Patents

Literature

67results about How to "Prevent microwave leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

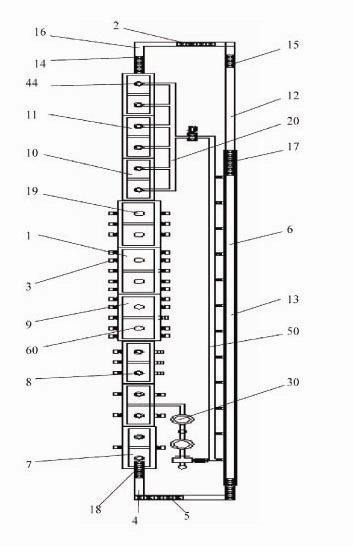

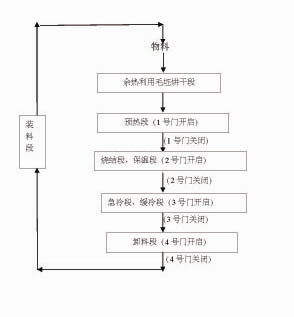

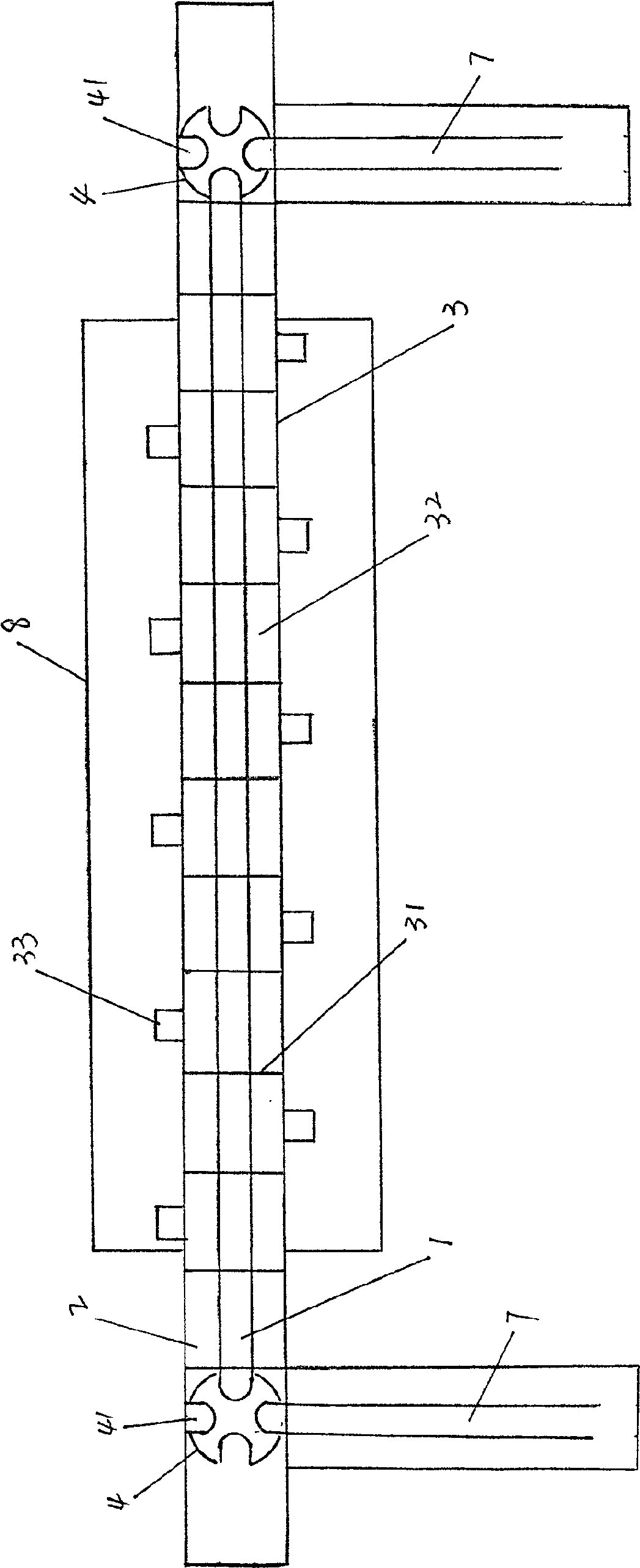

Fully-closed industrial microwave high-temperature roller continuous sintering kiln

InactiveCN102042749AConsistent shrinkageGood size consistencyMaintainance of heating chambersFurnace typesEnvironmental resistanceEngineering

