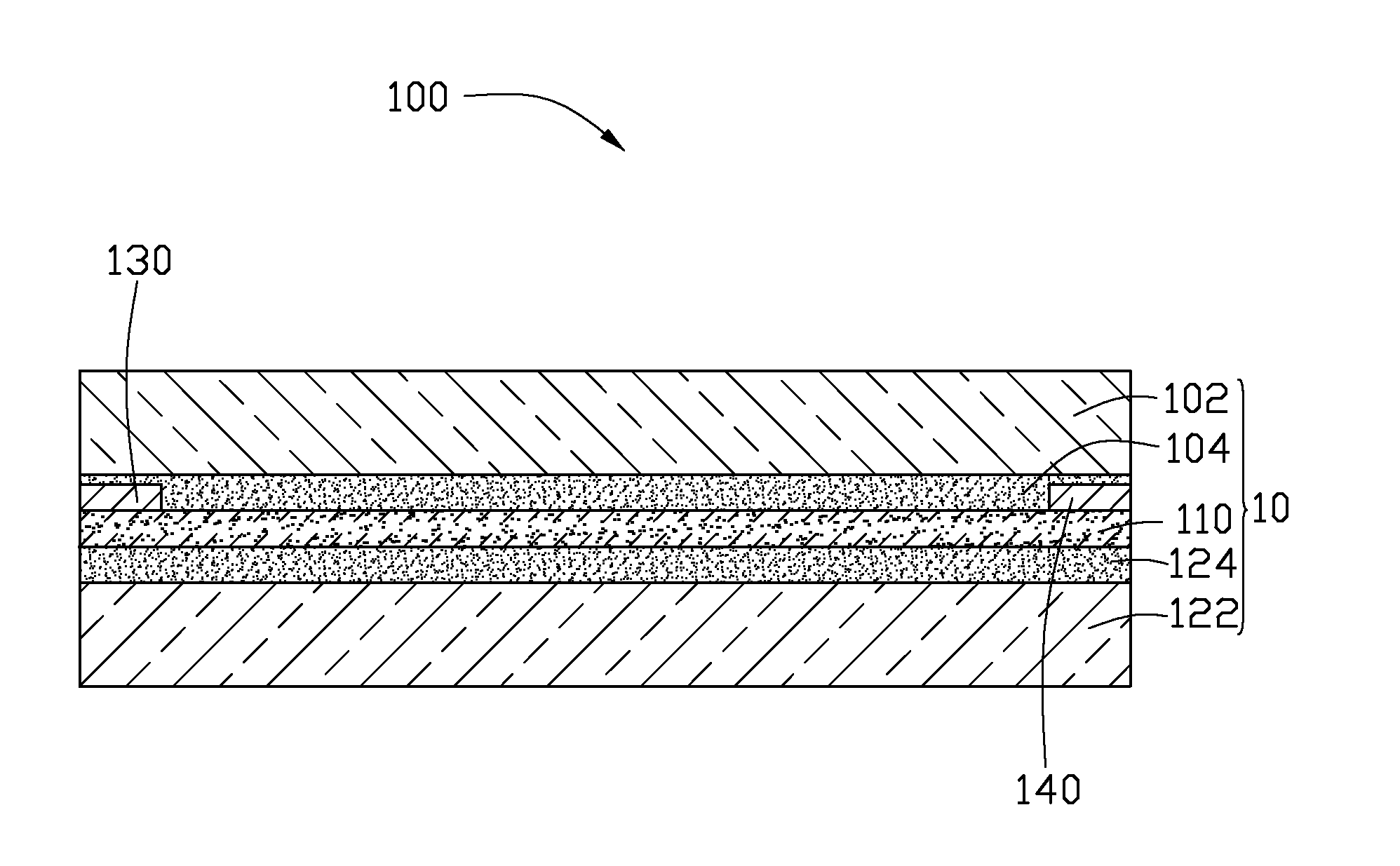

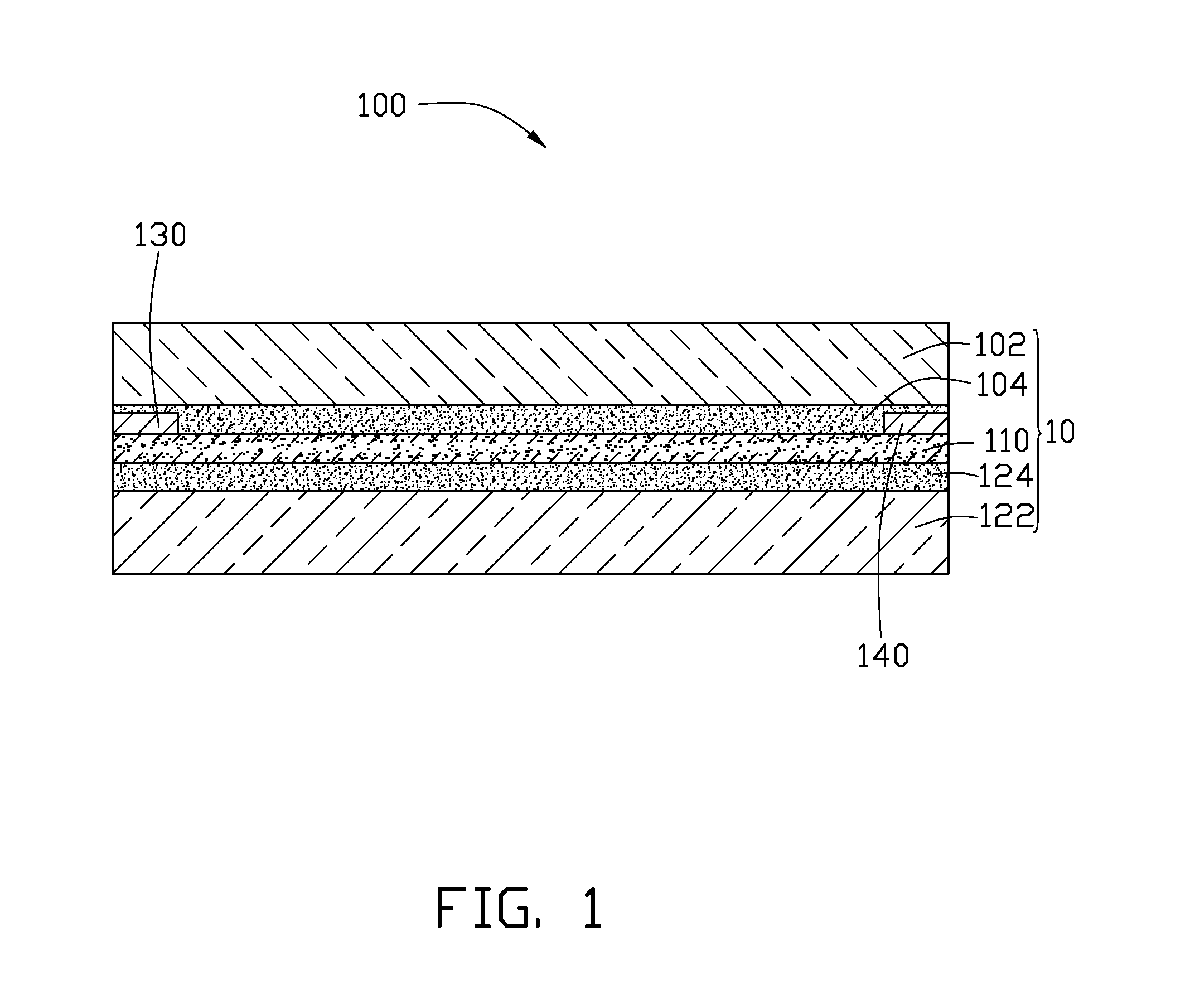

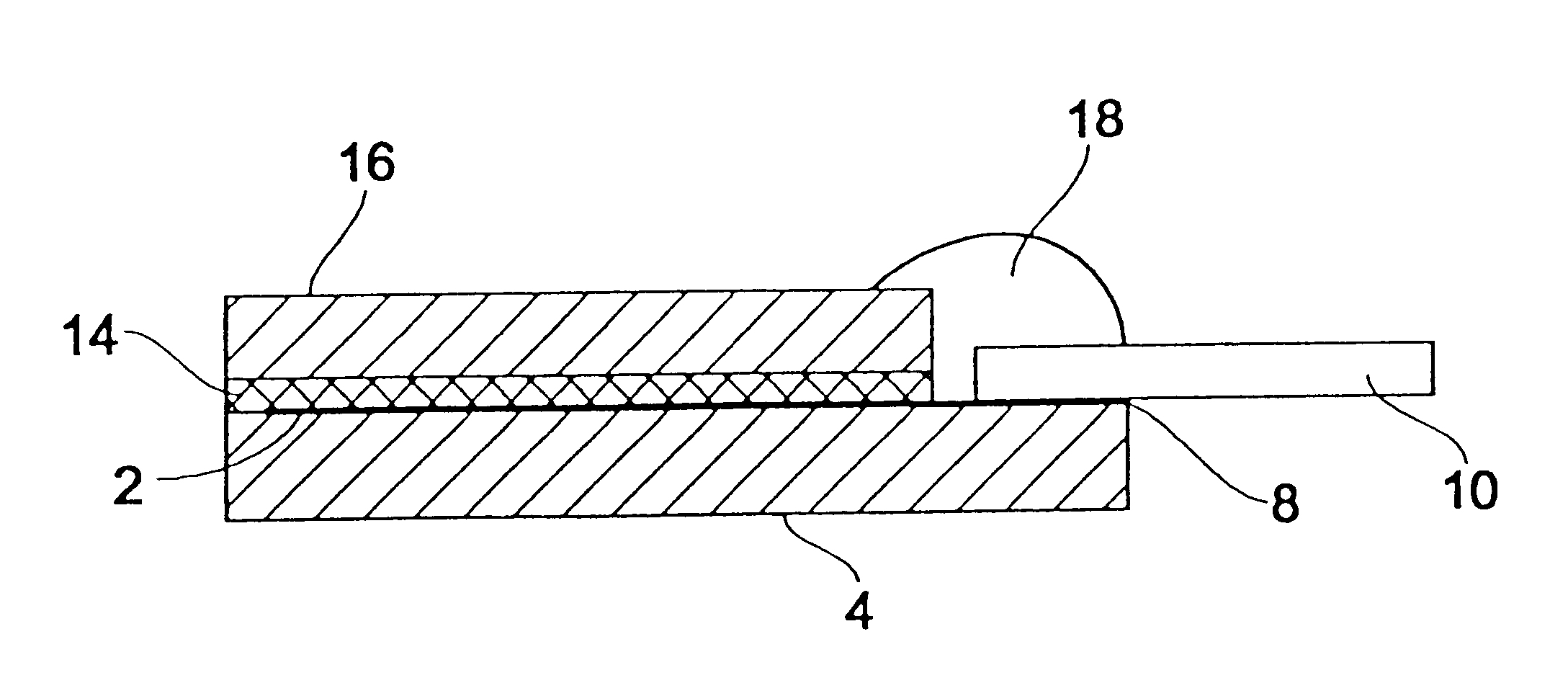

Heater and method for making the same

InactiveUS20110108545A1Improve conductivityGenerate lot of heatEnvelope/housing resistor manufactureHeater elementsCarbon nanotubeHeating element

A heater includes a first electrode, a second electrode, and a heating element. The second electrode is spaced from the first electrode. The heating element includes a first substrate, a second substrate, a first adhesive layer, a second adhesive layer and a carbon nanotube structure. The carbon nanotube structure is located between the first substrate and the second substrate, and combined with the first substrate by the first adhesive layer, and combined with the second substrate by the second adhesive layer. The carbon nanotube structure is electrically connected to the first electrode and the second electrode. A method for making the heater is also provided.

Owner:TSINGHUA UNIV +1

Electric grill and methods of providing the same

InactiveUS20110180527A1Cooking-vessel materialsDomestic stoves or rangesElectrical and Electronics engineeringEngineering

Owner:THERMOCERAMIX

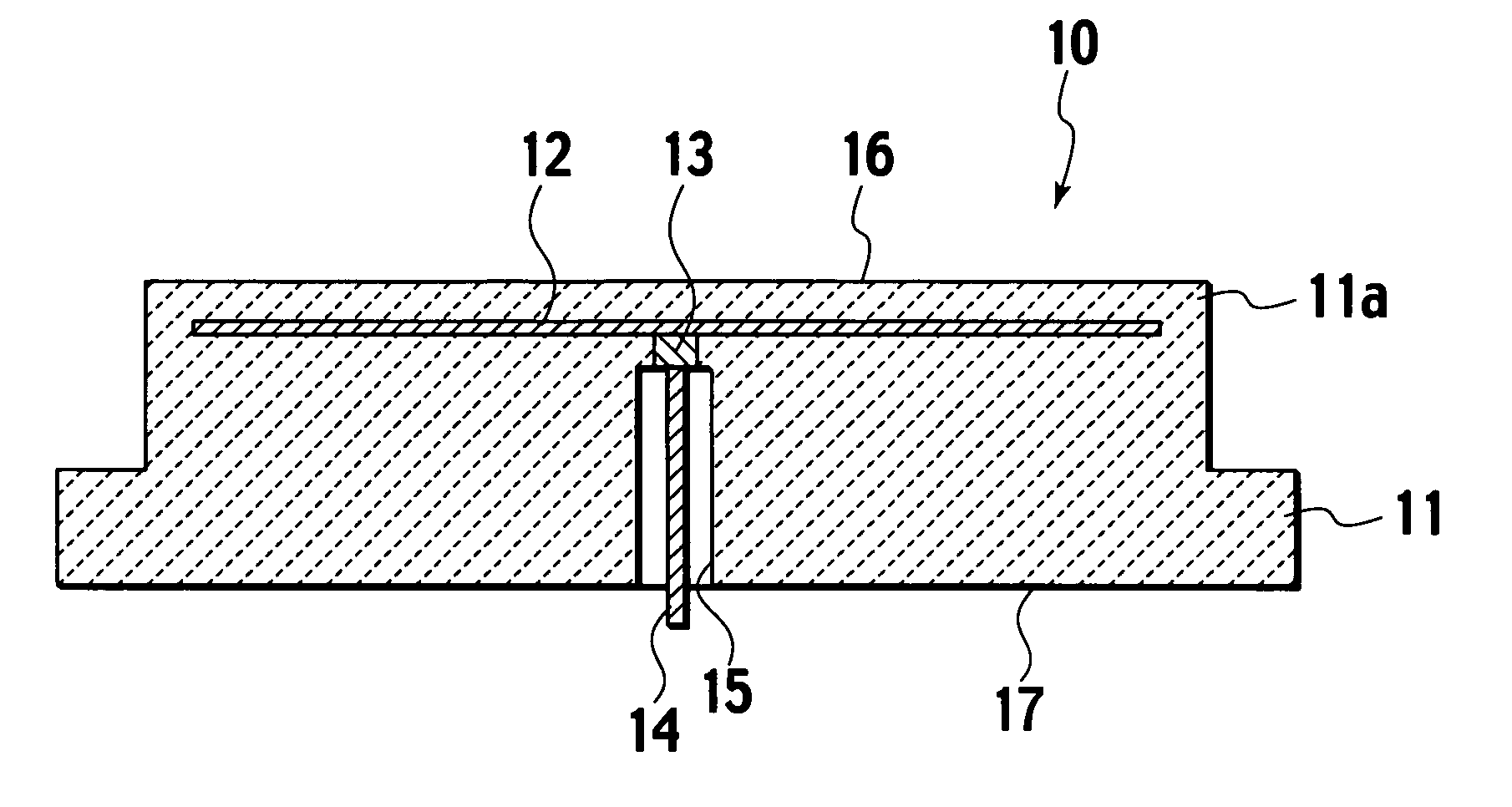

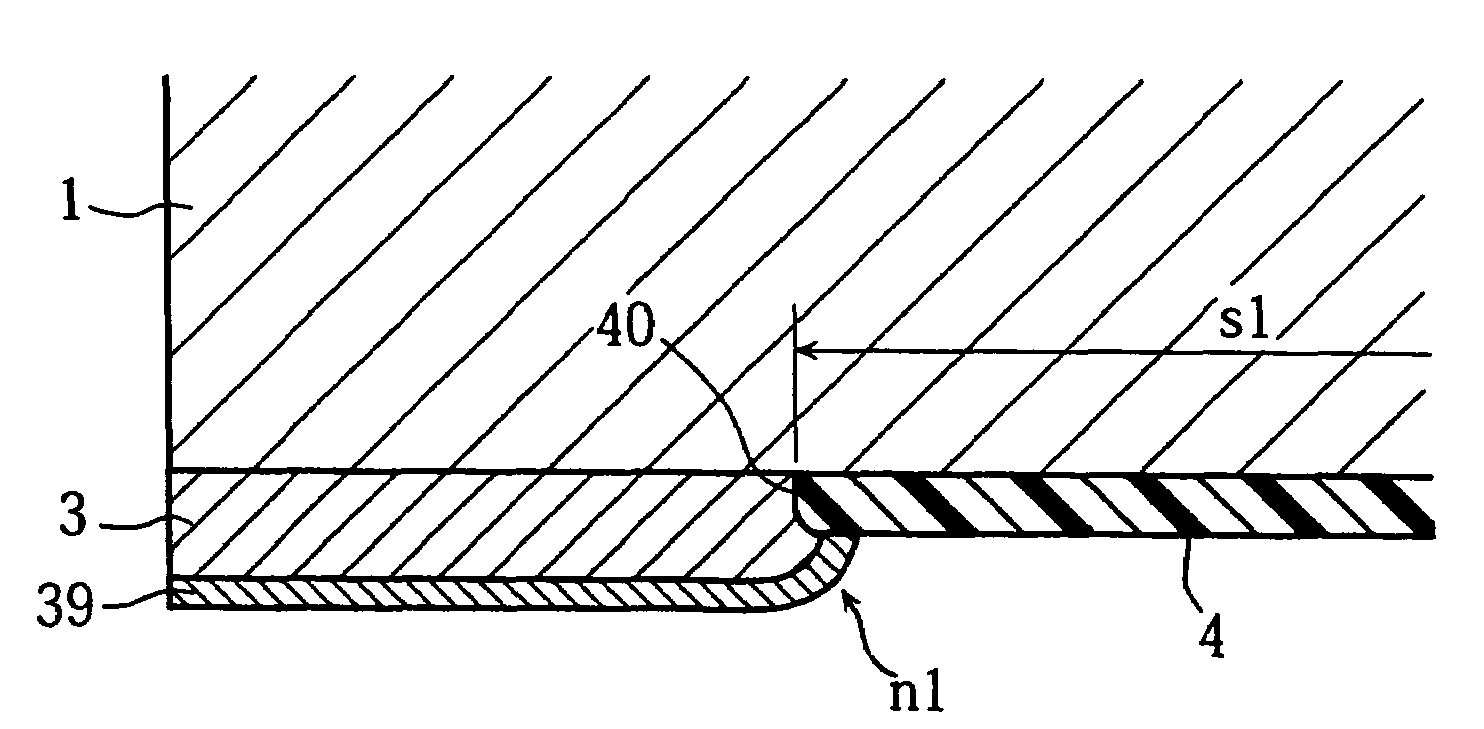

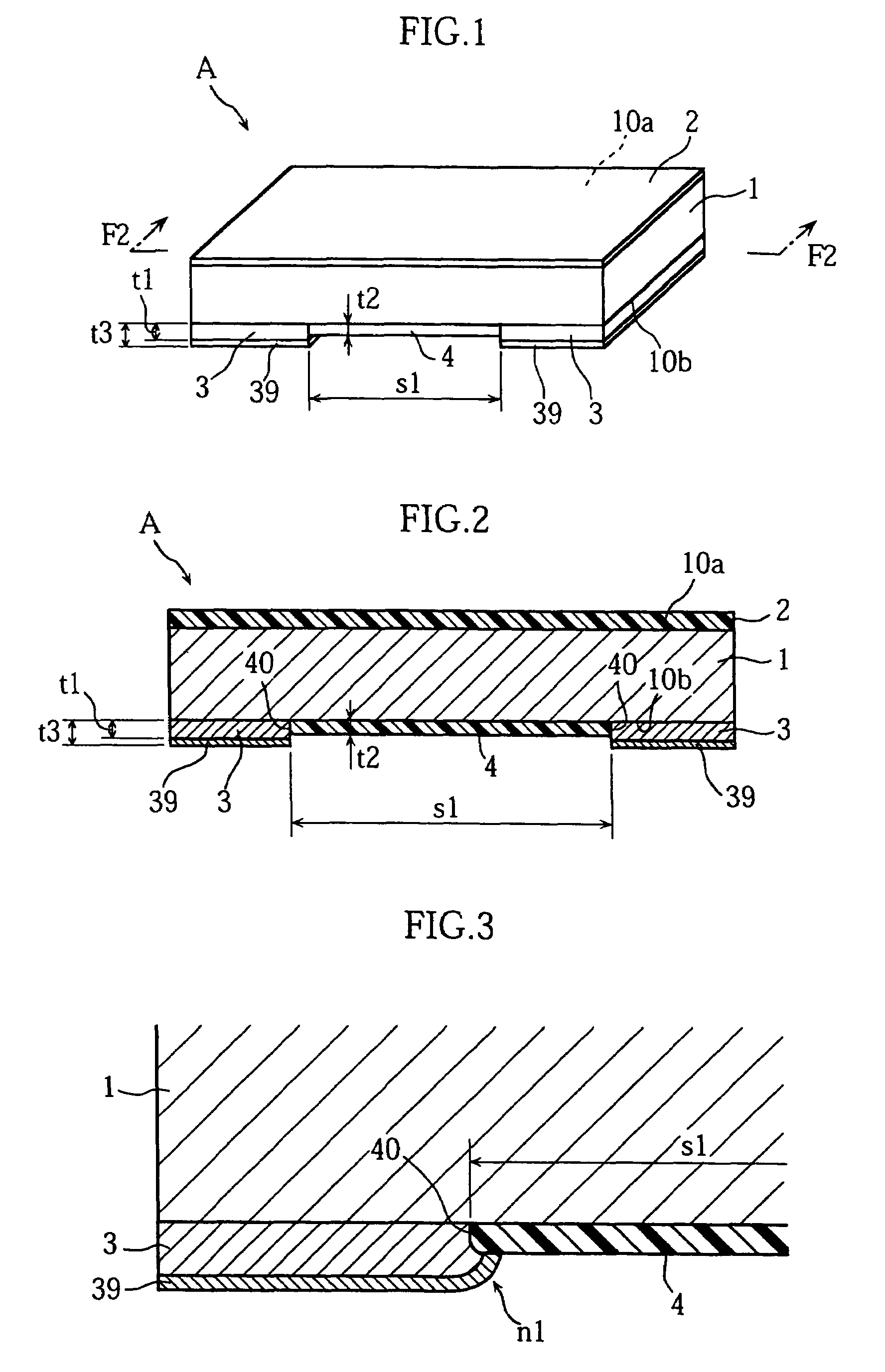

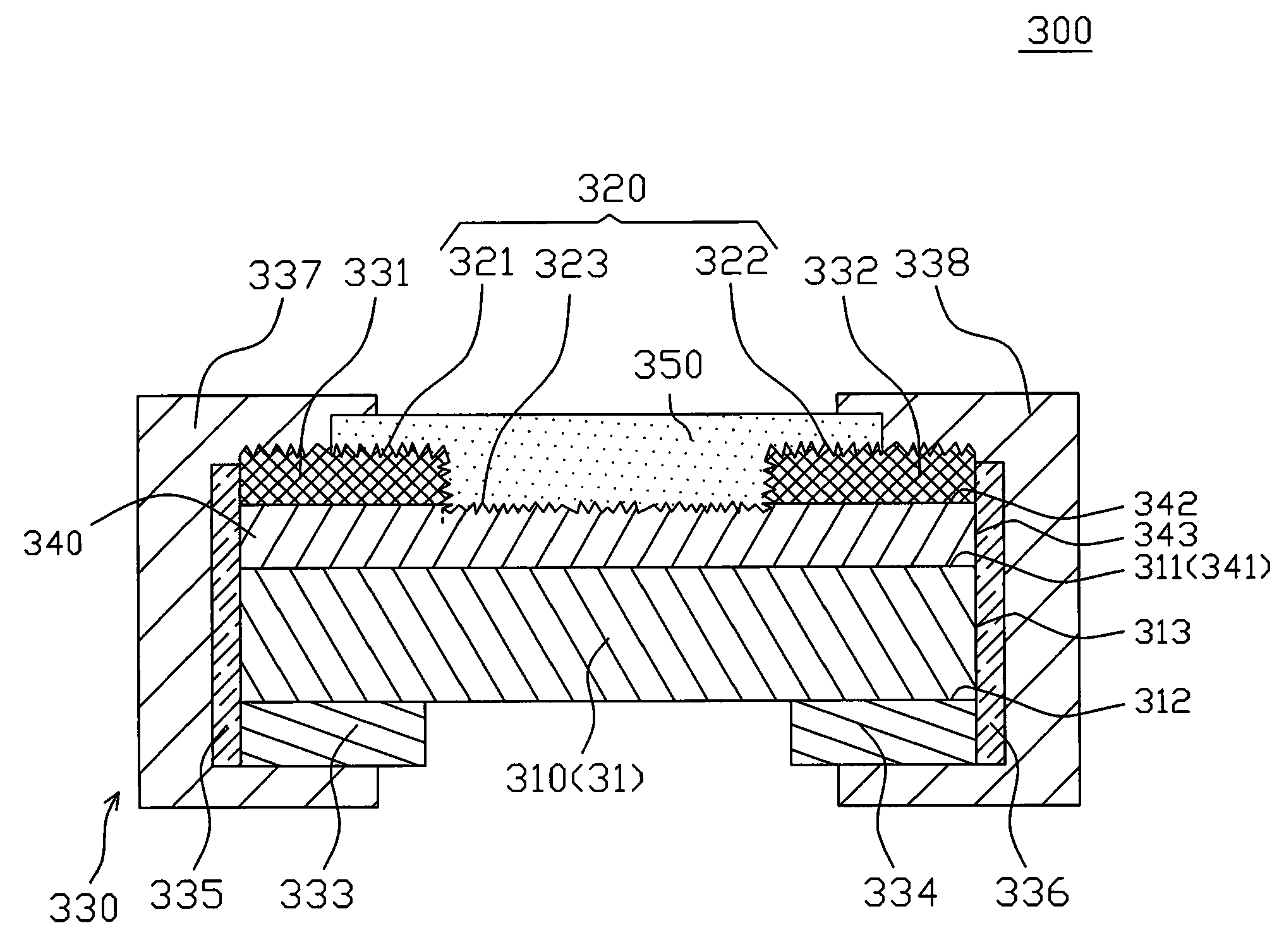

Alumina member and manufacturing method thereof

ActiveUS20060169688A1Bonded firmlyAvoid deformationEnvelope/housing resistor manufactureSemiconductor/solid-state device manufacturingThermal expansionMaterials science

An electrostatic chuck includes a base of a sintered body containing alumina, an electrode as a power-supplied member embedded in the base and supplied with electric power, a bonding member embedded in the base and bonded to the electrode, in which a difference in coefficient of thermal expansion from the sintered body is 2×10−6 / K or less, and a melting point is higher than baking temperature of the sintered body, and a terminal bonded to the electrode through the bonding member.

