Patents

Literature

386 results about "Horizontal transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Horizontal transmission is the transmission of infections between members of the same species that are not in a parent-child relationship. This has been generalized to include transmissions of cultural traits between humans.

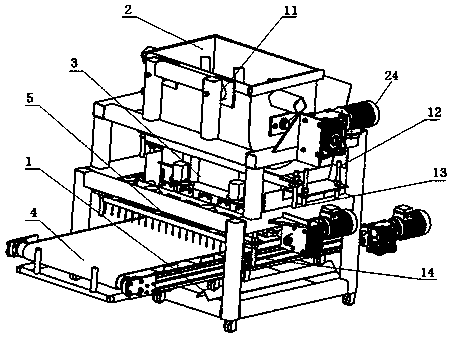

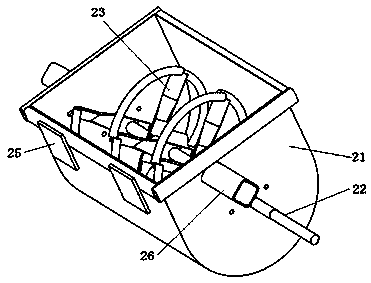

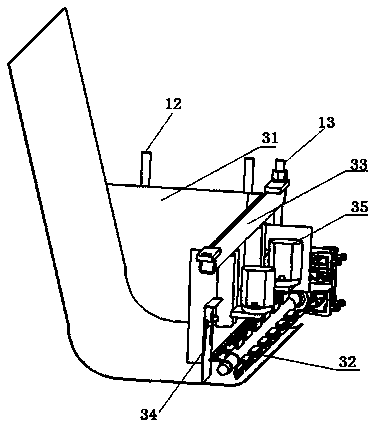

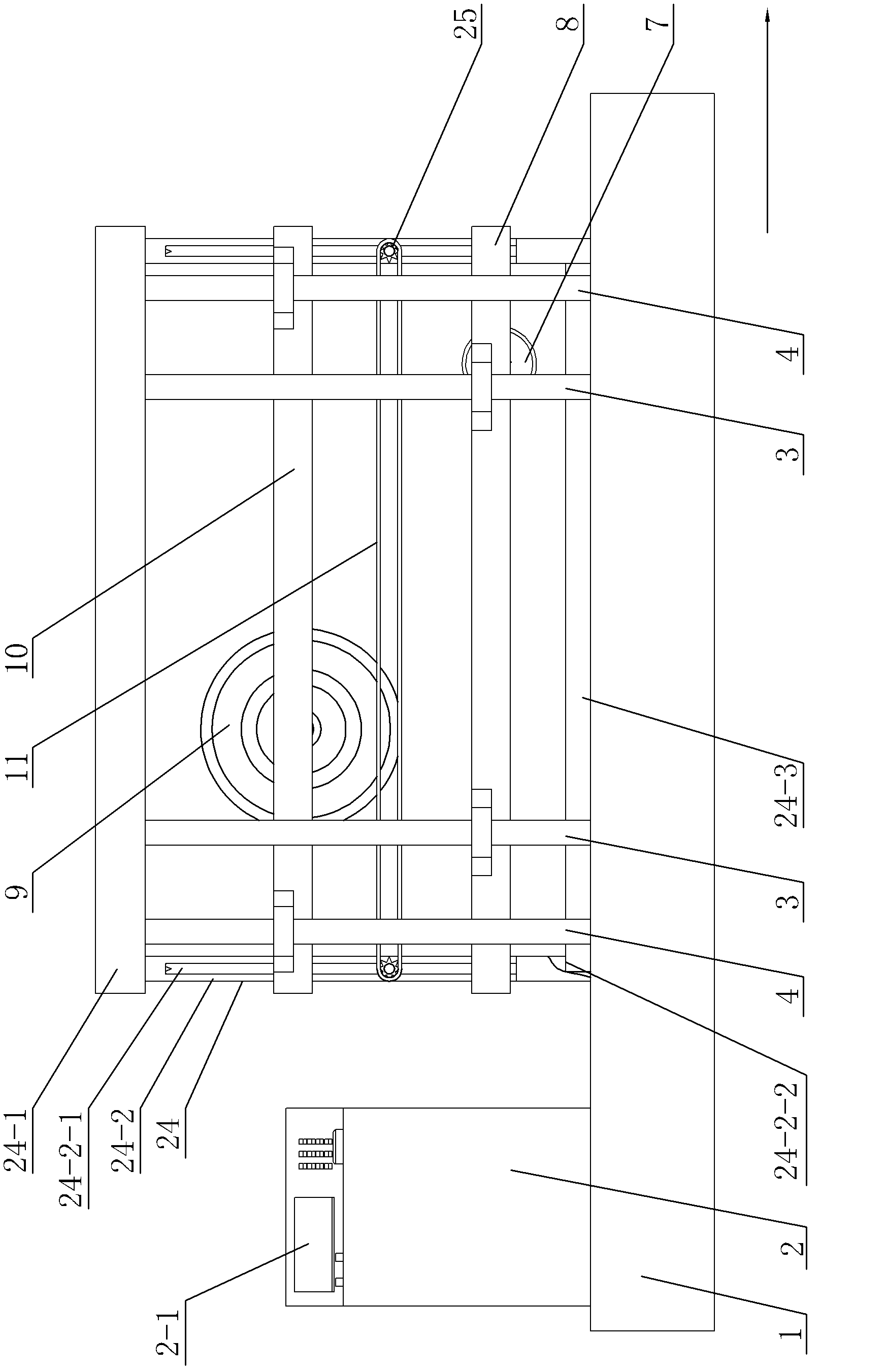

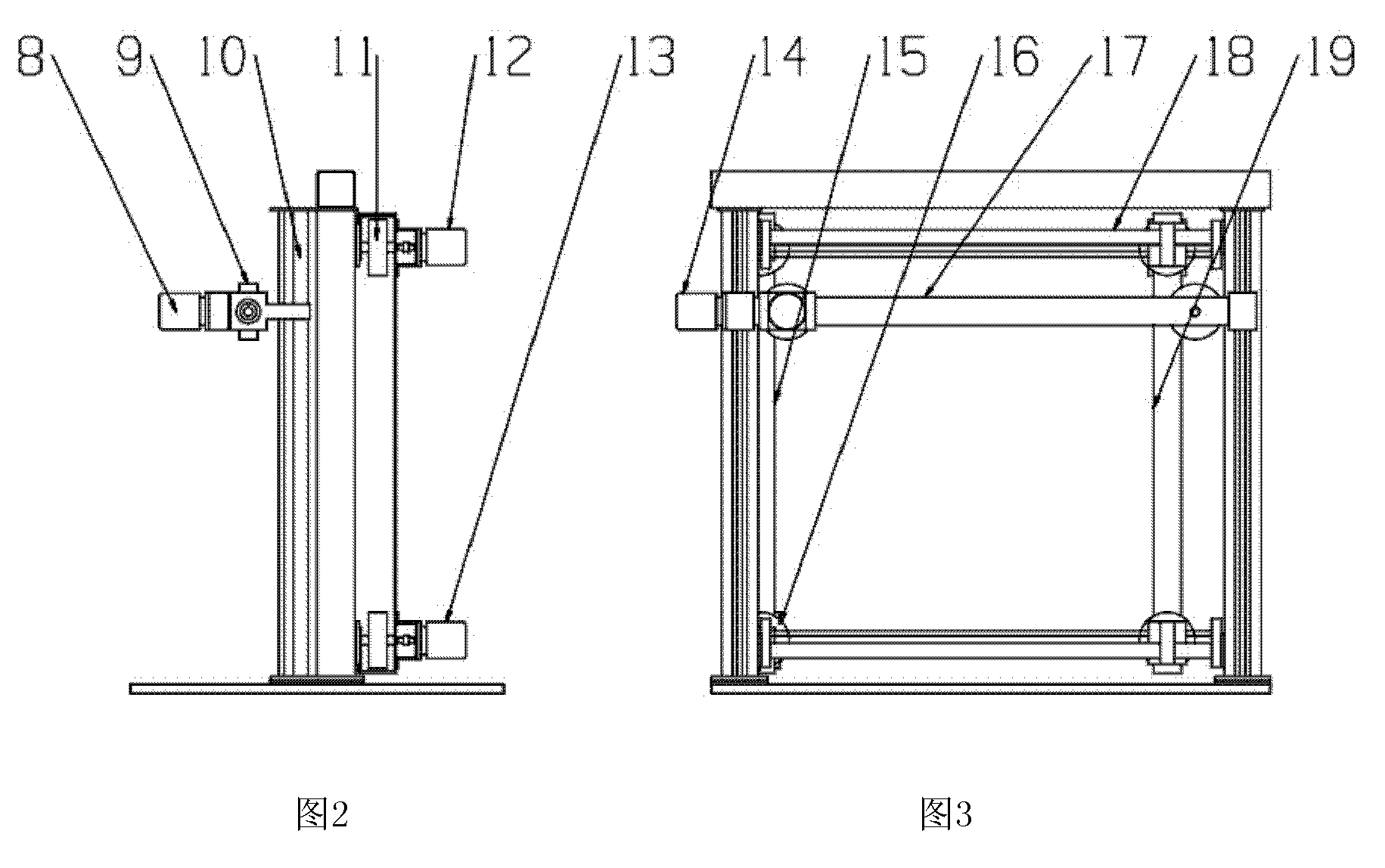

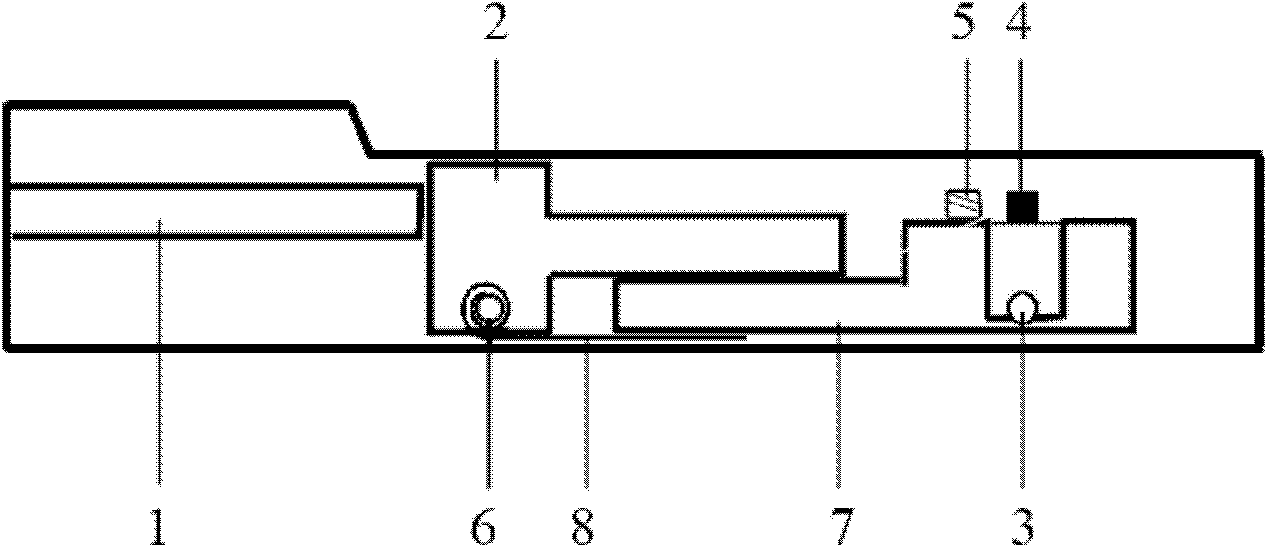

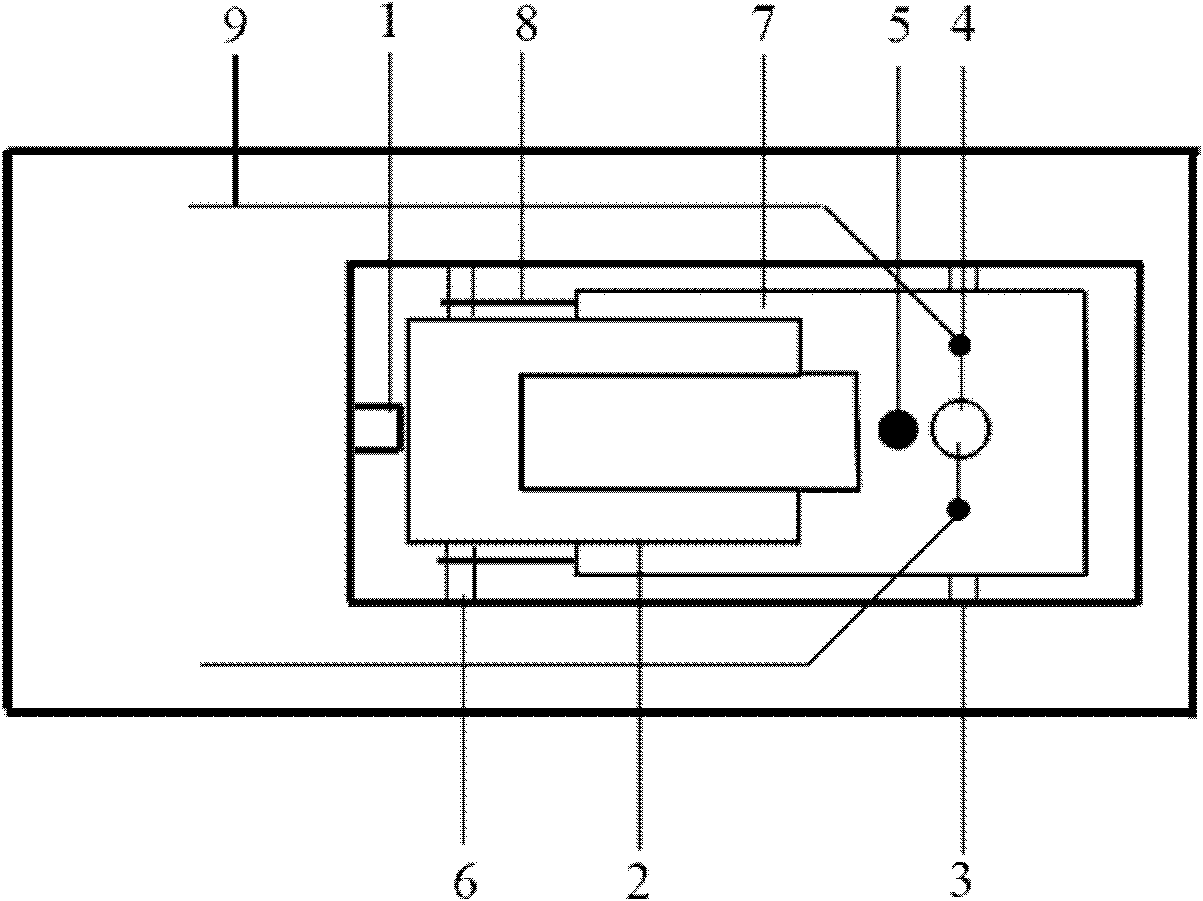

Automatic stirring mortar and tile coating mechanism and method

InactiveCN109435055AGuaranteed uniformityGuaranteed flatnessBuilding constructionsCement mixing apparatusHorizontal transmissionControl system

The invention discloses an automatic stirring mortar and tile coating mechanism and method. The mechanism comprises a machine frame with universal casters at the bottom; the machine frame is providedwith a stirring hopper assembly, a discharging hopper assembly, a horizontal conveying assembly and a scraping plate assembly, the stirring hopper assembly is used for stirring mortar raw materials toform mortar and pouring the mortar out, the discharging hopper assembly is used for receiving the mortar poured out by the stirring hopper assembly and outputting the mortar to tiles, the horizontalconveying assembly is located below the discharging hopper assembly and is used for driving the tiles to horizontally move, and the scraping plate assembly is used for scraping the mortar on the tiles; the scraping plate assembly locates above the horizontal conveying assembly and locates in front of a discharge port of the stirring hopper assembly, the back surfaces of the tiles face upwards andare placed on the horizontal conveying assembly, and the tiles are used for receiving the mortar which is output by the discharging hopper assembly along with the movement of the horizontal conveyingassembly; and the scraping plate assembly is used for scraping the mortar on the tiles during the movement process of the tiles, and the actions of the stirring hopper assembly, the discharging hopperassembly and the horizontal transmission assembly are uniformly coordinated and controlled through a control system. According to the mechanism and method, the mechanical automation level, the efficiency and the quality of the tile coating operation are improved, and the labor intensity of tile coating operation is reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

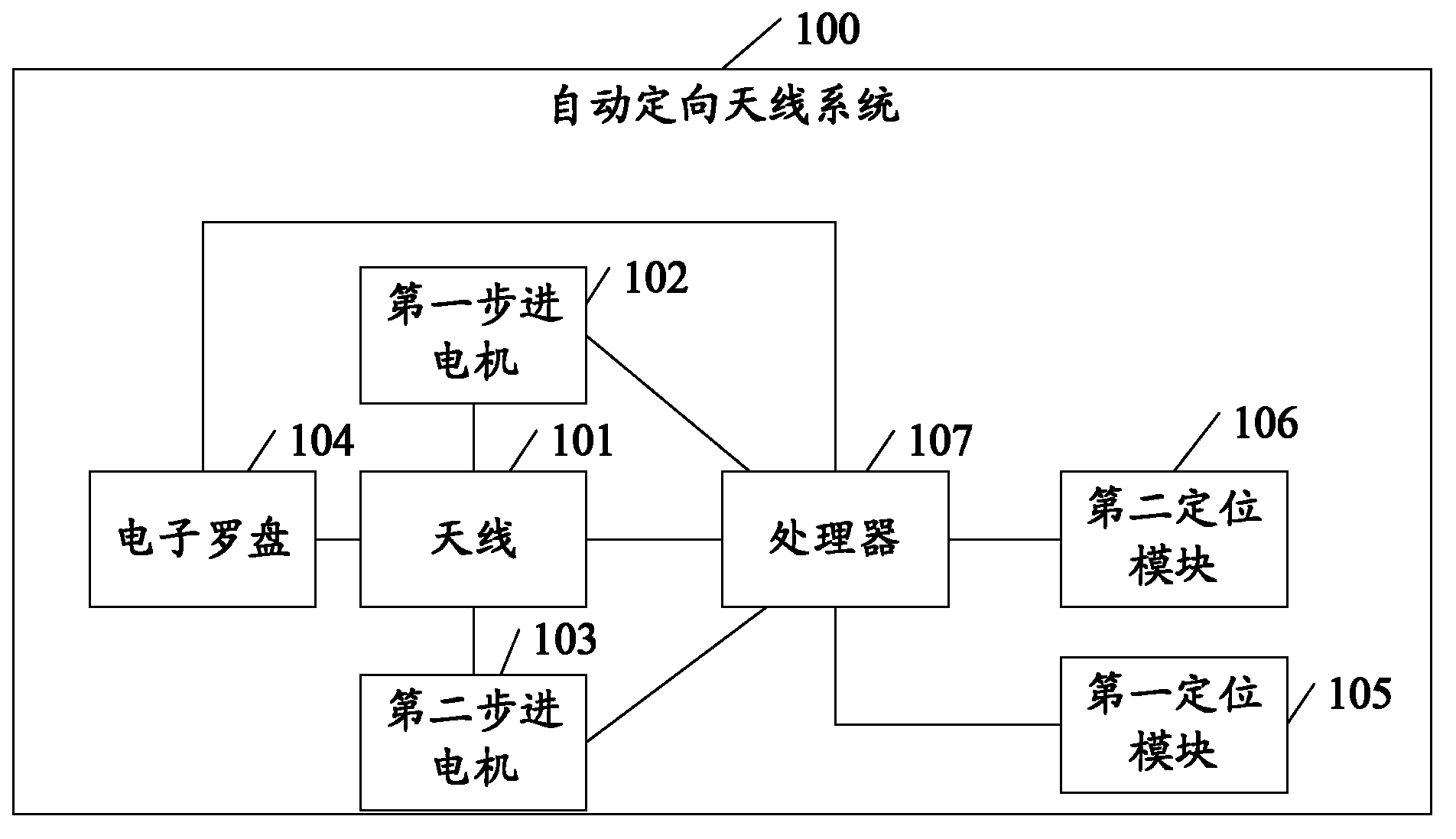

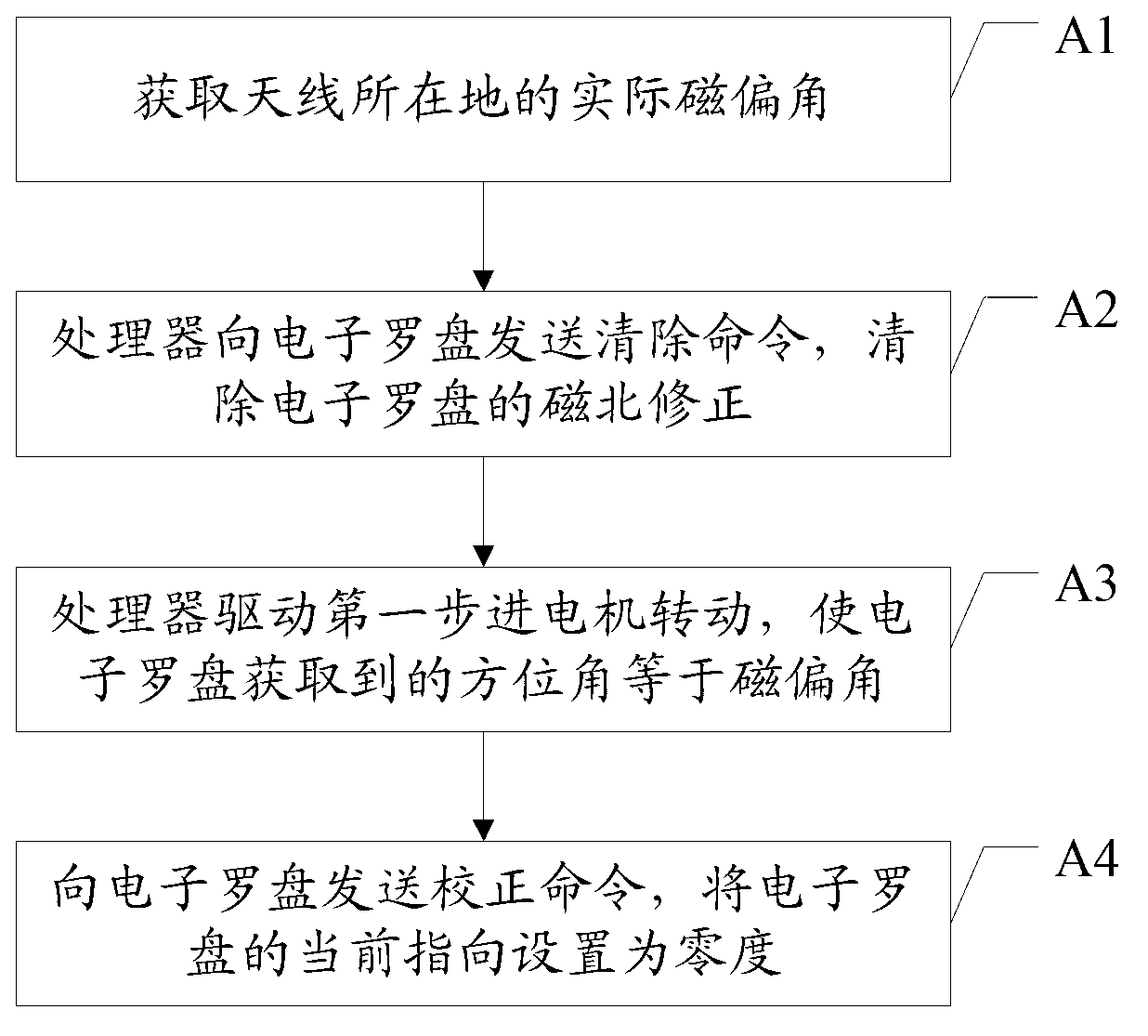

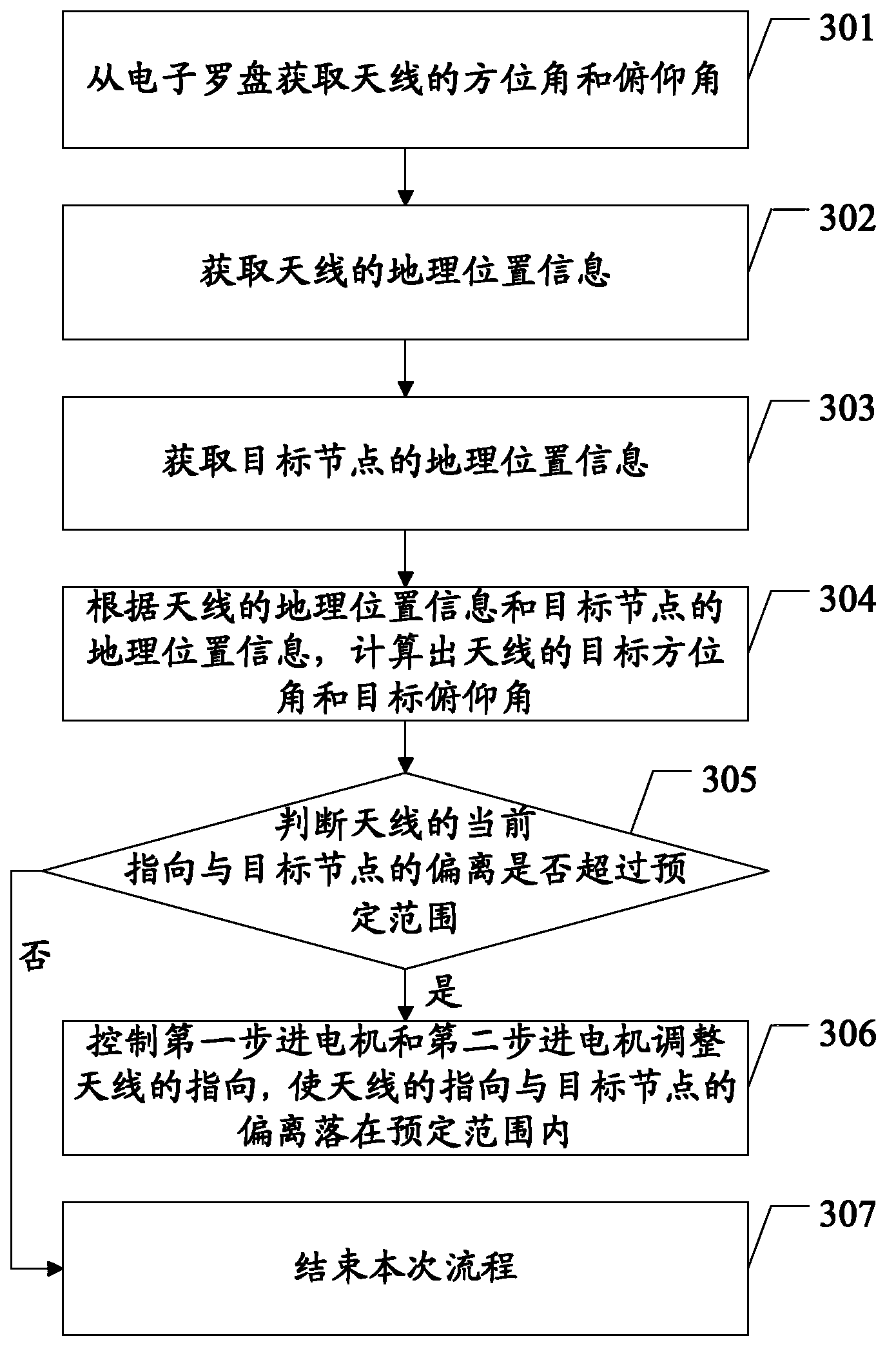

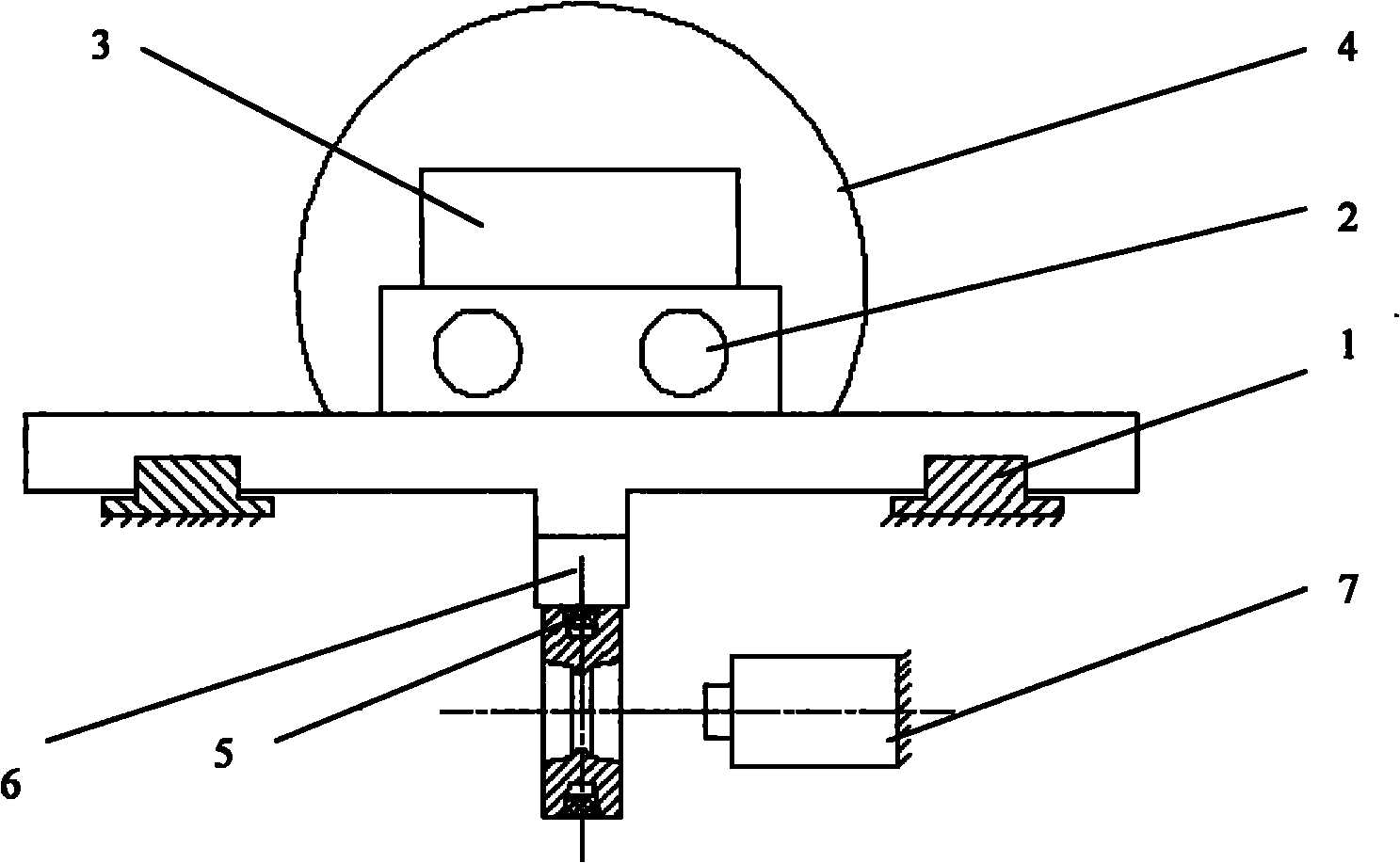

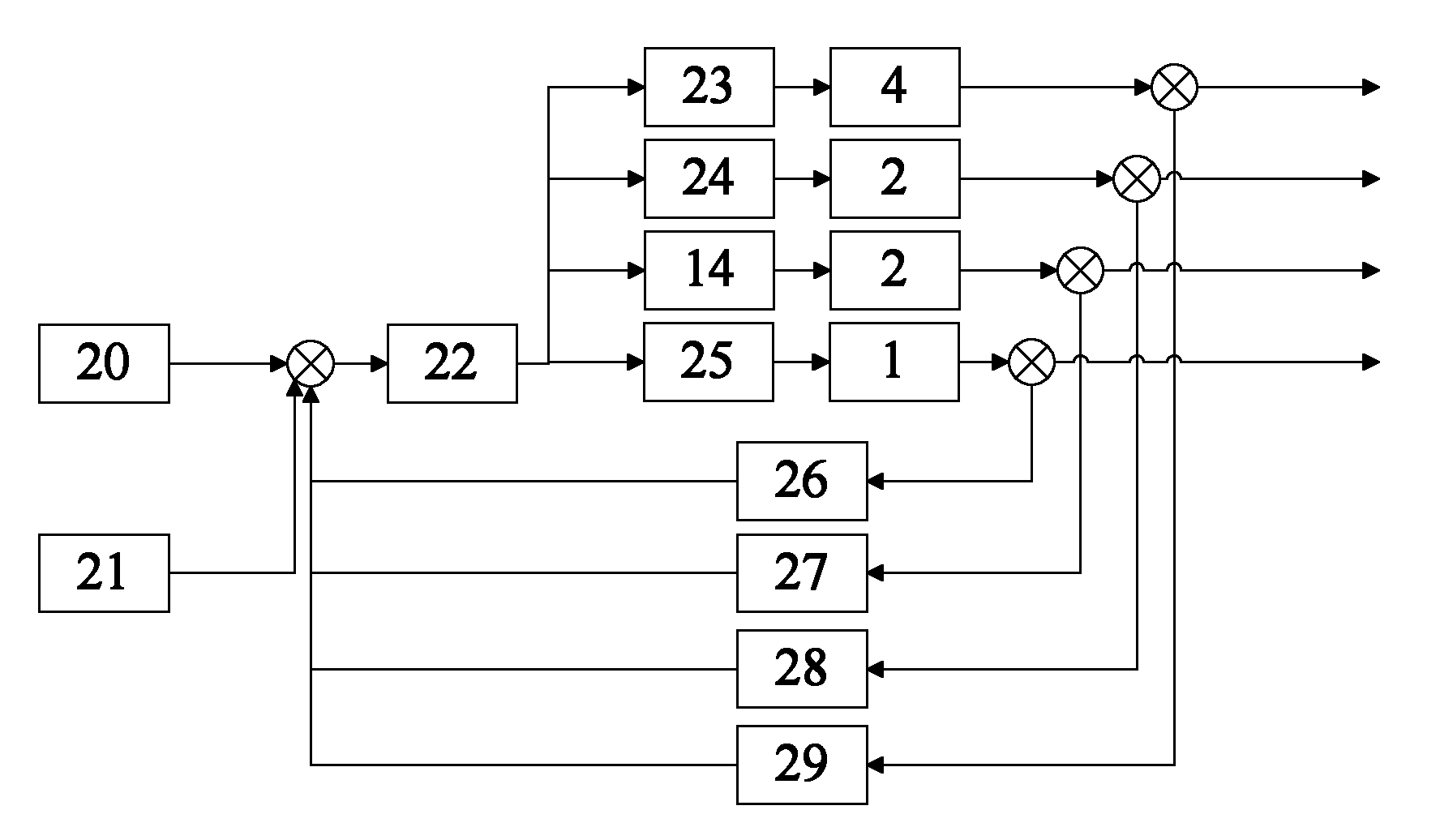

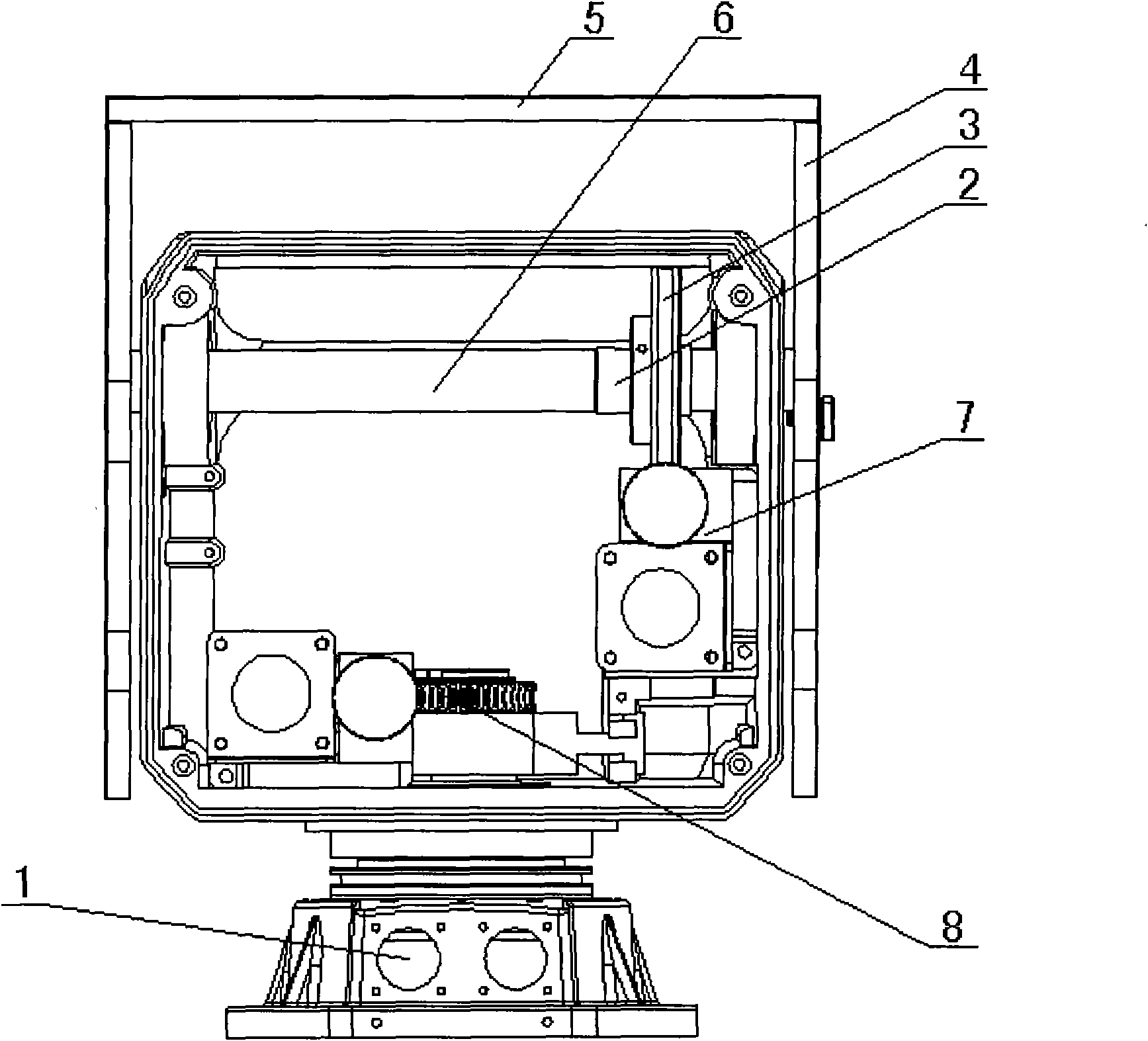

Automatic orientation antenna system, and method and device for automatic orientation of antennas

