Patents

Literature

37 results about "Clear ice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

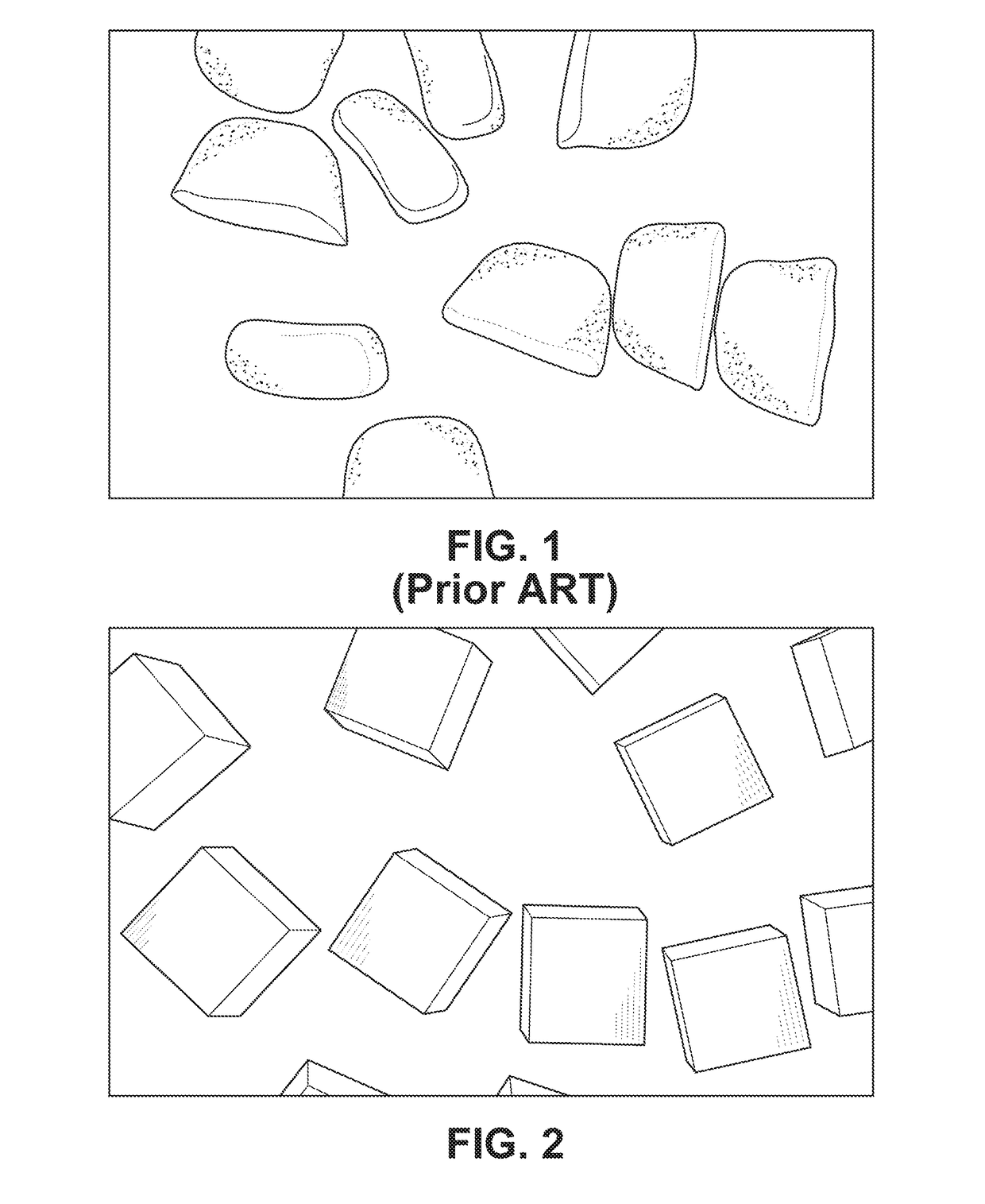

Clear ice means a solid precipitation which forms when air temperature is between 0 °C (32 °F) and −3 °C (27 °F) and there are supercooled, relatively large drops of water (from freezing fog). A rapid accretion and a slow dissipation of latent heat of fusion favor the formation of a transparent ice coating, without air or other impurities. A similar phenomenon occurs when freezing rain or drizzle hit a surface and is called glaze. Clear ice, when formed on the ground, is often called black ice, and can be extremely hazardous.

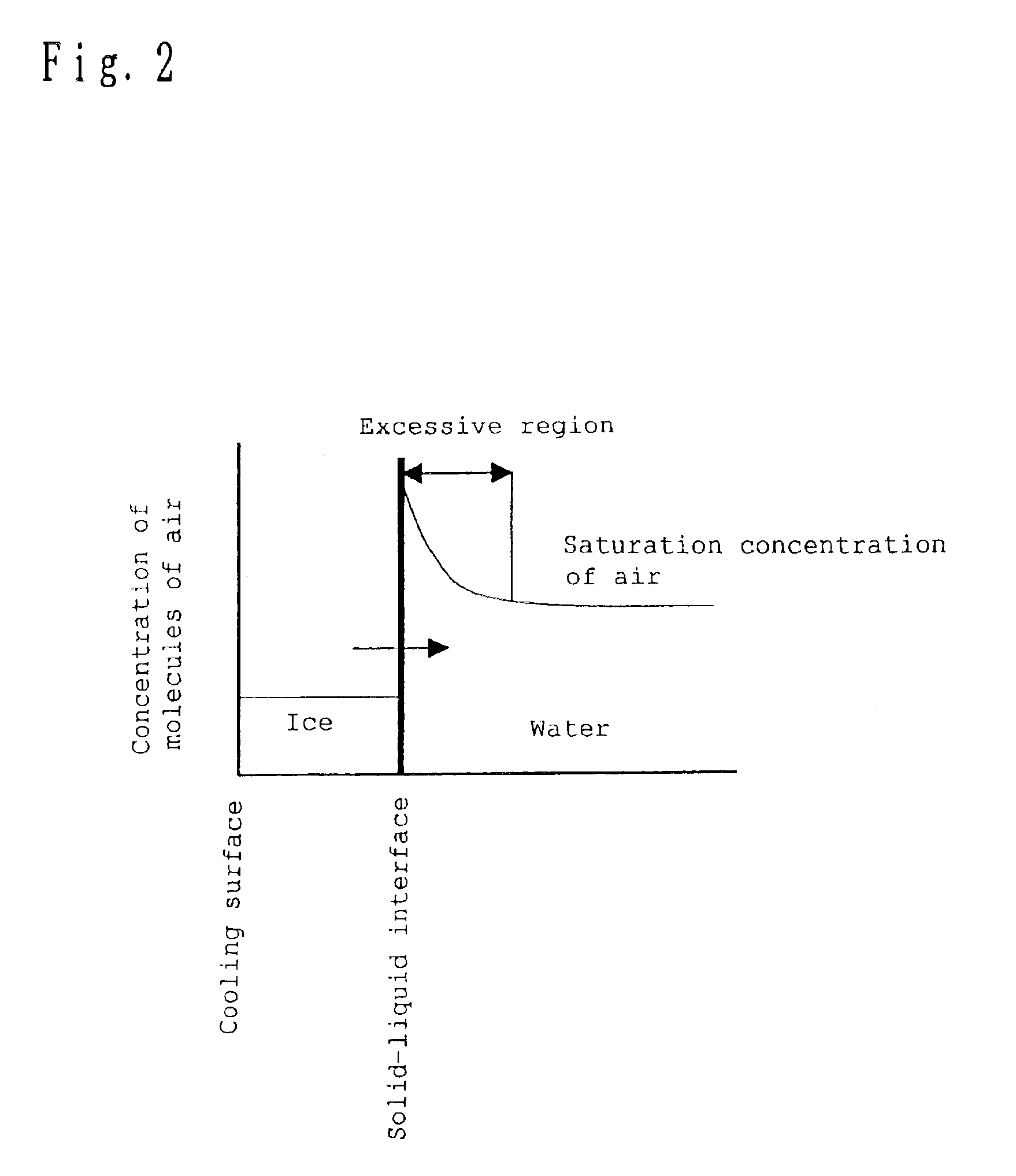

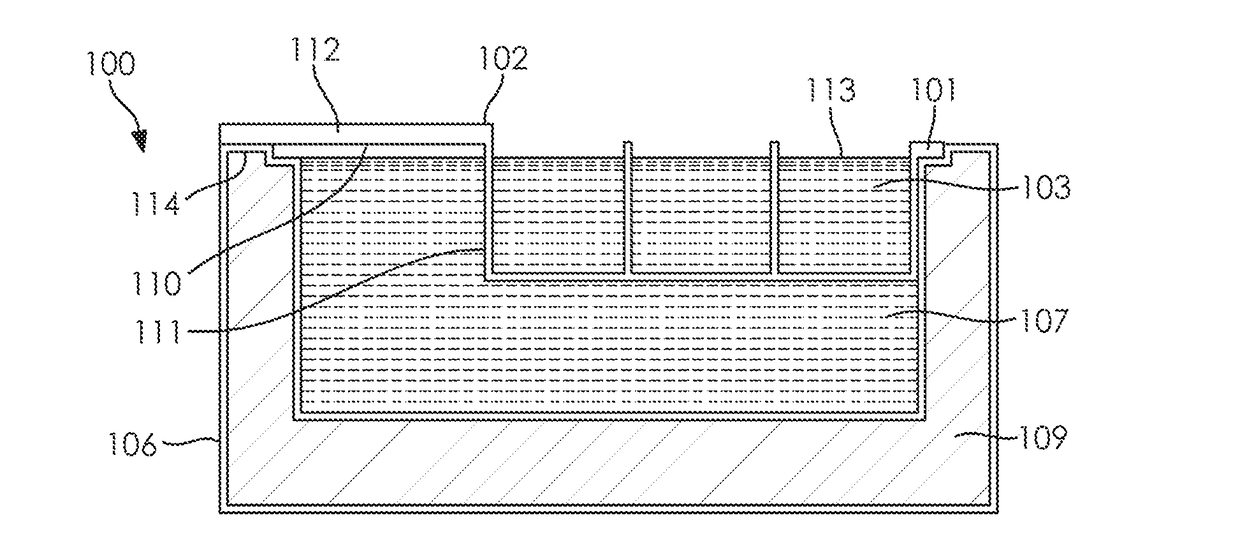

Clear ice making apparatus, clear ice making method and refrigerator

A clear ice making apparatus includes: a freezing space; a tray placed in the freezing space and having a lower temperature at a bottom part thereof than at an upper part thereof; and a water supply unit of supplying water to the tray from the top thereof, in which ice is made at an ice making rate of 5 μm / s or lower, a part of a liquid-phase section of water in the tray which part is in contact with atmosphere is frozen to complete the ice making, the liquid-phase section of water is not entirely supercooled before the ice making is completed, and the concentration of air in the liquid-phase section of water in the tray is equal to or lower than an excessive concentration of air.

Owner:PANASONIC CORP

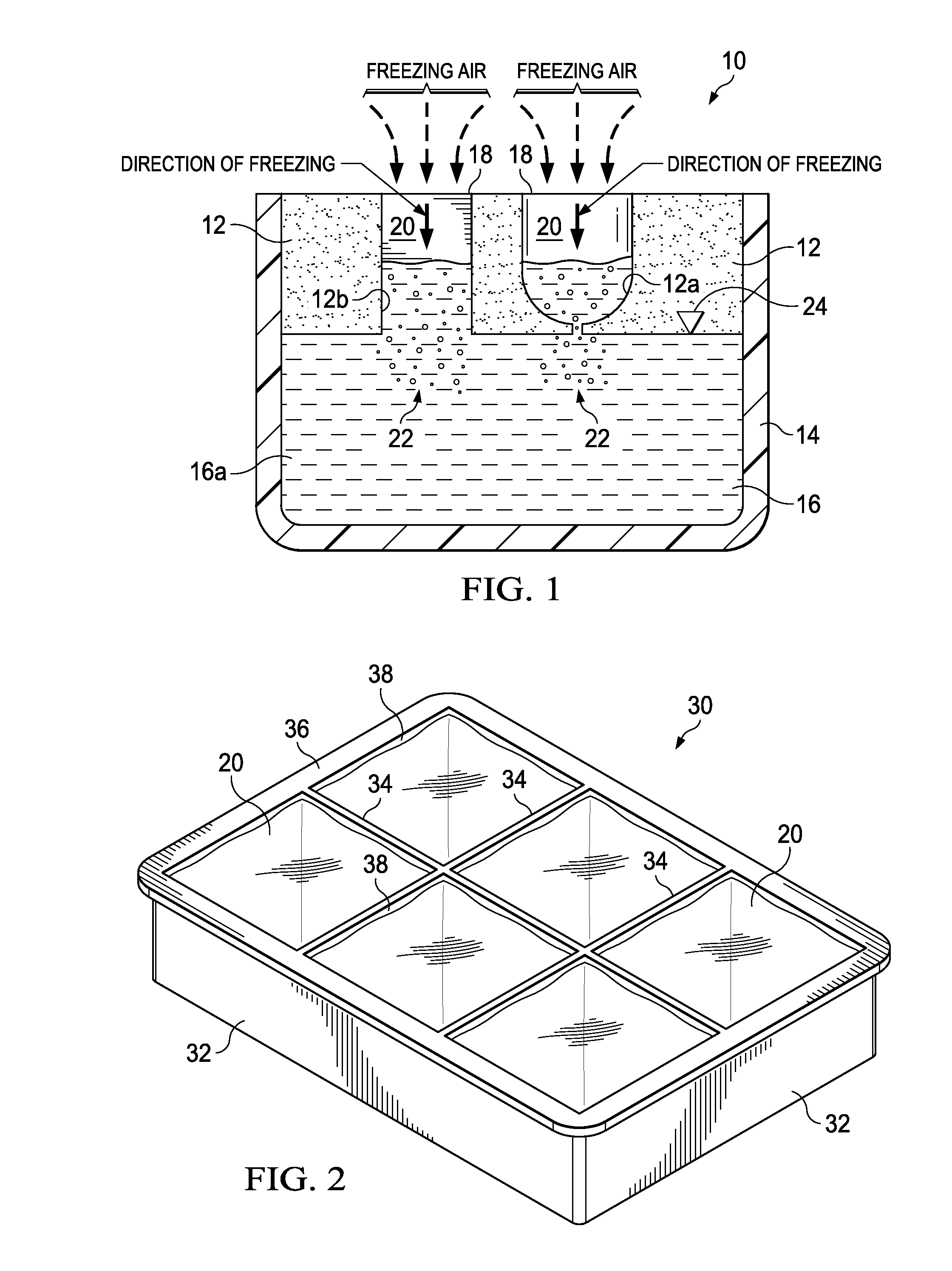

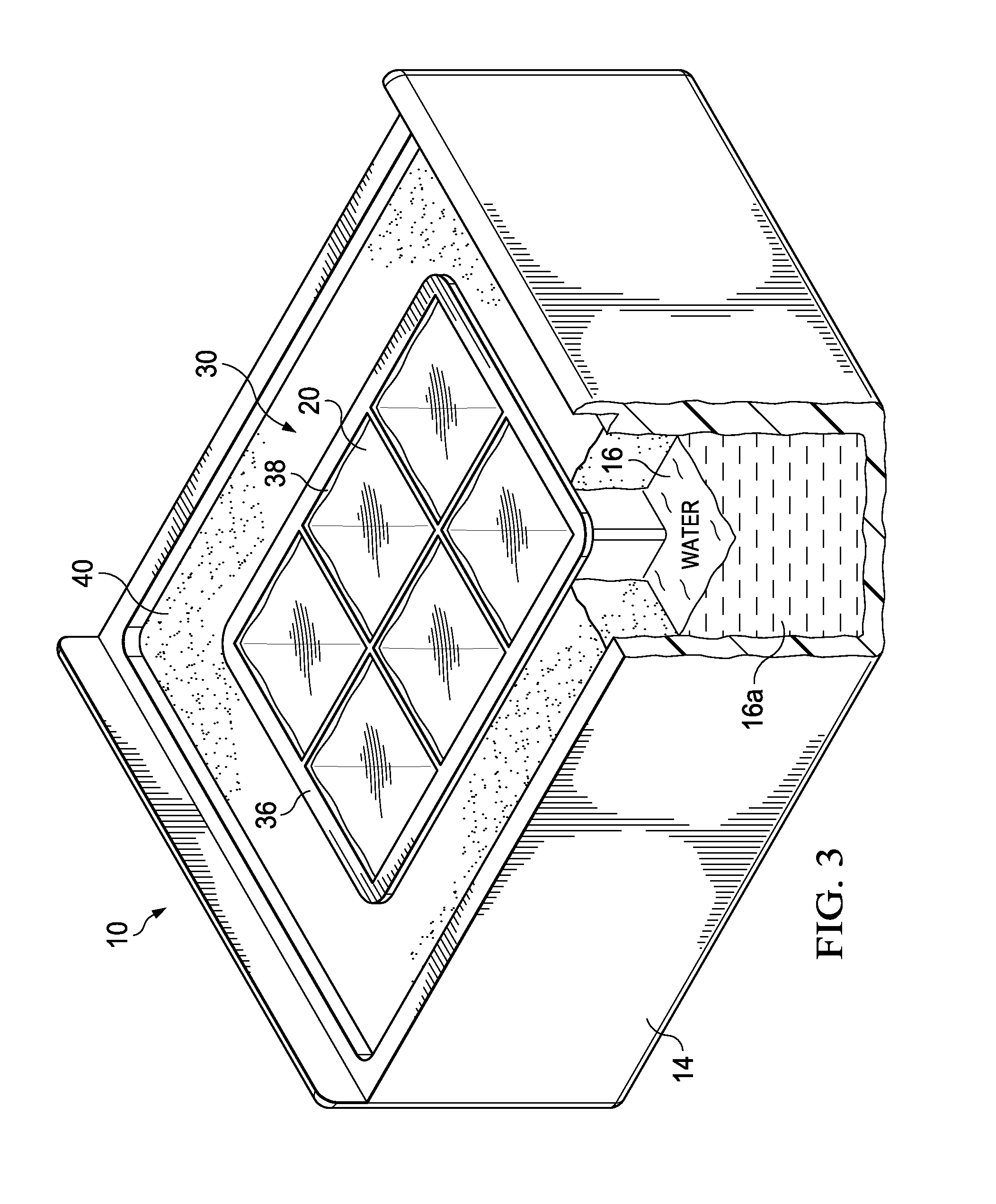

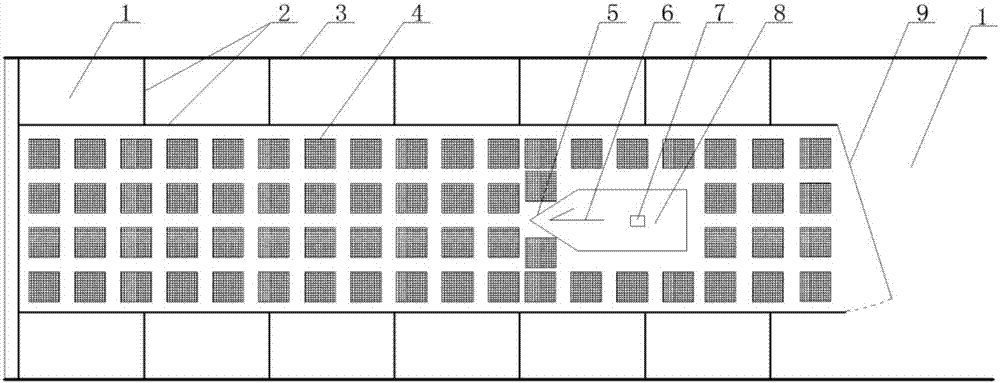

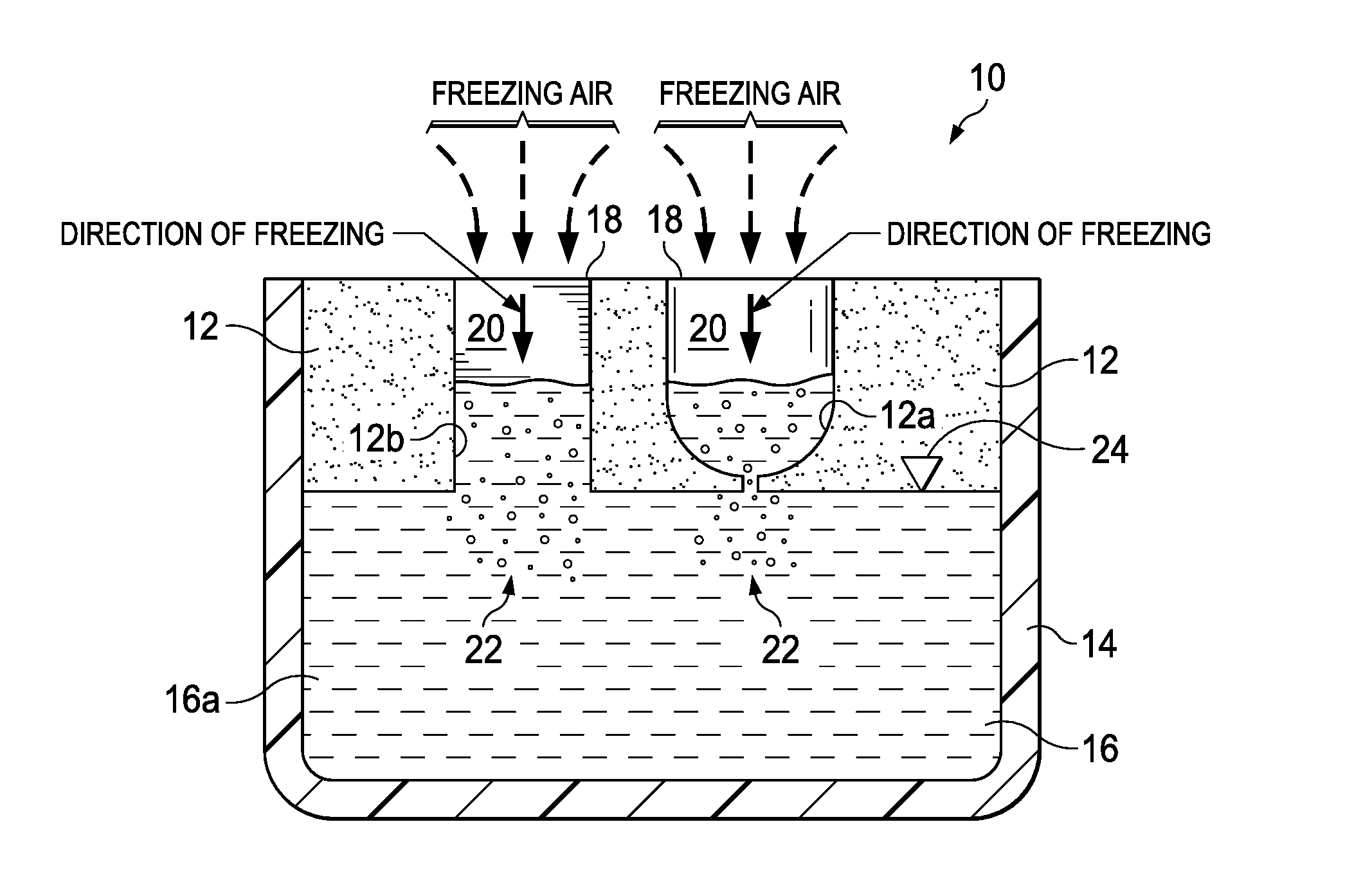

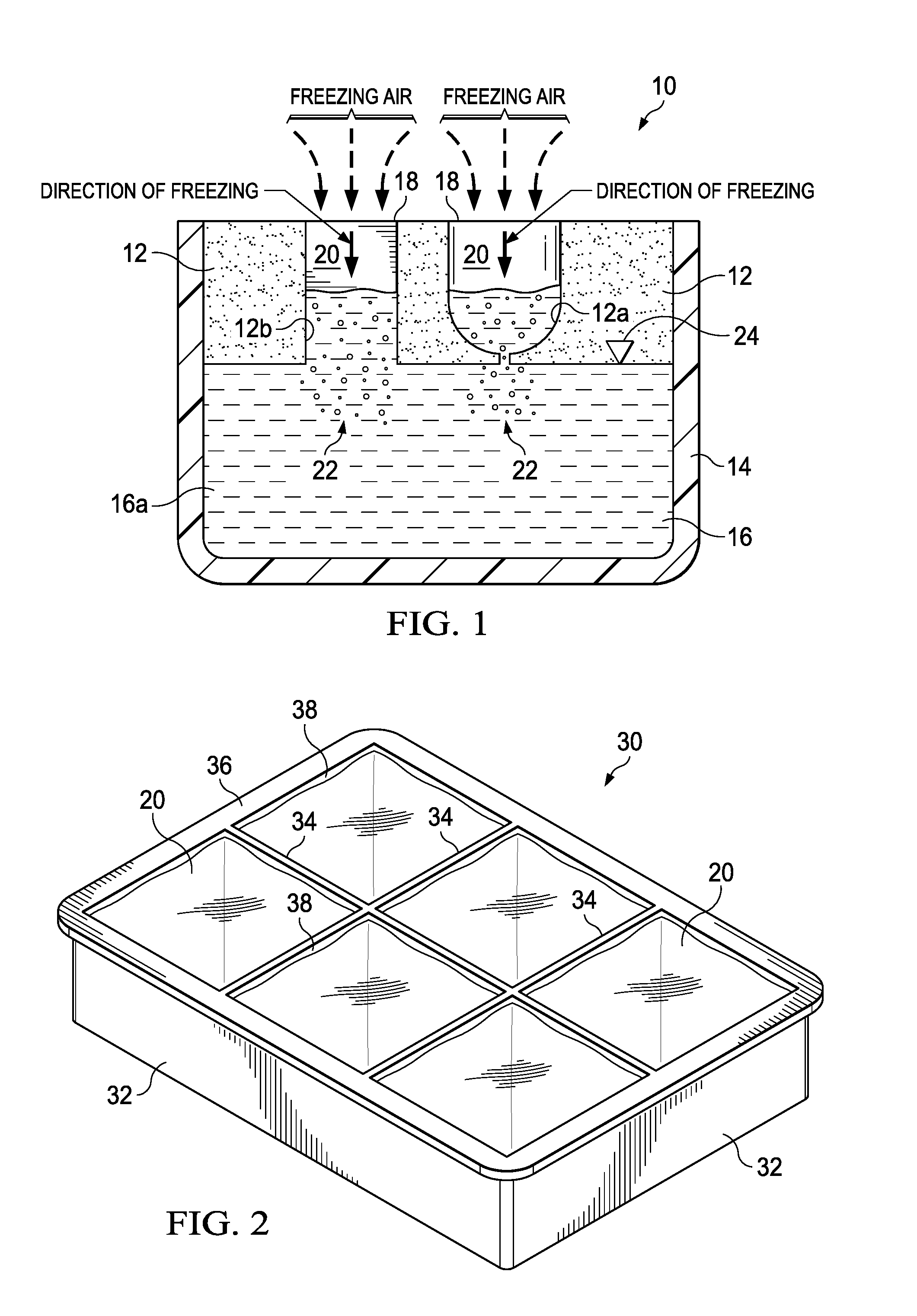

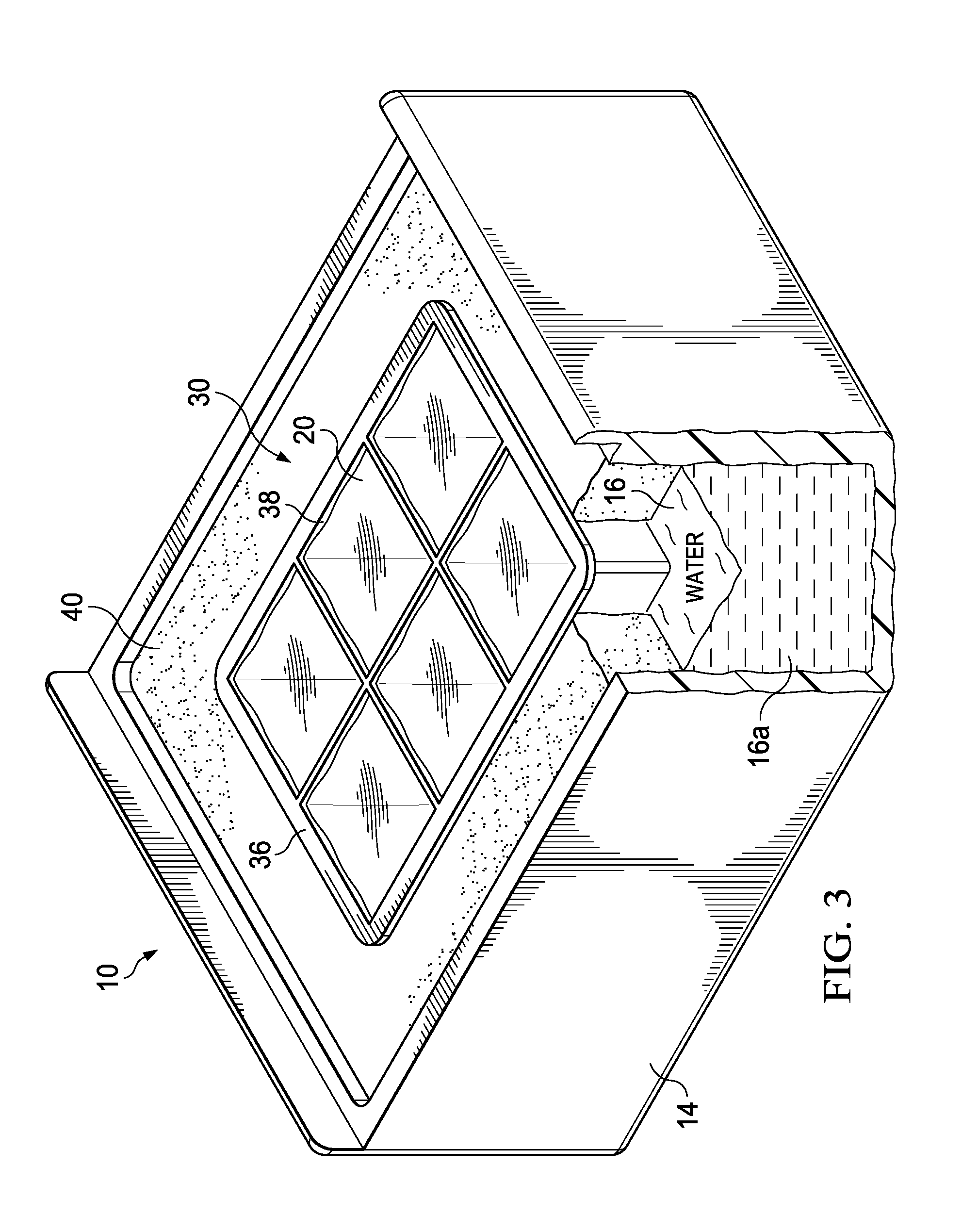

Transparent Ice Maker

InactiveUS20150107275A1Reduced surface area to volume ratioEasy to shapeLighting and heating apparatusFood processingLiquid waterEngineering

The present invention provides an apparatus and method for producing substantially clear ice in a variety of desired shapes. An insulated ice mold form containing one or more mold cells is suspended over a liquid water reservoir contained in an insulated container. Each ice mold cell is exposed to freezing air resulting in the formation of ice in each mold cell with ice formation progressing from the top to the bottom of each ice mold cell. A liquid water reservoir below each ice mold cell serves as an impurity sink into which impurities and gases are driven as ice crystals form in each ice mold cell and as a heat sink to substantially arrest ice shape growth beyond the bottom of each ice mold cell at or near the ice-reservoir water interface.

Owner:PAPALIA ROCCO

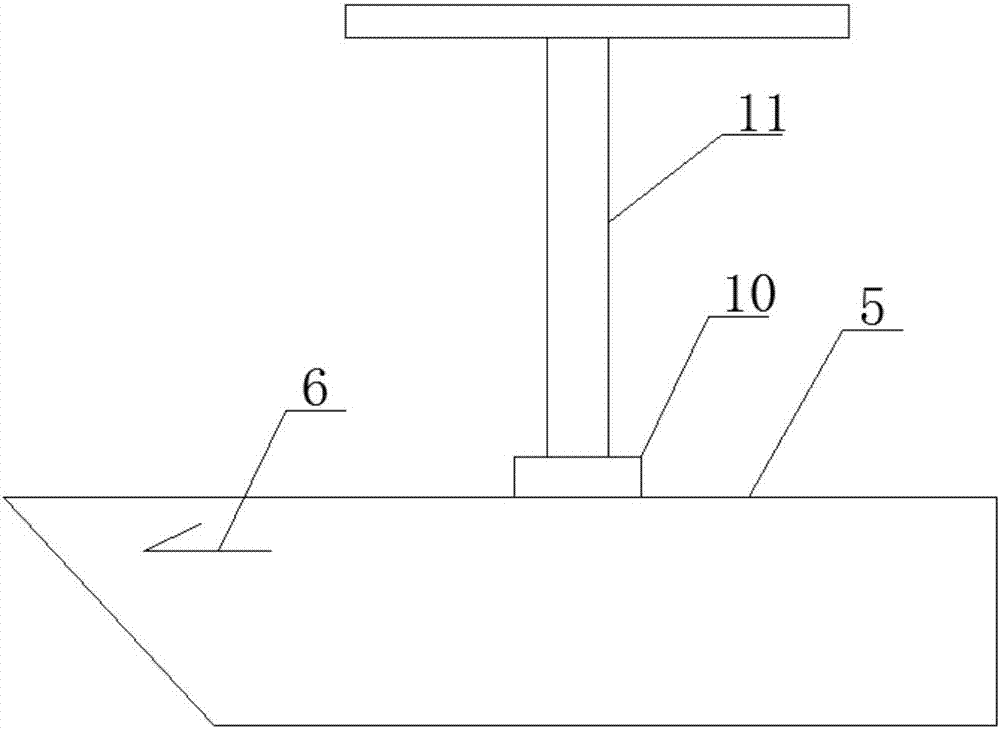

A measurement system and measurement method utilizing non-freezing model ice to obtain the ship model resistance in trash ice

InactiveCN107014587AUniversally applicableImprove economyHydrodynamic testingOpen waterAcquired resistance

The invention provides a measurement system and measurement method utilizing non-freezing model ice to obtain the ship model resistance in trash ice. First, by selecting non-freezing model ice from a conventional towing pool to replace frozen model ice in an ice pool, so that the towing pool without a low temperature environment is equipped with the condition of simulating ice trash working conditions; and then a unique buoy fence structure is designed on the surface of the towing pool to achieve simulation of an ice trash channel, and a force cell is used to realize measurement of the ship model resistance at different speeds. In addition, the invention adopts the means of firstly measuring the resistance of the open water and measuring the resistance at a very low speed (0.02m / s) under the floating ice condition, elements such as the open water resistance, the floating ice resistance and the clear ice resistance are separated, and the resistance performance of a corresponding ship model and a real boat in the working condition of trash ice is forecast. The measurement system and measurement method of the invention provides a new idea for measurement of the ship model resistance in the trash ice in a condition that now ice pool facilities in china are not perfect.

