Patents

Literature

167 results about "Reaction interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An interface dermatitis (ID) reaction, also known as autoeczematization, is an itchy rash with small, water-filled blisters that is caused in response to a primary infection, usually fungal.

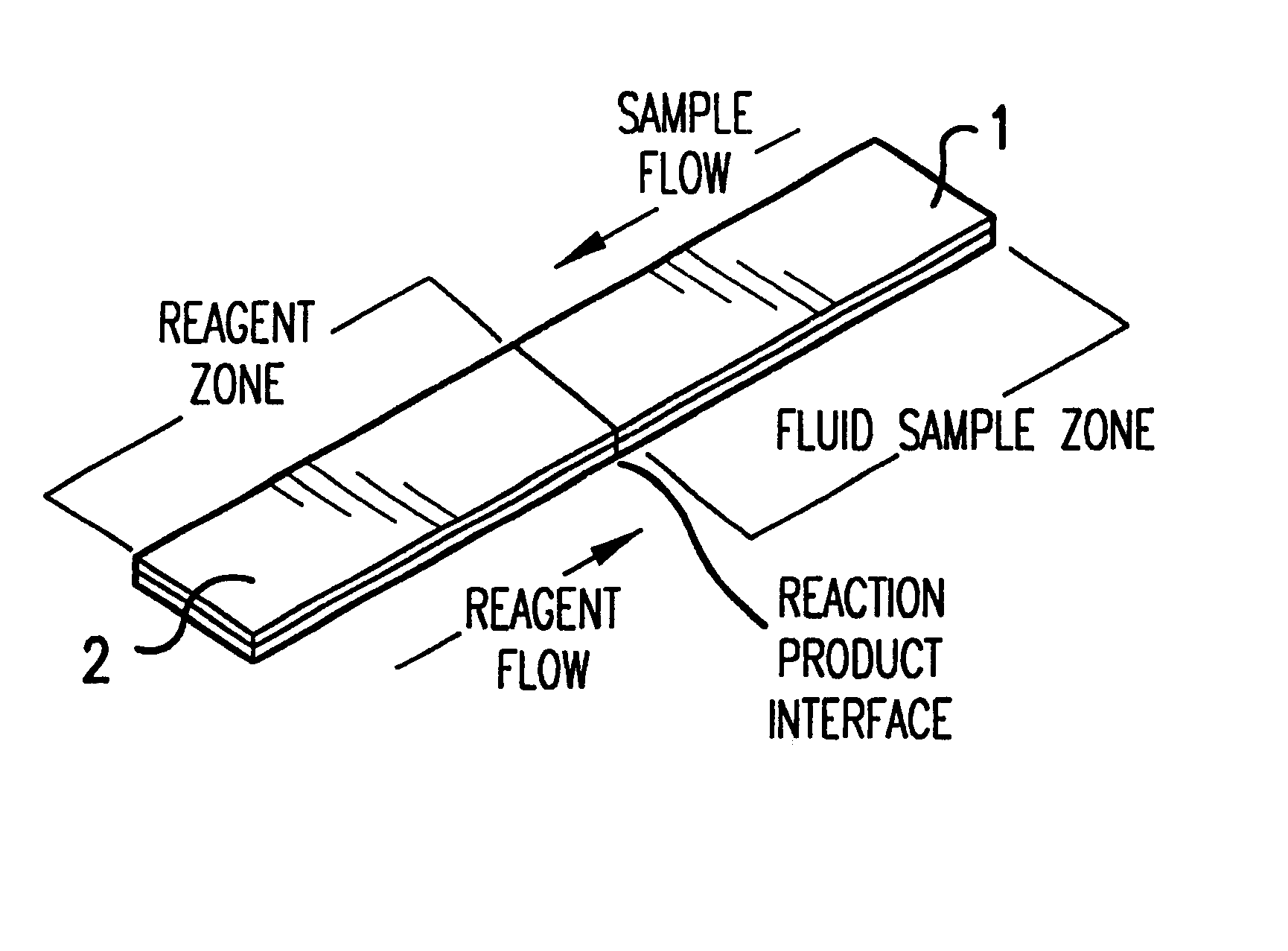

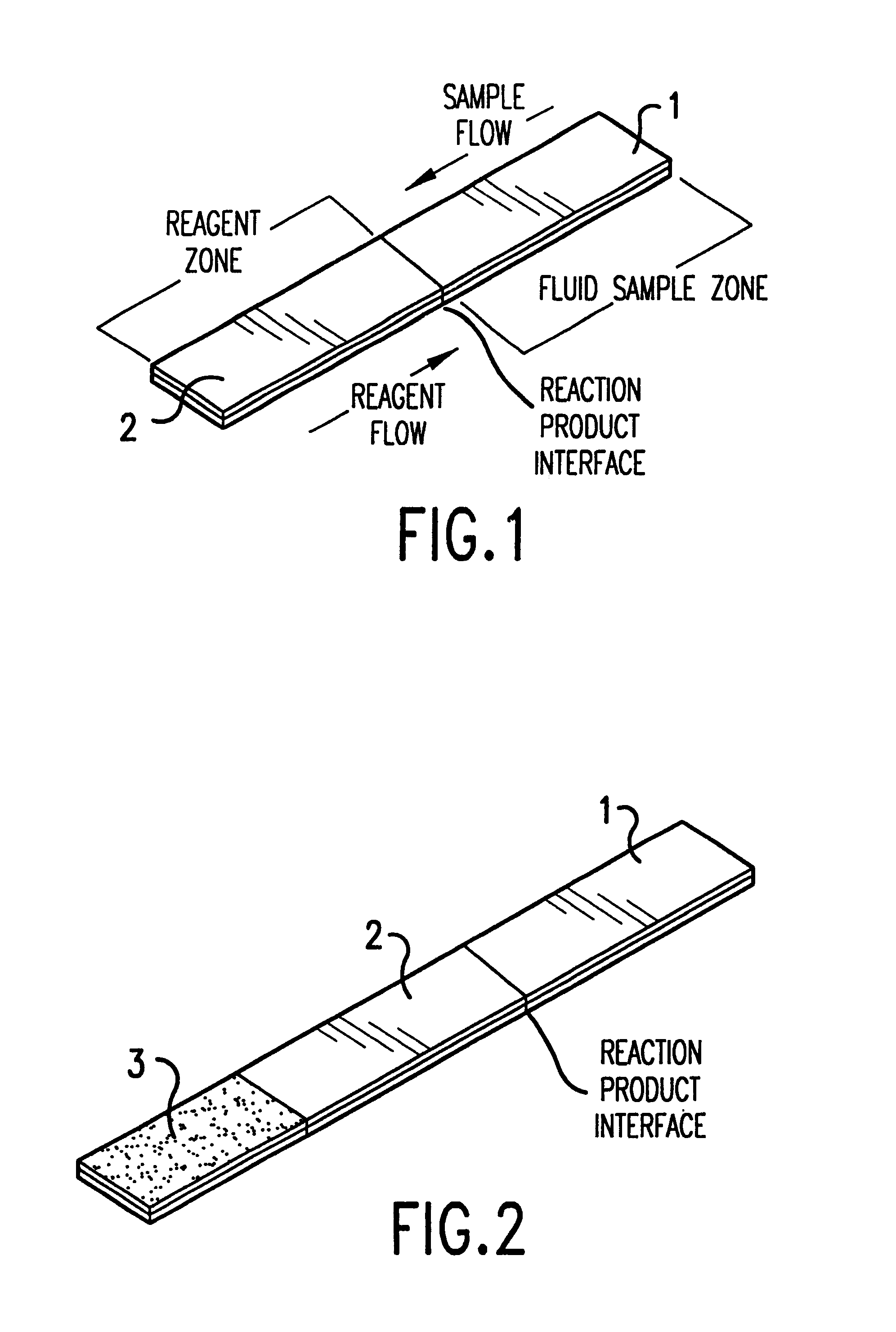

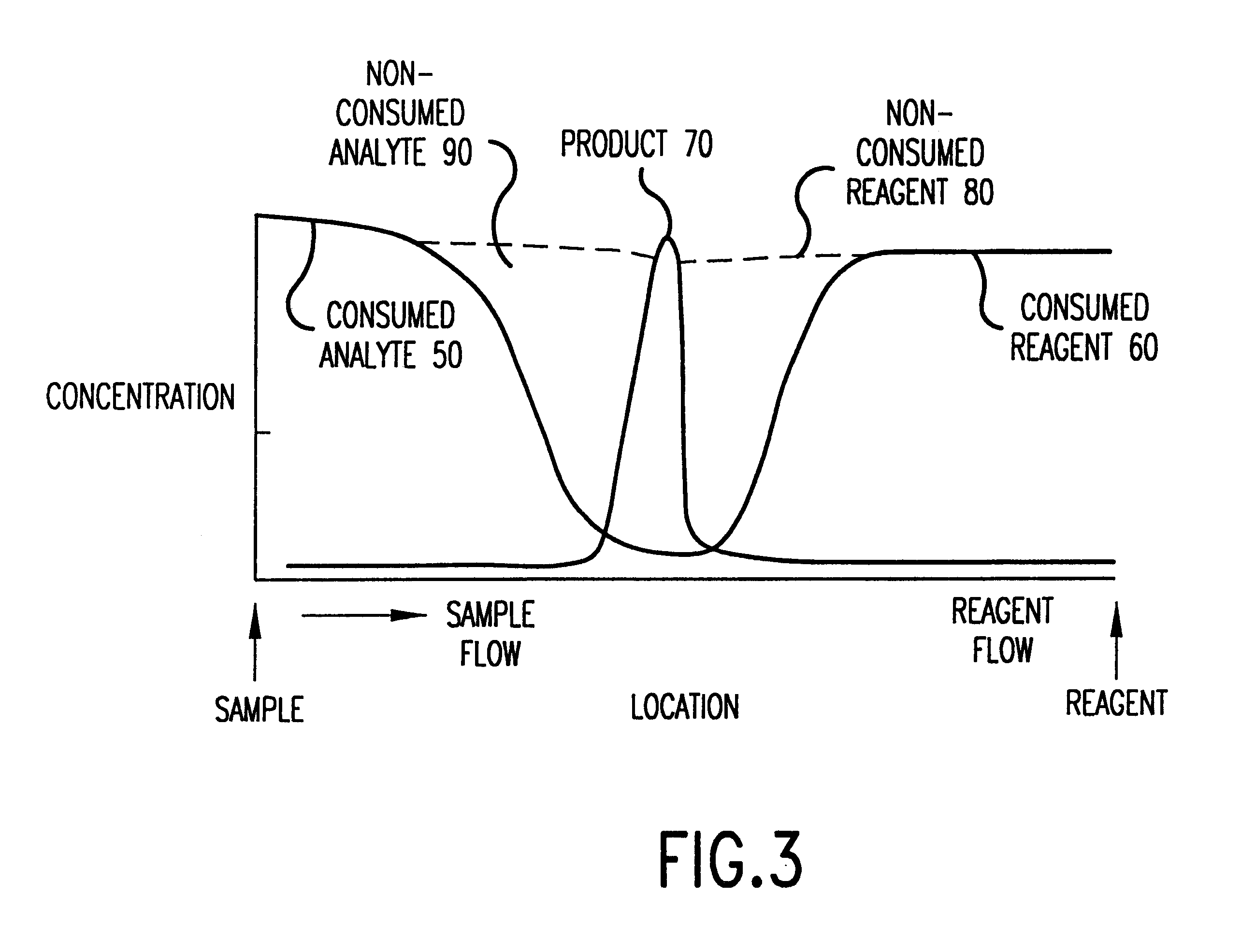

Method and device for detecting analytes in fluids

InactiveUS6602719B1Bioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationBlood plasma

Owner:IDEXX LABORATORIES

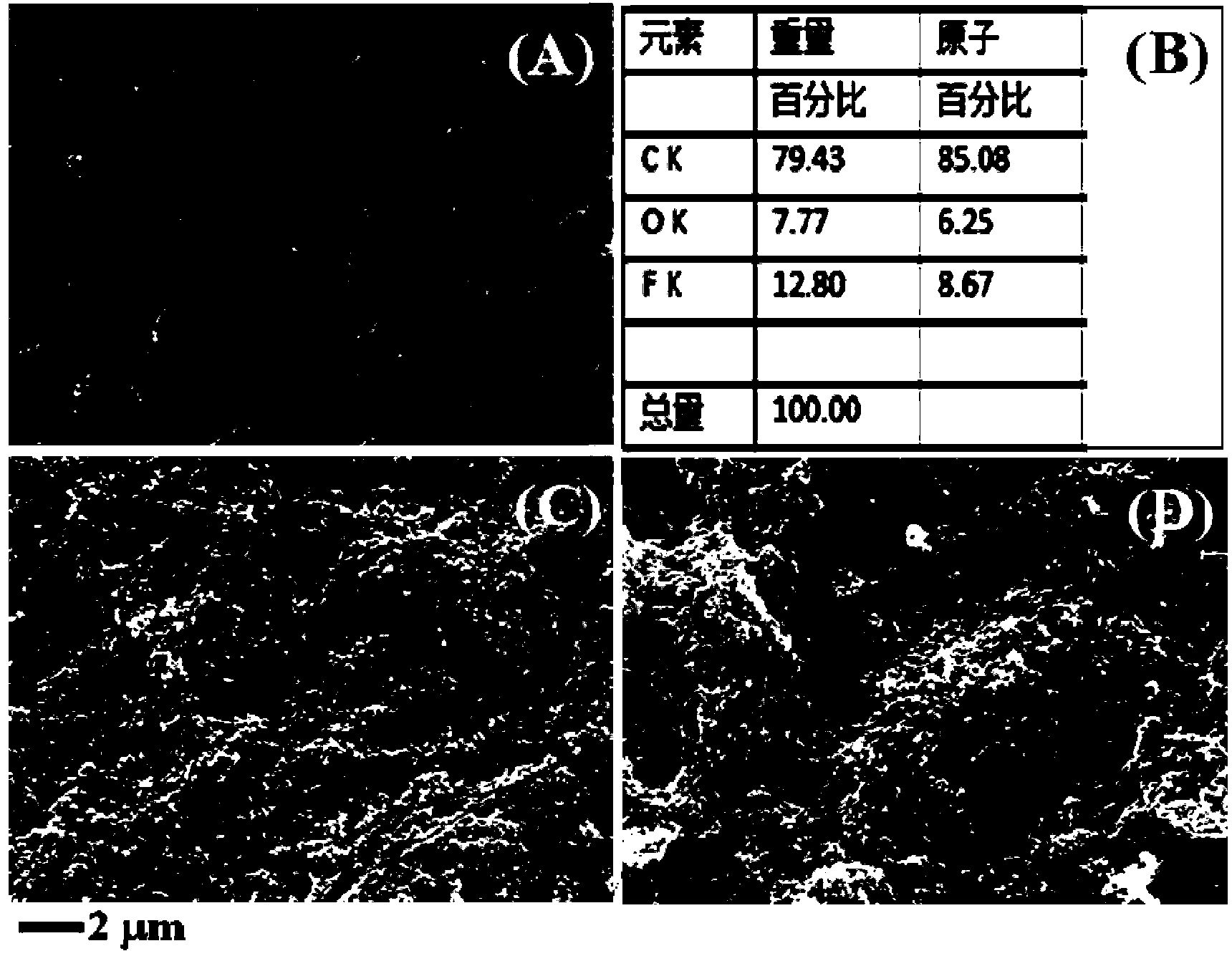

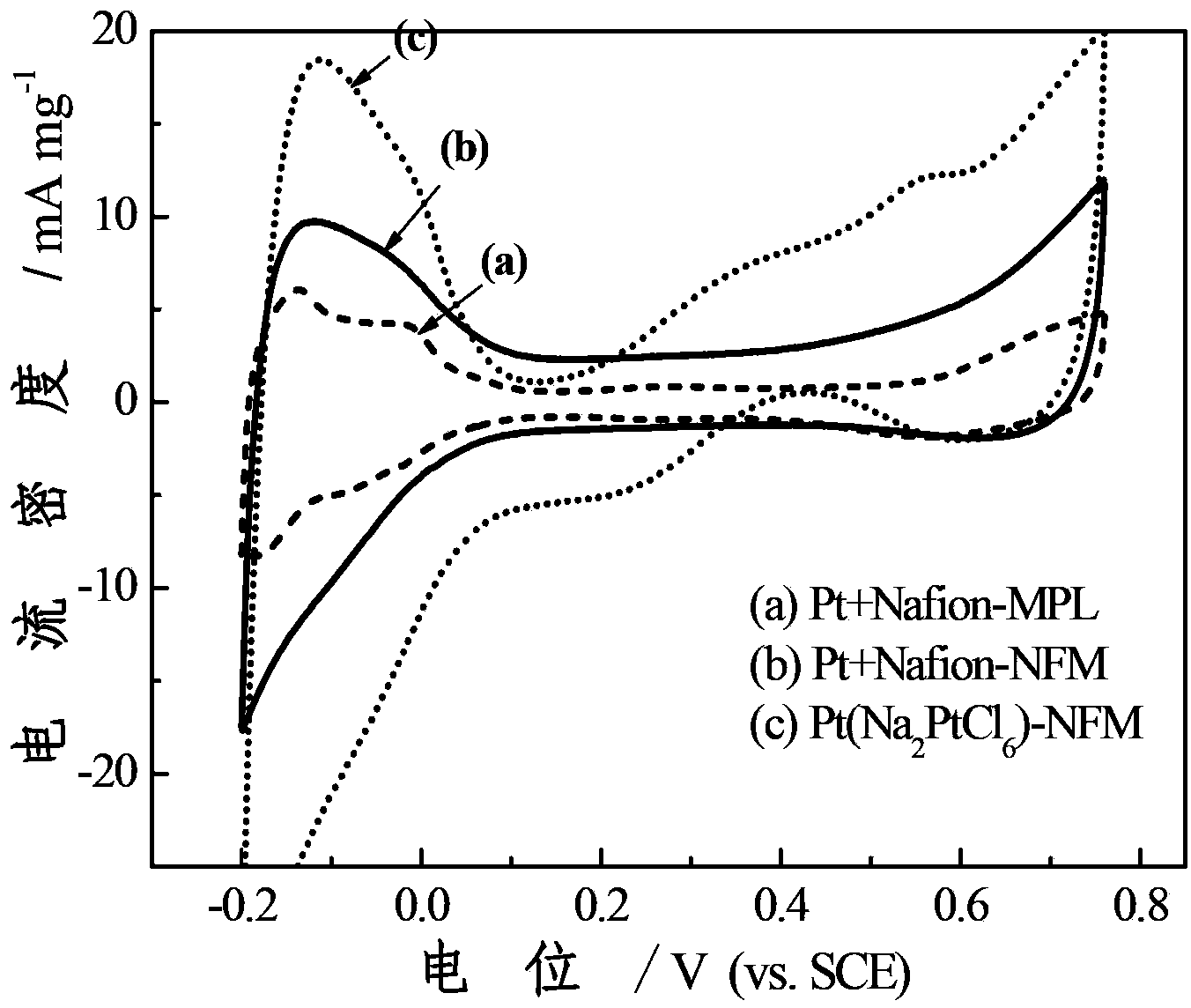

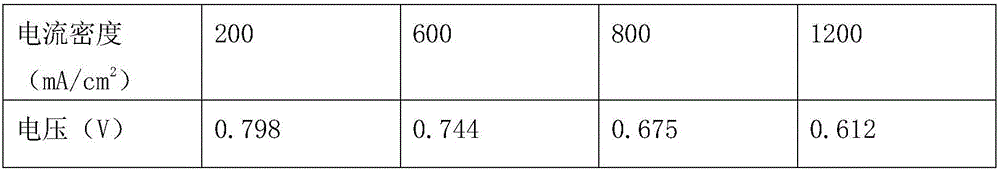

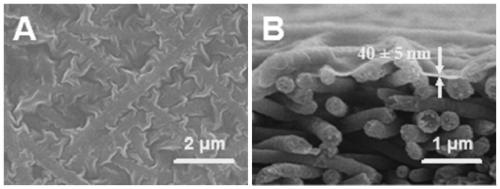

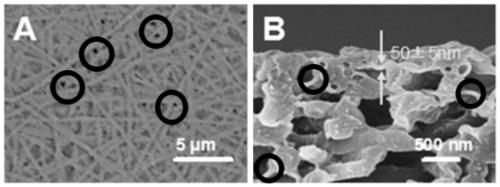

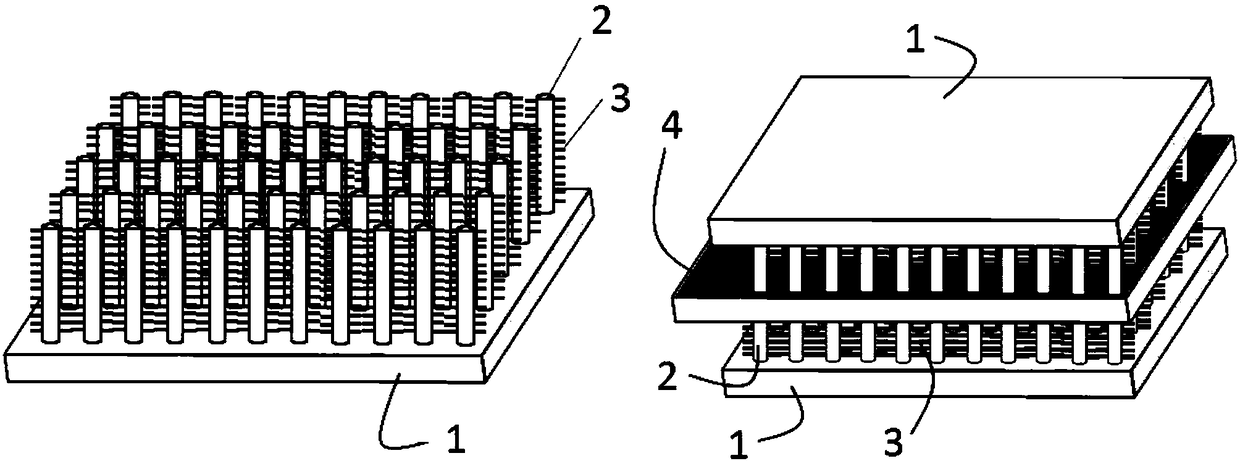

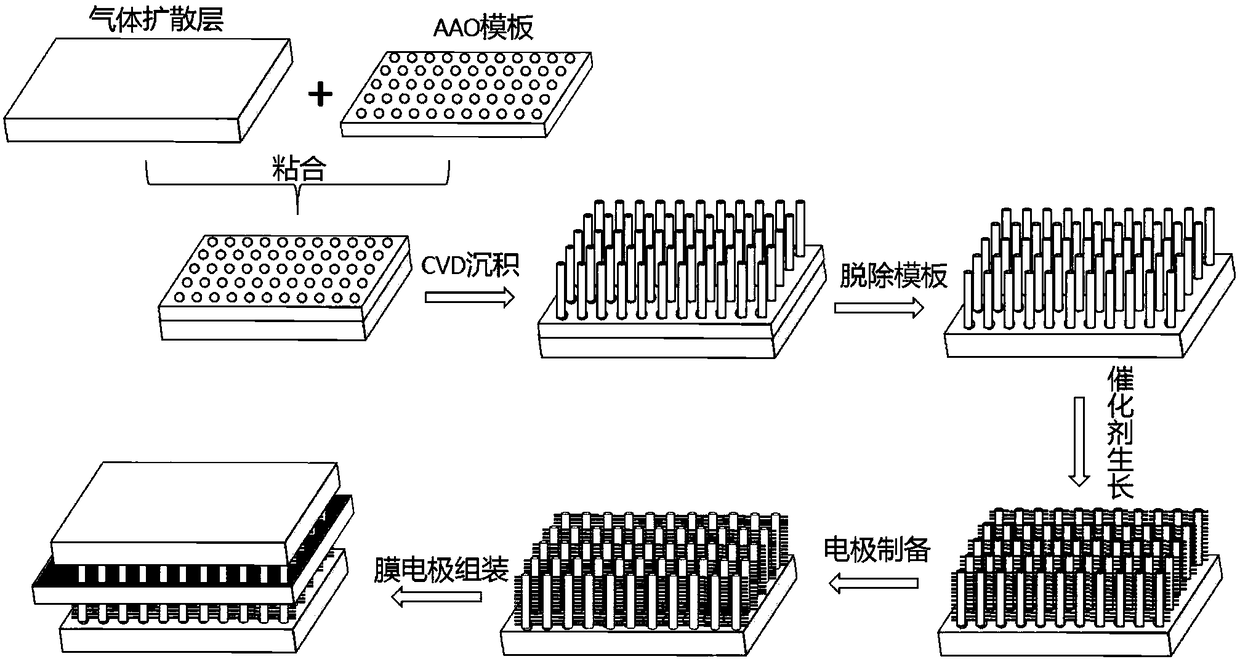

Fuel cell ordered porous nano-fiber single electrode, membrane electrode and preparation method