ActiveCN103022696AIncrease flexibilityImprove communication qualityAntennasHorizontal transmissionCommunication quality

An embodiment of the invention discloses an automatic orientation antenna system, and a method and a device for automatic orientation. The automatic orientation antenna system comprises a first stepping motor, a second stepping motor and an electronic compass, wherein the first stepping motor and the second stepping motor are connected with a horizontal transmission mechanism and a vertical transmission mechanism of an antenna respectively. By the first stepping motor and the second stepping motor, the antenna can rotate horizontally and vertically. Orientation of the antenna can be adjusted and controlled by acquiring azimuth angle and pitch angle of the antenna and geological information of the antenna and a target node, and accordingly when high altitude difference exists between the antenna and the target node, communication quality between the antenna and a signal transmitter can be improved by adjusting vertical orientation of the antenna, and flexibility of the automatic orientation antenna system is improved effectively.

Owner:SAIGE COMM SHENZHEN CITY

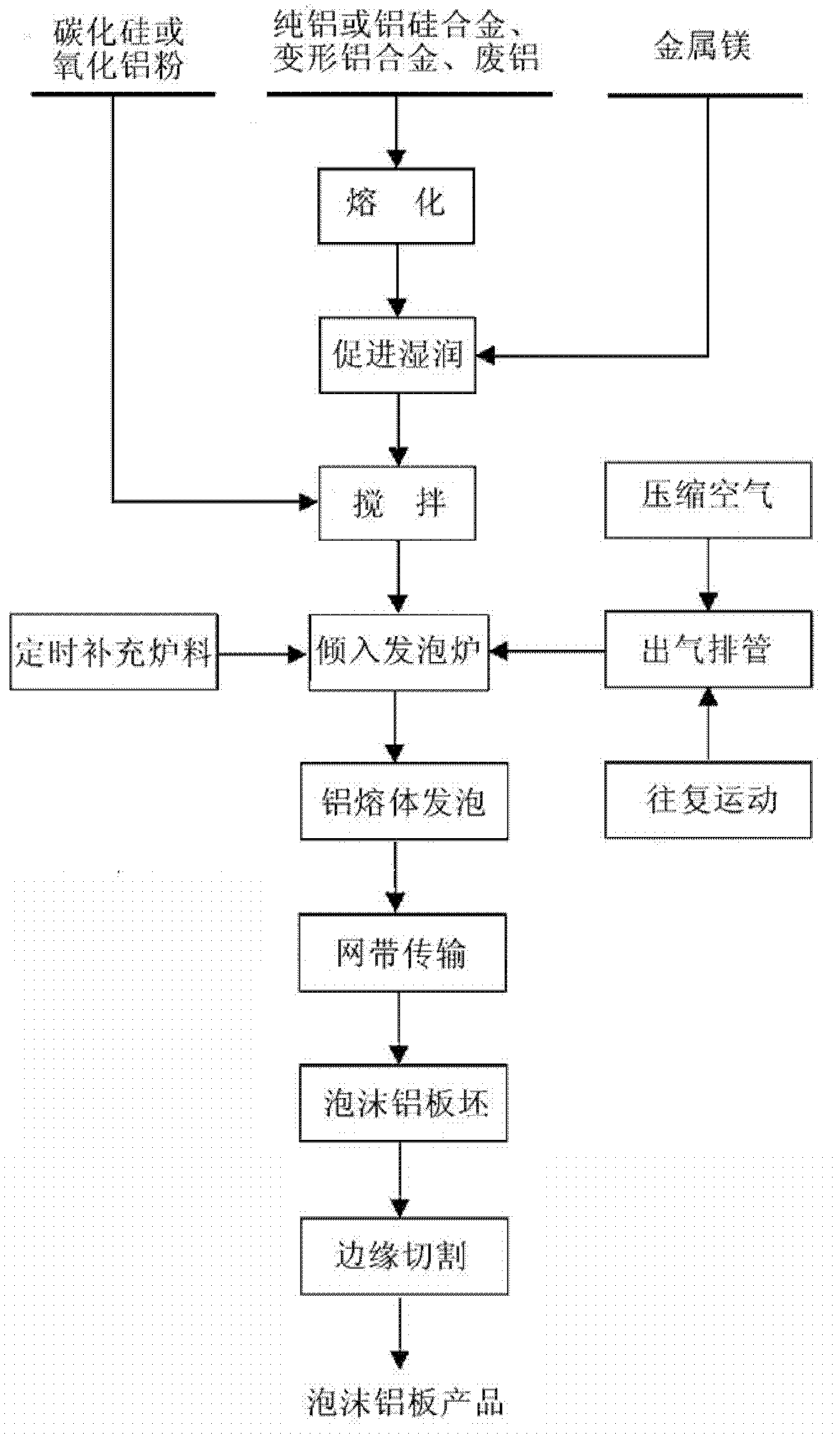

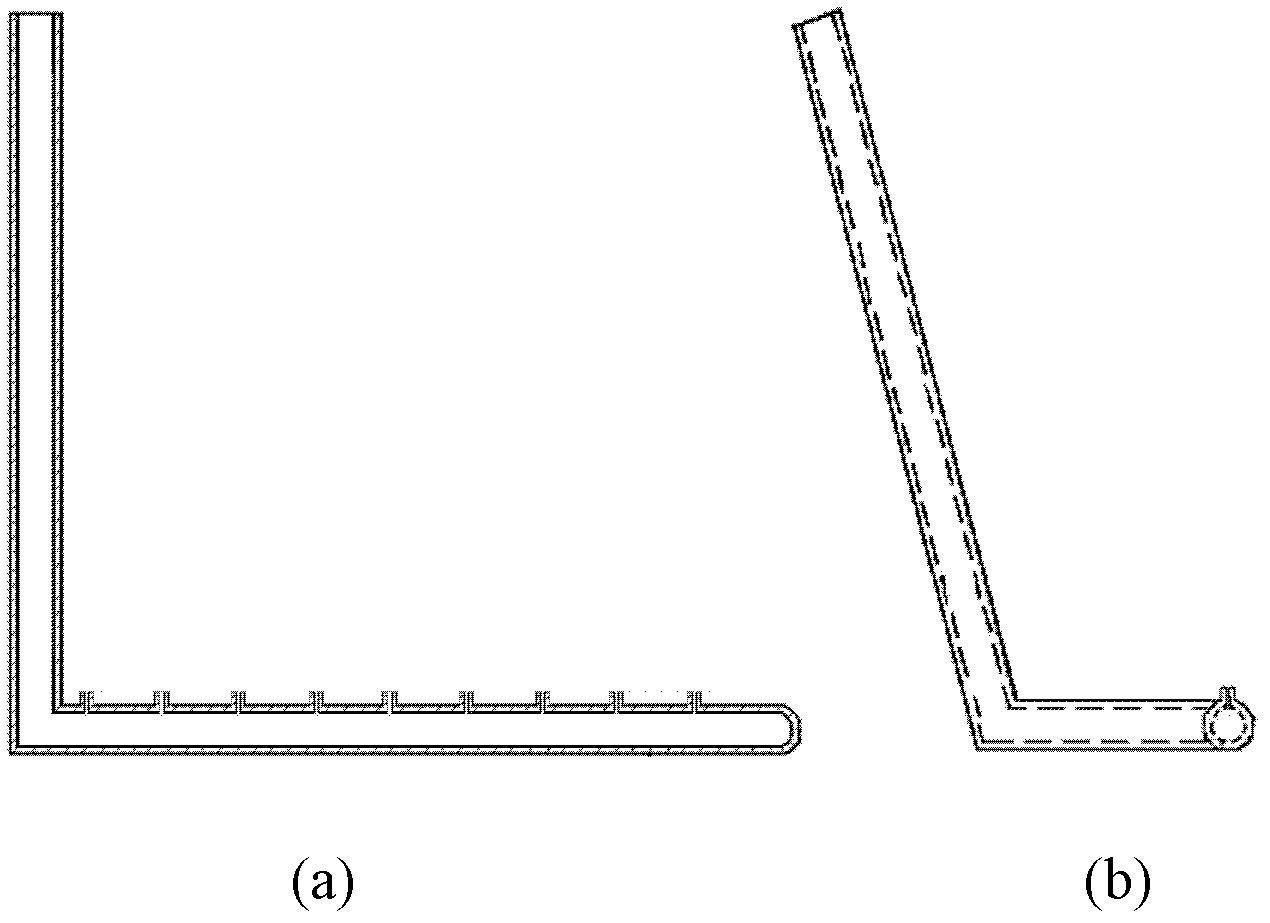

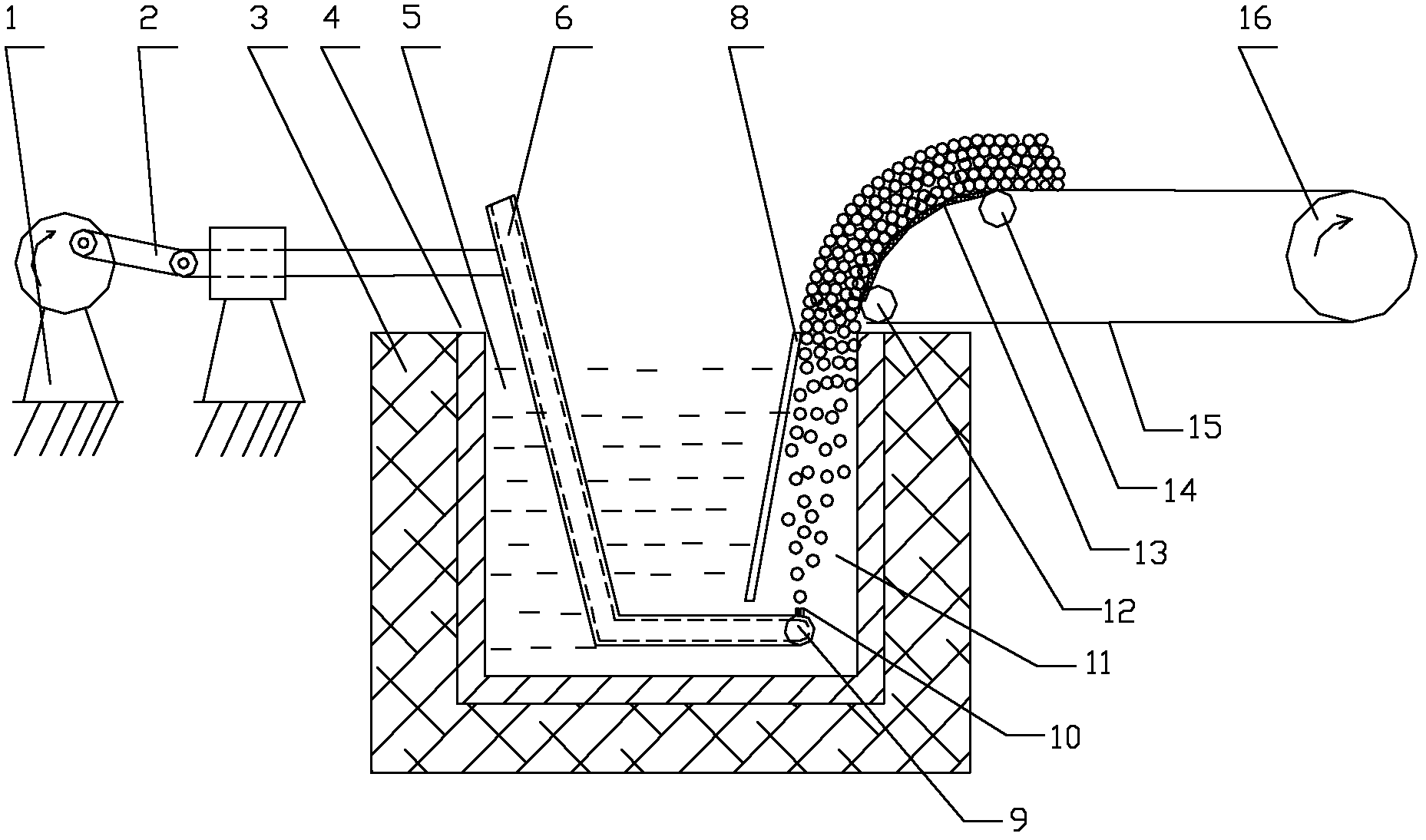

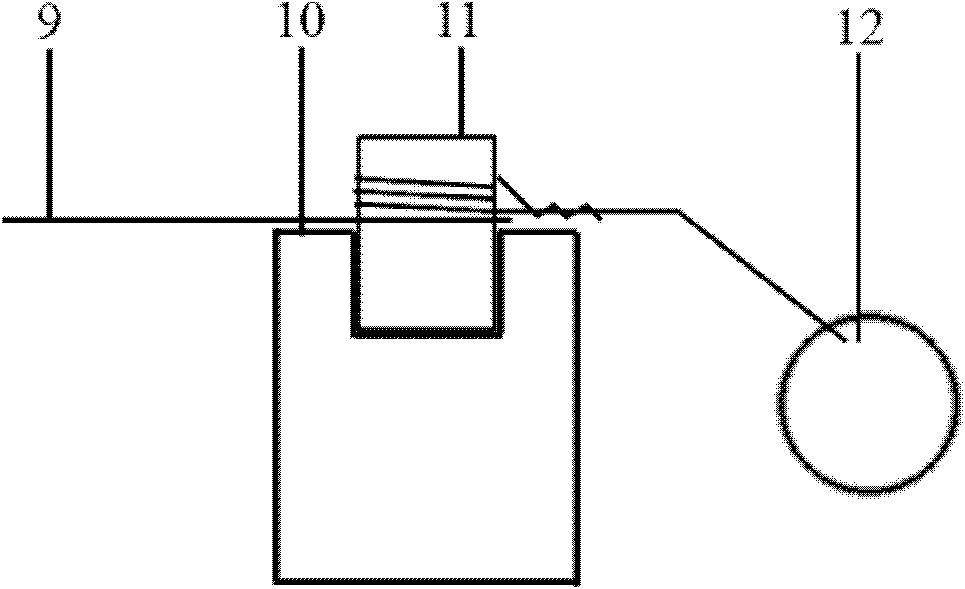

Process and apparatus for continuous production of closed-cell aluminum foam with blowing foaming

The invention relates to a process and an apparatus for continuous production of a closed-cell aluminum foam through blowing foaming. The process comprises the following steps: melting a raw material, adding with a ceramic tackifier and a moistening promoter, stirring to obtain molten aluminum with uniform component, carrying out continuous foaming with the apparatus for the continuous productionof the closed-cell aluminum foam with blowing foaming to obtain a molten aluminum foam with uniform foam size, and controllable density and productivity, and producing a foamed aluminum board by going through a net belt and transmitting with an arc transition mechanism and cutting. The apparatus is characterized in that: a simple crank link mechanism is adopted to realize the reciprocating motion of a horizontal outlet duct, and the arc transition mechanism allows the ascending lifting of the molten aluminum foam to be changed into horizontal transmission. According to the invention, the process and the apparatus are simple, the operation control is accurate, and a purpose that the pore size and the density of foamed aluminum products can be accurately controlled at a high efficiency anda low cost is realized because the foam size of the molten aluminum is adjusted by changing the frequency of the reciprocating motion of the outlet duct, the pressure and the flow of a compressed gasand the diameter of outlet micropores.

Owner:ANHUI NEOFOUND TECH

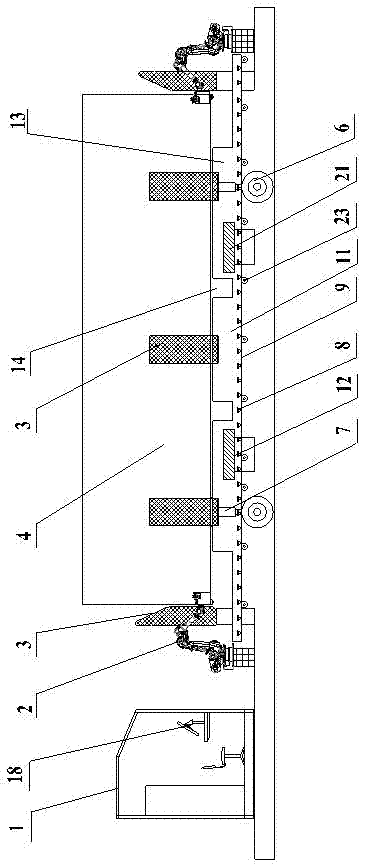

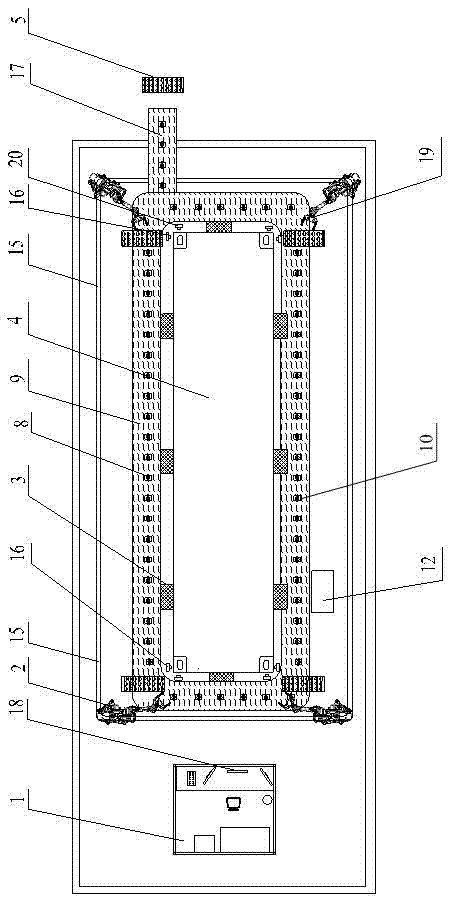

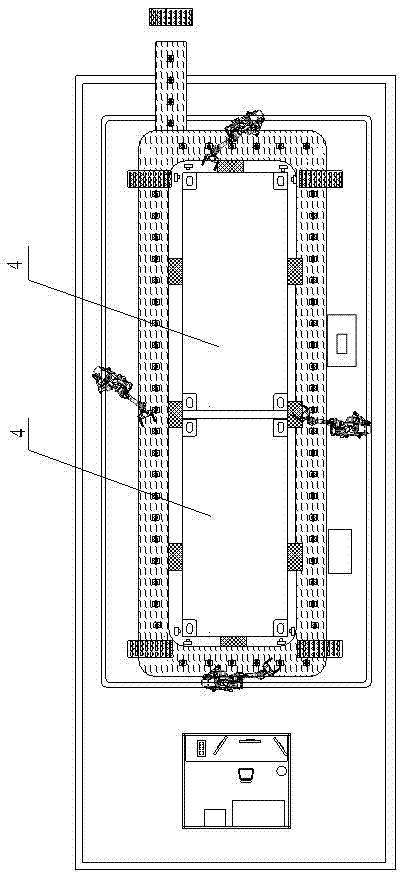

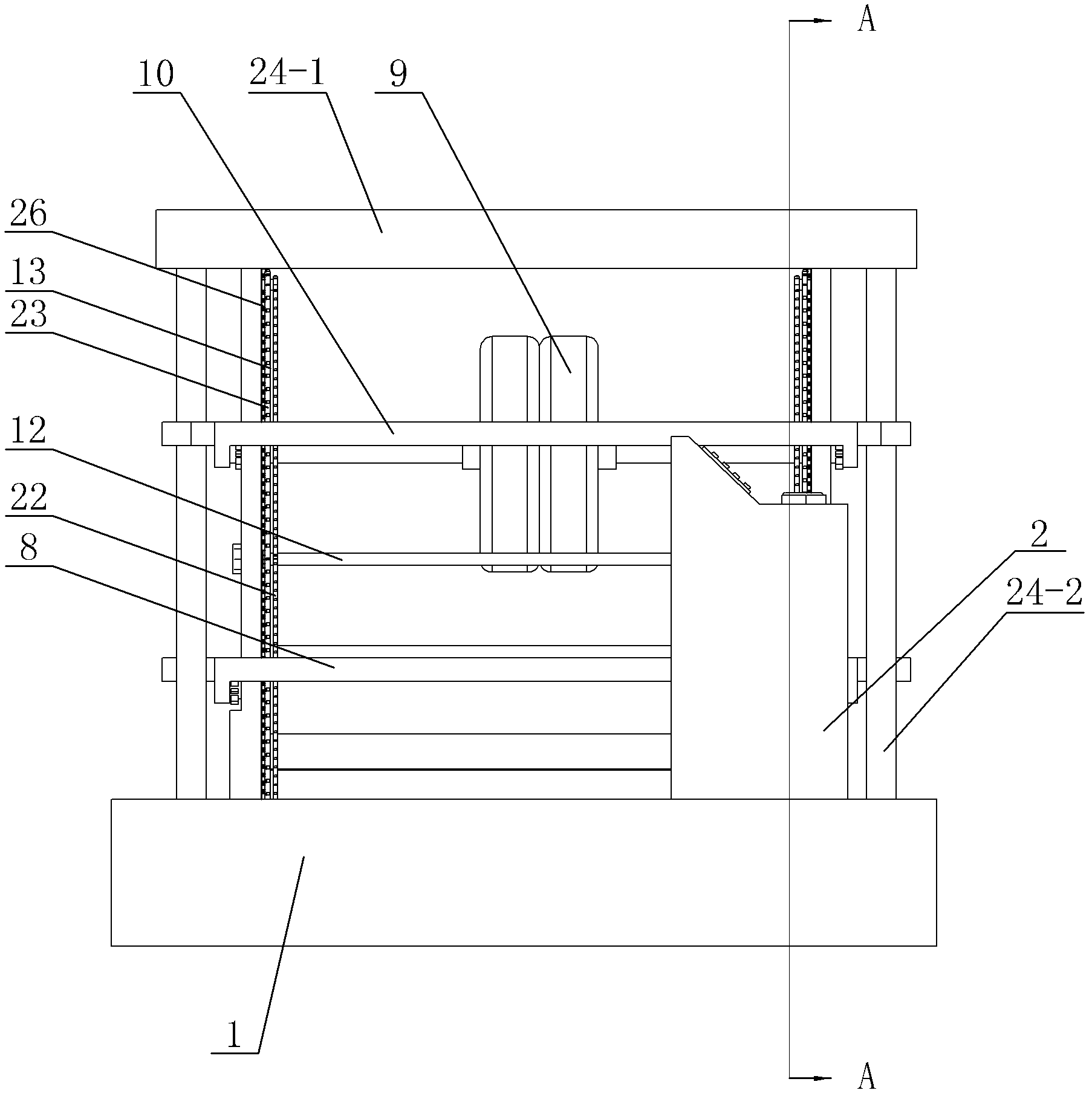

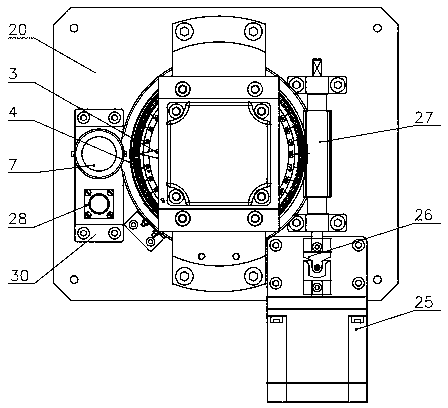

Automatic detachment and installation system of container fixed spin lock

ActiveCN104709623AAchieve installationIncrease the level of automationLarge containersMetal working apparatusHorizontal transmissionSpin locks

The invention discloses an automatic detachment and installation system of a container fixed spin lock. The system comprises a control device and a placing platform, the middle of the placing platform protrudes to form container carrying platforms used for supporting the middle of the bottom surface of a container, and the four corners of the container are impending; locating stoppers are arranged on the placing platform or at the outer side of the placing platform, and the locating stoppers are used for limiting the placing position of the container on each container carrying platform; a circle of horizontal transmission devices are arranged around the placing platform, spin lock locating holes are formed in the horizontal transmission devices, multiple intelligent mechanical arms are arranged at the outer sides of the horizontal transmission devices, and the intelligent mechanical arms are capable of picking up the spin locks on the horizontal transmission devices automatically and installing the spin locks into the lock holes of each container. By using the system, automatic installation and detachment of the fixed spin locks used for the container can be achieved, the number of field personnel can be greatly reduced, the labor cost is lowered, meanwhile, the safety management level of a wharf is promoted, and the working efficiency is improved.

