Telescopic horizontal transmission bench

A conveying table and telescopic technology, which is applied in metal processing, winding strips, roller tables, etc., can solve the problems of inconvenience in taking in and out, and a certain space for storage, and achieves stable structure, meets the needs of use, and is reliable. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

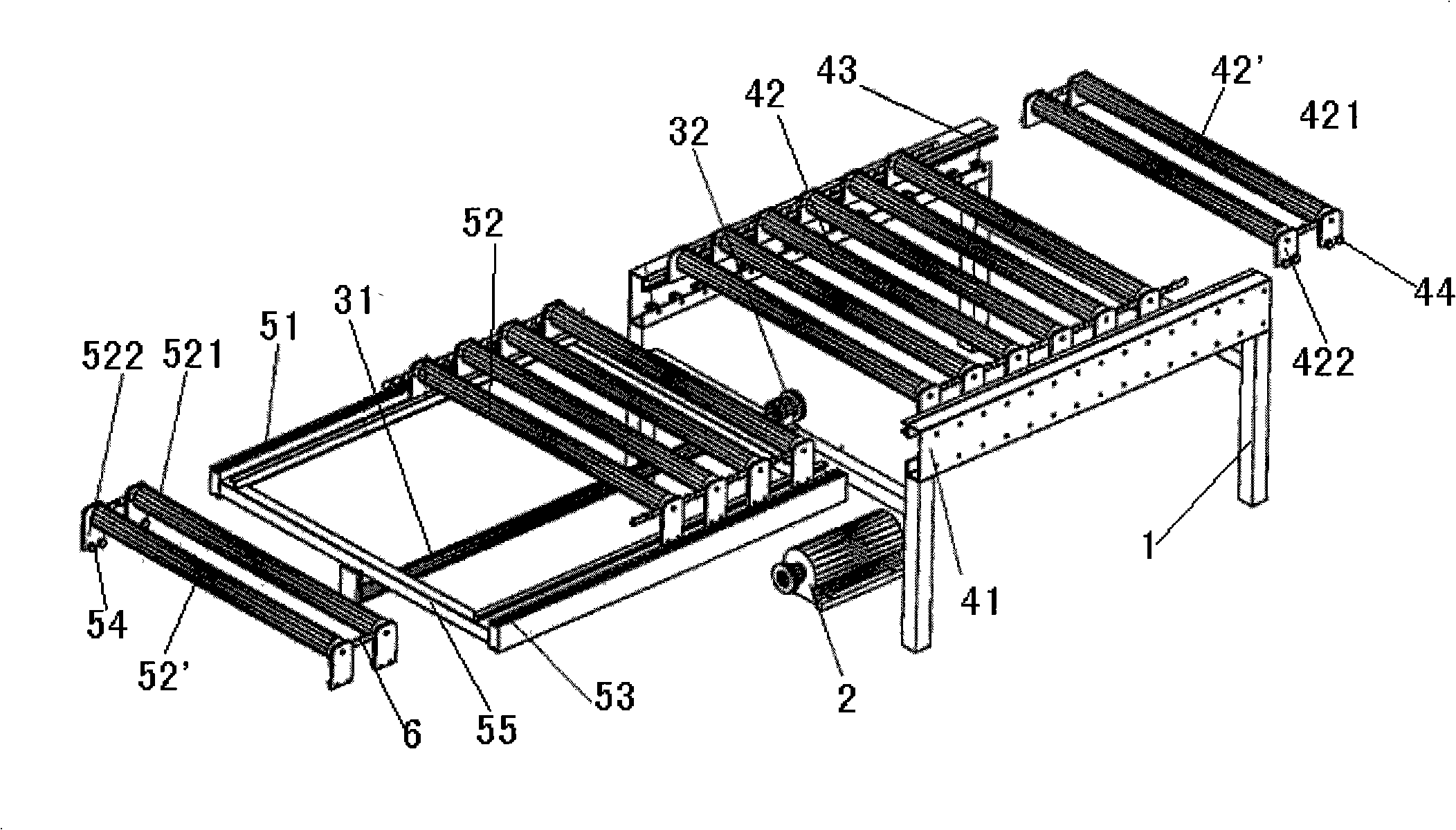

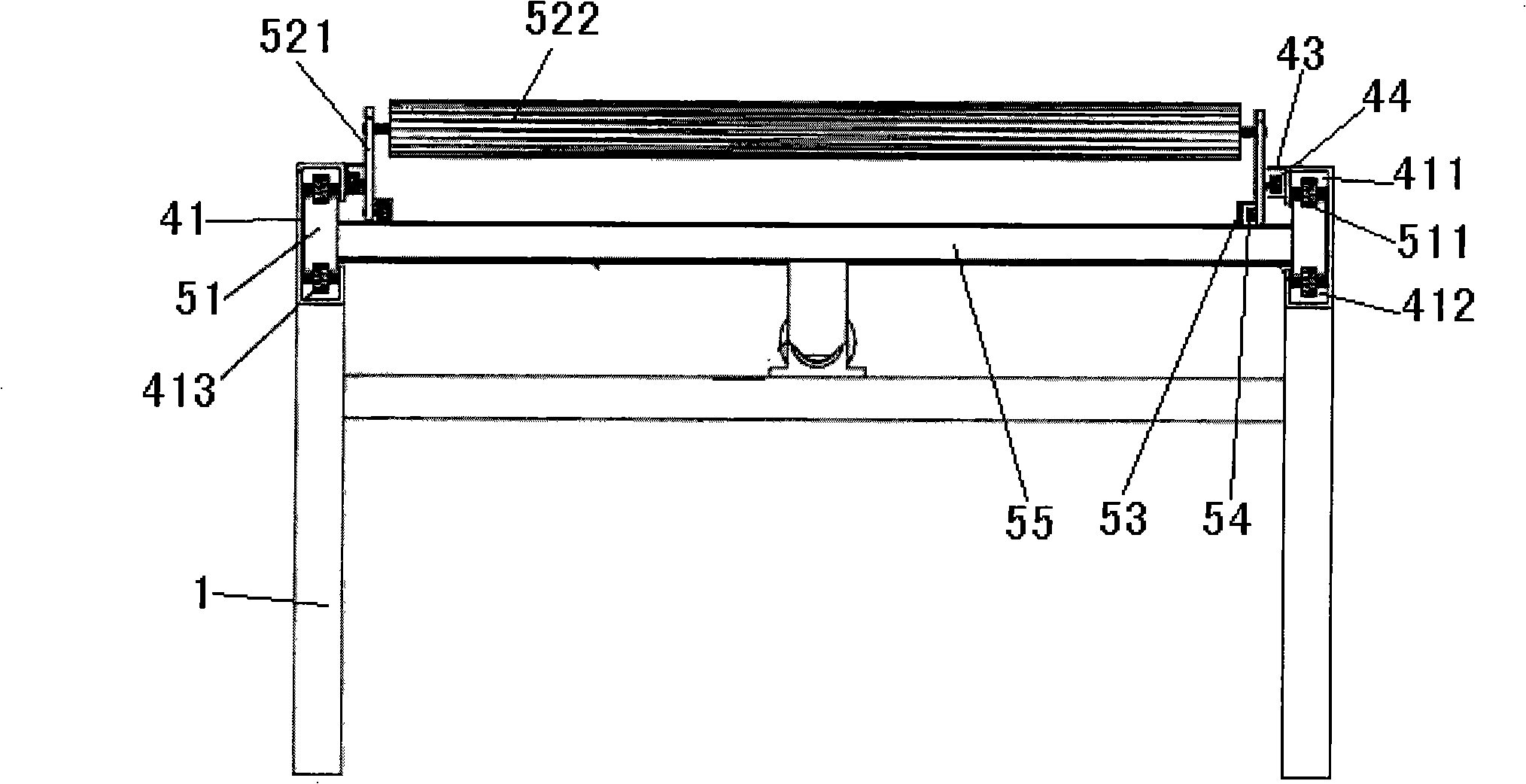