InactiveCN103413947AShorten the transmission distanceIncrease profitMaterial nanotechnologyCell electrodesPorositySlurry

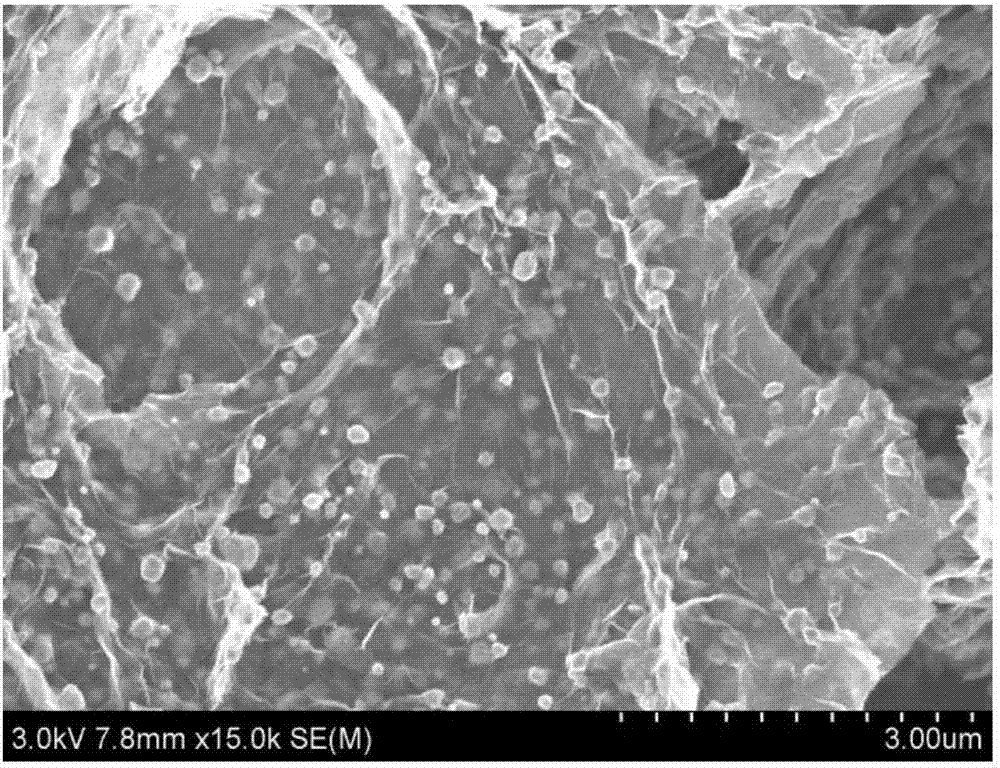

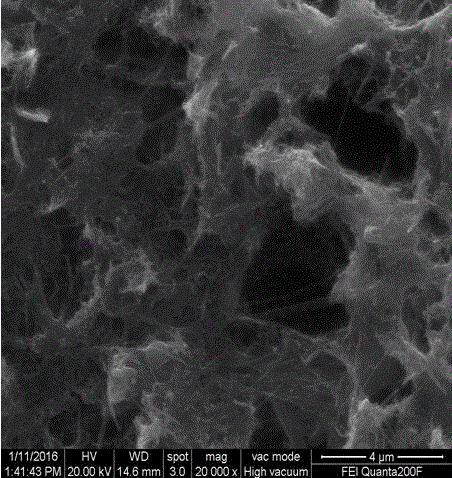

The invention discloses a fuel cell ordered porous nano-fiber single electrode, a membrane electrode and a preparation method. Polymer nano-fibers are deposited on one side of a gaseous diffusion material through an electro-spinning technology; metal nanoparticles with catalytic activity are deposited on the surfaces of the polymer nano-fibers by using magnetron sputtering and vacuum evaporation methods, or catalyst slurry is directly sprayed to one side of a nano-fiber thin film to form a porous single electrode; then two single electrodes and a layer of proton exchange membrane are combined into a three-in-one membrane electrode. The fuel cell ordered porous nano-fiber single electrode, the membrane electrode and the preparation method have the beneficial effects that the conventional micro-porous layer is substituted by the nano-fiber layer with high porosity and high specific surface area, prepared by electro-spinning, so that the catalytic activity area is increased and the three-phase reaction interface and the mass transfer are facilitated, and an active metal catalytic layer formed by magnetron sputtering and vacuum evaporation has high adhesion, is uniform in coating and has controllable thickness, so that the using amount of the active metal catalyst is reduced and the utilization rate of the catalyst is also greatly increased.

Owner:WUHAN UNIV OF TECH

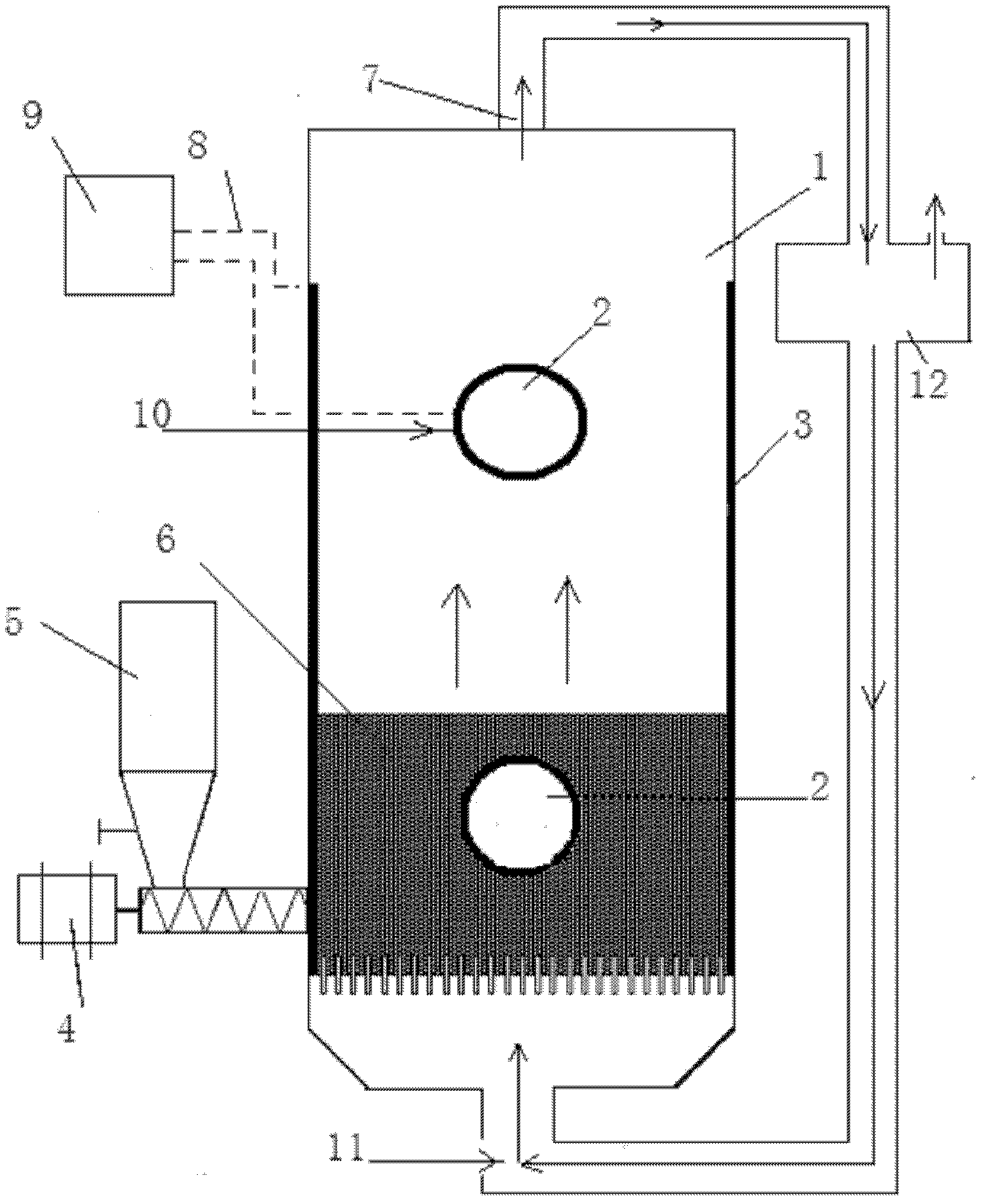

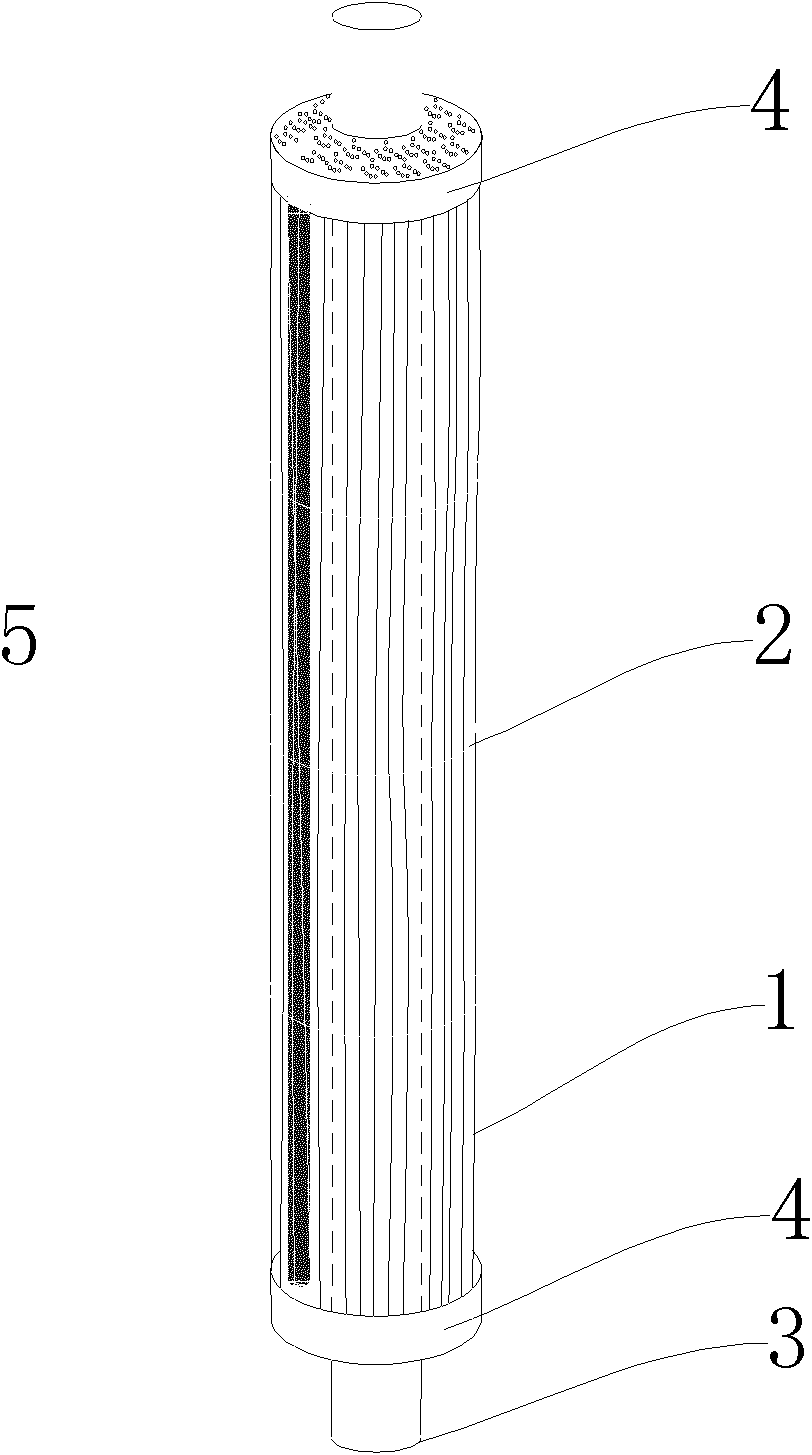

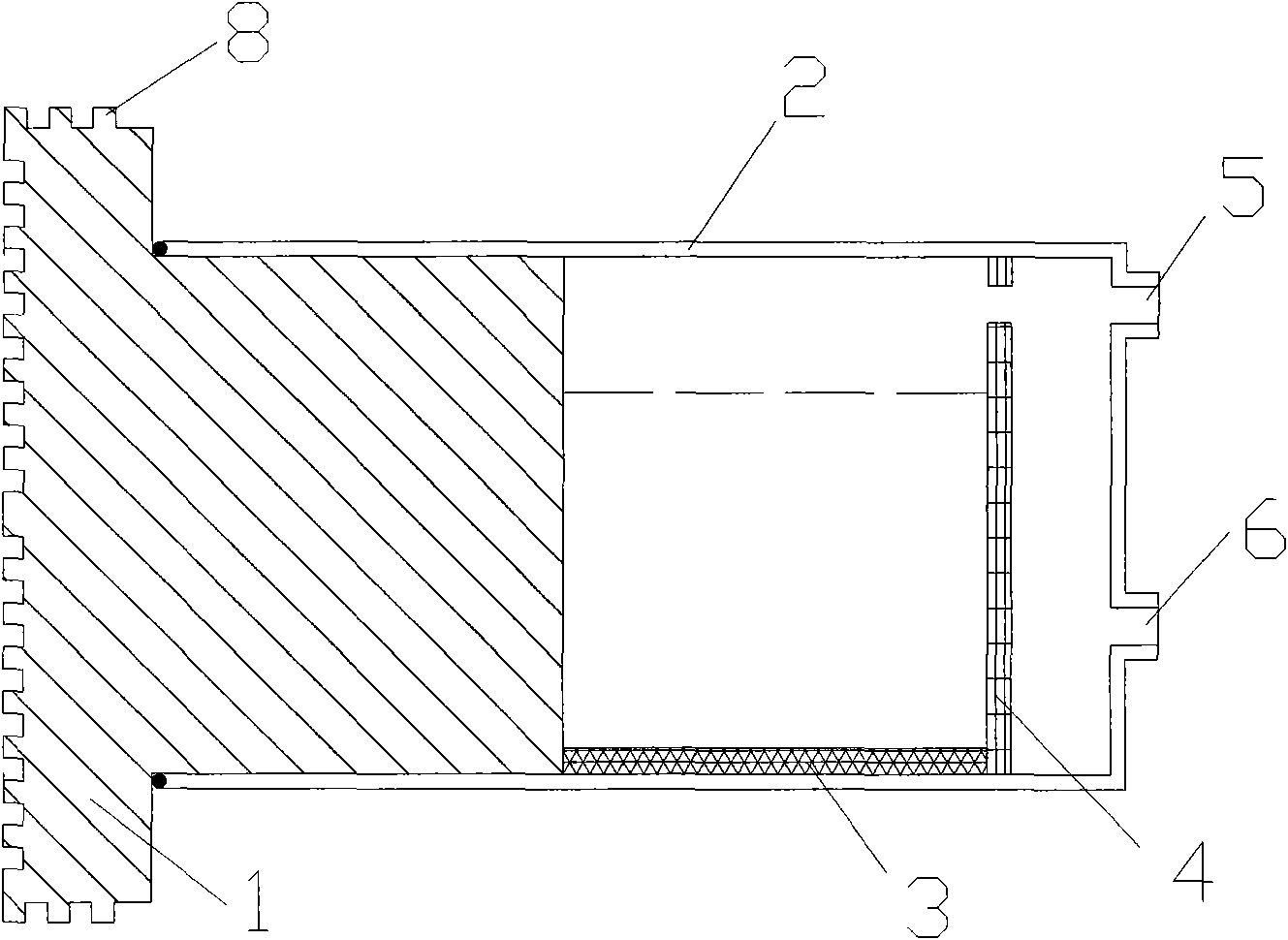

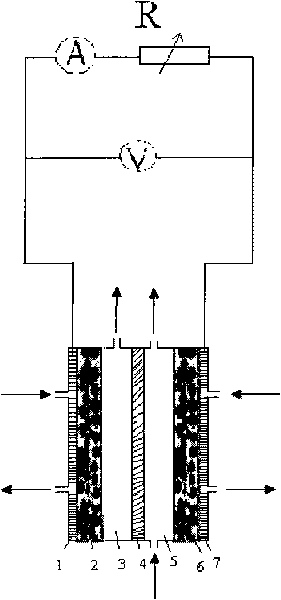

Fluid bed electrode direct carbon fuel cell device

InactiveCN102324539AImprove performanceEasy inflowCell electrodesFuel cell auxillariesElectrochemical responseSolid carbon

The invention discloses a fluid bed electrode direct carbon fuel cell device, which belongs to the technical field of clean energy. The device comprises a fluid bed, two or more tubular single cells, collector plates, a composite carbon fuel, a gas circulating device, a screw feeder and a fuel tank. In the device, a conductor catalyst is added into a solid carbon fuel on the basis of a solid oxide direct carbon fuel cell to expand a direct electrochemical reaction interface of carbon from a two dimension to a three dimension and promote the gasification reaction of the carbon, thereby improving the performance of the cell; the collector plates are distributed on the wall surface of a reactor, so current is convenient to collect; and simultaneously, a fluid bed reactor forms a fluid bed electrode to further enhance heat transfer and mass transfer in the electrode, so not only problems about feeding are solved, but also the performance of the solid oxide direct carbon fuel cell is further improved.

