Patents

Literature

978 results about "Microwave emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

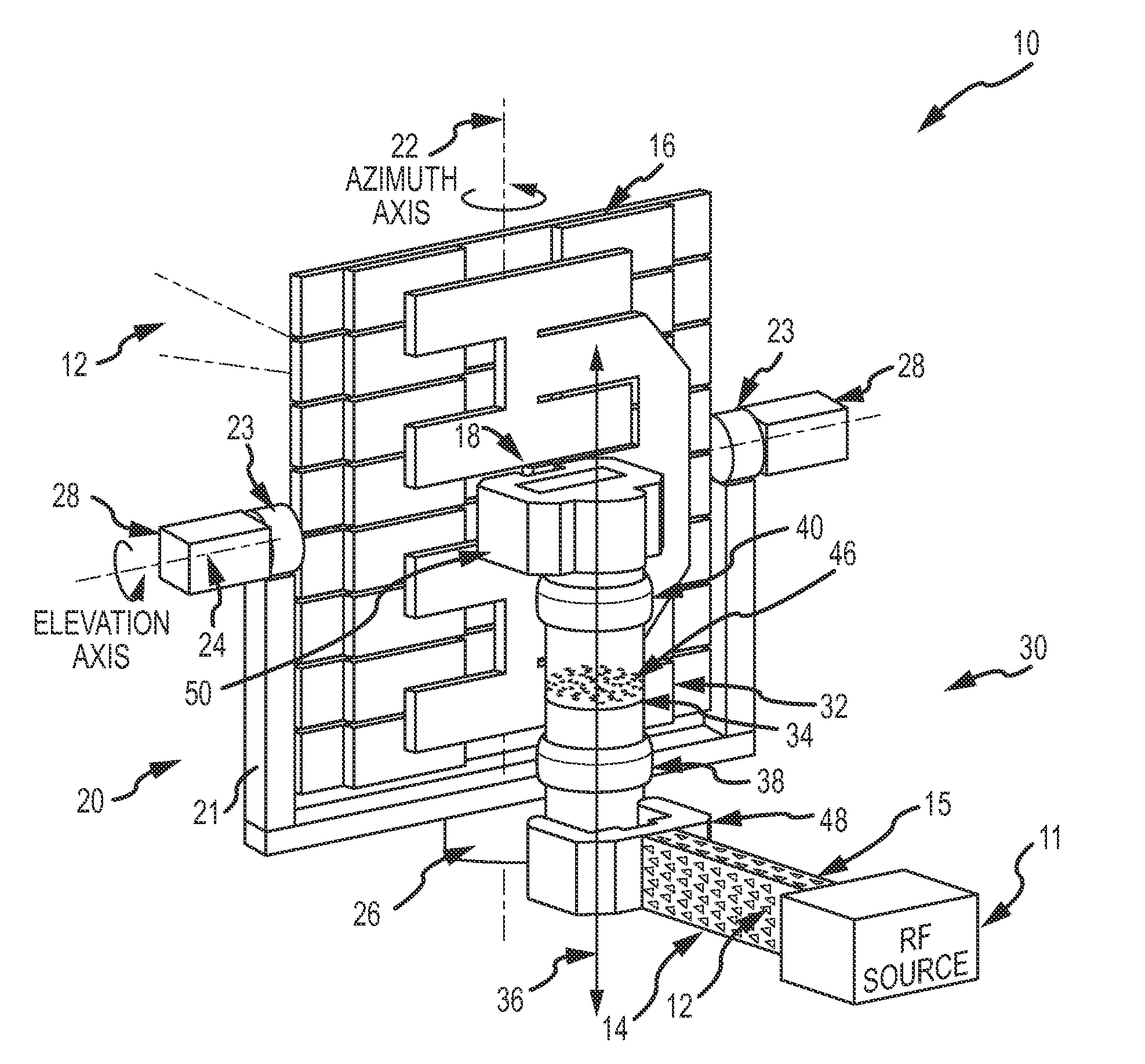

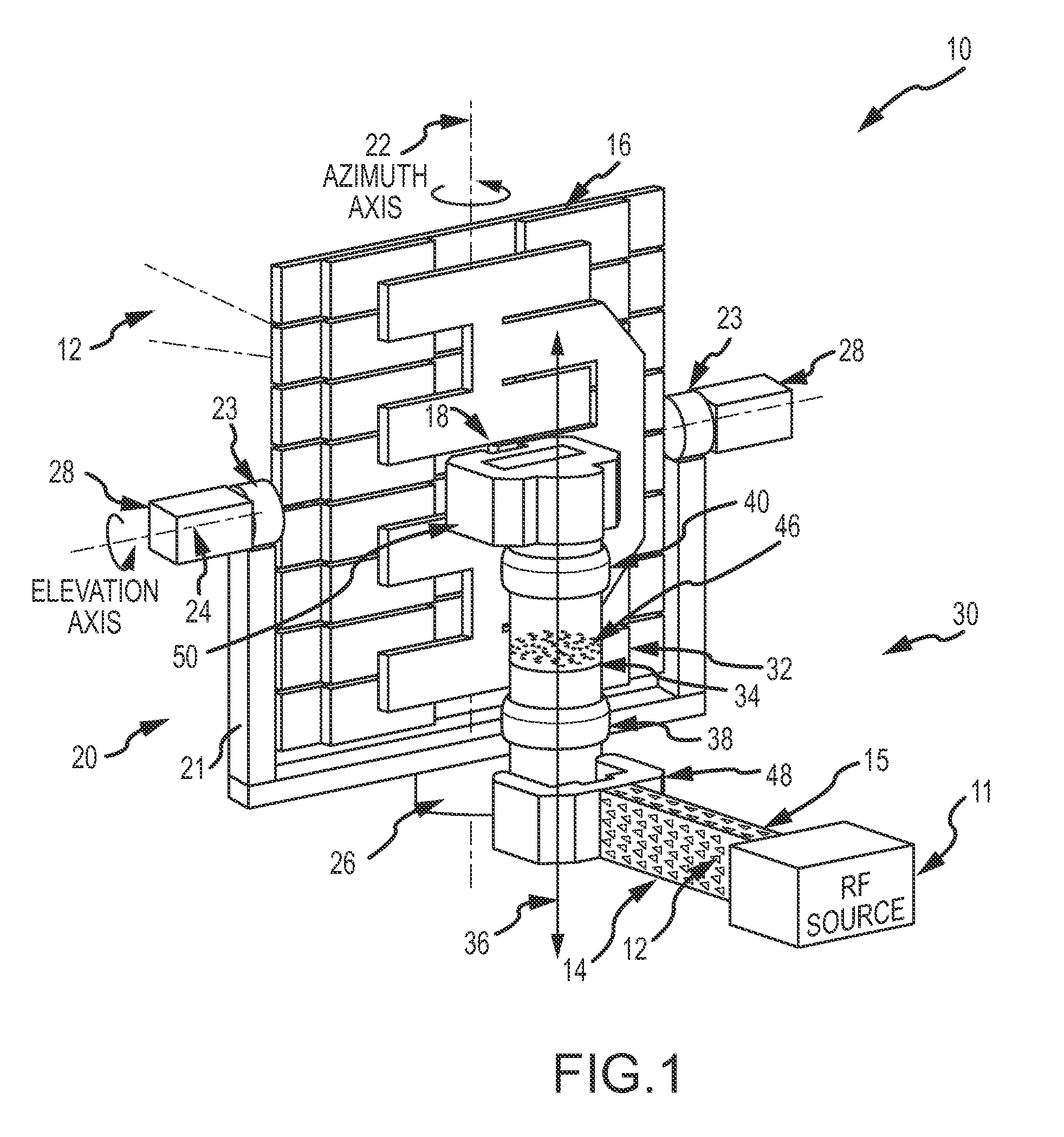

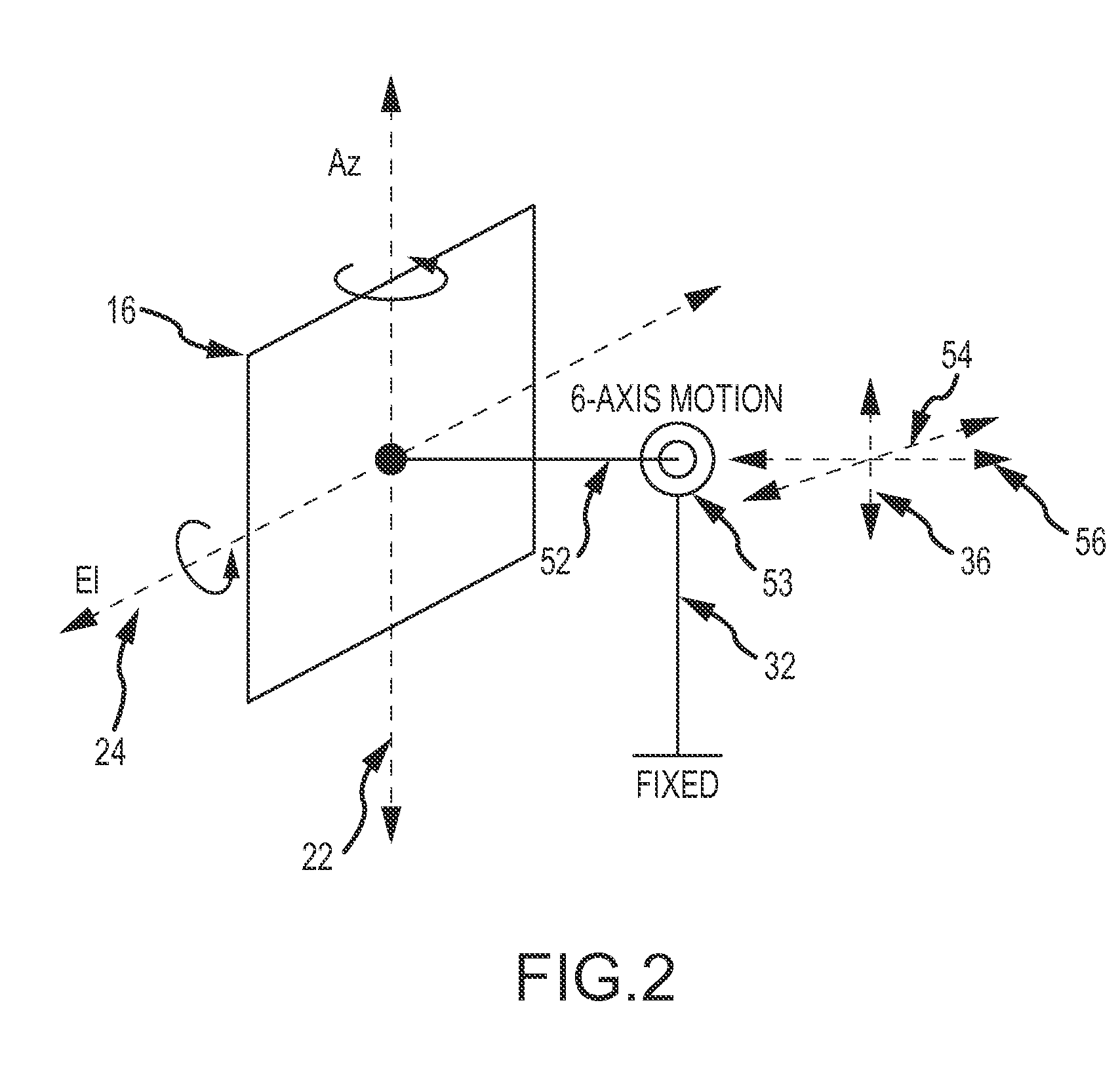

Universal microwave waveguide joint and mechanically steerable microwave transmitter

ActiveUS8963790B2Simple processSmall sizeWaveguide type devicesAntennasRange of motionUniversal joint

A universal joint comprising a pair of circular waveguide ball-joints and a slip-joint allows for simultaneous 3-axis rotation and 3-dimensional translation between an antenna and a stationary source. As such, the universal joint does not have to be physically aligned with the azimuth, and elevation, rotation axis of the antenna and mounted on the gimbal support, greatly simplifying the antenna steering mechanism. The universal joint allows the antenna to be mass-balanced in relation to the azimuth and elevation axis without adding any additional counter weights, thus reducing the size and power requirements of the azimuth and elevation rotation drive systems. Additional ball-joints may be provided to increase the allowed range of motion of the antenna.

Owner:RAYTHEON CO

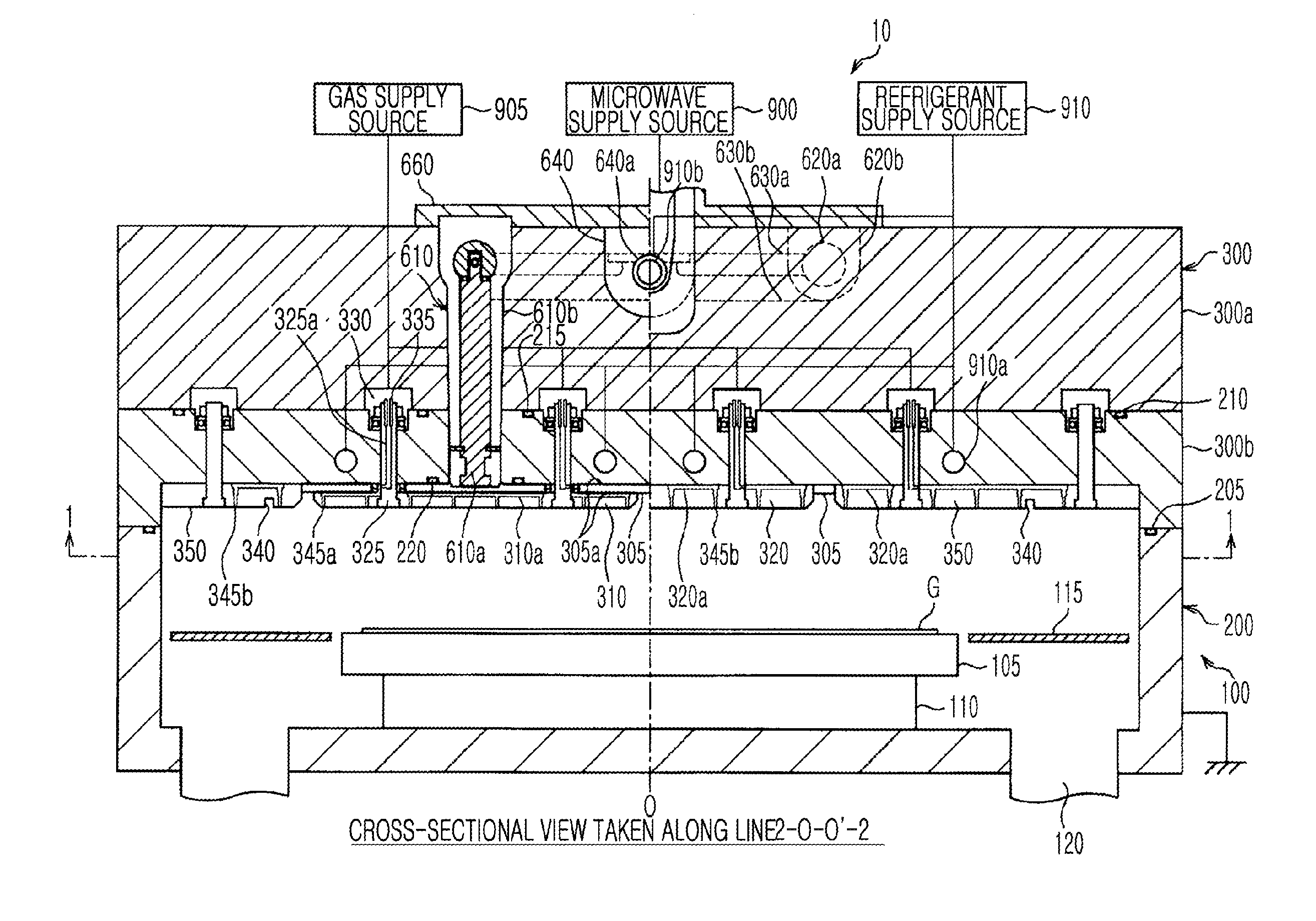

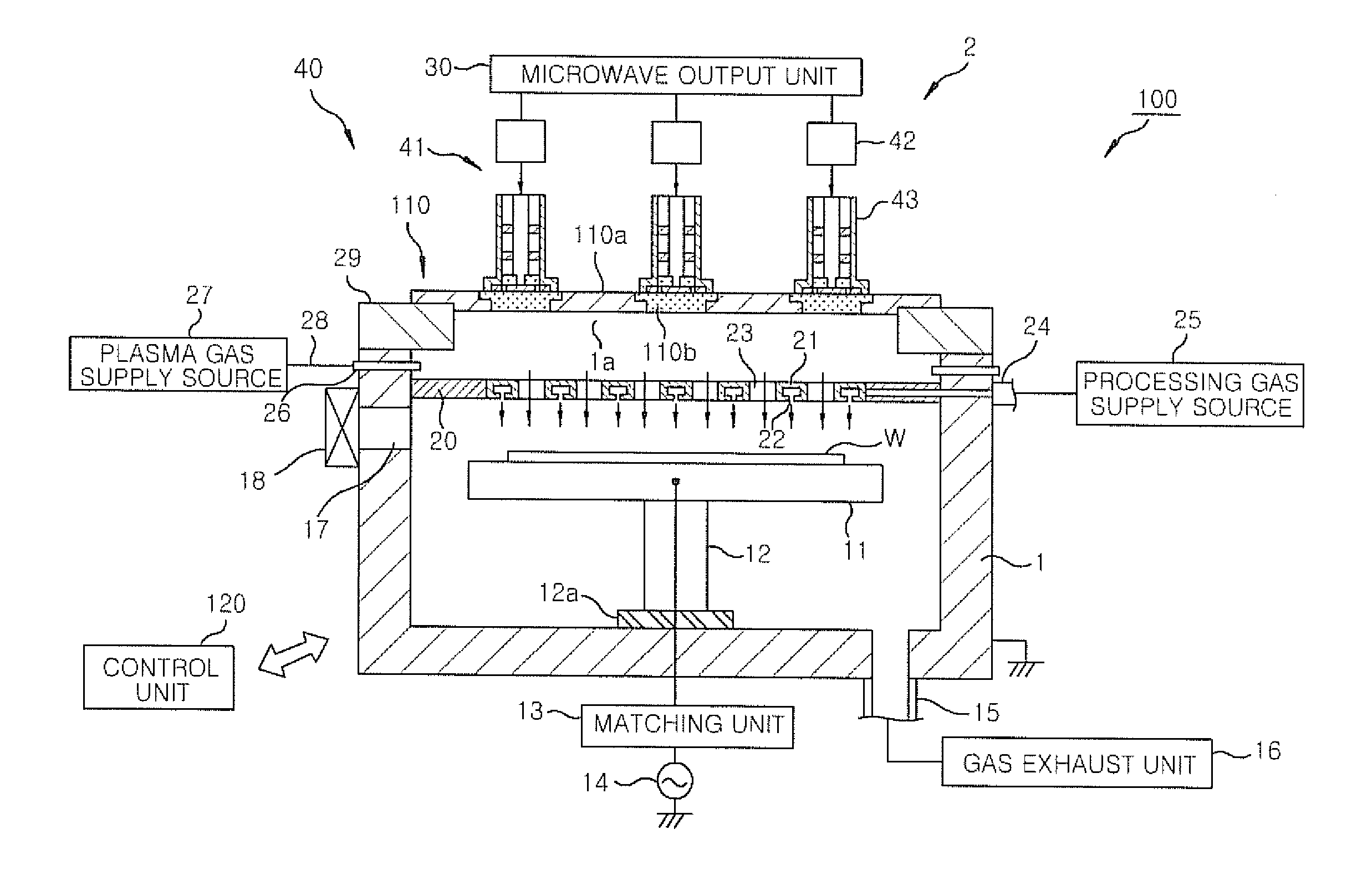

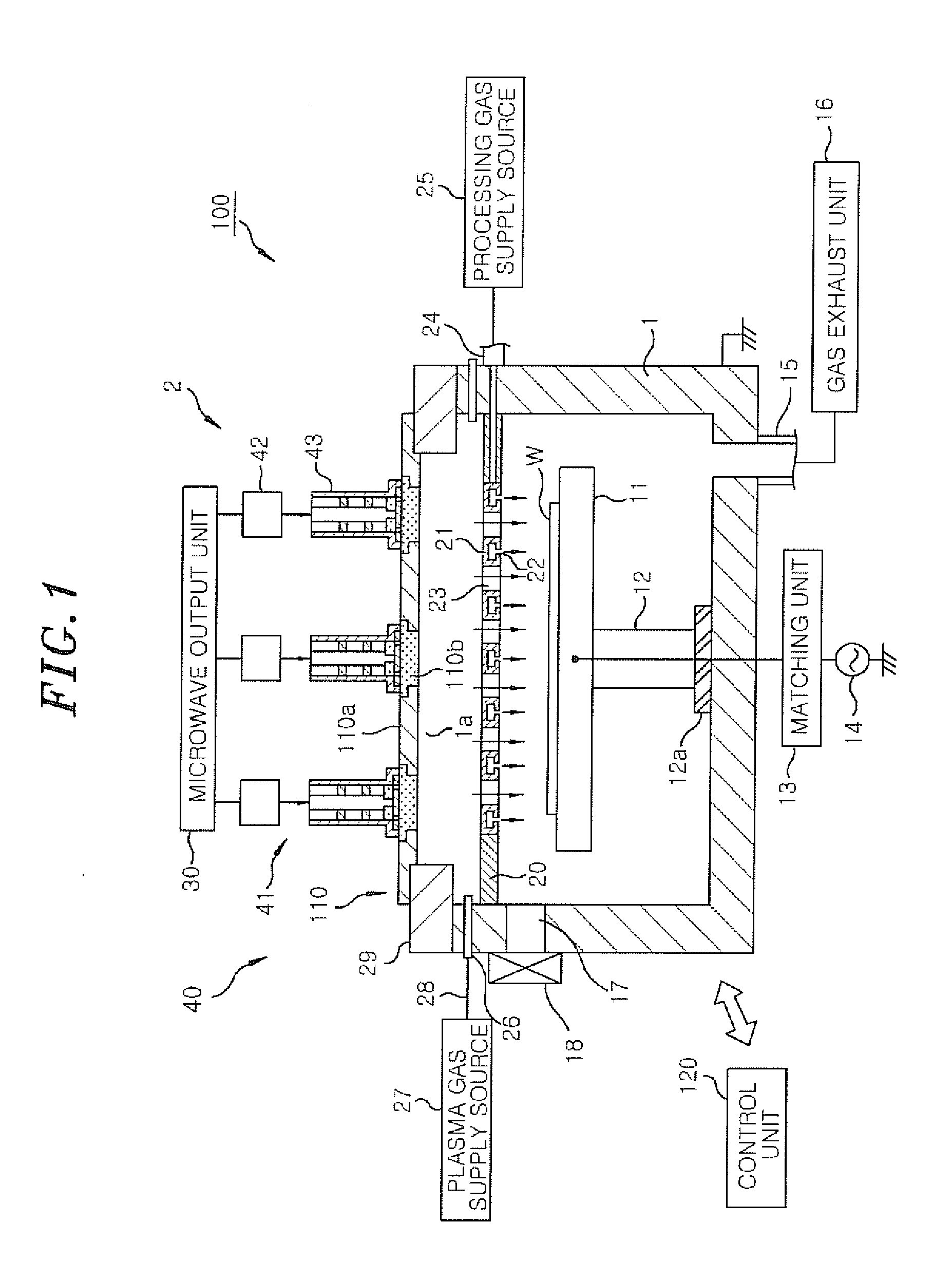

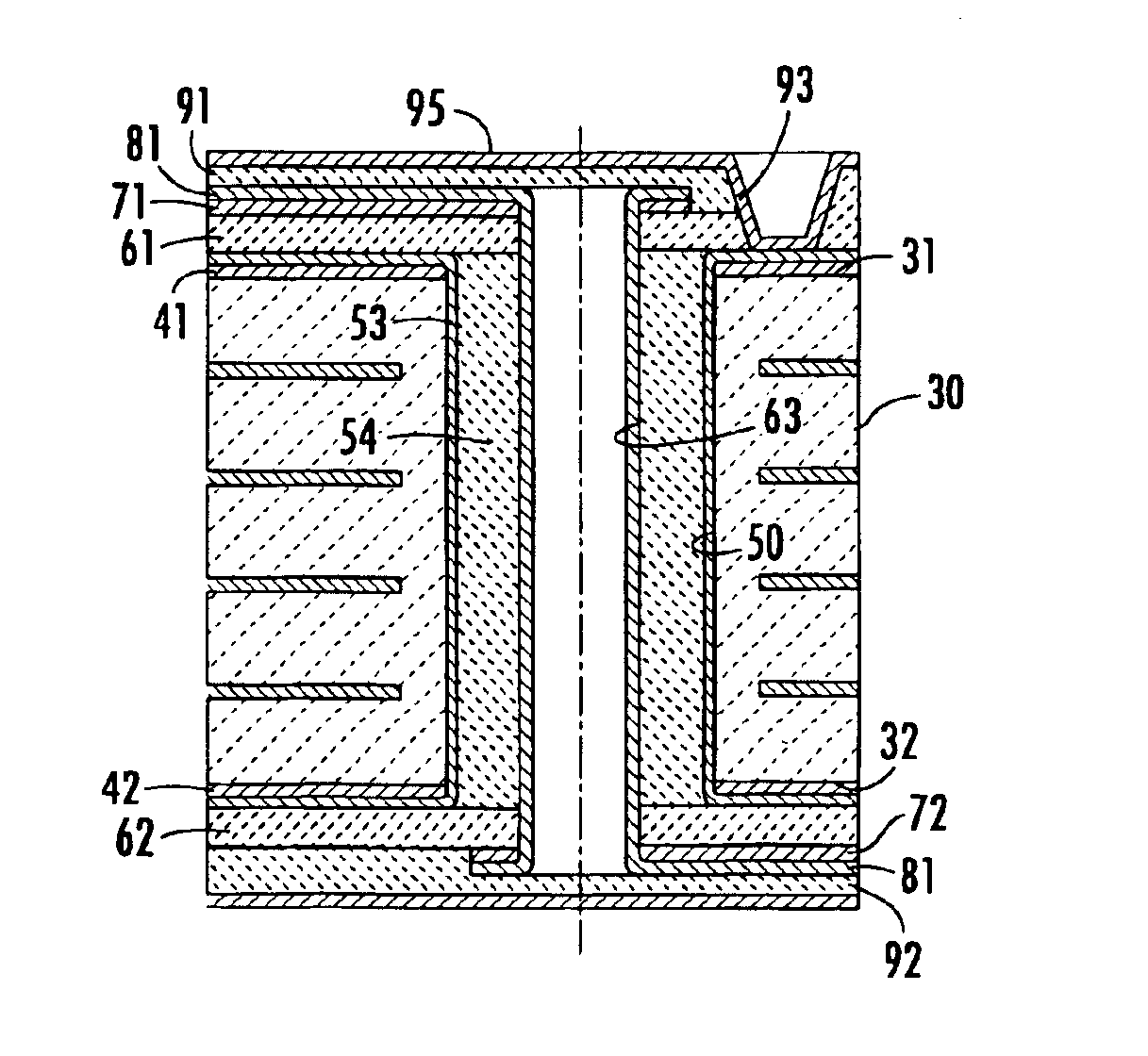

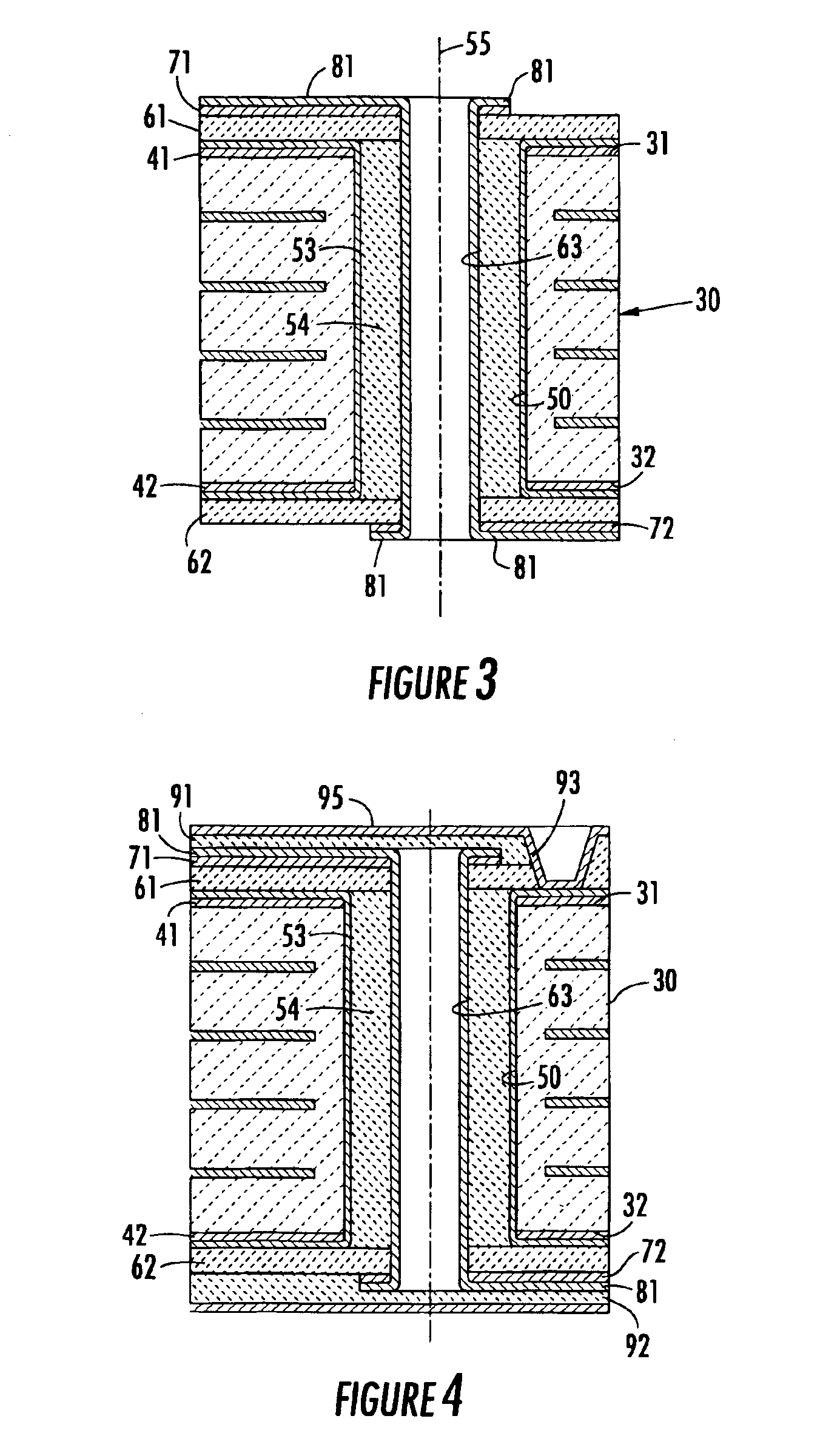

Plasma processing apparatus and plasma processing method

ActiveUS20110121736A1Different characteristic impedancePrevent fallingElectric arc lampsSemiconductor/solid-state device manufacturingElectricityElectrical conductor

Provided is a plasma processing apparatus having a coaxial waveguide structure in which characteristic impedance of an input side and characteristic impedance of an output side are different. A microwave plasma processing apparatus, which plasma-processes a substrate by exciting a gas by using a microwave, includes: a processing container; a microwave source, which outputs a microwave, a first coaxial waveguide, which transmits the microwave output from the microwave source; and a dielectric plate, which is adjacent to the first coaxial waveguide while facing an inner side of the processing container, and emits the microwave transmitted from the first coaxial waveguide into the processing container. A thickness ratio between an inner conductor and an outer conductor of the first coaxial waveguide is not uniform along a longitudinal direction.

