Patents

Literature

146 results about "Axial transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

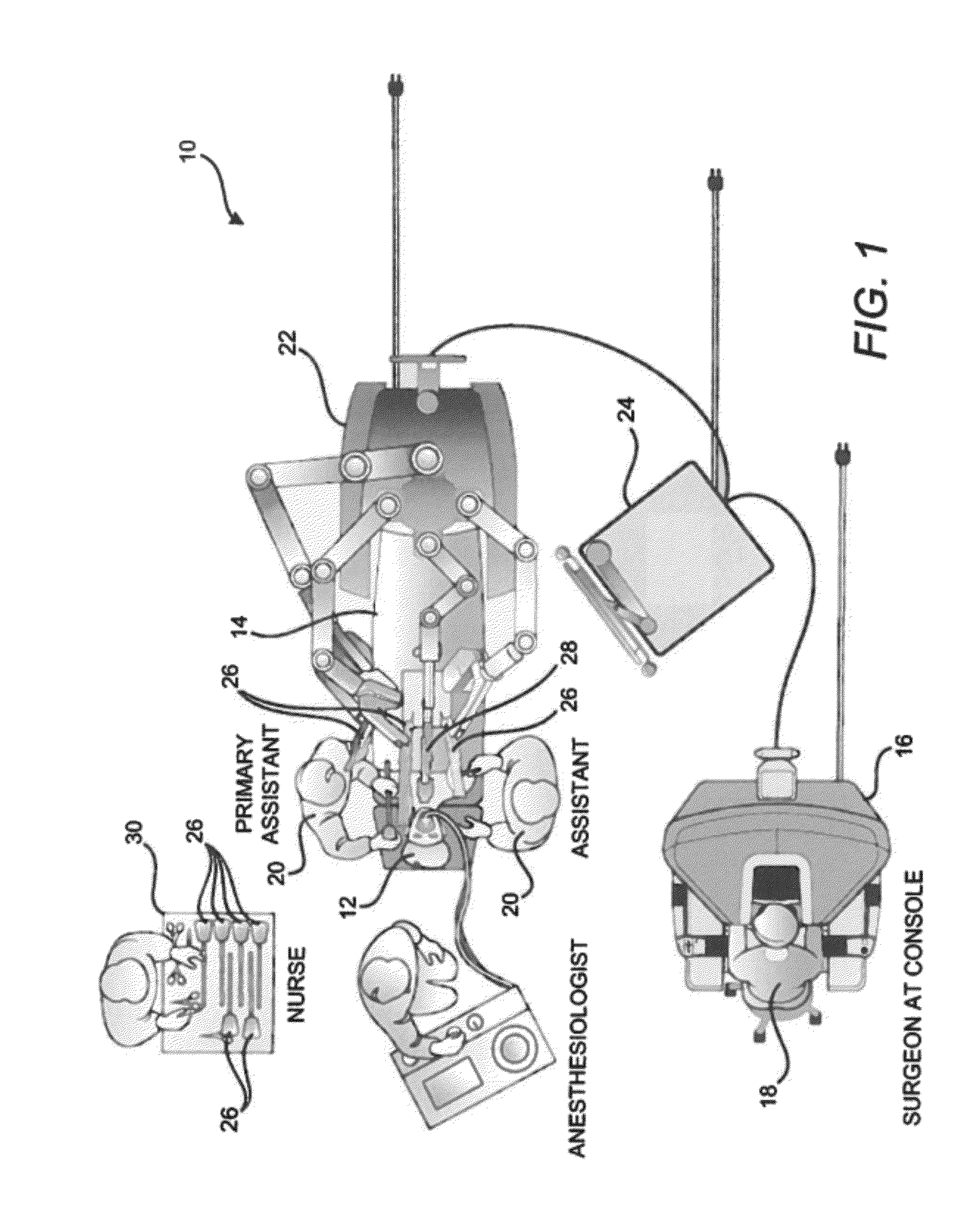

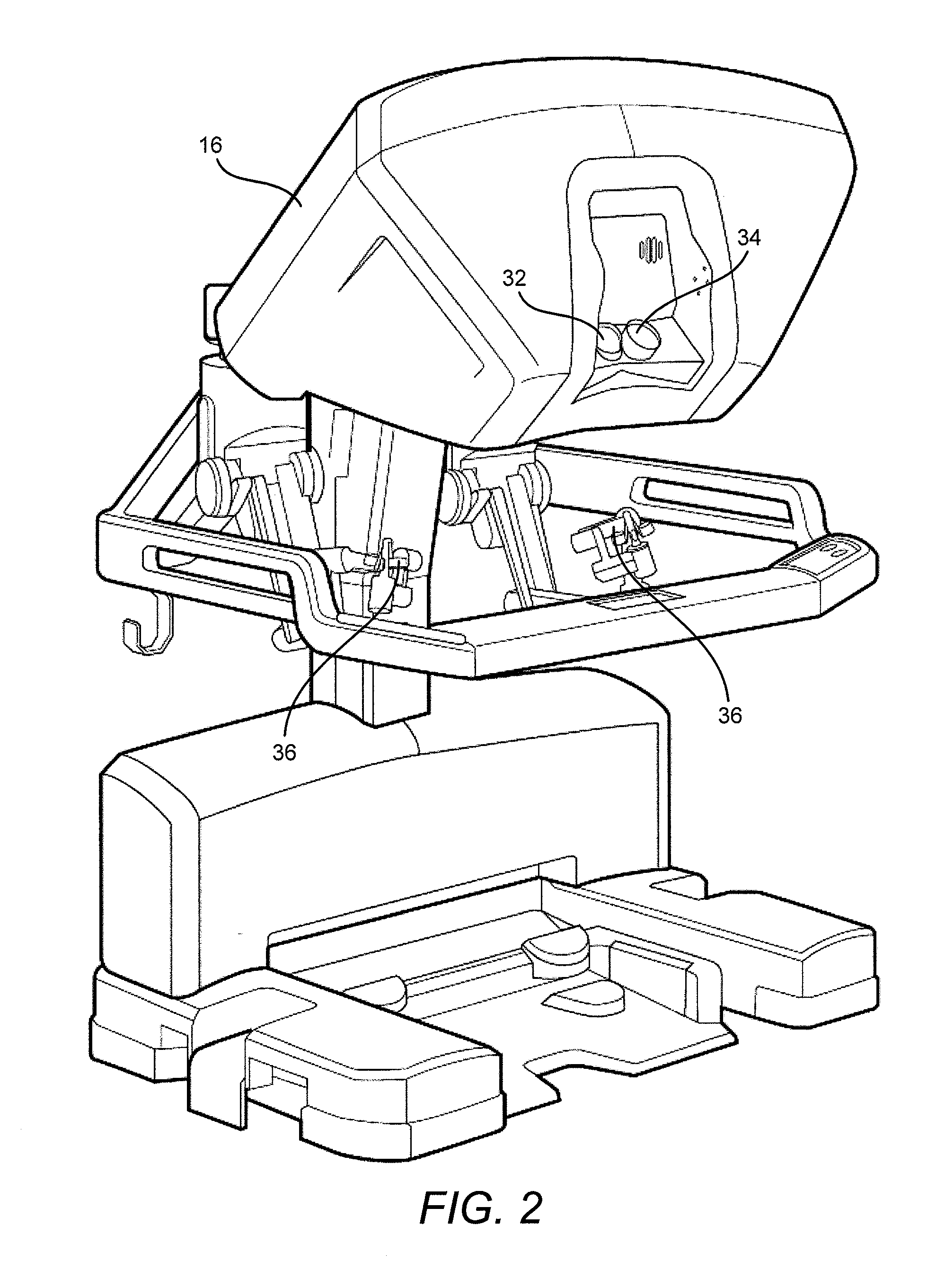

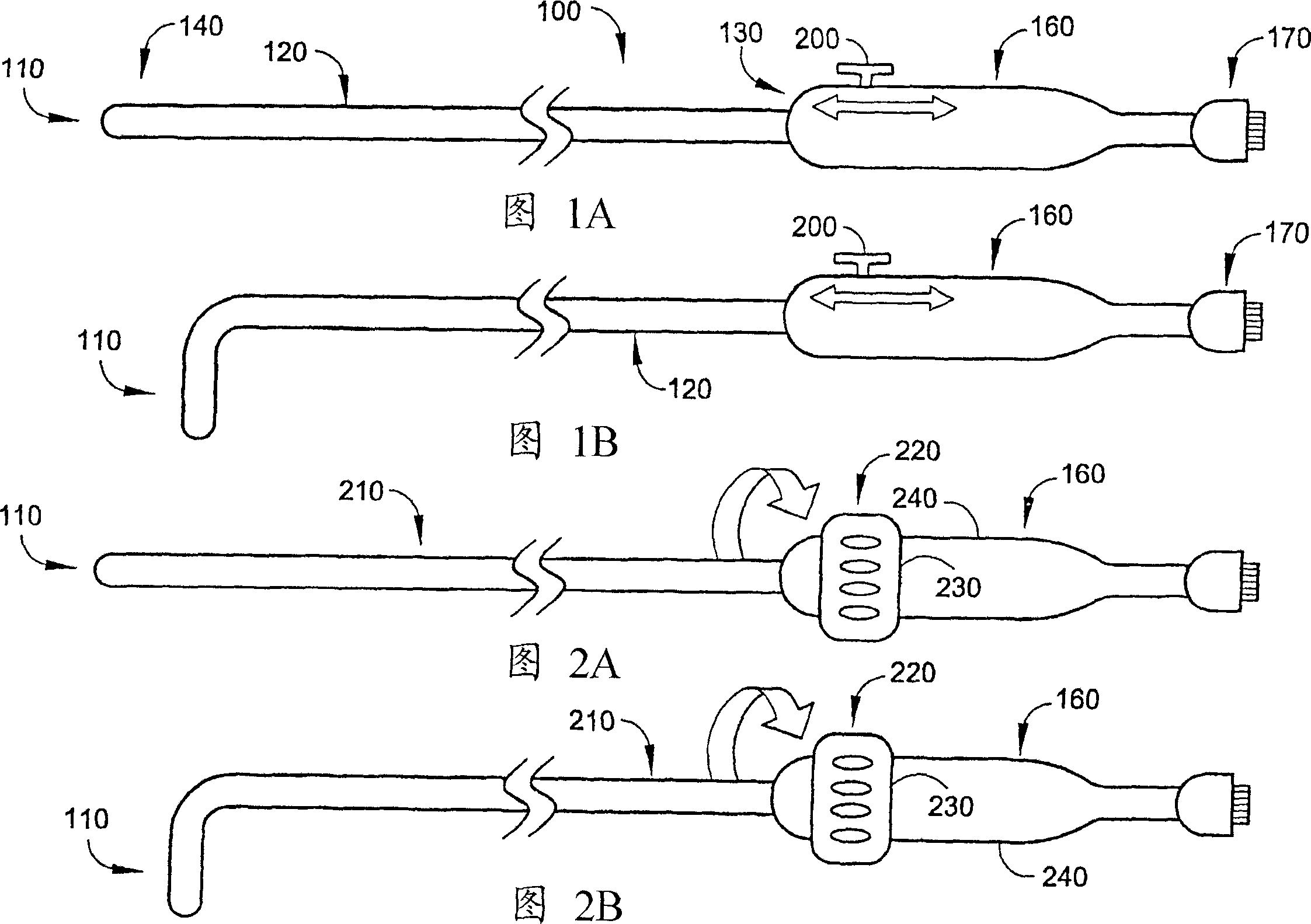

Seals and sealing methods for a surgical instrument having an articulated end effector actuated by a drive shaft

Owner:INTUITIVE SURGICAL OPERATIONS INC

Seals and sealing methods for a surgical instrument having an articulated end effector actuated by a drive shaft

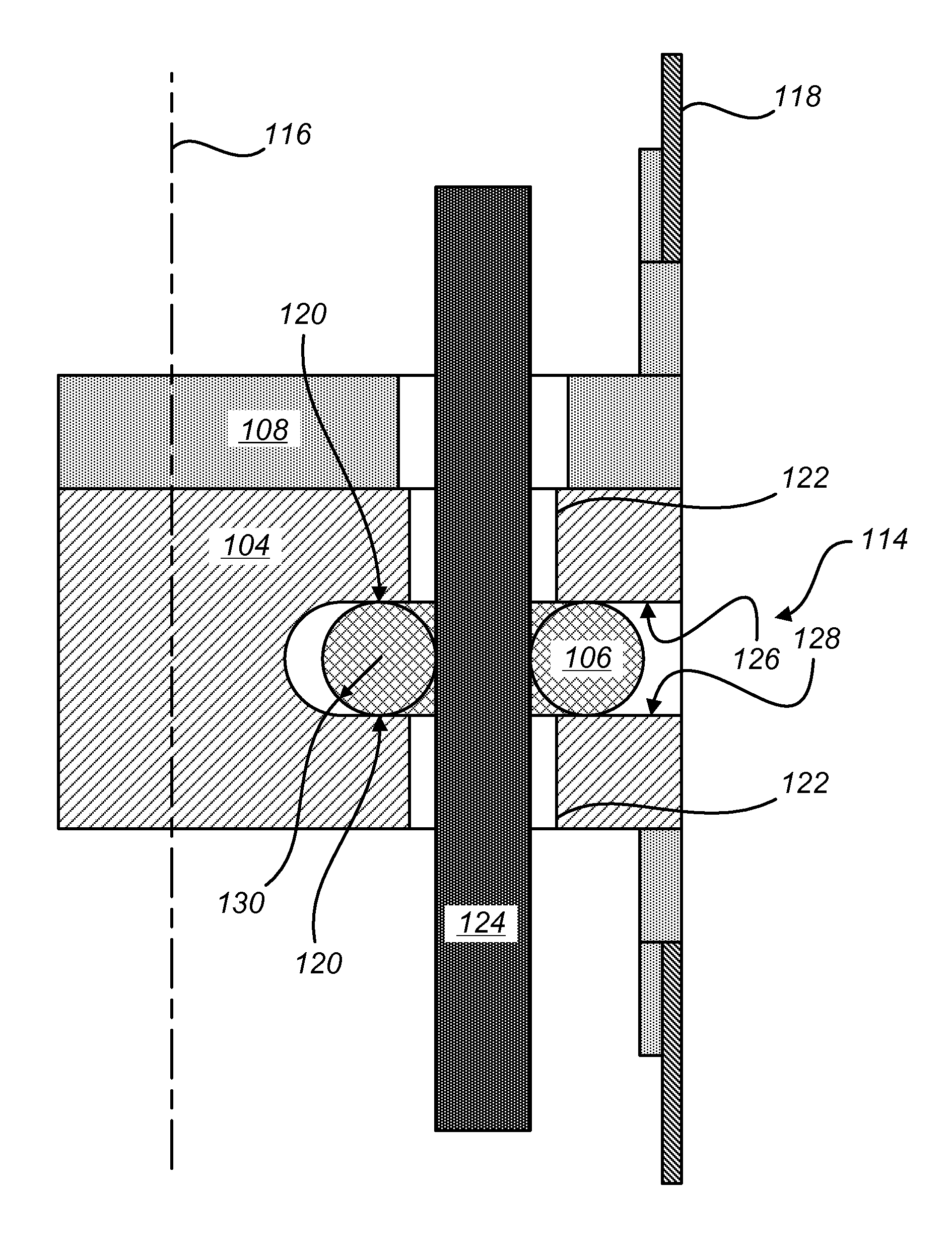

Sealing assemblies and methods are disclosed for sealing a surgical instrument having an internal drive shaft subject to lateral displacement. A sealing assembly includes a rigid portion shaped to interface with an instrument shaft of the surgical instrument. A laterally oriented slot is open at a radially perimeter location and configured to receive an o-ring seal via the perimeter location. Apertures are disposed on opposing sides of the slot and open to the slot. The apertures are configured to receive the drive shaft there through and are larger than the drive shaft to accommodate lateral displacement of the drive shaft. The slot includes opposing internal sides spaced to interface with opposed axial surfaces of the o-ring seal. The seal inhibits axial transmission of an insufflated gas and / or bodily fluids while accommodating lateral displacement of the drive shaft.

