Patents

Literature

1399 results about "Ice crystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ice crystals are solid ice exhibiting atomic ordering on various length scales and include hexagonal columns, hexagonal plates, dendritic crystals, and diamond dust.

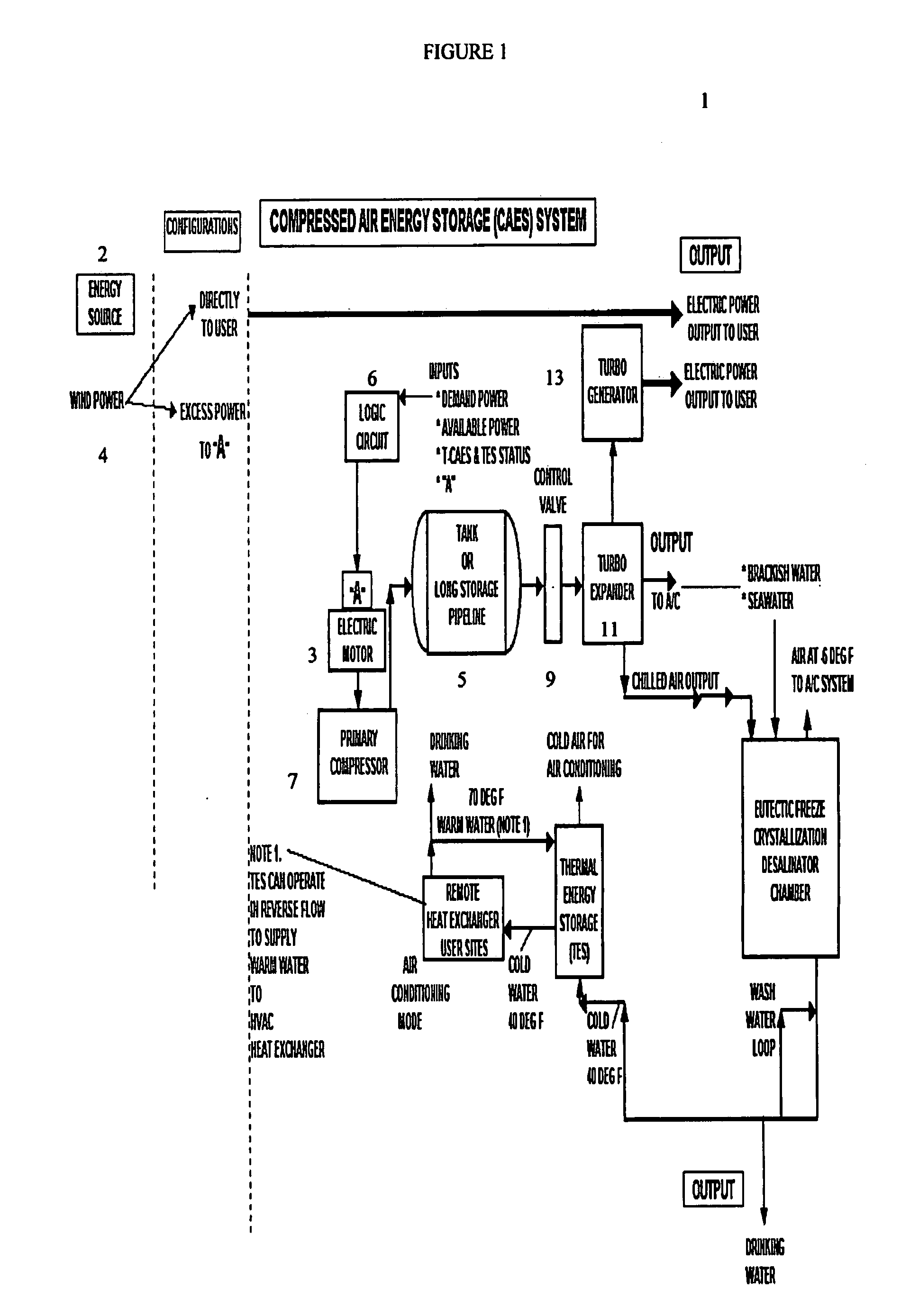

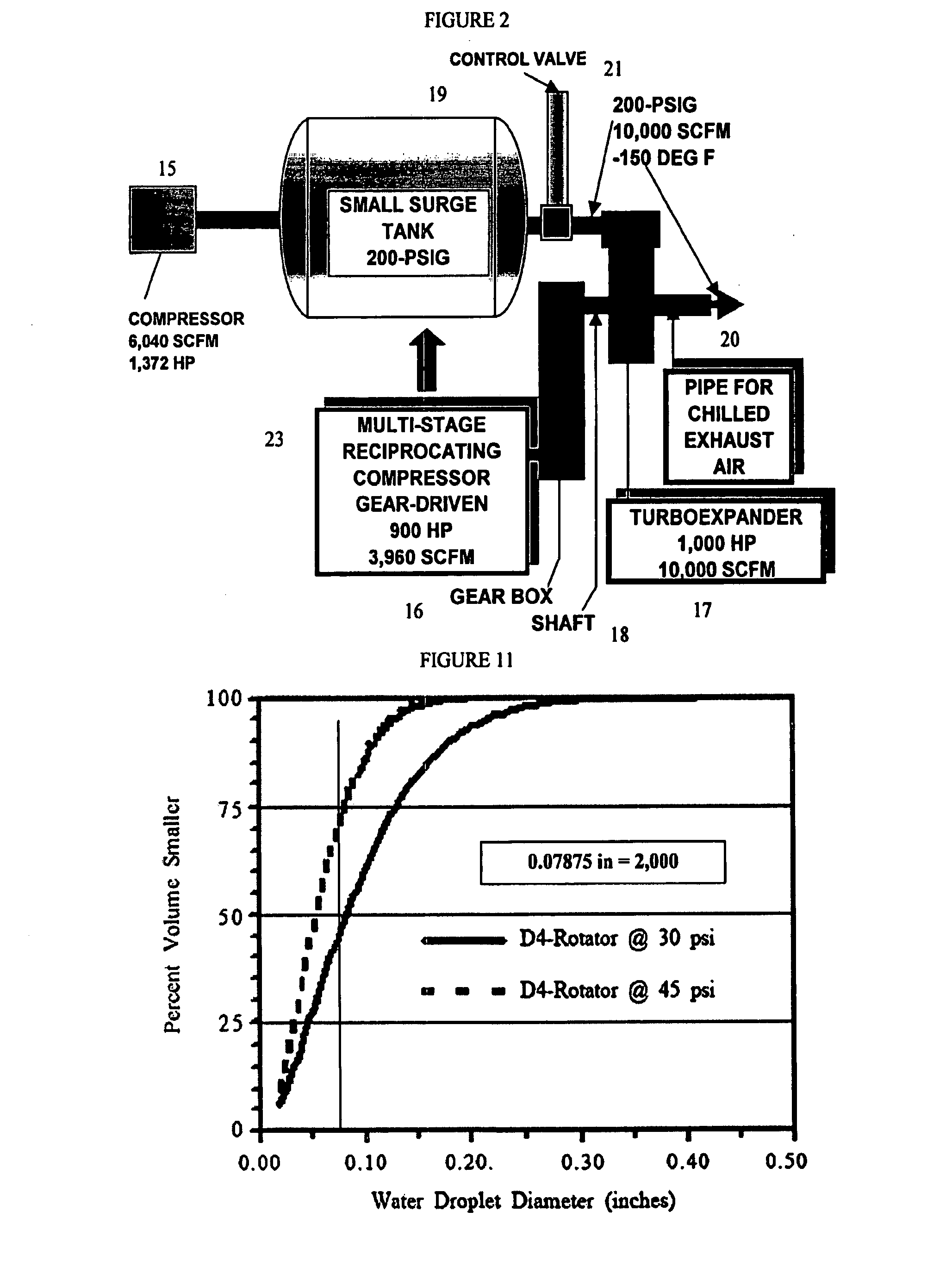

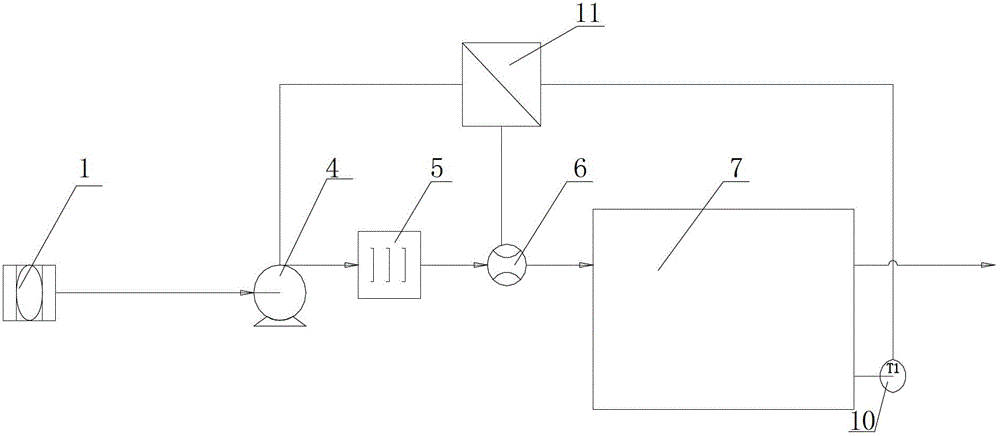

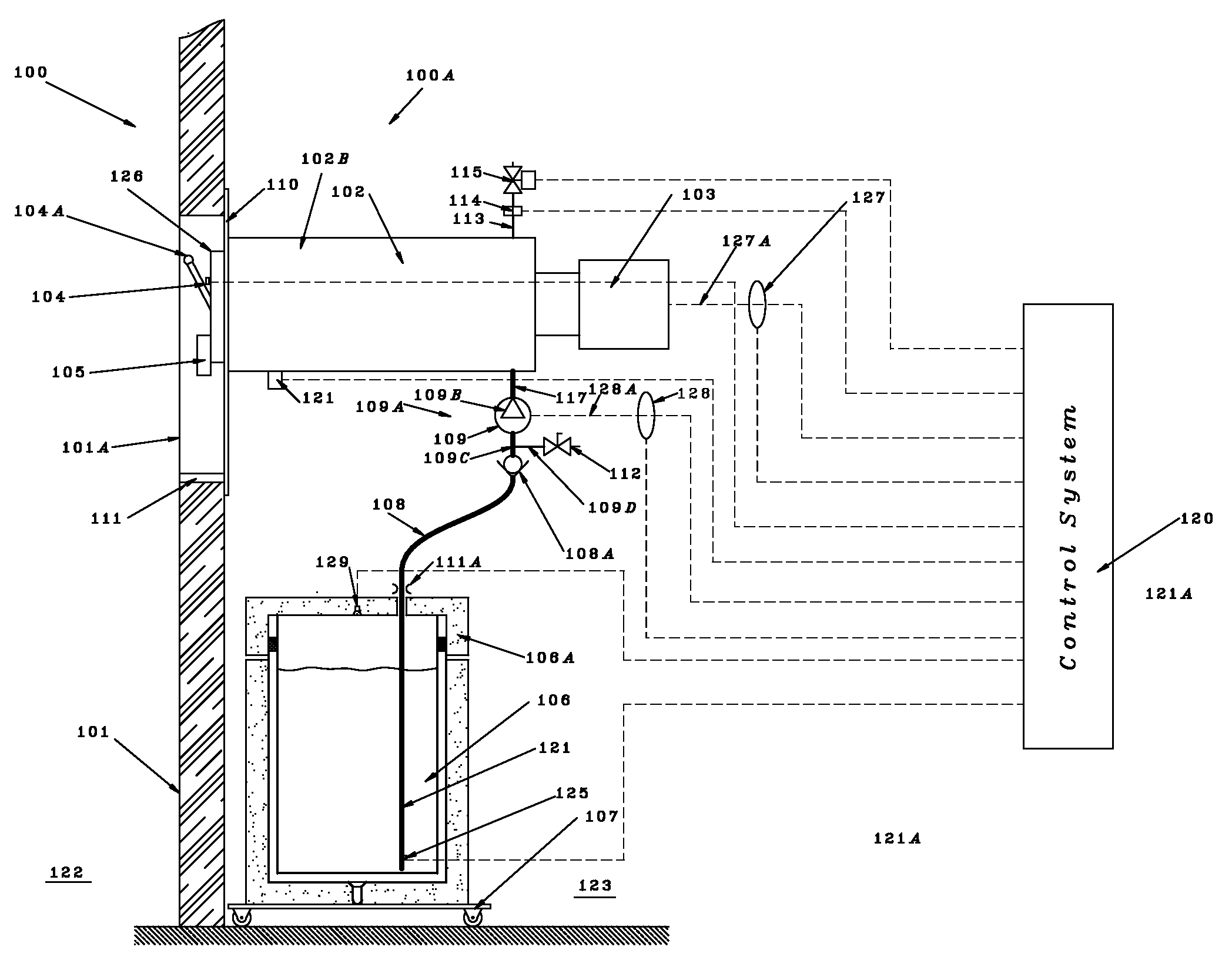

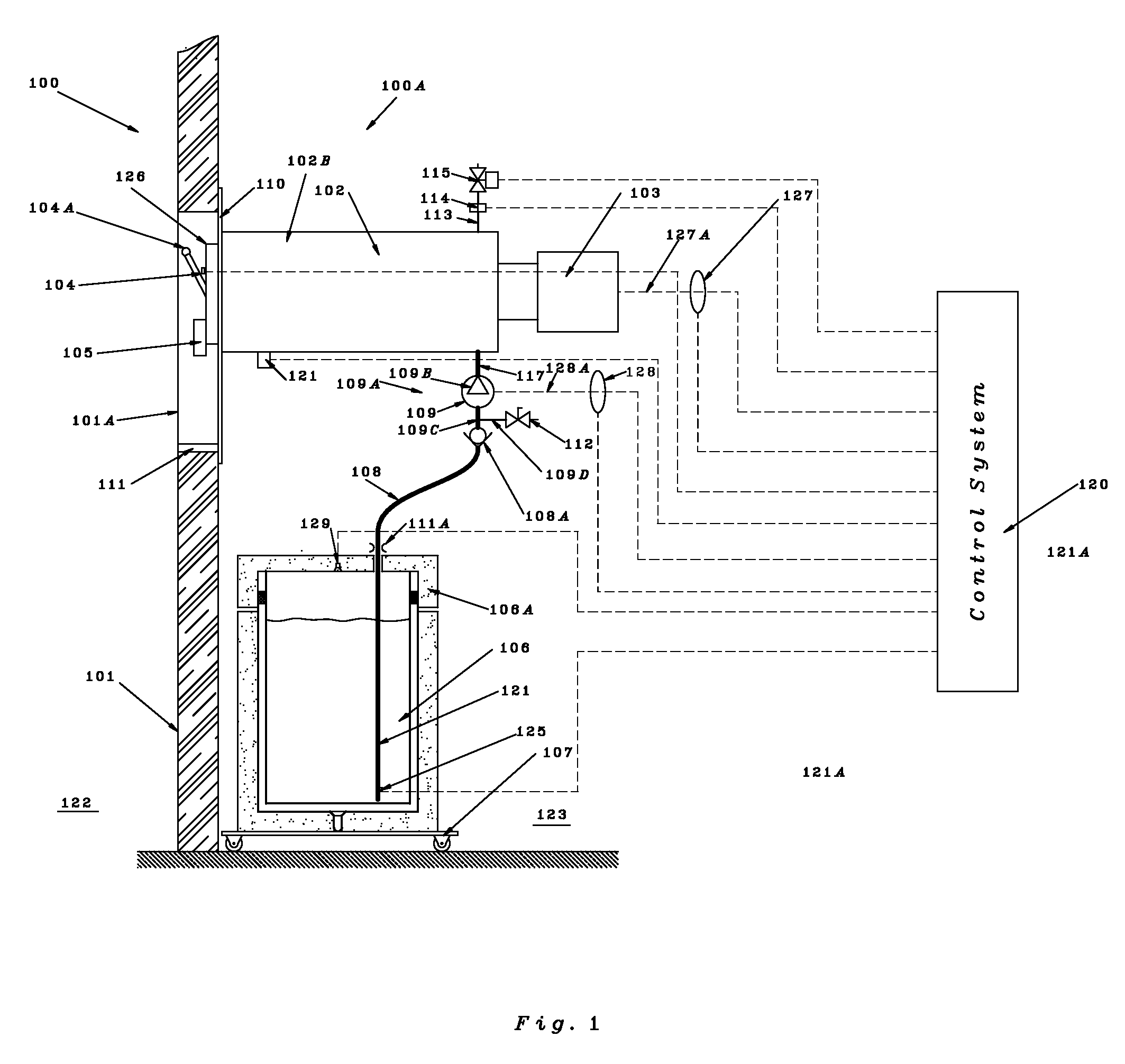

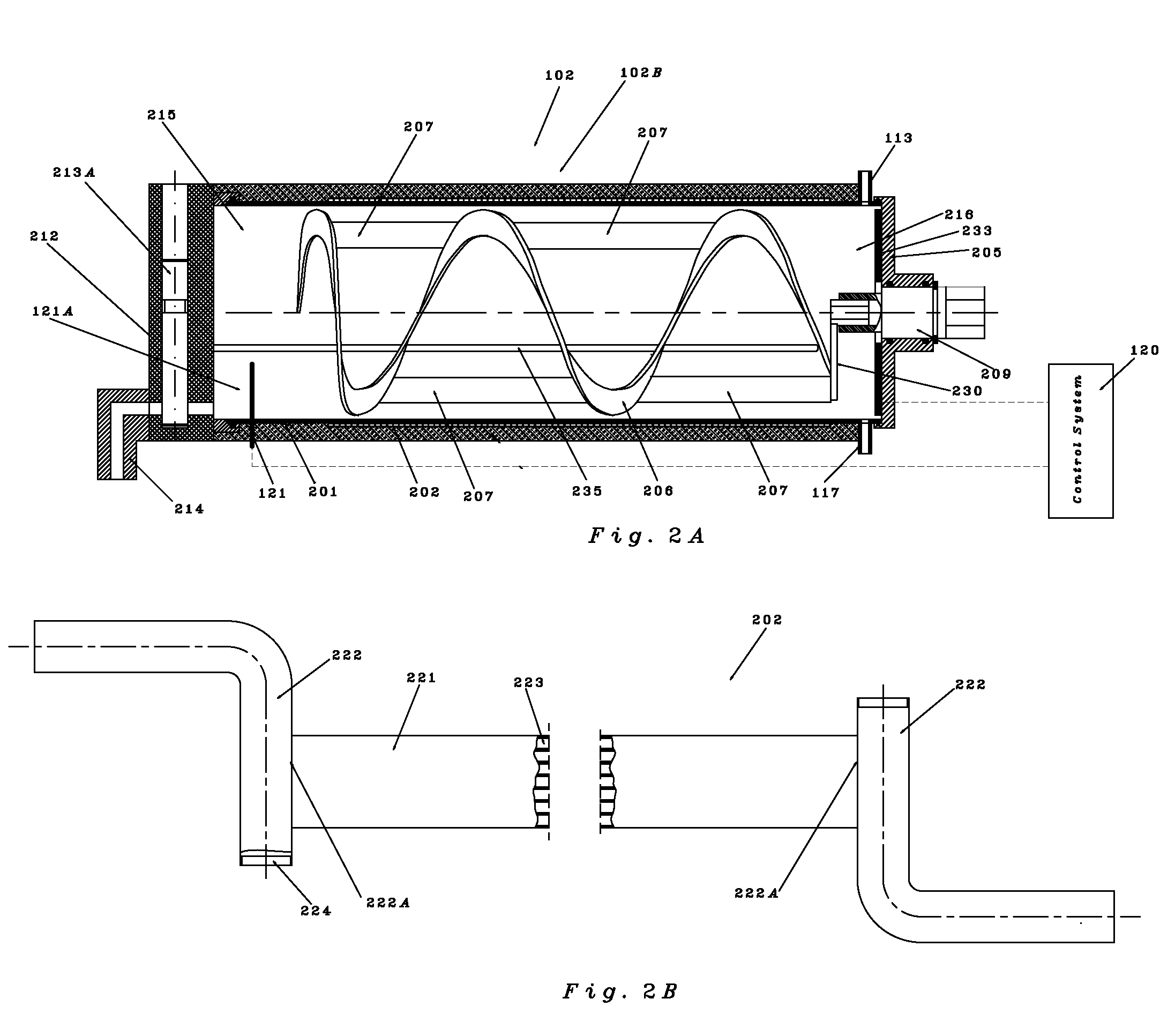

Desalination method and system using compressed air energy systems

InactiveUS20070295673A1Promote meltingFacilitate runoffWater treatment parameter controlWater cleaningSaline waterDesalination