Owner:TOKYO ELECTRON LTD +1

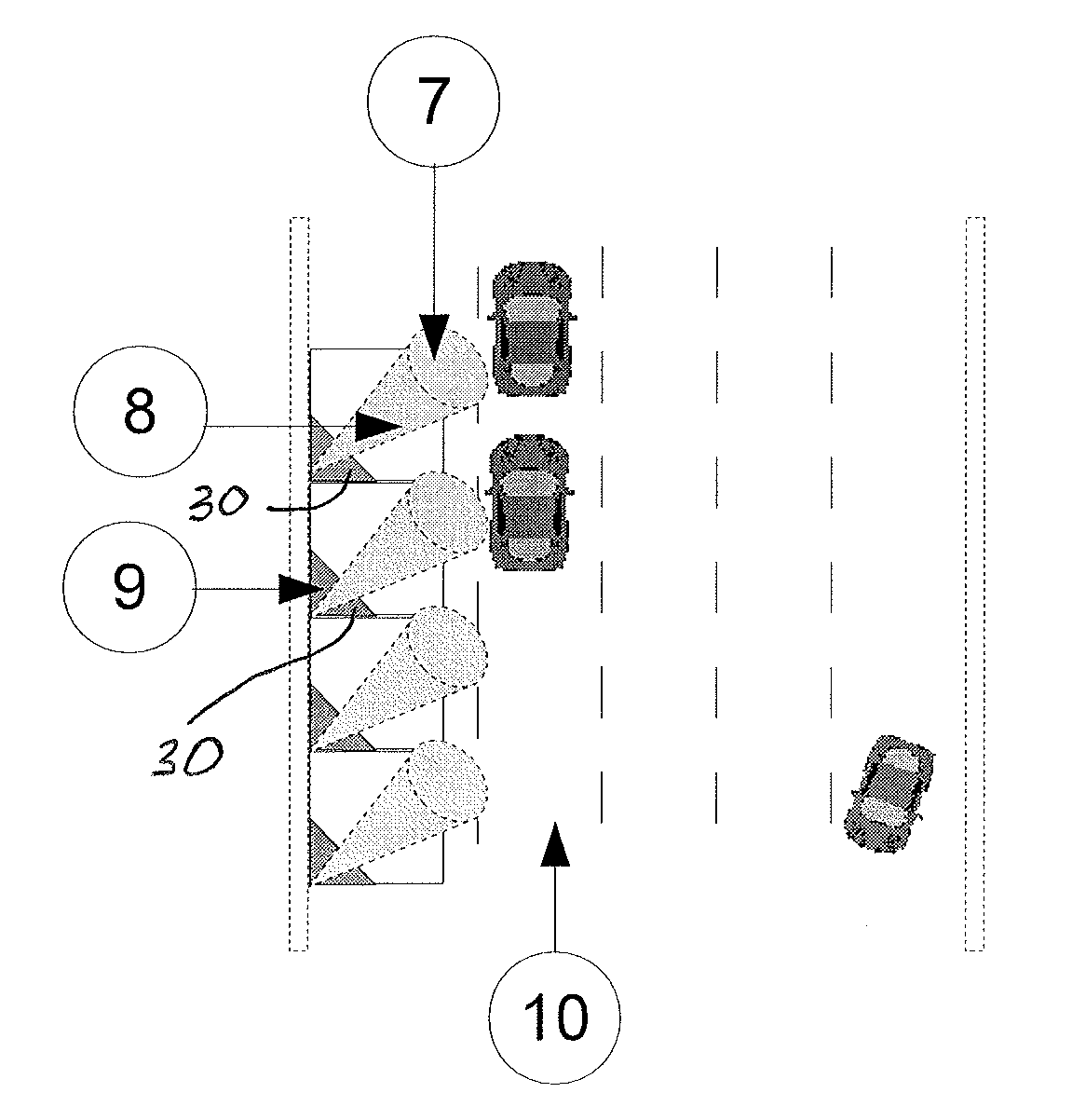

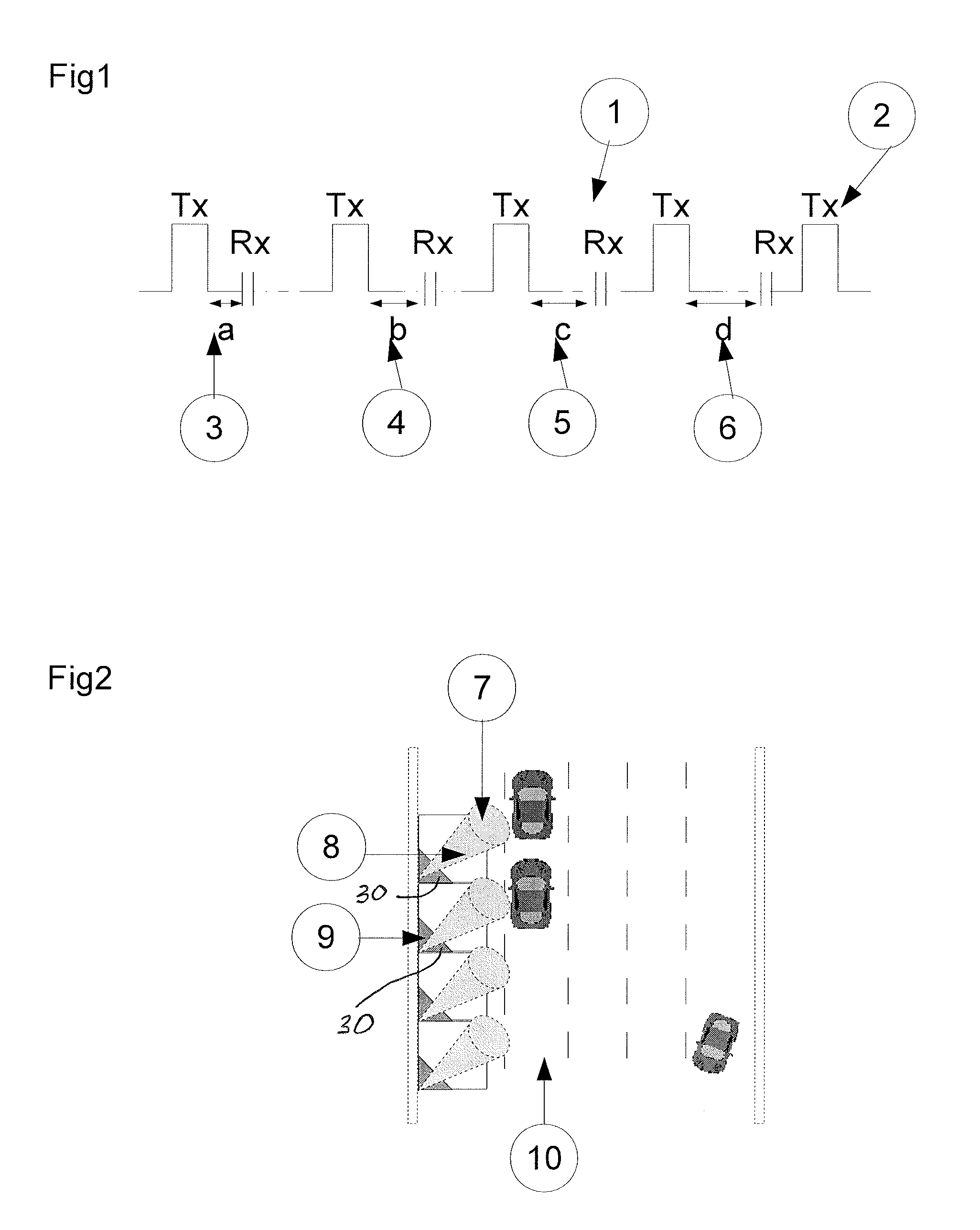

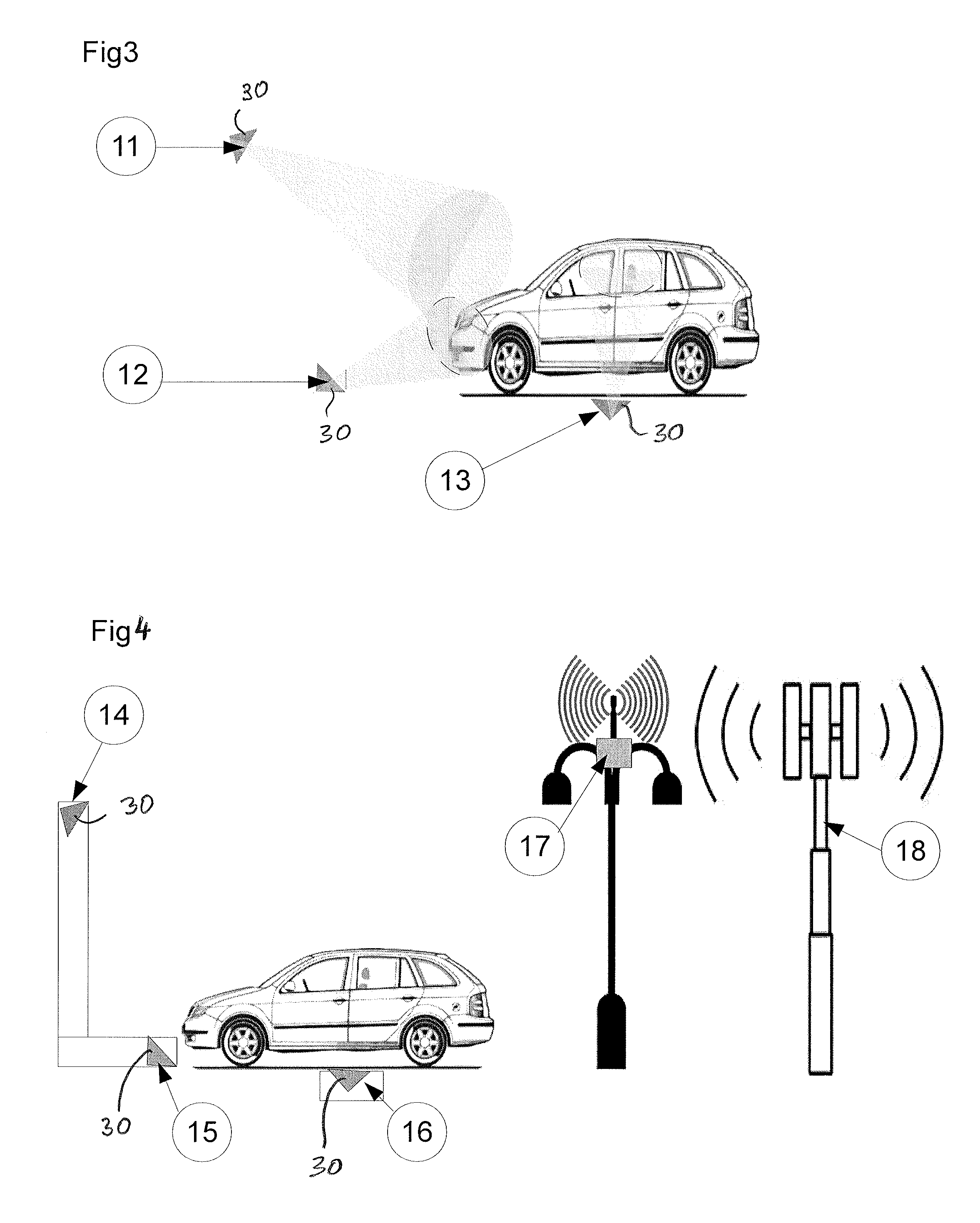

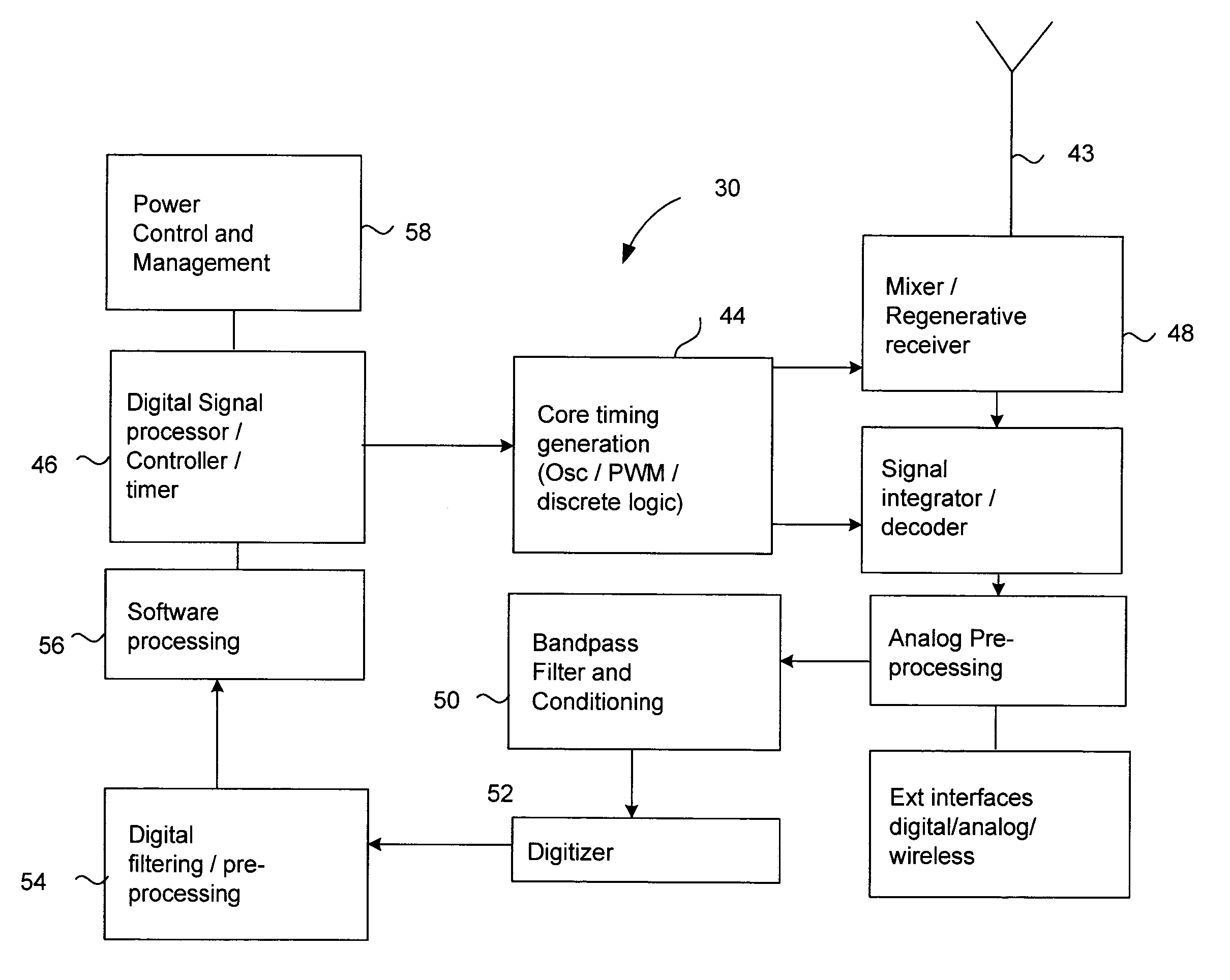

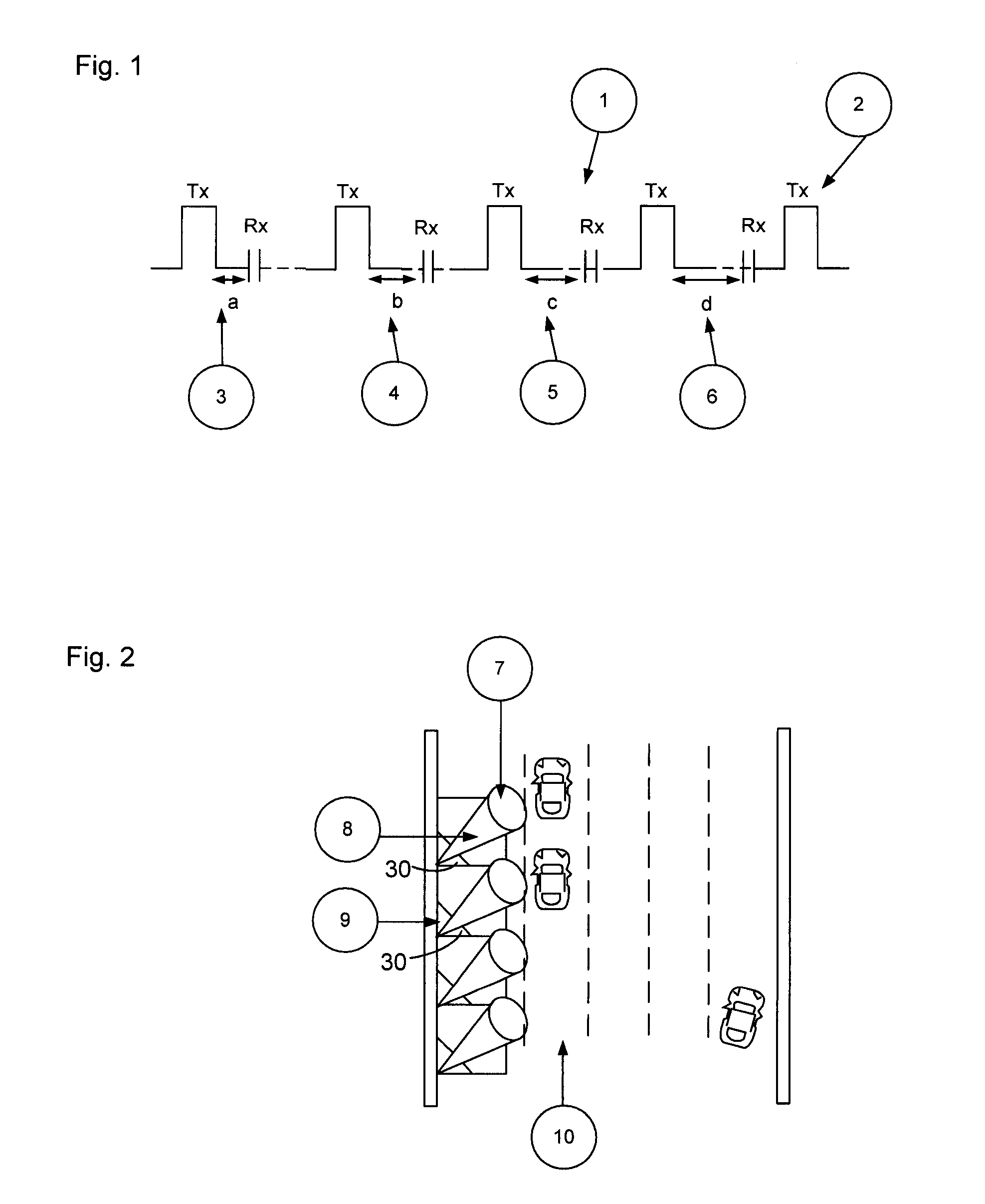

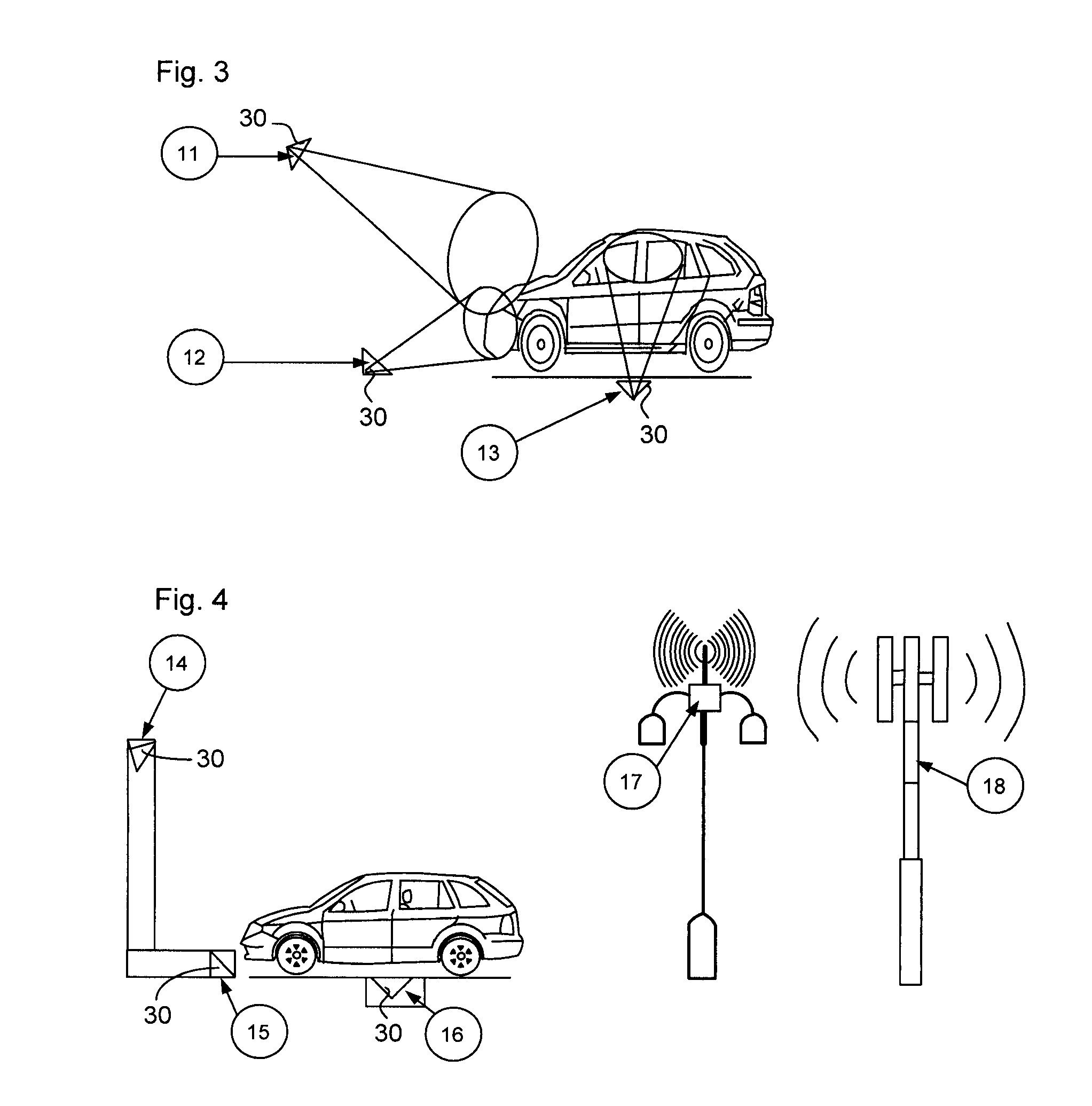

Directional speed and distance sensor

ActiveUS20130099943A1TightDifficult to separateArrangements for variable traffic instructionsParking metersDirectional antennaParking space

A method of using a directional sensor for the purposes of detecting the presence of a vehicle or an object within a zone of interest on a roadway or in a parking space. The method comprises the following steps: transmitting a microwave transmit pulse of less than 5 feet; radiating the transmitted pulse by a directional antenna system; receiving received pulses by an adjustable receive window; integrating or combining signals from multiple received pulses; amplifying and filtering the integrated receive signal; digitizing the combined signal; comparing the digitized signal to at least one preset or dynamically computed threshold values to determine the presence or absence of an object in the field of view of the sensor; and providing at least one pulse generator with rise and fall times of less than 3 ns each and capable of generating pulses less than 10 ns in duration.

Owner:SUBRAMANYA BALU

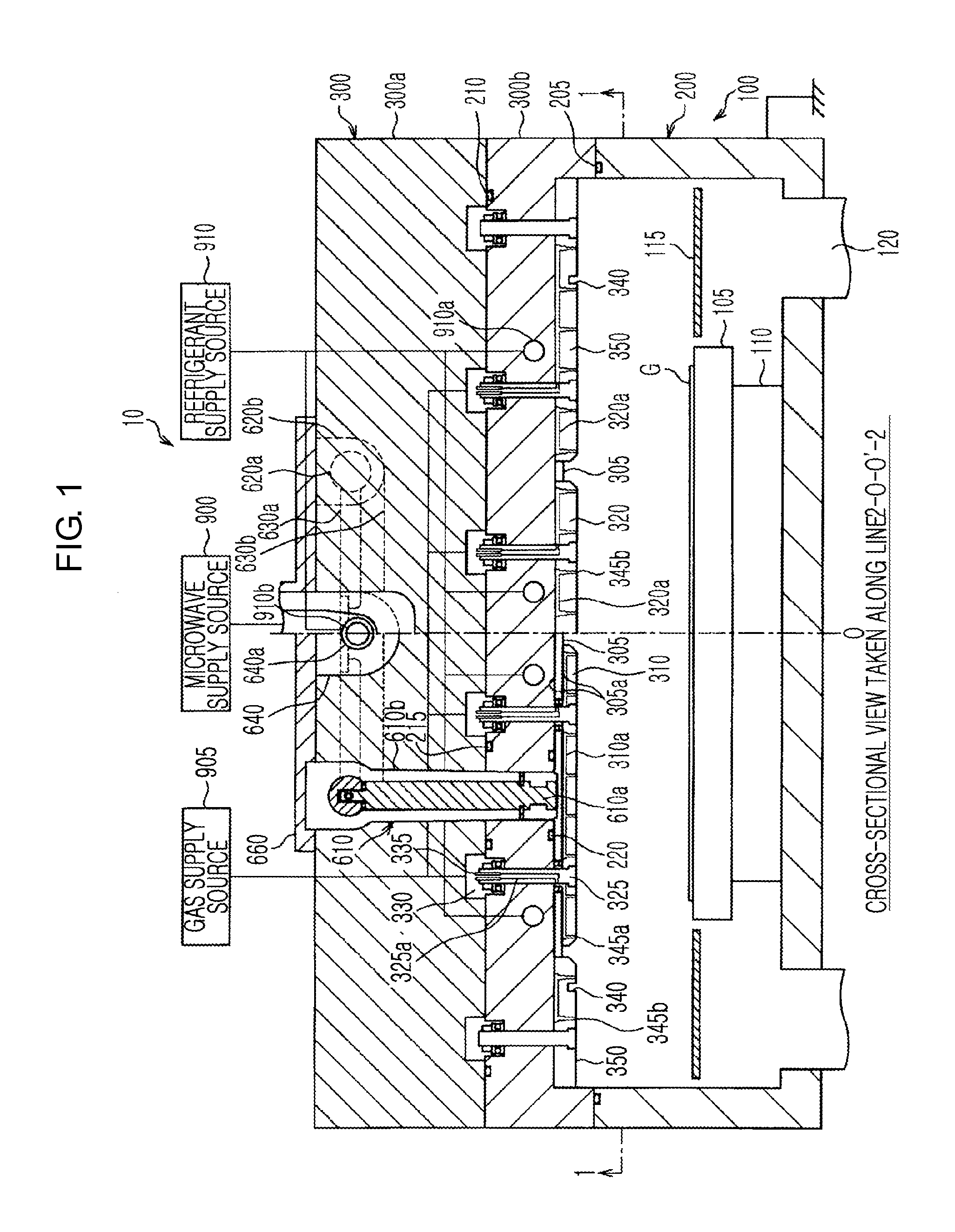

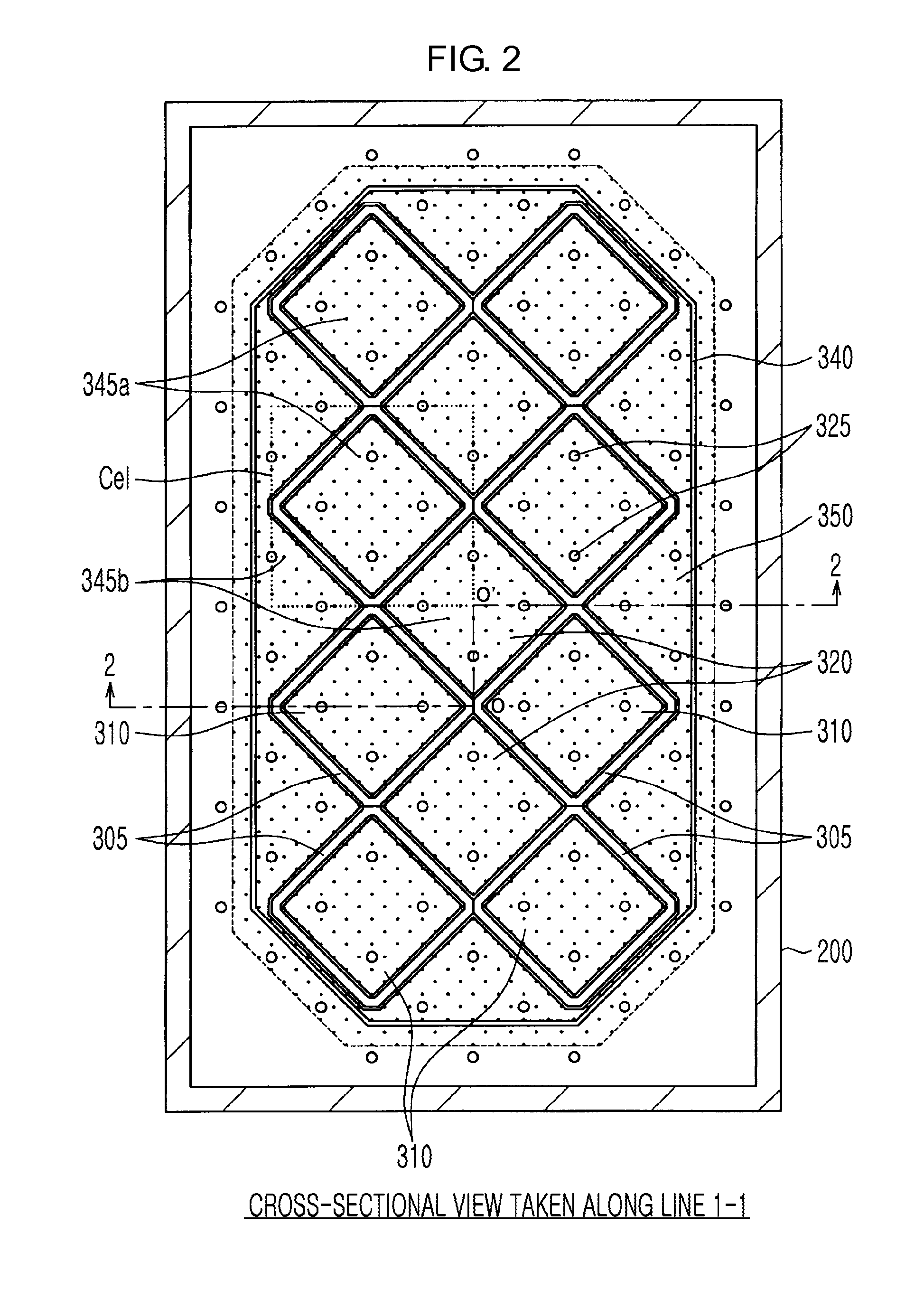

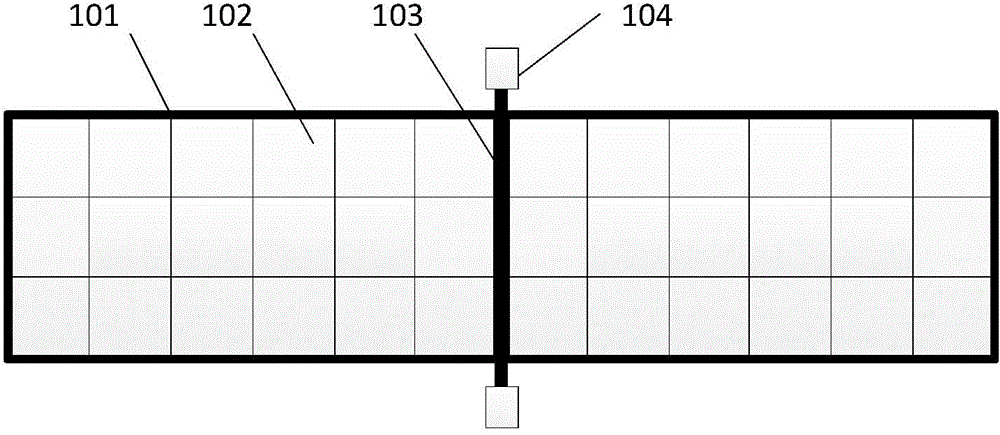

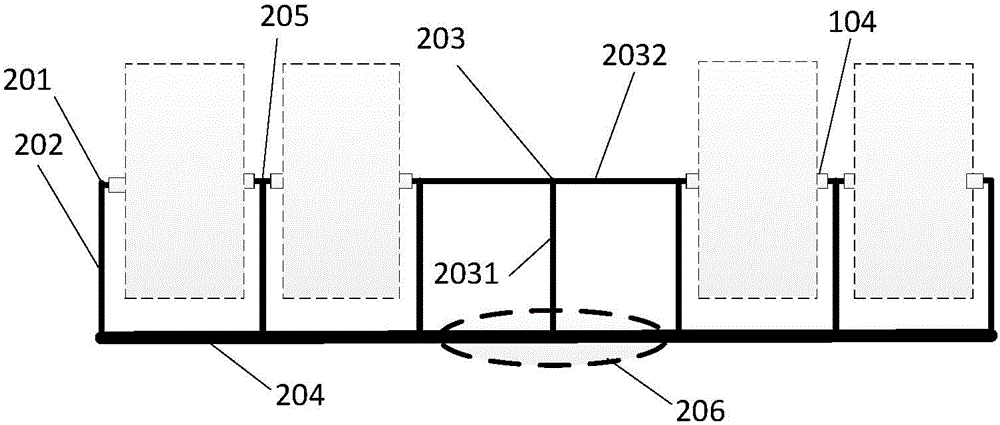

Microwave emission mechanism, microwave plasma source and surface wave plasma processing apparatus

ActiveUS20140361684A1Increase probabilityIncrease ratingsElectric discharge tubesAntenna supports/mountingsDielectricElectricity

A microwave emission mechanism includes: a transmission path through which a microwave is transmitted; and an antenna section that emits into a chamber the microwave transmitted through the transmission path. The antenna section includes an antenna having a slot through which the microwave is emitted, a dielectric member through which the microwave emitted from the antenna is transmitted and a closed circuit in which a surface current and a displacement current flow. A surface wave is formed in a surface of the dielectric member. The closed circuit has at least: an inner wall of the slot; and the surface and an inner portion of the dielectric member. When a wavelength of the microwave is λ0, a length of the closed circuit is nλ0±δ, where n is a positive integer and δ is a fine-tuning component including 0.

