Patents

Literature

853results about How to "Discharge fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

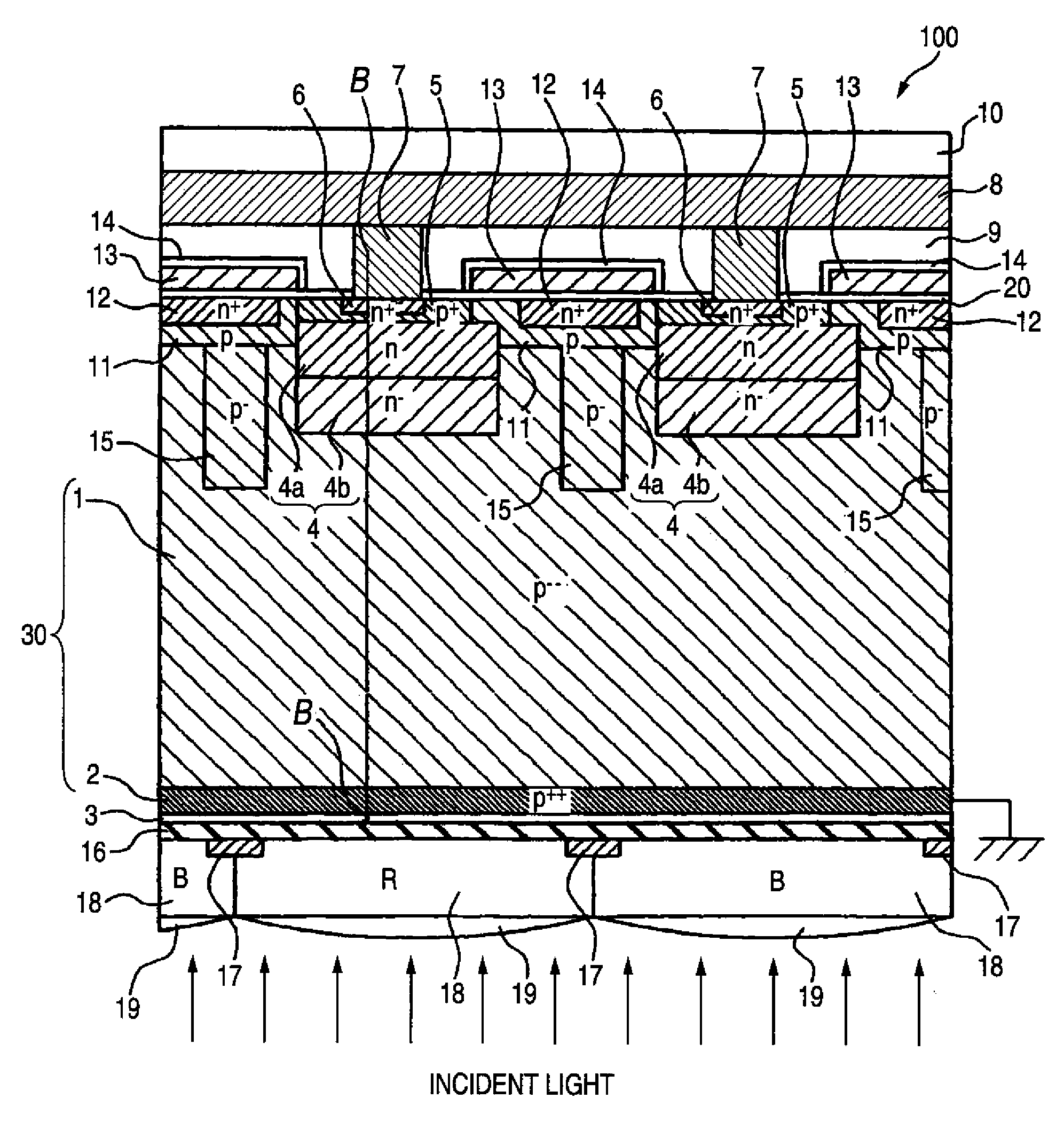

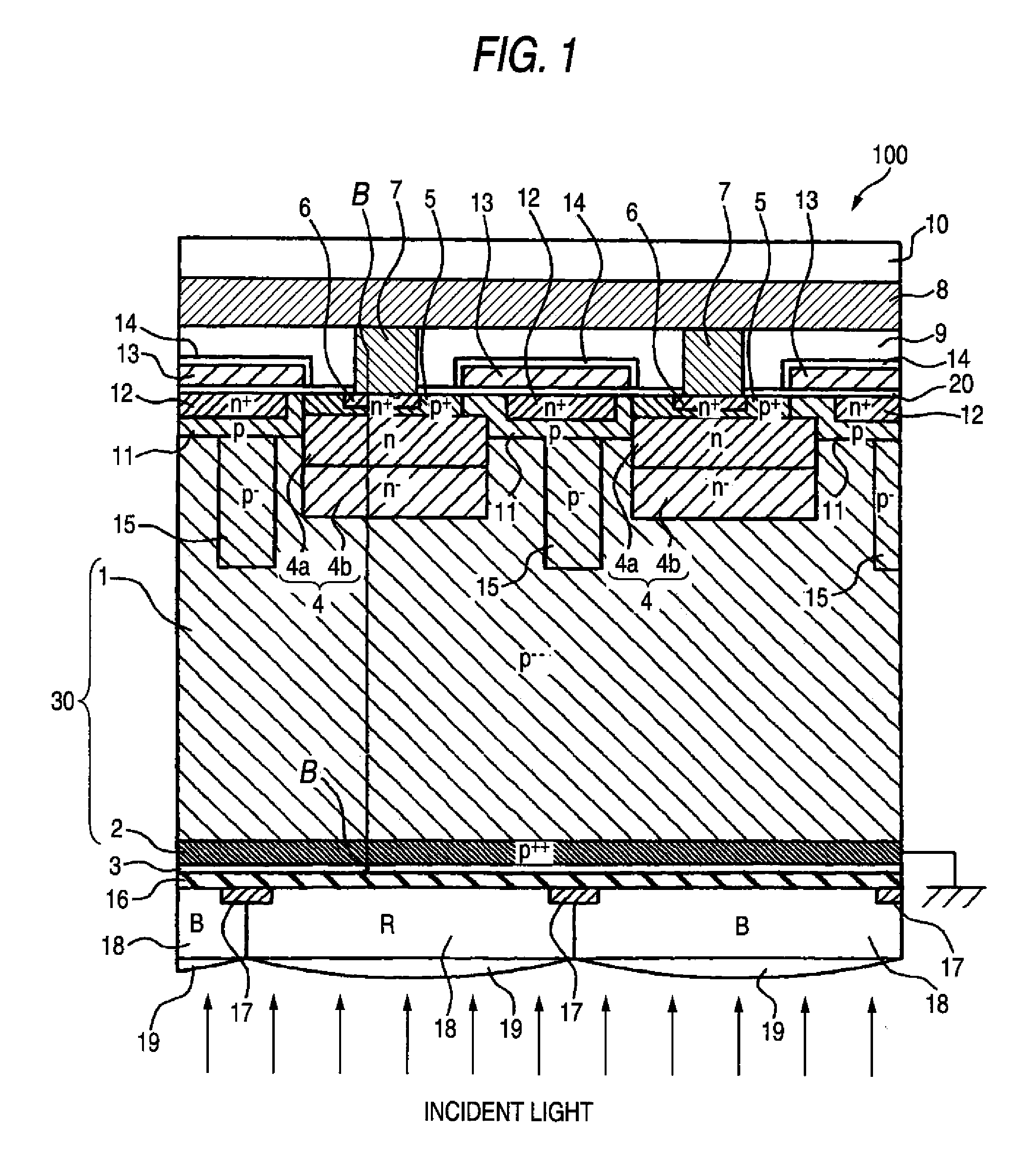

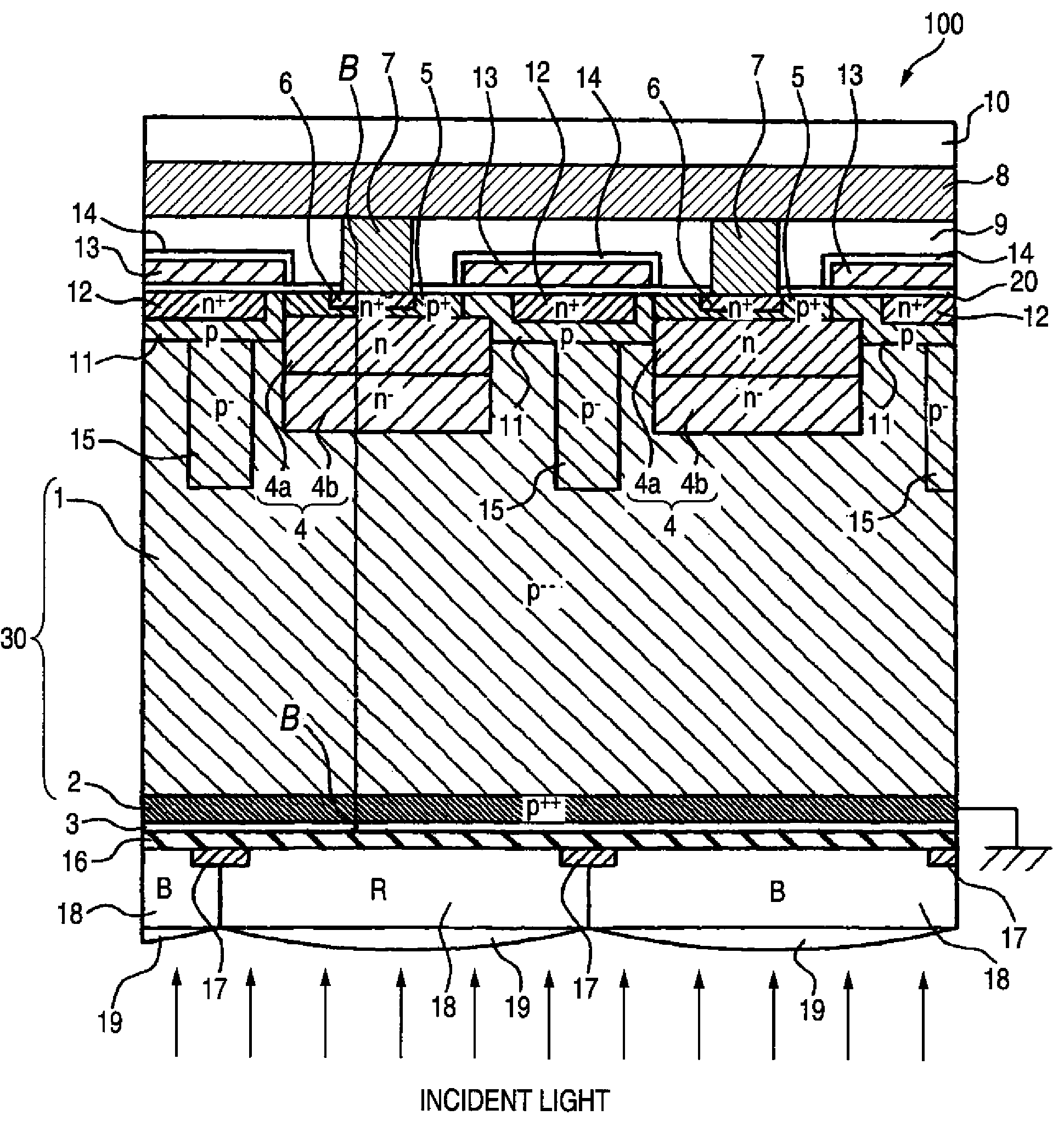

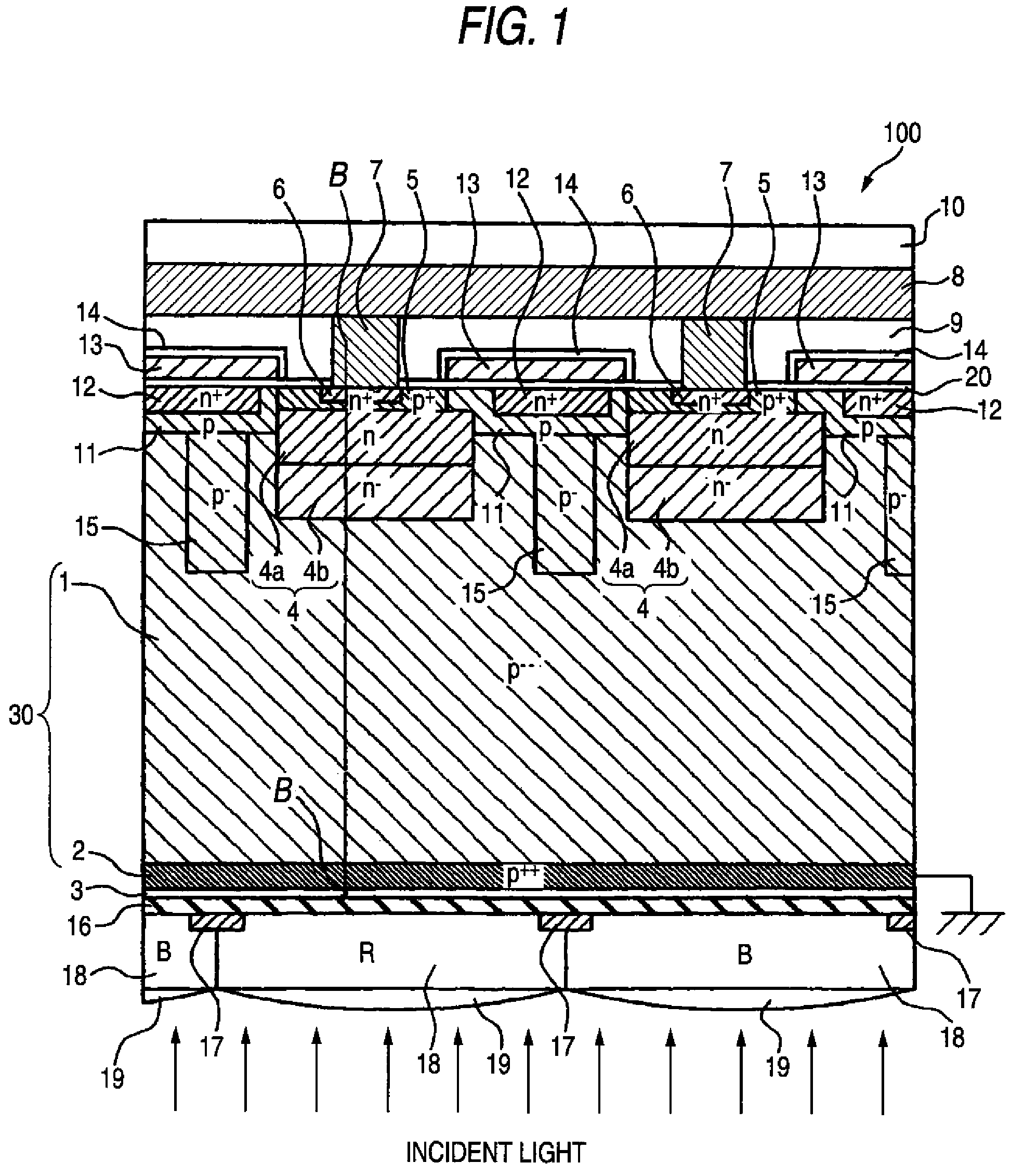

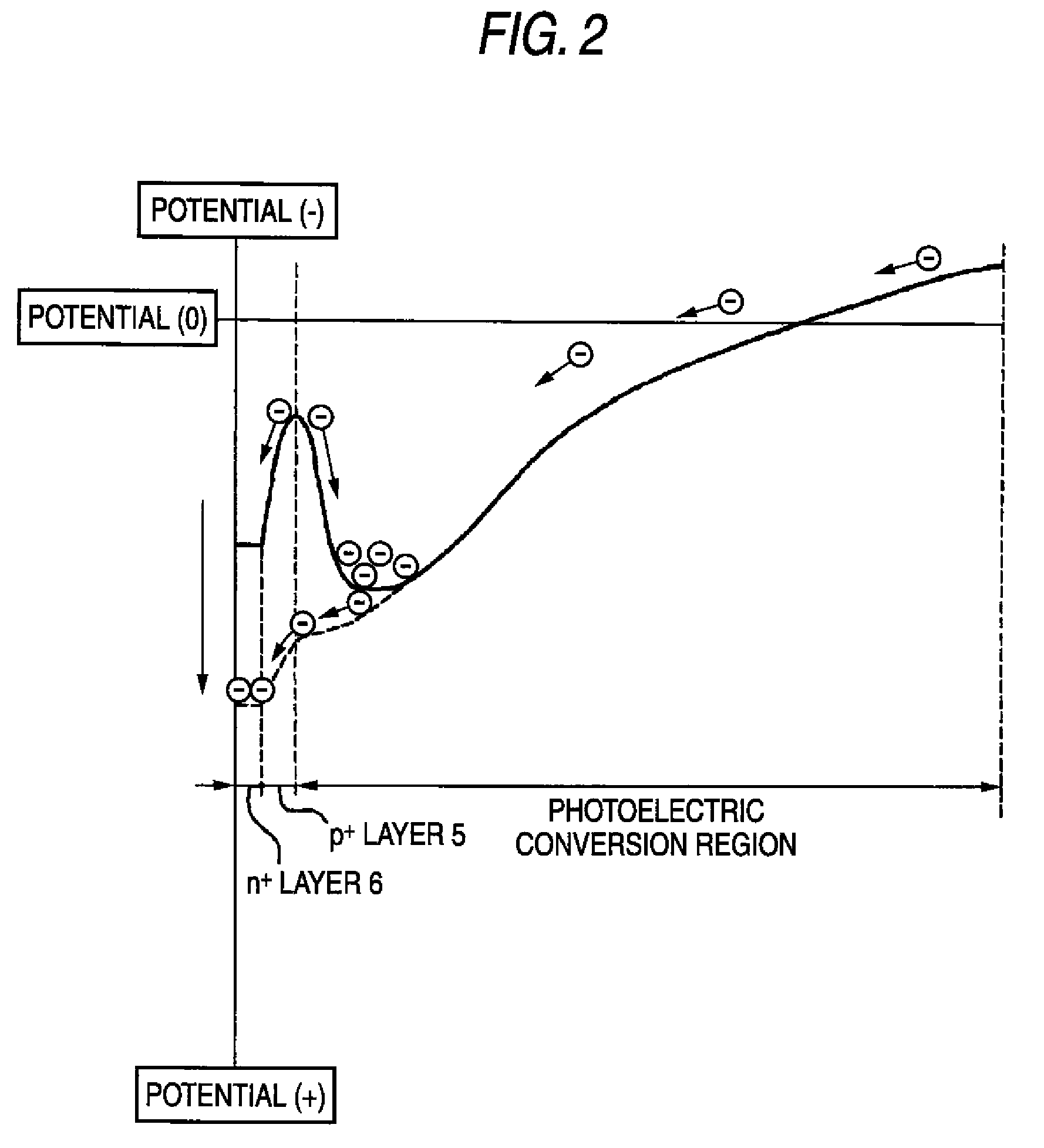

Backside illuminated imaging device, semiconductor substrate, imaging apparatus and method for manufacturing backside illuminated imaging device

InactiveUS20080283726A1High-quality image pickupStabilize gettering capabilitySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorElectrode

A backside illuminated imaging device performs imaging by illuminating light from a back side of a p substrate to generate electric charges in the substrate based on the light and reading out the electric charges from a front side of the substrate. The device includes n layers located in the substrate and on an identical plane near a front side surface of the substrate and accumulating the electric charges; n+ layers between the respective n layers and the front side of the substrate, the n+ layers having an exposed surface exposed on the front side surface of the substrate and functioning as overflow drains for discharging unnecessary electric charges accumulated in the n layers; p+ layers between the respective n+ layers and the n layers and functioning as overflow barriers of the overflow drains; and an electrode connected to the exposed surface of each of the n+ layers.