Owner:NGK INSULATORS LTD

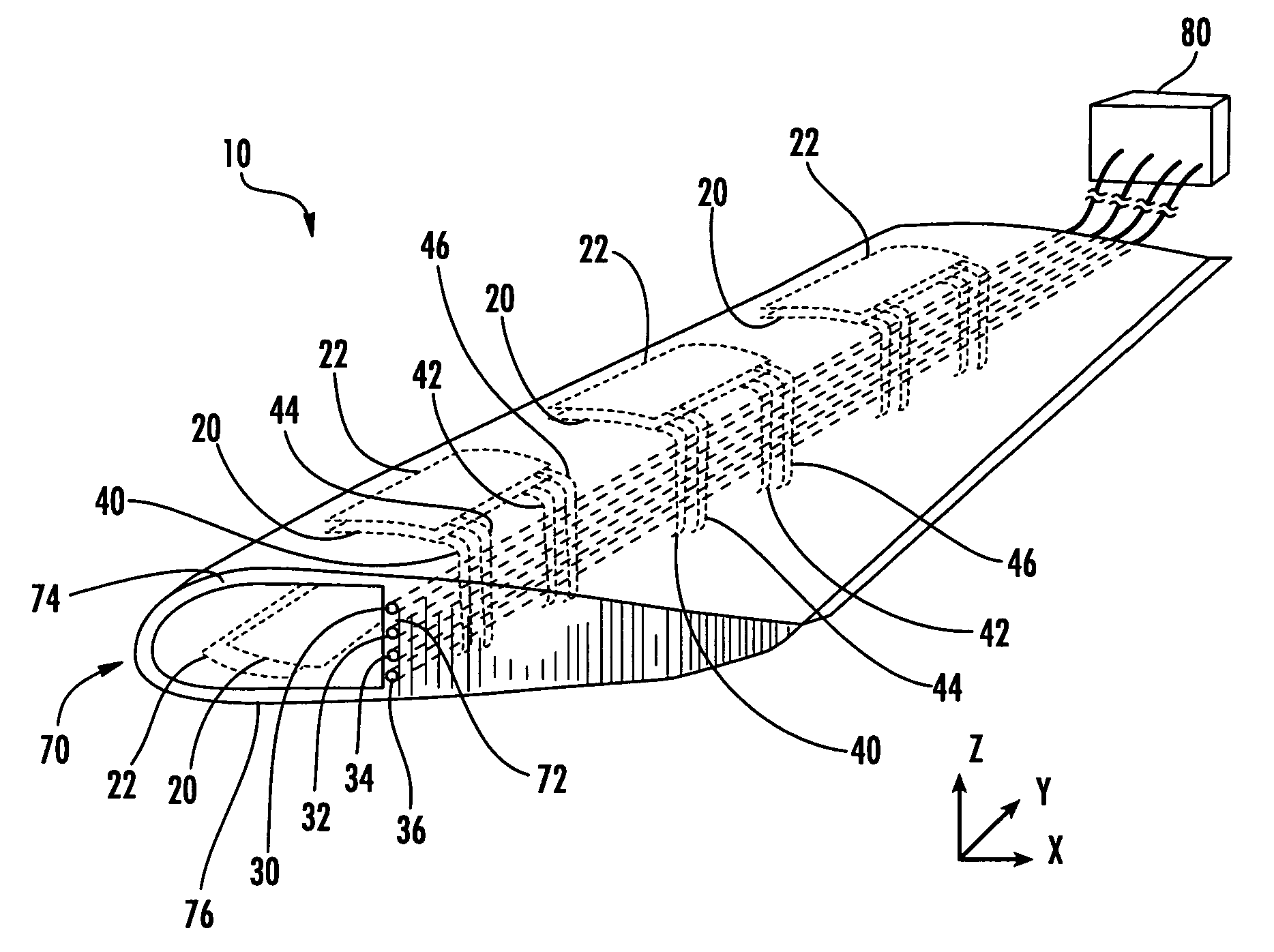

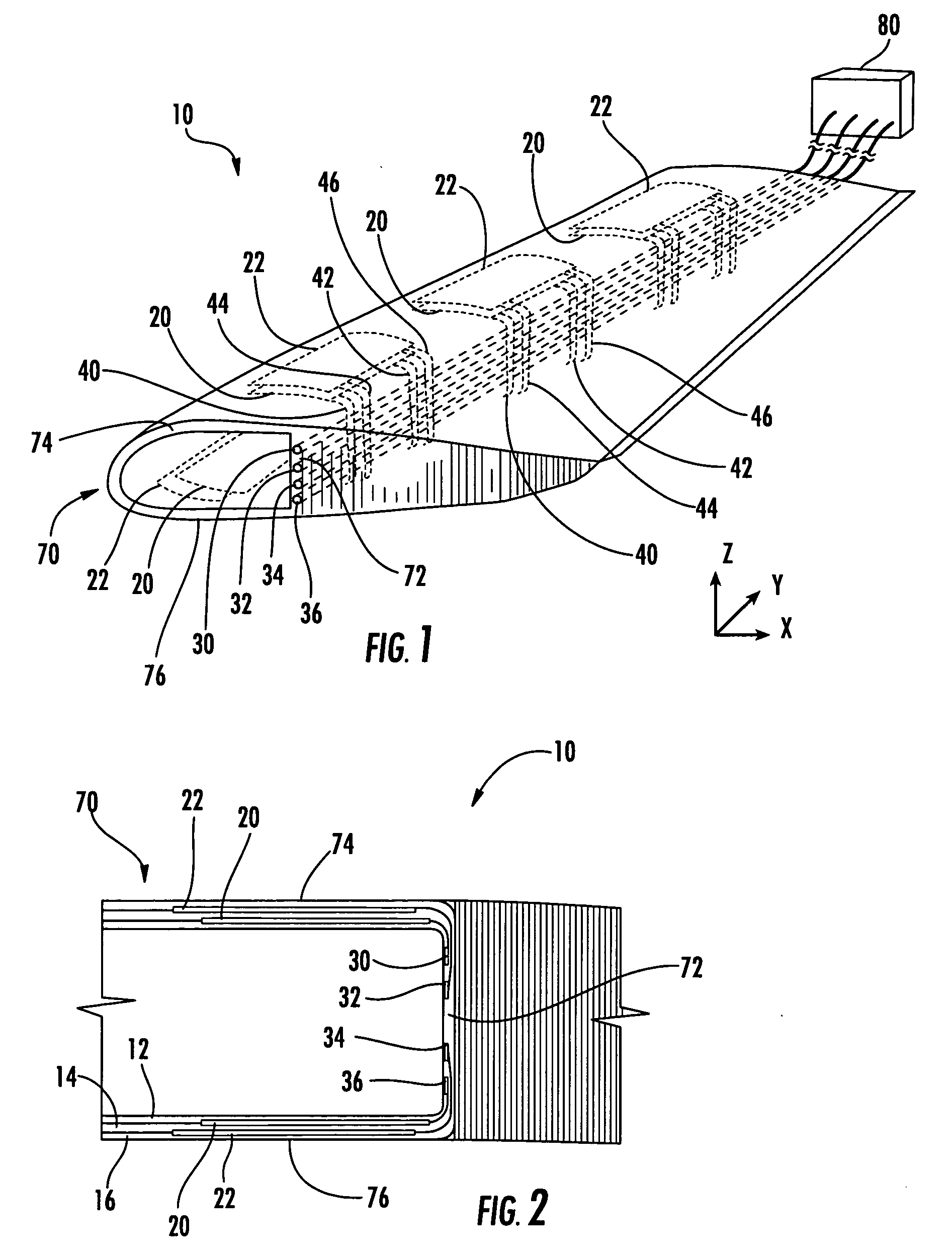

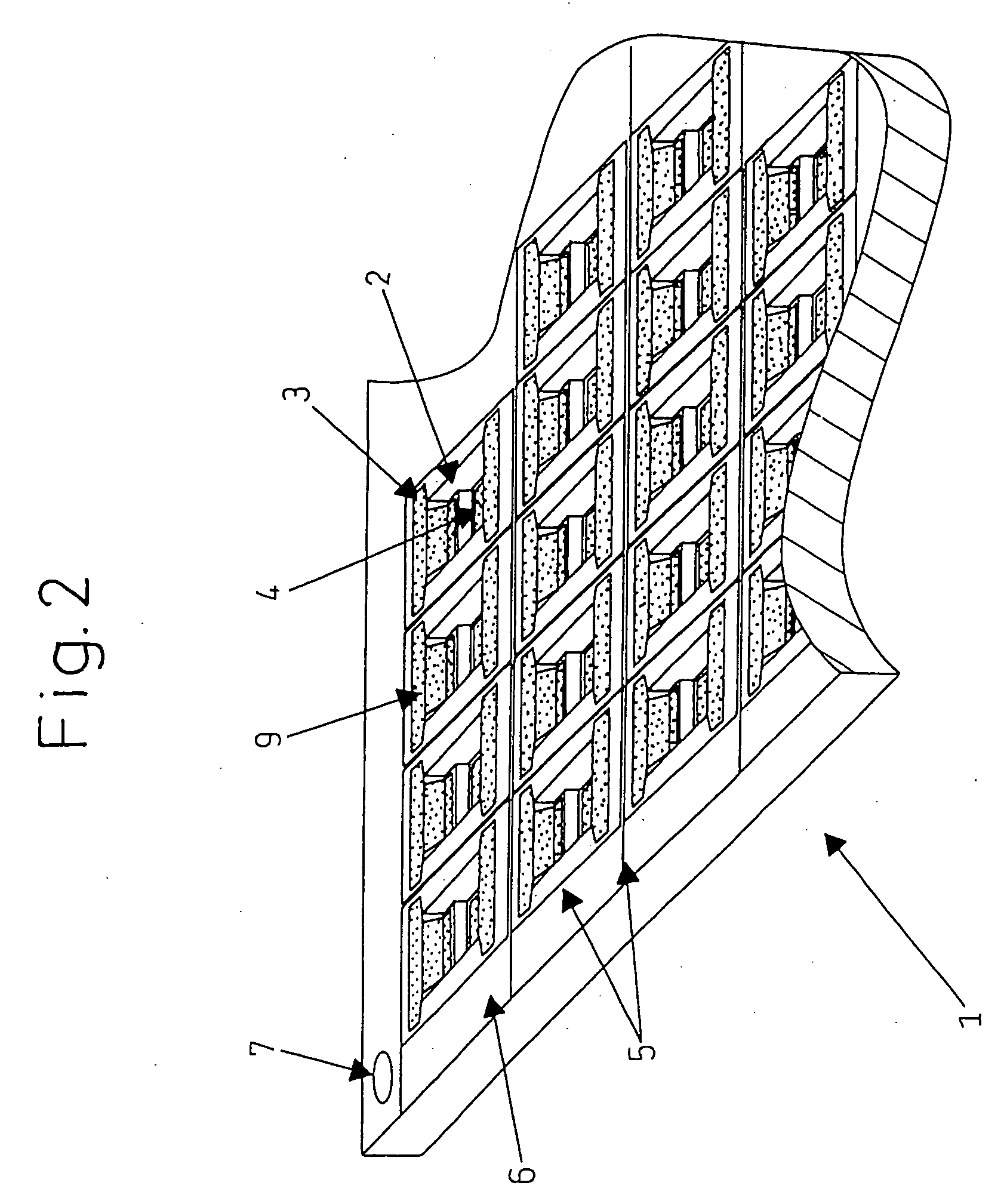

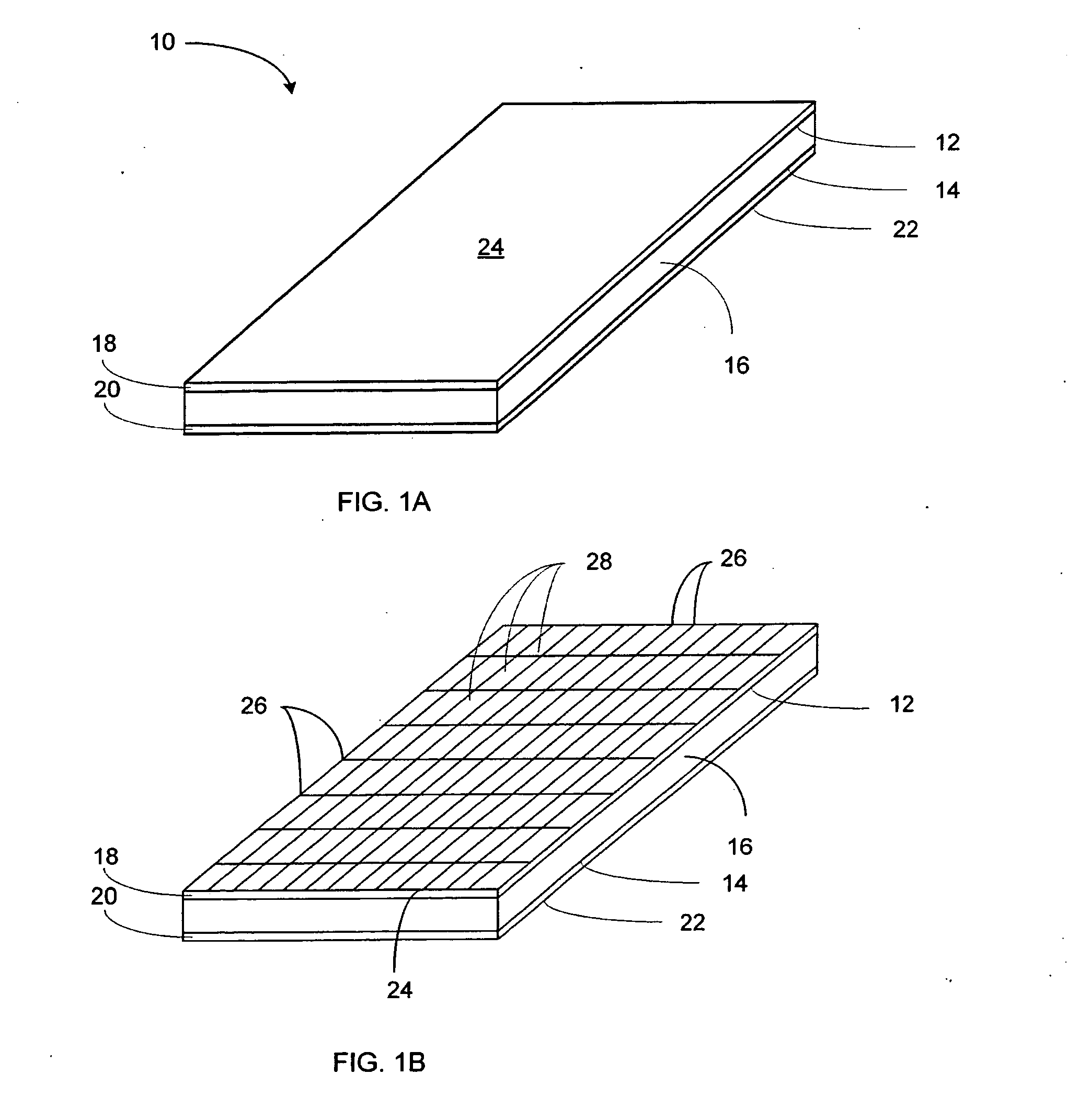

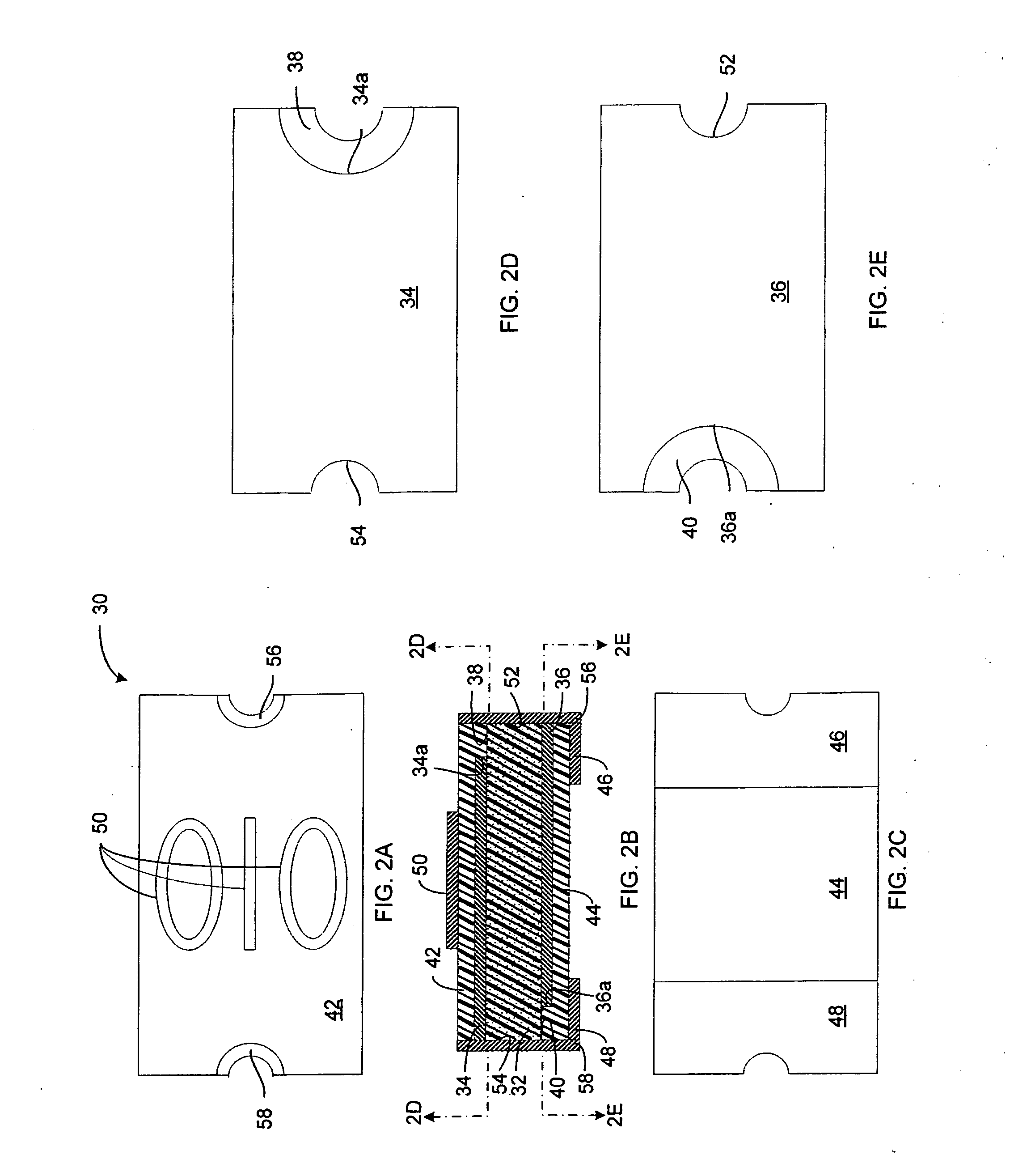

Structurally integrated circuit and associated method

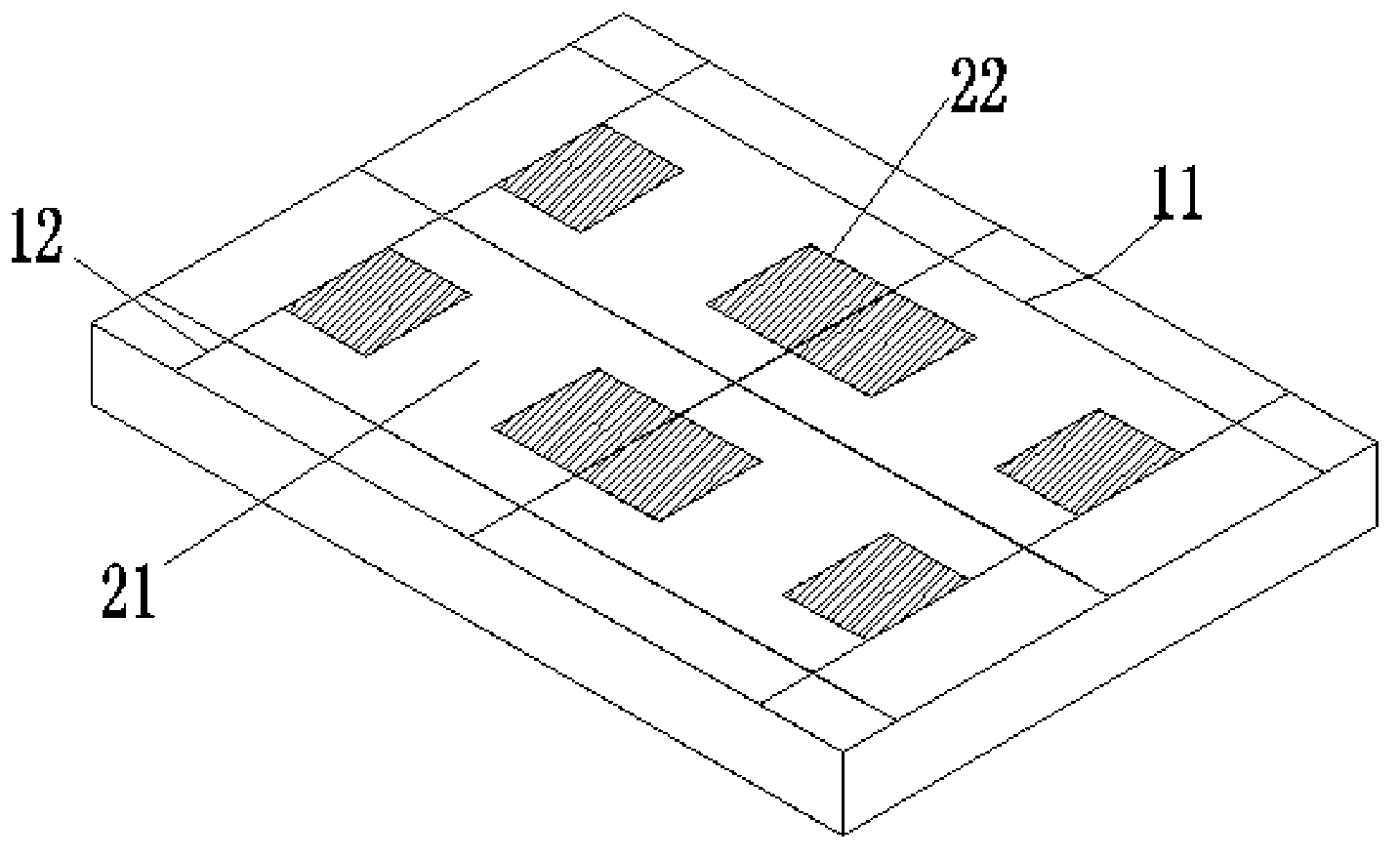

ActiveUS20050257956A1Envelope/housing resistor manufactureLaminating printed circuit boardsElectrical devicesIntegrated circuit

A composite structural member with an integrated electrical circuit and an associated method of manufacture are provided. The structural member includes a plurality of layers of structural reinforcement material, and two or more electrical devices are disposed at least partially between the layers with an intermediate layer of the structural reinforcement material disposed between the electrical devices. At least one electrical bus is disposed in the structural member, and each electrical device is connected to the bus by a conductive electrode. Thus, the electrodes can extend through the intermediate layer of the structural reinforcement material to connect each of the electrical devices to one or more of the buses.

Owner:THE BOEING CO

Platinum temperature sensor and its method of production

InactiveUS6653926B1Connected deterioration of property is preventedEnvelope/housing resistor manufactureThermometers using electric/magnetic elementsPlatinumMetallurgy

A Platinum temperature sensor comprises a ceramic substrate and a platinum thin-film resistor applied to said ceramic substrate, a ceramic cover layer and a connecting layer generated from a ceramic green layer by pressure and temperature treatment. The ceramic cover layer is connected with the ceramic substrate in such a way via the connecting layer that the platinum thin-film resistor is sealingly encapsulated with regard to the environment.

Owner:BORGWARNER BERU SYST

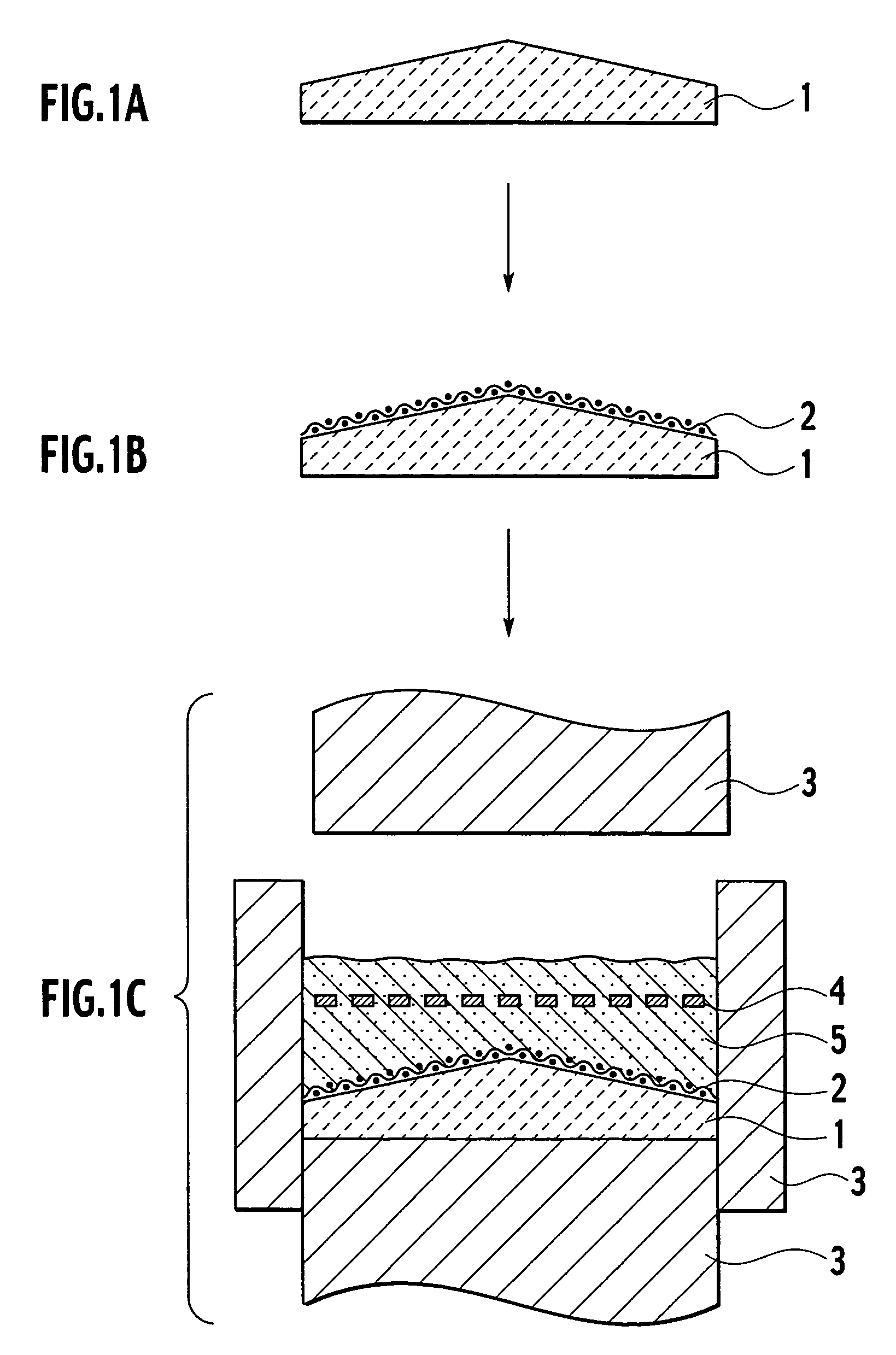

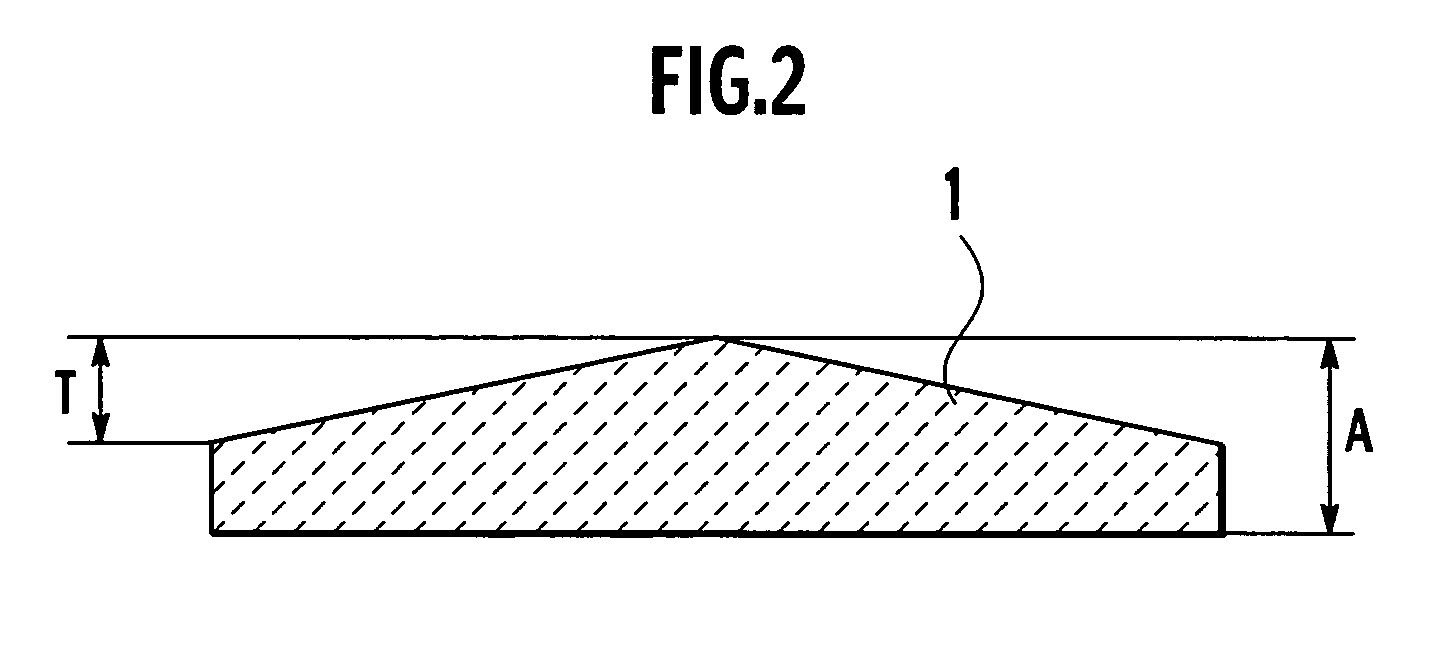

Method of manufacturing electrical resistance heating element

ActiveUS7275309B2Reducing range variationPrevent the sintered ceramicsEnvelope/housing resistor manufactureSemiconductor/solid-state device manufacturingMetalMelting point

A method of manufacturing an electrical-resistance heating element includes forming sintered ceramics or calcined ceramics, forming an electrode on the sintered ceramics or the calcined ceramics, and forming a ceramic base material having mainly a high melting point metal on the electrode embedded therein, thereby forming a heating element with built-in electrode.

Owner:NGK INSULATORS LTD

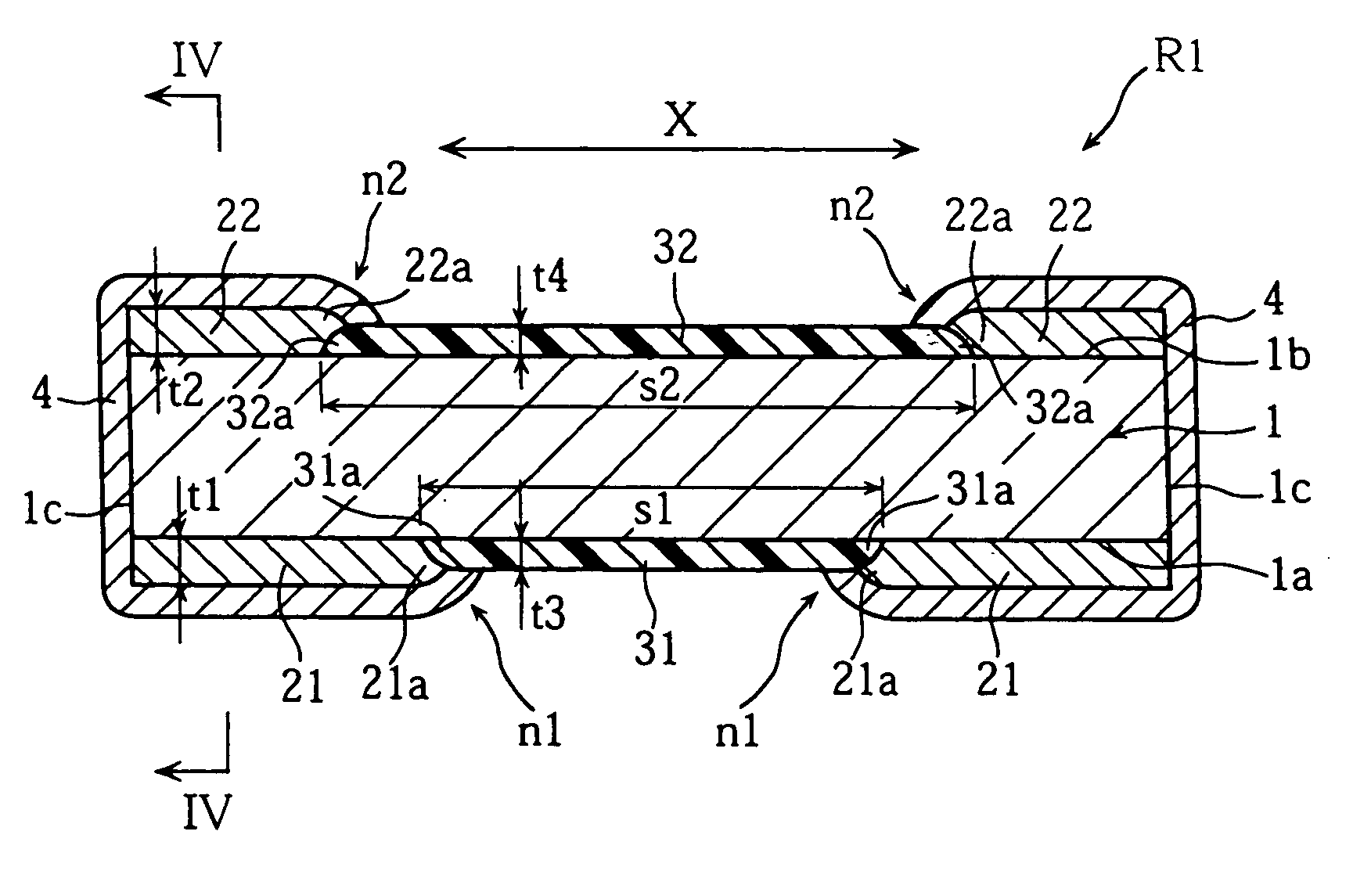

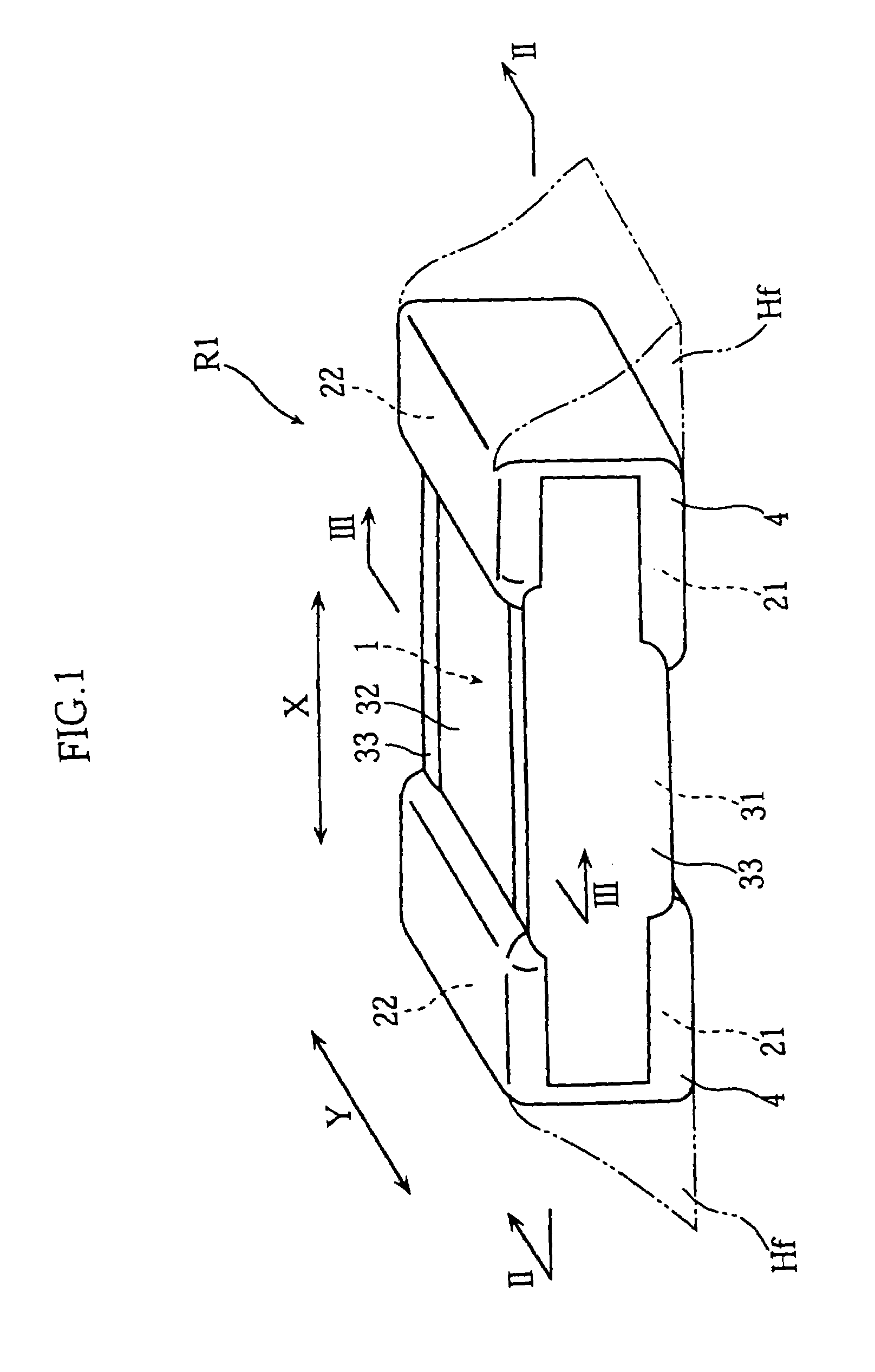

Chip resistor and manufacturing method therefor

ActiveUS7330099B2Easy to manufacturePrinted circuit assemblingResistor chip manufactureInsulation layerEngineering

Owner:ROHM CO LTD

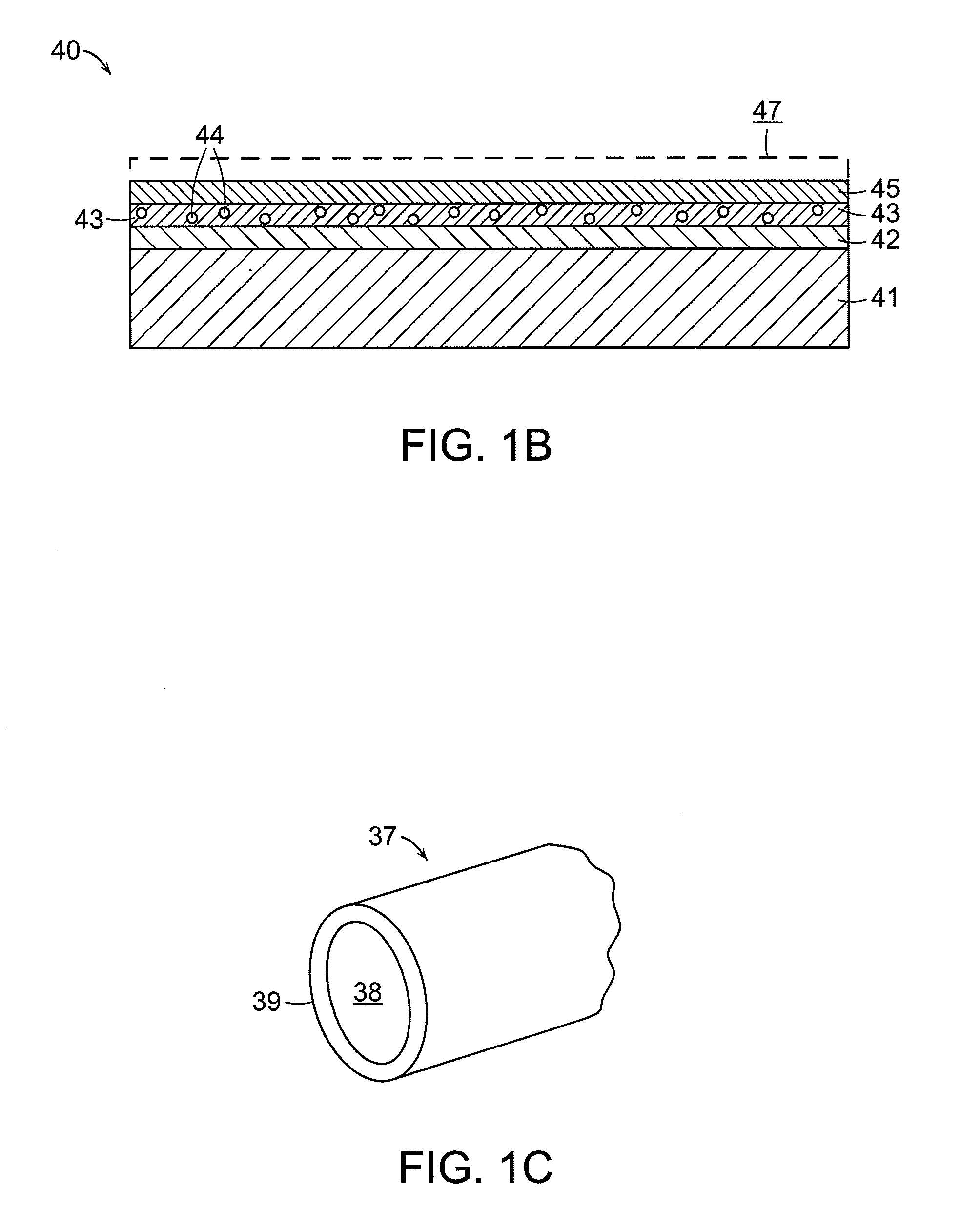

Activated carbon fiber soft electric heating product and manufacturing method thereof

InactiveUS20100062667A1Light weightUniform electric heating performanceEnvelope/housing resistor manufactureMedical devicesFiberEpoxy

An activated carbon fiber soft electric heating product and its manufacturing method for overcoming existing problems including uneven temperature rise and heat dissipation at surfaces of the product, unbendable feature, short life and poor safety. An activated carbon fiber cloth and a woven fiber cloth of the activated carbon fiber soft electric heating product are fixed by an epoxy resin layer, and a conducting copper net is disposed between the activated carbon fiber cloth and the epoxy resin layer and coupled to a power input wire. The manufacturing method includes the steps of: (1) spraying an epoxy resin on a surface of the woven fiber cloth, and bake-drying and hot pressing the woven fiber cloth; and (2) connecting the conducting copper net and the power input wire, laying the activated carbon fiber cloth, and performing a second-time hot pressing. Meanwhile, carbon fiber constitutes a heat generating surface with the advantages of a light weight, a soft texture, a bendable feature, a uniform electric heating performance, a fast temperature rise, a highly safe, reliable and long life feature. In addition, the method of the invention involves a simple technical skill and an easy operation.