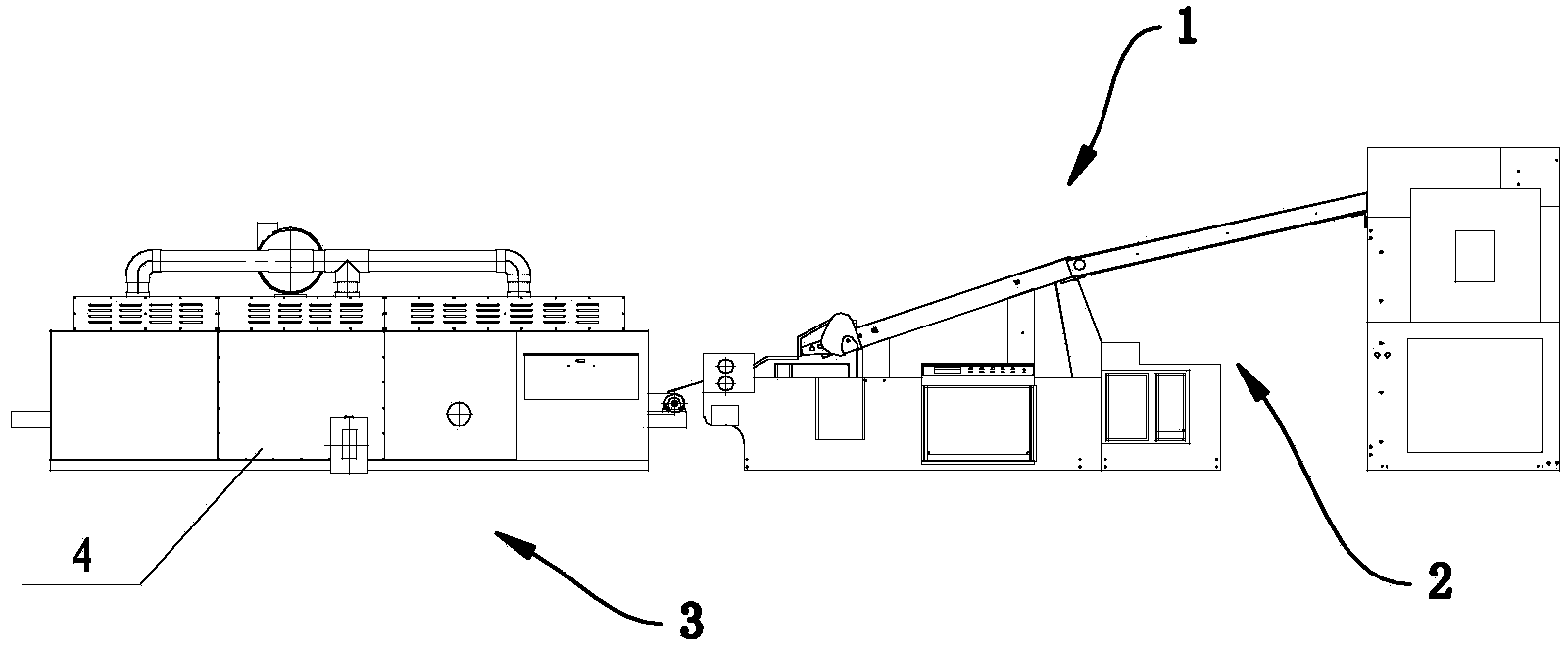

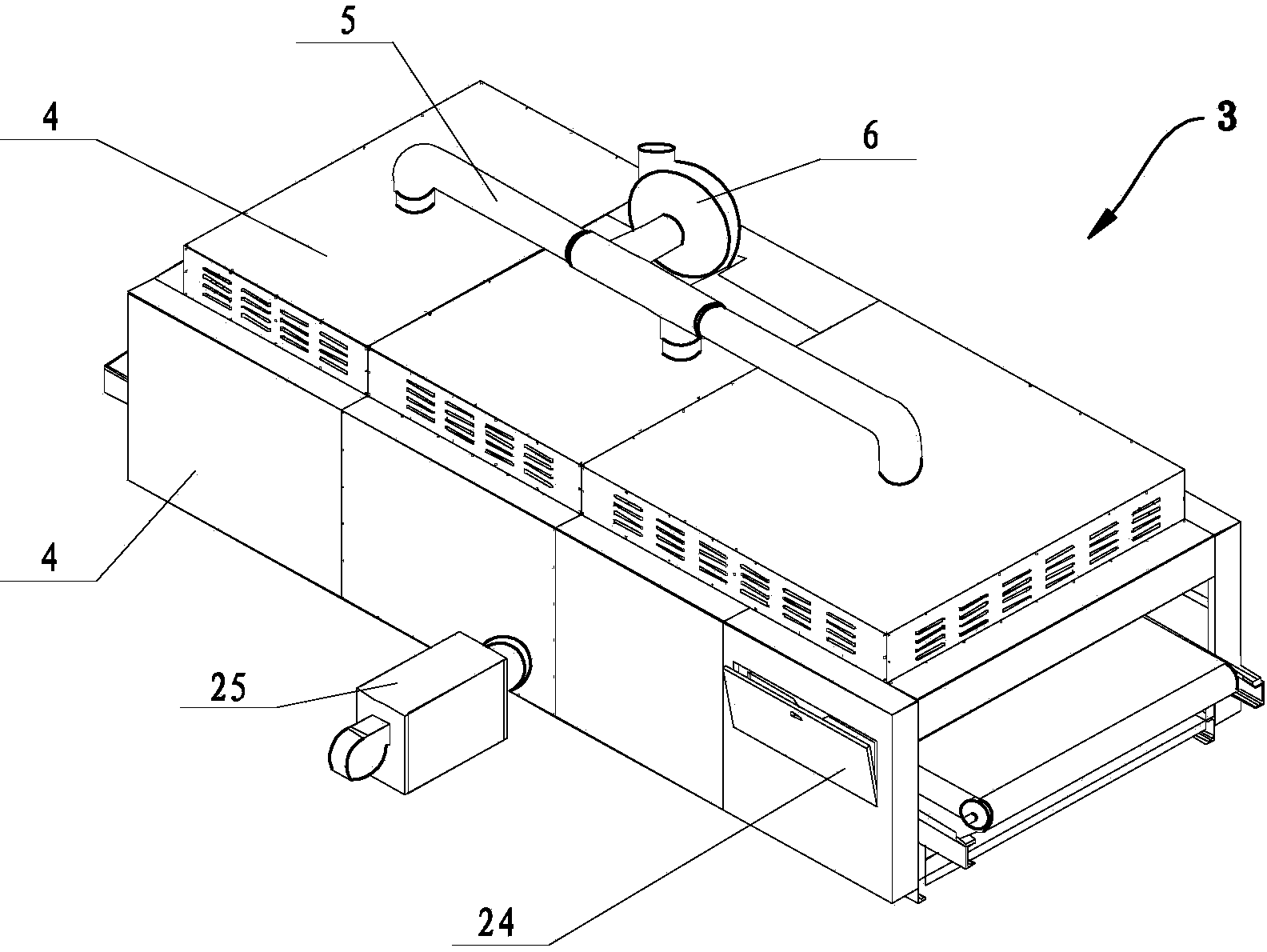

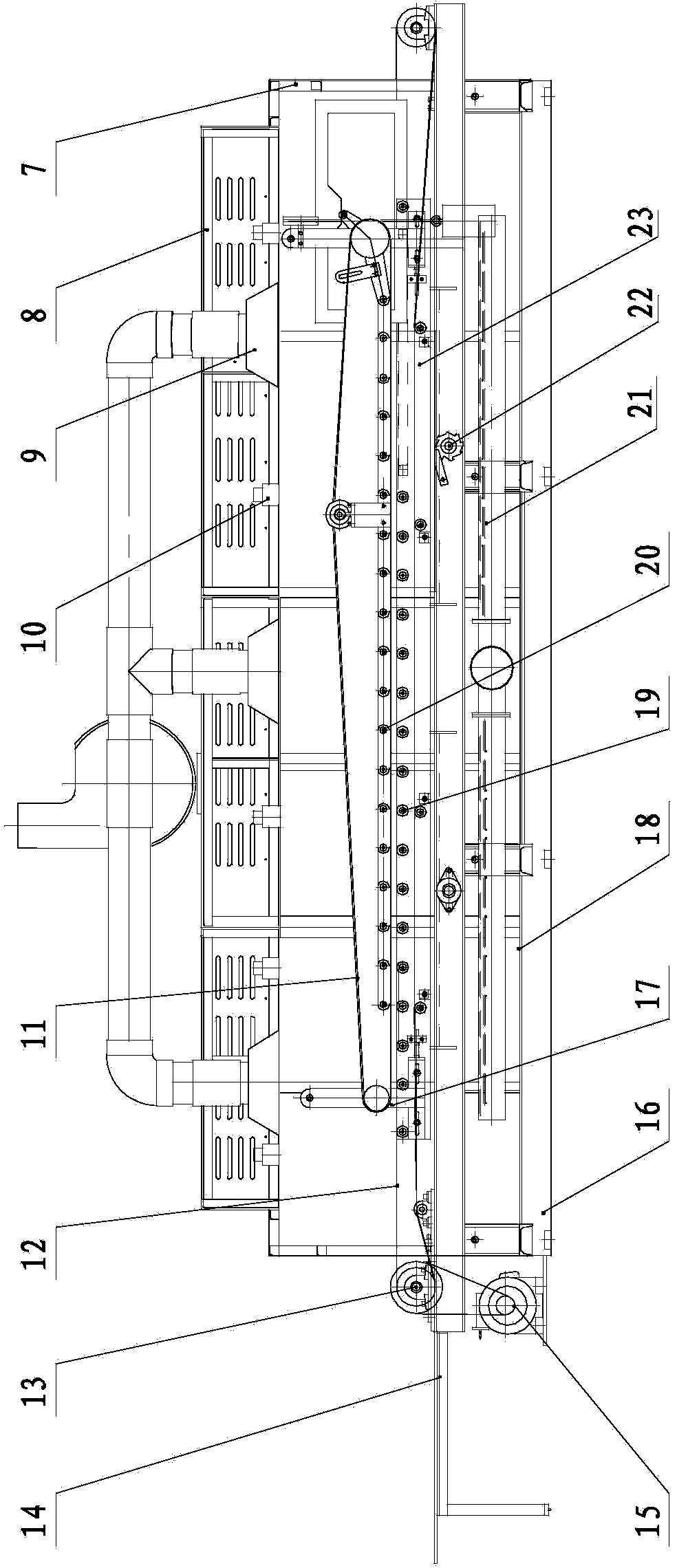

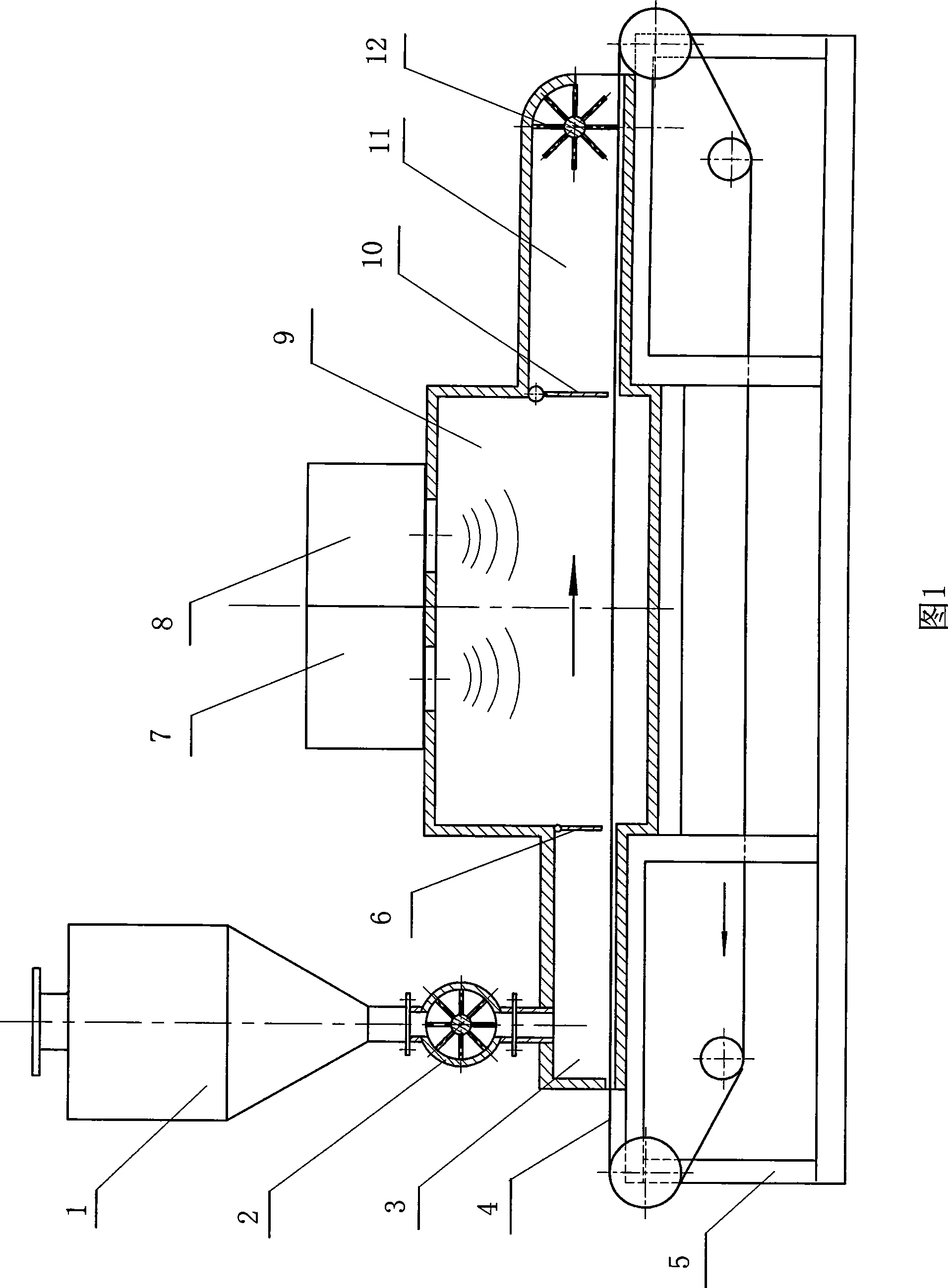

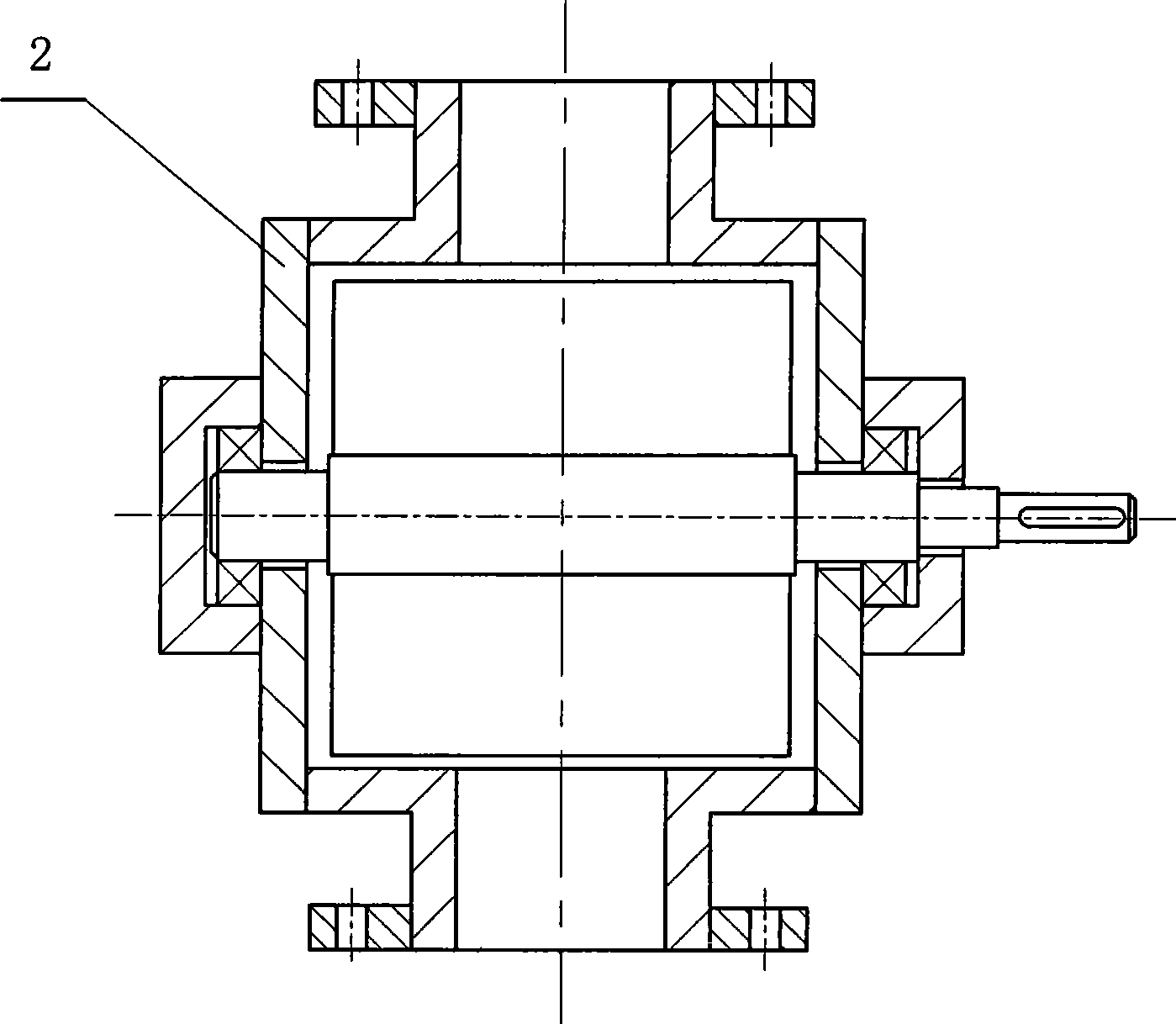

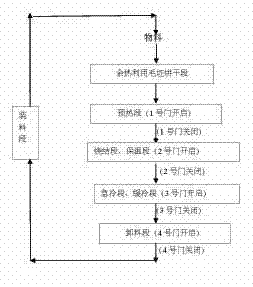

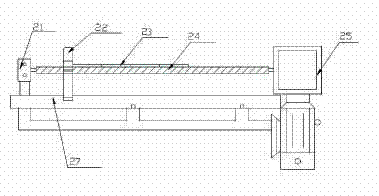

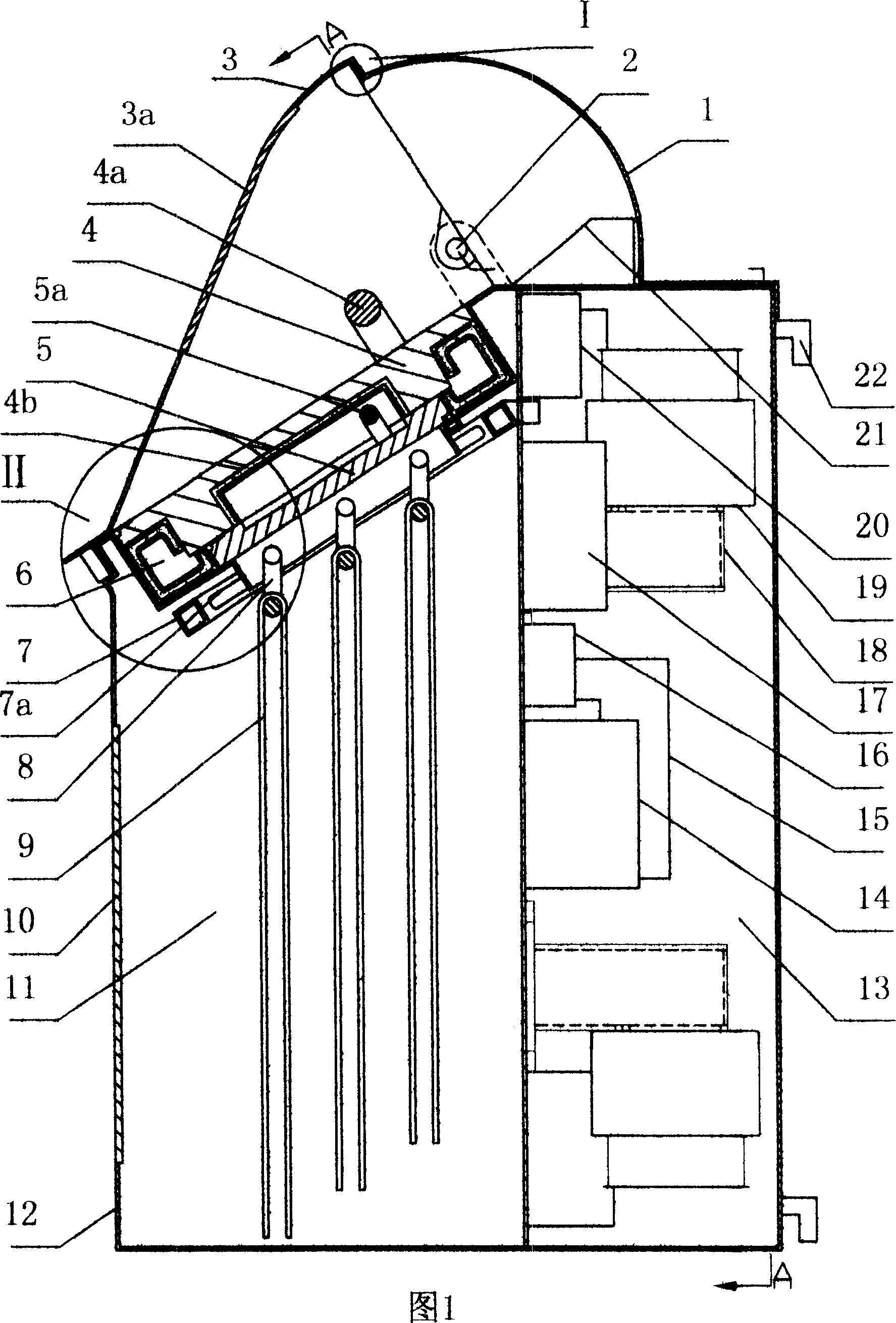

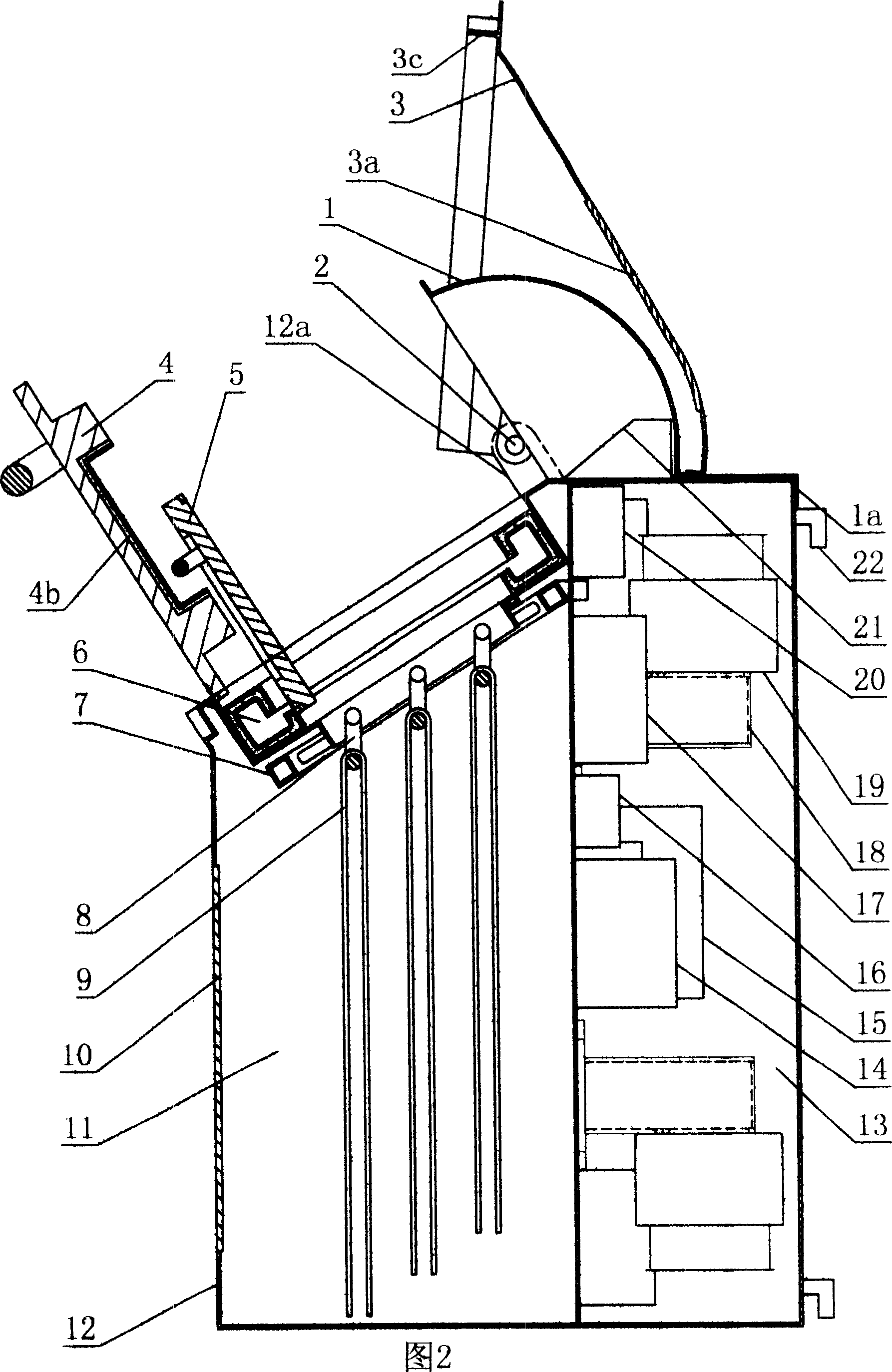

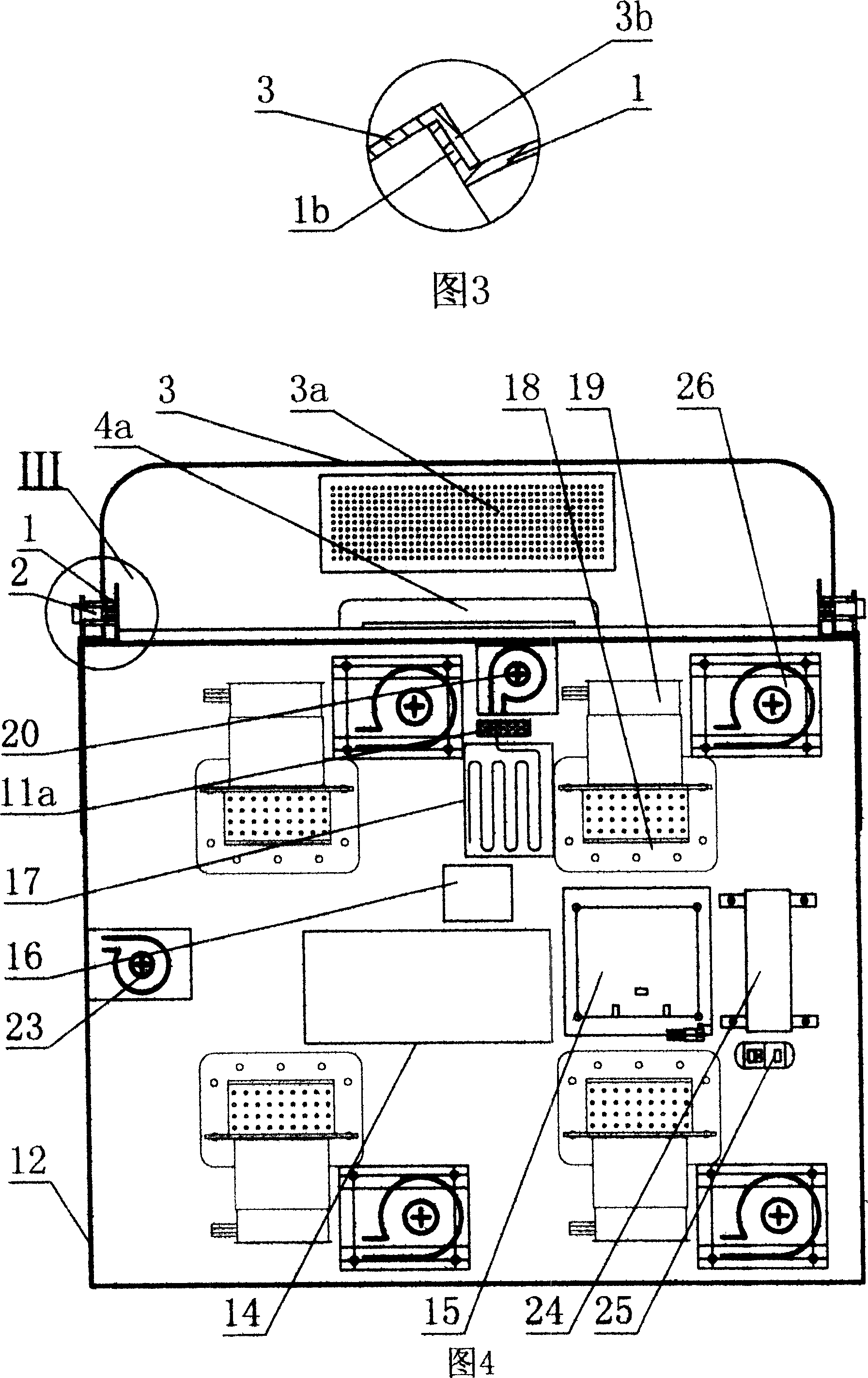

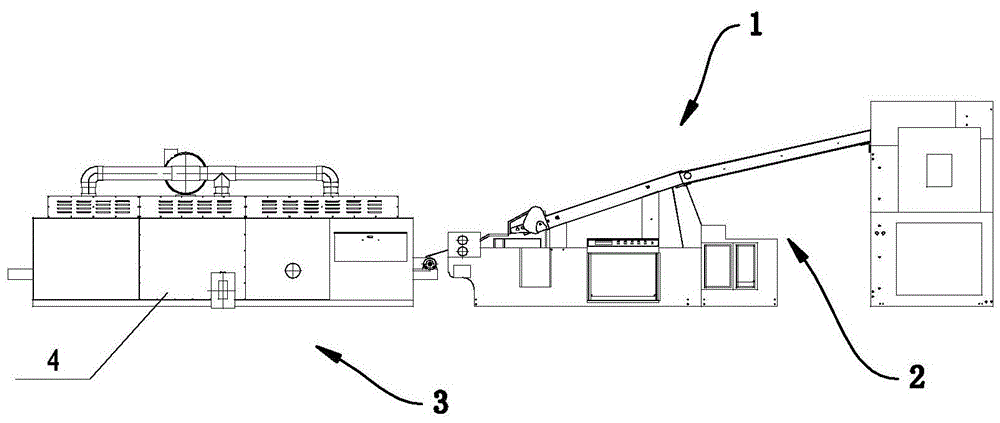

The invention discloses a closed microwave high-temperature sintering roller kiln, in particular a tunnel roller kiln with length of 10 to 50meters, and hearth sectional area of 0.06 to 0.3m<2>. The kiln comprises a main kiln body, a microwave transmission system, a turning channel mechanism, a roller power system, and a kiln door interlocking opening and closing system; the main kiln body is formed by connecting a water draining section, a preheating section, a sintering section, a heat preservation section, a quick cooling section, and a slow cooling section in turn; the turning channel mechanism is mainly formed by a material loading and unloading section and a residual-heat utilization blank drying section and comprises a turning channel, a turning channel roller, and a power system; the power system can poke a pushing plate from the outlet of the main kiln body onto the turning channel and feed the pushing plate into the inlet of the main kiln body through the residual-heat utilization blank drying section; and an inner roller for transmitting the material pushing plate, which is driven by the roller power system, is arranged on the bottom of an inner cavity of the main kiln body. The closed microwave high-temperature sintering roller kiln saves energy and reduces consumption and is environmental-friendly, the shrinkage of the sintered products is consistent and the sintered products have high size consistency, the yield is high, the production efficiency is high and the production cost is low.

Owner:湖南航天有限责任公司

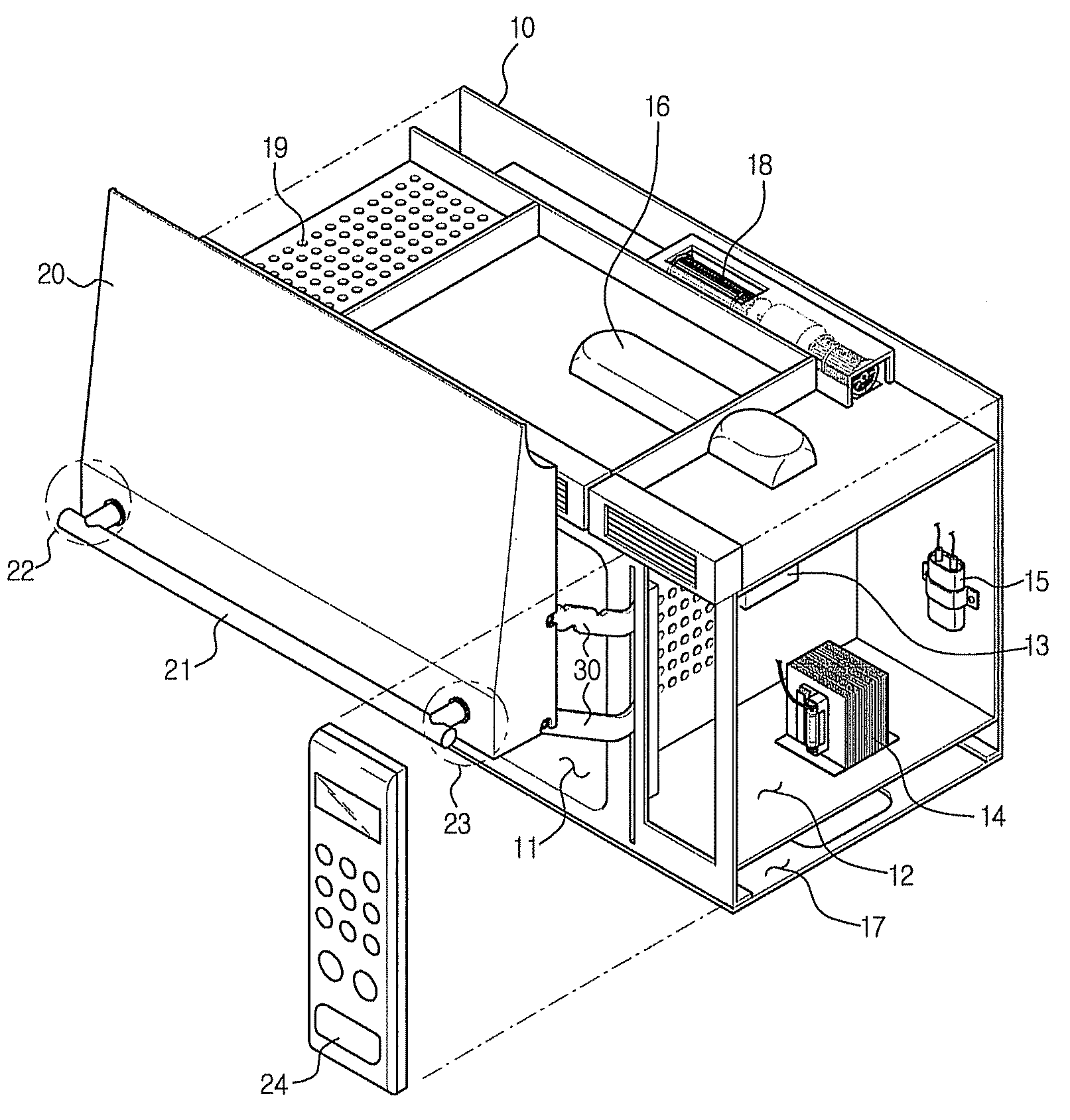

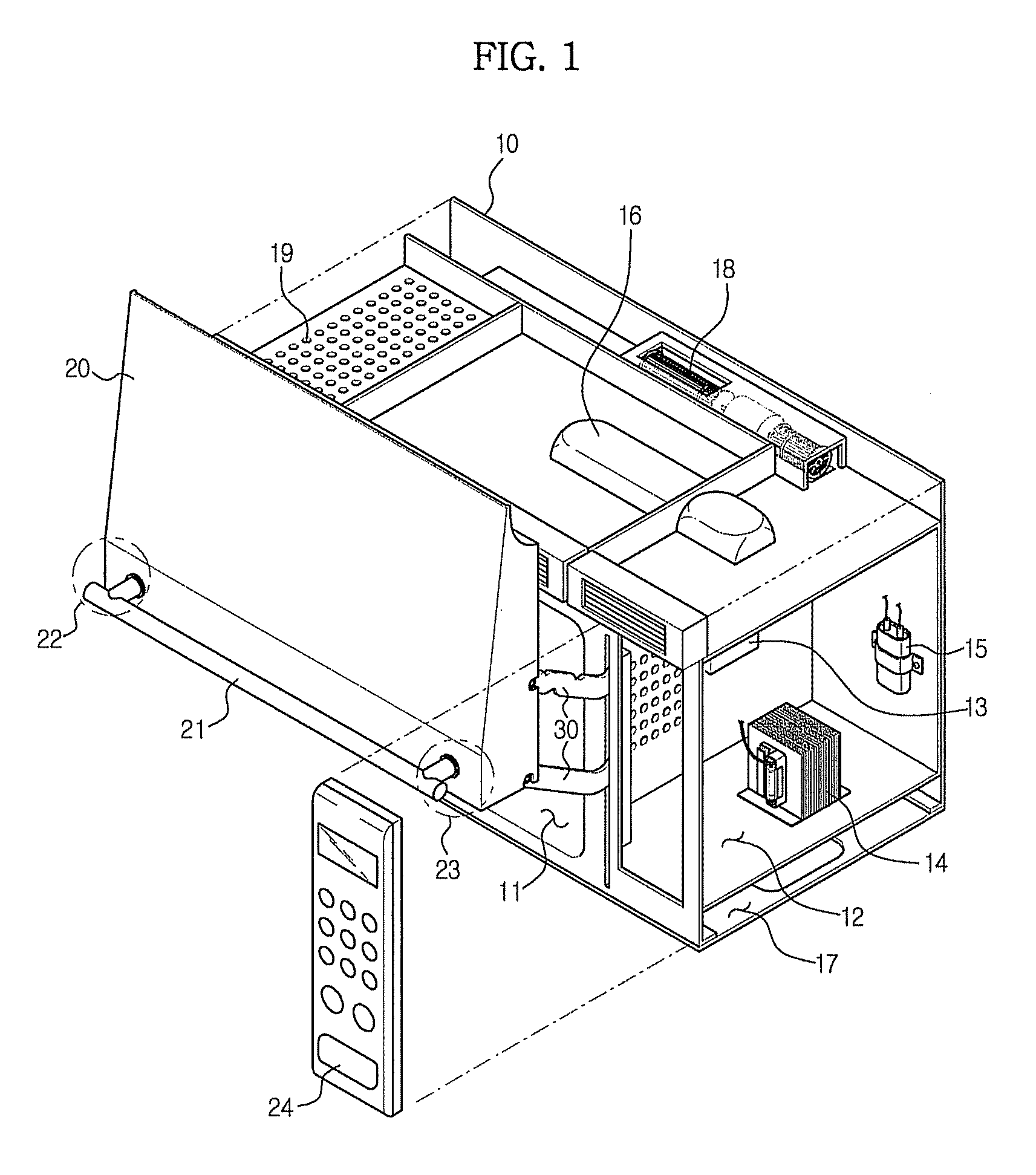

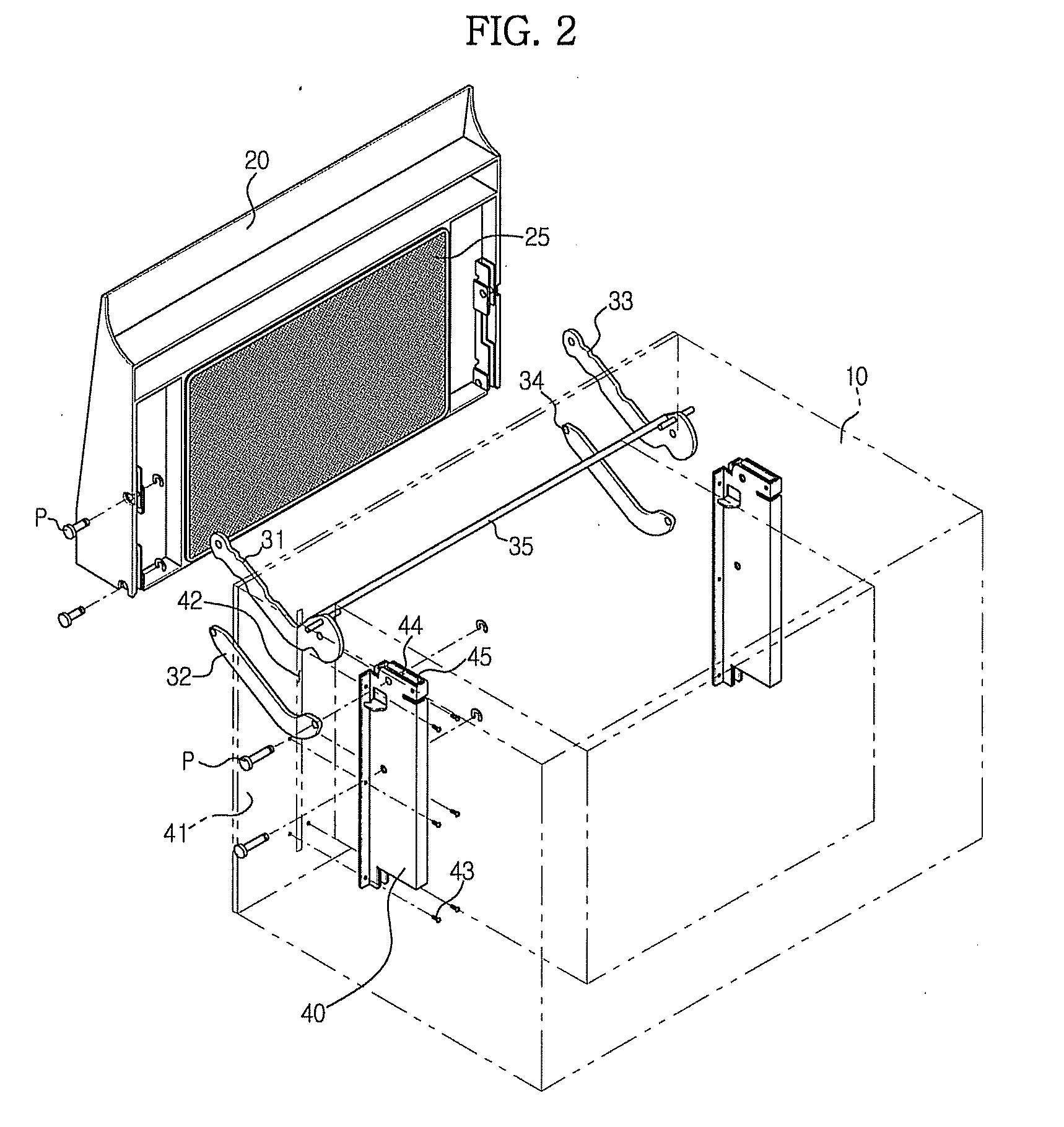

Cooking apparatus

InactiveUS20090321430A1Prevent rattlePrevent rattlingDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

An opening / closing structure of a door of a microwave oven is disclosed. The microwave oven includes a main body having a cooking chamber, a door link-coupled to the main body to open or close the cooking chamber, at least one link member including a cam portion hingedly coupled to the main body so as to be rotated when the door is opened or closed, and a link control device to press the cam portion to control rotation of the link member. Accordingly, the door can be securely opened or closed without rattling.

