Patents

Literature

4706results about "Ice production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

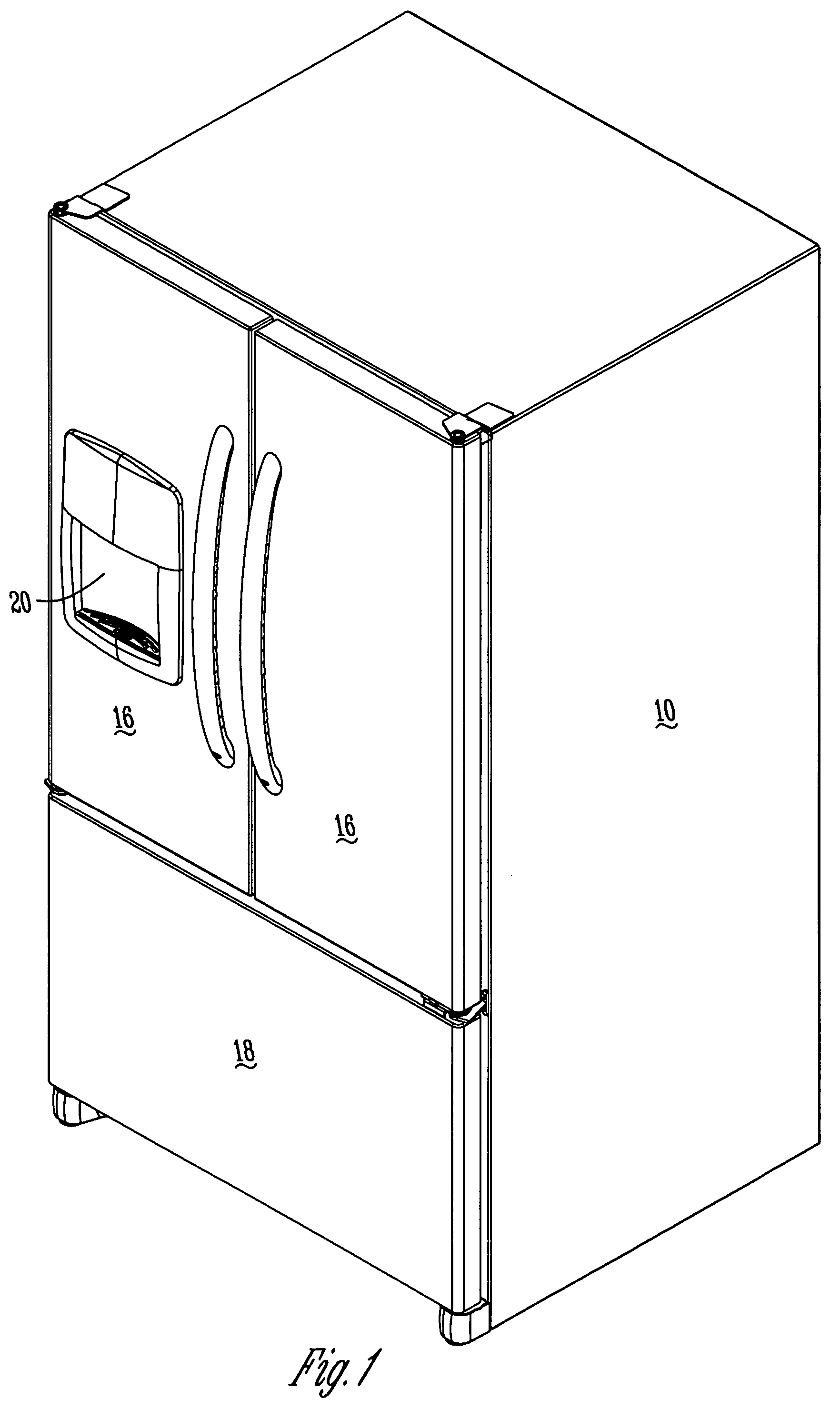

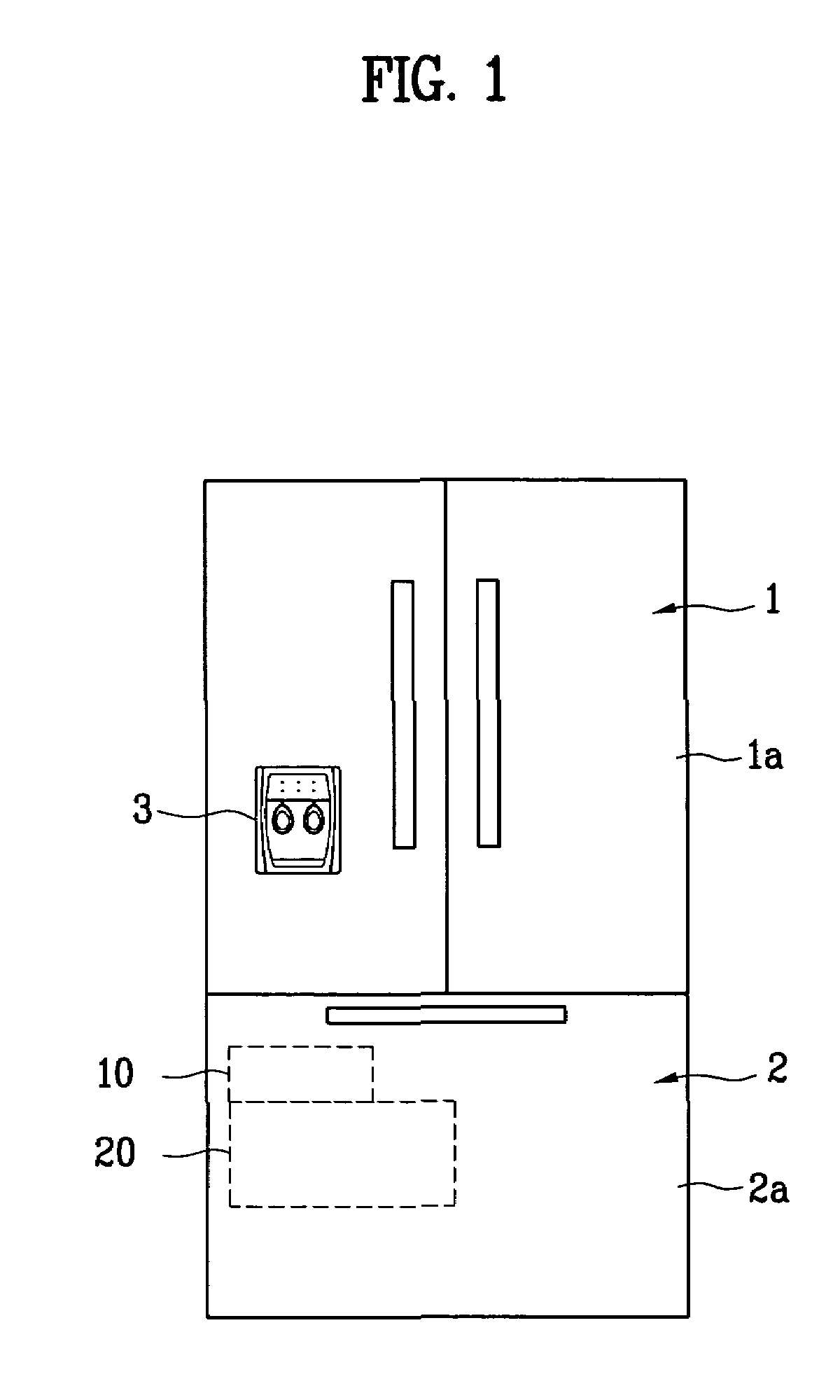

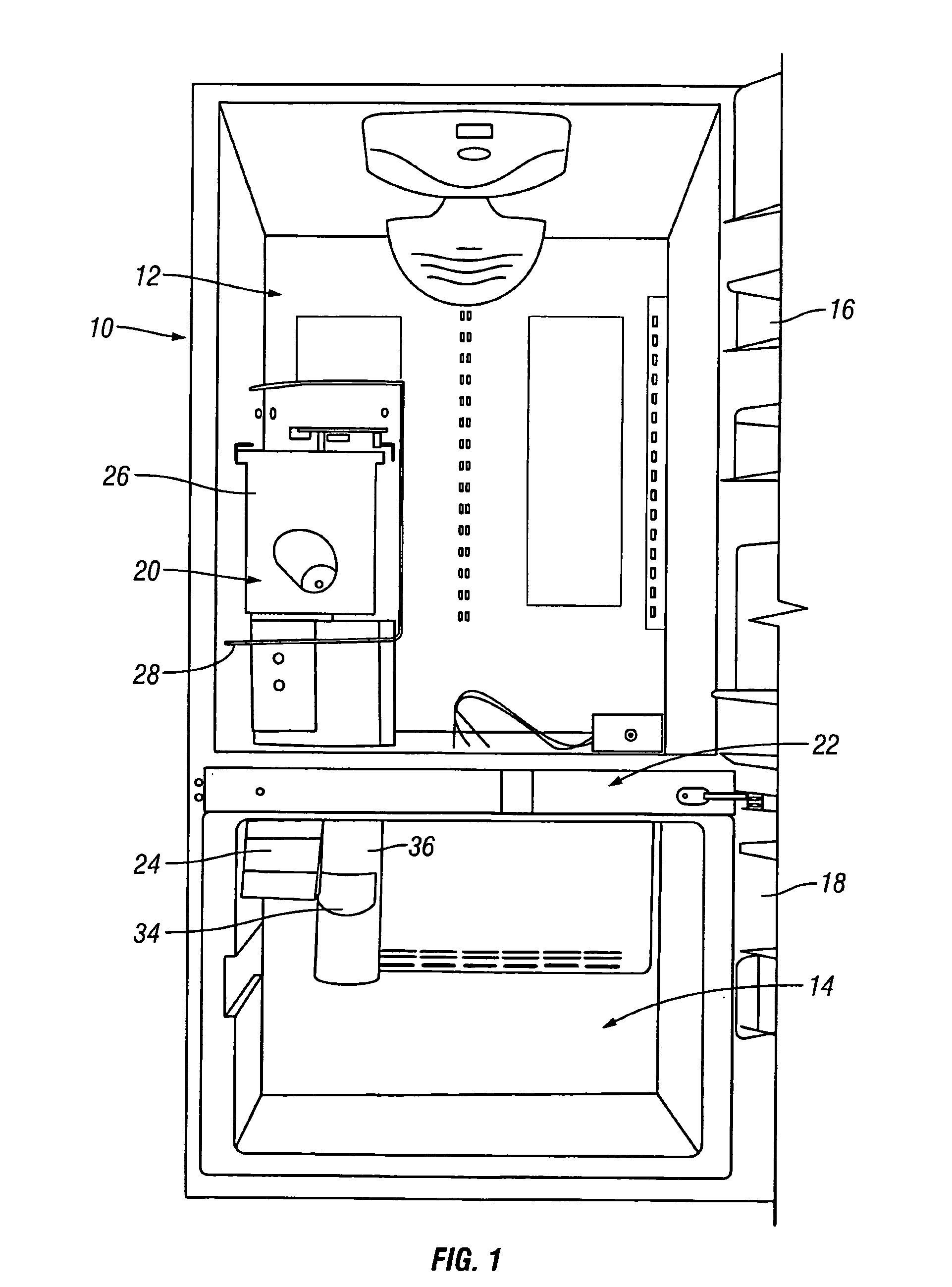

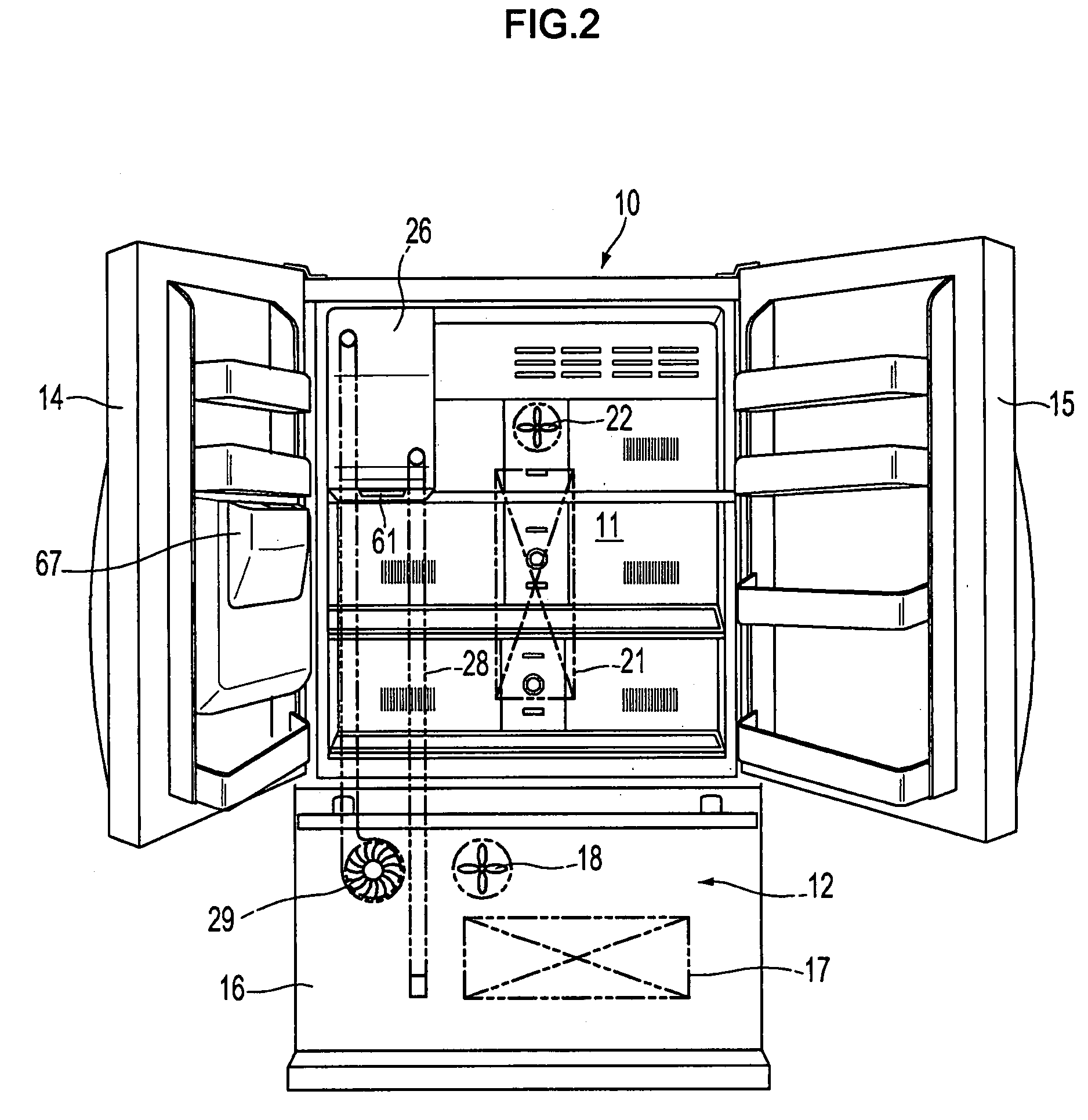

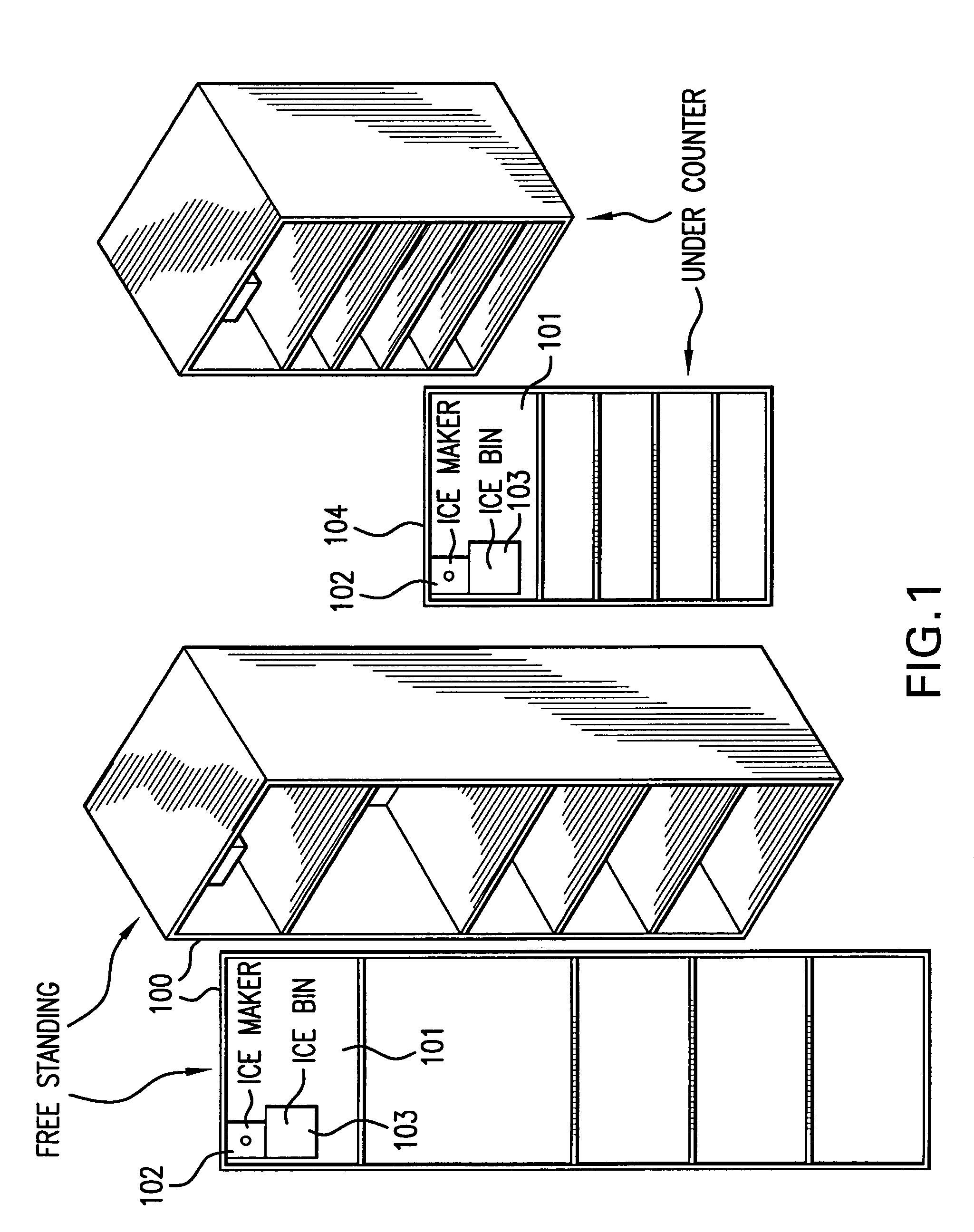

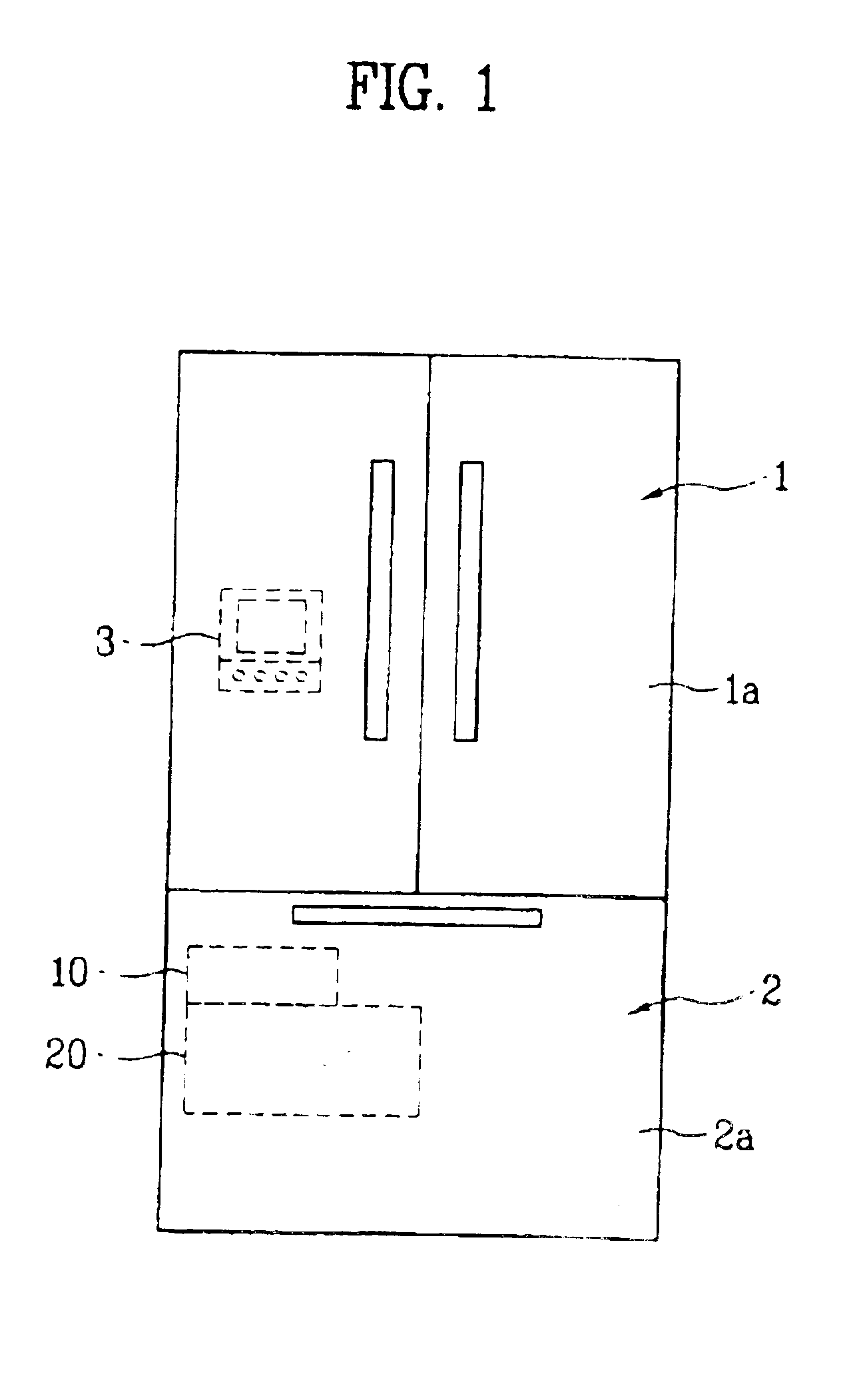

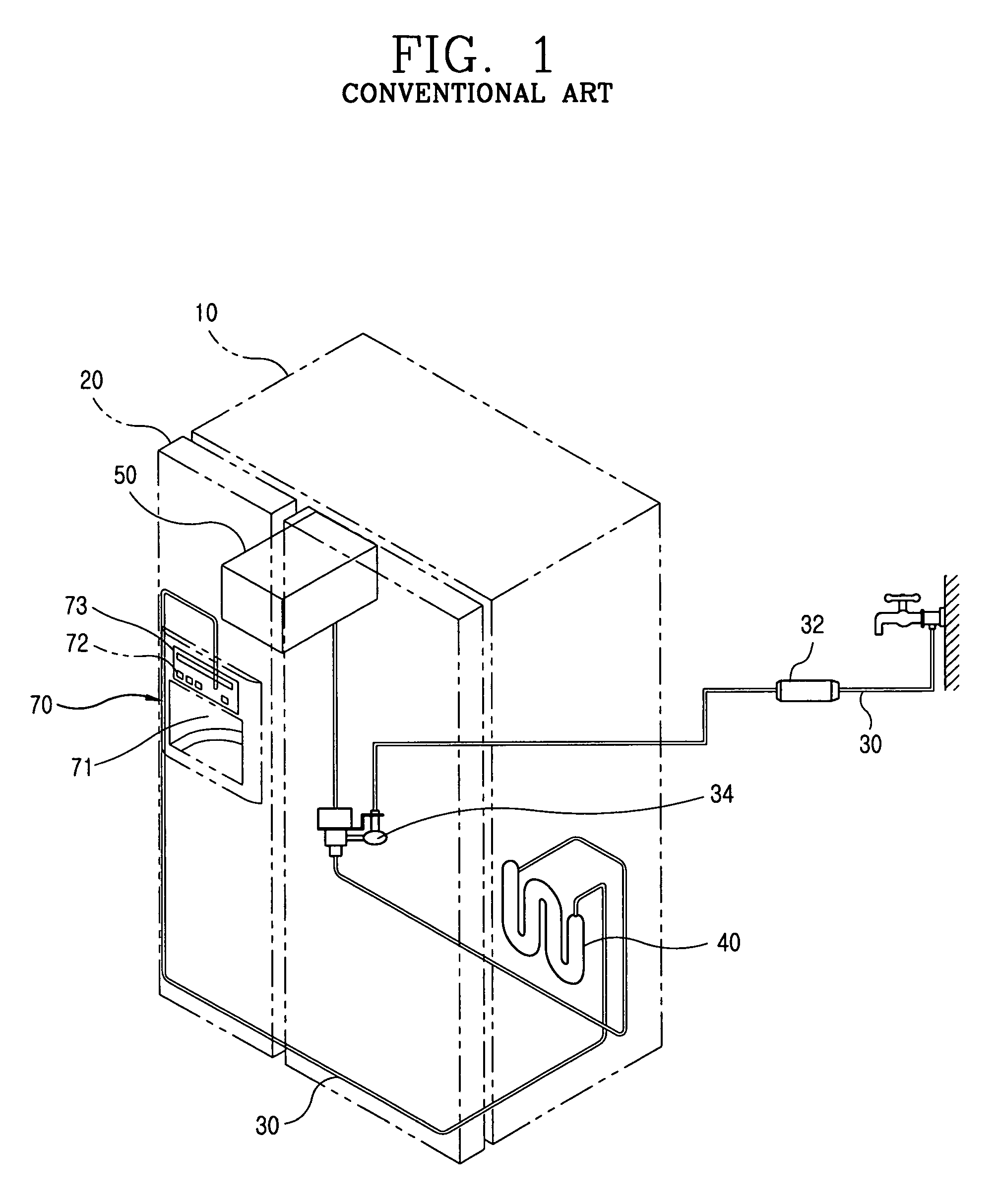

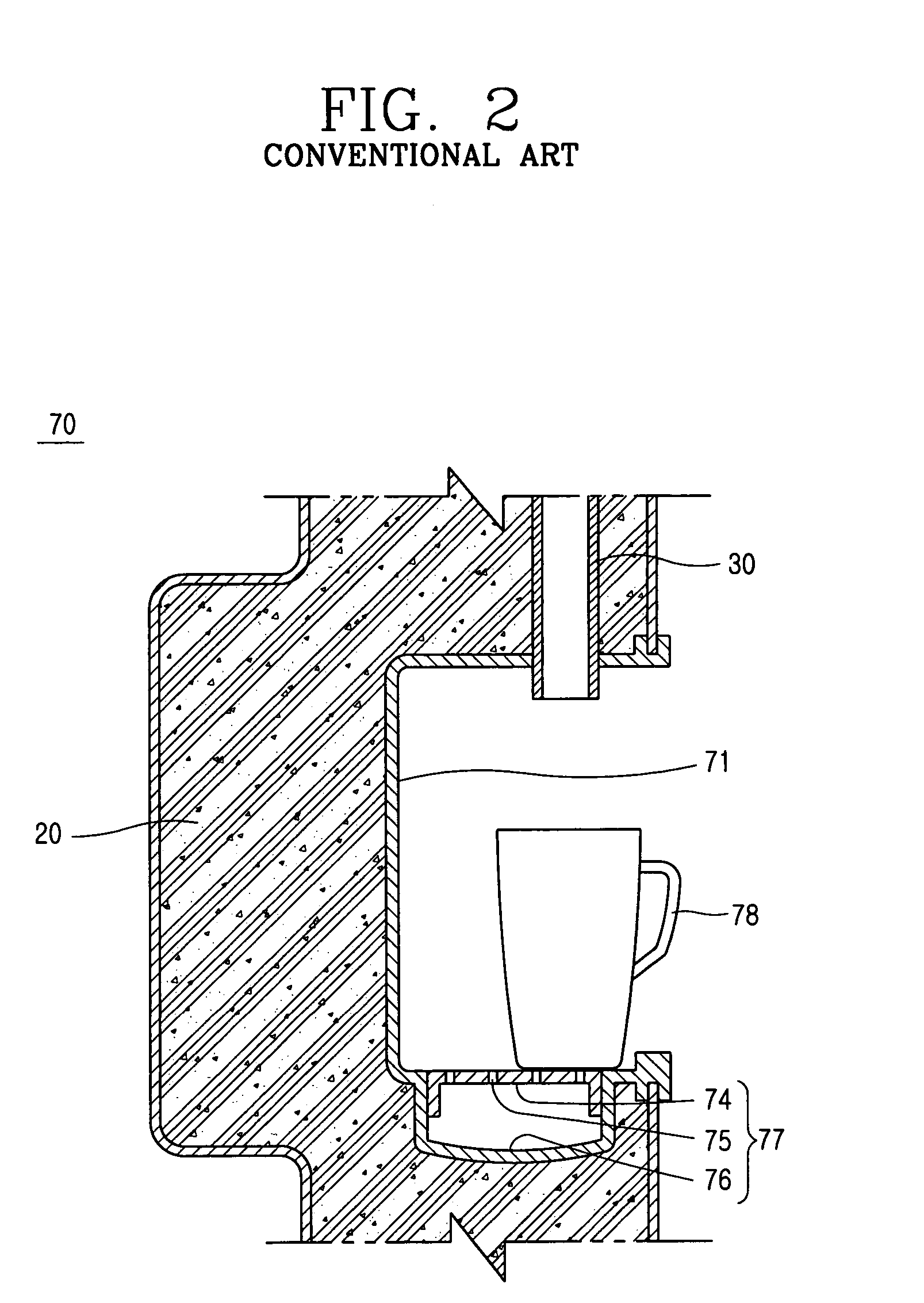

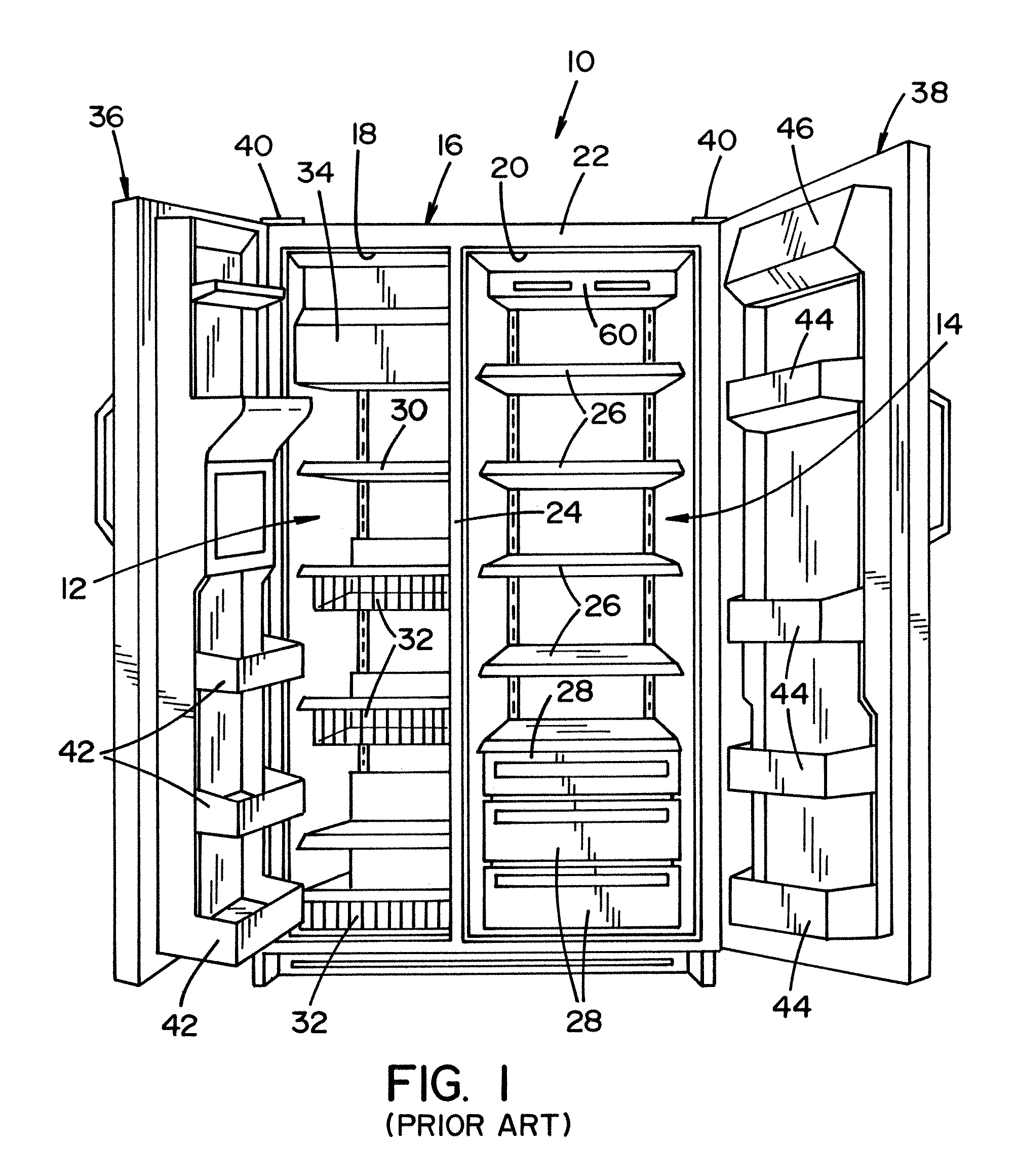

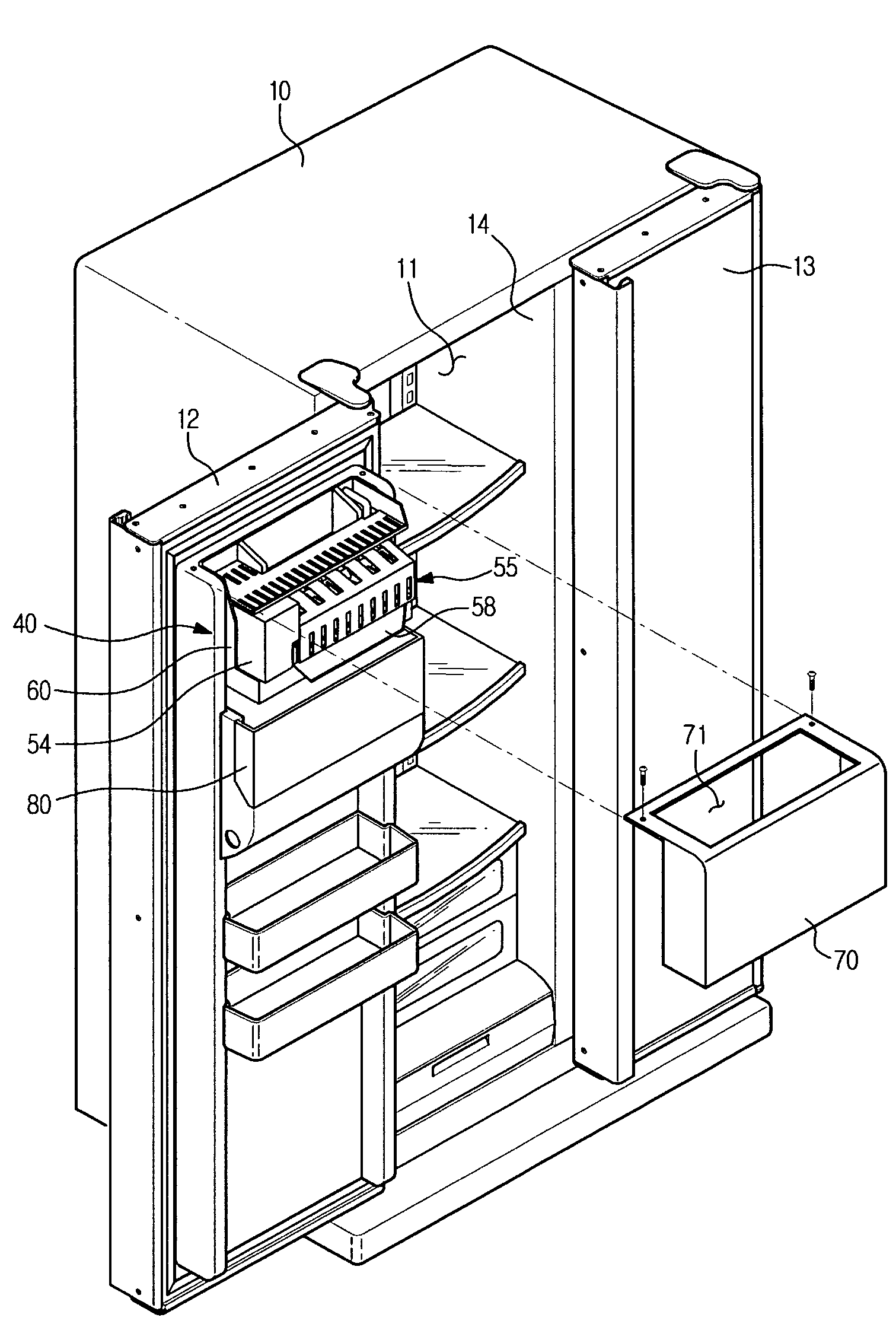

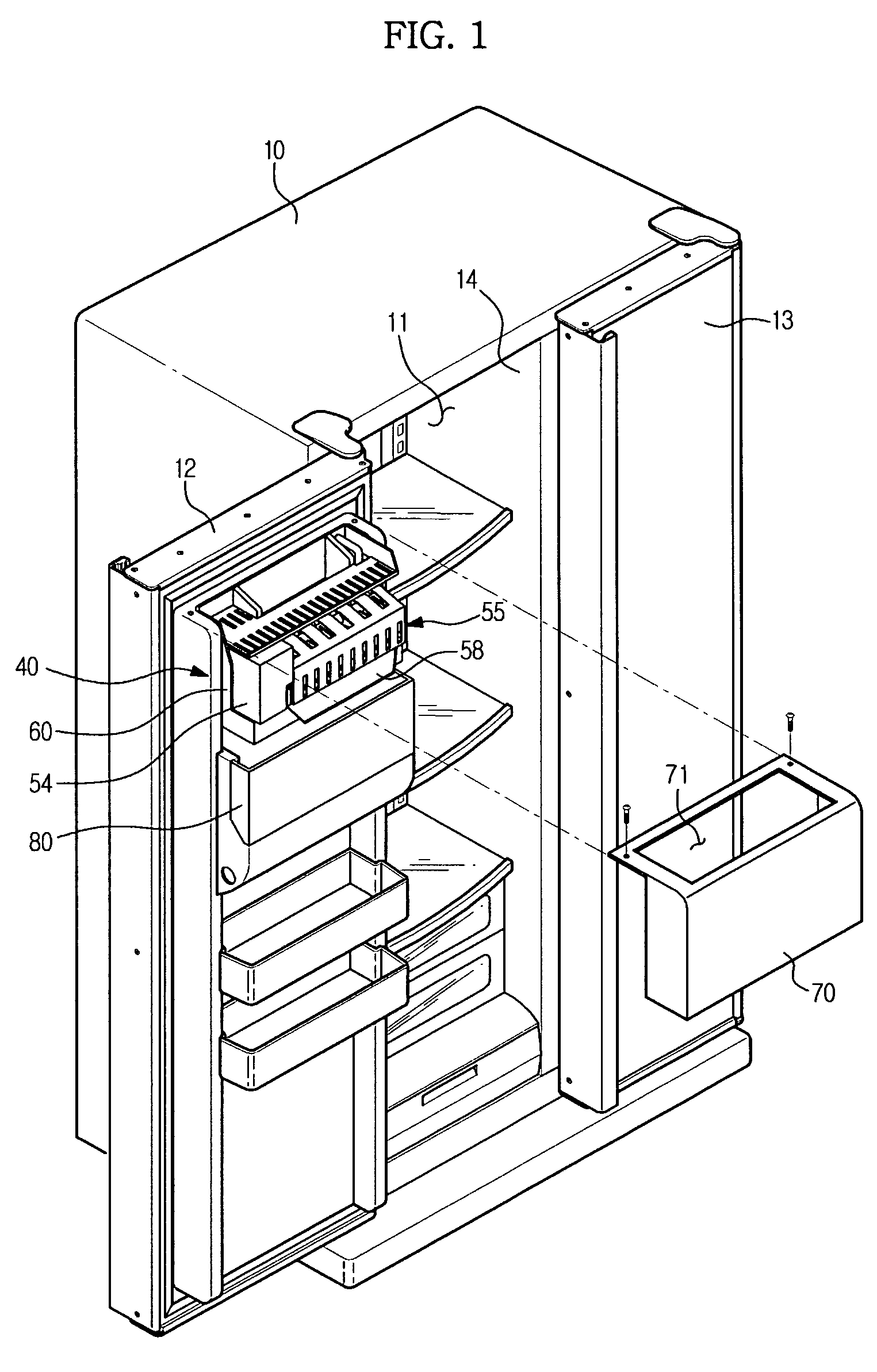

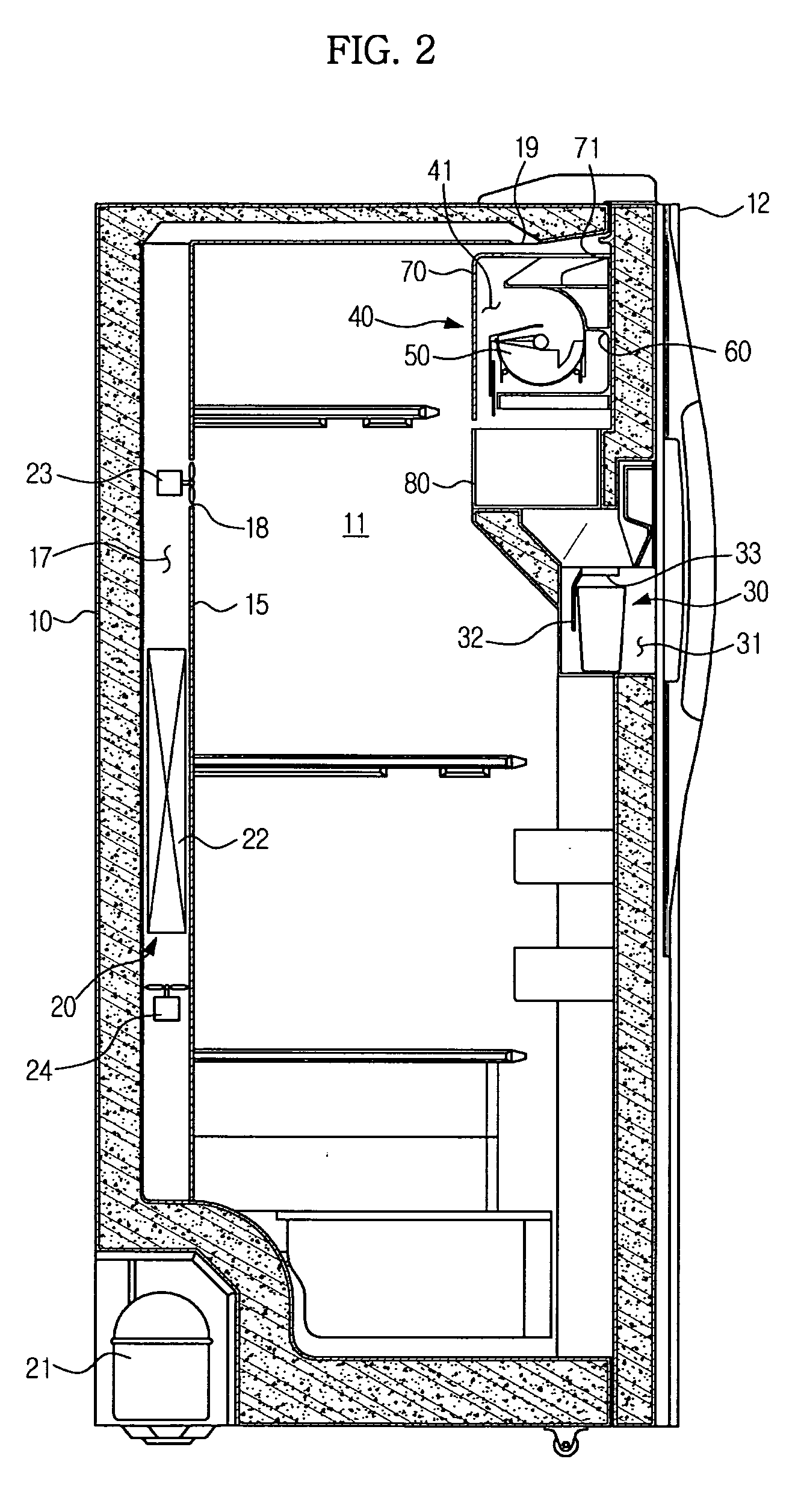

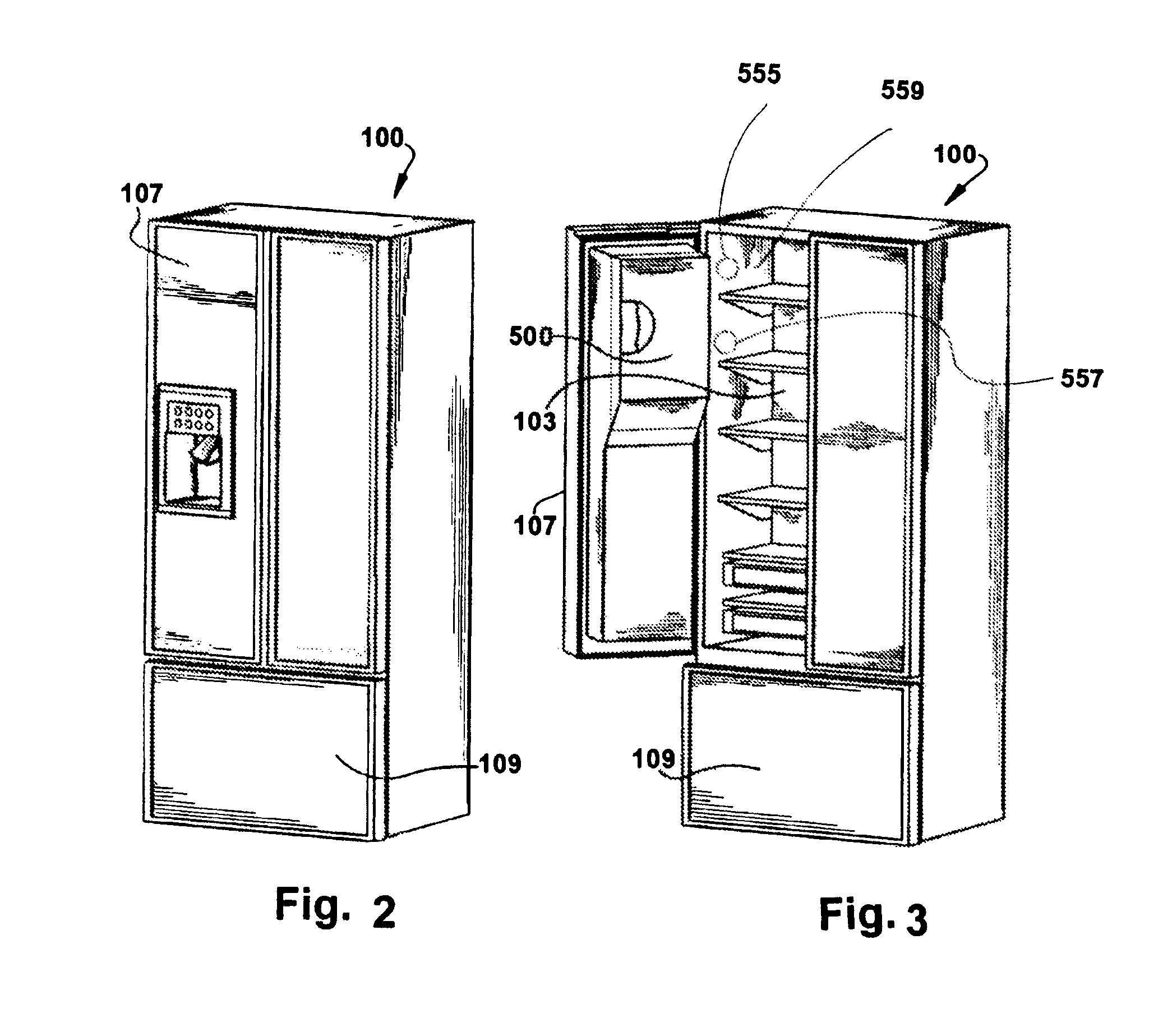

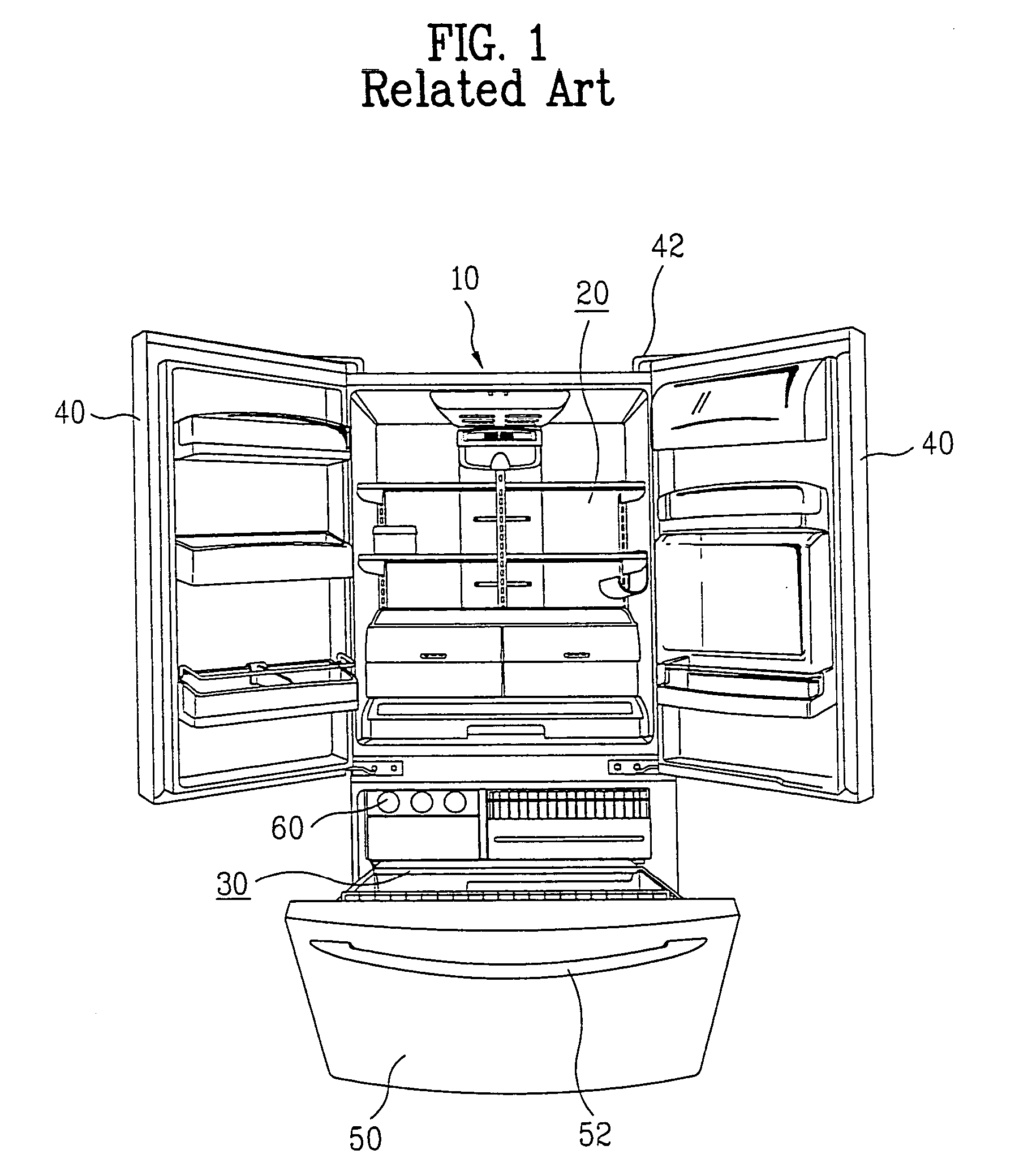

Refrigerator with icemaker

Disclosed is a refrigerator with an improved structure for supplying ices at an outside of a dispenser provided at a door. The refrigerator includes a supplementary freezer, a cavity, an icemaker and a dispenser. The supplementary freezer is provided in a cooling chamber of the refrigerator. The cavity is provided in the door and is connected with the supplementary freezer when the door is closed. The icemaker produces ices using cool air in the cooling chamber. The dispenser is connected with the cavity provided at the door. In this case, the icemaker is provided in the supplementary freezer or in the cavity.

Owner:LG ELECTRONICS INC

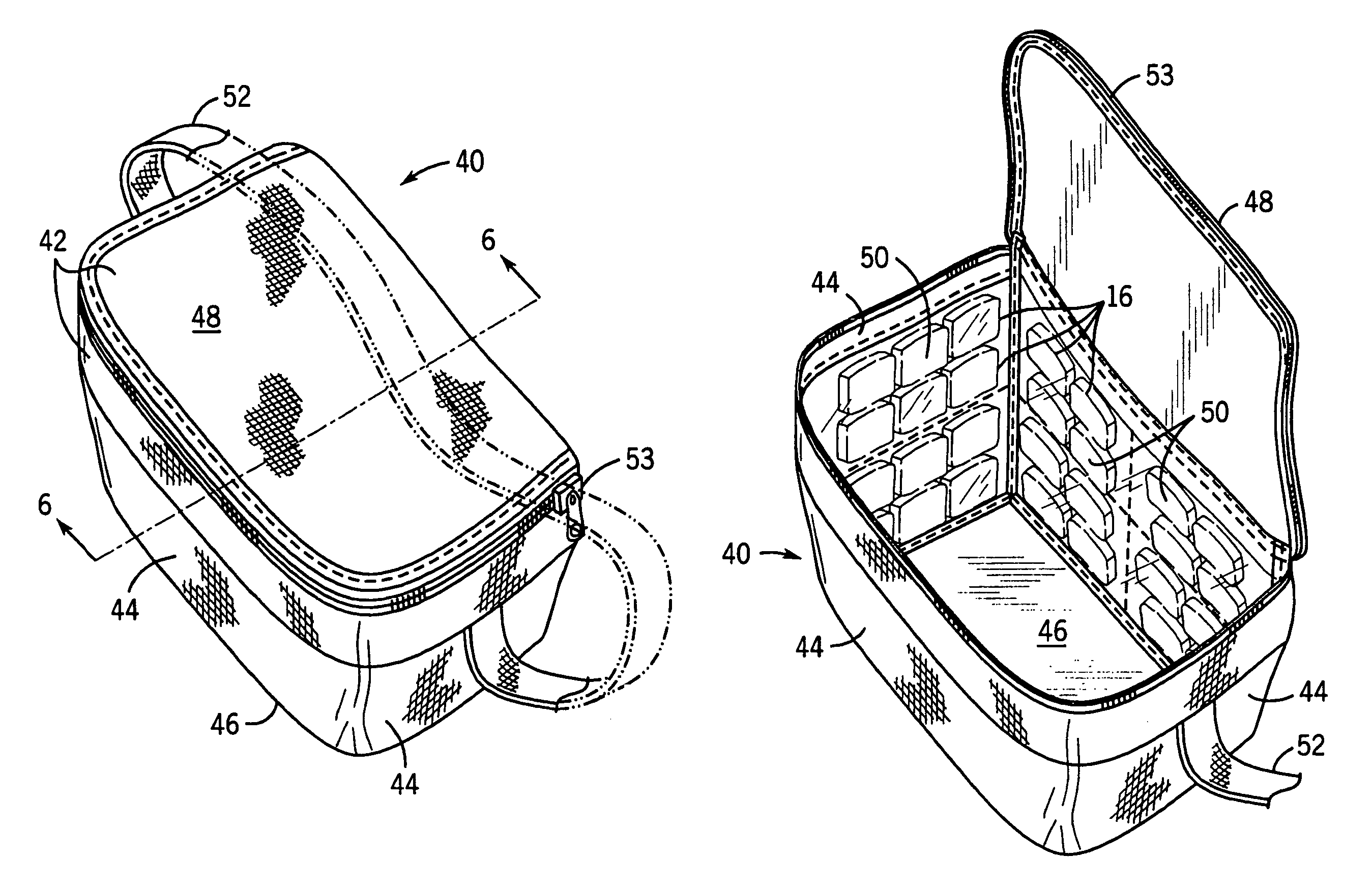

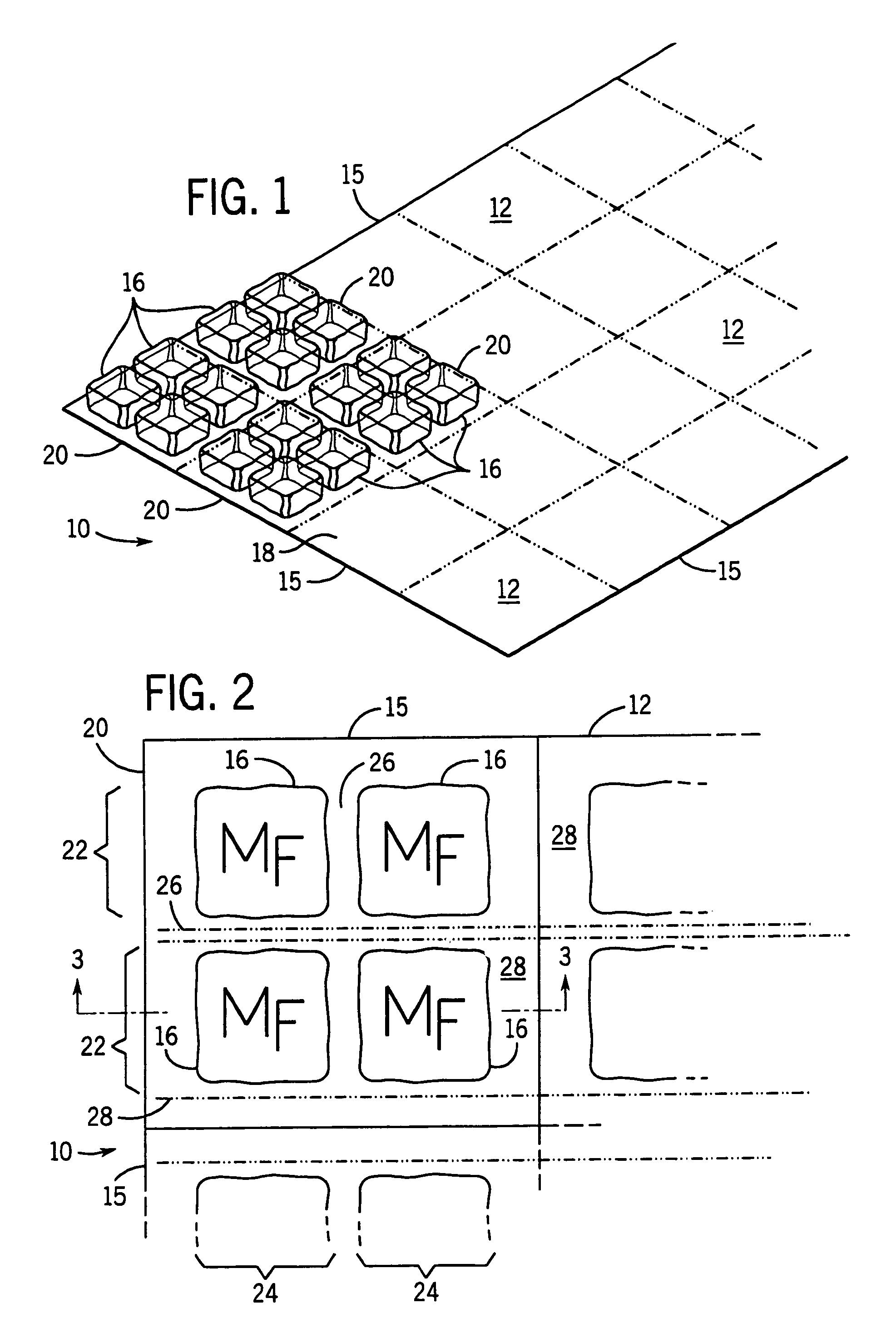

