Patents

Literature

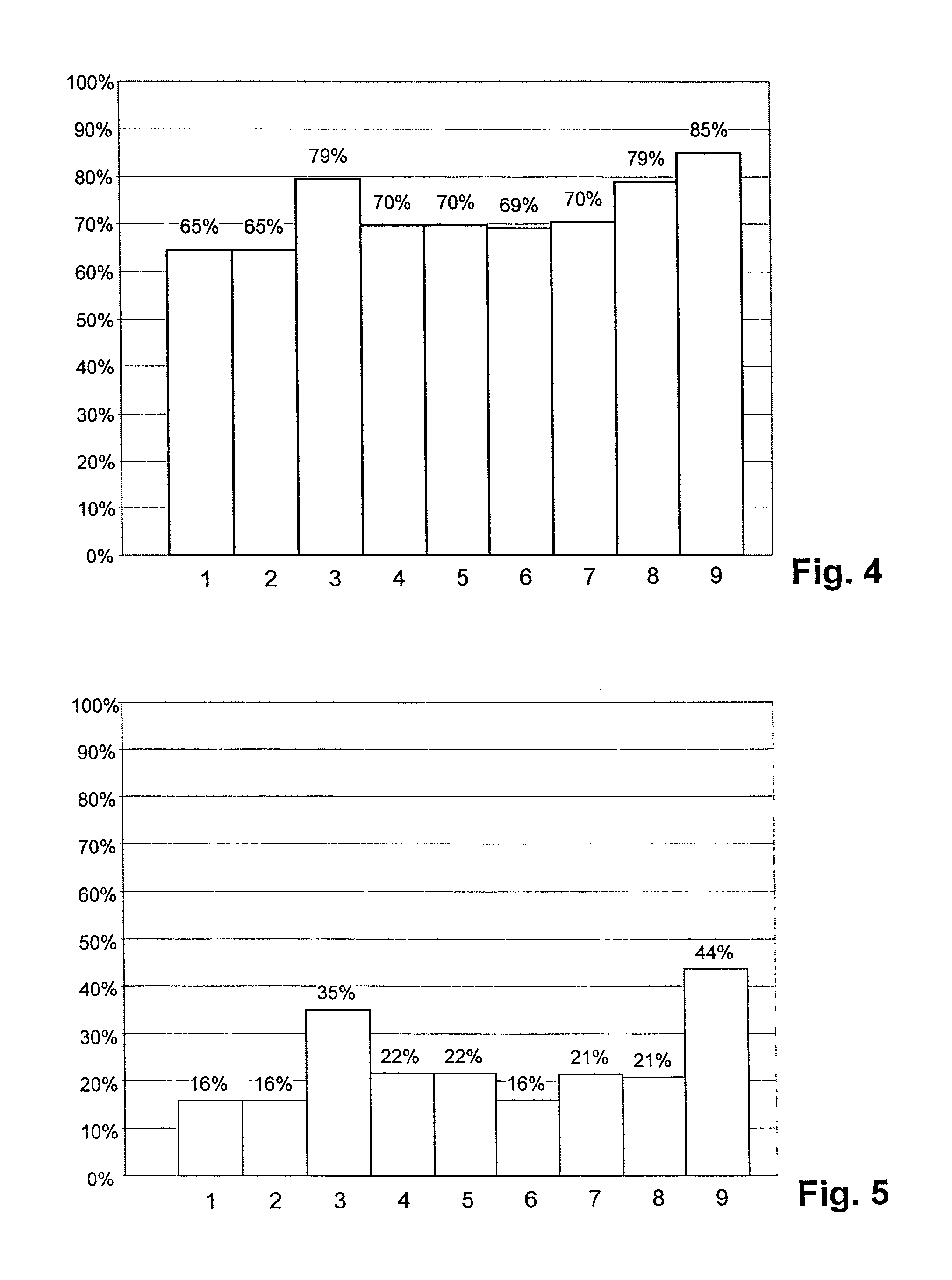

331results about How to "Excellent state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

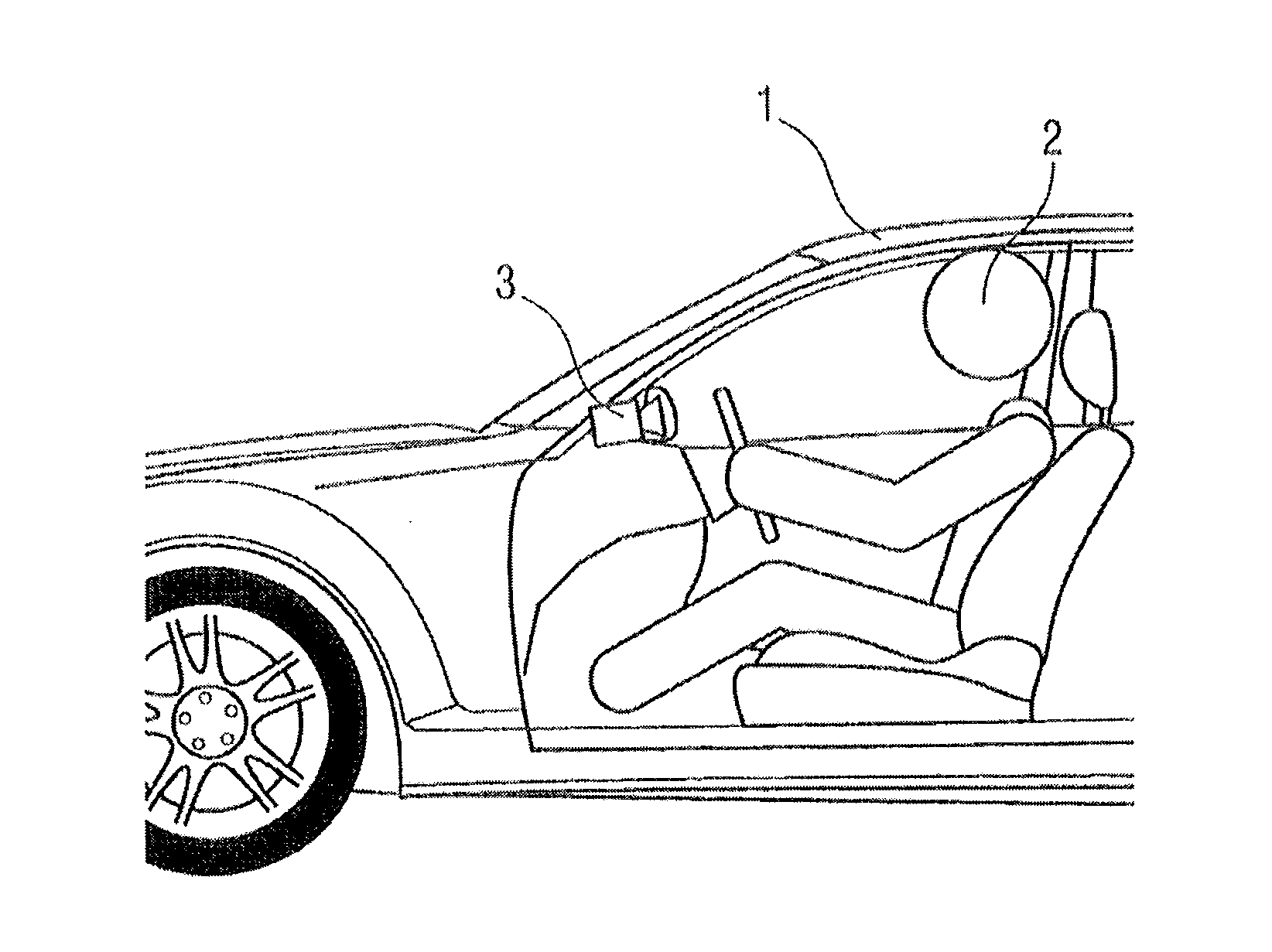

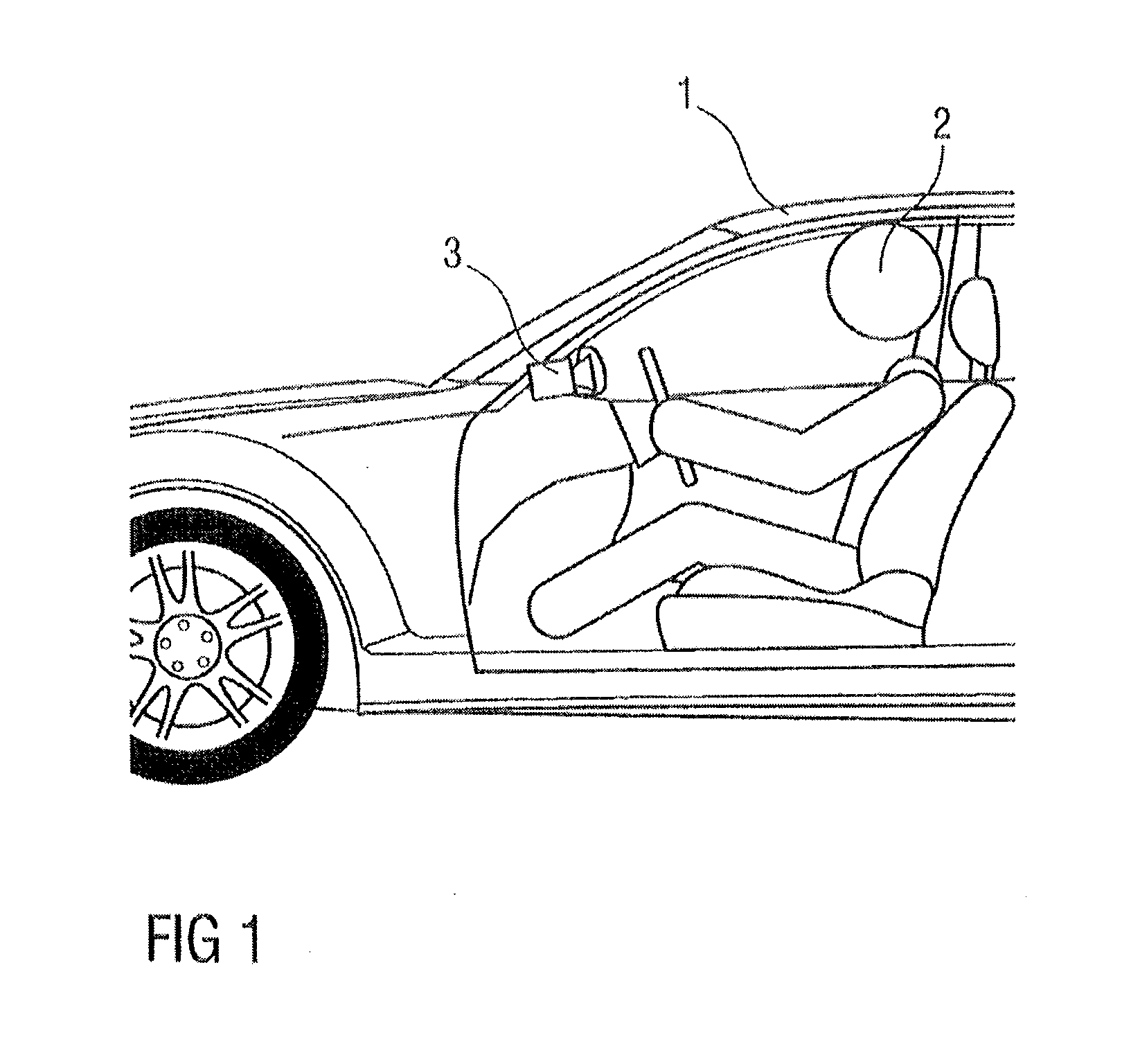

Method and Device for Monitoring at least one Vehicle Occupant, and Method for Operating at least one Assistance Device

ActiveUS20140104405A1Fast and adequate medical helpDeterioration can be determinedCharacter and pattern recognitionColor television detailsImaging processingImaging analysis

A method and device for monitoring at least one vehicle passenger in a vehicle involves capturing images of the vehicle passenger using an image capturing unit and analyzing the captured images using an image processing unit. At least one vital sign of the vehicle passenger is determined by the image analysis of the captured images, which can be used to operate at least one assistance device of a vehicle.

Owner:DAIMLER AG

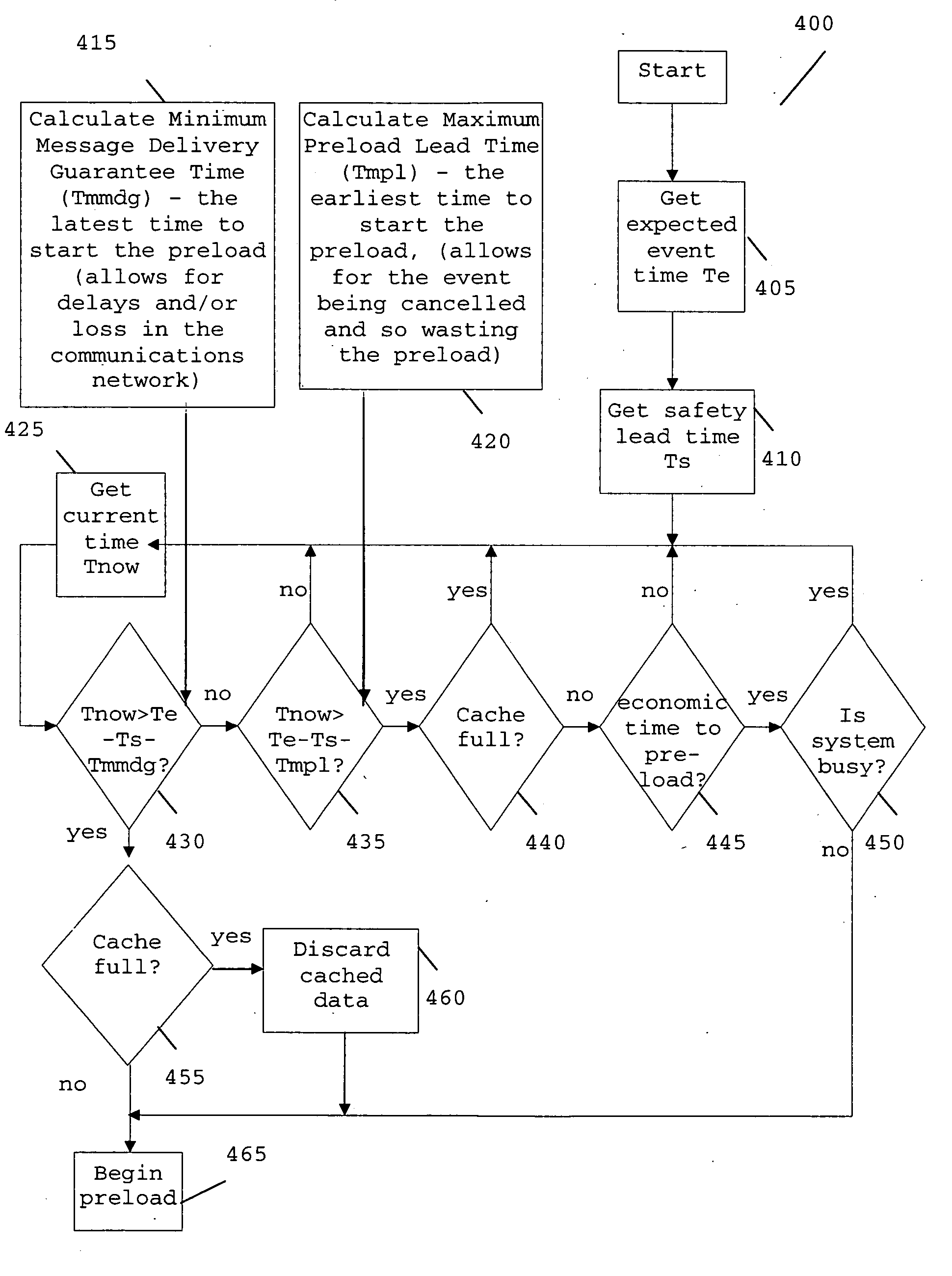

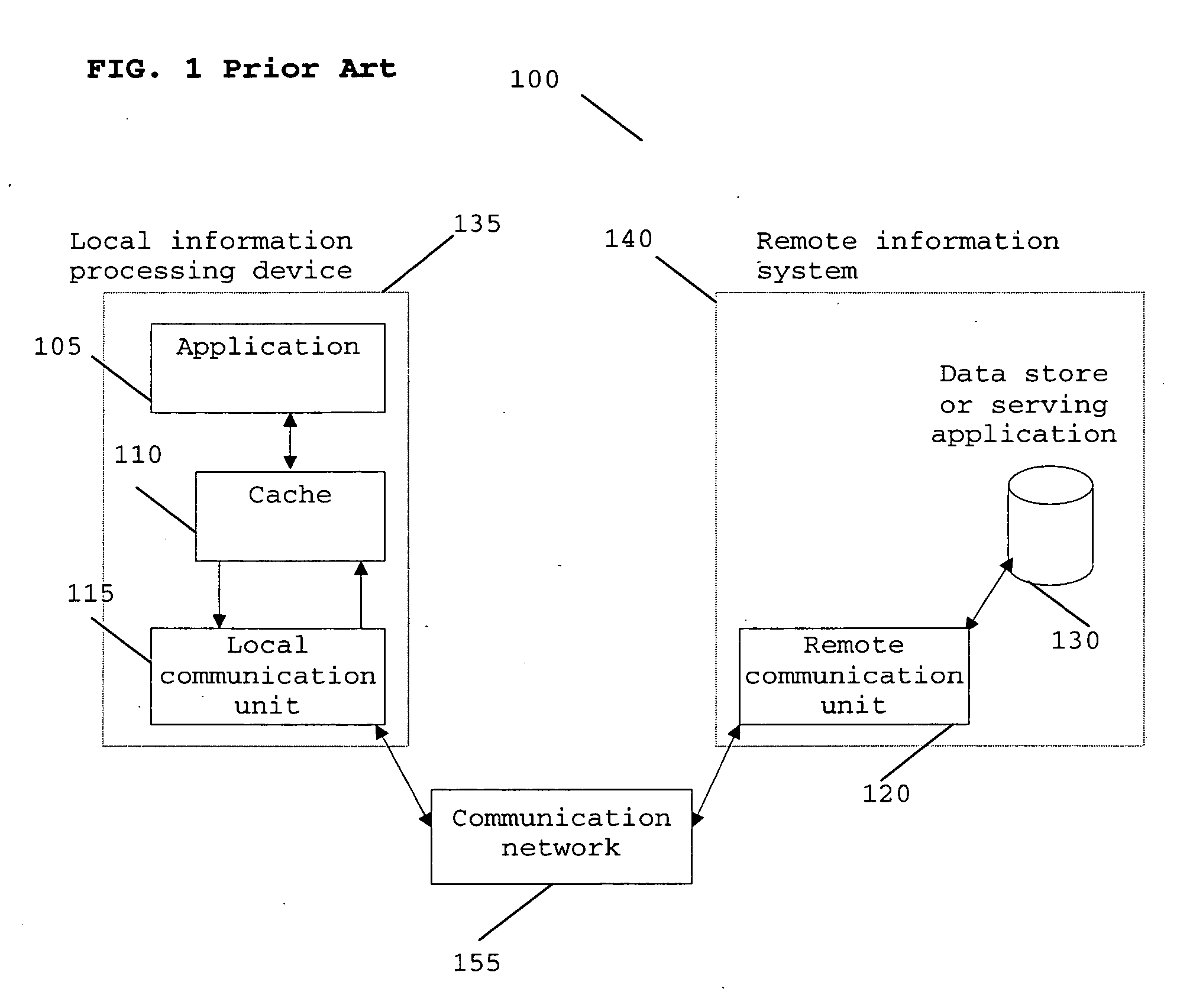

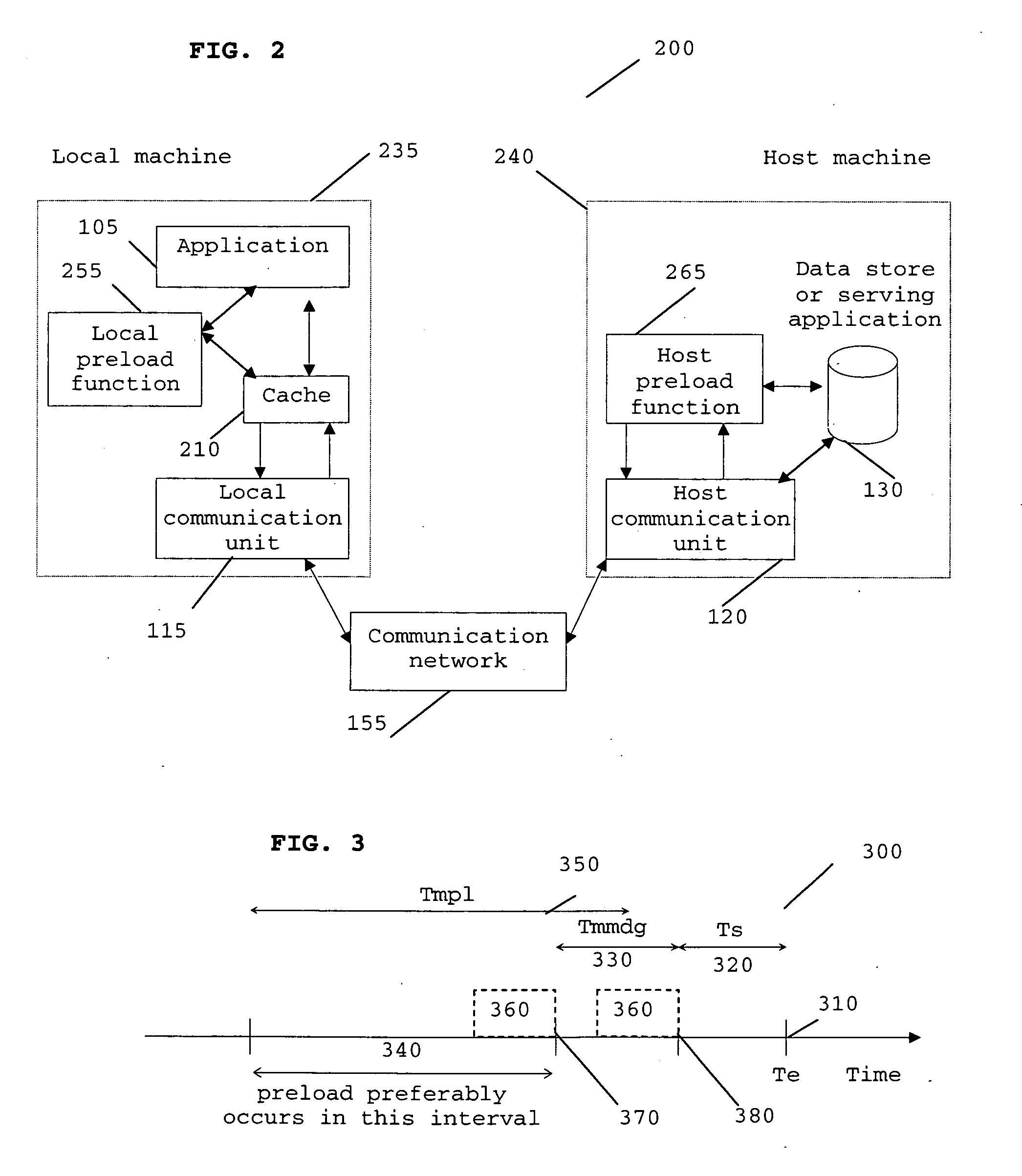

Method and apparatus for preloading caches

InactiveUS20060129766A1Optimization mechanismReduce decreaseDigital data information retrievalTransmissionCommunications systemConfigfs

A method (400) of preloading data on a cache (210) in a local machine (235). The cache (210) is operably coupled to a data store (130), in a remote host machine (240). The method includes the steps of determining a user behaviour profile for the local machine (235); retrieving data relating to the user behaviour profile from the data store (130); and preloading the retrieved data in the cache (210), such that the data is made available to the cache user when desired. A local machine, a host machine, a cache, a communication system and preloading functions are also described. In this manner, data within the cache is maintained and replaced in a substantially optimal manner, and configured to be available to a cache user when it is predicted that the user wishes to access the data.

