Chemical mechanical planarization device and wafer transmission method

A chemical-mechanical and flattening technology, applied in metal processing equipment, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of complex structure of transmission mechanism and low efficiency of wafer transmission, so as to improve transmission efficiency and efficiency The effect of increasing and reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

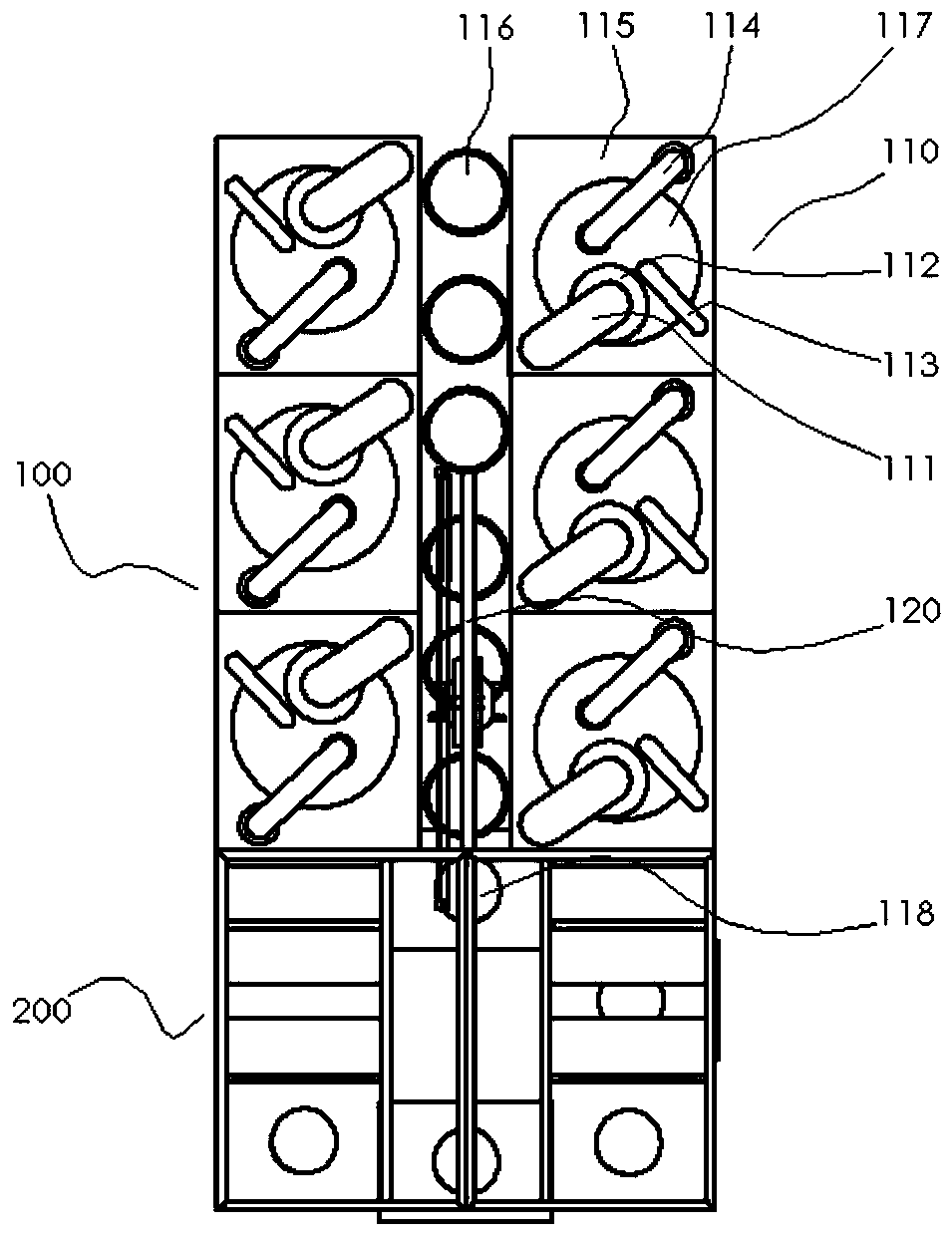

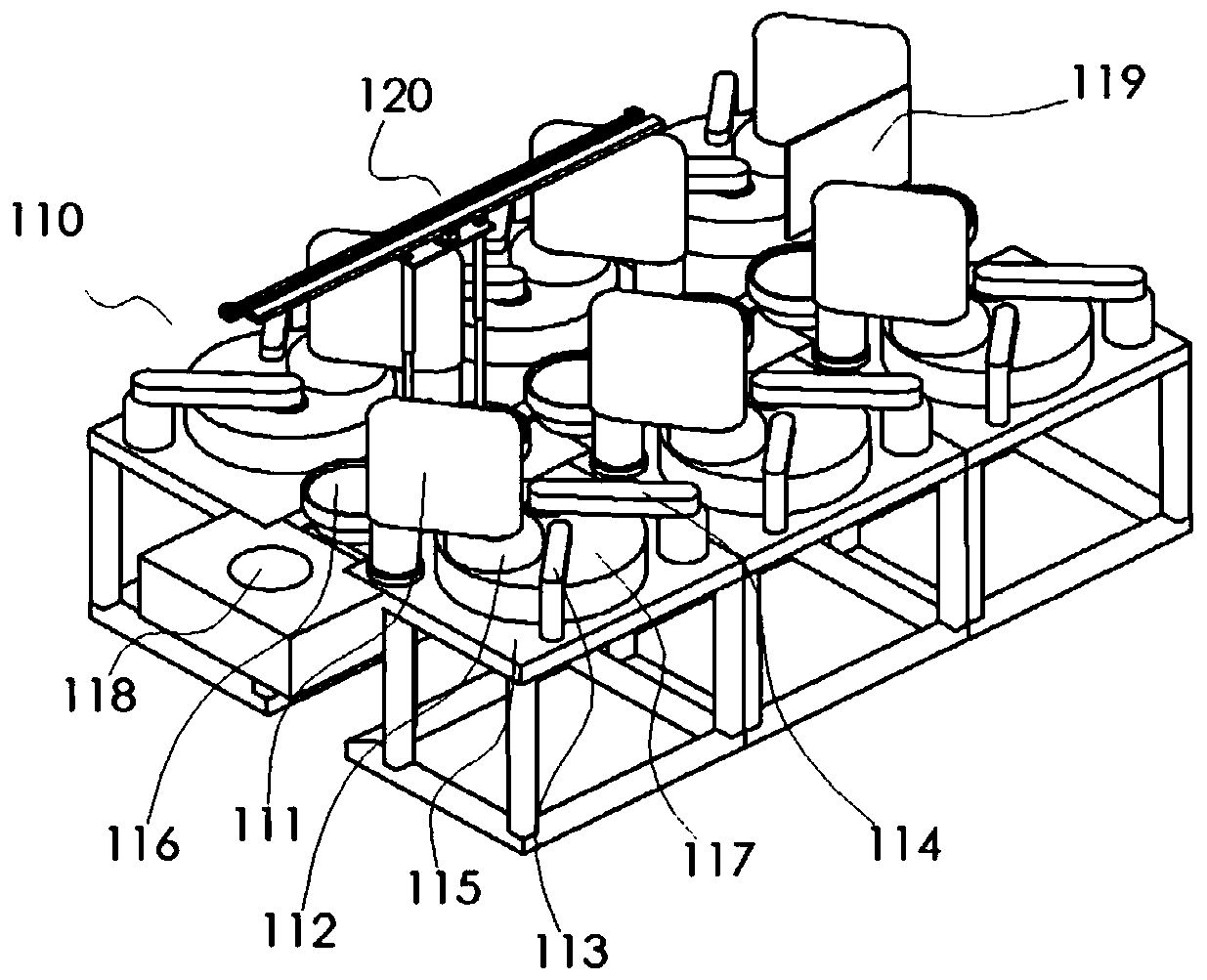

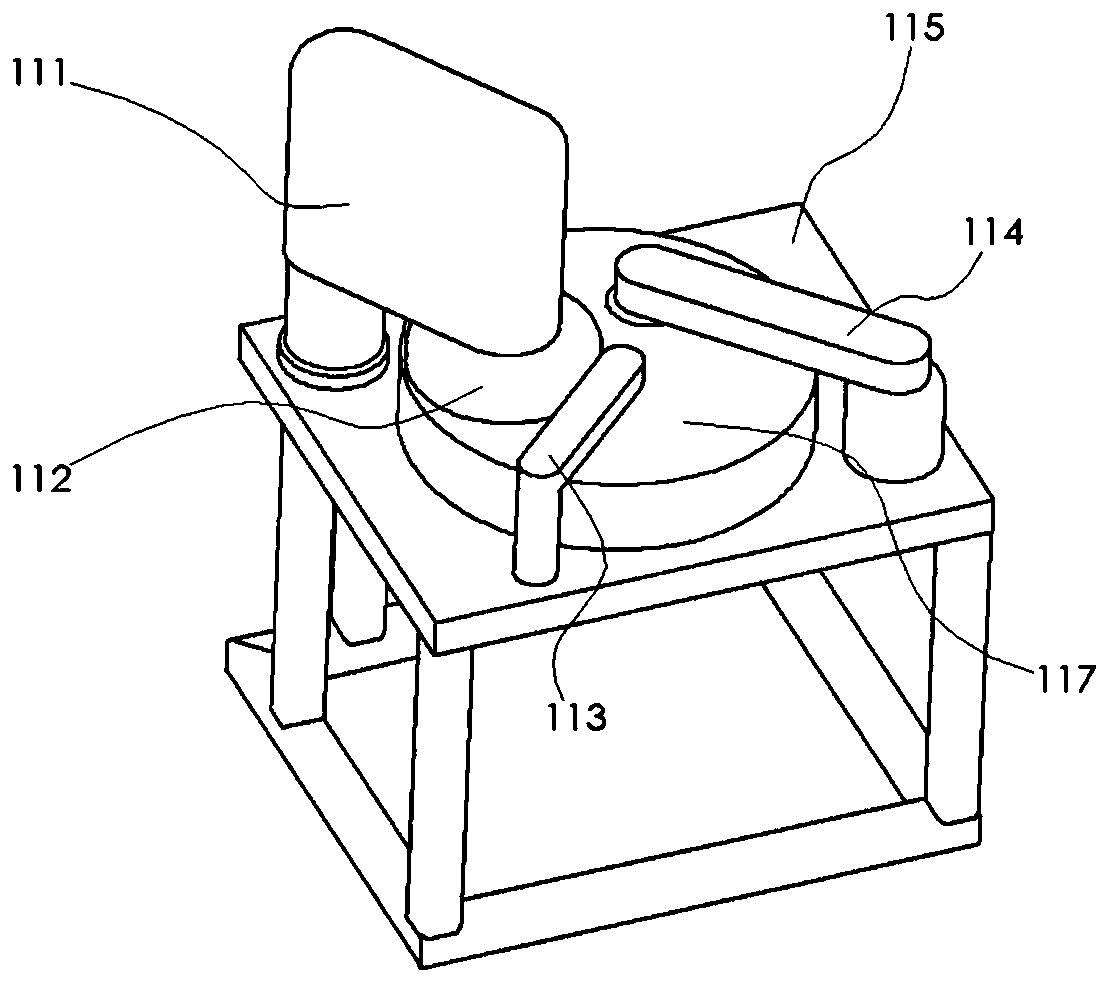

[0055] The chemical mechanical planarization device according to the present invention includes a polishing module composed of a plurality of polishing units and a plurality of cleaning modules. Each polishing unit includes a workbench, a polishing disc, a polishing head, a polishing arm, a dresser, a polishing liquid arm, and the like. Multiple polishing loading tables are arranged on one side of the multiple polishing units. The polishing disk, polishing head, polishing arm, dresser, and polishing liquid arm are arranged on the workbench according to the processing position. The polishing arm can carry the polishing head to move between the polishing disc and the polishing loading table. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com