Owner:TOKYO ELECTRON LTD

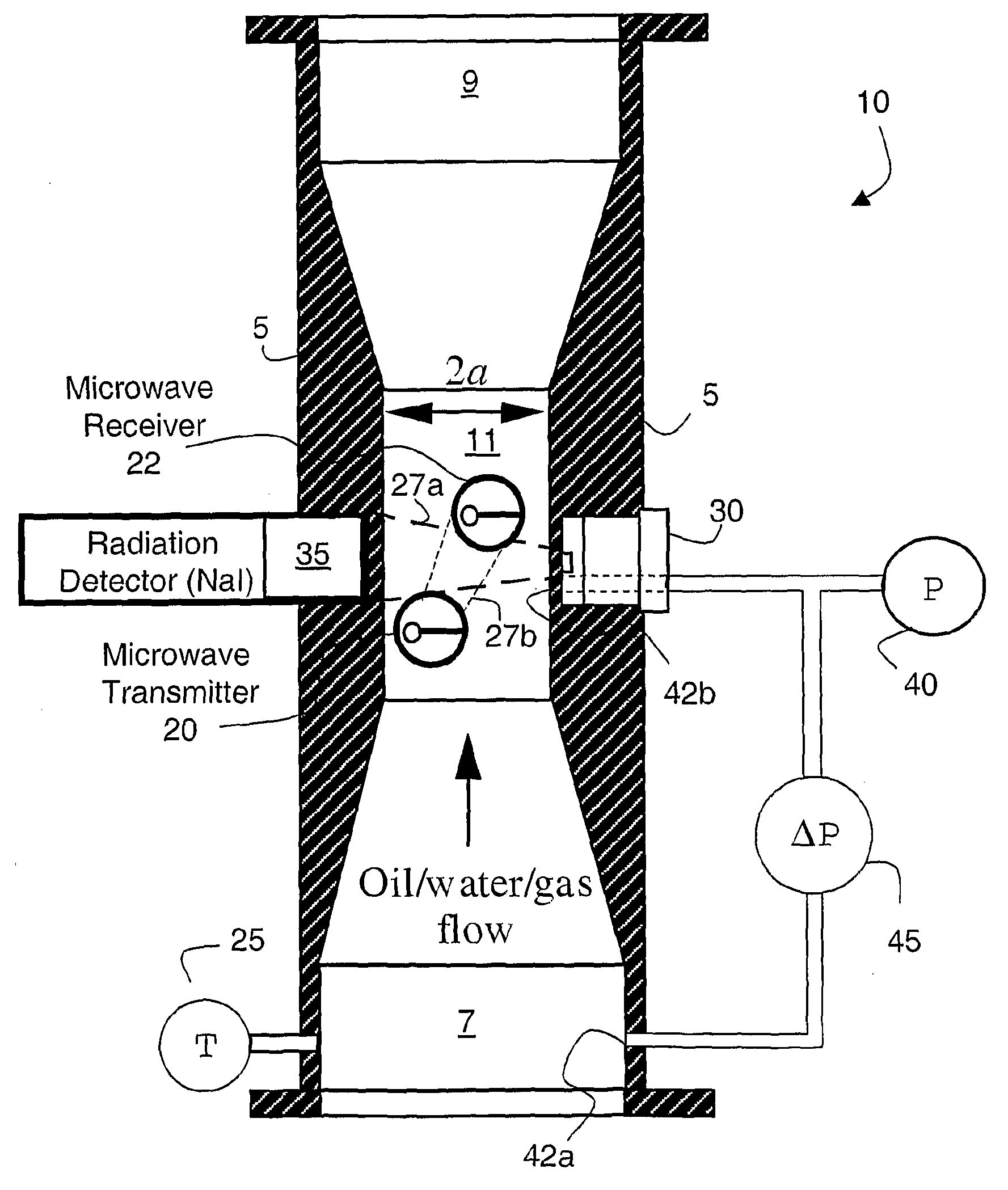

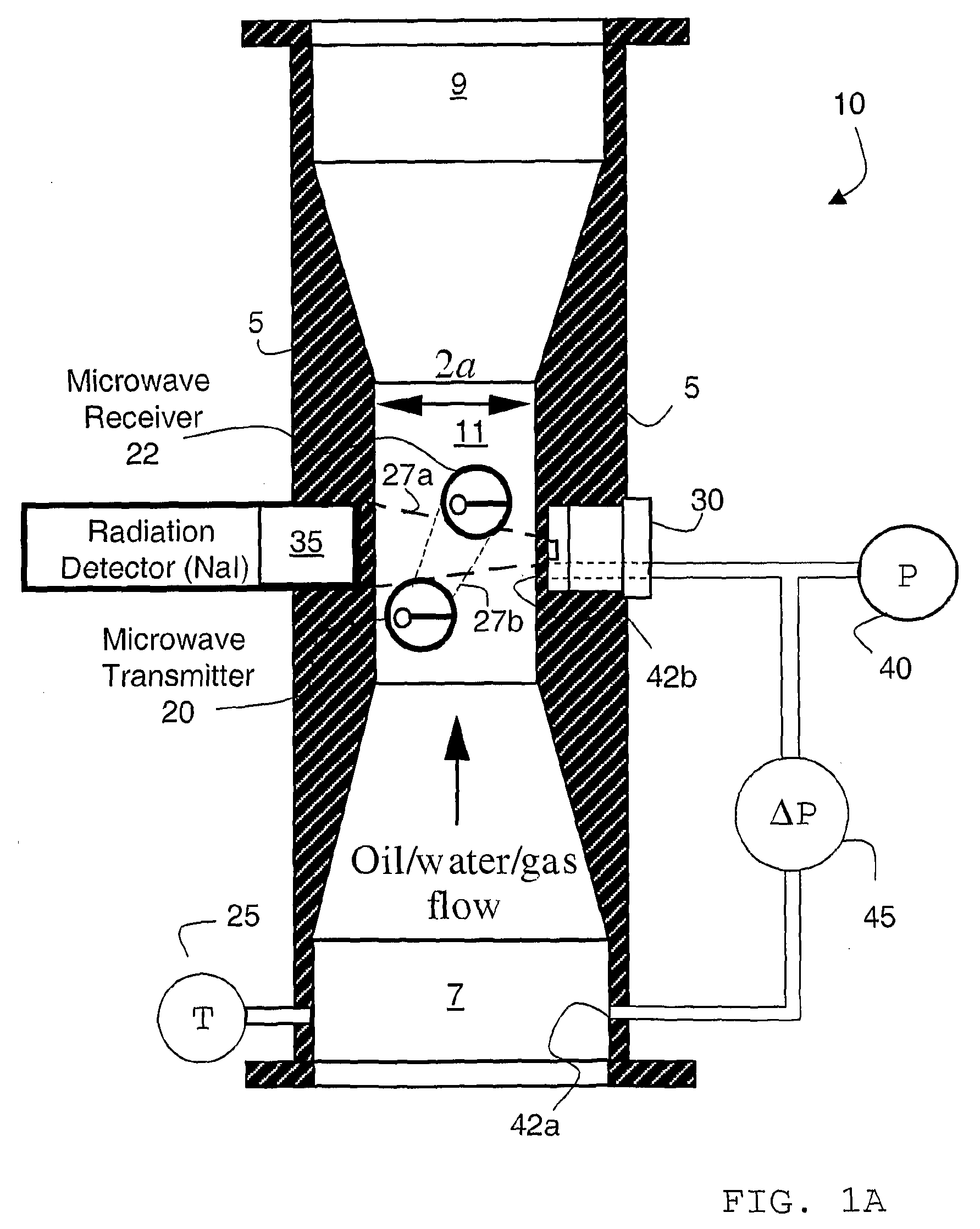

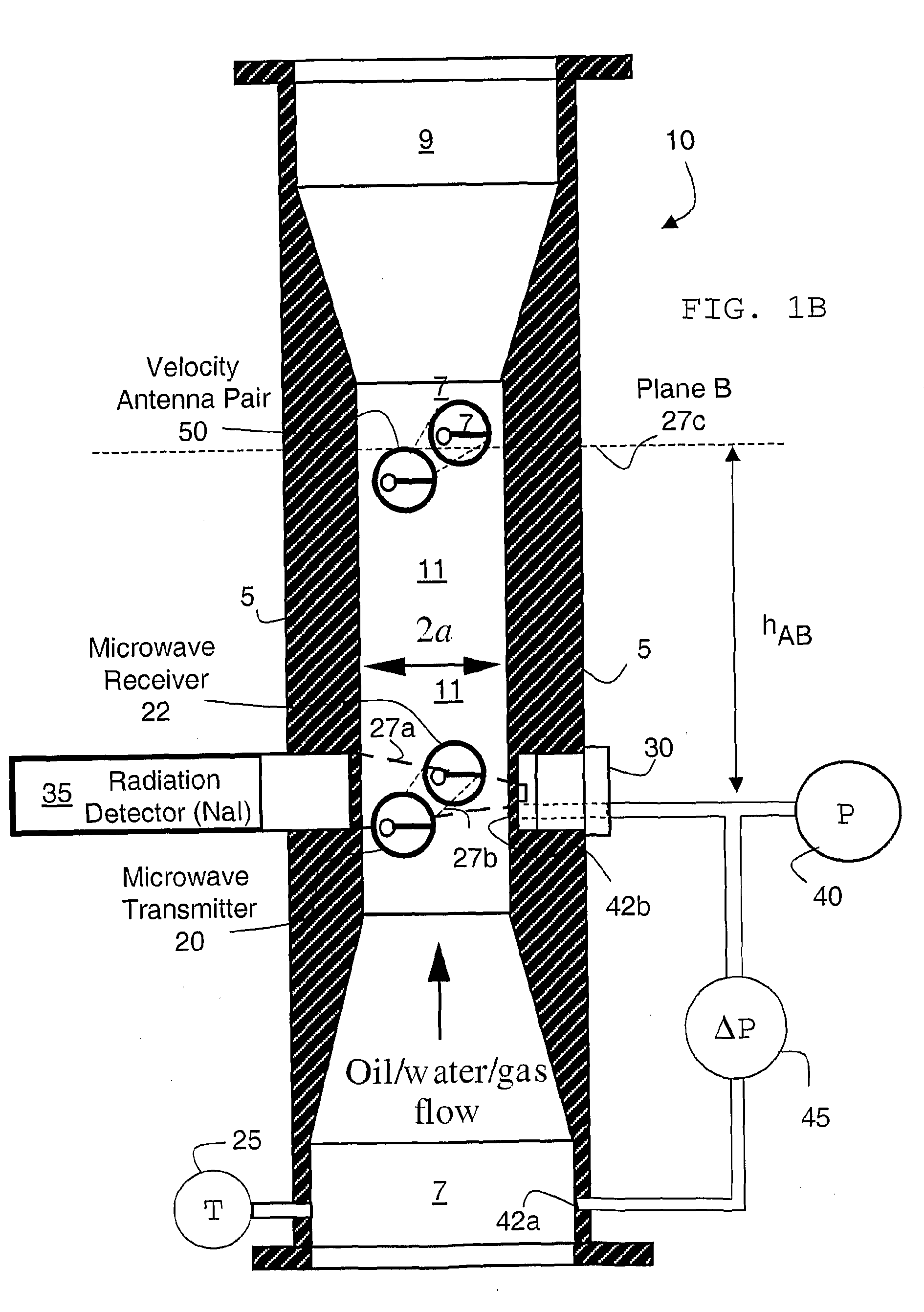

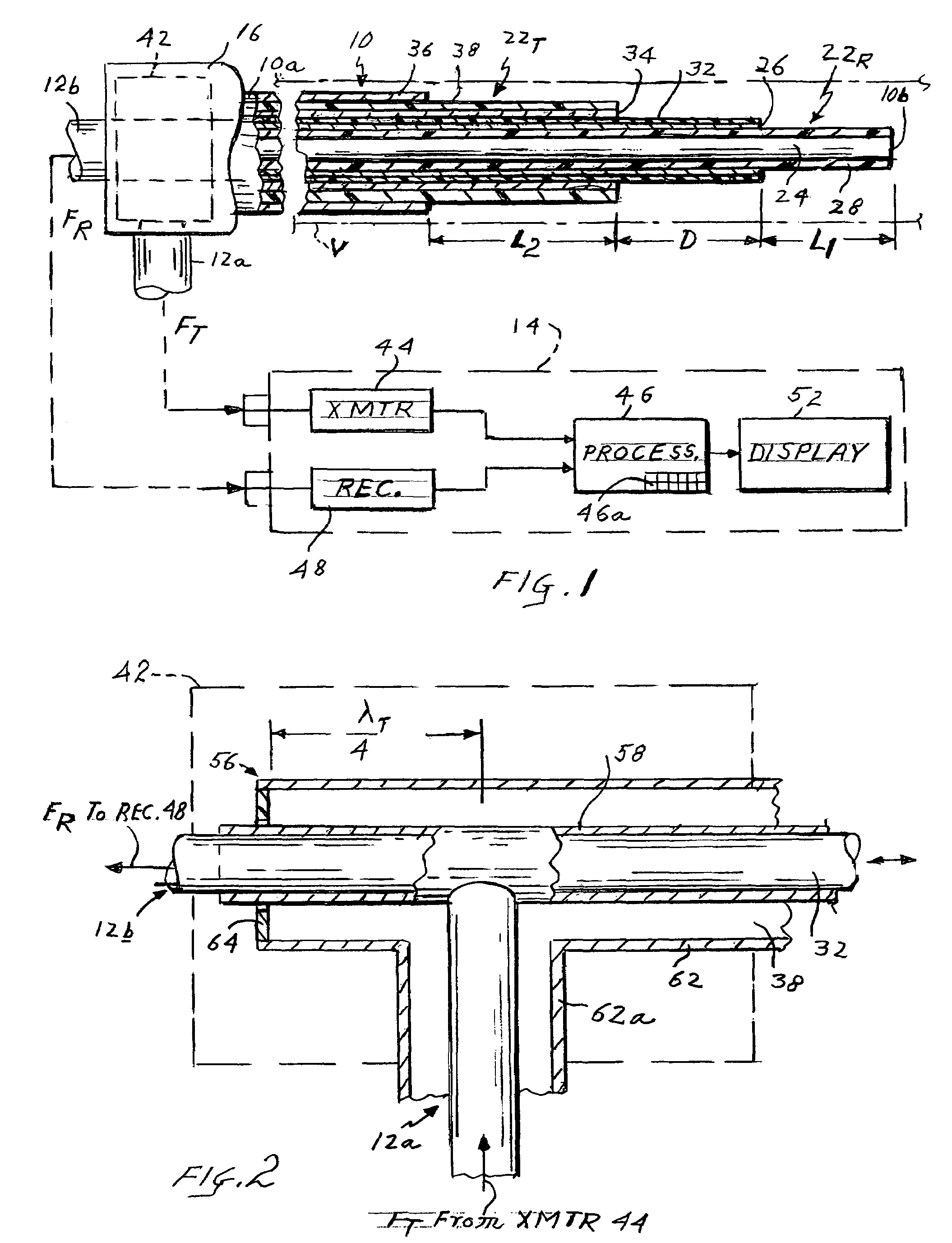

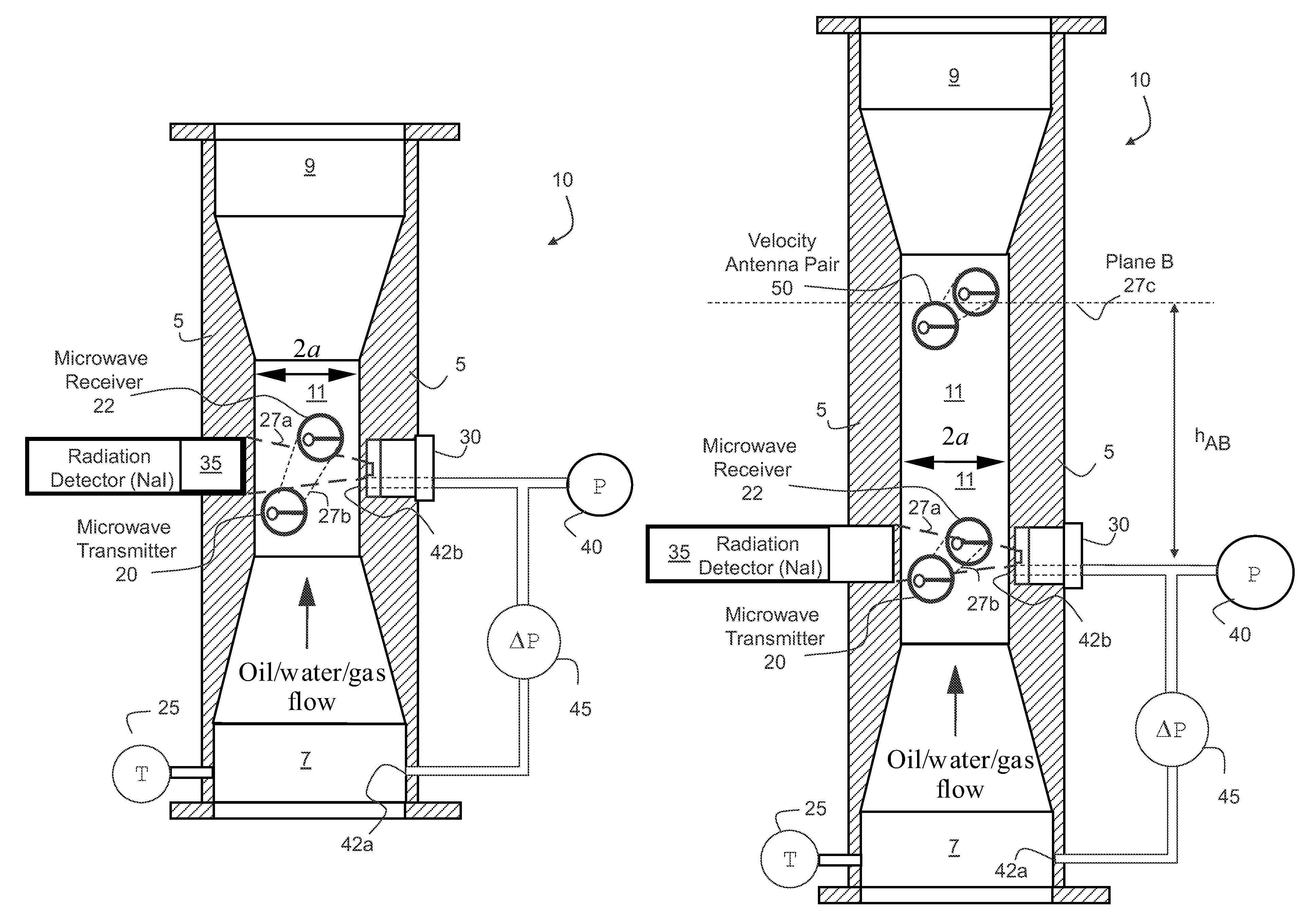

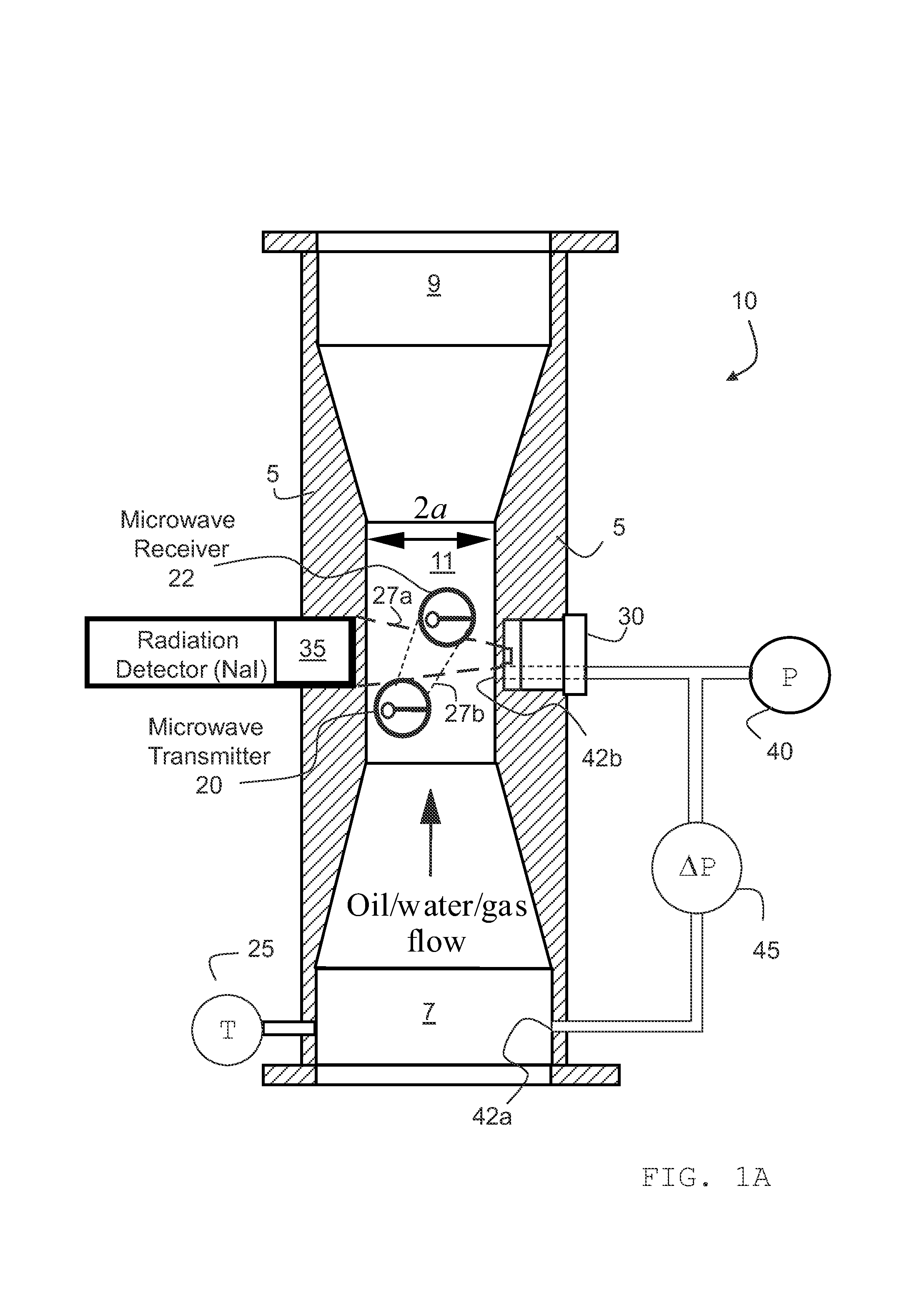

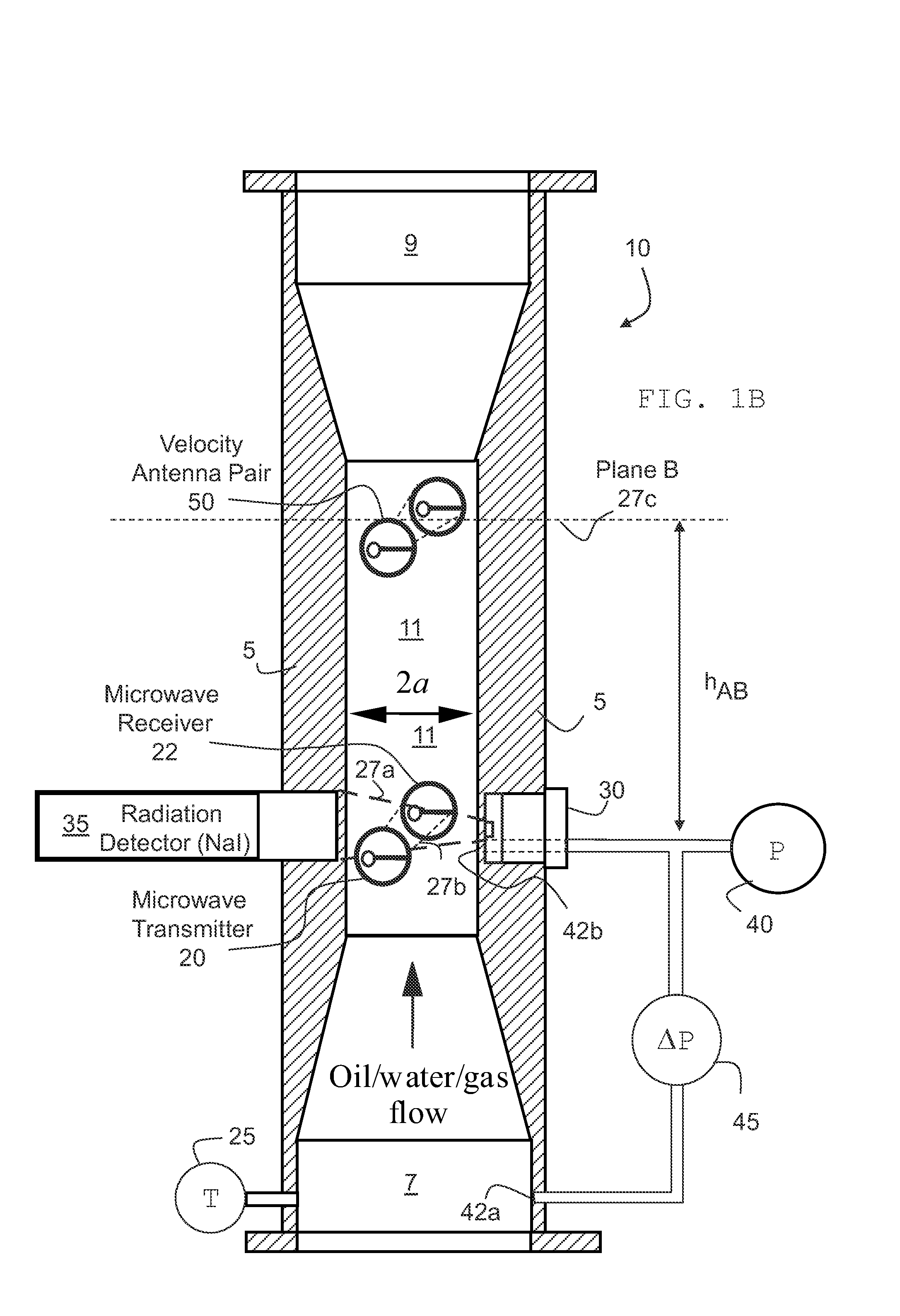

Systems and Methods For Measuring Multiphase Flow in a Hydrocarbon Transporting Pipeline

ActiveUS20080319685A1Material analysis using microwave meansMaterial testing goodsLow activityPressure difference

This disclosure relates in general to methods and systems for measuring multiphase flows in a pipeline using a combination of venturi, microwave and radiation techniques, where the pipeline is configured to transport hydrocarbons. More specifically, but not by way of limitation, certain embodiments of the present invention provide methods and systems in which low activity radiation sources may be used in combination with one or more microwave transmitter-receiver pairs and pressure differential sensors to measure the flow rates and fractions of phases in multiphase flows in a pipeline, such as may be encountered in producing hydrocarbon wells. Additionally, other embodiments of the present invention provide for the arrangement of one or more microwave transmitter-receiver pairs, one or more radiation source-detector pairs and / or one or more pressure sensor ports in the same cross-section of the throat of a venturi to measure multiphase flow in a hydrocarbon transporting pipeline.

Owner:SCHLUMBERGER TECH CORP

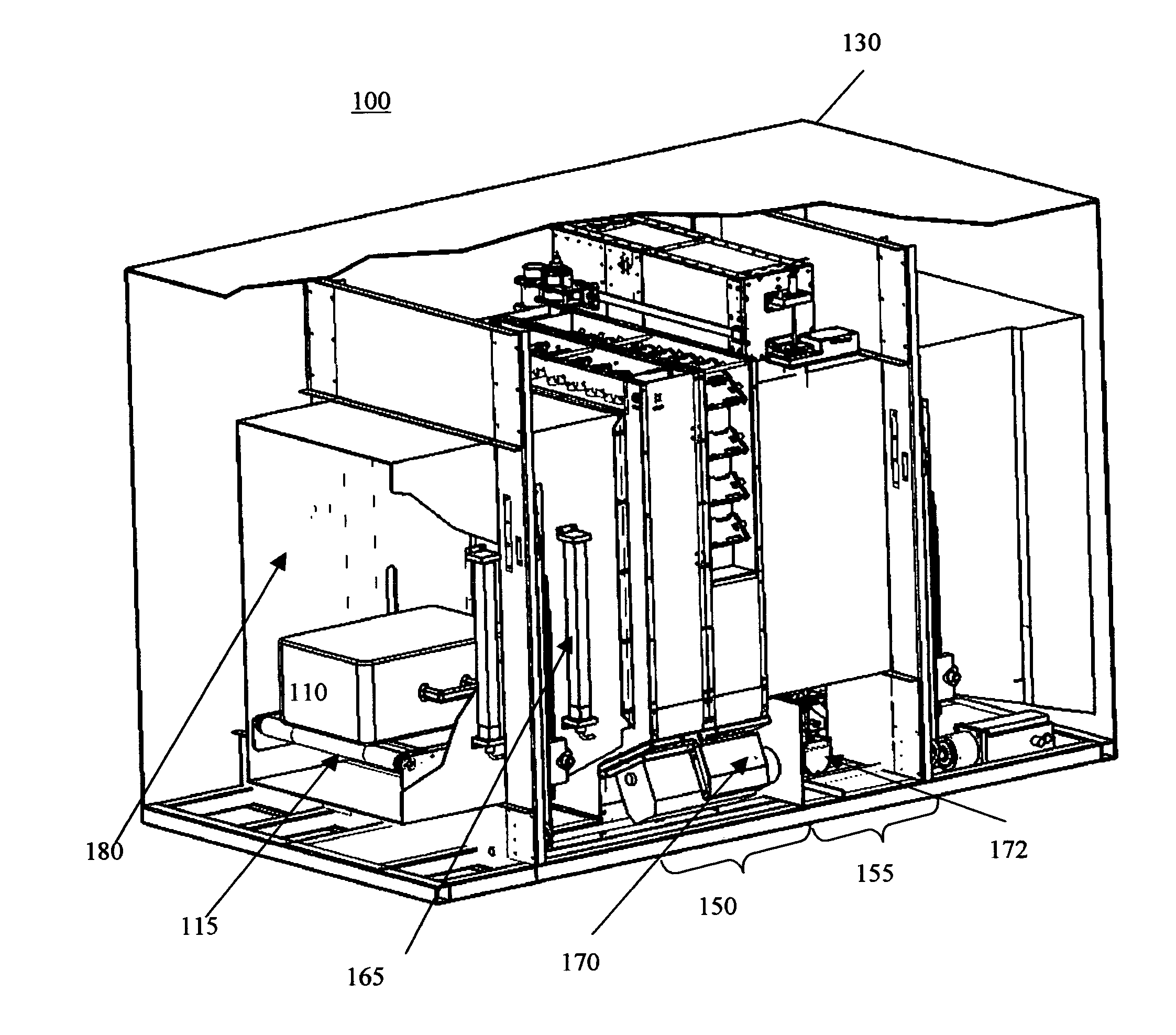

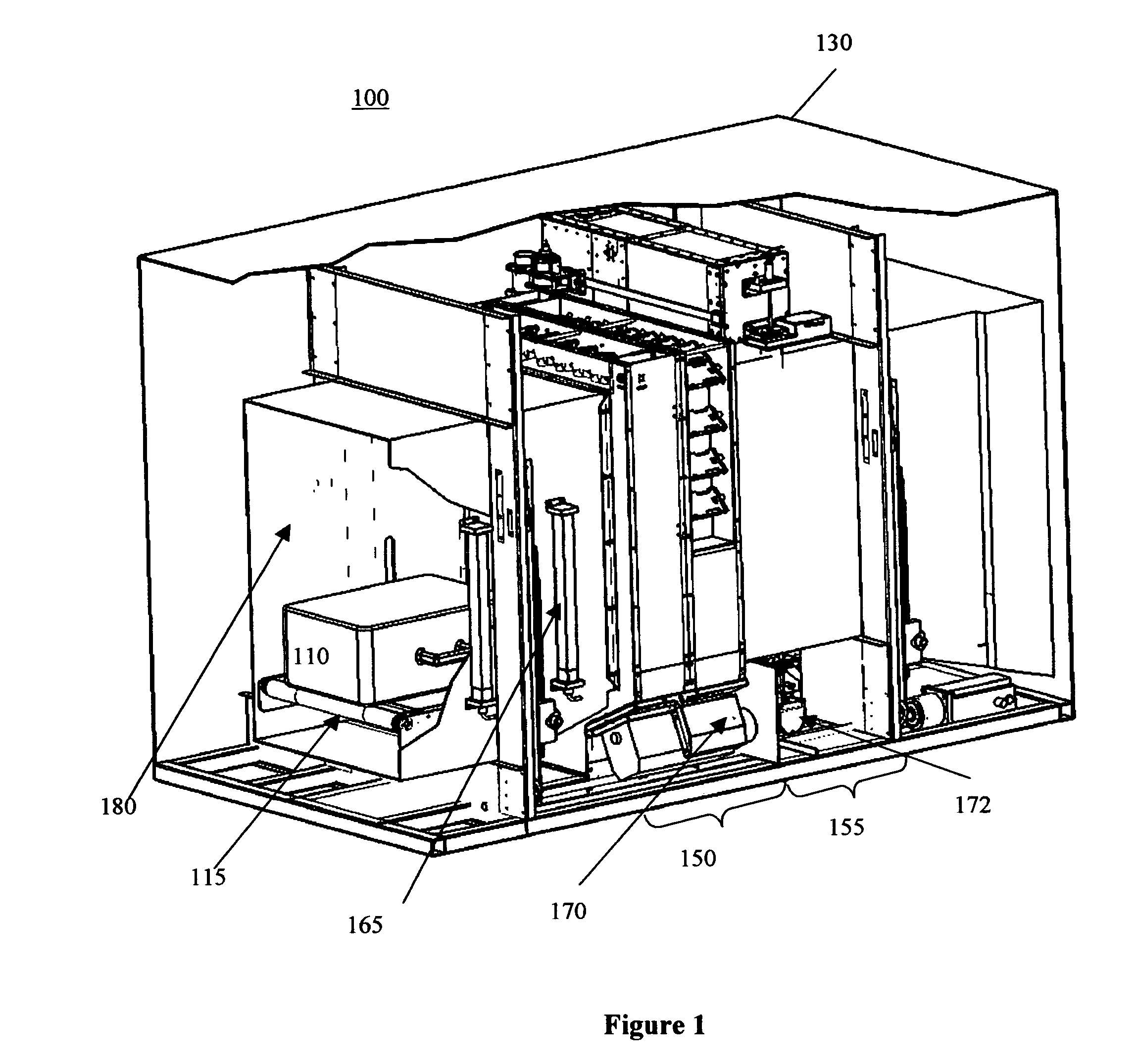

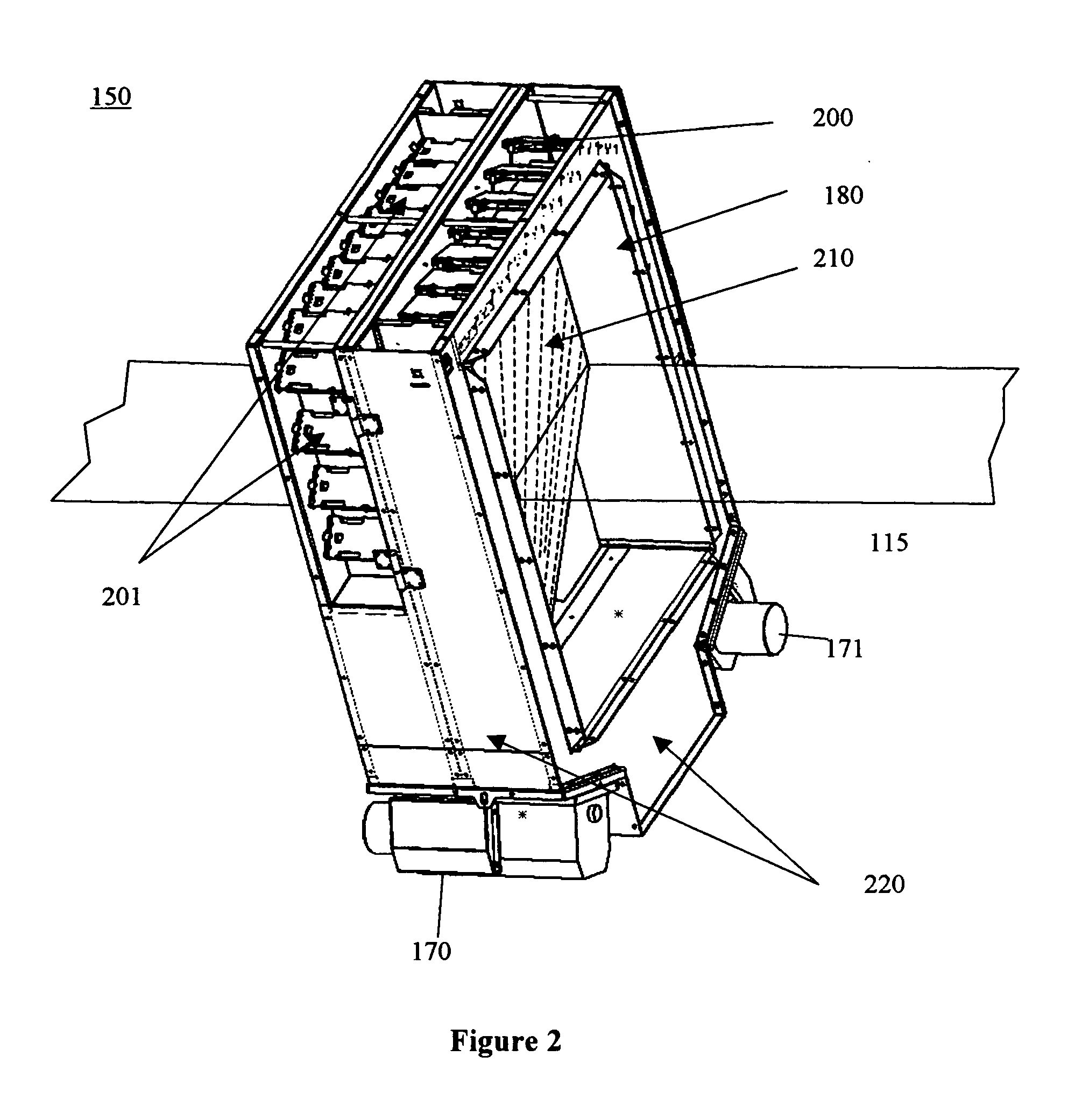

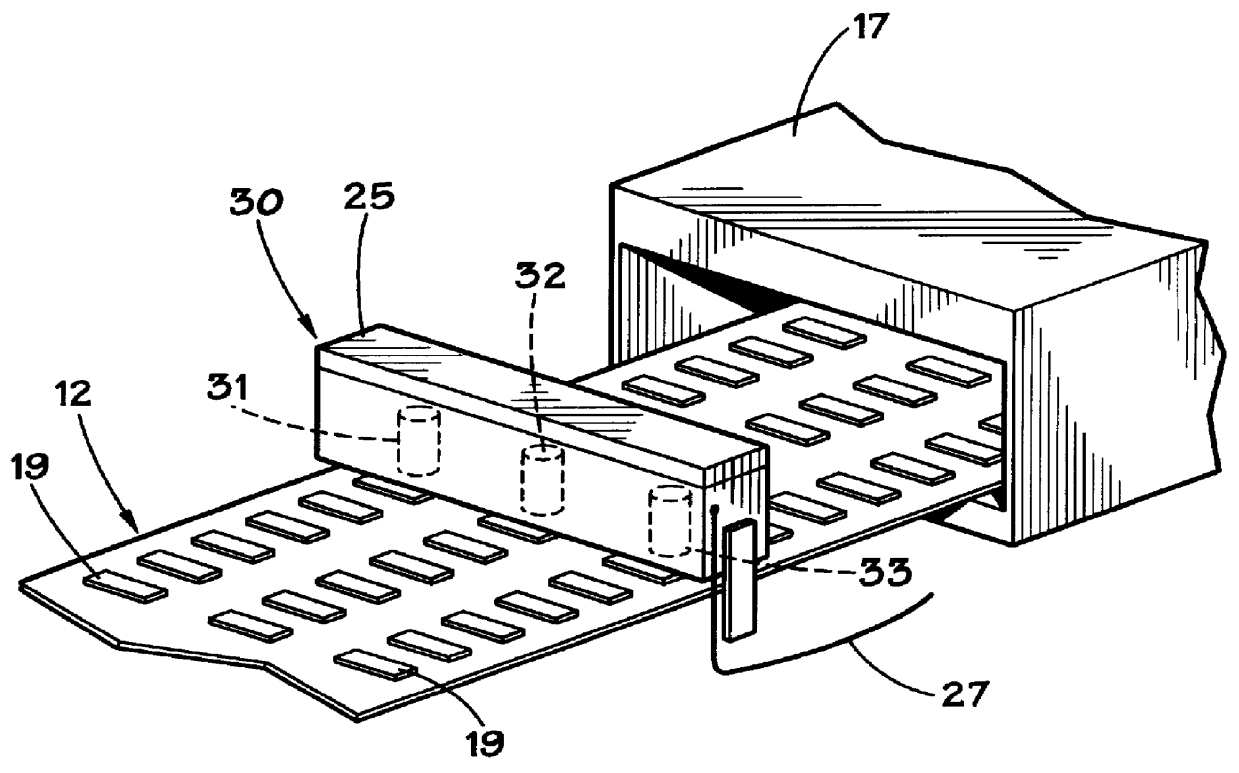

Methods and systems for the rapid detection of concealed objects

InactiveUS20050104603A1Reduce frequencyTrue natureAntenna arraysResistance/reactance/impedenceX-rayComputing tomography

The present invention provides for an improved scanning process having microwave arrays comprised of microwave transmitters in radiographic alignment with microwave receivers. The microwave array emits controllably directed microwave radiation toward an object under inspection. The object under inspection absorbs radiation in a manner dependent upon its metal content. The microwave radiation absorption can be used to generate a measurement of metal content. The measurement, in turn, can be used to calculate at least a portion of the volume and shape of the object under inspection. The measurement can be compared to a plurality of predefined threats. The microwave screening system can be used in combination with other screening technologies, such as NQR-based screening, X-ray transmission based screening, X-ray scattered based screening, or Computed Tomography based screening.

Owner:RAPISCAN SYST INC (US)