Owner:TSINGHUA UNIV

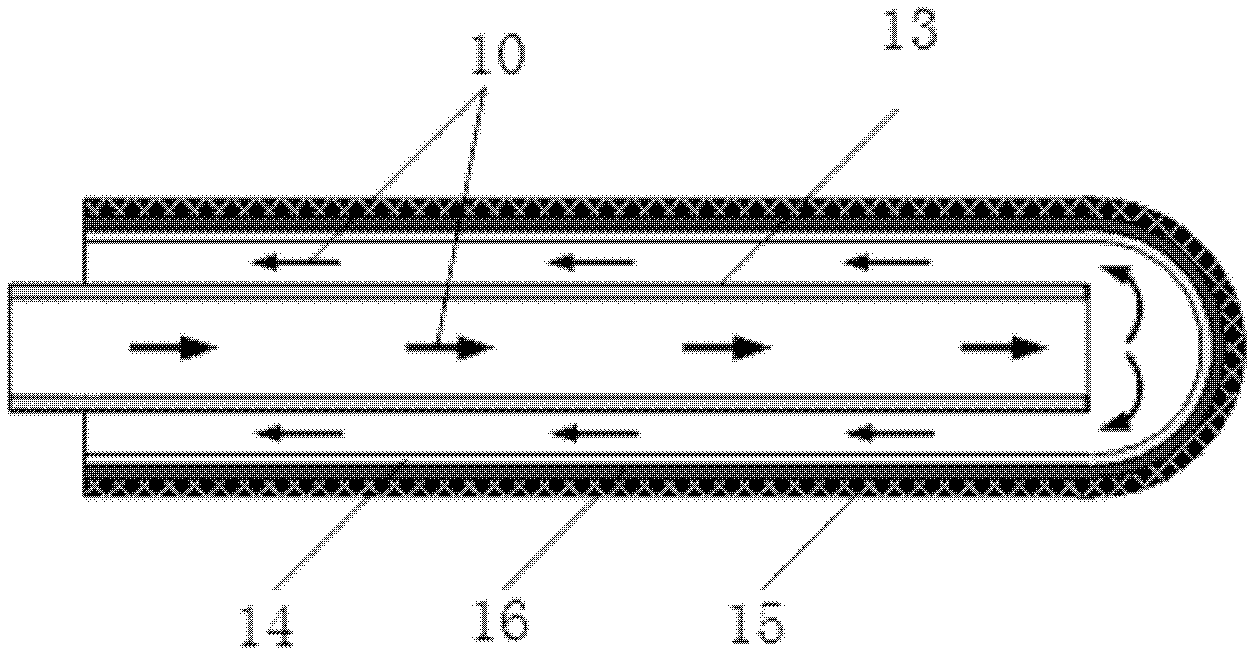

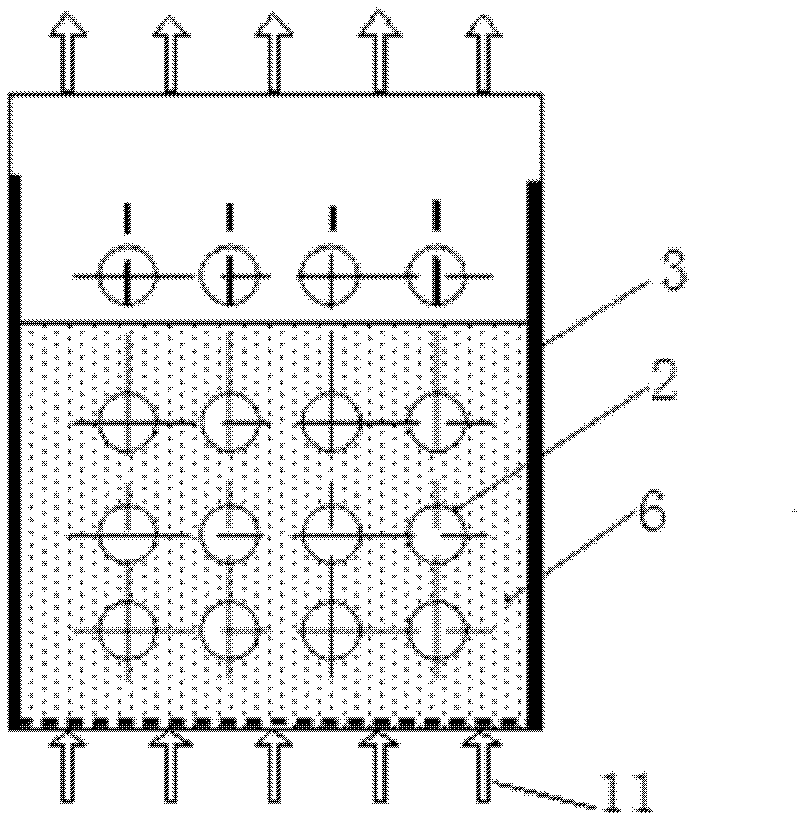

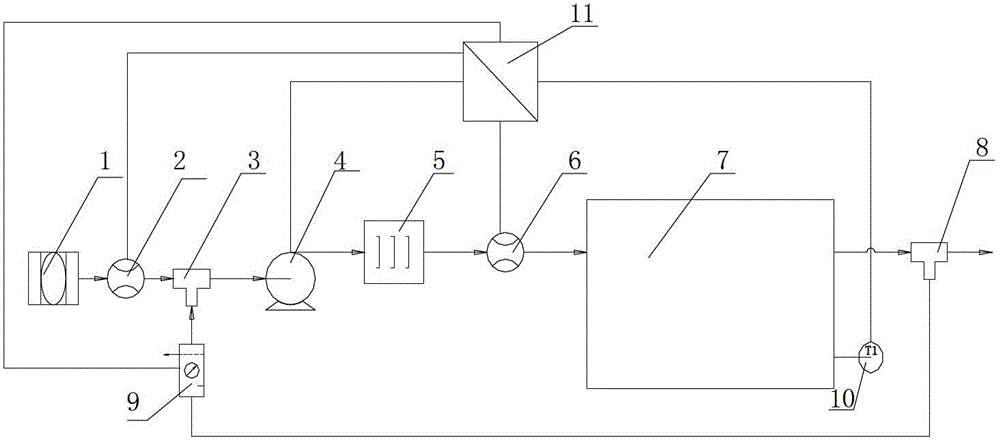

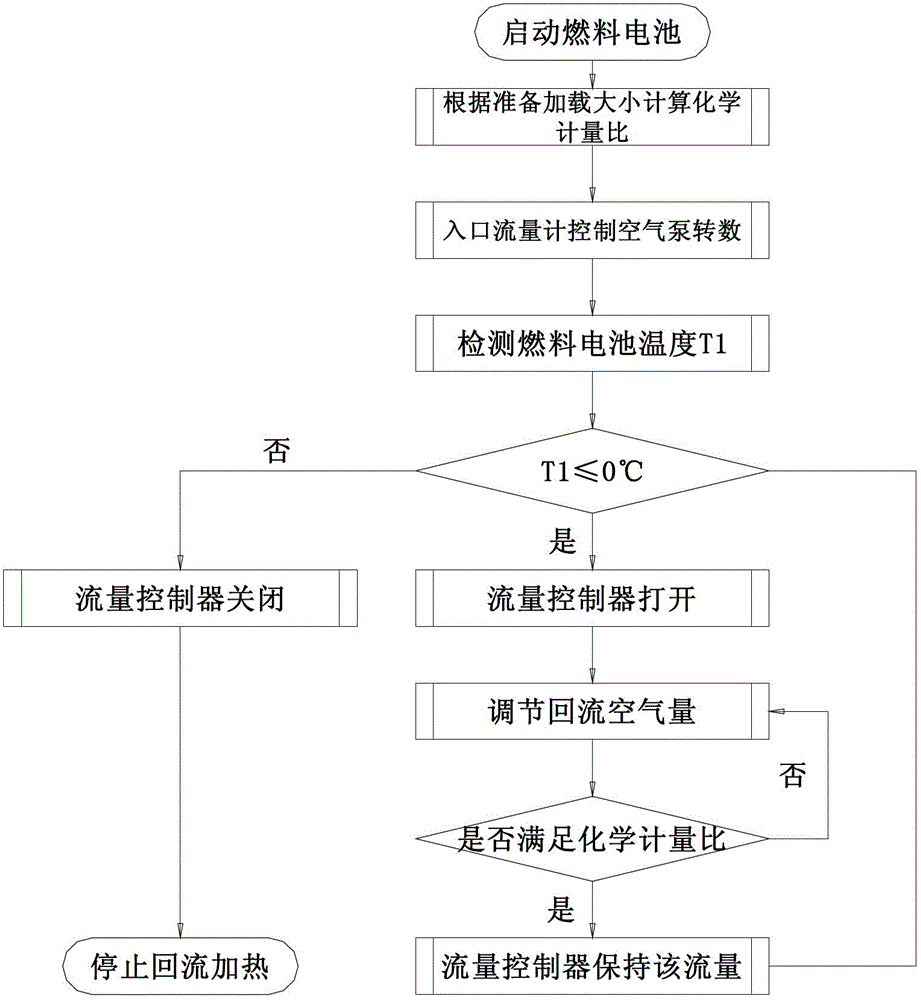

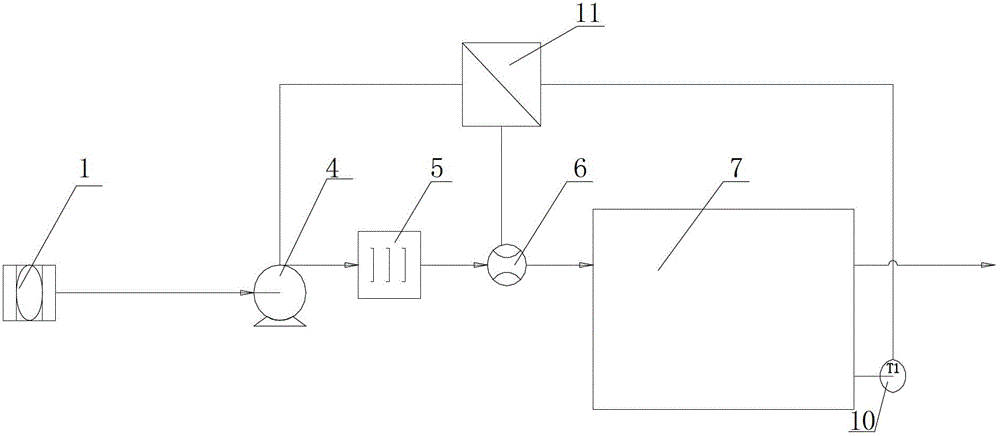

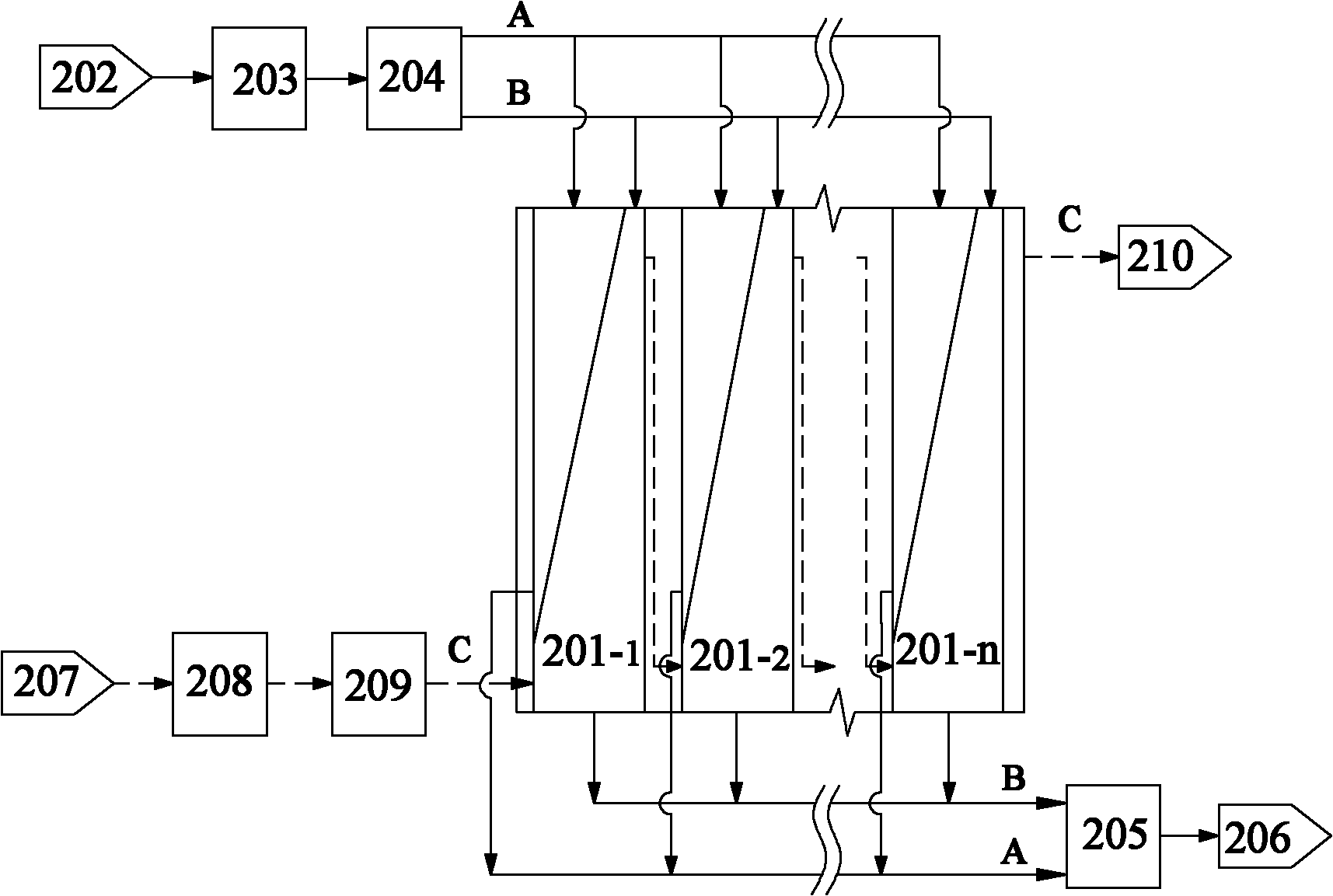

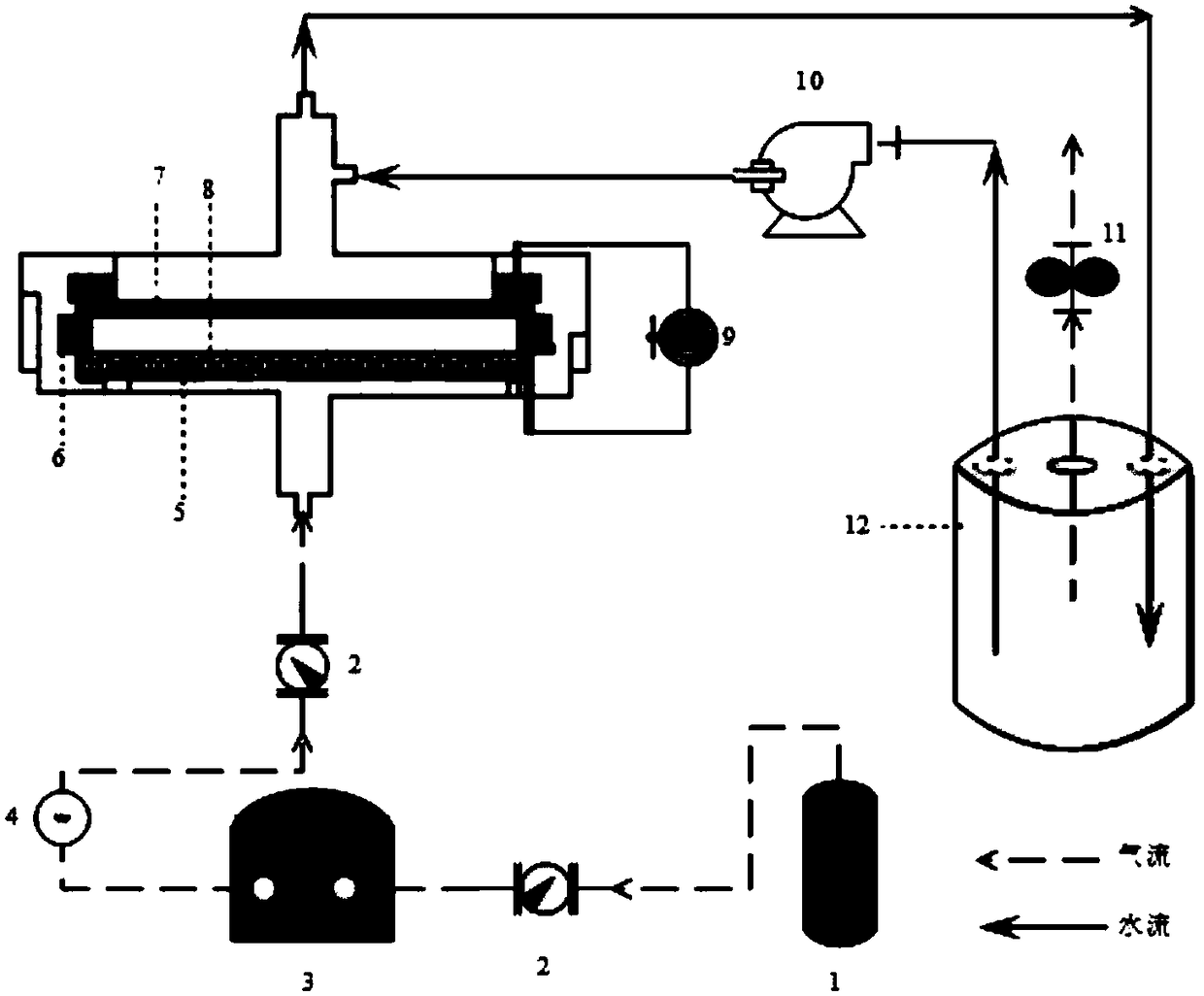

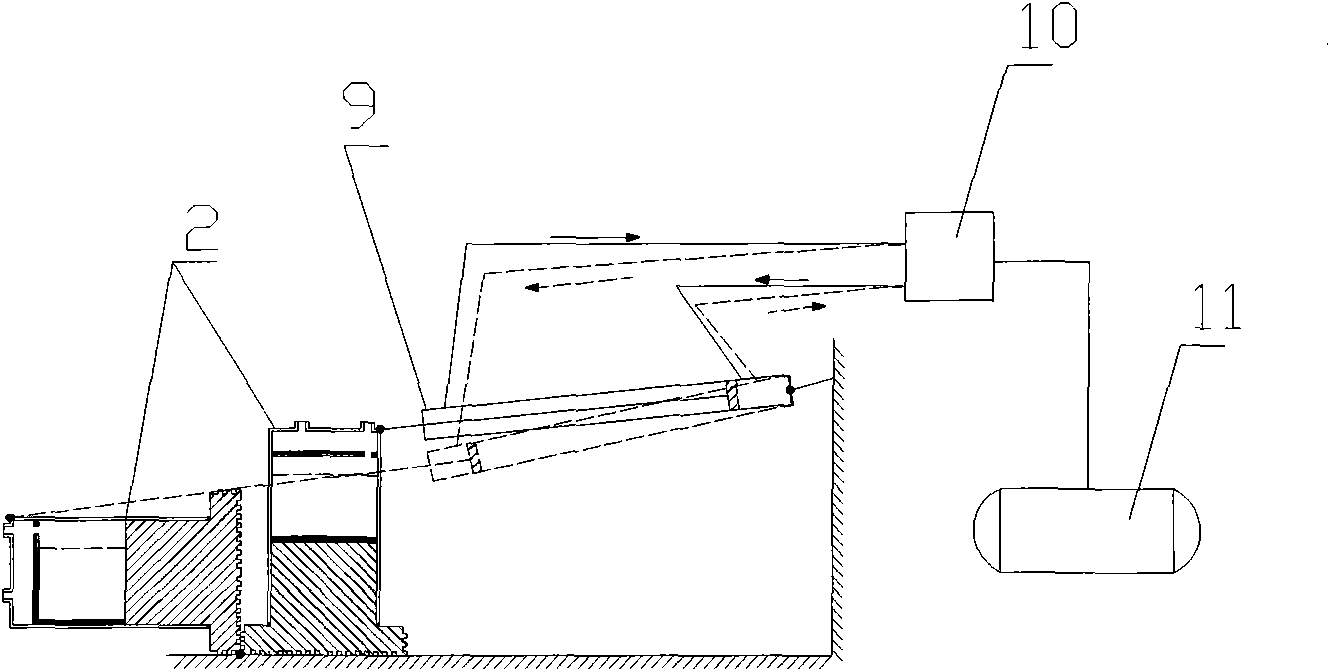

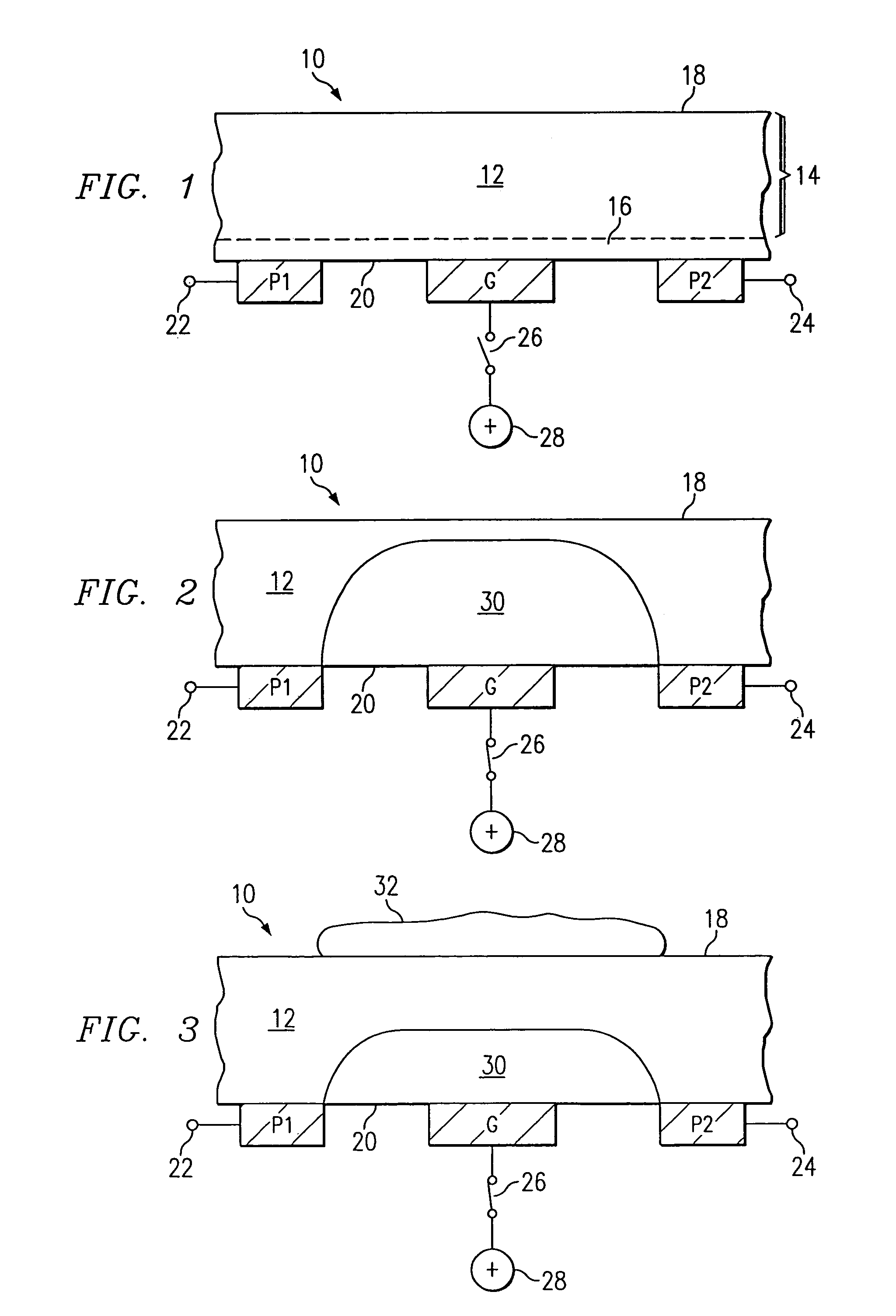

Heating system for starting fuel cell at low temperature with air backflow and heating method thereof

The invention discloses a heating system for starting a fuel cell at a low temperature with air backflow and a heating method thereof. The system comprises an air filter, an intakeport flowmeter, an intakeport tee, an air pump, a humidifier, an inlet flowmeter, a fuel cell stack, an outlet tee, an air flow controller, a temperature sensor and a controller. When the heating system provided in the invention works, heat-containing air compressed by the air pump heats an air reaction interface and other battery assemblies of the fuel cell stack, and then a part of or all the air tail gas of the fuel cell stack flows back and passes through the air pump through controlling of the flow controller so as to cyclically heat the air reaction interface and the other battery assemblies of the fuel cell stack. According to the invention, air tail gas containing waste heat of the air pump is cyclically used to heat the air reaction interface of the fuel cell stack, so melting of ice crystals on electrodes is accelerated, mass transfer of fuels and proton transfer are smoothly carried out, starting of fuel cells with a temperature lower than 0 DEG C is accelerated, and energy consumption of a storage battery used as an auxiliary power supply can be saved.

Owner:SUNRISE POWER CO LTD

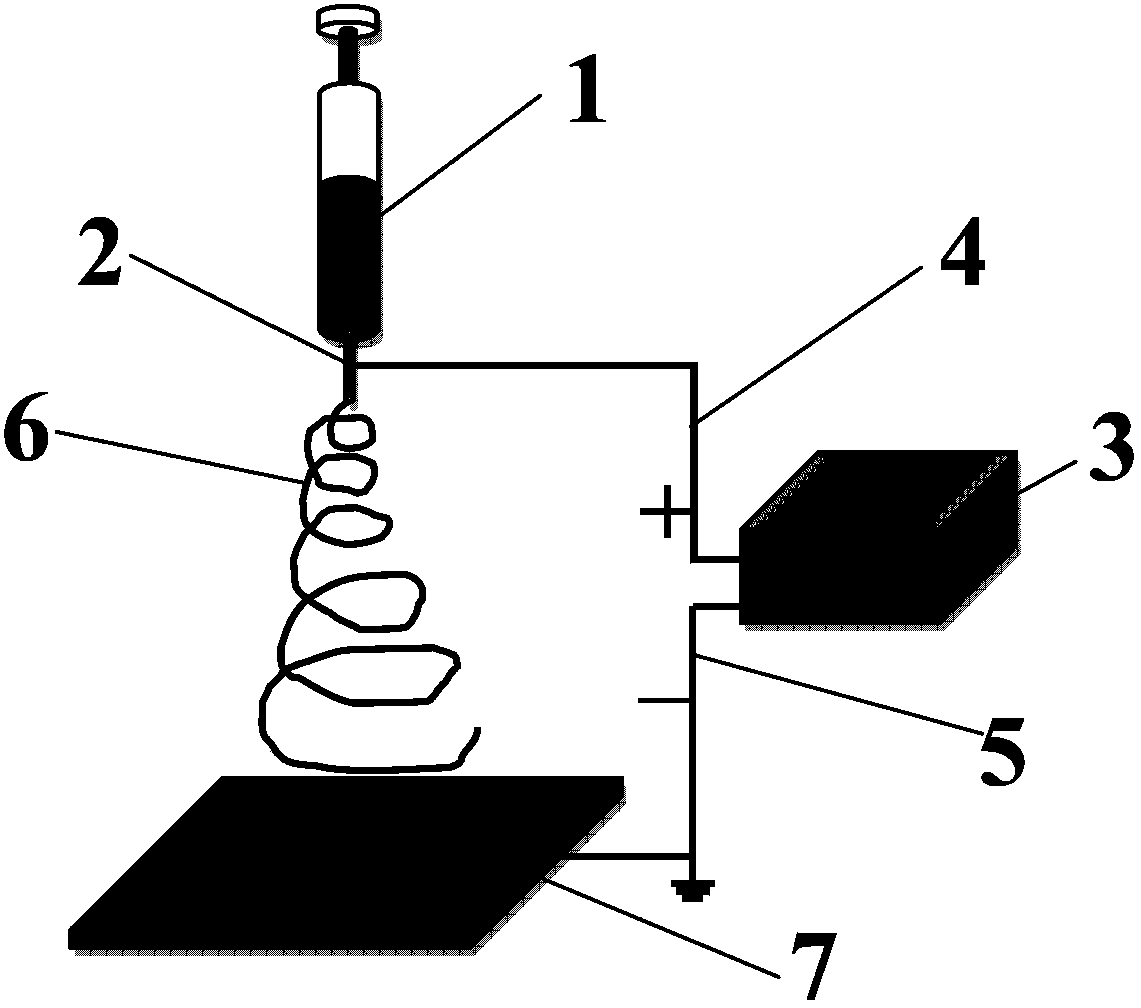

Preparation method of membrane electrode of direct methanol fuel cell

The invention relates to a preparation method of the membrane electrode of a direct methanol fuel cell. The method comprises the following steps: an electrostatic spinning technology is adopted to construct a nano-fiber network structure thin membrane mixed by active carbon powder and Nafion resin; a precious metal nano-catalyst is deposited on the surface of the manufactured nano-fiber network structure thin membrane, so that a cathode catalyst layer thin membrane and an anode catalyst layer thin membrane are manufactured respectively; or the mixture of the precious metal nano-catalyst and the Nafion resin is taken as raw materials to directly construct the cathode catalyst layer thin membrane and the anode catalyst layer thin membrane through the electrostatic spinning technology; a cathode gas diffusion layer, the anode catalyst layer thin membrane, a Nafion membrane, the cathode catalyst layer thin membrane and a cathode gas diffusion layer are hot-pressed finally, so that the aggregation of the membrane electrode of the direct methanol fuel cell is manufactured; the membrane electrode with a nano-fiber three-dimensional network structure is constructed through the electrostatic spinning technology, so that the maximization of the three-phase reaction interface of the membrane electrode is achieved, and the improvement of electrocatalytic activity, mass-transfer efficiency and utilization efficiency of the catalyst is achieved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

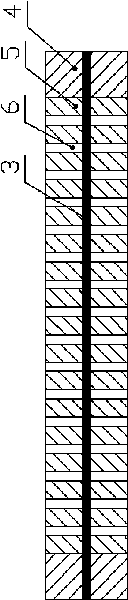

Fuel cell chip with nano structure film catalyst layer, film electrode and preparation method thereof

InactiveCN103413950AIncrease the catalytic active areaIncrease profitMaterial nanotechnologyCell electrodesFiberNanostructure

The invention relates to a fuel cell chip with a nano structure film catalyst layer, a film electrode and a preparation method thereof. Polymer nanometer fibers are deposited at both sides of a proton exchange membrane through an electrostatic spinning technology so as to form a porous polymerization nanofiber film is formed, and then a CCM (Coincident-Current Memory) is formed through depositing reactive metal catalysts on the polymer nanfiber by using a magnetron sputtering method, a vacuum evaporation method or a spraying method, then a gas diffusion layer material is stuck to both sides of the CCM to form a five-in-one film electrode by virtue of hot compression. The preparation method provided by the invention has the beneficial effects that a conventional micro-porous layer can be replaced by a nanofiber prepared through electrostatic spinning, and furthermore a nano structure with high porosity and high specific surface area can be used for increasing the catalytic activity area and is beneficial to a triphase reaction interface and mass transfer; the adhesiveness of the reactive metal catalyst layer obtained by magnetron sputtering and vacuum evaporation is good, a cladding is uniform, the thickness is controllable, and both the utilization ratio of a catalyst and the stability of the film electrode are improved.

