Aluminum hydrolization hydrogen production device and controlling method thereof

A technology of hydrolysis hydrogen production and control method, applied in the direction of hydrogen production, etc., can solve the problems of difficult handling of reaction products, inability to obtain hydrogen flow, and increase in system complexity, and achieve controllable hydrogen production rate, simple structure, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

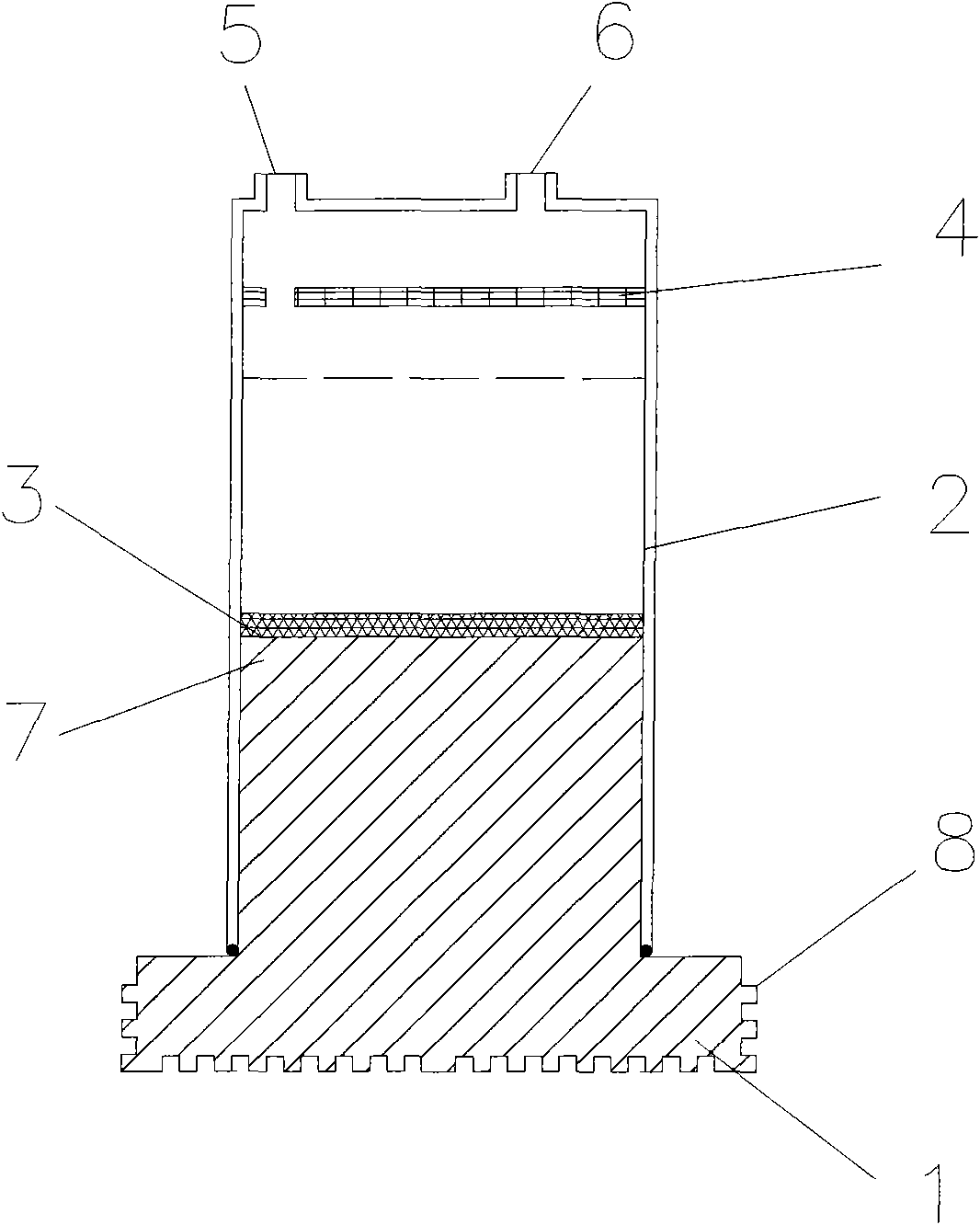

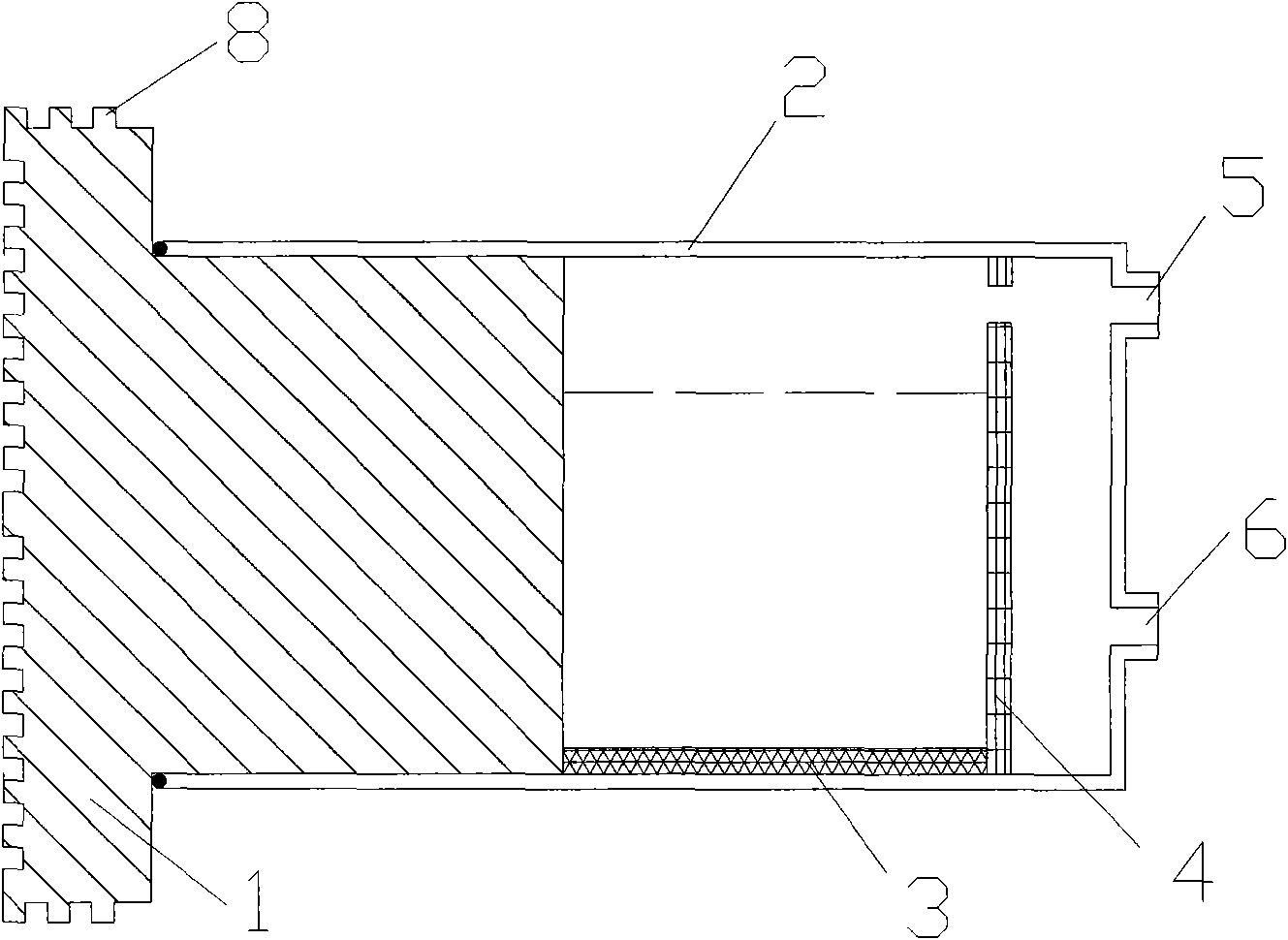

[0037] An aluminum hydrolysis hydrogen production device comprises an aluminum hydrolysis tank body 2, the tank body 2 is provided with an aluminum head 1, an amalgam 3, a baffle plate 4, a water inlet 5 and a hydrogen gas outlet 6. The tank body 2 is connected to the aluminum head 1 in a sealed manner, and the end of the aluminum head 1 is in the shape of fins 8 for heat dissipation. The amalgam 3 is zinc-containing amalgam, which covers the reaction interface between the aluminum head 1 and water. The baffle in the tank is welded on the tank body and is located on the upper part of the aluminum-water reaction interface 7. The water inlet and the hydrogen outlet are located on the top of the tank.

