Patents

Literature

118results about How to "Consistent shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

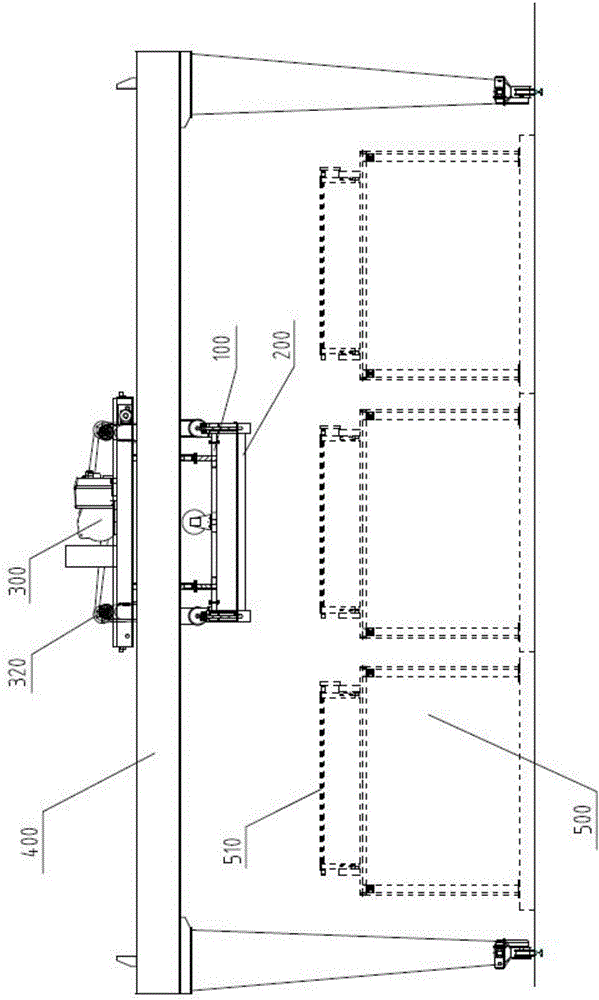

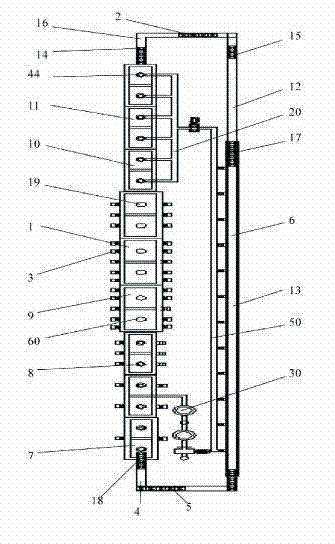

Fully-closed industrial microwave high-temperature roller continuous sintering kiln

InactiveCN102042749AConsistent shrinkageGood size consistencyMaintainance of heating chambersFurnace typesEnvironmental resistanceEngineering

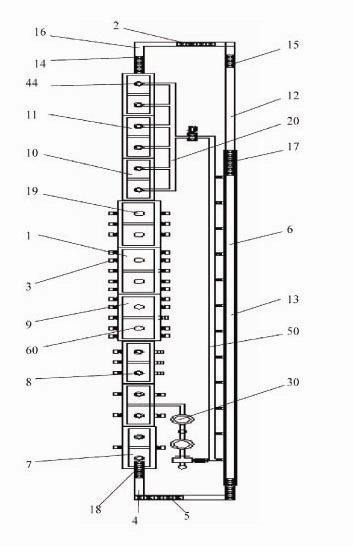

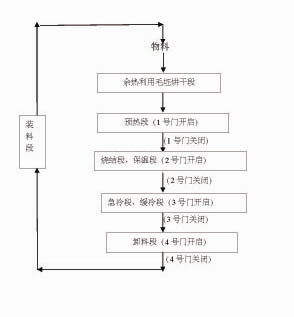

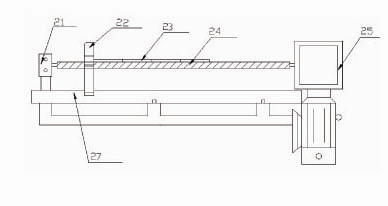

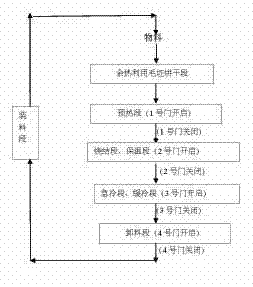

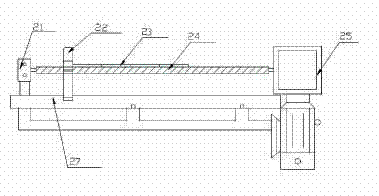

The invention discloses a closed microwave high-temperature sintering roller kiln, in particular a tunnel roller kiln with length of 10 to 50meters, and hearth sectional area of 0.06 to 0.3m<2>. The kiln comprises a main kiln body, a microwave transmission system, a turning channel mechanism, a roller power system, and a kiln door interlocking opening and closing system; the main kiln body is formed by connecting a water draining section, a preheating section, a sintering section, a heat preservation section, a quick cooling section, and a slow cooling section in turn; the turning channel mechanism is mainly formed by a material loading and unloading section and a residual-heat utilization blank drying section and comprises a turning channel, a turning channel roller, and a power system; the power system can poke a pushing plate from the outlet of the main kiln body onto the turning channel and feed the pushing plate into the inlet of the main kiln body through the residual-heat utilization blank drying section; and an inner roller for transmitting the material pushing plate, which is driven by the roller power system, is arranged on the bottom of an inner cavity of the main kiln body. The closed microwave high-temperature sintering roller kiln saves energy and reduces consumption and is environmental-friendly, the shrinkage of the sintered products is consistent and the sintered products have high size consistency, the yield is high, the production efficiency is high and the production cost is low.

Owner:湖南航天有限责任公司

Aluminum oxide ceramic substrate with high heat conductivity and preparation method thereof

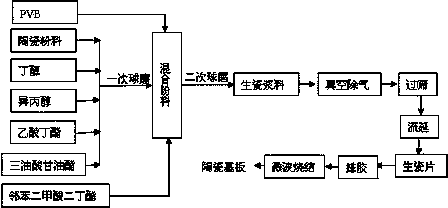

The invention discloses an aluminum oxide ceramic substrate with high heat conductivity. The aluminum oxide ceramic substrate is prepared by steps of stirring a ceramic powder material, a binder, a plasticizer, a dispersant and a solvent uniformly, preparing a ceramic raw-ceramic substrate through a tape casting method, glue discharging and sintering. The aluminum oxide ceramic substrate is characterized in that the solvent is a mixture of butanol, isopropanol and butyl acetate, and the ceramic powder material comprises aluminium oxide powder and auxiliary agents. The invention also discloses a preparation method for the aluminum oxide ceramic substrate with the high heat conductivity. According to the aluminum oxide ceramic substrate and the preparation method, the solvent system which comprises the butanol, the isopropanol and the butyl acetate are used as the main solvent in place of traditional toluene, thus enhancing dissolution of PVB by the solvent, thereby guaranteeing uniformity of raw ceramic slurry, making physical properties of sintered ceramic stable, reducing environmental influences of the exhausted gas during production processes compared to traditional modes of production, contributing to energy conservation and emission reduction, and reducing the cost.

Owner:NANJING ZHONGJIANG NEW MATERIAL TECH

Method for manufacturing a garment having a rigid front portion and a stretchable back portion

InactiveUS20160362820A1Consistent shrinkageSame character and shrinkage factorsHeating/cooling textile fabricsDyeing processEngineeringMechanical engineering

A method for making jeans. A material is weaved for use as a front portion of the jeans. The warp portion of the weave is spun with a combination of open-end and ring spinning. The weft portion of the weave is spun with open-end spinning. The resulting weaved material is then sulfur dyed, singed and pre-shrunk to form the front portion. Another material is weaved for use as a back portion of the jeans using a fabric composition which is 79% cotton, 20% filament fiber polyester, 1% spandex. The warp portion of the weave is spun using a combination of open-end and ring spinning. The weft portion of the weave is made from the filament fiber polyester. The resulting fabric composition weaved material is then indigo dyed and singed and then pre-shrunk to form the back portion. The two portions are cut and sewed together to produce the jeans.

Owner:4 WHAT ITS WORTH

Method for preparing zirconia ceramic denture

The invention discloses a method for preparing a zirconia ceramic denture. The method comprises S1, injecting a zirconia ceramic feed for preparing a denture into a standard blank mold and carrying out molding to obtain a standard green blank bigger than the desired denture, S2, pre-sintering the standard green blank to obtain a presintered blank and discharging at least one part of a binder, S3, processing the presintered blank to obtain a denture shape having the size is magnified proportionally than the desired denture, S4, sintering the processed product at a high temperature higher than the presintering temperature in the step S2 so that the presintered blank is further compacted so that the presintered blank is shrunk to the size the same to that of the desired denture, and S5, grinding and polishing the compacted product to obtain a desired denture. The method reduces a denture production cost and improves a product yield.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Powder material used for 3D printing and powder 3D printing forming method

InactiveCN106042408APrevent oxidationWon't clogAdditive manufacturing apparatusMaterials science3D printing

The present invention relates to a powder material used for 3D printing and a powder 3D printing forming method. The surface of a powder sectional material is wrapped by a layer of binder, a printing spray head sprays a curing agent and do not need to spray the binder, thereby avoiding blockage of the printing spray head. By adoption of the powder material and the method, the technical problem that the 3D printing spray head is easy to block is solved, products with complicated structures can be printed, no complicated and expensive manufacturing equipment is required, the printing cost is greatly lowered, and application of the 3D printing technology is further popularized.

Owner:武汉易制科技有限公司

Method of preparing high size precision profiled molybdenum parts

InactiveCN1686642AUniform densityConsistent shrinkagePolyureas/polyurethane adhesivesParaffin waxHigh density

A process for preparing molybdenum part with high size precision and compactness includes preparing adhesive from paraffin wax, high-density polyethene, polypropene and stearic acid through proportionally mixing, mixing it with molybdenum powder, injection moulding, degreasing, presintering, sintering, holding the temp for 1-10 hr, and post treating.