Owner:SAMSUNG ELECTRONICS CO LTD

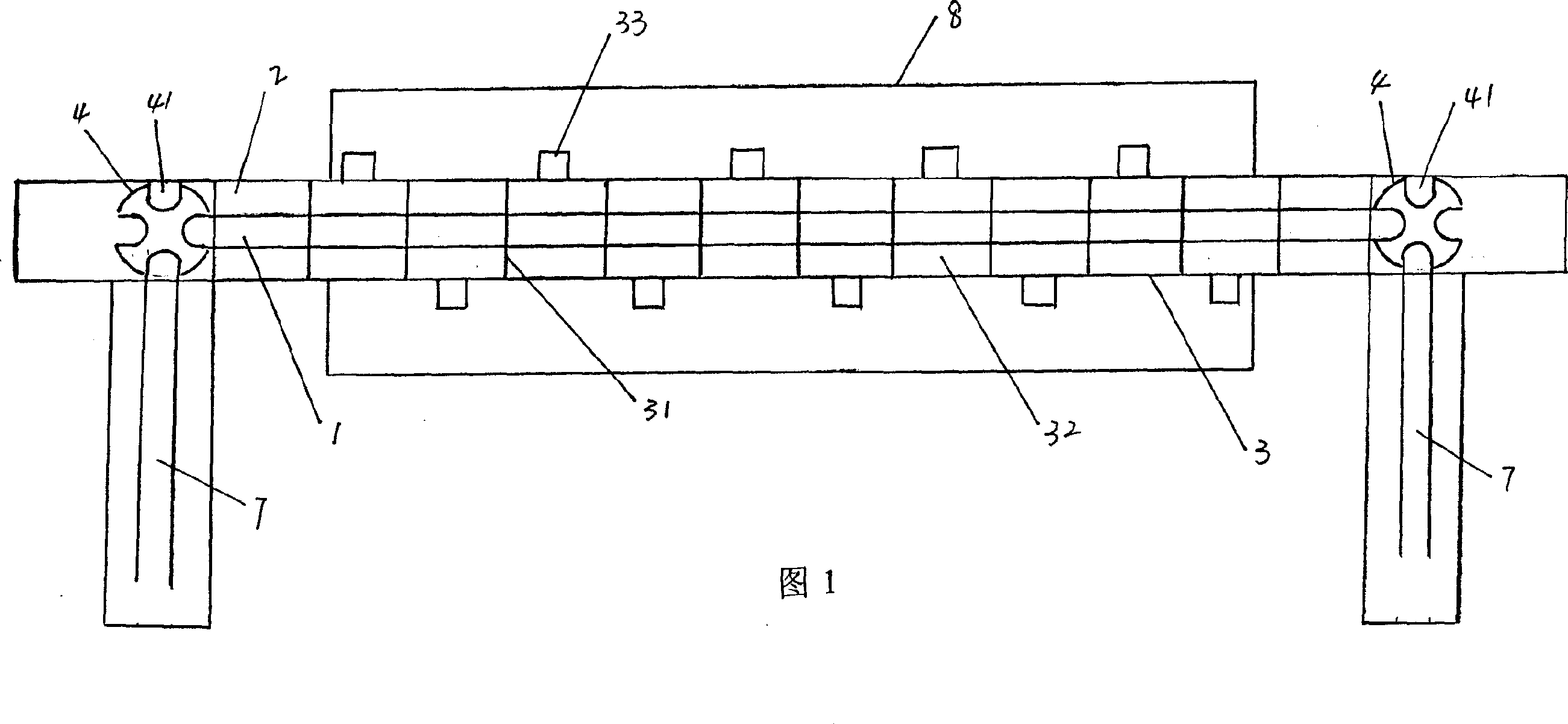

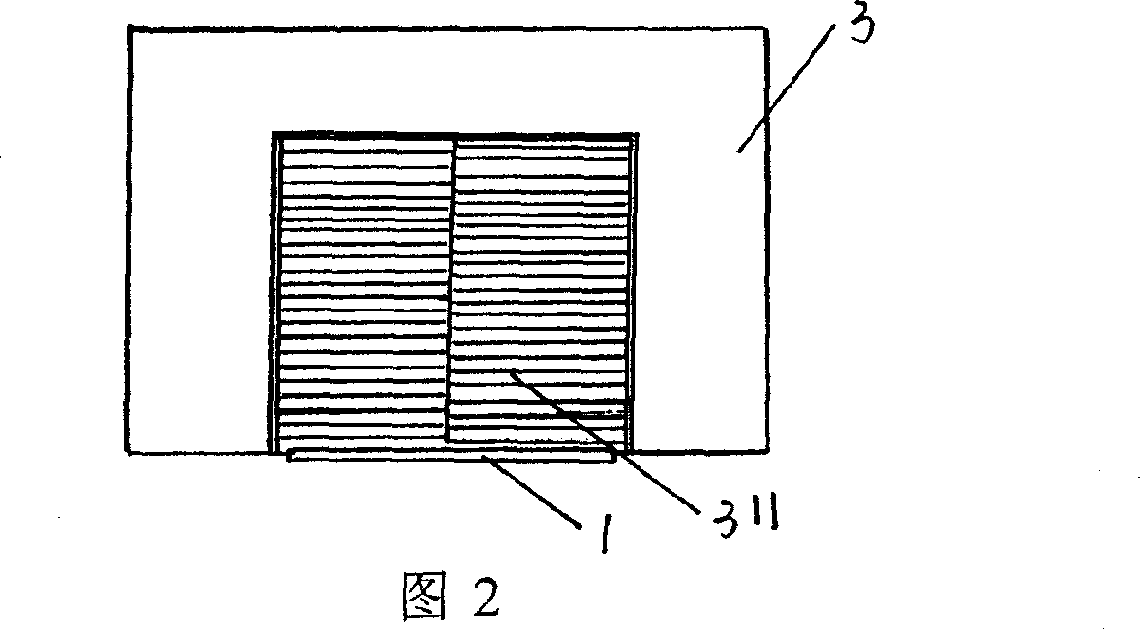

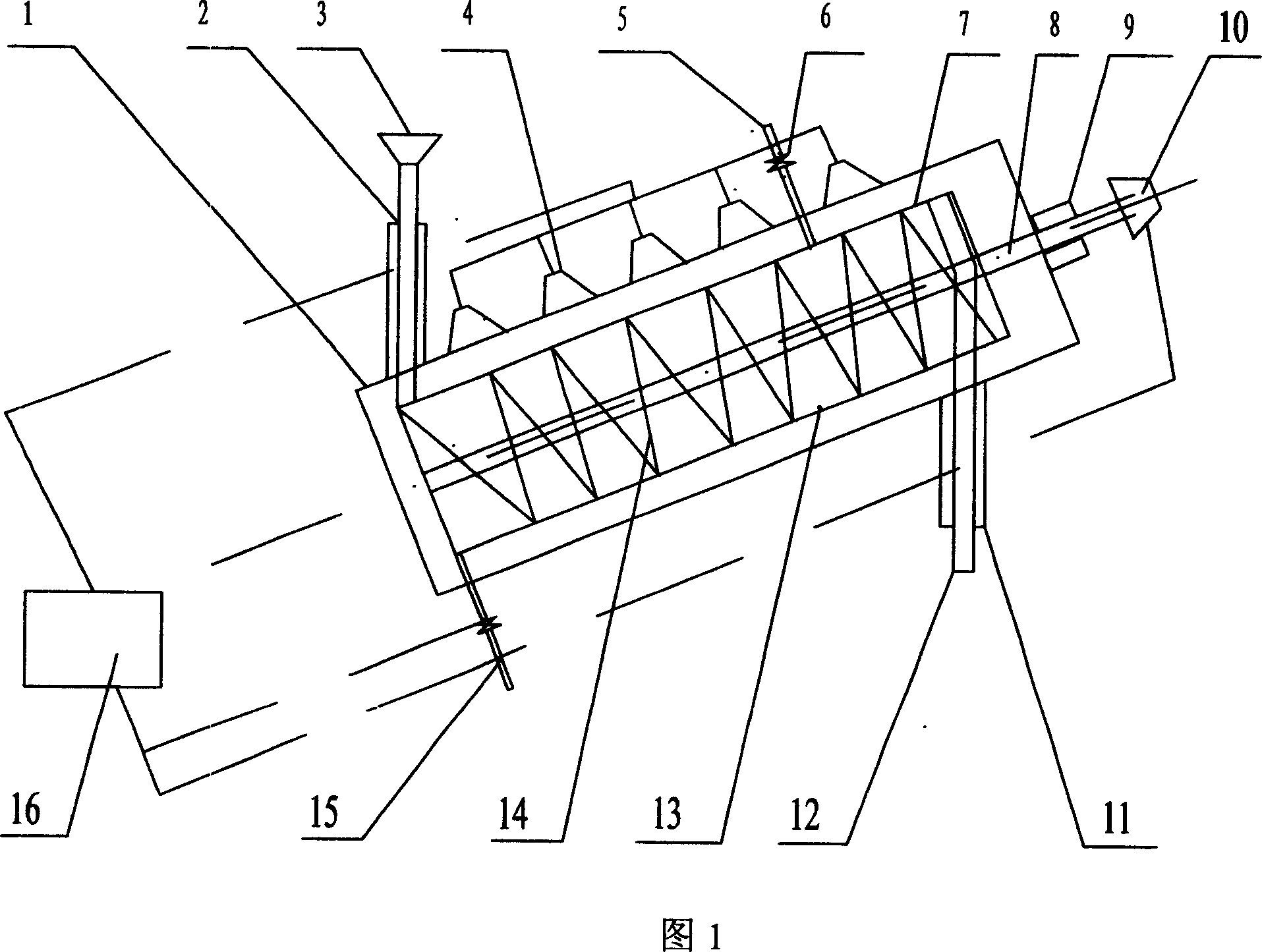

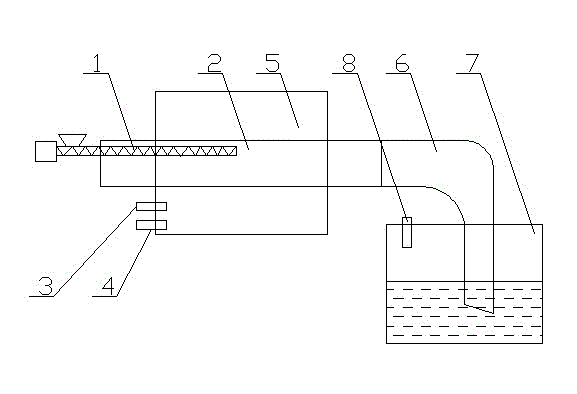

Microwave sterilizing device for sterilization in high performance under low temperature and normal pressure

InactiveCN101049175AEffective sterilizationHigh strengthPackage sterilisationFood preservationProcess engineeringMicrowave irradiation

A microwave sterilizing machine able to kill bacteria at low temp under ordinary pressure is composed of machine frame, conveying belt, microwave sterilizing region divided into several individual microwave irradiating chambers with individual microwave generator by metallic bulkheads, and material feeding and discharging units with anti-leakage mechanism for preventing microwave leakage.

Owner:王承辉

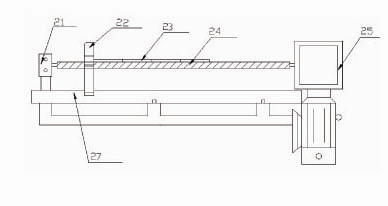

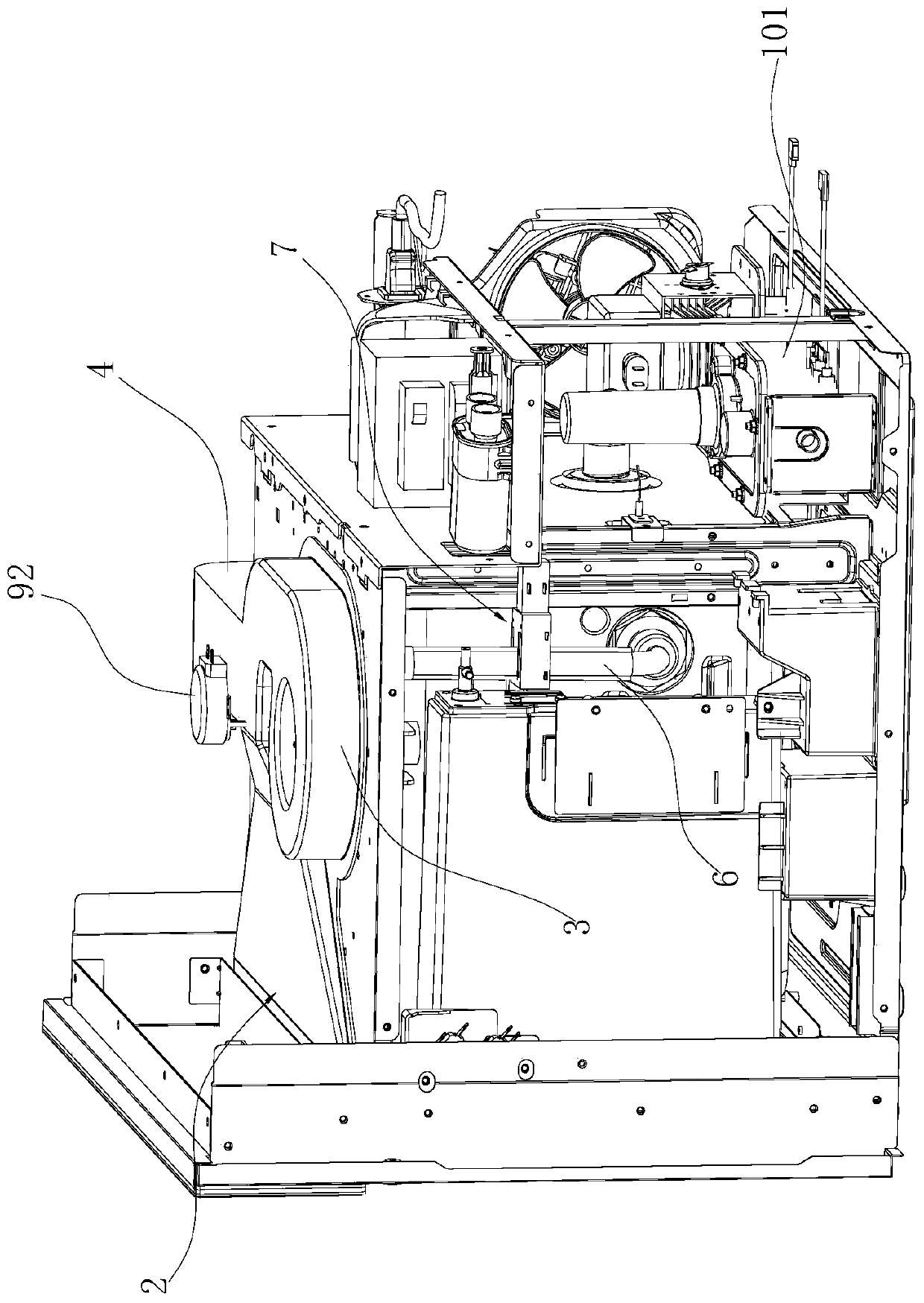

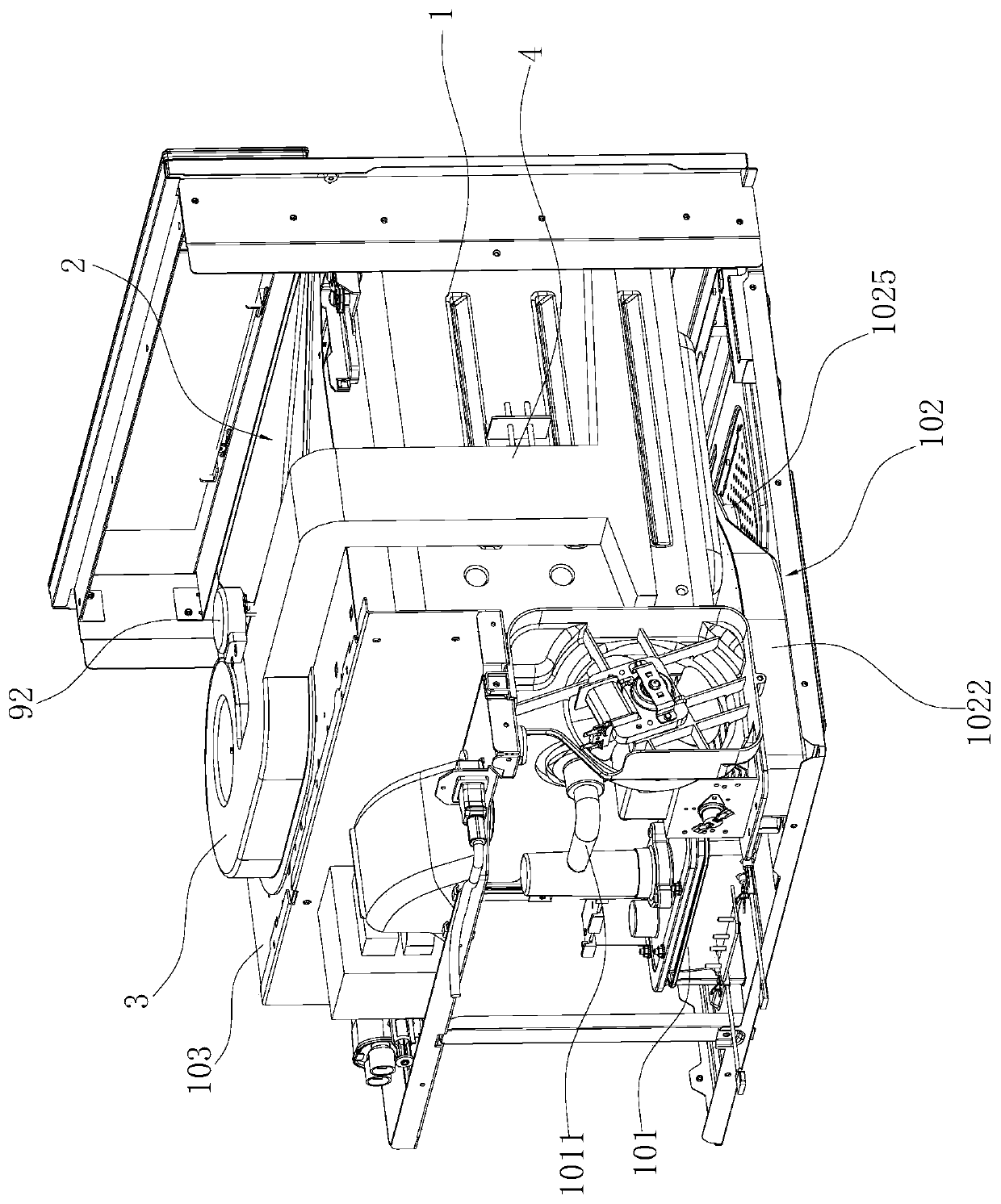

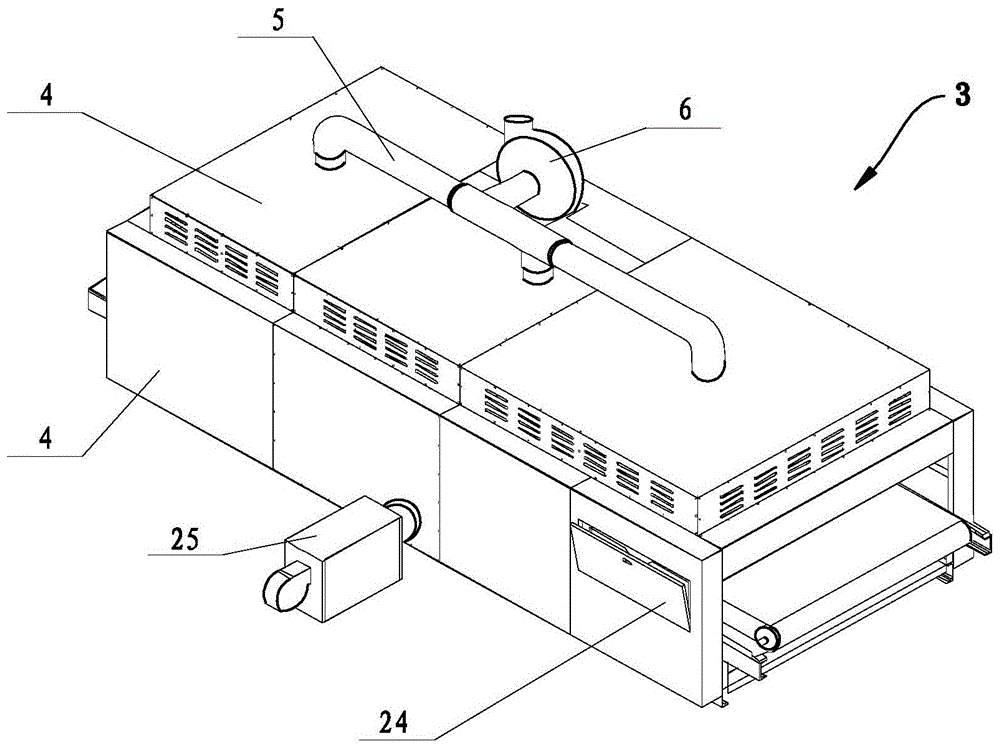

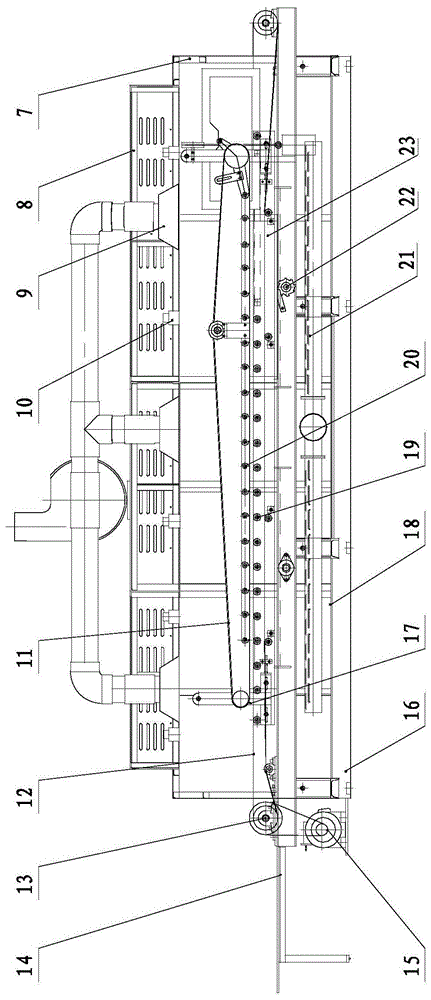

Paper mounting machine

ActiveCN103434329ADry evenlyImprove mildew resistanceMechanical working/deformationPaperhangingWater vaporPaperboard

The invention discloses a paper mounting machine, belonging to the technical field of packaging mechanical equipment. The paper mounting machine comprises a surface paper conveying device and a bottom paper conveying device, wherein the bottom paper conveying device is connected to a bottom paper gluing device, an output mechanism and a laminating device are sequentially arranged at the lower part of the bottom paper gluing device, the laminating device comprises a plurality of upper carrier rollers and lower carrier rollers which are arranged on a frame, laminating belts surround the upper carrier rollers, and conveying belts driven by a power device are arranged on the lower carrier rollers; a sealing cover is arranged on the periphery of the rack, and a heating element is arranged in the sealing cover; and a suction pipe communicated with the inner part of the sealing cover is arranged on the top of the sealing cover and is connected to a suction fan. The paper mounting machine has the advantages that water molecules inside paperboards are rapidly heated and discharged by using a heat source generated by the heating element in the processes of forwards pressing, flattening and transporting the paperboards by using the laminating belts and the conveying belts, water vapor is discharged through the suction fan and the suction pipe, the online rapid and uniform drying is realized, the curing time of glue is reduced, the anti-mildew capacity of the paper boards is improved, the defect of easiness in bending and deformation is overcome, and the strength and the manufacturing efficiency of the paper boards are improved.

Owner:SHANDONG CENTURY MACHINERY

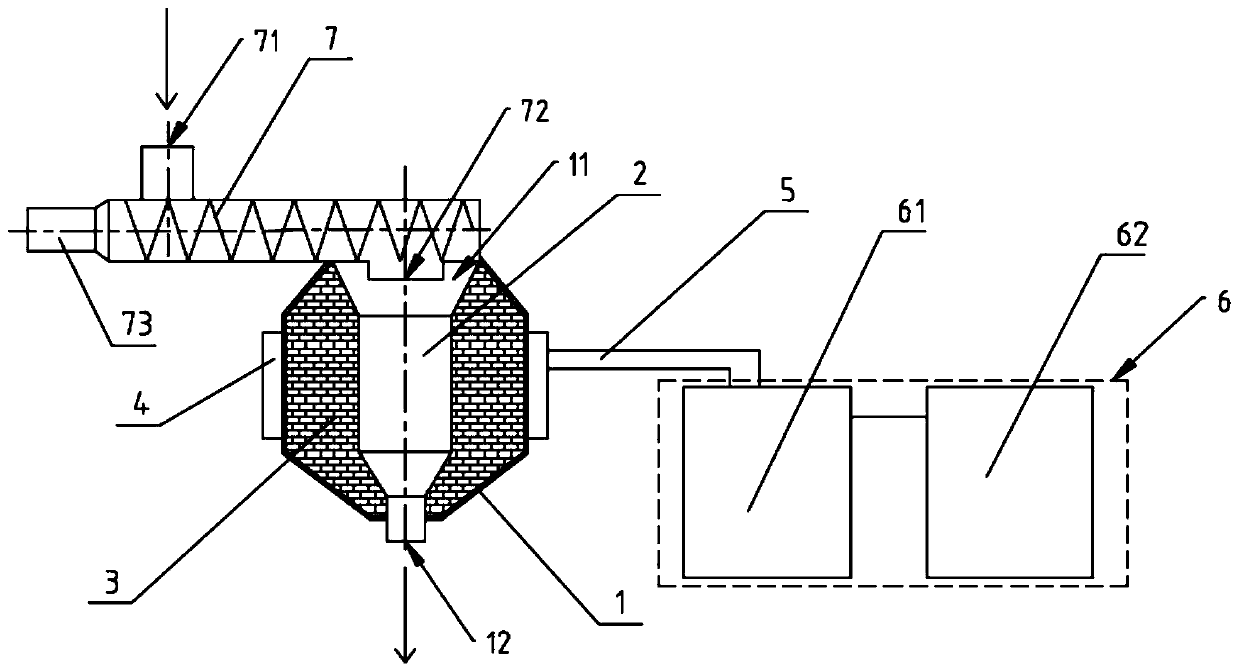

Microwave continuous graphite expansion apparatus

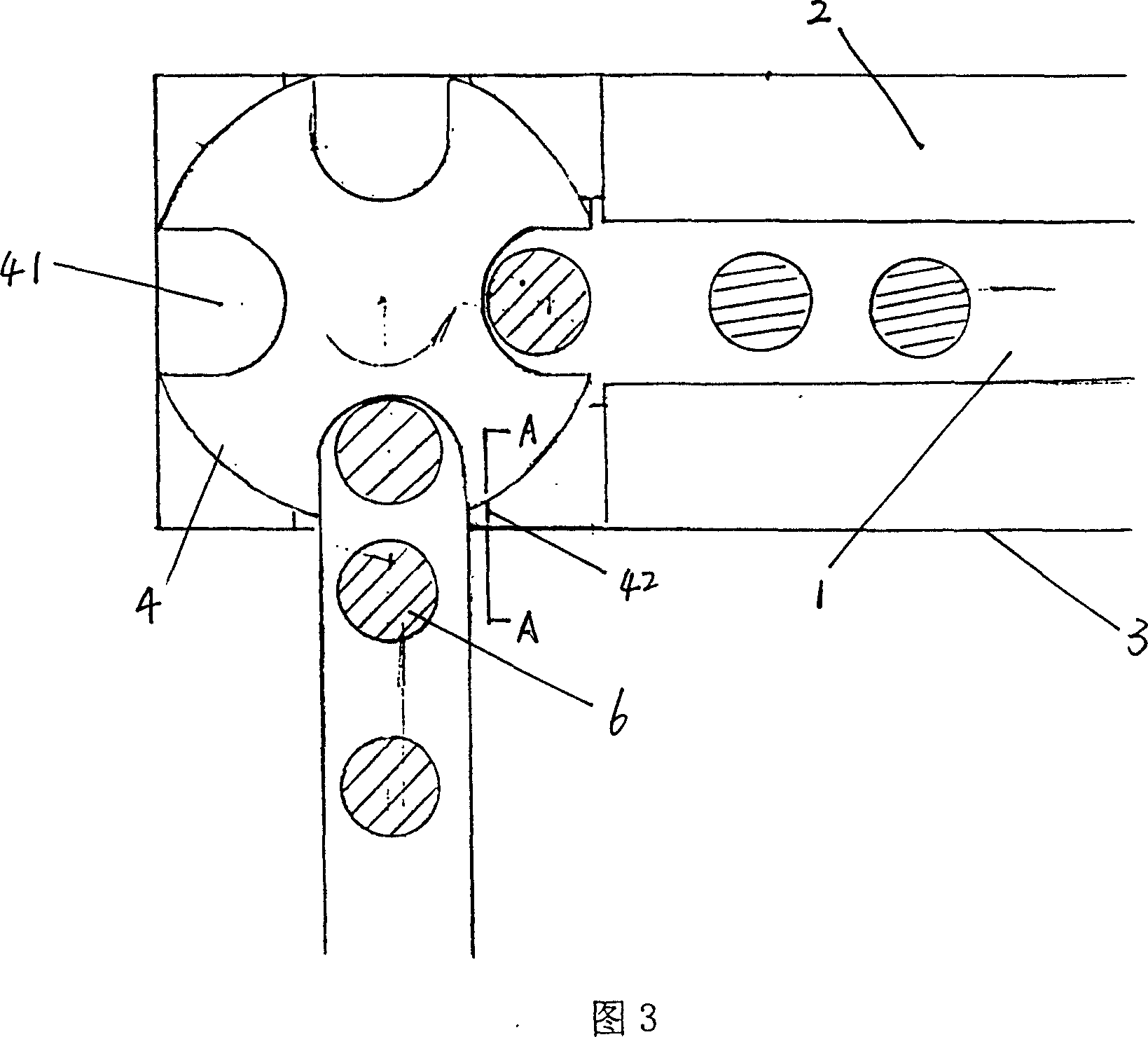

A microwave continuous graphite puffing device comprises a hopper; the lower part of the hopper is connected with a rotary feeder which is provided with a drive shaft and a rotary drum; a rotary vane is fixed on the rotary drum; the lower end of the rotary feeder is connected with a microwave feeding absorption chamber, the right end of which is connected with a microwave heating puffing chamber; a left microwave generator and a right microwave generator are arranged on the upper part of the microwave heating puffing chamber, the right end of which is connected with a microwave discharging absorption chamber; and the right end of the microwave discharging absorption chamber is provided with a rotary discharger. The conveyor belt of a belt conveyor respectively passes through the microwave feeding absorption chamber, the microwave heating puffing chamber, and the microwave discharging absorption chamber. The left end of the microwave heating puffing chamber is rotatablely connected with a feeding absorption chamber microwave baffle-board and the right end thereof is rotatablely connected with a discharging absorption chamber microwave baffle-board. The invention has the advantages of easy control, reliable operation, large material treatment quantity, can effectively prevent microwave leakage, and can realize continuous feeding and discharging as well as continuous microwave heating puffing graphite.

