Patents

Literature

451results about How to "Adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

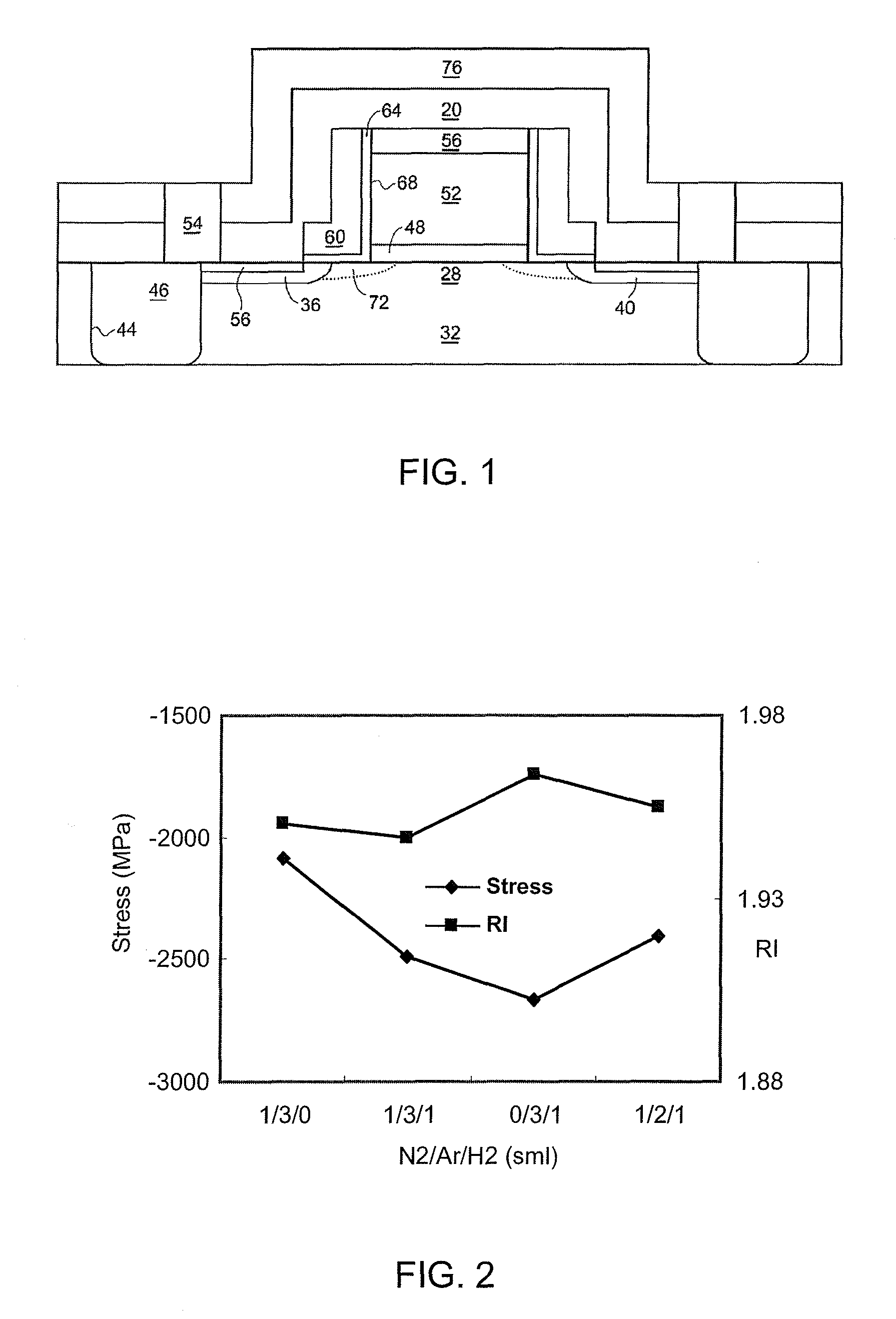

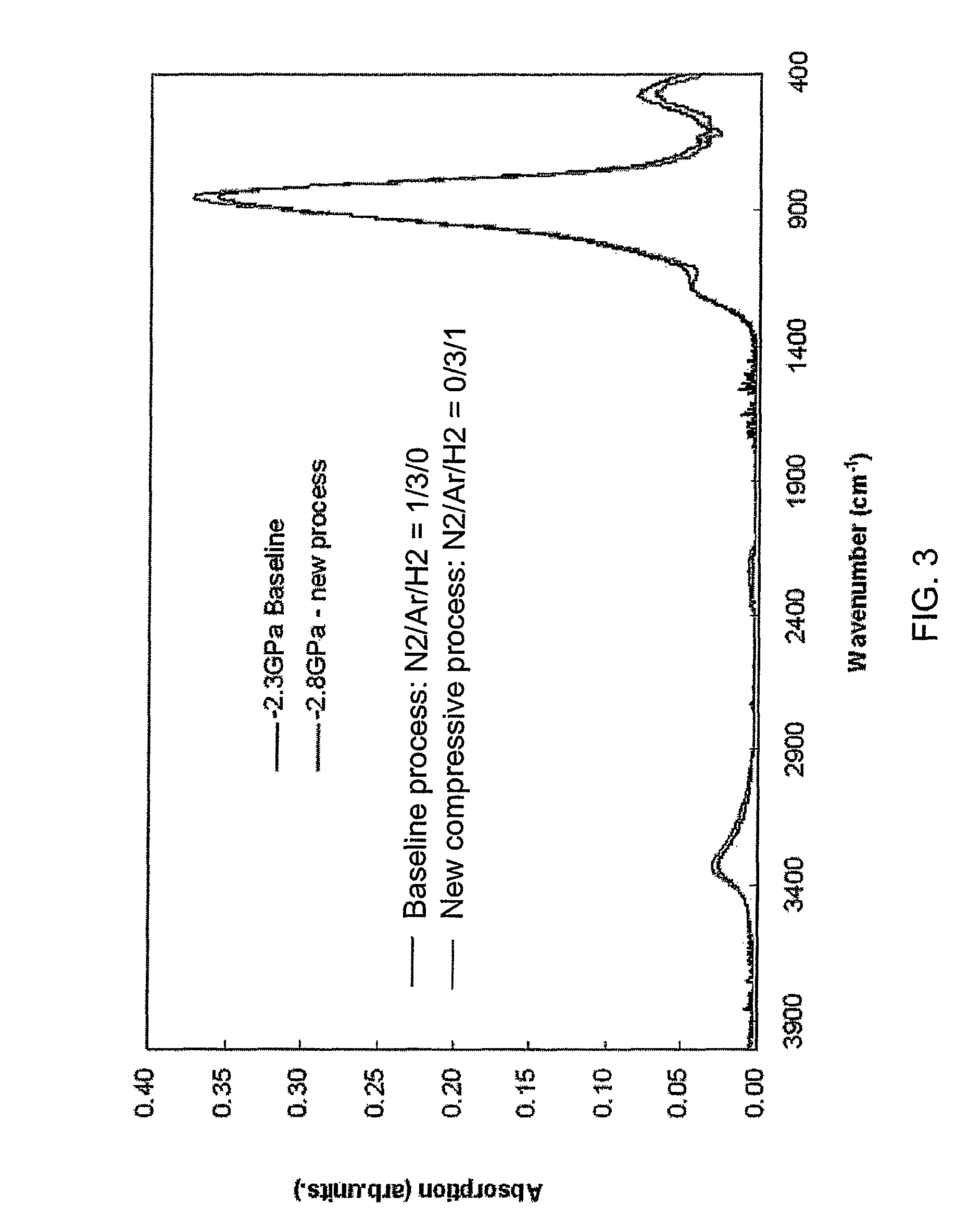

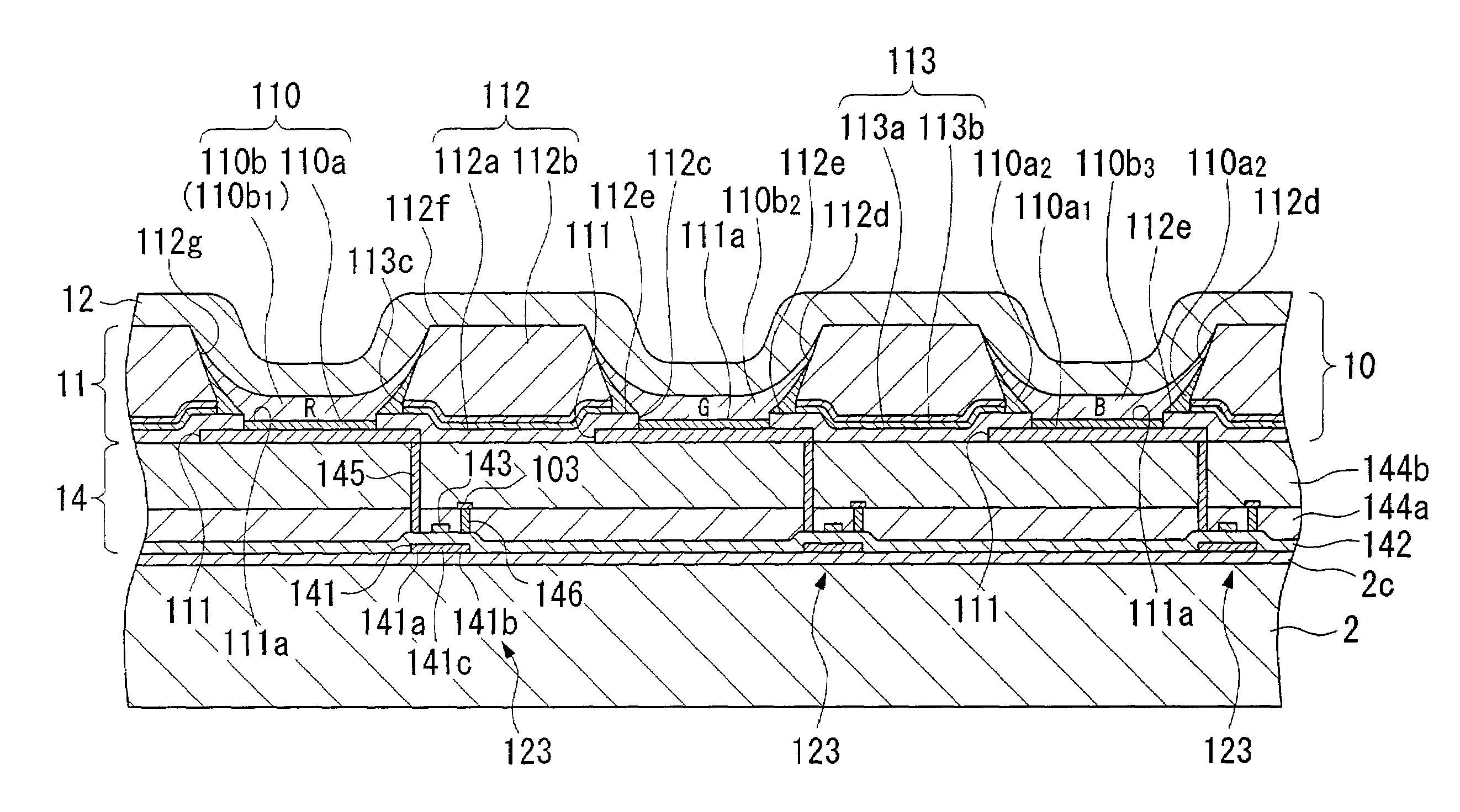

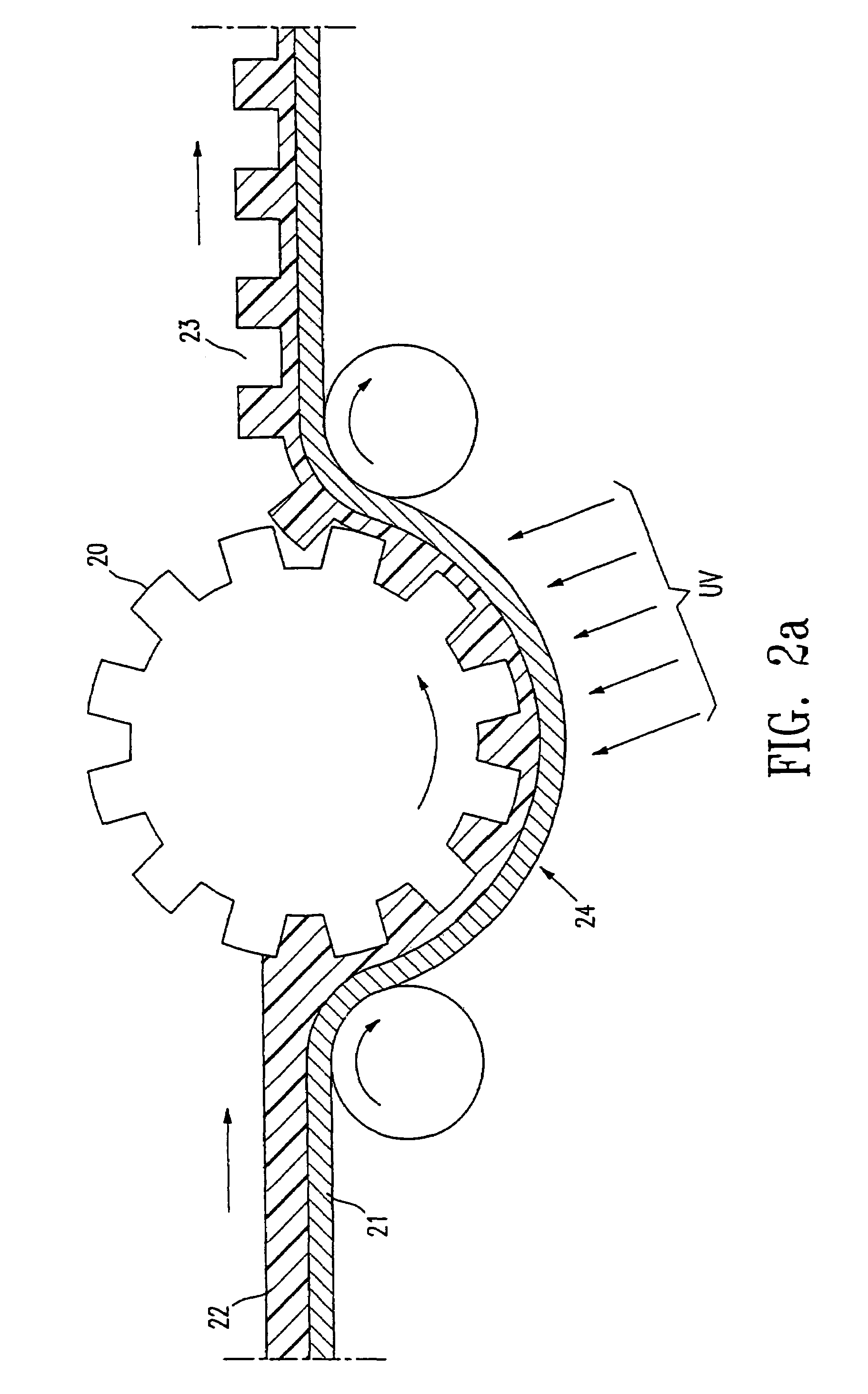

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

InactiveUS20120196450A1Increase pressureImprove performanceTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaHydrogen

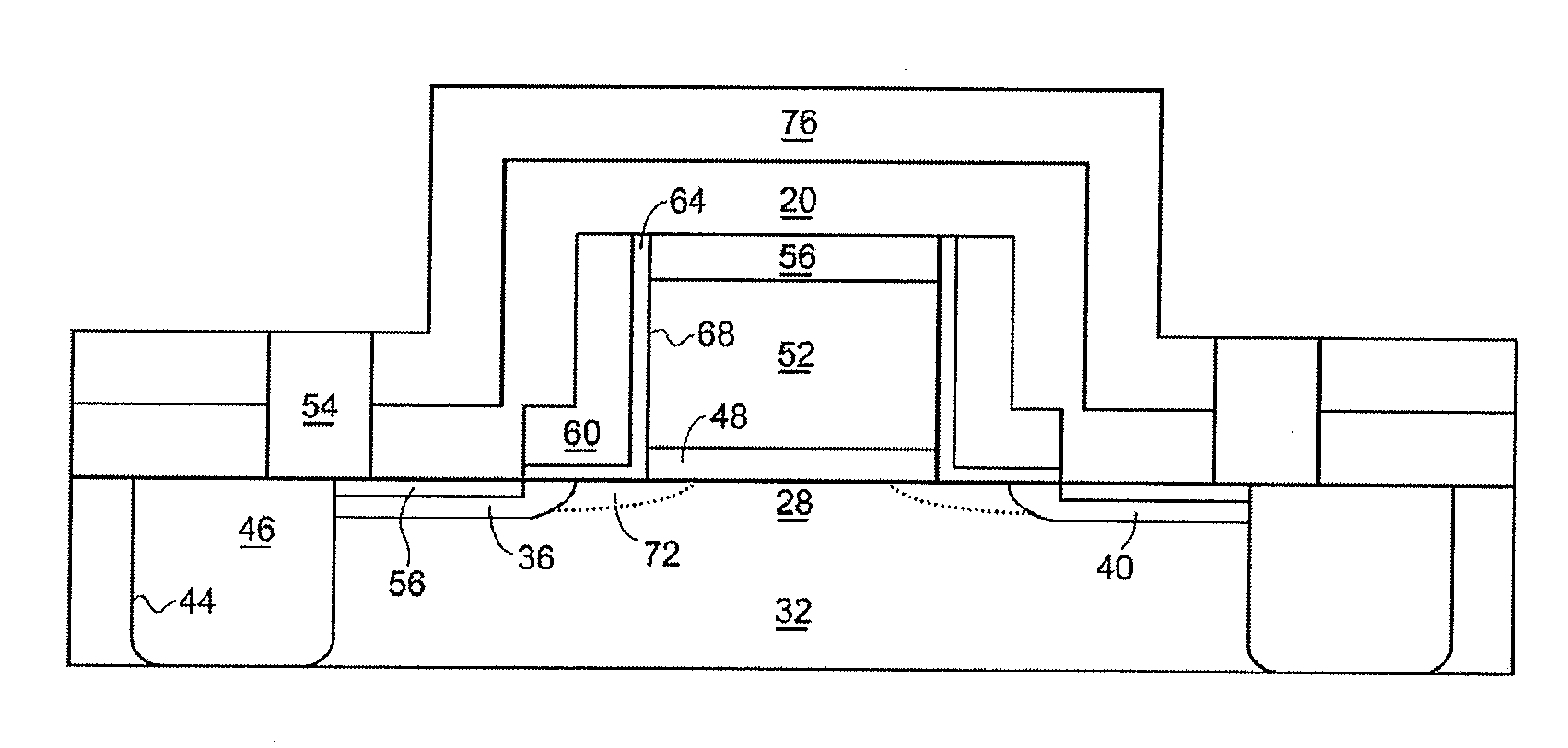

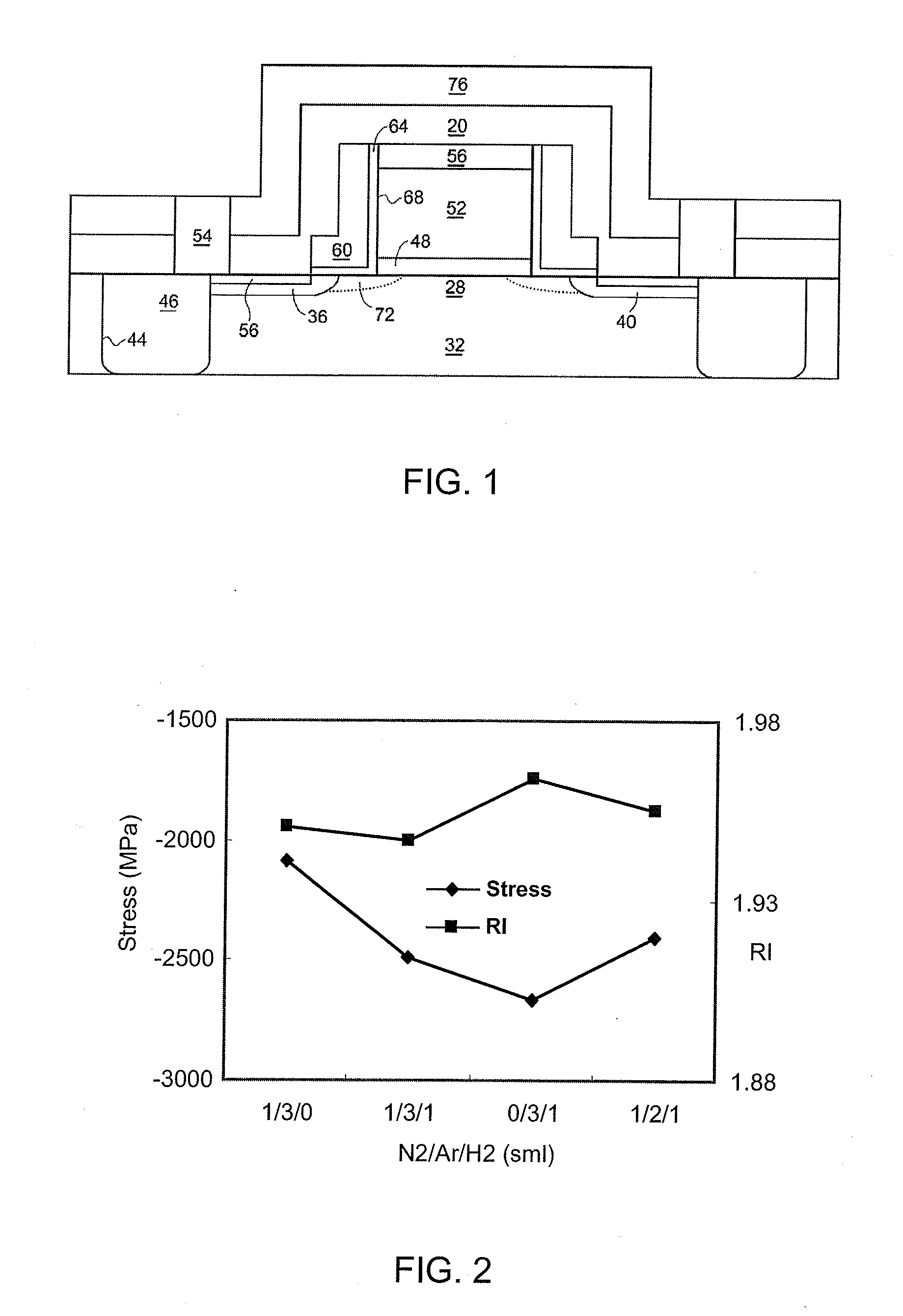

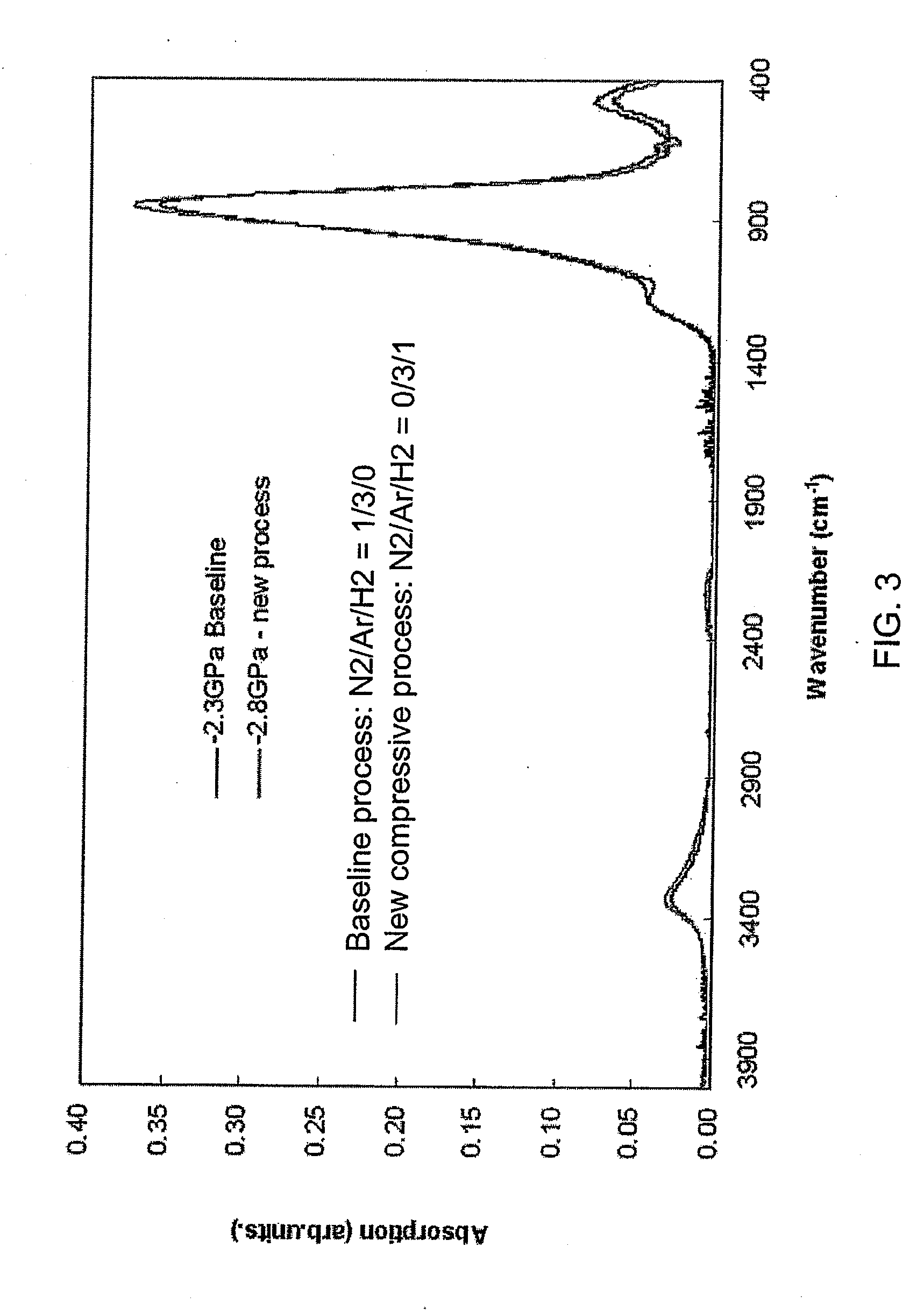

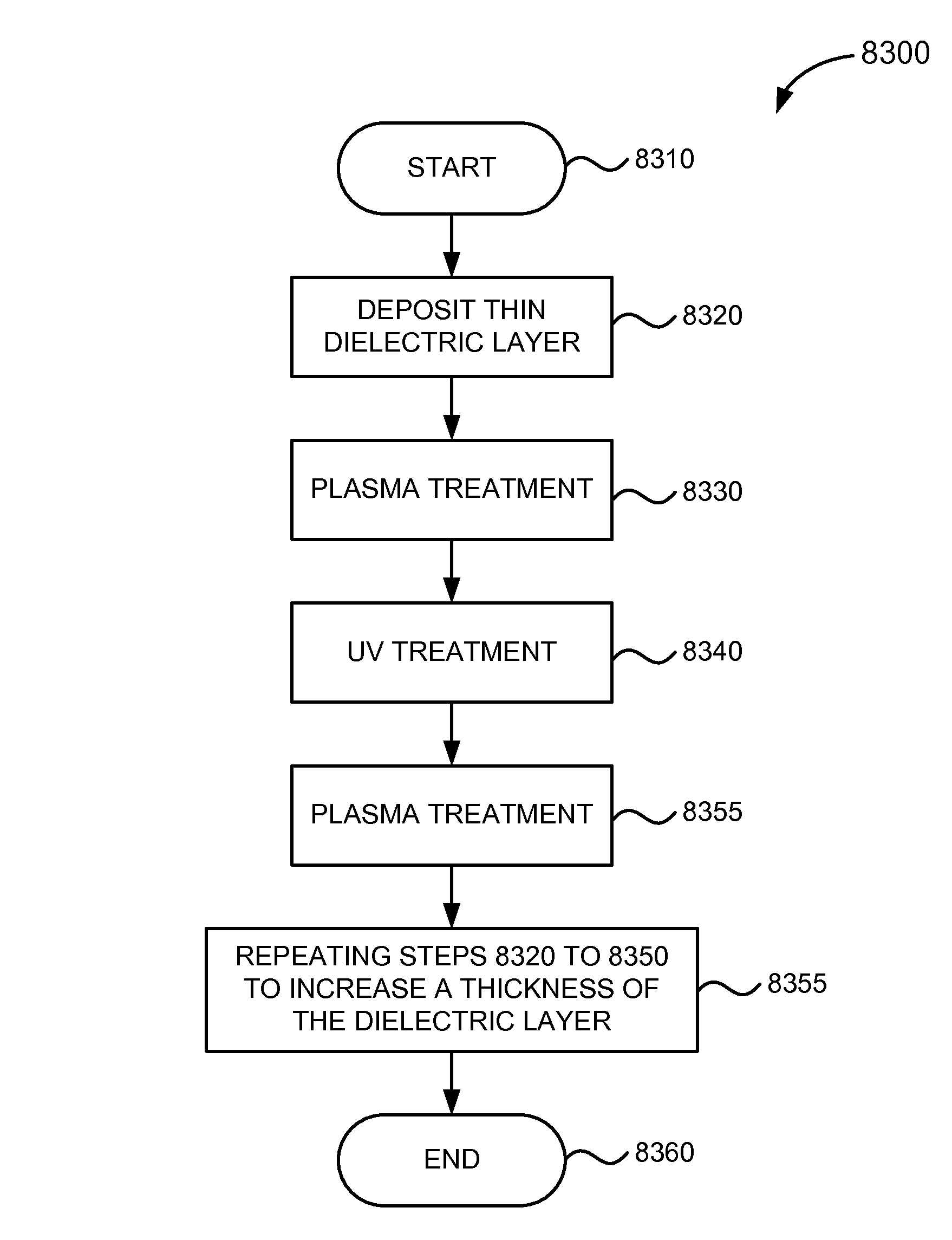

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with some embodiments, a deposited silicon nitride film is exposed to curing with plasma and ultraviolet (UV) radiation, thereby helping remove hydrogen from the film and increasing film stress. In accordance with other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

ActiveUS8138104B2Increase pressureImprove performanceTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaHydrogen

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with alternative embodiments, a deposited silicon nitride film is exposed to curing with ultraviolet (UV) radiation at an elevated temperature, thereby helping remove hydrogen from the film and increasing film stress. In accordance with still other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