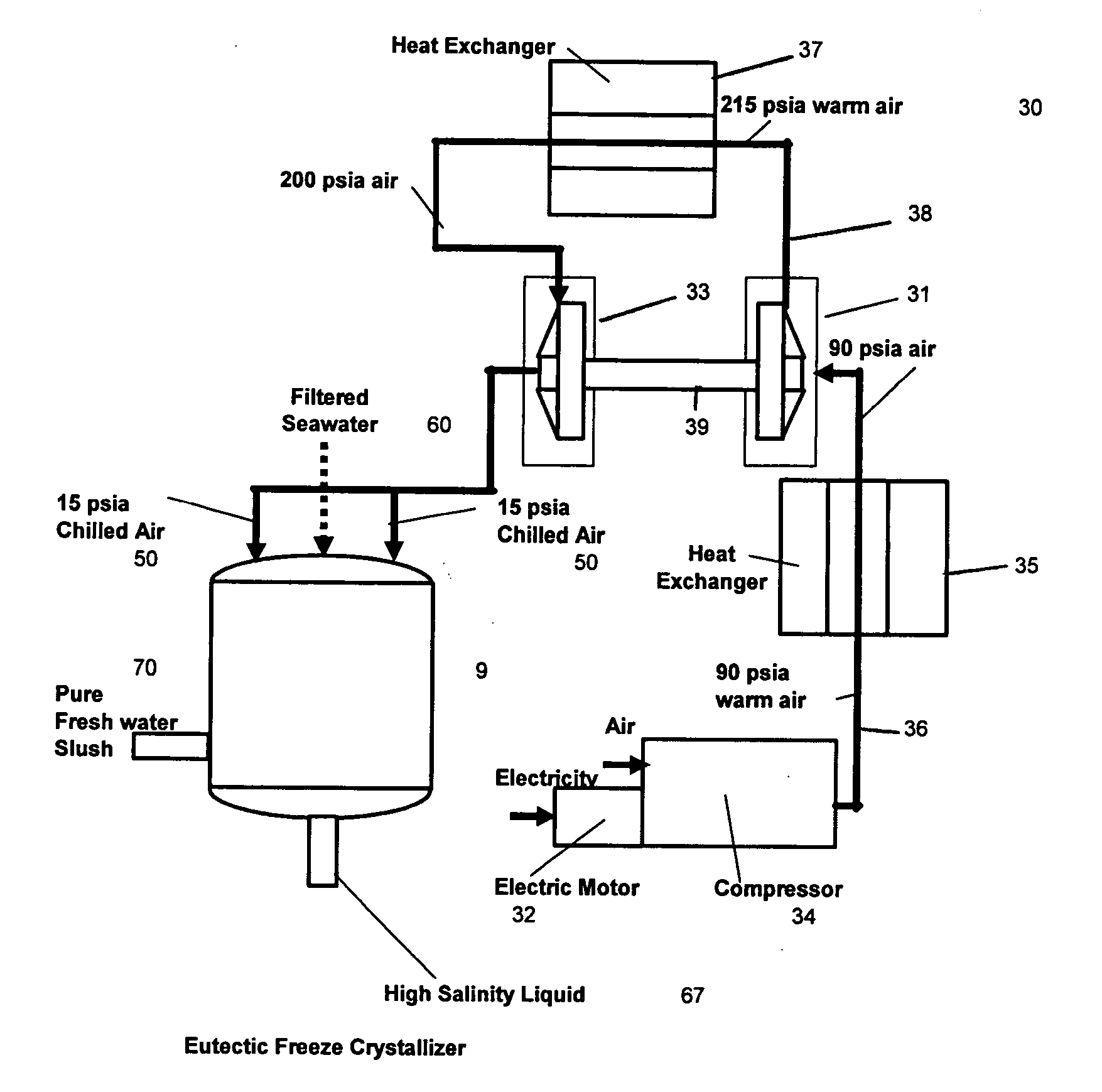

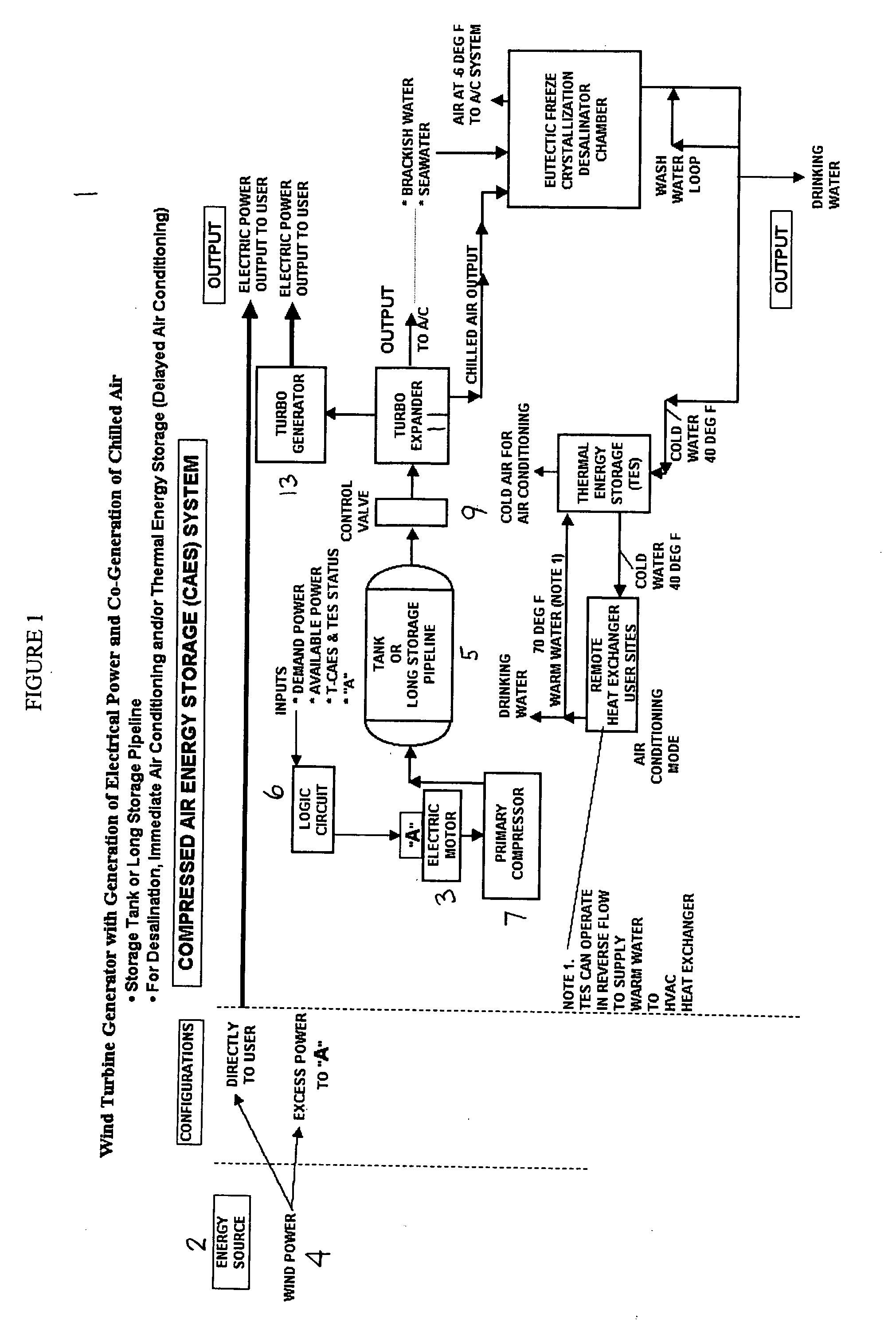

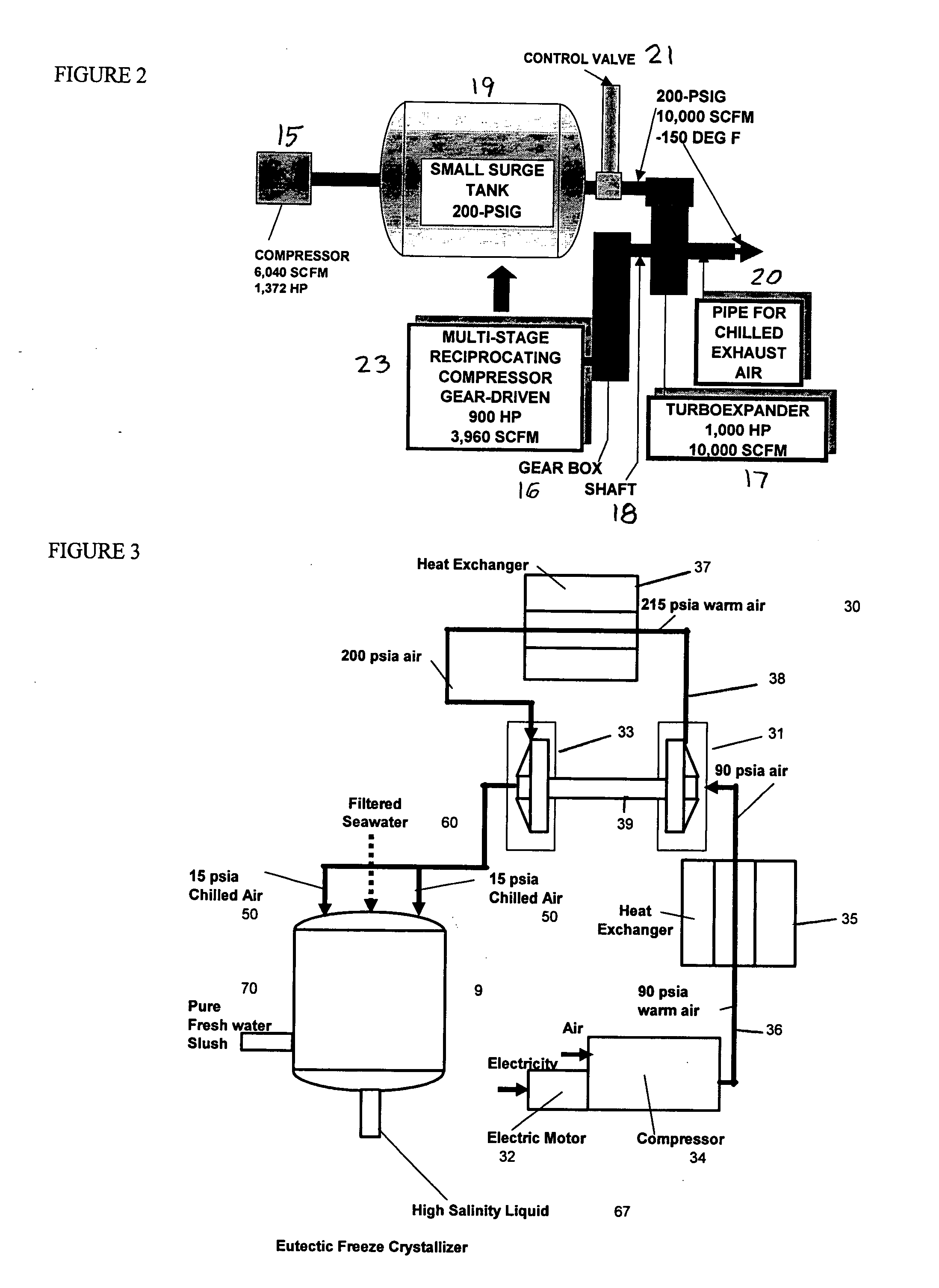

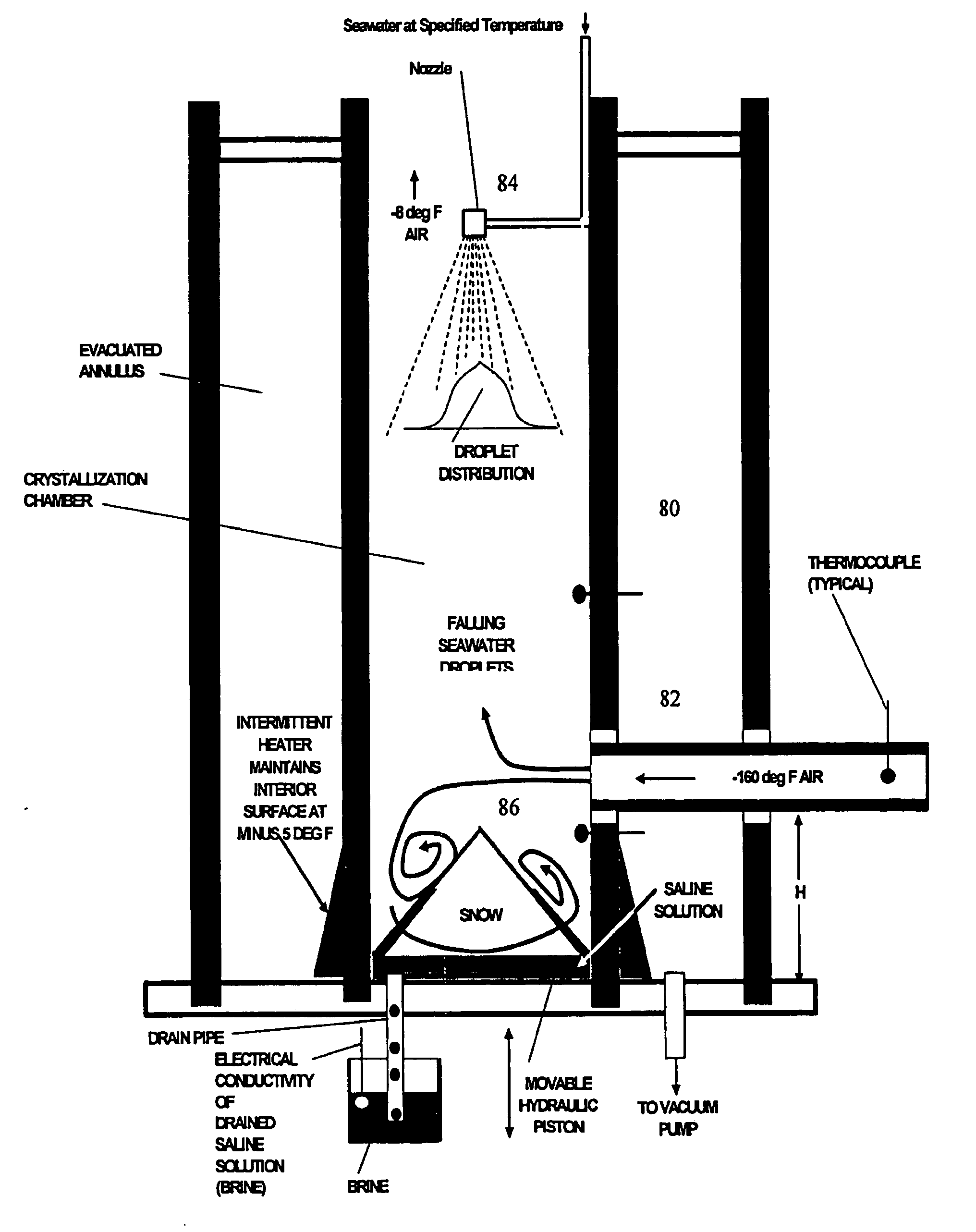

The invention relates to a desalination method and system that uses freeze crystallization technology that incorporates the use of compressed air energy as the source for freezing temperatures. When compressed air is released by a turbo expander, chilled air is produced as a by-product, wherein the chilled air is introduced into a crystallization chamber. Also injected into the chamber is a spray cloud of seawater droplets, which has been pre-chilled by heat exchange with the cold chamber walls, and which is then circulated and exposed to the chilled air in the chamber. The sizes of the droplets can vary, but are preferably predetermined, along with the relative temperatures, flows and speeds of the spray and chilled air, such that when the droplets are circulated within the chilled air, and settle at the bottom of the chamber, they are deposited at slightly above the eutectic temperature. This way, the ice / snow mass that forms at the bottom of the chamber will consist of frozen ice crystals, and a residue of salt water brine, which can runoff from the mass, either from the sides, or through any voids or channels that may form within the mass.

Owner:ENIS BEN M +1

Desalination Method and System Using Compressed Air Energy Systems

InactiveUS20100037653A1Facilitate runoffClean the ice massGeneral water supply conservationSeawater treatmentDesalinationSalt water

The invention relates to a desalination method and system that uses freeze crystallization technology that incorporates the use of compressed air energy as the source for freezing temperatures. When compressed air is released by a turbo expander, chilled air is produced as a by-product, wherein the chilled air is introduced into a crystallization chamber. Also injected into the chamber is a spray cloud of seawater droplets, which has been pre-chilled by heat exchange with the cold chamber walls, and which is then circulated and exposed to the chilled air in the chamber. The sizes of the droplets can vary, but are preferably predetermined, along with the relative temperatures, flows and speeds of the spray and chilled air, such that when the droplets are circulated within the chilled air, and settle at the bottom of the chamber, they are deposited at slightly above the eutectic temperature. This way, the ice / snow mass that forms at the bottom of the chamber will consist of frozen ice crystals, and a residue of salt water brine, which can runoff from the mass, either from the sides, or through any voids or channels that may form within the mass.

Owner:ENIS BEN M +1

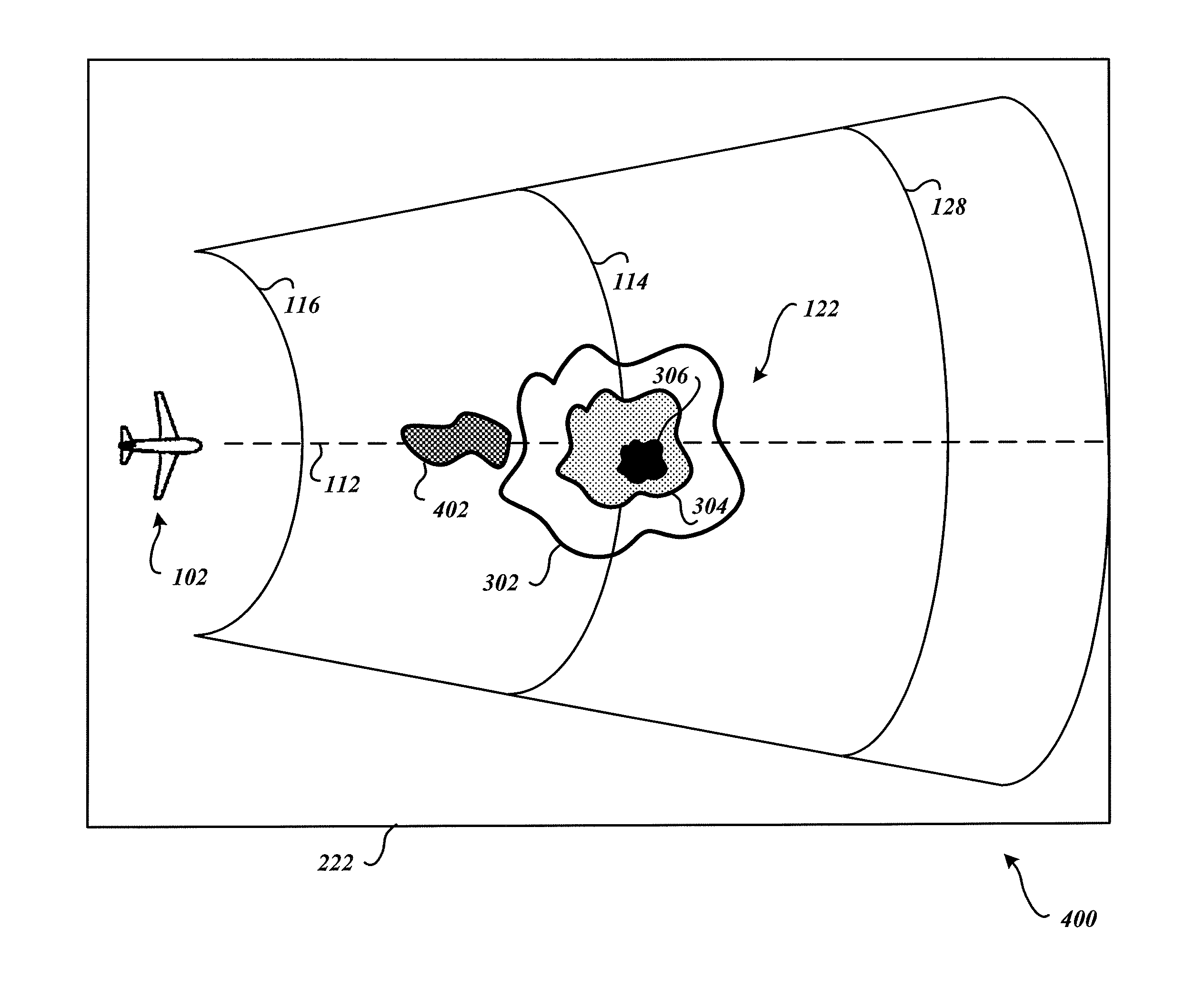

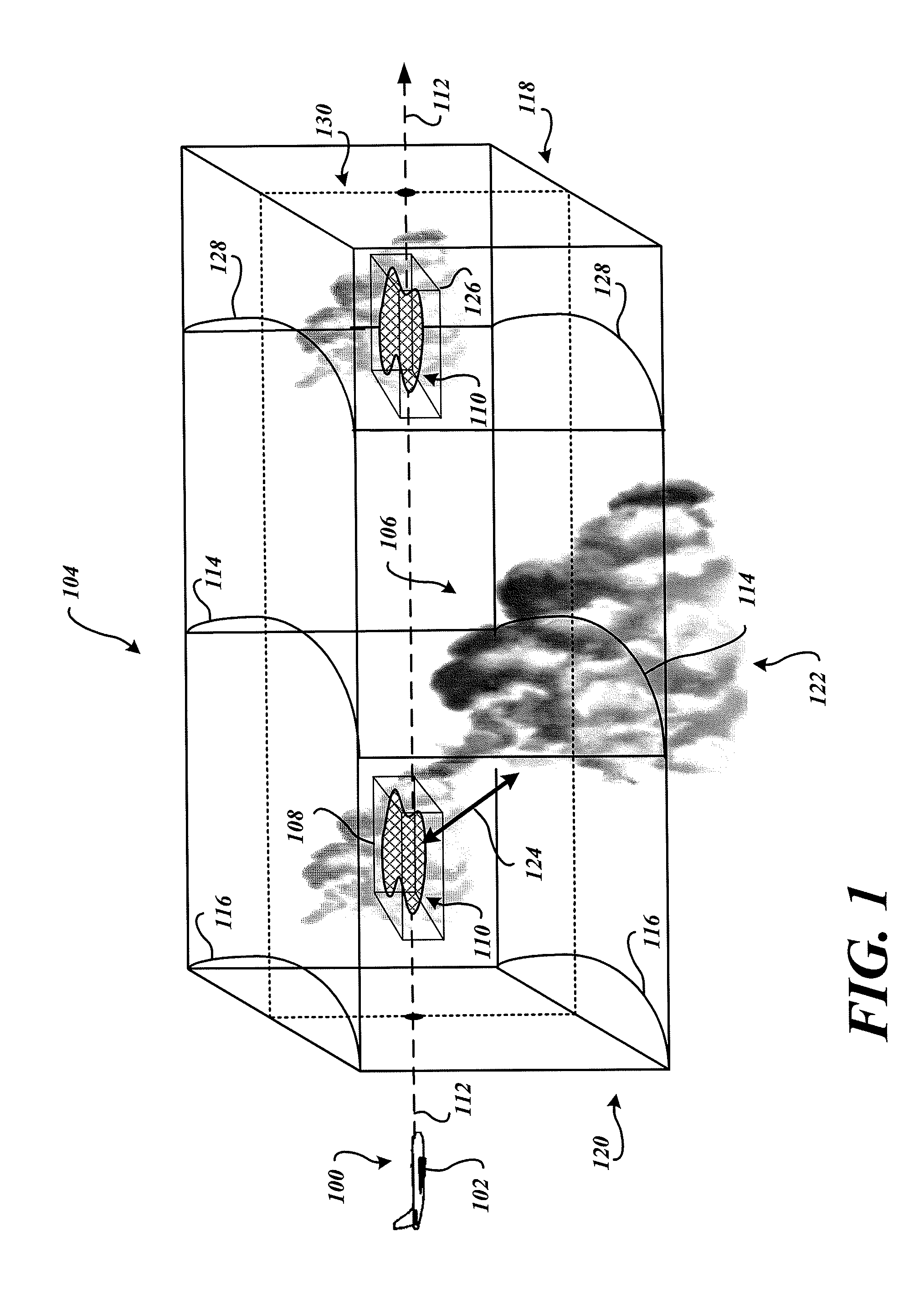

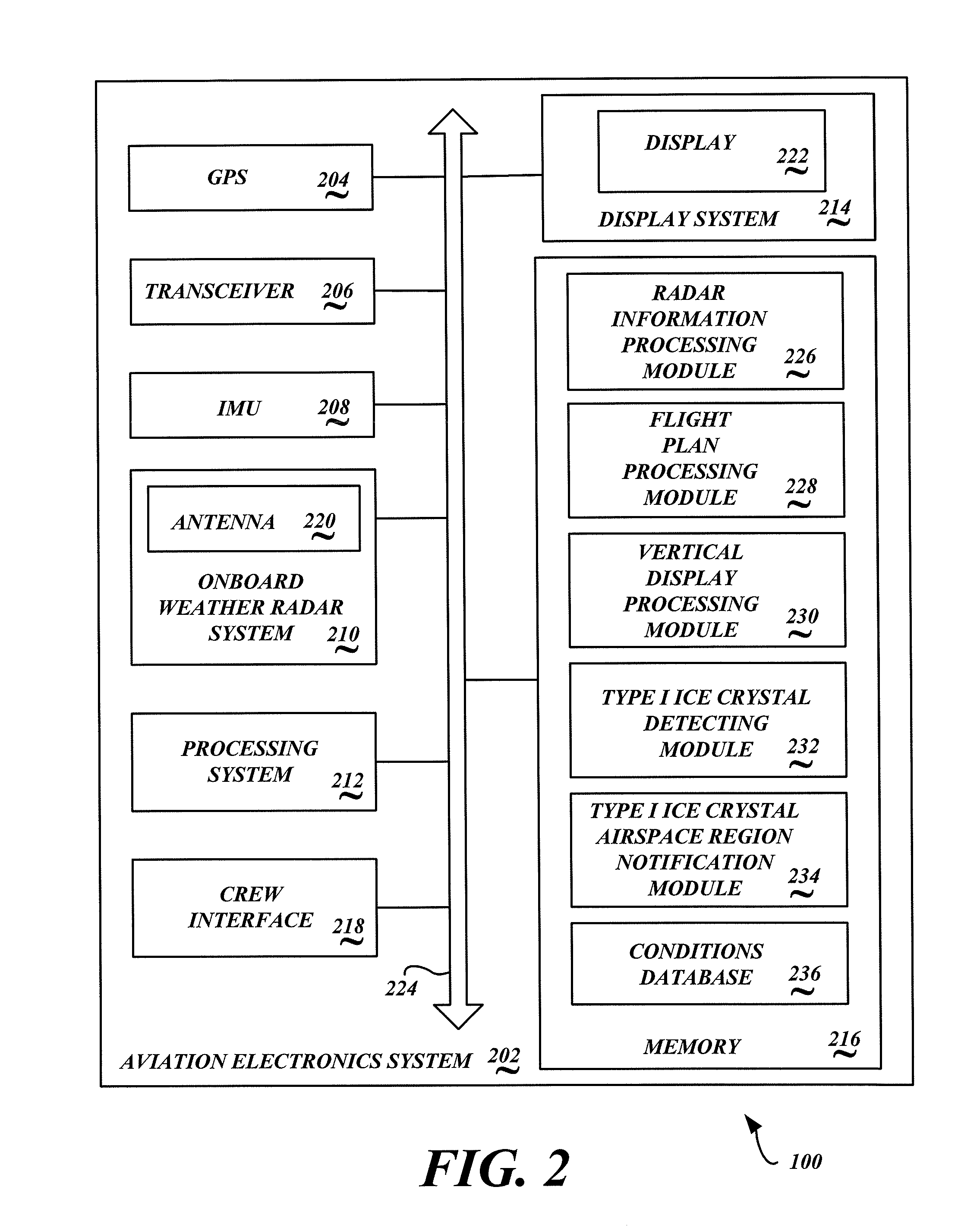

System and method to identify regions of airspace having ice crystals using an onboard weather radar system

ActiveUS20130234884A1Clear air turbulence detection/forecastingDe-icing equipmentsWeather radarAtmospheric sciences