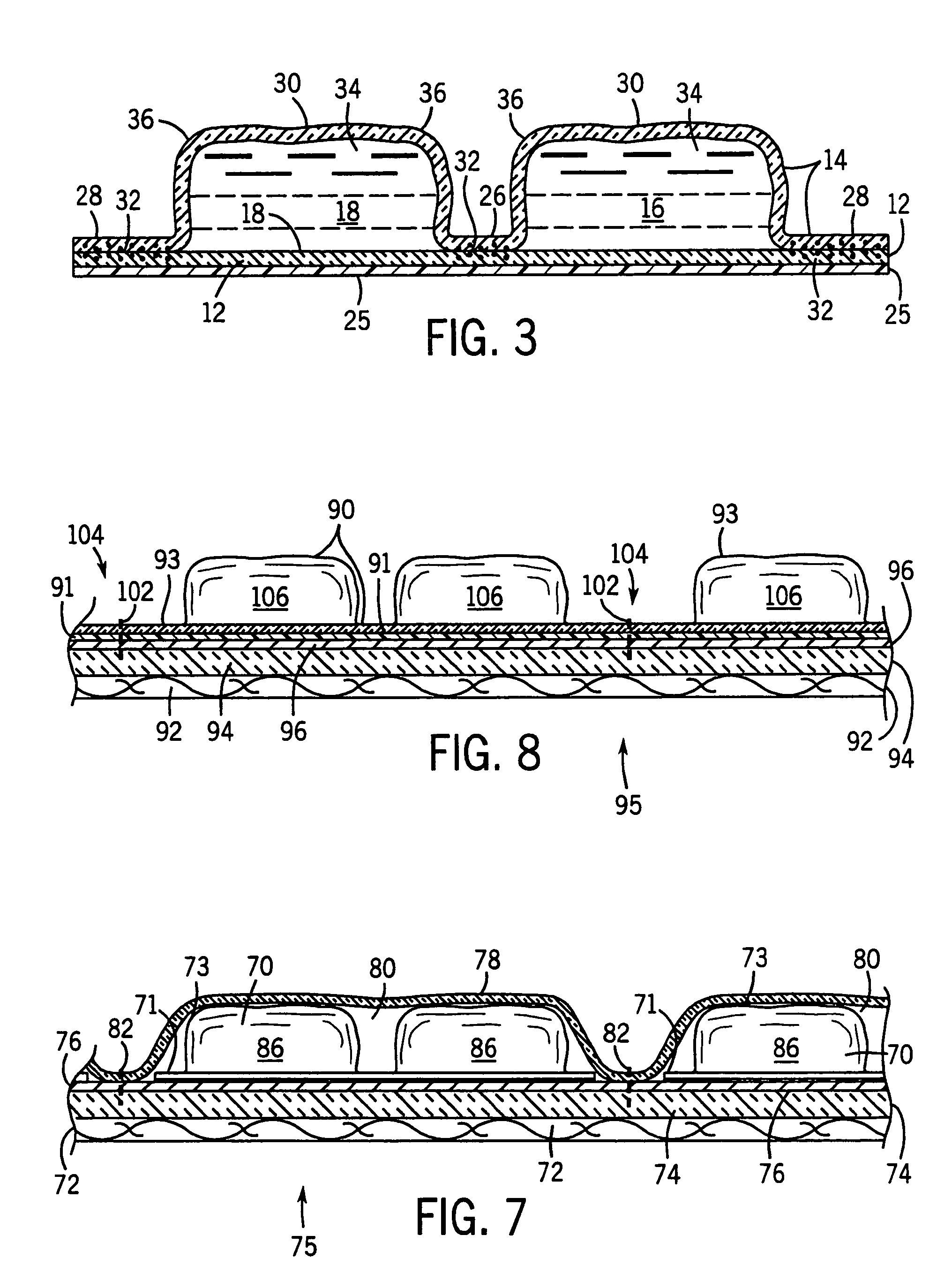

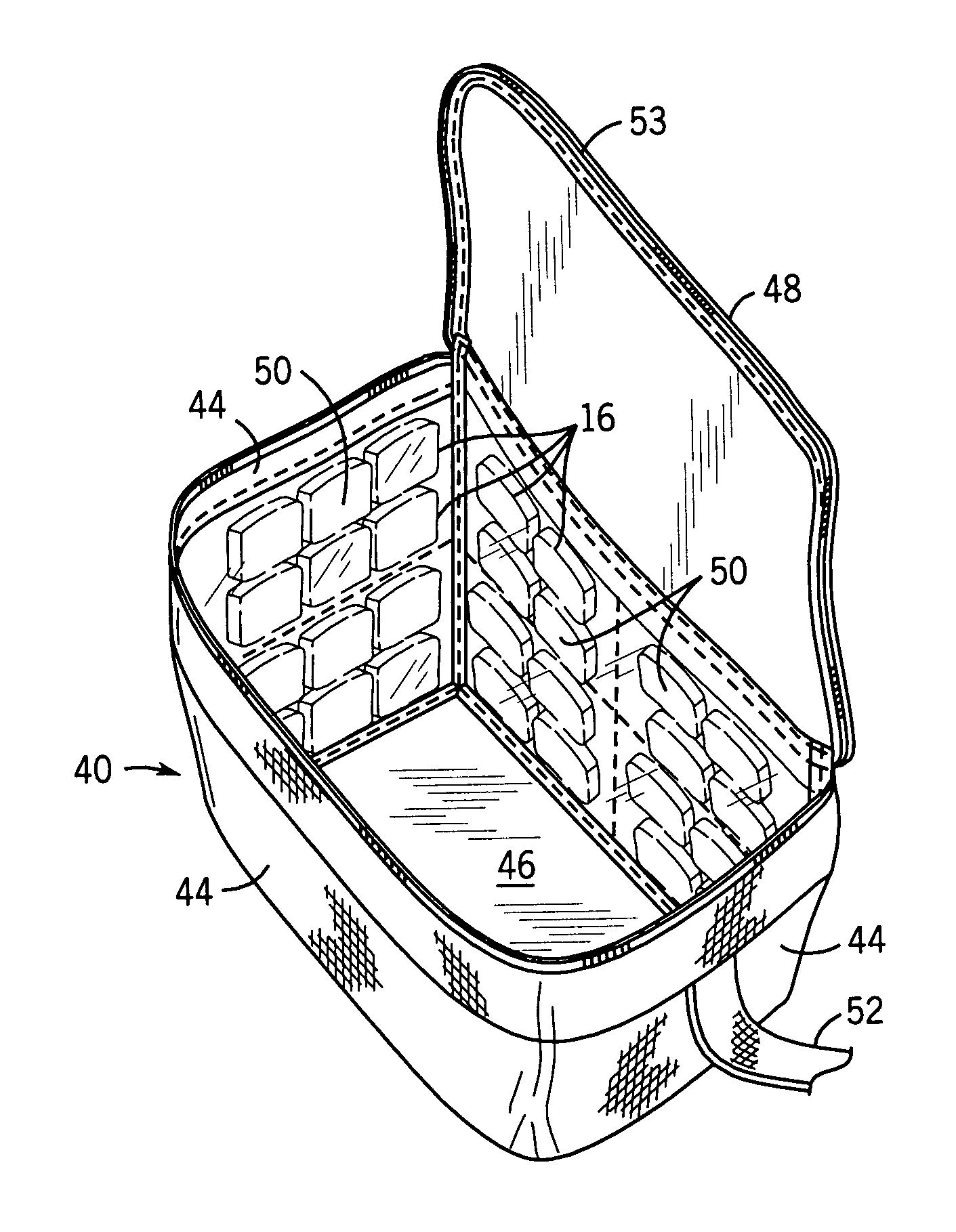

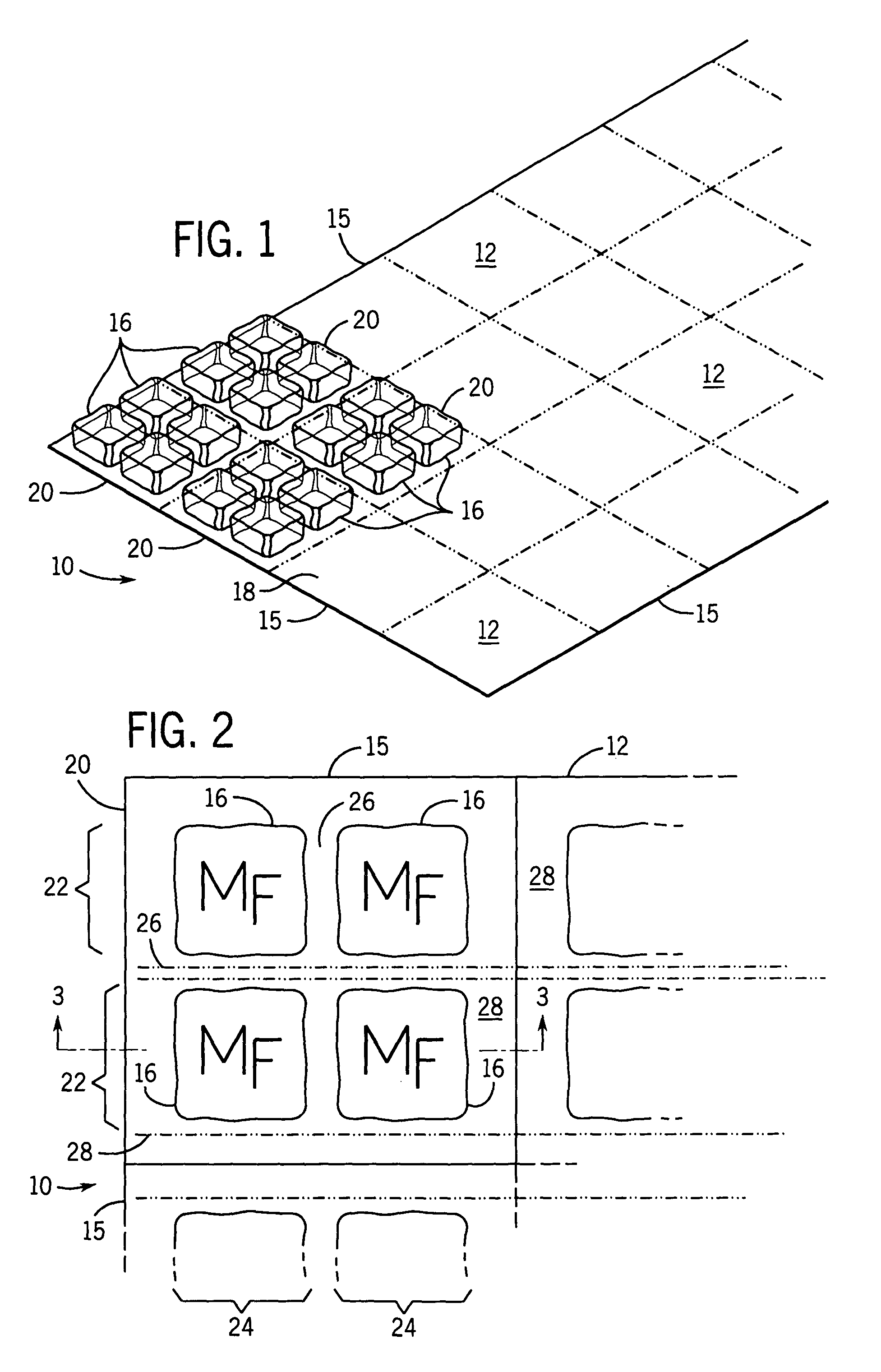

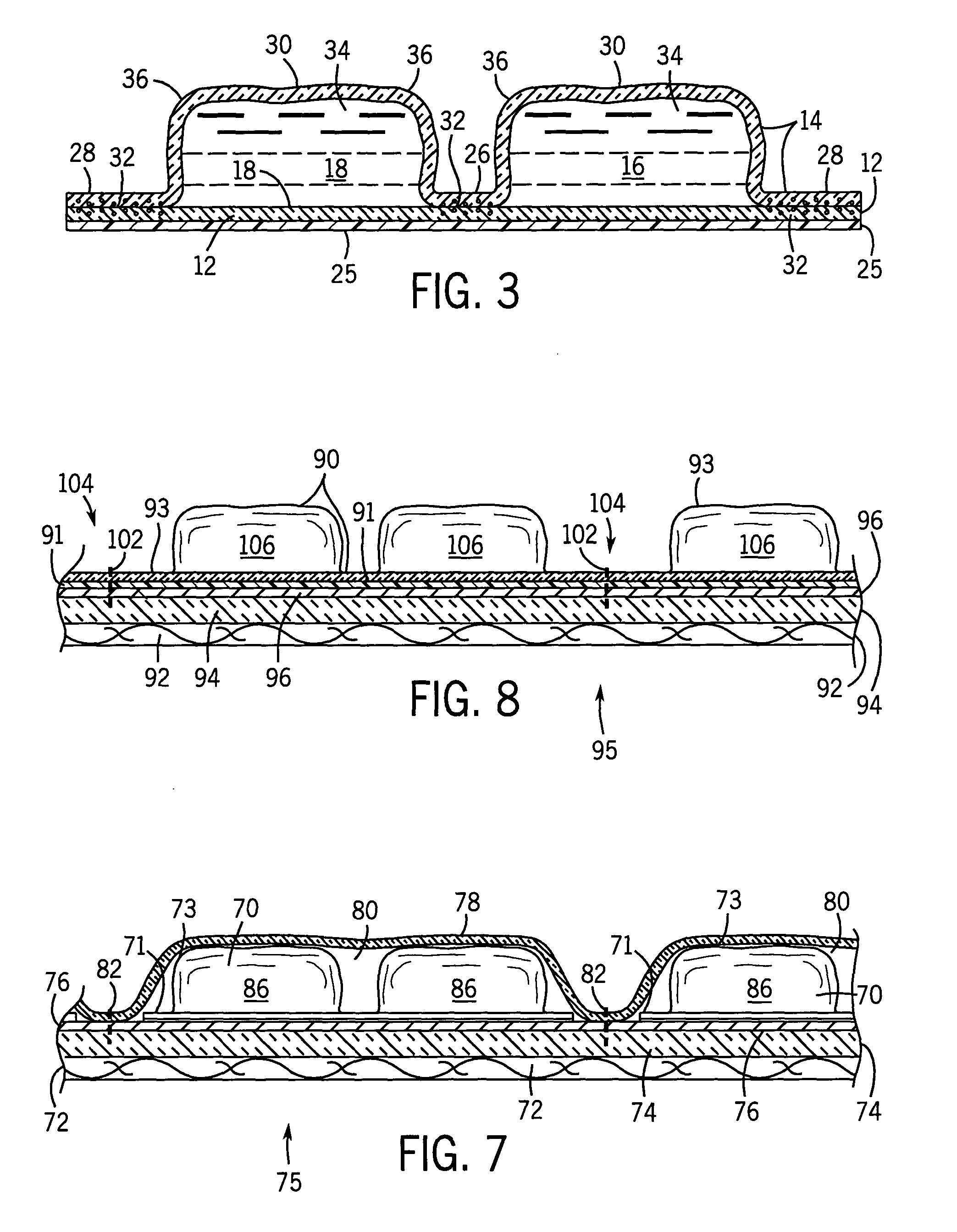

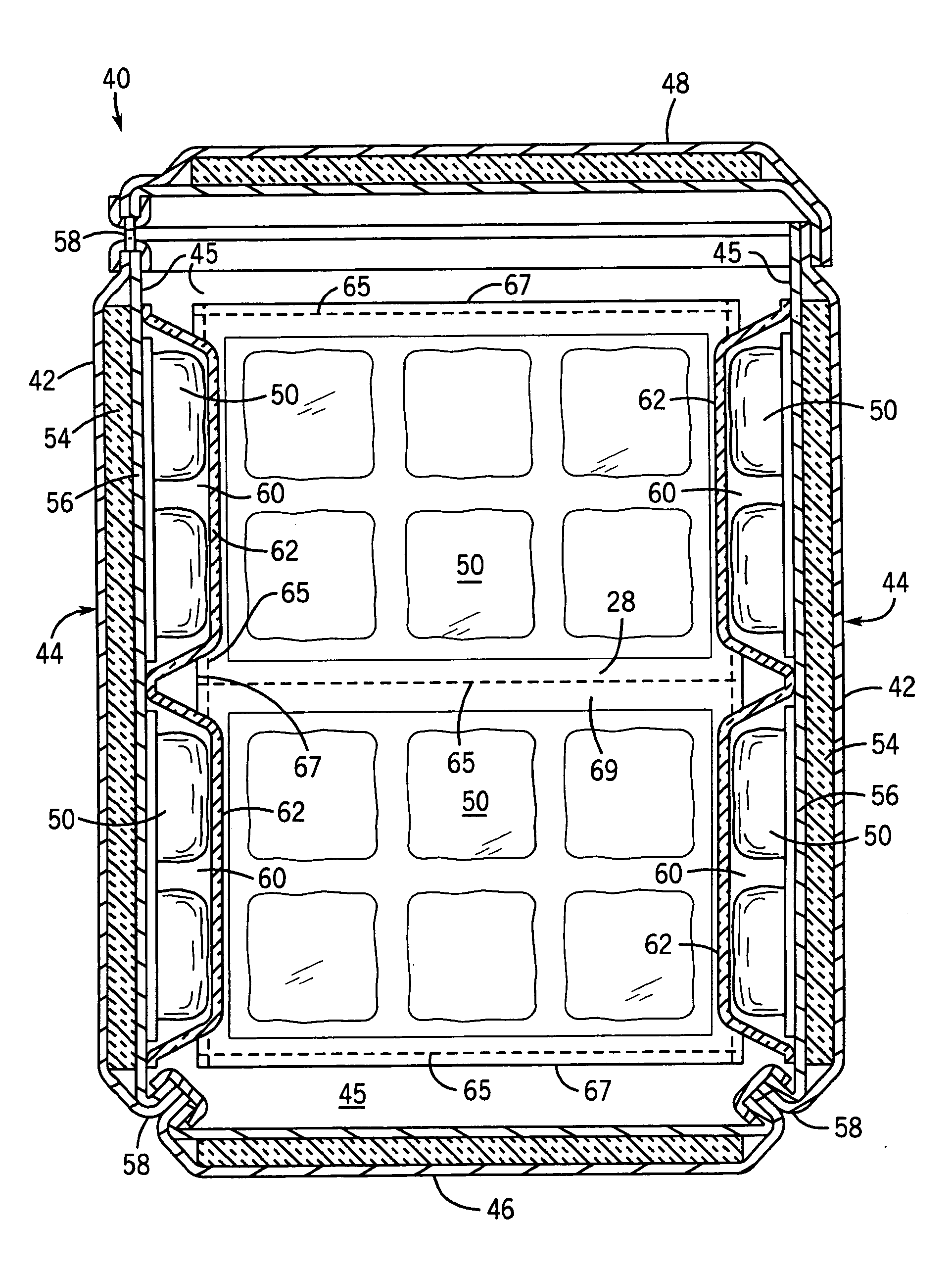

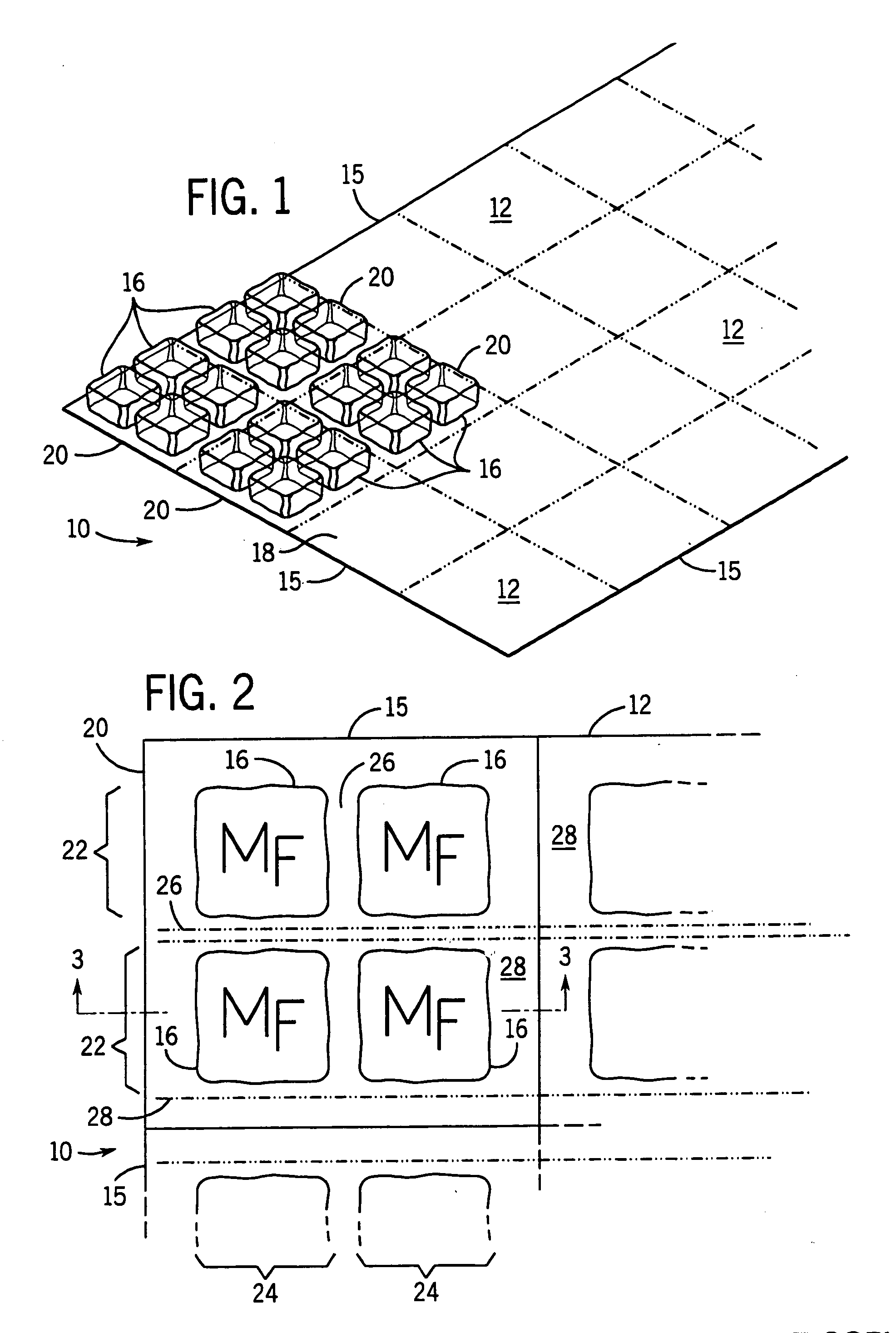

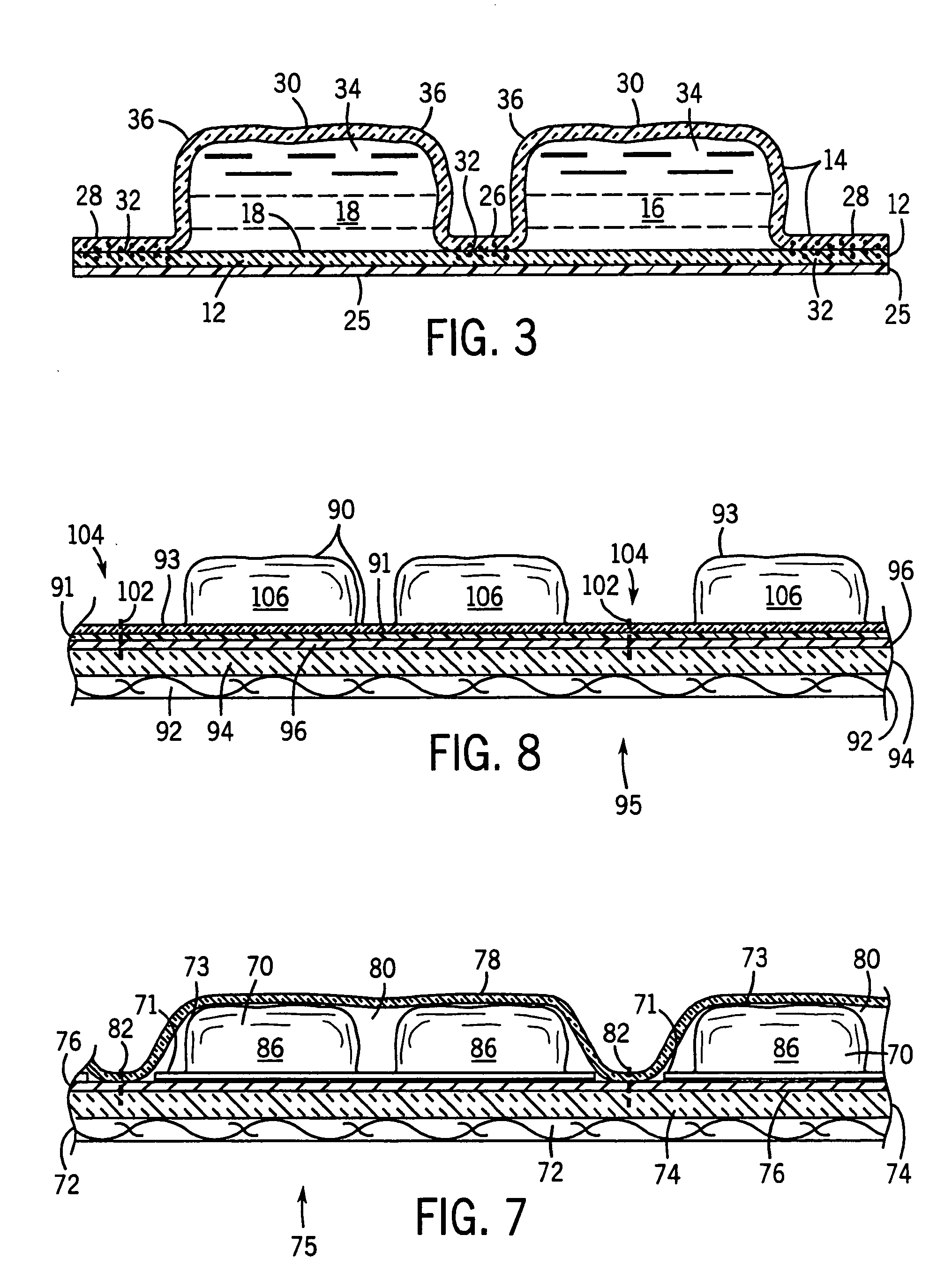

Portable cooler with built-in refrigerant cubes

ActiveUS7730739B2Effective mergerEasy to storeLighting and heating apparatusIce productionThermal insulationCooling effect

A portable cooler having one or more ice sheets including built-in refrigerant cubes. The cooler comprises an outer fabric shell and one or more sets of spaced apart refrigerant cubes encapsulated in plastic to form ice sheets that are attached to the interior walls of the cooler. The walls of the cooler may also include one or more layers of thermal insulation. The ice sheets provide a visually pleasing appearance to the inside of the cooler suggestive of cooling effects. The ice sheets may be retained along the walls of the cooler by seams sewn along the lanes passing between the refrigerant cubes, by being retained in pockets formed by sidewall liners or by being secured into chambers defined by the cooler's outer walls and a plastic insert fitted into the cooler. The cooler may include a hinged top and bottom that can be folded flat for allowing the cooler to assume a compact configuration during storage or freezing of the refrigerant cubes.

