Pohotonic crystal fiber and pohotonic crystal fiber sensor

A photonic crystal fiber and sensor technology, applied in cladding fibers, microstructure fibers, optical waveguides and light guides, etc., can solve the difficulty of filling metal nanocoatings and microfluids to be measured, unfavorable signal transmission, and loss of photonic crystal fibers in the measurement band Increase and other problems to achieve the effect of ensuring sensing accuracy, simple and fast operation process, and real-time sensing measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings.

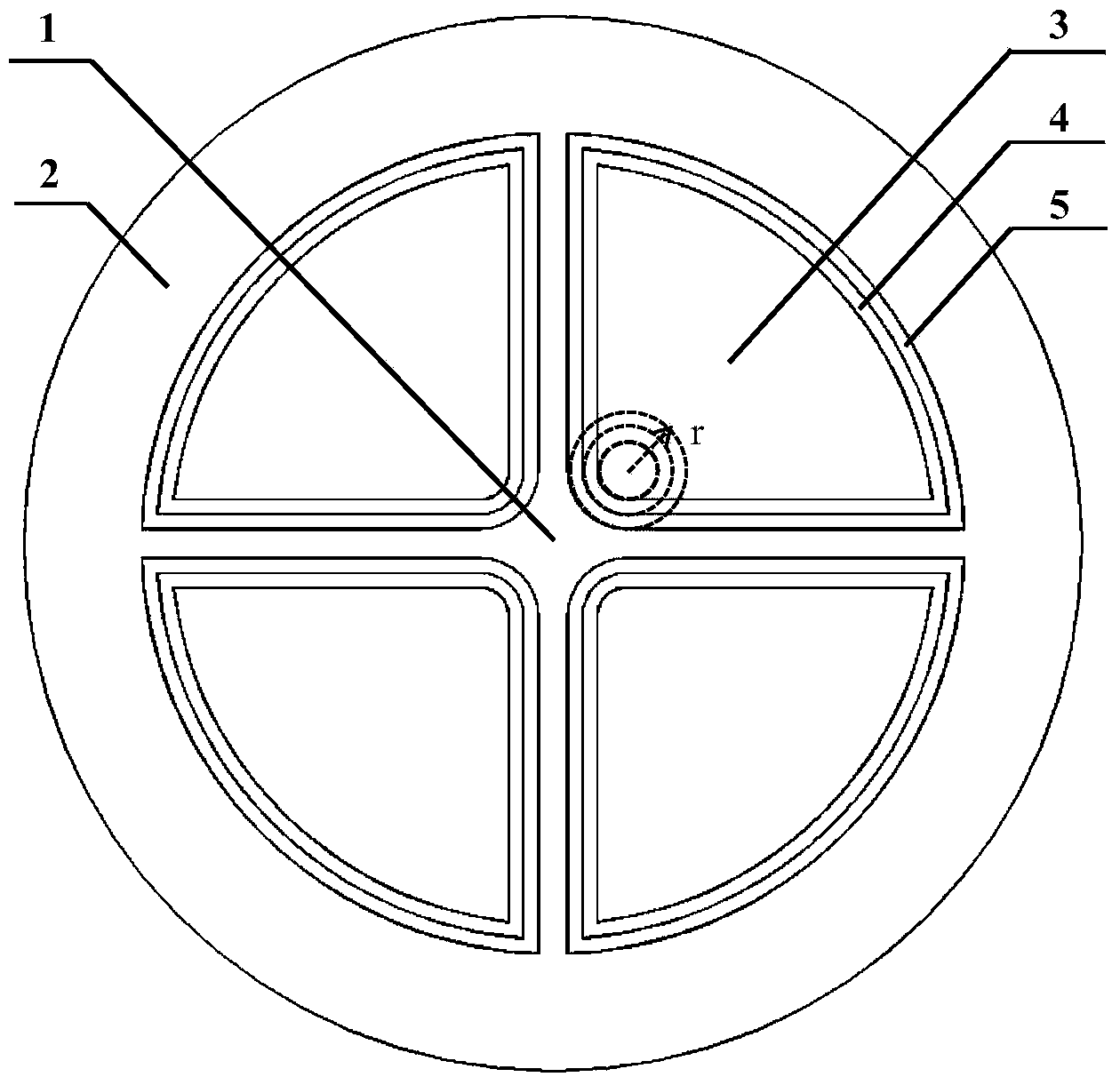

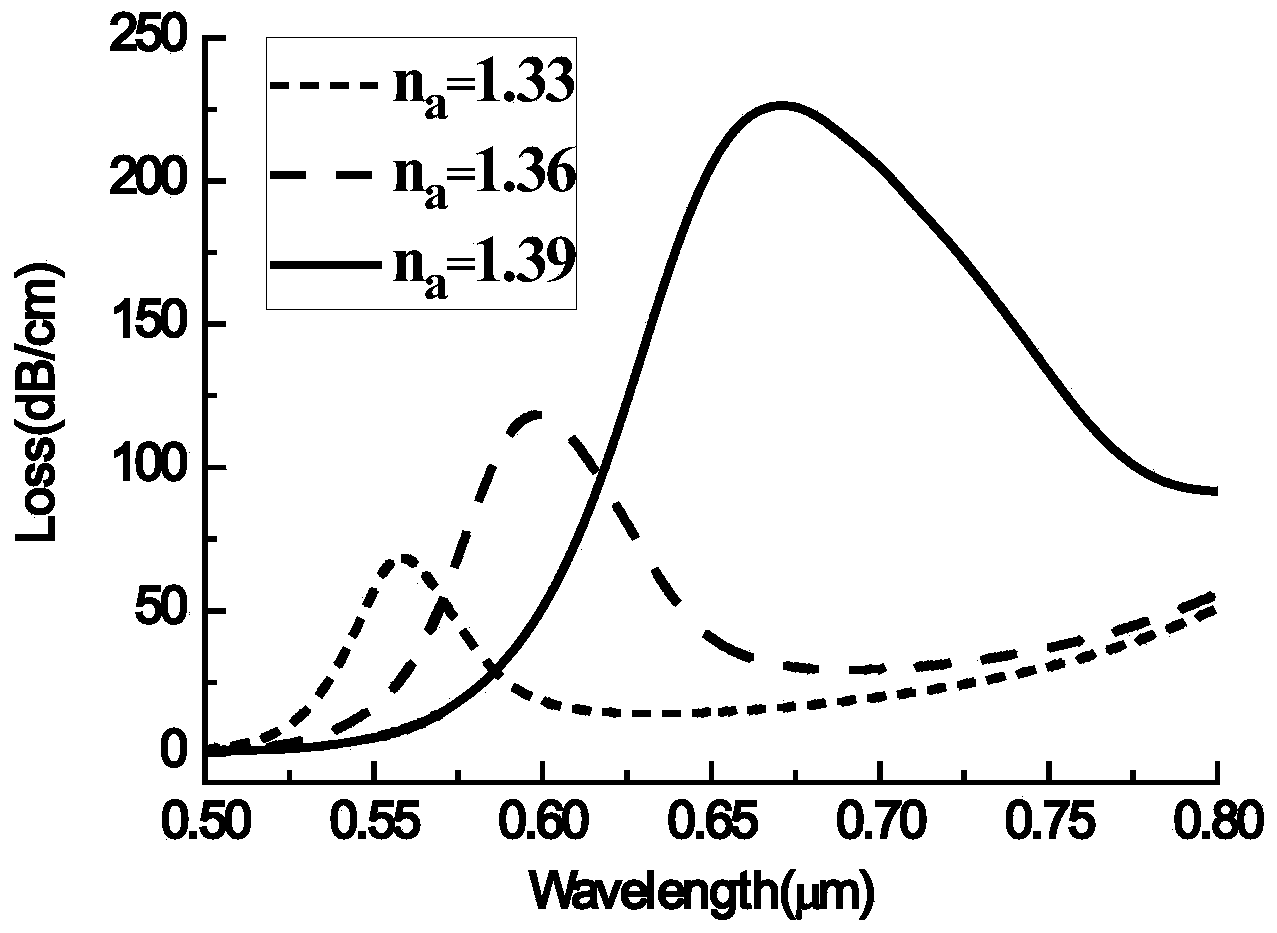

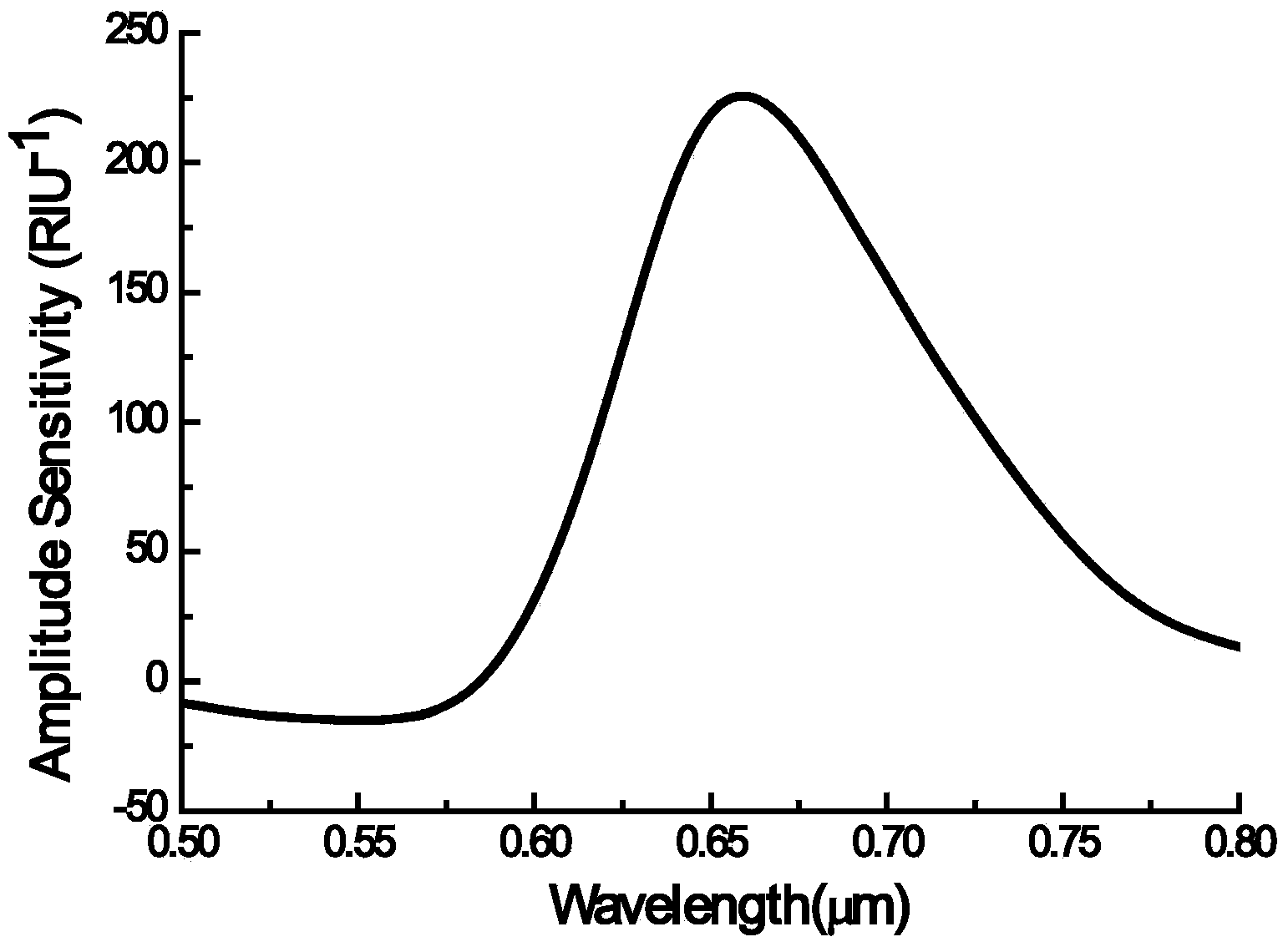

[0025] A photonic crystal fiber includes: a cladding, a core, and at least one air hole in the cladding; the cross section of the air hole is fan-shaped, the arc surface of the air hole is set away from the core, and the inner wall of the air hole is plated first There is a calcium fluoride film, followed by a gold nano film.

[0026] A photonic crystal fiber sensor includes a photonic crystal fiber. The photonic crystal fiber includes a cladding, a core, and at least one air hole in the cladding; the cross section of the air hole is fan-shaped, and the arc surface of the air hole is away from the fiber. The core is arranged, and the inner wall of the air hole is first plated with a calcium fluoride film and then with a gold nano film.

[0027] Based on the above technical solution and in conjunction with the drawings, the following specific implementation is given.

[0028] Suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com