Owner:姜红卫 +1

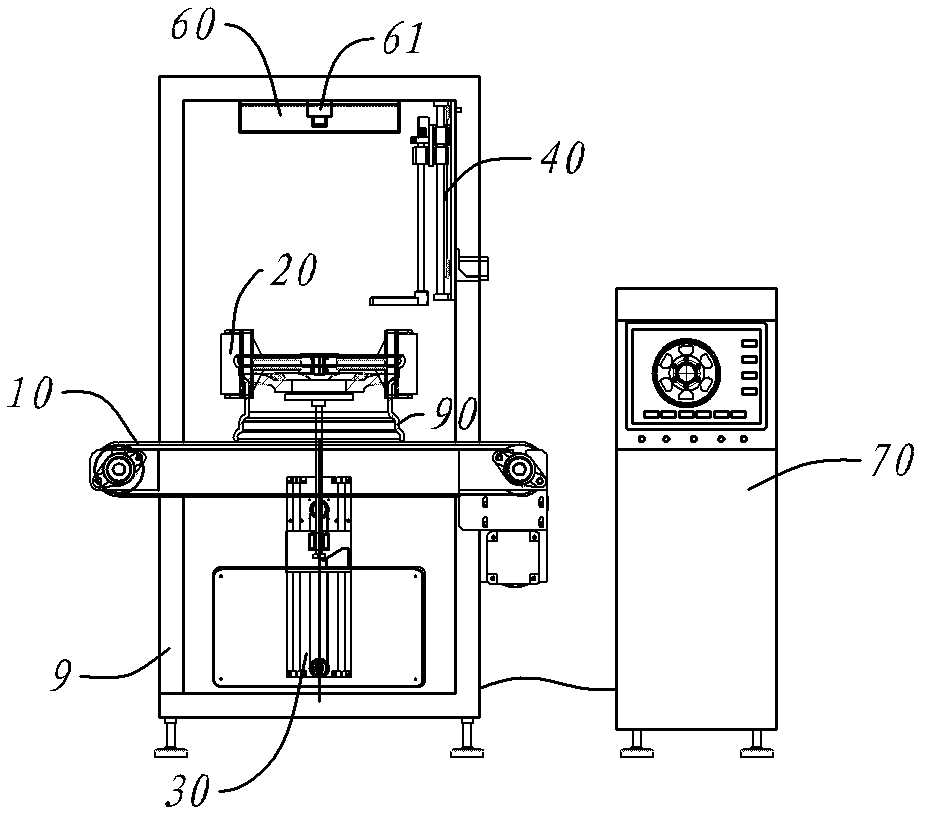

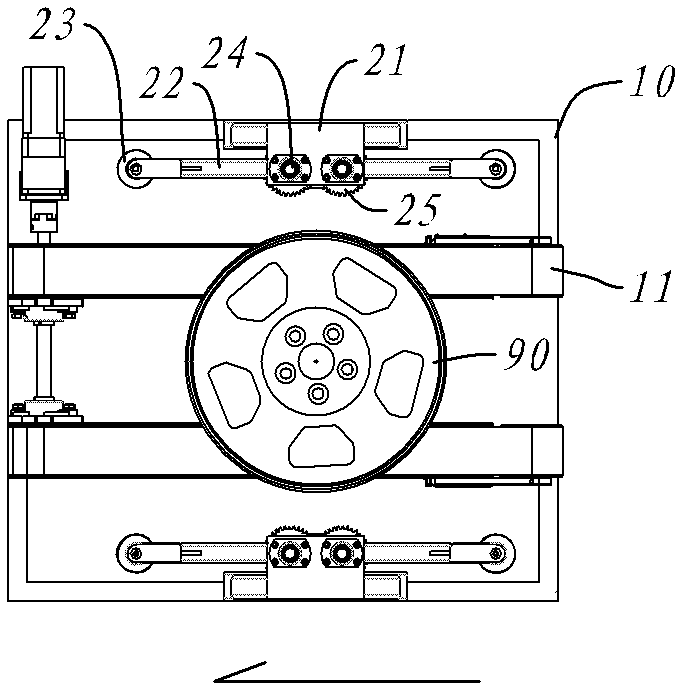

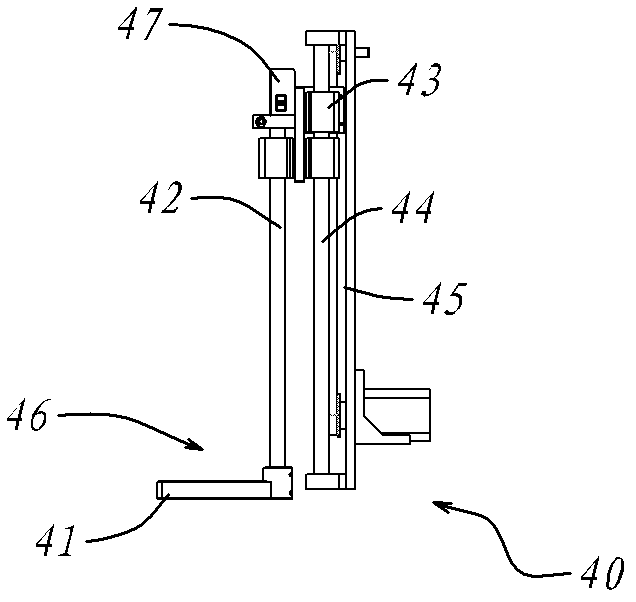

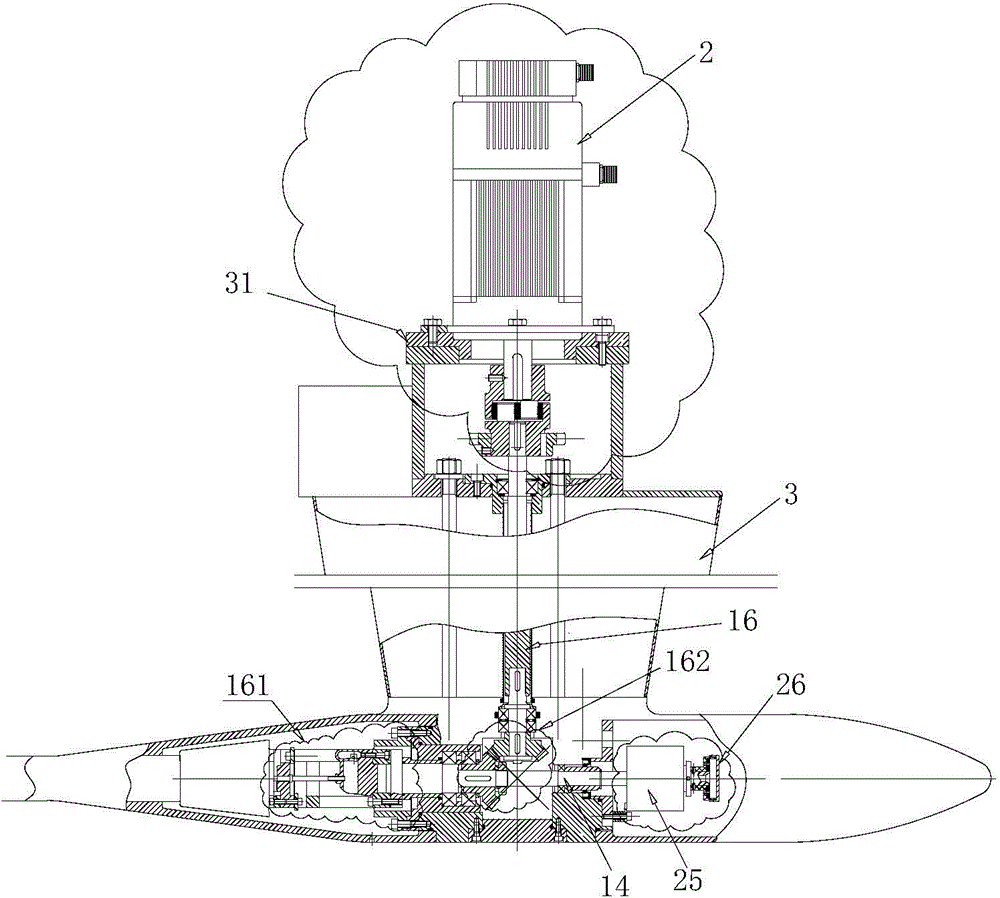

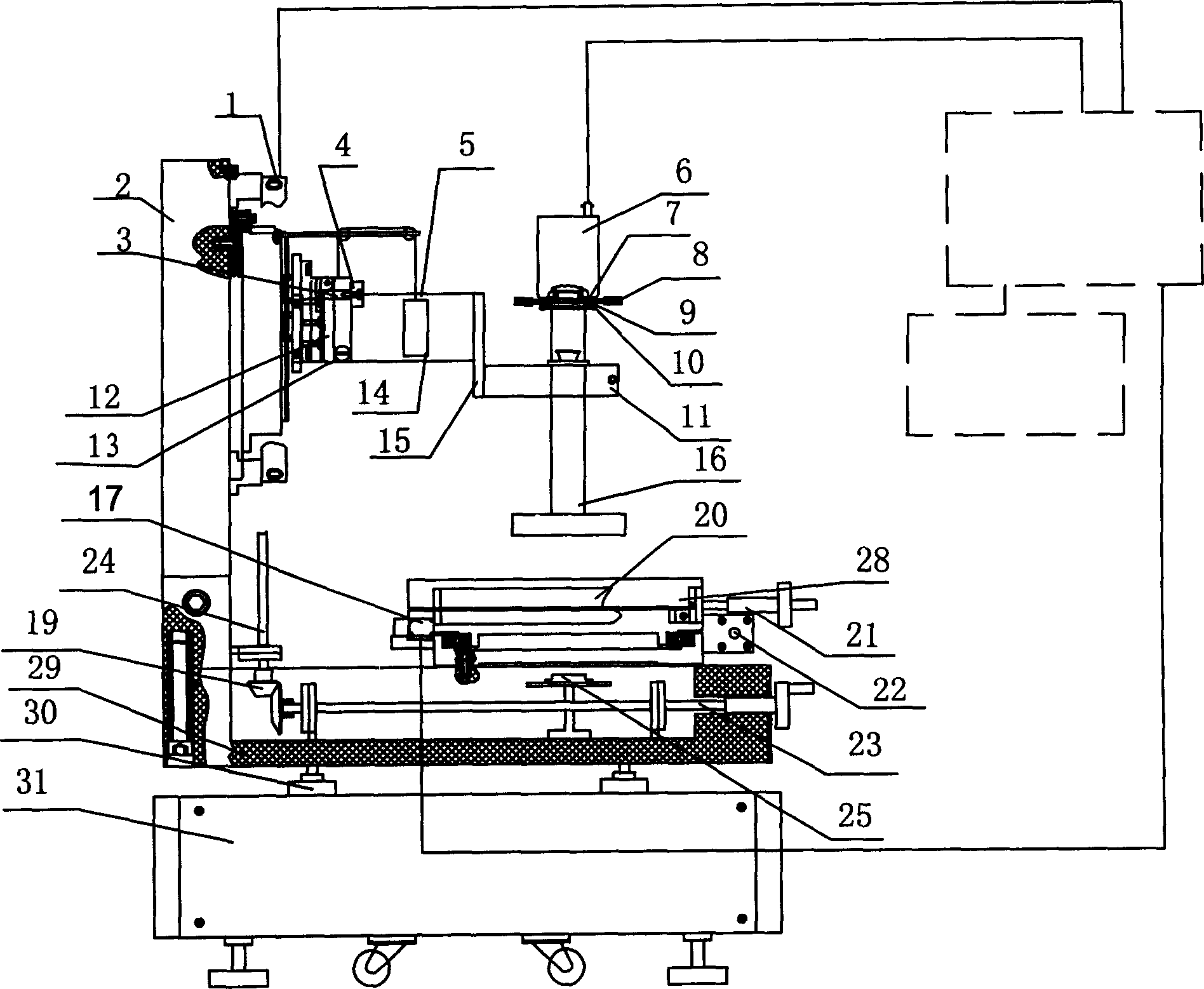

Hub characteristic detecting device for production line

InactiveCN102636093ASimple and reliable stepsNo additional displacementMechanical thickness measurementsUsing optical meansProduction lineHorizontal transmission

The invention discloses a hub characteristic detecting device for a production line. The hub characteristic detecting device is characterized by comprising a horizontal transmission mechanism, a positioning mechanism, an offset detecting mechanism, a thickness detecting mechanism and an imaging mechanism, wherein a rotating shaft of a hub is vertically arranged at one end of the horizontal transmission mechanism, moves to the position of the positioning mechanism horizontally and stands on a conveying belt naturally after being horizontally positioned; in the standing process, the offset detecting mechanism and the thickness detecting mechanism are controlled to acquire hub offset and thickness data, and carries out imaging processing from the top surface of the hub by the imaging mechanism; and finally, the hub is conveyed out by the horizontal transmission mechanism in a same posture. The posture of the hub is constant in the detecting process, the hub keeps standing after being horizontally positioned by the positioning mechanism once till being output finally, so that the step is simple and reliable, no additional displacement is caused. The hub characteristic detecting device disclosed by the invention has the advantages that low efficiency and worse consistency of manual operation are avoided, the detecting speed is high, the period is very short and the detecting consistency is good.

Owner:厦门宣凯精密制造有限公司

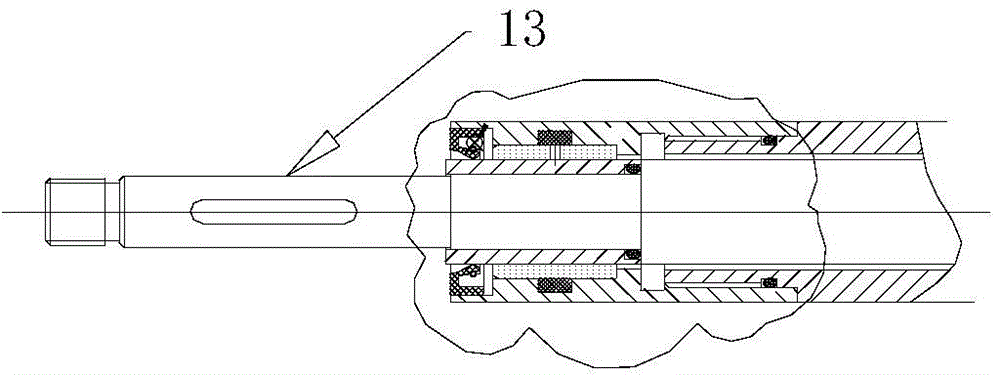

Strain propeller electric test dynamometer

ActiveCN103604600AEasy to assembleLow costMachine part testingForce measurementHorizontal transmissionStress conditions

The invention discloses a strain propeller electric test dynamometer which comprises a support, a servo motor arranged above the support, a vertical transmission shaft in transmission connection with the servo motor, and a horizontal transmission shaft in meshed transmission with the vertical transmission shaft through a gear set, wherein one end of the horizontal transmission shaft is connected with a thrust / torque sensing device; the thrust / torque sensing device is connected with a propeller through a horizontal spindle; a junction box is arranged at the other end of the horizontal transmission shaft through a sliding ring. The immersion depth tested by the dynamometer is 500mm, the dynamometer has high water tightness and normally operates at the temperature of 0-40 DEG C, the stress conditions of an underwater propeller in an operating state can be accurately measured, and the error is controlled to be 0.5 percent.

Owner:SHANGHAI ORIENTAL MARITIME ENG TECH CO LTD

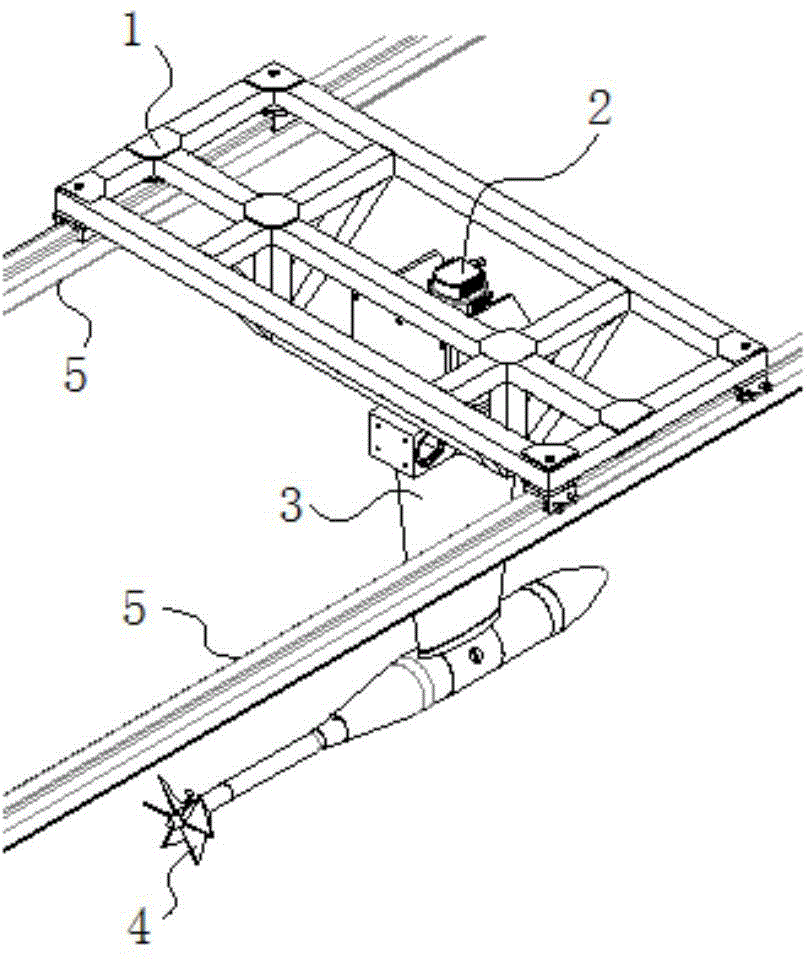

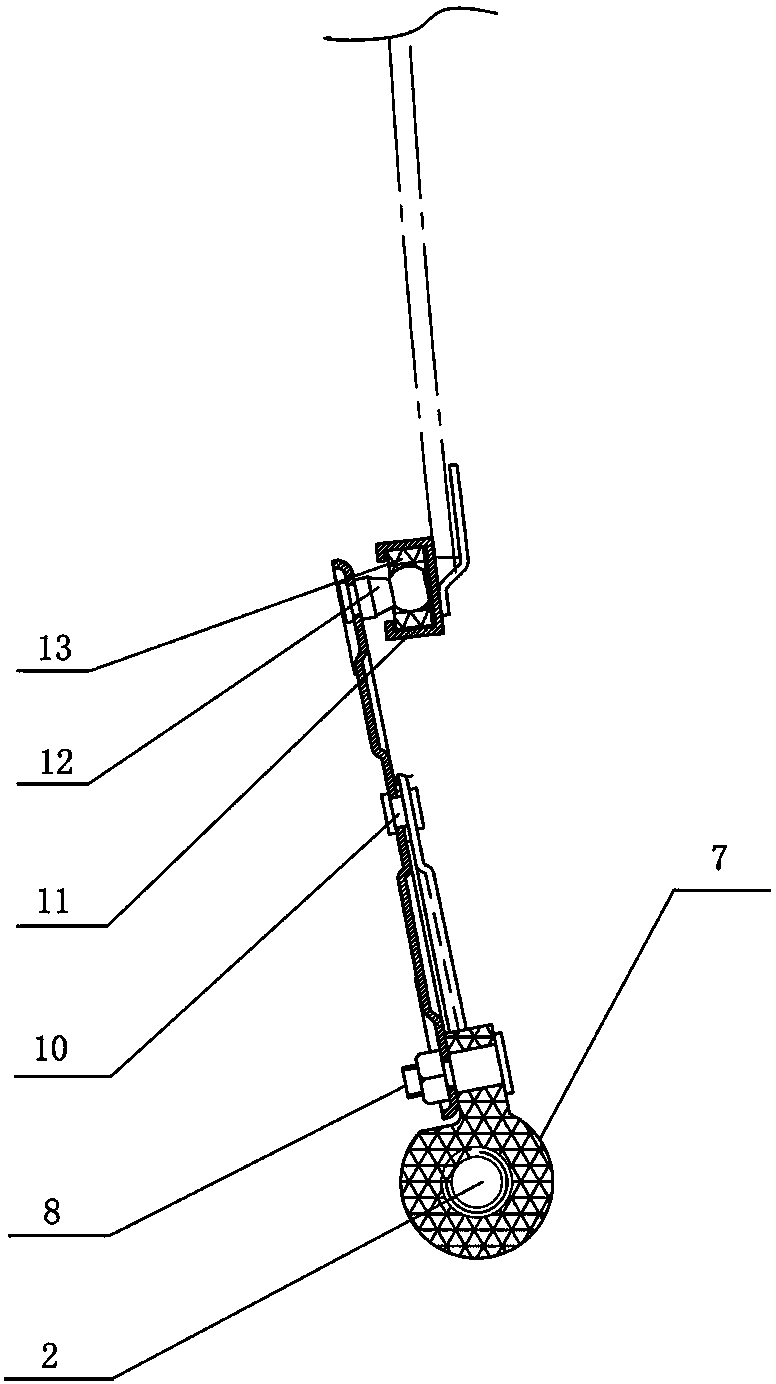

An underwater glider and an unmanned submersible vehicle retracting and releasing device

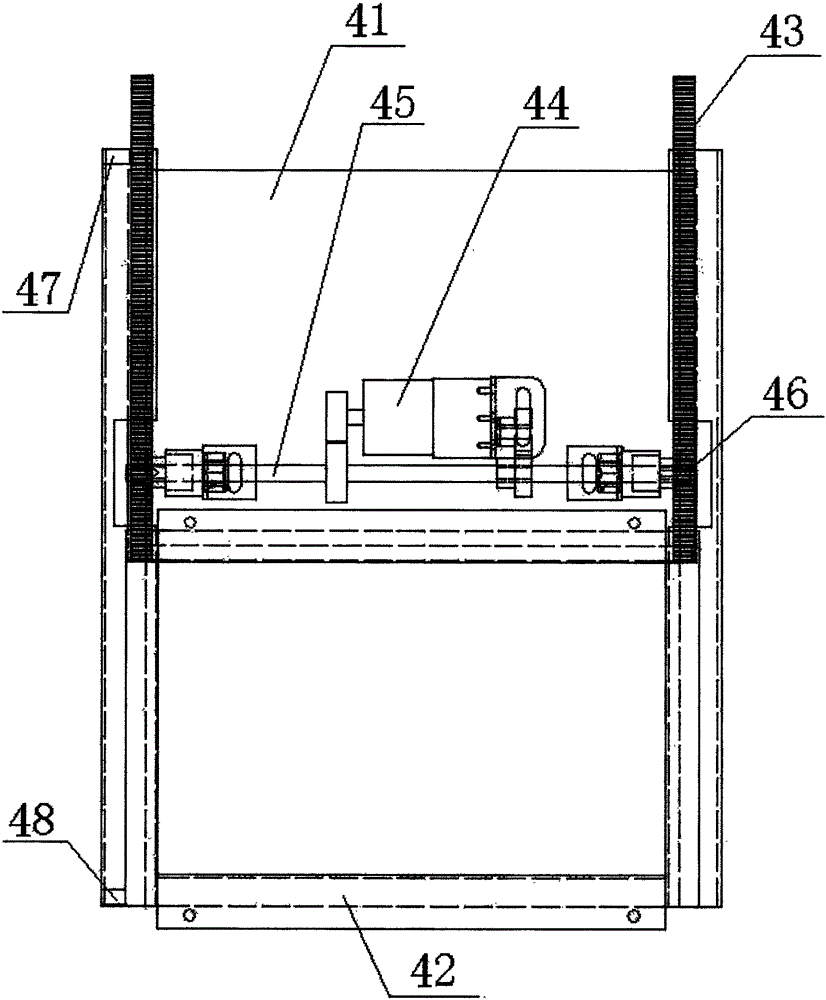

ActiveCN109050839AEasy to fixAchieve fixationProgramme-controlled manipulatorCargo handling apparatusHorizontal transmissionMarine engineering

The invention discloses a retracting and releasing device of an underwater glider and an unmanned submersible vehicle, An underwater glider and an unmanned submersible vehicle retracting and releasingdevice including chassis, A synchronous belt horizontal transmission component is instal on that chassis, A rail is mounted on the chassis, A movable trolley is slidably connected to the rail, and the lower surface of the moving trolley is fixedly connected to the horizontal transmission assembly of the synchronous belt, The movable trolley is provided with a recovery manipulator assembly, the movable trolley is rotatably connected with a retracting and placing tipping frame assembly, a glider is arranged on the retracting and placing tipping frame assembly, and two turnover cylinders are rotatably connected with the retracting and placing tipping frame assembly in a common symmetrical manner between the mobile trolley and the retracting and placing tipping frame assembly. The invention has the advantages of ingenious structure, low cost and use cost, little influence of wind and wave, low probability of equipment damage and personnel casualty, no need of manual rope operation, and large amount of time and energy of staff are saved.

Owner:QINGDAO CHENMING MARINE EQUIP TECH CO LTD

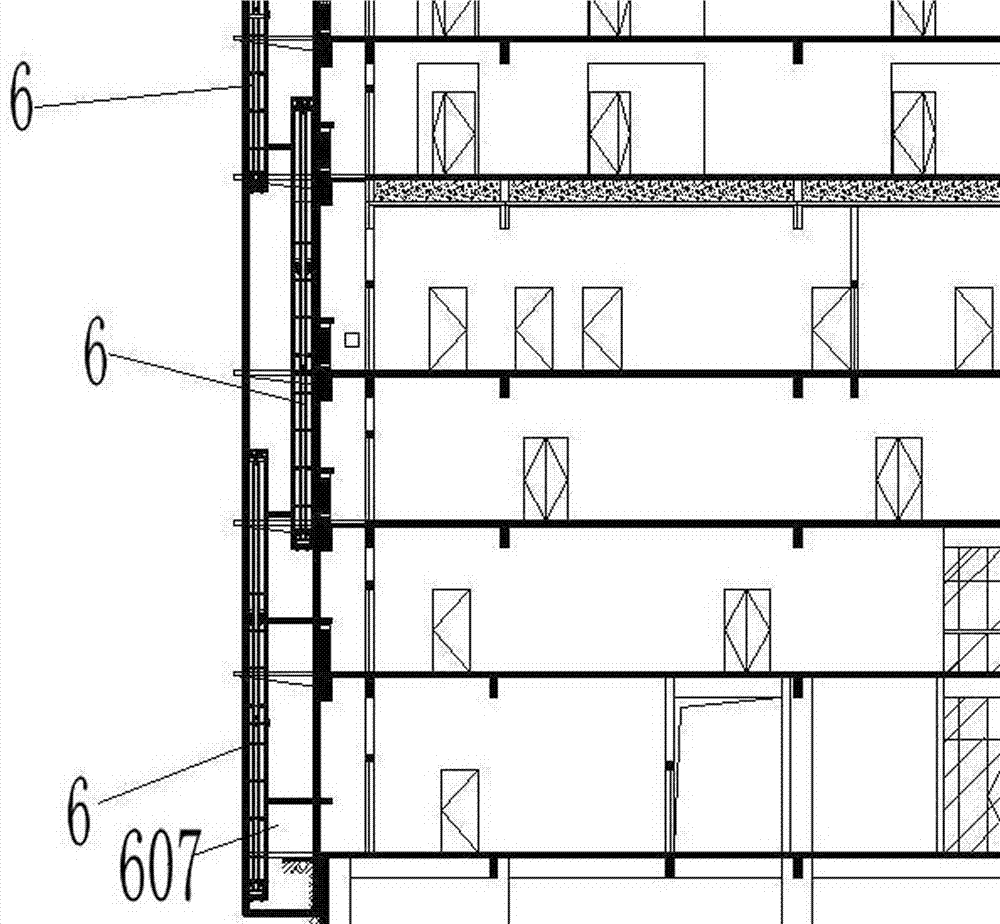

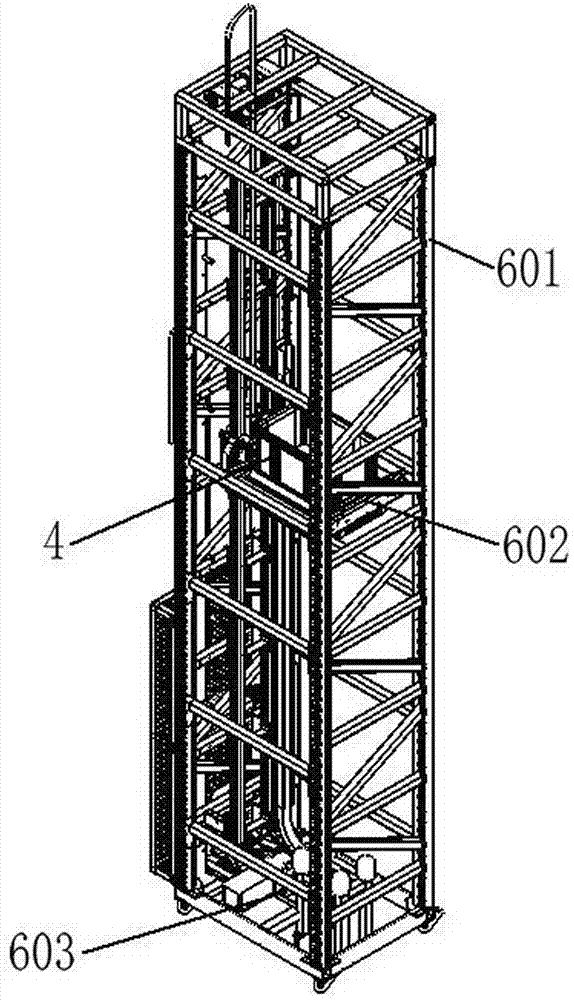

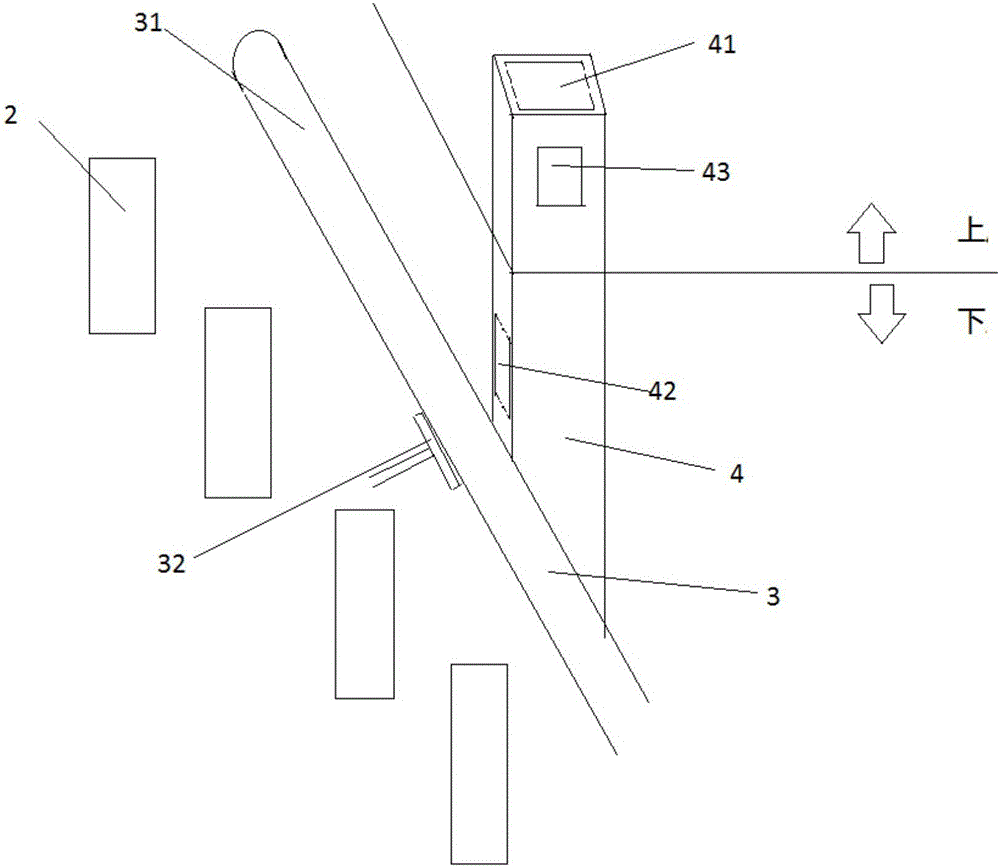

Intelligent logistics transmission system

ActiveCN107082245AMeet diverse needsFacilitate standardized managementBuilding liftsConveyor partsHorizontal transmissionLogistics management

The invention relates to an intelligent logistics transmission system which comprises a cargo transmission carrier, N transfer stations, a jacking transplanter, a vertical transmission system, a floor transmission system, a shuttle bus rail and a horizontal transmission system. The problems that hospital logistics transmission goods and materials are multiple in kinds and large in amount, and the distribution timeliness of medicines, intravenous injection fluid preparations and the like is high are solved to a large extent. By means of the system, all goods and materials in hospitals can be safely and efficiently sent to specified administrative offices or logistics stations in real time according to needs. The horizontal transmission system, the vertical transmission system and the cargo transmission carrier in the intelligent logistics transmission system are not limited to certain single logistics equipment any more, and appropriate local transmission subsystems can be systematically and flexibly customized according to the diversity of the hospital building layout and different transmission paths, transmission content and needs of different administrative offices or logistics stations. The category scope of the hospital transmission goods and materials is covered to a large extent, and the need of the hospital logistics transmission diversification is met.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