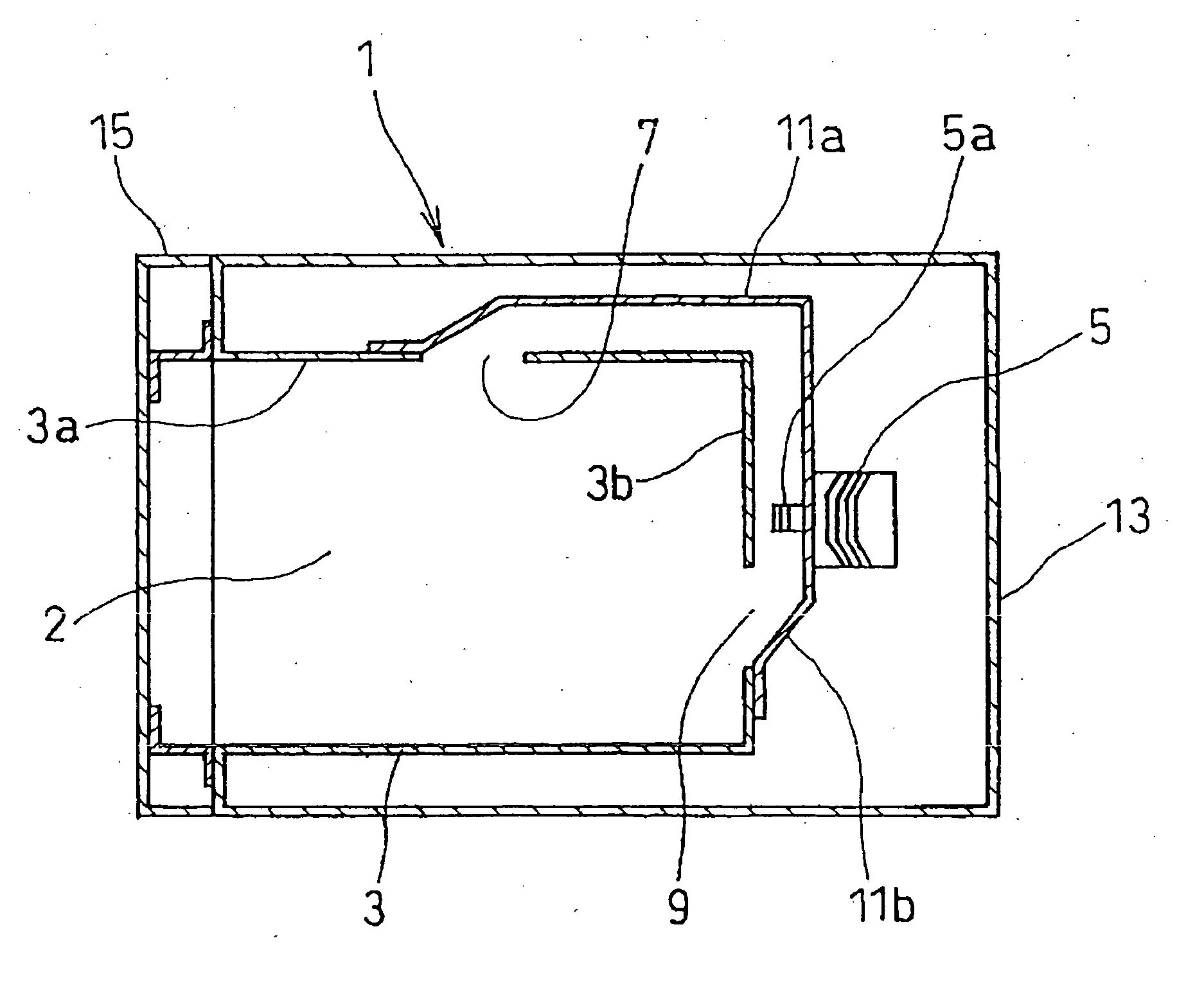

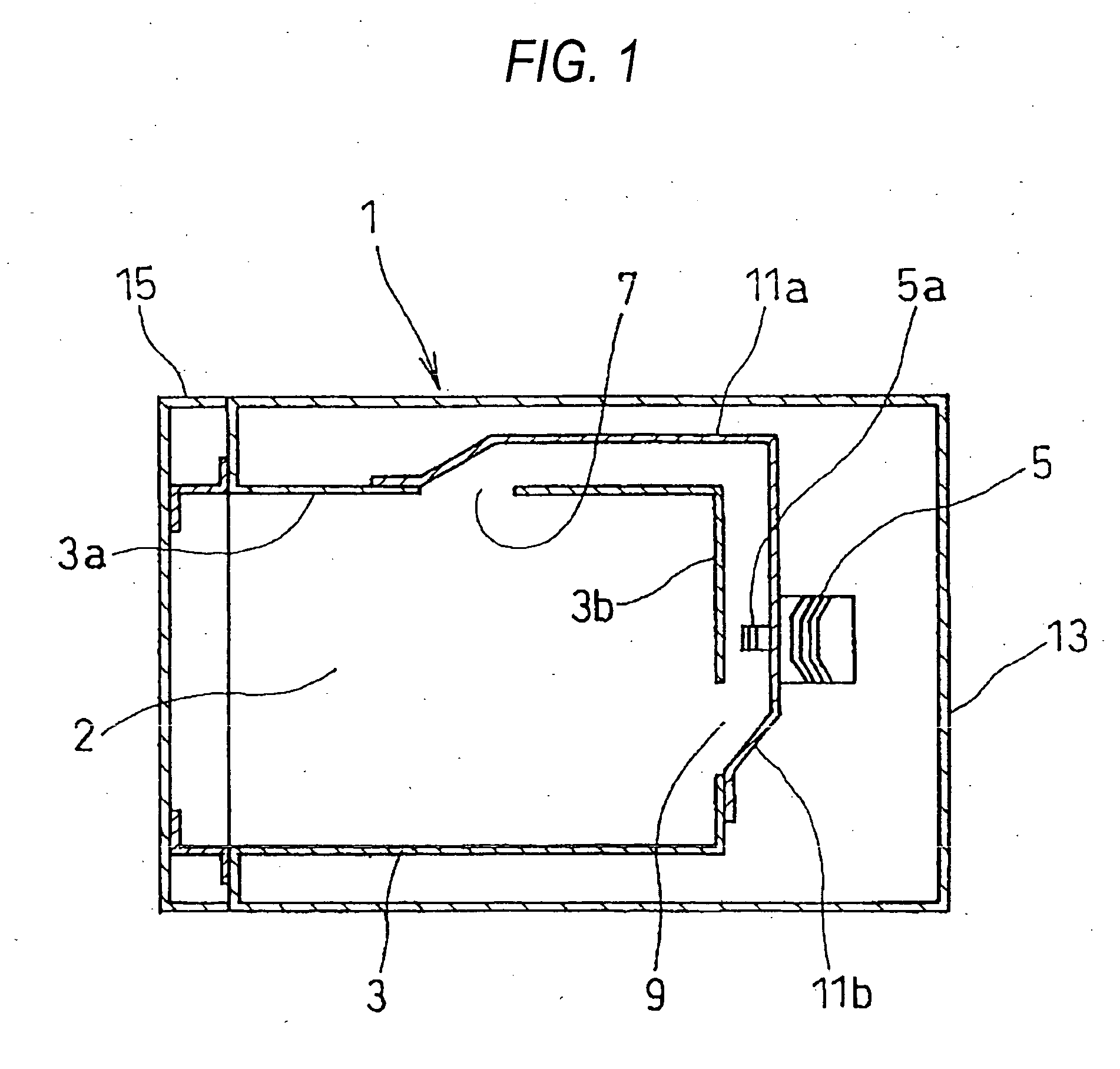

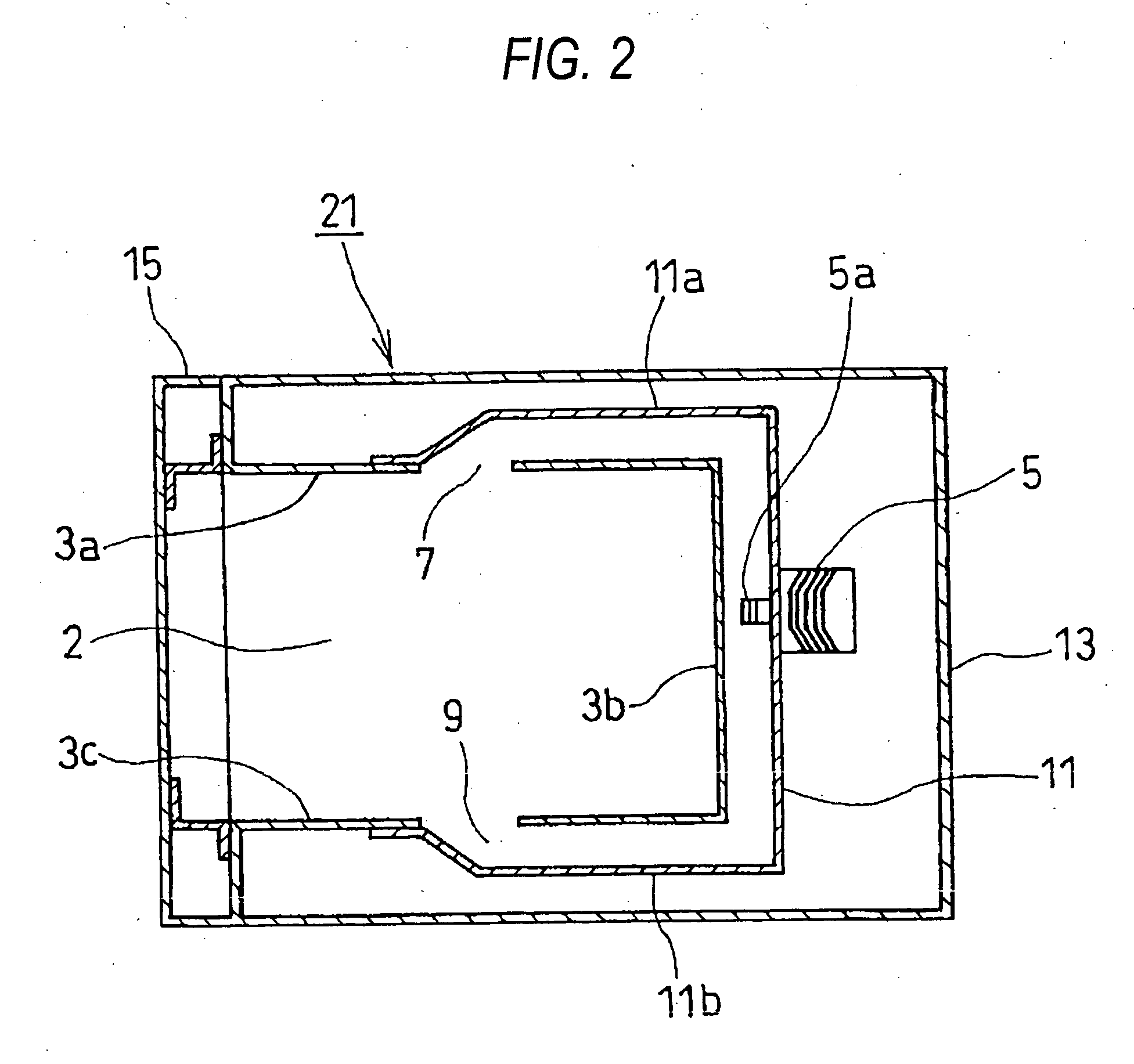

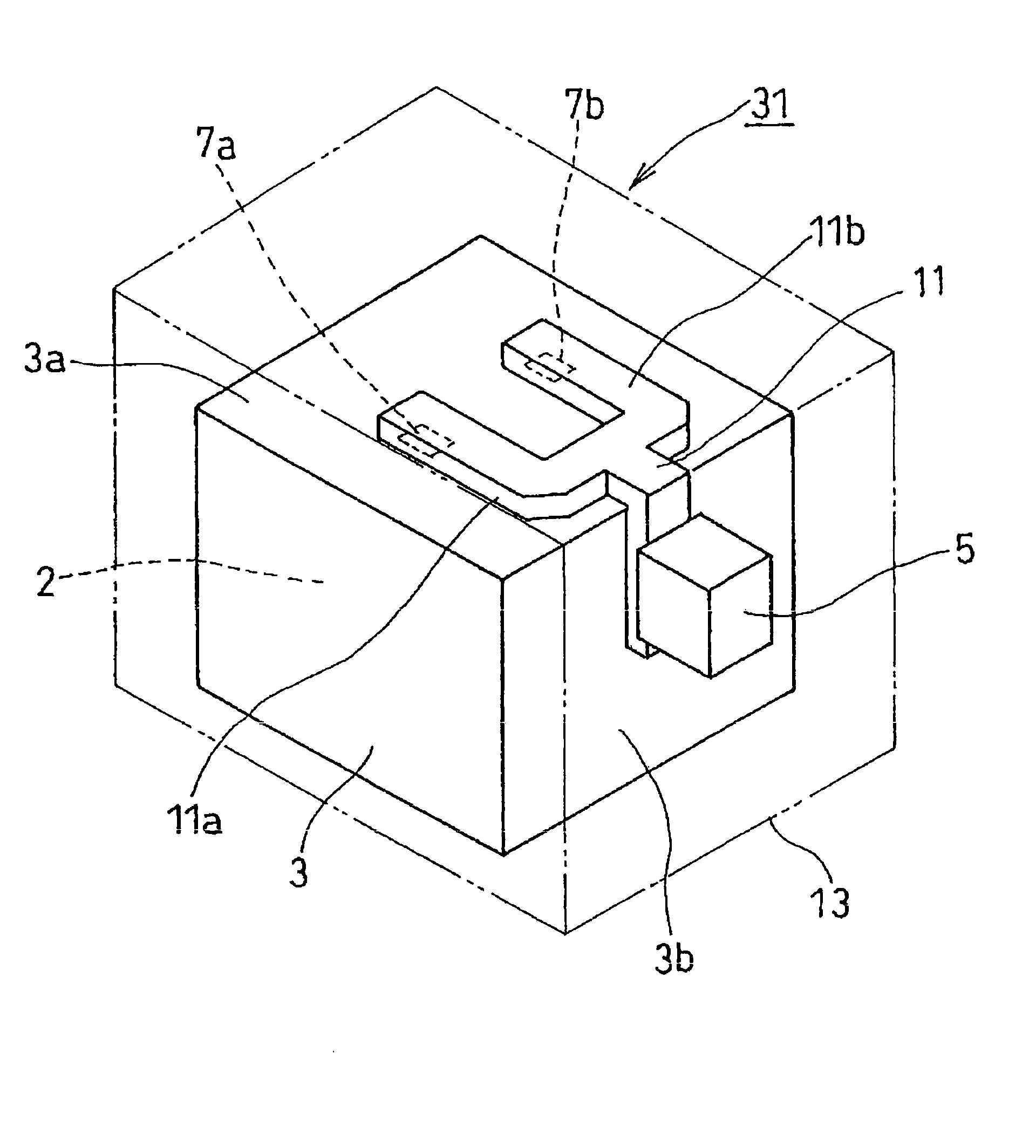

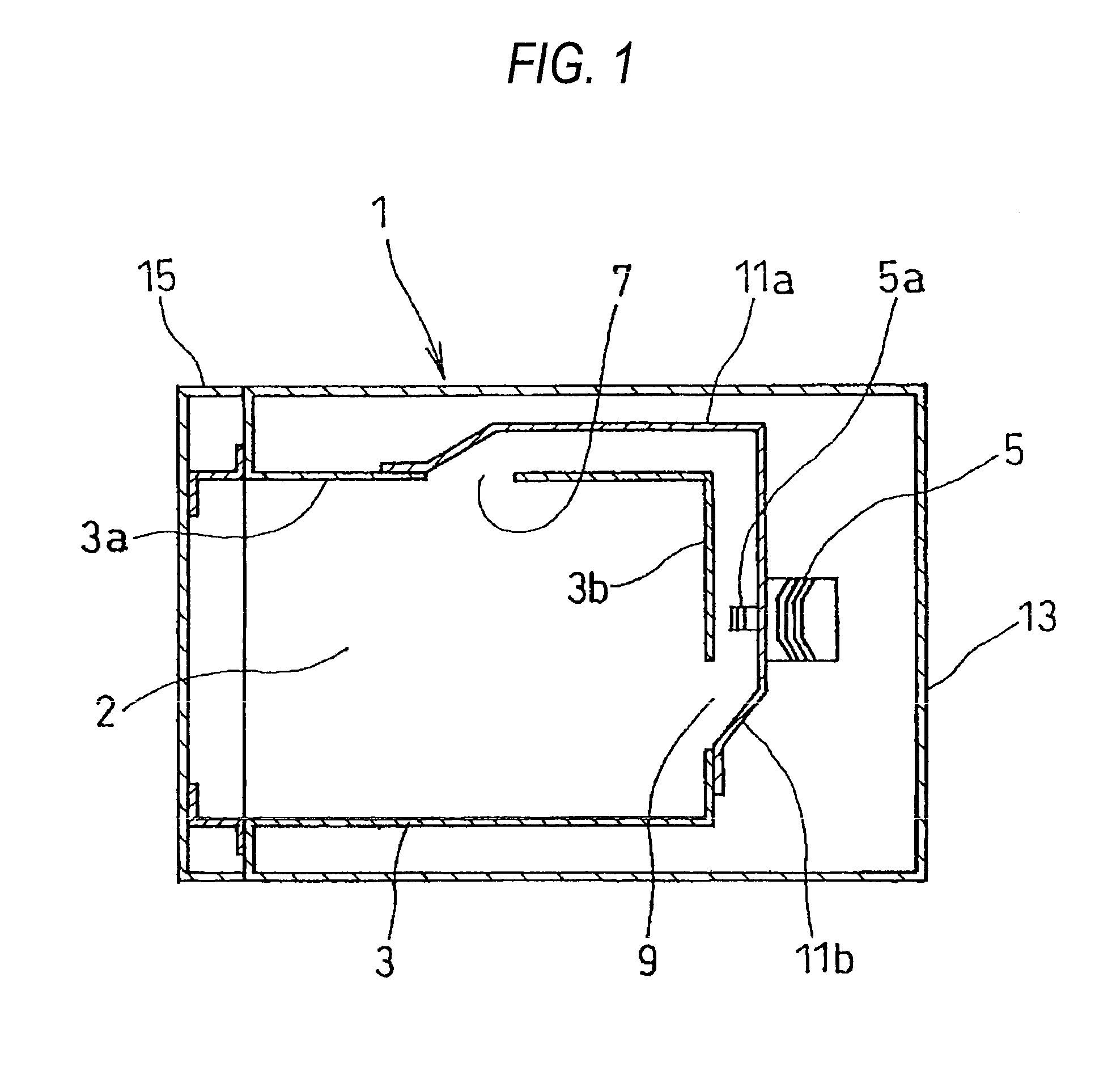

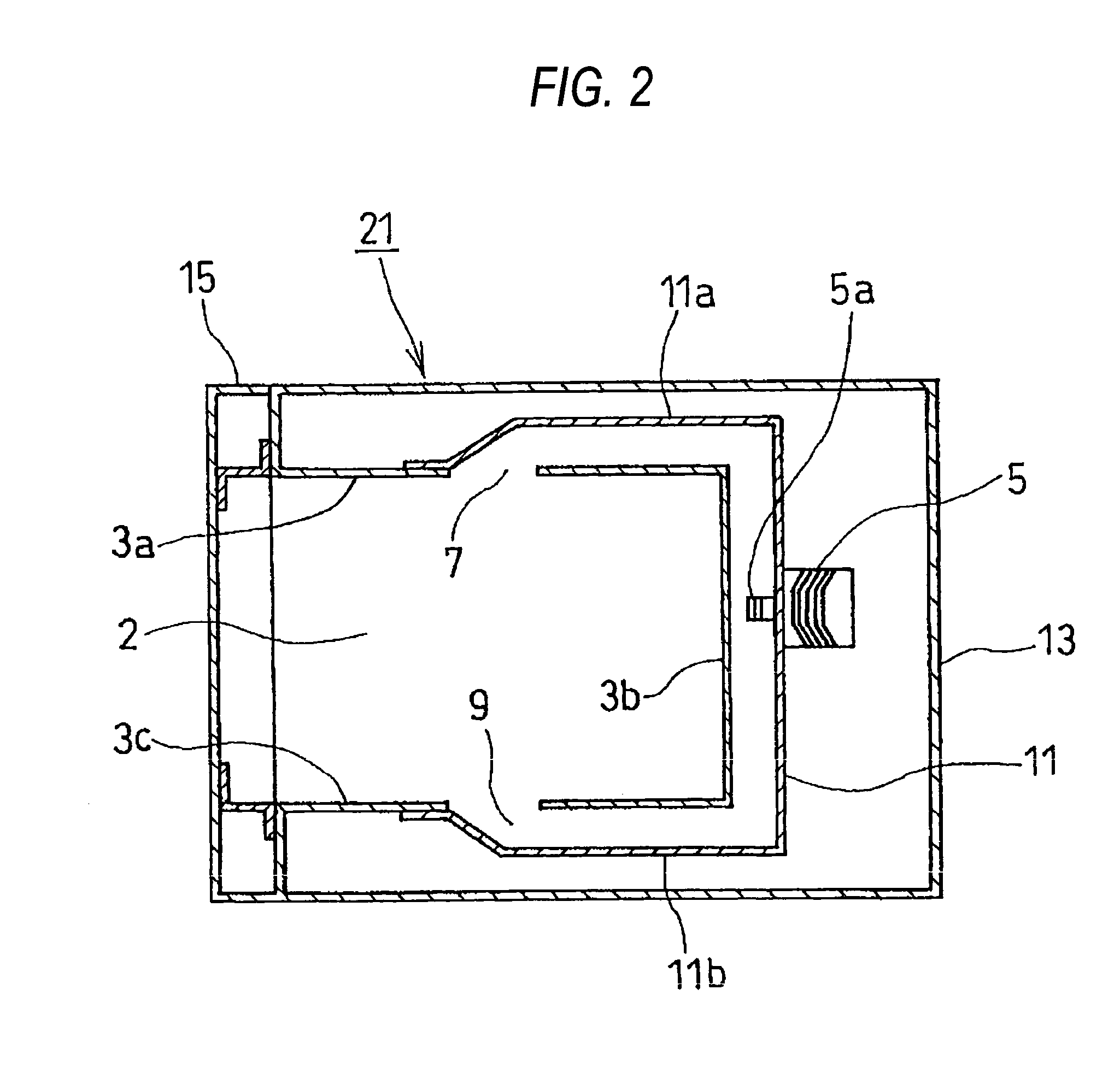

High-frequency heating device and method for controlling same

A problem of the invention is to provide a high frequency heating apparatus capable of realizing excellent heating without an irregularity in heating even for a thick-walled heated object. In order to resolve the above-described problem, according to a high frequency heating apparatus of the invention, a high frequency heating apparatus 1 for heating a heated object by irradiating a microwave having a frequency of 5.8 GHz to the heated object is constituted by mounting a plurality of pieces of wave guides 11a, 11b having feeding ports 7, 9 for emitting microwaves into a cavity 3 partitioning a heating chamber 2.

Owner:PANASONIC CORP

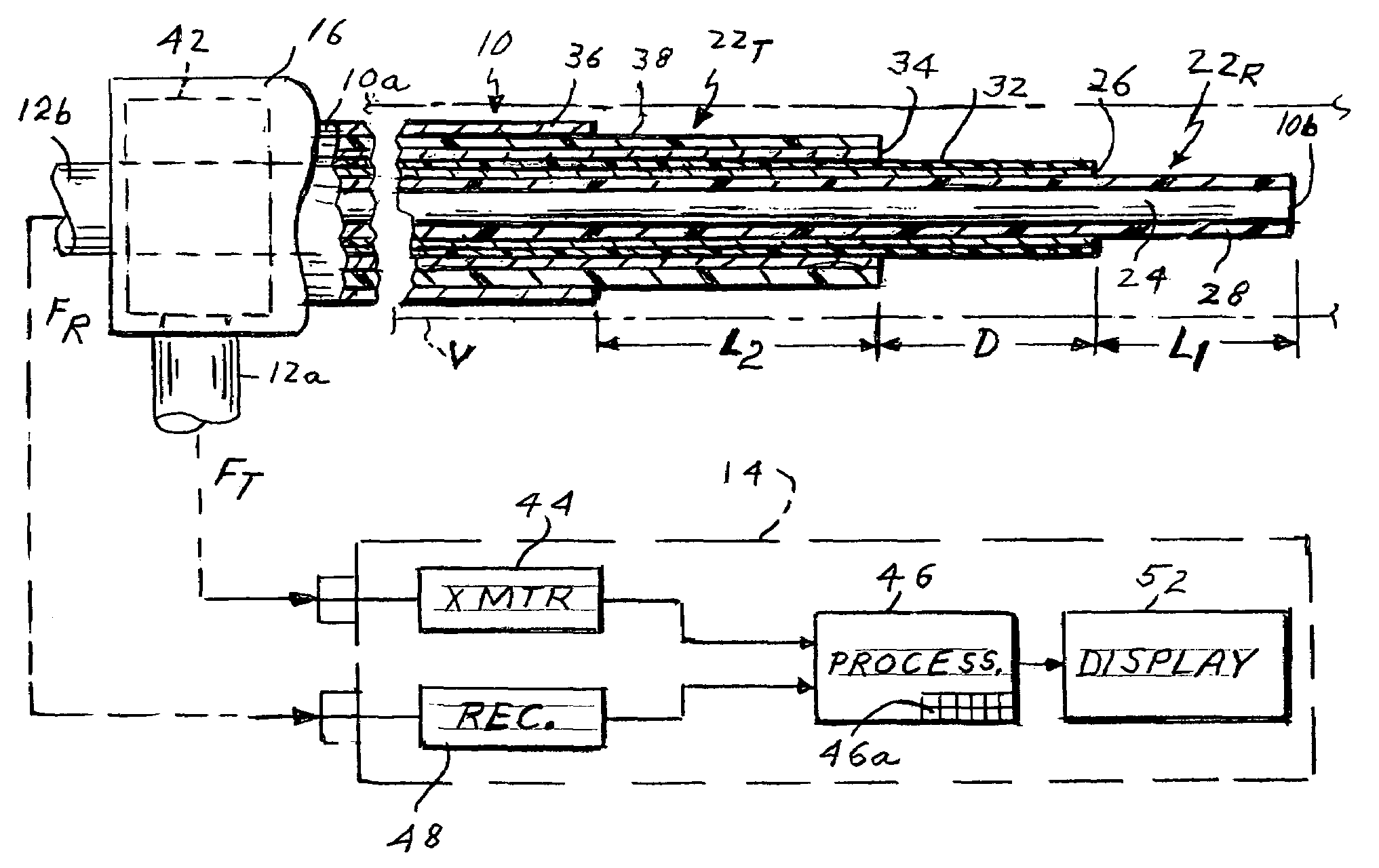

Apparatus for measuring intravascular blood flow

ActiveUS7263398B2Reduce usageQuickly and accurately measure blood flow rateCatheterSensorsCoaxial cableNormal blood volume

Microwave apparatus for measuring the blood flow rate in a patient's blood vessel includes an intravascular catheter having proximal and distal ends and containing an inner coaxial cable forming a first antenna and an outer cable coaxial with the inner cable and forming a second antenna, the first antenna extending axially beyond the second antenna a selected distance. The apparatus also includes a control unit including a microwave transmitter, a microwave receiver and a processor controlling the transmitter and receiver. A diplexer is connected between the first and second antenna and the control unit to couple signals from the transmitter to the second antenna but not to the receiver and to couple signals from the first antenna to the receiver but not to the transmitter. The transmitter transmits microwave pulses to the first antenna which heat blood around that antenna. When the heated blood volume flows to the second antenna this is detected at the receiver which produces a detect signal. The processor measures the time interval between each pulse a subsequent detect signal and divides that time interval into the axial distance between the two antennas to compute the flow rate.

Owner:CORAL SAND BEACH LLC

Systems and methods for measuring multiphase flow in a hydrocarbon transporting pipeline

ActiveUS7908930B2Material analysis using microwave meansMaterial testing goodsLow activityPressure difference

This disclosure relates in general to methods and systems for measuring multiphase flows in a pipeline using a combination of venturi, microwave and radiation techniques, where the pipeline is configured to transport hydrocarbons. More specifically, but not by way of limitation, certain embodiments of the present invention provide methods and systems in which low activity radiation sources may be used in combination with one or more microwave transmitter-receiver pairs and pressure differential sensors to measure the flow rates and fractions of phases in multiphase flows in a pipeline, such as may be encountered in producing hydrocarbon wells. Additionally, other embodiments of the present invention provide for the arrangement of one or more microwave transmitter-receiver pairs, one or more radiation source-detector pairs and / or one or more pressure sensor ports in the same cross-section of the throat of a venturi to measure multiphase flow in a hydrocarbon transporting pipeline.

Owner:SCHLUMBERGER TECH CORP

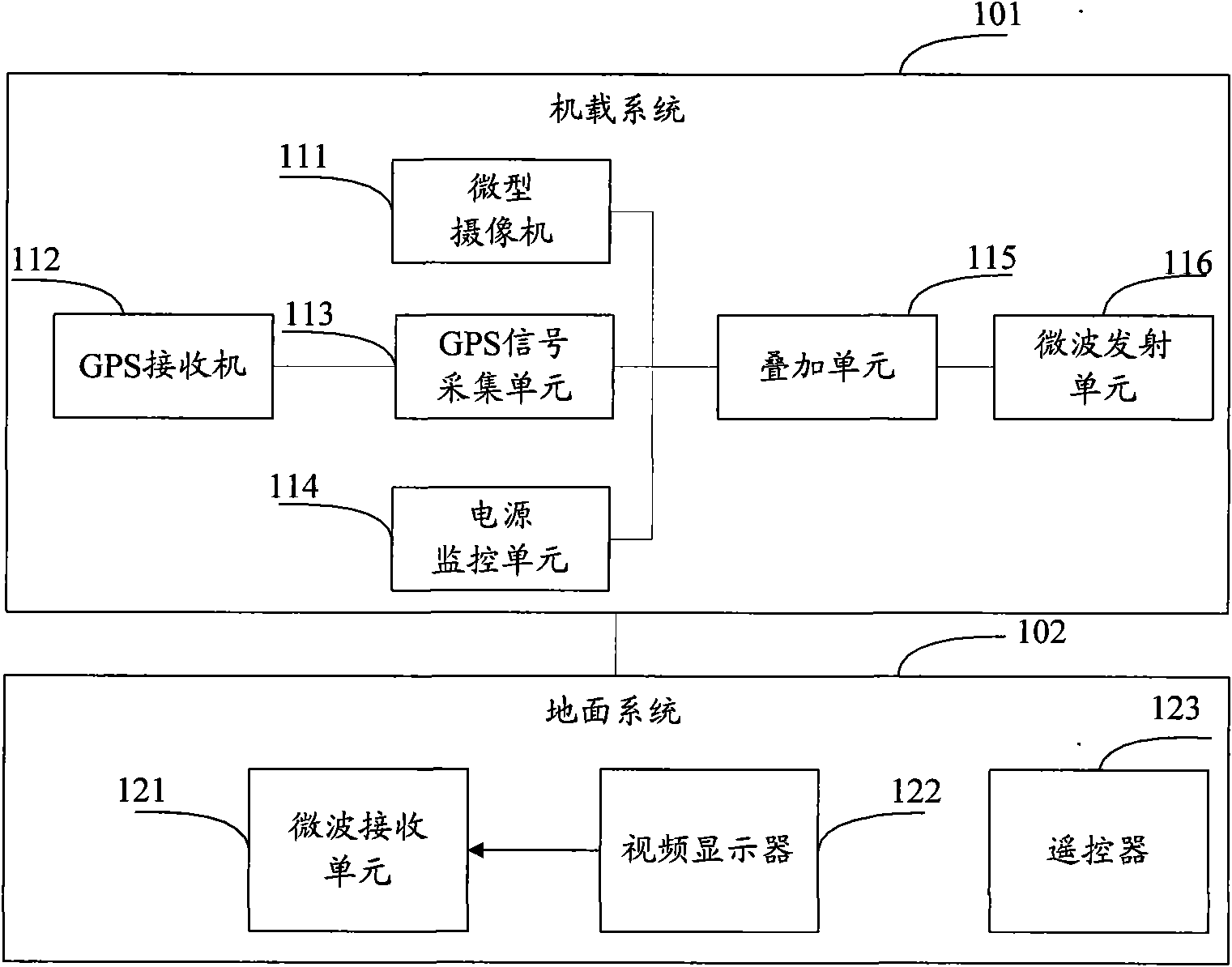

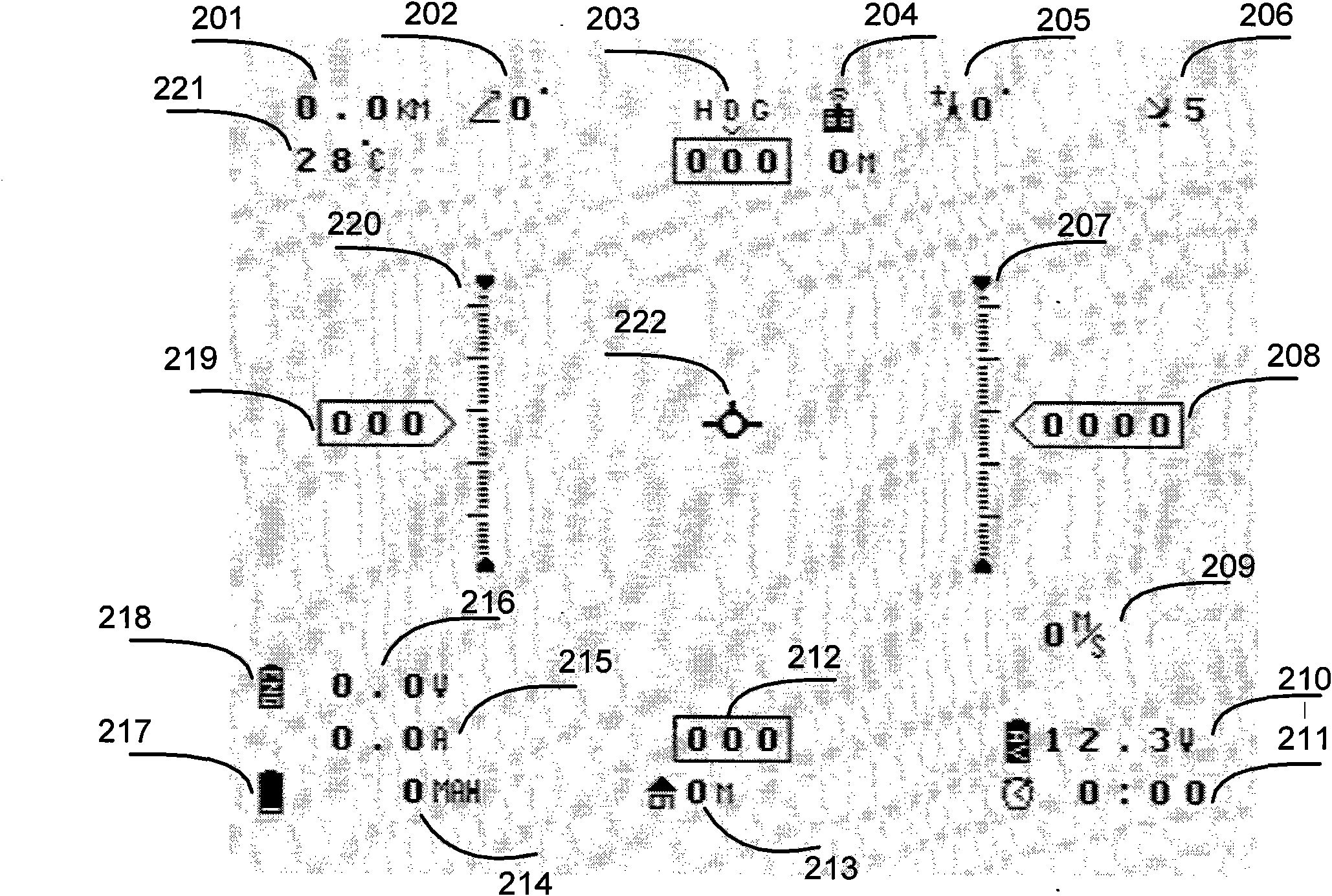

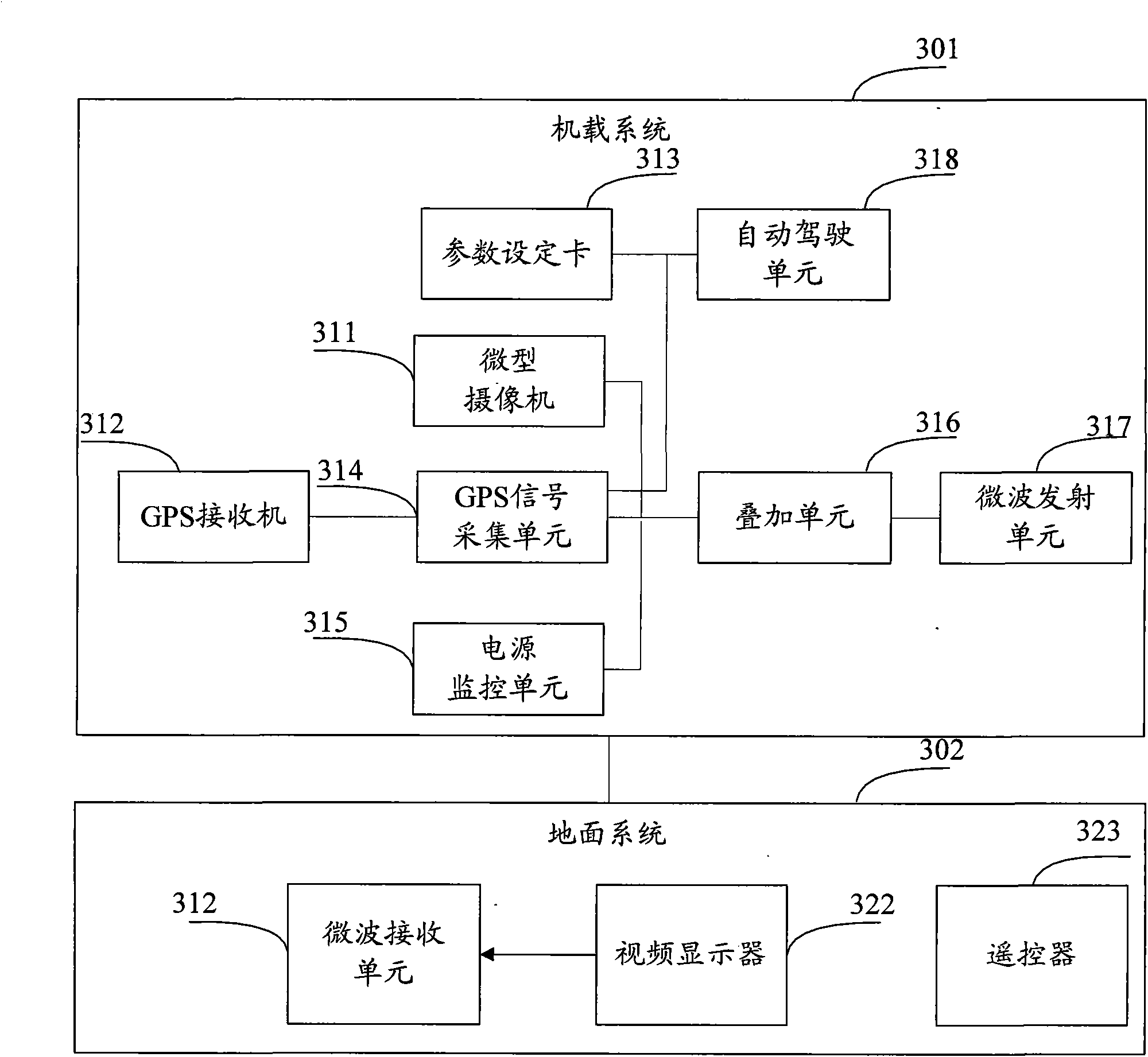

Flight control system

InactiveCN101866180ARealize remote control takeoffAchieve landingVehicle position/course/altitude controlPosition/direction controlRemote controlGround system

The invention provides a flight control system, which comprises an airborne system and a ground system, wherein the airborne system comprises a miniature video camera, a GPS receiver, a GPS signal collection unit, a power supply monitoring unit, an overlapping unit and a microwave emitting unit, the miniature video camera and the GPS receiver are arranged outside an unmanned plane, the GPS signal collection unit, the power supply monitoring unit, the overlapping unit and the microwave emitting unit are arranged inside the unmanned plane, and the ground system comprises a microwave receiving unit, a video display and a remote control, wherein the miniature video camera is used for monitoring video images right ahead the unmanned plane in real time, the GPS signal collection unit is used for collecting and processing data transmitted from the GPS receiver to obtain flight parameters, the power supply monitoring unit is used for detecting and obtaining the power supply information of the unmanned plane, the overlapping unit is used for overlapping the flight parameters and / or the power supply information onto the video images, and the microwave emitting unit is used for emitting the overlapping results to the ground system. The invention can perfectly control the unmanned plane.

Owner:TSINGHUA UNIV

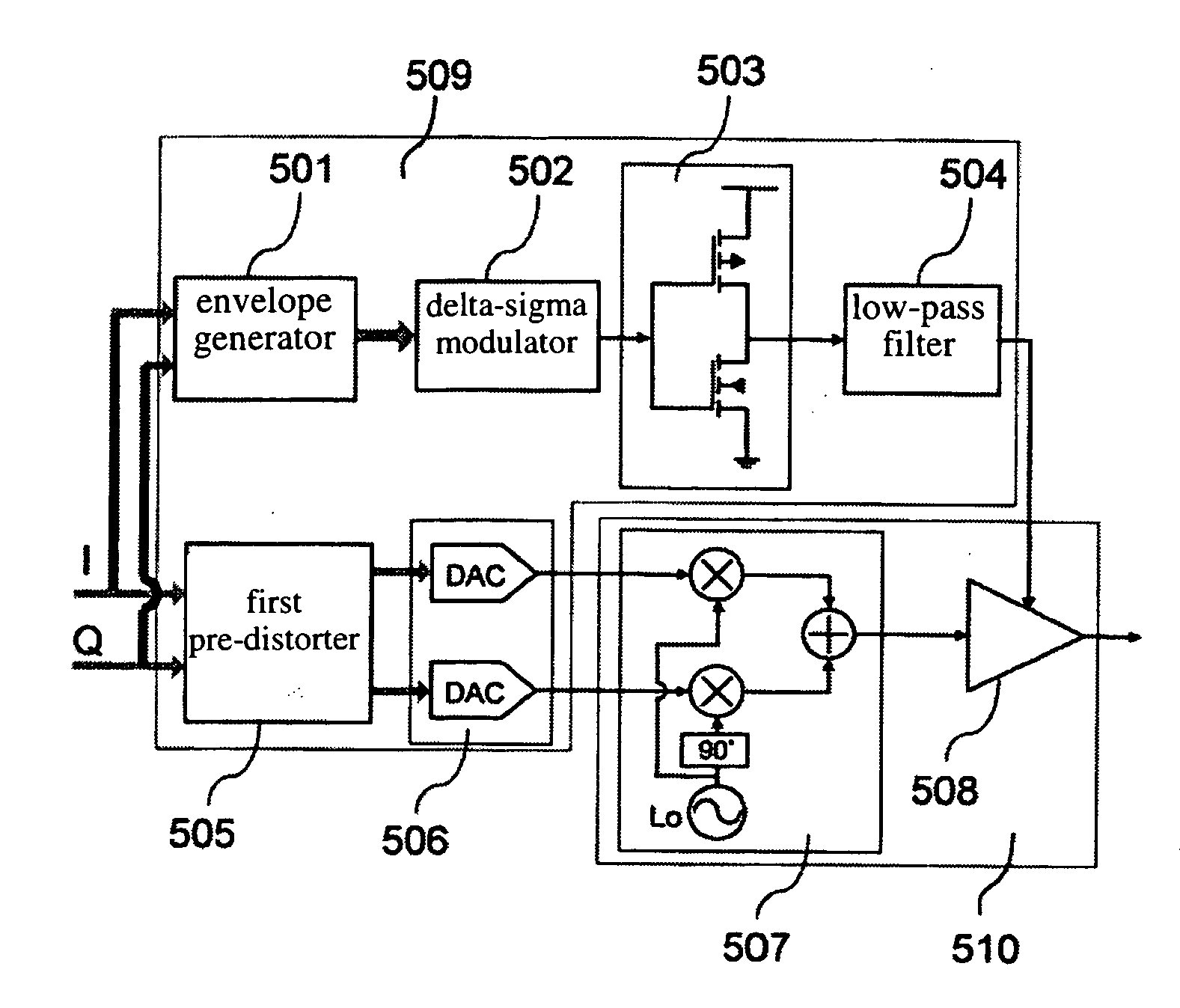

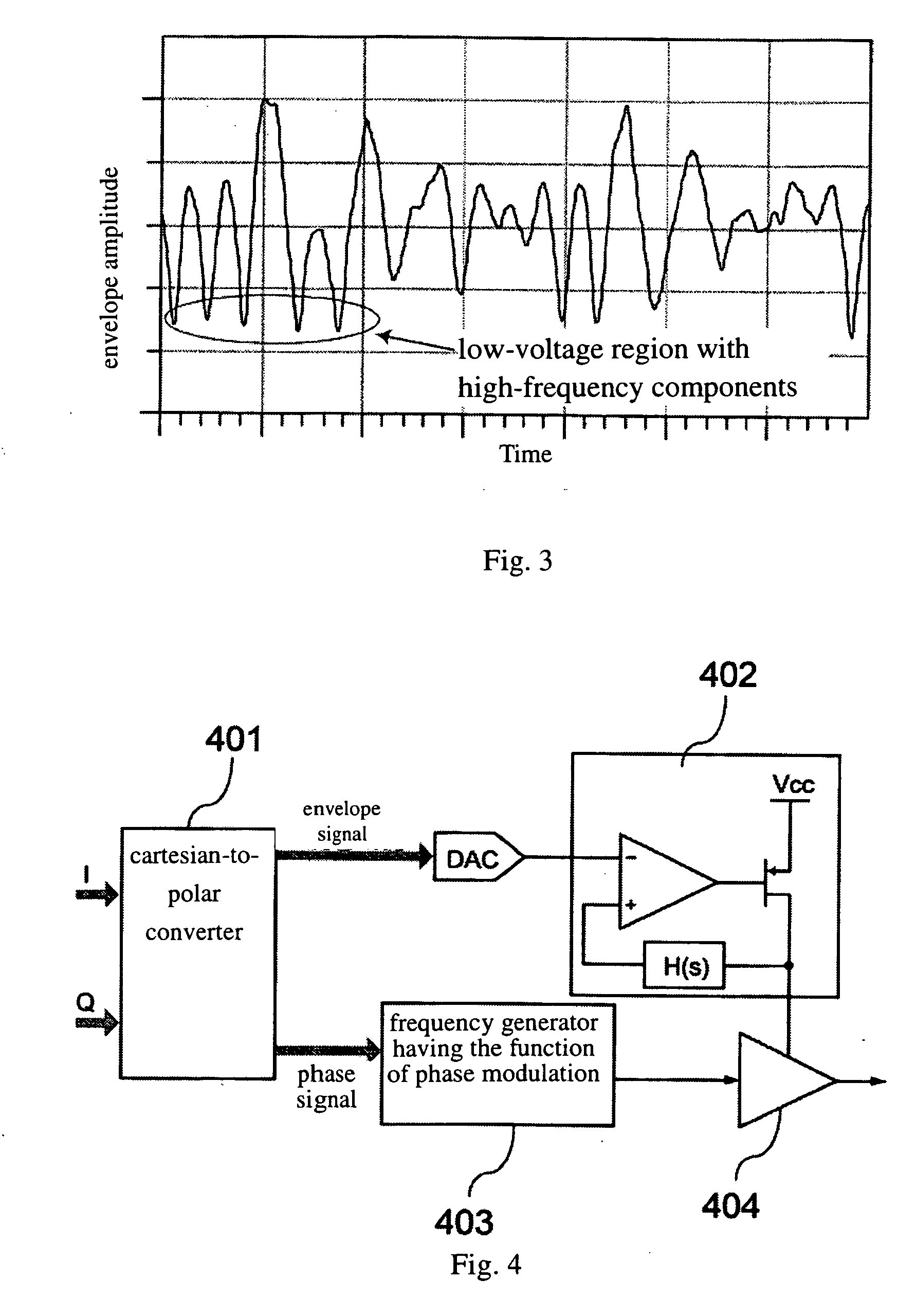

Microwave transmitter and the method for increasing envelope bandwidth

InactiveUS20070018718A1Low efficiencyPower flexibleAmplifier detailsDc amplifiers with modulator-demodulatorCarrier signalEngineering

The microwave transmitter of the present invention can perform two-terminal dynamic modulation with respect to the voltage supply terminal and the RF input terminal of a RF power amplifier. The microwave transmitter of the present invention comprises a first modulator and a second modulator. The first modulator uses the baseband digital delta-sigma modulation technique to process the envelope signal and outputs this signal to the voltage supply terminal of the RF power amplifier as a supply voltage. The second modulator uses the baseband digital pre-distortion technique to process the IQ-modulated carrier and outputs this signal to the RF input terminal of the RF power amplifier as a RF input signal. Thereby, the RF power amplifier can highly efficiently reconstruct the power-amplified RF modulated carrier without distortion at the RF output terminal. In addition, the baseband digital processing techniques used in the two modulators make the microwave transmitter of the present invention suitable for multi-mode operation.