Owner:INTUITIVE SURGICAL OPERATIONS INC

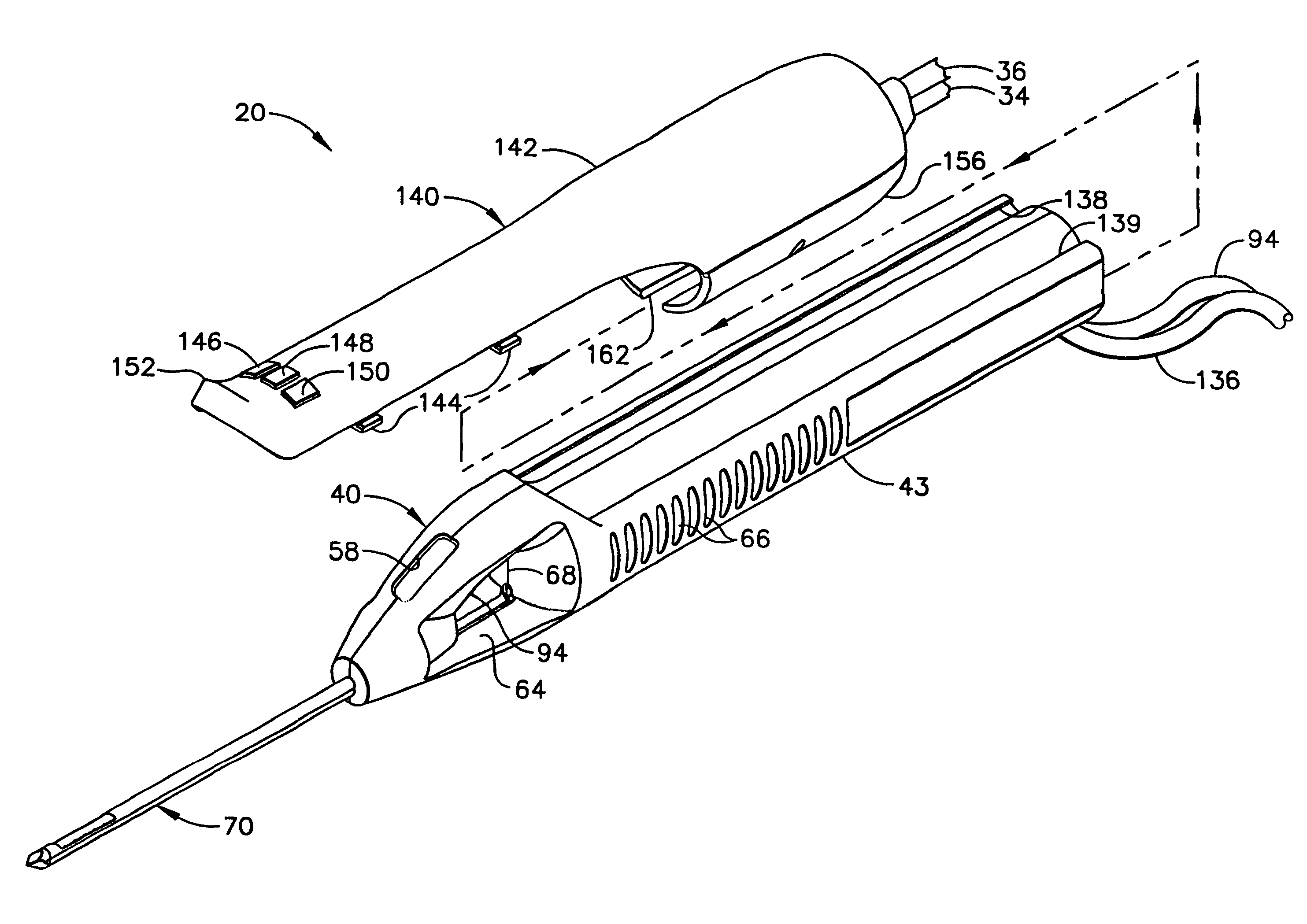

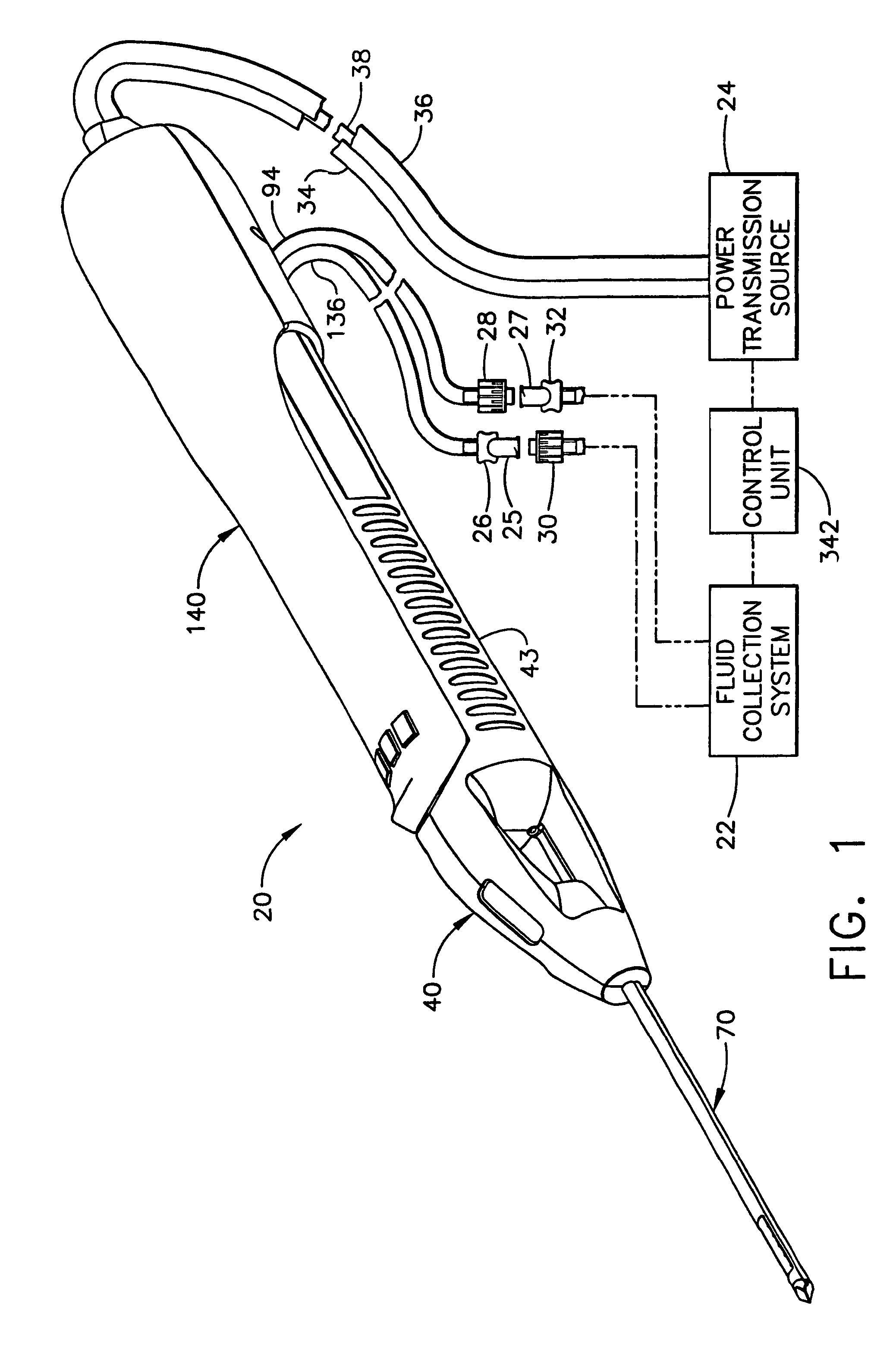

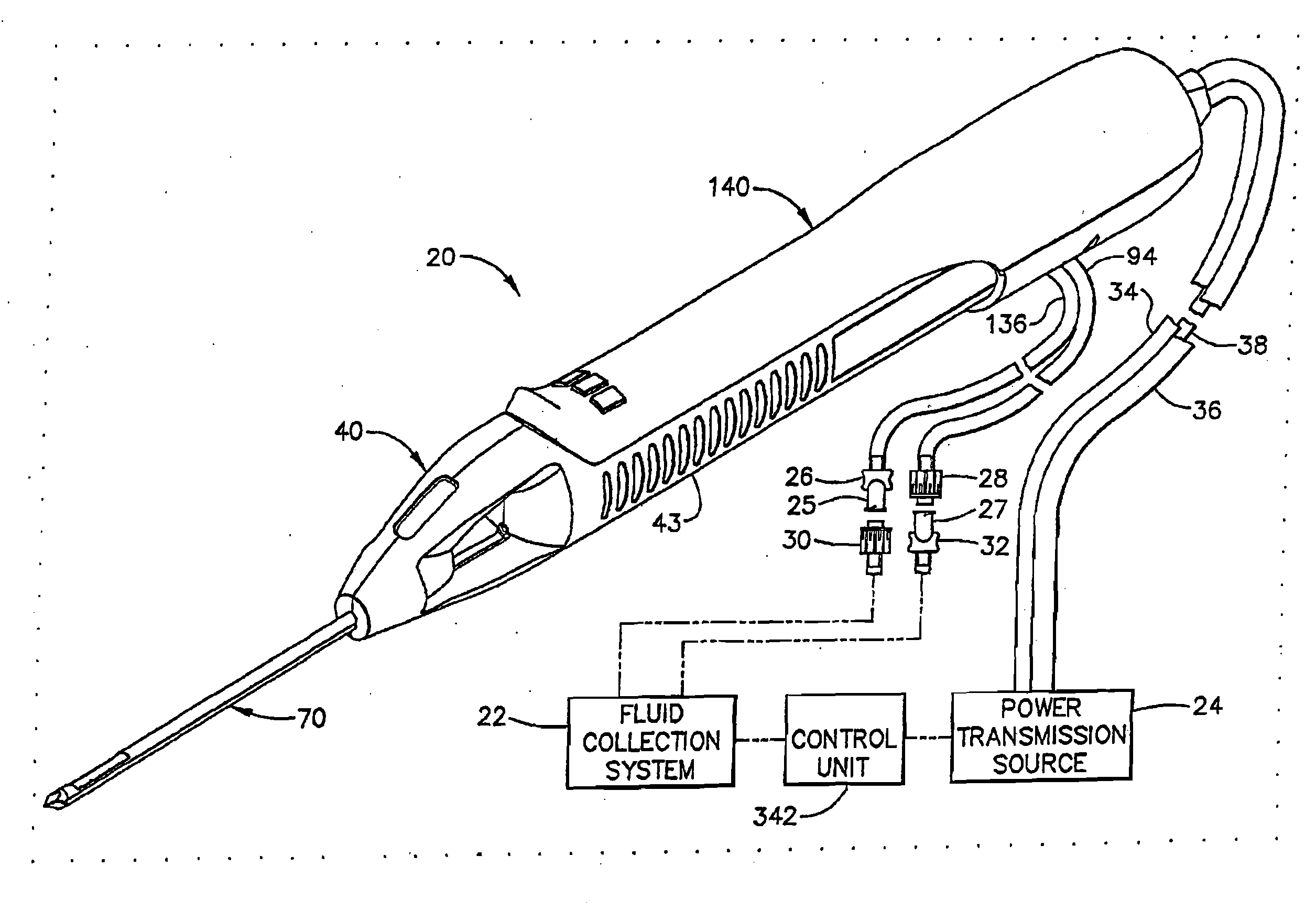

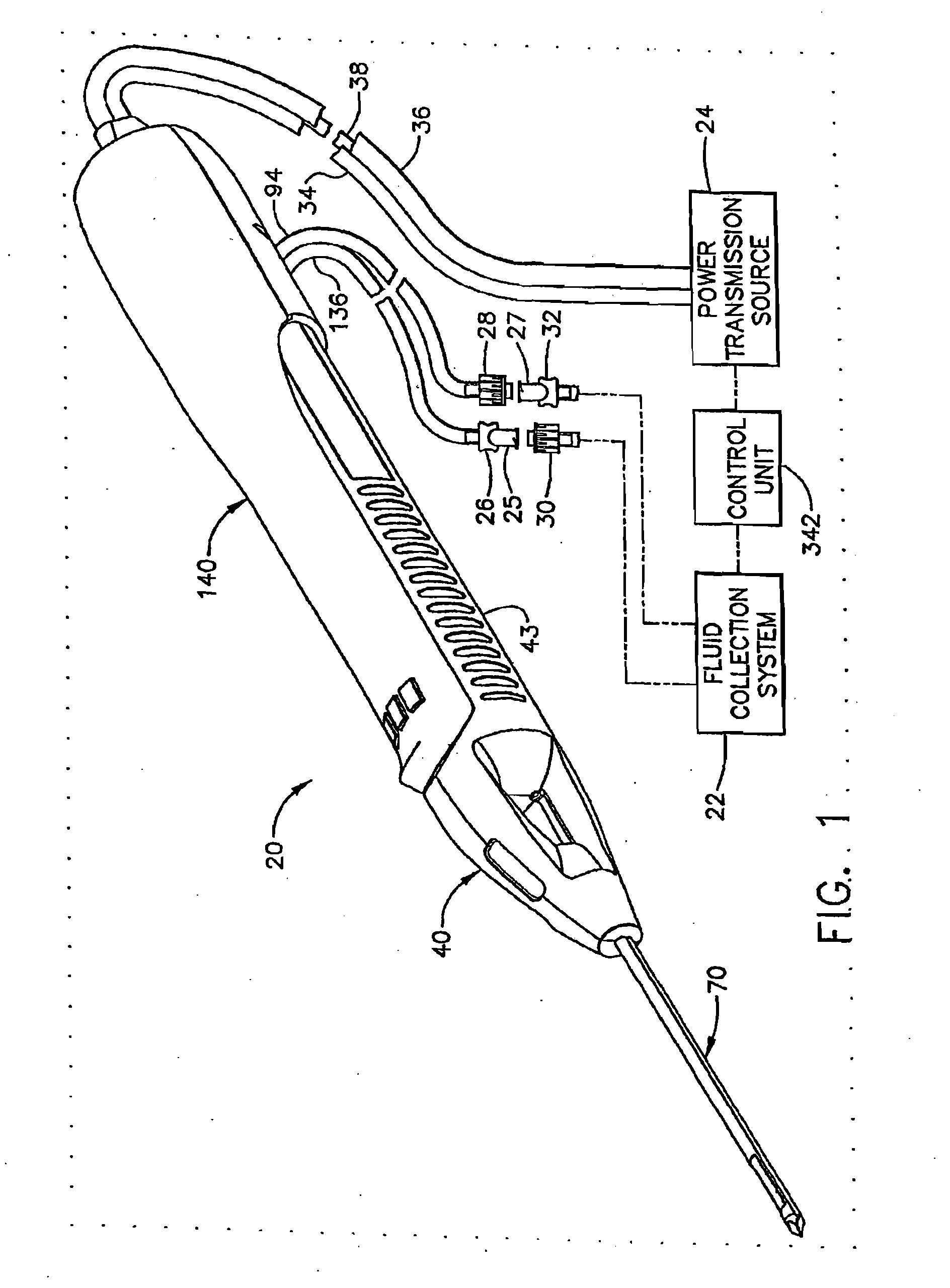

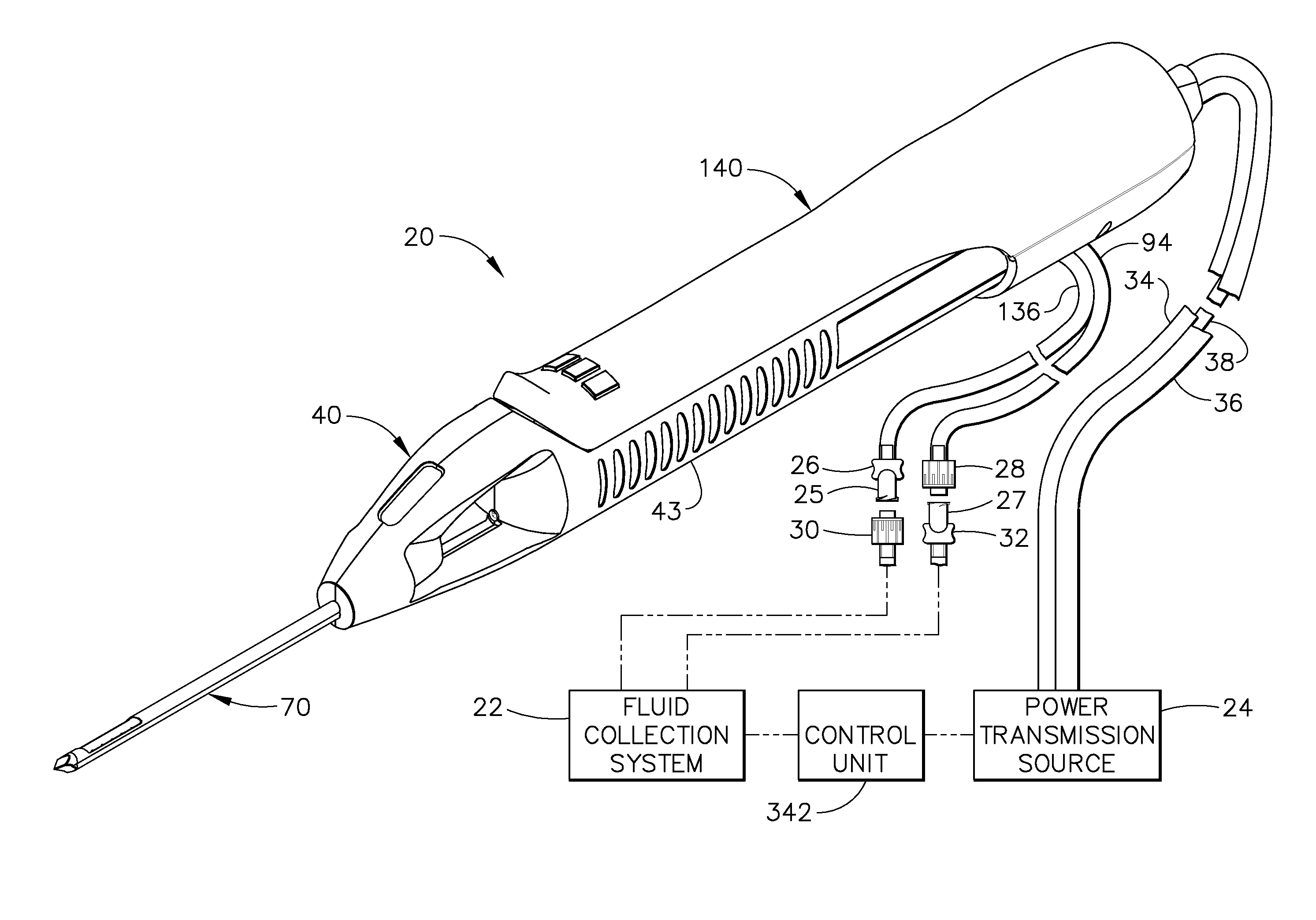

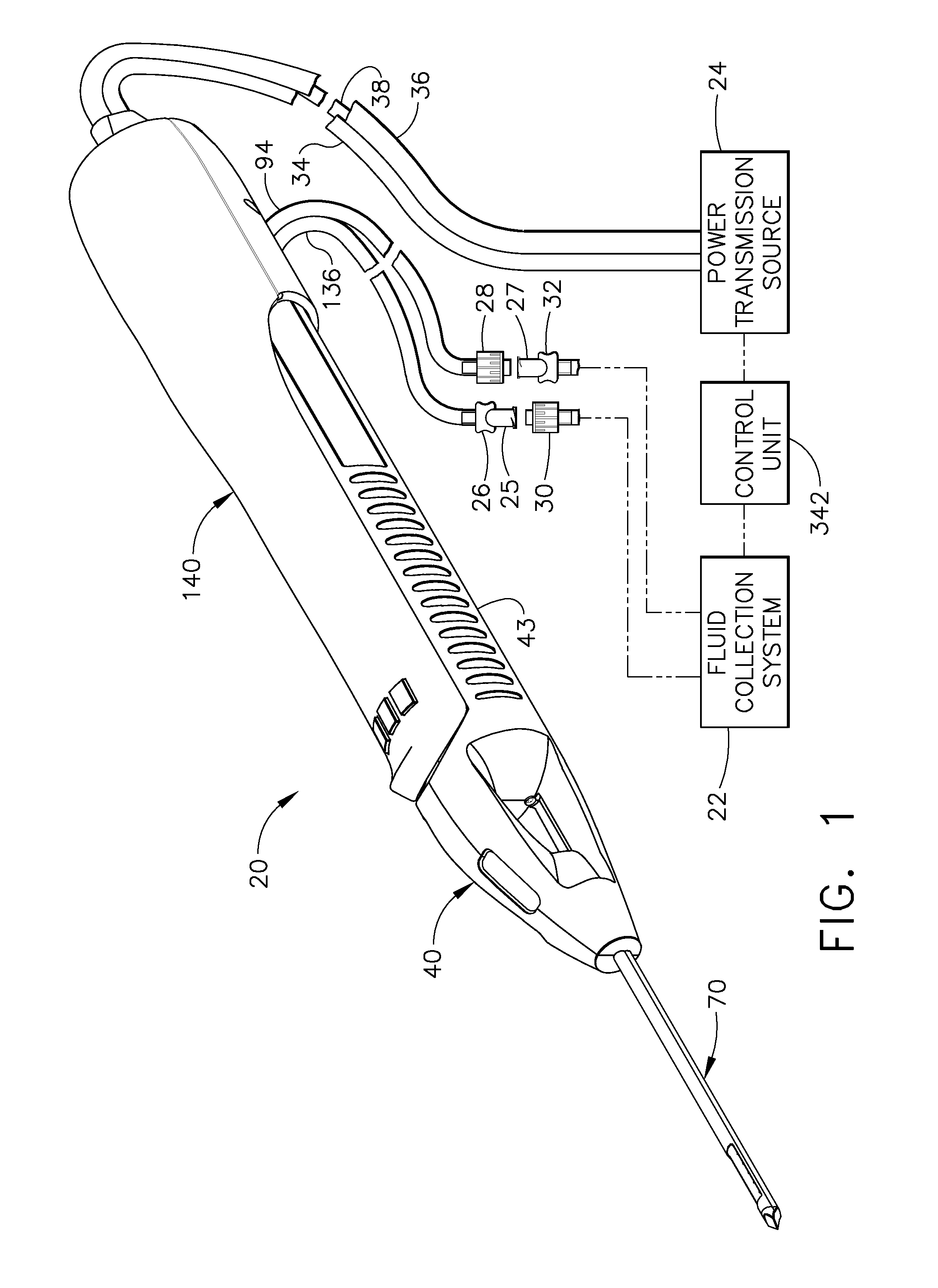

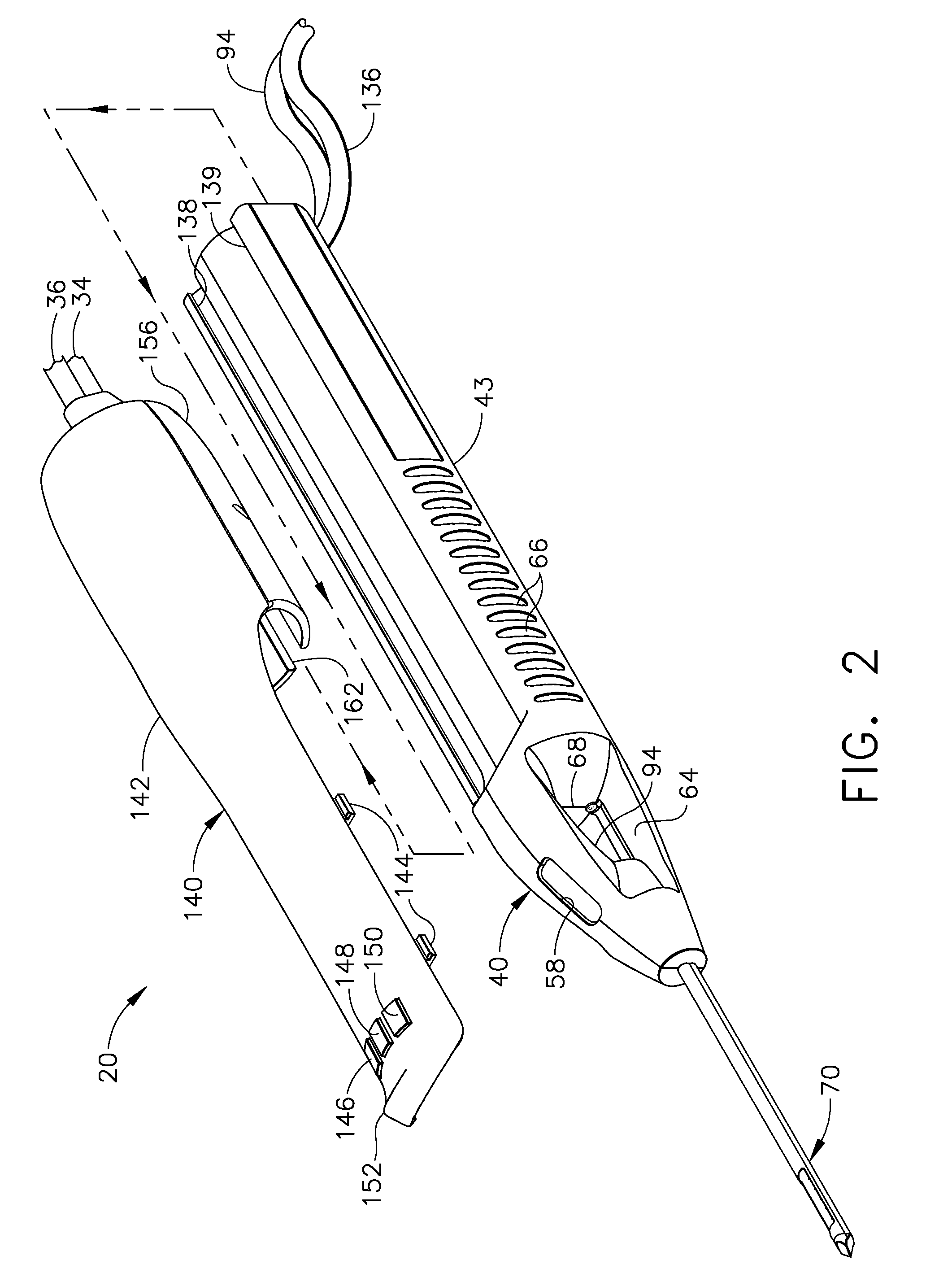

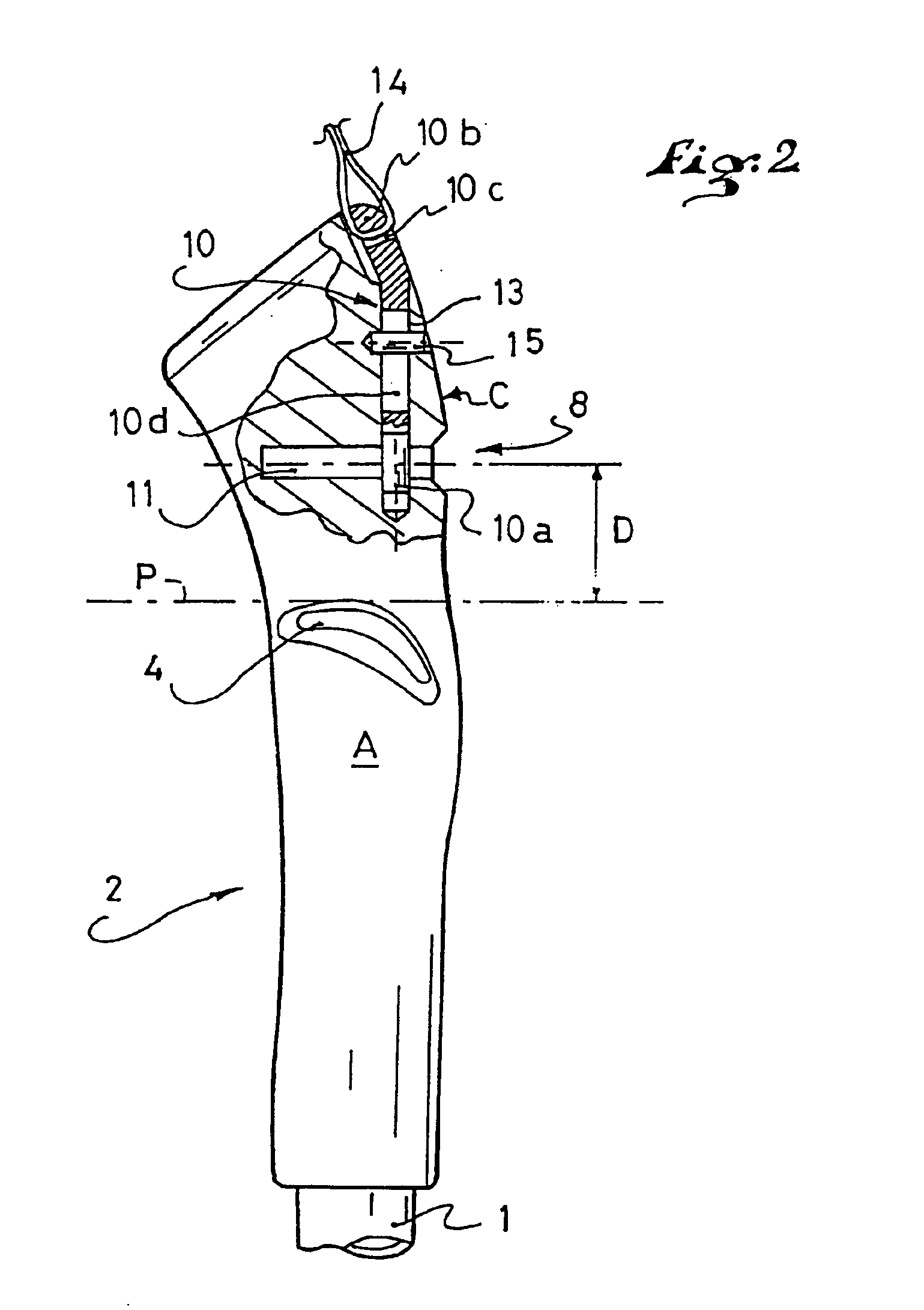

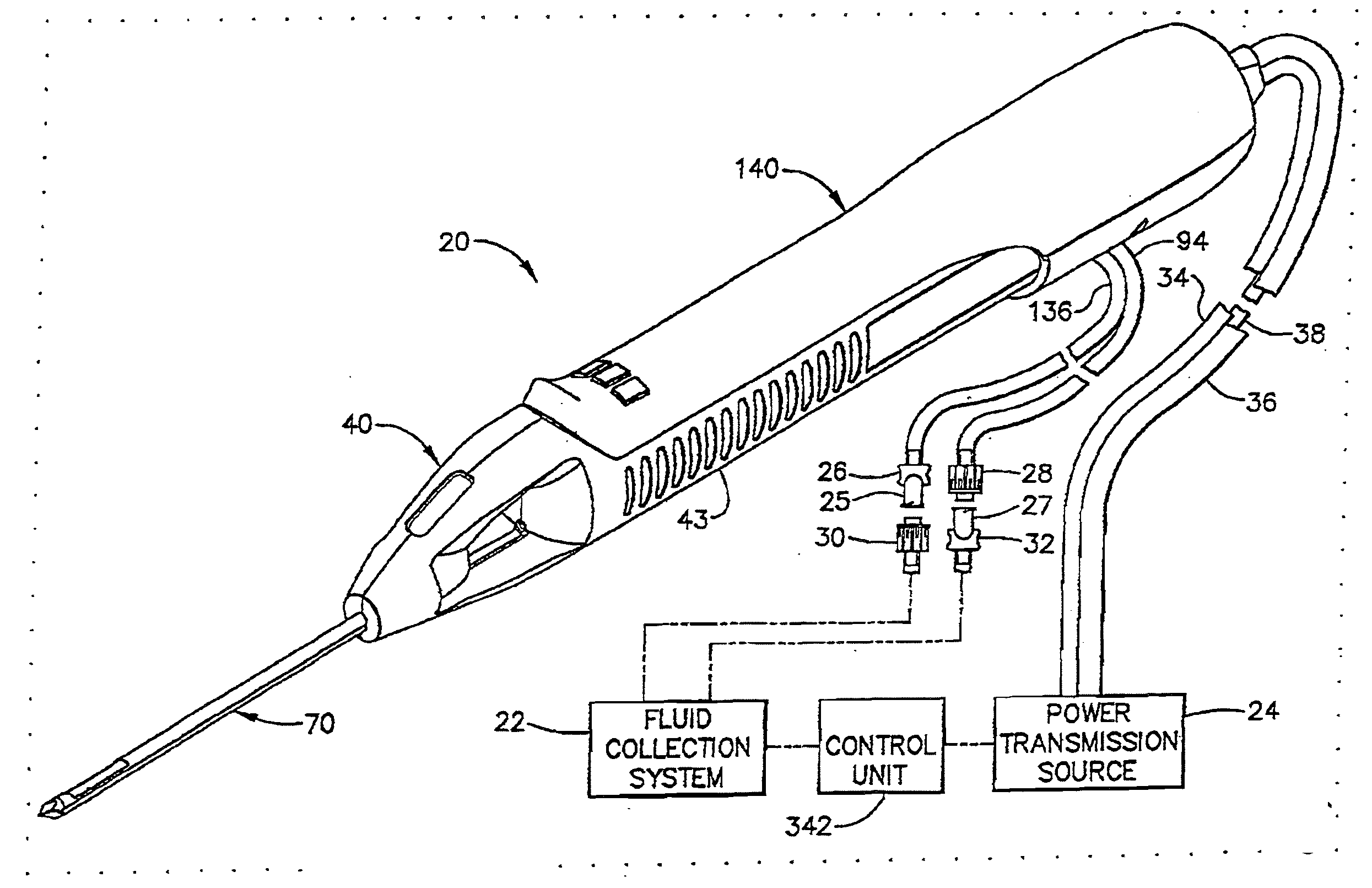

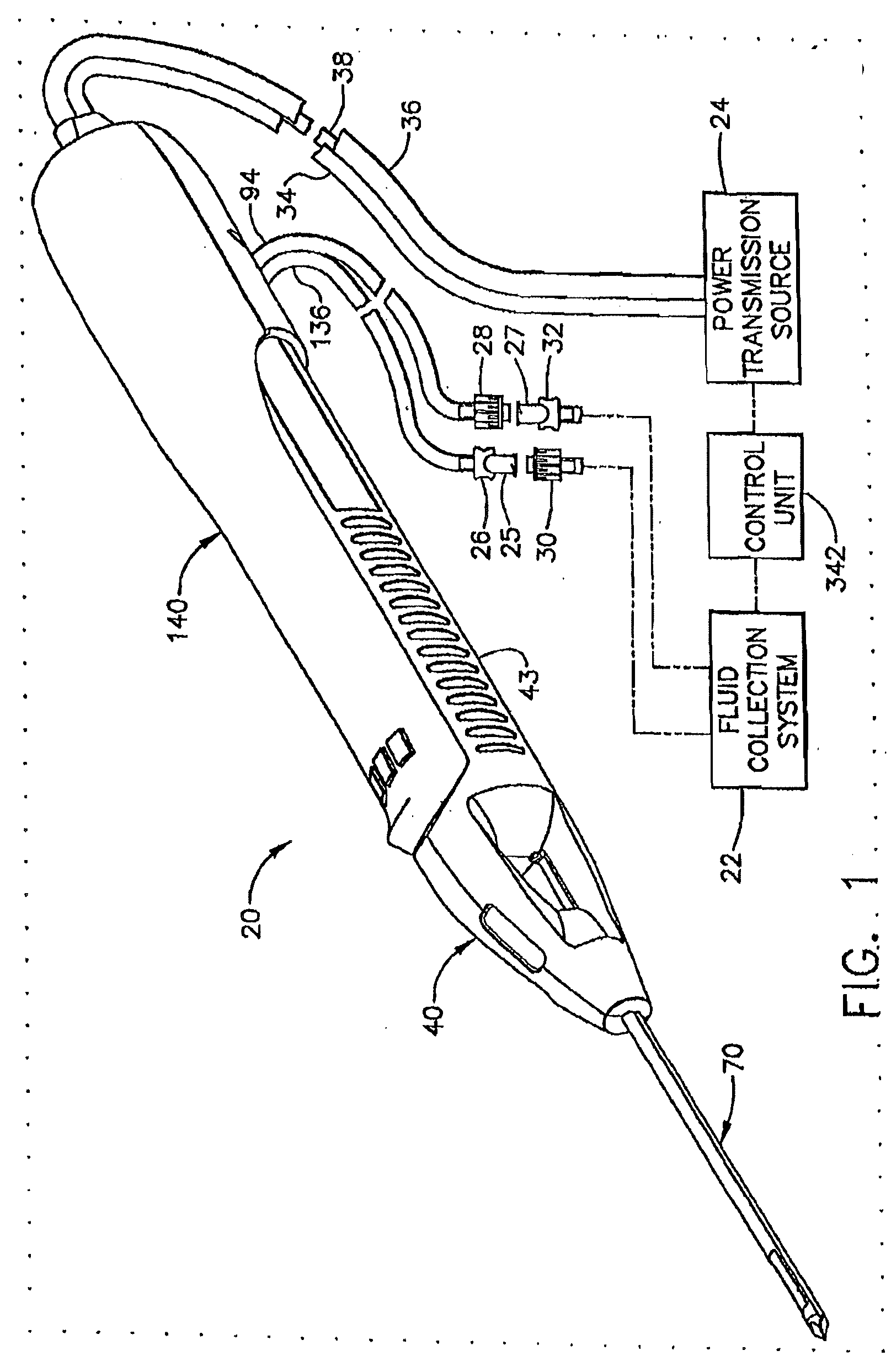

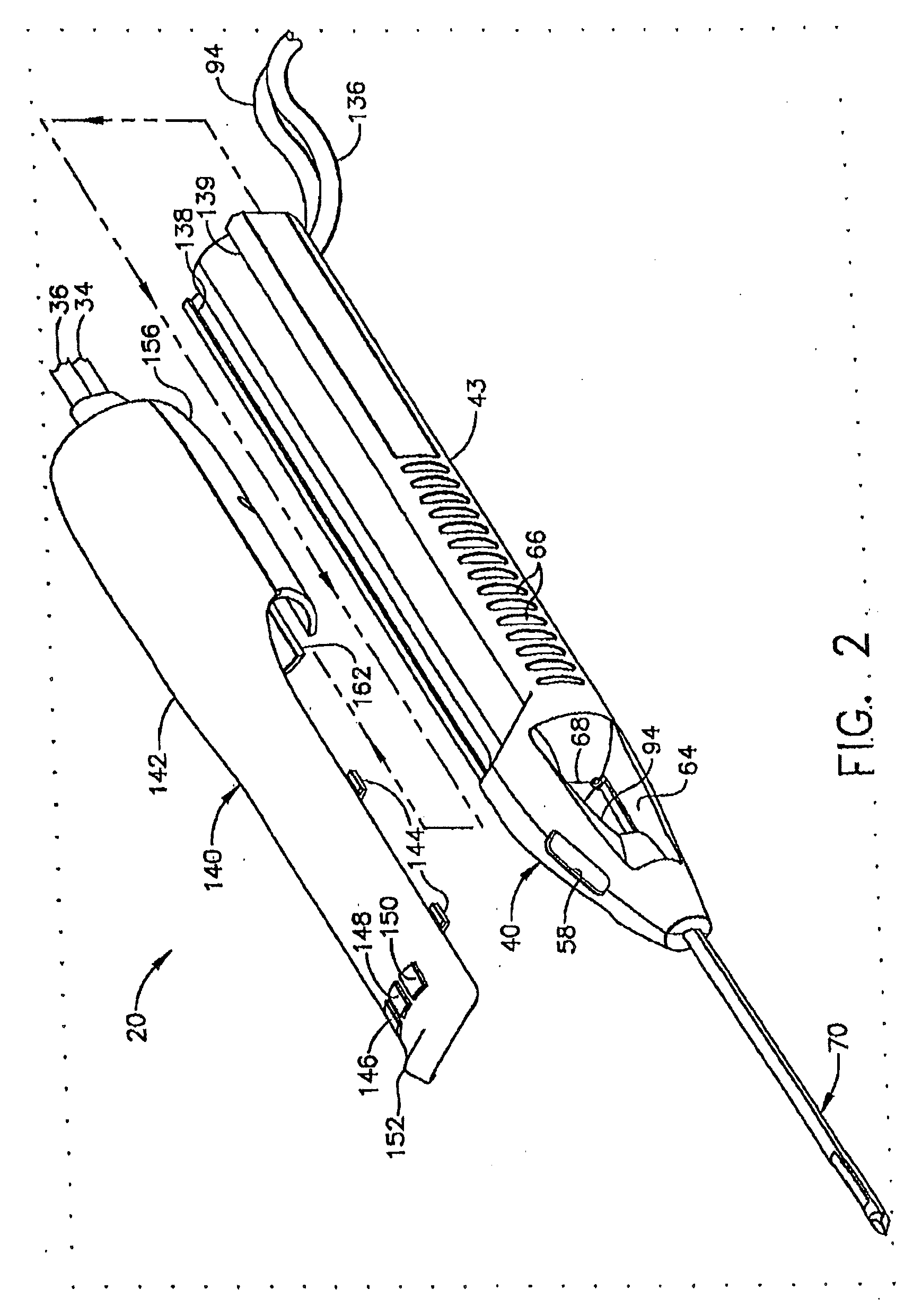

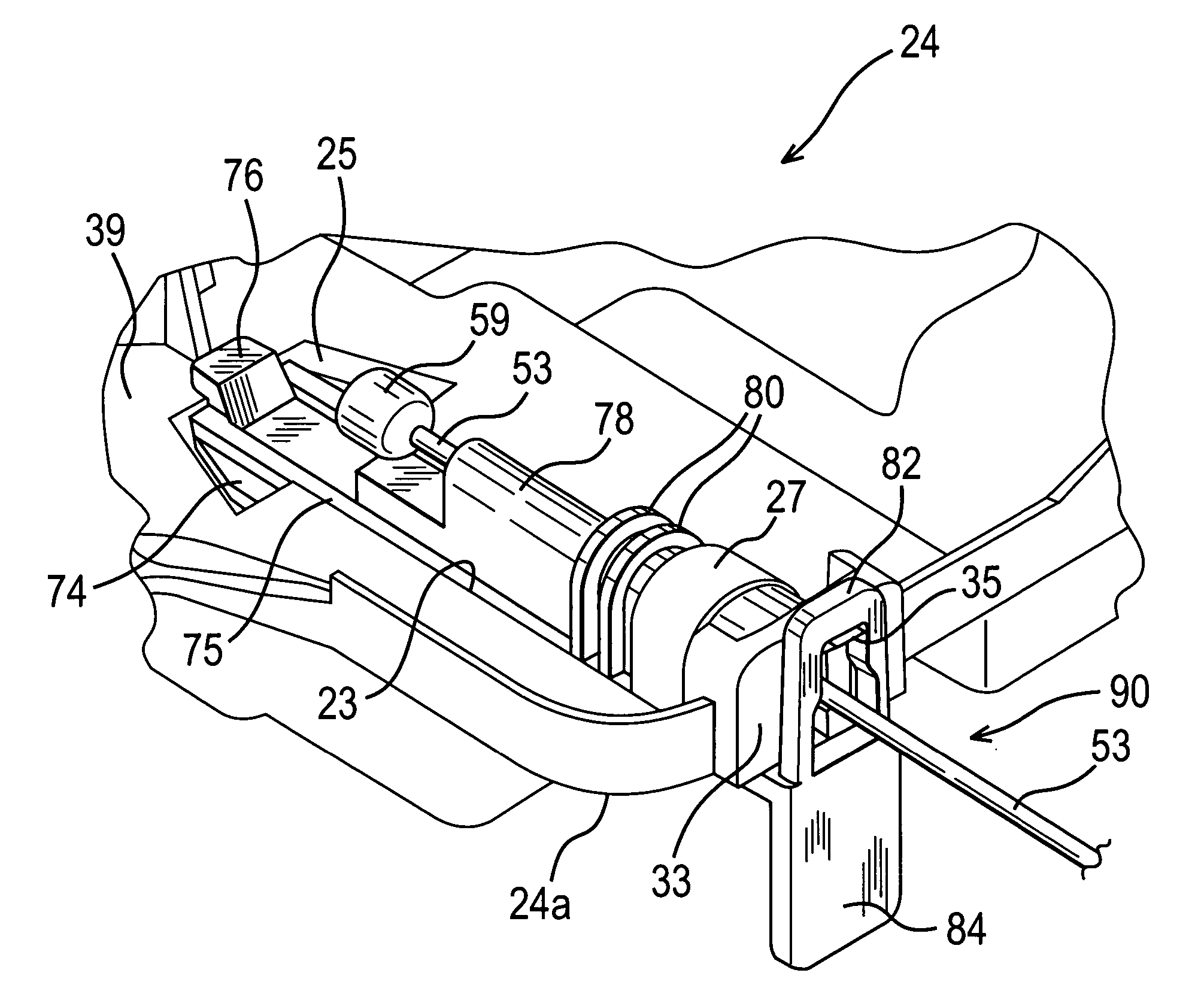

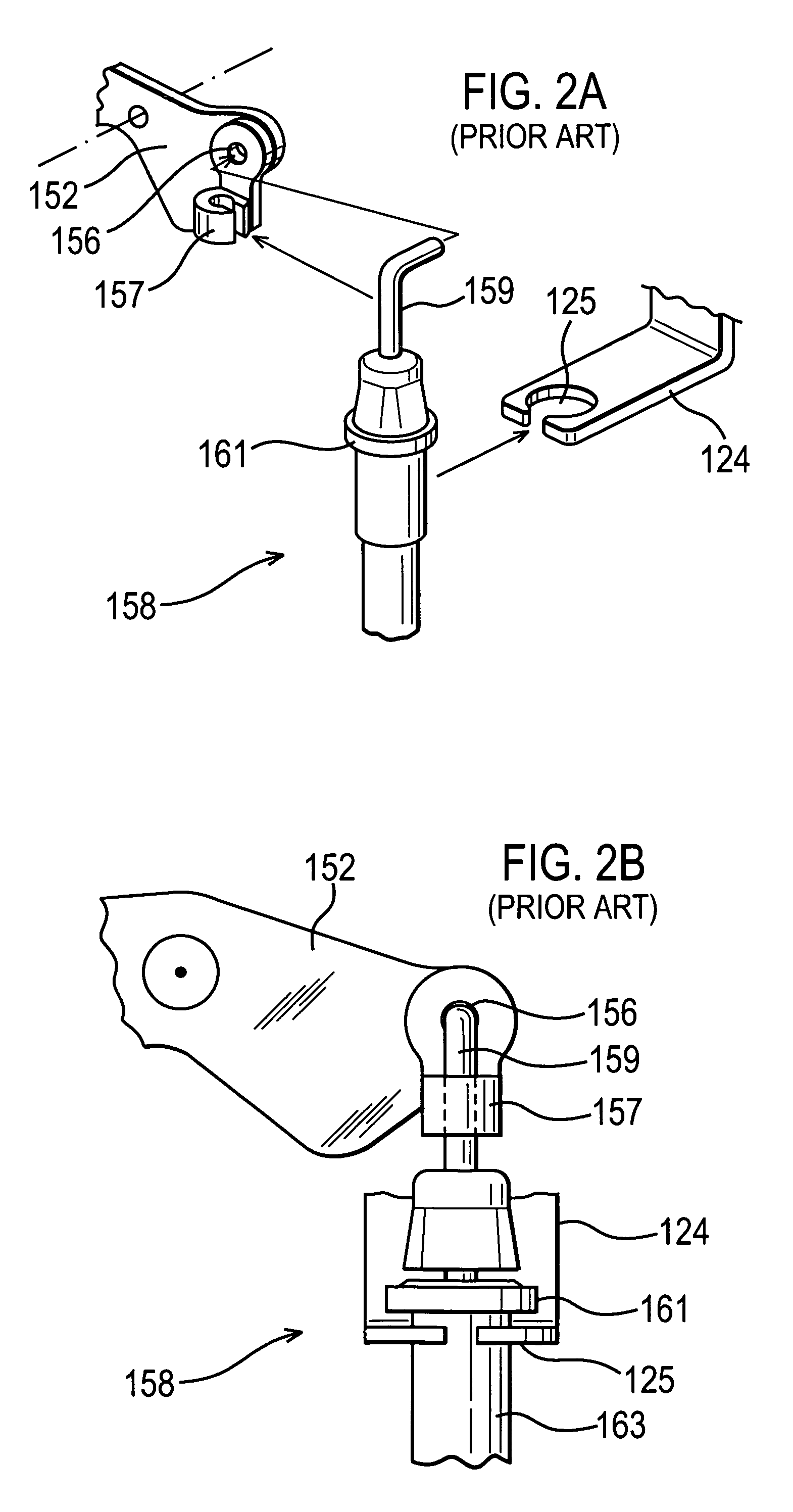

Surgical device for the collection of soft tissue

A handheld biopsy device is provided for the collection of soft tissue samples from a surgical patient. In a preferred embodiment, the biopsy device comprises a handpiece, a fluid collection system, and a power transmission source. The handpiece is configured for grasping by a single hand, and being independently manipulatable by hand for movement of the instrument toward and away from the patient. An elongated piercer extends from the distal end of the handpiece. The piercer has a sharpened distal end for entering the tissue and a port located proximal to the sharpened distal end for receiving a portion of tissue mass. An elongated cutter is disposed coaxially relative to a piercer lumen of the piercer. A distal blade of the cutter slides distally past the port of the piercer to severe the tissue portion drawn into the port by vacuum. The cutter is retracted to a most proximal position for removal of the tissue portion from a cutter lumen of the cutter. The handpiece further comprises a holster for detachably connecting a cutter rotational transmission and a cutter axial transmission to the power transmission source.

Owner:DEVICOR MEDICAL PROD

Surgical Device for The Collection of Soft Tissue

A handheld biopsy device is provided for the collection of soft tissue samples from a surgical patient. In a preferred embodiment, the biopsy device comprises a handpiece, a fluid collection system, and a power transmission source. The handpiece is configured for grasping by a single hand, and being independently manipulatable by hand for movement of the instrument toward and away from the patient. An elongated piercer extends from the distal end of the handpiece. The piercer has a sharpened distal end for entering the tissue and a port located proximal to the sharpened distal end for receiving a portion of tissue mass. An elongated cutter is disposed coaxially relative to a piercer lumen of the piercer. A distal blade of the cutter slides distally past the port of the piercer to severe the tissue portion drawn into the port by vacuum. The cutter is retracted to a most proximal position for removal of the tissue portion from a cutter lumen of the cutter. The handpiece further comprises a holster for detachably connecting a cutter rotation transmission and a cutter axial transmission to the power transmission source.