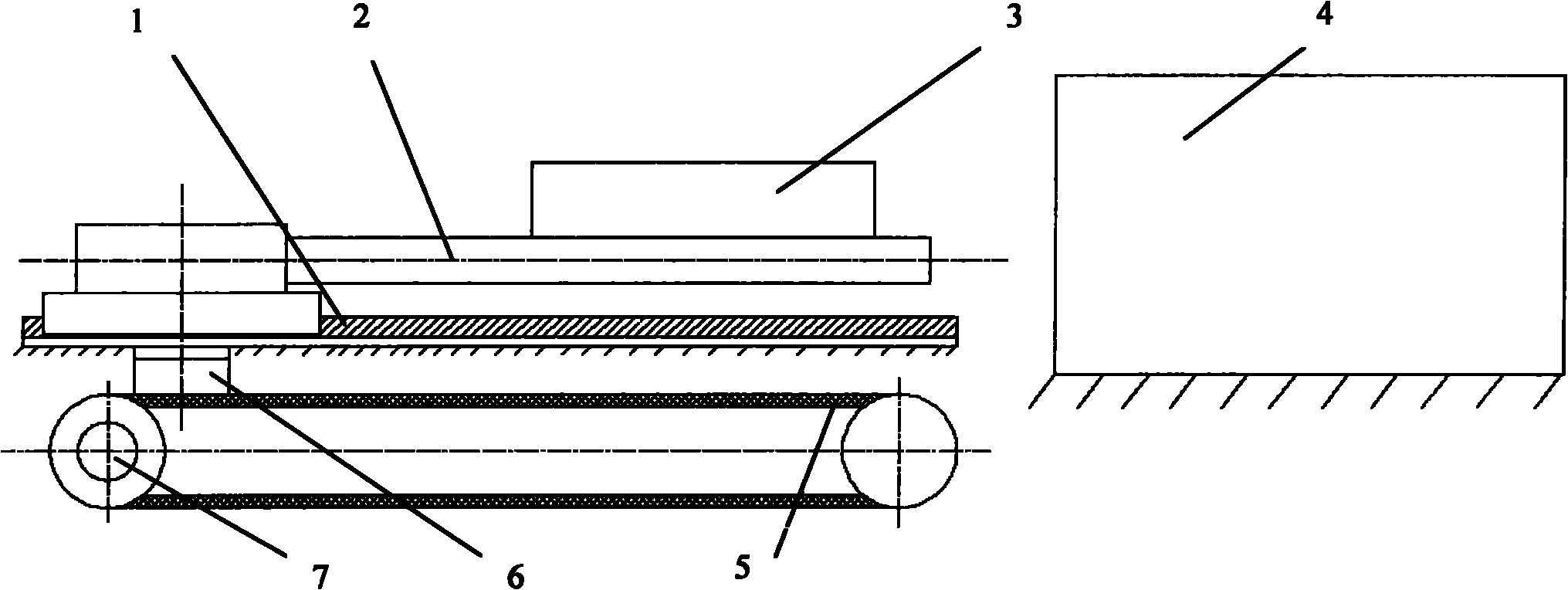

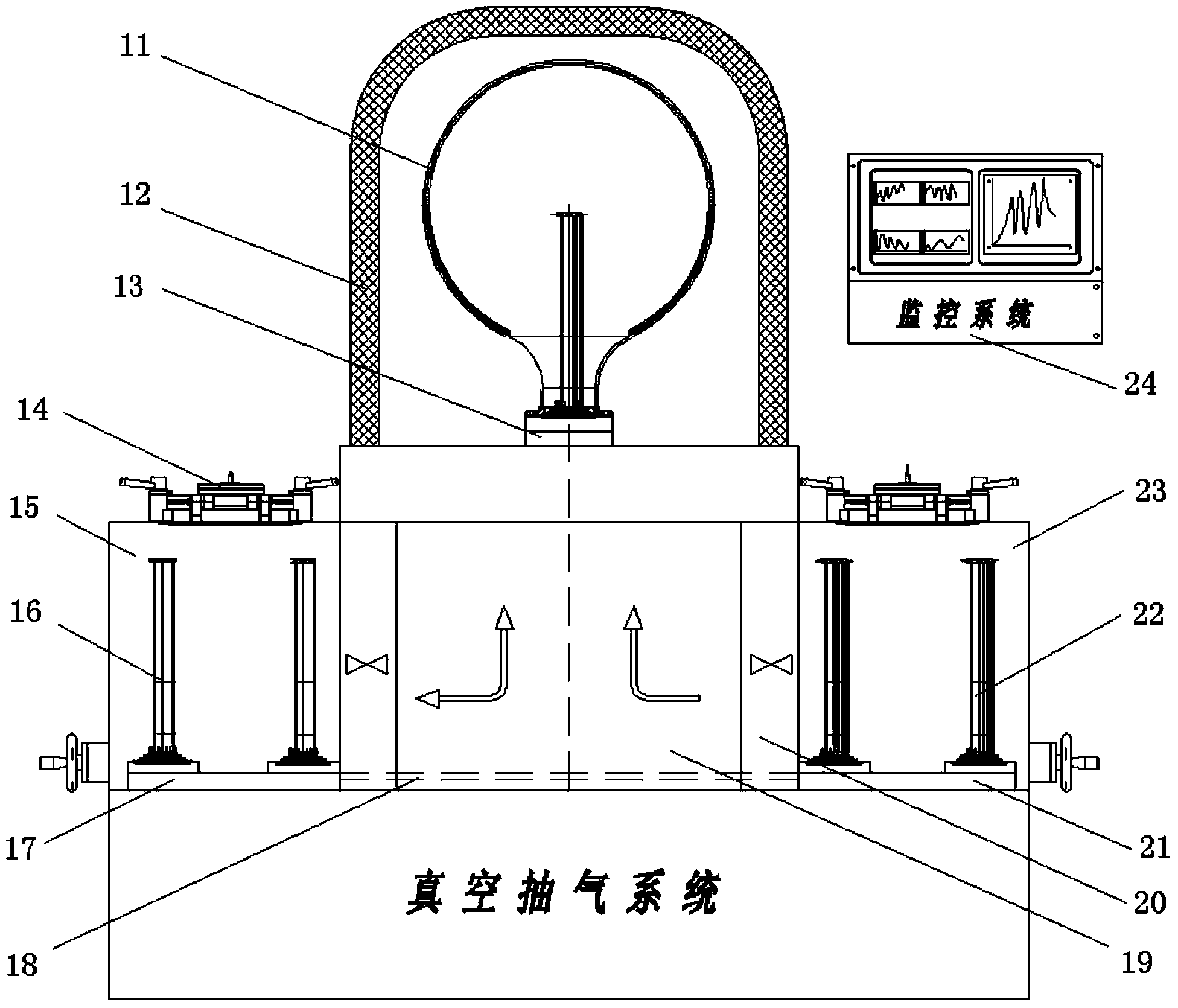

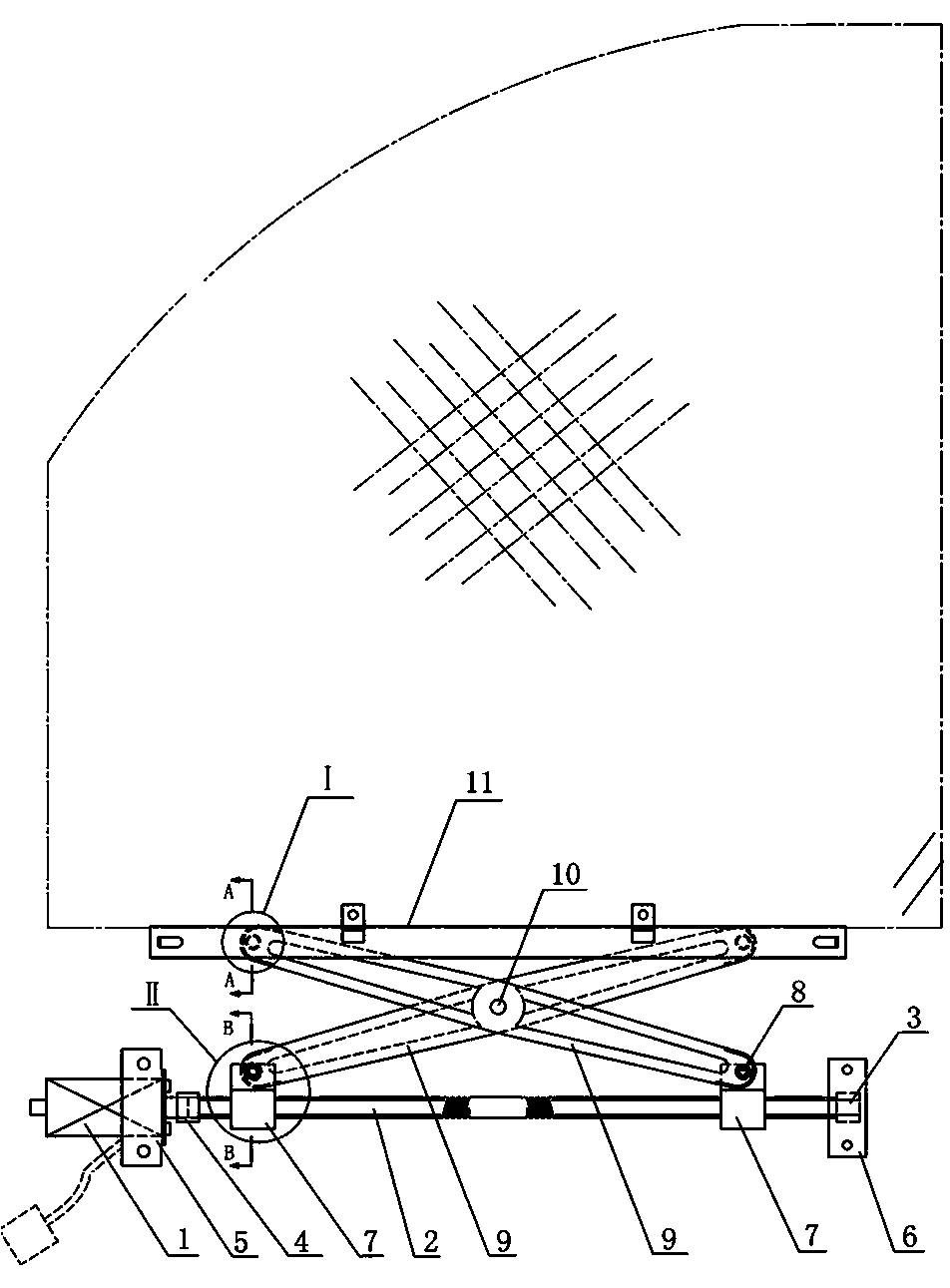

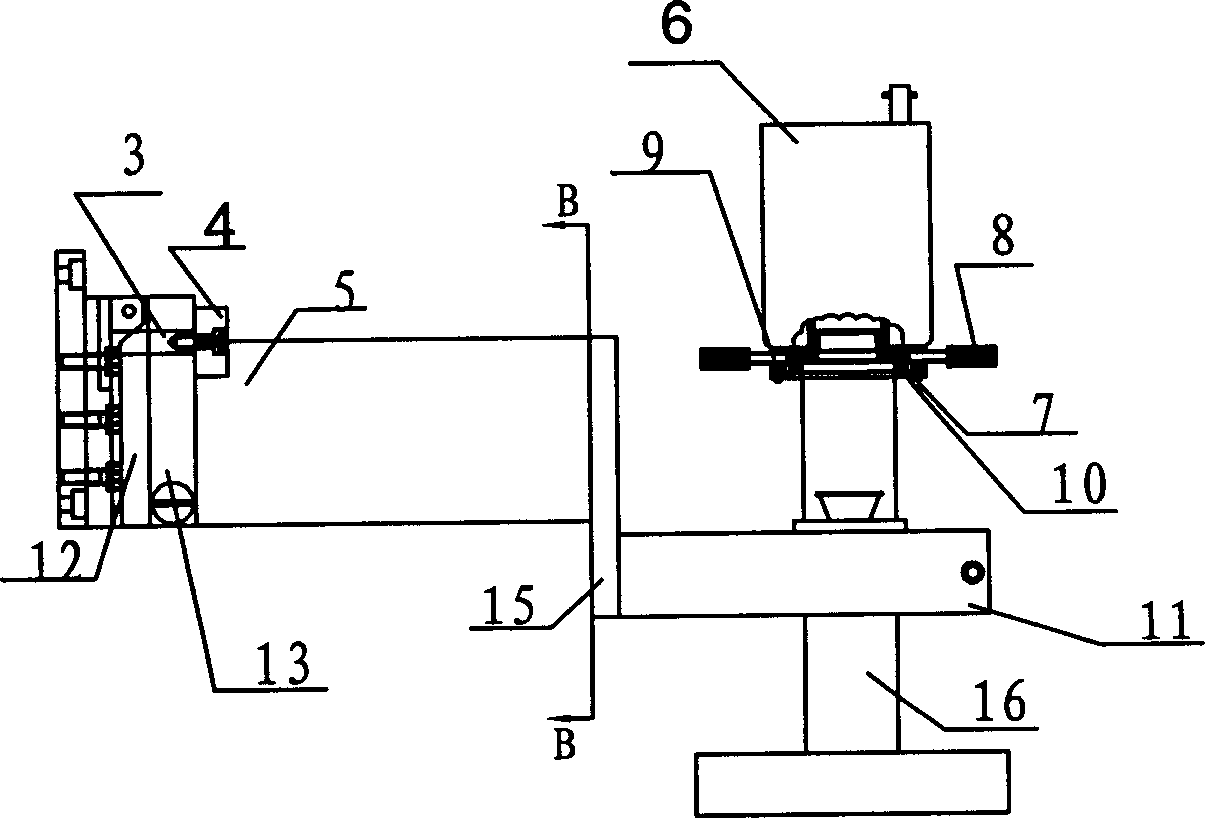

Accelerated loading test device for small full-size asphalt pavement

ActiveCN102607974AReflects anti-rutting performanceReduce trafficMaterial strength using repeated/pulsating forcesHorizontal transmissionMotor drive

An accelerated loading test device for a small full-size asphalt pavement relates to an accelerated loading test device for a full-size asphalt pavement, aiming at the problems of impossibility of accurately simulating the actual stress state of an asphalt pavement in an indoor wheel tracking test, as well as large equipment size, long test period, high test expense and complex operation process in an outdoor full-size pavement accelerated loading test. A two-way motor drives a drive big gear and a driven big gear to rotate; a transmission cross rod disposed on a rack is fixedly sleeved with a force-transferring pinion, as well as sleeved with a force-transferring big gear, a lifting gear and a transition chain wheel engaged with an annular horizontal transmission chain in a suspension manner; the force-transferring big gear and the force-transferring pinion are engaged with an annular vertical inner transmission chain and an annular vertical outer transmission chain; the lifting gear is engaged with a lifting guide rail; the movements of a rolling steel wheel and a loading wheel group are driven via the annular horizontal transmission chain; the up-and-down movement of a rectangular-frame steel wheel loading beam is driven via an inner oil pressure pump; and the up-and-down movement of a rectangular-frame wheel group loading beam is driven via an outer oil pressure pump. The invention is used for the accelerated loading test for the full-size asphalt pavement.

Owner:HARBIN INST OF TECH

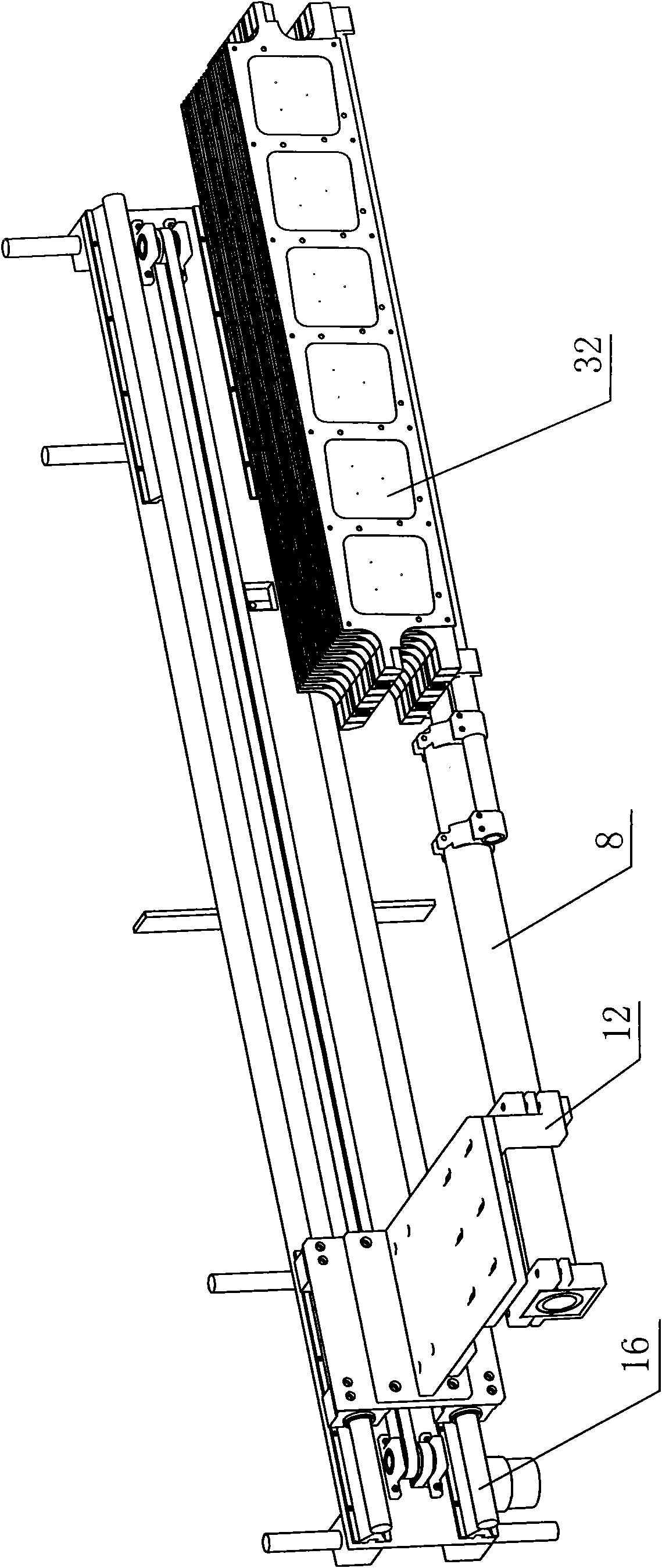

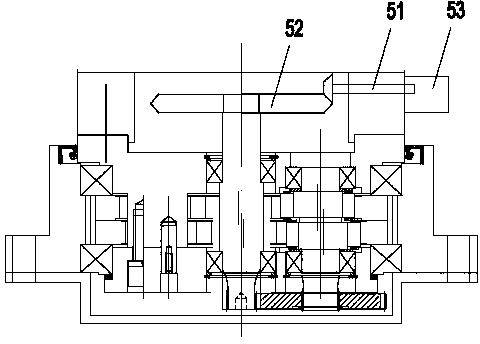

Cantilever-type push-pull boat system for plasma enhanced chemical vapor deposition (PECVD) device

InactiveCN102061456AImprove stabilityAvoid affecting normal movementChemical vapor deposition coatingConveyor partsHorizontal transmissionPush pull

The invention discloses a cantilever-type push-pull boat system for a plasma enhanced chemical vapor deposition (PECVD) device, comprising a cantilever pole mechanism, a side bindiny mechanism and a rolling linear guide sleeve assistant mechanism, wherein the rolling linear guide sleeve assistant mechanism which is used for guiding the horizontal movement and vertical movement of the cantilever pole mechanism is arranged on the rack of the PECVD device; the cantilever pole mechanism is fixed on the side bindiny mechanism; the side bindiny mechanism is connected with the rolling linear guide sleeve assistant mechanism; the rolling linear guide sleeve assistant mechanism comprises a fixed plate, a horizontal transmission assembly and a vertical transmission assembly; and the horizontal transmission assembly and the vertical transmission assembly respectively control the cantilever pole mechanism to drive raw materials to move horizontally and vertically. The cantilever-type push-pull boat system has the following advantages: a mode that an antilever pole extends into a reaction cavity to take and put a graphite boat is adopted, thus a transmission system is simplified, and the transmission efficiency is improved; a side fixing mode is adopted, thus silicon wafer fragments on the graphite boat can be prevented from falling on the system so as to prevent influence on the normal action of the system; and in addition, the space is saved, and a plurality of push-pull boats can simultaneously move.

Owner:SOUTH CHINA UNIV OF TECH

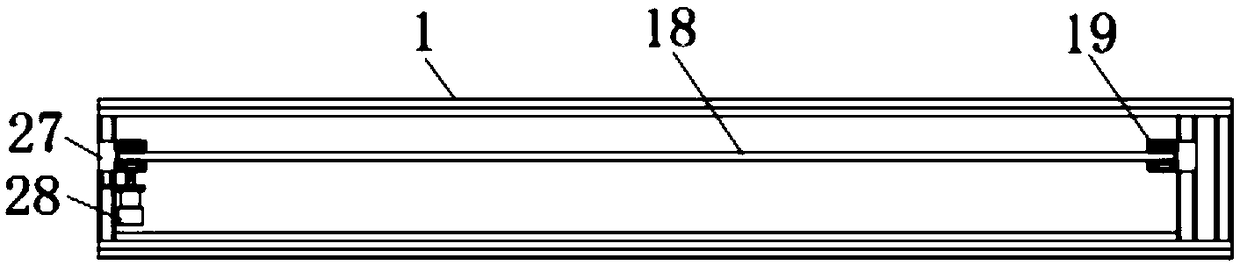

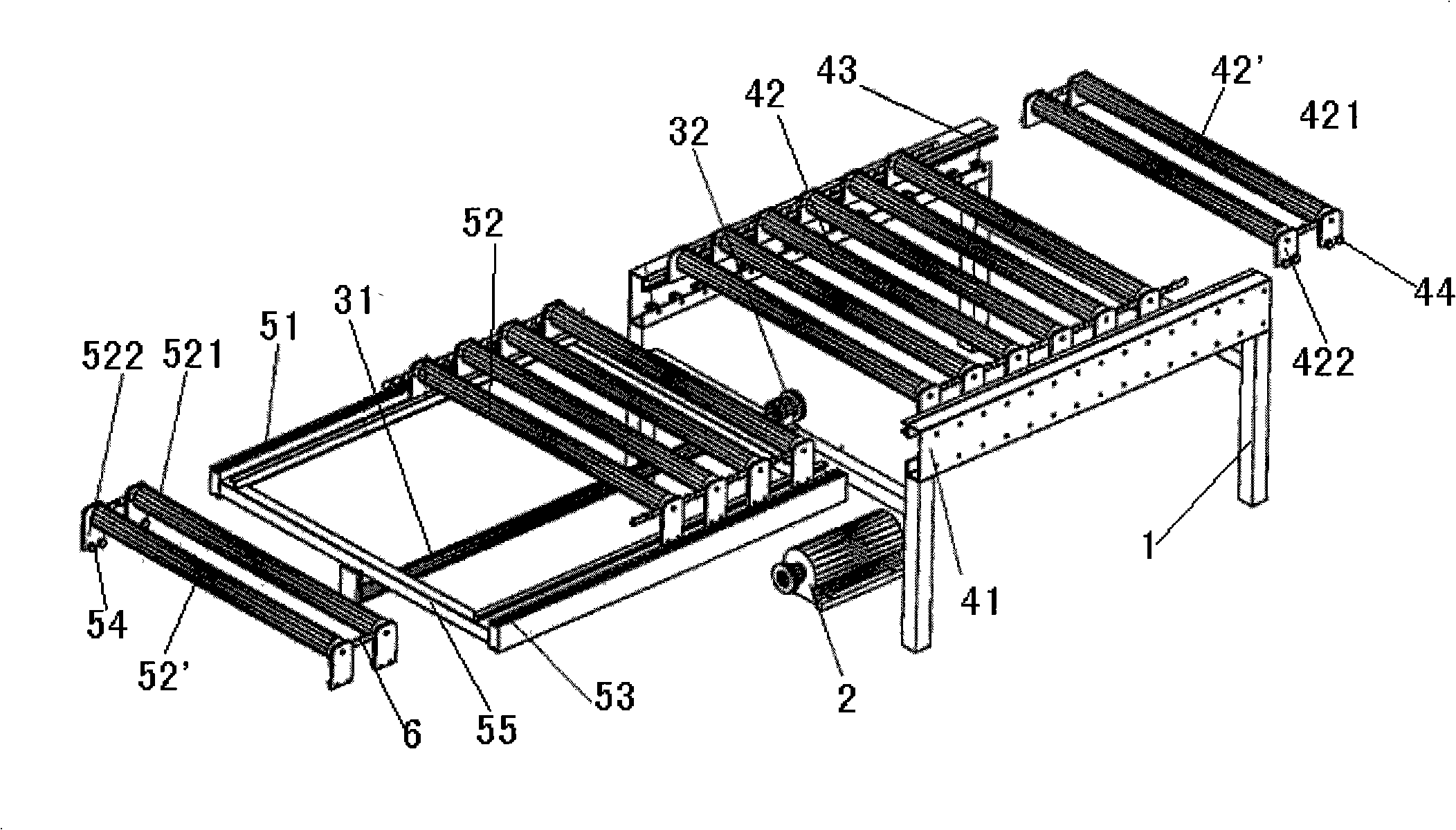

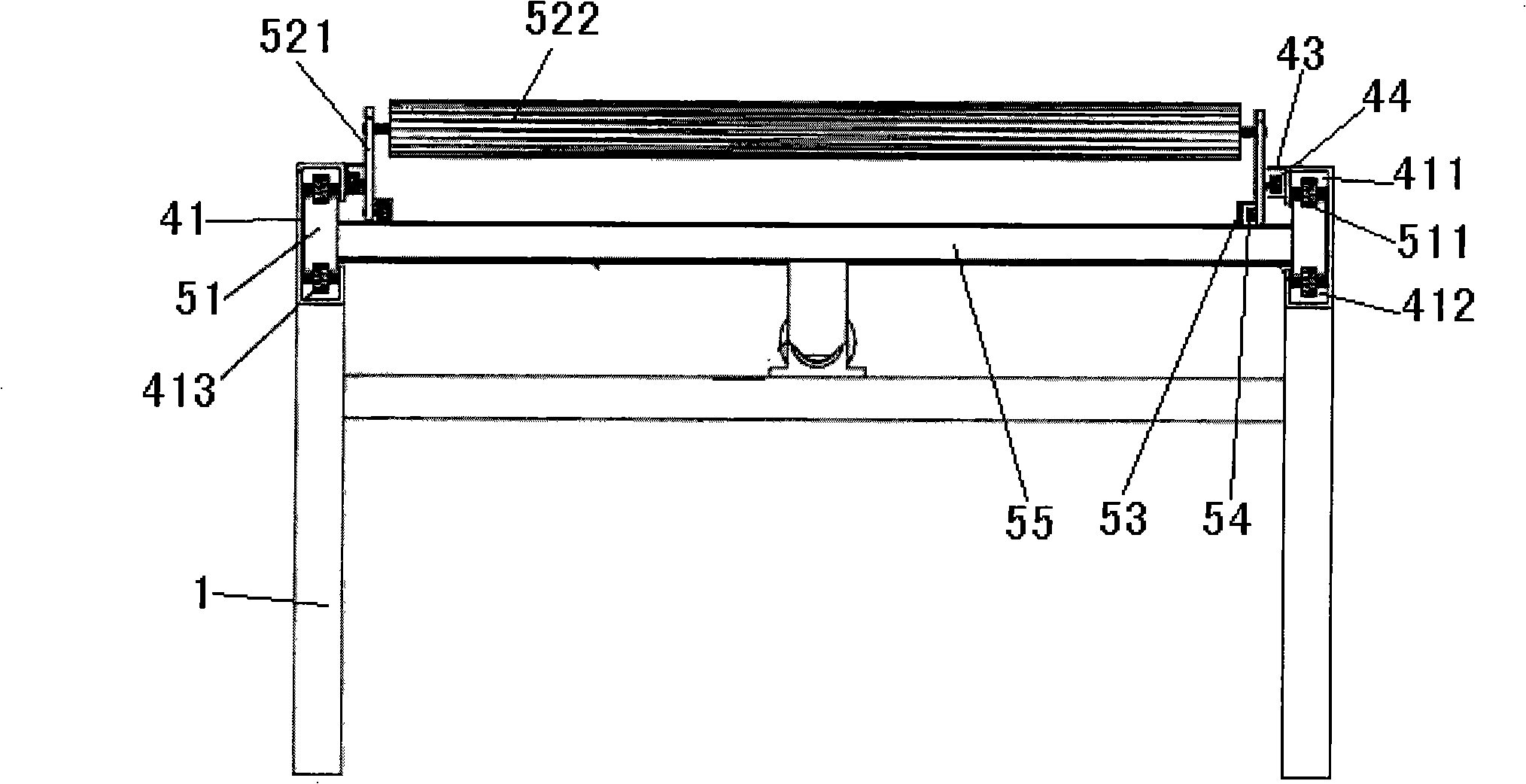

Telescopic horizontal transmission bench

InactiveCN101342988AMeet the needs of useStable structureMetal working apparatusRoller-waysHorizontal transmissionEngineering

The invention discloses a telescopic horizontal conveying platform which comprises a main body support, a conveying platform, a drive motor and a telescopic part; the conveying platform includes a fixed conveying platform and a telescopic conveying platform; the fixed conveying platform includes a slide groove, a plurality of back conveying components and back guide grooves; the telescopic conveying platform includes a telescopic rod, a plurality of front conveying components and front guide grooves; the telescopic rod is arranged in the slide groove and is able to slide relative to the slide groove; the adjacent conveying components, the adjacent front conveying component and the adjacent back conveying components are connected through flexible connecting pieces respectively; the upper conveying planes of the front conveying component and the back conveying component are in the same horizontal plane; one end of the telescopic part is connected with the drive motor and fixed on the fixed conveying platform; the other end is fixedly connected with the telescopic conveying platform. The telescopic horizontal conveying platform has the advantages of stable structure, reliability, convenient application, satisfying the application requirement of telescopic platform, being applicable to vehicle sheet punching shears and the conveying in other product production process.

Owner:上海赛科利汽车模具技术应用有限公司

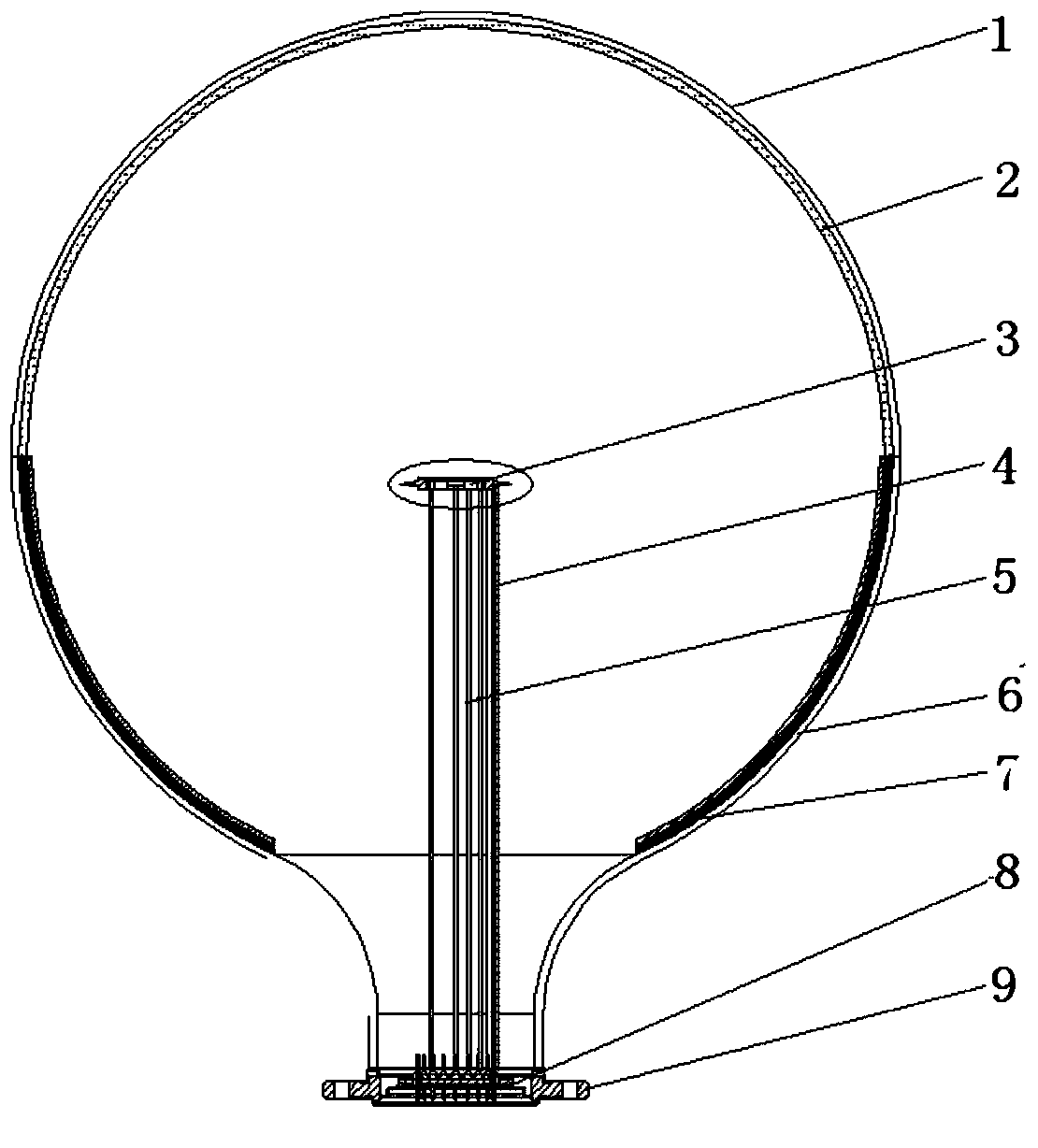

Photoelectric detection device transfer manufacturing system and method

ActiveCN103715034AIncrease ultimate vacuumImprove performanceCold cathode manufactureHorizontal transmissionVacuum pumping

The invention provides a photoelectric detection device transfer manufacturing system and method. The photoelectric detection device transfer manufacturing system comprises a cathode cavity, an anode cavity, a working transmission cavity, a transfer transmission system, a drying oven and a vacuum-pumping system, wherein the cathode cavity, the anode cavity and the working transmission cavity are separated through valves, the cathode cavity and the anode cavity are located on the two sides of the working transmission cavity respectively, the transfer transmission system comprises a horizontal transmission system and a lifting system, and the horizontal transmission system comprises an anode assembly containing device, a cathode assembly containing device and a horizontal transmission device. When a photoelectric detection device is manufactured through the manufacturing system, all other technological processes except the anode assembly assembling process are completed in a clean environment with ultrahigh vacuum, and therefore core devices of an MCP can be prevented from being polluted in the manufacturing process; the MCP anode assembly processing process and the photocathode manufacturing process are independent from each other so that non-cathode parts can be prevented from being polluted by cathode alkali metal and the MCP can be kept in a working state with the optimum performance.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Chemical mechanical planarization device and wafer transmission method

PendingCN110026879AImprove processing efficiencyReduced travel distancePolishing machinesGrinding feedersHorizontal transmissionRisk stroke

The invention discloses a chemical mechanical planarization device and a wafer transmission device and method. The wafer transmission device comprises at least one wafer polishing transmission mechanical arm, the wafer polishing transmission mechanical arm comprises a horizontal transmission mechanism, a vertical transmission mechanism and a wafer grabbing device, a polishing transfer table, a cleaning transfer table and a polishing loading table are arranged in the movable range, in the horizontal straight line moving direction, of the wafer grabbing device, according to the wafer transmission device, the wafer can be directly transmitted among the polishing transfer table, the polishing loading table and the cleaning transfer table, due to the fact that transfer is not needed, the wafertransfer frequency is reduced, the wafer transmission time is shortened, the transmission efficiency is improved, and the probability of damage generated by wafer transmission is reduced. Due to layout of the chemical mechanical planarization device, the transmission stroke is reduced, and machining efficiency of the chemical mechanical planarization device is obviously improved on year-on-year basis.

Owner:HANGZHOU ZHONGGUI ELECTRONICS TECH CO LTD

Numerically-controlled foam block cutting all-in-one machine

InactiveCN102303321AReduce wasteCompact and reasonable structureMetal working apparatusHorizontal transmissionControl system

The invention discloses a numerically-controlled foam block cutting all-in-one machine, which comprises a working platform, a portal tower frame, a top, front and back edge cutting device, a left side edge cutting device, a right side edge cutting device, a three-dimensional (3D) vision sensor and a control system, wherein a workpiece movement mechanism is arranged on the working platform; a front-back movement distance detection device is arranged between the working platform and the portal tower frame; a 3D vision sensor is arranged at the top of the portal tower frame; the top, front and back edge cutting device is arranged in the front of the portal tower frame through a lifting and descending transmission mechanism; the left side edge cutting device is arranged on the left side of the rear part of the portal tower frame through a horizontal transmission mechanism; the right side edge cutting device is directly arranged on the right side of the rear part of the portal tower frame in a fixed manner; and all electric parts and the sensor are respectively connected with the control system. By adoption of the numerically-controlled foam block cutting all-in-one machine, five facescan be automatically cut through one-time clamping, foam blocks can be sliced, automatic processing is realized, processing accuracy and production efficiency are improved, the waste of materials is reduced, and production cost is reduced.

