Ferrite modifying MXene layered gas diffusion electrode as well as preparation method and application thereof

A technology of gas diffusion electrode and diffusion electrode, which is applied in the field of water treatment, can solve the problems of limited removal capacity, low concentration, and heavy pollution of PPCPs of traditional treatment technology, and achieve improved electrochemical performance and catalytic ozonation activity, high treatment efficiency, The effect of high electrode strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

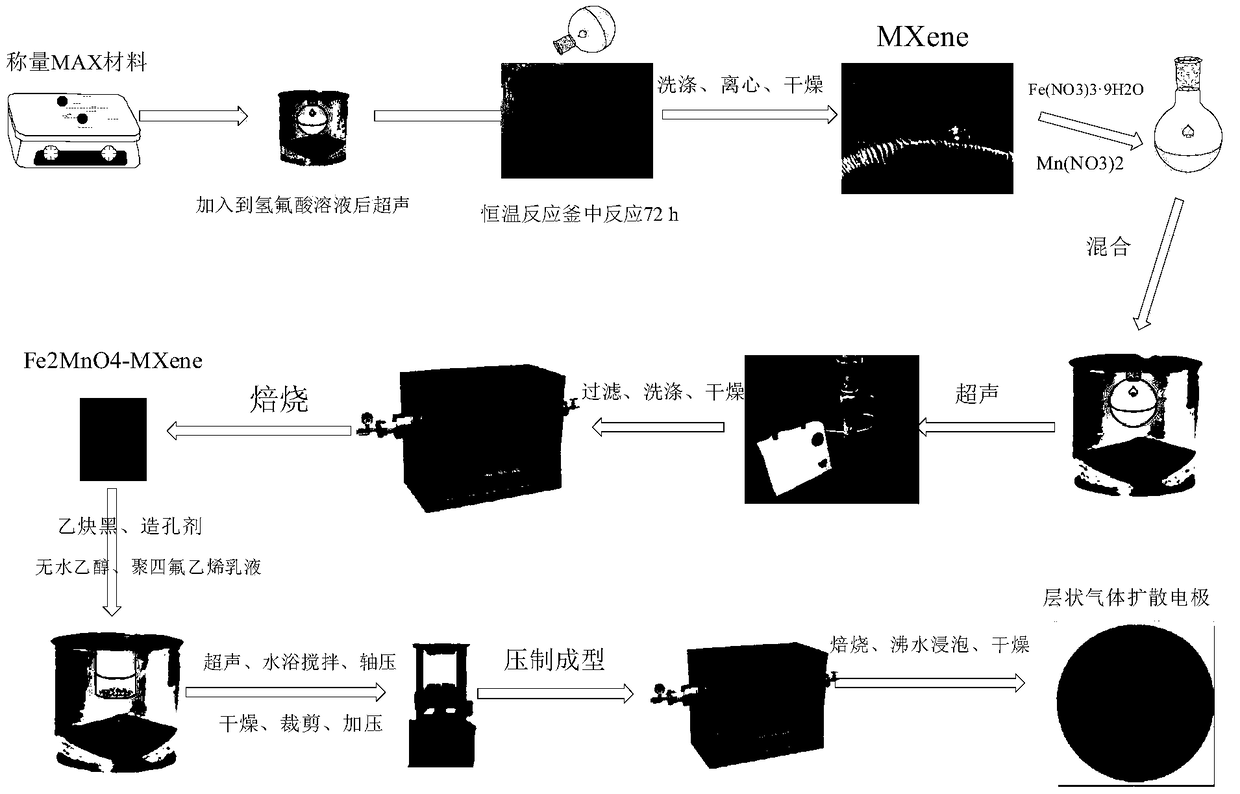

[0050] Embodiment 1 Preparation of Ferrite Modified MXene Layered Gas Diffusion Electrode

[0051] (1) Preparation of MXene material: weigh 2.0g Ti 3 AlC 2 Materials and Measure 200mL of hydrofluoric acid solution into a round bottom flask. After 1h of ultrasonic treatment, react in a constant temperature reactor at 40°C for 72h. After the solution is cooled, wash with ultrapure water and centrifuge several times. Remove surface residue impurities until the pH of the washing liquid is not lower than 6, and then fully dry in a vacuum oven at 60°C until a constant quality is obtained to obtain MXene materials.

[0052] 2) Ferrite modified MXene material: Accurately weigh 808mg Fe(NO 3 ) 3 9H 2 O solid and 125.84 mg MnCl 2 solid. Fe(NO) was added to 100 mL of ultrapure water 3 ) 3 9H 2 O solid and MnCl 2 Solid, stirred with a magnetic stirrer to make it evenly mixed and completely dissolved to obtain a mixed solution, in which Fe(NO 3 ) 3 0.02mol / L, MnCl 2 0.01mol / L,...

Embodiment 2

[0055]Example 2 Ferrite Modified MXene Layered Gas Diffusion Electrode

[0056] 1) Preparation of MXene material: Weigh 3.0g Ti 3 AlC 2 Materials and Measure 150mL of hydrofluoric acid solution into a round-bottomed flask. After 1h of ultrasonic treatment, react in a constant temperature reactor at 40°C for 72h. After the solution is cooled, wash with ultrapure water and centrifuge several times. Remove surface residue impurities until the pH of the washing liquid is not lower than 6, and then fully dry in a vacuum oven at 60°C until a constant quality is obtained to obtain MXene materials.

[0057] 2) Ferrite modified MXene material: Accurately weigh 808mg Fe(NO 3 ) 3 9H 2 O solid and 125.84 mg MnCl 2 solid, adding Fe(NO 3 ) 3 9H 2 O solid and MnCl 2 Solid, stirred with a magnetic stirrer to make it evenly mixed and completely dissolved to obtain a mixed solution, in which Fe(NO 3 ) 3 0.02mol / L, MnCl 2 0.01mol / L, add 5mL of polyethylene glycol to the mixed solutio...

Embodiment 3

[0059] Example 3 Ferrite Modified MXene Layered Gas Diffusion Electrode

[0060] 1) Preparation of MXene material: weigh 1.0g Ti 3 AlC 2 Materials and Measure 300mL of hydrofluoric acid solution into a round bottom flask. After 1h of ultrasonic treatment, react in a constant temperature reactor at 40°C for 72h. After the solution is cooled, wash with ultrapure water and centrifuge several times. Remove surface residue impurities until the pH of the washing liquid is not lower than 6, and then fully dry in a vacuum oven at 60°C until a constant quality is obtained to obtain MXene materials.

[0061] 2) Ferrite modified MXene material: Accurately weigh 1616mg Fe(NO 3 ) 3 9H 2 O solid and 251.68 mg MnCl 2 solid, adding Fe(NO 3 ) 3 9H 2 O solid and MnCl 2 Solid, stirred with a magnetic stirrer to make it evenly mixed and completely dissolved to obtain a mixed solution, in which Fe(NO 3 ) 3 0.04mol / L, MnCl 2 0.02mol / L, add 10mL of polyethylene glycol to the mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com