Owner:PAN

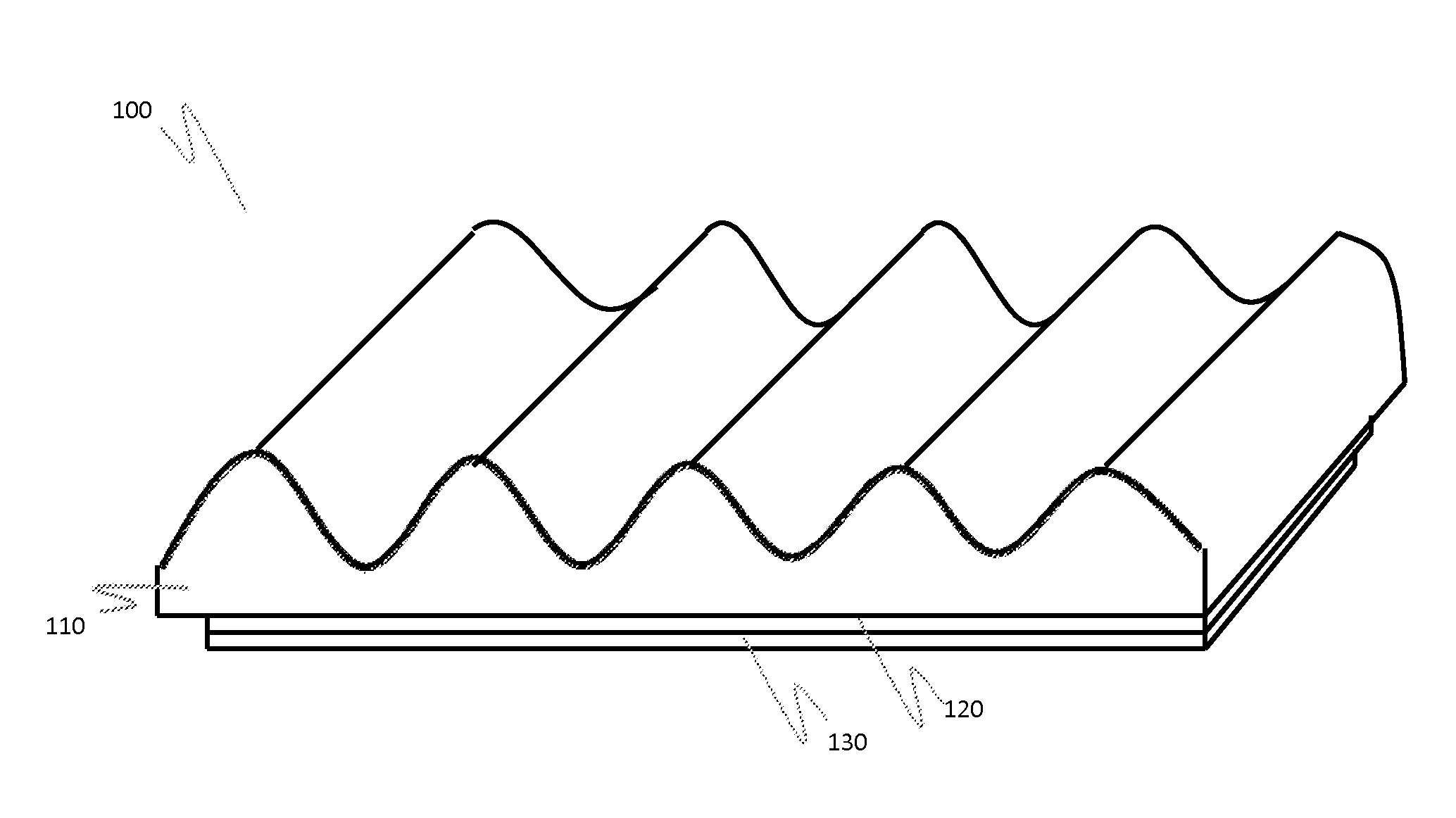

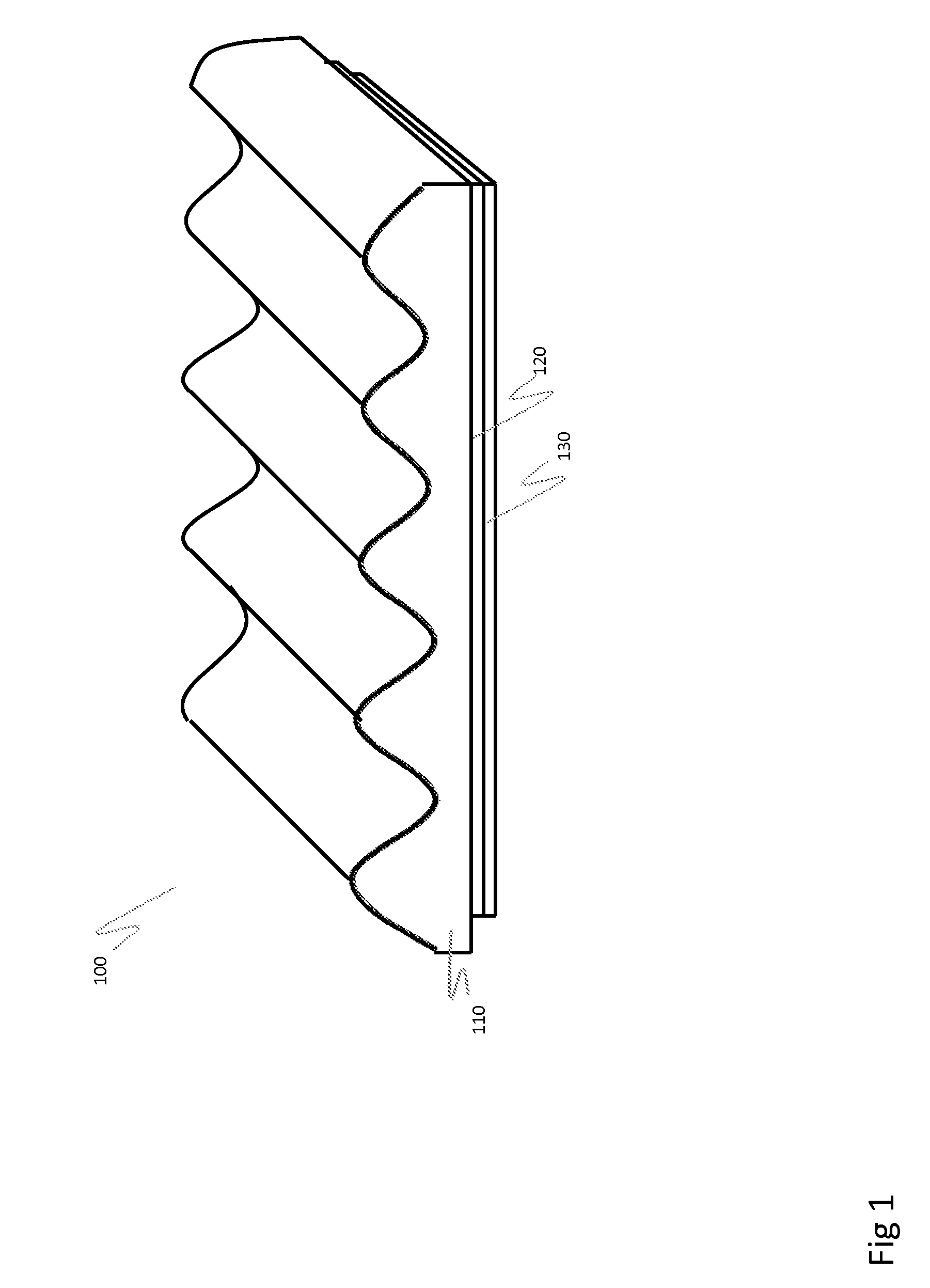

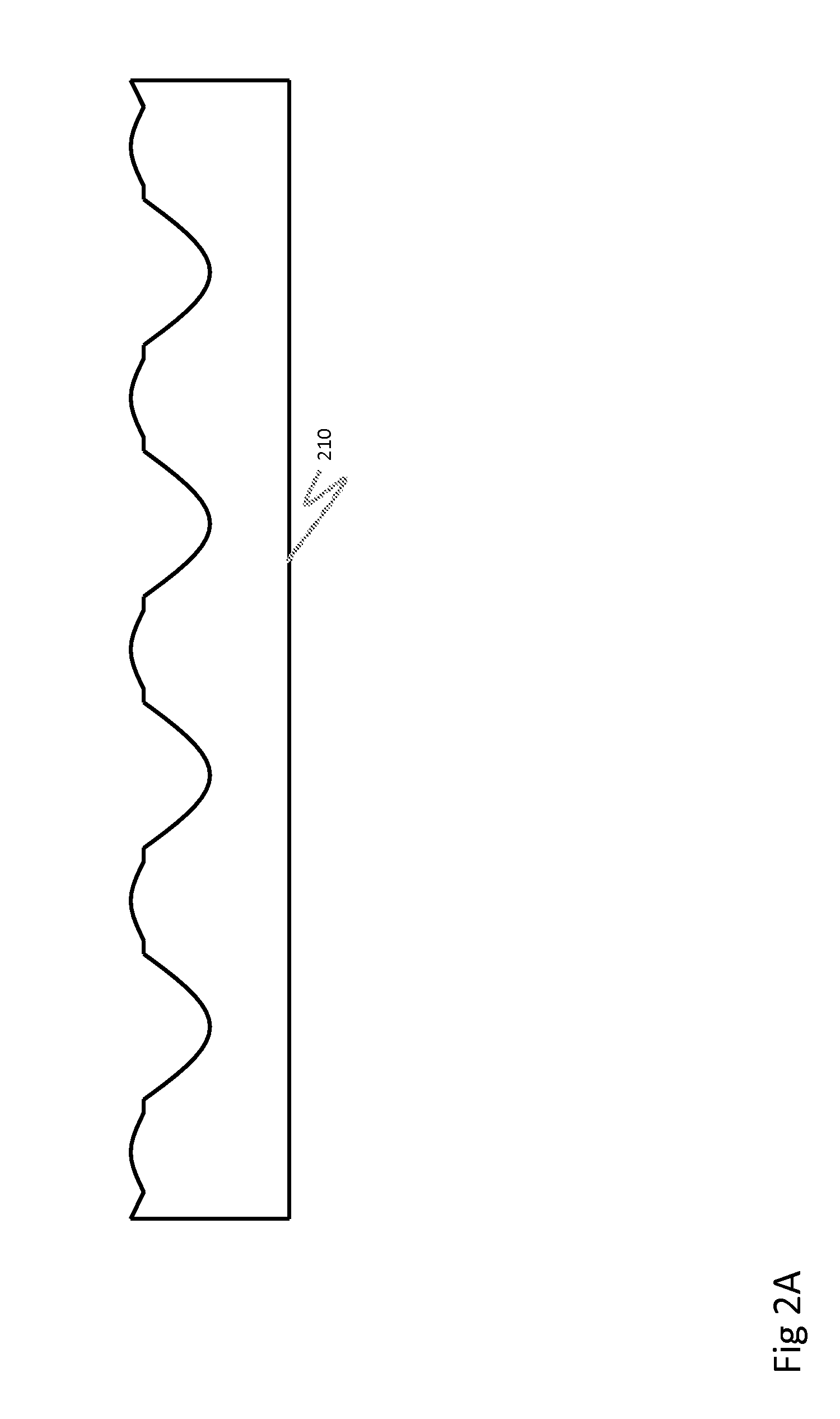

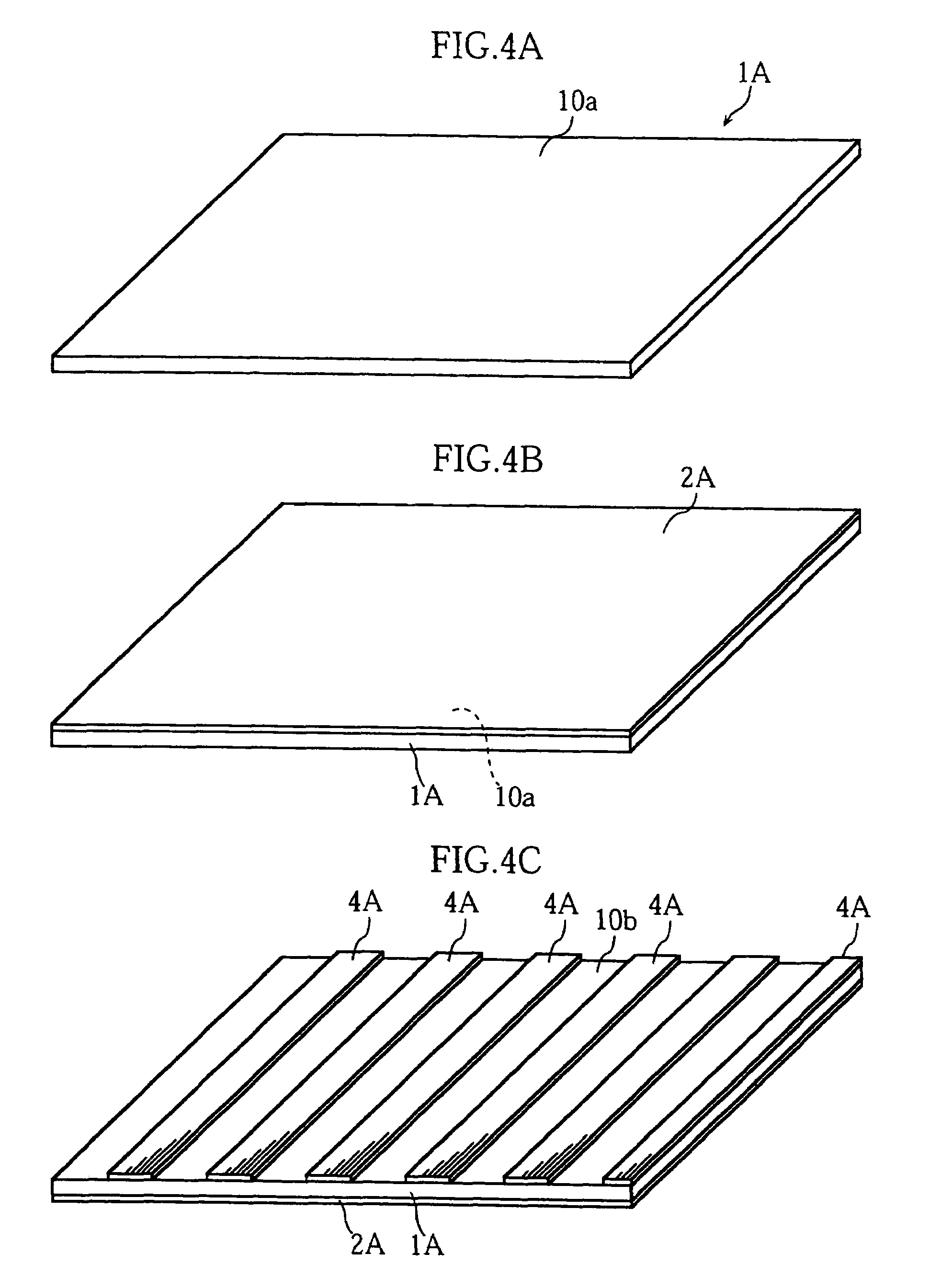

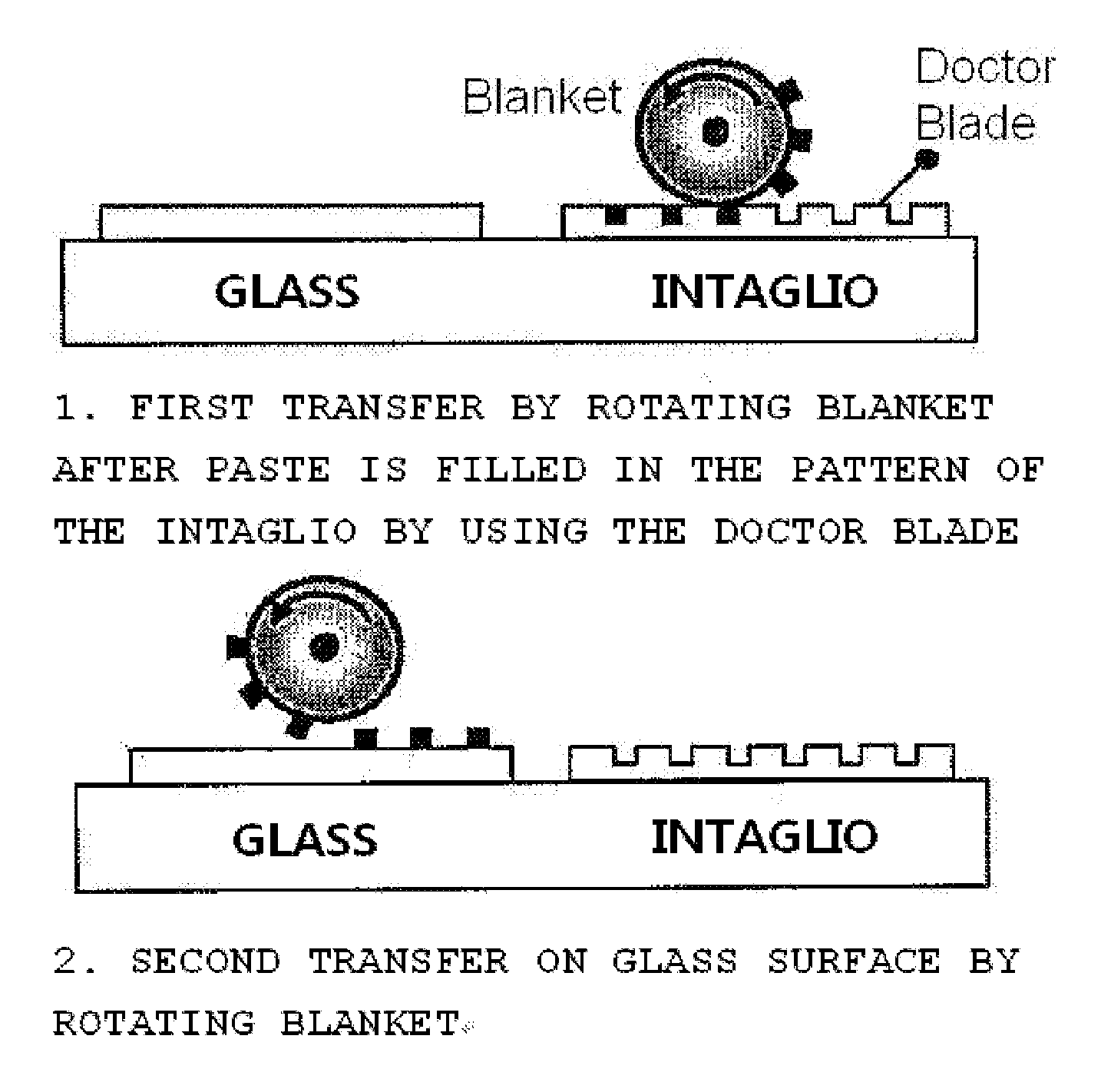

Heating element and manufacturing method for same

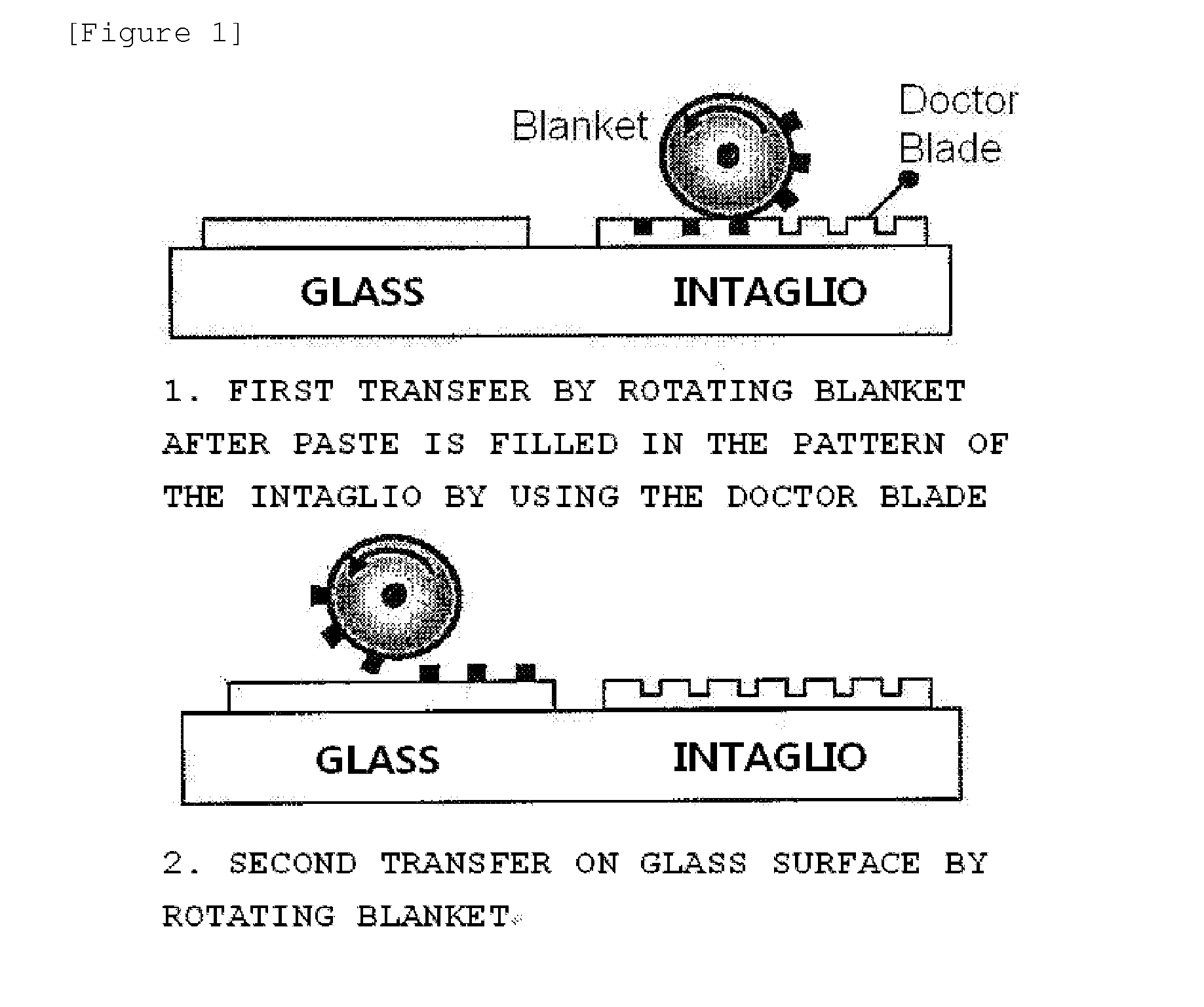

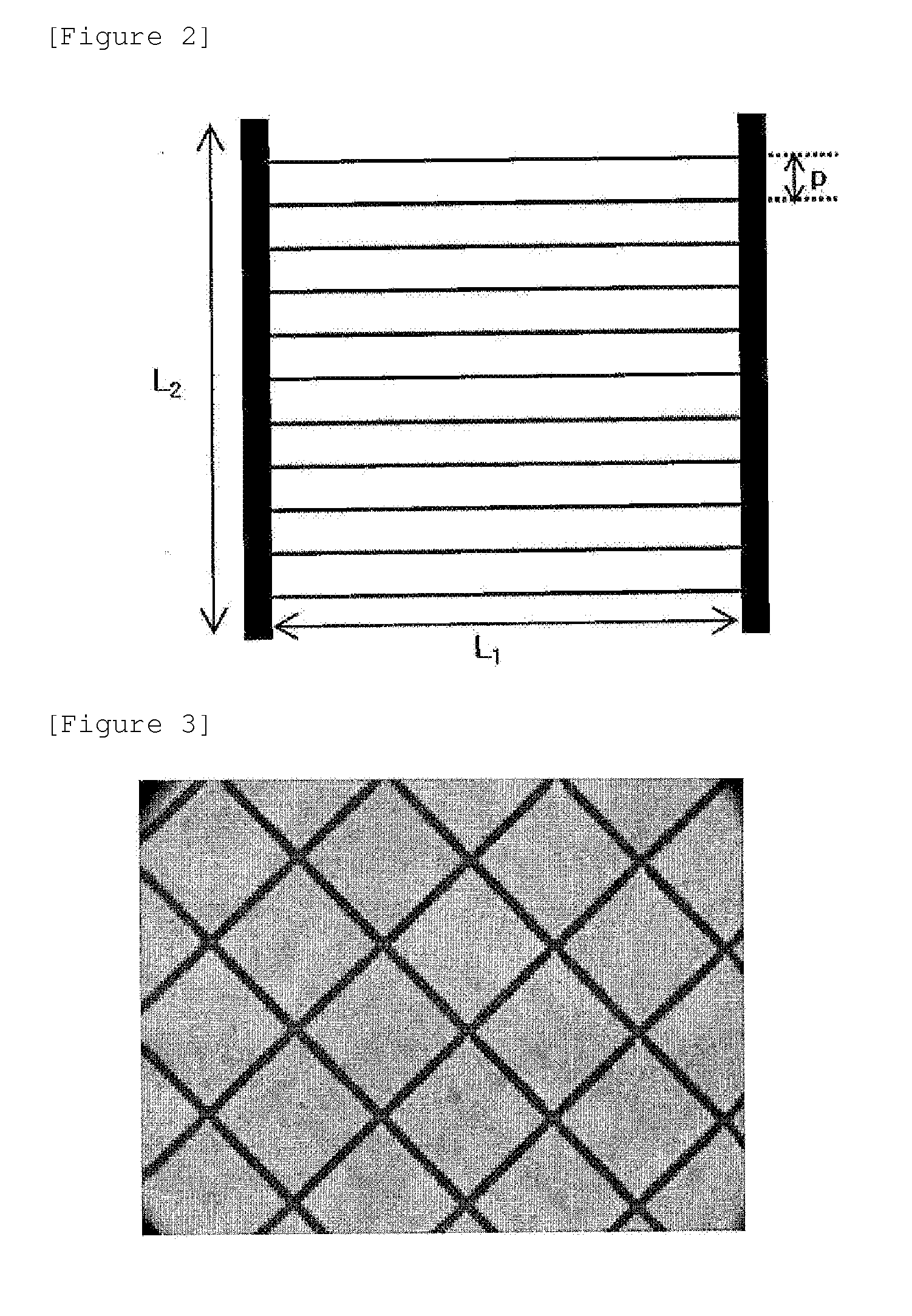

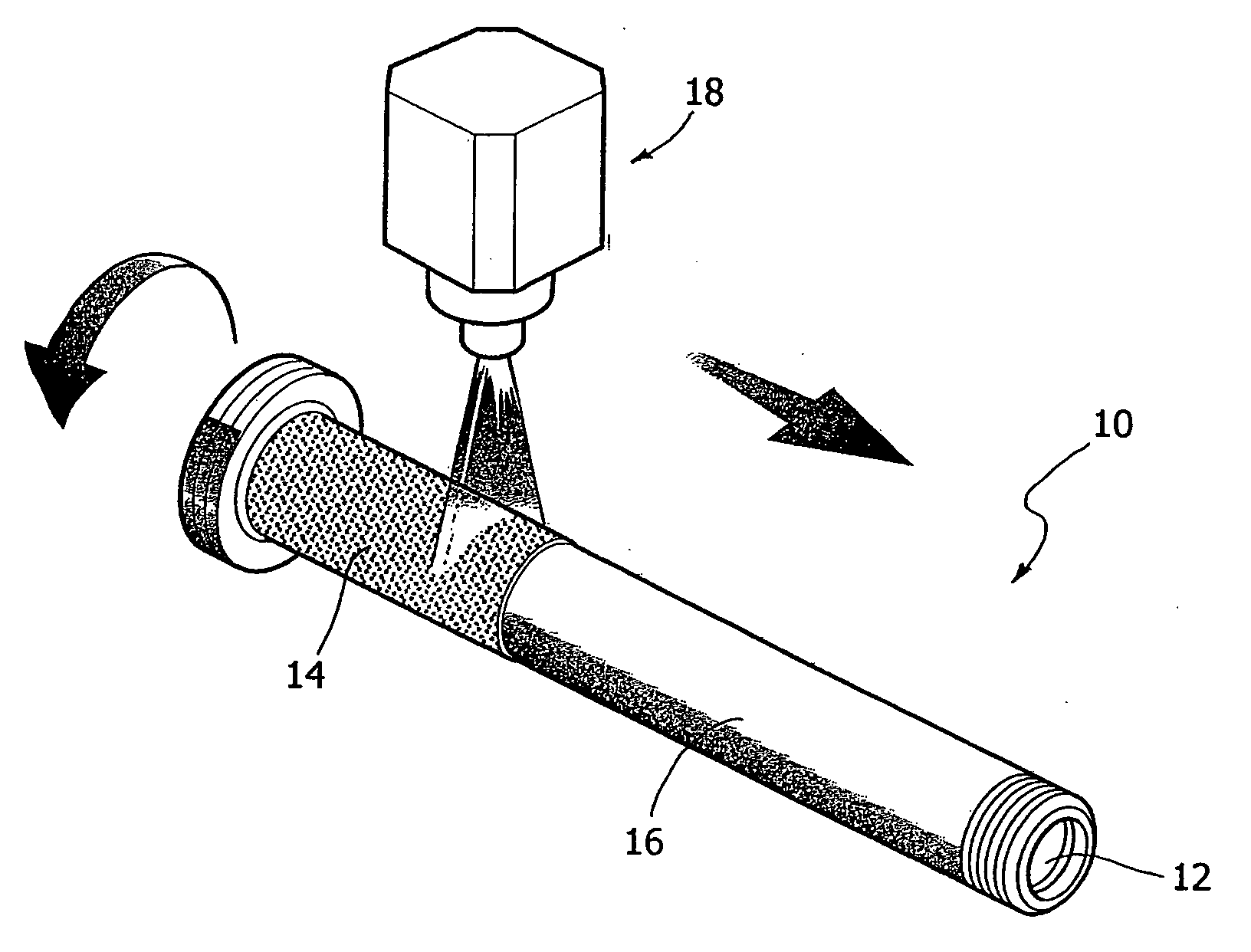

InactiveUS20110042370A1Lower resistanceImprove the heating effectEnvelope/housing resistor manufactureTransparent/reflecting heating arrangementsMicrometerHeating element

Provided is a method for manufacturing a heating element, which includes: determining a form of a pattern in which a line width is 100 micrometers or less and an opening ratio is in the range of 70% to 99%; printing a paste that includes the conductive heating material according to the determined pattern on at least one side of a transparent substrate; forming a conductive heating pattern by sintering the printed paste that includes the conductive heating material; forming bus bars on both sides of the conductive heating pattern; and providing a power portion that is connected to the bus bar, and a heating element that is manufactured by using the method.

Owner:LG CHEM LTD

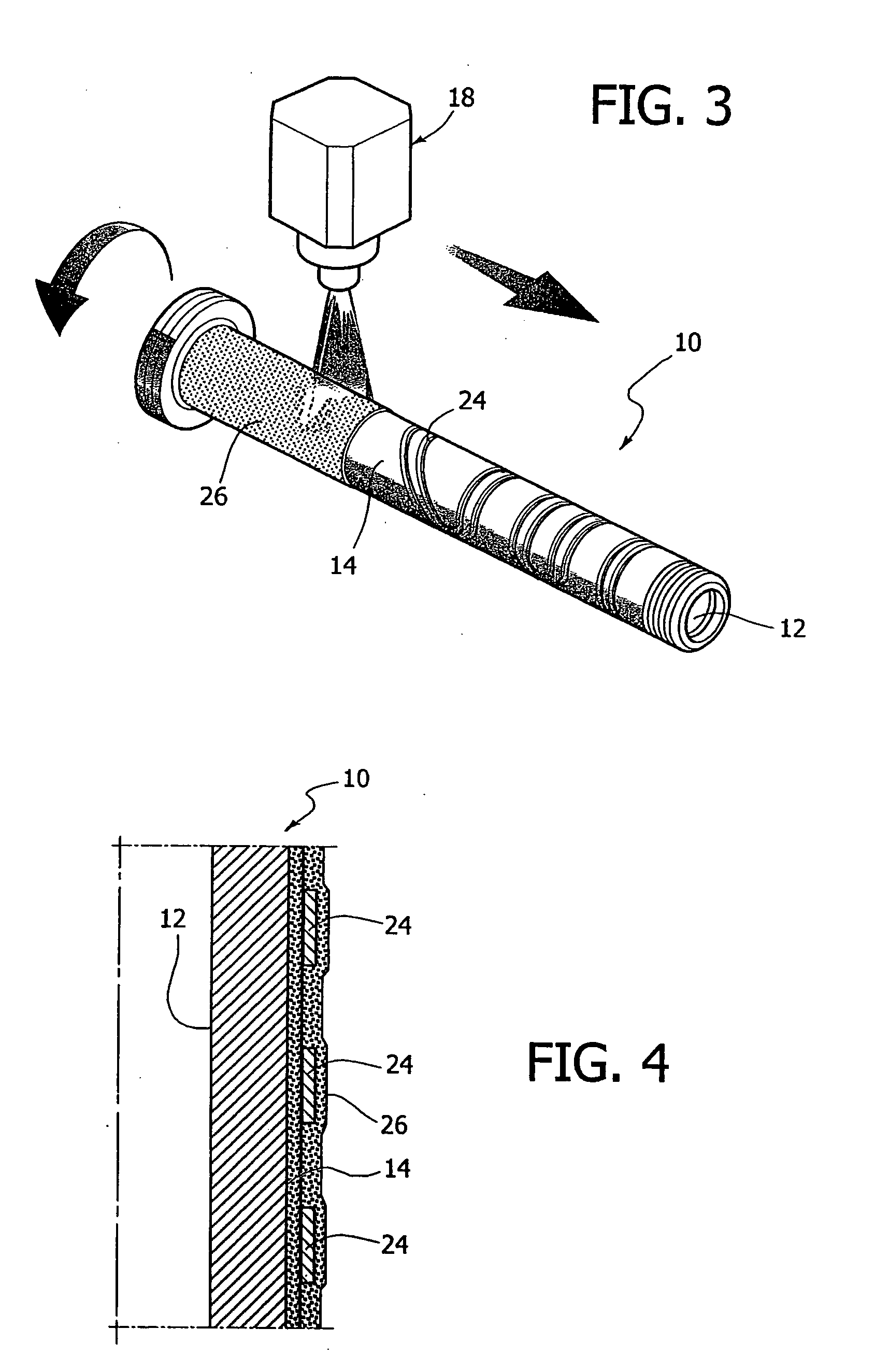

Method for producing heated components for injection moulding apparatus and heating equipment in general

InactiveUS20050257367A1Simple and cost-effectiveImprove reliabilityEnvelope/housing resistor manufactureMolten spray coatingElectrical resistance and conductanceElectricity

A method for producing components for injection moulding comprising a body made of thermally conducting material with expansion coefficient matching that of the insulating layers and provided with a passage for the material to be injected. At least one strip of electrically conducting material with high change of resistance with temperature, forming a heating resistor or inductor is applied on a electrically insulating base layer previously directly applied on the body. At least one final insulating layer with low thermal emissivity is then applied to optimise electrical efficiency. The method utilises thermal spray techniques and can be applied also for production of other heating equipment.