Owner:NAT SUN YAT SEN UNIV +1

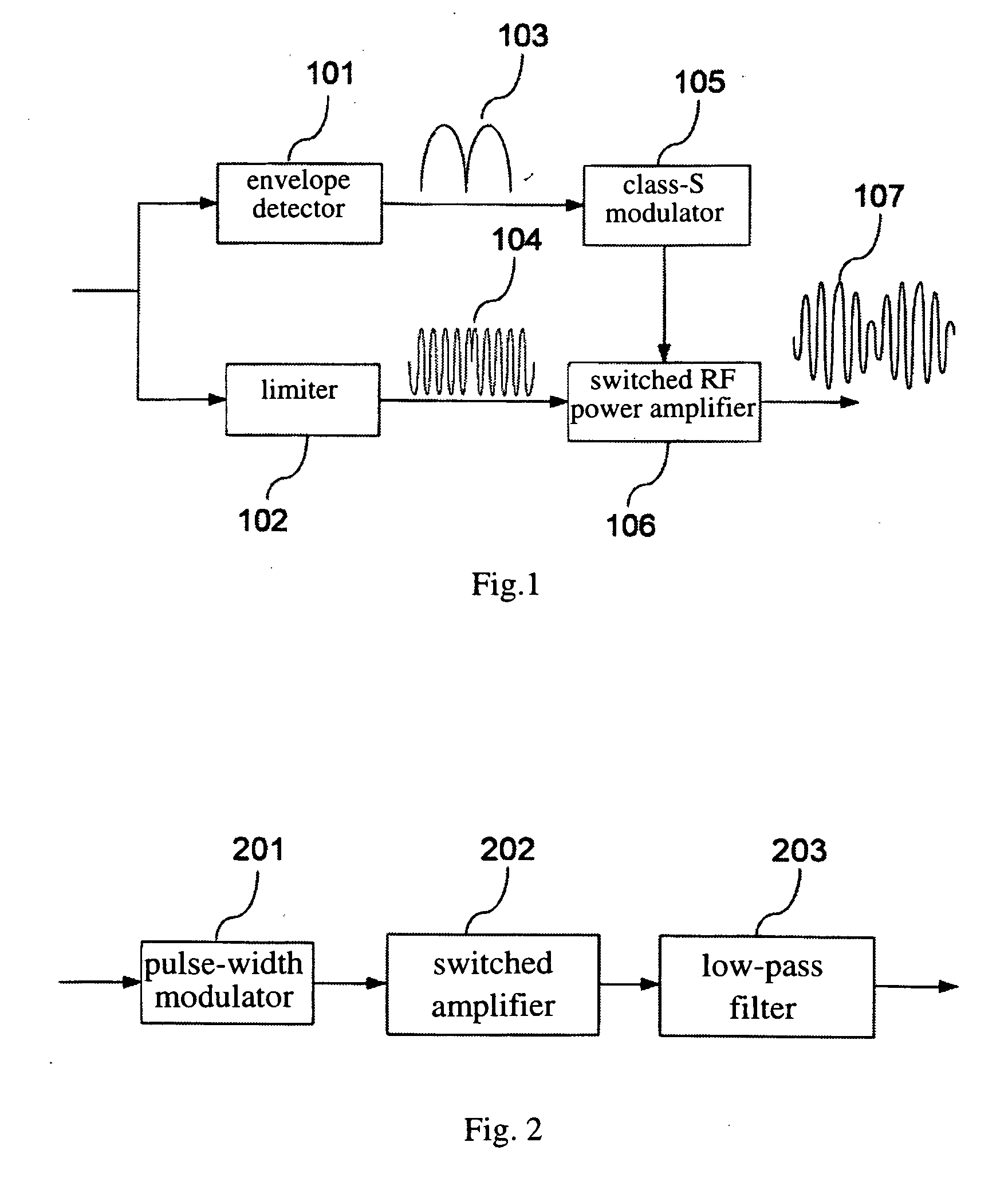

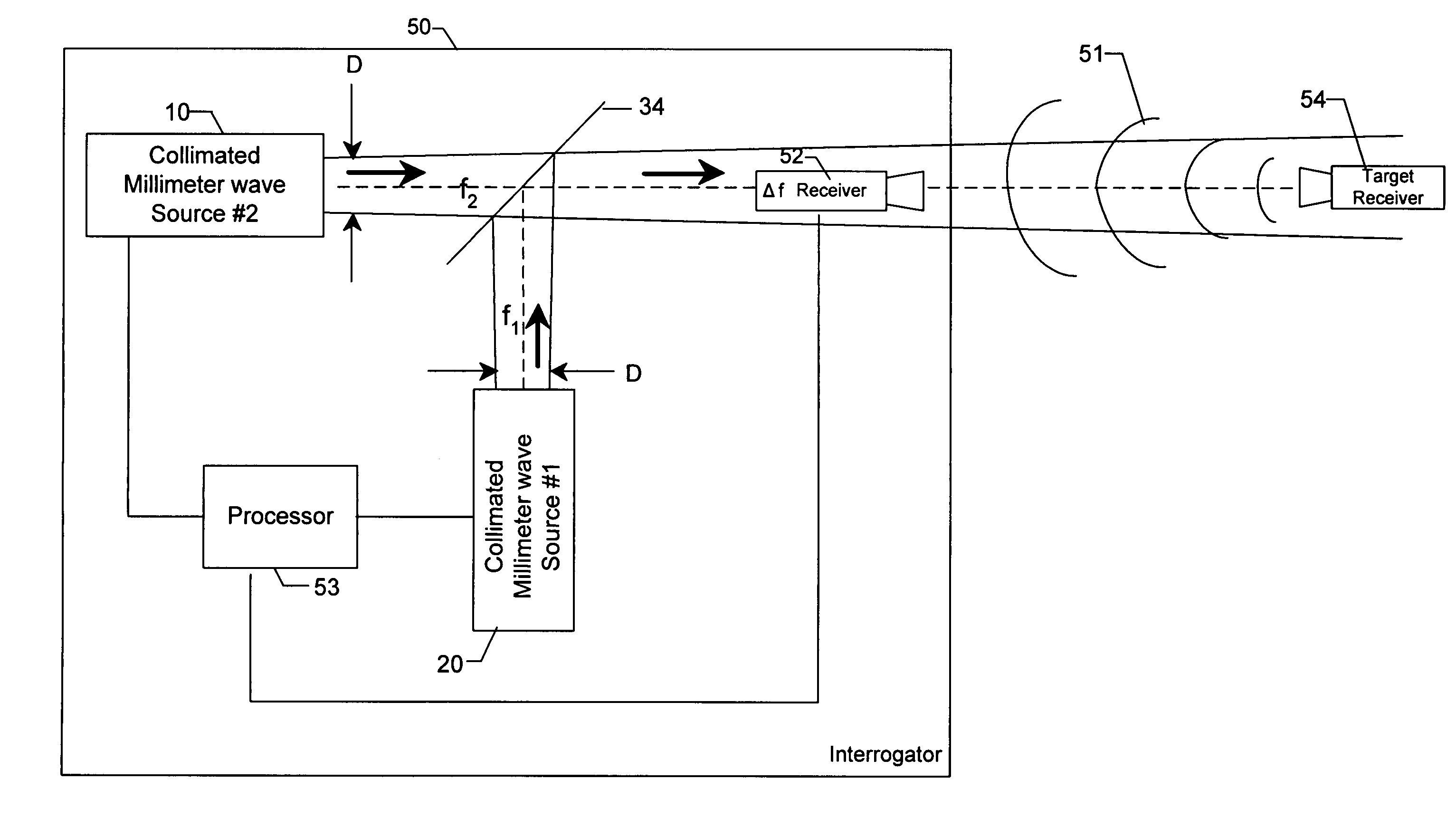

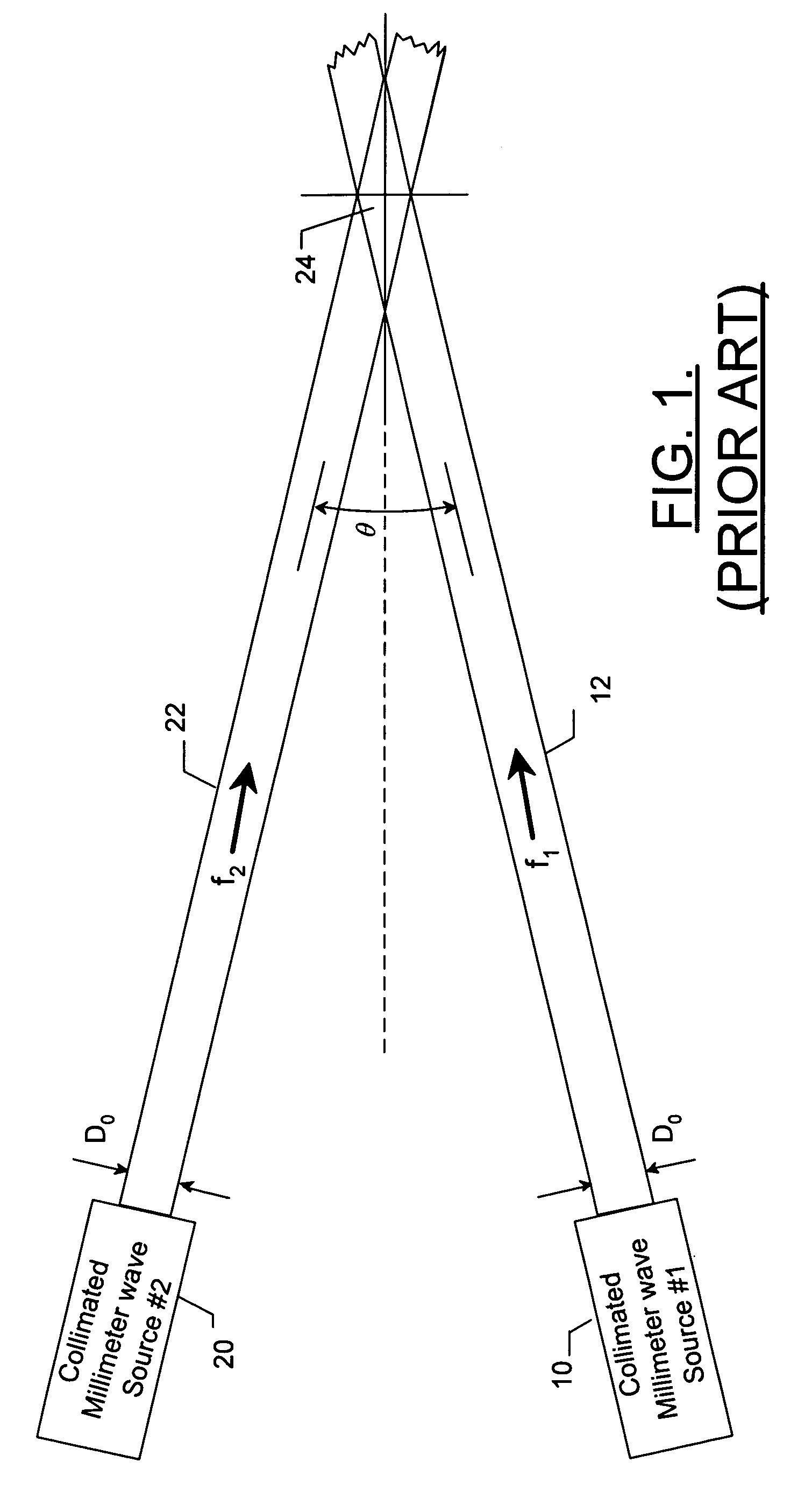

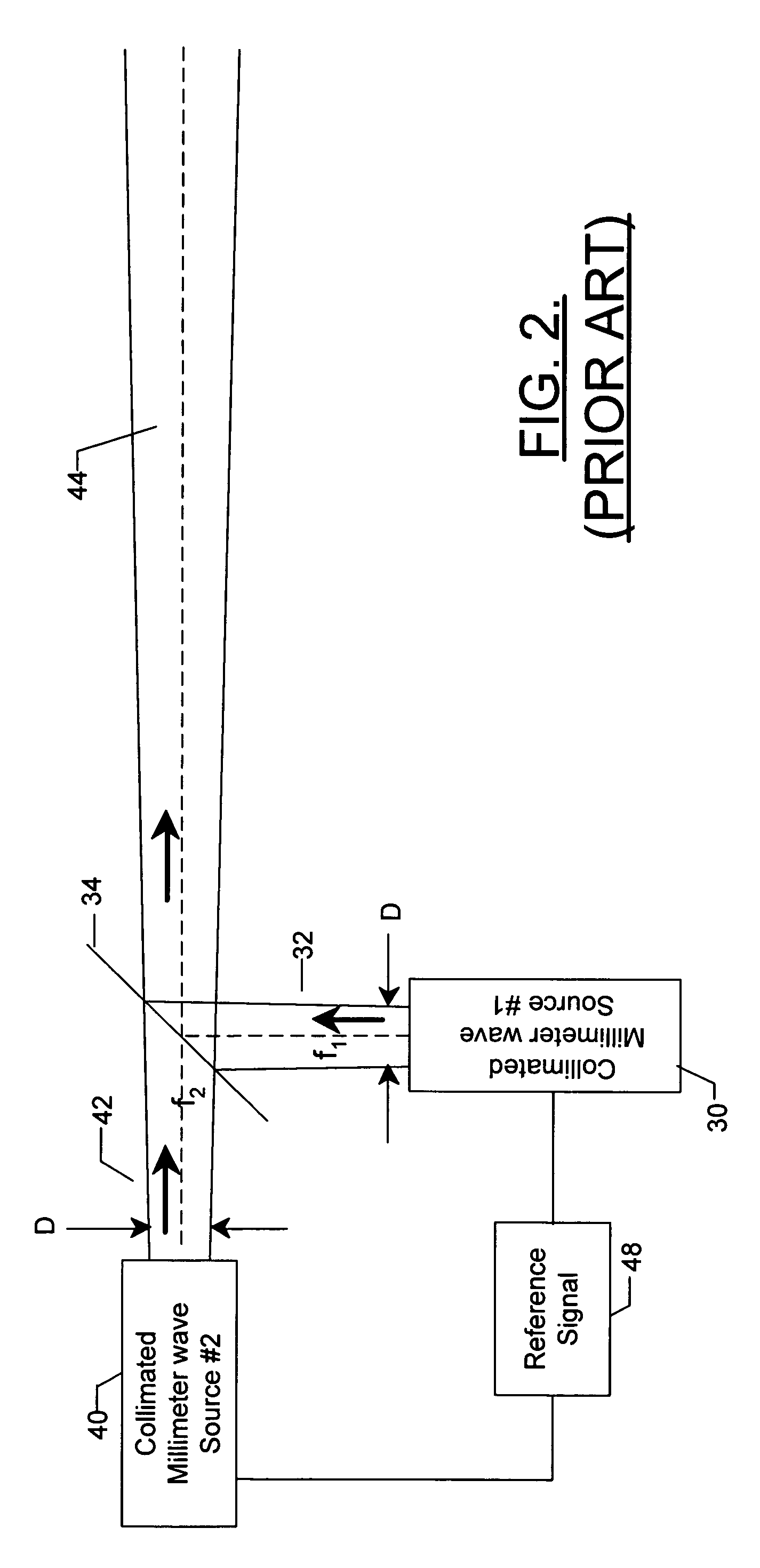

Method and apparatus for detecting, locating, and identifying microwave transmitters and receivers at distant locations

ActiveUS7142147B2Geological detection using milimetre wavesCommunication jammingLocation detectionLight beam

Methods and apparatuses for detecting, locating, and identifying microwave transmitters and receivers at distant locations are disclosed. First and second electromagnetic beams at first and second frequencies, respectively, are transmitted in first and second directions. The second frequency is offset from the first frequency to define an interference difference frequency. As such, the first and second electromagnetic beams interfere at a far field distance corresponding to an intersection of the first and second electromagnetic beams. In the far field the beams interfere with microwave devices that reradiate a return radiation at the difference frequency. The methods and apparatuses detect the return radiation at the difference frequency, such as by way of a receiver, and locate the interference zone to determine the location of the microwave device, such as by a processor.

Owner:THE BOEING CO

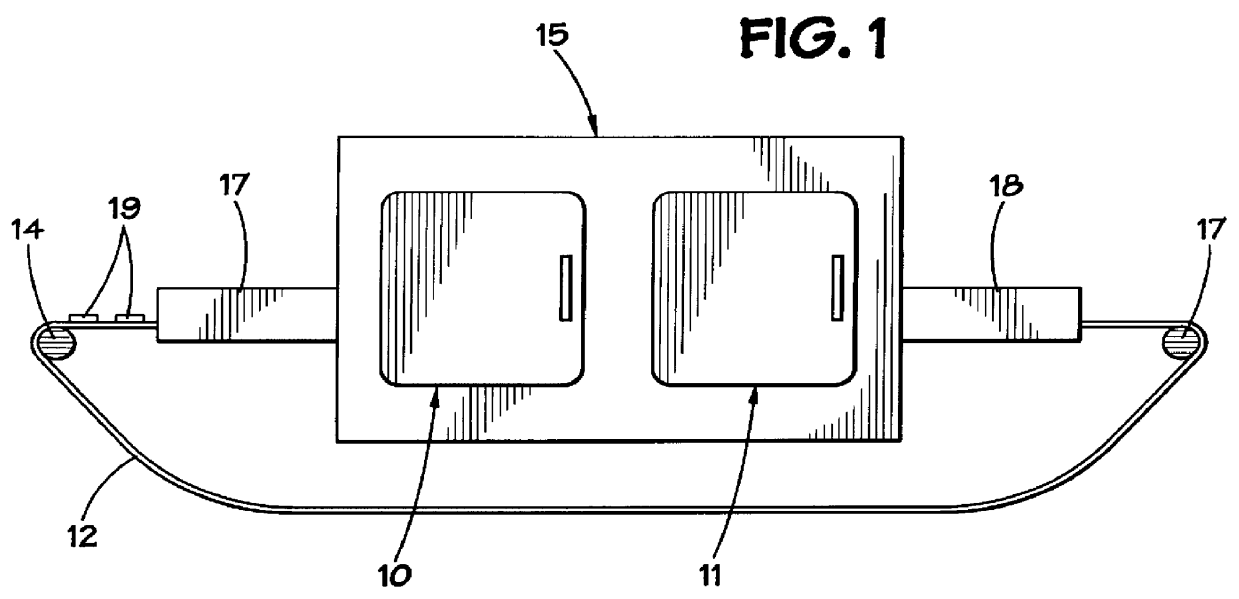

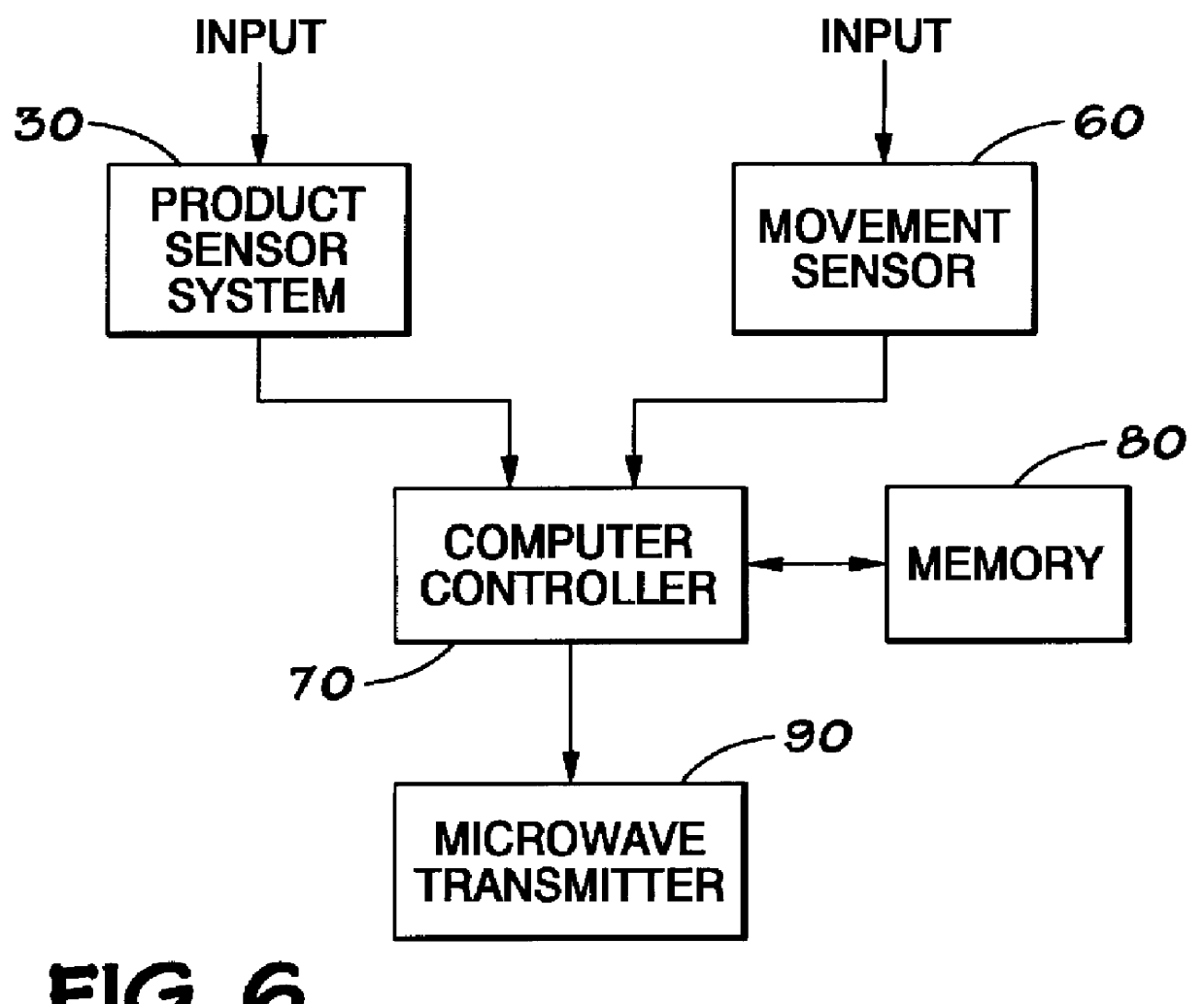

Product-based microwave power level controller

InactiveUS6157014AAdjust microwave powerAvoid powerMilk preservationDielectric heating circuitsMicrowave cavityProduct base

A microwave apparatus and system that monitors the amount of food products within a cavity and adjust the microwave power provided to the cavity. The apparatus and system uses a product sensor system and a movement sensor system to accurately determine the product load in the microwave cavity. A computer controller, based on the product load information provided by the product sensor system and the movement sensor system, operates to adjust the amount of power provide to the microwave cavities by the microwave transmitters.

Owner:AMANA +1

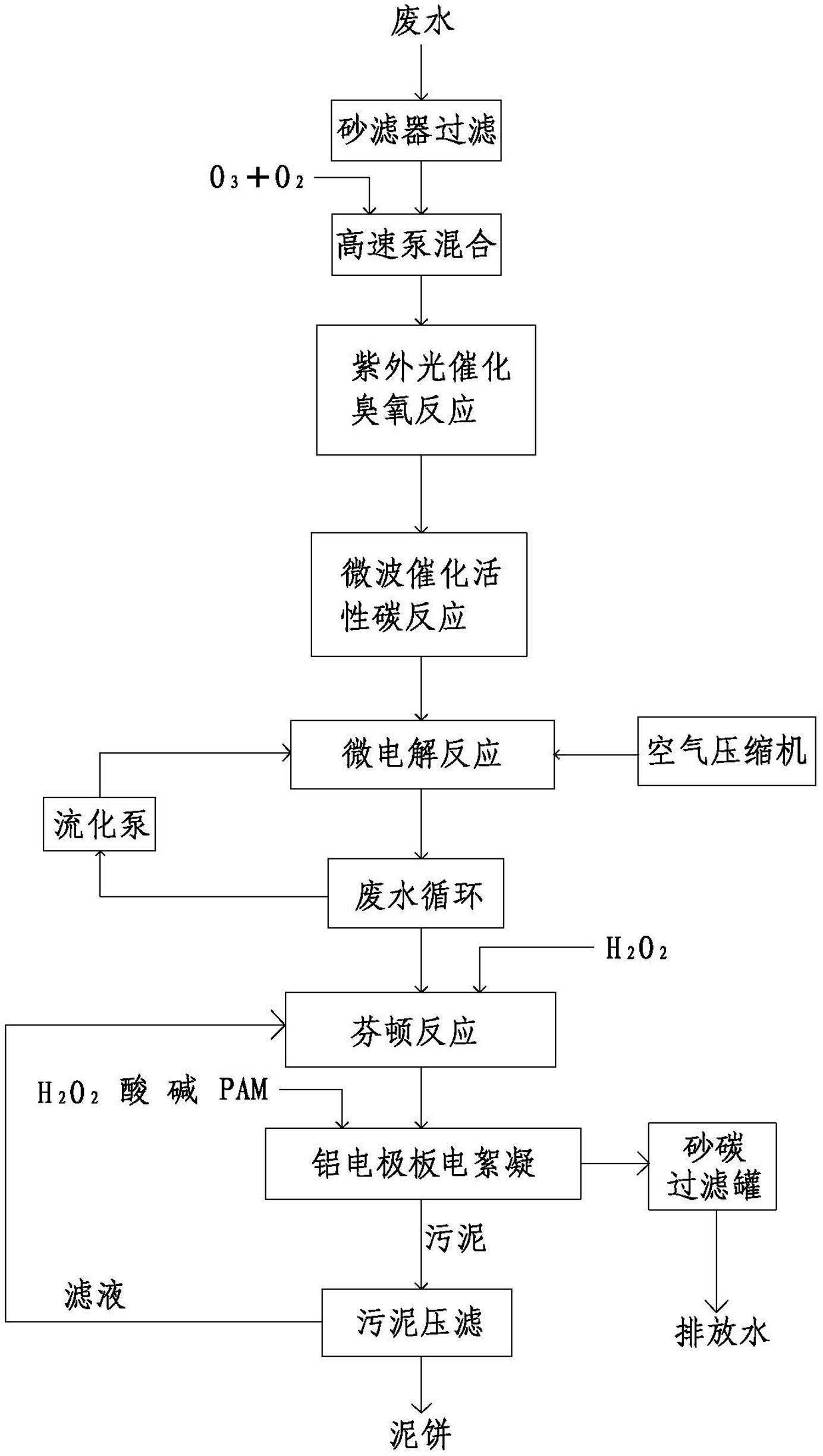

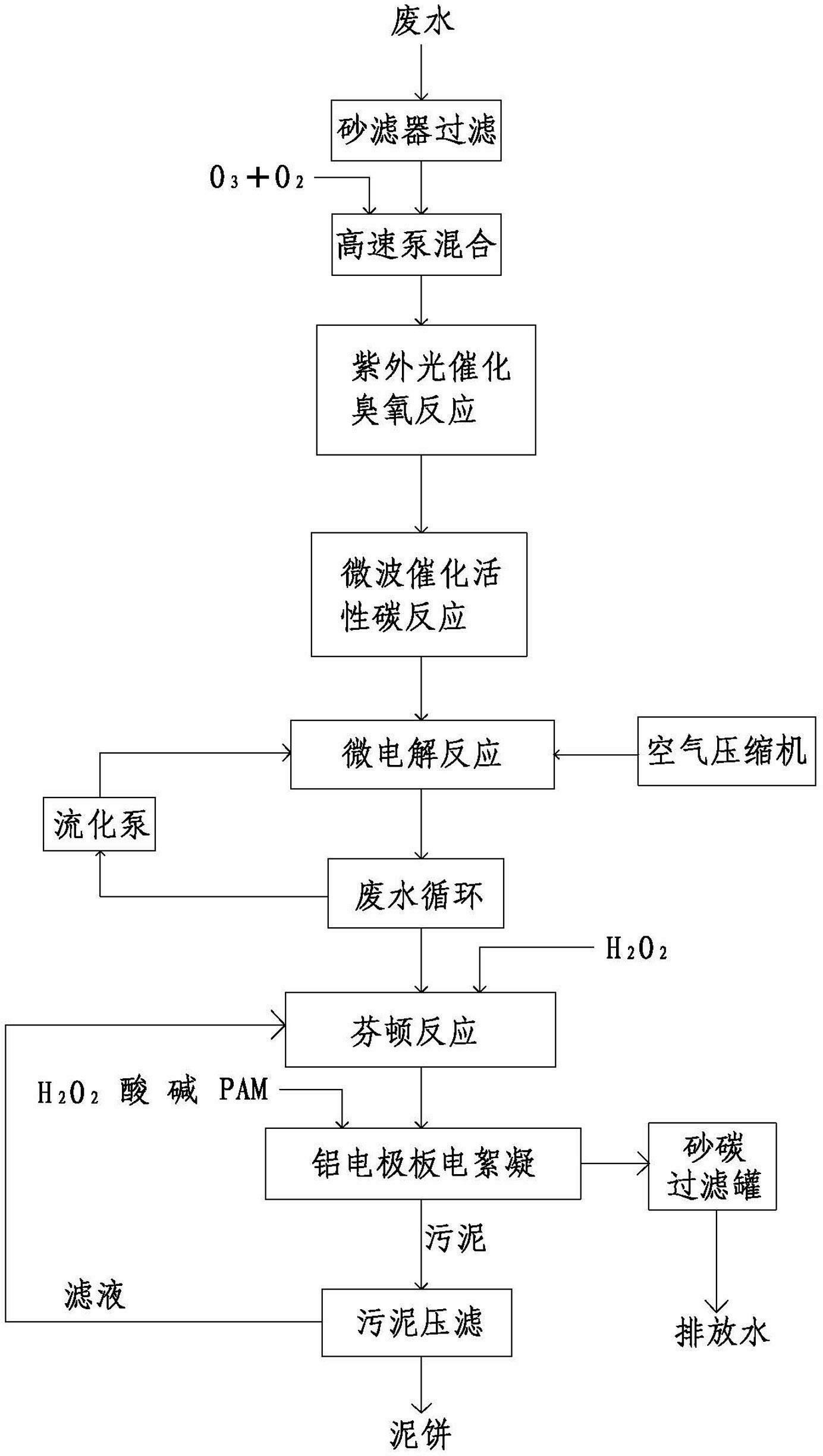

Complex heavy-metal waste water emergency quick treatment method

ActiveCN102603103AIncrease contact areaQuick responseMultistage water/sewage treatmentChemical oxygen demandSludge

The invention relates to a complex heavy-metal waste water emergency quick treatment method, comprising the following steps of: filtering by a sand filter; mixing by a high-speed pump; carrying out an ultraviolet catalyzing ozone reaction; carrying a microwave catalyzing active carbon reaction; carrying micro-electrolytic reaction; circulating waste water; carrying out a Fenton reaction; carryingout electric flocculation on an aluminum electrode plate; and pressing and filtering sludge. Waster water in a circulating slot is pumped into an iron carbon fluidized bed by a fluidizing pump to be circularly treated; an air compressor is connected with the iron carbon fluidized bed and prevents a filler in the iron carbon fluidized bed from blocking; and the microwave active carbon reactor is an active carbon filling tower, and a microwave emitter is arranged outside the body of the active carbon filling tower. The complex heavy-metal waste water emergency quick treatment method disclosed by the invention is used for treating the complex heavy-metal waste water, associated devices are simple, easy, quick, can meet an emergency, and can update and convert, no various chemical raw materials are fed, and various complex heavy-metal waste water with unknown elements can be quickly treated as long as the current magnitude is regulated, and thus the heavy metal in the waste water and chemical oxygen demand can immediately reach the standard and are discharged.

Owner:东莞市珠江海咸水淡化研究所有限公司

High frequency heating apparatus and its control method

A problem of the invention is to provide a high frequency heating apparatus capable of realizing excellent heating without an irregularity in heating even for a thick-walled heated object. In order to resolve the above-described problem, according to a high frequency heating apparatus of the invention, a high frequency heating apparatus 1 for heating a heated object by irradiating a microwave having a frequency of 5.8 GHz to the heated object is constituted by mounting a plurality of pieces of wave guides 11a, 11b having feeding ports 7, 9 for emitting microwaves into a cavity 3 partitioning a heating chamber 2.

