Welding machine

A welding machine and welding gun technology, applied in welding accessories, welding equipment, welding equipment, etc., can solve the problems of lower product quality, lower work efficiency, inconvenient use, etc., and achieve the effect of improving overall performance, improving product quality, and good welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

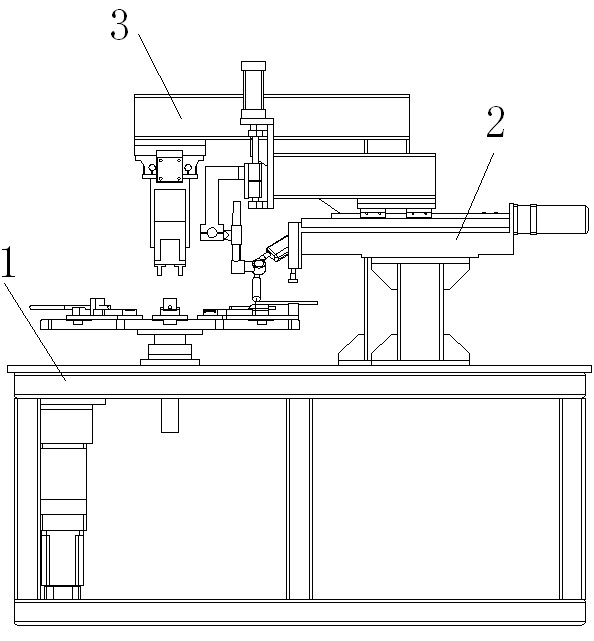

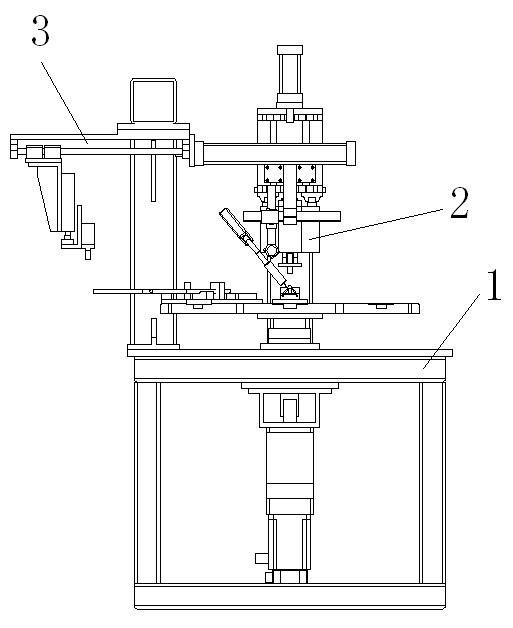

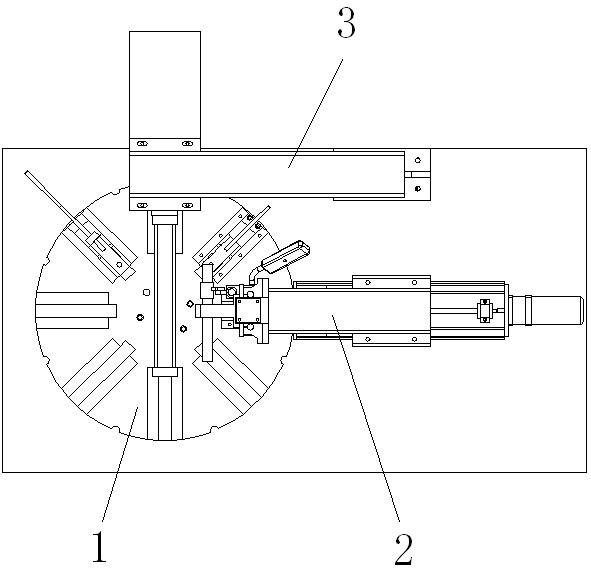

[0043] see Figure 1 to Figure 22 , the welding machine in this embodiment includes a turntable device 1, a welding torch device 2 and a manipulator device 3, the welding machine is mainly used for welding the feather board 68 and the stud 69, wherein the turntable device 1 includes a workbench 71, a turntable servo motor 72, a servo Reducer 73, limit cylinder 74, turntable 75 and eight clamps 76, turntable servo motor 72 is installed in the workbench 71 by servo reducer 73, turntable 75 is installed on the workbench 71, this turntable 75 and servo reducer 73 In cooperation, the turntable 75 can be driven to rotate by the turntable servo motor 72 .

[0044]Eight clamps 76 in the present embodiment are evenly installed on the turntable 75, and the clamps 76 are used to fix the product to be welded. The number of clamps 76 in the present invention can be set according to actual needs, usually 6-12, Preferably eight. Each clamp 76 in the present embodiment all comprises fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com