Owner:INGLASS SRL

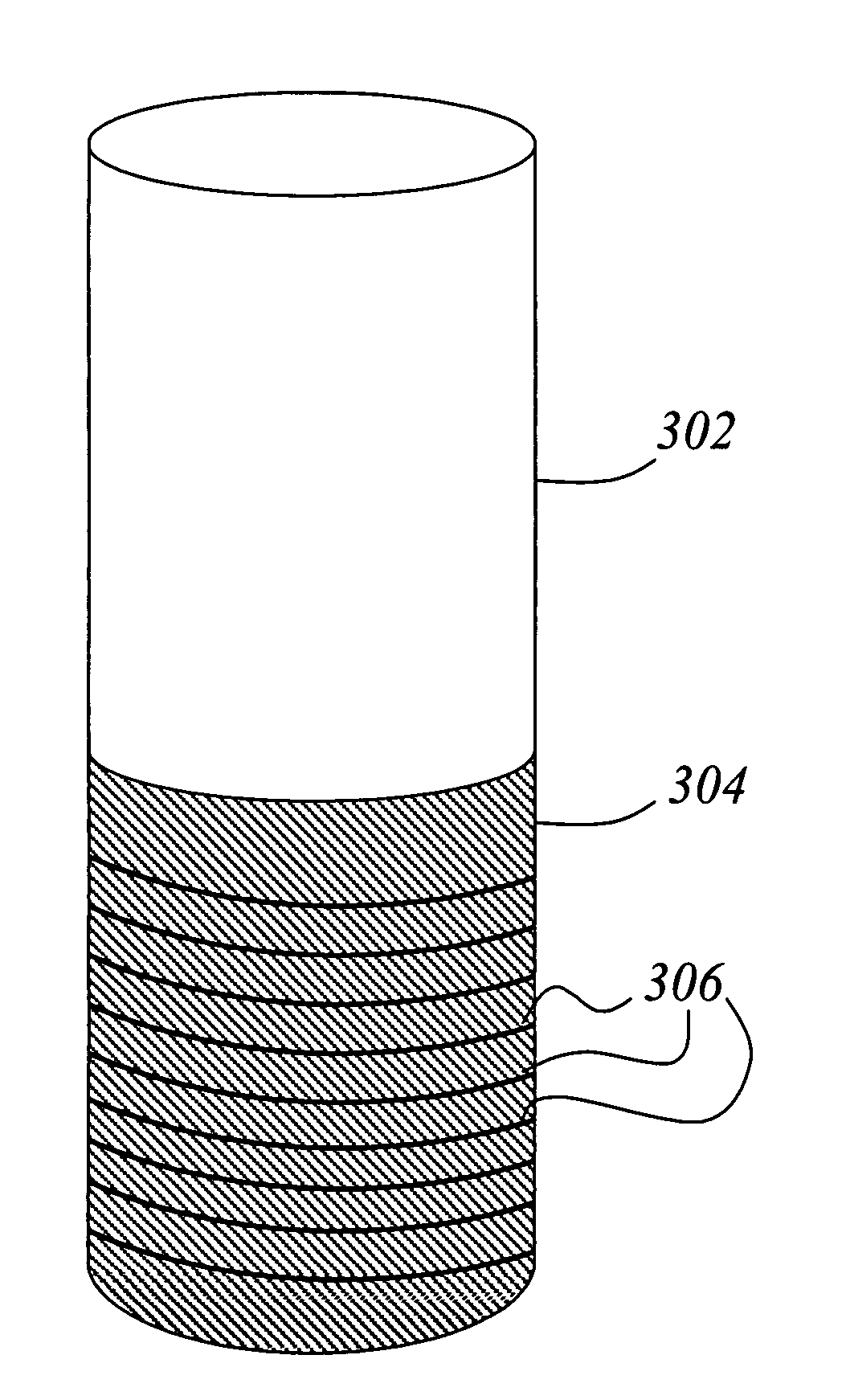

Radiant heating using heater coatings

InactiveUS20110188838A1Efficient Energy UtilizationReduce manufacturing costDomestic stoves or rangesEnvelope/housing resistor manufactureThermal sprayingRadiant heating

A radiant heating system comprises a thermally sprayed resistive heating layer bonded to an underlayment building material substrate. The substrate can comprise a sub-flooring material and the heating system can comprise a radiant floor heating system. The resistive heating layer can be thermally sprayed directly onto a sub-floor or similar underlayment material, including cementitious backing material or a sound reduction board. A finished floor surface, such as a tile, wood or laminate surface, can be provided over the substrate and thermally sprayed heater to provide a radiant floor heater. In other embodiments, a radiant heating system includes a thermally sprayed heater bonded to a flooring overlay, such as a laminate board, to a heater insert, such as a flexible polymer film or a mica-based material, or to a concrete substrate. Methods of fabricating radiant heating systems include thermally-spraying a resistive material on a sub-floor or flooring overlay.

Owner:THERMOCERAMIX

Temperature sensor and method for manufacturing the same

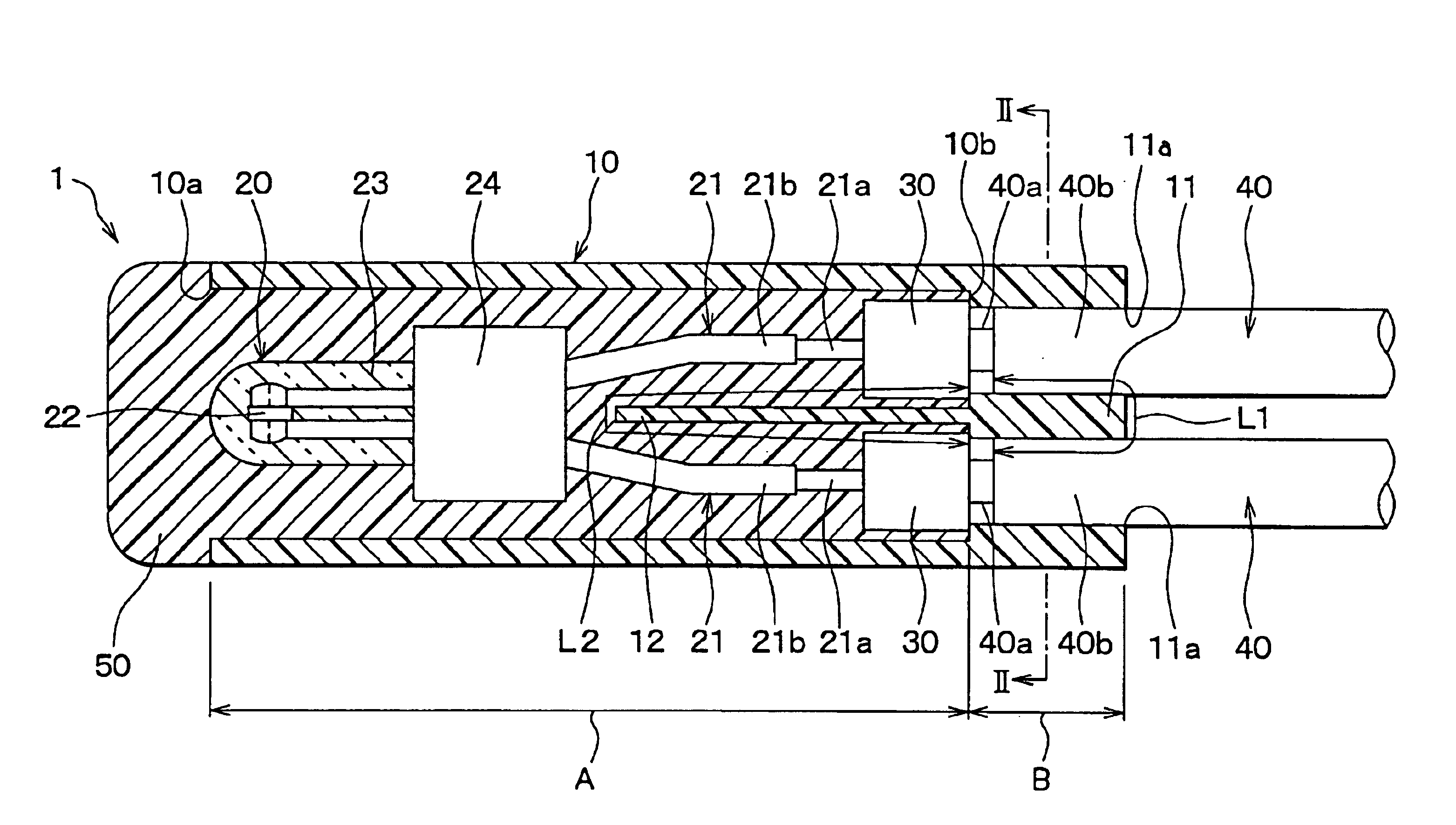

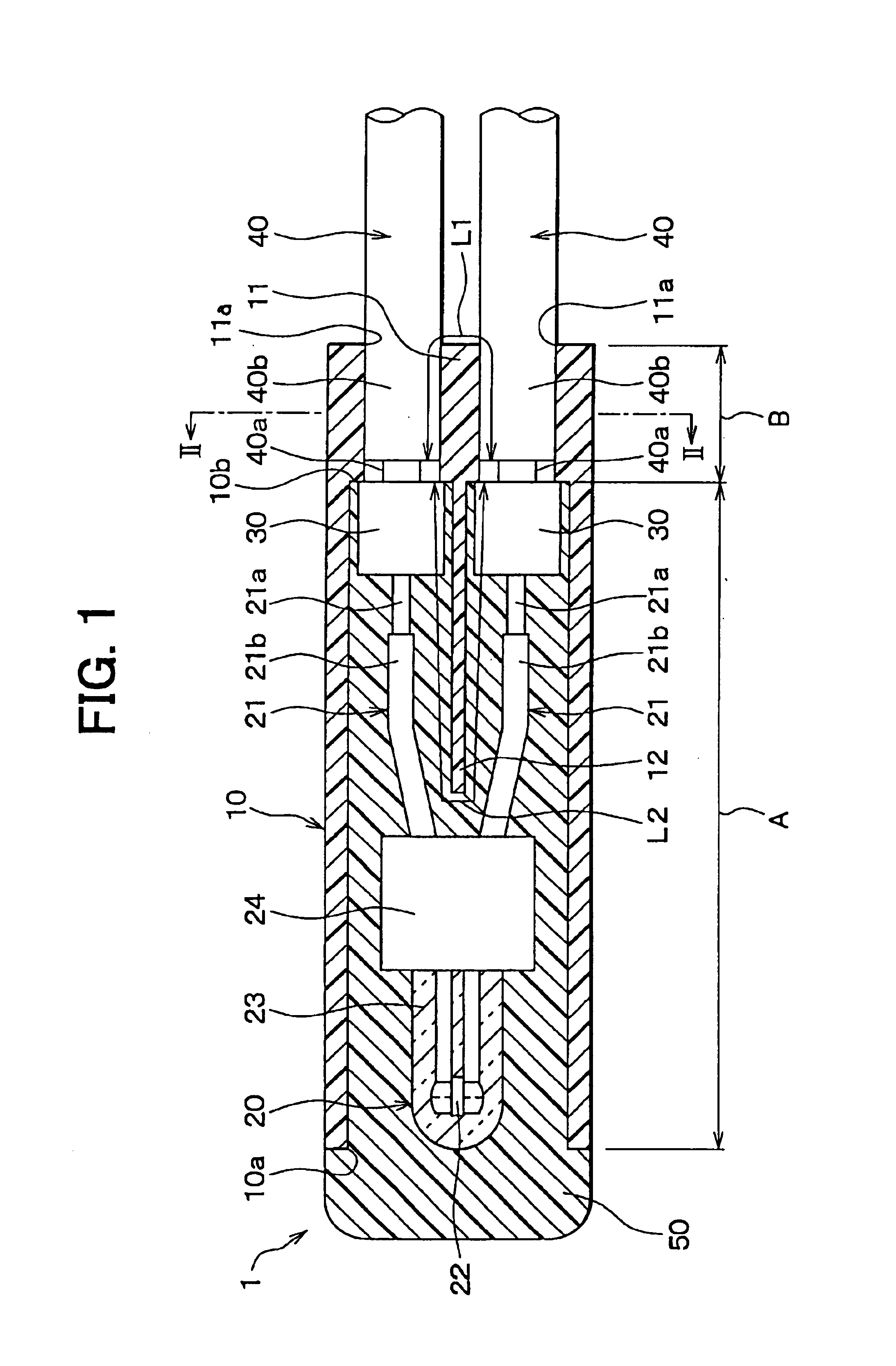

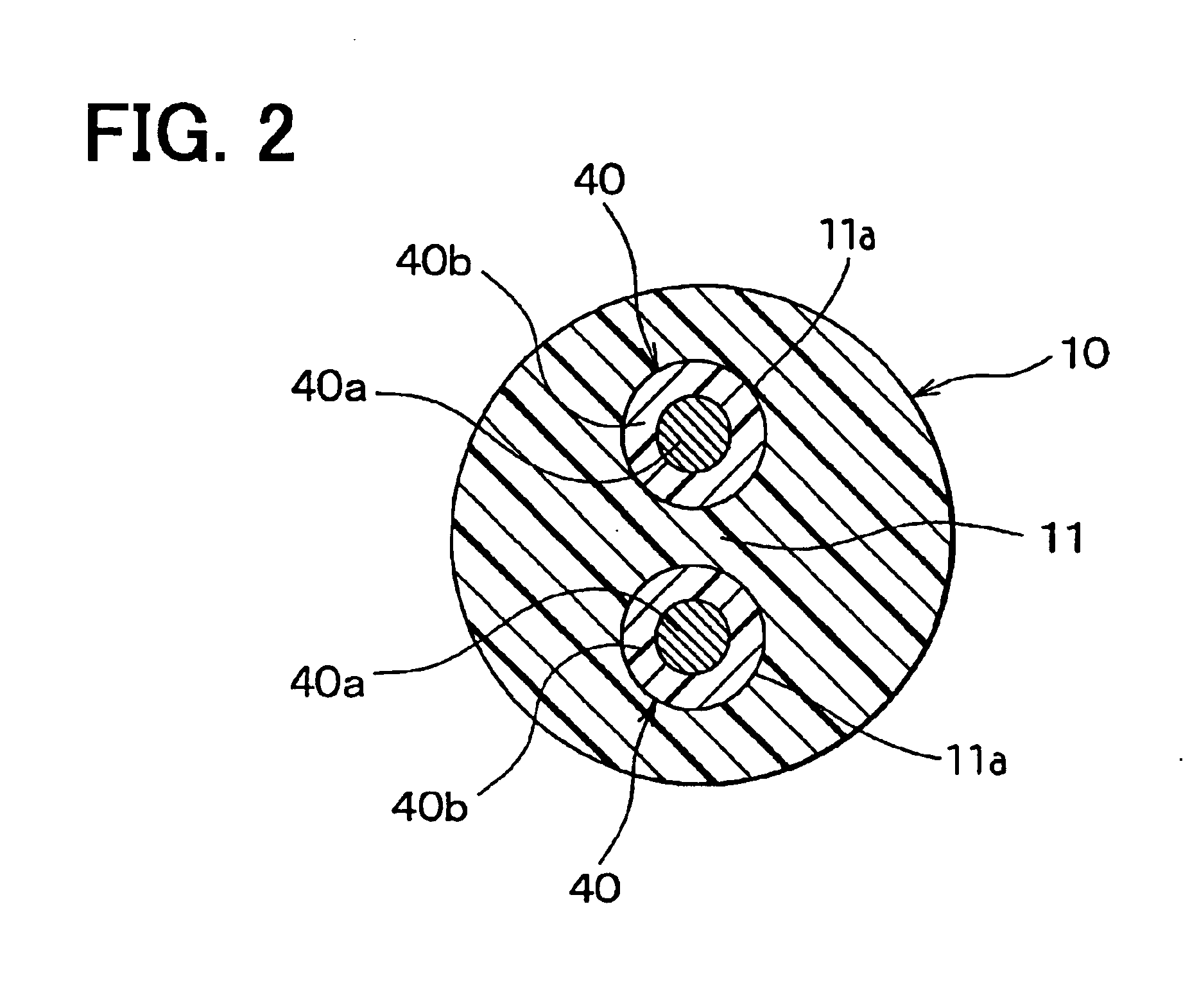

ActiveUS6918696B2Improve reliabilityReduce the possibilityThermometer detailsLine/current collector detailsBiomedical engineeringElectric wire

A temperature sensor includes a casing having a first part and a second part, a temperature detector for detecting temperature of fluid and a pair of outside wires connecting to the temperature detector. The casing further includes a mold portion and an insert portion. The mold portion is disposed in the first part of the casing. The insert portion is disposed in the second part of the casing, and includes a pair of holes for inserting the outside wires therein. The temperature detector is disposed in the first part of the casing. Each outside wire extends from the second part of the casing to an outside of the casing through the hole.

Owner:SHIBAURA ELECTRONICS CO LTD

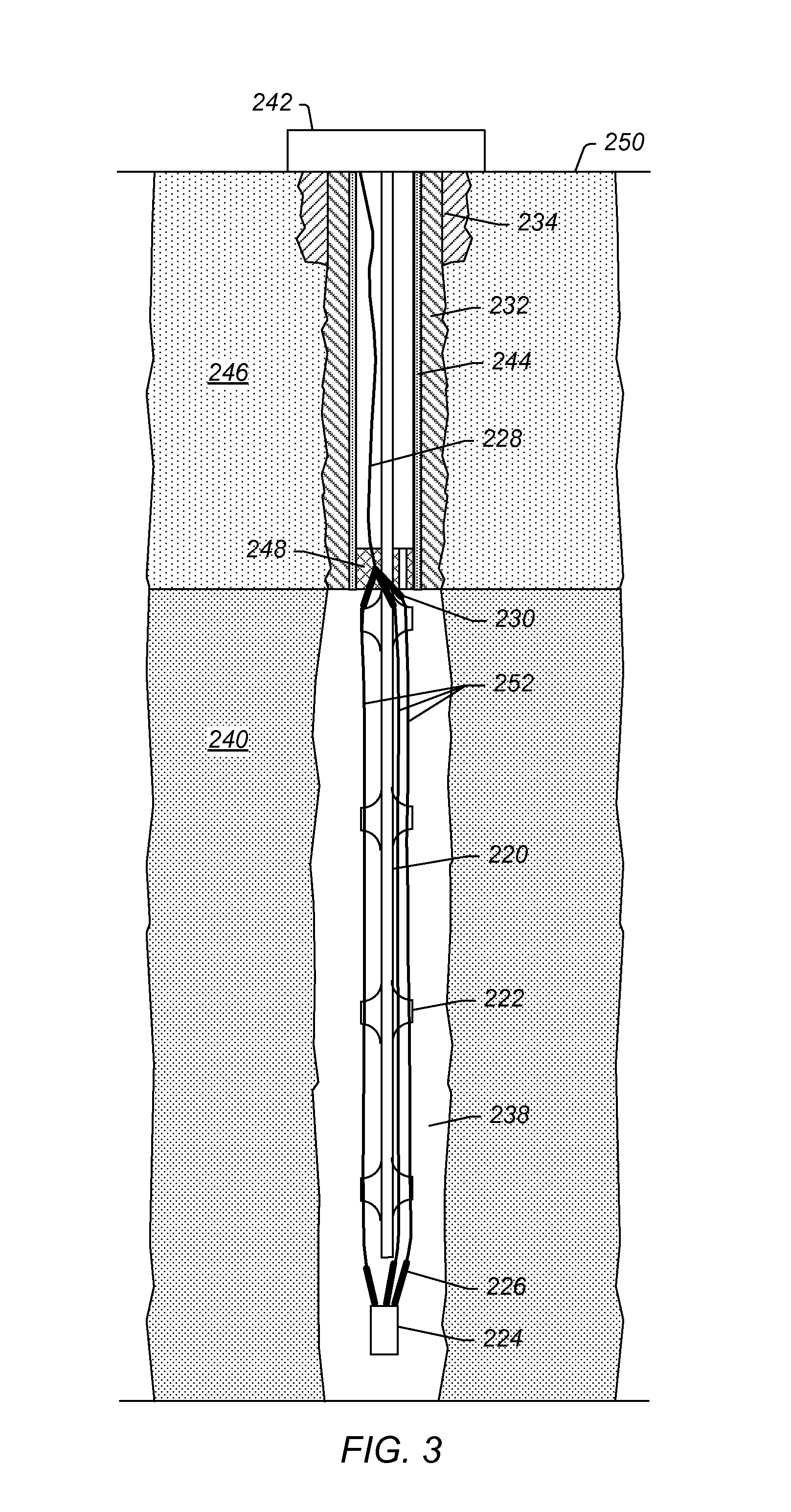

Insulating blocks and methods for installation in insulated conductor heaters

InactiveUS20110248018A1High resistivityEnvelope/housing resistor manufactureHeater elementsElectrical conductorElectrical current

Owner:SHELL OIL CO

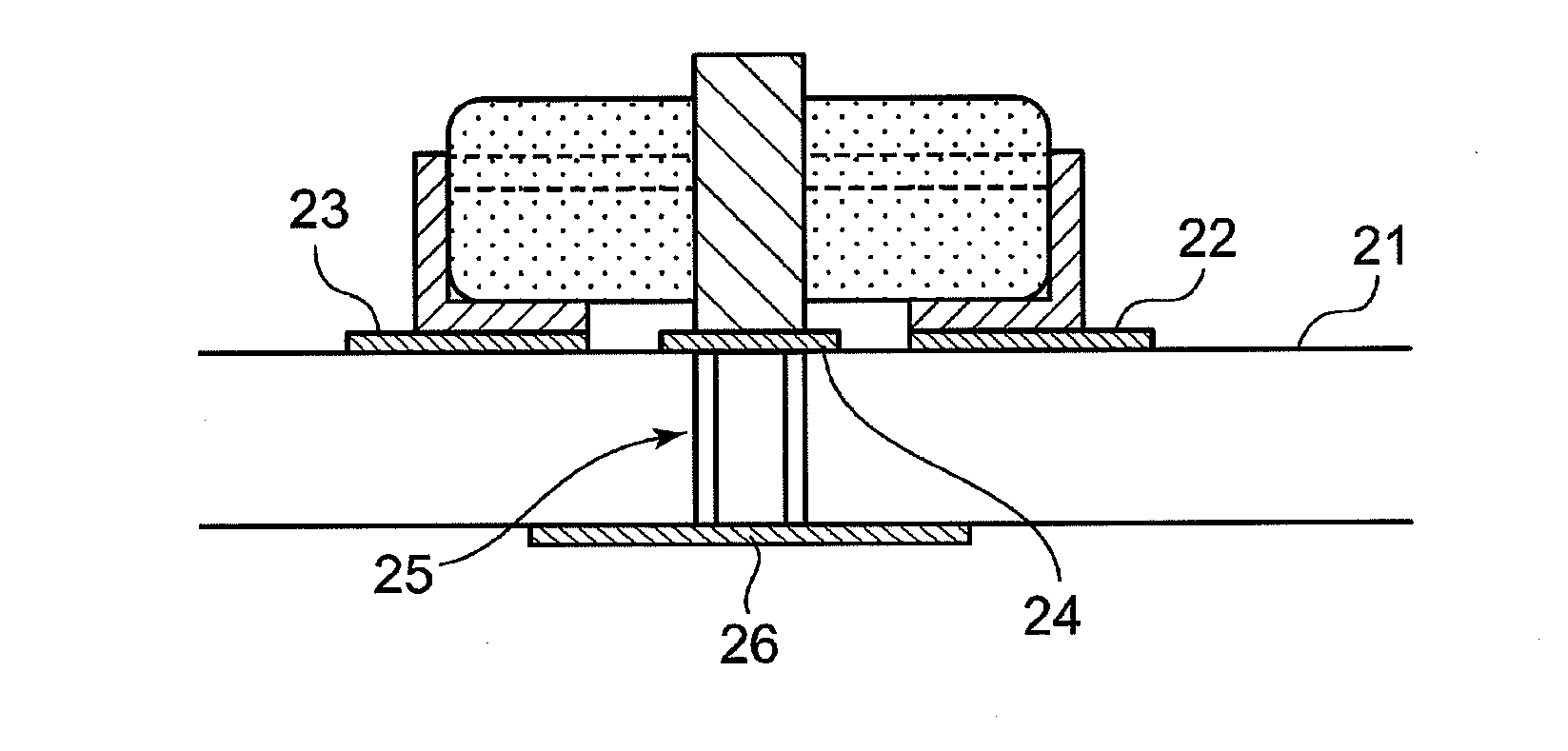

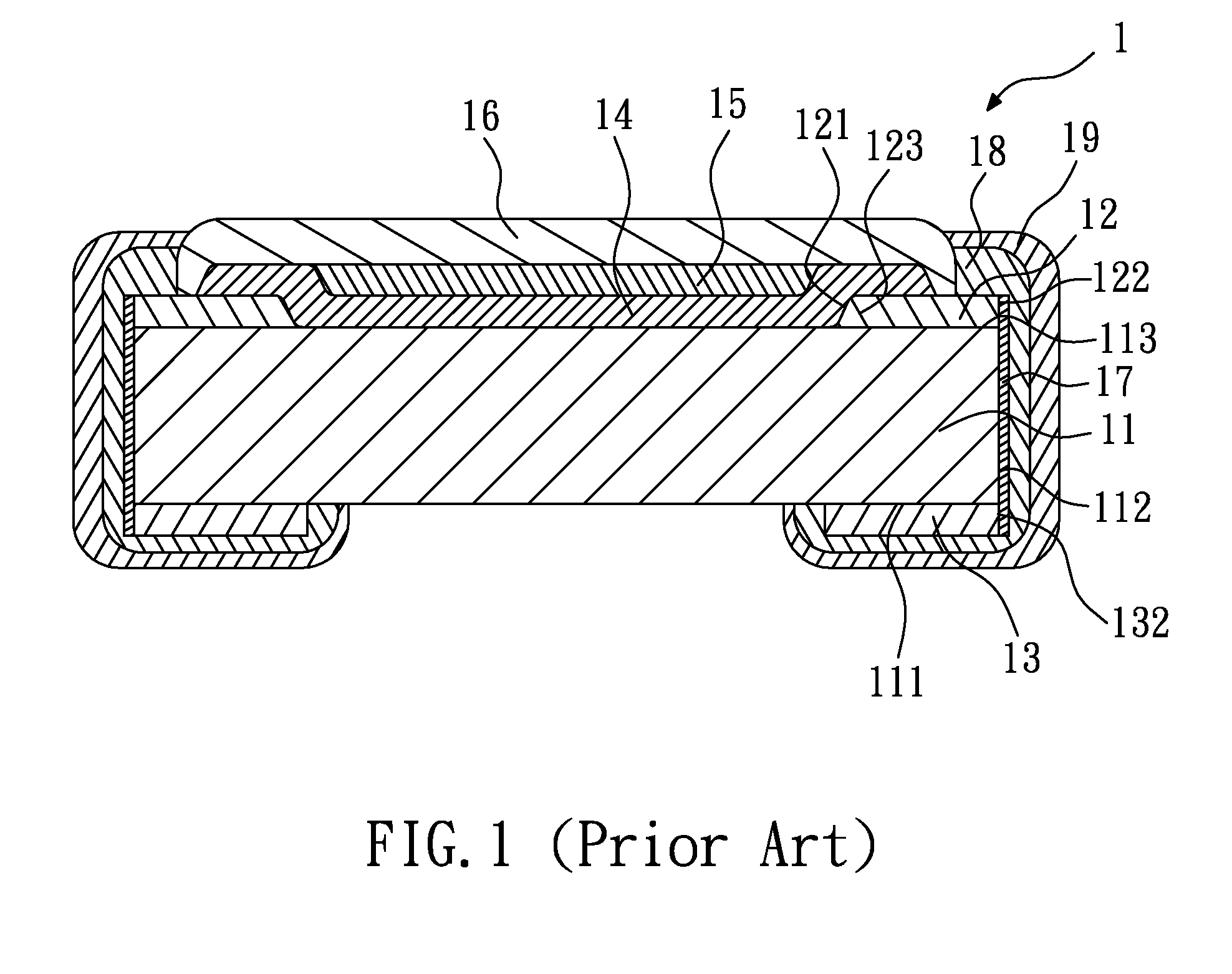

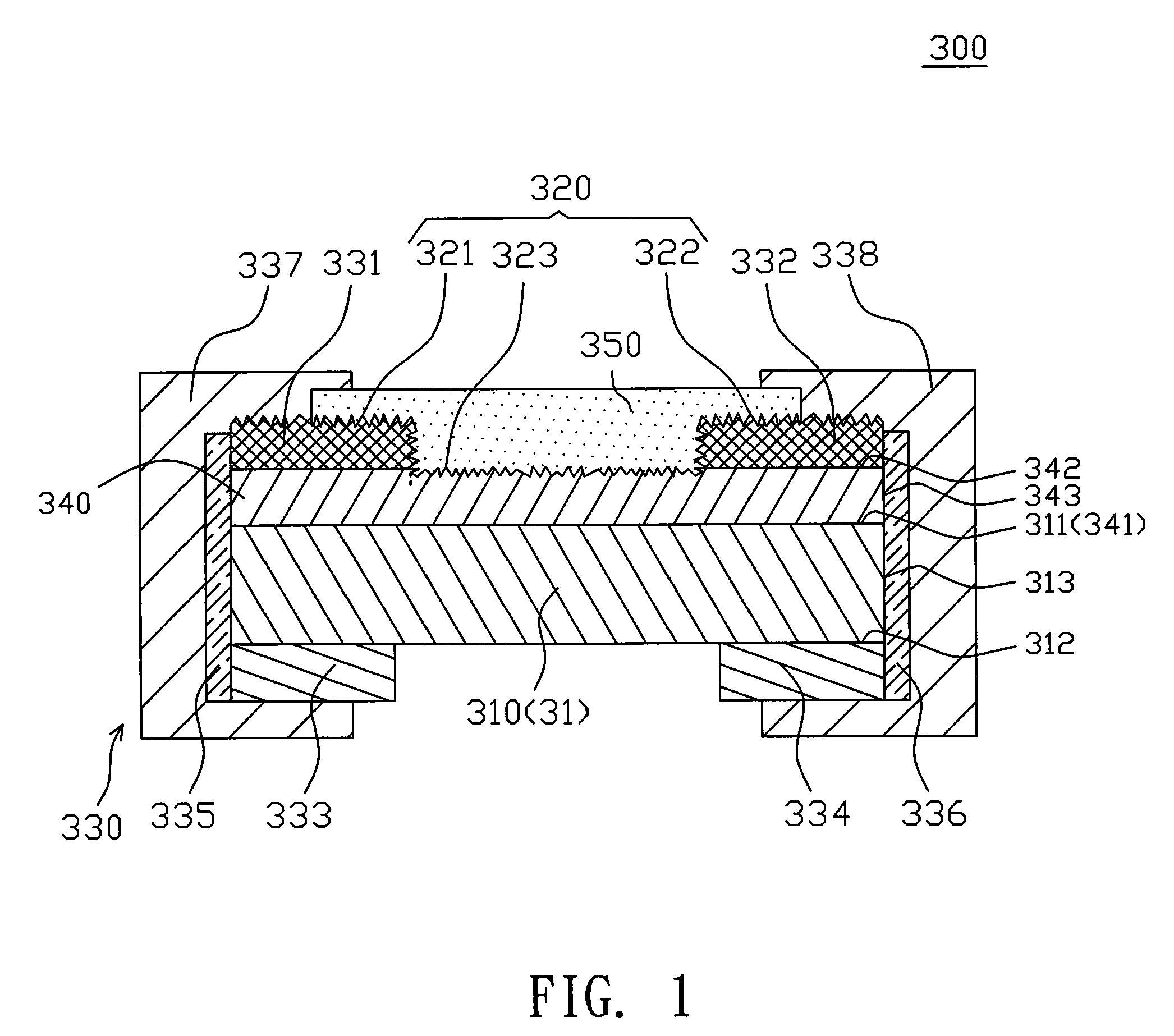

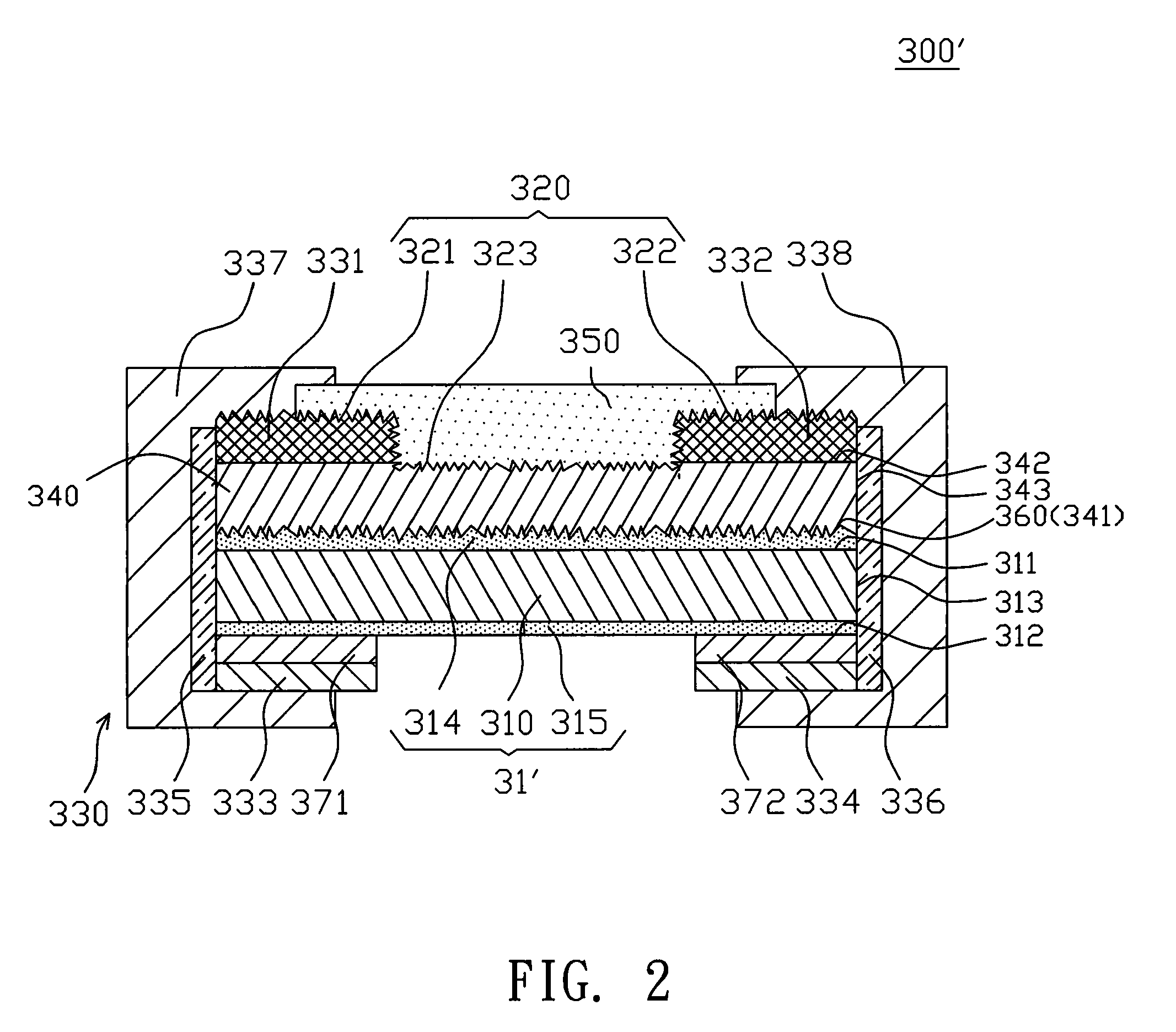

Chip resistor and method of making the same

A chip resistor includes a metal resistor element having a flat lower surface. The lower surface is formed with two electrodes spaced from each other, and an insulating resin film is formed between these electrodes. Each of the electrodes partially overlaps the insulating film so that a portion of the insulating film is inserted between each of the electrodes and the lower surface of the resistor element.