Owner:DEVICOR MEDICAL PROD

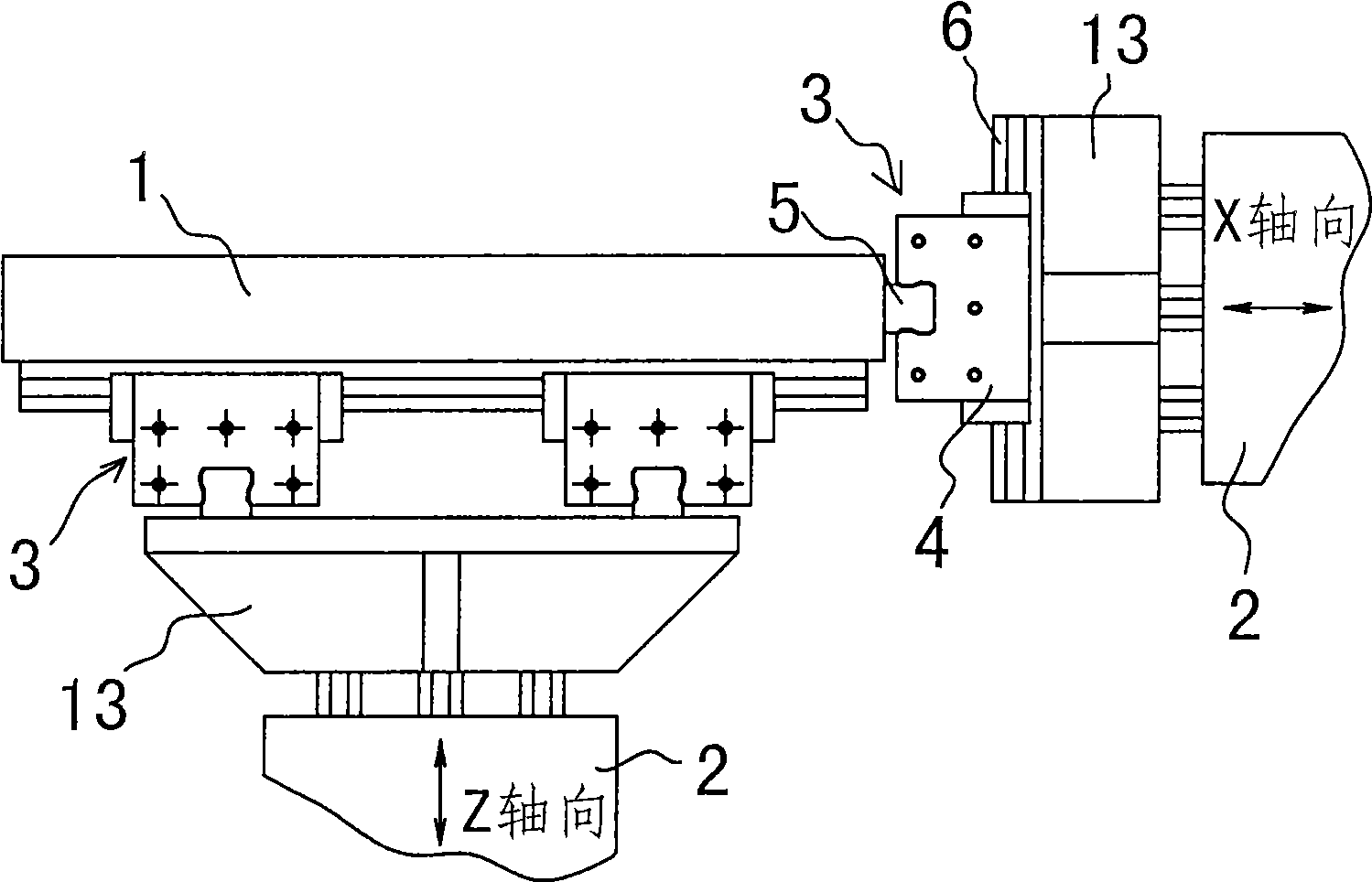

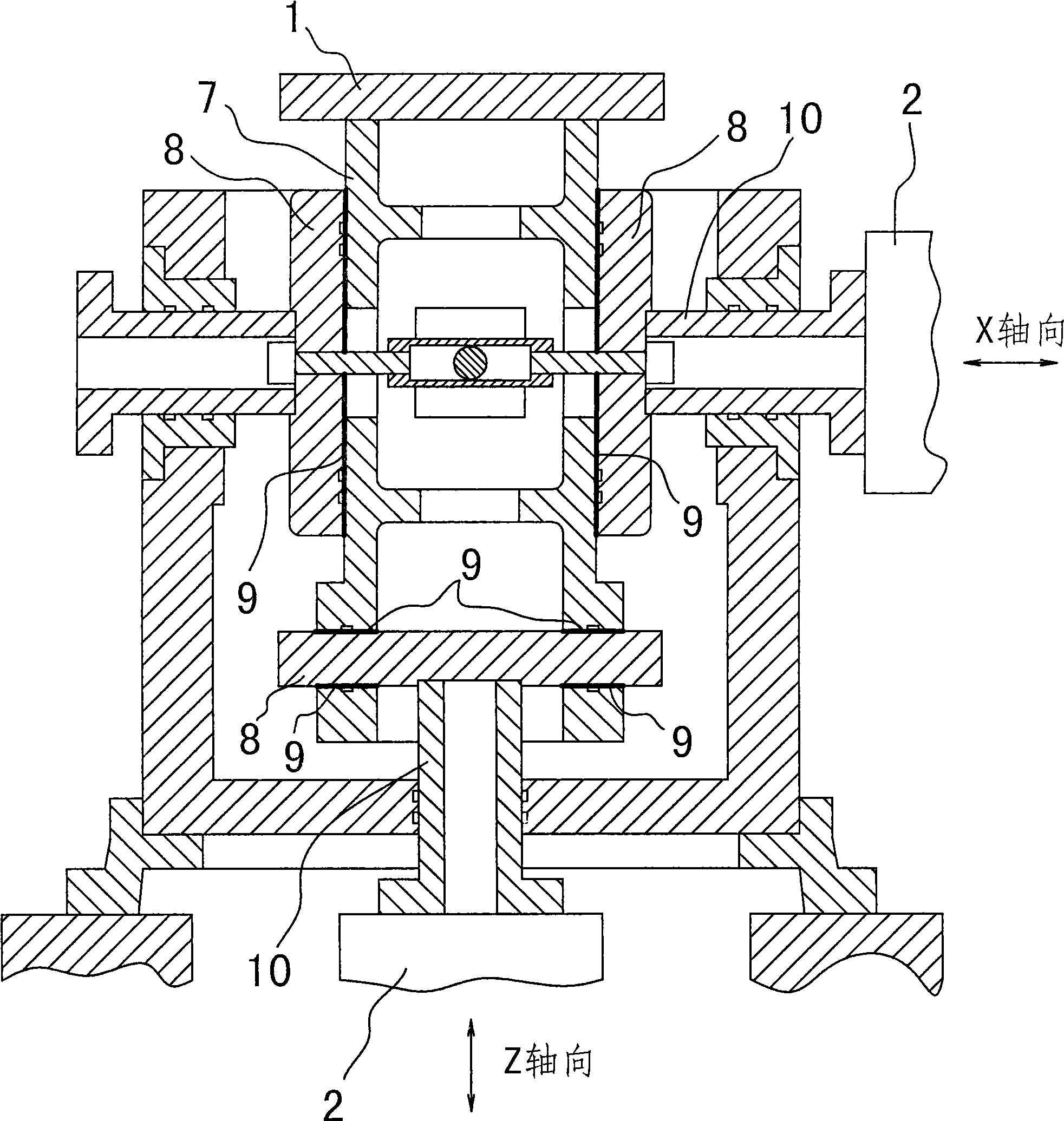

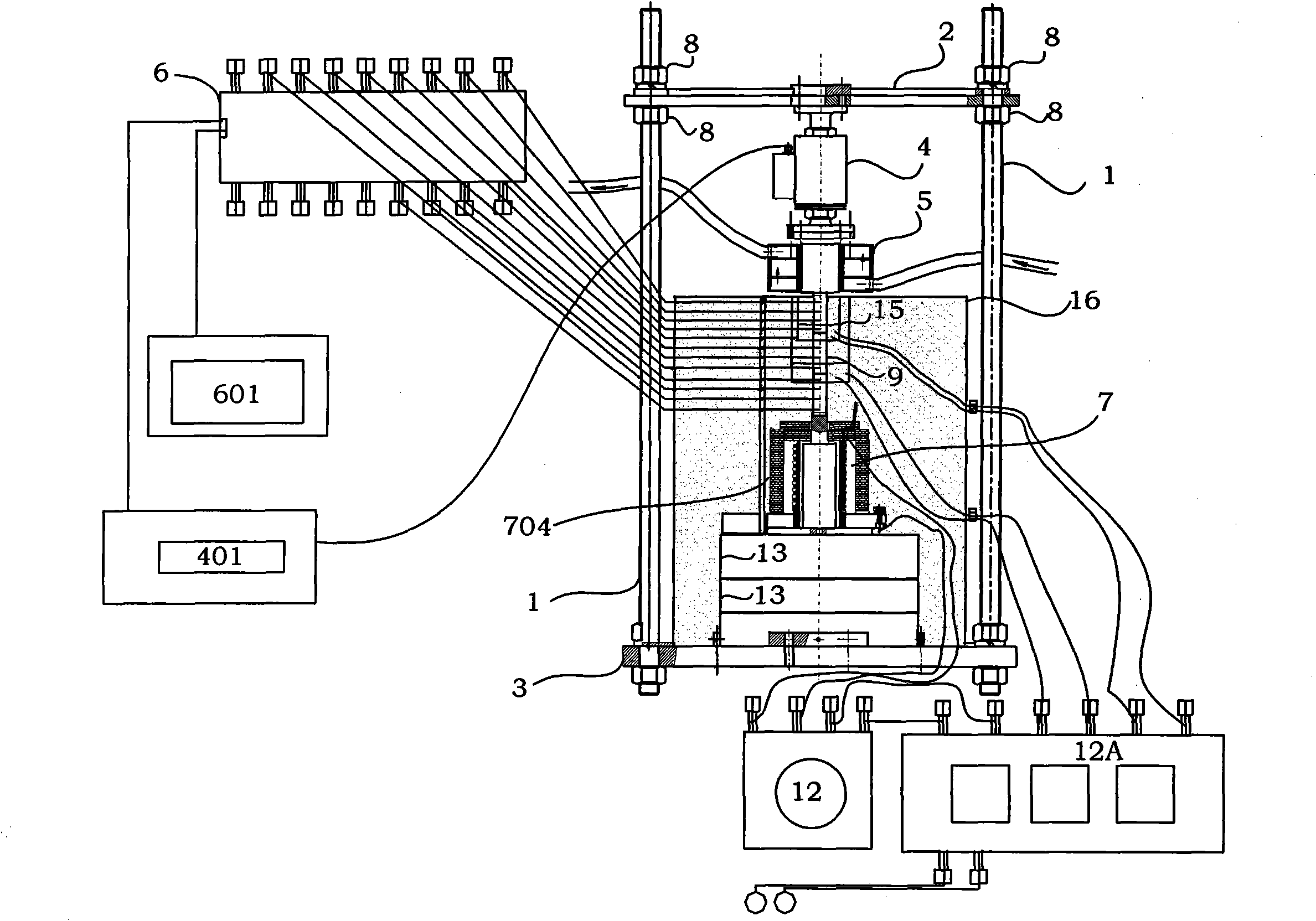

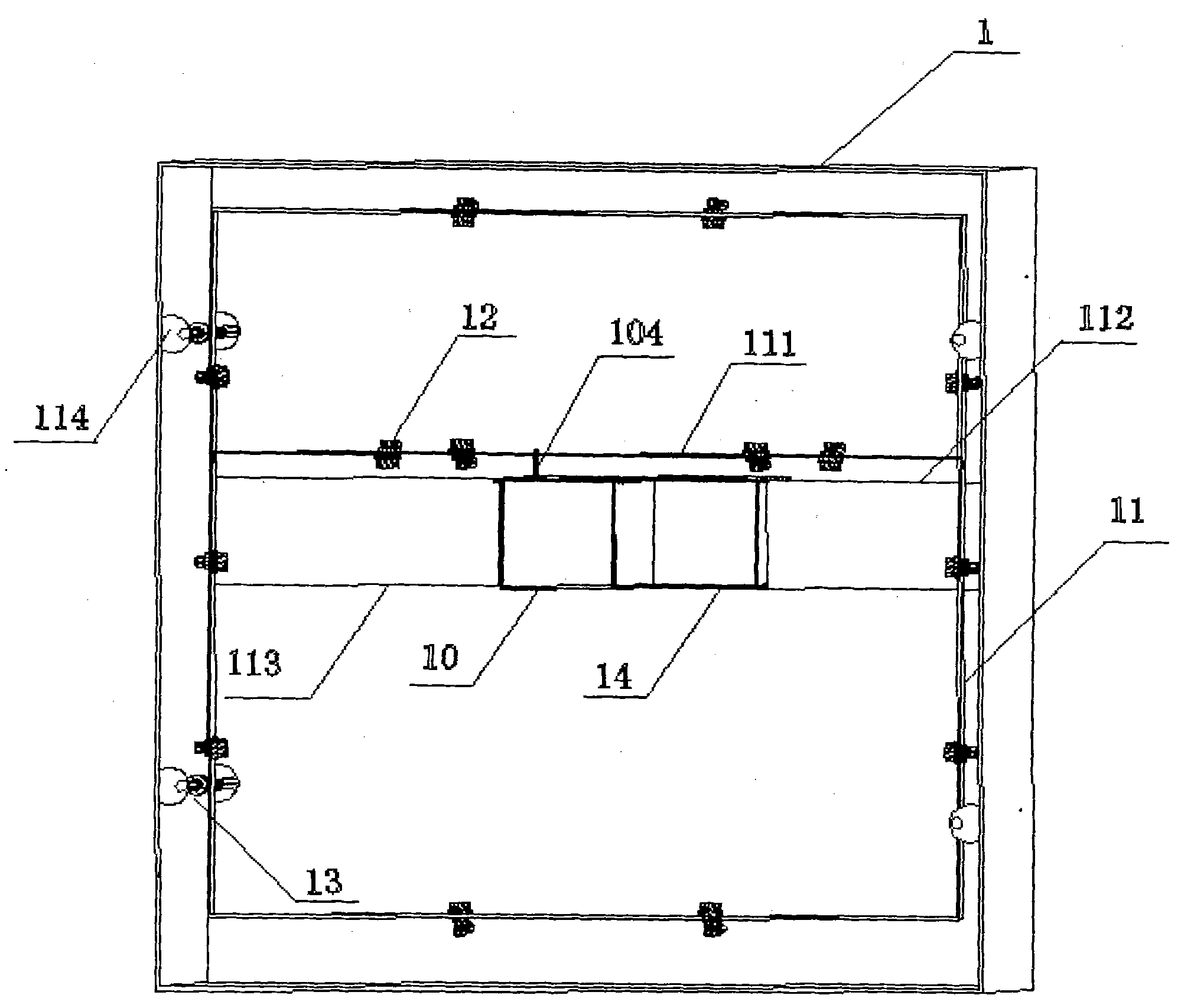

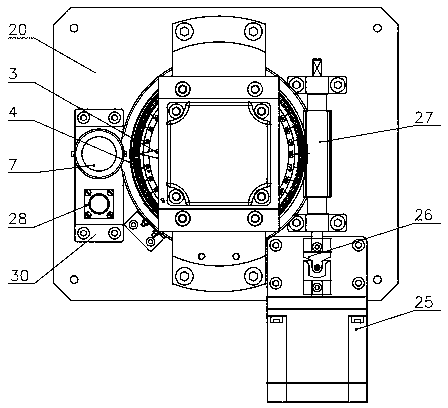

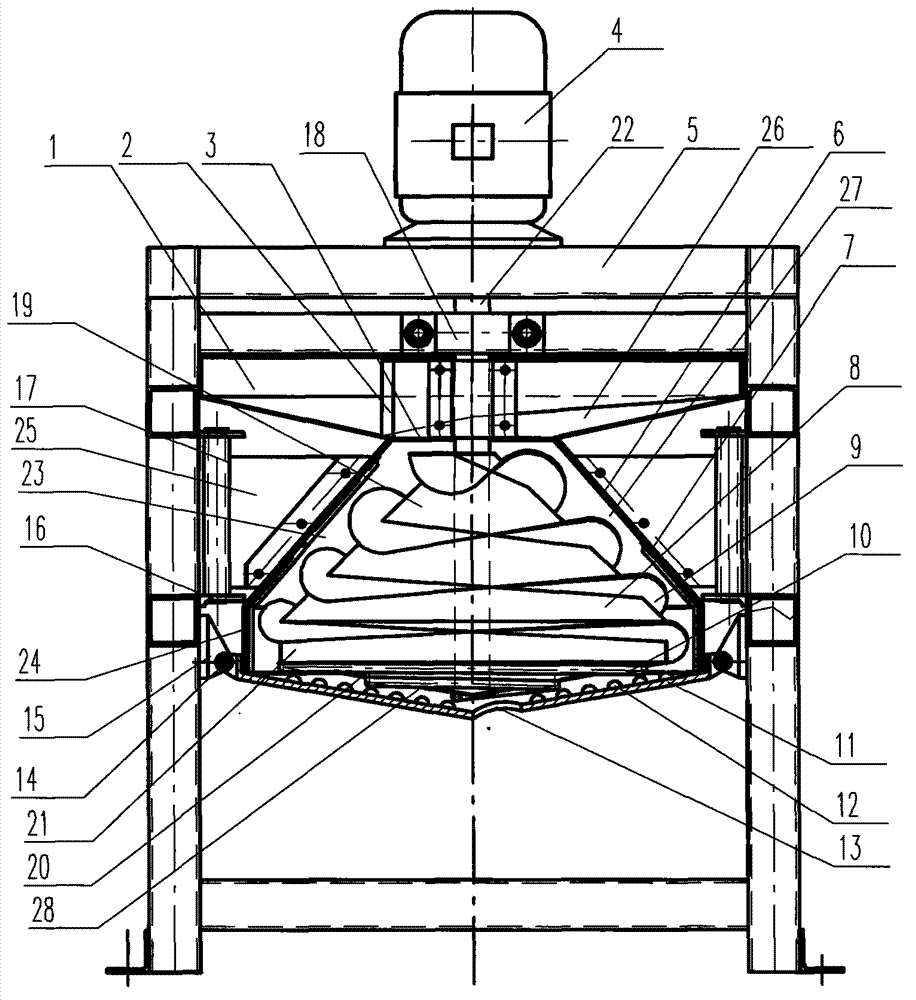

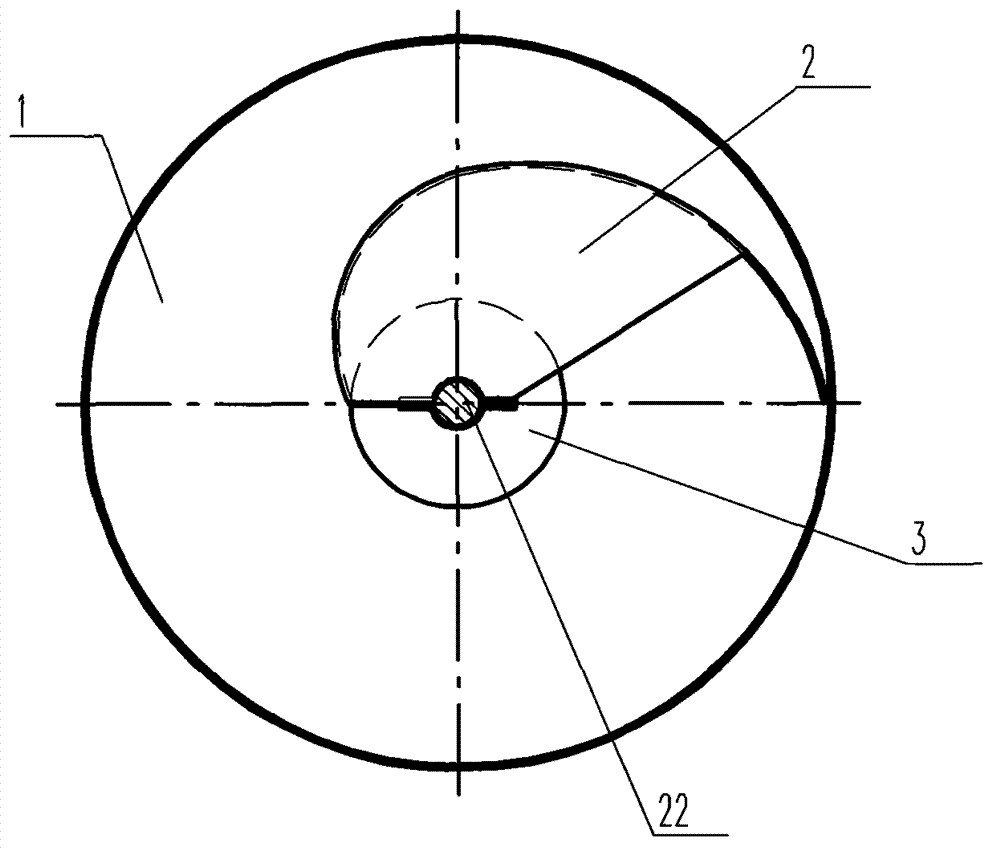

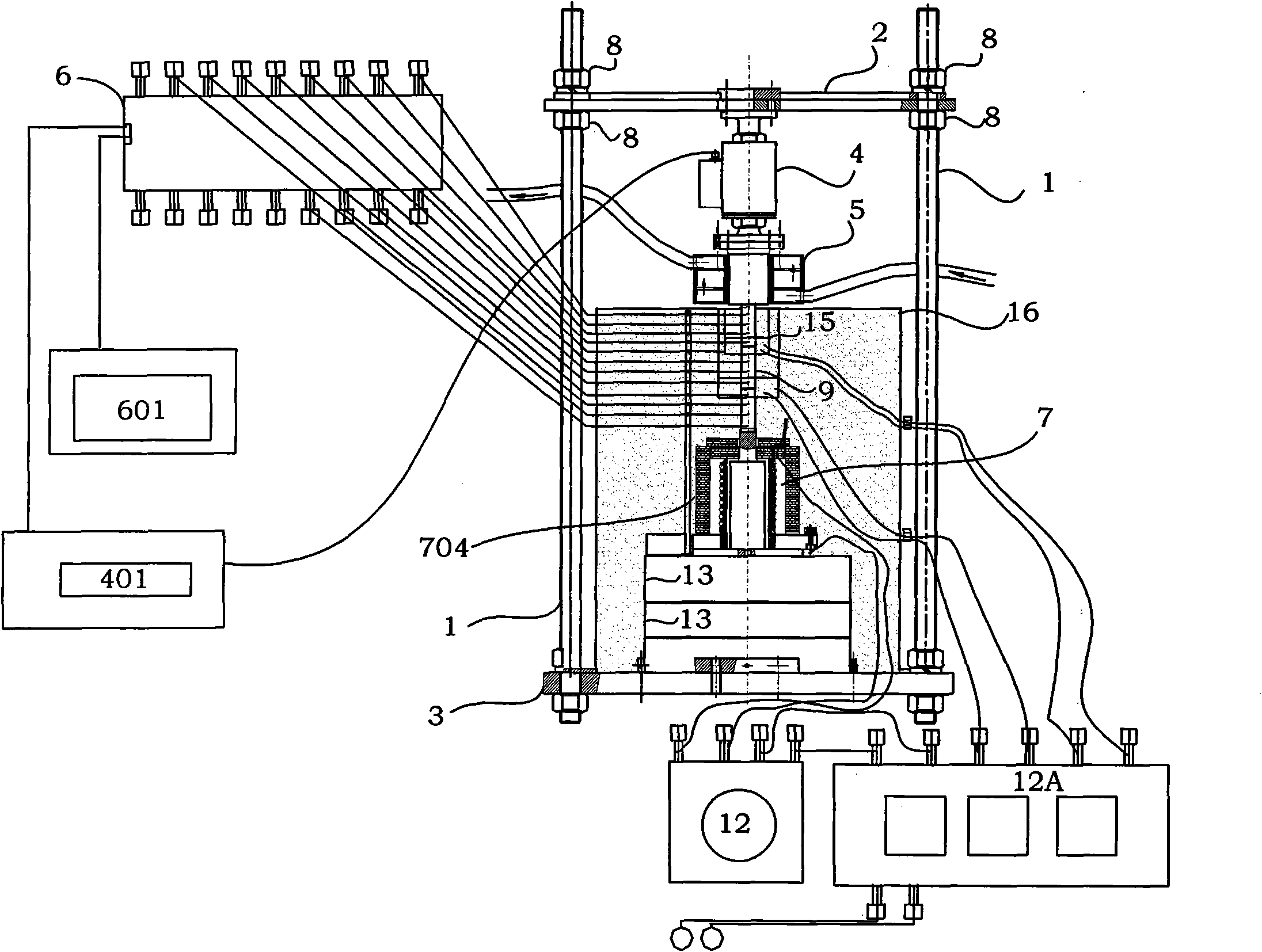

Three-axial vibration composite testing apparatus

A triaxial vibration composite testing device is provided with a worktable, and is characterized in that both a horizontal X-axis second axial transmission-vibration mechanism and a horizontal Y-axis third axial transmission-vibration mechanism are cross linear guide rail pairs, while a first axial transmission-vibration mechanism vertical to Z-axis comprises an upper clamp plate, a lower clamp plate and a central panel, wherein the upper clamp plate and the lower clamp plate are aligned vertically and arranged horizontally, the central panel is positioned between the upper clamp plate and the lower clamp plate, the upper clamp plate and the lower clamp plate oppositely clamp the central panel, the lower surface of the upper clamp plate and the upper surface of the central panel are in clearance fit to form an upper fit plane, the upper surface of the lower clamp plate and the lower surface of the central panel are in clearance fit to form a lower fit plane, and high-pressure oil is pumped into gaps of the upper fit plane and the lower fit plane to form static-pressure oil films so as to form a static-pressure plane bearing mechanism. The invention can further improve performance (working frequency in particular), improve capability of resisting capsizing moment, simplify structure, and lower manufacturing difficulty and cost.

Owner:SUZHOU SUSHI TESTING INSTR CO LTD

Surgical device for the collection of soft tissue

A handheld biopsy device is provided for the collection of soft tissue samples from a surgical patient. In a preferred embodiment, the biopsy device comprises a handpiece, a fluid collection system, and a power transmission source. The handpiece is configured for grasping by a single hand, and being independentyl manipulatable by hand for movement of the instrument toward and away from the patient. An elongated piercer extends from the distal end of the handpiece. The piercer has a sharpened distal end for entering the tissue and a port located proximal to the sharpened distal end for receiving a portion of tissue mass. An elongated cutter is disposed coaxially relative to a piercer lumen of the piercer. A distal blade of the cutter slides distally past the port of the piercer to severe the tissue portion drawn into the port by vacuum. The cutter is retracted to a most proximal position for removal of the tissue portion from a cutter lumen of the cutter. The handpiece further comprises a holster for detachably connecting a cutter rotational transmission and a cutter axial transmission to the power transmission source.

Owner:DEVICOR MEDICAL PROD

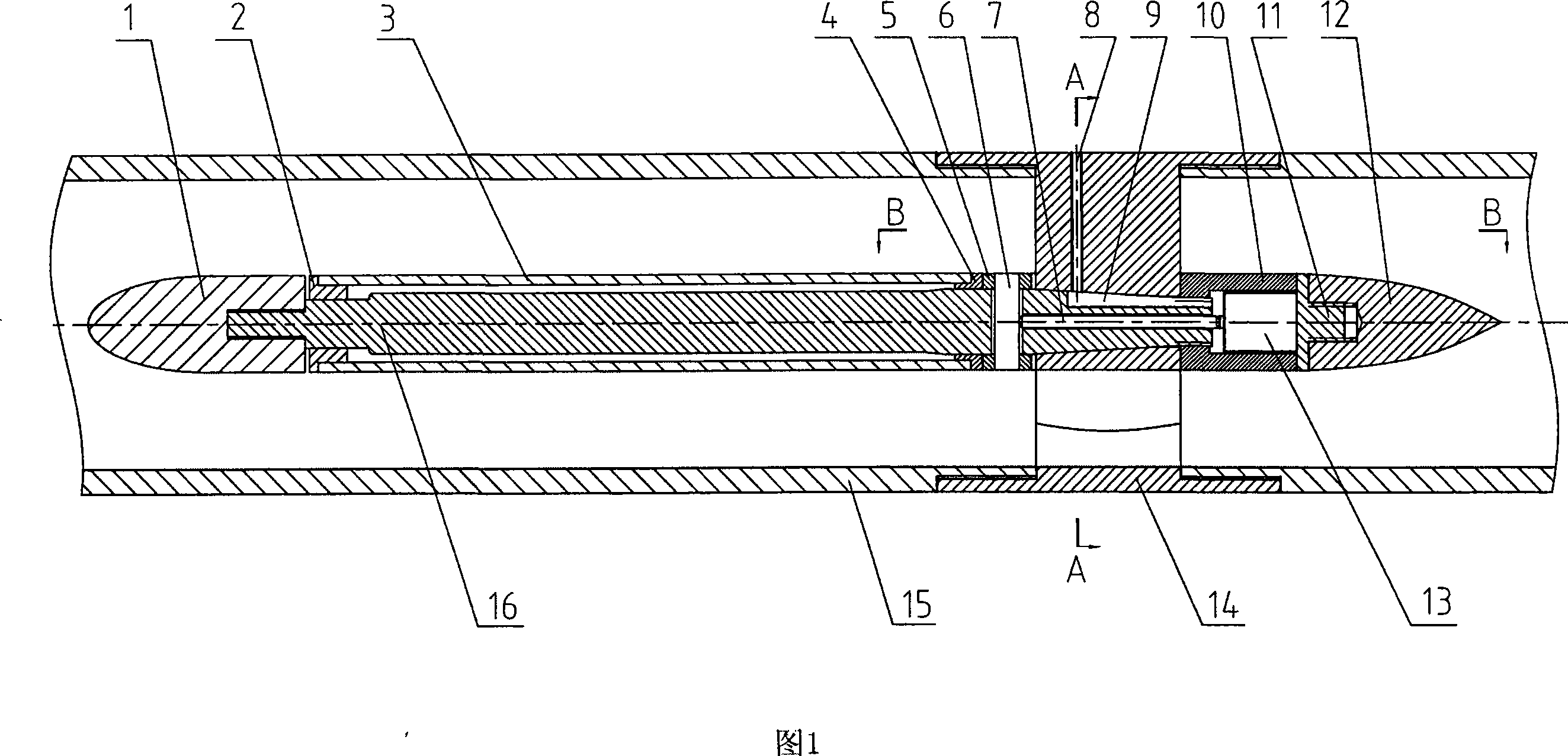

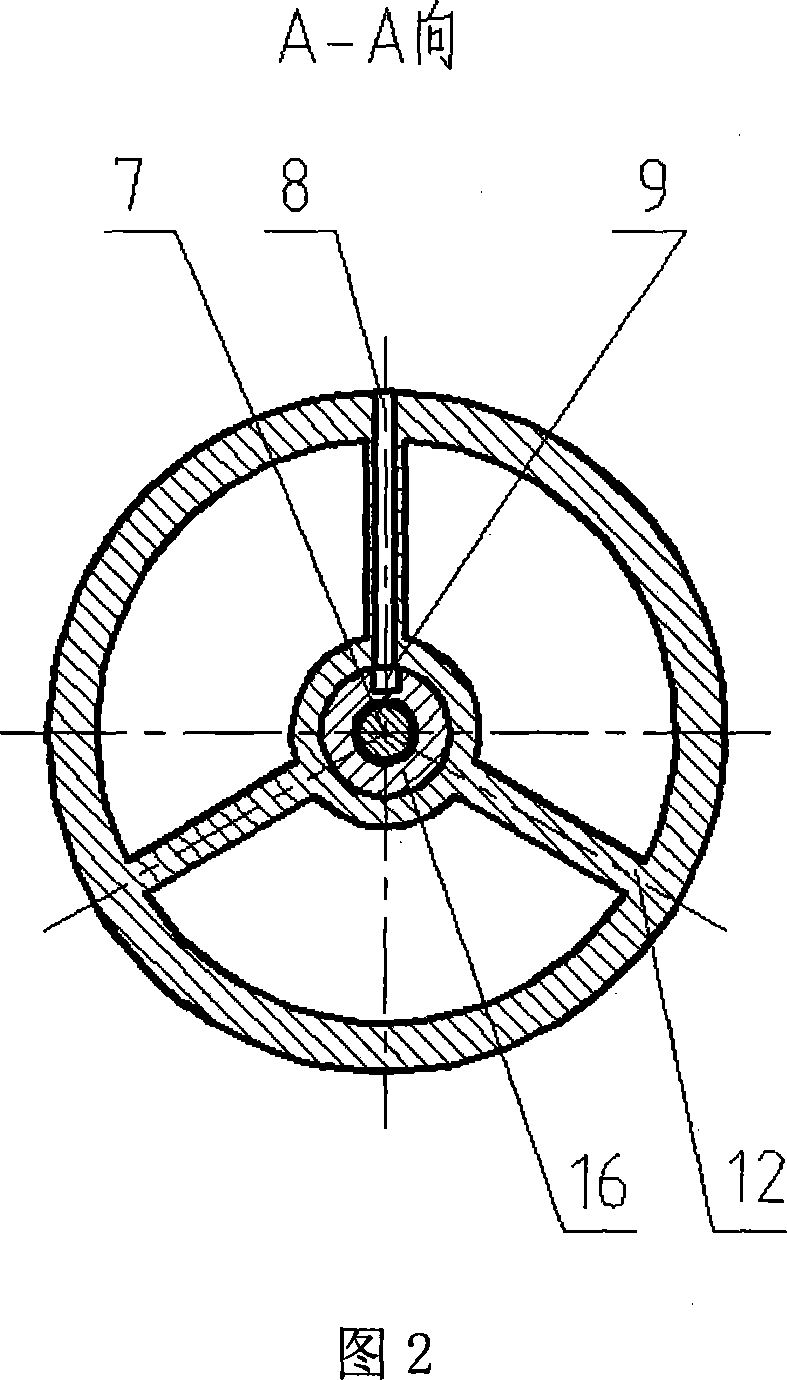

Detector for round cross section sample wall surface fluid friction resistance

InactiveCN101050995AIncrease frictional resistanceReduce the impactHydrodynamic testingMeasurement deviceFixed frame

A frictional resistance measurement device of wall-surface fluid on round section test sample consists of model support unit including model head, front slide support ring, back slide support ring, model tail, fixing frame and support rod; and resistance measurement unit including transmission ring, radial transmission pin, axial transmission pin, transducer support sheath, transducer and transducer base. It is featured a setting measured test sample to be cylindrical form, placing transducer in runner and leading signal line out through hole.