Owner:FUCHS MARK D

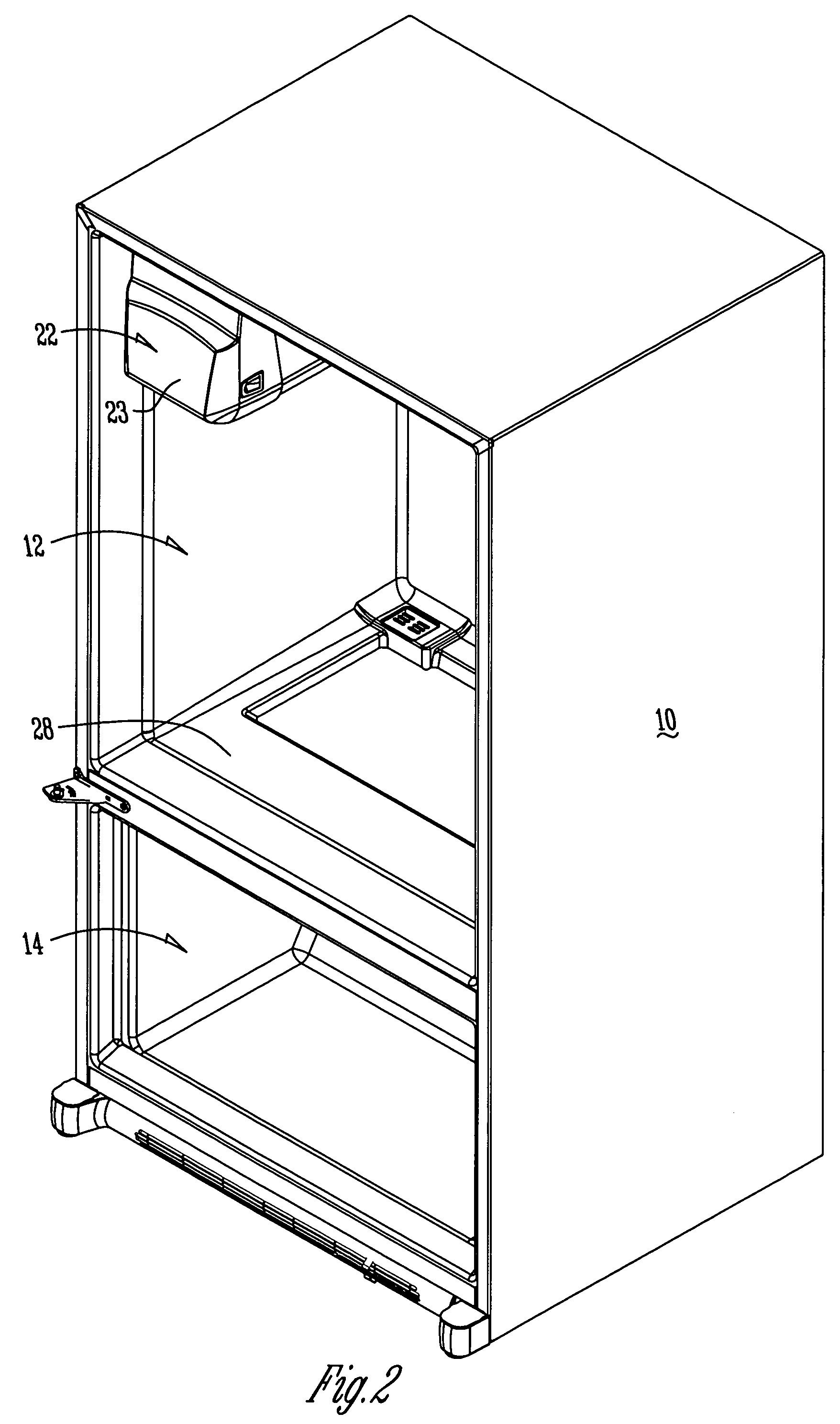

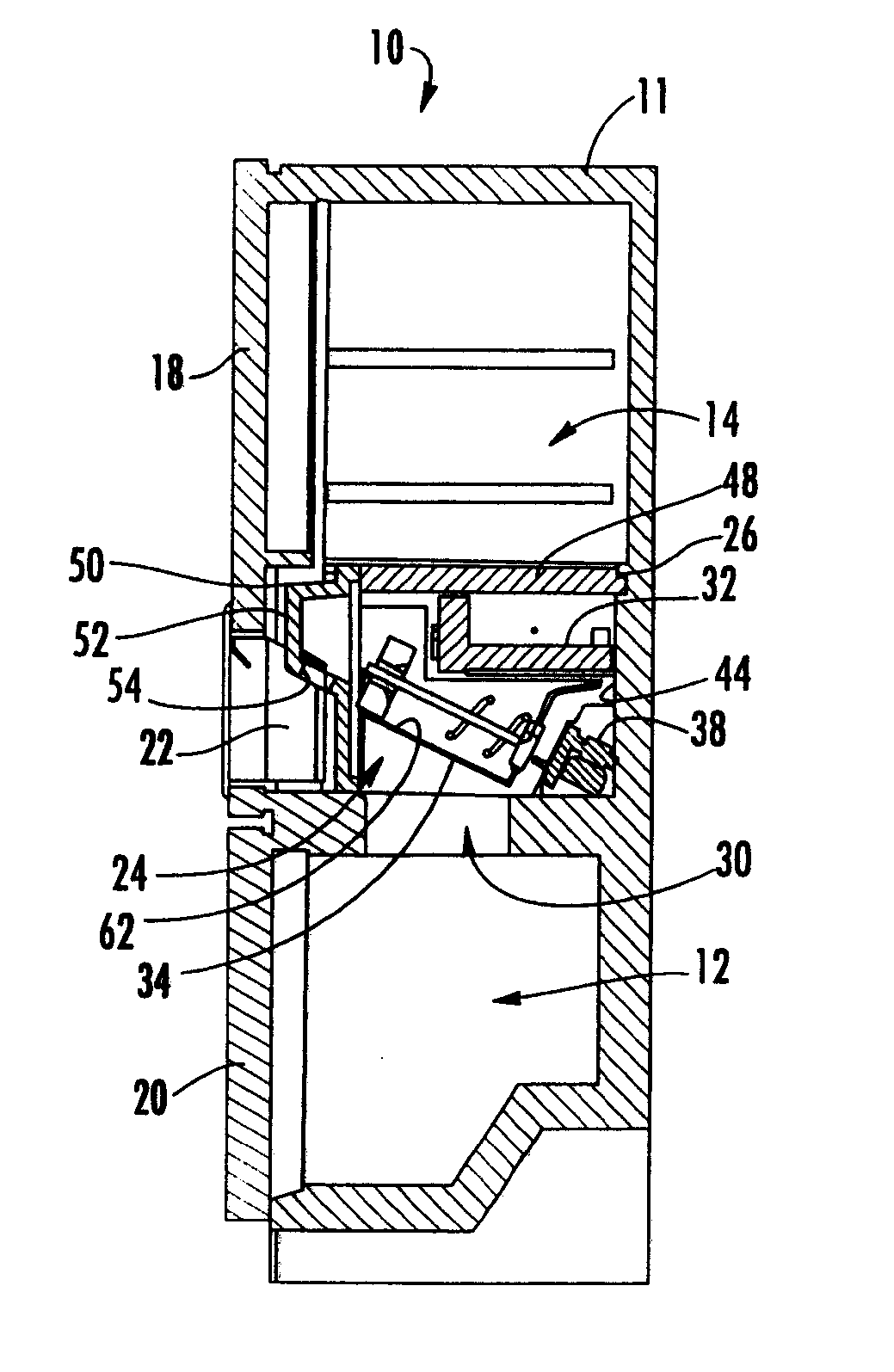

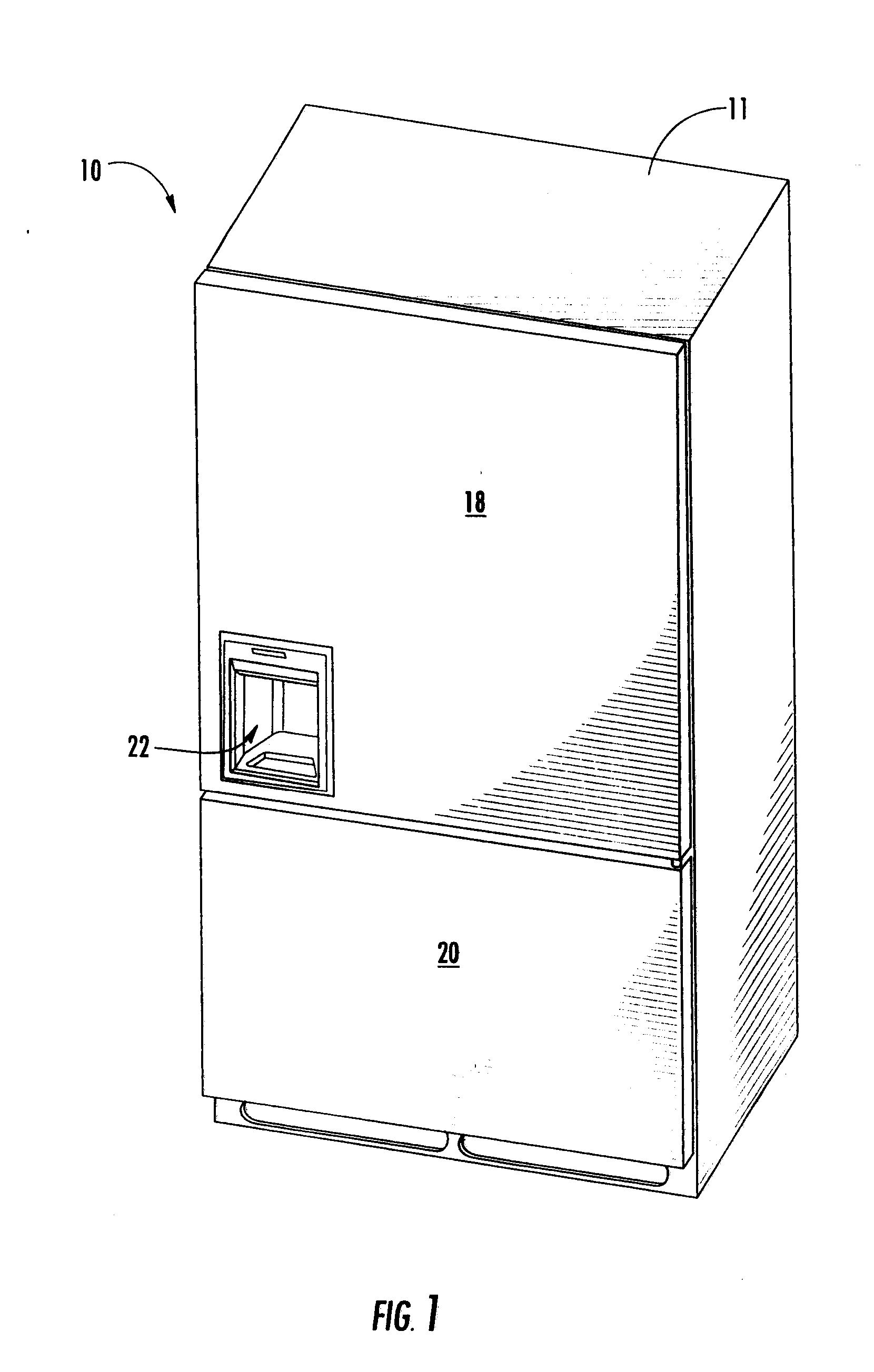

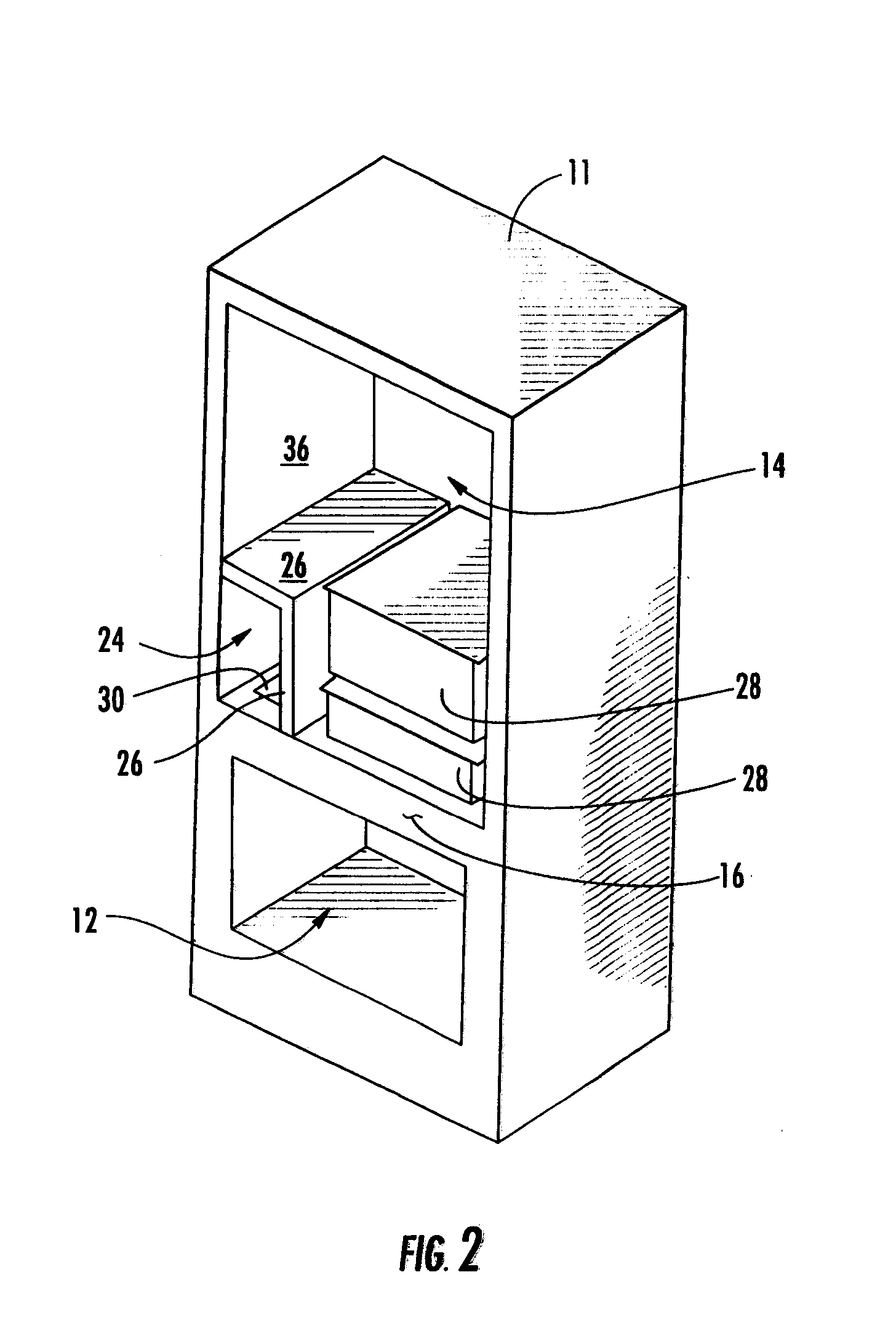

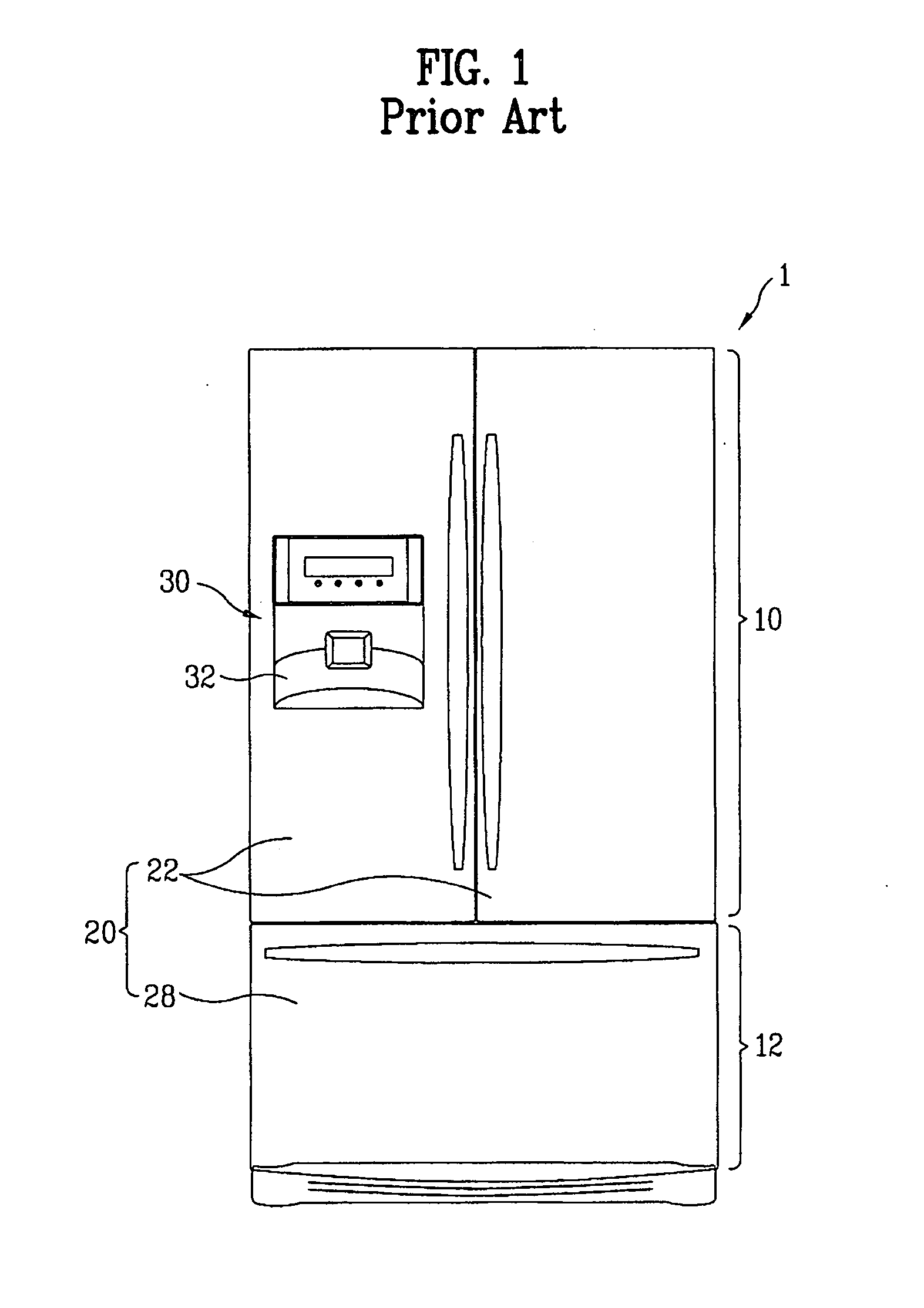

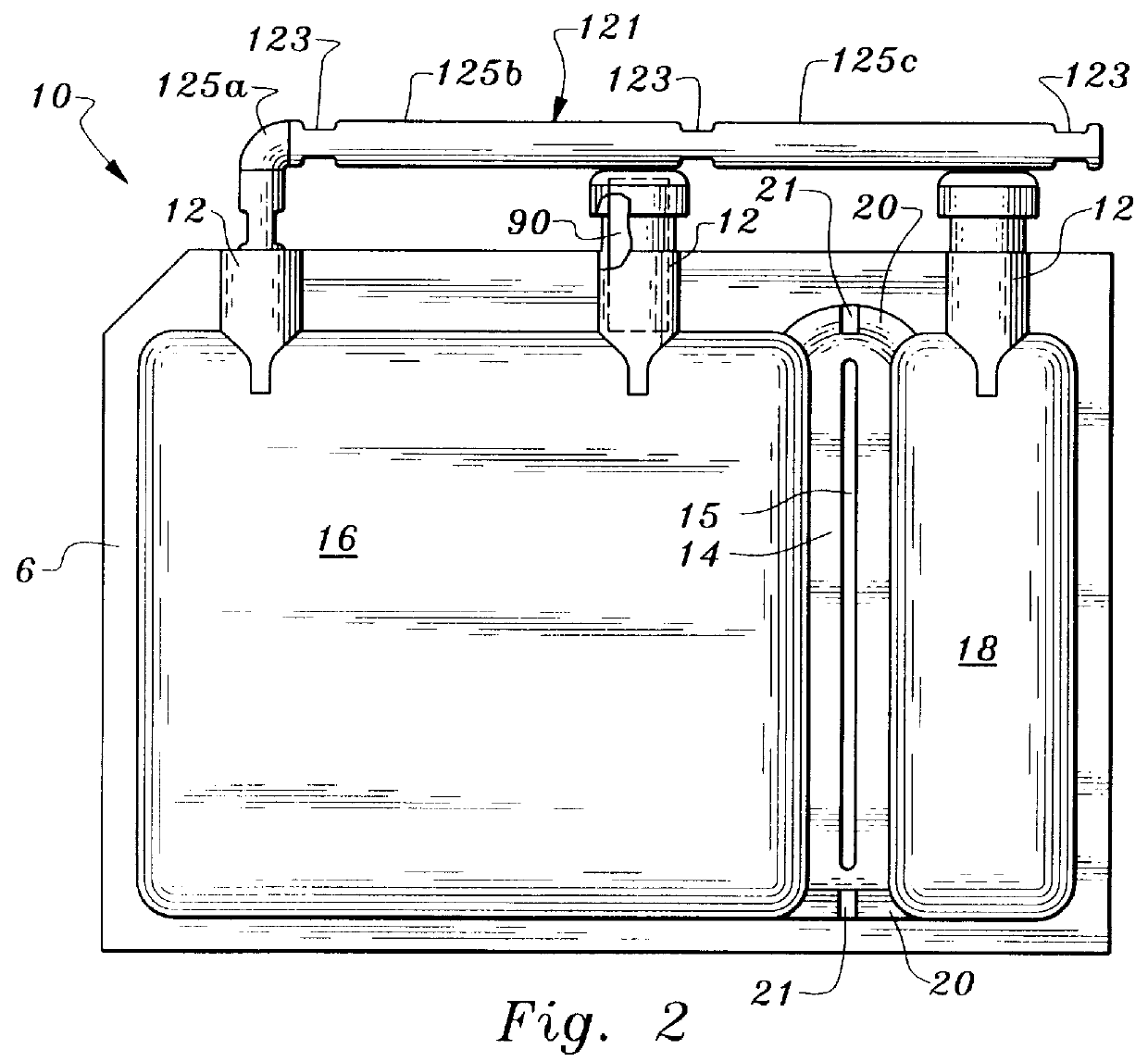

Refrigerator with intermediate temperature icemaking compartment

An icemaking compartment is provided in the refrigerator compartment of a bottom mount refrigerator. An icemaker is within the icemaking compartment. A cold air duct supplies cold air from the freezer compartment to the icemaker. The cold air duct is formed in the rear wall of the refrigerator. A fan controls the flow of air through the cold air duct. A return air duct is provided to direct a portion of the air from the icemaker back to the freezer compartment. An air vent in the icemaker directs another portion of air into the refrigerator compartment.

Owner:WHIRLPOOL CORP

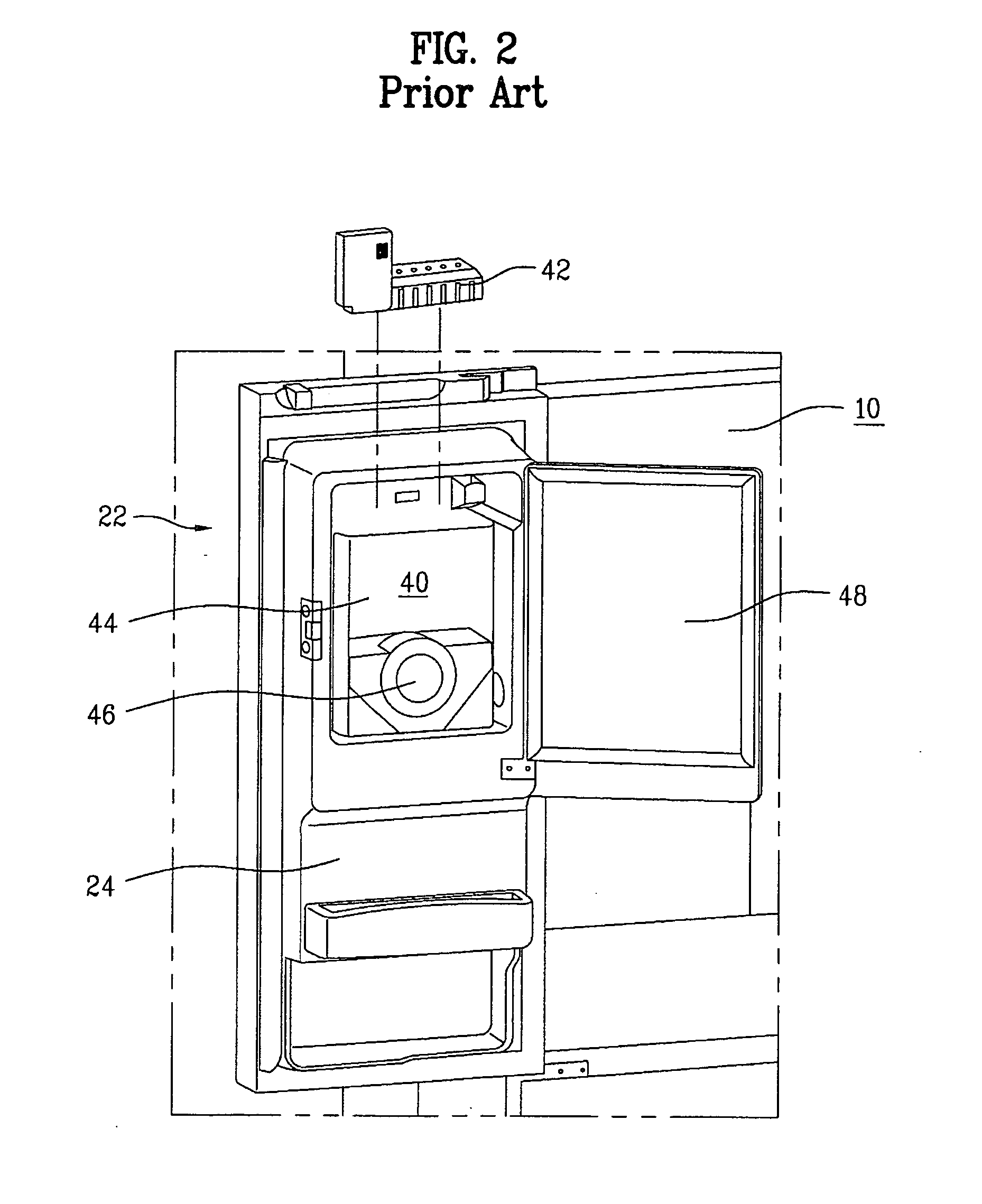

Refrigerator with icemaker

ActiveUS7076967B2Simple structureConvenient for userLighting and heating apparatusIce productionCold airCold store

Refrigerator with an icemaker including a cabinet having a mullion wall for compartmentalization of a freezing chamber and a refrigerating chamber, a case provided to a door on the refrigerating chamber, having a cavity therein, a first duct for supplying cold air from a neighborhood of an evaporator in the freezing chamber to the cavity, the icemaker in the cavity for producing ice, an ice container in the cavity for storing the ice, and a dispenser in the door in communication with the cavity, thereby having ice supplied to a user at an outside of the refrigerator through a dispenser provided to the door.

Owner:LG ELECTRONICS INC

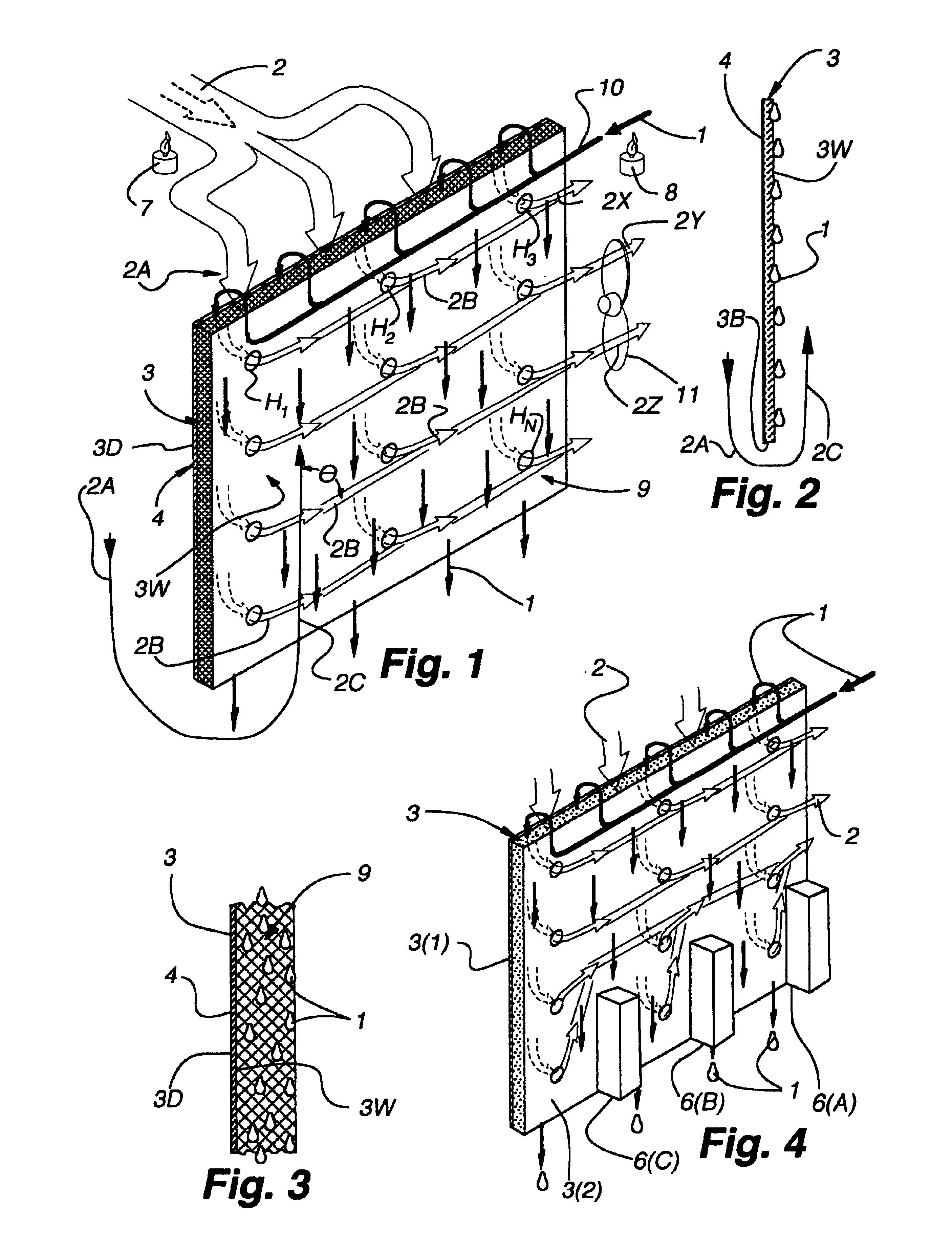

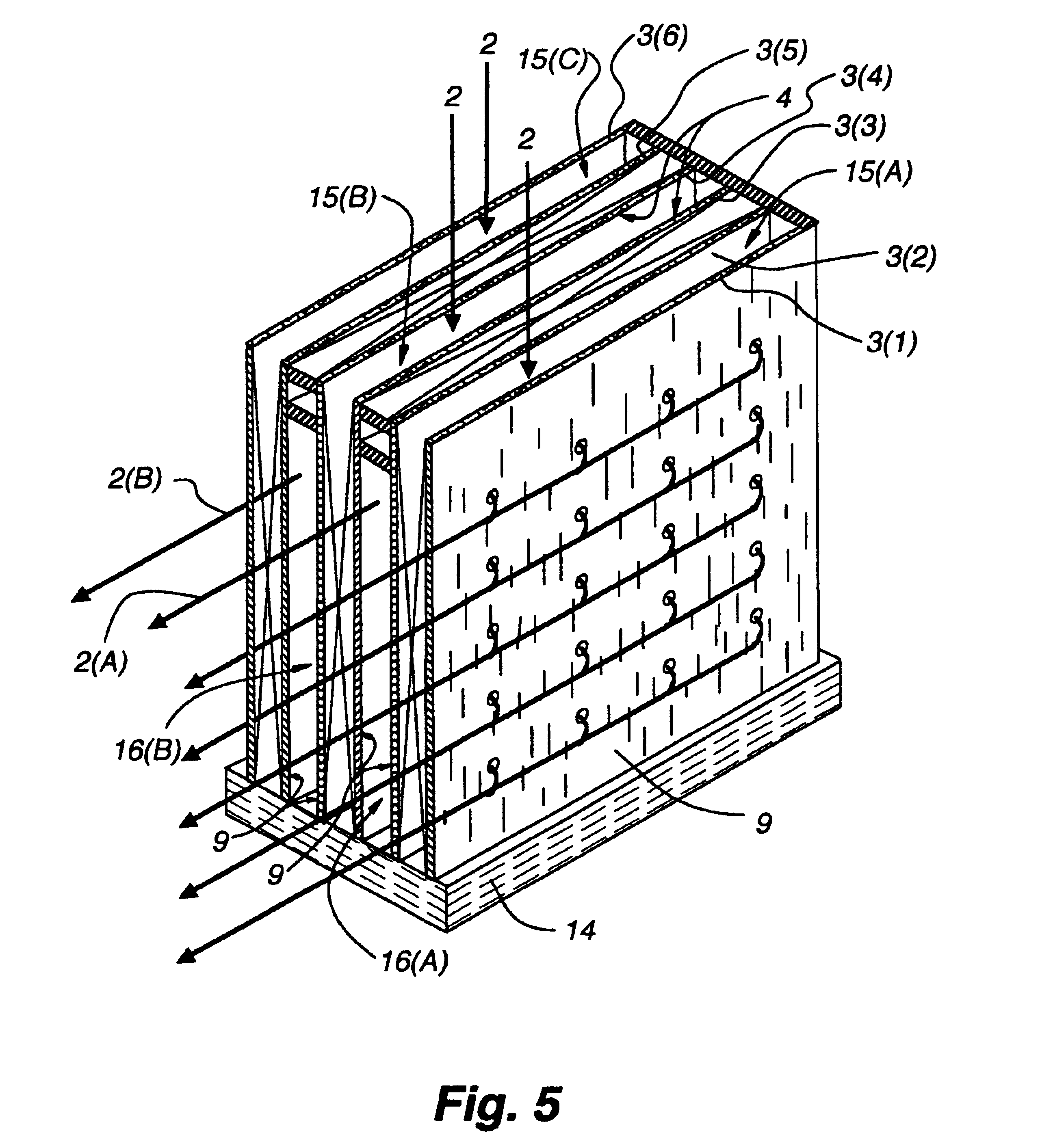

Method of evaporative cooling of a fluid and apparatus therefor

InactiveUS6854278B2Reduce the temperatureLess pressure dropMechanical apparatusSpace heating and ventilation safety systemsDesiccantMechanical engineering

The operating efficiency of indirect evaporative cooling processes and indirect evaporative cooling apparatus employing a dry side channel and a wet side channel separated by a heat exchange plate are improved by placement of holes in the heat exchange plate. Further improvements are obtained when the flow direction in the wet side channel is cross-current to the flow direction in the dry side channel. Placement of desiccant materials in the dry side channel also serve to improve the operating efficiencies of these processes and apparatus.

