Injection molding device

A technology of injection molding and cavity molding, which is applied in optics, instruments, light guides, etc., and can solve problems such as stress imbalance, long time, and cost of filling the molding cavity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

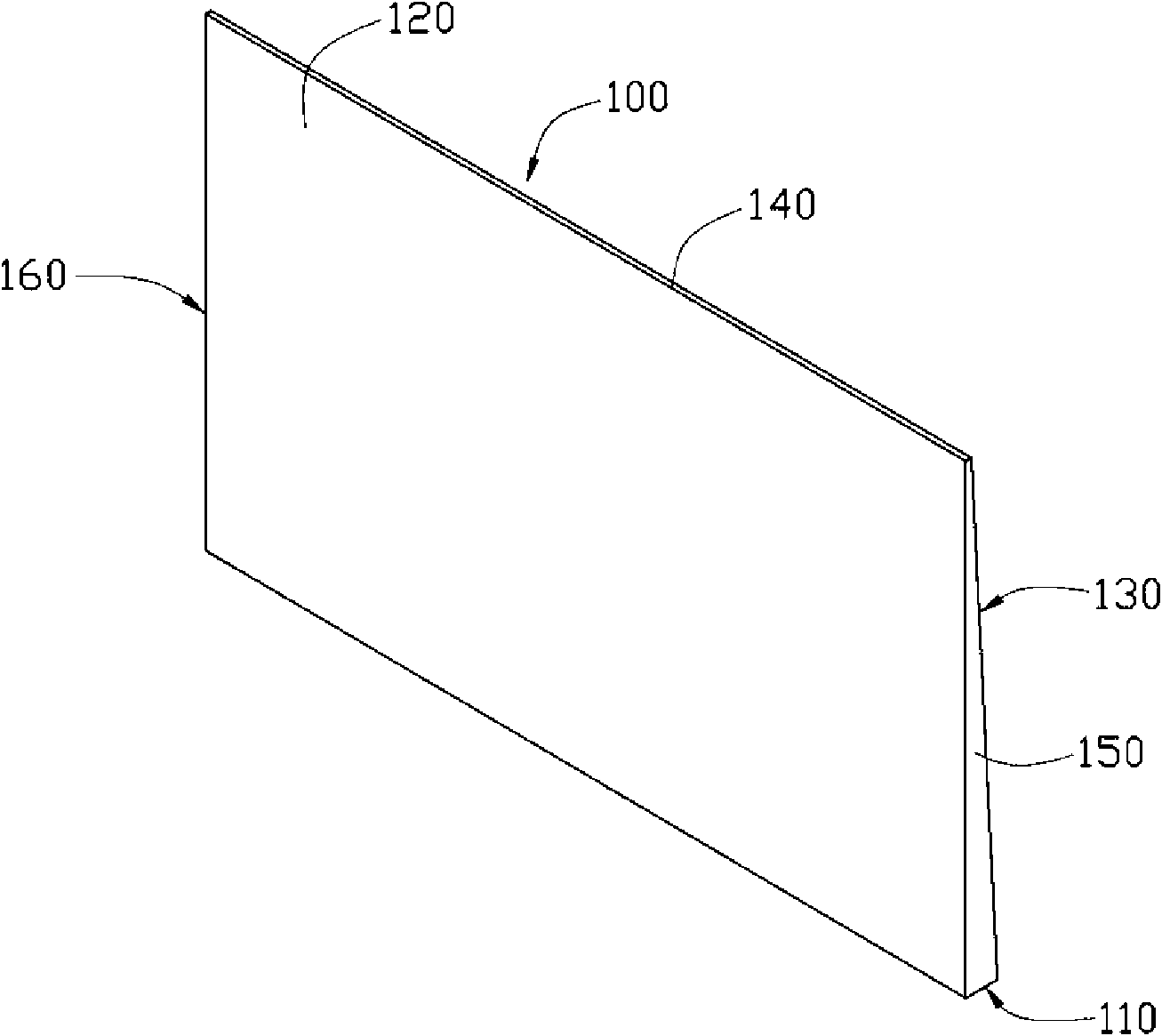

[0013] see figure 1 , the wedge-shaped light guide plate 100 has a light incident surface 110, a light exit surface 120 connected to the light incident surface 110, a bottom surface 130 opposite to the light exit surface 120, a first side 140 opposite to the light incident surface 110, and a light incident surface 110 connected And the opposite second side 150 and third side 160 .