Owner:UNIV OF SCI & TECH BEIJING

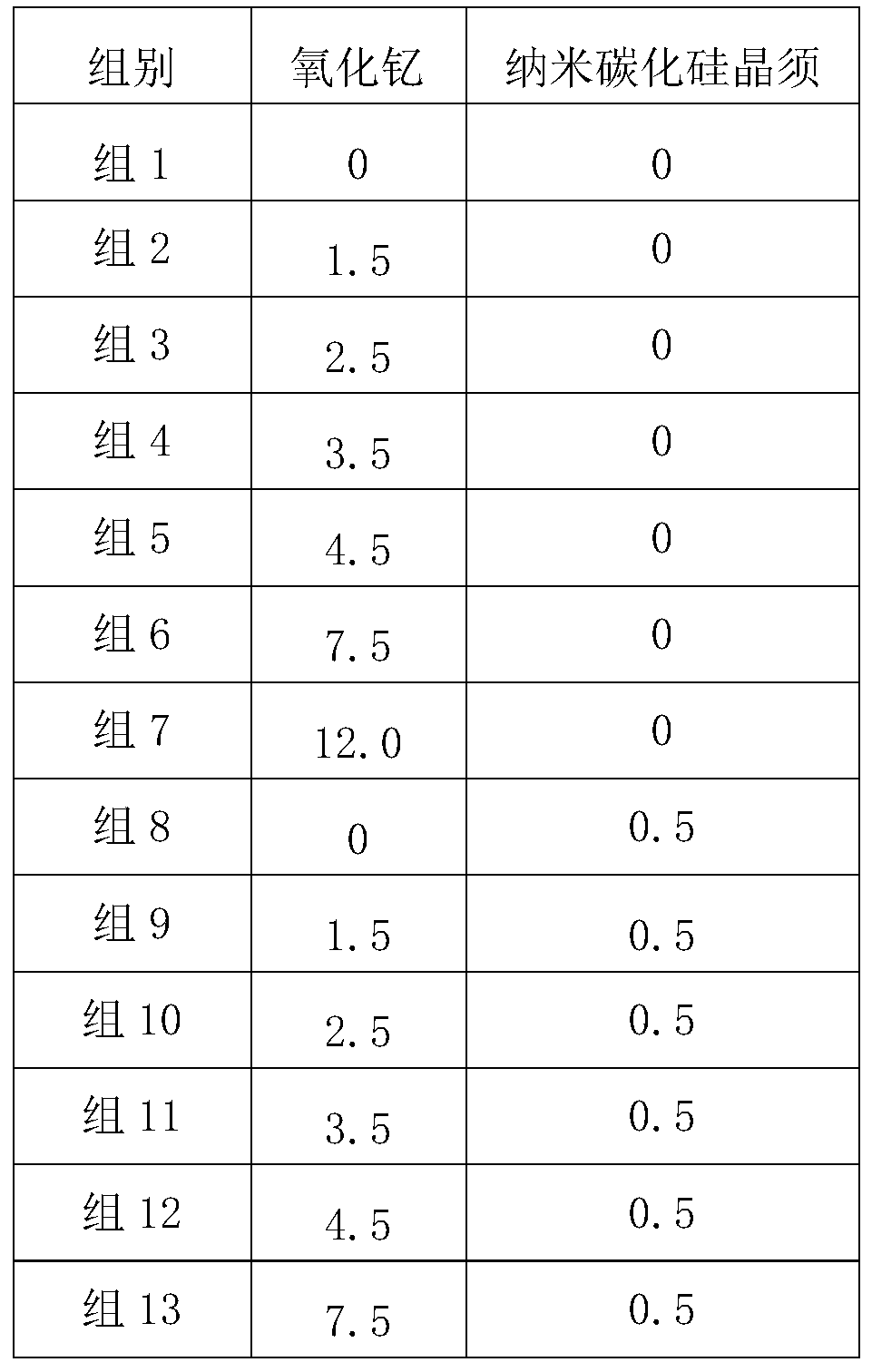

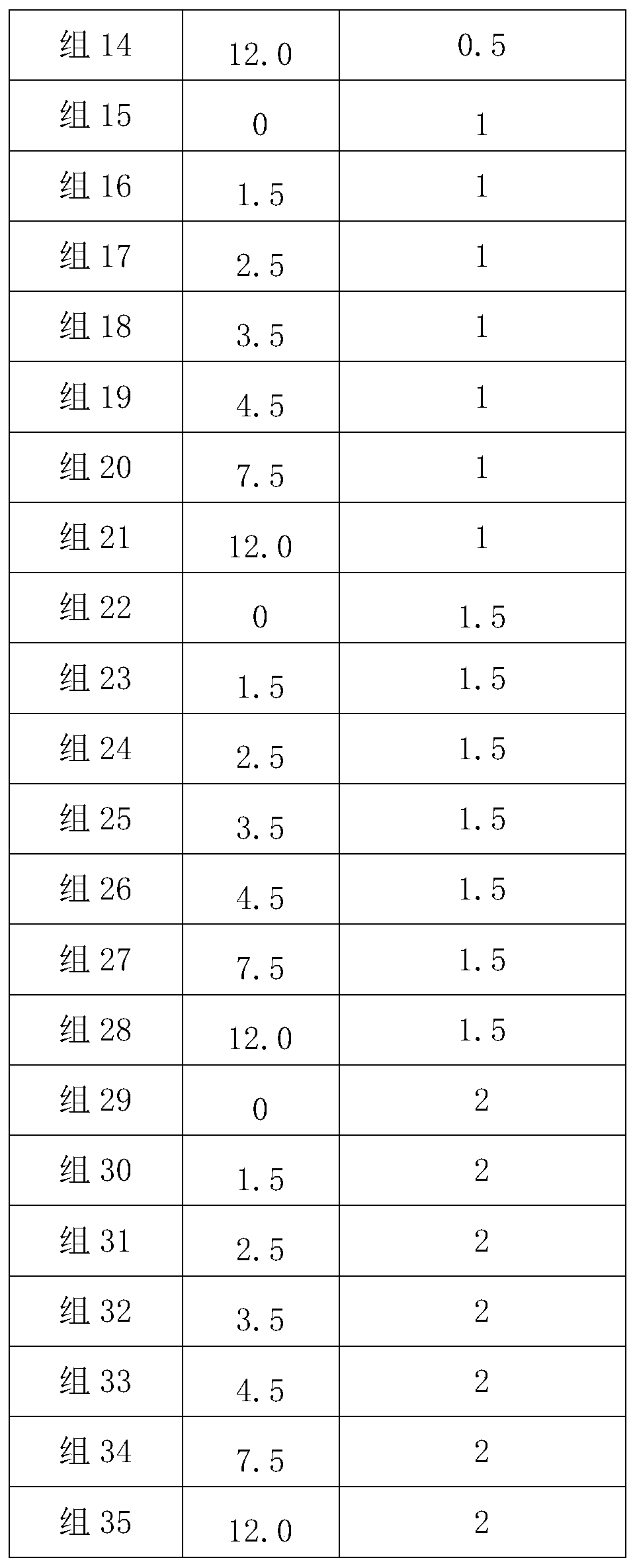

Processing technology capable of rapidly preparing multi-layer zirconia ceramic block with uniform transition

The invention belongs to the field of oral materials, in particular relates to a sintering process for rapidly preparing a zirconia ceramic block with uniform strength and color transition, and in particular relates to a high-toughness zirconia ceramic block, and the powder formula of the zirconia ceramic block comprises 1.5 to 12% of yttrium oxide, 0 to 2.5% of silicon carbide nano whiskers, 0 to1.5% of a coloring matter and the balance of zirconium oxide according to the mass fraction. Based on the ceramic block, the multilayer zirconia ceramic block with uniform transition of comprehensivemechanical properties, color and permeability is provided. At the same time, a process capable of completing the sintering of the zirconia ceramic block with high efficiency and high quality is provided. By using the process, the zirconia ceramic block with excellent comprehensive mechanical properties and uniform color and permeability transition can be obtained in as short a time as possible.

Owner:CHENGDU BESMILE BIOTECH

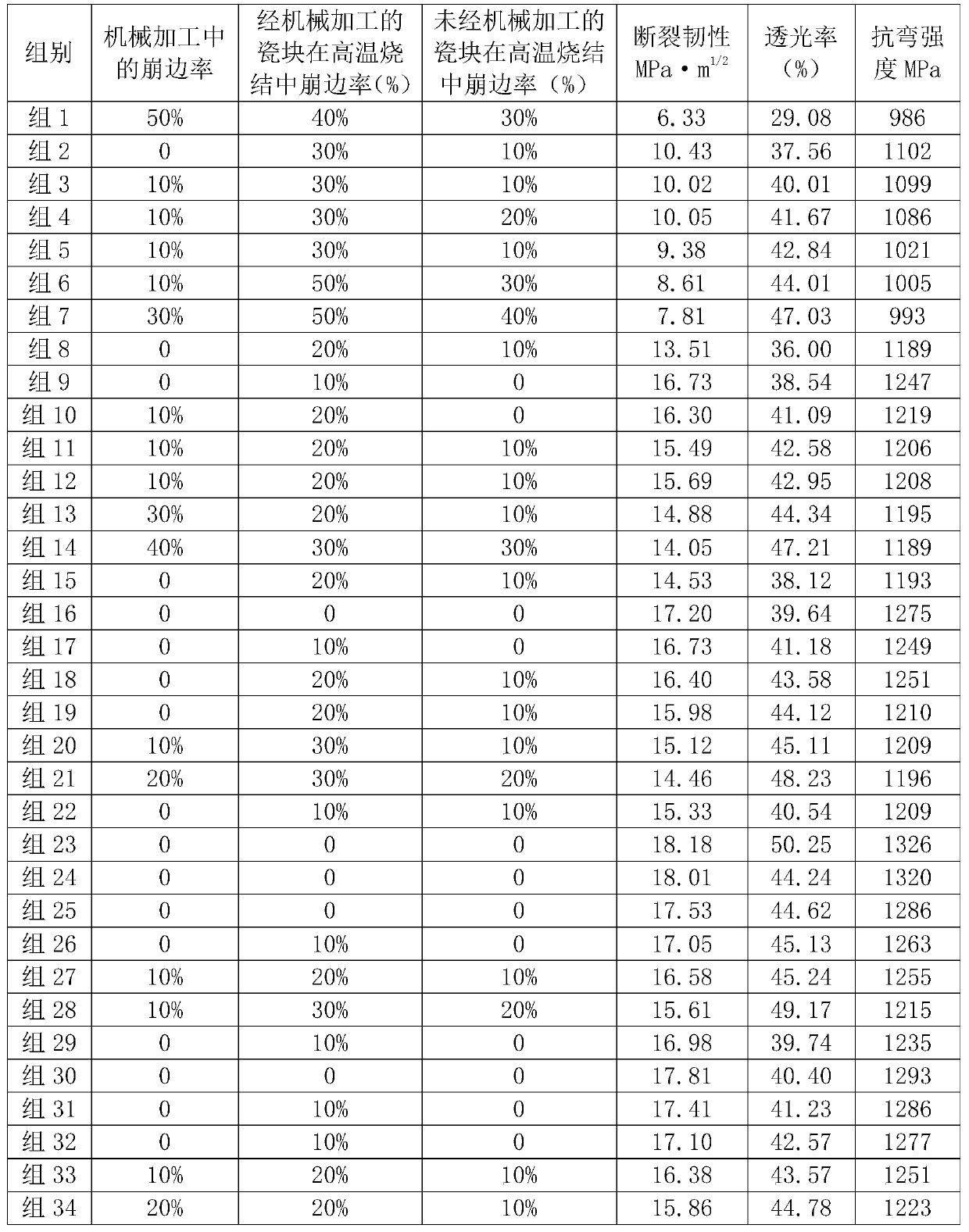

Layered zirconia porcelain block technology with even contraction of all layers

ActiveCN110317059AIncreasing the thicknessGuaranteed color needsImpression capsDentistry preparationsContraction rateTransition layer

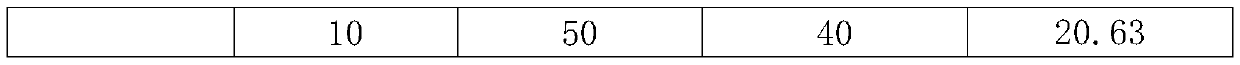

The invention belongs to the field of oral cavity materials and particularly relates to a layered zirconia porcelain block technology with even contraction of all layers. By adopting the technical scheme, according to the required colors, the component and content of zirconia powder formulas of all the layers are determined, and zirconia porcelain blocks of all the layers comprise shallowest layers, transition layers and deepest layers; according to the content of yttria in all the formulas, the particle diameter distribution of zirconia and yttria in the shallowest layers and the deepest layers is adjusted, so that it is guaranteed that the contraction rate diversity factor of the shallowest layers and the deepest layers after sintering is smaller than 0.3%; the adjusted shallowest layersand deepest layers are evenly mixed to obtain the transition layers; the shallowest layers, transition layers and deepest layers are placed layer by layer according to the color shade sequence and subjected to isostatic pressing, pre-sintering and high-temperature sintering, and preparation is completed. By adopting the technical scheme, the layered zirconia porcelain block with natural colors, natural penetrability transition and a basically-constant contraction rate can be obtained.