Owner:SHANDONG UNIV

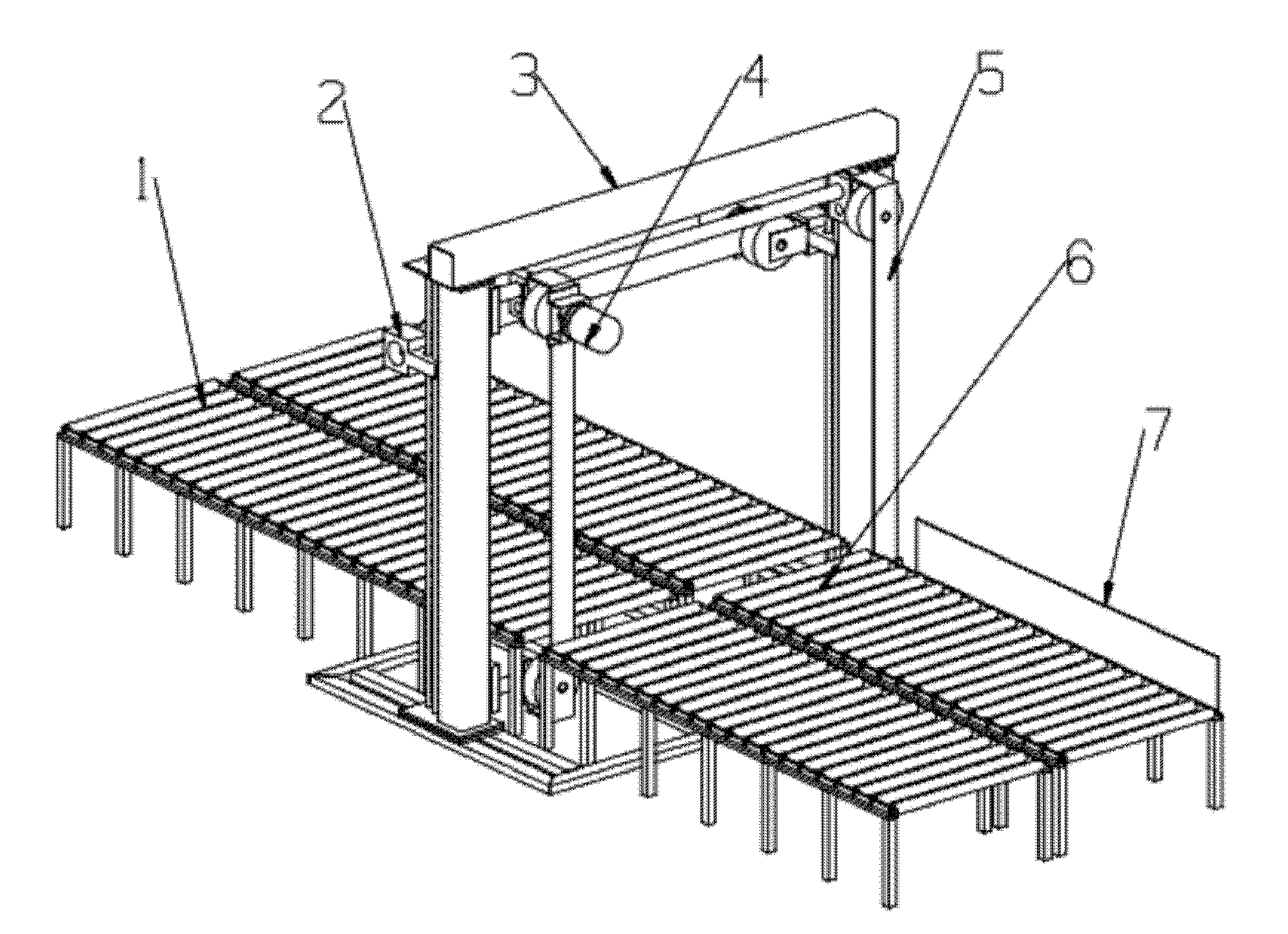

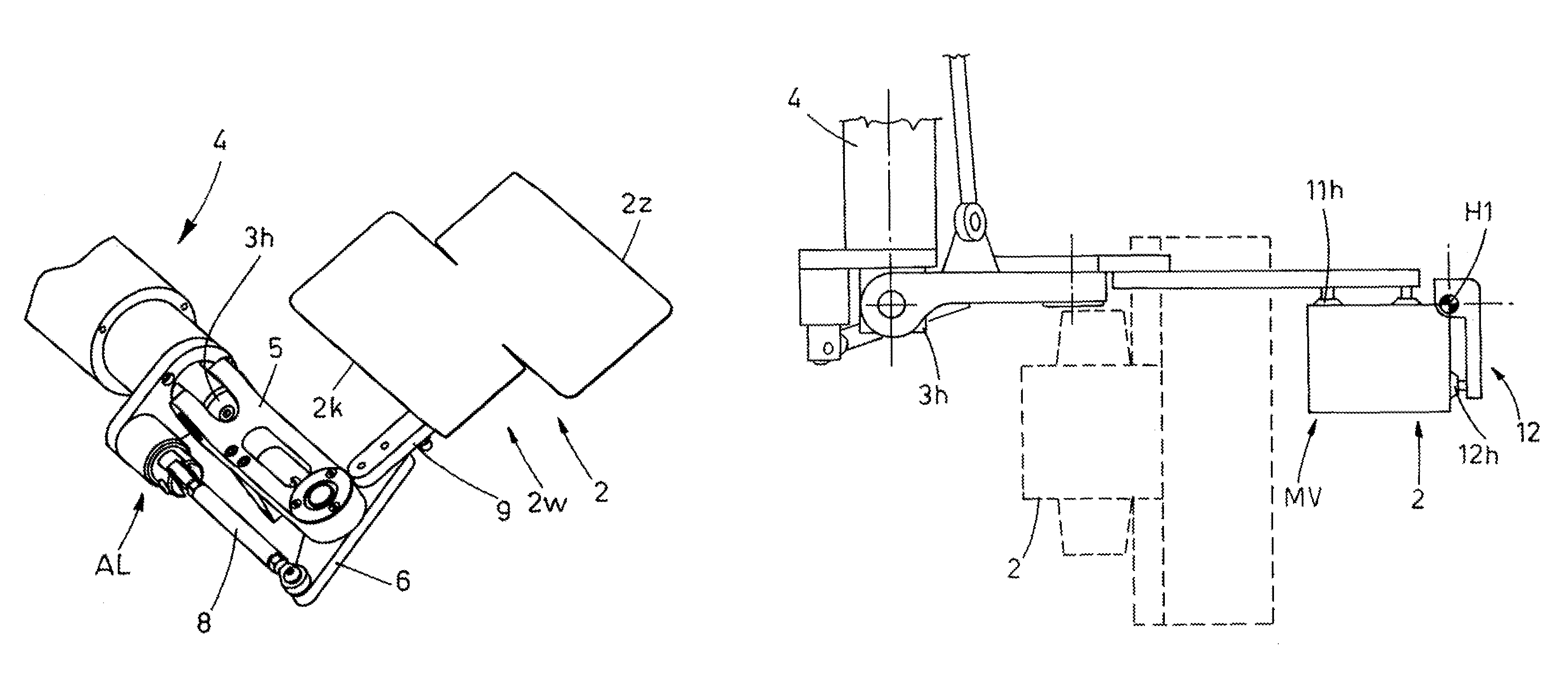

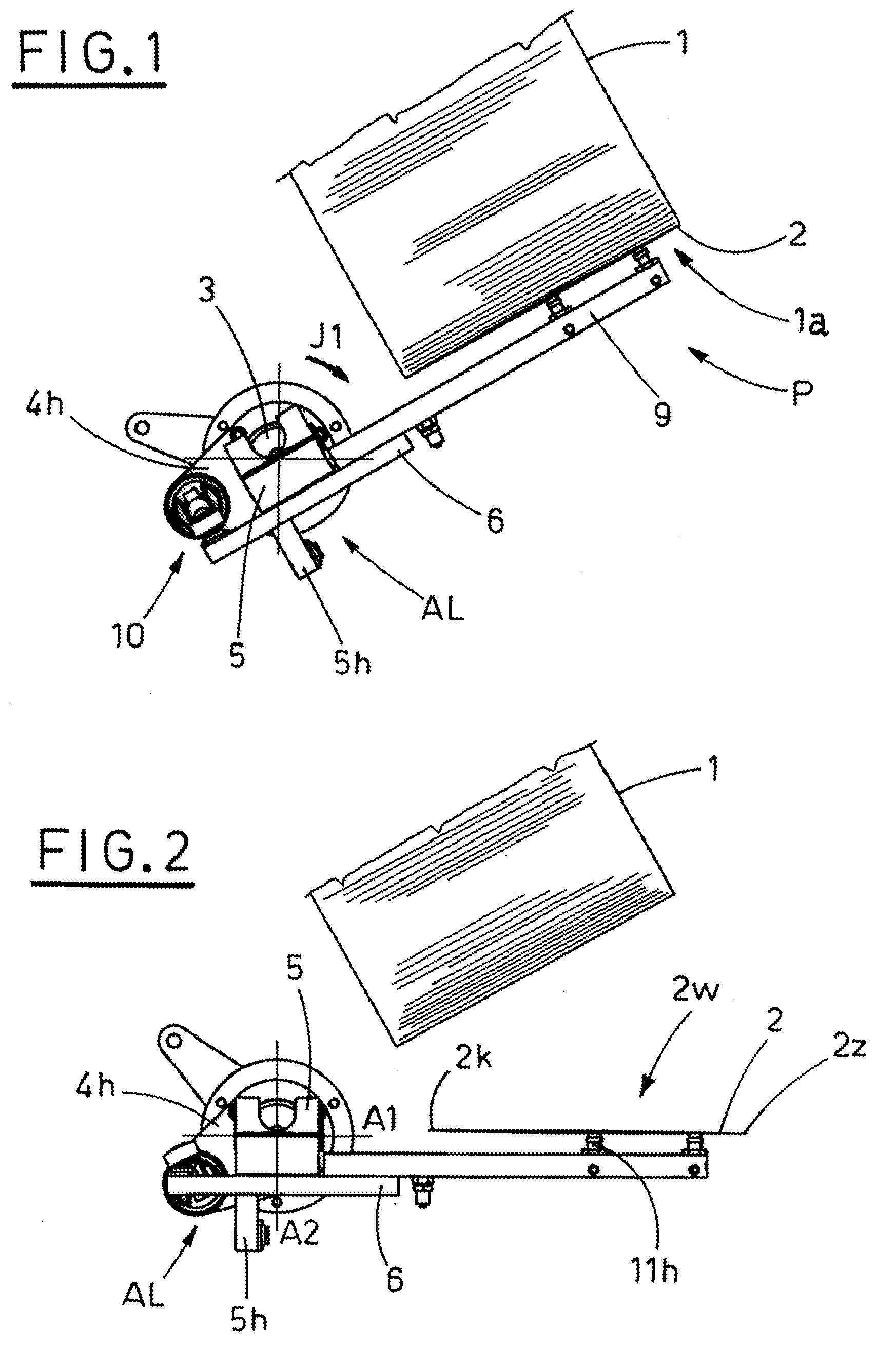

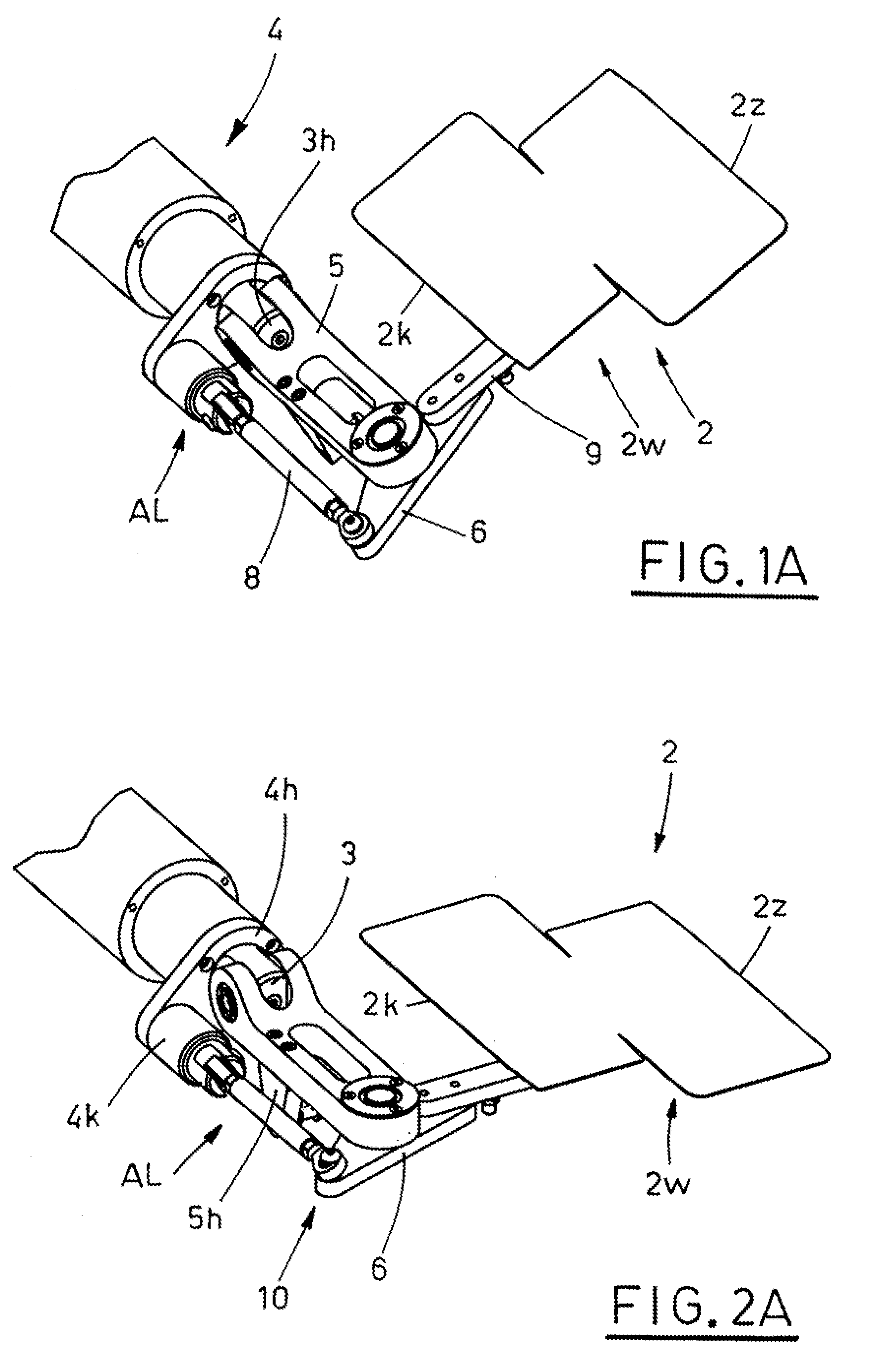

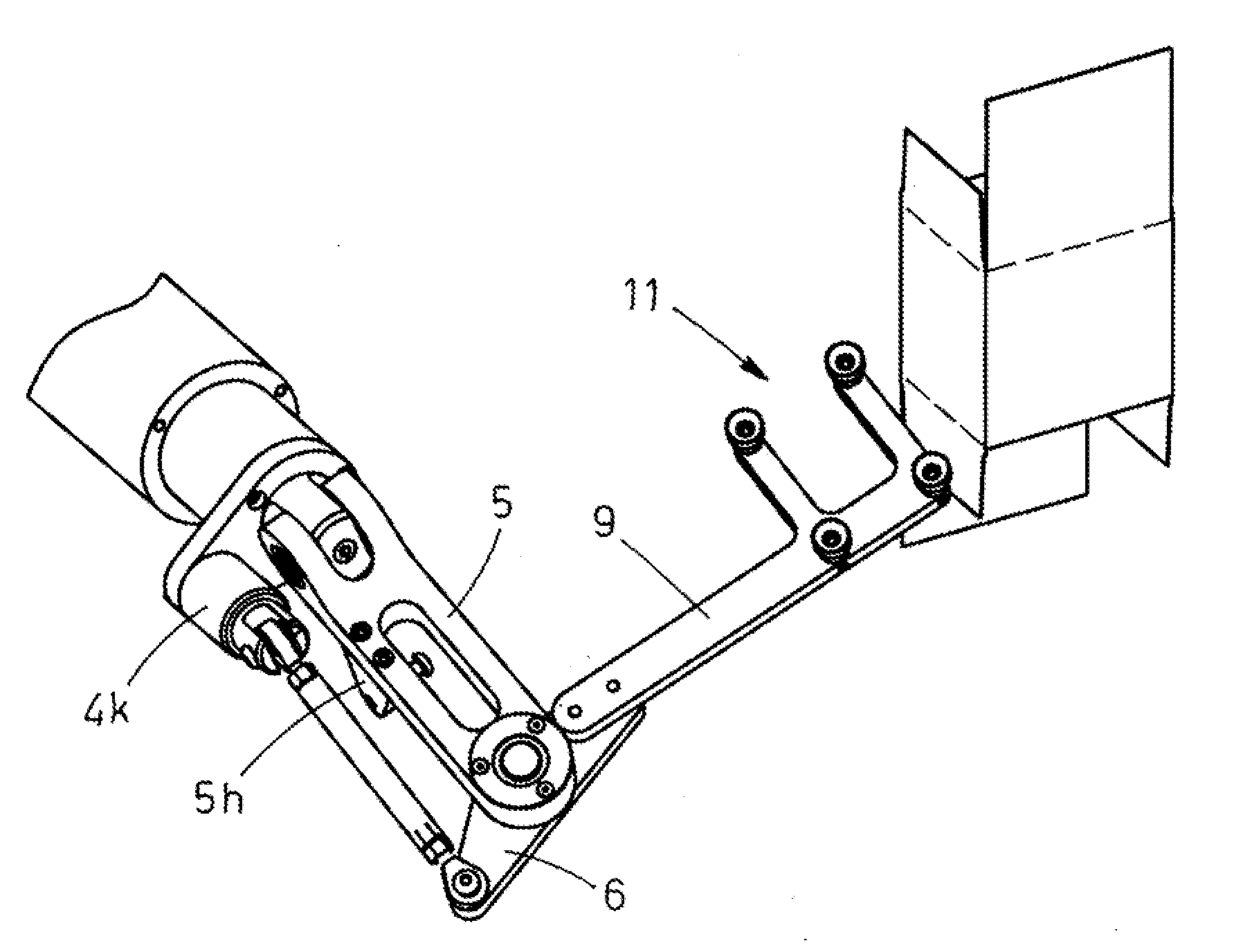

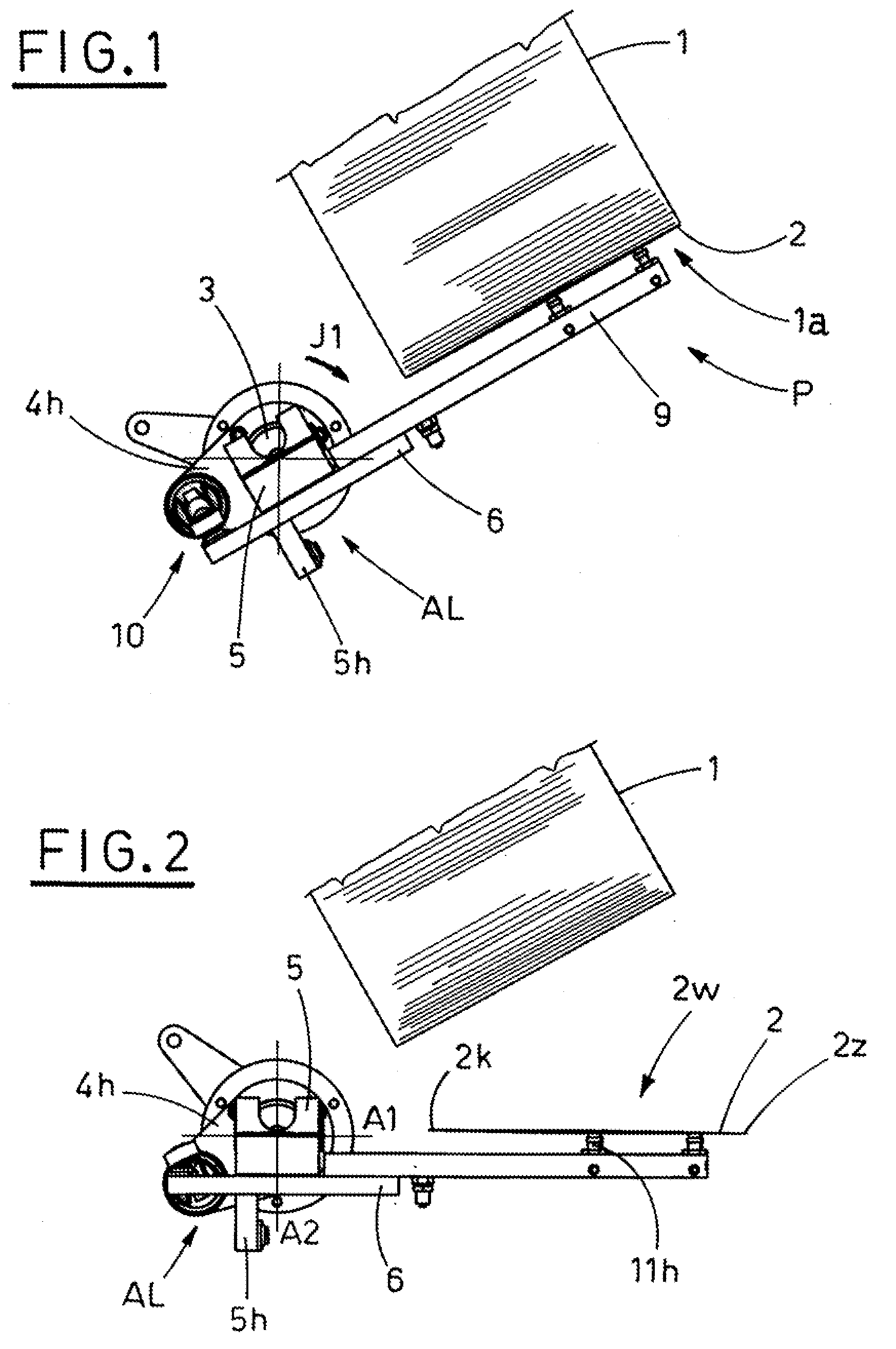

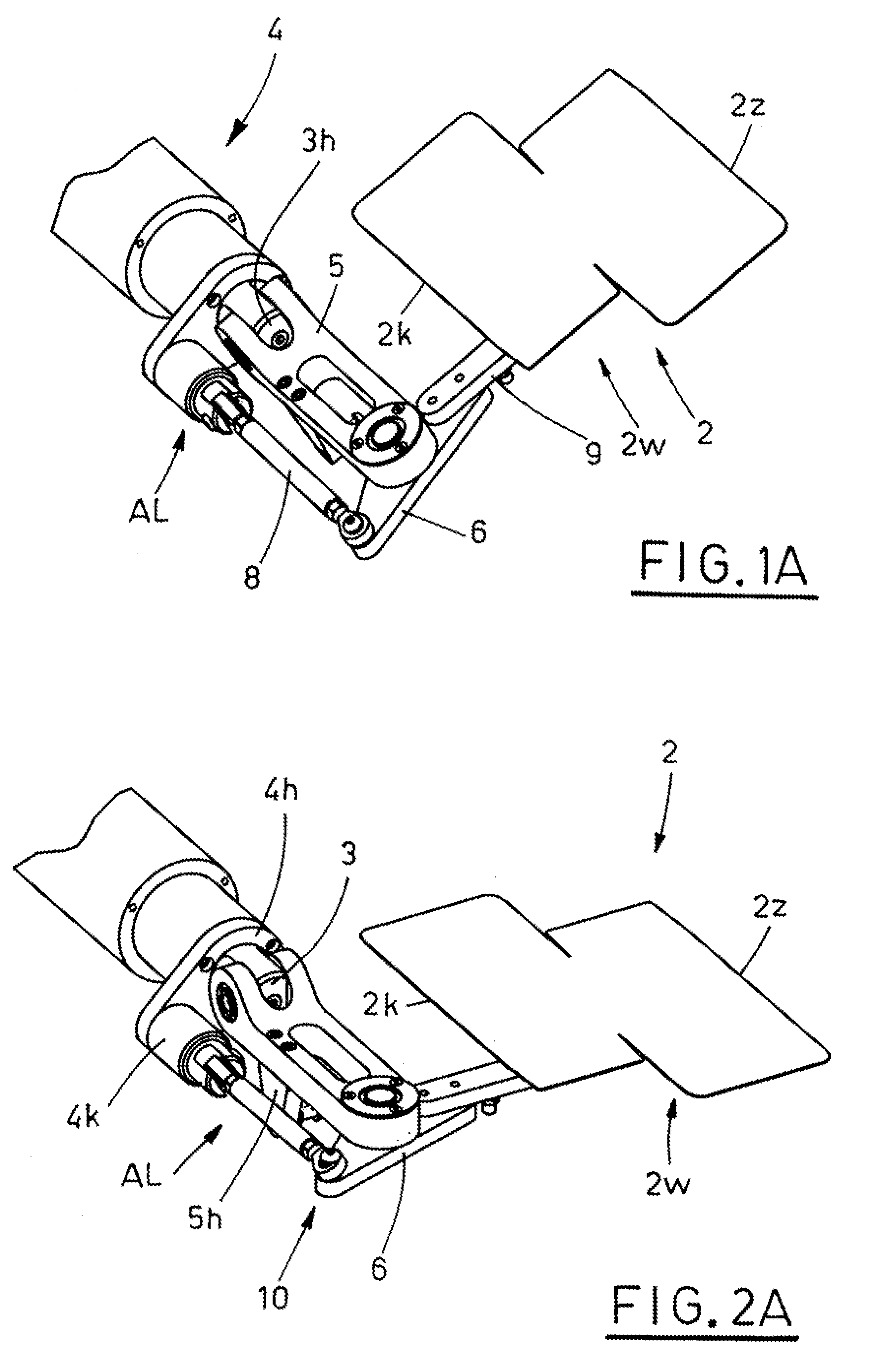

Method and an apparatus for picking up flat folded tubular blanks from a magazine and for moving them to an erecting station

InactiveUS7404788B2Increase chanceLow costBox making operationsPaper-makingHorizontal transmissionDrive shaft

In an apparatus for picking up flat folded tubular blanks from a magazine and for moving the blanks to an erecting station, a horizontal transmission shaft transmits a rotational movement about a first articulation axis to a functional arm hinged with one side to a terminal portion of the transmission shaft. Another side of the functional arm is hinged to an arrangement control mechanism for controlling arrangement of the functional arm about a second articulation axis. The functional arm is also operated into rotation about the first articulation axis between a position in alignment with the functional arm, and a square position arranged at 90 degrees with respect to the functional arm, and vice versa. A pick up arm is connected to arrangement control mechanism and carries suction cups for picking up a flat folded tubular blank through the open bottom of the magazine. The arrangement control mechanism is moved with respect to the second articulation axis for operating the apparatus, beside the operation of the functional arm affected by the transmission shaft, between a picking up station and an erection station for erecting the tubular blank, and vice-versa.

Owner:MARCHESINI GROUP SPA

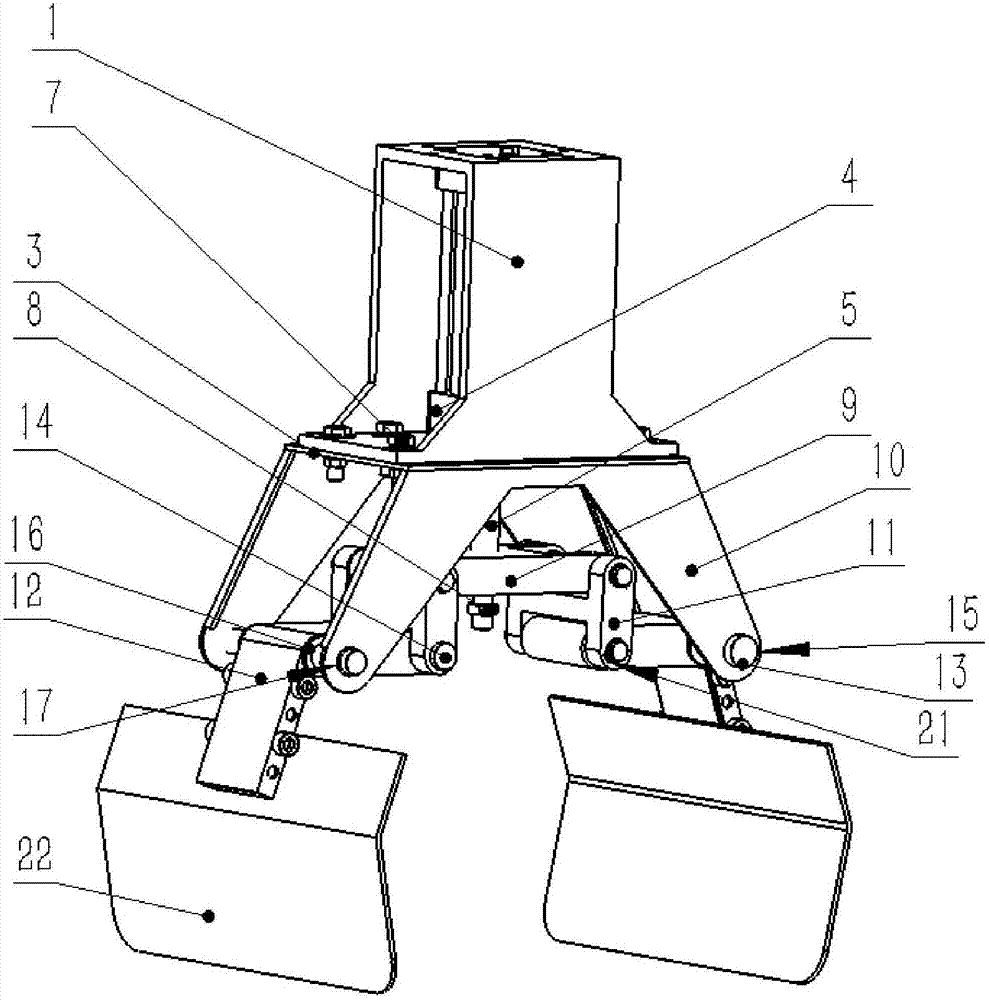

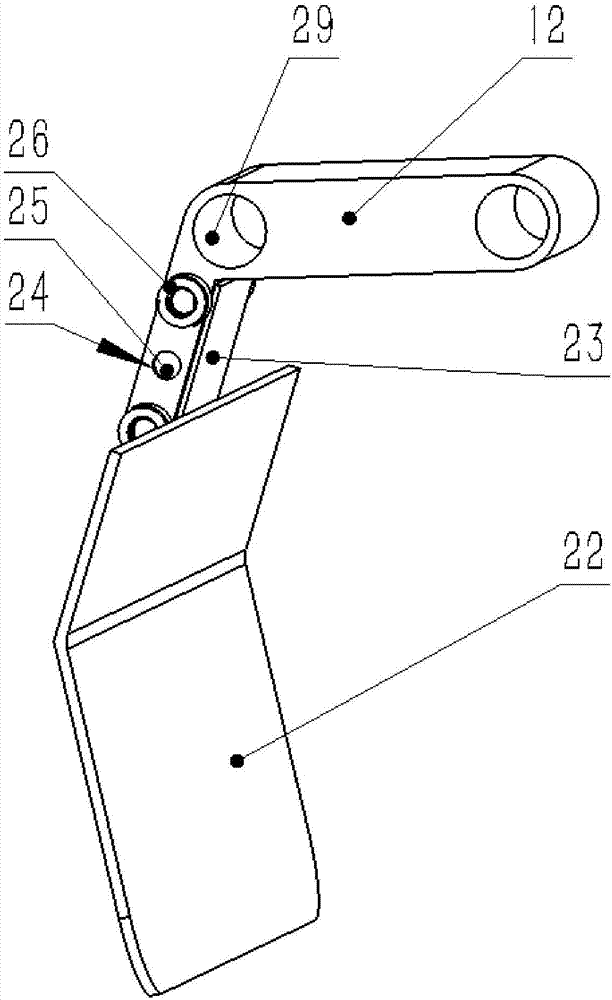

Flexible mechanical gripper and carrying robot with same

InactiveCN107322629AAchieve mechanical propertiesFully automatedGripping headsConveyor partsHorizontal transmissionControl system

The invention belongs to the field of industrial automation and relates to a flexible mechanical gripper used for grabbing stack-type bagged goods and materials. The flexible mechanical gripper comprises a connecting frame (1), a flat plate (3), a double-acting air cylinder, a driving mechanism, a transmission mechanism and a clamping mechanism. The transmission mechanism comprises a horizontal transmission block (9), transmission plates (10), vertical transmission blocks (11), connecting blocks (12), long pin shafts (13) and short pin shafts (14). The clamping mechanism comprises clamping distance adjusting mechanisms and clamping plates (22). The clamping distance adjusting mechanisms each comprise a connecting block (12) and a sliding block (23). The driving mechanism comprises a mechanical arm control system, an air pump, a 24 V power source module, a five-position three-way electromagnetic valve and a pneumatic switch. By adopting the thin clamping plates and the spacing-adjustable clamping mechanism, the gripper can be adapted to carry and grab the goods and materials of different specifications and sizes and has the characteristics of reliable grabbing, flexible moving and the like.