Owner:WUHAN UNIV OF TECH

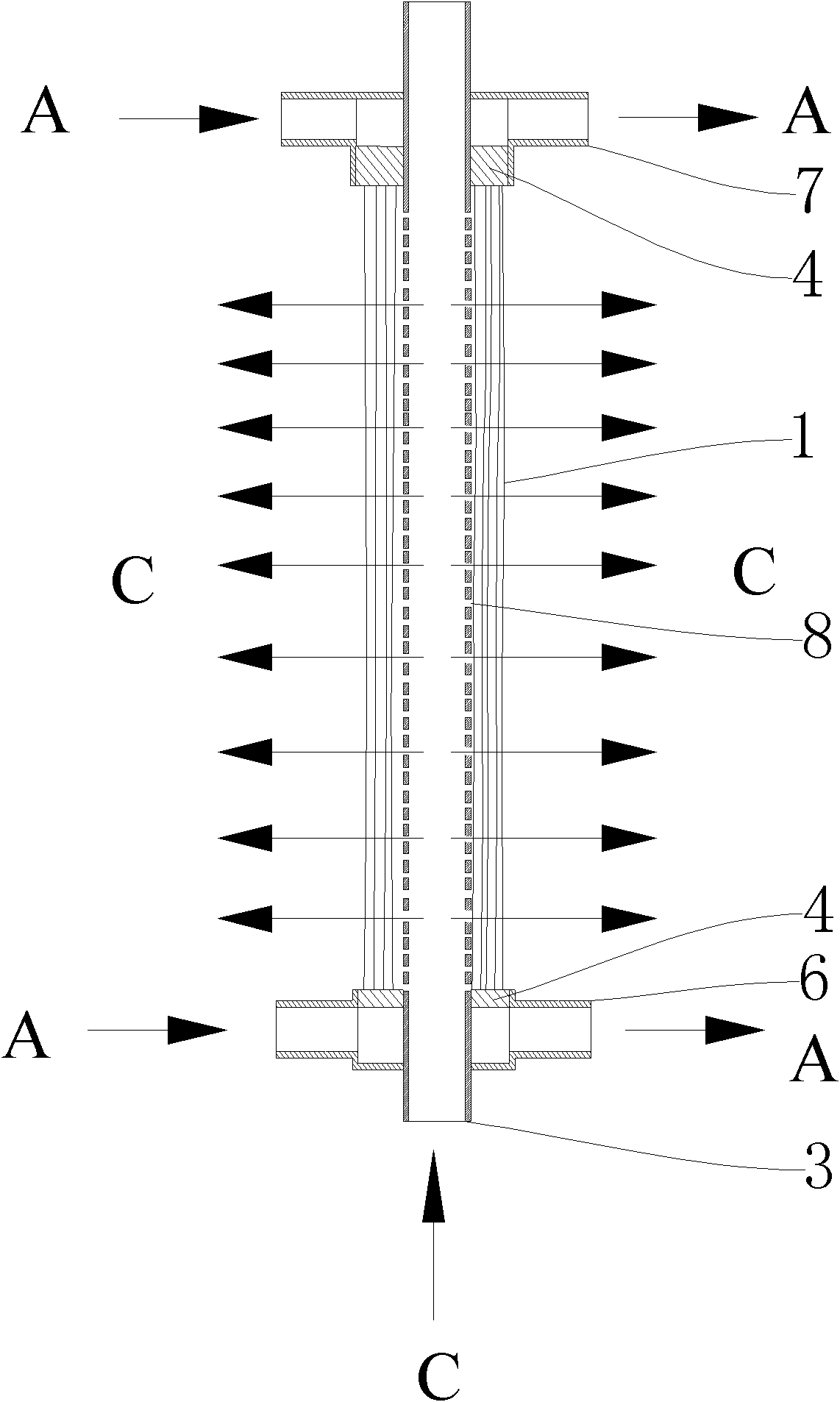

Device for desulfurizing flue gas by seawater through membrane absorption and its process

InactiveCN102485320AEvenly distributedGood seawater resistanceDispersed particle separationWater vaporGas phase

The invention discloses a device for desulfurizing flue gas by seawater through membrane absorption and its process, the flue gas is sent to a membrane absorber shell side by a supercharging blower fan, the pretreated seawater enters in a membrane absorber tube side through a sea water pump and is taken as absorption liquid, gas phase and liquid phase form a reaction interface at the micropore ofa hollow fiber membrane, SO2 in flue gas is reacted with seawater to generate sulfite and timely is taken away for realizing the flue gas desulphurization. Desulfurized seawater is discharged throughaeration sulfur fixation and pH value standard achieving. The device of the invention is composed of a one stage or multistage membrane absorber, the membrane absorber is composed of multi-group curtain type or column type hollow fiber film component group. The process has the characteristics of low air resistance of the device, small power consumption and high desulphurization efficiency. A design of an automatic on-line backwashing and cleaning technology is capable of controlling and mitigating membrane pollution, the device possesses small volume and light weight, and enables modularized integration; the flow velocity of the gas phase and the liquid phase can be independently controlled in a wide scope, and the problem of device corrosion caused by entrainment water vapor in flue gas in a traditional seawater method can be avoided.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

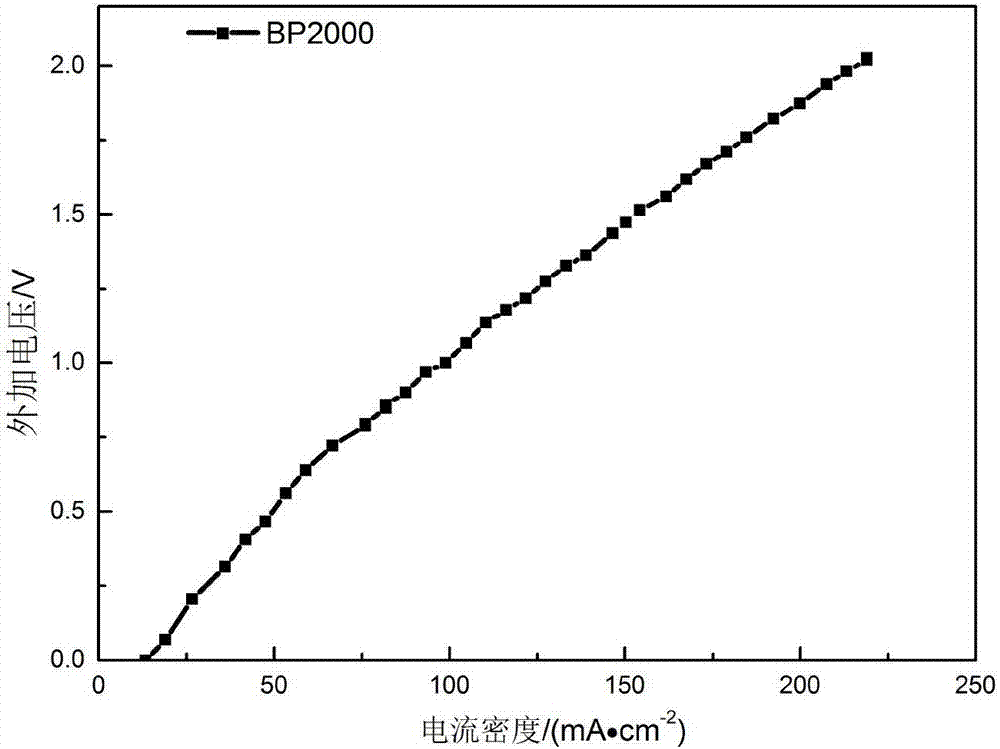

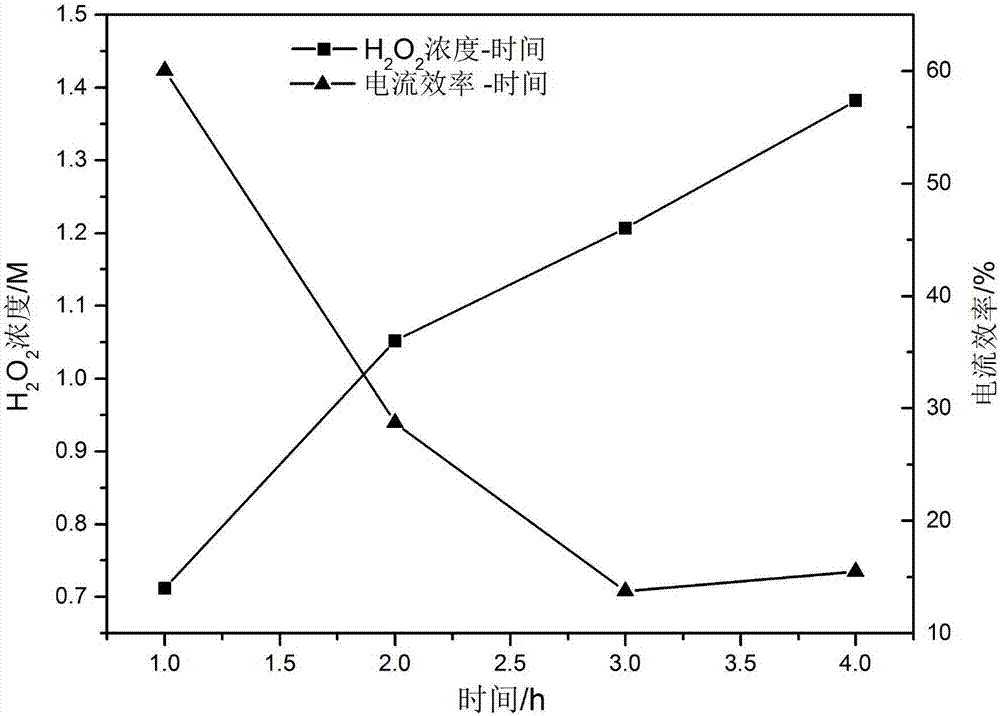

Electrochemical method for synthesizing acidic hydrogen peroxide

The invention relates to an electrochemical method for synthesizing acidic hydrogen peroxide. According to the electrochemical method, hydrogen, oxygen and an acidic solution serve as raw materials, and an acidic hydrogen peroxide aqueous solution is prepared in an in-situ electro-catalytic mode through a fuel battery type reactor. In the fuel battery type reactor, the oxygen and the hydrogen enter a negative pole and a positive pole through gas inlets of a negative pole end plate and a positive pole end plate correspondingly and conduct an electrochemical reaction on a gas diffusion pole carrying an electro-catalyst, obtained products enter an electrolyte rapidly, and thus the hydrogen peroxide is easily enriched; a proton exchange film is arranged in the middle, so that the explosion risk of direct reaction of the hydrogen and the oxygen is avoided, safety is high, the reactor is small in size, and the products can be simply separated from reactants. By adopting the gas diffusion pole carrying the electro-catalyst, the three-phase reaction interface is effectively increased, the utilization rate of the catalyst is increased, the reaction rate is increased, and the overpotential and energy consumption of the reaction are effectively reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

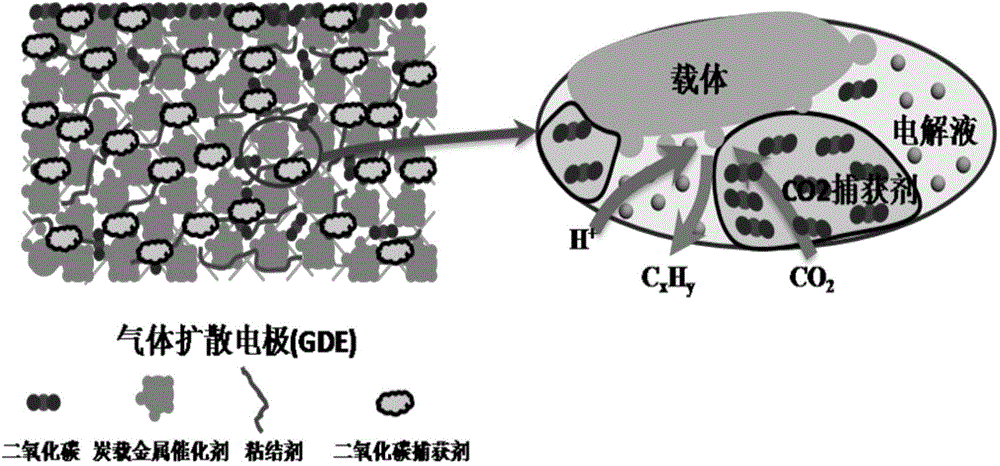

Gas diffusion electrode for carbon dioxide electrochemical reduction reaction and preparation method for gas diffusion electrode

ActiveCN105322185ARealize \"capture\"Realize functionCell electrodesGas concentrationTransformation ratio

The invention relates to a gas diffusion electrode for a carbon dioxide electrochemical reduction reaction. The gas diffusion electrode comprises a catalyst layer including a CO2 trapping agent, a catalyst and a binder, and a gas diffusion layer; the CO2 trapping agent is a material that can trap CO2 and can be coordinated with CO2. The gas diffusion electrode with the composition and structure can realize the functions of trapping and retaining the CO2, increase the CO2 gas concentration in a reaction interface, relieve the mass transfer polarization problem under a high overpotential reaction condition, provide a guarantee for the continuous efficient CO2 electroreduction reaction, and can relatively obviously improve the CO2 conversion efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

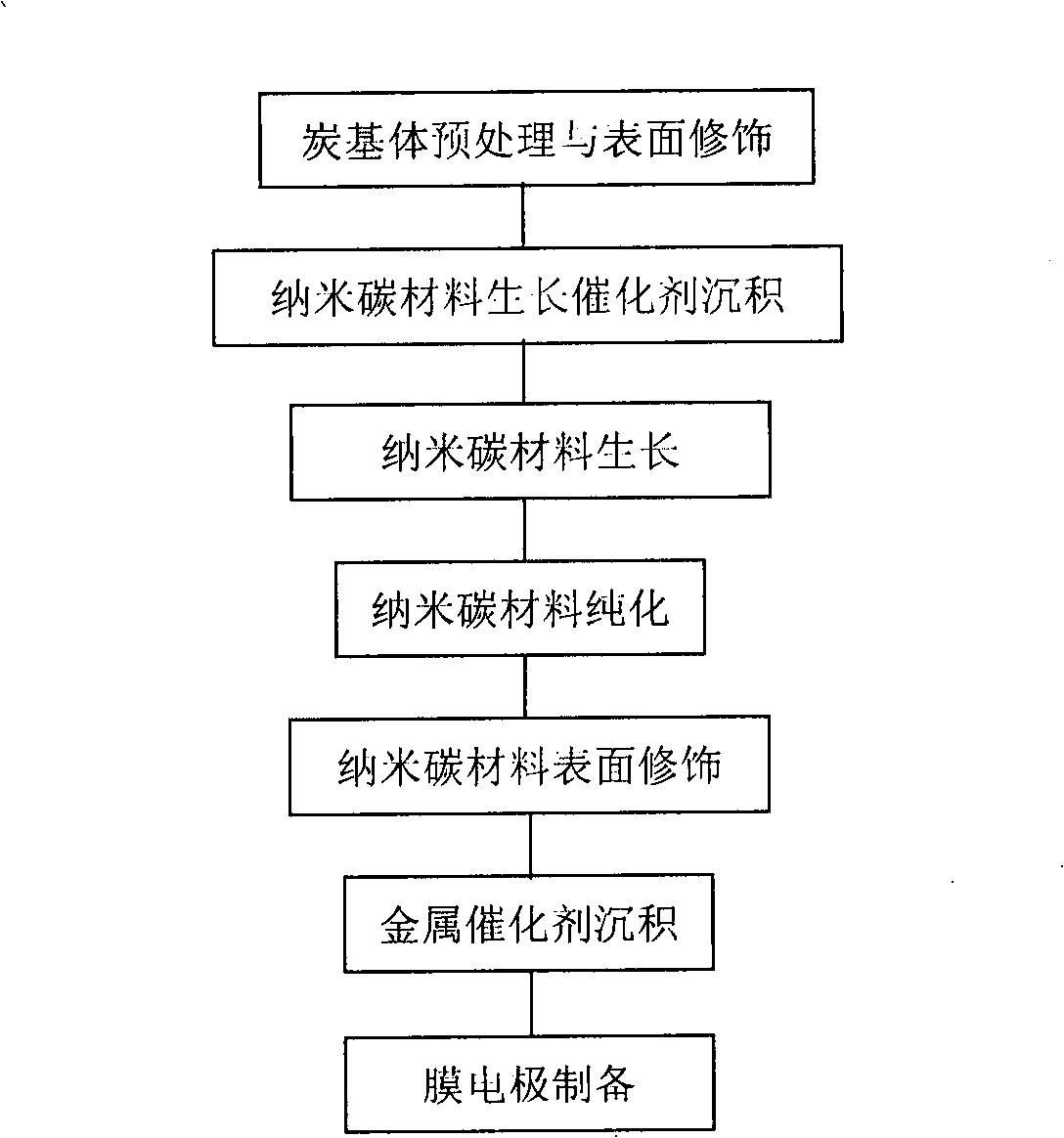

Novel membrane electrode component available for fuel cell, preparation method and application thereof

InactiveCN101515648AUniform structureStructure orderCell electrodesSolid electrolyte fuel cellsSurface modificationLiquid solid

The invention belongs to the technical field of electrocatalysis and energy transformation, in particular to a novel membrane electrode component available for fuel cells, a preparation method and the application thereof. The new membrane electrode component comprises catalyst active component, nanometer carbon material, carbon matrix complex, proton exchange membrane and other components. The specific steps are as follows: pretreatment and surface modification are carried out on the carbon matrix, catalyst needed by the growth of the nanometer carbon material is deposited on the carbon matrix, the carbon source is used for growing the nanometer carbon material on the carbon matrix, purification treatment and surface modification are carried out on the carbon matrix-nanometer carbon material complex, the needed fuel cell catalyst active component is deposited on the carbon matrix-nano carbon material, thereby obtaining the catalyst active component, the nanometer carbon material, the carbon matrix complex, the proton exchange membrane and other components, namely, obtaining the membrane electrode component available for the needed fuel cells. The structure of the membrane electrode component is more even and sequential, can obviously increase the reaction interface of gas-liquid-solid, accelerates the transmission of products and reactants, greatly increases the utilization factor of the catalyst active component, significantly reduces the usage of the catalyst active component, further plays an important role in increasing the power density and the like of the fuel cells.