Owner:任崇桂

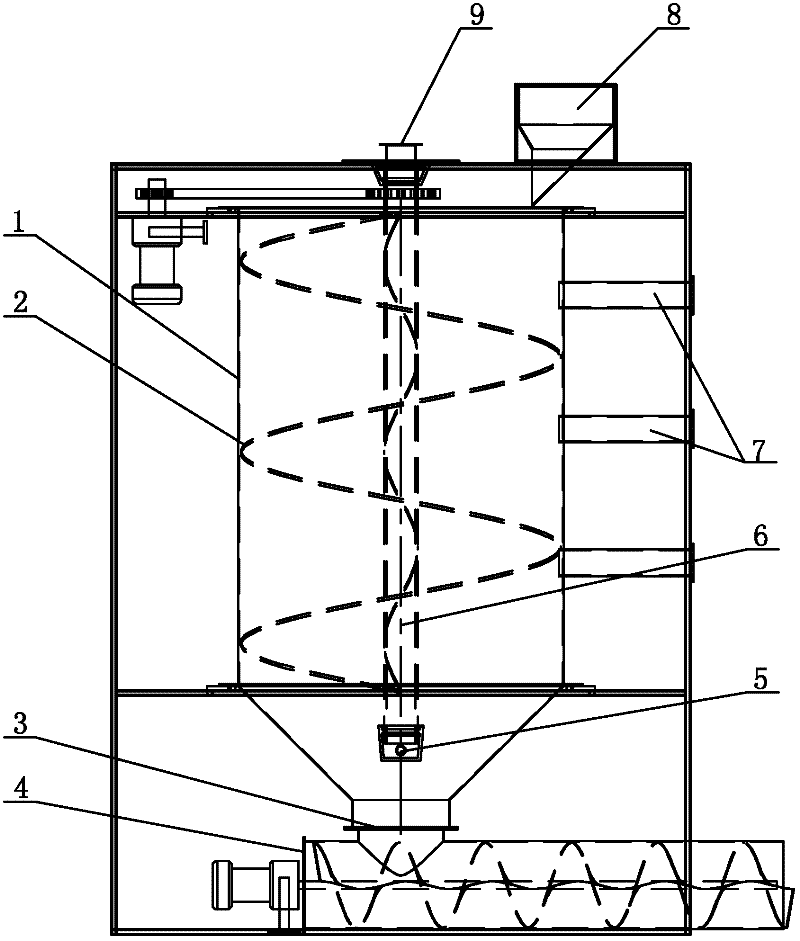

Vertical microwave drying coal furnace

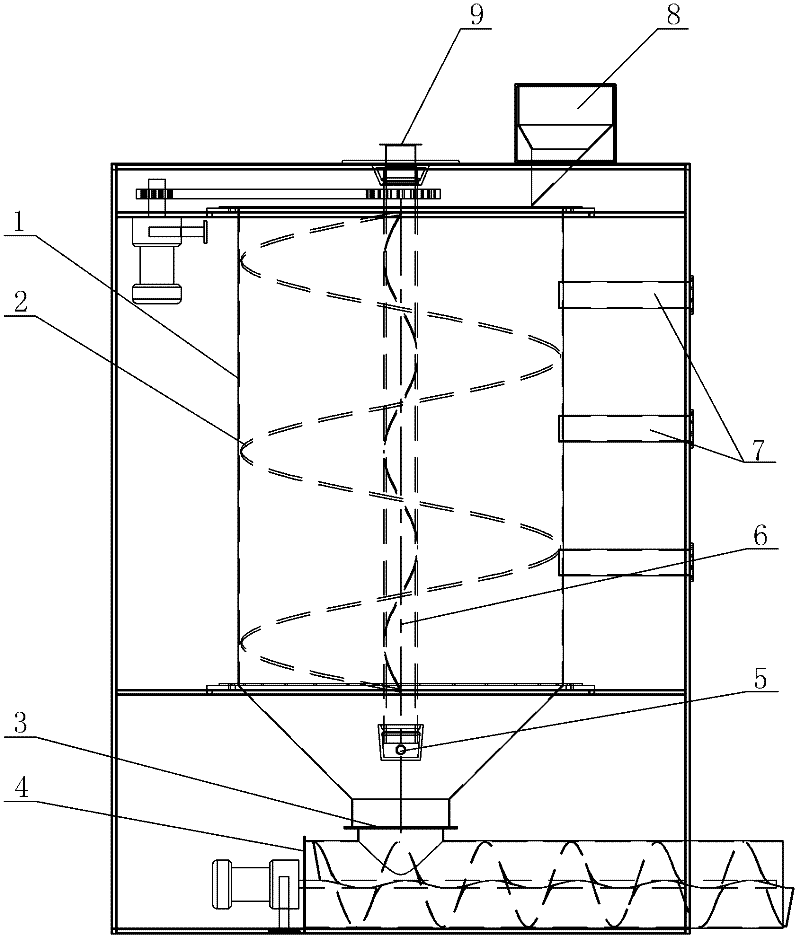

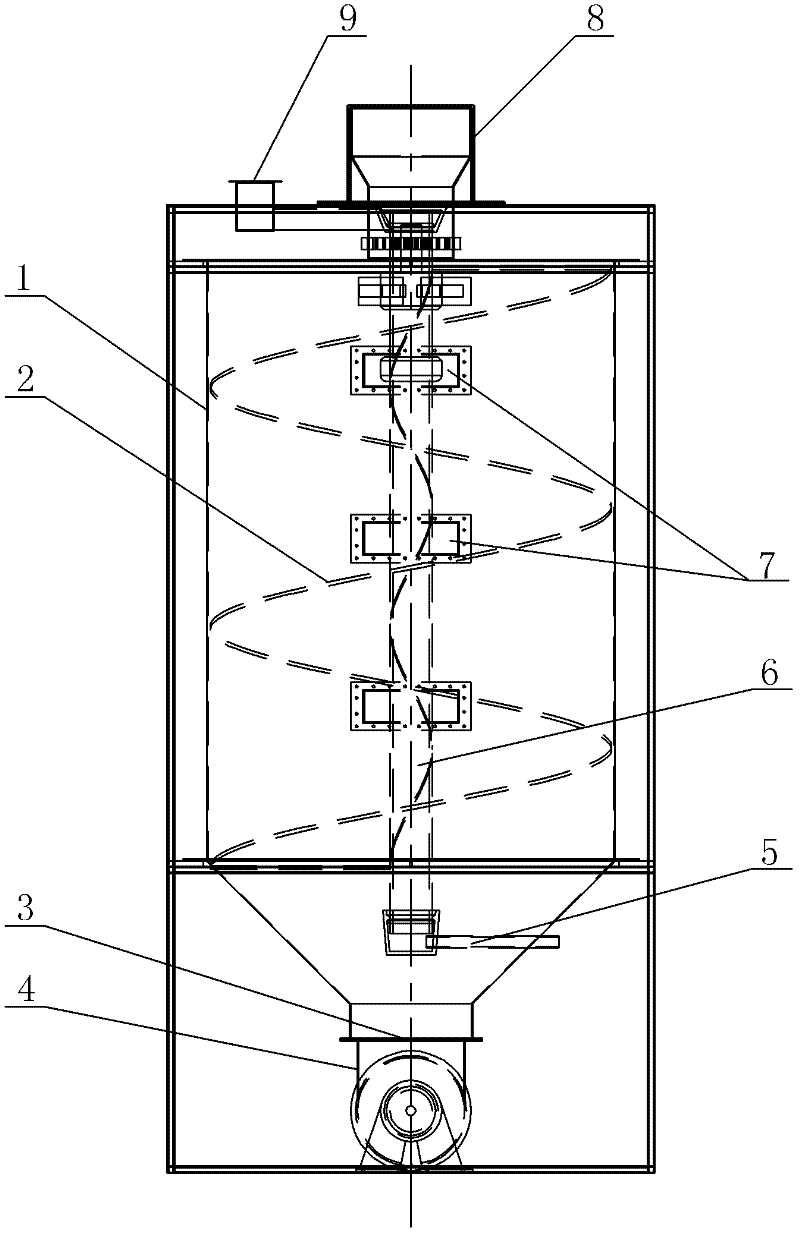

InactiveCN102393132ADry evenlyPrecise output controlDrying solid materials with heatHearth type furnacesMicrowaveWater vapor

The invention belongs to the field of material drying equipment, in particular relates to a vertical microwave drying coal furnace which comprises a microwave drying furnace body, wherein a feeding hopper is arranged at the top end of the microwave drying furnace body; a waveguide duct for conducting microwaves is installed on the microwave drying furnace body; a ventilation pipeline is arranged in the microwave drying furnace body; a gas inlet of the ventilation pipeline is connected with high-pressure nitrogen gas filling equipment, and a gas outlet of the ventilation pipeline is communicated to the outside; the ventilation pipeline is drilled; and a discharge valve is arranged at a discharge opening at the bottom of the microwave drying furnace body. In the invention, a vertical structure is adopted, thus the floor space is small, the structure is simple, and the manufacturing cost is lowered; the microwave heating is adopted, thus the coal can be dried quickly and uniformly; the coal is used as a heating element, thus the heat utilization efficiency is high, the energy is saved, and the environment is protected; the high-pressure nitrogen gas filled in the ventilation pipeline forms negative pressure in the pipeline, and a through hole only absorbs water vapor evaporated from the coal, thus the clogging or microwave leakage is avoided; and a helical conveyer below the discharge opening can be used for accurately controlling the discharge quantity and discharge speed of the coal.