Owner:CHENGDU BESMILE MEDICAL TECH CORP LTD

Manufacturing method of lightweight partition wall

InactiveCN104631694AThe strength meets the requirementsShort curing timeConstruction materialCeramic shaping apparatusPipe fittingFiberboard

The invention discloses a manufacturing method of a lightweight partition wall. The method comprises the steps of arranging a die; mixing and agitating; arranging a plurality of layers of reinforcing nets in the die; arranging a plurality of through pipe fittings in the direction vertical to the reinforcing nets, wherein the spacing is reserved between pipe fittings, and the pipe fittings are symmetrically arranged in proportion; grouting and processing; leveling the raw materials at a raw material inlet of the die; dismounting the die; drawing out the pipe fittings; solidifying and drying inner cores for 2 to 3 hours; pressing cement fibrolite boards and cutting; adhering the pressed and cut cement fibrolite boards on the surface plates on two surfaces of the inner cores; adhering and bearing the inner cores and the cement fibrolite boards; respectively arranging matched spliced protecting sleeves on two mutually-spliced side surfaces of the inner cores; standing to dry and maintaining. The lightweight partition wall can be produced by mass and mounted in places as requirement; the lightweight partition wall is fast and convenient to mount, and high in construction efficiency.

Owner:SHANGHAI SHDBM NEW MATERIALS

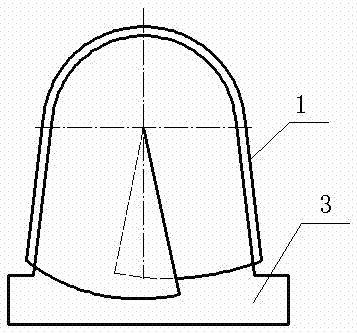

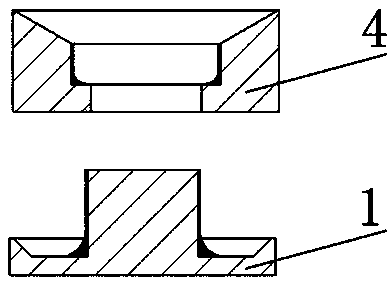

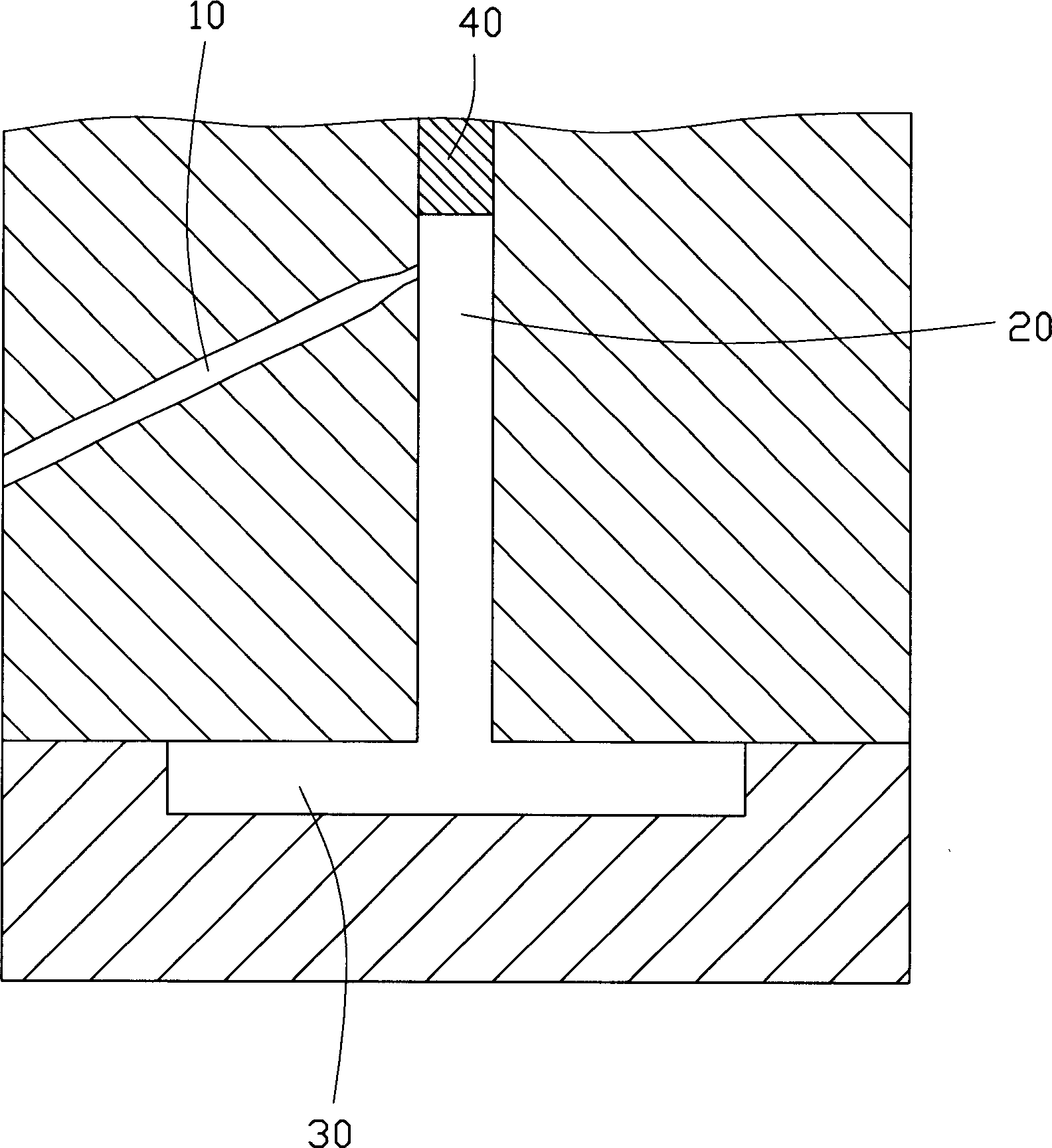

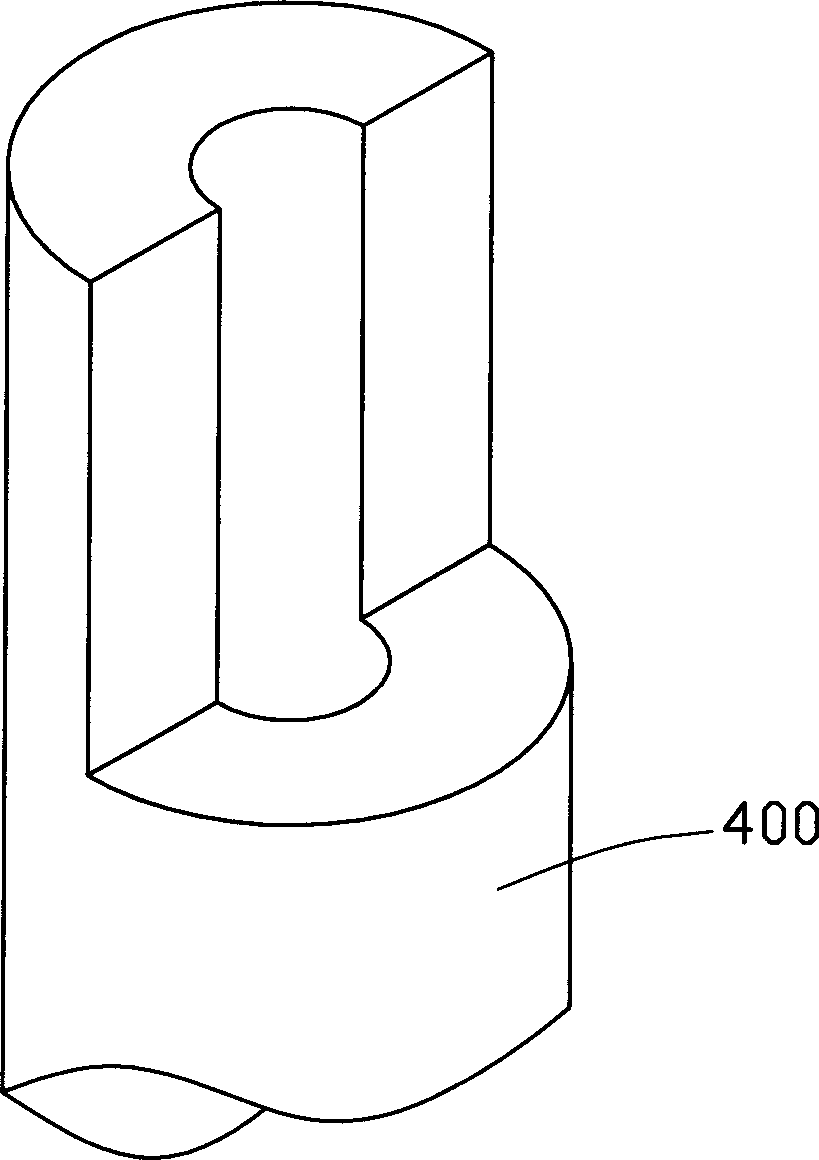

Ceramic body dry-pressing and forming process

ActiveCN102371616AUniform densityReduce manufacturing costCeramic shaping apparatusMicrowaveMetallurgy