Owner:IDALEX TECH INC

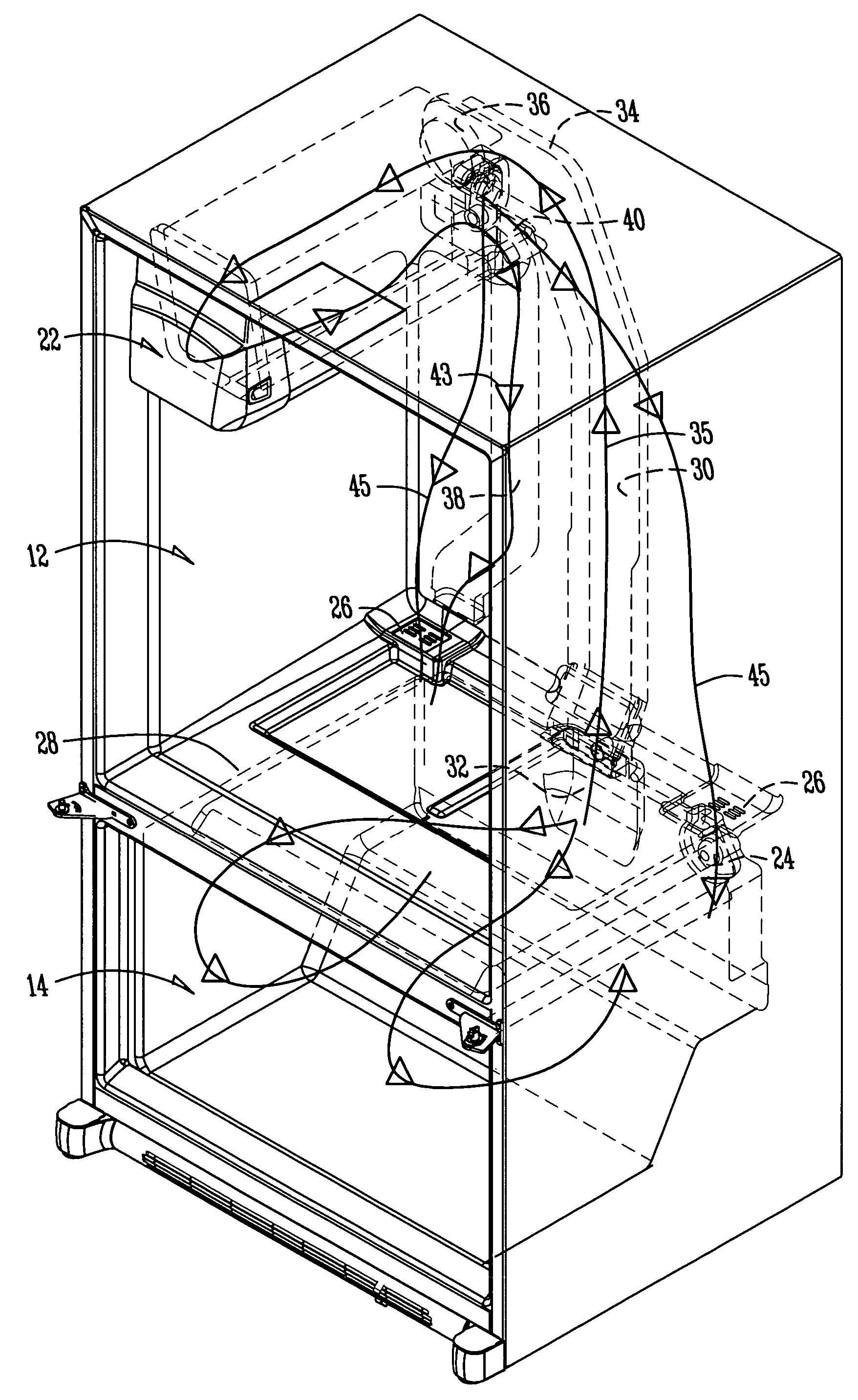

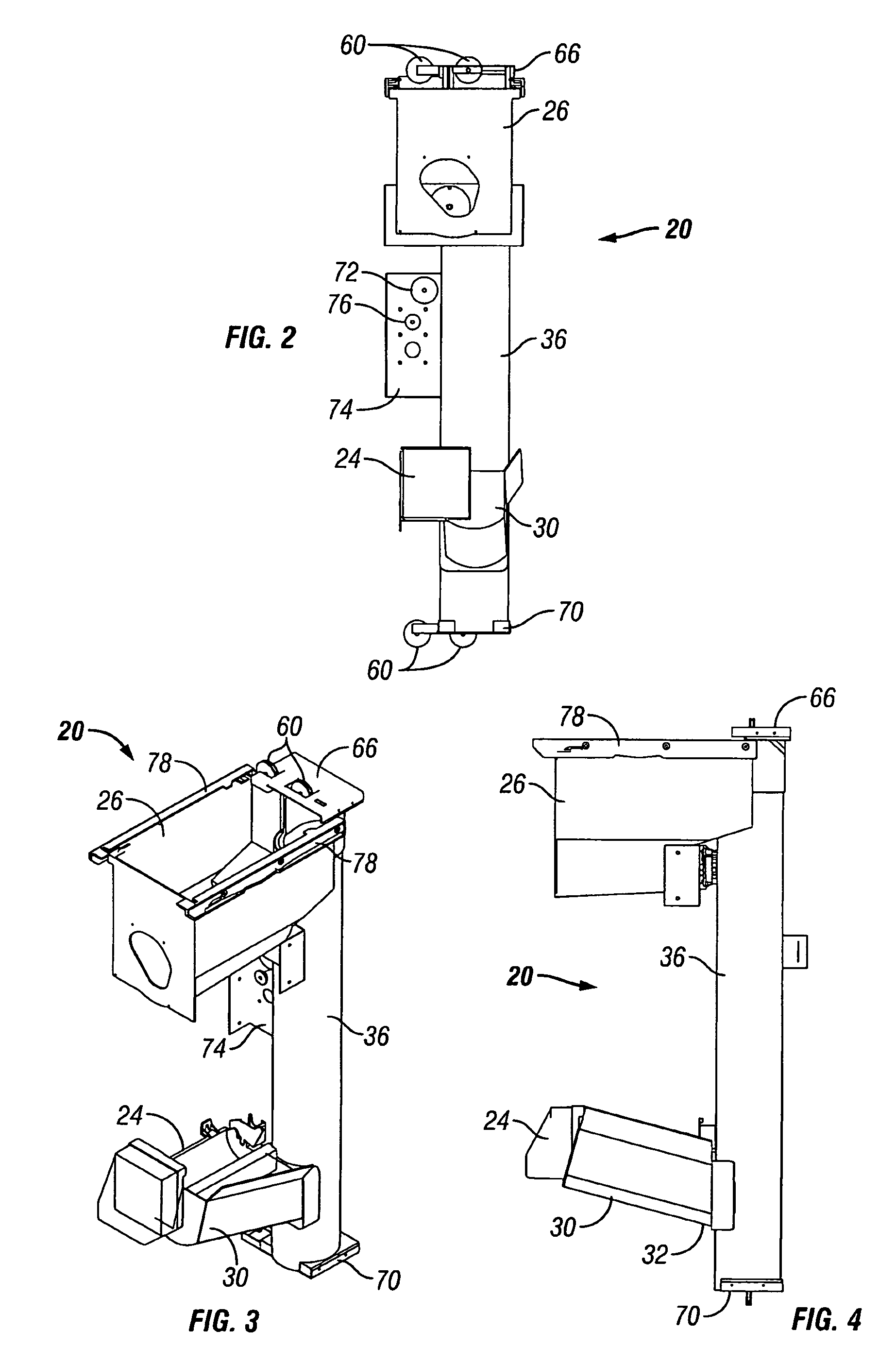

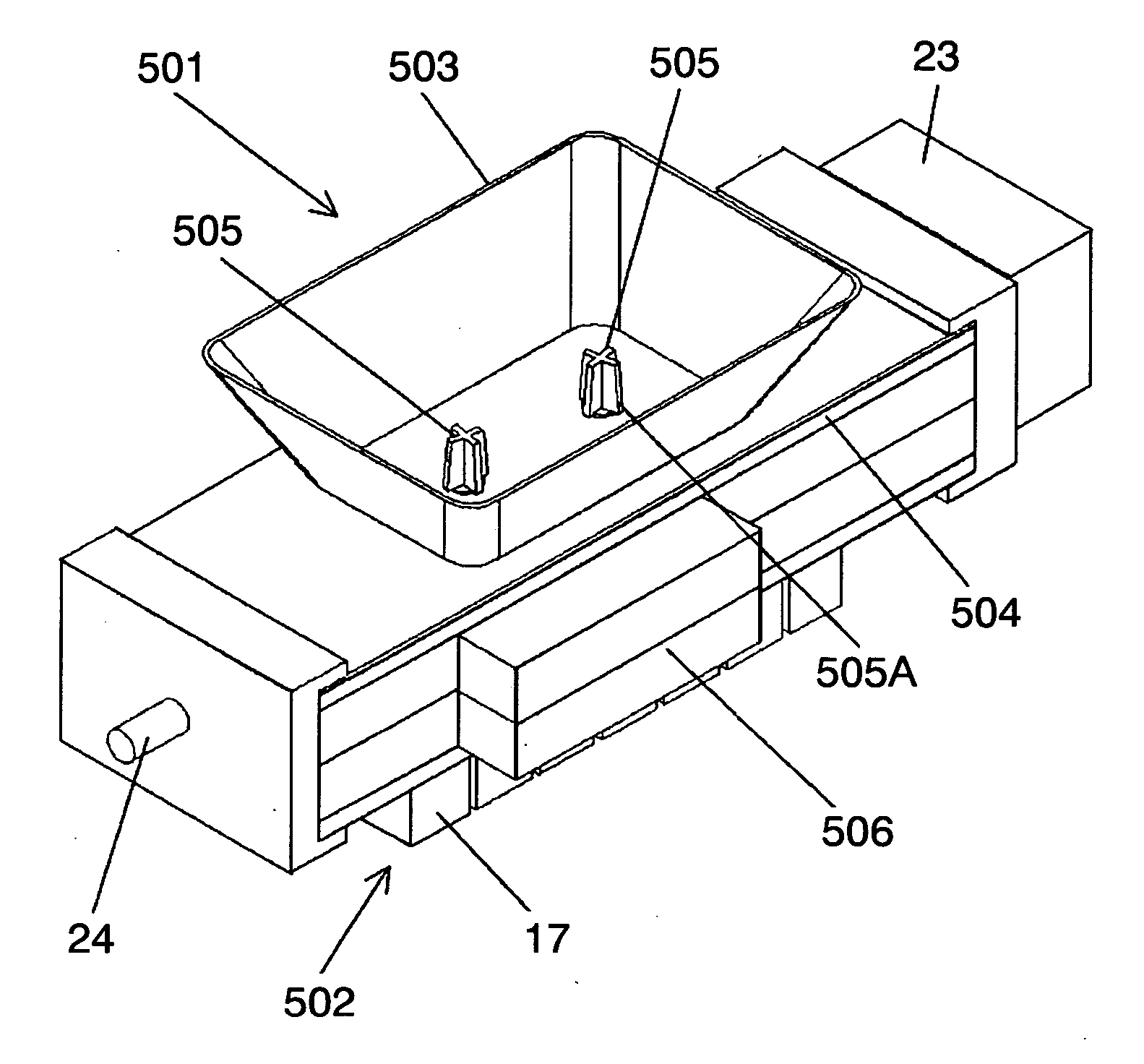

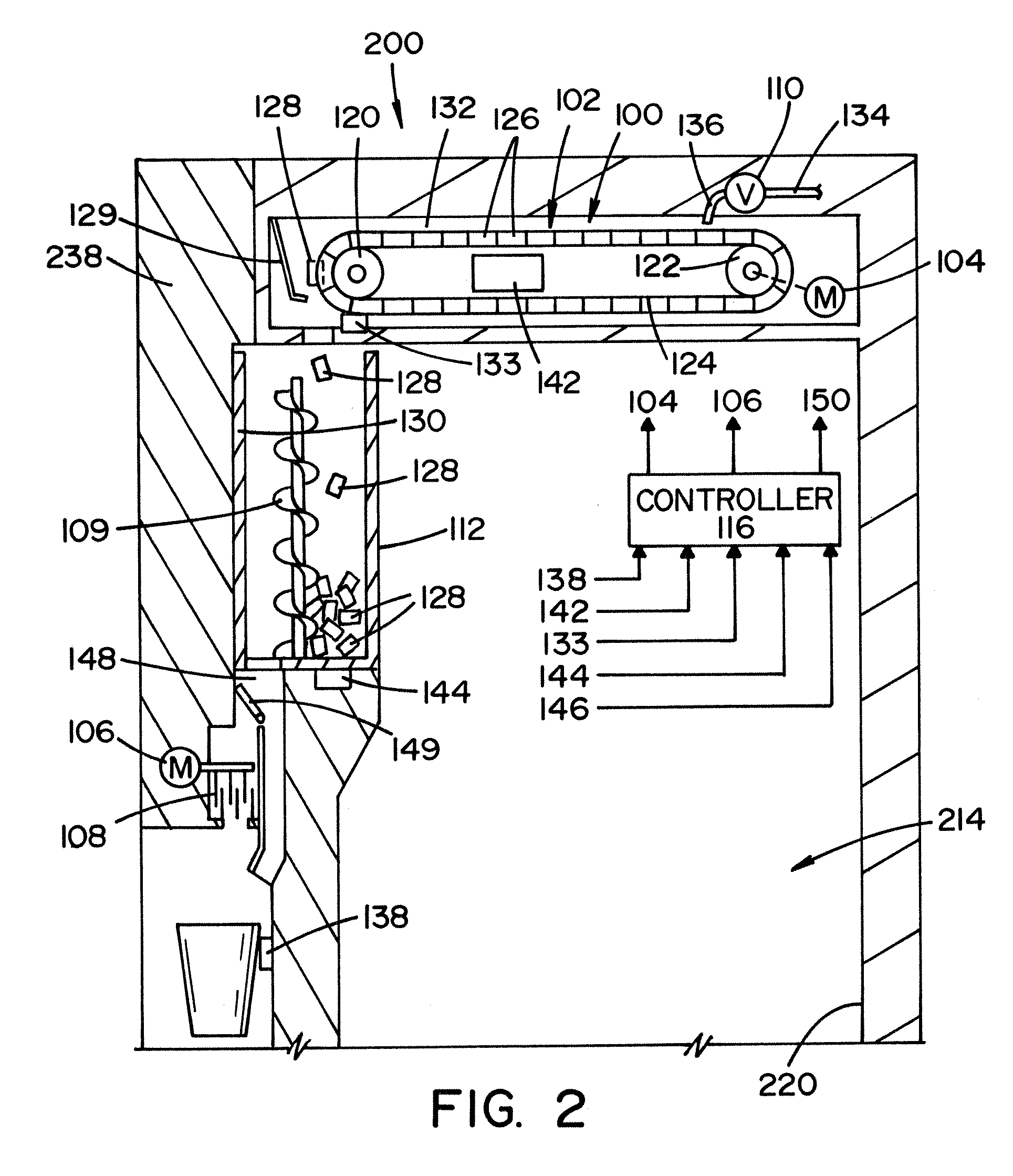

Ice dispenser for refrigerator with bottom mount freezer

ActiveUS7065975B1Maintain temperatureLighting and heating apparatusIce productionMotor driveEngineering

An ice dispensing system is provided for a refrigerator having a bottom freezer. The system includes an ice maker in the freezer compartment and an ice bucket in the refrigerator compartment. A shuttle carries ice from the ice maker to the bucket through a tube extending upwardly through the dividing wall between the freezer and refrigerator compartments. The bucket includes an auger in communication with an ice dispensing opening in the refrigerator door for ice on demand by a user. The shuttle is raised and lowered by a motor-driven cable.

Owner:IOWA STATE UNIV RES FOUND +1

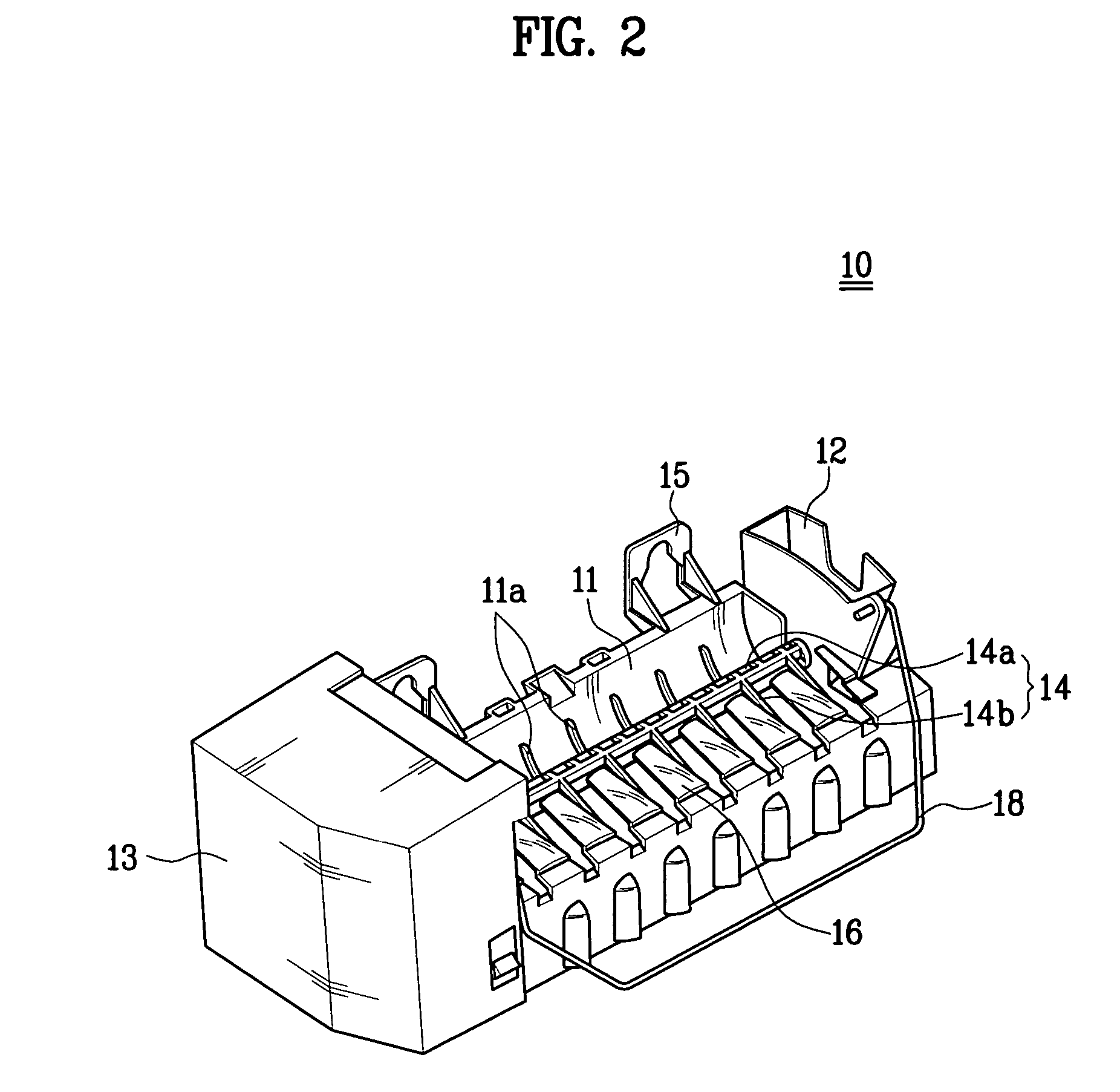

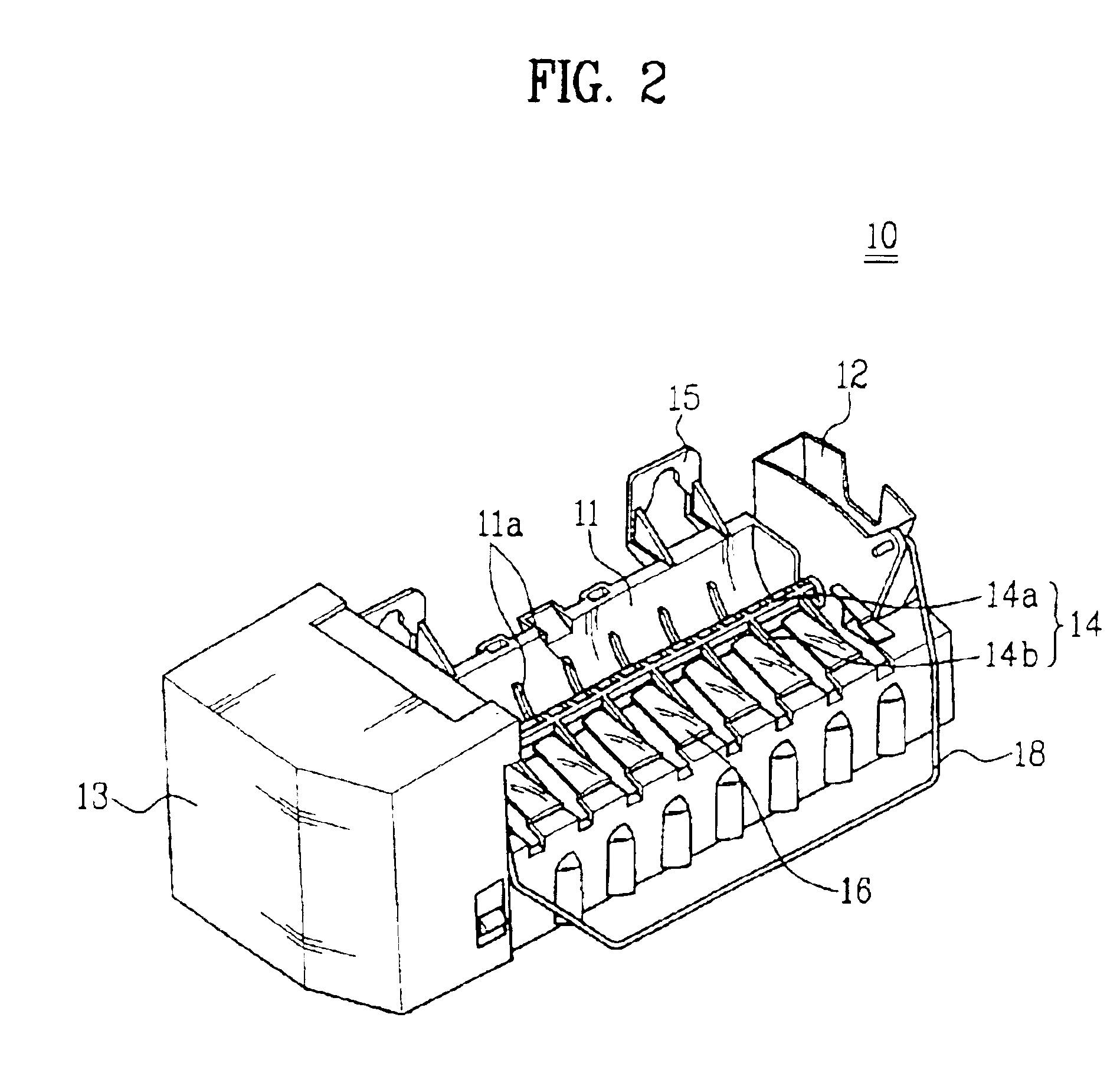

Ice making apparatus and refrigerator having the same

InactiveUS20080034780A1Shorten ice making timeEasy to removeLighting and heating apparatusIce productionCold airEngineering

An ice making apparatus capable of reducing an ice making time be rapid cooling of an ice making tray thereof while guaranteeing the making of transparent ice and a refrigerating having the ice making apparatus. The ice making apparatus includes the ice making tray to freeze water filled therein so as to make ice, and a cold air guiding device to guide cold air to a lower surface of the ice making tray. The cold air guiding device includes a cold air guiding plate installed below the ice making tray to be spaced apart from the lower surface of the ice making tray, and a plurality of protrusions provided at an upper surface of the cold air guiding plate to guide the cold air flowing along the upper surface of the cold air guiding plate in a direction toward the lower surface of the ice making tray.

Owner:SAMSUNG ELECTRONICS CO LTD

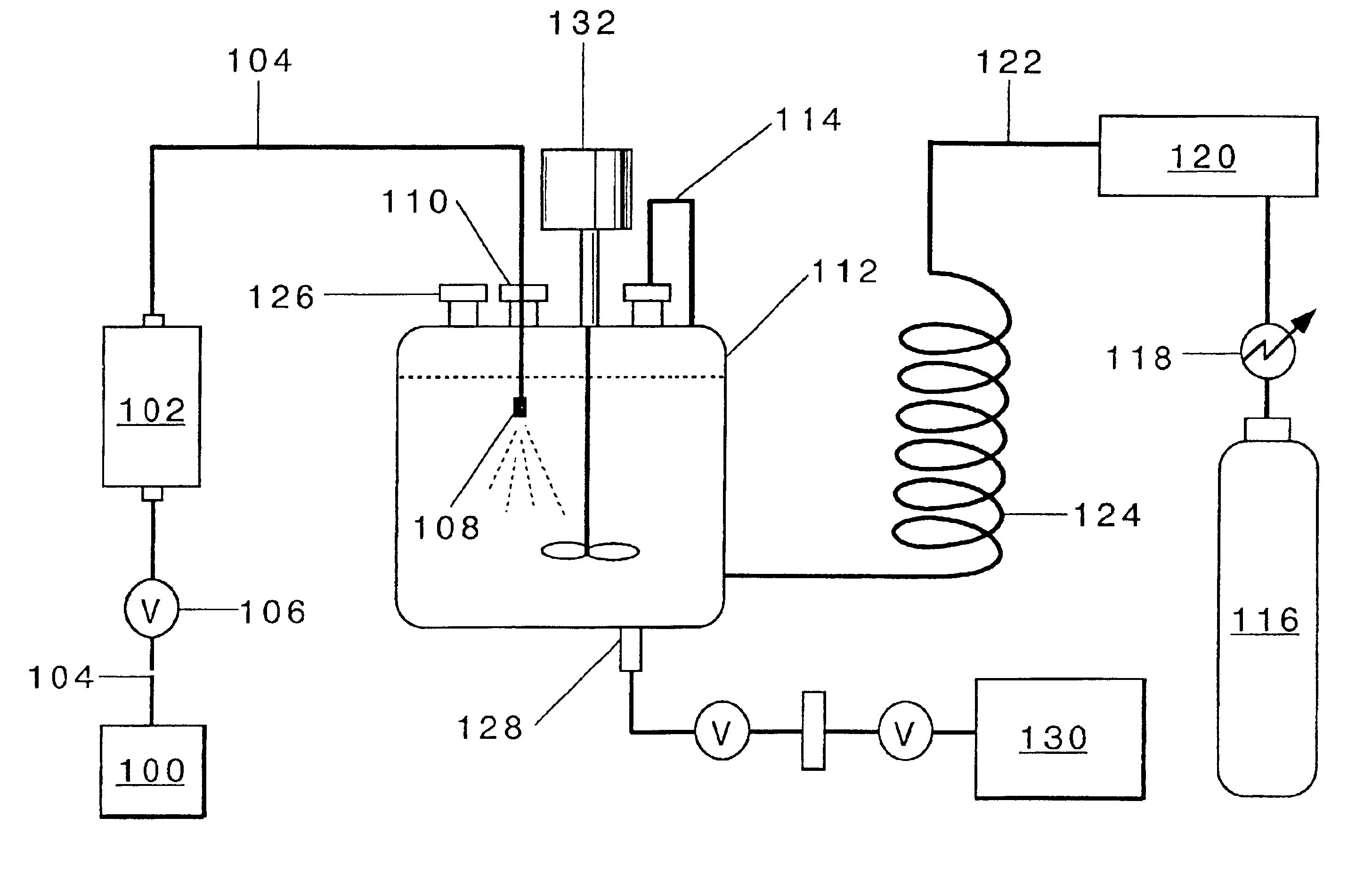

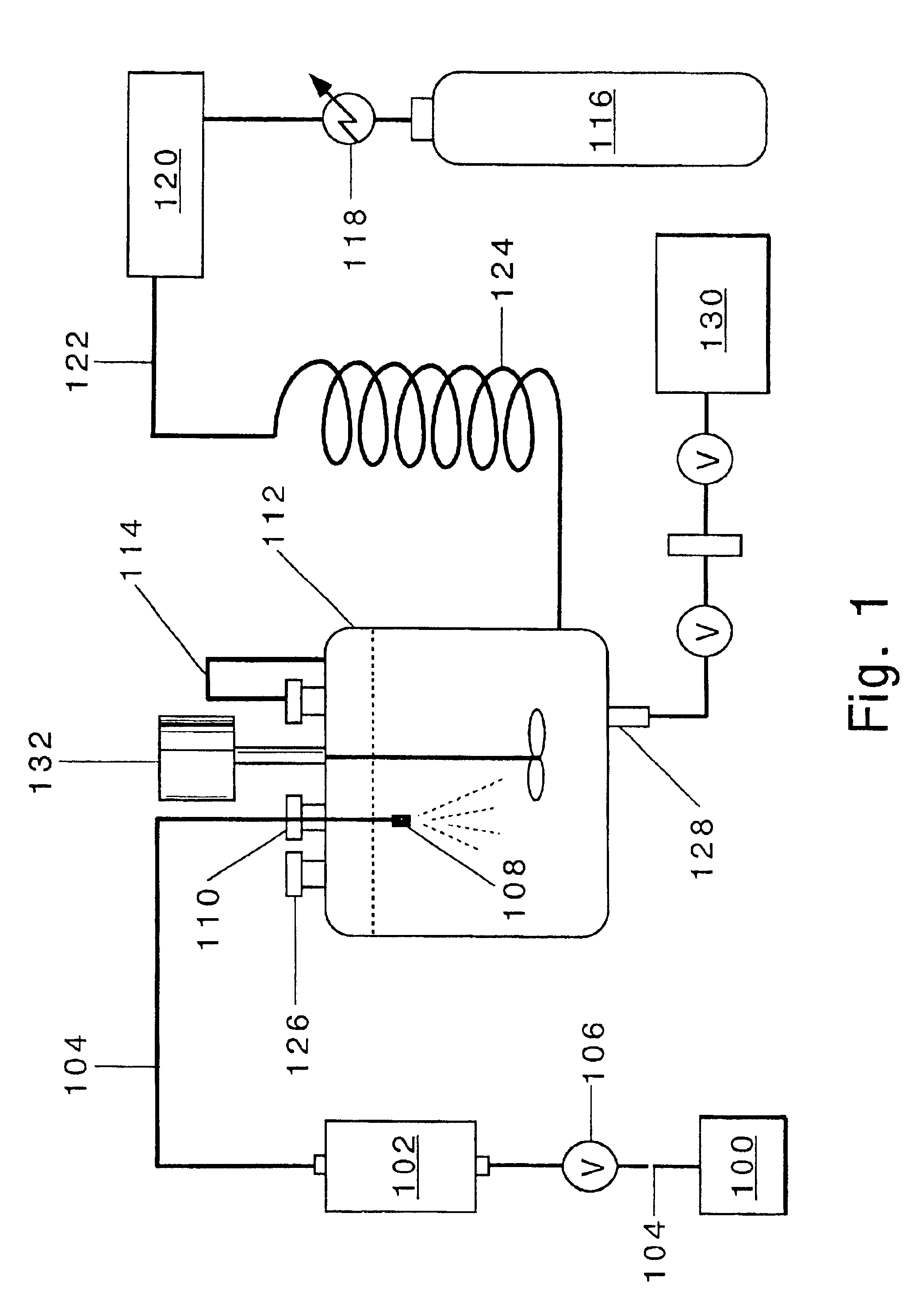

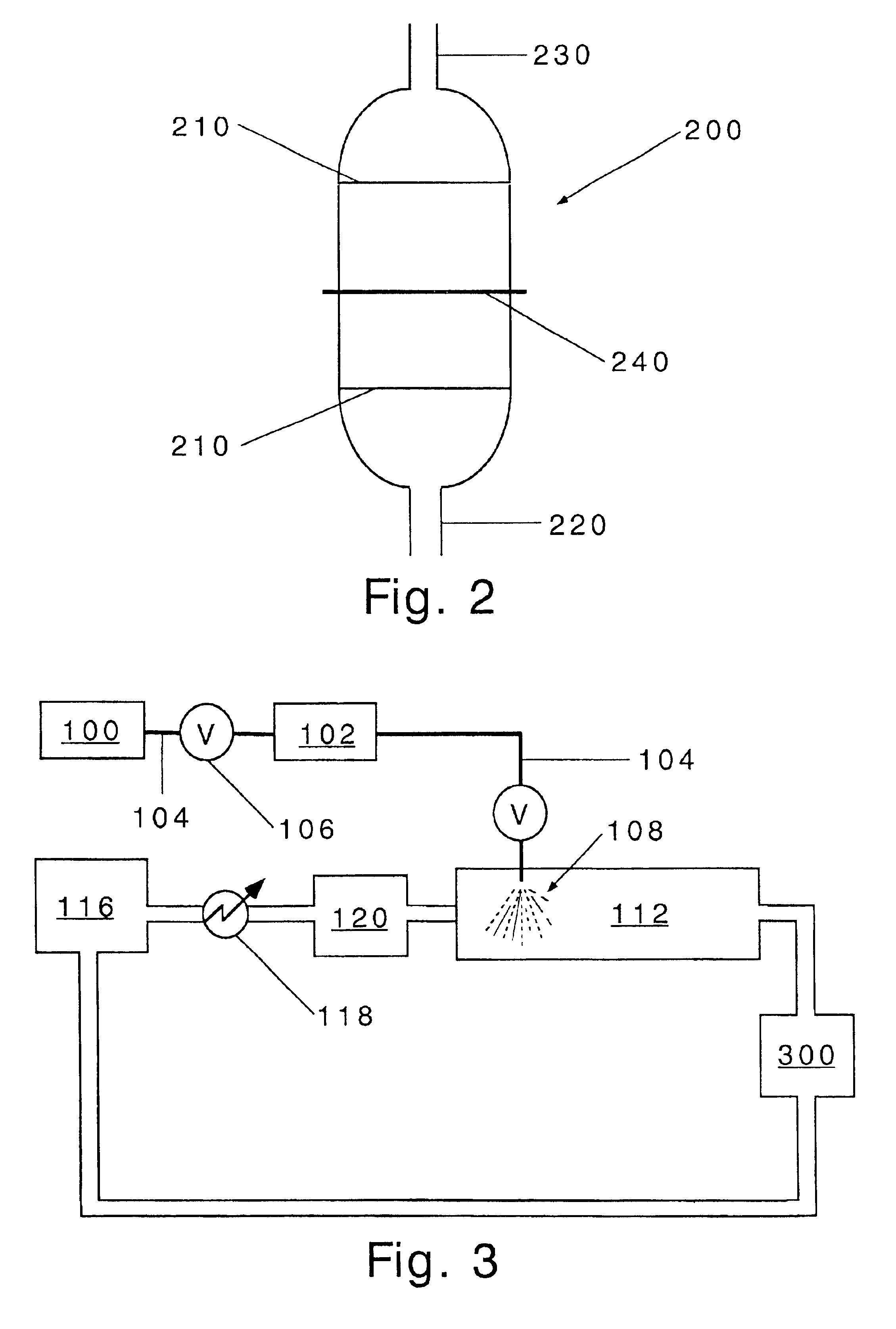

Process for production of nanoparticles and microparticles by spray freezing into liquid

InactiveUS6862890B2Improve efficiencyImprove efficacyPowder deliveryNervous disorderPorosityNanoparticle

The present invention provides a system and a method for the production of microparticles and nanoparticles of materials that can be dissolved. The system and method of the present invention provide quicker freezing times, which in turn produces a more uniform distribution of particle sizes, smaller particles, particles with increased porosity and a more intimate mixing of the particle components. The system and method of the present invention also produce particles with greater surface area than conventional methods. One form of the present invention provides a method for the preparation of particles. An effective ingredient is mixed with water, one or more solvents, or a combination thereof, and the resulting mixture is sprayed through an insulating nozzle located at or below the level of a cryogenic liquid. The spray generates frozen particles.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

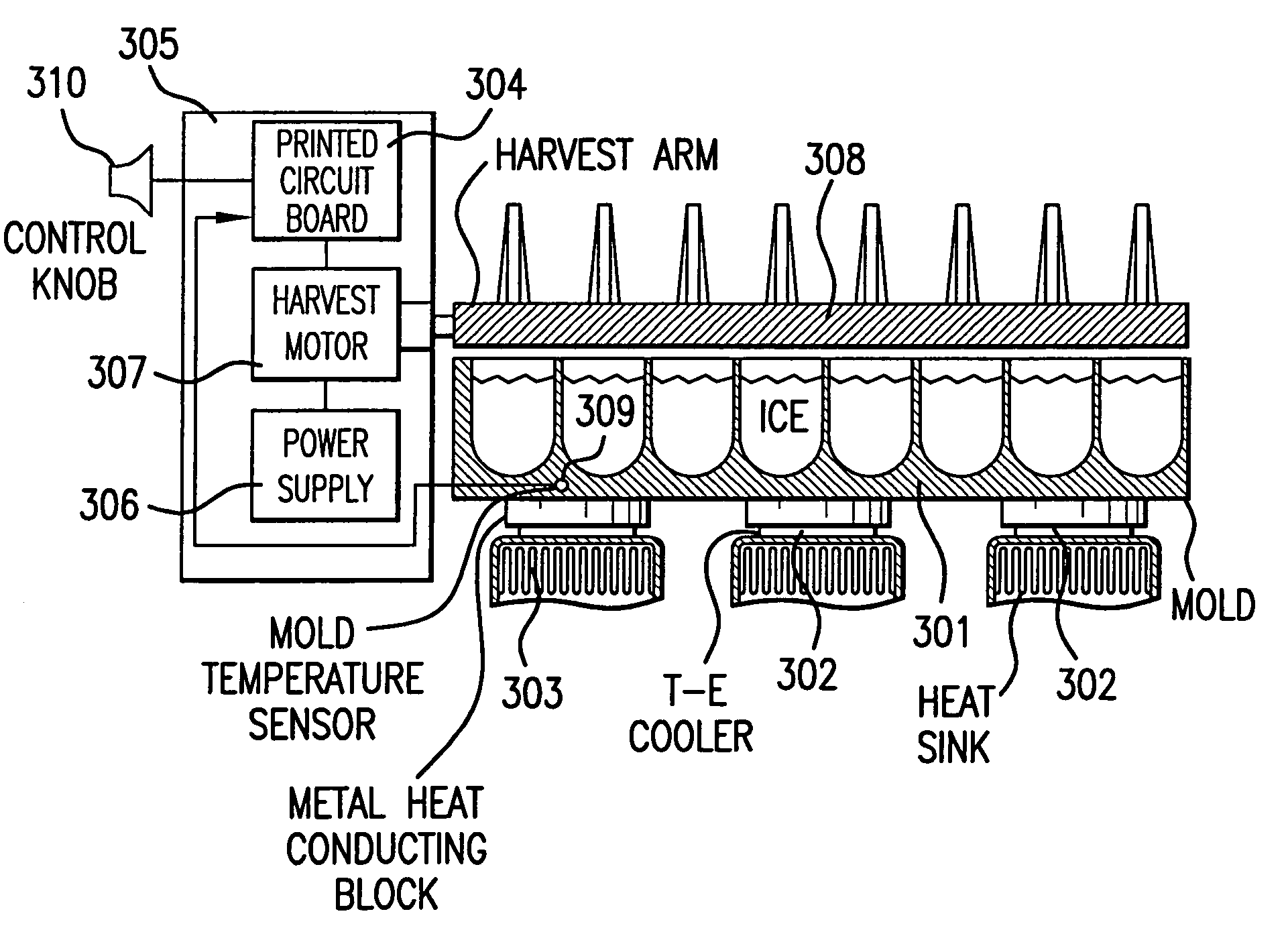

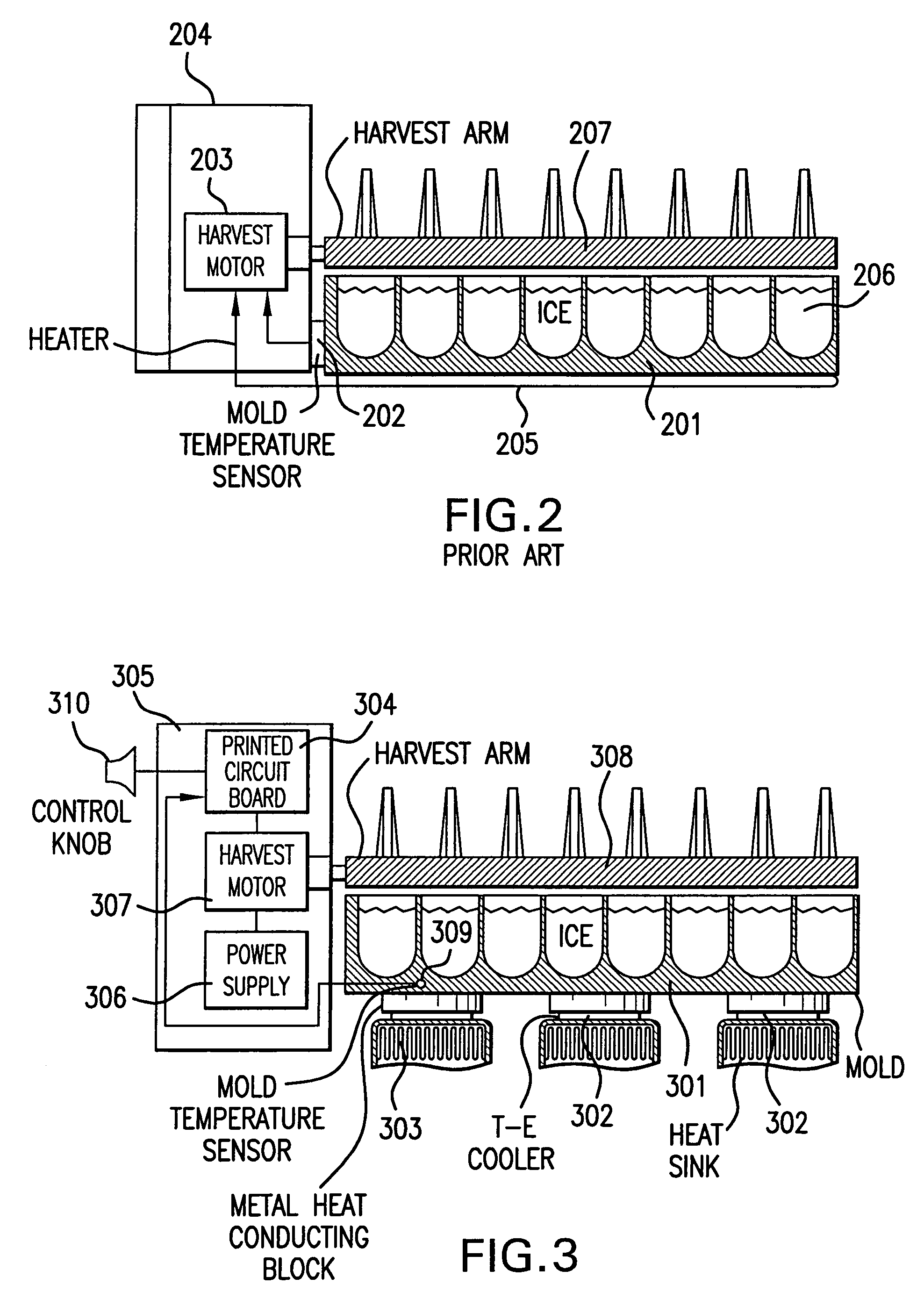

Variable rate and clarity ice making apparatus

InactiveUS6951113B1Improve cooling effectIce productionMachines using electric/magnetic effectsElectrical resistance and conductanceMicrocontroller

The icemaker presented here may use a microcontroller, and solid state refrigeration and heat transfer elements to create ice cube qualities ranging from “clear ice” to “fast ice” in a smooth, user selectable continuum. In one embodiment, this may be accomplished by fitting a standard, high production volume icemaker mold with (1) thermoelectric coolers operated in a controlled fashion to heat or cool the mold, (2) a mold temperature sensor (such as a thermistor), and (3) a microcontroller to monitor the process and to adjust the growth rate of ice forming in the mold by adjusting heat transfer rates to optimize particular cooling phases.

Owner:ADAMSKI JOSEPH R

Method for processing and preserving collagen-based tissues for transplantation

InactiveUS20060210960A1Minimize surface tension damageAugment selective preservationSsRNA viruses positive-senseViral antigen ingredientsOrganismBiology

A method for processing and preserving an acellular collagen-based tissue matrix for transplantation is disclosed. The method includes the steps of processing biological tissues with a stabilizing solution to reduce procurement damage, treatment with a processing solution to remove cells, treatment with a cryoprotectant solution followed by freezing, drying, storage and rehydration under conditions that preclude functionally significant damage and reconstitution with viable cells.