Owner:FLYINGSPARK

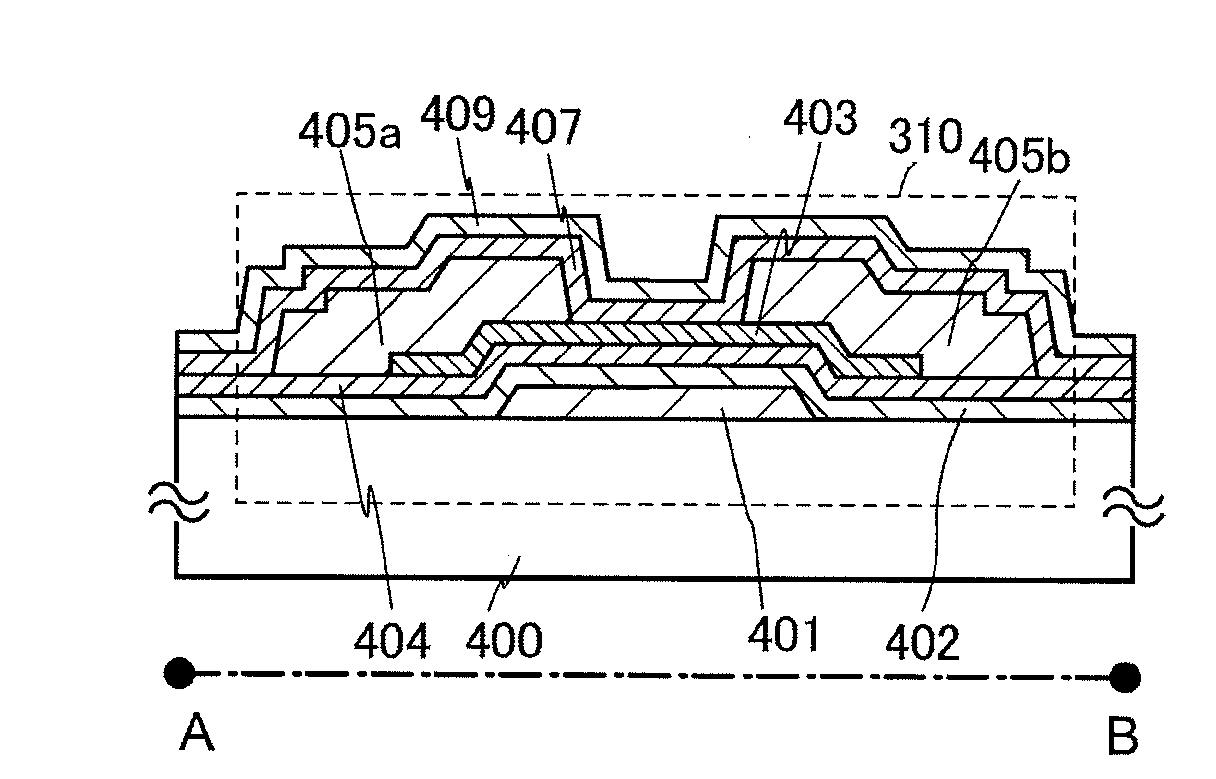

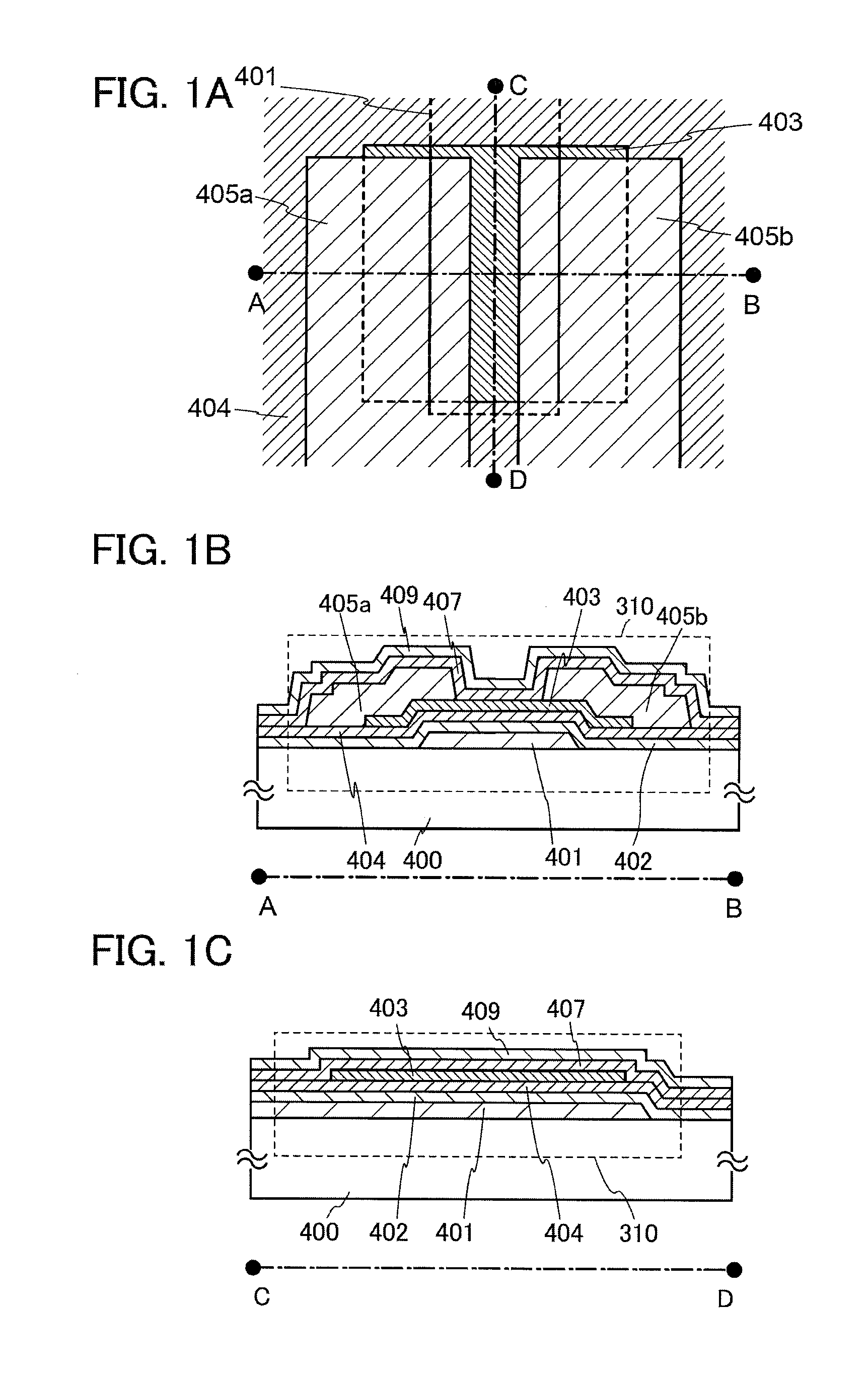

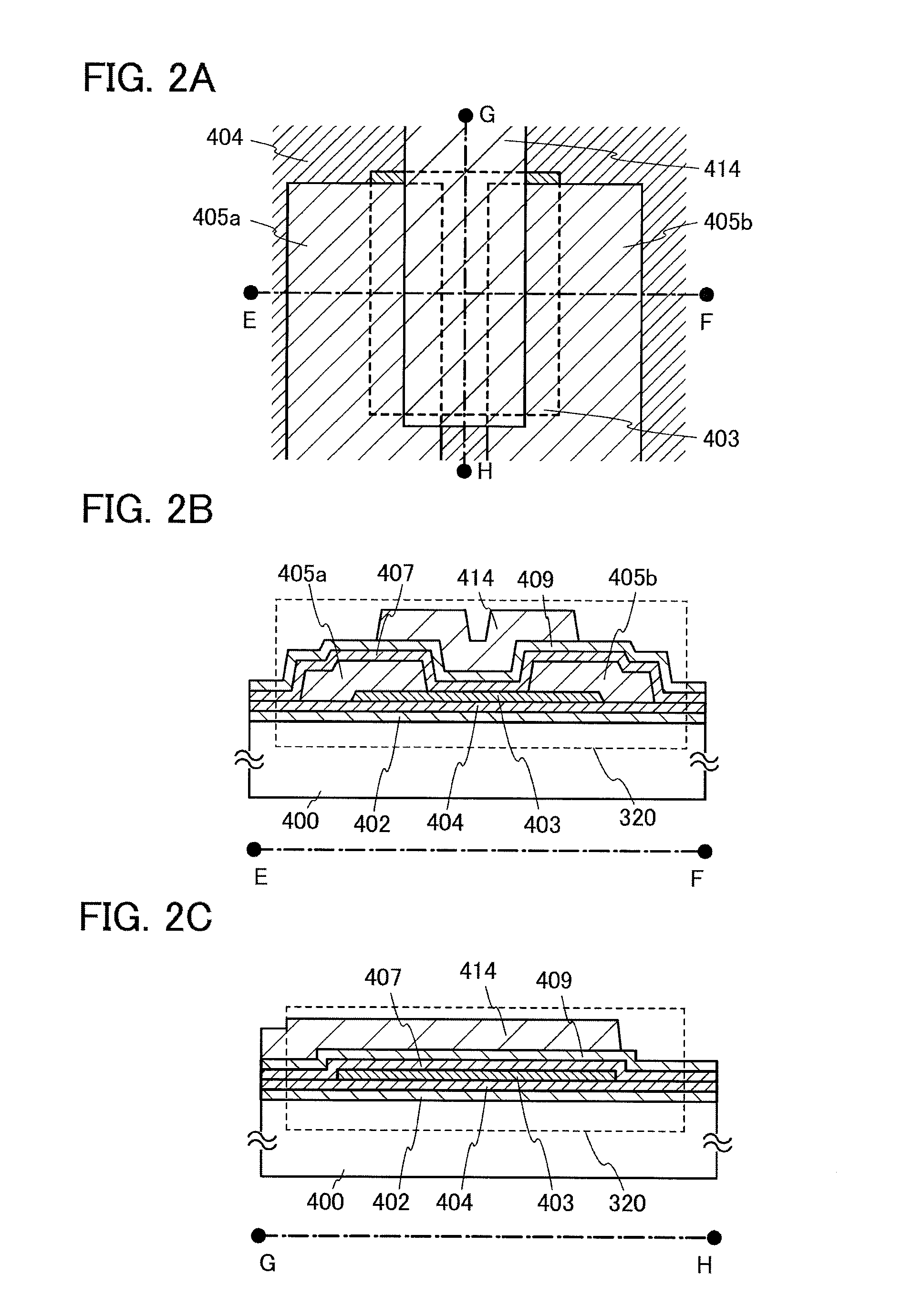

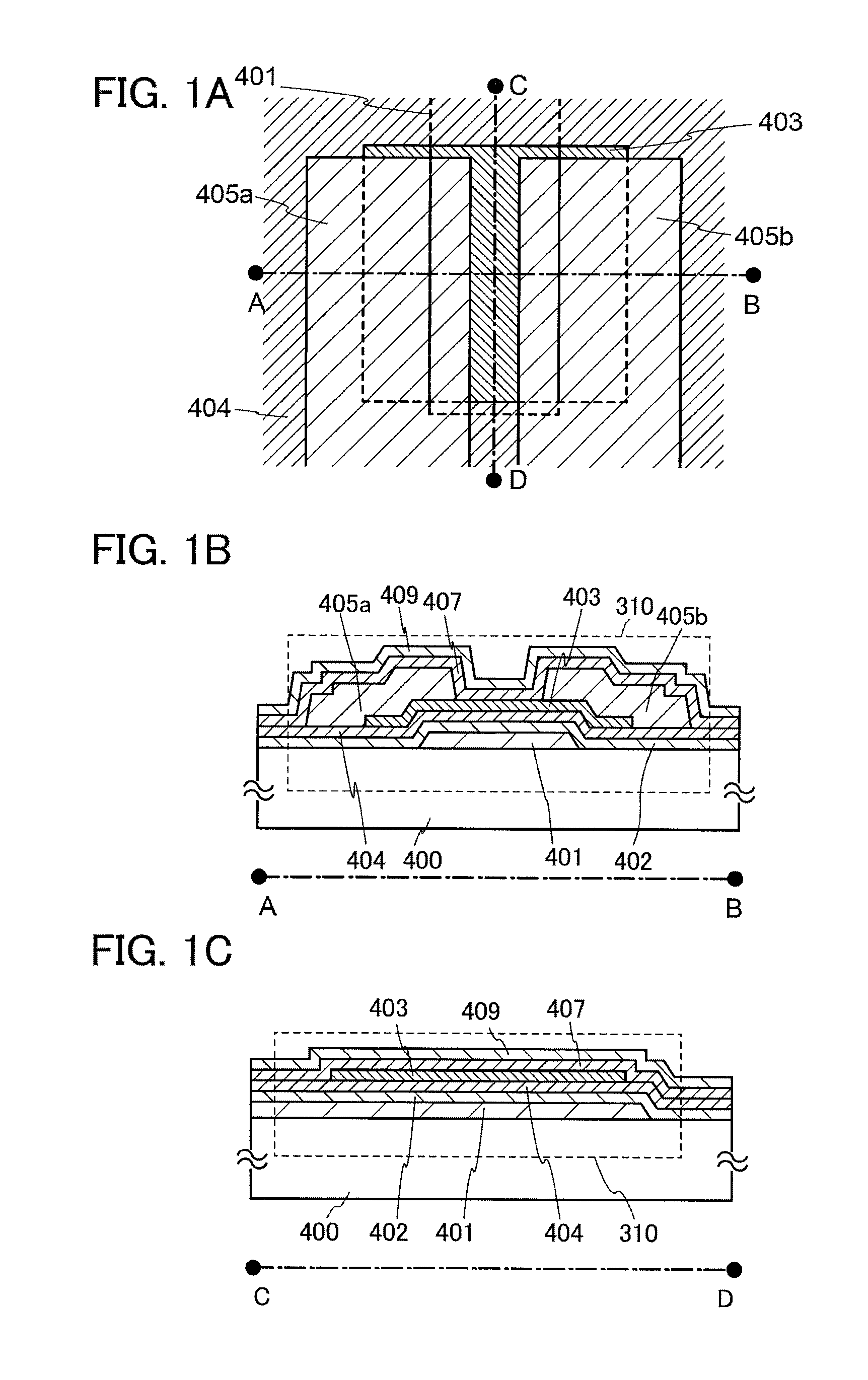

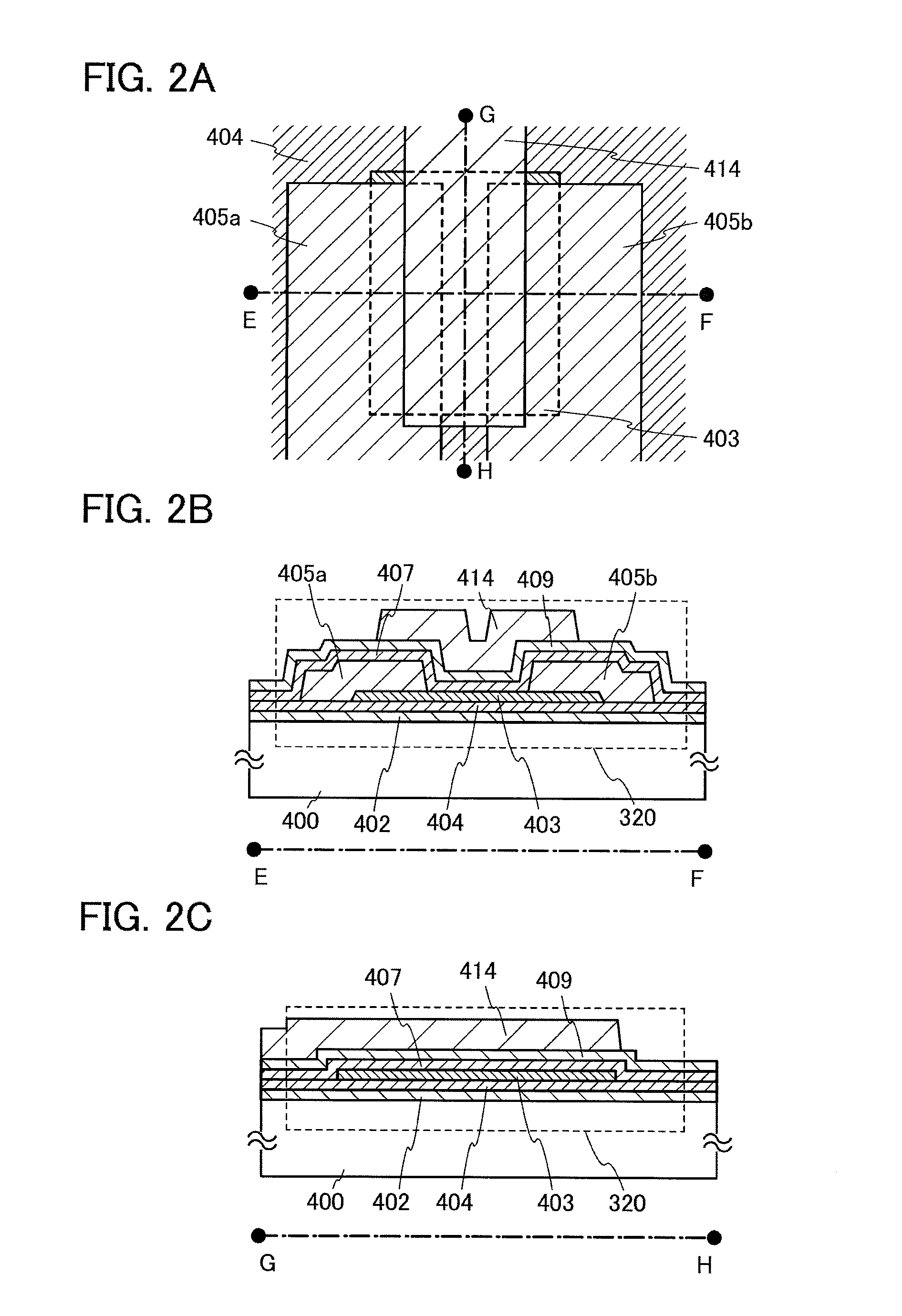

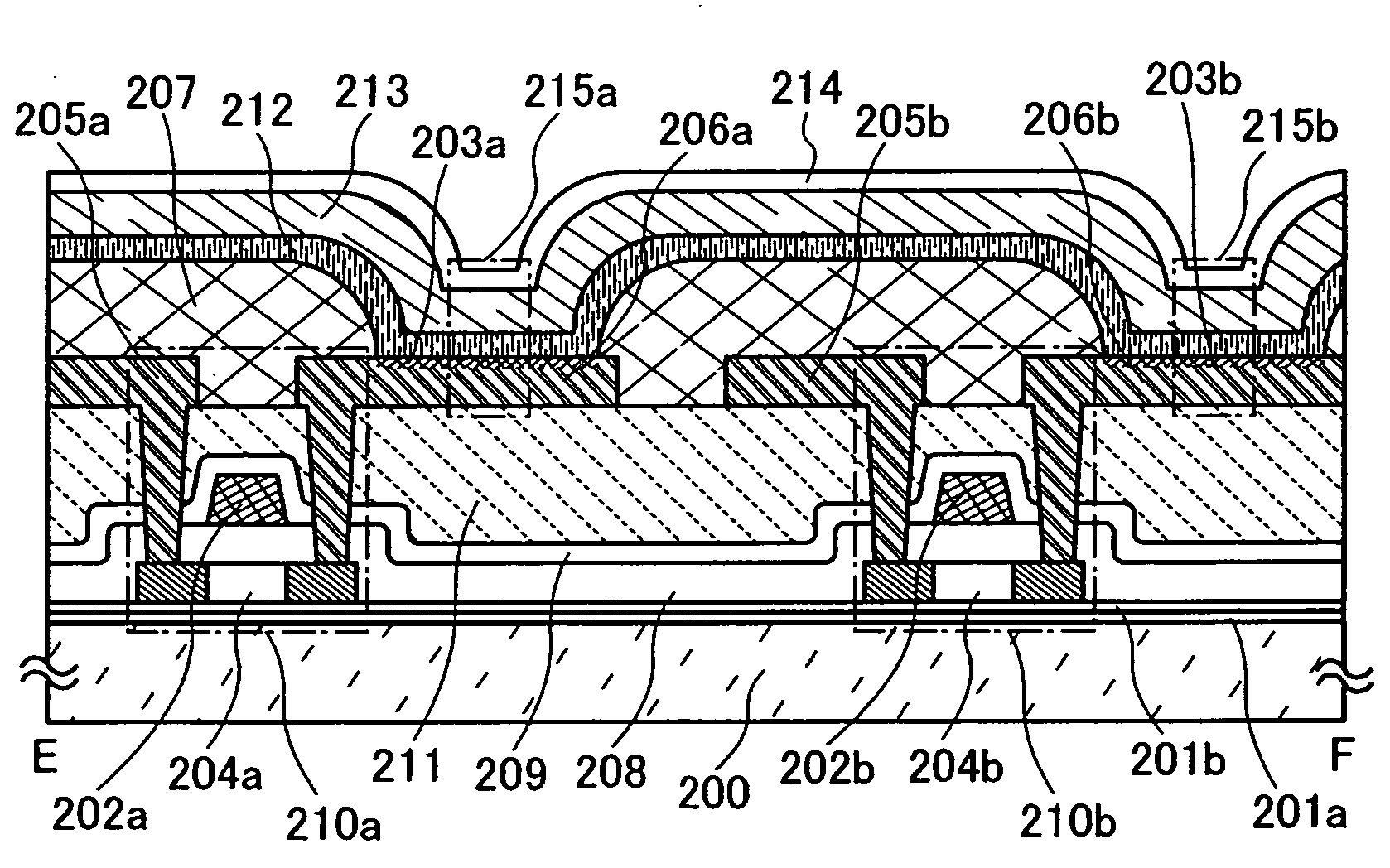

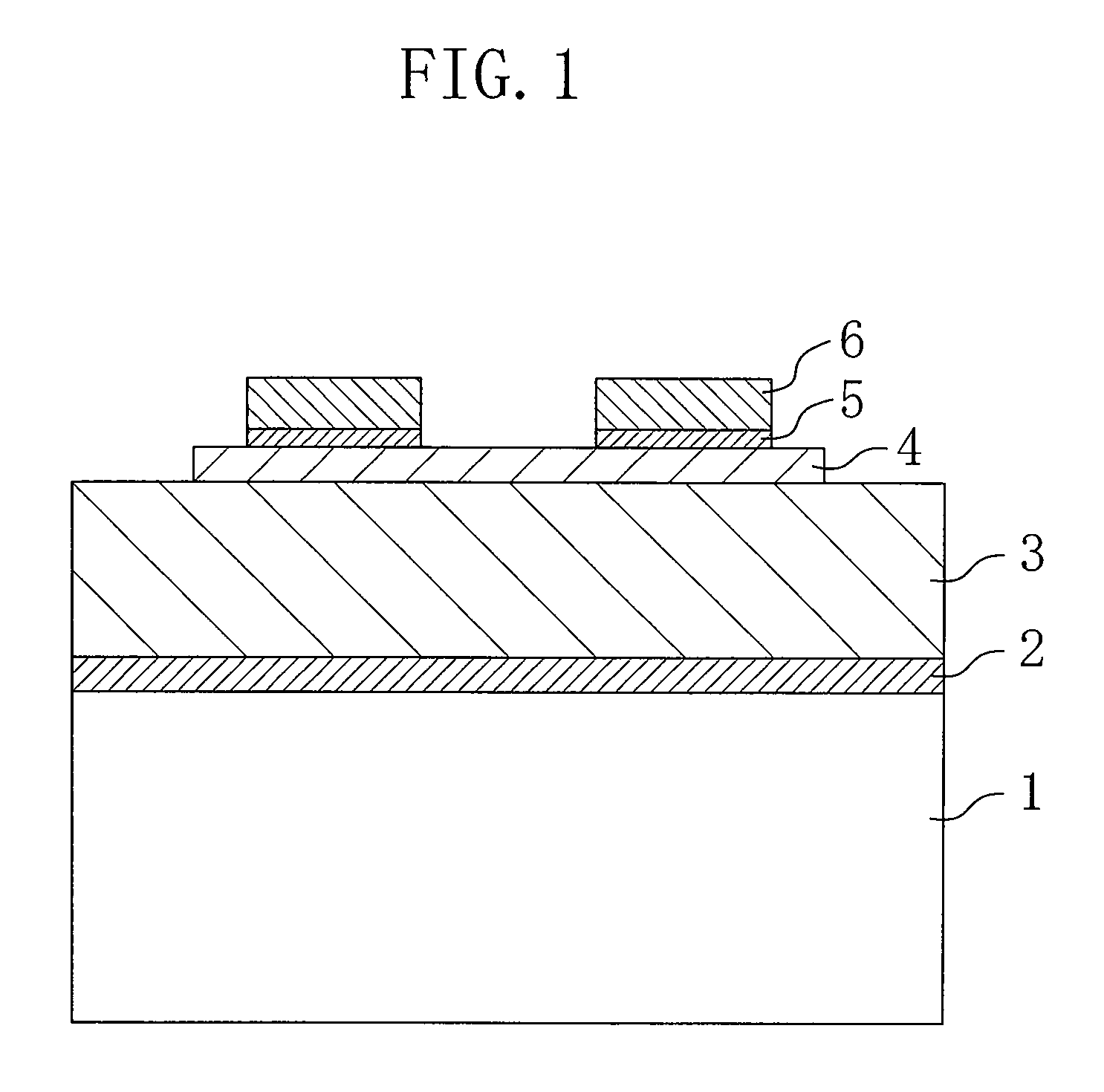

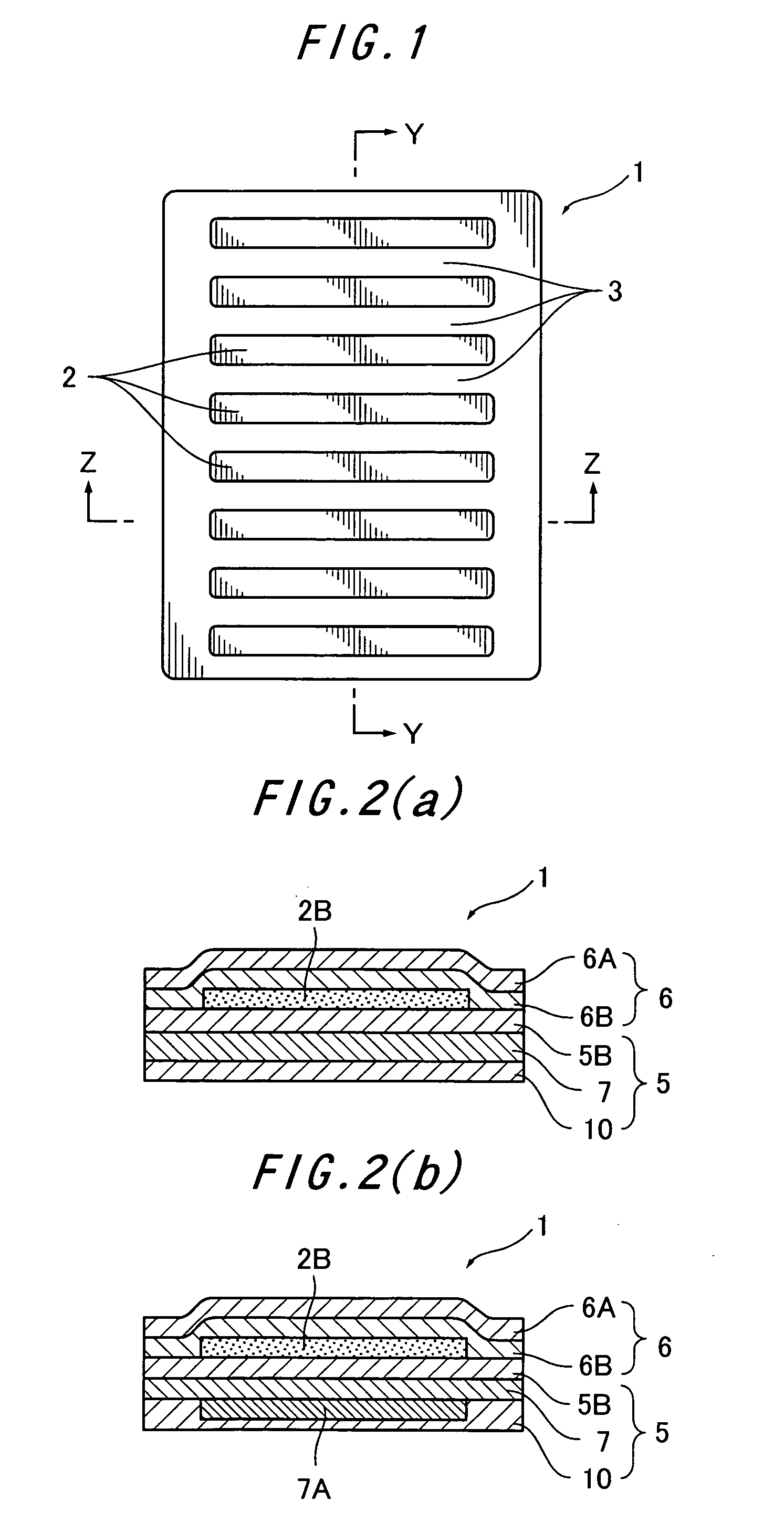

Semiconductor device

ActiveUS20120001170A1Stable electrical characteristicExcellent electrical characteristicTransistorSolid-state devicesOxide semiconductorAluminium

An object is to provide a semiconductor device including an oxide semiconductor, which has stable electrical characteristics and improved reliability. In a transistor including an oxide semiconductor film, insulating films each including a material containing a Group 13 element and oxygen are formed in contact with the oxide semiconductor film, whereby the interfaces with the oxide semiconductor film can be kept in a favorable state. Further, the insulating films each include a region where the proportion of oxygen is higher than that in the stoichiometric composition, so that oxygen is supplied to the oxide semiconductor film; thus, oxygen defects in the oxide semiconductor film can be reduced. Furthermore, the insulating films in contact with the oxide semiconductor film each have a stacked structure so that films each containing aluminum are provided over and under the oxide semiconductor film, whereby entry of water into the oxide semiconductor film can be prevented.

Owner:SEMICON ENERGY LAB CO LTD

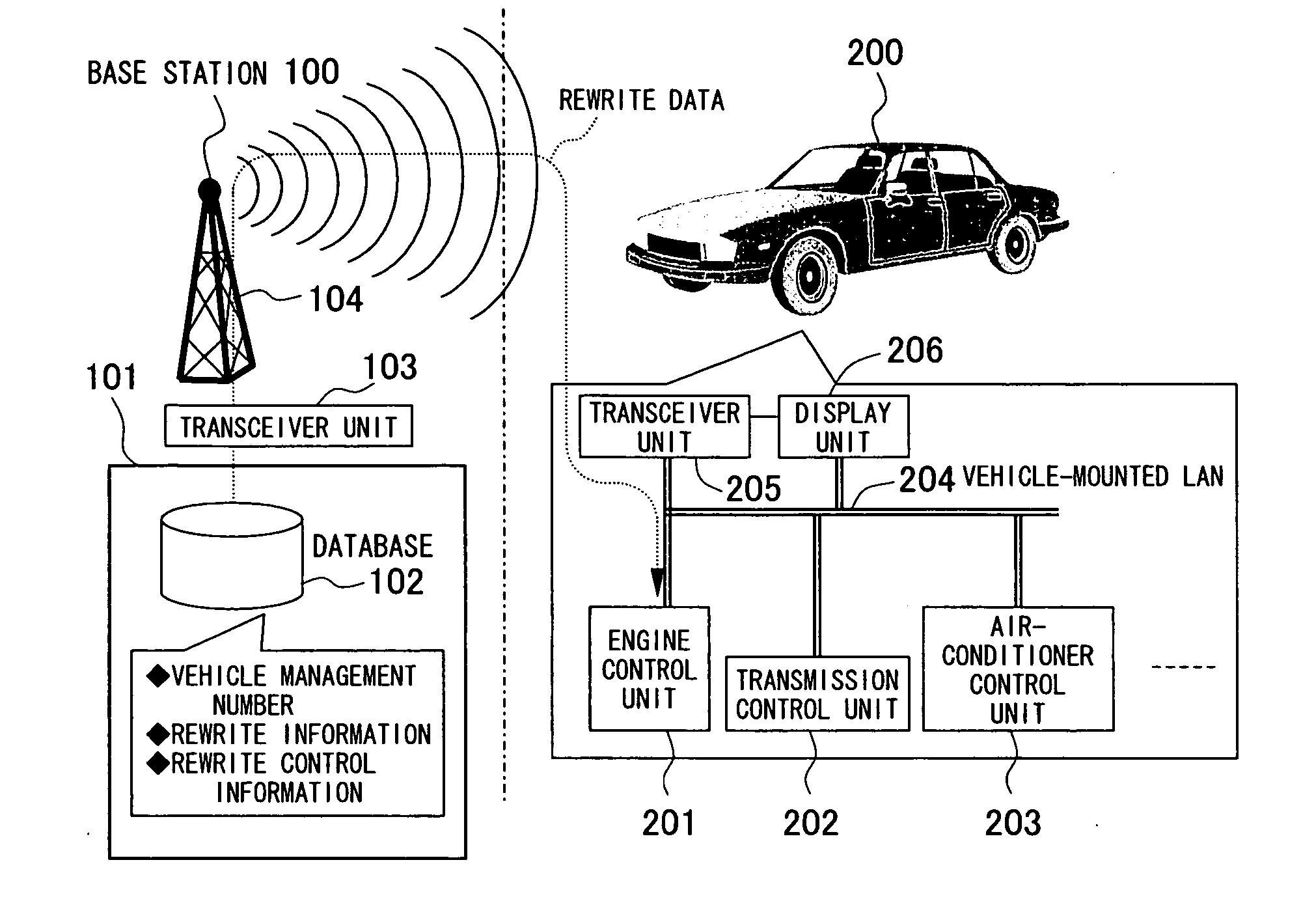

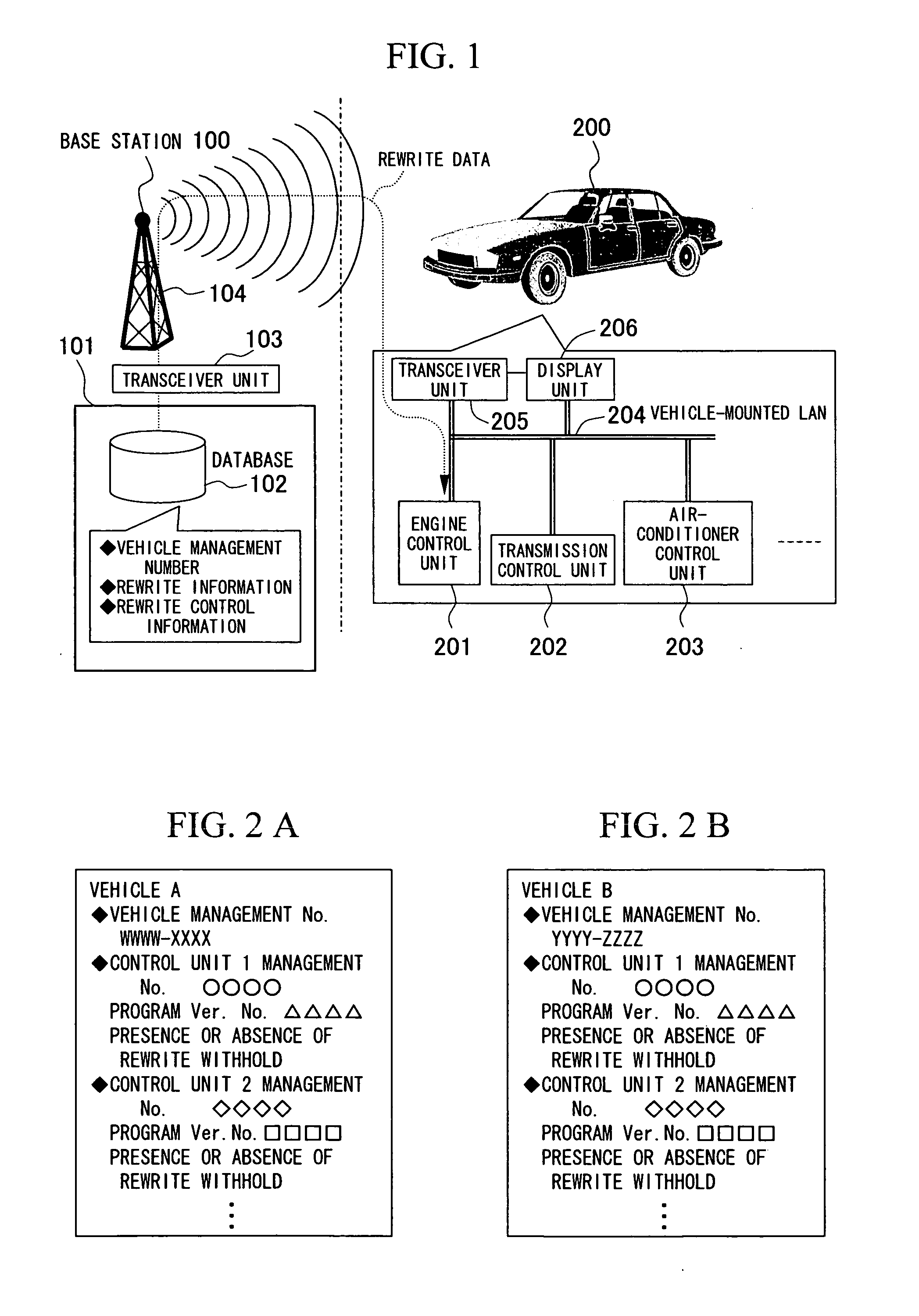

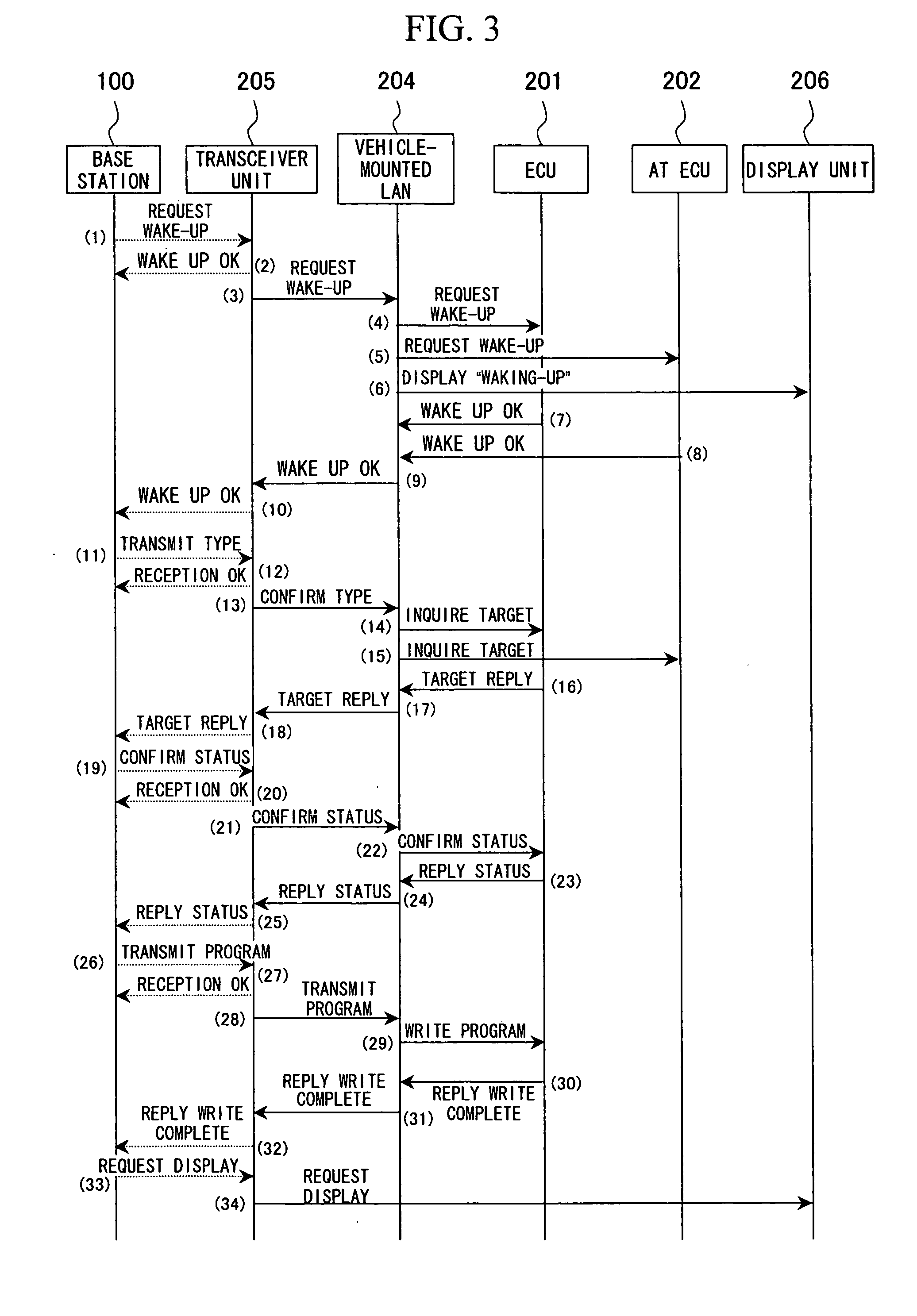

Information updating method of vehicle-mounted control apparatus, update information communication system, vehicle-mounted control apparatus, and information management base station apparatus

ActiveUS20070100513A1Excellent stateReliable updateVehicle testingArrangements for variable traffic instructionsControl equipmentReal-time computing

When an updating event occurs, an information management base station unit inquires all the vehicles under its management about the presence or absence of vehicle-mounted control units to be updated. Based on replies from the individual vehicles, the information management base station unit selects the vehicles to be updated, and then it automatically updates them via wireless communication.

Owner:HITACHI LTD

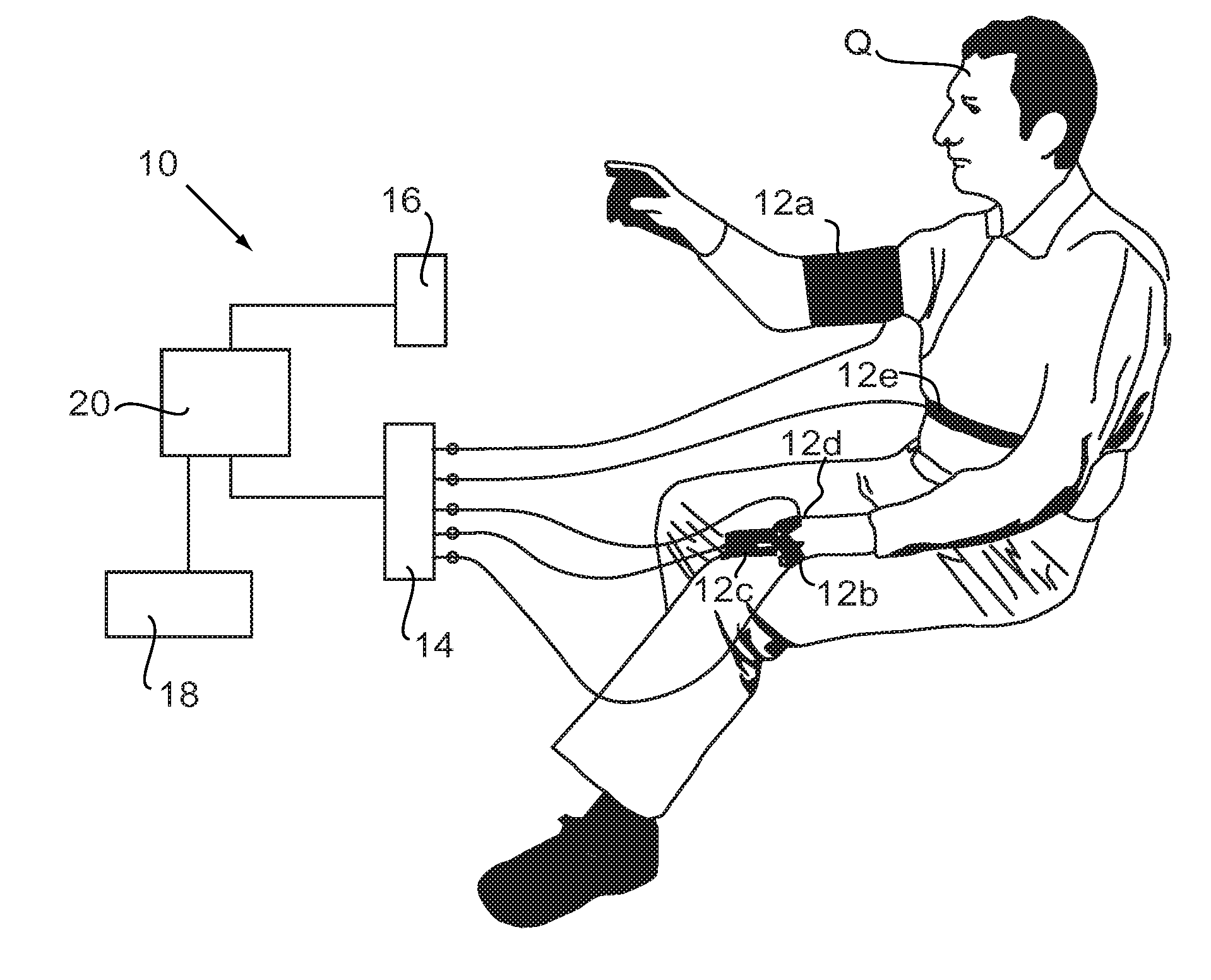

Behaviour Modification

InactiveUS20110183305A1Increased muscular relaxationLong exhalationMental therapiesSensorsBehaviour modificationComputer science

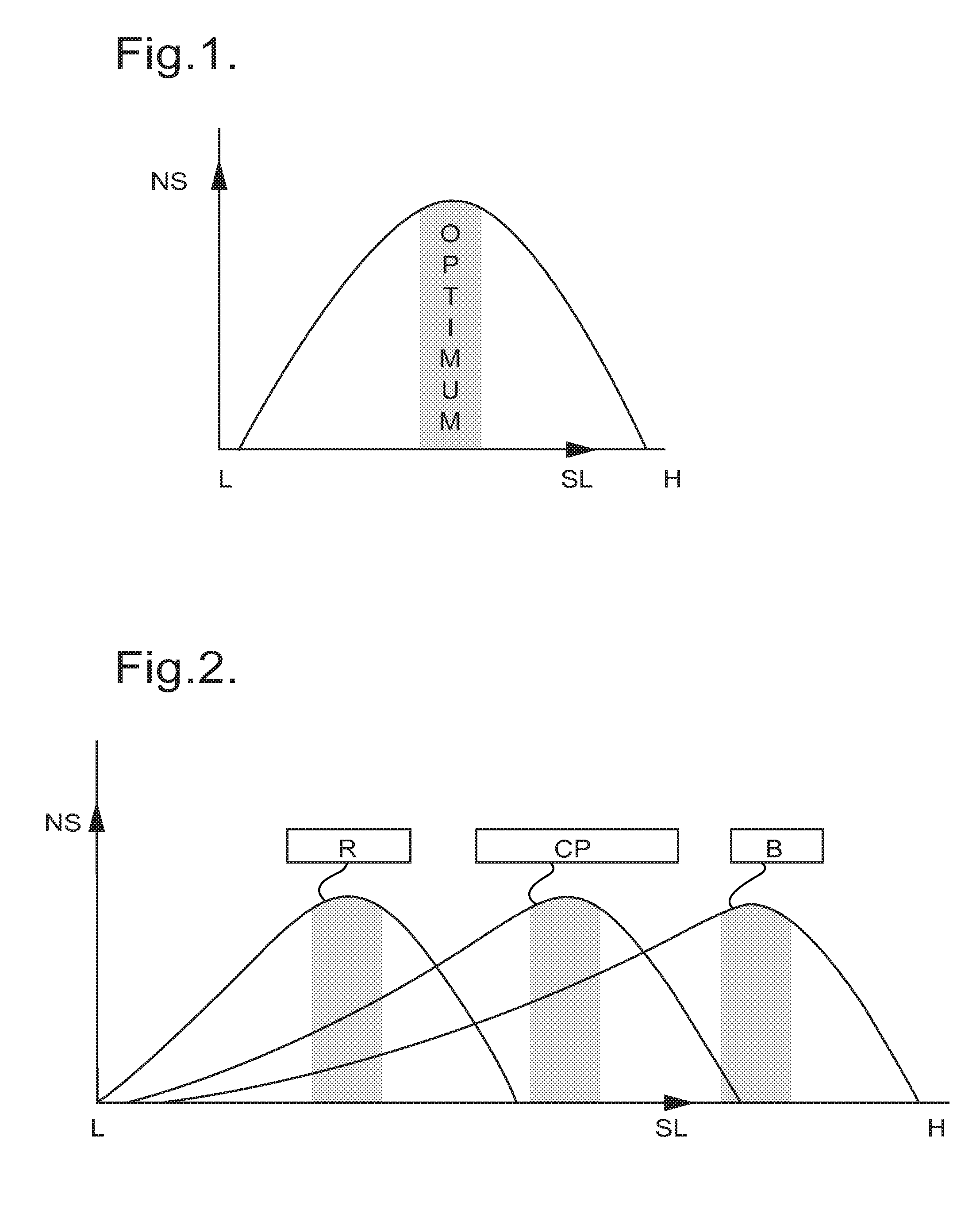

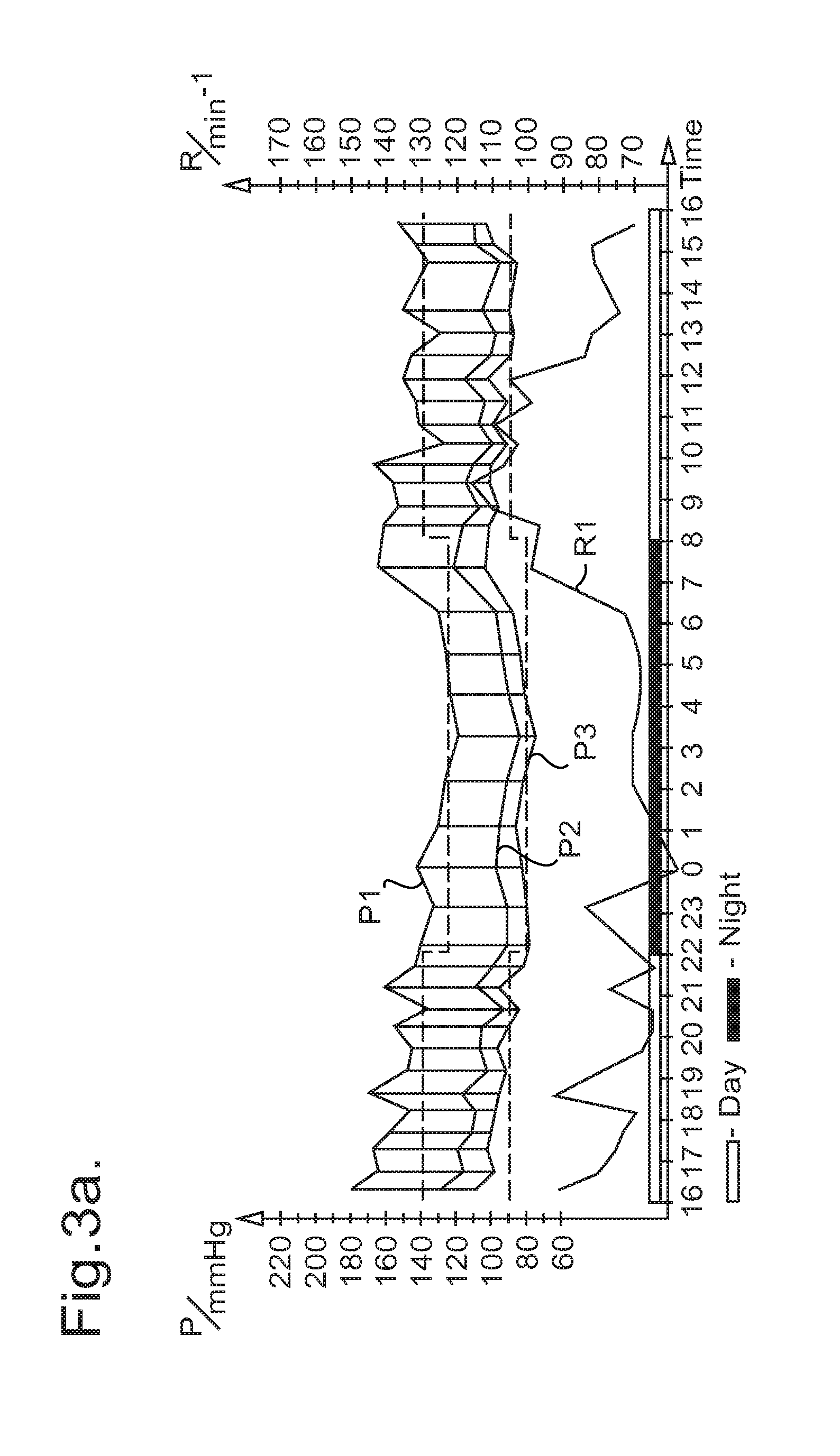

A behavioural modification system and method facilitates the achieving by a user (Q) of one or more objectives. The system includes sensors (12) to measure at least one physiological or psychological parameter of the user; a memory to store data concerning the physiological or psychological parameter or a range of physiological or psychological parameters for the user, based on information from the sensors at at least one point in time; and a comparator to compare the at least one measured parameter at subsequent points in time with stored data for the user. It also includes an indicator (16) to provide information to the user (Q) about one or more objectives; a monitor (20) that, based on comparisons made by the comparator, monitors the state of the user when working towards the at least one objective; and a moderator that, in response to the state of the user as monitored by the monitor, enables the at least one objective to be changed so that the user is able to maintain a desired state when attempting the at least one objective thereby maintaining engagement of the user to continue working towards the at least one objective.