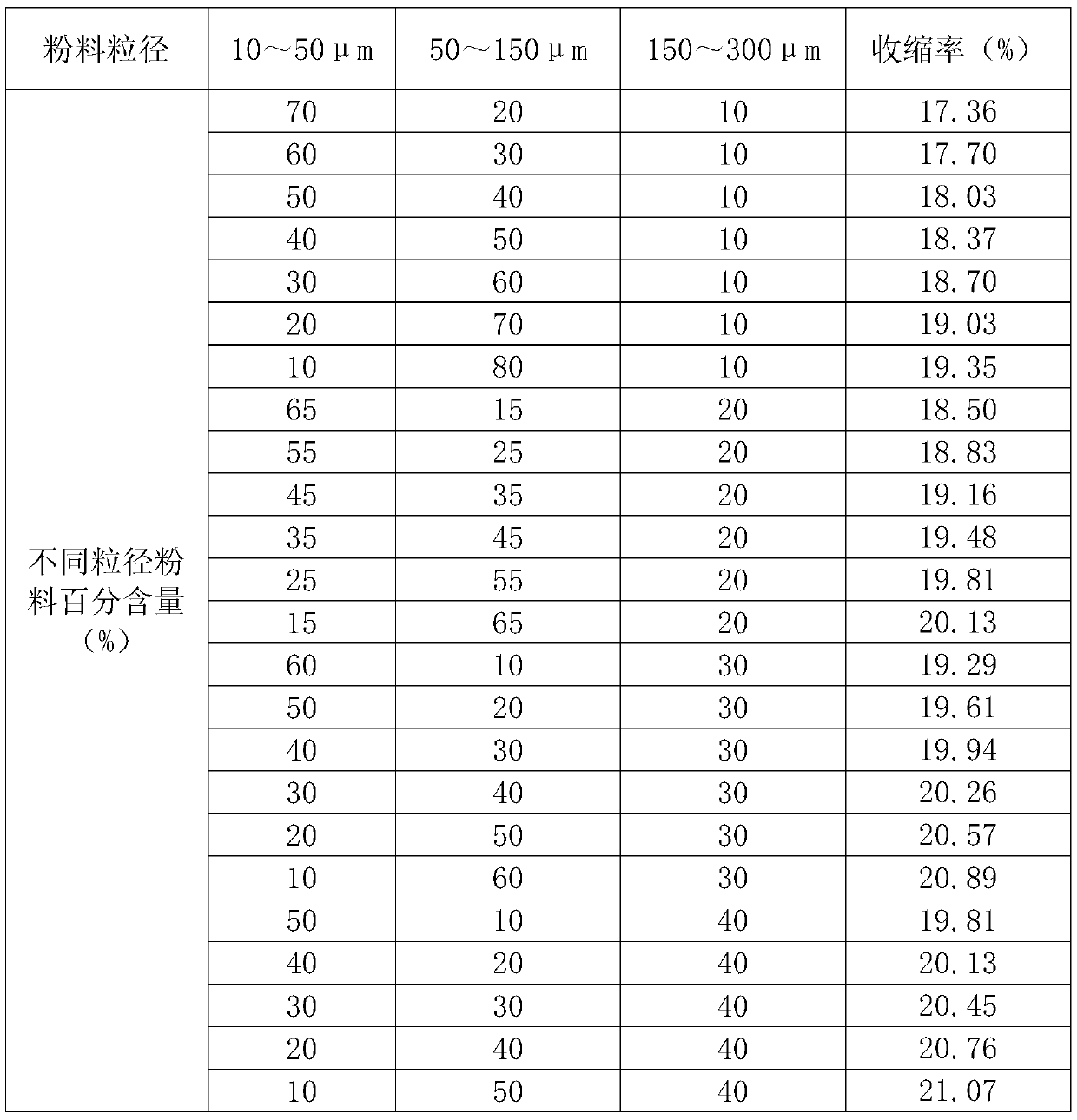

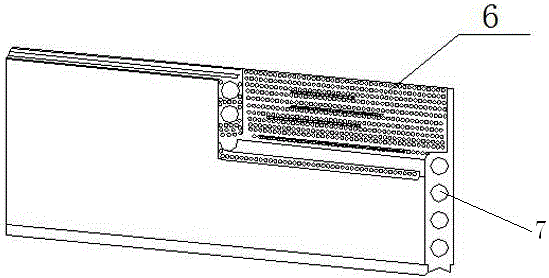

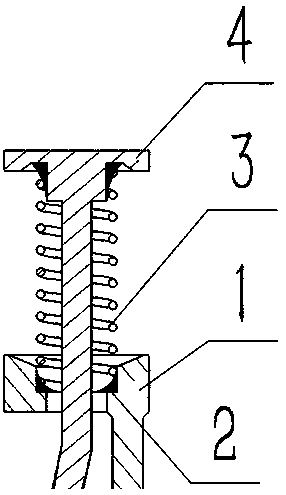

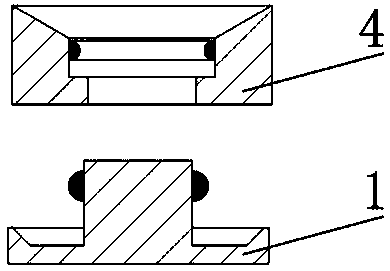

The invention discloses a ceramic body dry-pressing and forming process, which comprises the following steps of: (1) filling: adding material powder for manufacturing a ceramic body into a female die; (2) pre-pressing: lowering an upper punch, fixing the female die, and increasing the density of the material powder at the upper part of the female die; (3) synchronously pressing: synchronously and downwardly moving the female die and the upper punch, so that the density of the material powder at the lower part of the female die is increased; (4) pressing again: fixing the female die, continuously and downwardly pressing the upper punch, and pressing the material powder again; and (5) protectively demoulding: after pressing, pressing the upper punch on the surface of the ceramic body to demould, so that stress on the ceramic body is uniformly released to demould. According to the ceramic body dry-pressing and forming process disclosed by the invention, the crack and layering phenomenon of microwave medium ceramic parts is reduced; furthermore, the conical degrees of two ends of the ceramic body are reduced; and the product yield is increased.

Owner:WUHAN FINGU ELECTRONICS TECH

Multi-functional shirt and method for making the same

A multifunctional shirt with ironing-free, water-proof, oil-proof, anti-fouling, refreshing and hydroscopic functions features that its front pieces are made of the ironing-free, water proof, oil-proof and antifouling fabric, its back pieces are made of the ironing-free, refreshing and hydroscopic fabric, and its sleeves and collar are made of the ironing-free, water-proof and oil-proof fabric cleaned easily. Its making method includes such steps as providing said fabrics, adding resin, stacking, water washing, respectively adding proper assistants, stretching, baking, pre-shrinking, and sewing.

Owner:LUTAI TEXTILE

Support-matched large component powder injection molding method

InactiveCN107398559AConsistent shrinkageNo crackTransportation and packagingMetal-working apparatusInjection mouldingInjection molding machine

The invention discloses a support-matched large component powder injection molding method. The method comprises the following steps that a, metal powder and a binder are mixed uniformly and then prepared into feed particles; b, an injection molding machine is utilized for injecting the feed particles into a mold to form a blank; c, a support matched with the shape of the blank is pressed and molded, and a separation coating is brushed on the surface of the support; and d, after the blank is put on the surface of the support, the blank and the support are put in a sintering furnace together for degreasing and sintering, and sintering is completed to obtain a finished product. In the sintering step in the injection molding process, the blank is put on the support, the separation coating is brushed between the blank and the support, feed parameters and molding parameters are adjusted, then the blank and the support are sintered together, and it is guaranteed that the shrinking rates of the blank, the separation coating and the support during sintering are consistent; and meanwhile, the blank, the separation coating and the support are combined closely, the shapes are matched, no clearance exists between the blank, the separation coating and the support, no crack is generated to the blank during sintering, and the percent of pass and quality of the finished product are effectively improved.

Owner:江苏理成科技有限公司

Method for stitching crease-proofing shirts

InactiveCN1853517AComfortable to wearGood lookingGarmentsClothes making applicancesPolyesterWrinkle skin

A technique for preventing the wrinkle generation at the sewed position on shirt includes such steps as choosing proper adhesive liner belt consisting of a substrate layer made of polyester fibers or natural cotton fibers and an adhesive layer, sewing it between two cloth pieces, and hot pressing.