Owner:PANASONIC CORP

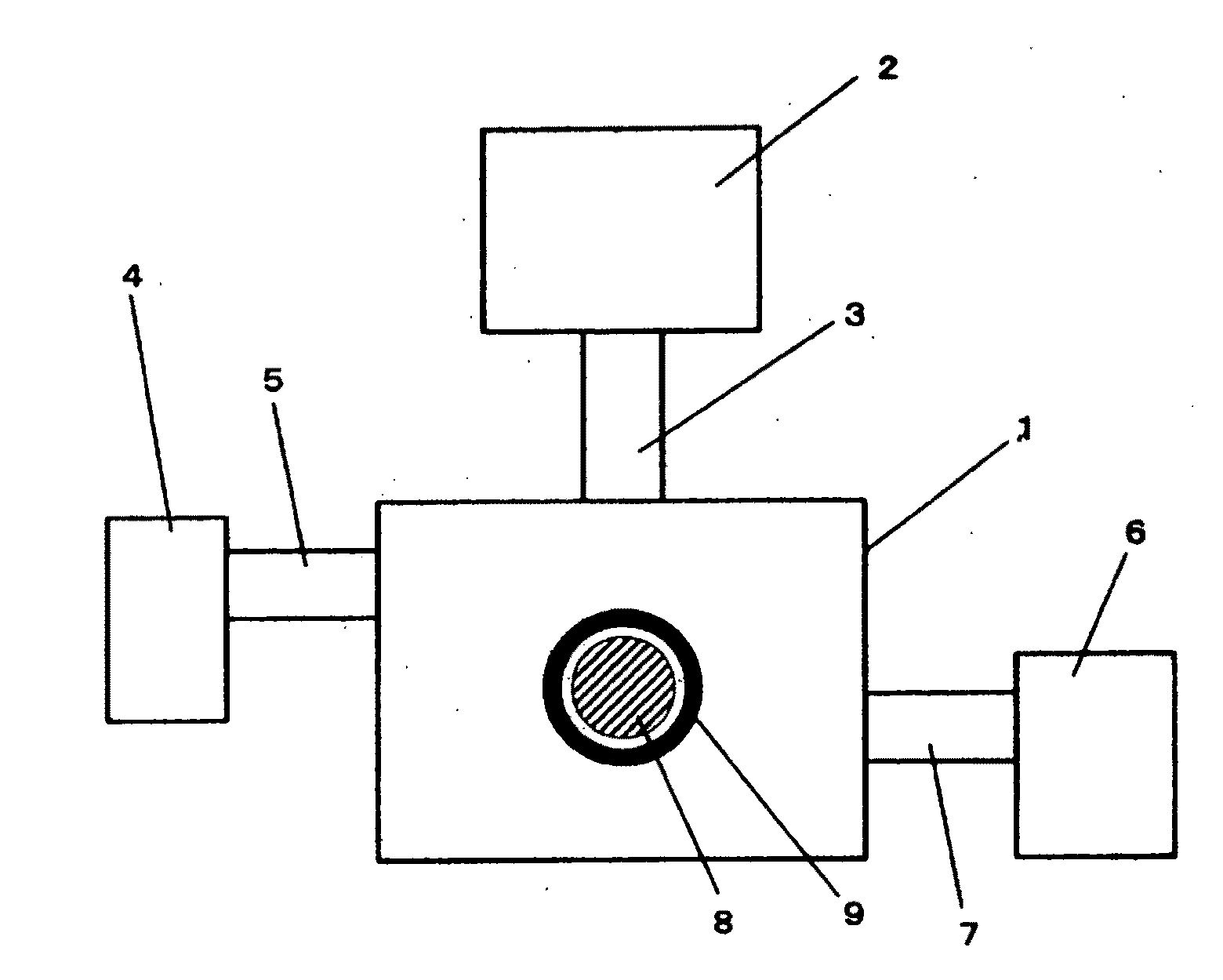

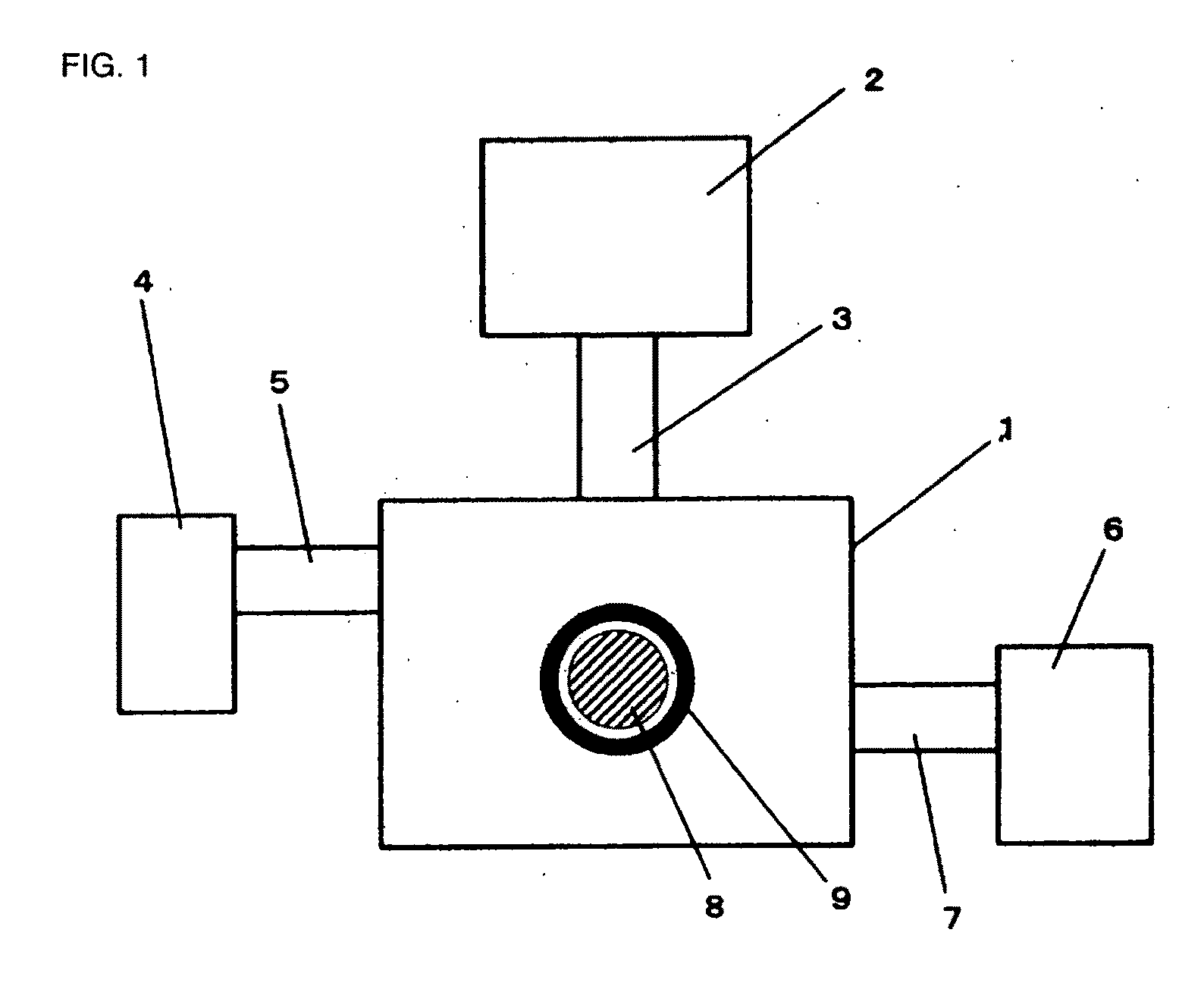

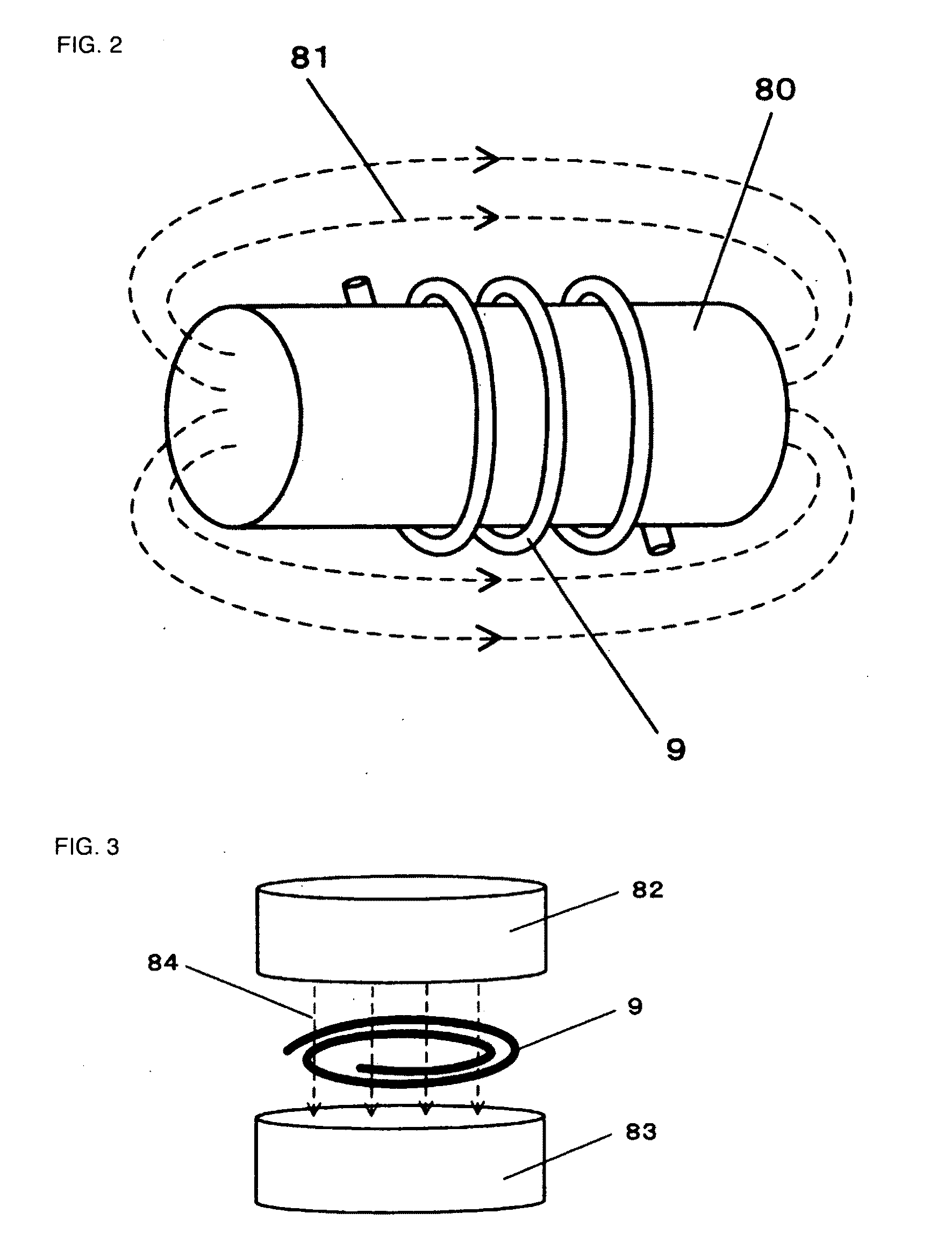

Plasma generating device and method

InactiveUS20110079582A1Highly clean stateHighly safe stateDecorative surface effectsSemiconductor/solid-state device manufacturingInternal pressureMicrowave emission

An object of the invention is to provide a plasma generating device and method for generating plasma through electrodeless discharge within a long tubule and carrying out a plasma process on the inside of the long tubule. The plasma generating device has a container 1 for containing a long tubule 9, the internal pressure of which can be adjusted, a magnetic field applying means 8 for applying a magnetic field in at least part of the long tubule, and a microwave supplying means 2 for emitting microwaves into the container, and is characterized in that plasma is generated within the long tubule by emitting microwaves into the container in such a state that a magnetic field is applied in at least part of the long tubule.

Owner:YONESU AKIRA +1

Conductor-within-a-via microwave launch

InactiveUS6937120B2Efficiency problemEffective expansionPrinted circuit aspectsHigh frequency circuit adaptationsElectrical conductorBand shape

A concentric ‘conductor within a via’ RF interconnect architecture, has an inner via through which at least one RF signal conductor passes. The inner conductive via is coaxially formed within and stably coaxially aligned within an outer conductive via, which serves as a coaxial ground plane that completely surrounds the inner conductive via. The outer conductive via passes through dielectric layers of microstrip or stripline structures on opposite sides of a multi printed circuit laminate.

Owner:NORTH SOUTH HLDG

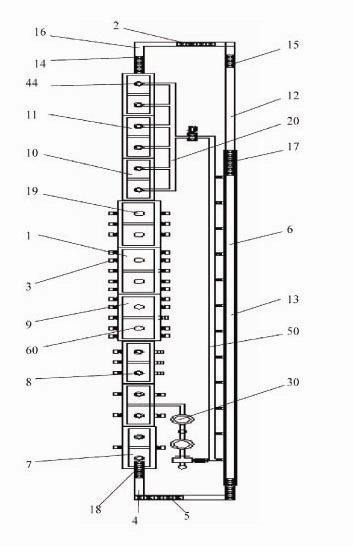

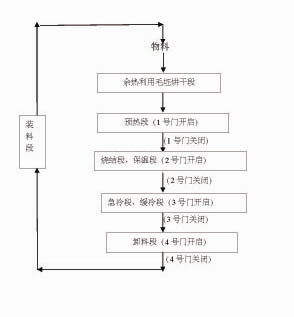

Fully-closed industrial microwave high-temperature roller continuous sintering kiln

InactiveCN102042749AConsistent shrinkageGood size consistencyMaintainance of heating chambersFurnace typesEnvironmental resistanceEngineering

The invention discloses a closed microwave high-temperature sintering roller kiln, in particular a tunnel roller kiln with length of 10 to 50meters, and hearth sectional area of 0.06 to 0.3m<2>. The kiln comprises a main kiln body, a microwave transmission system, a turning channel mechanism, a roller power system, and a kiln door interlocking opening and closing system; the main kiln body is formed by connecting a water draining section, a preheating section, a sintering section, a heat preservation section, a quick cooling section, and a slow cooling section in turn; the turning channel mechanism is mainly formed by a material loading and unloading section and a residual-heat utilization blank drying section and comprises a turning channel, a turning channel roller, and a power system; the power system can poke a pushing plate from the outlet of the main kiln body onto the turning channel and feed the pushing plate into the inlet of the main kiln body through the residual-heat utilization blank drying section; and an inner roller for transmitting the material pushing plate, which is driven by the roller power system, is arranged on the bottom of an inner cavity of the main kiln body. The closed microwave high-temperature sintering roller kiln saves energy and reduces consumption and is environmental-friendly, the shrinkage of the sintered products is consistent and the sintered products have high size consistency, the yield is high, the production efficiency is high and the production cost is low.

Owner:湖南航天有限责任公司

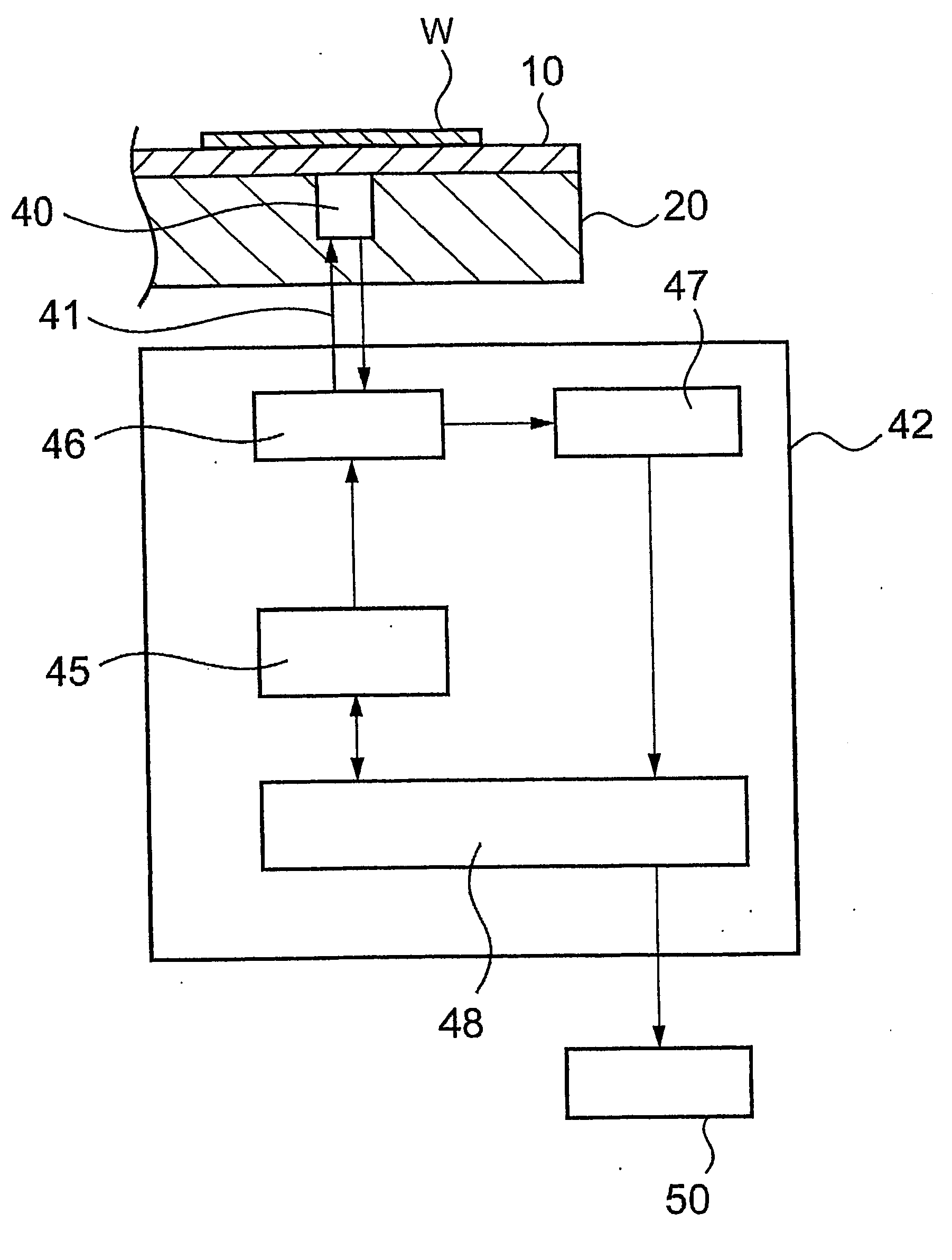

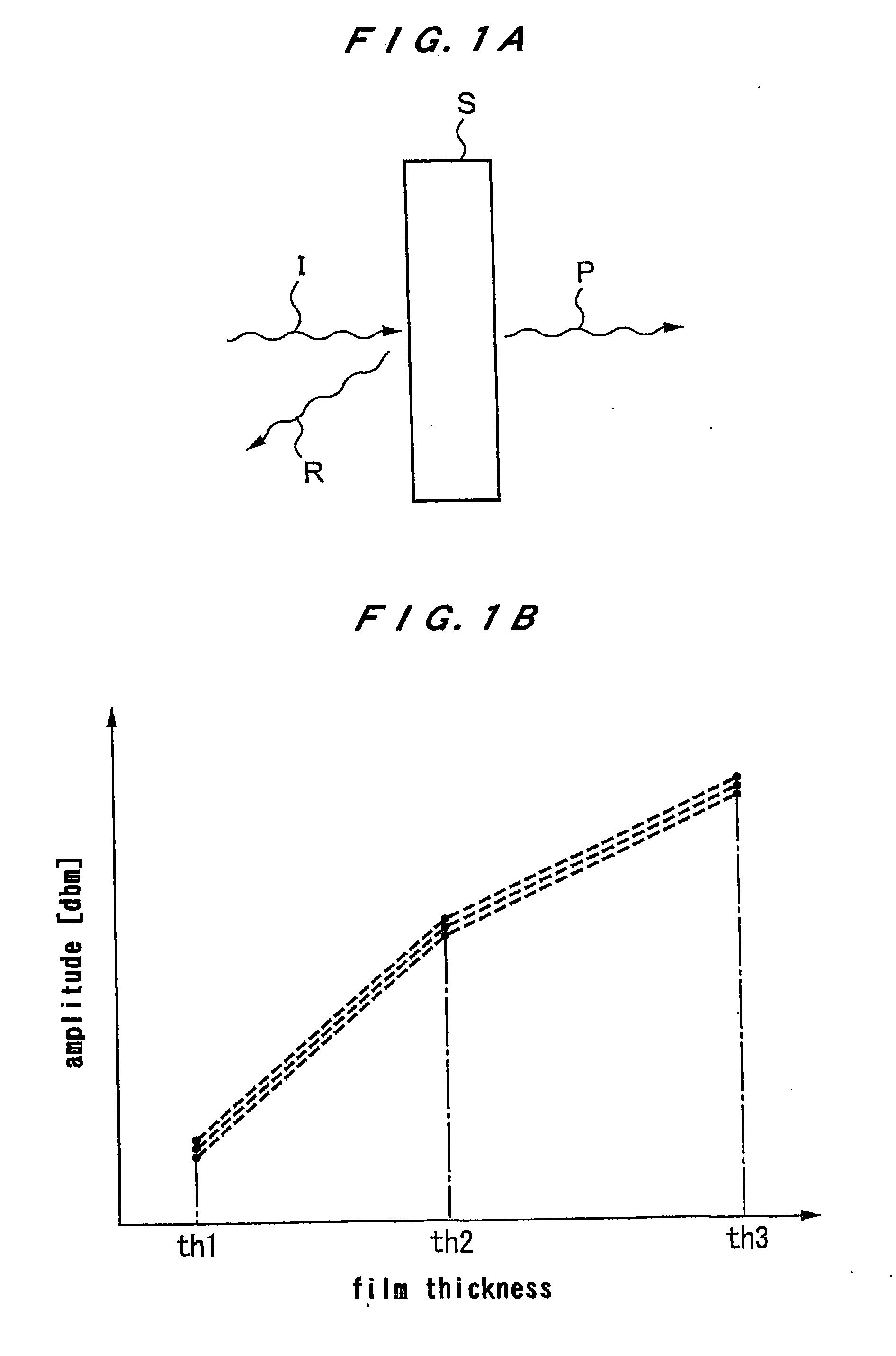

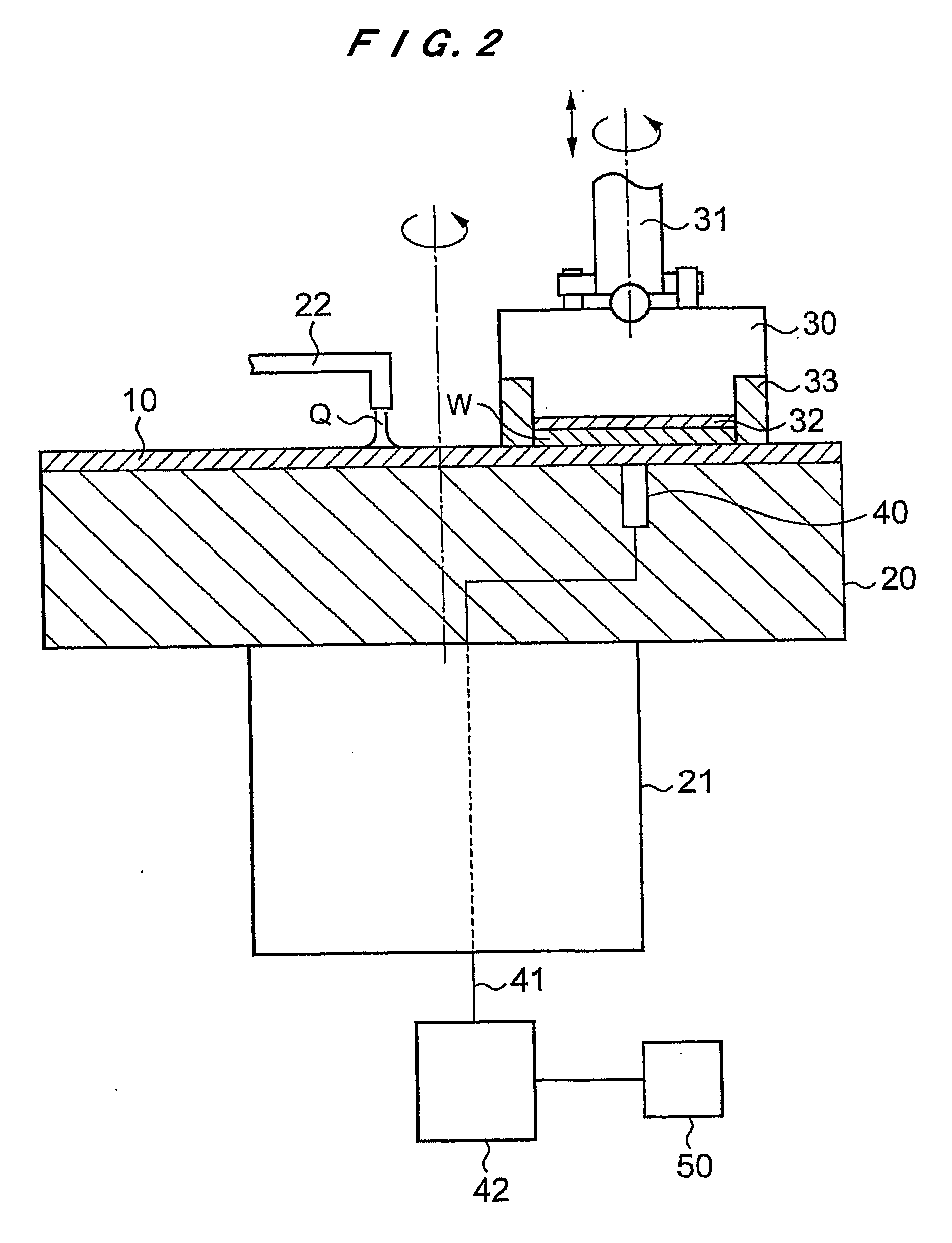

Measuring apparatus

InactiveUS20060164104A1Reduce manufacturing costAccurate measurementSemiconductor/solid-state device testing/measurementResistance/reactance/impedenceMeasurement deviceMeasuring instrument

The present invention relates to a measuring apparatus for measuring a thickness or the like of a thin film formed on a surface of a substrate such as a semiconductor wafer. The measuring apparatus includes a microwave emission device (40) for emitting a microwave to a substance, a microwave generator (45) for supplying the microwave to the microwave emission device (40), a detector (47) for detecting an amplitude or a phase of the microwave which has been reflected from or passed through the substance, and an analyzer (48) for analyzing a structure of the substance based on the amplitude or the phase of the microwave which has been detected by the detector (47).

Owner:EBARA CORP

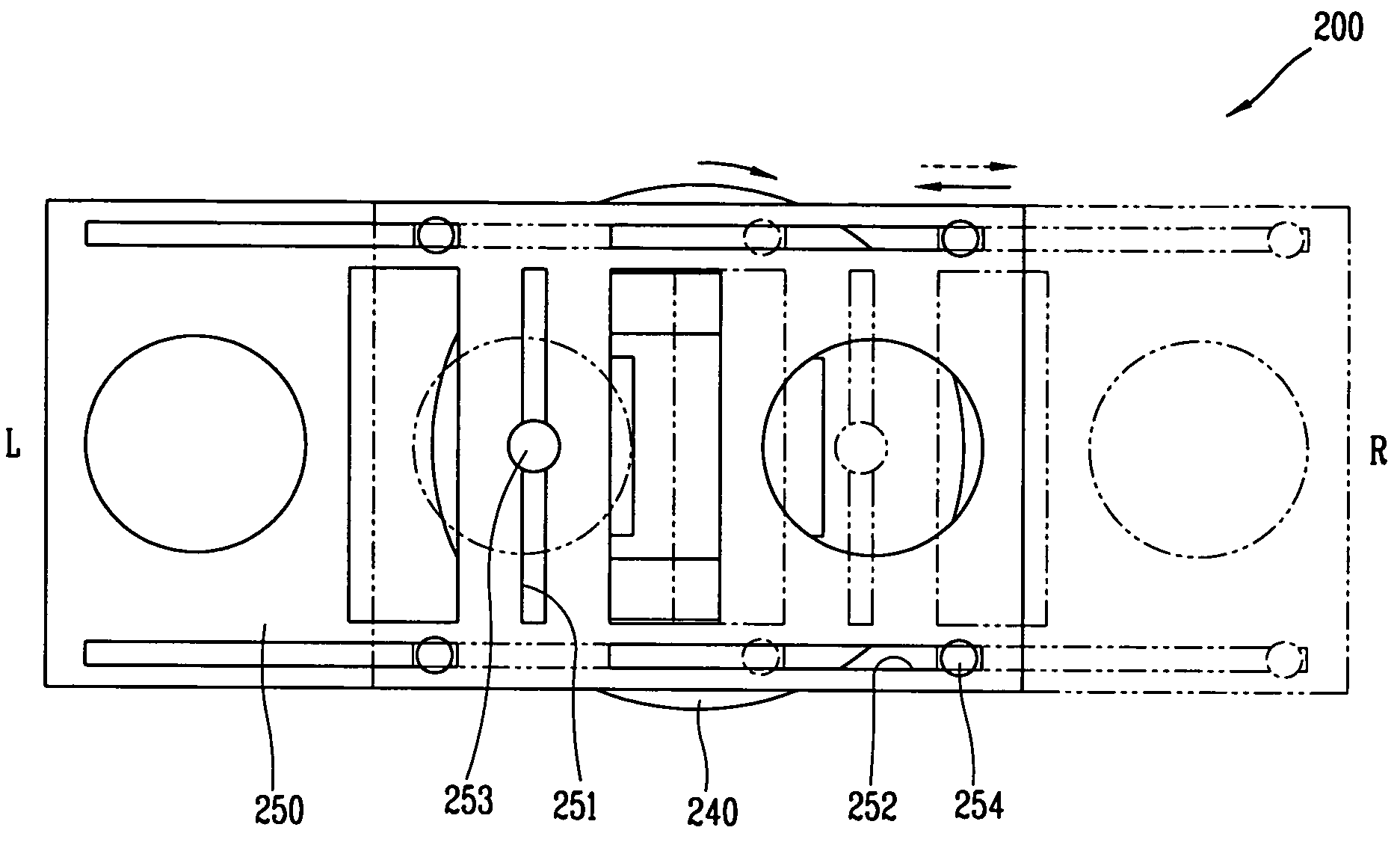

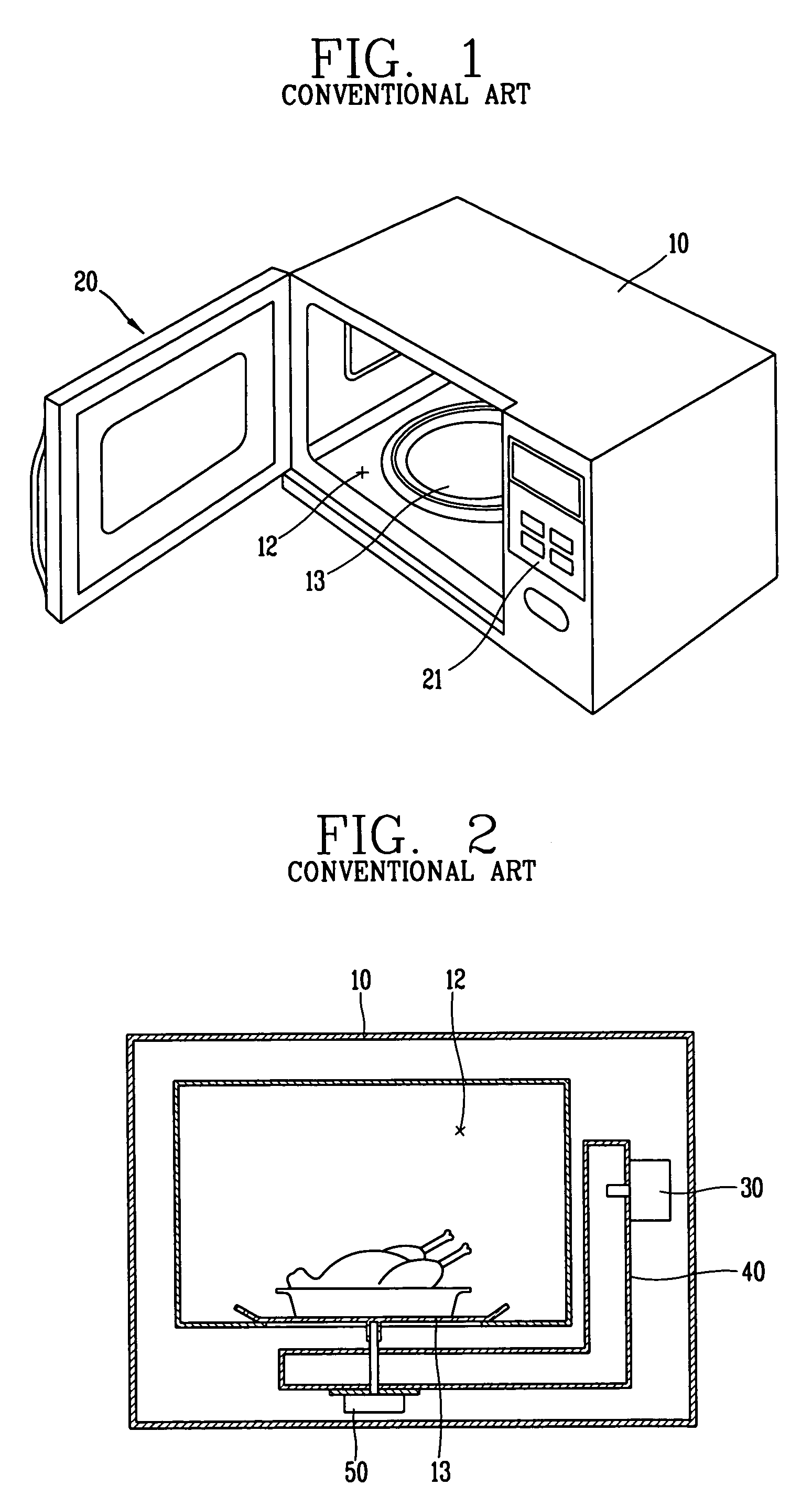

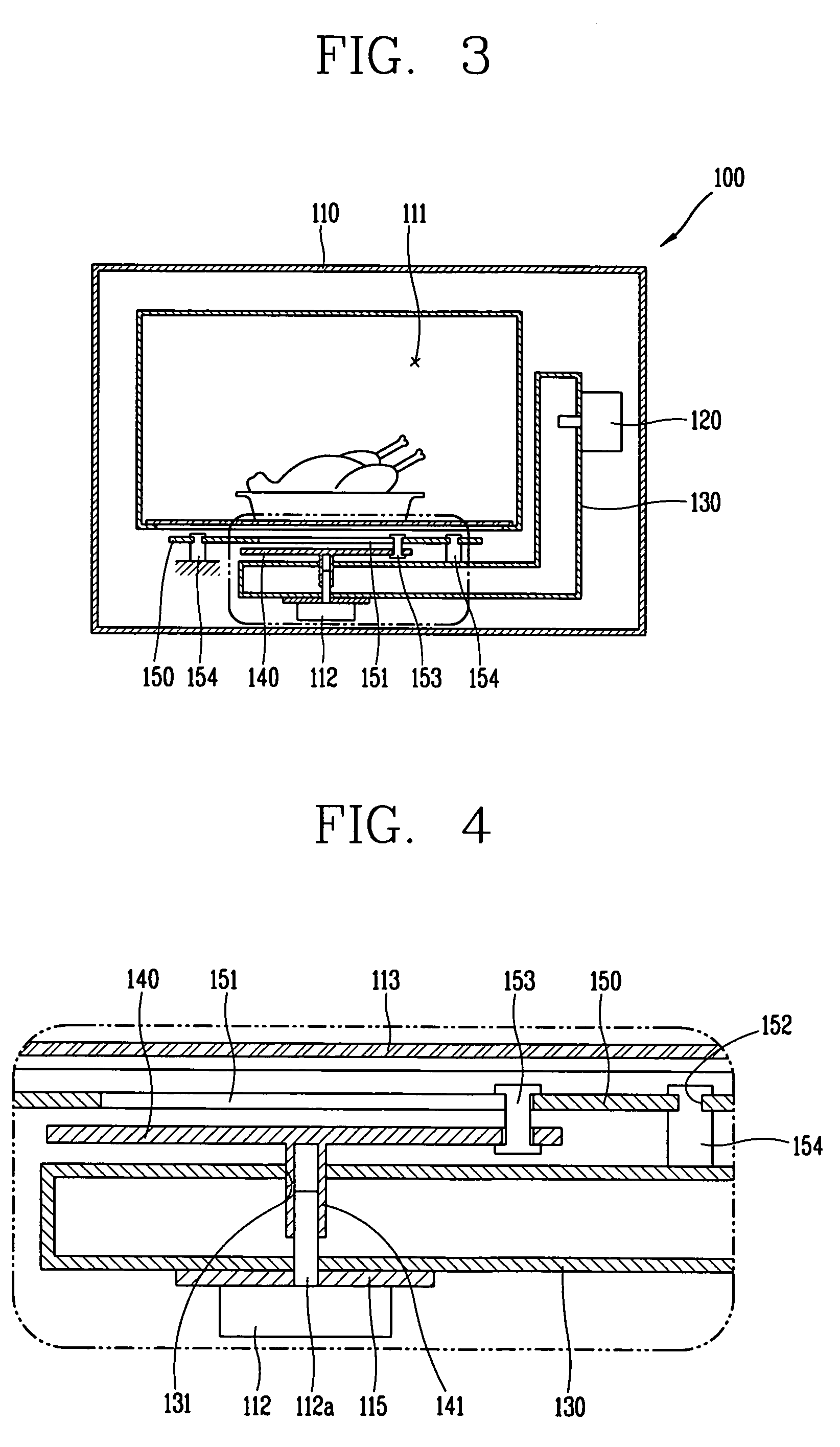

Microwave cooker having antenna in cooperation with movable stirrer

InactiveUS7145119B1Evenly heatedUniformly cooking foodStoves/ranges foundationsDomestic stoves or rangesMicrowave ovenDrive motor