Owner:LIFECELL

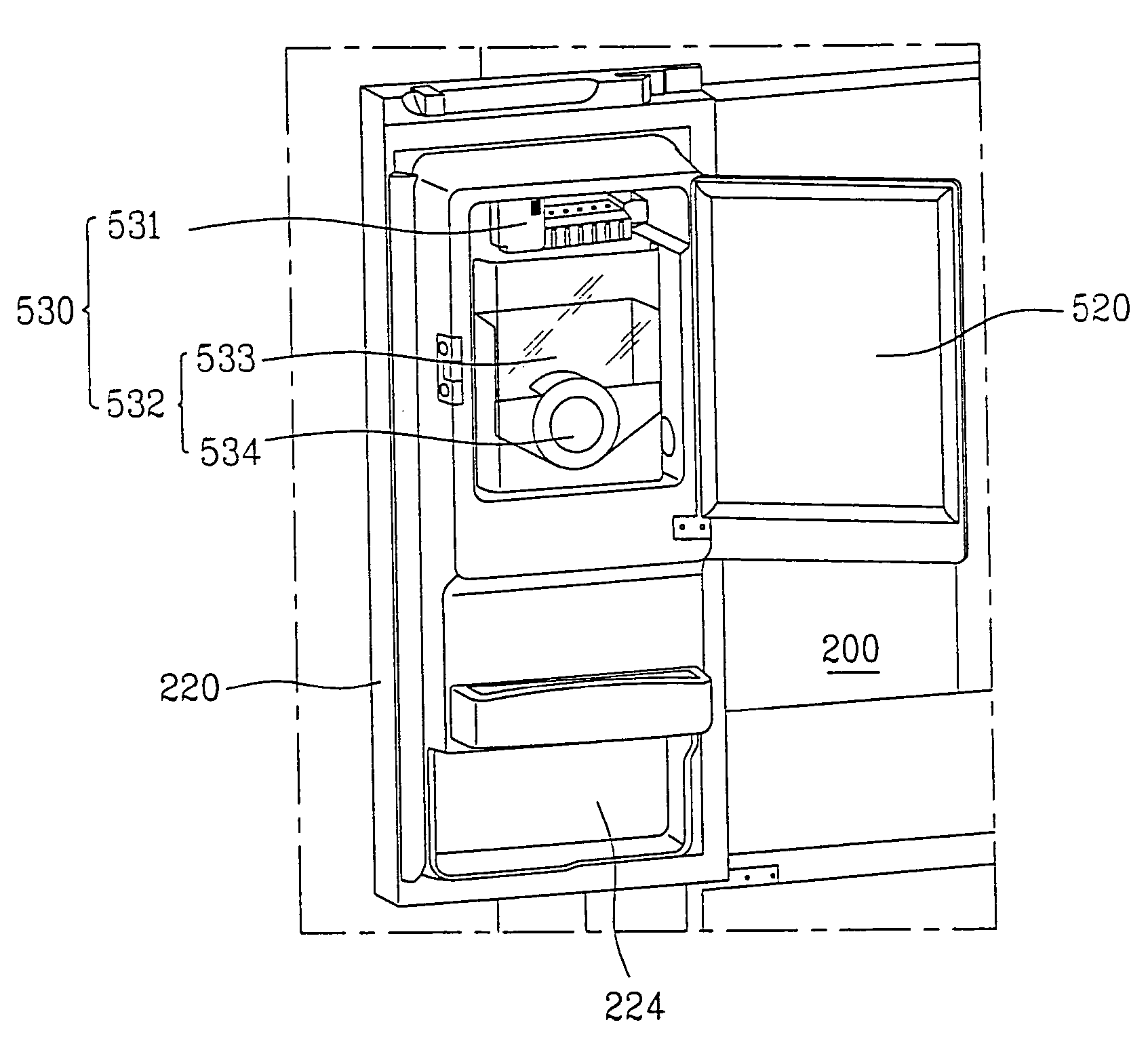

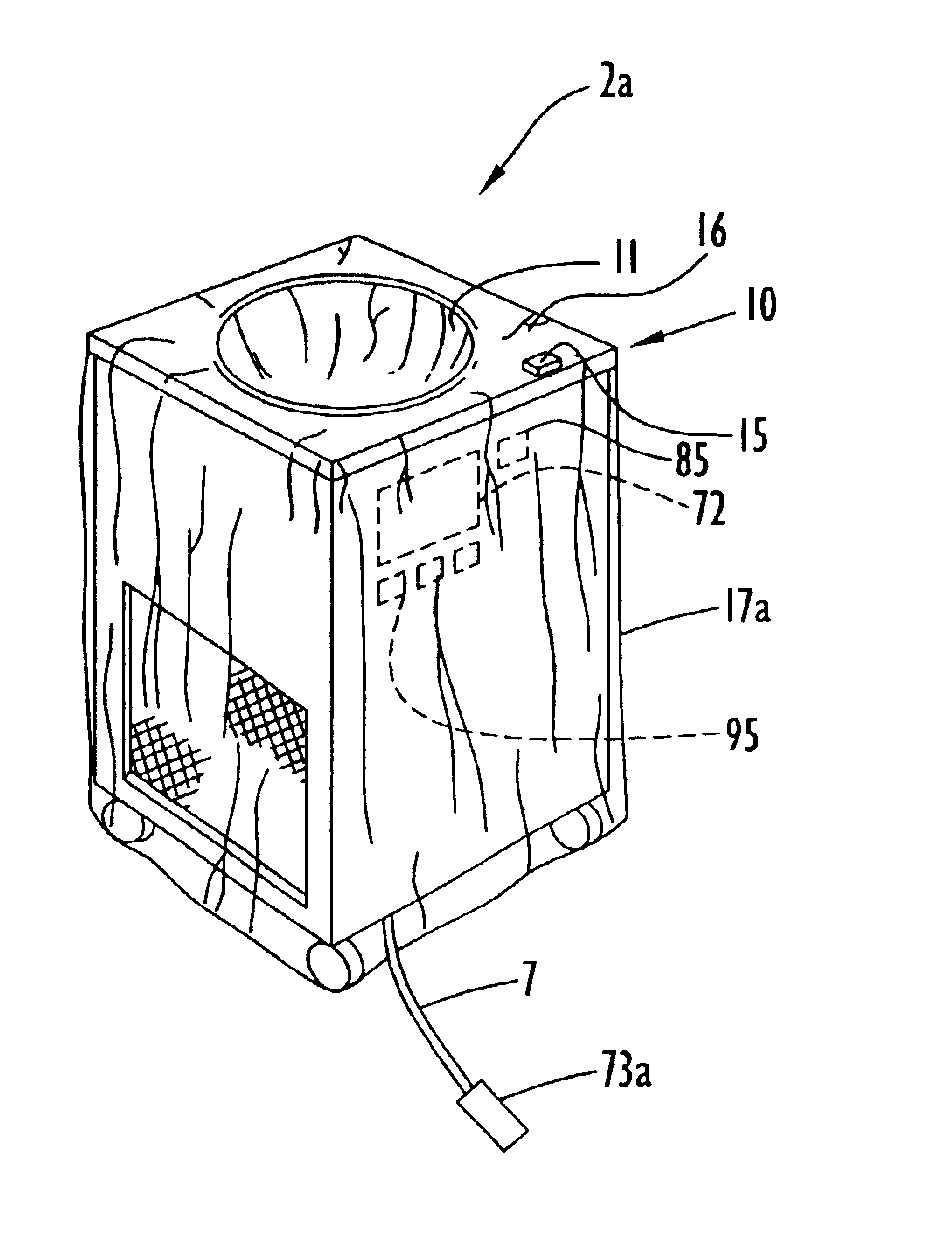

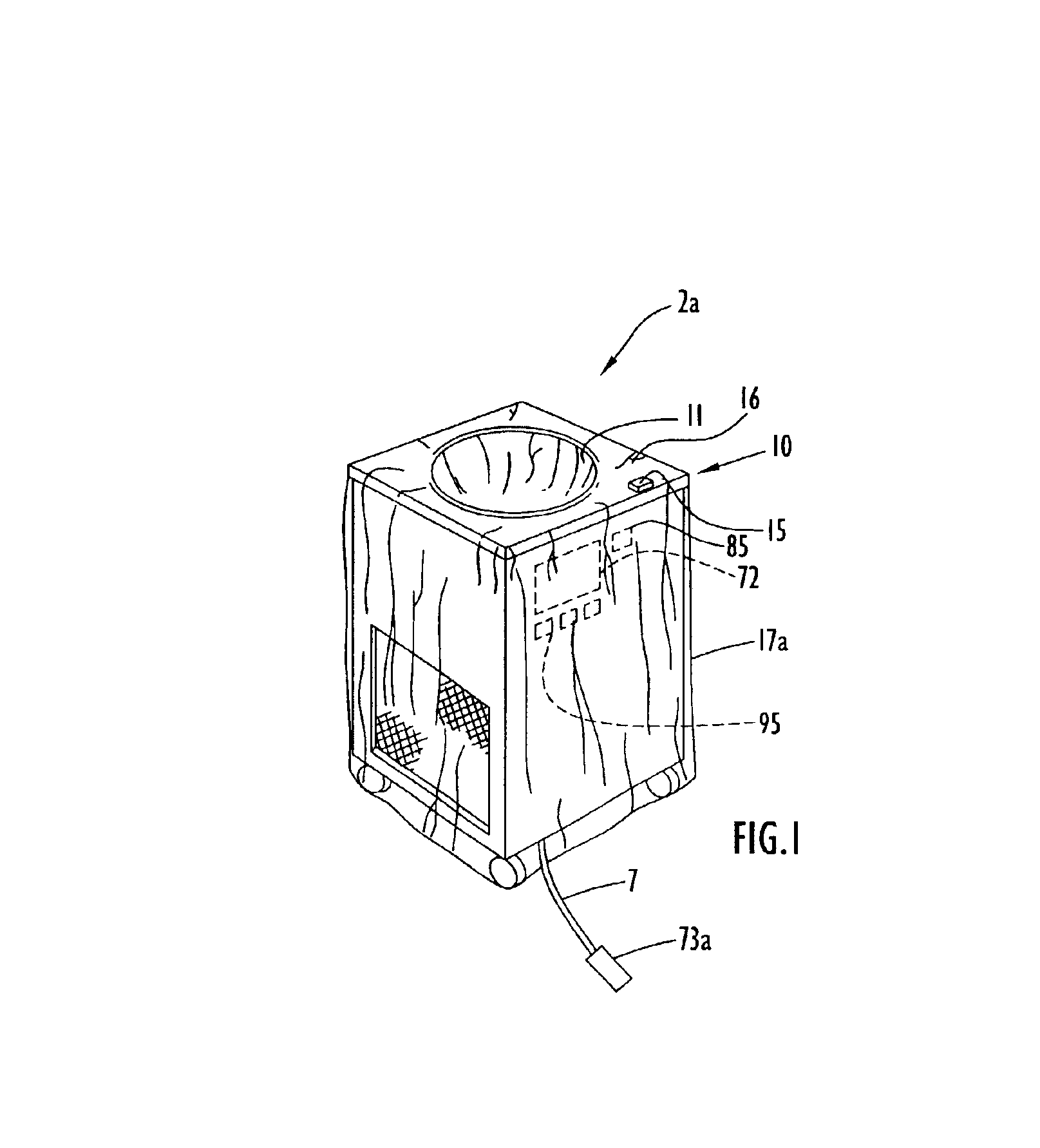

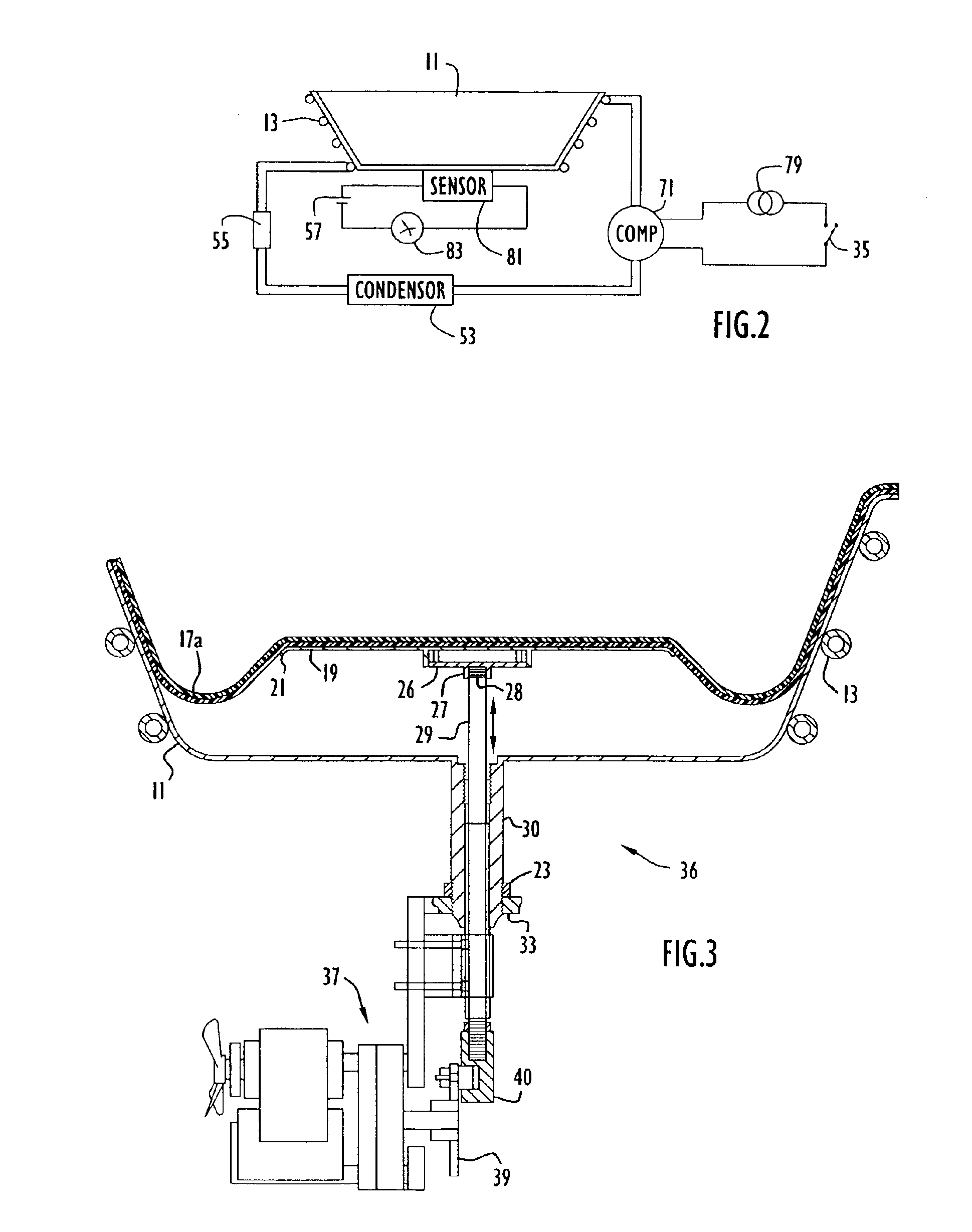

Refrigerator with an icemaker

ActiveUS6945068B2Simple structureImprove scalabilityLighting and heating apparatusIce productionEngineeringIcemaker

Owner:LG ELECTRONICS INC

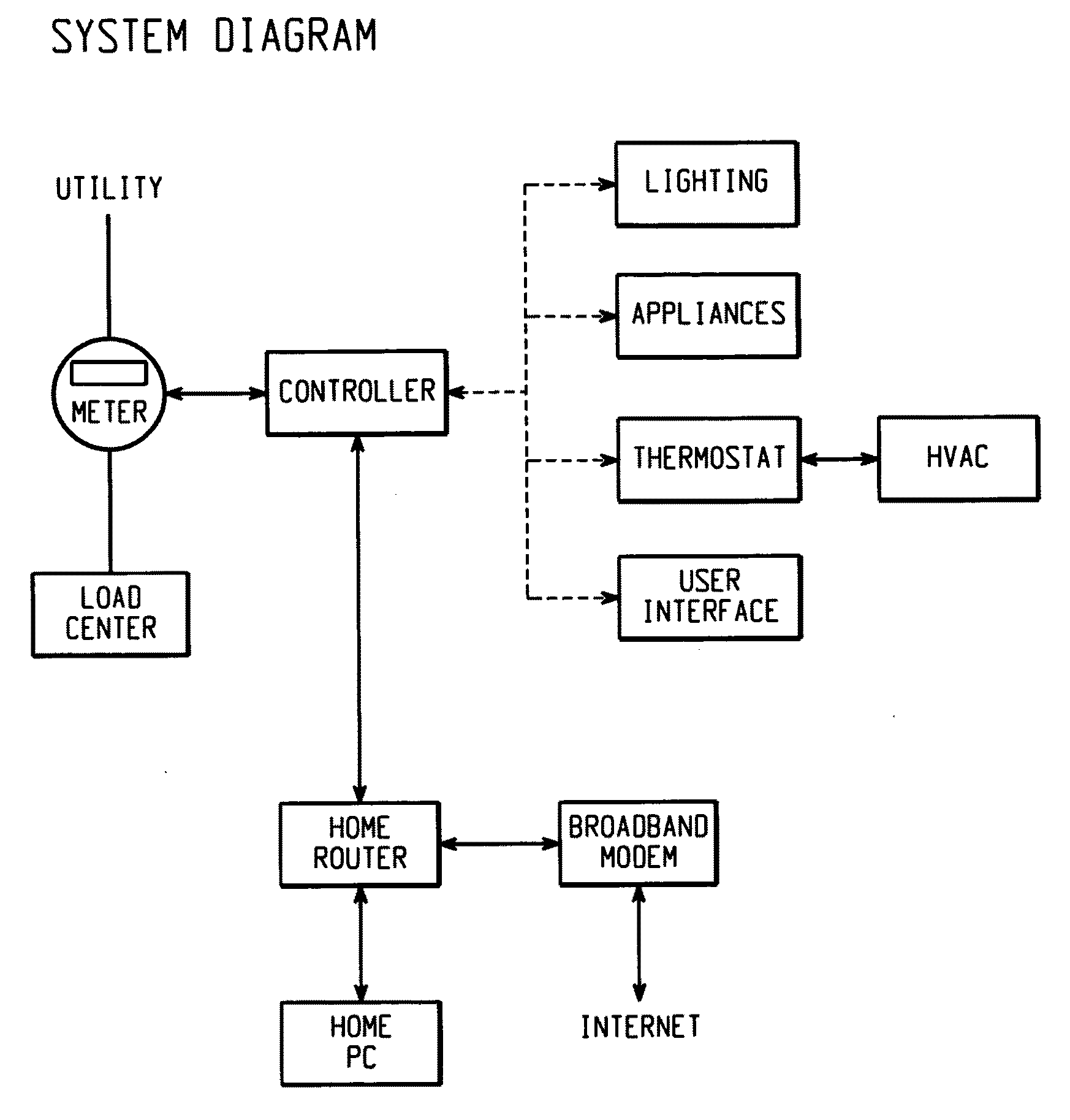

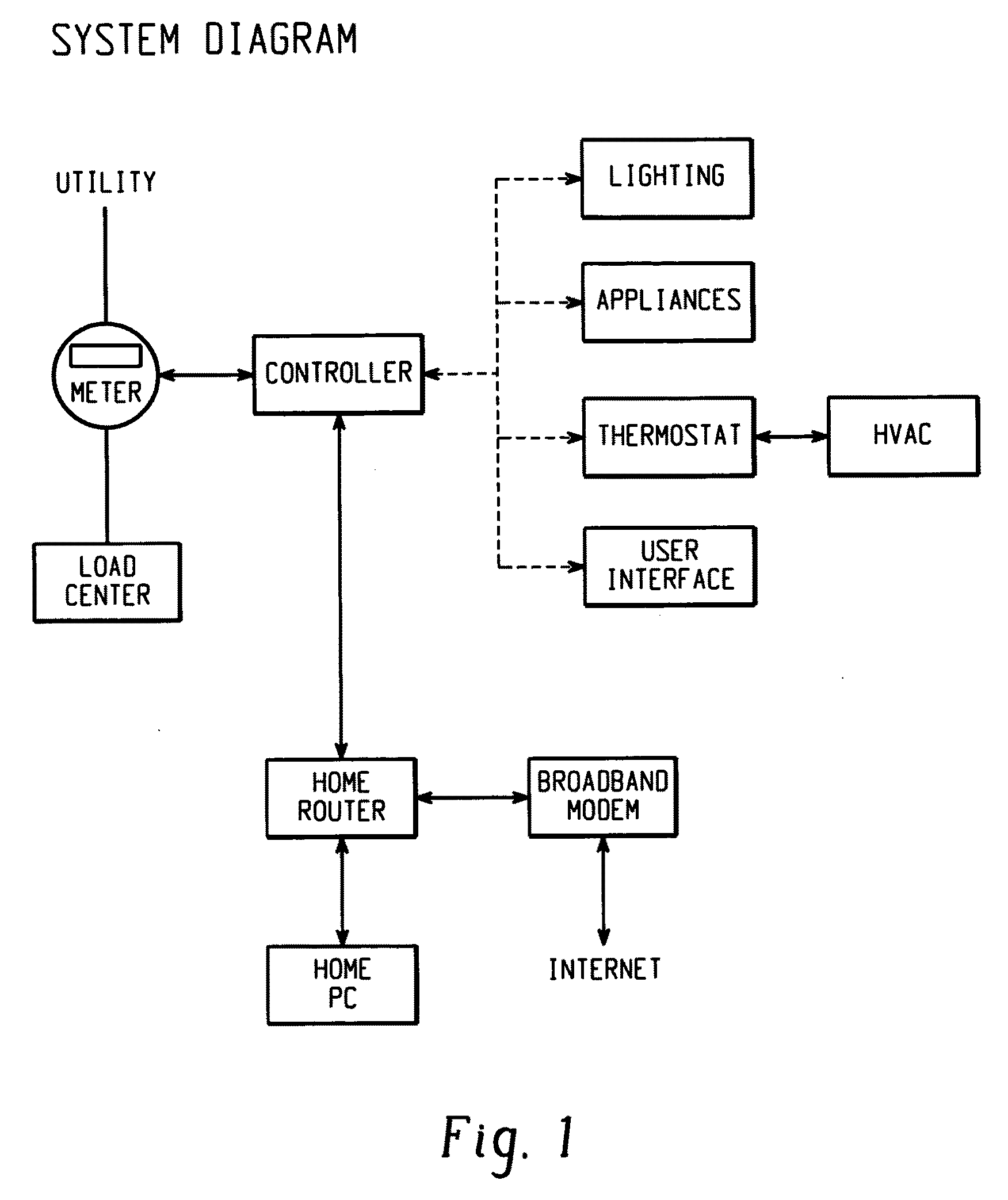

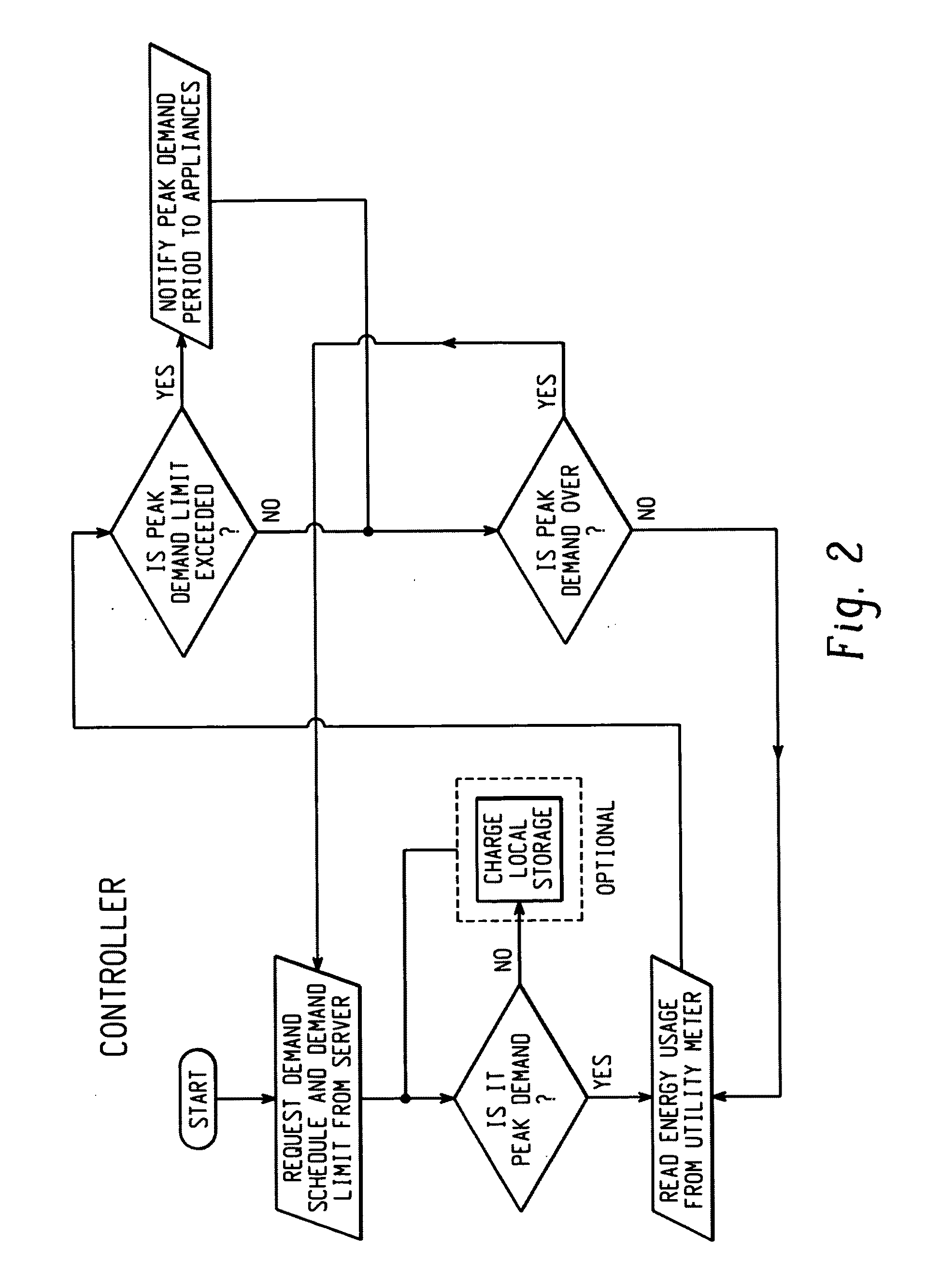

Energy management of household appliances

ActiveUS20100101254A1Lower energy requirementsReduce power consumptionLighting and heating apparatusTemperatue controlFresh foodHome appliance

A refrigerator comprises a fresh food compartment and a freezer compartment and one or more power consuming features / functions including a refrigeration system for cooling the fresh food compartment and the freezer compartment. A controller is operatively connected to the one or more power consuming features / functions. The controller is configured to receive and process a signal indicative of current state of an associated energy supplying utility. The controller operates the refrigerator in one of plurality of operating modes, including at least a normal operating mode and an energy savings mode, in response to the received signal. The controller is configured to at least one of selectively schedule, delay, adjust and deactivate at least one of the one or more power consuming features / functions to reduce power consumption of the refrigerator in the energy savings mode.

Owner:HAIER US APPLIANCE SOLUTIONS INC

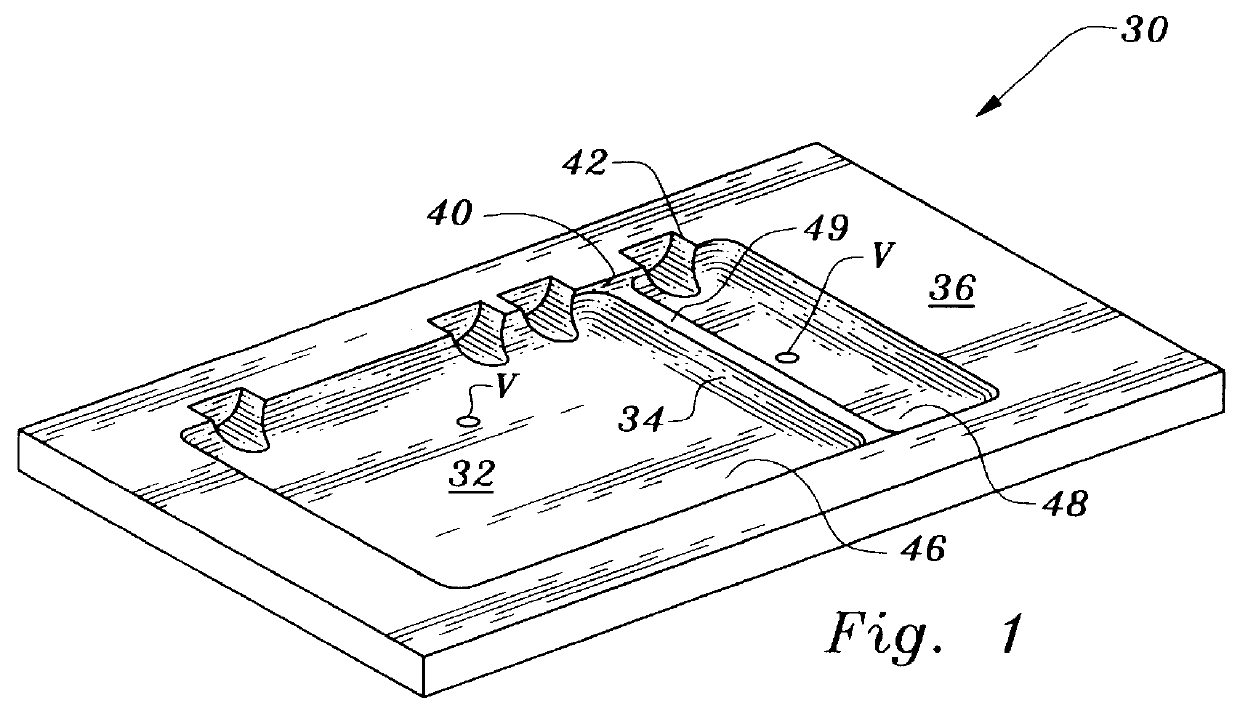

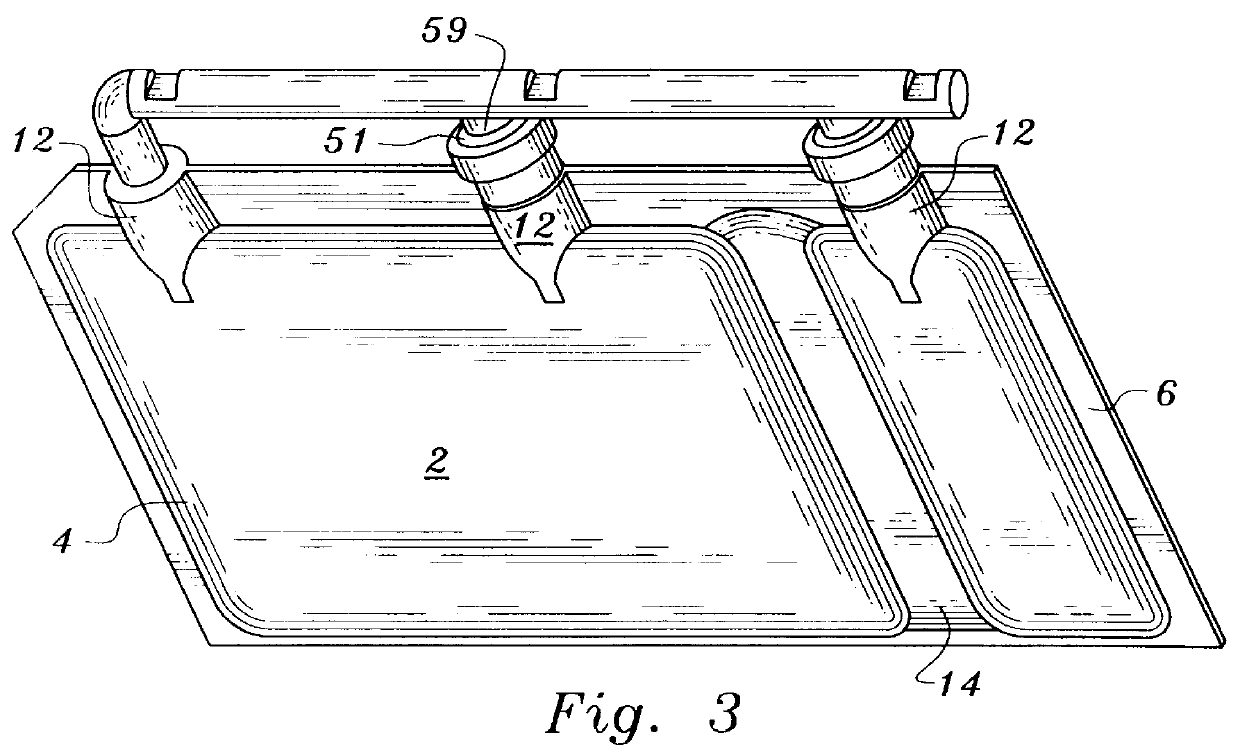

Portable cooler including ice sheet having refrigerant cubes

InactiveUS6925834B2Effective mergerLighting and heating apparatusIce productionThermal insulationEngineering

A portable cooler having one or more ice sheets including built-in refrigerant cubes. The cooler comprises an outer fabric shell and one or more sets of spaced apart refrigerant cubes encapsulated in plastic to form ice sheets that are attached to the interior walls of the cooler. The walls of the cooler may also include one or more layers of thermal insulation. The ice sheets provide a visually pleasing appearance to the inside of the cooler suggestive of cooling effects. The ice sheets may be retained along the walls of the cooler by seams sewn along the lanes passing between the refrigerant cubes, by being retained in pockets formed by sidewall liners or be being secured into chambers defined by the cooler's outer walls and a plastic insert fitted into the cooler.

Owner:FUCHS MARK D

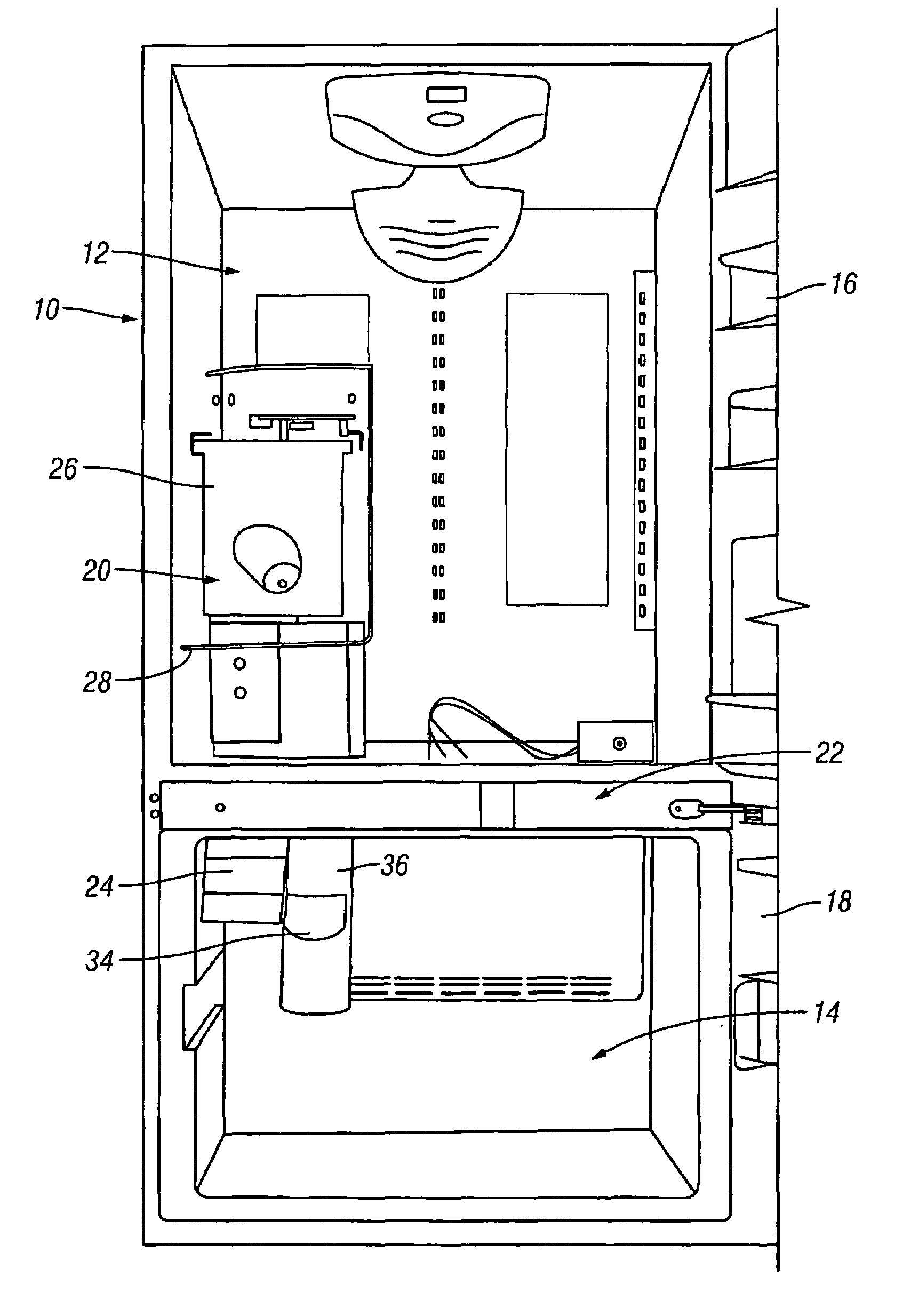

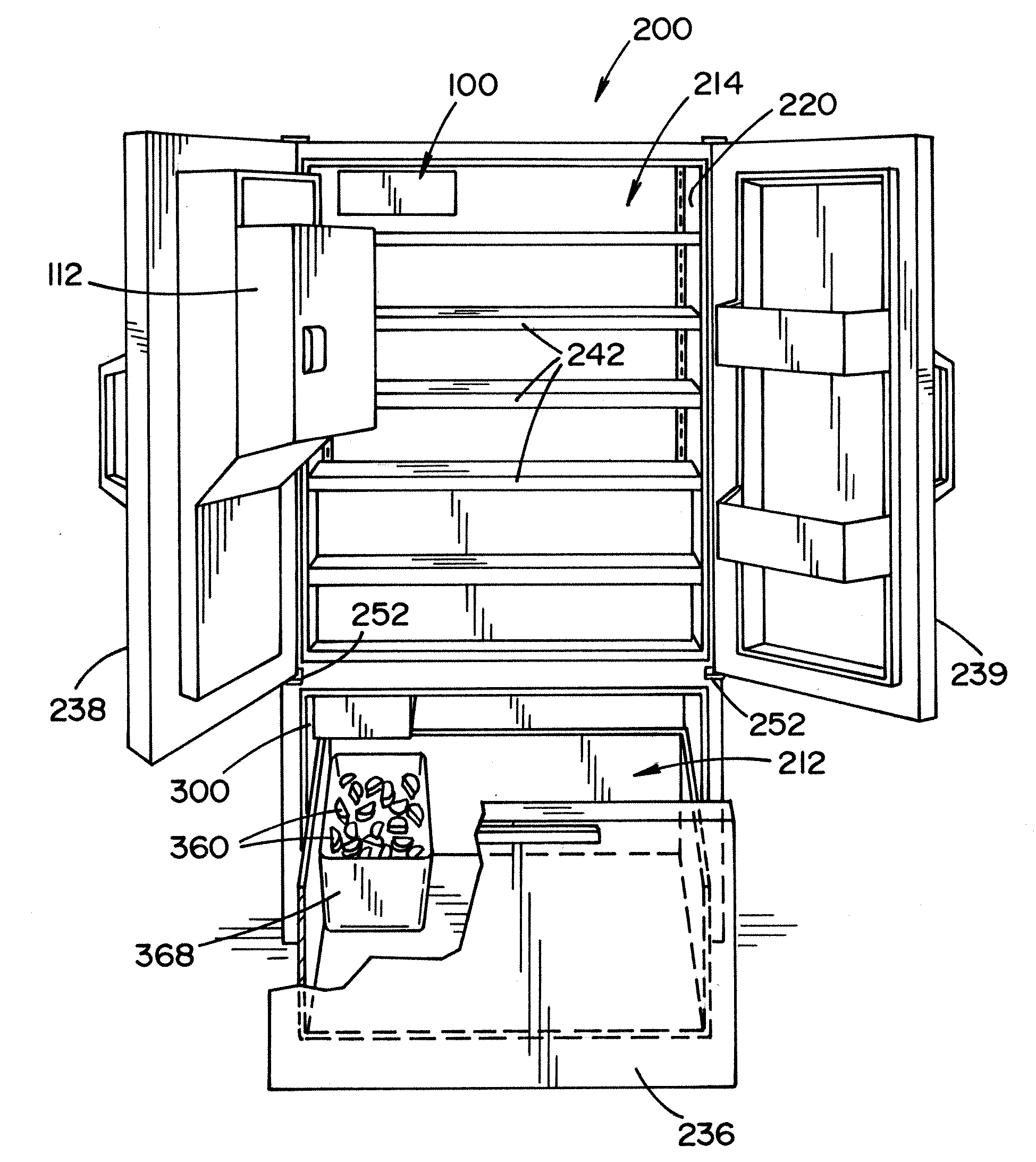

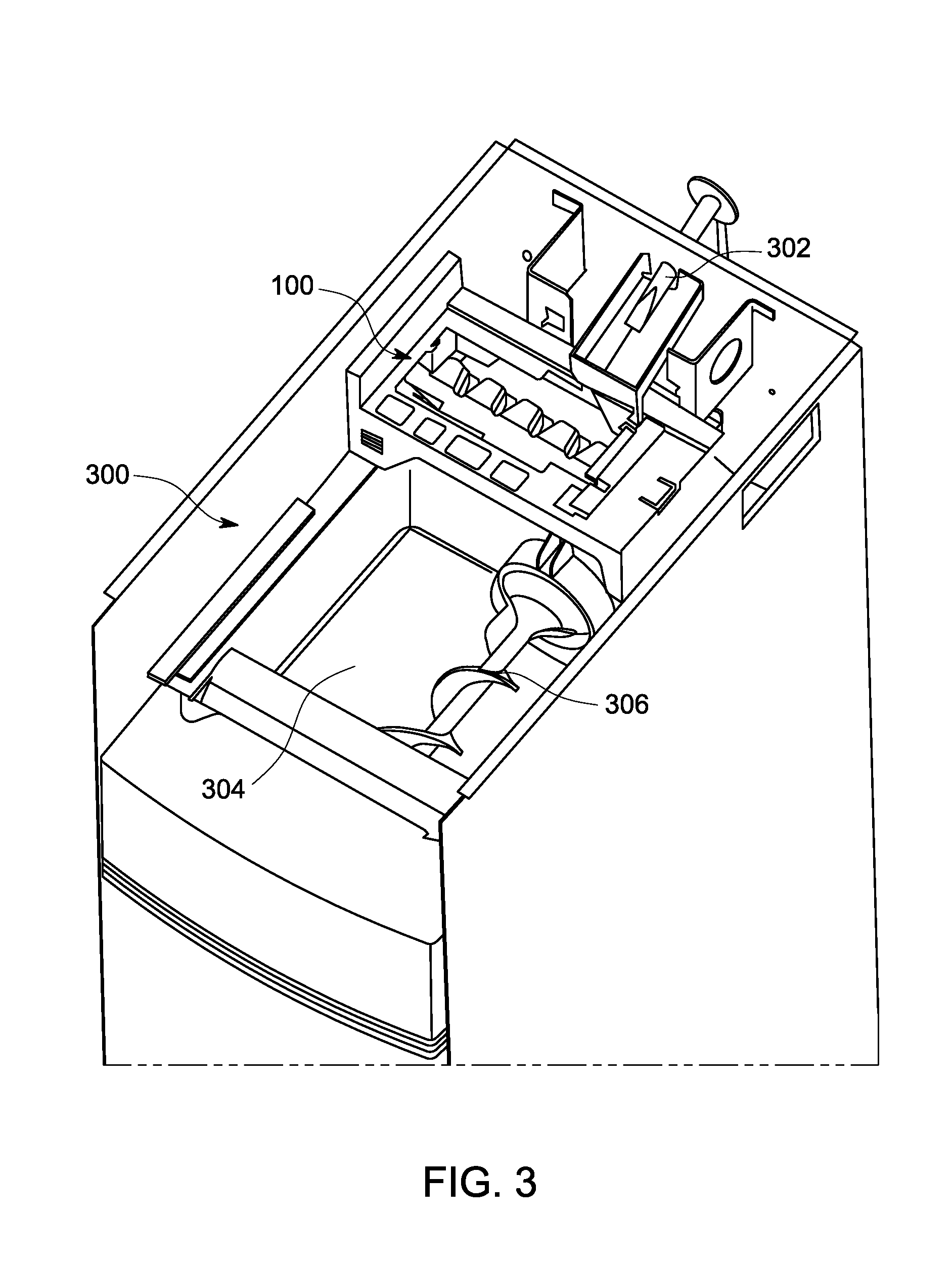

Ice maker and dispenser for a bottom mount refrigerator

A bottom mount household refrigerator is provided with an ice dispenser in the fresh food door to dispense ice from a sealed ice making compartment within the fresh food compartment. A conveyor carries ice from a storage bin in the ice compartment to the dispenser.

Owner:WHIRLPOOL CORP

Portable cooler with built-in refrigerant cubes

ActiveUS20050183446A1Easy to storeSpace minimizationLighting and heating apparatusIce productionThermal insulationCooling effect

A portable cooler having one or more ice sheets including built-in refrigerant cubes. The cooler comprises an outer fabric shell and one or more sets of spaced apart refrigerant cubes encapsulated in plastic to form ice sheets that are attached to the interior walls of the cooler. The walls of the cooler may also include one or more layers of thermal insulation. The ice sheets provide a visually pleasing appearance to the inside of the cooler suggestive of cooling effects. The ice sheets may be retained along the walls of the cooler by seams sewn along the lanes passing between the refrigerant cubes, by being retained in pockets formed by sidewall liners or by being secured into chambers defined by the cooler's outer walls and a plastic insert fitted into the cooler. The cooler may include a hinged top and bottom that can be folded flat for allowing the cooler to assume a compact configuration during storage or freezing of the refrigerant cubes.