Embodiment 2

[0039] An aluminum hydrolysis hydrogen production device comprises an aluminum hydrolysis tank body, the tank body is provided with an aluminum head 1 , an amalgam 3 , a baffle plate 4 , a water inlet 5 and a hydrogen gas outlet 6 . The aluminum head is an aluminum alloy head, and the aluminum alloy head is a cylindrical structure. The baffle in the tank is mounted on the tank body and is located at the upper part of the reaction interface between aluminum and water. Amalgam is an amalgam of zinc, silver and copper. All the other are with embodiment 1.

Embodiment 3

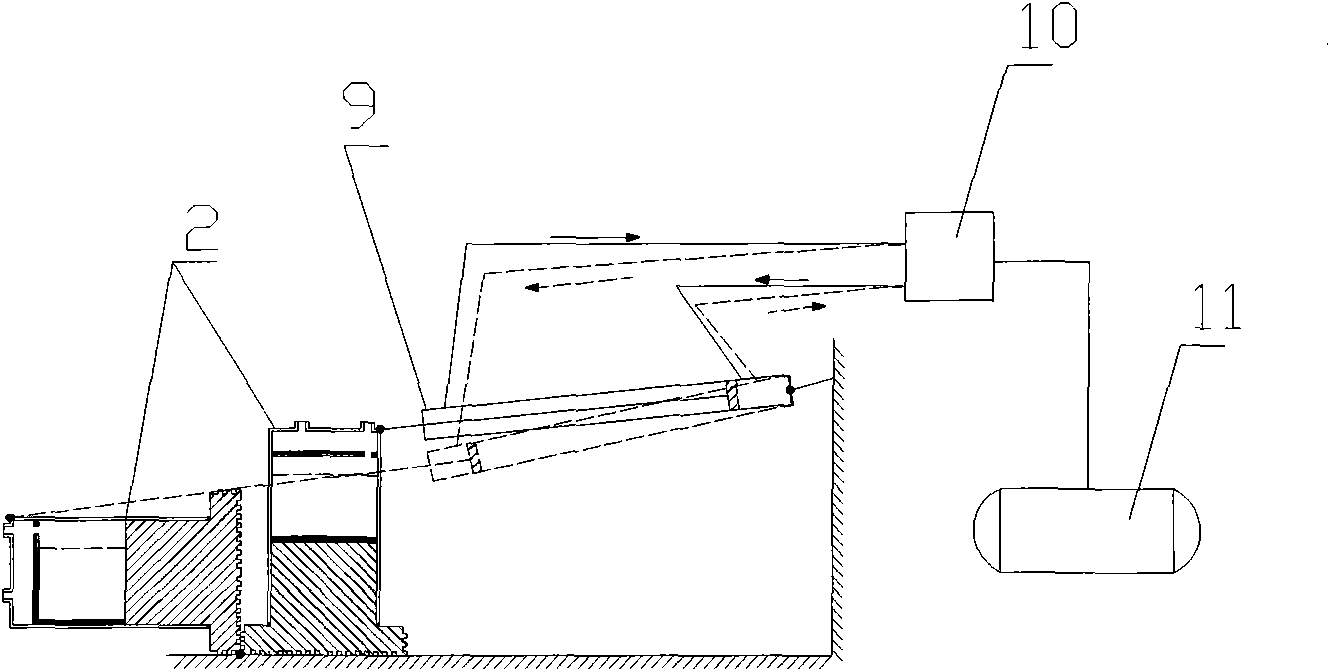

[0041] The control method of the aluminum hydrolysis hydrogen production device in Example 1 is to control the production of hydrogen by hydrolysis of aluminum. It is characterized in that the aluminum hydrolysis reaction is controlled by adjusting and controlling the contact surface between the amalgam and the reaction interface during the aluminum hydrolysis reaction in the tank. Adjusting and controlling the contact surface between the amalgam and the reaction interface is to control the contact or detachment of the amalgam and the reaction interface, so that the reaction proceeds or stops, and the hydrogen production rate is controlled. Under the action of the amalgam, the hydrogen gas produced by the aluminum hydrolysis reaction is exported through the hydrogen gas outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com