Owner:HARBIN ENG UNIV

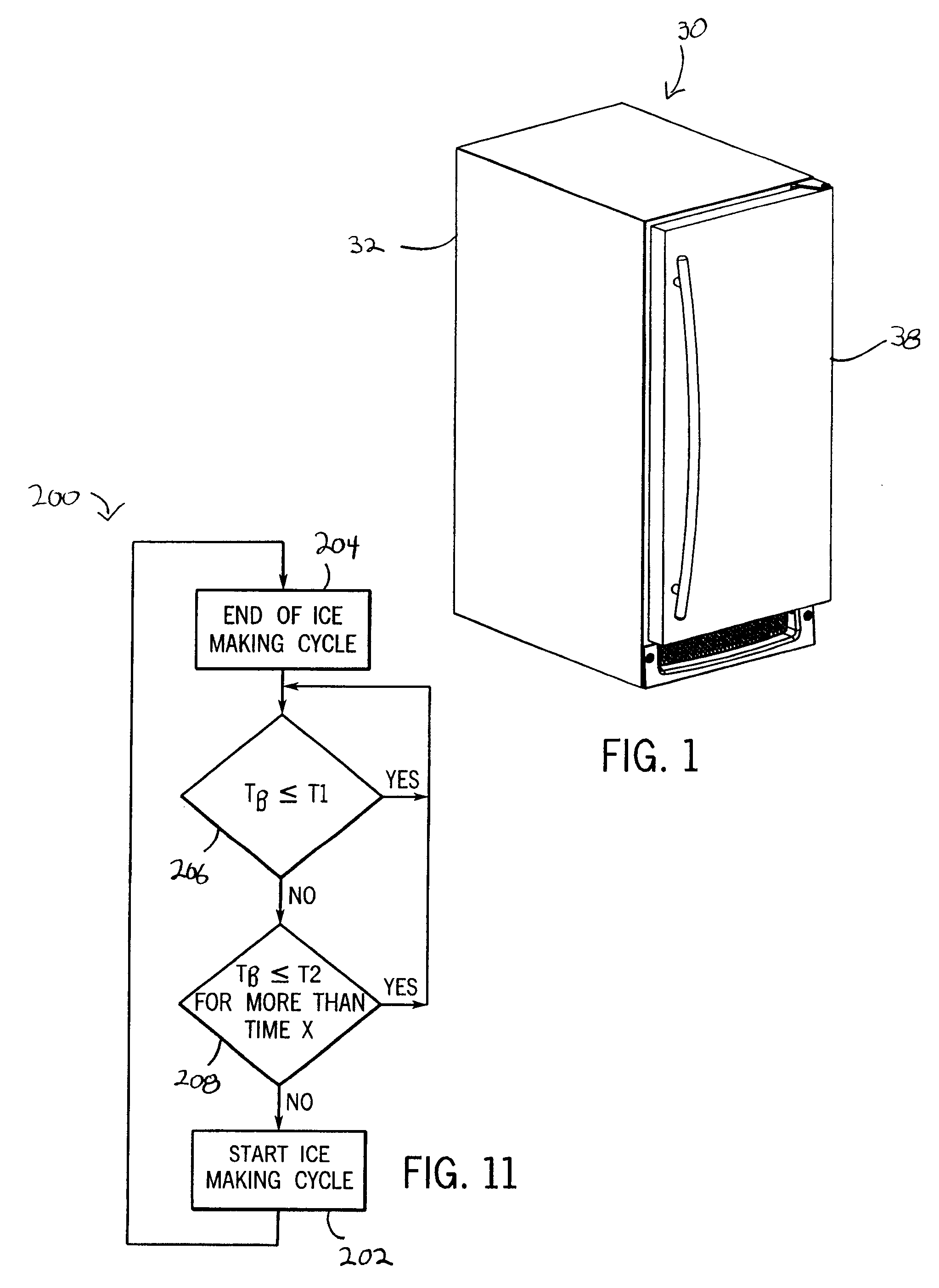

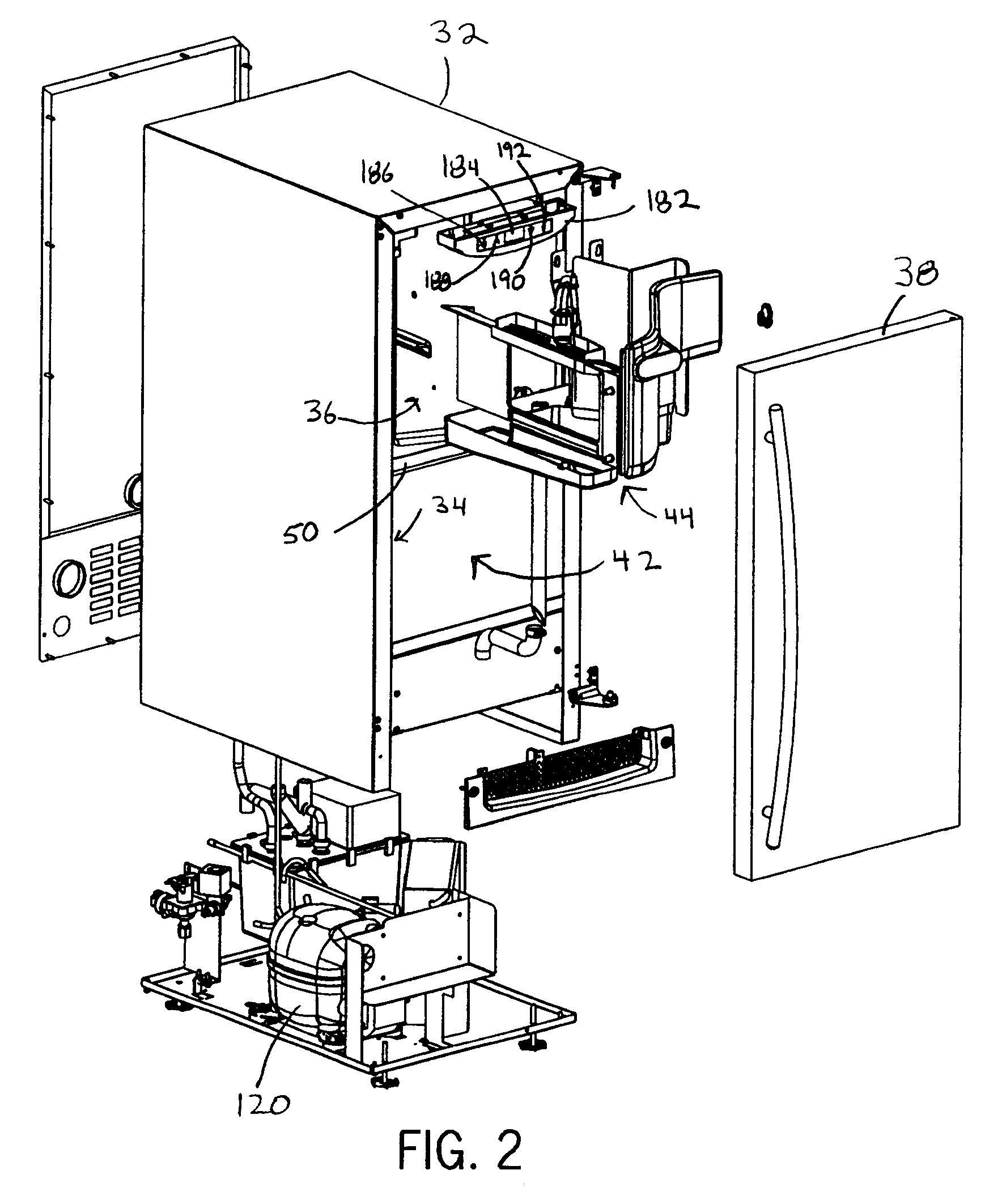

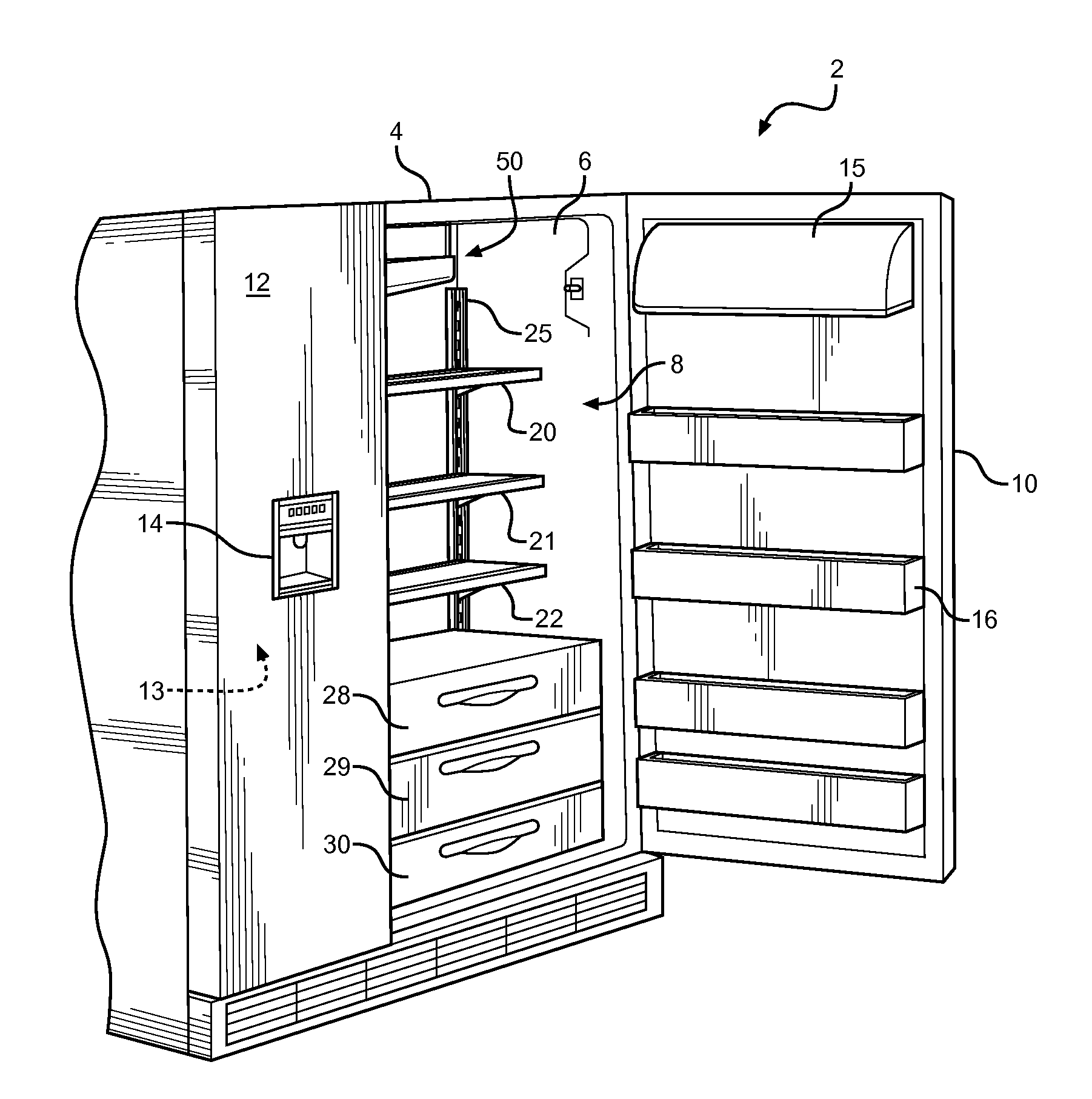

Ice maker with ice bin level control

InactiveUS20080092567A1Preventing initiationThe solution cannot be accurately determinedLighting and heating apparatusIce productionIce storageMarine engineering

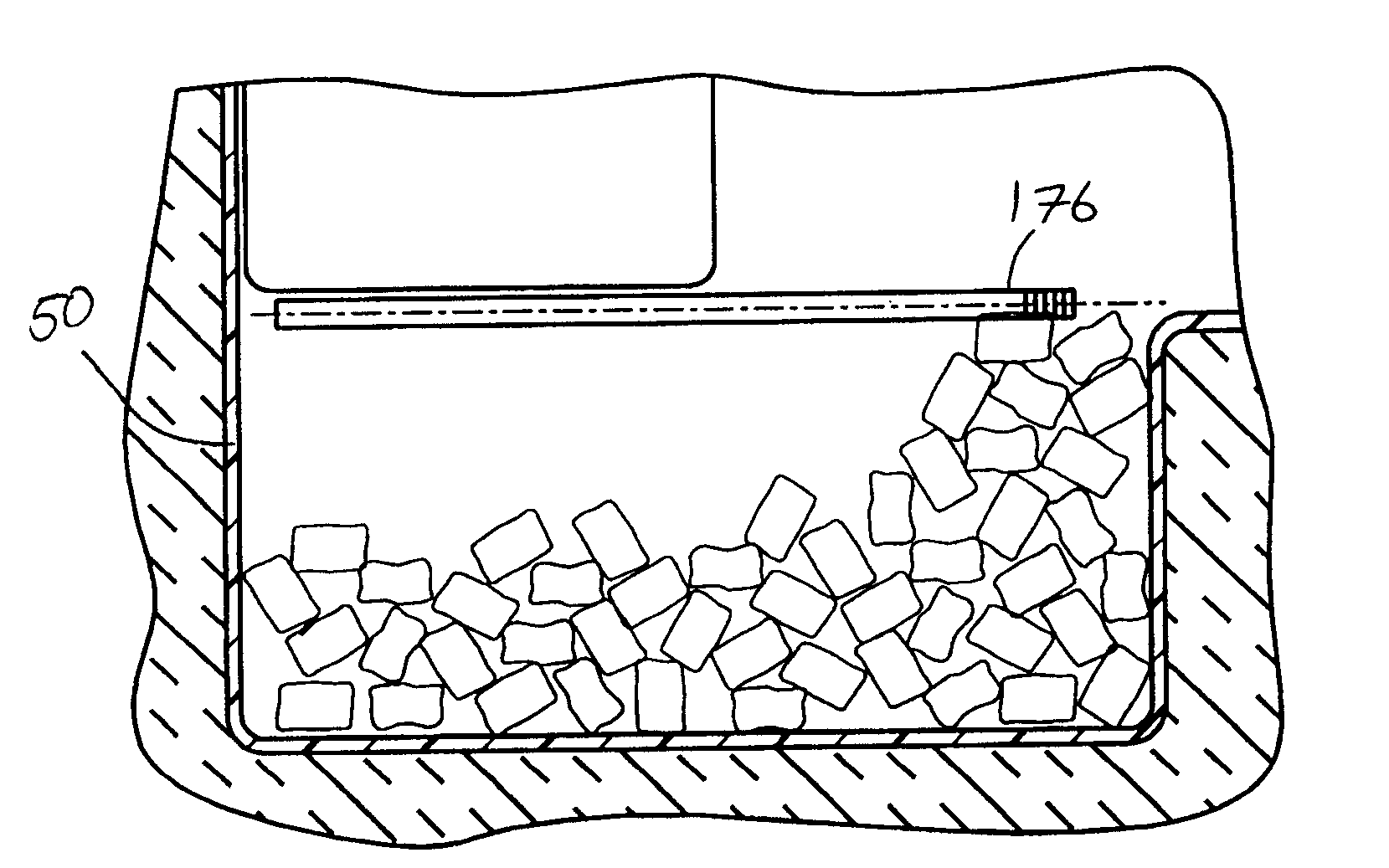

A clear ice maker unit has a clear ice maker mechanism with a cascading water evaporator configured to make clear ice during ice making cycles. A controller uses fuzzy logic to control the clear ice maker and determine whether to initiate a next ice making cycle based on input signals from a thermistor in the ice storage bin. The controller will prevent initiation of an ice making cycle when the ice bin is at or below a threshold temperature. The controller will also prohibit ice making when the ice bin is at or below a second, slightly higher temperature for more than a prescribed period of time. In this way, the clear ice maker can recognize an uneven distribution of ice and maintain an optimal amount of ice in the bin.

Owner:U LINE CORP A WI CORP

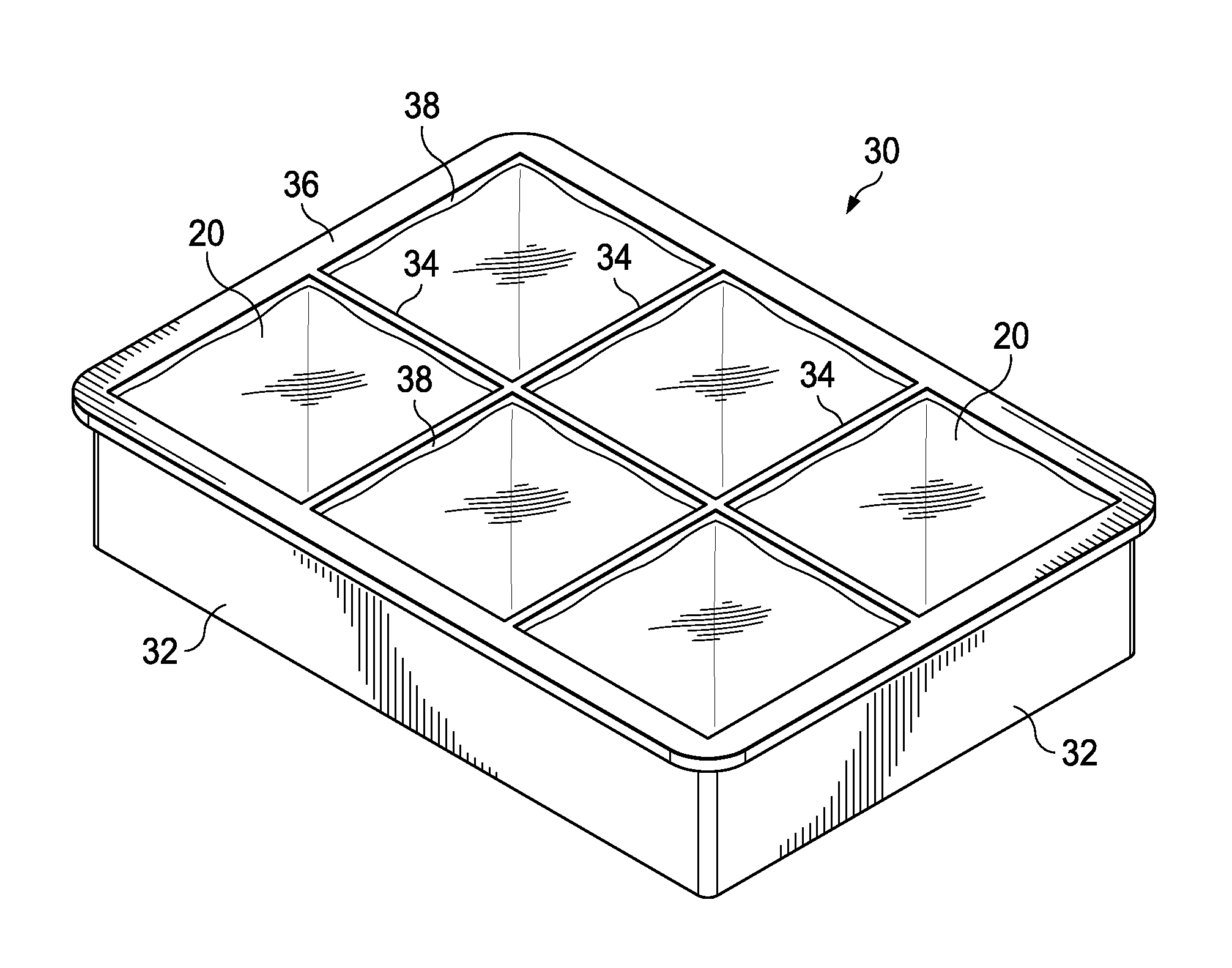

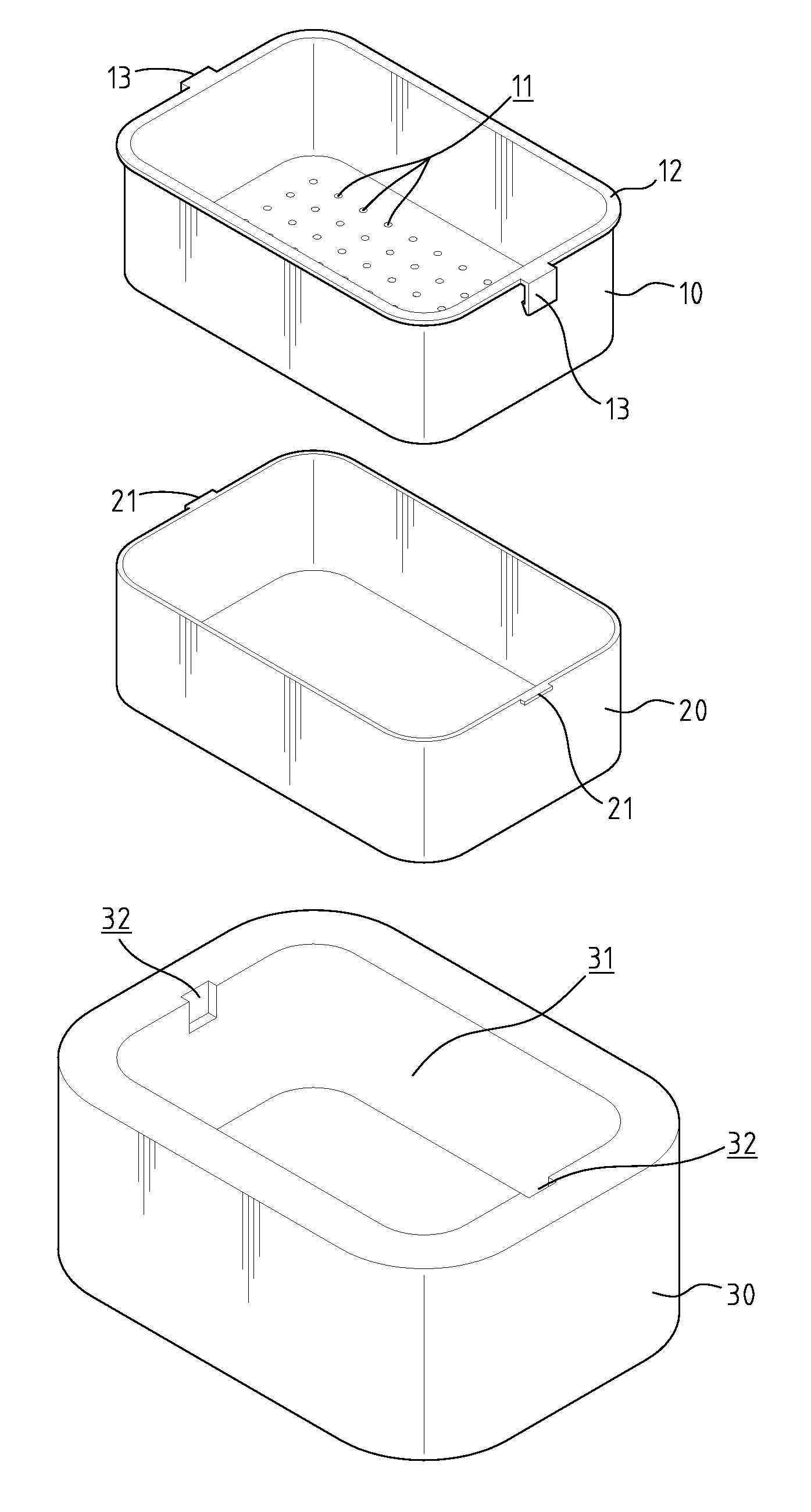

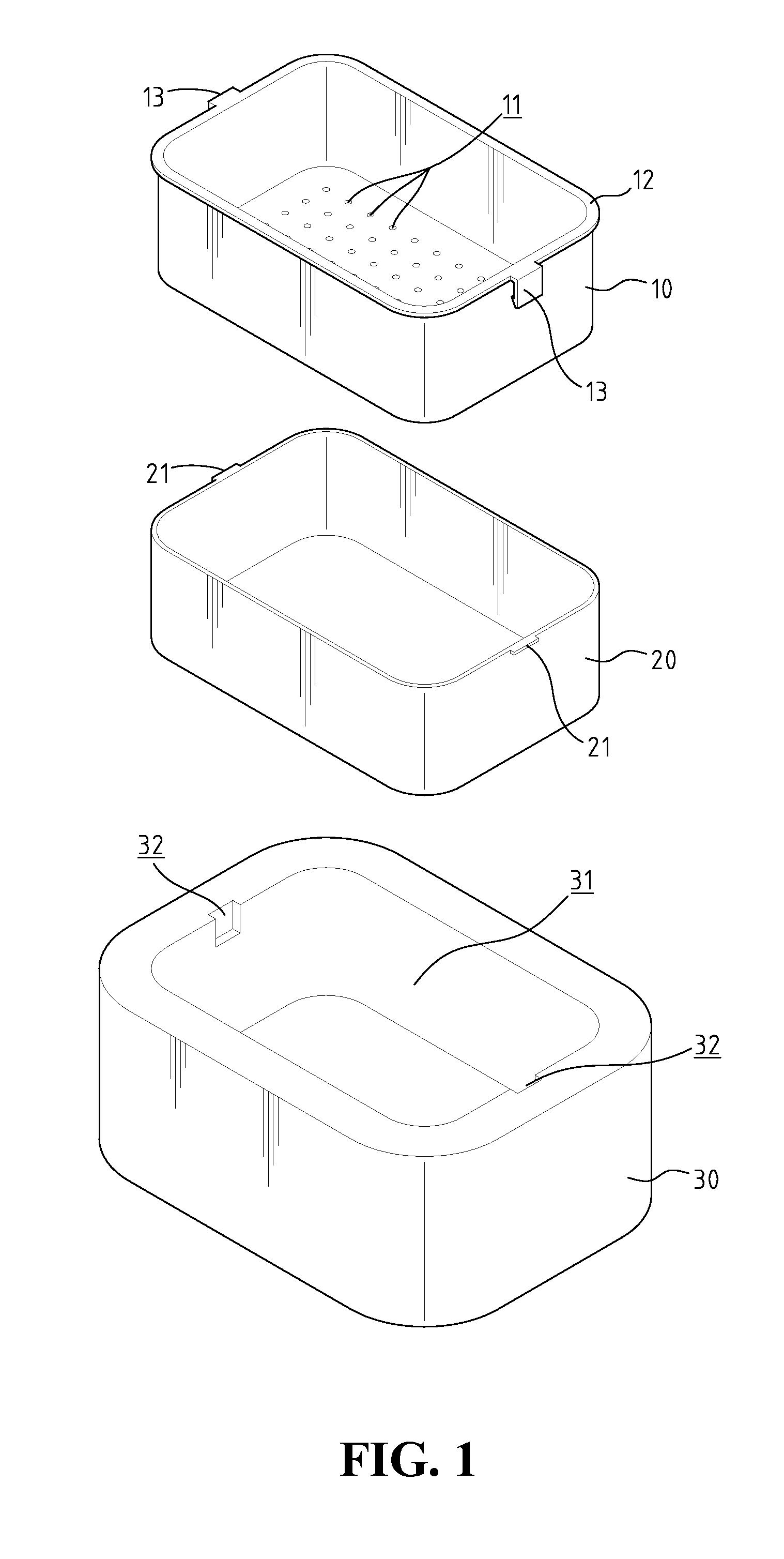

Clear Ice Cube Tray

InactiveUS20090152438A1Low costSuitable for commercial useLighting and heating apparatusIce productionEngineeringClear ice

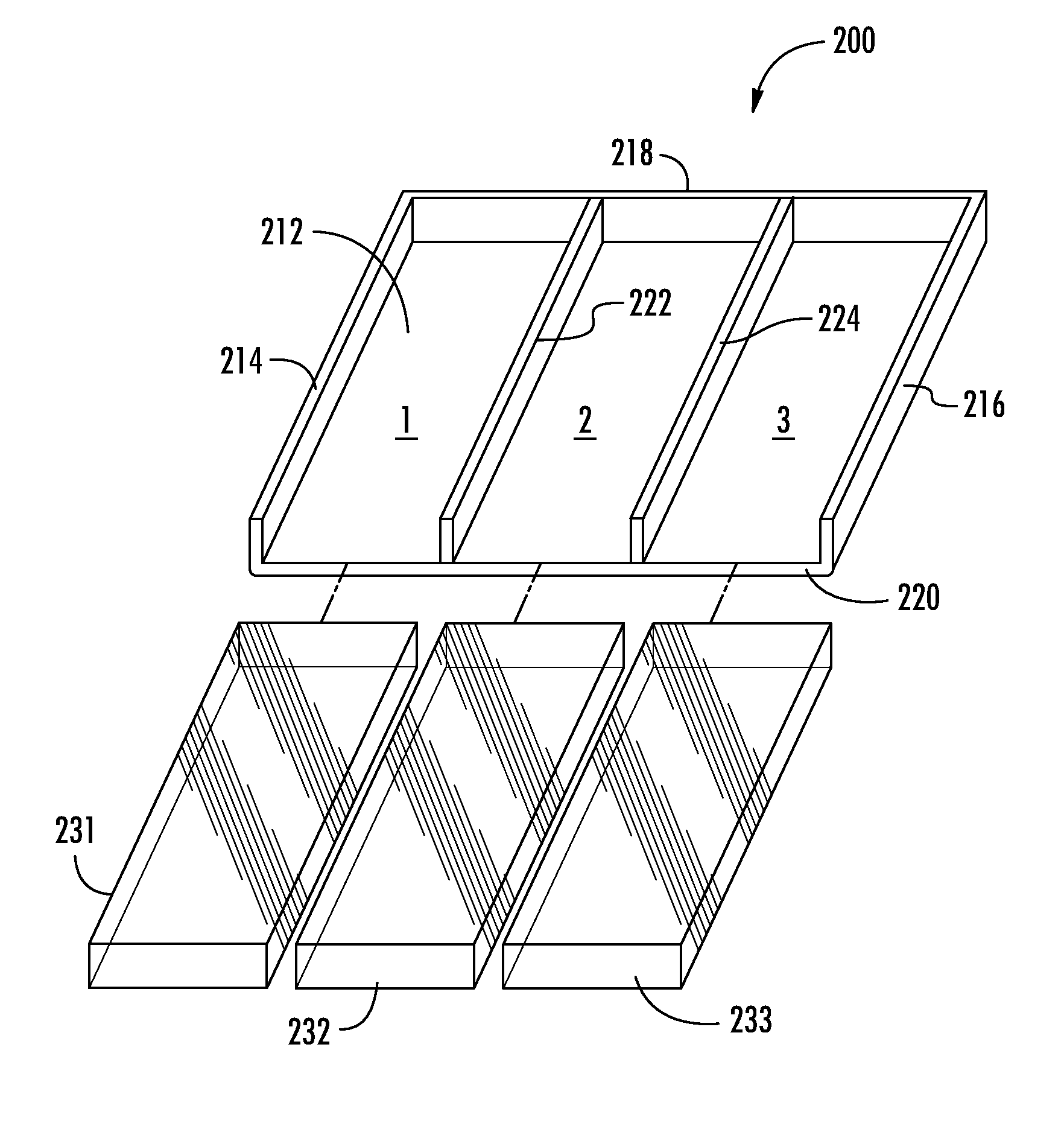

A clear ice cube tray includes an inner box having a plurality of holes formed through a bottom thereof, and the inner box is received in an outer box with a gap defined between the bottom of the inner box and the inner end of the outer box. The inner box is congruent in shape with the outer box. A heat isolation housing includes a space therein for accommodating the inner box and the outer box. The water is filled in the inner box and the outer box, and frozen from a surface of water in the inner box. The bubbles in the water are then pushed into the gap through the holes so that ice cubes made in the inner box is clear.