Owner:HONEYWELL INT INC

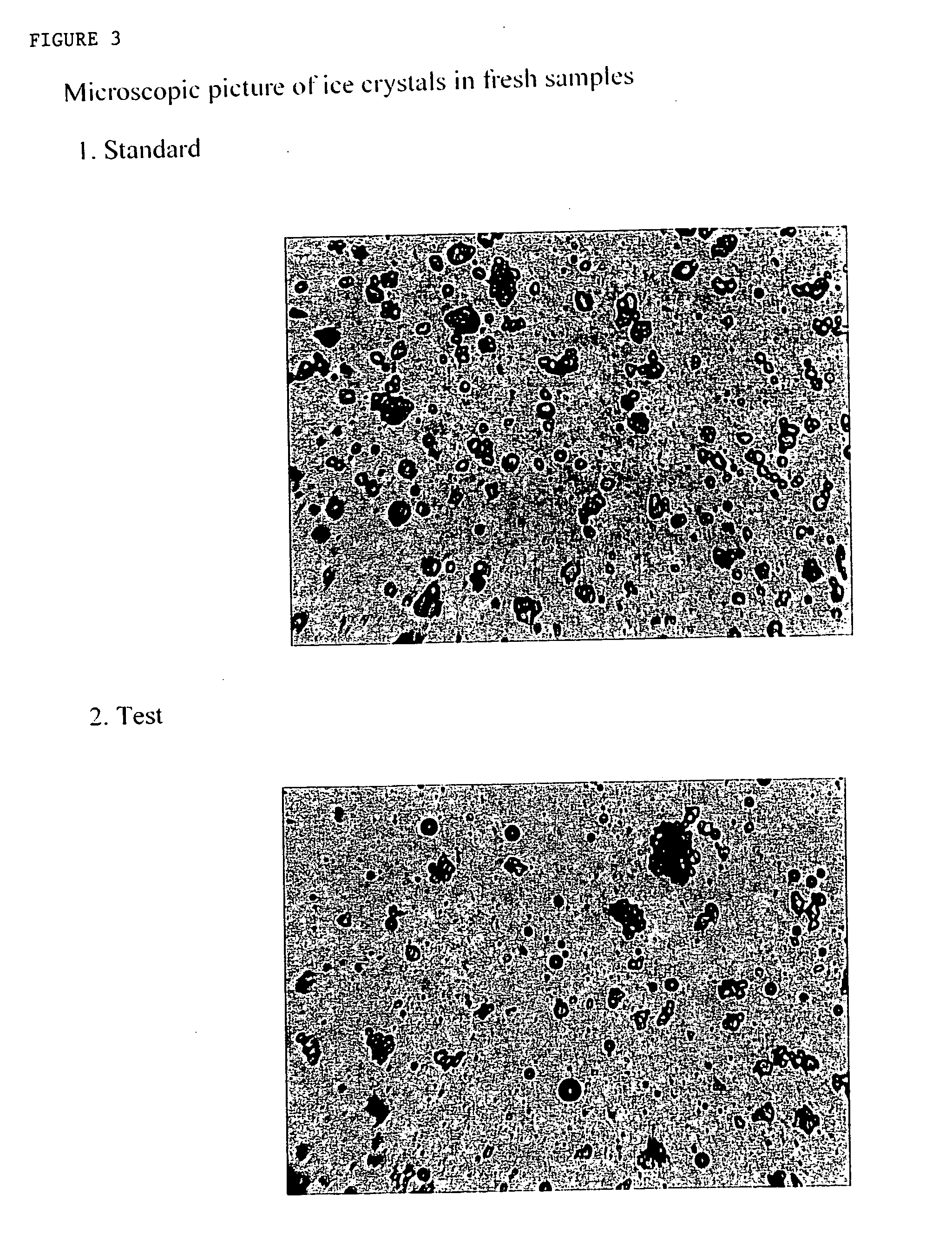

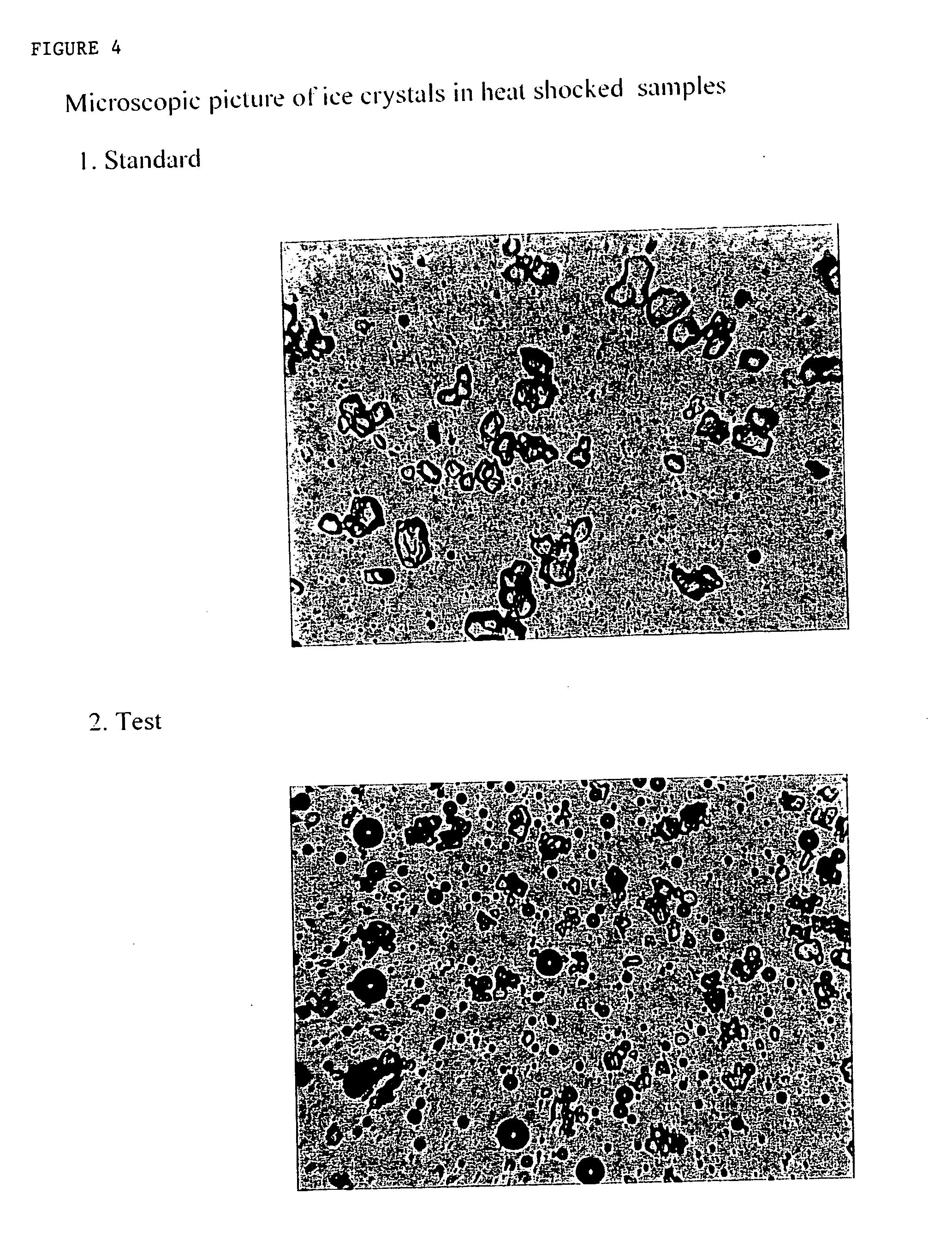

Frozen food product

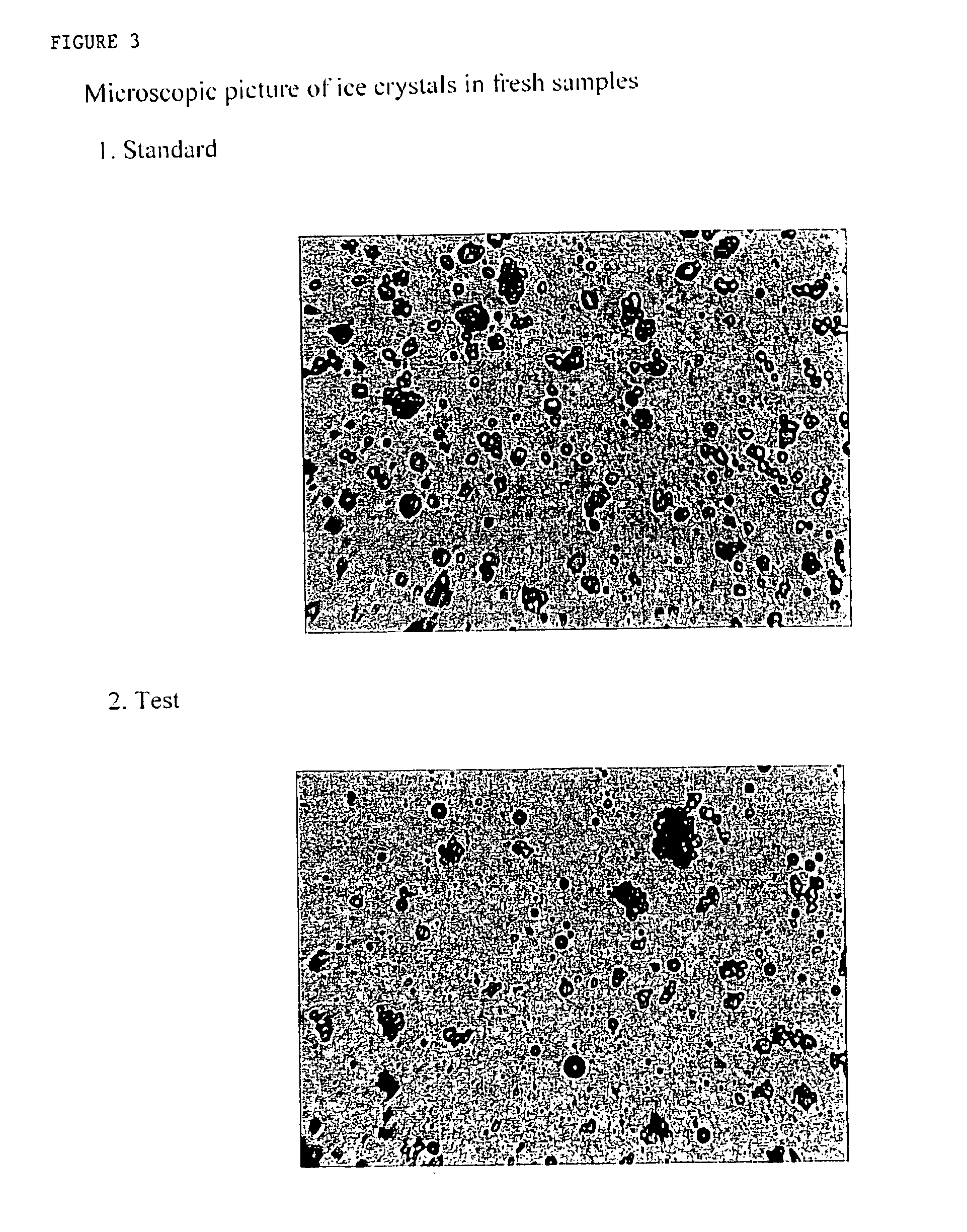

Plant anti freeze proteins can advantageously be incorporated into frozen confectionery products, provided they have the capability of limiting the growth of ice crystals

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

Aerated frozen products

Owner:SOC DES PROD NESTLE SA

Aerated frozen suspensions with adjusted creaminess and scoop ability based on stress-controlled generation of superfine microstructures

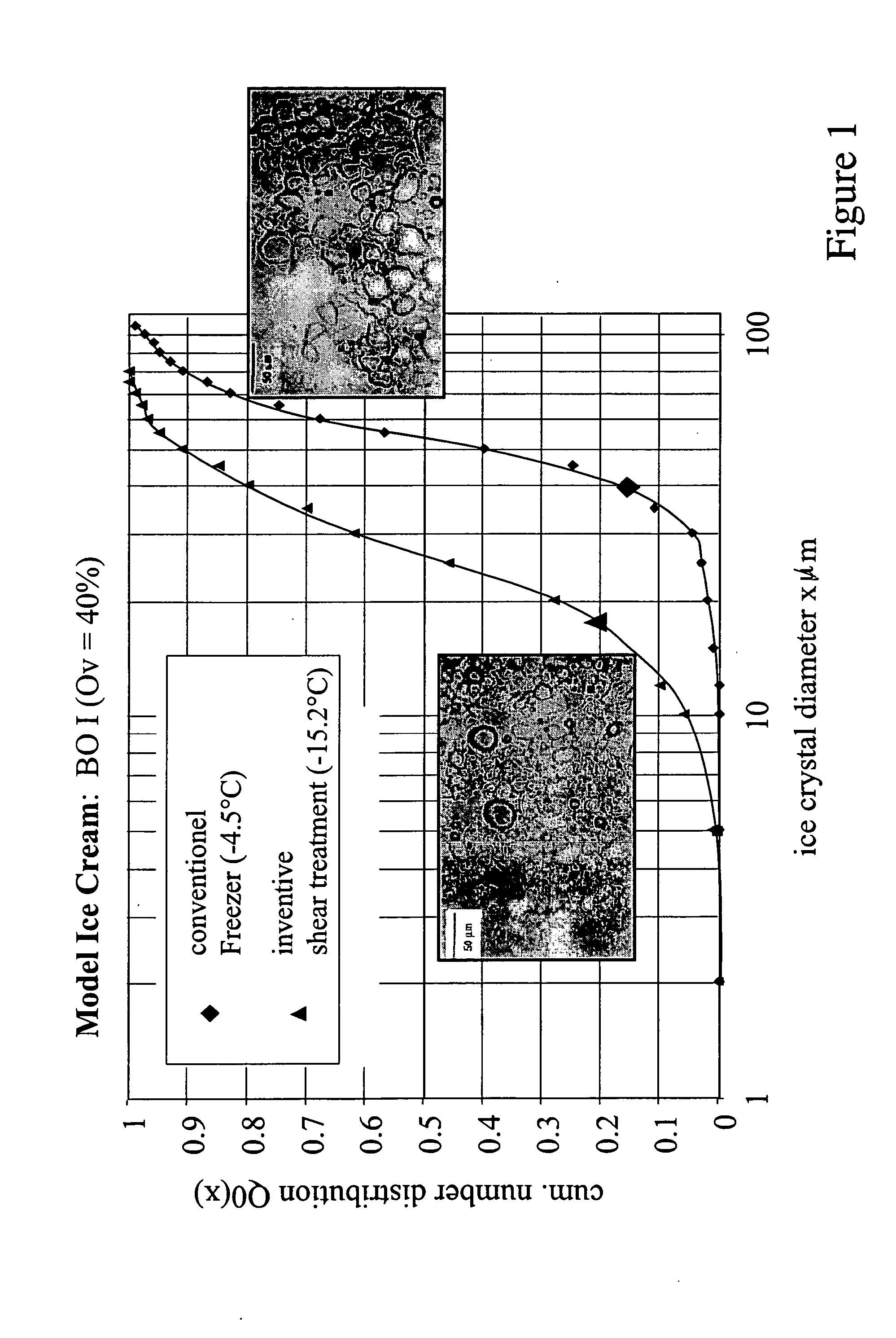

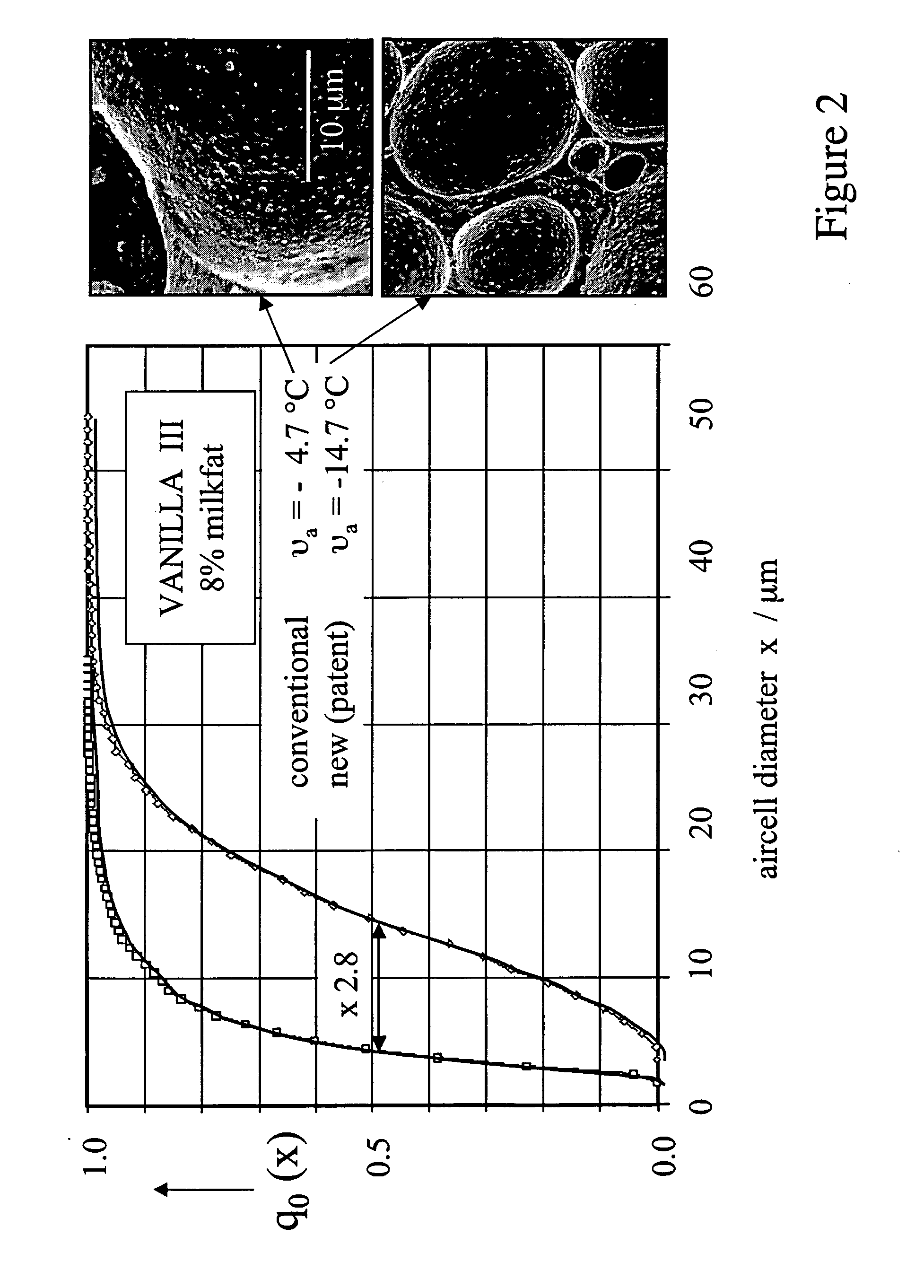

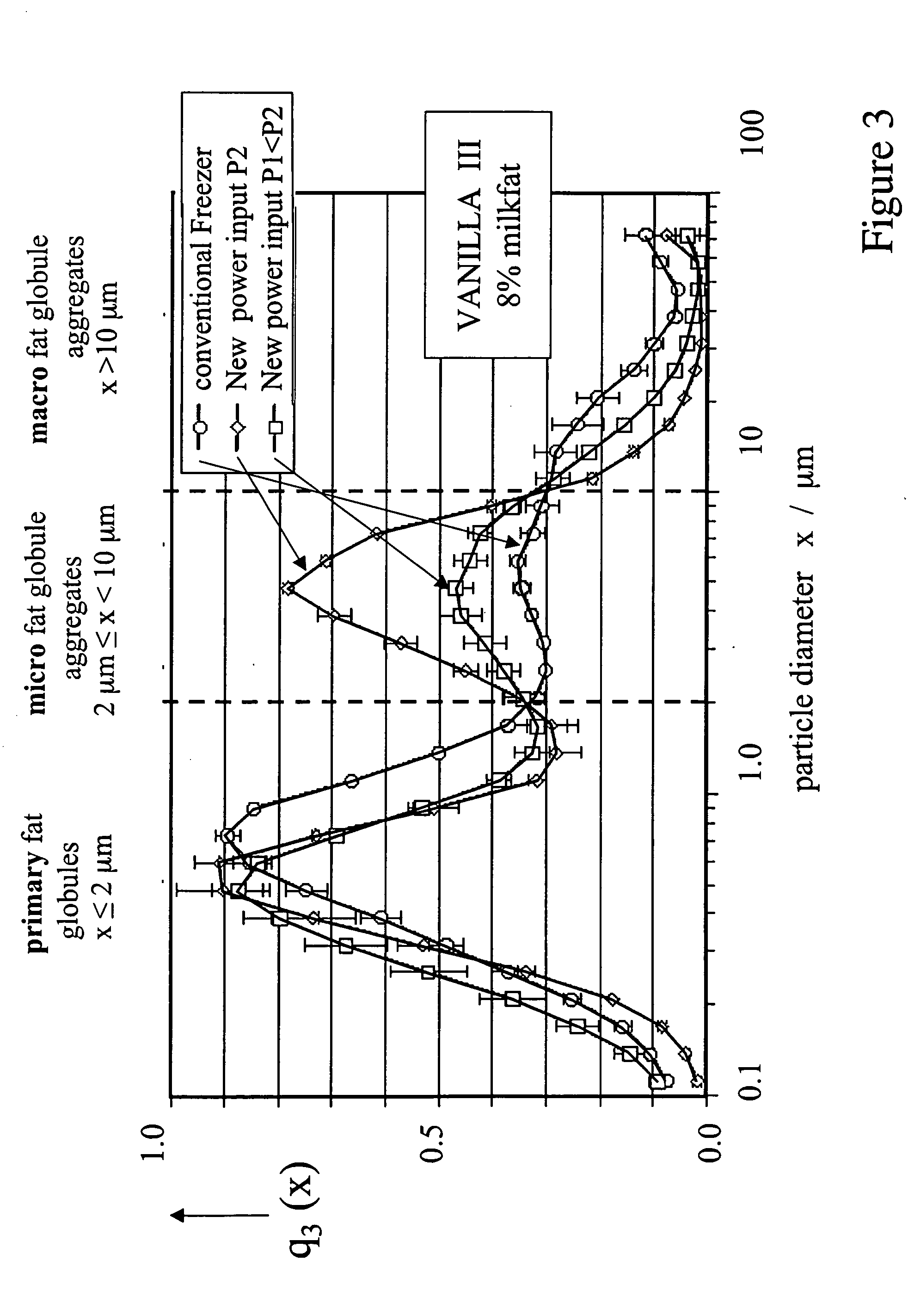

Products that are aerated multiphase systems containing an aqueous continuous fluid phase which may include solutes thus forming an aqueous syrup and disperse phases like gas / air cells, water ice crystals and solid / semi-solid fat globules or aggregates thereof, whereas the disperse phases are that finely structured that their mean diameters are below phase specific critical maximum values and thereby generate a most preferred by consumers, full rich silky-creamy mouth feel at much lower fat content than usual in conventional related products like premium and super premium ice creams.

Owner:SOC DES PROD NESTLE SA

Aerated frozen products

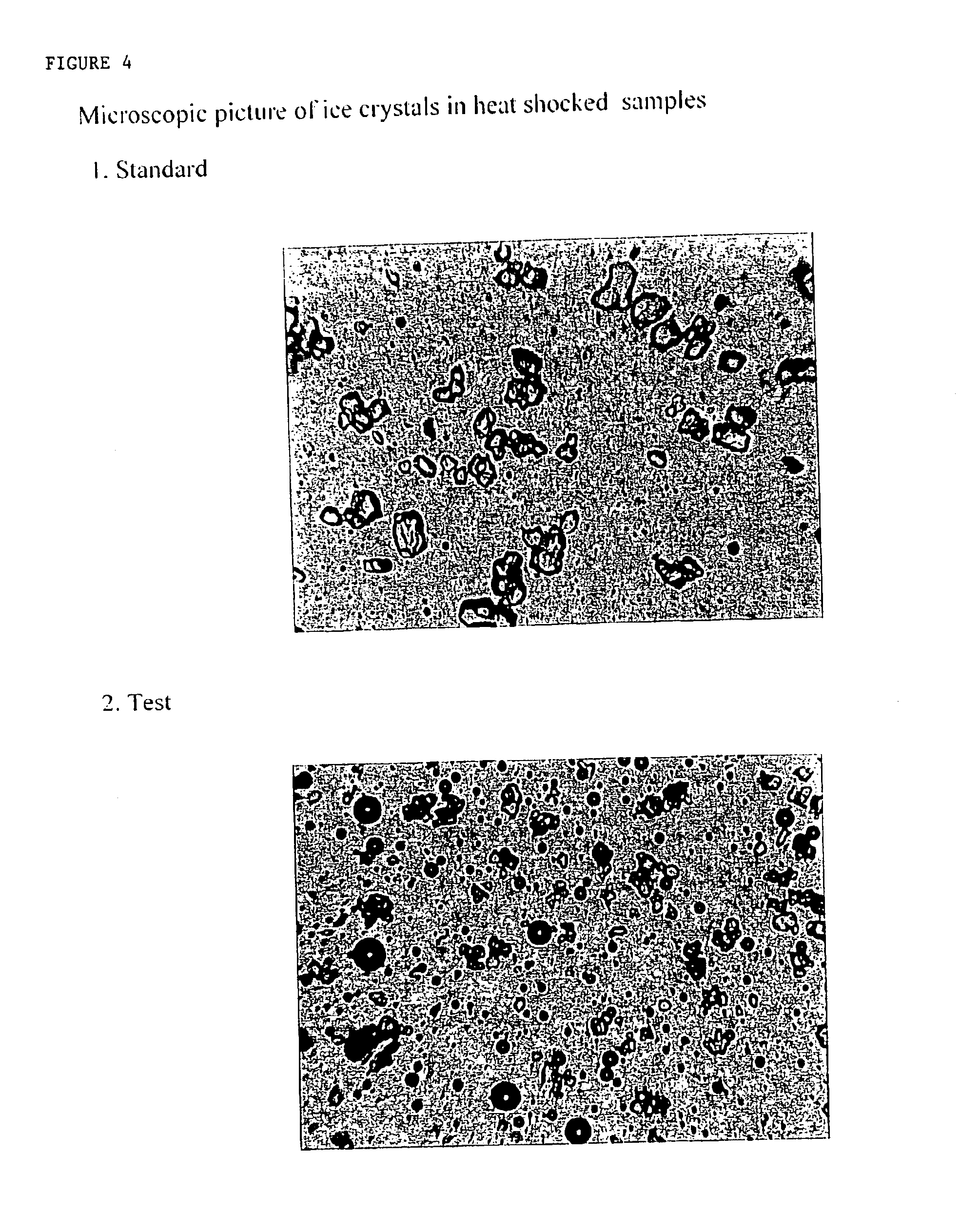

An aerated frozen ice cream comprising a mixture of ingredients suitable for frozen aerated ice cream and at least one emulsifier for facilitating formation and stabilization of fat alpha crystals, the ice cream having an overrun of about 20% to about 250%, uniformly distributed small air cells having an average size of less than about 50 microns, ice crystals, a smooth texture, and heat shock resistant.