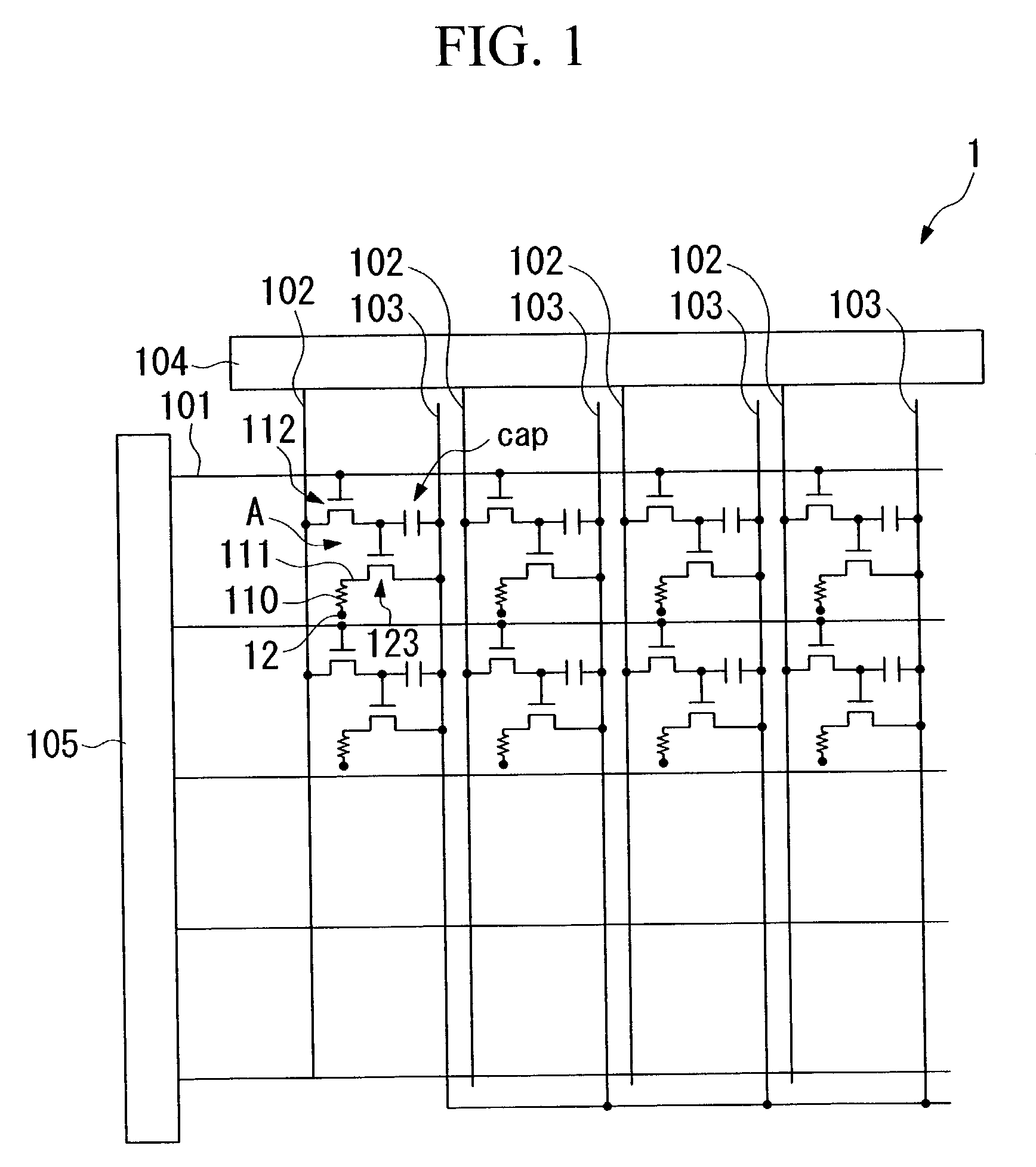

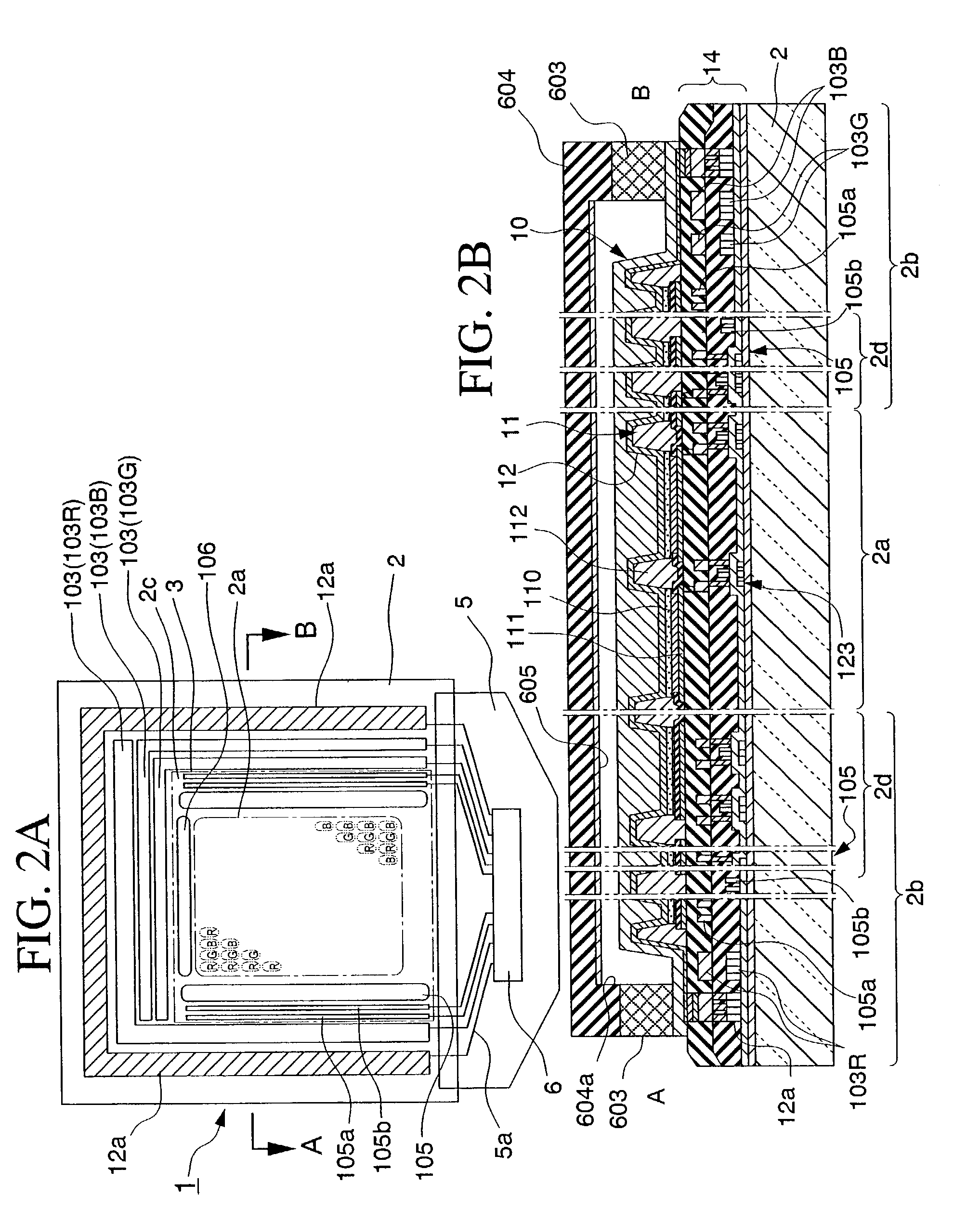

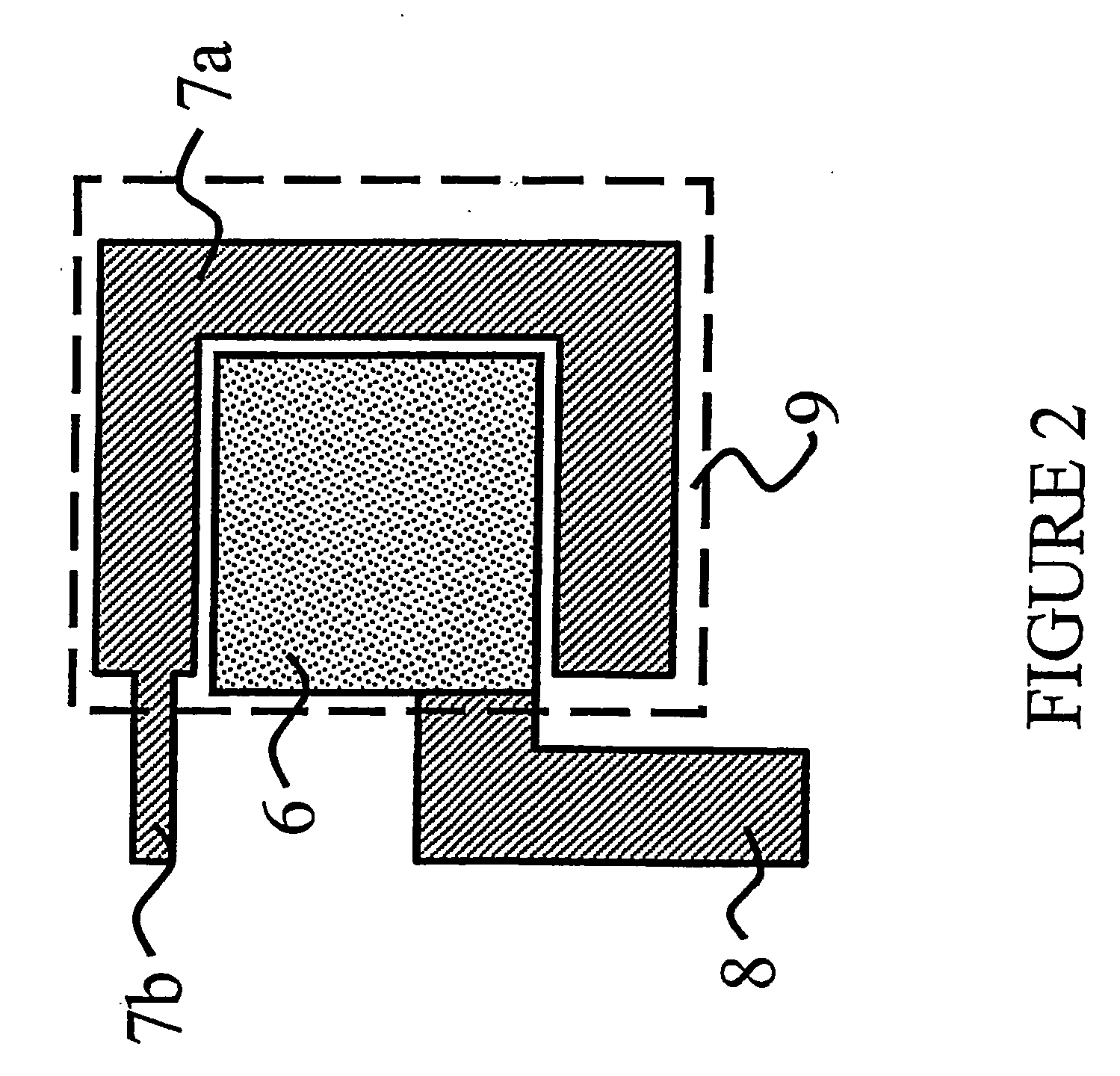

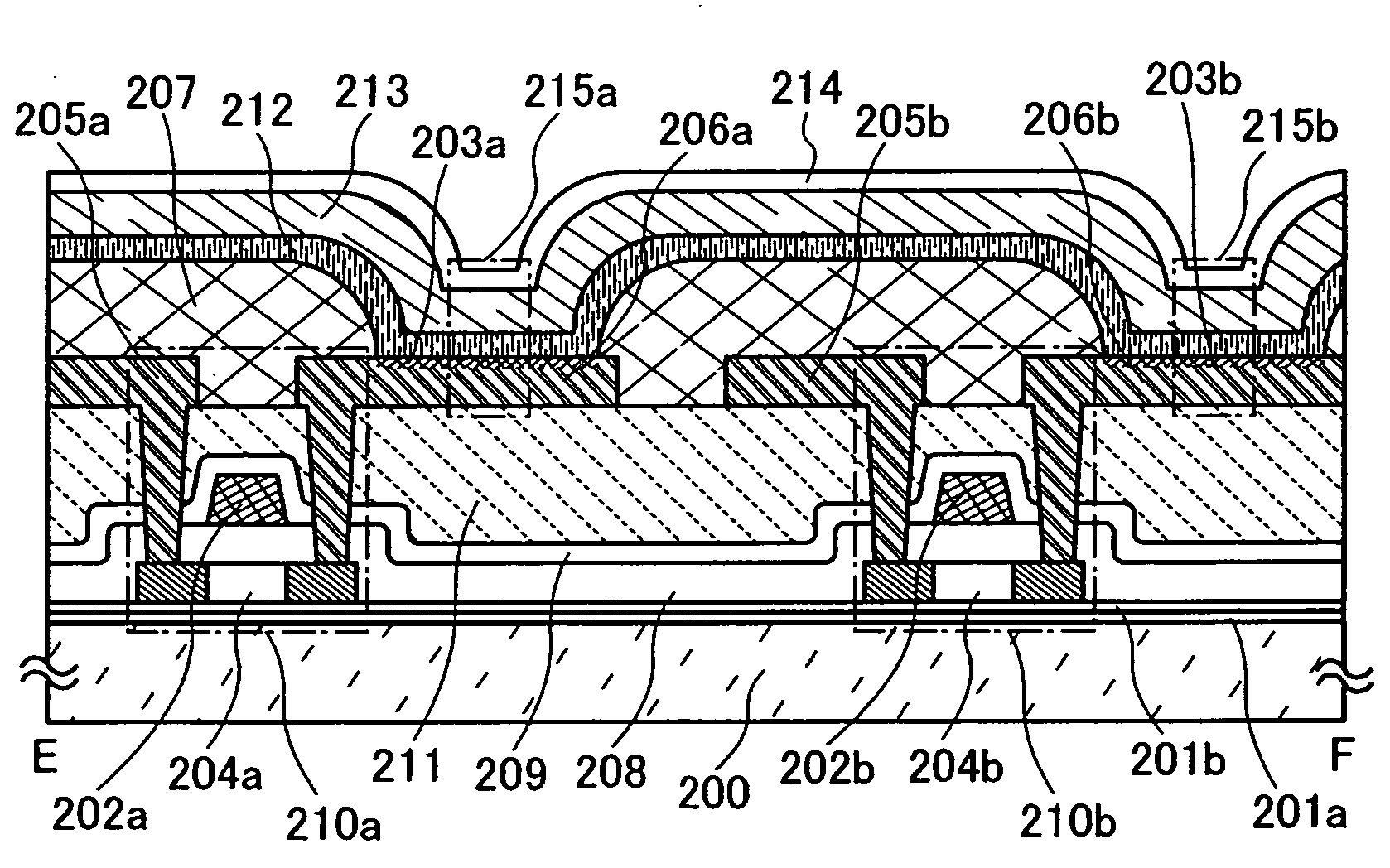

Display device having light blocking layer, and electric device

InactiveUS7012367B2AdhesionImprove adhesionDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceEngineering

A display apparatus is provided that prevents shortening of the life of the luminescent elements and has a superior contrast ratio. The display apparatus is composed by forming a plurality of luminescent elements on a substrate and providing bank sections between each of the luminescent elements. The bank sections are formed from a first bank layer located on the side of the substrate and a second bank layer formed on the first bank layer. A light blocking layer is then provided between the first bank layer and the second bank layer.

Owner:SEIKO EPSON CORP

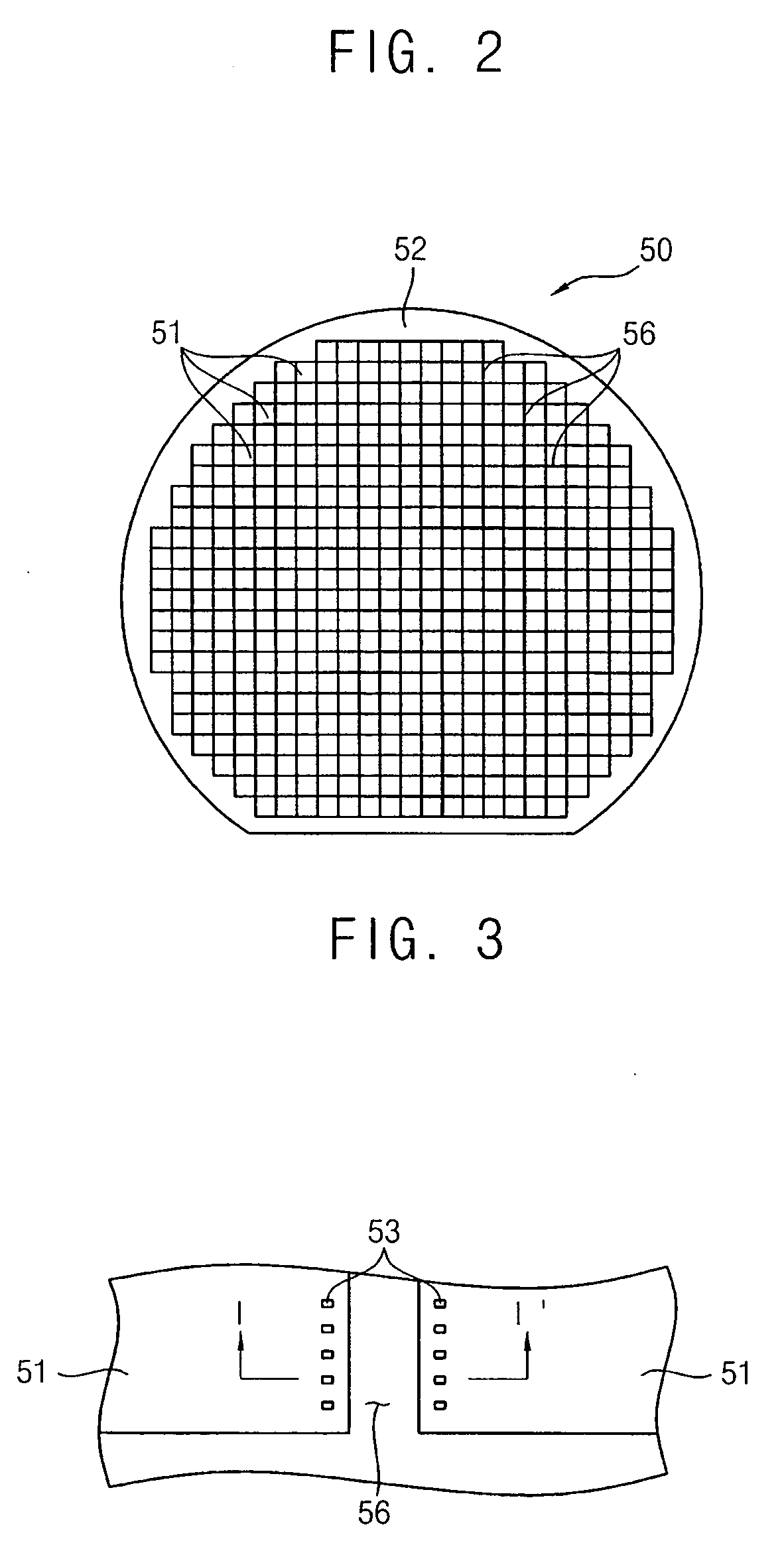

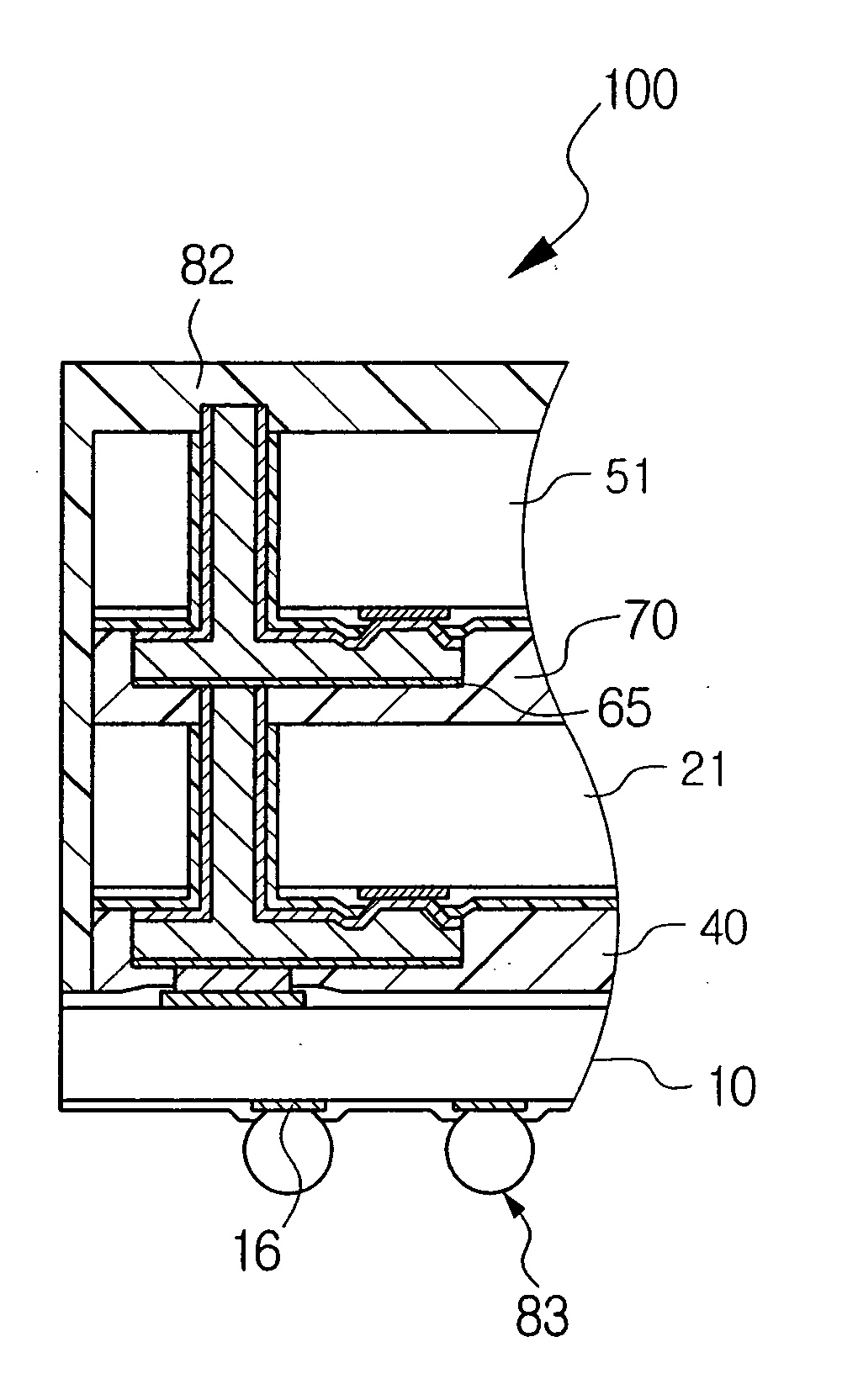

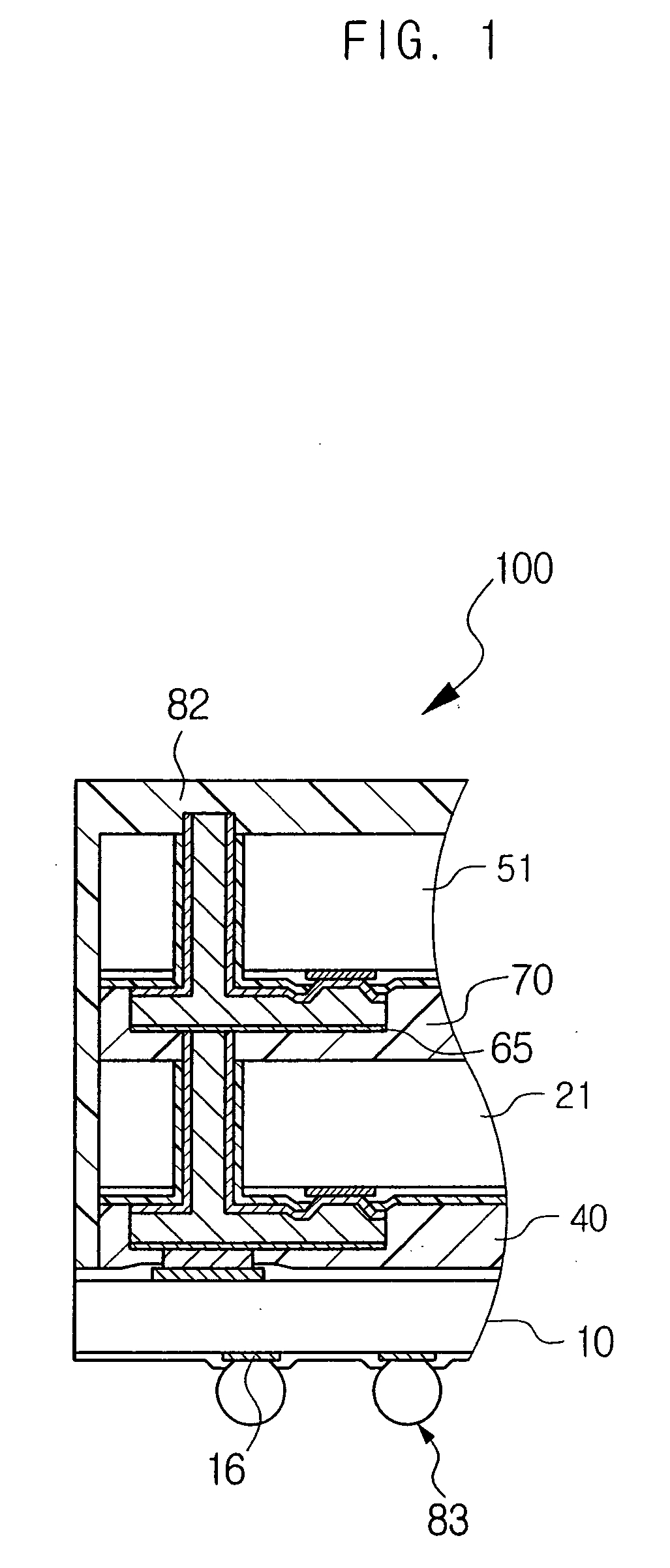

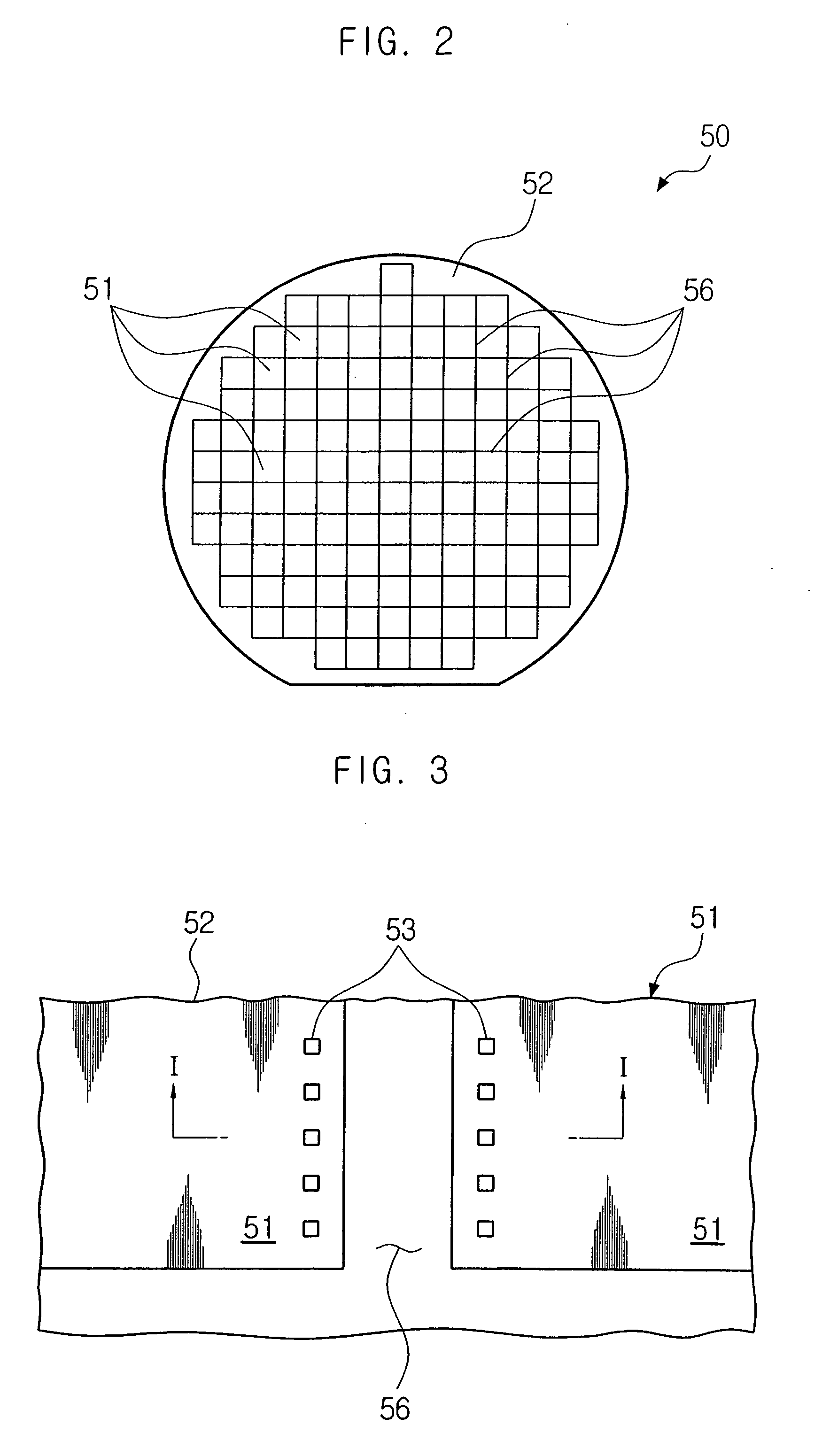

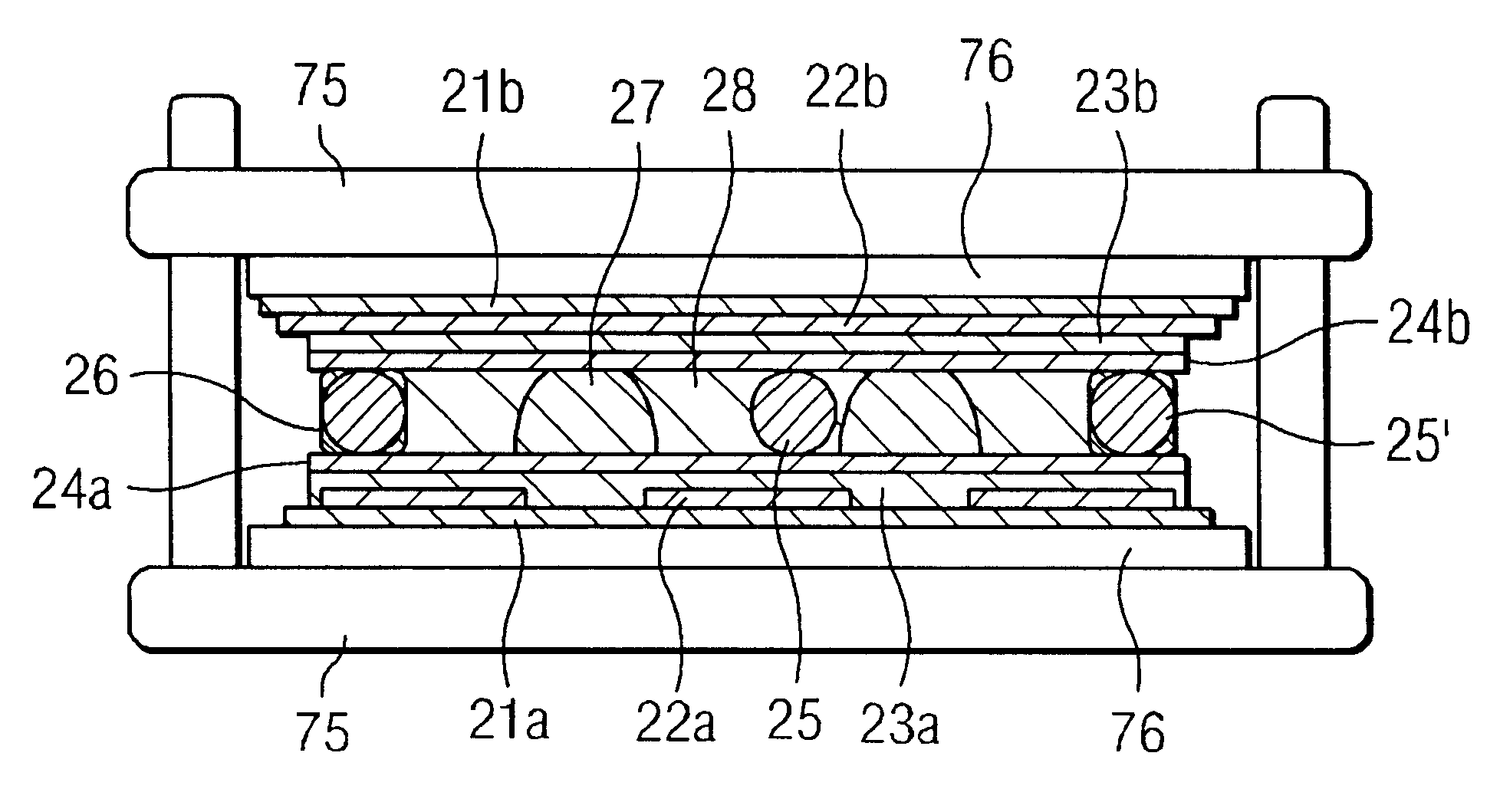

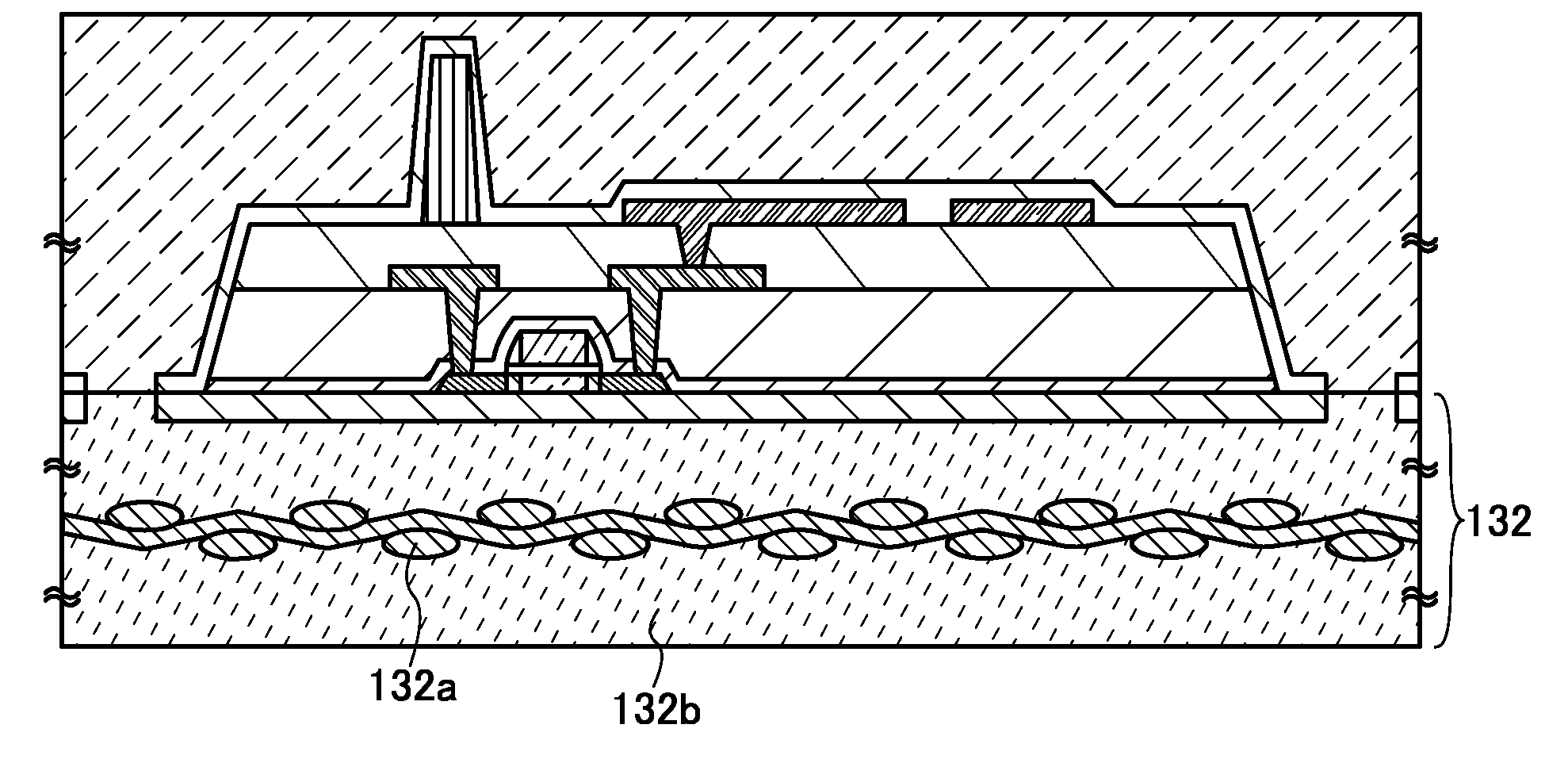

Stacked chip package using warp preventing insulative material and manufacturing method thereof

InactiveUS20070045836A1AdhesionHigh mechanical reliabilitySemiconductor/solid-state device detailsSolid-state devicesMechanical reliabilityPhotosensitive polymer

In a stacked chip configuration, and manufacturing methods thereof, the gap between a lower chip and an upper chip is filled completely using a relatively simple process that eliminates voids between the lower and upper chips and the cracking and delamination problems associated with voids. The present invention is applicable to both chip-level bonding and wafer-level bonding approaches. A photosensitive polymer layer is applied to a first chip, or wafer, prior to stacking the chips or stacking the wafers. The photosensitive polymer layer is partially cured, so that the photosensitive polymer layer is made to be structurally stable, while retaining its adhesive properties. The second chip, or wafer, is stacked, aligned, and bonded to the first chip, or wafer, and the photosensitive polymer layer is then cured to fully bond the first and second chips, or wafers. In this manner, adhesion between chips / wafers is greatly improved, while providing complete fill of the gap. In addition, mechanical reliability is improved and CTE mismatch is reduced, alleviating the problems associated with warping, cracking and delamination, and leading to an improvement in device yield and device reliability.

Owner:SAMSUNG ELECTRONICS CO LTD

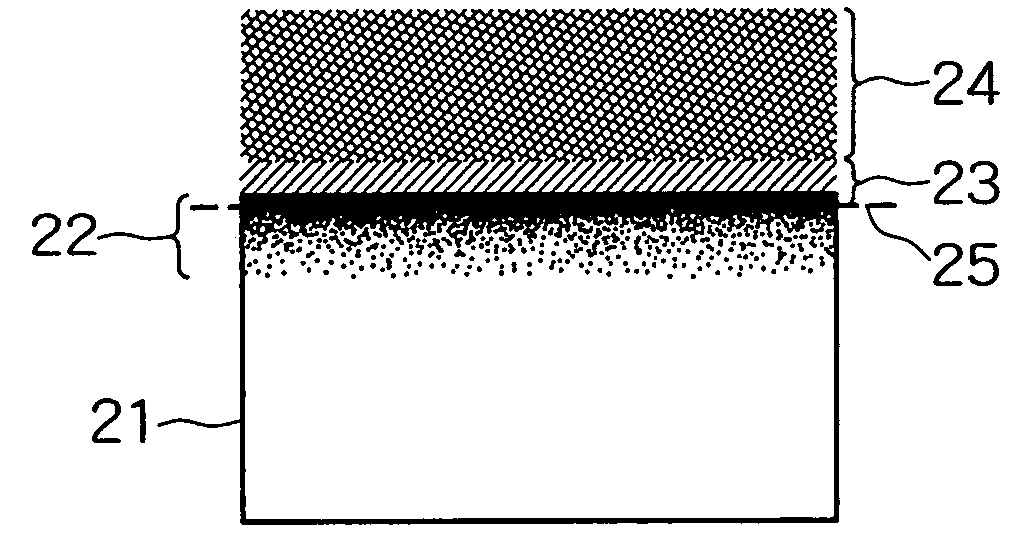

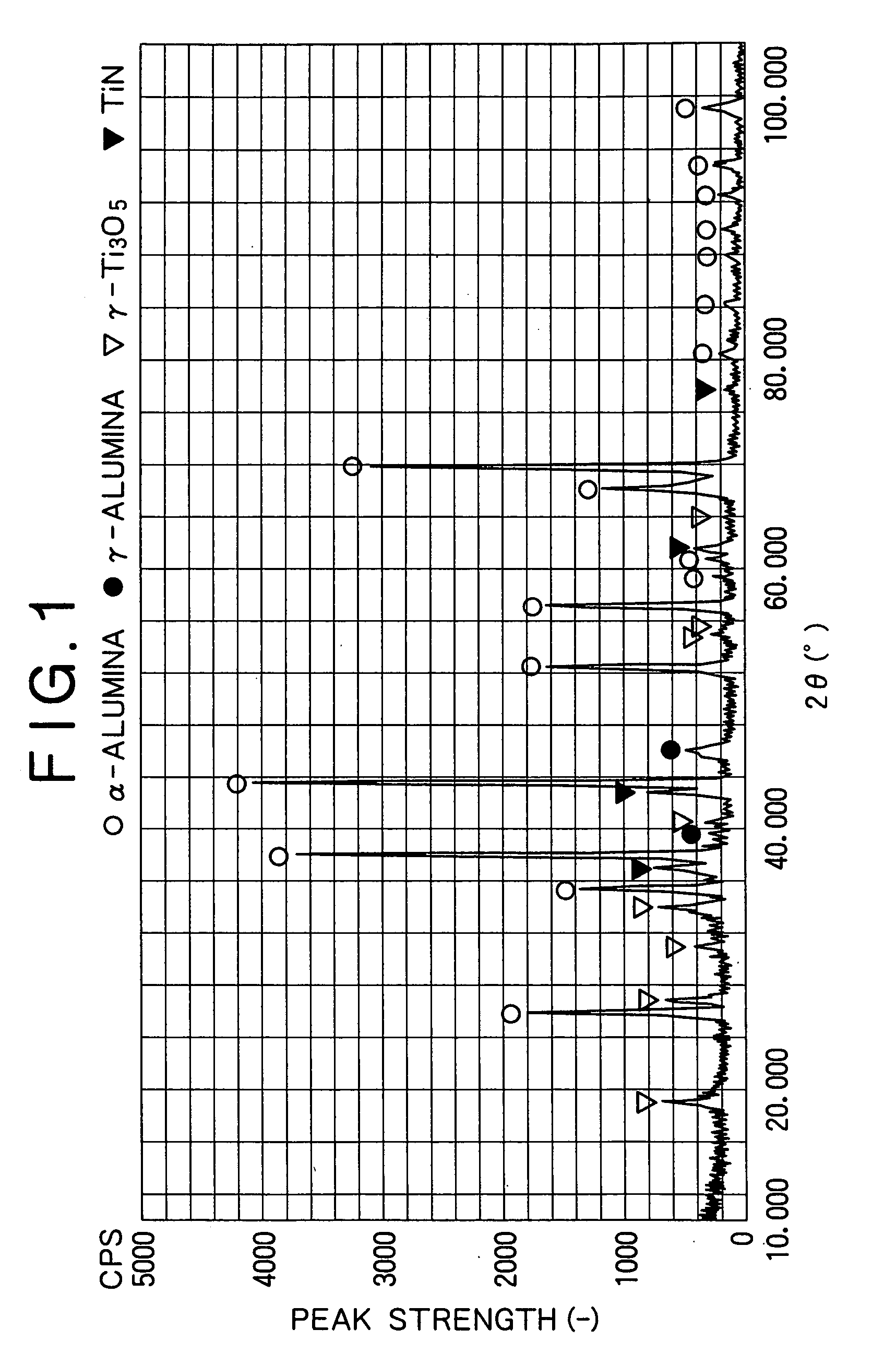

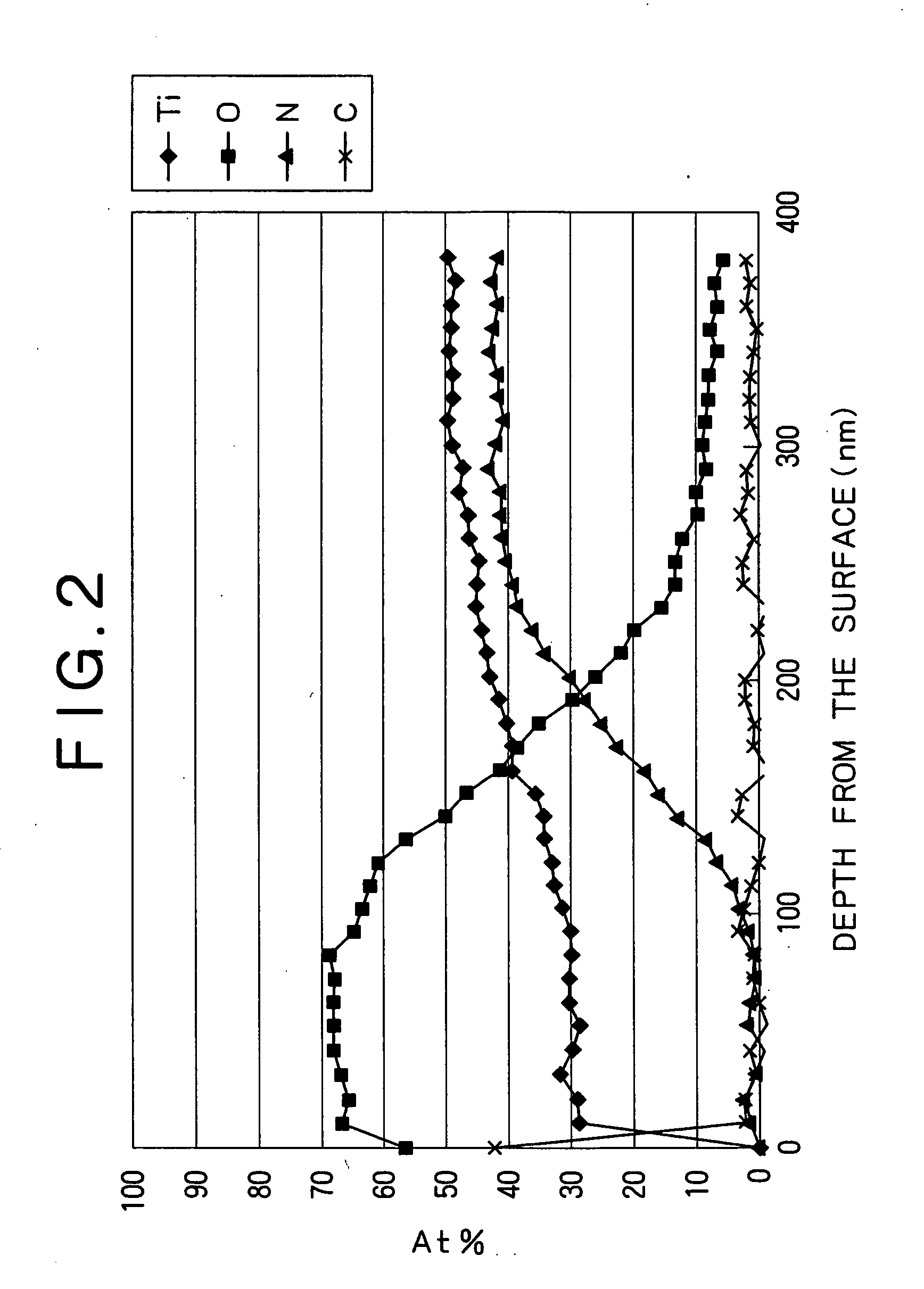

Process for producing alumina coating composed mainly of alpha-type crystal structure, alumina coating composed mainly of alpha-type crystal structure, laminate coating including the alumina coating, member clad with the alumina coating or laminate coating, process for producing the member, and physical evaporation apparatu

InactiveUS20050276990A1Improve heat resistanceImprove wear resistanceVacuum evaporation coatingPretreated surfacesFree energiesHeat resistance

A process for producing an alumina coating composed mainly of a-type crystal structure especially excelling in heat resistance, comprising (1) providing a laminate coating including a hard coating composed of a metal component containing Al and Ti as unavoidable elements and a compound of B, C, N, O, etc., oxidizing the hard coating to thereby form an oxide-containing layer, and forming an alumina coating composed mainly of a-type crystal structure on the oxide-containing layer. Alternatively, the process comprises (2) forming a hard coating composed of a metal whose standard free energy for oxide formation is greater than that of aluminum and a compound of B, C, N, O, etc., oxidizing the surface of the hard coating to thereby form an oxide-containing layer, and forming an alumina coating while being accompanied by reduction of the oxide at the surface of the oxide-containing layer.