Owner:CHU YUE LONG

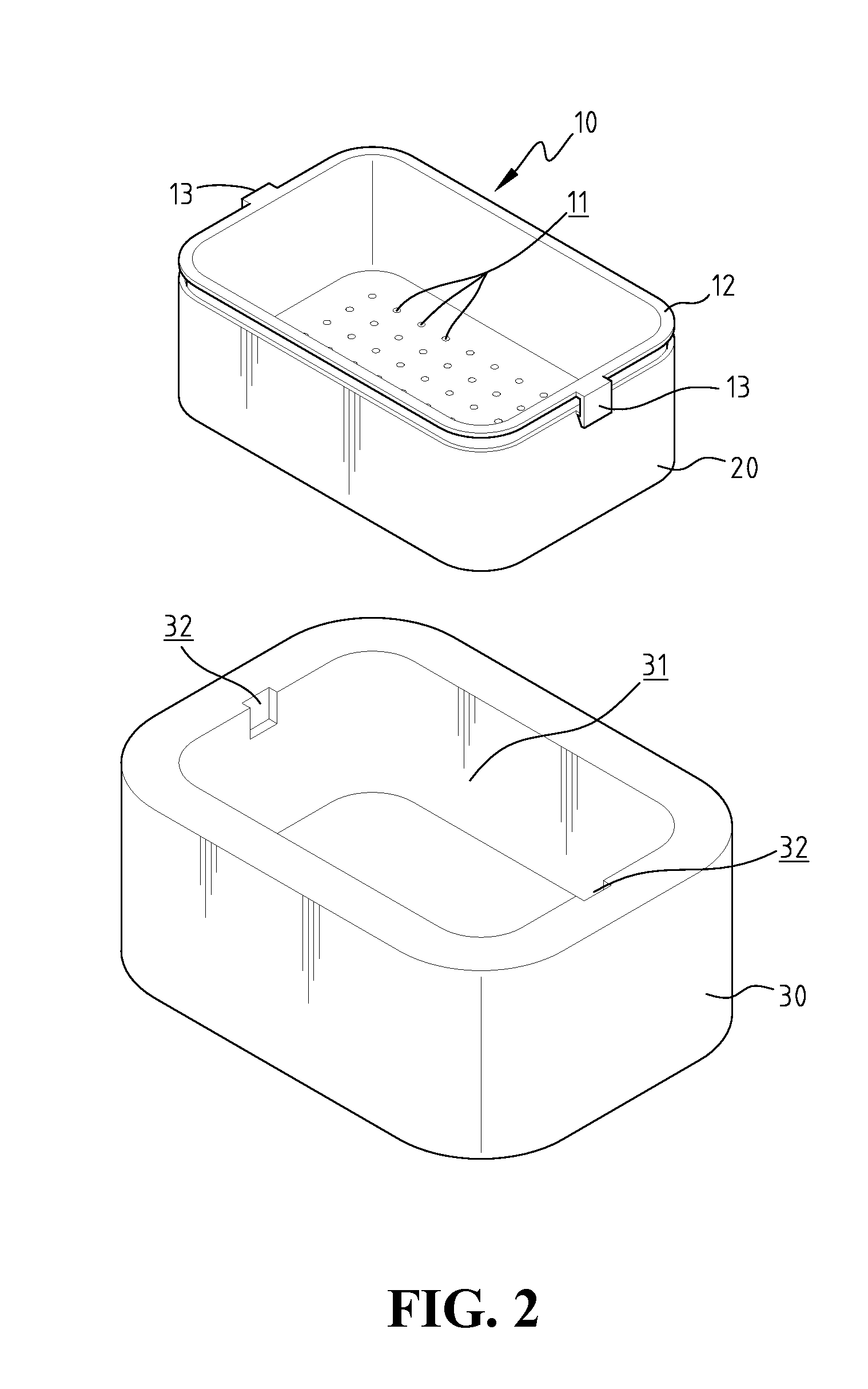

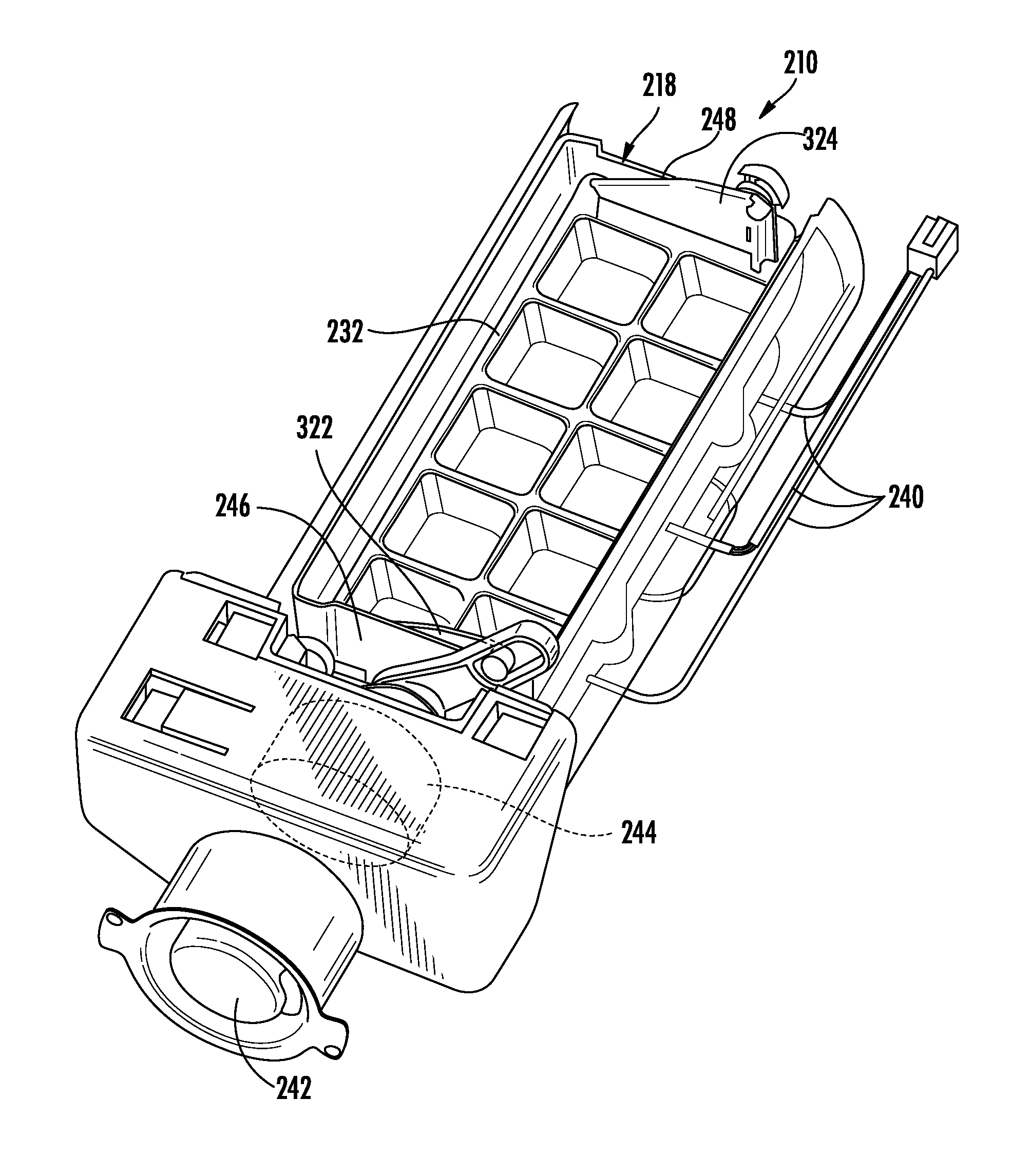

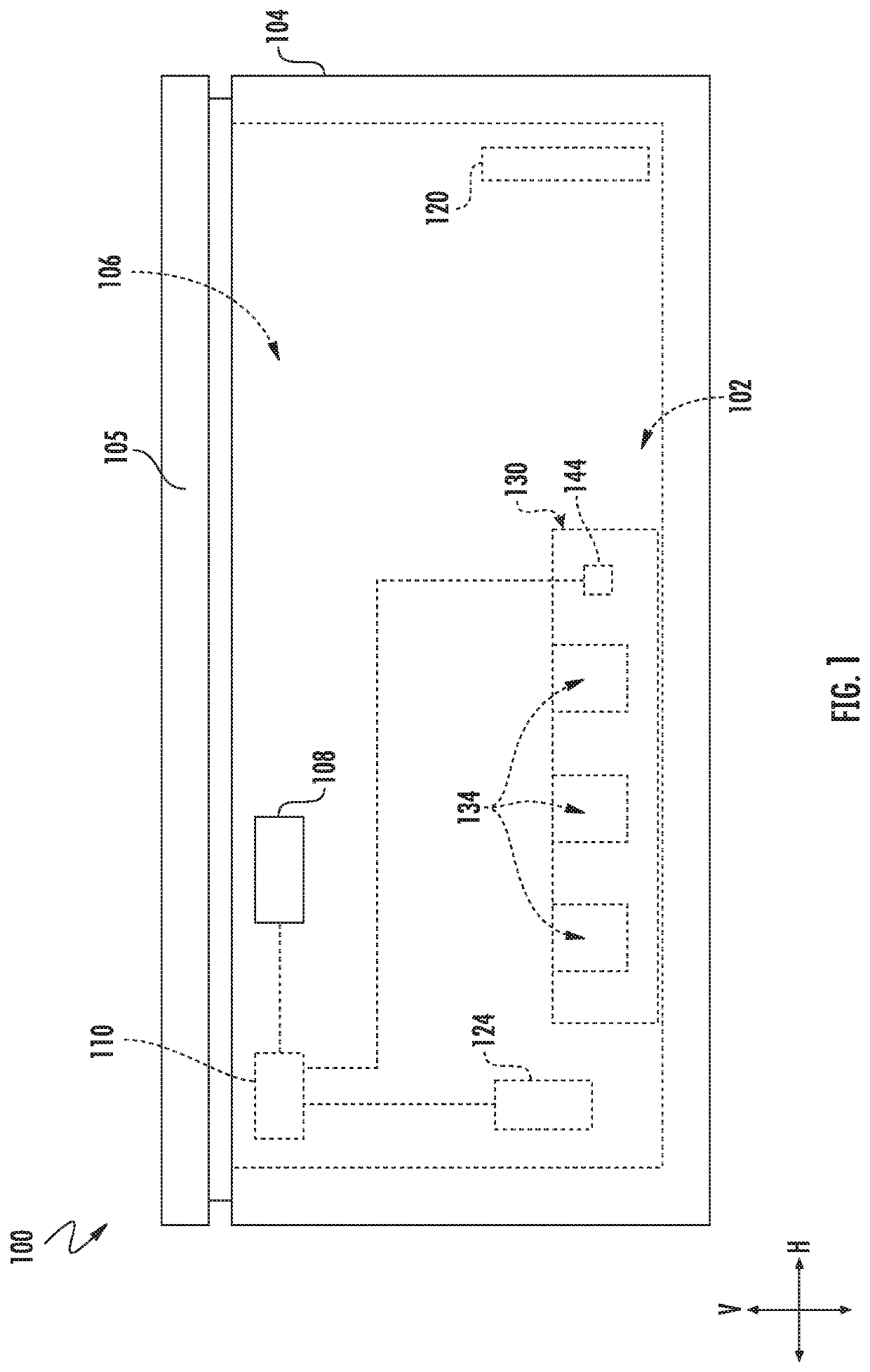

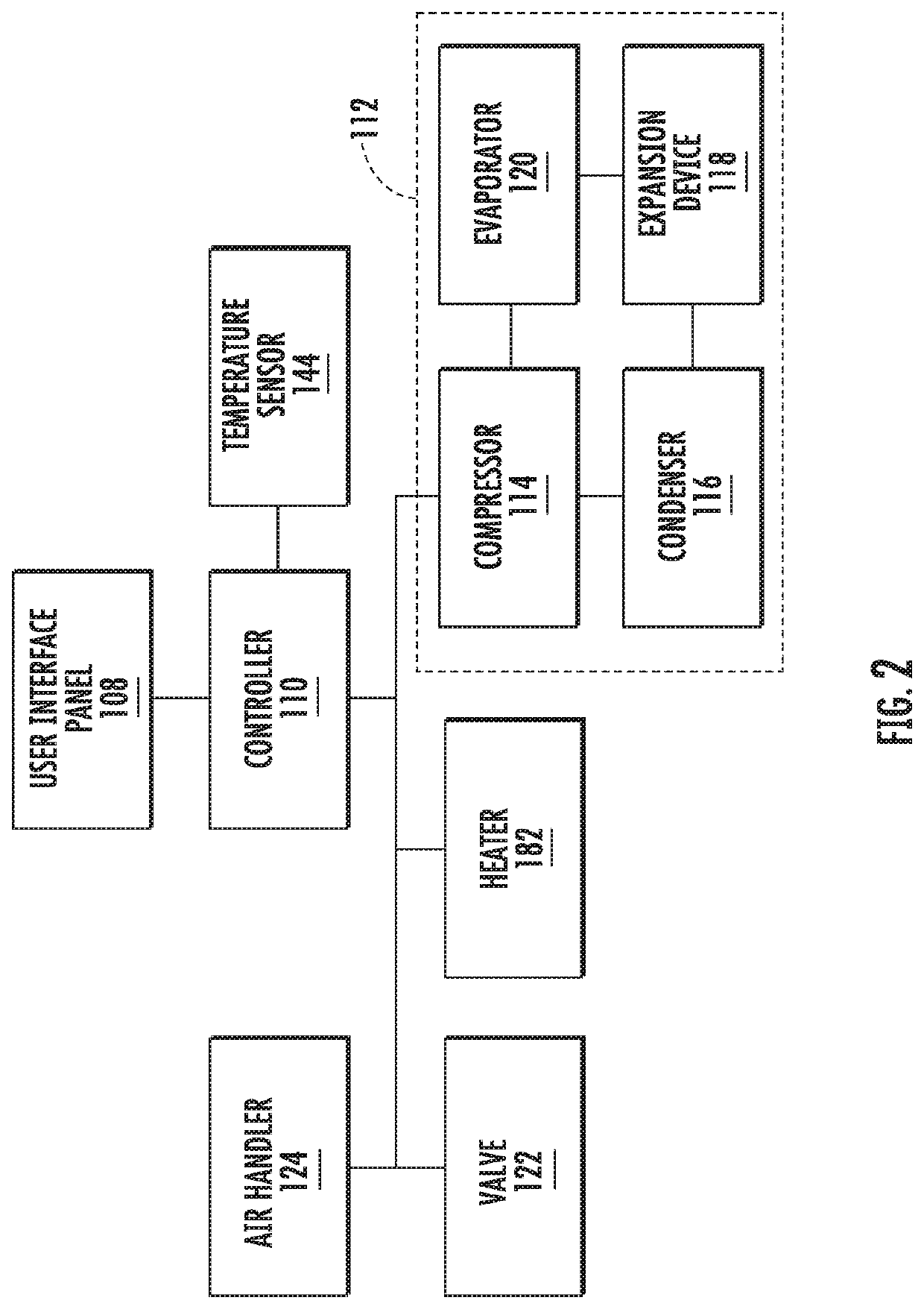

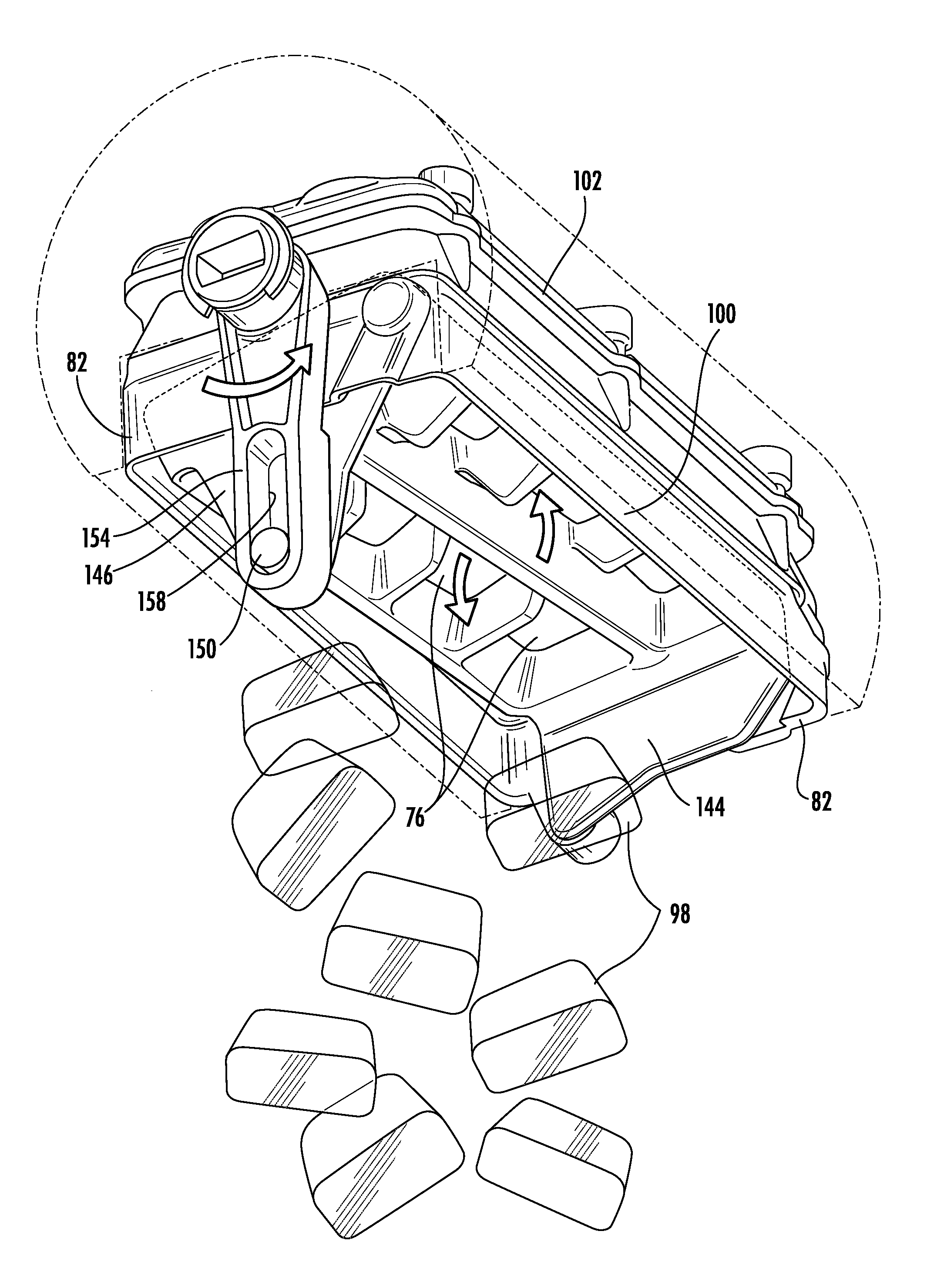

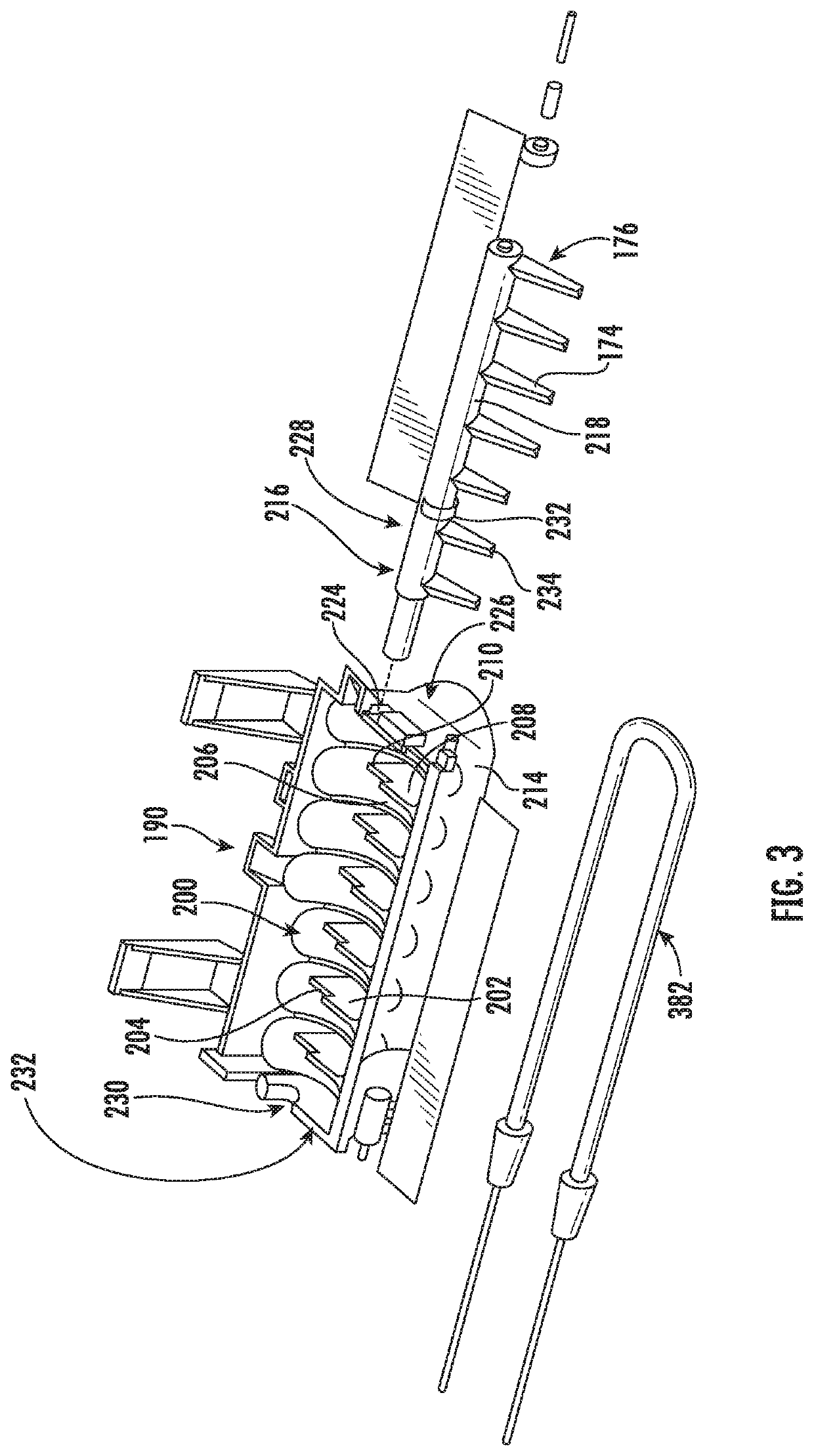

Clear ice maker and method for forming clear ice

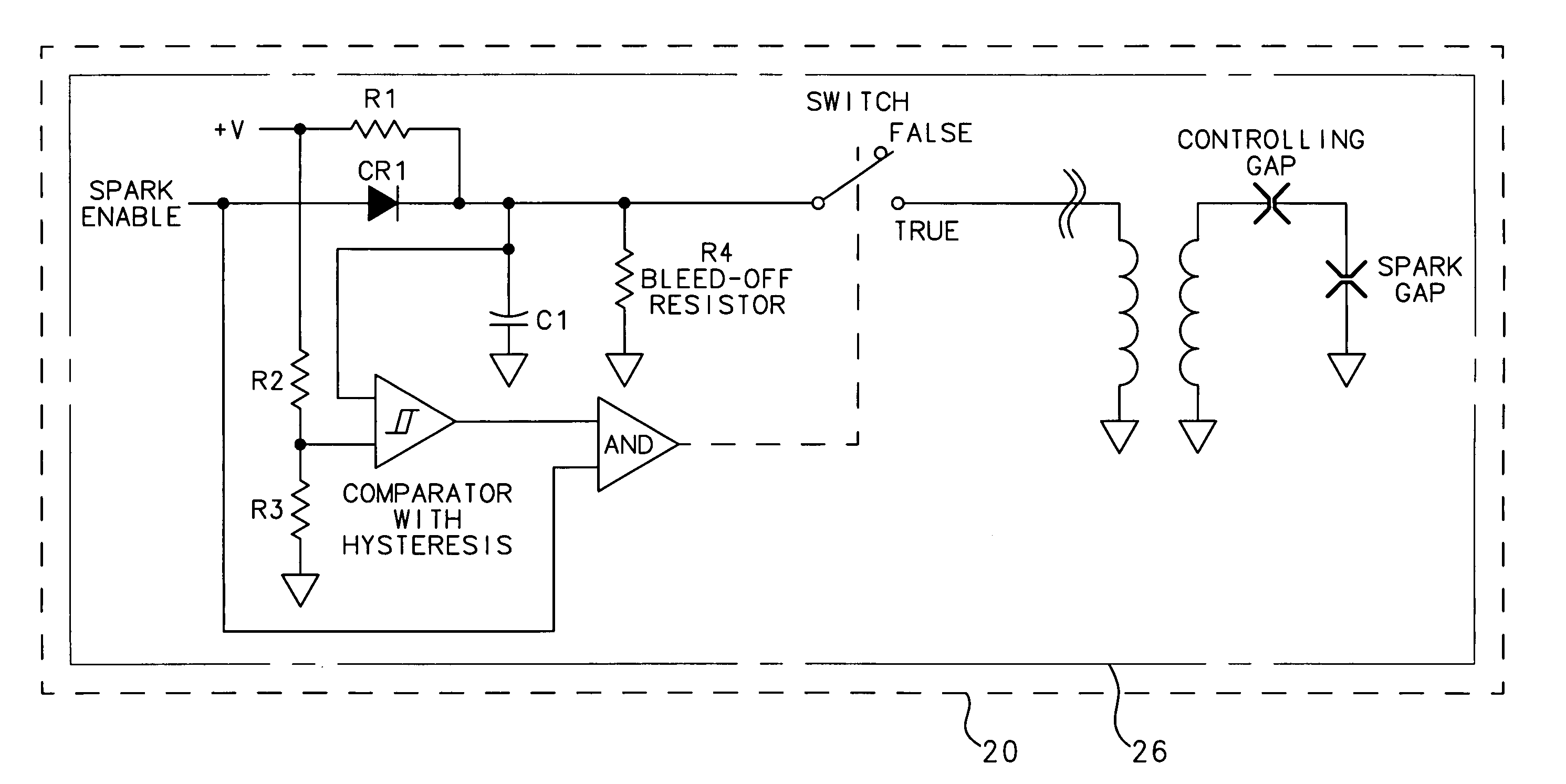

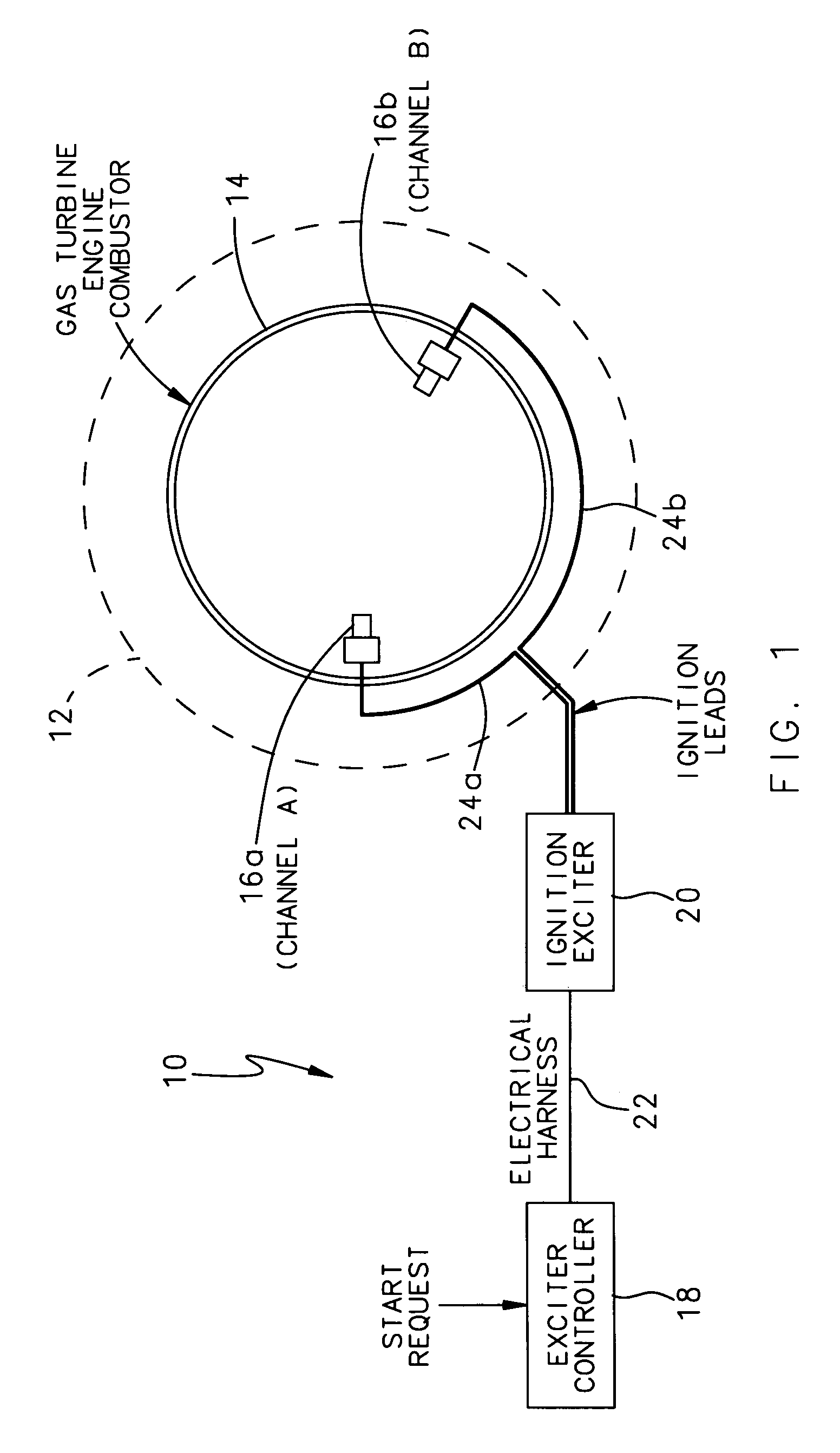

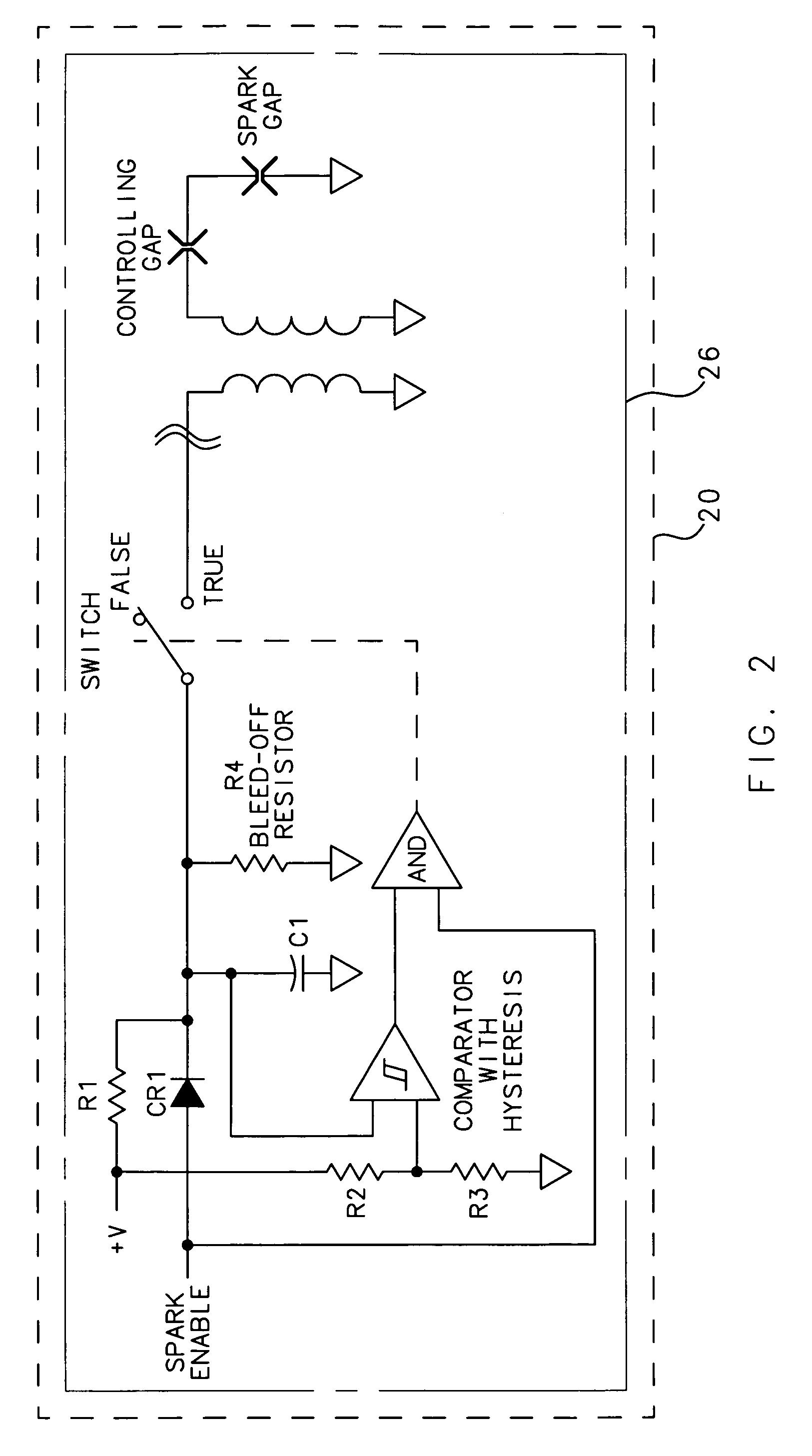

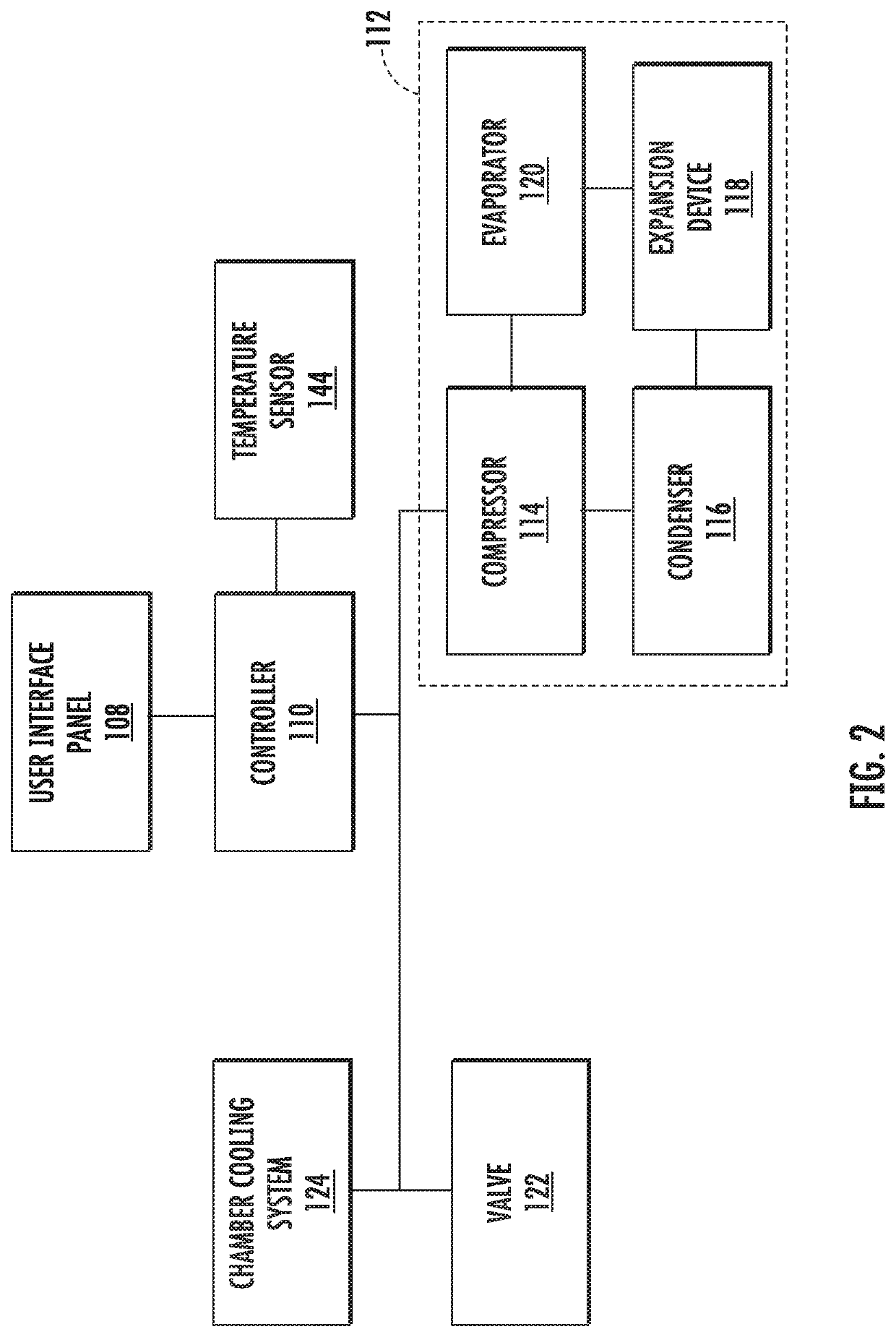

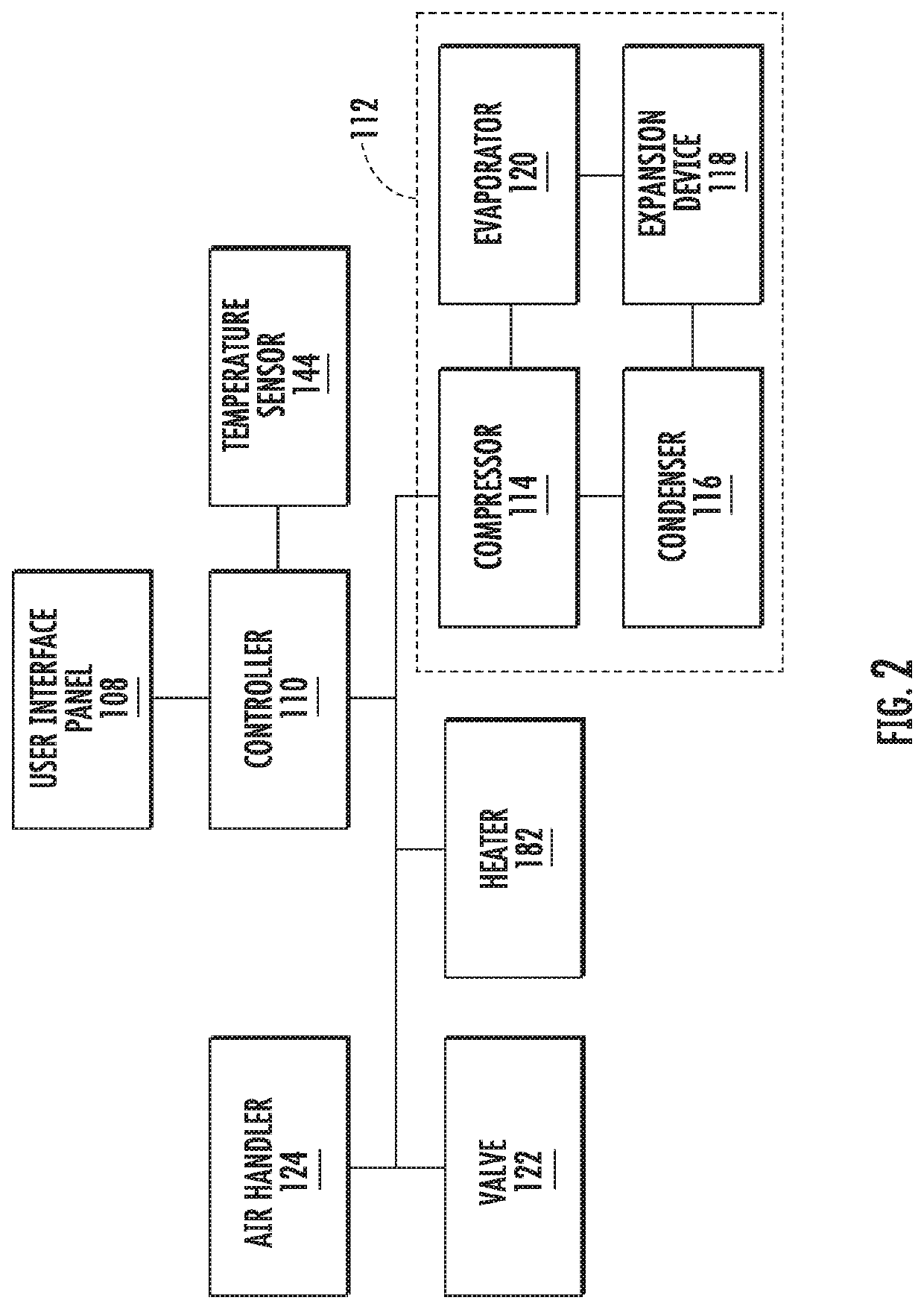

InactiveUS20140165602A1Ice productionAuxillary controllers with auxillary heating devicesTemperature controlCold air

An ice maker, including sensors to measure usage parameters and transmit the same to a controller. The controller is operably connected to a plurality of ice forming systems, and directs the systems to operate in a high energy mode or a low energy mode, based on the usage parameter. The usage parameters may include an ice level, a change in the ice level over time, the amount of time that a dispenser is actuated, the time of day, or historical usage patterns. The ice forming systems may include one or more of a thermoelectric device coupled to a bottom surface of an ice forming plate, a forced air system to circulate cold air, a forced air system to circulate warm air, and a temperature control system to maintain a temperature gradient between a first chamber above the ice forming plate and a second chamber below the ice forming plate.

Owner:WHIRLPOOL CORP

Clear ice maker

Owner:WHIRLPOOL CORP

Clear ice maker

ActiveUS20140165601A1Improve efficiencyEfficient productionIce productionMachines using electric/magnetic effectsEngineeringConductive materials