Owner:FUCHS MARK D

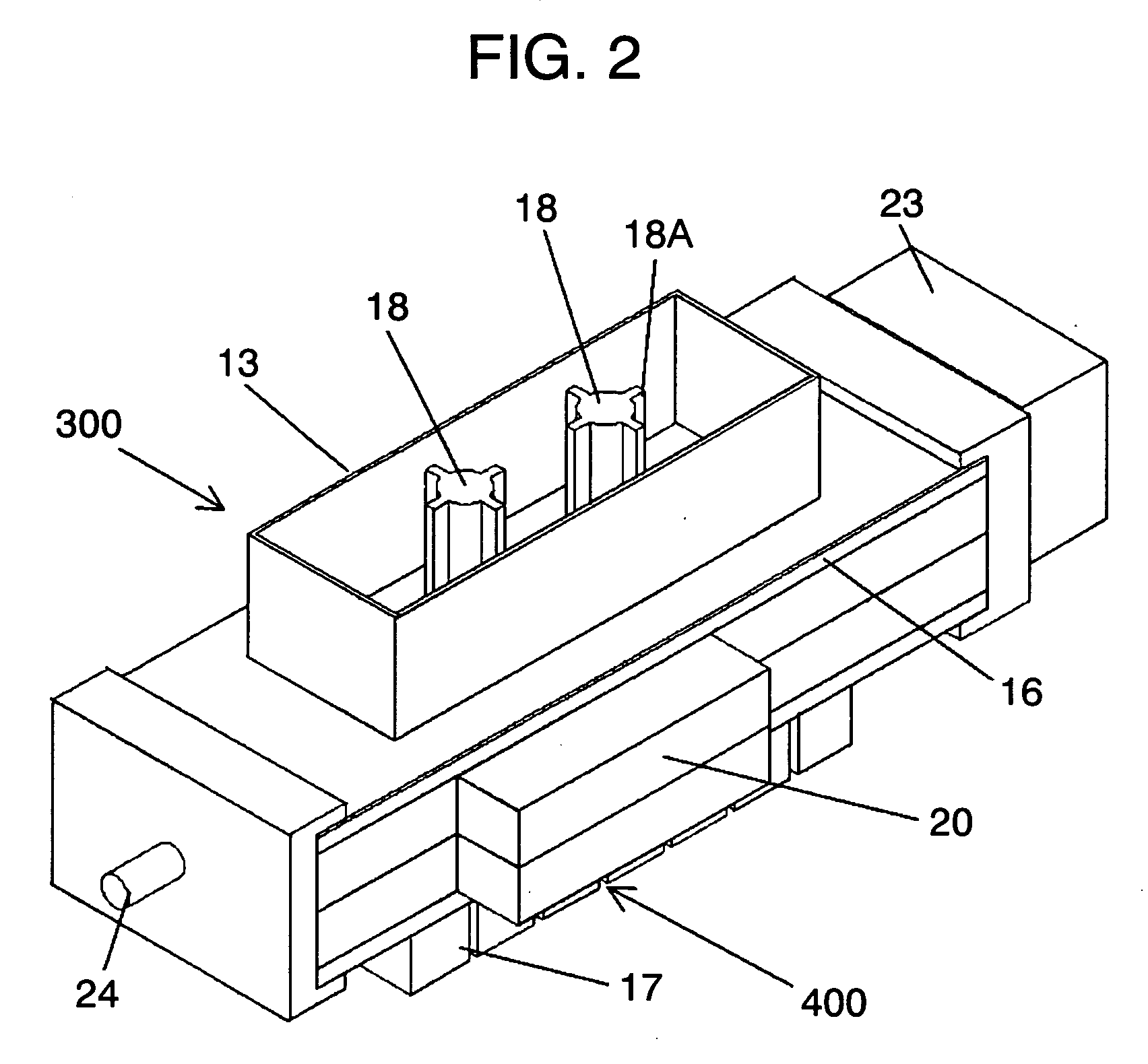

Ice-making device

InactiveUS20060168983A1Small sizeNice appearanceIce productionMachines using electric/magnetic effectsEngineeringMechanical engineering

A compact ice-making device is provided for making ice chips of varied shapes for use in glasses of whiskey and water, and the like purposes. Ice is made using an ice-making vessel (13) for making a plank-like block of ice with a shaft (18) inserted in advance in the vessel, the shaft (18) having ribs (18A) extending substantially radially from a rotating axis. Upon completion of the ice making, a gear unit (20) connected to the shaft (18) is driven by a motor to rotate the shaft (18), which cracks and divides the plank-like ice block into ice chips of varied shapes.

Owner:PANASONIC CORP

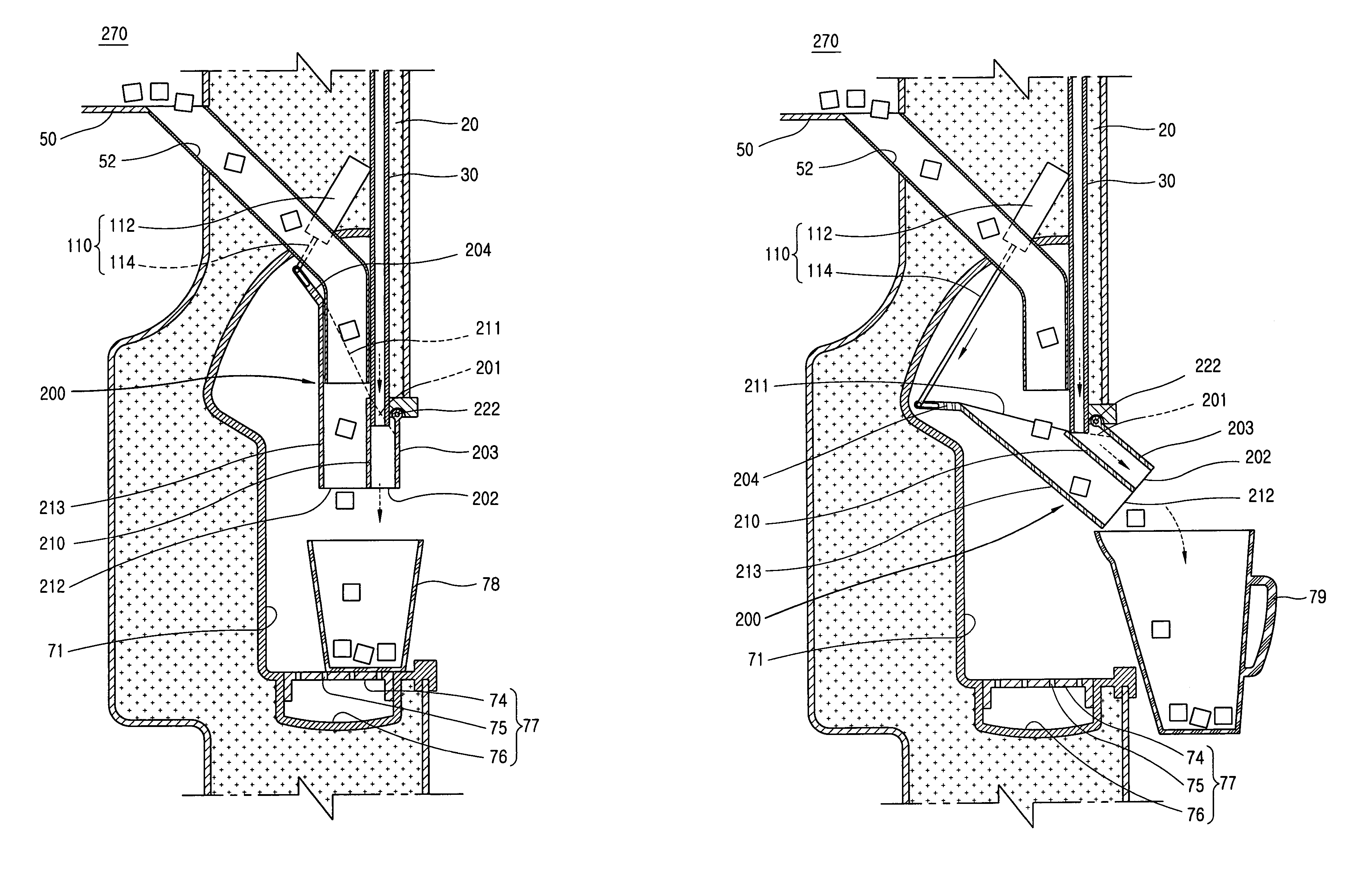

Dispenser of refrigerator

A dispenser of a refrigerator comprises a dispensing chamber recessed in one of doors for opening and closing freezing and refrigerating compartments, a chute member pivotally mounted in the dispensing chamber and connected with a water supply pipe for supplying water toward the dispensing chamber, and an operating means for rotating the chute member about a pivot axis of the chute member. Accordingly, water can be easily stored in a vessel regardless of the size of the vessel, utilization effect of an internal space of the refrigerator can be improved, and insulation effect of the refrigerator can be also improved because of an increase in a thickness for insulation of the refrigerator.

Owner:LG ELECTRONICS INC

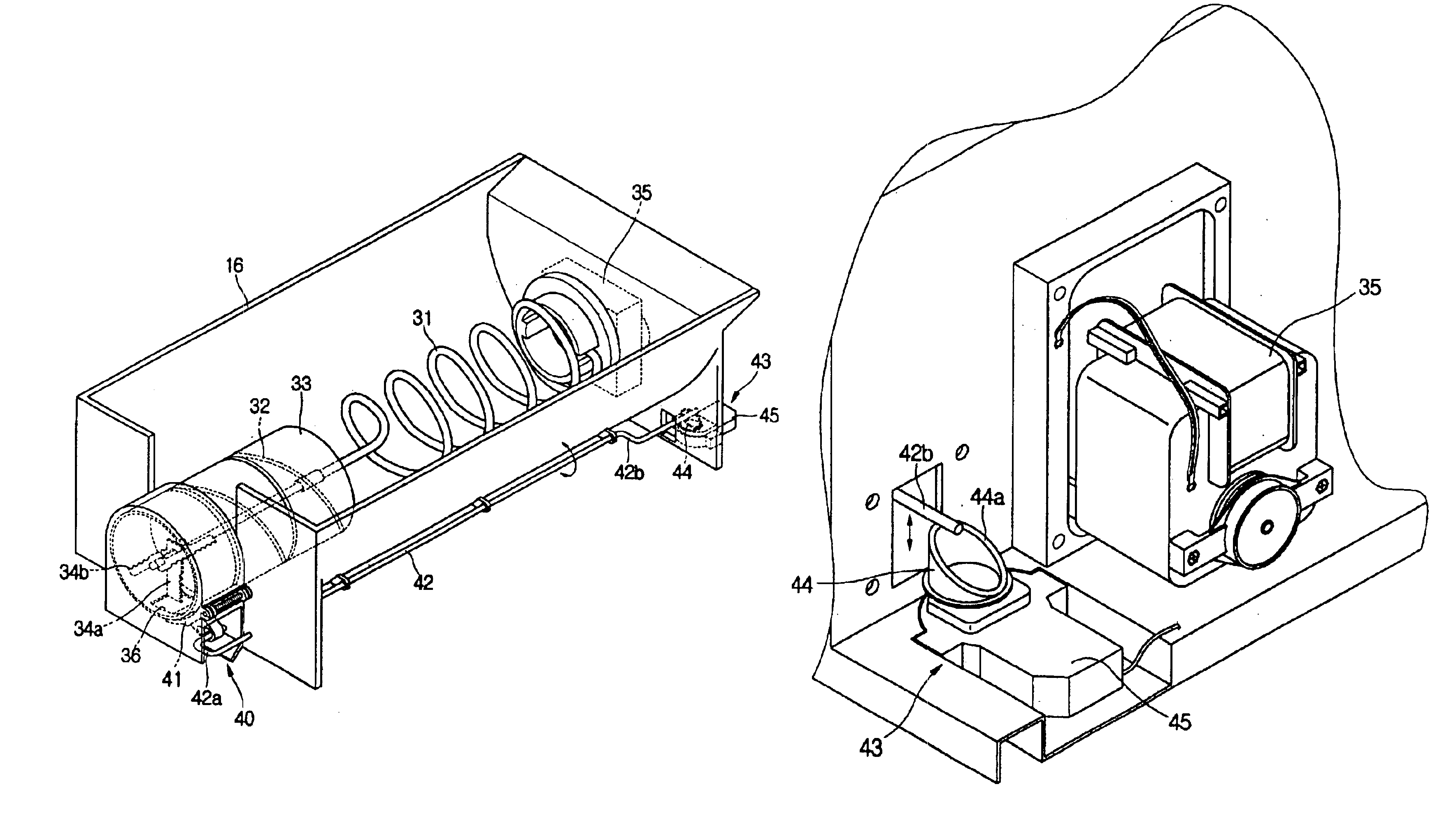

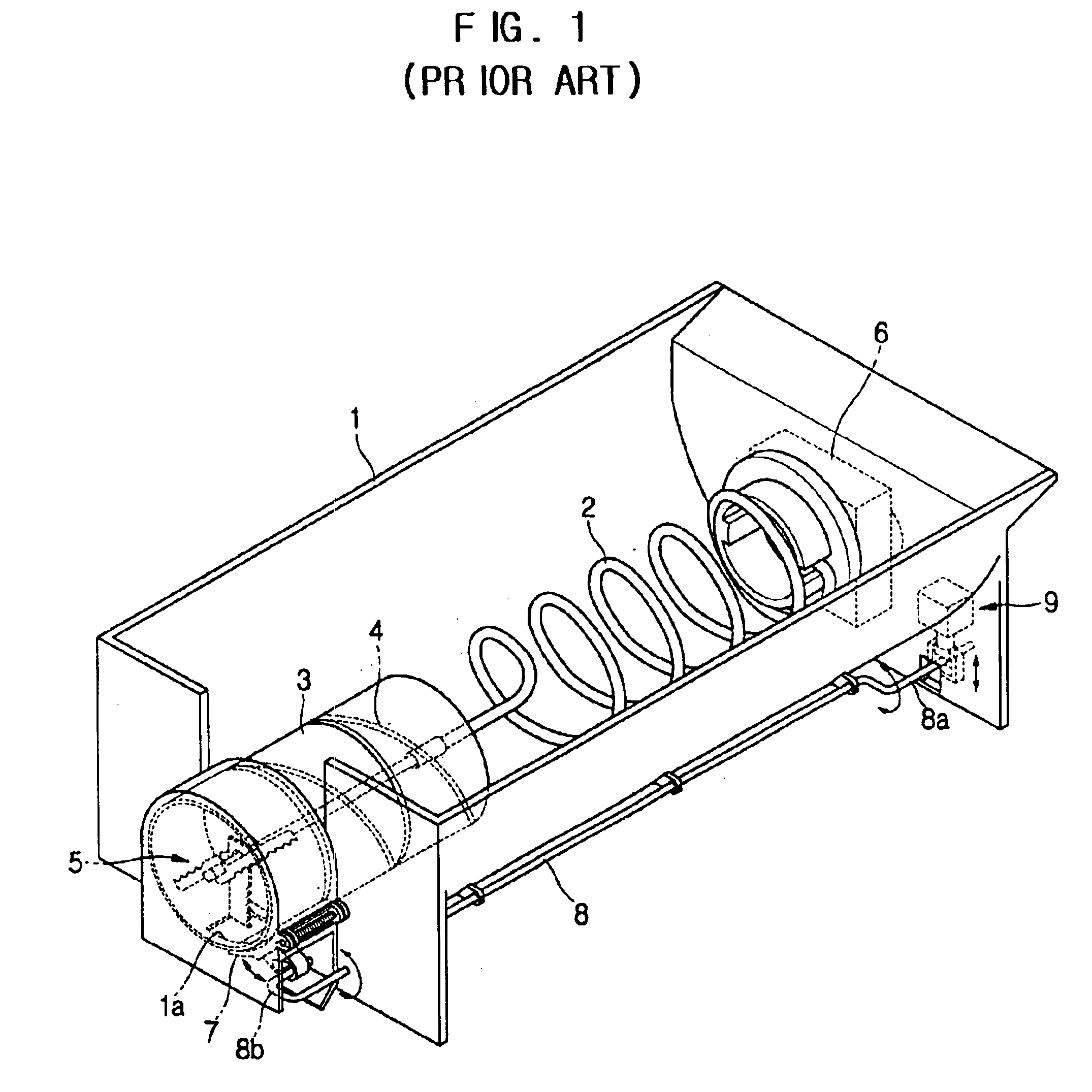

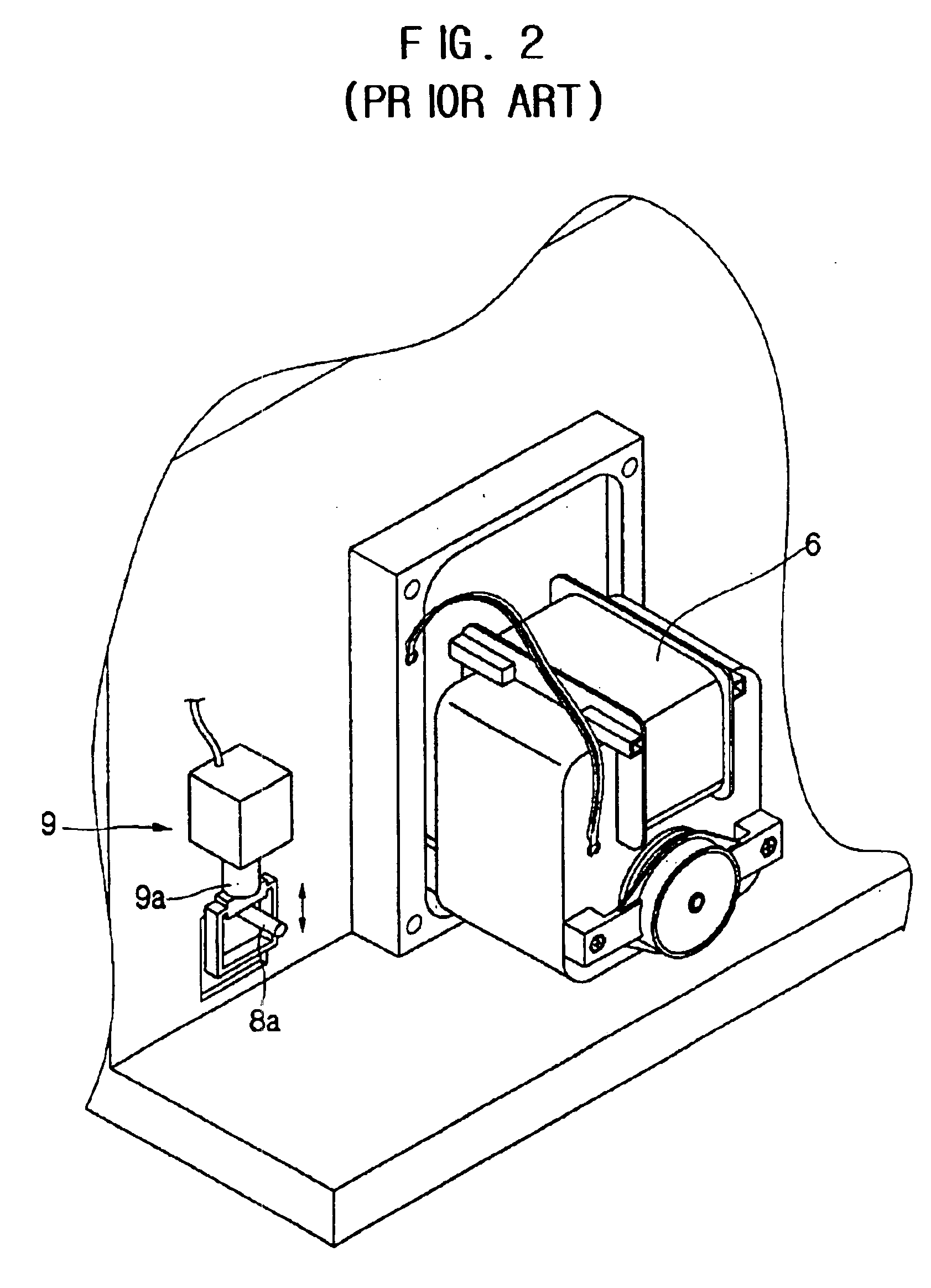

Refrigerator with ice feeding unit

InactiveUS6880355B2Operating means/releasing devices for valvesLighting and heating apparatusMotor driveIce storage

Owner:SAMSUNG ELECTRONICS CO LTD

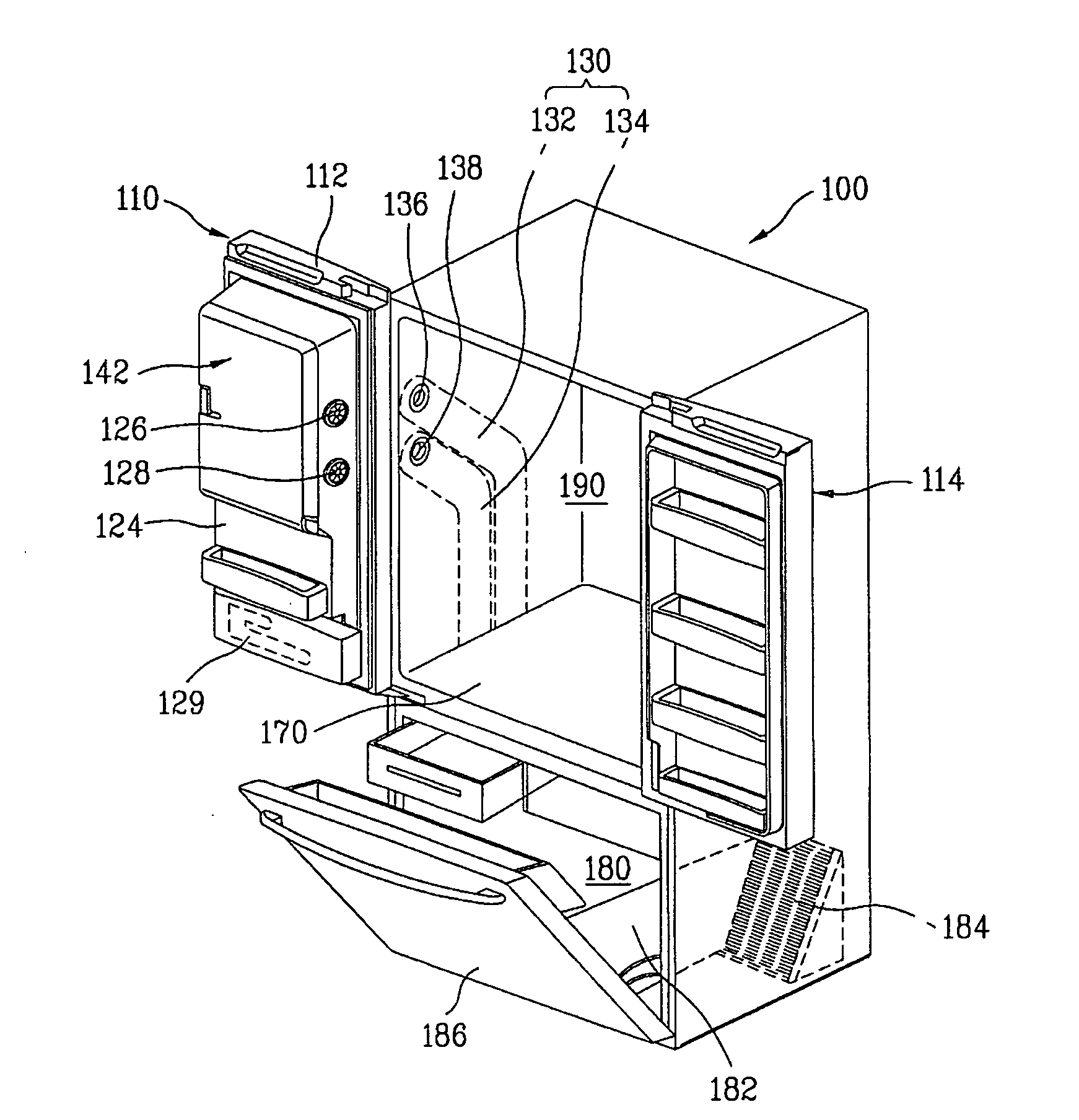

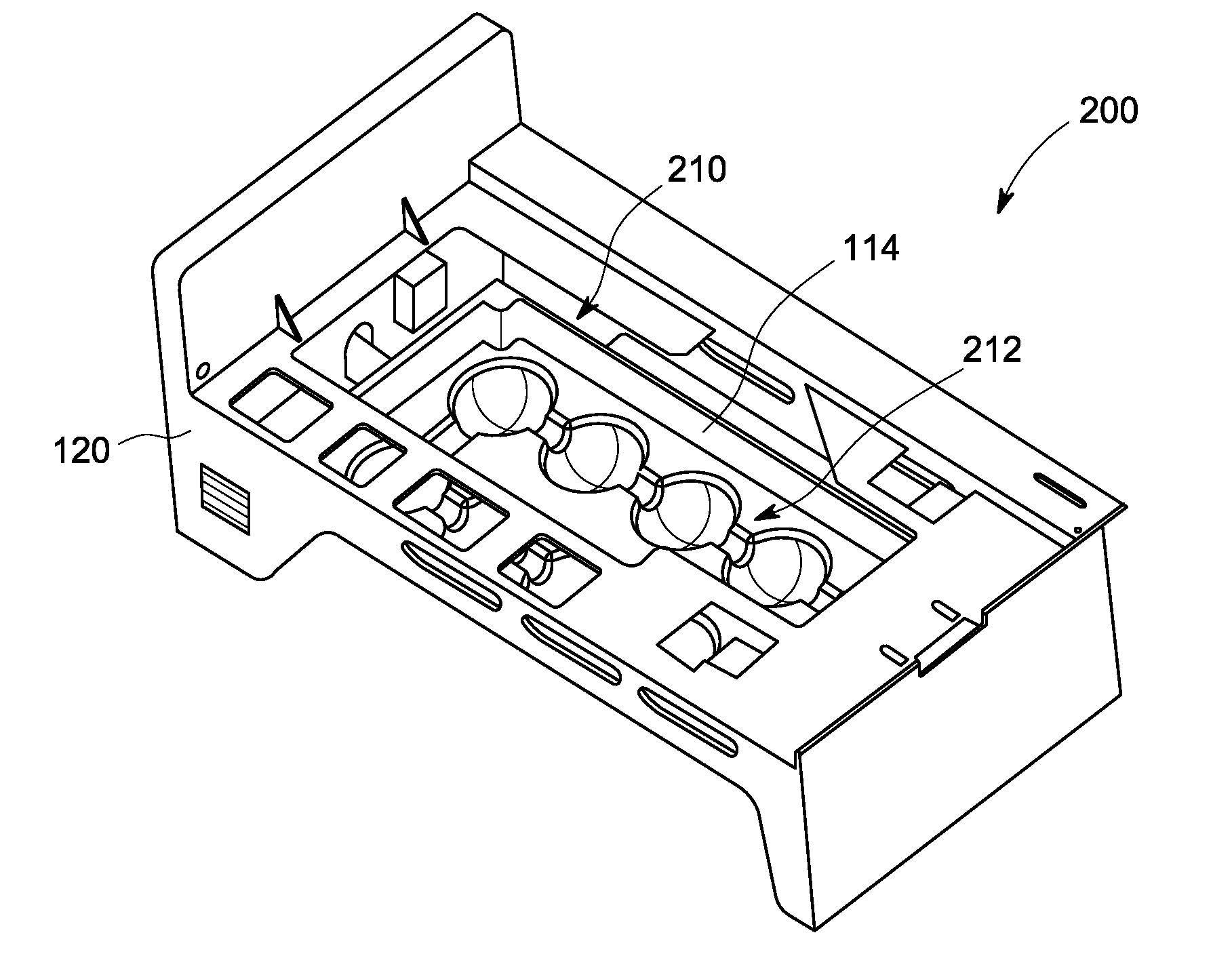

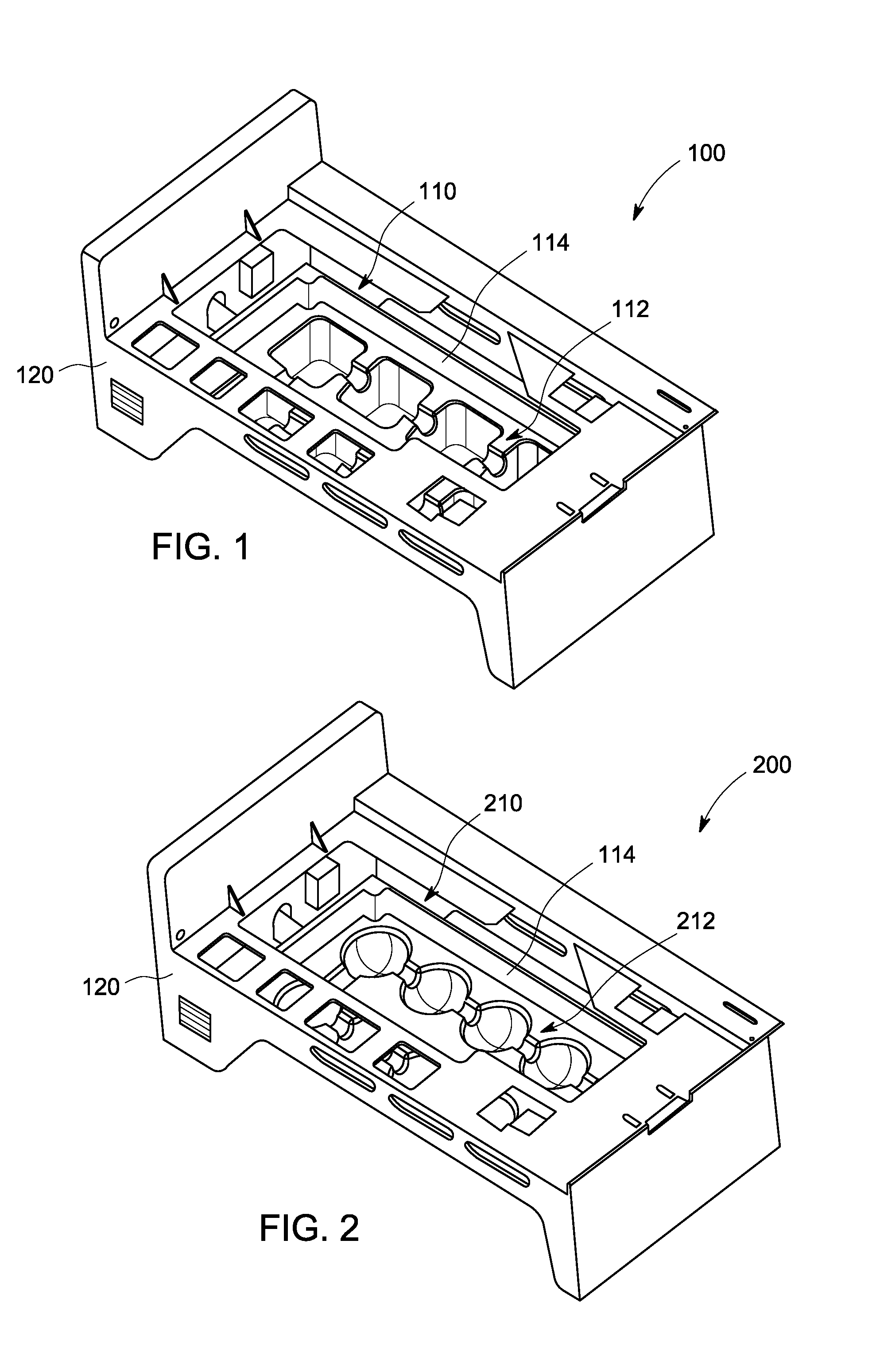

Icemaker combination assembly

In accordance with the present disclosure, an icemaker combination assembly is provided and comprises a refrigerator having a freezer compartment and a fresh food compartment. The freezer compartment can have a freezer door assembly and the fresh food compartment can have a fresh food door assembly. The icemaker combination further comprises a first icemaker having a first ice cube storage bin disposed within the freezer compartment and a second icemaker having a second ice cube storage bin disposed within the fresh food compartment. The first and second icemakers having a production activation level selected from the group consisting of the first icemaker active only, the second icemaker active only, the first and the second icemakers both active, and the first and the second icemakers both inactive. The first and second icemakers can selectively and simultaneously produce and independently store ice.

Owner:GENERAL ELECTRIC CO

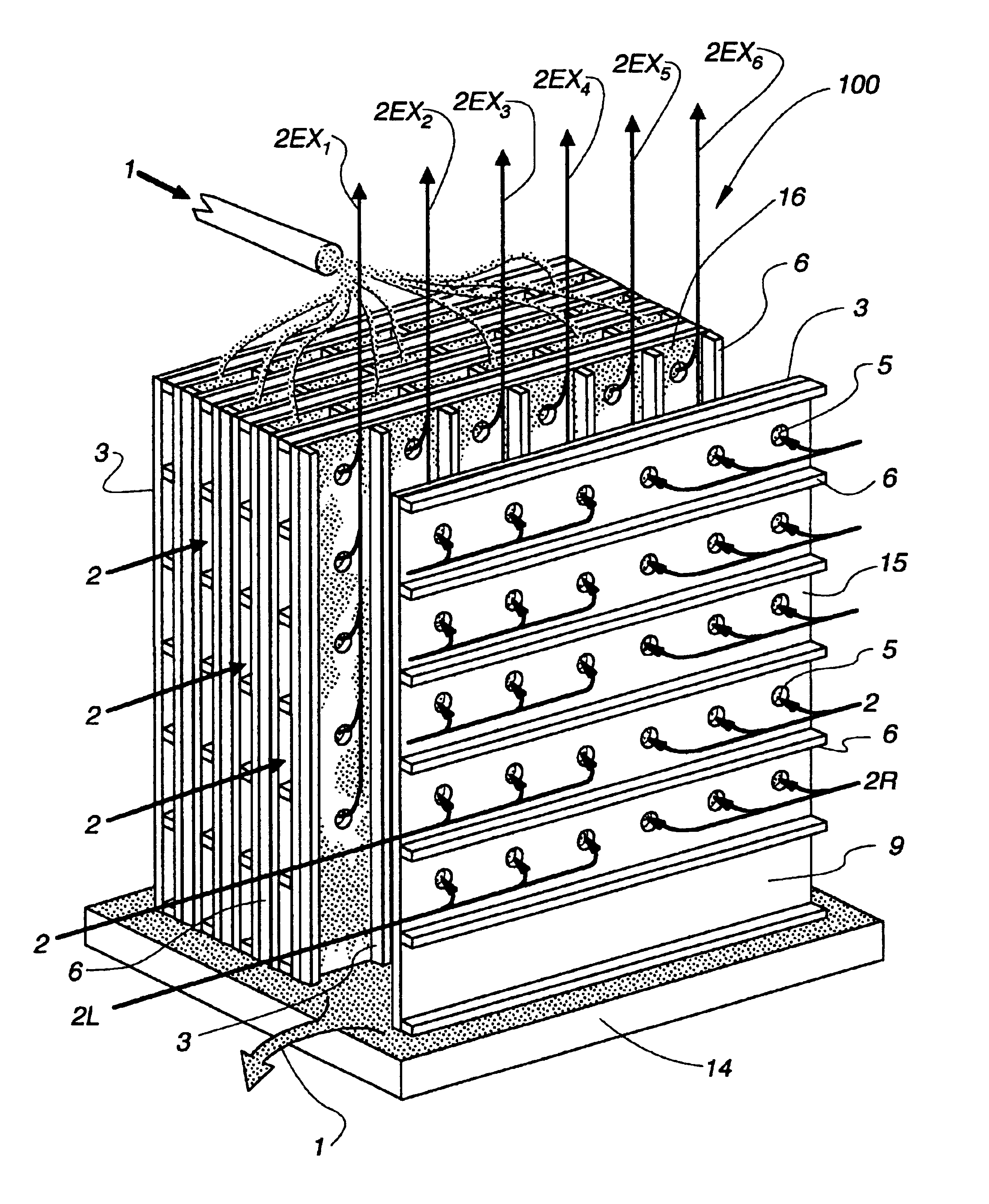

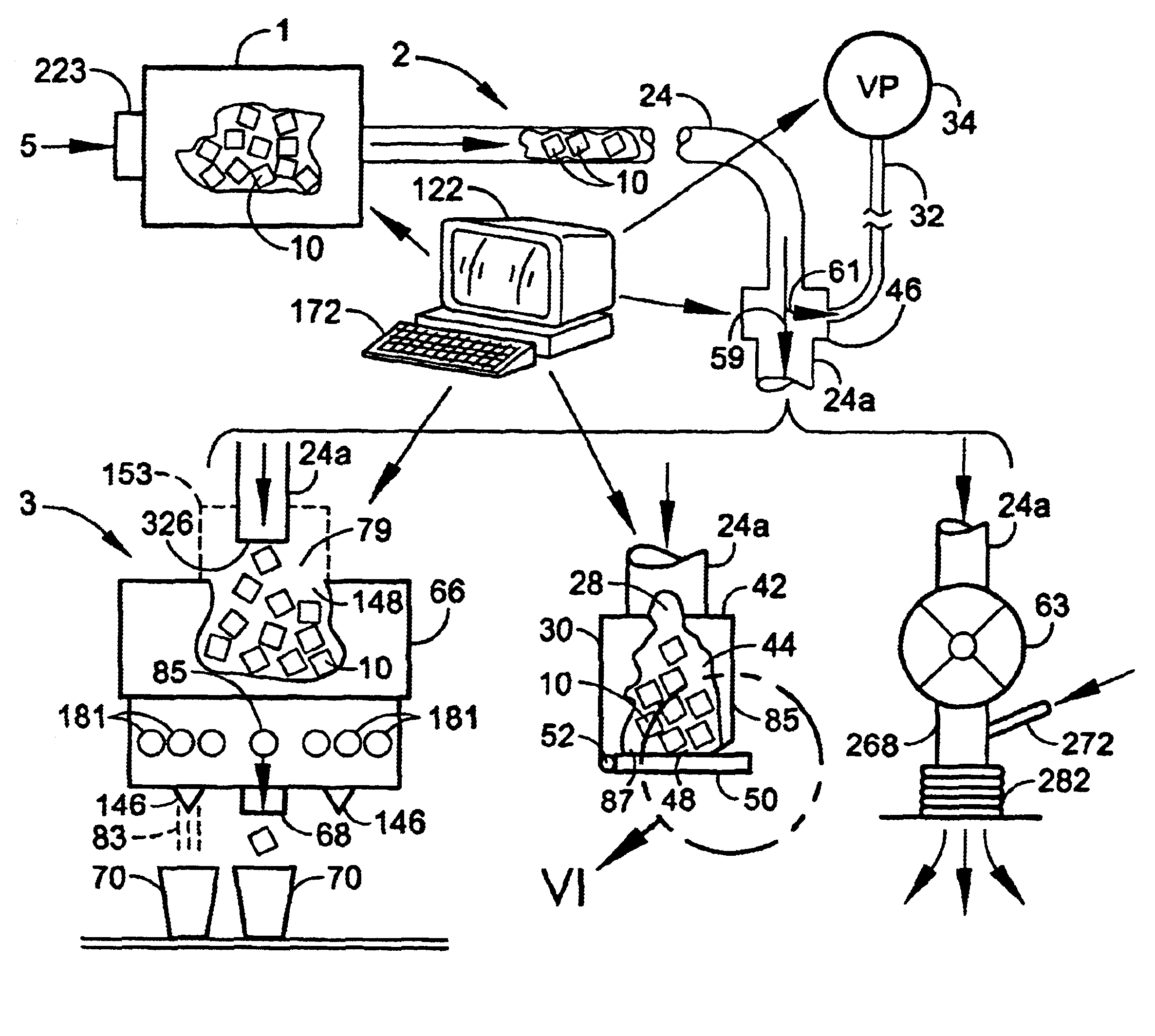

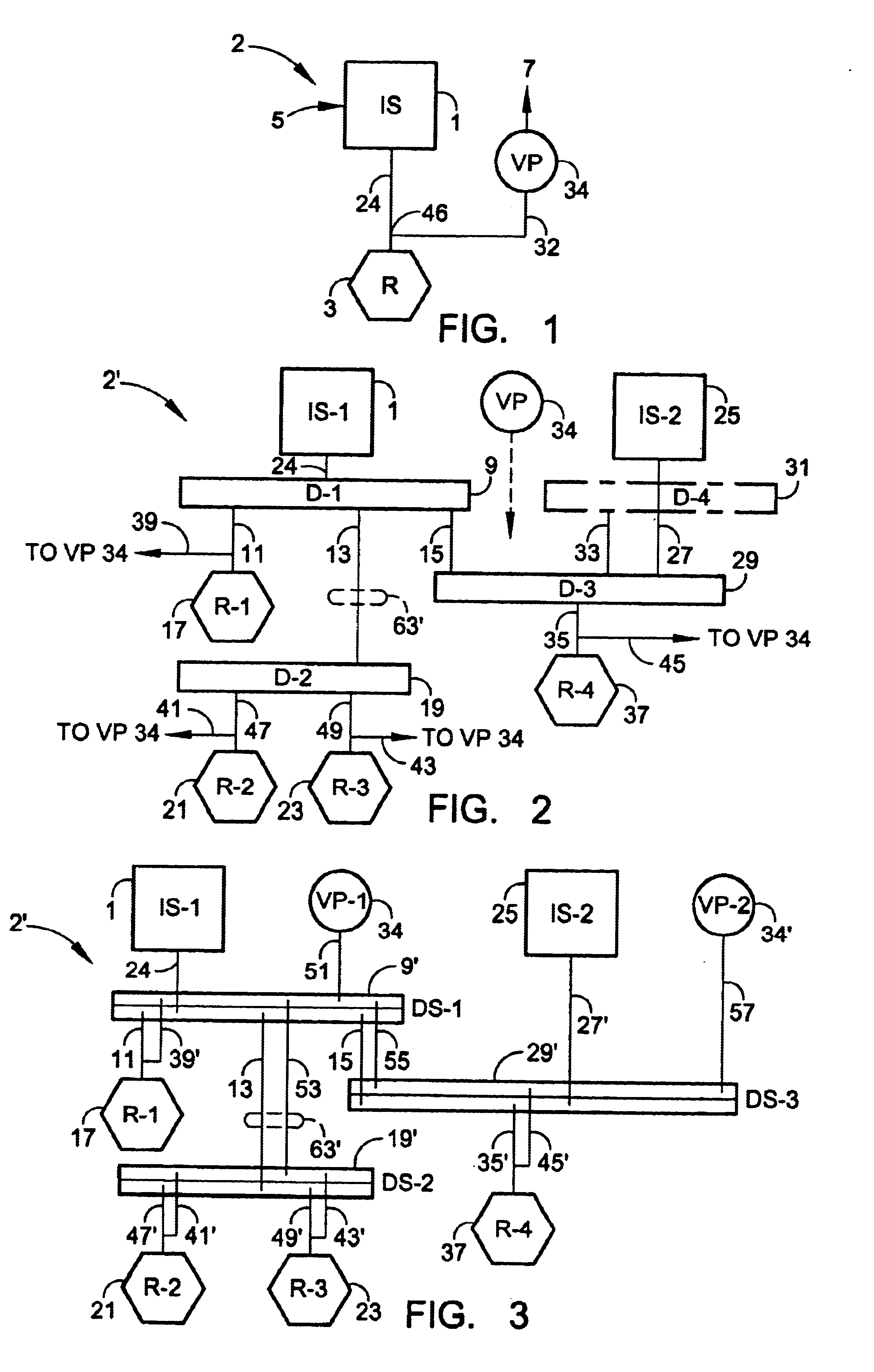

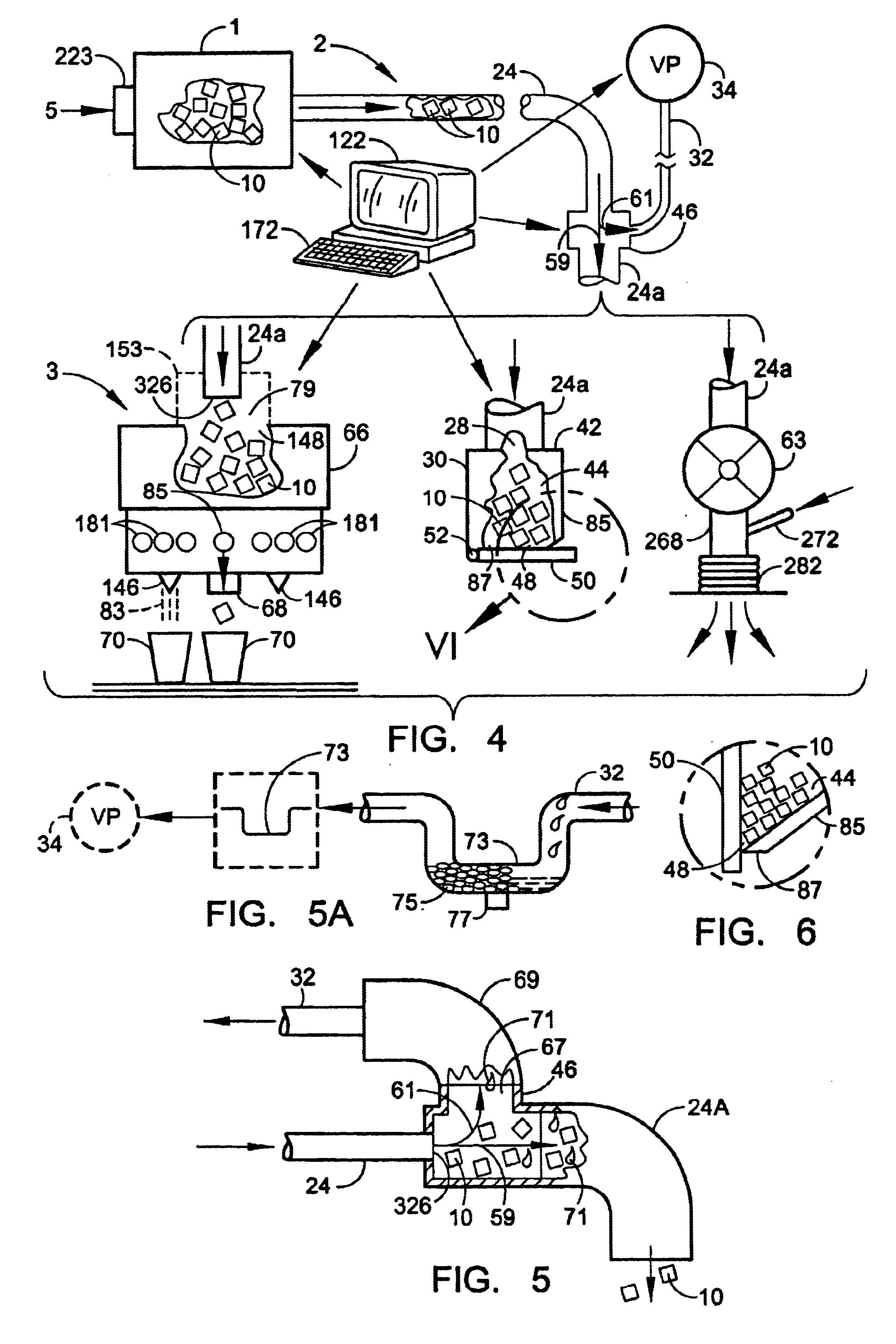

Vacuum pneumatic system for conveyance of ice

InactiveUS6827529B1Readily vacuum conveyedLess costlyLighting and heating apparatusIce productionSystem configurationEngineering

Vacuum pneumatic conveying apparatus and method are described to provide for a simple, economical, convenient (and preferably automatic) system for conveying ice on an as-required basis from a source such as an ice maker to one or more receptors at locations remote from that source. The system can be configured such that dispensing locations can be added or eliminated from the system or temporarily taken "off line" from the system without the need to change the basic system configuration or the central ice providing apparatus. The apparatus in various embodiments includes an ice source, a conveying conduit from the source to the receptor, a vacuum pump for moving the ice through the conduit by vacuum, and the receptor to collect the conveyed ice. The receptor may be an ice / beverage dispenser, an accumulator for retention and discharge to further devices, an intermediate storage dispenser, or an air lock device from where the ice can be projected over significant distances. Ice and vacuum may simultaneously be routed into different branched routes, utilizing a unique diverter / air shifter with the capability of providing routing to up to four different routes. Appropriate sensors and controllers, which may be microprocessor-based, may be used to automate the system. The entire system is easily cleanable. The system is advantageously used by restaurants, groceries, hotels and motels, hospitals, laboratories, and many other establishments where the providing of ice at various locations is desirable or required.