Owner:KOBE STEEL LTD

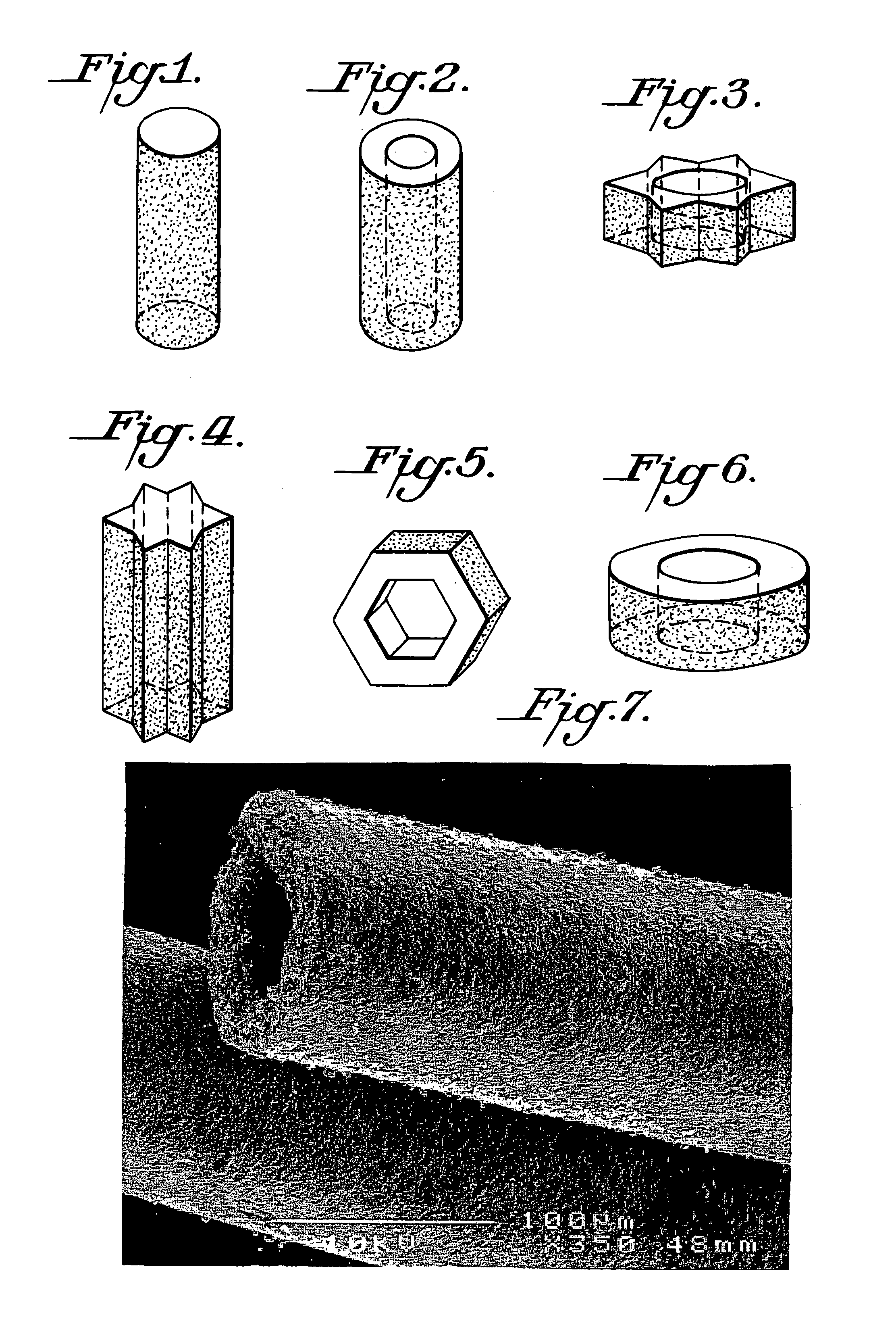

Microcrystalline alpha-Al2O3 shaped body, method for the production and use thereof

InactiveUS7169198B2Lower sintering temperatureHigh densityPigmenting treatmentOther chemical processesMetallurgySolvent

The invention relates to a method for the production of a sintered, microcrystalline α-Al2O3-based shaped body, which are used, for example, as abrasive bodies, wherein an α-Al2O3 powder is used as starting material, said powder having an average particle diameter of <2 μm, and processed with at least one binder and a solvent with the purpose of obtaining an extrudable material that is subsequently extruded. The extrudate is then further processed into a shaped body that is sintered at a temperature range of between 1300° C. and 1750° C.

Owner:IMERTECH SAS

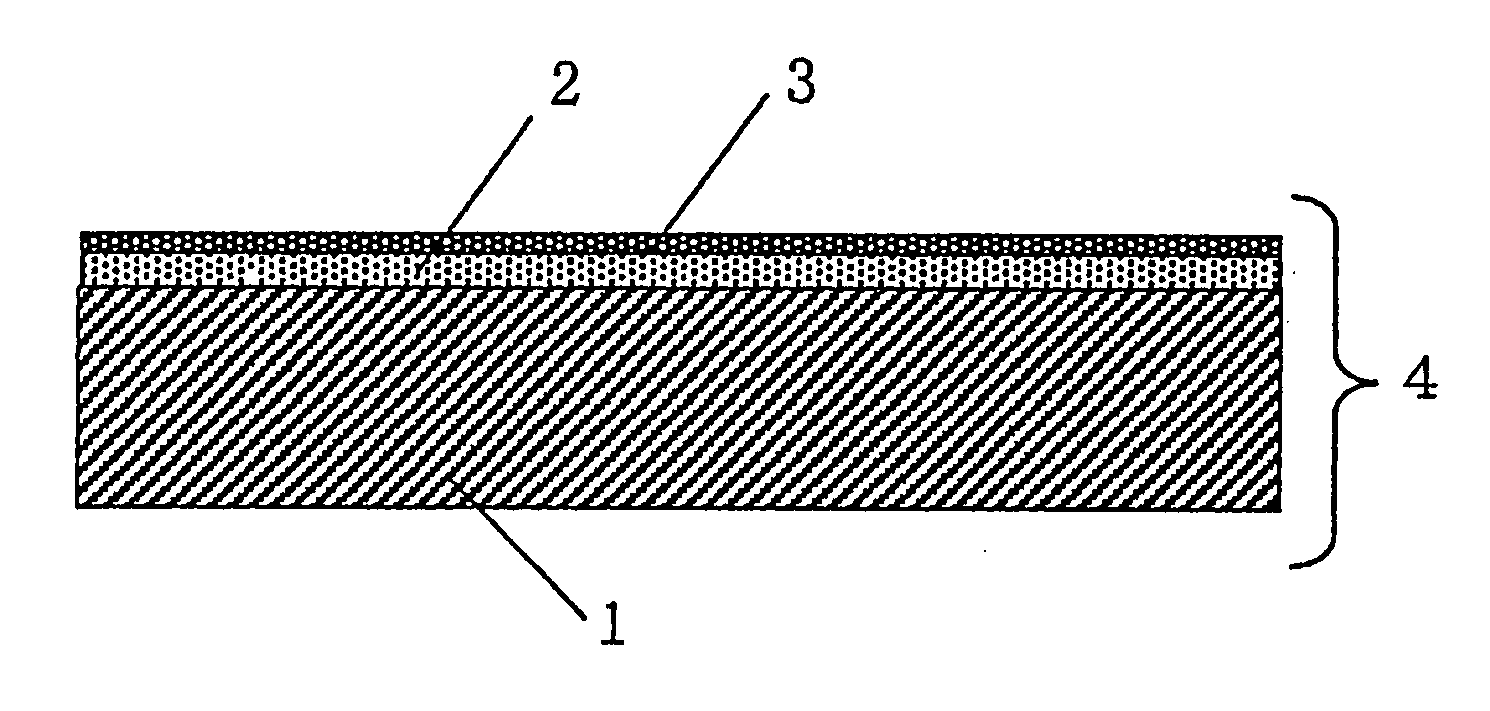

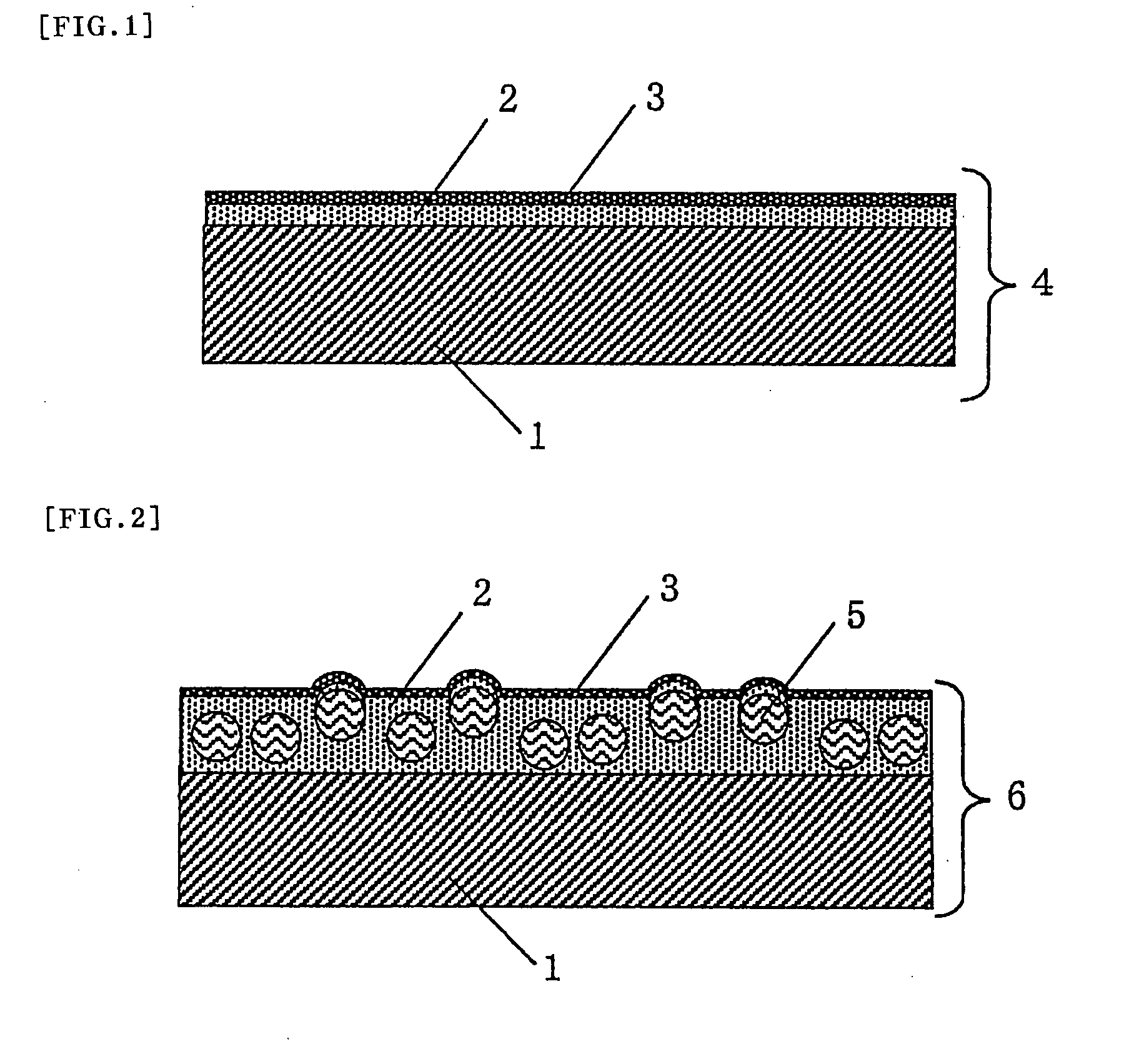

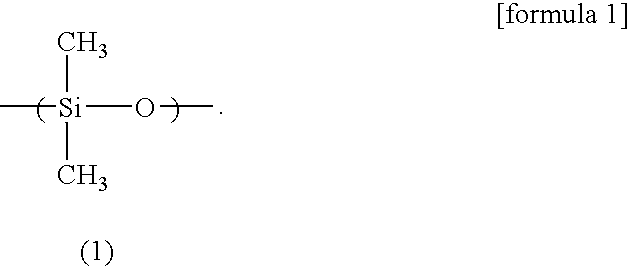

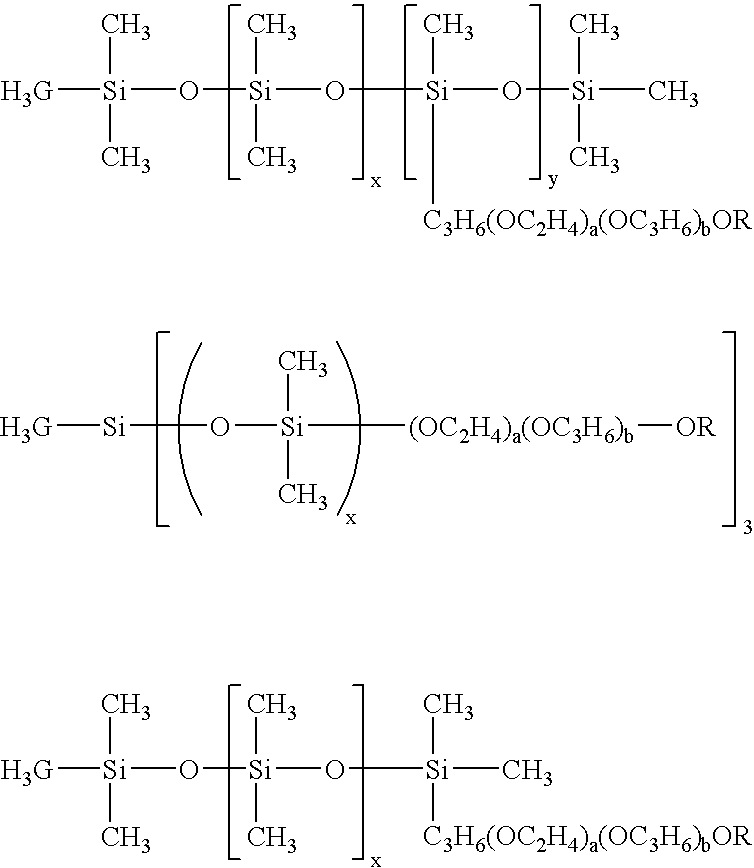

Antireflection Hard Coating Film, Optical Element and Image Display

ActiveUS20080160257A1Improve suppression propertiesImprove adhesionRoof covering using sealantsSynthetic resin layered productsMeth-Display device

An antireflection hard coating film of the invention comprises: a transparent plastic film substrate; and at least one hard coating layer of a cured coating layer and at least one antireflection layer that are formed in this order on at least one side of the transparent plastic film substrate, wherein a hard coating layer-forming material contains 100 parts by weight of a (meth)acrylate group-containing curable compound (A) and 0.01 to 3 parts by weight of a (meth)acrylate group-containing reactive silicone (B), and an antireflection layer-forming material contains a siloxane component-containing compound, at the interface between the hard coating layer and the antireflection layer being in direct contact with each other. The antireflection hard coating film has good adhesion between the hard coating layer and the antireflection layer, high hardness, and good scratch resistance without a reduction in antireflection properties.

Owner:NITTO DENKO CORP

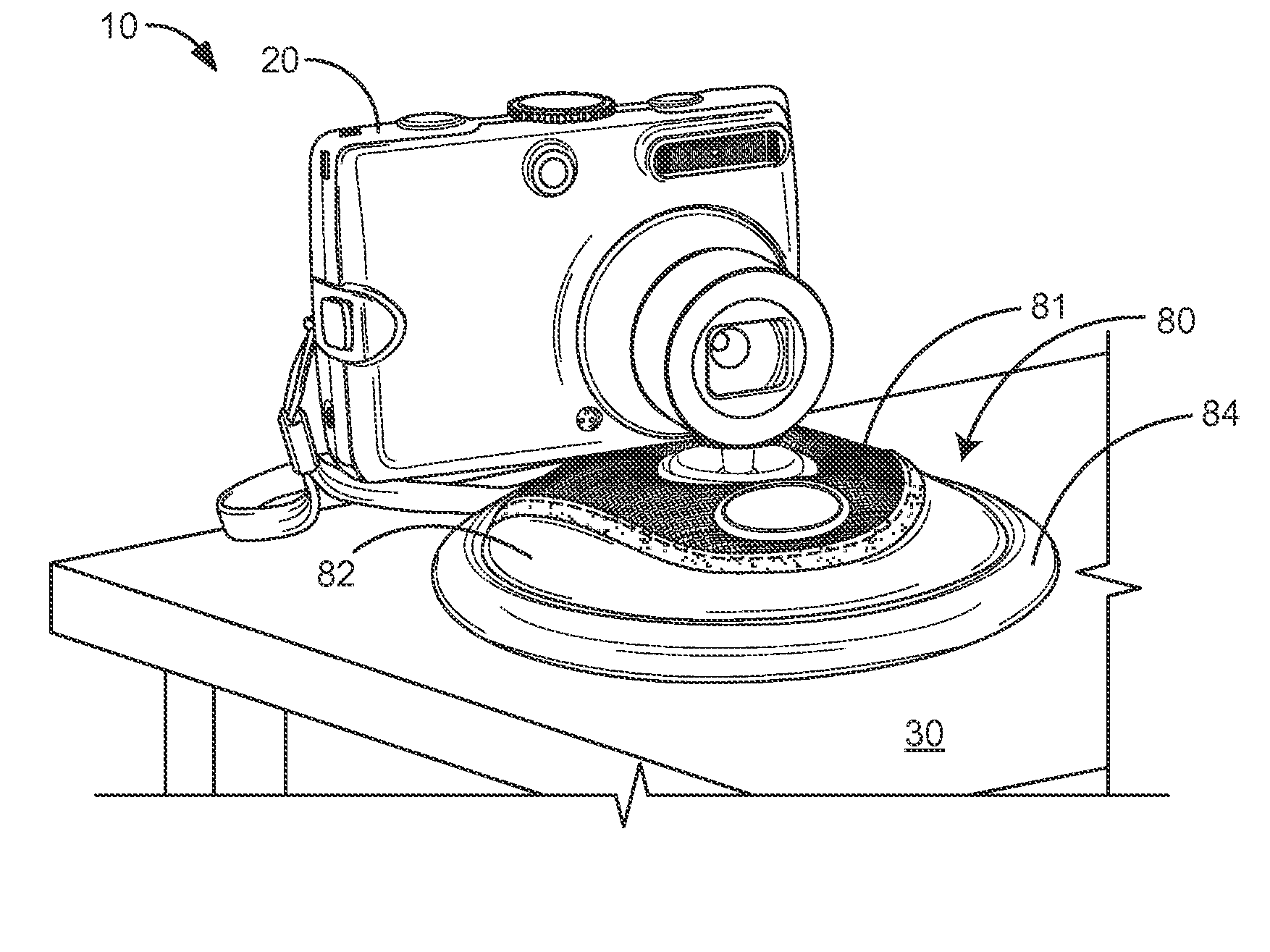

Viscoelastic Mounting Device

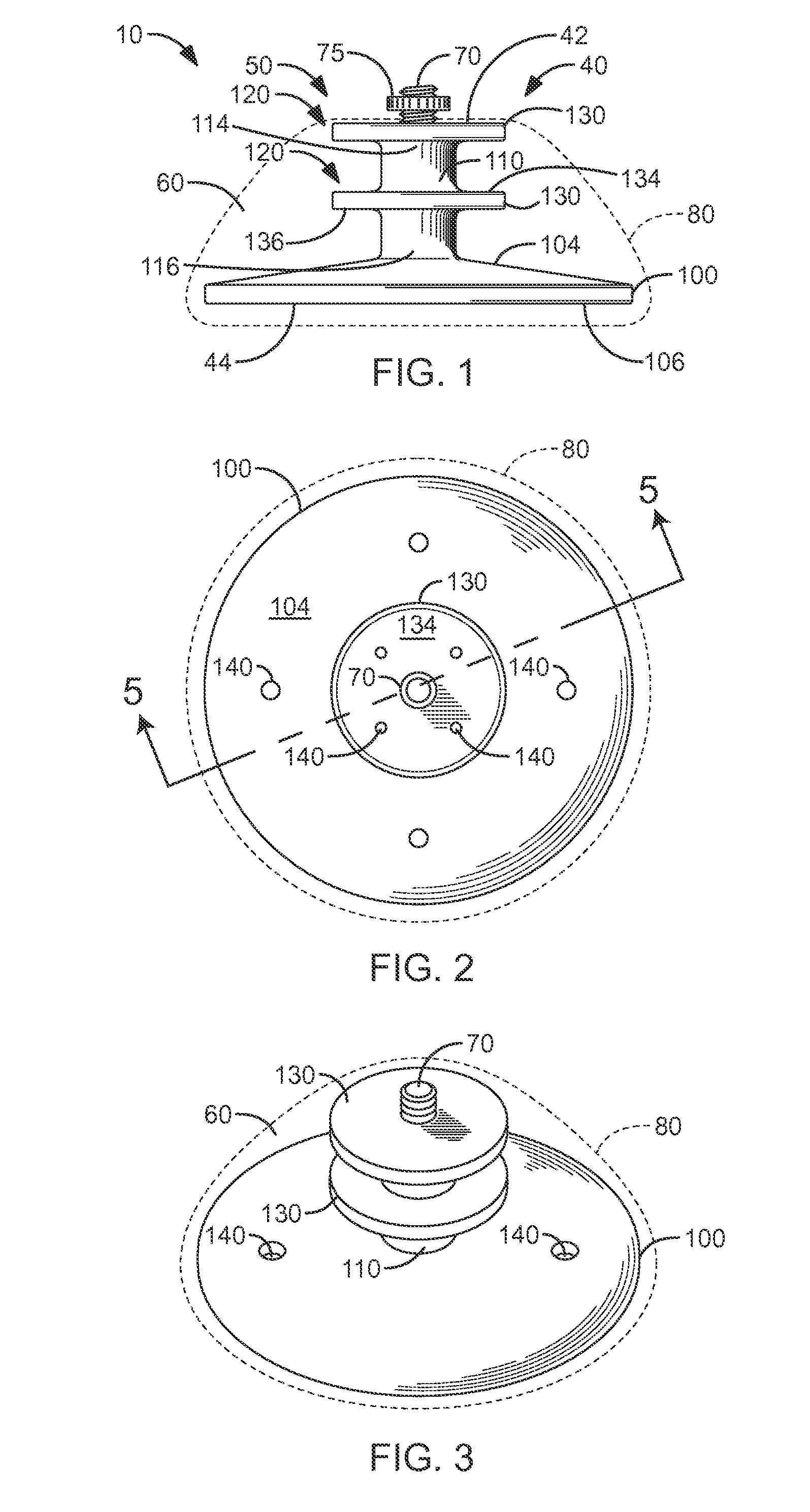

InactiveUS20070152117A1Increase surface areaAdhesionStands/trestlesKitchen equipmentDevices fixationCompound (substance)

An apparatus for selectively holding a device, such as a camera, to a surface is disclosed. An internal frame has at one end an attachment means, such as a threaded stud, for selectively attaching the device to the apparatus. The frame further includes a substantially circular flat base that has a first side and a second side. The flat base is substantially conformable to the shape of the surface. A longitudinal shaft is included that extends orthogonally from the first side of the base. A viscoelastic material is fixed about the internal frame and extends beyond a second end of the frame. The viscoelastic material is temporarily adhered to the frame and is capable of selectively adhering the apparatus to the surface. The viscoelastic material preferably includes an R.T.V.-type silicon-based compound, a dimethyl siloxane compound, a borosilicone rubber combination with silicone oil, a silicone polymer combination with boric oxide, or a combination thereof. As such, the viscoelastic material is able to temporarily adhere to most surfaces with enough strength to hold the apparatus and the device thereto, even against the force of gravity and in virtually any typical environmental temperature. At least one lateral frame member is included, projecting away from the longitudinal shaft for increasing the surface area of the frame to which the viscoelastic material adheres. An outer covering surrounds the viscoelastic material and the frame and serves as a barrier between the viscoelastic material and the device.

