Sludge treatment method improving dehydration efficiency

A technology for sludge treatment and sludge, which is applied in dehydration/drying/concentrated sludge treatment, sludge treatment, water/sludge/sewage treatment, etc. It can solve the problems of low dehydration efficiency, low sewage dehydration rate, and difficult treatment of filter residues Utilize and other problems to achieve the effect of strong practicability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

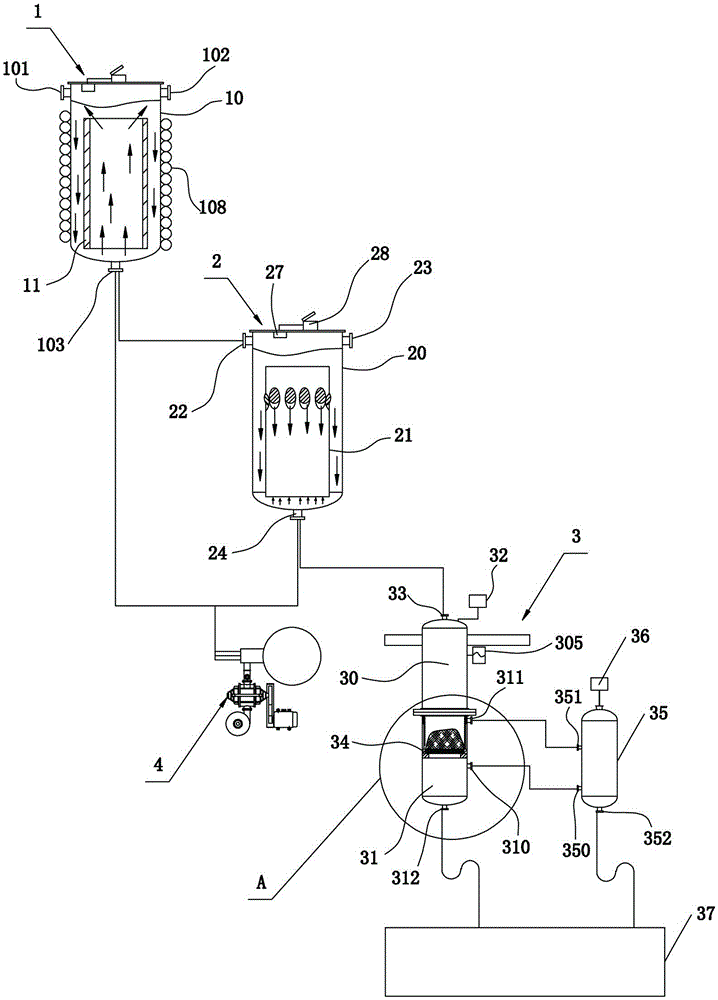

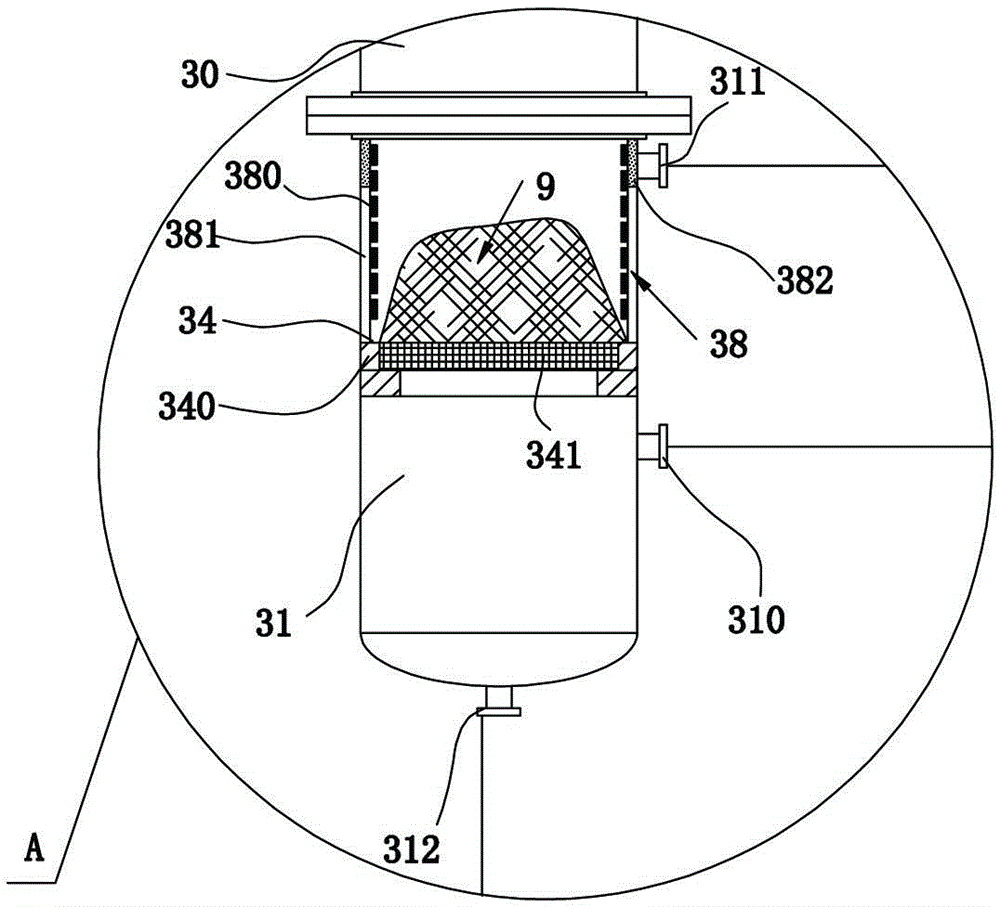

[0023] refer tofigure 1 and figure 2 . A sludge treatment device comprises a sludge heavy metal biochemical treatment tank 1 , a sludge dehydration conditioning tank 2 and a sludge dehydration drying tank 3 into which sludge 9 is sequentially fed.

[0024] refer to figure 1 and figure 2 . The sludge heavy metal biochemical treatment tank 1 includes a first tank body 10, a first drainage cover 11 arranged inside the first tank body 10, and a blower mechanism 4, and the first tank body 10 is provided with a A first feeding port 101 for putting in sludge raw materials containing heavy metals, a first feeding port 102 for putting in a nutrient solution containing thiobacterium oxidans, and a first vent 103 communicated with the blower mechanism 4, so The first vent 103 is located at the bottom of the first tank body 10, and the first drainage cover 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com