Owner:ROHM CO LTD

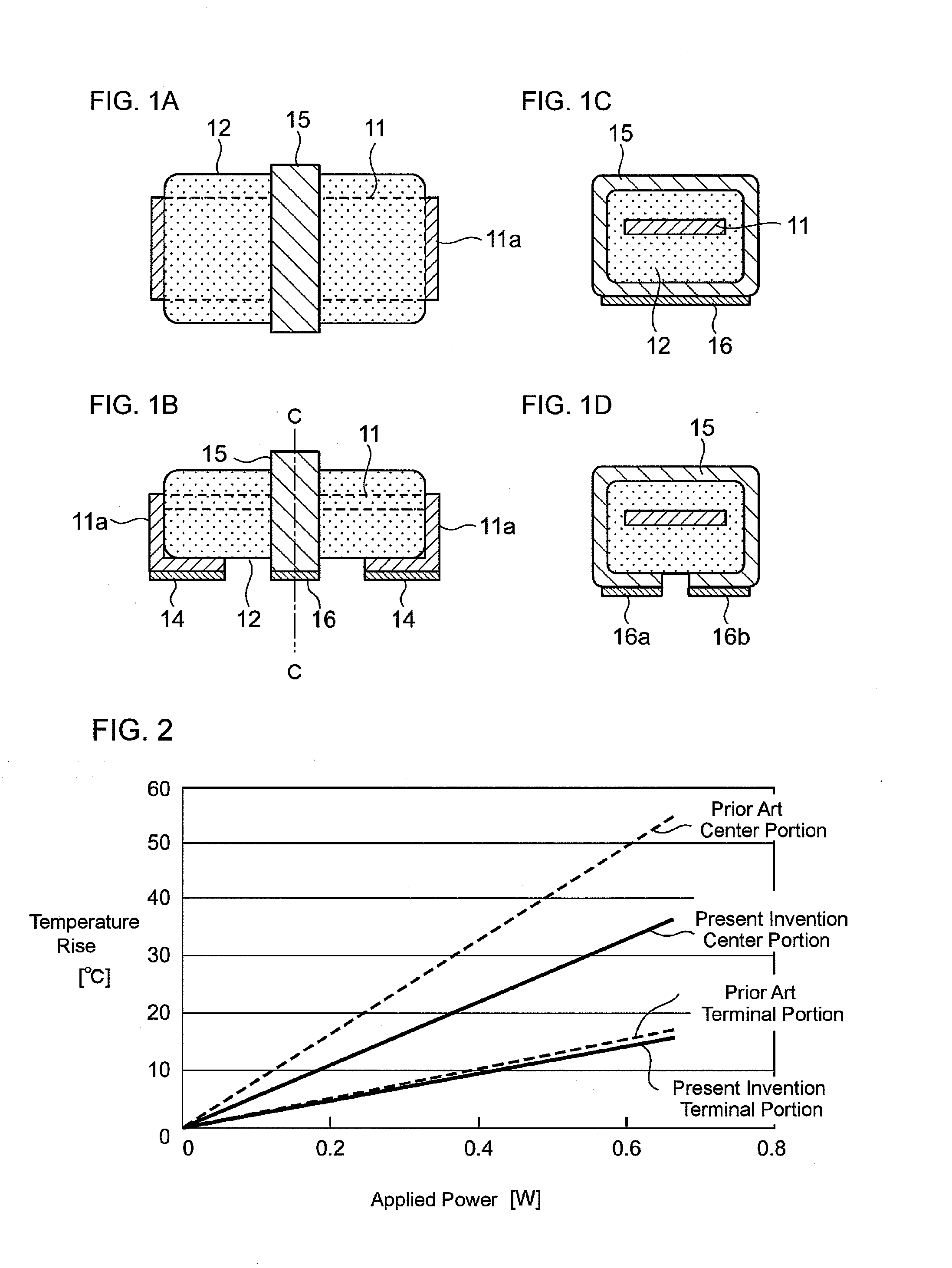

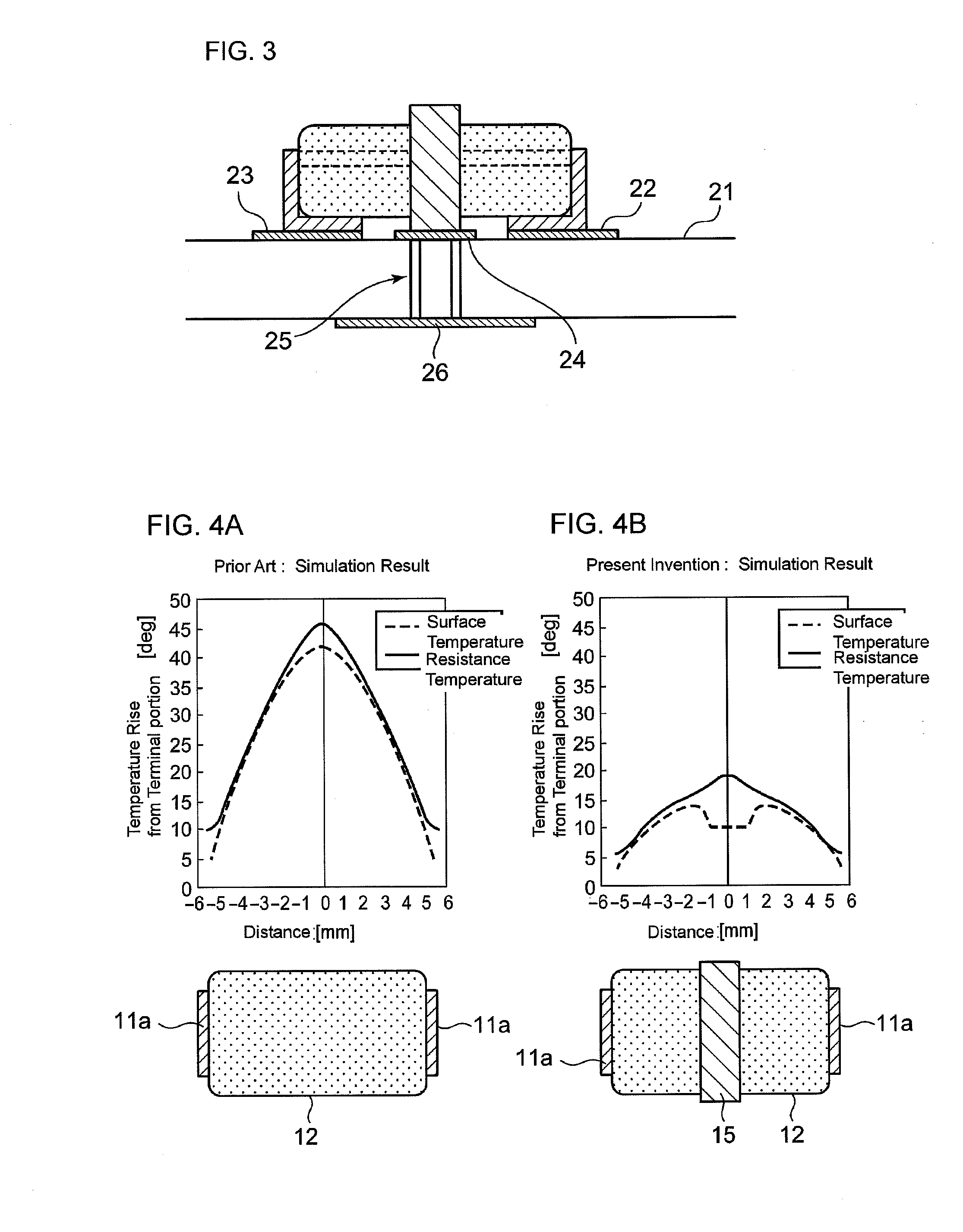

Resistor device

ActiveUS20100328021A1Effective absorptionIncreased power capacityEnvelope/housing resistor manufactureResistor terminals/electrodesElectrical resistance and conductanceSurface mounting

The resistor device is provided with a resistive plate (11) of metal plate material, which is used as a resistance body; a radiative plate (15) of metal plate material, which is spaced from the resistive plate and intercrossed on the resistive plate; a molded resin body (19), which encloses an intercrossing portion of the resistive plate and the radiative plate; terminal portions of the resistive plate (11a), which comprises so that both ends of the resistive plate extending from the molded resin body are bent along an end face and a bottom face of the molded resin body; and terminal portions of the radiative plate (15a), which comprises so that both ends of the radiative plate extending from the molded resin body are bent along an end face and a bottom face of the molded resin body. Accordingly, the surface-mountable resin-sealed metal plate resistor device is enabled to increase the power capacity drastically and to improve the reliability without changing most of the size.

Owner:KOA CORP

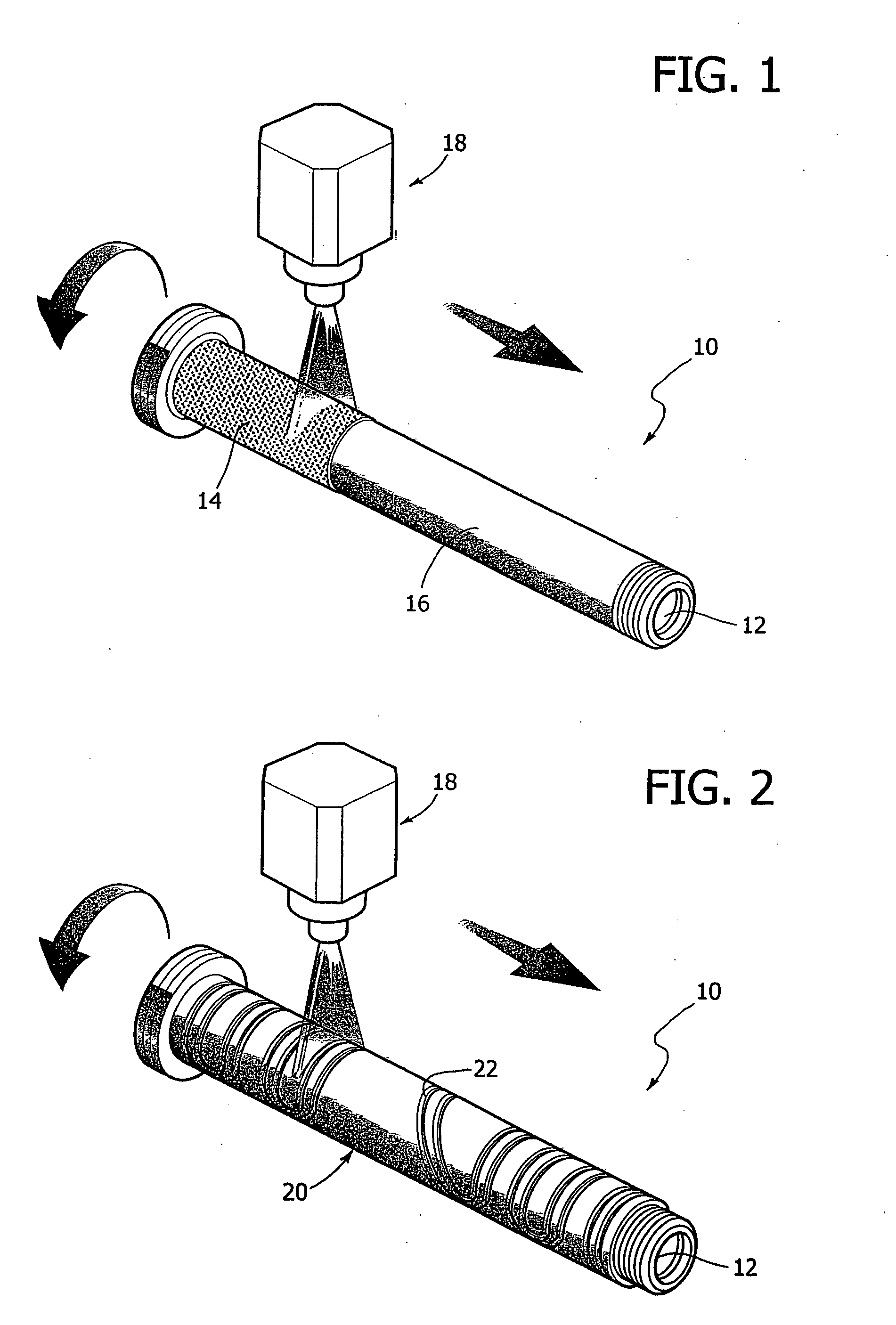

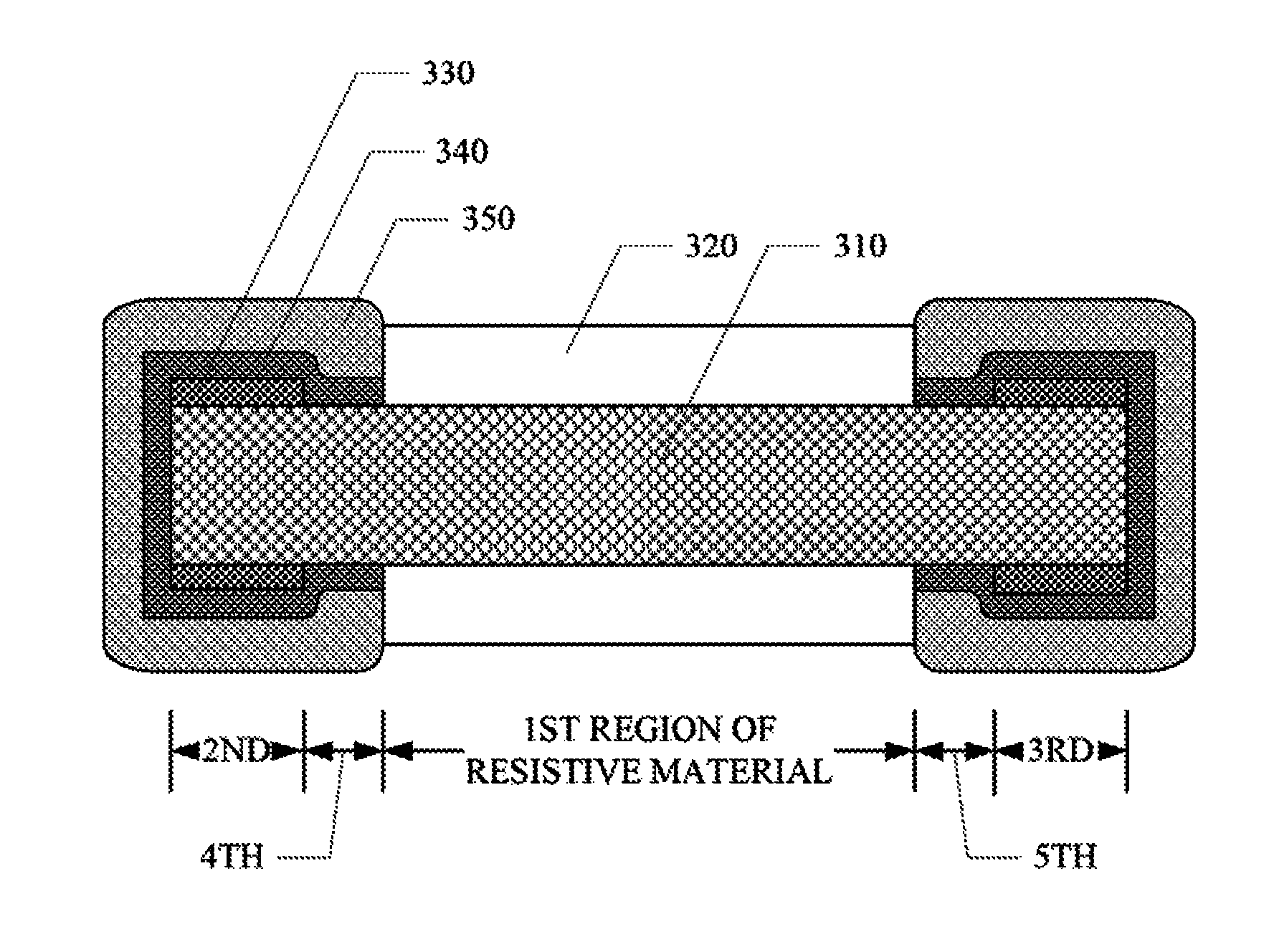

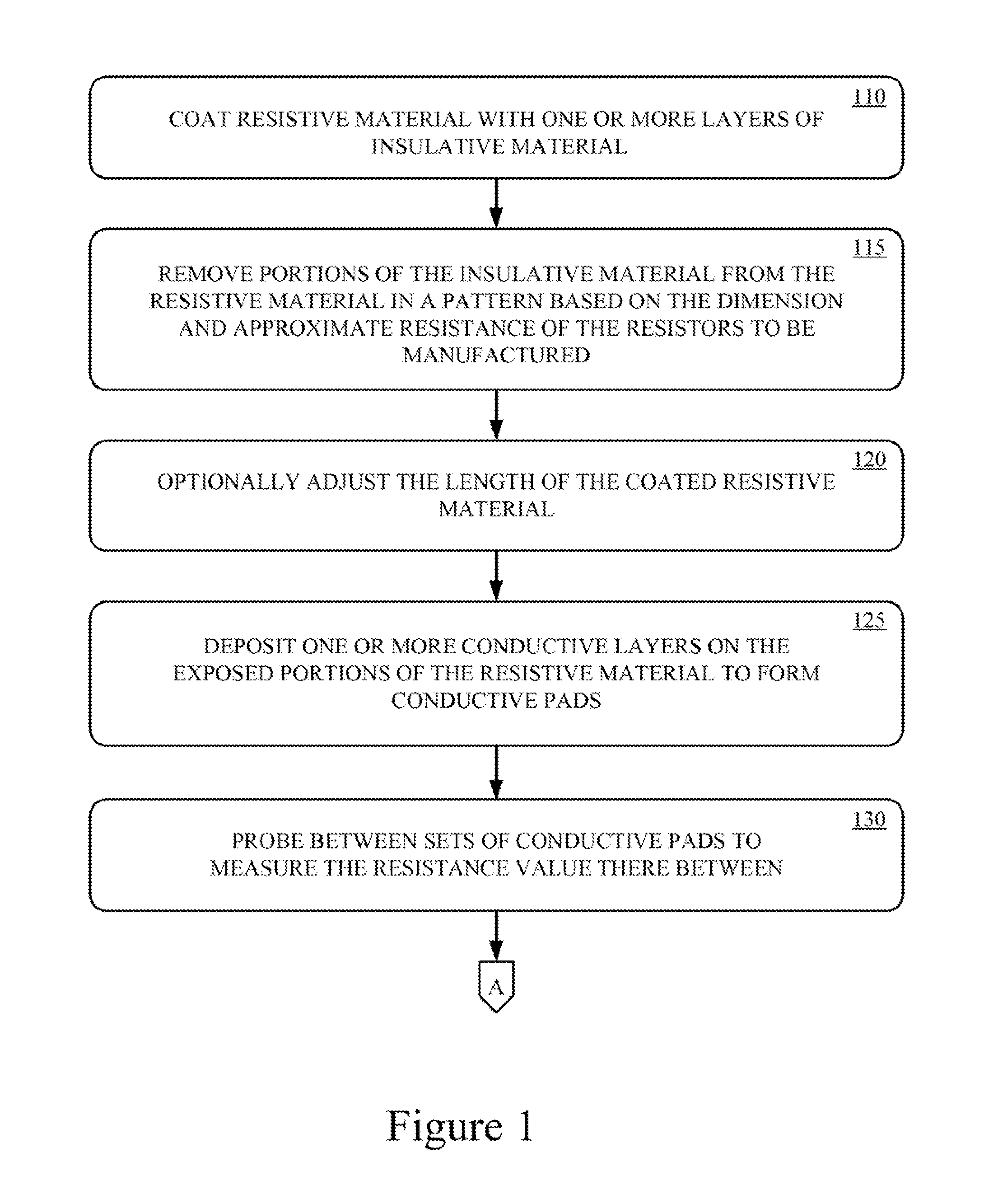

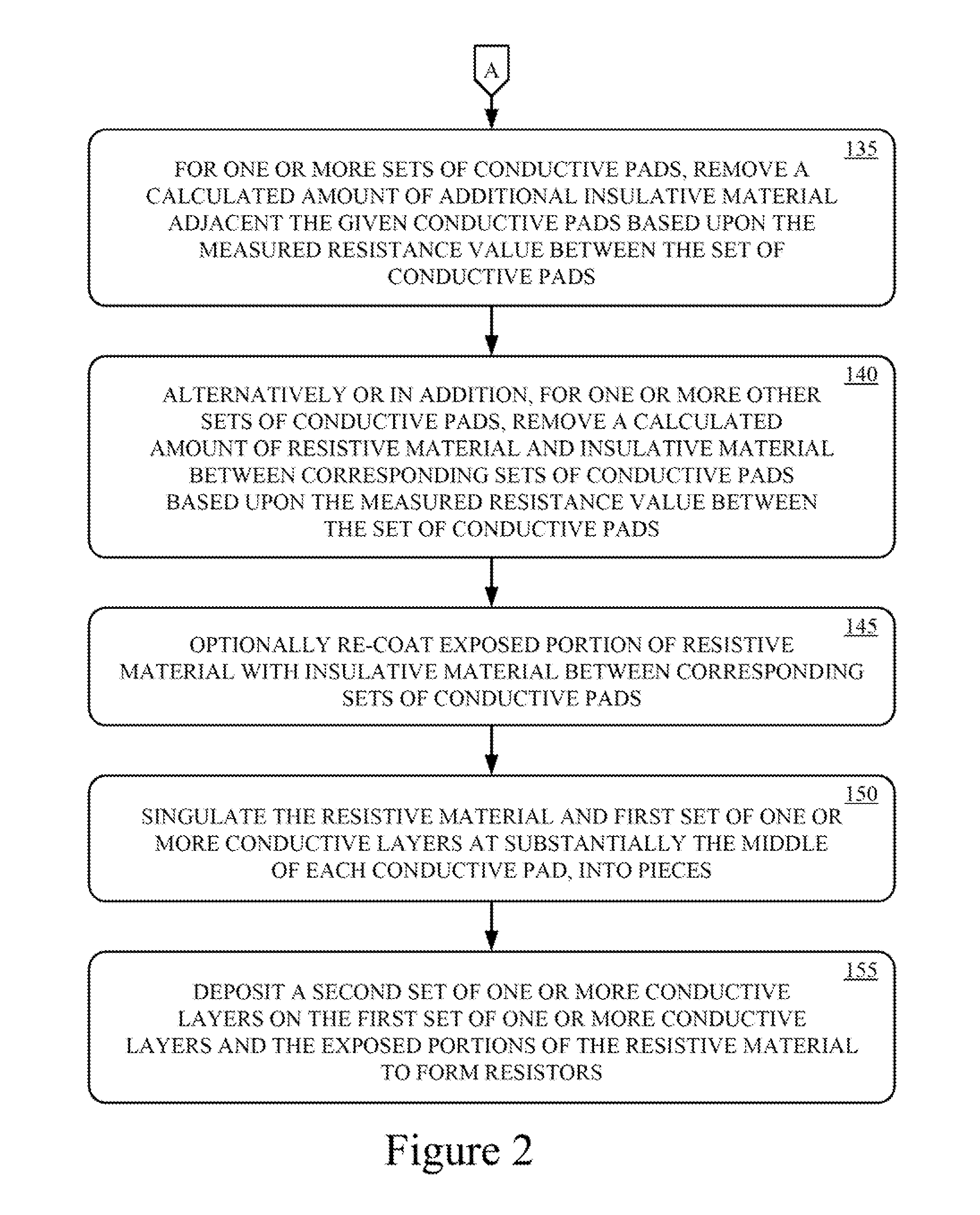

Resistor and method of manufacture

ActiveUS9396849B1Mass resistorsEnvelope/housing resistor manufactureResistorElectrical and Electronics engineering

The present technology is directed toward a resistor and method of manufacturing the resistor. One or more layers of insulative material are formed on a length of resistive material. Portions of the one or more layers insulative material are removed from the resistive material in a pattern based on a predetermined approximate dimension and predetermined approximate resistance value. A first set of one or more conductive layers are formed on the portions of the resistive material exposed by the insulative coating to form a plurality of conductive pads on the resistive material between the patterned insulative material. The sets of conductive pads are probed to measure a preliminary resistance value between the sets of conductive pads. For one or more sets of conductive pads, a calculated amount of additional insulative material adjacent the respective conductive pads is removed based upon the preliminary resistance value between the corresponding set of conductive pads and a final resistance value to exposed additional portions of resistive material. The conductive pads and resistive material is cut at substantially the middle of each conductive pad to form pieces. A second set of one or more conductive layers are formed on the first set of one or more conductive layers at opposing ends of each piece, and the additionally exposed portions of the resistive material.