Owner:LG ELECTRONICS INC

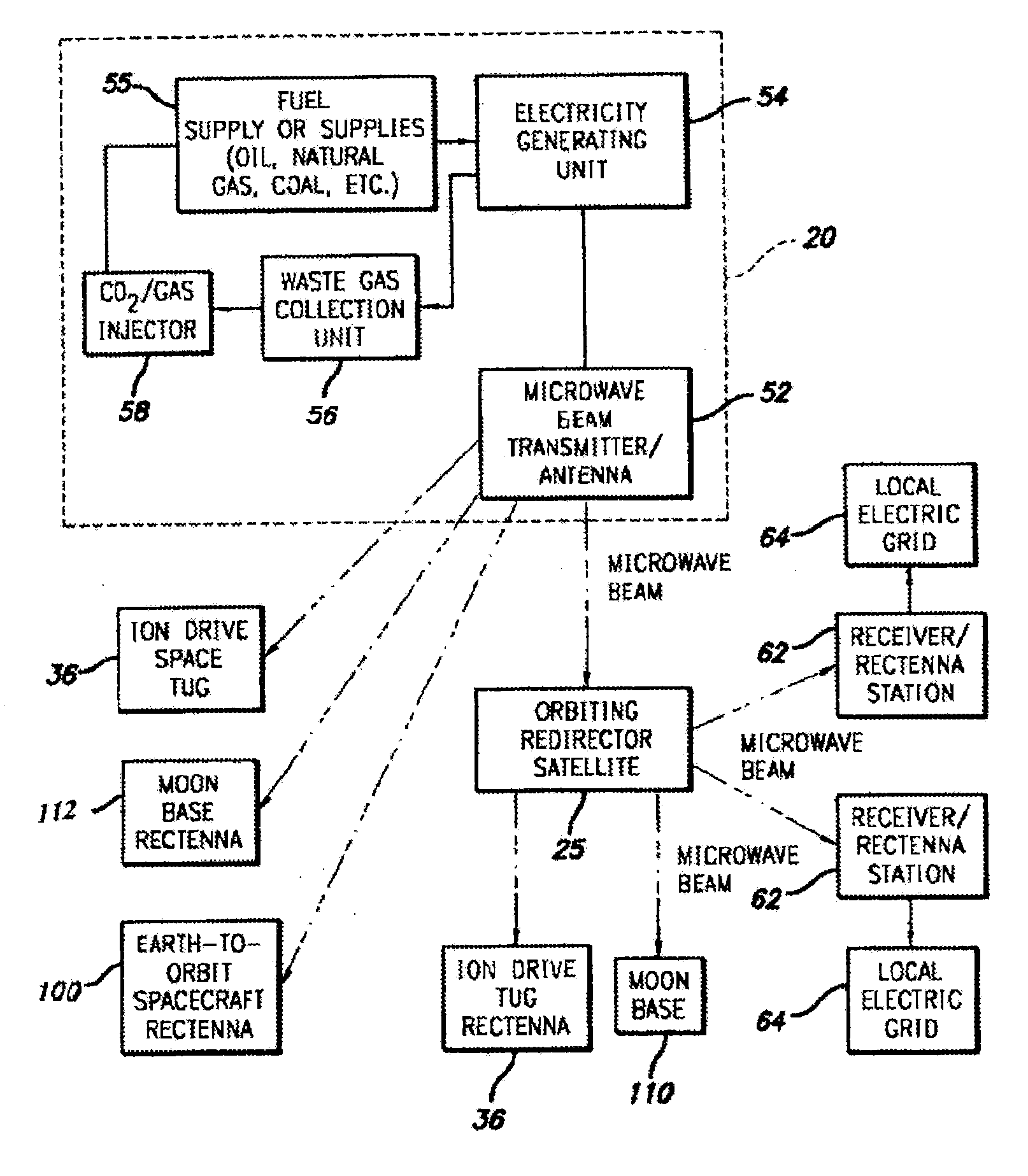

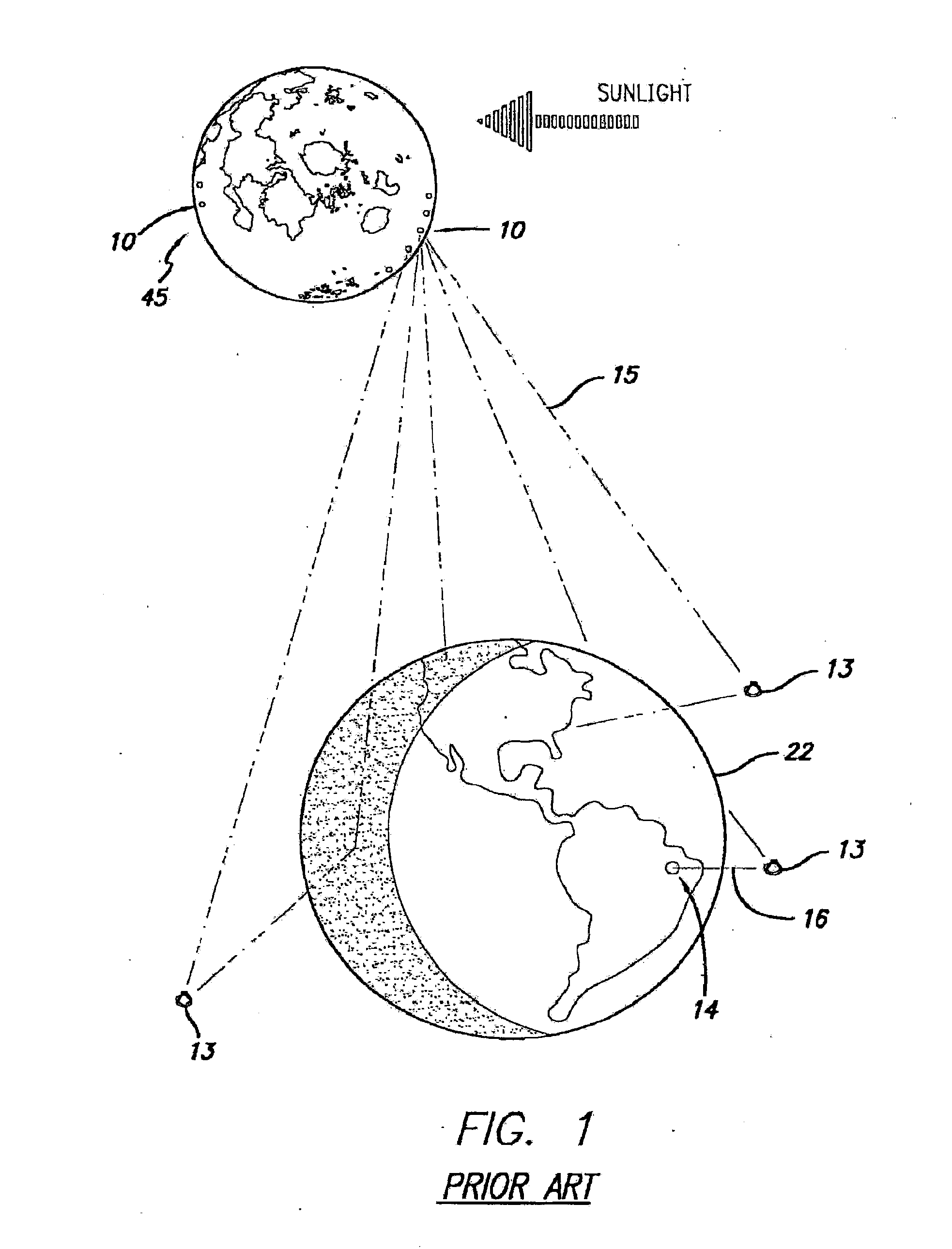

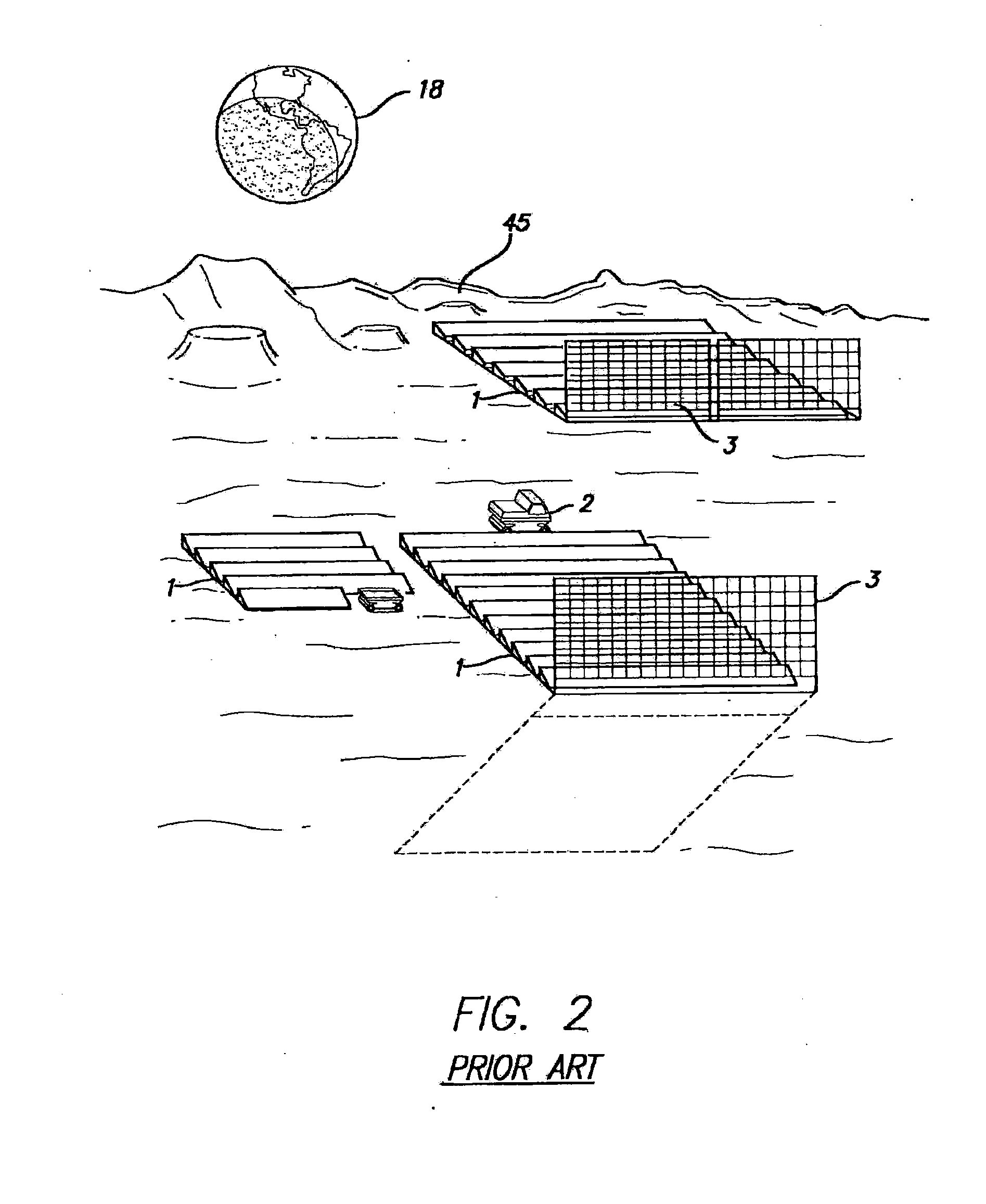

Power Generating and Distribution System and Method

ActiveUS20120153744A1Reduce and eventually eliminate dependenceLess expensiveElectromagnetic wave systemCosmonautic vehiclesDistribution systemEngineering

A power distribution network is provided comprising ground-based microwave transmitters, receivers and microwave redirectors. The ground-based microwave transmitters have their own directional, focus and amplitude controllers for aiming a focused microwave beam at a microwave redirector. The microwave redirectors each have a receiving antenna and a plurality of transmitting antennae such that the redirectors transmit focused microwave beams to at least two different stations (for example, being either ground-based microwave receivers or other microwave redirectors).

Owner:CRISWELL DAVID R DR

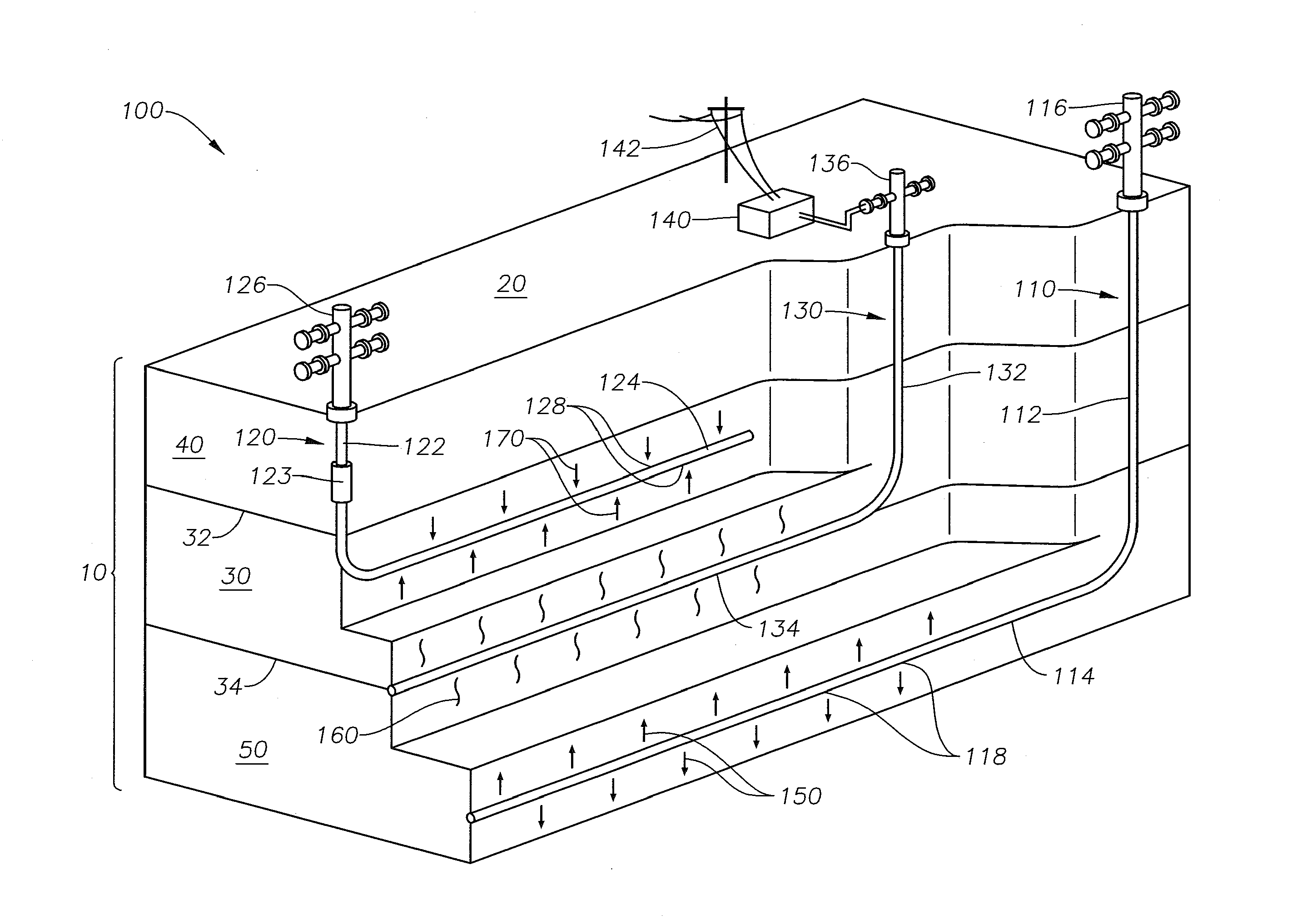

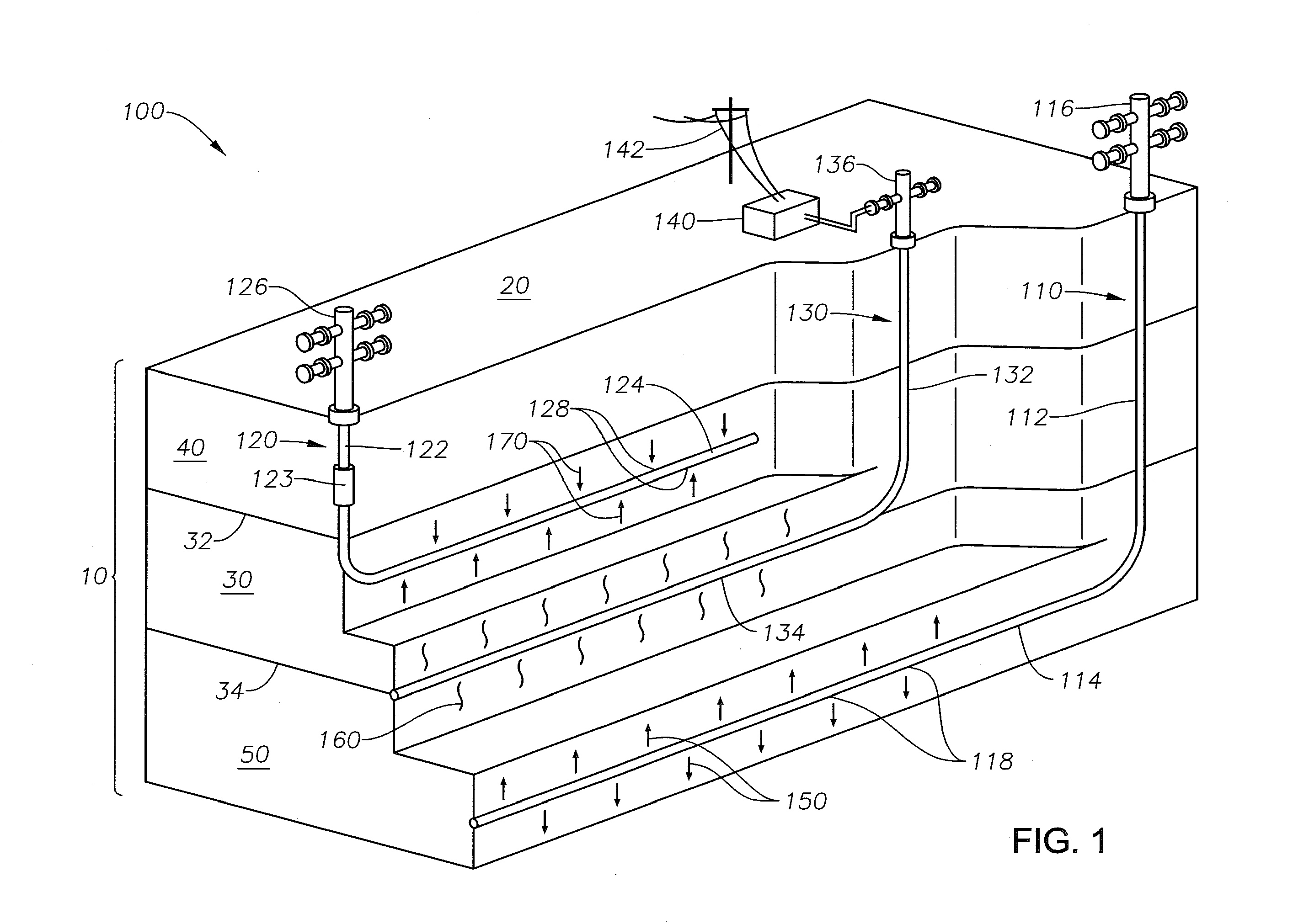

Utilization of microwave technology in enhanced oil recovery process for deep and shallow applications

ActiveUS20140027109A1Promote recoveryFluid removalDrilling compositionThermodynamicsHorizontal wells

Owner:SAUDI ARABIAN OIL CO

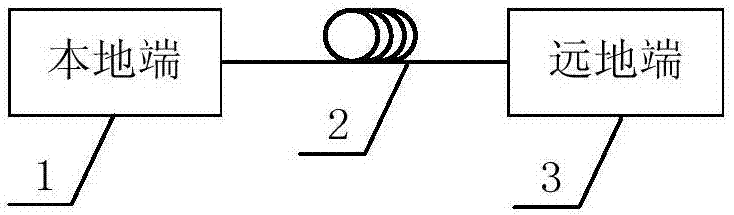

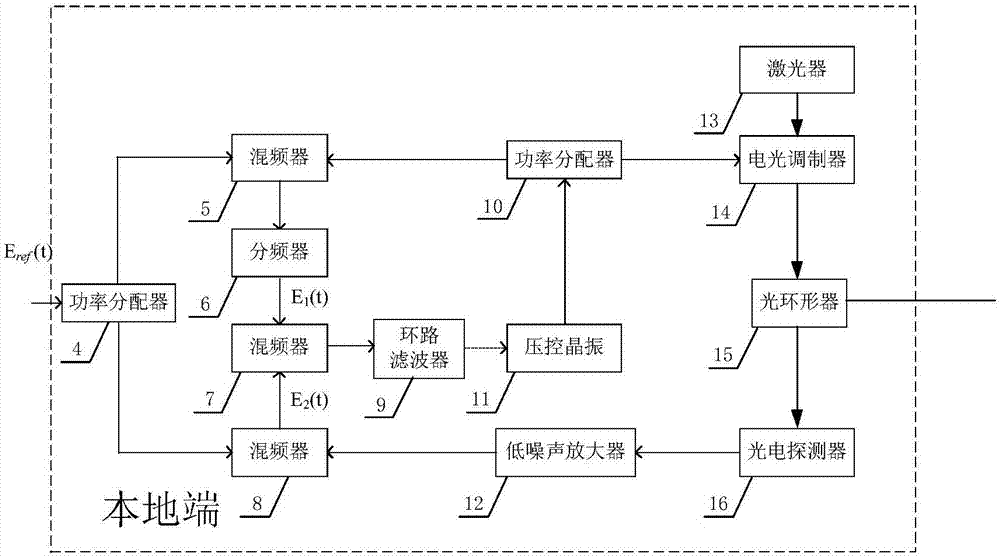

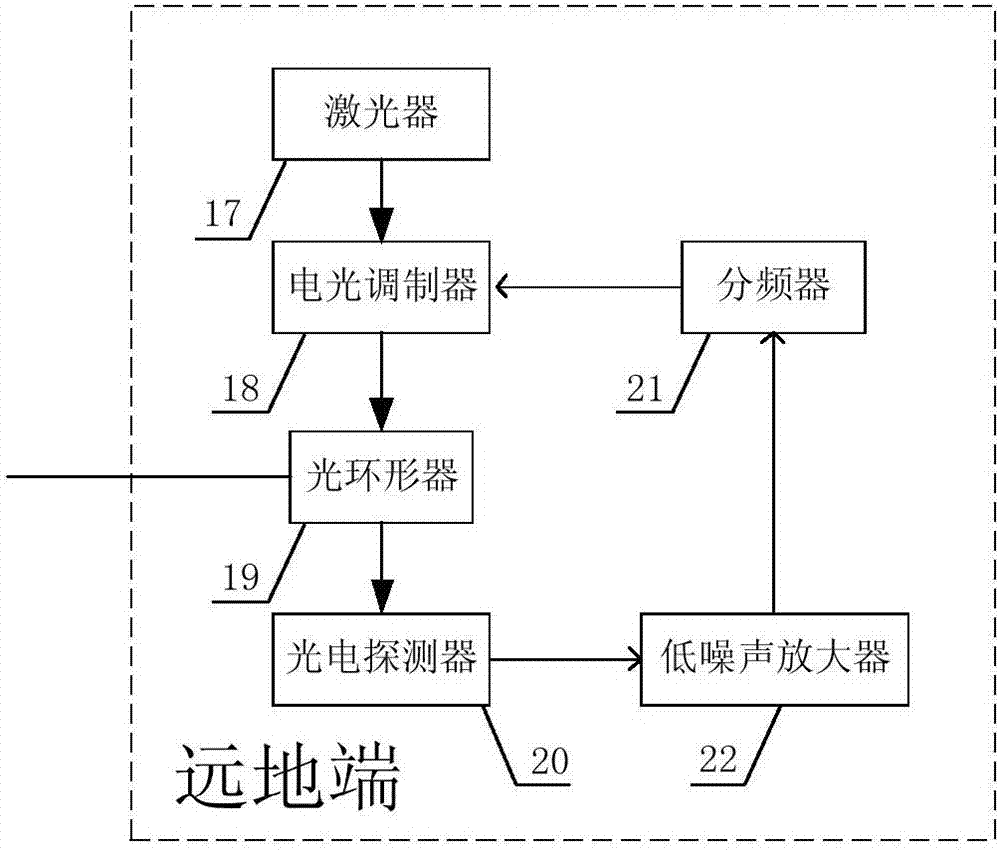

Frequency conversion compensating microwave frequency transmission system and method

ActiveCN108011667APrevent phase interferenceImprove stabilitySynchronisation by photonic/optical meansDistortion/dispersion eliminationPhase noiseMicrowave emission

The invention discloses a frequency conversion compensating microwave frequency transmission system and method. A phase pre-compensated microwave transmission signal is loaded into a laser signal, thelaser signal is transmitted to a remote end through utilization of an optical fiber, and the remote end restores the laser signal into a frequency signal synchronous with a microwave reference frequency signal of a local end through detection. According to a specific process, after a local signal is transmitted to the remote end, frequency conversion is carried out on a detection signal of the remote end, the detection signal is returned to the local end, a return signal comprises phase noise imported into an optical fiber link; the return signal and the local transmission signal are respectively mixed with the local reference signal, comparison is carried out to acquire pre-compensation quantity and a crystal oscillator generating the transmission signal is controlled according to the compensation quantity, so phase compensation of high precision frequency transmission is finished. Compared with existing frequency transmission, the method mainly has the advantages that frequencies ofthe signals transmitted by the local end and returned by the remote end are different, the phase interference of strong signals of stations at the two ends for detected and received weak signals is avoided, and the frequency transmission stability is further improved.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

Method and device for setting the fuse and/or correcting the ignition time of a projectile

To avoid mechanical and thermodynamic wear of a programming system, a microwave transmitter, preferably operating in the GHz range, is integrated in the system, while at the same time the advantages of measurement of the muzzle velocity and of a current compensated fuse setting are preserved. The microwave transmitter transmits the current fuse setting, for example, as determined by a fire control computer, to the ammunition, e.g., a projectile. A direct measurement of the actual muzzle velocity itself can be dispensed with, since the real muzzle velocity is determined by the current flight velocity information of the projectile, i.e., it is extrapolated back from this. On the basis of this current projectile velocity, the ignition time, which was preset with the ignition time of the projectile using a standard muzzle velocity, is corrected and used as the current fuse set time.

Owner:OERLIKON CONTRAVES BESCHRAENKTER HAFTUNG

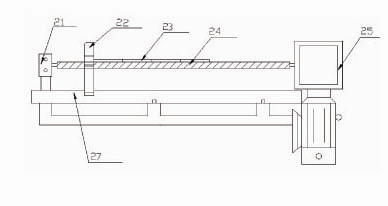

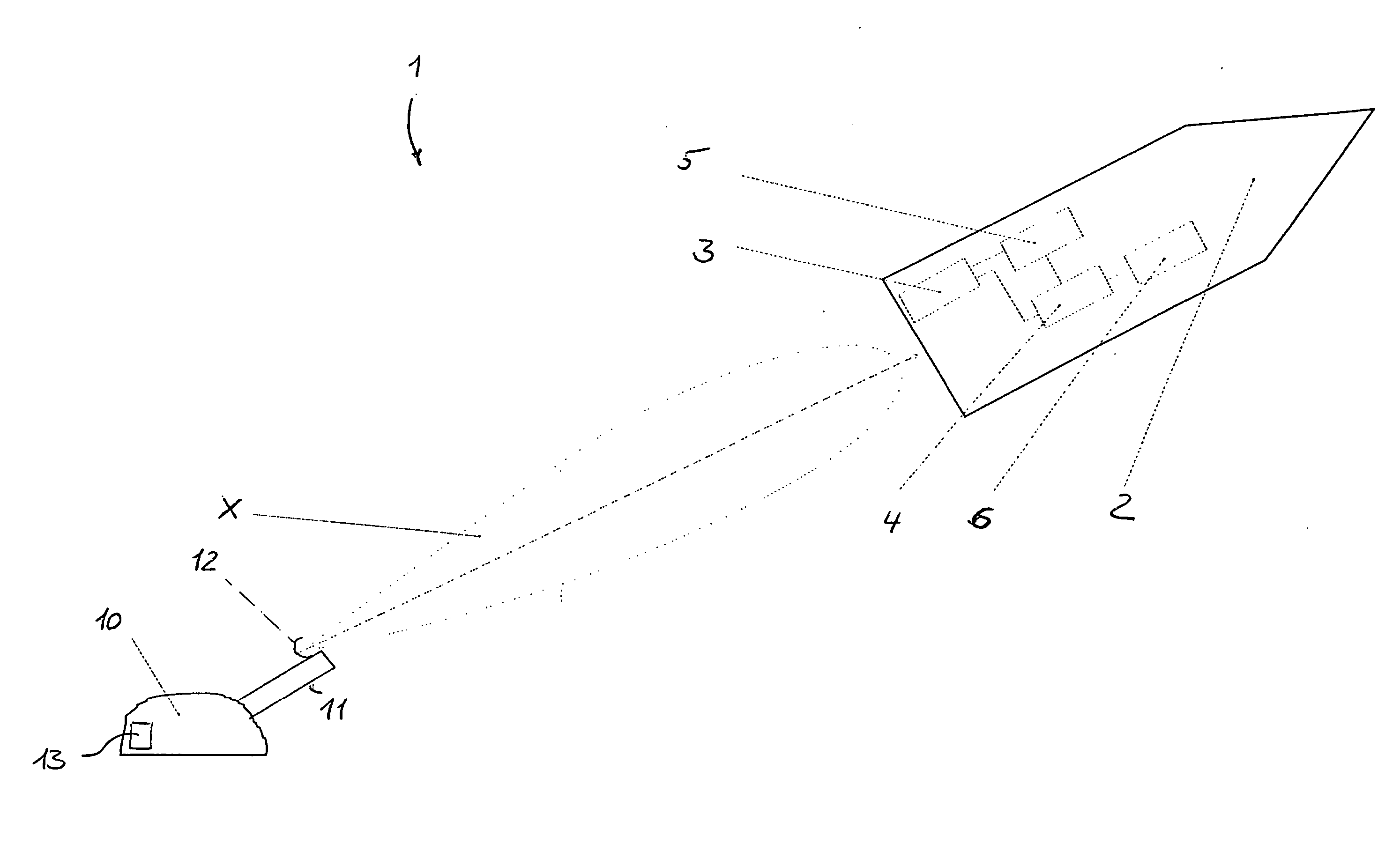

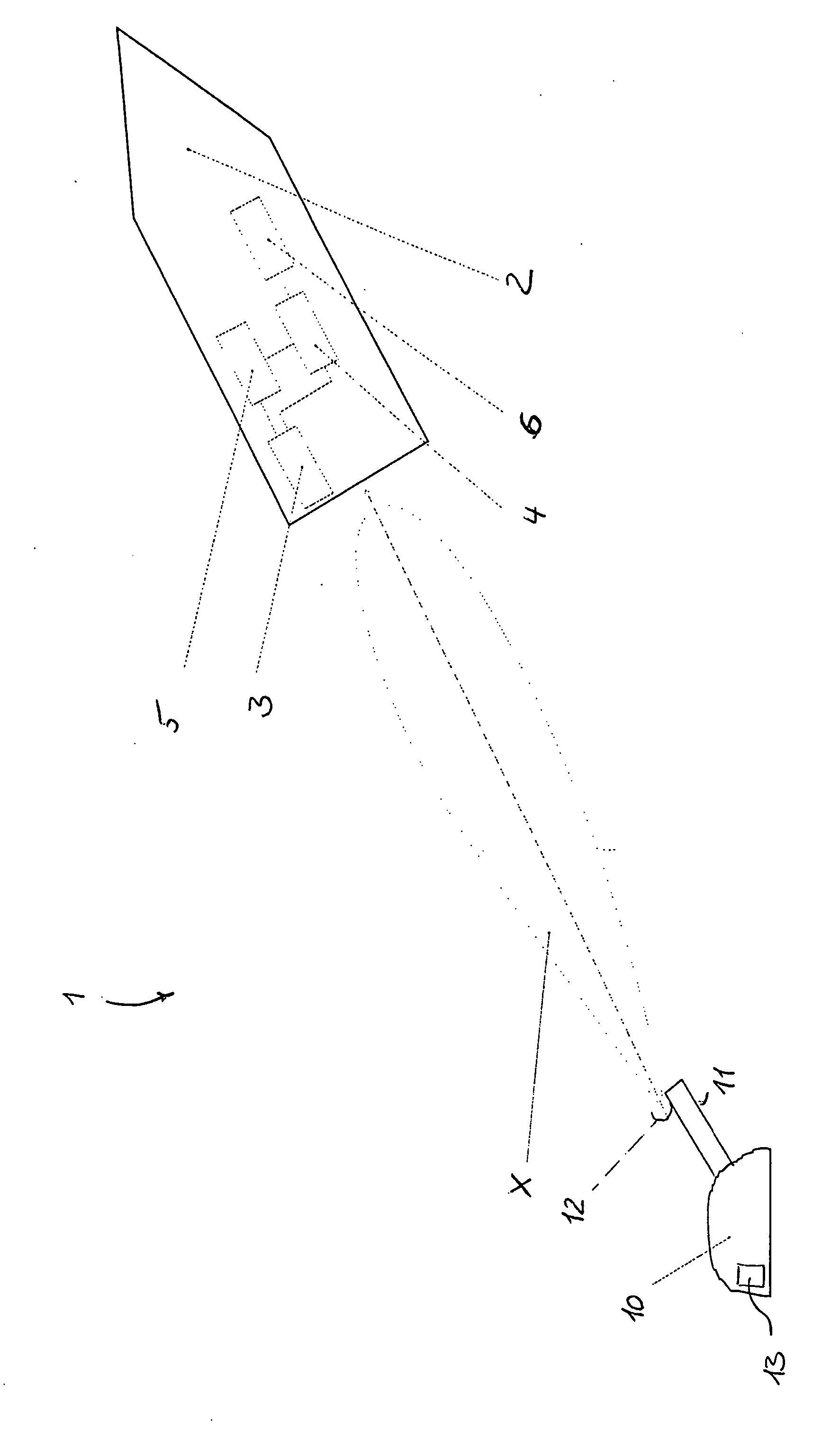

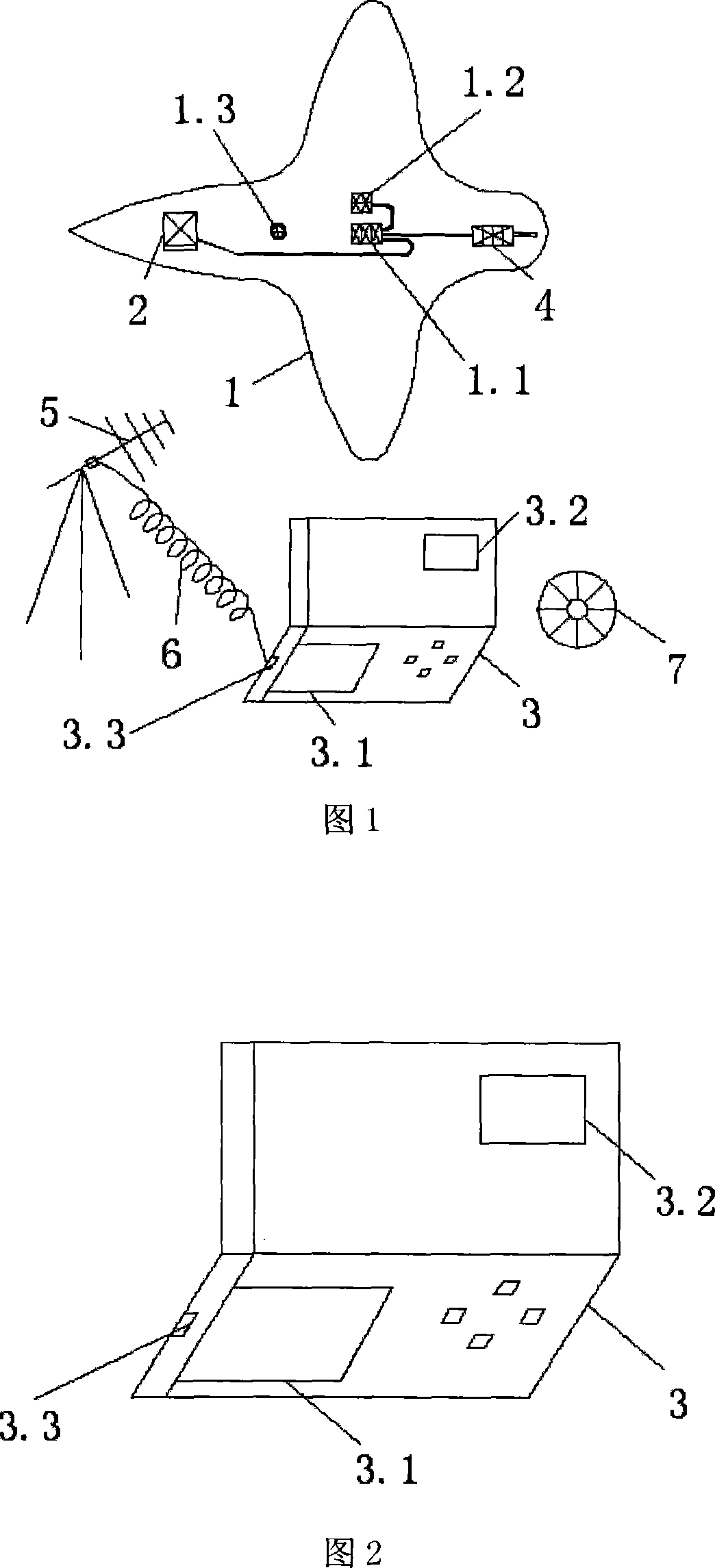

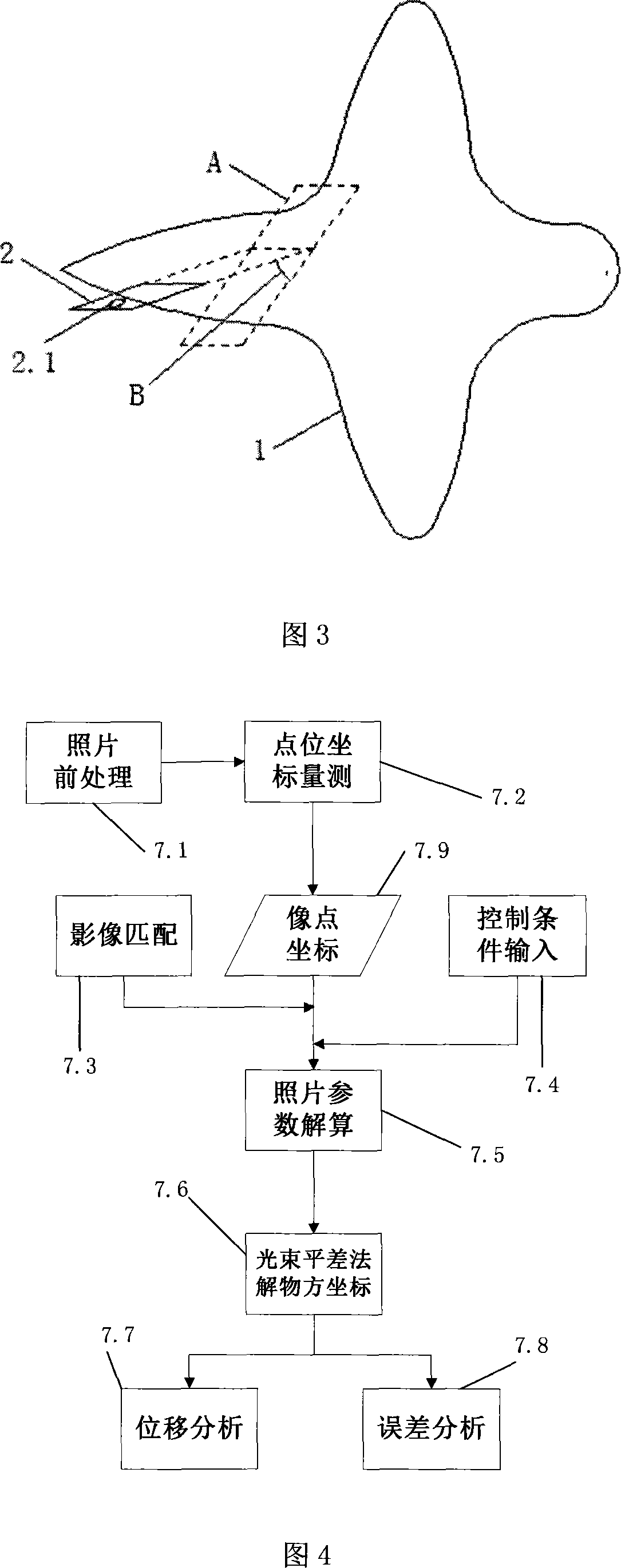

Avigation close range photography displacement measurement system based on unmanned aerial vehicle as well as measurement method thereof

InactiveCN101201248AImprove site adaptabilityHigh displacement measurement efficiencyPicture taking arrangementsUsing optical meansAviationFly control

The invention discloses an aero near view photography displacement measuring system based on a drone and a method of the system, and relates to an aero near view photography displacement measuring technology. The system comprises a drone (1), a digital camera (2), a ground control station (3), a microwave transmitter (4), a microwave receiving antenna (5), a data cable (6) and computer software (7); the drone (1) is provided with the digital camera (2) and the microwave transmitter (4) which are connected by a fly control board (1.1)of the mini model drone (1); the data cable connects a computer serial port (3.3) of the ground control station (3) and the microwave receiving antenna (5); the computer software (7) is installed in a notebook (3.1) of the ground control station (3). The invention can prevent some problems of traditional displacement measurement, and thus is applicable to displacement measurement to large displacement and large scale projects, in particular to displacement measurement to projects with difficult passage and in dangerous areas.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Directional speed and distance sensor

ActiveUS8872674B1Elegant and economical and effectiveLow powerArrangements for variable traffic instructionsParking metersDirectional antennaParking space

A method of using a directional sensor for the purposes of detecting the presence of a vehicle or an object within a zone of interest on a roadway or in a parking space. The method comprises the following steps: transmitting a microwave transmit pulse of less than 5 feet; radiating the transmitted pulse by a directional antenna system; receiving received pulses by an adjustable receive window; integrating or combining signals from multiple received pulses; amplifying and filtering the integrated receive signal; digitizing the combined signal; comparing the digitized signal to at least one preset or dynamically computed threshold values to determine the presence or absence of an object in the field of view of the sensor; and providing at least one pulse generator with rise and fall times of less than 3 ns each and capable of generating pulses less than 10 ns in duration.