Owner:LUTAI TEXTILE

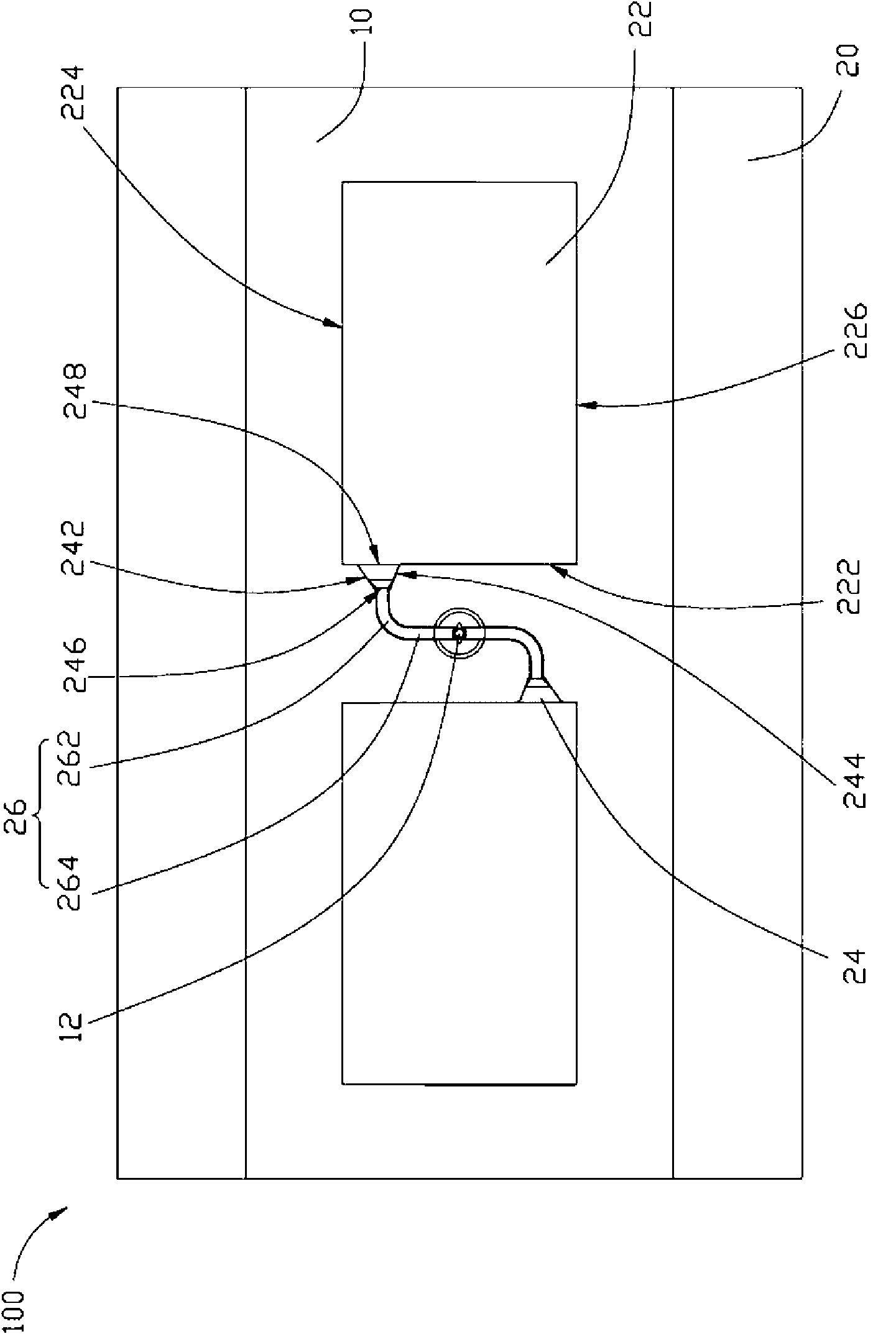

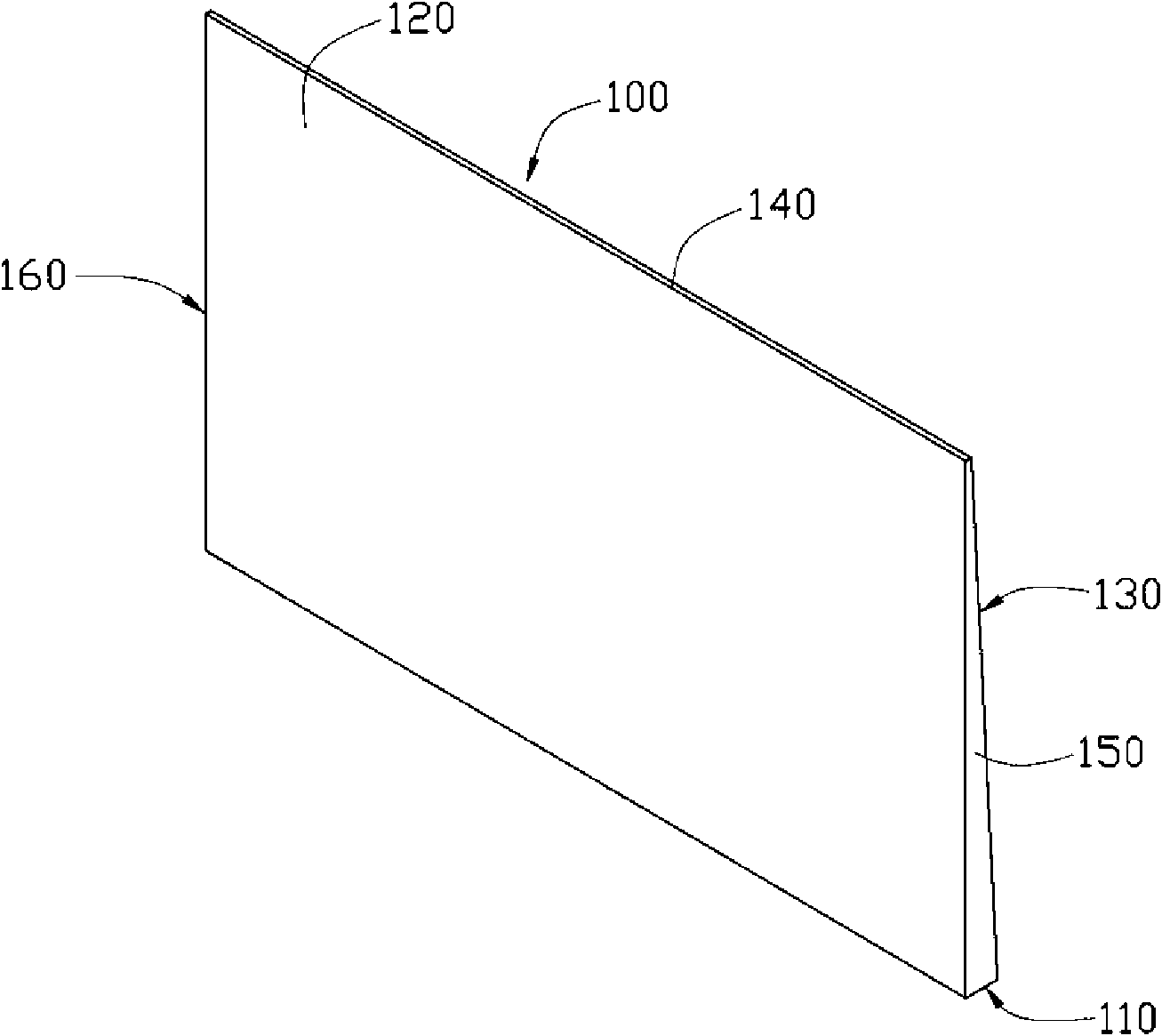

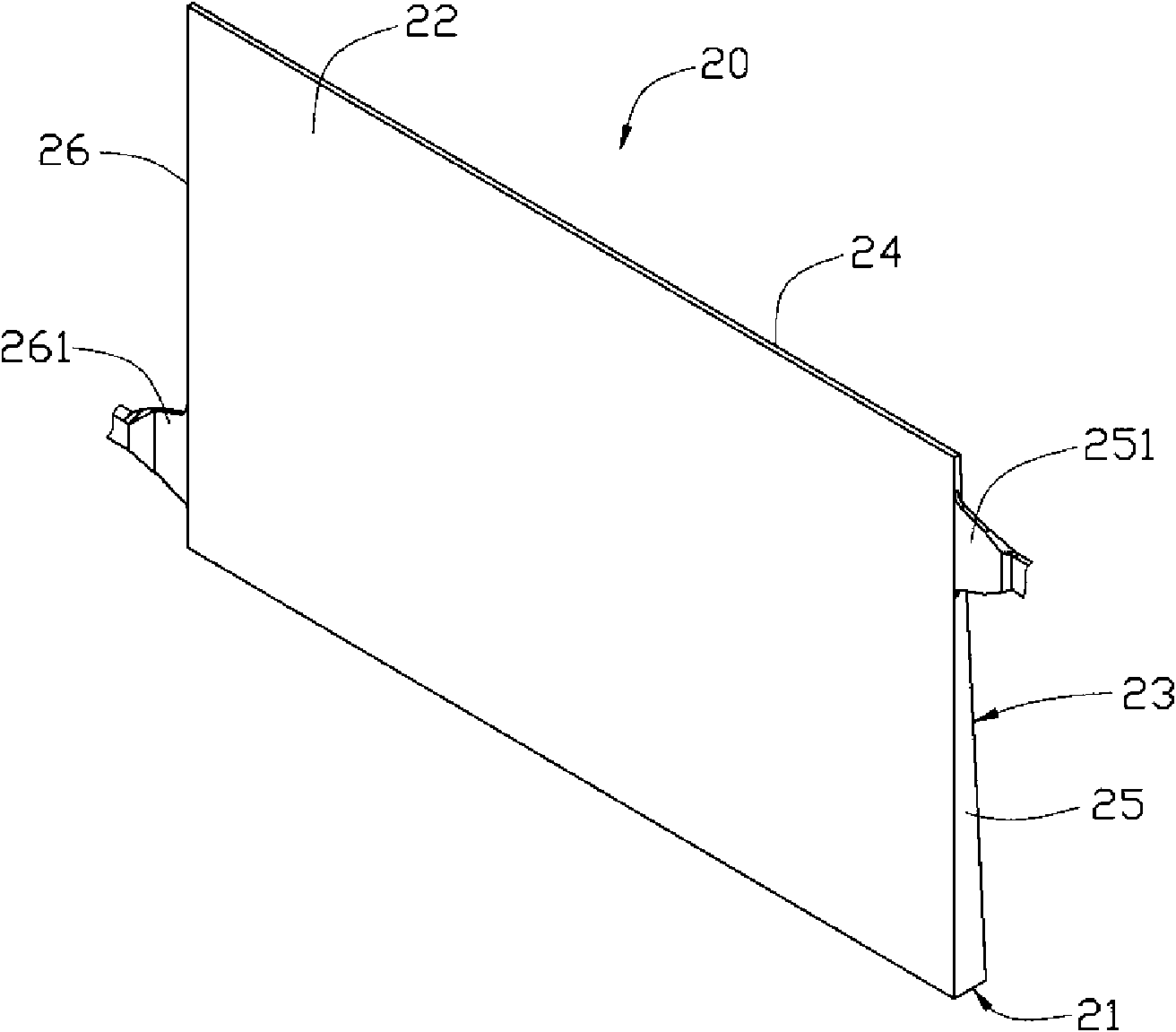

Die

InactiveCN101927554ASmall size errorImprove consistencyMechanical apparatusOptical articlesEngineeringWedge shape

The invention relates to a die, which comprises a first template and a second template, wherein the second template is provided with a surface opposite to the first template; the second template is provided, inwards from the surface, with a wedge-shaped die cavity and a sprue which is communicated with the wedge-shaped die cavity; the wedge-shaped die cavity is provided with a pouring end face connected with the sprue, and a first lateral end face and a second lateral end face which are connected to both sides of the pouring end face respectively; the depth of the first lateral end face of the wedge-shaped cavity is more than that of the second lateral end face; a distance between the sprue and the first lateral end face is less than that between the sprue and the second lateral end face; the sprue is provided with a first sidewall adjacent to the first lateral end face and a second sidewall adjacent to the second lateral end face; and an included angle between the first sidewall and the pouring end face is less than that between the second sidewall and the pouring end face.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

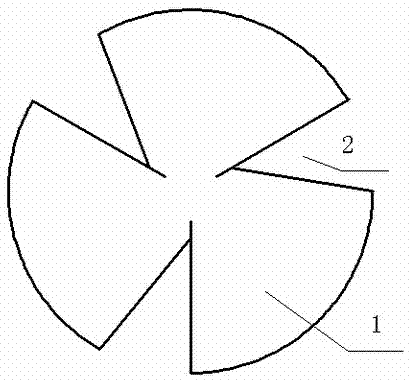

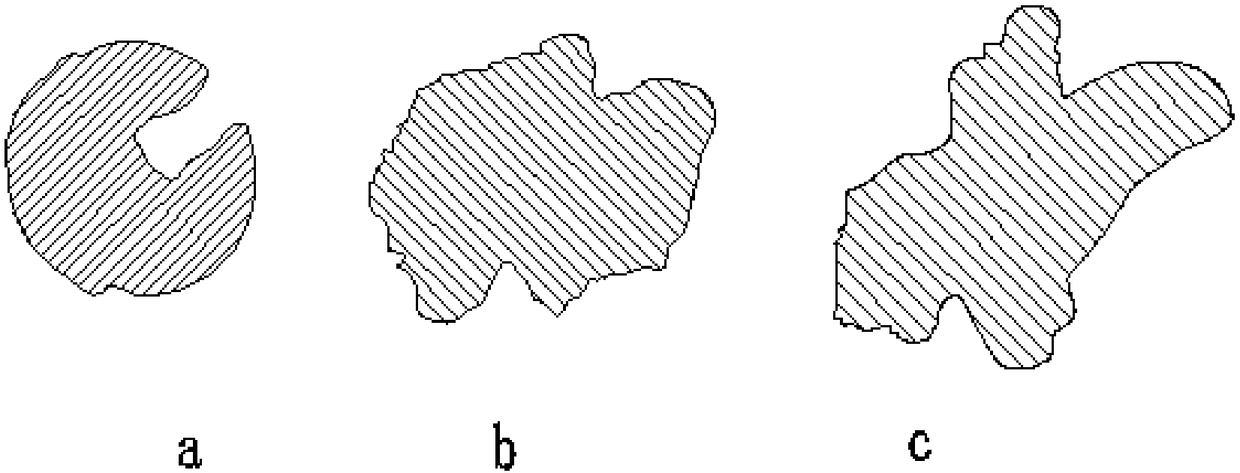

Thin silicon rubber and fabric composite product and mold pressing vulcanizing forming process thereof

The invention provides a thin silicon rubber and fabric composite product and a mold pressing vulcanizing forming process thereof. The thickness of the product is smaller than or equal to 1.2 mm. The mold pressing vulcanizing forming process comprises the following steps that (1) fabric degreasing is conducted; (2) surface treatment is conducted; (3) rubber cement preparation is conducted; (4) rubber coating is conducted; (5) silicon rubber preforming is conducted; (6) compositing is conducted, specifically, fabric is placed between two pieces of preformed silicon rubber, pressed and cut into a clover-shaped wafer with the corresponding diameter size; (7) mold preheating is conducted; (8) vulcanizing is conducted, specifically, a mold core is coated with the clover-shaped rubber wafer, and mold assembling, pressurizing and vulcanizing are conducted; (9) after being taken out from a vulcanizing machine, a mold is cooled; and (10) the product is taken out from a mold cavity and subjected to post vulcanizing for 4 h. According to the mold pressing vulcanizing forming process of the thin silicon rubber and fabric composite product, the silicon rubber and the fabric are subjected to mold pressing vulcanizing forming and are firmly connected, and the fabric is uniformly placed between the inner-layer silicon rubber and the outer-layer silicon rubber; demolding is conducted through cooling, the shrinkage rate of the silicon rubber is consistent with that of the fabric, and the product is strict in size control, not deformed and good in sealing performance; and the situation that the fabric is exposed and eccentric is avoided.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Preparation method for gradient nozzle

ActiveCN107214343AImprove thermal stabilityImproved erosion and wear resistanceTransportation and packagingMetal-working apparatusHigh energySpray nozzle

The invention relates to the field of part preparation in a composite material production technology, and particularly discloses a preparation method for a gradient nozzle. The method comprises the steps that metal powder and ceramic reinforced particles are uniformly mixed according to the design of the gradient nozzle so as to prepare 2-15 kinds of composite powder with different ceramic contents, the powder is subjected to high-energy ball mill mechanical alloying, gel solutions are added into the composite powder separately, the gel solutions and the composite powder are uniformly stirred to form composite material slurry with the good fluidity, then curing agents are sequentially added into the multiple kinds of slurry from outside to inside, the multiple kinds of slurry with the curing agents are sequentially poured into a vertical type centrifugal forming machine rotating at a high speed, and after curing is finished, demolding, drying and vacuum sintering are carried out so as to prepare the gradient nozzle, wherein the number of the gradient layers of the nozzle can reach more than 10, and the thickness of one single sintered layer is 0.3mm-10mm. The method has the advantages that the process is simple, the energy consumption is low, the composite material gradient nozzle with the large height-diameter ratio can be prepared, and the thermal stability and the erosion-abrasion resistance of the nozzle can be improved.