Owner:SHANDONG BO RUN IND TECH

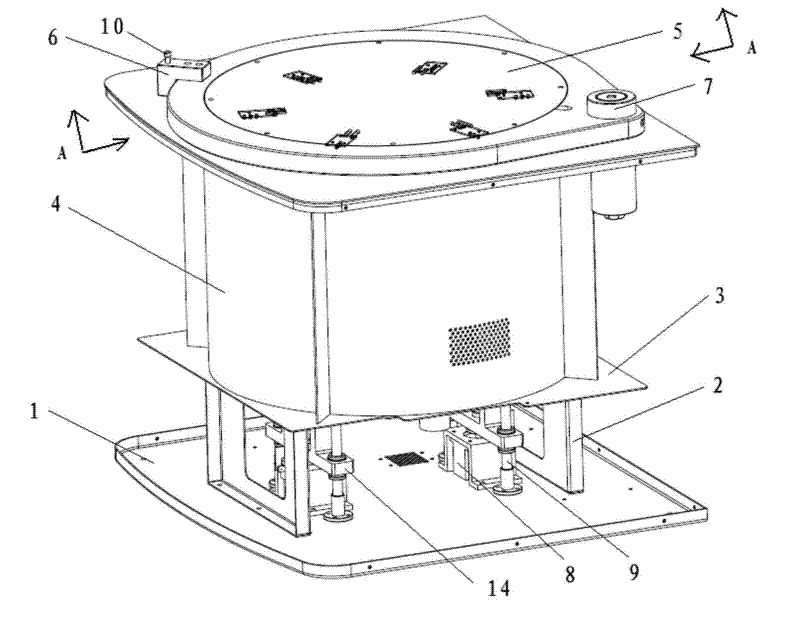

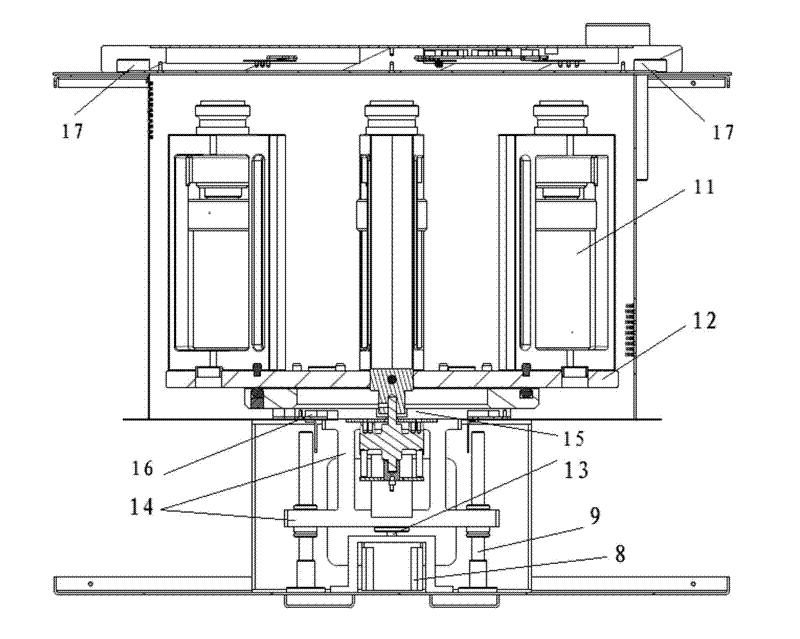

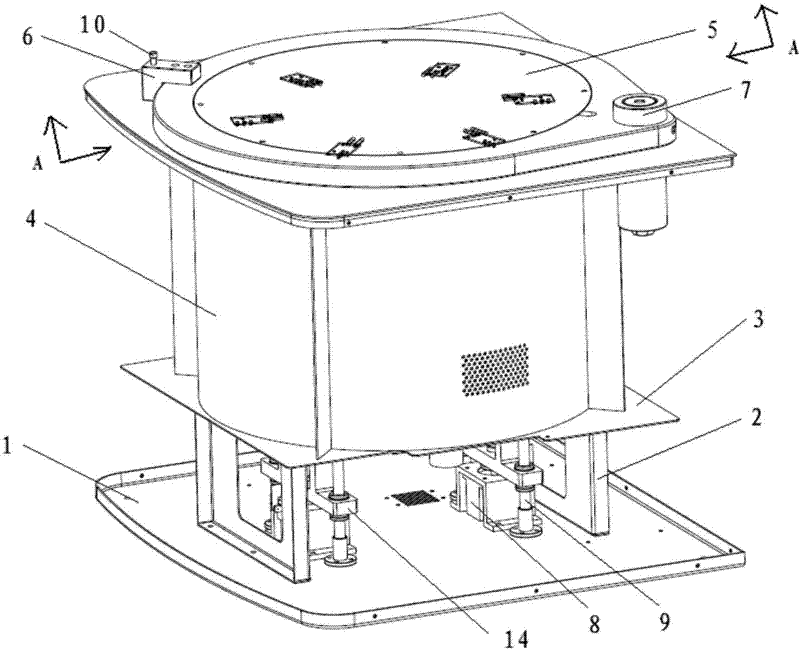

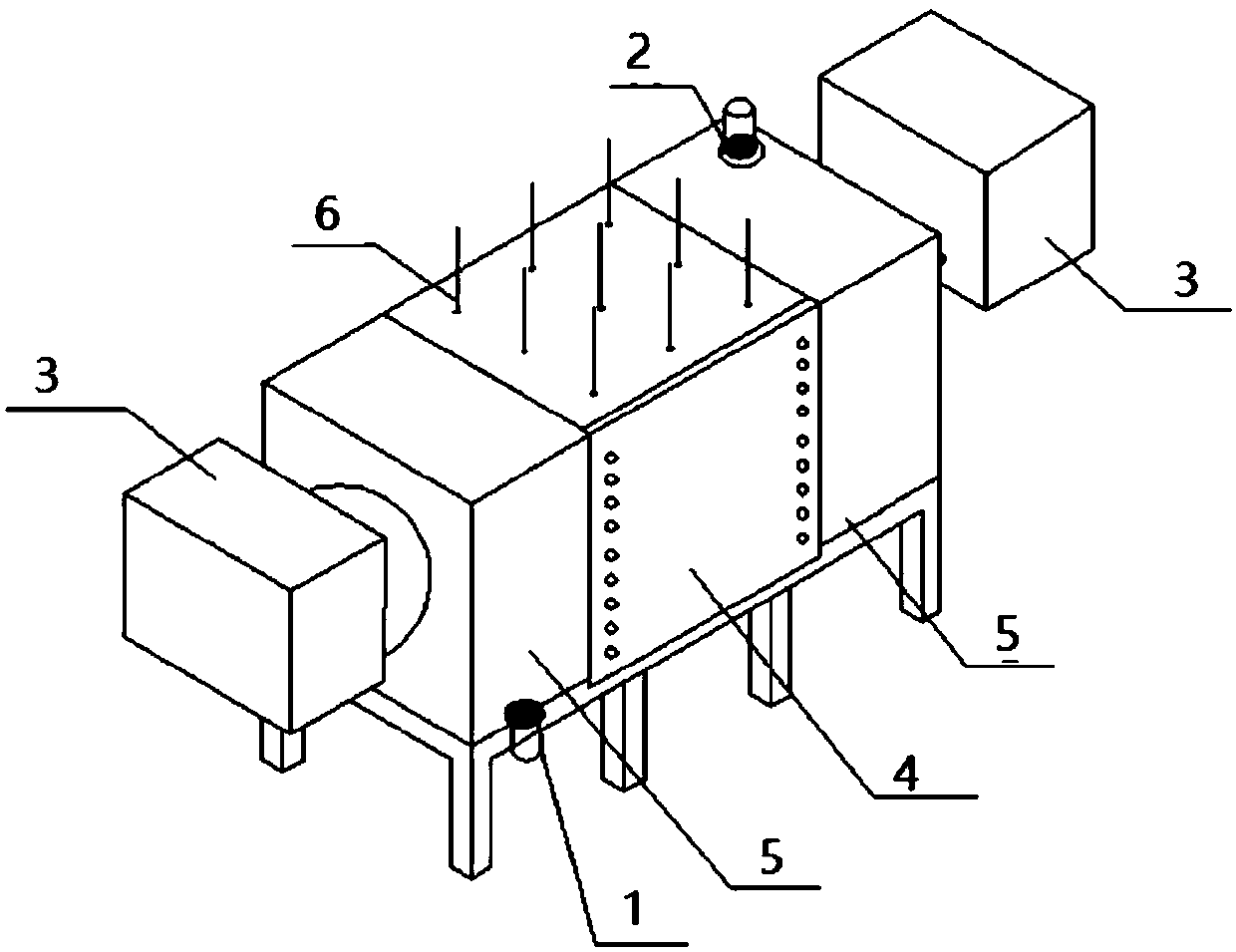

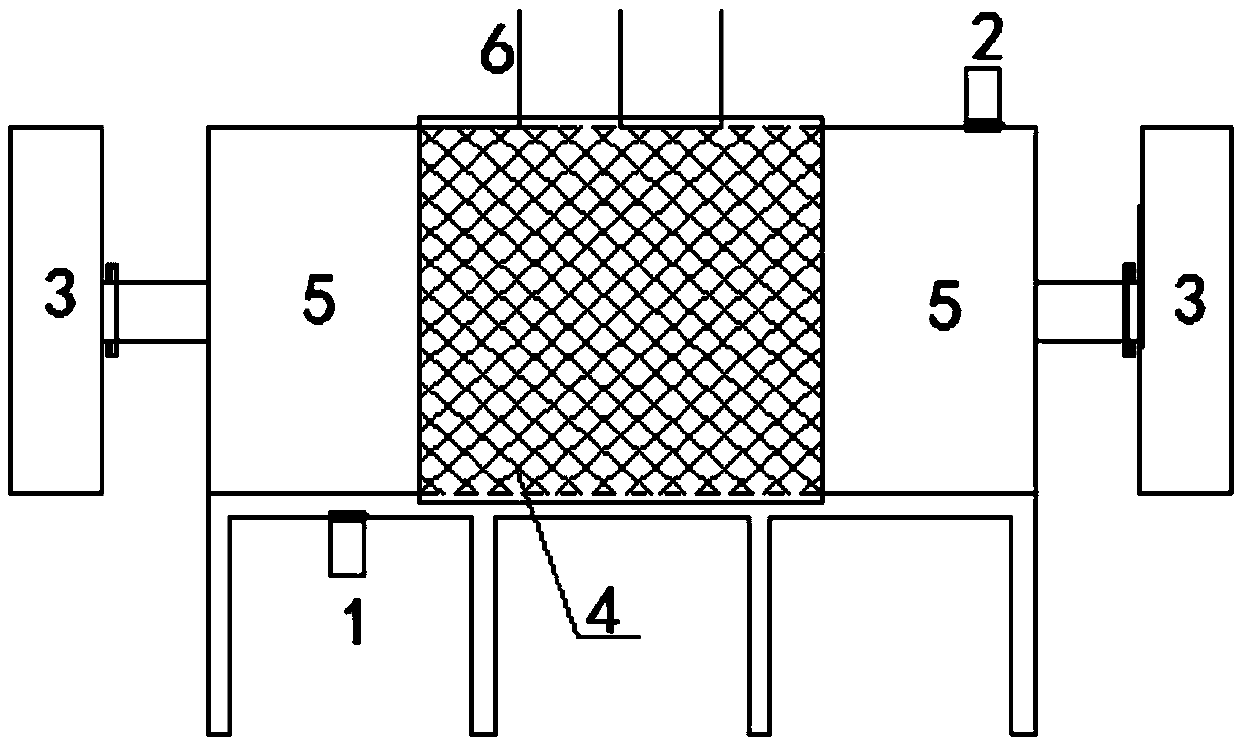

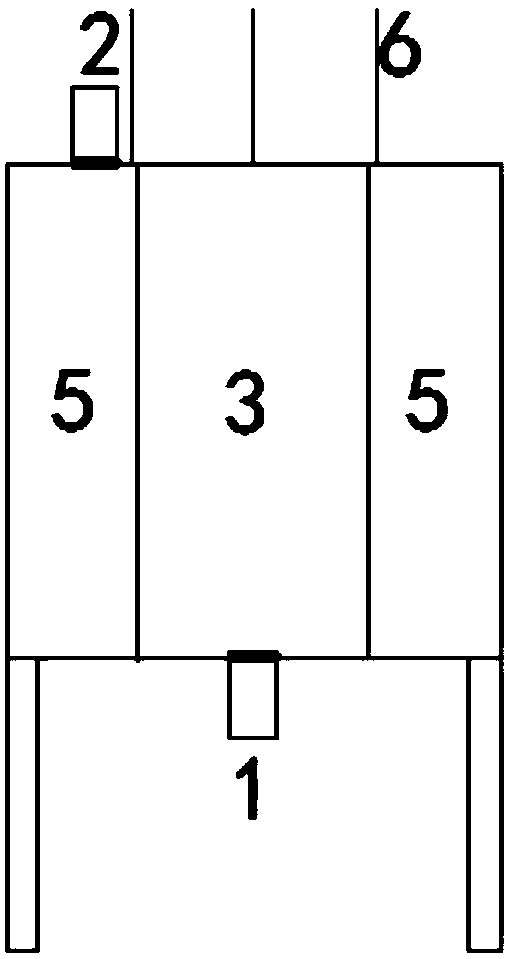

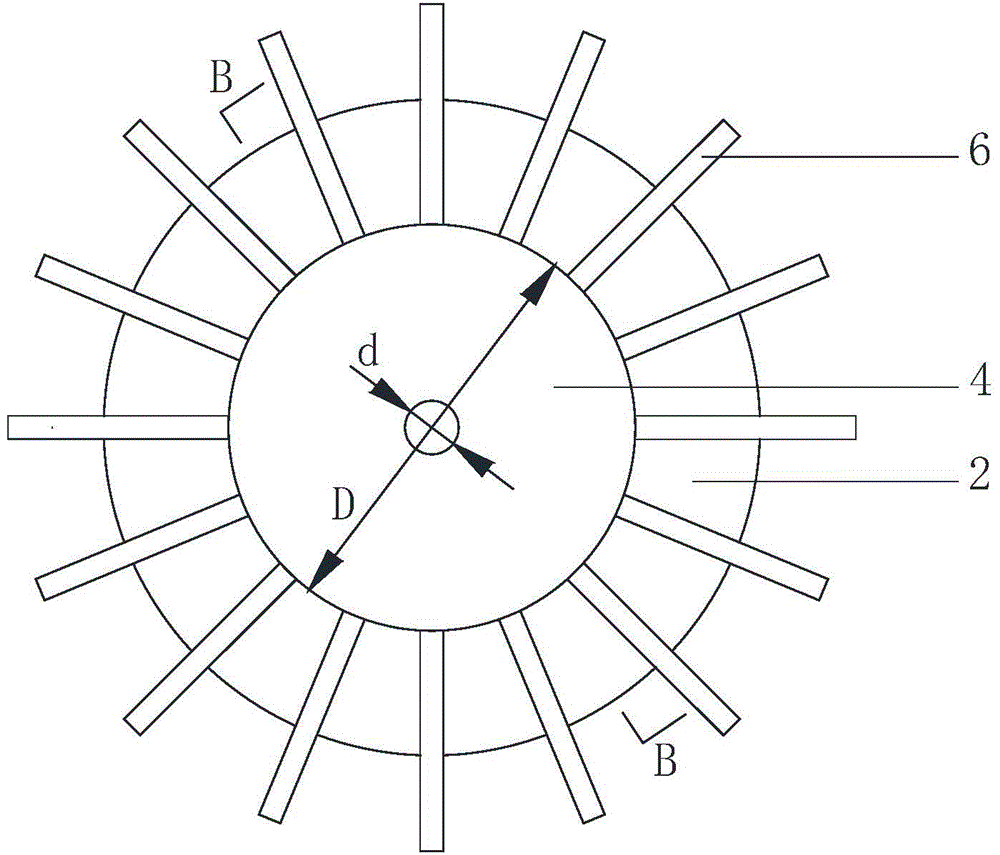

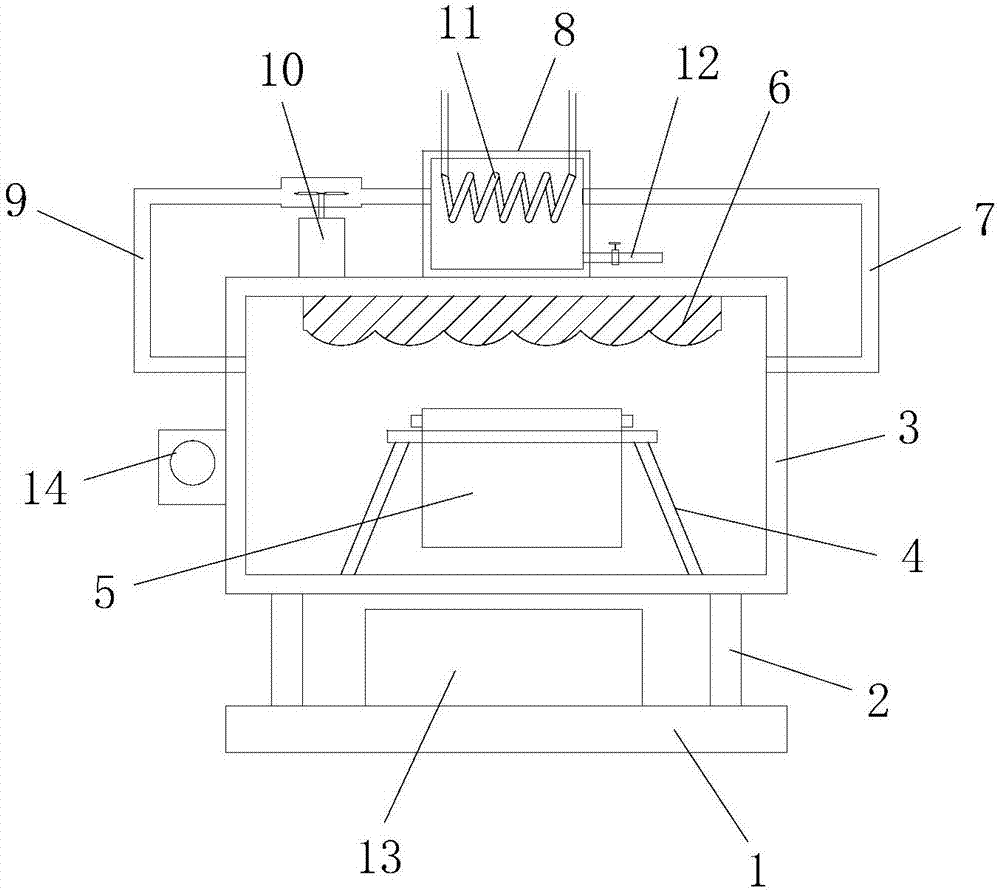

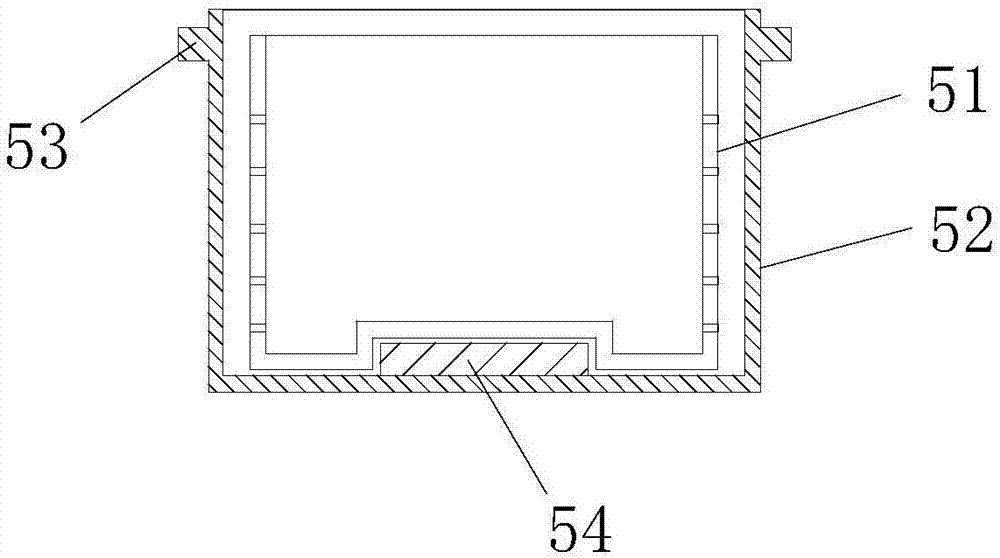

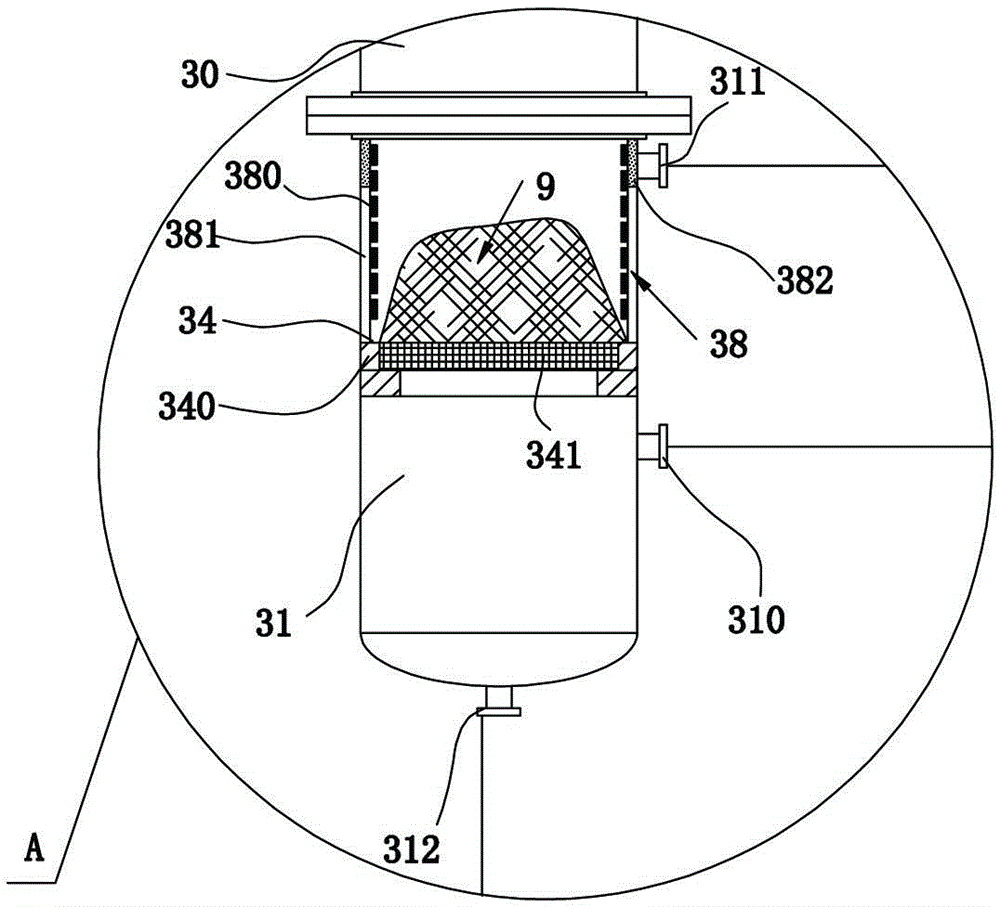

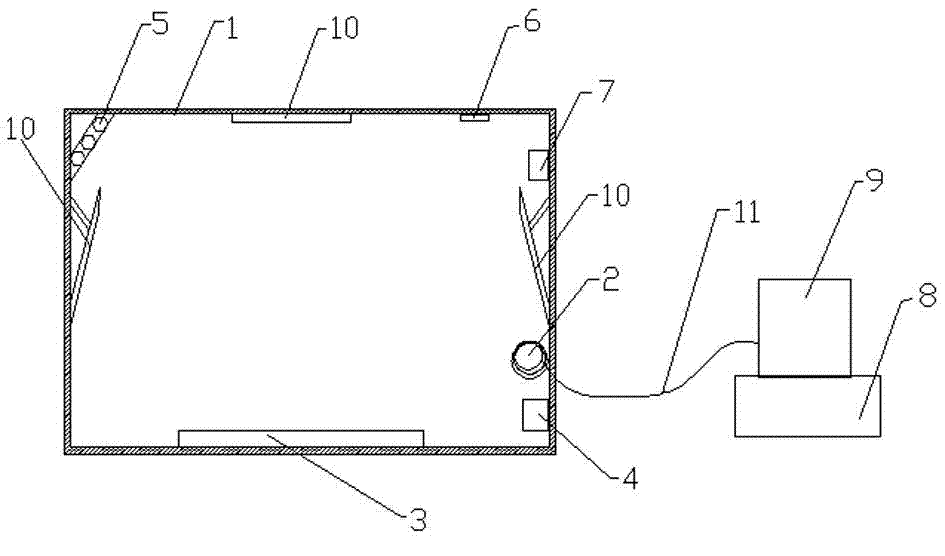

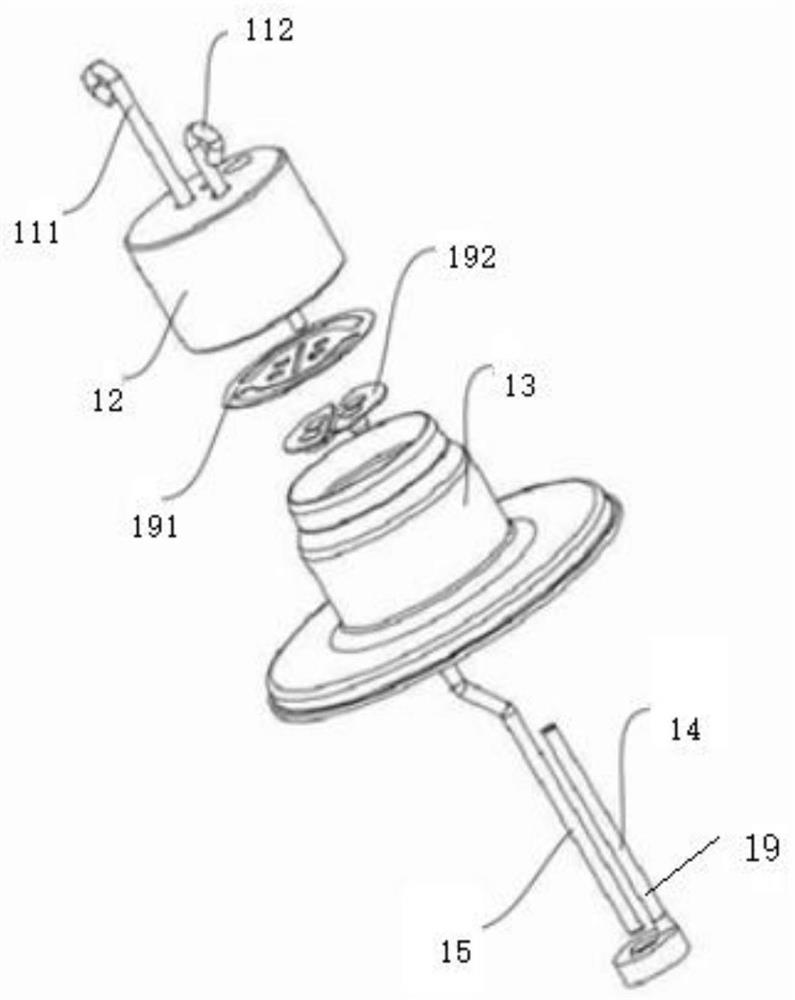

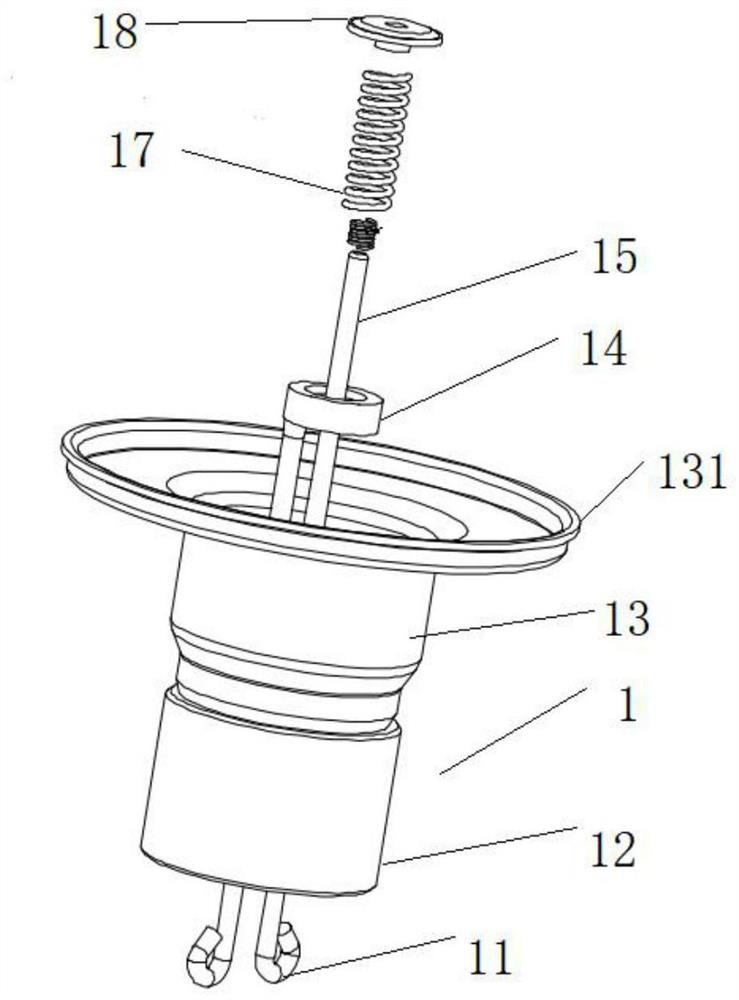

Microwave digestion furnace chamber

ActiveCN102313668APrevent microwave leakageEnsure personal safetyPreparing sample for investigationPersonnel safetyDigestion

Provided is a microwave digestion furnace chamber which comprises a pedestal, a cavity, a base plate which is fixed at the bottom of the cavity, a support which is fixed between the base plate and the pedestal, and a digestion pot. The microwave digestion furnace chamber is characterized by further comprising a rotary disc which is arranged at the bottom in a tank body of the cavity, wherein, thedigestion pot is arranged on the rotary disc, an elevating assembly which is arranged on the pedestal and comprises a movable base plate that is arranged between the rotary disc and the elevating assembly, located at a same horizontal plane where the base plate is located and provided with an anti-current groove, and a movable cover which is arranged at the upper end of the cavity, movably connected with the cavity through a rotating shaft and provided with an anti-current groove. The beneficial effects of the invention are as follows: microwave leakage can be prevented; personnel safety of surrounding workers can be ensured; manpower is saved; working efficiency is improved.

Owner:上海新拓分析仪器科技有限公司

Combustion device for volatile organic composites and simulating detection device and method of combustion device

ActiveCN109579033AIncrease heating speedImprove energy conversion efficiencyGas analyser construction detailsIncinerator apparatusCombustion chamberFixed bed

The invention discloses a combustion device for volatile organic composites and a simulating detection device and method of the combustion device. The combustion device comprises a microwave emittingsystem, a catalysis combustion chamber and a catalysis bed; a waste gas inlet and a waste gas outlet are formed in the catalysis combustion chamber; a catalyst is arranged on the catalysis bed; the catalysis bed is fixedly arranged in the catalysis combustion chamber; the waste gas inlet and the waste gas outlet are located on two sides of the catalysis bed; the microwave emitting system comprisesa microwave emitting device which is arranged on the catalysis combustion chamber; the microwave emitting device communicates with the catalysis combustion chamber through a waveguide pipe; and microwave emitted by the microwave emitting device can enter the catalysis combustion chamber through the waveguide pipe. According to the combustion device, the catalyst fixing bed is heated by microwave;VOCs waste gas is catalyzed, oxidized and mineralized high-efficiently; the degradation and mineralization rate can be improved; and reaction energy consumption is lowered.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

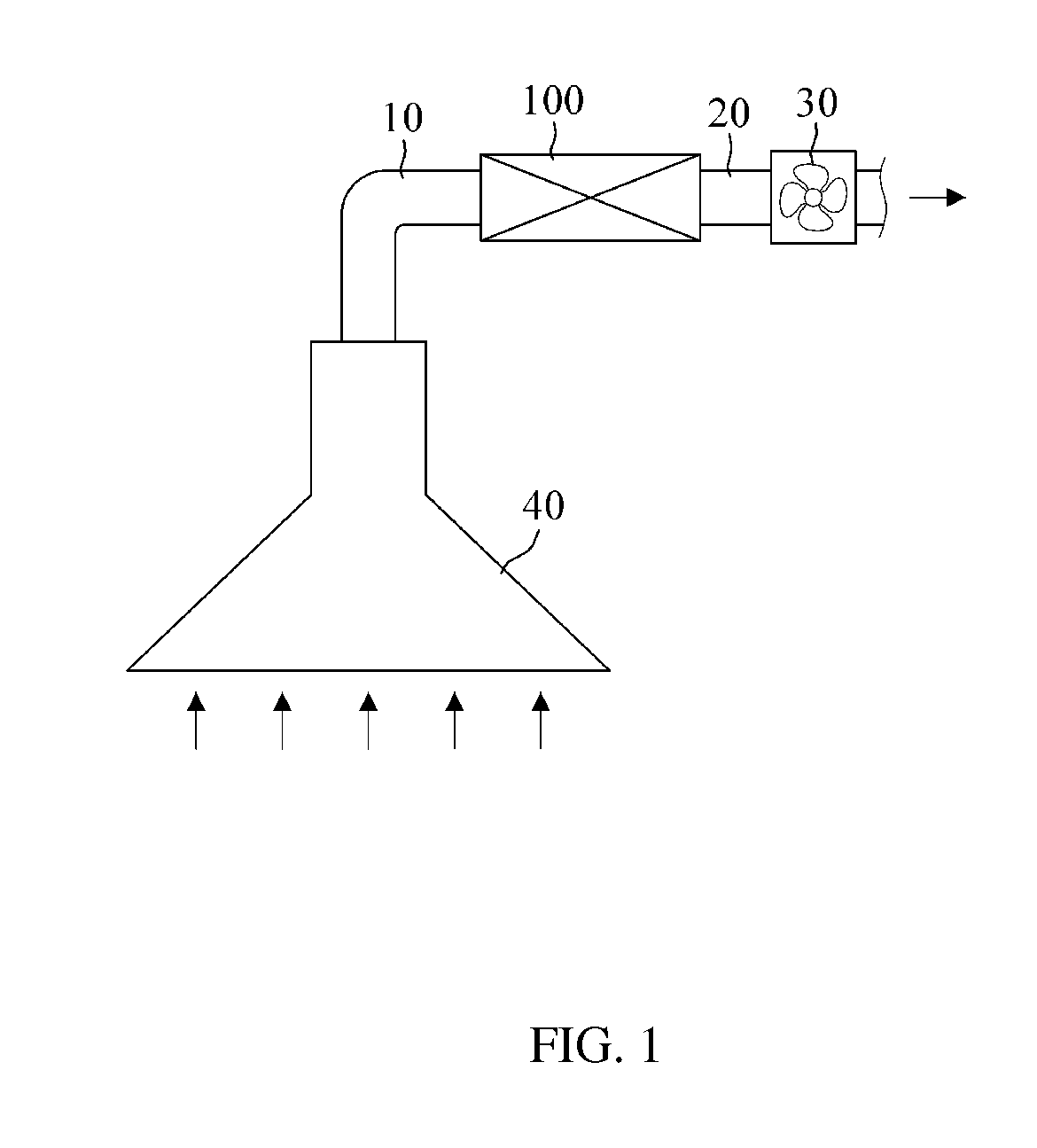

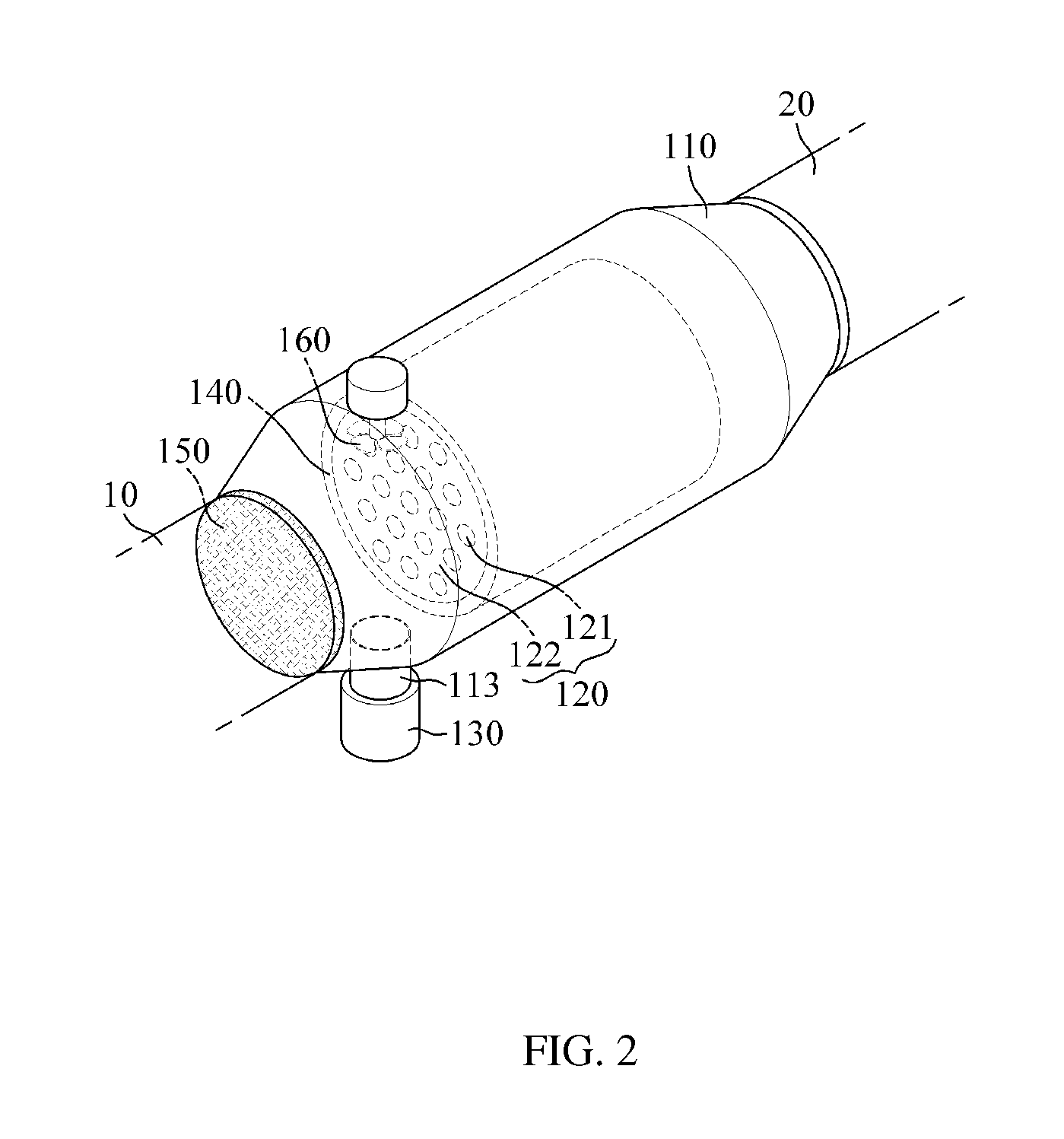

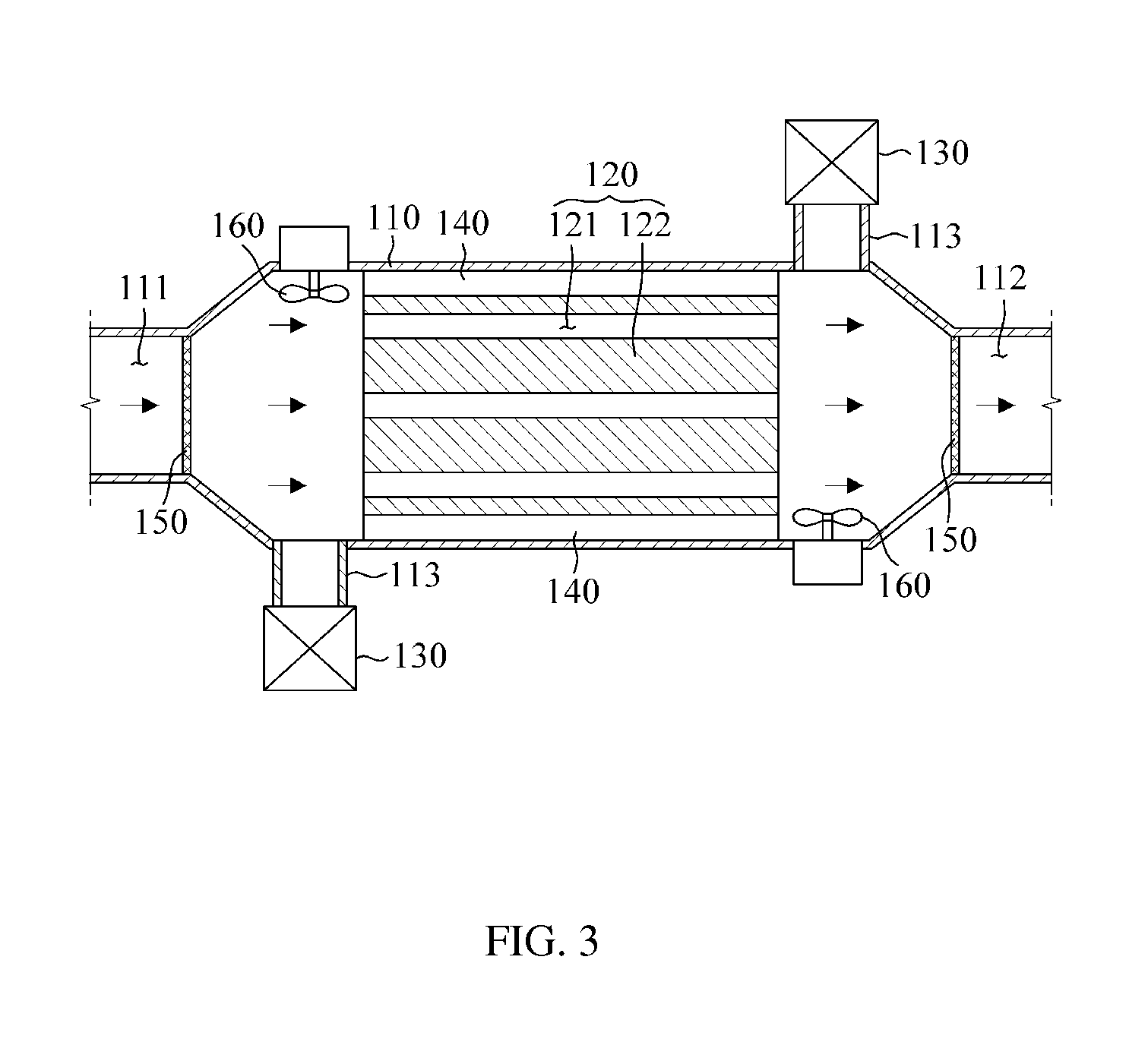

Air purifying apparatus using microwaves

ActiveUS20150004063A1Improve efficiencyImprove energy efficiencyDispersed particle separationFire rescueMicrowaveAir cleaning

In an air purifying apparatus for removing contaminants, such as soot and the like, by burning contaminated air while passing the contaminated air through a filter heated by microwaves, the apparatus includes: a housing, which is hollow, and comprises an inlet on one side and an outlet on the other side; a ceramic filter of a longitudinal material, which is arranged in the housing in a longitudinal direction of the housing, and includes a plurality of partition walls formed so that a flow path where contaminated air flows may be divided in plurality; and a microwave generator configured to generate microwaves to be supplied to one end surface of the ceramic filter in a longitudinal direction thereof to heat the one end surface of the ceramic filter in the longitudinal direction.