Owner:FUJIFILM CORP

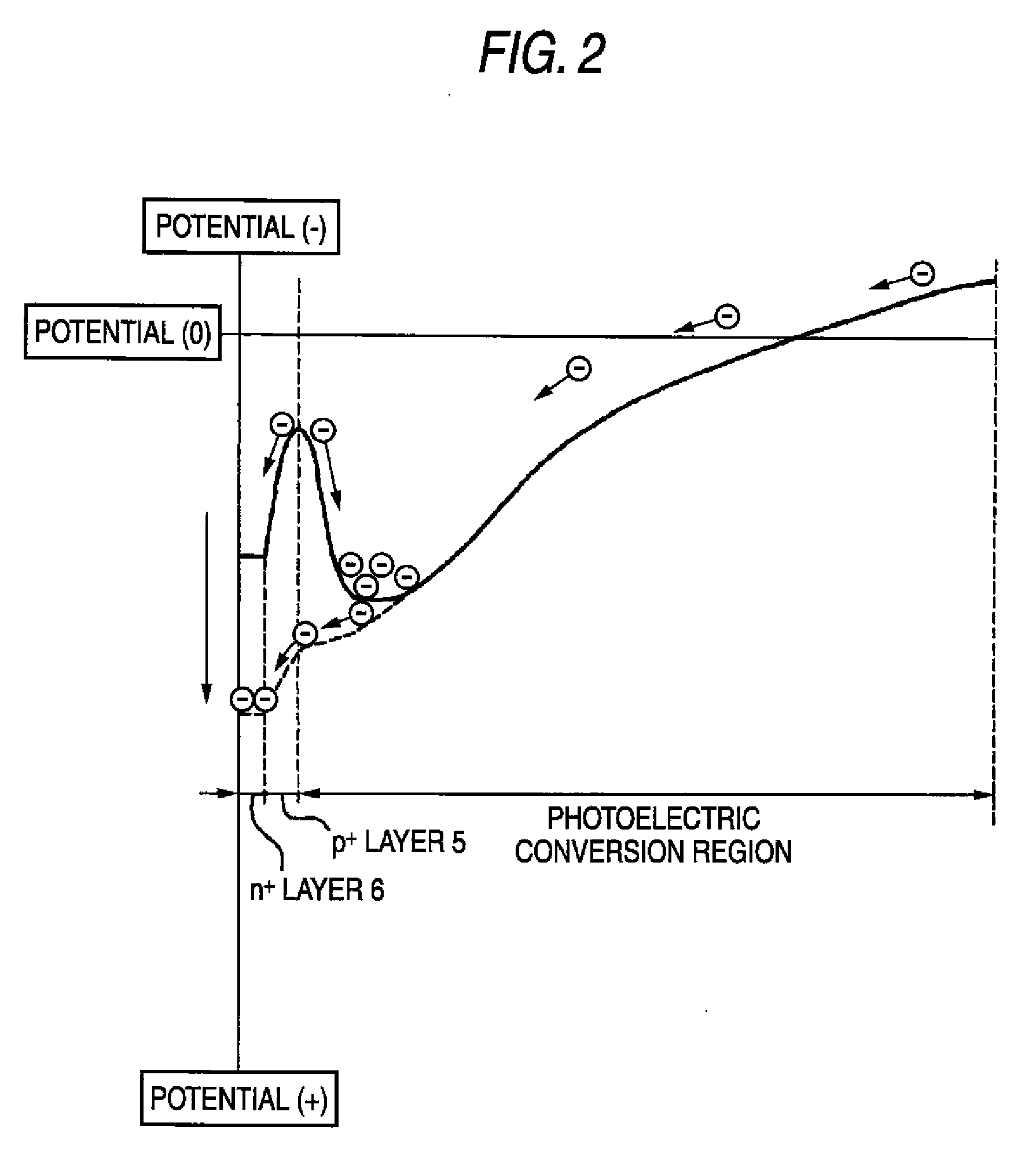

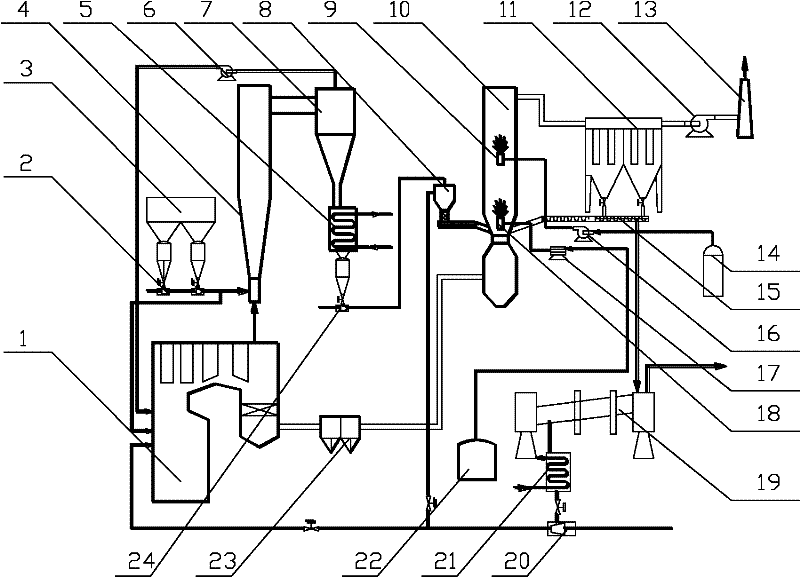

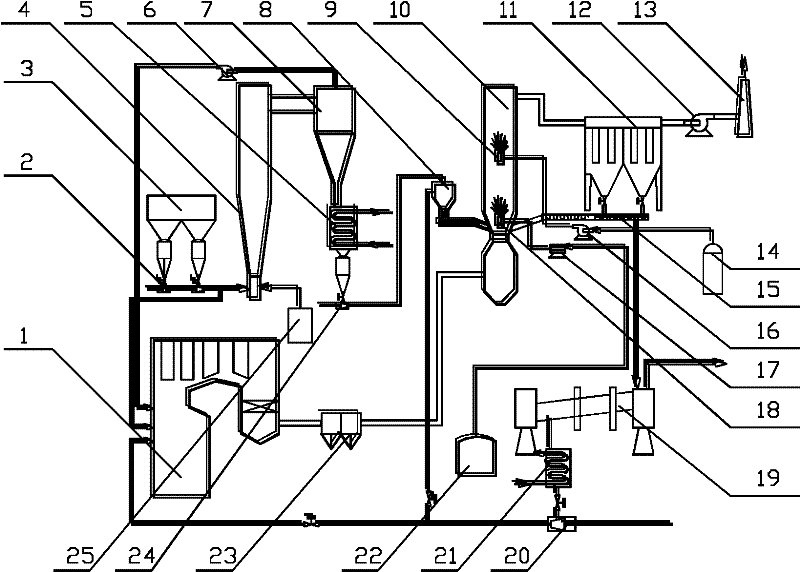

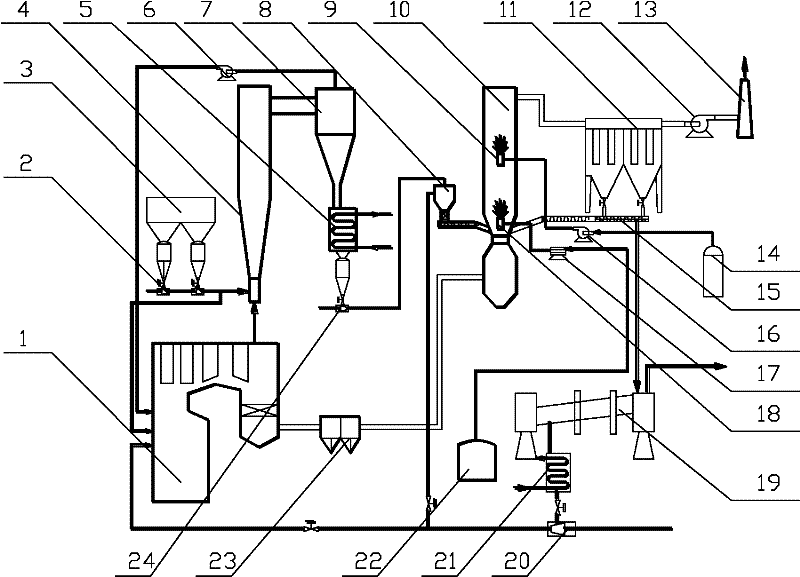

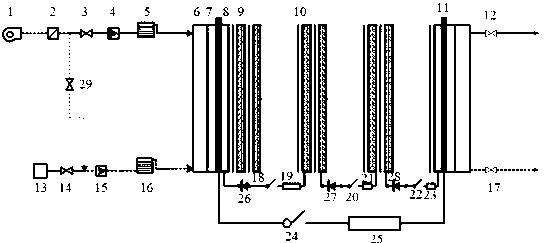

Coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and technology

InactiveCN102350214ARealize reburning and denitrificationFull joint removalDispersed particle separationResource utilizationCoal dust

The invention relates to a coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and a technology. The technology provided by the invention comprises the following steps of: using coal dust in a coal-fired power plant as a raw material, simultaneously carrying out carbonization and activation on coal dust in an activated coke preparation reactor to obtain powdered activated coke, using pyrolysis gas obtained during the preparation process as reburning fuel and sending it into a boiler so as to remove part of NOx; sending the powdered activated coke into a flue gas adsorption tower, adsorbing pollutants such as sulfur dioxide, mercury and the like at an appropriate temperature, injecting ammonia gas and nitrogen oxide to perform a catalytic reduction reaction so as to remove nitrogen oxide; reusing the adsorbed activated coke after regeneration; sending the activated coke into the boiler for combustion after multiple adsorption / regeneration; regenerating the activated coke after adsorbing sulfur dioxide to obtain high-density sulfur dioxide gas to realize resource utilization. By the utilization of coal resources in a coal-fired power plant, the comprehensive purification of flue gas and the resource utilization of sulfur dioxide are realized without discharge of waste water, exhaust gas and solid waste.

Owner:SHANDONG UNIV

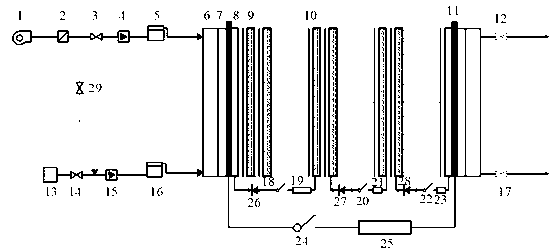

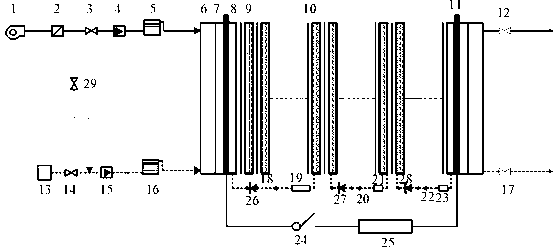

Starting and shutdown control method for proton exchange membrane fuel cell

InactiveCN103259031AReduce voltageReduce time consumptionFuel cell auxillariesLoad circuitElectrical battery

The invention provides a starting and shutdown control method for a proton exchange membrane fuel cell. According to the method, a whole fuel cell stack is divided into a plurality of cell modules; each cell module is connected with a modularized discharging circuit which is composed of a control switch, an auxiliary load and a crystal diode in mutual series connection; each modularized discharging circuit and a main load circuit are in series connection and are respectively connected with the cathode end and the anode end of the fuel cell; an air source is connected with the anode end of the fuel cell through an air blow-down valve; and air is used to purge residual hydrogen at the anode. During starting control, hydrogen is used to purge the anode, and the auxiliary load is used to control the voltage of the cell; and during shutdown control, introduction of air and introduction of hydrogen are successively stopped, a closed system of the auxiliary load is used for discharging, and introduction of air is cooperatively used for purging of the anode. The invention has the following advantages: consumption of time during shutdown of the fuel cell is reduced; the concentration of residual oxygen at the cathode is lowered down; reversal of poles of a single cell in the modules is prevented, and the phenomenon of reversal of poles of the fuel cell in the processes of shutdown discharging and air purging is prevented; and the system of the fuel cell is more simplified and is convenient to operate.

Owner:WUHAN UNIV OF TECH

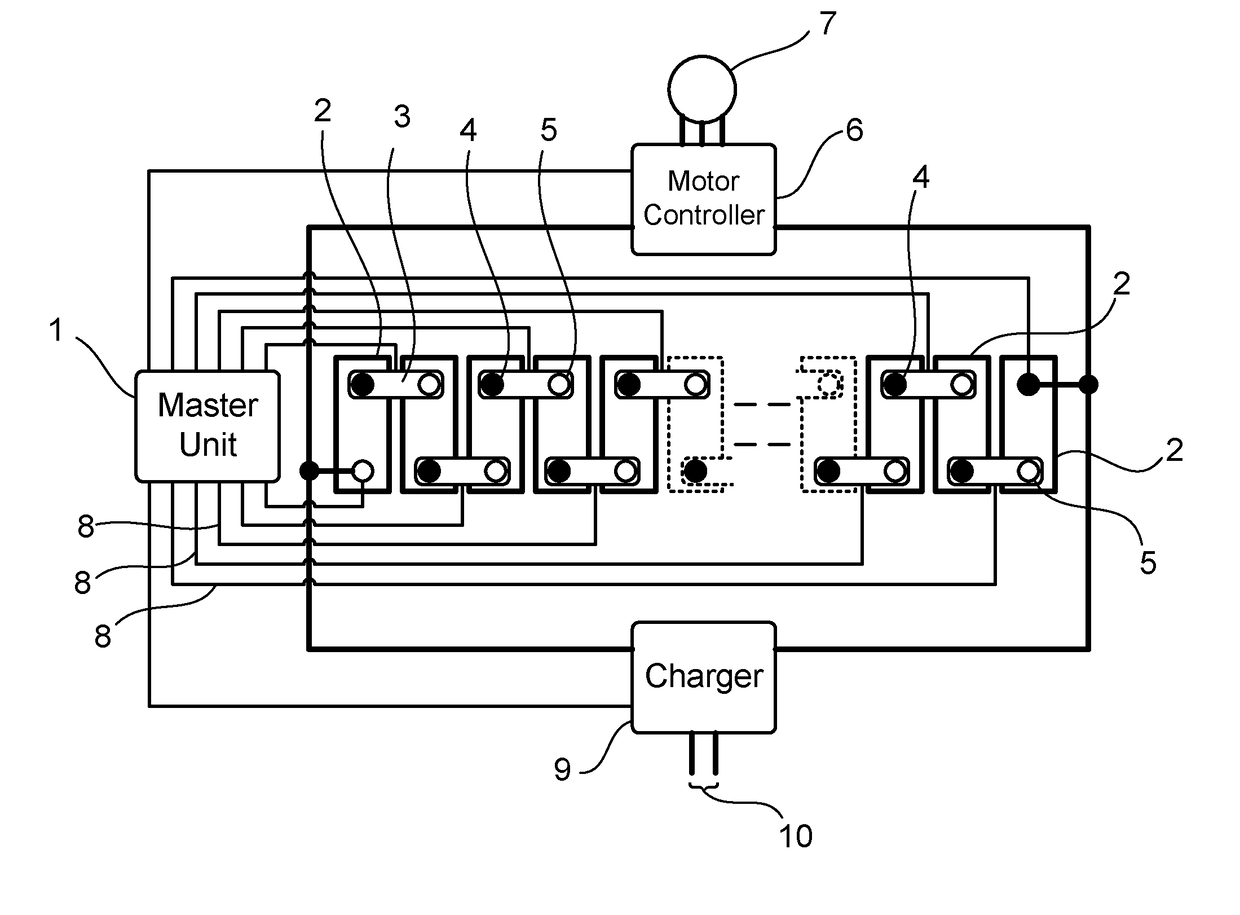

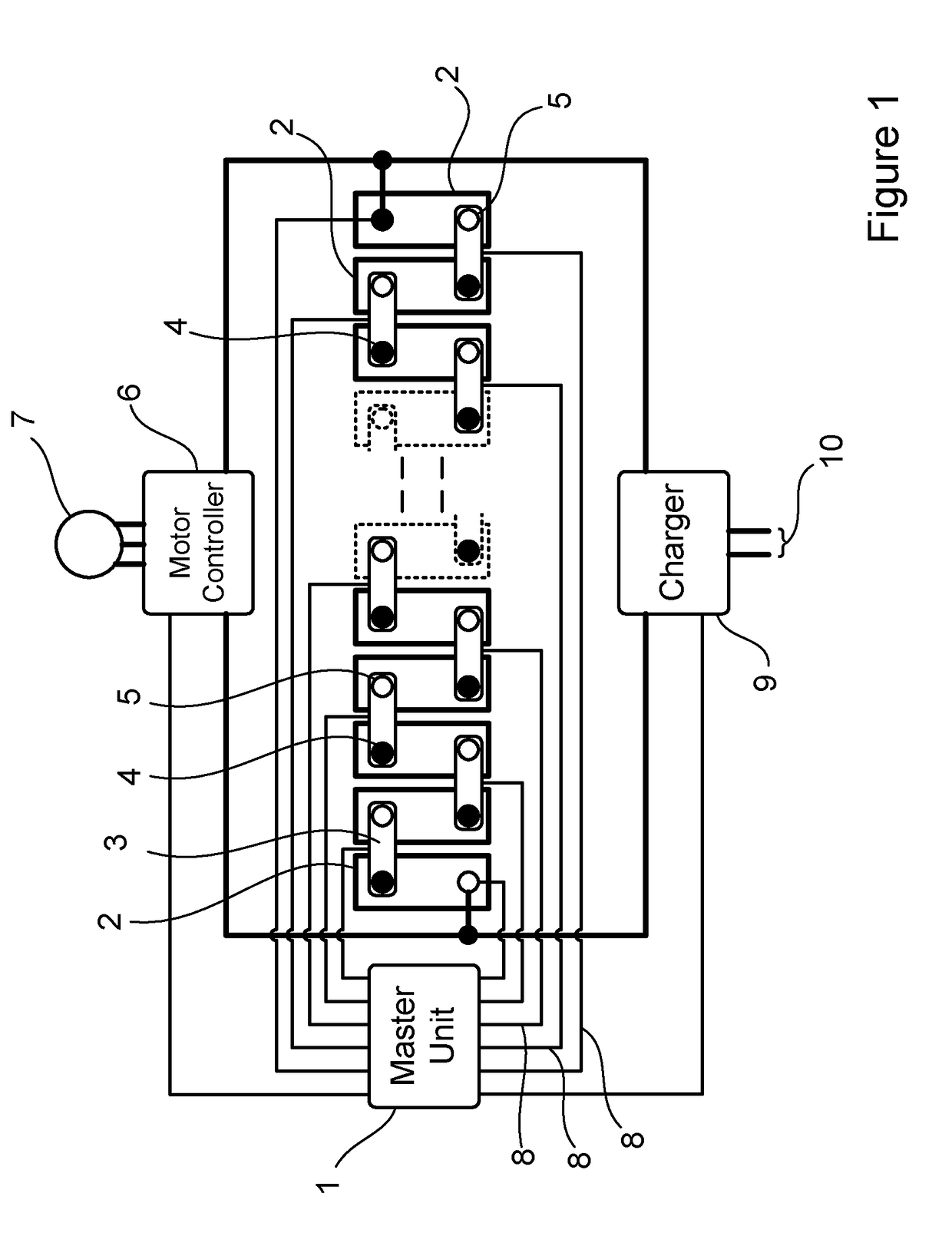

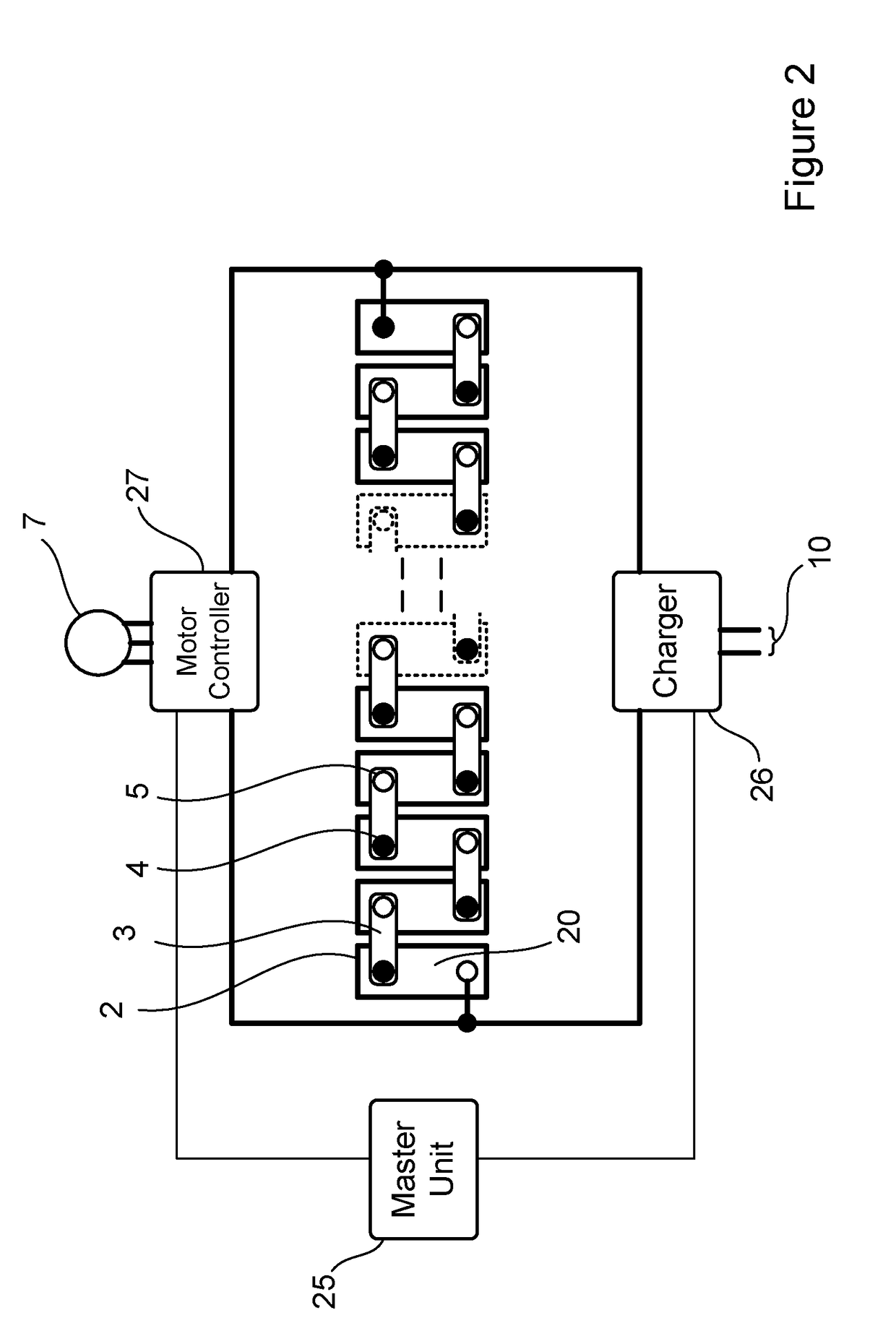

Battery management

ActiveUS20170214256A1Reducing shock hazardSimple methodCharge equalisation circuitSecondary cellsBattery chargeElectrical battery

The invention provides a method and apparatus for managing a battery comprising a plurality of series connected cells. The battery comprises a plurality of series connected statically balanced cells. The battery is arranged so that a substantially identical load is imposed on all of the cells, in use in order to maintain the balance. A battery charging controller is used for controlling the charging of the battery as is arranged to terminate charging prior to the cells reaching their maximum state of charge. The invention also provides a modified charging regime which controls individual cell voltage to avoid any single cell exceeding a desired voltage.