Owner:TONGJI UNIV

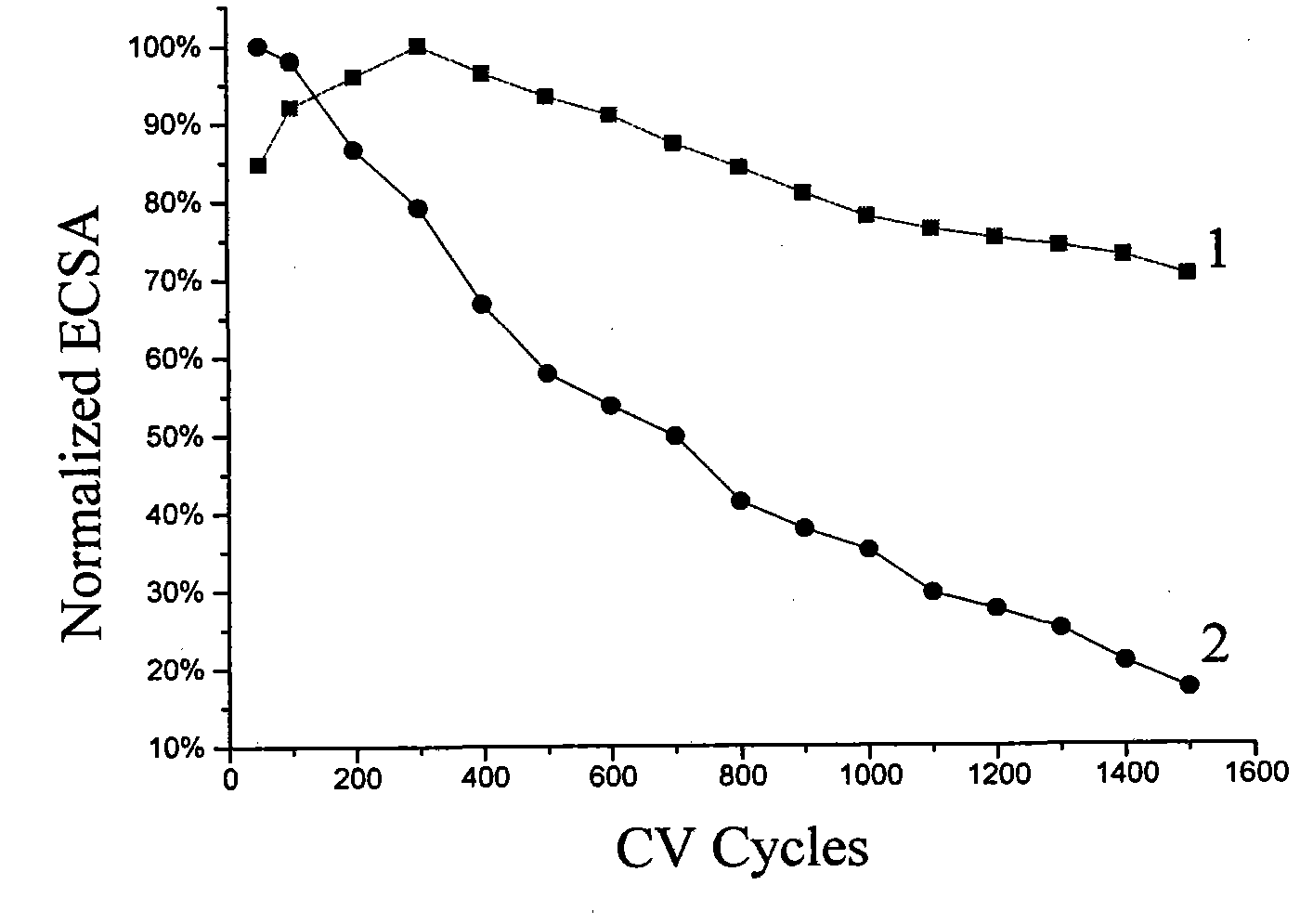

Method for improving stability of fuel cell catalyst and utilization rate of catalyst

InactiveCN102024965AInhibit migrationAvoid reunionCell electrodesFuel cell auxillariesElectrical conductorElectric vehicle

The invention provides a method for improving the stability of a fuel cell catalyst and the utilization rate of the catalyst, which belongs to the technical field of fuel cells. A layer of conductive polyaniline with conjugated large pai bond structure is modified on the carbon surface of a Pt / C (platinum / carbon) catalyst through the in-situ chemical oxidation polymerization method, on the one hand, migration, aggregation and growth of Pt nano-particles on the surface of a carbon carrier can be prevented by utilizing strong interaction between polyaniline and the Pt nano-particles, and the stability of the catalyst can be further improved; on the other hand, the polyaniline is an excellent proton-electron conductor and simultaneously has excellent oxygen permeability, by covering the polyaniline on the carbon carrier, the probability of exposing the Pt nano-particles on a three-phase reaction interface of the fuel cell can be increased, and the utilization rate of the catalyst can be further improved. The method is simple and easy for operation, the production cost is low, and the catalyst prepared by adopting the invention can be applied in the fuel cells taking proton exchange membranes as electrolytes. The fuel cells manufactured by using the invention can be widely applied in electric vehicles, various spacecrafts, portable electronic equipment such as cameras, notebook computers, electric toys and the like.

Owner:CHONGQING UNIV

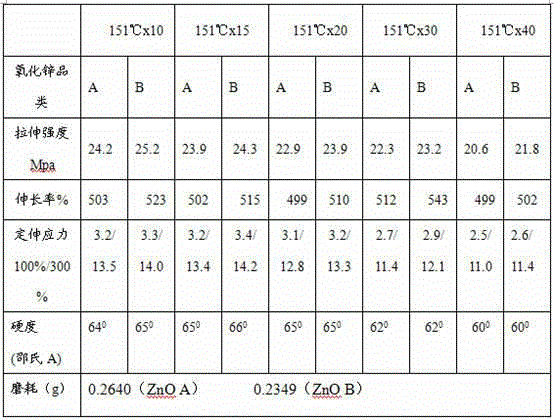

Production method of efficient zinc oxide

ActiveCN103818945AGood dispersionHigh activityZinc oxides/hydroxidesCalcium/strontium/barium sulfatesActive agentCore component

The invention discloses a production method of efficient zinc oxide. Magnesium oxide and active silica powder are used as core components to replace partial zinc oxide, but the zinc oxide covers the core surface to form a core-shell structure, so that the production method has higher reaction interface, high activity, large specific surface area (larger than 95 m<2> / g) and low content (about 56%) of the zinc oxide. Compared with the ordinary zinc oxide methods, each ton can save 42-45% of zinc resource; the production method accords with the development requirements of environmental protection, energy conservation and emission reduction. The invention further provides a method; the method uses secondary zinc oxide (flue ash) or materials with low zinc content as main raw materials, uses a total-wet method for producing, adopts active agent (a mixture of the magnesium oxide and the active silica powder) to replace partial zinc oxide, adopts sodium carbonate (sodium carbonate) as zinc precipitator to prepare the efficient zinc oxide, and adds sodium chloride in wastewater sodium sulfate to recover by-product barium sulfate.

Owner:LUOYANG LANTIAN CHEM TECH

Preparation method of nanoparticle-enhanced refrigerant hydrate phase-change cold storage working medium

InactiveCN102295917AImprove effective utilizationEvenly dispersedHeat-exchange elementsRational useWorking fluid

A method for preparing nanoparticle-enhanced refrigerant hydrate phase-change cold storage refrigerants, using the solubilization effect of compound surfactants, dissolving refrigerants in water to prepare thermodynamically stable refrigerant microemulsions, and then dispersing nanoparticles In the refrigerant microemulsion, a refrigerant hydrate phase-change cold storage working substance strengthened by nanoparticles is prepared. By stably dispersing nanoparticles in the refrigerant microemulsion system to enhance heat and mass transfer, increase the reaction interface, and induce heterogeneous nucleation, thereby significantly reducing the induction time and subcooling degree of hydrate formation, effectively achieving crystallization effect. The product of the invention can be widely used in fields such as peak shifting of electric power, building energy saving, cold storage air conditioner, refrigeration and preservation of agricultural products and biological products, high and low temperature cold storage and refrigerated logistics, etc., and can achieve the purpose of effective cold storage and release of cold and rational use of energy.

Owner:XI AN JIAOTONG UNIV

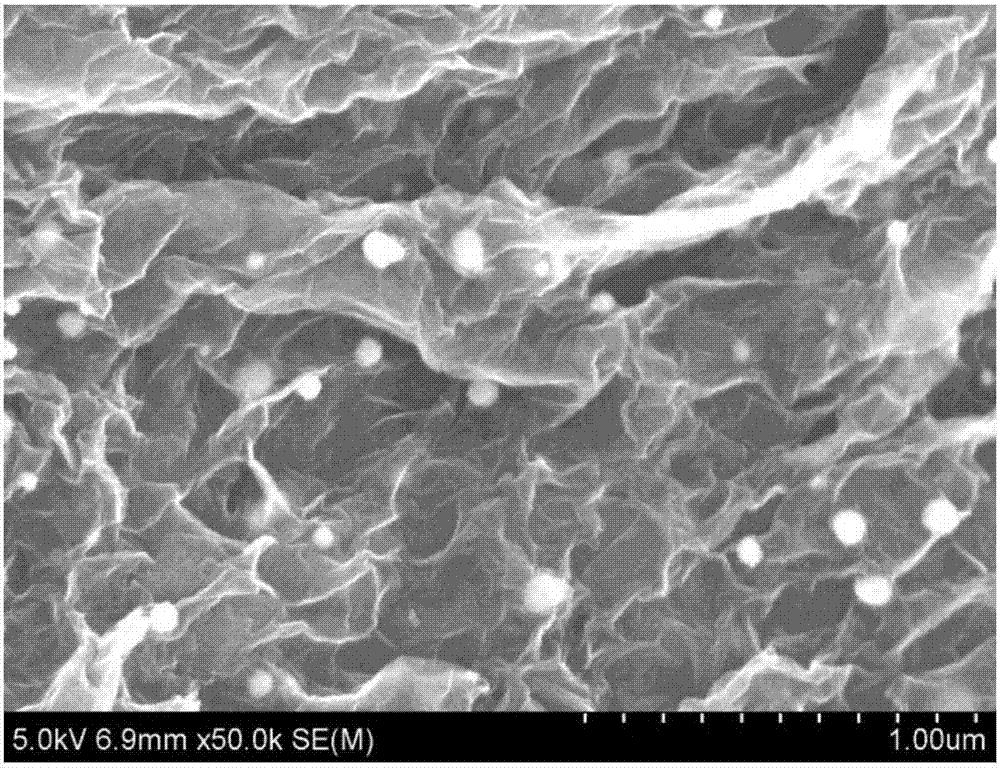

Composite material of nitrogen doped three-dimensional graphene supported nano silver and preparation method thereof

ActiveCN107248581AAvoid reunionLarge specific surface areaMaterial nanotechnologyCell electrodesOxygenNitrogen doped

The invention provides a composite material of nitrogen doped three-dimensional graphene supported nano silver, wherein the composite material is a porous three-dimensional network structure which is formed by the self assembly of a graphene sheet with a nitrogen doping amount of 2.3 to 8.8% under the action of temperature and pressure; silver particles with a particle size of 80 to 120nm are evenly dispersed on the three-dimensional grapheme surface and the loading capacity of the composite material is 12 to 51%. The preparation method of the composite material comprises the following steps: taking graphite paper as an anode, a carbon rod as a cathode, concentrated sulfuric acid as electrolyte, performing oxidization and exfoliation, and preparing a thin layer graphene oxide material; and orderly adding ethanediamine and silver nitrate into graphene oxide suspension, performing an one step hydrothermal reaction, and then drying, thus the composite material is obtained. The preparation method of the composite material of the nitrogen doped three-dimensional graphene supported nano silver provided by the invention is simple in operation and low in cost; in an electrocatalysis process, a porous structure of the composite material greatly increases a three-phase reaction interface, thereby improving the mass transfer rate of oxygen; and meanwhile, the composite material has higher electrical conductivity.

Owner:YANSHAN UNIV

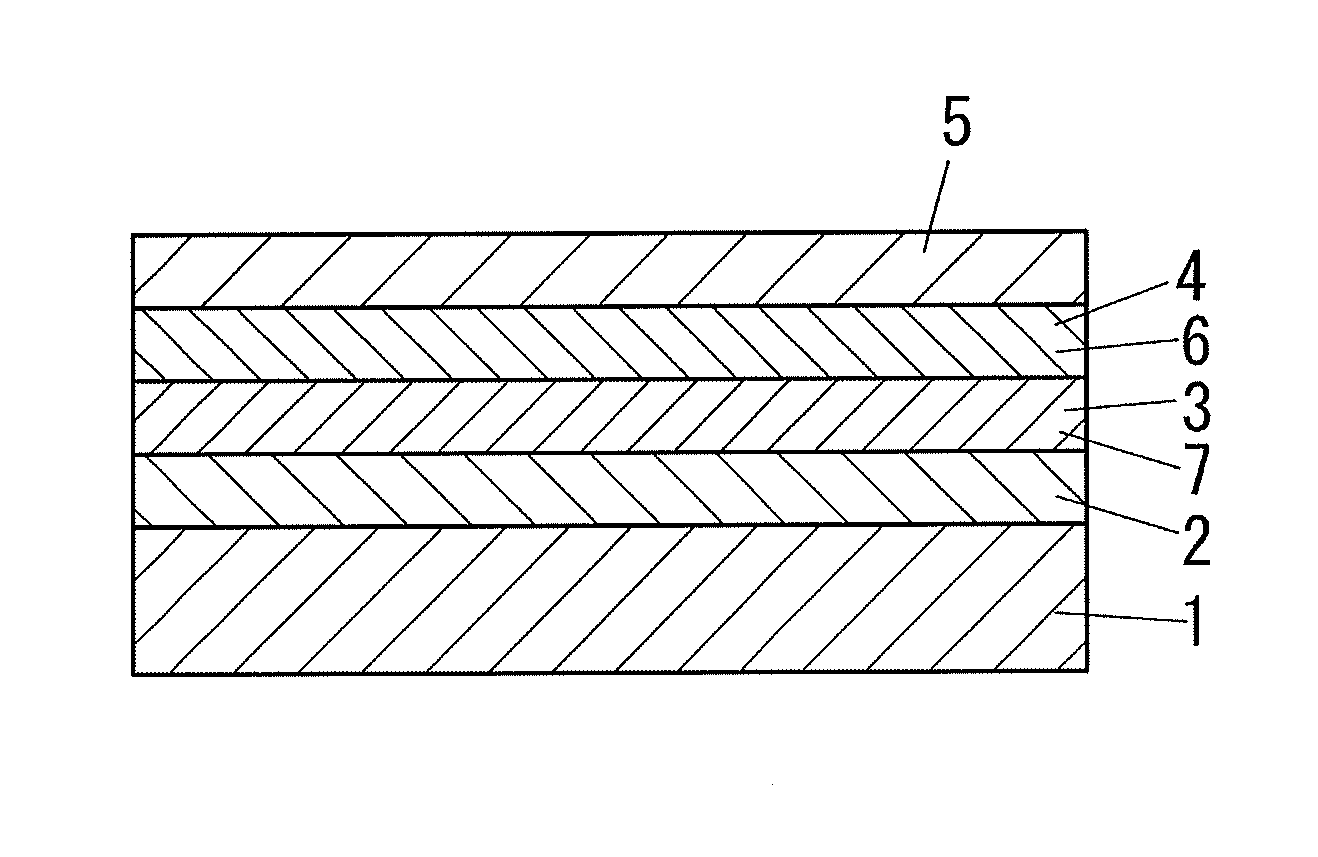

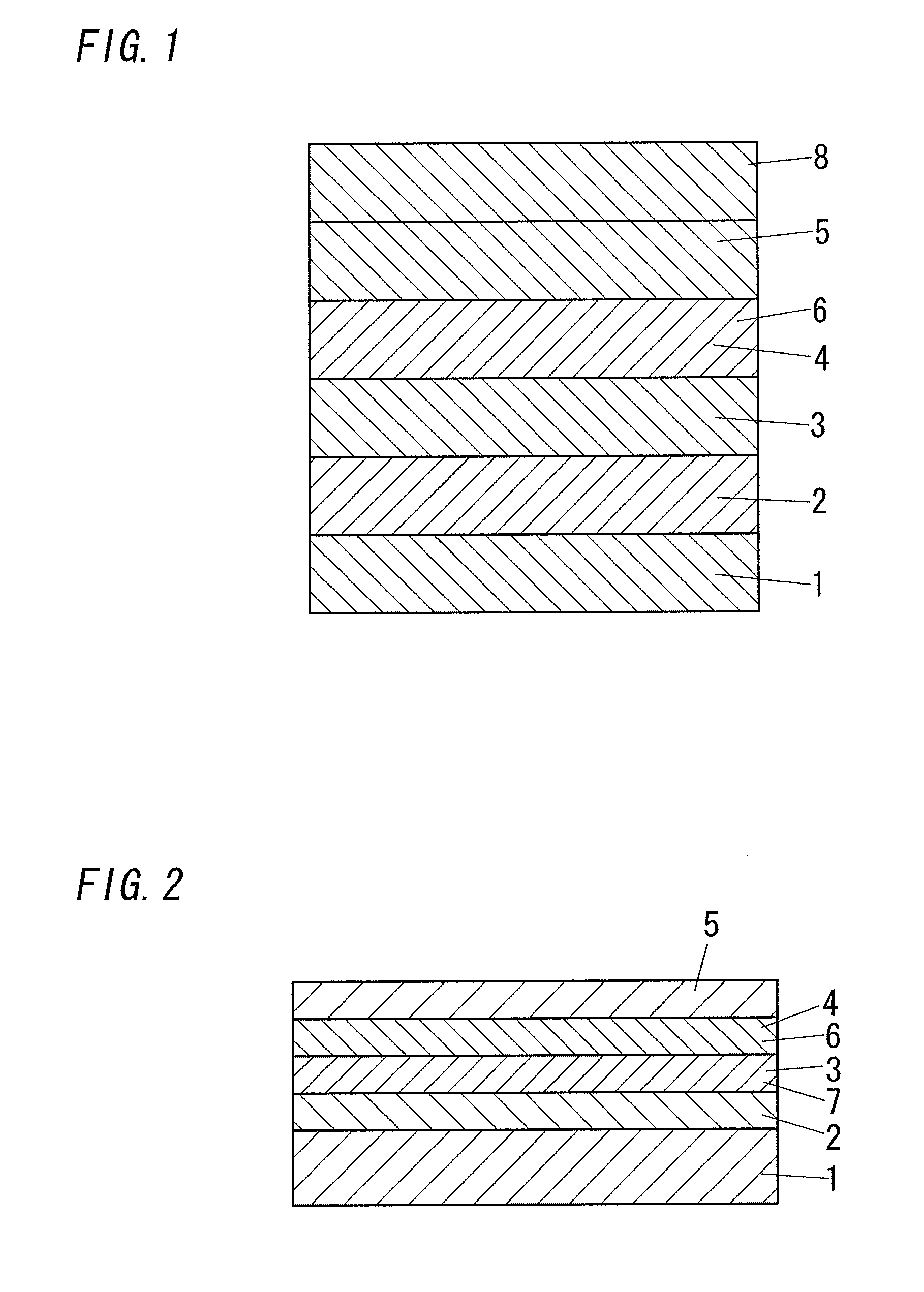

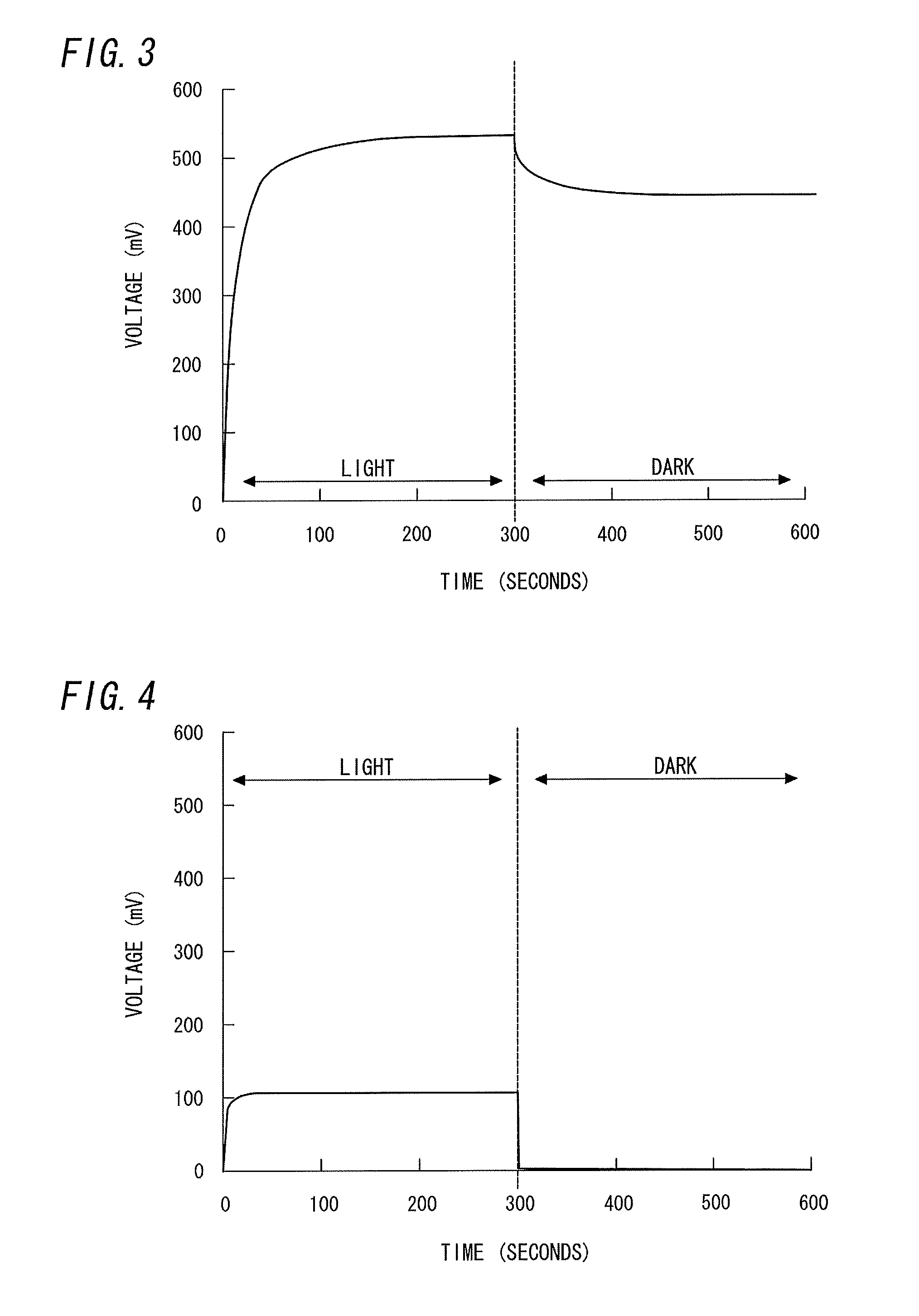

Photoelectric element

ActiveUS20120187387A1Improve conversion efficiencyEasy to transportElectrolytic capacitorsSolid-state devicesSimple Organic CompoundsRedox

Disclosed is a photoelectric element having an excellent conversion efficiency and provided with a hole transporting layer that is endowed with excellent hole transporting properties and a sufficiently large reaction interface.The photoelectric element of the invention has a pair of electrodes, an electron transporting layer and a hole transporting layer which are disposed between the electrodes, and an electrolyte solution. The hole transporting layer includes a first organic compound having a redox moiety capable of repeated oxidation and reduction. The electrolyte solution stabilizes a reduced state of the redox moiety. The organic compound and the electrolyte solution together form a first gel layer.

Owner:PANASONIC CORP +1

Conductive plastic composite electrode and manufacture method therefor

The invention relates to a conductive plastic composite electrode which comprises a conductive plastic collector plate, conducting resin and graphite felts, wherein the conductive plastic collector plate is made of a conductive plastic board in which a copper mesh is arranged, and four rectangular graphite felts uniformly distributed longitudinally and transversely are bonded onto the side surface of the conductive plastic collector plate through the conducting resin. The invention further discloses a manufacture method which comprises the following steps: 1, manufacturing the conductive plastic collector plate; 2, manufacturing bonding agent; 3, pretreating graphite felts; 4, coating the bonding agent in the step 2 on the surface of the conductive plastic collector plate obtained in the step 1, and then bonding and producing the graphite felts produced in the step 3, that is, the conductive plastic composite electrode is obtained. The conductive plastic composite electrode is taken as the electrode of a vanadium battery since the bonded graphite felts can not enable the composite electrode to meet the requirements of vanadium battery electrodes, the reaction interface of the electrode is enlarged, and acid etching resistance is achieved.