Owner:CHINA AGRI UNIV

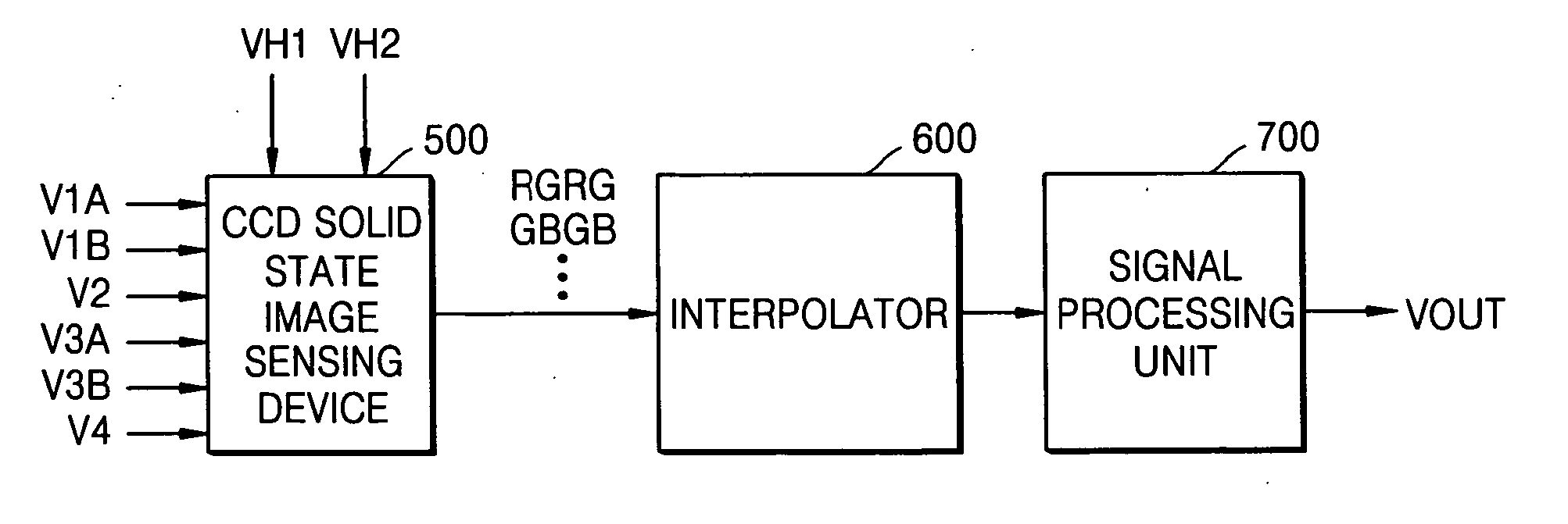

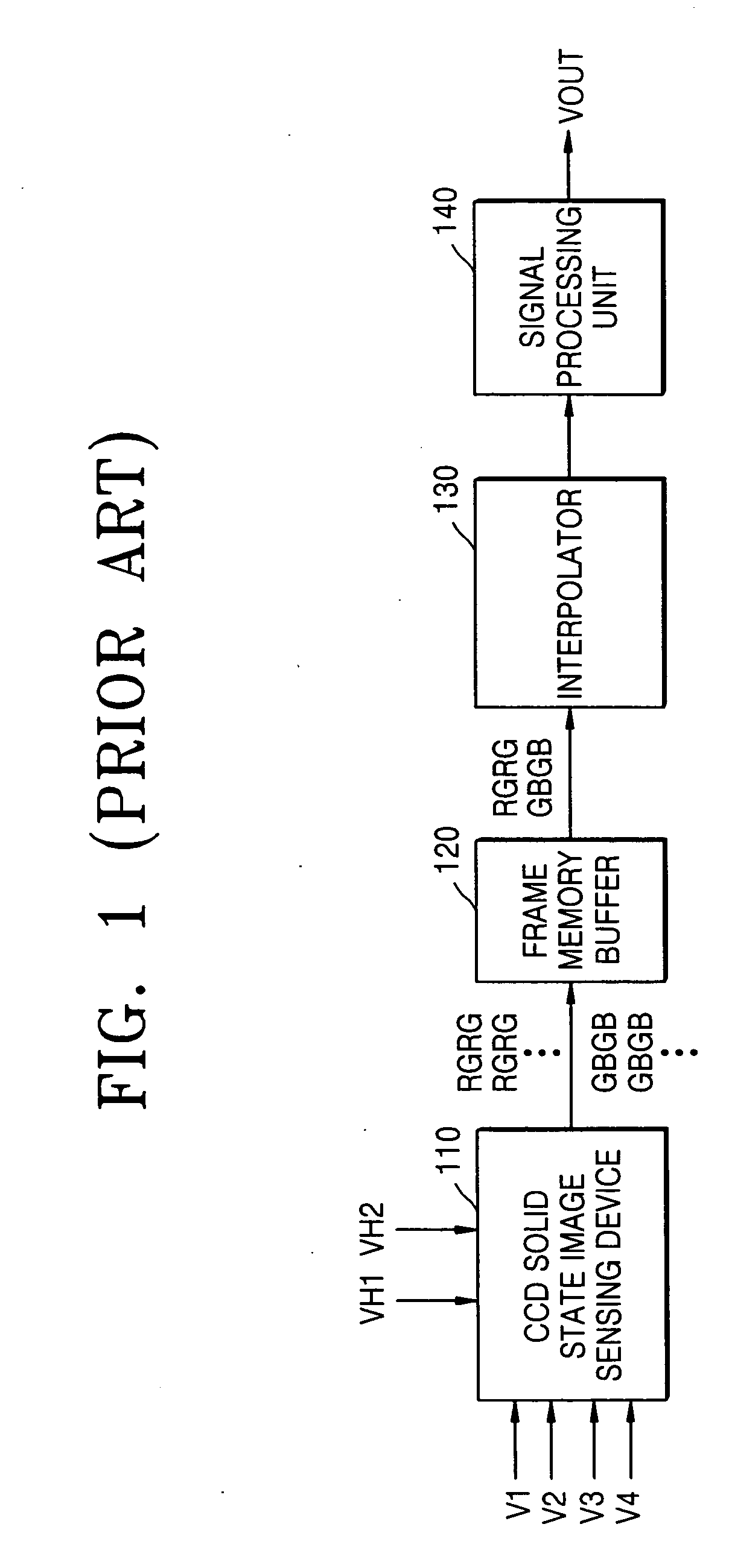

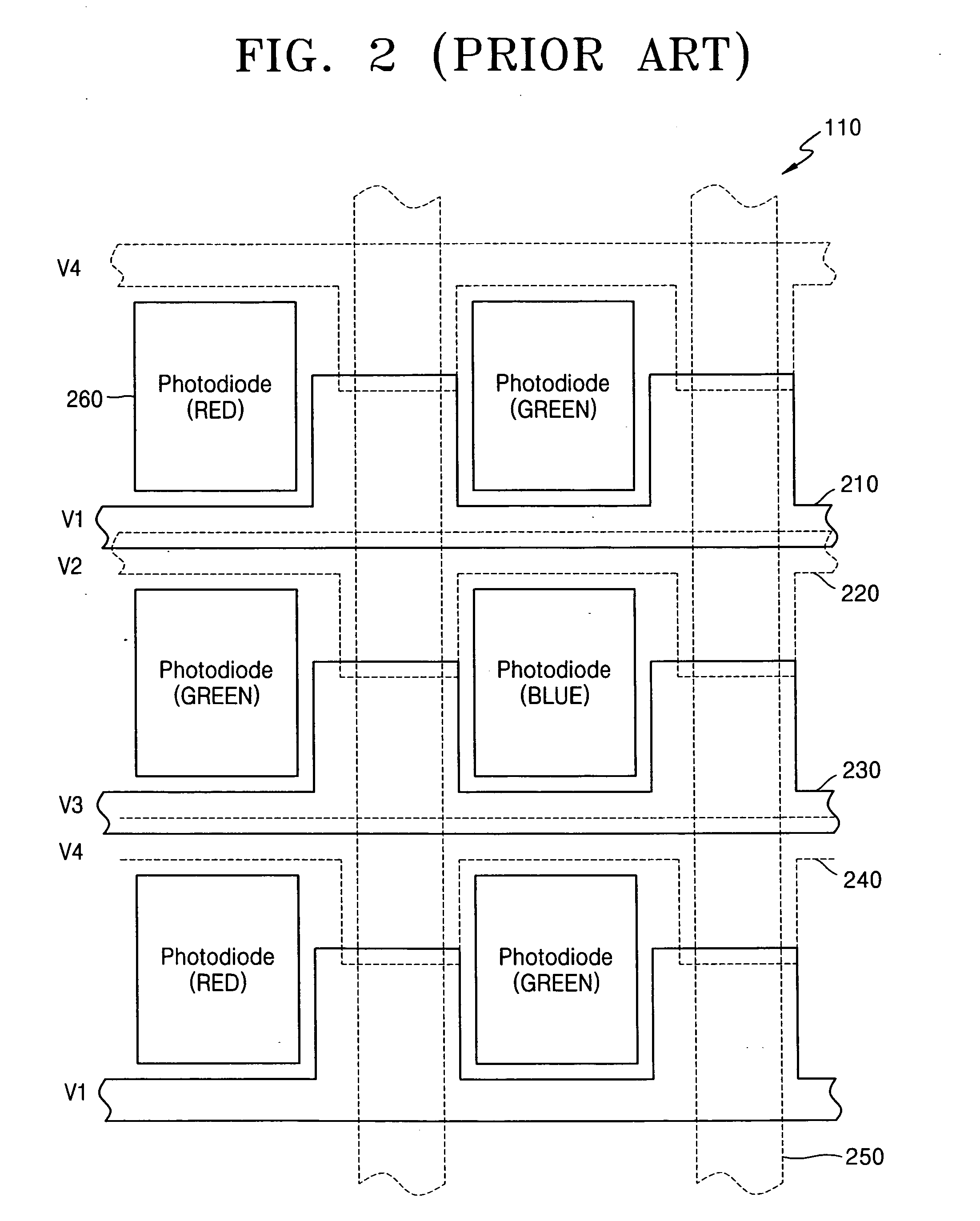

CCD imaging device and driving method for processing image data without frame memory buffer

InactiveUS20050140807A1Television system detailsTelevision system scanning detailsHorizontal transmissionVideo image

Owner:SAMSUNG ELECTRONICS CO LTD

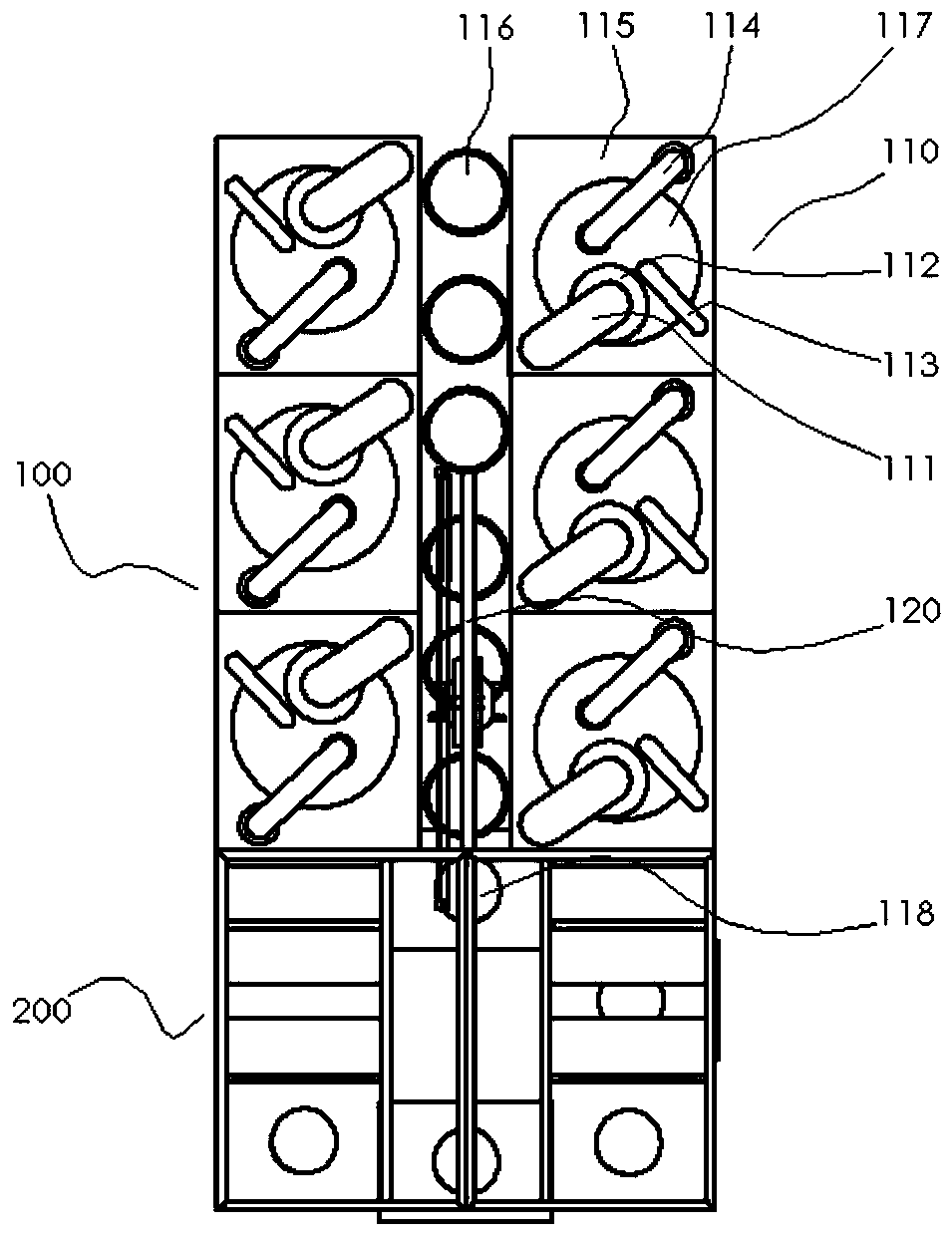

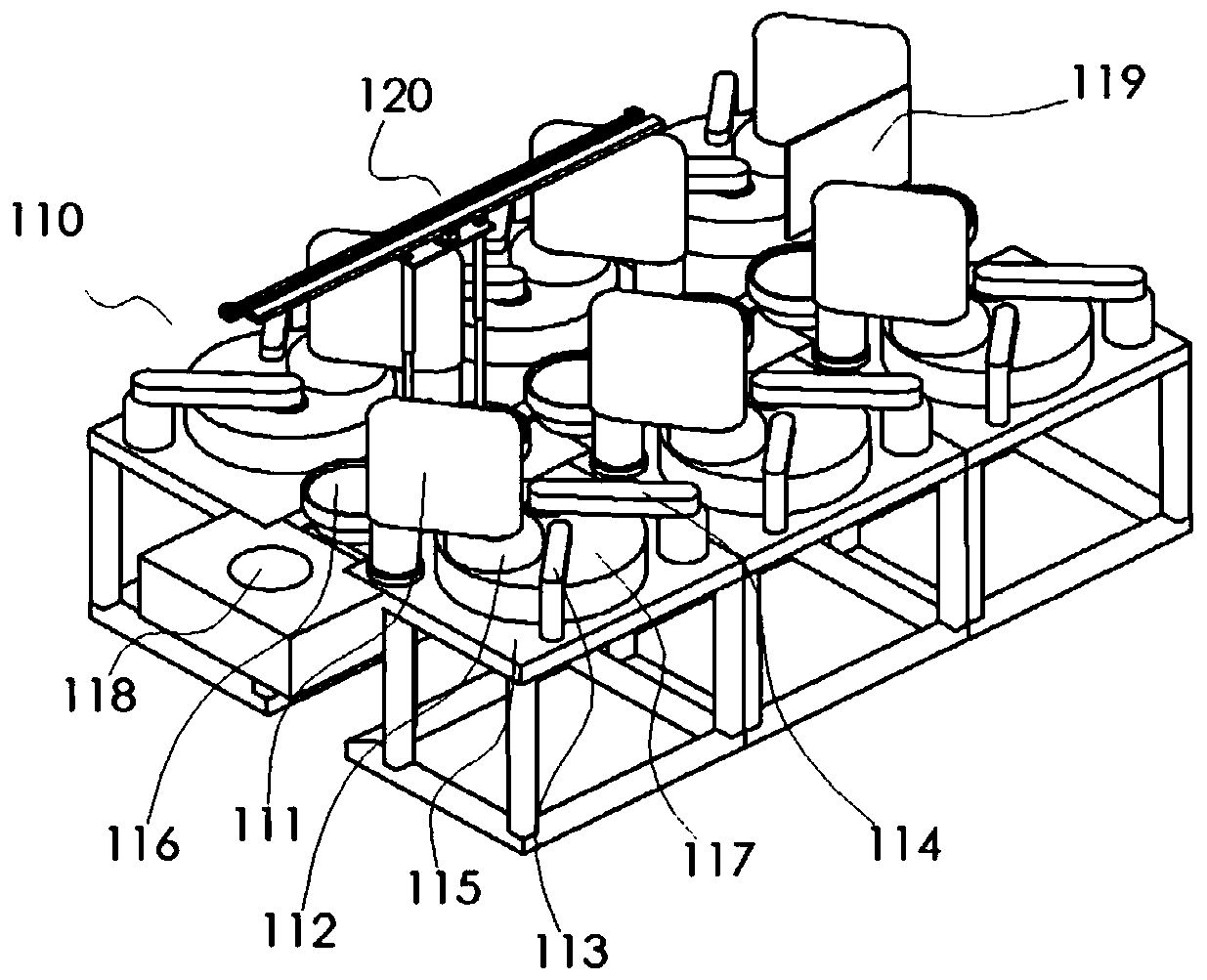

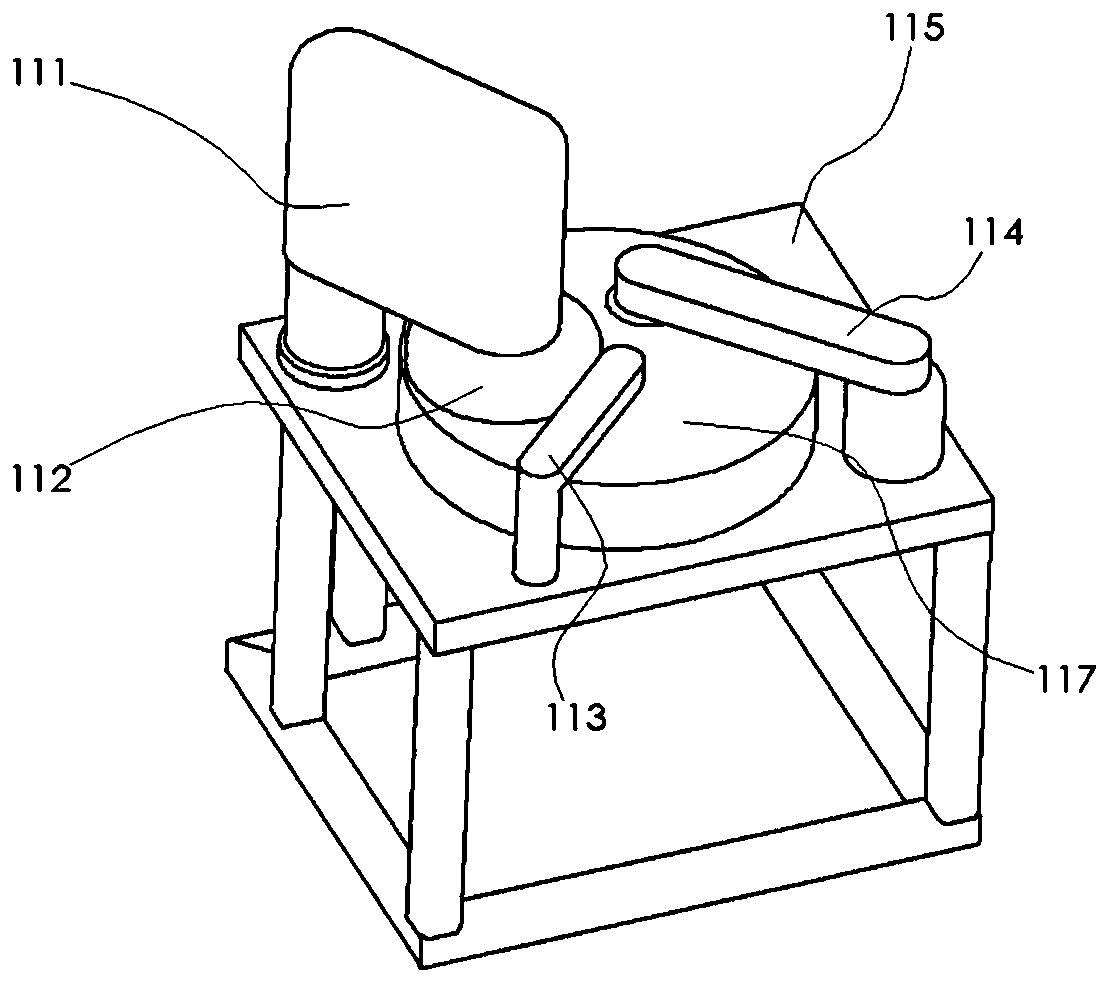

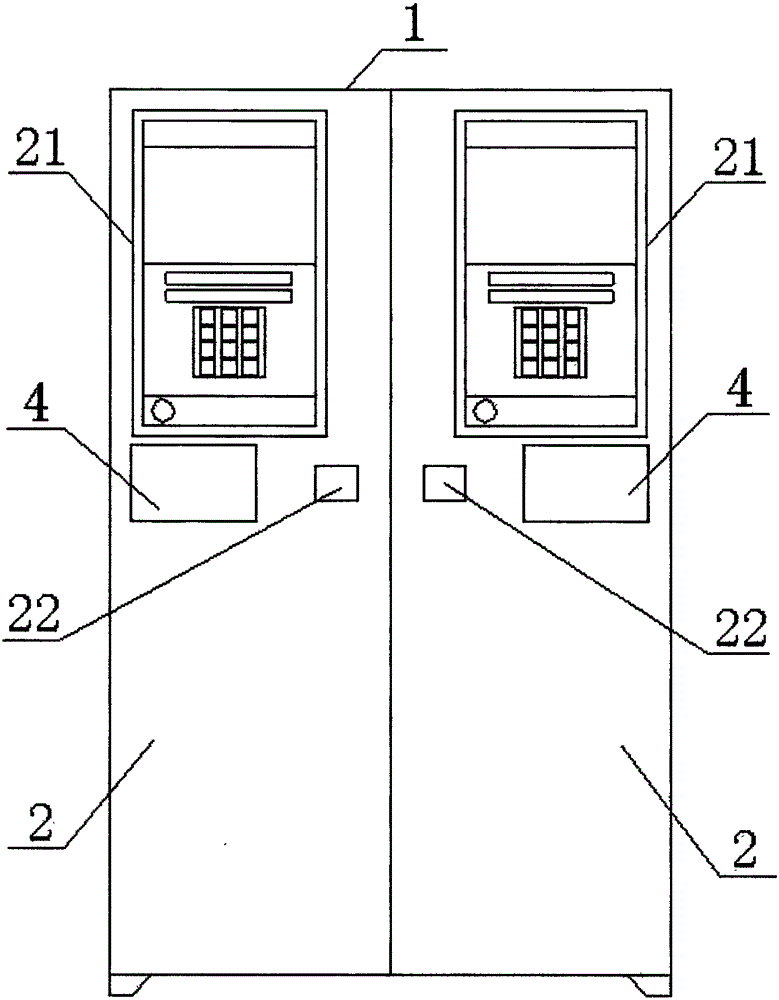

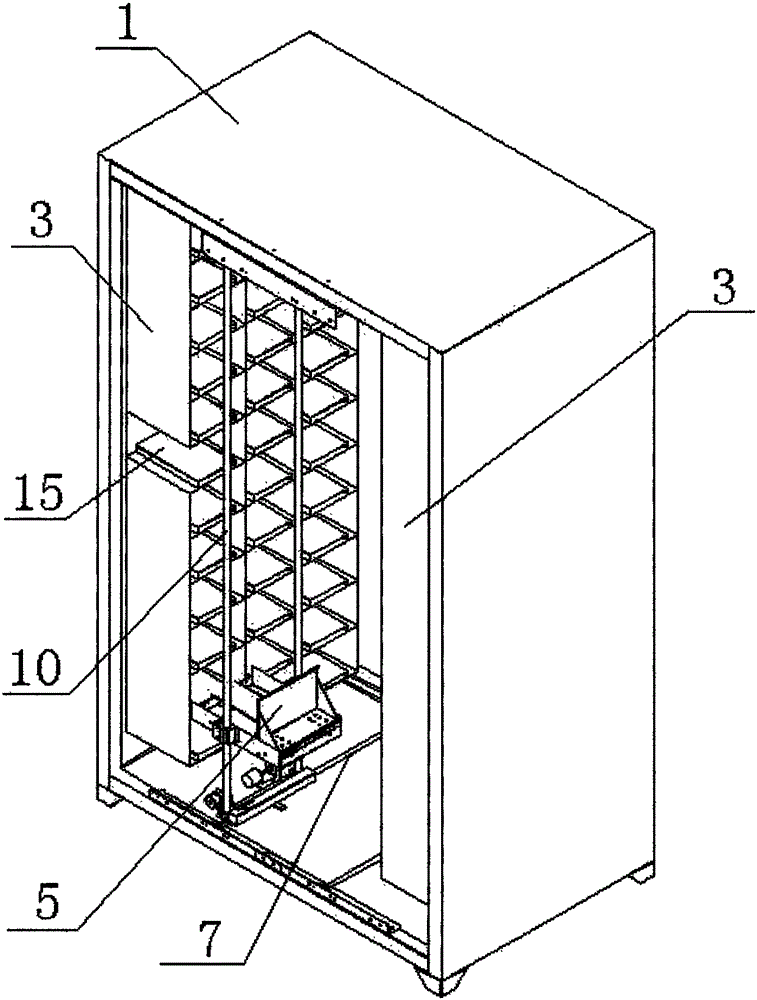

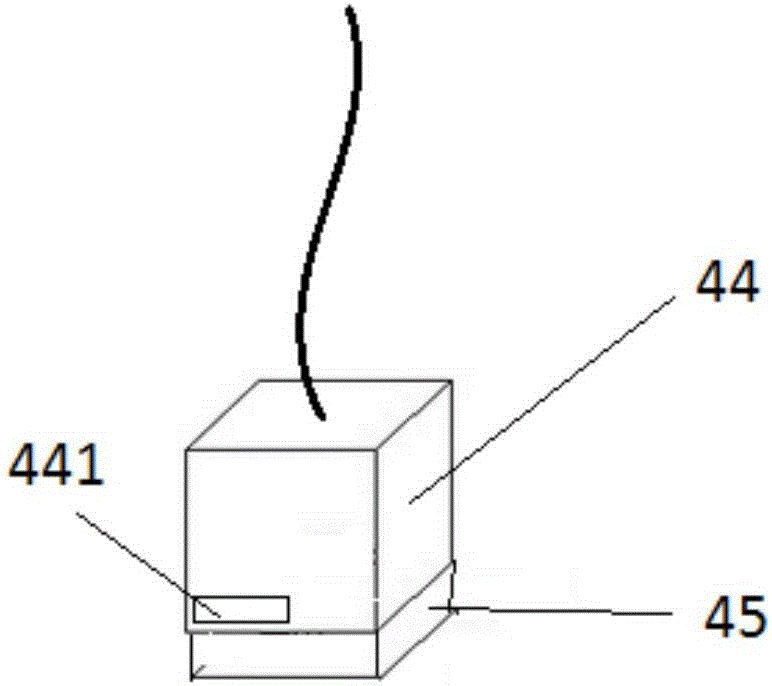

Self-service intelligent storing and taking device based on internet

InactiveCN105139523ASimple and low costReliable performanceCoin-freed apparatus detailsApparatus for dispensing discrete articlesHorizontal transmissionAutomatic control

The invention discloses a self-service intelligent storing and taking device based on the internet. The self-service intelligent storing and taking device comprises a cabinet body, cabinet doors and an automatic control system. Latticed storing boxes and an automatic storing and taking device are arranged in the cabinet body. Storing and taking doors are arranged on the cabinet doors. The automatic storing and taking device comprises a storing and taking trolley, a horizontal movement device and a vertical movement device. The horizontal movement device comprises a horizontal movement motor, a horizontal transmission device and two horizontal movement guide rails. The vertical movement device comprises a vertical movement motor, a vertical transmission device and two vertical movement guide rails and is connected to the two horizontal movement guide rails in a moving mode. The storing and taking trolley is provided with a telescopic bionic hand and connected to the two vertical movement guide rails in a moving mode. The automatic control system is connected with the internet. The storing and taking doors are provided with movement transmission devices. Goods taking windows are formed in the cabinet body and correspond to the storing and taking doors. The self-service intelligent storing and taking device is reliable in working reliability, high in volume fraction, high in compatibility, wide in application range, simplified in mechanism, low in cost and high in automation degree.

