Absorbent article

a technology of absorbent articles and absorbent sheets, applied in the field of absorbent articles, can solve the problems of easy compromise of the adhesion of the bottom-layer composite absorbent sheet to the discharge area, easy kink or wrinkle formation of the bottom-layer composite absorbent sheet, and uncomfortable wearing of articles, etc., to reduce the proliferation of microorganisms, easy to keep, and easy to suppress the occurrence of twisting or wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(1) EXAMPLE 1

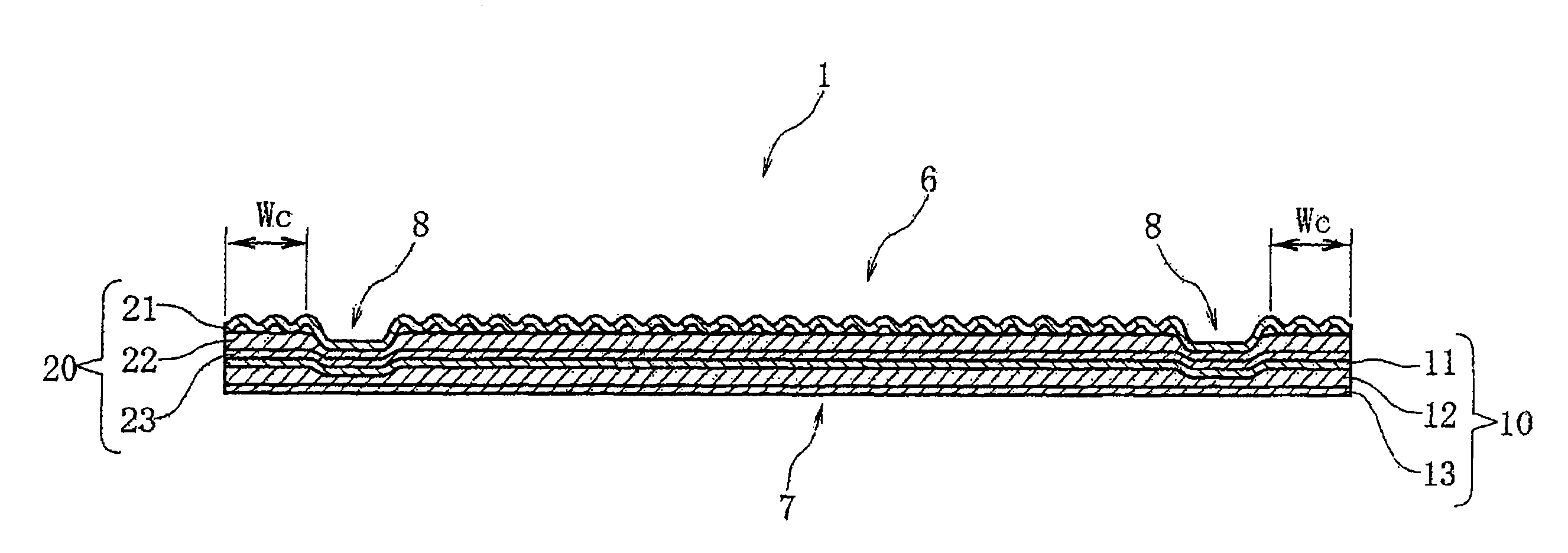

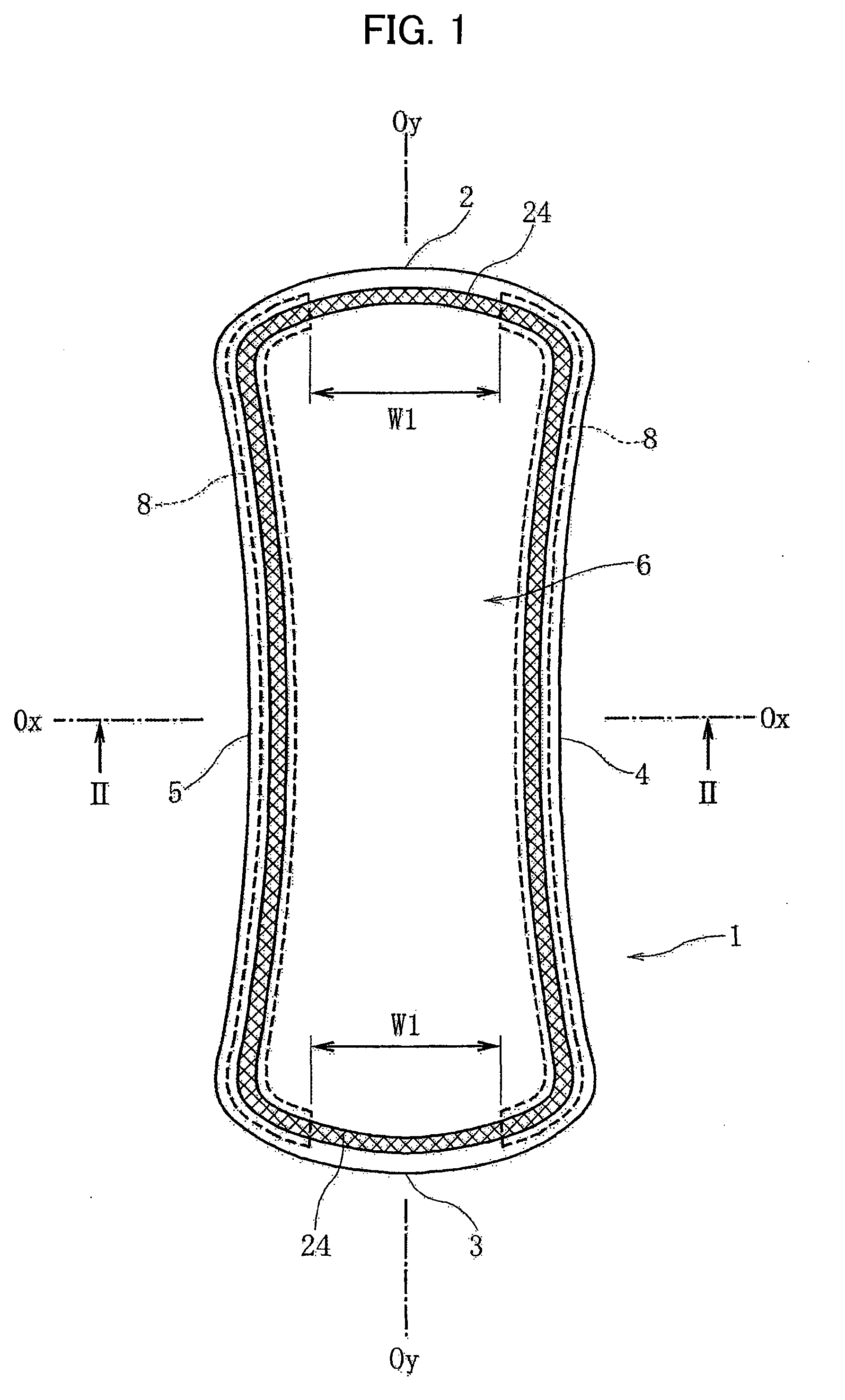

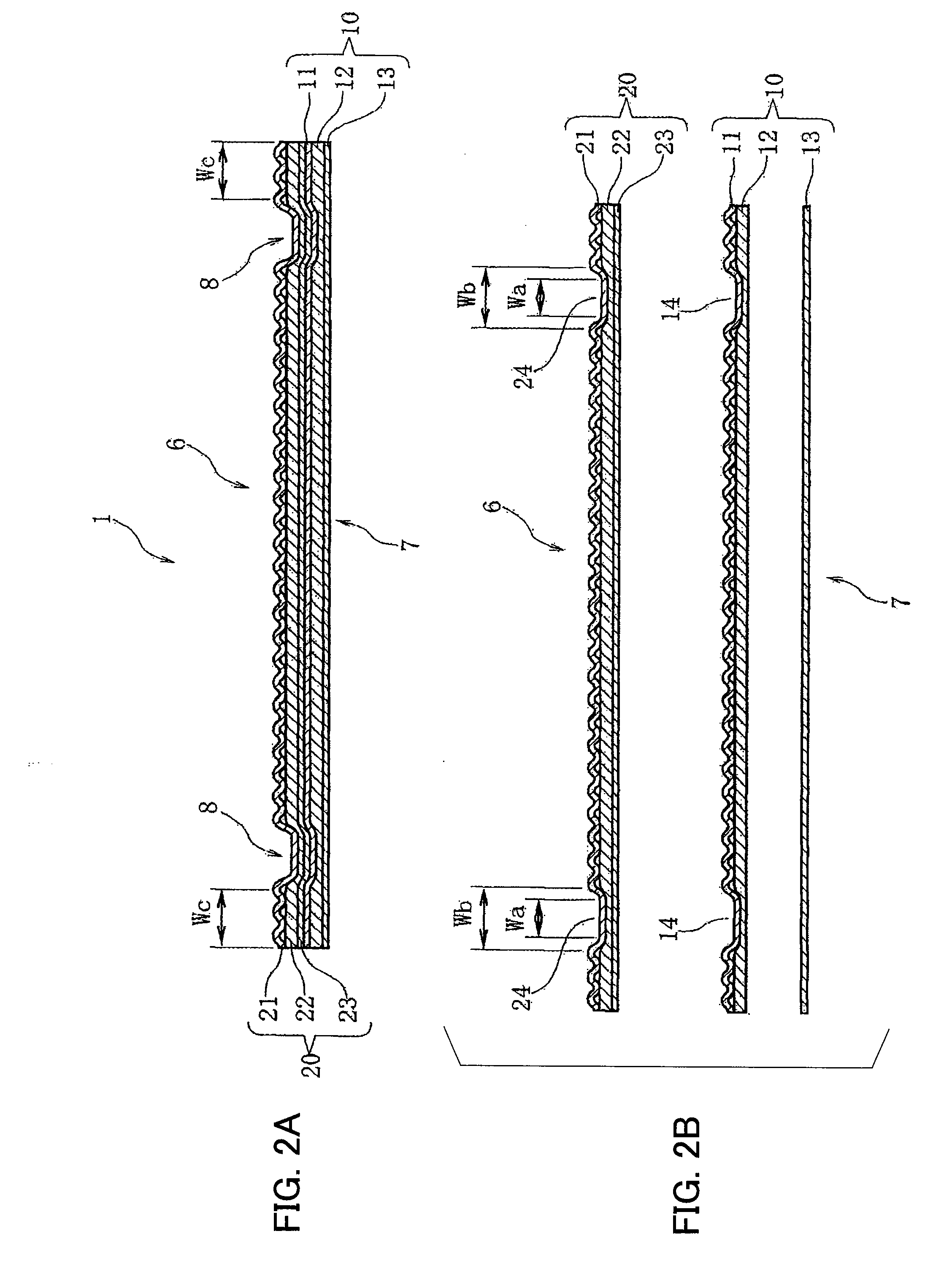

[0155] An absorbent article 1 having a two-layer structure that included a bottom absorbent component 10 and an upper absorbent component 20 was created as shown in FIGS. 2A and 2B.

[0156] The surface sheet 11 of the bottom absorbent component 10 and the surface sheet 21 of the upper absorbent component 20 were both formed from spunlace nonwoven cloth composed of 60% mass of rayon fibers and 40% mass of polyethylene terephthalate fibers. The weight thereof was 35 g / m2. Corrugation was applied to the surface sheet 11 and the surface sheet 21.