Owner:SOC DES PROD NESTLE SA

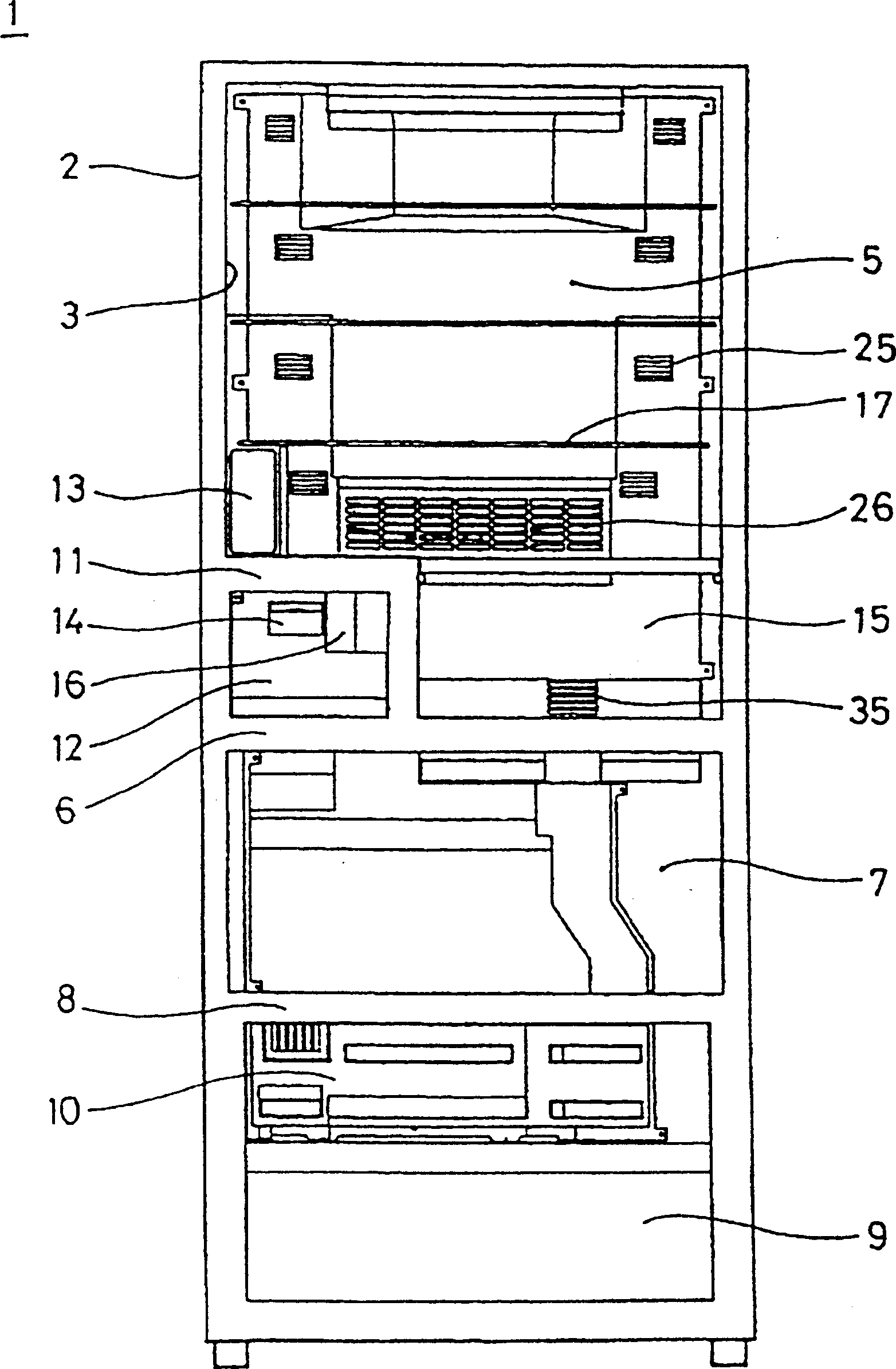

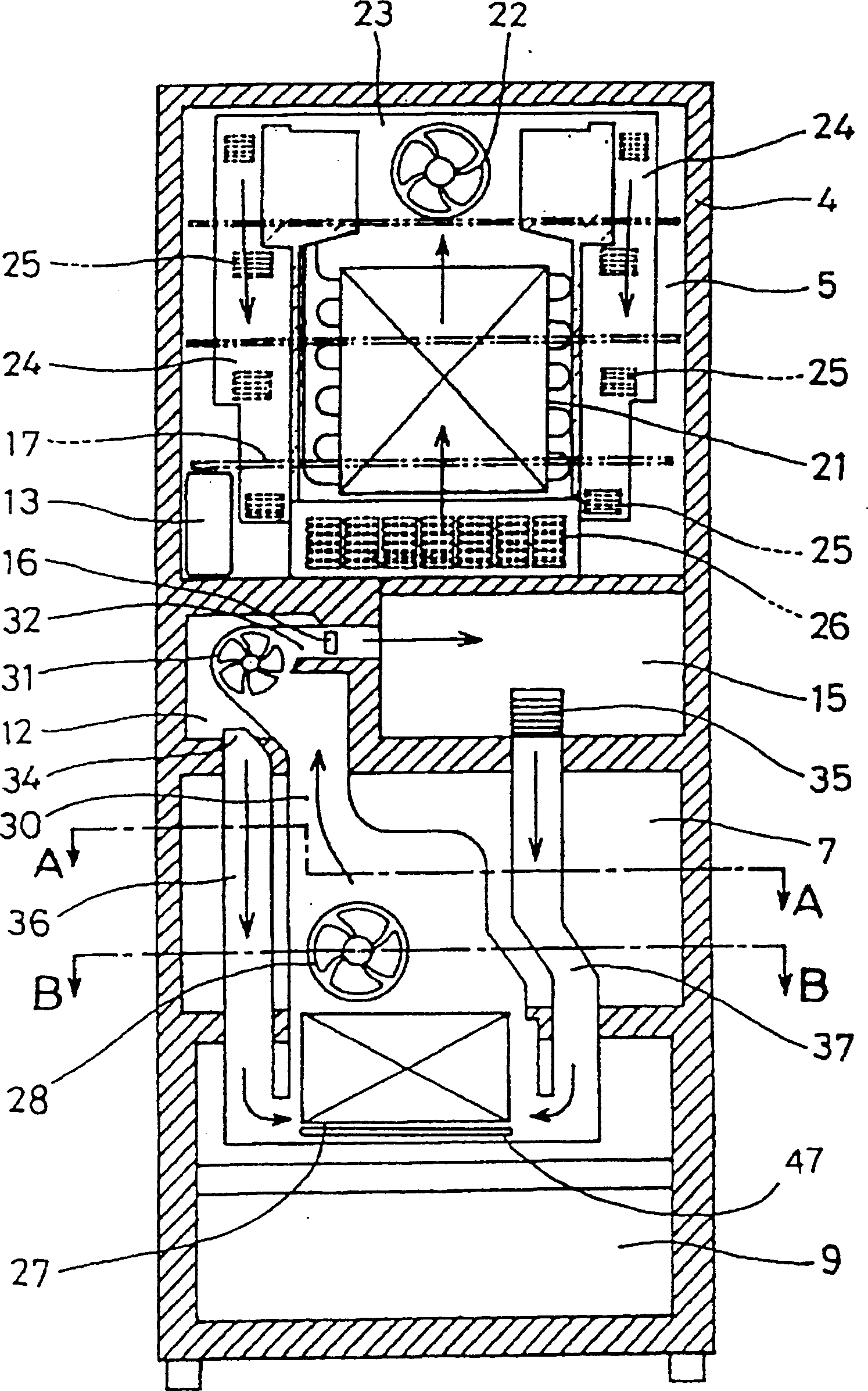

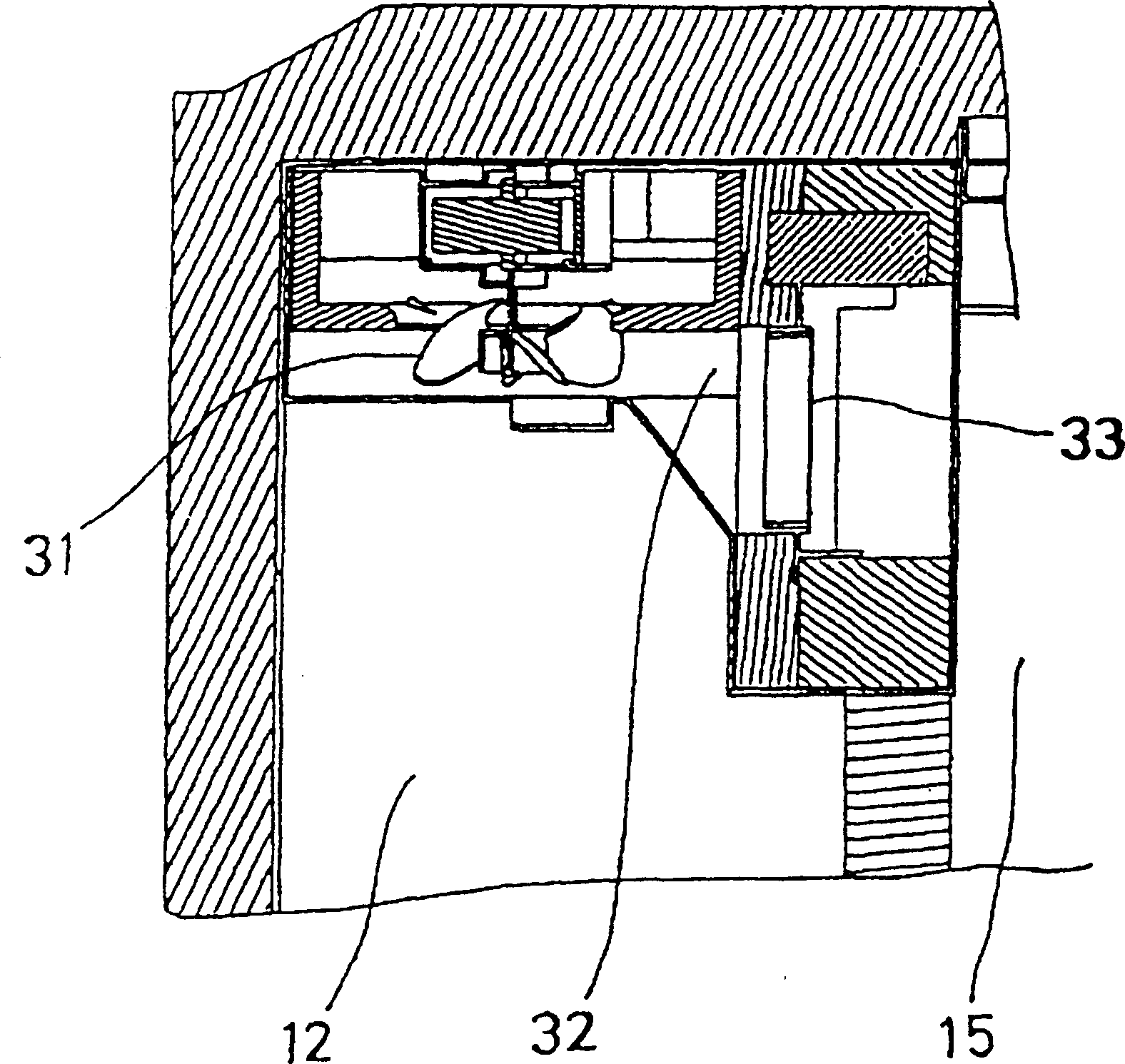

Refrigerator

InactiveCN1412509AEasy to useConvenient storage compartment layoutLighting and heating apparatusDomestic refrigeratorsPreserved FoodsUsability

A refrigerator comprises a refrigerating room(5)disposed in the upper part of a refrigerator body; a freezing room (9) disposed in the lower part of a refrigerator body; a vegetable room(7) provided between the refrigerating room and the freezing room; the ice making room (12) disposed in the corner of the bottom part of the refrigerating room having an automatic ice making device; and an ice making fan(31) provided in the rear part of the ice making room; The cooling air produced by the refrigeration cooler is sent to the ice making room via a duct(30) and the ice making fan(31), and a cooling air duct including the freezing fan and a return duct from the ice making room are jointly provided in the rear surface of the vegetable room; A weak freezing chamber (6) is disposed in a freezing space (40), and a damper (37) is disposed in a back face of the weak freezing chamber (6). wall in a freezing space (40) and a damper (37) is disposed in a back face of the weak freezing chamber (6). When weak freezing is performed for food in the weak freezing chamber (6), the damper (37) is made into an open state, cooling air is forced to flow in, resulting in a rapid freezing operation up to a maximum ice crystal generation zone or lower. Subsequently, a heater (43) is initiated and the food is maintained in the weak freezing temperature zone. The present invention provides a layout of a storage room of a usability, Furthermore, it may maintain fresh degree and taste of food with weak frozen temperature when preserving food.

Owner:KK TOSHIBA

Integral porous carbon-silicon carbide composite material, and preparation method and application thereof

The invention discloses an integral porous carbon-silicon carbide composite material, and a preparation method and an application thereof. The preparation method comprises the following steps: fully stirring and dispersing silicon carbide powder, silicon powder, carbon-containing powder and a sintering aid in water, preparing a green body by using an ice crystal pore formation technology or an organic polymer foam template pore formation technology, and carrying out high temperature sintering to prepare an integral silicon carbide core; and generating a stable carbon-containing shell with high mechanical strength in the pore channels of the porous SiC core through an in-situ generation technology or a carbon-containing precursor polymerization carborization technology. The composite material has the characteristics of high specific surface area, easy activation surface, acid and alkali corrosion resistance, good heat and electricity conduction property, high and stable mechanical strength, low gas passing pressure drop and low preparation cost, can be used as a metal catalyst loading carrier, or can be directly used as a nonmetal catalyst, so the defects of easiness in pulverization, easiness in obstruction, difficulty in molding and high price of present industrial active carbon catalysis carriers are avoided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Frozen food product

A process for the production of a frozen food product comprising AFP, wherein the conditions are chosen such that the ice-crystals in the product have an aspect ratio of from 1.9 to 3.

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

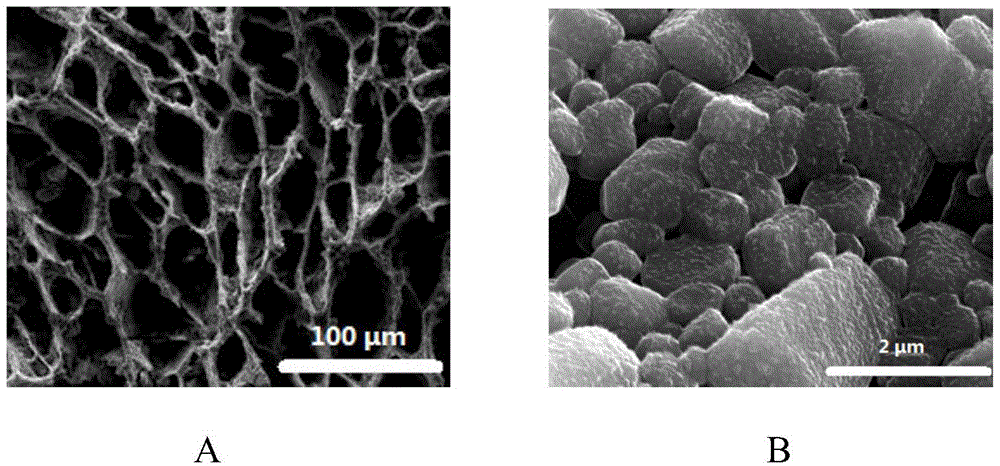

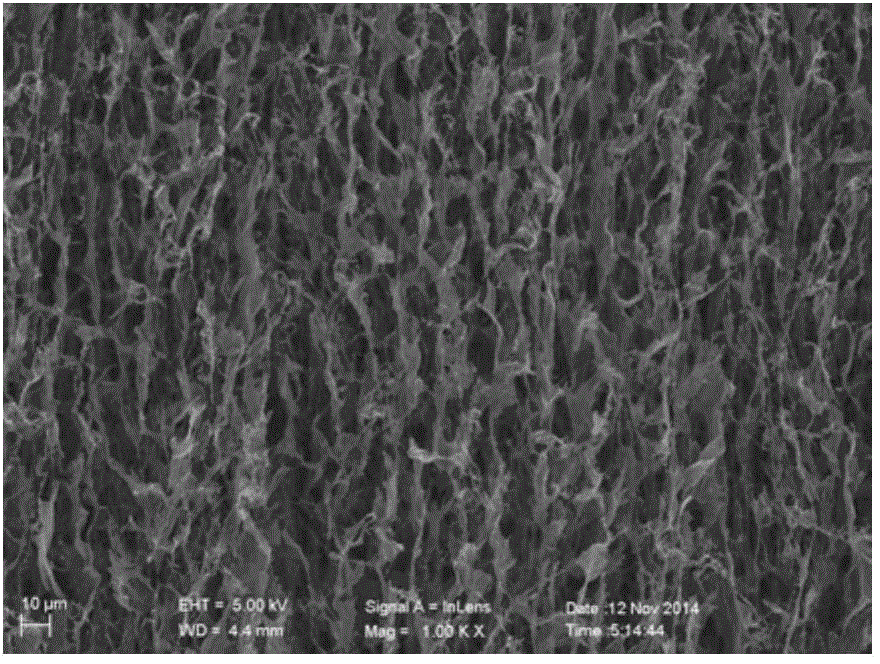

Preparation method of porous bacteria cellulose sponges

The invention relates to a preparation method of porous bacteria cellulose sponge. A bacterial cellulose hydrogel membrane and an ice crystal are completely mixed, pre-frozen is carried out at subzero 20 to subzero 50 DEG C and are prepared into a homogeneous dispersed system. At last, a freeze-drying method is used for preparing the porous bacteria cellulose sponge. Through the invention, bacteria cellulose sponge material containing large holes is simply, rapidly and efficiently manufactured by the invention, and the application of nanometer bacteria cellulose in the field of the tissue engineering stent can be greatly developed.

Owner:TIANJIN UNIV

Cocktail type cryoprotectant and application thereof

ActiveCN108207930AGood biocompatibilityLow toxicityDead animal preservationHigh concentrationIce crystals

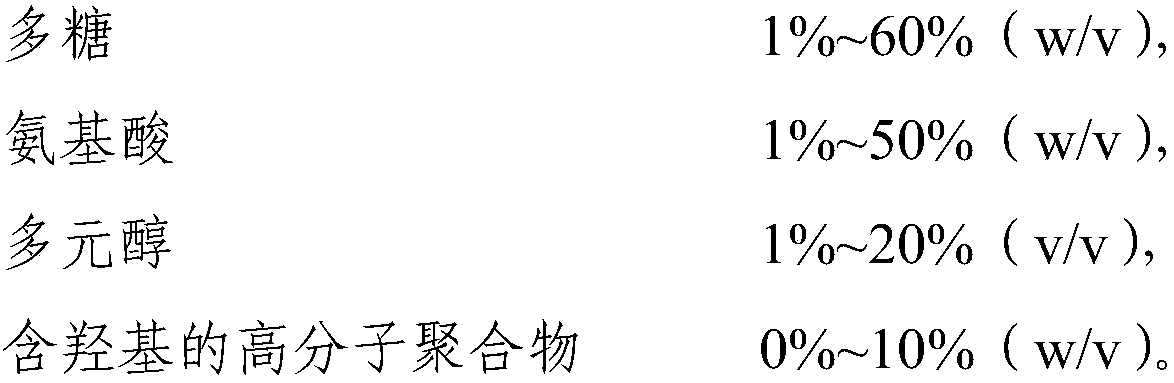

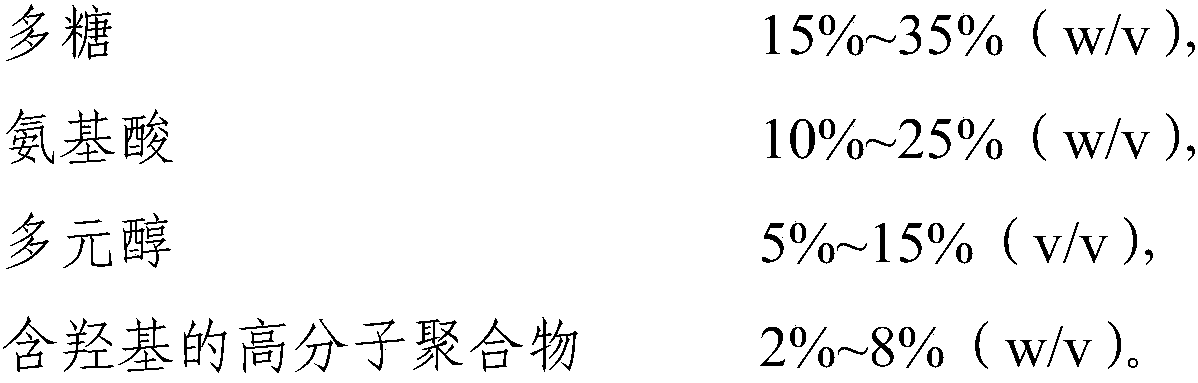

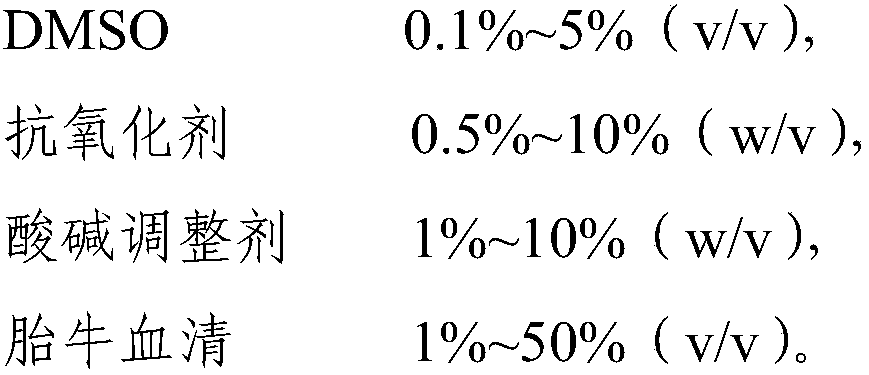

The invention relates to the field of biological medicines and in particular to cocktail type cryoprotectant and application thereof. The cocktail type cryoprotectant comprises the following components: 1-60% (w / v) of a polysaccharide, 1-50% (w / v) of an amino acid, 1-20% (w / v) of a polyhydric alcohol and 0-10% (w / v) of a hydroxyl-containing macromoleclar polymer. The polysaccharide, the amino acid, the polyhydric alcohol and the hydroxyl-containing macromoleclar polymer of the cryoprotectant are relatively low in toxicity with high concentrations, formation of intracellular ice crystals can beeffectively inhibited with the polysaccharide, the amino acid, the polyhydric alcohol and the hydroxyl-containing macromoleclar polymer of the proportions, cryopreserved cells can be alleviated fromdamage caused by low temperature environments, the survival rates of the cryopreserved cells after anabiosis culture can be increased, the toxicity of the cryopreserved cells can be greatly reduced, and thus the cocktail type cryoprotectant provided by the invention has very high security feasibility and application and popularization values.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Ice confection

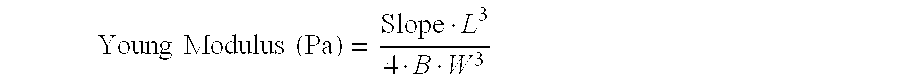

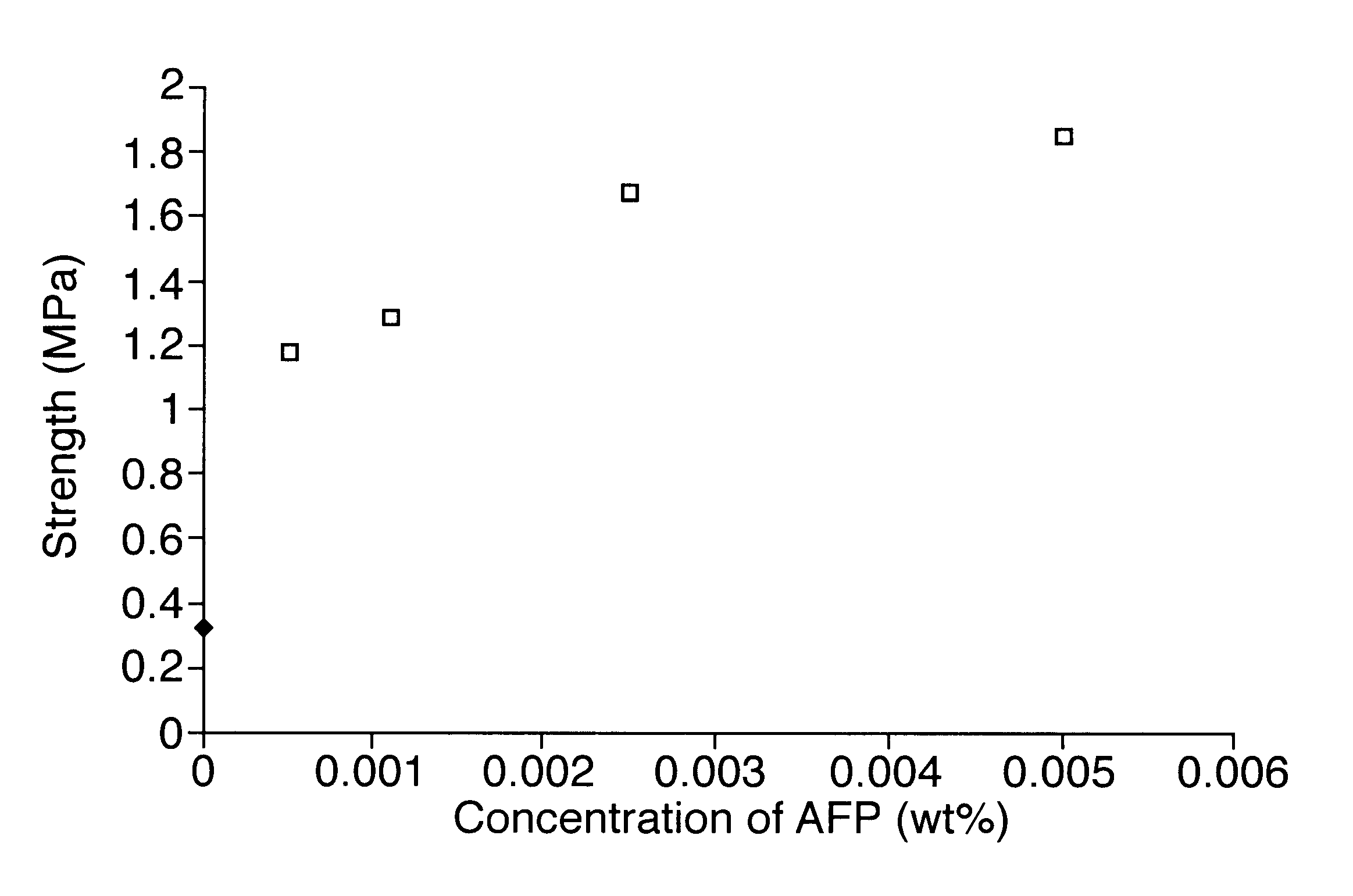

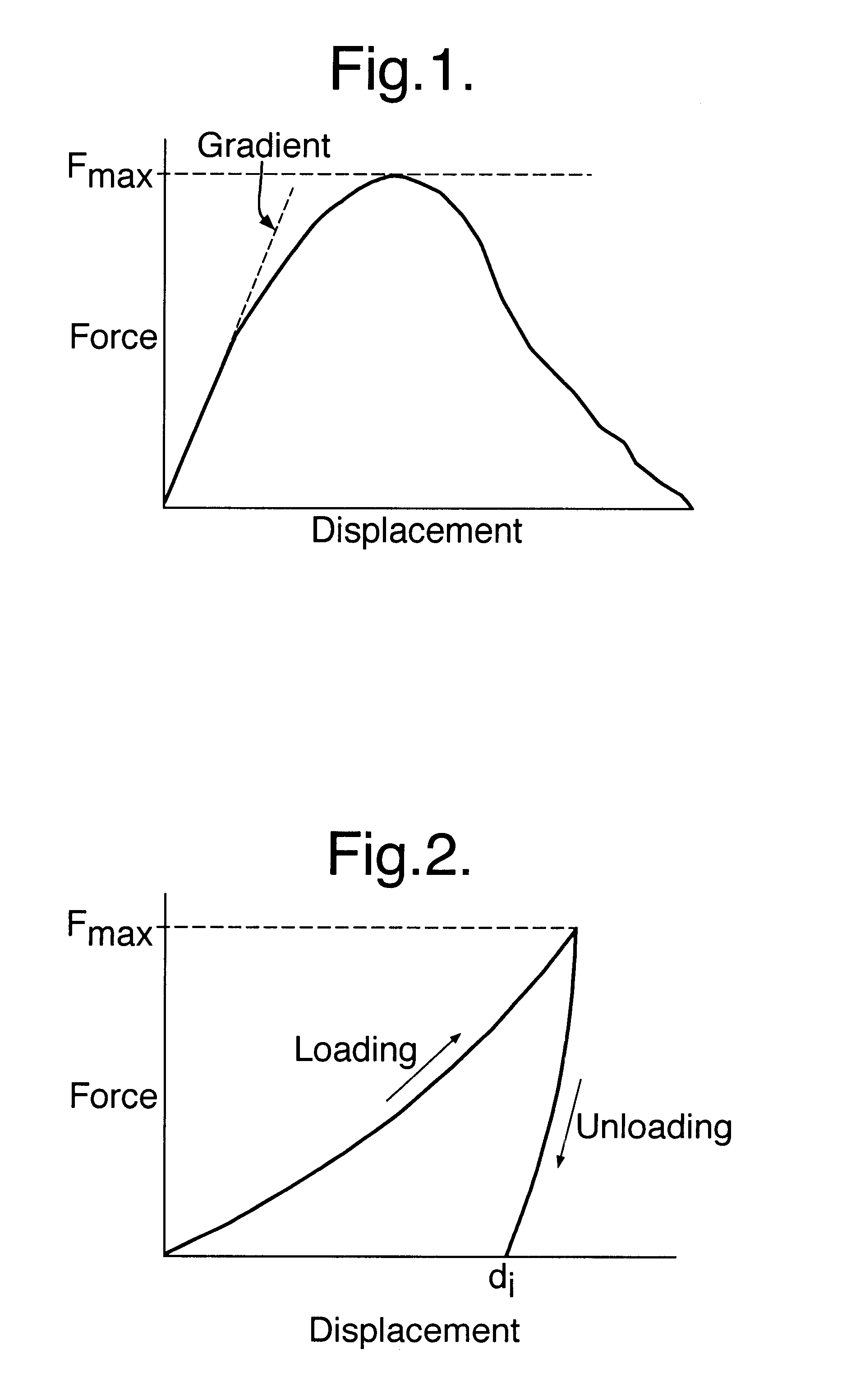

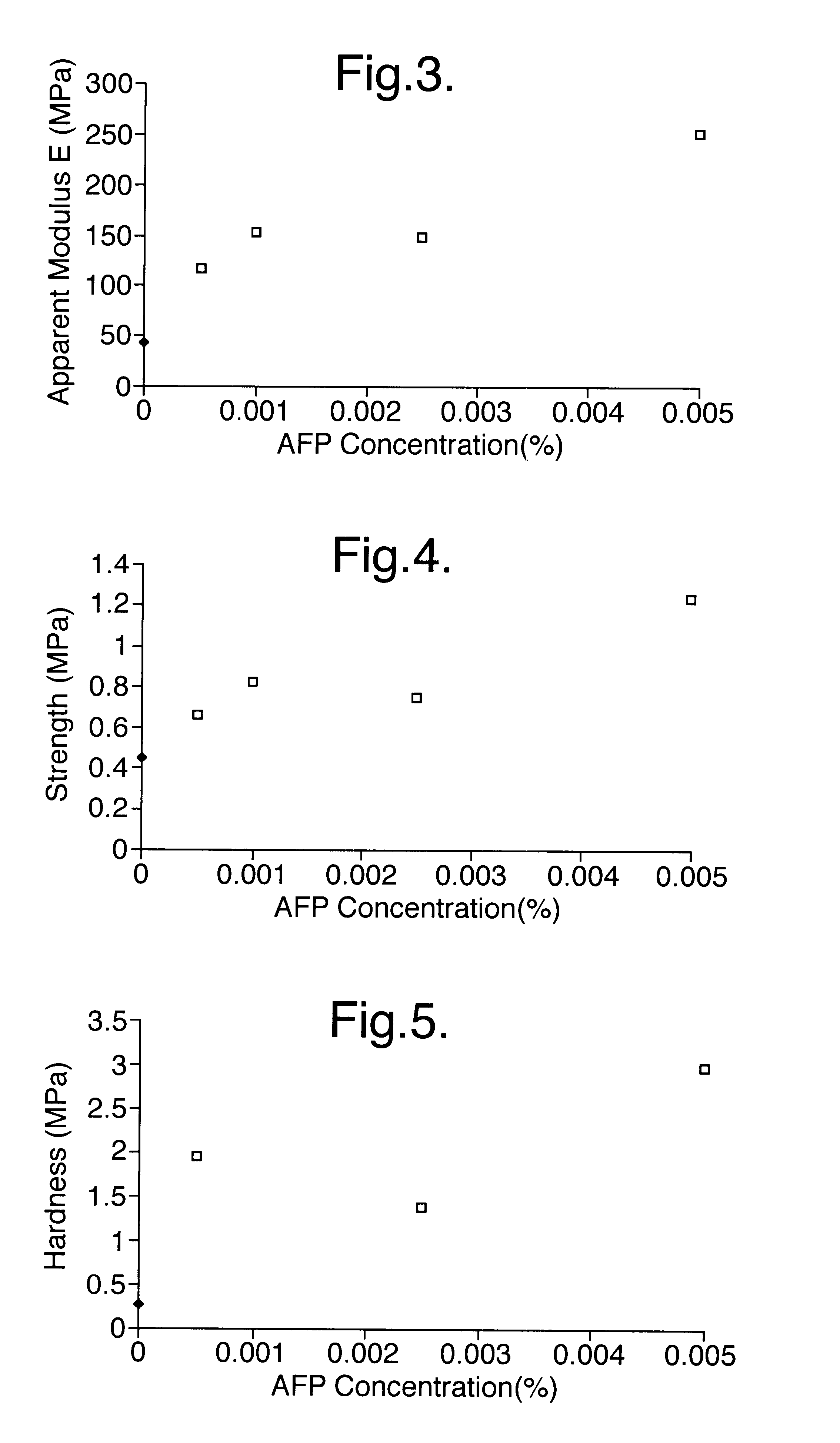

An ice confection comprising an antifreeze protein, whereinDELTA modulus / original modulus >=0.4, and / orDELTA strength / original strength >=0.4; providing that when DELTA modulus / original modulus <=6.0, DELTA modulus >=50 MPa, and / or when DELTA strength / original strength <=2.0,DELTA strength >=0.2 MPa. Such ice confections have a strong, close-packed continuous network of ice crystals and can be used to manufacture products having novel textures, properties and / or shapes.

