TBM microwave stress relief device and application for rockburst prevention and treatment

A stress release and microwave technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of insufficient stress release, slow speed, and insufficient prevention of rockbursts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

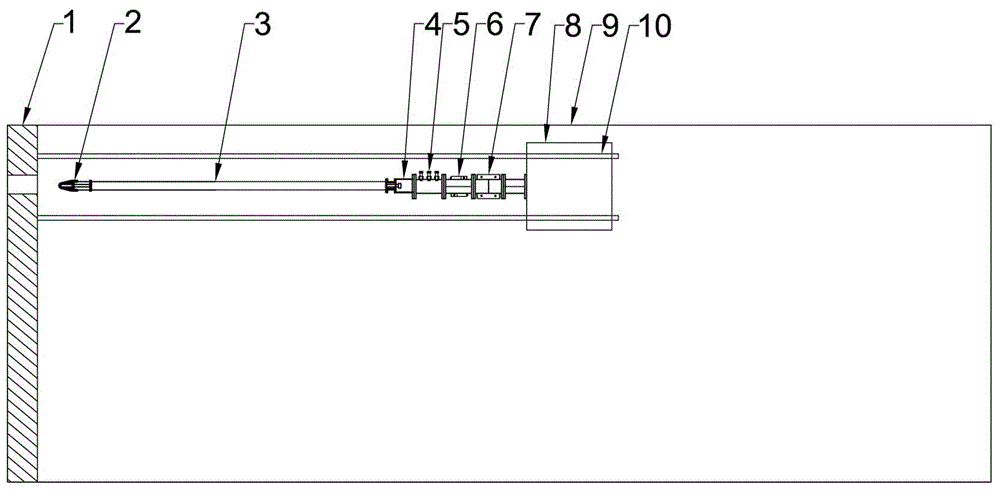

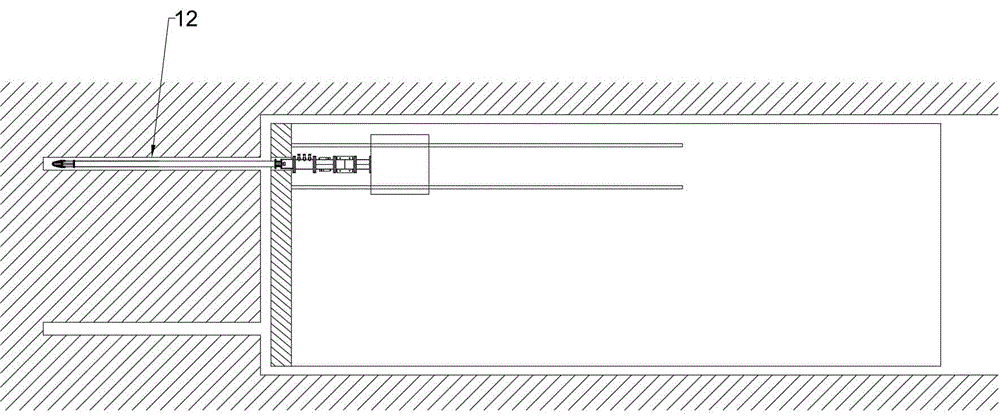

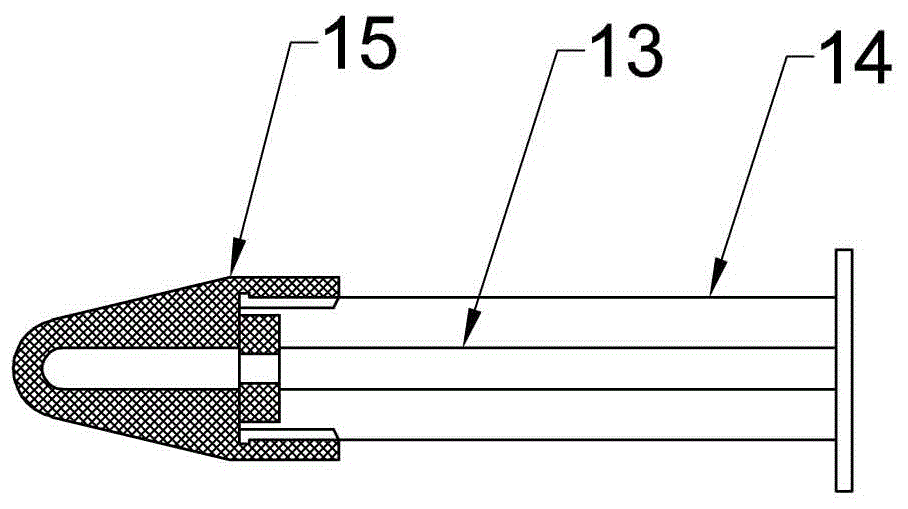

[0024] Such as figure 1 As shown, a microwave stress release device on a TBM for rockburst prevention and control, the TBM can be an open or shield type full-face rock boring machine, which is a continuous operation of rock breaking, slag removal and support Comprehensive mechanical equipment; an axial transmission screw 10 is arranged in the TBM frame 9, and a microwave cracking system is slidably connected to the transmission screw 10, and a microwave launching rod 2 is arranged at the end of the microwave cracking system; at the end of the TBM frame 9 There is a TBM cutter head 1 at the bottom, and a through hole is arranged on the TBM cutter head 1. The microwave fracturing system slides along the transmission screw 10, and the microwave emitting rod 2 protrudes from the through hole to send microwaves into the drilled rock.

[0025] The structure of the microwave fracturing system is that the output port of the microwave source 8 is sequentially connected to the circulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com