Owner:HEALTH SMART

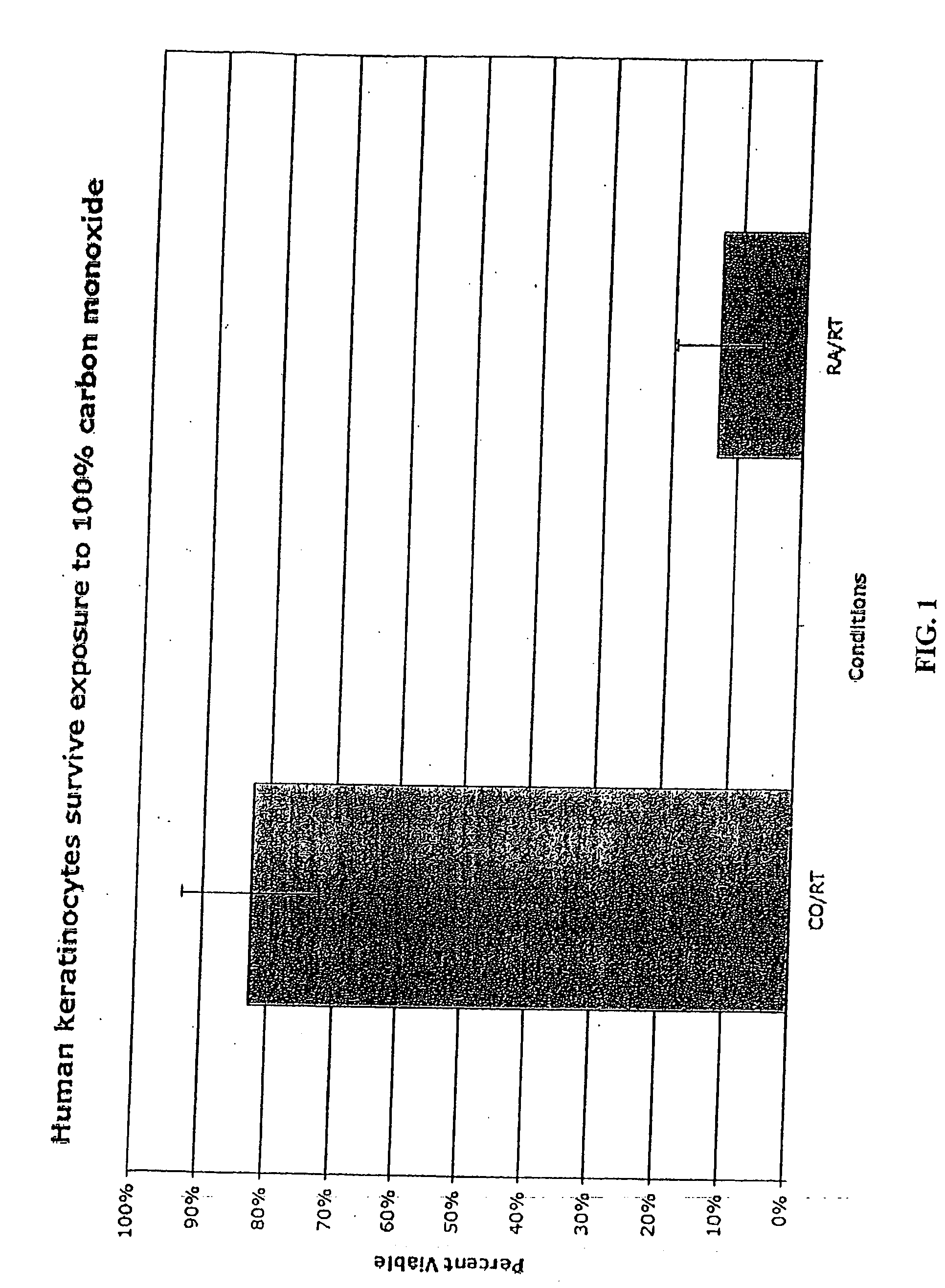

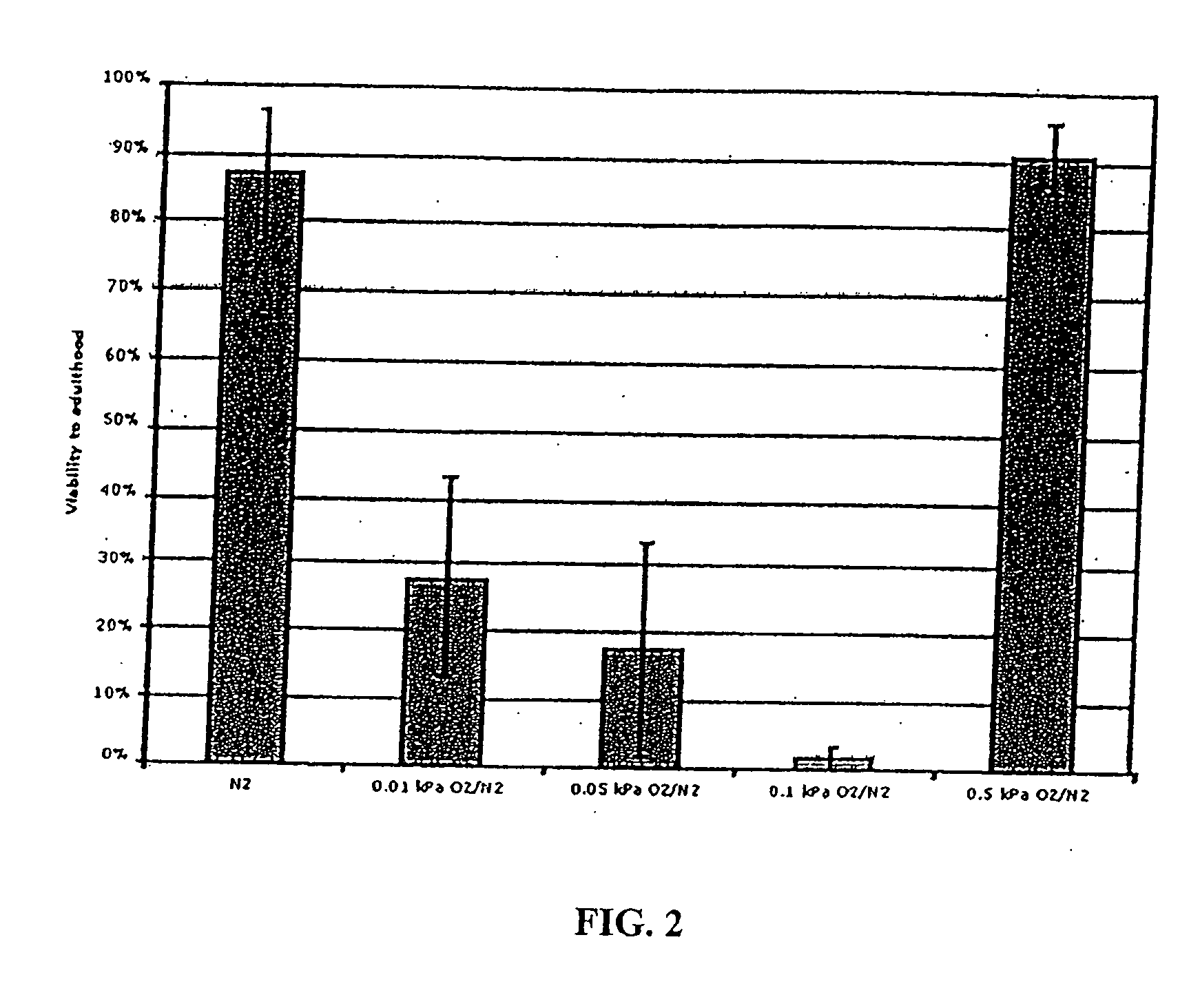

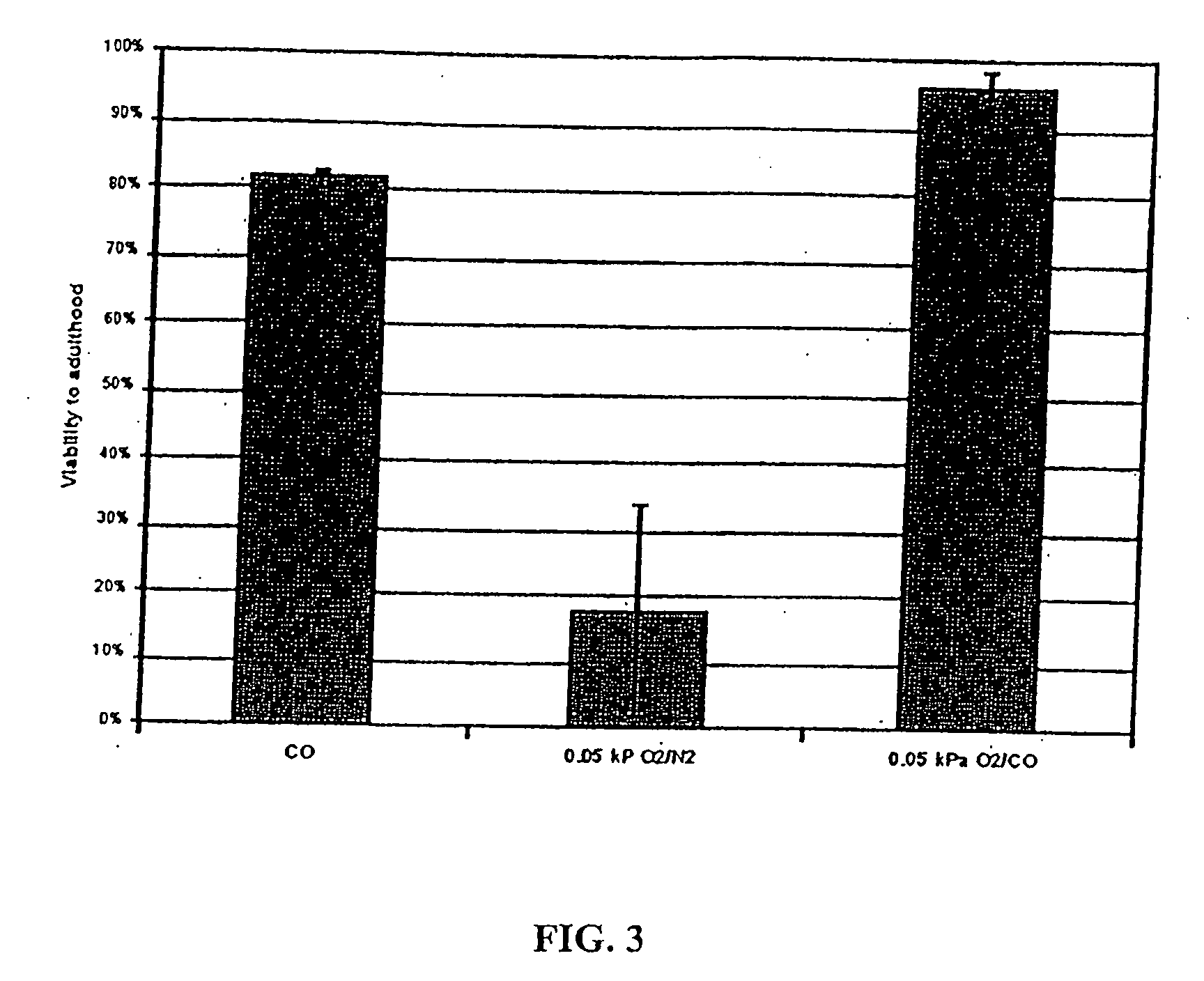

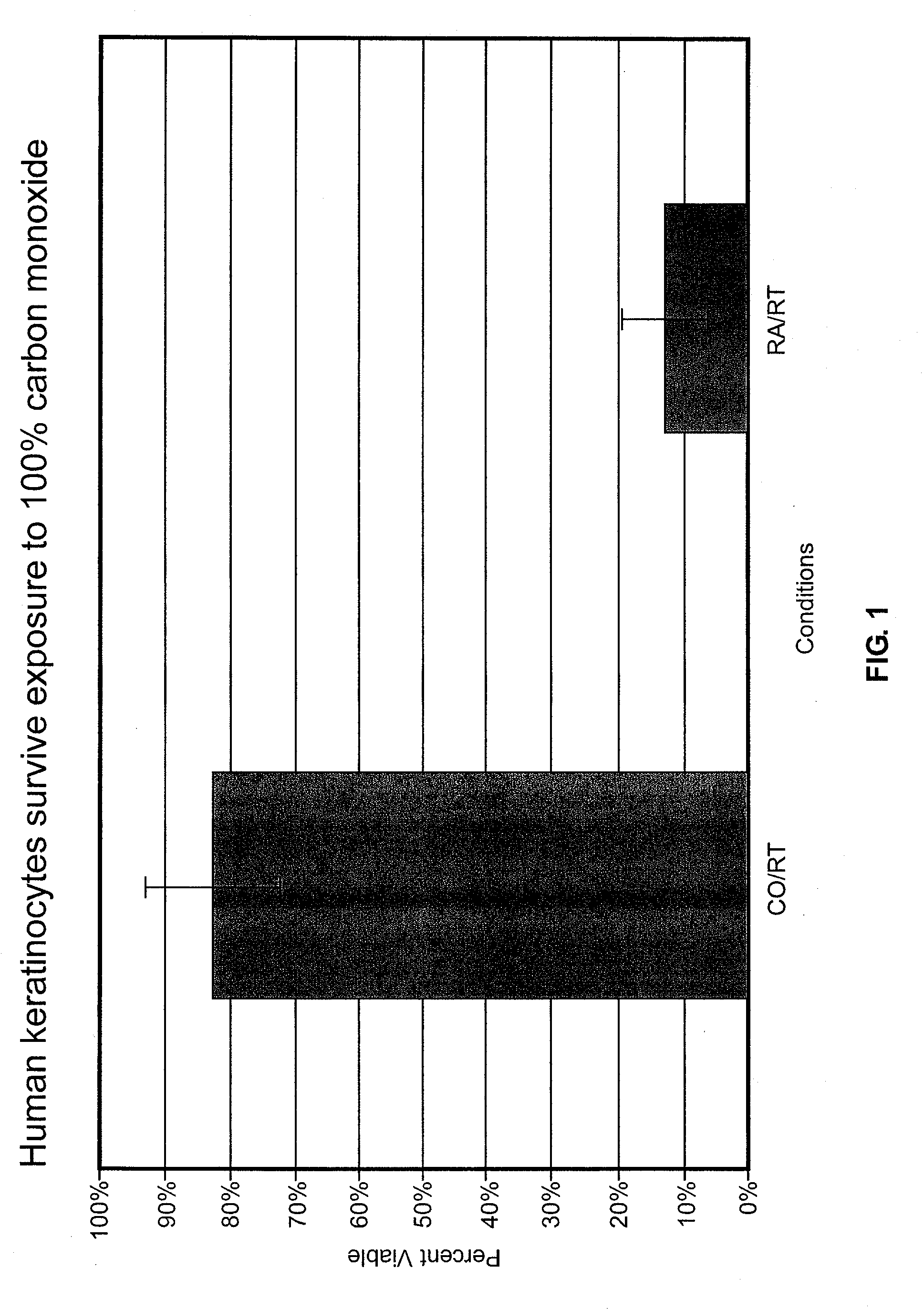

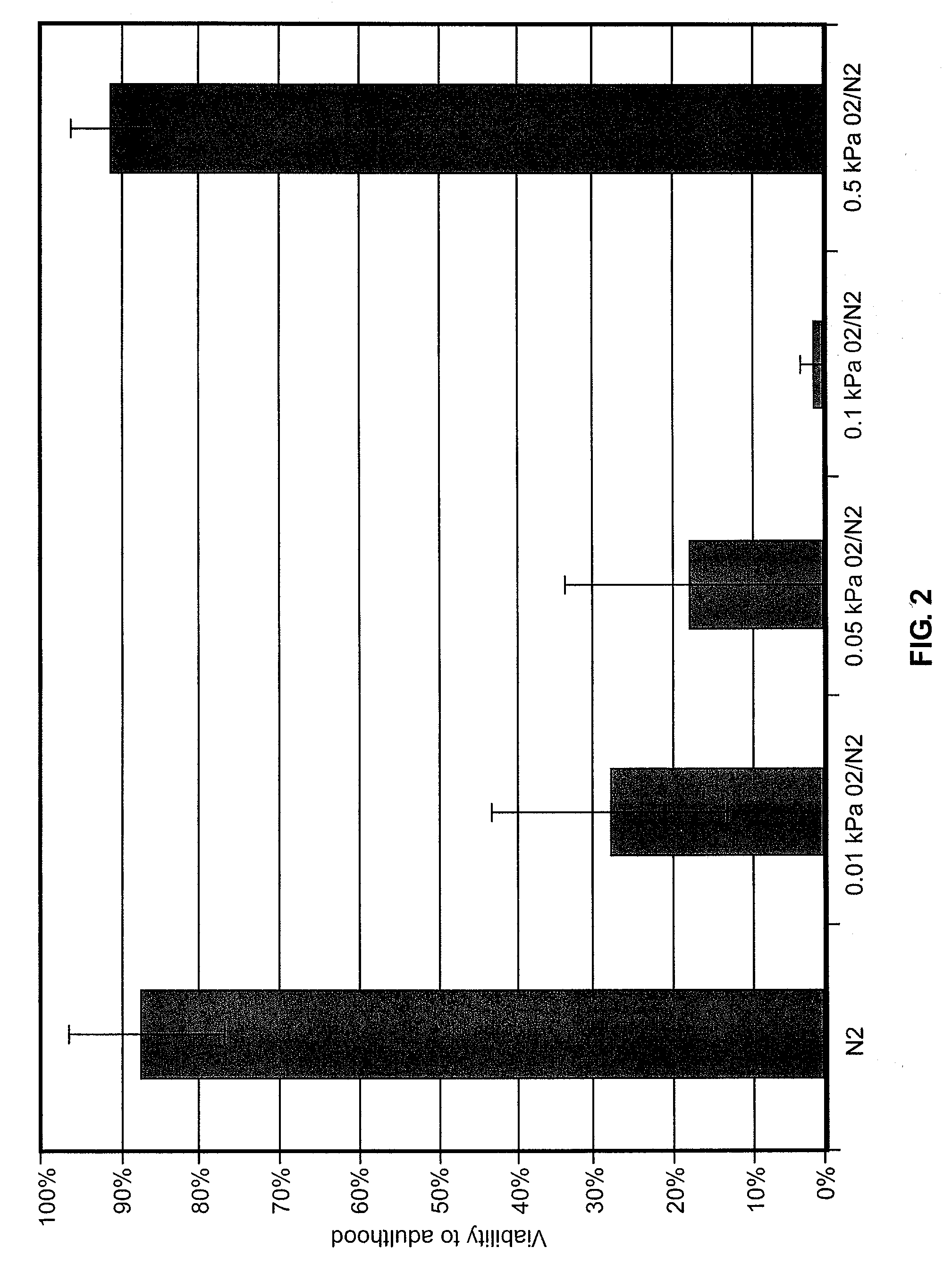

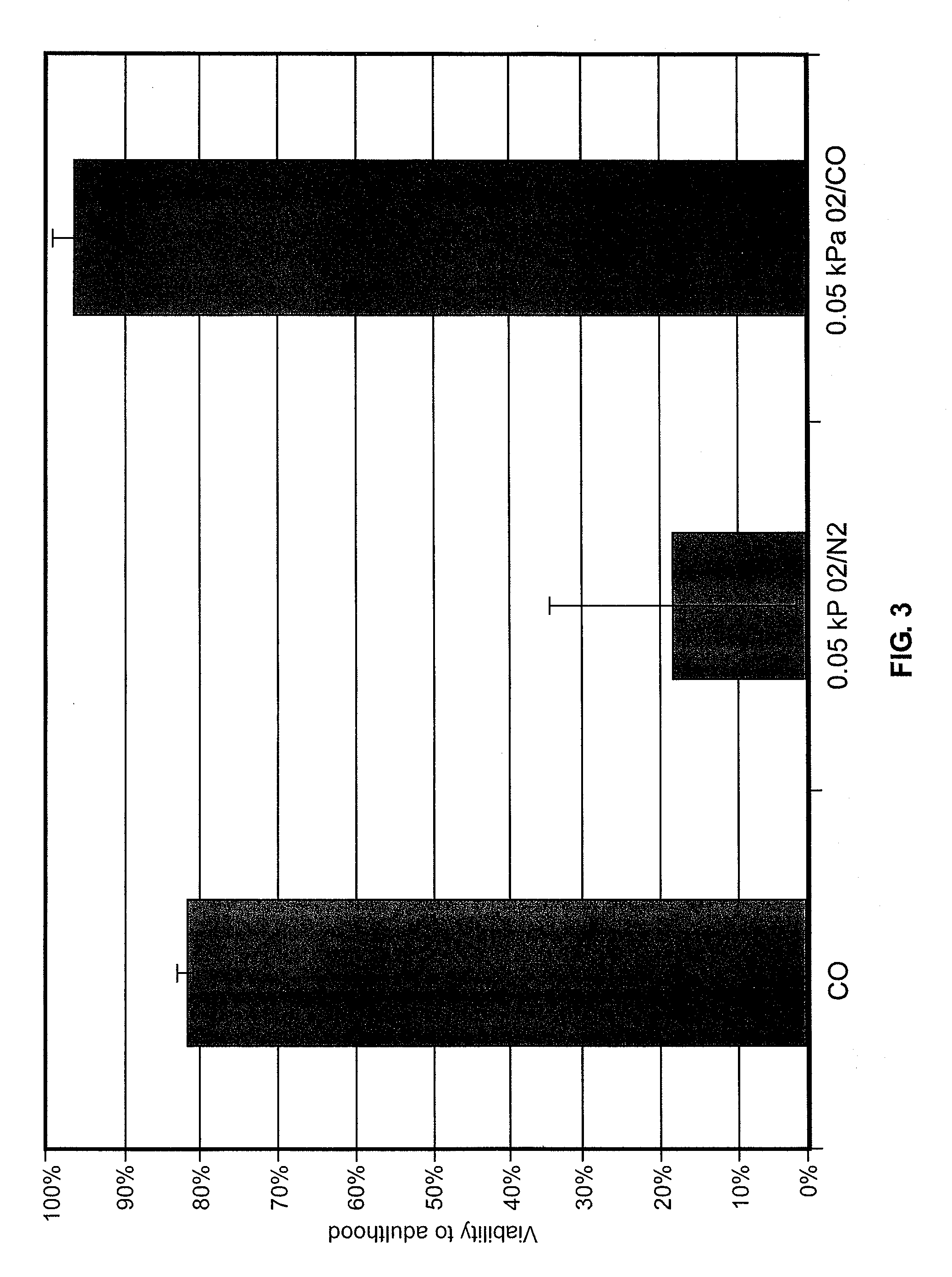

Methods, compositions and articles of manufacture for enhancing survivability of cells, tissues, organs, and organisms

InactiveUS20070078113A1Easily damagedImprove survivabilityBiocideSulfur/selenium/tellurium active ingredientsSurvivabilityOxygen

The present invention concerns the use of oxygen antagonists and other active compounds for inducing stasis or pre-stasis in cells, tissues, and / or organs in vivo or in an organism overall, in addition to enhancing their survivability. It includes compositions, methods, articles of manufacture and apparatuses for enhancing survivability and for achieving stasis or pre-stasis in any of these biological materials, so as to preserve and / or protect them. In specific embodiments, there are also therapeutic methods and apparatuses for organ transplantation, hyperthermia, wound healing, hemorrhagic shock, cardioplegia for bypass surgery, neurodegeneration, hypothermia, and cancer using the active compounds described.

Owner:FRED HUTCHINSON CANCER RES CENT

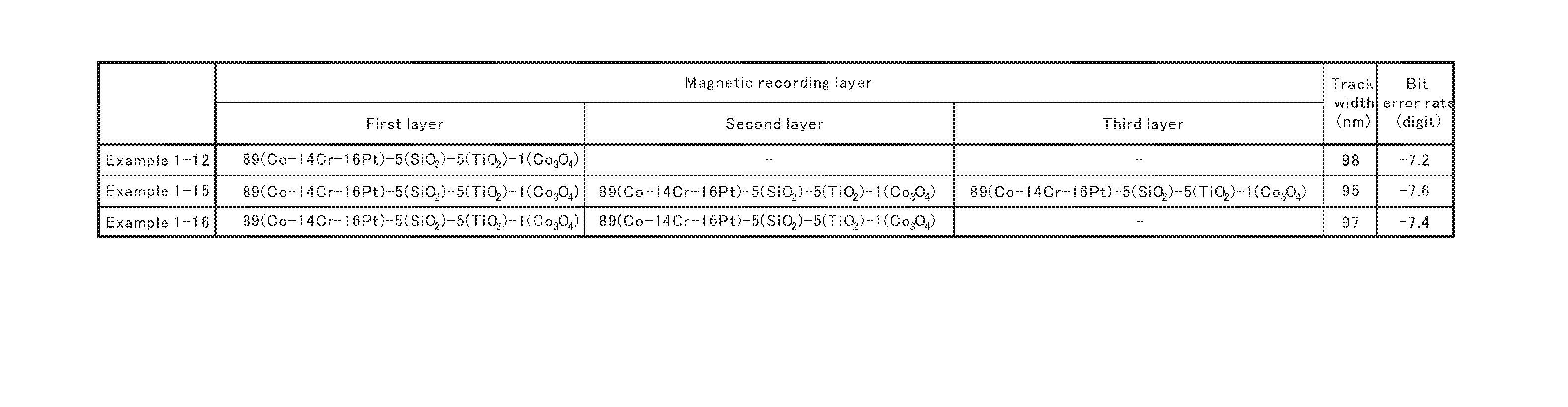

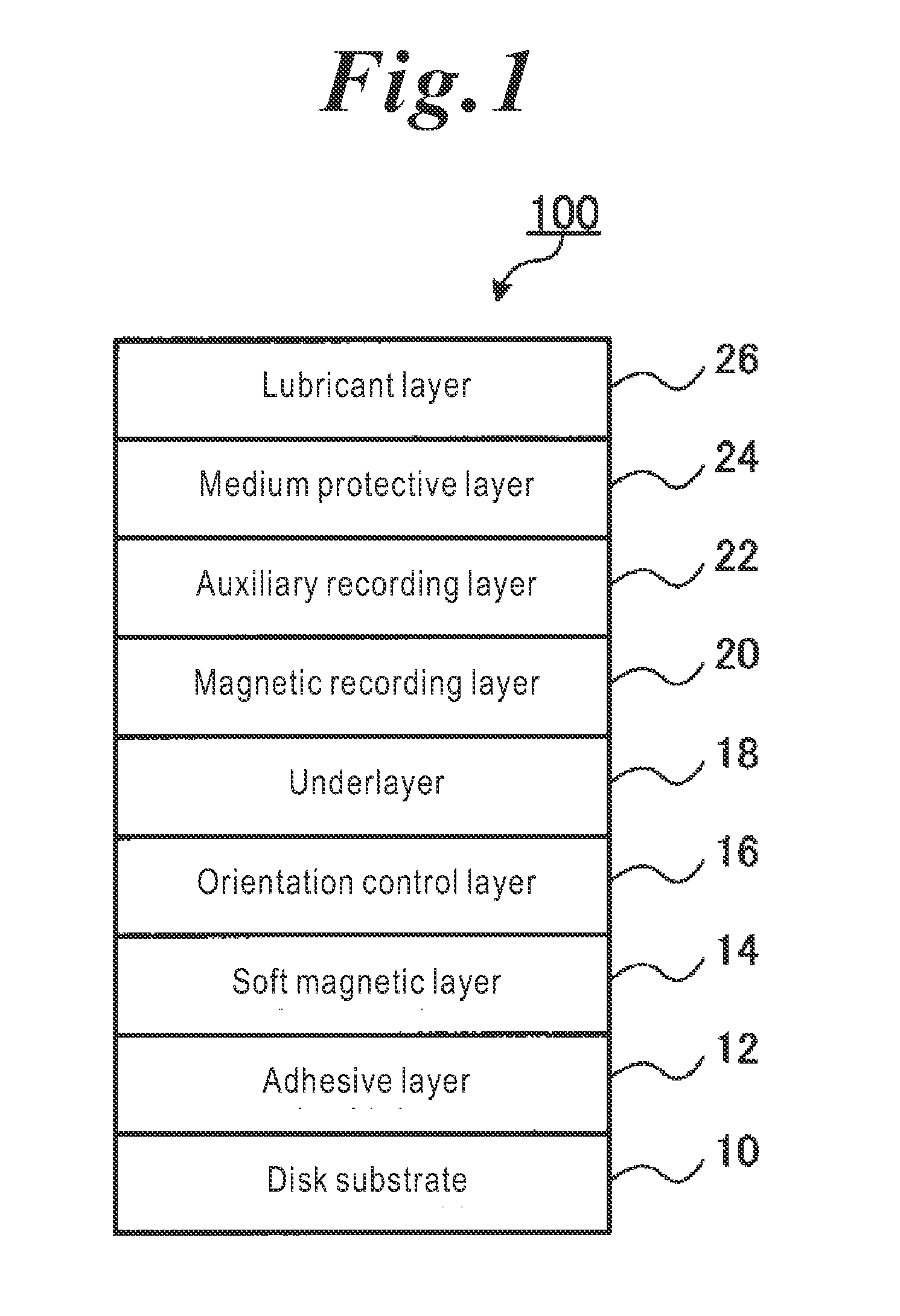

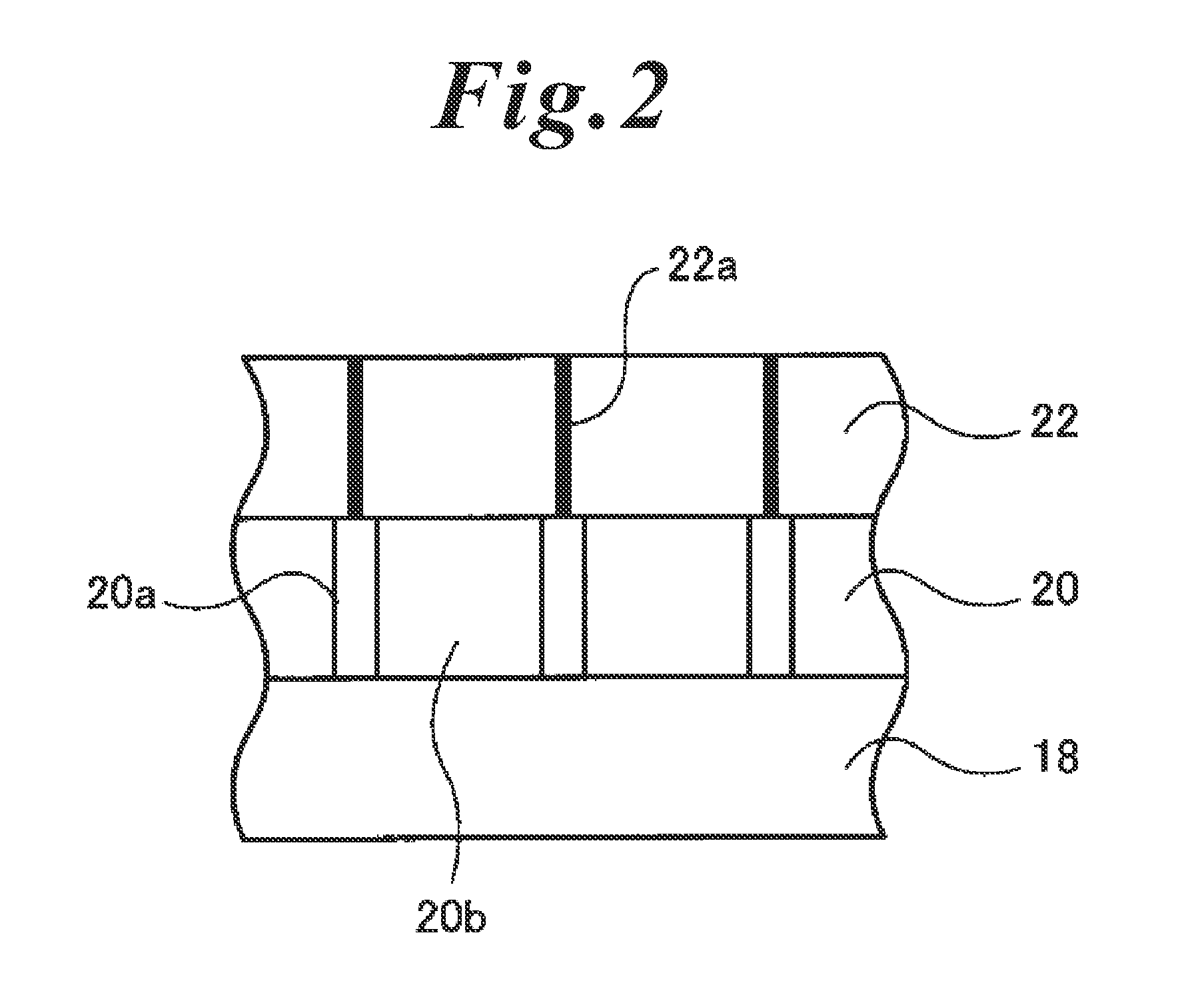

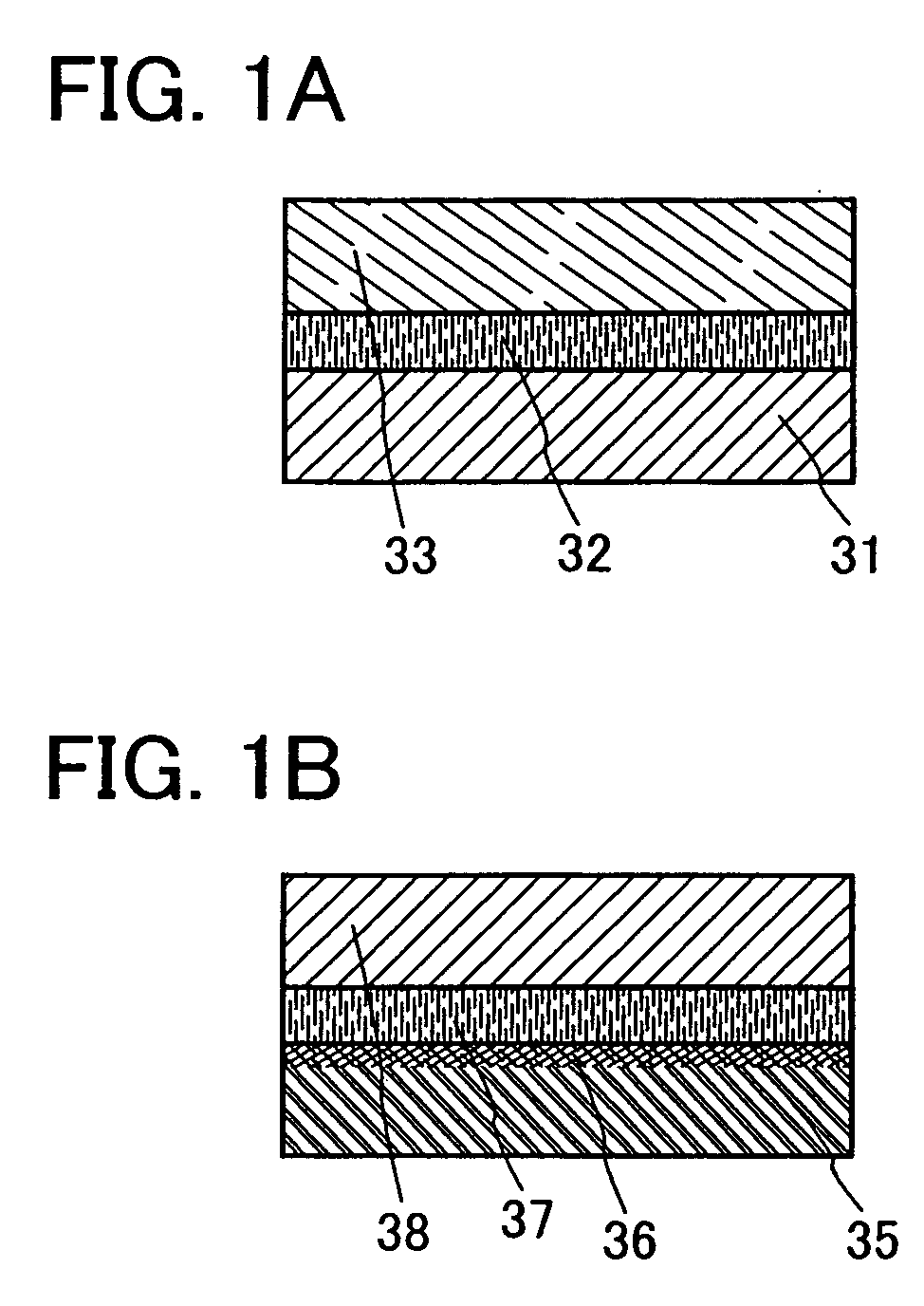

Magnetic disk and method for manufacturing same

ActiveUS20110311841A1Reduce noiseImprove recording densityMagnetic materials for record carriersVacuum evaporation coatingOxygenRecording layer

Provided are a magnetic disk comprising a granular magnetic recording layer which causes less noise even with a recording capacity thereof of 250 G or more bits per square inch; and a method for manufacturing the same. The magnetic disk according to the present invention comprises: a granular magnetic recording layer (20) which is formed on a disk substrate 10 directly or via an intermediate layer and which has non-magnetic regions between granular columnar particles; and an auxiliary recording layer (22) which is formed on the granular magnetic recording layer 20 and which causes exchange interaction among the granular columnar particles, wherein the auxiliary recording layer (22) contains 0.1 to 3 moles of oxygen.

Owner:WESTERN DIGITAL TECH INC

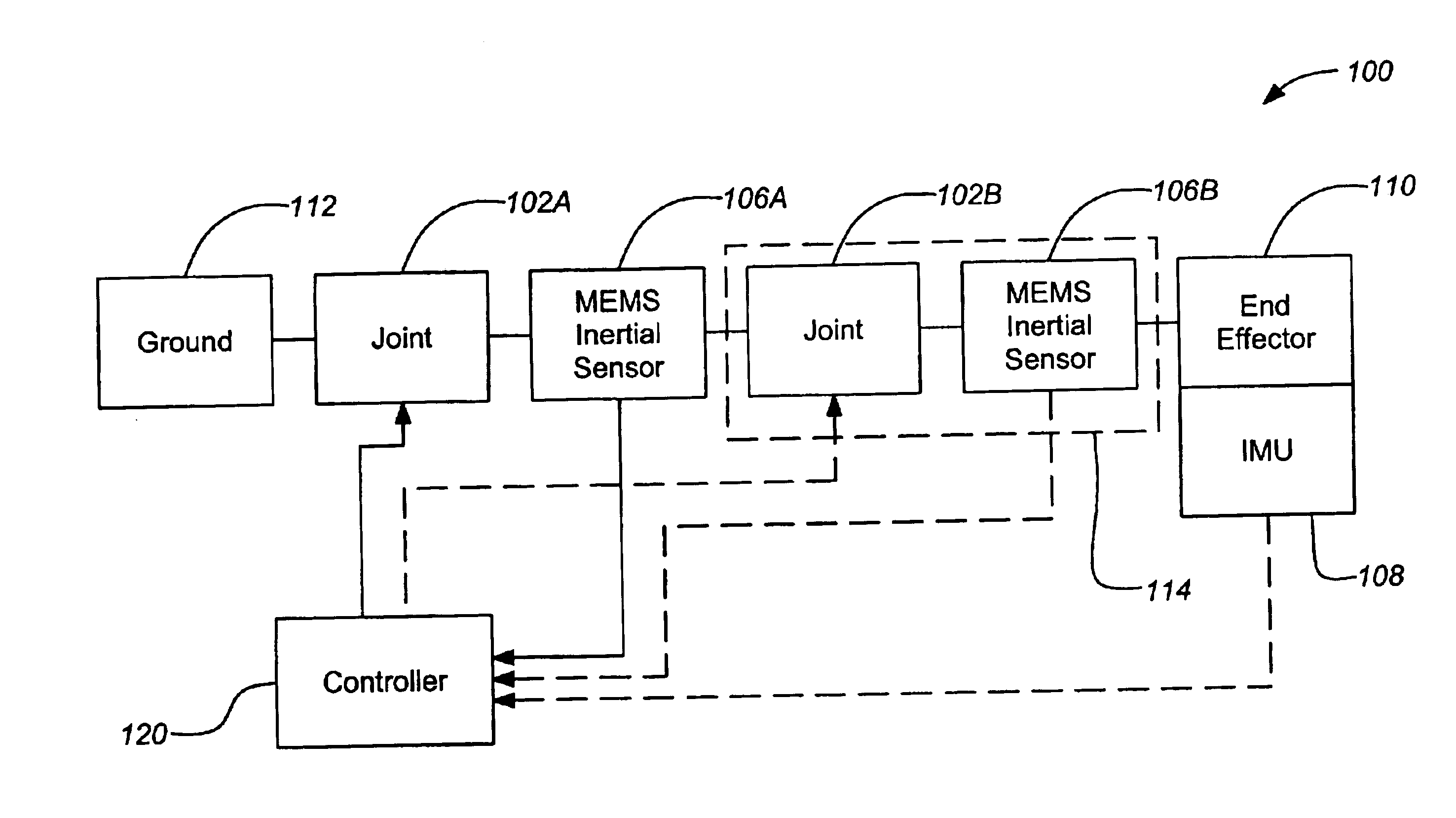

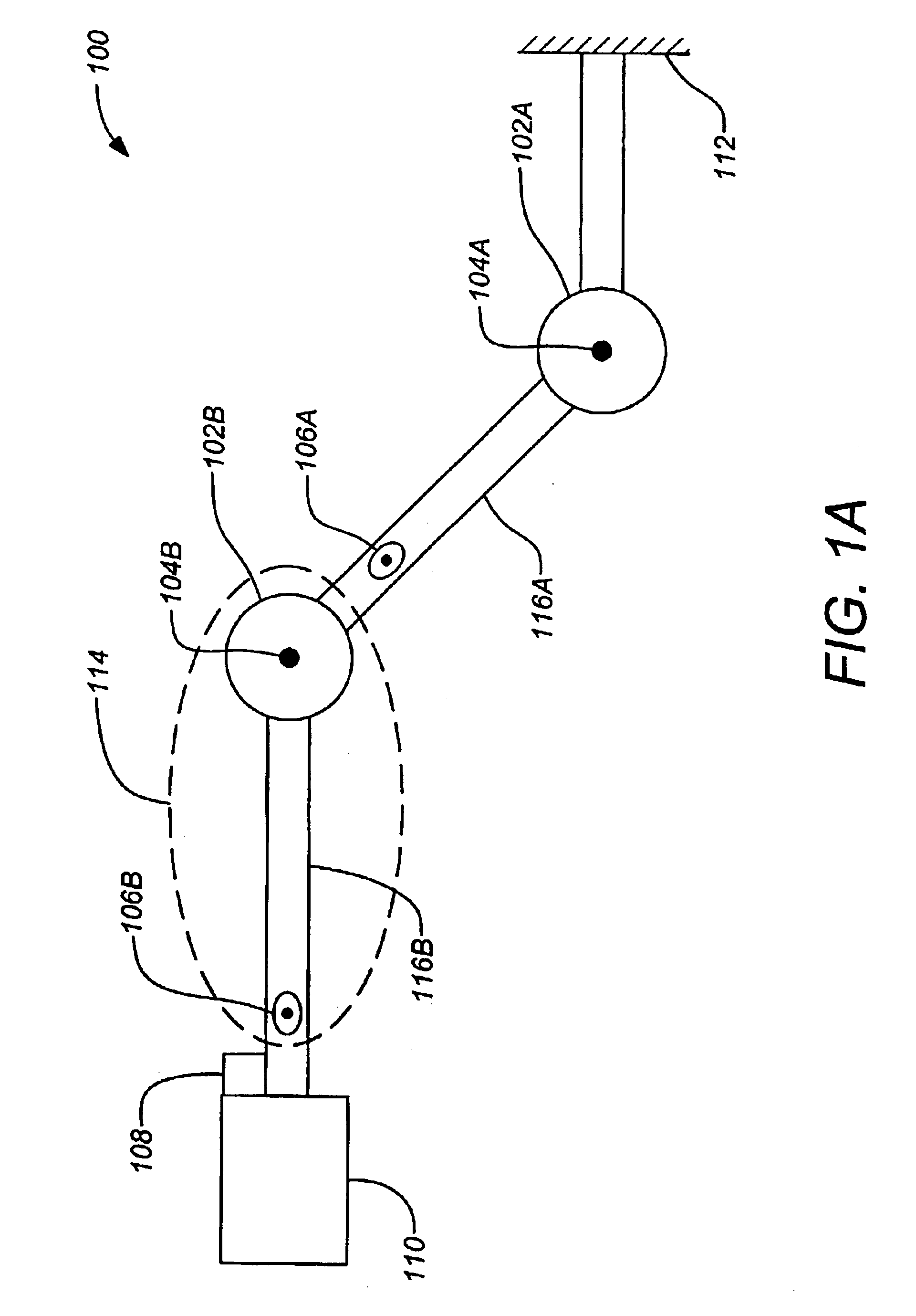

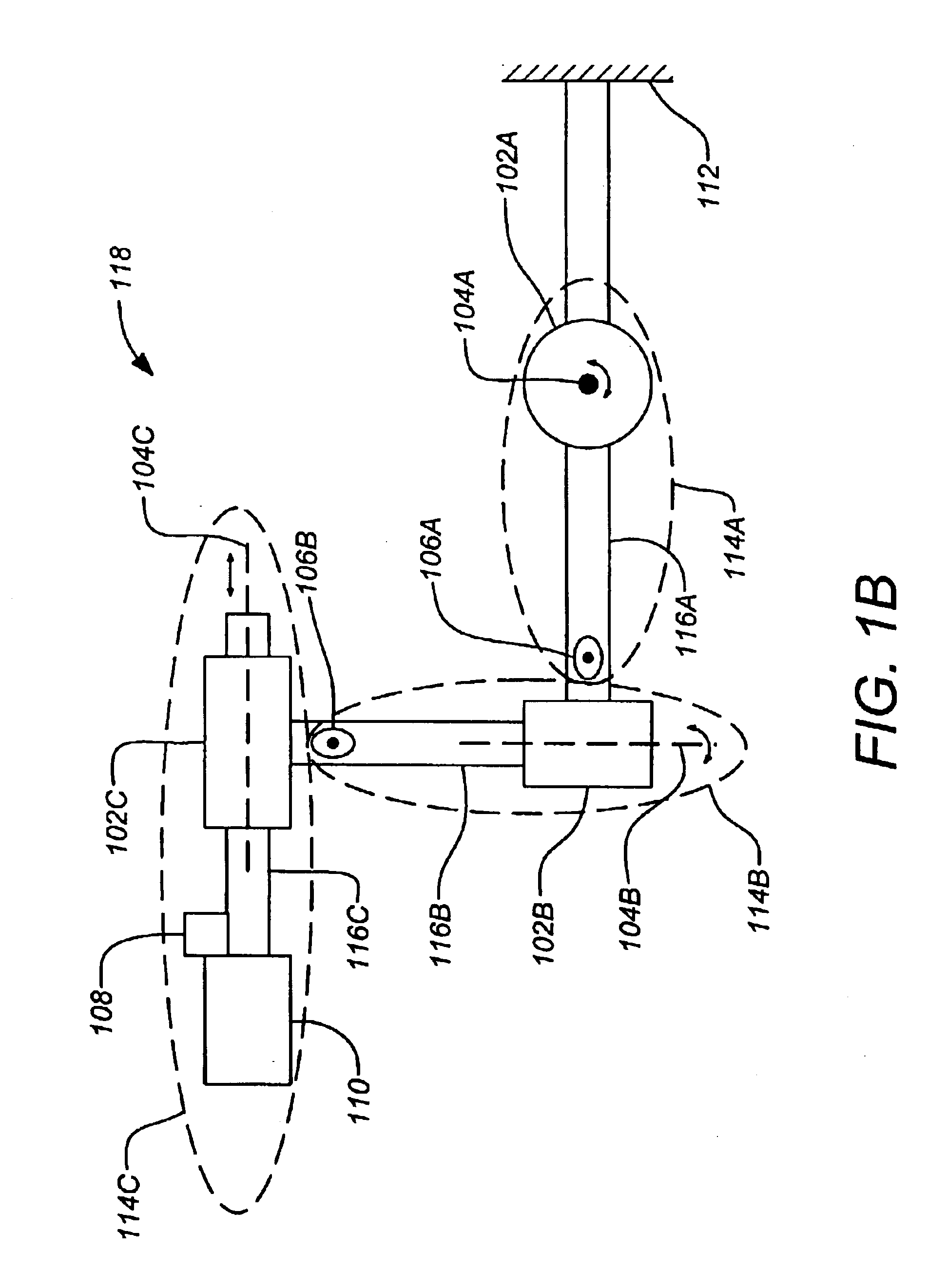

Low cost robot manipulator

InactiveUS6995536B2Reduce business operating costsRobust servo controlProgramme-controlled manipulatorSafety arrangmentsEngineeringMems sensors

The present invention discloses a robotic manipulator, comprising at least one joint, each joint having a drive axis and at least one microelectromechanical system (MEMS) inertial sensor aligned with at least one drive axis providing sensing of a relative position of the drive axis. The robotic manipulator can include an inertial measurement unit (IMU) coupled to the robotic manipulator for determining the end effector position and orientation. A controller can be used, receiving a signal from at least one MEMS inertial sensor and controlling at least one joint drive axis in response to the signal to change the relative position of the joint drive axis. Rate information from MEMS sensors can be integrated to determine the position of their respective drive axes.