[0014] The width of the second side 150 and the third side 160 gradually decreases from the light incident surface 110 to the first side 140, so that the thickness of the light incident surface 110 is greater than the thickness of the first side 140, that is, the light incident surface 110 is the thick end, the second One side 140 is a thin end.

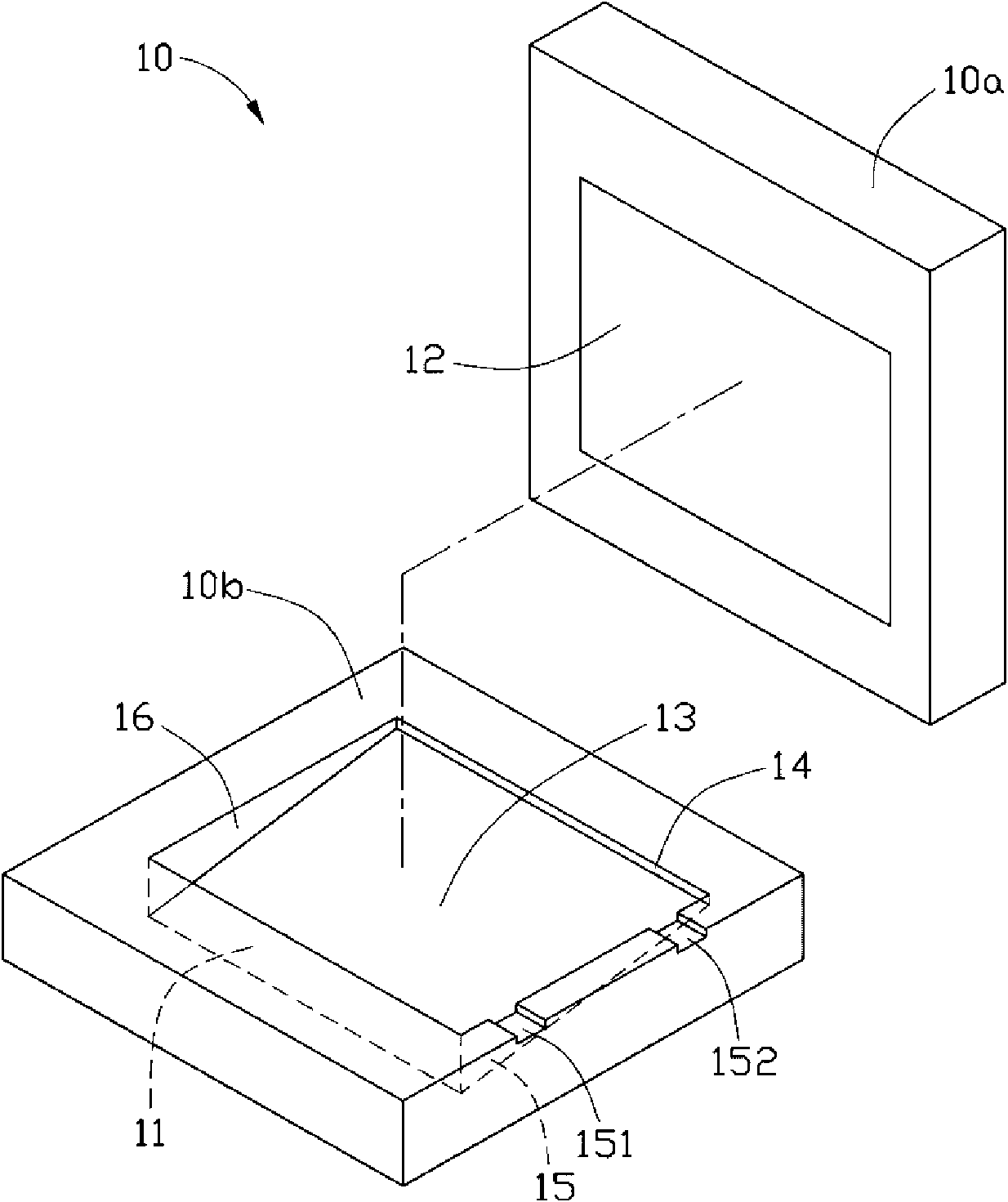

[0015] Such as figure 2 As shown, the injection molding device 10 for manufacturing the wedge-shaped light guide plate 100 provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com