Owner:WHIRLPOOL CORP

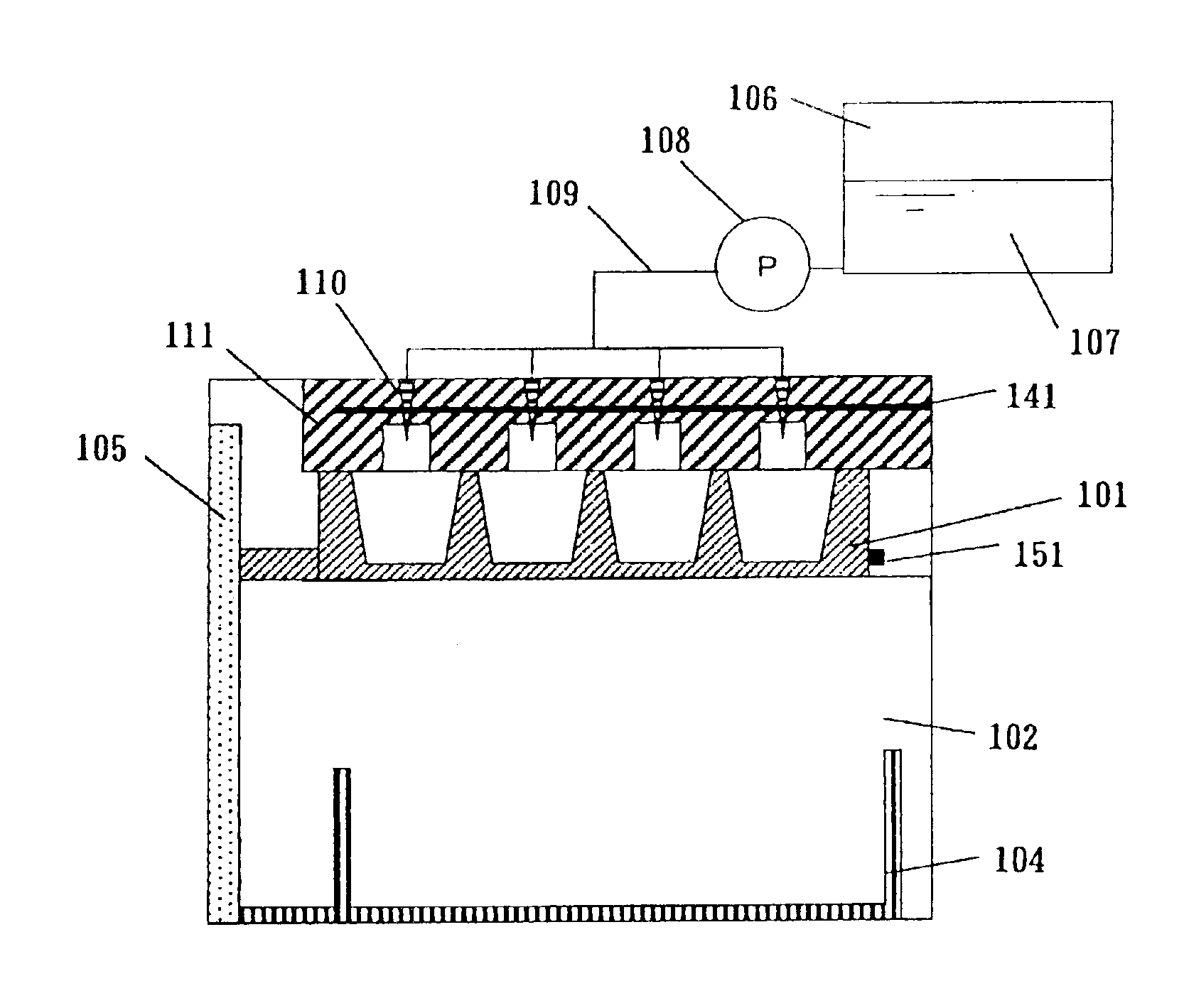

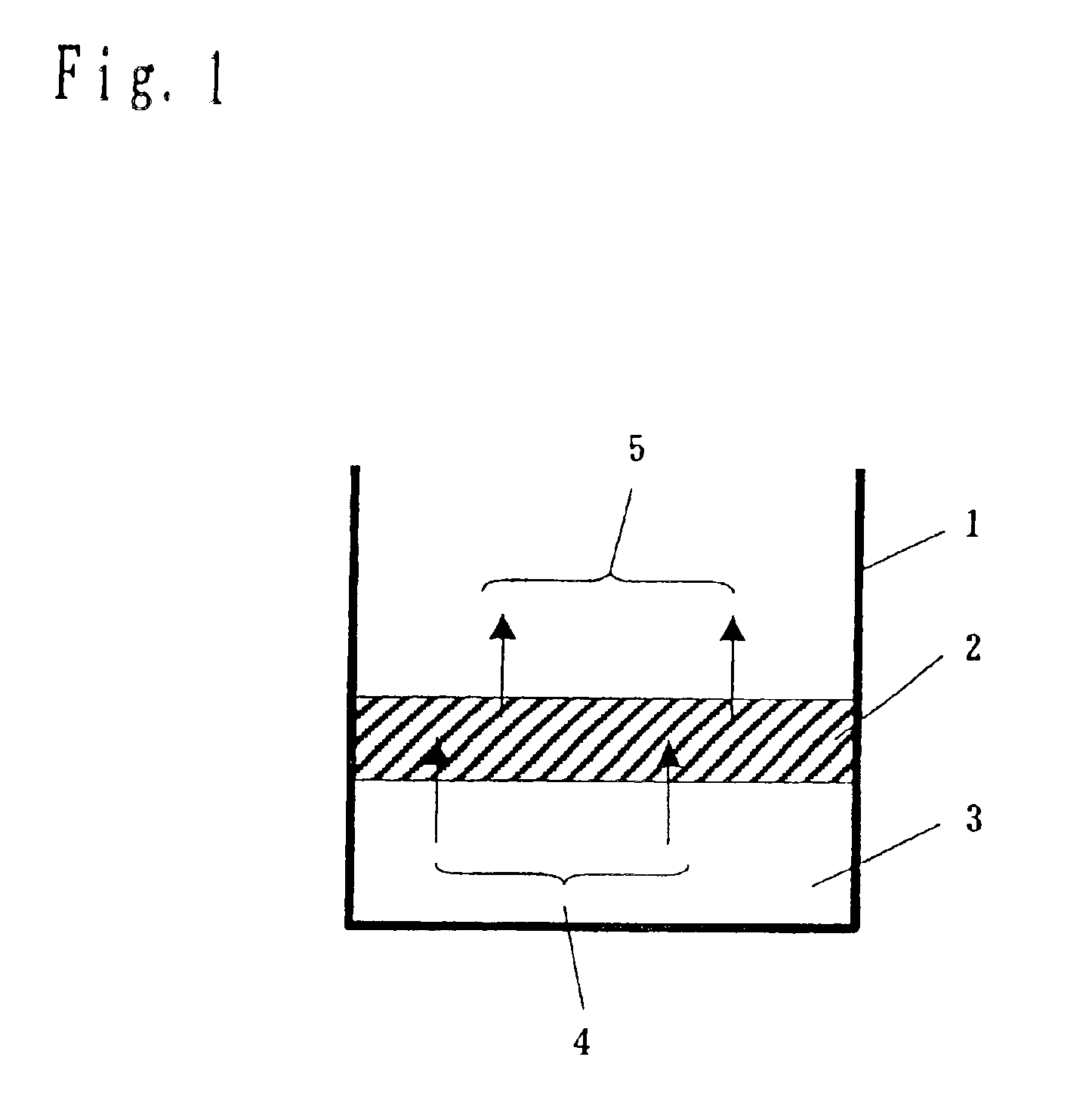

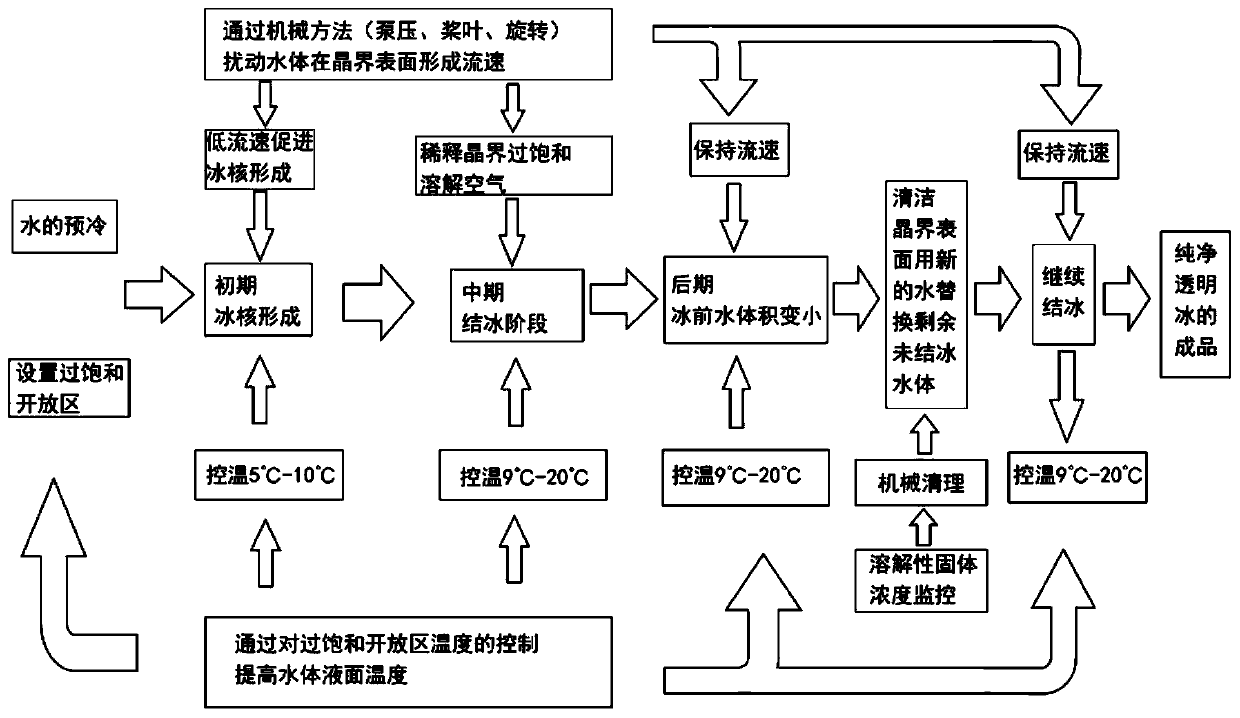

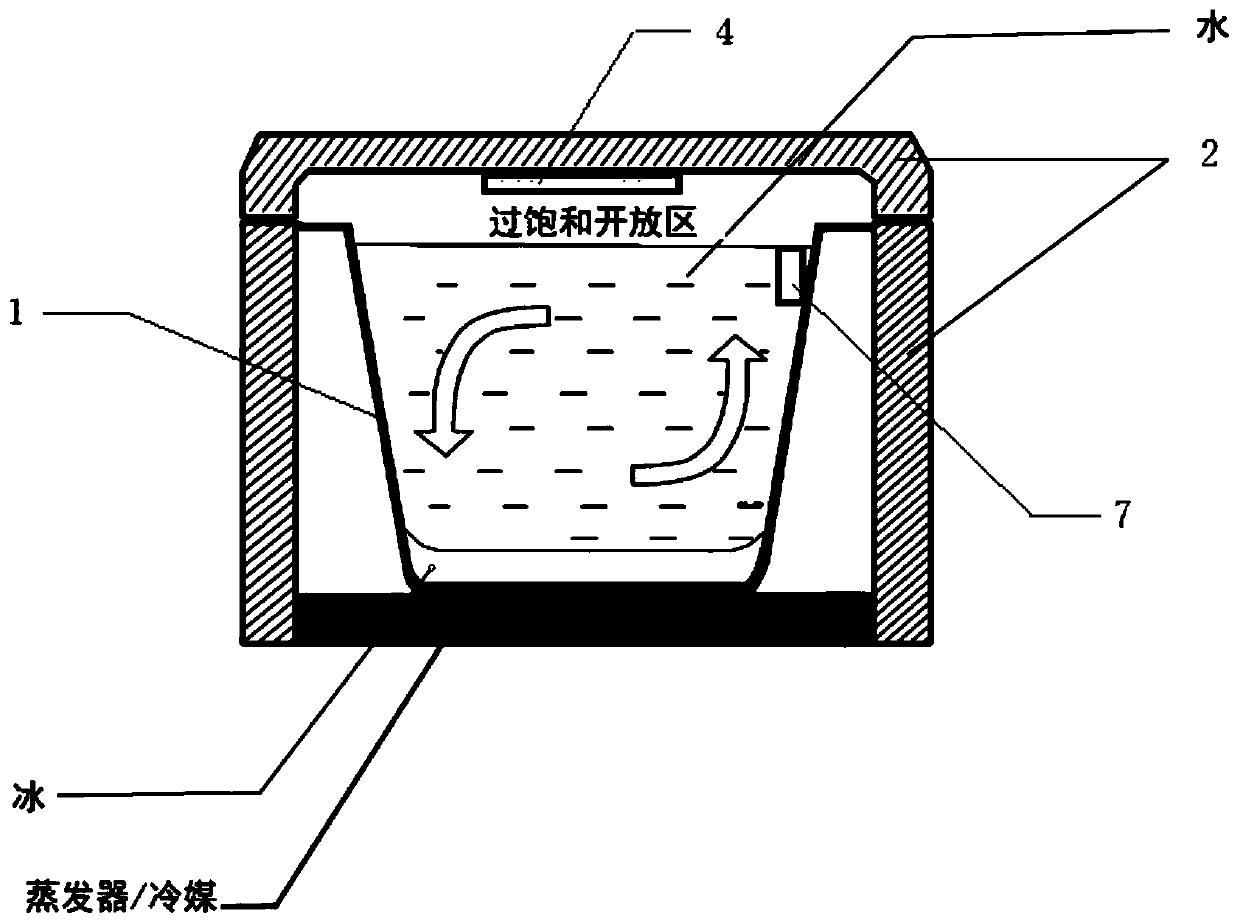

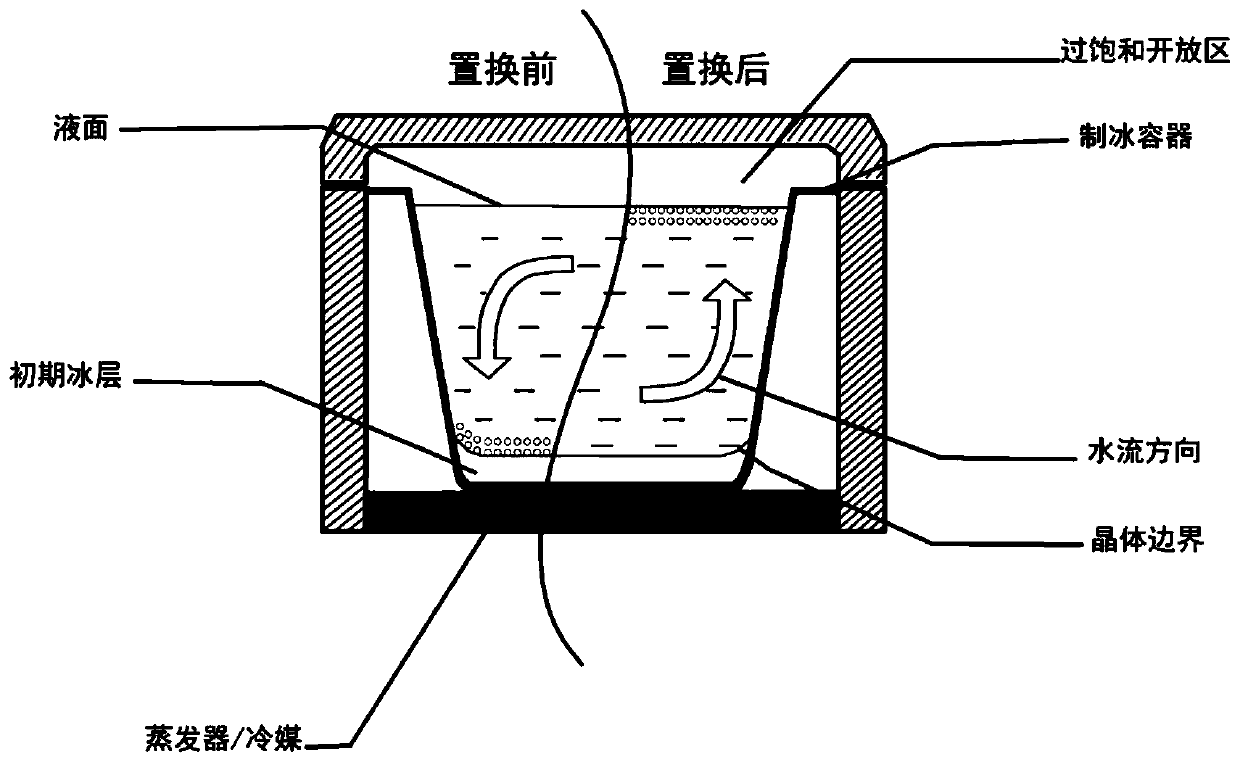

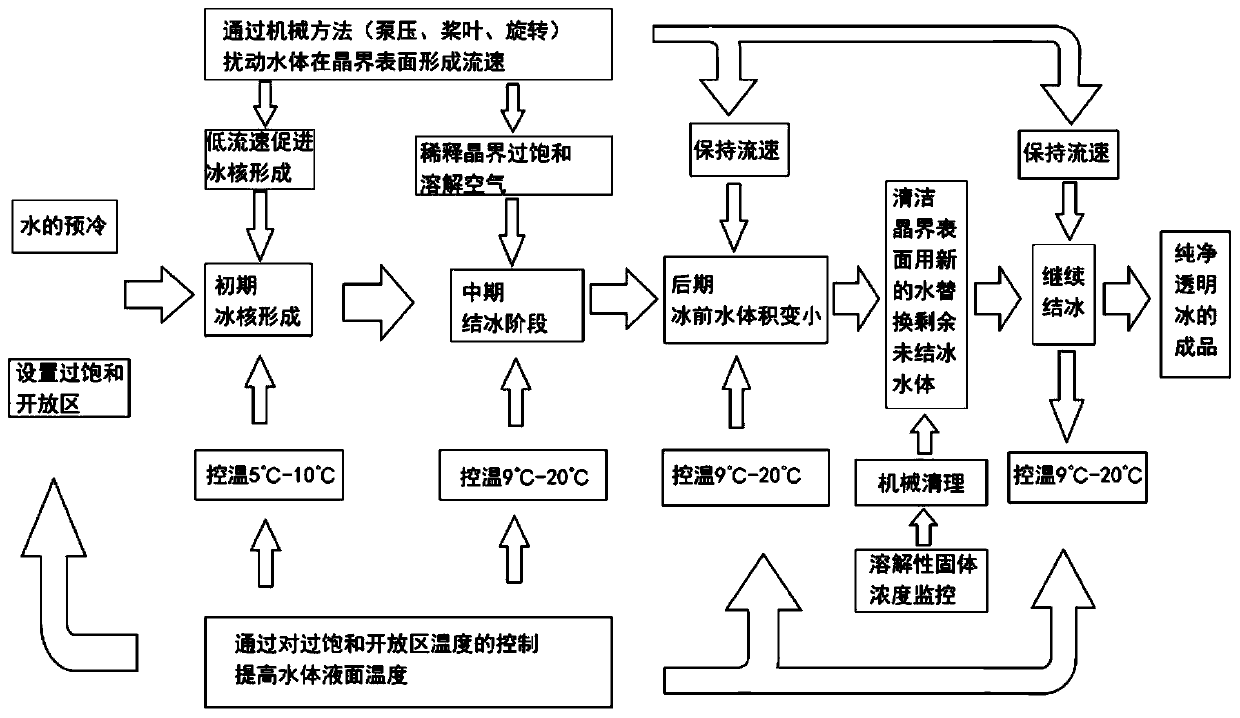

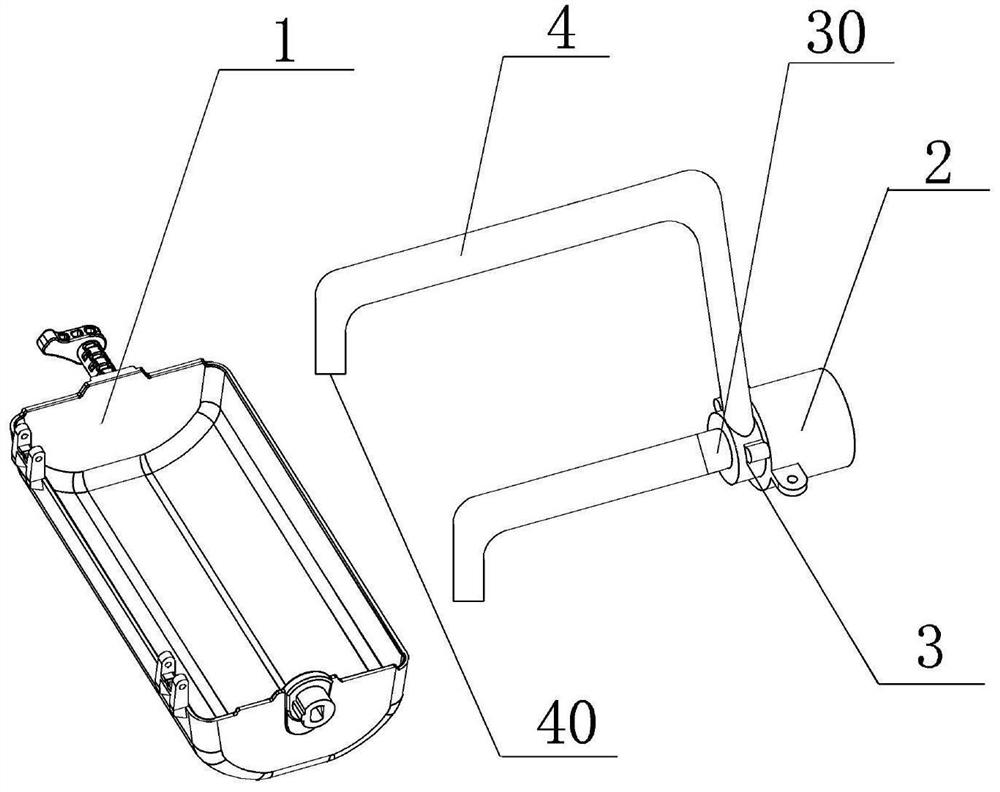

Making method and making device of clean transparent ice

ActiveCN109883097AHigh transparencyImprove purityLighting and heating apparatusIce productionEngineeringImpurity

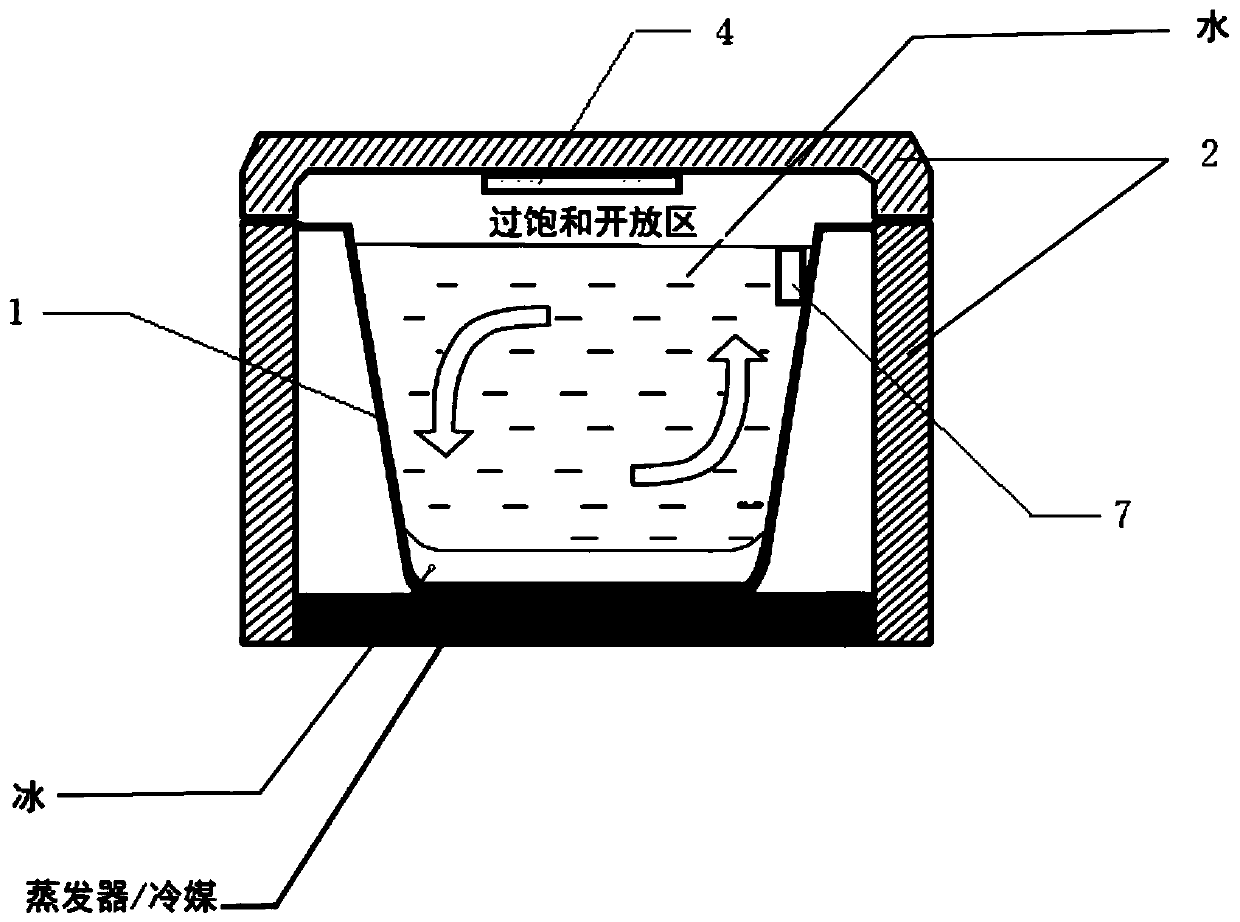

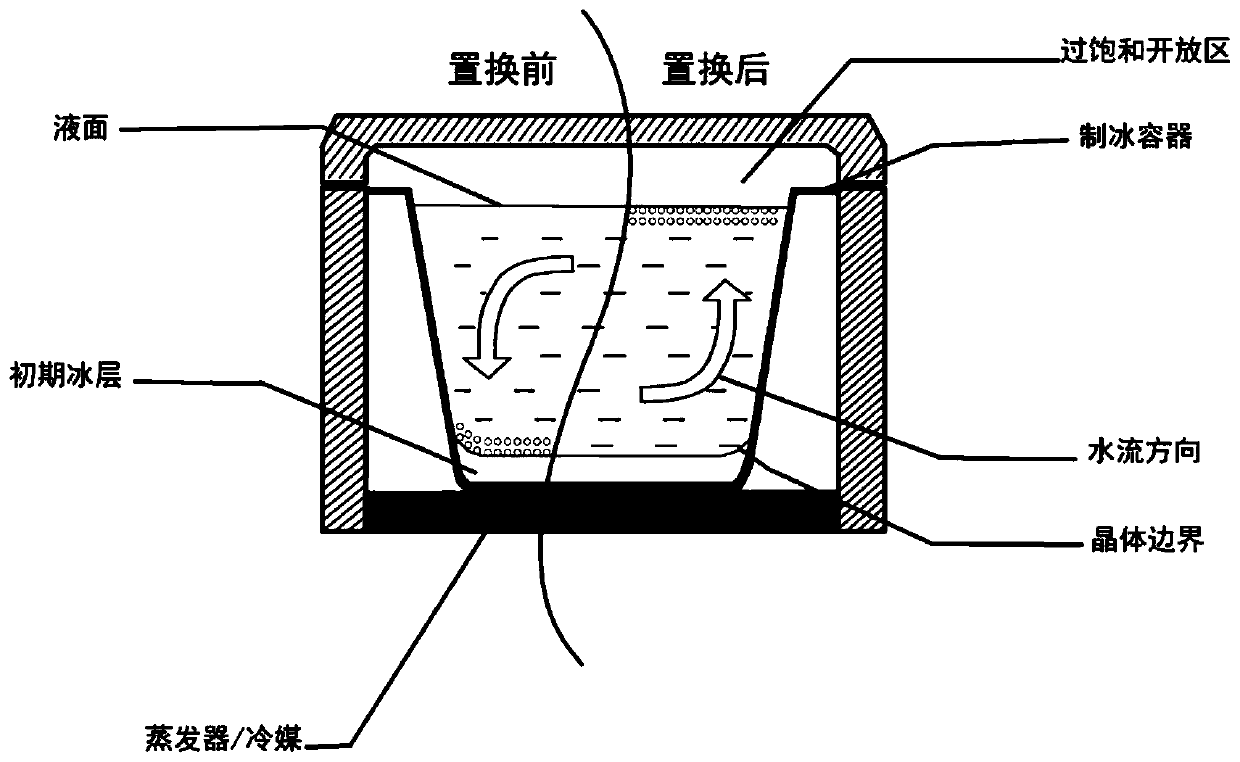

The invention relates to a making method and a making device of clean transparent ice, and belongs to the field of ice making. The making method and the making device solve the problem that an existing ice making technology cannot discharge air dissolved in water in the freezing process. The making method and the making device are characterized in that a dissolved air supersaturated open area is arranged in an ice making container, in particular, the supersaturated open area is formed between the liquid level in the ice making container and an upper opening of the ice making container, the supersaturated open area keep to communicate with external atmosphere, and the temperature of the supersaturated open area is controlled; a mechanical disturbance mode is selected according to the volumeof the ice making container, the crystal interface is washed at a constant flow rate, the dissolved air supersaturated zone formed by the crystal interface is diluted or replaced, the temperature ofthe supersaturated open area is controlled, and the water body liquid level temperature is improved; and a clean transparent ice body is obtained by controlling the physical conditions in the icing environment. According to the making method and the making device, dissolved air and impurities in water are discharged in the icing process, and meanwhile, the ice making device which is simple in structure and convenient to use is provided for making the clean transparent ice.