Owner:BYRD RANDEL LOUIS

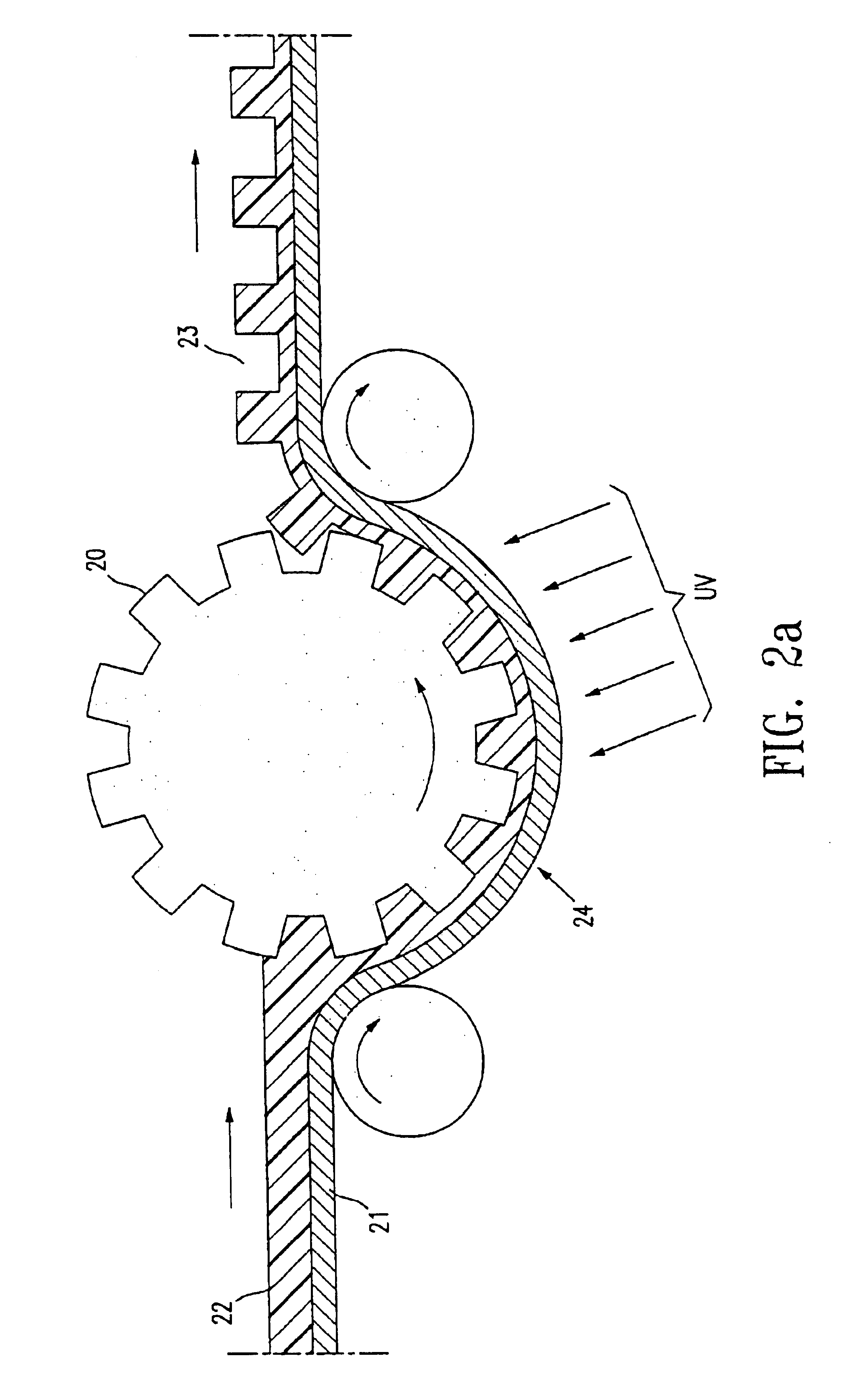

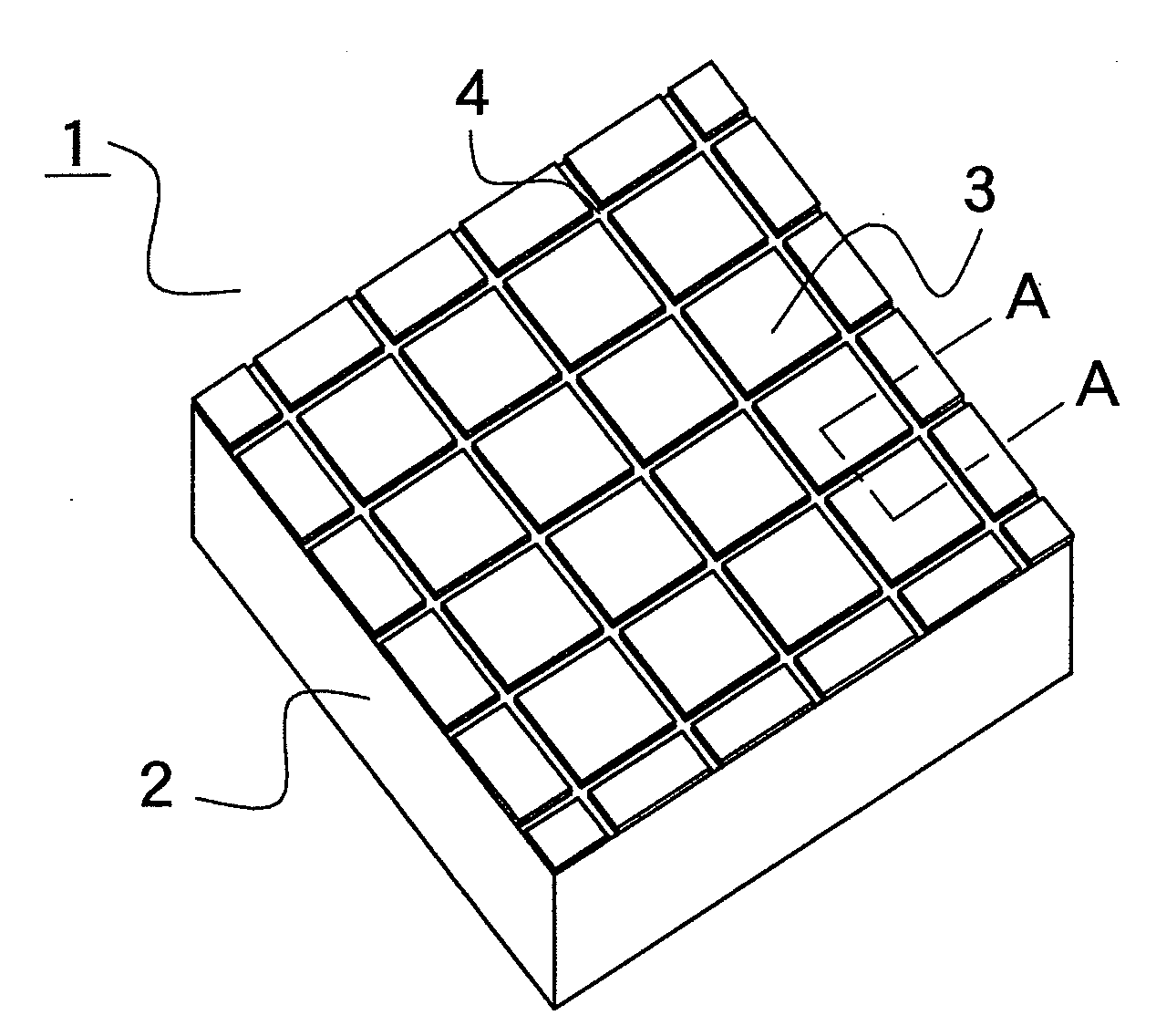

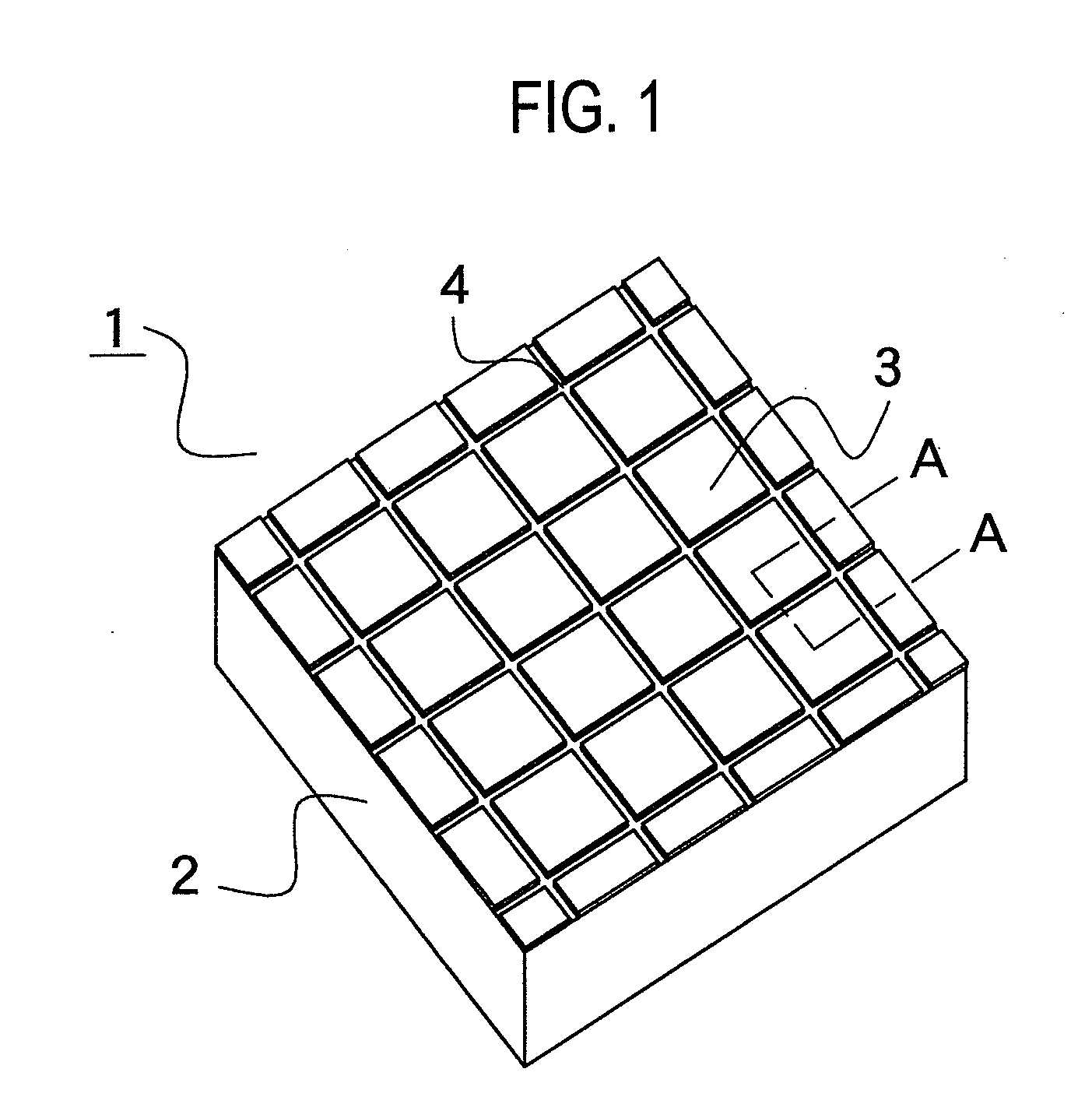

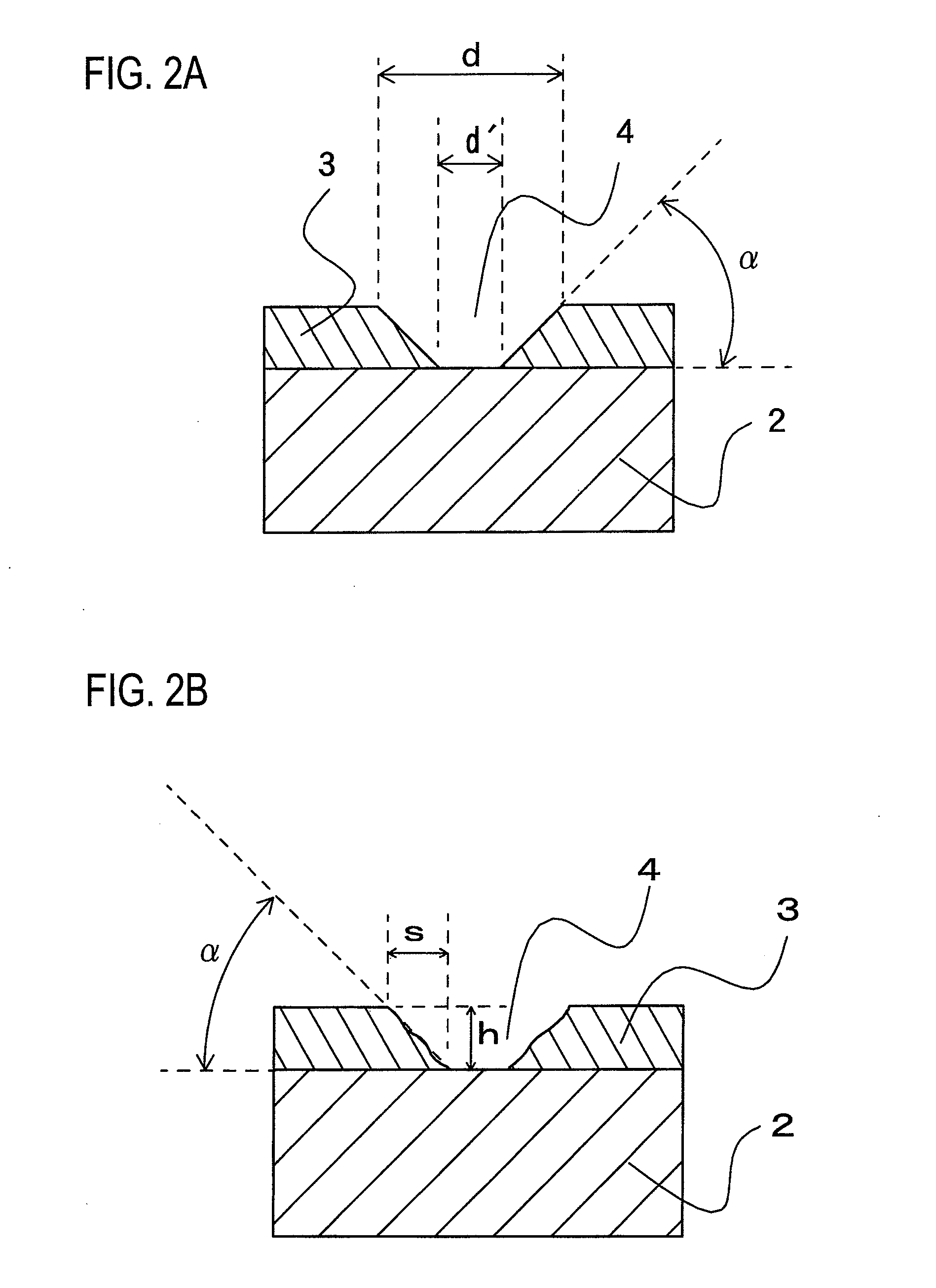

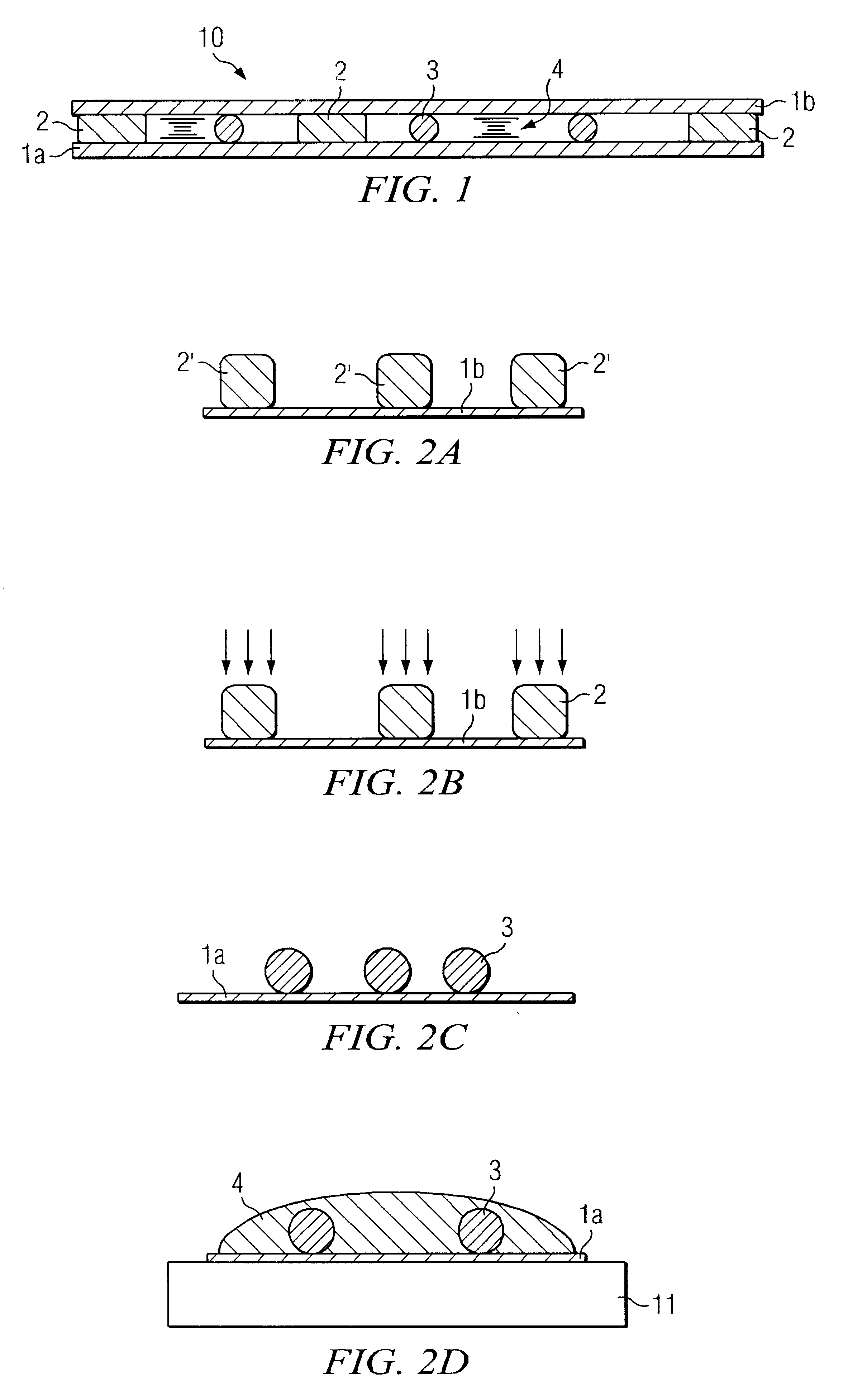

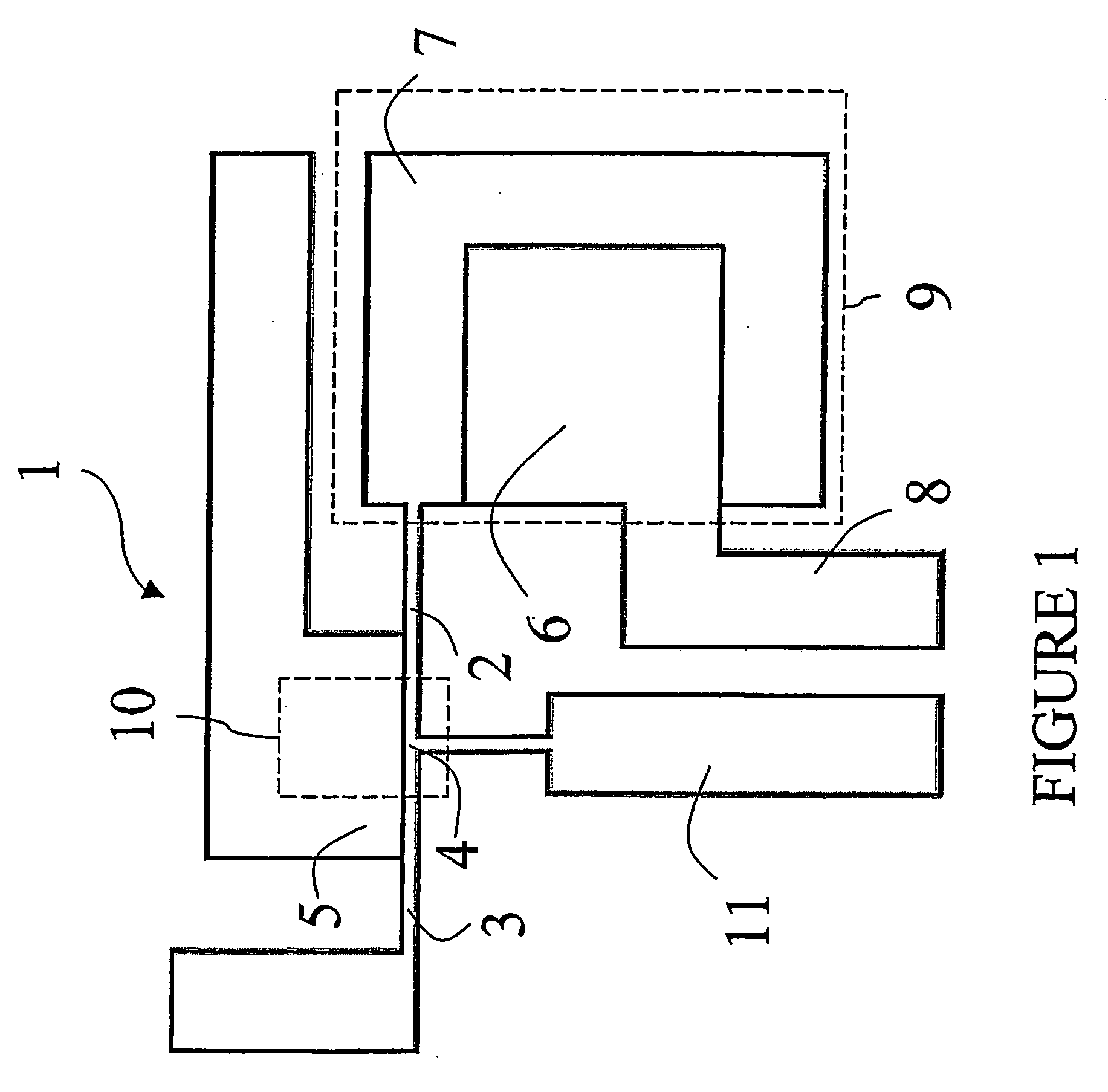

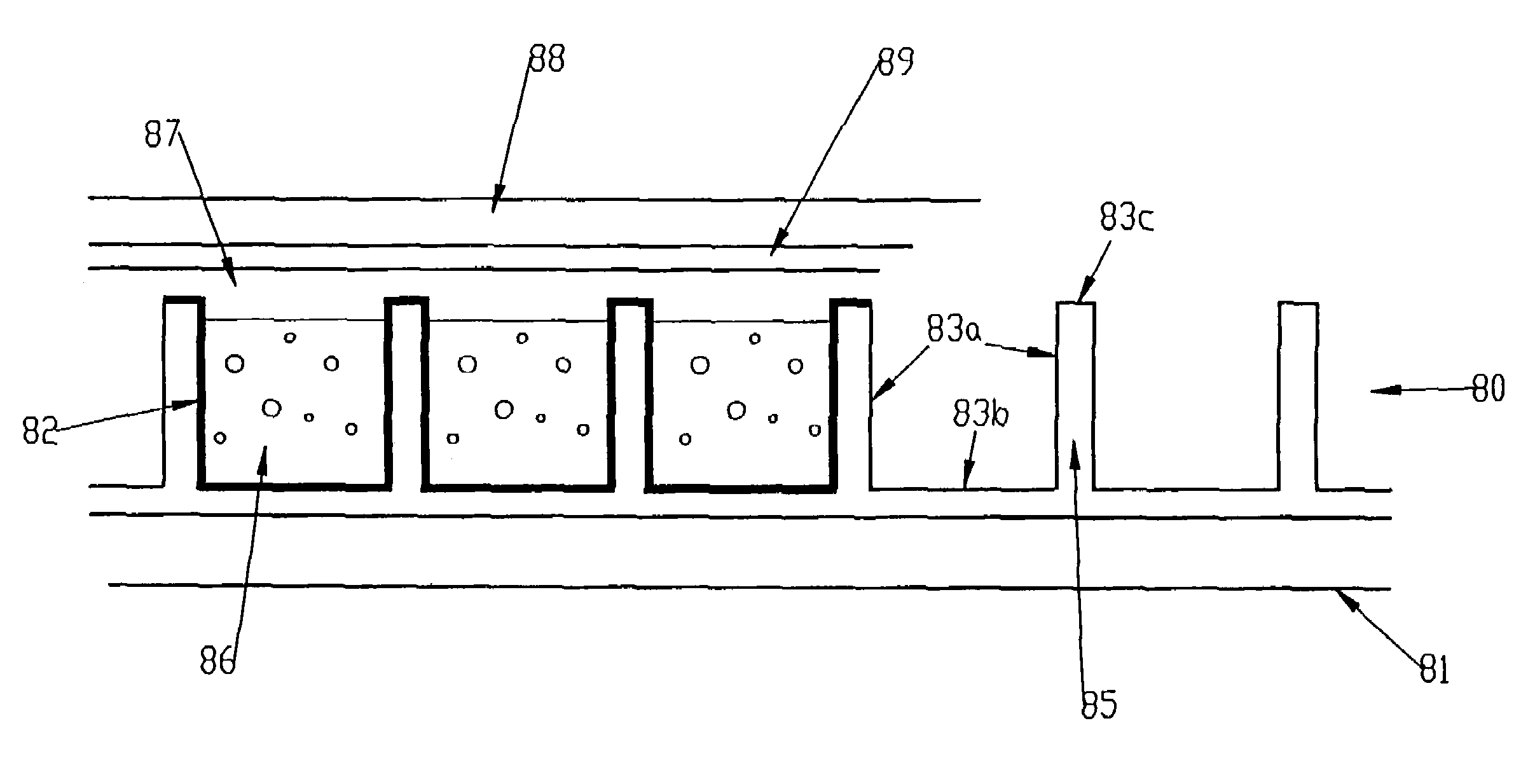

Electrophoretic display and novel process for its manufacture

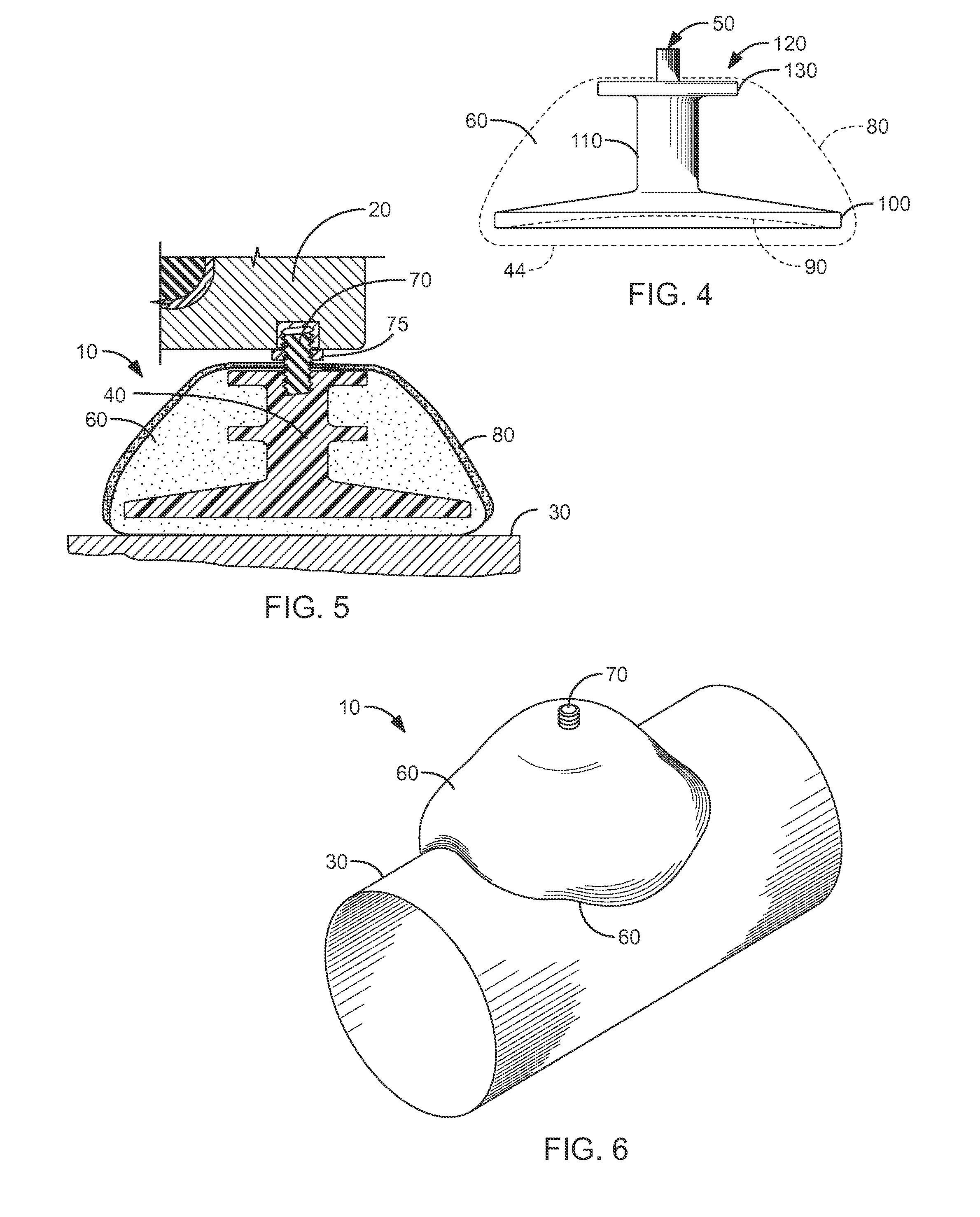

InactiveUS6865012B2Increase volumeLow cost productionStatic indicating devicesElectrographic processes using photoelectrophoresisElectrophoresisDisplay device

This invention relates to an electrophoretic display comprising cells of well-defined shape, size and aspect ratio which cells are filled with charged pigment particles dispersed in a solvent, and novel processes for its manufacture.

Owner:E INK CALIFORNIA

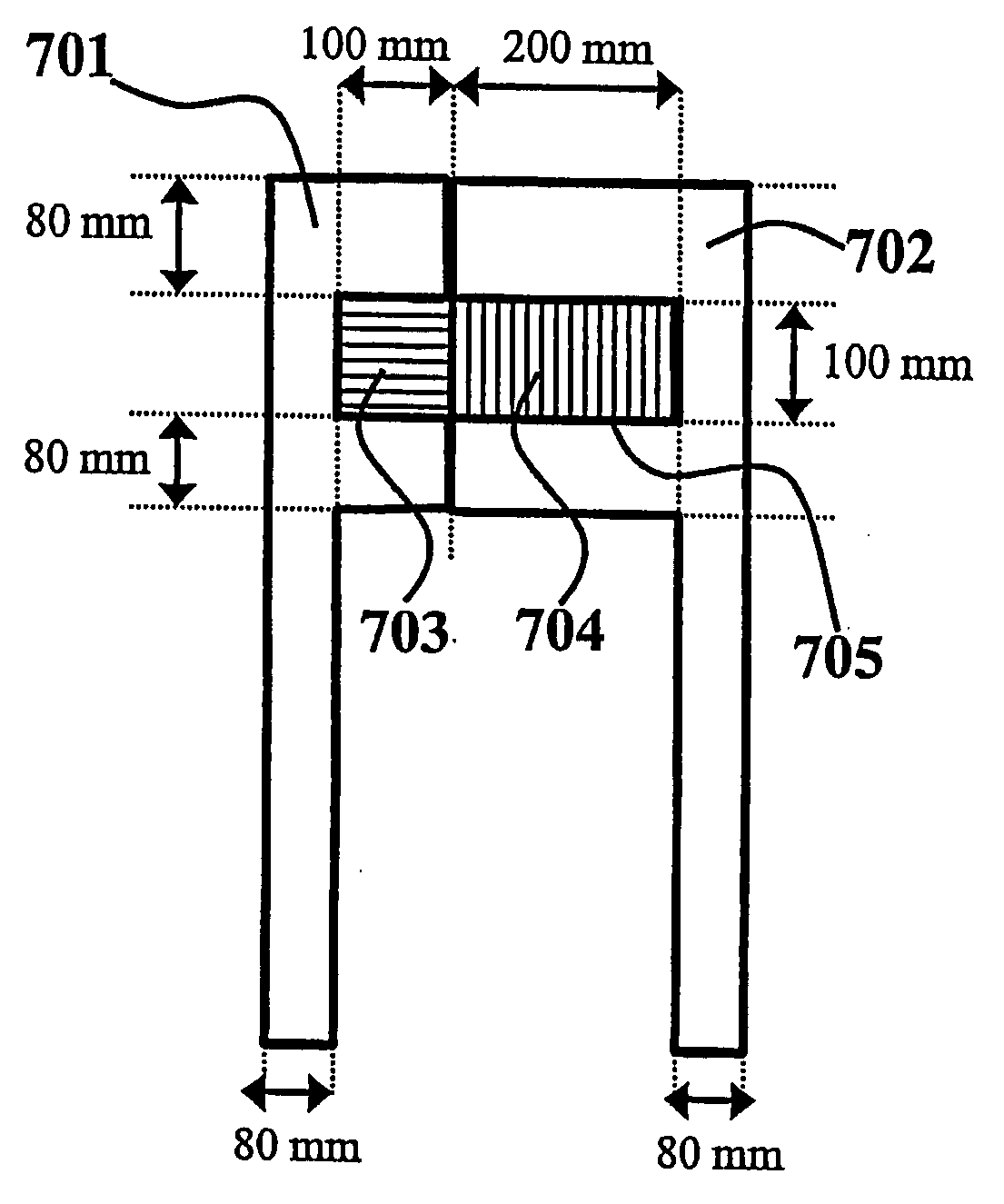

Engraved plate and substrate with conductor layer pattern using the same

InactiveUS20100021695A1High precision and miniaturization of patterningFlat surfaceMagnetic/electric field screeningLayered productsElectrical conductorEngineering

Owner:HITACHI CHEM CO LTD

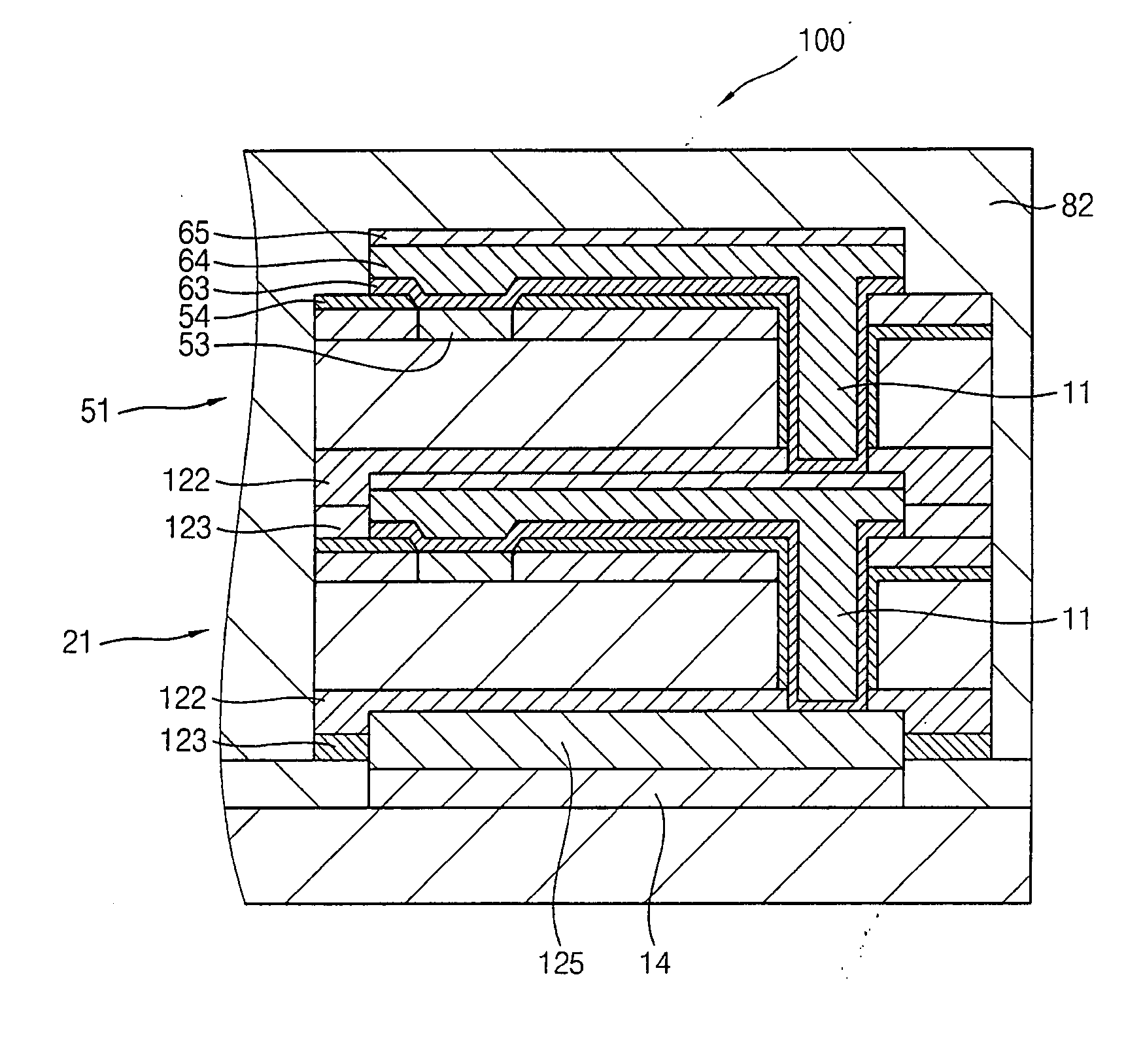

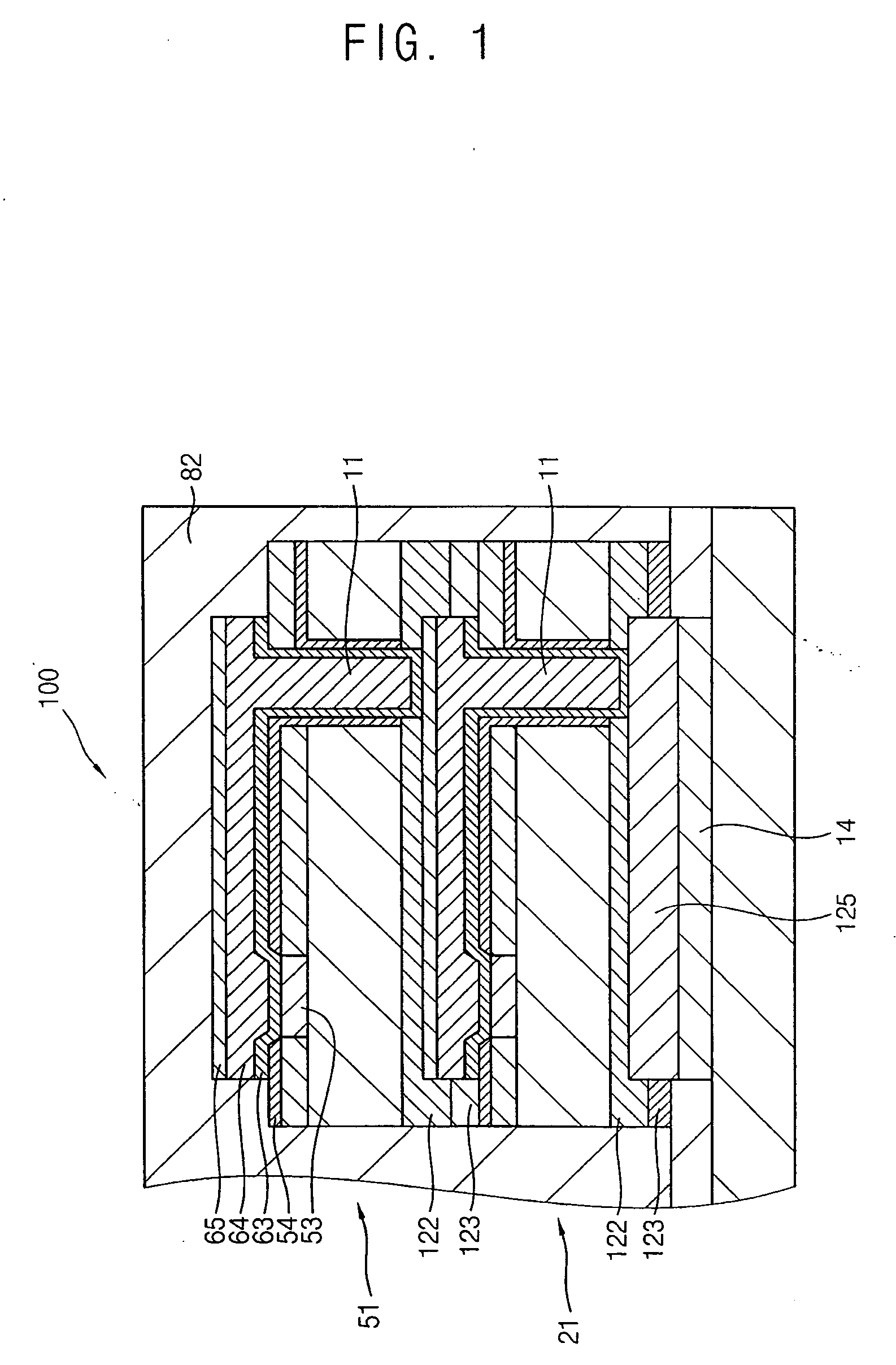

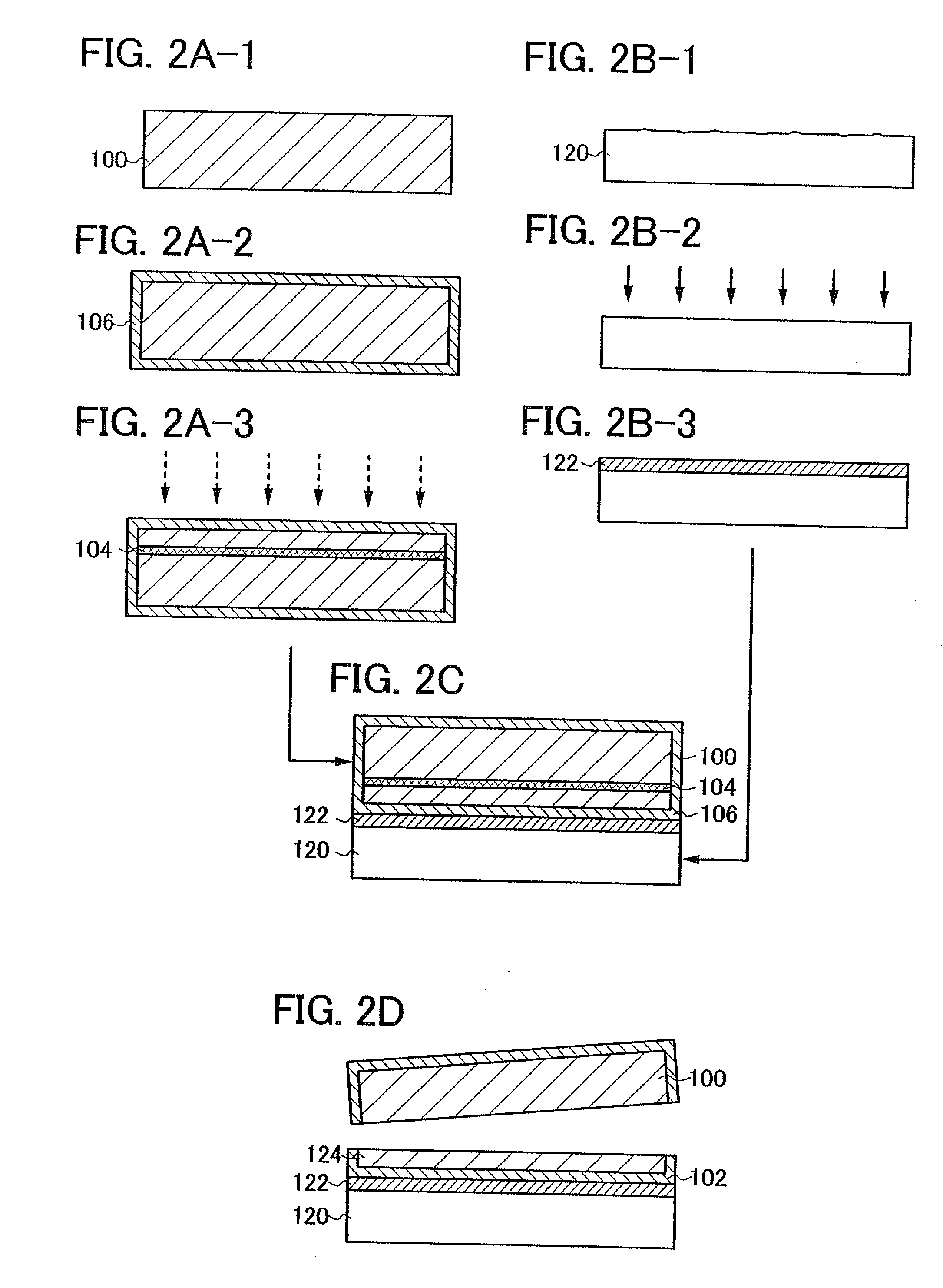

Stacked chip package using photosensitive polymer and manufacturing method thereof

ActiveUS20070048969A1Reduce decreaseImprove device reliabilitySemiconductor/solid-state device detailsSolid-state devicesMechanical reliabilityPhotosensitive polymer

In a stacked chip configuration, and manufacturing methods thereof, the gap between a lower and an upper chip is filled completely using a relatively simple process that eliminates voids between the lower and upper chips and the cracking and delamination problems associated with such voids. The present invention is applicable to both chip-level bonding and wafer-level bonding approaches. A photosensitive polymer layer is applied to a first chip, or wafer, prior to stacking the chips or stacking the wafers. The photosensitive polymer layer is partially cured, so that the photosensitive polymer layer is made to be structurally stable, while retaining its adhesive properties. The second chip, or wafer, is stacked, aligned, and bonded to the first chip, or wafer, and the photosensitive polymer layer is then cured to fully bond the first and second chips, or wafers. In this manner, adhesion between chips / wafers is greatly improved, while providing complete gap fill. In addition, mechanical reliability is improved, alleviating the problems associated with cracking and delamination, and leading to an improvement in device yield and device reliability.