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

Frozen products

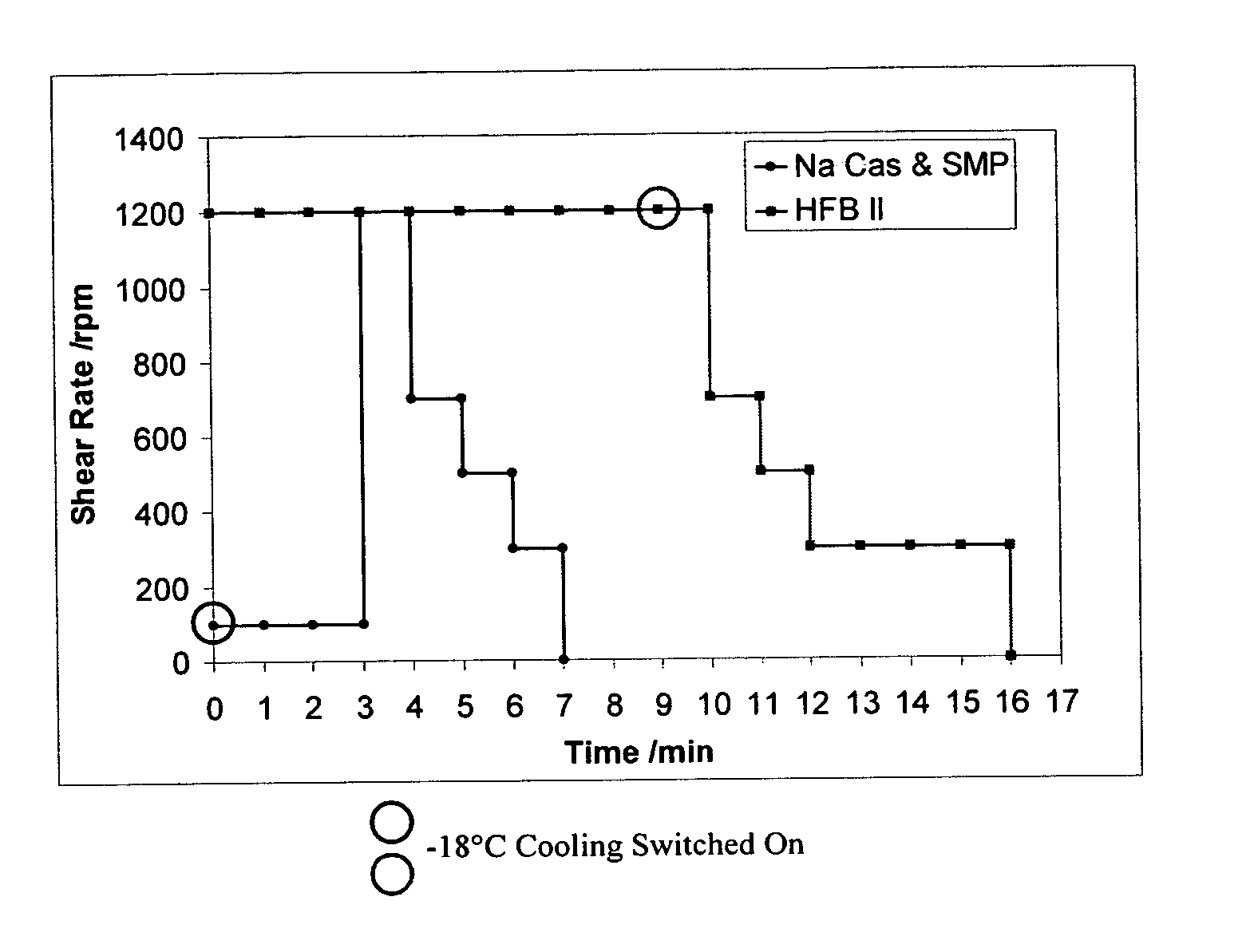

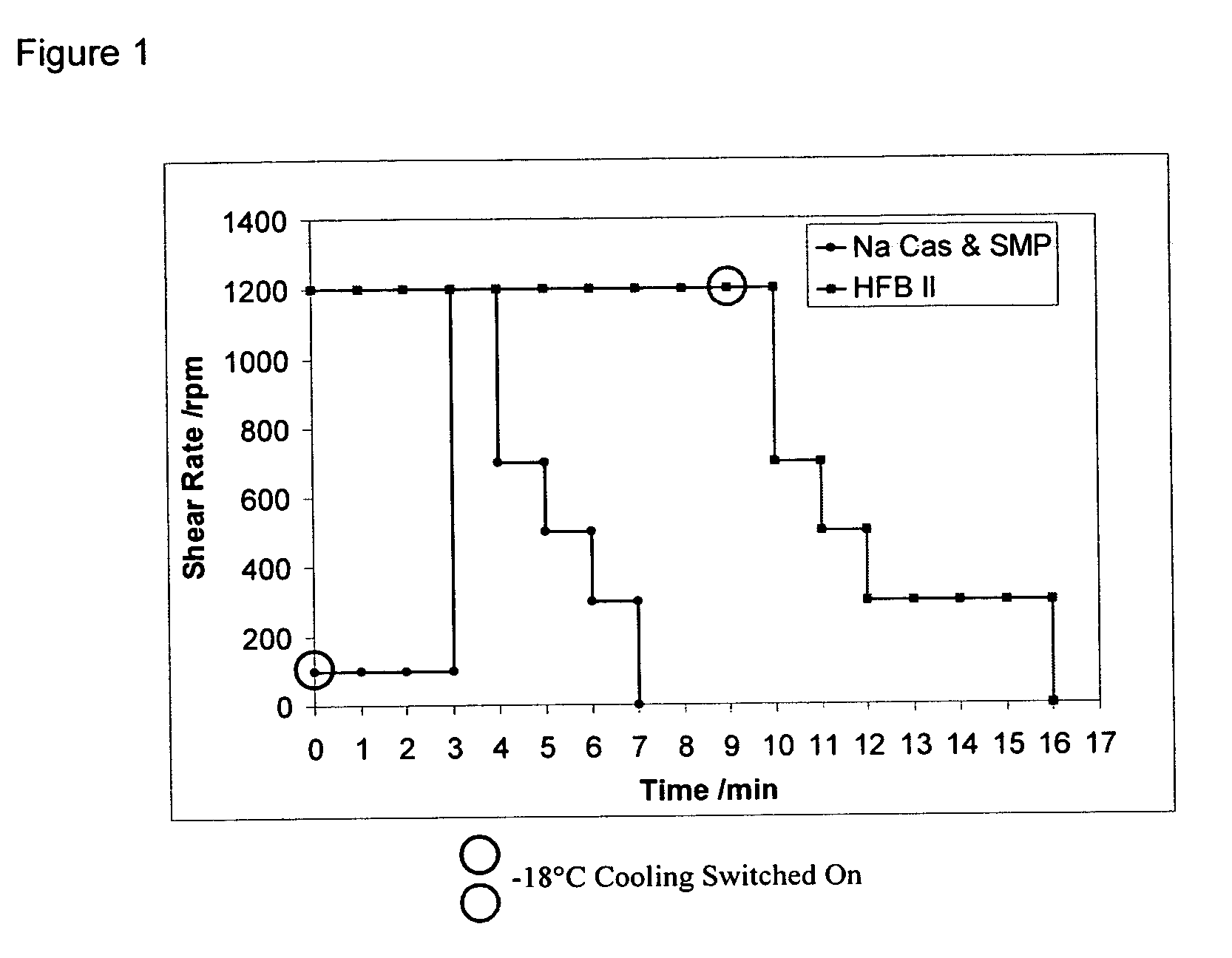

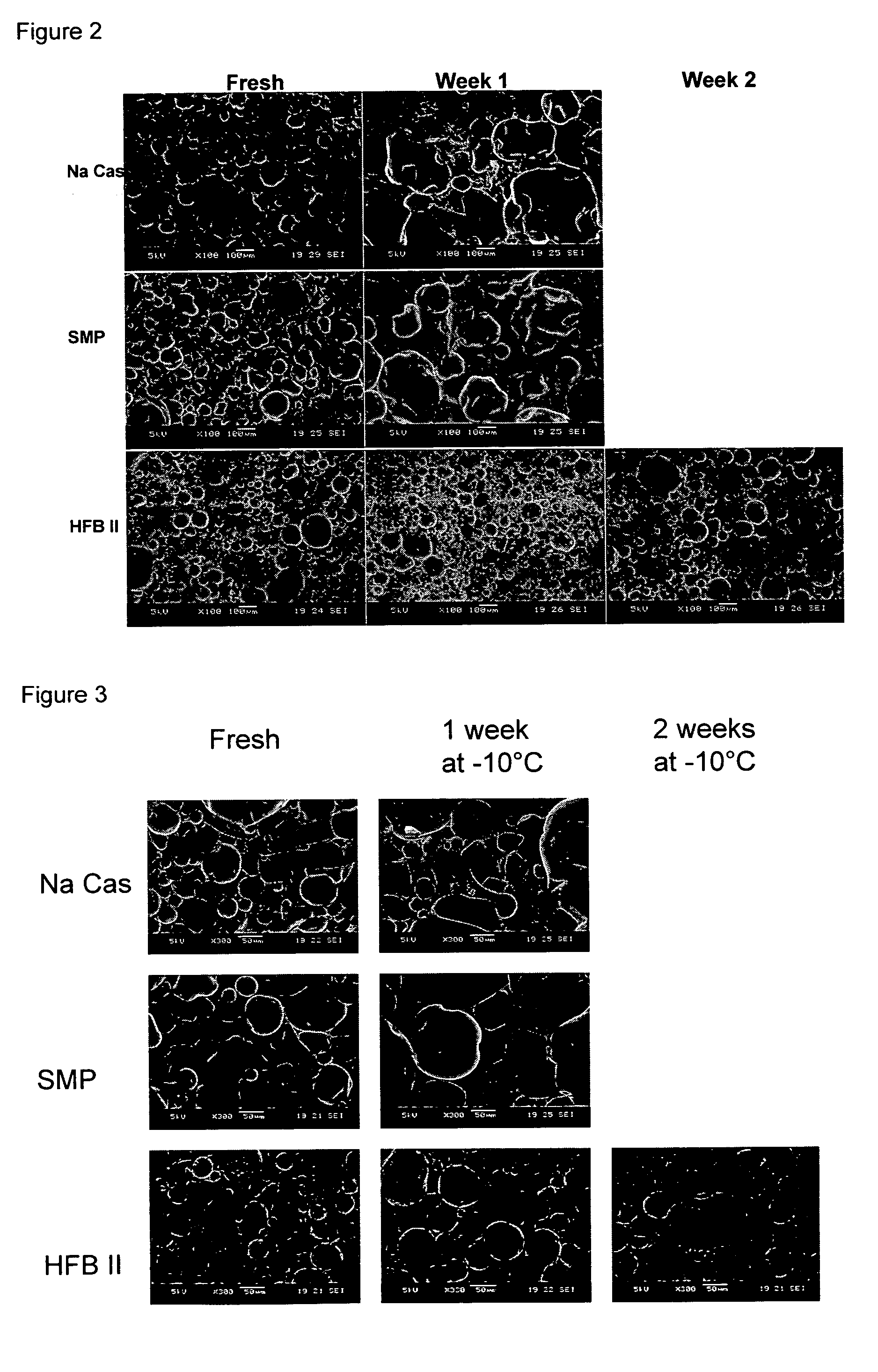

InactiveUS20060024419A1Reduce volumeExtended shelf lifeMilk preparationFrozen sweetsHydrophobinIce crystals

A frozen composition is provided which includes hydrophobin. Also provided is the use of hydrophobin in inhibiting ice crystal growth and / or modifying ice crystal habit in frozen food products.

Owner:CONOPCO INC D B A UNILEVER

Preparation method of self-adhesive hydrogel having anti-freezing/heat-resistant performance

The invention discloses a preparation method of a self-adhesive hydrogel having anti-freezing / heat-resistant performance. The method adopts a hydrogel solvent system consisting of glycerin and a watermixed system, and powerful hydrogen-bond interaction between glycerin and water enables water to be stably immobilized in a polymer network, can destroy the formation of ice crystal lattices at a lowtemperature and prevent moisture volatilization at a high temperature, and endows the hydrogel with long-term stability, anti-freezing performance and heat resistance. Besides, synergy between polydopamine, glycerin and polymer network enhances the mechanical property of hydrogel, so that the hydrogel has high strength, high toughness and good restorability. Furthermore, the addition of the polydopamine component makes hydrogel have good adhesion, and hydrogel can be adhered to surfaces of substrates with different chemical properties. The self-adhesive hydrogel with the anti-freezing / heat-resistant performance prepared with the method can be used as a wearable dressing to protect skin from cold injury or burn injury in an extremely cold or hot environment.

Owner:SOUTHWEST JIAOTONG UNIV

Transparent Ice Maker

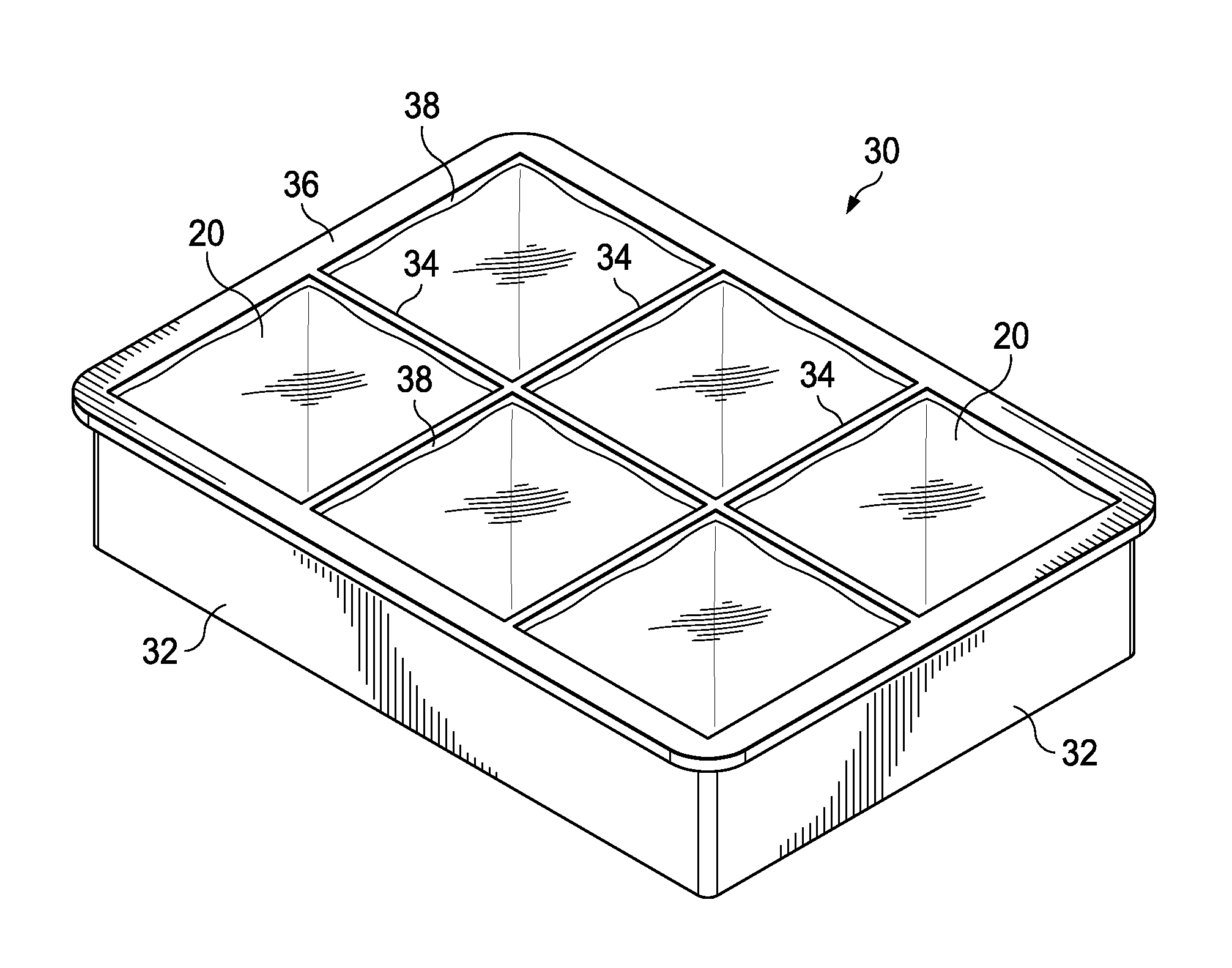

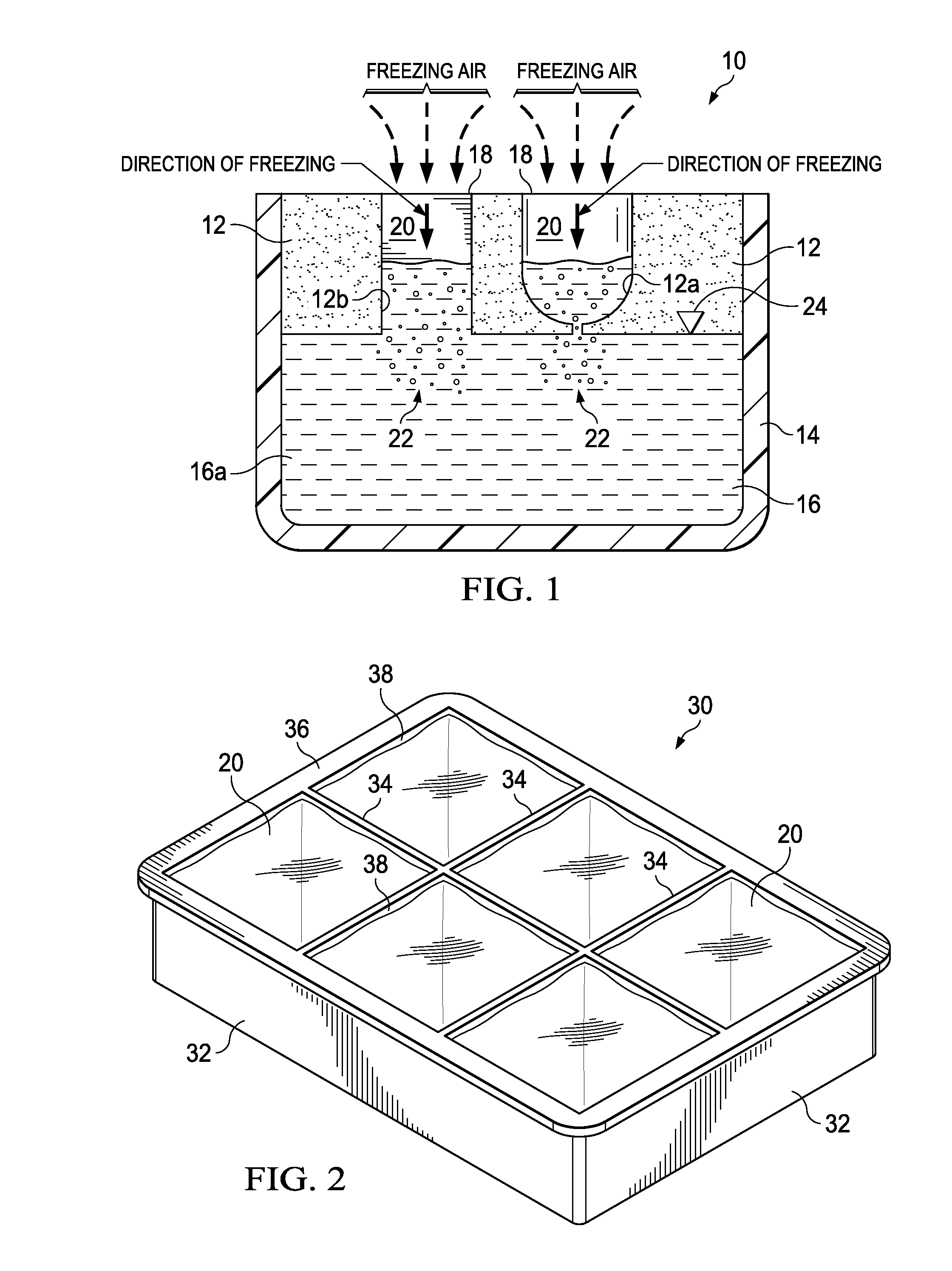

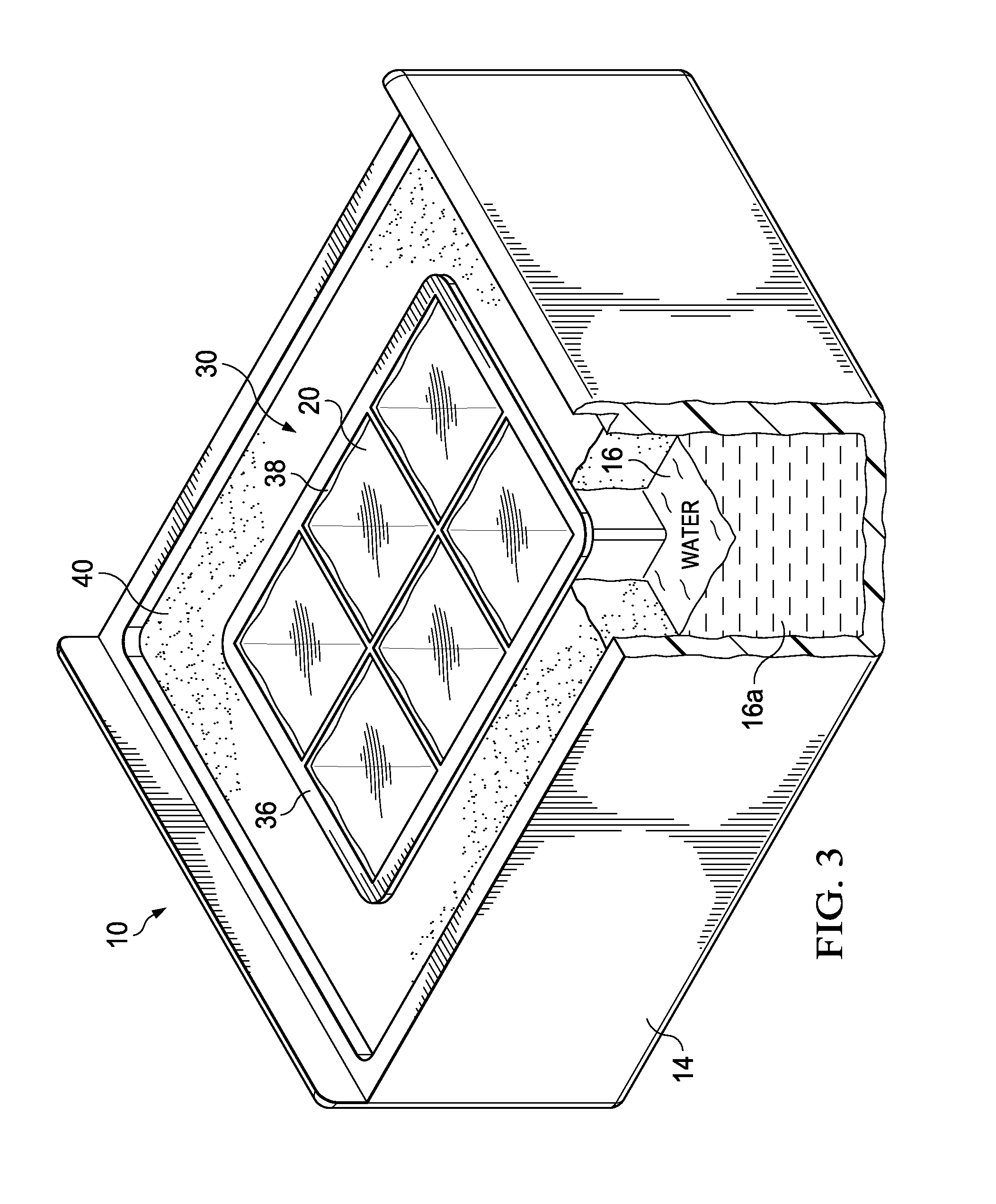

InactiveUS20150107275A1Reduced surface area to volume ratioEasy to shapeLighting and heating apparatusFood processingLiquid waterEngineering

The present invention provides an apparatus and method for producing substantially clear ice in a variety of desired shapes. An insulated ice mold form containing one or more mold cells is suspended over a liquid water reservoir contained in an insulated container. Each ice mold cell is exposed to freezing air resulting in the formation of ice in each mold cell with ice formation progressing from the top to the bottom of each ice mold cell. A liquid water reservoir below each ice mold cell serves as an impurity sink into which impurities and gases are driven as ice crystals form in each ice mold cell and as a heat sink to substantially arrest ice shape growth beyond the bottom of each ice mold cell at or near the ice-reservoir water interface.

Owner:PAPALIA ROCCO

Method for producing photo catalytic self-cleaning enamel

InactiveCN101067207ASimple processReduce manufacturing costPhysical/chemical process catalystsQuenchingChemical stability

The process of preparing photocatalytic self-cleaning enamel includes the following steps: 1. preparing enamel clinker with enamel material quartz, feldspar, borax, etc, through mixing, smelting in a crucible, water quenching and stoving; 2. mixing enamel clinker with clay, dielectric and deionized water, grinding, sieving and stoving to form the enamel; 3. derusting and degreasing steel plate or iron casting, stoving, coating the enamel, stoving and firing to form enameled plate; and 4. soaking the enameled plate in titania colloid solution, vertically drawing, stoving and sintering to form enameled plate with titania film. The process is simple and low in cost, and the prepared self-cleaning enamel material has excellent photocatalytic performance and high chemical stability.