Owner:TEK SOLUTIONS

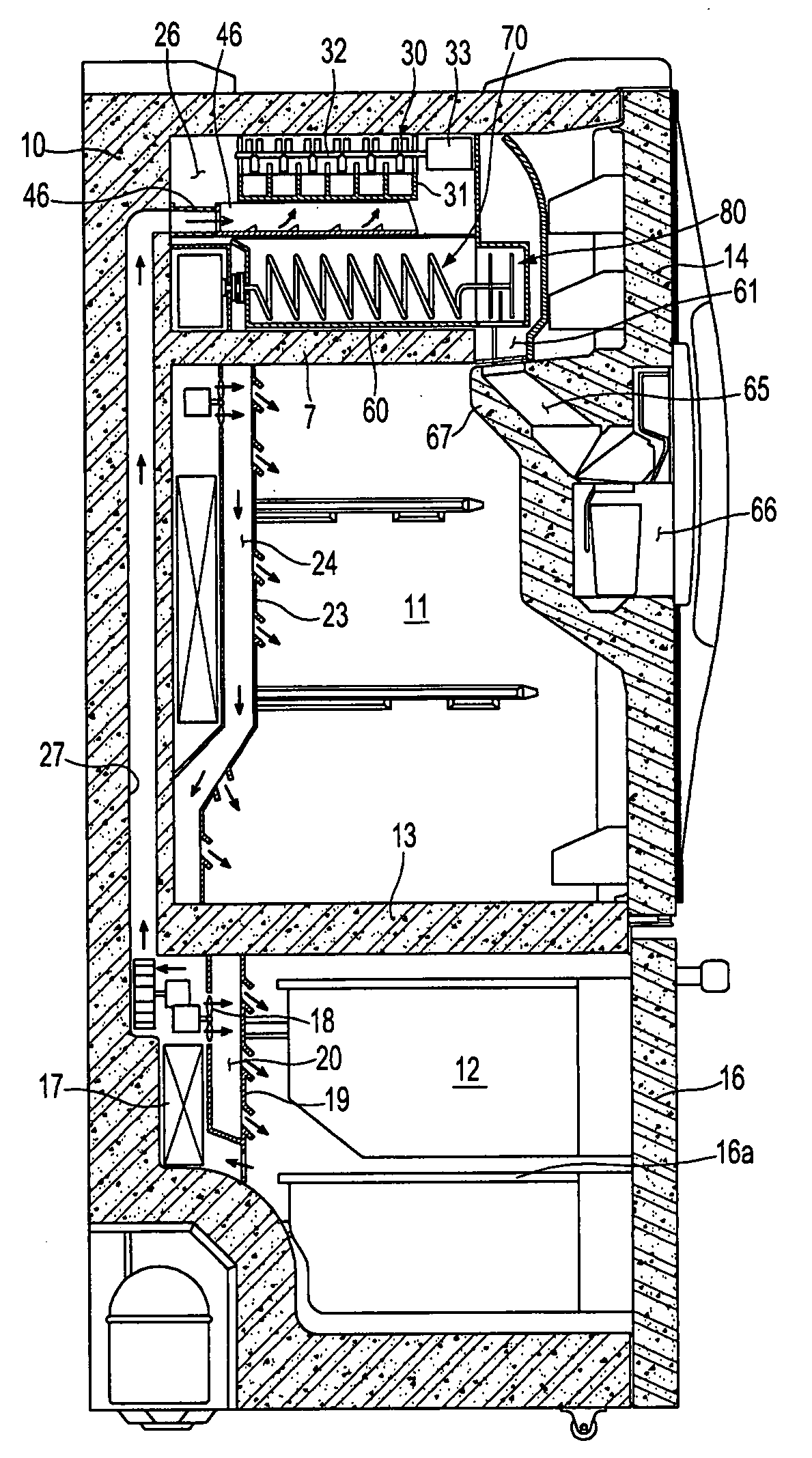

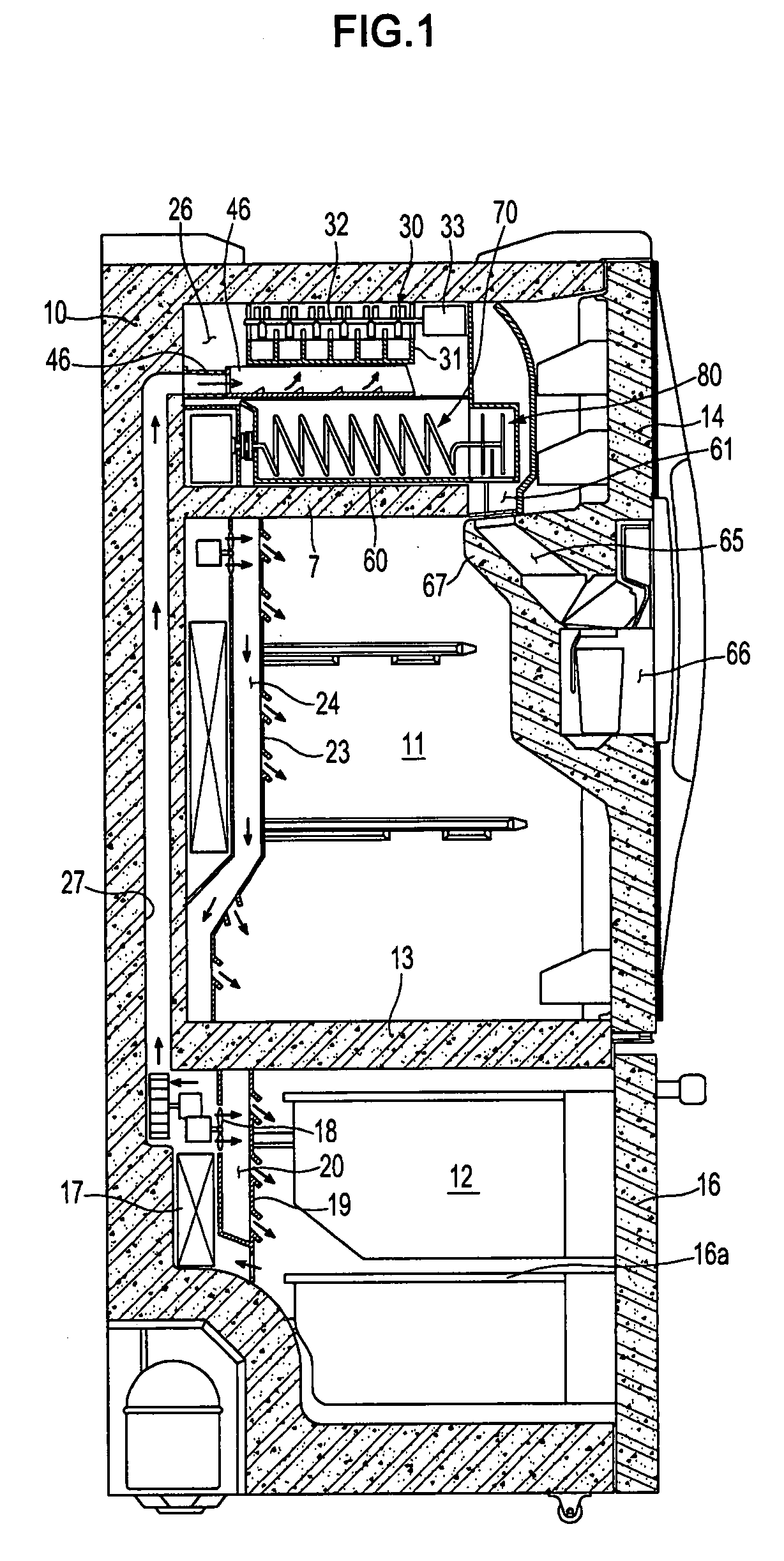

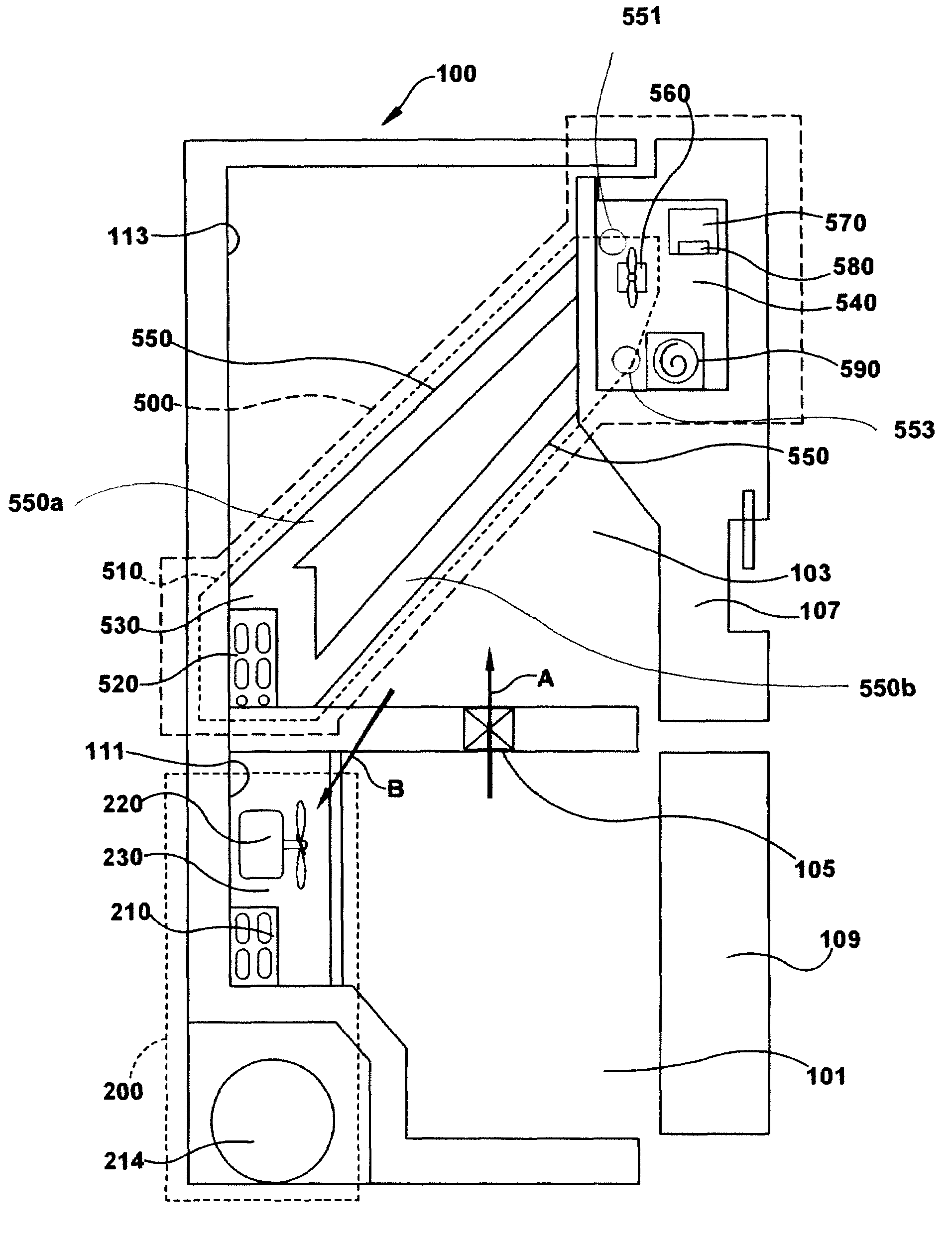

Ice producing apparatus and method

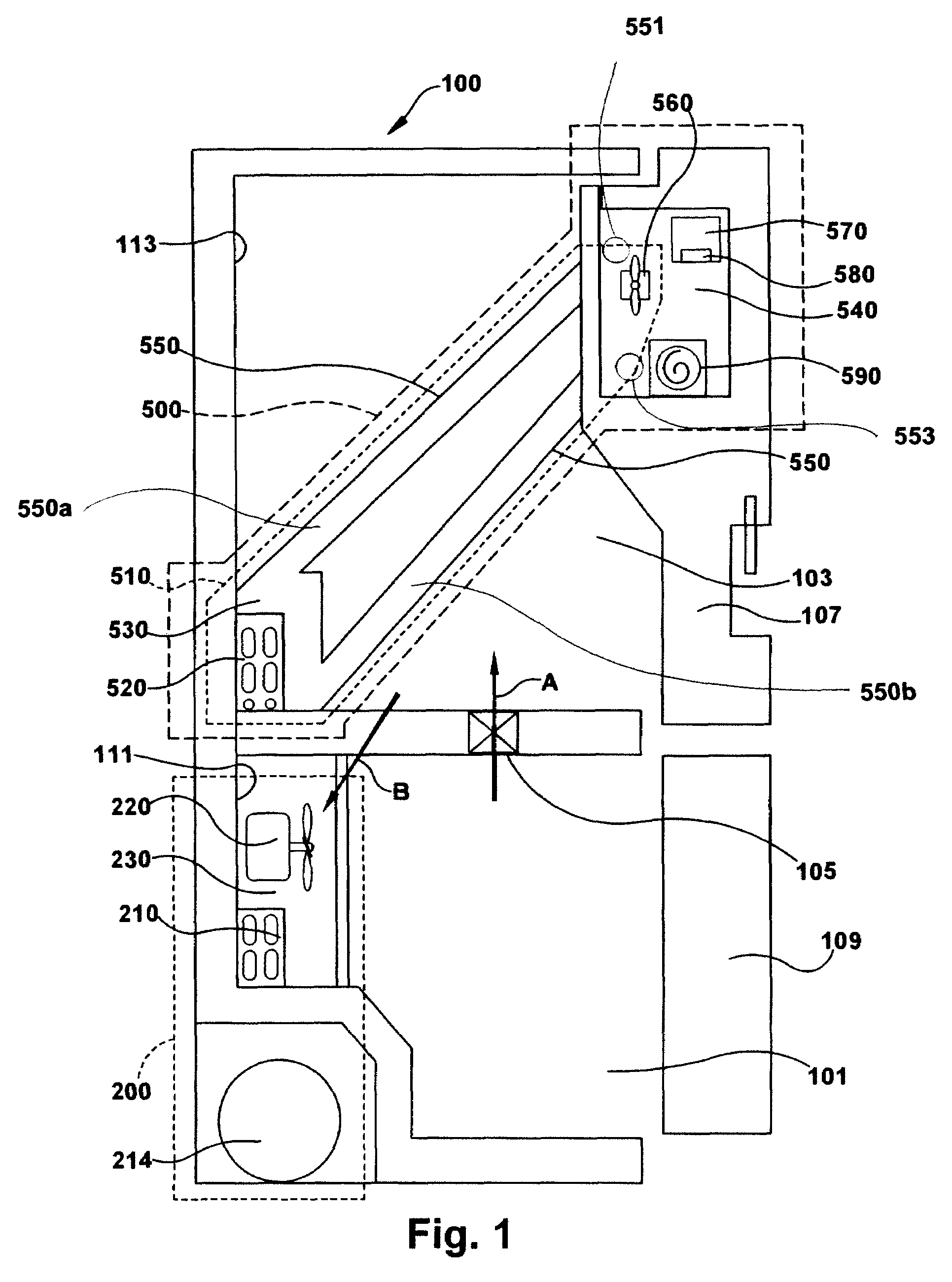

A refrigerator includes a first storage compartment defining a first interior volume. A first evaporator is disposed in a first evaporator compartment and is configured to provide cool air to the first interior volume. A second storage compartment defines a second interior volume, the second interior volume configured to be cooled by cool air received from the first interior volume. A door is positionable to permit and prohibit access to the second interior volume through a front of the second interior volume. A third interior volume is defined in an interior of the door. A second evaporator is disposed in a second evaporator compartment and is configured to provide cool air to the third interior volume. An air flow channel extends from the second evaporator compartment to the third interior volume. A fan is disposed in the third interior volume. A mold is disposed in the third interior volume and is configured to receive water and to retain the water during cooling of the water.

Owner:HAIER US APPLIANCE SOLUTIONS INC

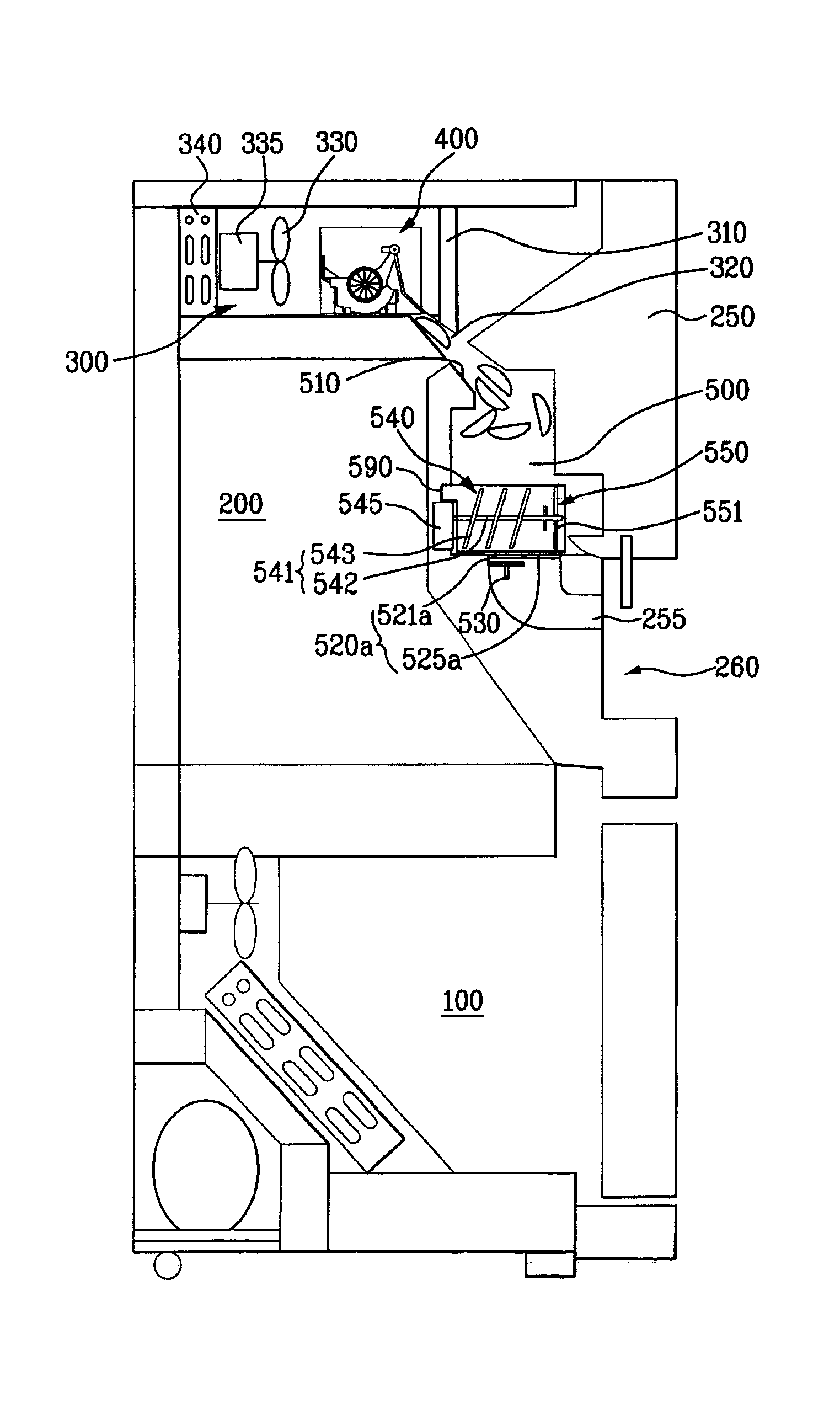

Ice maker and refrigerator having the same

InactiveUS20080295539A1Shorten ice making timeQuality improvementLighting and heating apparatusIce productionEngineeringCooling down

A refrigerator includes a refrigerator main body having a storage chamber, a door coupled to the refrigerator main body to be opened or closed, a cool air supplying device which generates cool air, an ice maker including an ice making tray having ice making cells to produce ice and a cool air guide member installed in the door, coupled to the ice making tray and having a cool air line that guides the cool air supplied from the cool air supplying device to flow around the ice making tray. The cool air line disposed on the cool air guide member to supply the ice making tray guides the cool air supplied from the cool air supplying device to move along the surrounding of the ice making tray, thereby uniformly cooling down the ice making tray.

Owner:SAMSUNG ELECTRONICS CO LTD

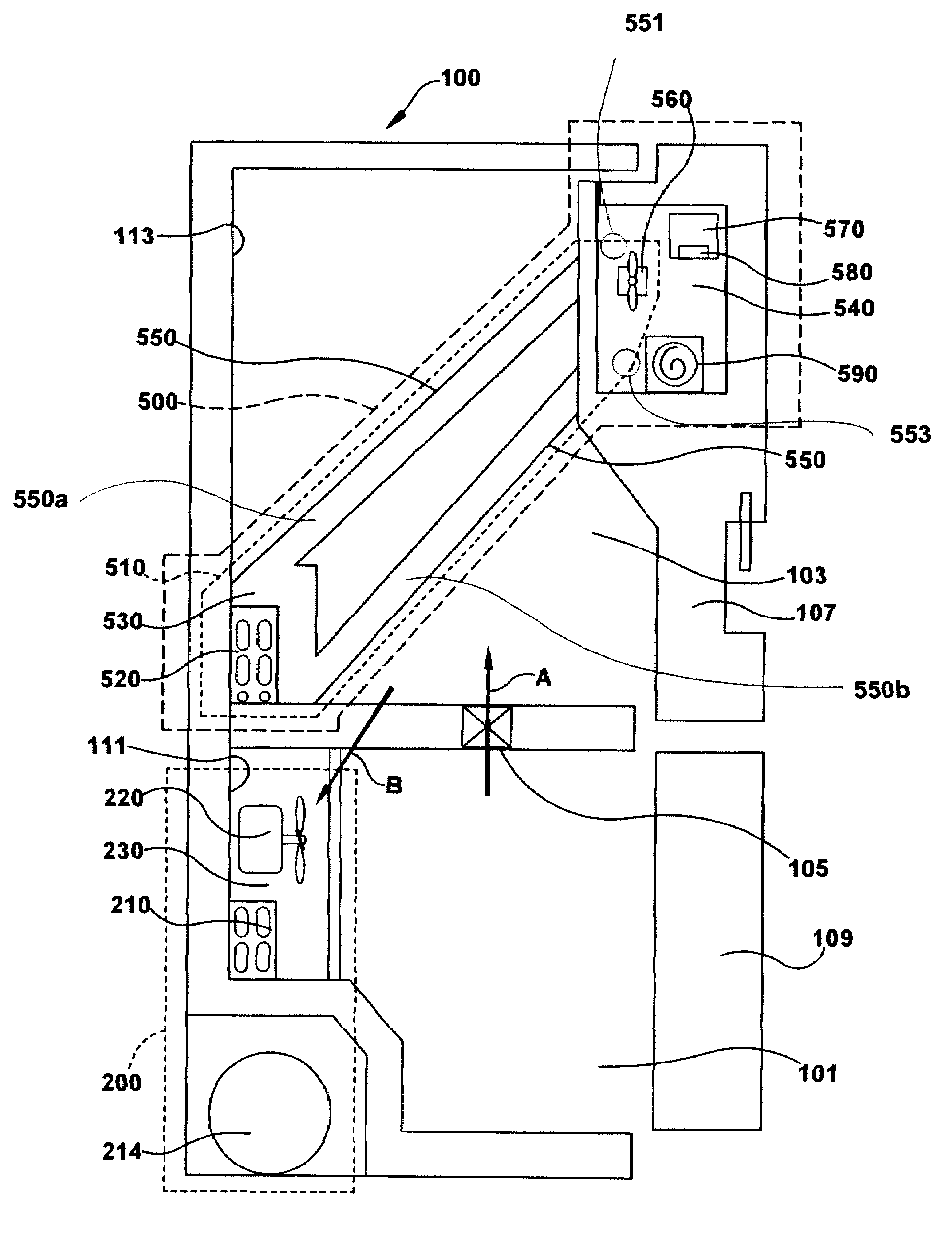

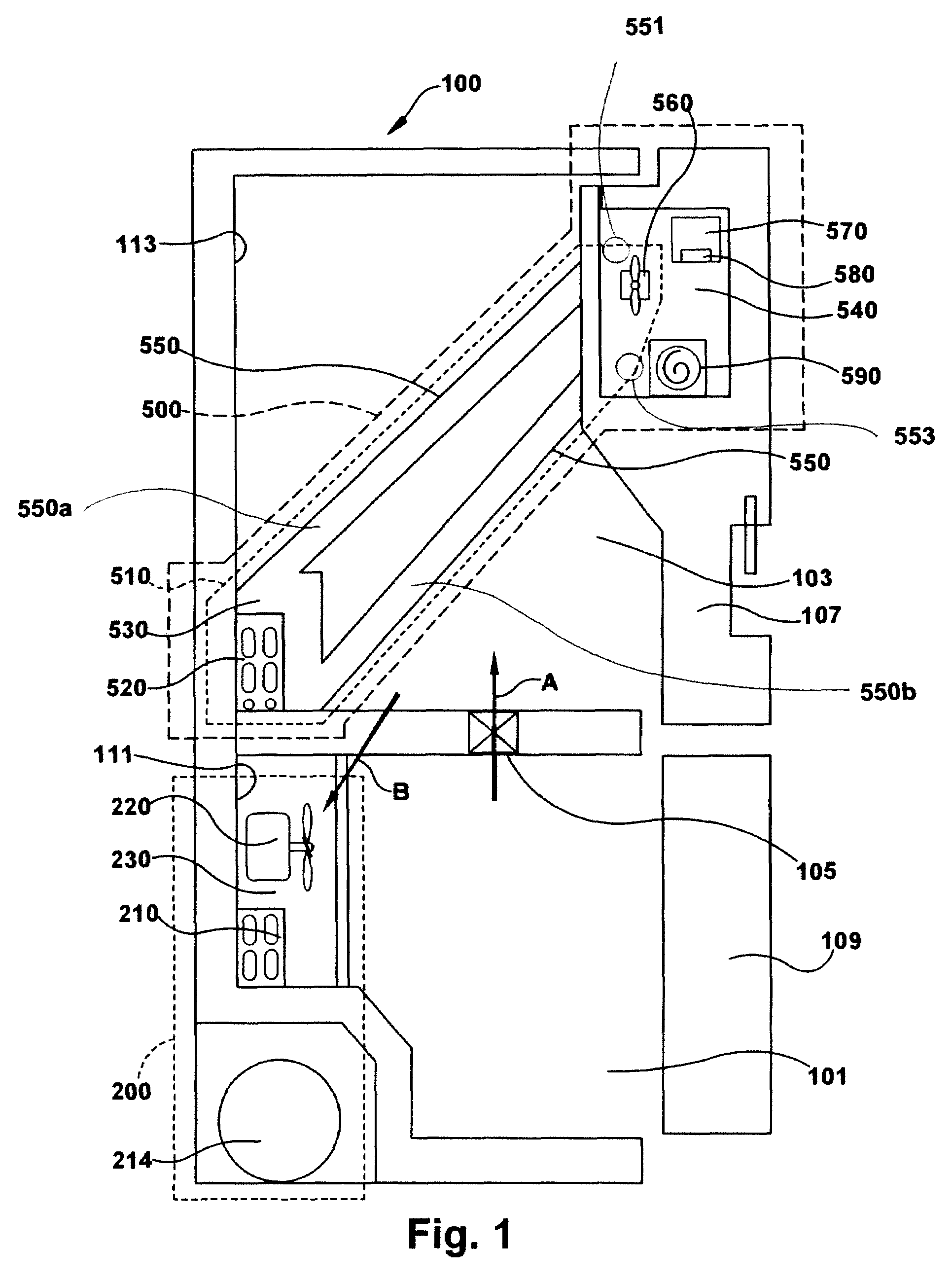

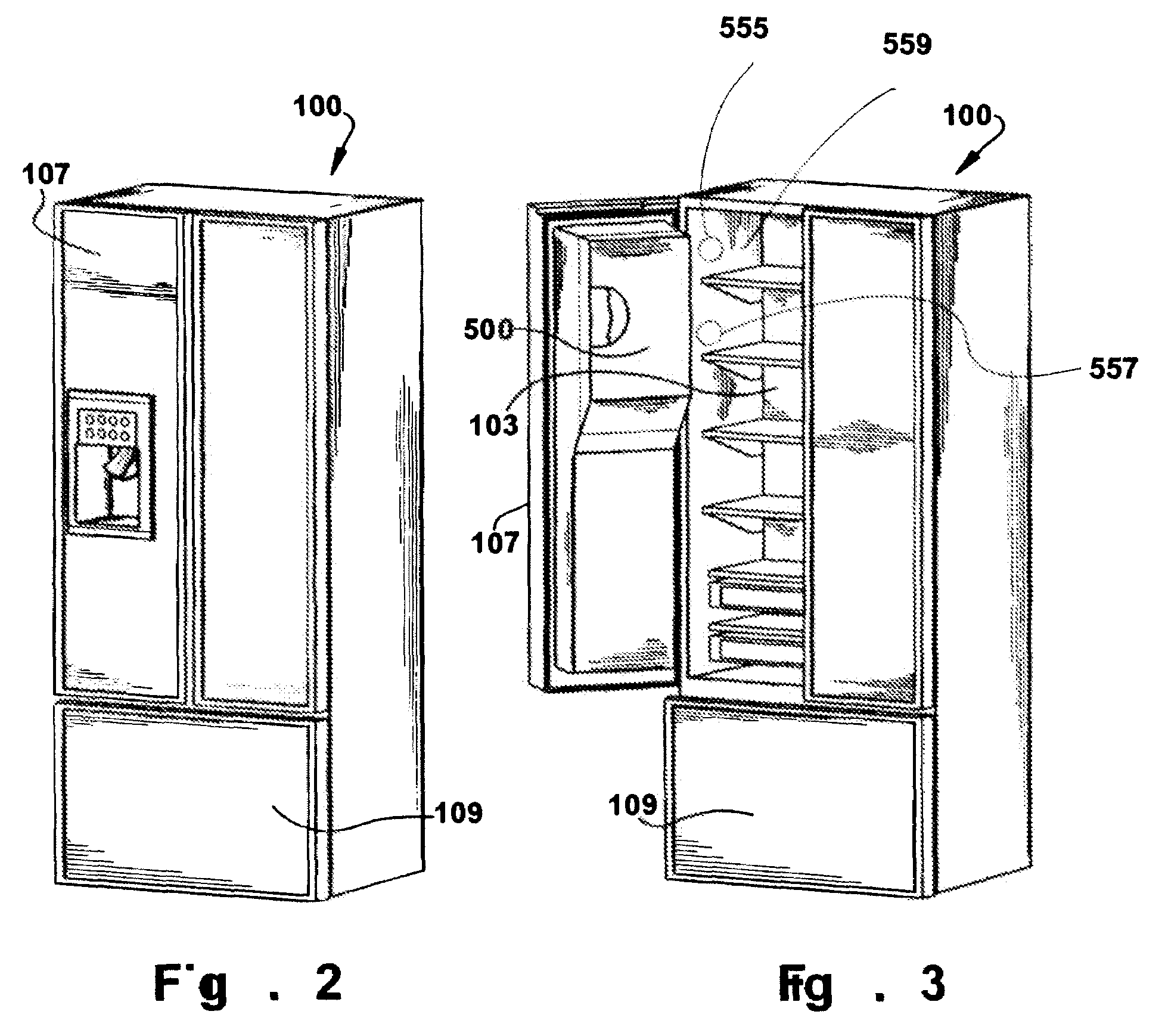

Ice producing apparatus and method

A refrigerator includes a first storage compartment defining a first interior volume. A first evaporator is disposed in a first evaporator compartment and is configured to provide cool air to the first interior volume. A second storage compartment defines a second interior volume, the second interior volume configured to be cooled by cool air received from the first interior volume. A door is positionable to permit and prohibit access to the second interior volume through a front of the second interior volume. A third interior volume is defined in an interior of the door. A second evaporator is disposed in a second evaporator compartment and is configured to provide cool air to the third interior volume. An air flow channel extends from the second evaporator compartment to the third interior volume. A fan is disposed in the third interior volume. A mold is disposed in the third interior volume and is configured to receive water and to retain the water during cooling of the water.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Refrigerator door

ActiveUS20070074527A1FillAvoid breakingLighting and heating apparatusIce productionMechanical engineeringRefrigerated temperature

A refrigerator door is provided. The refrigerator door has an outer case forming a shape of the refrigerator door, an inner case provided within the outer case to configure a backside of the refrigerator door wherein a space between the inner case and the outer case is charged with a foaming liquid, an ice making unit provided to one side of the inner case to make ice, a fixing unit provided to the space charged with the foaming liquid between the inner case and the outer case and fixing the ice making unit to the refrigerator door, and a dispenser provided to one side of the outer case to discharge the ice supplied by the ice making unit.