Owner:HARBIN ENG UNIV

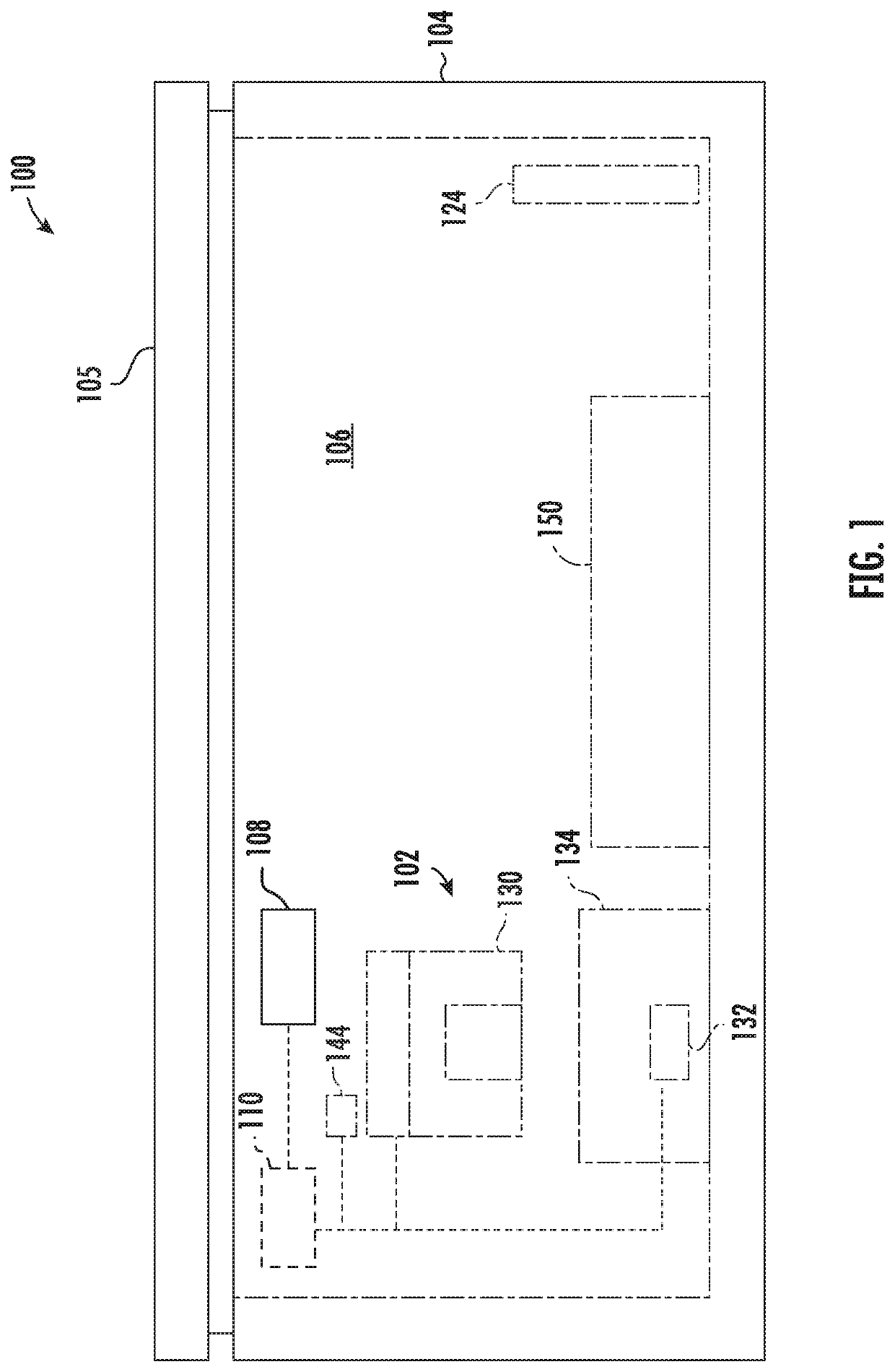

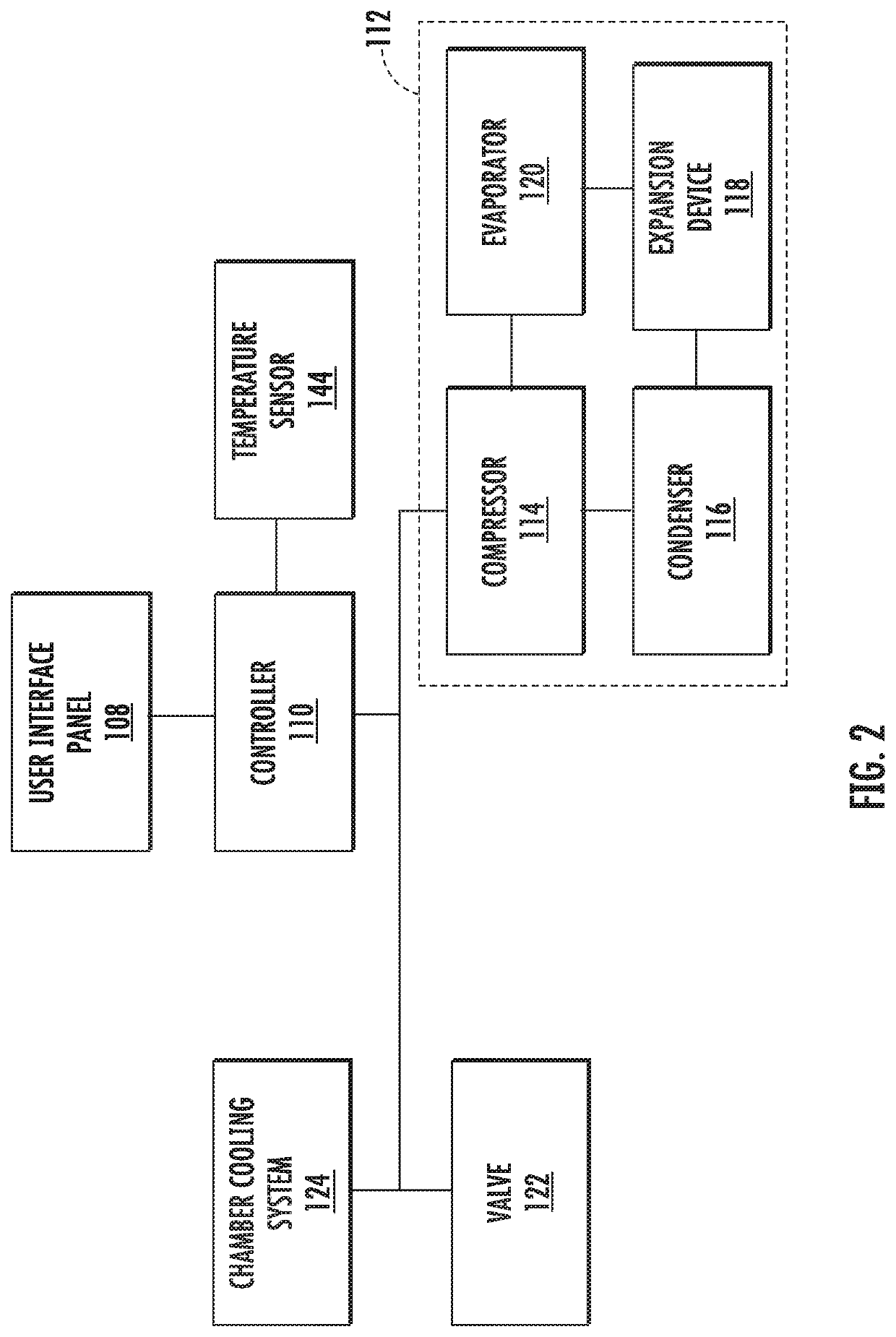

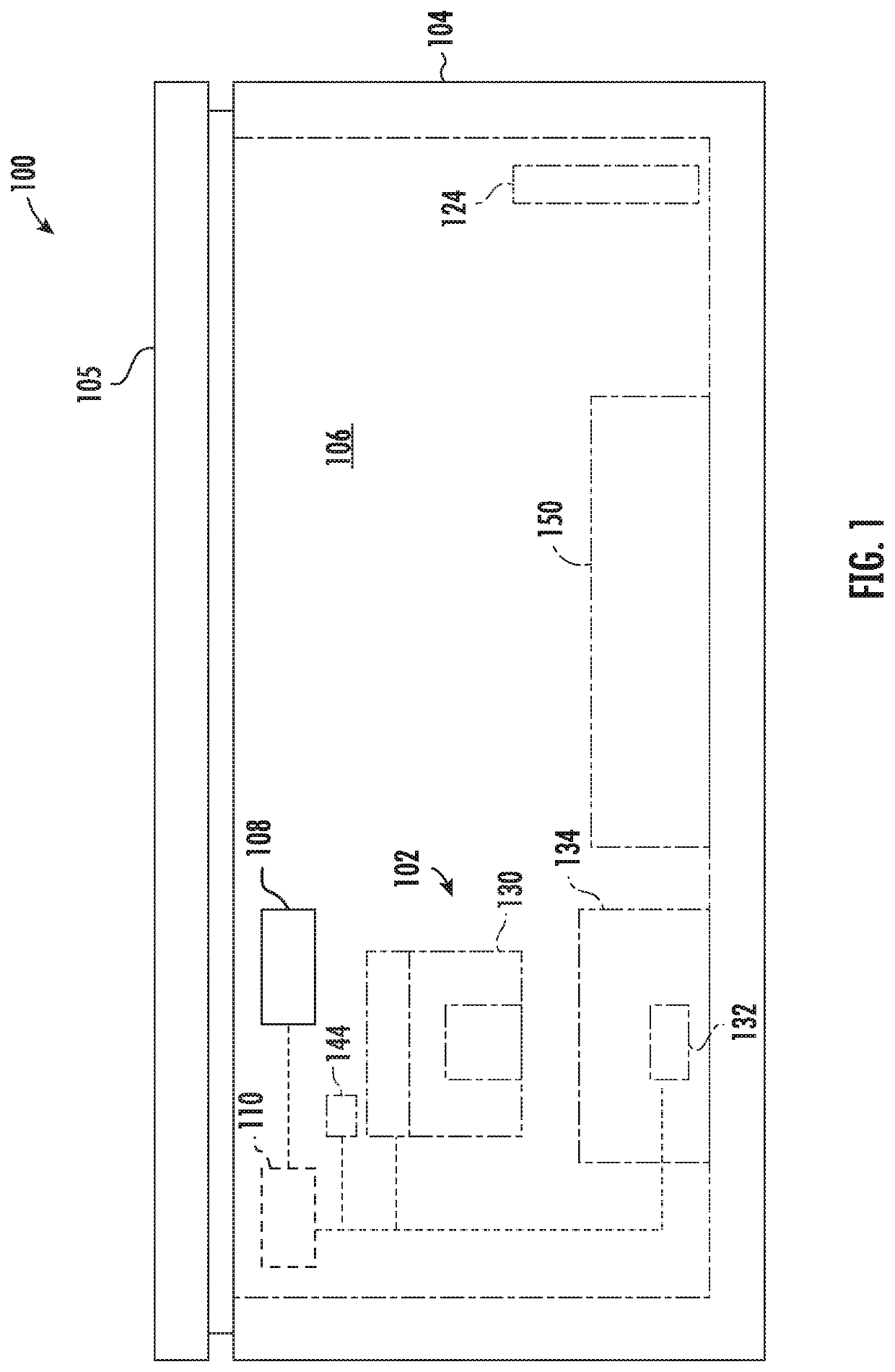

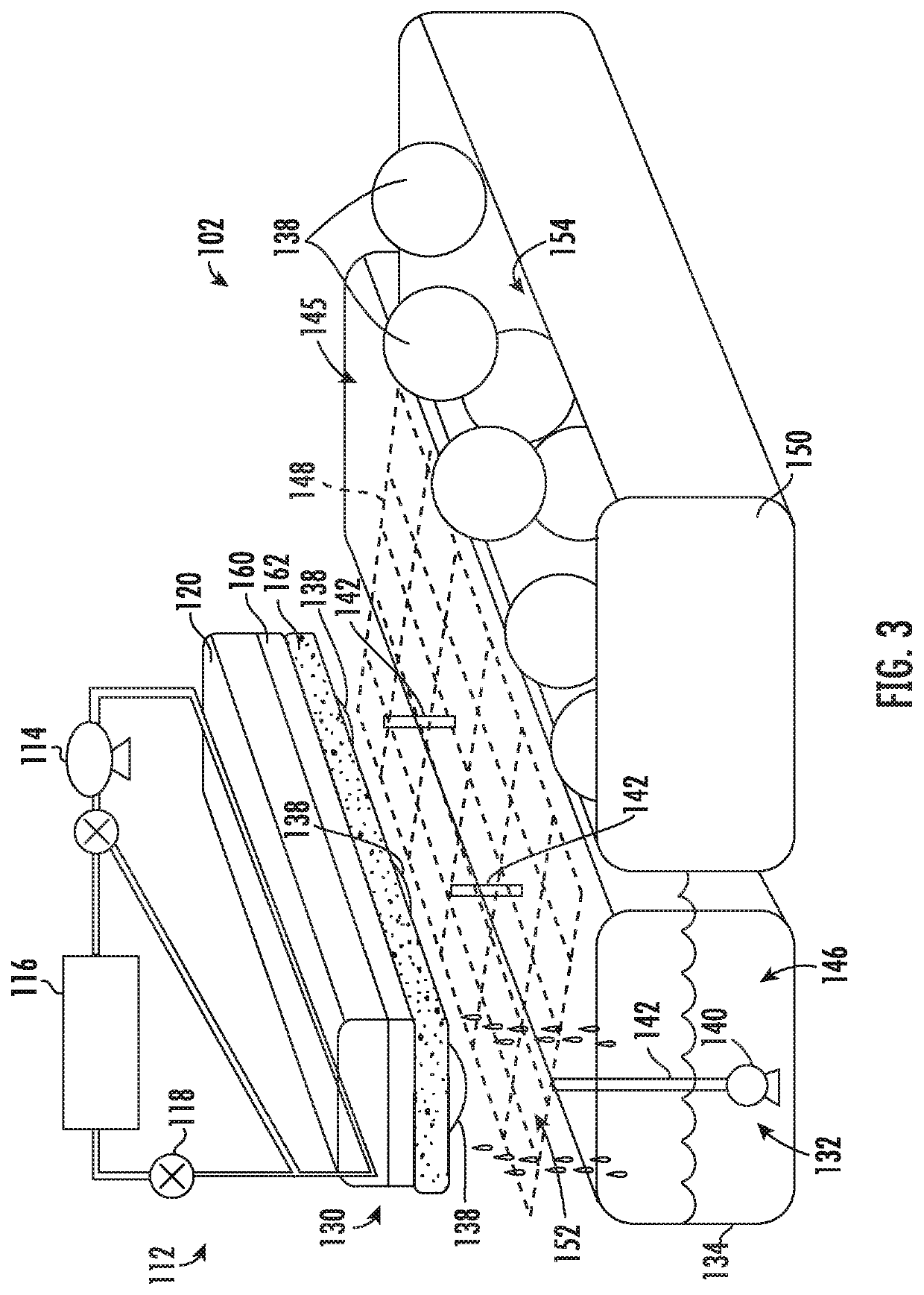

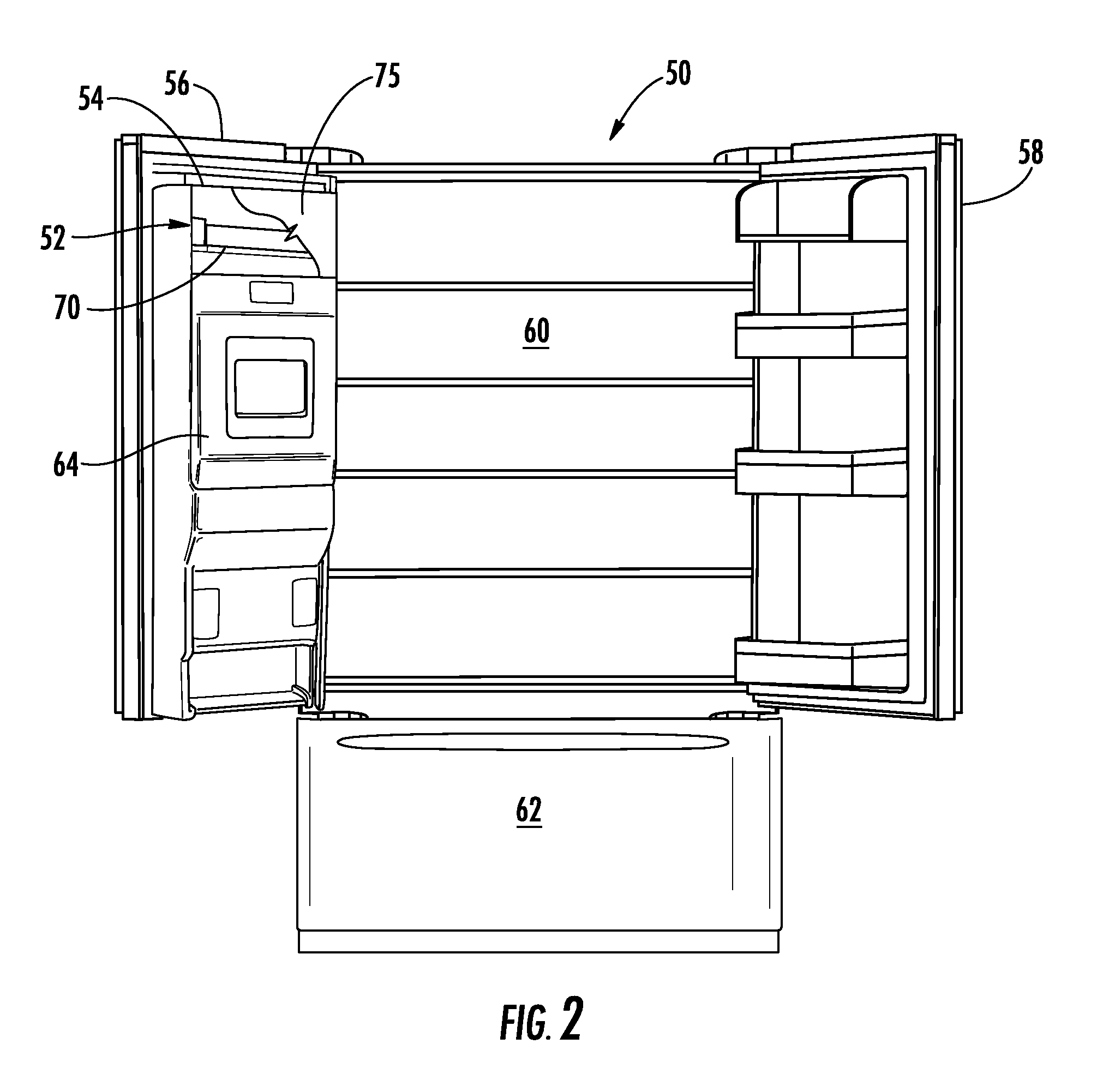

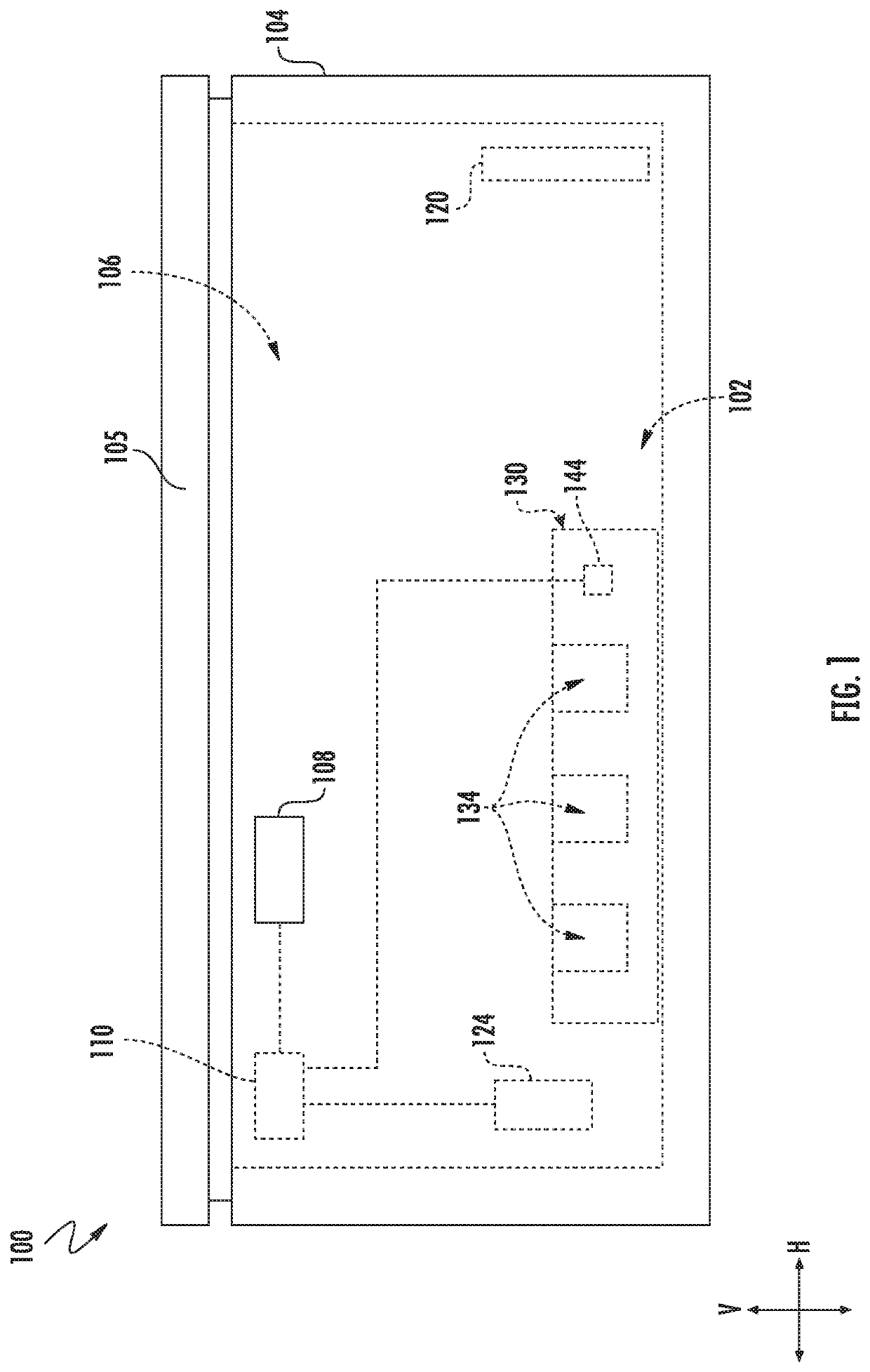

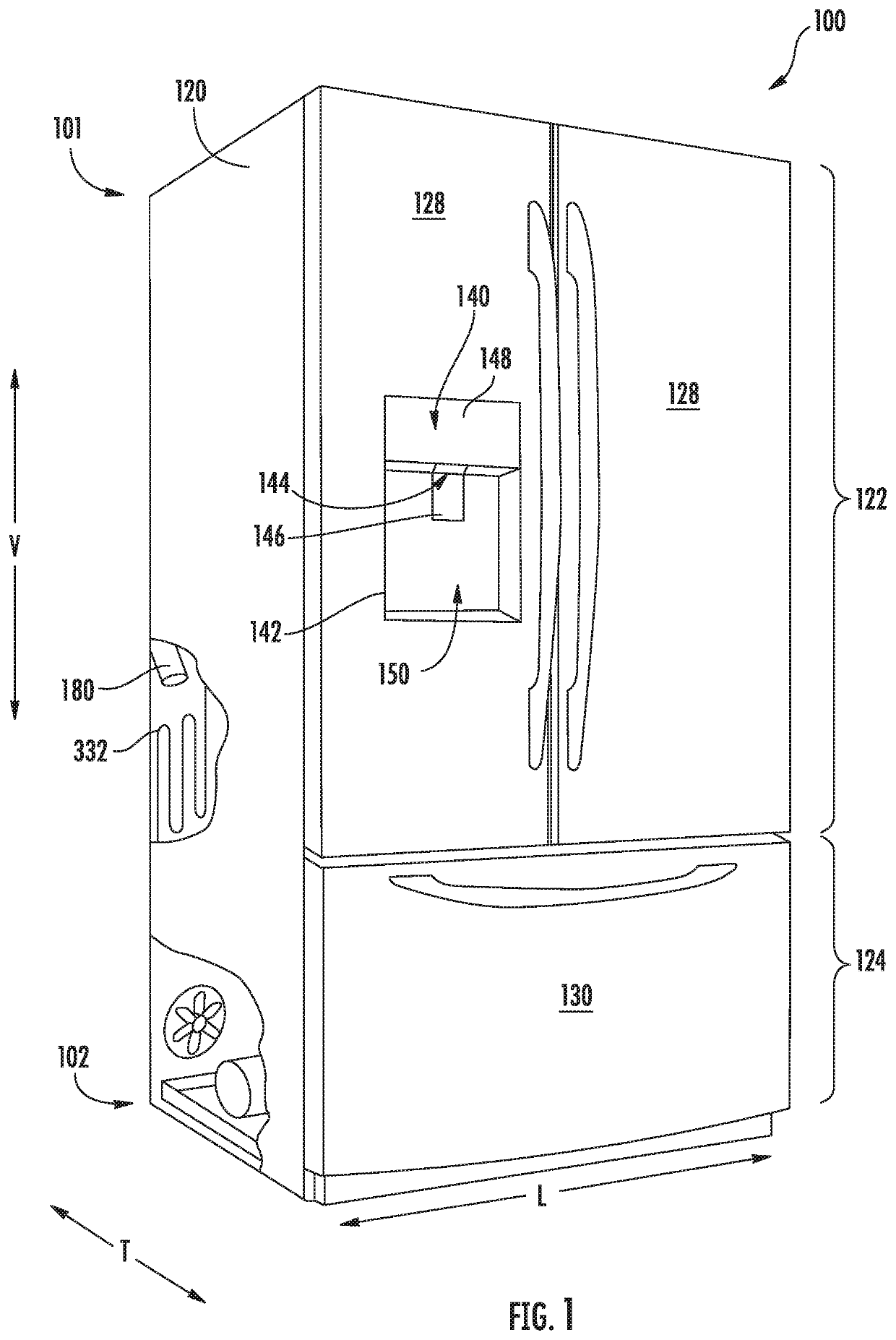

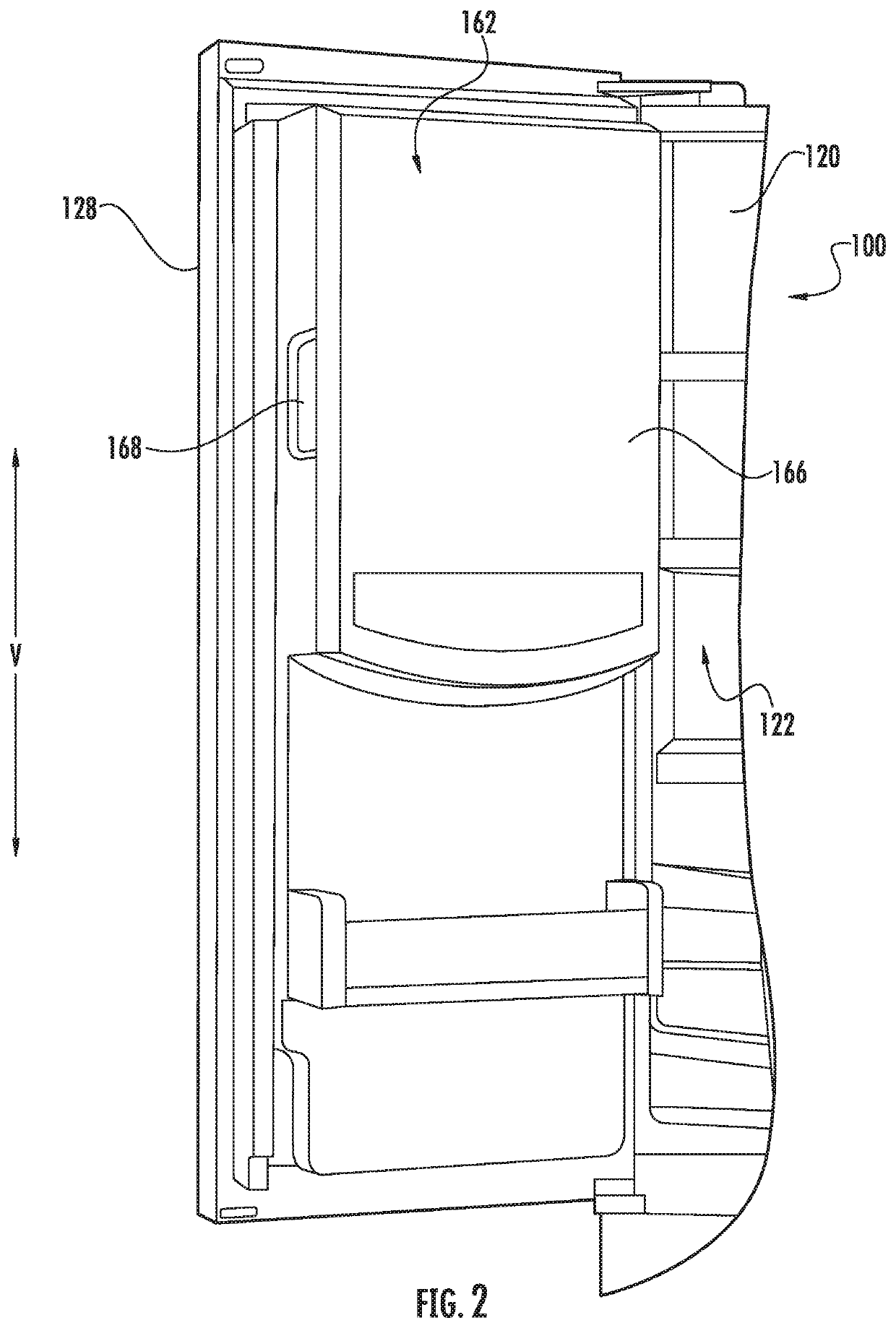

Clear ice maker with warm air flow

An ice-making apparatus for an appliance having a housing with an interior volume and an ice tray horizontally suspended in the interior volume. The ice tray has a cold plate with a top surface and a bottom surface and a containment wall surrounding an edge portion of the cold plate to retain water. A cooling source is thermally coupled to the bottom surface of the cold plate. An intake conduit extends into the interior volume over the ice tray and is configured to draw ambient air into the interior volume over the ice tray, and the ambient air is above freezing.

Owner:WHIRLPOOL CORP

Ice melting device and method for electric transmission and distribution circuit in winter

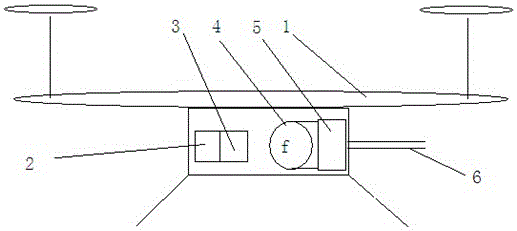

InactiveCN105977895AAvoid failures such as damageGuaranteed uptimeOverhead installationApparatus for overhead lines/cablesThermodynamicsFlight vehicle

The invention belongs to the technical field of power equipment maintenance, and discloses an ice melting device and method for an electric transmission and distribution circuit in winter. The ice smelting device adopted by the method comprises an ice smelting aircraft; the ice smelting aircraft is composed of a monitoring device 2, an ice smelting device and a flying device 1; one side of the lower part of the flying device 1 is provided with a monitoring device, and the other side of the lower part of the flying device 1 is provided with the ice smelting device; the monitoring device is composed of a detector 2 and an actuator 3; the ice smelting device is composed of an f fan 4, a heating device 5 and an air duct 6; an air outlet of the f fan 4 is communicated with an input end of the heating device 5; and an output end of the heating device 5 is communicated with the air duct 6. The ice melting device and the method for the electric transmission and distribution circuit in winter provided by the invention can monitor and clear ice covering of the electric transmission and distribution circuit in a running process, maintain power transmission and transformation, and guarantee the reliable operation of electric transmission and transformation equipment.