Owner:SHENYANG AIRCRAFT CORP

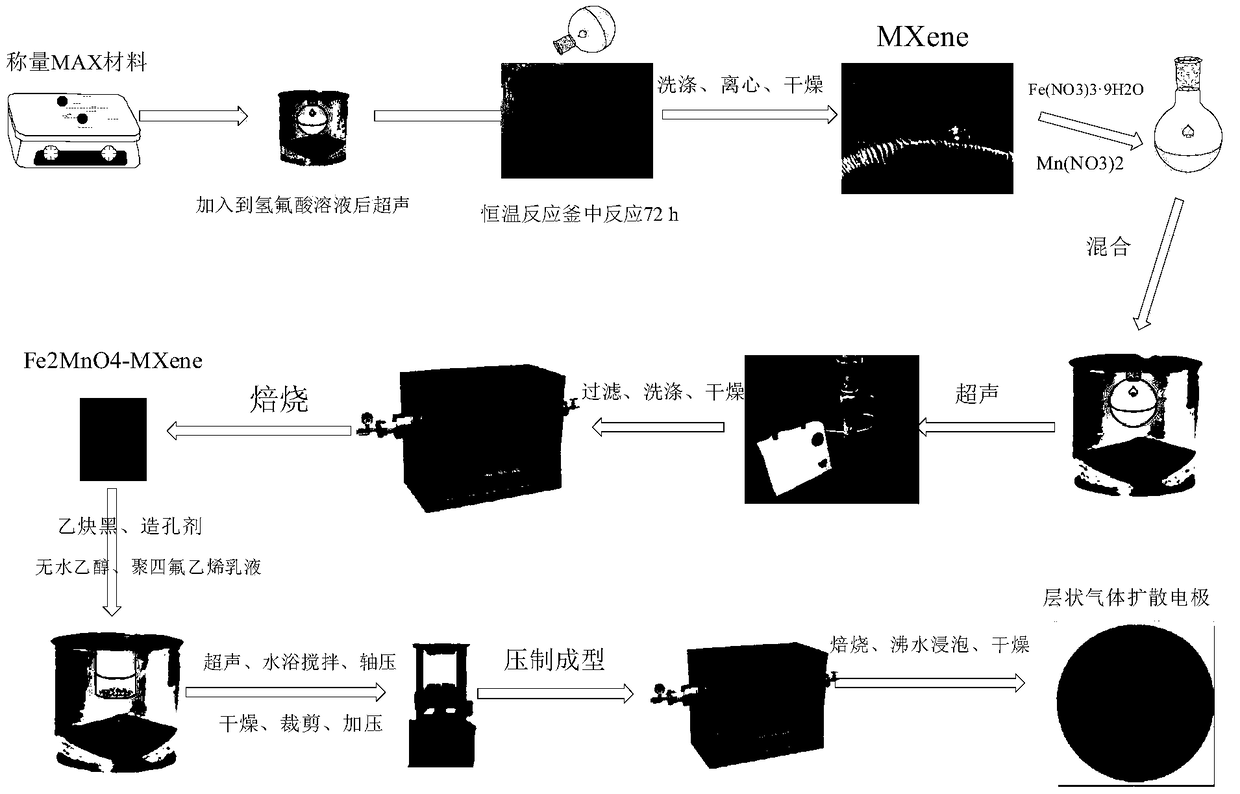

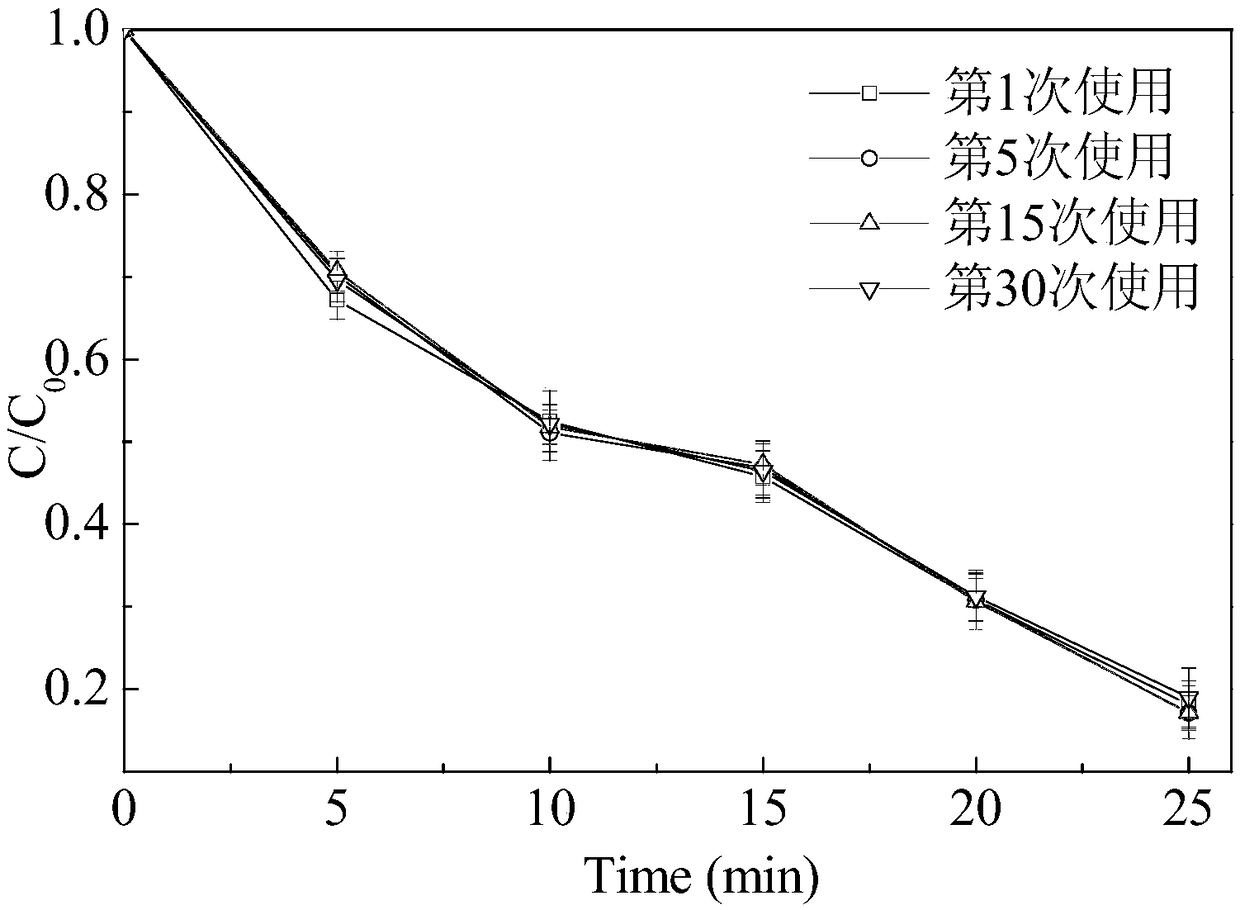

Ferrite modifying MXene layered gas diffusion electrode as well as preparation method and application thereof

ActiveCN108975462AGood dispersionRich sourcesWater contaminantsWater/sewage treatment apparatusDispersityGas diffusion electrode

The invention discloses a preparation method of a ferrite modifying MXene layered gas diffusion electrode. The preparation method comprises the following steps that (1) an MXene material is prepared;(2) ferrite modifies the MXene material; and (3) the layered gas diffusion electrode is prepared. The invention further discloses the ferrite modifying MXene layered gas diffusion electrode and application thereof. The ferrite modifying MXene layered gas diffusion electrode can be used for preparing electrochemical cathode materials which are applied to an electrochemical / ozone coupling water treatment system. The preparation method can easily get the raw materials, the technological operation is simple, the cost is low, the electrode strength is high, the electrochemical catalytic activity ishigh, the dispersity is good, and the water treatment technique consumes low energy and has the high efficiency. The ferrite modifying MXene layered gas diffusion electrode prepared by adopting the method has the wide application prospects on degradation treatment of PPCPs (pharmaceutical and personal care products) pollutants on the three-phase reaction interface.

Owner:CENT SOUTH UNIV

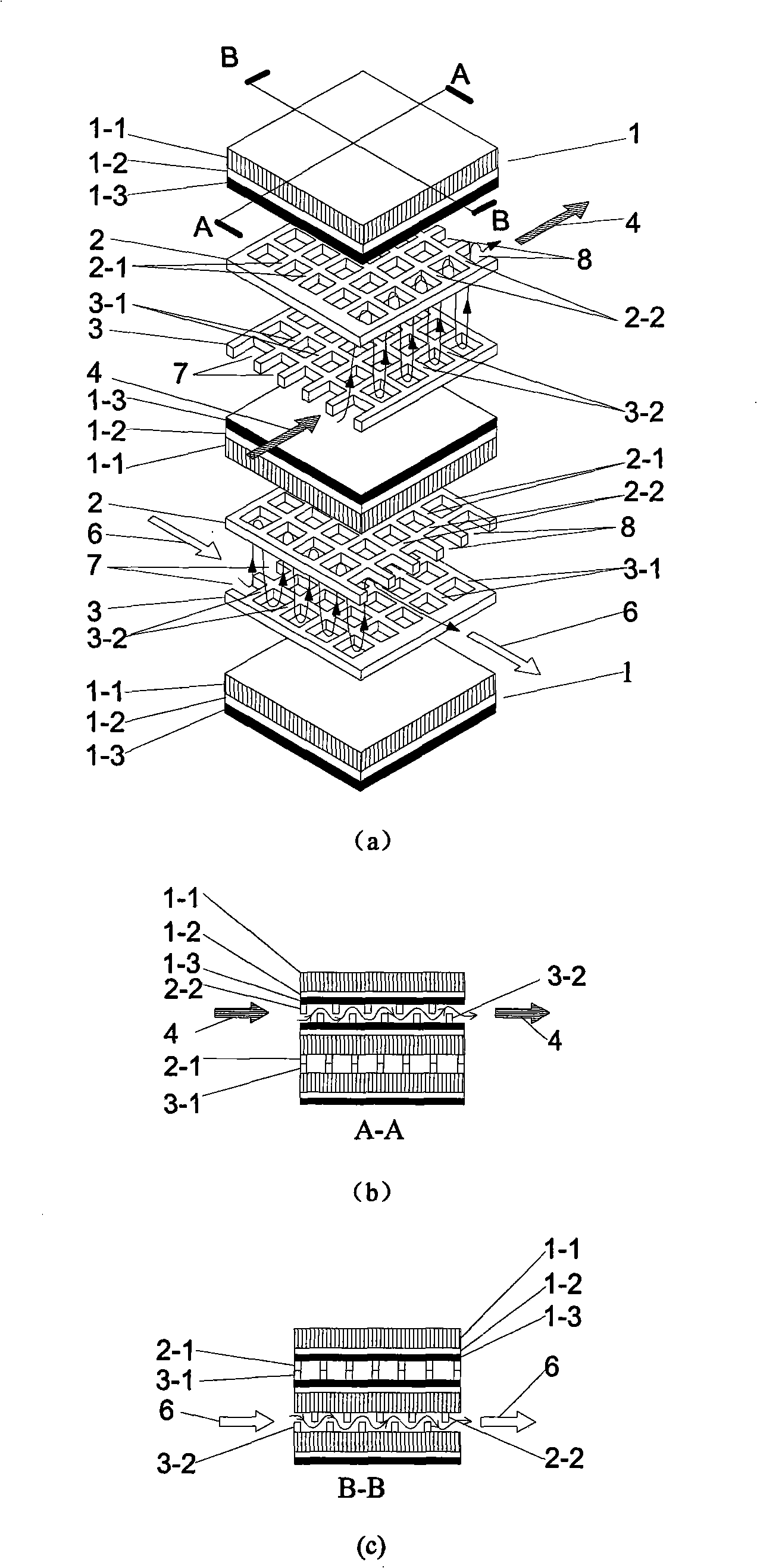

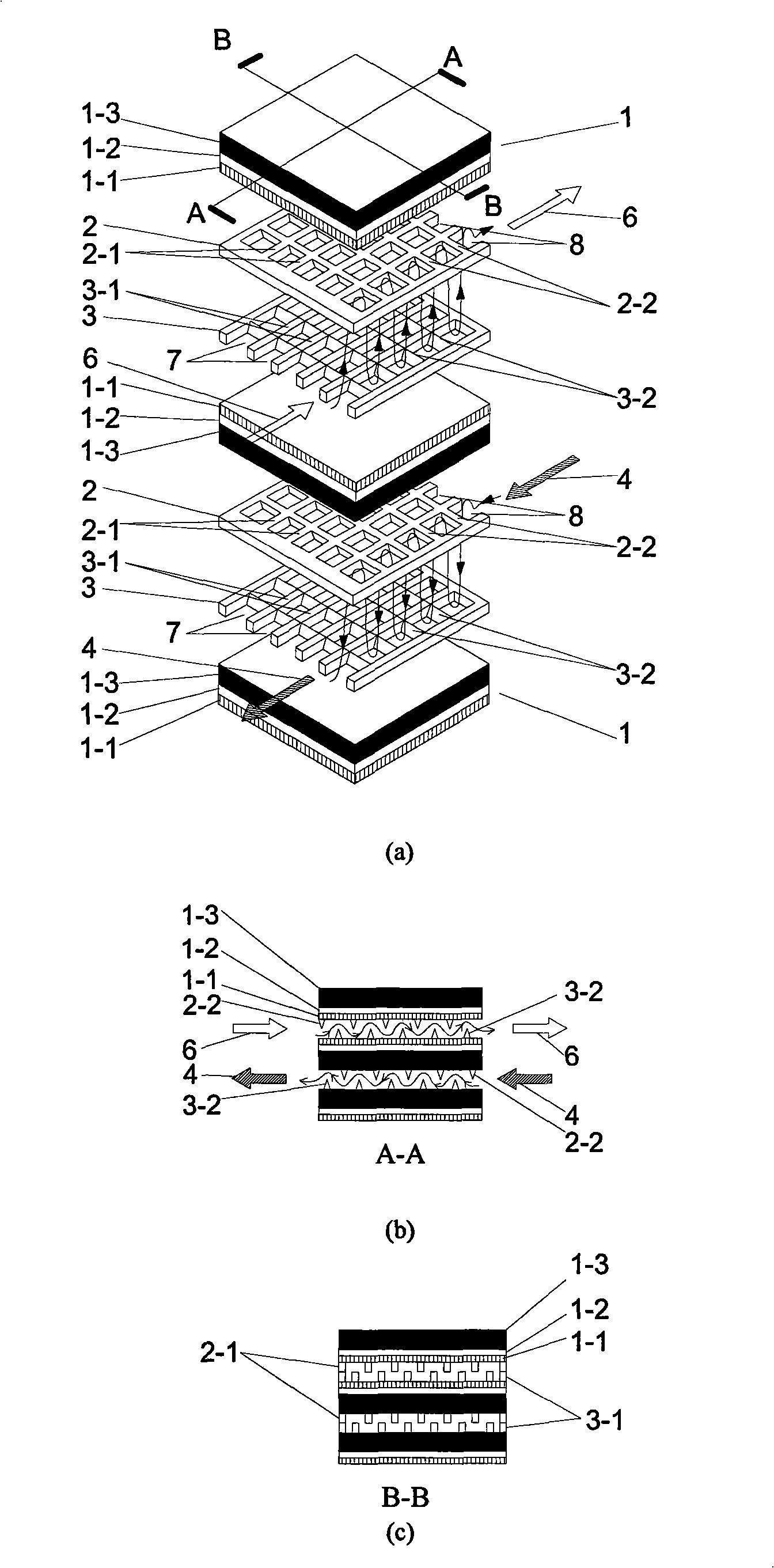

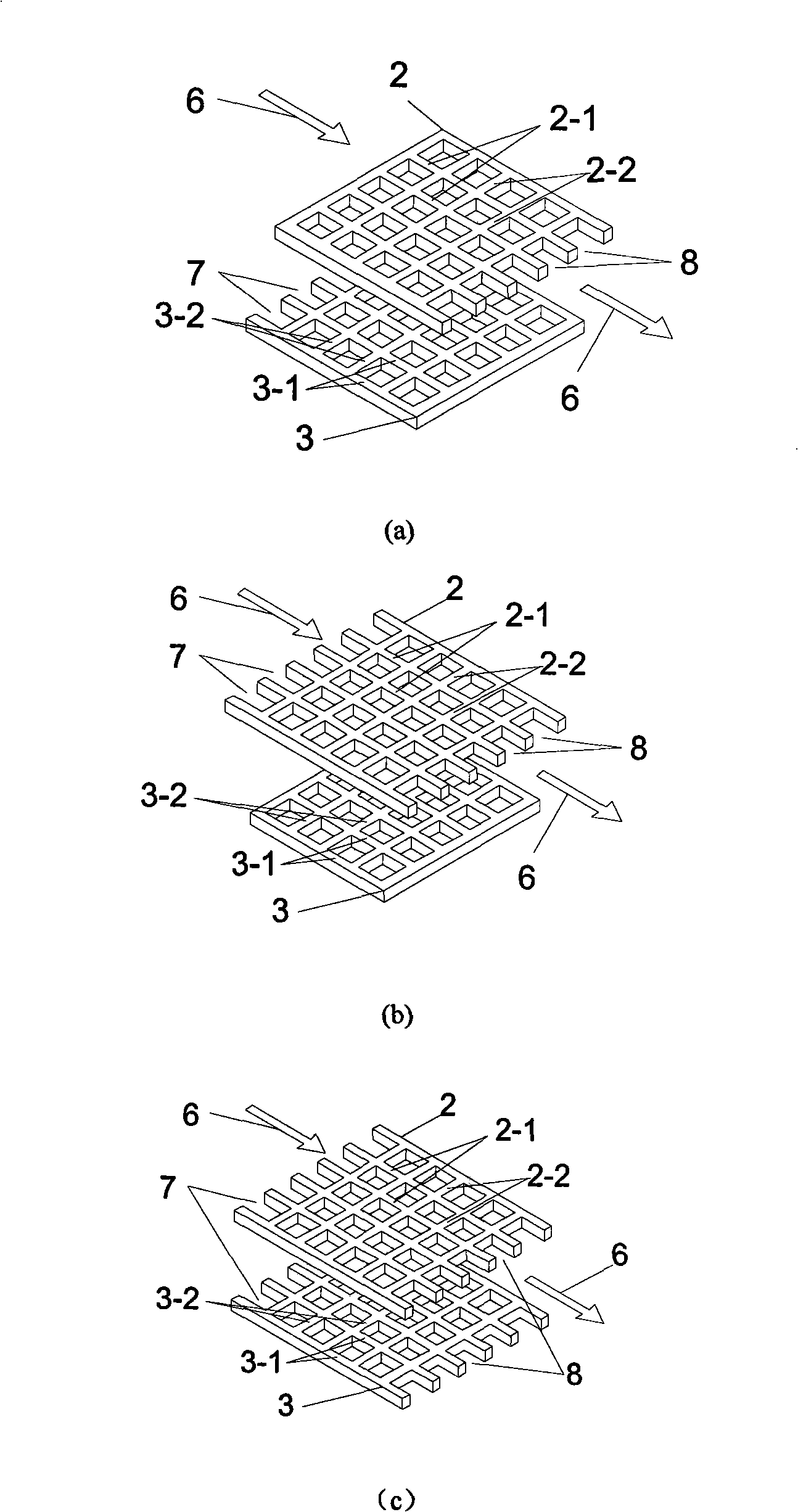

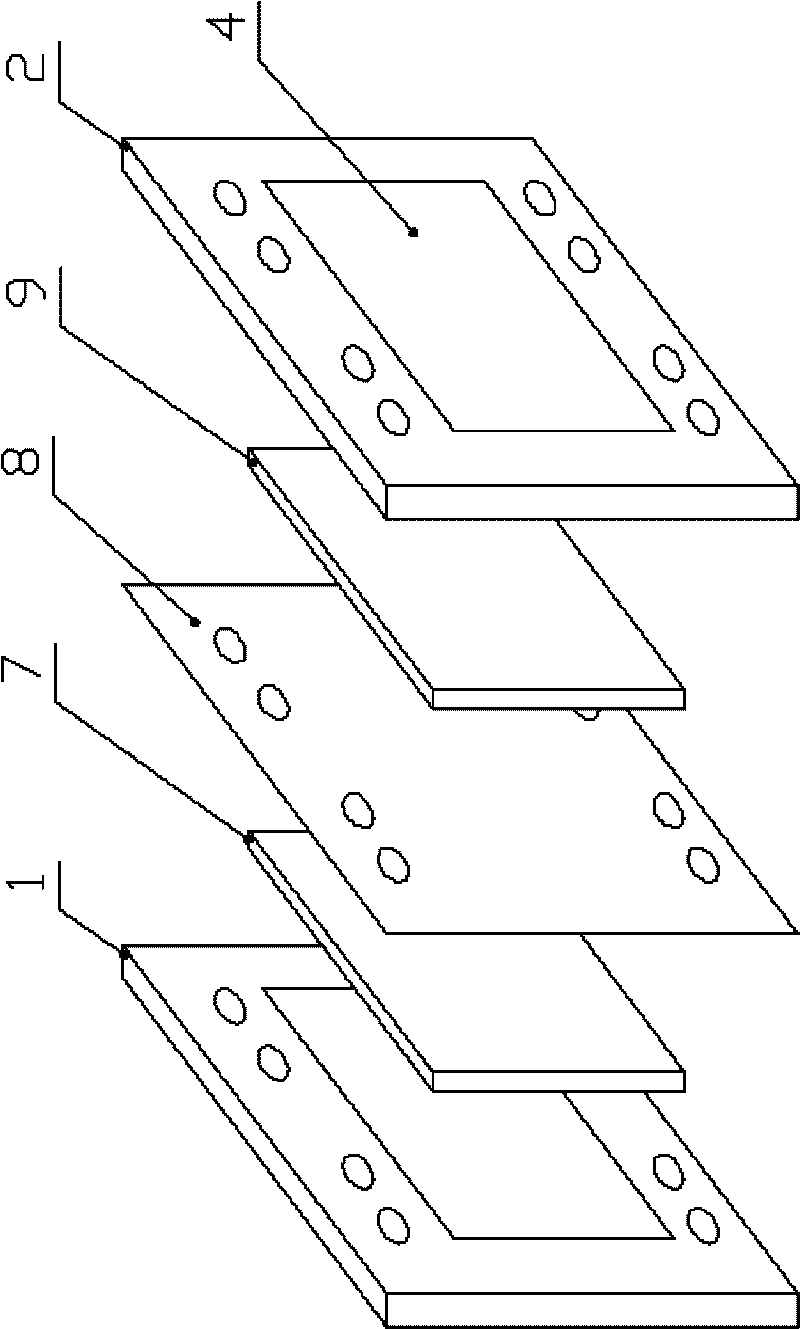

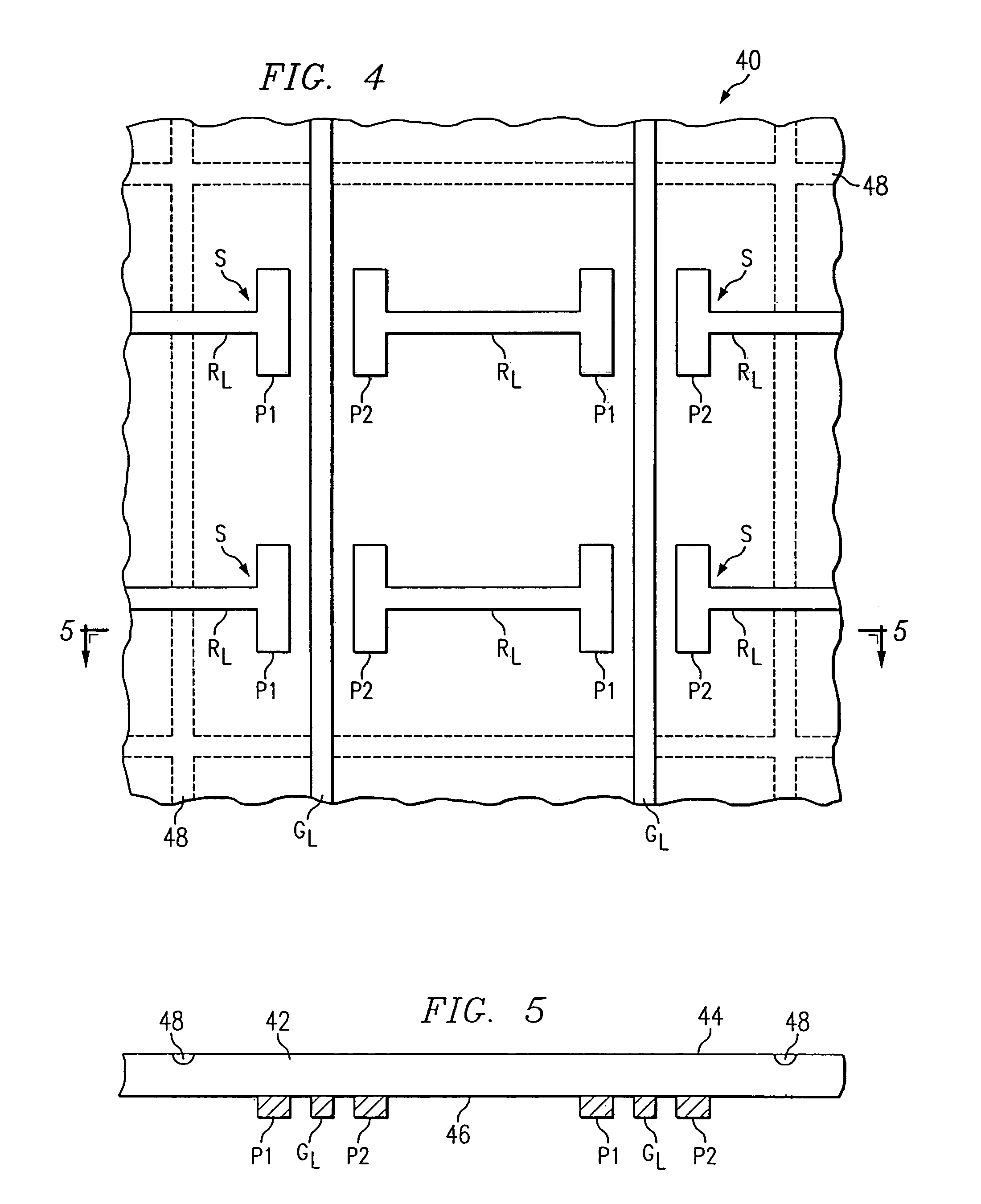

Flat-plate solid-oxide fuel battery stack for double-layer connector

ActiveCN101355177AImprove applicabilityFuel cells groupingSolid electrolyte fuel cellsFuel cellsEngineering

The invention relates to a solid oxide fuel battery stack for a flat plate for a double-layer connecting body, comprising a connecting body and a plurality of single batteries formed by an anode, an electrolyte layer and a cathode. The plurality of the single batteries are arranged in the way that the anode of one piece of single battery is over against the anode of another single battery, and the cathode of one piece of the single battery is over against the cathode of another single battery. The connecting body is a double-layer connecting body formed by a first connecting body and a second connecting body, cross rods of the first connecting body and the second connecting body are arranged in a staggered way, and the gas flows in a winding way after the cross rods are perturbed. The solid oxide fuel battery stack can perturb fuel gas and the oxidized gas from the plane perpendicular to the single battery, and effectively increase the concentration of the fuel gas of the solid oxide fuel battery stack close to the side of the anode and the oxidized gas concentration of the solid oxide fuel battery stack close to the side of the cathode so as to intensify mass transfer; and the reaction interfaces on two sides are respectively formed in an anode gas duct and a cathode gas duct, thereby sufficiently utilizing the fuel gas and the oxidized gas and greatly increasing the power density of the flat plate typed solid oxide fuel battery stack.