Owner:HEBEI COLLEGE OF IND & TECH

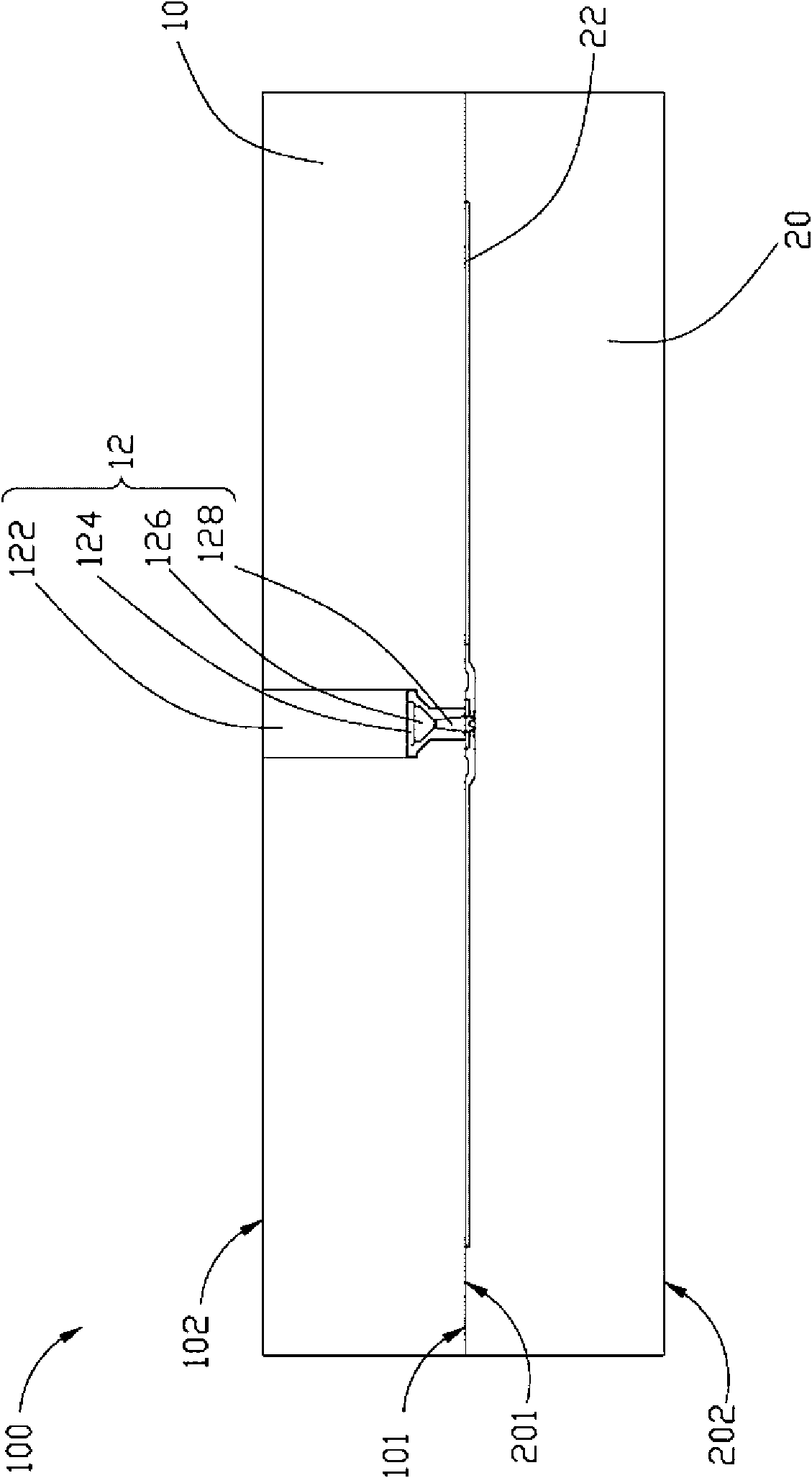

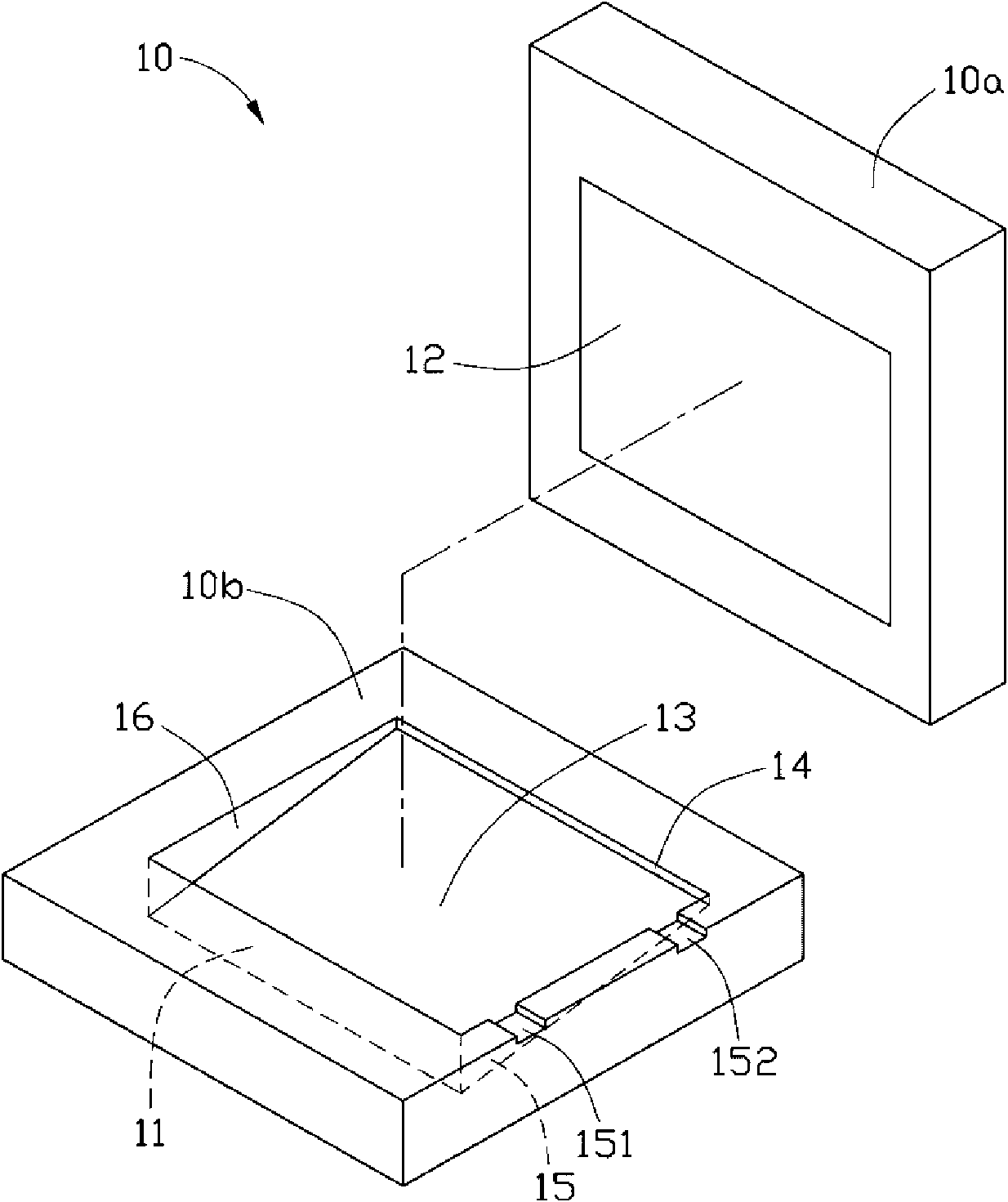

Injection molding device

InactiveCN101885222AShorten the timeUniform stressOptical articlesOptical light guidesLight guideOptoelectronics

The invention relates to an injection molding device, which comprises a molding chamber. The molding chamber is used for manufacturing a wedge-shaped light guide plate which comprises a light incoming surface, a light outgoing surface connected with the light incoming surface, a first side face opposite to the light incoming surface, two second side faces connected with and opposite to the light incoming surface, and a bottom surface opposite to the light outgoing surface; the width of the second side faces is reduced gradually from the light incoming surface to the first side face; the molding chamber is provided with a first inner wall corresponding to the light incoming surface, a second inner wall corresponding to the light outgoing surface, a third inner wall corresponding to the bottom surface, a fourth inner wall corresponding to the first side face, and two fifth inner walls corresponding to the two second side faces; at least one of the fifth inner walls is provided with a first sprue and a second sprue which are used for filling the molding material for the light guide plate; and the distance between the position of the first sprue and the first inner wall is less than that between the position of the second sprue and the second inner wall.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

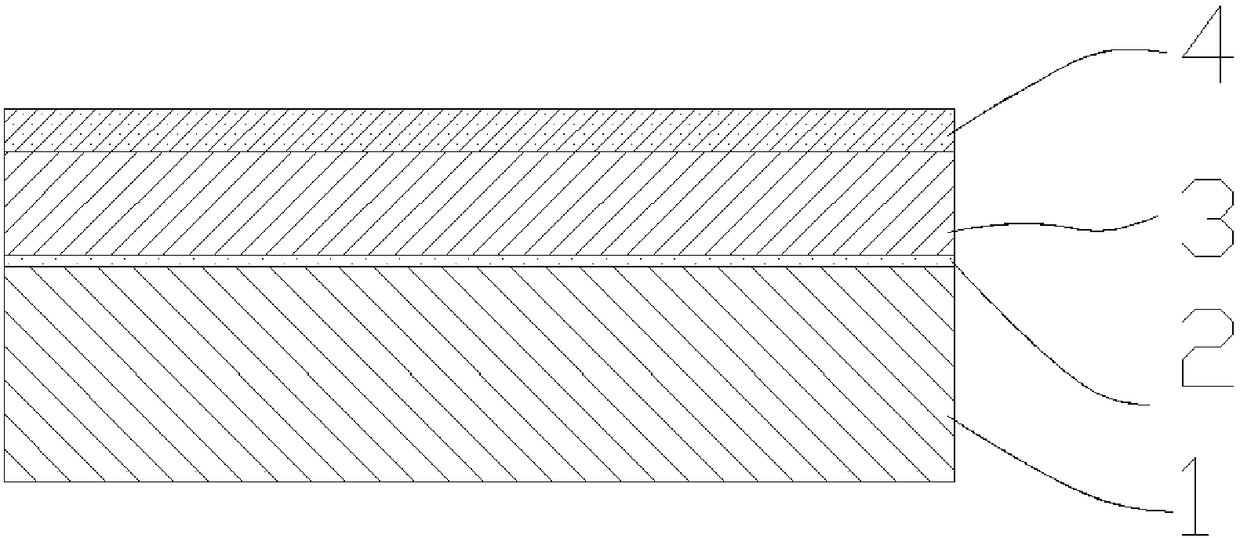

Composite ceramic tile with smooth glaze and manufacturing method

PendingCN108484108AReduce tile costsLow costCeramic shaping apparatusClaywaresCeramic glazeCeramic tiles

The invention discloses a composite ceramic tile with a smooth glaze. The composite ceramic tile comprises a first blank, an adhesive layer, a second blank and a glaze layer which are arranged from bottom to top in sequence, wherein the first blank is adhered to the second blank through the adhesive layer; the first blank is made of a powder material through pressing; the powder material is made through dry-method powdering; the second blank is made of a powder material through pressing; the latter powder material is made through wet-method powdering. A manufacturing method of the composite ceramic tile with the smooth glaze comprises the following steps: (1) manufacturing the first blank; (2) manufacturing the second blank; (3) manufacturing a composite blank; (4) performing glazing; (5)sintering the composite ceramic tile with the smooth glaze. As the blanks of two powder materials are compounded, the glaze is positioned on the surface of the blank made through wet-method powdering,and not only is the ceramic tile with the smooth and flat glaze made, but also the cost of the ceramic tile can be reduced.