Owner:VISHAY DALE ELECTRONICS INC

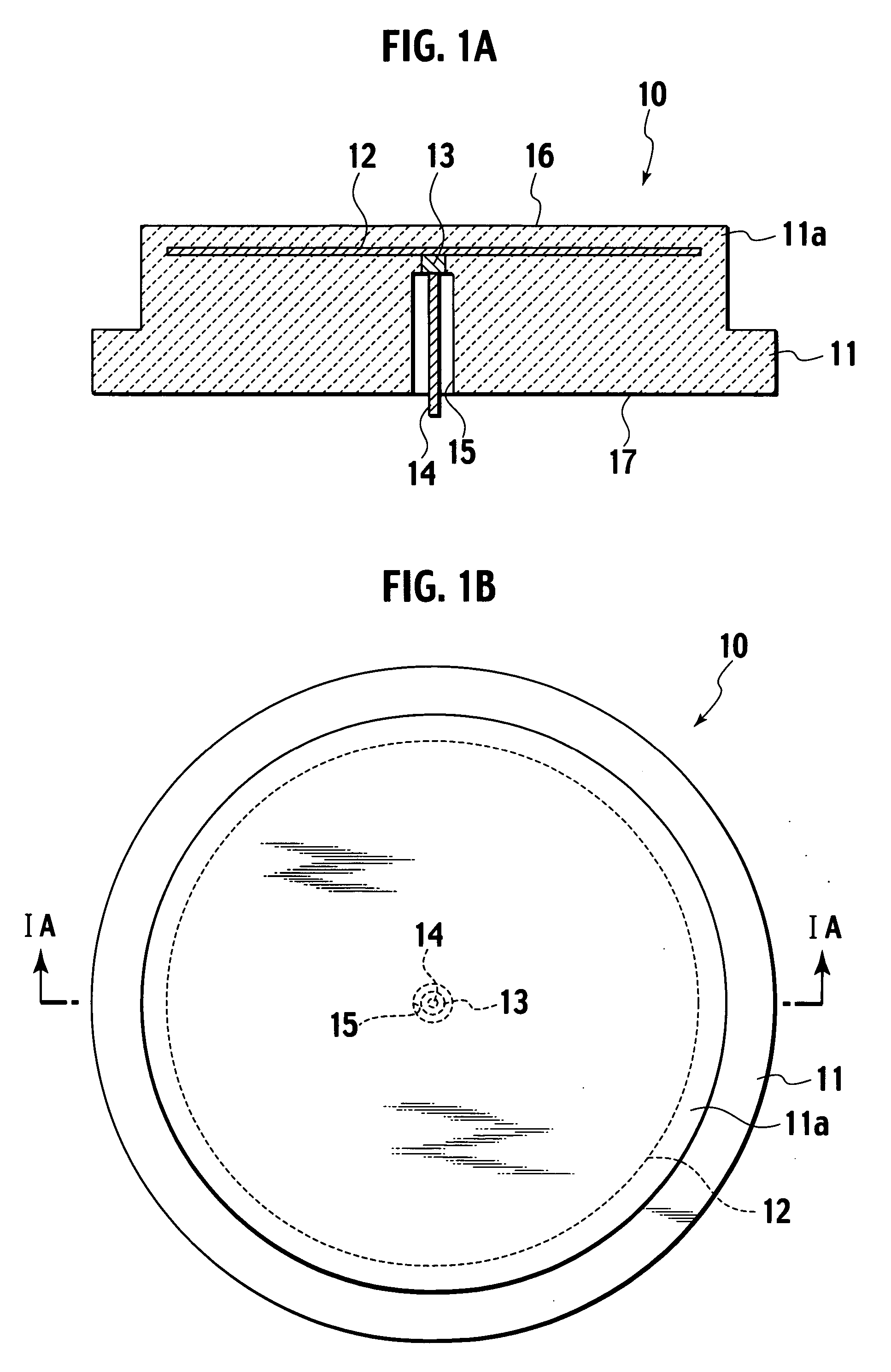

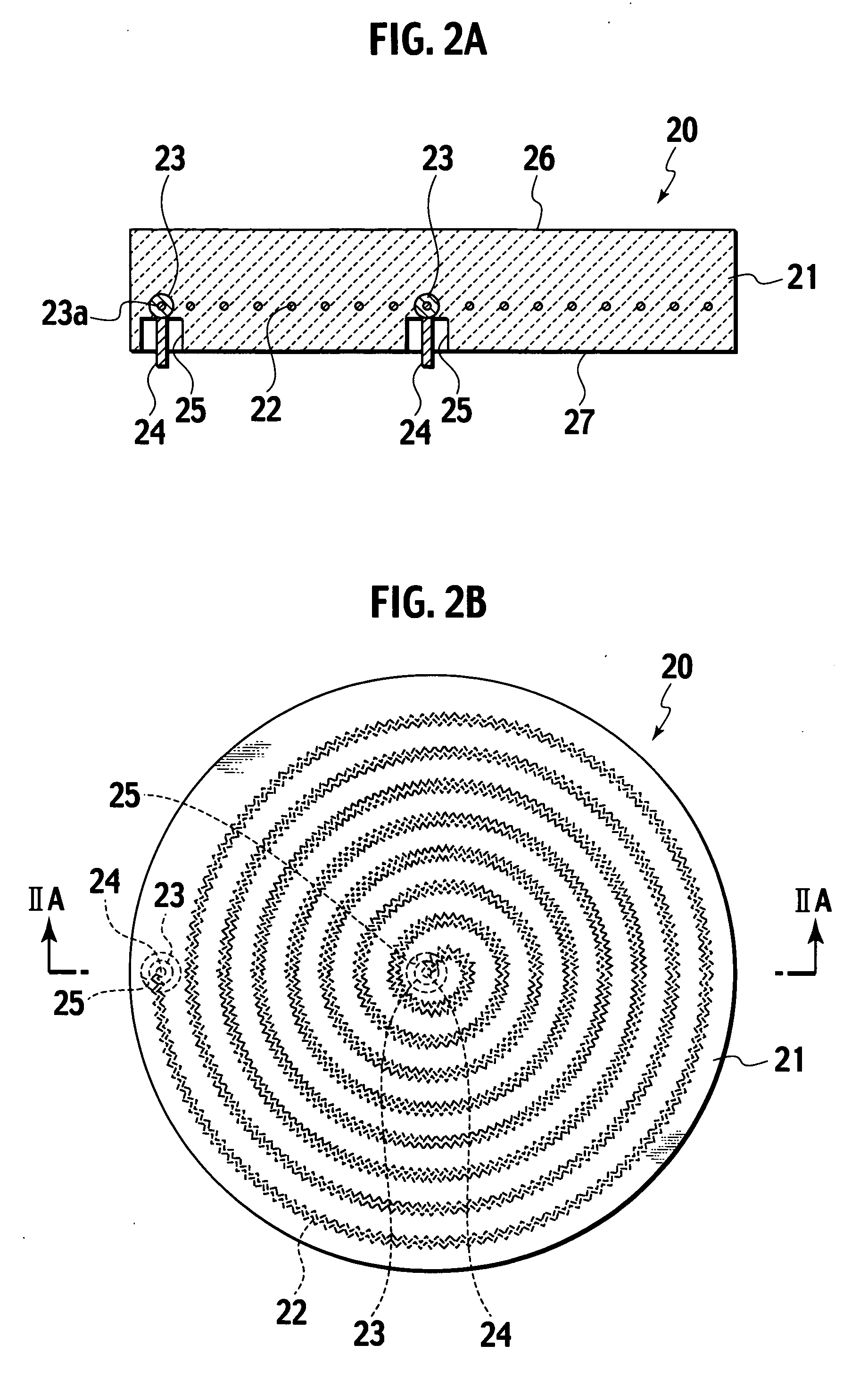

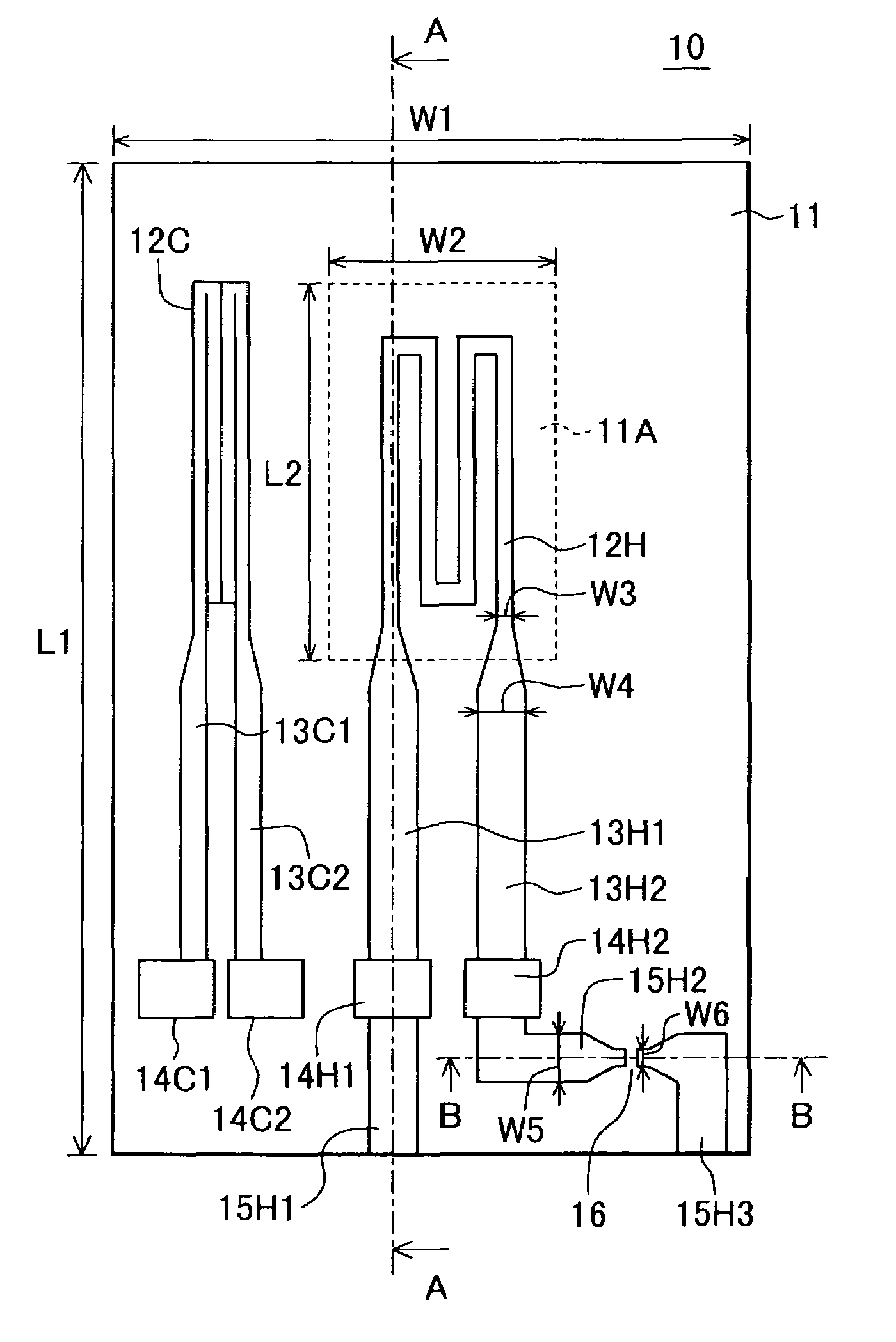

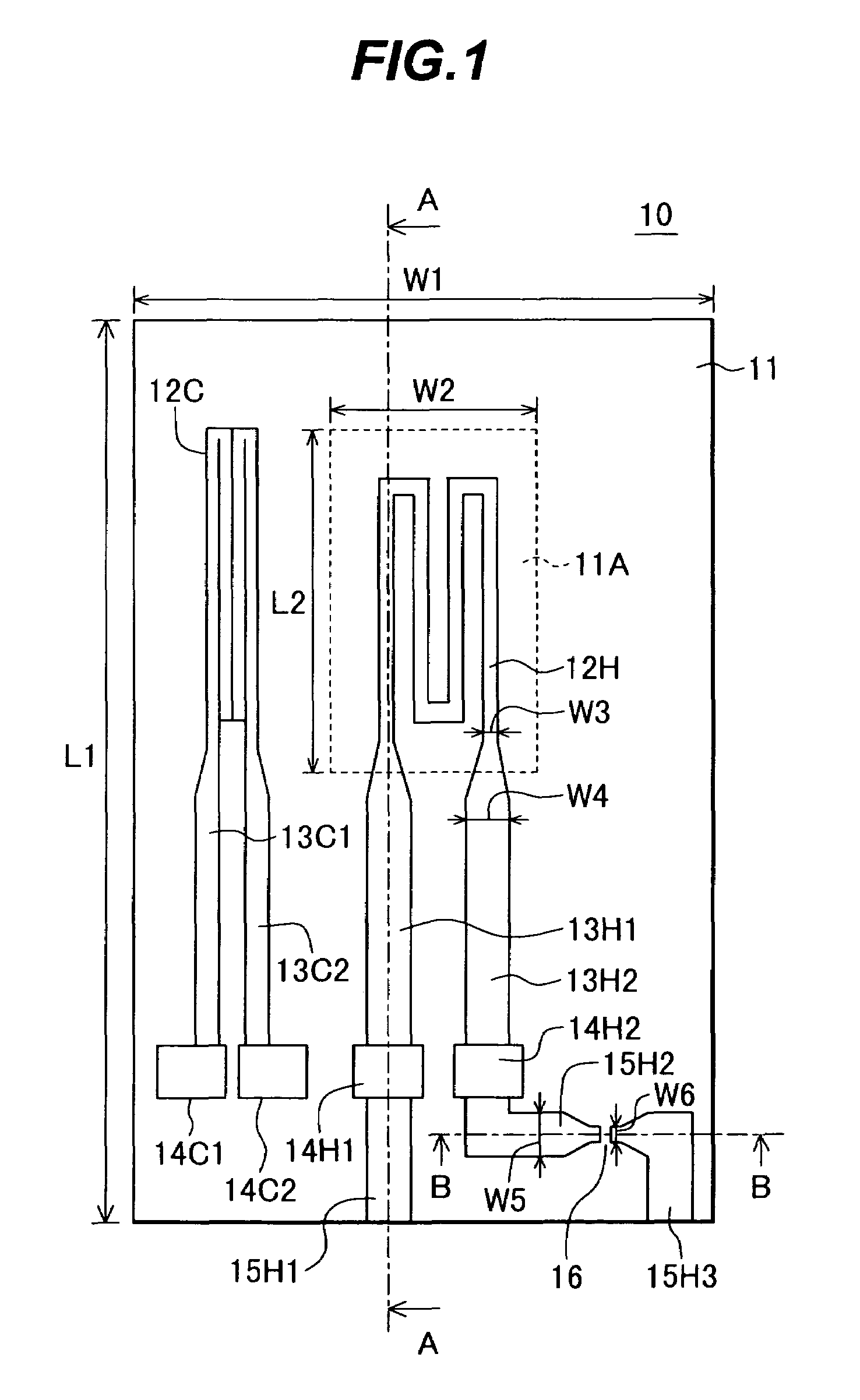

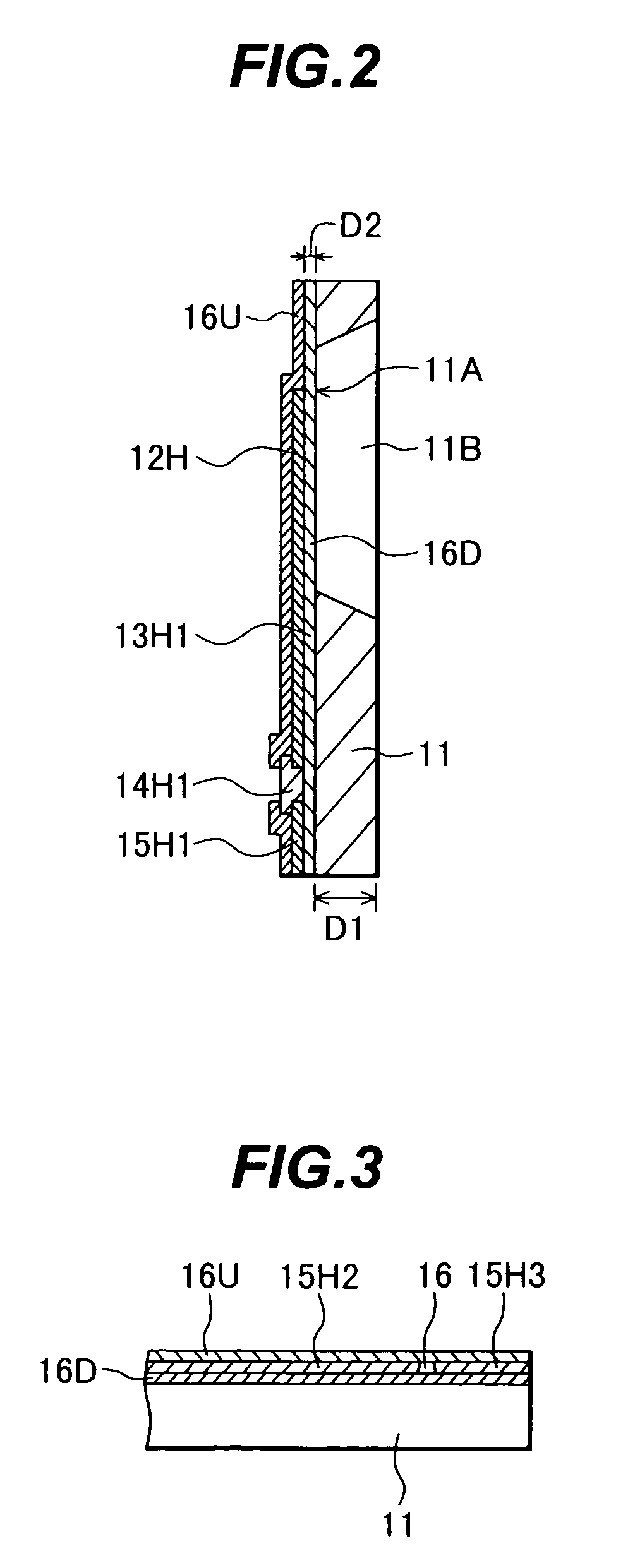

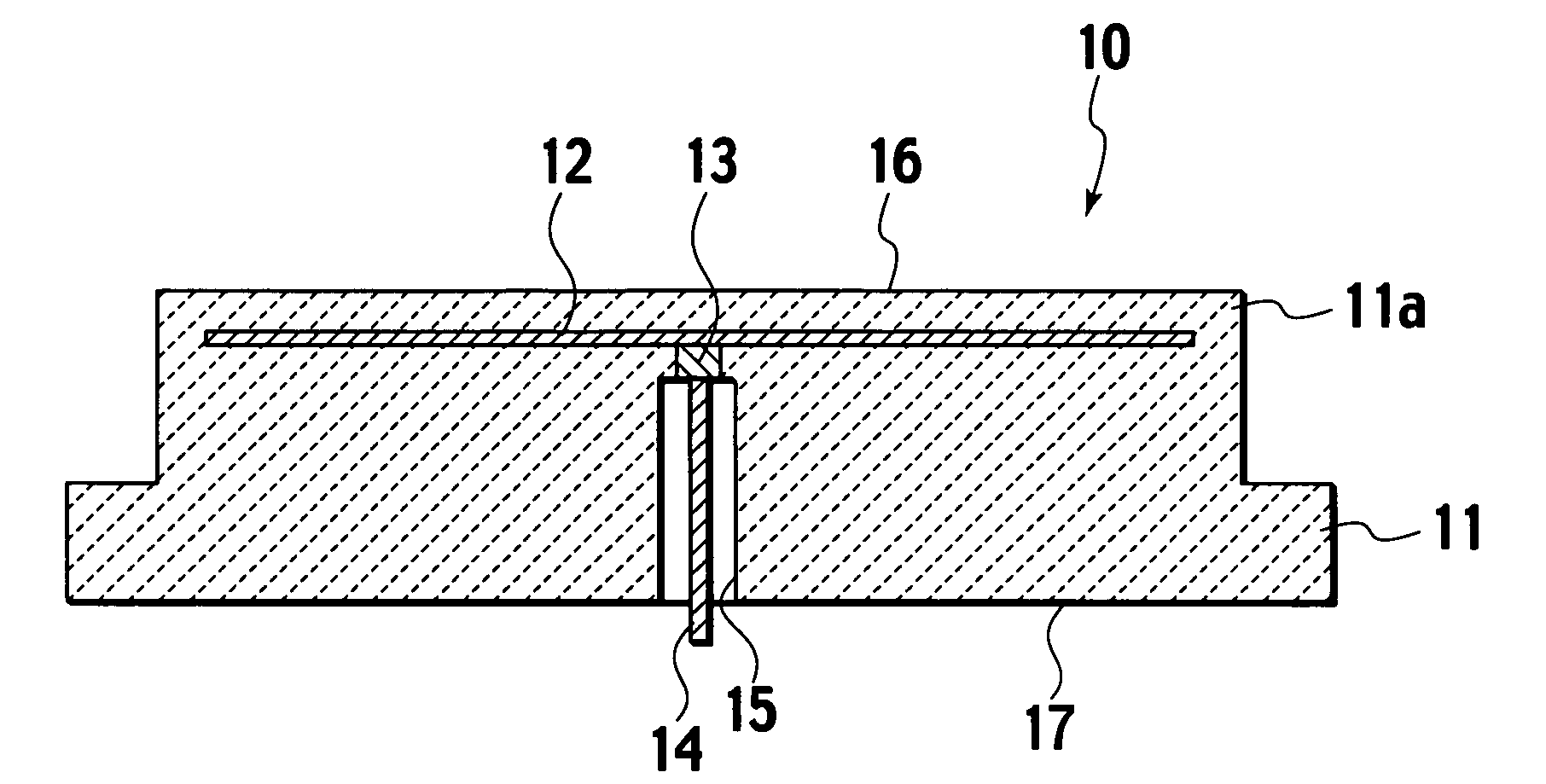

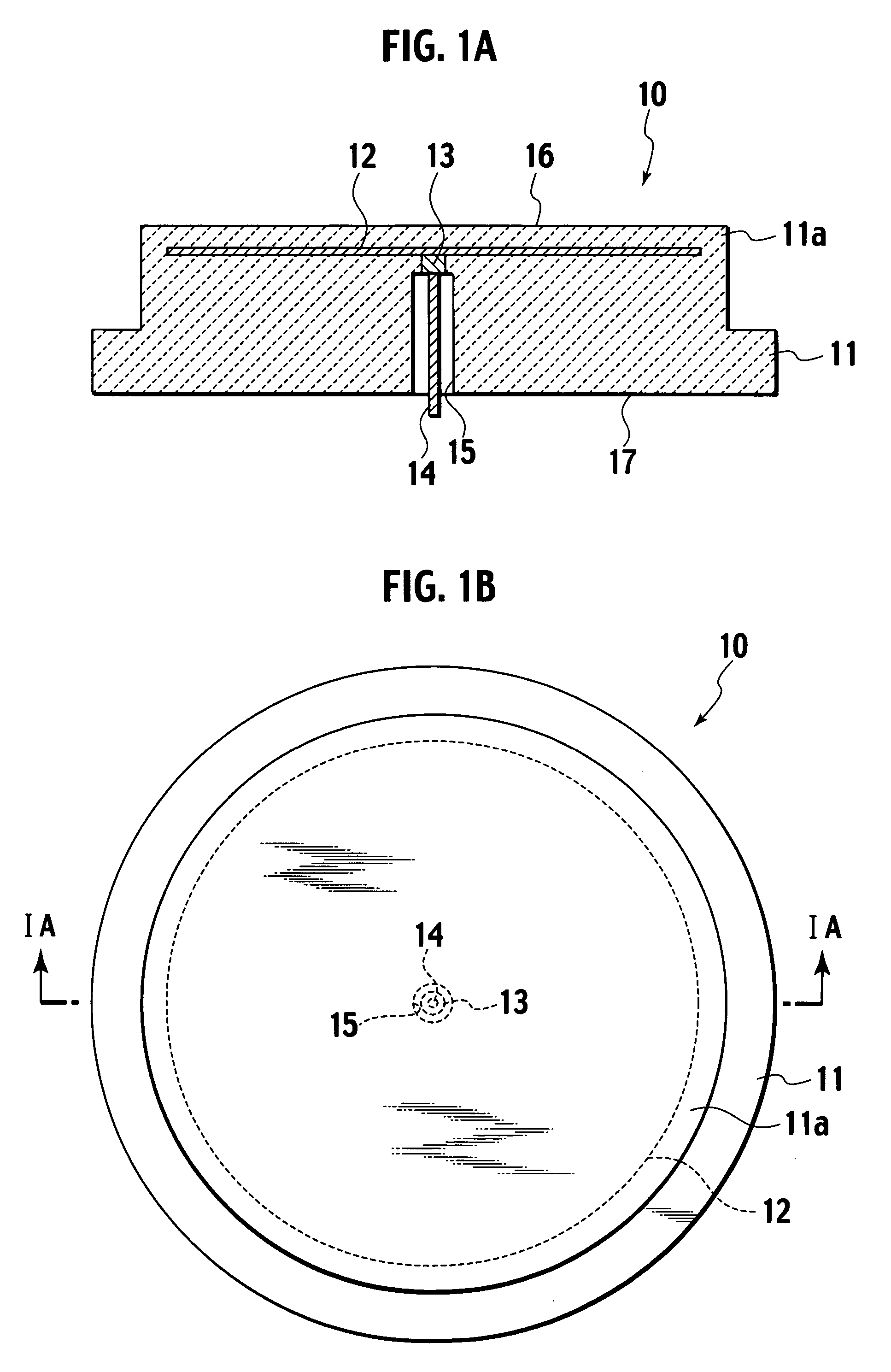

Physical quantity detecting device having second lead conductors connected to the electrodes and extending to the circumference of the substrate

InactiveUS6988399B1Improve reliable controlImprove reliabilityAcceleration measurement using interia forcesElectrical controlElectricityControl system

It is an object of the present invention to provide a simple-structure physical quantity detecting device whose resistance does not vary irrespective of use for long periods, a method for manufacturing thereof and a motor vehicle control system using the physical quantity detecting sensor to improve its reliability. An airflow sensor (20) is equipped with a heat generating resistor (12H) and a temperature measuring resistor (12C), formed on a semiconductor substrate (11). The heat generating resistor (12H) is formed in a thin-wall portion (11A). Both end portions of the heat generating resistor (12H) are connected through first lead conductors (13H1, 13H2) to electrodes (14H1, 14H2), respectively. A second lead conductor (15H1) connected to the electrode (14H1) extends to an outer circumferential portion of the airflow sensor (10). A second lead conductor (15H2, 15H3) connected to the electrode (14H2) also extend to the outer circumferential portion of the airflow sensor (10), but a disconnection portion (16) is made in the middle thereof to establish electrical non-conduction.

Owner:HITACHI LTD +1

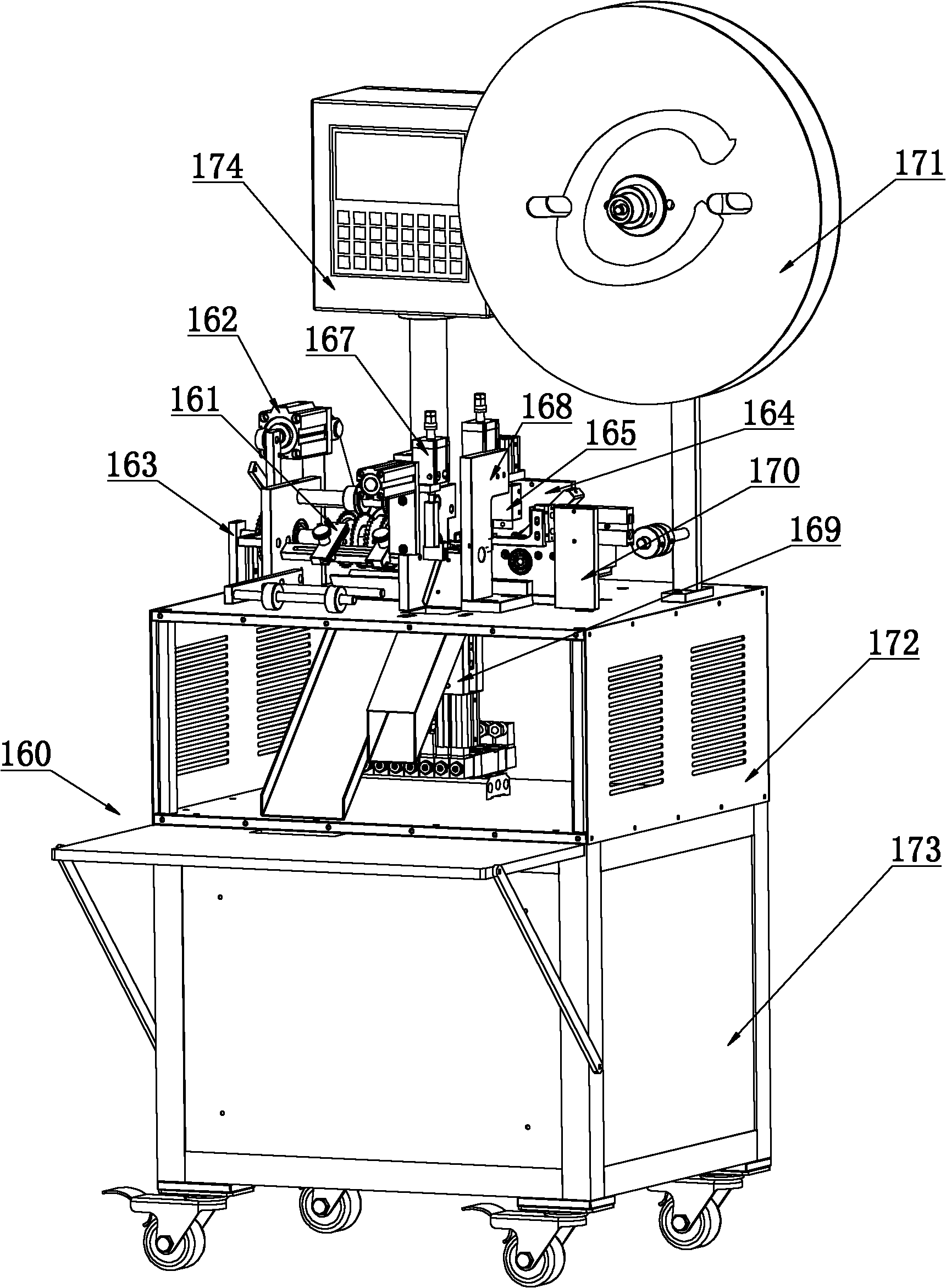

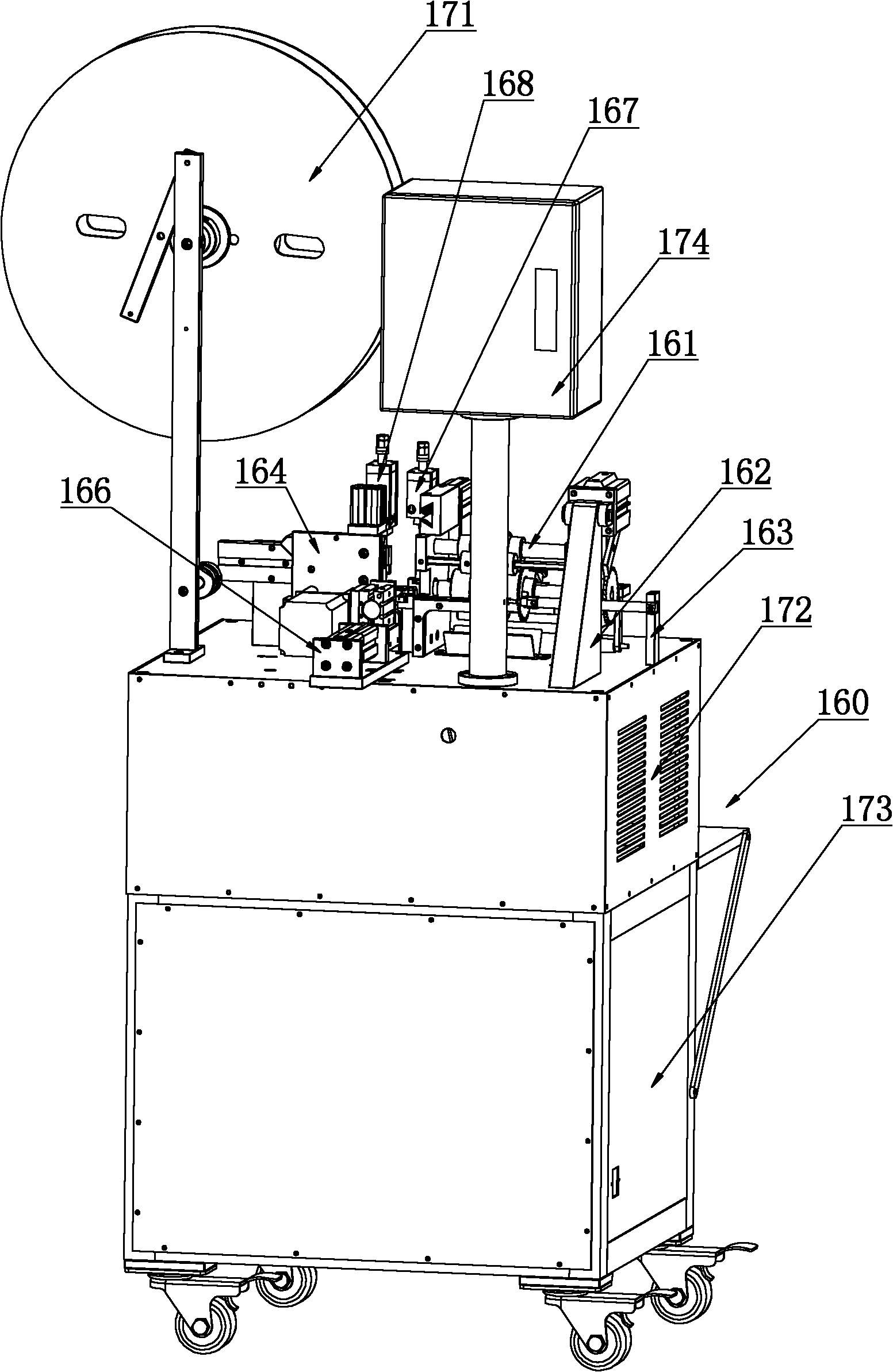

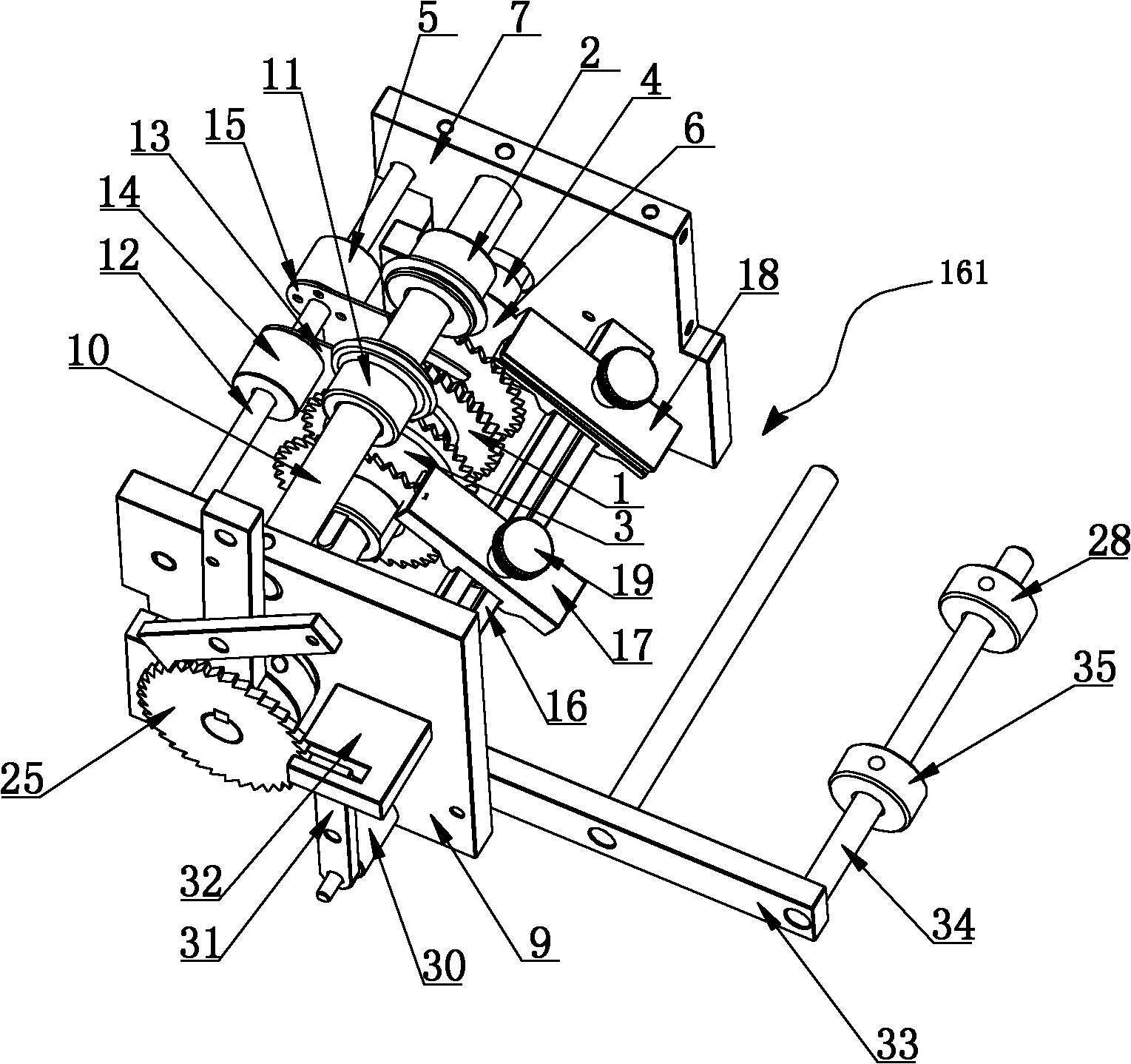

Automatic molding machine for resistor automatically sleeved rubber tube

ActiveCN102496435AHigh tube forming efficiencyImprove product qualityEnvelope/housing resistor manufactureMolding machineEngineering

The invention discloses an automatic molding machine for an automatically-sleeved rubber tube used for a resistor. The machine comprises a rack; the rack is provided with a feed foot-cutting mechanism, a ratchet cylinder indexing mechanism, a rubber tube sleeving mechanism, a rubber tube feeding mechanism, a rubber tube cutting mechanism, a hitch feeding mechanism, a material pressing and discharging mechanism, a K-foot beating mechanism, a lower molding mechanism and a side molding mechanism; the feed foot-cutting mechanism cuts a band-like resistor into single resistors through the ratchet cylinder indexing mechanism, the rubber tube feeding mechanism conveys rubber tubes on a rubber tube mount to the rubber tube cutting mechanism for cutting, the cut rubber tubes are conveyed to the rubber tube sleeving mechanism through the hitch feeding mechanism for automatic sleeving of the rubber tubes on the resistors, the resistors sleeved with the rubber tubes are conveyed to the K-foot beating mechanism through the hitch feeding mechanism for molding, the material pressing and discharging mechanism compacts the resistors, the lower molding mechanism bends K-foot of the resistors, the side molding mechanism carries out bending and molding on the K-foot of the resistors again, and the material pressing and discharging mechanism discharges the resistors which have been sleeved with the rubber tubes and have been molded to a discharge spout. According to the invention, automatic molding of automatically-sleeved rubber tubes used for resistors is realized.

Owner:东莞以利沙科技有限公司

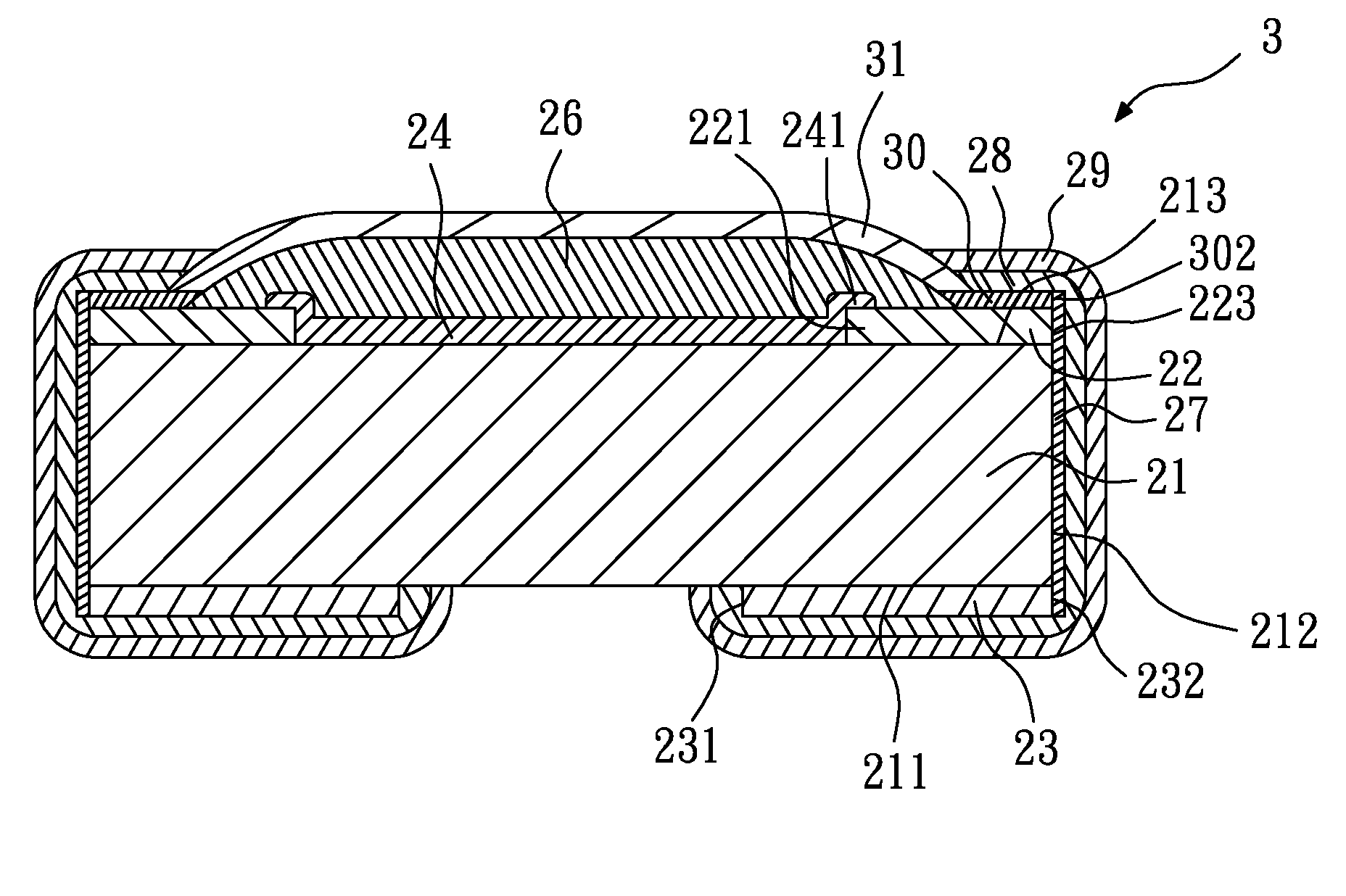

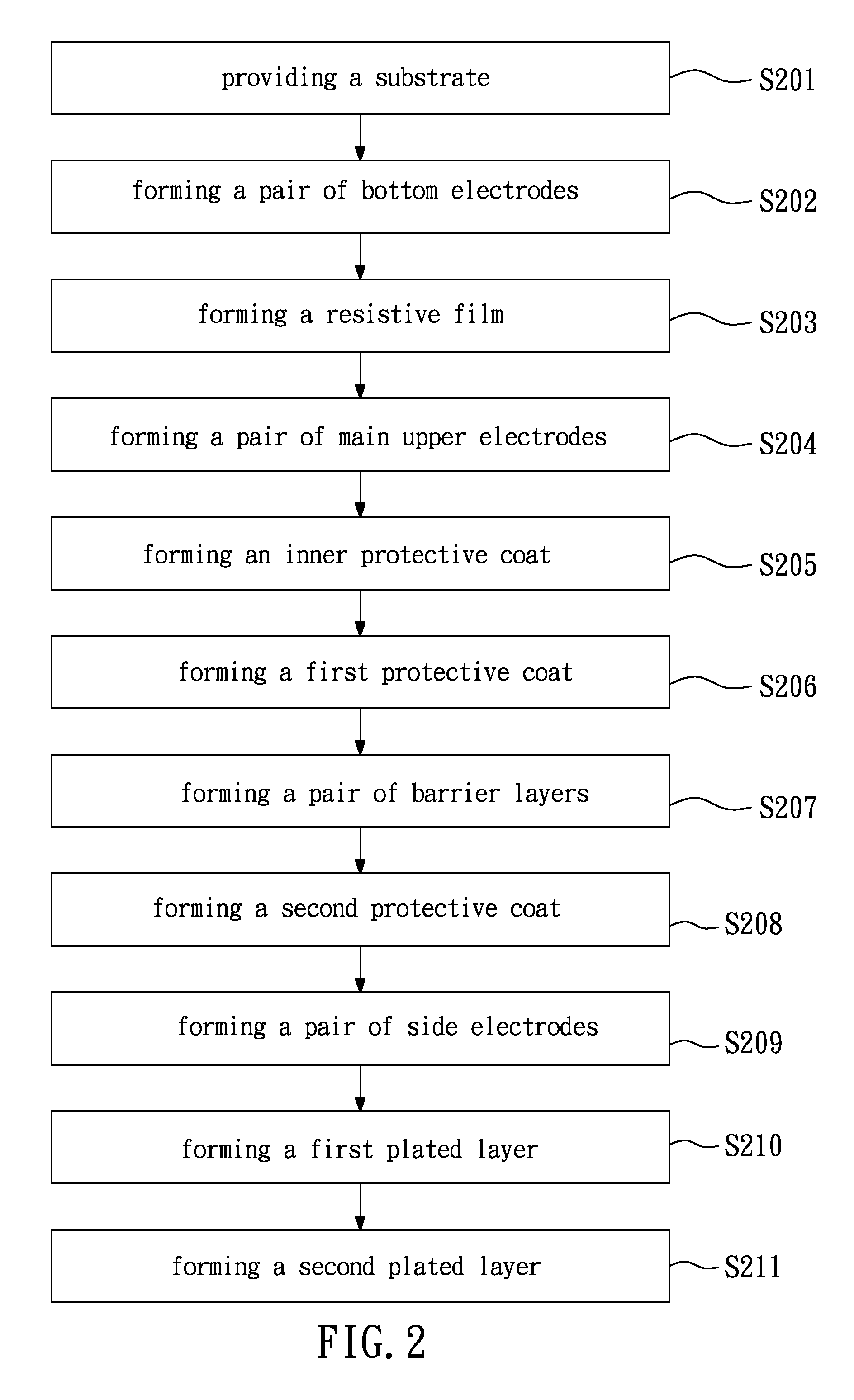

Chip resistor and method for making the same

ActiveUS20100201477A1Effective protectionEasily affectedResistor chip manufactureEnvelope/housing resistor manufactureCorrosionElectrical and Electronics engineering

The present invention relates to a chip resistor and method for making the same. The chip resistor includes a substrate, a pair of bottom electrodes, a resistive film, a pair of main upper electrodes, a first protective coat, a pair of barrier layers, a second protective coat, a pair of side electrodes and at least one plated layer. The first protective coat is disposed over the resistive film, and covers part of the main upper electrodes. The barrier layers are disposed on the main upper electrodes, and cover part of the first protective coat. The second protective coat is disposed on the first protective coat, and covers part of the barrier layers. The plated layers cover the barrier layers, the bottom electrodes and the side electrodes. As a result, the chip resistor features high corrosion resistance.