Owner:INTERCALUK LTD

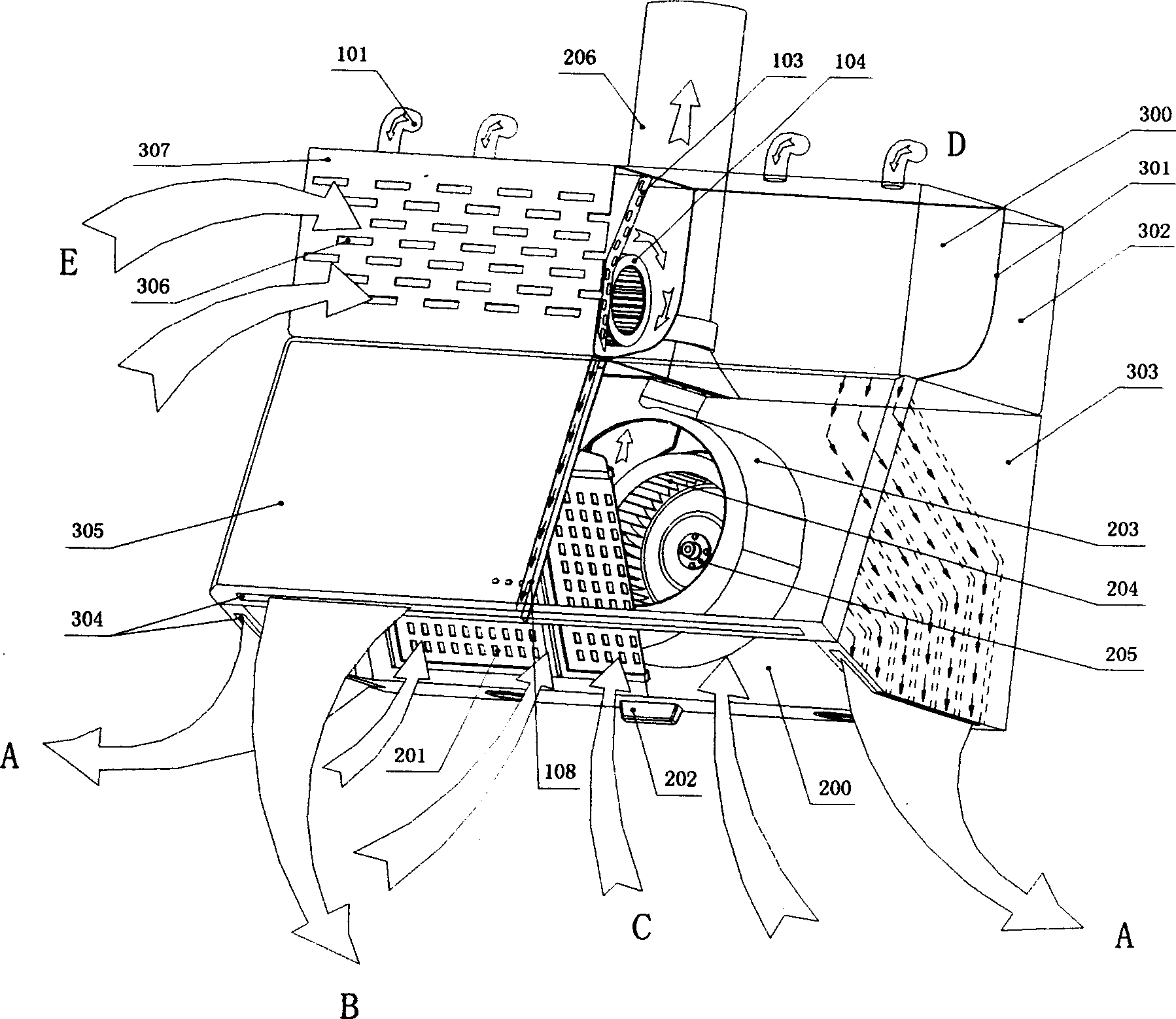

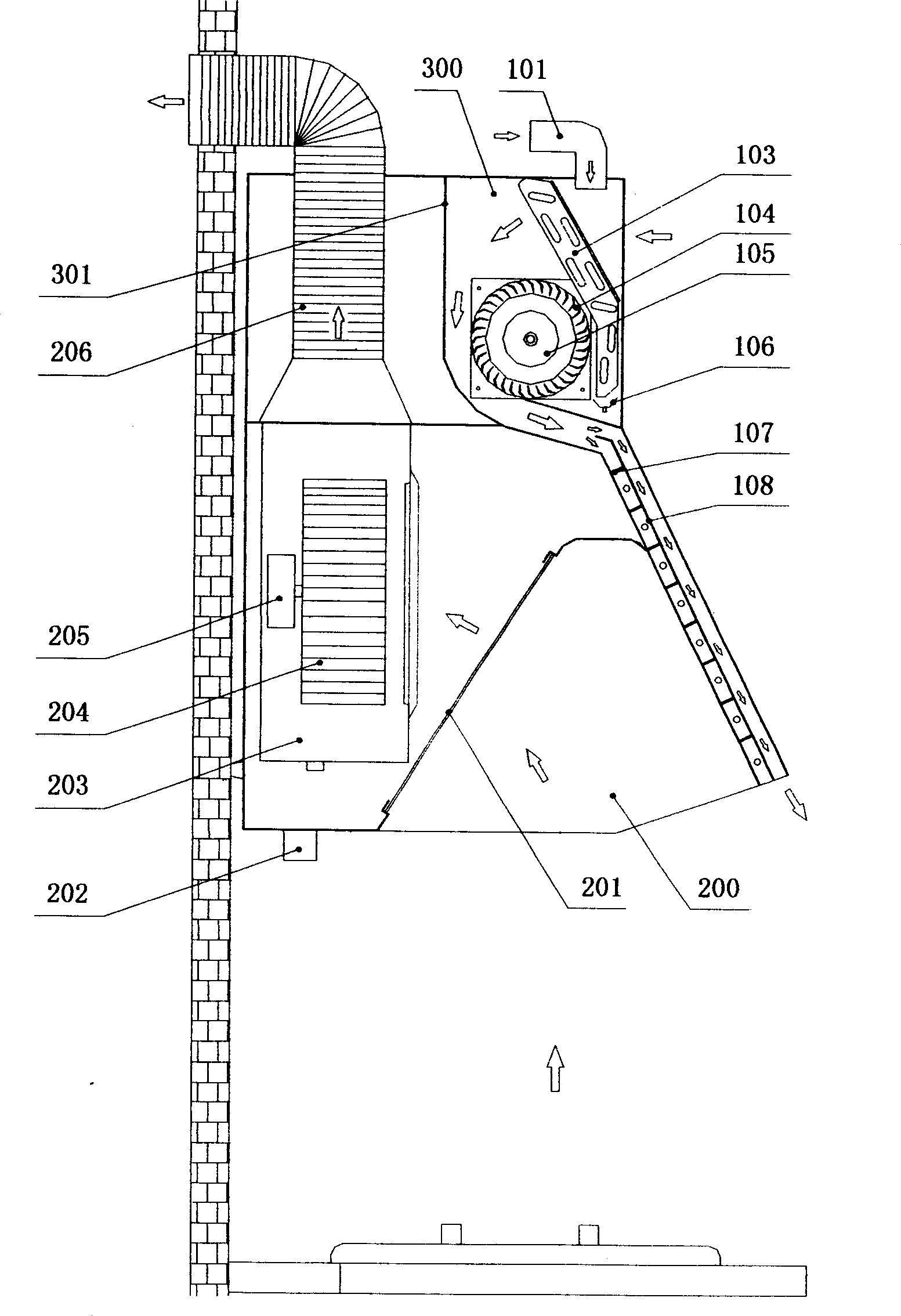

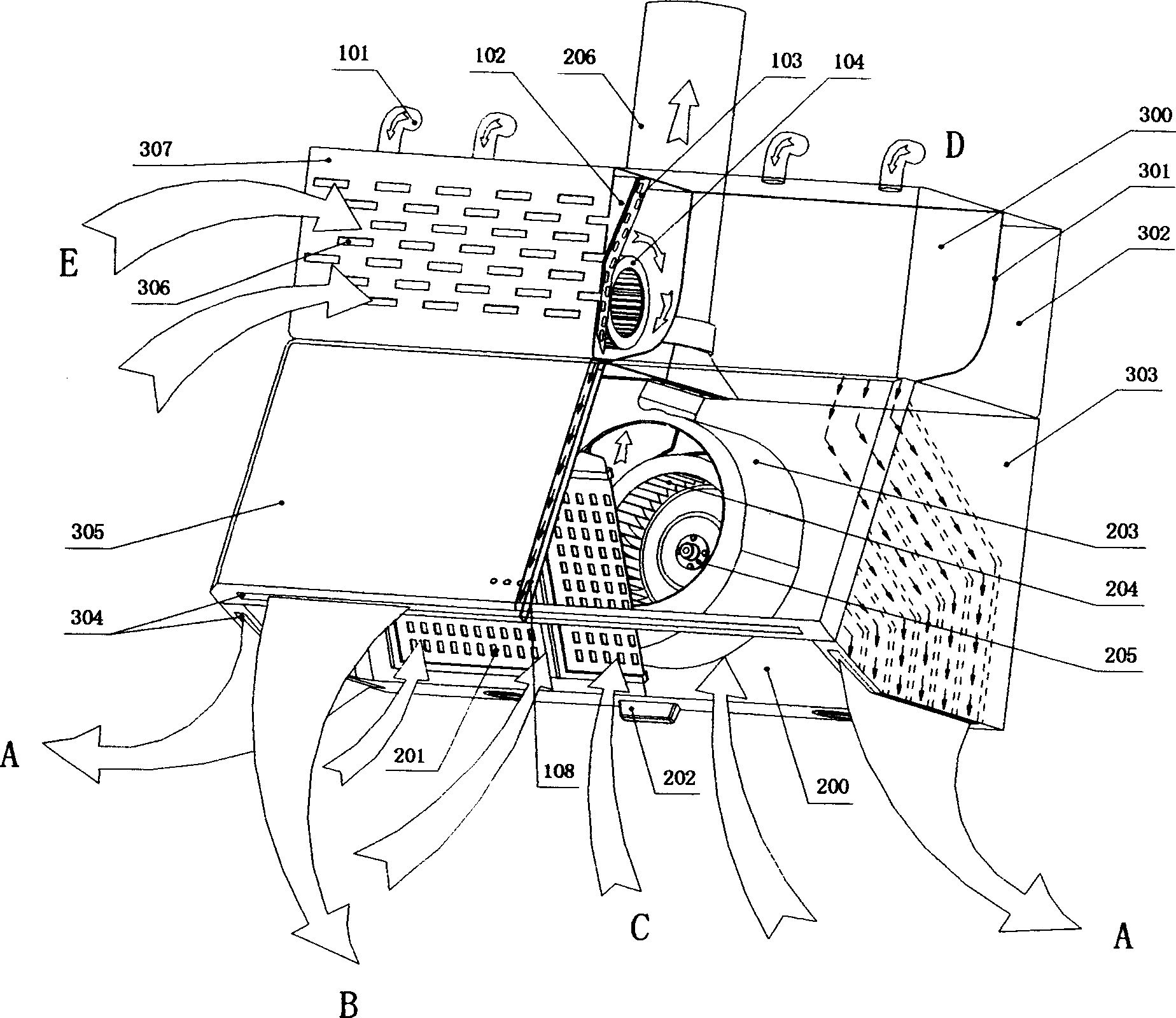

Cooking fume exhauster with refrigerating and air purifying treatment functions

InactiveCN1451913ASolve the problem of overheatingSolve high temperatureDomestic stoves or rangesLighting and heating apparatusControl systemExhaust fumes

A cooking fume exhauster with refrigerating and air-cleaning functions for exhausting cooking fume fully and lowering temp of kitchen is composed of casing, cooking fume exhausting system, refrigerating system and electric control system. The compressor, condenser and axial-flow fan of said refrigerating system are installed in the outdoor unit, and its evaporator and cross flow fan are installedin the heat exchange chamber of indoor unit.

Owner:NINGBO OULIN KITCHEN APPLIANCE

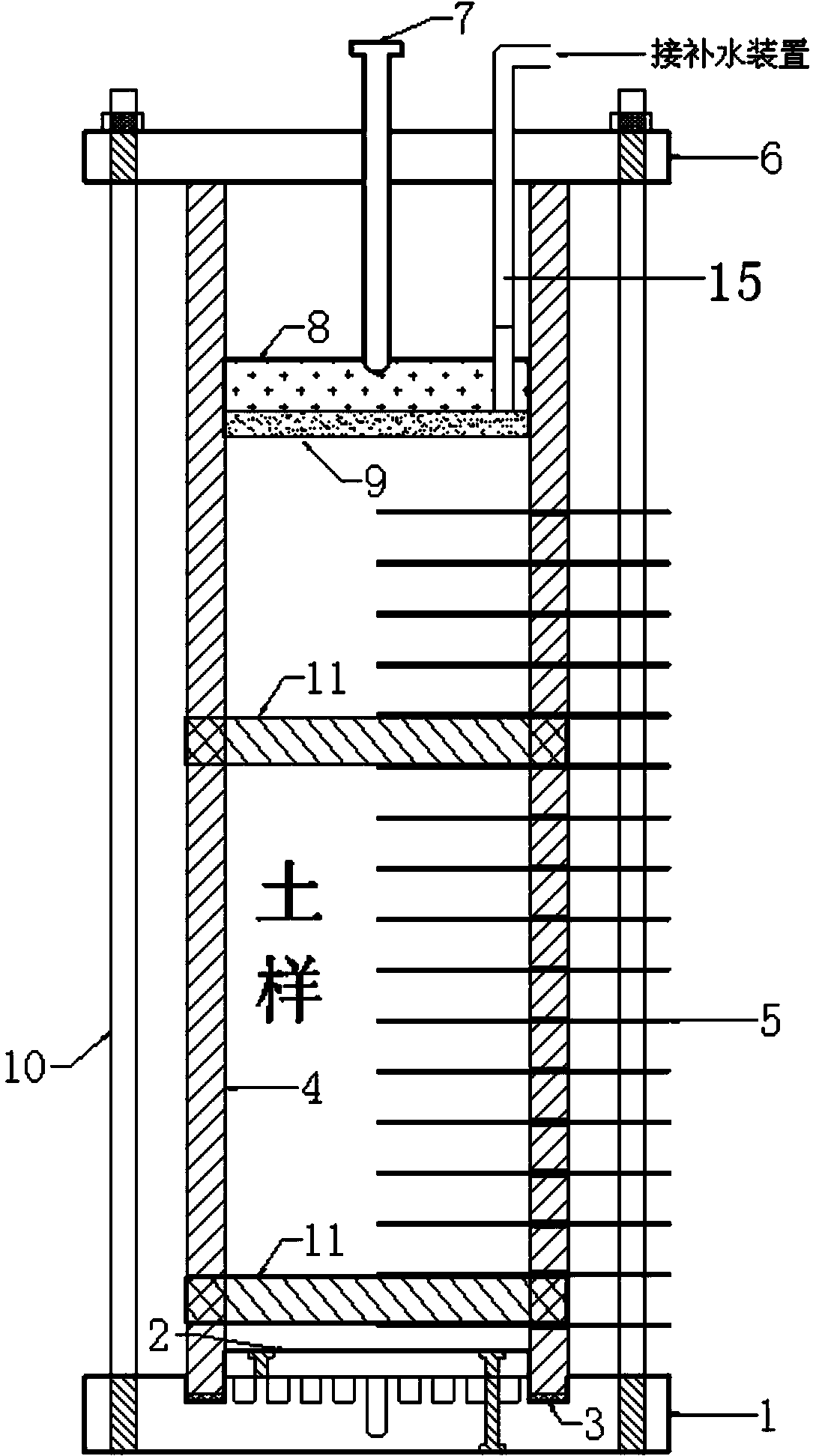

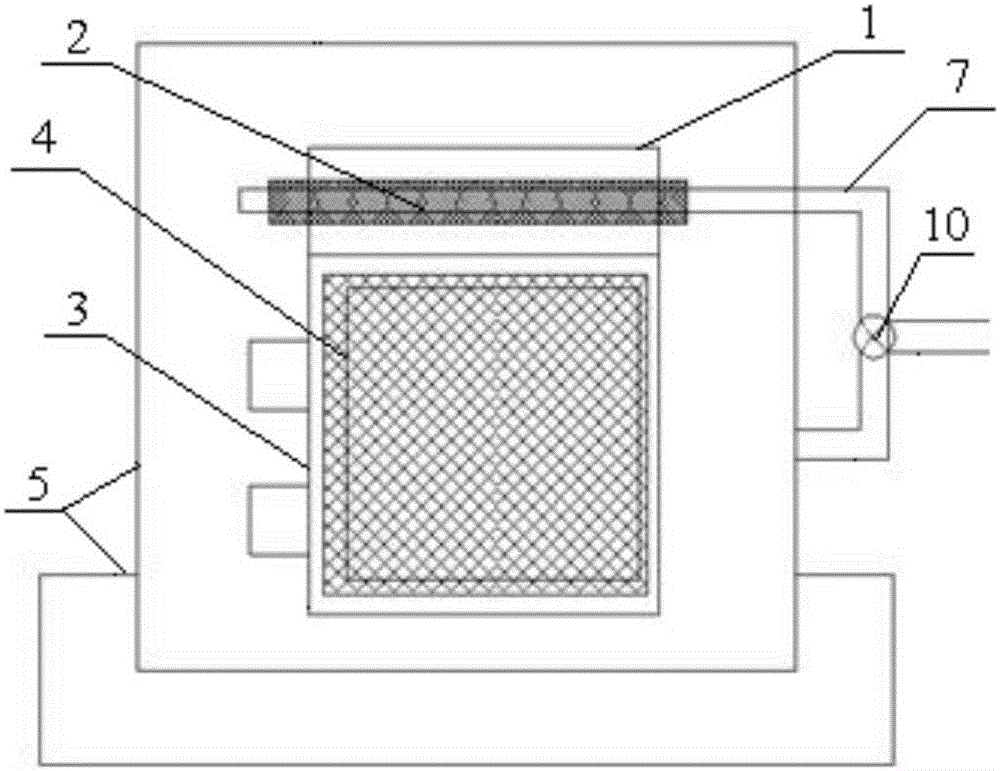

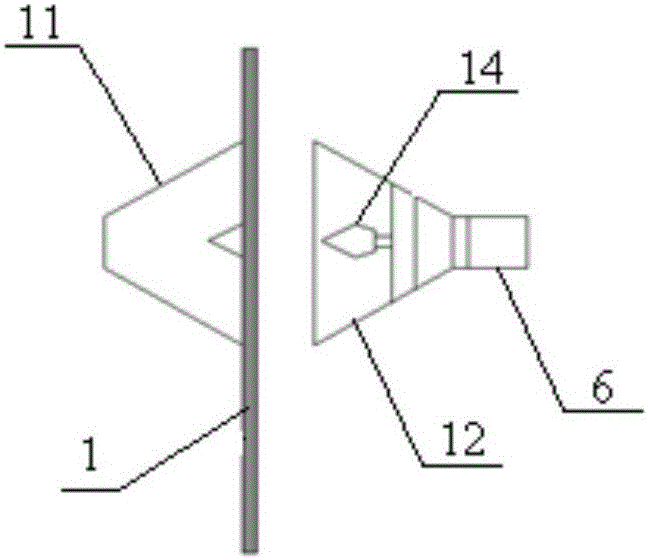

Test device for making research on soil freezing and thawing temperature field, water migration and deformation law

InactiveCN103969282AEvenly distributedGas dischargeMaterial thermal analysisGround freezingEngineering

The invention relates to a test device for making a research on a soil freezing and thawing temperature field, water migration and a deformation law. The test device comprises a freezing bottom plate for feeding freezing liquid into the device, a split soil sample cavity which is arranged on the freezing bottom plate and used for storing soil samples, a top cover arranged at the top of the split soil sample cavity in a covering manner, a soil sample cover plate which is arranged in the split soil sample cavity and used for compacting the soil samples, a water replenishing connection pipe which is connected with a water replenishing device and used for adding water into the soil samples, and a bracket connected between the top cover and the freezing bottom plate. Compared with the prior art, the test device is simple in structure and convenient to operate, and a certain basis is provided for construction using an artificial ground freezing method.

Owner:TONGJI UNIV

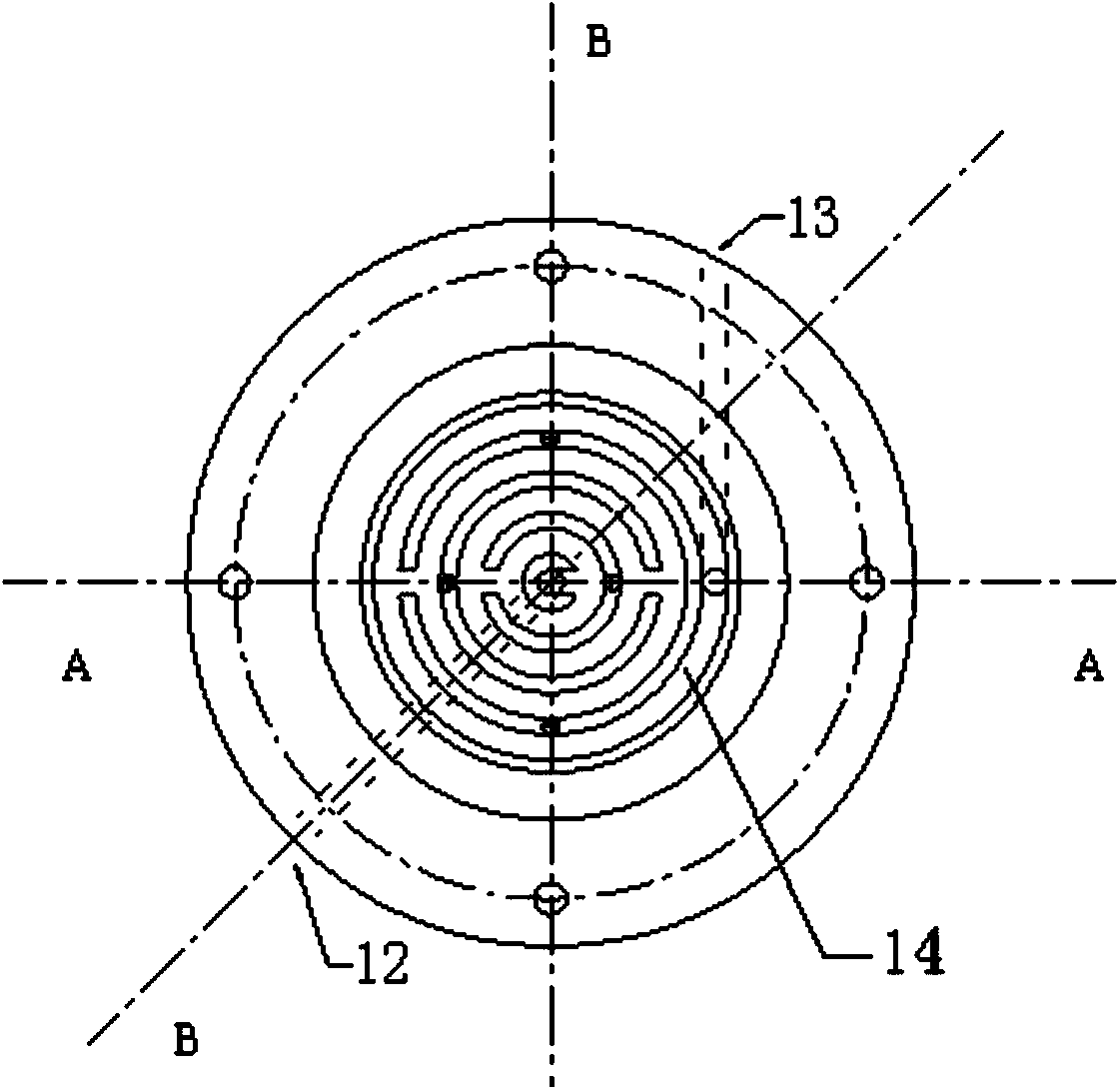

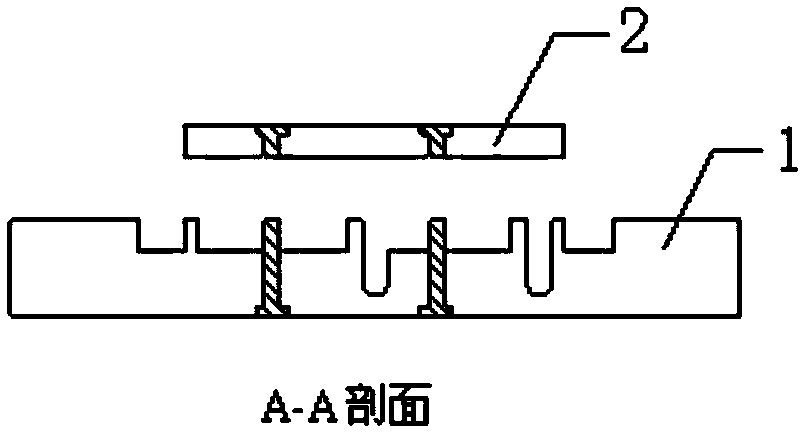

Method for quickly generating lamination flexible package lithium ion battery

ActiveCN106099202ADischarge fullyRestructuring and StabilityFinal product manufactureSecondary cells charging/dischargingSurface reactionPole piece

The invention belongs to the technical field of lithium ion batteries and particularly relates to a method for quickly generating a lamination flexible package lithium ion battery. The method comprises a stage of forming a solid electrolyte phase interface film and a stage of discharging formation gas. The main theoretical foundation is that the solid electrolyte phase interface film is mainly formed at the initial stage of formation charging, accompanied with the discharging of the formation gas. The formation of an SEI film is subjected to the influences of current density and temperature and the like. Under a small current density, first organic lithium salt is formed on the surface of a cathode and then inorganic lithium salt is formed, so that the formed SEI film is denser, and ingredients are more stable. At this stage, a high-pressure pressurization formation mode is adopted, the reaction activity can be increased, the reaction is accelerated, battery surface pressure is increased, the ionic migration distance can be shortened, and formation efficiency and pole piece surface reaction consistency are improved. Compared with a conventional formation process, according to the method, the formation time is shortened, the formed SEI film is denser and more stable, and the method can be widely applied to industrial production.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

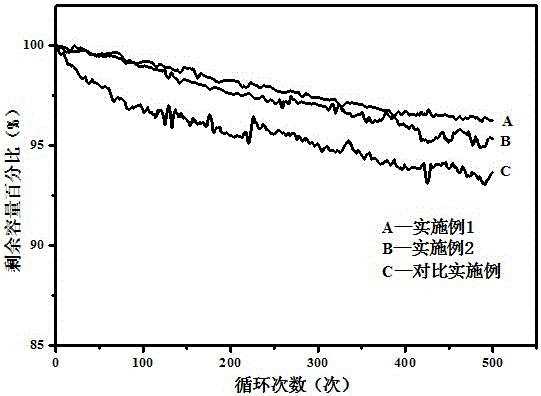

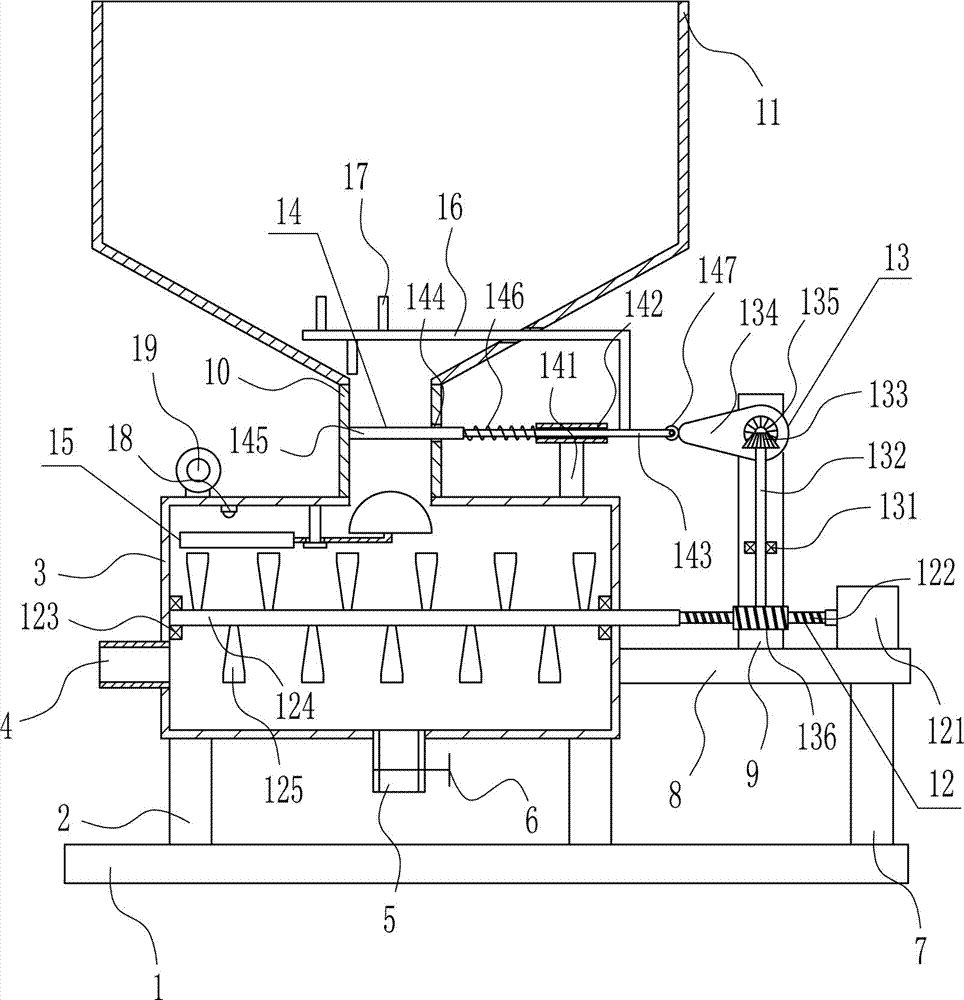

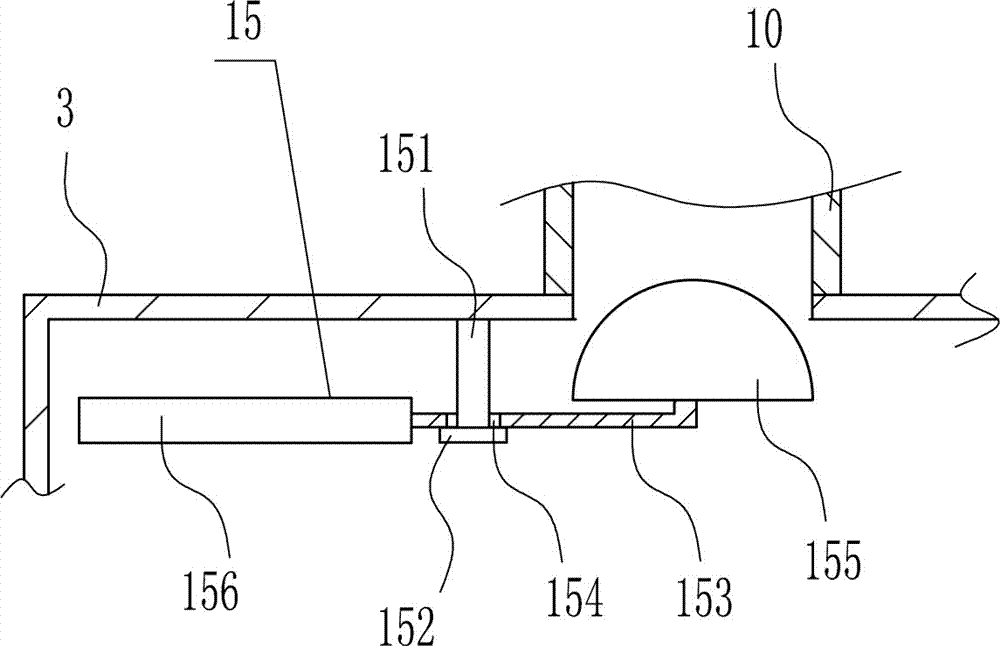

Coating line with full-automatic control and manual spray coating

ActiveCN104525442AExhaust gasDischarge fullyPretreated surfacesCoatingsProduction lineAutomatic control

The invention relates to a coating line with full-automatic control and manual spray coating. A linear speed-multiplied conveyor chain is disposed on a ground surface manual operation plane; an inlet of the conveyor chain is a to-be-sprayed area; the end of a workpiece charging conveyor chain is a workpiece discharging area; a coating production line, a turning platform and another coating production line are orderly disposed between the to-be-sprayed area and the member discharging area; the structure of a spraying chamber, a leveling chamber and a drying chamber is that the spraying chamber, an inlet lifting device, the leveling chamber, the drying chamber, a cooling chamber, and an outlet lifting device are orderly disposed on the conveyor chain from the inlet to the outlet; throughout the whole conveyor chain, accumulating systems are disposed at stations with manual operation, and the accumulating systems are connected with an externally-disposed full-automatic control system. The coating line realizes that the coating work of a workpiece can be accomplished from charging of the workpiece and through the production line; stepwise rhythmical production is realized; the production efficiency is greatly improved; problems of large land occupation and disordered production sites caused by on-site part cross transfer are prevented.