Owner:TSINGHUA UNIV

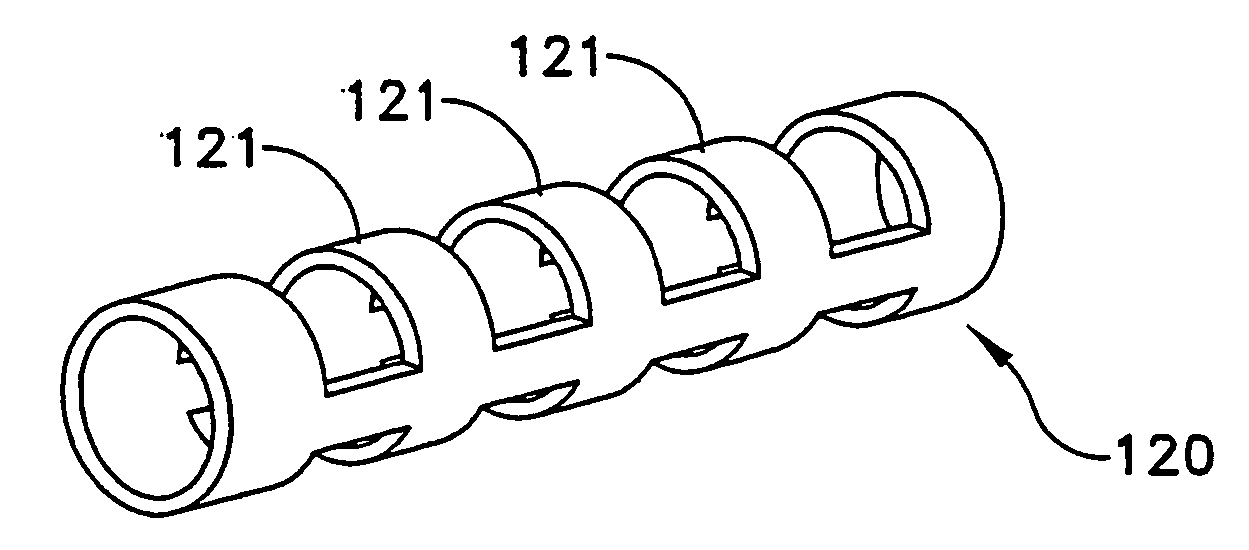

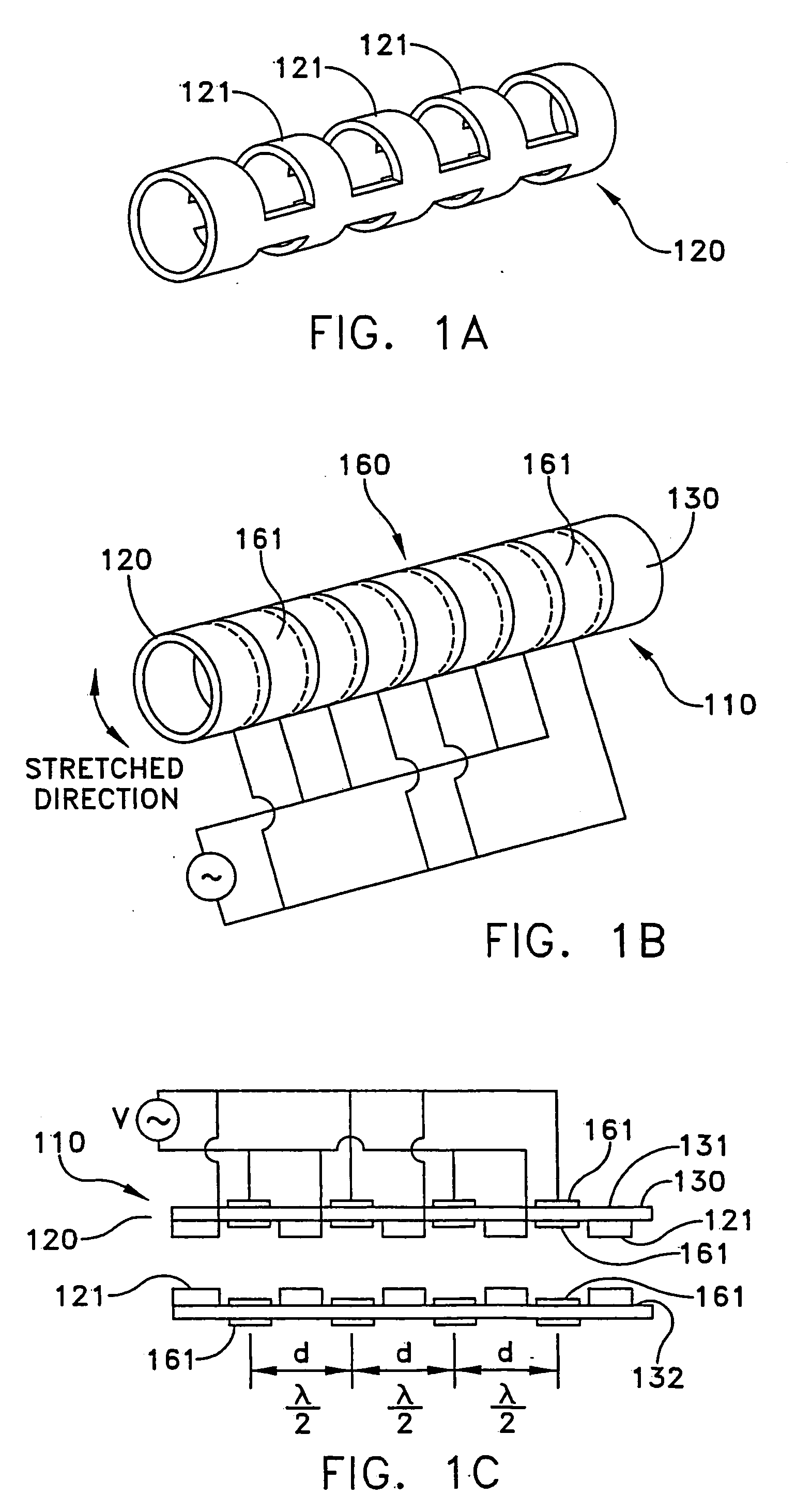

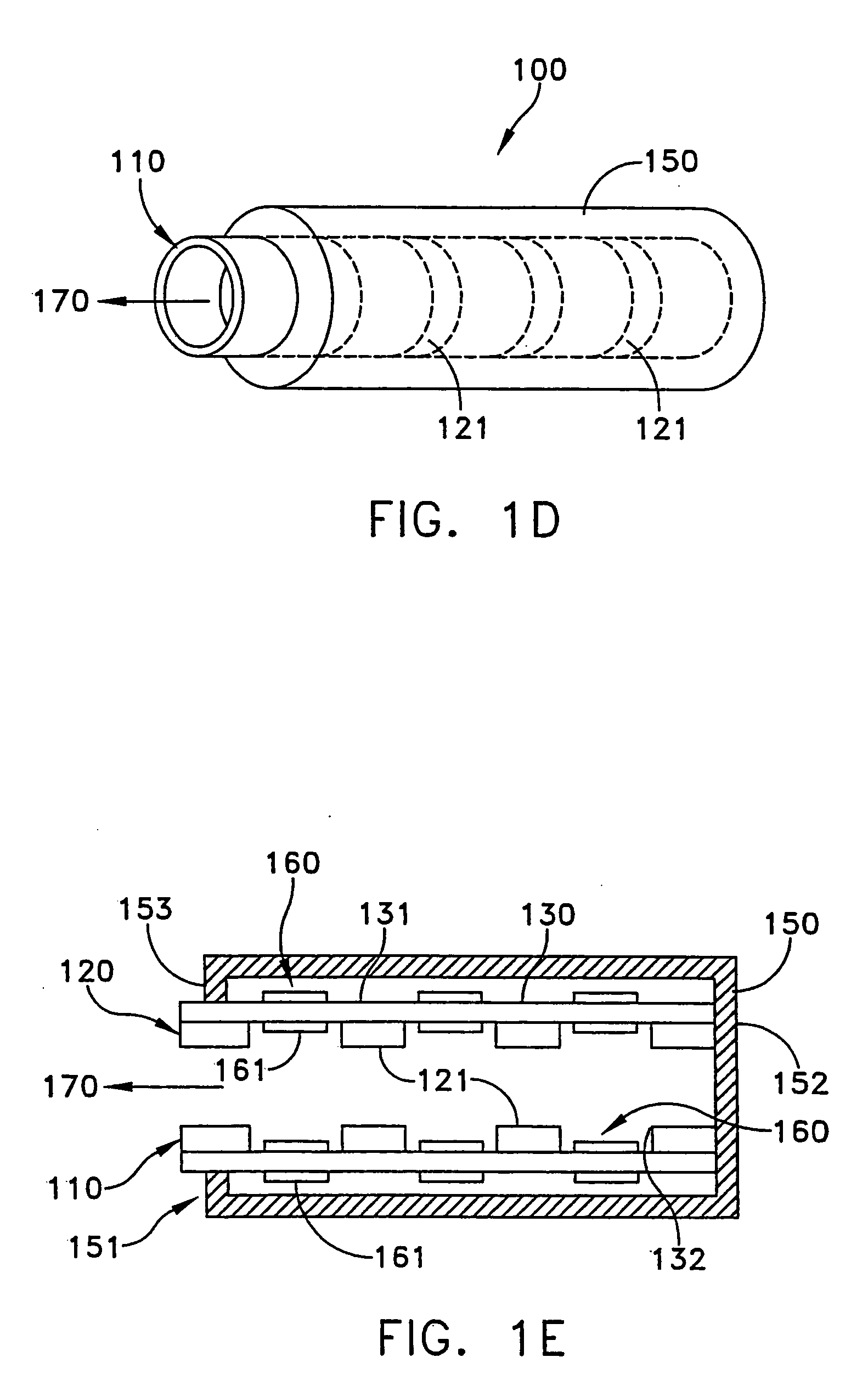

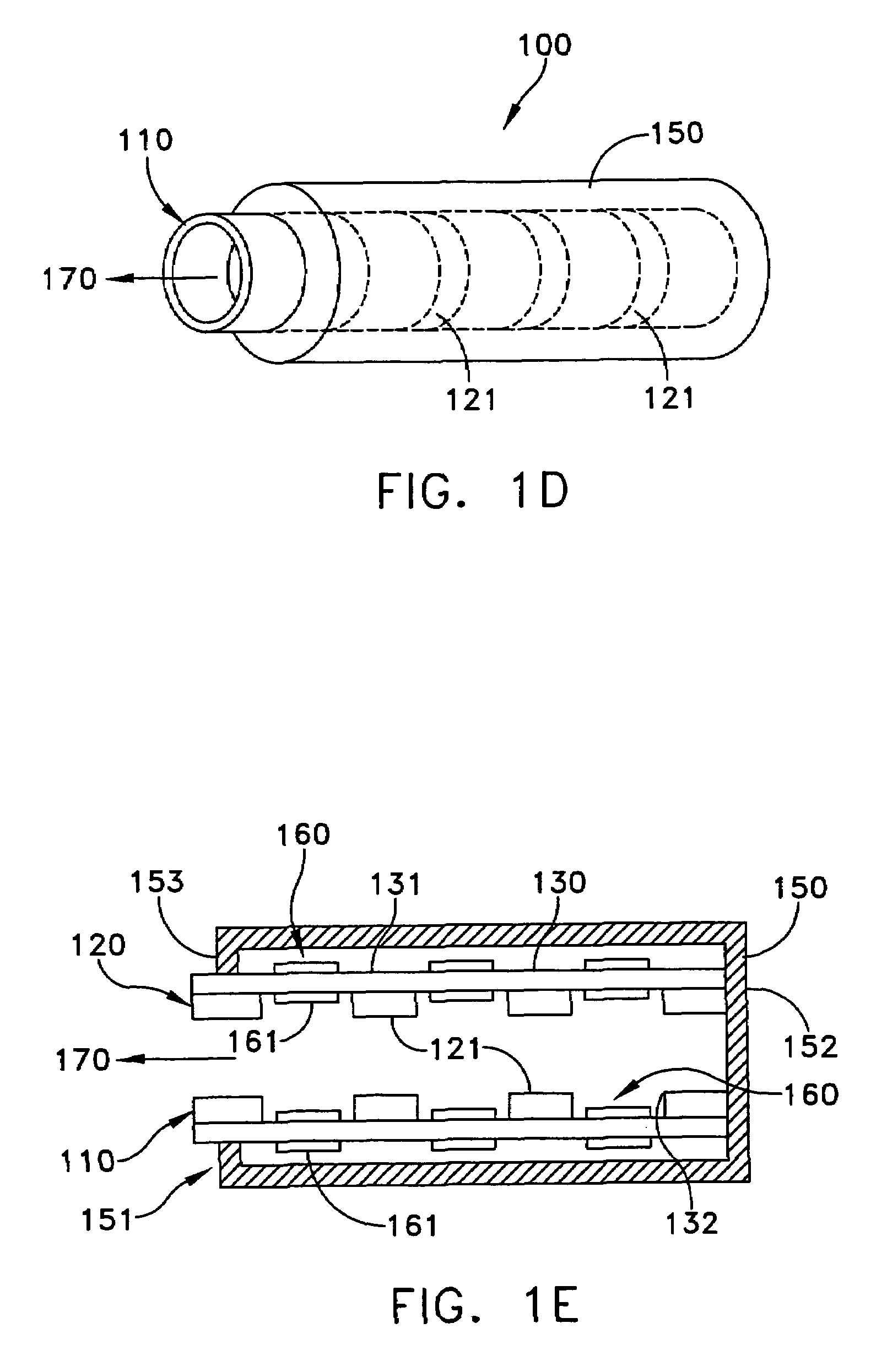

Handheld device having ultrasonic transducer for axial transmission of acoustic signals

InactiveUS20060273696A1Ultrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesUltrasonic sensorTransducer

A handheld stylus having an elongated housing, a writing and drawing implement disposed within the housing and including a tip extending through an opening at an end of the housing where ultrasonic waves radiate therefrom and are used for determining a position of the stylus; and at least one ultrasonic transducer disposed within the housing. The transducer may be a cylindrical piezoelectric transducer having a holder and a cylindrical piezoelectric film spanning between at least two spaced apart cylindrical surfaces of the holder, or a flat transducer having a diaphragm, and a piezoelectric material disposed on a surface of the diaphragm.

Owner:MEASUREMENT SPEC

Thermal contact resistance testing device with cooling device

The invention discloses a thermal contact resistance testing device with a cooling device, which mainly comprises a support, a top plate, a bottom plate, a stress loading device, the cooling device, a data acquisition system and a heating device, wherein the heating device, a test sample, the cooling device and the stress loading device are arranged between the bottom plate and the top plate from bottom to top in sequence. The cooling device is arranged at the top end of the test sample and is a cooling water tank, the center of the cooling water tank is provided with a central through hole, and the inner diameter of the central through hole is greater than the outer diameter of a force conducting rod. The temperature of cooling water in the cooling water tank is directly conducted to the force conducting rod, and the upper cold end of the test sample is cooled by reducing the temperature of the force conducting rod. A cooling channel is arranged in the cooling water tank, is spiral and surrounds the central through hole, a cooling water inlet is arranged at the bottom of the cooling water tank, and the top is provided with a cooling water outlet. The hot end and the cold end of the test sample have great temperature difference by using the cooling device, and the one-dimensional axial transmission of a heat flow is realized.

Owner:BEIHANG UNIV

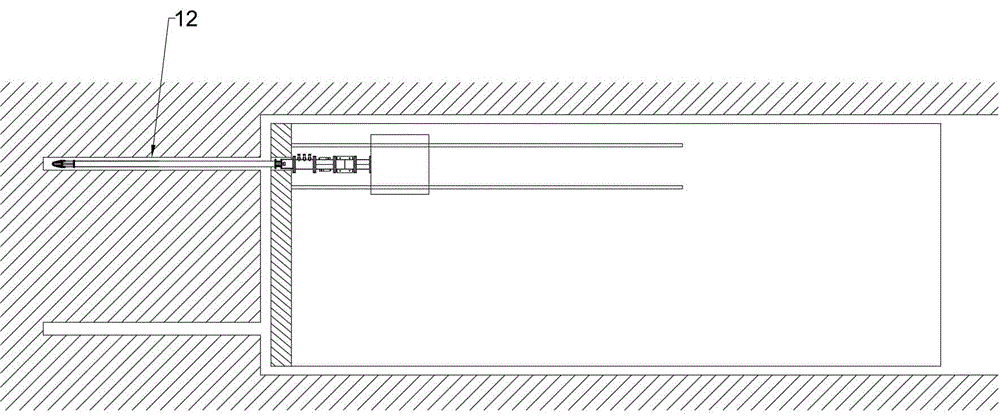

TBM microwave stress relief device and application for rockburst prevention and treatment

ActiveCN106761796AOvercome limitationsTo achieve the effect of stress reliefTunnelsStress reliefEngineering

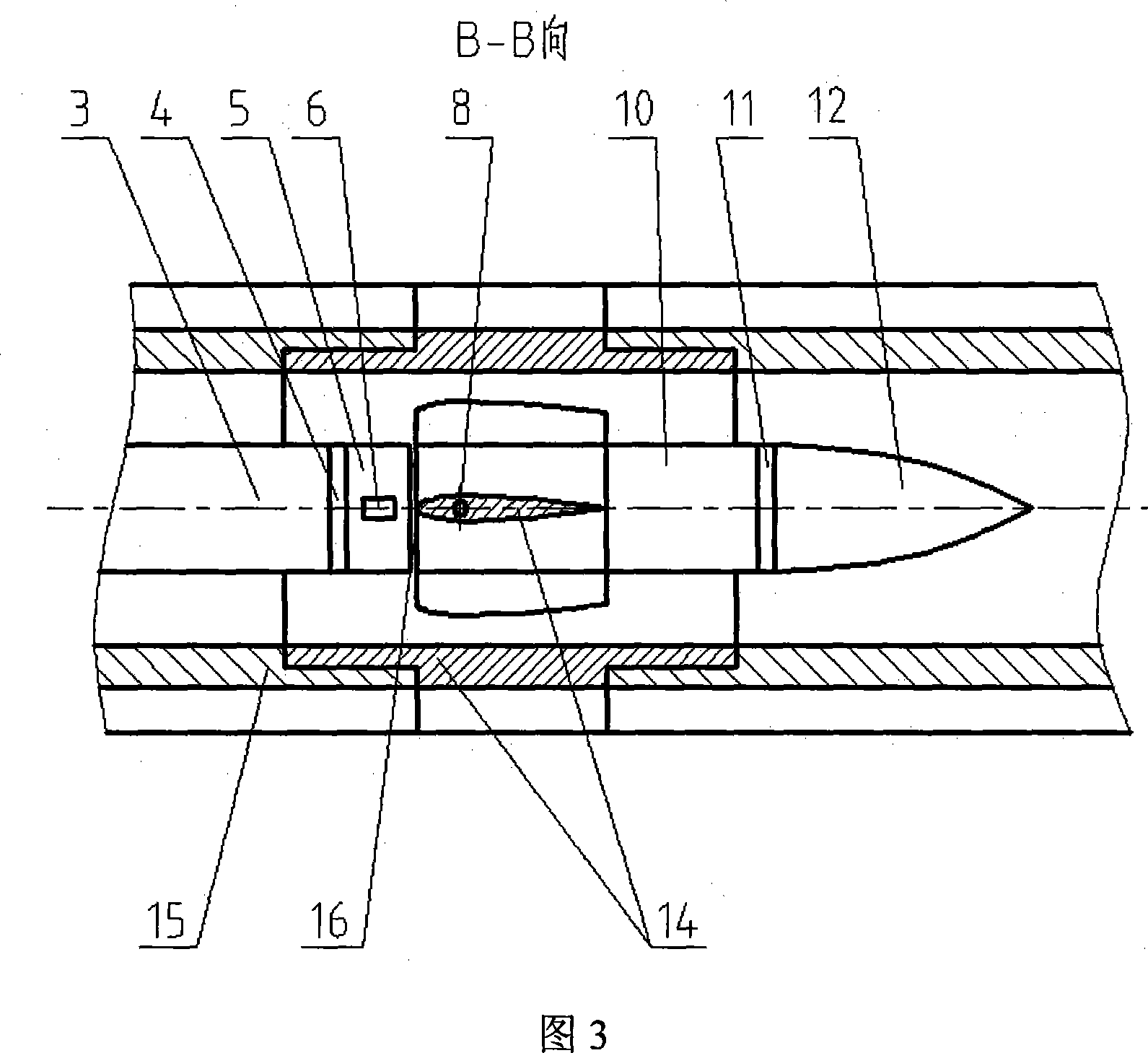

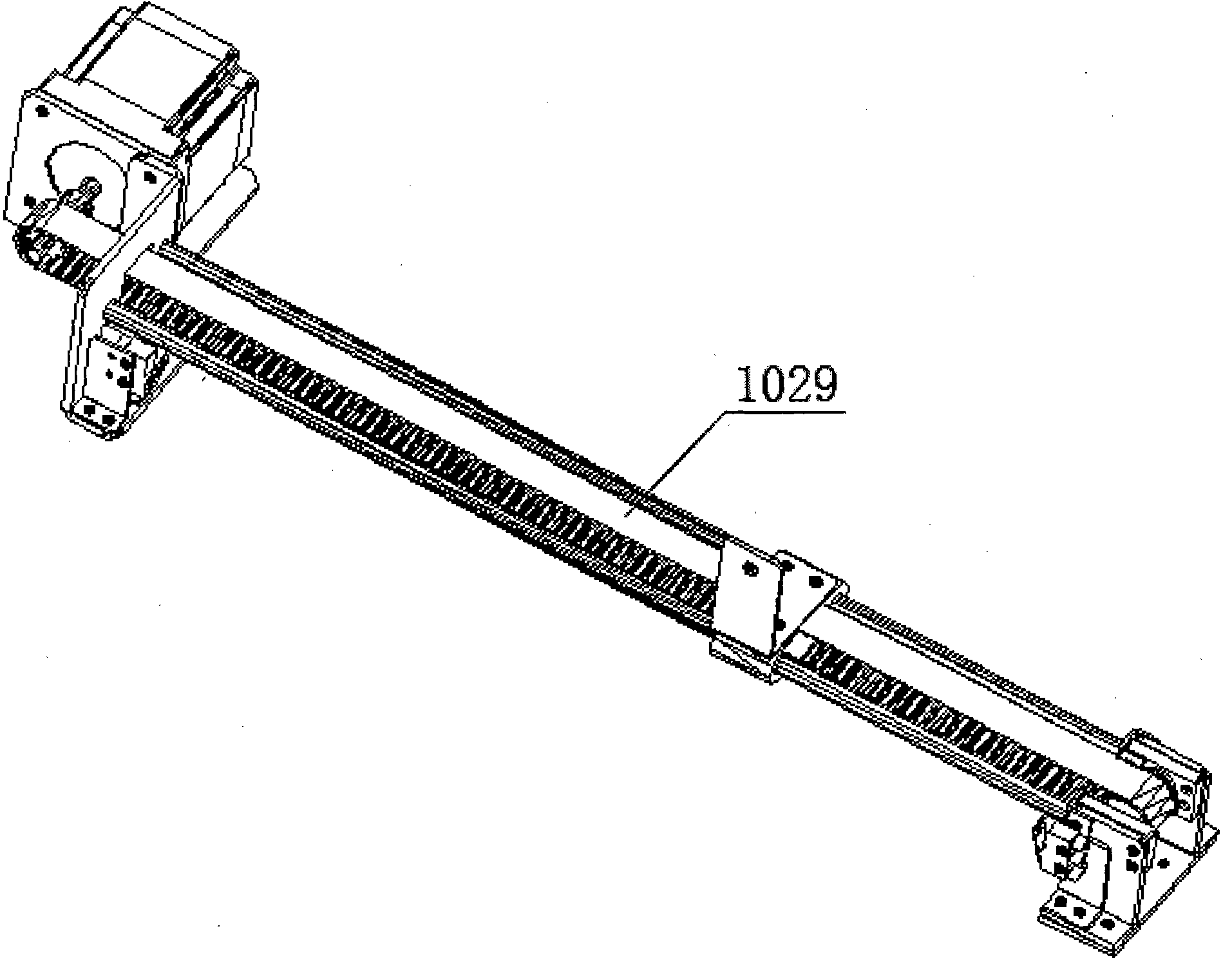

The invention relates to a TBM microwave stress relief device and application for rockburst prevention and treatment. According to the structure of the TBM microwave stress relief device, an axial transmission lead screw is arranged in a TBM rack, the transmission lead screw is in slide connection with a microwave fracturing system, and a microwave transmitting bar is arranged at the tail end of the microwave fracturing system; a TBM cutterhead is arranged at the end of the TBM rack, a through hole is formed in the TBM cutterhead, the microwave fracturing system slides along the transmission lead screw, and the microwave transmitting bar stretches out of the through hole and sends microwaves into drilled rock. The device and application aim to break through the limit that a TBM cannot cope with extremely powerful or powerful rockburst when tunneling a deep tunnel, before TBM hob work, microwave energy is used for carrying out microwave radiation on advance boreholes to presplit the borehole surrounding rock so as to relieve stress, and the purpose of rockburst prevention in the deep tunnel tunneling of the TBM is achieved.

Owner:NORTHEASTERN UNIV

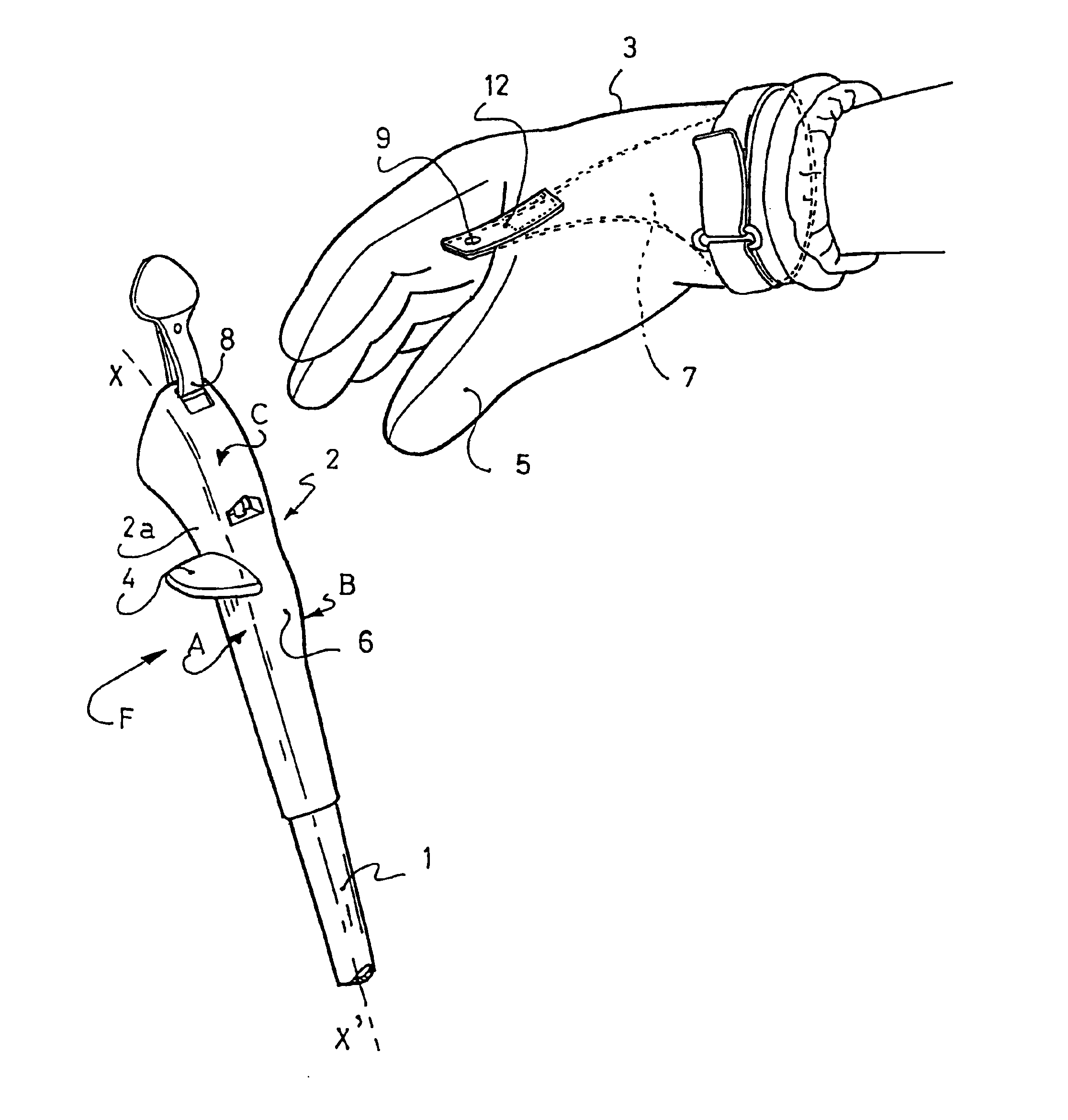

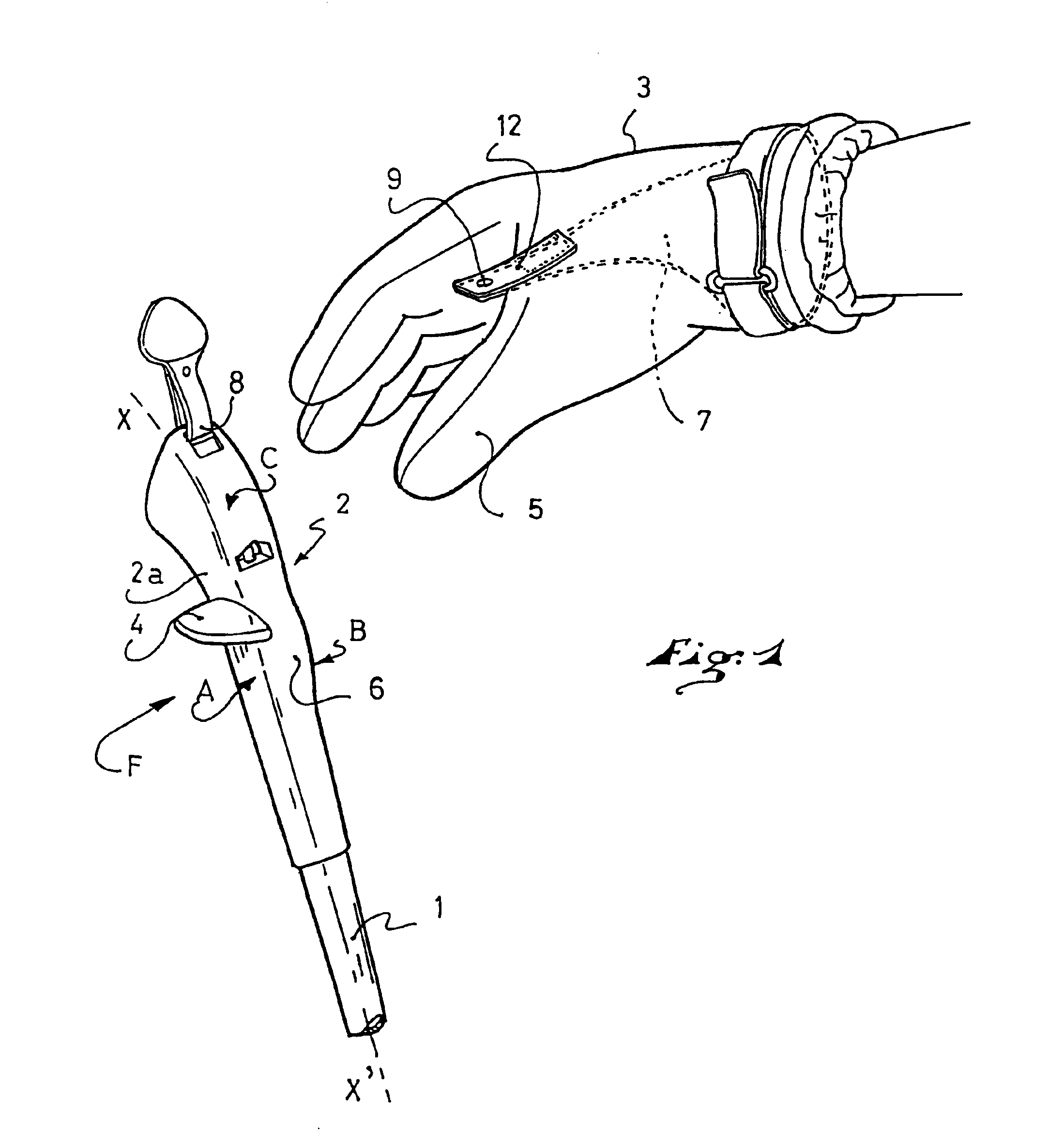

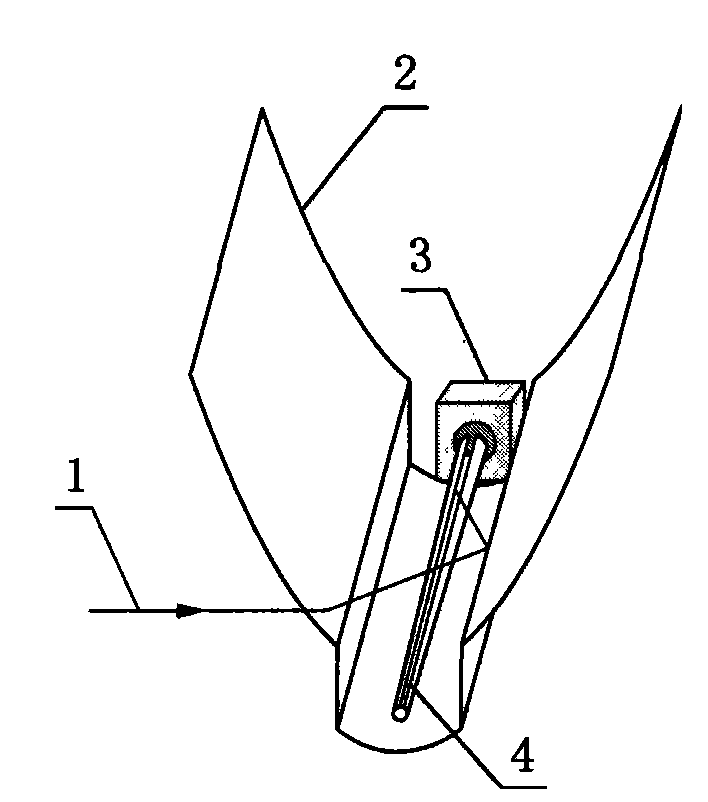

Grip for a sports pole, and a sports pole having such grip

InactiveUS6988745B2Improved force transmissionImproving grip and contactSnowboard bindingsGlovesEngineeringAxial transmission

A pole, for use in skiing or other sport, of the type that includes a grip handle at its upper end, wherein the handle includes a support extending from its side wall and adapted to cooperate with the thumb of a user, so as to constitute an additional mechanism for the axial transmission of forces, by the thumb, when the hand is closed on the handle of the pole.