Owner:LEE YEON SU +1

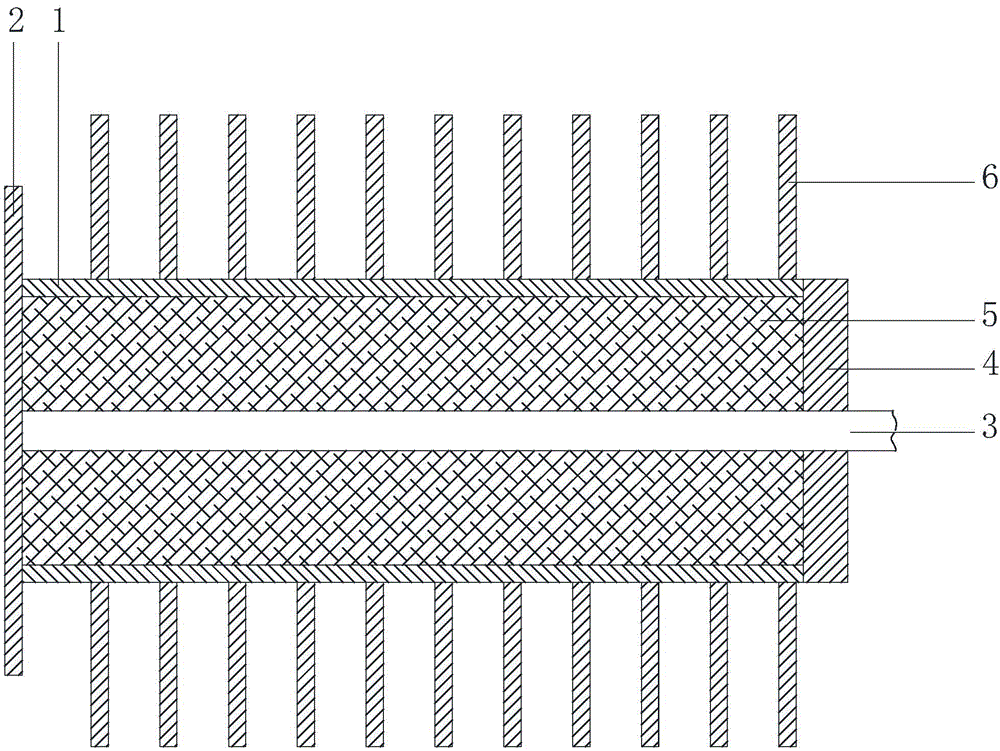

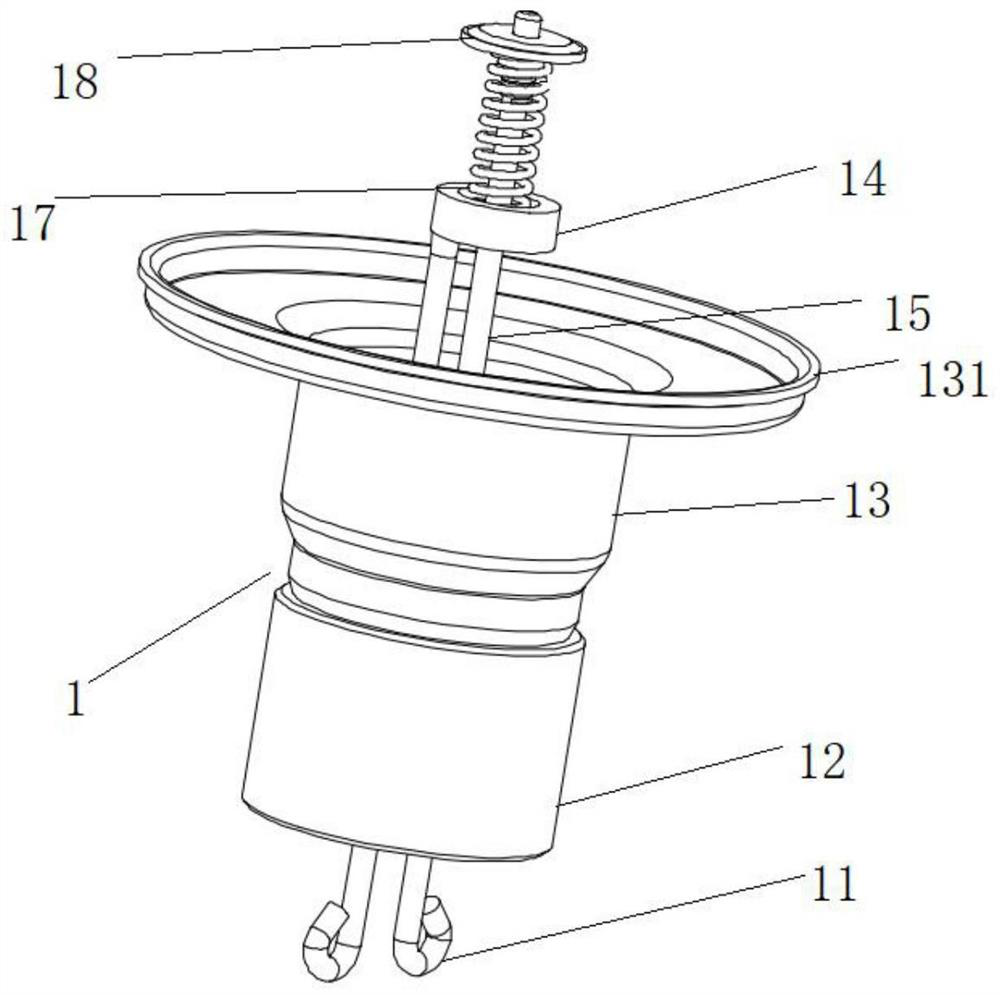

Magnetron cathode cable microwave leakage protective device

The invention relates to a magnetron and discloses a magnetron cathode cable microwave leakage protective device for preventing microwave leakage by use a coaxial structure and a wave-absorbing material. The magnetron cathode cable microwave leakage protective device comprises a junction surface, a cathode cable, a sleeve and a short-circuit plate; the junction surface is mounted at the starting end of the sleeve, while the short-circuit plate is mounted at the tail end of the sleeve; the cross section of the sleeve is circular; a cooling fin is mounted on the sleeve; the cathode cable penetrates through the short-circuit plate along the central axis of the sleeve to be connected with the junction surface; the wave-absorbing material is arranged between the sleeve and the cathode cable. The magnetron and discloses a magnetron cathode cable microwave leakage protective device has the beneficial effects that the microwave energy leaked by the magnetron cathode cable is absorbed thoroughly by the wave-absorbing material arranged between the sleeve and the cathode cable in the transmission process of the coaxial transmission line, the converted heat is dissipated to the surrounding space by the cooling fin, and therefore, the normal work of the coaxial line transmission system is guaranteed, the reliability of the protective device is improved and the microwave leakage is stopped.

Owner:SOUTHWEST JIAOTONG UNIV

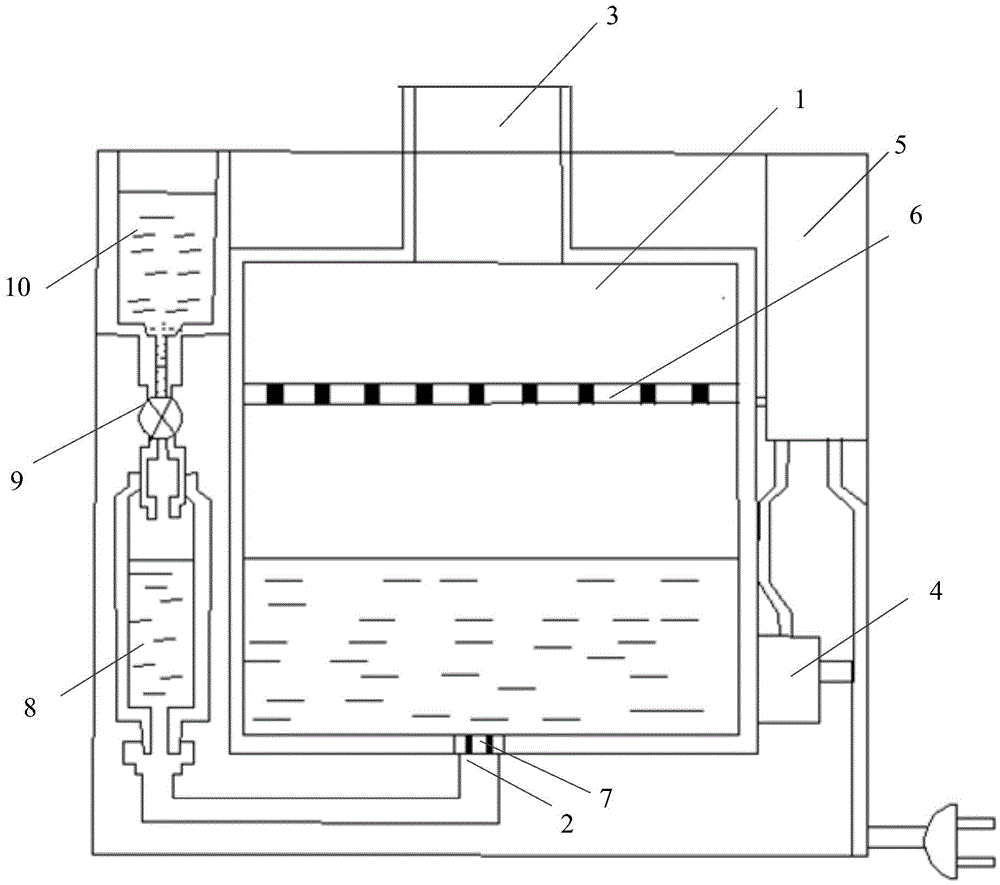

Microwave steam generating device and microwave humidifying device

PendingCN105570857AEnsure safetyAvoid damageSteam generation heating methodsAir humidification systemsMicrowaveEngineering

The invention relates to steam generating devices, in particular to a safe microwave steam generating device capable of preventing microwave leakage. The microwave steam generating device comprises a cavity body, a magnetron and a microwave controller, wherein the cavity body is provided with a water filling port and a steam outlet; the magnetron is connected with the cavity body; the microwave controller is used for controlling the magnetron. An upper microwave separation net located at the steam outlet and a lower microwave separation net located at the water filling port are further arranged inside the cavity body. By the adoption of the technique, microwave leakage can be prevented, human body safety is effectively guaranteed, and damage caused by microwave leakage is avoided.

Owner:HUIZHOU UNIV

Equipment and process for industrially producing graphene by microwaves

The invention relates to equipment and process for industrially producing graphene by microwaves. The equipment comprises a spiral feeder, a furnace tube, a microwave cavity, a material discharging pipe and a product collector, wherein the furnace tube is connected to the microwave cavity in a penetrating manner; the input end of the furnace tube is connected with the spiral feeder; the output end of the furnace tube is connected with the product collector through the material discharging pipe; an inert gas inlet and a compressed air inlet are formed in the input end of the furnace pipe. Graphite is oxidized into oxidized graphite under the action of strong acid and strong oxidant such as H2SO4, HNO3 and HClO4s or is hydrolyzed into oxidized graphite under the electrochemical peroxidation effect; the oxidized graphite is prepared after being subjected to filtering, granulation and the like; inert gas is used for replacing air in the furnace tube; under the inert gas atmosphere, the oxidized graphite is dissociated by the microwaves and is reduced into flocculent graphene easy to fly; the compressed air inlet is opened, and the reduced graphene enters the product collector along with the compressed air and is completely absorbed by water pre-stored in the device; suspension is filtered and dried to be solid powder, so that the production process for the graphene is finished.

Owner:江苏江大环保科技开发有限公司

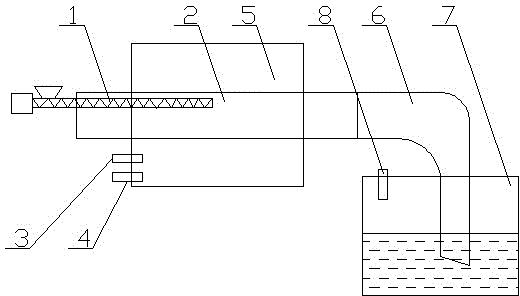

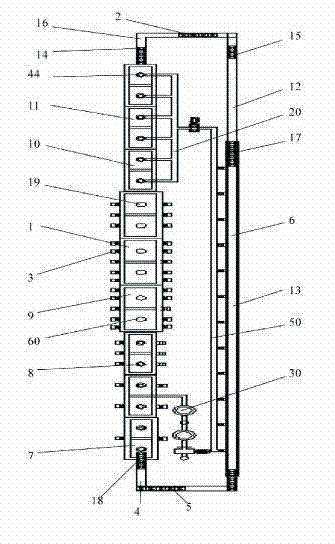

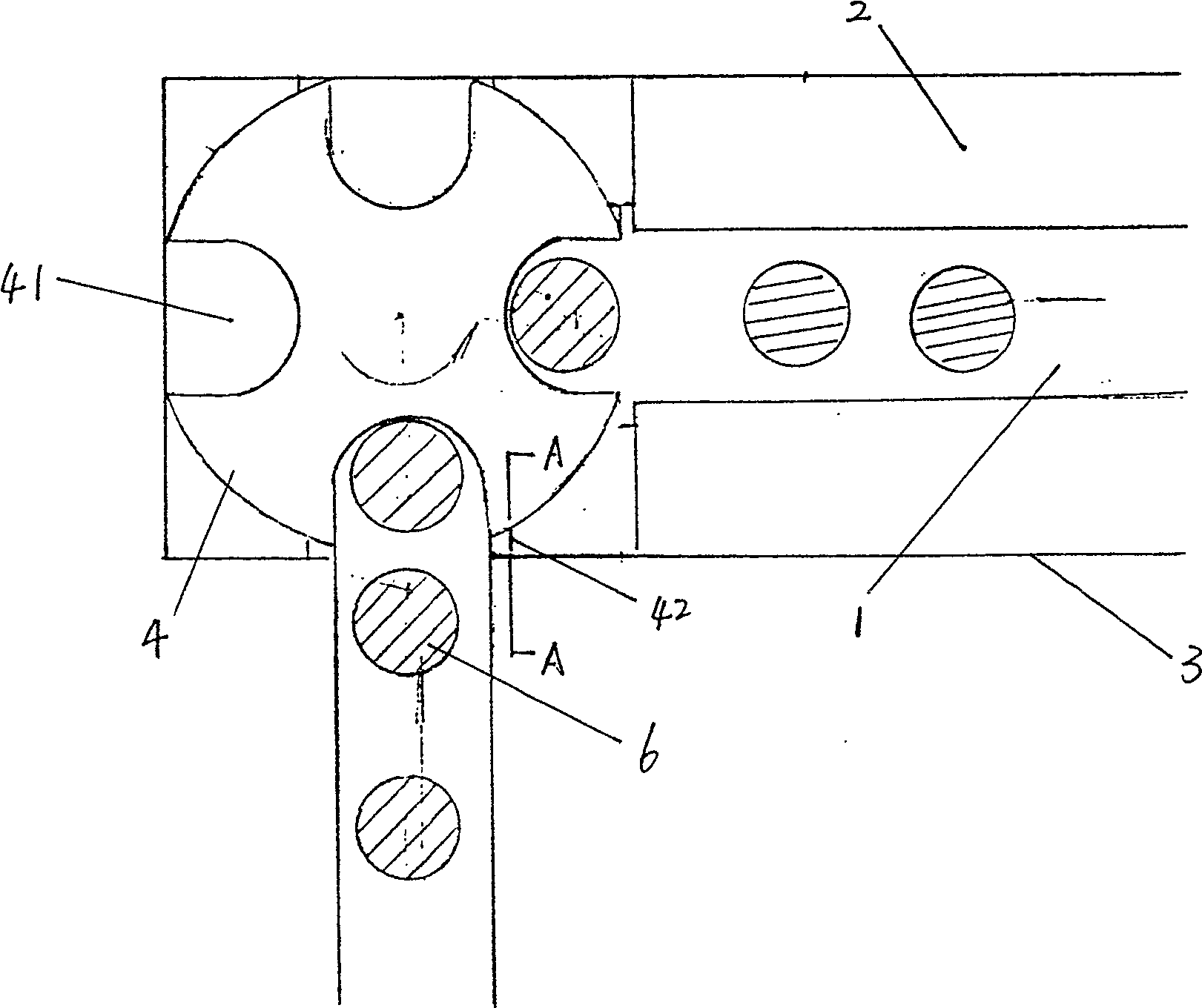

A continuous microwave solid-liquid extraction system

InactiveCN1994511APrevent microwave leakageSystem equipment is compactEnergy based chemical/physical/physico-chemical processesSolid solvent extractionSolventSlag

The invention relates to a continuous microwave solid-liquid extracting system, wherein it comprises a hollow chamber (1) with outside microwave magnetic control tube (4), an extracting room (7), and a solid-liquid transmitter; the transmitter is formed by transmission blade (14), rotation axle (8) an the motor driving axle (8) and speed changer (10) that in the extracting room (7) and connected to the rotation axle (8); the extracting room (7) is incline; the bottom of transmitter has solid inlet (3) and liquid outlet (15); the top has solid slag outlet (12) and solvent medium inlet (5); the extracting room is in the hollow chamber (1); the inlet (3), liquid outlet (15), inlet (5) and slag outlet (12) via chamber (1) are connected to the room (7). Compared with present technique, the invention has high microwave utilization and low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH

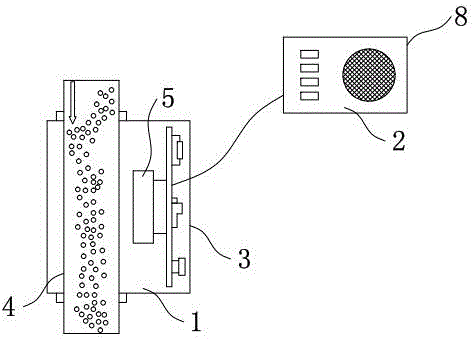

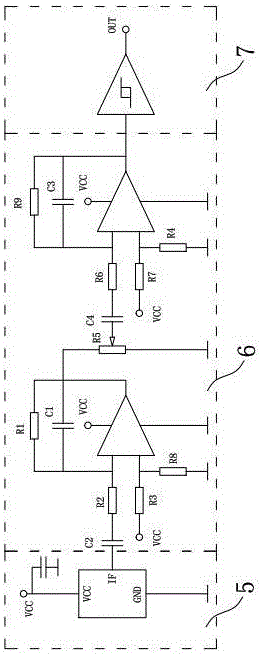

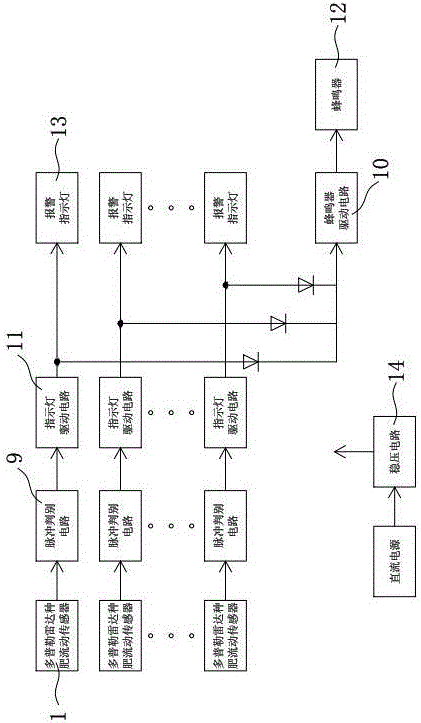

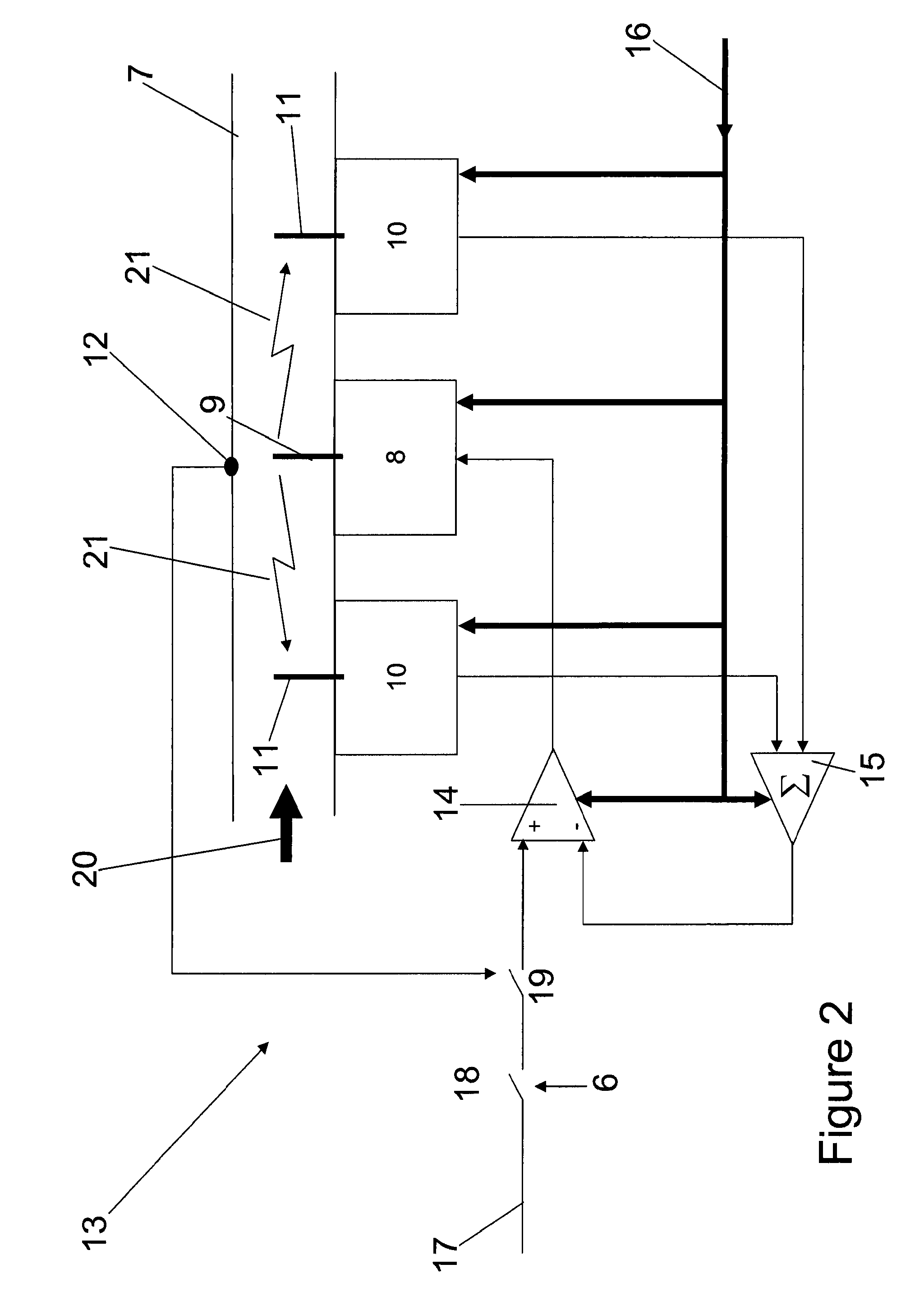

Microwave Doppler radar seed manure flow alarm

InactiveCN106205067AMonitor flowOvercome disadvantagesSpadesFertiliser distributersSchmitt triggerMicrowave

The invention discloses a microwave Doppler radar seed manure flow alarm and relates to a state alarm. The microwave Doppler radar seed manure flow alarm is composed of multiple Doppler radar seed manure flow sensors and an alarm device. Each Doppler radar seed manure flow sensor comprises a metal shell, a through pipe, a Doppler radar sensor, an amplification circuit and a schmitt trigger circuit, wherein the through pipe longitudinally penetrates through the sealed metal shell, the Doppler radar sensor, the amplification circuit and the schmitt trigger circuit are in circuit connection sequentially to form a detection circuit and installed on the inner wall of the metal shell, and the Doppler radar sensor faces the through pipe. The detection circuits in the multiple Doppler radar seed manure flow sensors are connected in parallel and are in circuit connection with the alarm device. By the adoption of the microwave Doppler radar seed manure flow sensors, the flow condition of seeds or manure can be monitored under the non-contact condition, defects of photoelectric seed manure sensors are completely overcome, influences of dust are avoided, and the whole system is reliable in performance and ideal in using effect.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Organic matter dehydration device with microwave drying device

InactiveCN107152839APrevent microwave leakageHeating evenlyDrying solid materials with heatDrying chambers/containersEngineeringMicrowave

The invention discloses an organic matter dehydration device with a microwave drying device, which comprises a base, a bracket, and a box body. A storage dish for holding materials is placed on the top, the storage dish includes an inner shell and an outer shell sleeved outside the inner shell, the side wall of the inner shell is provided with a plurality of air holes, and the top of the outer shell is provided with Convex. The present invention heats and dehydrates the materials in the holding dish through microwaves, the heating is uniform, and the phenomenon of burning outside and burning inside is avoided. The air permeability is strong, which is convenient for water evaporation, and the gas is circulated through the first circulation pipe and the second circulation pipe. The water vapor is condensed through the condensation pipe in the condensation box and discharged from the liquid discharge pipe, avoiding the direct discharge of the gas generated by heating, and protecting the environment.

