Portable aluminum-alkali-reaction hydrogen production plant and control method thereof

A hydrogen production device and control method technology, applied in the field of hydrogen molecular medicine, can solve the problems of difficult control of the liquid-solid reaction area, inability to achieve stable hydrogen flow, inconvenience of miniaturization, etc., and achieve controllable hydrogen production rate, simple structure, The effect of little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

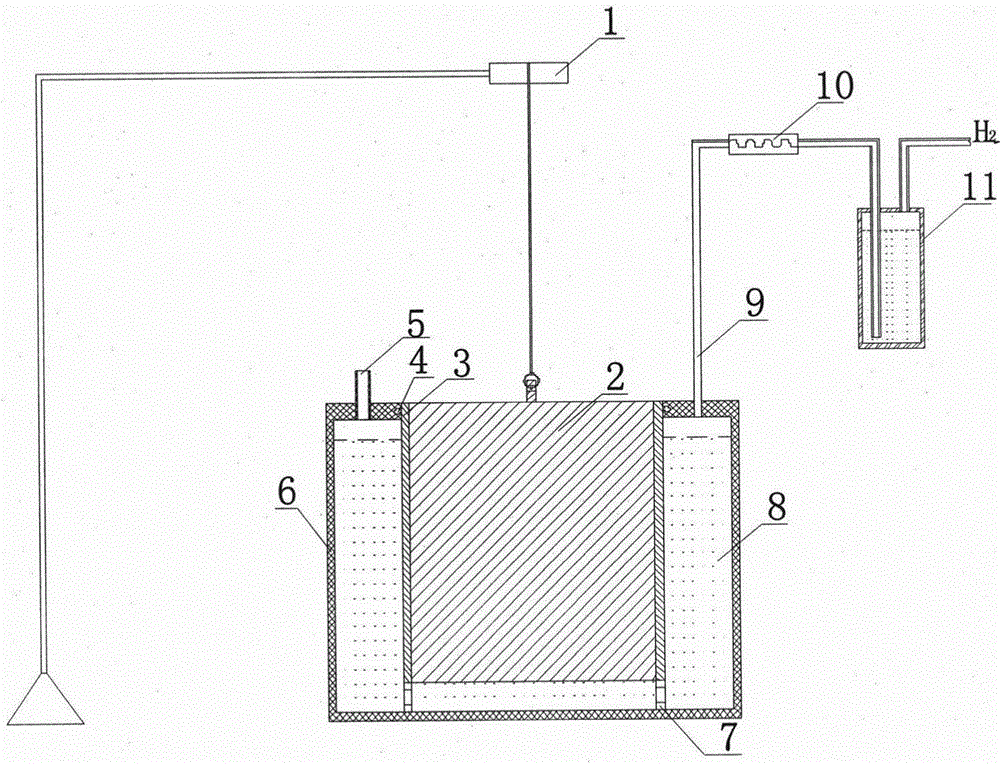

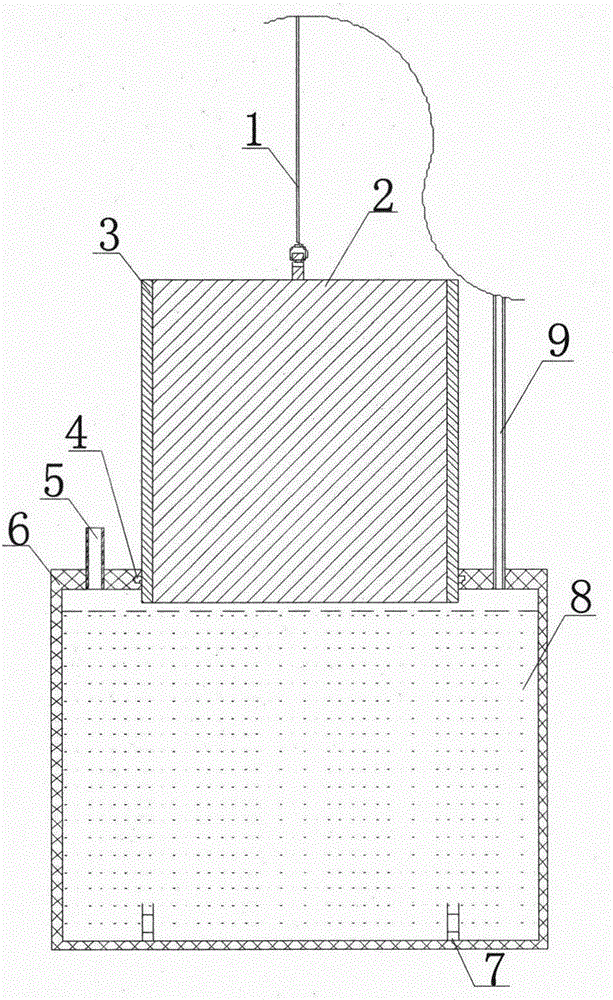

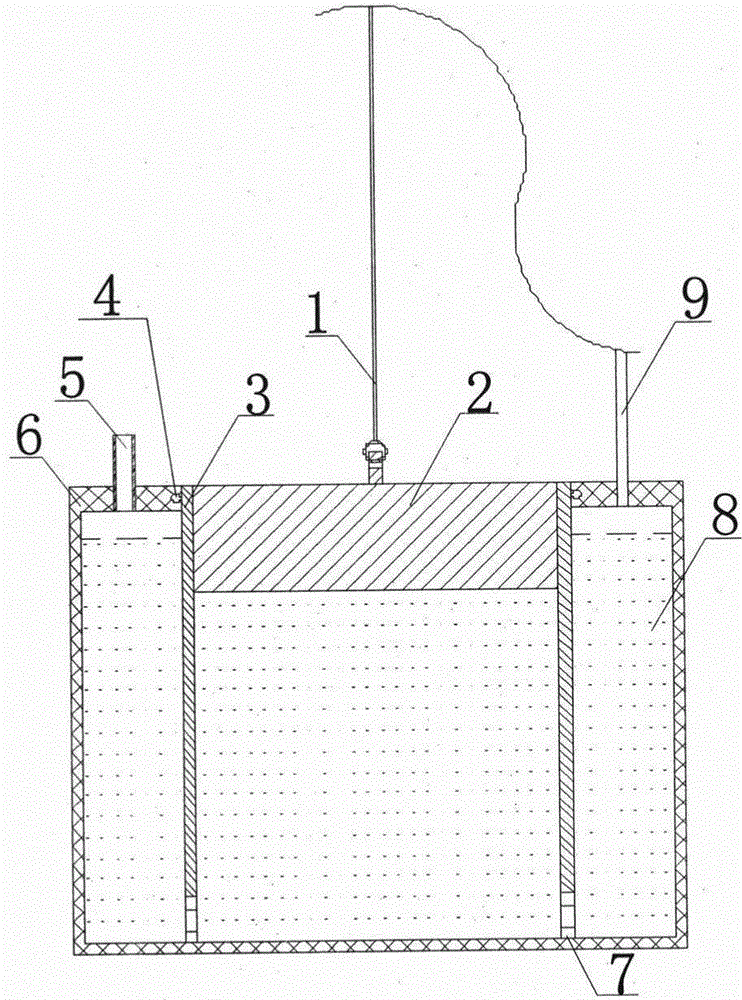

[0036] A portable aluminum-alkali reaction hydrogen production device, including a lifting mechanism 1, an aluminum rod 2, a casing 3, a reactor 6, a condenser 10 and a gas washing bottle 11; the aluminum rod 2 is installed in the casing 3, and connected with the casing 3 Sealed connection, the upper part of the aluminum rod 2 is connected with the lifting mechanism 1; the upper part of the reactor 6 is equipped with an "O" ring 4, and the reactor 6 and the casing 3 are sealed by the "O" ring 4, and the bottom of the reactor 6 is equipped with a belt A hole support 7; a liquid filling port 5 and a gas outlet 9 are respectively installed on the upper part of the reactor 6; a condenser 10 and a gas washing bottle 11 are installed on the gas outlet pipeline.

Embodiment 2

[0038] A portable aluminum-alkali reaction hydrogen production device, including a lifting mechanism 1, an aluminum rod 2, a casing 3, a reactor 6, a condenser 10 and a gas washing bottle 11; the aluminum rod and the casing are sealed by a sealant; the casing is resistant to Corroded 304 stainless steel; reactor and casing are sealed with "O" rings. The aluminum rod is an aluminum alloy containing 1% lithium and 1% silicon, the alkali solution is 0.5M NaOH solution, the diameter of the aluminum rod is 35 mm, and the hydrogen flow rate is 55 cc / min.

Embodiment 3

[0040] A portable aluminum-alkali reaction hydrogen production device, including a lifting mechanism 1, an aluminum rod 2, a casing 3, a reactor 6, a condenser 10 and a gas washing bottle 11; the aluminum rod and the casing are sealed by a sealant; the casing is resistant to Corroded 316 stainless steel; reactor and casing sealed with "O" rings. The aluminum rod is an aluminum alloy containing 1% magnesium and 1% calcium, the alkali solution is 0.5M KOH solution, the diameter of the aluminum rod is 35 mm, and the hydrogen flow rate is 45 cc / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com