Owner:DONGHUA UNIV

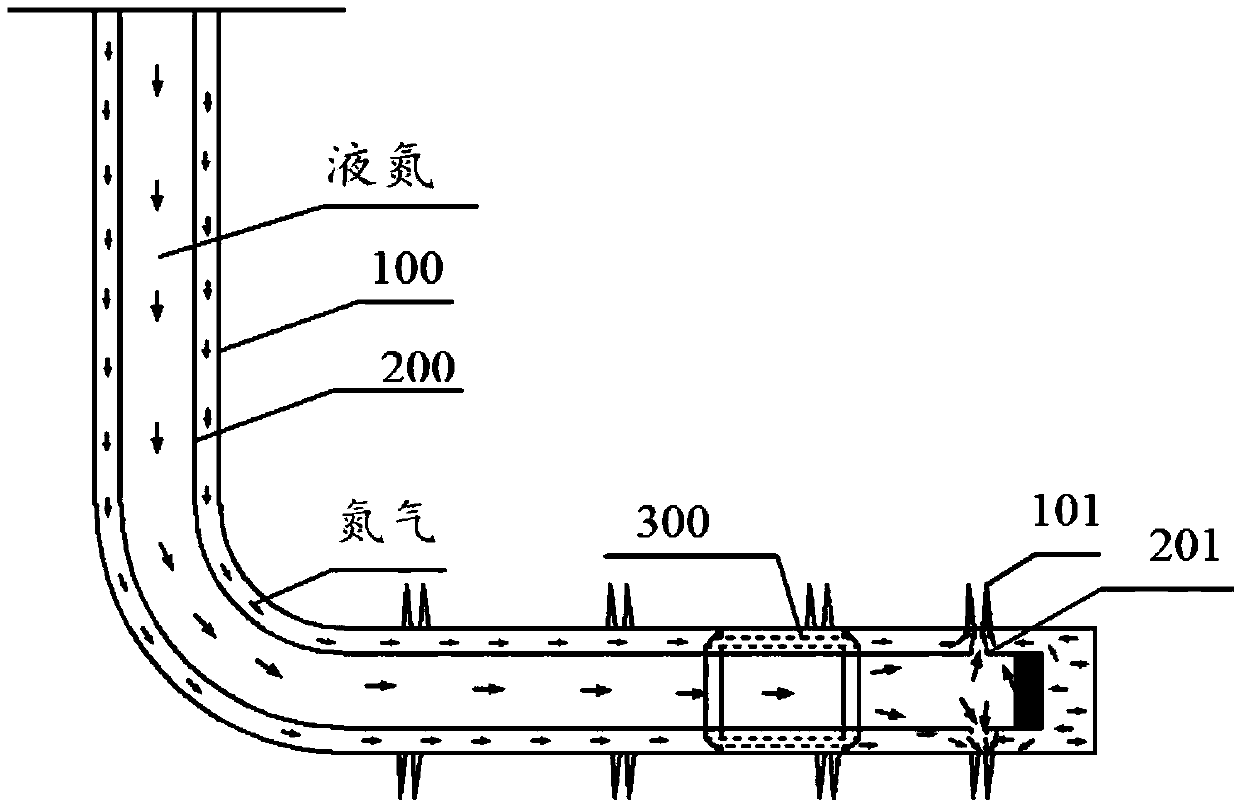

Horizontal well liquid nitrogen ice crystal temperature plugging staged fracturing method for coalbed methane

The invention provides a horizontal well liquid nitrogen ice crystal temperature plugging staged fracturing method for coalbed methane and belongs to the technical field of well fracturing. The method includes: perforating a stratum interval to discharge wellbore liquid, then using liquid nitrogen to open a stratum crack through pressing, allowing the liquid nitrogen to enter the crack, and injecting water to the inlet of the crack to form ice crystal temperature plugging due to the fact that the water freezes at the inlet of the crack under the effect of the liquid nitrogen so as to complete the fracturing of the stratum interval. The fracturing method has the advantages that the coal rock permeability around the crack can be increased effectively, coalbed methane discharge area can be increased, and yield can be increased evidently; in addition, an extremely-low reservoir environment is produced in a reservoir by using liquid nitrogen fracturing, the injected water freezes at the inlet of the crack and around the inlet of the crack to form the ice crystal temporary plugging, only one single-channel packer is needed to achieve the staged fracturing effect, and the method is simple in procedures, easy to operate, capable of saving time and space and capable of increasing operation efficiency.

Owner:SOUTHWEST PETROLEUM UNIV

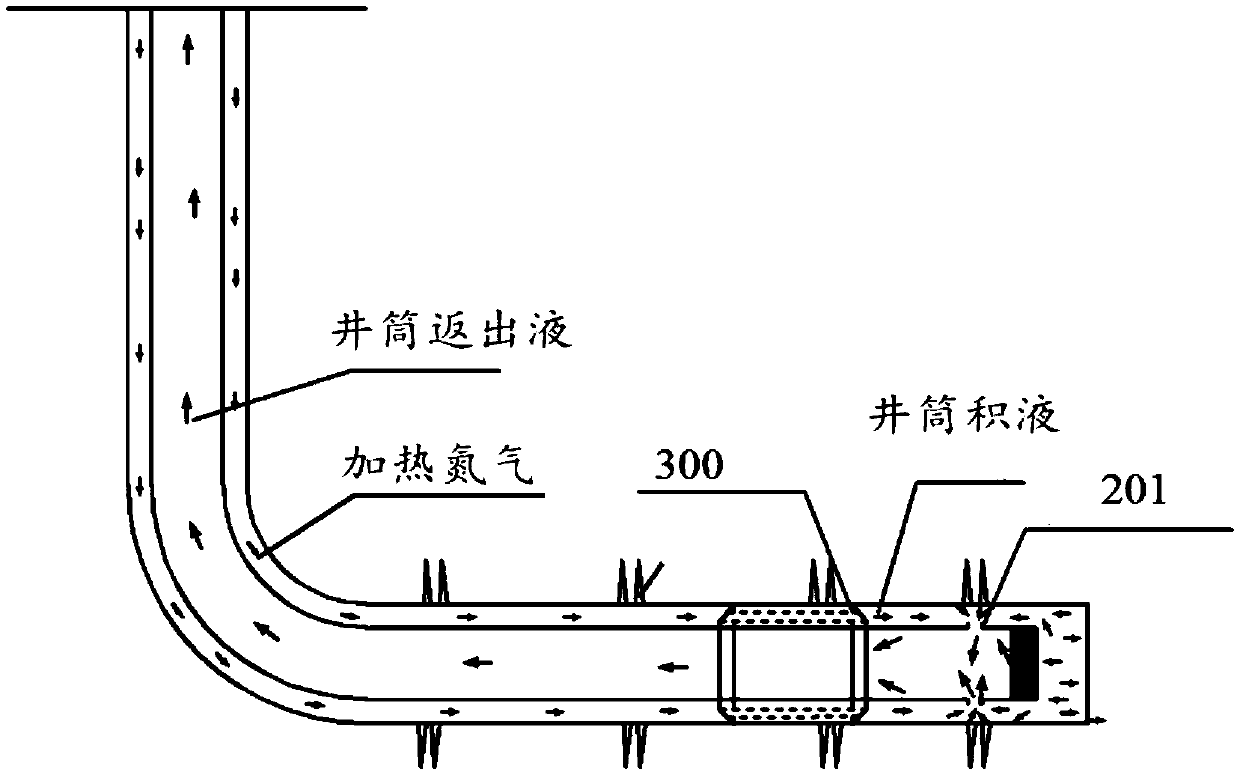

Processing soft tissue, methods and compositions related thereto

InactiveUS20100112543A1Long-term durabilityLong-term functionVertebrate cellsDead animal preservationCellular componentMedicine

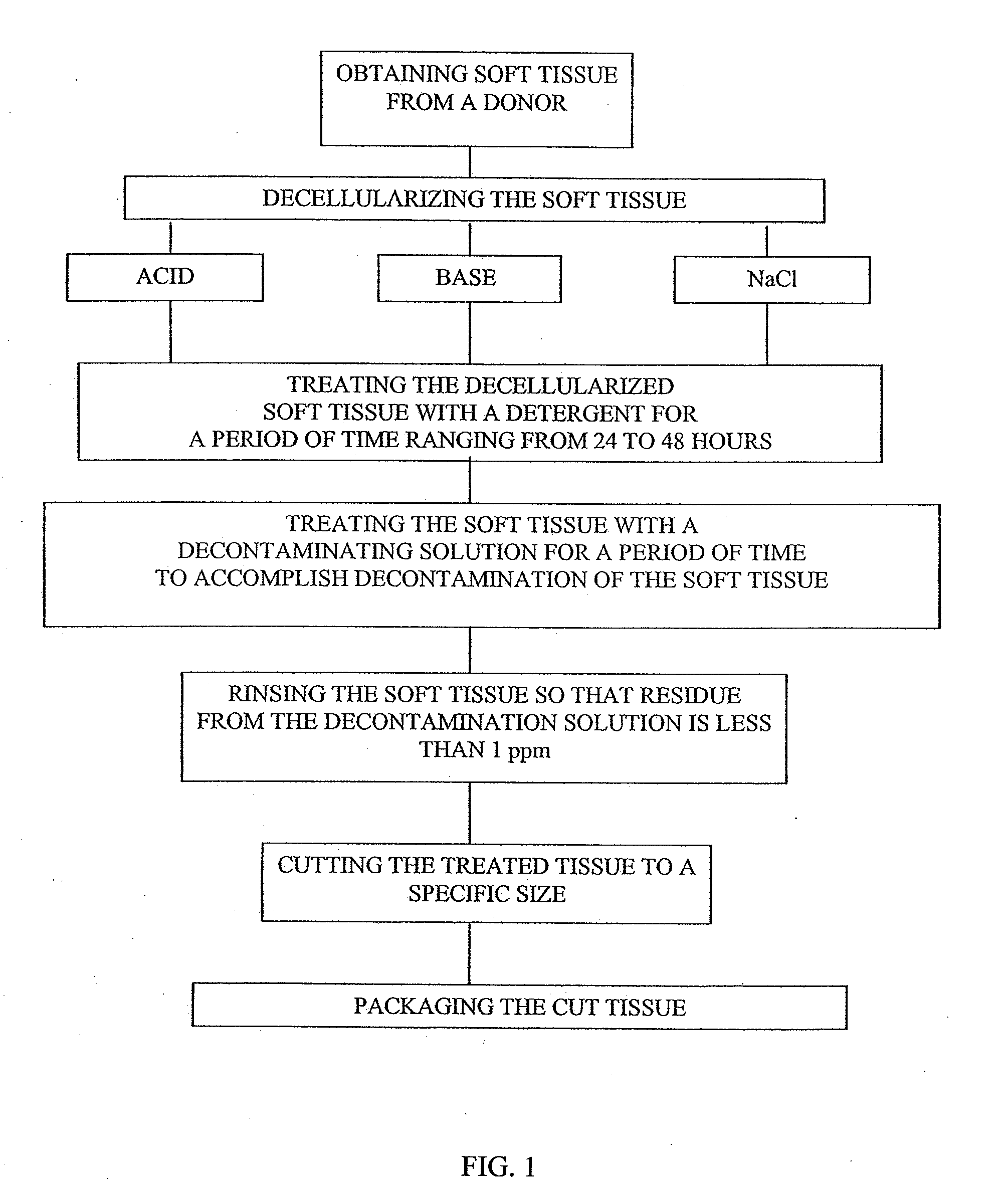

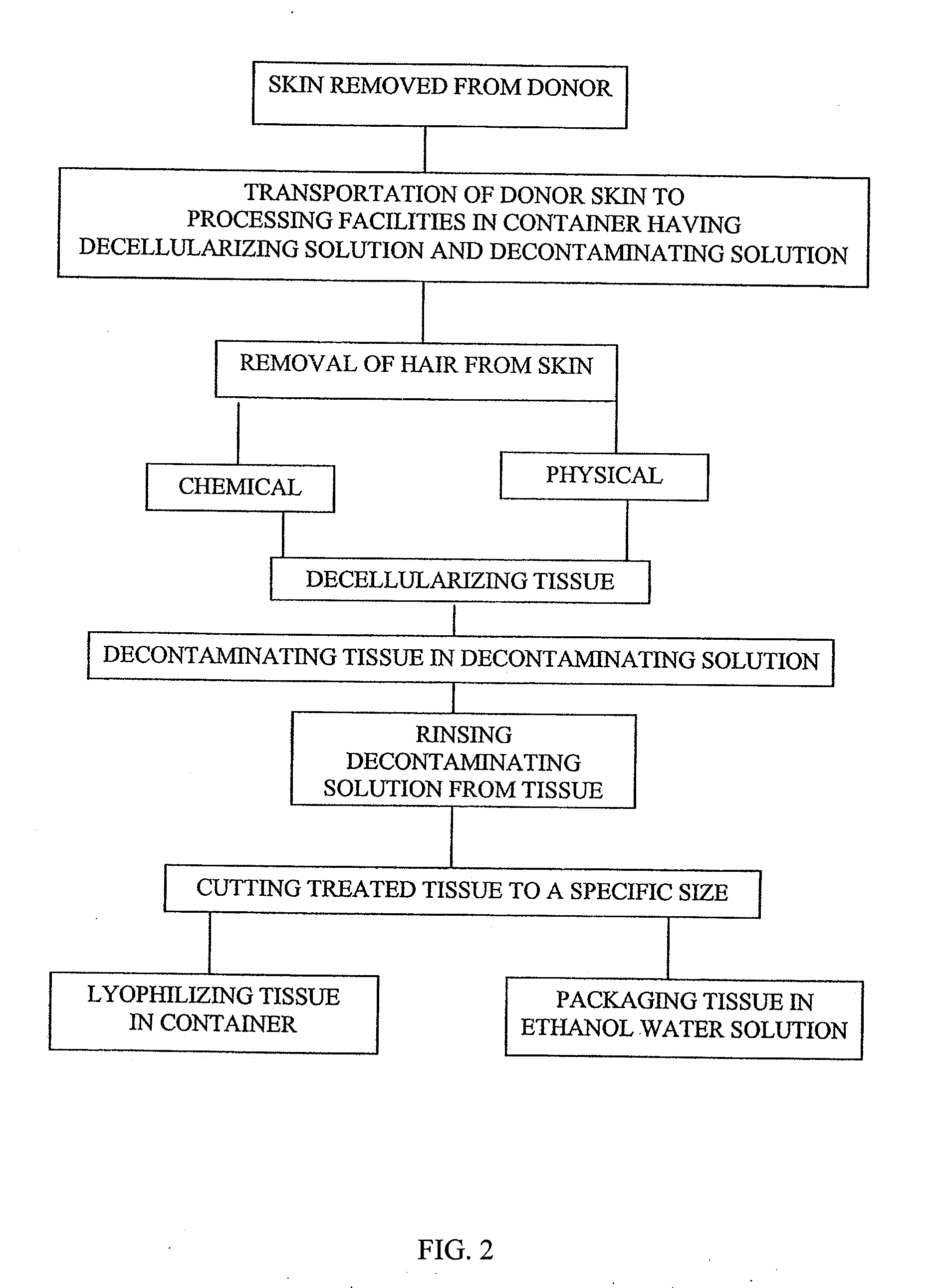

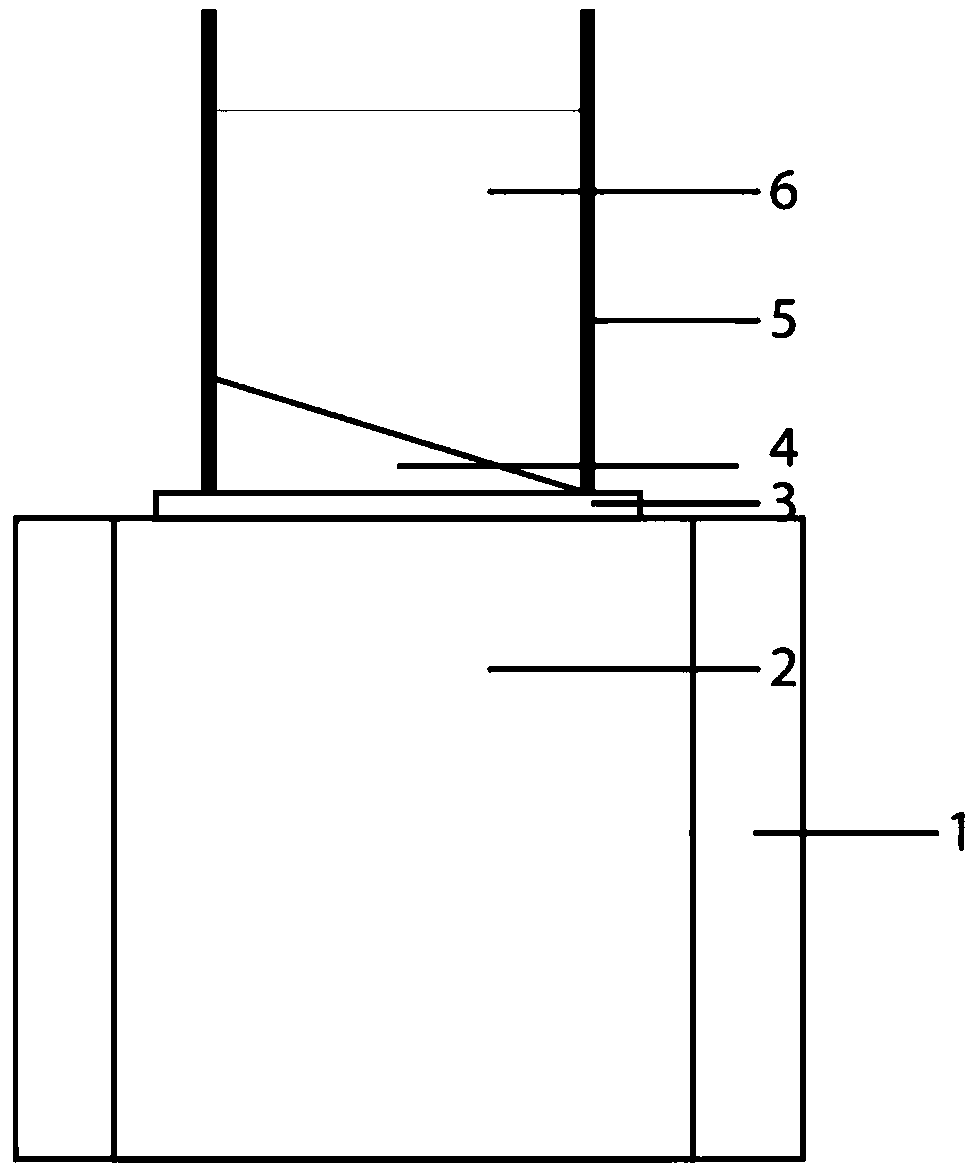

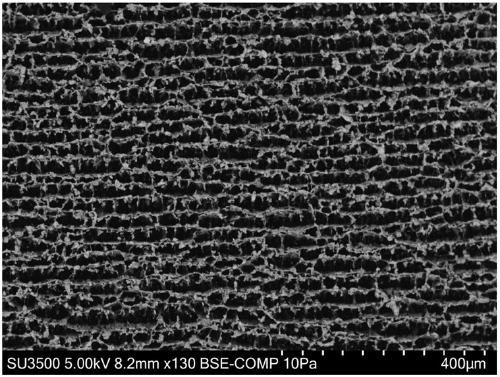

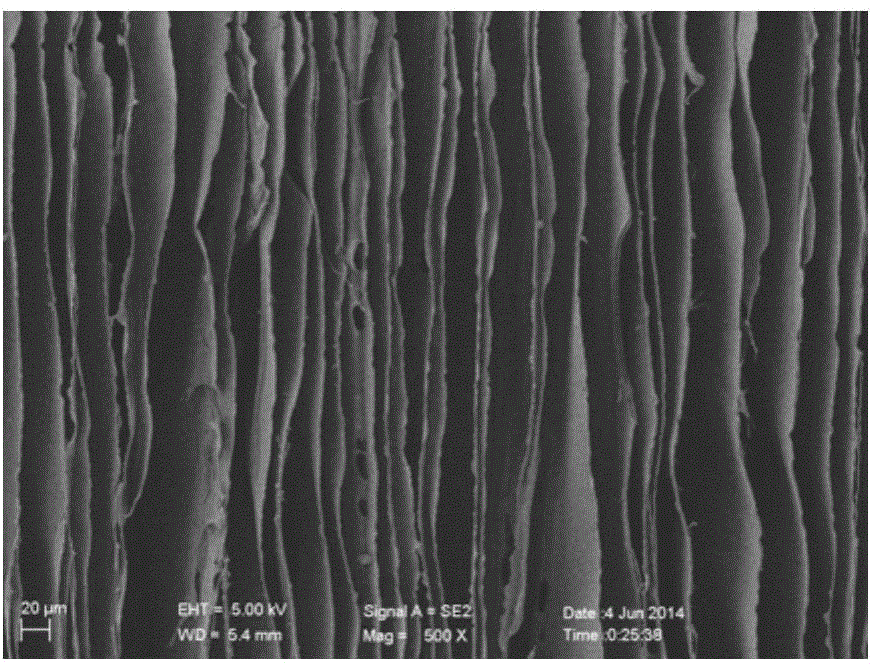

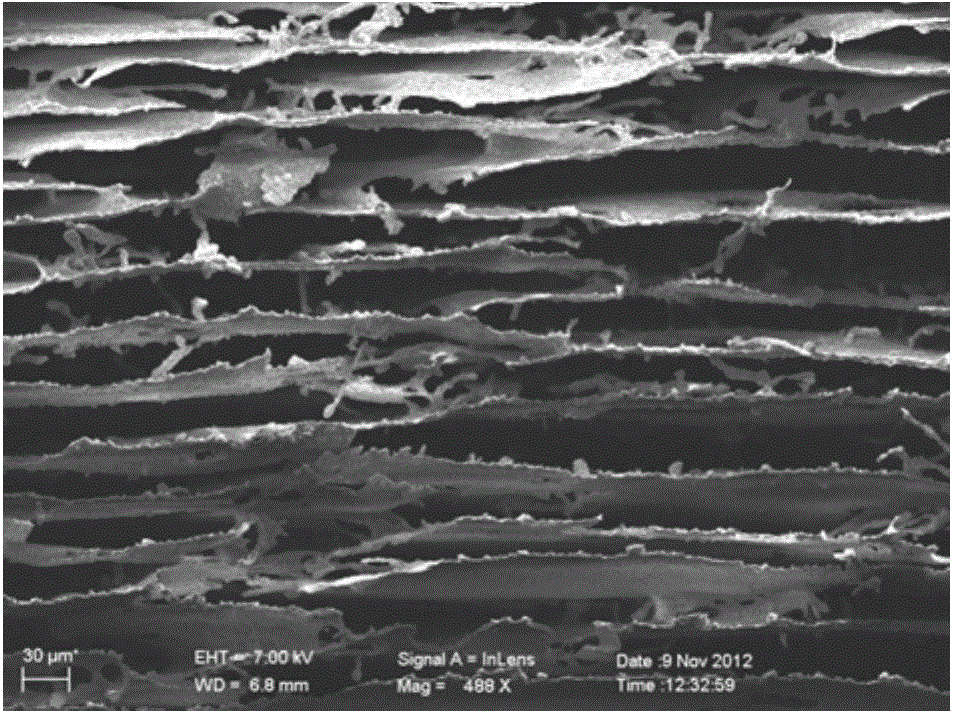

In certain embodiments, the present invention relates to a process for preparing skin removed from a human donor, including a living human donor, and removing cellular components and forming a decellular matrix having as major components collagens and elastins while disinfecting the tissue. In other embodiments, the present invention relates to a process for treating a decellularized soft tissue by freezing the same at a plurality of decreasing temperatures at atmosphere or higher such that there is formation of ice crystals having a size greater than 2.0 and lyophilizing the soft tissue under vacuum to remove the water to less than 6% forming a porous matrix.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

Boron nitride/epoxy resin composite and preparation method and application thereof

ActiveCN109666263AImprove thermal conductivityIncreased anisotropyHeat-exchange elementsEpoxyBoron nitride

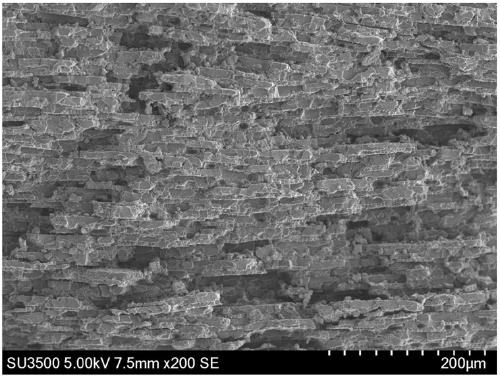

The invention relates to boron nitride / epoxy resin composite and a preparation method and application thereof. The preparation method includes: 1) dispersing boron nitride nanosheet and a binder in water to form a mixed solution; 2) subjecting the mixed solution to bidirectional freezing, and removing ice crystal by lyophilization to obtain boron nitride aerogel with lamellar oriented structure; 3) filling the lamellar oriented structure of the boron nitride aerogel with cured epoxy resin to obtain the boron nitride / epoxy resin composite. The preparation method is simple to perform, is available to large-scale preparation and is suitable for industrial scaled application.

Owner:ZHEJIANG UNIV

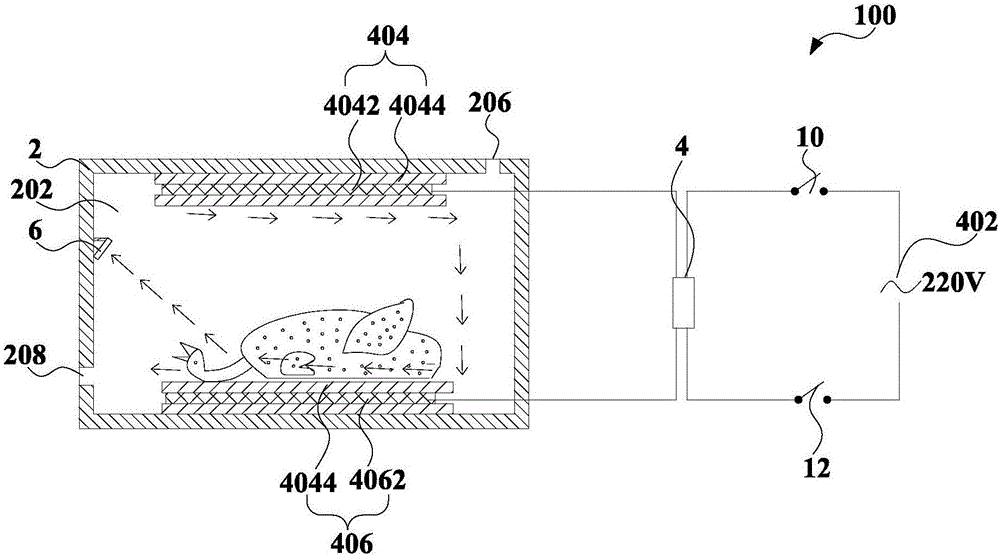

Microwave vacuum freeze-drying apparatus for food and drug production

InactiveCN101126596ABreak through the status quo of uneven heatingEvenly heatedDrying using combination processesDrying solid materials with heatFreeze-dryingProcess engineering

The utility model relates to a metal core which has replaced the traditional metal cores of the cold stores; after an access is opened in the microwave radiation of the heat energy in the vacuum freeze-drying, the microwave radiation provides energy directly to the material at low pressure or ultra low pressure, so as to make the water molecules in the internal and external parts of the ice crystal sublime rapidly; the change not only has an advantage that the microwave can heat the internal and external part of the material at the same time, but also reserves an advantages that the prior vacuum freeze-drying equipment can decrease temperature instantly when pre-freezing and maintain the temperature in the later period of the desorption. The main microwave heating source is arranged in the centre of the material with no metal wall in the utility model, which overcomes the insufficiency of heating way by the prior microwave and makes the material heated evenly; during the period of desorption, the utility model combines the microwave heating and the shelf silicone oil heating and makes the shelf silicone oil heating as the last safeguard for the dry quality of the products, which enables the microwave overheating never take effect on the quality of the products. The utility model introduces the infrared sensor to the microwave vacuum freeze-drying equipment, which can use the microwave energy scientifically, powerfully and accurately.