Owner:上海益焓能源科技有限公司

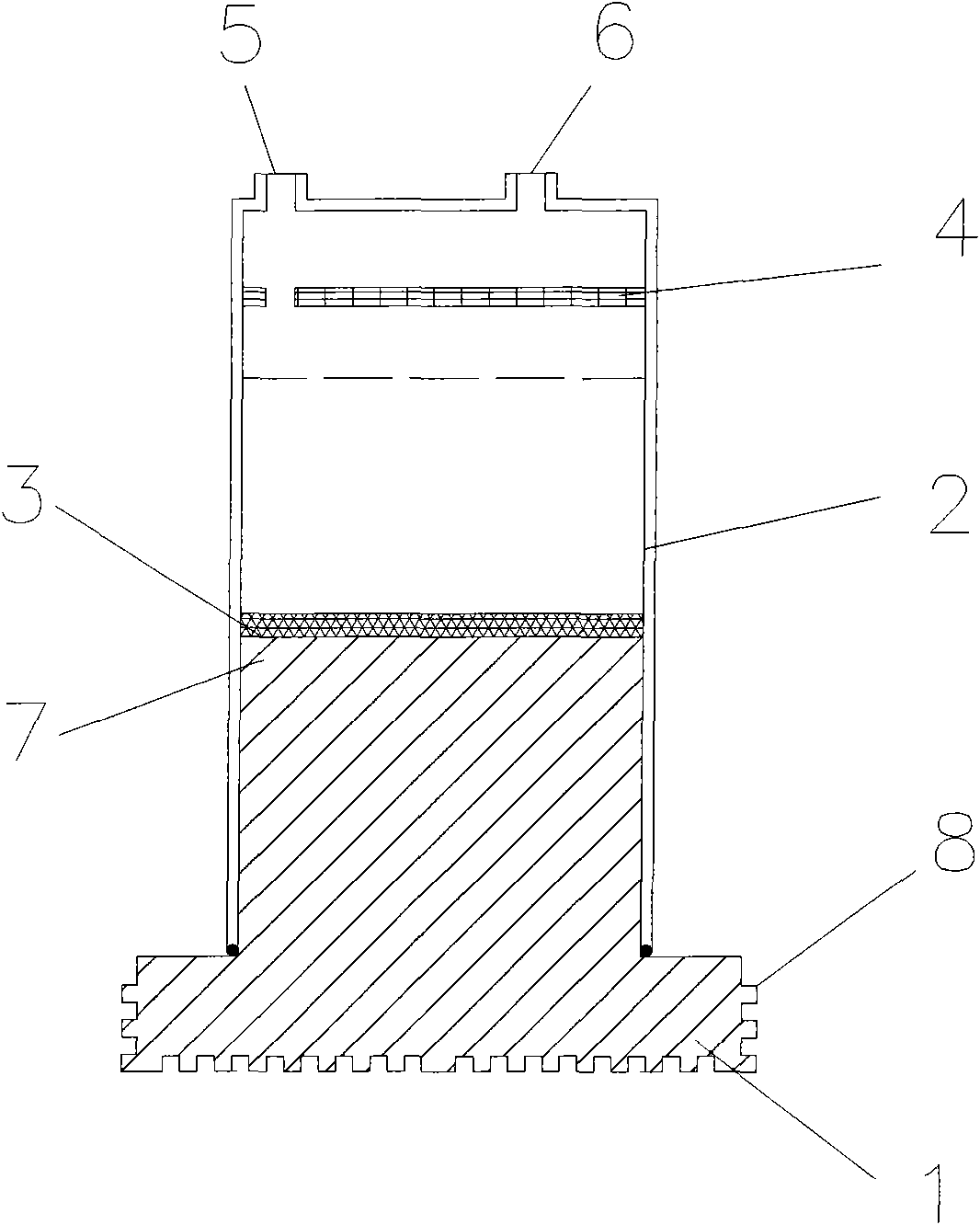

Aluminum hydrolization hydrogen production device and controlling method thereof

InactiveCN101671003AControllable hydrogen production rateHigh purityHydrogen productionFuel cellsBiochemical engineering

The invention relates to an aluminum hydrolization hydrogen production device and a controlling method thereof, which belongs to the technical field of hydrogen preparation. The aluminum hydrolizationhydrogen production device comprises an aluminum hydrolization tank body; an aluminum end socket, an amalgam, a baffle, a water inlet and a hydrogen outlet are arranged on the tank body; the tank body is connected with the aluminum end socket in a sealing way; the amalgam is covered on the aluminum end socket and a water reaction interface; the baffle in the tank body is positioned at the upper part of the aluminum and the water reaction interface; and the hydrogen outlet is positioned at the top part of the tank body. The controlling method of the aluminum hydrolization hydrogen production device is characterized in that during the reaction of aluminum hydrolization in the tank body, the temperature of the reaction interface is regulated and controlled to realize the rate controlling foraluminum production; or the amalgam is regulated and controlled to contact with or be separated from the reaction interface to control the starting or closing of the aluminum hydrolization reaction;and the hydrogen produced during aluminum hydrolization under the action of the amalgam is led out through the hydrogen outlet. The aluminum hydrolization hydrogen production device and the controlling method thereof have the advantages of simple structure, convenient operation, good controllability, wide application scope, less power consumption and less pollution, and are especially applicable to the application of portable fuel cell power systems.

Owner:CHINA JILIANG UNIV

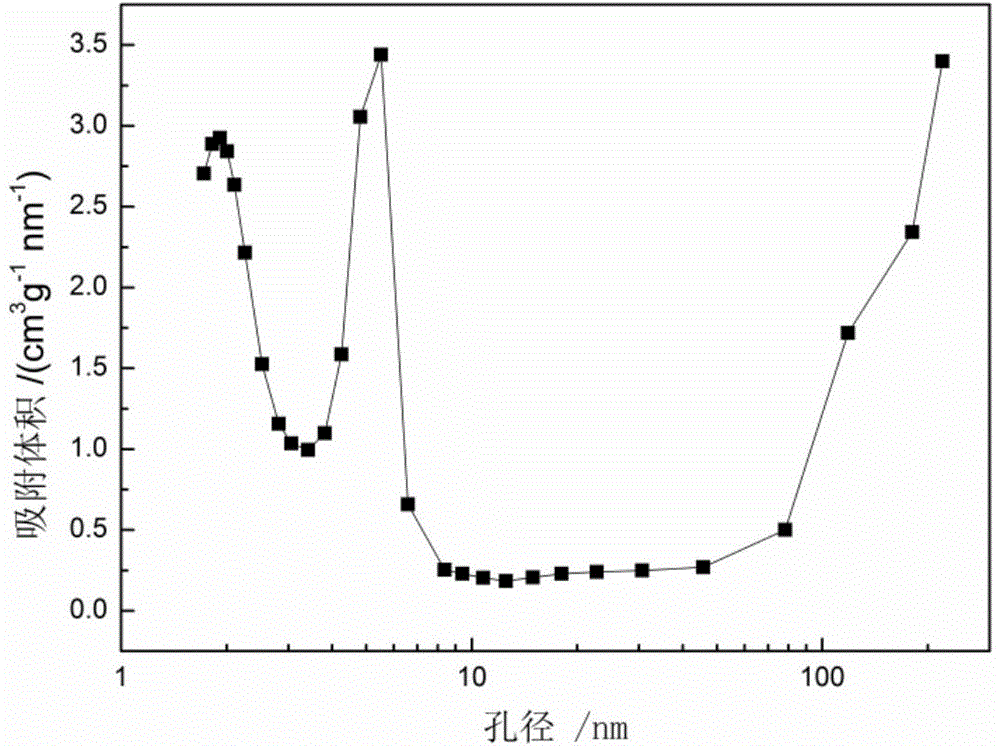

Preparation method of graded porous carbon material

InactiveCN105712313AImprove power performanceSufficient Response InterfaceElectrochemical responsePorous carbon

The invention relates to a preparation method of a graded porous carbon material. The preparation method comprises the following steps: evenly mixing a carbon source precursor, n-ethyl silicate, a soft template agent, a hard template agent, and a dispersant to prepare sol, evaporating the sol to remove the dispersant so as to obtain gel; carbonizing the gel, removing the templates, and pulverizing and grinding the obtained product so as to obtain the carbon material, which is rich in micropores, mesopores, and macropores. Because the carbon material comprises micropores, mesopores, and macropores, when the carbon material is used in an electrochemical device, the abundant micropores and mesopores can supply enough reaction interfaces for electrochemical reactions, at the same time, large mesopores and macropores can be used as mass transfer channels to deliver the reactants, the mass transfer is enhanced, and thus the carbon material is widely used in electrochemical devices.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Electrospinning and electrostatic spraying method for membrane electrode CCM

PendingCN106848355AIncrease active areaIncrease profitLiquid surface applicatorsCell electrodesPorosityConcentration polarization

The present invention discloses an electrospinning and electrostatic spraying method for a membrane electrode CCM. According to the present invention, the catalyst layer having the nanometer film structure is obtained by using the electrospinning and electrostatic spraying method, wherein the catalyst layer structure has a high specific surface area so as to increase the three-phase reaction interface, increase the active area of the catalytic layer, and improve the catalyst utilization rate; the polymer nano-fiber membrane has high porosity, such that the mass transfer is easily performed, and the concentration polarization is effectively reduced; and the nano-scale catalytic particles obtained through electrostatic spraying are uniformly distributed on the nano-fiber structure so as to reduce the platinum loading and improve the catalytic performance.

Owner:NANJING UNIV

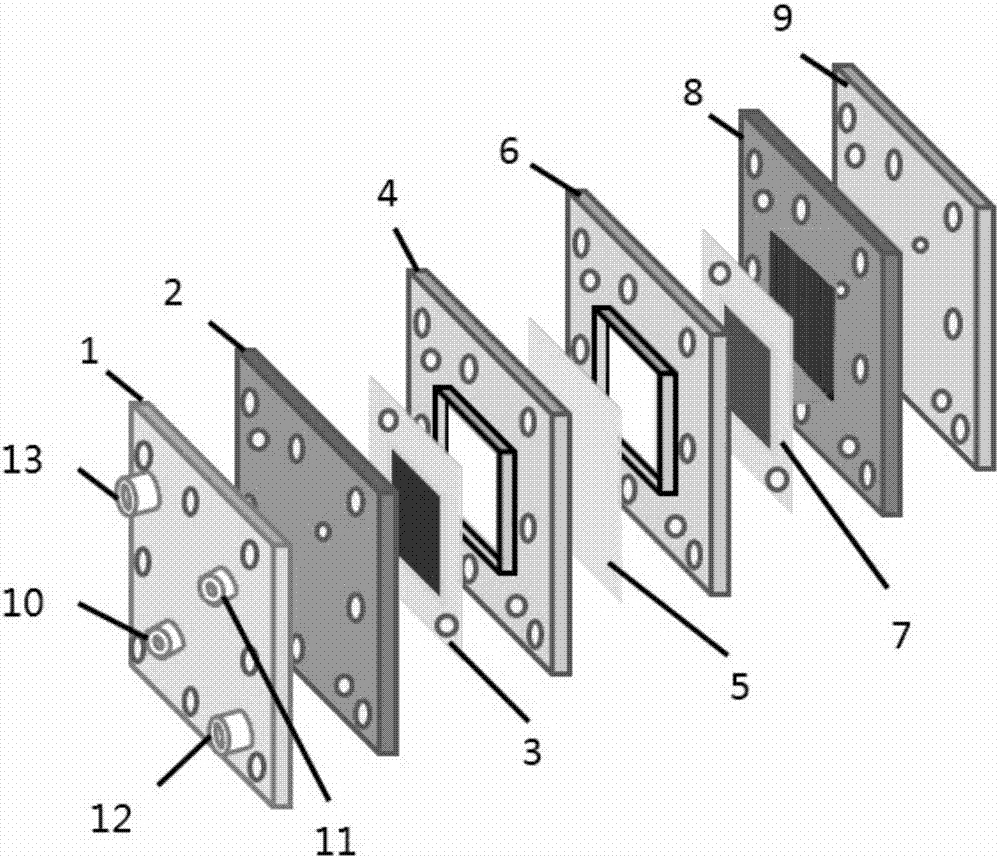

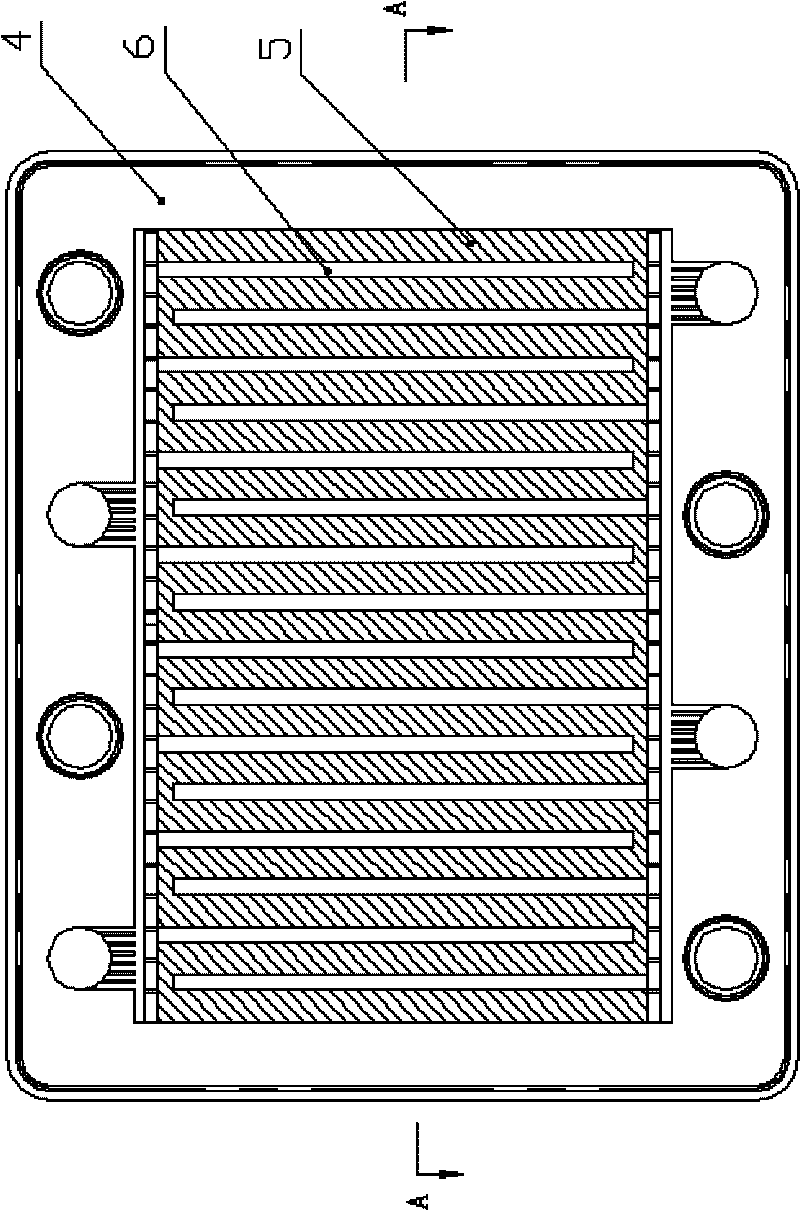

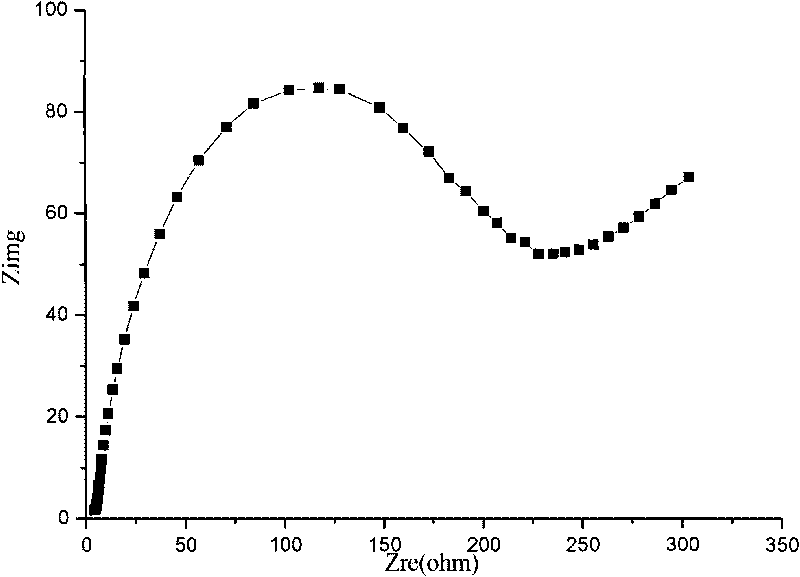

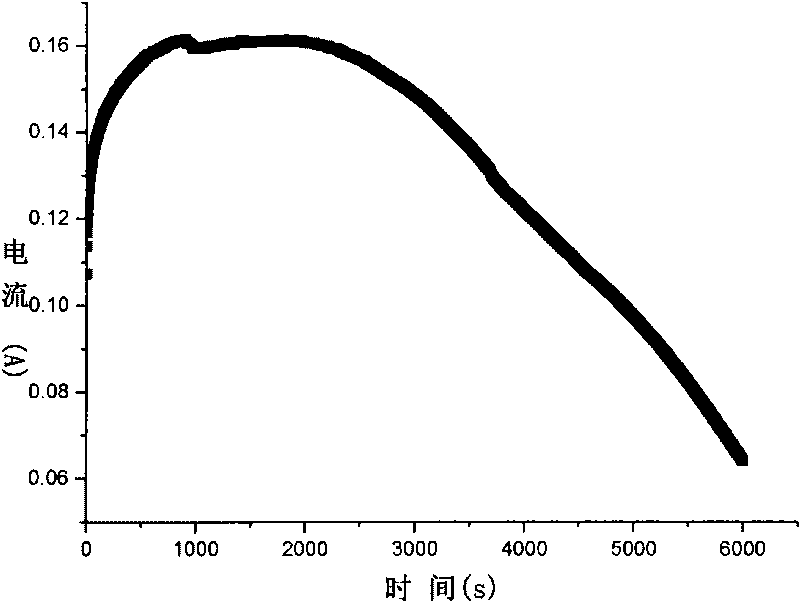

Pile structure of redox flow battery

InactiveCN101719556ASpeed up the flowIncrease current densityFuel cells groupingCell electrodesElectrochemical responseChemical reaction

The invention discloses a pile structure of a redox flow battery for storing energy through chemical reaction, which has the characteristic of improving the flowing uniformity of electrolyte. The pile structure of the redox flow battery comprises a battery stack formed by a plurality of single battery connected in series; each single battery comprises a positive pole sealing frame and a negative pole sealing frame; a collector plate which has a porous electrode and a conductive double electrode is arranged in the positive pole sealing frame; and flow field plates dividing the porous electrode into a plurality of flow guide areas are arranged in the porous electrode. The arranged flow field plates make the electrolyte flow in the porous electrode according to the flow guide areas separated by the flow field plates, increase the area of an electrochemical reaction interface and the flow speed at which the electrolyte passes through the porous electrode, make the flow of the electrolyte in the porous electrode more uniform, accelerate the electrochemical redox reaction, improve the current density of an electrochemical flow battery and obviously improve the efficiency of the conversion and storage of the electric energy and chemical energy in the electrochemical flow battery.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