Owner:FOSHAN DONGPENG CERAMIC +2

Glass glaze and manufacturing technology thereof

The invention relates to glass glaze and the manufacturing process thereof. The invention is characterized in that the ingredient of the glass glaze mainly comprises by weight percentage: quartz powder is 5 to 18 percent, boric acid is 9 to 23 percent, red lead is 40 to 65 percent, and expansion stabilizing agent is 8 to 17 percent. The manufacturing process is realized by that: (a) the materials are mixed fully according to the weight percentage; (b) the mixture is fused to be thick and sticky at the temperature of 1000 to 1200 DEG C; (c) the fused mixture is cooled to be the glass base glaze block with original color; (d) the glaze block is crashed into powder to be fully mixed with paint to form colored glaze. The glass glaze and the manufacturing process thereof of the invention provide the glass glaze which keeps the designs and characters on the surface of a glass product having embossing effect and high ornamental value.

Owner:冯庆铭

Method for producing components and parts made of aluminium nitride ceramics in high thermal conductivity and high dimensional accuracy

The present invention provides an aluminium nitride ceramic compnoent with high heat conductivity and high size accuracy and its preparation method. Said method includes the following steps: uniformly mixing aluminium nitride AlN powder and yttrium oxide Y2O3 powder according to mixing ratio of 90-98:2:10, adding binding agent, mixing them into uniform feeding material, the volume ratio of powder in the feeding material is 54-68%, injection moulding, injection temperature is 120-170 deg.C and injection pressure is 80-140 MPa, after the injected blank body is grease-removed and presintered, sintering in the flowing nitrogen gas atmosphere in the sintering furnace with 1700-2000 deg.C, heat-insulating for 1-10 hr, so as to obtain the aluminium nitride ceramic component.

Owner:UNIV OF SCI & TECH BEIJING

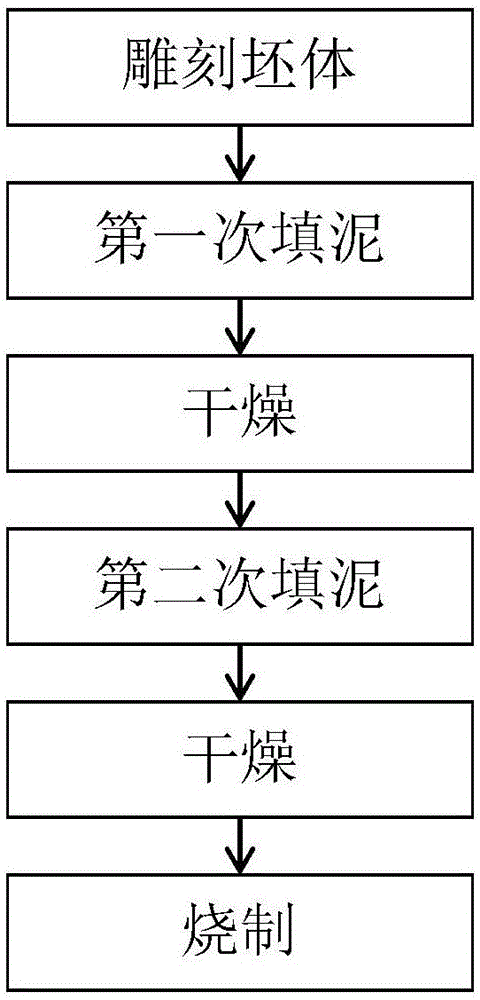

Multi-layer mud filling method of Nixing ceramic

InactiveCN106747327AConsistent shrinkageNixing pottery has a high yieldClaywaresMaterials scienceTitanium dioxide

The invention relates to a making and mud filling method of ceramic, in particular to a multi-layer mud filling method of Nixing ceramic. The multi-layer mud filling method comprises the following steps: engraving on a green body, performing first mud filling, drying, performing second mud filling, drying and firing; pug used for the first mud filling is mixed from colored clay and titanium dioxide powder according to the weight ratio of 100:(5-8); pug used for the second mud filling is mixed from colored clay, titanium dioxide powder and table salt according to the weight ratio of 100:(1-3):(1-2). The Nixing ceramic prepared by the multi-layer mud filling method provided by the invention is higher in rate of finished products and has higher artistic values.

Owner:GUANGXI UNIV

Method for modifying surface of graphite particle

InactiveCN1539887AUniform particle sizeSmall granularityInorganic pigment treatmentPhosphoric acidHigh pressure

A process for modifying the surface of graphite particles used for the negative electrode of lithium battery includes adding graphite powder to high-pressure reactor, adding deionized water, stirring, adding inorganic acid chosen from concentrated sulfuric acid, nitric acid, phosphoric acid, hydrochloride acid, and glacial acetic acid, heating to 80-140 deg.C, holding the temp for 10 hrs, natural cooling, filtering, immersing in deionized water, pumping filter, washing until pH=7 and low-temp baking.

Owner:UNIV OF SCI & TECH OF CHINA

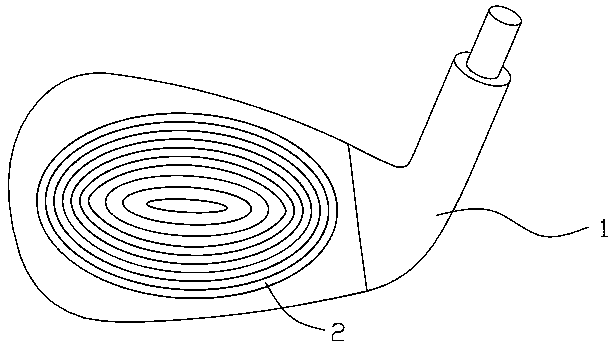

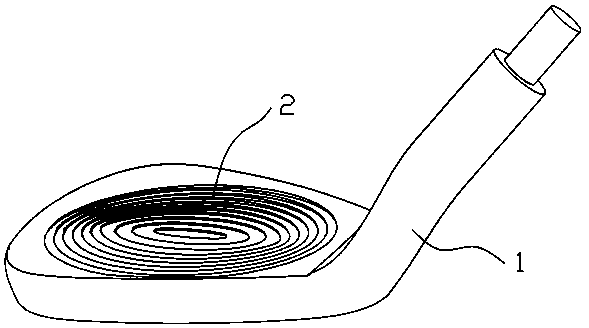

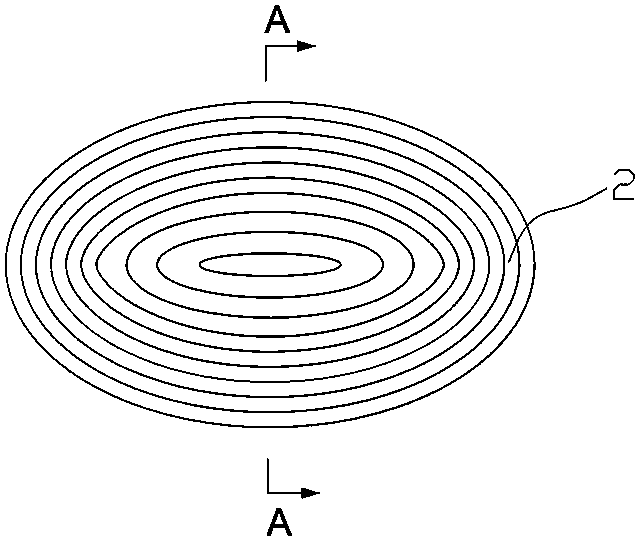

Golf club head

PendingCN108273248AHigh elastic limitHigh hardnessGolf clubsRacket sportsEngineeringQuality performance

The invention discloses a golf club head. The golf club head is an amorphous alloy golf club head, the amorphous alloy golf club head has higher elastic limit, better tensile strength and better hardness, and is capable of meeting the requirements of the golf club head on the elastic limit, the tensile strength, the hardness and the toughness. By combining material characteristics of amorphous alloy, the golf club head is in a hollow shape on the basis that the golf club head is the amorphous alloy golf club head, and the elastic performance of the golf club head is further increased through the hollow golf club head. Through the design of a golf ball hitting surface, the amorphous alloy golf club head is capable of limiting the deformation degree of the golf club head in a hitting direction, a material of the golf ball hitting surface can spring back within a short time, energy transmission can be quickly realized, and a frictional force can be generated during ball hitting so as to prevent a golf ball from slipping. Through the combination of the structural design of the amorphous alloy golf club head and the golf ball, the elastic limit and the tensile strength of the golf clubhead can be greatly improved, and the quality performance of the golf club head can be further improved.

Owner:SHENZHEN GO ON MATERIAL TECH CO LTD

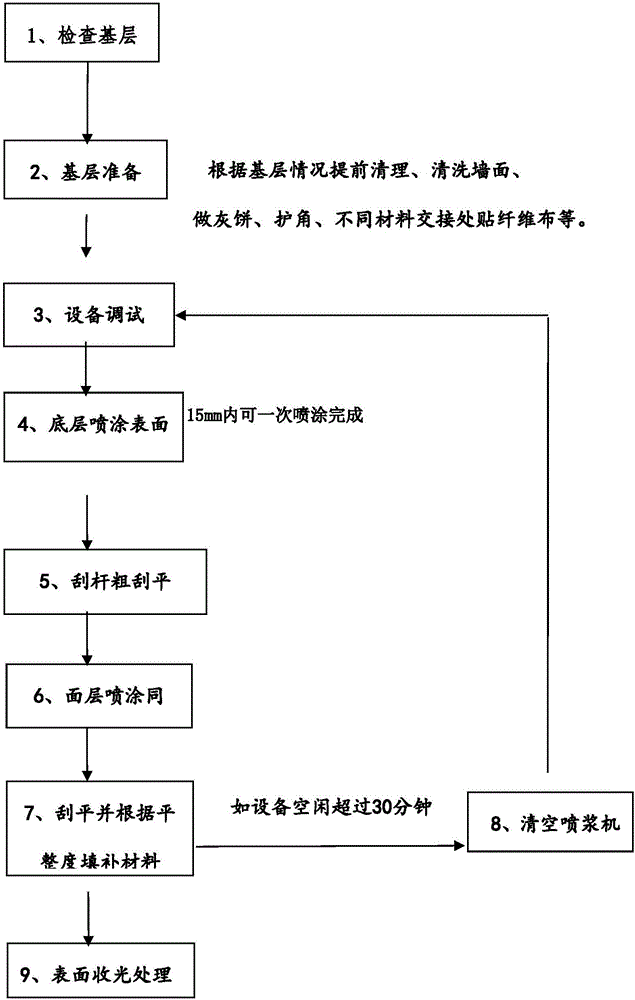

Construction method for spraying building wall face with machine-made sand aggregate dry-mixed mortar

InactiveCN106836683AConsistent shrinkageSolve common quality problemsCovering/liningsCrack resistanceSurface layer

The invention discloses a construction method for spraying the wall surface of a building with machine-made sand aggregate dry-mixed mortar, which comprises the following steps: wall surface base treatment; construction preparation; spraying construction; surface layer spraying; finishing; The dry-mixed mortar is stirred into a slurry, and the spraying machine sprays the mixed mortar slurry onto the base layer immediately. The whole process takes about 8 seconds from stirring to spraying; the process is completed by scraping when the mortar consistency is at its best and the workability is at its best; The thickness of 15mm is sprayed at one time; the spraying thickness of the surface layer is controlled to be consistent (about 8-10mm), and the shrinkage of the surface layer is kept consistent; the leveling and finishing processes are done before the final setting of the mortar; the problem of shortage of natural sand resources is effectively solved; the machine-made sand The efficiency of aggregate mortar spraying is 2 to 3 times higher than that of manual painting; machine-made sand mortar spraying finishes have excellent properties such as anti-cracking, no hollowing, no peeling, and high bonding strength; it overcomes the limitations of plastering in the prior art Common quality problems, improve the overall quality of architectural decoration.