Owner:SUBRAMANYA BALU

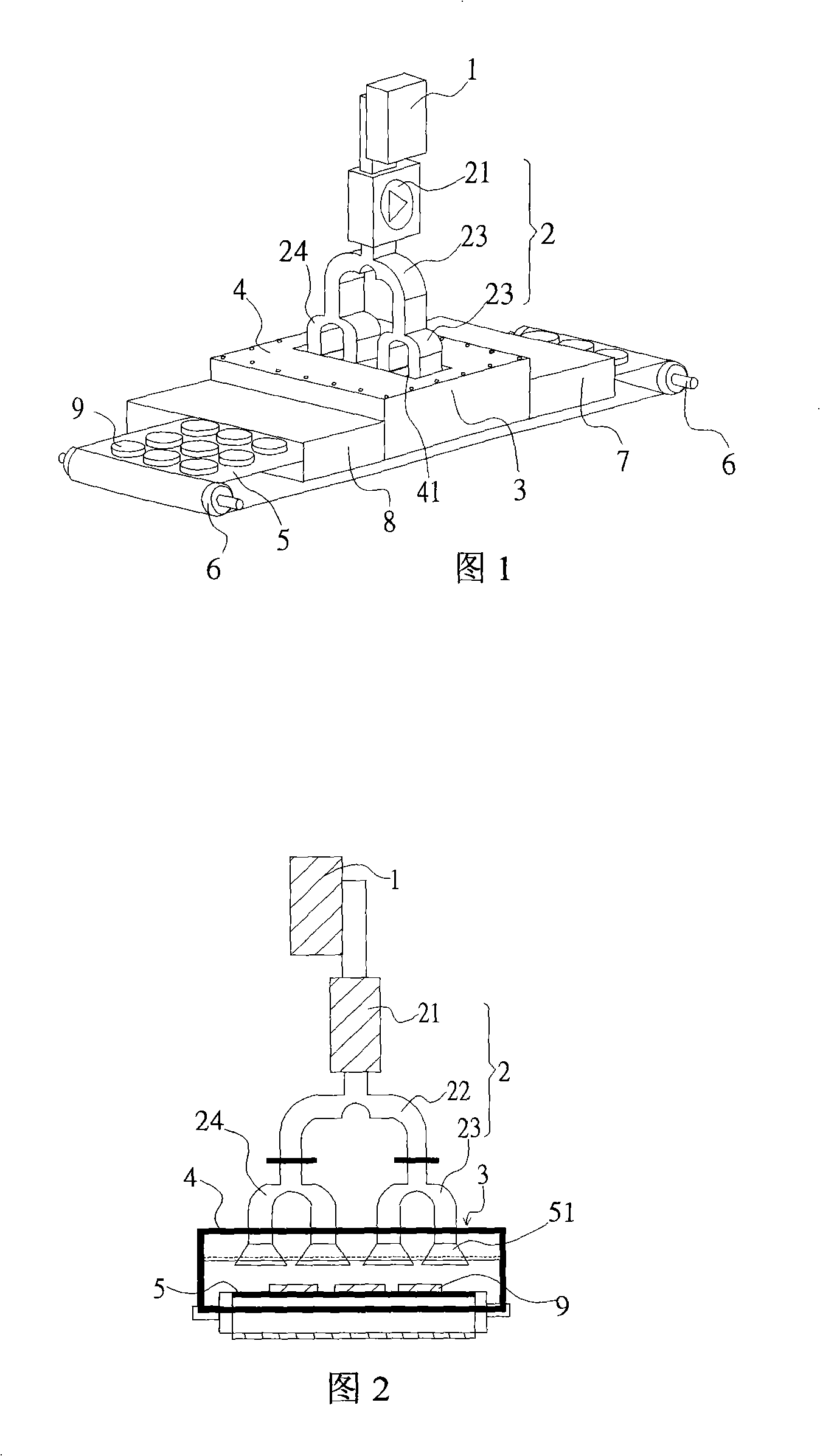

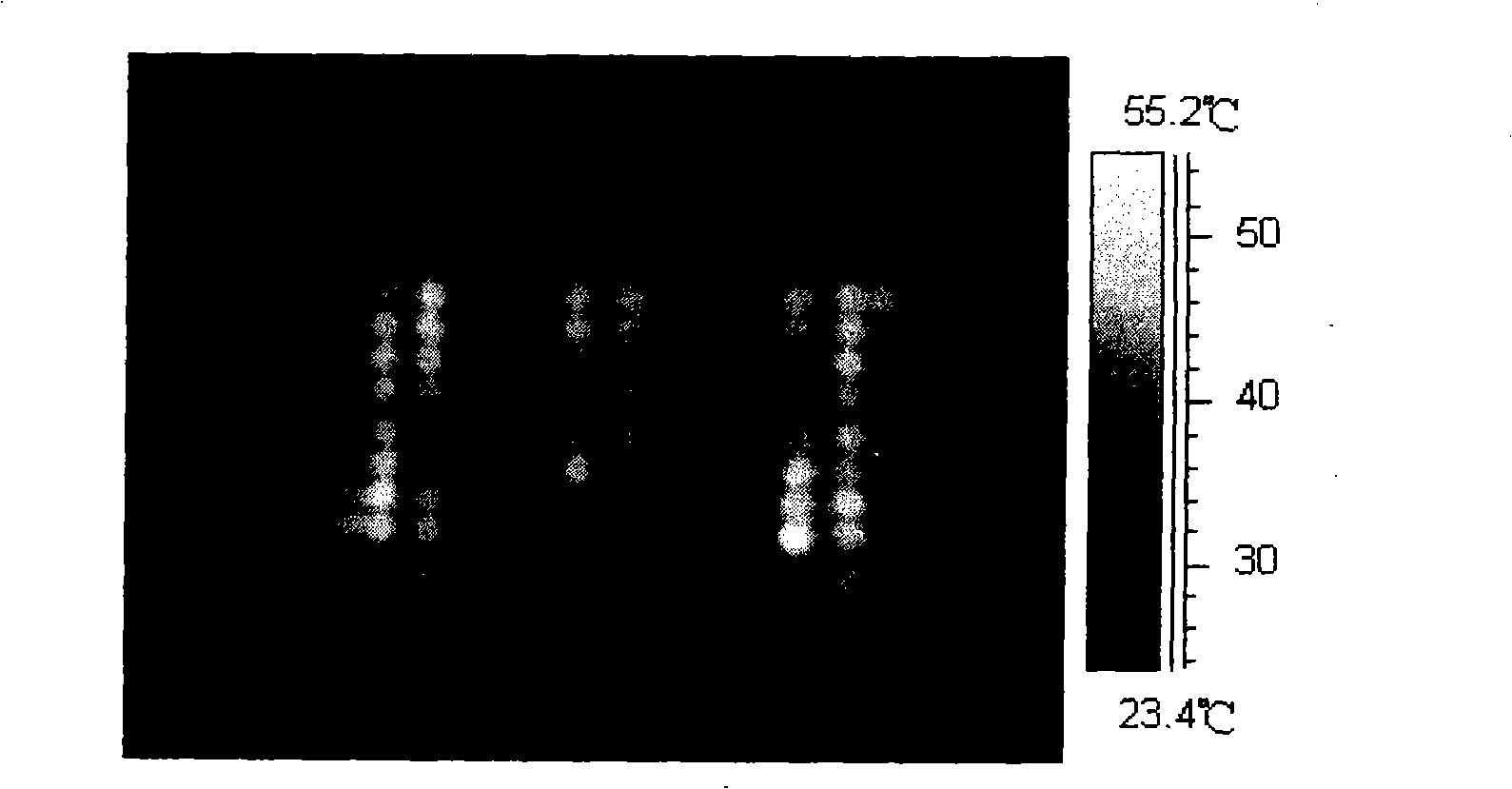

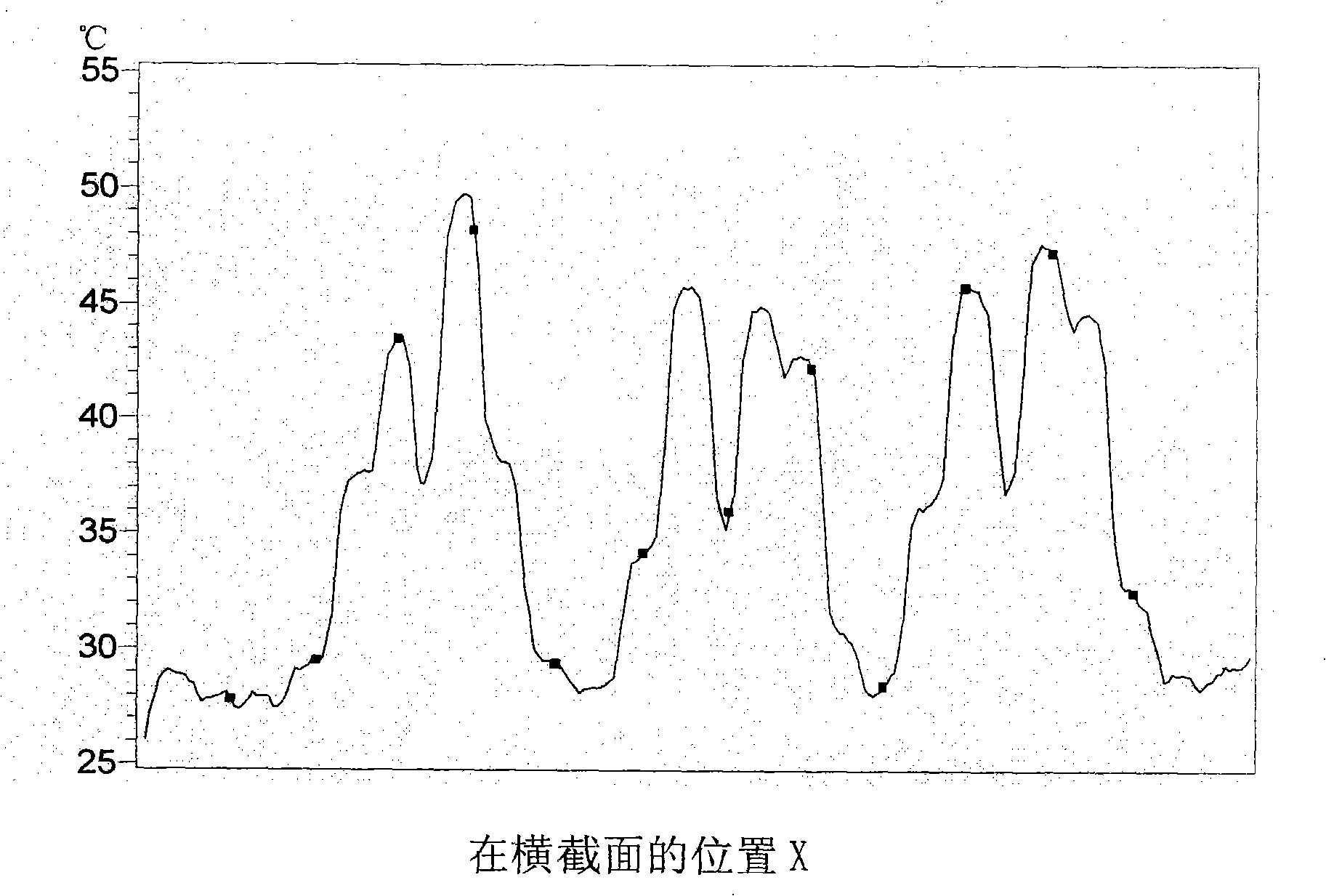

Continuous microwave heating apparatus

The present invention provides a continuous microwave heating device comprising microwave emitting part and microwave irradiating part which are connected with each other; a transmitting part is installed at lower part of the microwave irradiating part; the microwave irradiating part has a plurality of microwave irradiating unit which are configured adjacent to each other; causing the microwave of the single microwave energy from the microwave emitting part to heat the dielectric material passing through lower part of the microwave irradiating part via the movement of the transmitting part through the irradiation of the microwave irradiating unit, which is able to play the system production equipment needed by the single microwave energy and reduce the space possessed by the system and the producing cost.

Owner:FOOD IND RES & DEV INST

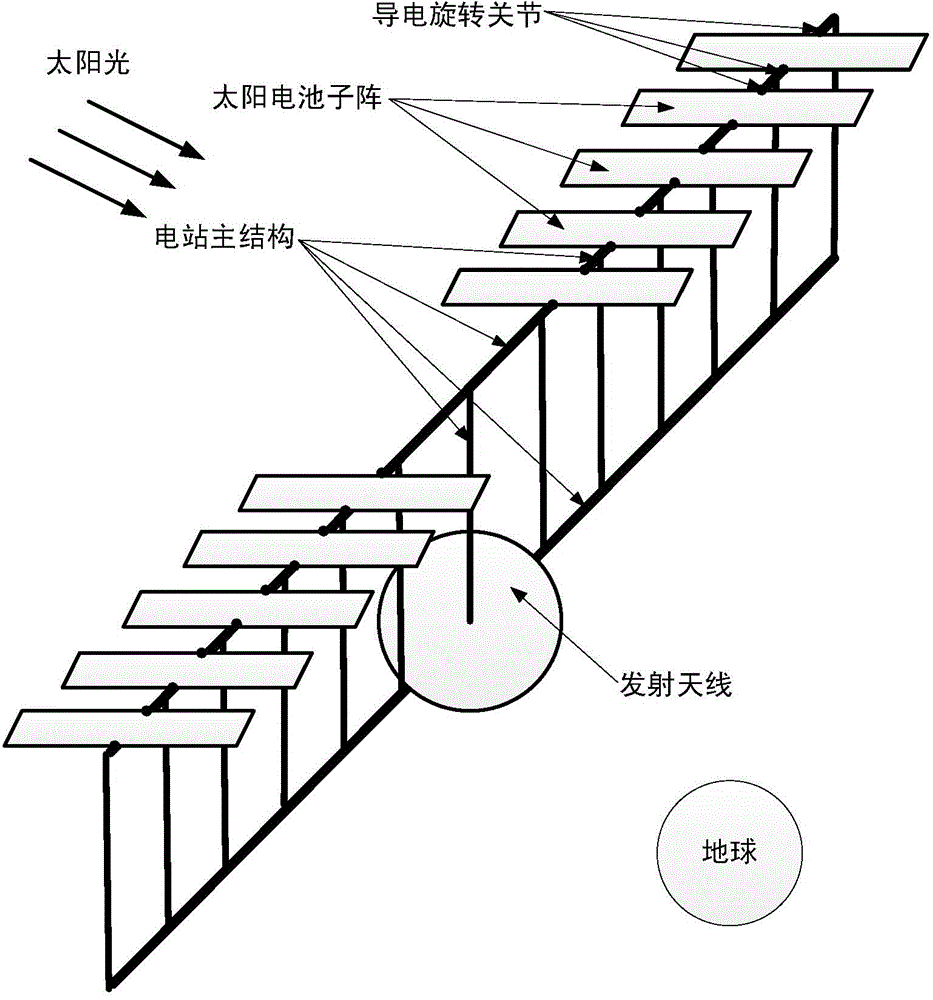

Non-condensing space solar power station

InactiveCN104158471ABeneficial technical effectReduce conduction powerPhotovoltaic supportsElectromagnetic wave systemPower stationElectrical battery

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

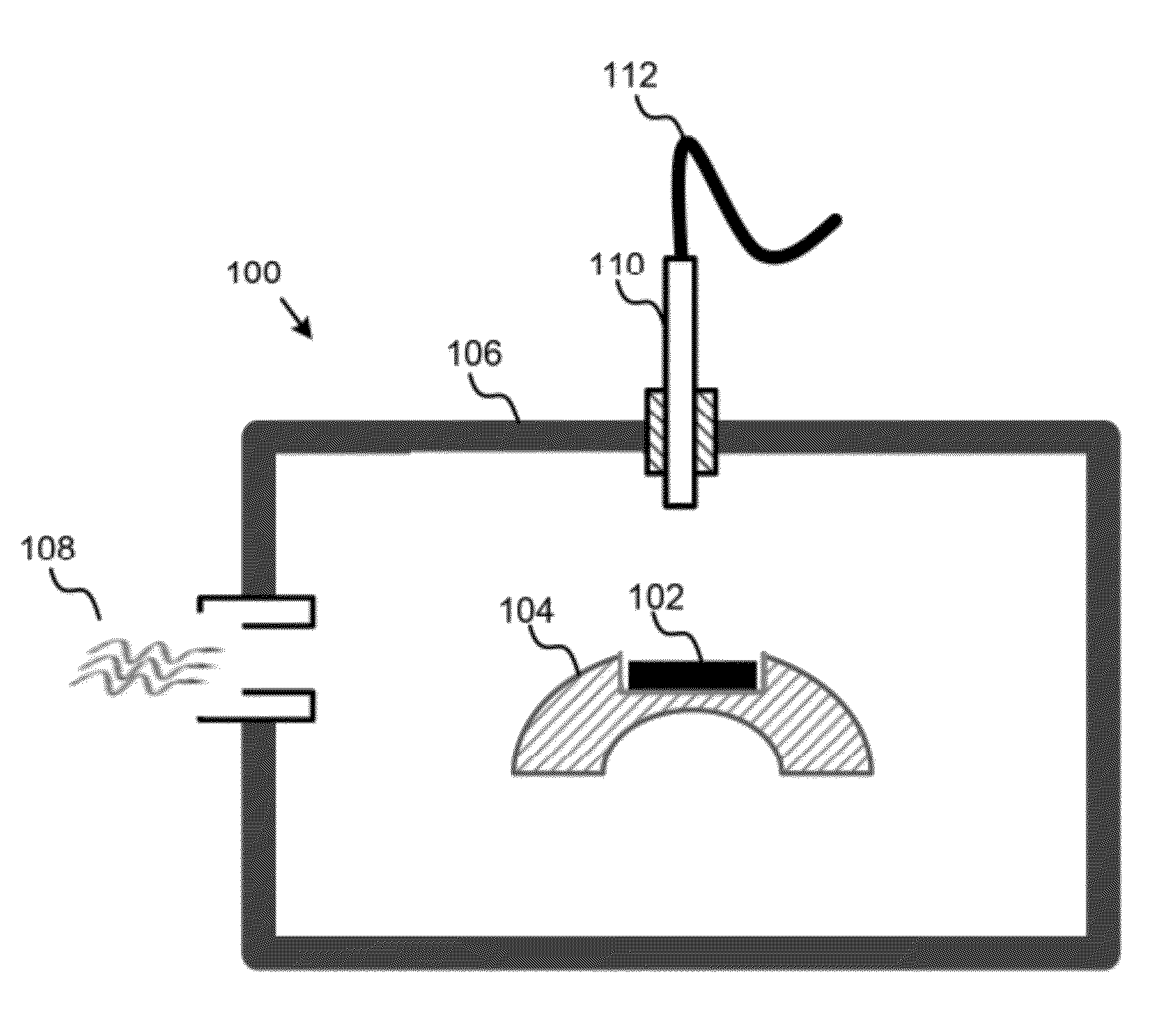

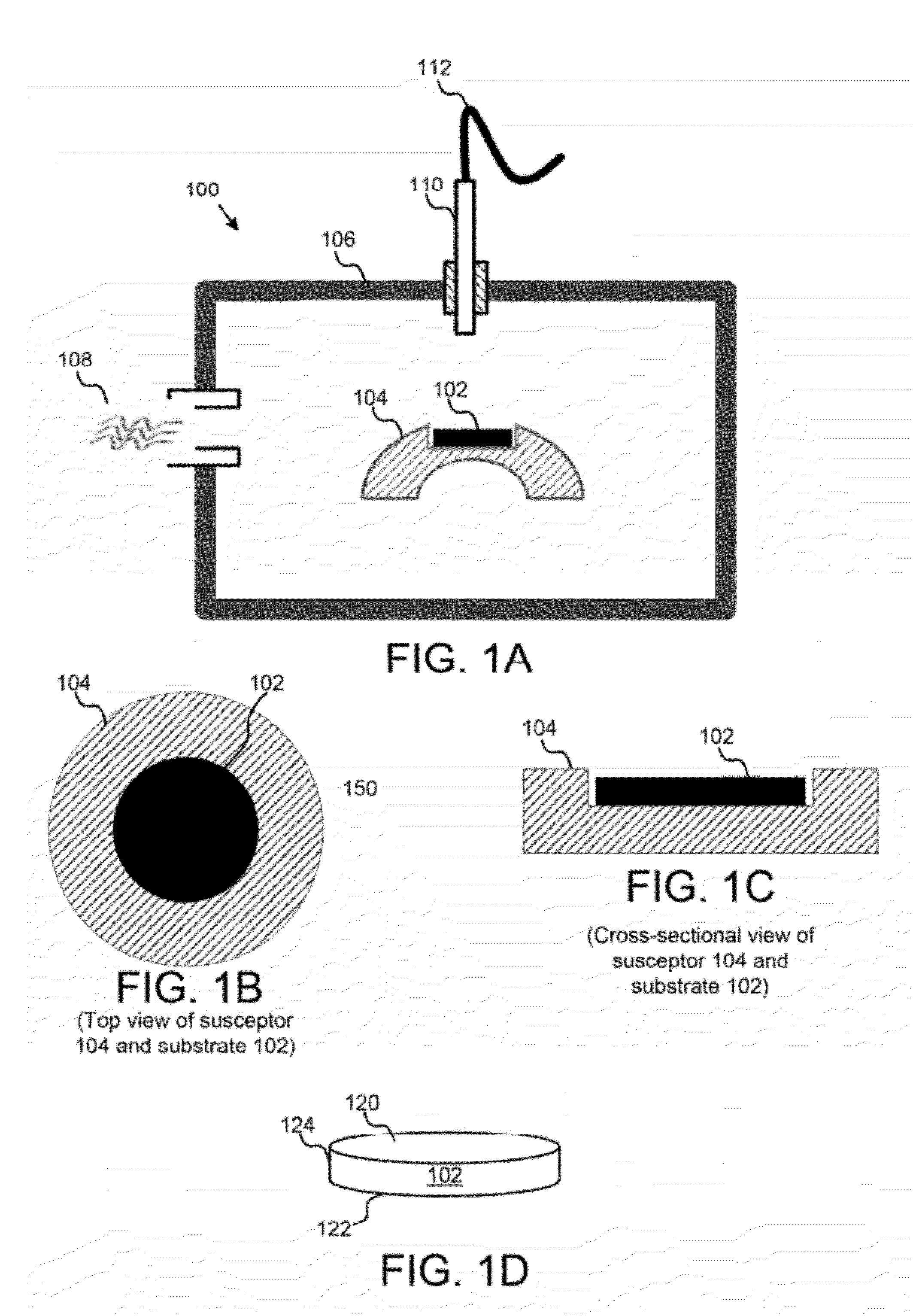

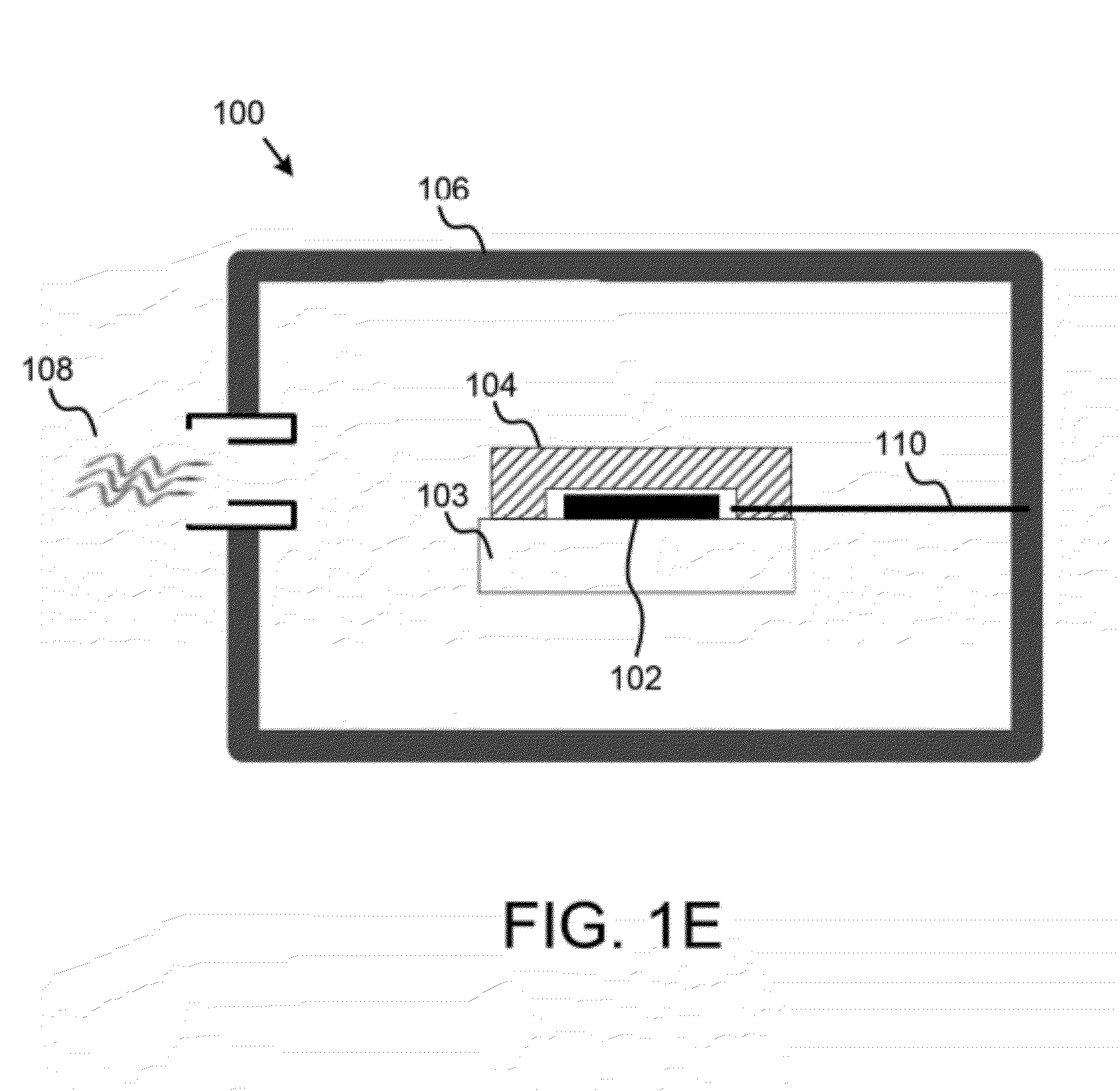

Systems and Methods for Susceptor Assisted Microwave Annealing

InactiveUS20120196453A1Semiconductor/solid-state device manufacturingMicrowave heatingSusceptorMicrowave emission

Systems and methods for microwave annealing are disclosed. In some embodiments, the system may comprise a microwave emitter configured to emit a microwave at a single frequency during an anneal time. In some embodiments, the system may further comprise an anneal unit to be annealed, the anneal unit having a top side, a bottom side, and one or more edge sides. In some embodiments, the system may further comprise a susceptor configured to absorb microwave energy, where the susceptor is adjacent to the edge side and at the bottom side of the anneal unit.

Owner:ARIZONA STATE UNIVERSITY

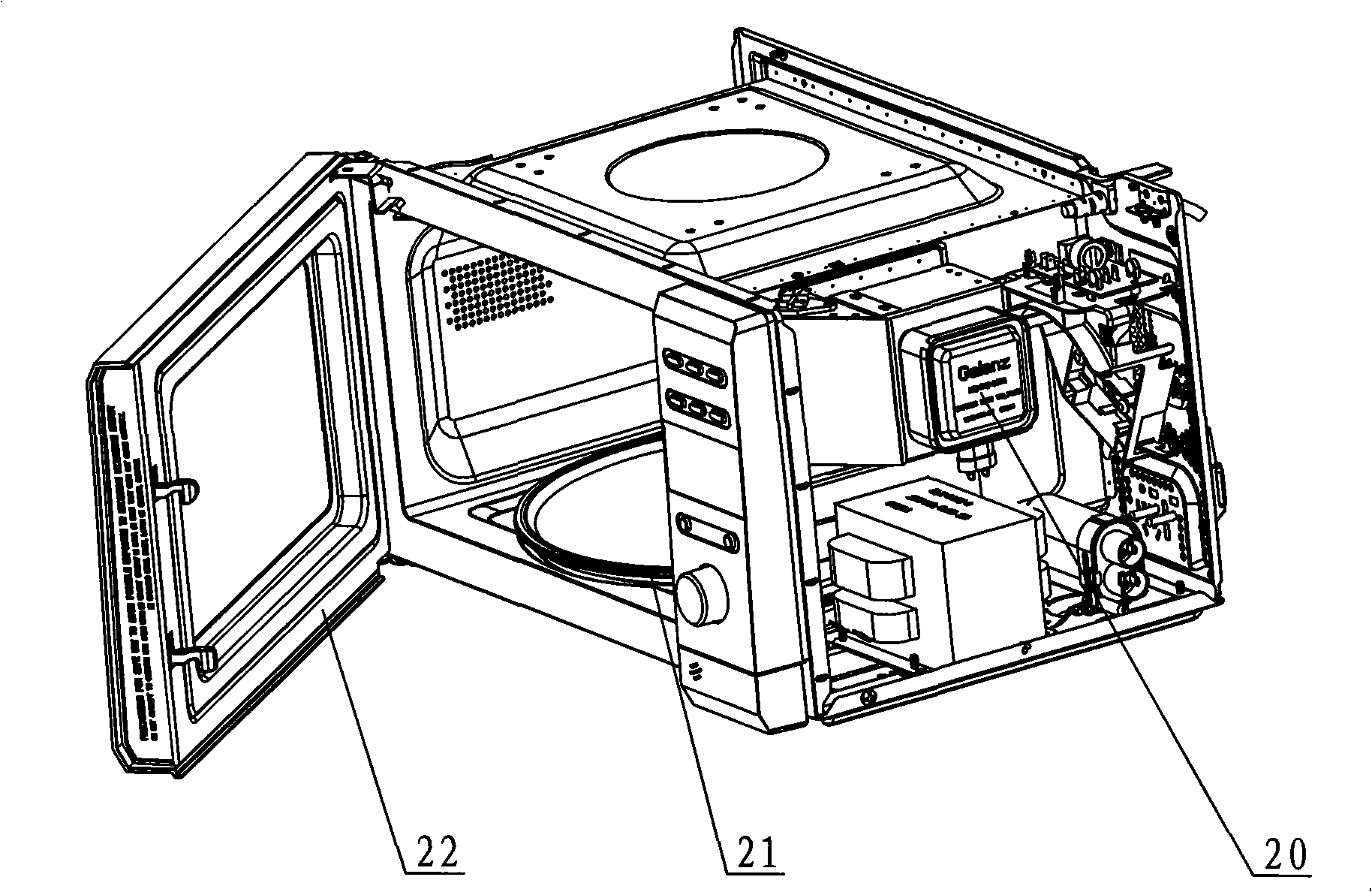

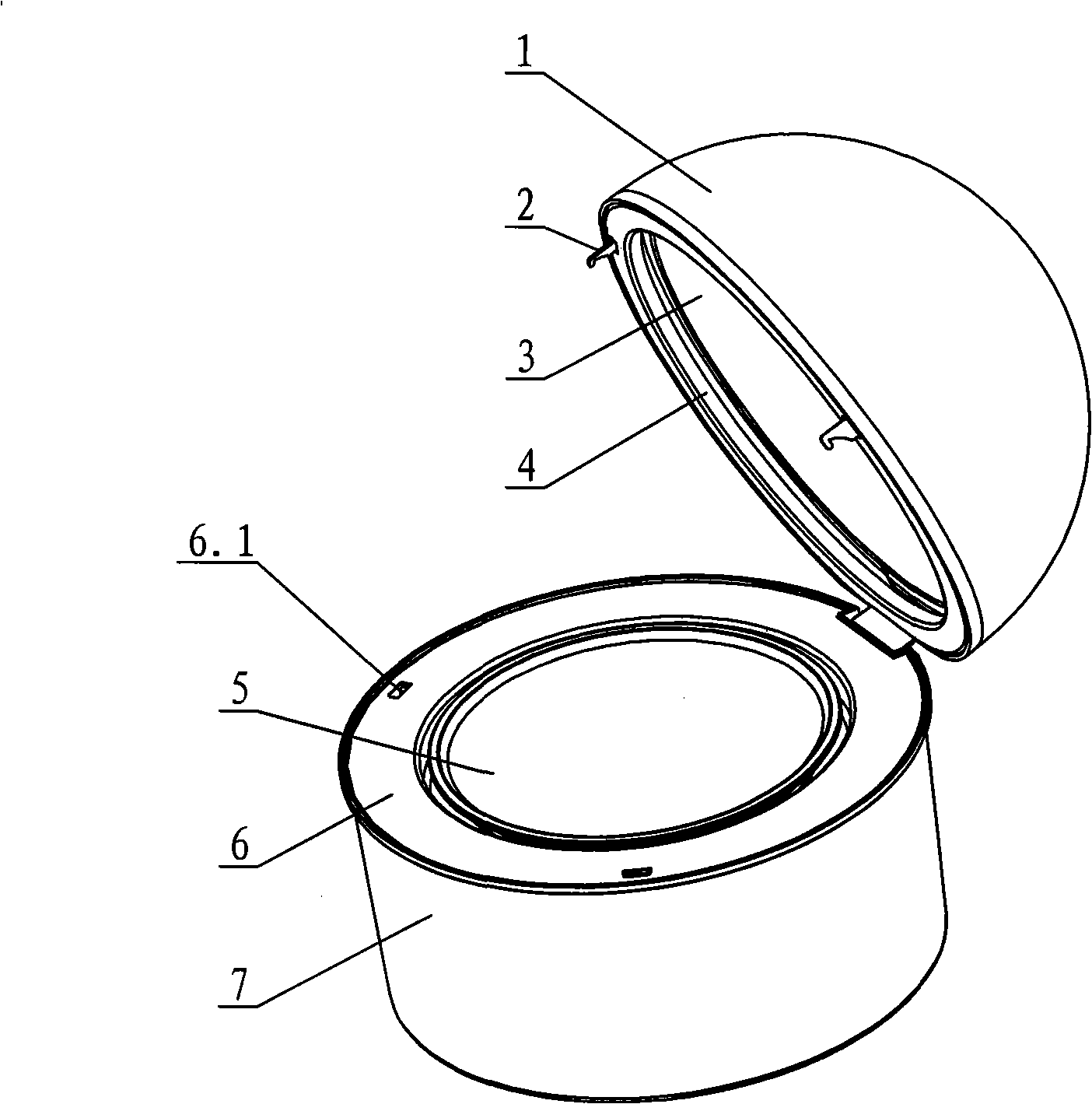

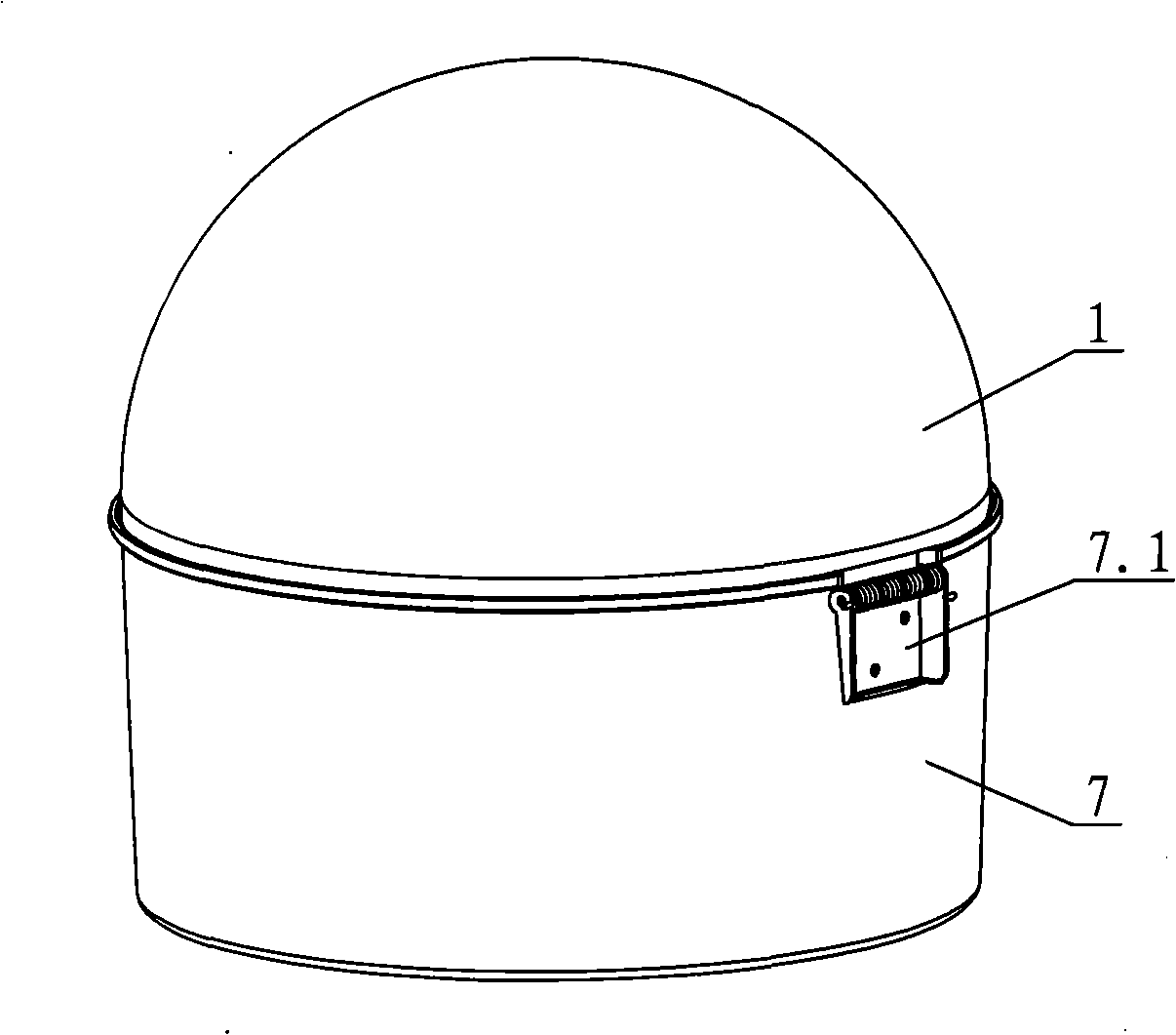

Micro-wave oven

InactiveCN101493235AEasy to operateEasy to cleanDomestic stoves or rangesLighting and heating apparatusMicrowave ovenProcess engineering

A microwave oven comprises an oven seat, a microwave generating unit and a cooking cavity. The cooking cavity is composed of a cavity enclosed by a supporting mechanism arranged on the oven seat and a microwave shielding cover; the microwave shielding cover can be opened or locked relative to the oven seat and / or the supporting mechanism; the supporting mechanism comprises an oven cover on the oven seat; the oven cover is tabulate, discal or kettle-shaped and the surface of the oven cover is equipped with microwave through holes corresponding to a microwave emitting area. The microwave oven cooking cavity of the invention directly consists of the supporting mechanism for holding food and the microwave shielding cover; the oven seat equipped with the microwave generating unit is positioned below the cooking cavity; the microwave from the microwave generating unit is emitted to the cooking cavity from bottom to top to heat the materials in the cooking cavity, thus breaking through the design of the traditional microwave ovens. In addition, the heated materials are put on a supporting plate of the supporting mechanism from the upward side, thereby facilitating the operation and cleaning. The microwave oven features simple and reasonable structure, easy manufacturing and processing, high heating efficiency and small floor area.

Owner:GUANGDONG GALANZ GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com