Owner:SAMSUNG ELECTRONICS CO LTD

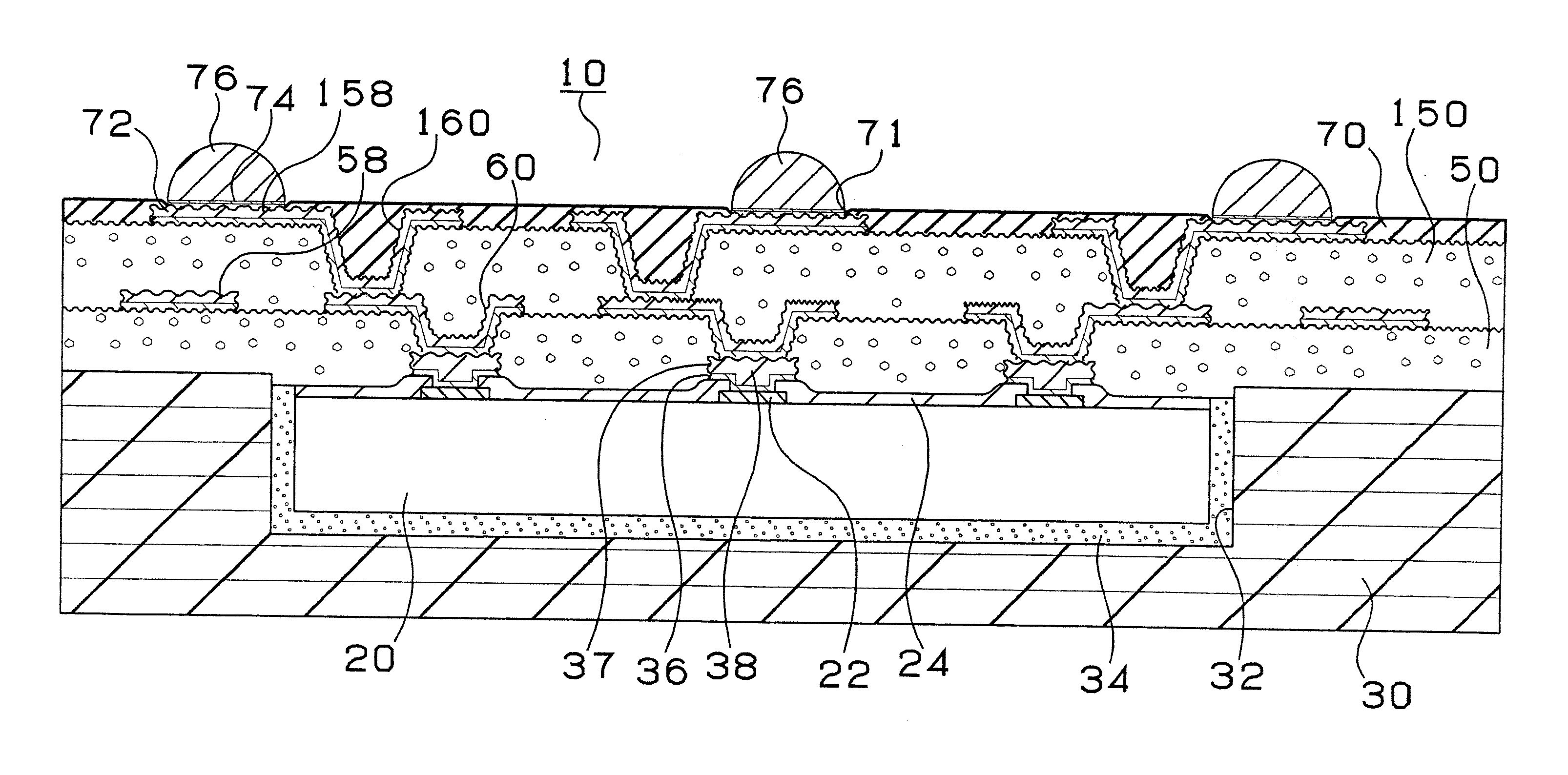

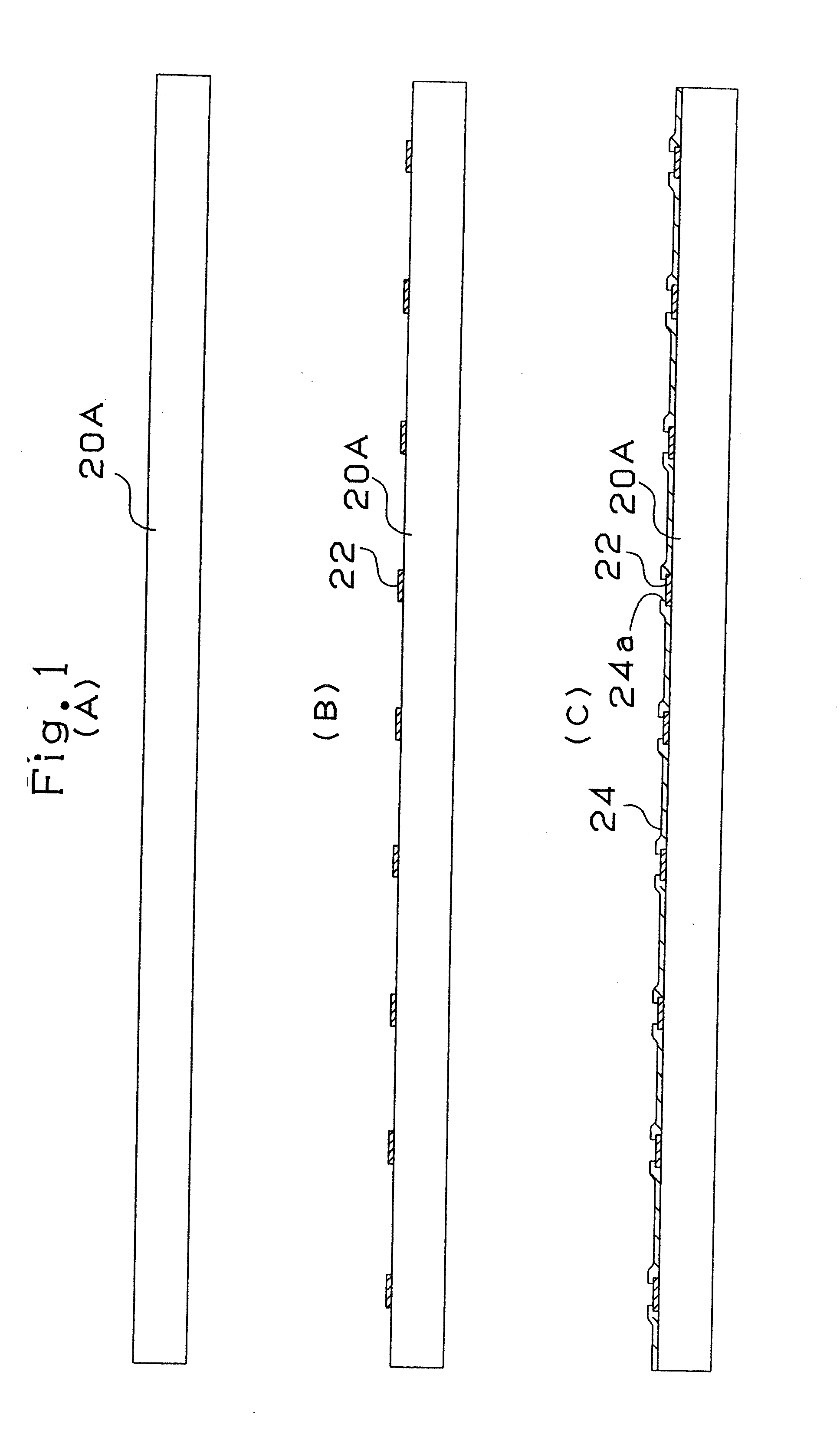

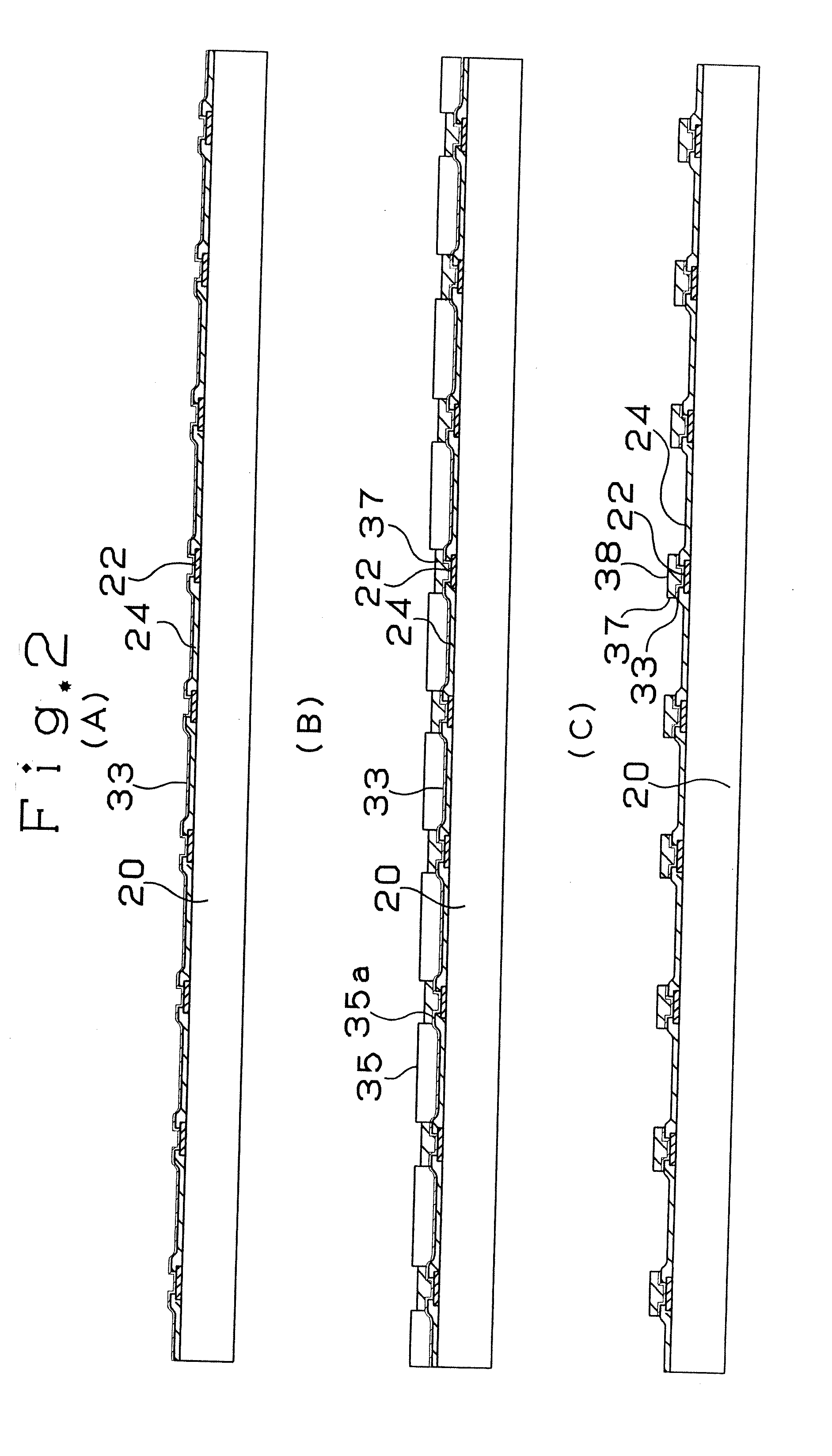

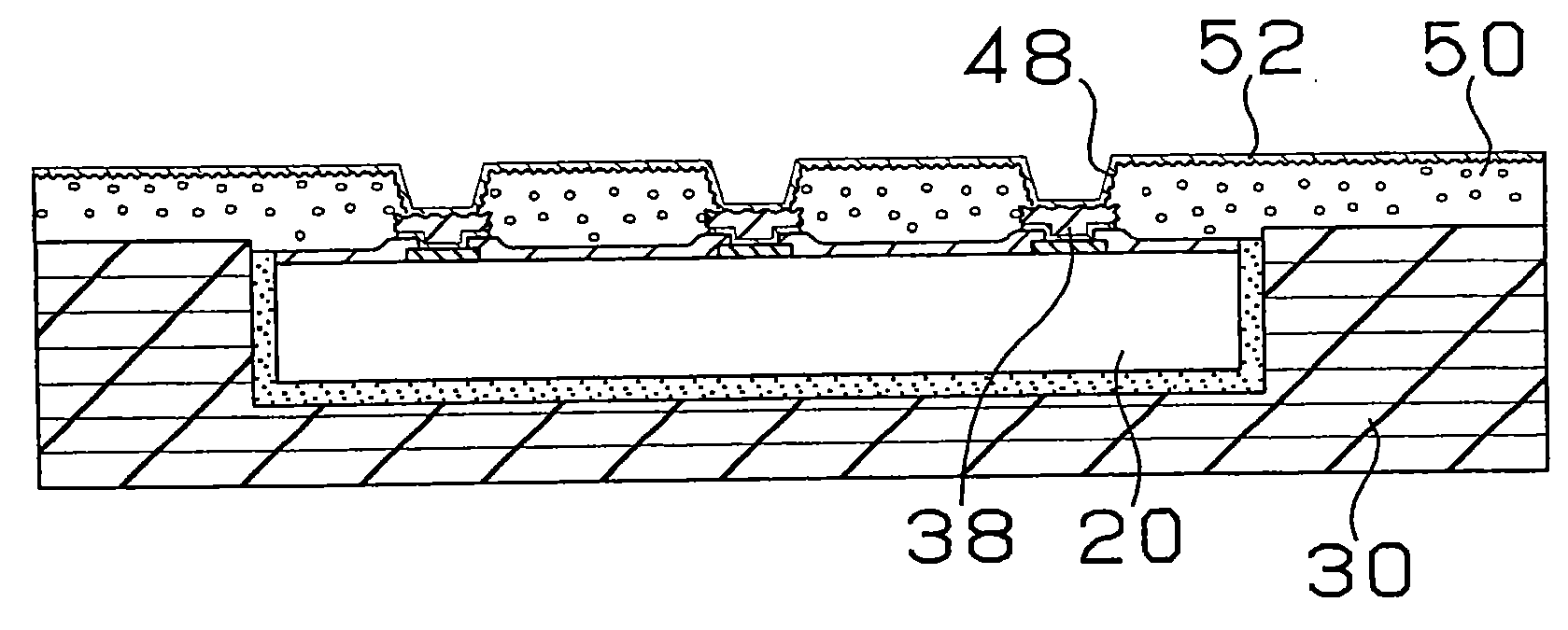

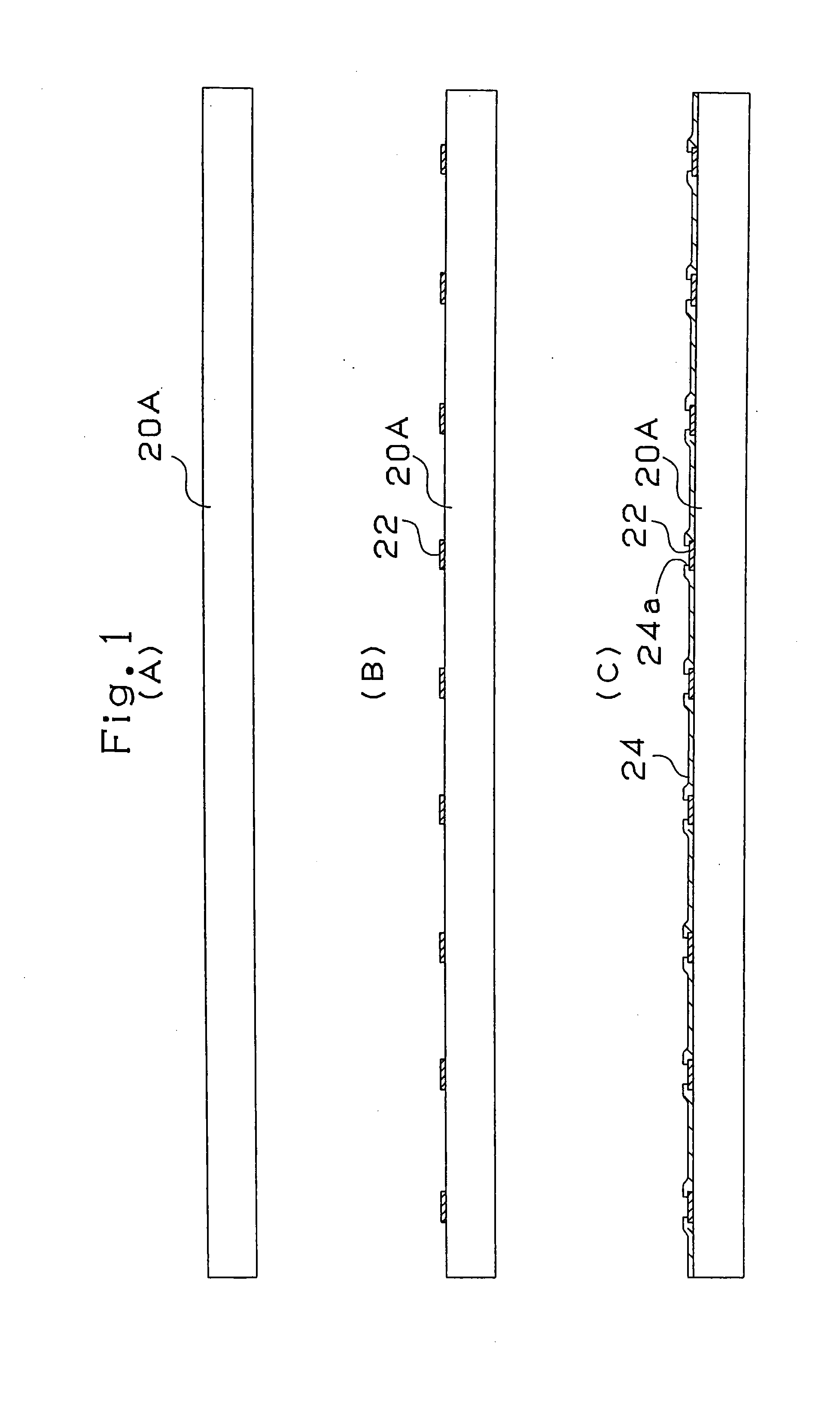

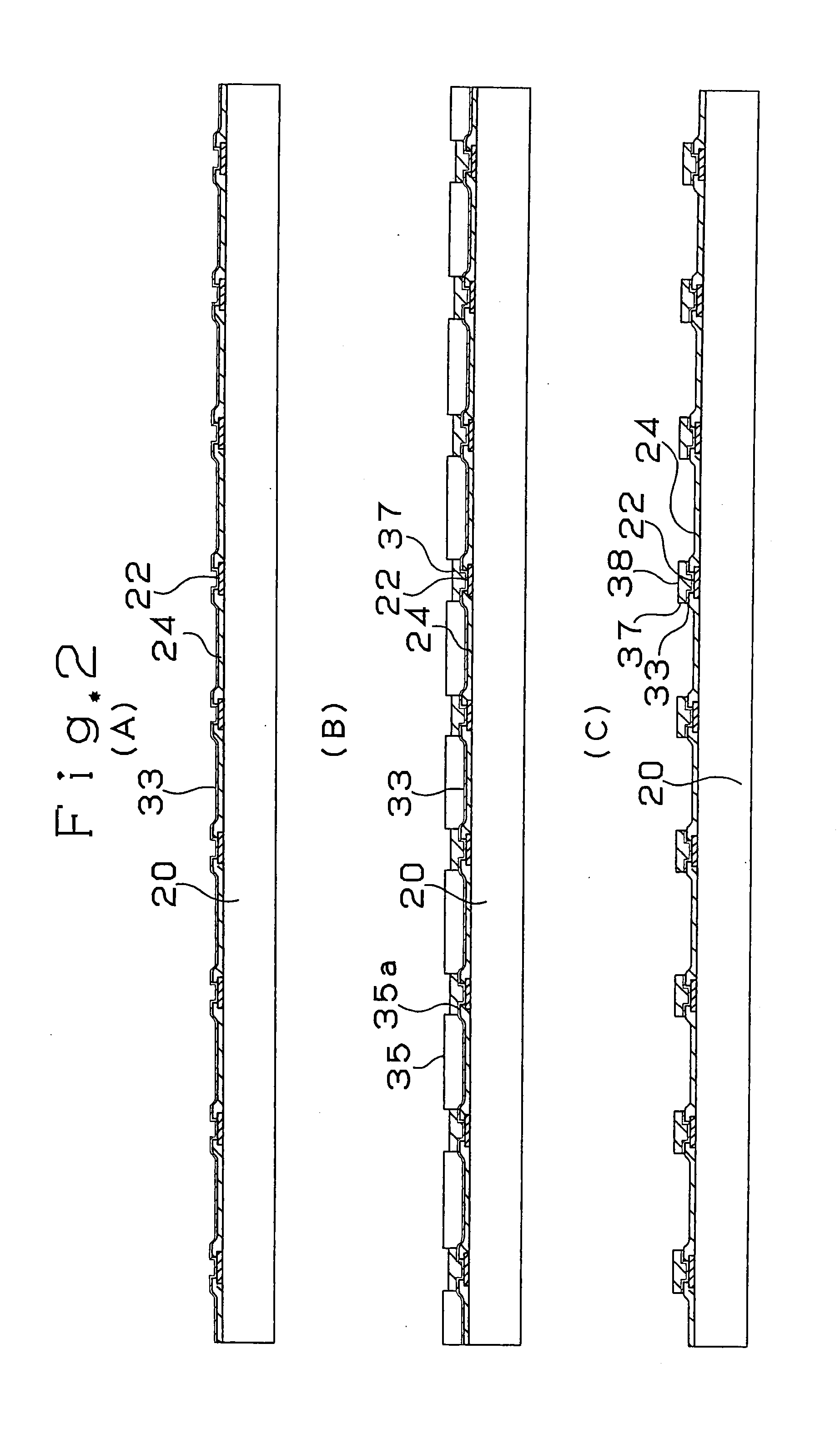

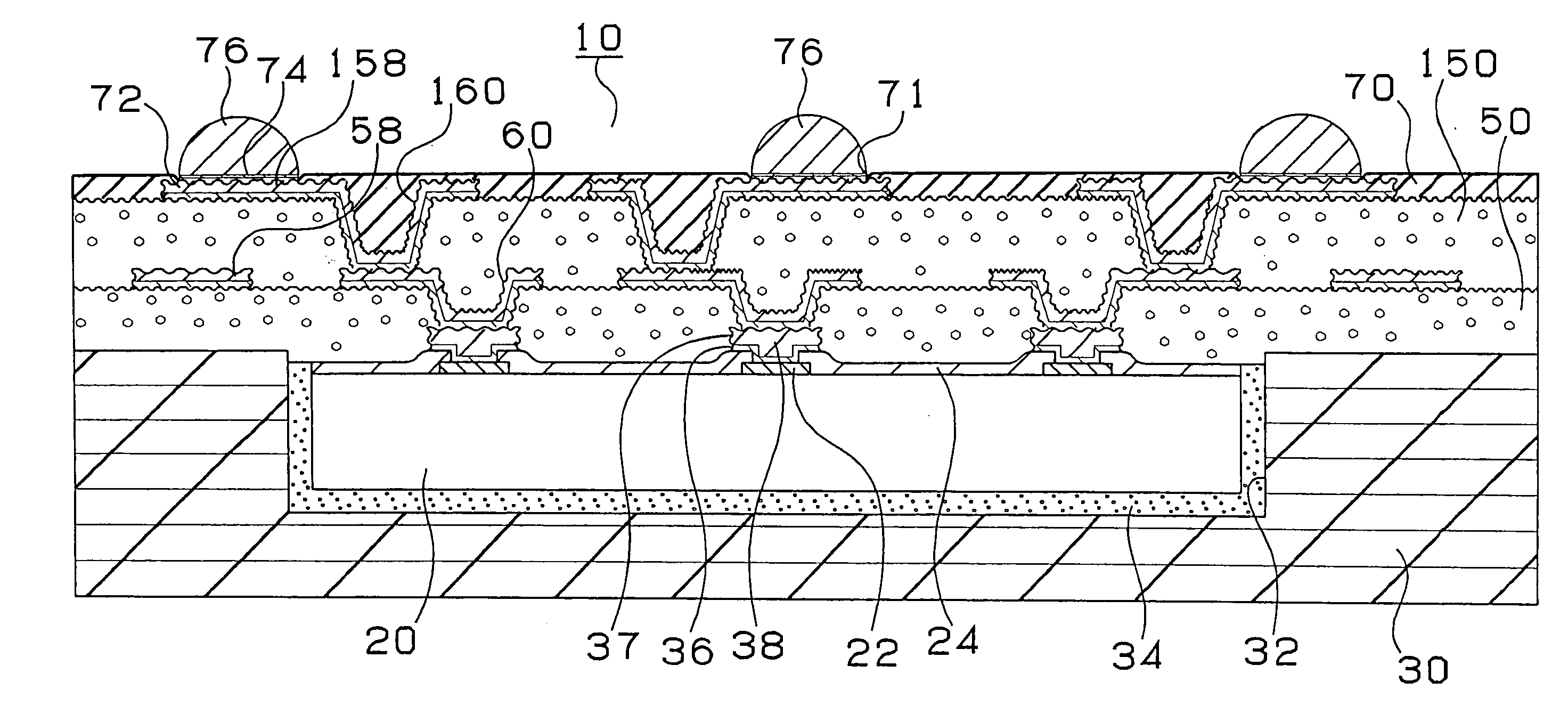

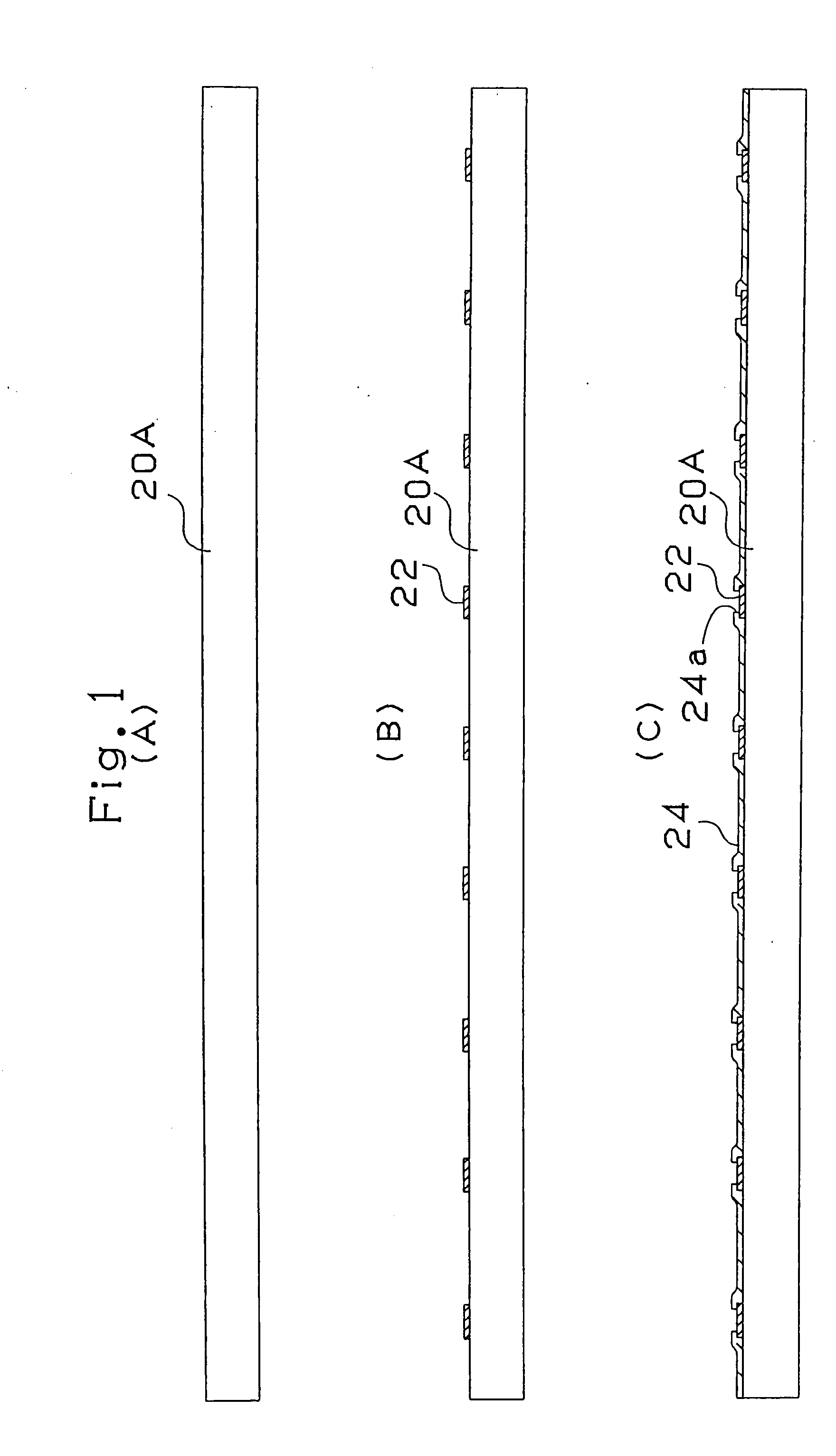

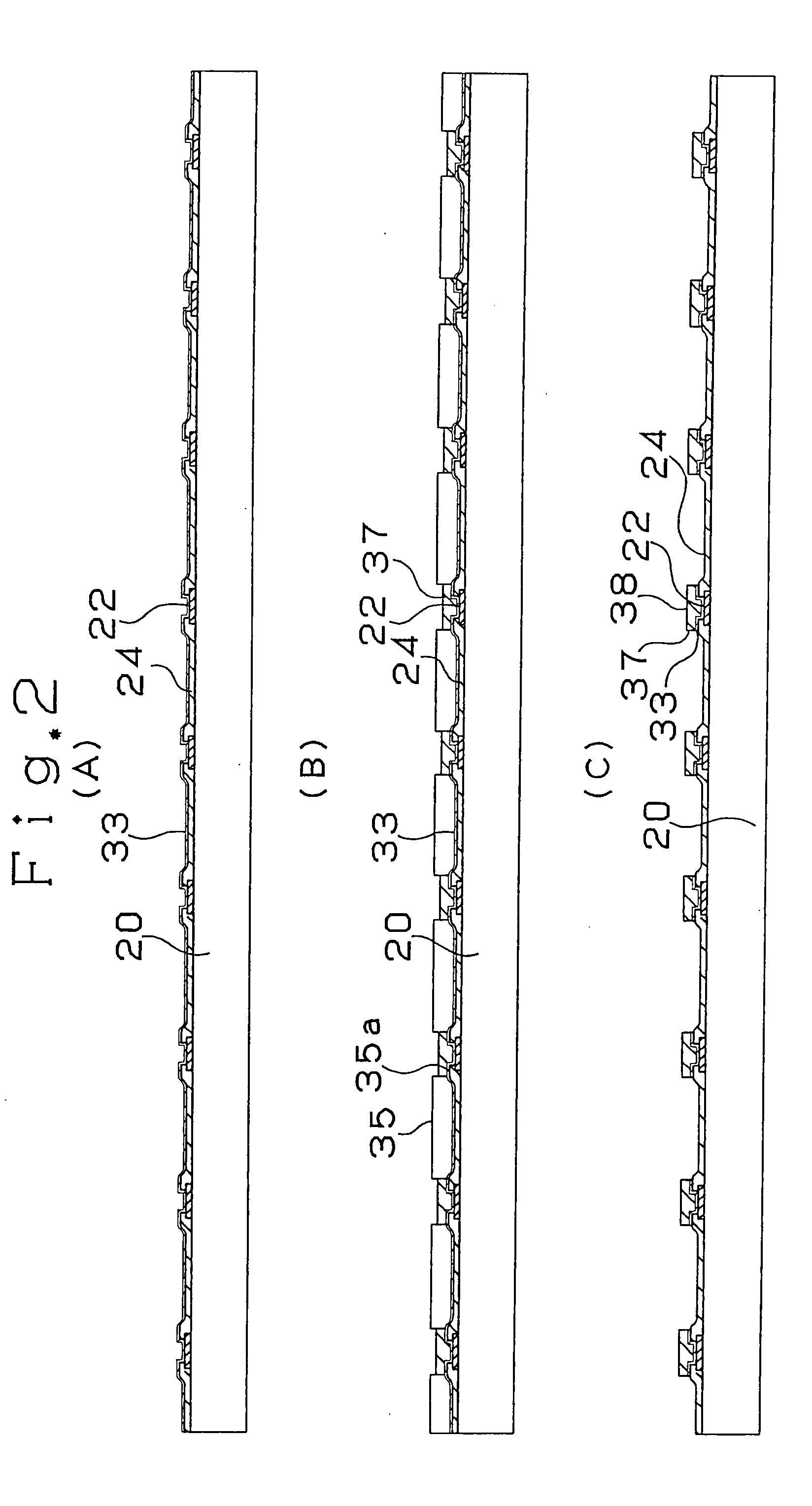

Semiconductor element, method of manufacturing semiconductor element, multi-layer printed circuit board, and method of manufacturing multi-layer printed circuit board

InactiveUS20070209831A1Improve adhesionAvoid crackingPrinted electric component incorporationSemiconductor/solid-state device detailsEngineeringCopper

A transition layer 38 is provided on a die pad 22 of an IC chip 20 and integrated into a multilayer printed circuit board 10. Due to this, it is possible to electrically connect the IC chip 20 to the multilayer printed circuit board 10 without using lead members and a sealing resin. Also, by providing the transition layer 38 made of copper on an aluminum pad 24, it is possible to prevent a resin residue on the pad 24 and to improve connection characteristics between the die pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

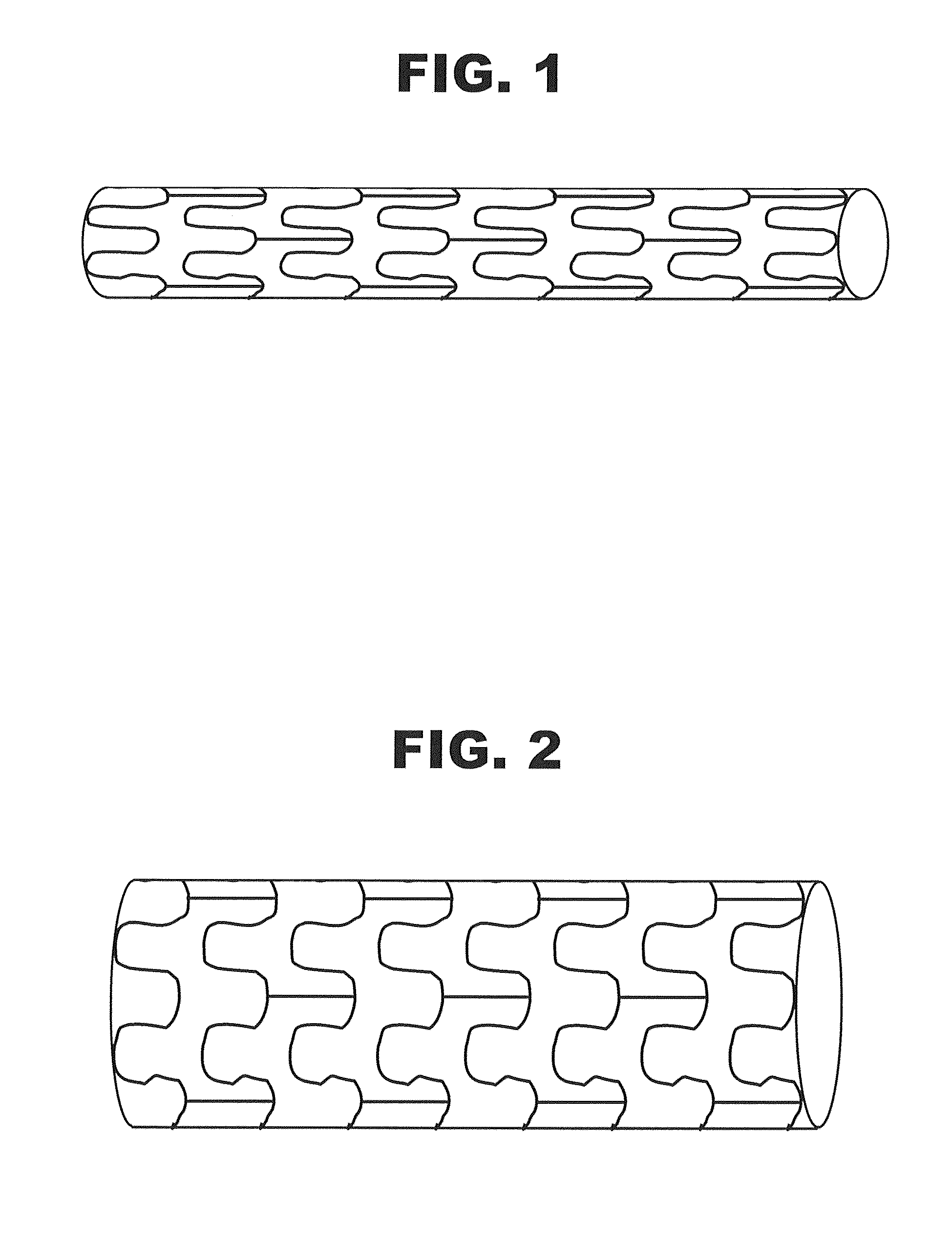

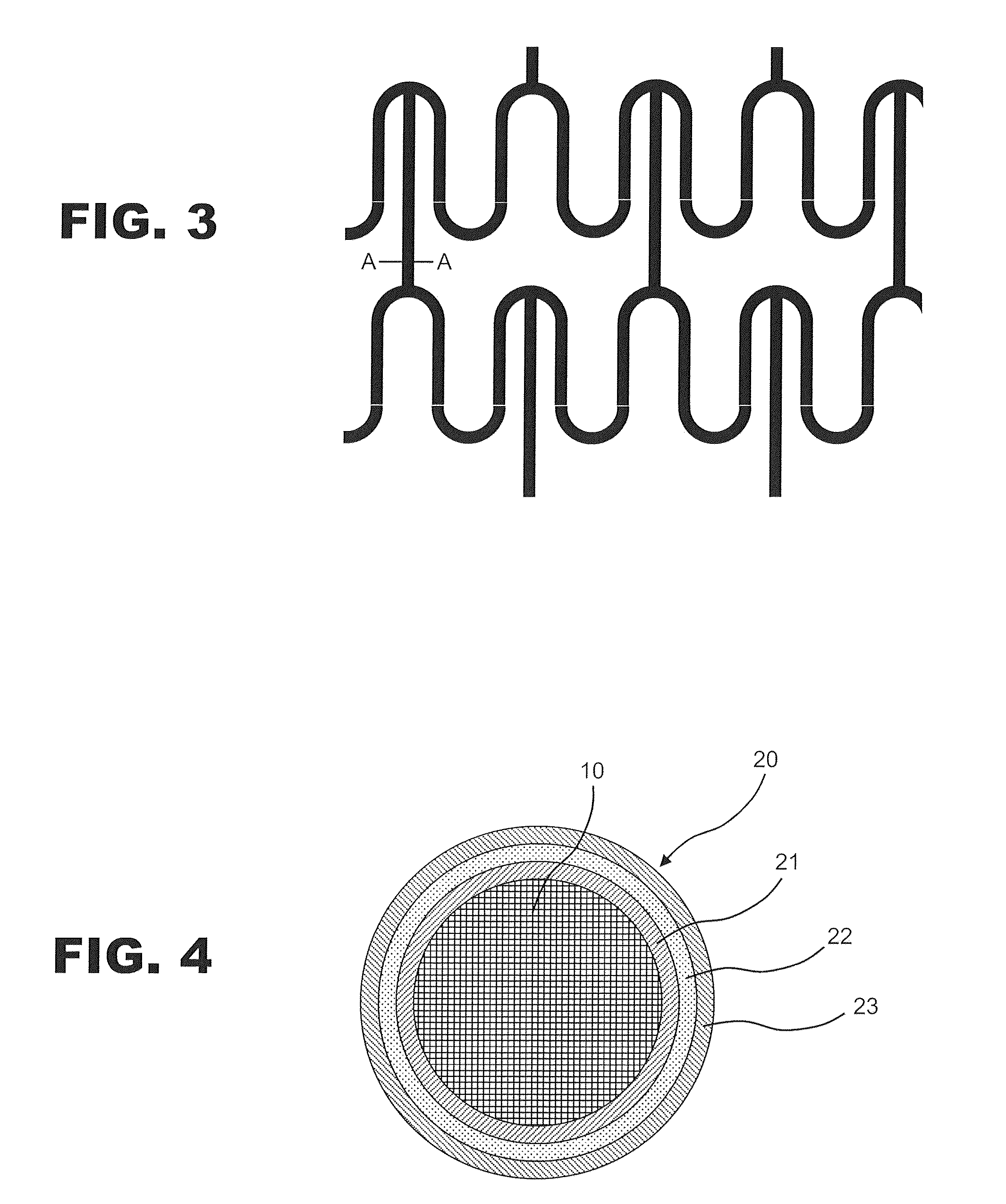

Vascular stent

Owner:GELITA AG

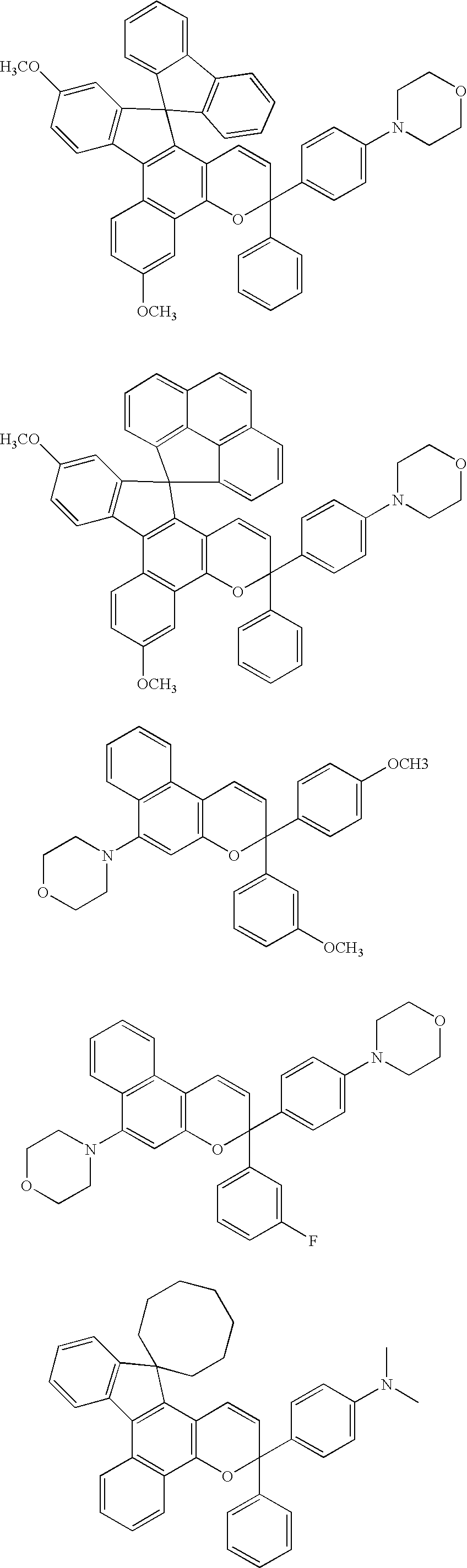

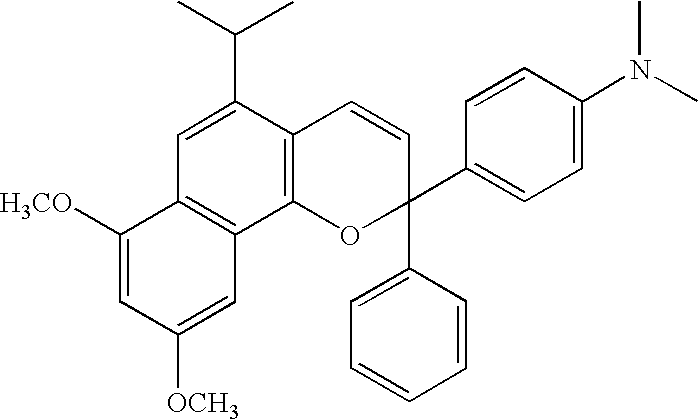

Layered product, optical part, processes for producing these, and coating fluid

ActiveUS20060269741A1Characteristic is not deterioratedImprove impact resistanceSynthetic resin layered productsPretreated surfacesSolubilityAdditive ingredient

A laminated product has a multilayer structure comprising an optical base and a cured polyurethane resin layer formed thereon from a moisture-curable polyurethane resin and / or a precursor therefor. The polyurethane resin layer is formed by applying a coating fluid comprising a moisture-curable polyurethane resin and / or precursor therefor and a solvent having a boiling point of 70° C. or higher and a solubility parameter of 8 or larger. Also provided is a coating material comprising a radical-polymerizable monomer ingredient, a silicone or fluorochemical surfactant, and a photochromic compound. In producing a photochromic optical article, excellent adhesion between a base and a photochromic layer is attained.