Owner:LG ELECTRONICS INC

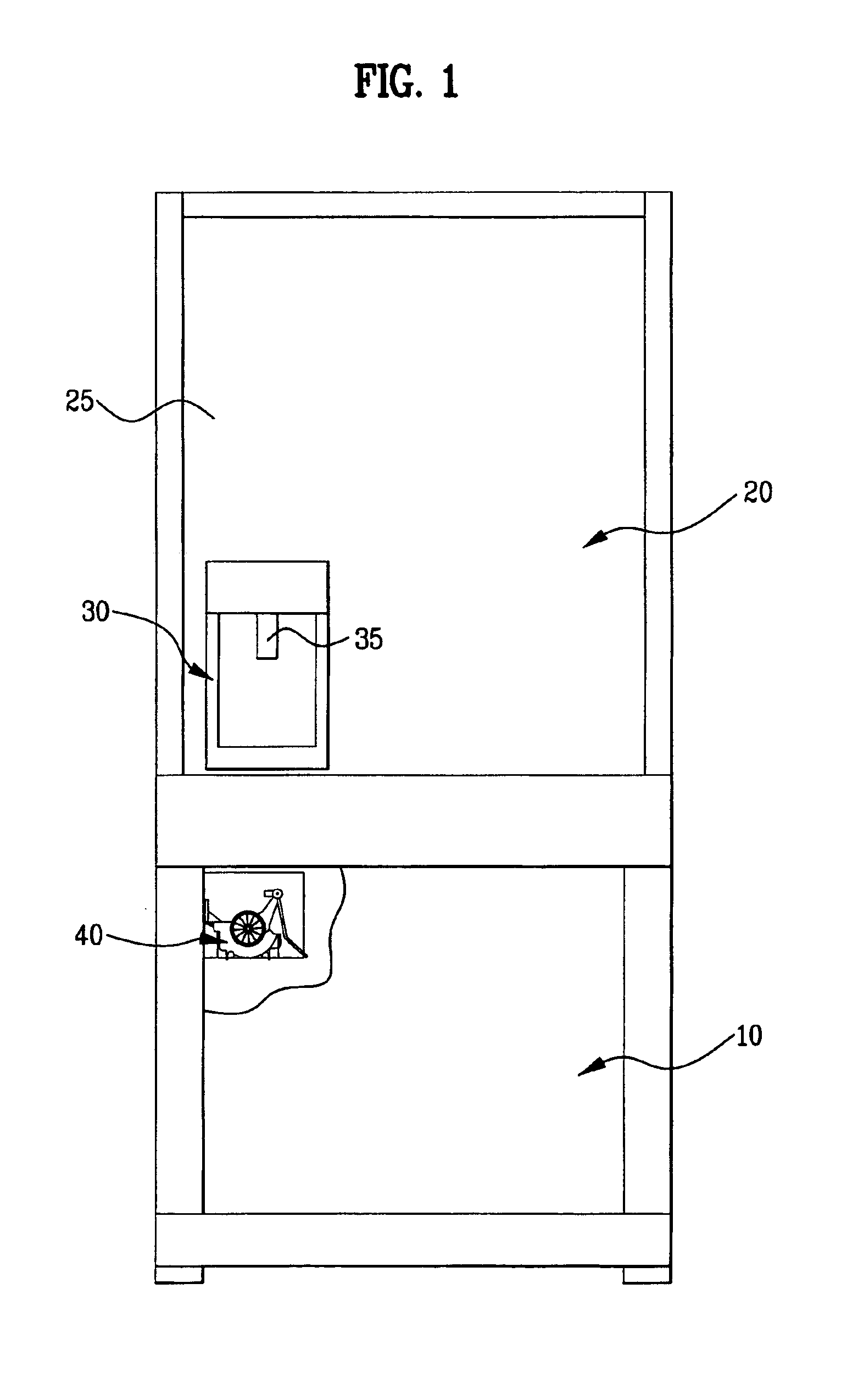

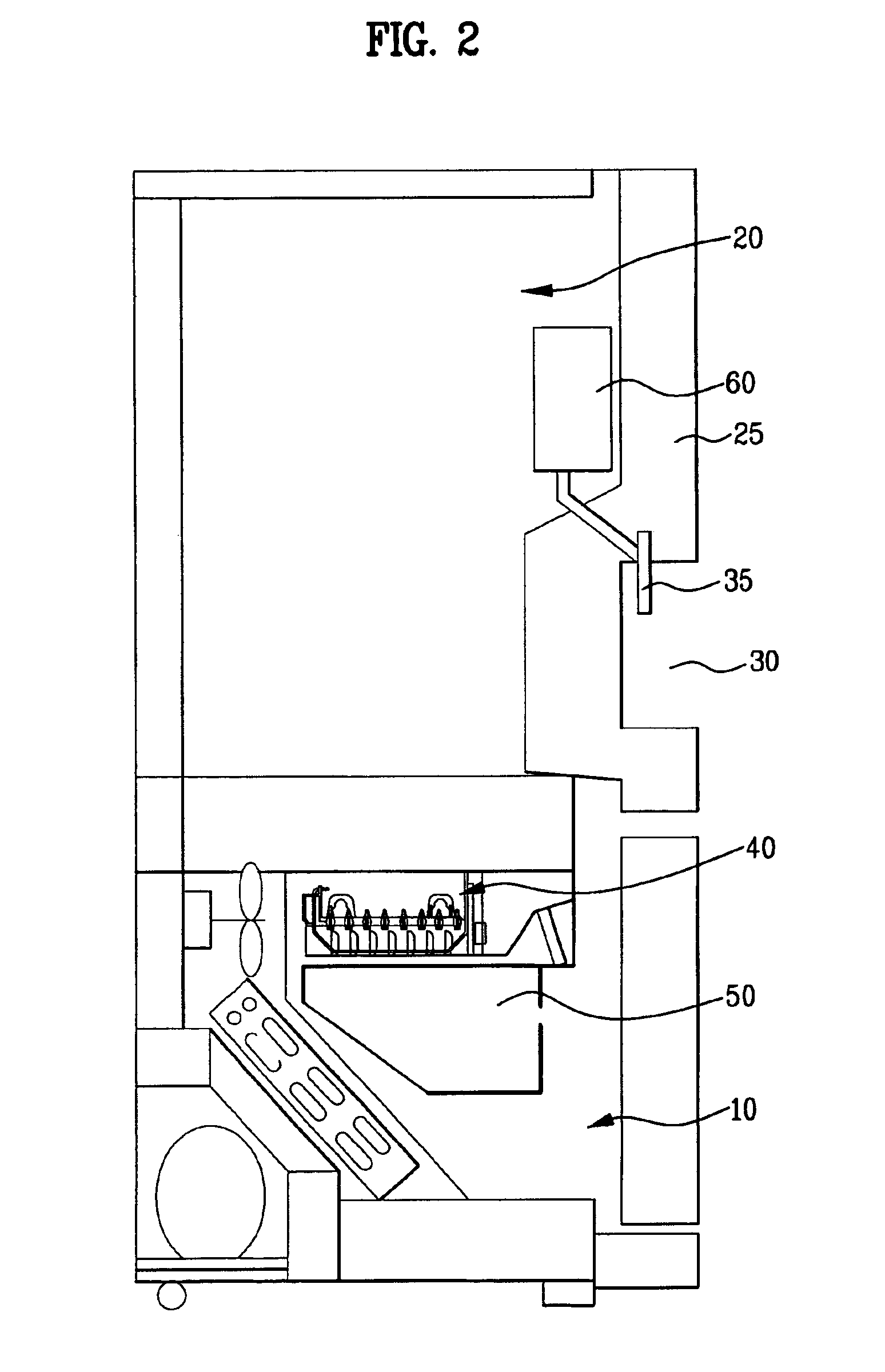

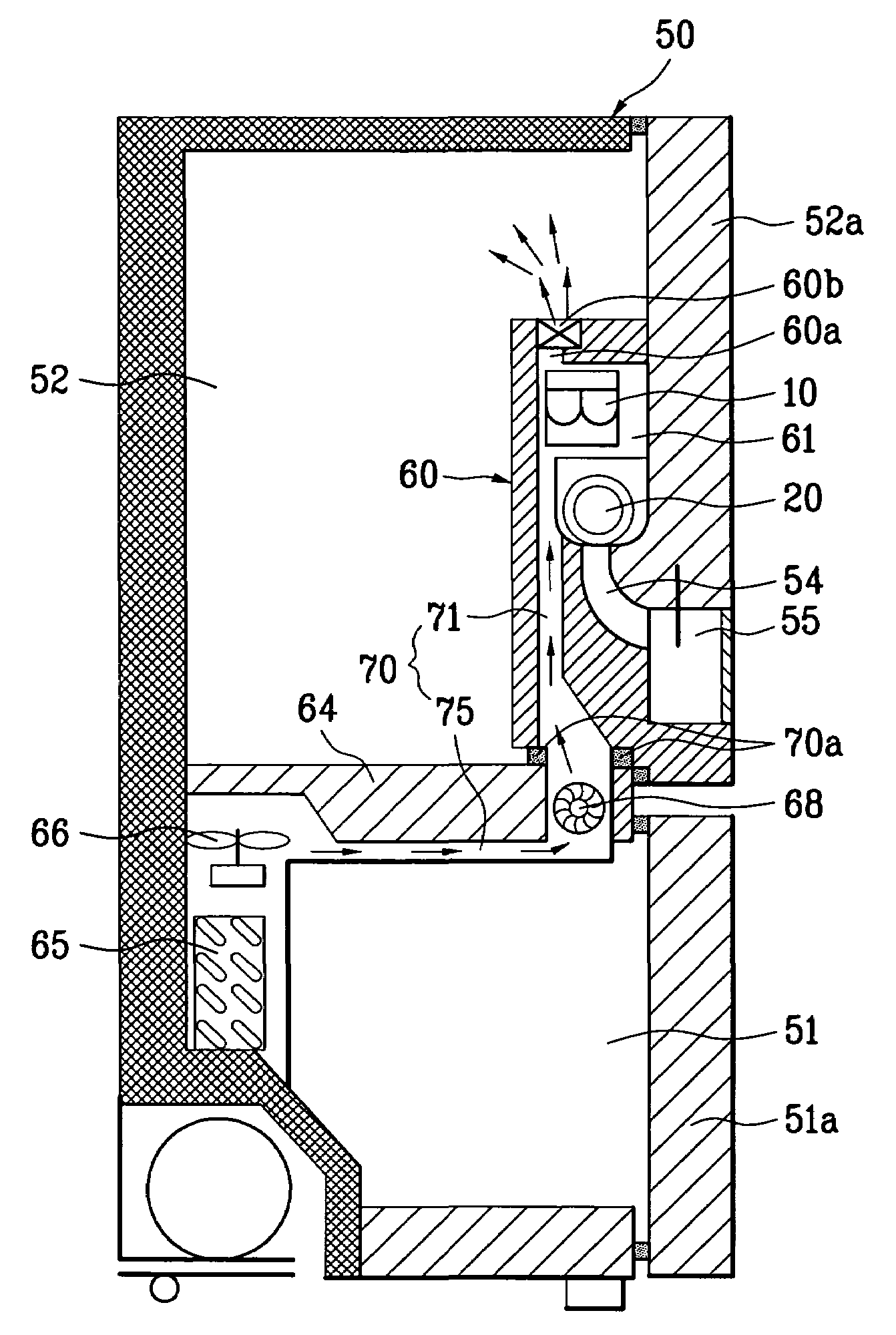

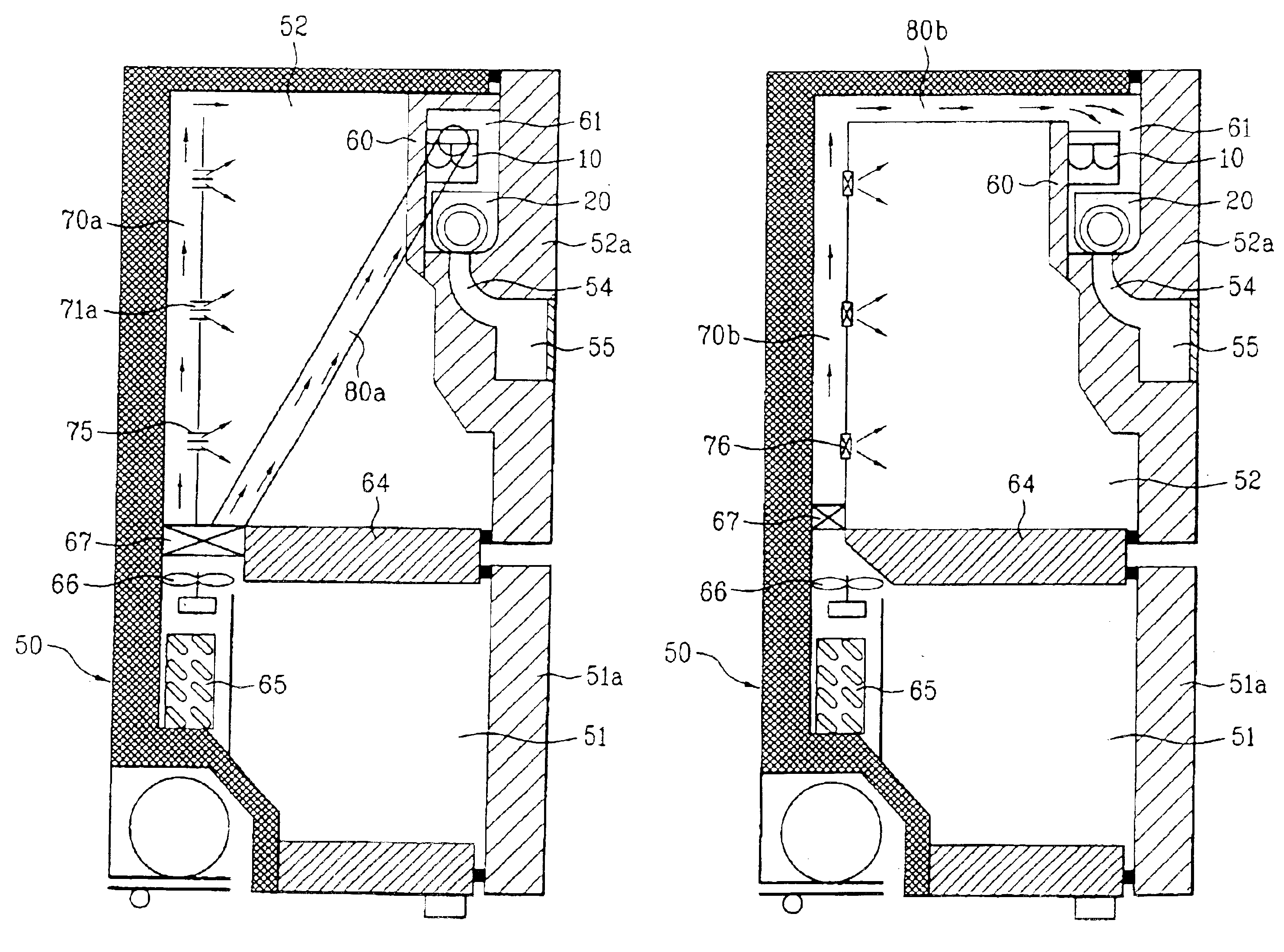

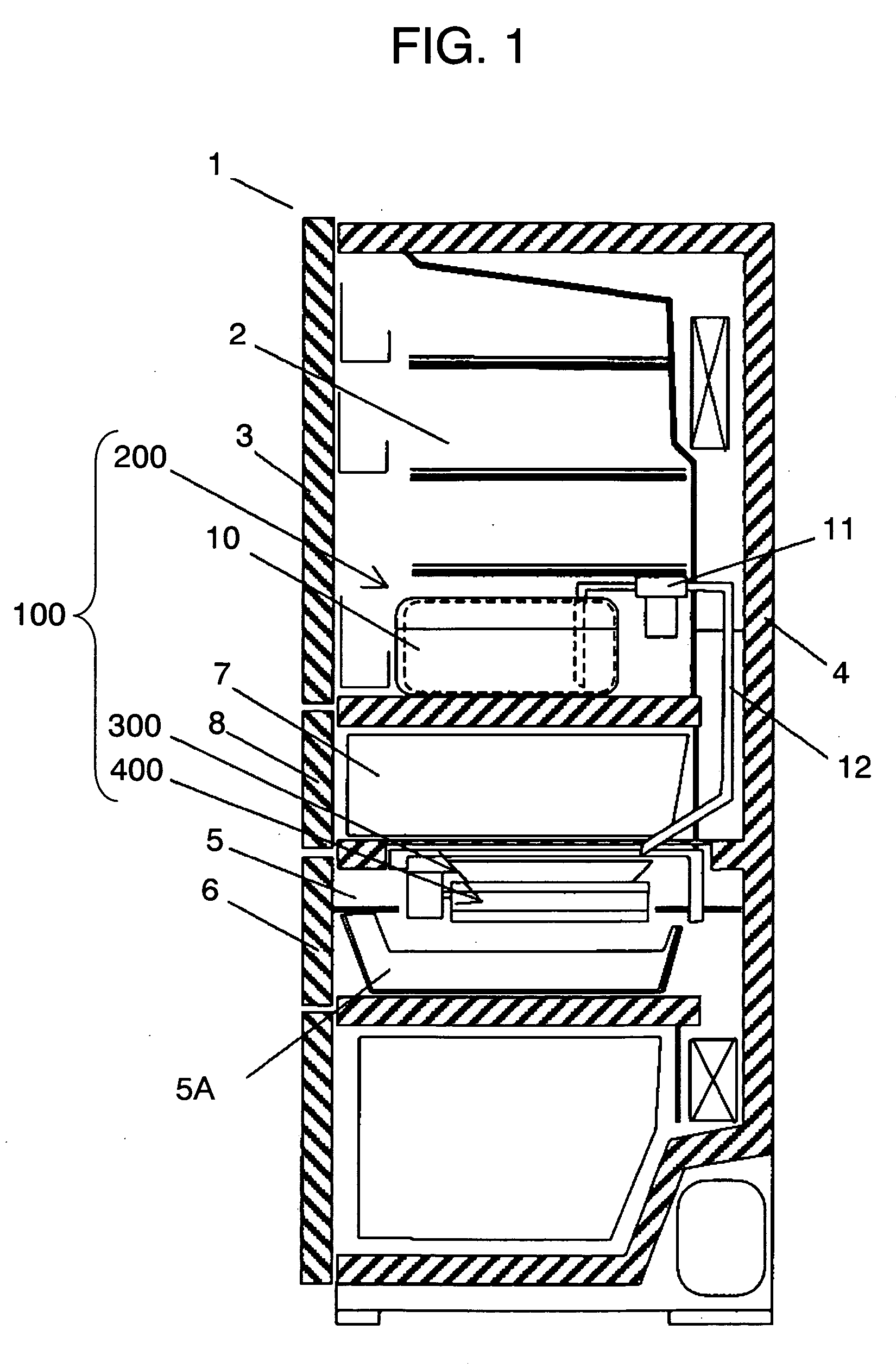

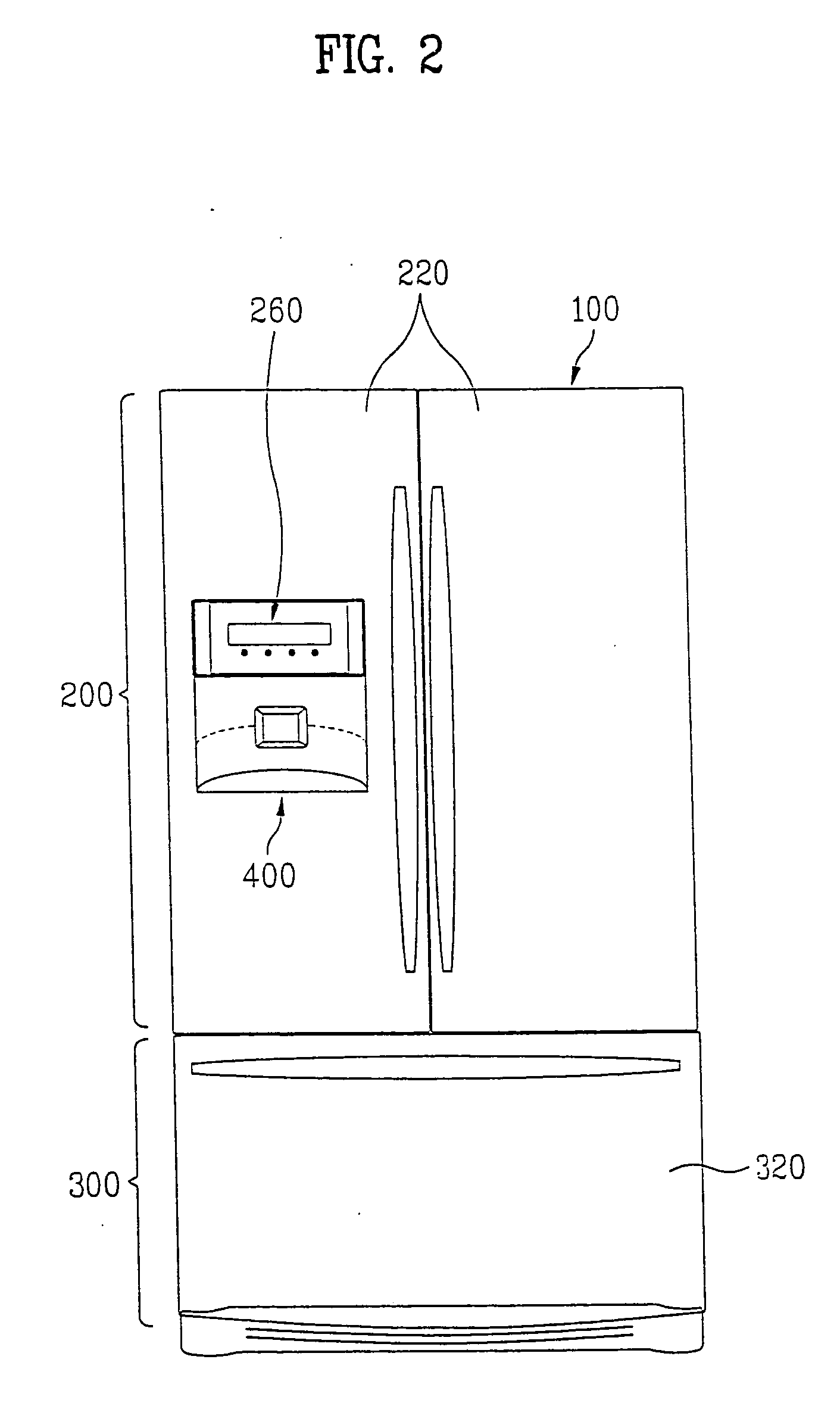

Refrigerator

ActiveUS20060196214A1Reduce in quantityLighting and heating apparatusIce productionCold airEngineering

A refrigerator has a freezing chamber at the bottom, and a refrigerating chamber over the freezing chamber. The refrigerator includes an ice making unit and an ice dispenser mounted in a refrigerating chamber door that allows ice to be dispensed without opening the door. A sub-PCB is mounted in the refrigerating chamber door for controlling operations of the ice making unit and the dispenser. A cold air supply duct supplies cold air from a cold air supply unit to the ice making unit.

Owner:LG ELECTRONICS INC

Thermal treatment system and method for controlling the system to thermally treat sterile surgical liquid

A thermal treatment system for thermally treating a sterile medium is controlled via a controller selectively manipulable by a user during system operation. The system facilitates entry of a desired temperature range for thermally treating the sterile medium and includes an alarm to notify the user of a status of the measured temperature relative to the desired temperature range.

Owner:MICROTEK MEDICAL

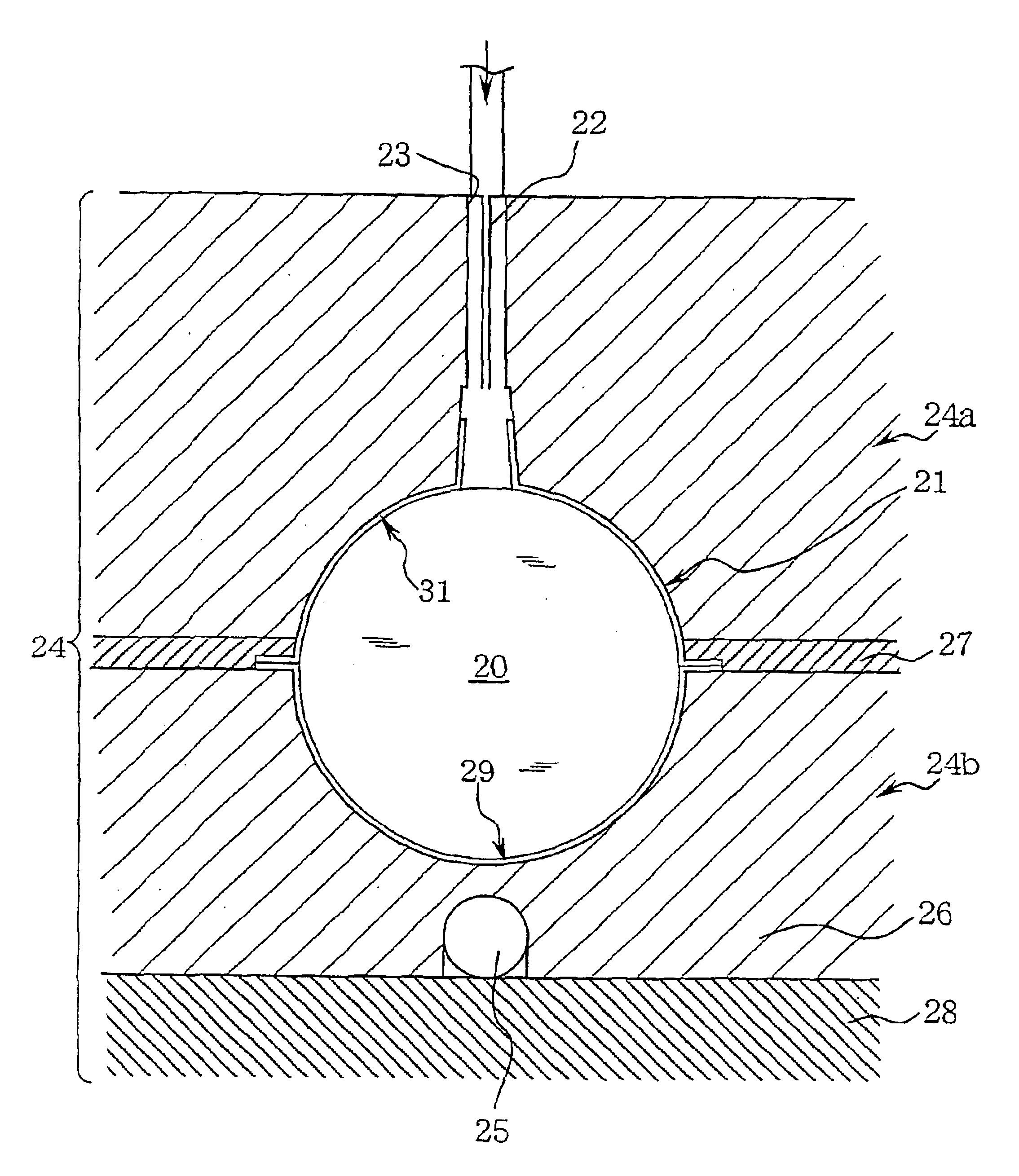

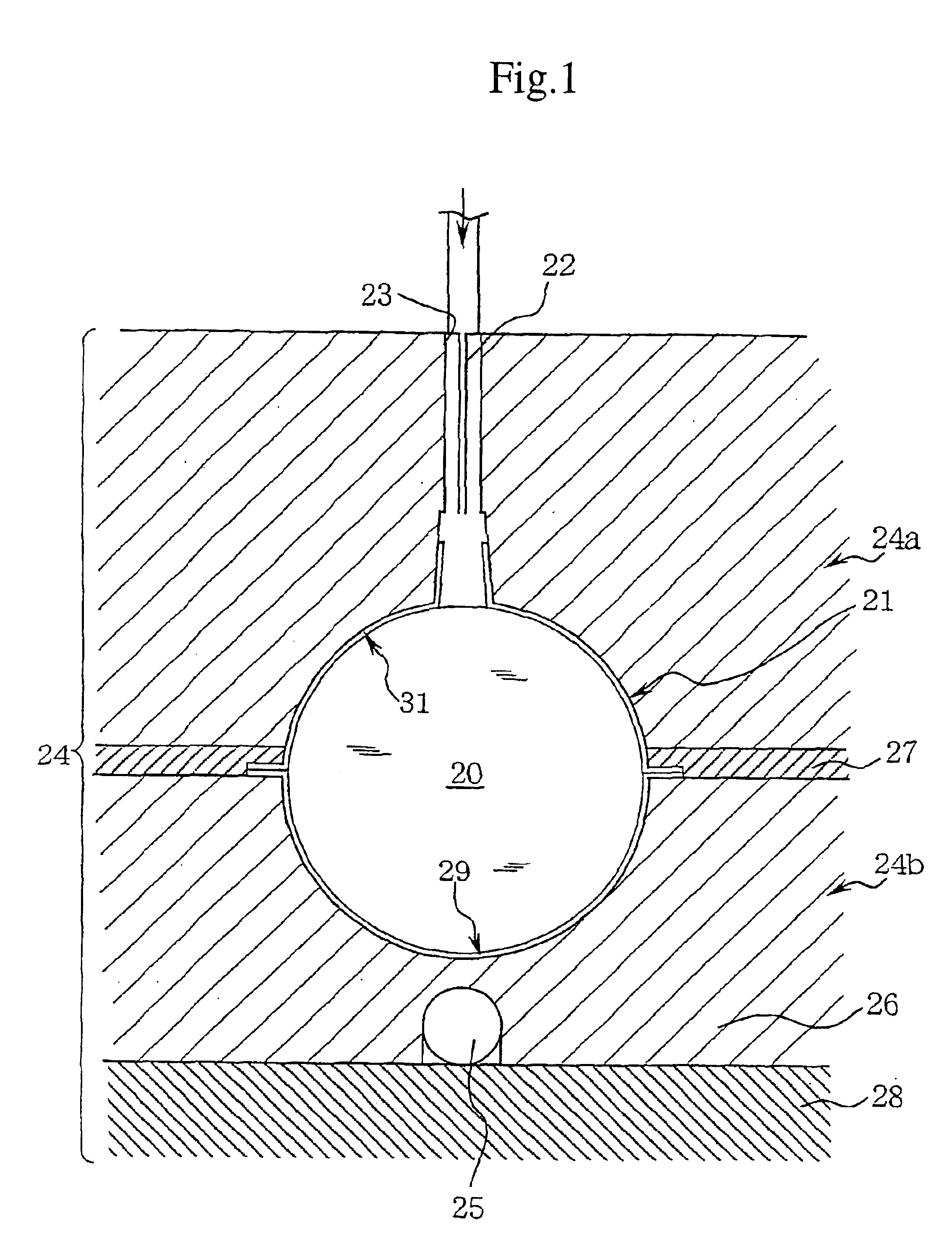

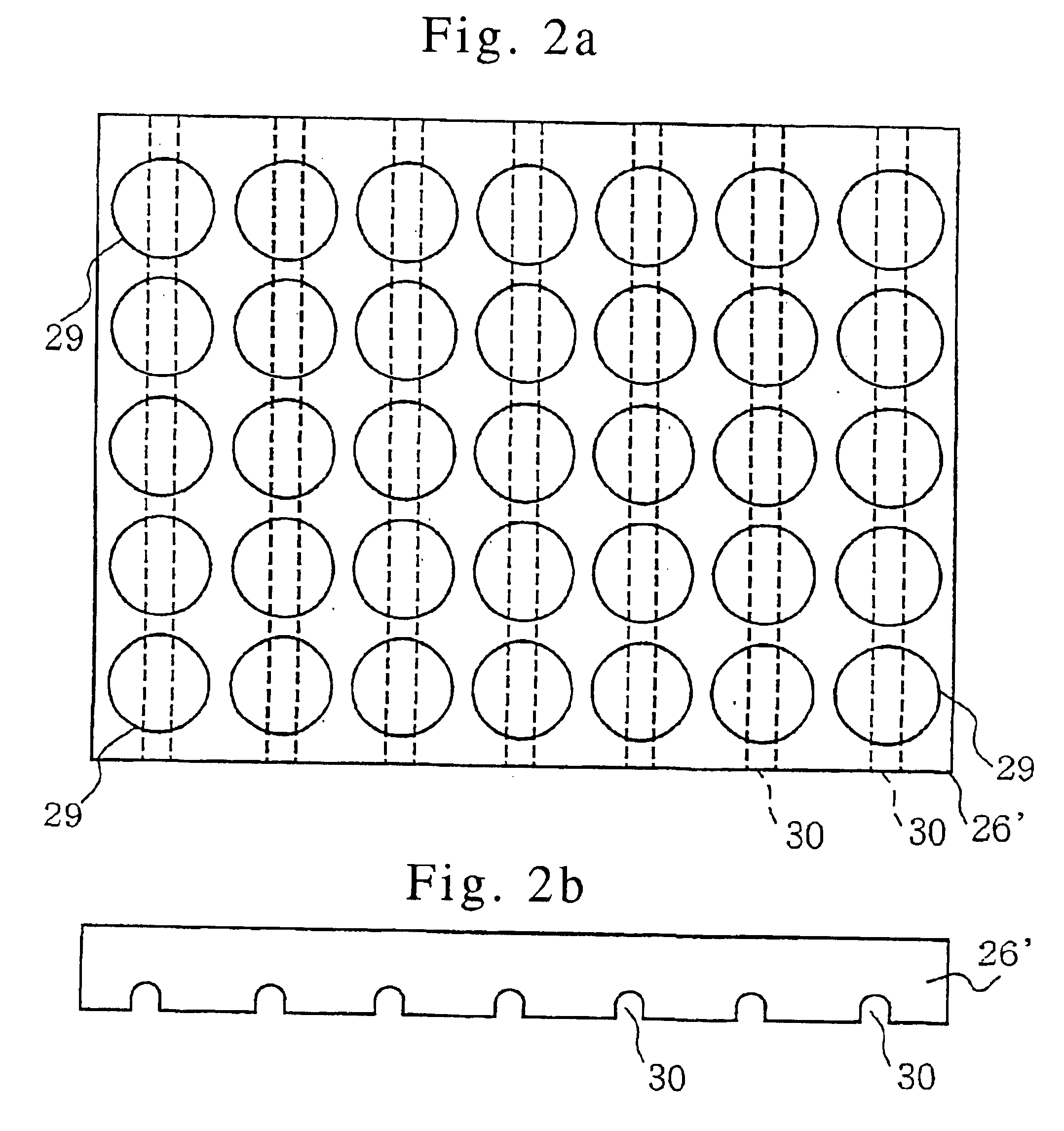

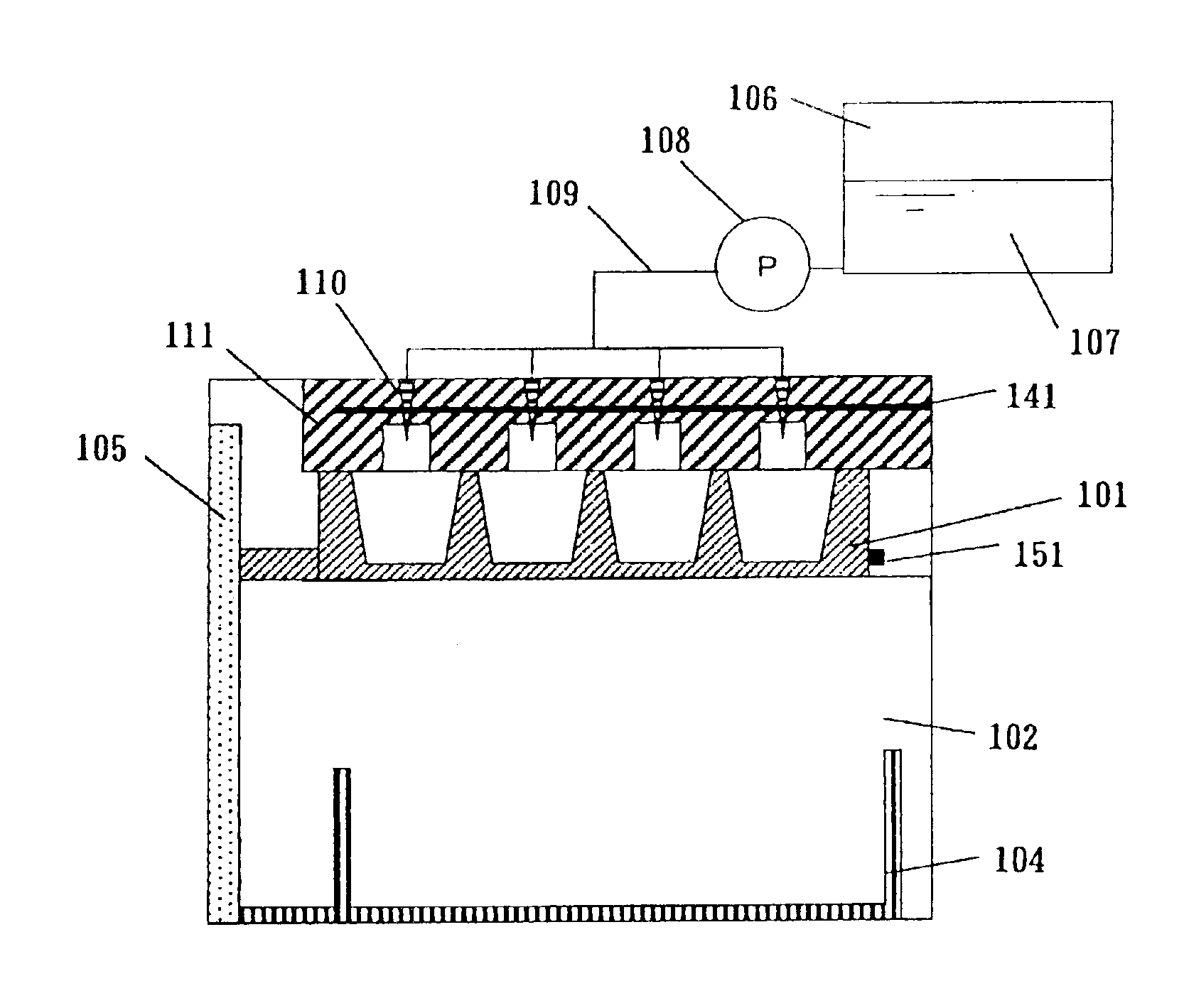

Process and equipment for manufacturing clear, solid ice of spherical and other shapes

InactiveUS6857277B2Less tight contactGood precisionLighting and heating apparatusIce productionEngineeringWater cooling

The process and equipment, according to this invention, for manufacturing clear, solid ice of spherical and other shapes are capable of making clear ice balls and block ice of other shapes in the mold quickly, efficiently, and with effective energy utilization. This process is characterized in the steps of:a) preparing a mold for making ice balls and block ice of other shapes, which comprises an upper mold (24a) made of an insulating material and provided with a vertical injection hole (23) drilled therein and a water-injection nozzle (22) fitted in the hole; and a lower mold (24b) made of a water-freezing block (26) having coolant pipe (25) embedded therein;b) preparing for a domed lid (21a) or the lid of a different shape made of an insulating sheet, said lid (21a) having a shape that fits in with the surface shaped for the upper mold (24a) and being provided with a cylinder for being fitted into the vertical injection hole (23); and a shaped hemispherical cup (21b) of the same insulating sheet, which similarly fits in with the shaped surface of the lower mold (24b);c) assembling both halves of the mold (24) after the lid (21a) and the cup (21b) have been attached tightly to each other and placed in the mold;d) then, keeping the liquid to be frozen cooled at a predetermined temperature and spraying the liquid intermittently in the direction of the water-freezing block (26) that has been cooled to a predetermined freezing temperature;e) repeating the spraying operation to freeze the sprayed liquid in the container (21), layer by layer, until clear ice balls (20) or block ice of other shapes are formed; andf) disassembling the halves of the mold under the ice-releasing effect, which the ice container (21) has on the ice-making mold (24), and immediately taking out We shaped ice balls (20) or the block ice of a different shape.

Owner:SOMURA KATSUZO

Twist tray ice maker system

InactiveUS20120023996A1Improve heat transfer performanceIncrease volumeLighting and heating apparatusIce productionMetallic materialsEngineering

Techniques for use in ice maker systems are disclosed. In one example, an ice tray apparatus includes an ice mold body formed substantially of a metal material, and a holder for holding the ice mold body, the holder including a rotation-stopping feature formed thereon. The ice tray assembly may be used in an ice maker system mounted in a storage compartment of a refrigerator appliance.

Owner:GENERAL ELECTRIC CO

Freezing and thawing bag, mold, apparatus and method

InactiveUS6146124AHigh strengthImprove integrityLighting and heating apparatusConfectioneryFreeze and thawCryopreservation

A mold is disclosed for forming a freezable and thawable bag of uniform thickness, especially useful for cryopreservation of thermolabile substances. The mold features one or more recessed planar surfaces, including radiused peripheral walls about the recesses, a planar top surface, and means for conforming a blank sheet to the mold. Two mold halves combine to form a completed bag. The mold halves may be complimentary.

Owner:CESCA THERAPEUTICS

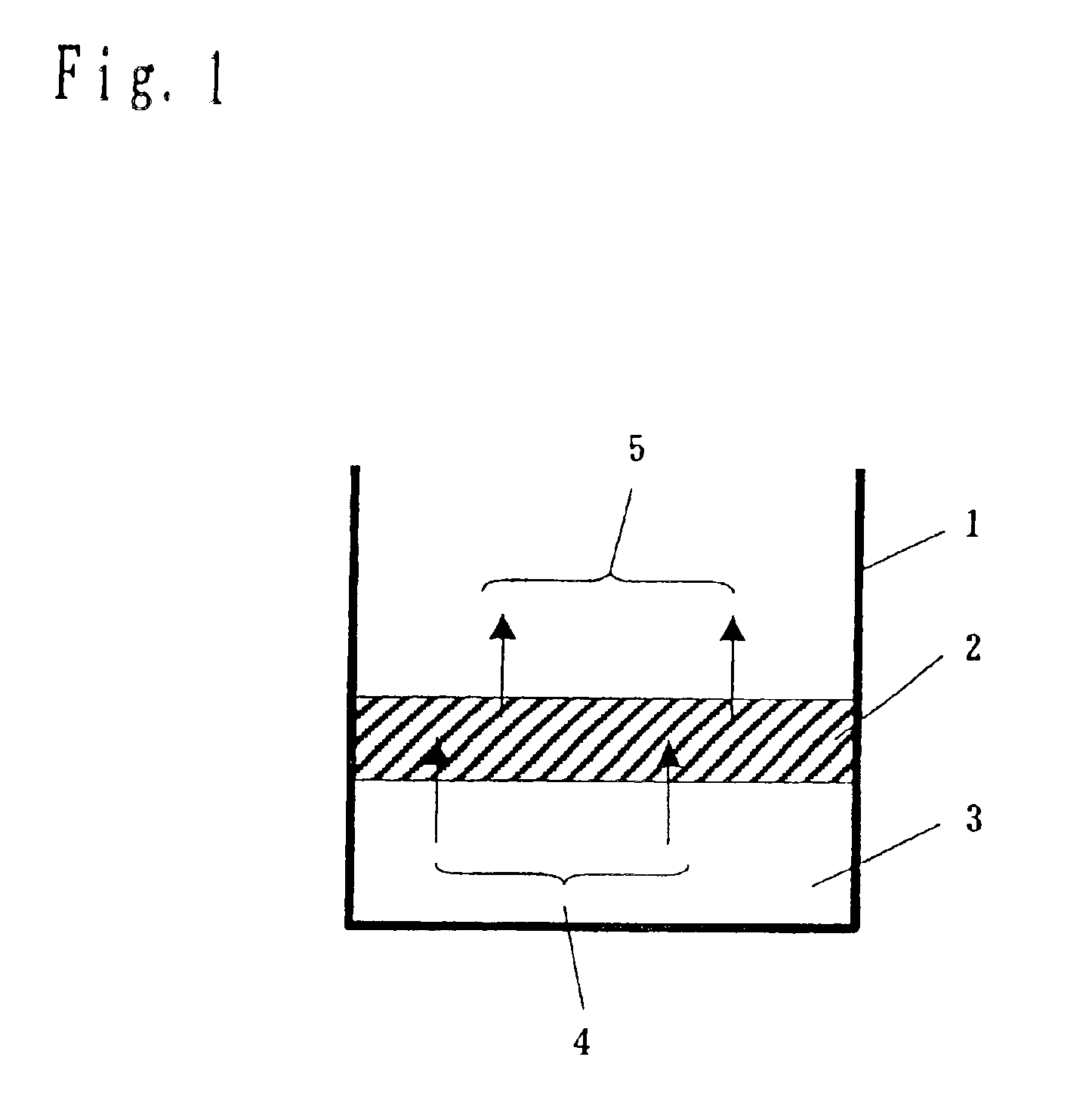

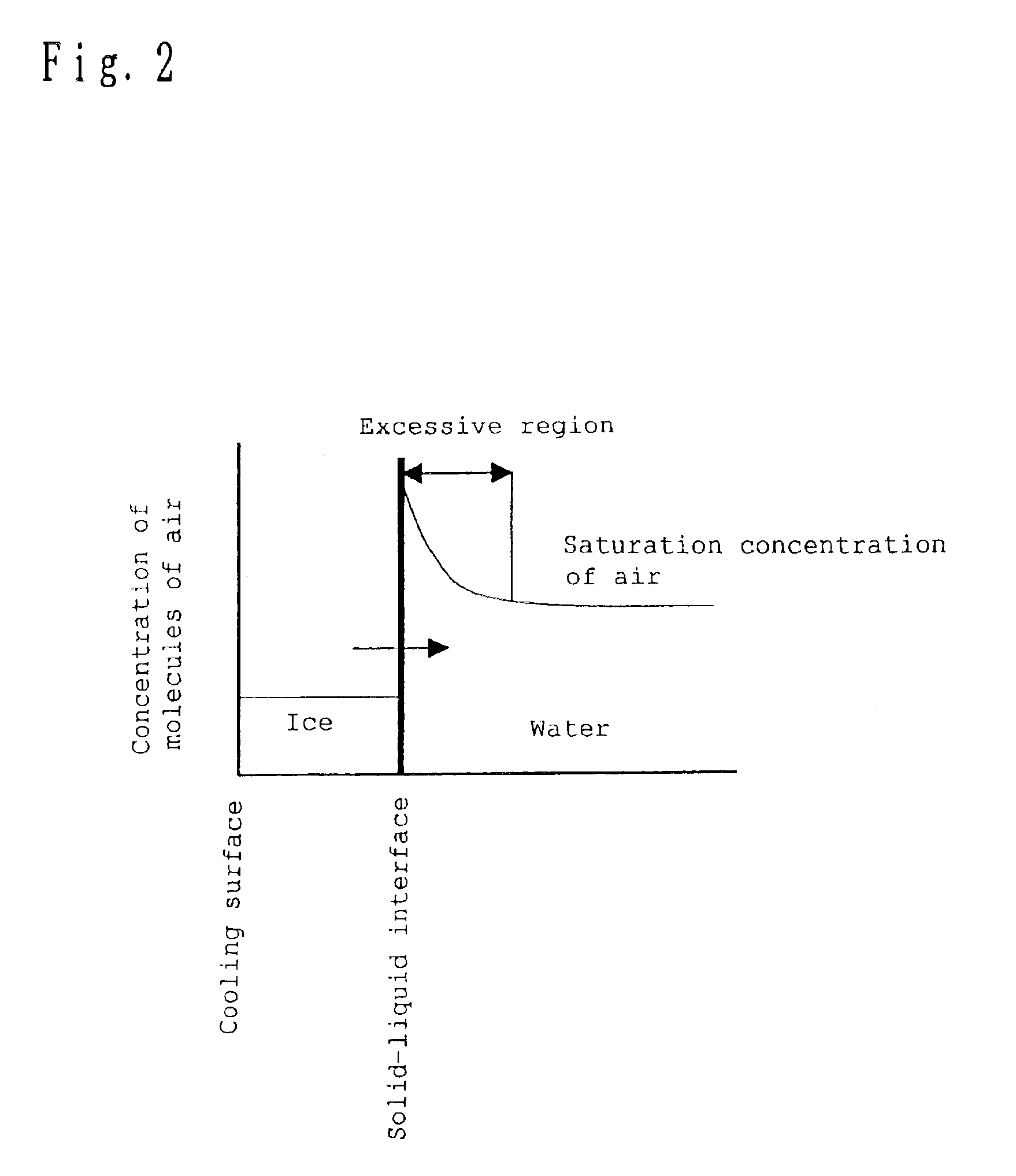

Clear ice making apparatus, clear ice making method and refrigerator

A clear ice making apparatus includes: a freezing space; a tray placed in the freezing space and having a lower temperature at a bottom part thereof than at an upper part thereof; and a water supply unit of supplying water to the tray from the top thereof, in which ice is made at an ice making rate of 5 μm / s or lower, a part of a liquid-phase section of water in the tray which part is in contact with atmosphere is frozen to complete the ice making, the liquid-phase section of water is not entirely supercooled before the ice making is completed, and the concentration of air in the liquid-phase section of water in the tray is equal to or lower than an excessive concentration of air.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com