Reconfigurable long-period optical fiber grating coupler

A fiber grating, long-period technology, applied in the direction of cladding fiber, optical waveguide light guide, etc., can solve the problem of non-reconfigurable fiber coupler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

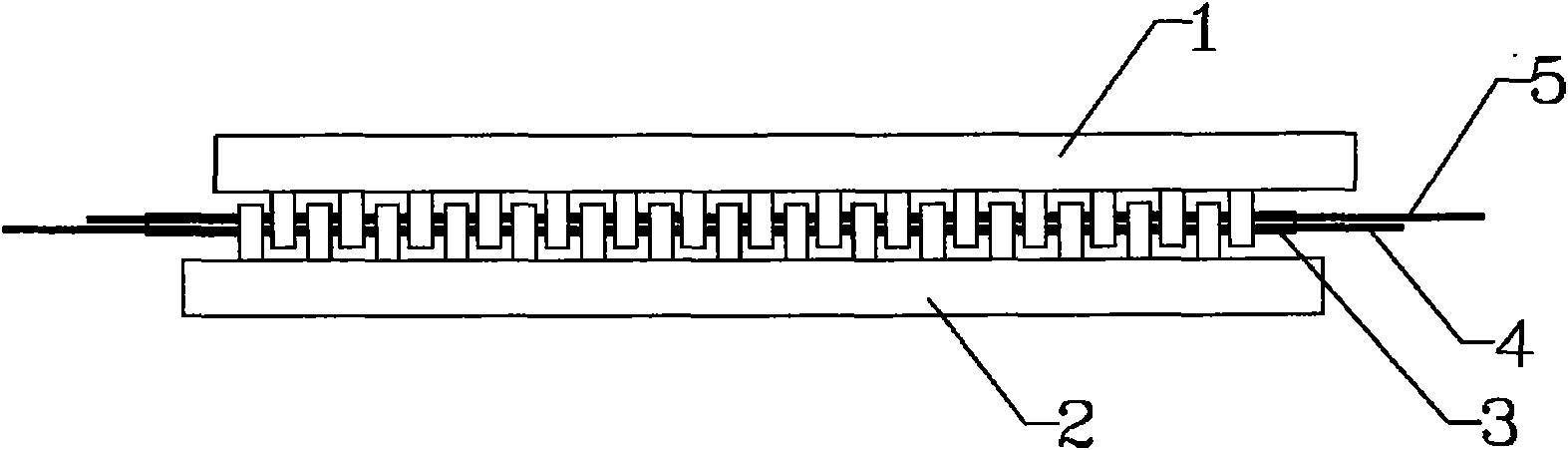

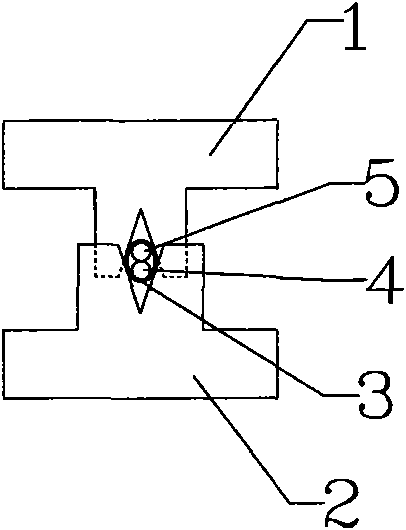

[0029] figure 1 It is a structural diagram of a specific implementation of the long-period fiber grating coupler of the present invention, figure 2 Is its side view.

[0030] In this embodiment, the reconfigurable long-period fiber grating coupler is a dual-fiber long-period fiber grating coupler, which can be implemented according to the following steps:

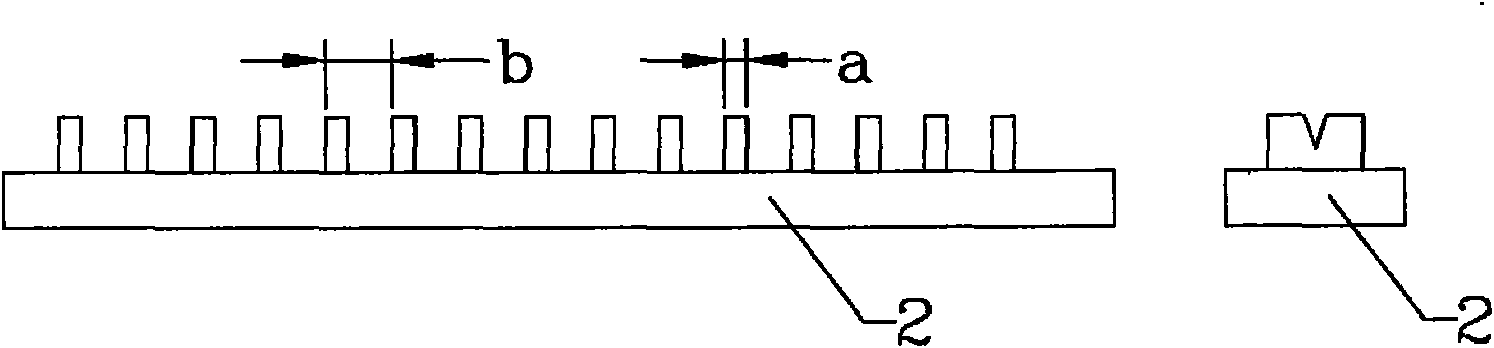

[0031] 1. Put the two single-mode bare fibers coated with liquid matching medium into the protective sleeve 3, and put the protective sleeve 3 with two single-mode bare fibers inside into the bottom of the force applying unit 2 of the force applying device , In this embodiment, such as image 3 As shown, the force application unit 2 is a plug-in V-shaped groove, and its angle can be 1°~180°;

[0032] 2. The force applying unit 1 of the force applying device, in this embodiment, is as Figure 4 As shown, the force applying unit 1 is a plug-in V-shaped groove, the angle of which can be 1°~180°, and it is inserted into the force app...

Embodiment 2

[0039] Such as Image 6 As shown, in this embodiment, the reconfigurable long-period fiber grating coupler is a dual-insertion right-angle ∏-shaped slot-paired dual-fiber coupler. In the figure, force applying units 1 and 2 are plug-in right-angle ∏-shaped grooves, 3 are protective sleeves, and 4 and 5 are single-mode bare fibers.

Embodiment 3

[0041] Such as Figure 7 As shown, in this embodiment, the reconfigurable long-period fiber grating coupler is a dual-insertion type U-slot paired dual-fiber coupler. In the figure, the force applying units 1 and 2 are plug-in U-shaped grooves, 3 is a protective sleeve, and 4 and 5 are single-mode bare fibers.

[0042] In Embodiments 1 to 3, any one of the single-mode bare fibers 4 and 5 can be used as a transmission fiber, and the other fiber is a coupling fiber, and they can form a 2×2 fiber coupler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com