Owner:TOKUYAMA CORP

Semiconductor element, method of manufacturing semiconductor element, multi-layer printed circuit board, and method of manufacturing multi-layer printed circuit board

InactiveUS20080148563A1Improve connection characteristicsAvoid residuePrinted circuit assemblingSemiconductor/solid-state device detailsInter layerCopper

Owner:IBIDEN CO LTD

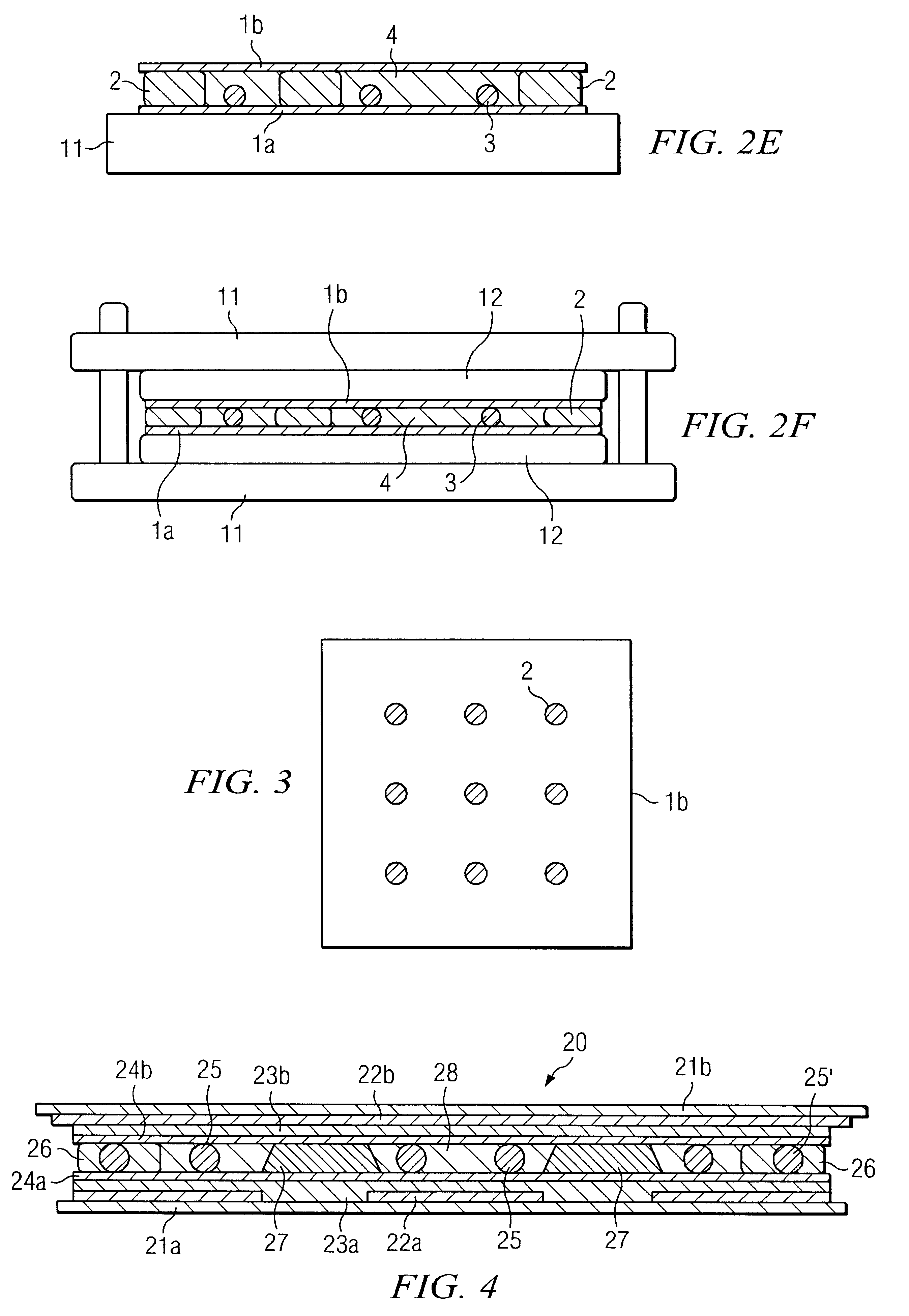

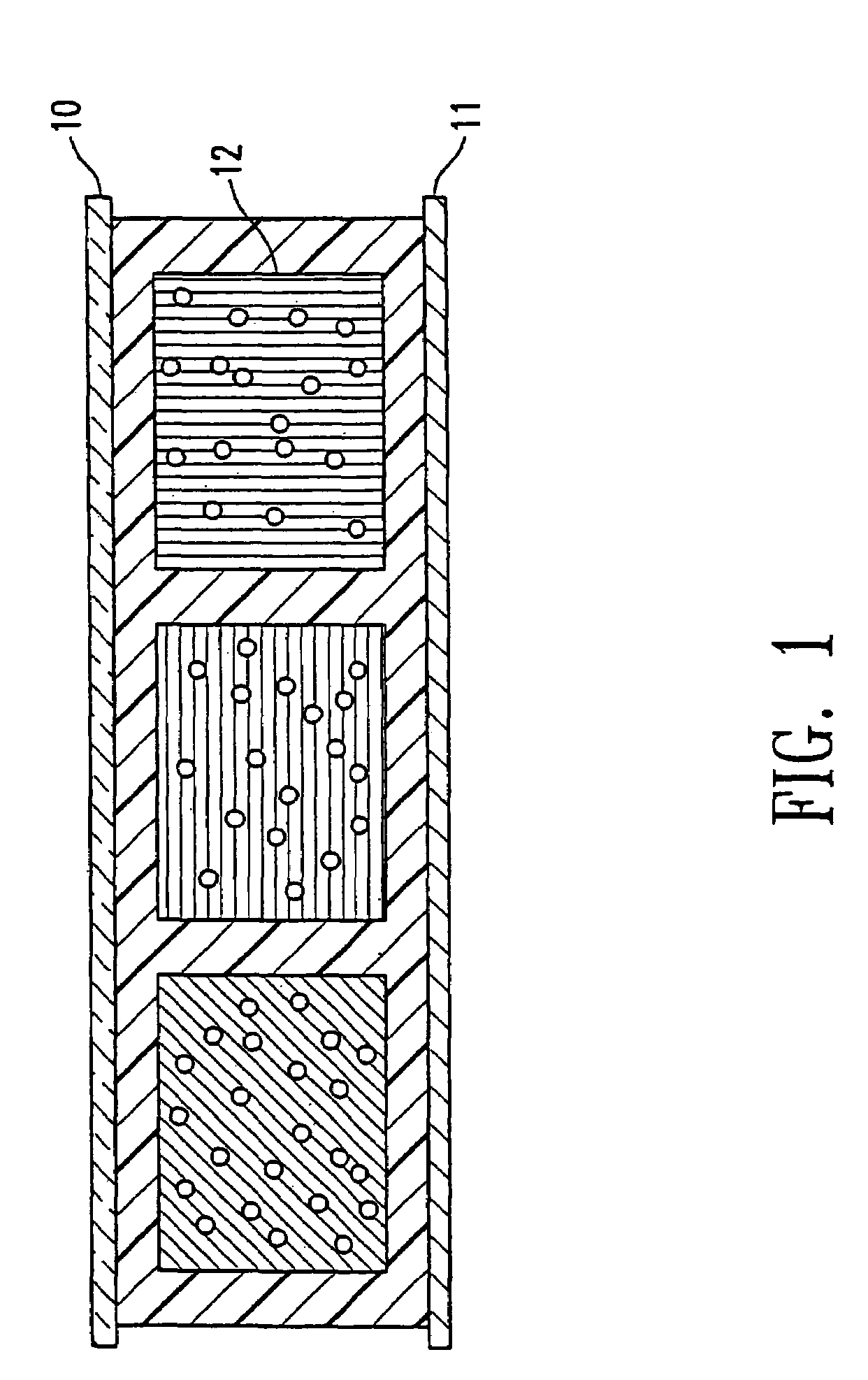

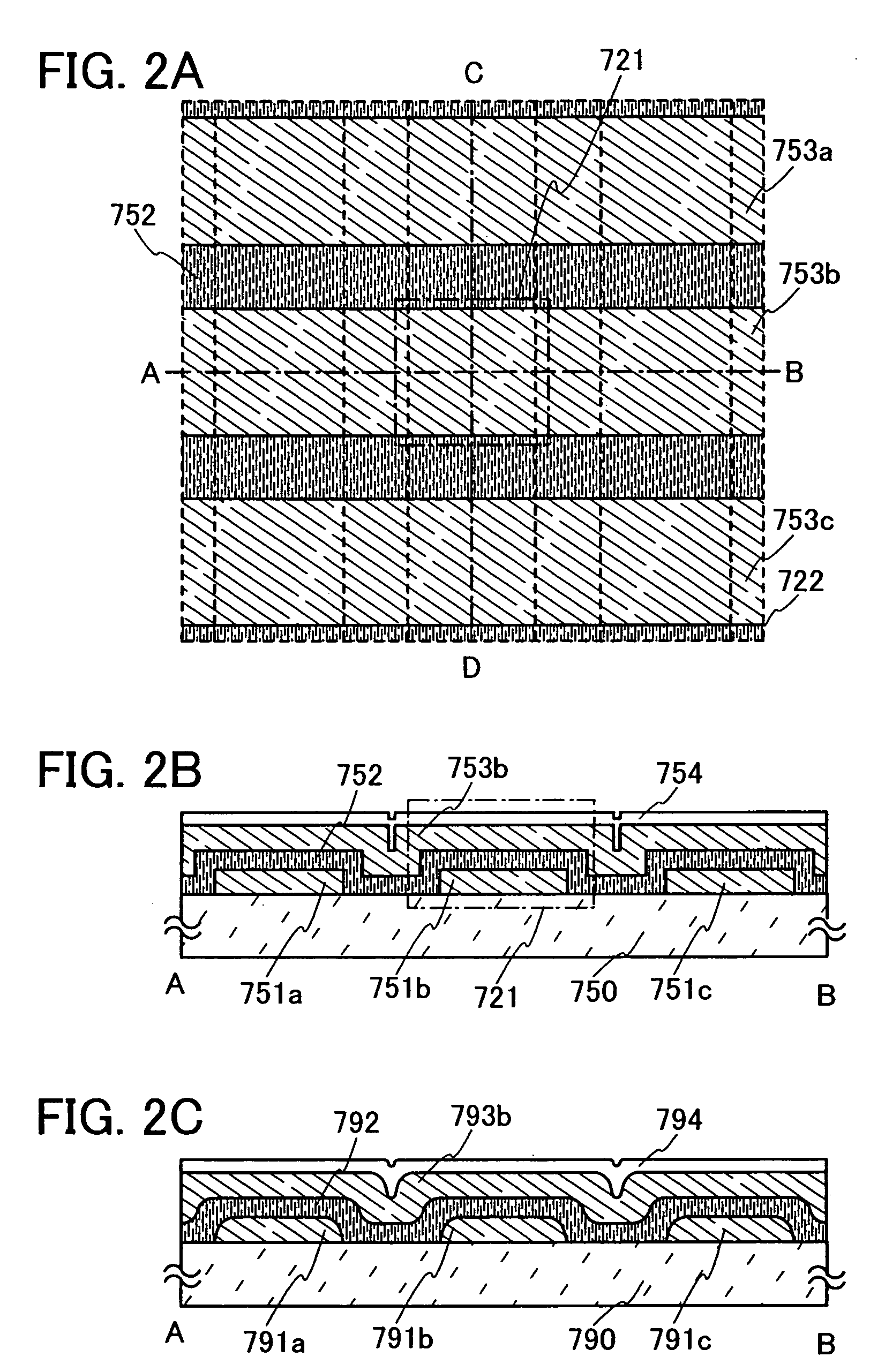

Liquid crystal light modulating device and a method for manufacturing same

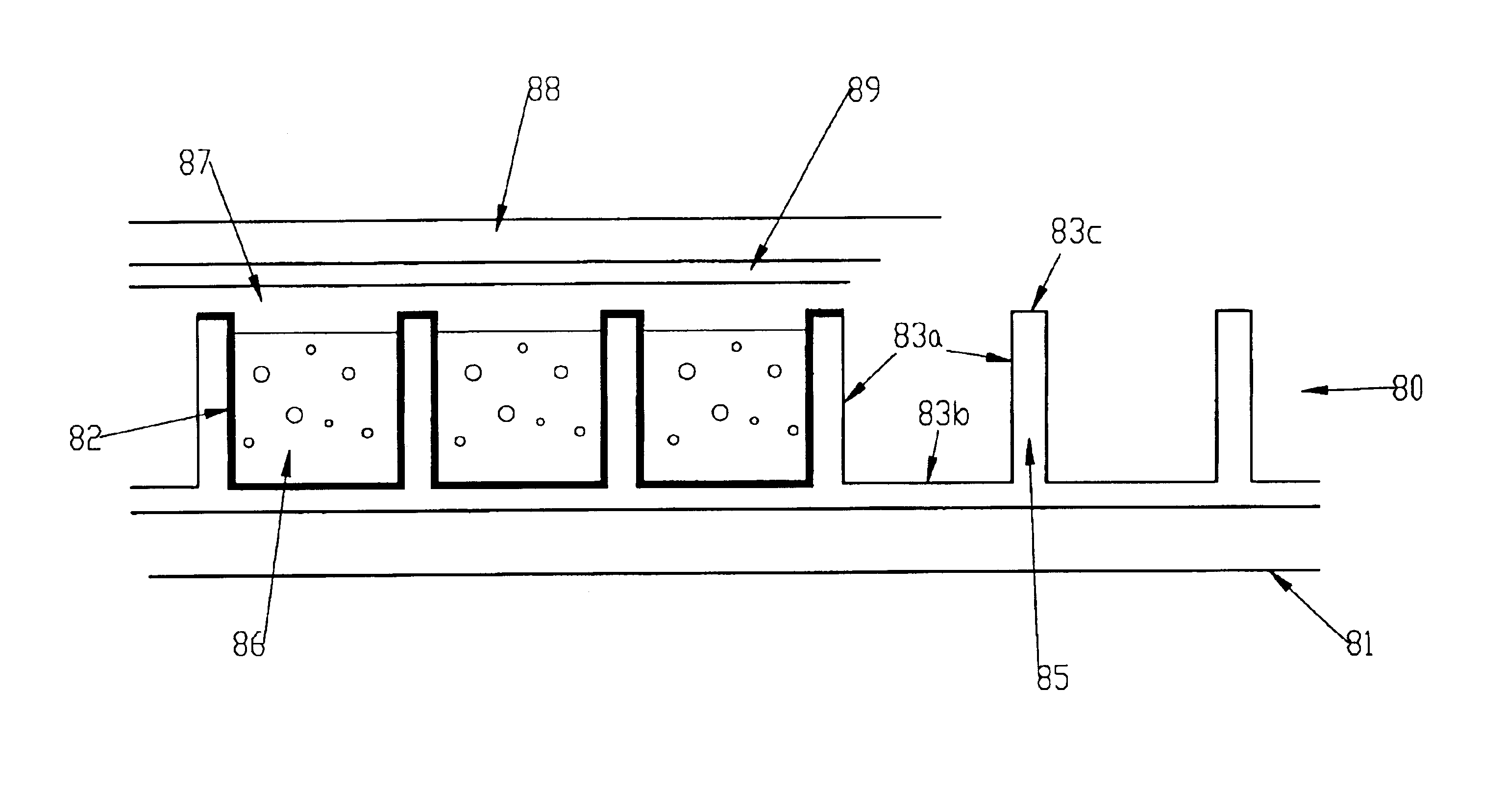

InactiveUS6650393B1High quality displayAvoid normal displayNon-linear opticsEngineeringLiquid crystal

Disclosed is a liquid crystal light modulating device and method for amufacturing the same. The liquid crystal light modulating device has a plurality of resin columns adhering two substrates between which a liquid crystal material is filled. The resin columns are arranged in a predetermined arrangement within a display region of the device. Each columns is made from a curable resin material as a main component, and forms a macromolecular material having thermoplasticity after curing.

Owner:MINOLTA CO LTD

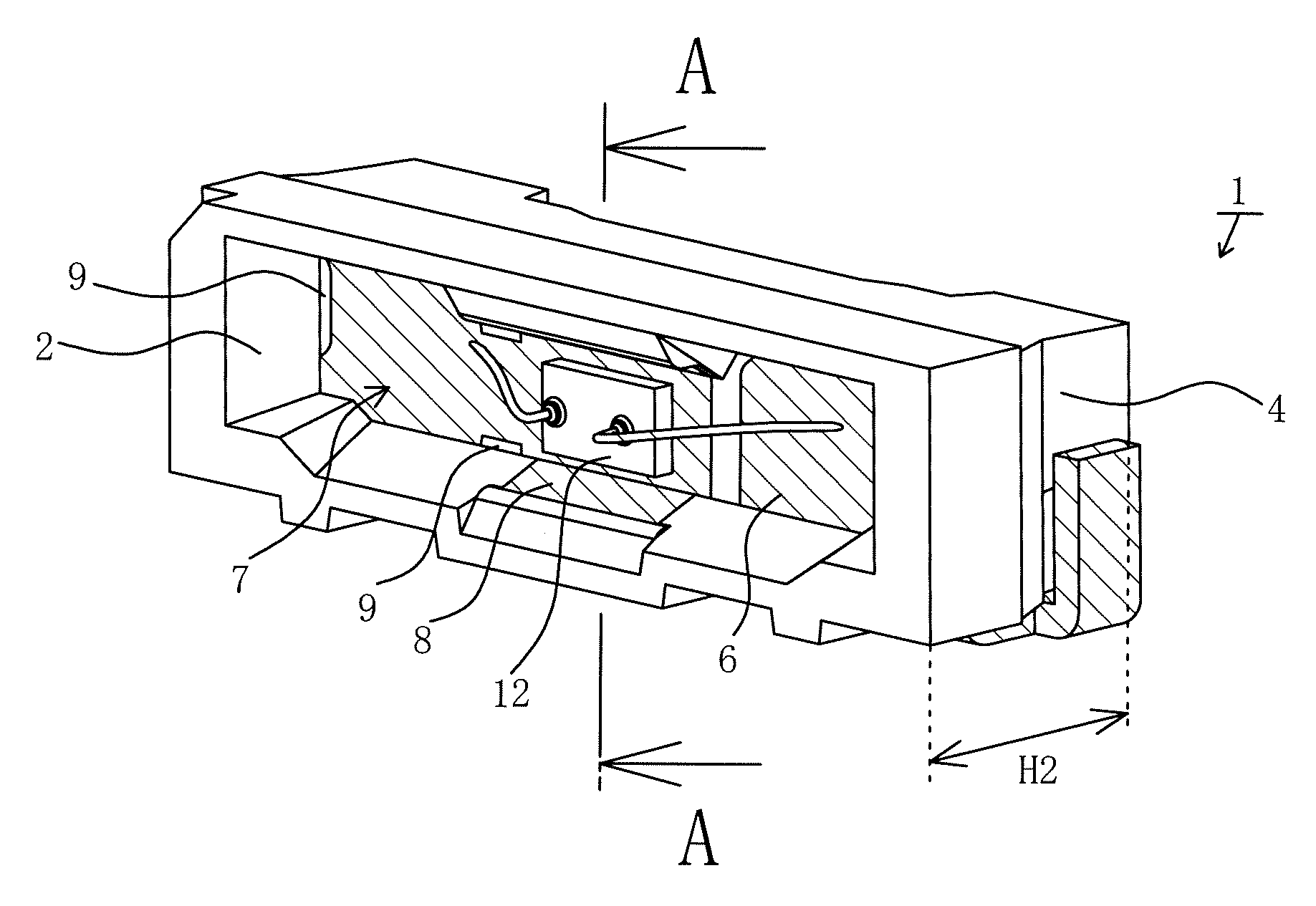

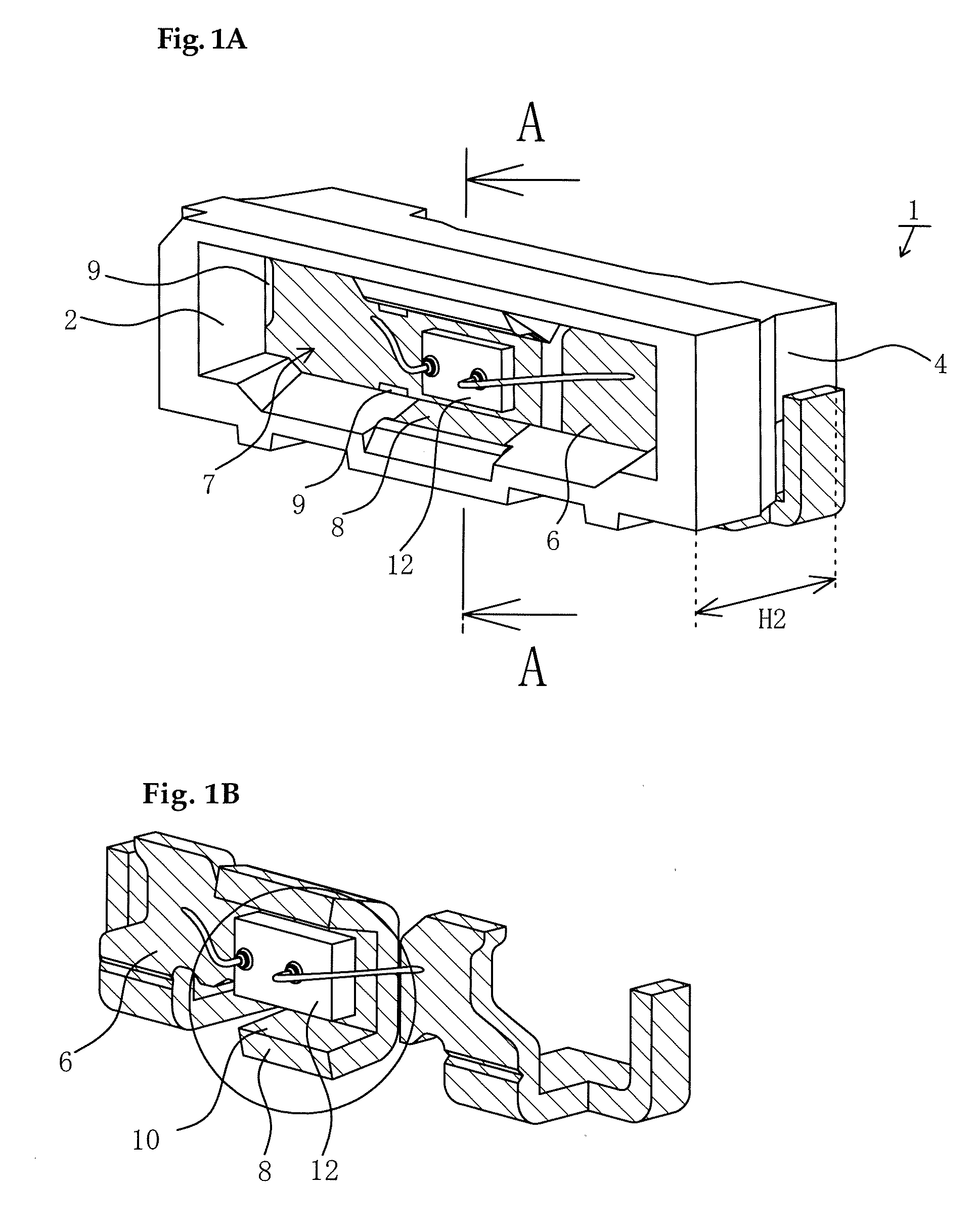

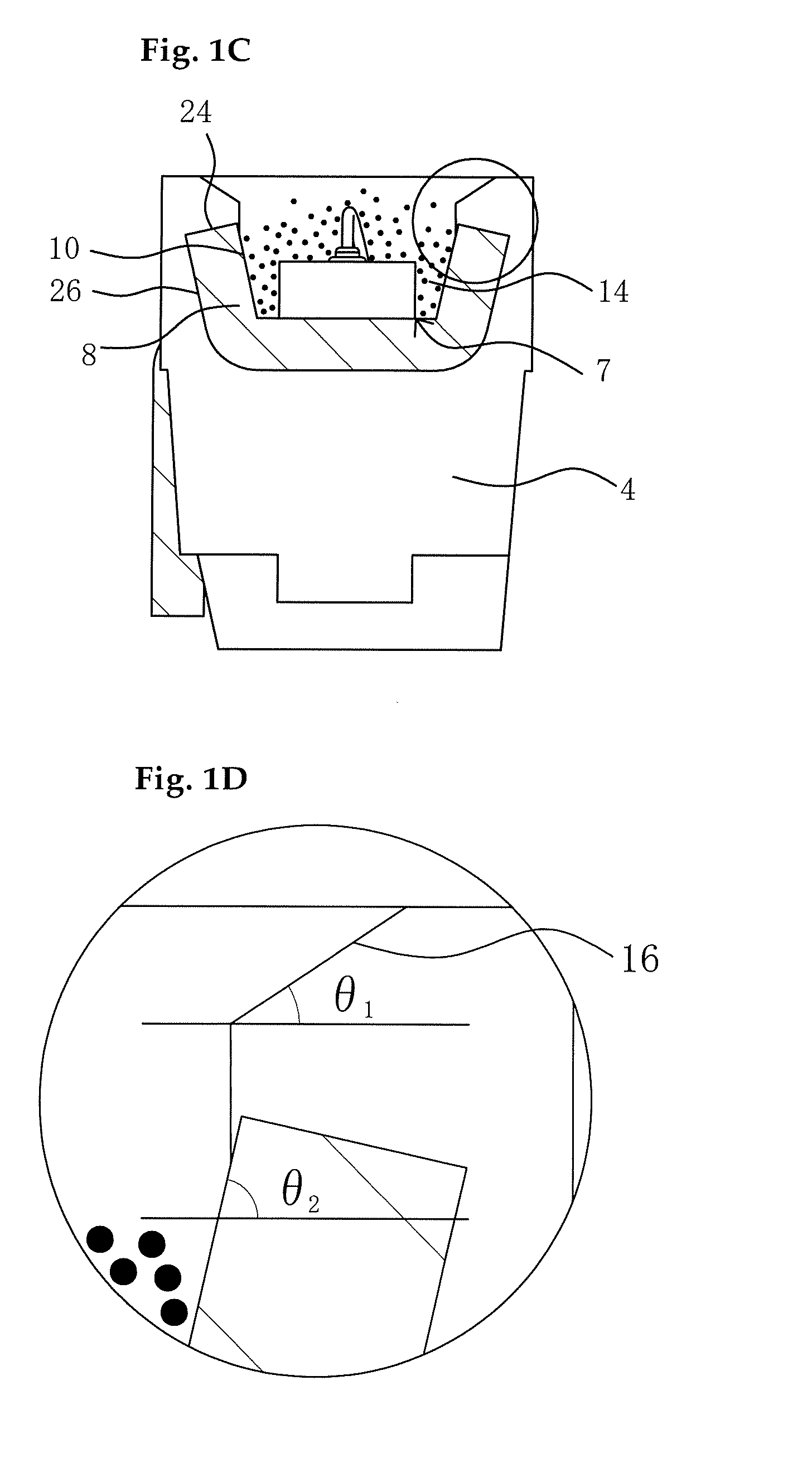

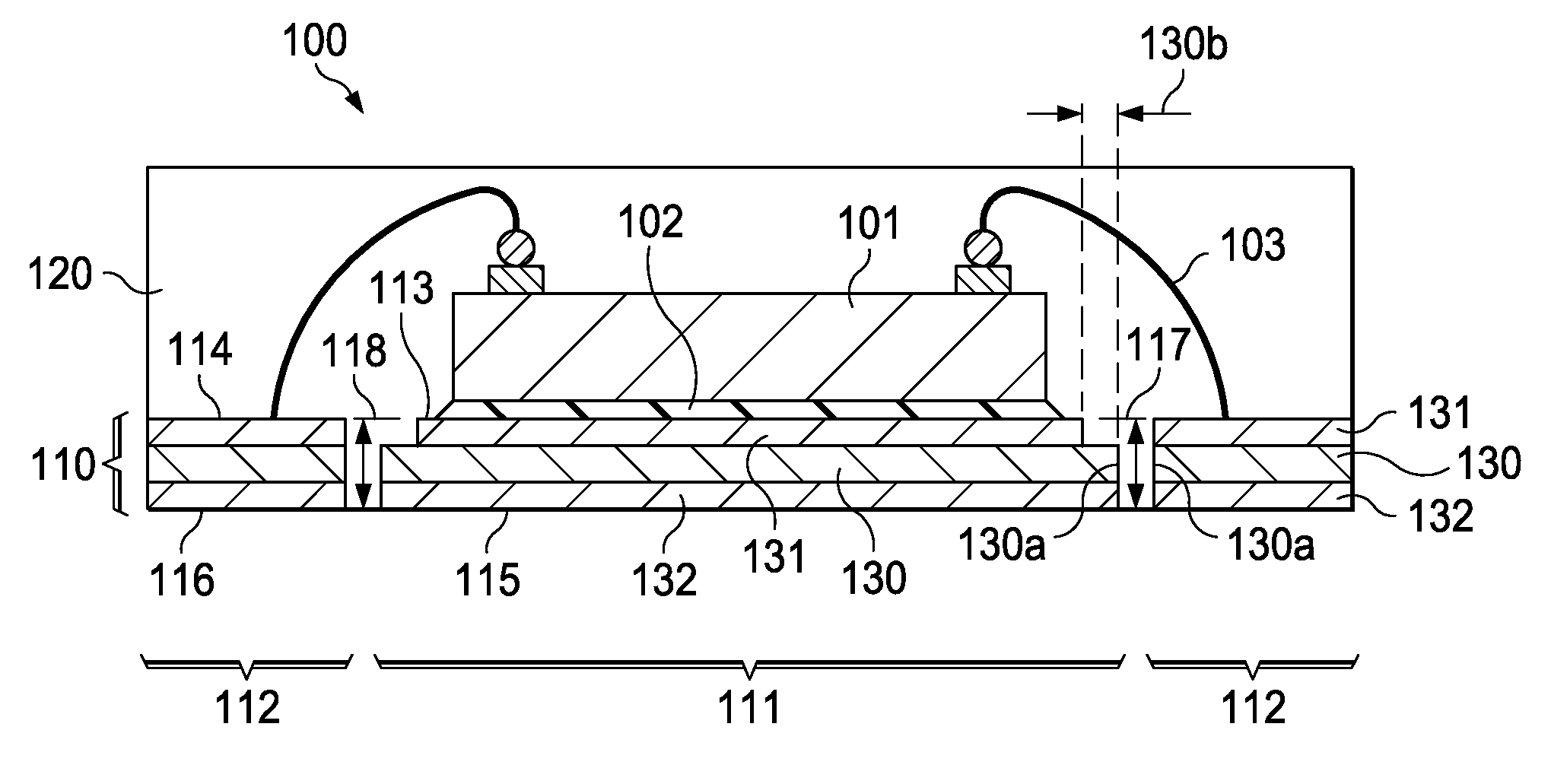

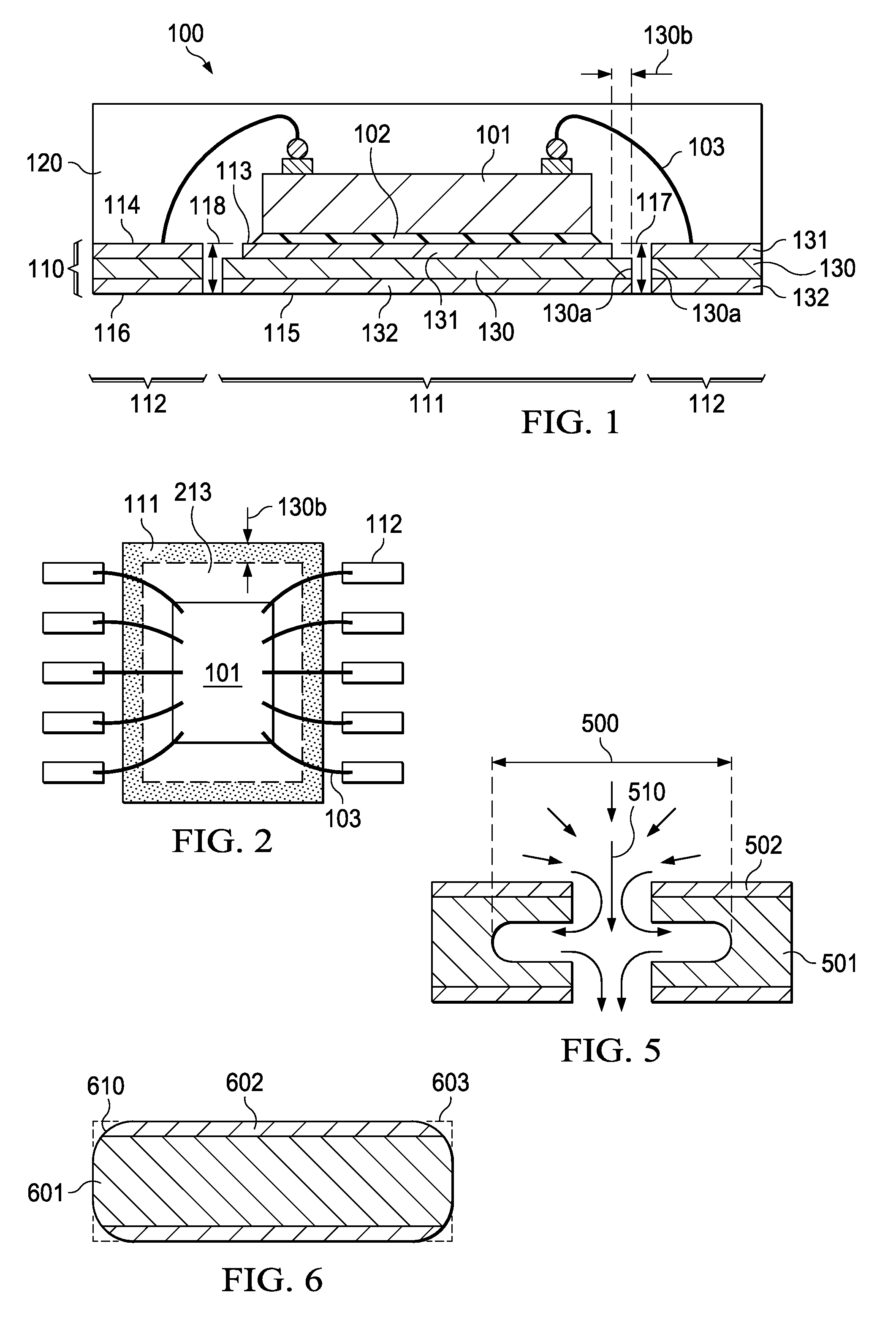

Light emitting device

ActiveUS20110175127A1Improve adhesionPrevent interfacial peelingSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

A light emitting device has a package having an opening provided with a side surface and a bottom surface, and a lead frame exposed to the bottom surface. The lead frame includes a reflection portion bent on the side surface, and a portion of an inner wall surface of the reflection portion is positioned in an inner portion of the package. A light emitting device has a package having a recessed portion on a front surface, a lead frame exposed to a bottom surface of the recessed portion, a light emitting element disposed on the lead frame, and a sealing resin filled into the recessed portion. The lead frame includes a bent portion bent towards the front surface of the package in the recessed portion, and a projecting portion bent to project from the package towards an outer portion, and disposed on a face opposed to the front surface.

Owner:NICHIA CORP

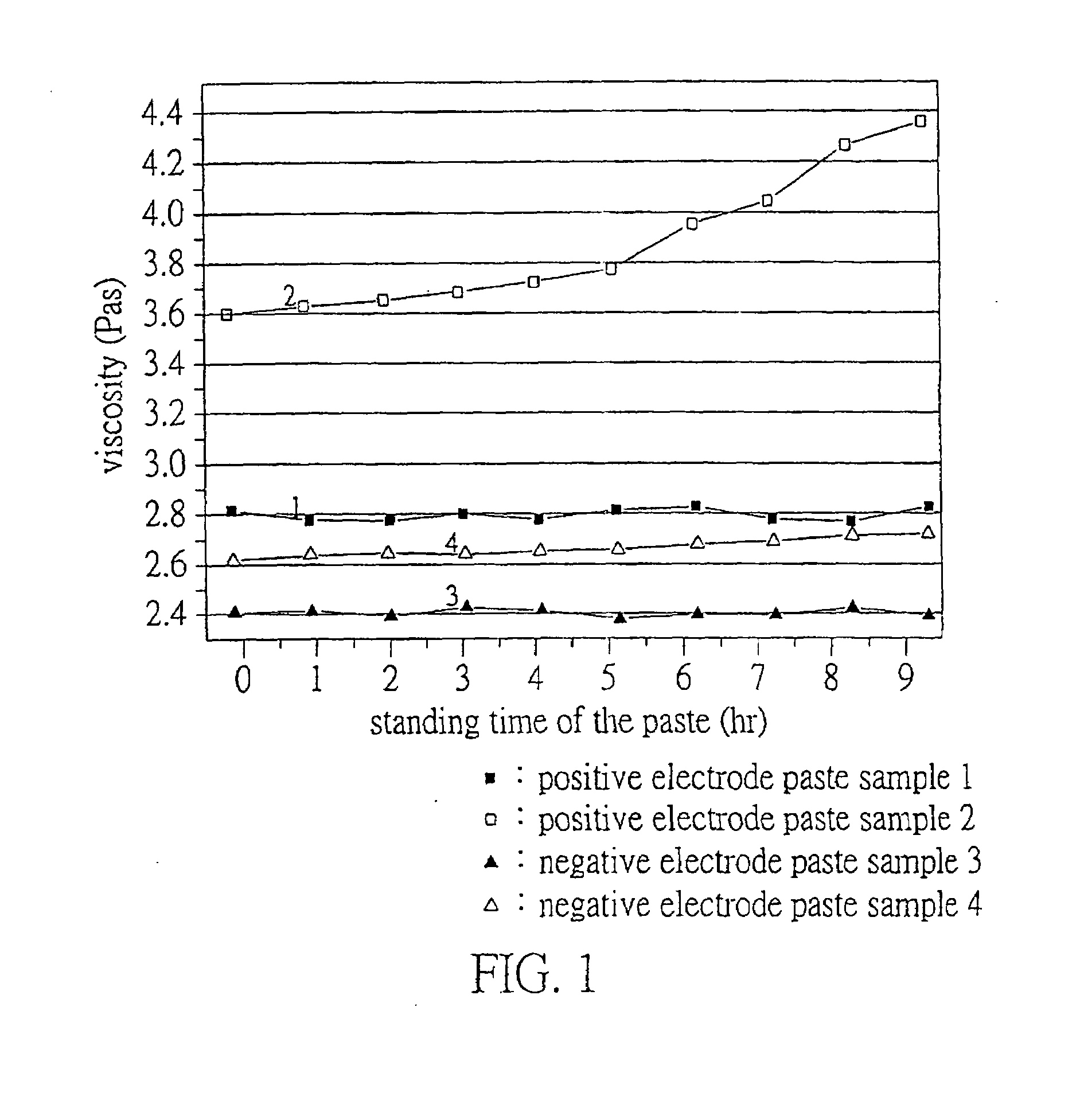

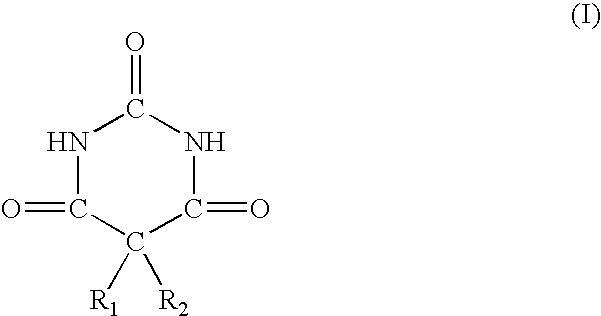

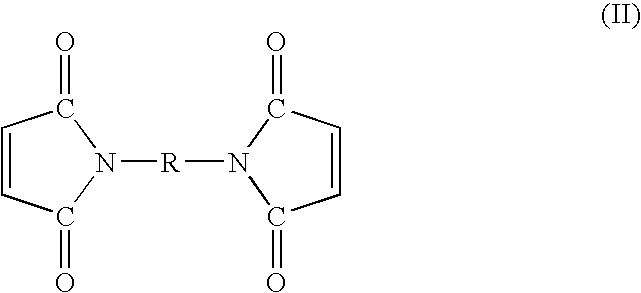

Battery electrode paste composition containing modified maleimides

ActiveUS20080160405A1Good dispersionLow viscositySecondary cellsActive material electrodesSolventMetal substrate

A battery electrode paste composition containing modified maleimide(s) is provided, which has an electrode active material, a conductive additive, a binder and modified maleimide(s) as dispersant. The modified maleimide as the dispersant in the battery electrode paste composition has dendrimer-like hyperbranched structures, which can form a stable complex with the electrode active material. Therefore, owing to the excellent compatibility of the modified maleimide with the solvent in the electrode paste, the storage stability of the paste is increased. Furthermore, through formation of stable bonding between the modified maleimide and the current-collecting metal substrate, the adhesive force between the electrode film and the current-collecting metal substrate is enhanced and the cycling life of the battery product is extended.