Owner:AVIC SAC COMML AIRCRAFT

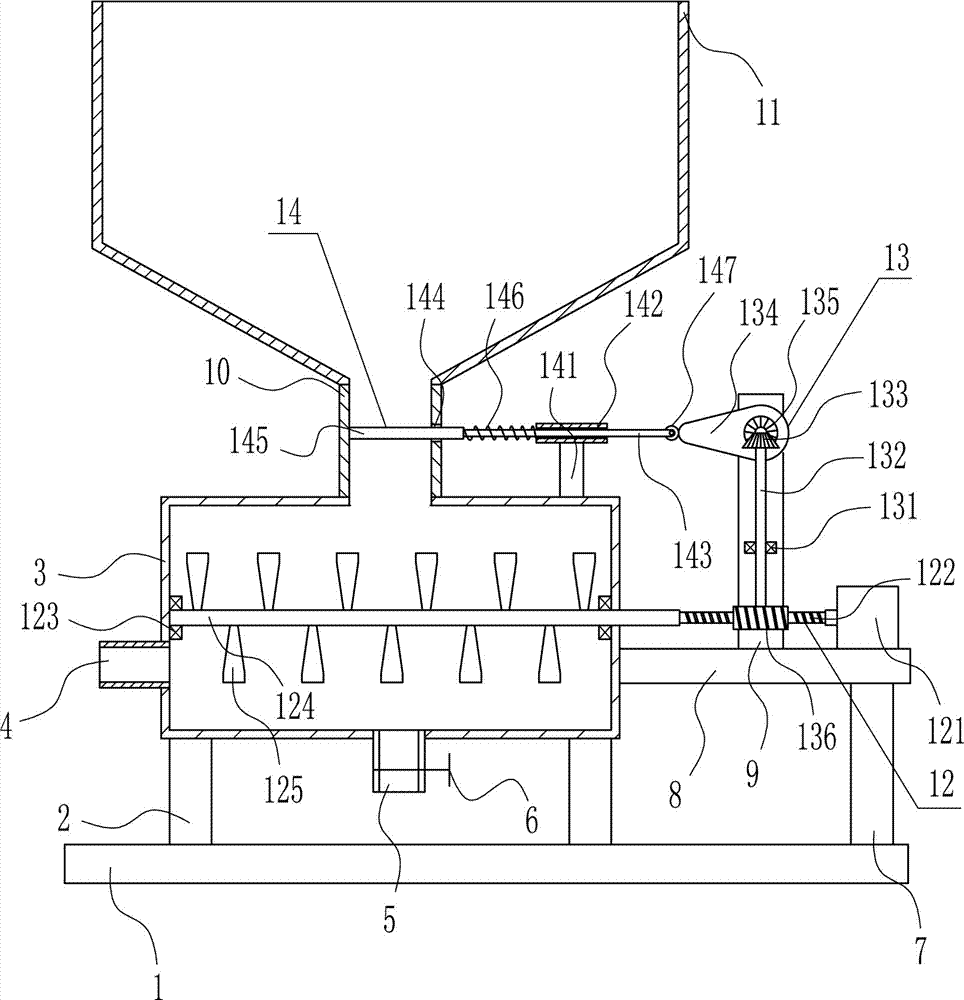

Fishpond disinfection device for aquaculture

ActiveCN107873620AImprove water qualityPrevent inflowPisciculture and aquariaWater/sewage treatment using germicide/oligodynamic-processMedicineWater quality

The present invention relates to a disinfection device, and especially relates to a fishpond disinfection device for aquaculture. The technical problem to be solved is to provide a fishpond disinfection device for aquaculture, disinfection powder is not required to be poured into a fishpond manually, water in the fishpond can be pumped out to be mixed thoroughly with the disinfection powder and then discharged, the disinfection effect is good, and water quality is improved. To solve the technical problem, the present invention provides a fishpond disinfection device for aquaculture, comprisinga base plate, supporting rods, a box, a water inlet pipe, and a water outlet pipe; the supporting rods are installed at left and right sides of the top of the base plate, and the box is installed between the top ends of the supporting rods at the left and right sides. The water in the fishpond and the disinfection powder can be mixed through a mixing device, so that the water quality is improved,and the fish can grow healthier. The effects that the disinfection powder is not required to be poured into the fishpond manually, the water in the fishpond can be pumped out to be mixed thoroughly with the disinfection powder and then discharged, the disinfection effect is good, and the water quality is improved are achieved.

Owner:阳江市泰益农业科技发展有限公司

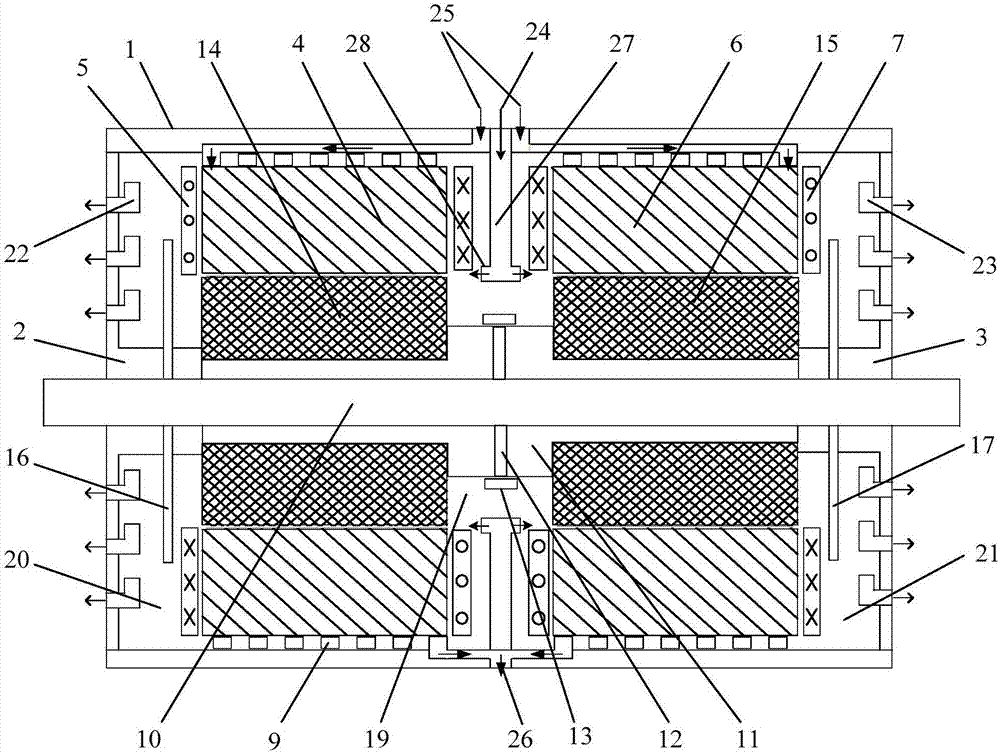

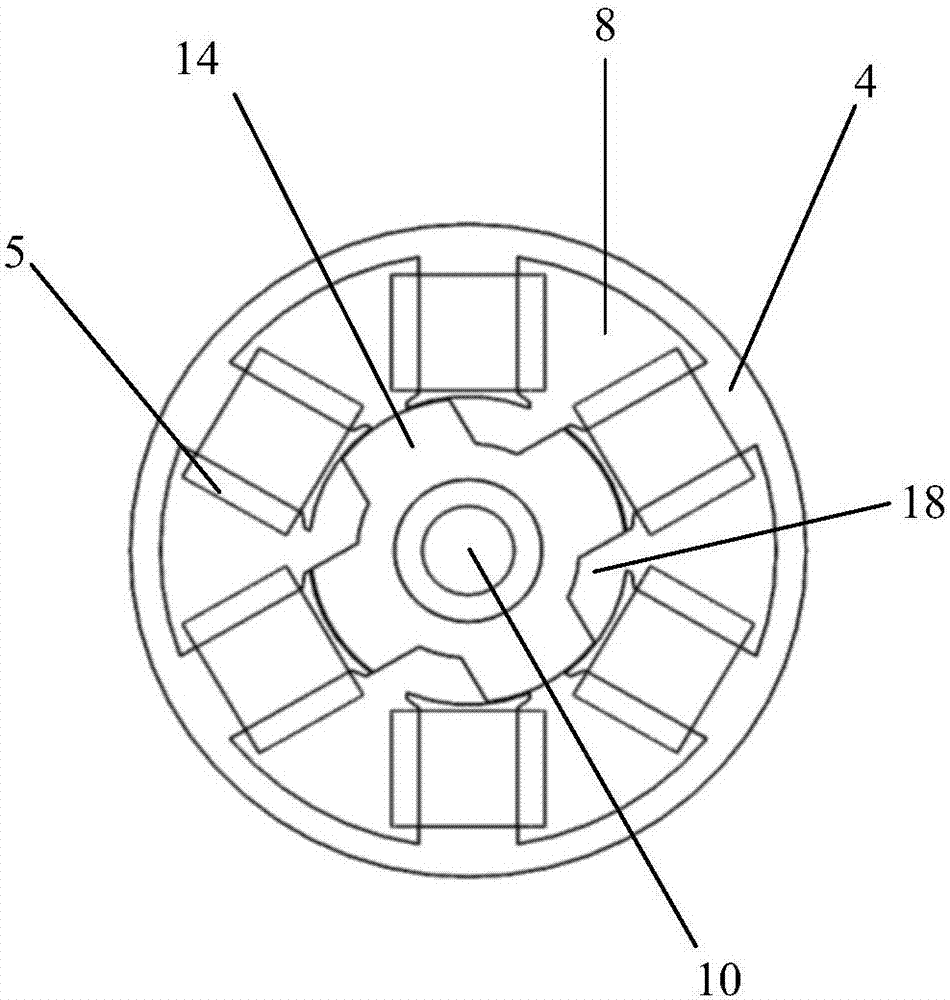

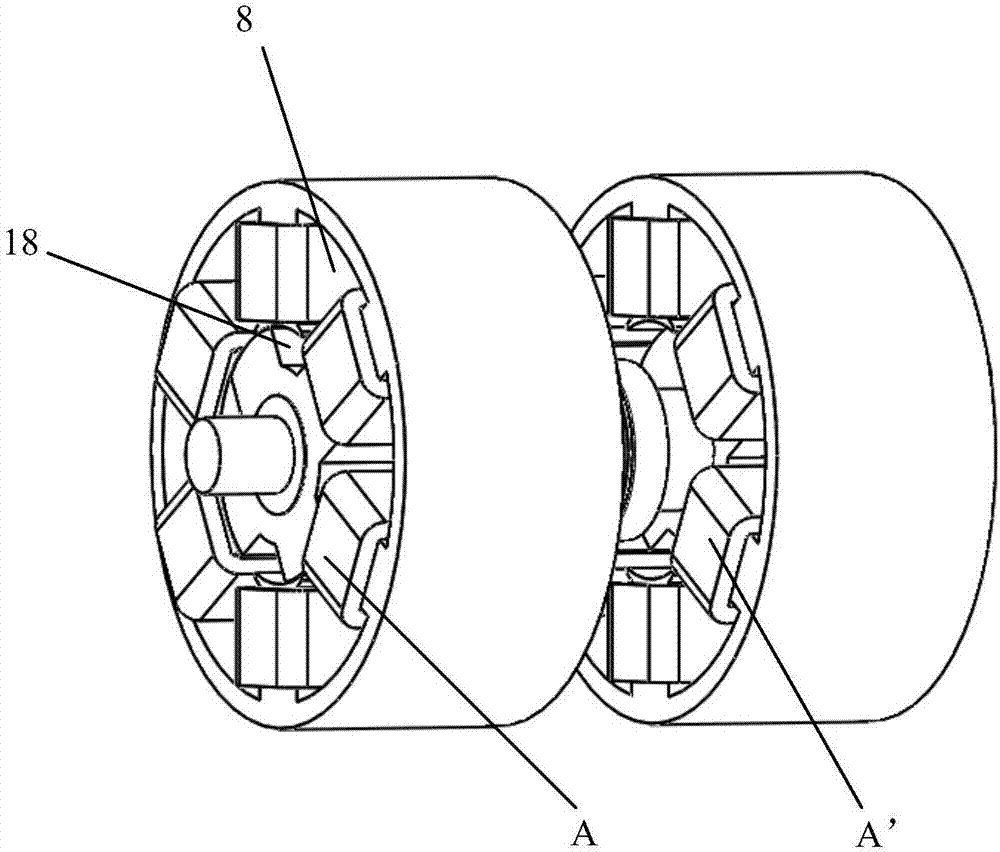

Axial permanent magnet assisted radial reluctance high-speed motor with hybrid cooling structure

PendingCN107147260AReduce consumptionReduce copper consumptionMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic reluctance

The invention provides an axial permanent magnet assisted radial reluctance high-speed motor with a hybrid cooling structure, and relates to the technical field of motors. The motor provided by the invention is provided with an air cooling and water cooling structure on the basis of a dual group 6 / 4-pole switched reluctance motor structure. The motor comprises a casing, a front end cover, a rear end cover, a rotor and a stator, and is characterized in that an inter-tooth slot of the stator and the rotor form a cooling air channel, each end cover is provided with air discharging holes, the casing is provided with a cooling air inlet, a cooling water inlet pipe opening, a cooling water outlet pipe opening and a circumferential ring-shaped air guiding channel, the back of a ring yoke of the stator is provided with a spiral water channel pipe, and two ends of the rotor are provided with self-cooling fans respectively. According to the invention, a cooling structure combining the air cooling stator and the water cooling stator is adopted, and a water cooling function and an air cooling function are opposite in direction and complementary in cooling region, so that the stator and the rotor of the motor are effectively enabled to be reduced in temperature, a problem of difficult heat dissipation of the motor under a high-speed operating condition is avoided, thus long-term safe and stable running of the motor is ensured, and the service life of the motor is effectively prolonged.

Owner:SHENYANG POLYTECHNIC UNIV

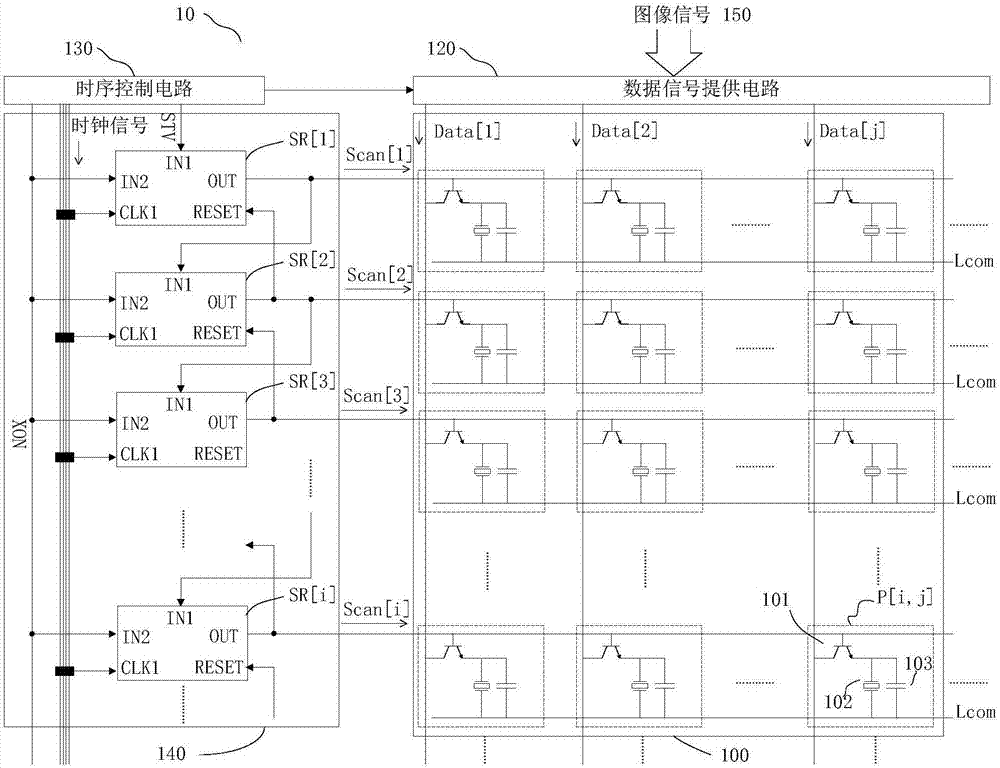

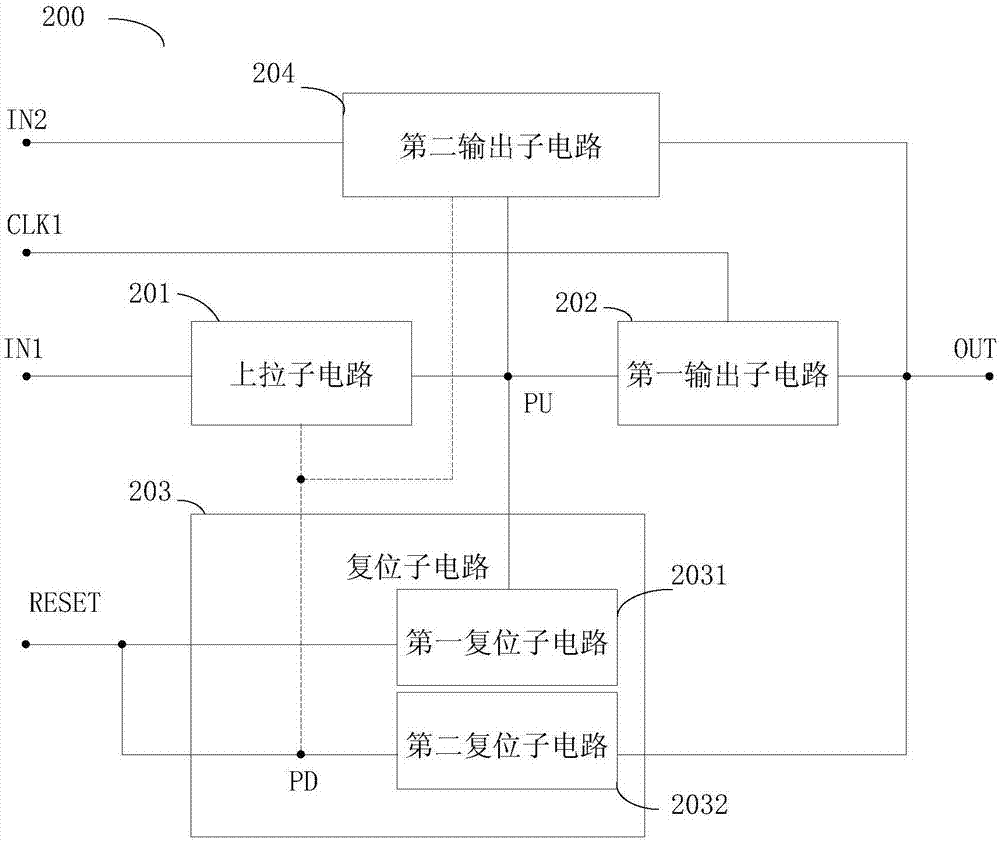

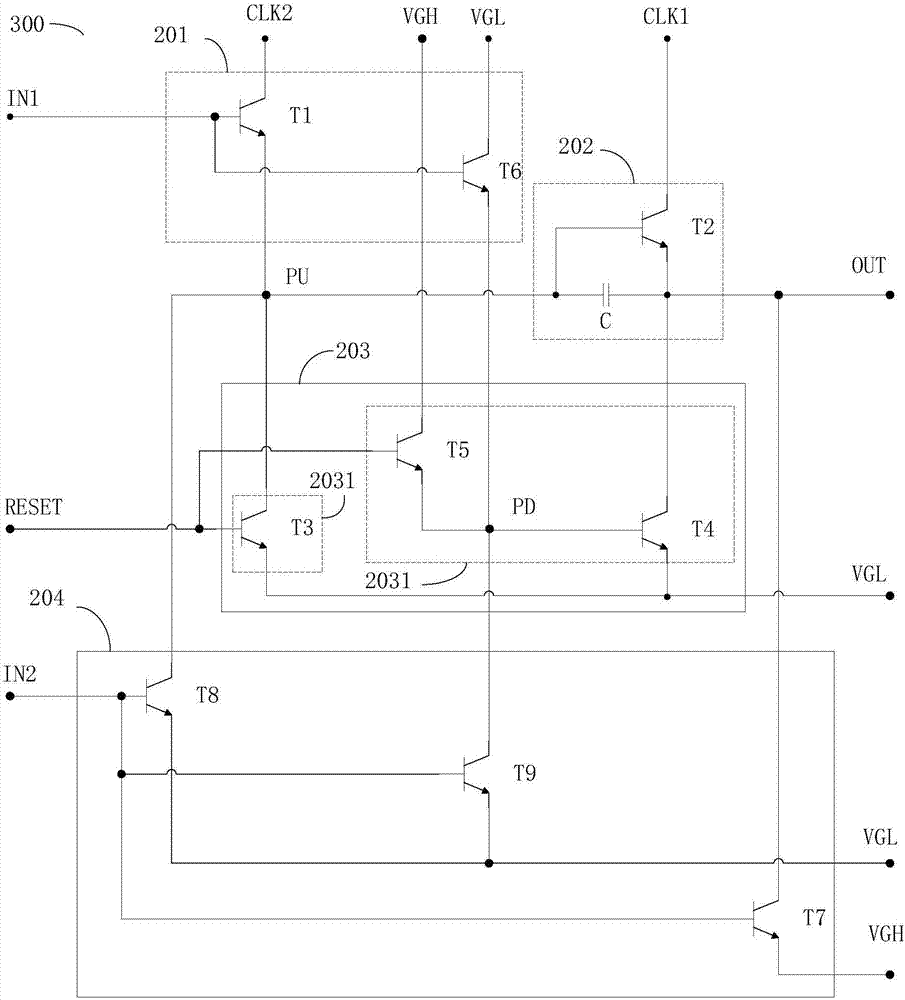

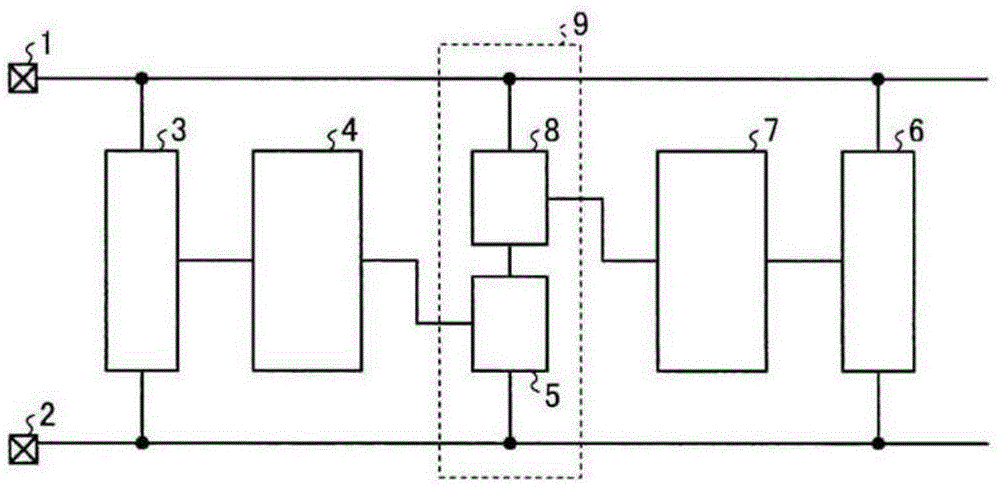

Shifting register and grid driving circuit and driving method thereof and liquid crystal display device

ActiveCN107134268ADischarge fullyStatic indicating devicesDigital storageShift registerLiquid-crystal display

The invention provides a shifting register and a grid driving circuit and a driving method thereof and a liquid crystal display device. The shifting register comprises a pull-up sub-circuit, a first output sub-circuit, a reset sub-circuit and a second output sub-circuit, wherein when a first input end receives first input signals, the pull-up sub-circuit sets the potential of a pull-up node as a wording potential; when the potential of the pull-up node is the working potential, the first output sub-circuit outputs grid driving signals at an output end according to first clock signals which are received by a first clock signal end; when reset signals are received by a reset end, the reset sub-circuit sets the potential of the pull-up node and the output end as reset potential; when second input signals are received by a second input end, the second output sub-circuit outputs the grid driving signals at the output end in the time bucket apart from the period of displaying a one frame picture.