Owner:SALOMON SA

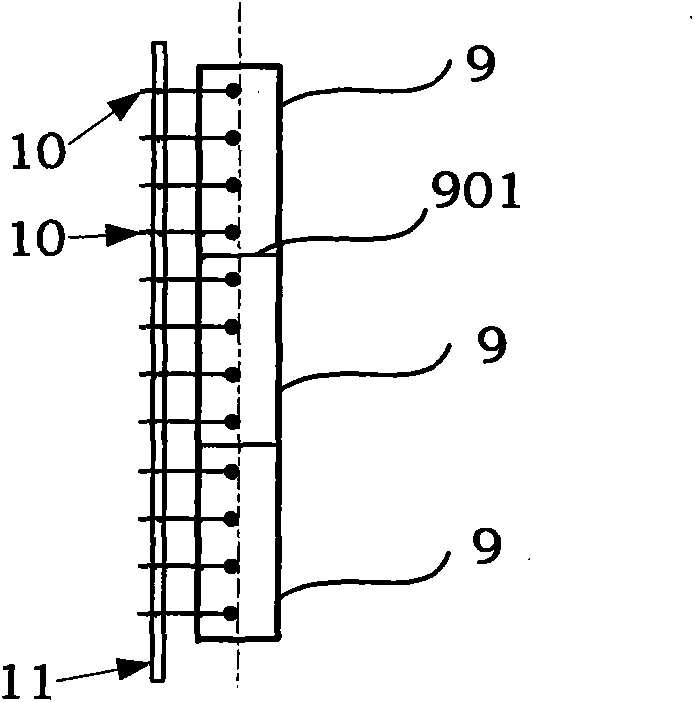

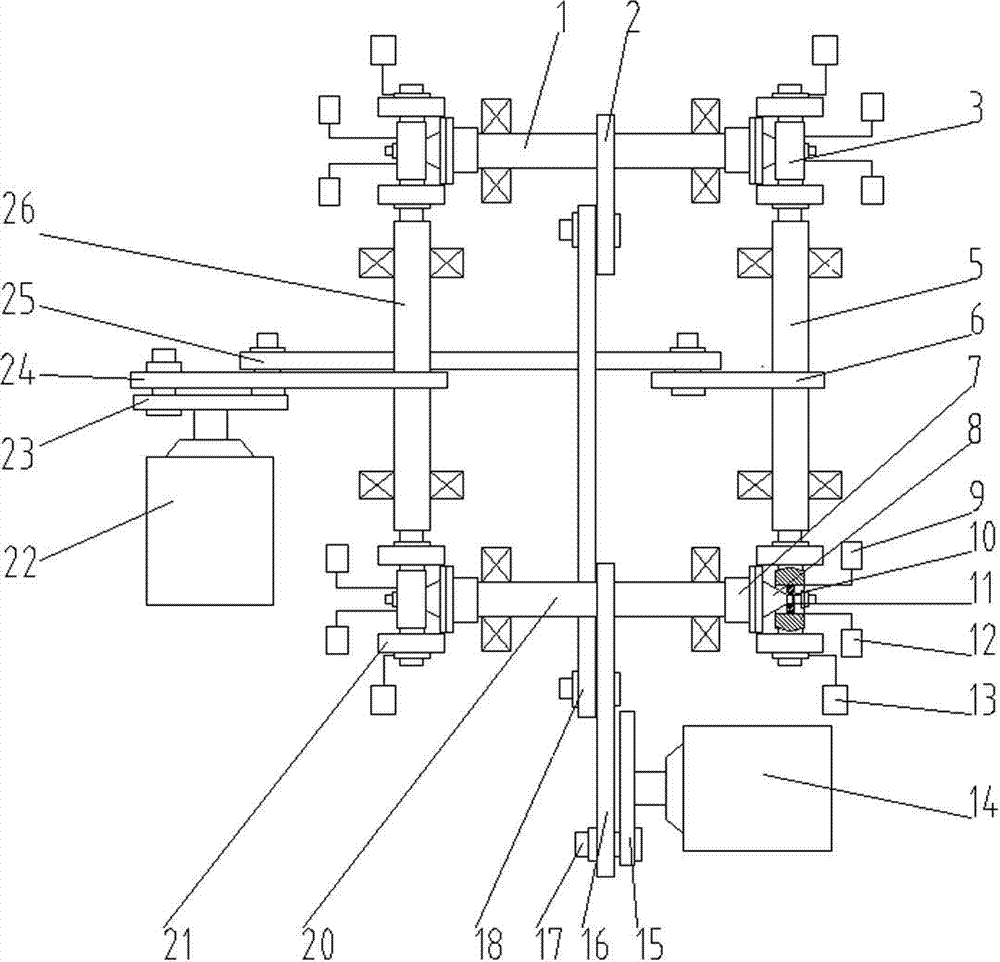

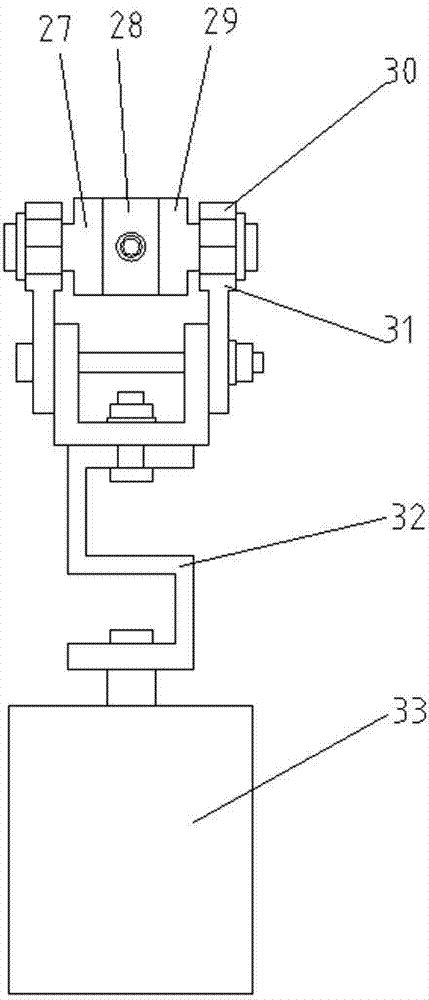

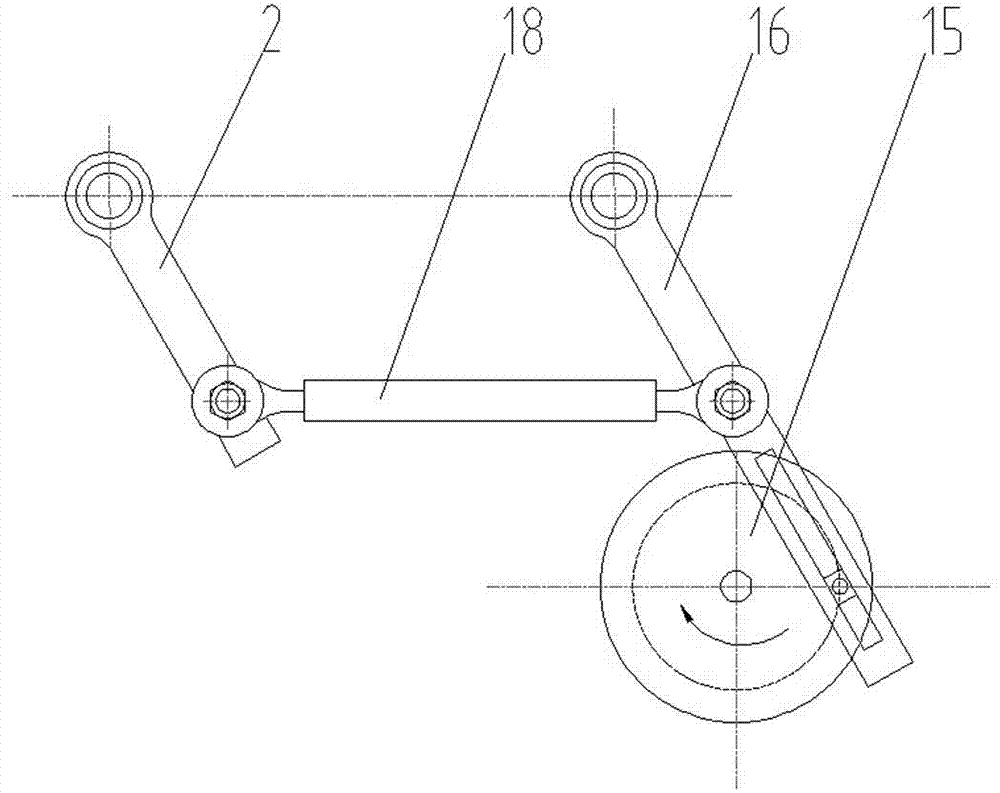

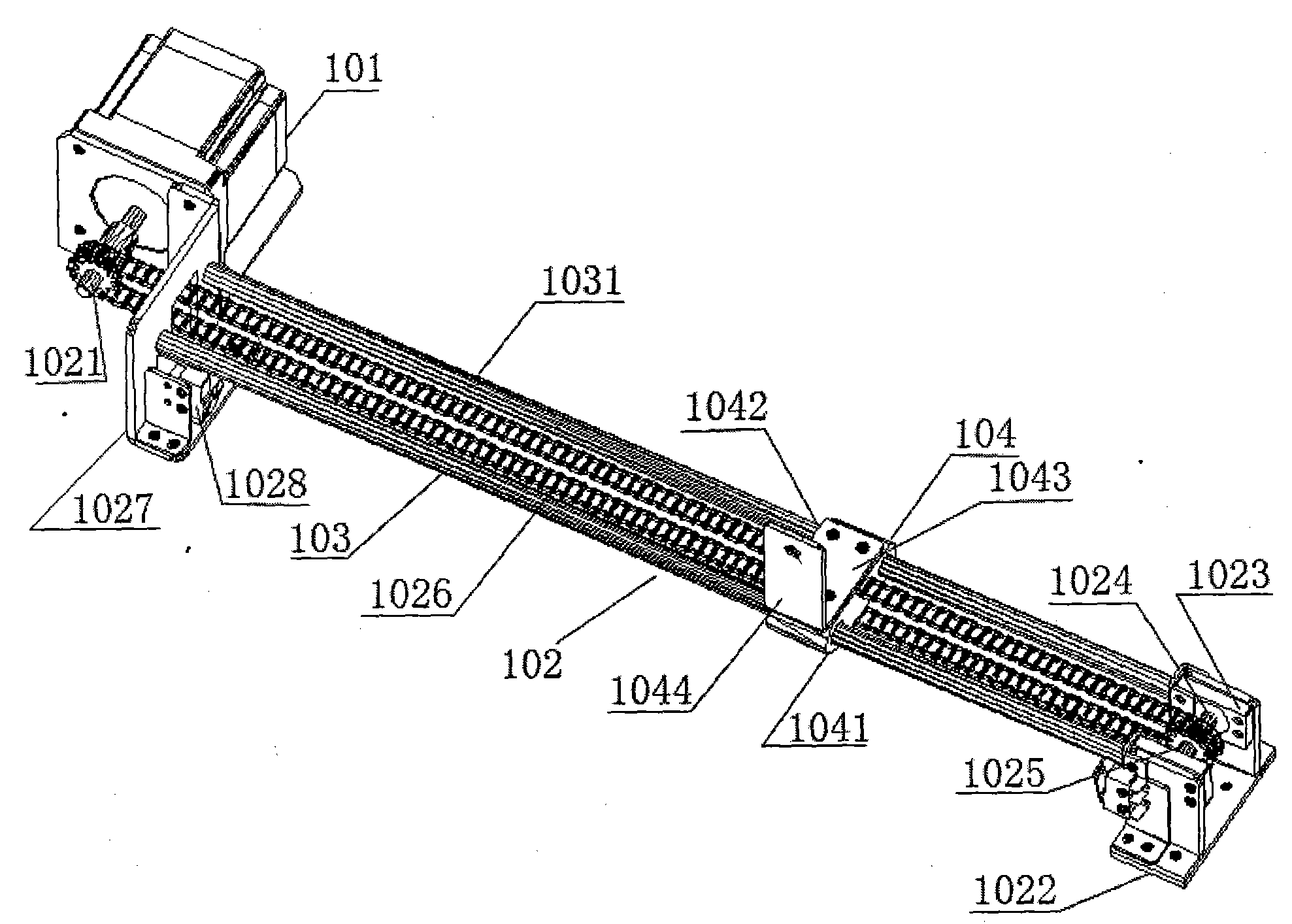

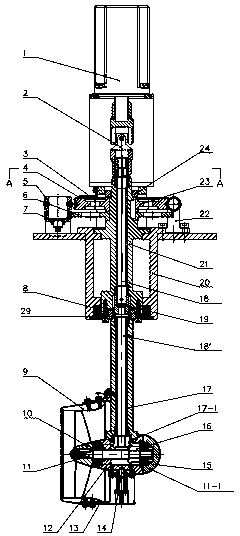

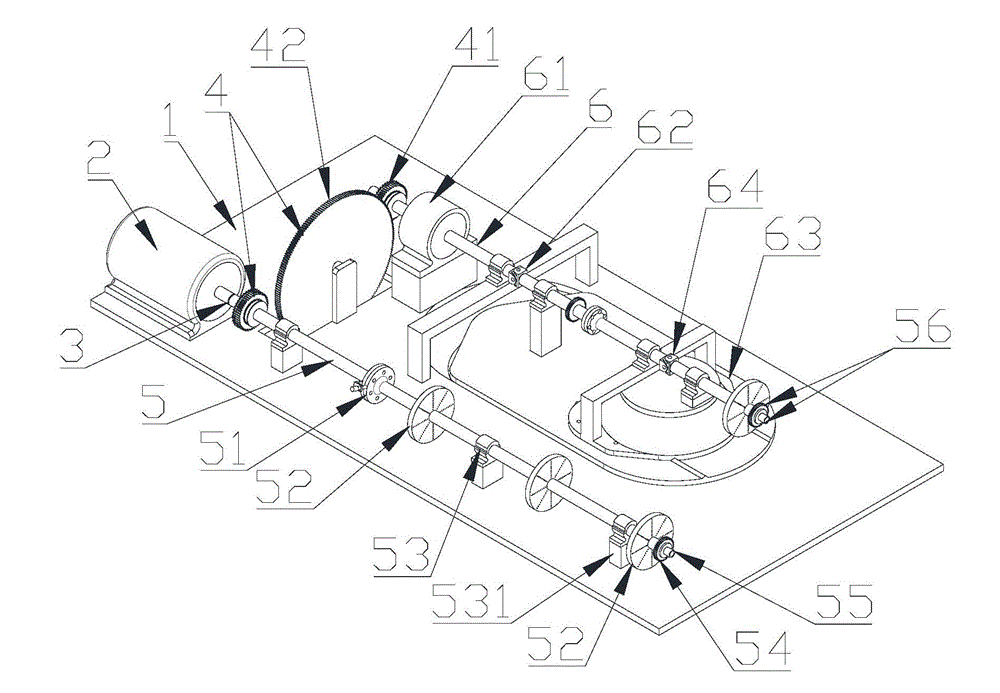

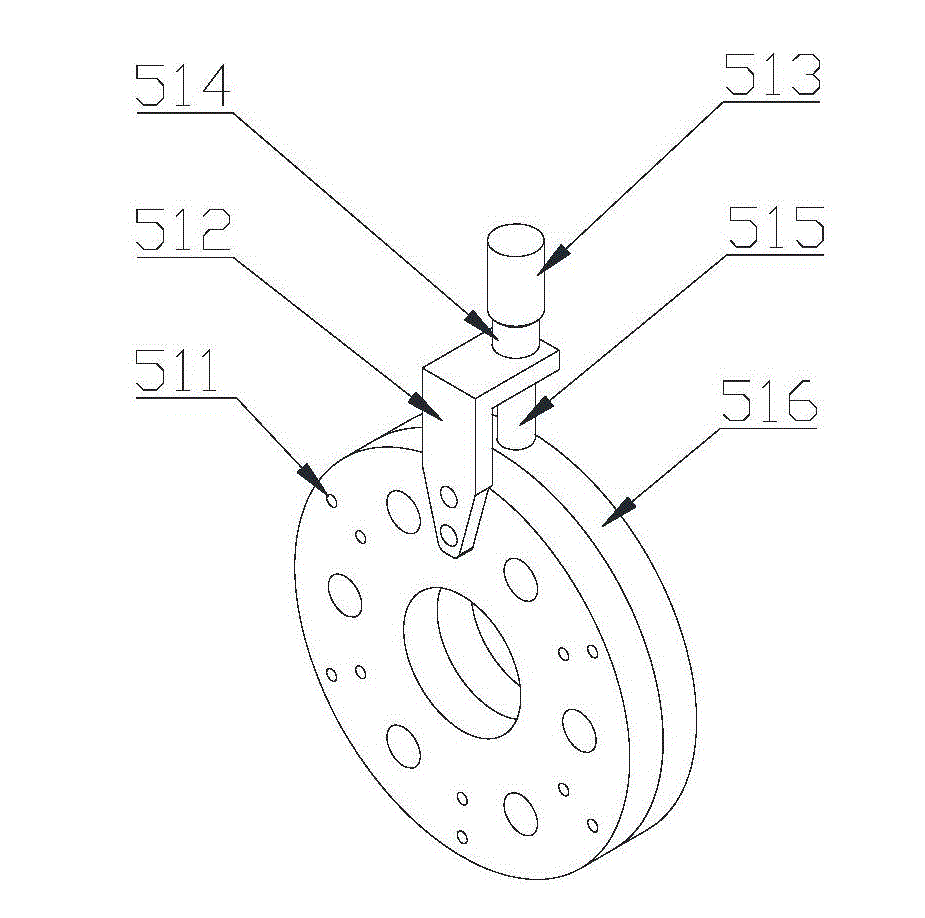

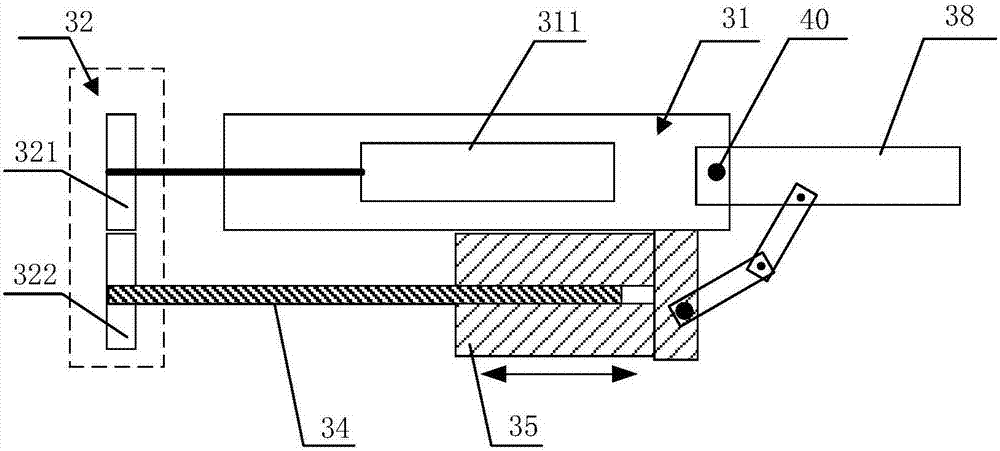

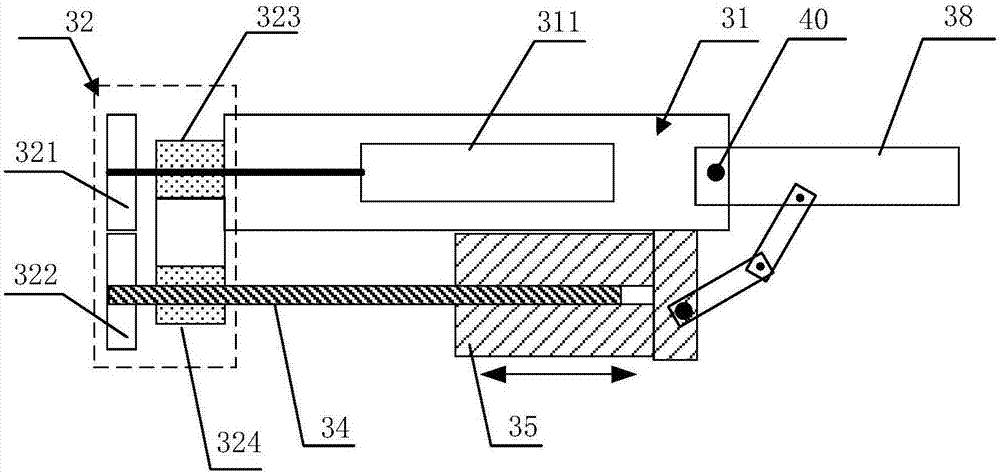

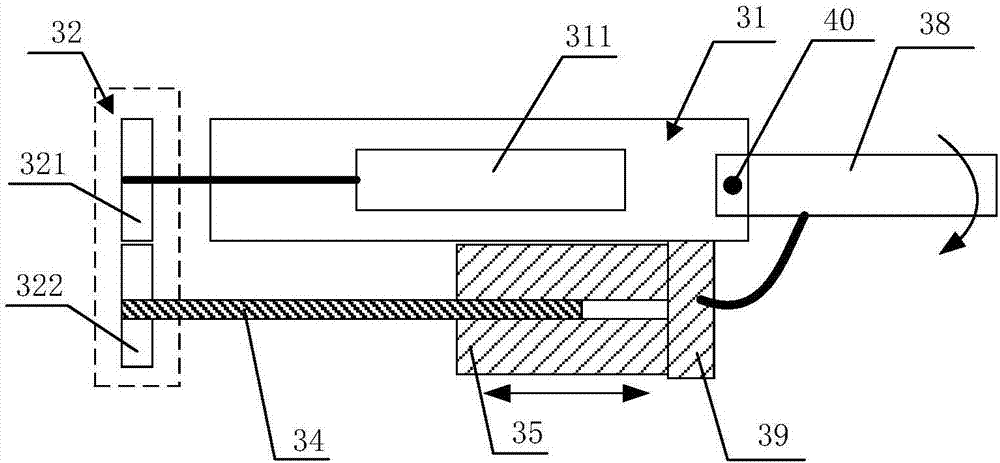

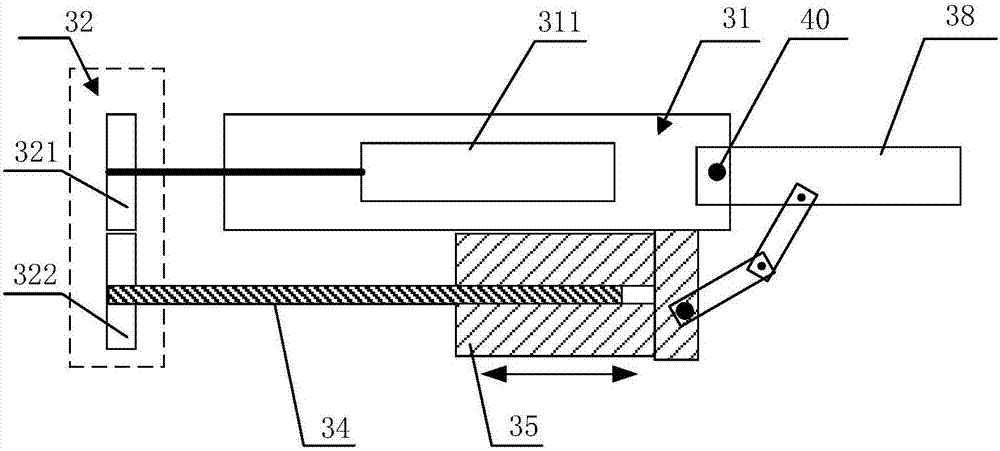

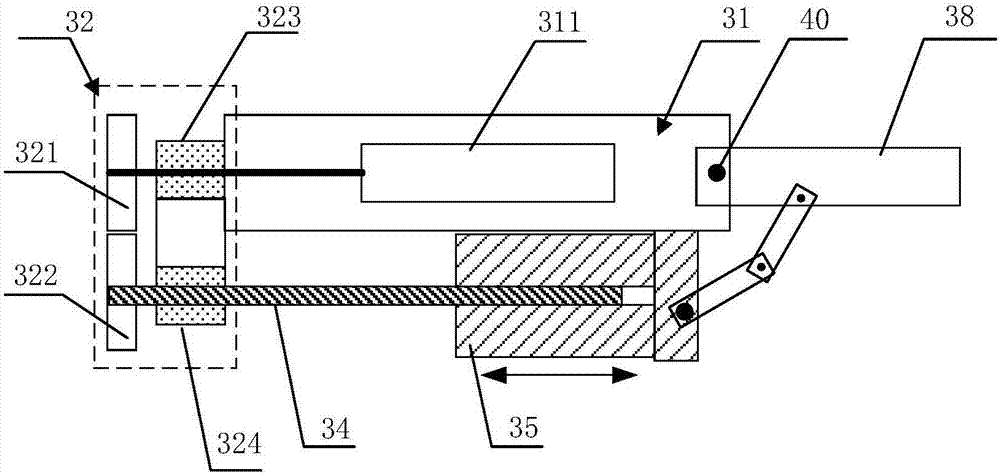

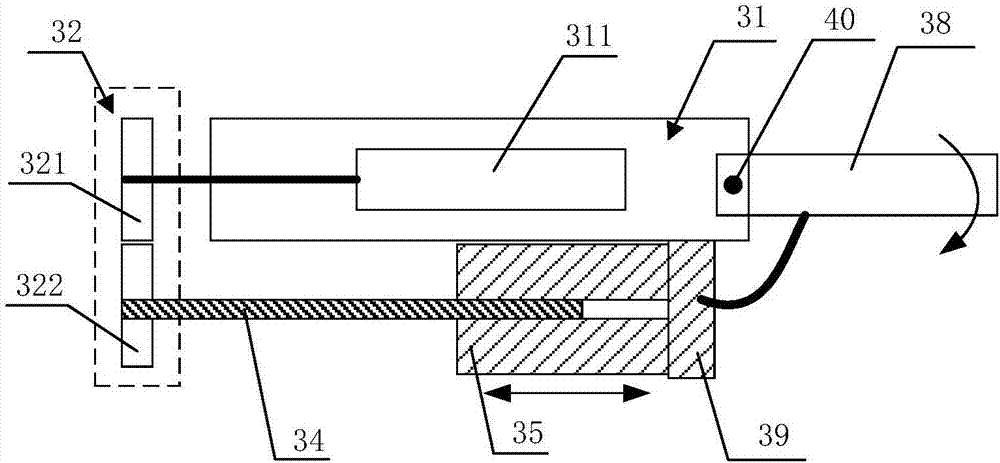

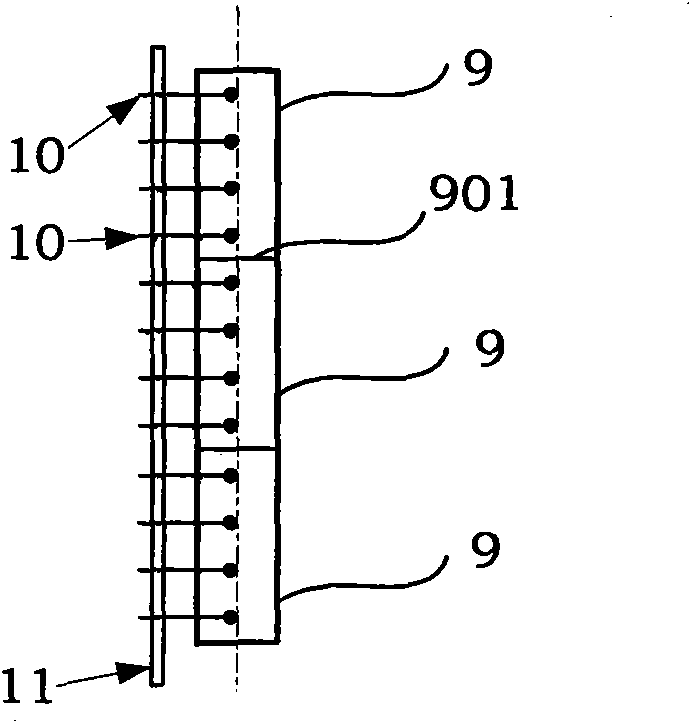

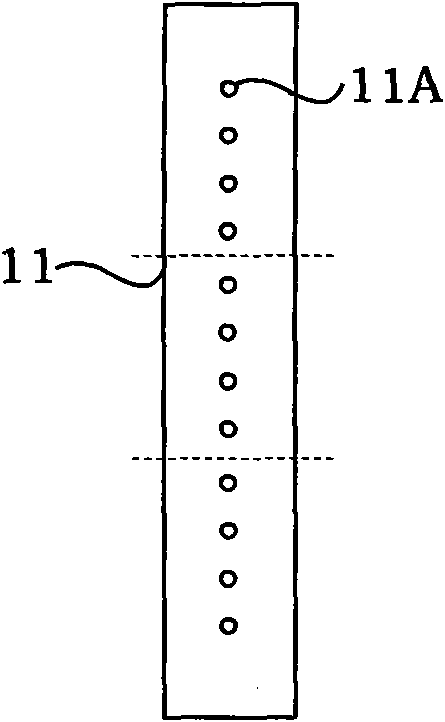

Composite swing type joint bearing service life testing machine

ActiveCN103323241AImprove life test efficiencyImprove test accuracyMachine bearings testingTest efficiencyDrive shaft

The invention discloses a composite swing type joint bearing service life testing machine. The composite swing type joint bearing service life testing machine comprises axial transmission shafts which are in coaxial transmission connection with inner rings of joint bearings, bearing clamps for clamping outer rings of the joint bearings and radial transmission shafts which are in transmission connection with the bearing clamps. The axes of the radial transmission shafts and the axes of the axial transmission shafts are vertically intersected, and the axial transmission shafts and the radial transmission shafts are all in transmission connection with corresponding driving devices for driving the corresponding transmission shafts to rotate and swing in a reciprocating mode. The at least two axial transmission shafts and / or the at least two radial transmission shafts are respectively parallelly arranged. The radial transmission shafts and the axial transmission shafts are crossed to form a testing machine rack for simultaneously testing at least two joint bearings. The testing machine rack is provided with at least two crossed positions which are formed by correspondingly intersecting the axes of the radial transmission shafts and the axes of the axial transmission shafts, and a bearing clamp is correspondingly arranged at each crossed position. The composite swing type joint bearing service life testing machine can simultaneously test at least two joint bearings, and the service life testing efficiency of the joint bearings is improved.