Owner:XINAN COUNTY ELECTRIC POWER +1

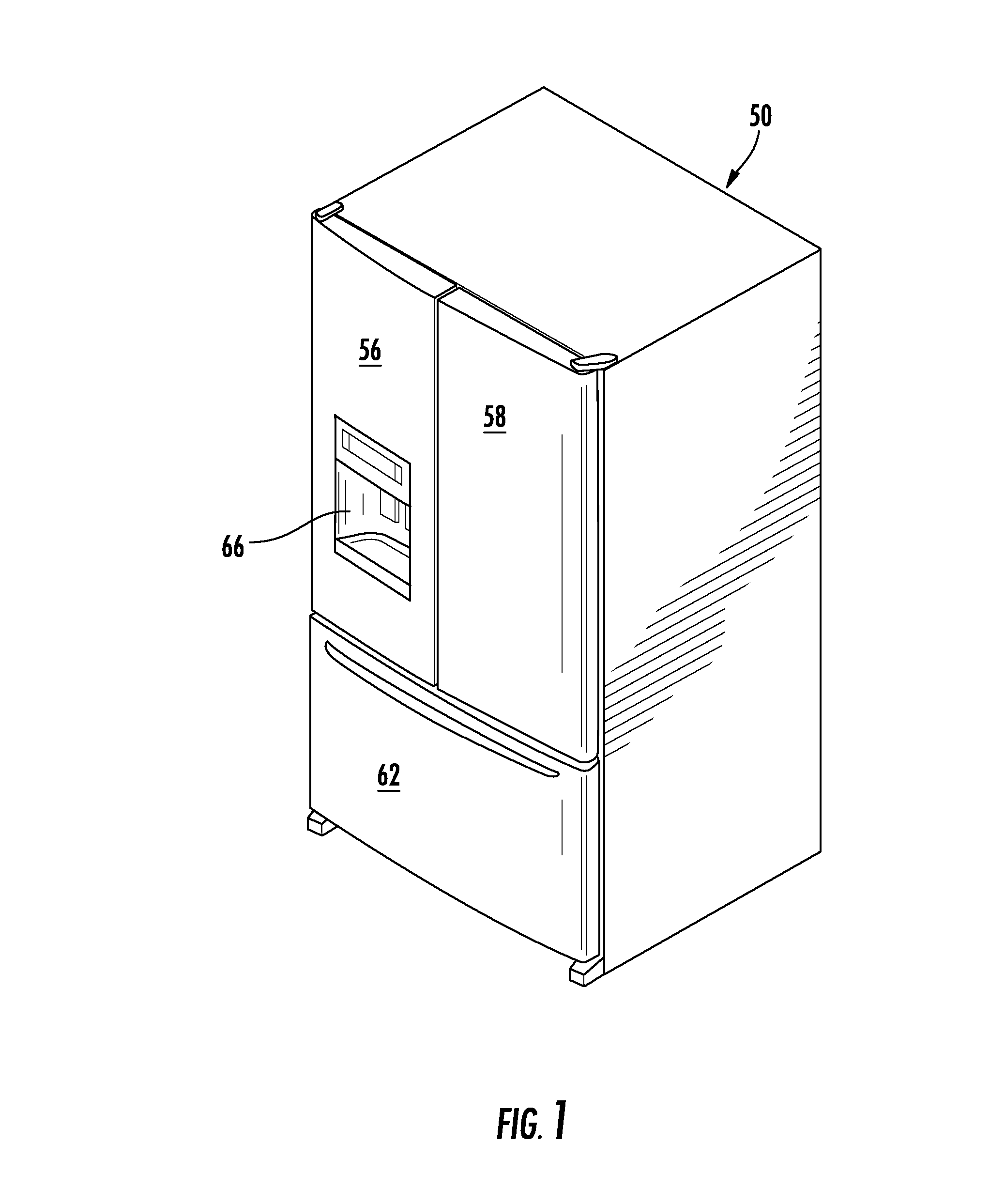

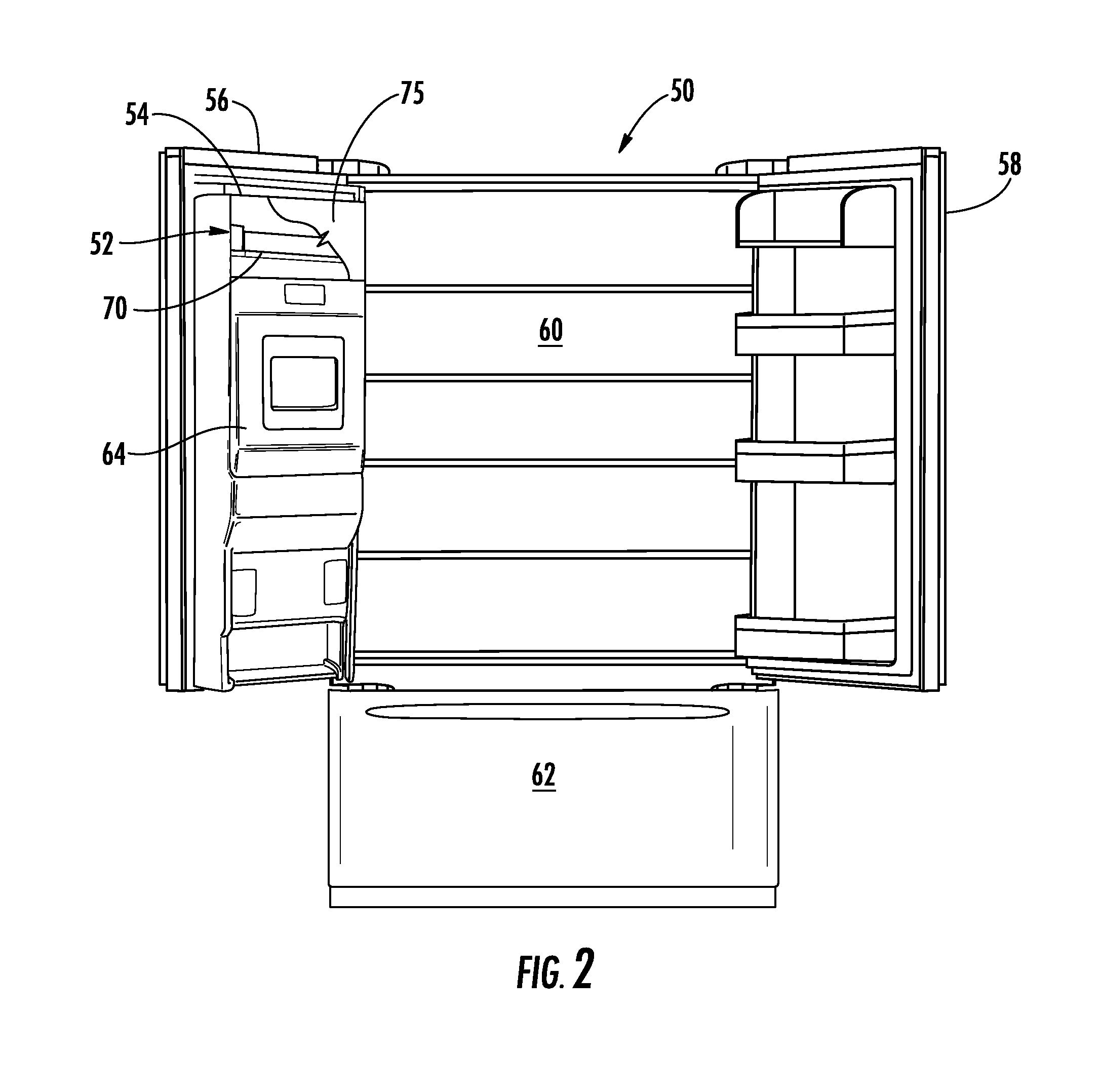

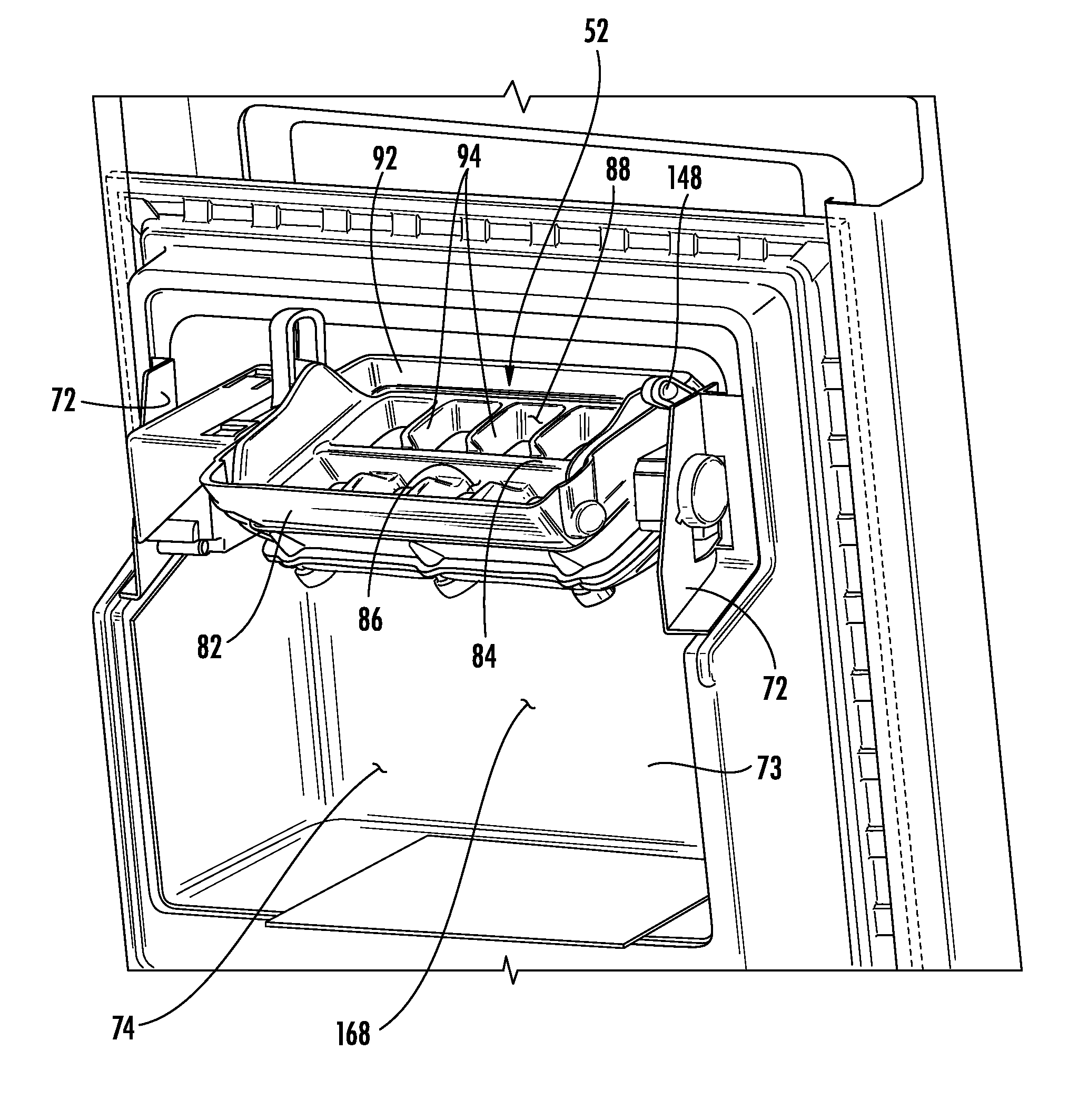

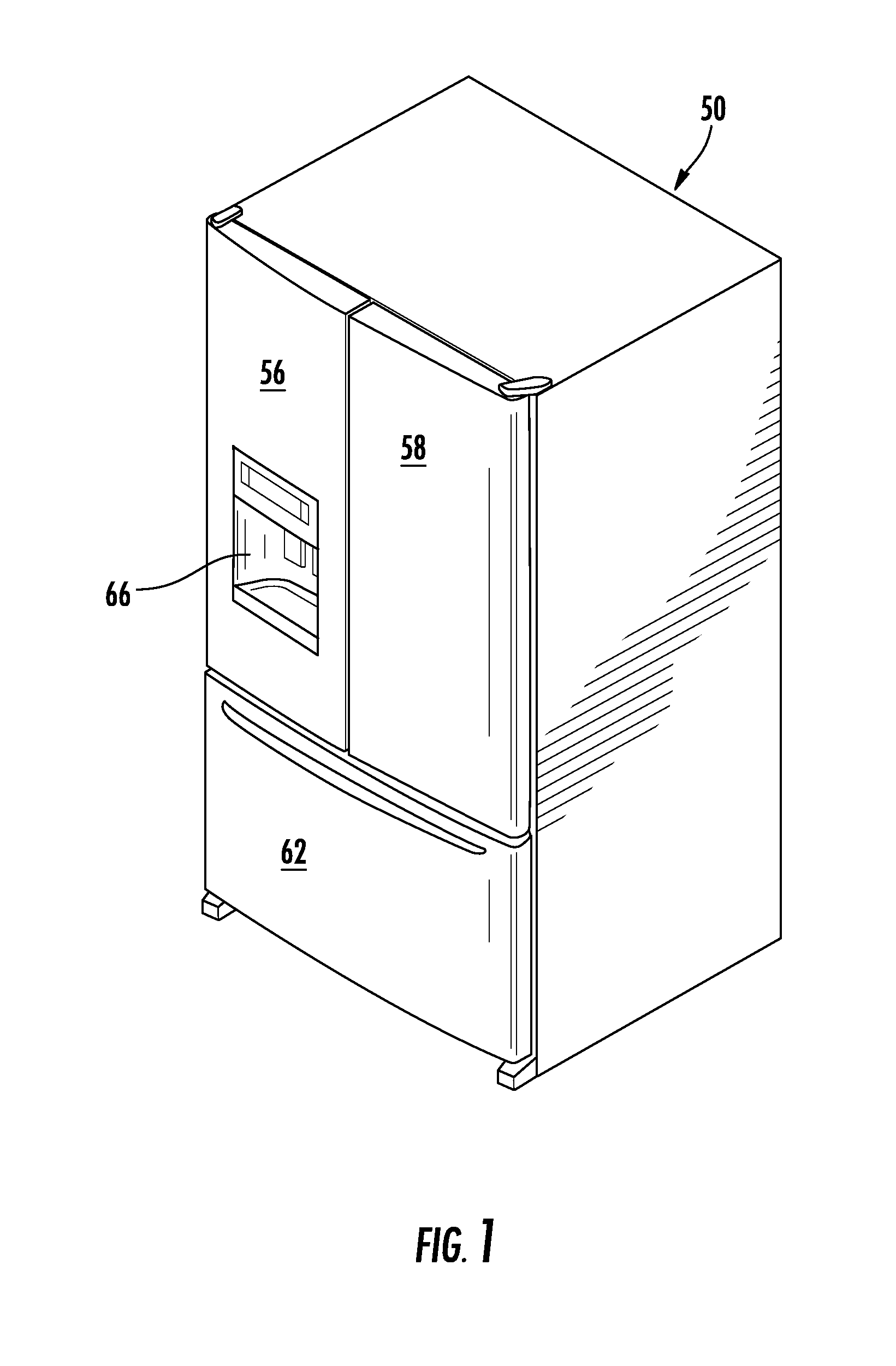

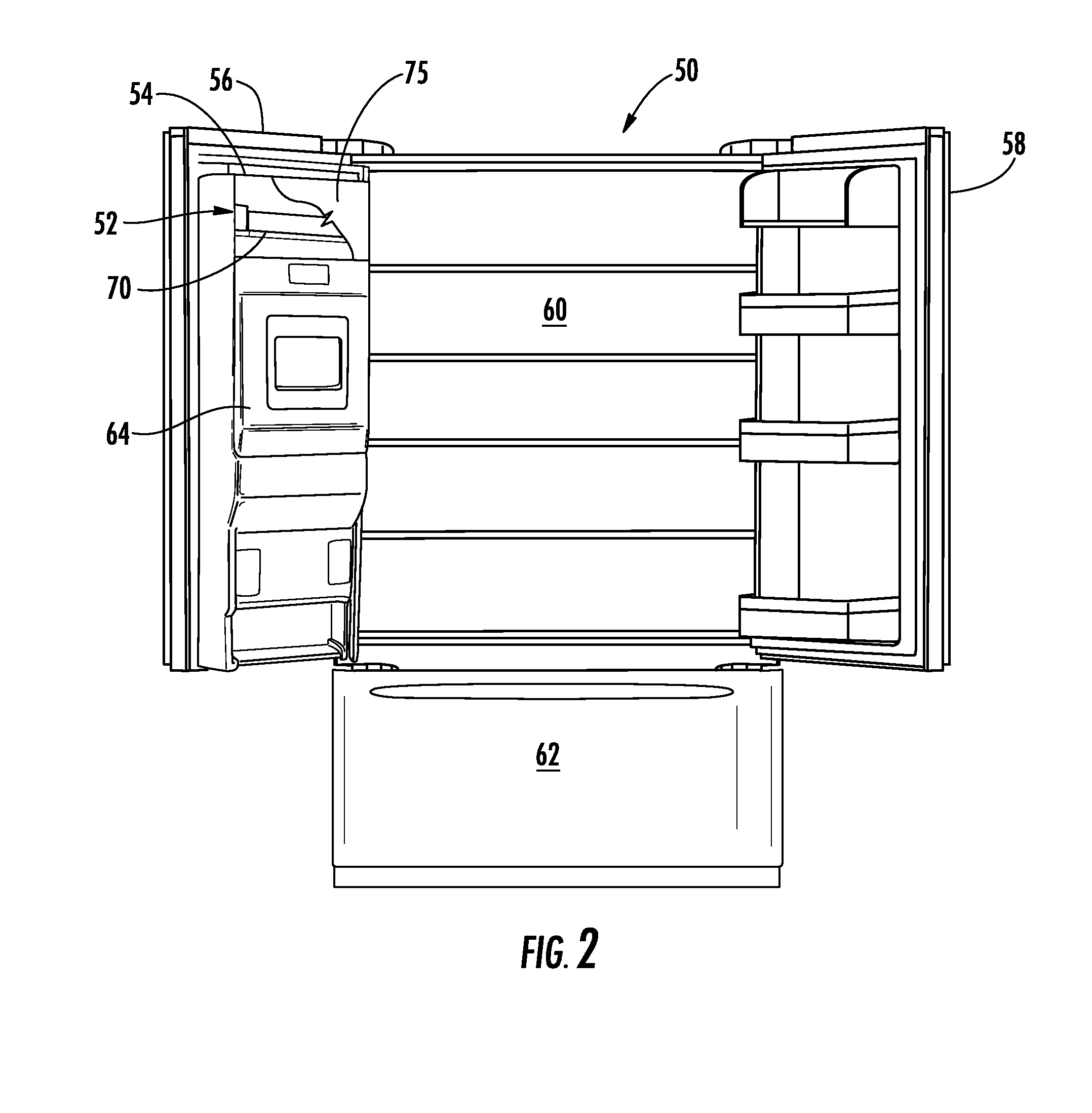

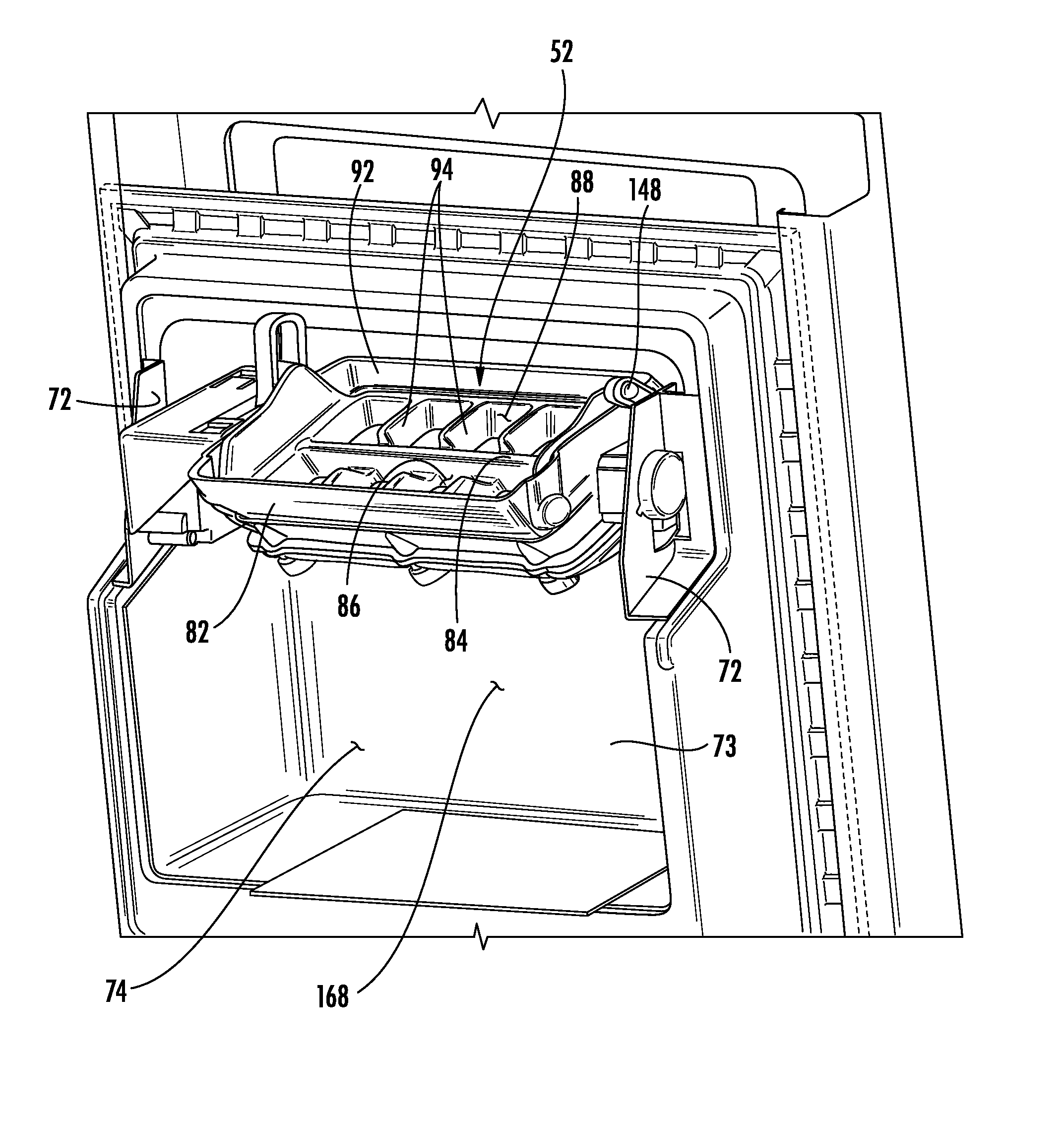

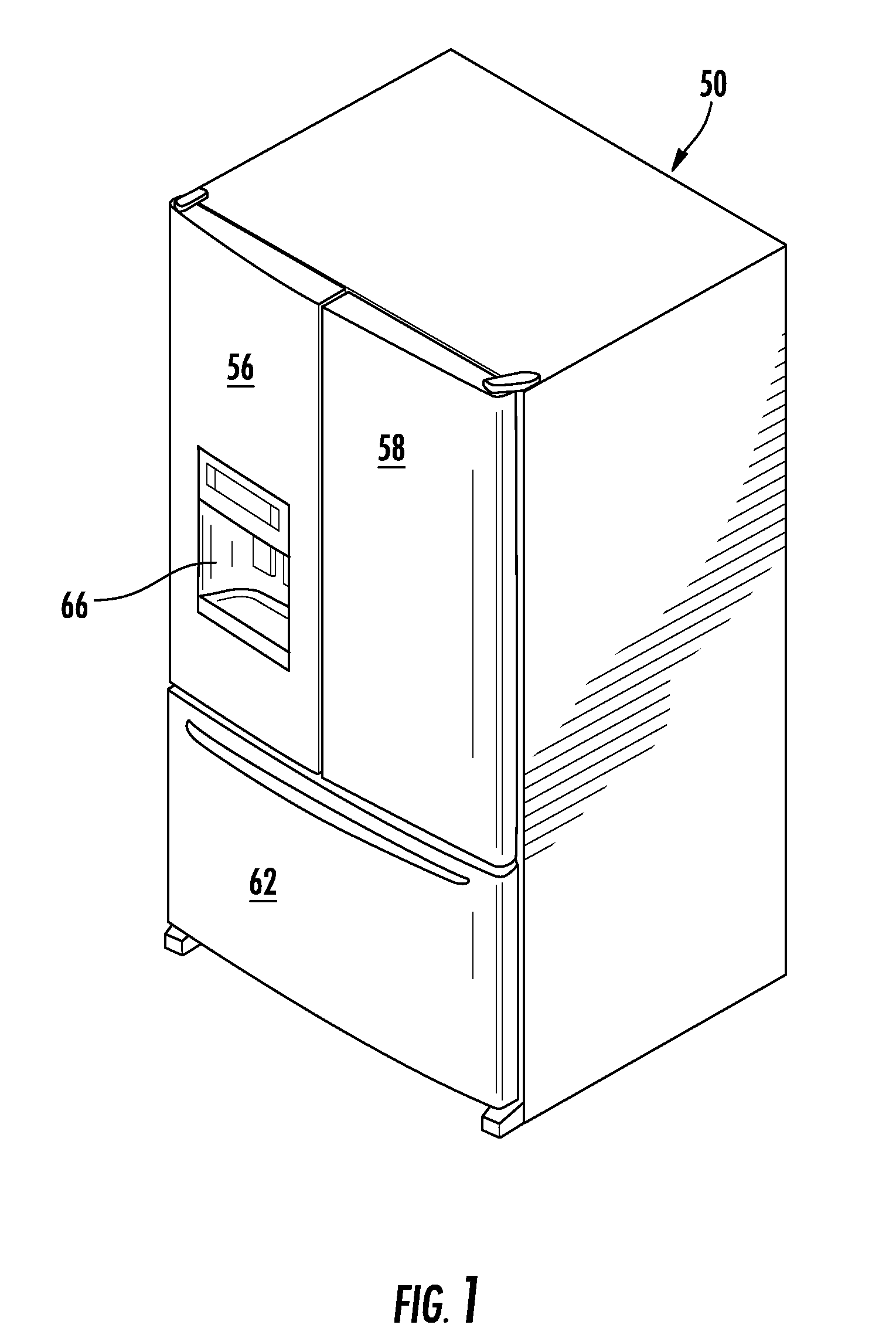

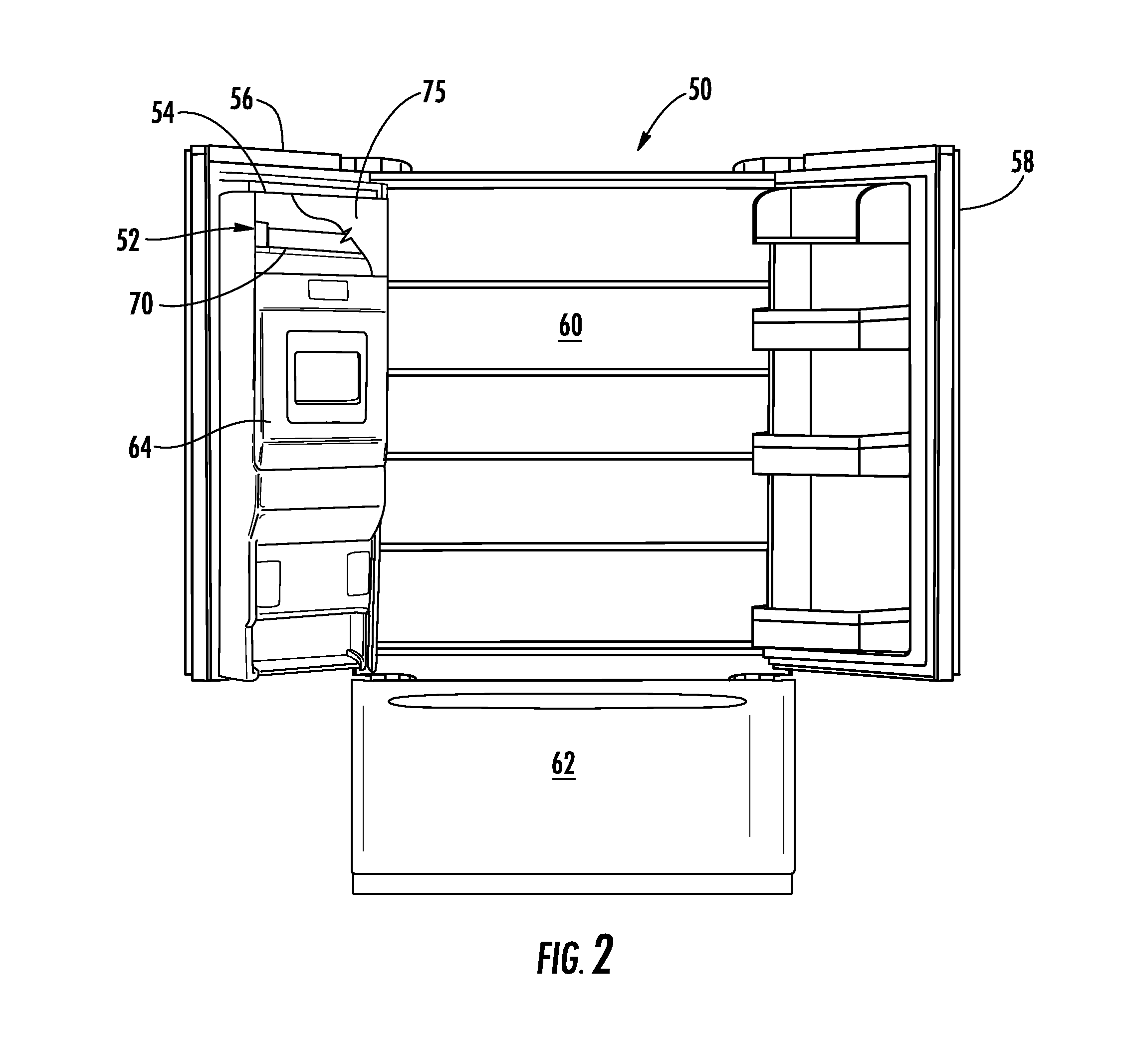

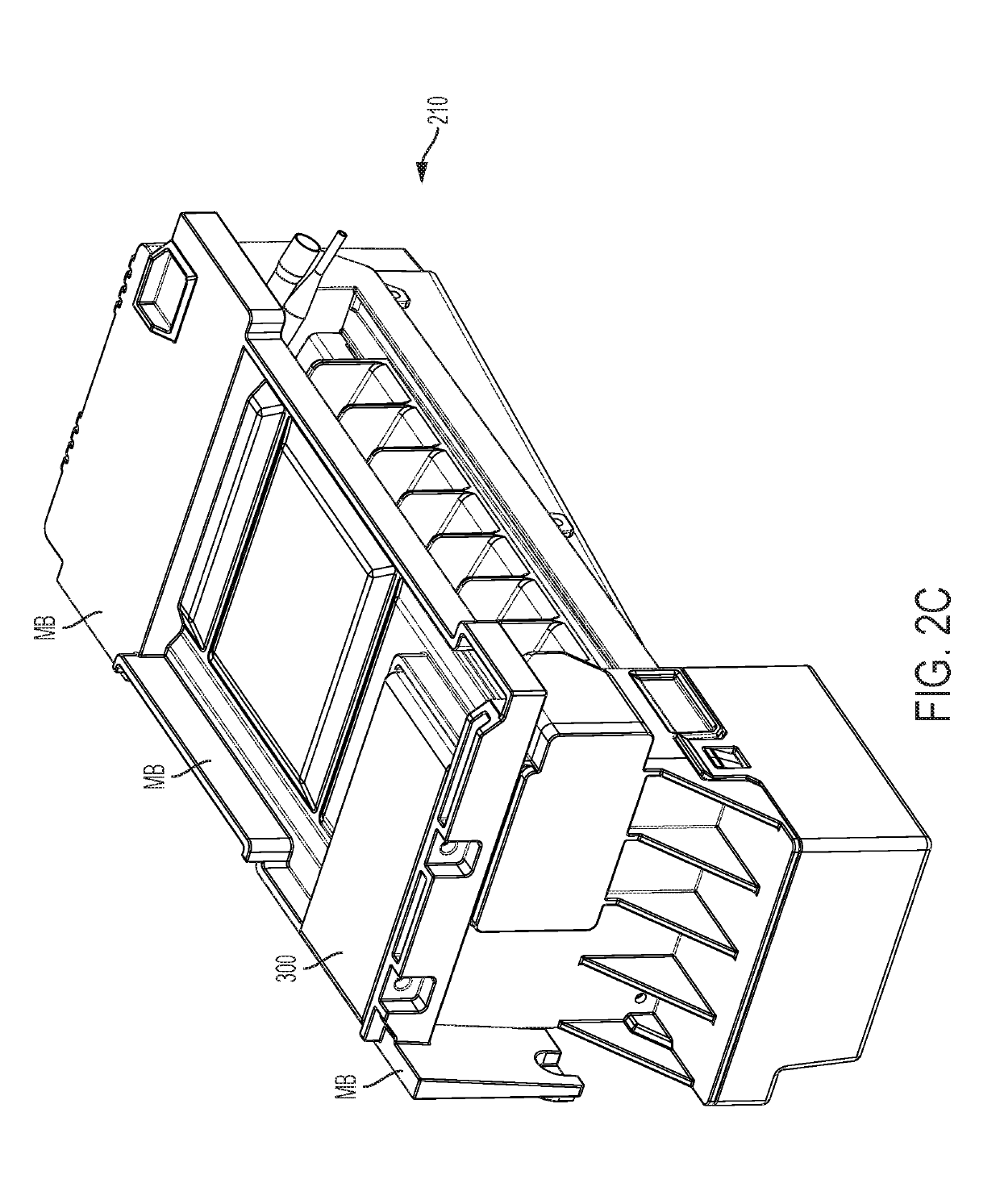

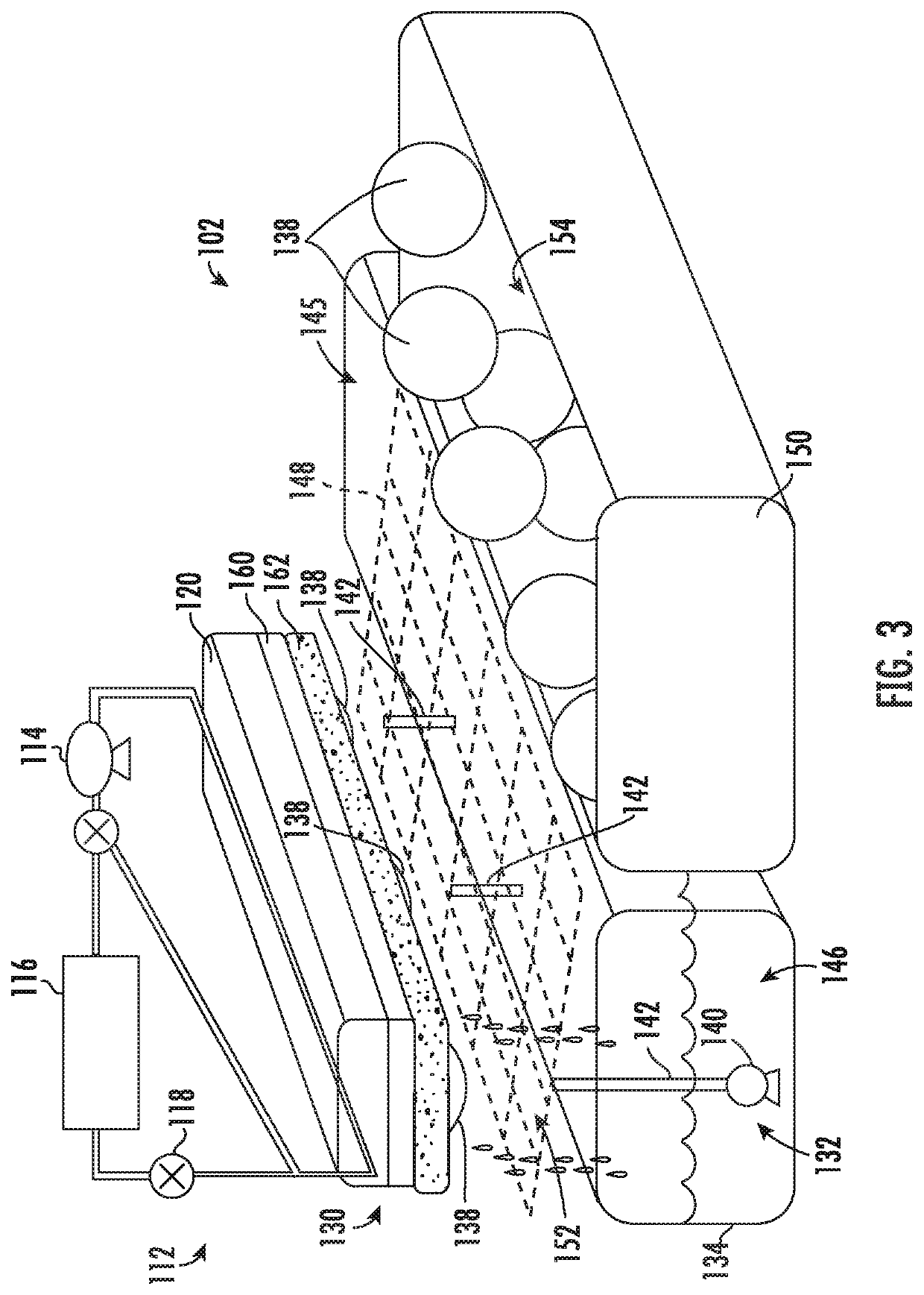

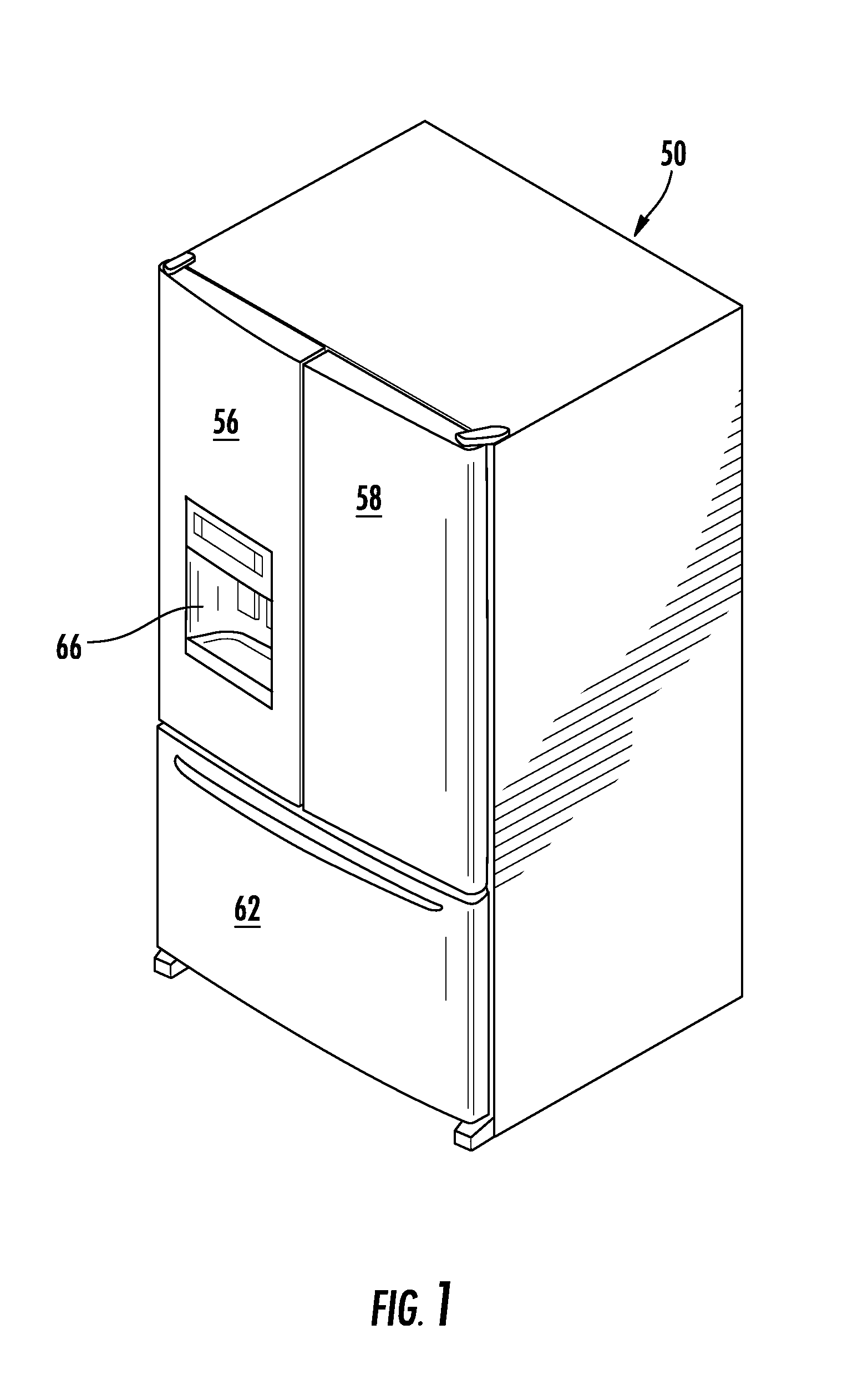

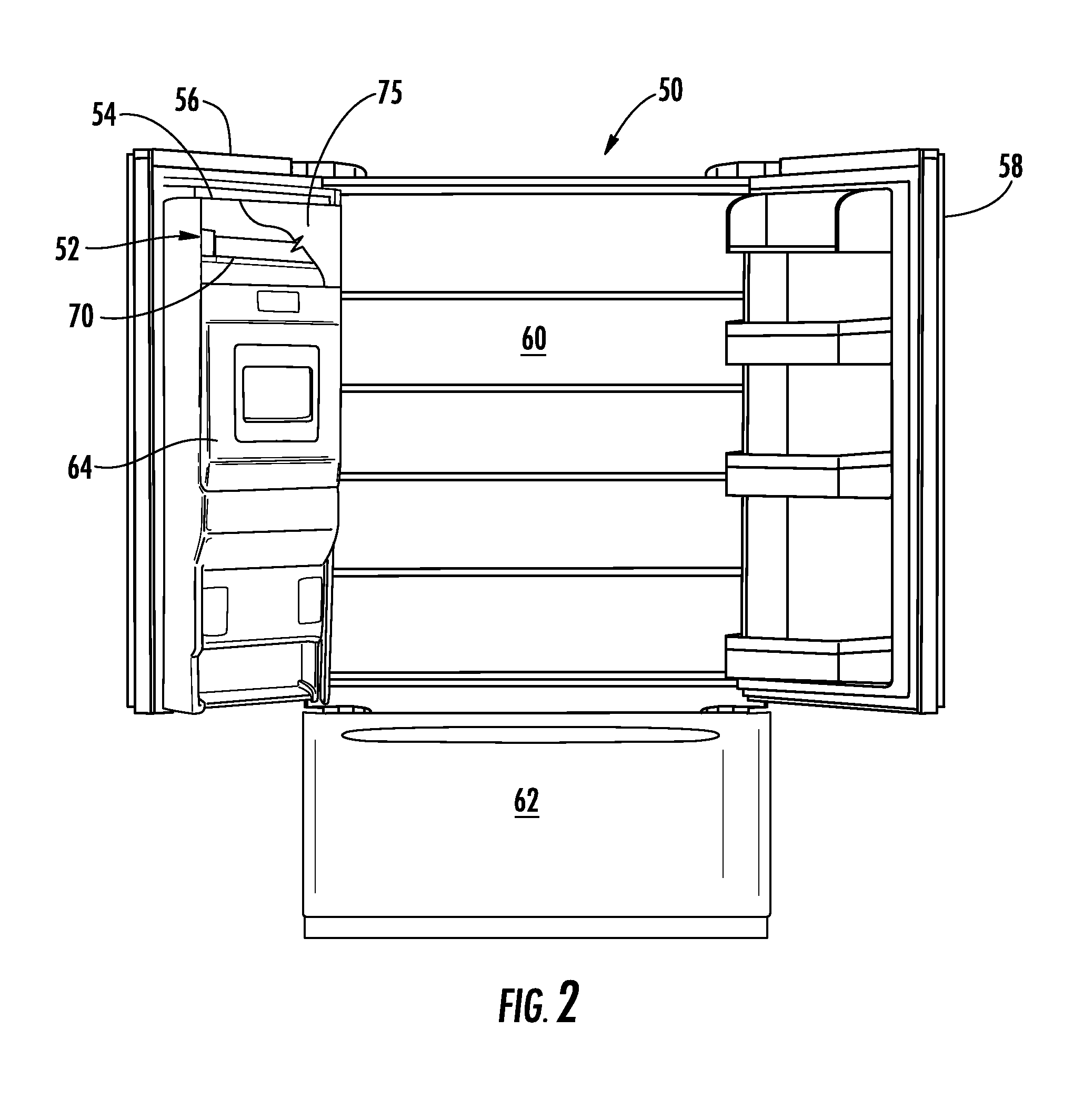

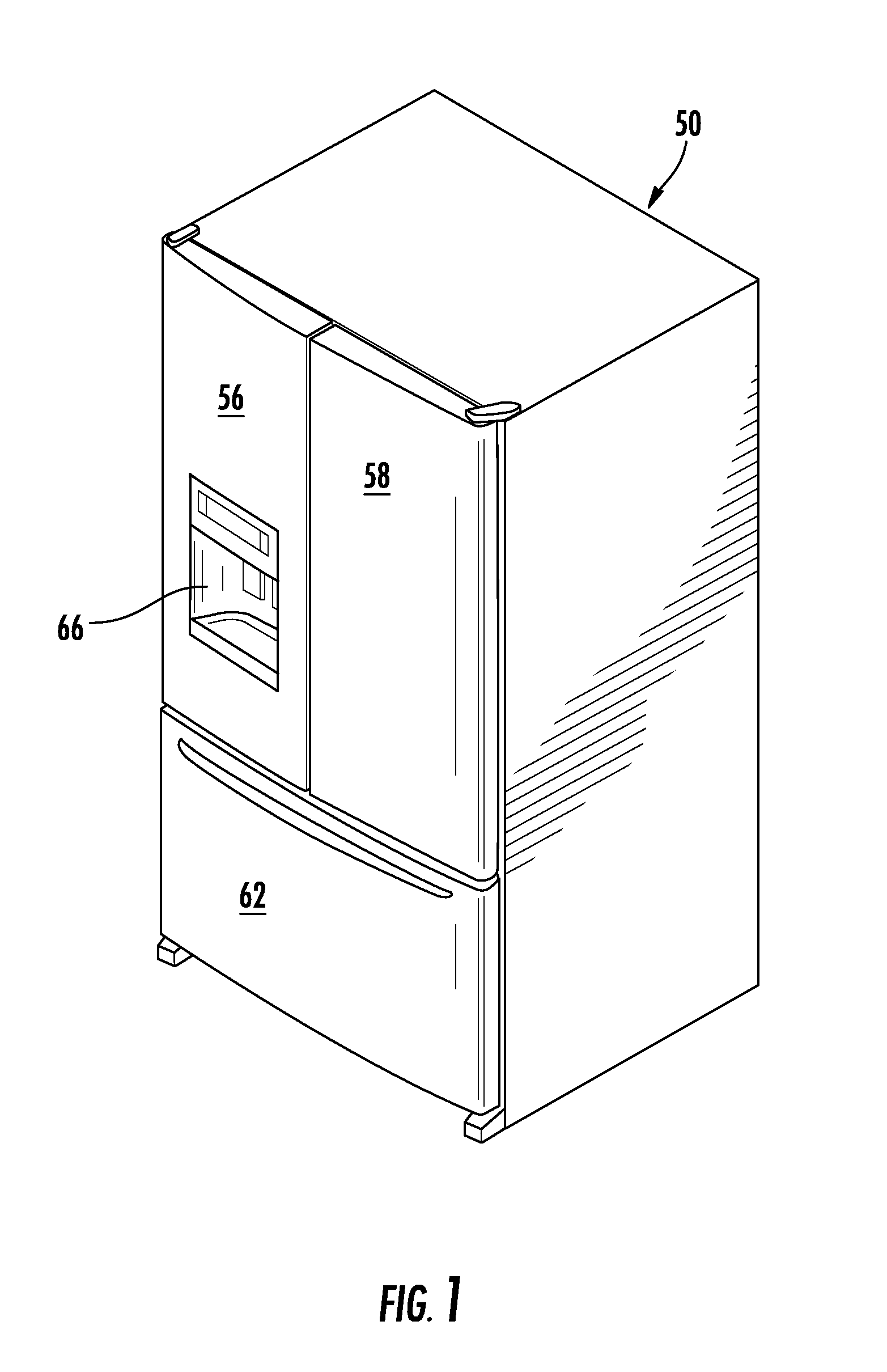

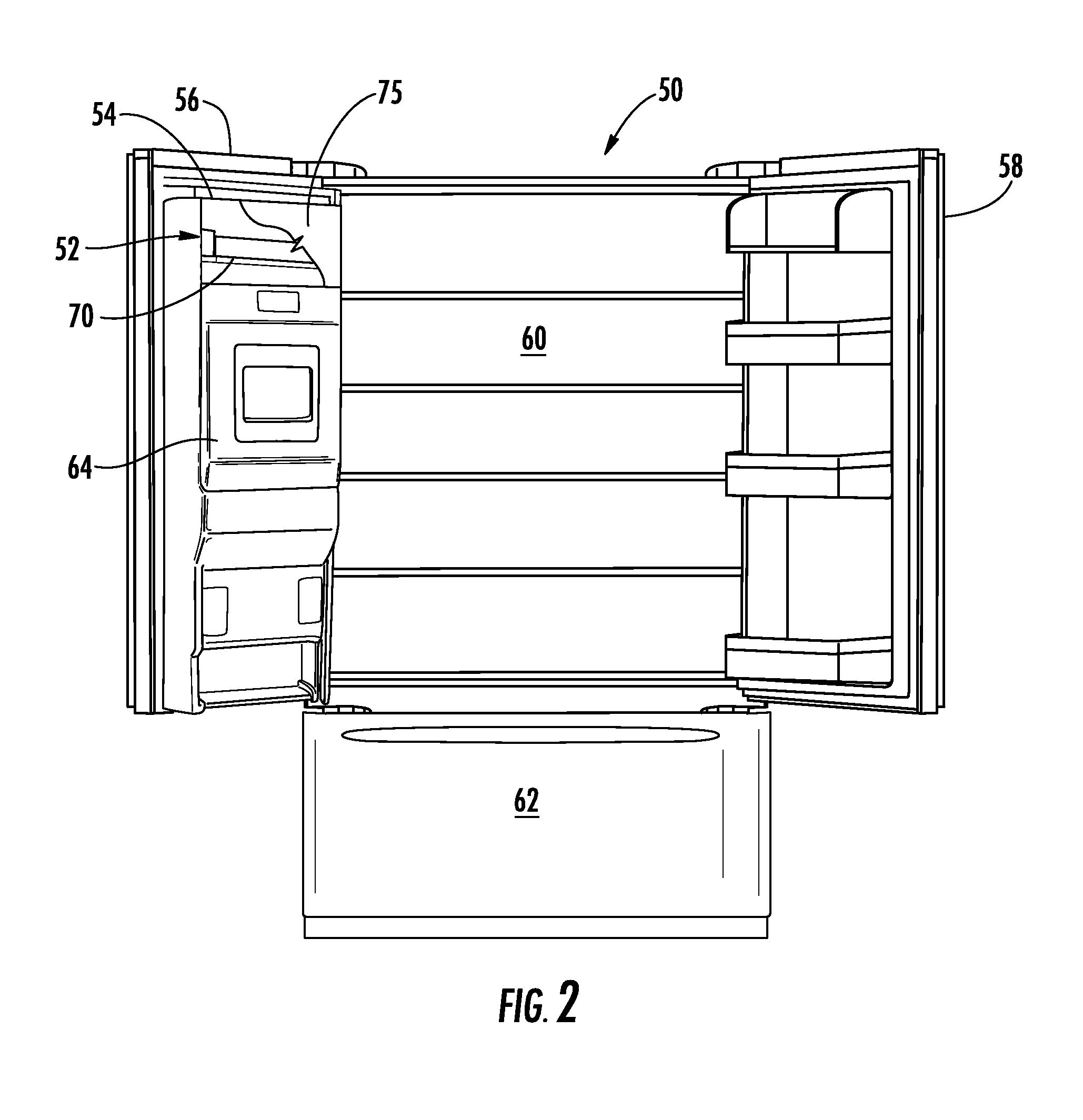

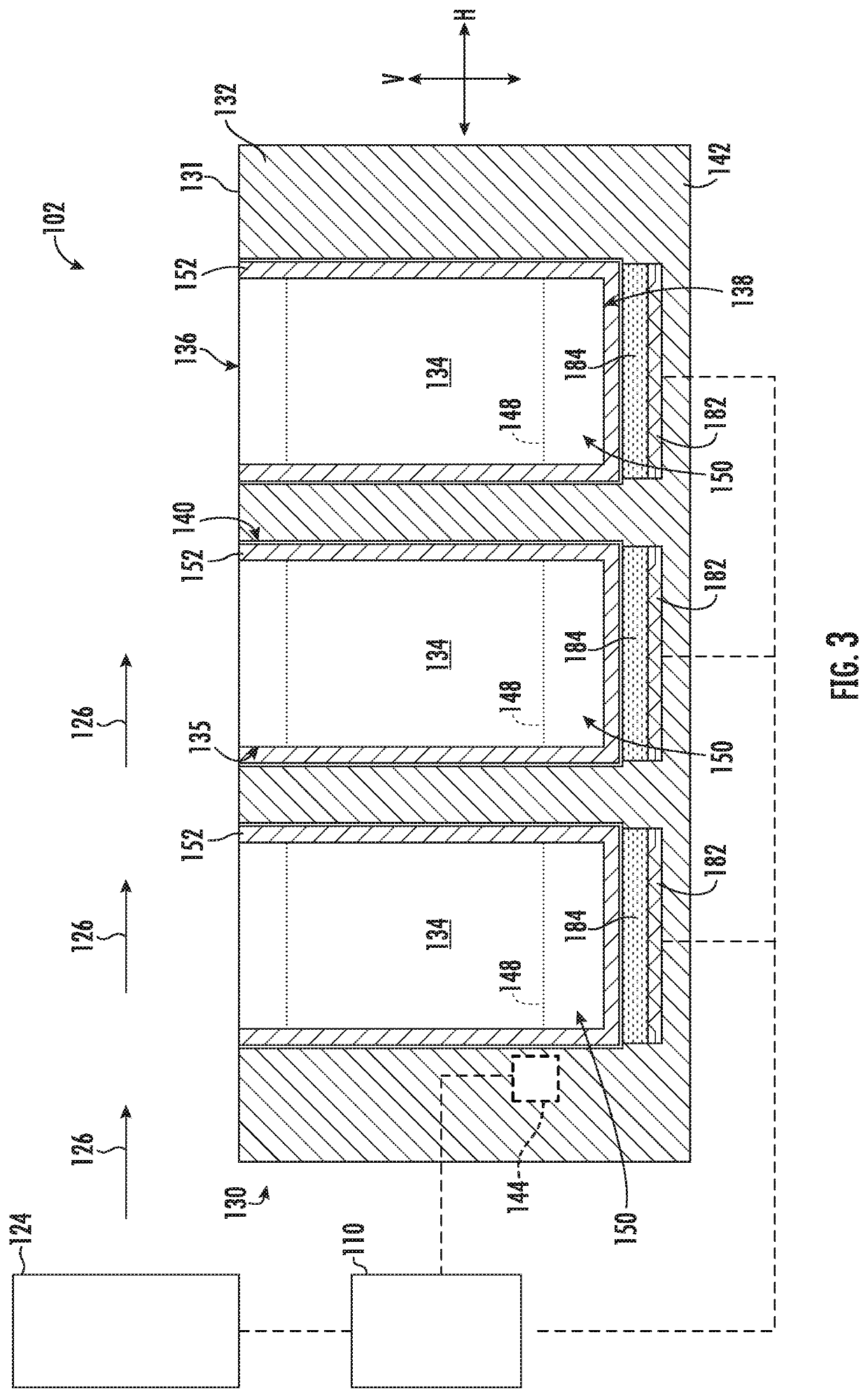

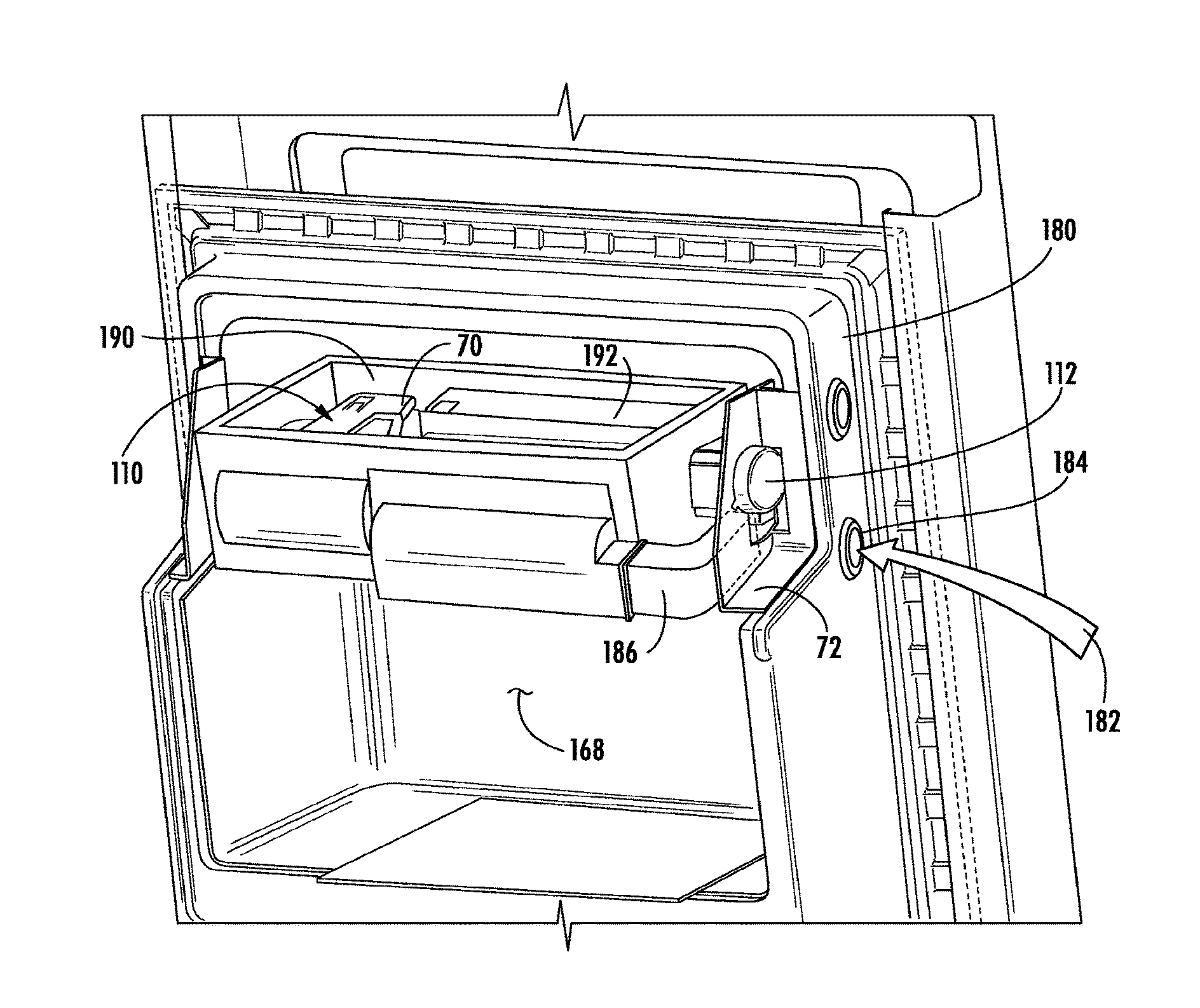

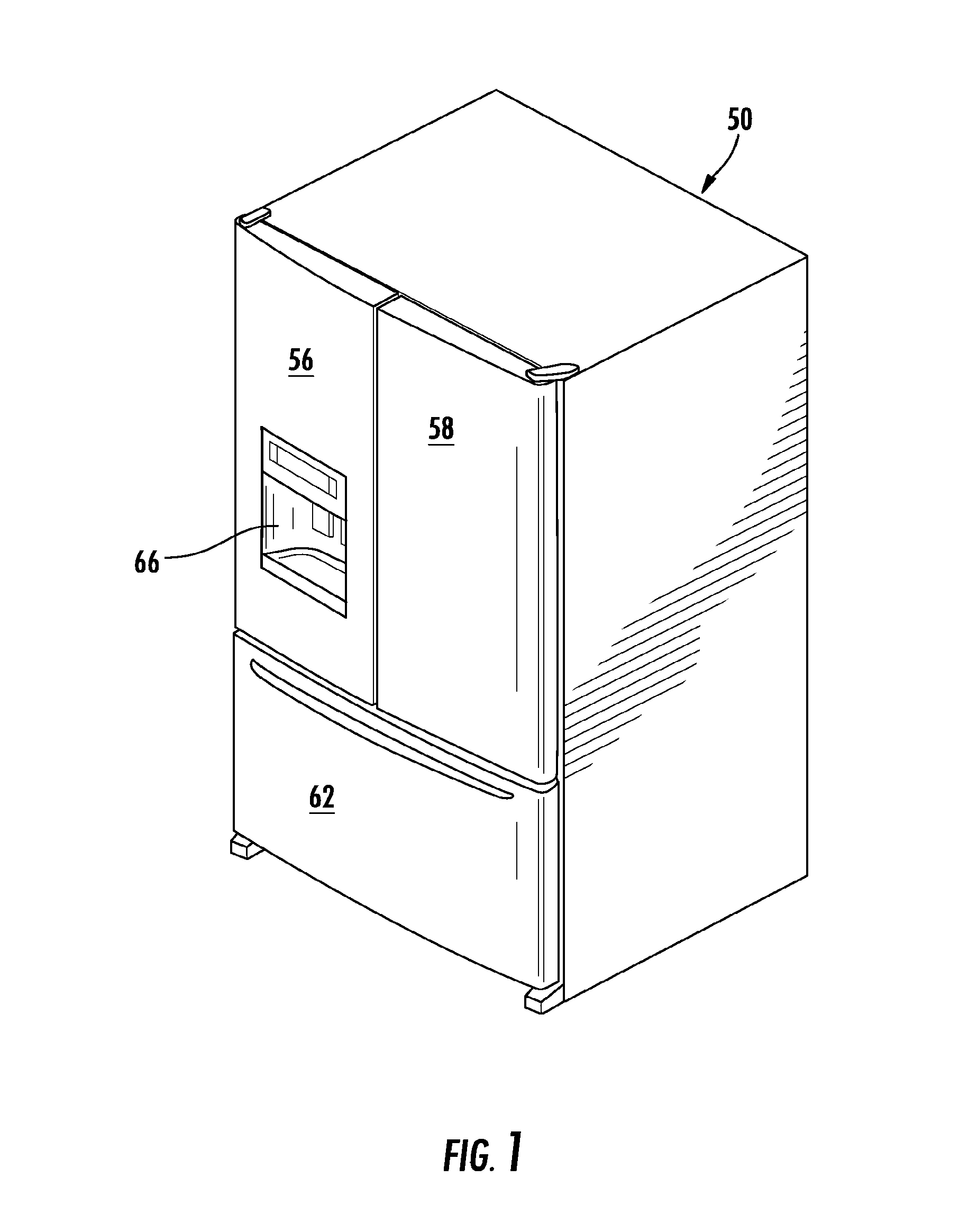

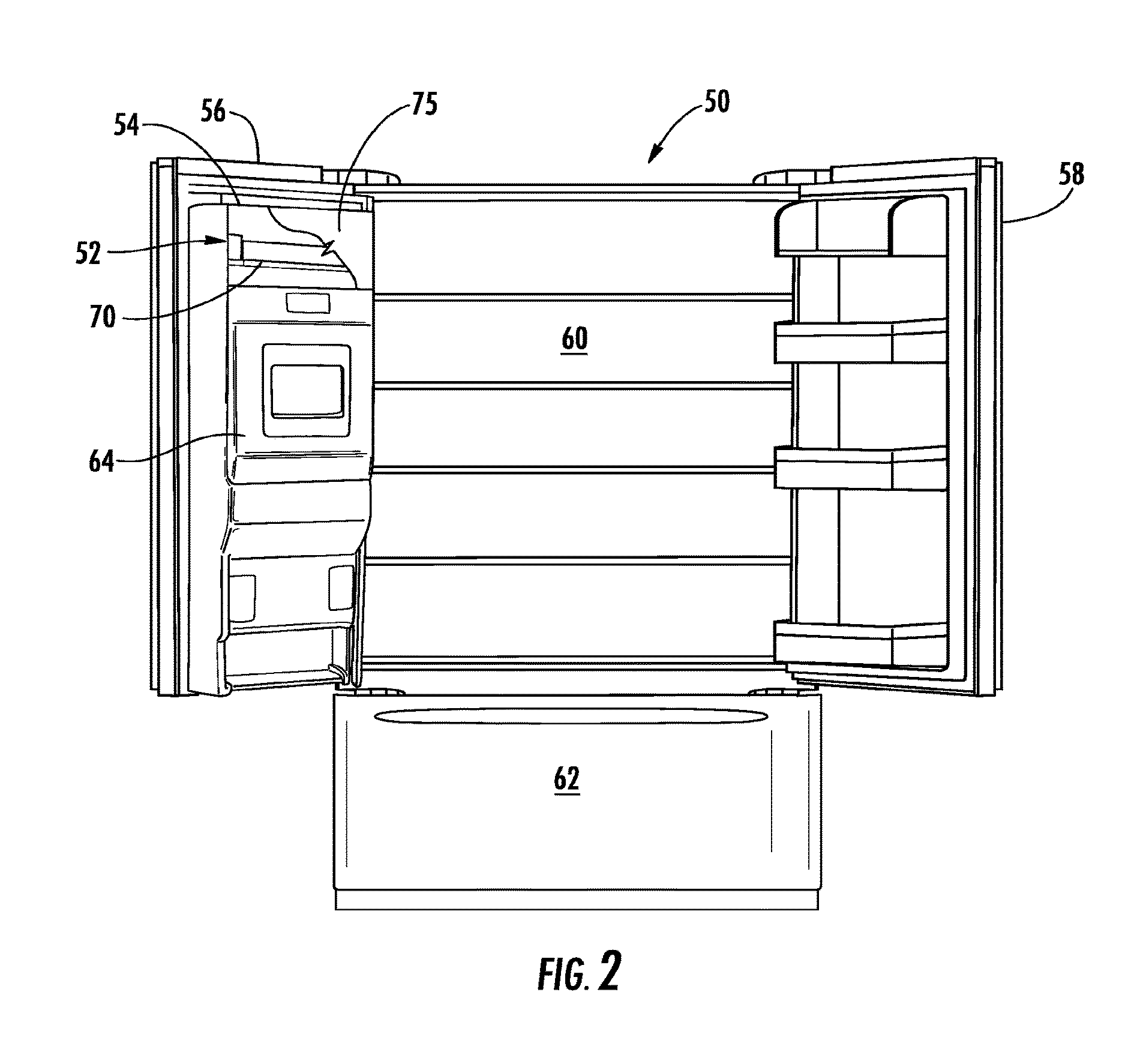

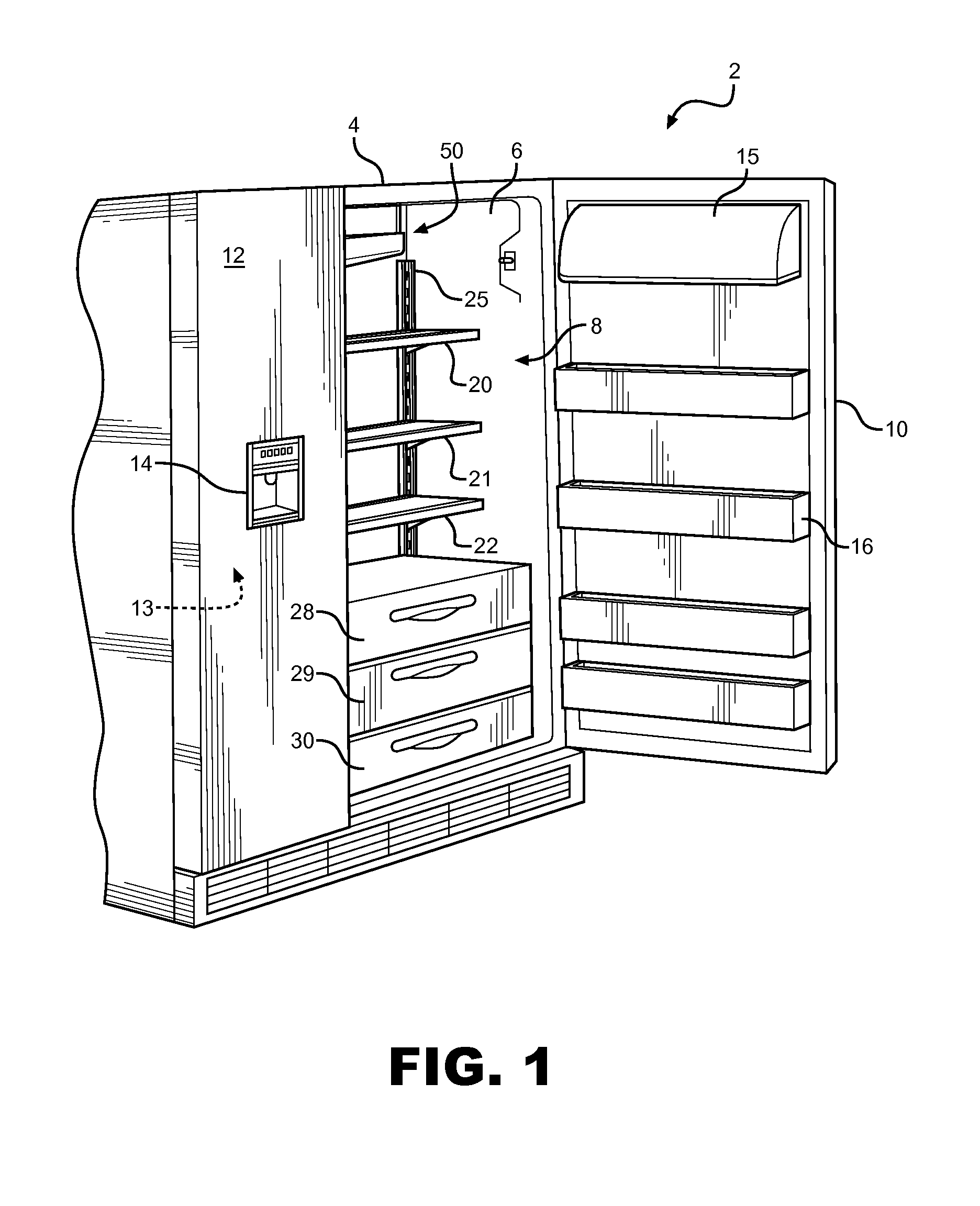

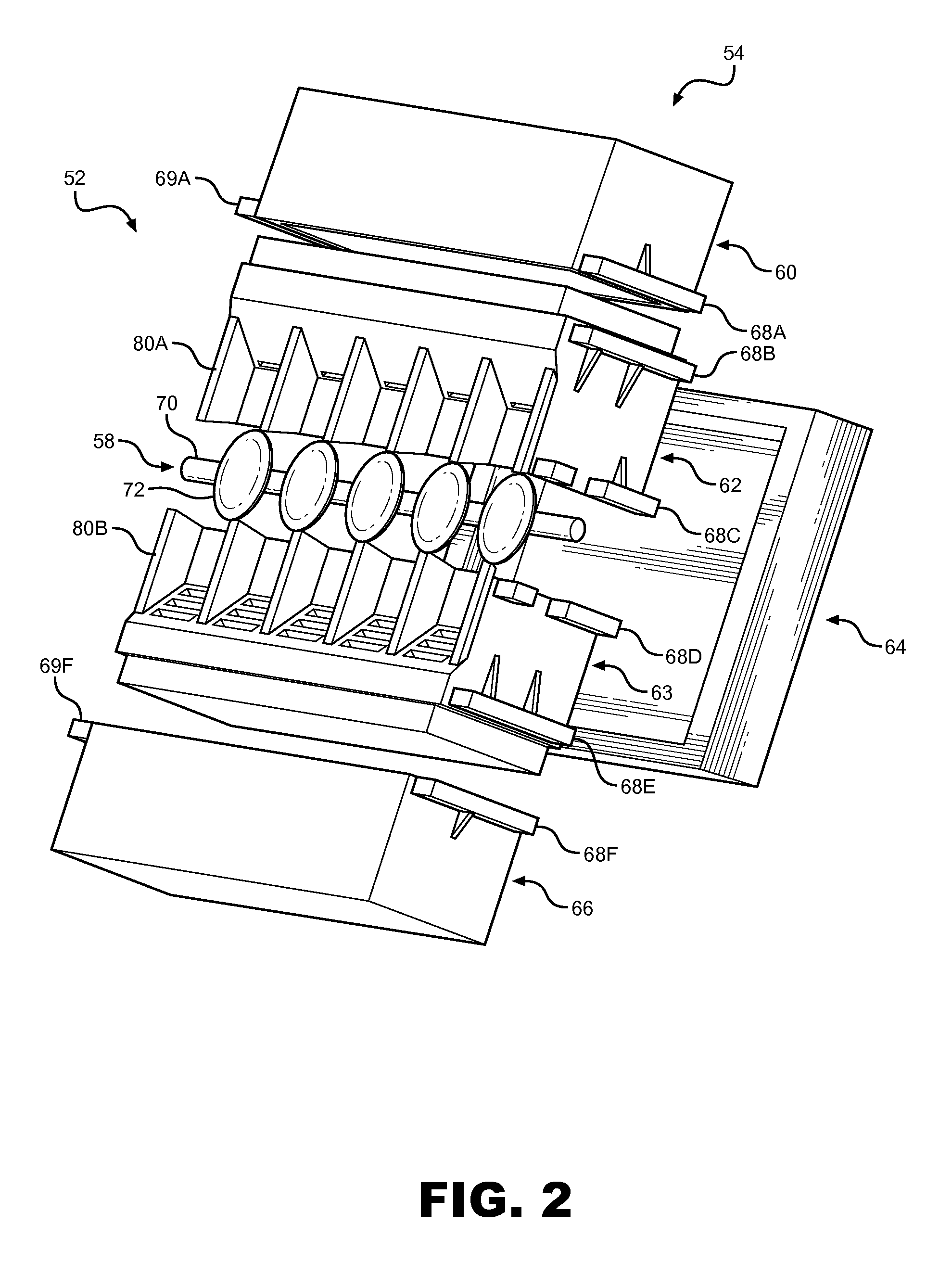

Clear ice maker assembly for producing clear ice for refrigerator appliance

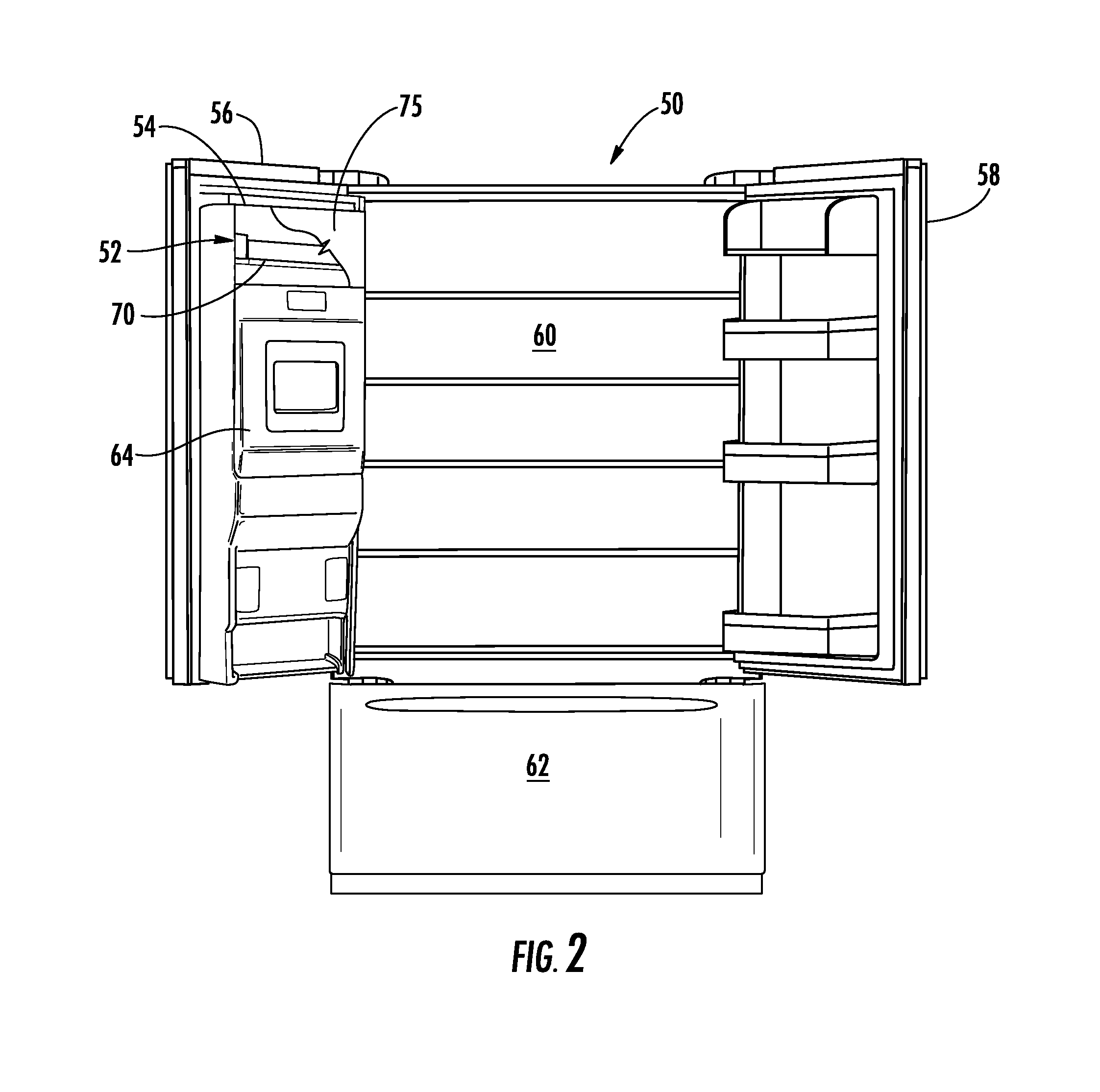

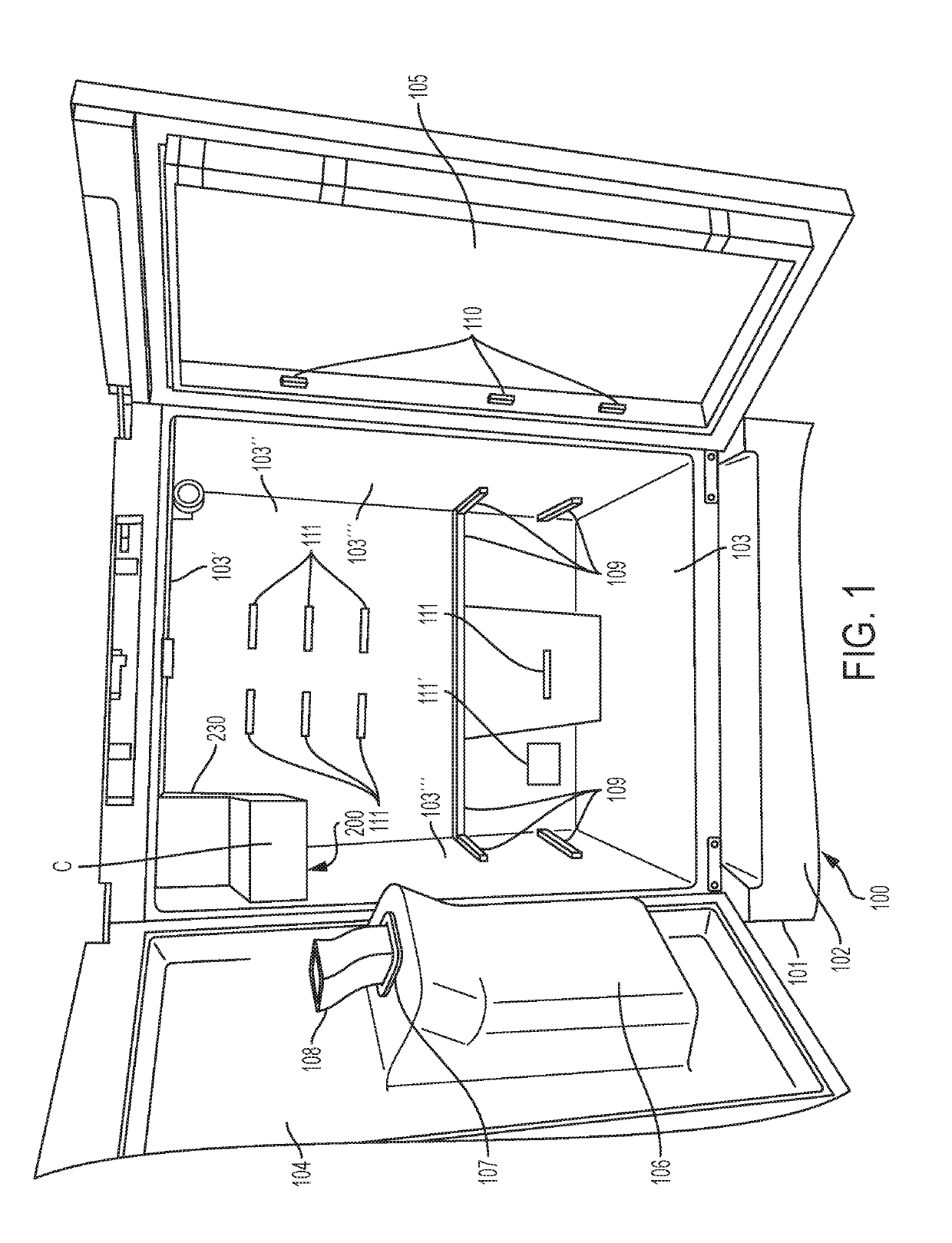

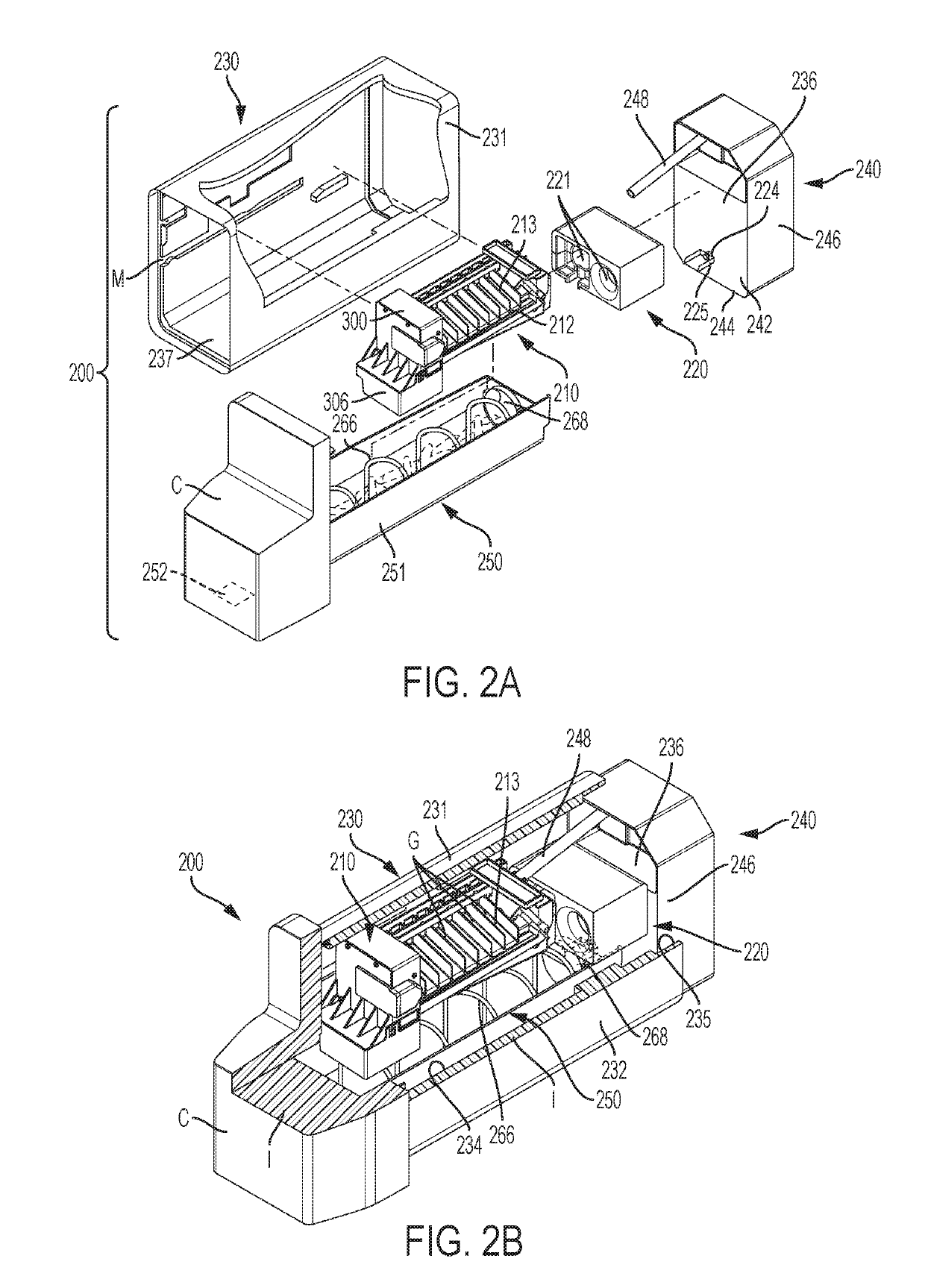

A refrigerator includes an ice compartment region disposed in at least one of a fresh food compartment or a freezer compartment; a clear ice maker assembly disposed in the ice compartment region and configured to make clear ice pieces; and an ice bucket configured to store the clear ice pieces made by the clear ice maker assembly. The clear ice maker assembly includes an ice maker tray portion having a plurality of cavities for forming clear ice pieces; a water distribution assembly configured to distribute a non-pressurized, even flow of water to each of the cavities of the ice maker tray portion; a water reservoir tank and a pump for supplying water to the water distribution assembly; and a water collection and return duct that is disposed below and extends along an edge of the ice maker tray portion to collect and return excess water to the water reservoir tank.

Owner:BSH HOME APPLIANCES CORP +1

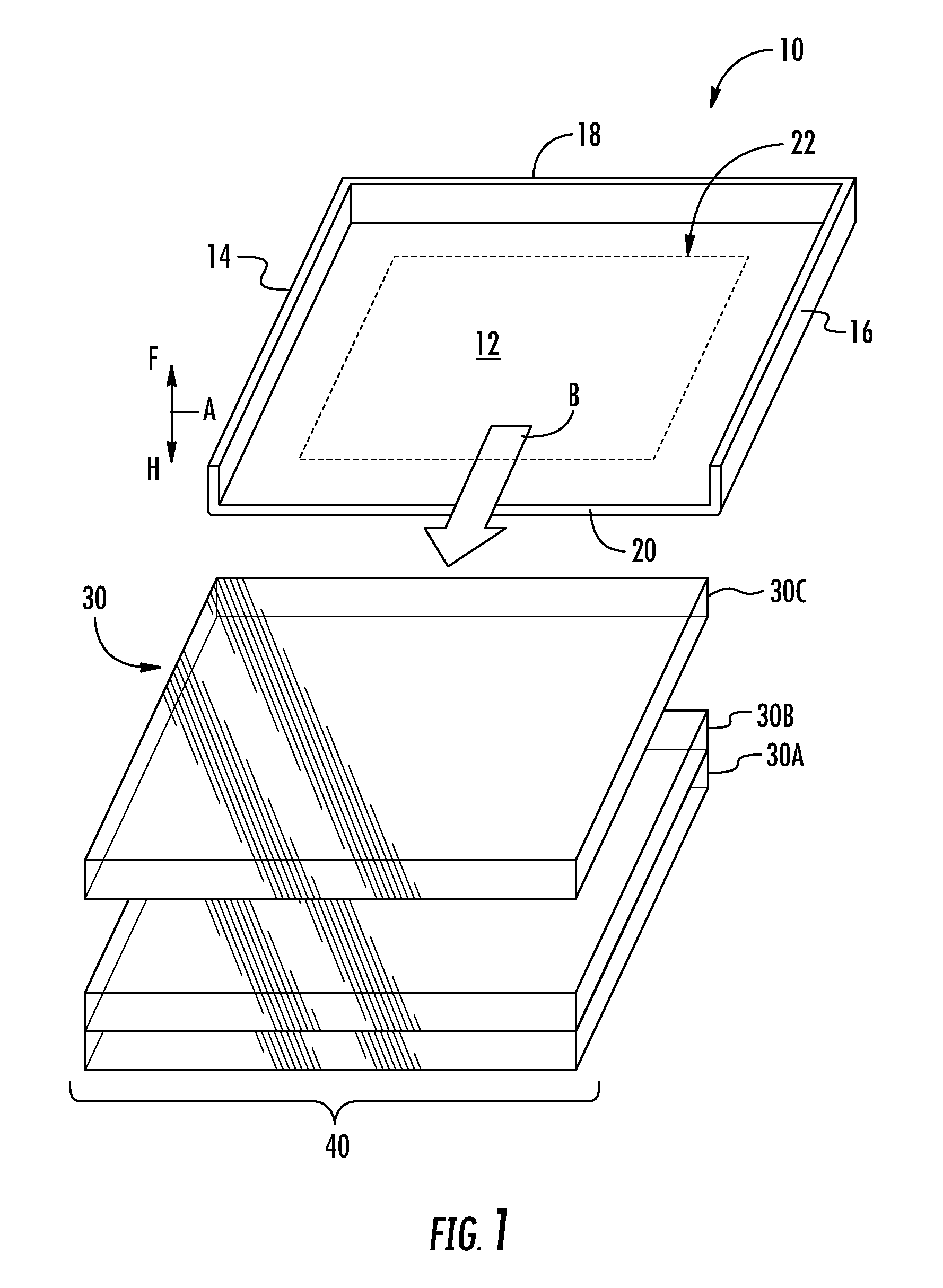

Transparent Ice Maker

InactiveUS20170038112A1Easy to shapeSmall surface areaLighting and heating apparatusFood processingIce waterLiquid water

An apparatus and method for producing substantially clear ice in a variety of desired shapes. The apparatus and method in the described embodiments generally provide for an insulated ice mold containing one or more mold cells, each mold cell with an open top, open bottom, and insulated side walls, that is suspended over a liquid water reservoir surrounded and contained in an insulated container. The top surface of the water residing in each mold cell is exposed to freezing air. The insulated walls forming the