Owner:钟高锋

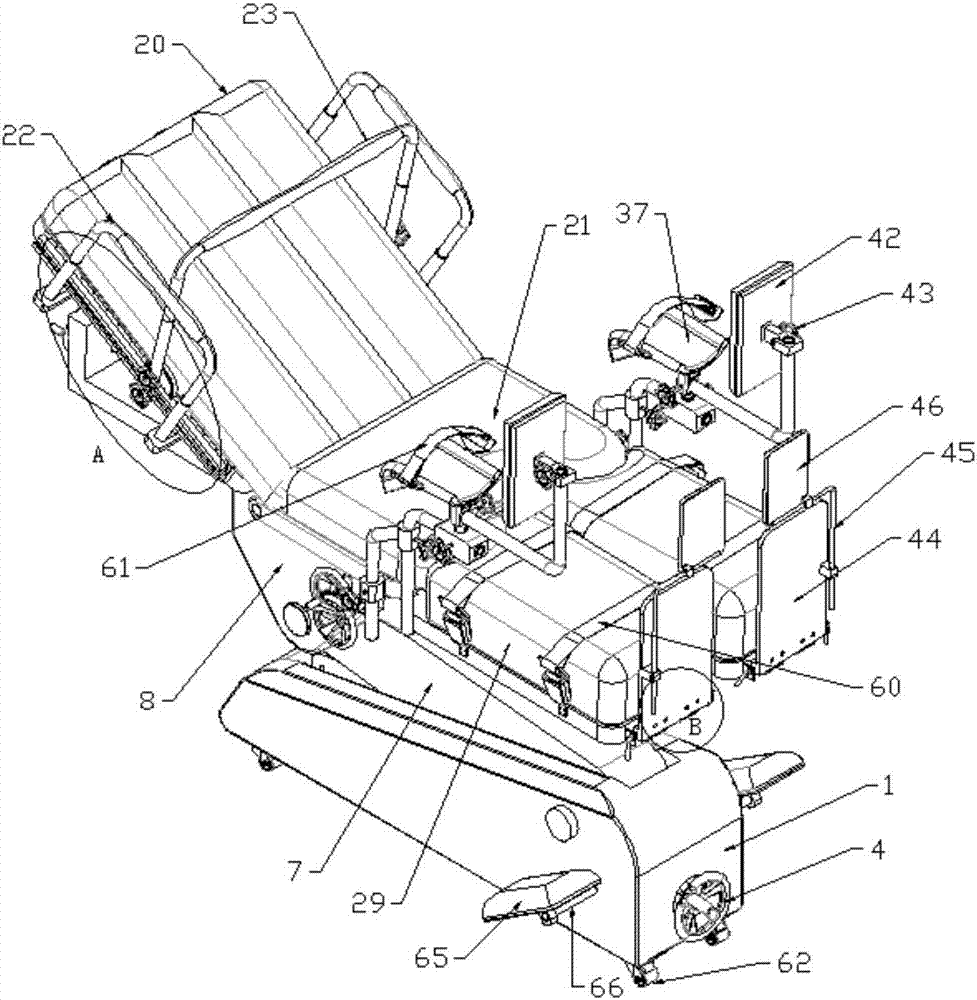

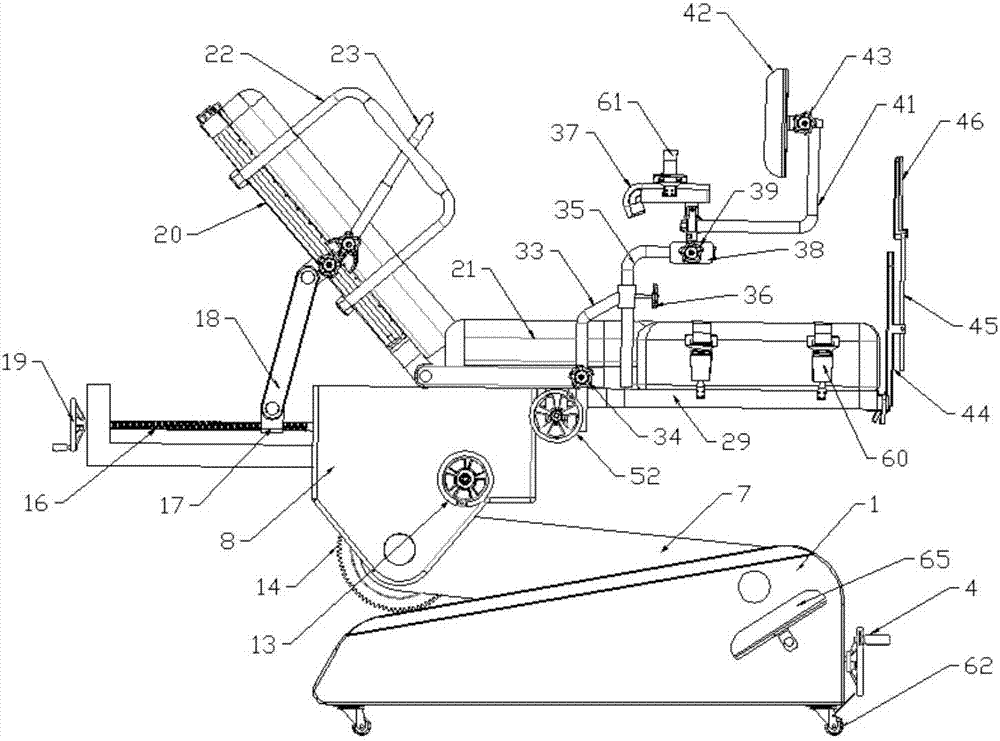

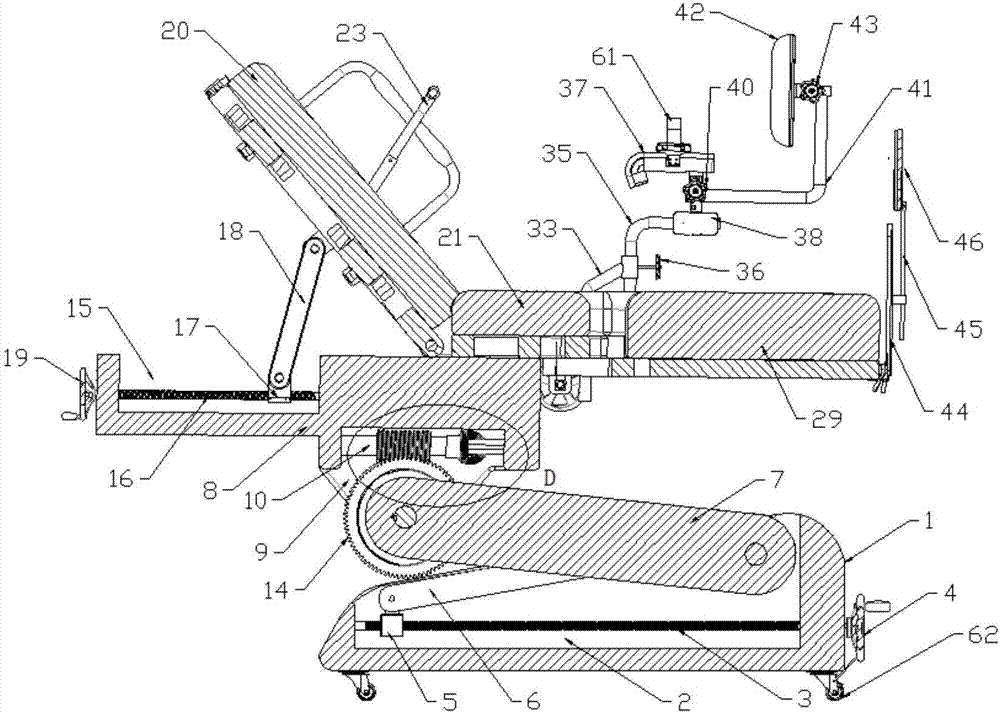

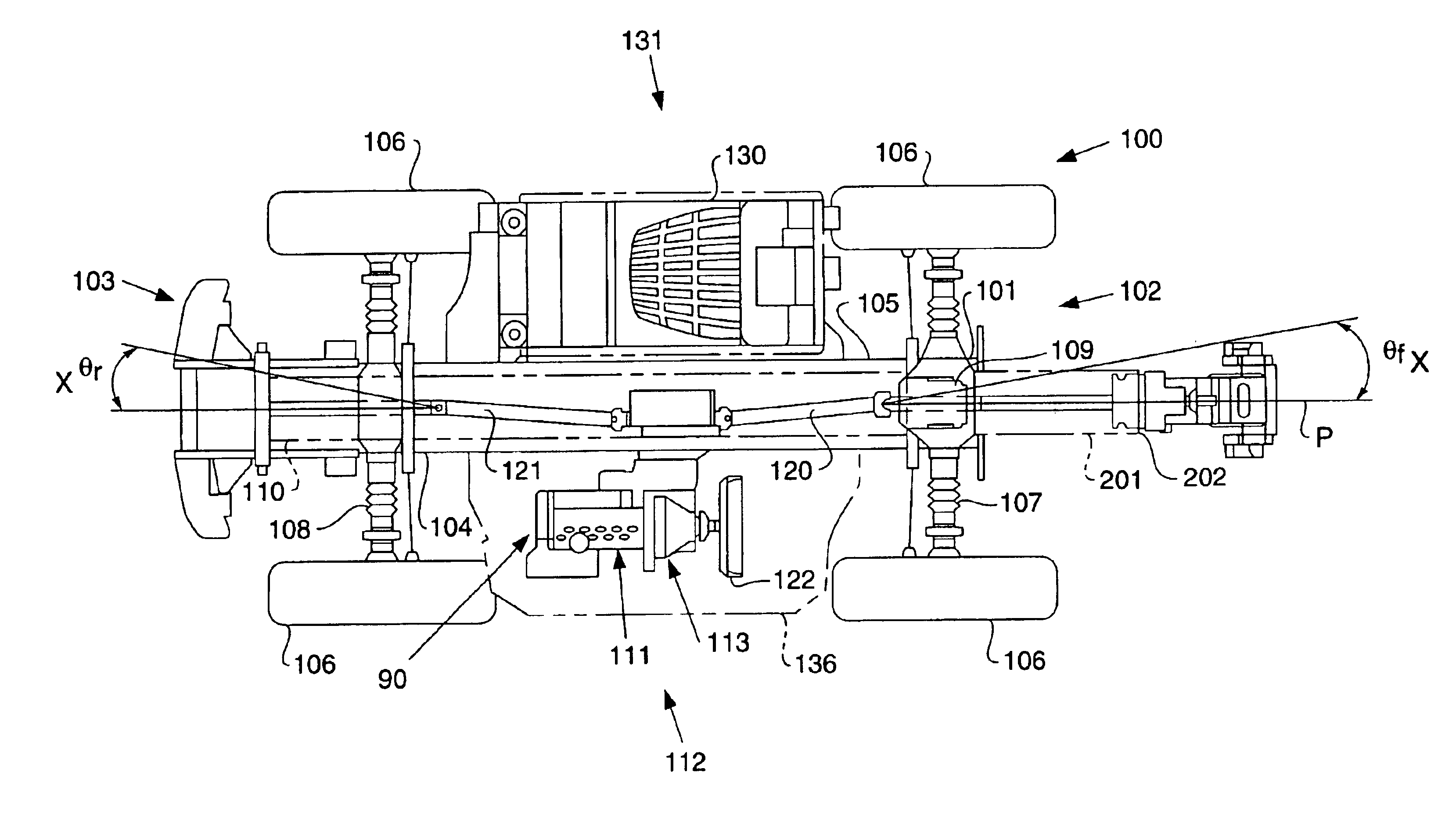

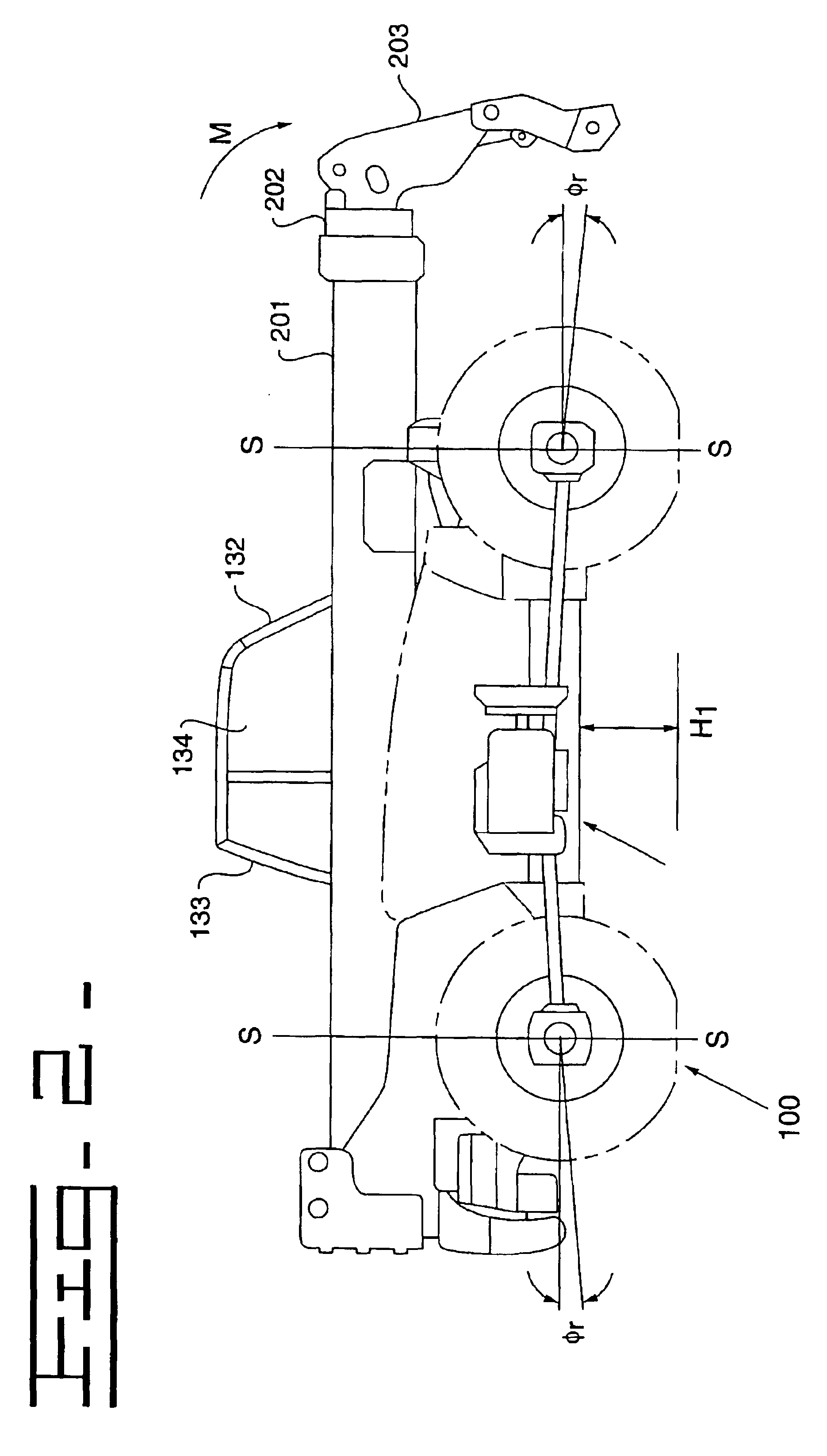

Obstetric delivery table with body position changing freedom

The invention relates to an obstetric delivery table with body position changing freedom. The obstetric delivery table comprises a lifting device, a support cradle head, a table and a pitching mechanism. The lifting device comprises a horizontal transmission mechanism, a support column and a vertical transmission mechanism, the lower end of the support column is connected with the horizontal transmission mechanism, and the upper end of the support column is connected with the vertical transmission mechanism; the support cradle head is connected with the vertical transmission mechanism; the table is positioned on the support cradle head and is divided into an upper-section table, a middle-section table and a lower-section table, and the middle-section table is fixedly connected with the support cradle head; the pitching mechanism is arranged between the upper-section table and the support cradle head; the upper-section table is divided into a left turnover body, a middle fixing body and a right turnover body, the left turnover body is hinged to the middle fixing body, and the middle fixing body is hinged to the right turnover body. The obstetric delivery table has the advantages that requirements of delivery women on supine positions, lateral positions, semi-recumbent positions, sitting positions, squatting positions and standing positions can be met, and accordingly the multiple body positions can be freely changed.

Owner:TIANJIN MEDICAL UNIV

Method and an Apparatus For Picking Up Flat Folded Tubular Blanks From a Magazine and for Moving Them to an Erecting Station

InactiveUS20070197364A1Increase chanceLow costBox making operationsPaper-makingHorizontal transmissionDrive shaft

In an apparatus for picking up flat folded tubular blanks from a magazine and for moving the blanks to an erecting station, a horizontal transmission shaft transmits a rotational movement about a first articulation axis to a functional arm hinged with one side to a terminal portion of the transmission shaft. Another side of the functional arm is hinged to an arrangement control mechanism for controlling arrangement of the functional arm about a second articulation axis. The functional arm is also operated into rotation about the first articulation axis between a position in alignment with the functional arm, and a square position arranged at 90 degrees with respect to the functional arm, and vice versa. A pick up arm is connected to arrangement control mechanism and carries suction cups for picking up a flat folded tubular blank through the open bottom of the magazine. The arrangement control mechanism is moved with respect to the second articulation axis for operating the apparatus, beside the operation of the functional arm affected by the transmission shaft, between a picking up station and an erection station for erecting the tubular blank, and vice-versa.

Owner:MARCHESINI GROUP SPA

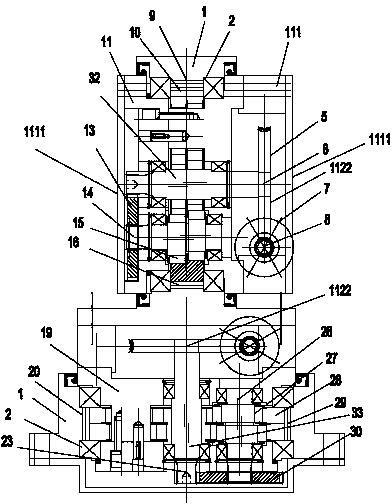

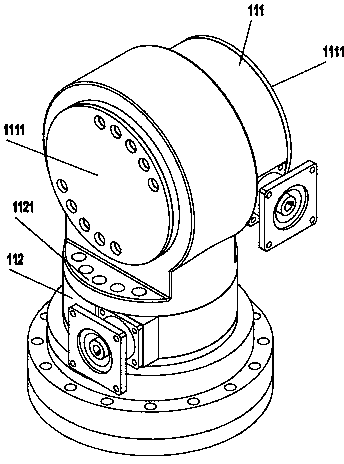

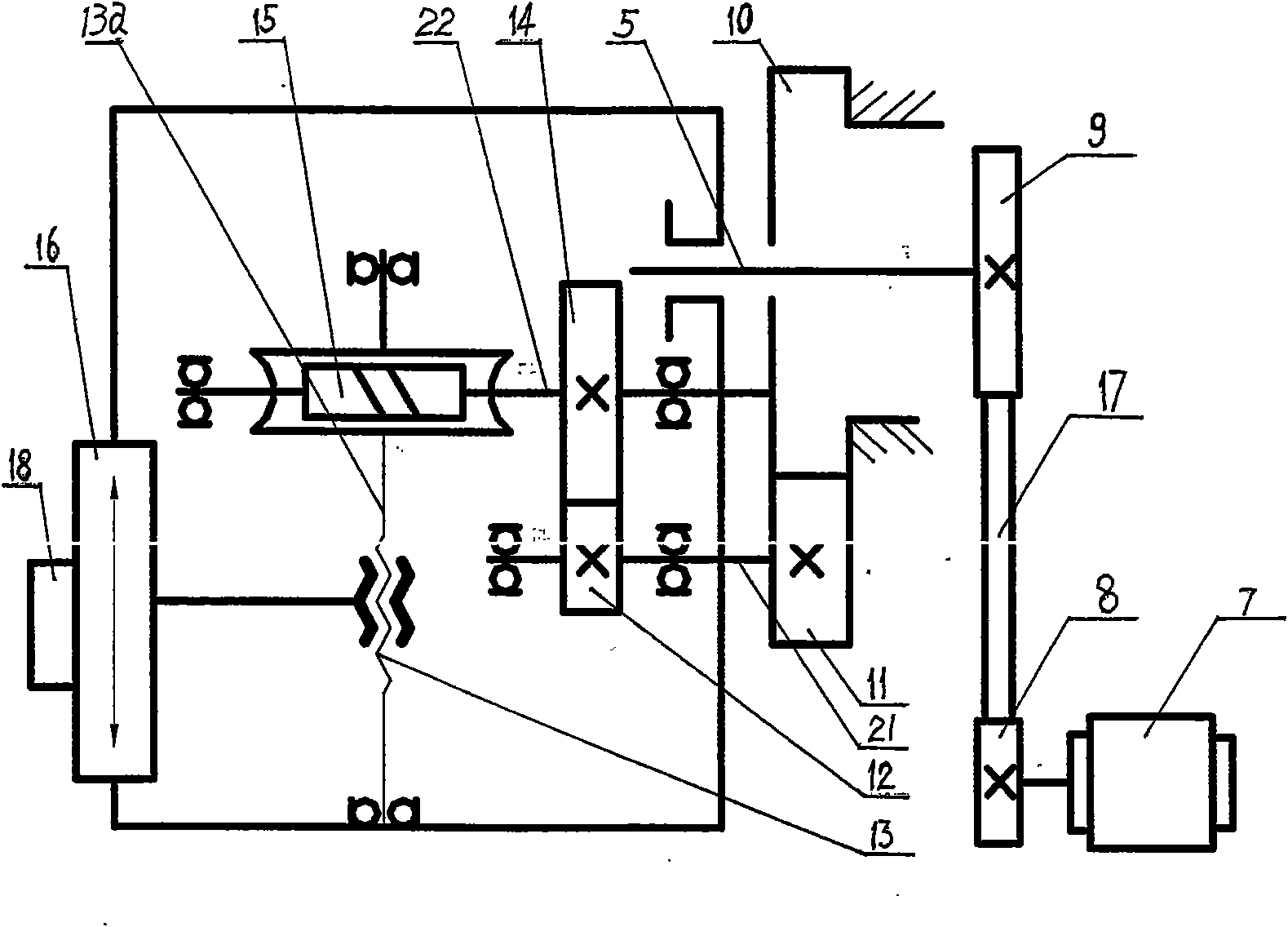

Double-axis positioning transmission mechanism

ActiveCN104358839AImprove rigidityCompact and practicalToothed gearingsTransmission elementsHorizontal transmissionHigh volume manufacturing

The invention discloses a double-axis positioning transmission mechanism, and mainly solves the problems that the existing double-axis positioning transmission mechanism is complicated in structure, low in transmission efficiency, poor in rigidity and short in service life. The double-axis positioning transmission mechanism is characterized by comprising a vertical rotating box and a horizontal rotating box which are arranged on a fixed frame, wherein motors on the vertical rotating box and the horizontal rotating box respectively drive a vertical transmission mechanism and a horizontal transmission mechanism through first transmission mechanisms; the vertical transmission mechanism and the horizontal transmission mechanism drive output pieces to respectively drive the corresponding rotating box to rotate; output surfaces which are connected with a load are arranged on the vertical rotating box and the horizontal rotating box. The double-axis positioning transmission mechanism is compact in structure, simple, practicable, large in the output shaft and rigidity, capable of realizing outputting at the two ends, light in the whole weight, suitable for industrialized large-batch production, high in transmission ratio and transmission efficiency, low in return difference, high in bearing capability and shock resistance, and long in service life.

Owner:ZHEJIANG HENGFENGTAI REDUCER MFG

Method and device for lifting door/window glass of car

InactiveCN103742019ASimple structureFlexible operationPower-operated mechanismHorizontal transmissionLinear motion

The invention provides a method and a device for lifting door / window glass of a car. A motor drives a lead screw of a screw pair to rotate, rotary motion is changed into linear motion to generate a relatively great transmission ratio, a relatively great axial thrust is obtained by the virtue of a relatively small torque so as to drive glass on a lifting drive arm or a glass dragging plate to move up and down to realize lifting. The method is high in transmission precision and strong in self-locking performance. The device for realizing the method has two modes, i.e., a horizontal transmission mode and a vertical transmission mode, and comprises a motor, the screw pair and a bearing; one end of the lead screw of the screw pair is connected to the output shaft of the motor while the other end thereof is supported through the bearing; a nut support of the screw pair is connected to the lifting drive arm or the glass dragging plate; the lifting drive arm is connected to a sliding guide rail; glass is mounted on the sliding guide rail or the glass dragging plate. The device is simple in structure, flexible to operate, low in cost, long in service life, and suitable for glass doors / windows with different camber lines.

Owner:十堰华恒机电科技有限公司

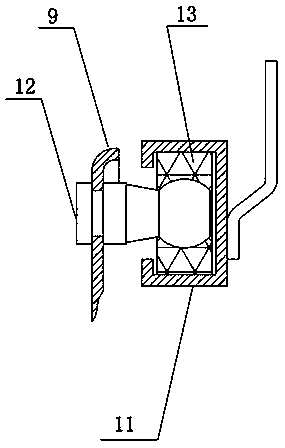

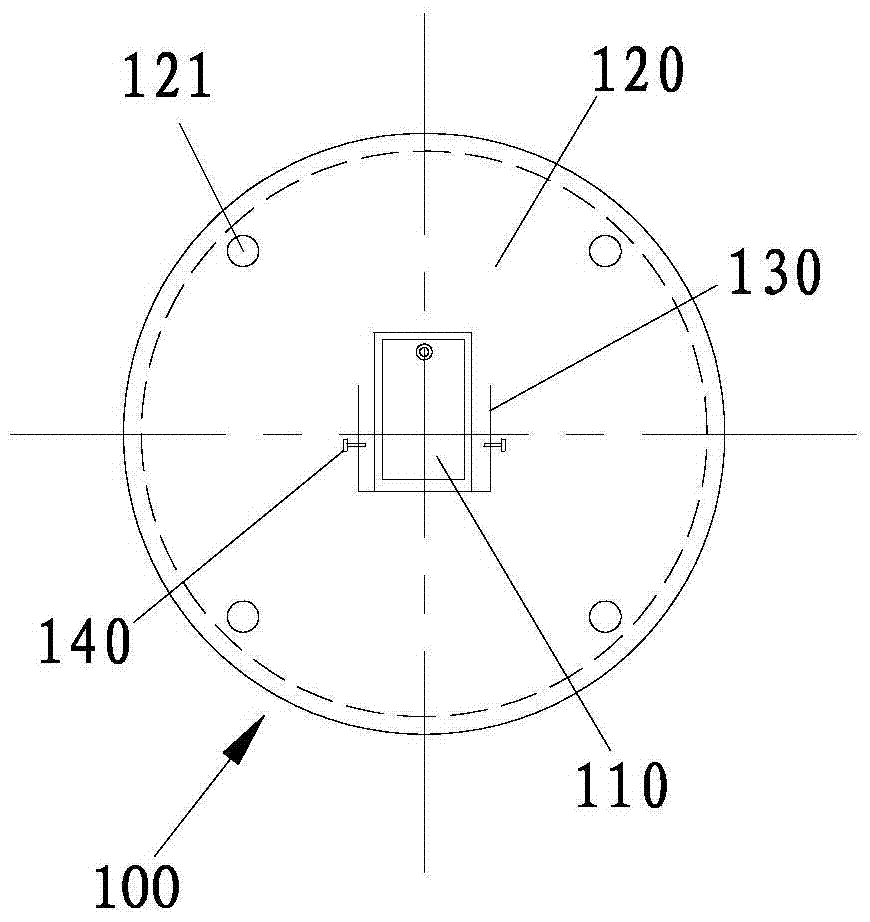

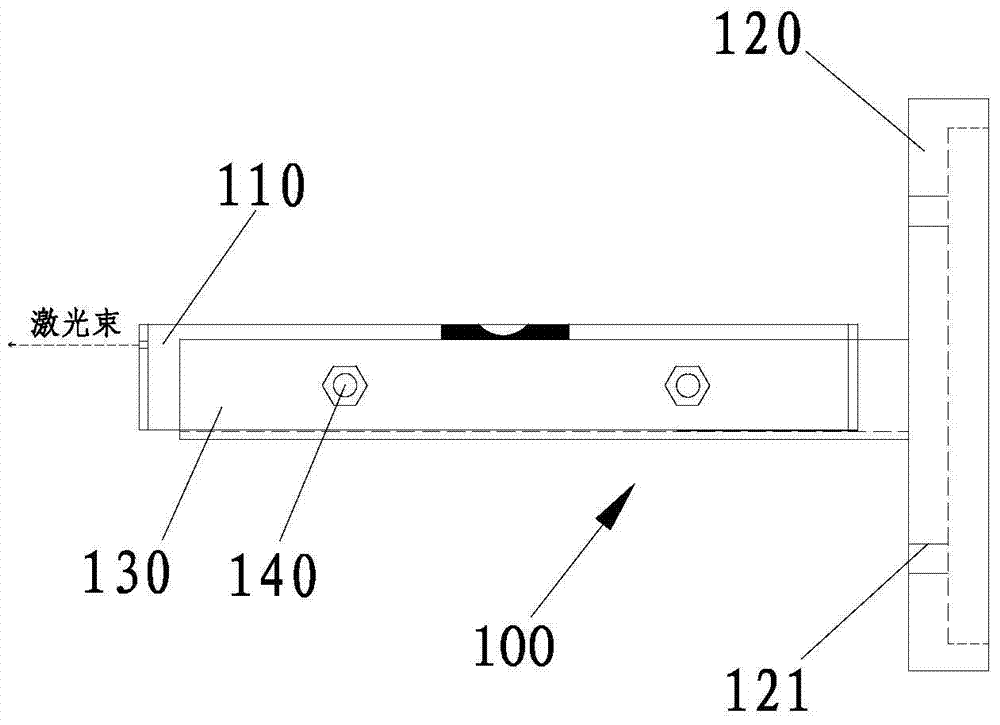

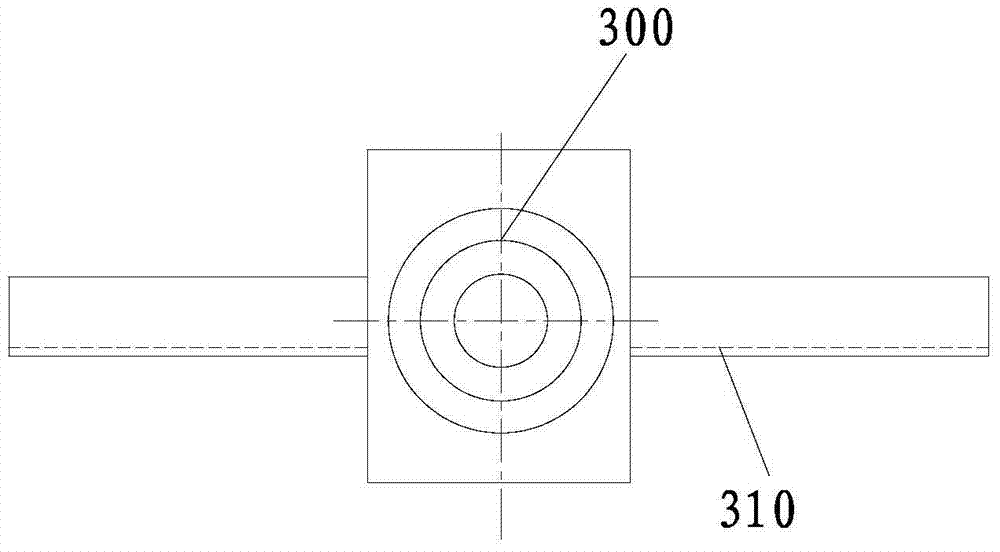

Gear box centering based laser centering tool of ship shaft system and centering mounting method

ActiveCN104759861AImprove installation accuracyHigh precisionVessel designingMetal working apparatusHorizontal transmissionMarine engineering

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

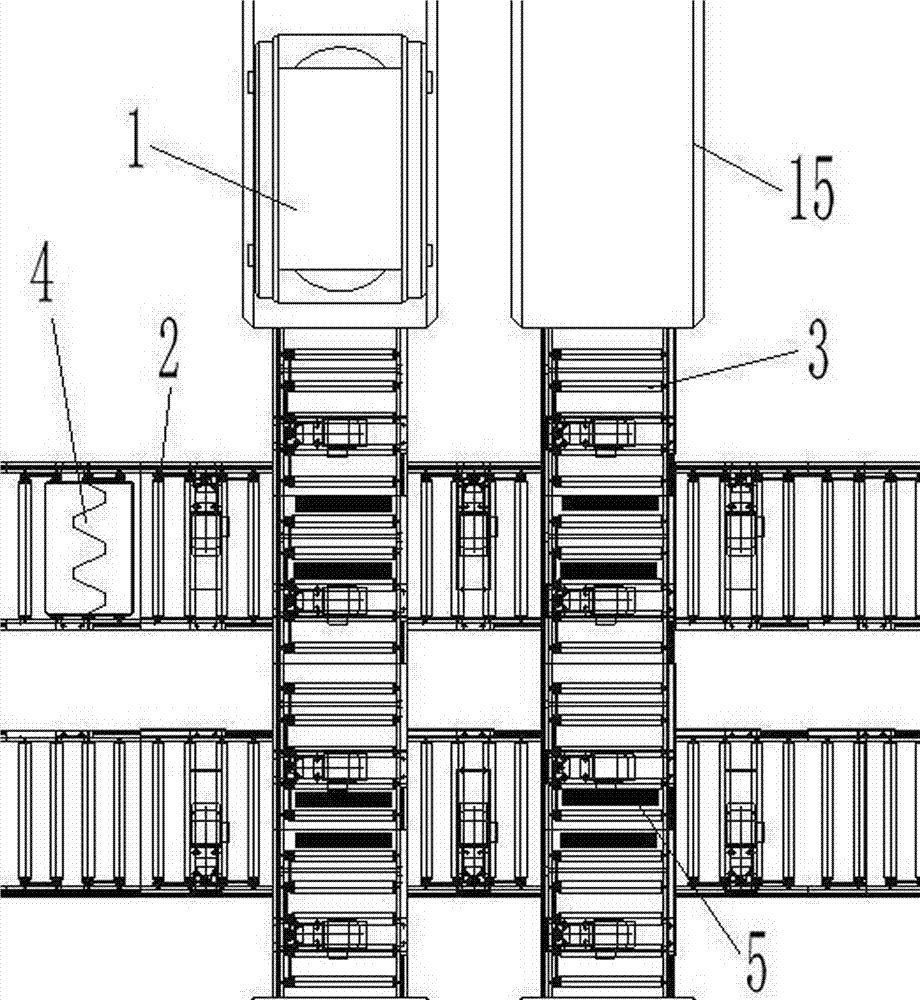

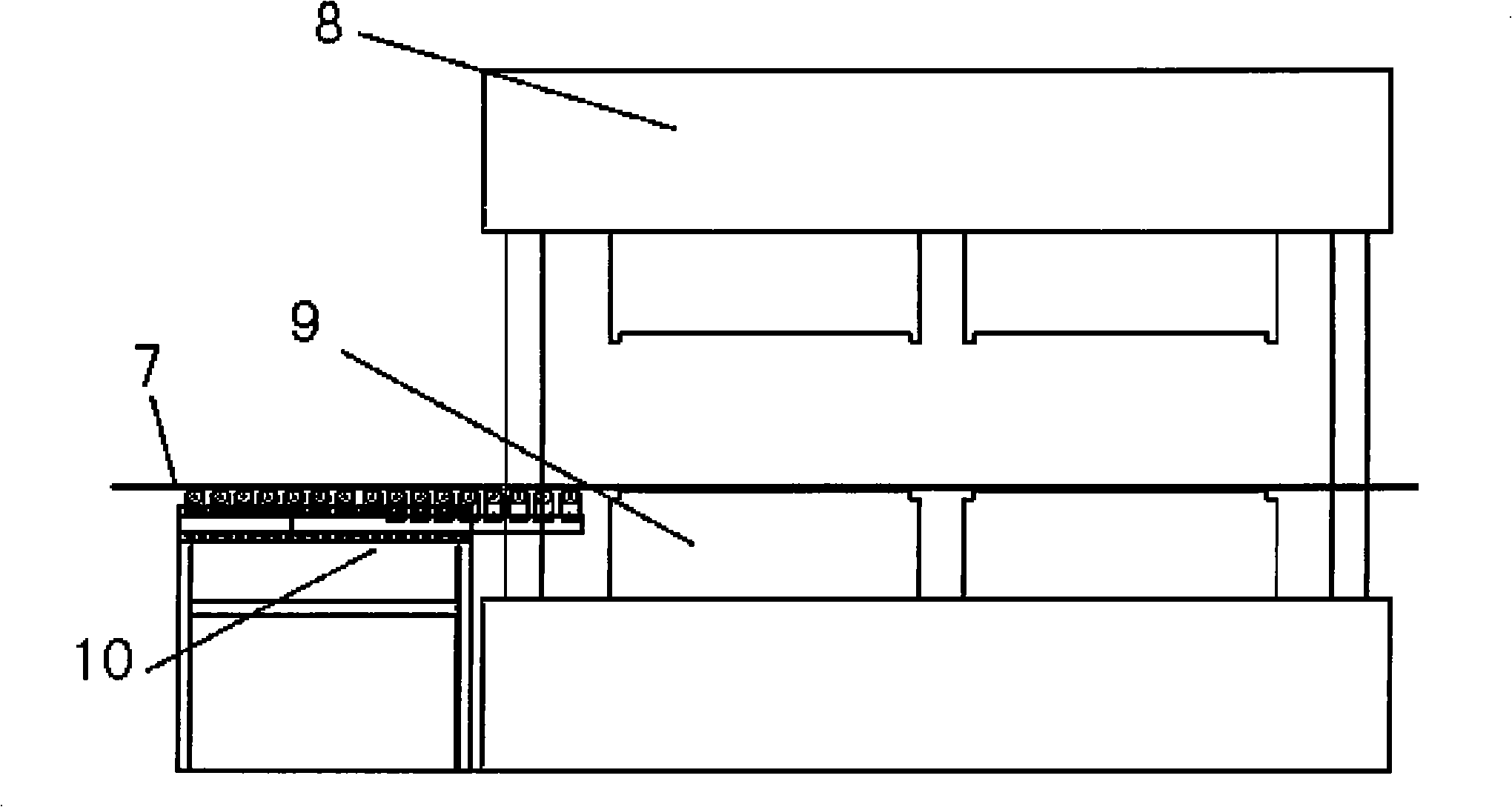

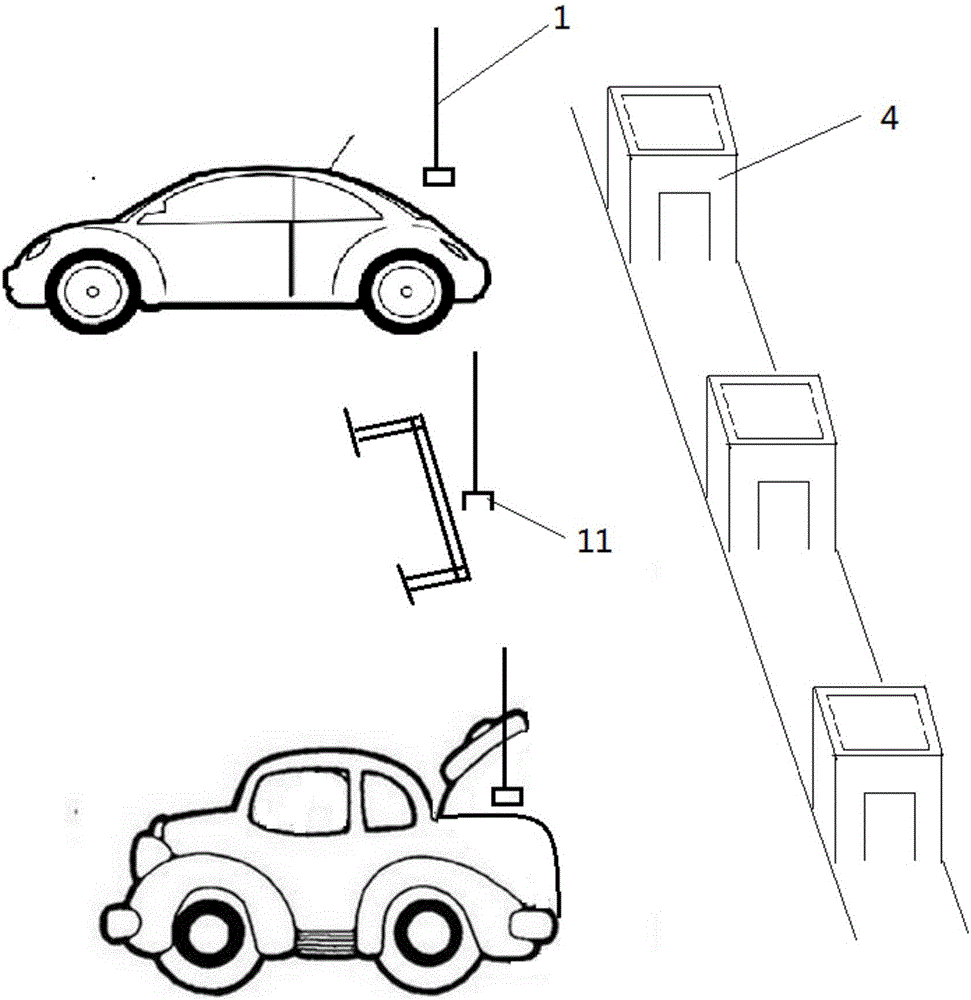

Electric vehicle power battery automatic replacing station and replacing method thereof

InactiveCN106080538ASolve battery lifeEasy to driveElectric propulsion mountingPropulsion by batteries/cellsHorizontal transmissionPower battery

The invention relates to an electric vehicle power battery automatic replacing station. The electric vehicle power battery automatic replacing station is at least of a two-layer structure and comprises a power battery replacing device arranged at the upper layer, a power battery storage device and a power battery horizontal transmission device which are arranged at the lower layer as well as multiple power battery vertical transmission devices which are used for communicating the lower layer with the upper layer; and a power battery stored on the power battery storage device is transmitted to one power battery vertical transmission device by virtue of the power battery horizontal transmission device and is transmitted to a position above the ground, and then the power battery is replaced to the electric vehicle by virtue of the power battery replacing device. The electric vehicle power battery automatic replacing station has the beneficial effects that the problem of charging of a pure electric vehicle is solved, charging time of the electric vehicle is shortened to be as short as the time of a gas station for filling a vehicle with gas, the pure electric vehicle can conveniently travel on a road as a fuel vehicle, and naturally the bottleneck problem of popularizing the pure electric vehicle is solved.