Owner:THE BOEING CO

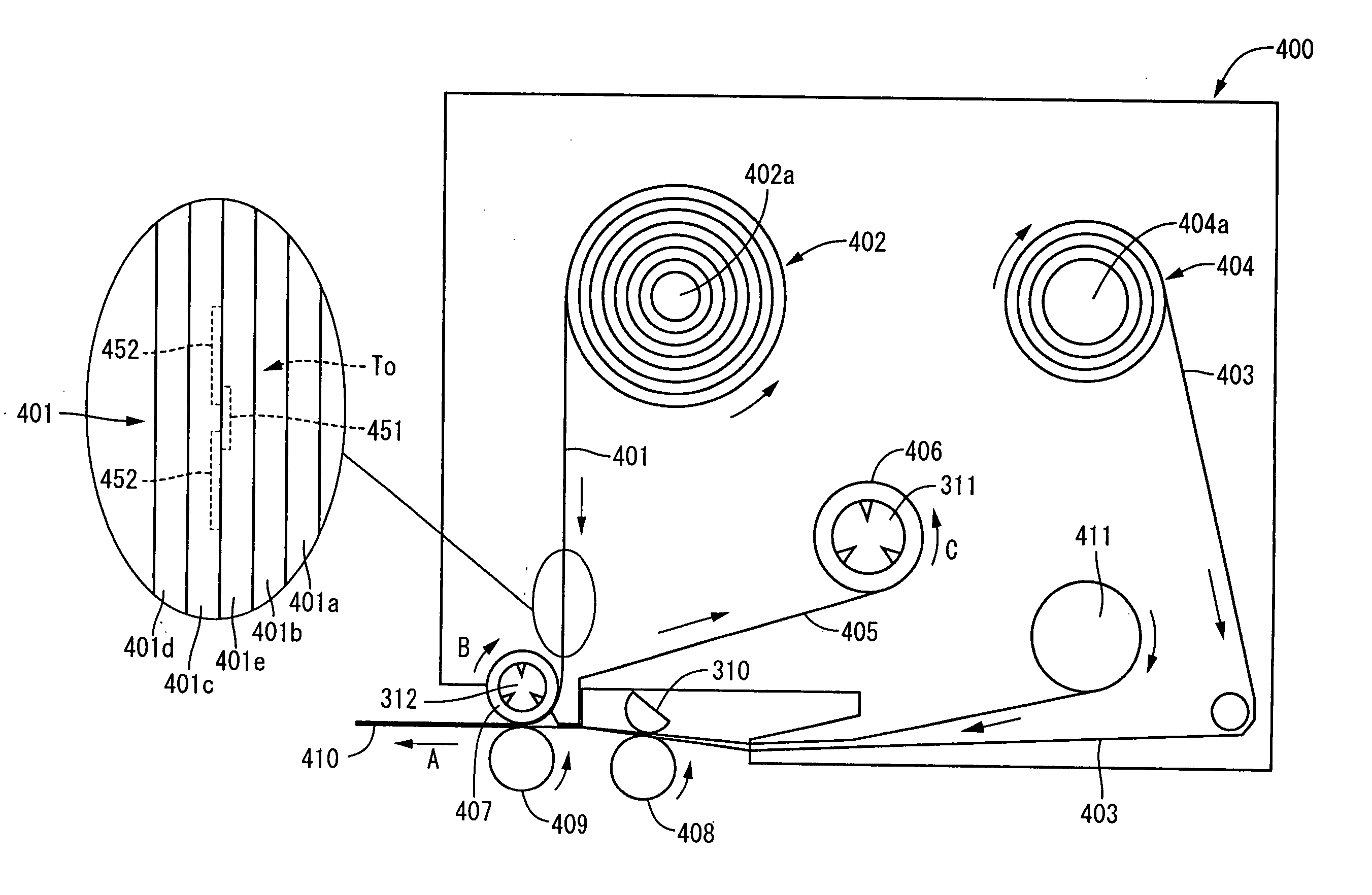

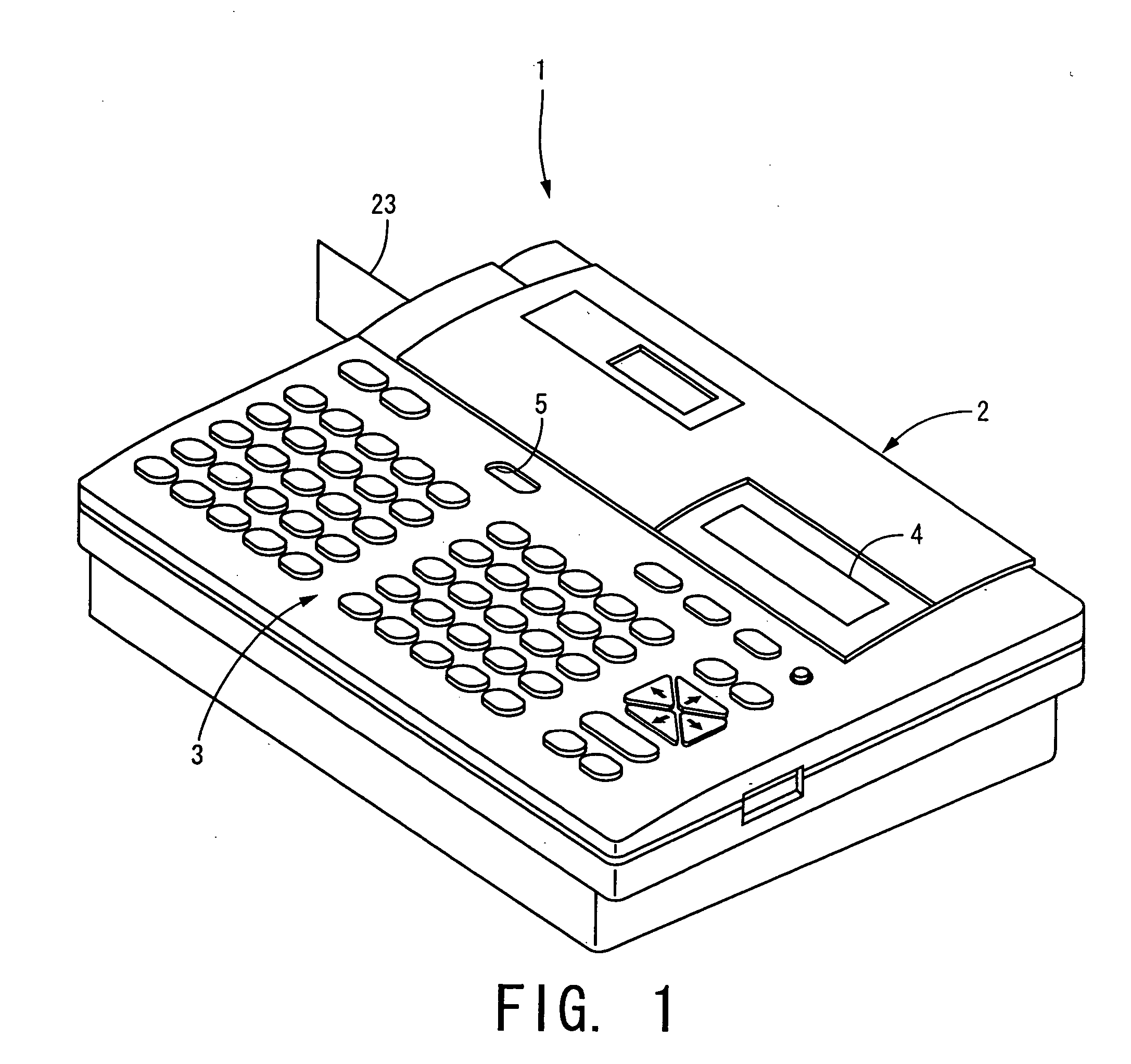

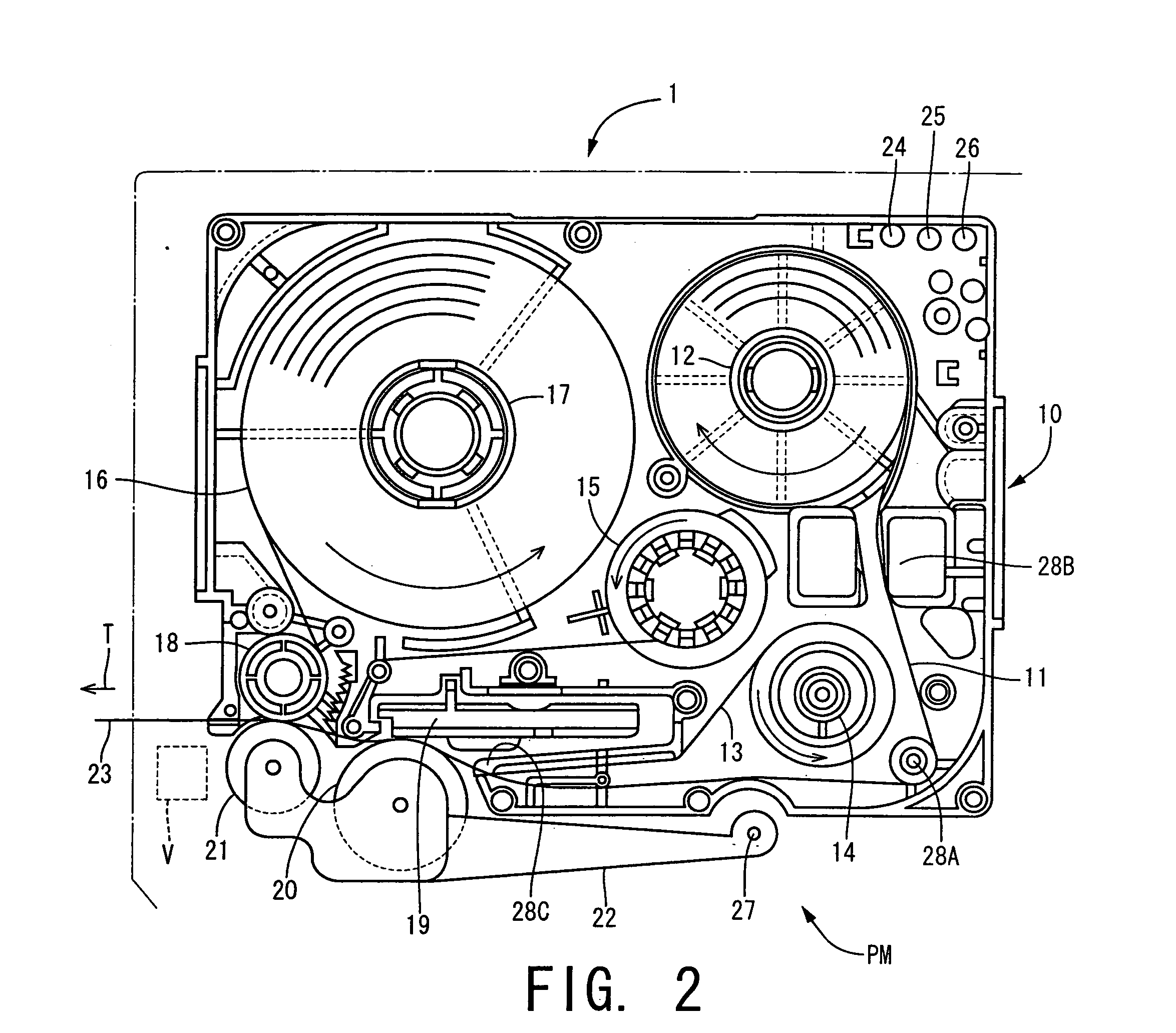

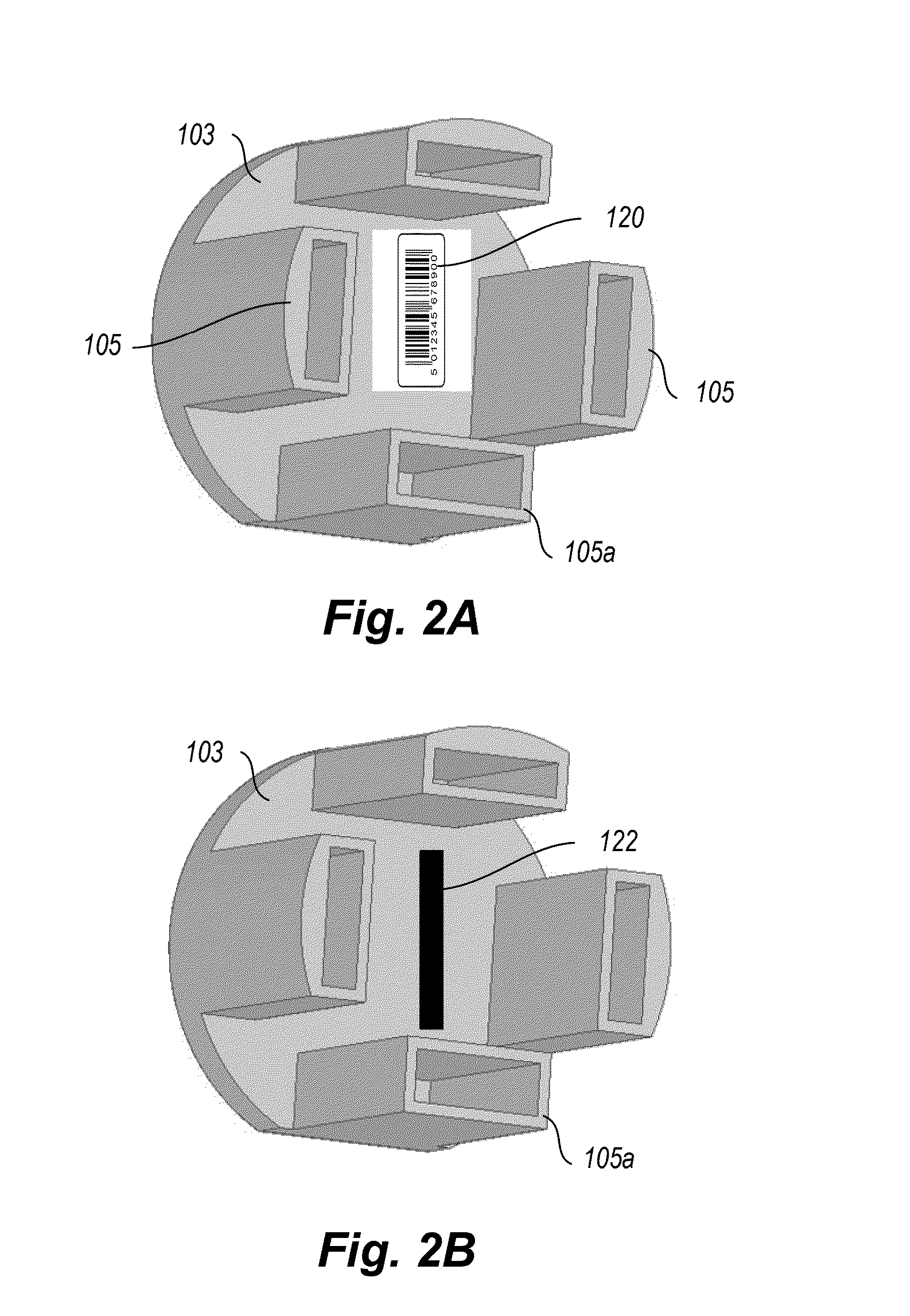

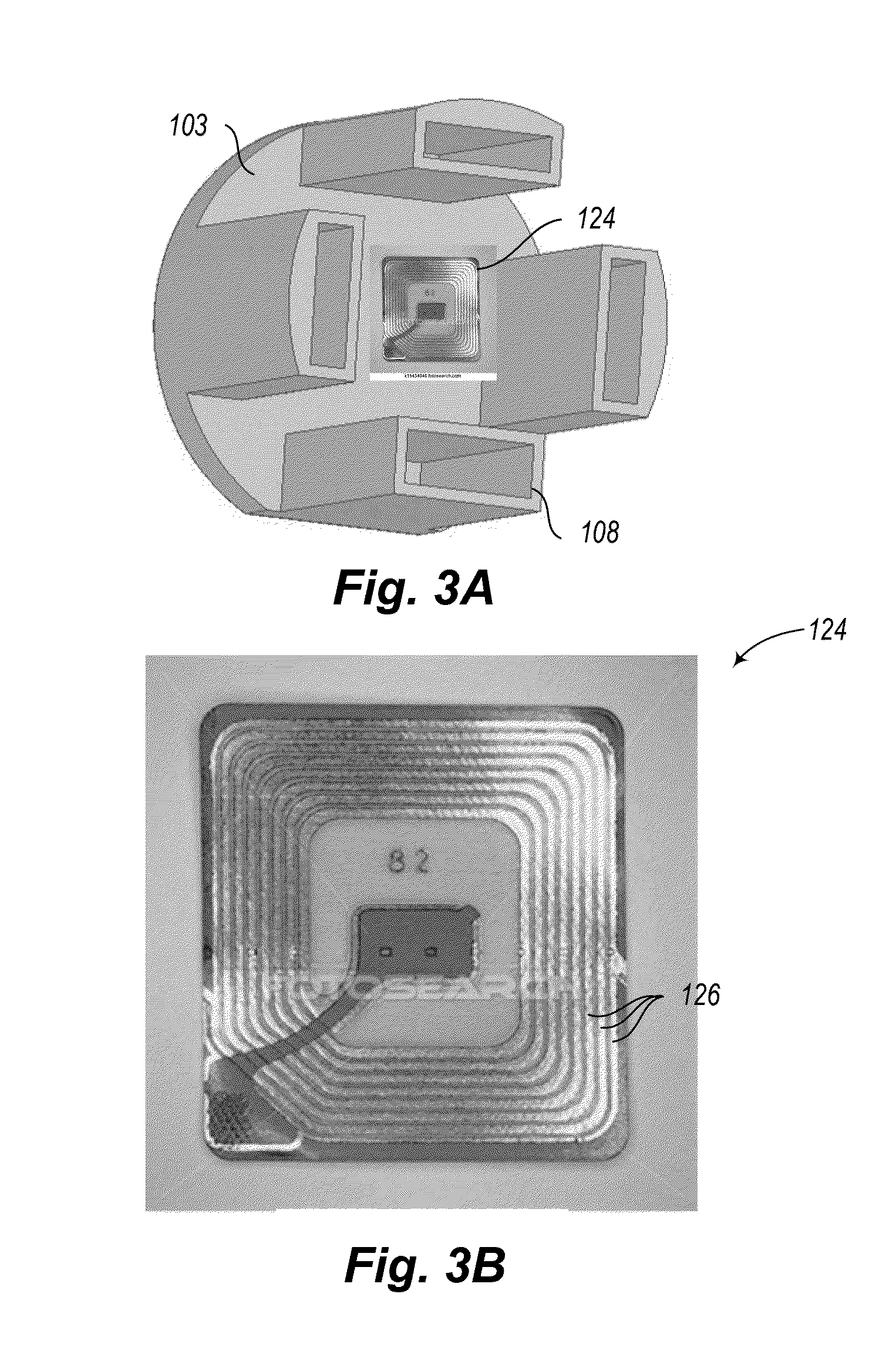

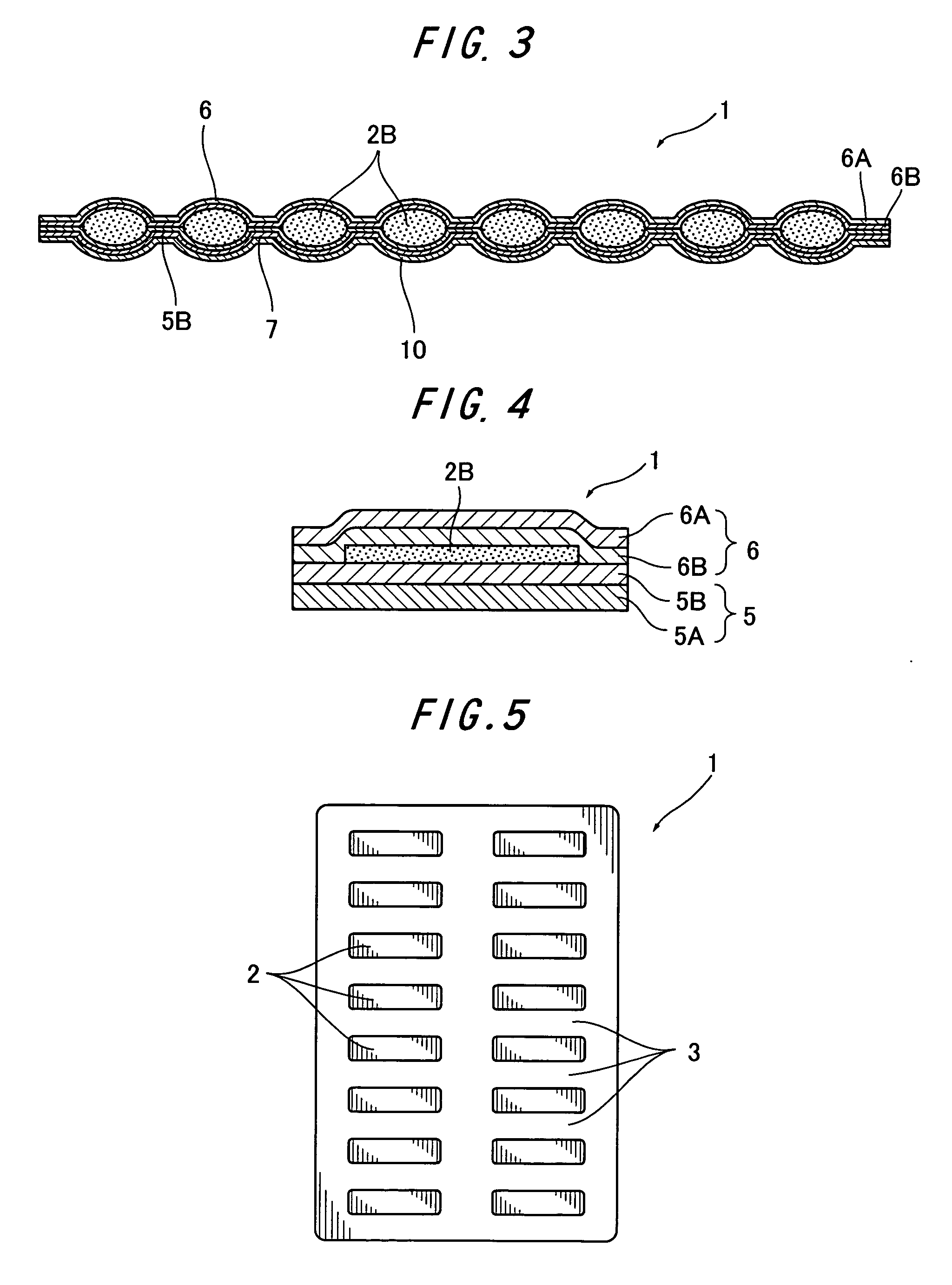

RFID label, method for producing the RFID label, device for producing the RFID label, sheet member (tag sheet) used for the RFID label, and cartridge attached to the device for producing the RFID label

ActiveUS20060118229A1Avoid wear and tearExcellent statePaper/cardboard articlesAntenna supports/mountingsElectrical conductorEngineering

A method for producing a RFID label comprises conveying a first label base material which is transparent from a first holding portion holding the first label base material, forming an image on a surface of the first label base material, conveying a second label base material including at least one of a RFID antenna conductor and an IC chip from a second holding portion holding the second label base material and joining the second label base material and the first label base material on which an image has been formed together, wherein, when an image is formed on the first label base material, the image is formed on a surface of the first label base material, the surface being joined to the second label base material.

Owner:BROTHER KOGYO KK

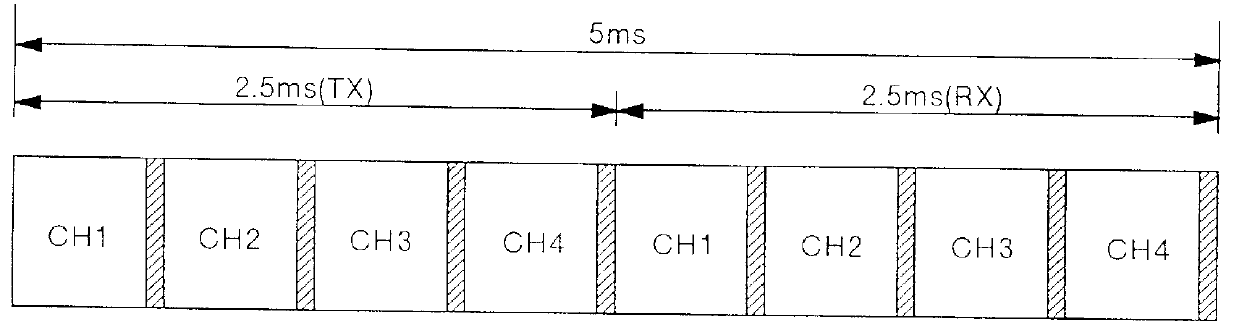

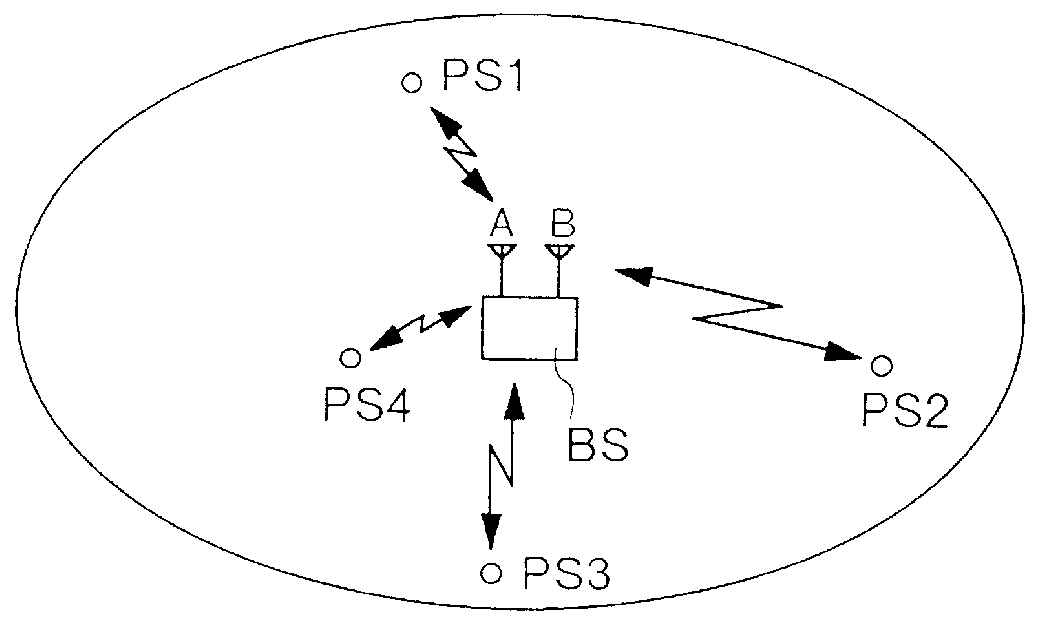

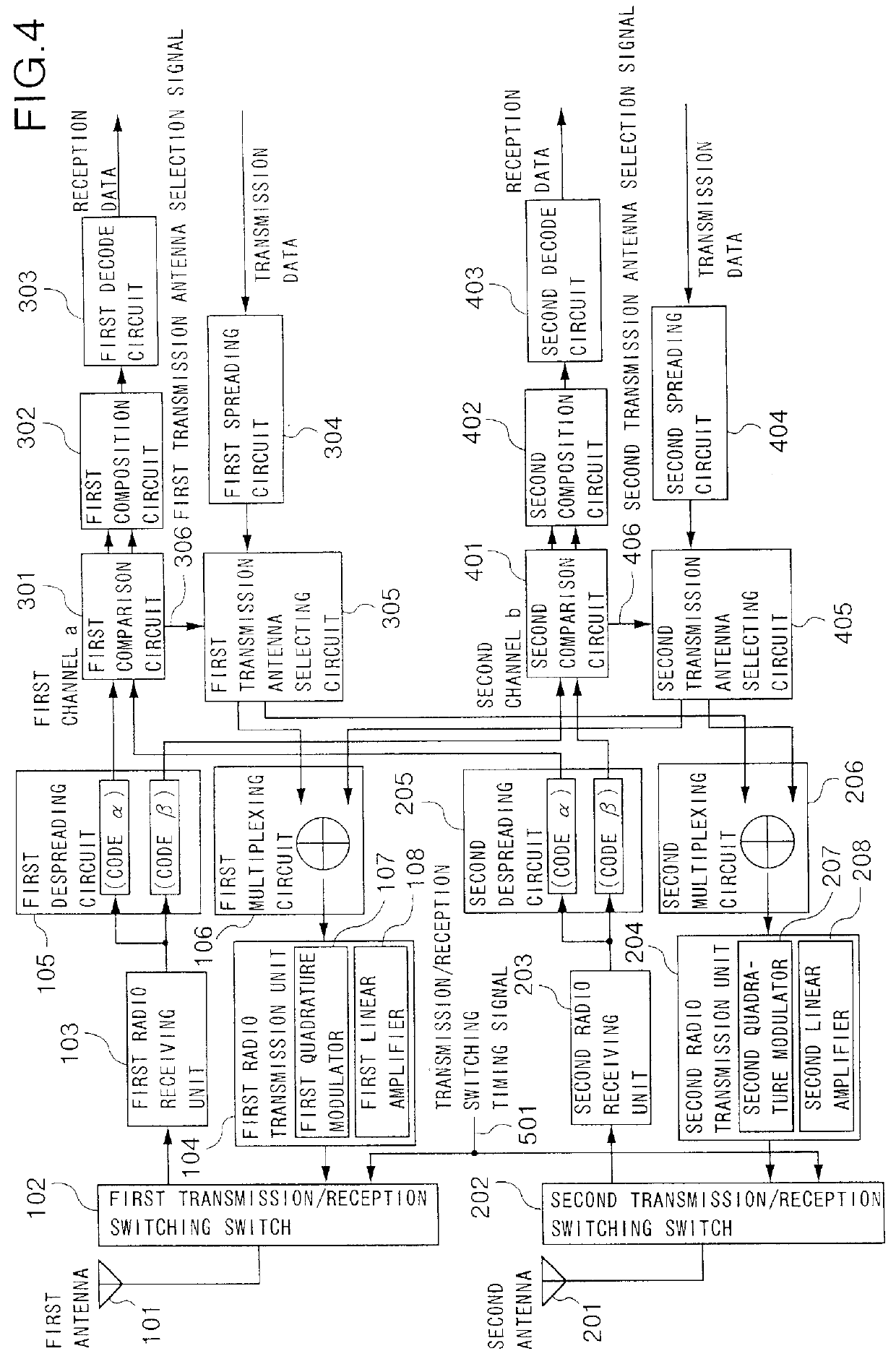

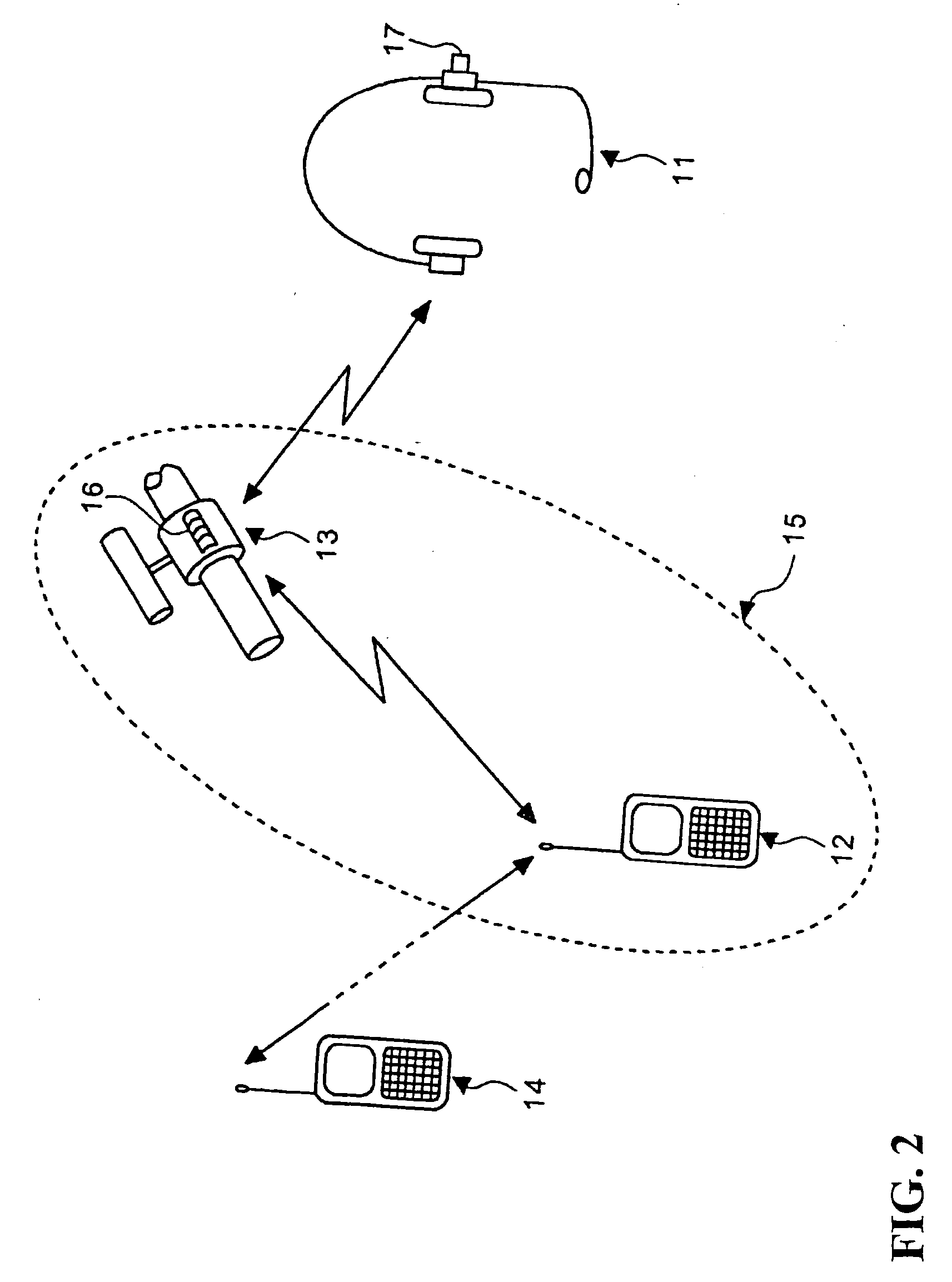

Transmission diversity for a CDMA/TDD mobile telecommunication system

InactiveUSRE36591E1Improve communication qualityExcellent stateSpatial transmit diversityModulated-carrier systemsMultiplexingEngineering

In a base station which has a plurality of antennas, each of a plurality of comparison circuits operates to compare correlation levels, which are obtained by despreading received signals for a plurality of channels, with each other with respect to the antennas. Each of a plurality of transmission antenna selecting circuits operates to determine from which antenna a transmission signal is to be transmitted for every channel. Each of a plurality of multiplexing circuits operates to multiplex the transmission signals of the individual channels, which are spread, for every antenna. As a result, on the basis of the result of the comparison of the correlation levels with respect to the antennas, a transmission antenna is selected for every channel, and the signals of the channels that are to be transmitted by a given antenna are multiplexed, whereby the base station achieves transmission diversity.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

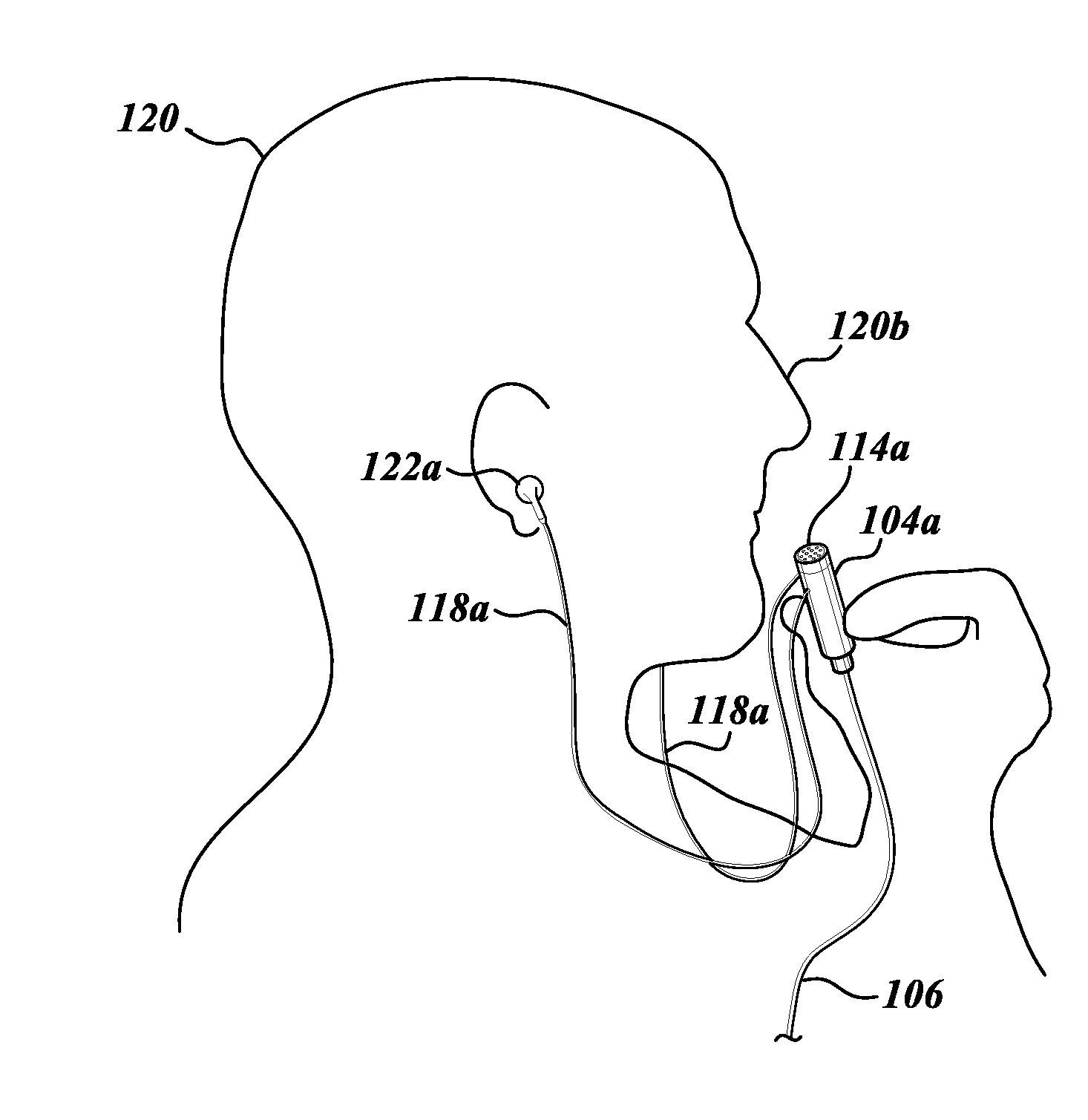

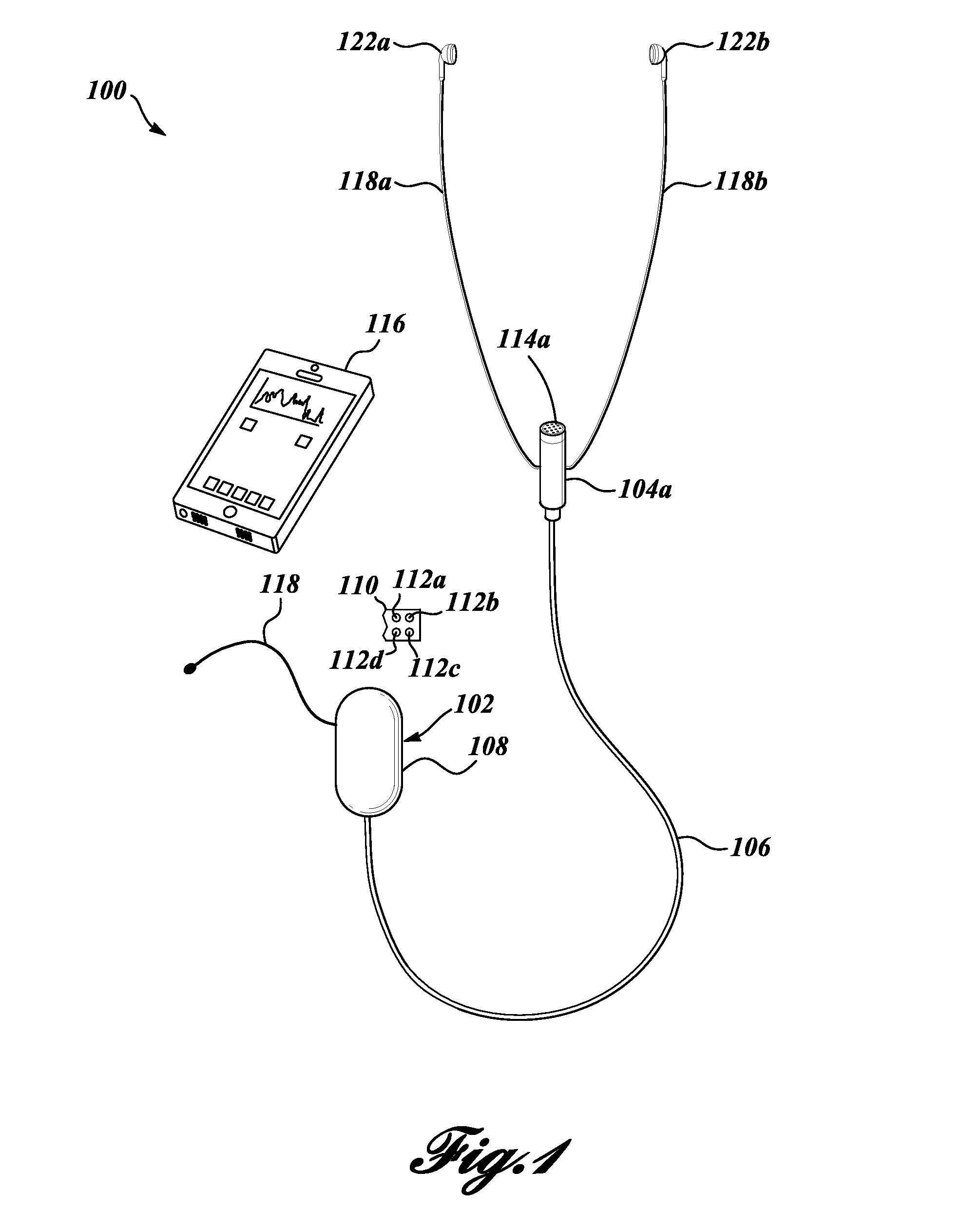

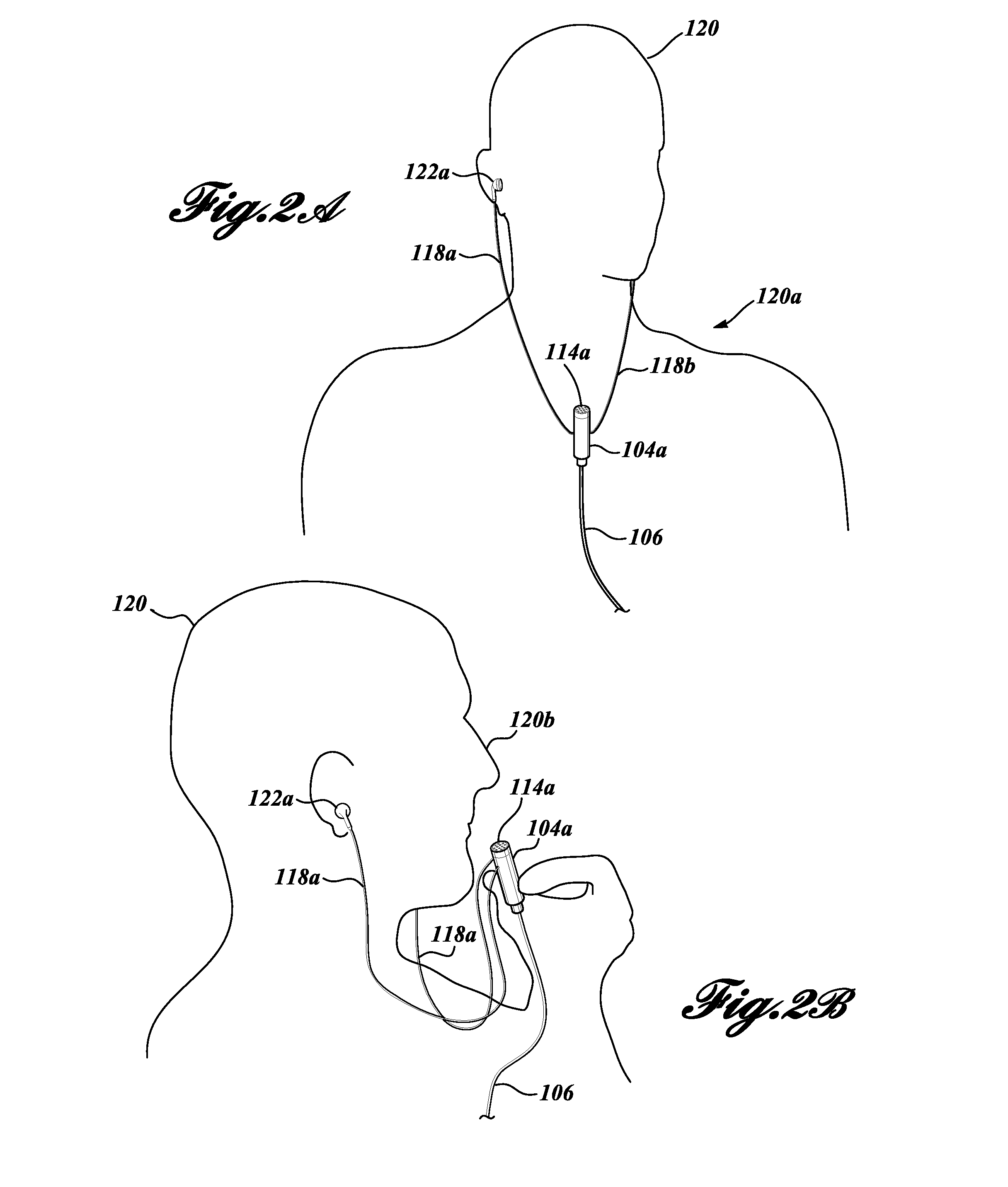

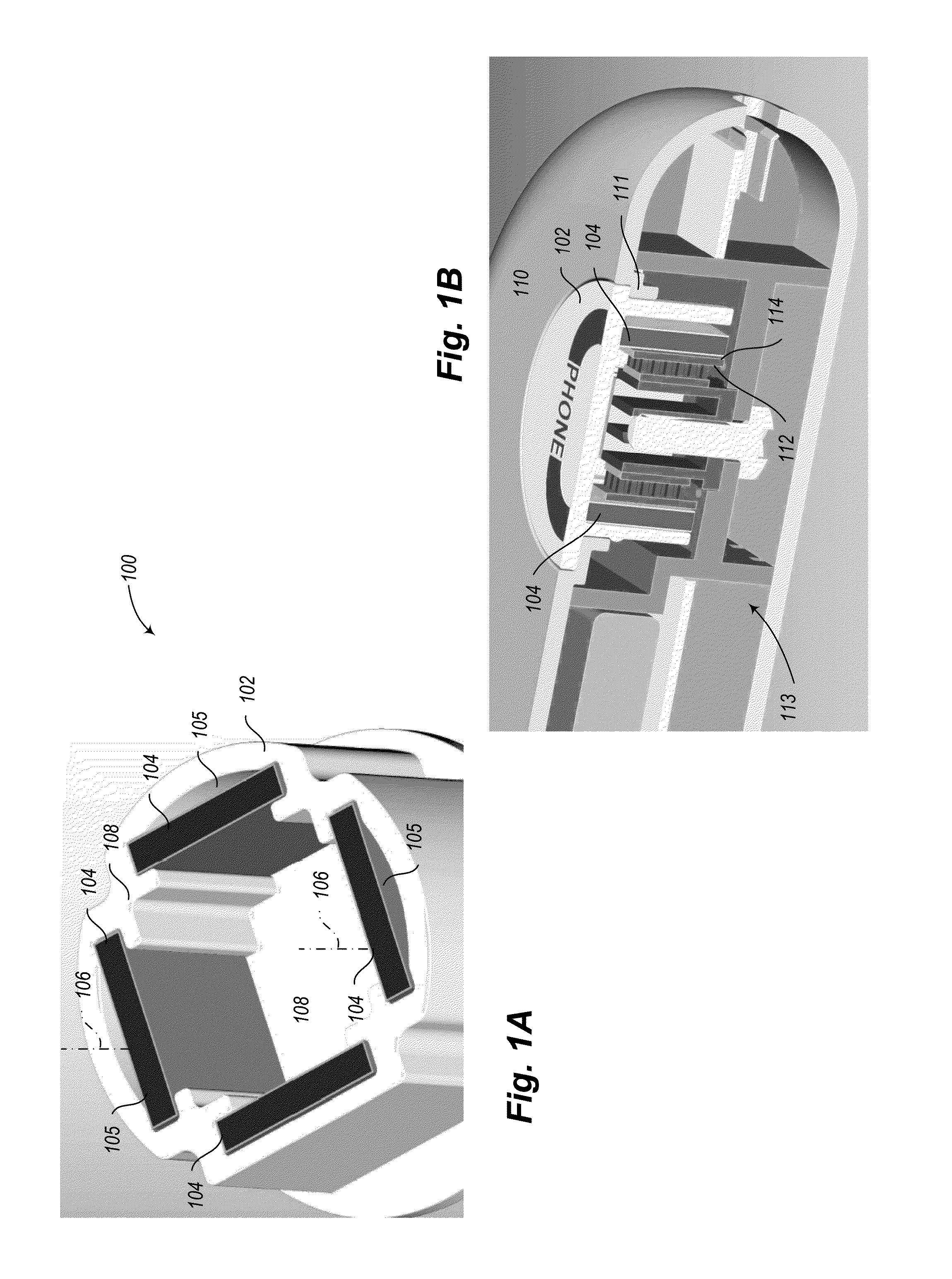

Systems, methods and articles to provide olfactory sensations

ActiveUS20150048178A1Improve impactMinimize impactLiquid surface applicatorsStage arrangementsActive coolingEngineering

A system to provide scents includes a scent receiver to replaceable receive scent carriers that carry scent media, a scent actuator operable to controllable release scent, and a configurable circulation subsystem. Peltier devices may used to induce active heating and active cooling of scent media according to defined scent sequence information or scent tracks. The system is also operable to collect air, including scents, from an ambient environment, and temporarily retaining such for sampling by a user. Scent tracks may be defined and shared amongst users and other entities.