Owner:IND TECH RES INST

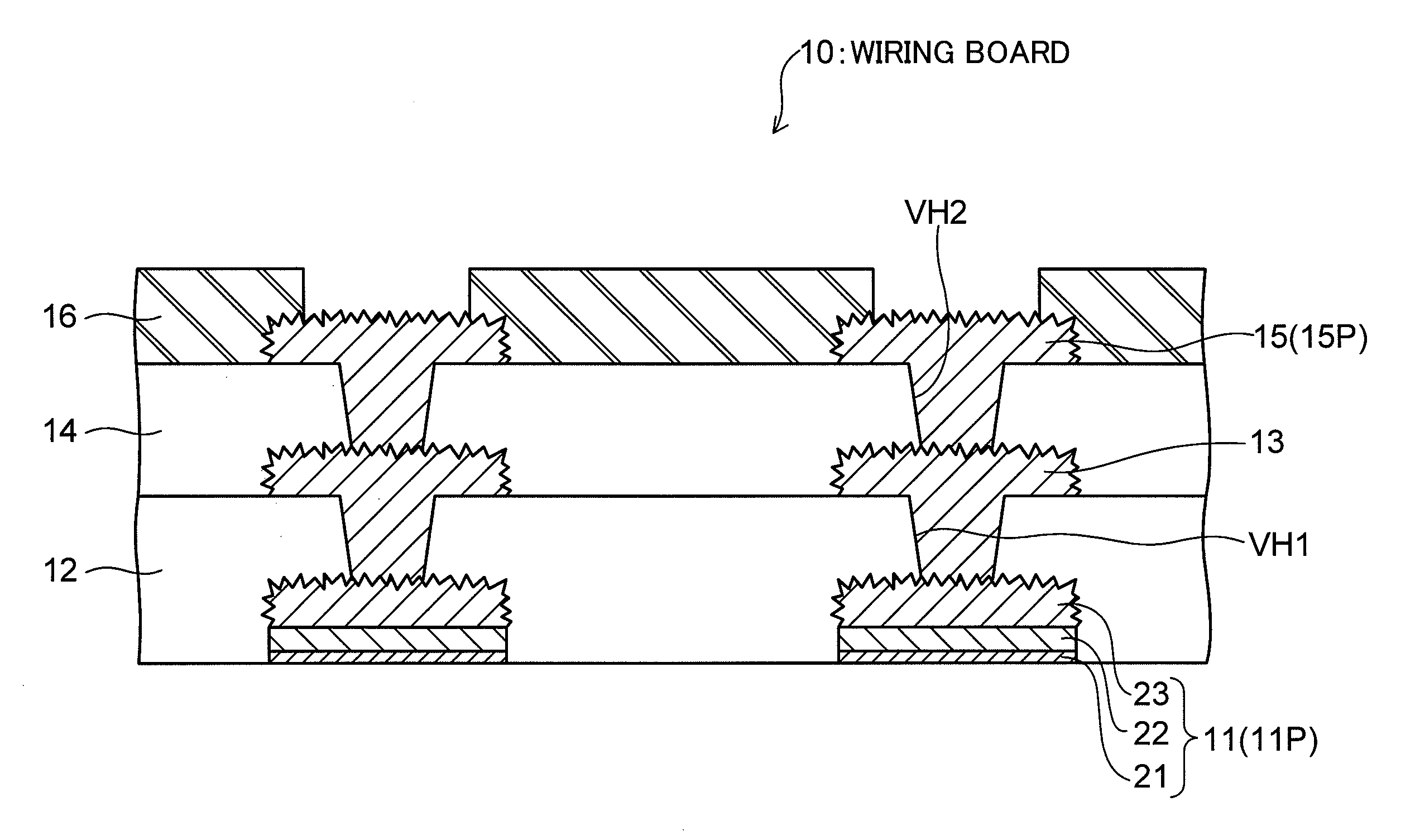

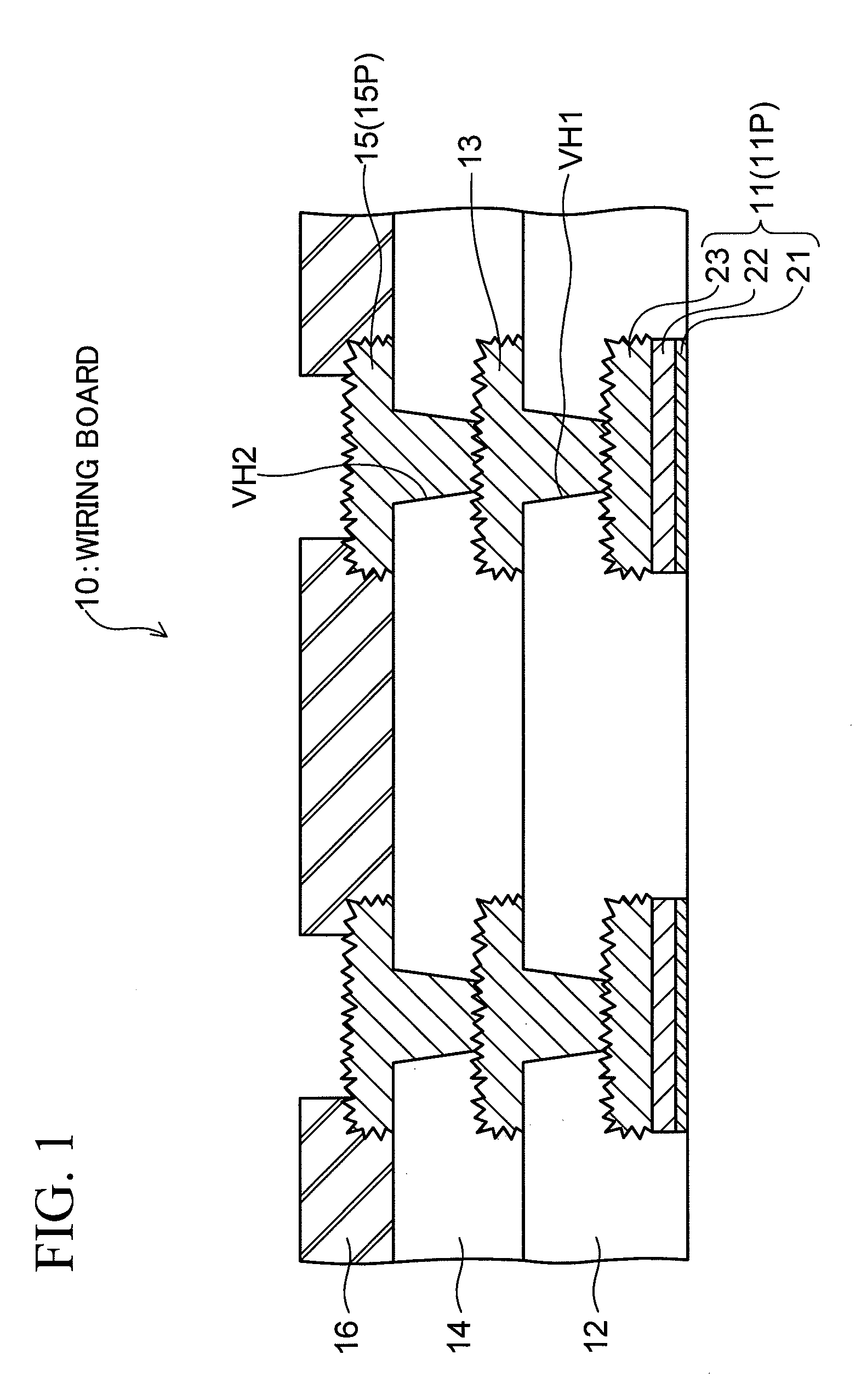

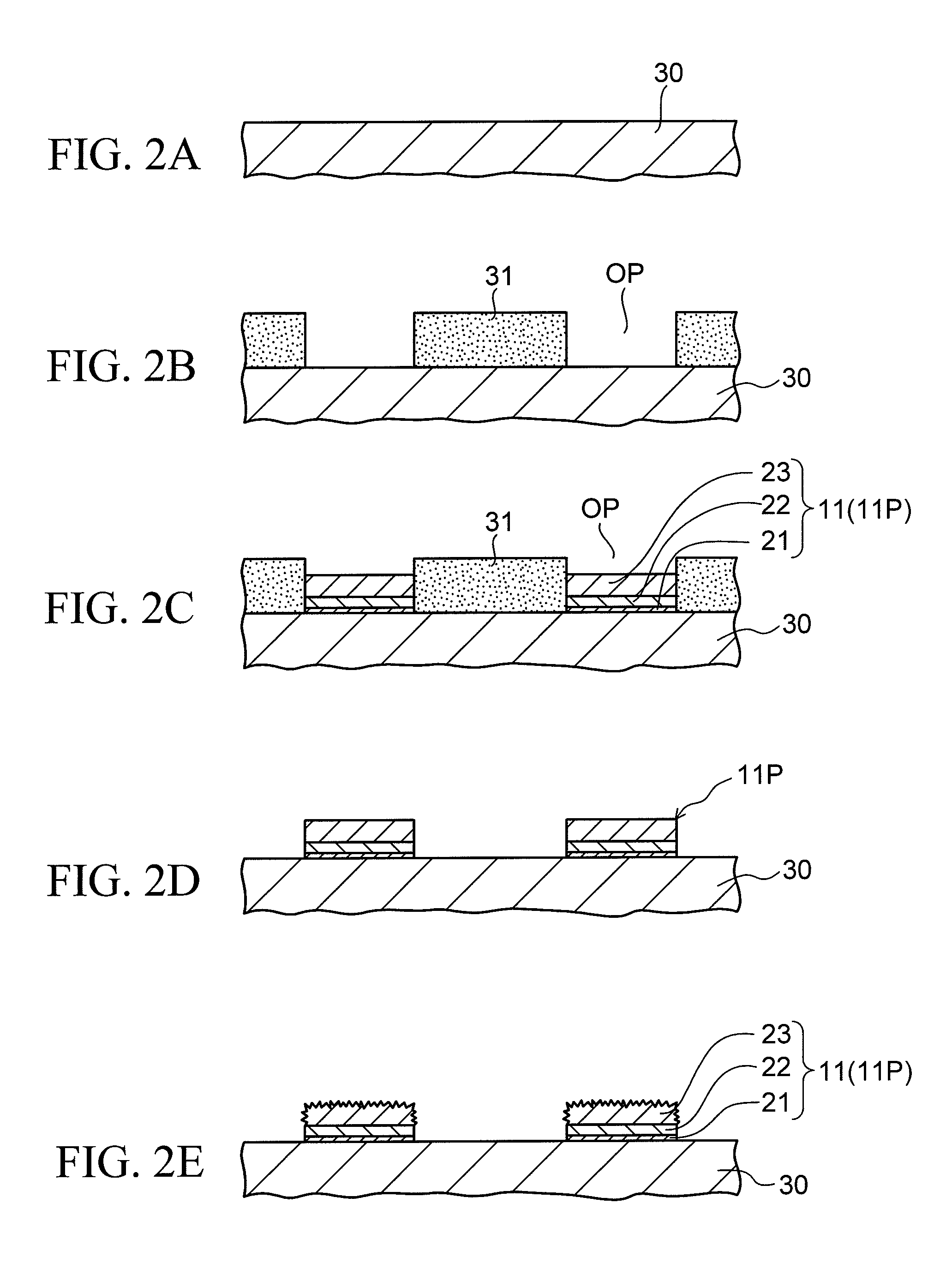

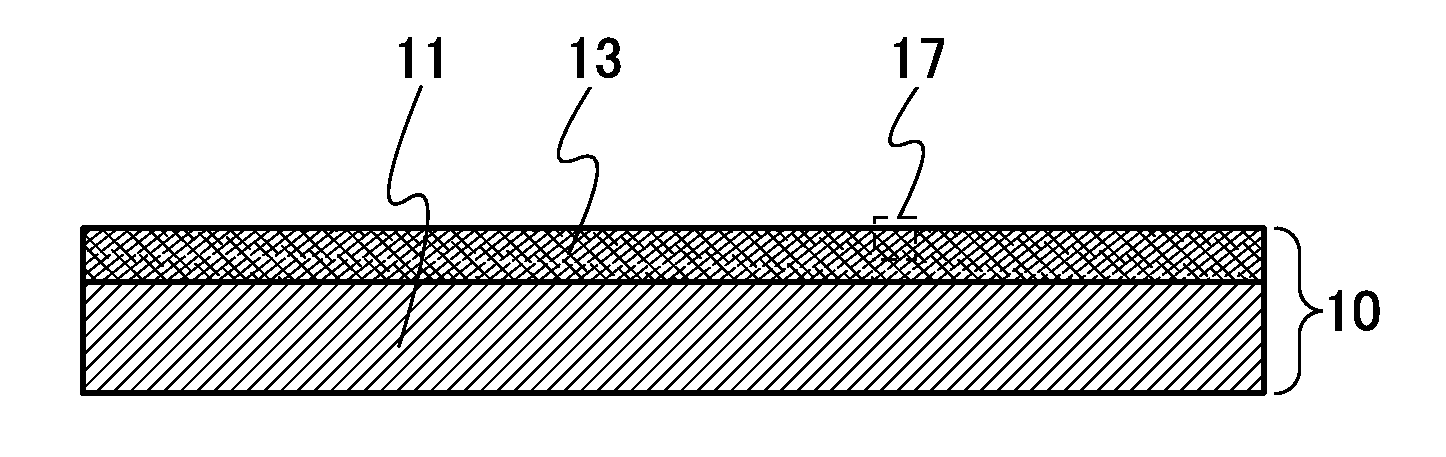

Wiring board and method of manufacturing the same

ActiveUS20100065322A1Improve tensile strengthDecreasingSemiconductor/solid-state device detailsSolid-state devicesMetalMaterials science

A wiring board includes a pad exposed from an opening portion of an outermost insulating layer. The pad includes: a first metal layer a surface of which is exposed from the wiring board; a second metal layer provided on the first metal layer and formed of a material effective in preventing a metal contained in a via inside the board from diffusing into the first metal layer; and a third metal layer provided between the second metal layer and the via, and formed of a material harder to be oxidized than that of the second metal layer. The thickness of the third metal layer is relatively thick, and is preferably selected to be three times or greater than a thickness of the second metal layer. A side surface of the third metal layer and a surface of the third metal layer to which the via is to be connected are roughed.

Owner:SHINKO ELECTRIC IND CO LTD

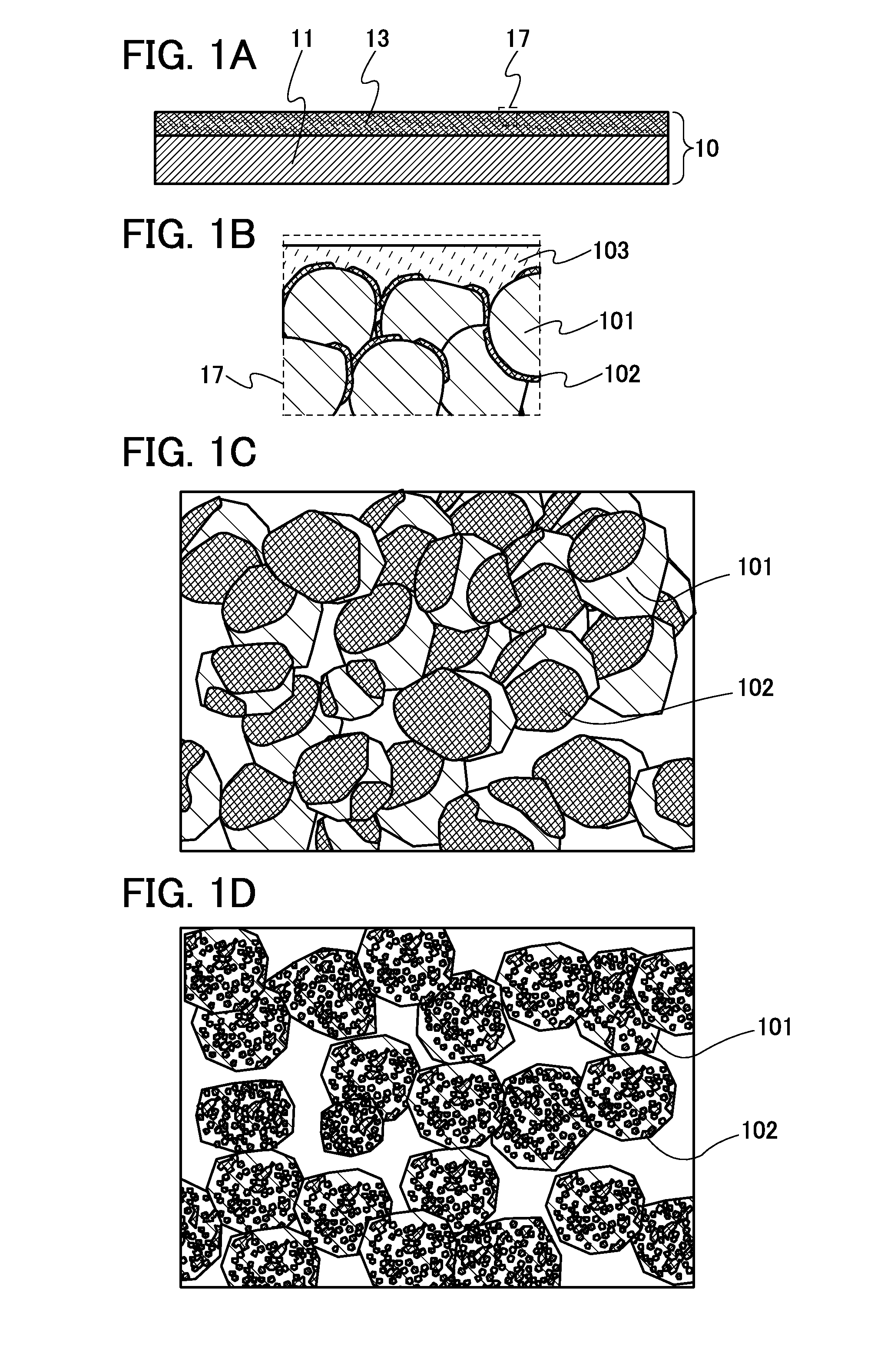

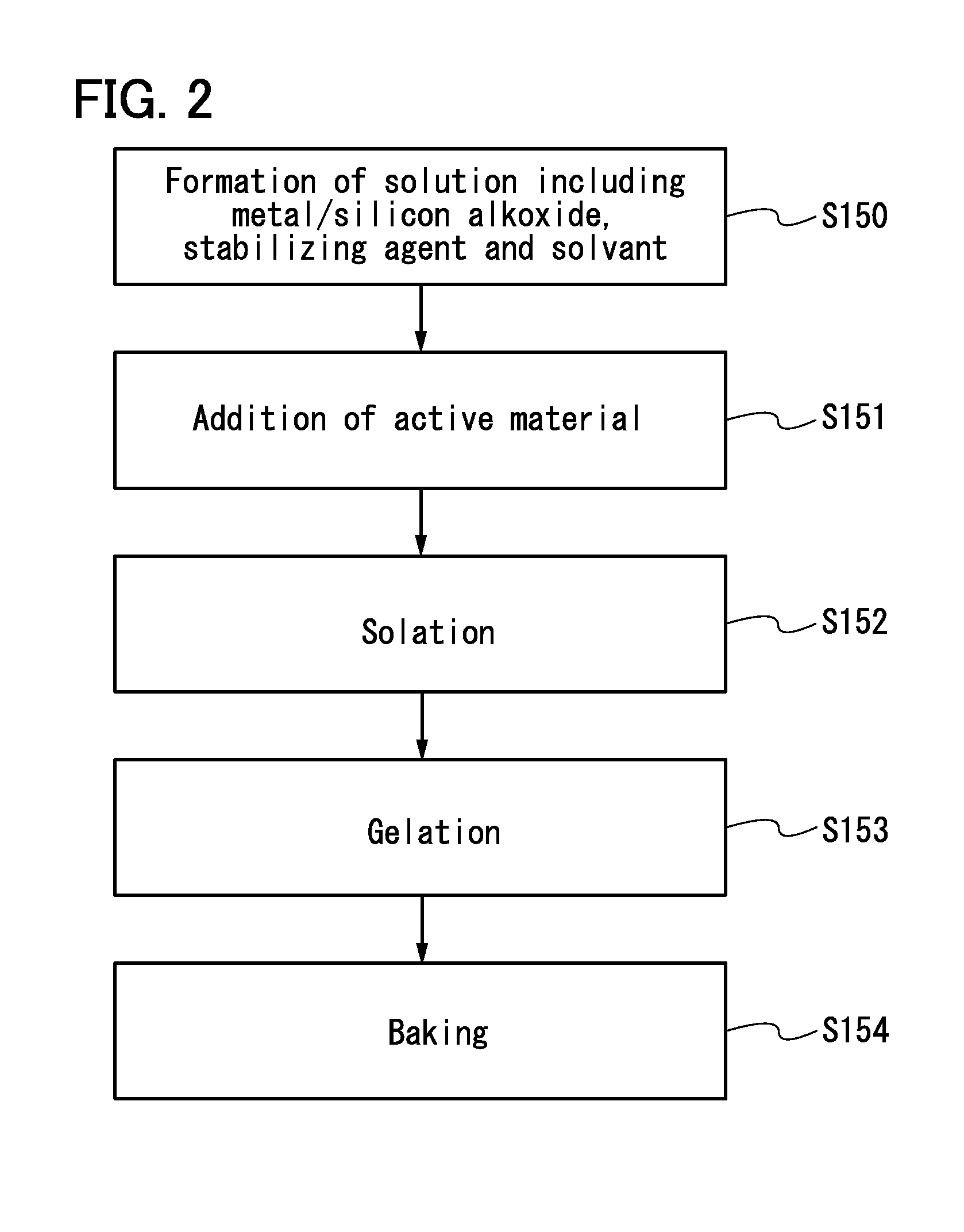

Negative electrode for power storage device and power storage device

ActiveUS20130323585A1AdhesionImprove adhesionHybrid capacitor electrolytesHybrid capacitor electrodesDecompositionLithium-ion capacitor

A decomposition reaction of an electrolyte solution and the like caused as a side reaction of charge and discharge is minimized in repeated charge and discharge of a lithium ion battery or a lithium ion capacitor, and thus the lithium ion battery or the lithium ion capacitor can have long-term cycle performance. A negative electrode for a power storage device includes a negative electrode current collector and a negative electrode active material layer which includes a plurality of particles of a negative electrode active material. Each of the particles of the negative electrode active material has an inorganic compound film containing a first inorganic compound on part of its surface. The negative electrode active material layer has a film in contact with an exposed part of the negative electrode active material and part of the inorganic compound film. The film contains an organic compound and a second inorganic compound.

Owner:SEMICON ENERGY LAB CO LTD

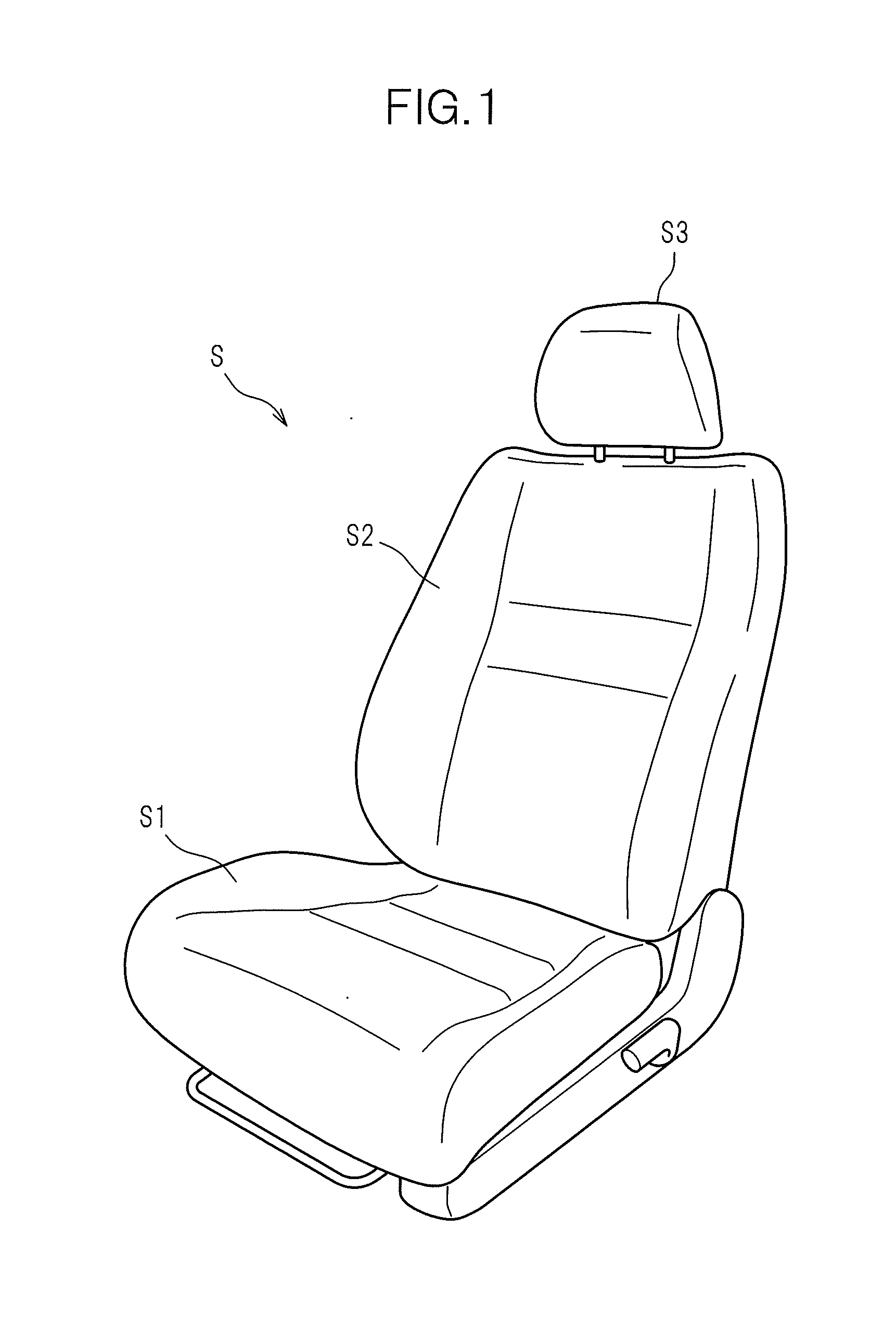

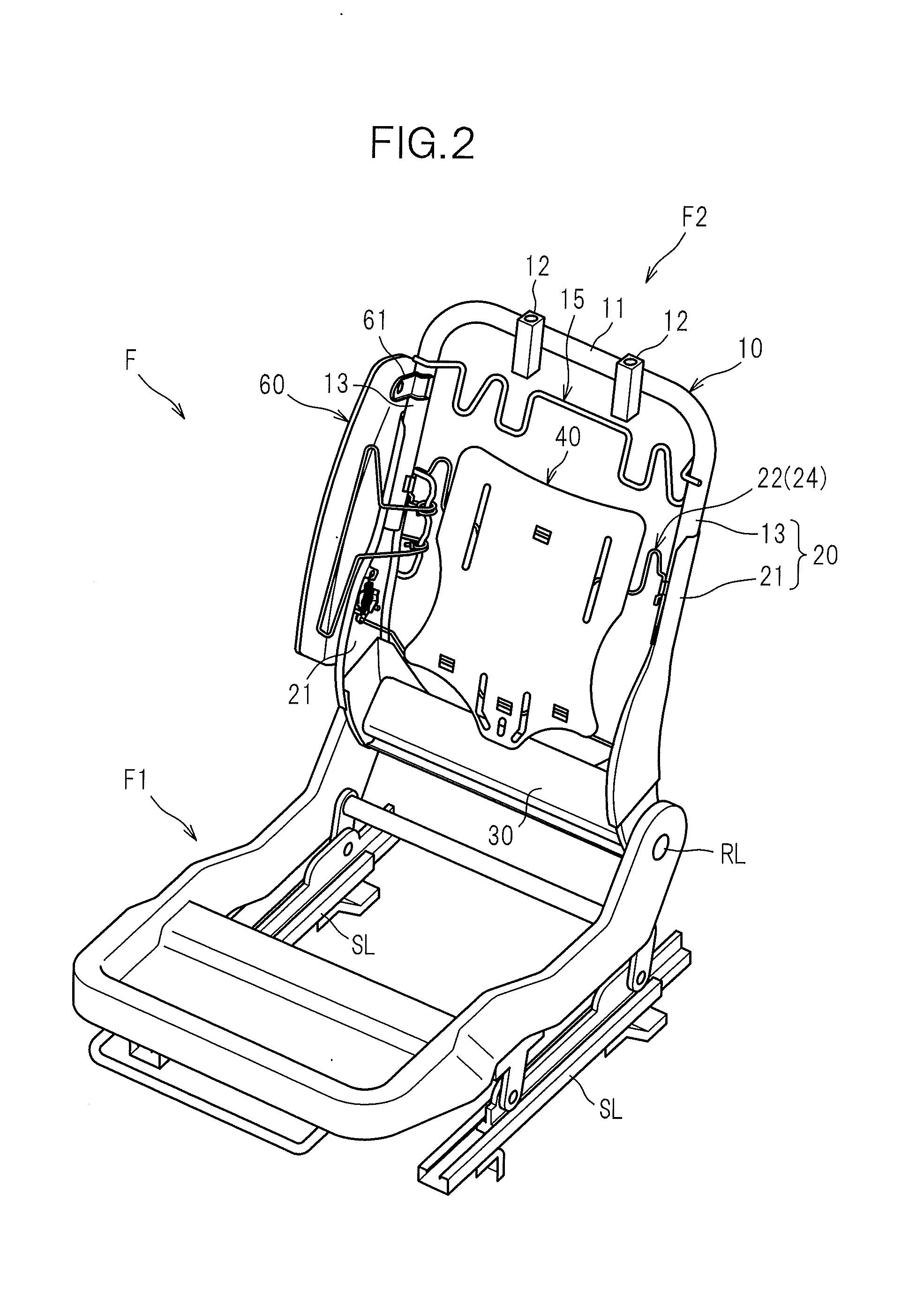

Vehicle seat

ActiveUS20130270878A1Prevent excessive deformationAdhesionBack restsPedestrian/occupant safety arrangementEngineeringRear-end collision

A seat back pad 70 has a groove 73 for tucking a skin material therein, formed at borders between a central portion 71 and side portions 72. A hole (slot hole 74) is formed in a bottom of the groove 73 along the groove 73. A tuck-in wire 76 for tucking the skin material in includes a plurality of tuck-in portions 76A provided along the groove 73, and a connecting portion (detour portion 76B) detouring around the hole and connecting the tuck-in portions 76A. With this configuration, when an upper body of an occupant P subsides into a seat back S2 in a rear-end collision of a vehicle, the central portion 71, defined by the groove 73 as a border, is easily and sufficiently moved rearward relative to the left and right side portions 72. Furthermore, the tuck-in wire 76 is not exposed through the hole, and thus adhesion between the seat back pad 70 and the tuck-in wire 76 can be improved.

Owner:TS TECH CO LTD

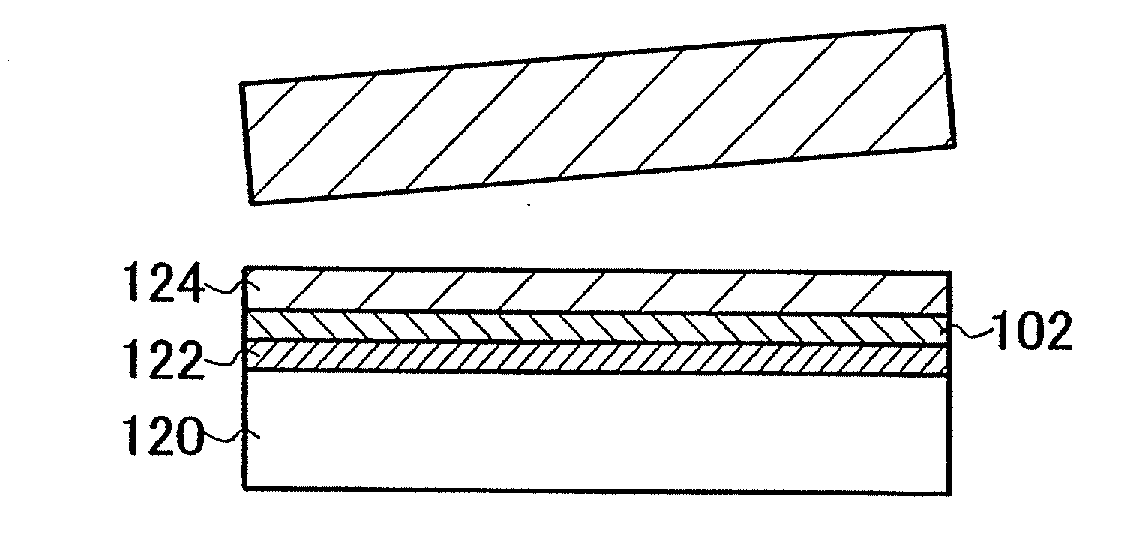

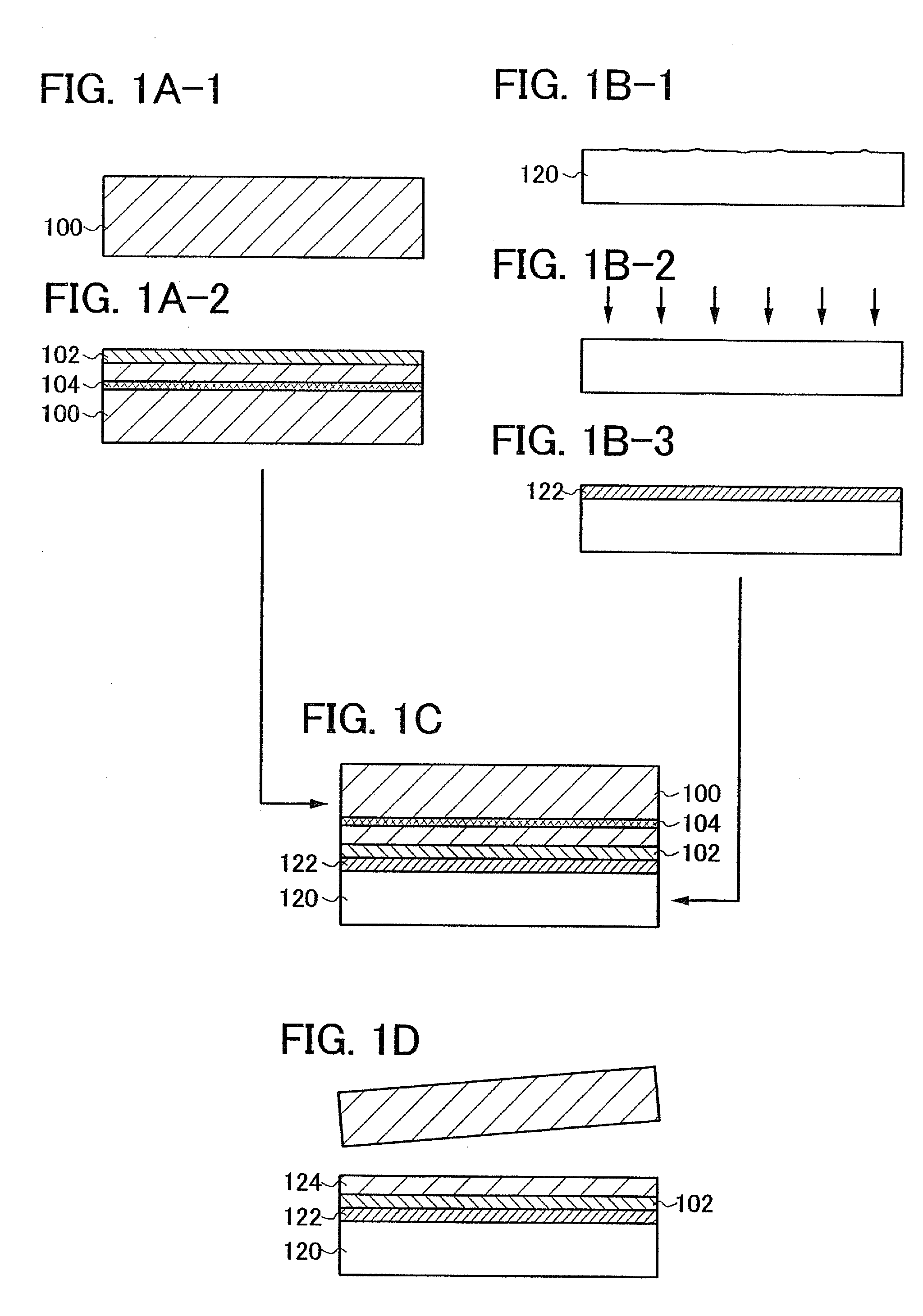

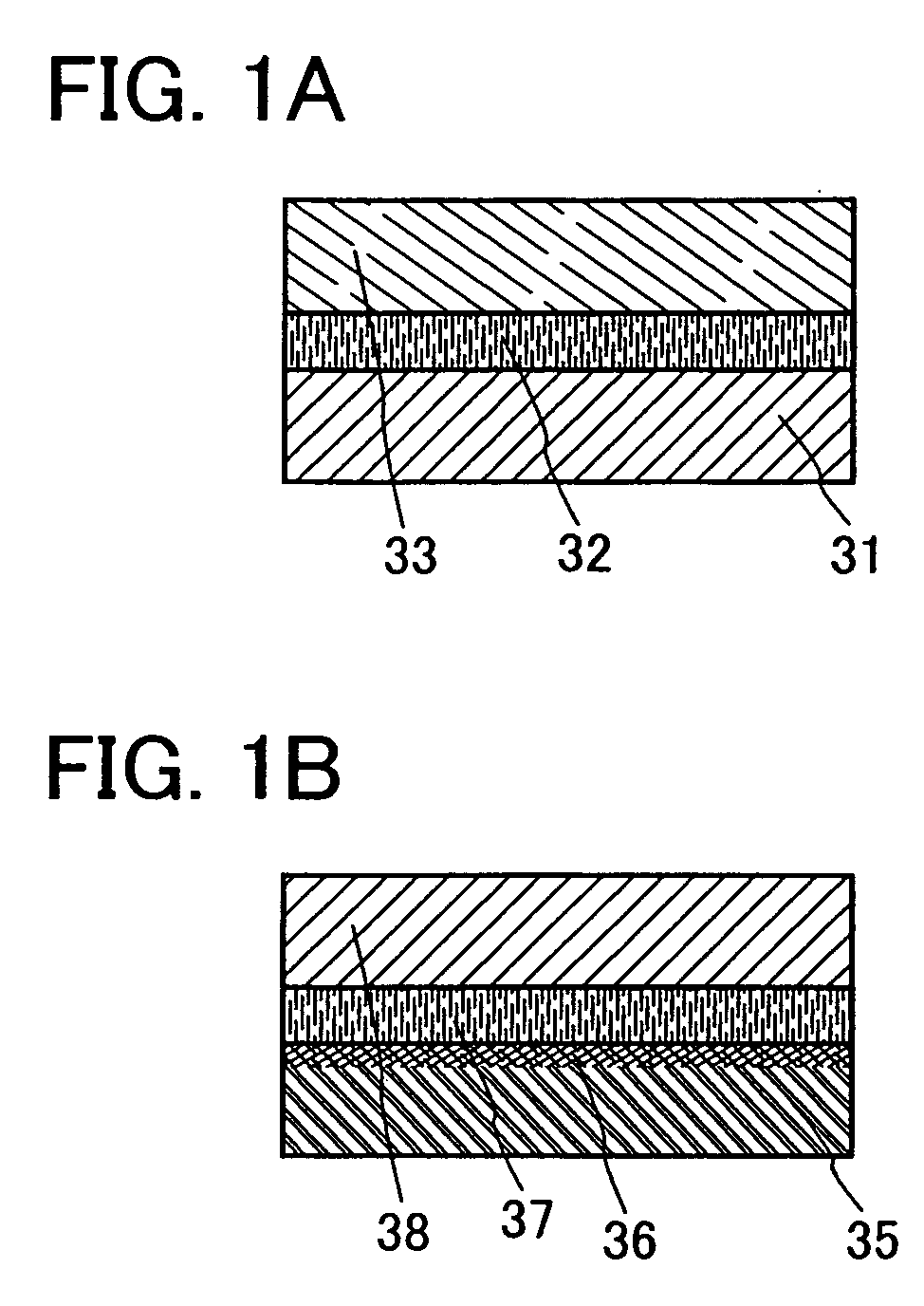

Method for manufacturing soi substrate

InactiveUS20090170287A1AdhesionReduce occurrence of defectSemiconductor/solid-state device manufacturingIonPlasma treatment