Owner:LIANGXI XUZHONG GENERAL MACHINERY DESIGN STUDIO

Equipment for industrially producing graphene by microwaves

The invention relates to equipment for industrially producing graphene by microwaves. The equipment comprises a spiral feeder, a furnace tube, a microwave cavity, a material discharging pipe and a product collector, wherein the furnace tube is connected to the microwave cavity in a penetrating manner; the input end of the furnace tube is connected with the spiral feeder; the output end of the furnace tube is connected with the product collector through the material discharging pipe; an inert gas inlet and a compressed air inlet are formed in the input end of the furnace pipe. Graphite is oxidized into oxidized graphite under the action of strong acid and strong oxidant such as H2SO4, HNO3 and HClO4s or is hydrolyzed into oxidized graphite under the electrochemical peroxidation effect; the oxidized graphite is prepared after being subjected to filtering, granulation and the like; inert gas is used for replacing air in the furnace tube; under the inert gas atmosphere, the oxidized graphite is dissociated by the microwaves and is reduced into flocculent graphene easy to fly; the compressed air inlet is opened, and the reduced graphene enters the product collector along with the compressed air and is completely absorbed by water pre-stored in the device; suspension is filtered and dried to be solid powder, so that the production process for the graphene is finished.

Owner:江苏江大环保科技开发有限公司

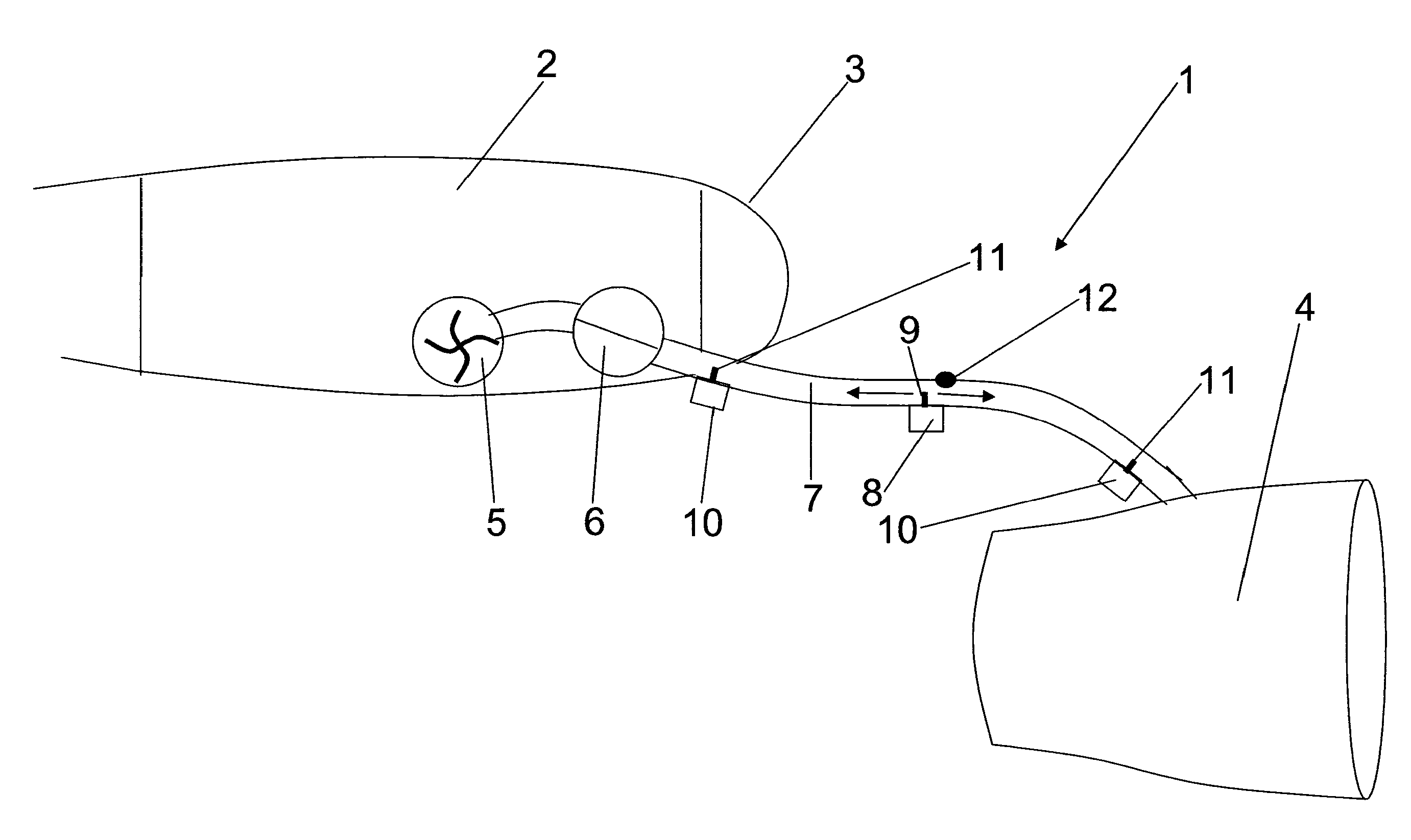

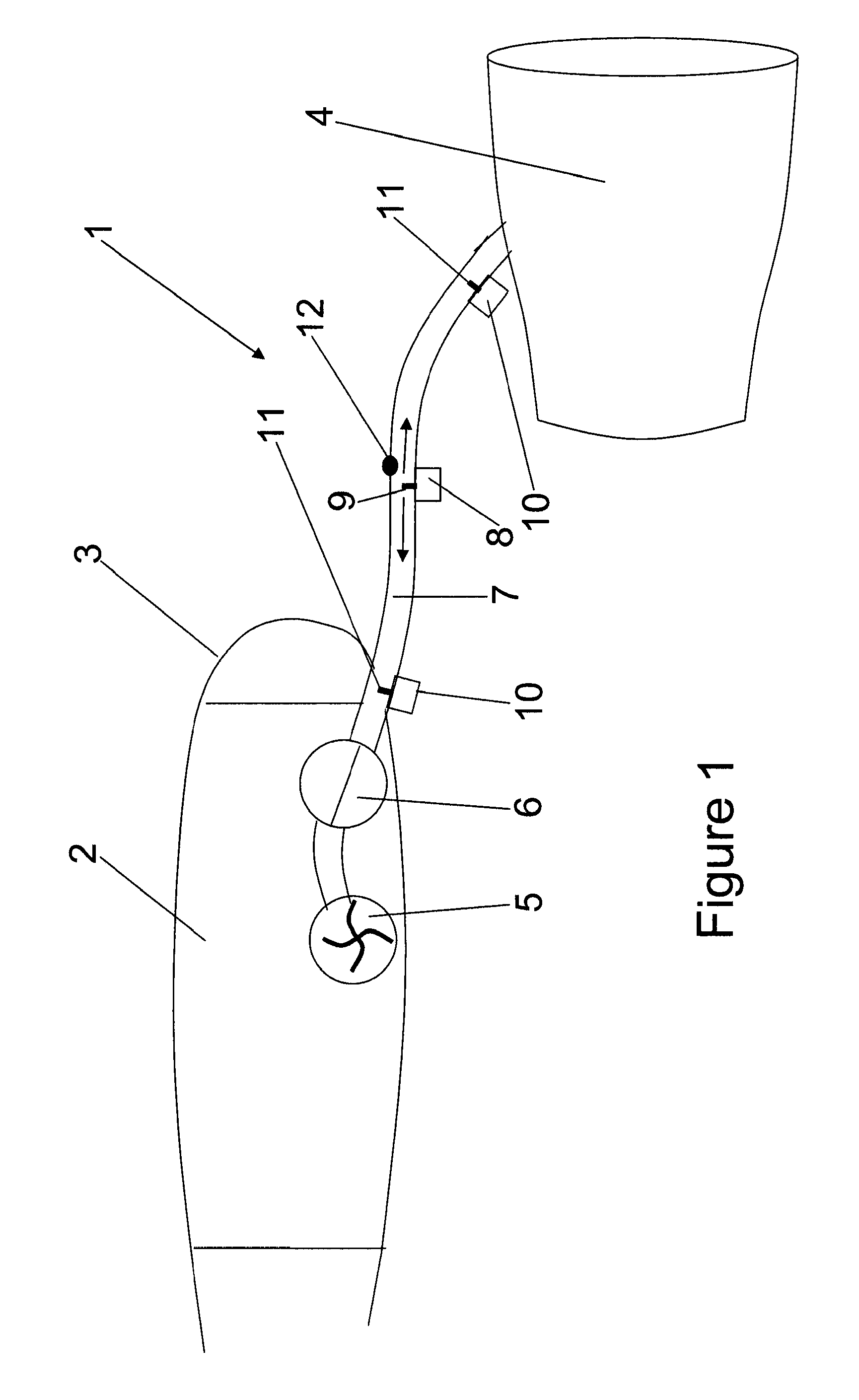

Aircraft fuel system

InactiveUS8876056B2Energy efficiencyMaximize efficiencyPower plant fuel tanksFuel tank safety measuresAircraft fuel systemMicrowave

Owner:AIRBUS OPERATIONS LTD

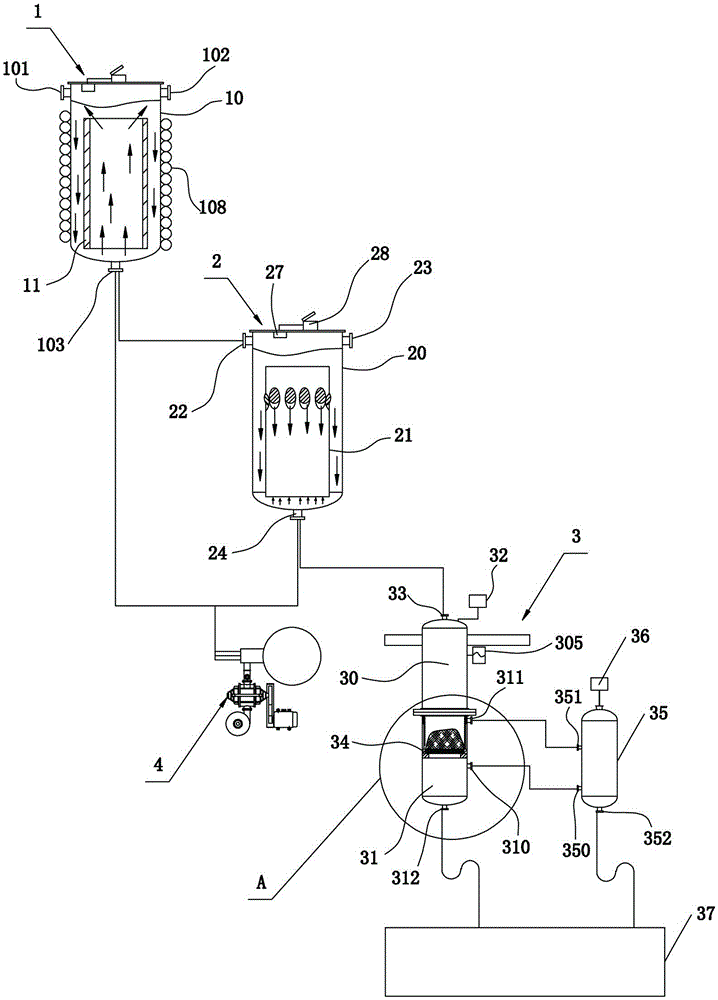

Sludge treatment method improving dehydration efficiency

ActiveCN105366901ASimple processPracticalSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesHeavy metalsMicrowave

A sludge treatment method improving dehydration efficiency includes the following steps of 1, biochemical treatment of heavy metal, 2, dehydration conditioning of sludge, and 3, dehydration drying of the sludge. In the step of dehydration drying of the sludge, the pressure in an upper tank body is increased through a pressurization device, the pressure in a lower tank body is decreased through a vacuum tank till the interior of the lower tank body is in a vacuum state, and thus a large pressure difference is formed between the upper tank body and the lower tank body; water in water-containing sludge mixed liquid in the upper tank body can pass through a filter layer quickly, the sludge remains on the filter layer, and quick solid-liquid separation is guaranteed due to the fact that the pressure difference can be formed between the upper tank body and the lower tank body; after solid-liquid separation is finished, a microwave emitting device is started to release microwaves, and the microwaves interact with water molecules in the sludge to heat the water molecules, so that the water molecules in the sludge disperse and volatilize into the air, and the effect of drying the sludge is achieved.

Owner:JINJIANG SHILONG KITCHEN EQUIP CO LTD

Fully-closed industrial microwave high-temperature roller continuous sintering kiln

InactiveCN102042749BConsistent shrinkageGood size consistencyMaintainance of heating chambersFurnace typesHearthEngineering

The invention discloses a closed microwave high-temperature sintering roller kiln, in particular a tunnel roller kiln with length of 10 to 50meters, and hearth sectional area of 0.06 to 0.3m<2>. The kiln comprises a main kiln body, a microwave transmission system, a turning channel mechanism, a roller power system, and a kiln door interlocking opening and closing system; the main kiln body is formed by connecting a water draining section, a preheating section, a sintering section, a heat preservation section, a quick cooling section, and a slow cooling section in turn; the turning channel mechanism is mainly formed by a material loading and unloading section and a residual-heat utilization blank drying section and comprises a turning channel, a turning channel roller, and a power system; the power system can poke a pushing plate from the outlet of the main kiln body onto the turning channel and feed the pushing plate into the inlet of the main kiln body through the residual-heat utilization blank drying section; and an inner roller for transmitting the material pushing plate, which is driven by the roller power system, is arranged on the bottom of an inner cavity of the main kiln body. The closed microwave high-temperature sintering roller kiln saves energy and reduces consumption and is environmental-friendly, the shrinkage of the sintered products is consistent and the sintered products have high size consistency, the yield is high, the production efficiency is high and the production cost is low.

Owner:湖南航天有限责任公司

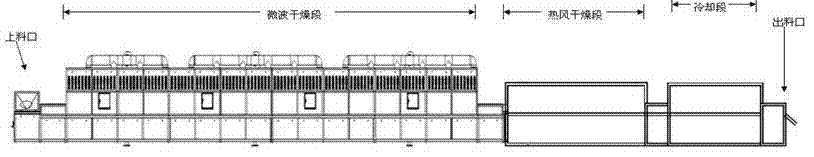

Drying process of sulfonate

ActiveCN103712420AThe lines are neatly arrangedClearly markedDrying solid materials with heatHearth type furnacesWater contentChemistry

The invention discloses a drying process of sulfonate. The drying process of the sulfonate comprises the following steps: (1) uniformly distributing paste sulfonate with an active matter in a concentration of 37-65% and water in a content of 63-35% on a conveying belt to enter a microwave dryer and obtain sulfonate with water in a content of 5-10% in a microwave drying stage; (2) feeding the sulfonate with water in the content of 5-10% into a hot air dryer to obtain sulfonate with water in a content of less than or equal to 1% in a hot air drying stage; and (3) obtaining slice sulfonate with the water in the content of less than or equal to 1% in a cold air cooling state. Water molecules in a material vibrate with a high frequency directionally and rub against each other, so that the overall material forms a radiation body; microwave directly acts on the water molecules, so that conduction loss is avoided, the drying time is short and only lasts for several minutes or dozens of minutes; the microwave directly acts on the water molecules, so that temperature is easily controlled; the microwave transmits and heats selectively; the drying is uniform; quality of the material can be improved; and energy utilization rate is high.

Owner:安阳市兴亚洗涤用品有限责任公司

Visible microwave dryer

InactiveCN103673575AQuality assurancePrevent microwave leakageDrying solid materialsEngineeringMicrowave

The invention discloses a visible microwave dryer which comprises a dryer case, a microwave generator, a drying disc, a microwave control system, LEDs, a camera, a temperature sensor, a remote control device and a remote display device. Metal protective nets are arranged on the outer surface of the temperature sensor and the outer surface of a camera body, the LEDs are arranged downwards obliquely at one upper corner inside the dryer case, and mirror surfaces are arranged in the dryer case. Compared with the prior art, the visible microwave dryer is clear in image frame, convenient to use and practical.