Owner:VAPOR COMM +1

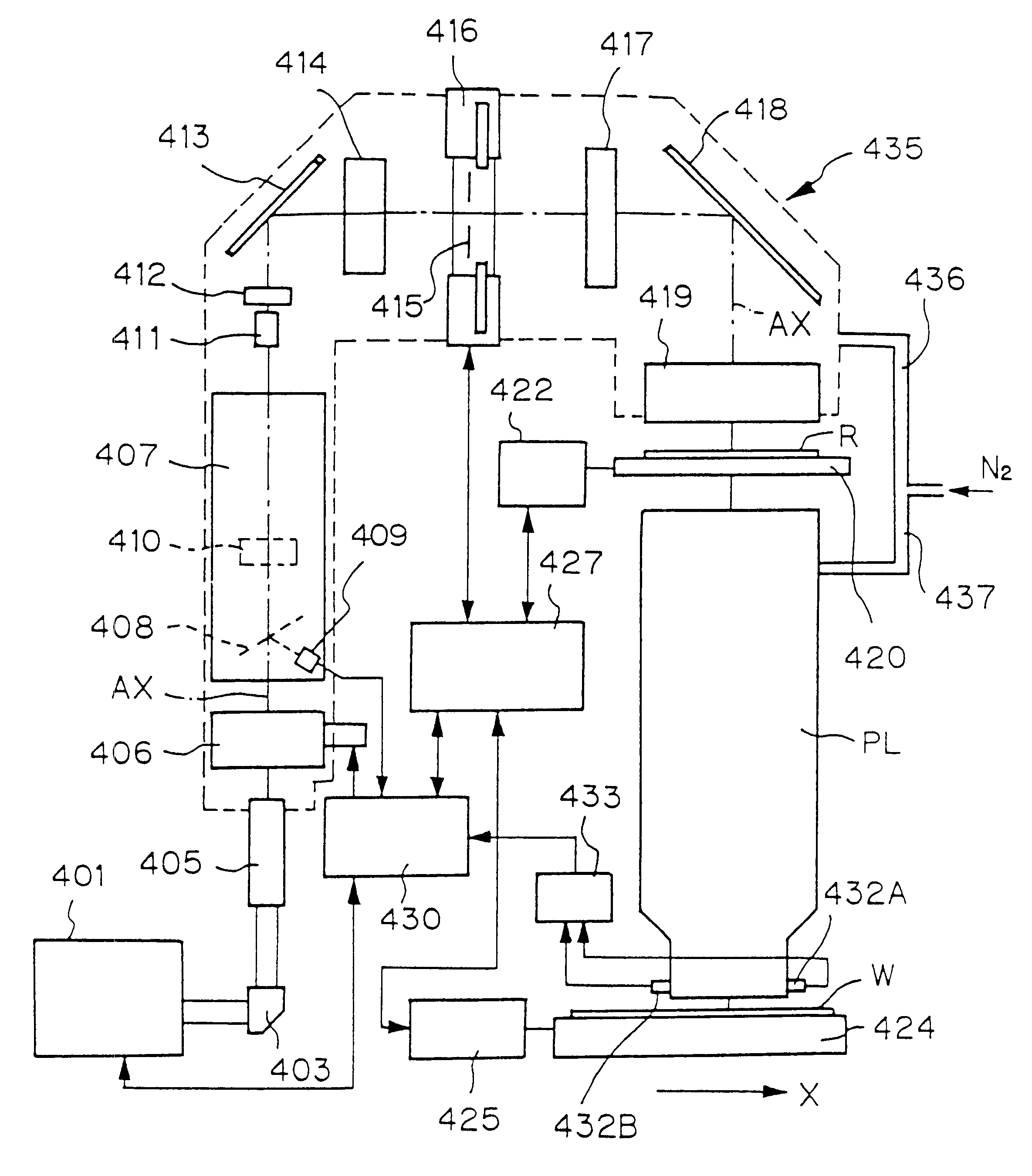

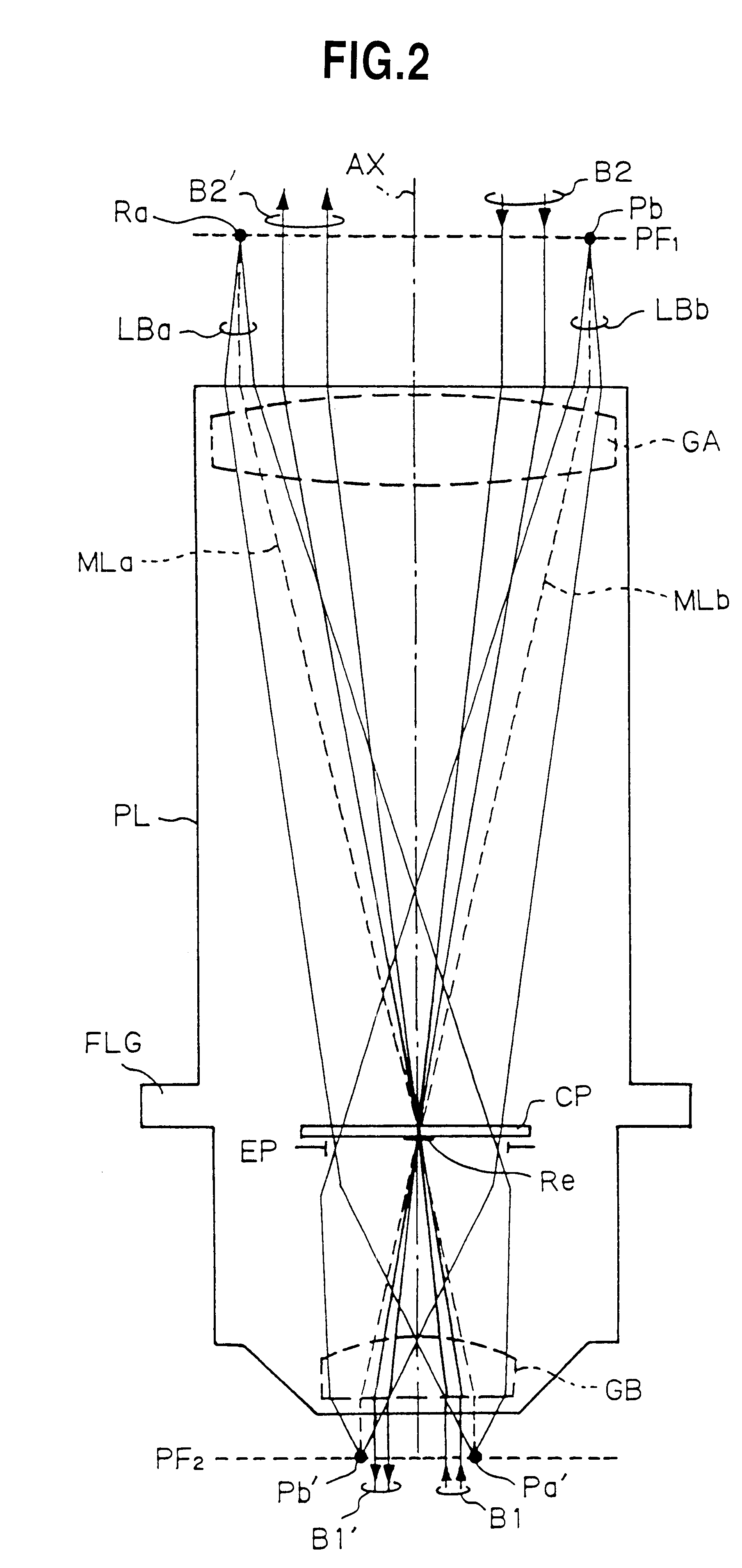

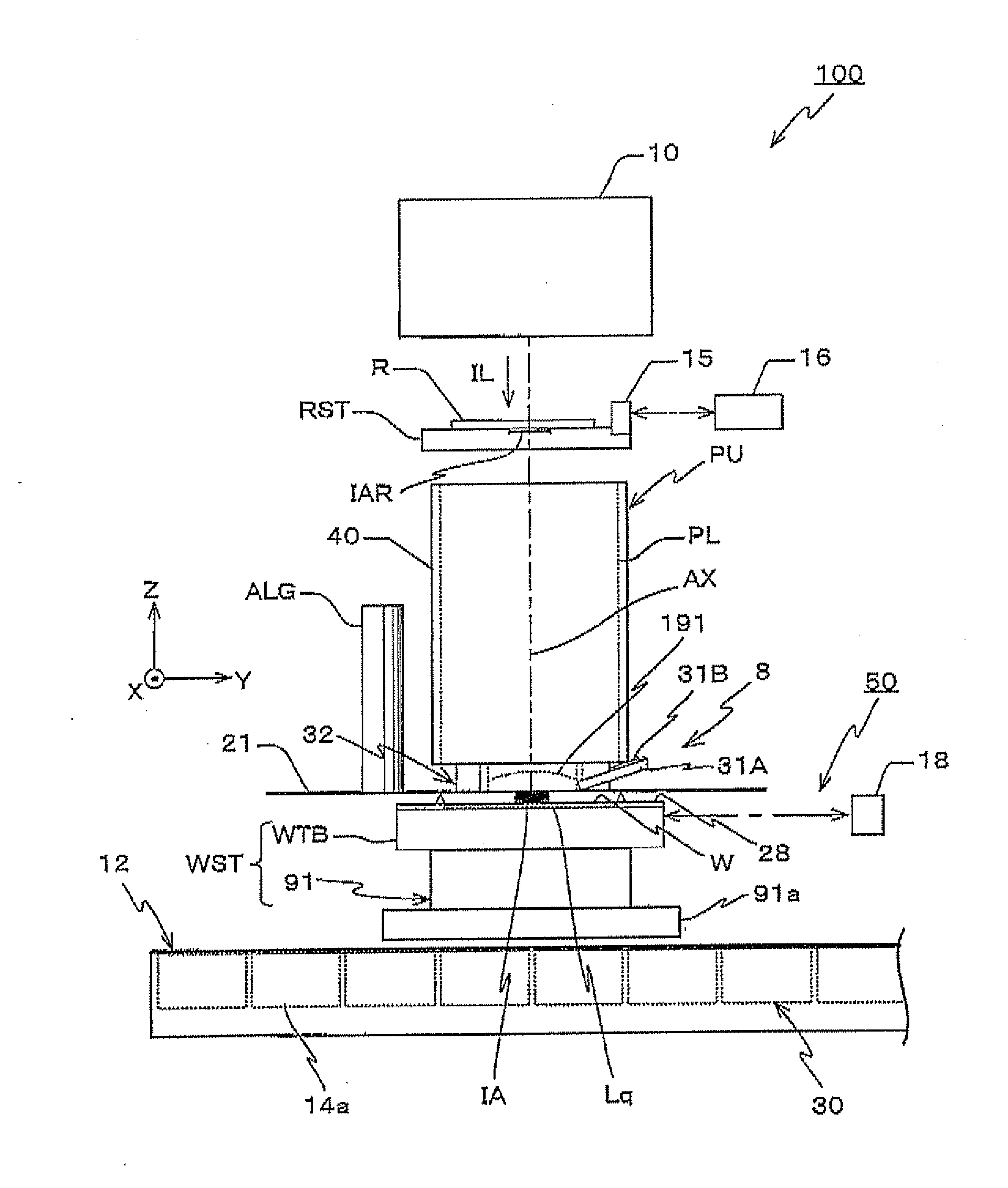

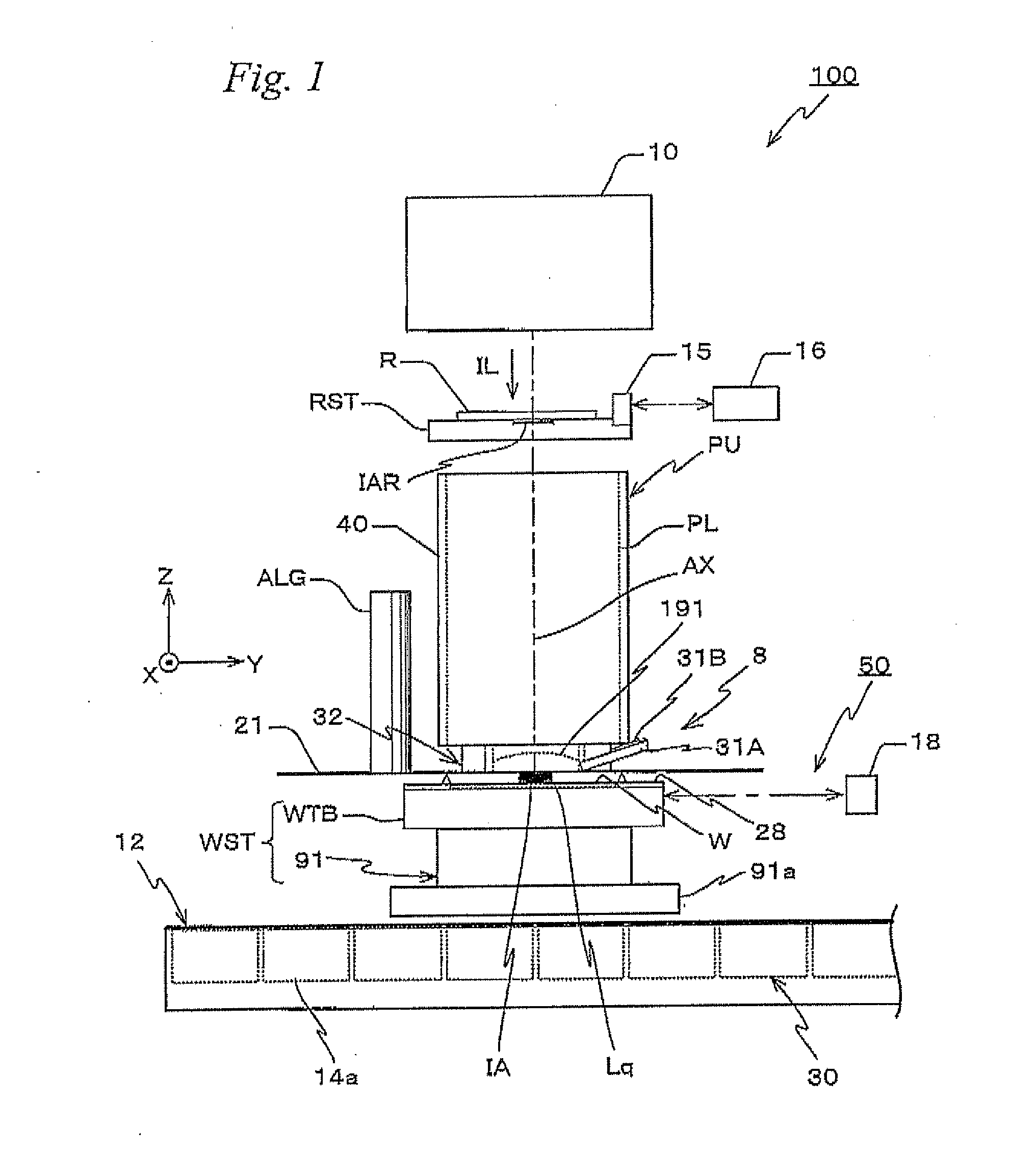

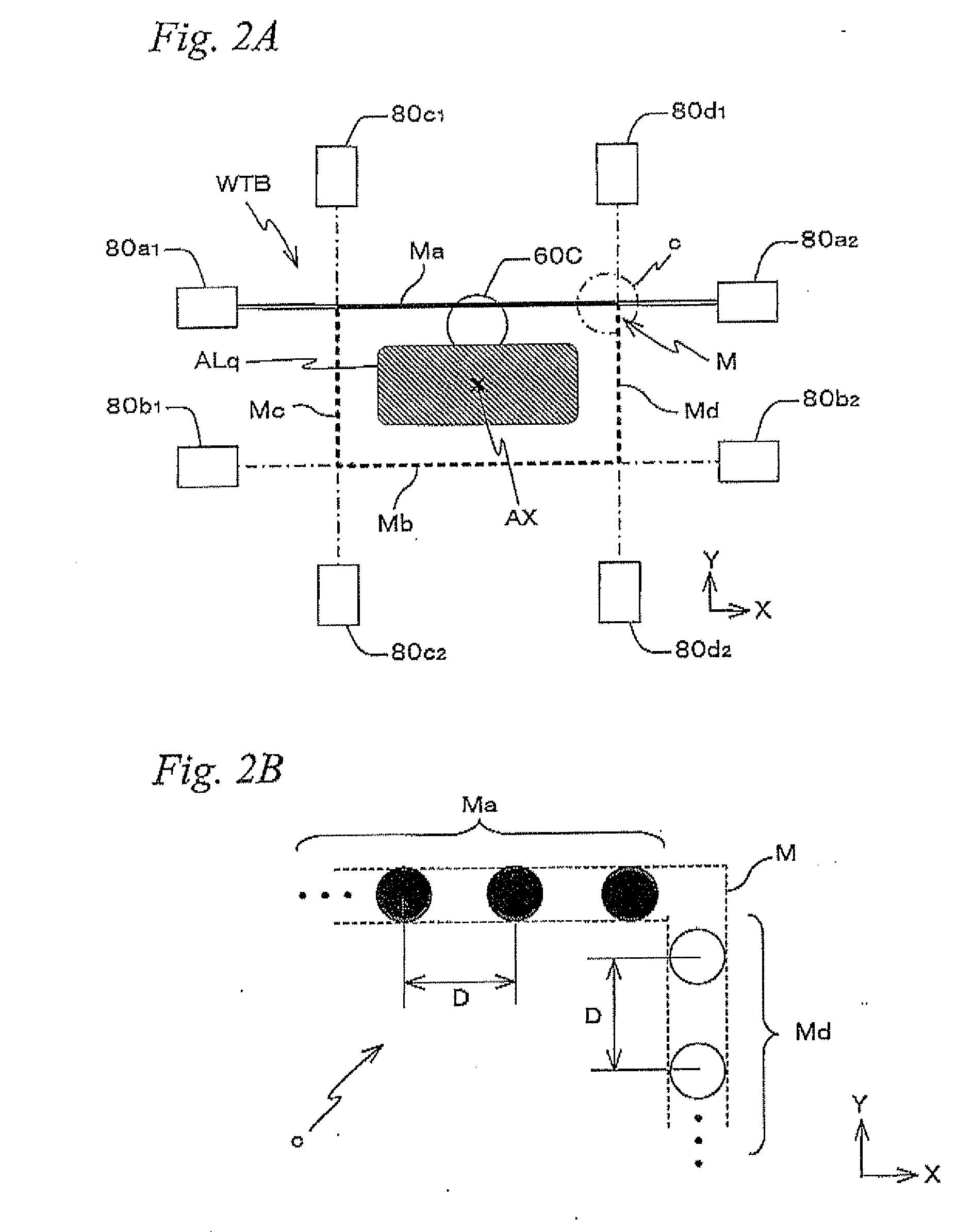

Exposure apparatus, exposure method using the same and method of manufacture of circuit device

InactiveUS6414743B1Favorable imaging stateExposed to lightPhotomechanical exposure apparatusMicrolithography exposure apparatusUltrasound attenuationTransmittance

Owner:NIKON CORP

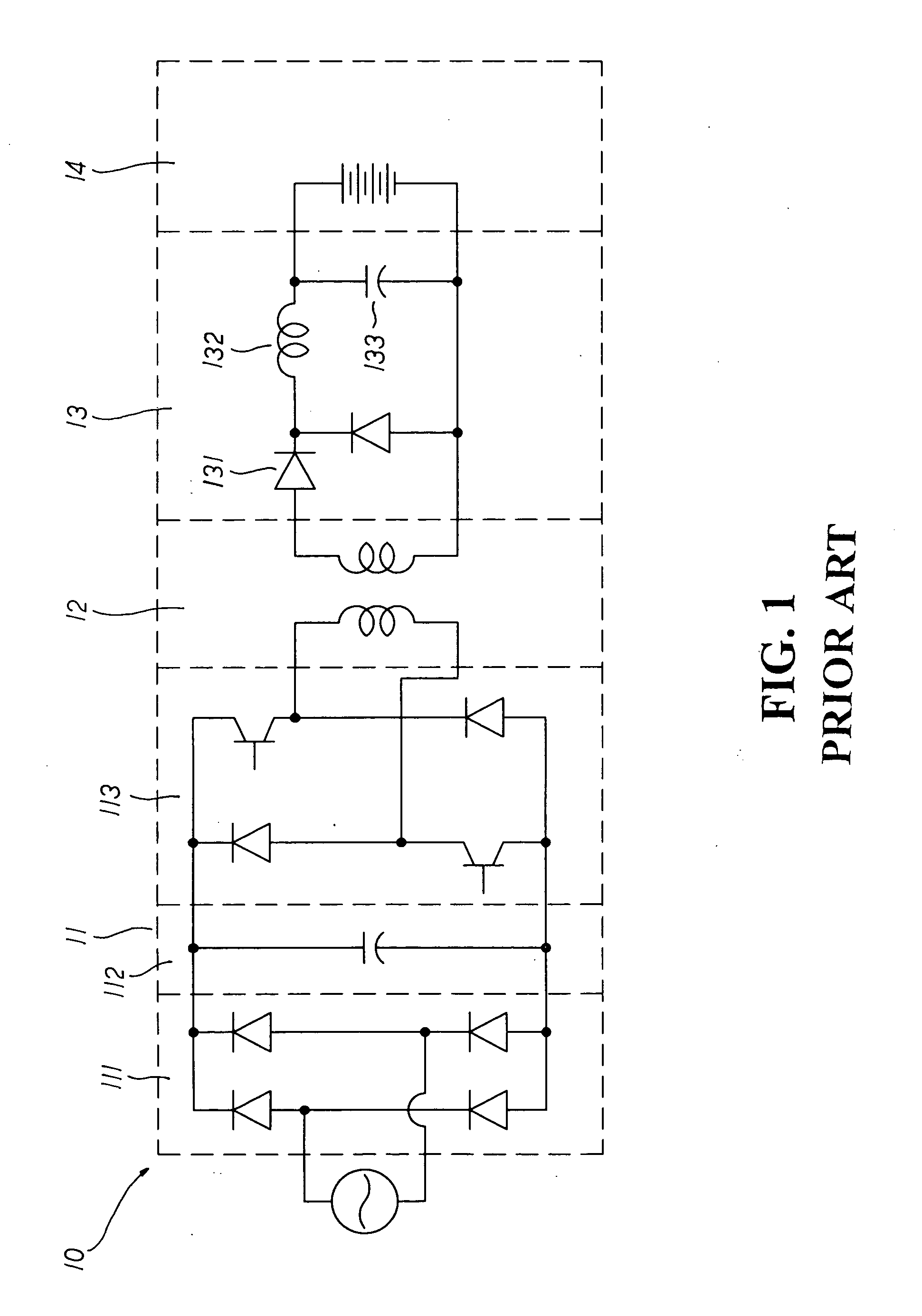

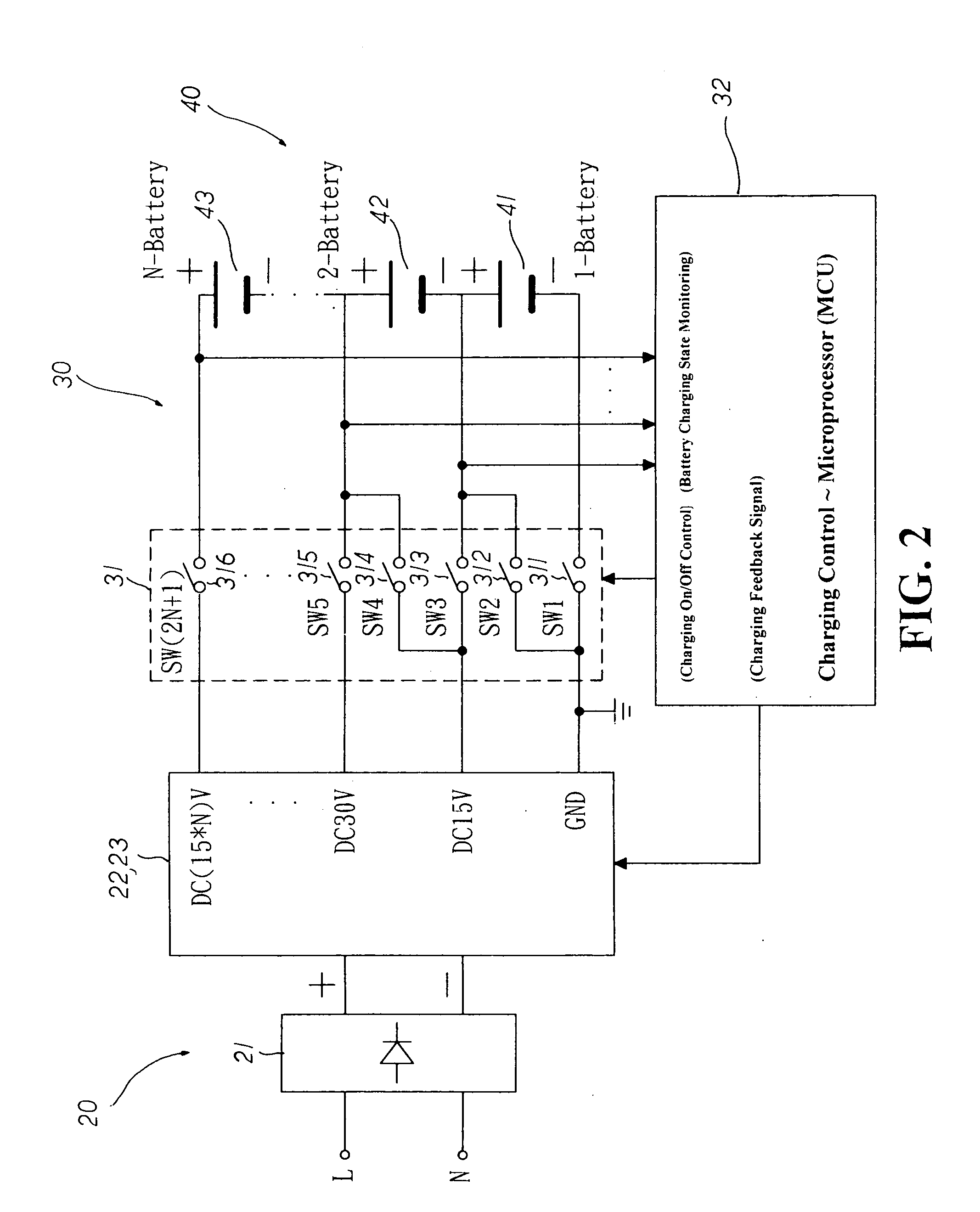

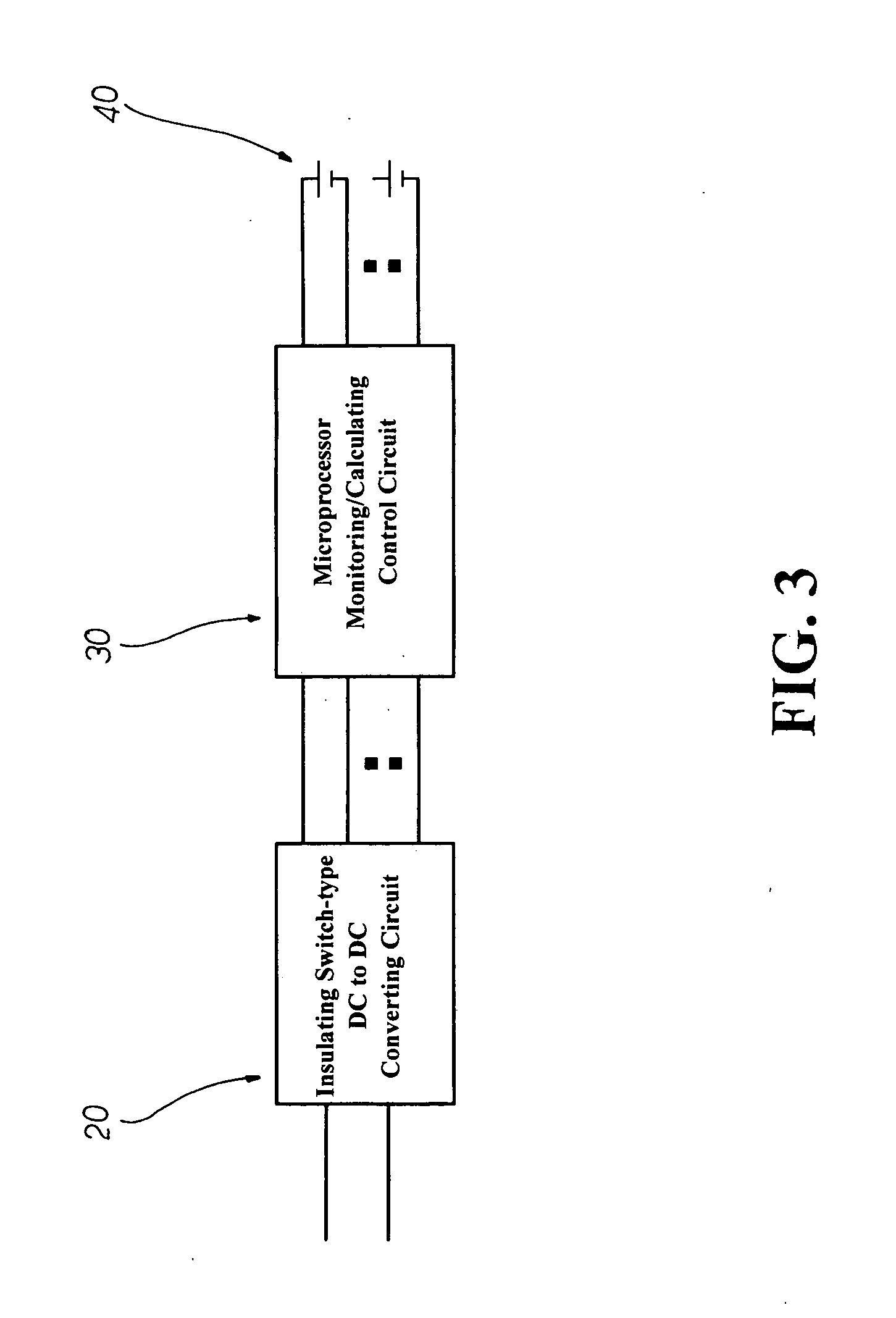

Intelligent equalizing battery charger having equalization charging circuitry

InactiveUS20070145946A1Excellent stateIncrease blockingCharge equalisation circuitDc-dc conversionTransformerCharge control

An intelligent equalizing battery charger having equalization charging circuitry is disclosed, comprising an insulating switch-type DC to DC converting circuit, a microprocessor monitoring / calculating control circuit, and a charging battery set wherein the insulating switch-type DC to DC converting circuit is composed of a power supply switch circuit, an insulating transformer, and a rectification converting circuit. The microprocessor monitoring / calculating control circuit includes multiple switch elements and a charging control microprocessor. Via the aforementioned structure, each individual cell of the charging battery set can be appropriately charged in equalization, which can not only increase the charging / discharging times of the battery set, but also efficiently extend the battery life in application.

Owner:SINO AMERICAN ELECTRONICS

Methods, Compositions and Articles of Manufacture for Enhancing Survivability of Cells, Tissues, Organs, and Organisms

InactiveUS20080171726A1Improve survivabilityPrevent and reduce damageBiocideSulfur/selenium/tellurium active ingredientsSurvivabilityIn vivo

The present invention concerns the use of oxygen antagonists and other active compounds for inducing stasis or pre-stasis in cells, tissues, and / or organs in vivo or in an organism overall, in addition to enhancing their survivability. It includes compositions, methods, articles of manufacture and apparatuses for enhancing survivability and for achieving stasis or pre-stasis in any of these biological materials, so as to preserve and / or protect them. In specific embodiments, there are also therapeutic methods and apparatuses for organ transplantation, hyperthermia, wound healing, hemorrhagic shock, cardioplegia for bypass surgery, neurodegeneration, hypothermia, and cancer using the active compounds described.

Owner:ROTH MARK B +3

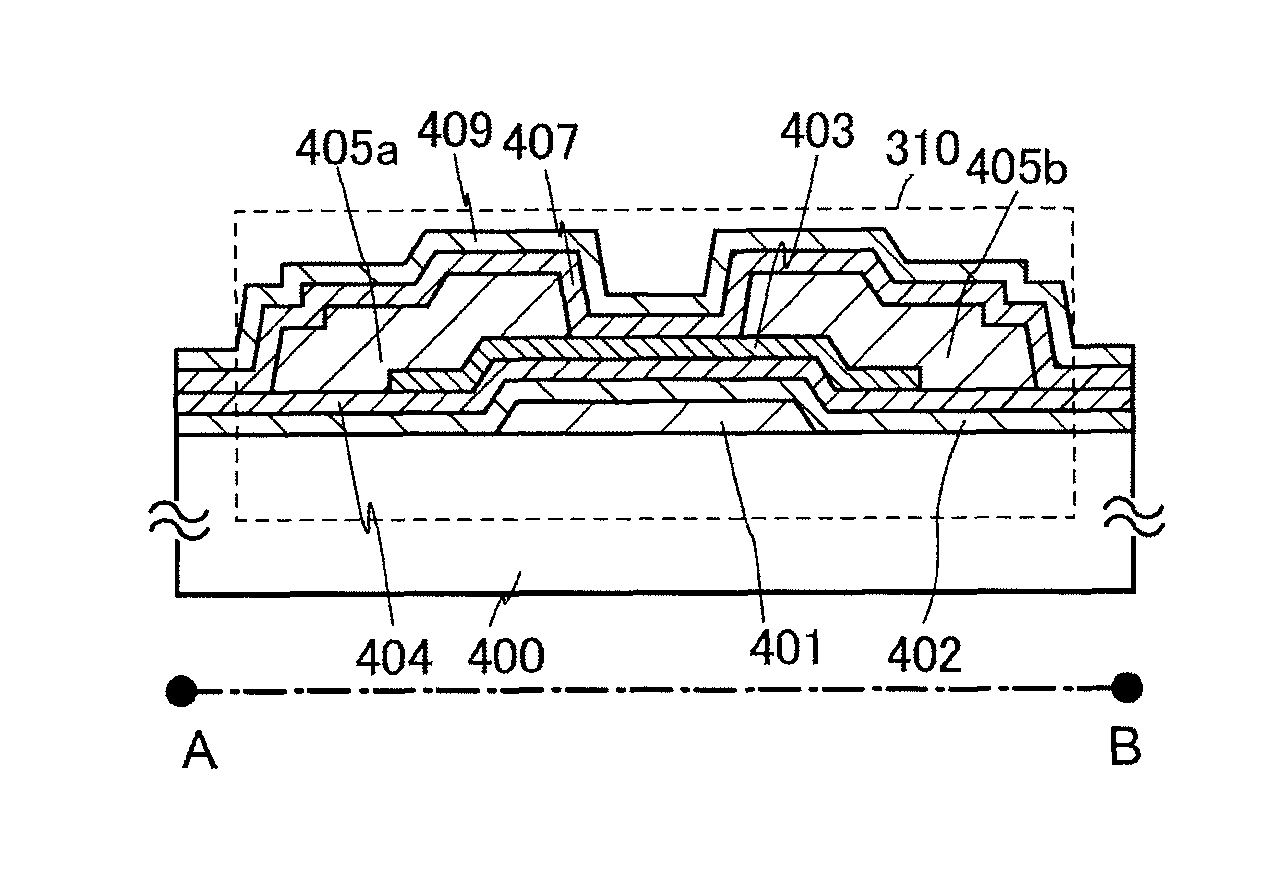

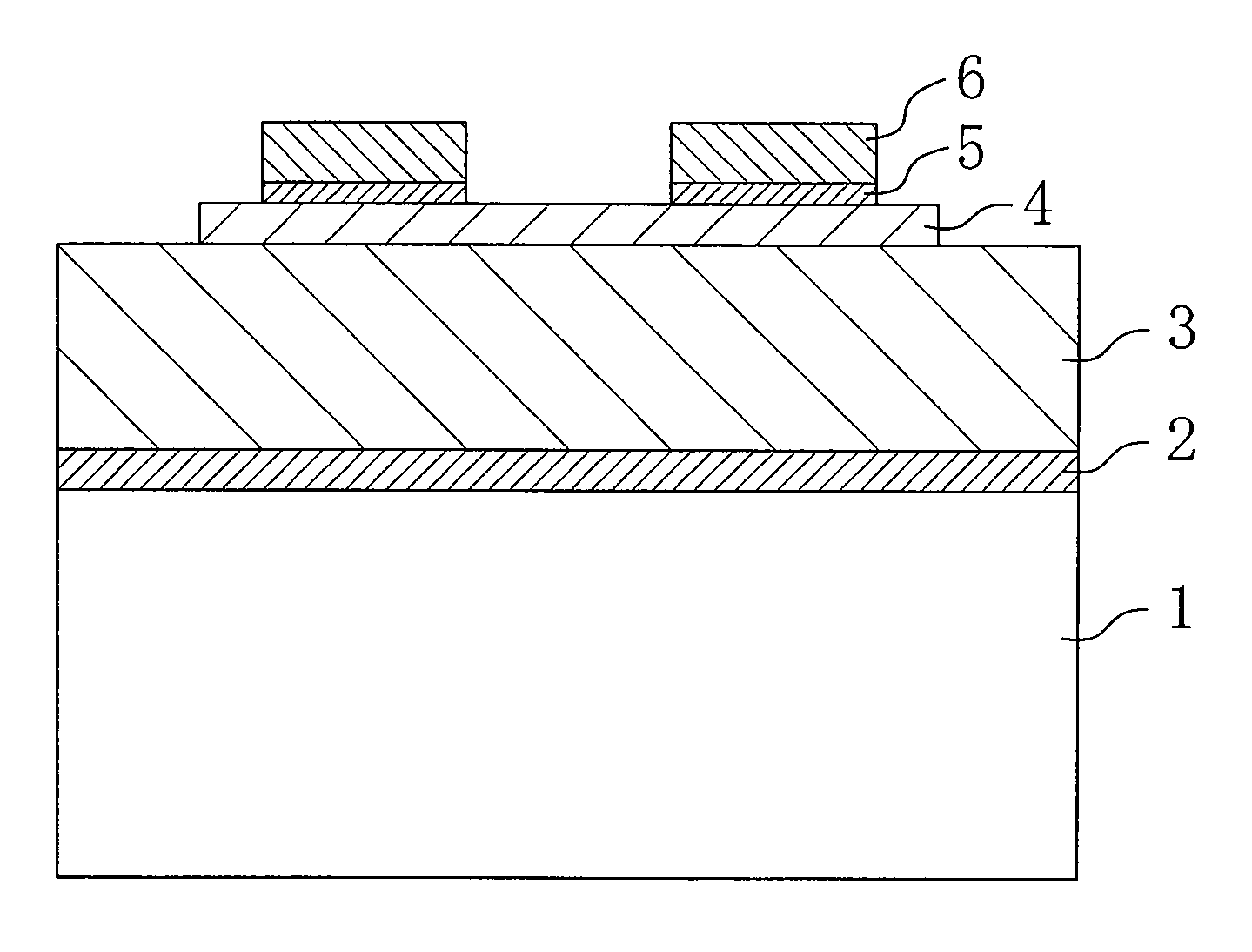

Semiconductor device including oxide semiconductor and metal oxide

ActiveUS8878173B2Stable electrical characteristicsImprove reliabilityTransistorSolid-state devicesOxygenSemiconductor

An object is to provide a semiconductor device including an oxide semiconductor, which has stable electrical characteristics and improved reliability. In a transistor including an oxide semiconductor film, insulating films each including a material containing a Group 13 element and oxygen are formed in contact with the oxide semiconductor film, whereby the interfaces with the oxide semiconductor film can be kept in a favorable state. Further, the insulating films each include a region where the proportion of oxygen is higher than that in the stoichiometric composition, so that oxygen is supplied to the oxide semiconductor film; thus, oxygen defects in the oxide semiconductor film can be reduced. Furthermore, the insulating films in contact with the oxide semiconductor film each have a stacked structure so that films each containing aluminum are provided over and under the oxide semiconductor film, whereby entry of water into the oxide semiconductor film can be prevented.

