Integral porous carbon-silicon carbide composite material, and preparation method and application thereof

A composite material and a monolithic technology, applied in the field of monolithic porous carbon-silicon carbide composite materials and their preparation, can solve problems such as the inability to reflect the thermal conductivity and electrical conductivity of SiC, hindered heat transfer, and reduced electrical conductivity and thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

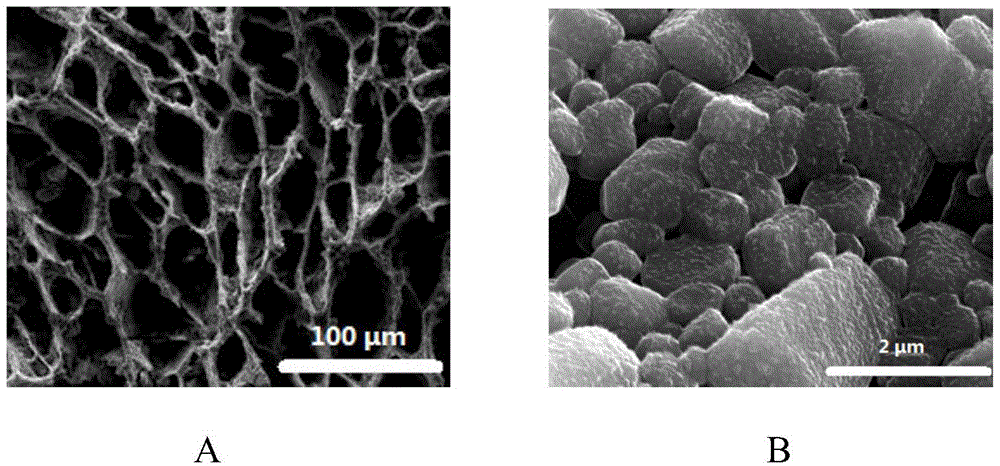

Image

Examples

Embodiment 1

[0041] Weigh 10.0g of 100-mesh SiC powder, 6.5g of 100-mesh Si powder, 2.8g of acetylene charcoal powder, and 1.5g of 100-mesh Fe powder, pour into 24mL of 0.5% agarose solution, and stir at 80°C for 30min. The formed slurry was poured into a cylindrical polytetrafluoro mold with an inner diameter of 2 cm and a length of 10 cm, cooled at room temperature for 2 hours, and then placed in a -30° C. refrigerator for 2 hours. The frozen material was taken out and placed in a freeze dryer for 48 hours to obtain embryo bodies. Put the embryo body in a graphite crucible, raise the temperature to 500°C under 50mL / min Ar gas, the heating rate is 1°C / min, and raise the temperature to 1000°C under 50mL / min Ar gas, the heating rate is 10°C / min, in 50mL The temperature was raised to 1500 °C under the Ar gas of / min, the heating rate was 2 °C / min, the vacuum was kept for 2 hours, and then the vacuum was kept for 2 hours, and the temperature was lowered in the furnace to prepare the integral ...

Embodiment 2

[0046] Weigh 10.0g of 100 mesh SiC powder, 6.5g of 100 mesh Si powder, 2.8g of acetylene carbon powder, Cr(NO 3 ) 3 Powder 1.0g, Ni(NO 3 ) 2 Powder 0.5g, pour into 24mL of 2% gelatin solution, stir at 60°C for 30min. The formed slurry was poured into a cylindrical polyethylene mold with an inner diameter of 2 cm and a length of 10 cm, cooled at room temperature for 1 h, and then placed in a -60° C. refrigerator for 5 h. The frozen material was taken out and placed in a freeze dryer for 48 hours to obtain embryo bodies. Put the embryo body in the corundum crucible, and raise the temperature to 500°C under 50mL / min of Air gas, the heating rate is 0.5°C / min, and under 50mL / min of H 2 Raise the temperature to 1000°C under gas, the heating rate is 10°C / min, switch to 50mL / min CH 4 The gas was kept at 1000°C for 1h, and the temperature was raised to 1600°C under 50mL / min of Ar gas at a heating rate of 2°C / min. After holding for 2 hours, the temperature was cooled in the furnace...

Embodiment 3

[0049] Weigh 28.9g of 400 mesh SiC powder, 0.5g of acetylene carbon powder, B 2 o 3 Powder 0.5g, poured into 24mL of 5% ethyl orthosilicate (pH1) solution, stirred at 30°C for 2h. The formed slurry was poured into a cylindrical polyethylene mold with an inner diameter of 2 cm and a length of 10 cm, cooled at room temperature for 5 h, and then frozen in liquid nitrogen for 0.2 h. The frozen material was taken out and placed in a freeze dryer for 48 hours to obtain embryo bodies. Put the embryo body in a graphite crucible, raise the temperature to 500°C under 50mL / min Ar gas, the heating rate is 1°C / min, and raise the temperature to 1000°C under 50mL / min Ar gas, the heating rate is 10°C / min, in 50mL / min under Ar gas to raise the temperature to 1600 °C, the heating rate is 2 °C / min, and the temperature is lowered at 3 °C / min to prepare a monolithic porous SiC core body.

[0050] Seal the SiC nuclei into a quartz tube, raise the temperature to 800°C under 50mL / min Ar gas, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com