Owner:YAGEO CORP

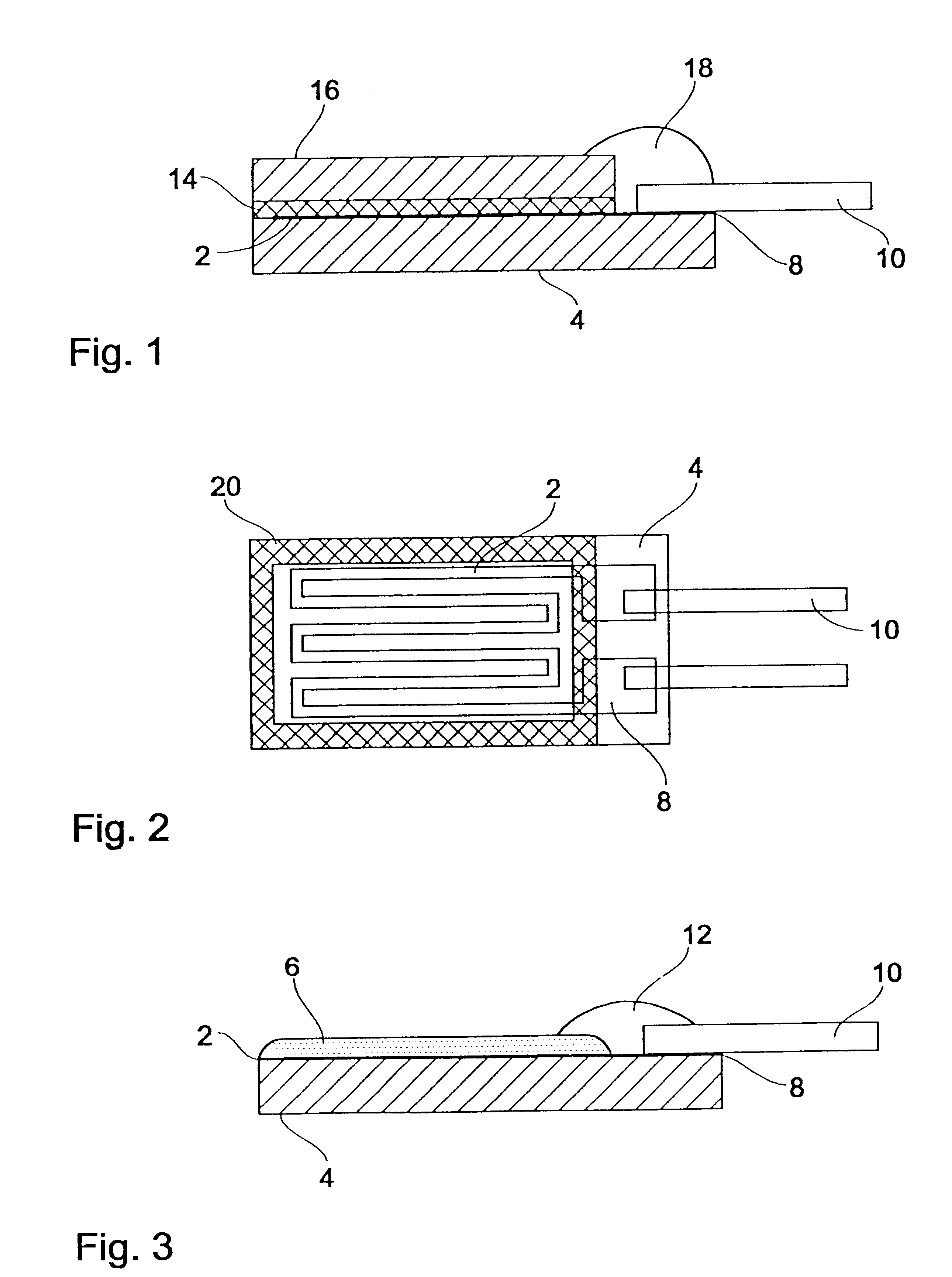

1200°C Film Resistor

ActiveUS20090115567A1Inhibit migrationInexpensive productionThermometer detailsEnvelope/housing resistor manufactureElectrical resistance and conductanceElectrical conductor

For production of a high-temperature sensor, in which a platinum resistance film is applied on a metal-oxide substrate, in particular sapphire or a ceramic plate, and a ceramic intermediate layer is laid on the resistance film, a self-supporting cover, in particular a ceramic or glass-ceramic cover, is bonded on the ceramic intermediate layer or a glass ceramic is mounted on the intermediate layer over its entire surface. Advantageously, the glass ceramic is electrically conductive or an ion conductor above 750° C. and is laid on up to the cathode of the resistance film up to beyond the intermediate layer. In particular, the cover is bonded with a metal-doped glass ceramic, which is laid on the cathode of the resistance film up to beyond the intermediate layer. Preferably, the electrically insulating intermediate layer is coated with a glass ceramic or a glass ceramic doped with metal, which coating has a resistance of at most one megaohm per square at 850° C. or above.

Owner:HERAEUS NEXENSOS GMBH

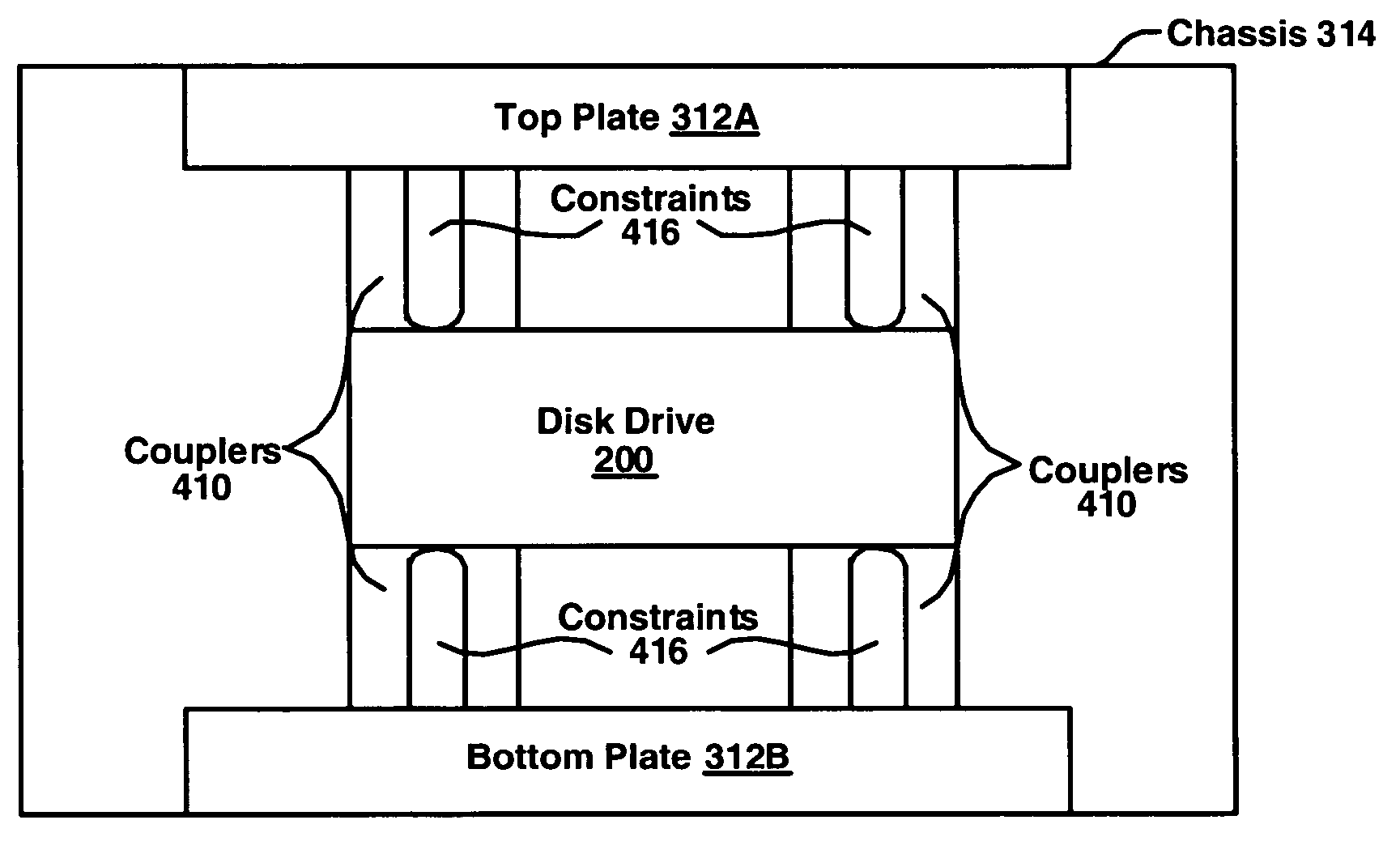

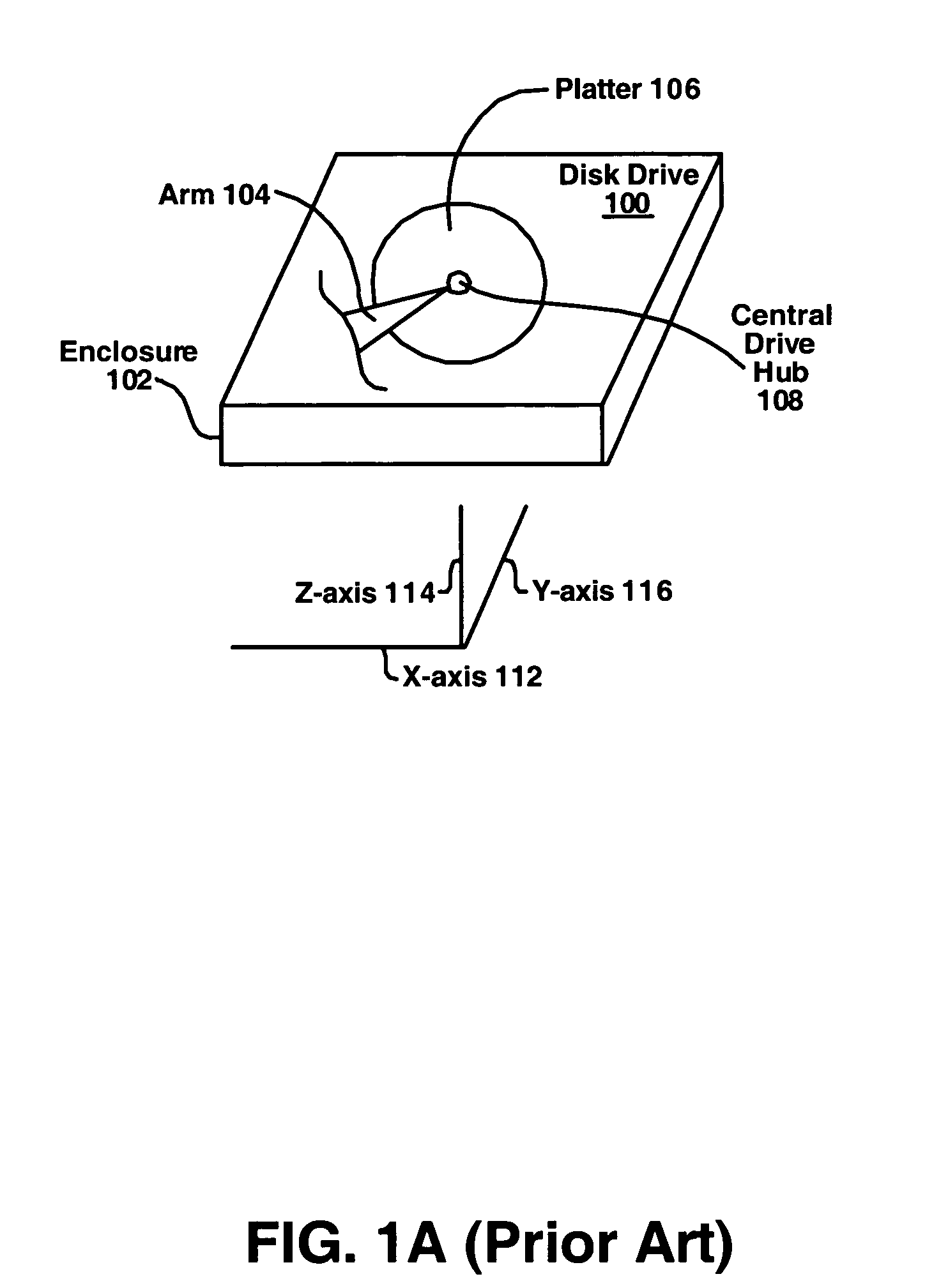

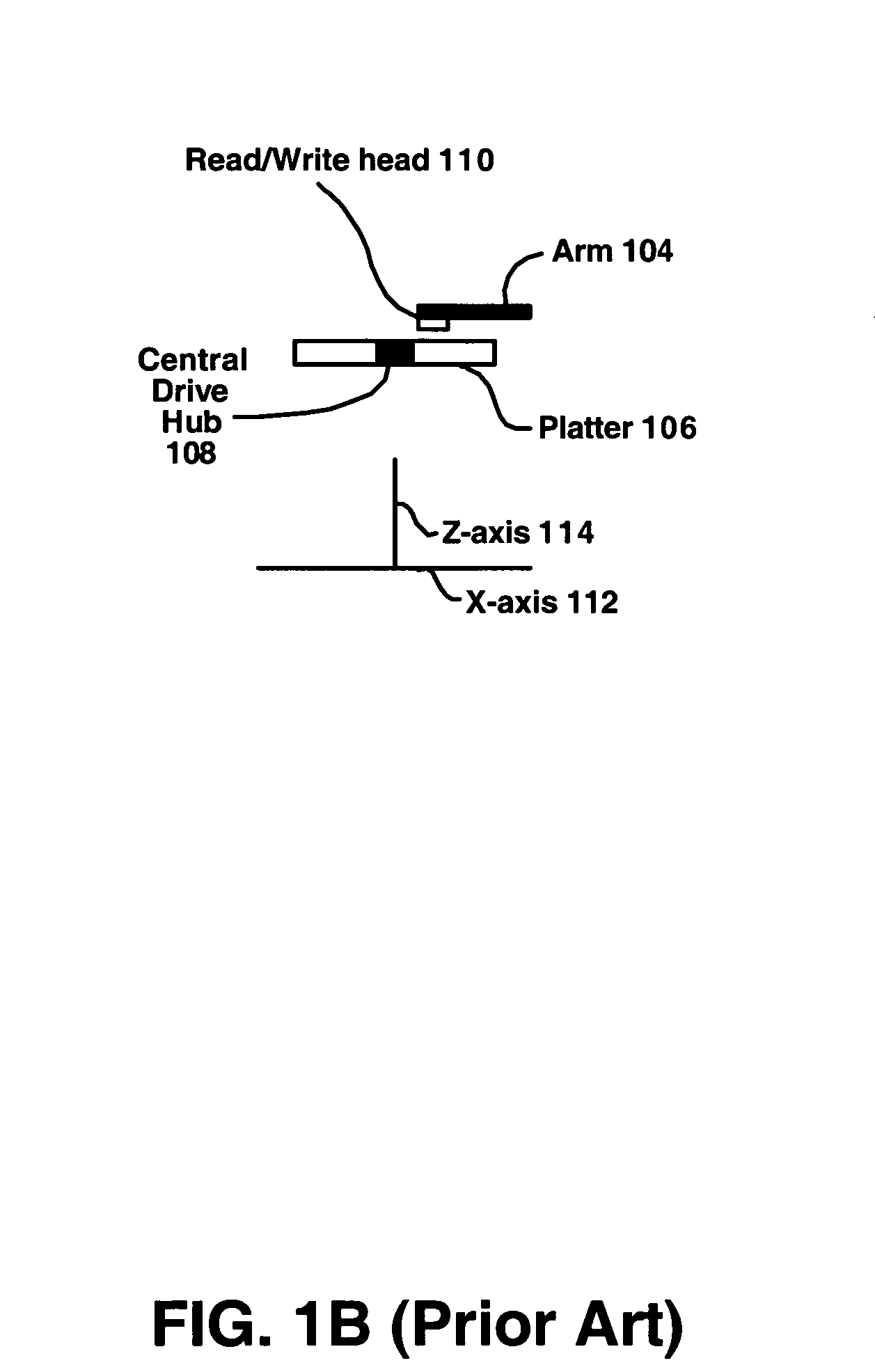

System and method for rigidly coupling a disk drive to a chassis of a computer

Embodiments of the present invention pertain to a method of manufacturing a disk drive coupling apparatus for rigidly coupling a disk drive to a chassis of a computer. In one embodiment, a disk drive to chassis coupler is formed and a disk drive to chassis coupler engaging mechanism is created. One end of the disk drive to chassis coupler can be coupled to the chassis. The disk drive to chassis coupler engaging mechanism can be used to cause the second end of the disk drive to chassis coupler to apply pressure to the disk drive, thus, the disk drive can be rigidly coupled to the chassis.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Ceramic package and chip resistor, and method for manufacture thereof

InactiveUS20050082648A1Low costGuaranteed to workResistor chip manufactureEnvelope/housing resistor manufactureMethacrylateConductive paste

A ceramic package and a chip resistor obtained by forming, on a plastic ceramic green sheet comprising 100 parts by weight of a ceramic powder mainly composed of borosilicate glass, into which 10 to 30 parts by weight of an acrylic copolymer obtained by polymerizing 100 parts by weight of a (meth)acrylic acid ester and 1 to 10 parts by weight of a monomer having a functional group of a hydroxyl group, acid amide group, or amino group and having a Tg in the range of −30° C. to +10° C. is compounded, a conductor layer using a plastic conductive paste obtained by compounding, into 100 parts by weight of a conductive powder, 5 to 20 parts a mixture of an acrylic copolymer having a Tg of not more than −30° C. and an ethylcellulose-based binder, press forming the resultant single layer of ceramic green sheet, and calcining the resultant ceramic green sheet having the integrally formed bottom, opening and opening circumferential edge and a method for producing the same.

Owner:NIPPON CARBIDE KOGYO KK

Method of suppressing sublimation in advanced thermoelectric devices

InactiveUS7480984B1Suppresses mass lossOvercome disadvantagesLine/current collector detailsEnvelope/housing resistor manufactureThermoelectric materialsMetal foil

A method of applying a physical barrier to suppress thermal decomposition near a surface of a thermoelectric material including applying a continuous metal foil to a predetermined portion of the surface of the thermoelectric material, physically binding the continuous metal foil to the surface of the thermoelectric material using a binding member, and heating in a predetermined atmosphere the applied and physically bound continuous metal foil and the thermoelectric material to a sufficient temperature in order to promote bonding between the continuous metal foil and the surface of the thermoelectric material. The continuous metal foil forms a physical barrier to enclose a predetermined portion of the surface. Thermal decomposition is suppressed at the surface of the thermoelectric material enclosed by the physical barrier when the thermoelectric element is in operation.

Owner:NASA

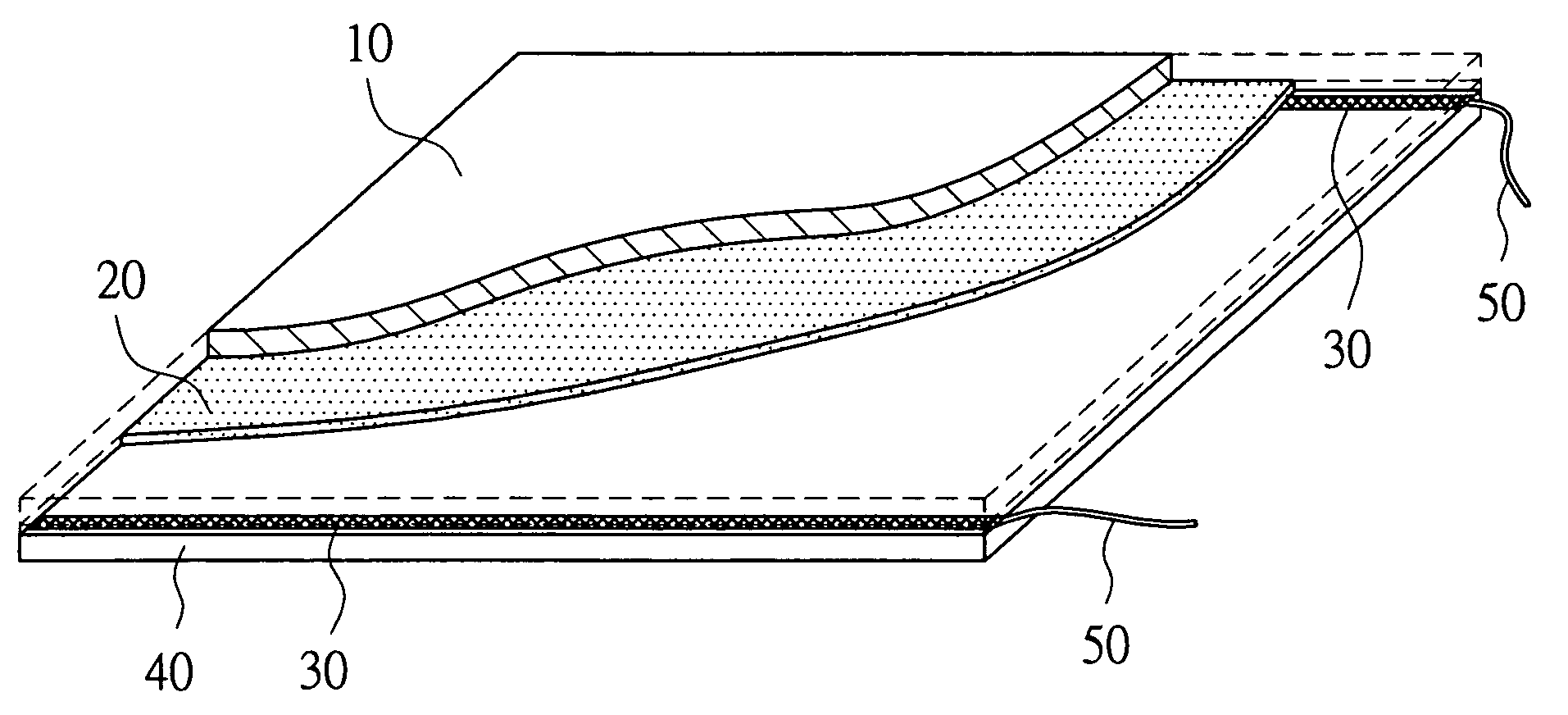

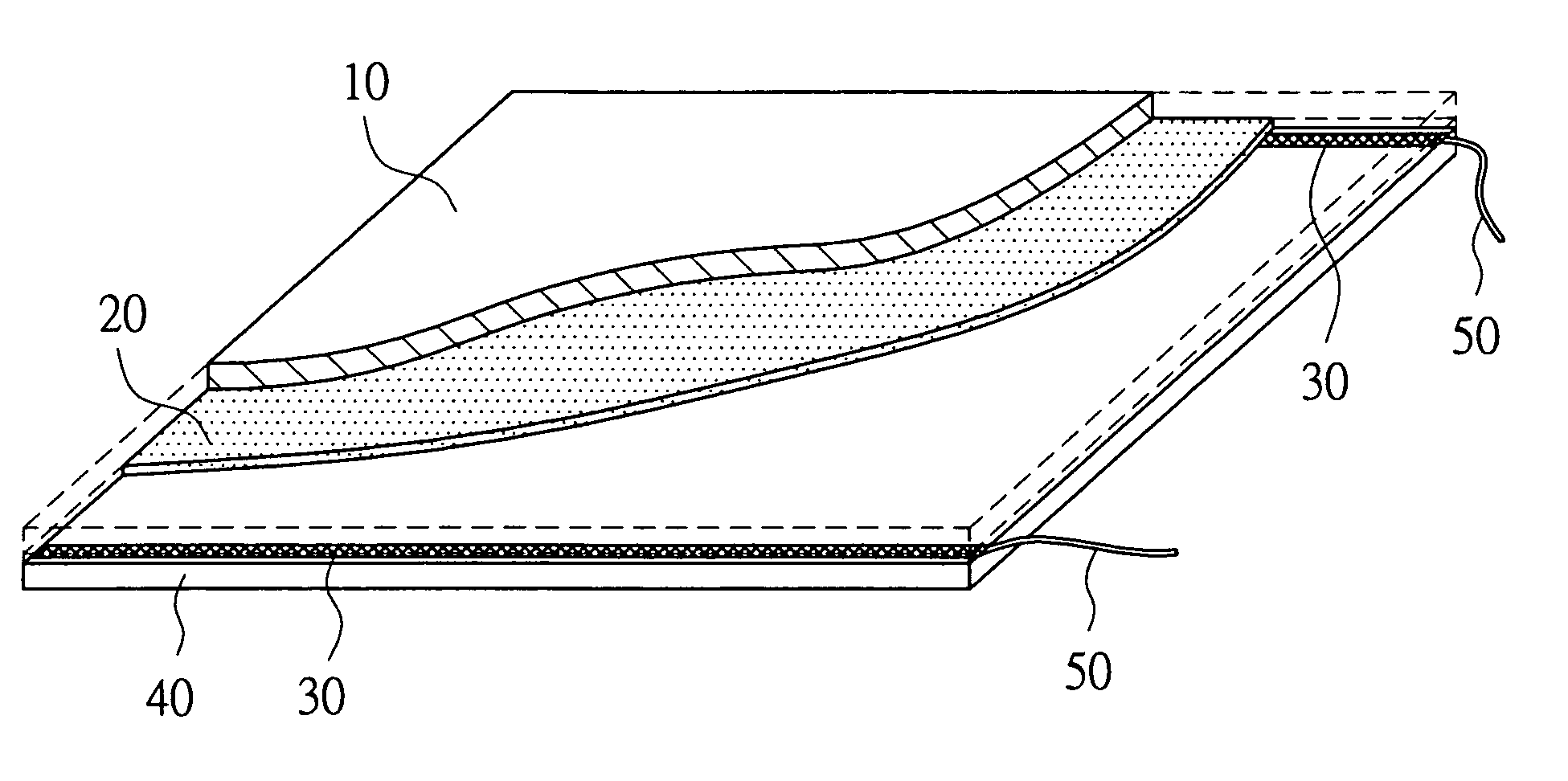

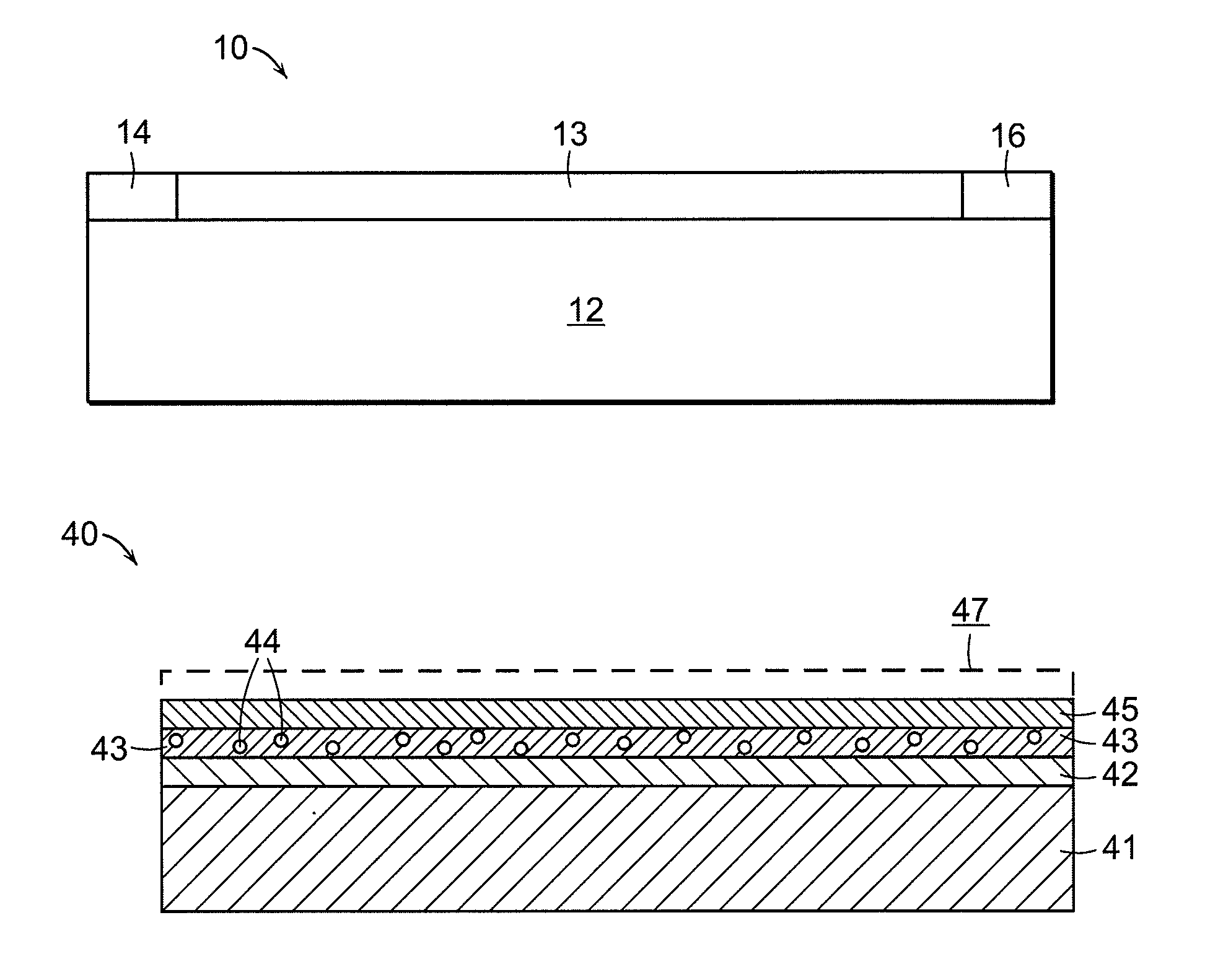

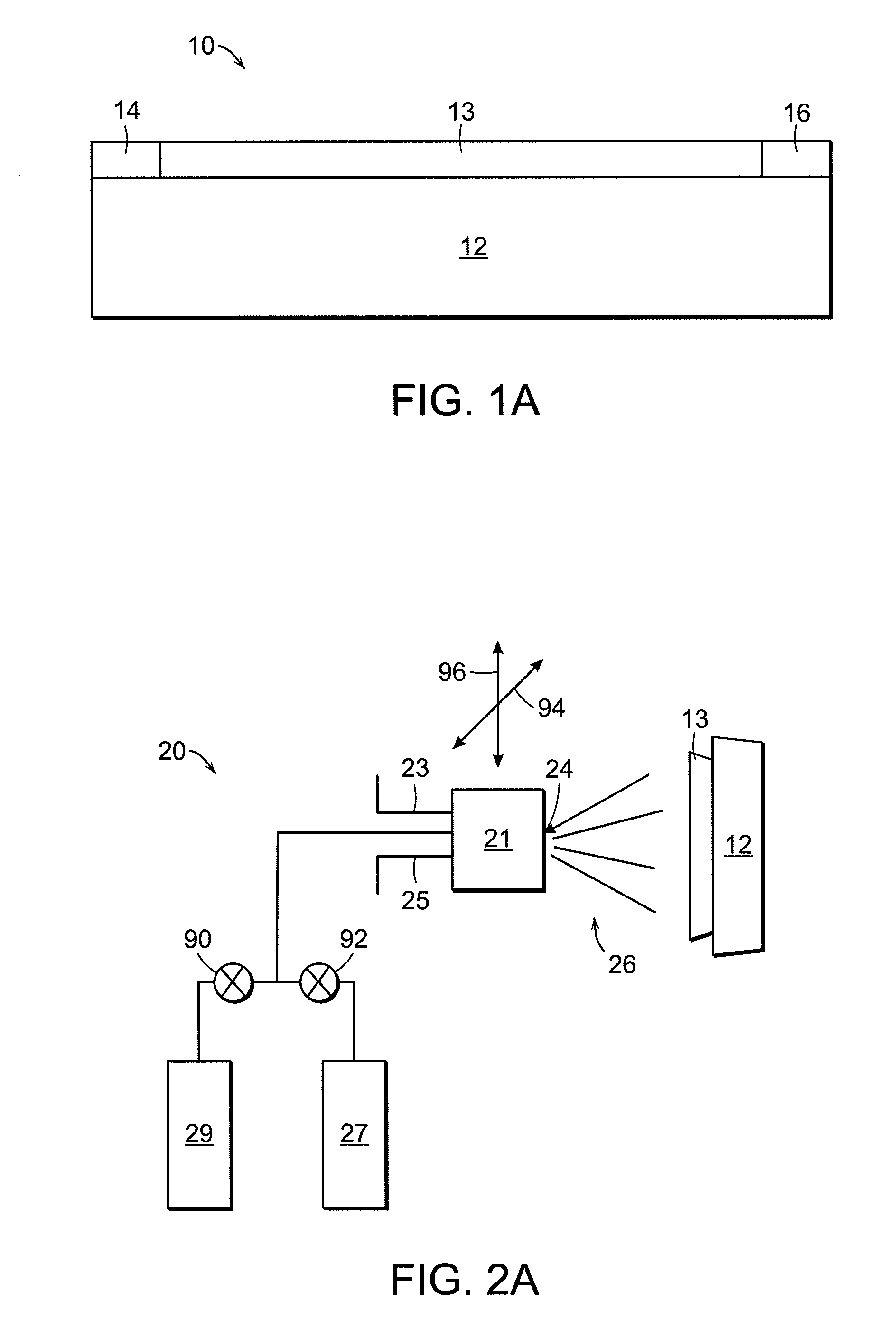

Conductive polymer electronic devices with surface mountable configuration and methods for manufacturing same