Owner:BOE TECH GRP CO LTD +1

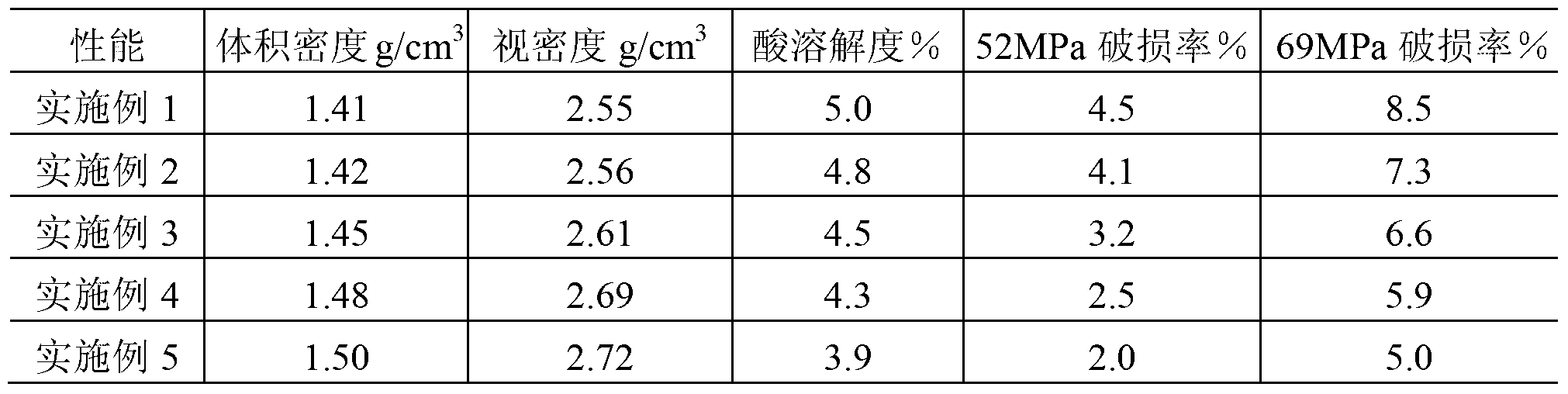

Method for preparing special fracturing propping agent for shale gas by utilizing industrial waste

InactiveCN103288426AImprove protectionSave natural resourcesChemical industryFluid removalMicro structureOil shale gas

The invention provides a method for preparing a special fracturing propping agent for shale gas by utilizing industrial wastes. The method comprises the following steps of: calcining fly ashes and / or coal gangues, grinding by using an air-current mill, screening, so as to form waste residue powders; weighing the waste residue powders, kaolin and polycrystalline silicon powders in proportion, putting in a mixer to mix uniformly, and prilling to balls; putting particles after balling into a crucible, sintering in an electric furnace, and taking out after natural cooling, thereby obtaining the special fracturing propping agent for the shale gas. The method provided by the invention has the advantages that the raw material is extensive in source, the micro structure of a porcelain body is improved, the firing temperature is low, the firing period is short, the method is energy-saving, low-carbon and environment-friendly, and the integrated performance of products is improved; the prepared propping agent has the excellent characteristics of low density, high intensity, high-temperature resistance and corrosion resistance and the like, and can provide a fracturing material with good performance for middle / deep-layer shale gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

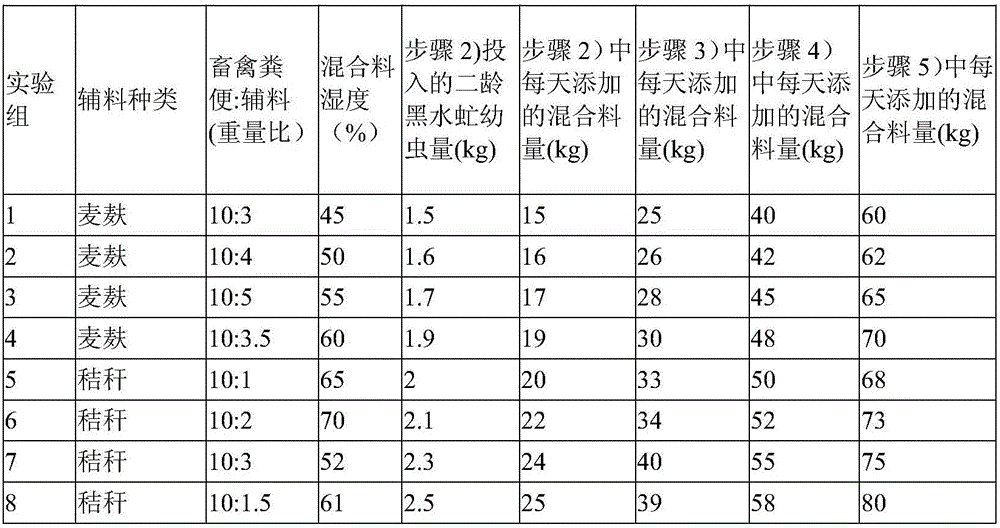

Method and ecological recirculating culture method for treating livestock and poultry manure by using Hermetia illucens

The invention discloses a method for treating livestock and poultry manure by using Hermetia illucens; the method comprises the steps of 1) mixing well livestock and poultry manure, an auxiliary material and livestock and poultry urine, wherein the mixture has humidity of 45-70%, the auxiliaries include wheat bran, straws or oil cake, the weight ratio of the livestock and poultry manure to the auxiliary material, to be specific, the livestock and poultry manure to wheat bran or oil cake, is 10:(3-5), or the weight ratio of the livestock and poultry manure to straws is 10:(1-3); 2) adding larvae of Hermetia illucens, adding the mixture, and feeding to third instar; 3) adding 25-40 kg of the mixture each day for feeding; 4) adding 40-60 kg of the mixture each day for feeding; 5) adding 60-80 kg of the mixture each day for feeding until a six-instar prepupal stage. An ecological recirculating culture method for treating livestock and poultry manure by using Hermetia illucens is also disclosed; Hermetia illucens is used as a feed in poultry or aquatic culture, the excrement of Hermetia illucens is used in earthworm culture, earthworms is used as a feed, poultry excrement is treated with Hermetia illucens, and the excrement of earthworms is made into fertilizer for planting industry.

Owner:北京申城生物科技集团有限公司

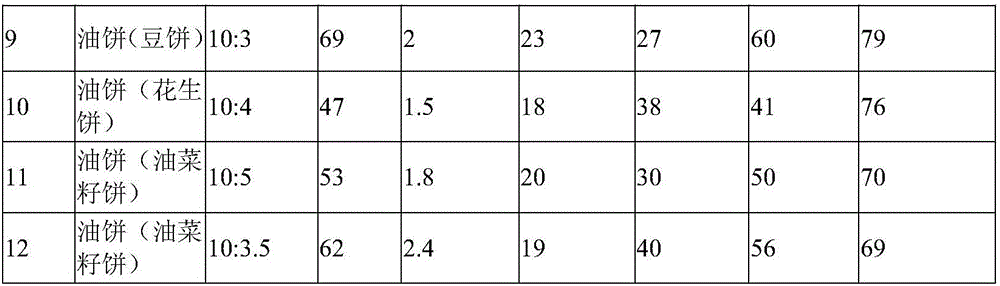

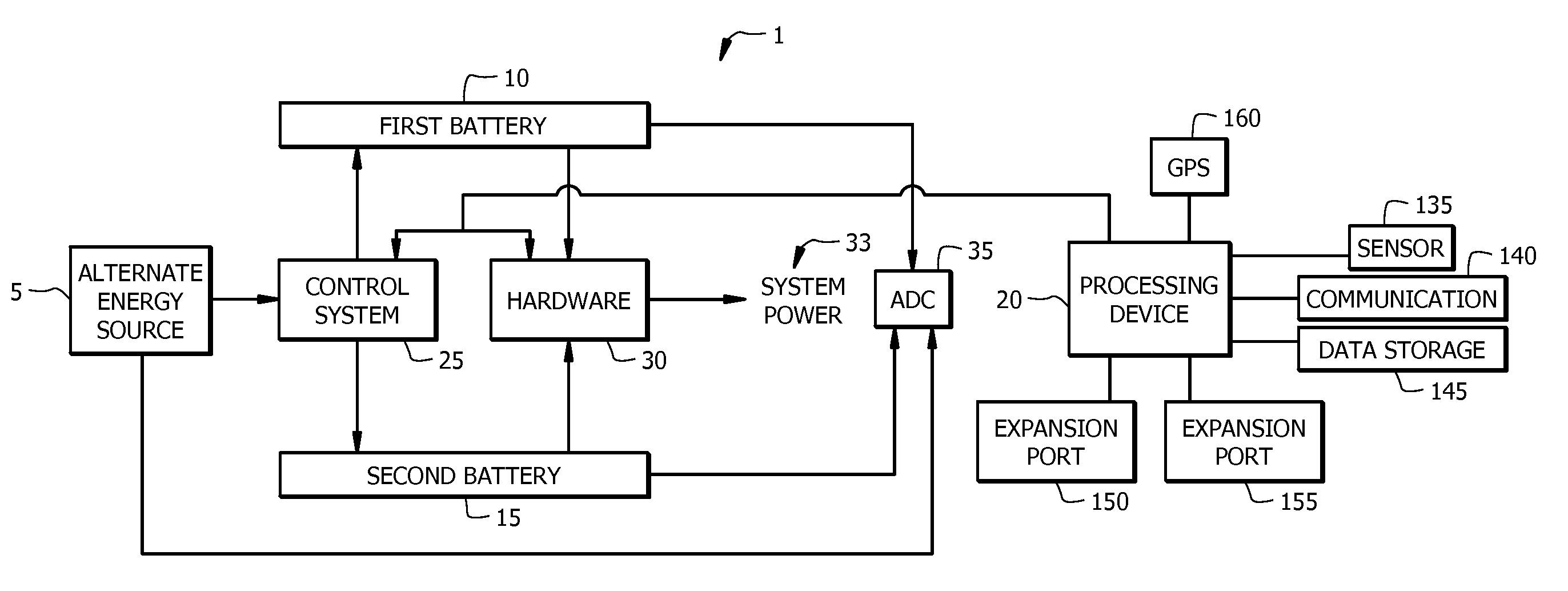

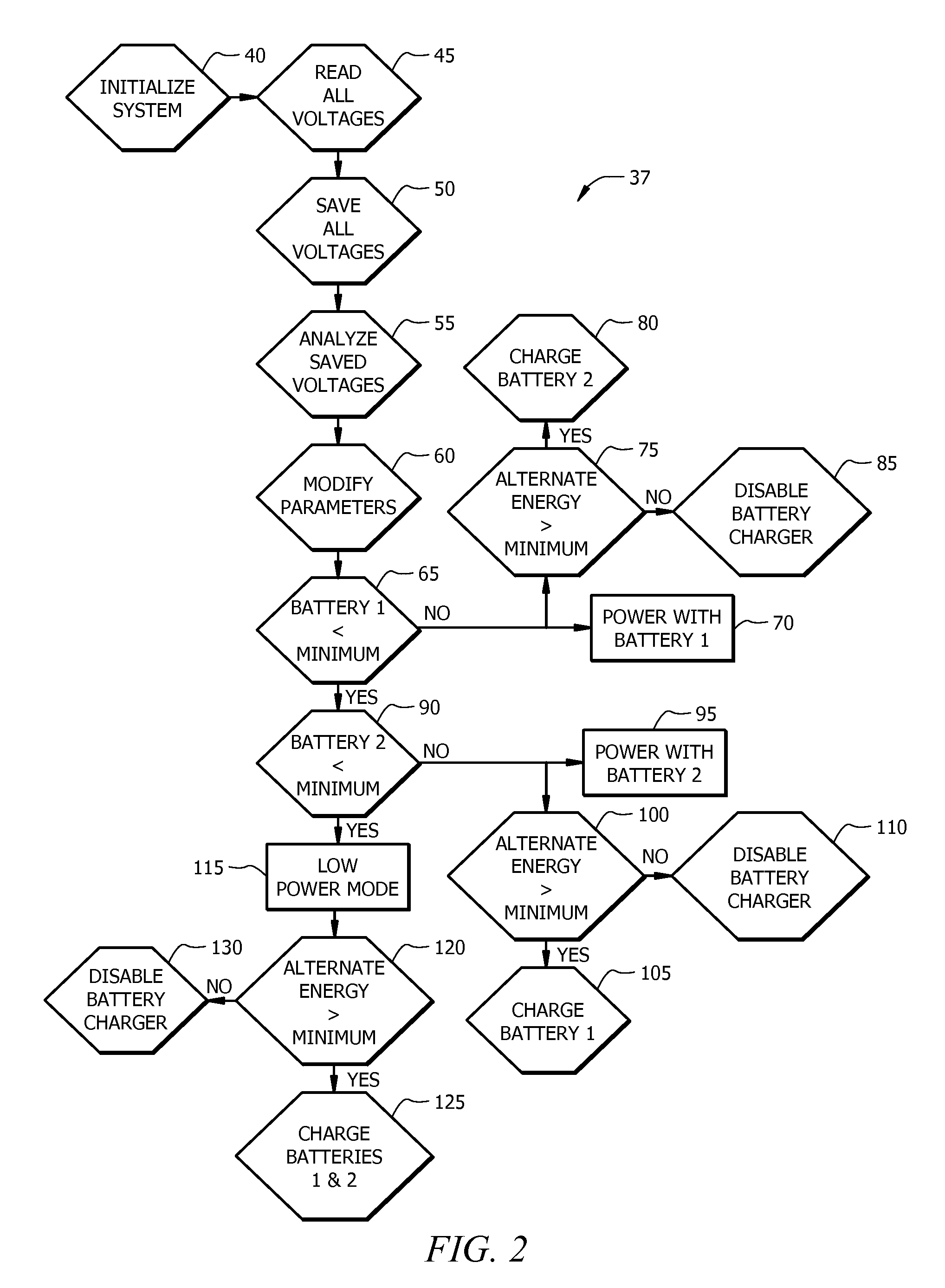

Adaptive power system

InactiveUS7385374B2Increased lifetime and uptimeProblems with reduction in battery life and battery memoryCharging managementDc source parallel operationElectric power systemEngineering

A power system having an extended life and a system and method for extending the life of a battery powered device. In one embodiment, the method comprises providing a plurality of power sources and an alternate energy source. The method also comprises measuring the voltage of the power sources and the alternate energy source. The method further comprises selecting a power source to provide voltage to the device, wherein the selected power source provides voltage to the device. In addition, the method comprises optionally charging any power source that is providing voltage to the device. Moreover, the method is repeated after a variable delay. Further embodiments include switching to providing the voltage to the device from a power source while charging another power source.