Owner:HENAN UNIV OF SCI & TECH

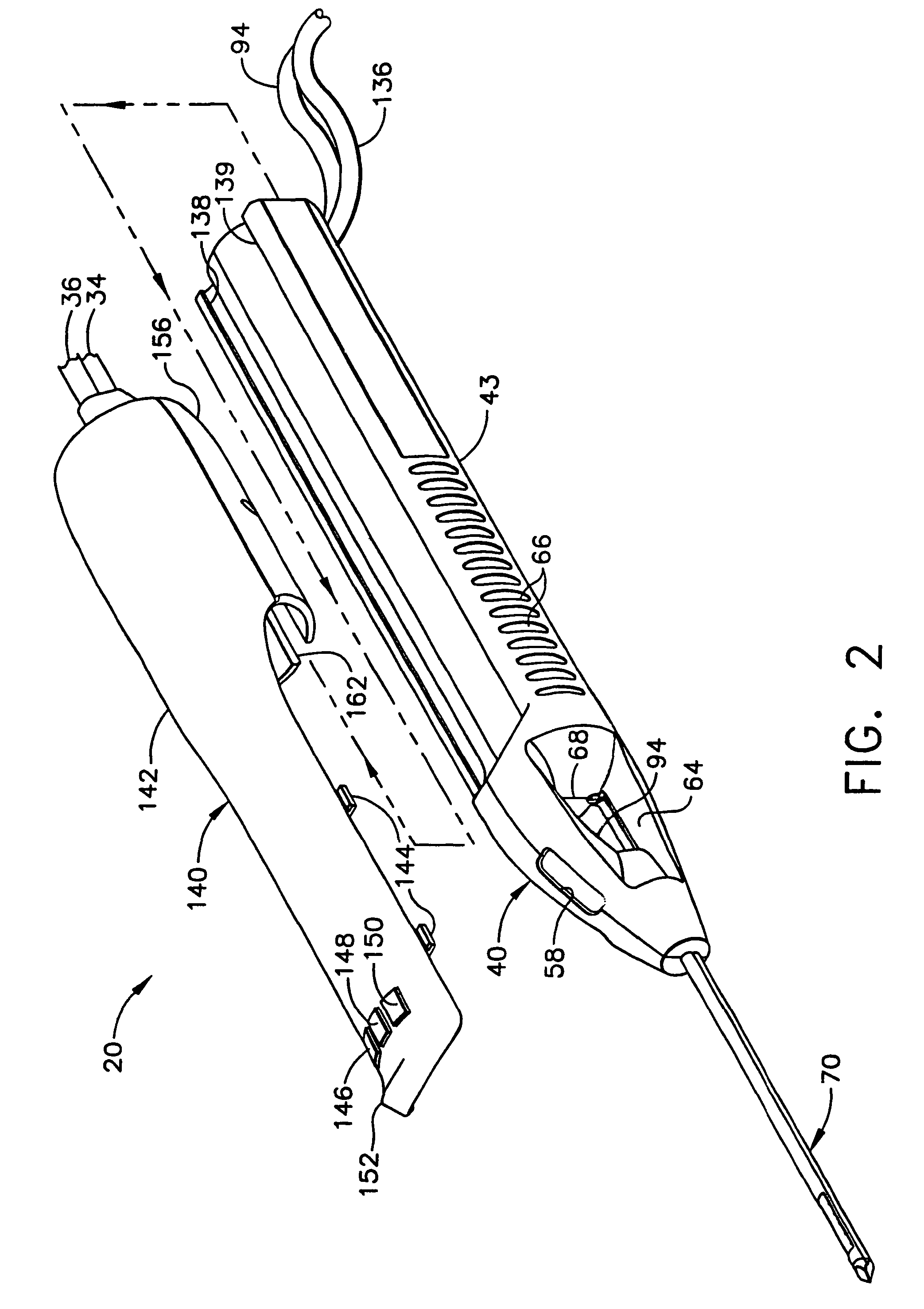

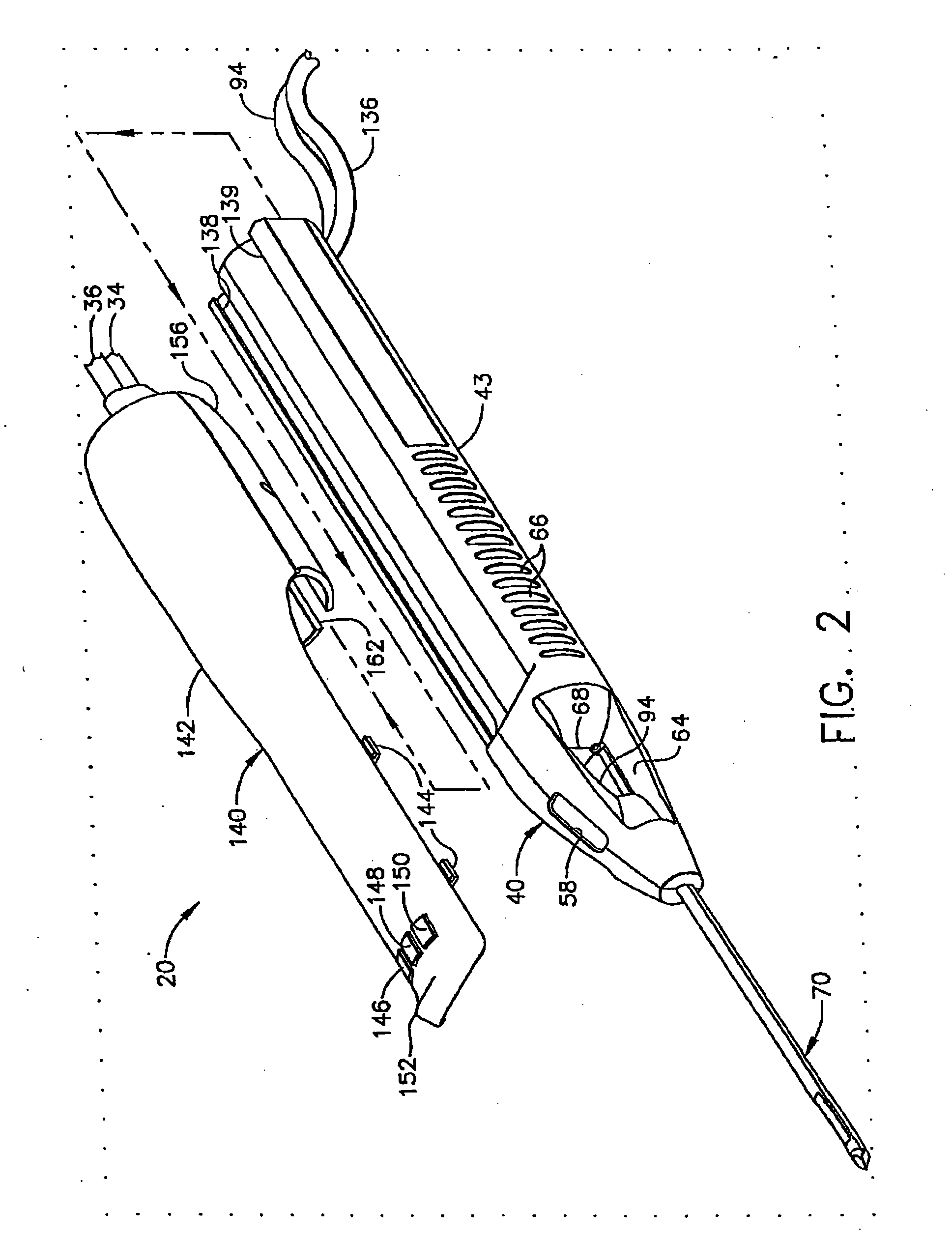

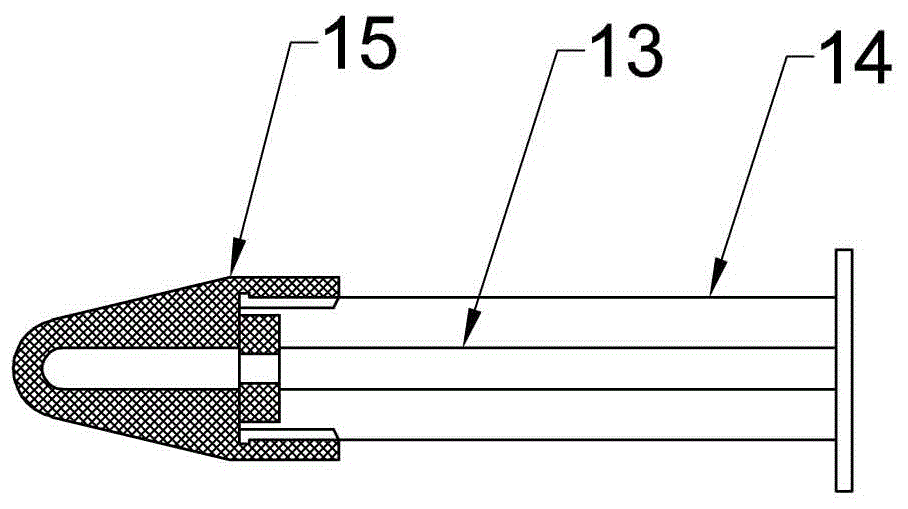

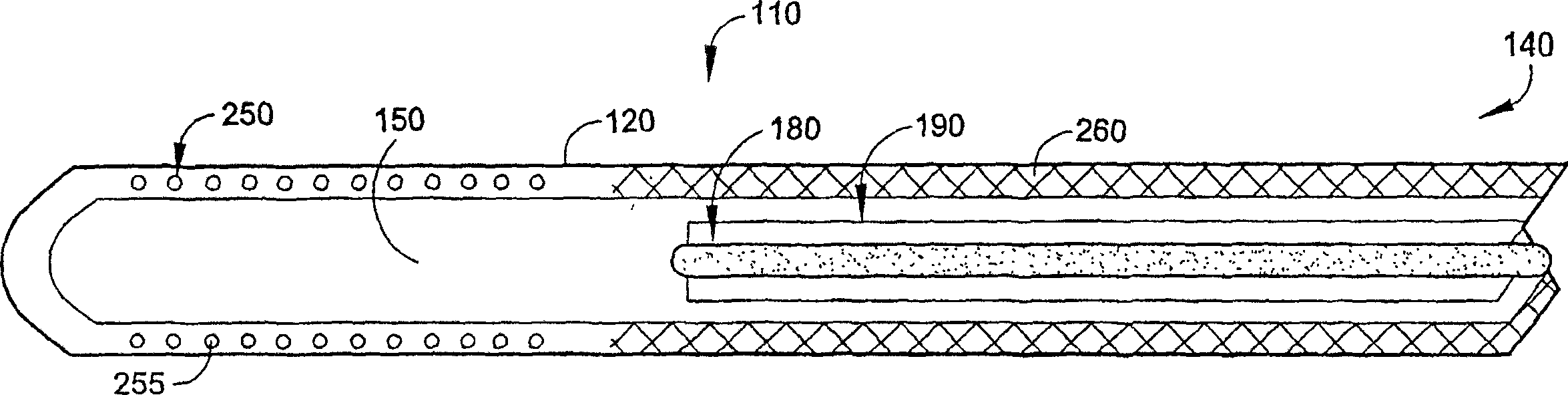

Surgical device for the collection of soft tissue

InactiveUS20110125055A1Surgical needlesVaccination/ovulation diagnosticsCollection systemBiopsy device

A biopsy device comprises a handpiece, a fluid collection system, and a power transmission source. The handpiece is configured for grasping by a single hand, and is independently manipulatable by hand for movement of the instrument toward and away from the patient. An elongated piercer extends from the distal end of the handpiece. The piercer has a sharpened distal end for entering the tissue and a port located proximal to the sharpened distal end for receiving a portion of tissue mass. An elongated cutter is disposed coaxially relative to a piercer lumen of the piercer. A distal blade of the cutter slides distally past the port of the piercer to sever the tissue portion drawn into the port by vacuum. The handpiece further comprises a holster for detachably connecting a cutter rotational transmission and a cutter axial transmission to the power transmission source.

Owner:DEVICOR MEDICAL PROD

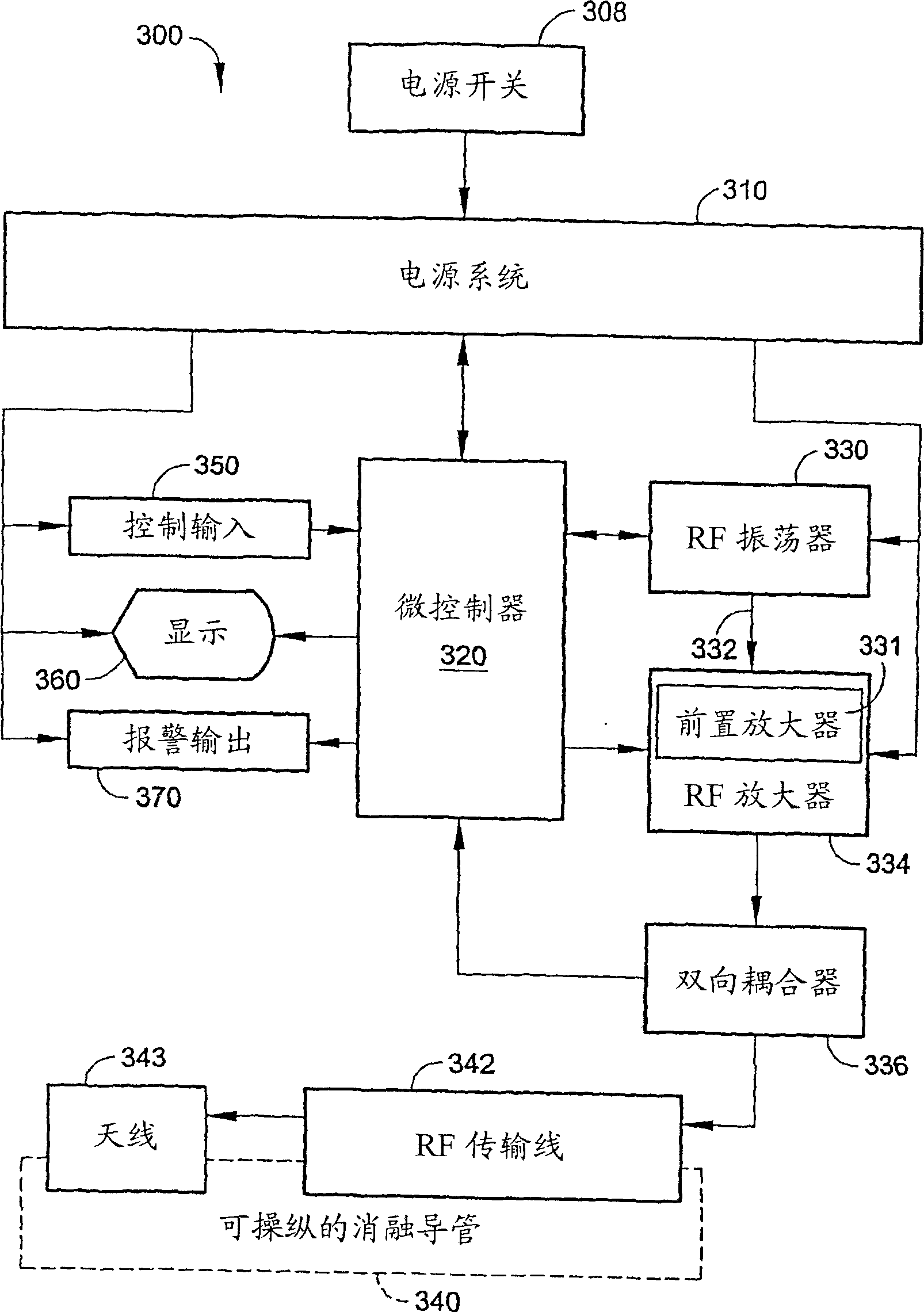

Radio-frequency based catheter system and method for ablating biological tissues

An improved radio-frequency based catheter system and method for ablating biological tissues within the body vessel of a patient comprises a radio-frequency ('RF') generator for selectively generating high frequency energy in a deployable catheter having a RF co-axial transmission line with a hollow lumen, a RF antenna mounted on the distal portion of the catheter, and steering control lines in the lumen of the transmission line for steering catheter while being inserted into the body vessel and for deflecting the RF antenna to accommodate the contour of the body vessel where tissue ablation is needed.

Owner:MEDWAVE INC

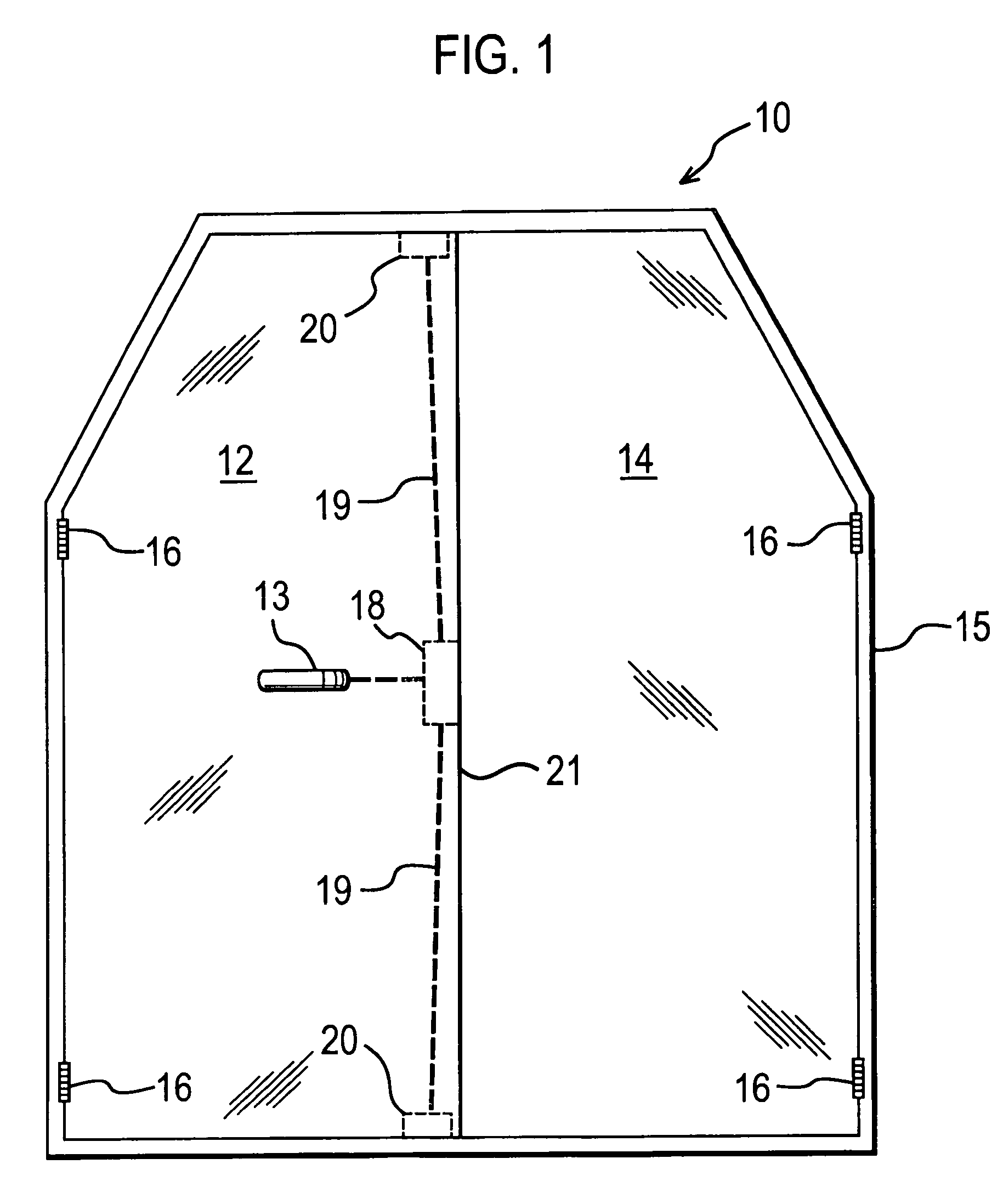

Movable flushing system for dish-washing machine

InactiveCN103815853AQuick washComprehensive cleaningTableware washing/rinsing machine detailsDriving currentAutomatic control

The invention provides a movable flushing system for a dish-washing machine. An automatic control technology is adopted to realize accurate fixed-point and fixed-distance movable cleaning. The movable flushing system is arranged in a dish-washing machine shell, is used for flushing washed objects, and comprises a first axial flushing device arranged on the inner wall of the machine shell; the first axial flushing device comprises a first control unit, a first motor which is connected with the first control unit and is used for receiving driving current transmitted by the first control unit, a first axial transmission device which is connected with the first motor and is driven to move axially by using the first motor, first guiding devices arranged on both sides of the first axial transmission device, and a first spray head connecting device which is arranged on the first axial transmission device and moves axially according to the first axial transmission device; the first spray nozzle connecting device is in sliding fit with the first guiding device. By adopting the movable flushing system, the washed objects can be flushed movably from multiple angles and multiple directions, the washing time is shortened, the water consumption is saved, and the energy saving and emission reduction are facilitated.

Owner:傅宇宙

Axial-flow fluid vortex generator used on oil and gas pipeline

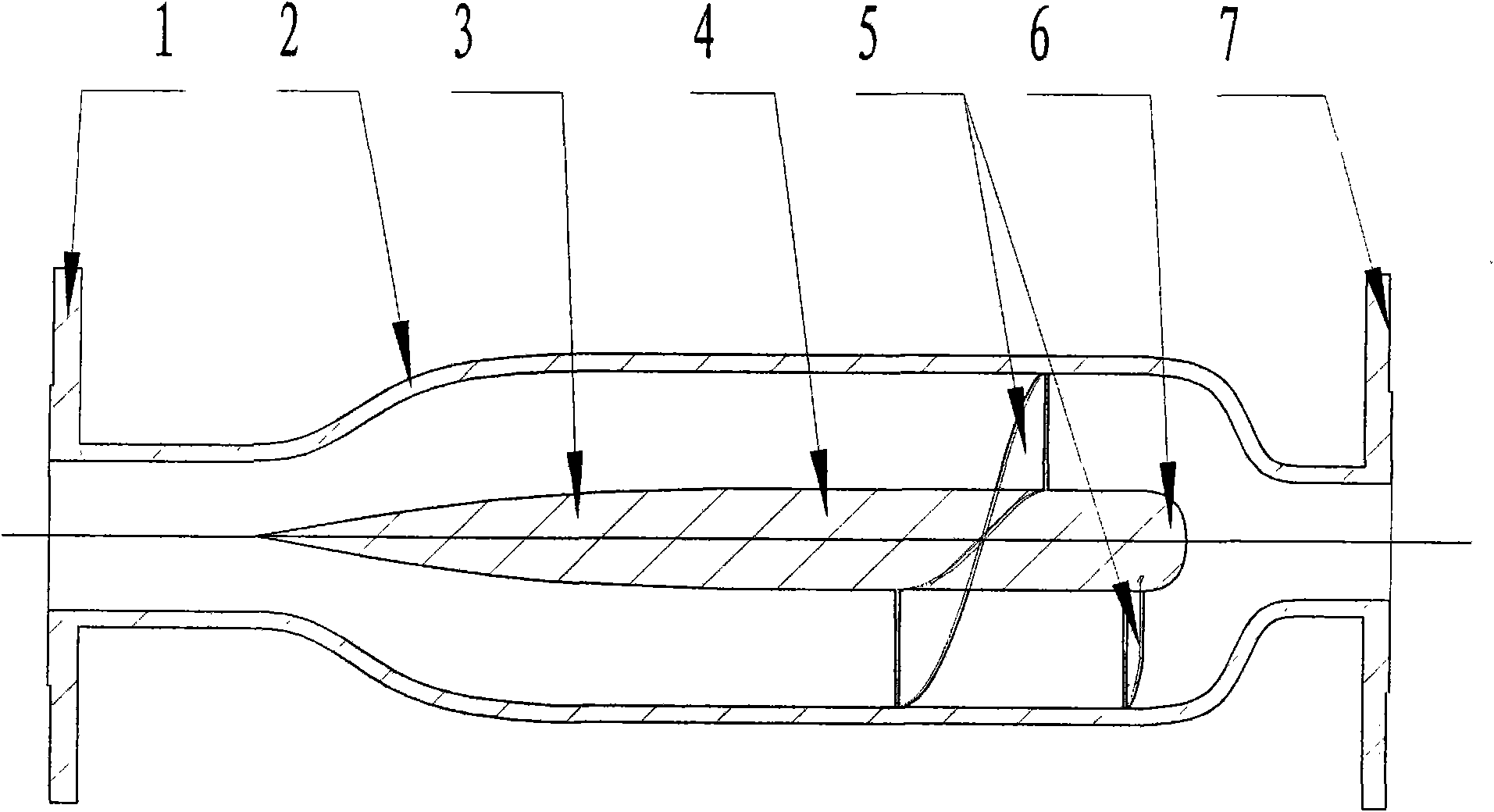

InactiveCN101603628AReduce workloadReduce transmission kinetic energy lossPipeline systemsWaxDevice form

The invention relates to a conveying device for the fluid of the mixture of oil and gas. The axial-flow fluid vortex generator used on oil and gas pipelines is formed by connecting an inlet end, a housing and an outlet end; a group of devices formed by connecting an inlet flow guiding cone, a helicallobe, a midbody and an outlet flow guiding cone are arranged in the housing; an inner end of the helicallobe is fixed on the midbody, and an outer end thereof is fixed on the housing. The invention ensures that the mixture fluid can flow in a pipeline in the modes of spiral and layering, so that compared with the traditional pure axial transmission, the deposition amount of paraffin and encrustment transmitted by the pipeline is decreased by more than 90%; meanwhile, the workload on cleaning paraffin precipitation sediment incrustation is reduced, the transmission kinetic energy loss is reduced, the transmission efficiency is improved, and the transmission cost is reduced. Meanwhile, the invention is also suitable for transmitting the mixture fluid in the fields of chemical engineering, medicine, food and the like.

Owner:XIAN HUAYANG ENERGY TECH ENG

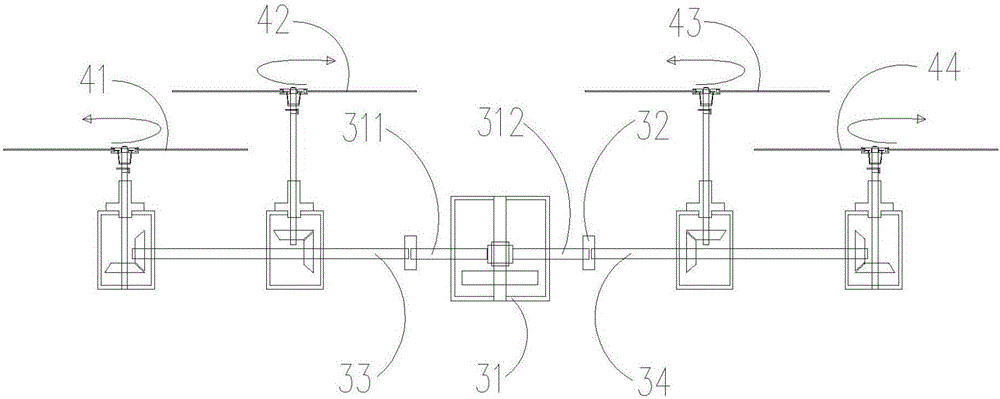

Ship model full circle swinging pushing device

InactiveCN103129730AMeet the installationSatisfy the propeller thrustSteering by propulsive elementsHorizontal transmissionDrive shaft

The invention relates to a ship model full circle swinging pushing device which is composed of an axial transmission mechanism and a circular rotating mechanism. The axial transmission mechanism comprises an upper section inner shaft which is arranged inside an installation base in a penetrating mode, one end of the upper section inner shaft is connected with a first servo motor, the other end of the upper section inner shaft is stretched out of the installation base and is connected one end of a lower section inner shaft, the other end of the lower section inner shaft is connected with a horizontal transmission shaft through a bevel gear, and the horizontal transmission shaft is provided with a propeller. The circular rotating mechanism comprises a circular transmission shaft, the periphery of the circular transmission shaft is connected with a worm gear and a worm, the worm is connected with the output end of a second servo motor, the circular transmission shaft is further connected with one end of an outer shaft through a cover board, and the other end of the outer shaft is matched with a shell on the periphery of the propeller. The ship model full circle swinging pushing device is compact in structure, and small and exquisite in size, can simultaneously achieve axial pushing of the propeller and circular 360-degree rotation of the propeller, meets requirements of installation of models in a water pond, pusher pushing force and locating tests, and obtains good testing effects.

Owner:中国船舶重工集团公司第七〇二研究所

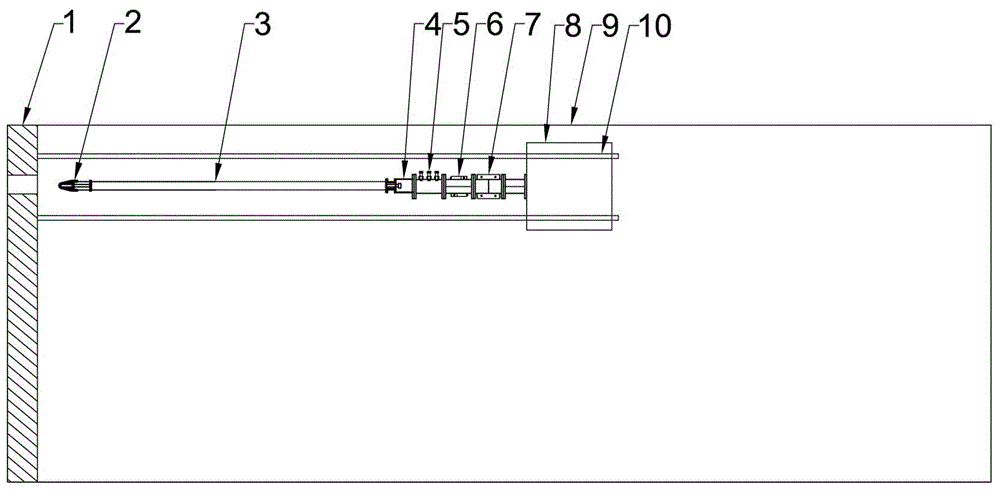

Ship propulsion shafting whirling vibration and twisting vibration simulation experiment device

The invention discloses a ship propulsion shafting whirling vibration and twisting vibration simulation experiment device. The experiment device comprises a pedestal, a motor, an inter-axial transmission mechanism, a whirling vibration shaft and a twisting vibration shaft; the motor is fixed to the pedestal, the whirling vibration shaft and the twisting vibration shaft are in parallel arranged above the pedestal; the inter-axial transmission mechanism is used for driving said two shafts, and comprises a combination wheel and inter-axial gears, and belts, gears or chains are driven as needed; the whirling vibration shaft is provided with an alignment flange, a counterweight disc, an adjustable displacement bearing and measurement interfaces; the twisting vibration shaft is provided with a shock excitation motor, universal joints, an universal joint angle control apparatus and measurement interfaces, and the rotor of the shock excitation motor is connected to the shaft and used for simulating and generating twisting vibration. The experiment device is simple in structure and strong in pertinence, and can be applied to simulation study of shafting whirling vibration and twisting vibration and impact of shafting alignment status and transmission manner to whirling vibration and twisting vibration.