Owner:SEMICON ENERGY LAB CO LTD

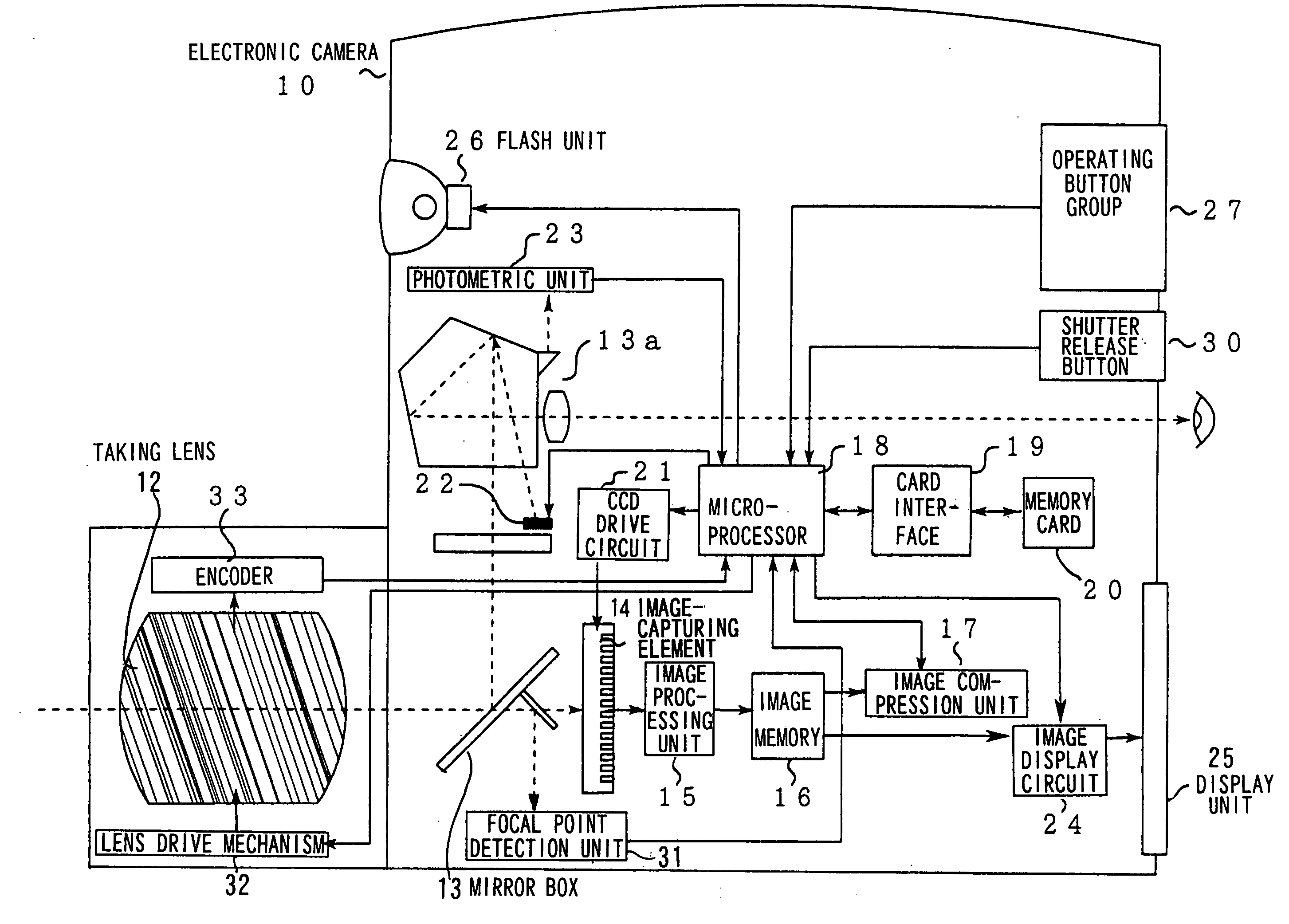

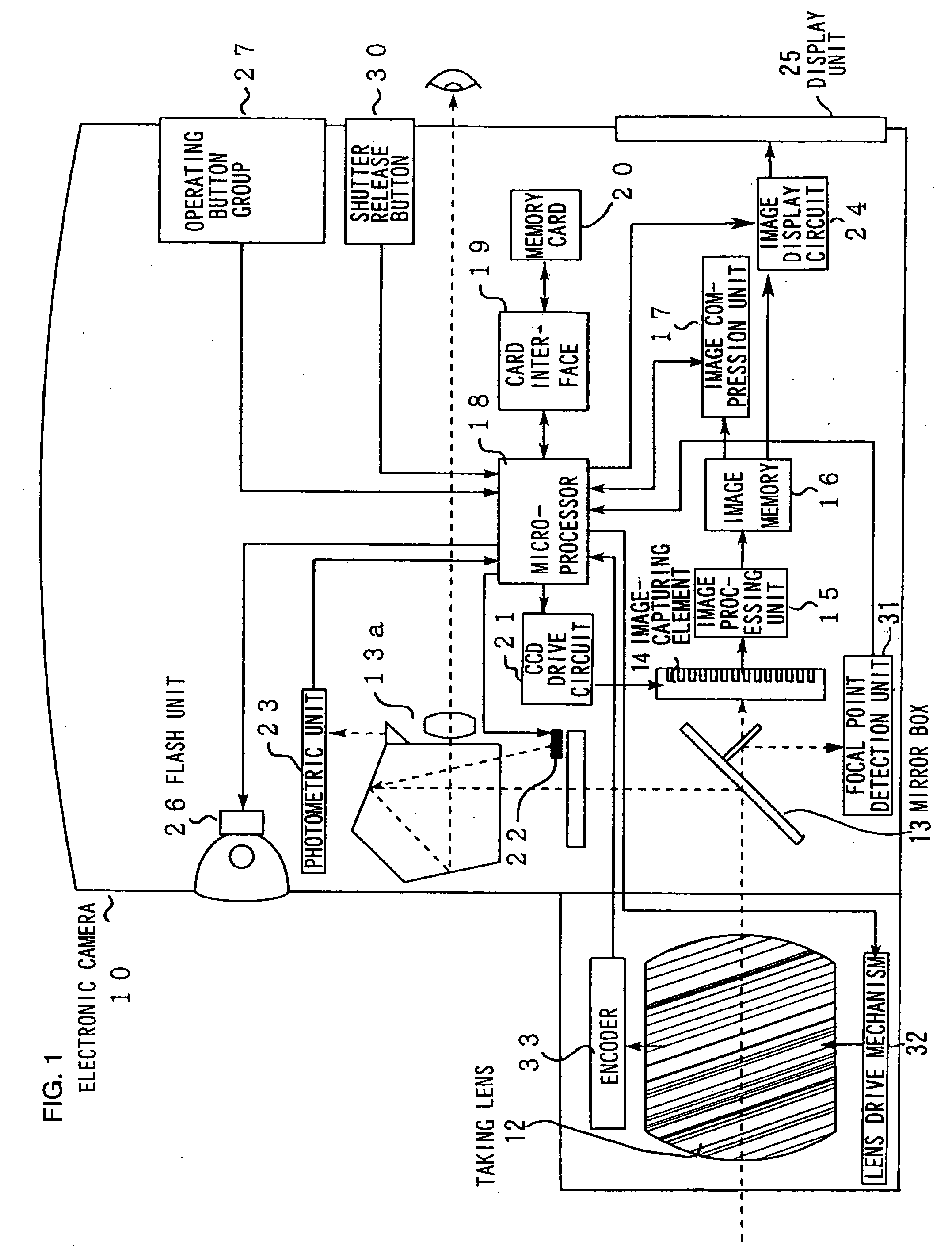

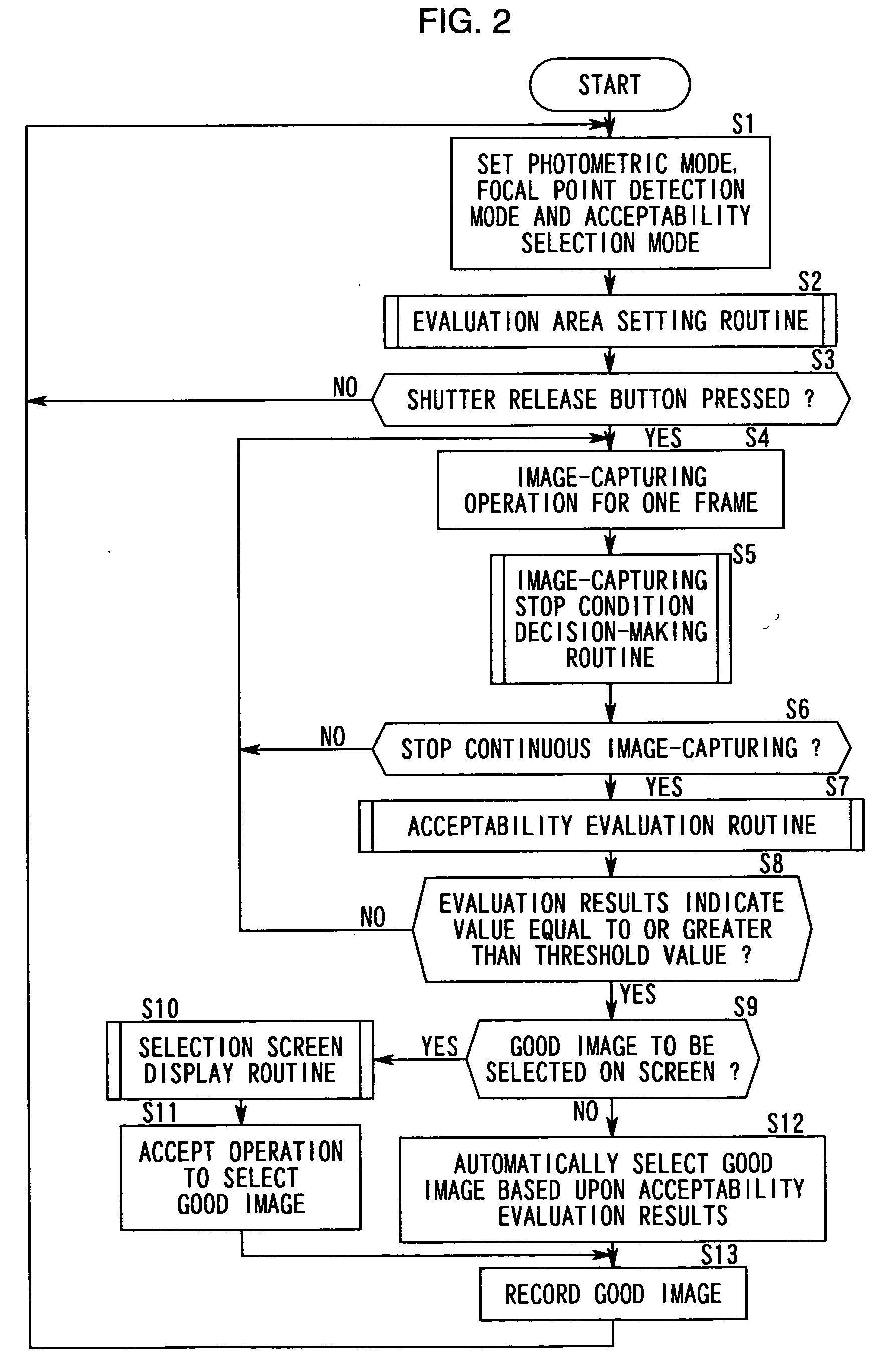

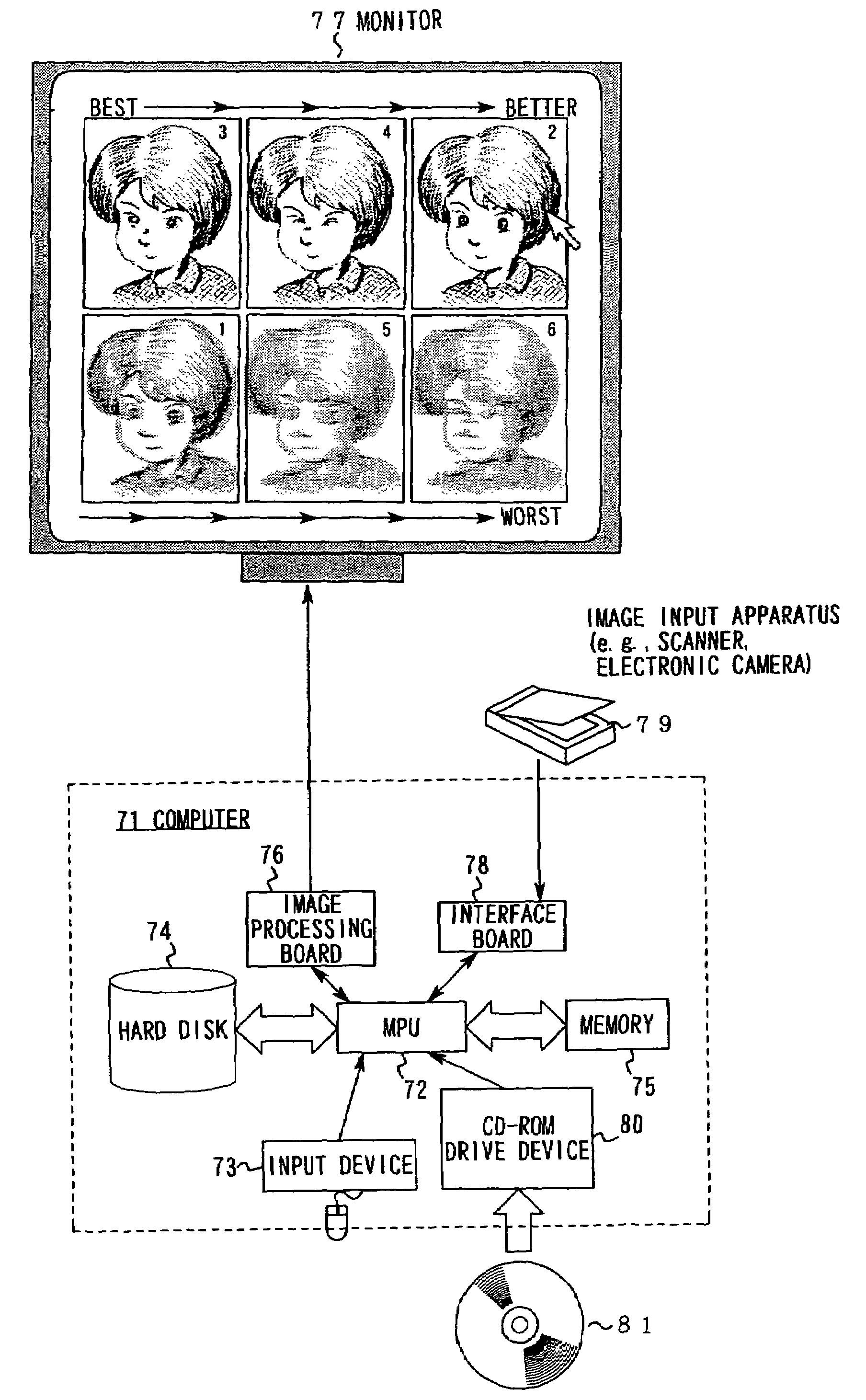

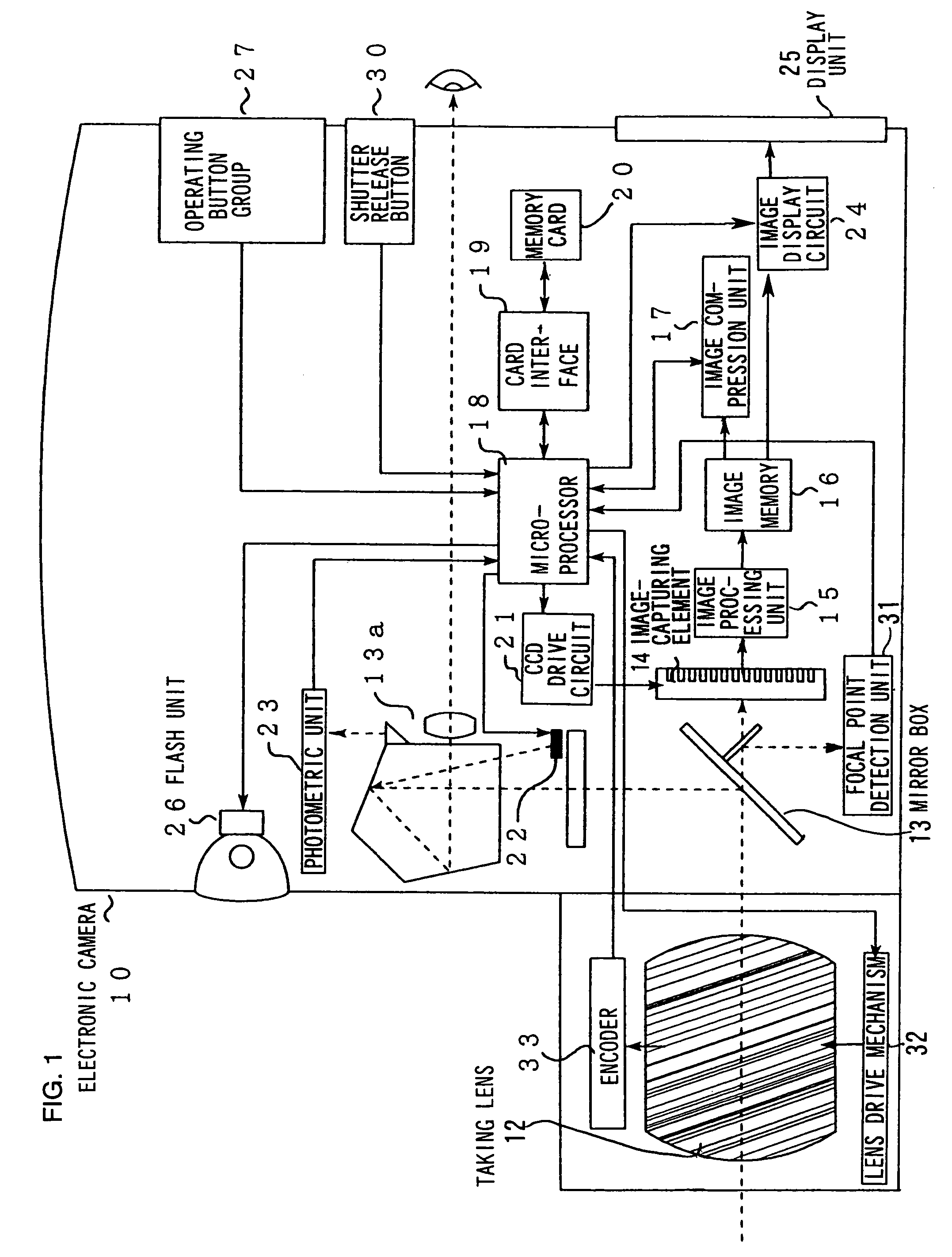

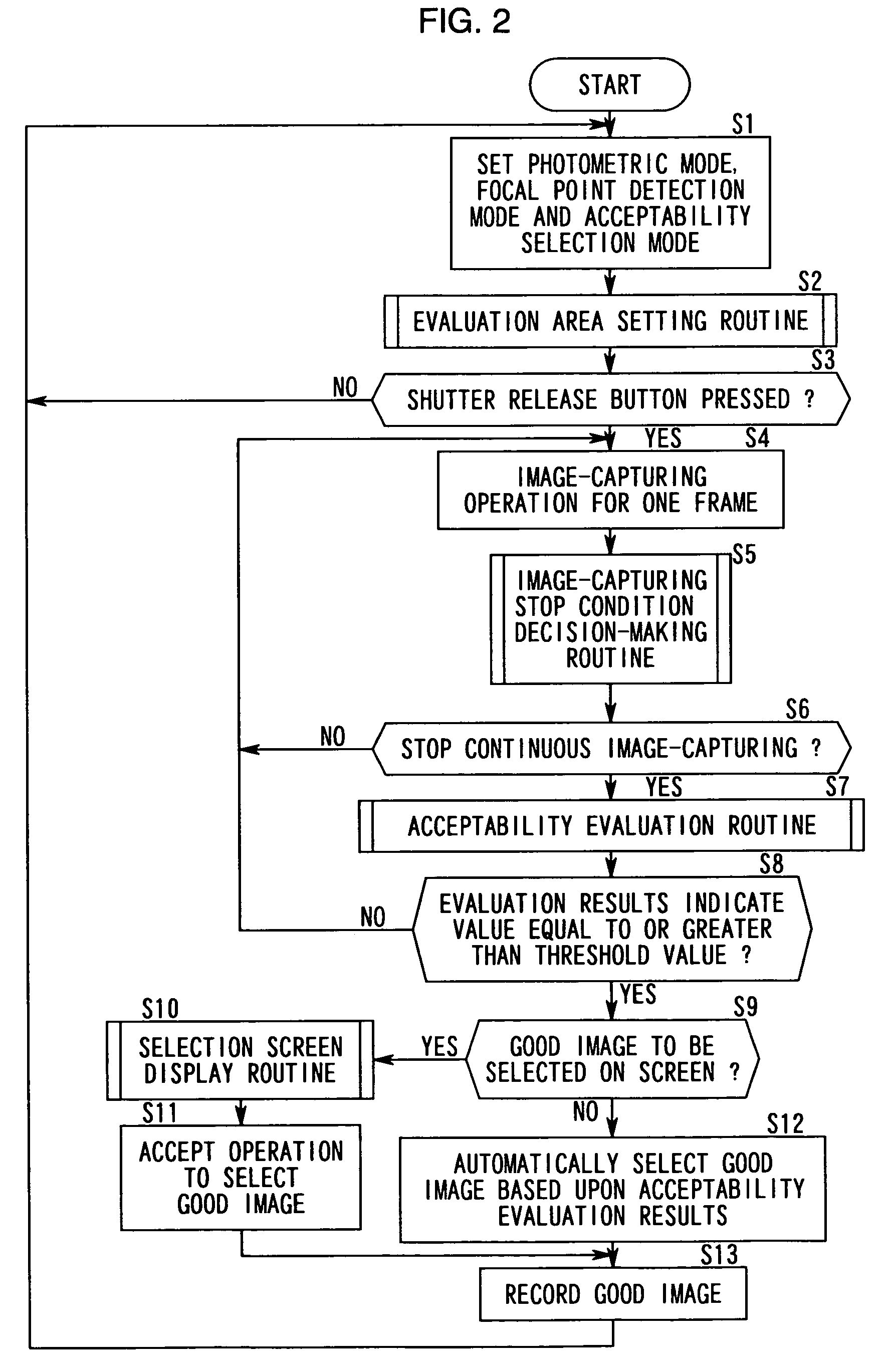

Image processing apparatus having image selection function, and recording medium having image selection function program

InactiveUS20050219666A1Improve image qualityExcellent stateTelevision system detailsCharacter and pattern recognitionImage selectionComputer graphics (images)

An image processing apparatus having an image selecting function, includes: an evaluation device that takes in a plurality of sets of image data of a subject obtained through image-capturing and performs acceptability evaluation on each of the plurality of sets of image data; and an acceptability selection device that selects image data ranked high in the acceptability evaluation among the plurality of sets of image data having undergone the acceptability evaluation performed at the evaluation device.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

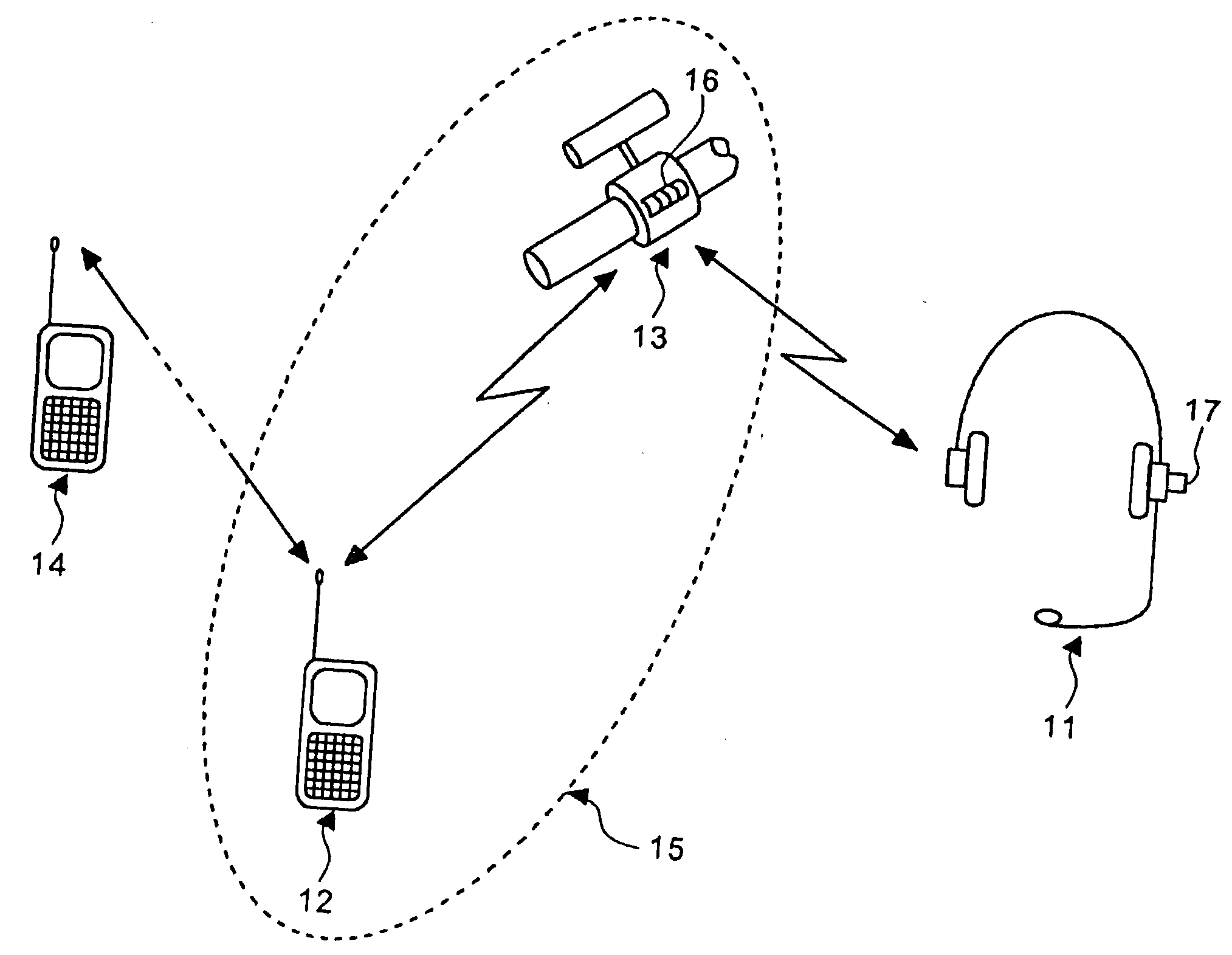

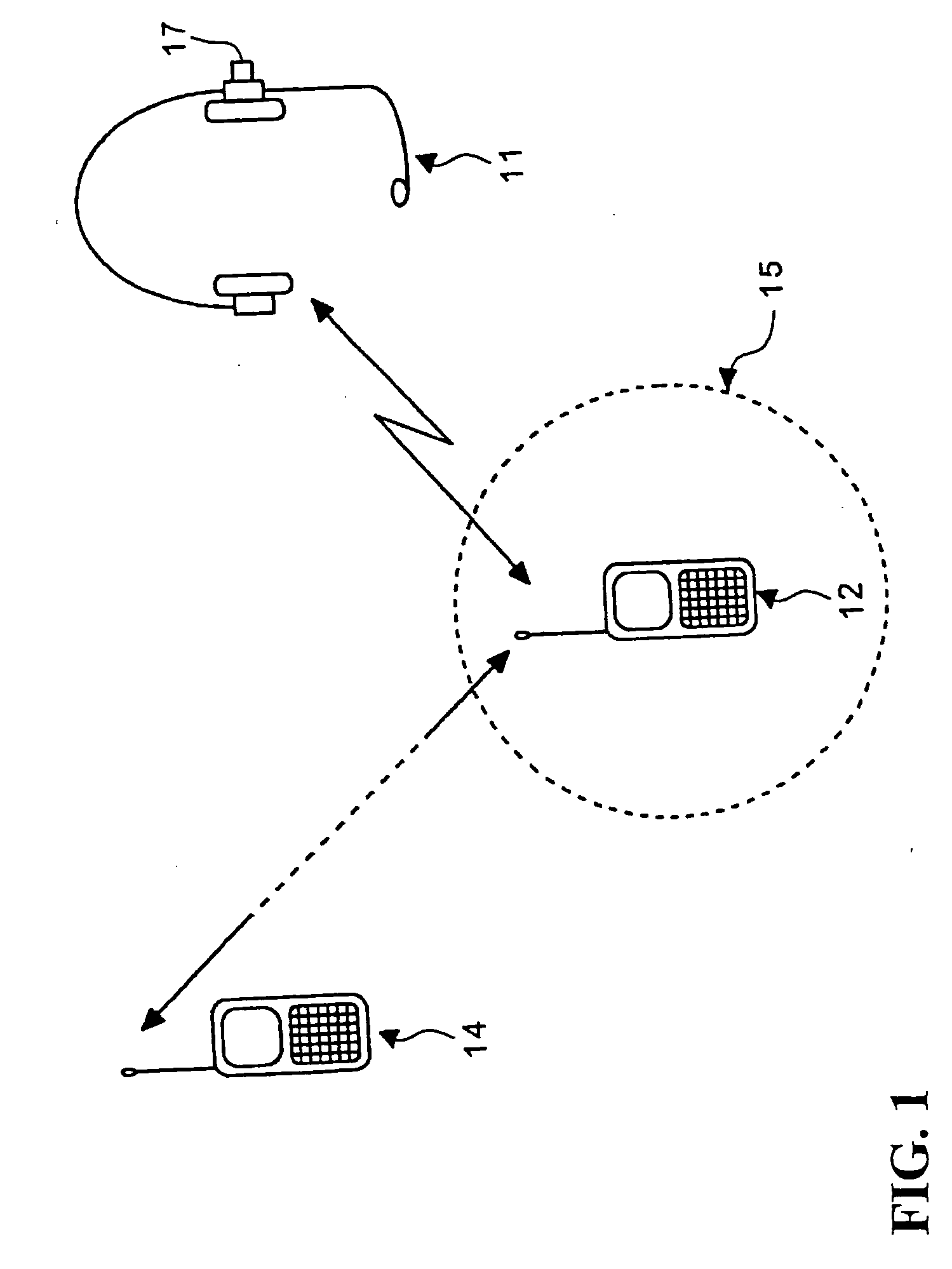

Systems, methods and articles to provide olfactory sensations

InactiveUS20140377130A1Improve impactMinimize impactComputer controlSimulator controlTelecommunicationsPhase change

A scent release system includes scent cartridges containing temperature activated scent media. The scent cartridges may bear machine-readable identification that specifies which scent media are carried by the cartridge. The scent release system can be controlled by a timer to initiate a phase change of the scent media to selectively release one or more scents, followed by a reverse phase change to selectively stop release of the respective scents. A scent release system in conjunction with a mobile electronic device, such as a smart phone, allows sending and receiving scent messages. The scent release system can be built into a case for the mobile electronic device, eliminating the need for a separate unit. A private scent delivery device in the form of a headset can be worn by users of a scent release system or by scent message recipients.

Owner:VAPOR COMM

Bluetooth terminal

InactiveUS20050135297A1Excellent stateMaintenance becomes necessaryEnergy efficient ICTInterconnection arrangementsCall terminationEngineering

A Bluetooth terminal, relay, and system for determining a network configuration automatically and for transferring to an optimal waiting state. A Bluetooth terminal is provided with a profile functioning as a headset for communicating a terminal on the partner side via a voice gateway terminal, includes an input key for accepting an input operation including a transmitting operation, a receiving operation, and a call termination operation. A waiting state selecting member is provided for selecting a waiting state to be transferred upon call termination from a first waiting state in which an SCO link is disconnected and an ACL link is maintained, a second waiting state in which the SCO link and the ACL link are both disconnected. The waiting state selecting member selects the first waiting state after communication without input key operation being terminated, and selects the second waiting state after communication with input key operation being terminated.

Owner:HONDA MOTOR CO LTD

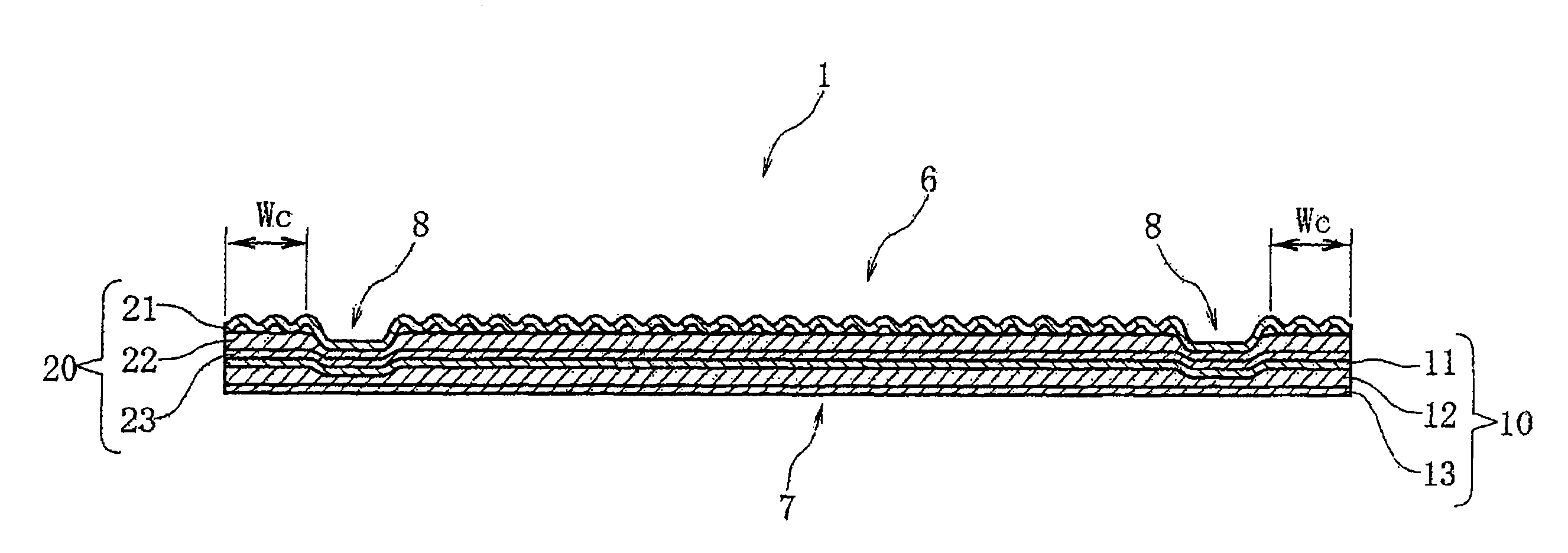

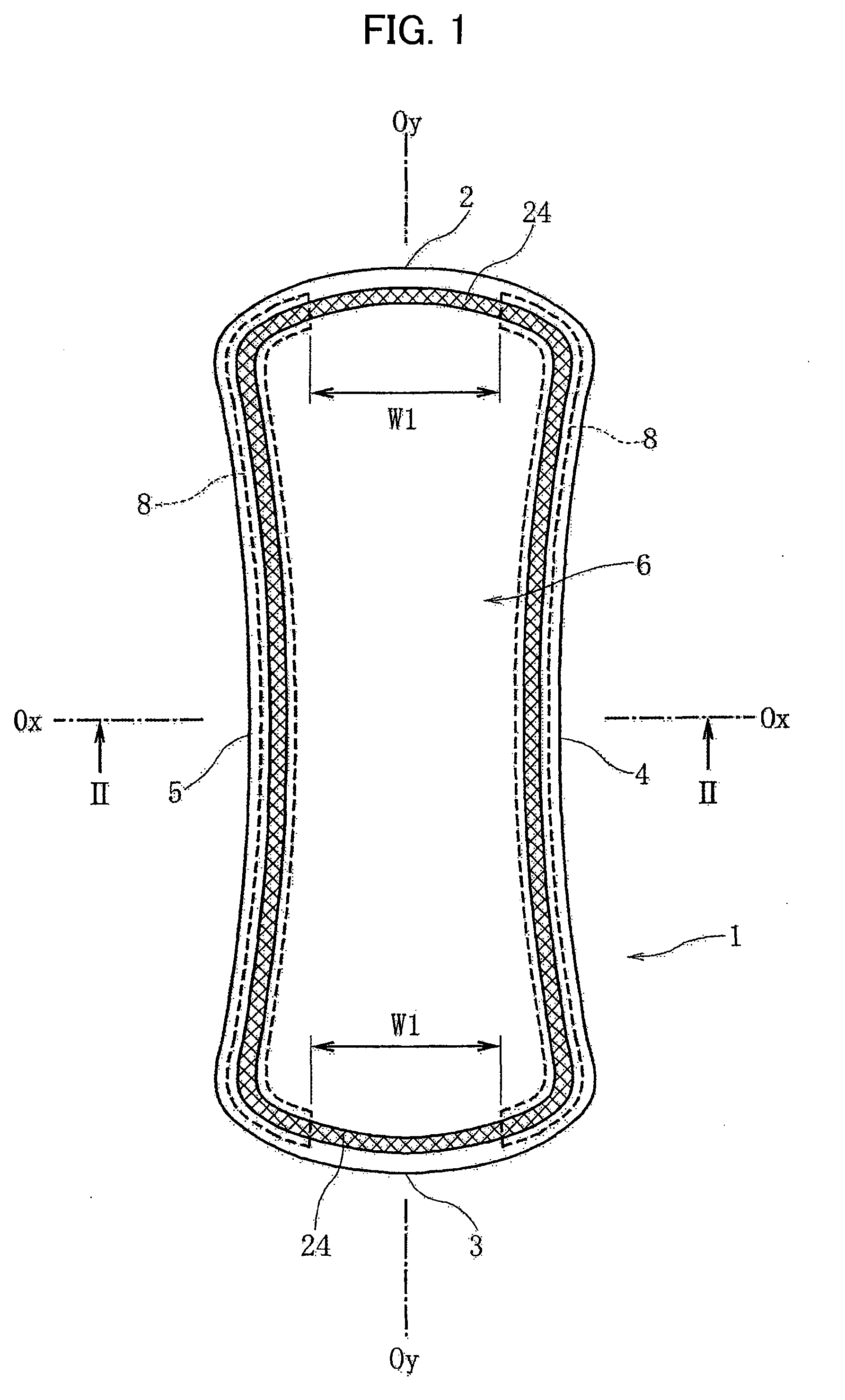

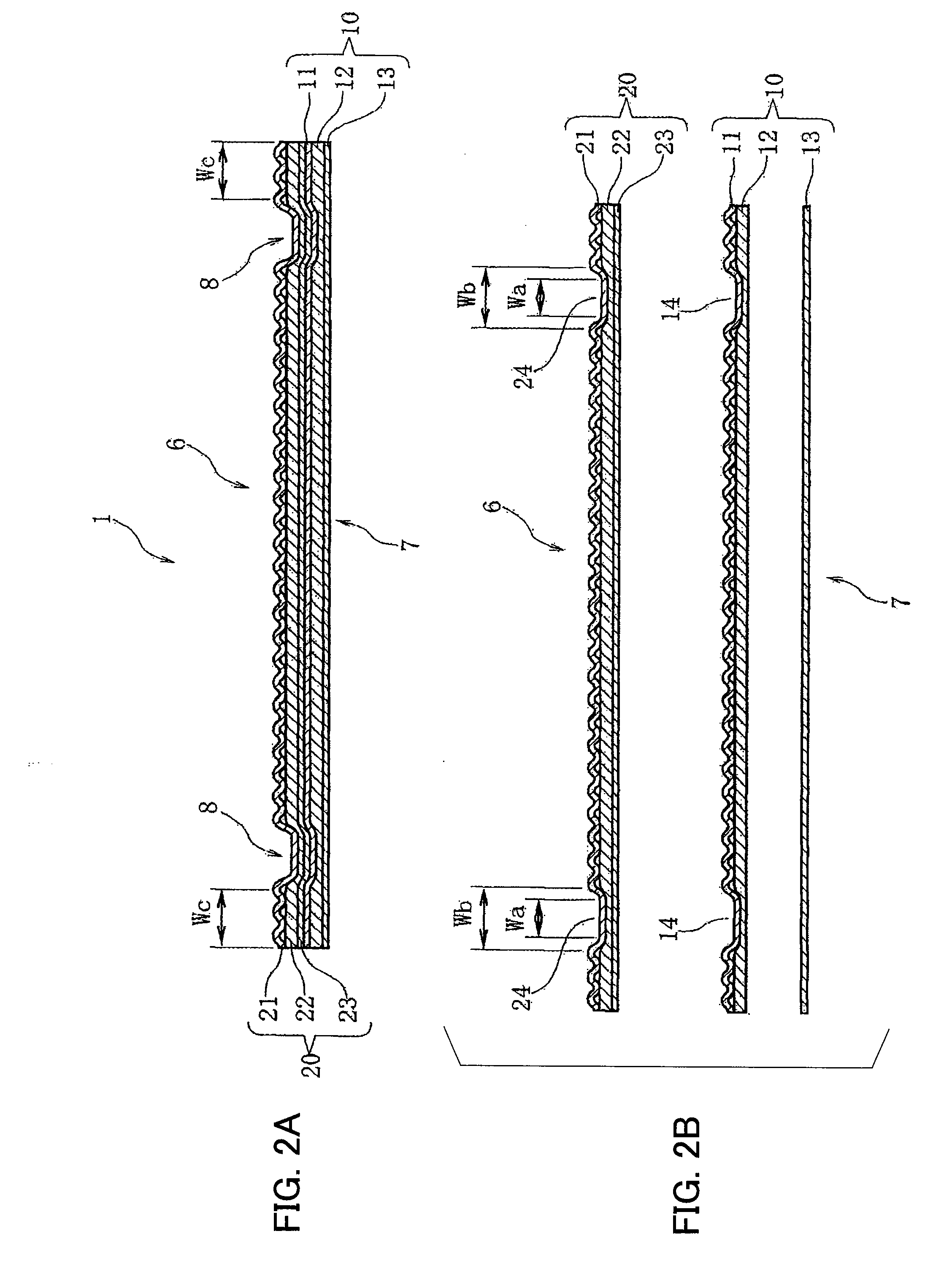

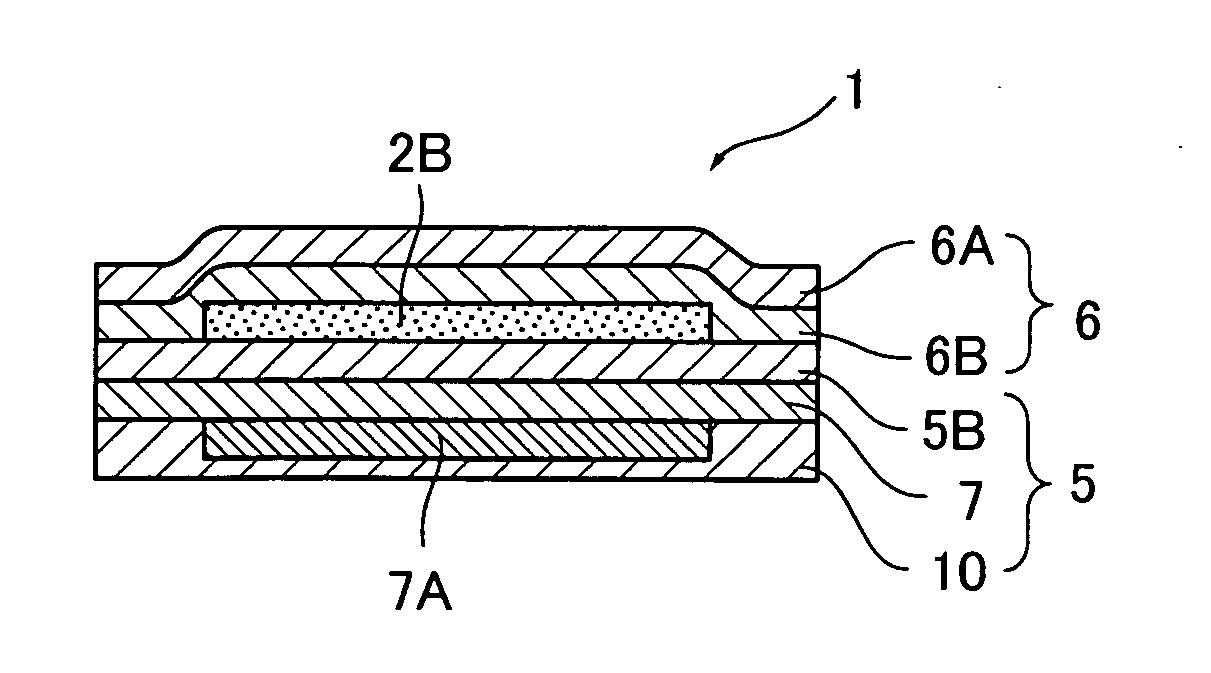

Absorbent article

InactiveUS20060247590A1Easy to storeMinimizing proliferationSanitary towelsBaby linensEngineeringFlexural rigidity

An absorbent article in which a plurality of absorbent components is layered, and the absorbent component on top is peeled off after use. The article is configured to inhibit twisting or wrinkling during use. In the absorbent article, the upper absorbent component is layered on the skin-facing surface of the bottom absorbent component and peelably bonded by the temporal adhesive member. The bottom absorbent component has higher flexural rigidity than the upper absorbent component, and the compression recovery rate of the bottom absorbent component is also set so as to be higher than that of the upper absorbent component. It is thereby possible to prevent the bottom absorbent component from twisting and wrinkling when the upper absorbent component is placed against the discharge area, and after the upper absorbent component is peeled off, the volume of the bottom absorbent component is restored, and comfort during contact thereof with the discharge area is improved.