[0157] The middle sheet 12 of the bottom absorbent component 10 and the middle sheet 22 of the upper absorbent component 20 were both formed from through-air nonwoven cloth composed of 50% mass of polyethylene fibers and 50% mass of polypropylene fibers. The polyethylene fibers and polypropylene fibers used both had a fineness of 2.2 dtex and a fiber length of 40 mm, and the weight thereof was 25 g / m2. The through-air nonwoven cloth...

example 2

(2) EXAMPLE 2

[0162] An absorbent article having a two-layer structure was created in the same manner as in Example 1.

[0163] The surface sheet 11, middle sheet 12, and article backing sheet 13 of the bottom absorbent component 10 were the same as those used in Example 1.

[0164] The surface sheet 21 of the upper absorbent component 20 was formed from through-air nonwoven cloth composed of 50% mass of polyethylene fibers and 50% mass or polypropylene fibers. The polyethylene fibers and polypropylene fibers that were used both had a fineness of 2.2 dtex and a fiber length of 40 mm, and the weight thereof was 25 g / m2. The nonwoven cloth that was used was neither heat-treated for volume recovery nor corrugated.

[0165] An air-laid nonwoven cloth in which pulp was laminated by an air-laying method and the fibers were bonded together by a binder was used as the middle sheet 22 of the upper absorbent component 20. The weight thereof was 35 g / m2. The back surface sheet 23 of the upper absorbe...

example 3

(3) EXAMPLE 3

[0168] An absorbent article 101 having the three-layer structure shown in FIG. 3 was created as in Example 3.

[0169] The surface sheet 111 and middle sheet 112 of the bottom absorbent component 110 were the same as the surface sheet 11 and middle sheet 12 used in Example 1. A laminate of SMS composite nonwoven cloth having a weight of 20 g / m2 and an air-permeable polyethylene film having a basis weight of 20 g / m2 were used as the article backing sheet 113.

[0170] A corrugated spunlace nonwoven cloth composed of 60% mass of cotton fibers and 40% mass of polyethylene terephthalate fibers was used as the middle sheet 122 of the upper absorbent component 120. An air-permeable polyethylene film having a basis weight of 35 g / m2 was used as the back surface sheet 123.

[0171] A non-corrugated spunlace nonwoven cloth having a weight of 35 g / m2 composed solely of cotton fibers was used as the middle sheet 132 of the top absorbent component 130. An air-permeable polyethylene film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com