Owner:王世宏

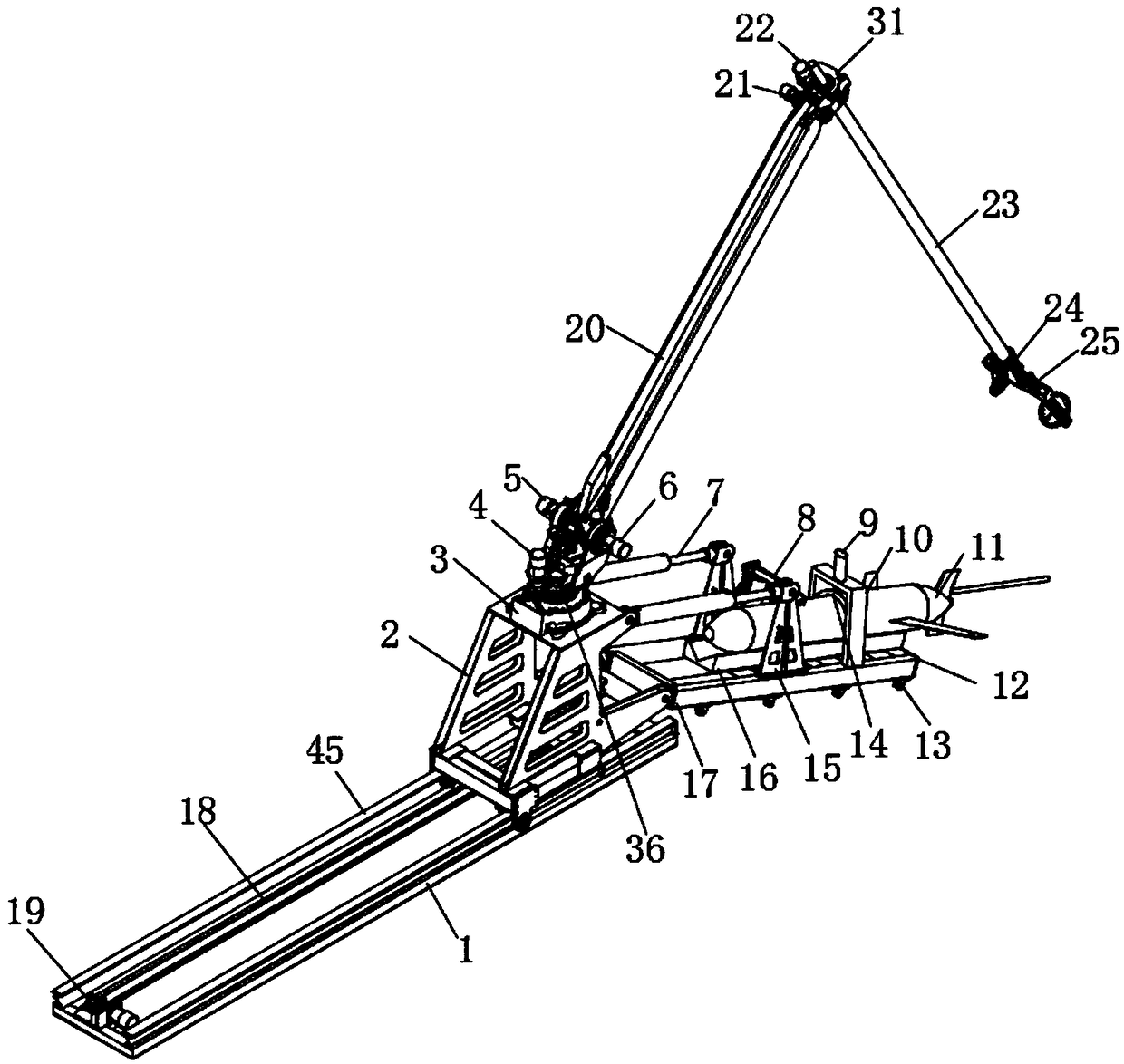

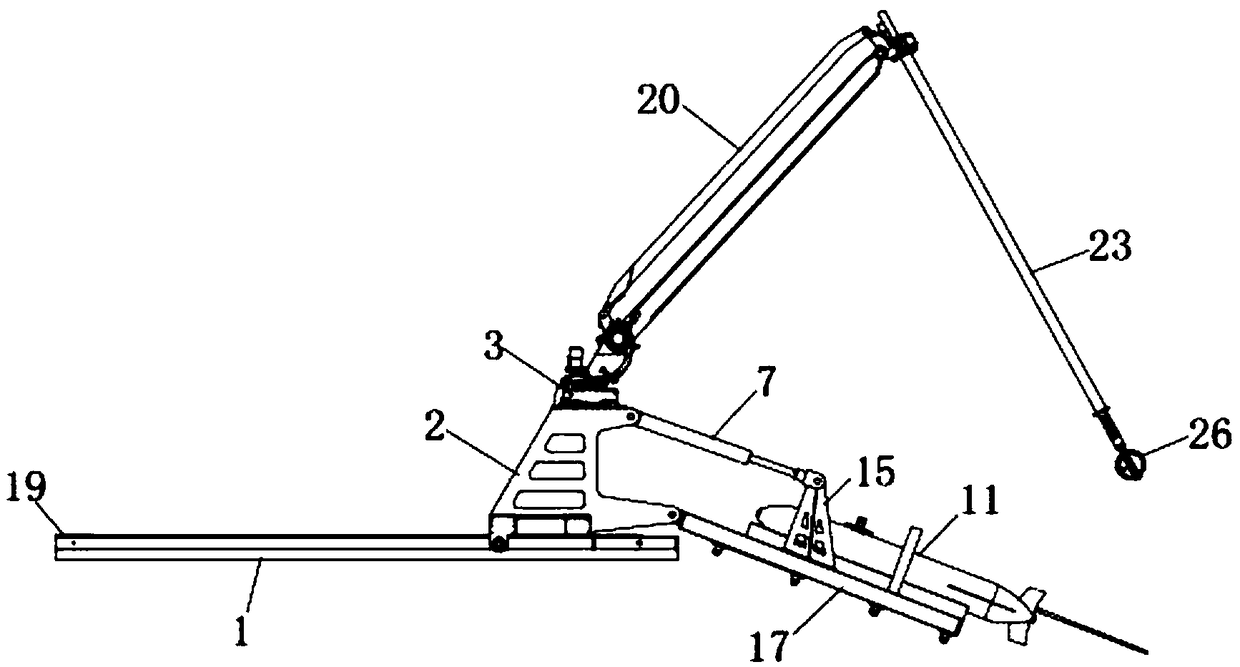

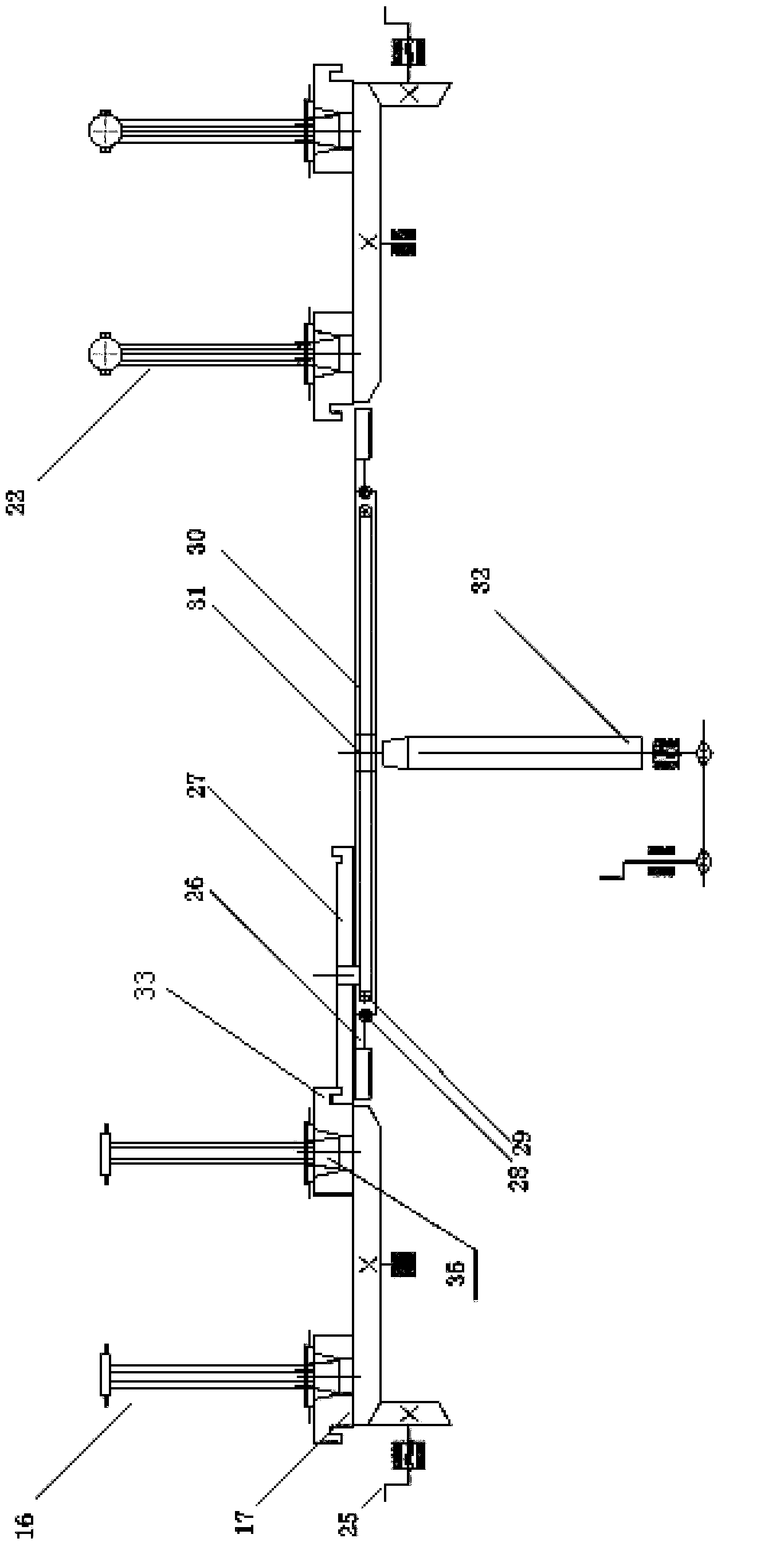

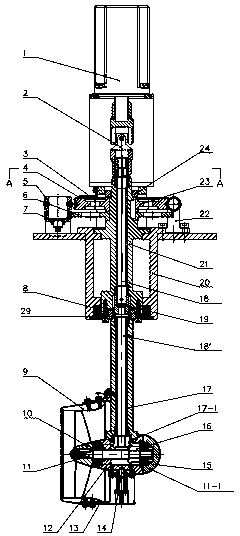

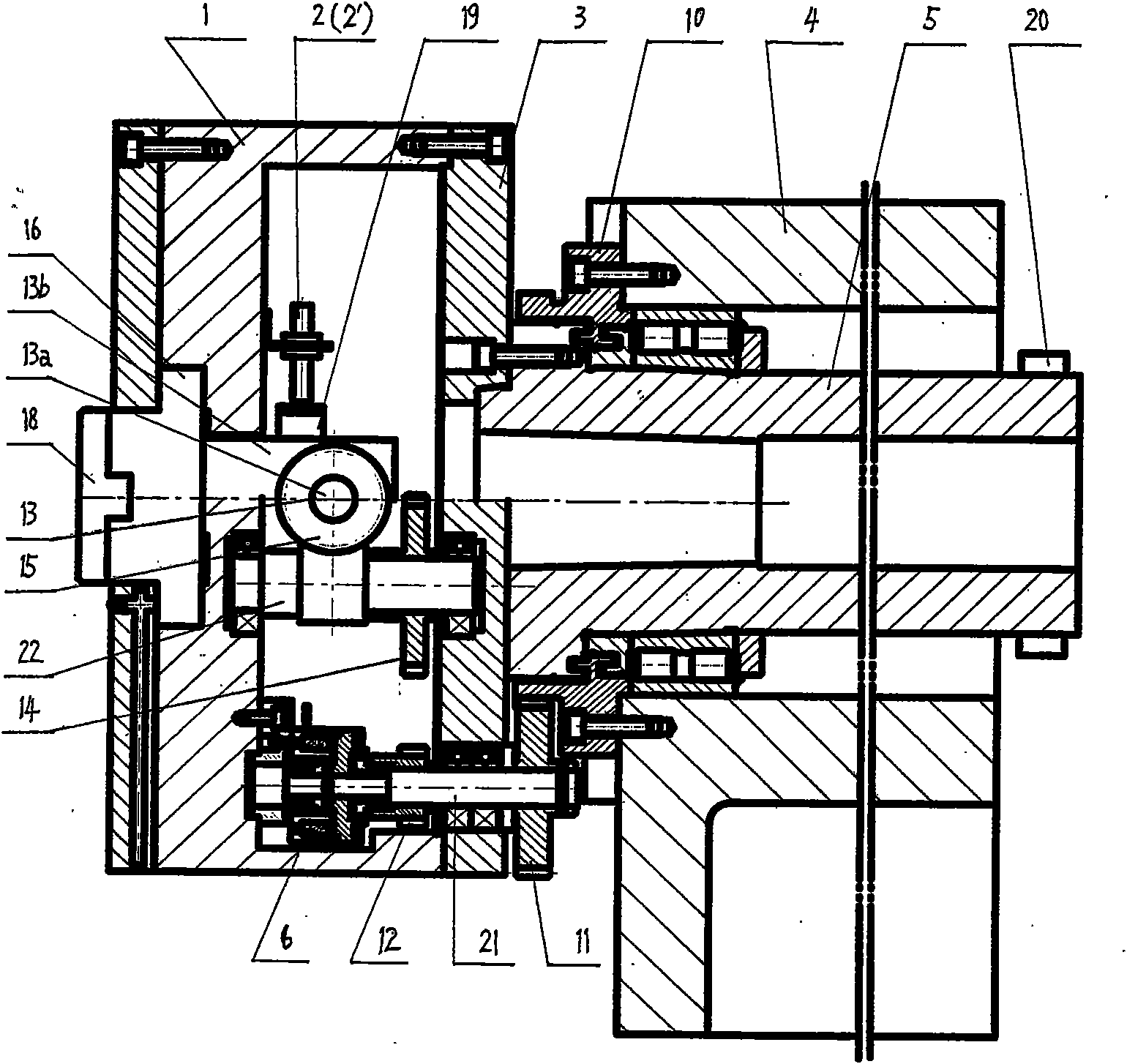

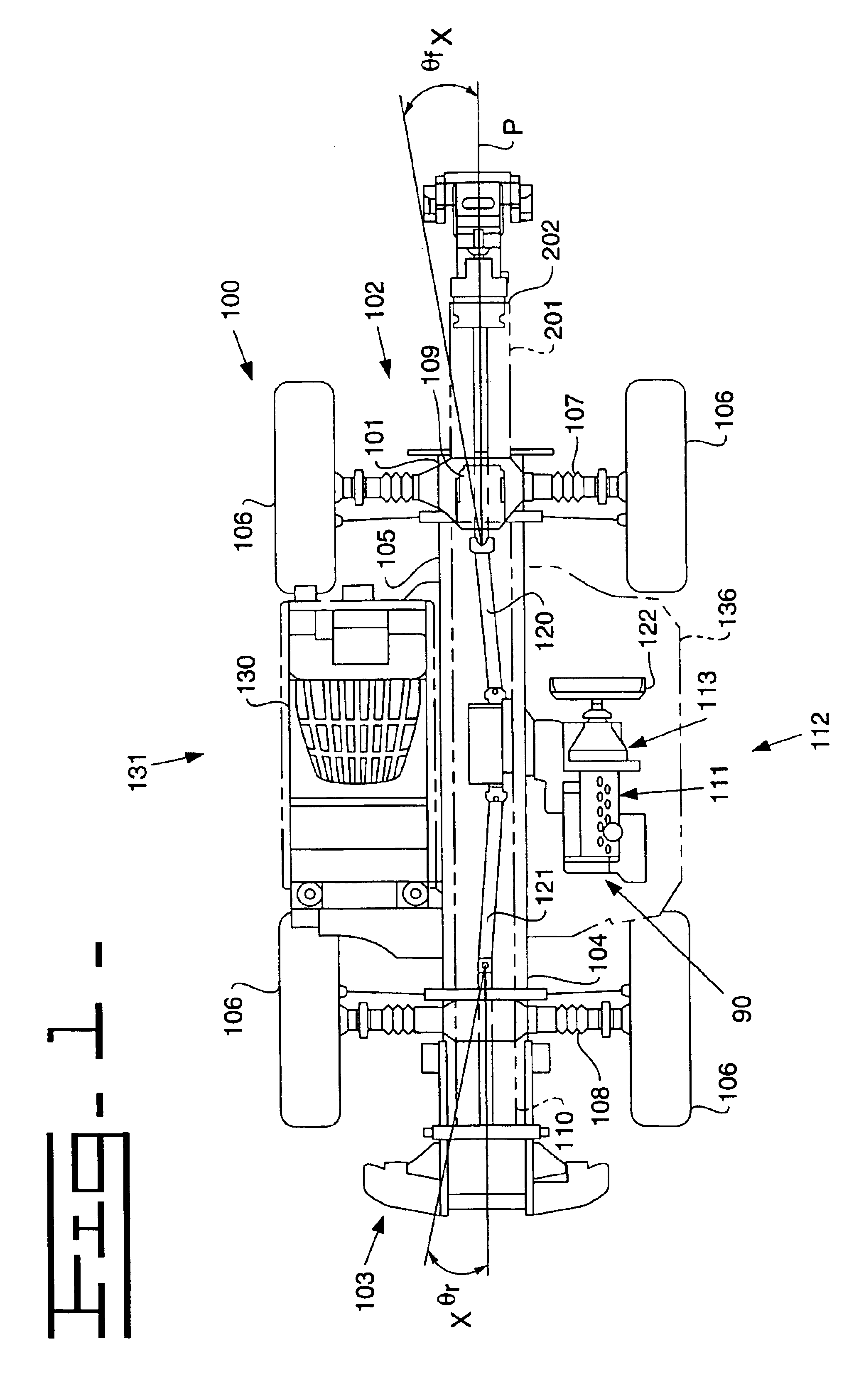

Ship model full circle swinging pushing device

InactiveCN103129730AMeet the installationSatisfy the propeller thrustSteering by propulsive elementsHorizontal transmissionDrive shaft

The invention relates to a ship model full circle swinging pushing device which is composed of an axial transmission mechanism and a circular rotating mechanism. The axial transmission mechanism comprises an upper section inner shaft which is arranged inside an installation base in a penetrating mode, one end of the upper section inner shaft is connected with a first servo motor, the other end of the upper section inner shaft is stretched out of the installation base and is connected one end of a lower section inner shaft, the other end of the lower section inner shaft is connected with a horizontal transmission shaft through a bevel gear, and the horizontal transmission shaft is provided with a propeller. The circular rotating mechanism comprises a circular transmission shaft, the periphery of the circular transmission shaft is connected with a worm gear and a worm, the worm is connected with the output end of a second servo motor, the circular transmission shaft is further connected with one end of an outer shaft through a cover board, and the other end of the outer shaft is matched with a shell on the periphery of the propeller. The ship model full circle swinging pushing device is compact in structure, and small and exquisite in size, can simultaneously achieve axial pushing of the propeller and circular 360-degree rotation of the propeller, meets requirements of installation of models in a water pond, pusher pushing force and locating tests, and obtains good testing effects.

Owner:中国船舶重工集团公司第七〇二研究所

Mechanical flat rotating disk

InactiveCN101602174AHigh precisionCompact structureFeeding apparatusHorizontal transmissionDrive shaft

The invention provides a mechanical flat rotating disk. The disk comprises a horizontal spindle (5) which is arranged in a spindle box (4) and has one end in external connection with a transmission mechanism, wherein the other end of the spindle is fixedly provided with a flange (3); a fixed gear (10) concentric with the spindle is arranged on the spindle box; a planetary gear (11) meshing with the fixed gear is arranged outside the fixed gear; a horizontal transmission shaft (22) and a leadscrew pair (13) perpendicular to the transmission shaft are arranged in the flange; the transmission shaft is connected with a worm gear pair (15) and provided with a driven gear (14); the worm gear pair and the leadscrew pair are connected through a leadscrew; a driving gear (12) and a clutch (6) are arranged on a central shaft (21) of the planetary gear; the driving gear meshes with the driven gear; the outer end of the flange is fixedly connected with a sliding plate (16); and a tool holder (18) is arranged on the sliding plate. The disk has the advantages of simple structure, convenient maintenance, low manufacturing cost and capability of meeting the demand of special machine tools.

Owner:YUNNAN CY GRP

Horizontal transmission and oil system for telehandlers

InactiveUS6904994B2Electric propulsion mountingGas pressure propulsion mountingHorizontal transmissionEngineering

A power train arrangement having a prime mover and a transmission coupled to the prime mover for driving a cooling system with the prime mover through the transmission. The transmission is positioned intermediate to the prime mover and the cooling system in a manner to optimize the mechanical and functional operation of the work machine.

Owner:JLG IND INC

Manual image measuring instrument

InactiveCN1776355AGuaranteed to be verticalReduce resistanceUsing optical meansHorizontal transmissionCamera lens

Through adjusting gear, CCD camera and zoom lens are connected; and through lens clamp, CCD camera and zoom lens are fixed on fixation adjustment device for camera and microscope. Through bolt, the camera and microscope is connected to the connection base plate in z-axis. The connection base plate in z-axis is fixed on a nut in z-axis. Through screw thread, transmission shaft in z-axis is connected to the nut in z-axis. Through bearing seats, the fixed transmission shaft is connected to horizontal transmission shaft through helical beval gear. Rotating handwheel installed on the horizontal transmission shaft makes transmission shaft in z-axis rotate so that nut and the connection base plate are moved along guide rail in z direction up and down.

Owner:东莞市升力智能科技有限公司

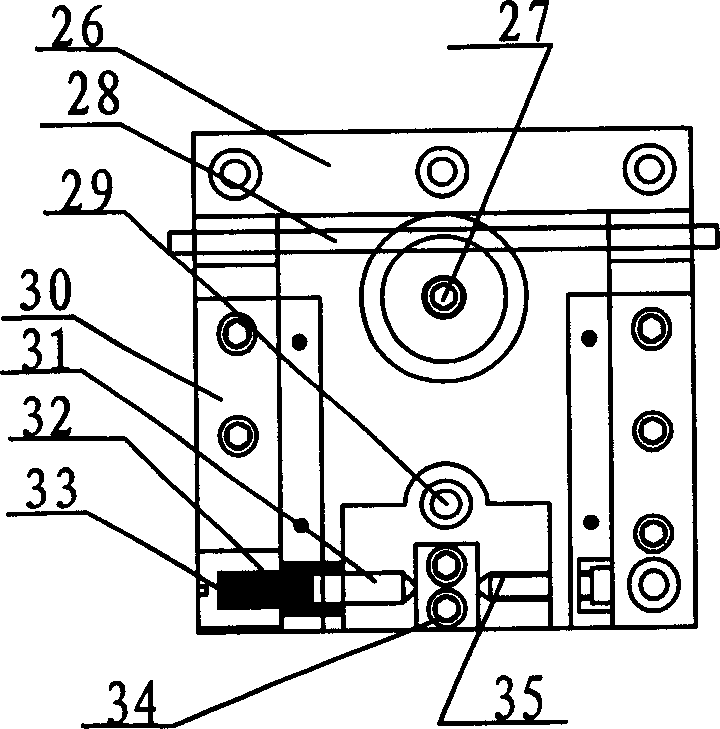

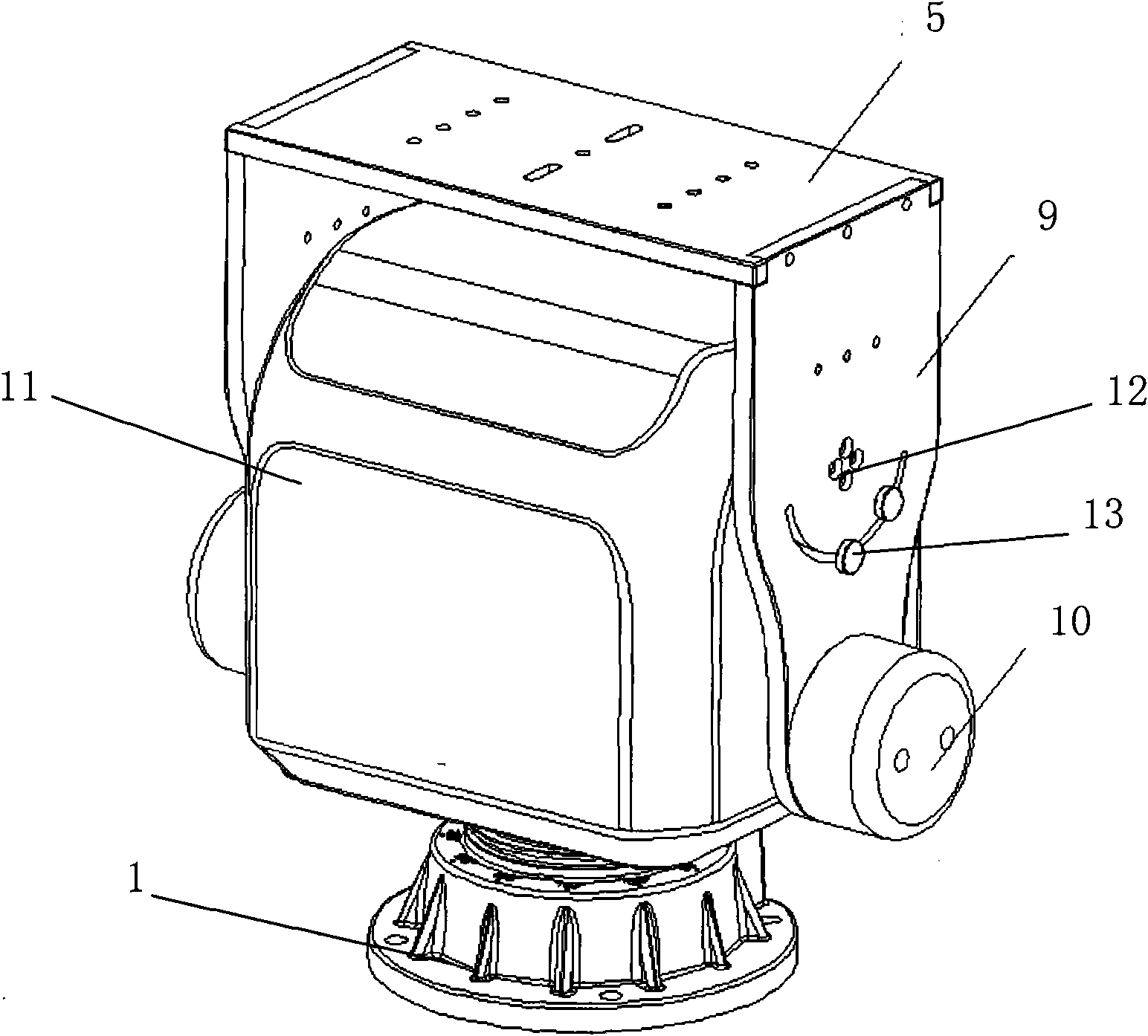

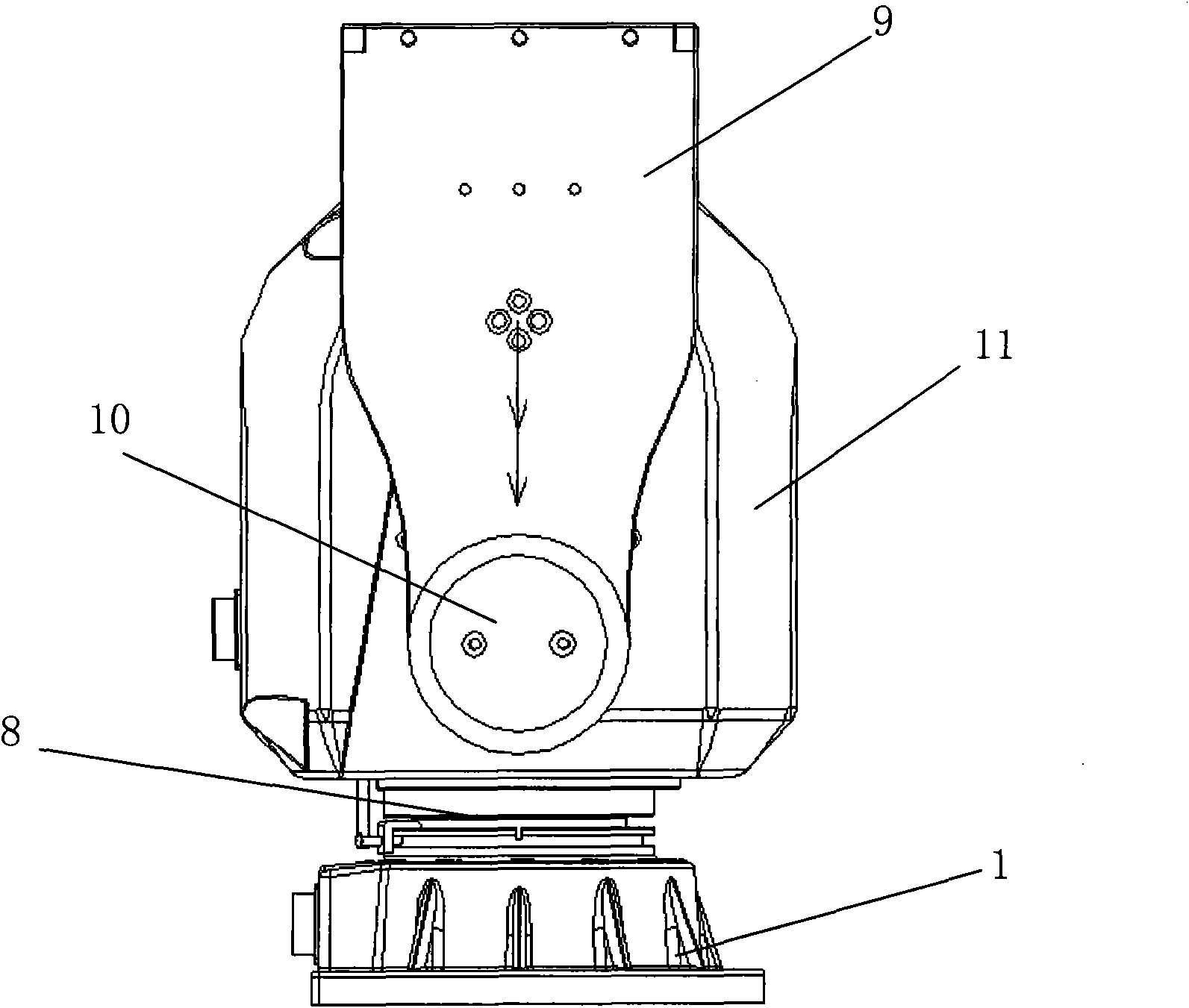

Heavy-load cradle head

InactiveCN102096282ASmooth Angle TransformationThe shooting picture is stableStands/trestlesCamera body detailsHorizontal transmissionDrive shaft

The invention relates to a heavy-load cradle head which comprises a base, a deck mechanism, a shell, a protective cover and a transmission mechanism, wherein end plates at two sides are respectively provided with a gravity compensation part, and the gravity compensation parts and a protective cover connecting plate are respectively arranged at two sides of a fixing position of a vertical transmission shaft and the end plates. In the invention, the moments generated by the gravity compensation parts can be equal to the moments generated by a camera and the protective cover connecting plate through changing the weight of the gravity compensation parts so as to ensure that the whole gravity center of the protective cover structure connected with the camera falls into the center of a horizontal transmission shaft, i.e. the bearing center of the whole cradle head; and when the camera rotates in the vertical direction, because the camera and the protective cover rotate in a gravitational equilibrium state, the camera can stably finish angle conversion in the vertical direction so as to ensure that the shooting picture of the camera is more stable.

Owner:TIANJIN TIANDY DIGITAL TECH

Preparation method of in situ double-tilt electronic microscope sample rod

ActiveCN102543637AInnovative design ideasMature usabilityElectric discharge tubesImaging qualityElectric field

The invention belongs to the technical field of material analysis and testing, and relates to a manufacturing method of an in situ double-tilt electronic microscope sample rod for which an electric field and a light signal can be added externally; the method comprises the following steps that: first, three independent channels are arranged in a hollow copper bar of a sample rod based on an existing single-title electronic microscope sample rod in an insulated and closed way; the three independent channels are respectively distributed to a horizontal transmission rod, a lead and an optical fiber and are insulated and sealed; the sample rod tilts rotationally along a Y axis through a stepper motor which is arranged outside the sample rod and is connected with the horizontal transmission rod; then an electric field terminal is arranged on a sample cup and is more than 10cm away from an optical axis, so that the concentration of charge and the affection of the imaging quality are prevented; then an optical fiber fixed column is arranged on the sample cup, metal is sprayed onto the surface of a transmitting optical fiber and the optical fiber is connected in, and a laser led-in sample is formed into an in situ transmission double-tilt sample rod; and according to the preparation method of the in situ double-tilt electronic microscope sample rod, a design idea is novel, the used equipment and technologies are mature, the manufacturing cost is low, the market blank is filled, experimental needs are met, and the practicality and test results are good.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com