Owner:UNI CHARM CORP

Image processing apparatus having image selection function, and recording medium having image selection function program

InactiveUS7088865B2Improve image qualityExcellent stateTelevision system detailsCharacter and pattern recognitionImaging processingComputer graphics (images)

An image processing apparatus having an image selecting function, includes: an evaluation device that takes in a plurality of sets of image data of a subject obtained through image-capturing and performs acceptability evaluation on each of the plurality of sets of image data; and an acceptability selection device that selects image data ranked high in the acceptability evaluation among the plurality of sets of image data having undergone the acceptability evaluation performed at the evaluation device.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

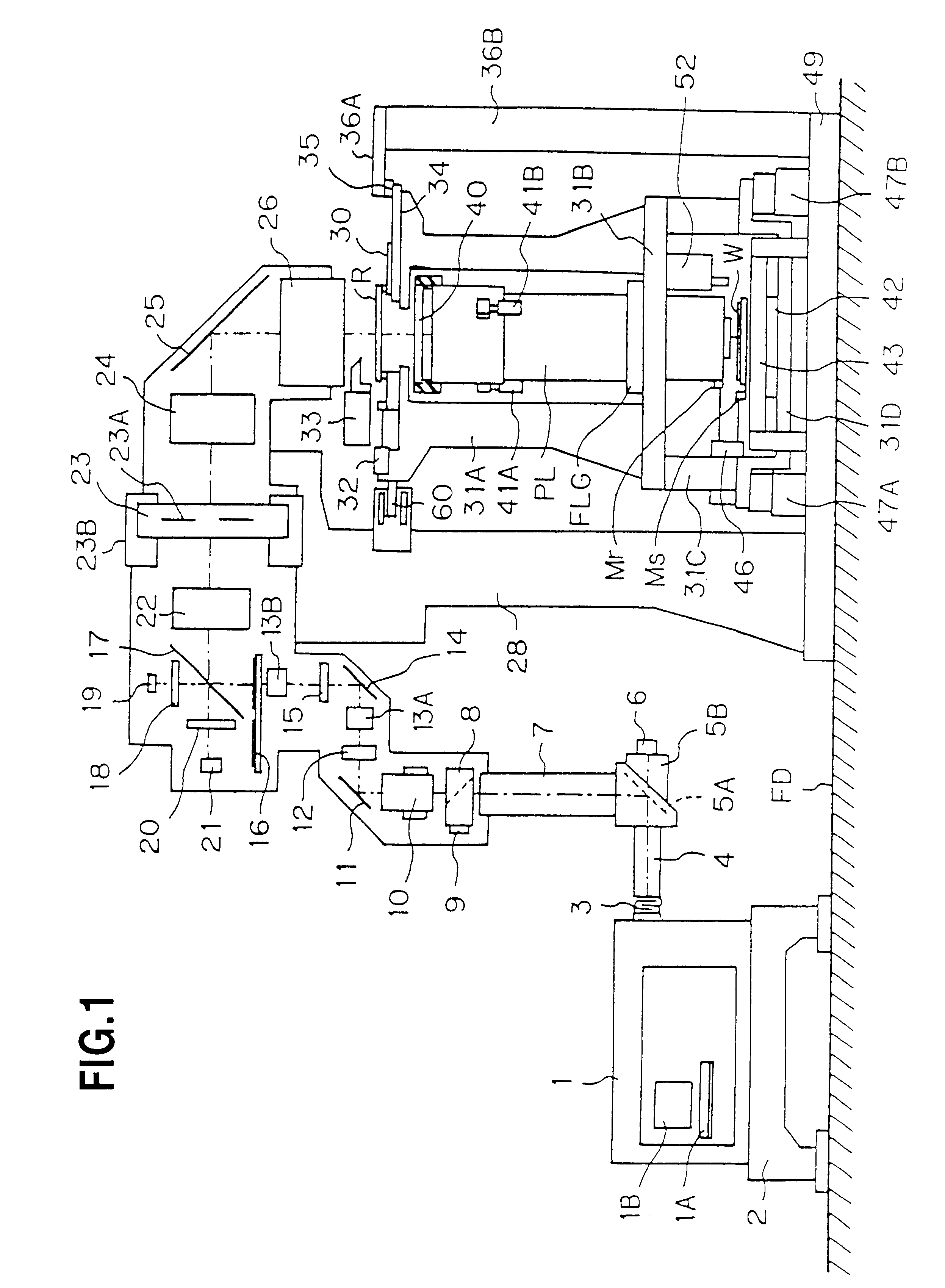

Exposure apparatus, exposure method, and device manufacturing method

ActiveUS20090284716A1Improve accuracyExcellent statePhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineering

In an exposure apparatus of a liquid immersion exposure method, there is a case when a wafer table holding a wafer moves, a liquid immersion area formed by liquid supplied in a space between a wafer table and a projection optical system passes over a head mounted on the wafer table. Therefore, for a head over which the liquid immersion area has passed, the residual presence of the liquid is detected based on an amount of light of a reflected light received by the light receiving element which receives the reflected light from the wafer table surface. And, of a plurality of heads, positional information of the wafer table is measured, based on measurement values of a head that had no liquid remaining in the detection.

Owner:NIKON CORP

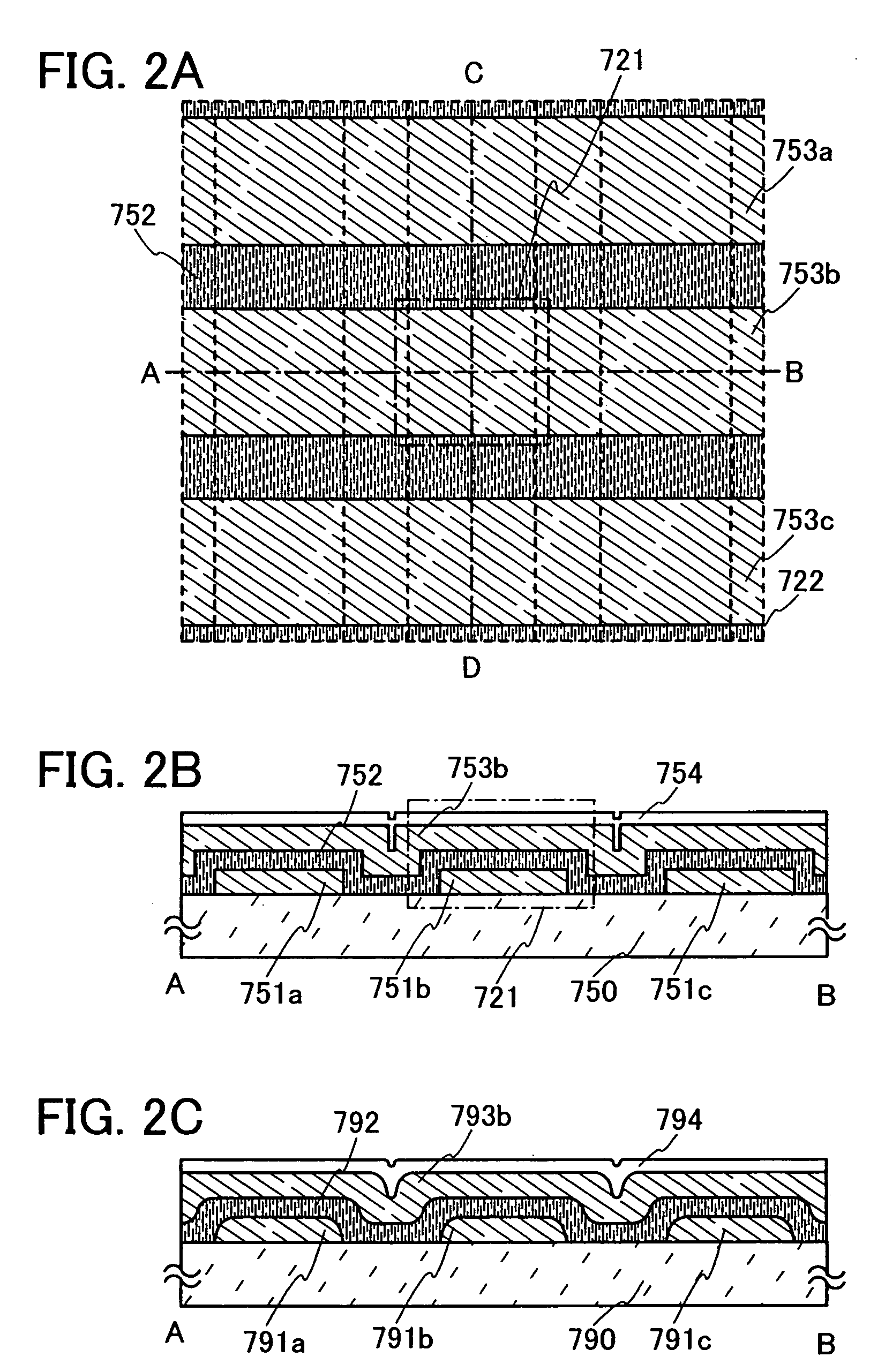

Semiconductor device and manufacturing method thereof

InactiveUS20070105285A1Improve adhesionExcellent stateNanoinformaticsSolid-state devicesIndiumOrganic compound

To provide a semiconductor device which is higher functional and reliable and a technique capable of manufacturing the semiconductor device with a high yield at low cost without complexing the apparatus or process. At least one of a first conductive layer and a second conductive layer is formed containing one kind or plural kinds of indium, tin, lead, bismuth, calcium, manganese, or zinc; or oxidation treatment is performed at least one of interfaces between an organic compound layer and the first conductive layer and between the organic compound layer and the second conductive layer. The first conductive layer, the organic compound layer, and the second conductive layer which are formed over a first substrate with a peeling layer interposed therebetween can be peeled from the first substrate with the peeling layer, and transposed to a second substrate.

Owner:SEMICON ENERGY LAB CO LTD

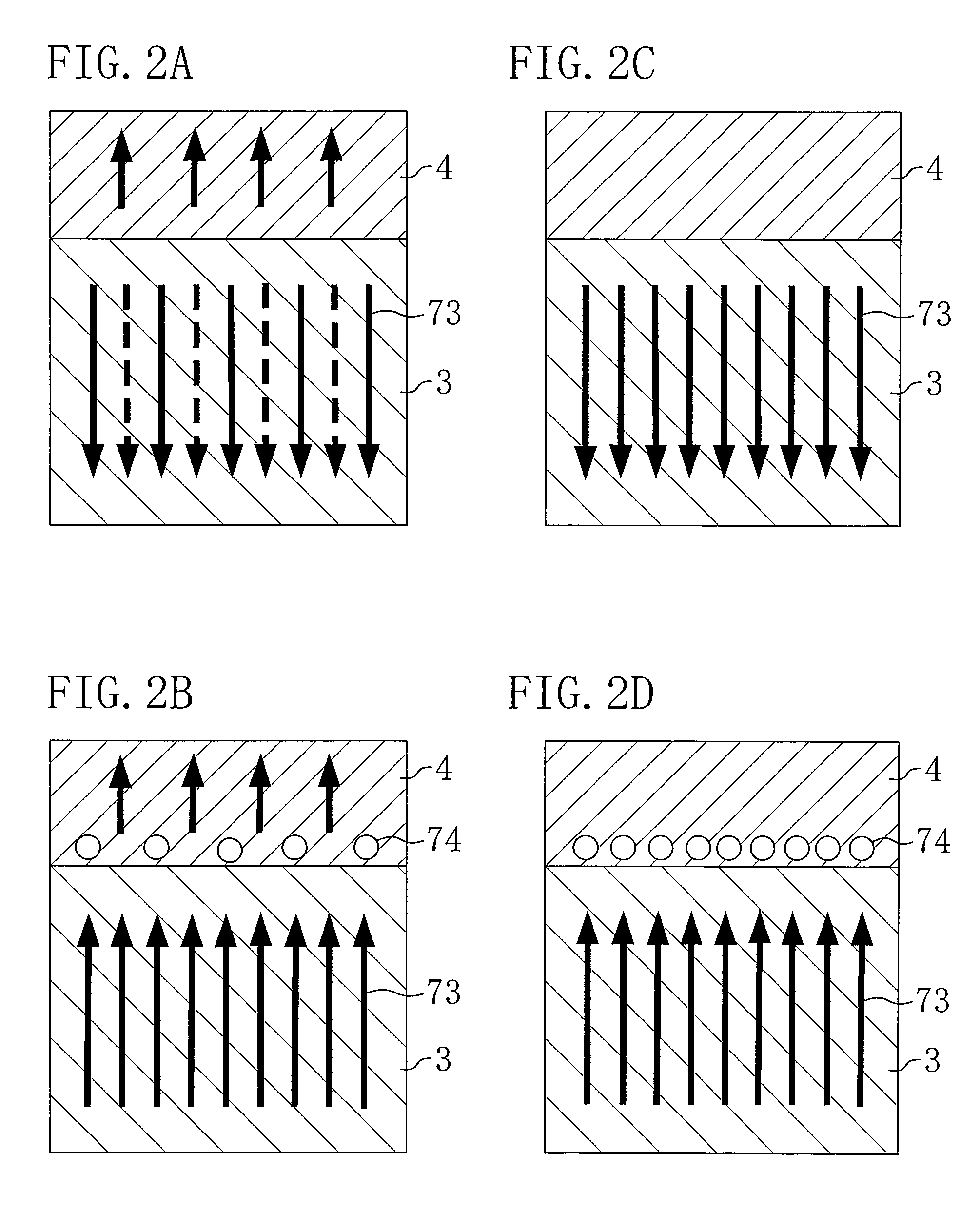

Semiconductor memory device including a semiconductor film made of a material having a spontaneous polarization and method for fabricating the same

InactiveUS7732847B2Large on-off ratioImproved retention characteristicSolid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorSemiconductor

A semiconductor memory device is composed of a field effect transistor using the interface between a ferroelectric film and a semiconductor film as the channel and including a gate electrode to which a voltage for controlling the polarization state of the ferroelectric film is applied and source / drain electrodes provided on both ends of the channel to detect a current flowing in the channel in accordance with the polarization state. The semiconductor film is made of a material having a spontaneous polarization and the direction of the spontaneous polarization is parallel with the interface between the ferroelectric film and the semiconductor film.

Owner:PANASONIC CORP

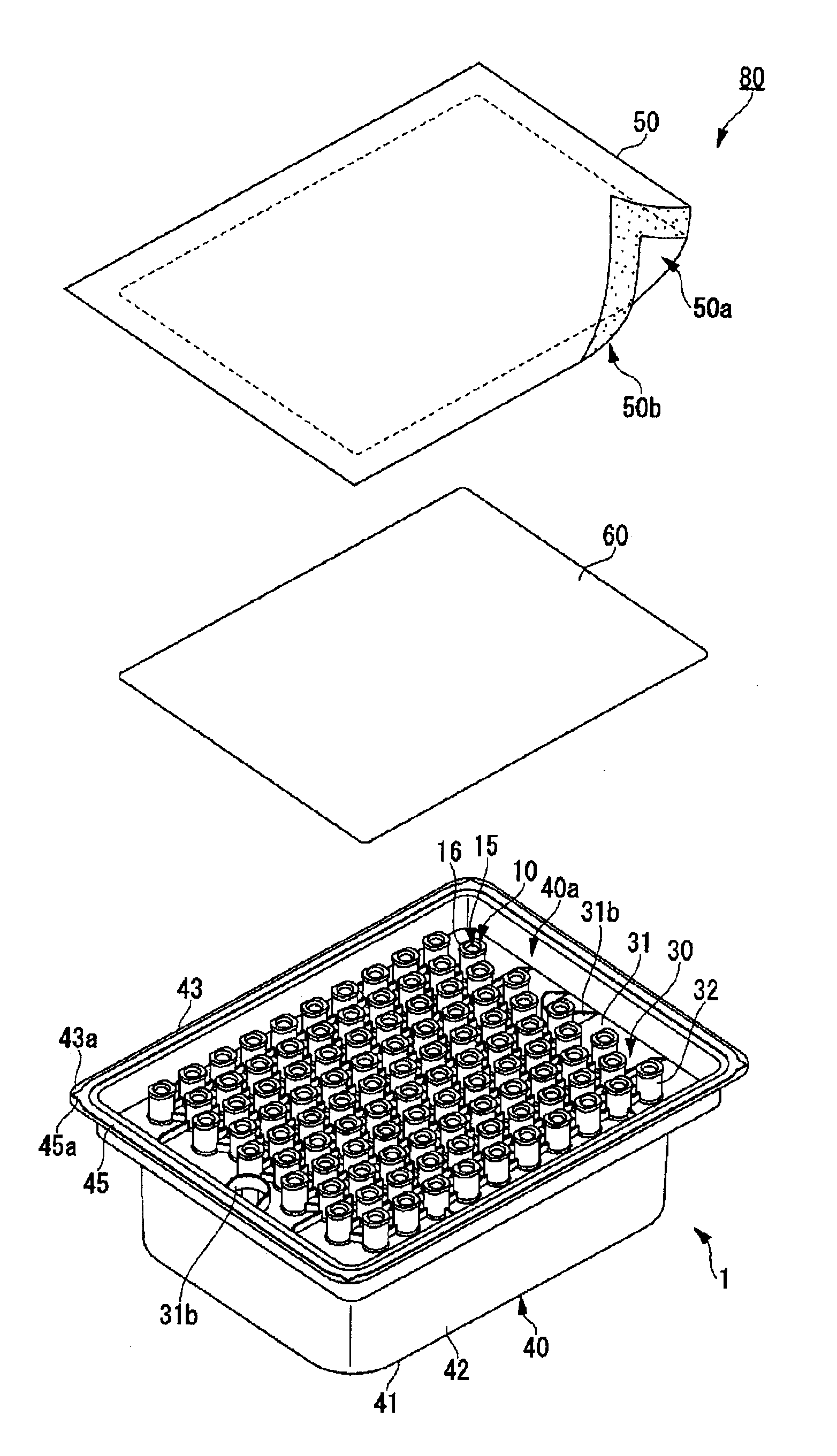

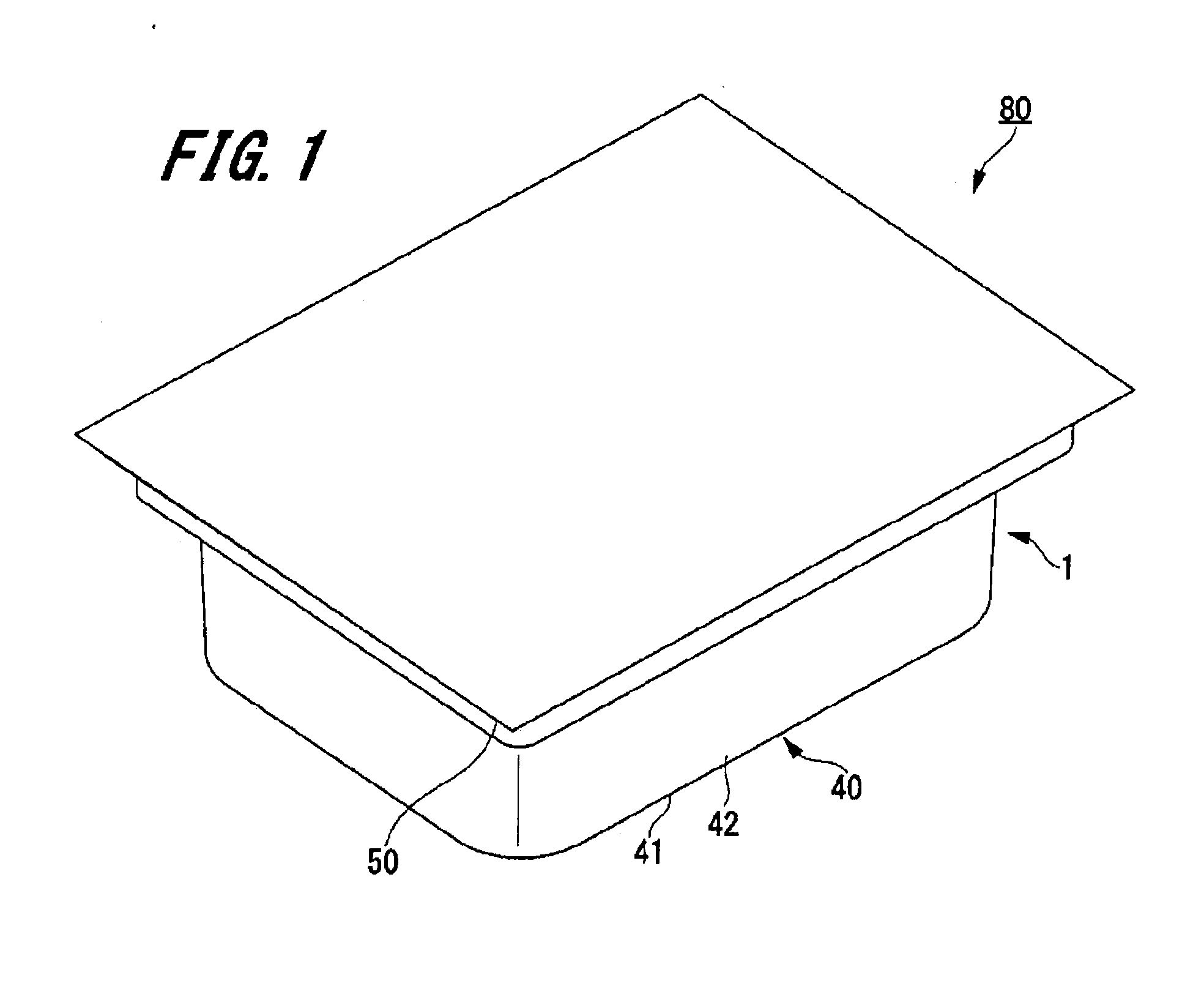

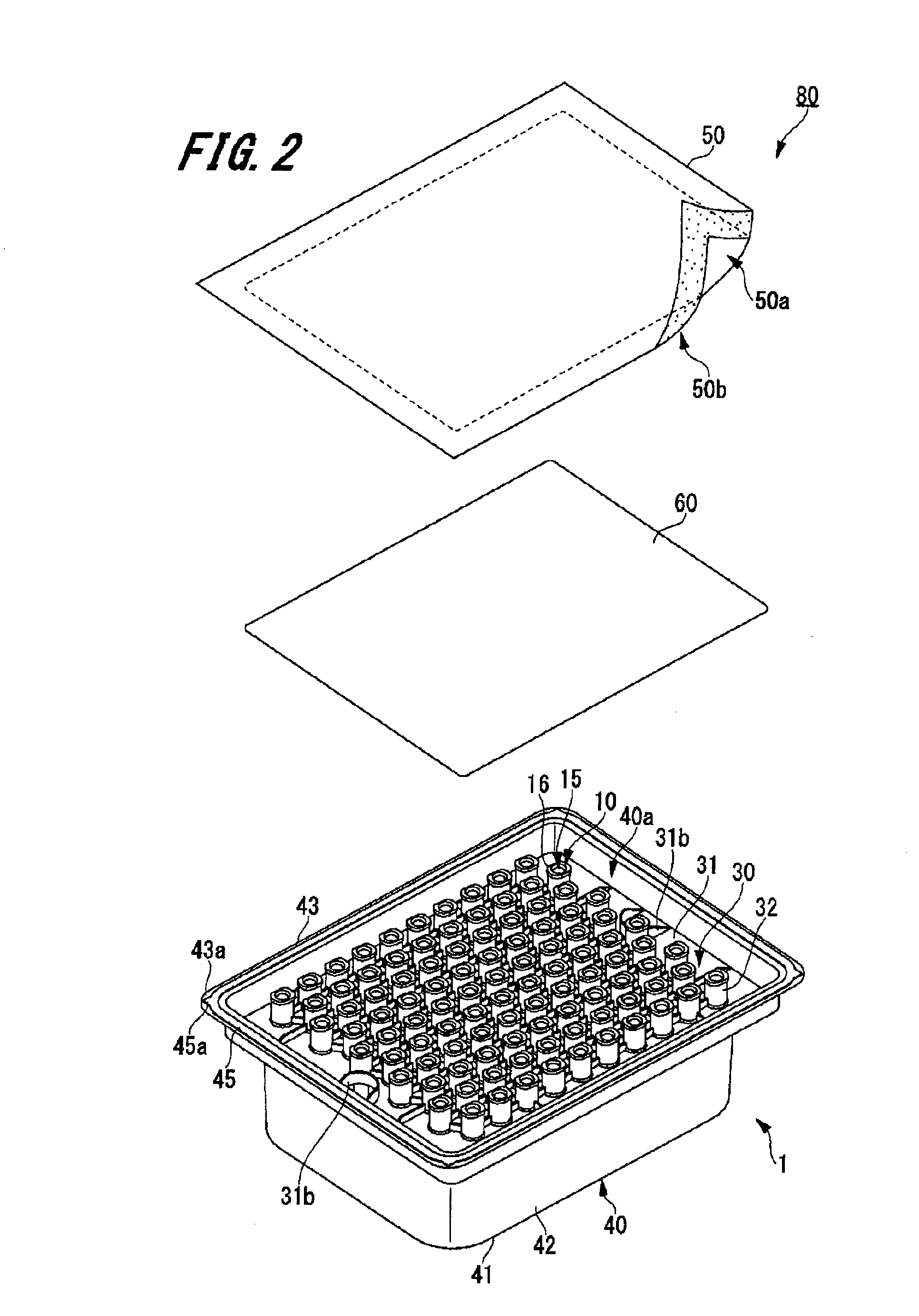

Medical device package

A medical device package includes a medical device including a first end surface and a second end surface; and a medical device storage container configured to store the medical device, the medical device storage container including a container main body and a holding unit located in the storage space, and configured to hold the medical device such that the first end surface faces upward; and a sheet-like sealing member adapted to be glued to the container main body to seal an opening of the container main body. A surface of the sealing member that faces the container main body includes an adhesive applied area on which an adhesive is applied and an adhesive non-applied area on which the adhesive is not applied, the adhesive non-applied area being an area facing at least the first end surface of the medical device held by the holding unit.

Owner:TERUMO KK

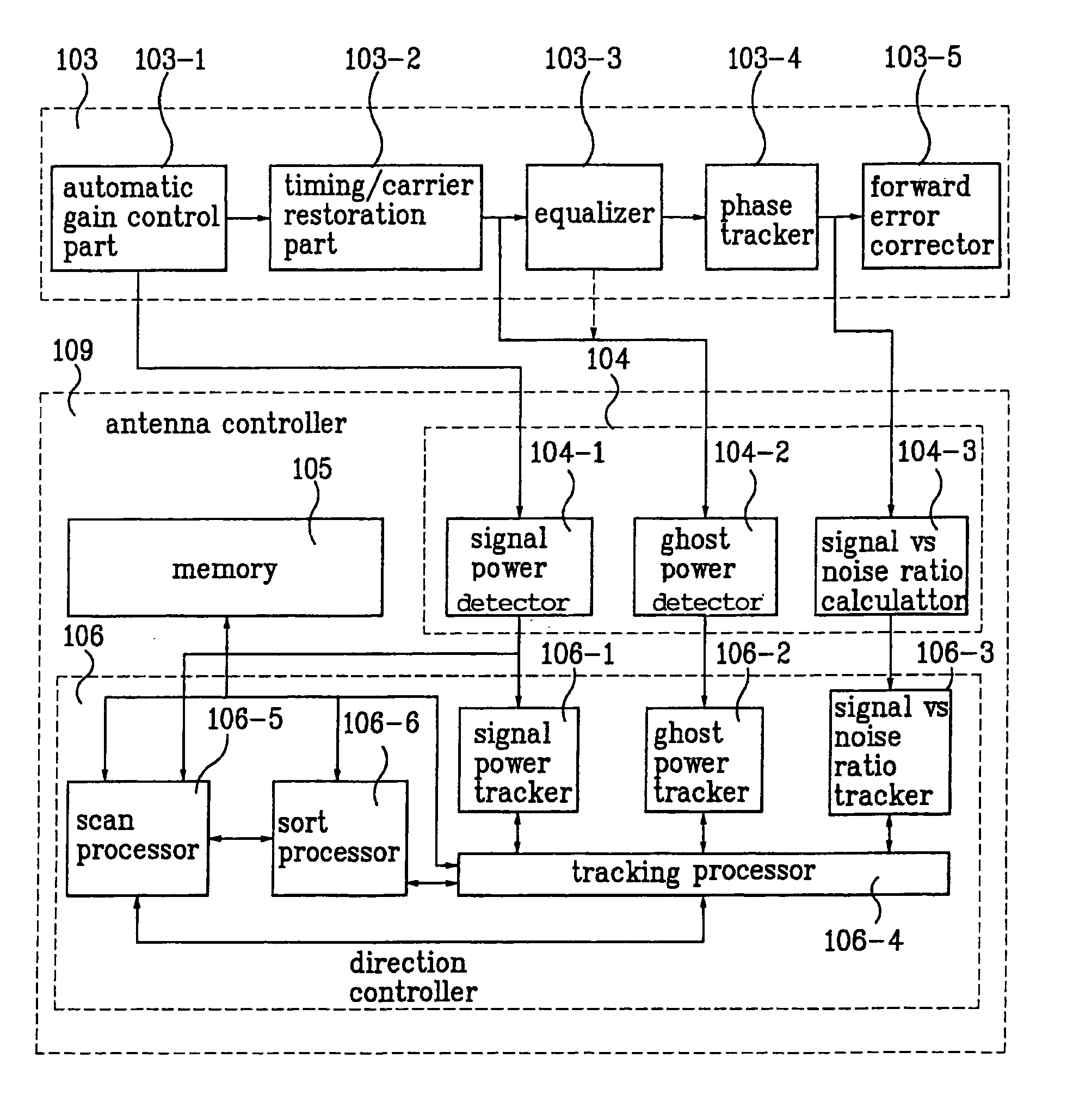

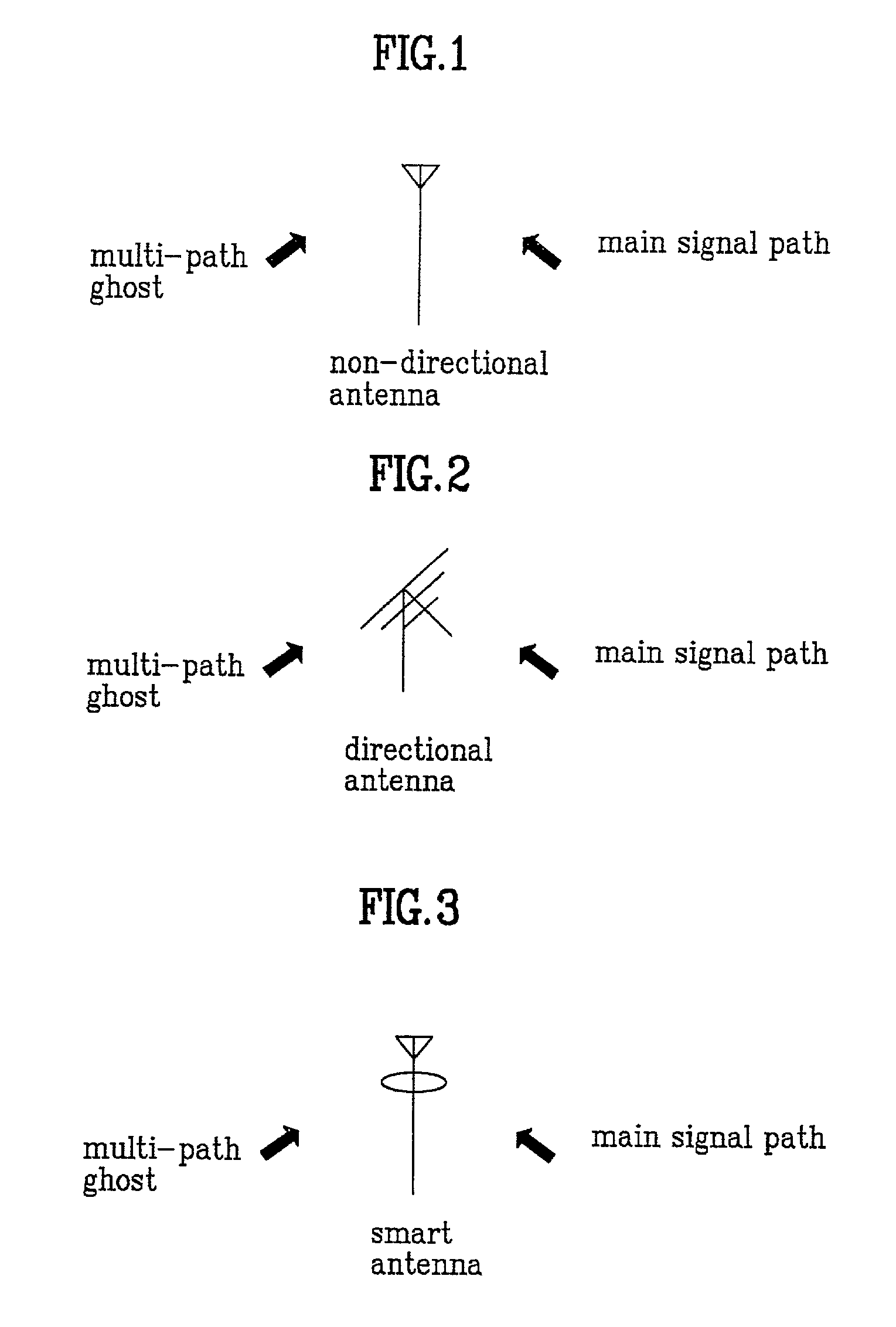

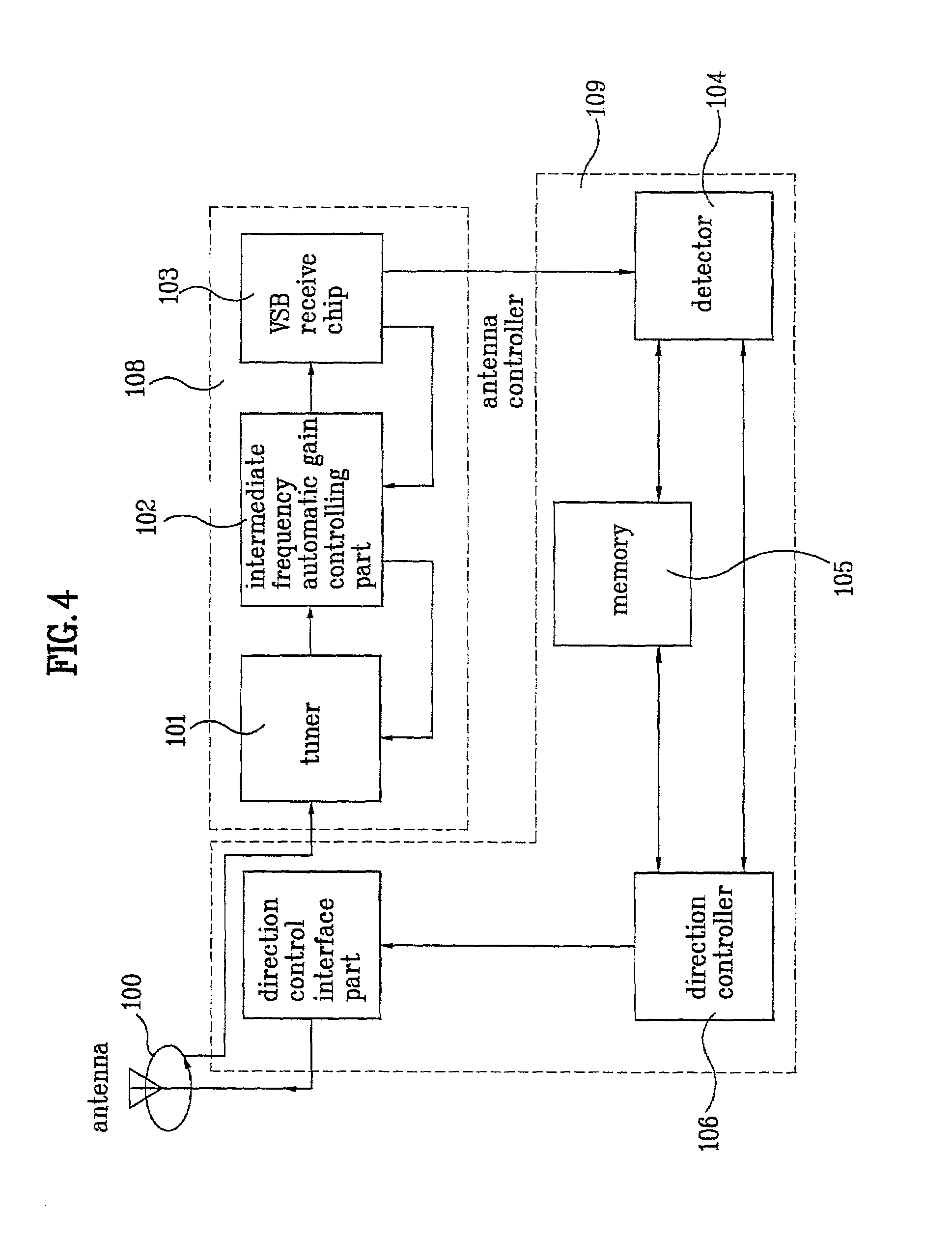

Digital television receiver and method of controlling antenna of the same

InactiveUS7136113B2Low production costSimple hardwareTelevision system detailsAntenna supports/mountingsControl signalSignal classification

Disclosed is an antenna controller of a digital television receiver and a controlling method thereof including an antenna receiving channel signals of digital television broadcasting and having a directionality dependent on a control signal, a signal processing part tuning a wanted channel signal from the channel signals and processing the tuned channel signal as a wanted form, a detection part detecting state signals of the channel signal outputted from the signal processing part, a memory, when every new state signal is detected, storing the detected new state signal sorted with previously-detected state signals, a control part producing the control signal corresponding to an optimal direction of the antenna by comparing the new state signal to the previous state signals, and an interface part providing the antenna with the control signal, thereby enabling to increase the integration of the receiver.

