Flat-plate solid-oxide fuel battery stack for double-layer connector

A solid oxide and fuel cell stack technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell grouping, etc., can solve problems such as high concentration of oxidizing gas, disturbing fuel gas and oxidizing gas, and reducing the performance of SOFC stacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

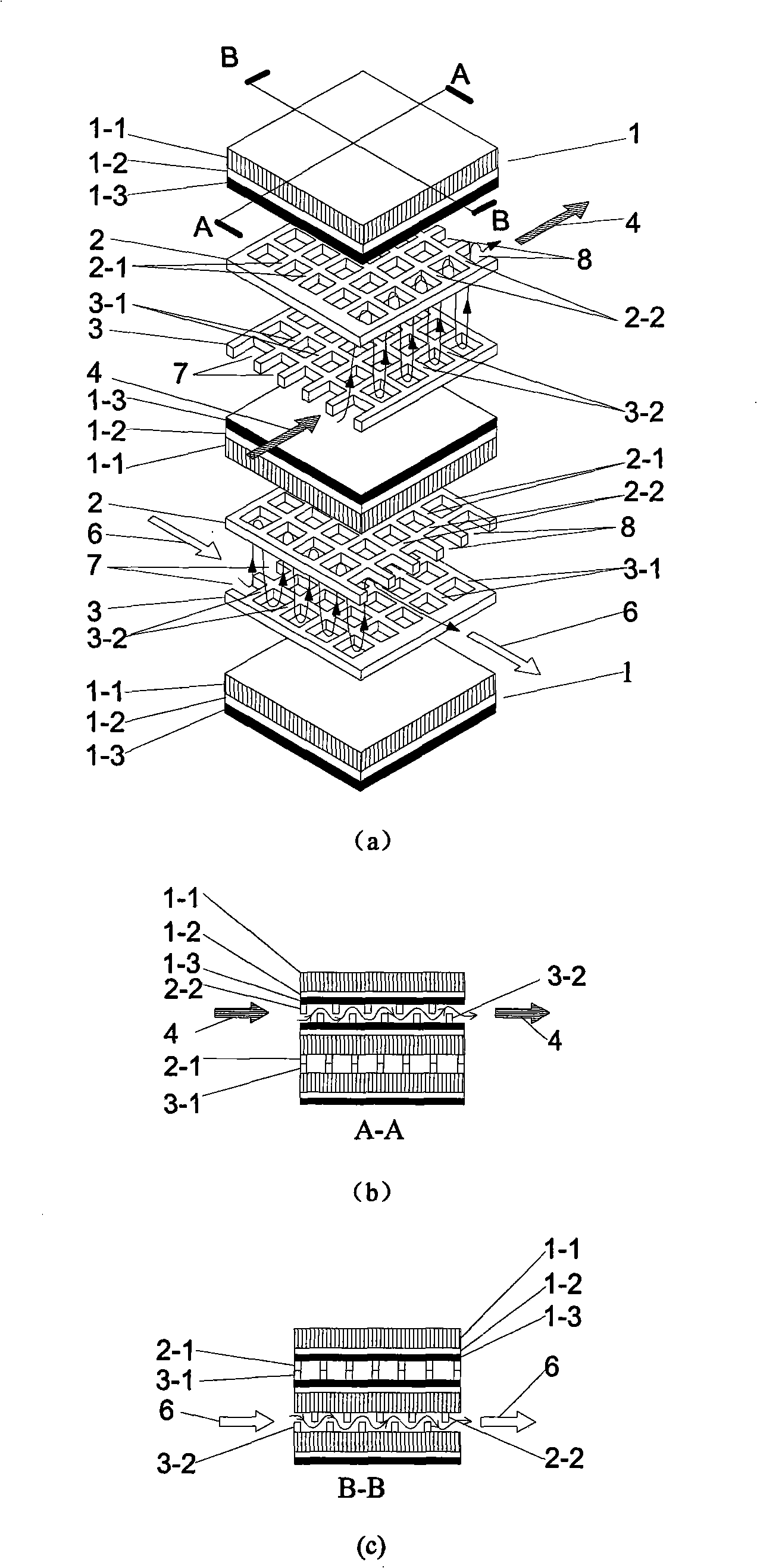

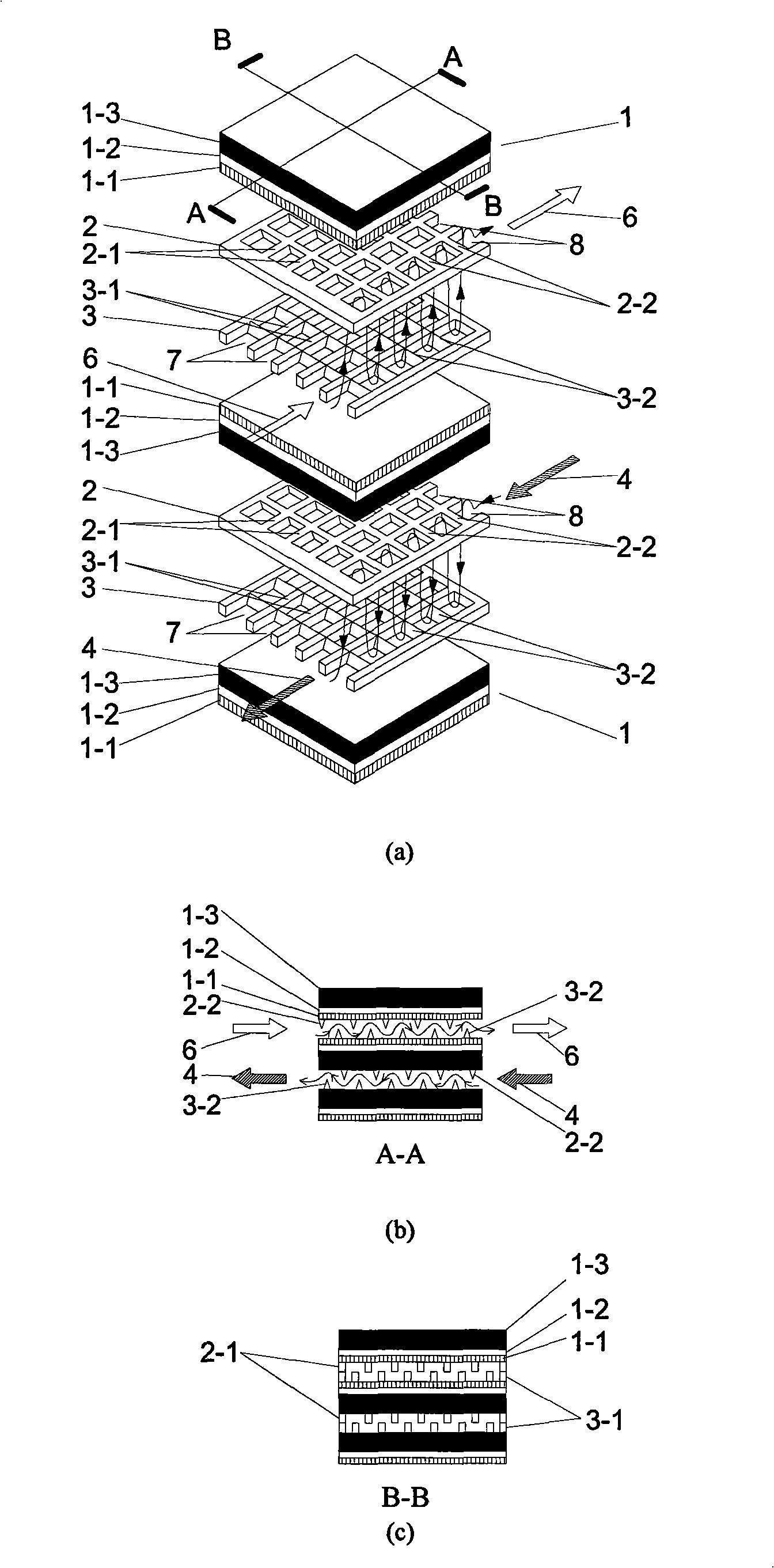

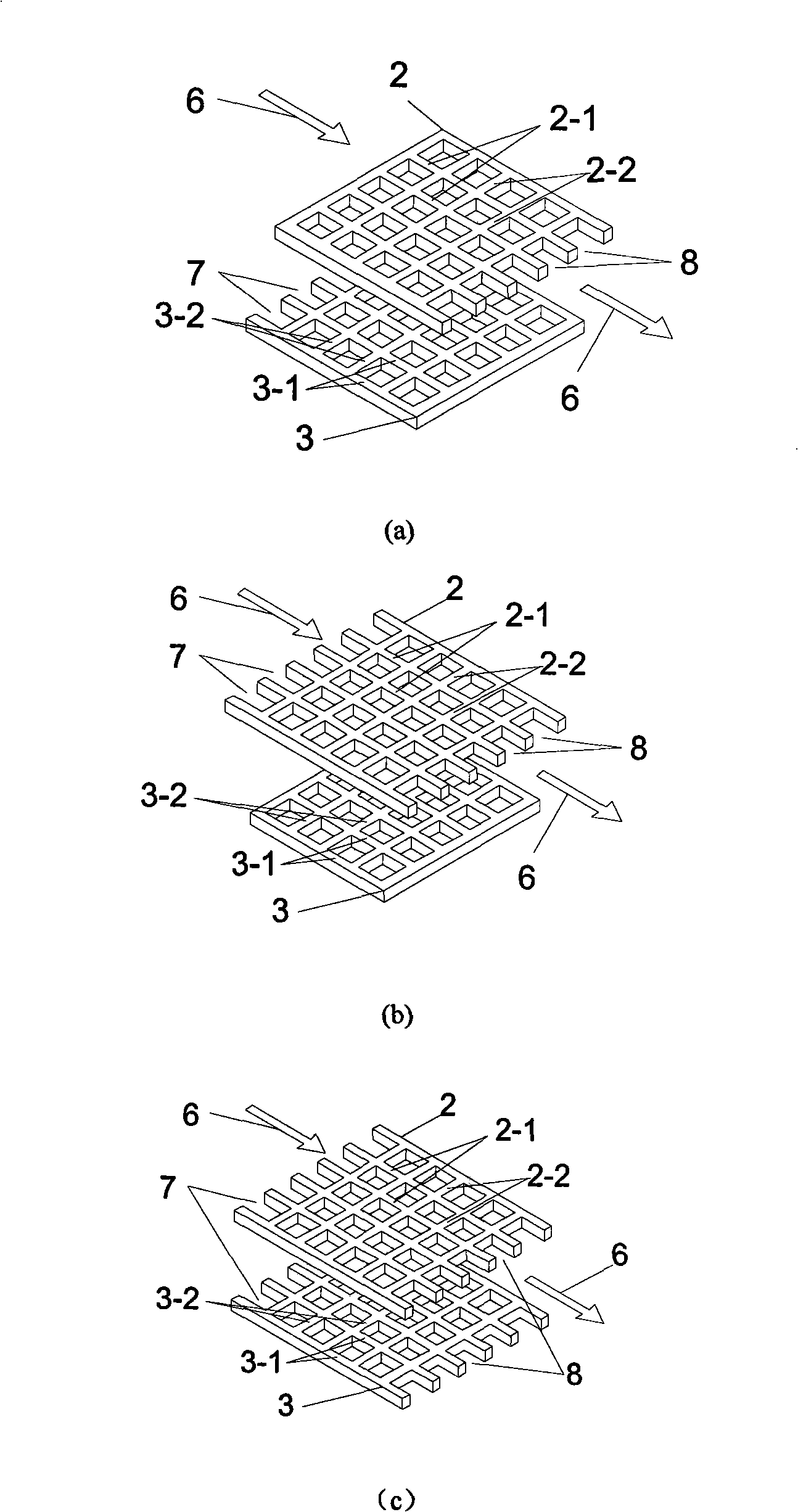

[0029] refer to figure 1 (a), figure 1 (b), figure 1As shown in (c), a double-layer connector flat solid oxide fuel cell stack of the present invention includes a plurality of single cells 1 composed of an anode 1-1, an electrolyte layer 1-2, and a cathode 1-3. Connectors are provided between adjacent single cells 1, and the arrangement of multiple single cells 1 is such that the anode 1-1 of one single cell 1 faces the anode 1-1 of another single cell 1, and the cathode 1-1 of one single cell 1 -3 is facing the cathode 1-3 of another single cell 1, and the connecting body is a double-layer connecting body composed of the first connecting body 2 and the second connecting body 3, and the first connecting body 2 is made of a gas parallel to the fuel gas 6 or the oxidizing gas. 4 The first connecting body vertical bar 2-1 in the flow direction and the first connecting body horizontal bar 2-2 perpendicular to the flow direction of the fuel gas 6 or oxidizing gas 4 form a network...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com