Owner:HUAIBEI MINING GRP ENG CONSTR

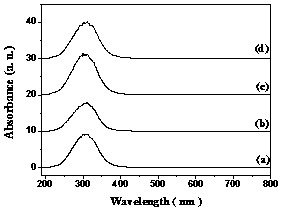

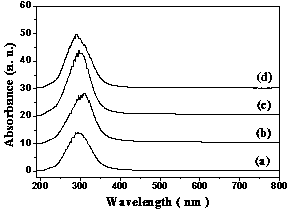

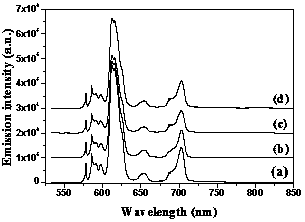

Method for firing photoluminescence fluorescence glaze ceramic through roller kiln

ActiveCN110590327ALow costSimple processLuminescent compositionsClaywaresPyrophyllitePhotoluminescence

The invention provides a method for firing photoluminescence fluorescence glaze ceramic through a roller kiln, and belongs to the technical field of building ceramic production. The method comprises the following steps: mixing dolomite, quartz, europium oxide, yttrium oxide and aluminum hydroxide, adding water, carrying out ball milling, drying and calcining to obtain a photoluminescence fluorescent powder material, mixing kaolin, talc, pyrophyllite, a medium-temperature frit and the photoluminescence fluorescent powder material, adding water, and carrying out ball milling to obtain a fluorescent glaze material; mixing kaolin, feldspar and quartz, adding water, and carrying out ball milling, drying, powdering and compression molding to obtain a green body; and finally, applying the fluorescent glaze material to the green body, and firing at a high temperature in the roller kiln to obtain the photoluminescence fluorescence glaze ceramic. According to the photoluminescence fluorescence glaze ceramic produced by the method, the compatibility of the glaze and the green body is good, red fluorescence is emitted, the fluorescence intensity can be regulated and controlled, and the requirements in the fields of anti-counterfeiting marks, real-time display and light response can be met.

Owner:SHANDONG UNIV OF TECH

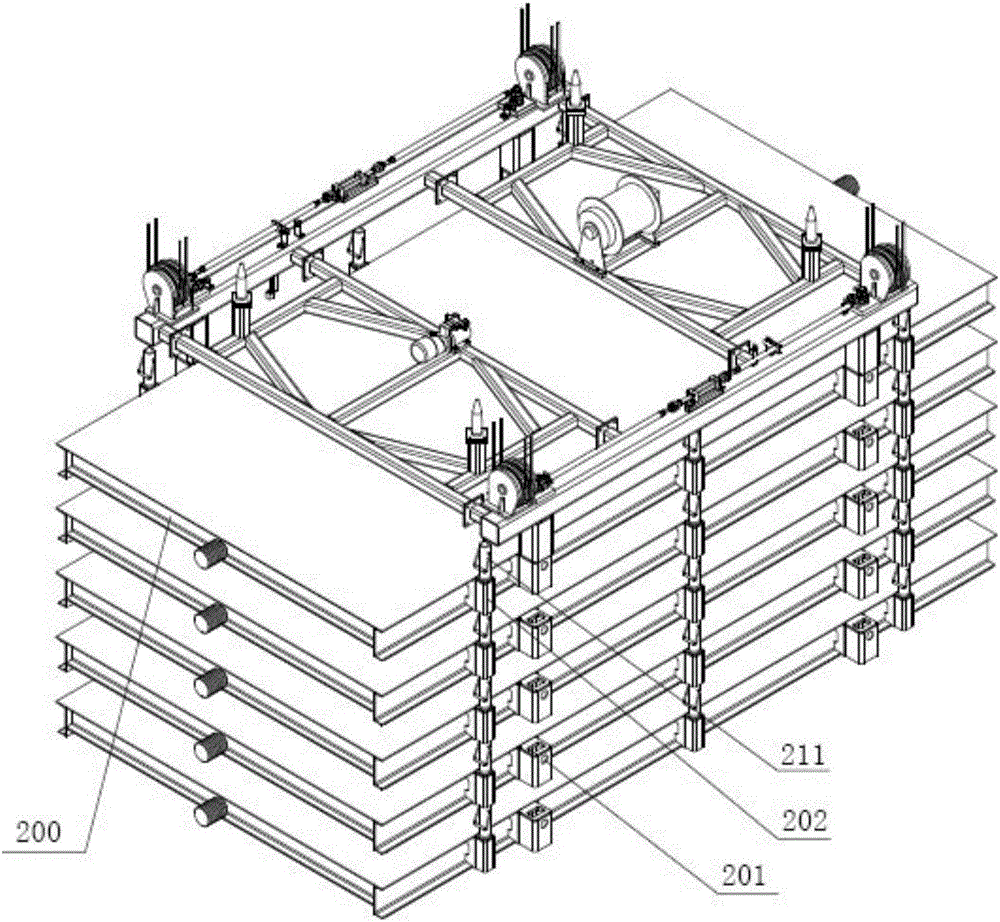

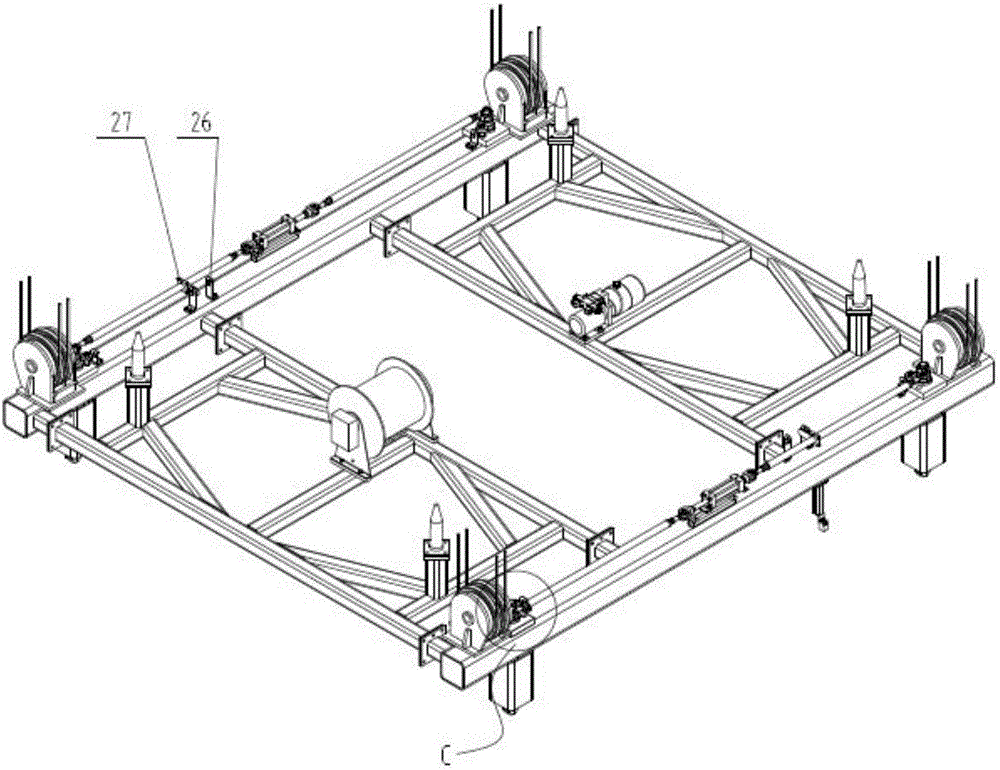

Stacking machine capable of being stably operated to realize rapid transportation

The invention discloses a stacking machine capable of being stably operated to realize rapid transportation. The stacking machine comprises a hoisting mechanism and a stacking disc matched with the hoisting mechanism, wherein the hoisting mechanism comprises a movable hanging frame, a hoisting mechanism and a driving mechanism which is arranged on a movable hanging frame transverse beam to drive the hoisting mechanism to move leftward and rightward; the driving mechanism is provided with four first hoisting wheels which are connected with second hoisting wheels arranged at four corners of the upper end face of a hoisting bottom frame of the hoisting mechanism; rotary locking mechanisms are arranged at left and right ends of the upper end face of the hoisting bottom frame along an edge of the hoisting bottom frame; the stacking disc is provided with a locking part for fixing the rotary locking mechanisms; the rotary locking mechanisms are controlled to rotate through retraction of a retraction device and then are tightly locked with or separated from the locking part. The stacking machine provided by the invention has a simple structure and the stacking disc is firmly fixed; the stress on the hoisting mechanism is uniform, and the hoisting mechanism is horizontally hoisted; the stacking machine is stable and does not swing in a transportation process; when the stacking disc is placed, the whole stacking is ordered, an occupied space is reduced and the stacking is safer; the working efficiency is greatly improved.

Owner:HEBEI XINDADI ELECTROMECHANICAL MFG +1

Fully-closed industrial microwave high-temperature roller continuous sintering kiln

InactiveCN102042749BConsistent shrinkageGood size consistencyMaintainance of heating chambersFurnace typesHearthEngineering

The invention discloses a closed microwave high-temperature sintering roller kiln, in particular a tunnel roller kiln with length of 10 to 50meters, and hearth sectional area of 0.06 to 0.3m<2>. The kiln comprises a main kiln body, a microwave transmission system, a turning channel mechanism, a roller power system, and a kiln door interlocking opening and closing system; the main kiln body is formed by connecting a water draining section, a preheating section, a sintering section, a heat preservation section, a quick cooling section, and a slow cooling section in turn; the turning channel mechanism is mainly formed by a material loading and unloading section and a residual-heat utilization blank drying section and comprises a turning channel, a turning channel roller, and a power system; the power system can poke a pushing plate from the outlet of the main kiln body onto the turning channel and feed the pushing plate into the inlet of the main kiln body through the residual-heat utilization blank drying section; and an inner roller for transmitting the material pushing plate, which is driven by the roller power system, is arranged on the bottom of an inner cavity of the main kiln body. The closed microwave high-temperature sintering roller kiln saves energy and reduces consumption and is environmental-friendly, the shrinkage of the sintered products is consistent and the sintered products have high size consistency, the yield is high, the production efficiency is high and the production cost is low.

Owner:湖南航天有限责任公司

Magnetron cathode assembly and silicon-molybdenum solder integrated preparation method

InactiveCN111128640AEasy to shapeReduce the impactTransportation and packagingMetal-working apparatusSlurrySilicon

The invention discloses a magnetron cathode assembly and silicon-molybdenum solder integrated preparation method, and the method is characterized by comprising the following steps: (1) selecting materials and performing proportioning; (2) performing grinding and uniform mixing; (3) performing screening; (4) preparing an organic carrier; (5) preparing silicon-molybdenum solder slurry; (6) performing coating; (7) performing presintering; (8) performing high-temperature sintering; (9) performing welding. The preparation method is simple in production process, low in cost and easy to realize automation.

Owner:佛山市海欣光电科技有限公司

Novel membrane transfer-printing process

InactiveCN106379066AReduce preforming processConsistent shrinkagePolyureas/polyurethane adhesivesOther printing apparatusPolyesterAdhesive

The invention discloses a novel membrane transfer-printing process. The novel membrane transfer-printing process comprises the following steps: (1) pre-treating PET (Polyester) and coating a printing release layer; (2) printing patterns and a gloss oil adhesive; (3) performing injection molding. According to the novel membrane transfer-printing process disclosed by the invention, the PET is separated from an ink layer, and the ink layer is retained on an injection-molded part, so a sheet performing step is reduced, and a required good-looking effect is realized; the PET is totally separated from the ink layer, the product is consistent in contraction, free of deformation, high in efficiency and capable of being printed and injection-molded by adopting a reel-to-reel way.

Owner:WUXI KEHONG LABEL

Feeding structure of die and die employing same

The invention discloses a die casting gate structure and die using this structure. The die casting gate structure includes: thimble, thimble sleeve, first gate area and second gate area. The first gate area communicates with the second gate area in certain angle. The thimble passes through the thimble sleeve, one part of which is hold and fixed inside the thimble sleeve, and the rest is hold in the second gate area. With the die casting gate structure and die using this structure of the invention, flux of moulding injection can be increased, and surface property of the product is improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com