sides of one or more mold cells act to ensure that each ice shape forms and grows from the top surface, down and towards the bottom of each mold cell. The liquid water reservoir, which contacts the bottom surface of the ice shape, remains in a liquid phase and serves as an impurity sink into which the impurities and gases contained in the freezing water are driven as ice forms downward in the mold cell. The liquid water reservoir acts to arrest ice growth below the bottom of the mold cell, while the water in the mold cells freezes into a solid above the ice-water interface.

Owner:PAPALIA ROCCO

Clear ice maker

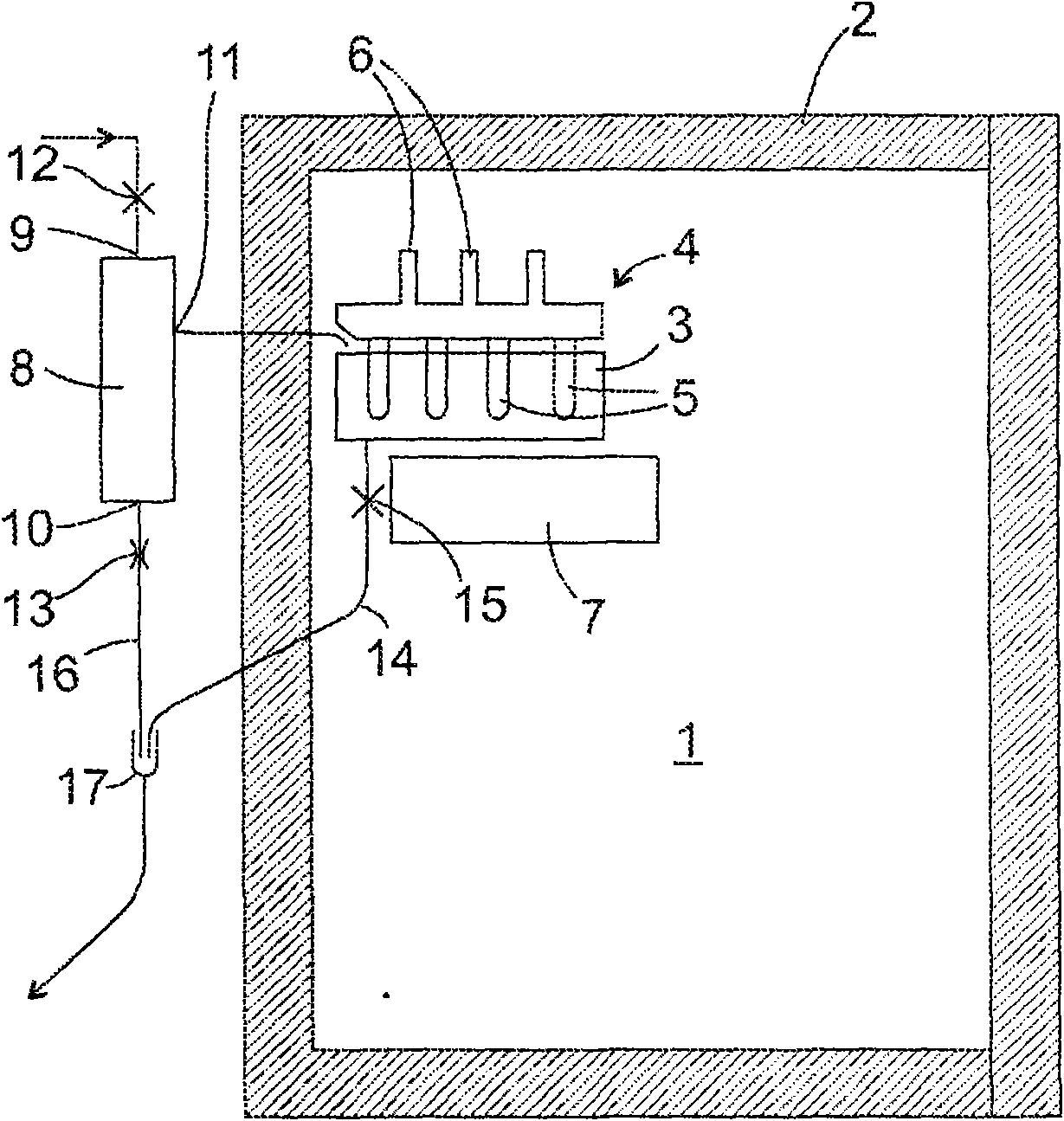

The invention relates to a clear ice maker for a refrigeration device, comprising a water container (3) and a supply line for filling the water container with fresh water. In said ice maker, an osmosis filter (8) is connected in series in the supply line.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

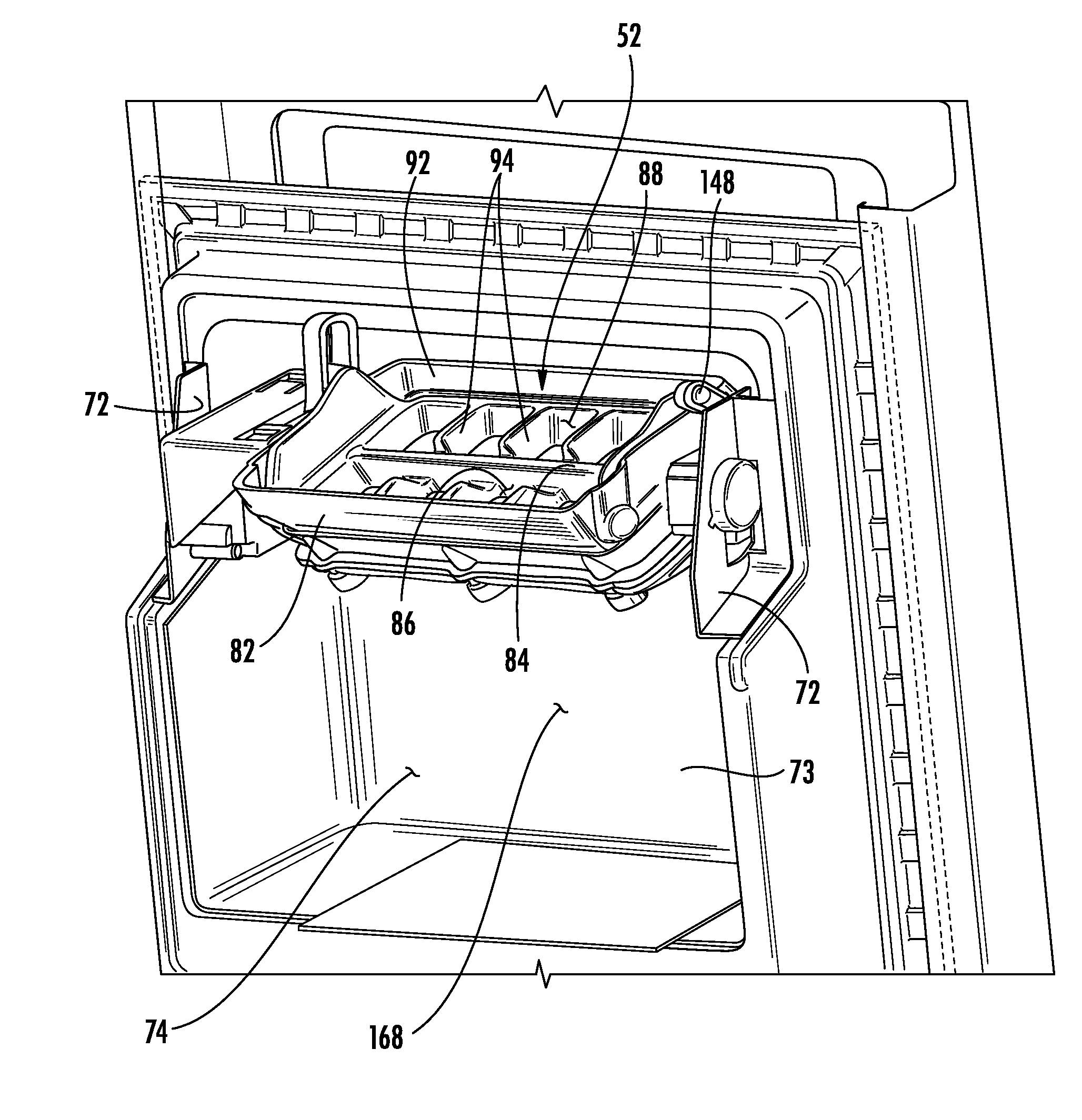

Ice making assemblies for making clear ice

In one exemplary aspect of the present disclosure, an ice making assembly is provided for making clear ice. The ice making assembly may include a conductive ice mold, an insulation jacket, and a water dispenser. The conductive ice mold may define an upper portion of a mold cavity extending from a top end to a bottom end. The insulation jacket may extend downward from the conductive ice mold. The insulation jacket may define a lower portion of the mold cavity. The lower portion of the mold cavity may be a vertically open passage aligned with the upper portion of the mold cavity. The water dispenser may be positioned below the insulation jacket to direct an ice-building spray of water to the mold cavity through the vertically open passage of the insulation jacket.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Ice making assemblies for making clear ice

In one exemplary aspect of the present disclosure, an ice making assembly is provided for making clear ice. The ice making assembly may include a conductive ice mold, an insulation jacket, and a water dispenser. The conductive ice mold may define an upper portion of a mold cavity extending from a top end to a bottom end. The insulation jacket may extend downward from the conductive ice mold. The insulation jacket may define a lower portion of the mold cavity. The lower portion of the mold cavity may be a vertically open passage aligned with the upper portion of the mold cavity. The water dispenser may be positioned below the insulation jacket to direct an ice-building spray of water to the mold cavity through the vertically open passage of the insulation jacket.