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

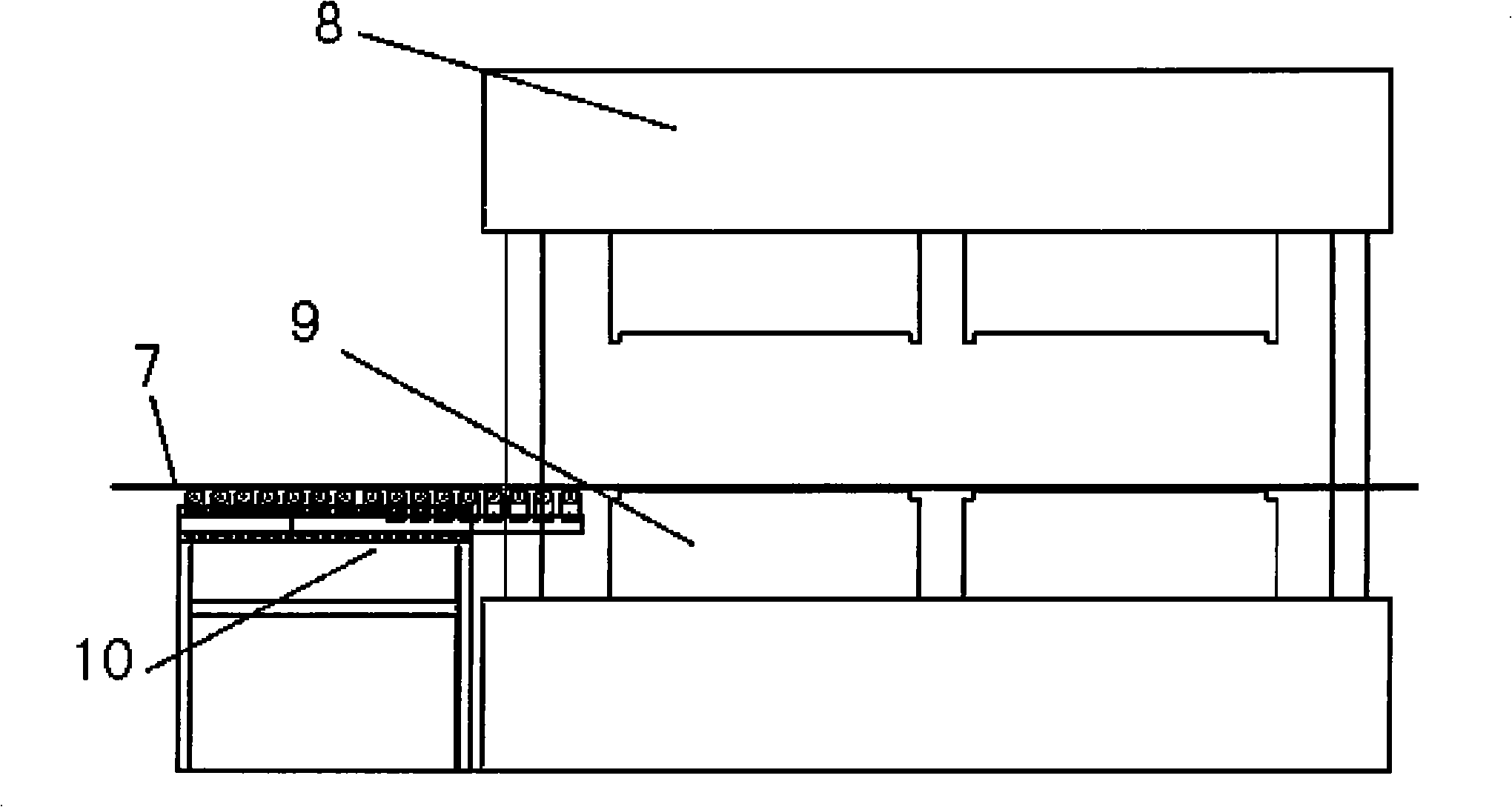

[0018] like Figure 1~5 As shown, the retractable horizontal transfer table of the present invention includes a main body support 1, a transfer platform arranged on the main body support 1, a drive motor 2 and a telescopic component 3; the transfer platform includes a fixed transfer table 4 and a telescopic transfer table 5; The fixed transfer platform 4 includes a chute 41, several rear transfer assemblies 42 and rear guide slots 43, the chute 41 is arranged on both sides of the main body support 1 in parallel, and the rear transfer assembly 42 straddles the chute 41 on both sides Between, the lower ends of both sides of each rear transmission assembly 42 are provided with rear rollers 44, and the chains 6 are connected between two adjacent rear transmission assemblies 42. The rear guide groove 43 is arranged parallel to the chute 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com