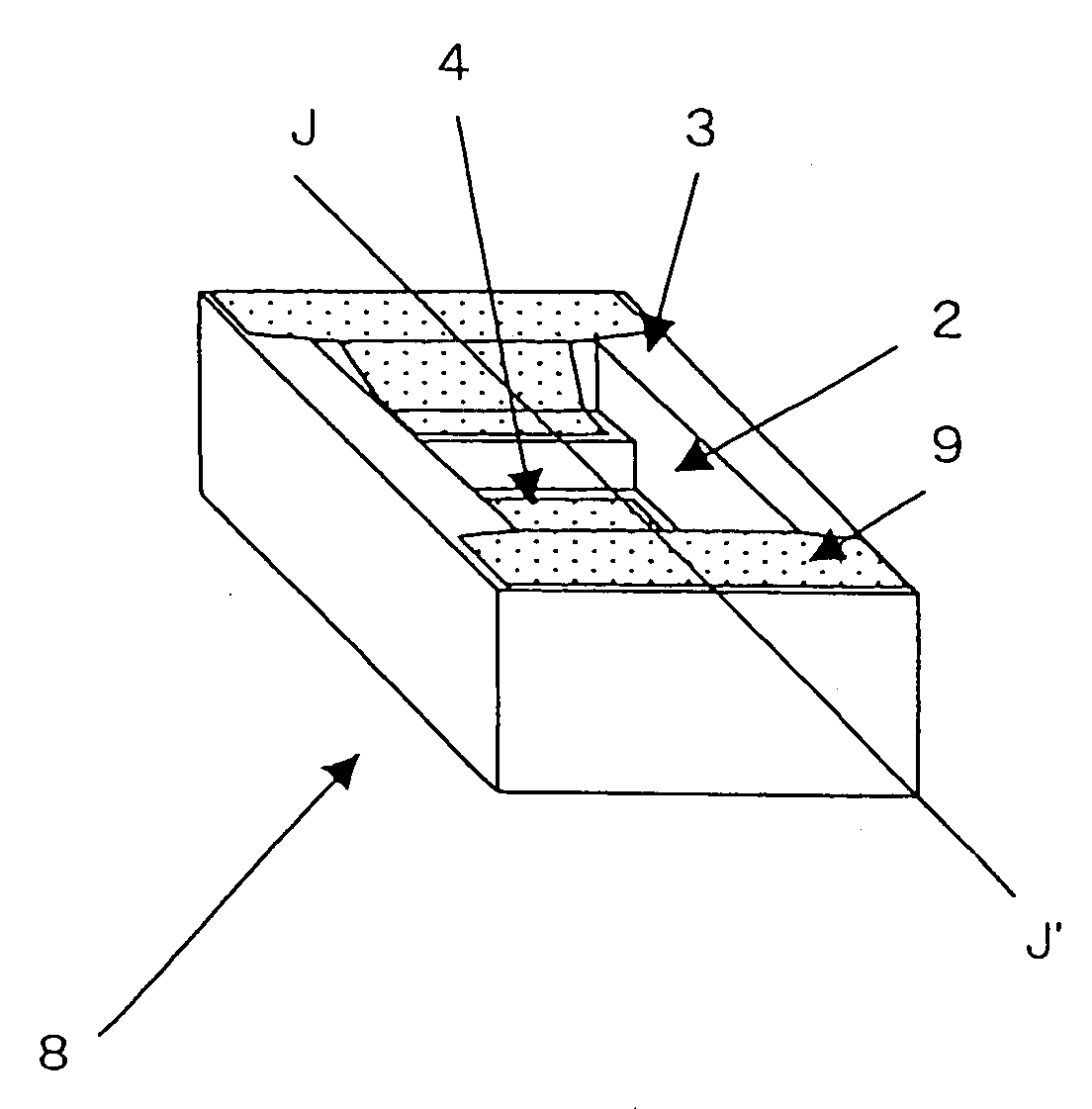

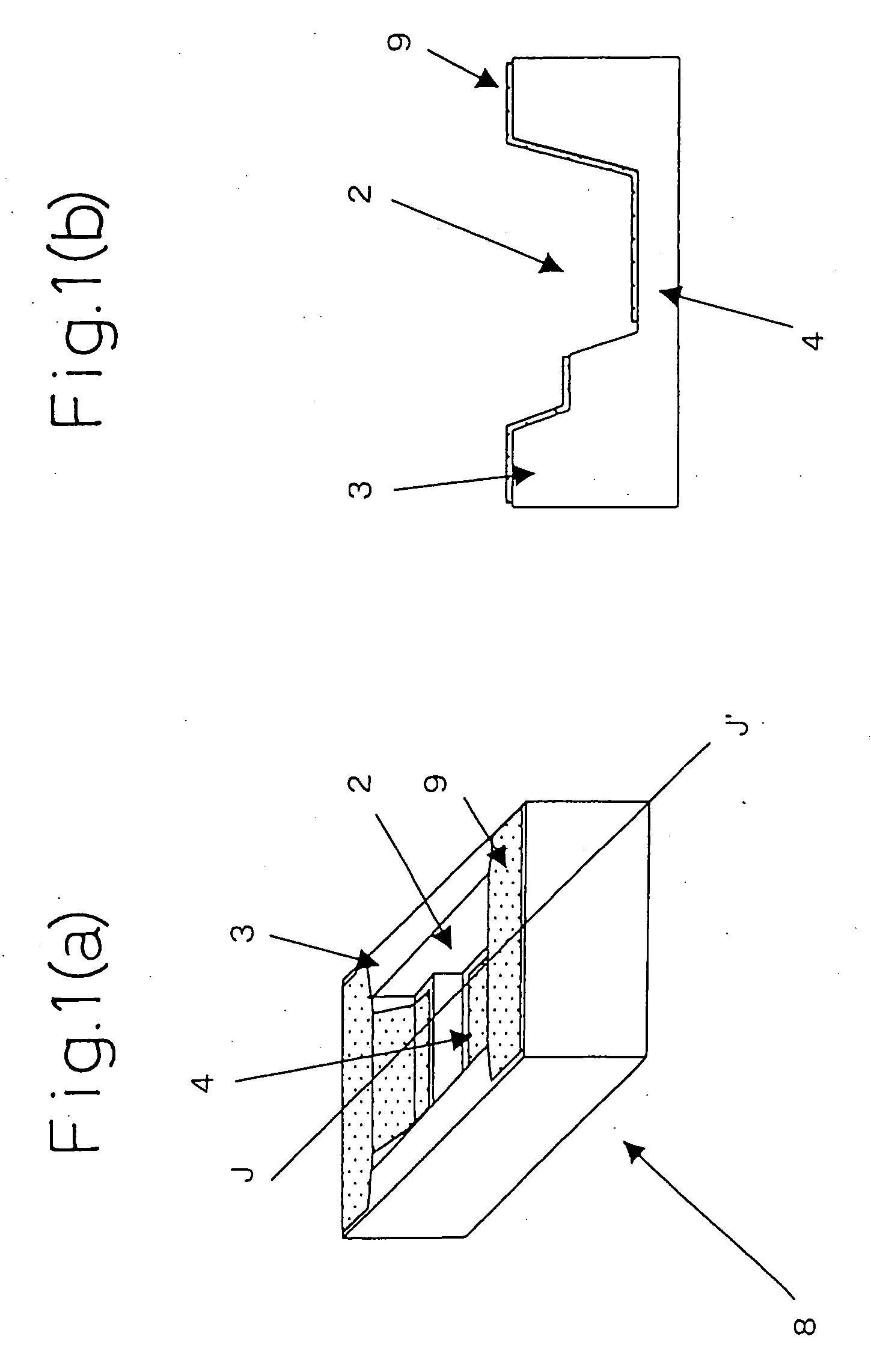

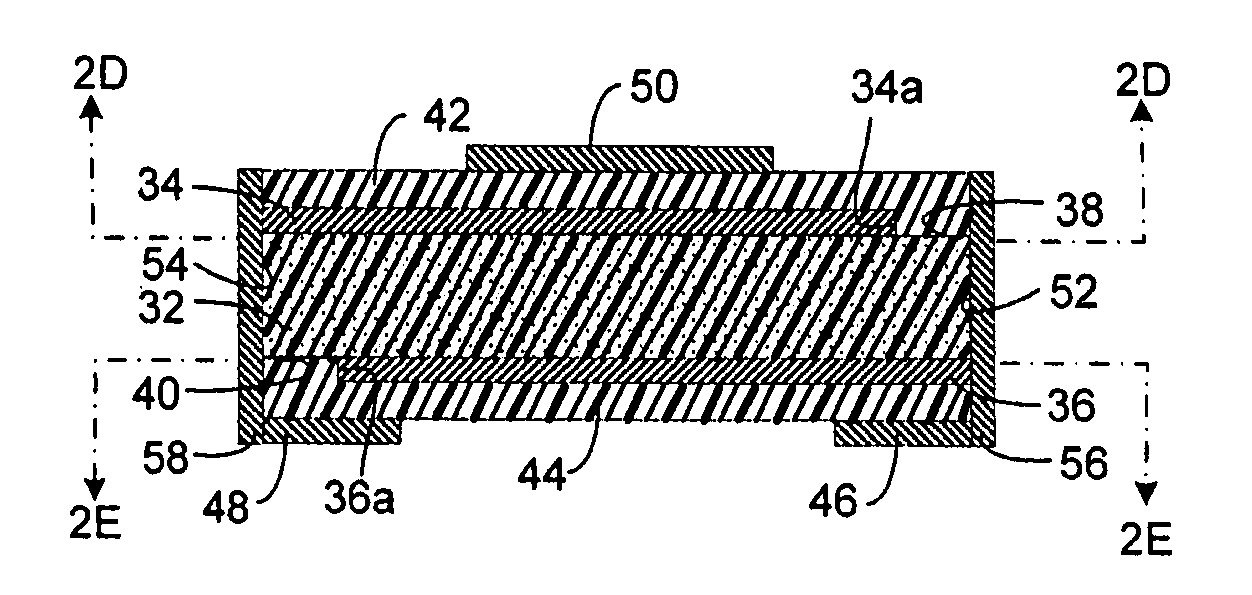

ActiveUS20110175700A1Envelope/housing resistor manufactureCurrent responsive resistorsInsulation layerElectrical conductor

Surface-mountable conductive polymer electronic devices include at least one conductive polymer active layer laminated between upper and lower electrodes. Upper and lower insulation layers, respectively, sandwich the upper and lower electrodes. First and second planar conductive terminals are formed on the lower insulation layer. First and second cross-conductors are provided by plated through-hole vias, whereby the cross-conductors connect each of the electrodes to one of the terminals. Certain embodiments include two or more active layers, arranged in a vertically-stacked configuration and electrically connected by the cross-conductors and electrodes in parallel. Several embodiments include at least one cross-conductor having a chamfered or beveled entry hole through the upper insulation layer to provide enhanced adhesion between the cross-conductor and the insulation layer. Several methods for manufacturing the present surface-mountable conductive polymer electronic devices are also provided.

Owner:BOURNS INC

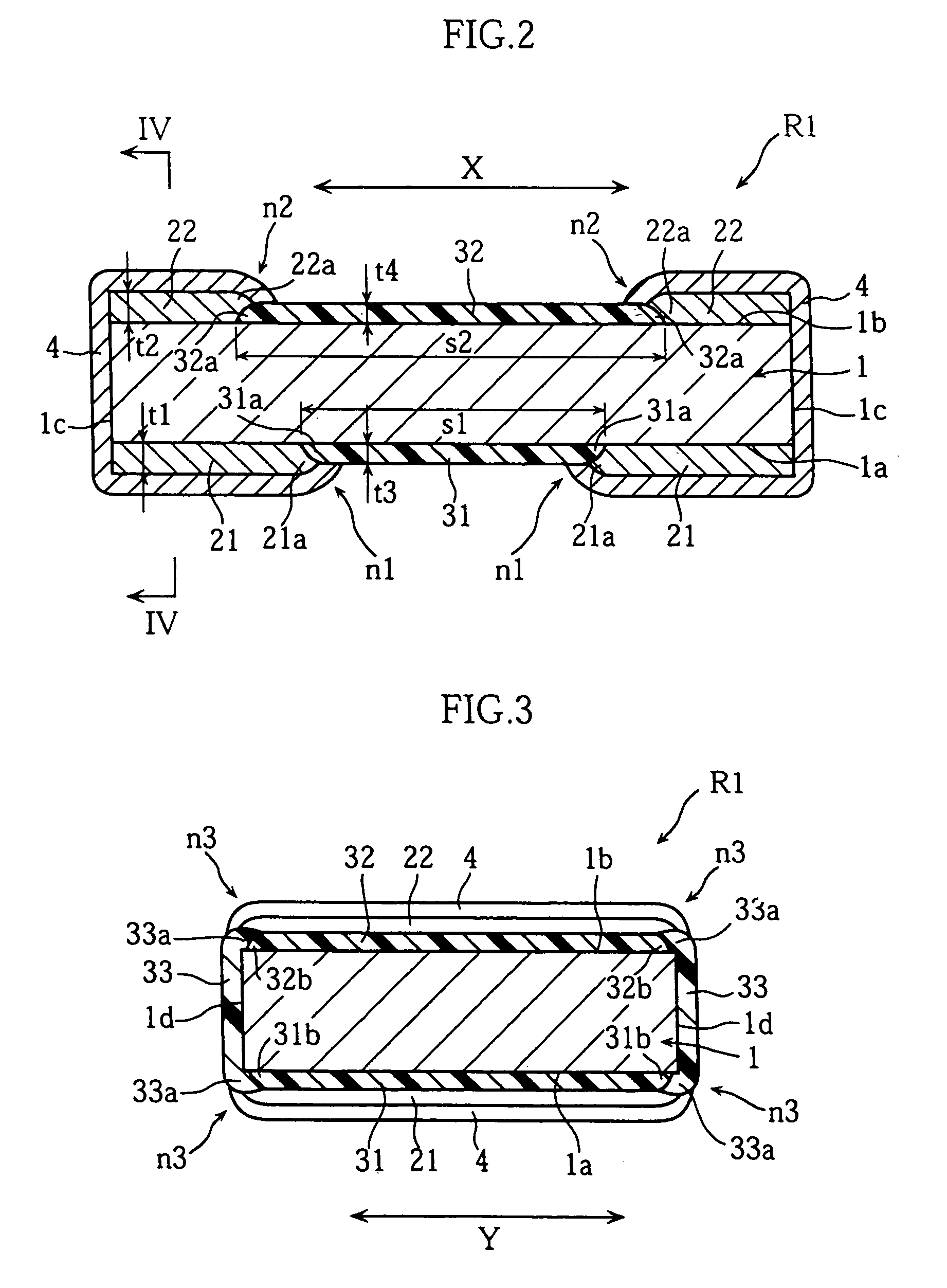

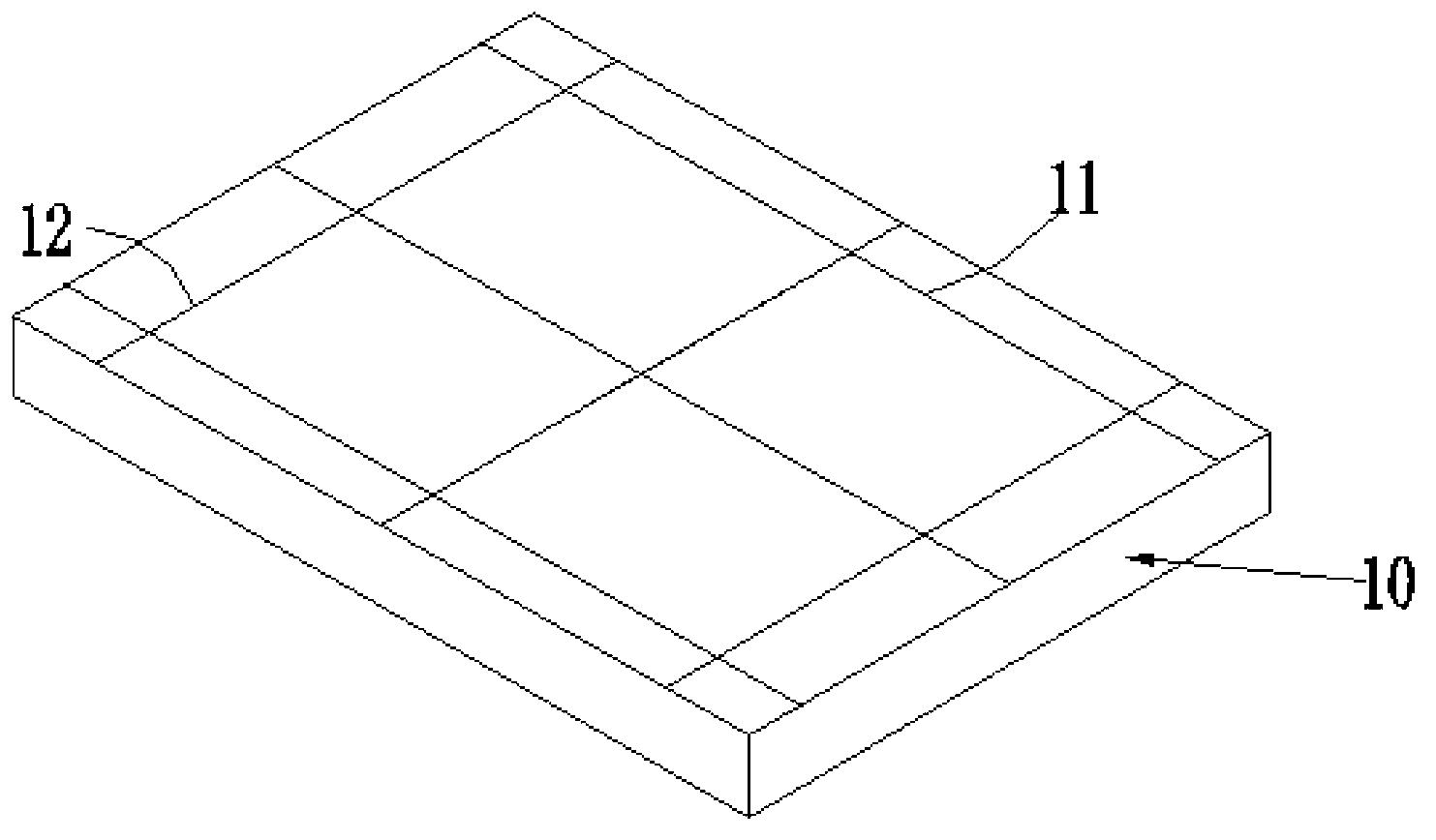

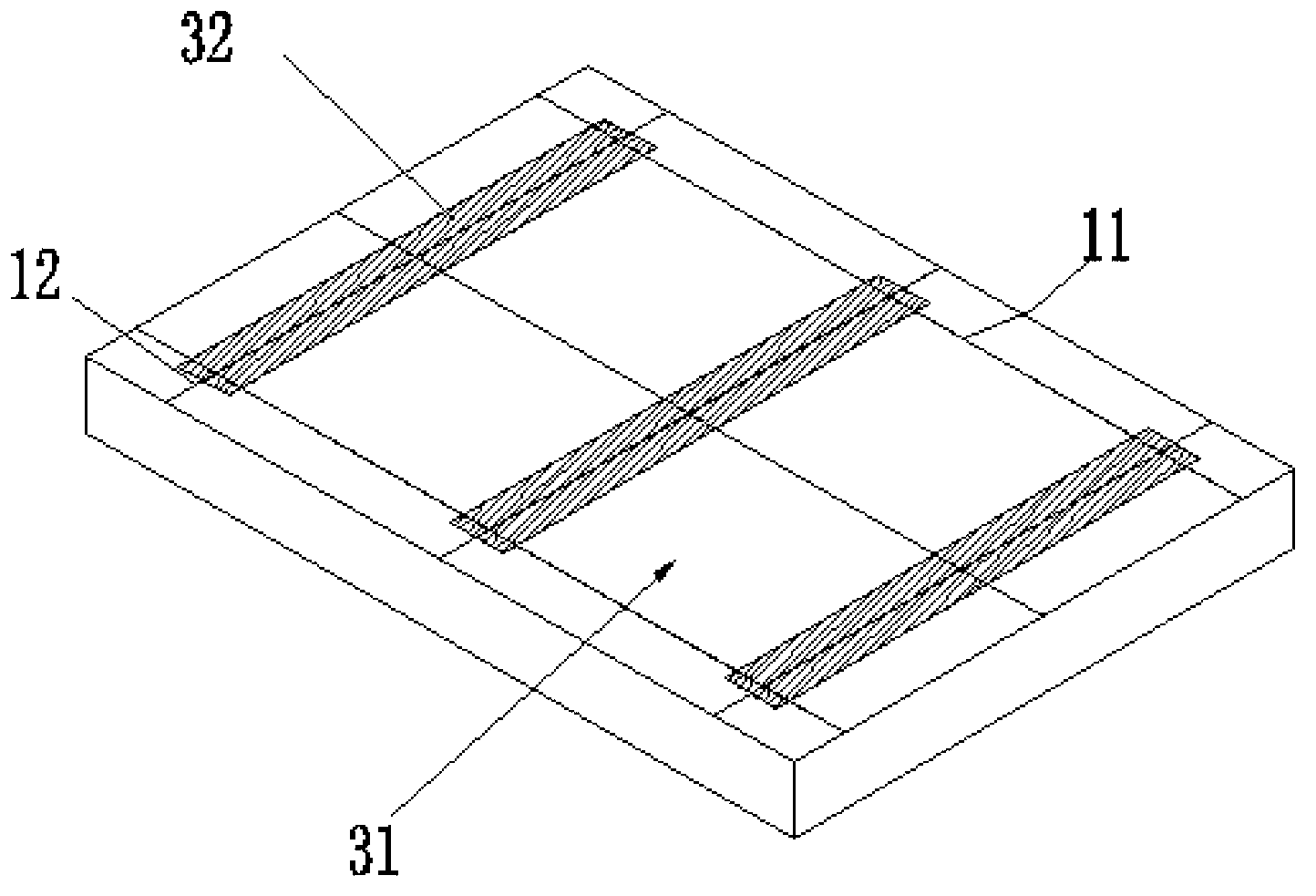

Resistive component and method of manufacturing the same

ActiveUS20100039211A1Improve stabilityAdhesionResistor chip manufactureEnvelope/housing resistor manufactureElectrical resistance and conductanceOptoelectronics

A resistive component suitable for detecting electric current in a circuit and a method of manufacturing the resistive component are provided. The resistive component includes a carrier, a resistive layer, an electrode unit, an upper oxide layer and a protective layer. The resistive layer comprises copper alloy and is disposed on the carrier. The electrode unit is electrically connected to the resistive layer. The upper oxide layer is disposed on a part of a surface of the resistive layer and includes oxides of the resistive layer. The protective layer covers at least a part of the upper oxide layer.

Owner:CYNTEC

Thick-film anti-vulcanization paster resistor and manufacturing method thereof

ActiveCN103165250AImprove anti-sulfur performanceProlonged vulcanization pathEnvelope/housing resistor manufactureResistor housing/enclosing/embeddingTinningVulcanization

The invention discloses a thick-film anti-vulcanization paster resistor and a manufacturing method thereof. A second front side electrode is added to a first front side electrode so as to form an overlapped and intersected structure of the second front side electrode and a resistor layer as well as the second front side electrode and a first protecting layer; and the expansion coefficient of a second protecting layer is matched with that of the second front side electrode. Due to the structural method design, a vulcanization route is greatly prolonged, so that the anti-vulcanization property of the paster resistor is improved, and moreover, the phenomenon that the electrode is corroded by vulcanization gas from cracks caused in wave peak soldering or reflow soldering of a PCB (Printed Circuit Board) of the resistor because of the difference of expansion coefficients of an electro-nickelling layer, an electro-tinning layer and the second protecting layer. Therefore, the production cost of the thick-film anti-vulcanization paster resistor is greatly lowered, and the thick-film anti-vulcanization paster resistor can be widely applied to ordinary electronic products.

Owner:UNIROYAL ELECTRONICS IND

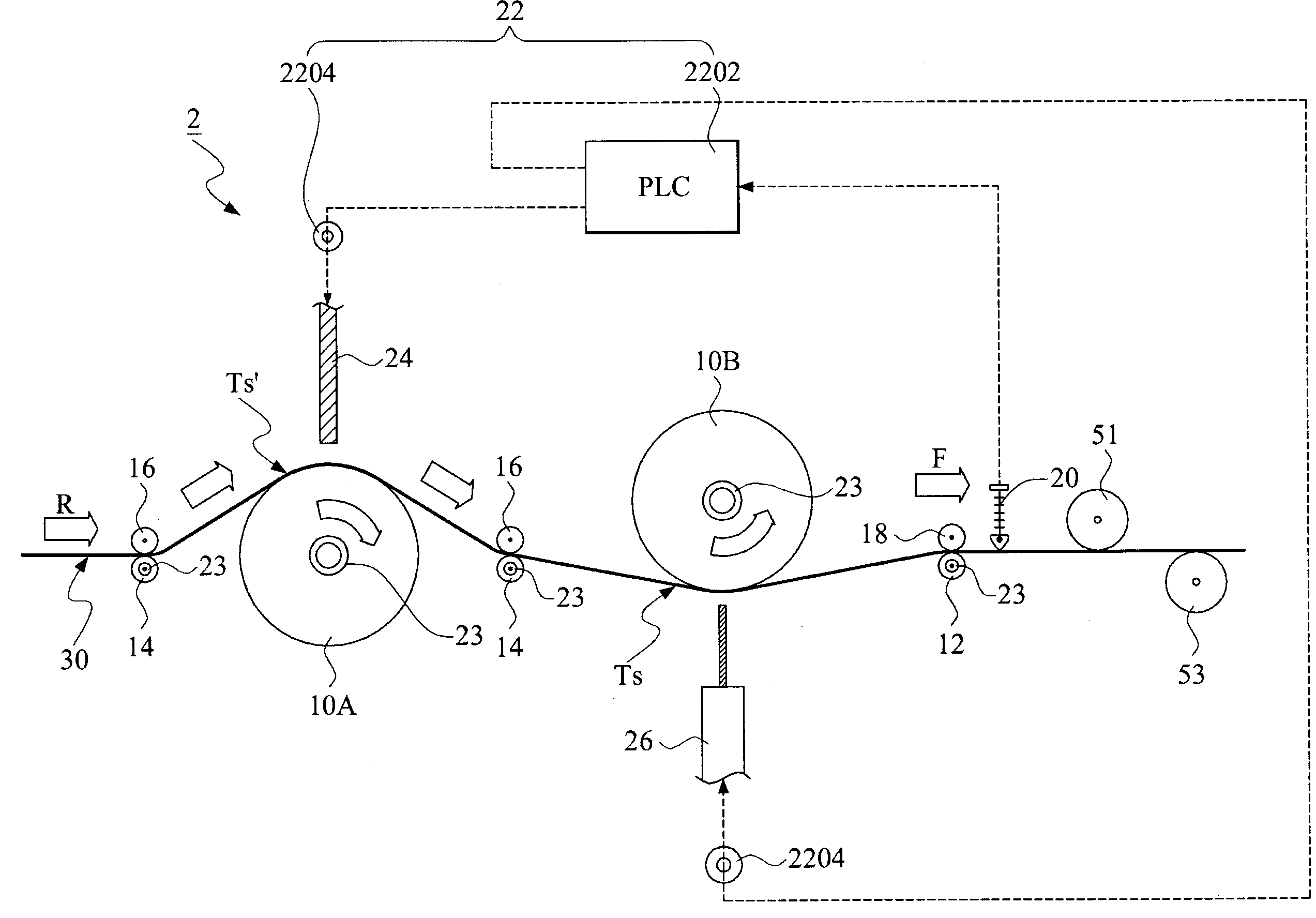

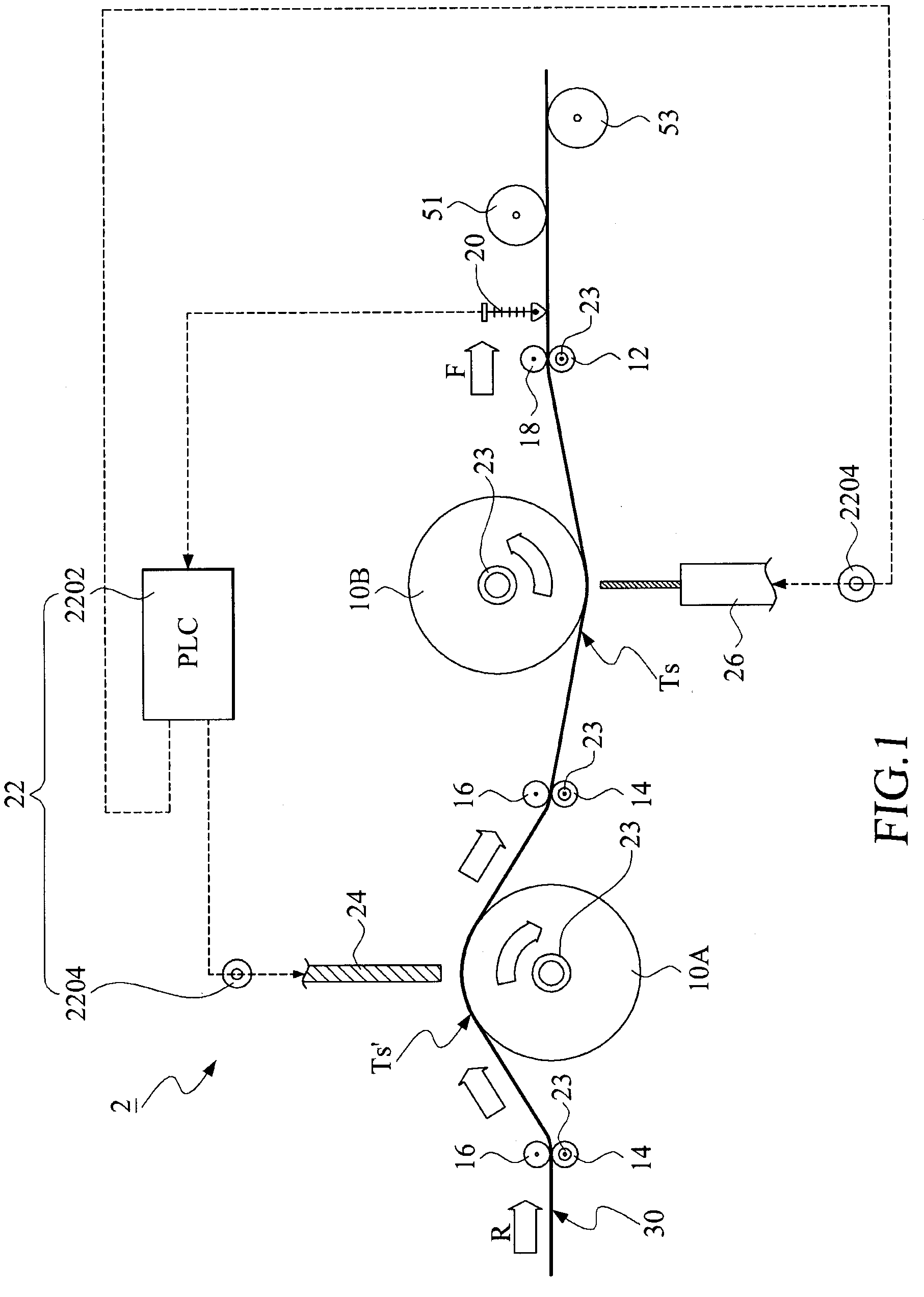

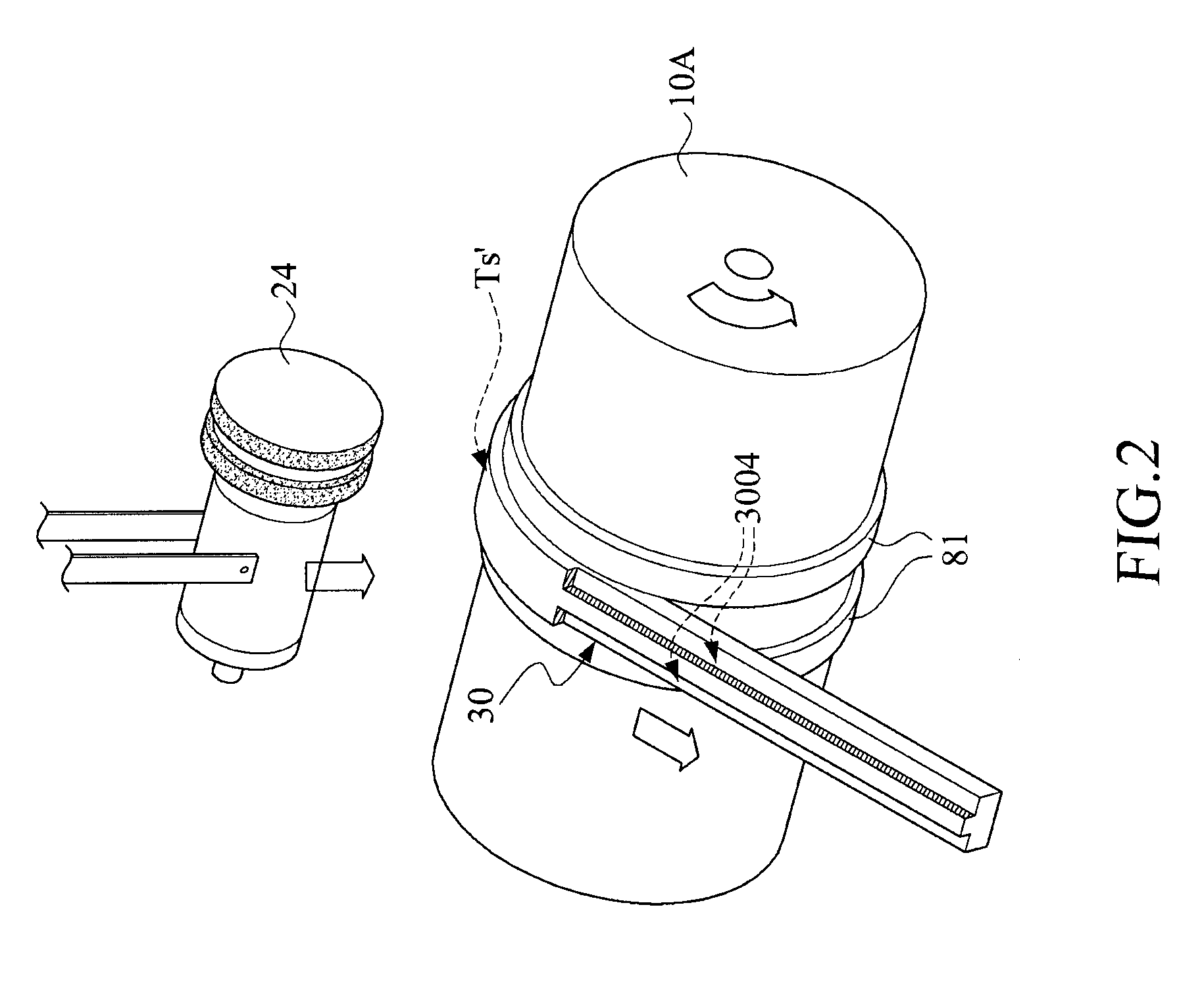

Method and apparatus for manufacturing ultralow-resistance current sensors

ActiveUS20090272169A1Easy maintenanceSmall sizeEnvelope/housing resistor manufactureElectrical measurement instrument detailsElectrical resistance and conductanceCurrent sensor

A method for manufacturing ultralow-resistance current sensors of size 0402 to 4518 of IEEE specifications includes the steps of: a raw metallic strip being pressed to roll over a first tension roller, a cutting tool over the first tension roller being fed to cut the raw metallic strip so as to form a deep groove thereof along the moving metallic strip, an insulating material being filled into and along the deep groove so as to form an lengthwise insulating portion of the metallic strip, and the metallic strip with the insulating portion being segmented into a plurality of ultralow-resistance current sensors.

Owner:PAN JEN HUAN

Alumina member and manufacturing method thereof

ActiveUS7564008B2High strengthHigh melting pointEnvelope/housing resistor manufactureSemiconductor/solid-state device manufacturingThermal expansionElectric power

An electrostatic chuck includes a base of a sintered body containing alumina, an electrode as a power-supplied member embedded in the base and supplied with electric power, a bonding member embedded in the base and bonded to the electrode, in which a difference in coefficient of thermal expansion from the sintered body is 2×10−6 / K or less, and a melting point is higher than baking temperature of the sintered body, and a terminal bonded to the electrode through the bonding member.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com