Owner:丛繁滋

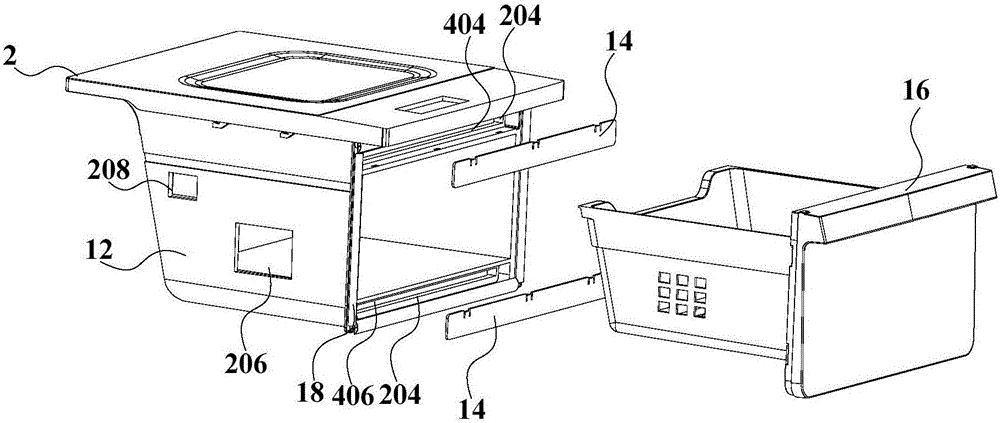

Unfreezing device and refrigerator

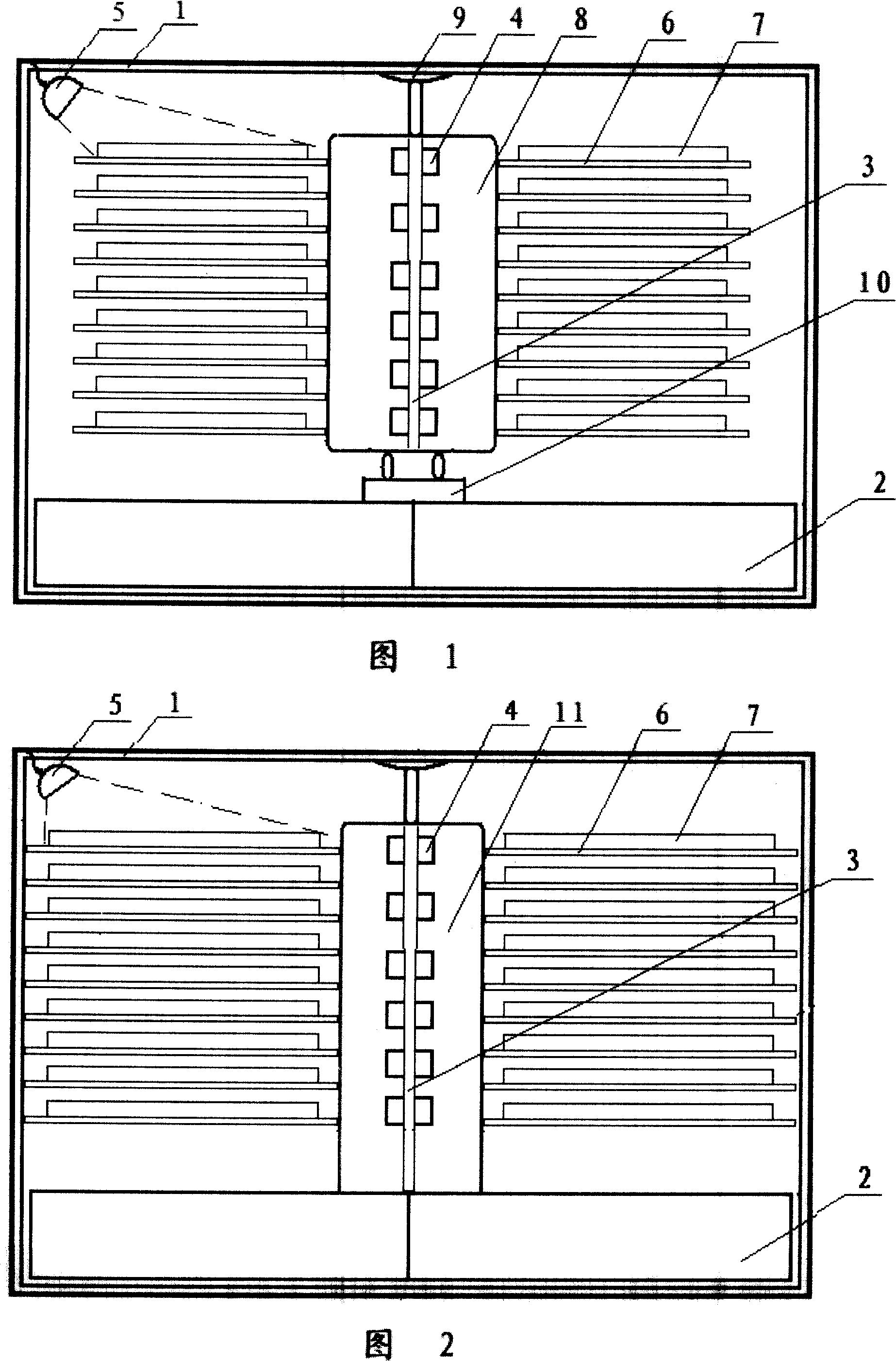

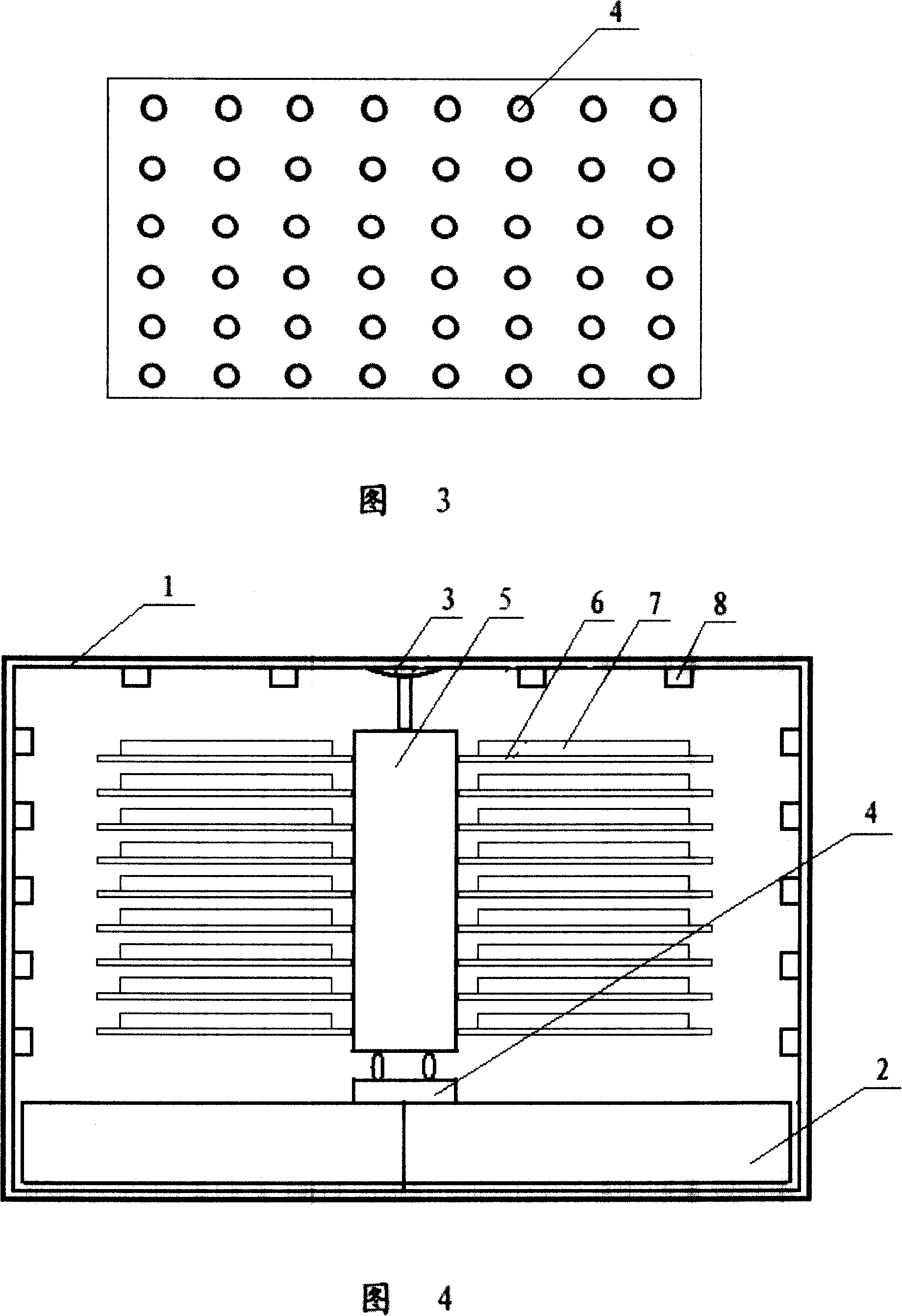

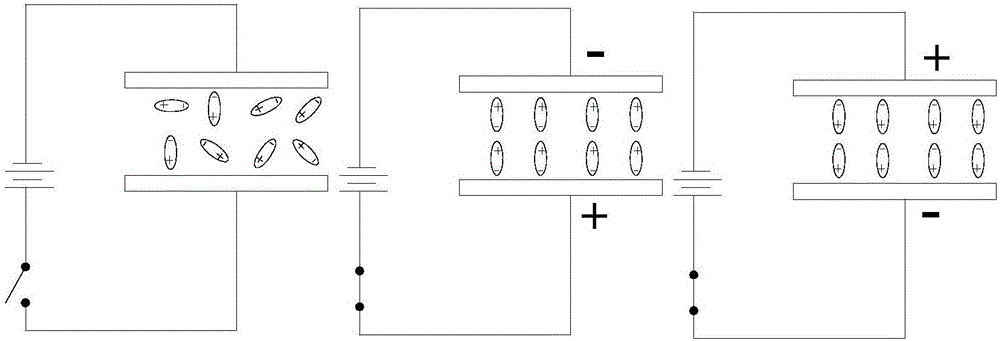

InactiveCN106387607AUniform temperatureFast thawingLighting and heating apparatusDielectric heating circuitsEngineeringRefrigerated temperature

The invention provides an unfreezing device and a refrigerator. The unfreezing device comprises an unfreezing device body and a high-frequency generator, wherein the unfreezing device body is provided with a cavity which is used for allowing foods to be unfrozen to be placed; and the high-frequency generator comprises one or more pairs of electrode plate assemblies arranged in the cavity. High-frequency waves generated by the electrode plate assemblies act on the foods to be unfrozen, so that all the molecules of the foods to be unfrozen are in the action of the high-frequency waves, the polarity of the polar molecules is subjected to high-frequency changes, the inside and the outside of the unfrozen foods are heated and unfrozen at the same time, the temperature of the unfrozen foods is uniform, the unfreezing speed is high, and the possibility of microbial contamination is reduced; besides, the foods to be unfrozen are quickly dissolved through a largest ice crystal dissolving band, so that the loss of dropping liquid is reduced, the nutrient loss of the unfrozen foods is effectively avoided, and the quality of the unfrozen foods is promoted; and besides, large foods can be unfrozen, and the user experience can be promoted.

Owner:HEFEI HUALING CO LTD +2

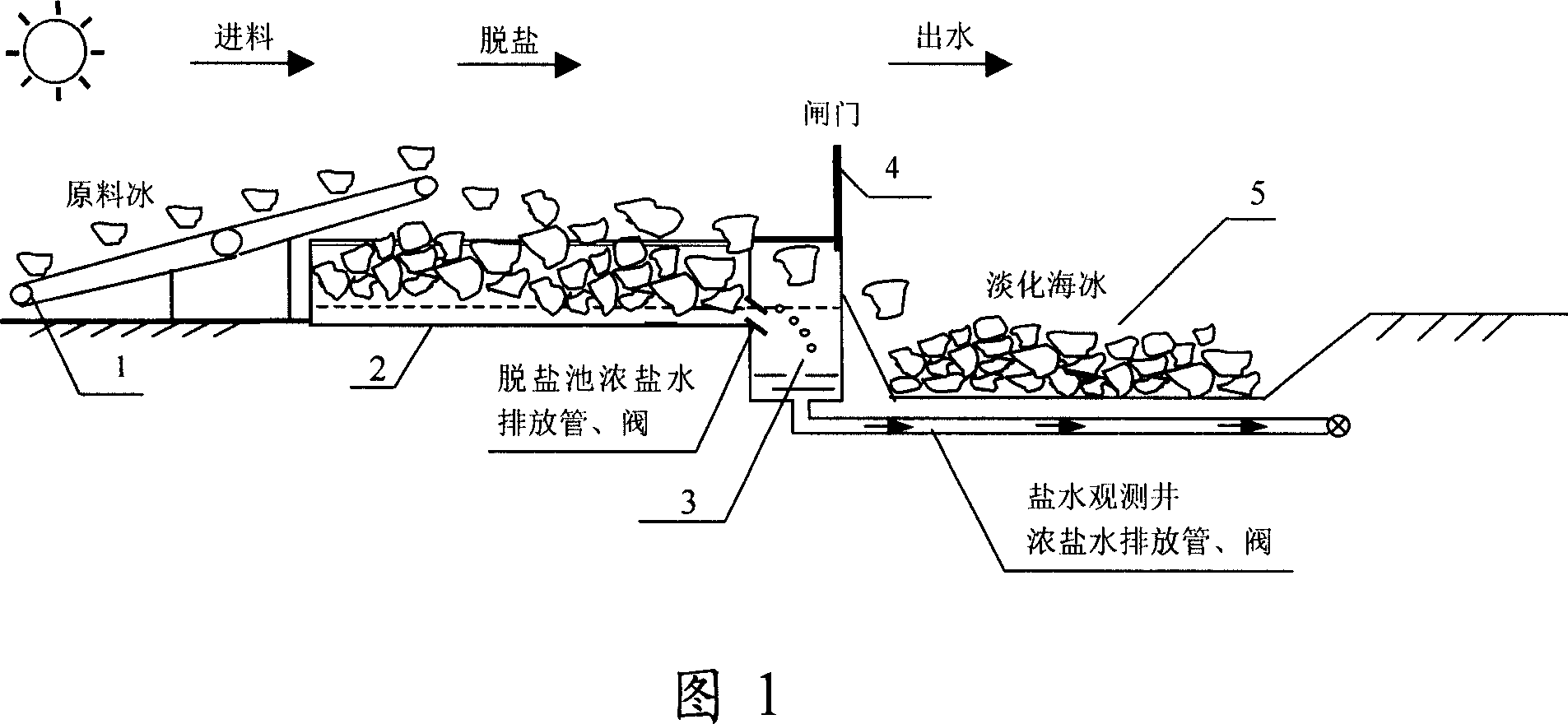

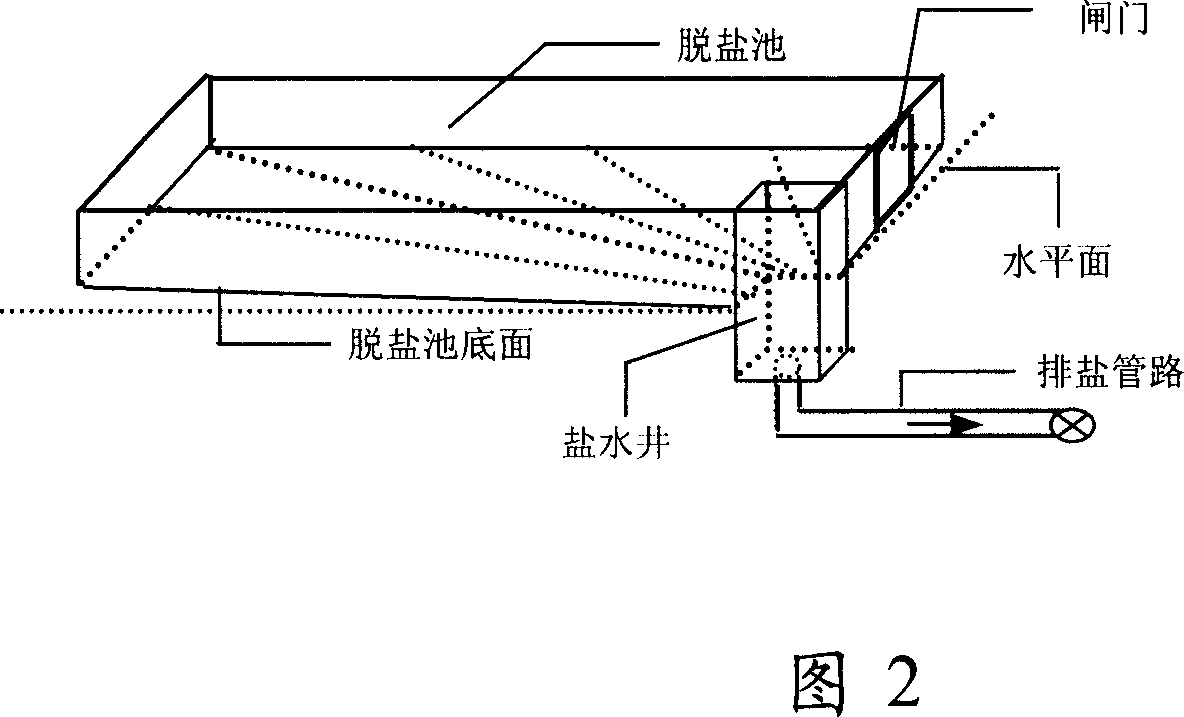

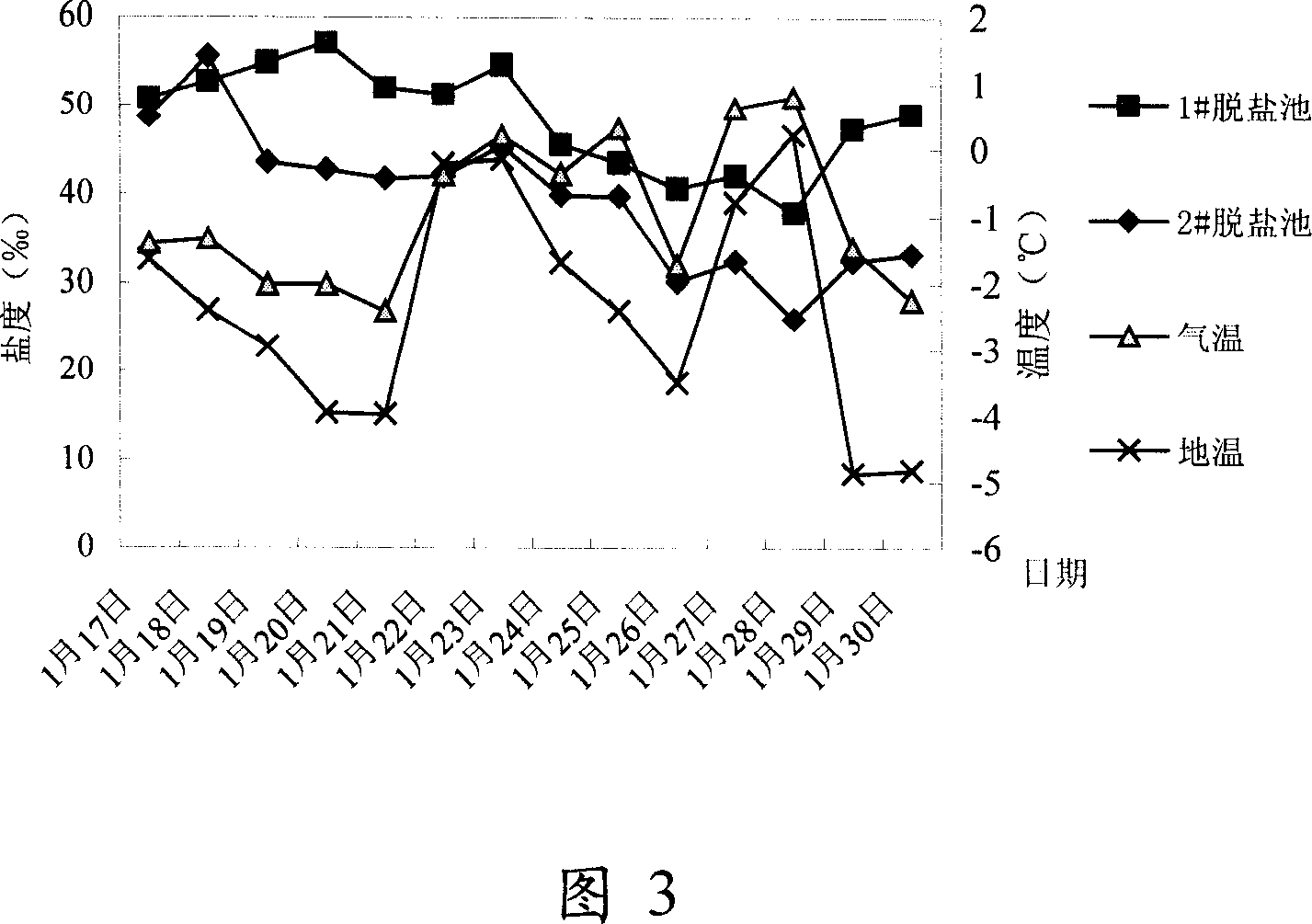

Sea ice desalinization facilities with gravity method and sea ice solid-state gravity desalinization method

ActiveCN1919742AIncrease profitReduce energy consumptionSeawater treatmentWater/sewage treatmentWater desalinationSea ice

The invention discloses a sea ice solid gravity desalinizing method, which comprises the following parts: feed device, gravity desalinization pool, salt water observing pump, product transmitting device and reservoir, wherein the sea ice solid gravity desalinizing method comprises the following steps: fetching sea ice in the gravity desalinizing pool through feed device; discharging bittern in the ice part acted by gravity; collecting solid cryolite; transmitting in the reservoir; melting naturally.

Owner:BEIJING NORMAL UNIVERSITY

Process for frozen dairy product

A process for producing a soft frozen fruit flavored dairy product is disclosed. The process requires two freezing steps wherein a flavored concentrate mix is frozen before milk fat is added to the mix. The flavored concentrate mix together with the contained milk fat is then frozen again without mixing or stirring to allow ice crystals to form, preferably of small size, to develop a mouthfeel with components of the fruit flavor.

Owner:BAKER ROBERT S

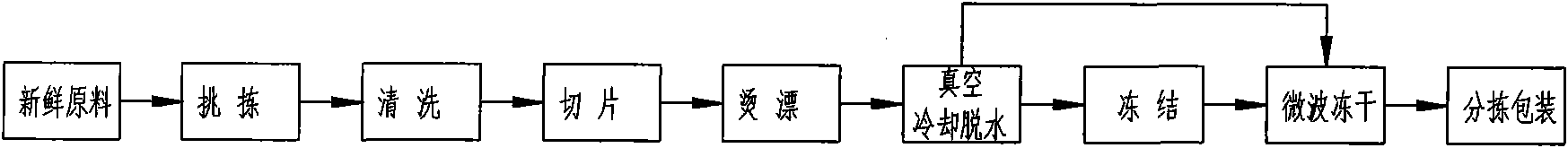

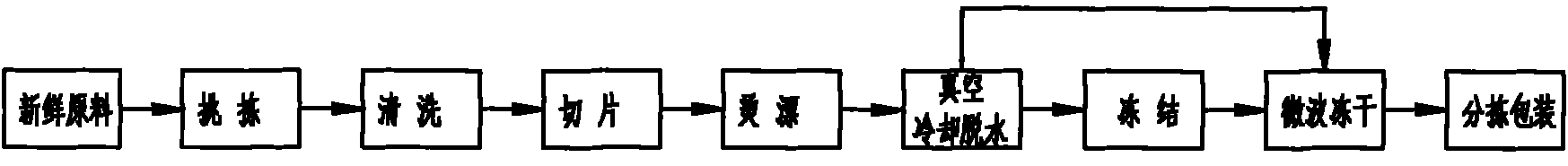

Microwave freeze-drying and dehydrating method of fruits and vegetables

InactiveCN101849573AShort drying time for dehydrationReduce energy consumptionFruit and vegetables preservationMicrowaveFreeze-drying

The invention relates to a microwave freeze-drying and dehydrating method of fruits and vegetables, belonging to the field of a fruit and vegetable food treatment technology. The method comprises the following steps of: cleaning, blanching, pre-drying, freezing, microwave freeze-drying and taking out. The method is suitable for various forms of freeze-drying products, integrates blanching and cooling working procedures into a whole, does not need the cooling working procedure after blanching, not only is thorough to blanch and cool, but also has high speed, especially removes partial internal water at the same time of removing water on the surface of materials, and avoids forming crystals on the surface of the materials in the freezing process, thereby being beneficial to increasing the microwave freeze-drying speed and effectively restraining the microwave low-pressure discharge problem in the early freeze-drying process.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