Owner:HAIER US APPLIANCE SOLUTIONS INC

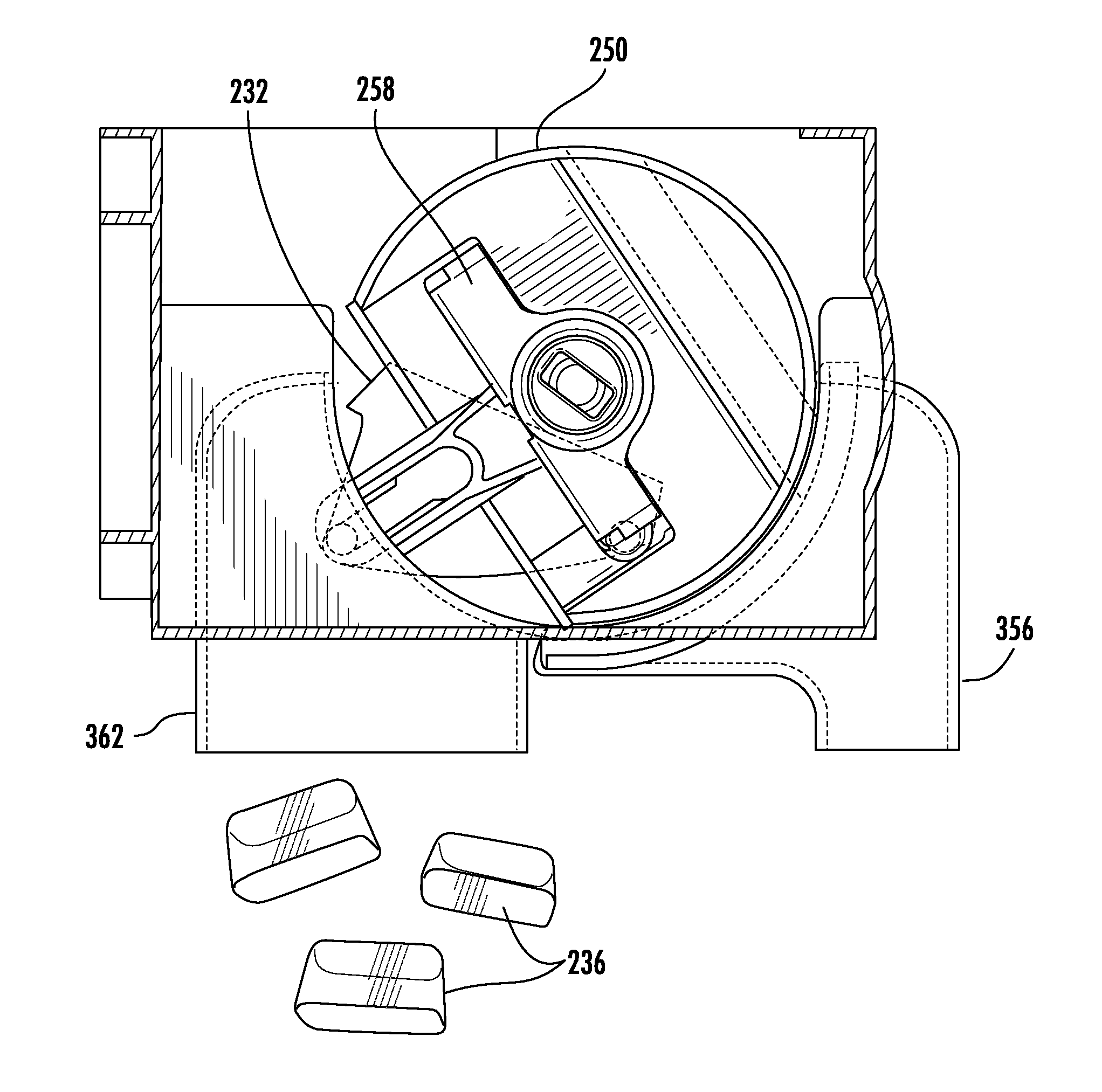

Clear ice maker and method for forming clear ice

A clear ice maker having an ice tray with a thermally conductive cold plate, where the cold plate has a top surface and a bottom surface, with a thermoelectric cooling device thermally coupled to the bottom surface. Water is dispensed onto the top surface, and the bottom surface is cooled such that a portion of the water adjacent the top surface is frozen, to form a layer of ice. Then the ice tray is oscillated about a transverse axis of the ice tray, such that the water freezes in successive layers from the top surface of the cold plate upwards.

Owner:WHIRLPOOL CORP

Clear ice maker

ActiveUS9518773B2Ice productionMachines using electric/magnetic effectsClear iceMechanical engineering

Owner:WHIRLPOOL CORP

Ice making assemblies and methods for making clear ice

An ice making assembly and method for making clear ice utilizing an ice making appliance are provided herein. The ice making appliance may include a cabinet, an ice mold, a heating element, and a controller. The ice mold may be positioned within the freezer chamber and define a mold cavity. The heating element may be mounted within the ice mold in conductive thermal communication with the mold cavity. The controller may be configured to initiate an ice making operation. The ice making operation may include maintaining the freezer chamber below a first sub-freezing during an ice formation cycle subsequent to a volume of water being received within the mold cavity, and heating the ice mold during the ice formation cycle at the heating element as a portion of the volume of water freezes to a frozen volume.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Clear ice maker and method for forming clear ice

ActiveUS9476629B2Ice productionMachines using electric/magnetic effectsThermoelectric coolingTransverse axis

A clear ice maker having an ice tray with a thermally conductive cold plate, where the cold plate has a top surface and a bottom surface, with a thermoelectric cooling device thermally coupled to the bottom surface. Water is dispensed onto the top surface, and the bottom surface is cooled such that a portion of the water adjacent the top surface is frozen, to form a layer of ice. Then the ice tray is oscillated about a transverse axis of the ice tray, such that the water freezes in successive layers from the top surface of the cold plate upwards.

Owner:WHIRLPOOL CORP

Apparatus for producing clear ice cubes in a freezer

InactiveUS20170307271A1High purityLong to meltLighting and heating apparatusIce productionEngineeringClear ice

Embodiments of the present invention are generally directed towards apparatuses for producing ice cubes. In particular, embodiments of the present invention are directed to trays for making ice cubes in a manner that allows for ice to be produced with a clear or semi-clear transparency through the elimination of gaseous water during the freezing process.

Owner:MYERS JOSEPH FRANKLIN

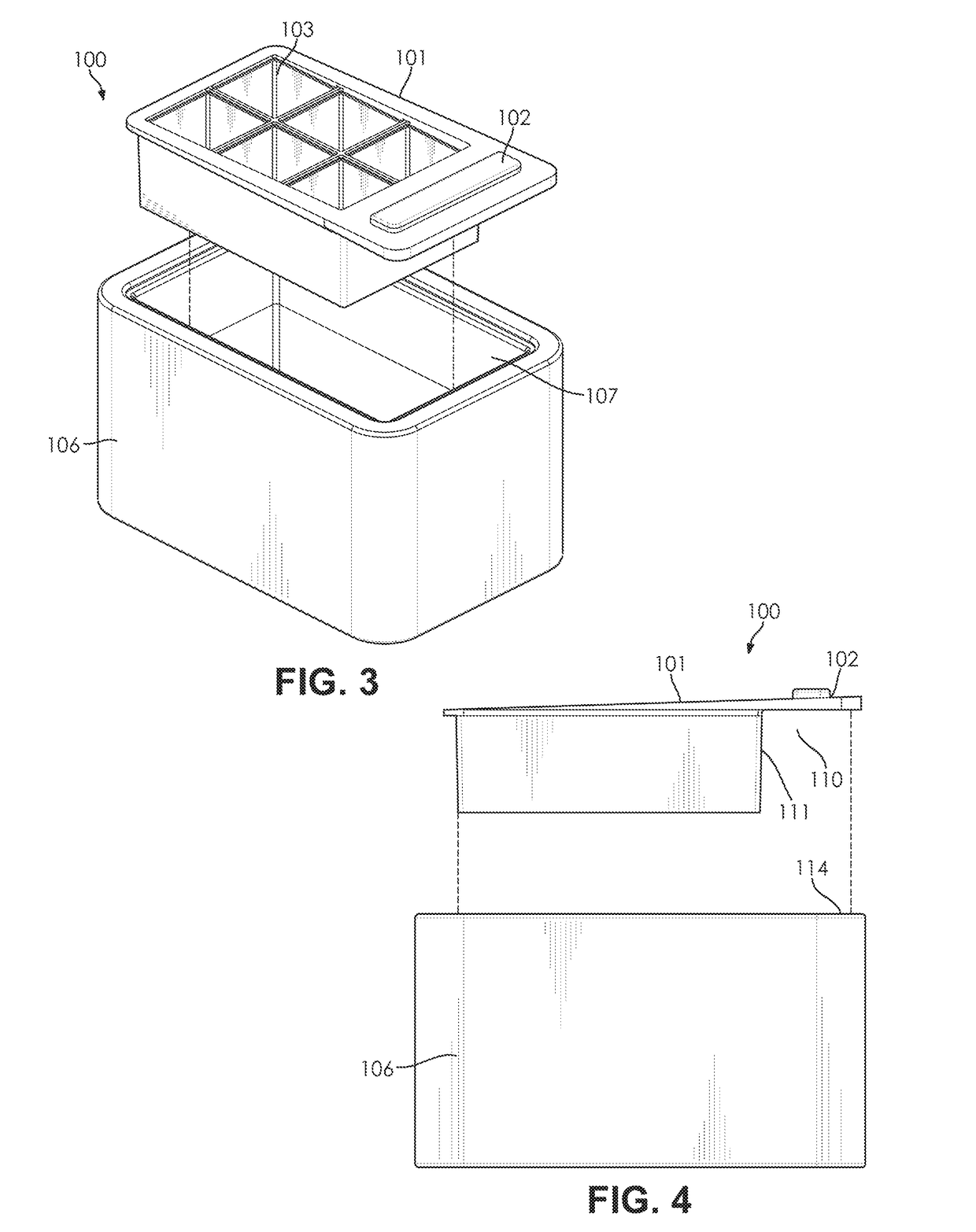

Multi-sheet spherical ice making

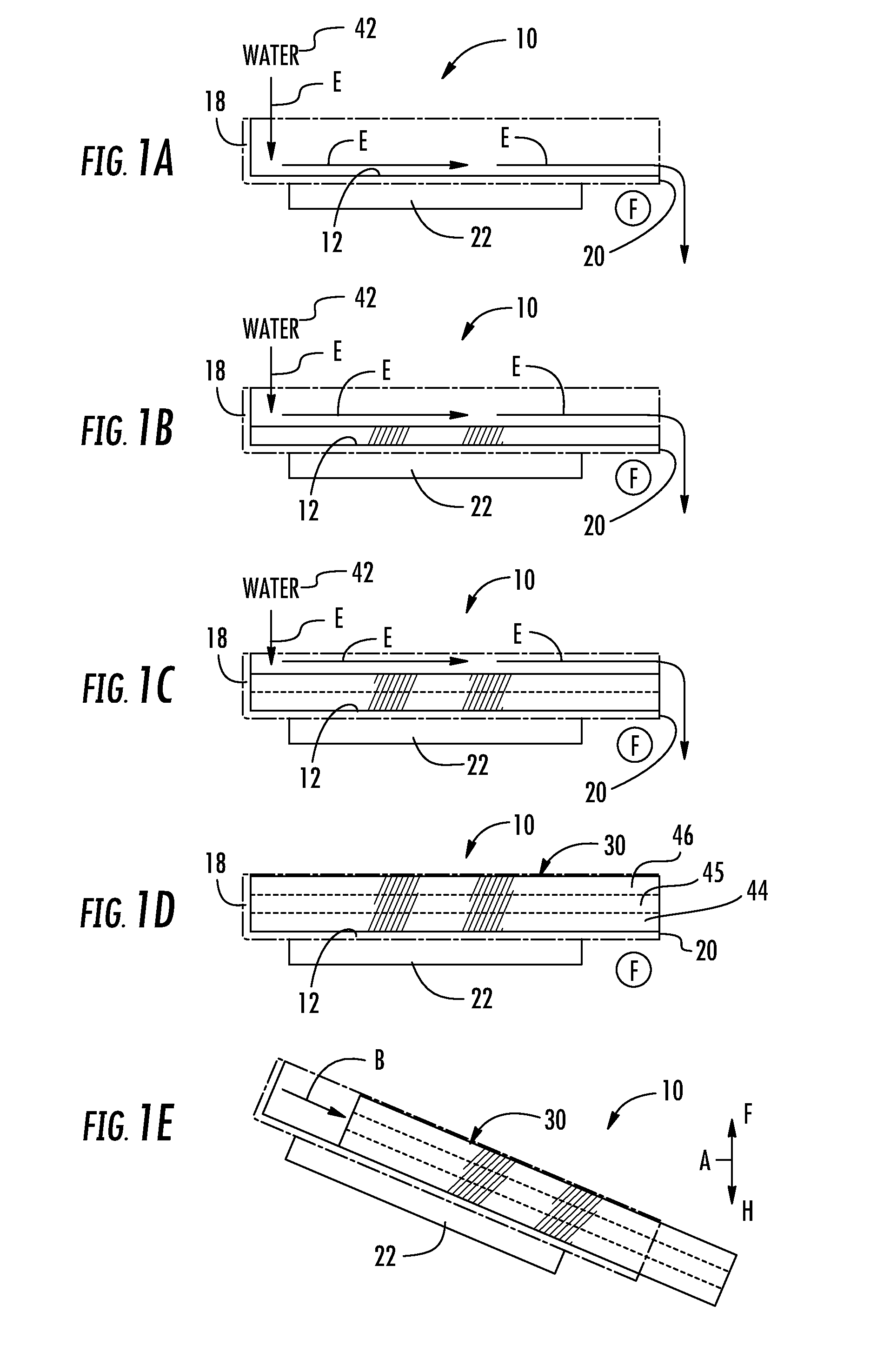

A unitary clear ice sheet is formed from a plurality of individual clear ice sheets which are fused together to give the unitary ice sheet a predetermined thickness. The fused unitary ice sheet is a clear unitary ice sheet due to the formation of the plurality of individual clear ice sheets by running water over a cold plate apparatus or evaporator mechanism to form the ice sheets in a gradual layer-by-layer process. The fused unitary clear ice sheet is used to mold or shape clear ice structure therefrom, such as clear ice spheres in a mold apparatus.

Owner:WHIRLPOOL CORP

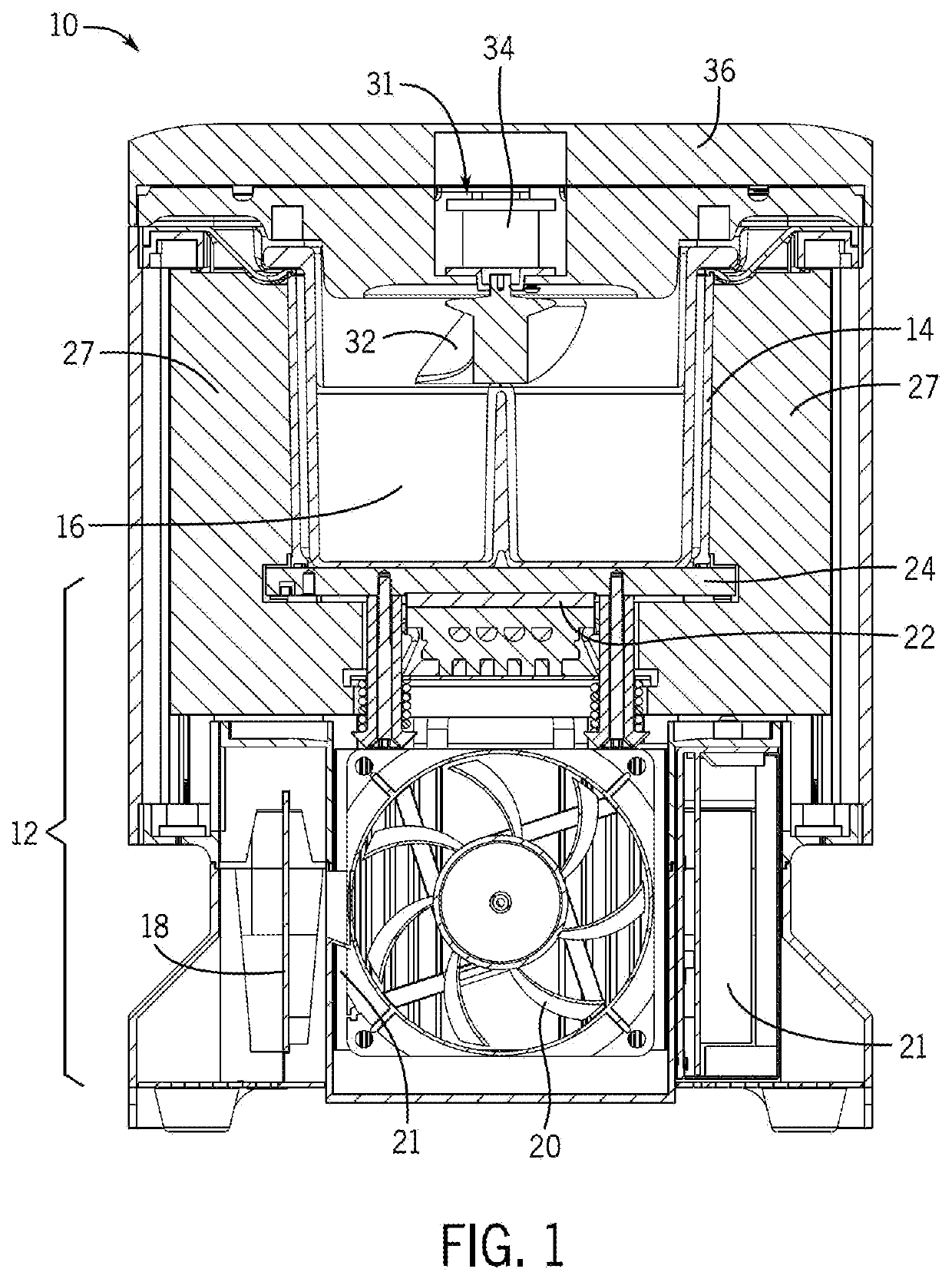

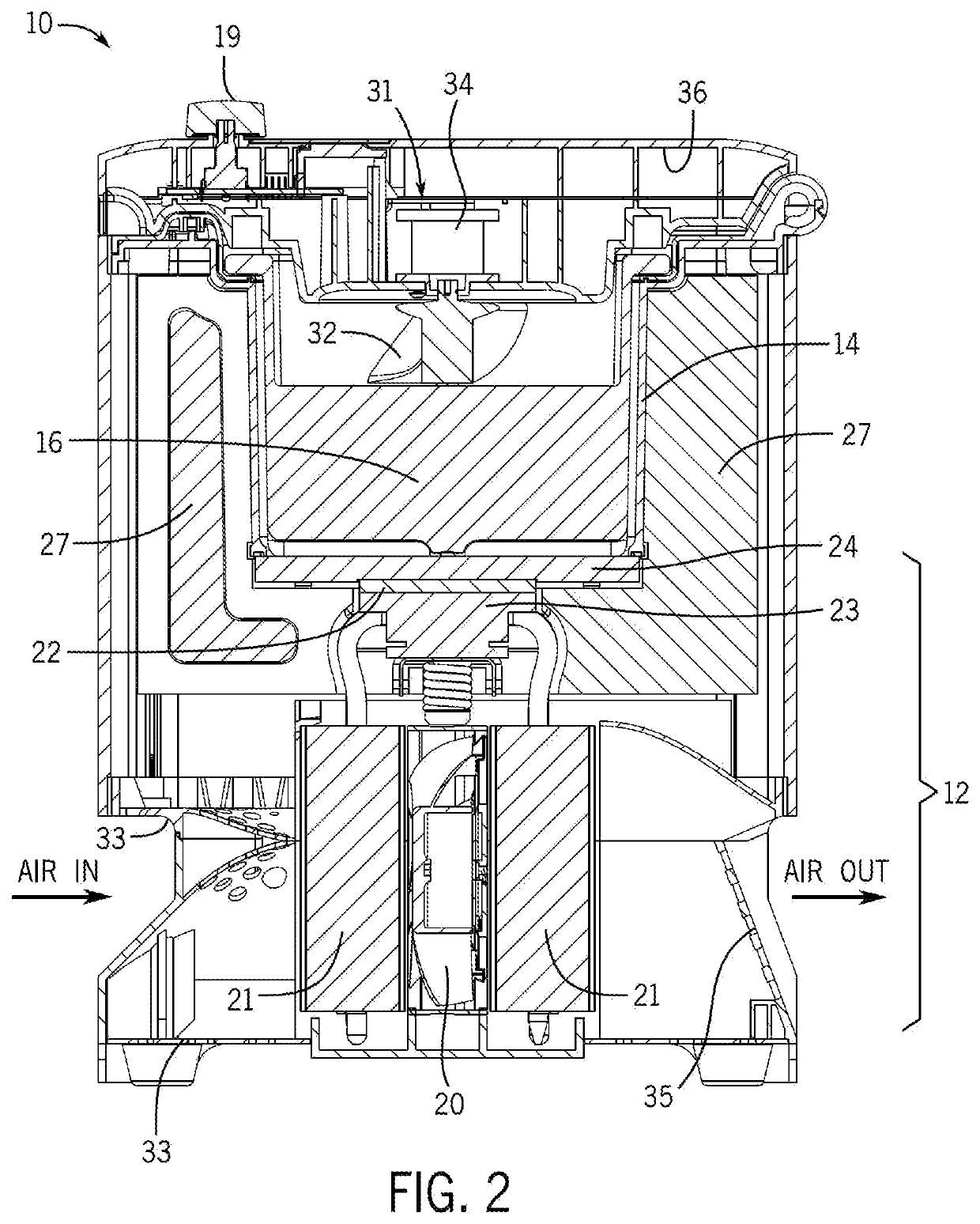

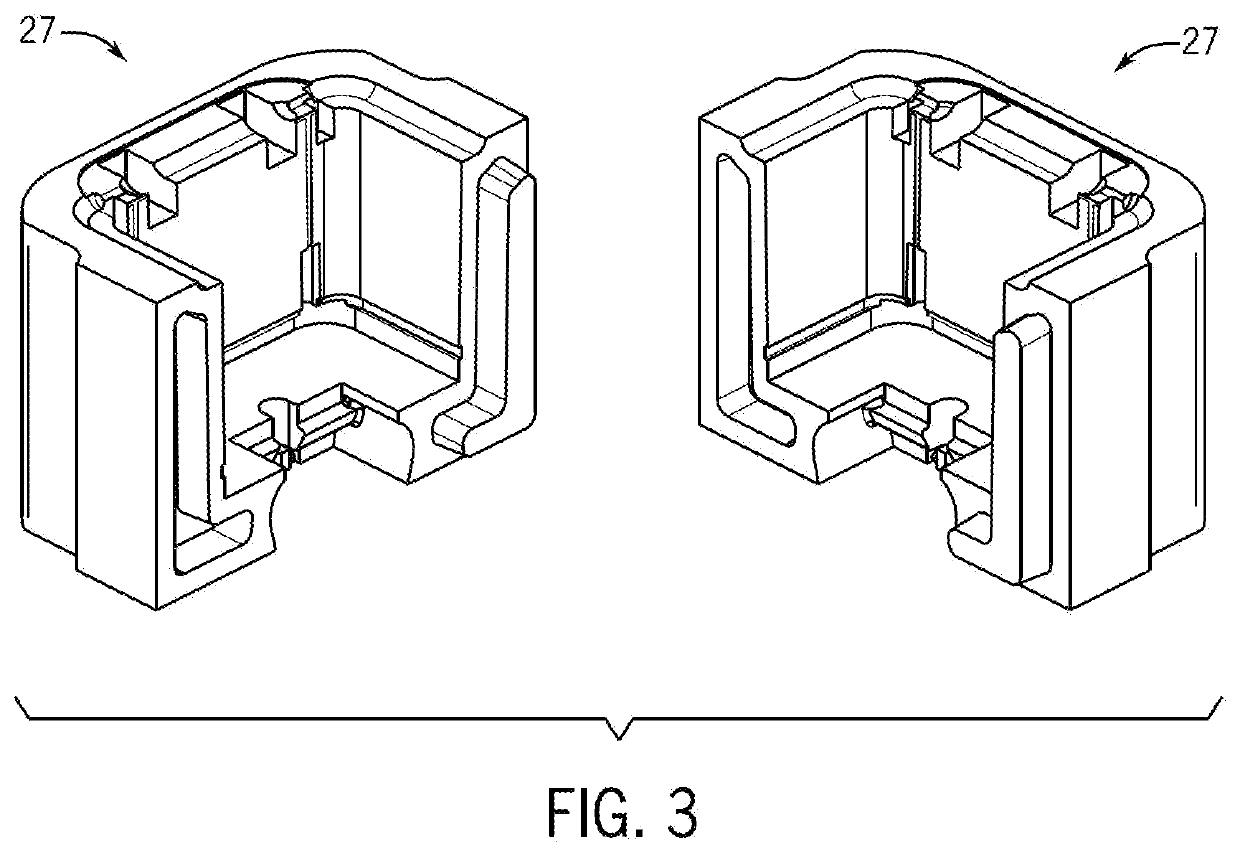

Systems and methods for producing ice

PendingUS20220146175A1Consistent and pleasant ice harvesting experienceFaster and more consistent ice growthIce productionMachines using electric/magnetic effectsEnergy transferRoom temperature

In accordance with the principals of the present invention, an ice machine, tray, and process for producing high-quality, substantially clear ice is provided. A heat exchanger in the ice machine removes energy from liquid, cooling the liquid from room temperature to freezing temperature, then overcomes the heat of fusion to form ice. The tray containing a liquid is received in a freezing / mixing chamber. The tray includes an energy transfer surface in thermal contact with the heat exchanger to define a liquid / ice boundary layer. The tray further includes at least one freezing cavity having geometry defining surfaces to form the geometry of the ice. An egress area is defined in the tray above the geometry defining surfaces. A mixing mechanism is provided in operative communication with the liquid to create a velocity profile at the liquid / ice boundary layer to create a directional freezing process starting from the energy transfer surface of the tray in thermal contact with the heat exchanger and growing through the freezing cavity up to the egress area. The velocity profile at liquid / ice boundary enables impurities to be washed away during the freezing process, deterring impurities from getting entrapped in the ice. Impurities in the liquid are thereby washed away and concentrate in a pool away from the ice, ultimately in the egress area of the tray to be purged. In addition, in embodiments sensors can be provided to provide various functions selected from the group consisting of, for example, determining ice creation status, determining freezing height, varying ice creation, determining tray presence, detecting freezing / mixing chamber door position, determining liquid level, and combinations thereof.

Owner:NICELABS LLC

Ice making assemblies and methods for making clear ice

An ice making assembly and method for making clear ice utilizing an ice making appliance are provided herein. The ice making appliance may include a cabinet, an ice mold, a heating element, and a controller. The ice mold may be positioned within the freezer chamber and define a mold cavity. The heating element may be mounted within the ice mold in conductive thermal communication with the mold cavity. The controller may be configured to initiate an ice making operation. The ice making operation may include maintaining the freezer chamber below a first sub-freezing during an ice formation cycle subsequent to a volume of water being received within the mold cavity, and heating the ice mold during the ice formation cycle at the heating element as a portion of the volume of water freezes to a frozen volume.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Method and device for producing clean transparent ice

ActiveCN109883097BSmall chance of escapeEliminate aggregationLighting and heating apparatusIce productionProcess engineeringEnvironmental engineering

The invention relates to a making method and a making device of clean transparent ice, and belongs to the field of ice making. The making method and the making device solve the problem that an existing ice making technology cannot discharge air dissolved in water in the freezing process. The making method and the making device are characterized in that a dissolved air supersaturated open area is arranged in an ice making container, in particular, the supersaturated open area is formed between the liquid level in the ice making container and an upper opening of the ice making container, the supersaturated open area keep to communicate with external atmosphere, and the temperature of the supersaturated open area is controlled; a mechanical disturbance mode is selected according to the volumeof the ice making container, the crystal interface is washed at a constant flow rate, the dissolved air supersaturated zone formed by the crystal interface is diluted or replaced, the temperature ofthe supersaturated open area is controlled, and the water body liquid level temperature is improved; and a clean transparent ice body is obtained by controlling the physical conditions in the icing environment. According to the making method and the making device, dissolved air and impurities in water are discharged in the icing process, and meanwhile, the ice making device which is simple in structure and convenient to use is provided for making the clean transparent ice.

Owner:HARBIN ENG UNIV

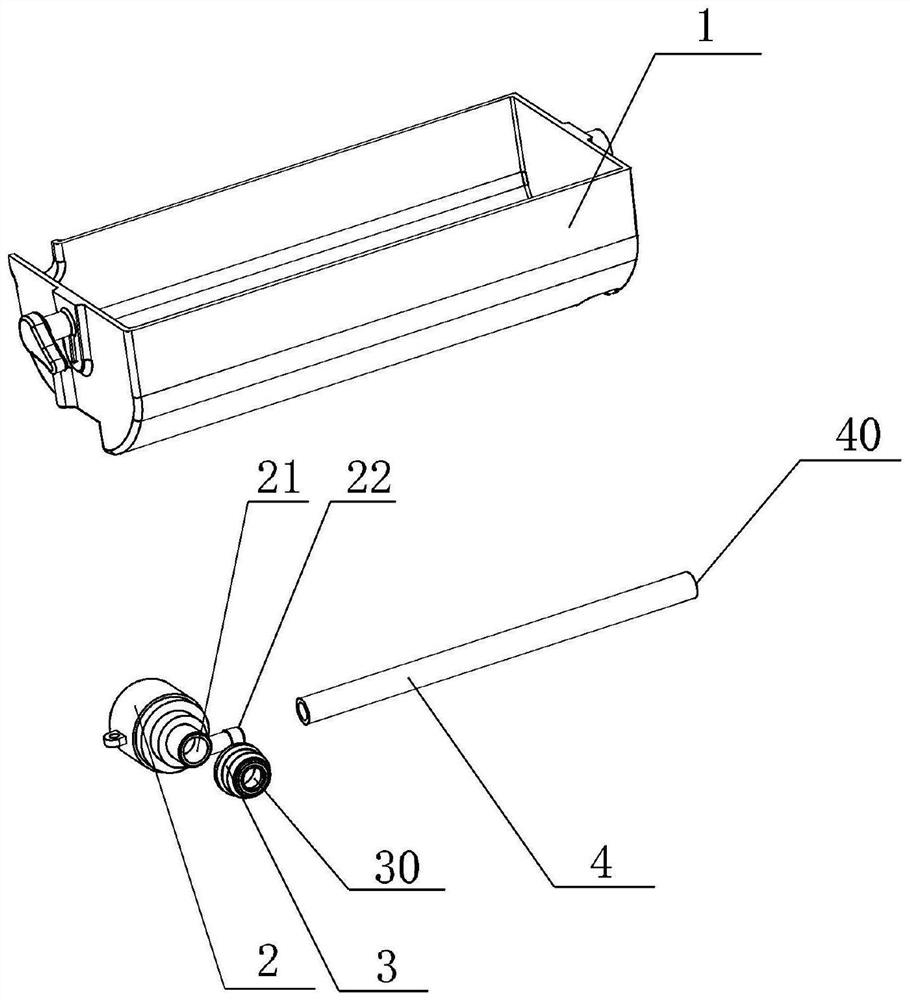

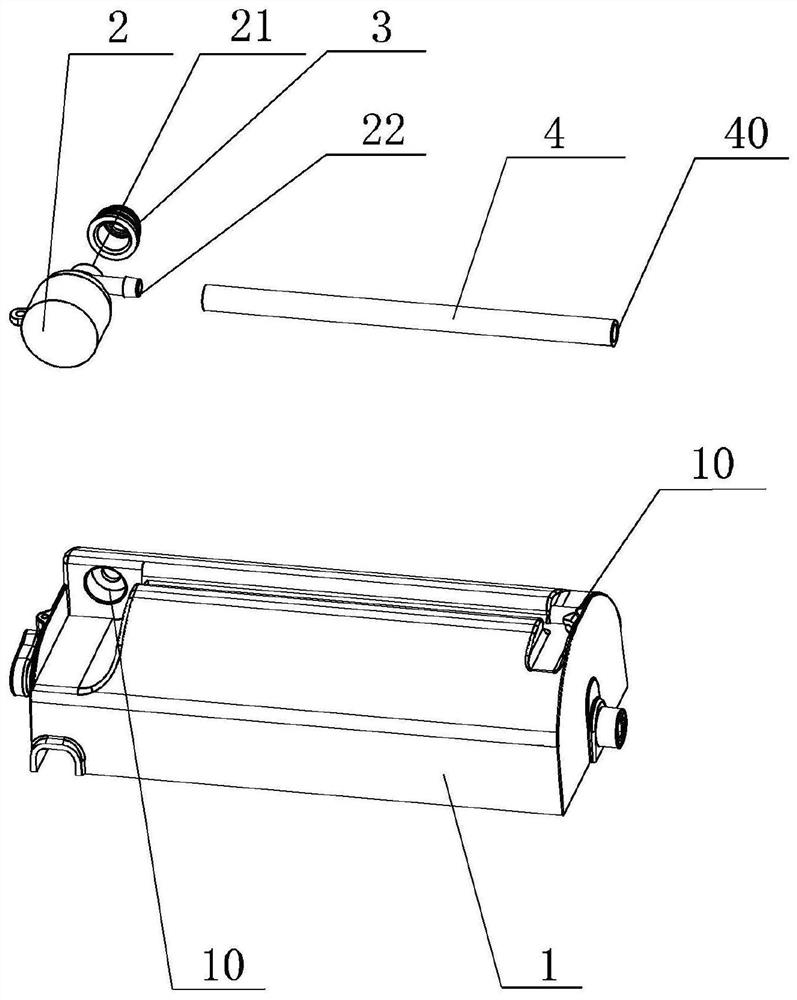

Ice-making water box for clear ice maker

PendingCN112229117ABeautiful appearanceHigh hardnessLighting and heating apparatusIce productionIce waterWater flow

The invention discloses an ice-making water box for a clear ice maker. The ice-making water box comprises a water box and a water circulation assembly communicating with the water box, wherein the water circulation assembly comprises a water pump, a water pump sealing ring and a water outlet pipe; the water pump sealing ring and the water outlet pipe are separately connected to a water inlet portand a water outlet port of the water pump; a water inlet of the water pump sealing ring communicates with the water box; and a water outlet of the water outlet pipe is used for enabling water pumped from the water box by the water pump to flow into the water box. According to the ice-making water box for the clear ice maker, the water in the water box can be kept flowing in the ice-making process,so that clear ice blocks can be made by the ice maker. The clear ice blocks are sparkling and crystal-clear in appearance, relatively high in hardness, and not prone to melting.

Owner:ZHONGSHAN DONLIM WEILI ELECTRICAL APPLIANCES CO LTD

Clear ice maker

Owner:WHIRLPOOL CORP

Ice making system for creating clear ice and associated method

An ice making system for creating clear ice and an associated method are provided. The ice making system employs a first sealed refrigerant system connected to a heat exchanger. A second sealed refrigerant system is also connected to the heat exchanger for cooling a first refrigerant of the first sealed refrigerant system. A heat exchanger heater is at least partially contained with the heat exchanger for heating the first refrigerant. A pump in the first refrigerant system is activated after heat exchanger heater has warmed the first refrigerant, enabling a cooling cycle to begin. Once sufficient clear ice has been generated, the pump is deactivated.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Vertical ice maker producing clear ice pieces

An ice making assembly and method utilizes a housing having an upper fluid chamber, a plurality of distinct, substantially vertical fluid channels, and at least one drain aperture in fluid communication with a fluid reservoir. Ice forming members extend from an ice forming evaporator into respective fluid channels. During an ice making event, fluid continuously supplied to the upper fluid chamber flows into each of the fluid channels and out through at least one drain aperture into a fluid reservoir below. The ice forming members are cooled such that fluid flowing across the fluid channels freezes on the ice forming members over time, forming clear ice pieces. The ice pieces are subsequently released from the ice forming members and transferred for storage and / or dispensing.

Owner:WHIRLPOOL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com