Owner:RICE UNIV

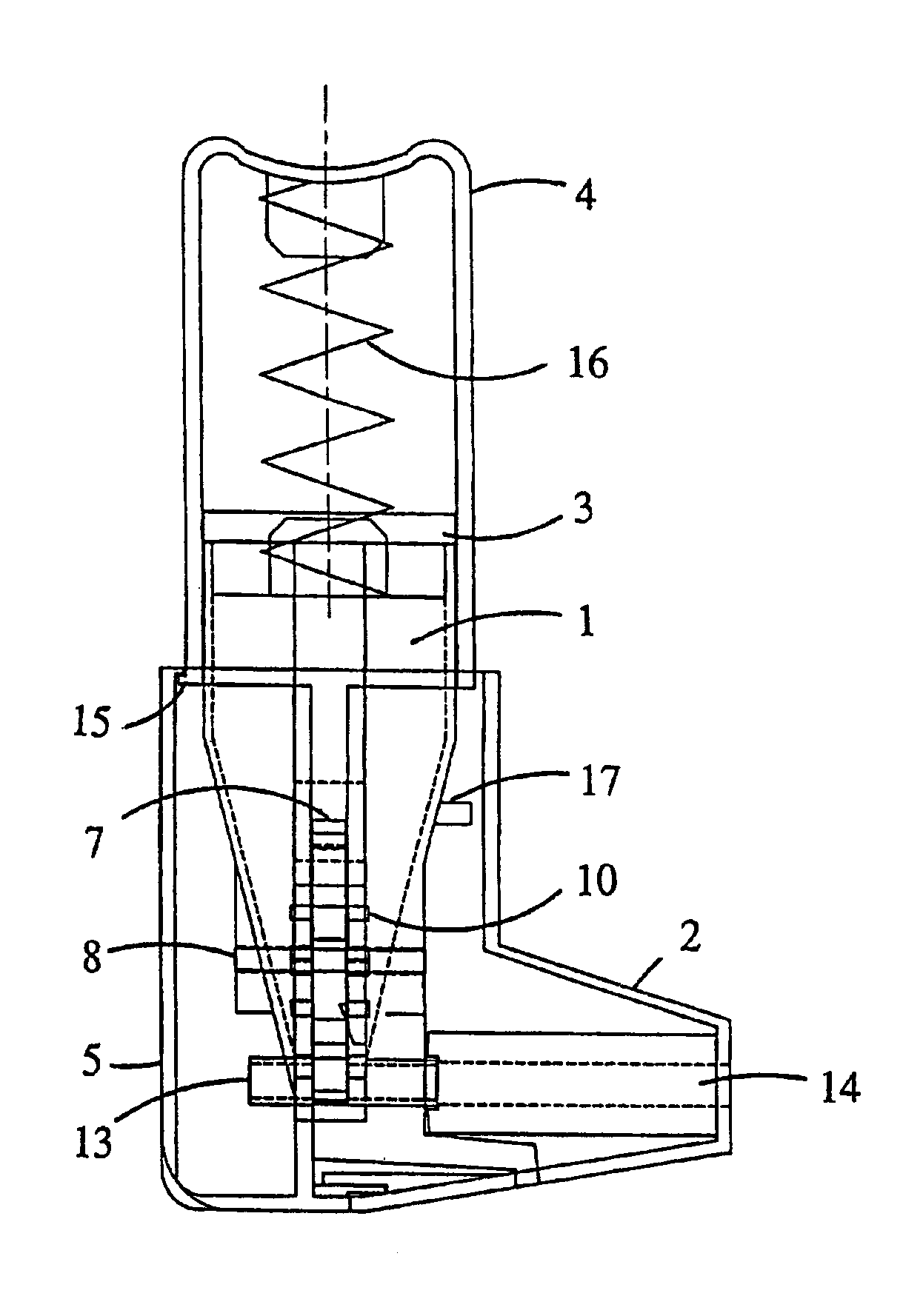

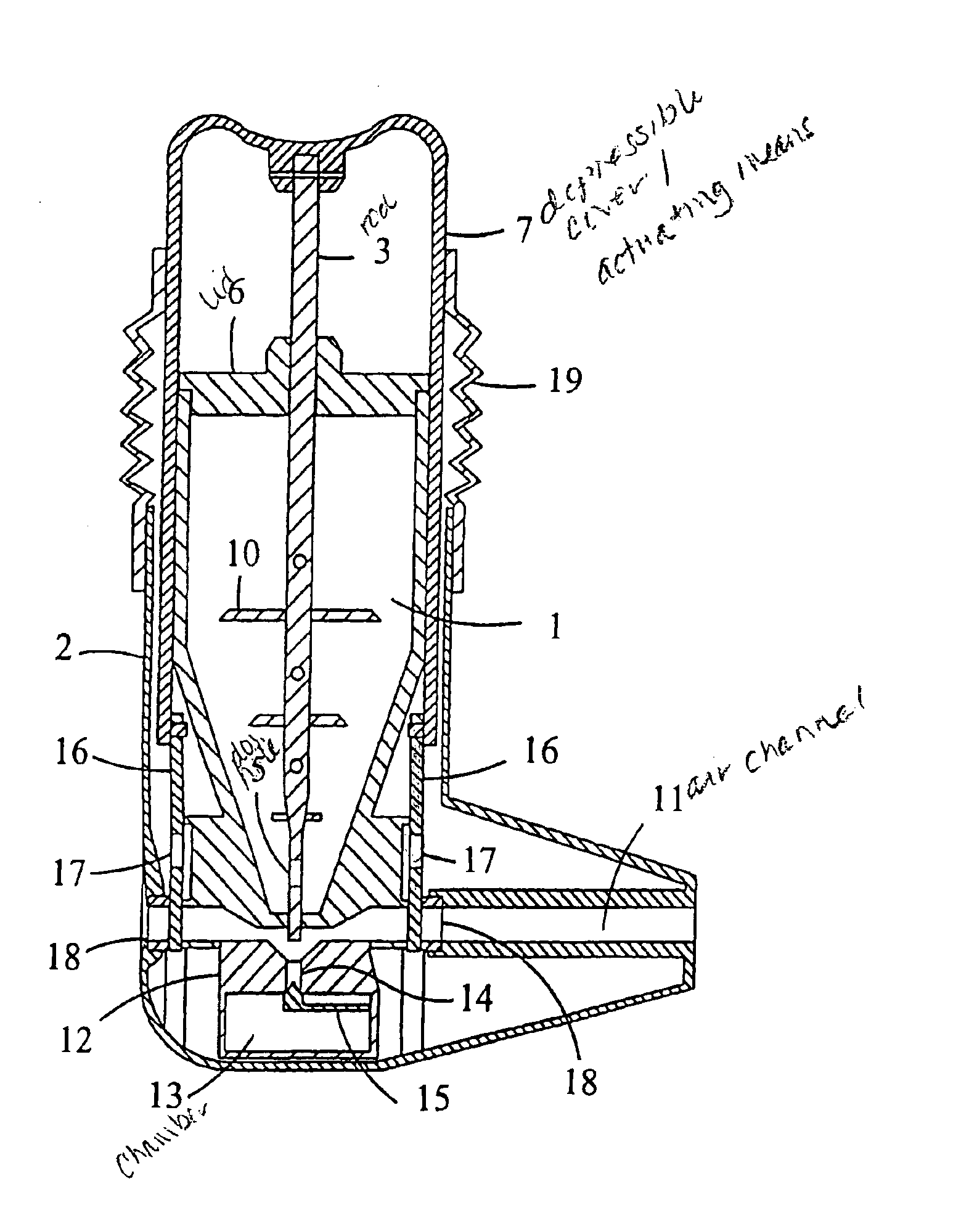

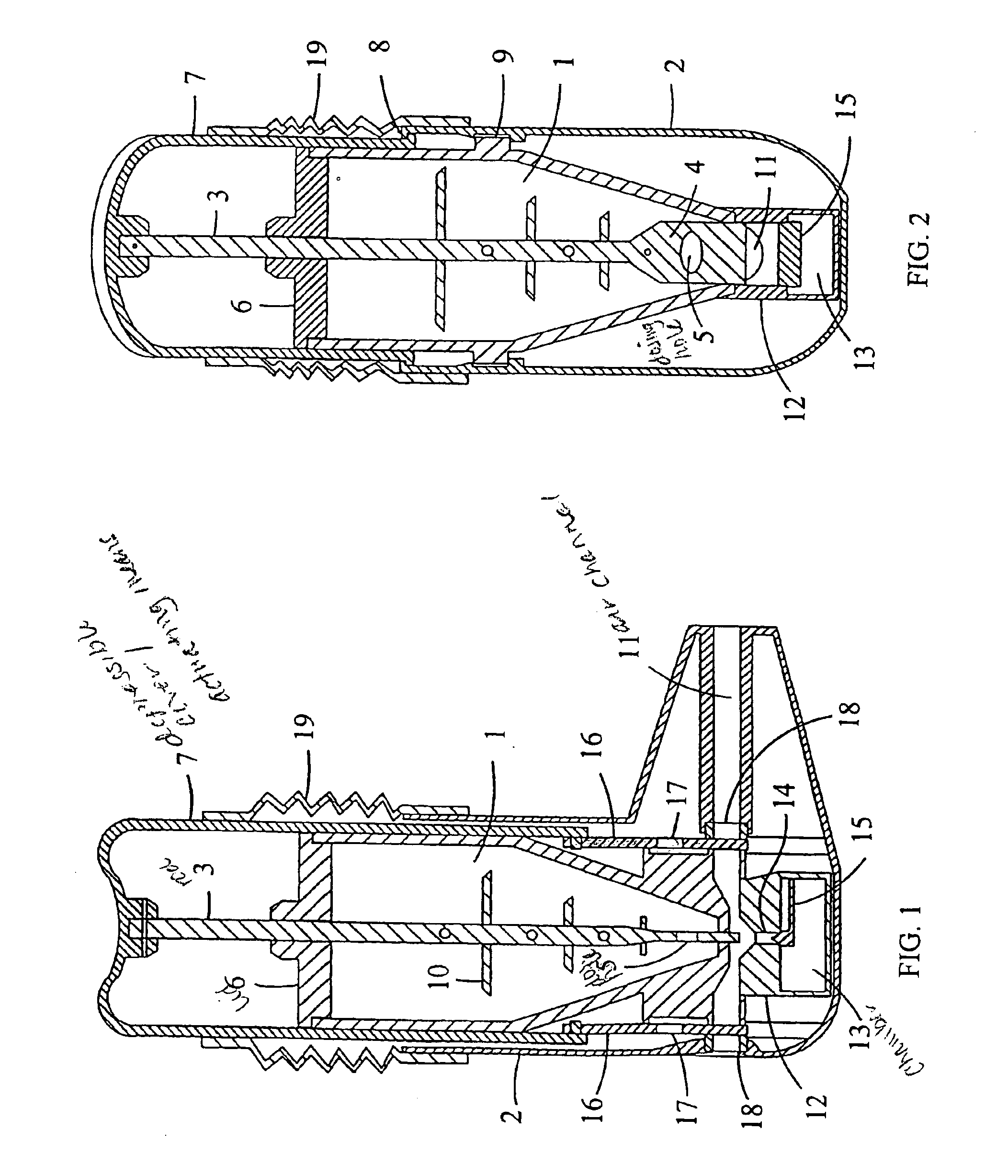

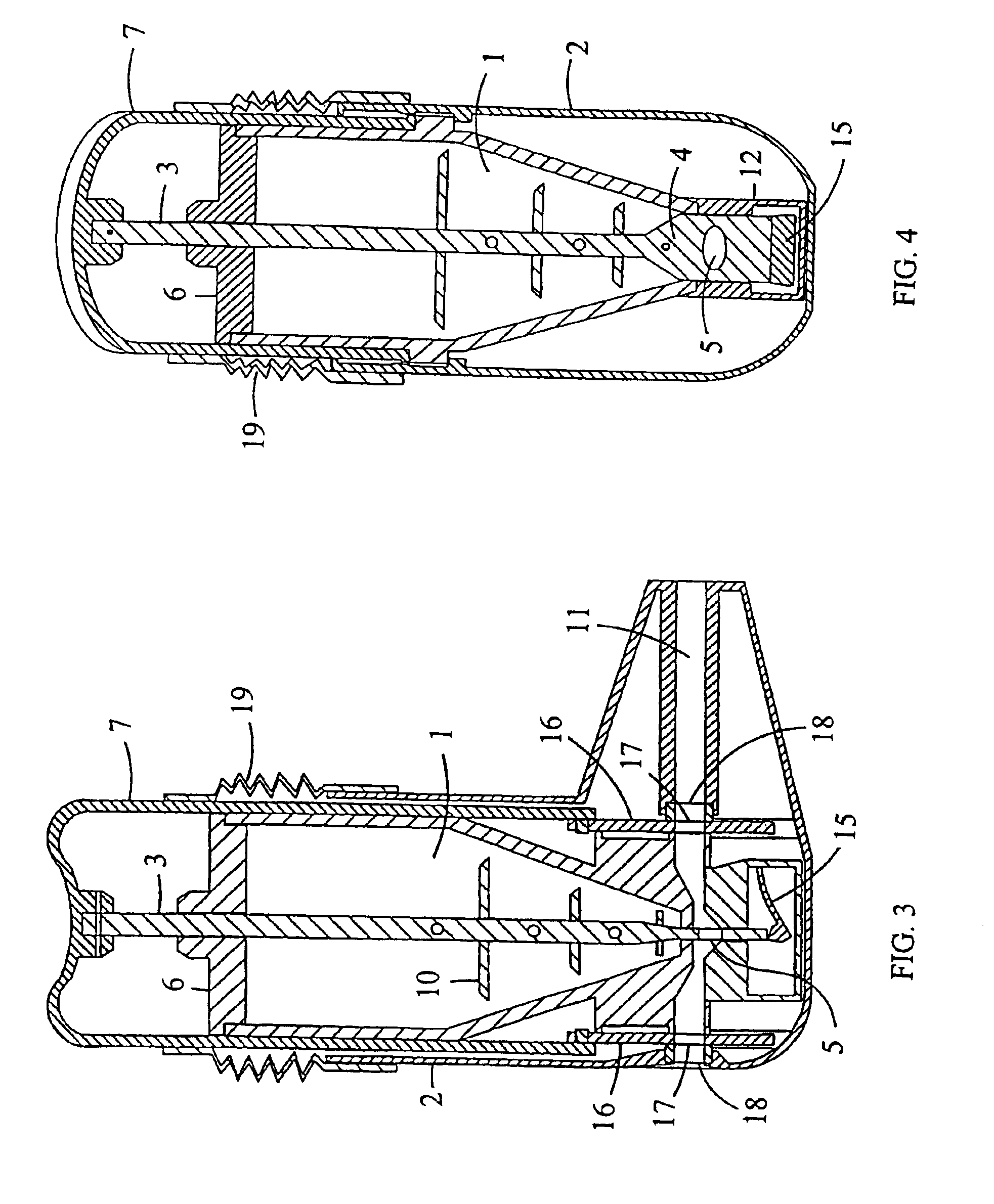

Multidose powder inhaler

InactiveUS6926003B2Good metering accuracyReduce capacityRespiratorsLiquid surface applicatorsDrugBiomedical engineering

A powder inhaler comprises a medicament container, a rotatable metering disc extending into the interior of the medicament container and an air channel through which air is drawn via a mouthpiece. The metering disc has one or more peripherally located dosing grooves extending axially through the metering disc. The dosing grooves are filled with a metered dose of the medicament while being inside the medicament container and are transferred to the air channel wherein the stream of inhaled air discharges the dose of the medicament directly from the dosing groove.

Owner:ORION CORP

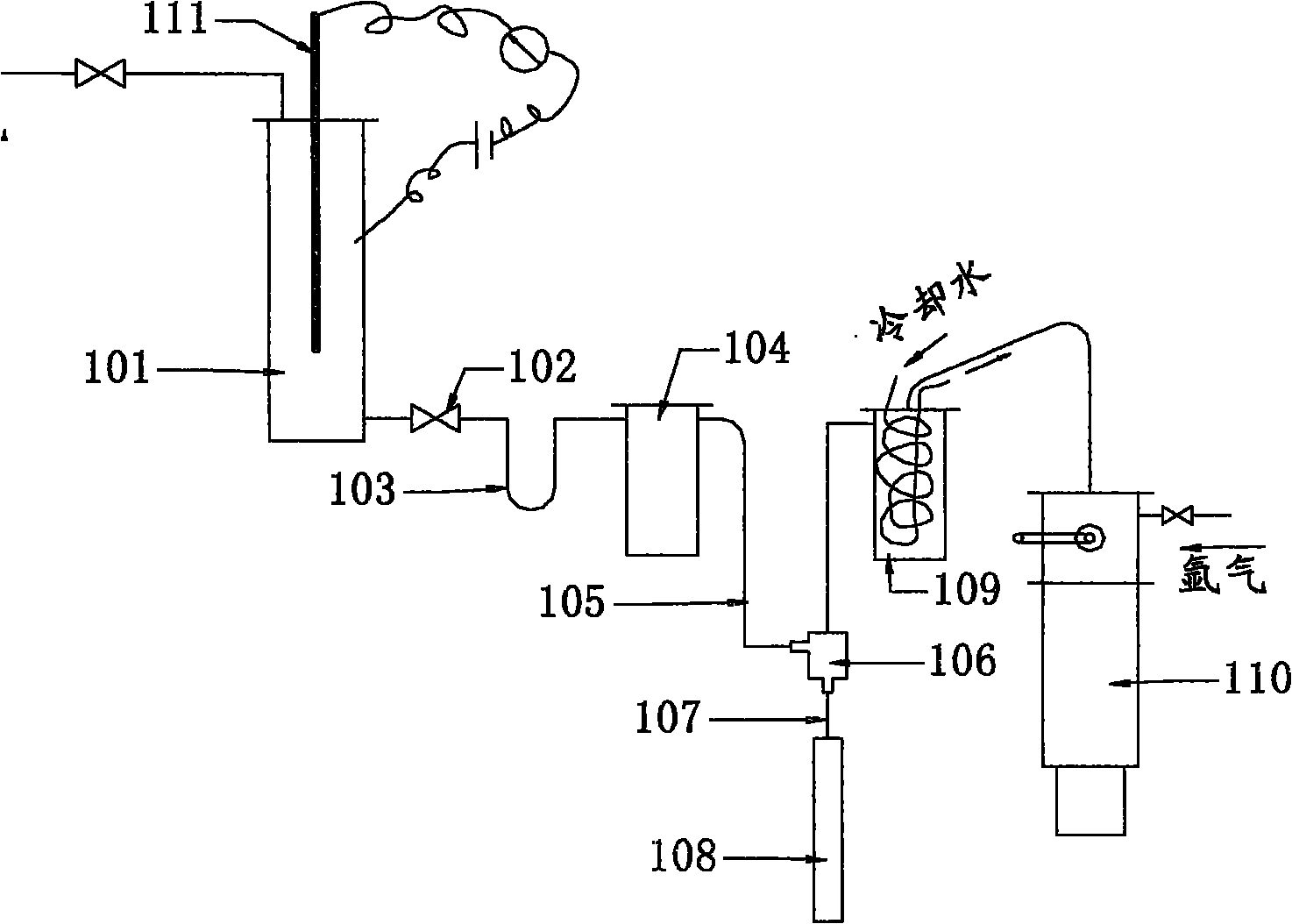

Accurate filling equipment and method for high temperature heat pipe requiring small amount of alkali metal working medium

InactiveCN102735084AEliminate throttling effectEasy accessIndirect heat exchangersProcess engineeringWater cooling

The invention discloses accurate filling equipment and an accurate filling method for a high temperature heat pipe requiring a small amount of alkali metal working medium and relates to a heat pipe technology. The accurate filling equipment comprises a main pipe, a branch, a branch sealing flange, a branch pipe storage tank, a branch pipe storage tank sealing upper flange, a heater, a first ultrahigh vacuum sealing valve, a second ultrahigh vacuum sealing valve, an ultrahigh vacuum molecule local unit, a main gas inlet pipe, an inert gas inlet pipe, an inert gas slim tube, a circulating water cooling pipe, an exhaust pipe and a transparent chamber for placing the solid working medium to be filled into the storage tank. The invention provides the high-efficiency accurate quantitative filling equipment and the high-efficiency accurate quantitative filling method for a small amount of alkali metal; and the oxidation of the alkali metal is reduced to the lowest degree.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

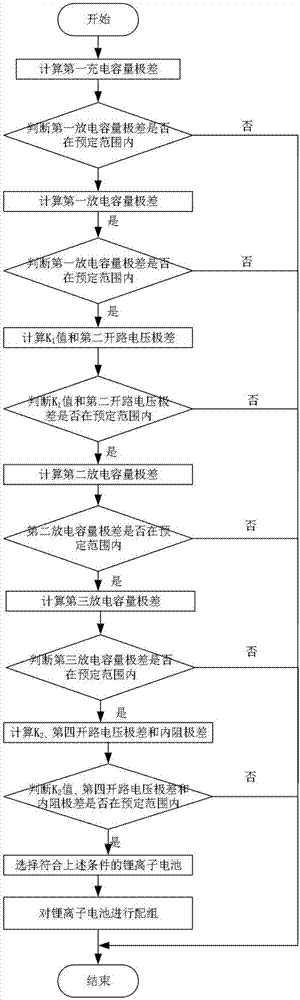

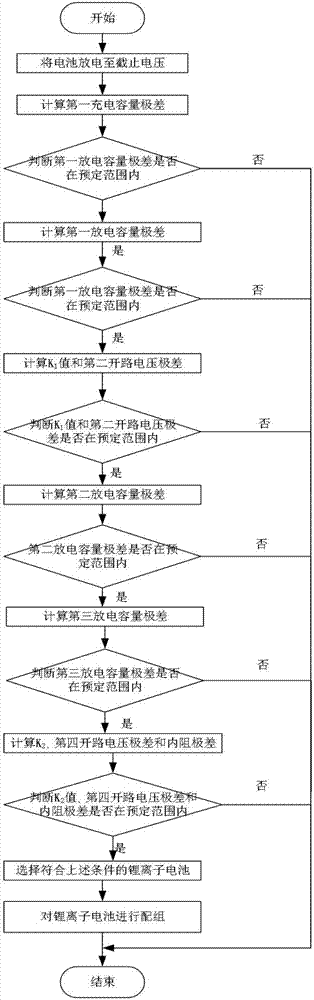

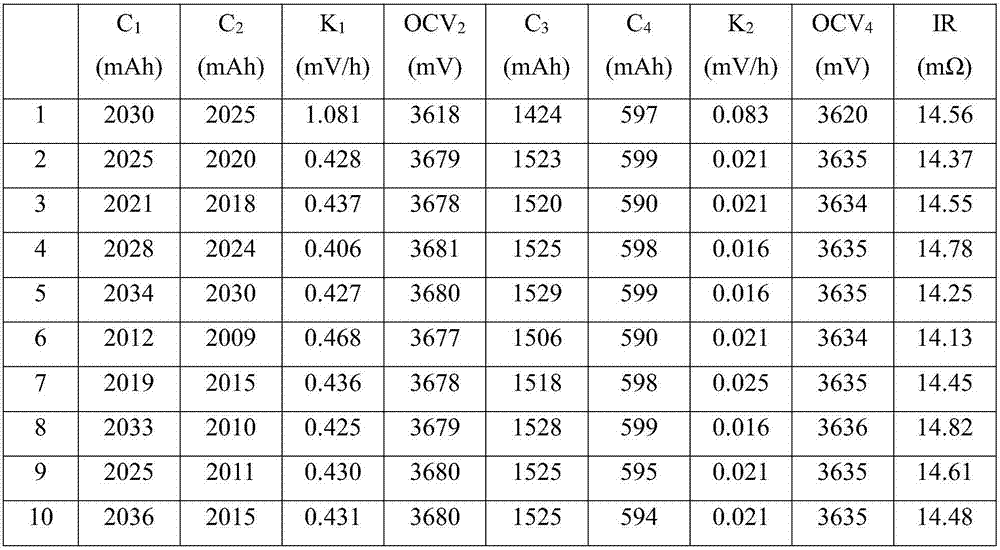

Combing method for lithium ion batteries

InactiveCN107579298AImprove consistencyReduce charge and discharge differencesFinal product manufactureSecondary cells charging/dischargingInternal resistanceLithium-ion battery

The invention relates to the technical field of lithium ion batteries, and specifically relates to a combing method for lithium ion batteries. The combining method for the lithium ion battery comprises the following steps: carrying out repeated charging and discharging on a plurality of lithium ion batteries under different charging and discharging conditions, measuring and calculating charging capacity range, discharging capacity range, open-circuit voltage, self-discharge value and the internal resistance of the batteries in the charging and discharging process, screening the lithium ion batteries, and combining the lithium ion batteries meeting conditions so as to form a battery pack. Screening for combining conditions is carried out on the lithium ion batteries under different electricquantities, so that the voltage electrode range of the single lithium ion batteries at the tail end moment of high-current discharging fro the single lithium ion batteries in the same group after screening is small, and the discharging uniformity of the lithium ion batteries is improved.

Owner:江苏海四达电源有限公司

Three-degree-of-freedom self-walking minitype shield machine

Owner:CHINA UNIV OF MINING & TECH

Backside illuminated imaging device, semiconductor substrate, imaging apparatus and method for manufacturing backside illuminated imaging device

InactiveUS7781715B2Reduce sensitivityPrevent degradationSolid-state devicesMaterial analysis by optical meansSemiconductorElectrode

A backside illuminated imaging device performs imaging by illuminating light from a back side of a p substrate to generate electric charges in the substrate based on the light and reading out the electric charges from a front side of the substrate. The device includes n layers located in the substrate and on an identical plane near a front side surface of the substrate and accumulating the electric charges; n+ layers between the respective n layers and the front side of the substrate, the n+ layers having an exposed surface exposed on the front side surface of the substrate and functioning as overflow drains for discharging unnecessary electric charges accumulated in the n layers; p+ layers between the respective n+ layers and the n layers and functioning as overflow barriers of the overflow drains; and an electrode connected to the exposed surface of each of the n+ layers.