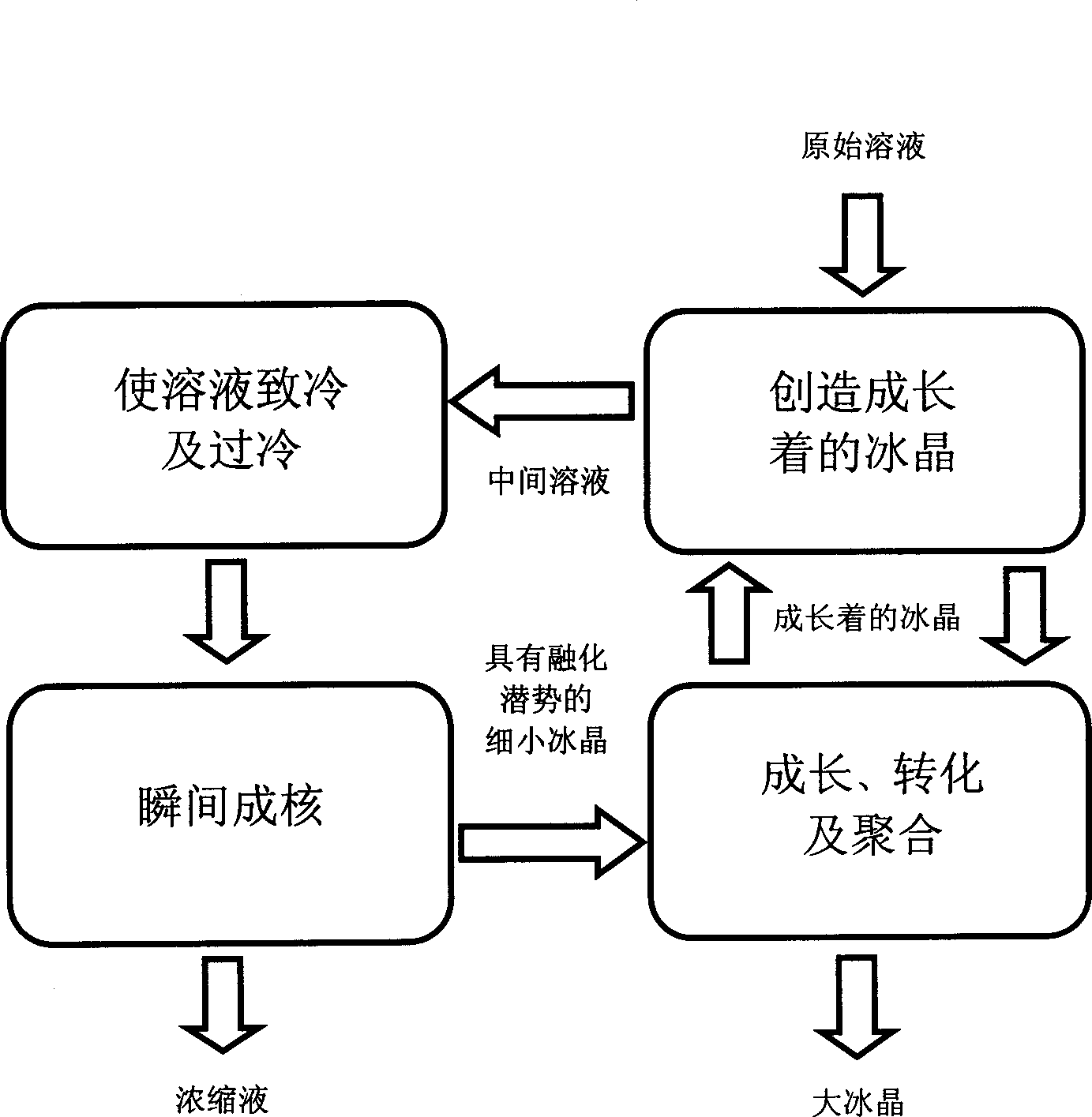

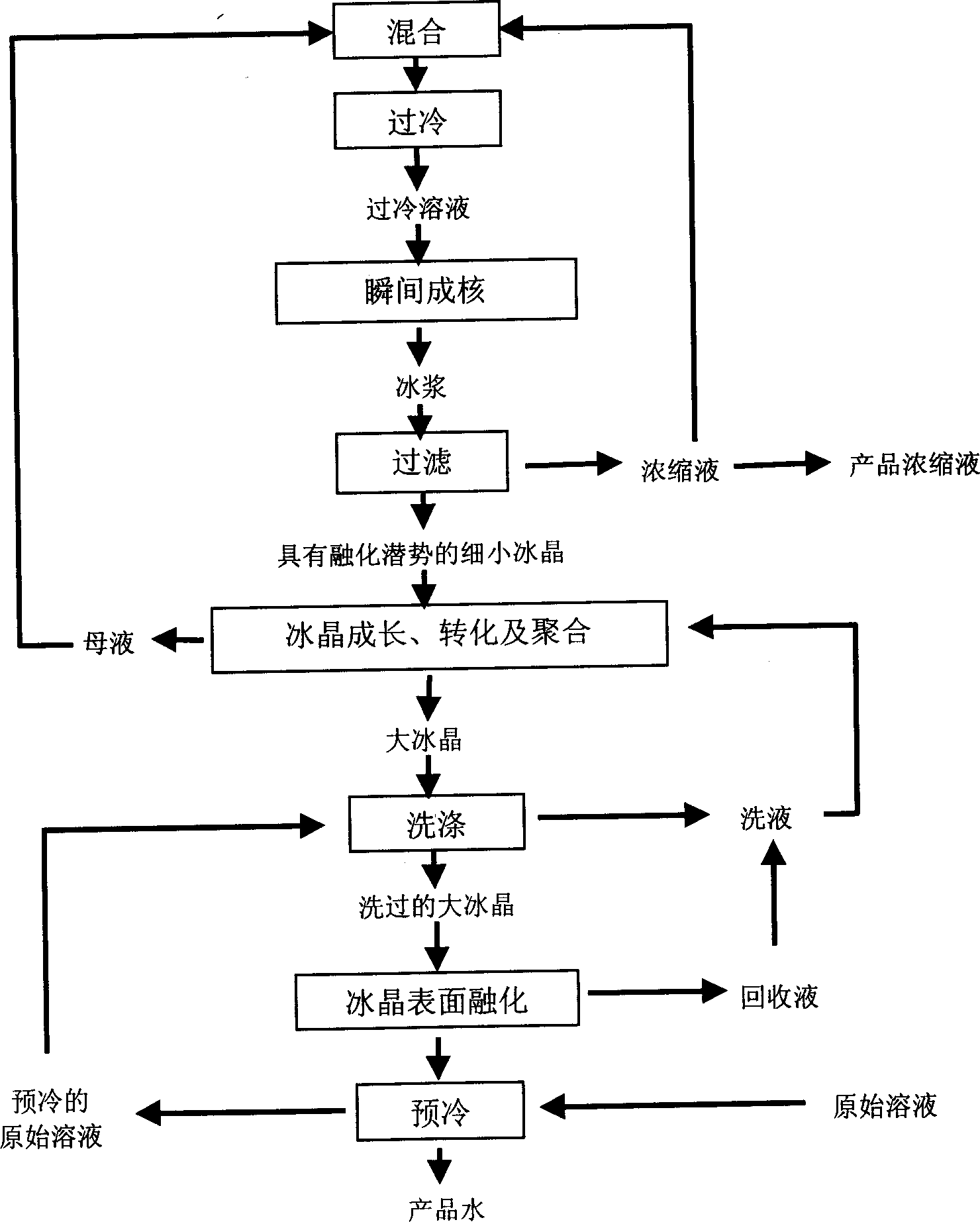

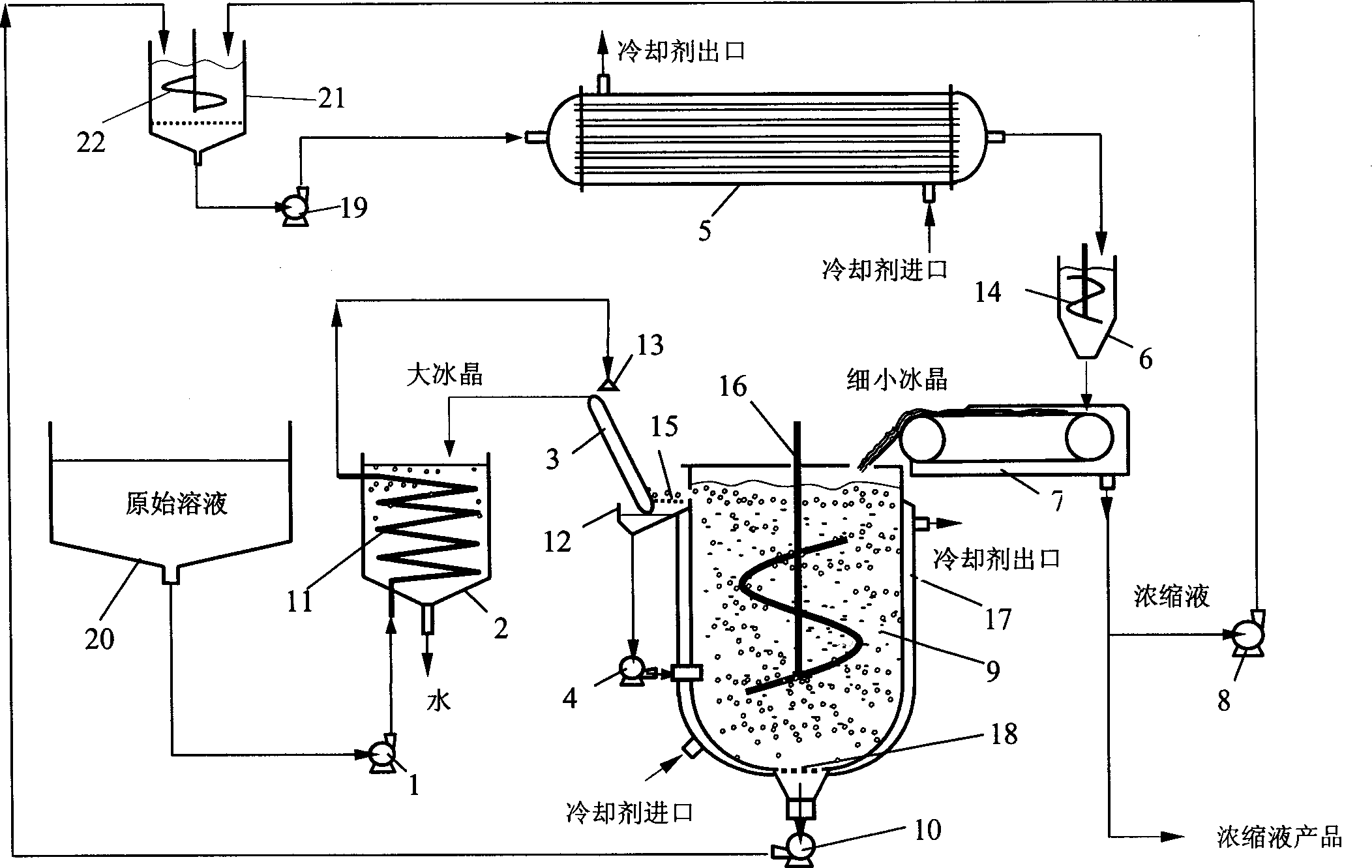

Freeze concentration for aqueous solutions

The invention is an efficient physical method of freezing and concentrating aqueous solutions based on the transformation of ice crystals. It results in a very high ice crystal growth rate, produces granular, aggregated large ice crystals without internal entrainment, and avoids scraping of ice crystals during freezing to save energy. The method mainly consists of the following processes: cooling the solution to a supercooled state without nucleation or ice formation on the heat transfer surface; instantly nucleating the supercooled solution to produce fine ice crystals and concentrating the solution; with the help of absorption-exotherm The growth, transformation and polymerization of ice crystals in a well-balanced and controlled environment produce large, granular or spherical ice crystals at high rates. Both single-stage and multi-stage operations can be used in this method and the main steps can be arranged flexibly. The equipment for implementing this method mainly includes refrigeration heat exchangers, nucleators, filters and multifunctional crystallizers, each of which has its own characteristics to meet the requirements of the method.

Owner:梁保民 +1

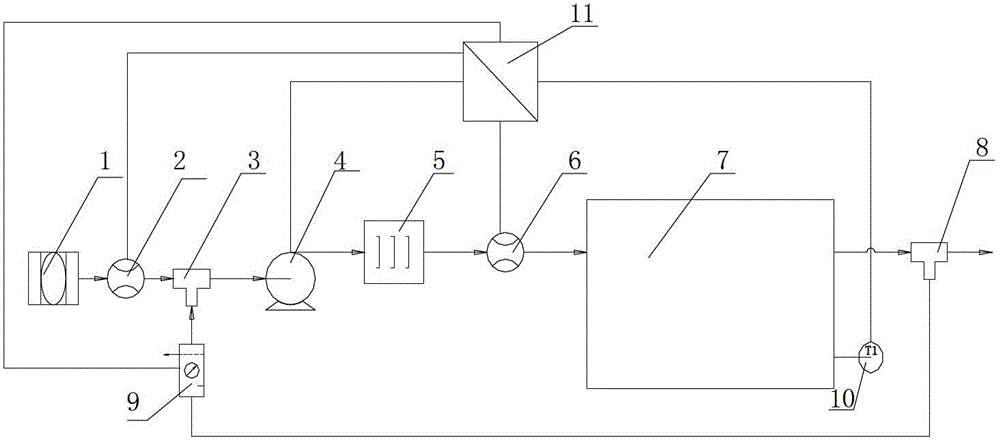

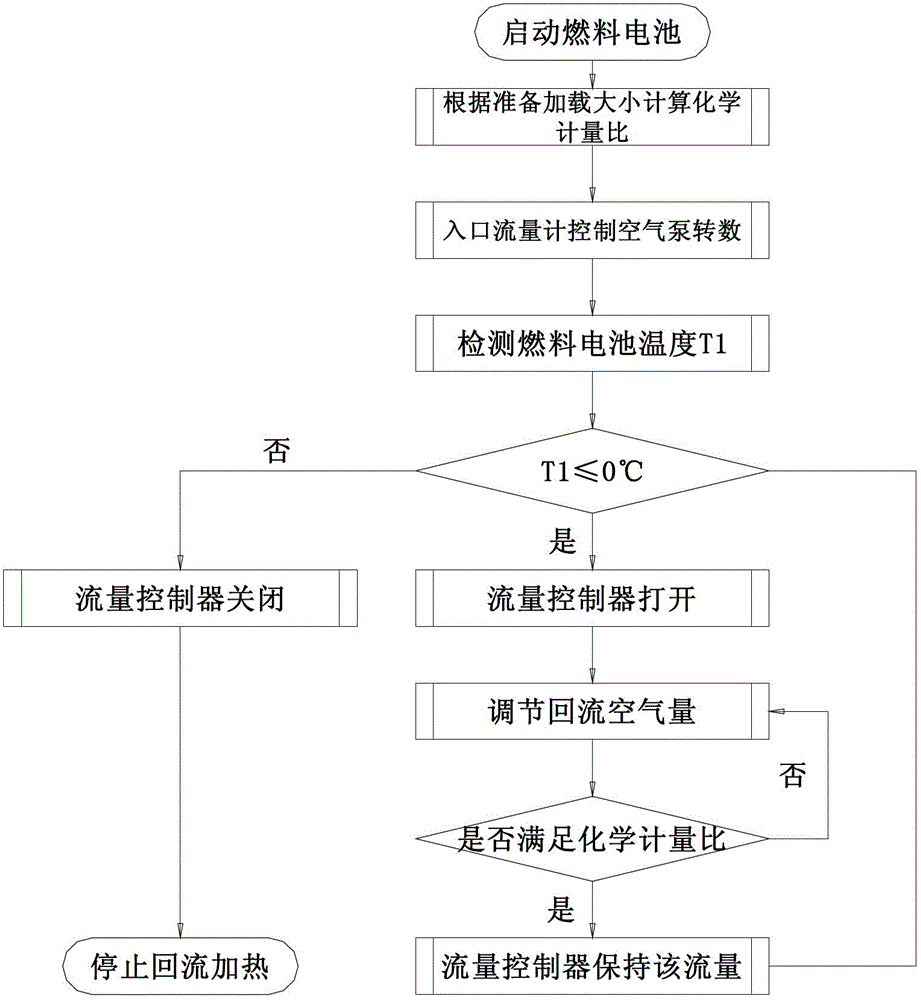

Heating system for starting fuel cell at low temperature with air backflow and heating method thereof

The invention discloses a heating system for starting a fuel cell at a low temperature with air backflow and a heating method thereof. The system comprises an air filter, an intakeport flowmeter, an intakeport tee, an air pump, a humidifier, an inlet flowmeter, a fuel cell stack, an outlet tee, an air flow controller, a temperature sensor and a controller. When the heating system provided in the invention works, heat-containing air compressed by the air pump heats an air reaction interface and other battery assemblies of the fuel cell stack, and then a part of or all the air tail gas of the fuel cell stack flows back and passes through the air pump through controlling of the flow controller so as to cyclically heat the air reaction interface and the other battery assemblies of the fuel cell stack. According to the invention, air tail gas containing waste heat of the air pump is cyclically used to heat the air reaction interface of the fuel cell stack, so melting of ice crystals on electrodes is accelerated, mass transfer of fuels and proton transfer are smoothly carried out, starting of fuel cells with a temperature lower than 0 DEG C is accelerated, and energy consumption of a storage battery used as an auxiliary power supply can be saved.

Owner:SUNRISE POWER CO LTD

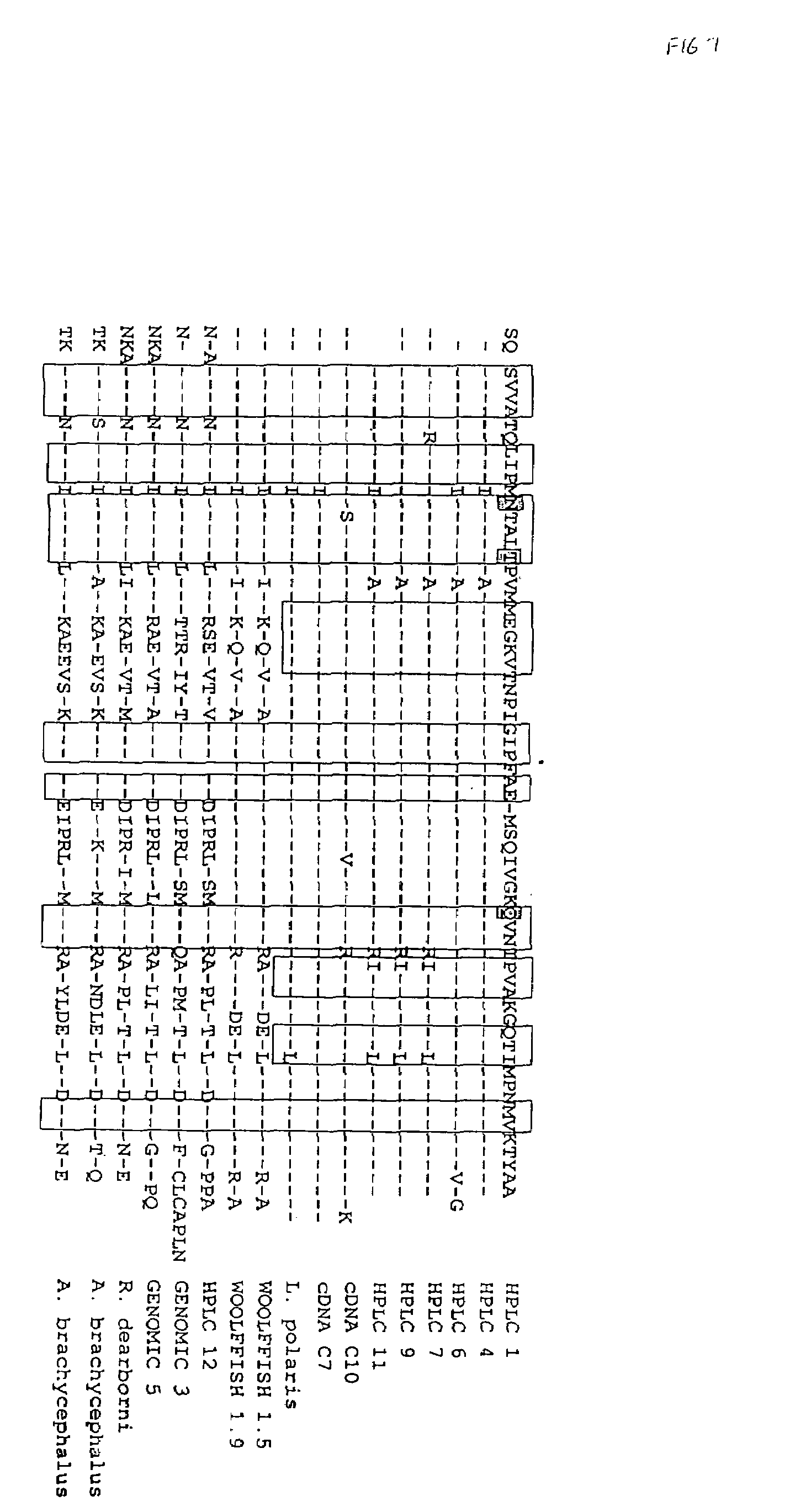

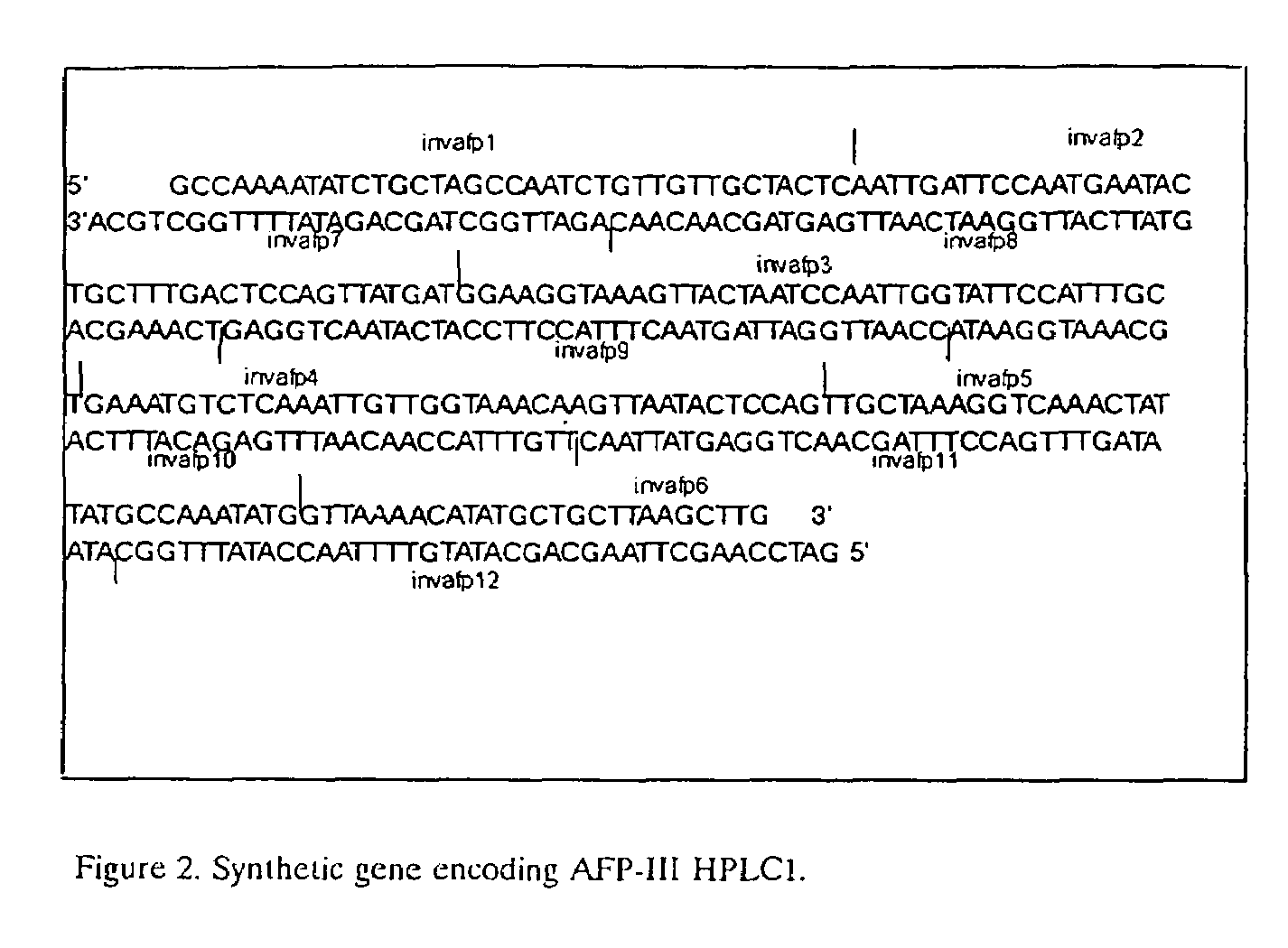

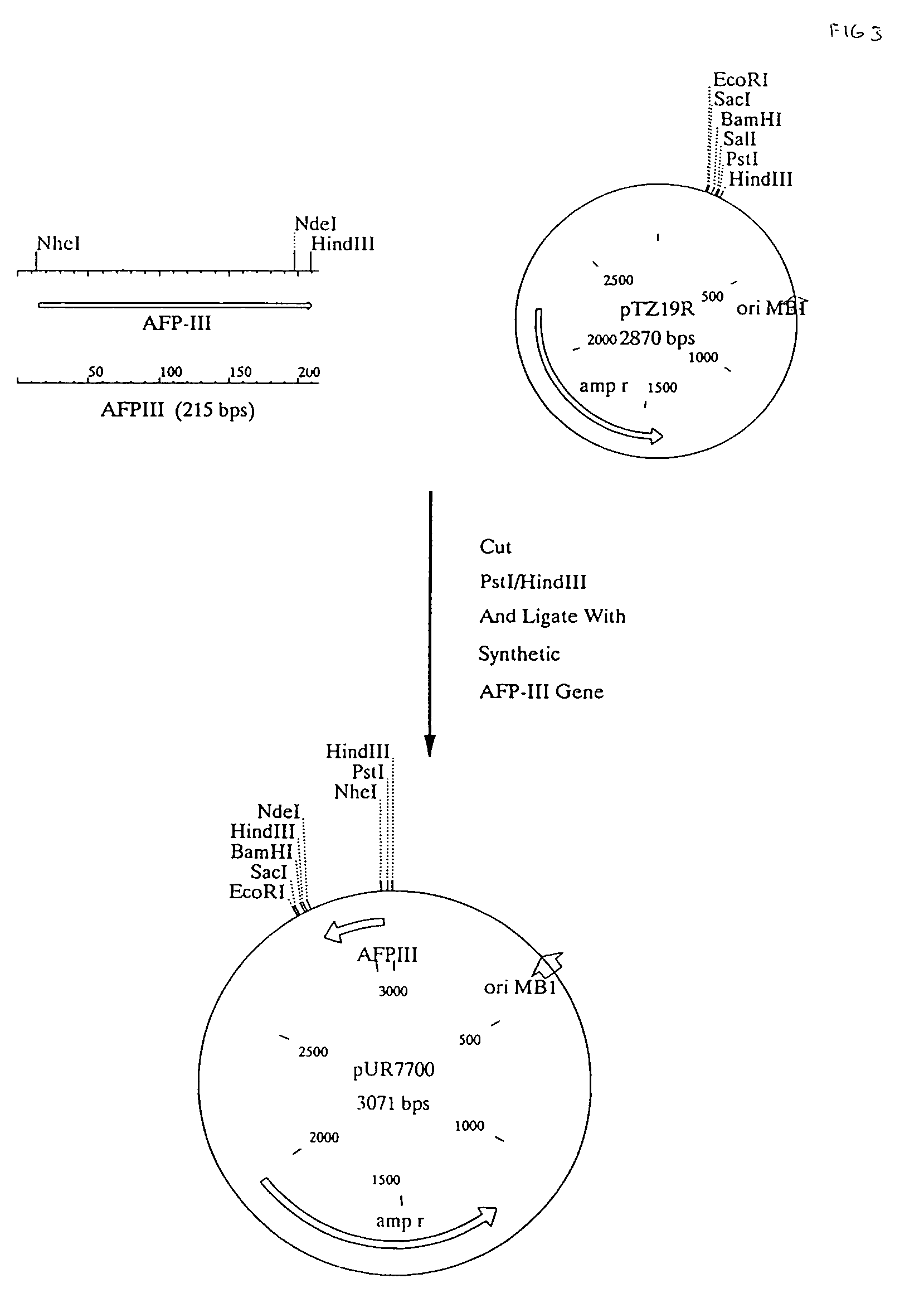

Recombinant peptide

InactiveUS7297516B2Simple and efficientHigh specific recrystallisation inhibiting activitiesFungiBacteriaRecombinant peptideAntifreeze activity

Use of a polypeptide or protein with amino acid sequence corresponding substantially to AFP-type III HPLC 12 as additive in a product for improvement of said product, said improvement residing in improved properties of modification of ice crystal growth processes influencing size and shape characteristics of ice in particular in regrowth thereby e.g. minimising potential freezing damage e.g. by preventing or inhibiting ice recrystallisation of the product upon freezing, said use occurring in a manner known per se for anti freeze peptides to obtain higher specific modification activity in particular antifreeze activity than obtainable with the same amount of Winter Flounder AFP.

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

Freezing method of material with microcosmic lamellar structure

The invention discloses a freezing method of a material with a microcosmic lamellar structure. The freezing method is characterized by comprising the steps of firstly dispersing precursor components of a to-be-prepared lamellar material into a water solution to prepare a precursor solution, adding the precursor solution into a freezing mold, regulating and controlling the temperature gradient of a freezing surface to prompt ice crystals to perform parallel lamellar oriented growth in a freezing process of the solution to extrude the precursor components in the solution to be between the adjacent ice crystals so as to assemble the precursor components into corresponding parallel lamellar structures, and then carrying out freeze drying so as to obtain the material with the microcosmic lamellar structure. The freezing method is suitable for preparing an organic polymer bracket material with the microcosmic lamellar structure or a composite material of the organic polymer bracket material, is especially suitable for preparing a nanometer-material macro-function assembly with the microcosmic lamellar structure and therefore has an important application value in the field of novel materials.

Owner:UNIV OF SCI & TECH OF CHINA

Multi-outlet soft frozen dessert apparatus for a self-service restaurant

A multi-outlet soft frozen dessert apparatus for a self-service restaurant with multiple freezers attached to the wall dividing the client area of the restaurant from the kitchen area is provided. The freezers of apparatus may include an evaporation tube comprised of an aluminum alloy micro-channel parallel flow extruded tape. The mix vats of the apparatus may include circulating water in a hydraulic system having added antifreeze to suppress a freezing temperature in the range of −2° C. to −5° C. to assure adequate approach temperature to cool a mix in the mix vat. The apparatus may include scrape blades mounted on a helical part of the beater-scraper that scrape a thin layer of ice crystals from an internal surface of the inner cylinder and fold the ice crystals inside the mix bulk.

Owner:REICH DANIEL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com