Owner:南京研正微波设备厂

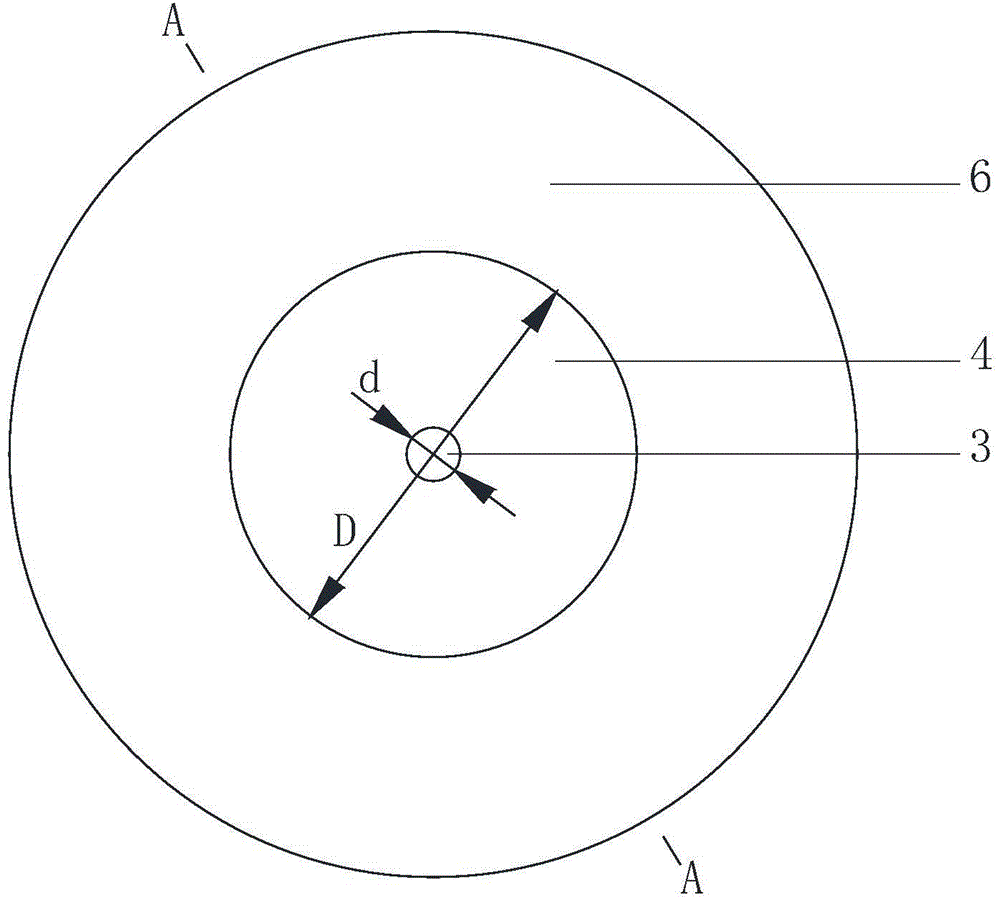

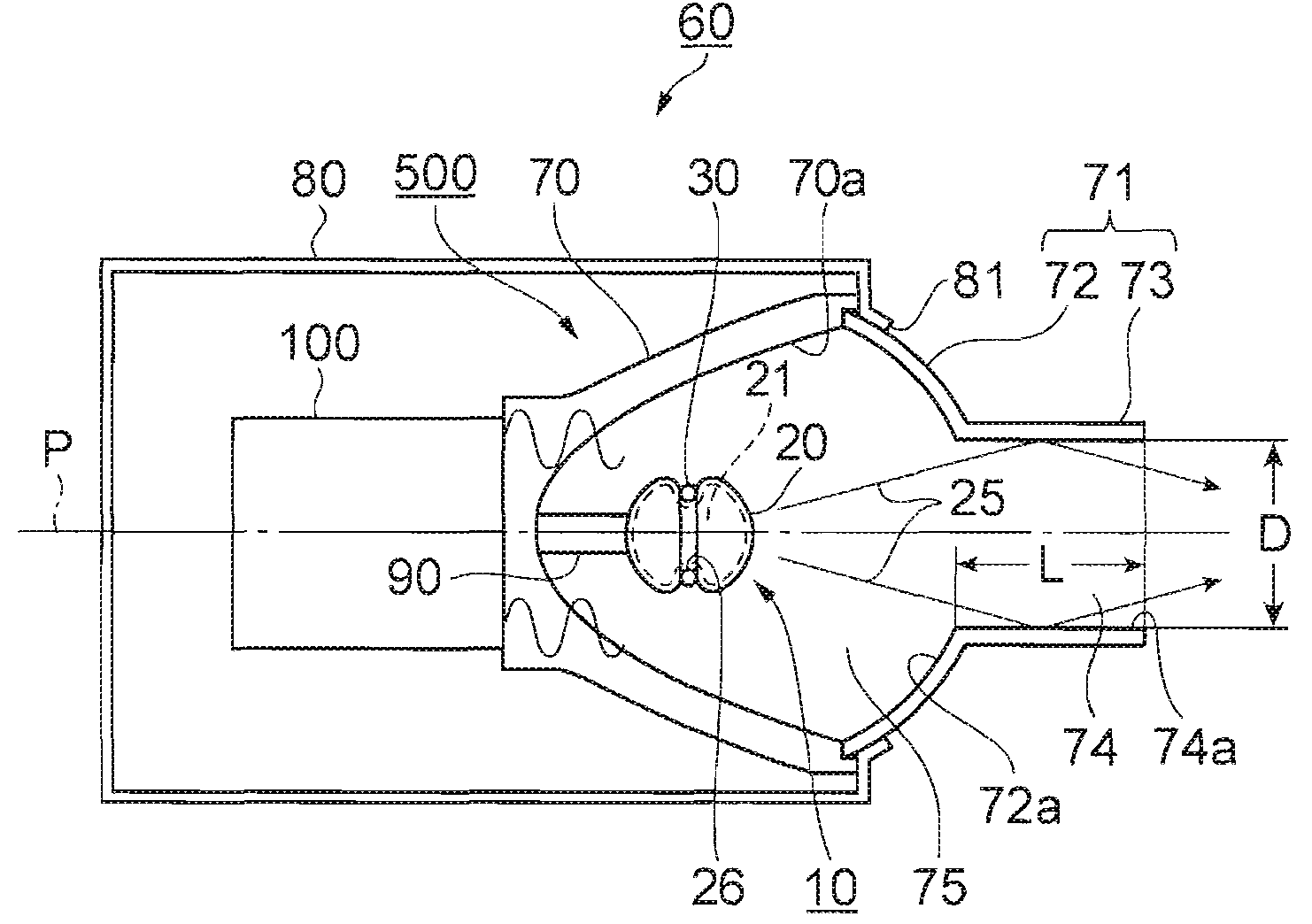

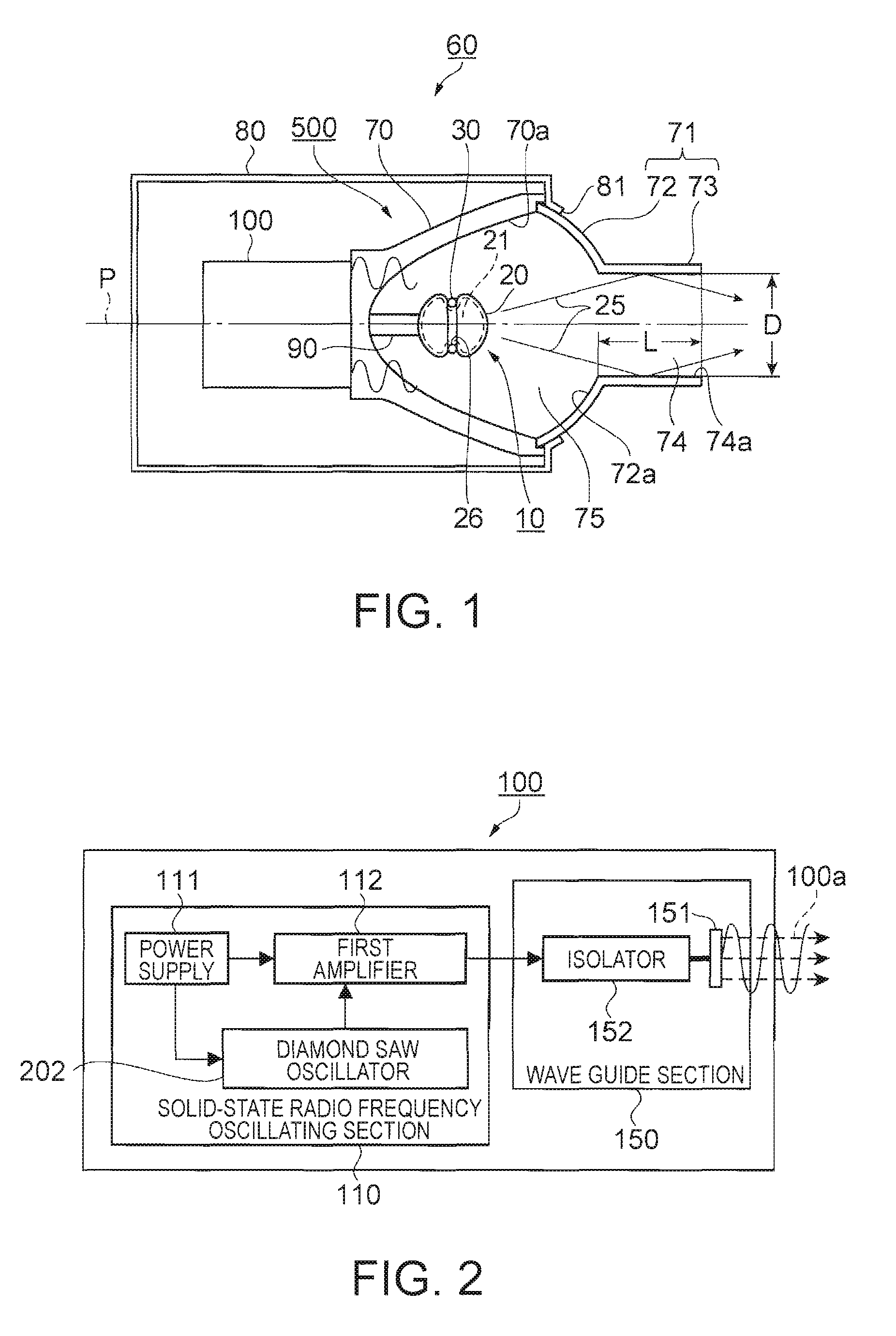

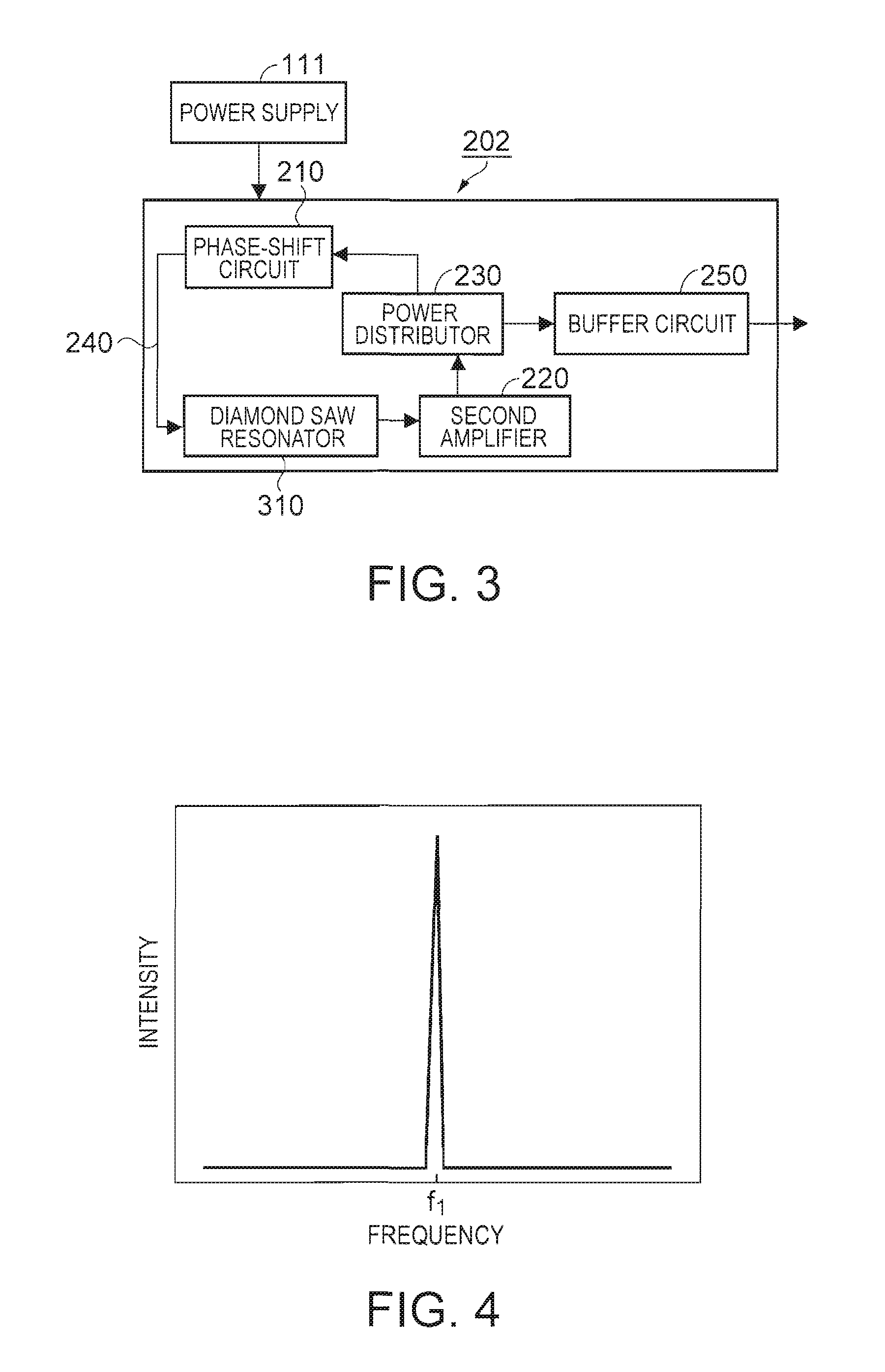

Light source device and projector

InactiveUS20080186457A1Improve lighting efficiencyPrevent microwave leakagePoint-like light sourceProjectorsLuminous fluxMicrowave

A light source device includes a microwave generating section for generating a microwave, a reflector connected to the microwave generating section, and a microwave electrodeless lamp disposed inside a cavity, the cavity including the reflector and a metallic chamber covering an opening section of the reflector. The chamber includes a tube member having an opening section for communicating the inside and the outside of the cavity to lead a light flux out of the chamber, and a bore diameter, D of the opening section, a length L of the tube member, a wavelength λ of the microwave, and a wavelength Λ of the light flux satisfy Λ<D≦(¼)λ, L≧(¼) λ, and D+L=(½)λ.

Owner:SEIKO EPSON CORP

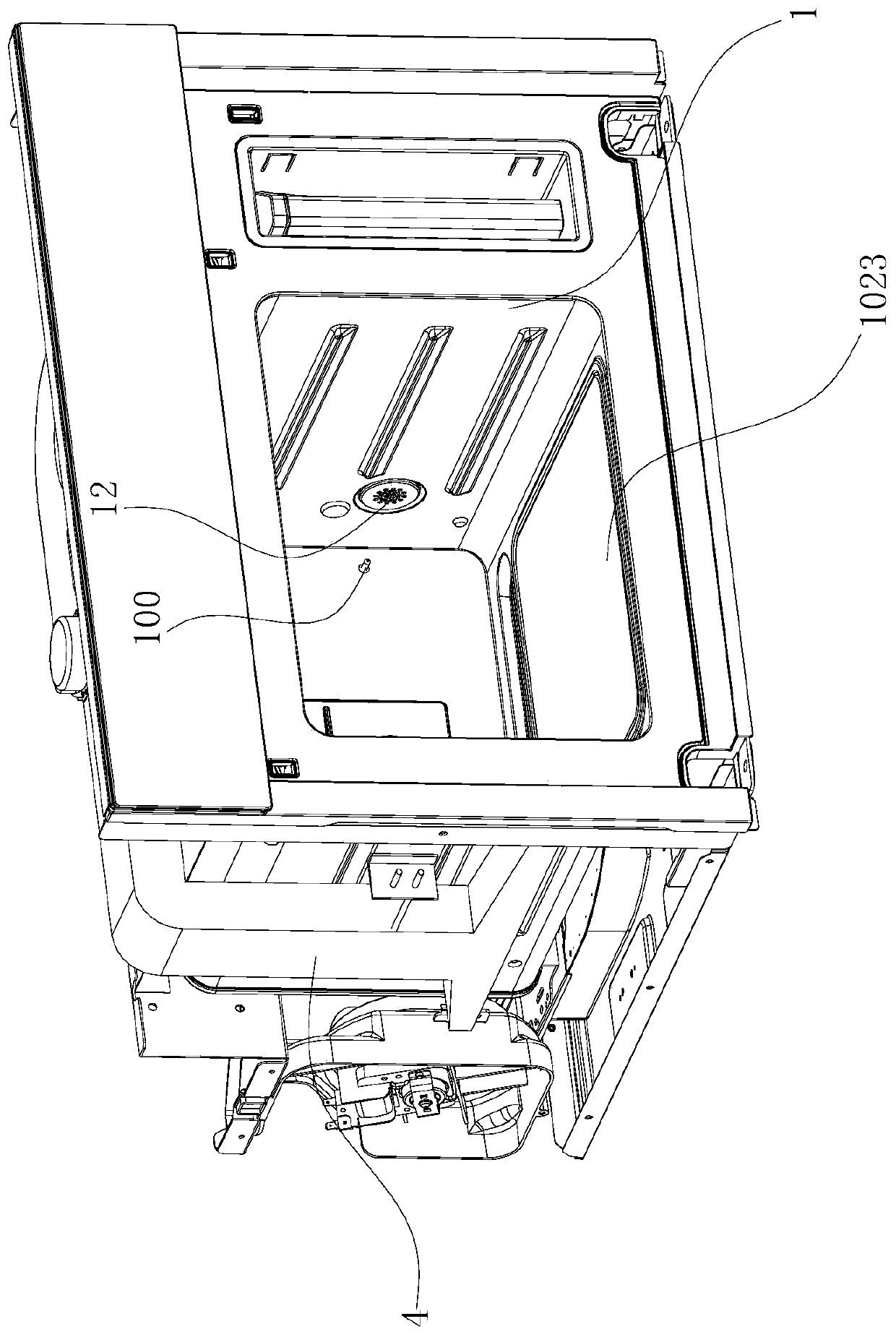

Steam-microwave all-in-one machine

ActiveCN110840233AIncrease temperatureImprove exhaust efficiencyDomestic stoves or rangesLighting and heating apparatusThermodynamicsEngineering

The invention relates to a steam-microwave all-in-one machine. The steam-microwave all-in-one machine comprises a liner, wherein microcrystalline glass is arranged on the inner bottom surface of the liner; an exhaust channel with an exhaust fan is arranged above the liner; an auxiliary air outlet capable of being opened and closed is formed in the side wall of the exhaust channel; air outlet holesis formed in the side wall of the liner; the auxiliary air outlet is communicated with the air outlet holes through an airflow channel; and a heating device is arranged in the airflow channel. According to the all-in-one machine, the drying effect on condensed water on the microcrystalline glass by the air from the air outlet holes can be improved by virtue of the auxiliary air outlet, the airflow channel and the air outlet holes; in addition, the water vapor in the airflow can be removed by heating, so that the drying effect on the microcrystalline glass can be further improved, and the steam in the liner can be promoted to be exhausted out of the exhaust channel under the action of the exhaust fan. In addition, the auxiliary air outlet is connected with the air outlet holes through theairflow channel, and meanwhile, the heating device is arranged in the airflow channel, so that the problems of microwave leakage and steam leakage can be effectively avoided.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Assembly process of die assembly

ActiveCN112242282AImprove yield rateHighly corporatedTube/lamp vessels exhaustionElectrode assembly manufactureMagnetic polesMechanical engineering

The invention provides an assembly process of adie assembly. The assembly process comprises the following steps of S1, assembling, namely assembling a cathode assembly, assembling an anode assembly and assembling an exhaust pipe assembly; S2, assembling the die assembly, namely assembling the assembled cathode assembly, anode assembly and exhaust pipe assembly together to form the die assembly; and S3, assembling the die assembly and other assemblies to obtain a magnetron finished product, wherein the assembly of the die assembly comprises pressing a magnetic pole K side, connecting the anodeassembly and the magnetic pole K side and then pressing; pressing the cathode, and assembling the cathode assembly and the anode assembly together; after the cathode is pressing, assembling the anodeassembly and the exhaust pipe assembly together to form the die assembly, and welding overall; carrying out leak detection and exhaust operations on the die assembly, removing an oxide layer of the anode assembly, and installing an antenna cap; deburring and aging. The assembled die assembly has the advantages of no damage to each component, high yield, no crack, no leakage hole, and tight weldingbetween the assemblies.

Owner:GUANGDONG GALANZ MICROWAVE OVEN & ELECTRICAL APPLIANCES MFG +1

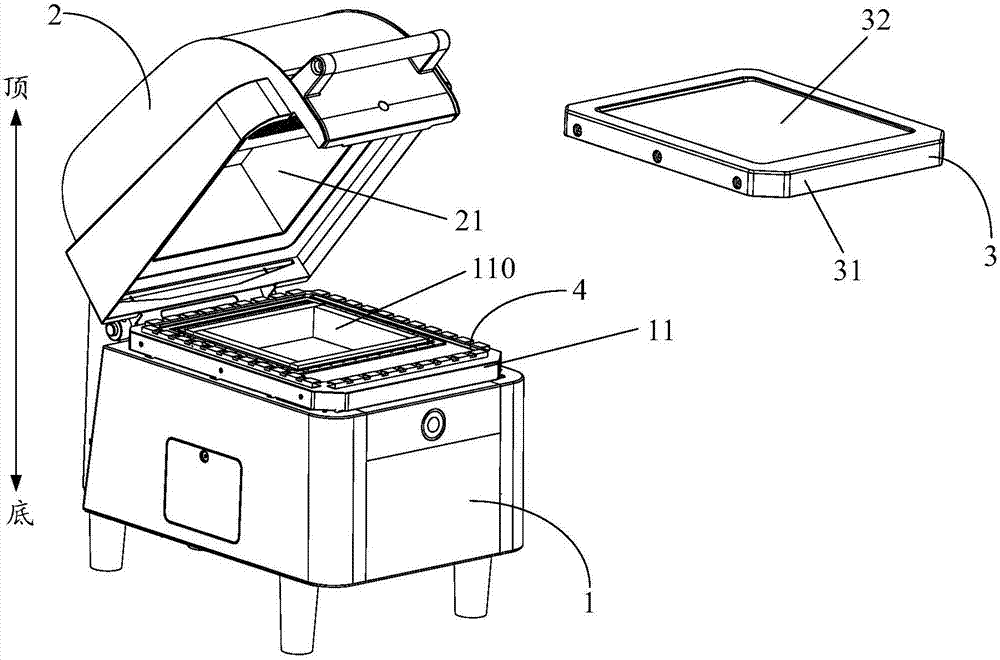

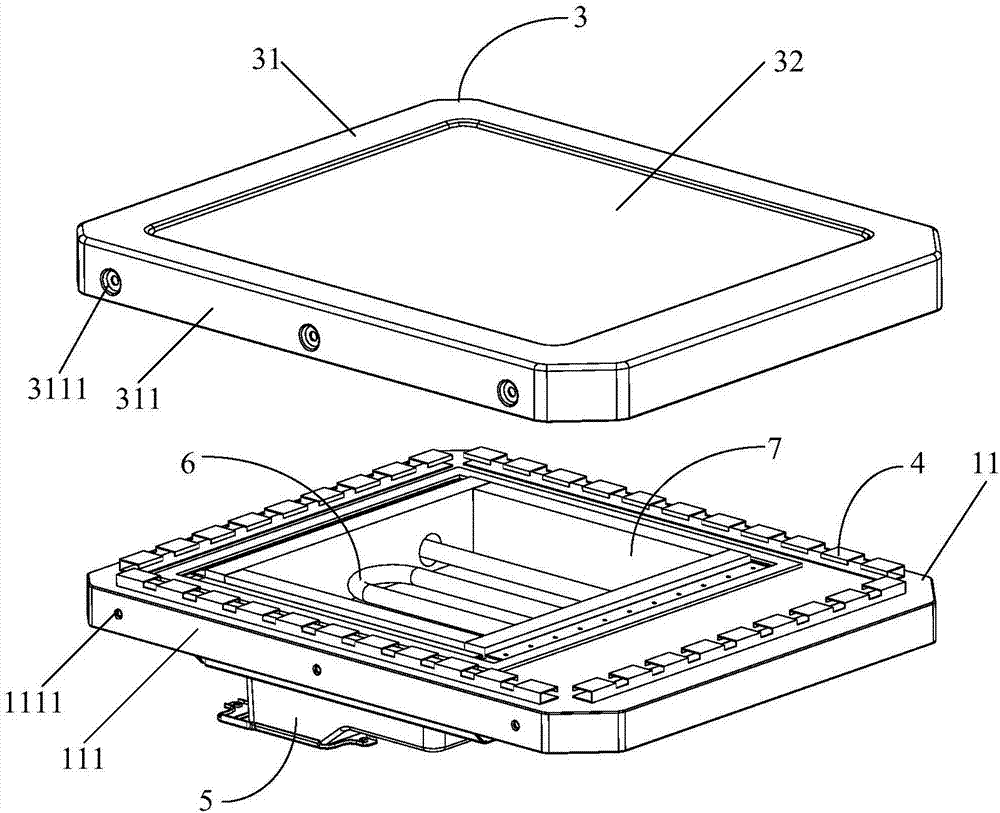

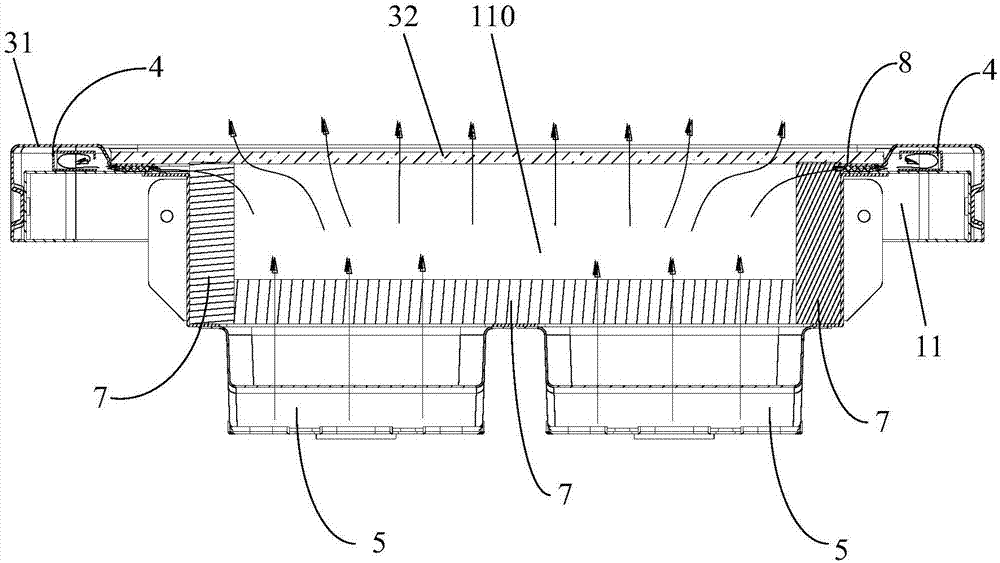

Cooking device

PendingCN106974560AEasy maintenanceShort timeBaking vesselsRoasters/grillsPhysicsMicrowave shielding

The invention provides a cooking device. The cooking device comprises a base and a furnace door hinged to the base, and further comprises a cooking platform and a microwave shielding piece, the cooking platform comprises a border and an object loading plate installed on the border, the object loading plate is made from a non-microwave shielding material, the border is detachably installed on a top plate of the base, an abutting support surface is formed between the lower surface of the border and the upper surface of the top plate, the bottom of the top plate is provided with a magnetron, the magnetron is used for transmitting microwaves to the object loading plate from the inner side of the support surface, and the microwave shielding piece is installed on the top plate, is surrounded at the outer side of the support surface, and is used for shielding microwaves leaked from the position of the support surface. In the cooking device, the object loading plate and the top plate of the base adopt separated type design, the object loading plate is detachably installed on the top plate of the base through the border, so that the object loading plate is convenient to replace, moreover, the top plate of the base is provided with the microwave shielding piece, and the microwave shielding piece is surrounded at the outer side of the support surface between the border and the top plate of the base to prevent microwave leakage.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Wall type micro-wave apparatus for drying and sterilizing towels

InactiveCN101002955APrevent microwave leakageGood heat utilizationDrying using combination processesDrying solid materials with heatAutomatic controlChemical residue

A wall-type microwave baking and sterilizing machine for towels is composed of a casing with a control panel, a microwave heater consisting of magnetron and wave guide tube and with an oblique open top, a microwave sucking cavity in said oblique open top, several towel hangers, and a temp controller.

Owner:王宝根

Laminating machine

ActiveCN103434329BDry evenlyImprove mildew resistanceMechanical working/deformationPaperhangingWater vaporPaperboard

The invention discloses a paper mounting machine, belonging to the technical field of packaging mechanical equipment. The paper mounting machine comprises a surface paper conveying device and a bottom paper conveying device, wherein the bottom paper conveying device is connected to a bottom paper gluing device, an output mechanism and a laminating device are sequentially arranged at the lower part of the bottom paper gluing device, the laminating device comprises a plurality of upper carrier rollers and lower carrier rollers which are arranged on a frame, laminating belts surround the upper carrier rollers, and conveying belts driven by a power device are arranged on the lower carrier rollers; a sealing cover is arranged on the periphery of the rack, and a heating element is arranged in the sealing cover; and a suction pipe communicated with the inner part of the sealing cover is arranged on the top of the sealing cover and is connected to a suction fan. The paper mounting machine has the advantages that water molecules inside paperboards are rapidly heated and discharged by using a heat source generated by the heating element in the processes of forwards pressing, flattening and transporting the paperboards by using the laminating belts and the conveying belts, water vapor is discharged through the suction fan and the suction pipe, the online rapid and uniform drying is realized, the curing time of glue is reduced, the anti-mildew capacity of the paper boards is improved, the defect of easiness in bending and deformation is overcome, and the strength and the manufacturing efficiency of the paper boards are improved.

Owner:SHANDONG CENTURY MACHINERY

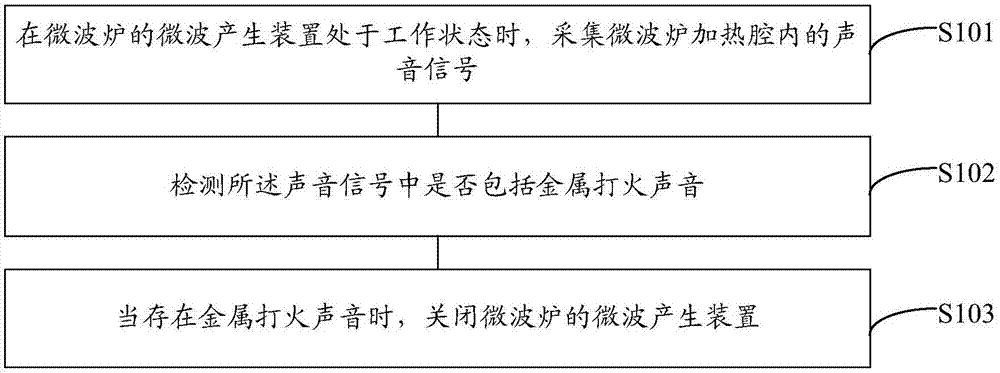

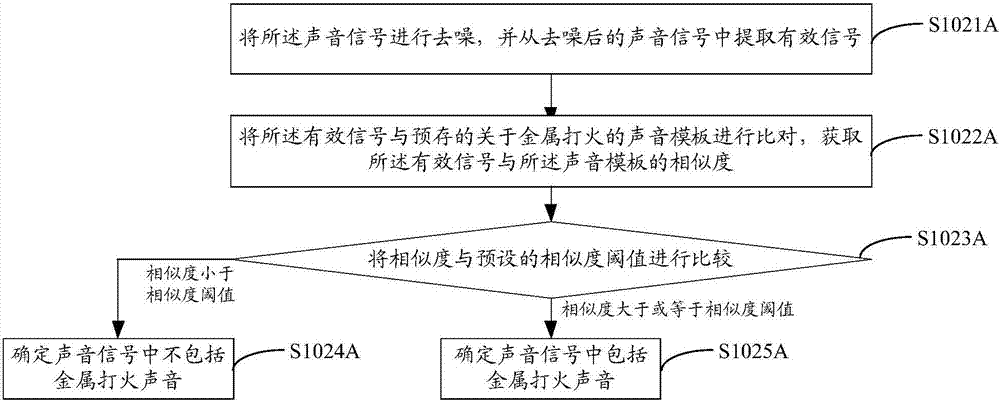

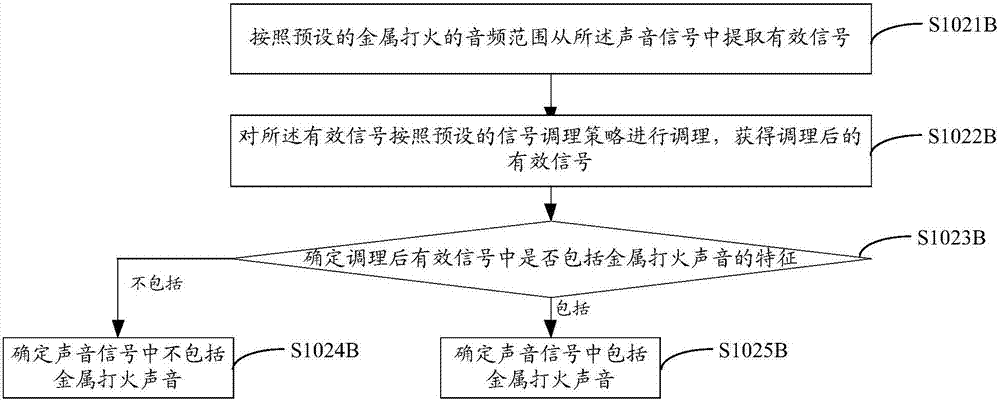

Detection method and microwave oven

InactiveCN106879097APrevent microwave leakageSimple structureMicrowave heatingMicrowave ovenEngineering

The invention provides a detection method and a microwave oven. The method comprises the steps that a sound signal in the heating chamber of the microwave oven is acquired when the microwave generating device of the microwave oven is in a working state; whether the sound signal includes a metal ignition sound is detected; and when the metal ignition sound exists, the microwave generating device of the microwave oven is turned off. A metal utensil is detected without drilling in the heating chamber. Microwave leakage is avoided. The microwave oven has the advantages of simple structure, low cost and high integration.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Production method using microwaves to melt aluminum silicate minerals and microwave equipment

ActiveCN109896529ASolve the problem of energy consumptionFix security issuesAluminium silicatesMicrowave heatingMicrowaveAluminum silicate

The invention belongs to a production method using microwaves to melt aluminum silicate minerals and microwave equipment. The production method has the advantages that the aluminum silicate minerals are calcined, crushed, powdered and pelletized and then molten in the microwave equipment, the problem that traditional aluminum silicate mineral melting is high in energy consumption and potential safety hazard is solved, production efficiency is increased, and energy consumption is lowered by more than 30%. The microwave equipment has the advantages that based on the production method, the feed inlet of the microwave equipment is adjusted, a microwave damping spiral feeder is used, and efficient feeding is achieved while radiation harm, caused by microwave leakage, to human bodies is prevented by microwave damping; the material of a furnace discharge outlet is regulated to guarantee the service life of the microwave equipment and the continuity of aluminum silicate mineral microwave melting.

Owner:唐山顺浩环保科技有限公司

Microwave sterilizing device for sterilization in high performance under low temperature and normal pressure

InactiveCN100525656CEffective sterilizationHigh strengthFood preservationPackage sterilisationProcess engineeringMicrowave irradiation

A microwave sterilizing machine able to kill bacteria at low temp under ordinary pressure is composed of machine frame, conveying belt, microwave sterilizing region divided into several individual microwave irradiating chambers with individual microwave generator by metallic bulkheads, and material feeding and discharging units with anti-leakage mechanism for preventing microwave leakage.

Owner:王承辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com