Owner:FUJIFILM CORP

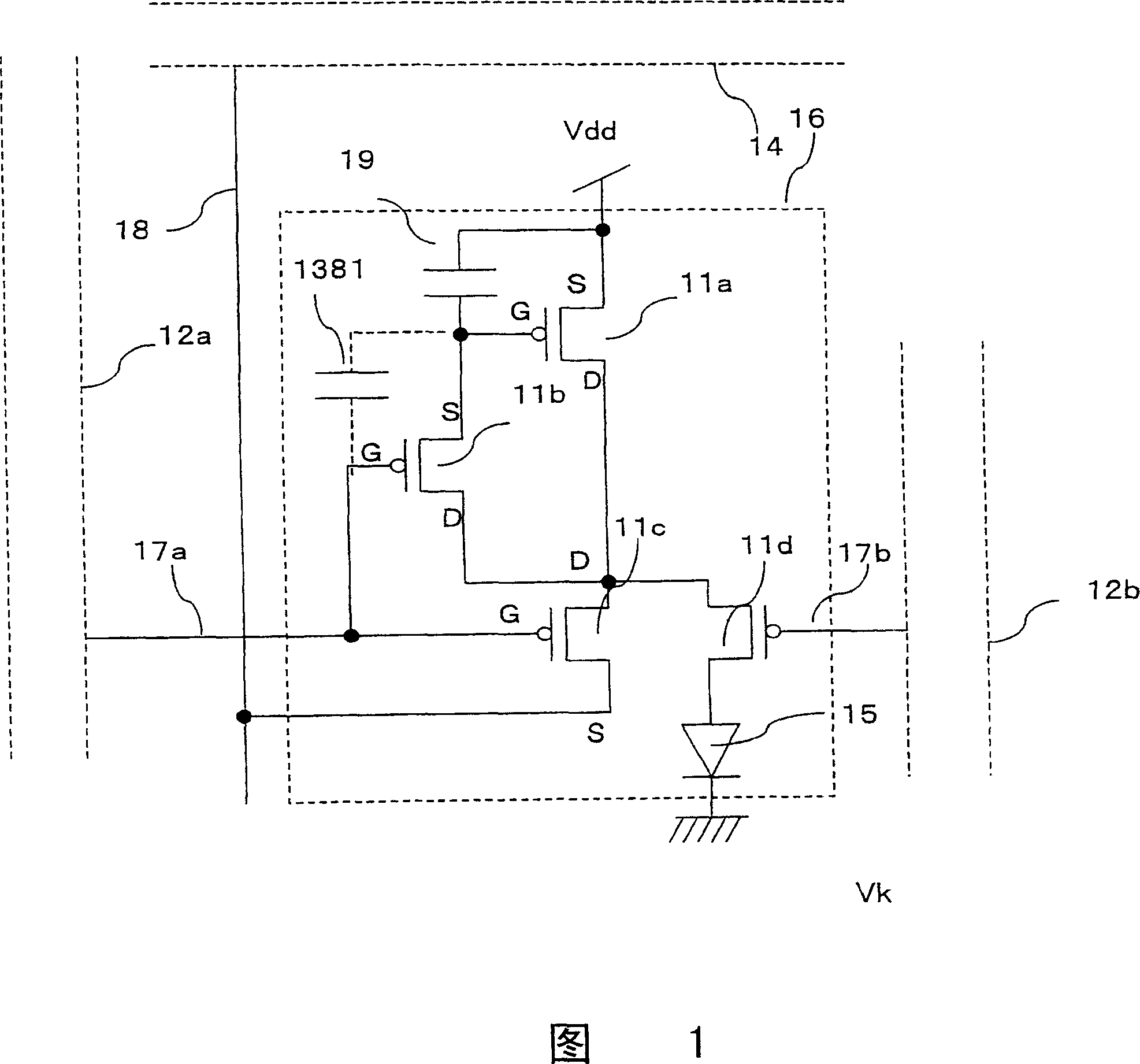

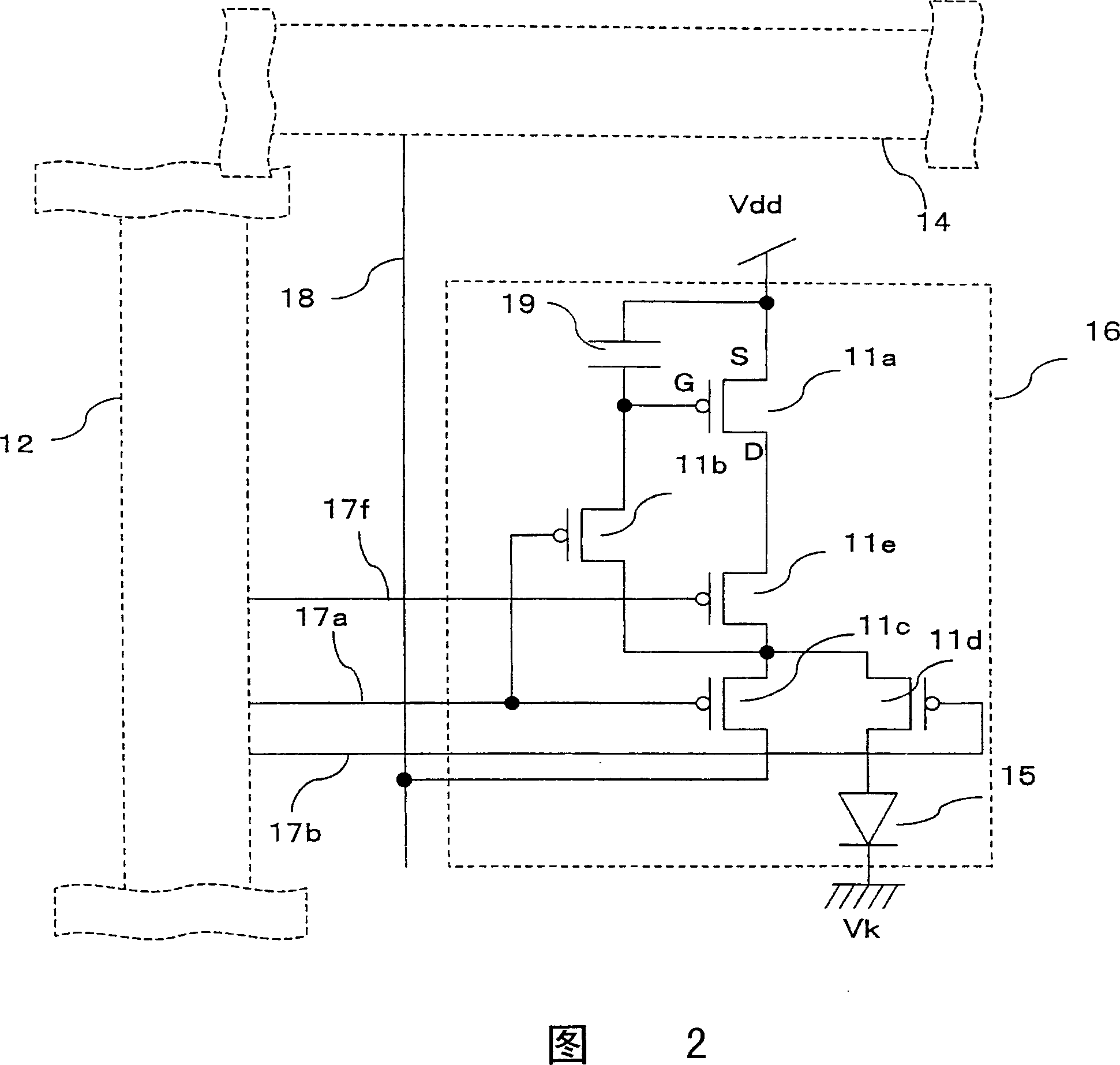

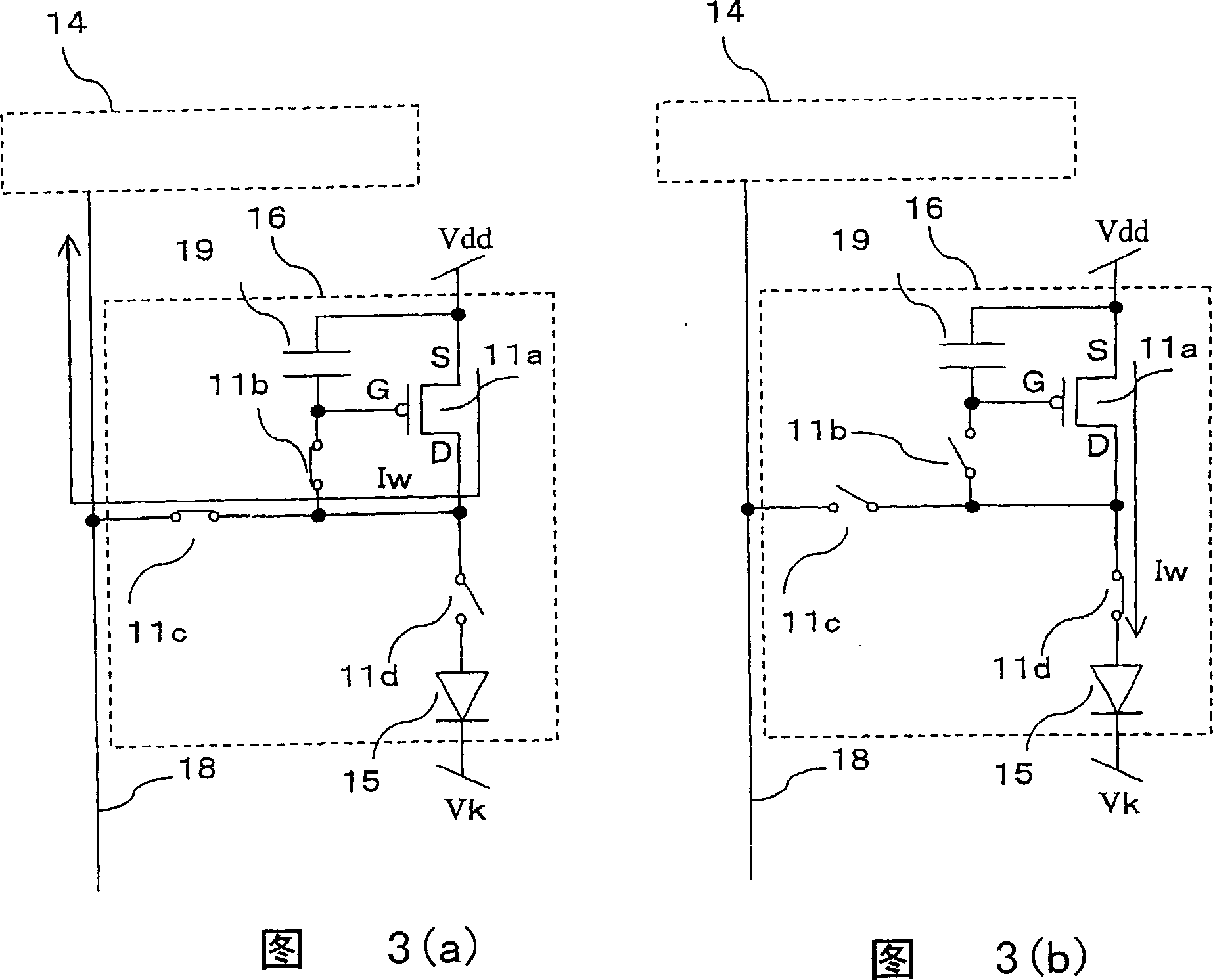

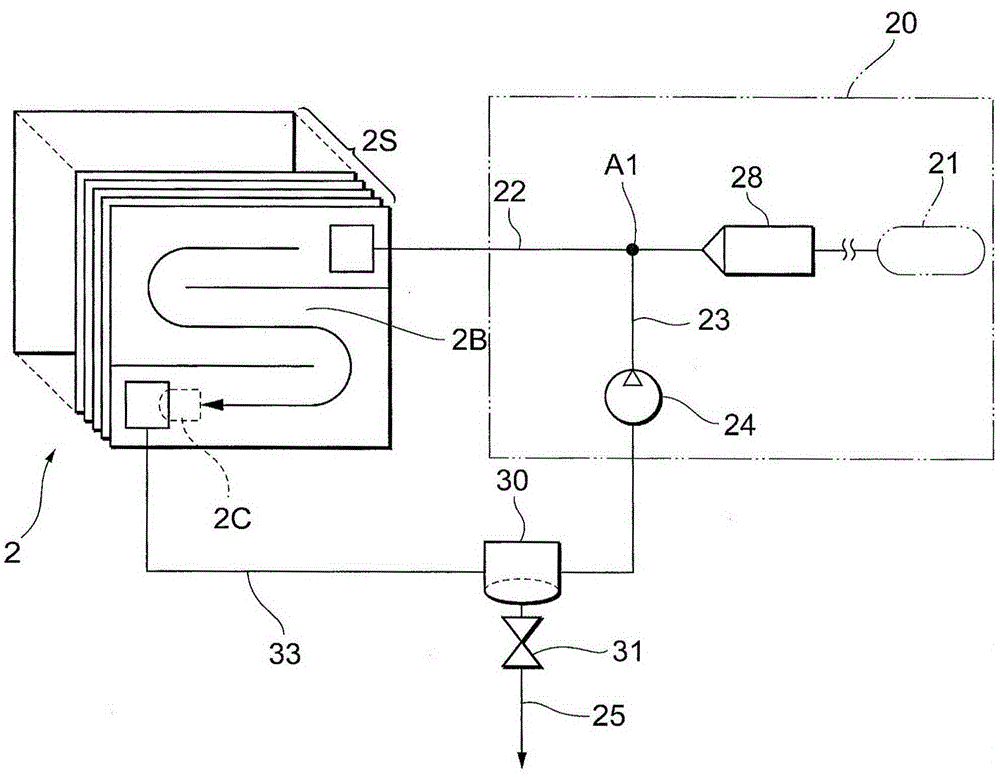

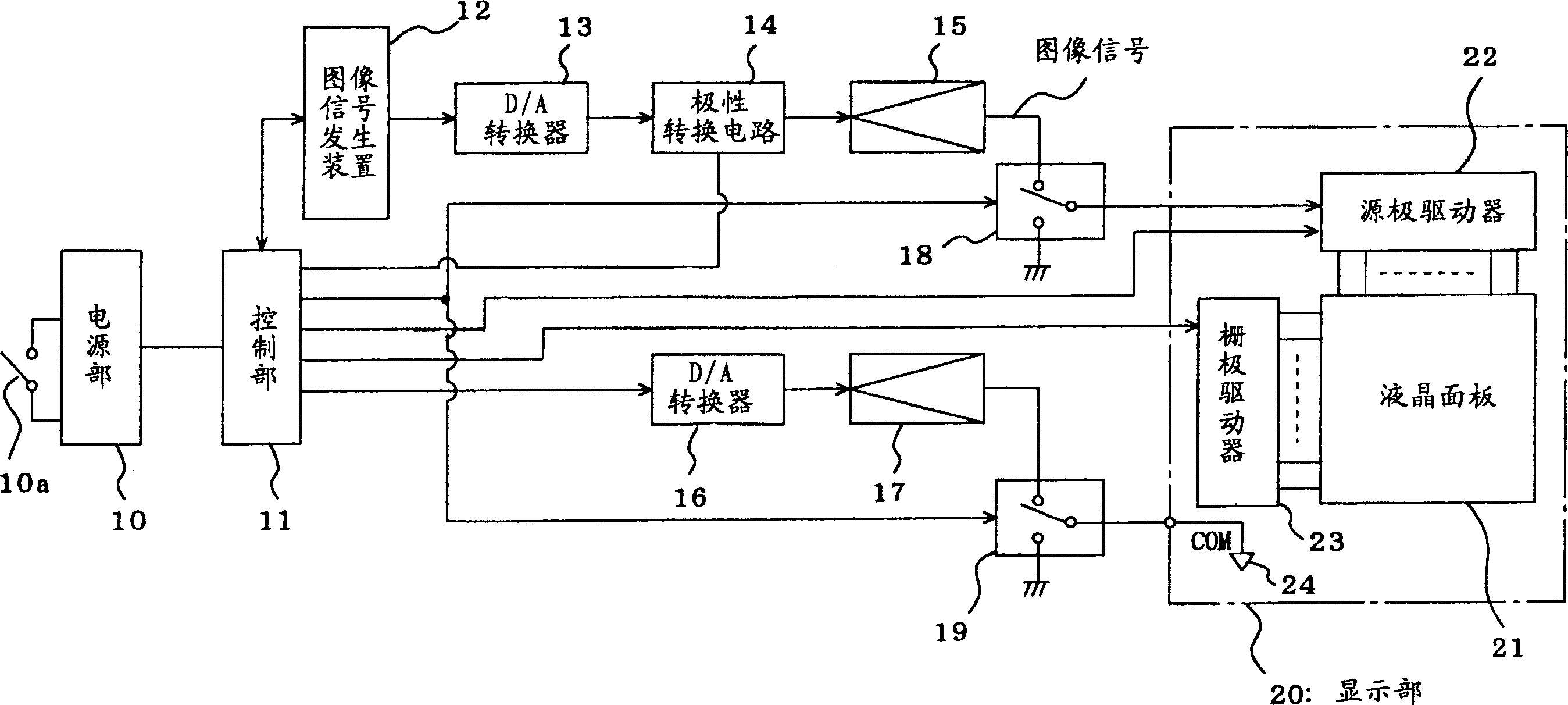

Electroluminescence display device and its detection method

InactiveCN1971695AFully chargedDischarge fullyCurrent/voltage measurementStatic indicating devicesParasitic capacitanceDisplay device

In order to adequately charge / discharging a parasitical capacitor of a source signal line and program a predetermined current value to a pixel transistor, a relative large current must be outputted from a source excited circuit. However, if a so large current flows through the source signal line, the current value is programmed into pixels, that induces a current large than a needed current passed through an EL component 15. For example, if programing is performed by using a 10 times current, the 10 times current flows through the EL component 15 so that the EL component 15 is lighted with a 10 times lightness. The time for current flowing through the EL component is reduced to 1 / 10 of a frame (1F) to obtain a predetermined transmitting lightness.

Owner:JAPAN DISPLAY CENTRAL CO LTD

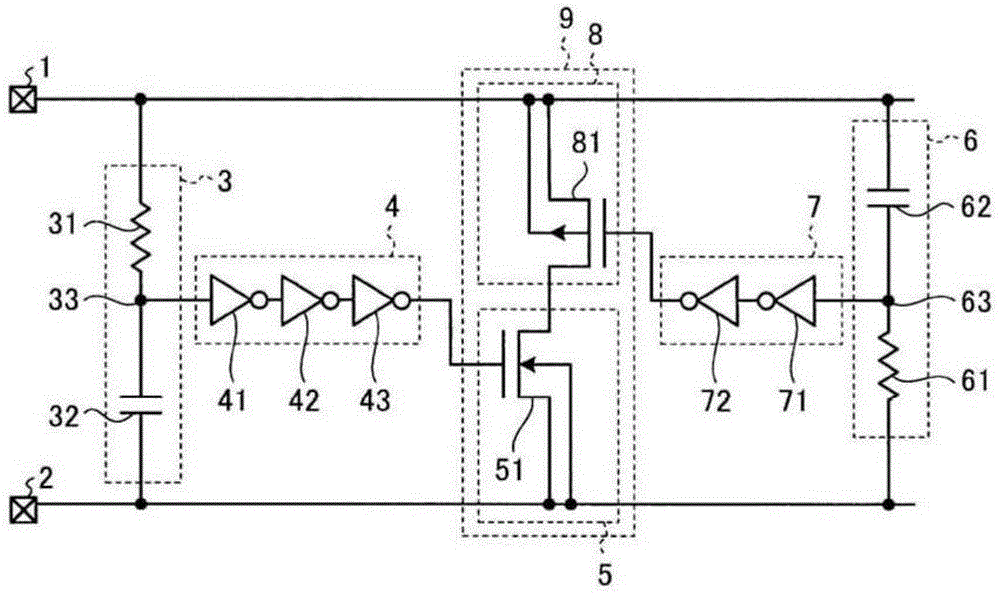

Electrostatic protection circuit

InactiveCN104836217ADischarge fullySolid-state devicesEmergency protective arrangements for limiting excess voltage/currentEngineeringElectrical and Electronics engineering

According to one embodiment, an electrostatic protection circuit includes a first trigger circuit that is connected between a first power supply terminal and a second power supply terminal, and a second trigger circuit. The circuit includes a first buffer circuit that outputs a drive signal in response to a trigger signal of the first trigger circuit, and a second buffer circuit that outputs a drive signal in response to a trigger signal of the second trigger circuit. A shunt circuit includes a first switch circuit and a second switch circuit connected in series between the first and second power supply terminals. A conduction of the first switch circuit is controlled by a drive signal of the first buffer circuit, and a conduction of the second switch circuit is controlled by a drive signal of the second buffer circuit.

Owner:KK TOSHIBA

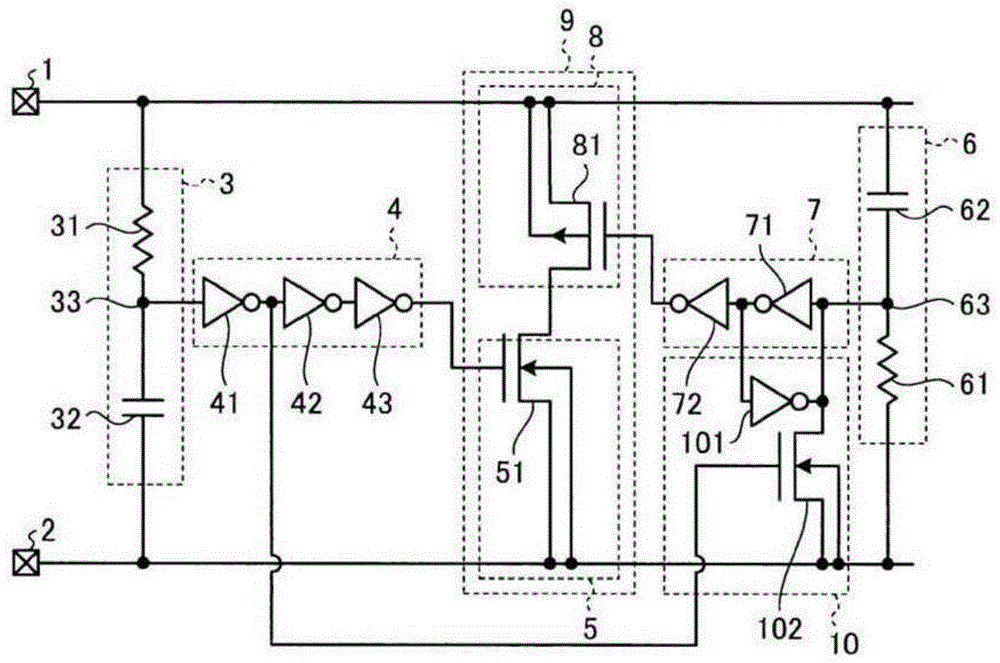

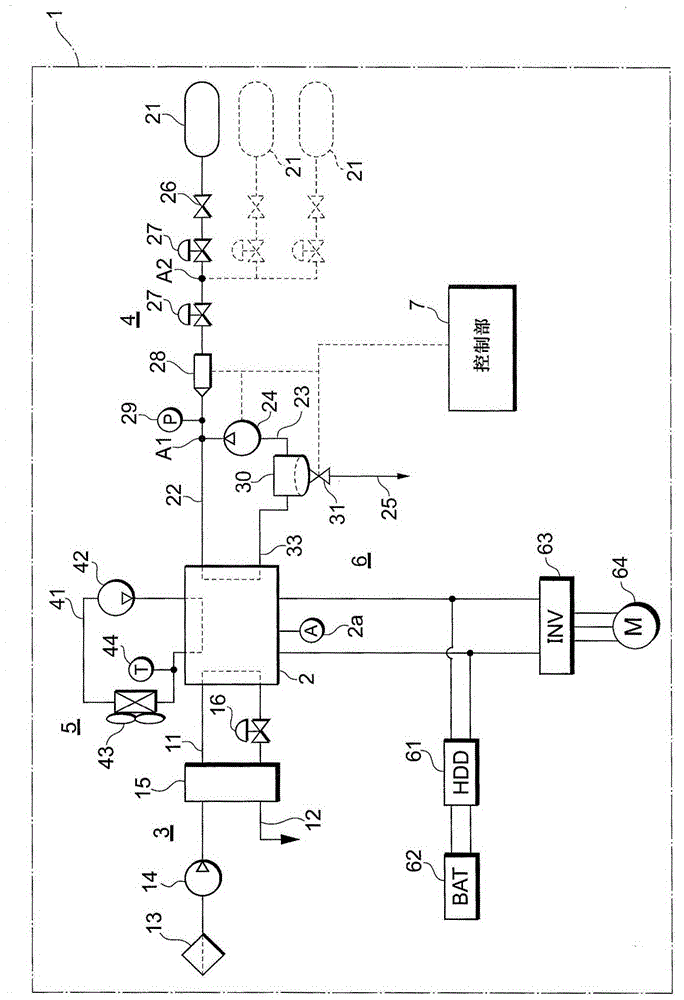

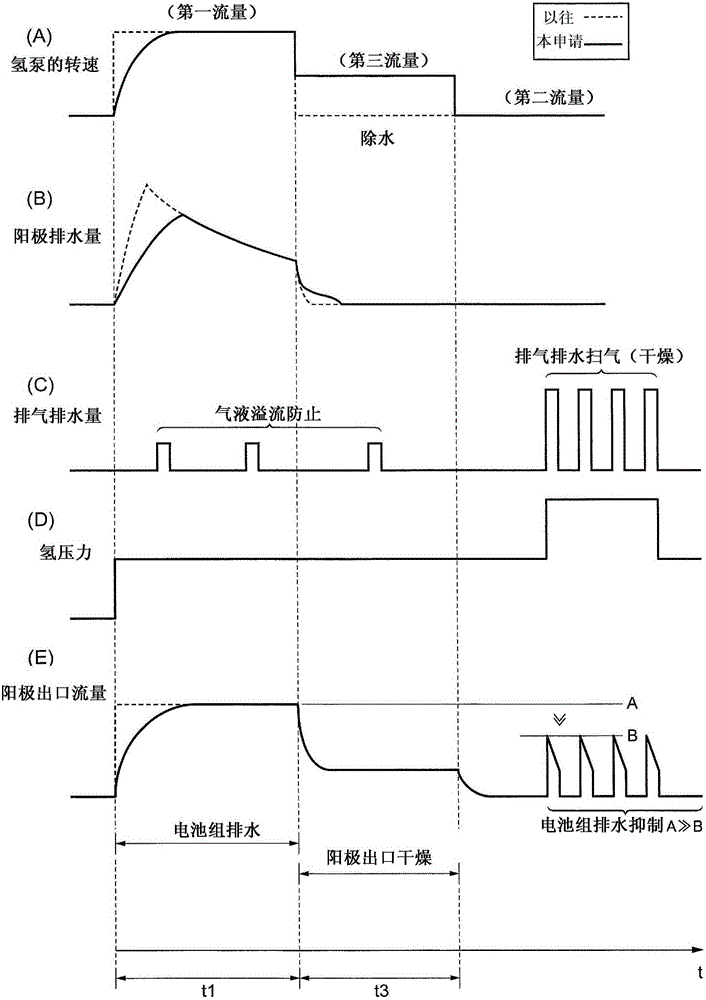

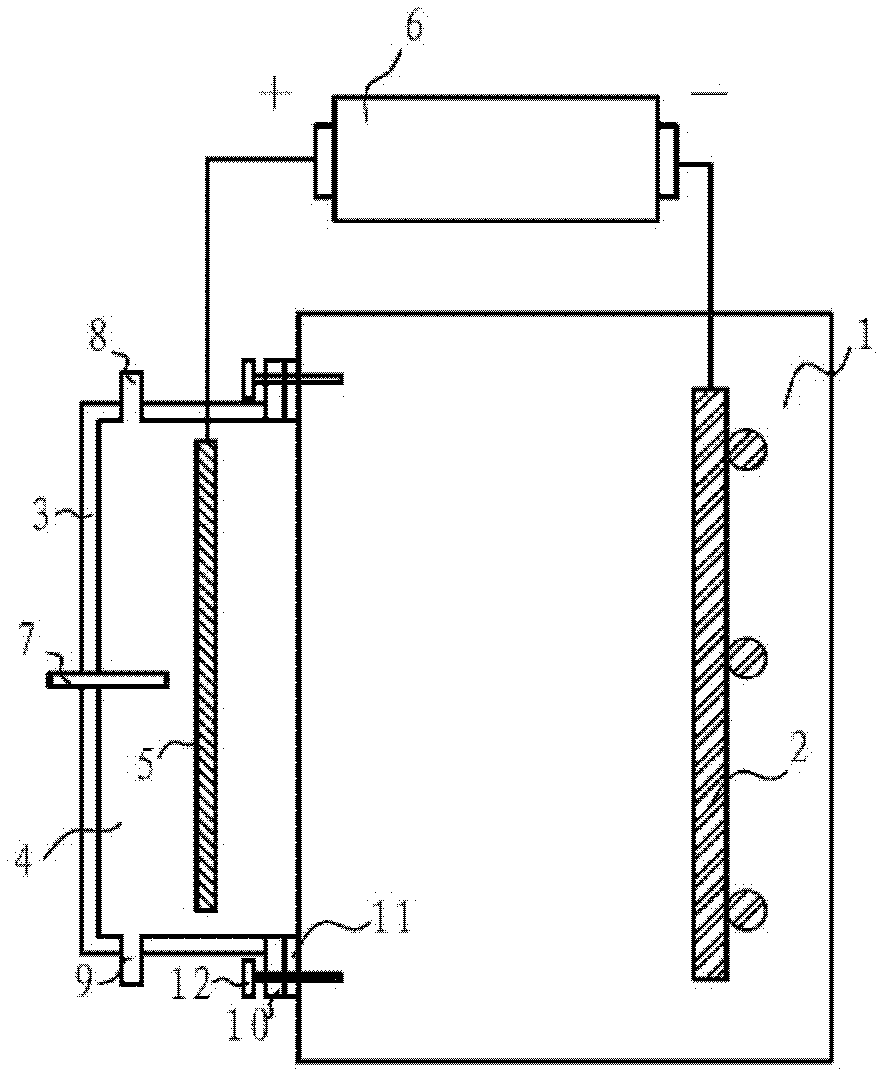

Fuel cell system and method for discharging fluid in the system

ActiveCN105609827AAvoid residueDischarge fullyReactant parameters controlWater management in fuel cellsHydrogenFuel cells

There is provided a fuel cell system, wherein a controller configured to set the flow volume of a fluid in an anode flow path at an outlet of an anode of the fuel cell to a first flow volume, then set thereafter the flow volume of the fluid in the anode flow path at the outlet of the anode to a second flow volume which is smaller than the first flow volume, and discharge the water in the hydrogen discharge flow path by opening an exhaust and drain valve while the fluid is flowing at the second flow volume.