Owner:WUHAN UNIV OF TECH

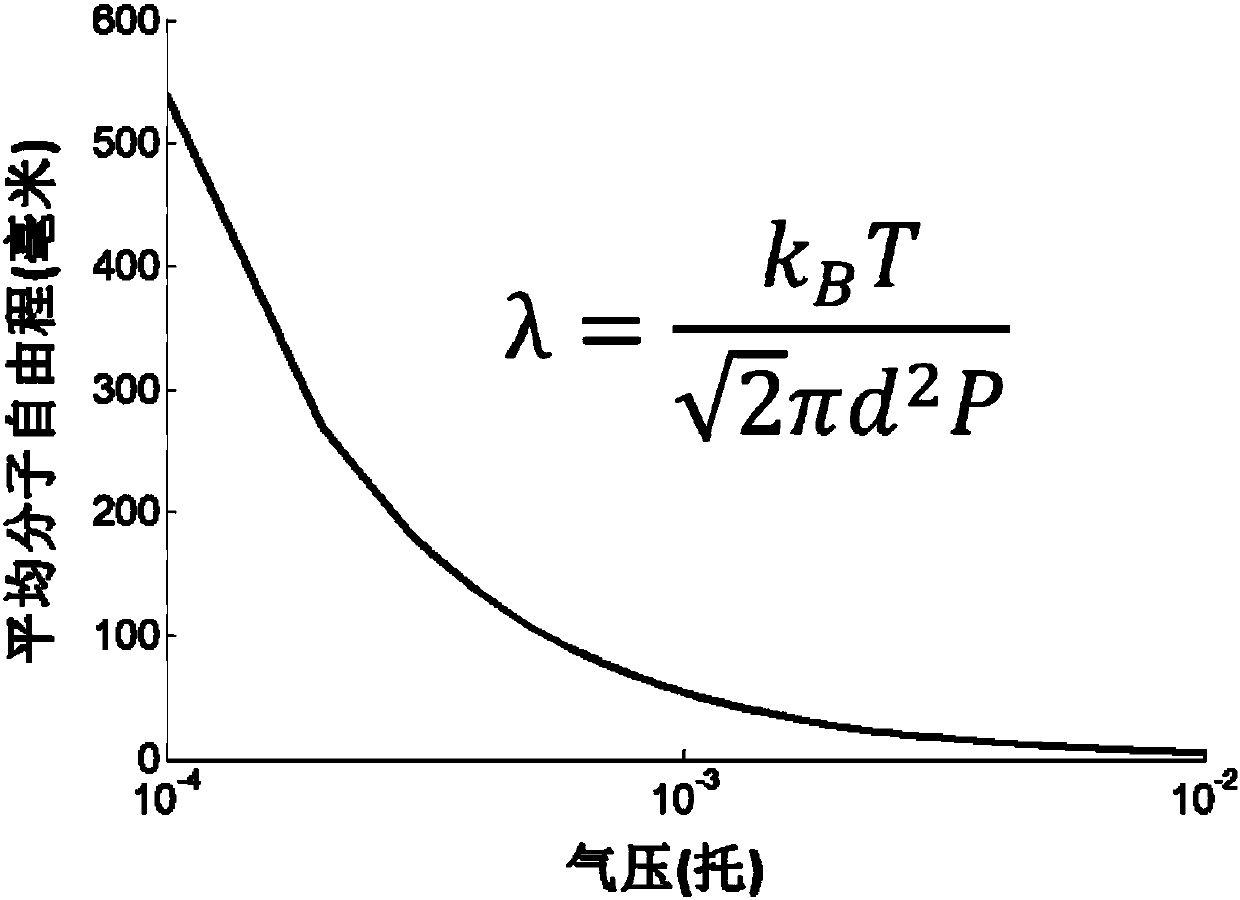

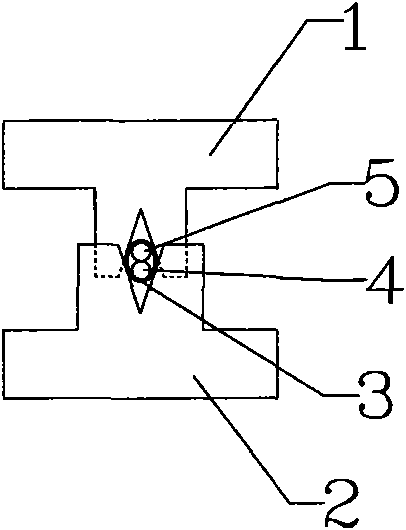

Mass spectrometer

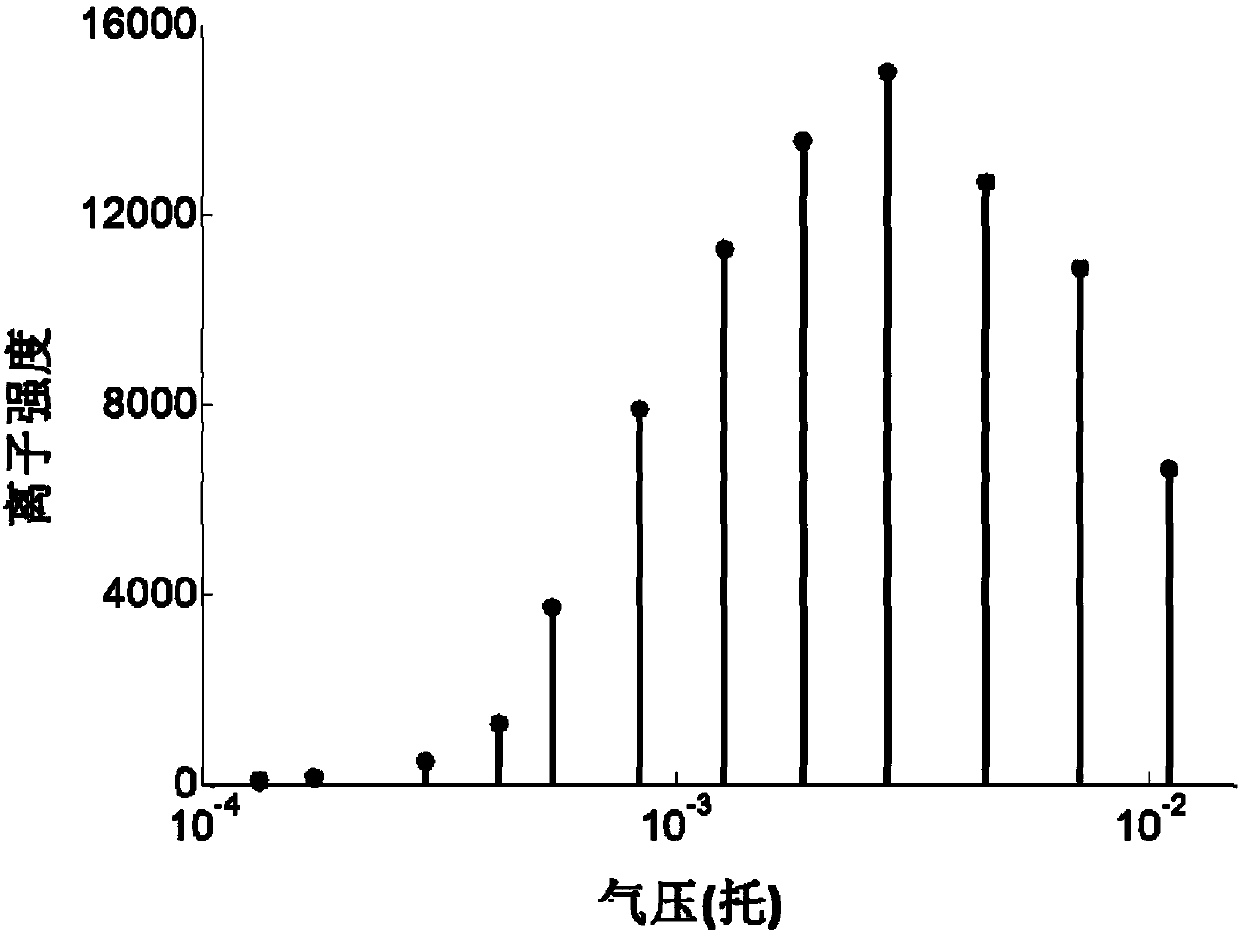

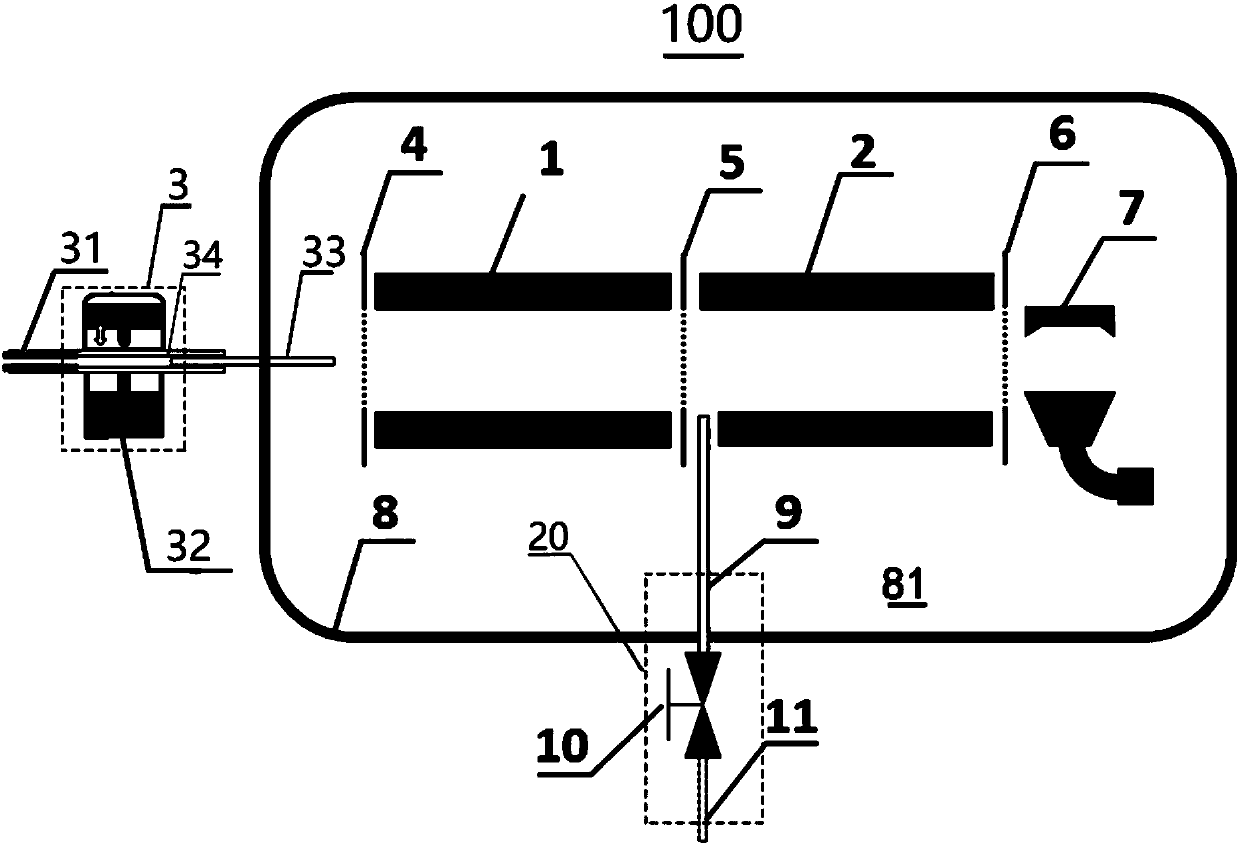

ActiveCN107799384AImprove axial transmission efficiencyStability-of-path spectrometersTube vacuum systemsMass analyzerAtmospheric pressure

The invention discloses a mass spectrometer. The mass spectrometer comprises a cavity structure, an air pressure adjustment apparatus, a vacuumizing apparatus and an ion detector, wherein the cavity structure defines a vacuum cavity with a sample inlet; a first ion trap and a second ion trap in the vacuum cavity form mutually connected ion channels; the inlet ends of the ion channels are oppositeto the sample inlet; a first electrode is arranged at the front end of the first ion trap; a second electrode is arranged at the back end of the second ion trap; a third electrode is arranged betweenthe first ion trap and the second ion trap; the air pressure adjustment apparatus is arranged on the cavity structure and used for adjusting the air pressure value in the vacuum cavity; the vacuumizing apparatus is arranged on the cavity structure and used for performing vacuumizing in the vacuum cavity; and the ion detector is arranged in the vacuum cavity and used for performing quality analysison ions in the ion channels. According to the mass spectrometer provided by the embodiment of the invention, the air pressure adjustment apparatus used for adjusting the air pressure in the vacuum cavity is arranged on the cavity structure, so that the air pressure in the vacuum cavity can be kept within a certain range, thereby improving ion axial transmission efficiency.

Owner:TSINGHUA UNIV +1

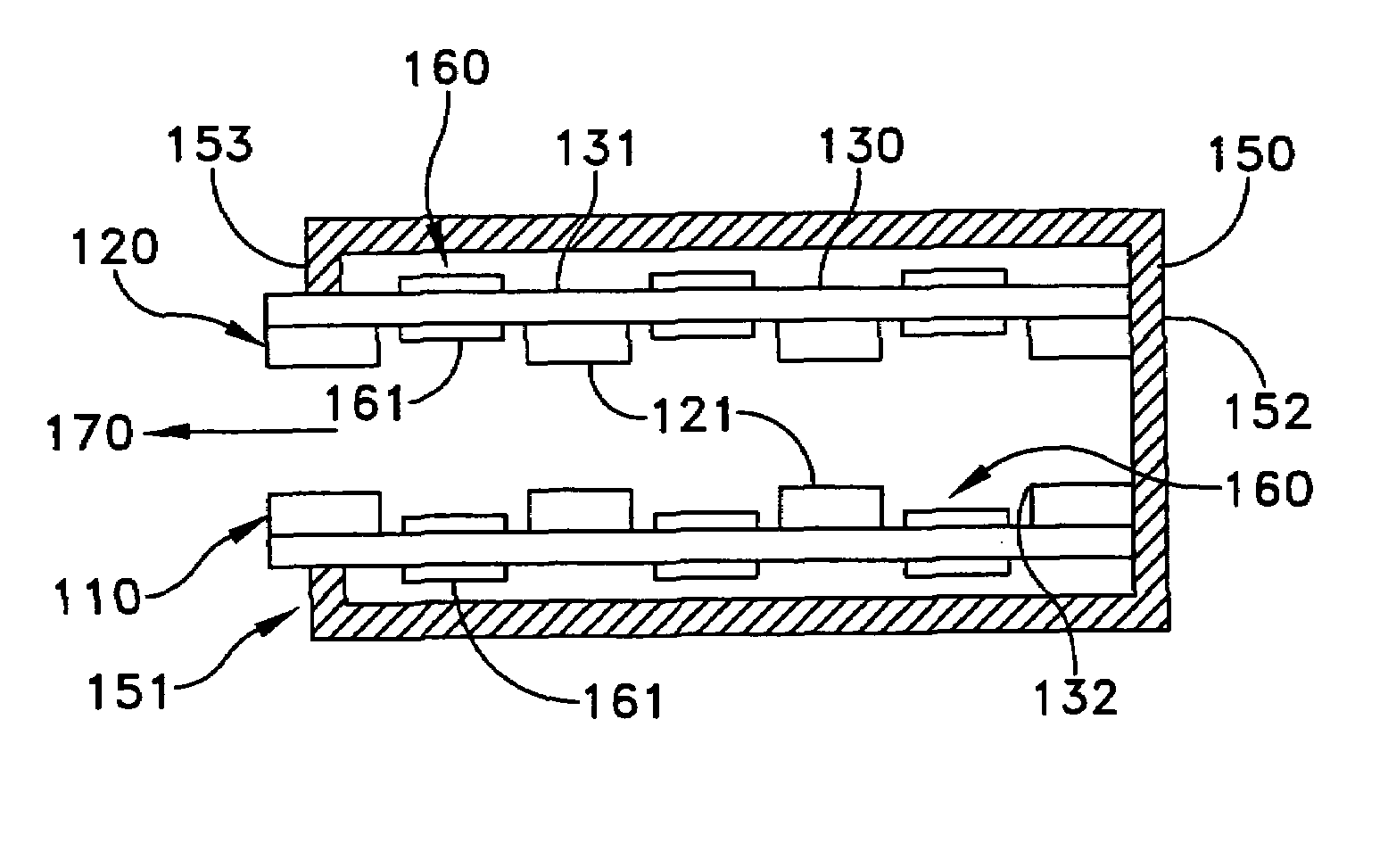

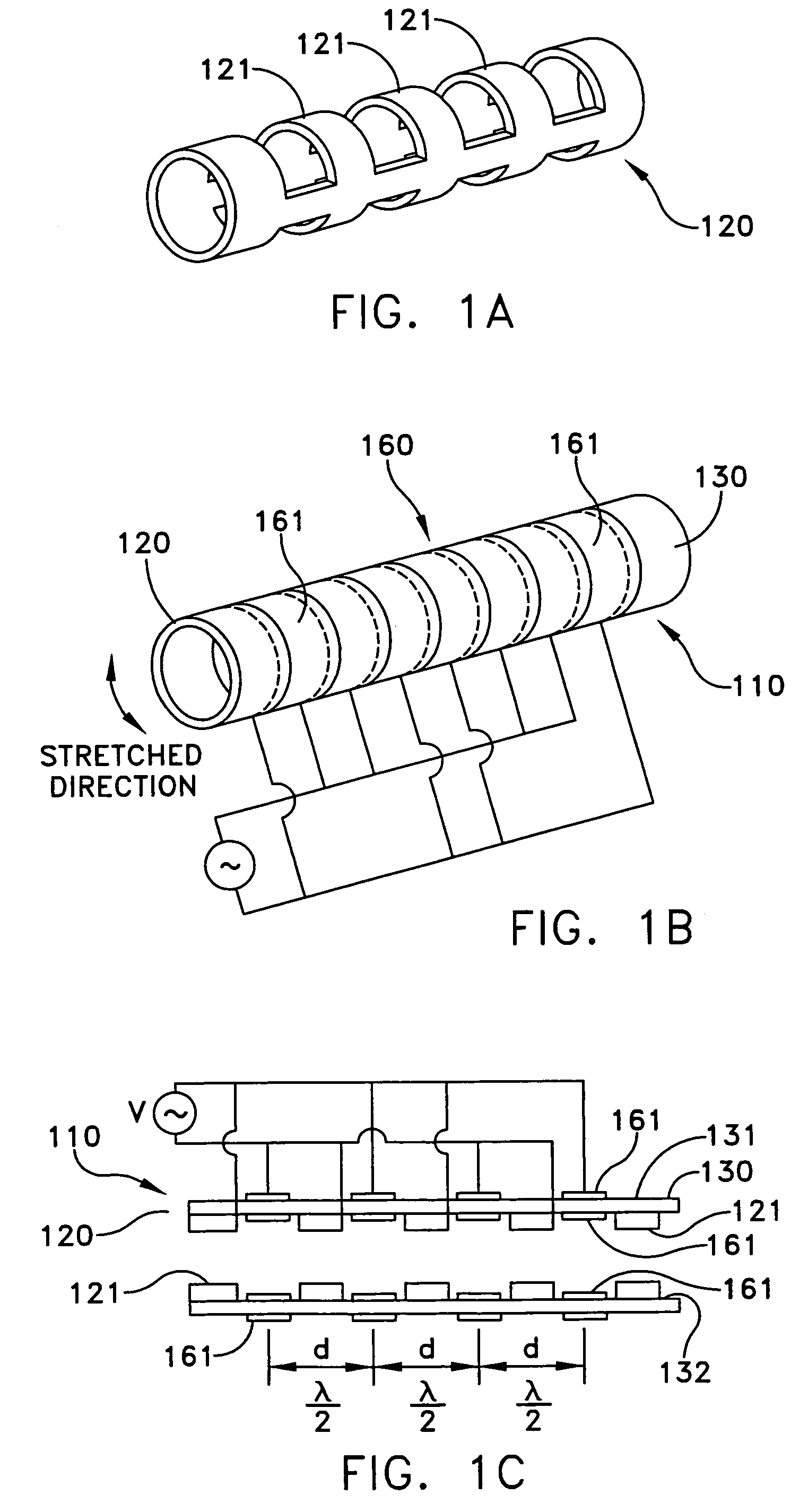

Handheld device having ultrasonic transducer for axial transmission of acoustic signals

InactiveUS7218040B2Ultrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesUltrasonic sensorTransducer

A handheld stylus having an elongated housing, a writing and drawing implement disposed within the housing and including a tip extending through an opening at an end of the housing where ultrasonic waves radiate therefrom and are used for determining a position of the stylus; and at least one ultrasonic transducer disposed within the housing. The transducer may be a cylindrical piezoelectric transducer having a holder and a cylindrical piezoelectric film spanning between at least two spaced apart cylindrical surfaces of the holder, or a flat transducer having a diaphragm, and a piezoelectric material disposed on a surface of the diaphragm.

Owner:MEASUREMENT SPEC

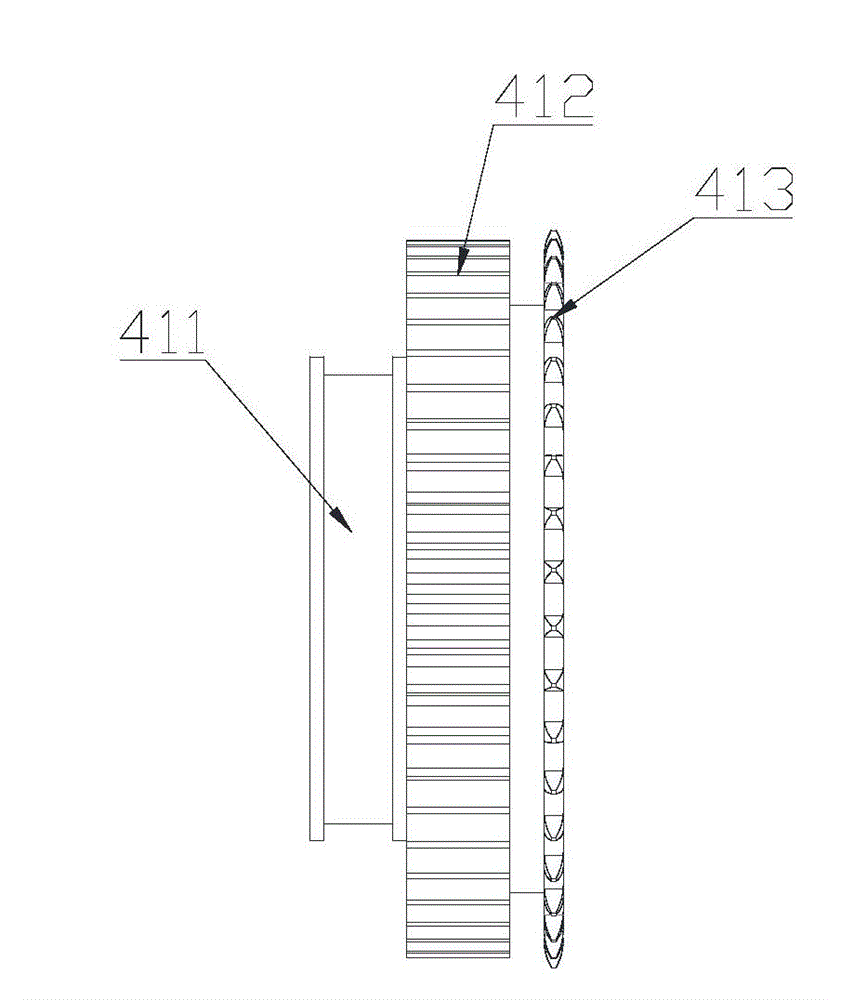

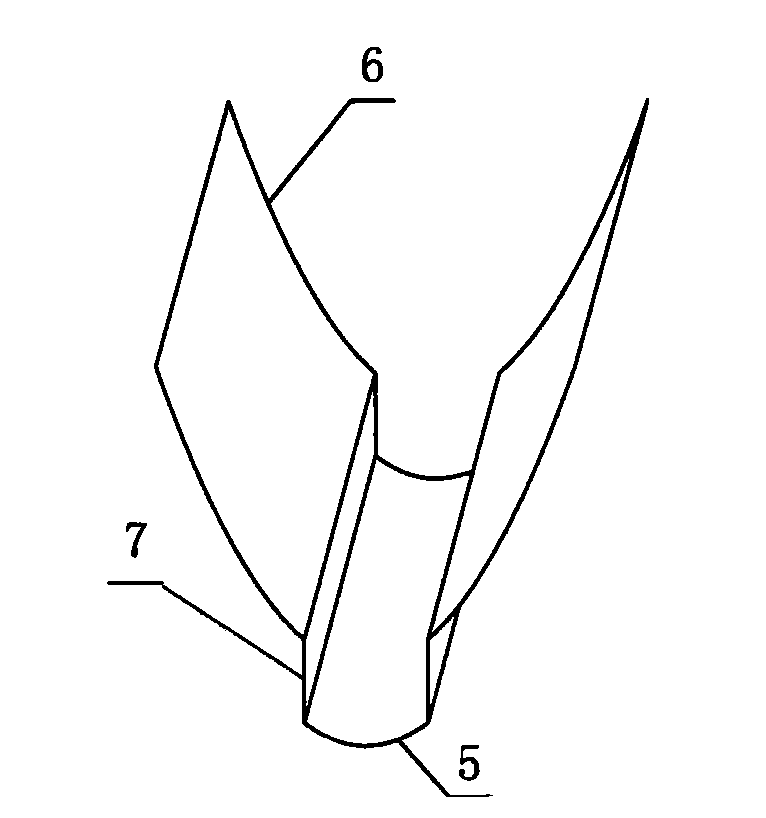

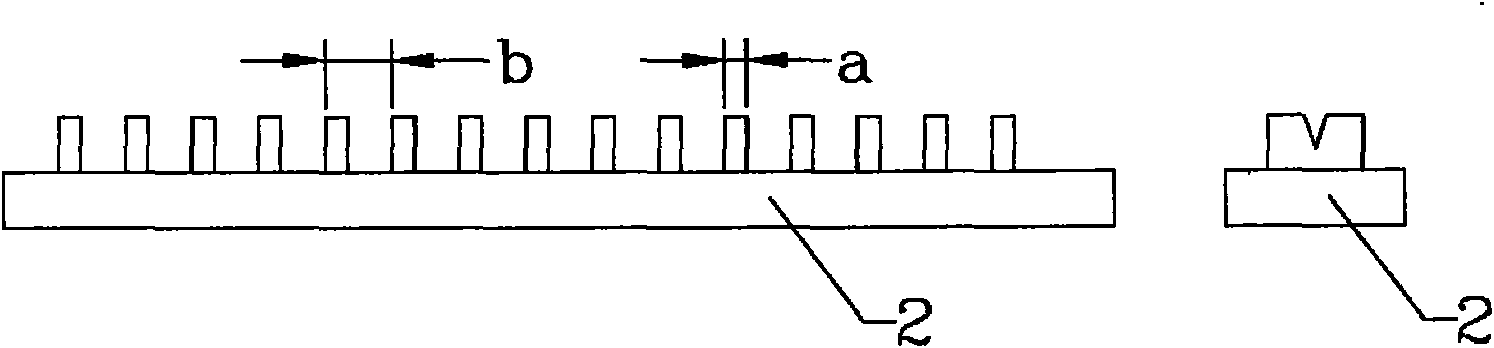

Continuous tea twisting machine

ActiveCN102771583ASolve cleaning problemsEasy to cleanPre-extraction tea treatmentCircular discDrive shaft

The invention relates to a continuous tea twisting machine, which comprises a frame, a twisting device and a transmission mechanism, wherein the twisting device comprises a feeding hopper, a material sweeper, a twisting core, a shell and a kneading plate; the feeding hopper and the material sweeper are arranged above the twisting core; the material feeder is arranged inside the feeding hopper; the twisting core is arranged in a space formed by the shell and the kneading plate; the kneading plate is arranged below the twisting core; a discharge hole is arranged at the bottom part of the twisting plate; the center of the discharge hole deviates from the center of the kneading plate; the kneading core is composed of a cone and a disk of which the middle part sinks; spiral guide-leaf plates are arranged at the upper part and middle part of the twisting core; a spiral guide-leaf rib is arranged at the bottom part of the twisting core; the feeding hopper and the material sweeper form a primary conglobation area; the upper part of the twisting core and the shell form a kneading transition area; the bottom part of the twisting core and the kneading plate form a twisting forming area; the shell is vertically halved; the left and right halves can be opened; the kneading plate can be opened downwards; an axial transmission shaft is arranged at the upper end part of the twisting core; and a bearing block of the transmission shaft is arranged on the frame, and the transmission shaft and the transmission mechanism are in transmission connection.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

End fitting for a cable

An end fitting for a cable provides for the axial transmission of an input movement or an output movement to or from a moveable body relative to a fixed body. The end fitting has a pivot portion spaced from a clip portion. The pivot portion is engageable with a pivot region of the fixed body to allow the end fitting to rotate about the pivot portion to rotatably engage the clip portion with a clip region of the fixed body, securing the cable to the fixed body.

Owner:MERITOR TECH

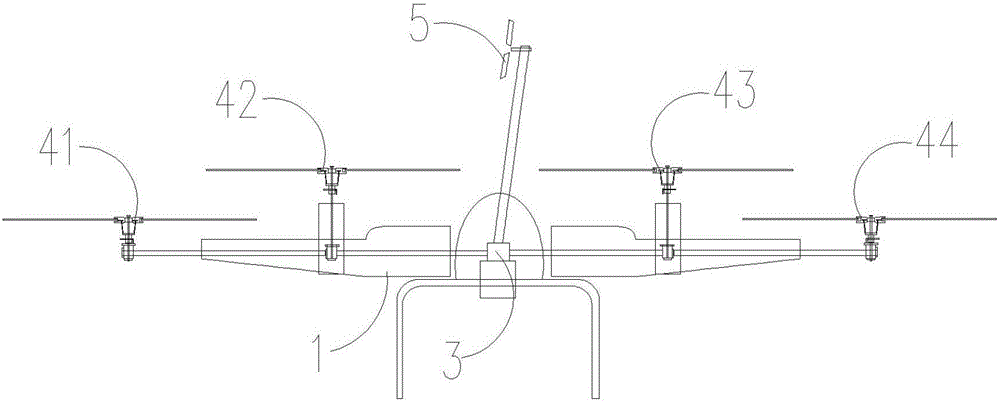

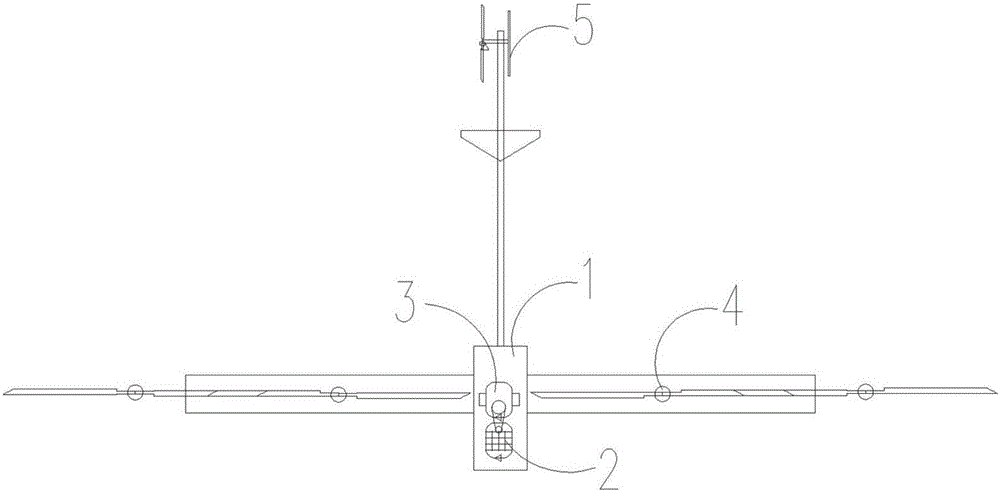

Oil-drive transverse type four-rotor agricultural plant protection unmanned helicopter

The invention provides an oil-drive transverse type four-rotor agricultural plant protection unmanned helicopter. A rotor mechanism is composed of four rotors. The four rotors are fixedly and transversely arranged on the two sides of a fuselage correspondingly. Every two rotors on the two sides are symmetrical in position and structure along the central axis of the fuselage. The same axial transmission shaft is adopted by the four rotors for constant-speed transmission. The rotating directions of the two rotors on each side are opposite, and the rotating directions of every two rotors in symmetrical positions of the two sides are opposite. The oil-drive transverse type four-rotor agricultural plant protection unmanned helicopter has the beneficial effects that the rotors of the fuselage are arranged in a balanced mode, the transmission speed is stable, the gravity range is wide, the helicopter can fly for work in windy environments, and the flight performance is good; the rotor mechanism is transversely arranged, the rotating speeds in symmetrical positions of the rotor mechanism are the same, the rotating directions in symmetrical positions of the rotor mechanism are opposite, and thus counter torsion generated by high-speed rotation of the rotors is eliminated reasonably; and through the transverse overlapping arrangement way, vortex disturbance of blade tips of the rotors of the helicopter is eliminated, the influence on pesticide spraying of a spray lance is eliminated, and sprayed pesticides can fully act on plants through downward airflow, the pesticide application effect is improved, and the pesticide utilization rate is increased.

Owner:赵新宁

Double-layer turn-back driving finger mechanism

The embodiment of the invention provides a double-layer turn-back driving finger mechanism. A finger body and a finger rack are rotatably connected through a first rotating shaft; a motor is connected with a first gear; a screw and a nut are arranged on the lower portion of the finger rack, the screw is connected with a second gear, and the nut is arranged on the lower portion of the finger body, connected with the finger body through a flexible connecting part or a bendable connecting part and used for driving the finger body to rotate relative to the finger rack through moving of the nut in the axial direction; and a resetting mechanism is arranged in the connecting position of the finger body and the finger rack. According to the double-layer turn-back driving finger mechanism, a double-layer turn-back transmission structure is adopted, and the special design of the screw and the nut is matched, so that original output of a power source and driving output to the finger body are located on the two layers correspondingly, and accordingly the space occupied by axial transmission output is saved.