A single crystal semiconductor substrate and a base substrate are prepared; a first insulating film is formed over the single crystal semiconductor substrate; a separation layer is formed by introducing ions at a predetermined depth through a surface of the single crystal semiconductor substrate; plasma treatment is performed on the base substrate so as to planarize a surface of the base substrate; a second insulating film is formed over the planarized base substrate; a surface of the first insulating film is bonded to a surface of the second insulating film by making the surface of the single crystal semiconductor substrate and the surface of the base substrate face each other; and a single crystal semiconductor film is provided over the base substrate with the second insulating film and the first insulating film interposed therebetween by performing separation at the separation layer.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor element, method of manufacturing semiconductor element, multi-layer printed circuit board, and method of manufacturing multi-layer printed circuit board

InactiveUS20080151522A1Improve connection characteristicsAvoid residuePrinted electric component incorporationSemiconductor/solid-state device detailsInter layerEngineering

An intermediate layer 38 is provided on a die pad 22 of an IC chip 20 and integrated into a multilayer printed circuit board 10. Due to this, it is possible to electrically connect the IC chip 20 to the multilayer printed circuit board 10 without using lead members and a sealing resin. Also, by providing the intermediate layer 38 made of copper on an aluminum pad 24, it is possible to prevent a resin residue on the pad 24 and to improve connection characteristics between the die pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

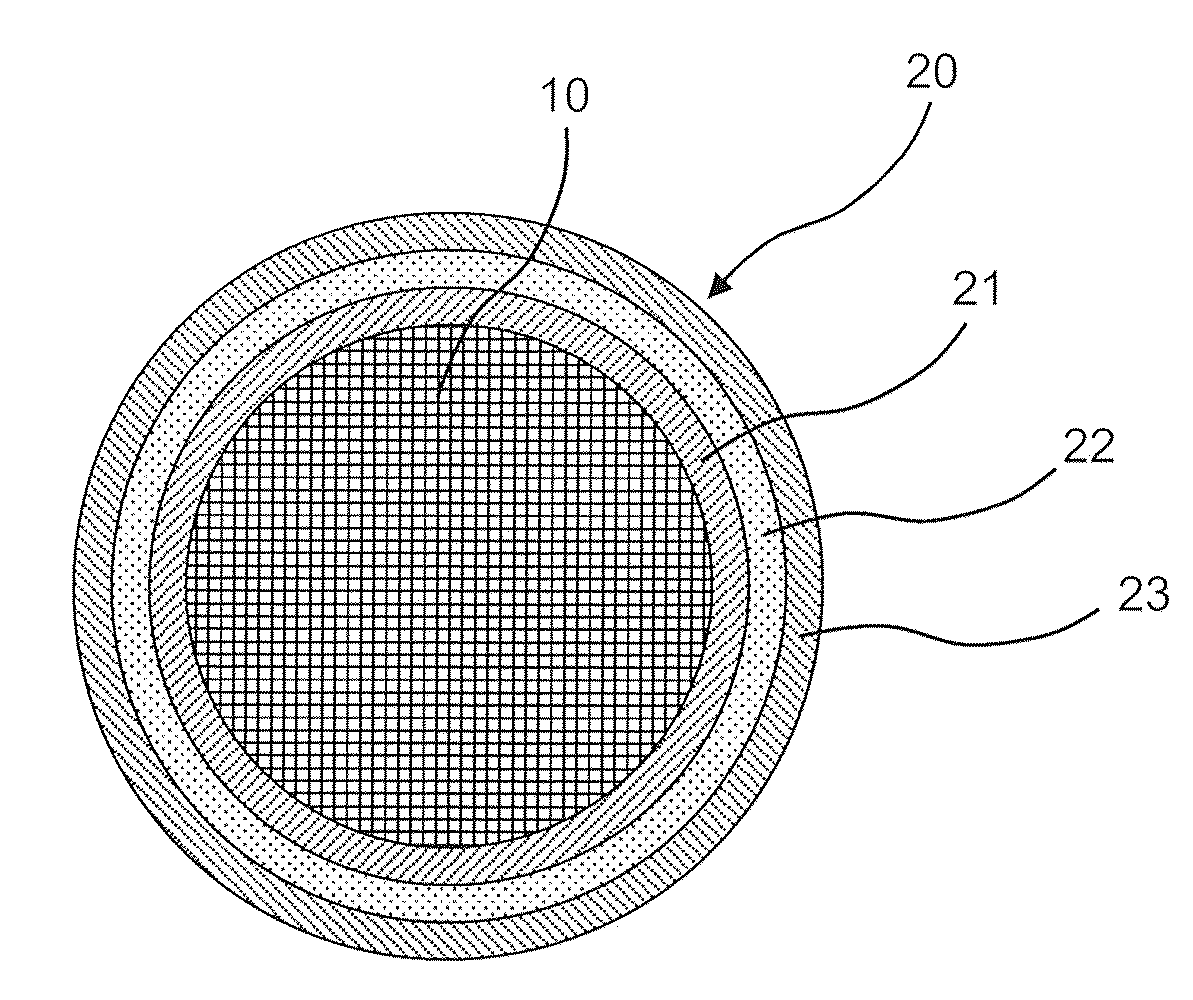

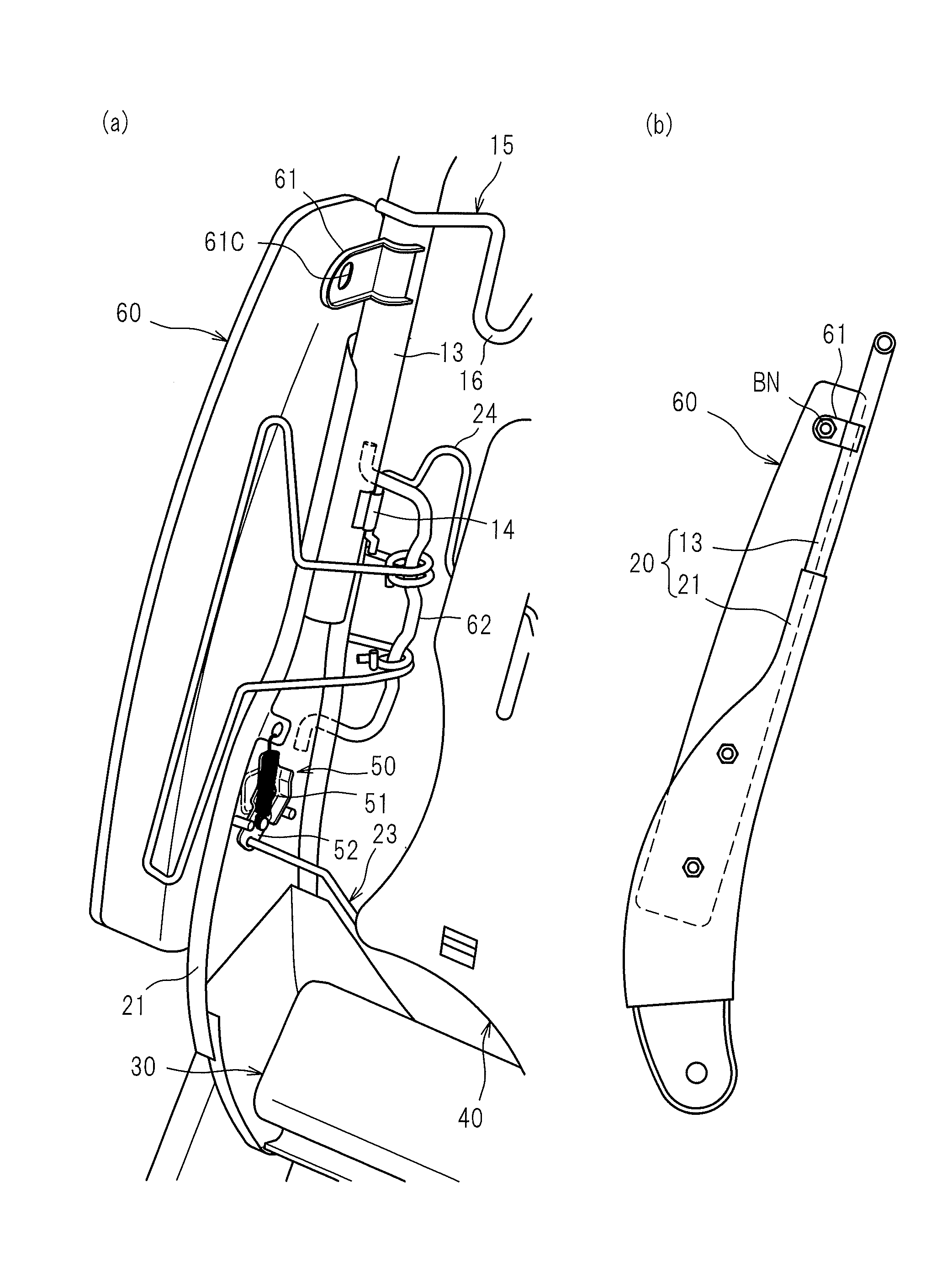

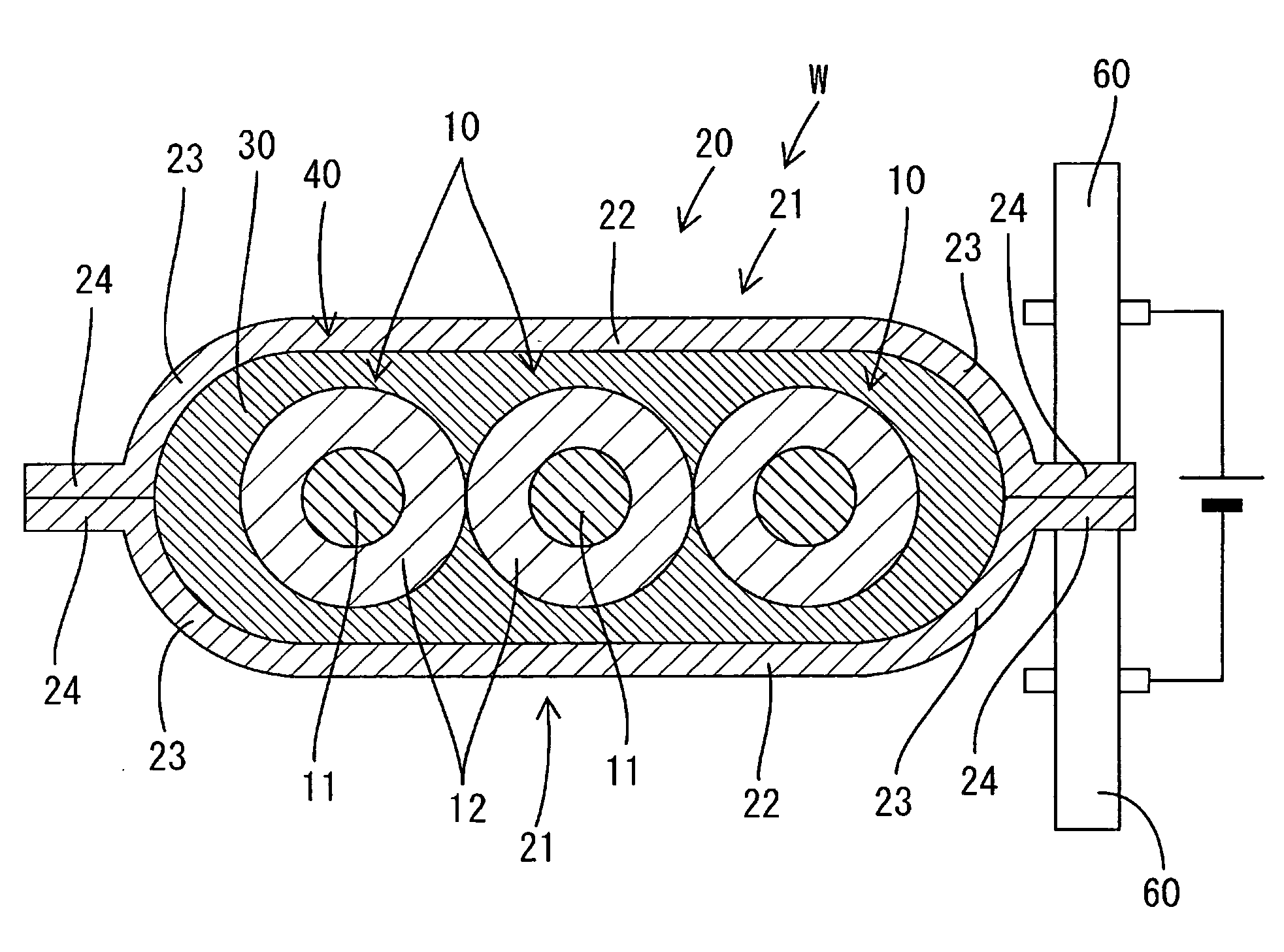

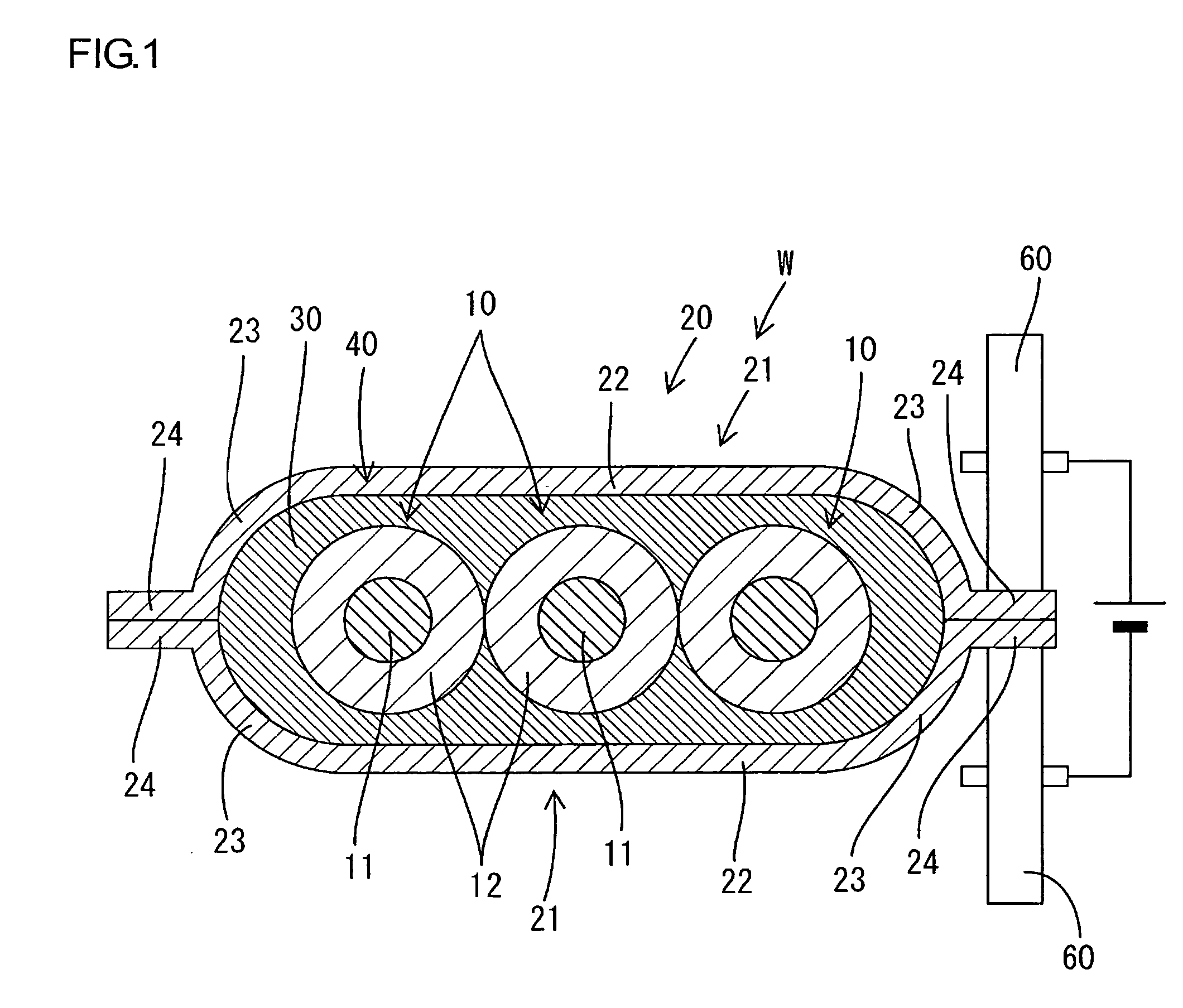

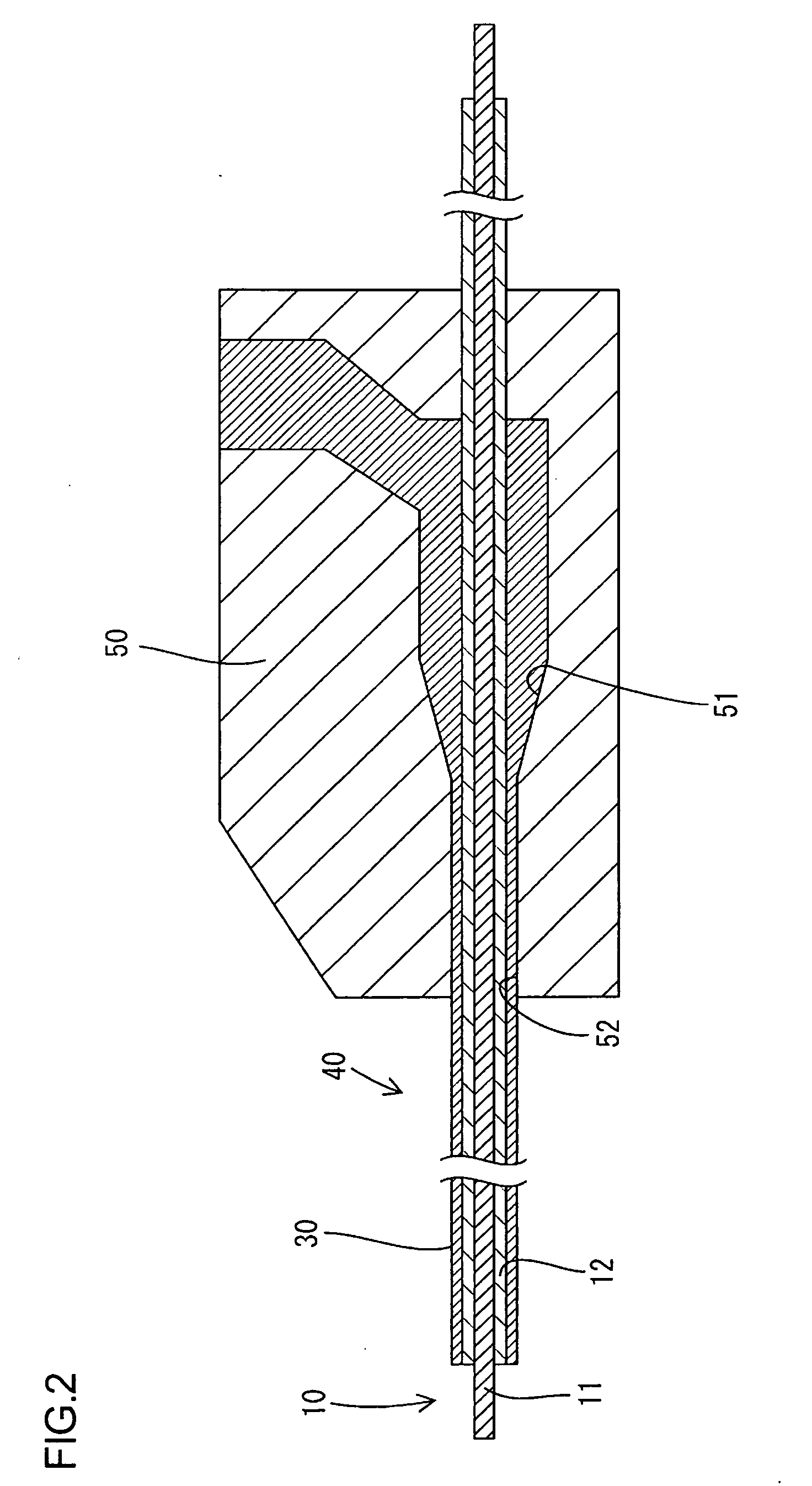

Shield conductor and shield conductor manufacturing method

InactiveUS20100051314A1Simplifying outer circumferential shapeAdhesionLaminationPower cables with screens/conductive layersElectrical conductorEngineering

A shield conductor W comprises: a plurality of wires 10, a heat transfer member 30 made of synthetic resin and formed so as to tightly attach to the outer circumference of the wires and moreover collectively enwrap the wires 10, and a metal pipe 20 assembled in a manner so as to tightly attach to the outer circumference of the heat transfer member 30. The heat generated in the wires 10 is transmitted from the outer circumference of the insulating coating 12 to the heat transfer member 30, then transmitted within the heat transfer member 30, and then transmitted from the outer circumferential surface of the heat transfer member 30 to the inner circumference of the pipe 20, and is finally released to the air from the outer circumference of the pipe 20.

Owner:AUTONETWORKS TECH LTD +2

Electrodes with improved adhesion between activator and collector and methods of making the same

InactiveUS6228533B1AdhesionCapacity of discharge is not deterioratedElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesAcrylic polymerMaterials science

The present invention relates to electrodes consisting of an electrode activator and a metallic collector whose adhesion between the activator and the collector is improved. The electrode activator's binder is made of a fluoroplastic grafted with at least one acrylic polymer.

Owner:ELF ATOCHEM SA

Electrochemical device

InactiveUS20050068603A1Improve adhesionConvenient coatingElectrical apparatusElectroluminescent light sourcesFistElectricity

An electrochromic device is provided comprising: at least one electrochromic element comprising (i) at least one material that is electrically conducting in at least one oxidation state and (ii) at least one electrochromic material, wherein said materials (i) and (ii) can be the same or different; at least one layer of a solidified electrolyte which is in direct electrical contact with said electrochromic element; and at least two electrodes comprising PEDOT-PSS, arranged side by side in a common plane and adapted for application of a voltage therebetween, one of said electrodes being in direct electrical contact with a component selected from said electrochromic element(s) and the other electrode(s) being in direct electrical contact with a component selected from said electrolyte layer(s) and said electrochromic element(s). Furthermore an electrochemically active element is provided comprising: a first layer comprising PEDOT-PSS mixed with an adhesion promoter, and a second layer comprising PANI, the second layer being deposited on top of and in direct electrical contact with 25 the fist layer.

Owner:ACREO

Electrophoretic display

InactiveUS7233429B2AdhesionExcellent solventStatic indicating devicesElectrographic processes using photoelectrophoresisElectrophoresisSolvent

This invention relates to an electrophoretic display comprising cells of well-defined shape, size and aspect ratio which cells are filled with charged pigment particles dispersed in a solvent, and novel processes for its manufacture.

Owner:E INK CALIFORNIA

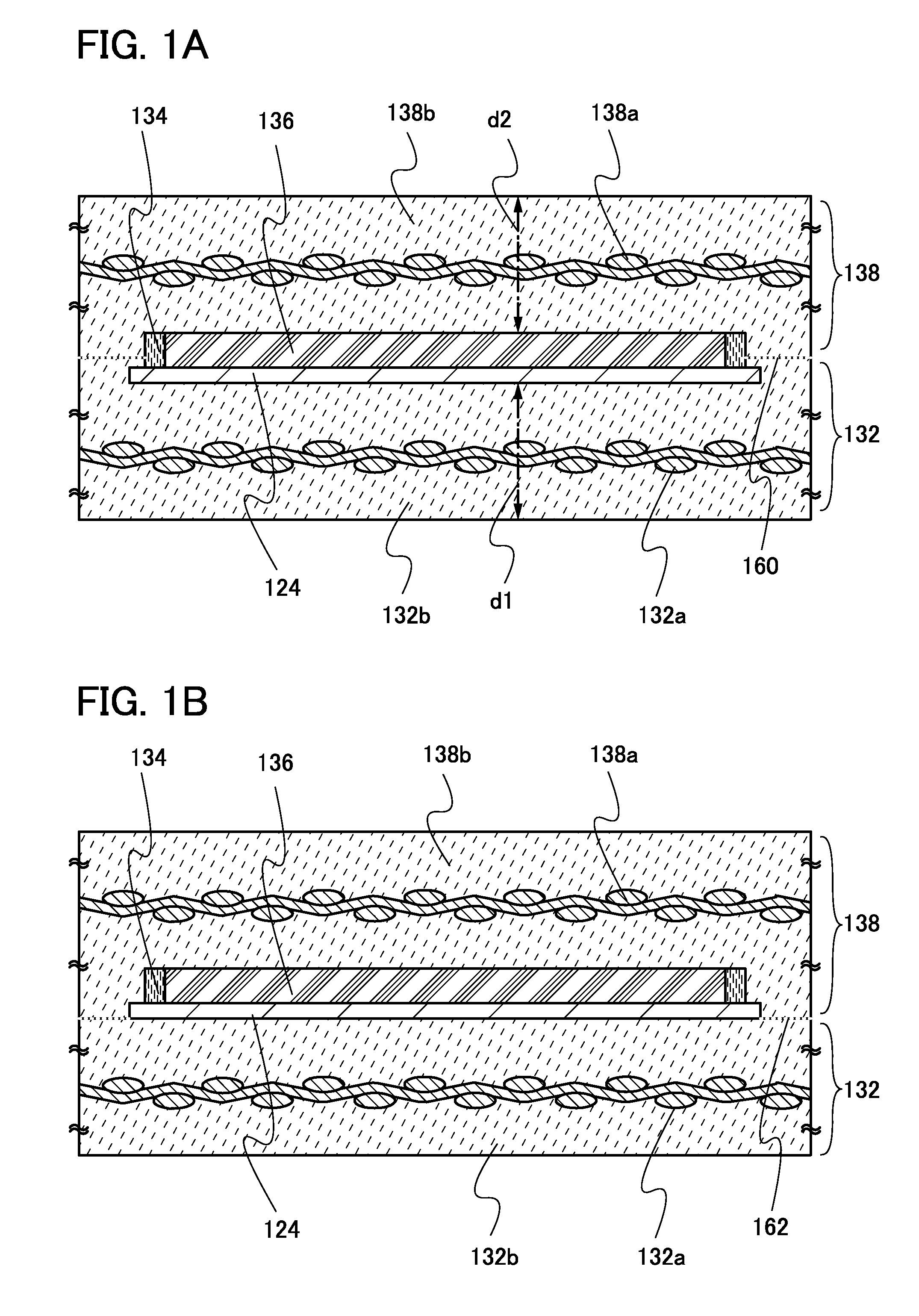

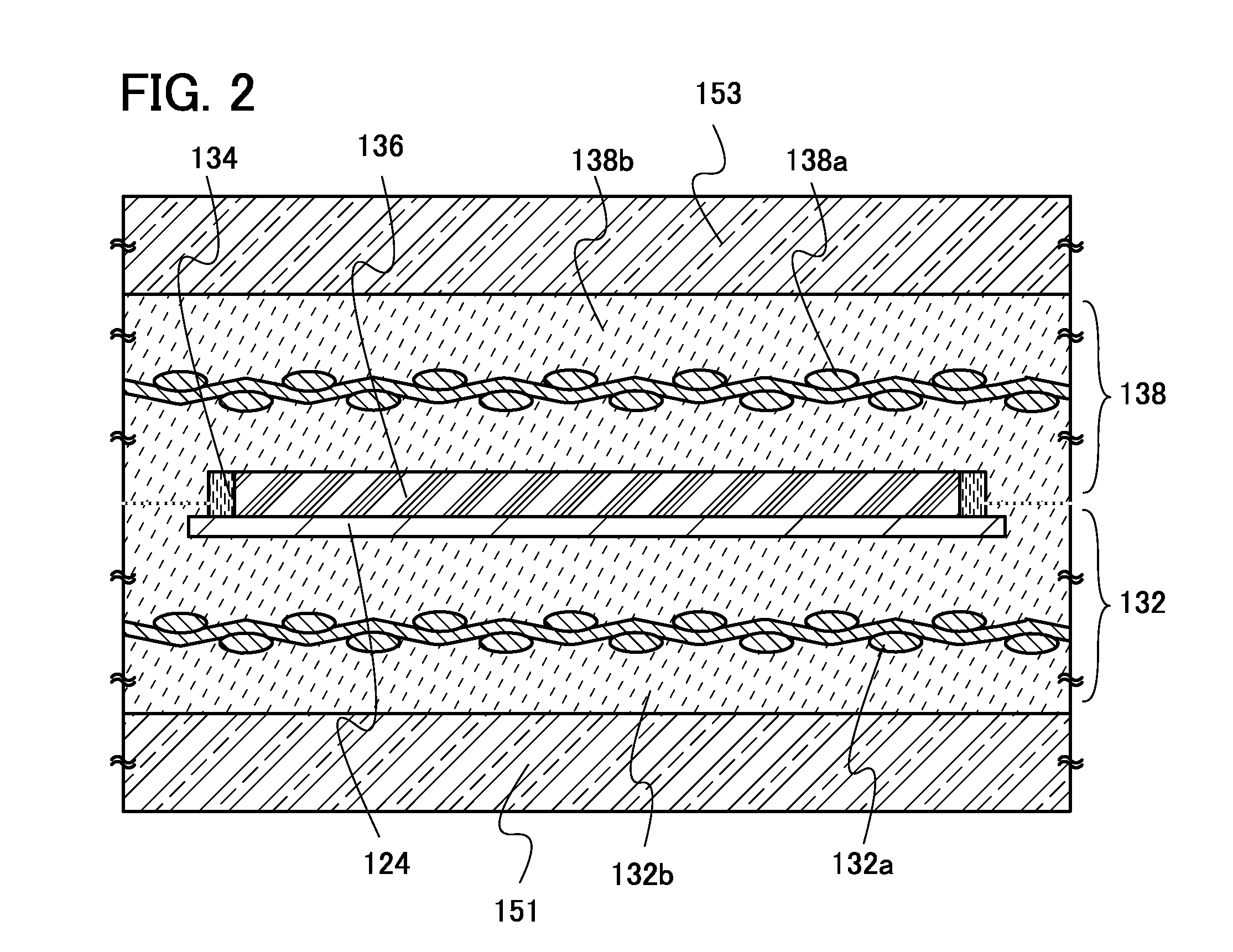

Liquid crystal display device and method for manufacturing the same

InactiveUS20100007829A1Reduce image qualityReduce harmNon-linear opticsLiquid-crystal displayEngineering

A flexible and highly reliable liquid crystal display device which is not easily damaged even if subjected to external pressure is provided. A method for manufacturing, with high yield, a flexible and highly reliable liquid crystal display device which is not easily damaged even if subjected to external pressure is also provided. A liquid crystal display device including a first structure body including a first fibrous body and a first organic resin, a second structure body including a second fibrous body and a second organic resin, a liquid crystal interposed between the first and second structure bodies, and a seal member for fixing the first and second structure bodies and for enclosing the liquid crystal. The first and second fibrous bodies are impregnated with the first and second organic resins, respectively, and the first structure body and the second structure body are in contact with each other.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and manufacturing method thereof

InactiveUS20070105285A1Improve adhesionExcellent stateNanoinformaticsSolid-state devicesIndiumOrganic compound

To provide a semiconductor device which is higher functional and reliable and a technique capable of manufacturing the semiconductor device with a high yield at low cost without complexing the apparatus or process. At least one of a first conductive layer and a second conductive layer is formed containing one kind or plural kinds of indium, tin, lead, bismuth, calcium, manganese, or zinc; or oxidation treatment is performed at least one of interfaces between an organic compound layer and the first conductive layer and between the organic compound layer and the second conductive layer. The first conductive layer, the organic compound layer, and the second conductive layer which are formed over a first substrate with a peeling layer interposed therebetween can be peeled from the first substrate with the peeling layer, and transposed to a second substrate.

Owner:SEMICON ENERGY LAB CO LTD

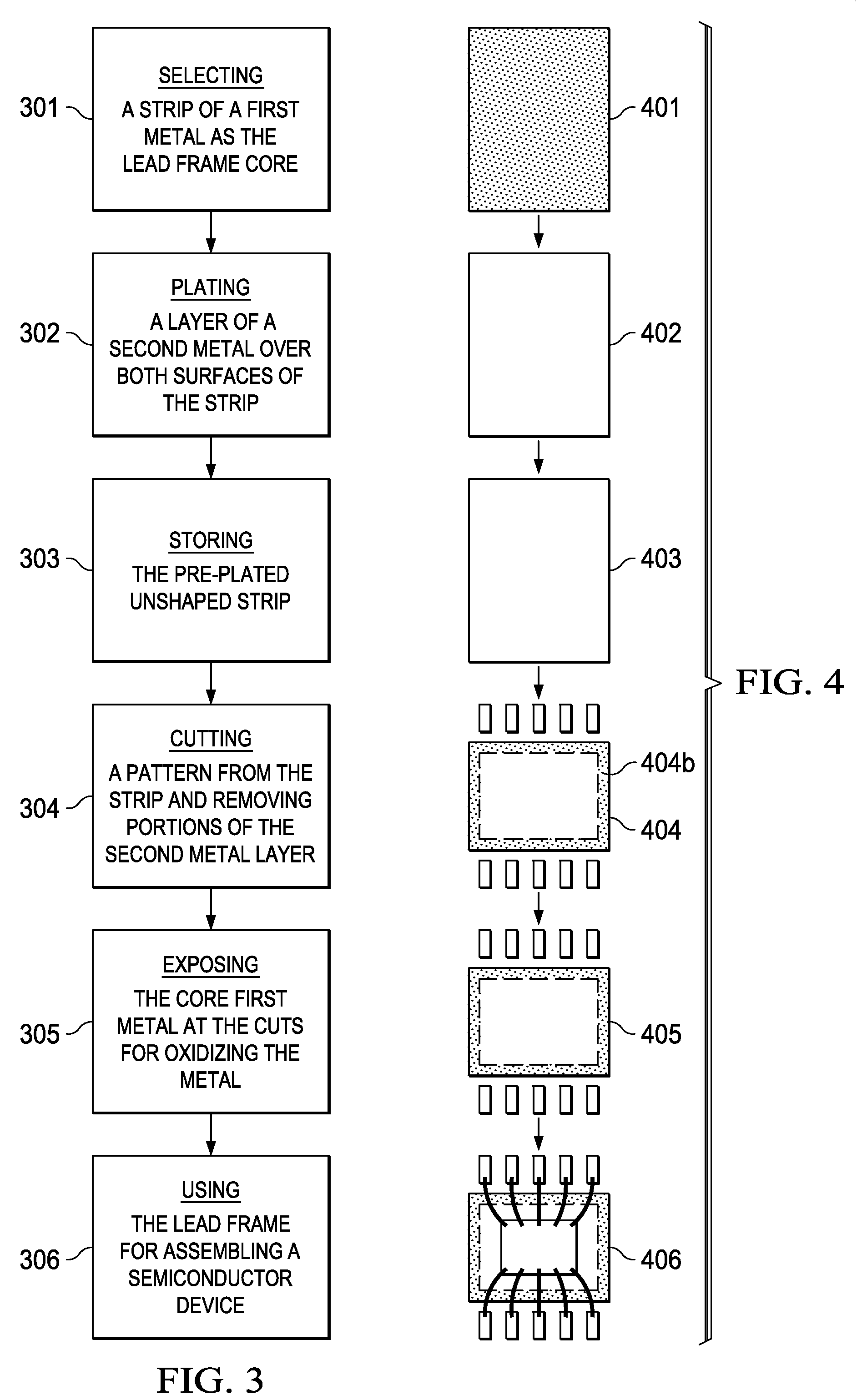

Method for Semiconductor Leadframes in Low Volume and Rapid Turnaround

ActiveUS20100295161A1Simple designImprove functionalitySemiconductor/solid-state device detailsSolid-state devicesNumerical controlLaser cutting

A method for fabricating a leadframe for a QFN / SON semiconductor device by selecting (301) a strip of a first metal as the leadframe core, then plating (302) a layer of a second metal over both surfaces of the strip, then cutting (304) a pattern from the pre-plated strip and further removing (304) portions of the second metal layer over a surface to expose the underlying core first metal. The exposed core first metal oxidized (305) before using (306) the leadframe for assembling the semiconductor device. The steps of cutting and removing are performed programmable machining techniques such as computer numerical controlled tools (CNC), electrical discharge machining (EDM), laser cutting, and water jet cutting.

Owner:TEXAS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com