Hydrolysis hydrogen production system

A technology for producing hydrogen and hydrogen by hydrolysis, applied in hydrogen production, hydrogen/synthesis gas production, inorganic chemistry, etc., can solve problems such as imperfect controllability, a large number of auxiliary parts, complex structure, etc., and achieve a controllable hydrogen production rate , short response time, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but those skilled in the art understand that the present invention is not limited thereto.

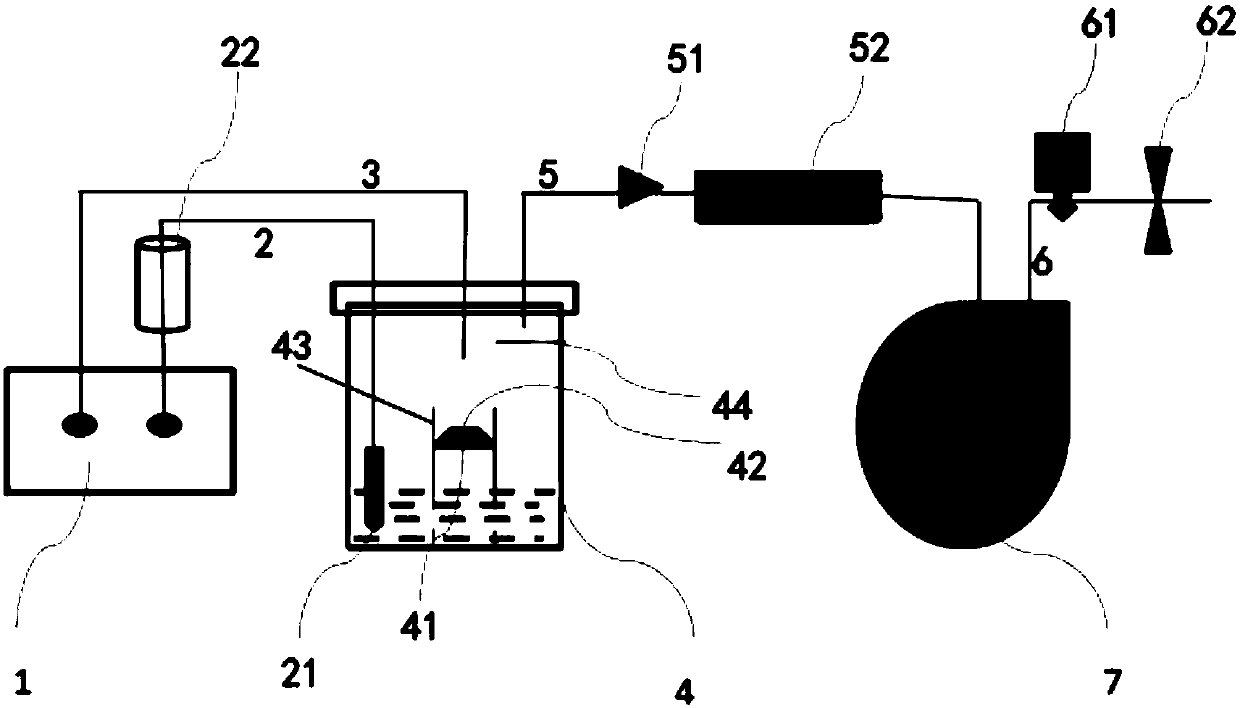

[0022] Such as figure 1 As shown, in one embodiment, the hydrolysis hydrogen production system includes a reaction vessel 4, a water delivery device 1, a water inlet pipe 2, a water outlet pipe 3 and a first filter device 21; wherein, the reaction vessel 4 is provided with The hydrogen gas outlet is, for example, the hydrogen gas outlet arranged on the top or upper side wall of the reaction vessel, so as to discharge the hydrogen gas obtained by hydrogen hydrolysis.

[0023] The inside of the reaction vessel 4 is provided with a shelf 41 for shelving the reactant block 42 to be hydrolyzed to produce hydrogen and leaving a distance between the reactant block 42 and the bottom of the reaction vessel 4 for hydrolysis During the hydrogen production reaction, the reactant block 42 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com