Owner:ZORPIA ROBOT CO LTD

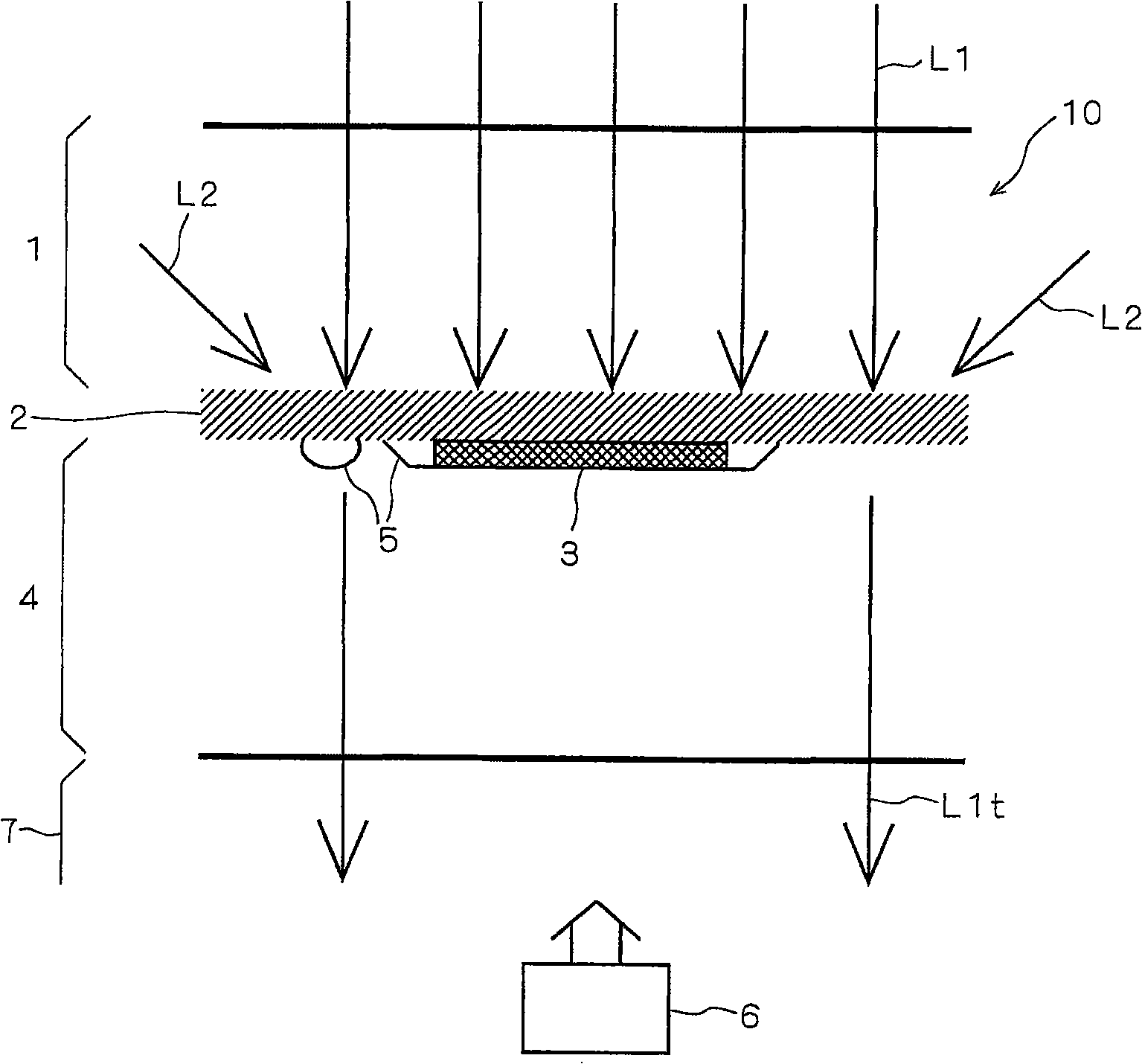

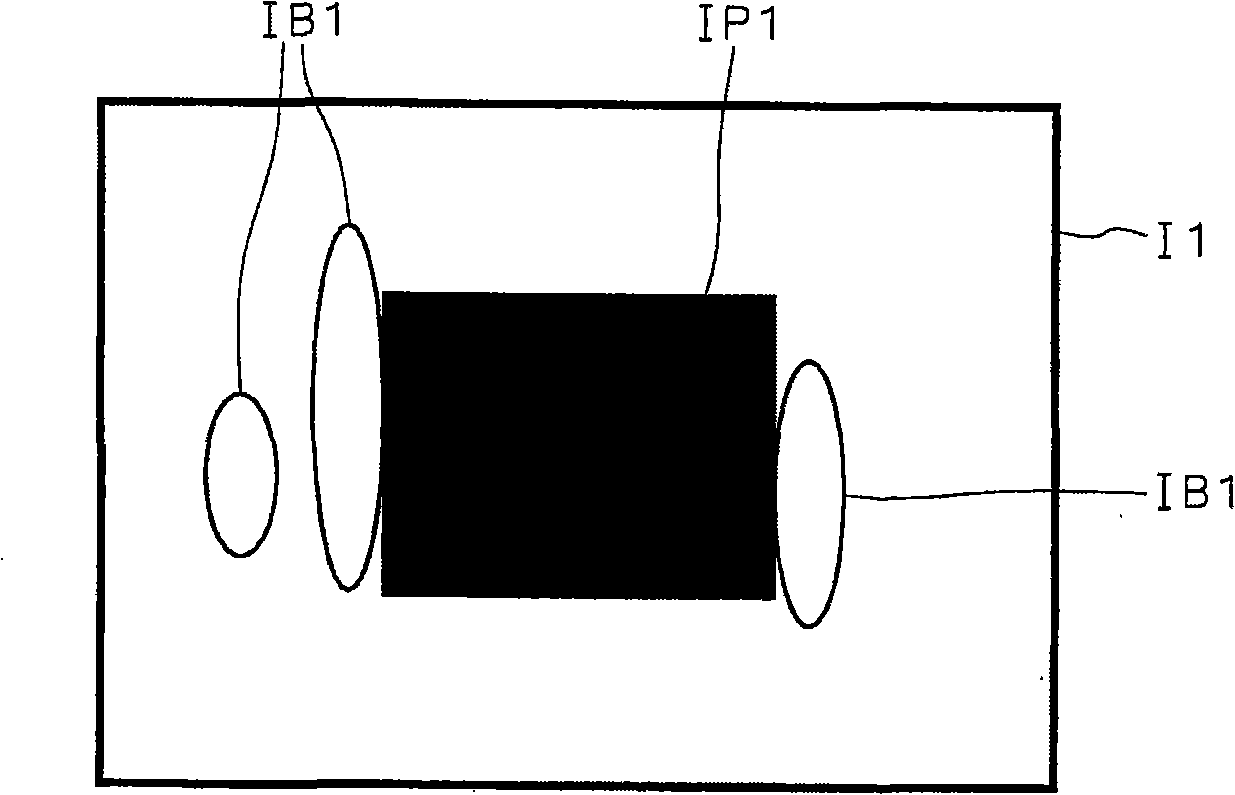

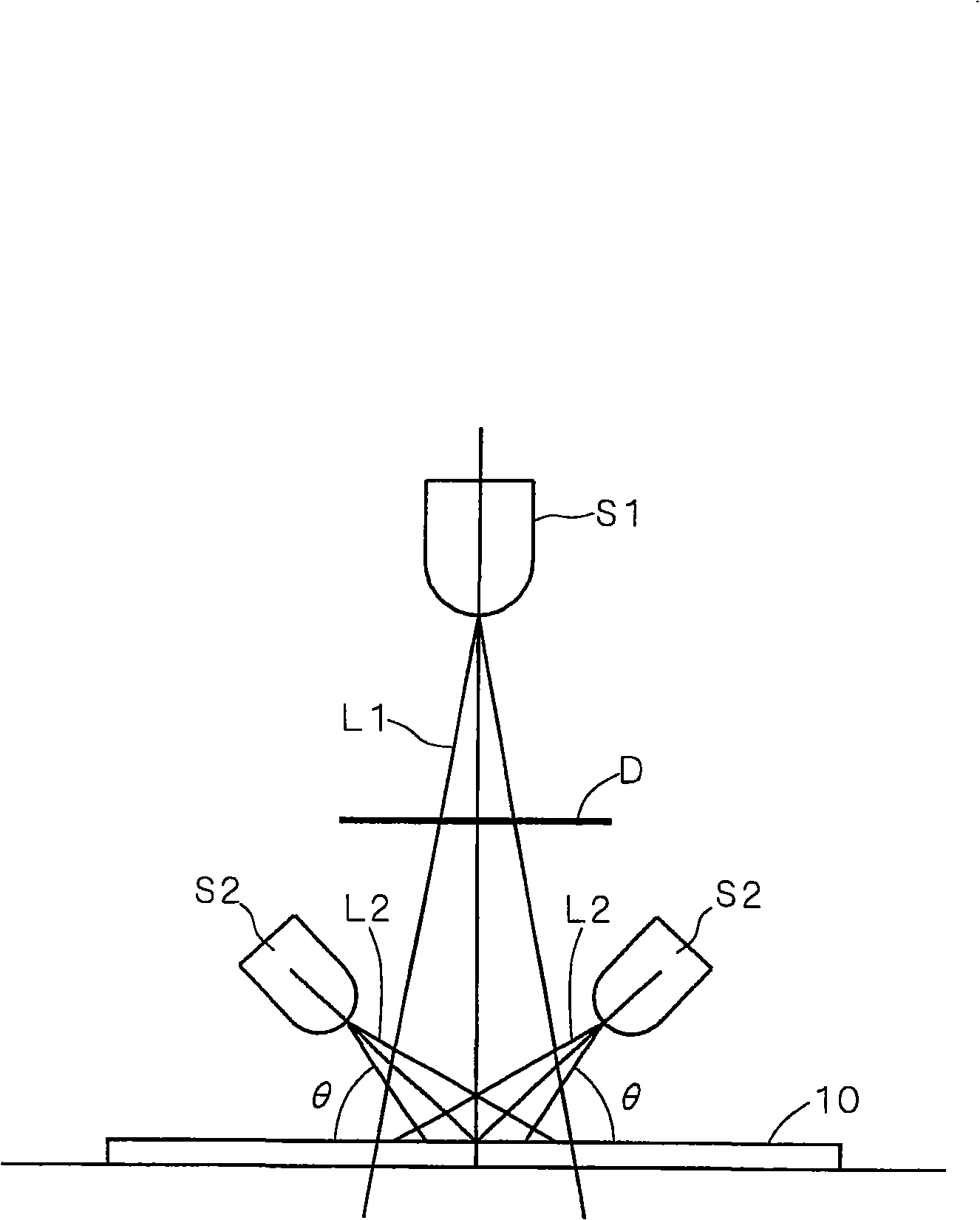

Laser processing device, positioning device; observing device and obserbing method

ActiveCN101274392AClearly determineClearly define the shapeLaser beam welding apparatusLaser processingObservation unit

An observation method and an observation device capable of definitely identifying an opaque device pattern formed on a transparent substrate in an observation image d are provided. A bonding plate (4) is bonded to one side formed with the device pattern (3), the transparent substrate is fixed at a transparent carrying table (7) above which an axial transmission irradiation light (L1) and an inclined transmission irradiation light (L2) irradiate in an overlap manner, and the observation is performed via the carrying table (7) by using a back observation unit (6) from the lower direction of the carrying table (7); in the observation image, the dark (black) device pattern images and the bright part other than the device pattern images are observed corresponding to the device pattern (3). Furthermore, the part corresponding to bubbles are quite bright such that the shape of the device pattern (3) can be definitely determined in the observation image.

Owner:MITSUBOSHI DIAMOND IND CO LTD

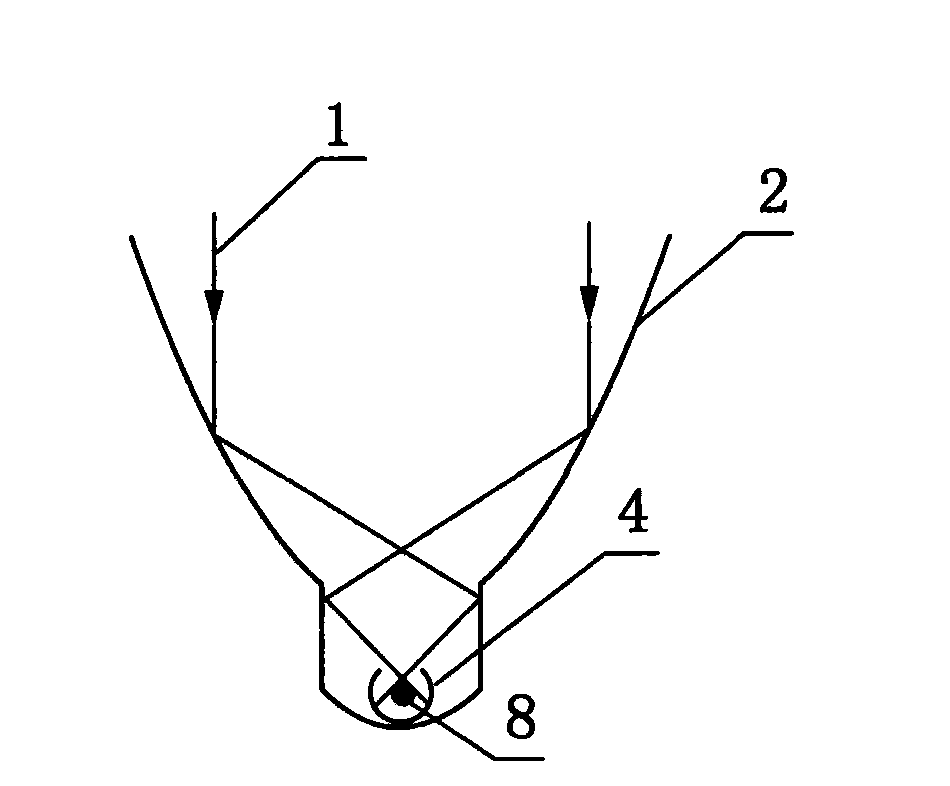

Trough-type consequent focus solar condensator for axial light transmitting

InactiveCN101581502AEasy to receivePromote conversionSolar heating energySolar heat devicesLight pipeLight guide

The invention provides a trough-type consequent focus solar condensator for axial light transmitting, belonging to the technical field of solar condensing and solar medium-high temperature heat collection. The trough-type consequent focus solar condensator is formed by connecting a trough-type consequent condensator, a light guide, a light pipe and a heat collector, etc. After entering the trough-type consequent condensator, the sunlight is reflected by the inner surface of the trough-type consequent condensator and focuses on the focus line of the trough-type consequent condensator; the outer wall of the light guide is provided with a gap through which the rays enter; the gap coincides with the focus line; the light enters the light guide via the gap, is projected on the inner wall of the light pipe after being reflected by the light guide, is reflected by inner wall of the light pipe and is axially transmitted, and finally enters the heat collector, thereby realizing solar high temperature collection. The trough-type consequent focus solar condensator can collect the sunlight with low energy-flux density in a very small zone after reflection and axial transmission so as to form high temperature heat energy.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

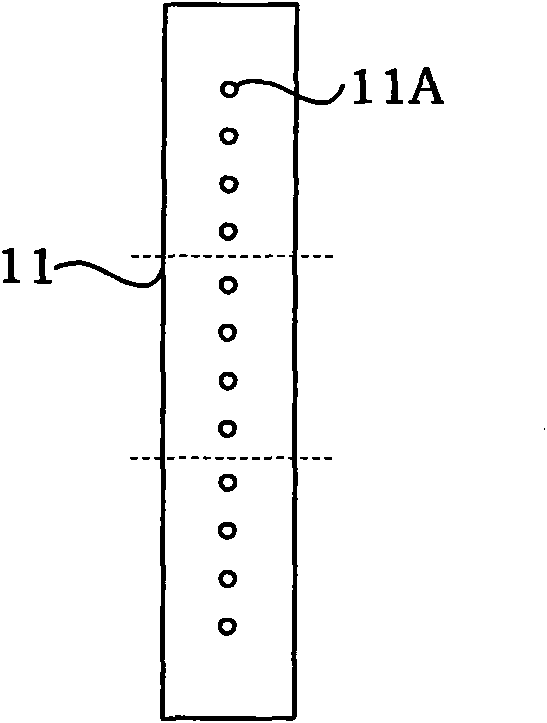

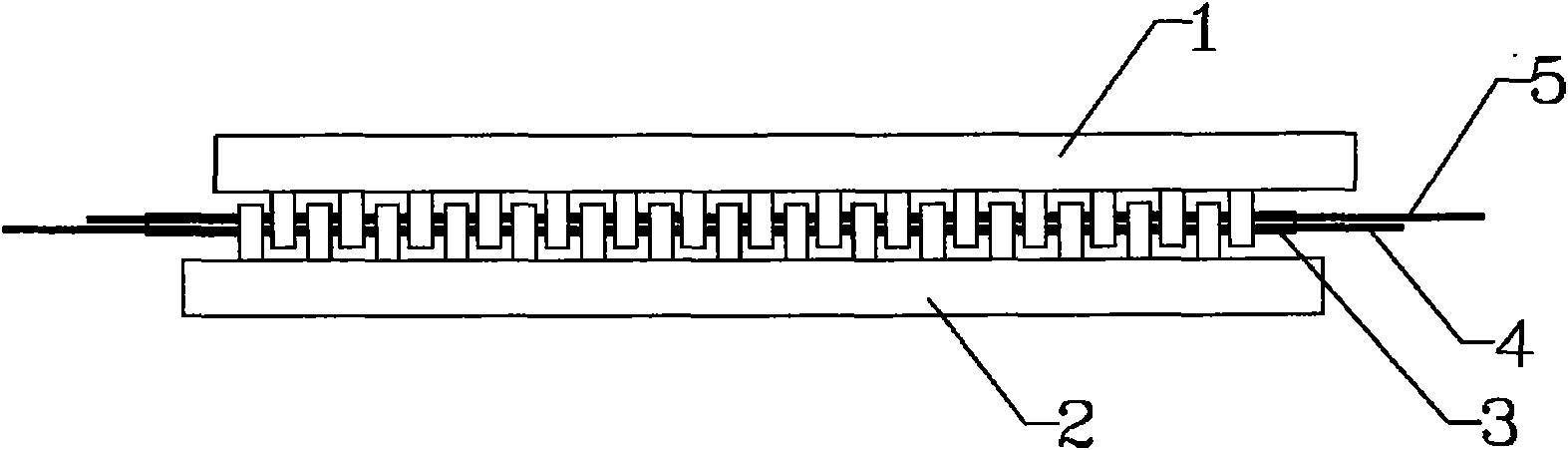

Reconfigurable long-period optical fiber grating coupler

InactiveCN101943766AWrite easyEasy to eraseCladded optical fibreOptical waveguide light guideFiberGrating

The invention discloses a reconfigurable long-period optical fiber grating coupler, comprising a force applying device and a plurality of tightly-arranged single-mode naked optical fibers arranged in a protective sleeve; and the force applying device periodically applies the radial pressure in the axial transmission direction of the single-mode naked optical fibers, thus gratings with the same space change period are written on the axial transmission direction of the single-mode naked optical fibers due to the microbend effect and the photoelastic effect. When the space period of the optical fiber grating leads a fiber core base mode and a high-order cladding mode to satisfy the phase matching condition, the fiber core base mode and the cladding modes between the optical fibers are coupled with each other; the cladding mode between the optical fibers are coupled with each other through the action of a vanishing field; the coupler function is realized on the plurality of naked optical fibers based on the coupling and period radial pressure; as being generated only by the external force, the long-period optical fiber grating is an optical fiber grating coupler which is easy to write and erase, can be used in the optical network to serve as a devices such as flexible add-drop multiplexers and optical power distributors and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Double-layer retracing driven two-stage rotation finger mechanism

The embodiment of the invention provides a double-layer retracing driven two-stage rotation finger mechanism. Base knuckles are connected with finger racks and connected with close knuckles, first pull rods are connected with the finger racks and connected with the close knuckles, and motors are connected with first gears of gear transmission sets; and screws and nuts are arranged below the finger racks, one ends of the screws are connected with second gears of the gear transmission sets, the first gears are in transmission connection with the second gears, the nuts are connected with the base knuckles, and reset mechanisms are arranged on the connecting positions of the base knuckles and the finger racks. According to the double-layer retracing driven two-stage rotation finger mechanism, a double-layer retracing transmission structure is adopted, and the special design of the screws and the nuts is matched, so that original output of a power source and driving output of finger bodies are located on two layers correspondingly, and the space occupied by axial transmission output is saved.

Owner:ZORPIA ROBOT CO LTD

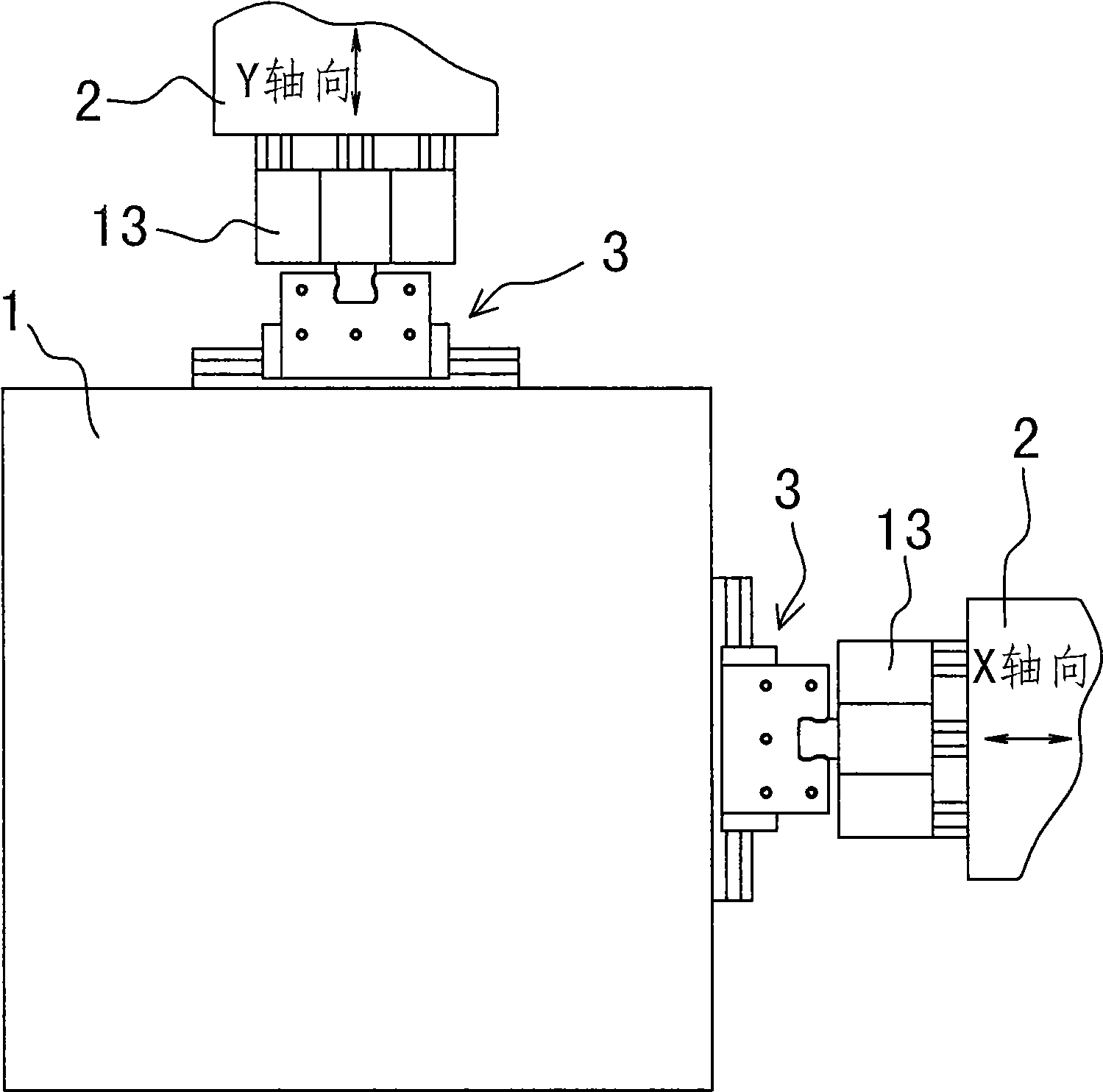

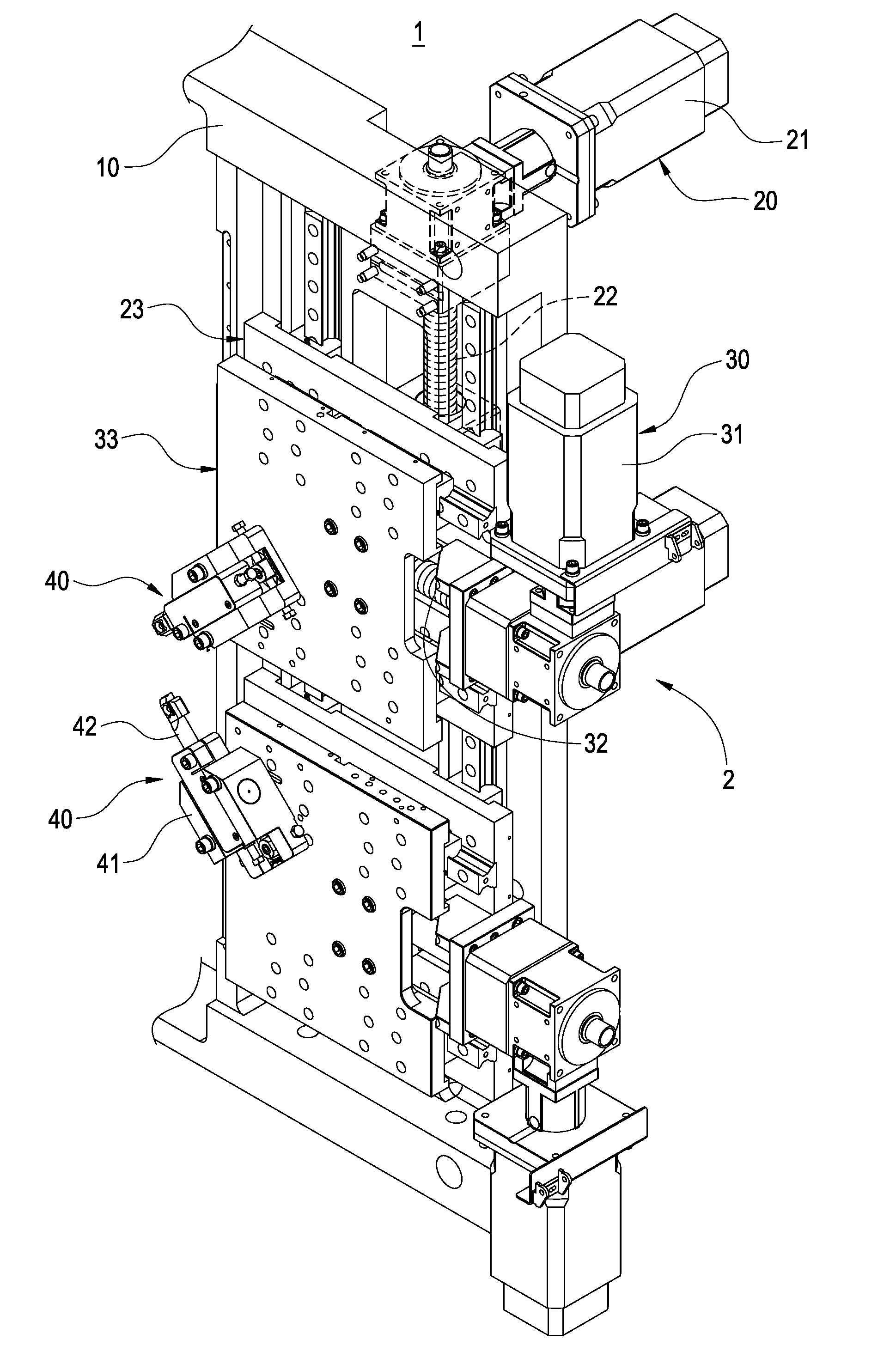

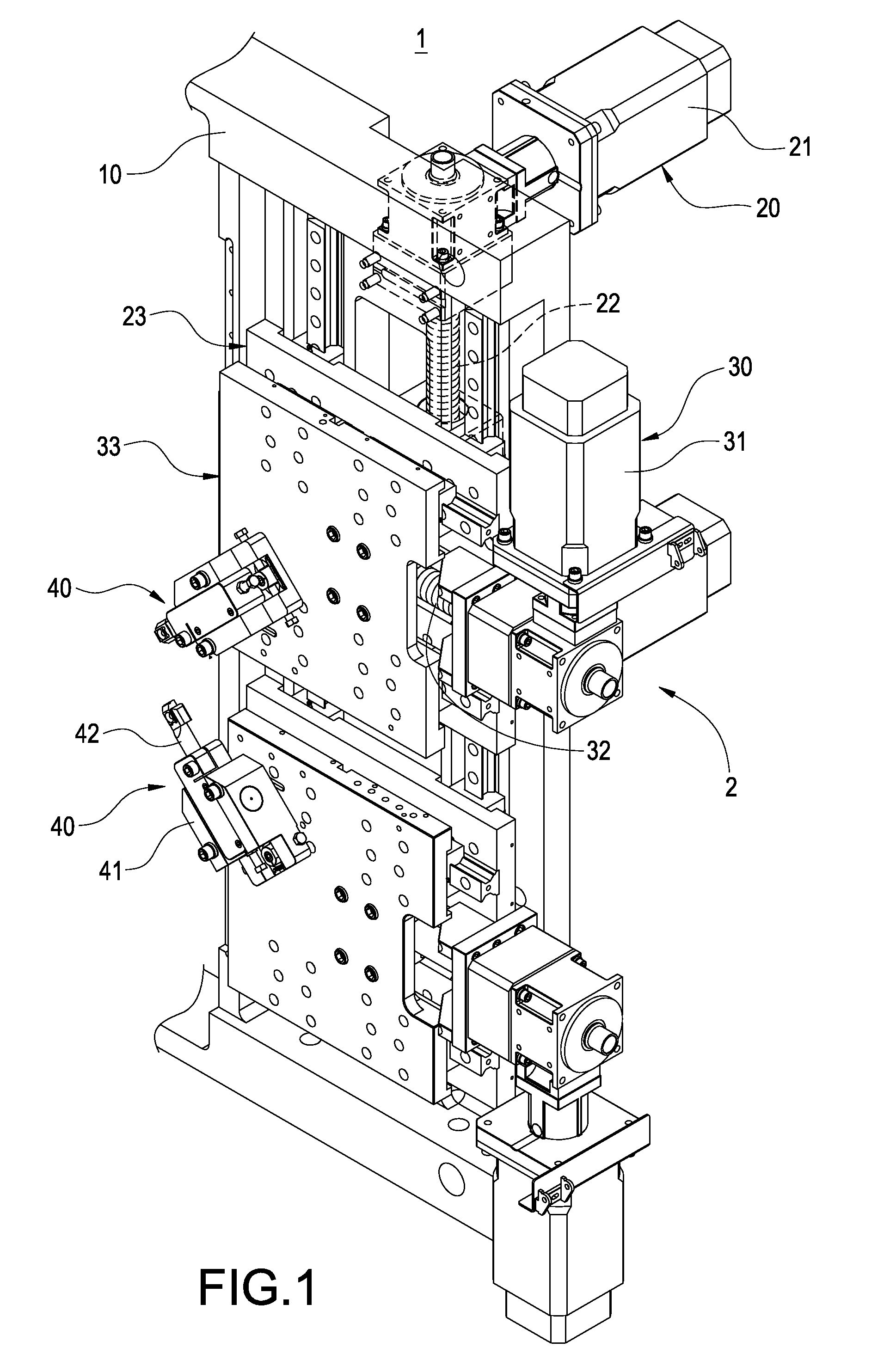

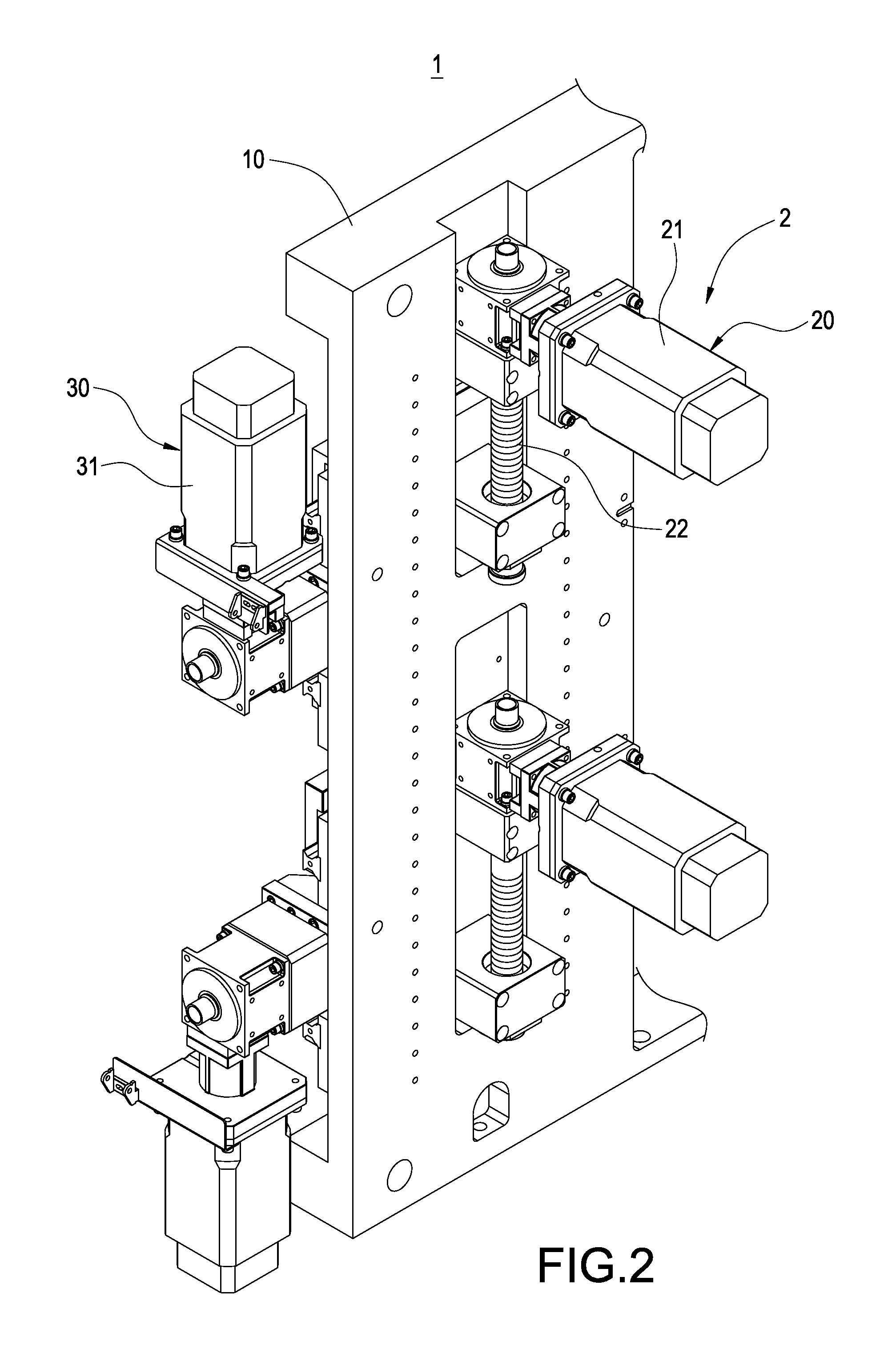

Abutting apparatus of spring configuration machine

InactiveUS20110114217A1Increase flexibilityPrecise positioningWire springsDegrees of freedomEngineering

An abutting apparatus of spring configuration machine which has a machine platform includes a first and second axial transmission mechanisms and an abutting assembly. The first axial transmission mechanism includes a first actuator, a first lead screw and a first sliding seat screwed with the first lead screw. The second axial transmission mechanism includes a second actuator fixed to the first sliding seat, a second lead screw driven to rotate by the second actuator and a second sliding seat screwed with the second lead screw and linearly moved relatively to the first sliding seat. Via the first and second axial transmission mechanisms, the abutting assembly fixed to the second sliding seat can make a 2-D movement in vertical and horizontal directions relative to the machine platform, such that the degree of freedom to adjust the abutting assembly can be enhanced significantly.

Owner:NUCOIL IND

Thermal contact resistance test equipment with compensating heating device

InactiveCN101915781AChange temperatureAvoid lostMaterial heat developmentData acquisitionEngineering

The invention discloses a thermal contact resistance test equipment with a compensating heating device, mainly comprising a support frame, a top plate, a bottom plate, a stress loading device, a cooling device, a data acquisition system, a heating device and a temperature compensating device, wherein the compensating heating device comprises a thermoelectric couple and an annular heater, wherein the thermoelectric couple is arranged on the annular heater; the annular heater is arranged on the radial surface positioned on a contact interface of every two samples; the thermoelectric couple is connected with a temperature controller; and the temperature controller controls the on-off of the annular heater through temperature data fed back by the thermoelectric couple. The invention can control the heating temperature of the annular heater to be within a theoretical conducting temperature by regulating a temperature control point of the temperature controller so as to maximize the axial transmission of thermal flows on the contact interface of the samples, thereby preventing the horizontal thermal flows from dissipating and realizing the axial one-dimensional transfer of the thermal flows.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com