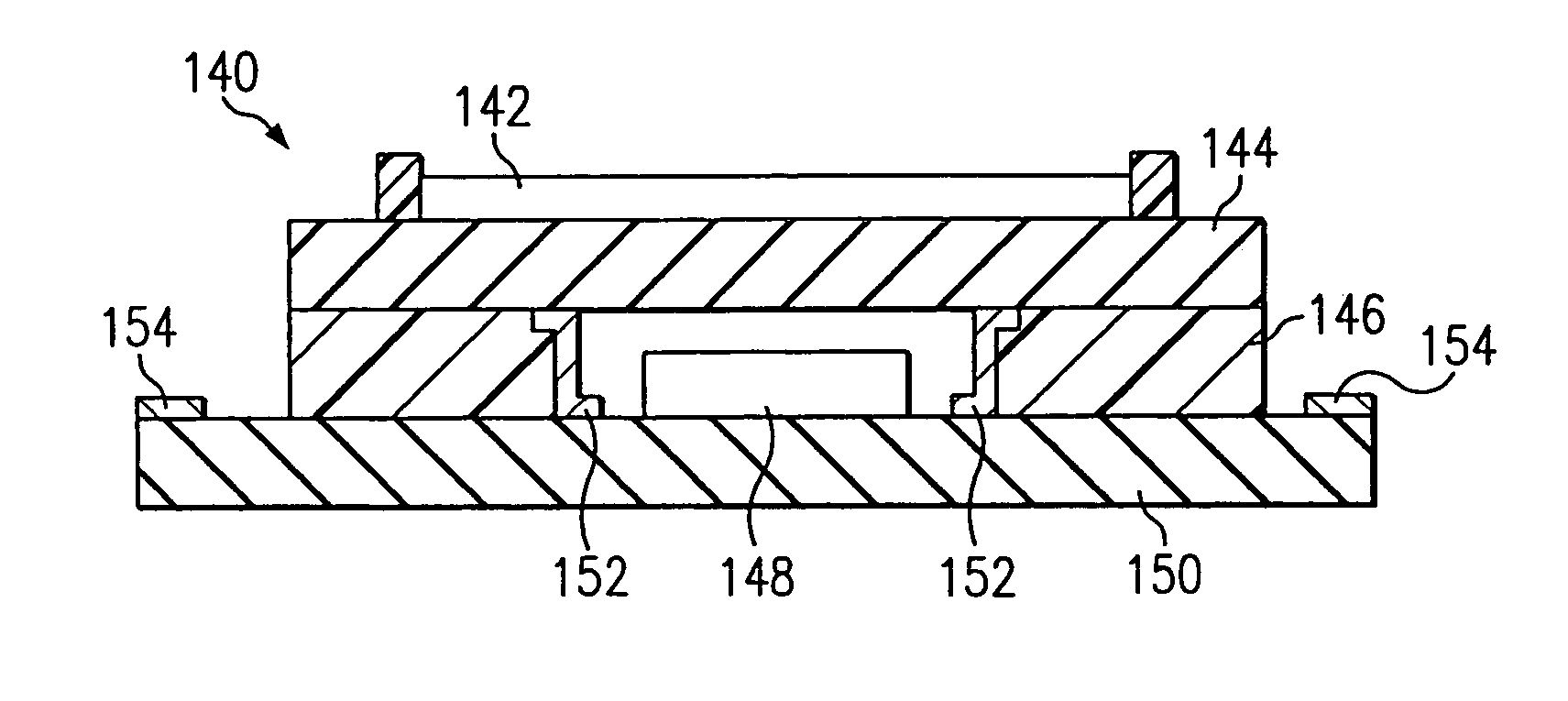

Method for preparing nanofiber-based composite nanofiltration membrane by low-temperature reverse interfacial polymerization

InactiveCN110124517AIncrease water fluxSimple and optimized structureSeawater treatmentReverse osmosisVolumetric Mass DensityOil phase

The invention discloses a method for preparing a nanofiber-based composite nanofiltration membrane by low-temperature reverse interfacial polymerization. The method comprises the following steps: electrospinning a polymer solution to obtain a nanofiber nonwoven fabric, and performing cold pressing treatment to obtain a nanofiber porous base film; adding the nanofiber porous base film to a low-temperature oil phase monomer solution in order to infiltrate the surface of the base film; adding the infiltrated base film to an aqueous phase monomer solution, and carrying out a reverse interfacial polymerization; and carrying out heat treatment to obtain the nanofiber-based composite nanofiltration membrane. The temperature of the oil phase solution is controlled to reduce the volatilization rateof the oil phase at a low temperature, provide a complete and uniform reaction interface for the reverse interfacial polymerization and overcomes the skin layer defect and infiltration due to fast volatilization of the oil phase during the reverse interfacial polymerization, and the temperature of the oil phase solution and the reverse interface polymerization parameters are controlled to optimize the thickness, uniformity and density of a functional barrier layer in order to enhance the nanofiltration performance of the composite membrane.

Owner:DONGHUA UNIV

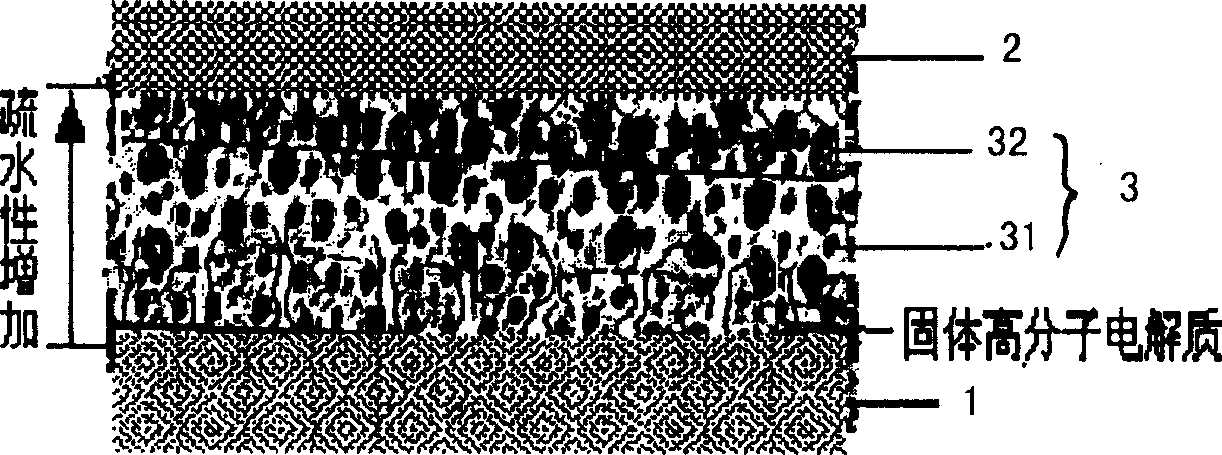

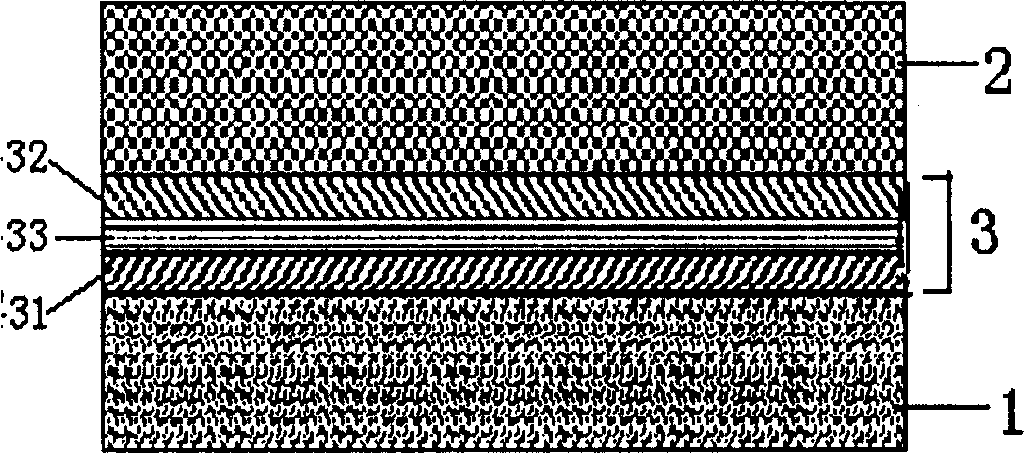

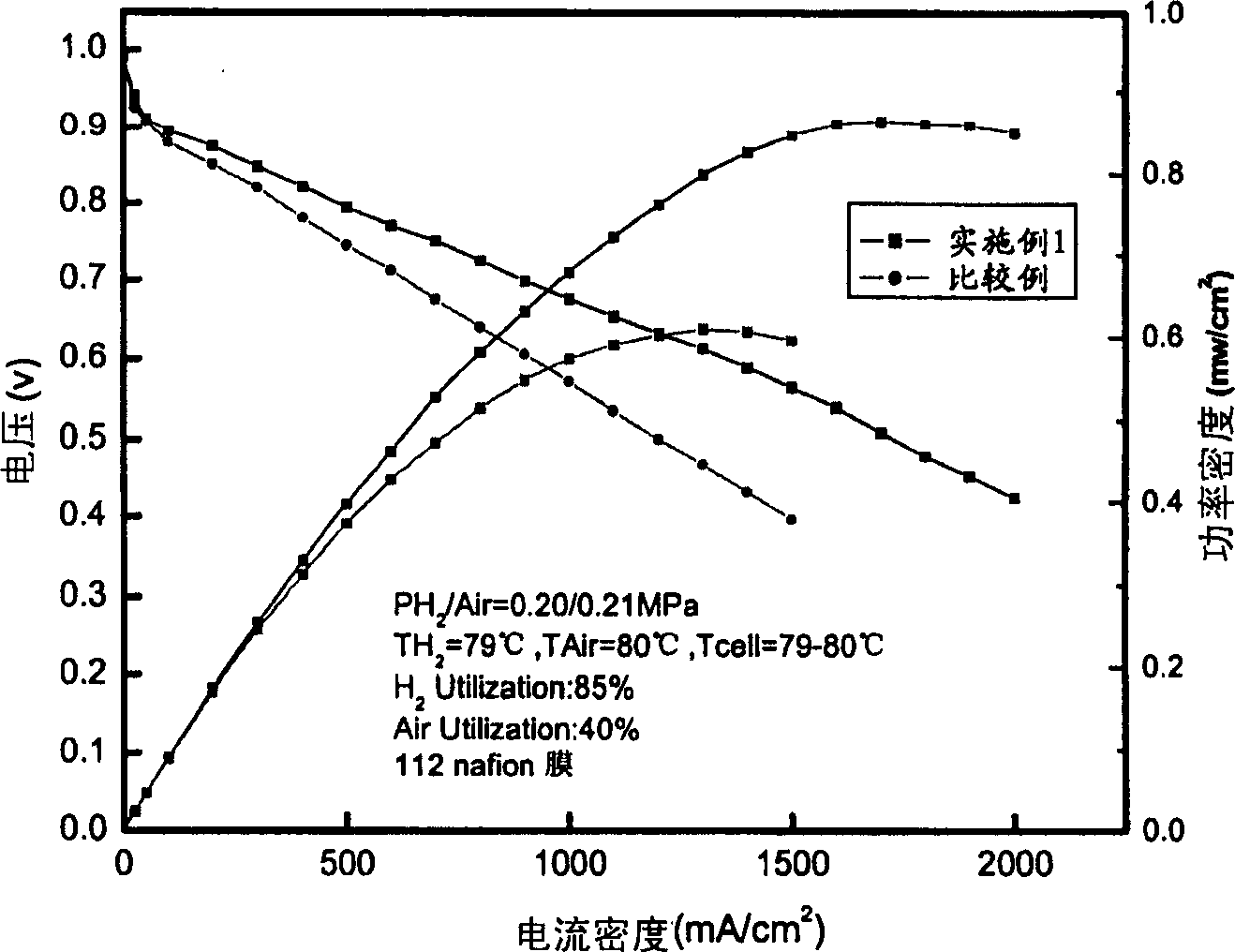

Composite catalytic layer proton exchange membrane fuel cell electrode and its preparing method

ActiveCN1744360AFacilitates electron conductionImprove proton conductivityCell electrodesSlurrySolvent

Catalysis layer including more than one layer of containing hydrophobicity material (such as PTFE) and catalysis of platinum carried by carbon (Pt / C) is prepared on surface at side of leveling layer of gas diffusion layer. The leveling layer is processed by hydrophobicity and carbon powder in advance. After being baked under protection of inert gases at 320-380 deg.C, the catalysis layer is spray coated by solid polyelectrolyte in certain quantity. Then, more than one layer of slurry composed of solid polyelectrolyte, electrode catalyst and solvent in specific proportion is prepared on the catalysis layer. After being baked under protection of inert gases at 100-380 deg.C, electrode of fuel cell composed of composite catalysis layers in different hydrophobicity and hydrophilicity is obtained. Advantages are: satisfied conduction of protons and electrons, better transmission or diffusivity of gases and water, expanded reaction interface, and raised power density.

Owner:SUNRISE POWER CO LTD

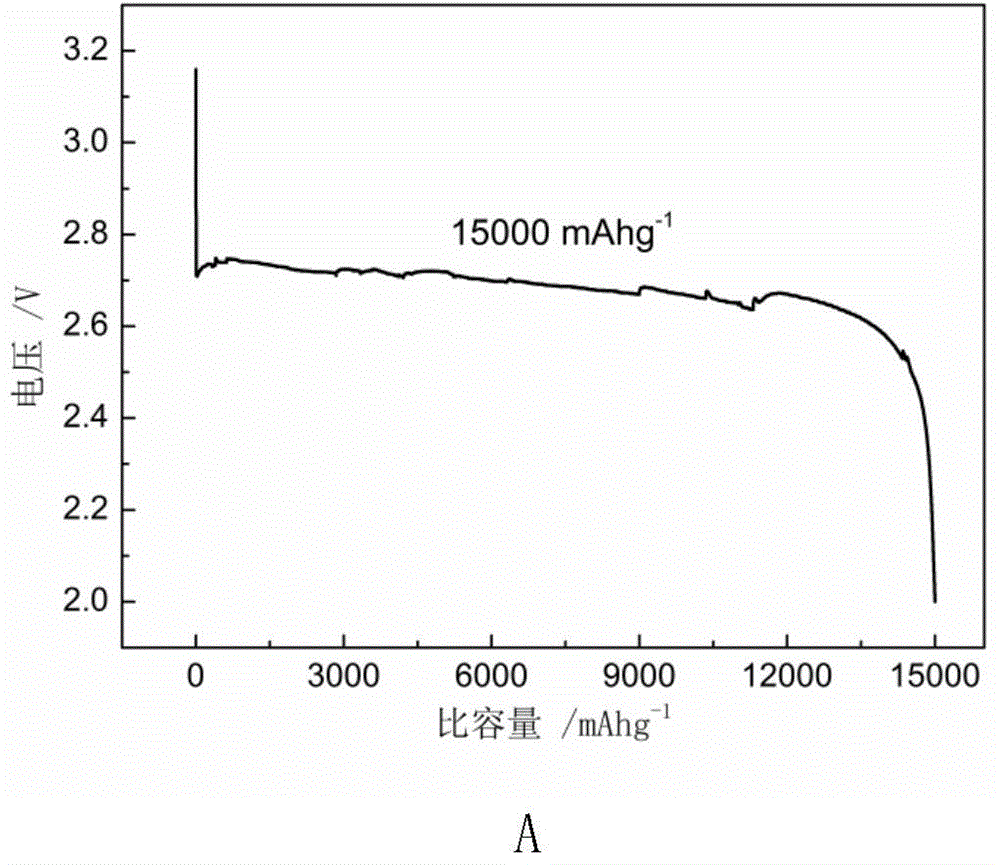

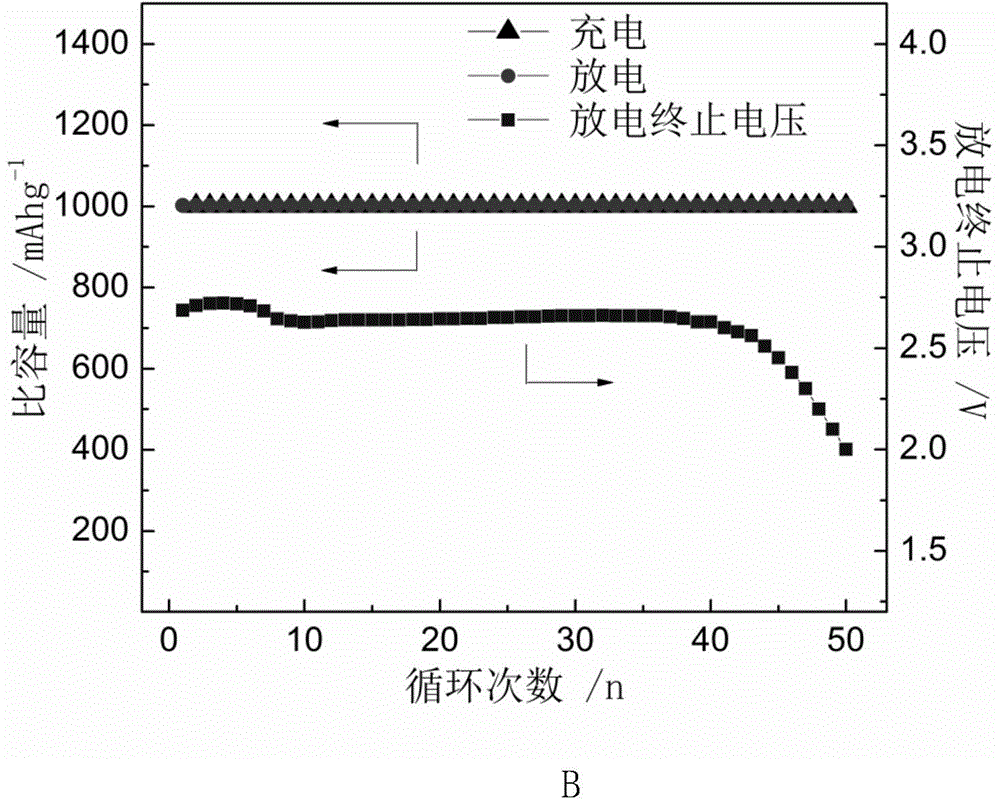

Method for preparing lithium-sulfur battery by taking graphitized carbon nanotube flexible film as current collector of lithium-sulfur battery

InactiveCN106374113AImprove conductivityFacilitate depositionElectrode carriers/collectorsElectrochemical responseLithium–sulfur battery

A method for preparing a lithium-sulfur battery by taking a graphitized carbon nanotube flexible film as a current collector of the lithium-sulfur battery comprises the following steps of (1) taking sulfur as an active material, adding a conductive agent and a binding agent, taking N-methylpyrrolidone or deionized water as a solvent, and mixing paste; (2) coating the active material subjected to paste mixing already on the graphitized carbon nanotube flexible film, performing drying after coating, cutting the graphitized carbon nanotube flexible film to a product with the same size as a negative pole plate, and performing vacuum drying to obtain a positive pole plate; and (3) taking a lithium sheet as the negative pole plate, adding an electrolyte in a vacuum glove box, and assembling the battery according to a sequence of a negative electrode shell, the negative pole plate, a separator, the positive pole plate, foamed nickel and a positive electrode shell. The nanotube flexible film has a large amount of micropores with different sizes, the sulfur are very favorably deposited and absorbed into the micropores, thus, sulfur loading quantity in the positive pole plate and electrochemical reaction interface area are effectively increased, electron and ion conduction are enhanced, and the charge / discharge performance of the lithium-sulfur battery can be substantially improved.

Owner:NANCHANG UNIV

Method for removing ceramic core of hollow blade of turbine of aircraft engine

A method for removing a ceramic core of a hollow blade of a turbine of an aircraft engine comprises the four steps of primary core removing, secondary core removing, third core removing and ultrasonic cleaning. The concentration of KOH alkali liquor used in primary core removing is 40%, the concentration of KOH alkali liquor used in secondary core removing is 30%, and the concentration of KOH alkali liquor used in third core removing is 40%. Every time core removing is conducted, the temperature of the alkali liquor ranges from 160 DEG C to 200 DEG C, the pressure of the alkali liquor fluctuates between 0.4 MPa and 0.5 MPa, water is added every six hours, and soaking time is 48 hours. According to the method, the concentration of the alkali liquor is reduced, the water is added every six hours, and it is guaranteed that salt generated due to reactions is sufficiently dissolved; the alkali liquor is replaced every 48 hours, the concentration of the alkali liquor changes in a stepped mode, and it can be guaranteed that the chemical reactions are conducted effectively; the pressure of the alkali liquor fluctuates in a pulse mode, core cracking can be facilitated, the reaction interface between the alkali liquor and the core is enlarged, and the reacting dose is increased. Through the method, the ceramic core removing period can be shortened to six days from over twenty days, and the first pass yield of core removing can be higher than 90%.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Water coagulation processing method

InactiveCN101475248AIncrease particle concentrationDamage protectionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by oxidationSuspended particlesColloid

The invention discloses a water coagulation treatment method. The method comprises that: a coagulating agent is adopted to carry out coagulation treatment on water; and in the process of water coagulation treatment, a catalyst and an oxidant are thrown into the water. Through the addition of the catalyst and the oxidant in the process of the water coagulation treatment, the catalyst forms a solid-liquid reaction interface in the water; and the oxidant undergoes rapid oxidation reaction on the interface and oxides organisms to destroy the protective function of the organisms on suspended particles. The adsorptive action of the catalyst can combine with colloid particles in the water to form a microfloc nucleus so as to increase the concentration of particles in the water and be favorable for the formation and growth of floc in the coagulation reaction.

Owner:SUN YAT SEN UNIV

Organic semiconductor sensor device

InactiveUS7141839B2Modulating the depletion regionSolid-state devicesForce measurementSemiconductor materialsPolymer substrate

Owner:STMICROELECTRONICS INC

Method for preparing alkaline hydrogen peroxide in situ

ActiveCN101748422ASave spaceYield amplificationCellsElectrodesElectrochemical responseOver potential

The invention relates to a method for preparing alkaline hydrogen peroxide in situ, which is used for taking hydrogen, oxygen and an alkaline solution as raw materials to prepare an alkaline hydrogen peroxide water solution by direct electrocatalysis in situ. The preparing method adopts a membrane reactor, the oxygen and the hydrogen enter cathode and anode by the air inlets of a cathode end plate and an anode end plate and generate electrochemical reaction on the gas diffusion electrode loading with nano electro-catalyst, and the obtained product rapidly enters an electrolyte solution to be beneficial to the enrichment of the hydrogen peroxide. The middle adopts a cation-exchange membrane, so the explosion hazard of direct reaction of the hydrogen and the oxygen is avoided, and the safety is high. The volume of the reactor is small, and the product can be simply separated from reactants. Adopting the gas diffusion electrode loading with the nano electro-catalyst, the preparing method effectively increases the three-phase reaction interface, improves the utilization ratio of the catalyst, and increases the reaction rate. The use of the nano electro-catalyst can effectively reduce the over potential of reaction and energy consumption.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

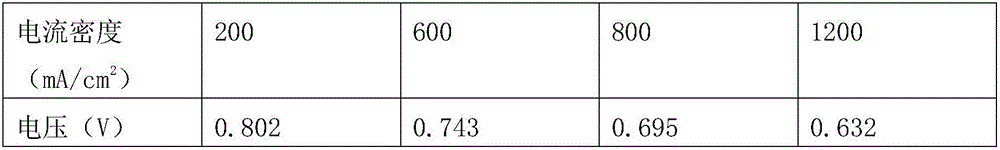

Preparation method of electrode and membrane electrode for fuel cell with fully-ordered catalyst layer structure

ActiveCN108448138AHigh catalytic activityImprove catalytic stabilityCell electrodesFuel cellsElectrochemical responseElectrical conductor

The invention discloses a preparation method of an electrode and a membrane electrode for a fuel cell with a fully-ordered catalyst layer structure, and relates to the field of fuel cells. In the electrode and the membrane electrode for the fuel cell prepared by the method, the components of the catalyst layer comprise a catalyst activity component, a catalyst carrier and an ion conductor which are of ordered array structures. The fully-ordered catalyst layer structure is of an extremely high three-phase reaction interface, and efficient electron, ion and matter transfer passages can be provided, so that the matter transfer resistance, load transfer resistance and electrochemical polarization resistance inside the electrode are reduced effectively, and the electrochemical reaction efficiency and energy conversion efficiency in the electrode are improved effectively. Through monocell performance test and electrochemical characterization, the electrode and the membrane electrode preparedby the preparation method is obviously improved in the aspects of monomer performance and catalyst layer activity compared with an electrode and a membrane electrode prepared by a traditional method.

Owner:广东泰极动力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com