Owner:LG ELECTRONICS INC

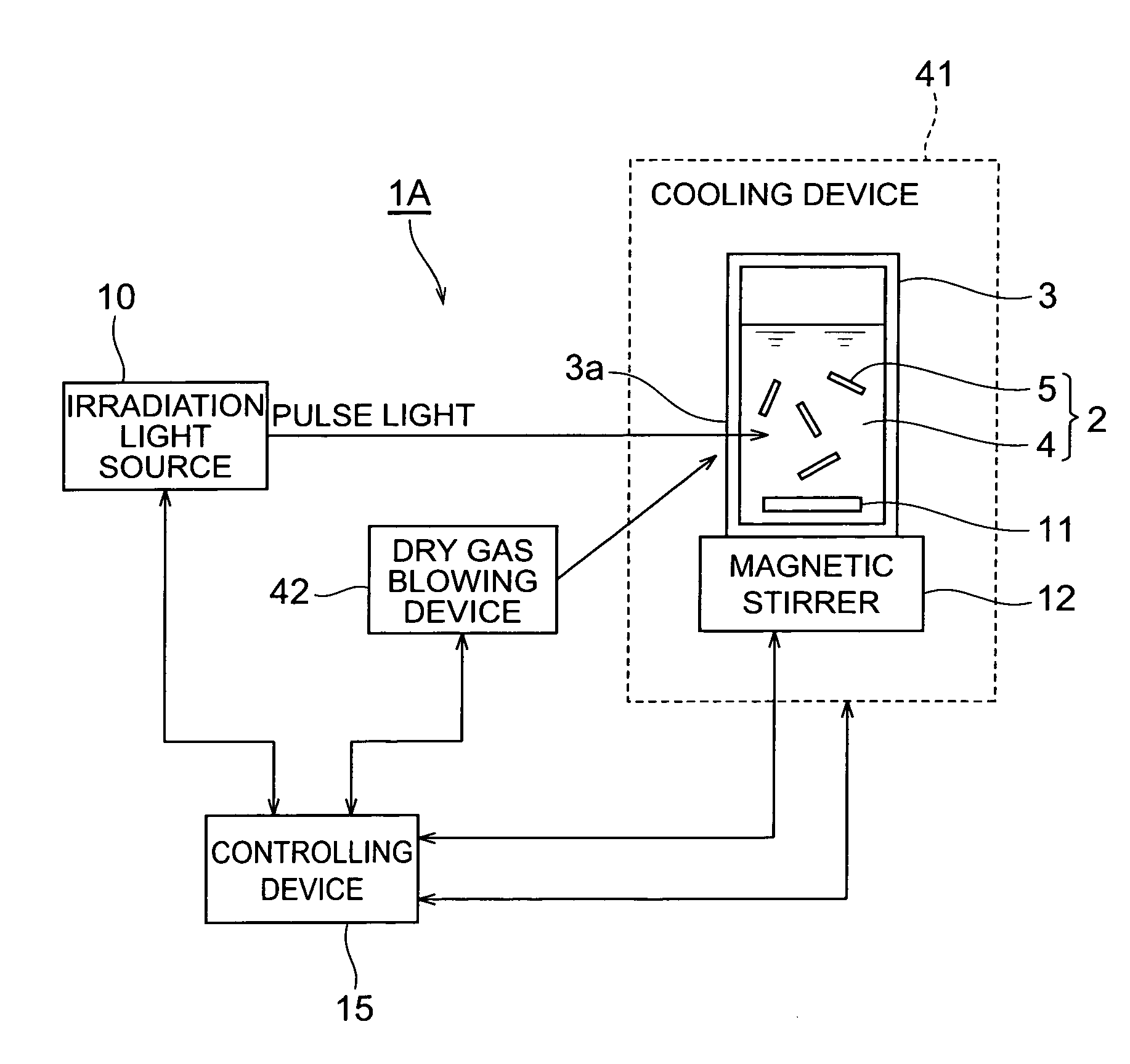

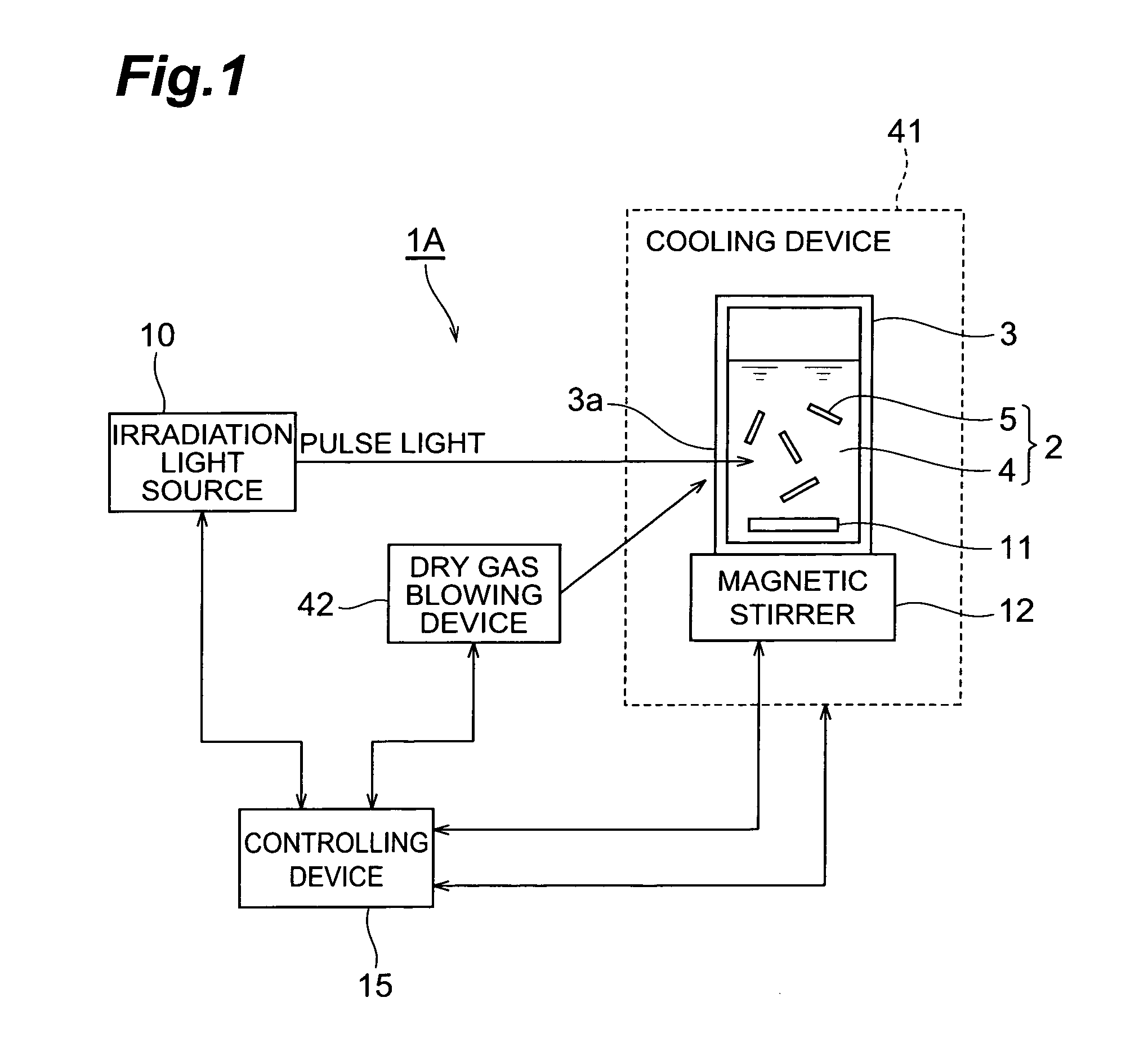

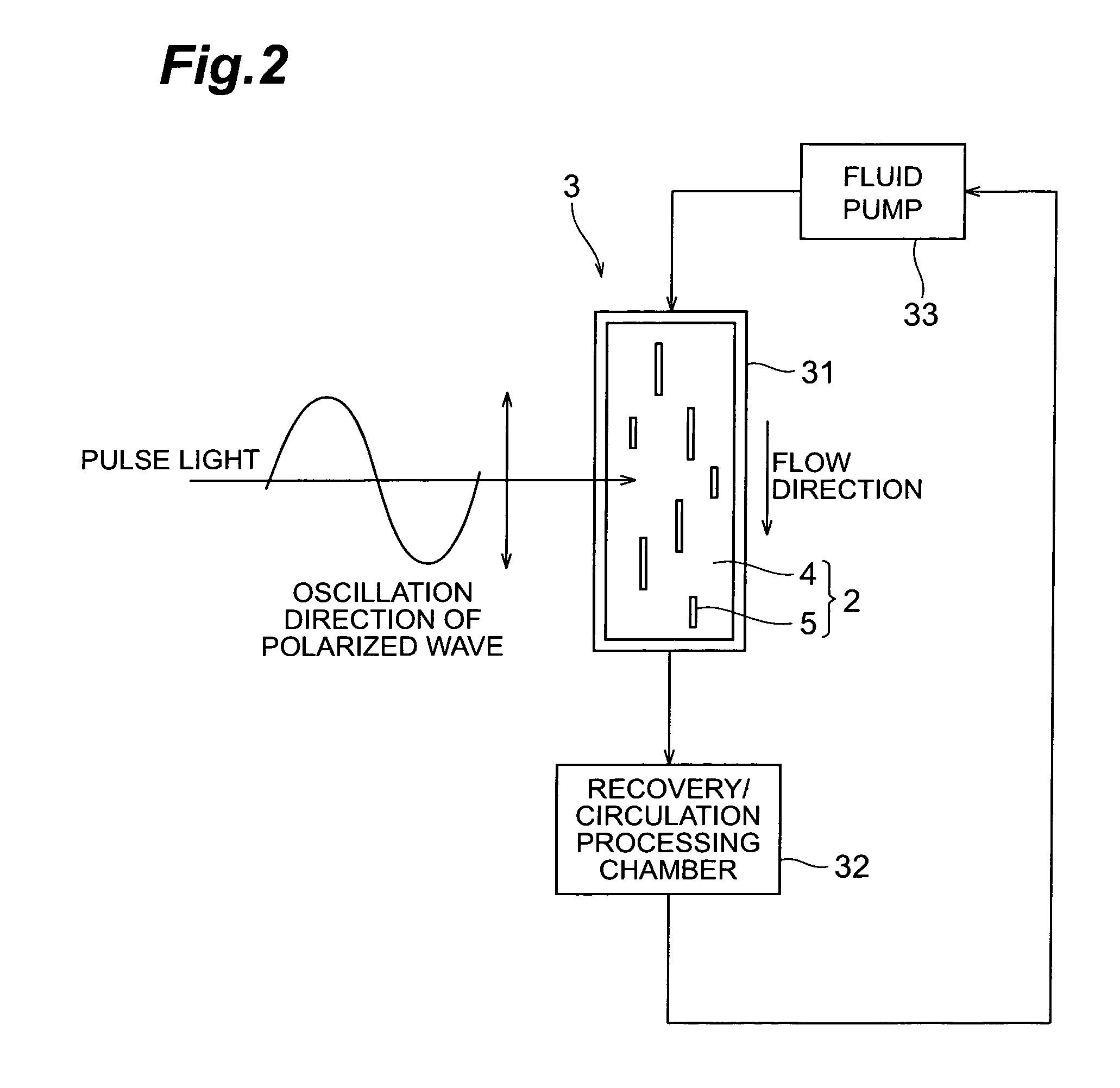

Carbon nano tube processing method, processing apparatus, and carbon nano tube dispersion liquid, carbon nano tube powder

InactiveUS7838843B2Low capability of cutting tubeImproving bundle stateMaterial nanotechnologyPigmenting treatmentCarbon nanotubeSolvent

Owner:HAMAMATSU PHOTONICS KK

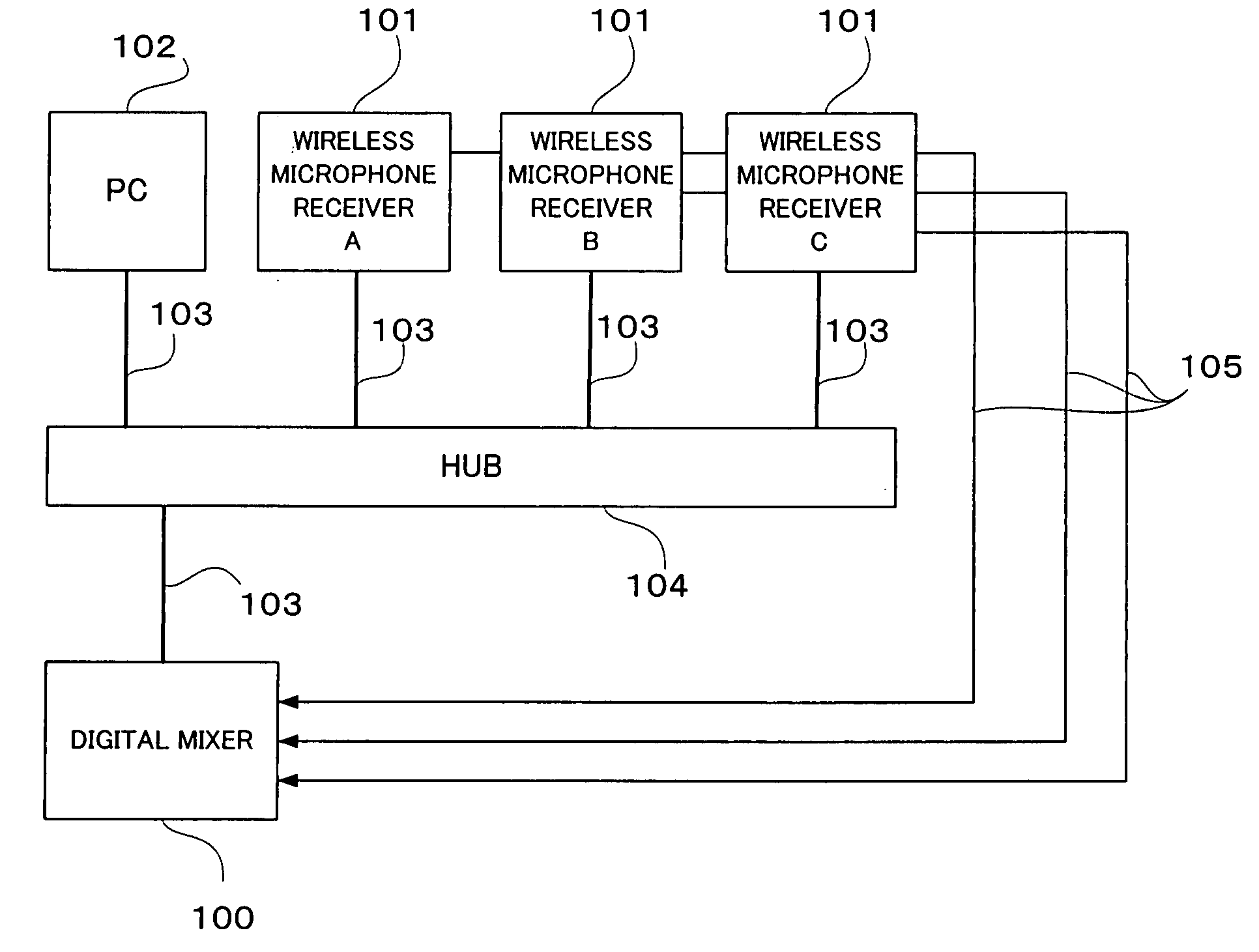

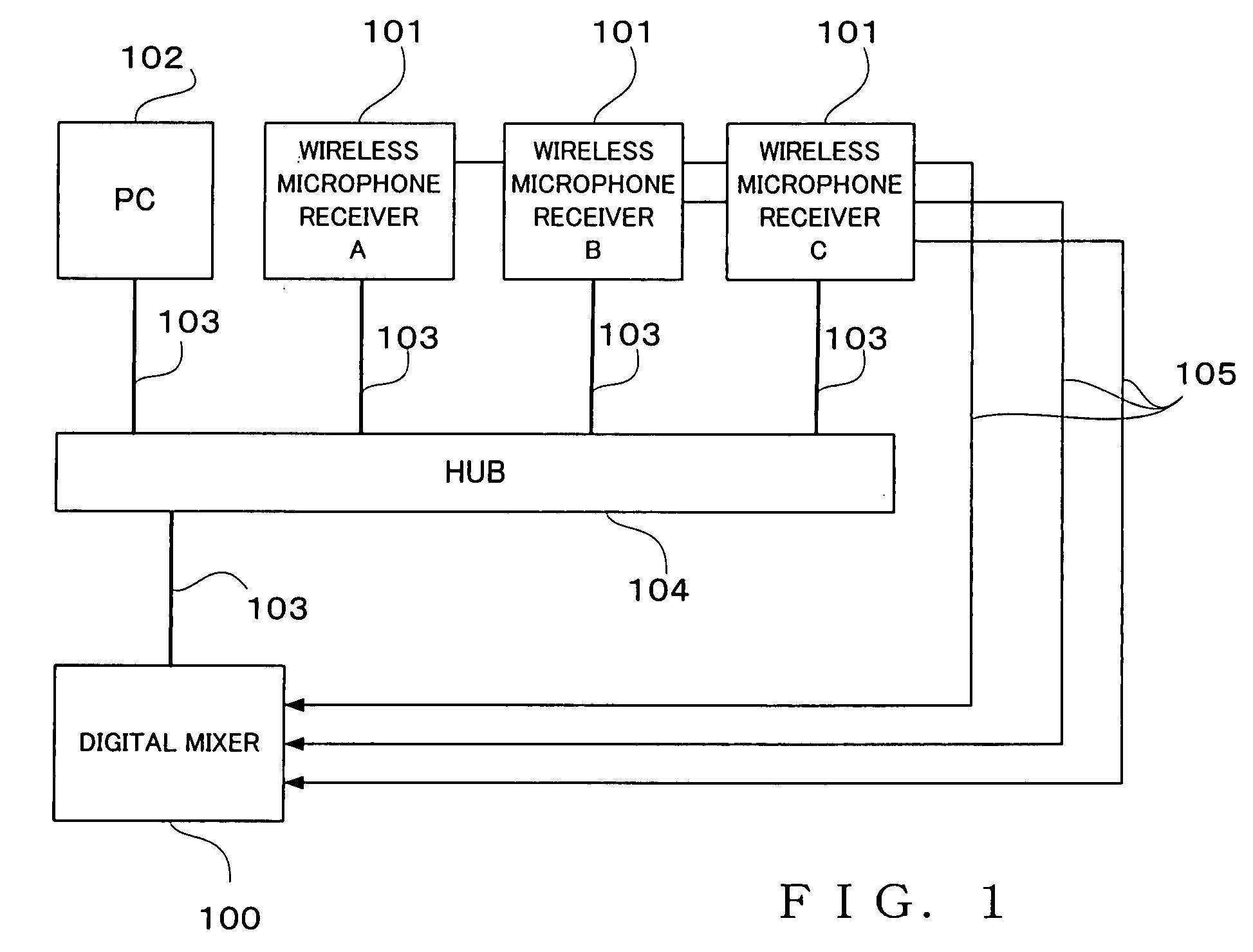

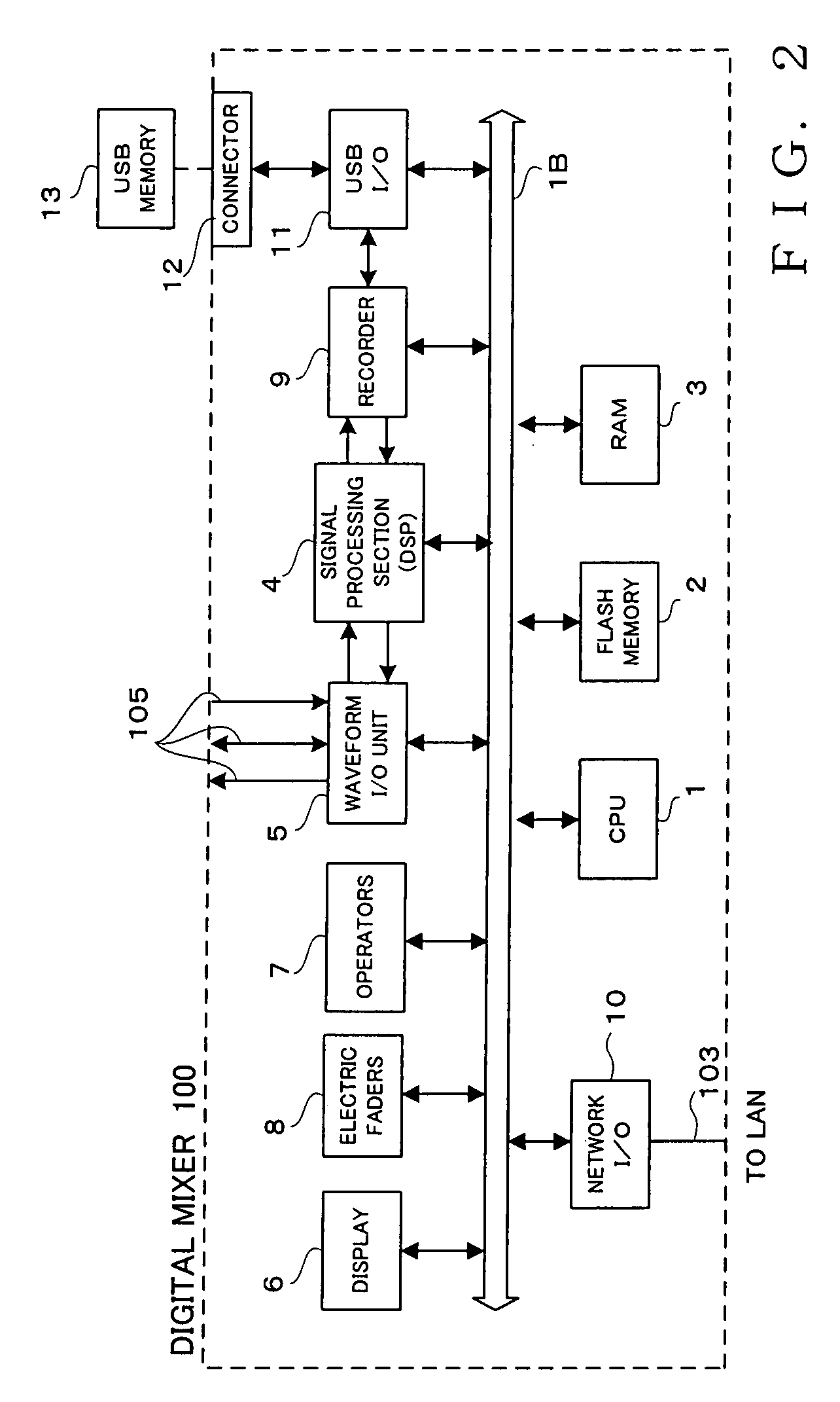

Mixer and communication connection setting method therefor

ActiveUS20080175413A1Reduce the amount requiredReduce laborElectrophonic musical instrumentsData switching by path configurationNetwork addressingNetwork address

Mixer and one or more external devices, related to audio signal processing, are interconnected via a communication network, such as a LAN. For a particular one of the external devices for which communication with the mixer via the communication network is to be established, a network address unique to the particular external device and a communication protocol to be used for data communication with the particular external device are designated by entry operation by a user. Logical connection is established such that data communication is performed, in accordance with the designated communication protocol, between the mixer and the particular external device corresponding to the designated network address. Thus, data communication is performed, via the communication network, between the mixer and the particular external device for which the logical connection has been established.

Owner:YAMAHA CORP

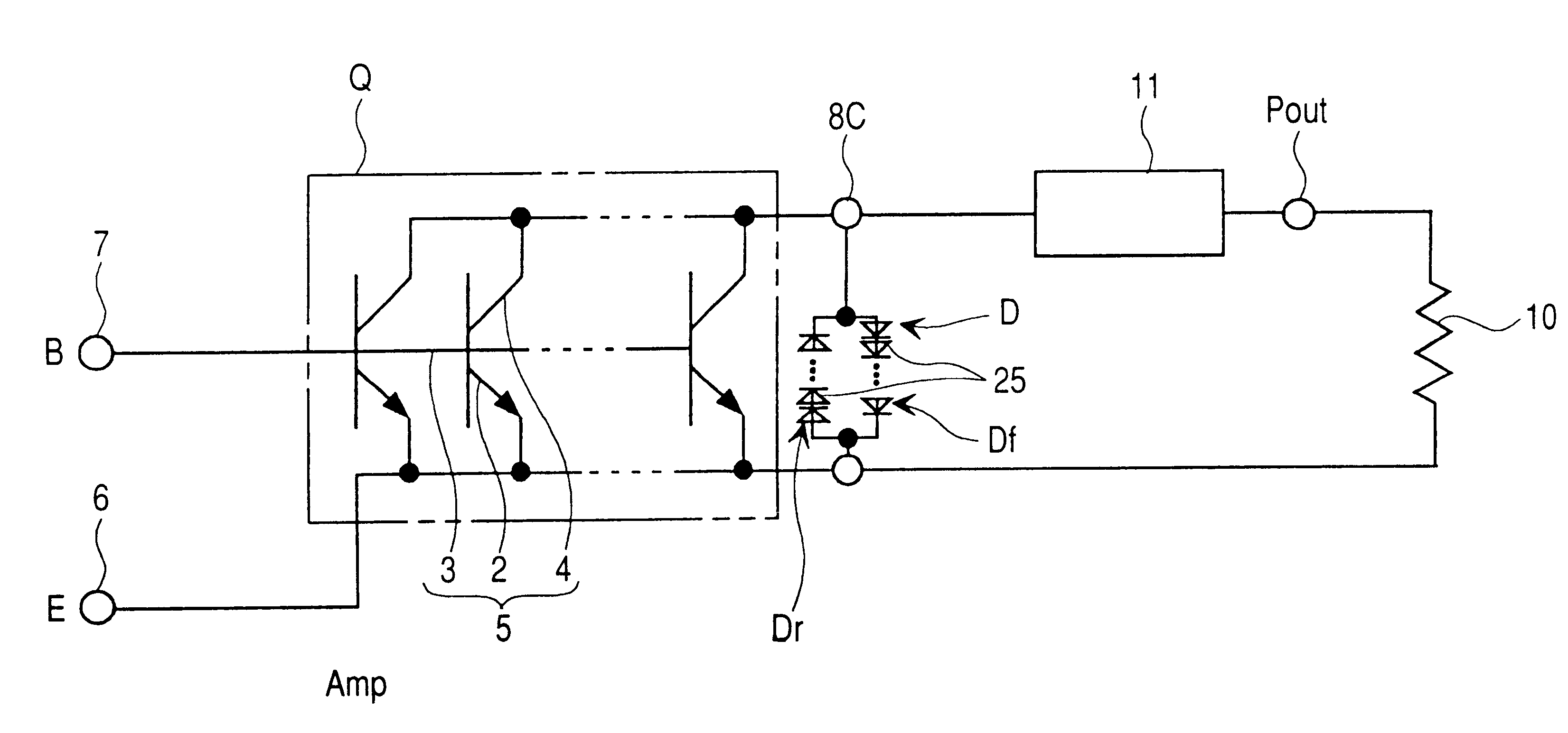

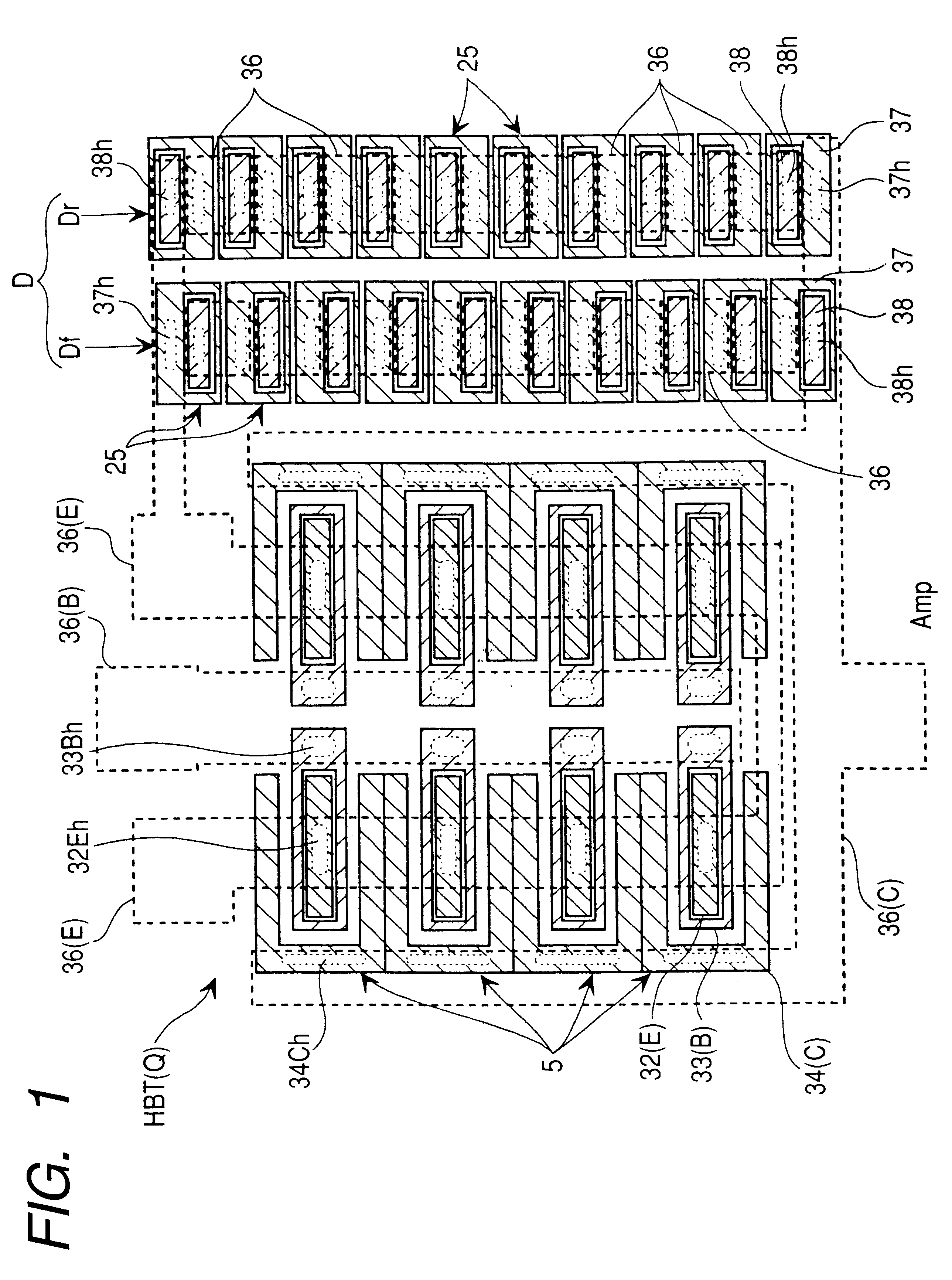

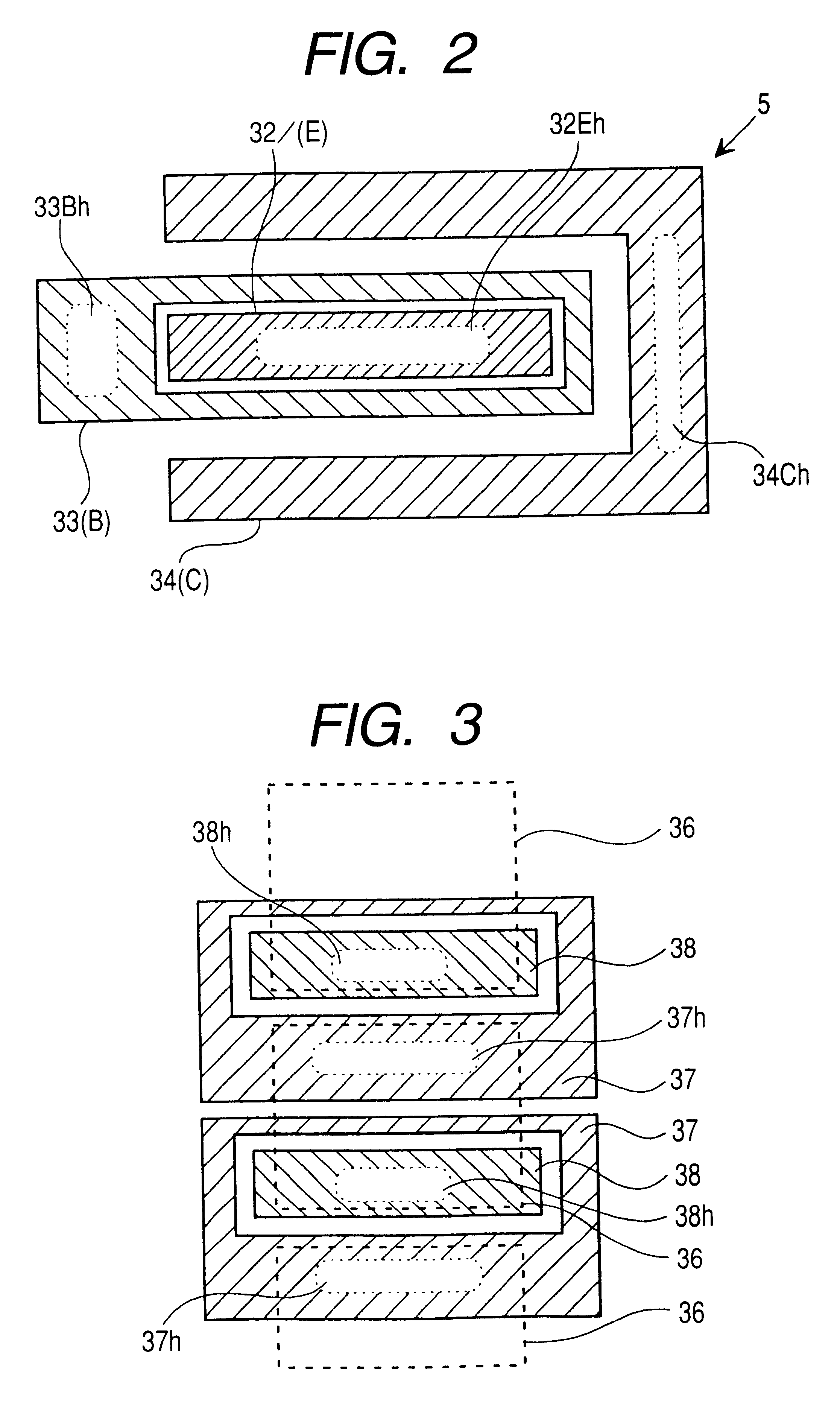

High-frequency power amplification module and radio communication device

InactiveUS6636118B1Stable communicationConvenient wireless communicationPulse automatic controlHigh frequency amplifiersHeterojunctionOvervoltage

In a high frequency power amplifier module of a multi-stage structure in which a plurality of heterojunction bipolar transistors (npn-type HBTs) are cascade-connected, a protection circuit in which a plurality of pn junction diodes are connected in series is connected between the collector and emitter of each HBT. The p-side is connected to the collector side, and the n-side is connected to the emitter side. A protection circuit in which pn junction diodes of the number equal to or smaller than that of the pn junction diodes are connected in series is connected between the base and the emitter. The p-side is connected to the base side, and the n-side is connected to the emitter side. With the configuration, in the case where an overvoltage is applied across the collector and emitter due to a fluctuation in load on the antenna side, the collector terminal is clamped by an ON-state voltage of the protection circuits, so that the HBT can be prevented from being destroyed. Since the similar protection circuit is assembled between the base and emitter, even when the operator touches the module at the time of manufacturing the high frequency power amplifier module, the HBT can be prevented from being destroyed by the clamping effect of the protection circuit between the base and emitter and the protection circuit between the collector and emitter. Thus, an improved manufacturing yield of the high frequency power amplifier module and a wireless communication apparatus can be achieved, and destruction caused by fluctuation in load impedance of the wireless communication apparatus can be prevented.

Owner:RENESAS ELECTRONICS CORP

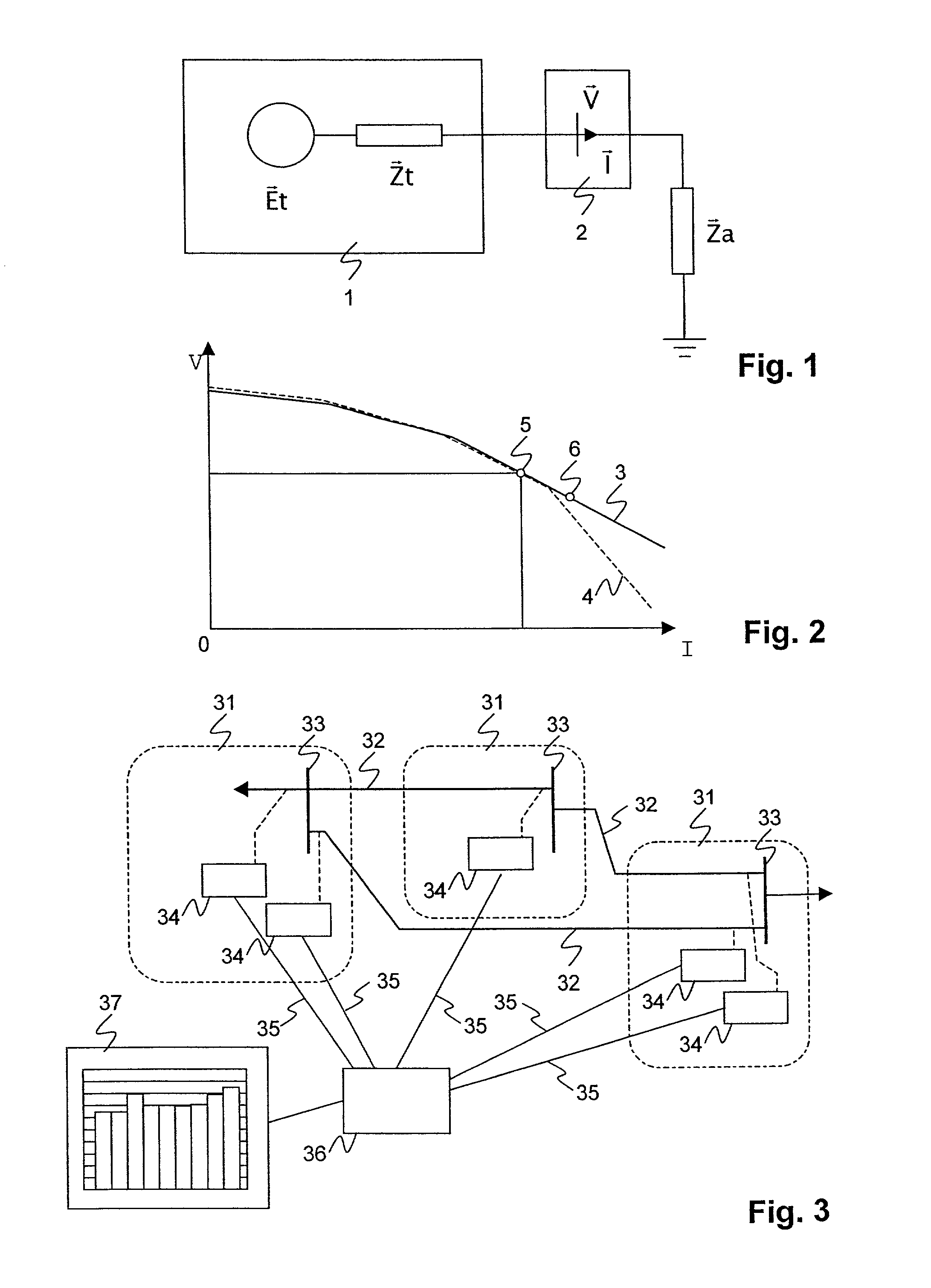

Method and device for assessing the stability of an electric power transmission network

InactiveUS20020123849A1Excellent stateElectric devicesPower oscillations reduction/preventionElectric power transmissionPower flow

In a method and devices for assessing the stability of an electric power network, for each of a plurality of measurement locations with associated voltage and current measurements, a normalized power margin value dSn is computed, which is defined as a result of dividing an associated power margin value by an associated maximum allowable power flow. In a preferred embodiment of the invention, the normalised power margin value dSn is computed from an apparent load impedance Za and a Thévenin impedance Zt, that are perceived from the measurement location, as <math-cwu id="MATH-US-00001"> <number>1< / number> dSn = ( Za - Zt Za + Zt ) 2 . <mathematica-file id="MATHEMATICA-00001" file="US20020123849A1-20020905-M00001.NB" / > <image id="EMI-M00001" wi="216.027" he="18.00225" file="US20020123849A1-20020905-M00001.TIF" imf="TIFF" ti="MF" / > < / math-cwu> Normalised power margin values from several measurement locations in the network therefore show power margins relative to a local maximum capacity, which makes them comparable to one another.

Owner:ABB POWER GRIDS SWITZERLAND AG

Heat Cloth and Process for Producing the Same

InactiveUS20080251062A1Thin and flexibleReduced flexibilityExothermal chemical reaction heat productionOther heat production devicesHuman bodyIron powder

To provide a heat cloth which is thin and flexible; even when as a reaction of an air-permeable heat cloth proceeds, a heat generating composition becomes massive so that flexibility is lowered, or a part of an accommodating bag rides up by shrinkage and curling as caused by heat generation, well keeps the bonding and holding state so that it does not fall off easily; is supple like cloths; is excellent in flexing properties; easily and surely fits to flexible places such as elbows and knees; is able to take warmth; is applicable with good follow-up deformation properties to various places of a human body such as curved parts including shoulders, arms, a neck and feet; and hardly causes an uncomfortable feeling and a process for producing the same.A heat cloth having a heat generating composition molded body resulting from molding a heat generating composition containing surplus water as a connecting substance accommodated in an accommodating bag, wherein the accommodating bag is constituted of a substrate and a covering material; the covering material covers the heat generating composition molded body as provided on the substrate; the periphery of the heat generating composition molded body is heat sealed to form irregularities; sectional exothermic parts of a convex in which the heat generating composition molded body is accommodated are disposed while holding a sectioned part of a concave as a heat seal part; and the exothermic part is formed of a gathering of the sectional exothermic parts, which is characterized in that the substrate is substantially planar and does not contain a pocket, an accommodating division or an accommodating section; that the heat generating composition contains, as essential components, an iron powder, a carbon component, a reaction accelerator and water, does not contain a flocculant aid, a flocculant, an agglomeration aid, a dry binding material, a dry binding agent, a dry binder, a sticky raw material, a thickener and an excipient, contains surplus water so as to have a water mobility value of from 0.01 to 20, with the water in the heat generating composition not functioning as a barrier layer, and is capable of causing an exothermic reaction upon contact with air; that a volume of the heat generating composition molded body is from 0.1 to 30 cm3; that a capacity of the sectional exothermic parts to a ratio of the volume of the heat generating composition molded body is from 0.6 to 1.0; that a maximum height of the sectional exothermic parts is from 0.1 to 10 mm; that a width of the sectioned part as a space between the sectional exothermic parts is from 0.3 to 50 mm; that a minimum bending resistance on the surface orthogonal to at least a thickness of the heat cloth is not more than 100 mm; that a part of the accommodating bag has air permeability; and the surroundings of the accommodating bag are sealed.

Owner:MYCOAL PRODS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com