Owner:TOYOTA JIDOSHA KK

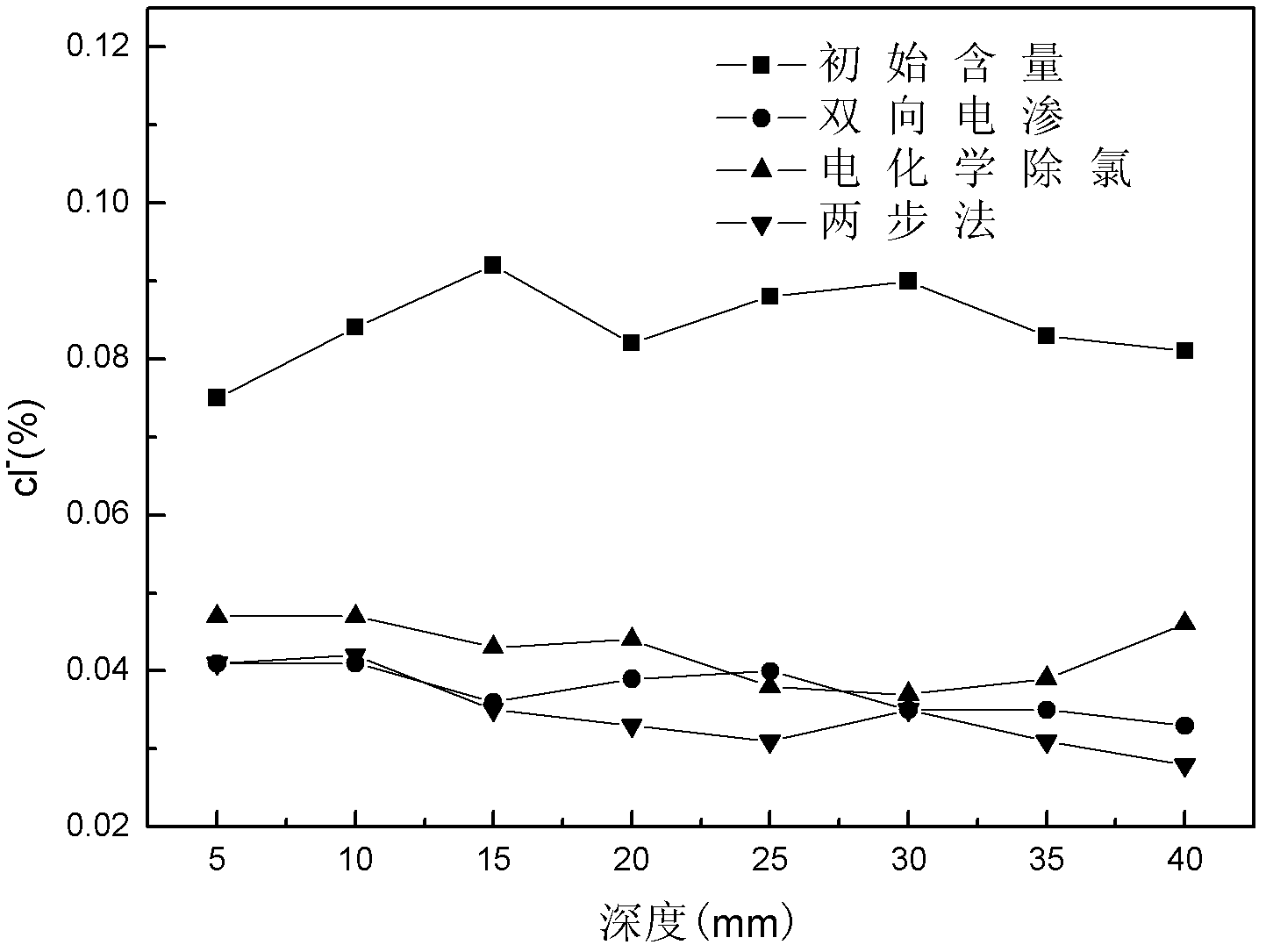

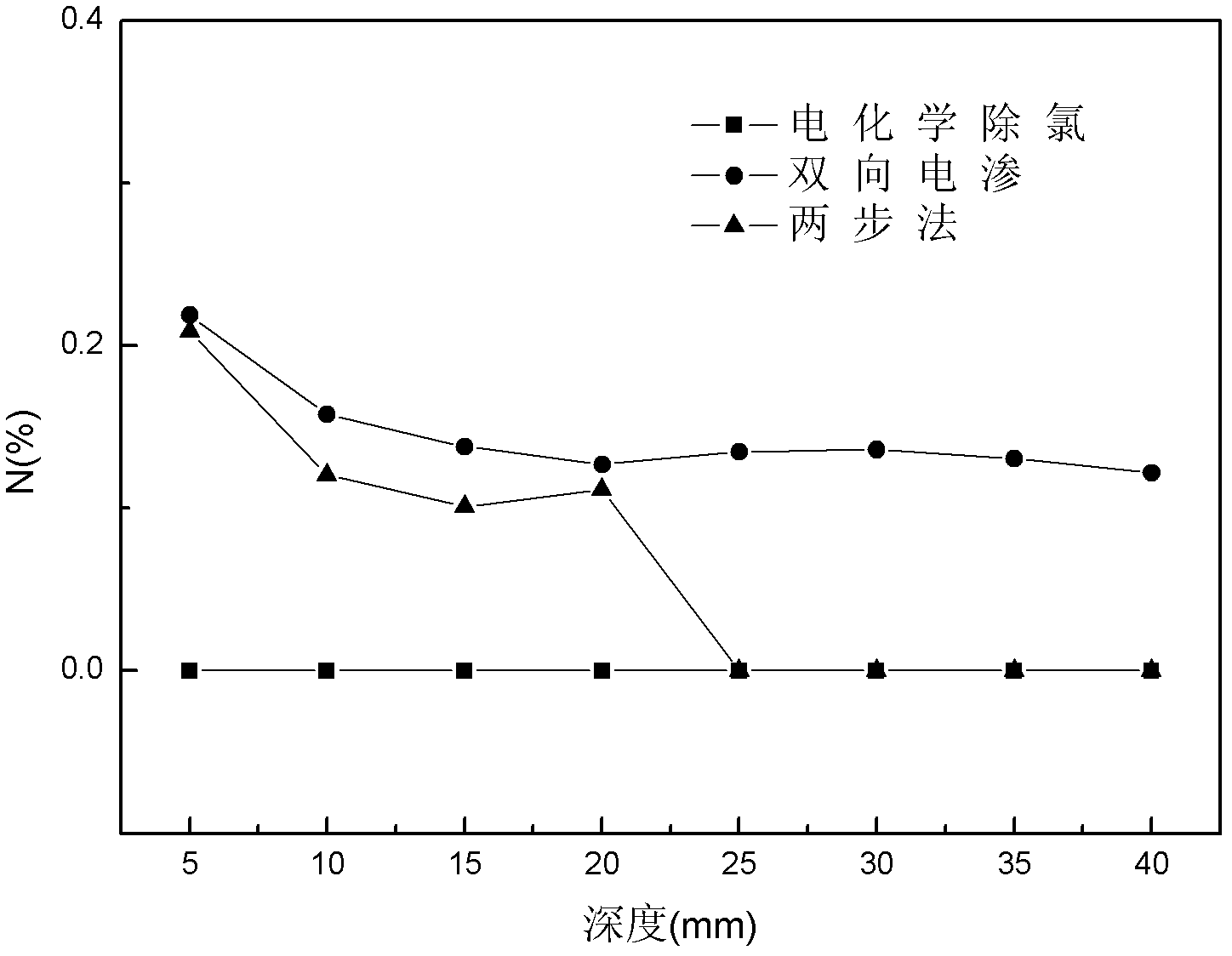

Device and method for repairing concrete structure damaged by salt through two-step process

The invention discloses a device for repairing a concrete structure damaged by salt through two-step process, including a steel bar that acts as a cathode and is disposed in concrete, an electrolytic tank whose mouth is in seal seal fit with a surface of the concrete, electrolyte disposed in the electrolytic groove, an anode immersed in the electrolyte and a direct current power supply for providing power to the cathode and the anode, wherein the electrolytic groove is provided with an electrolyte inlet, an electrolyte outlet and a pH indicator, a probe of the pH indicator penetrating througha wall of the electrolytic groove and contacting with the electrolyte. The device provided in the invention is capable of timely replacement of electrolyte which is conducive to full discharge of chloride ions, and is capable of real-time monitoring of the ph value of the electrolyte, being applicable to concrete structures of various kinds of shapes; in addition, the device has the advantages ofsimple structure, convenient operation and effective removal of the chloride ions in a concrete protective layer with the removal efficiency achieving about 60%; further, the device can raise the corrosion potential of a corroded steel bar, decrease corrosion rate, realize the repassivation and maximumly repair a concrete structure damaged by salt.

Owner:浙大宁波理工学院

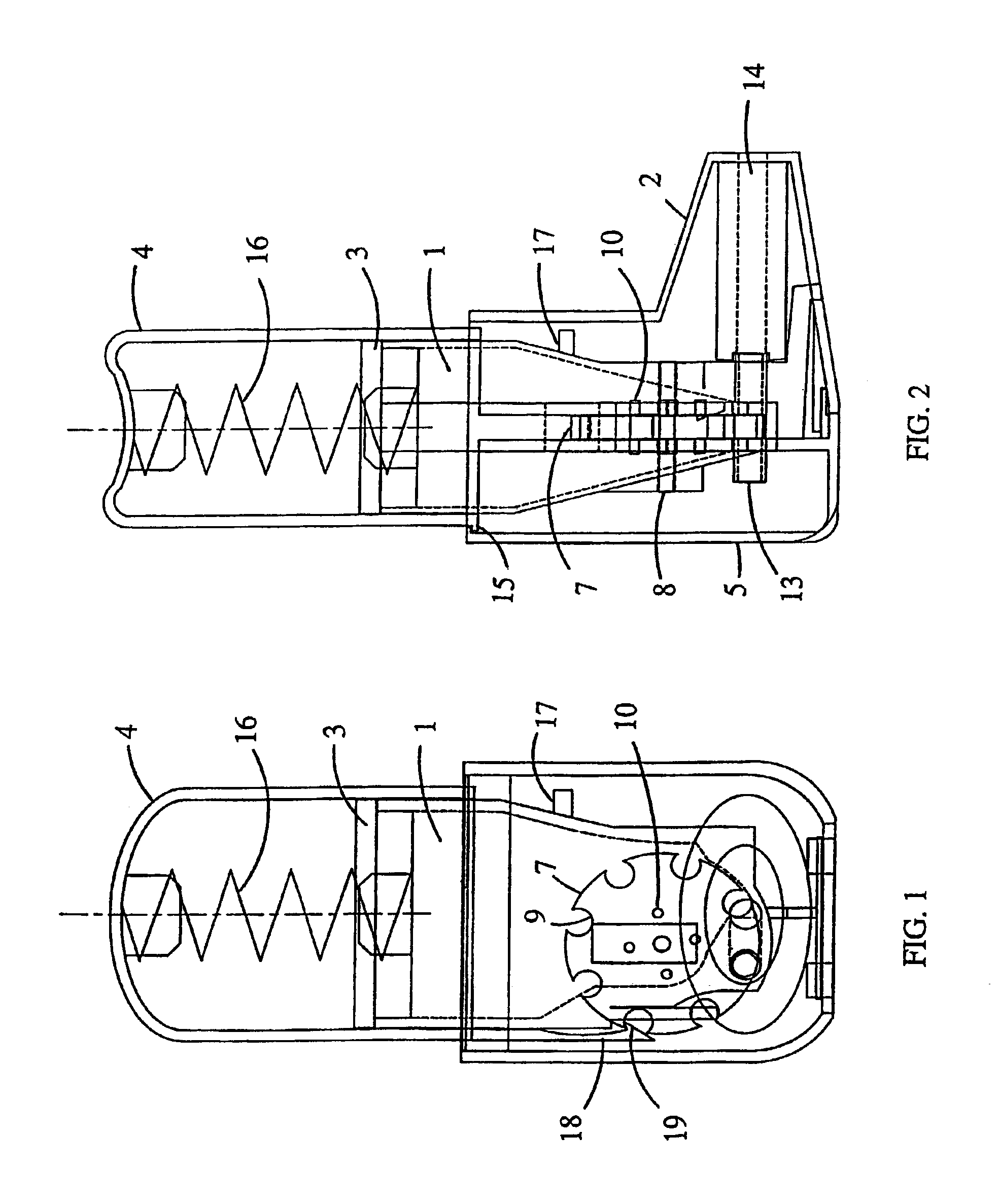

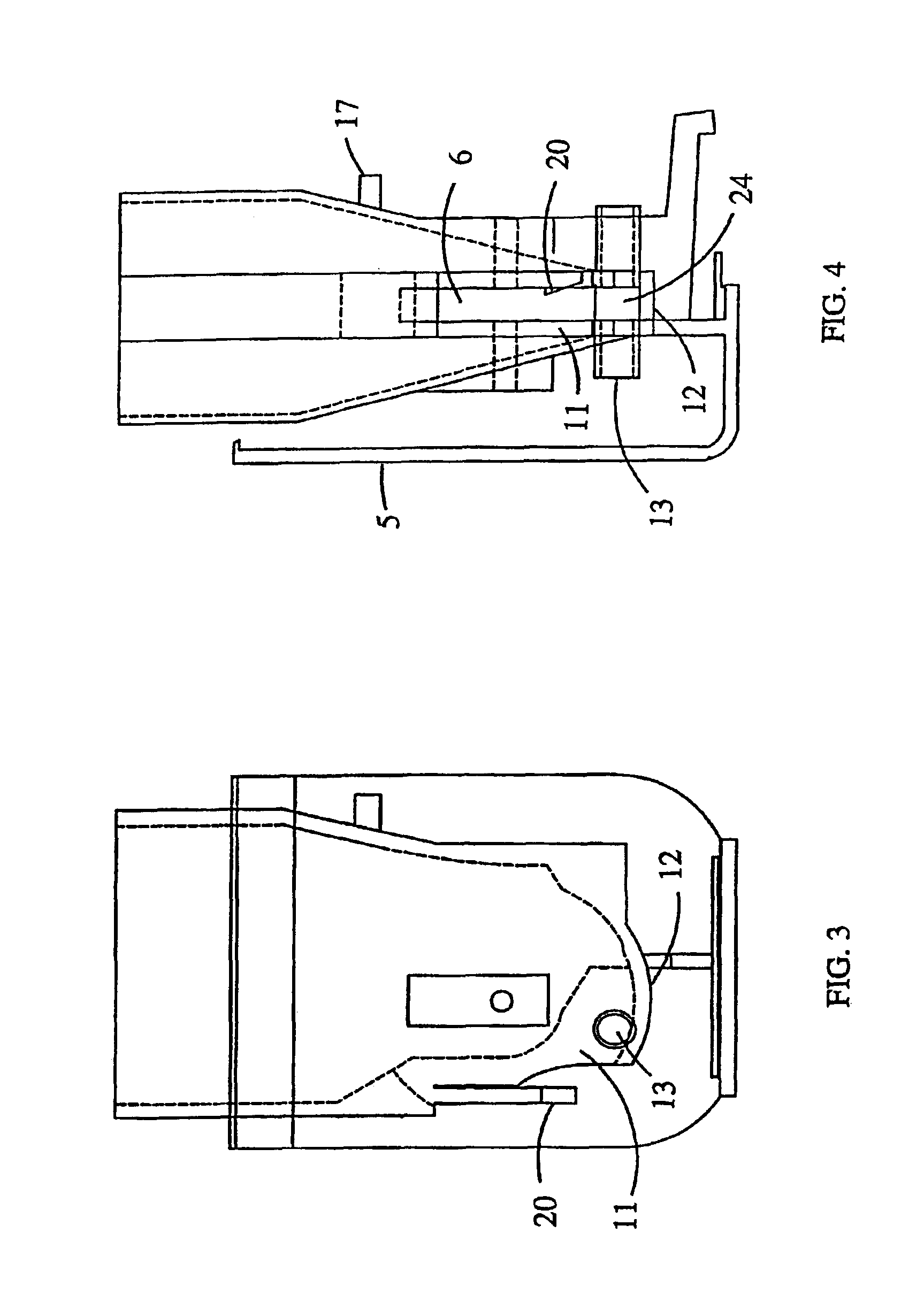

Moisture protected powder inhaler

InactiveUS6886560B1Improve accuracyAvoid disadvantagesRespiratorsLiquid surface applicatorsPowder InhalerInhalation

A powder inhaler comprising a powder container, an air channel, a metering member equipped with a dosing recess, an actuating means for the displacement of the metering member between the filling and the inhalation position, and a closure element for plugging the air channel in a substantially water-proof manner when the metering member is in the filling position and opening the air channel when the metering member is in the inhalation position. When the inhaler is not in use, the closure element prevents moisture and dirt from entering the sensitive parts of the device.

Owner:ORION CORPORATION

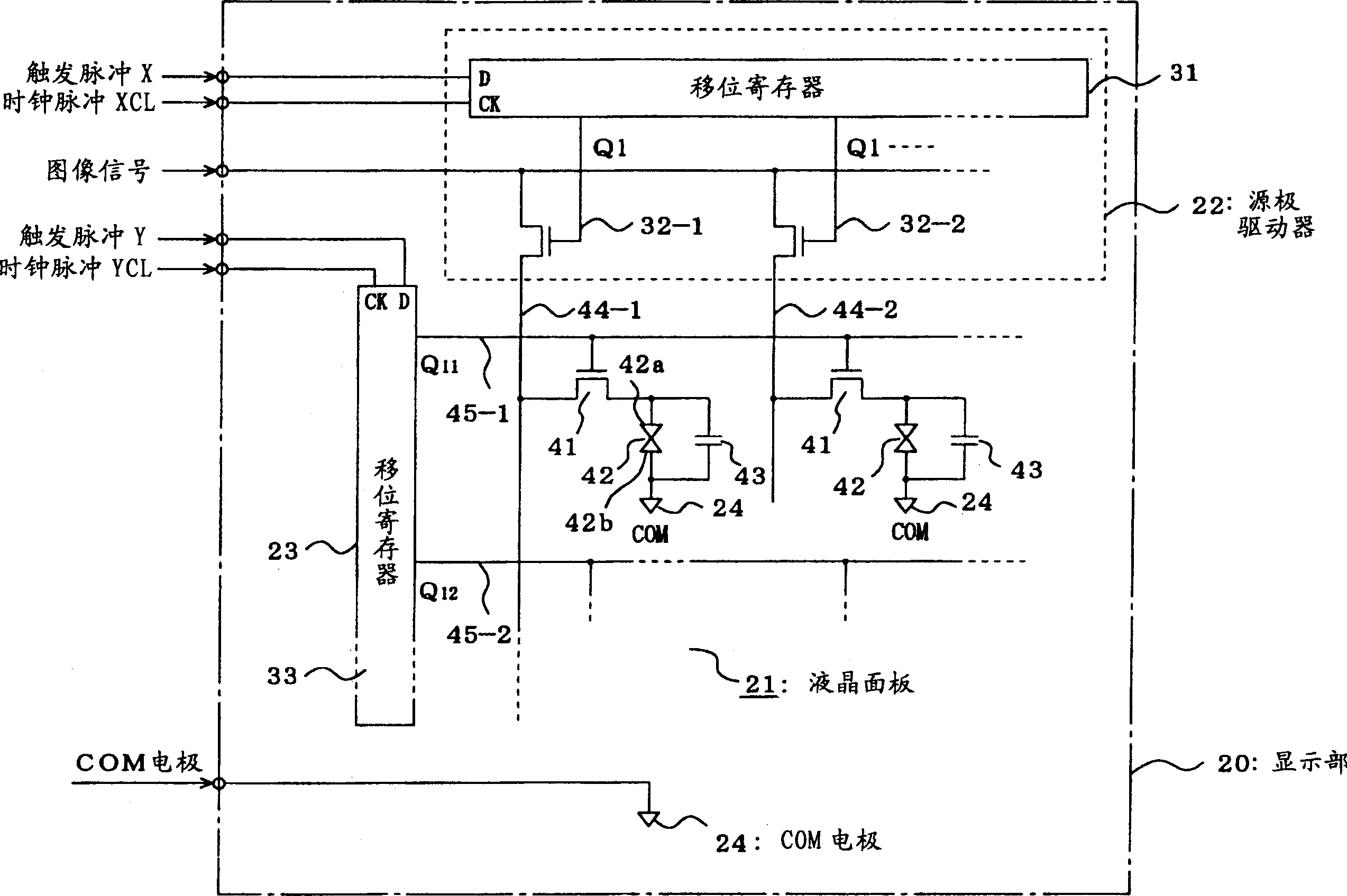

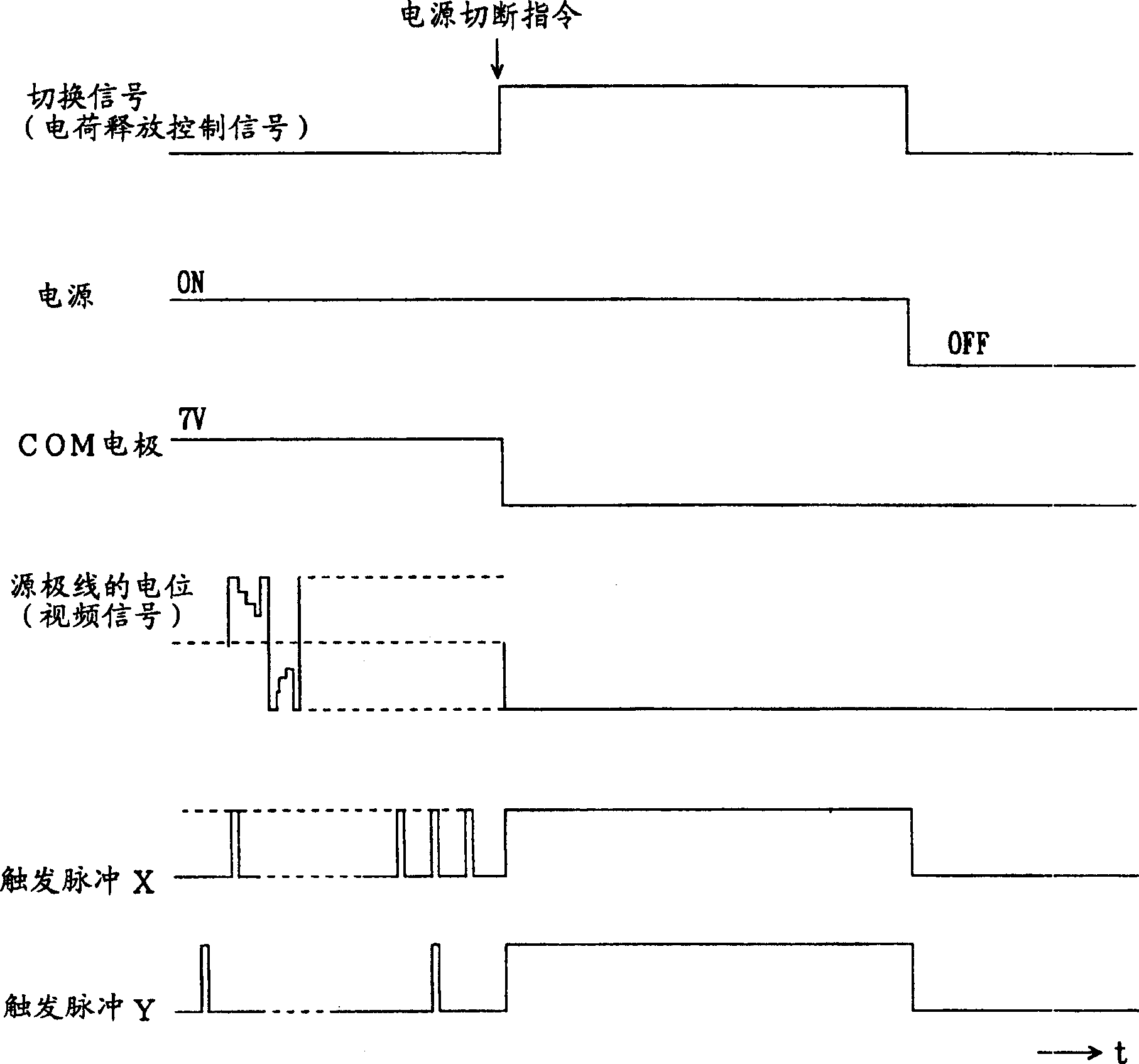

Display panel, drive circuit, display device, and electronic equipment

ActiveCN1734533AInhibit deteriorationDischarge fullyStatic indicating devicesDriver circuitLiquid-crystal display

The display device is equipped with the liquid crystal panel 21 equipped with thin film transistors corresponding to respective pixels, a source driver 22 which supplies a video signal to source lines of the thin film transistors, a source driver 23 which supplies a gate voltage to gate lines of the thin film transistors, and a control part 11 which supplies a ground potential to the source lines of the thin film transistors through the source driver 22 instead of the video signal and also supplies the ground potential to a common electrode 24 of the liquid crystal panel after it is commanded that the power source is turned off or after the power source is turned off to control the potential of the source lines and the potential of the common electrode 24 to the same potential for at least one vertical period.

Owner:SEIKO EPSON CORP

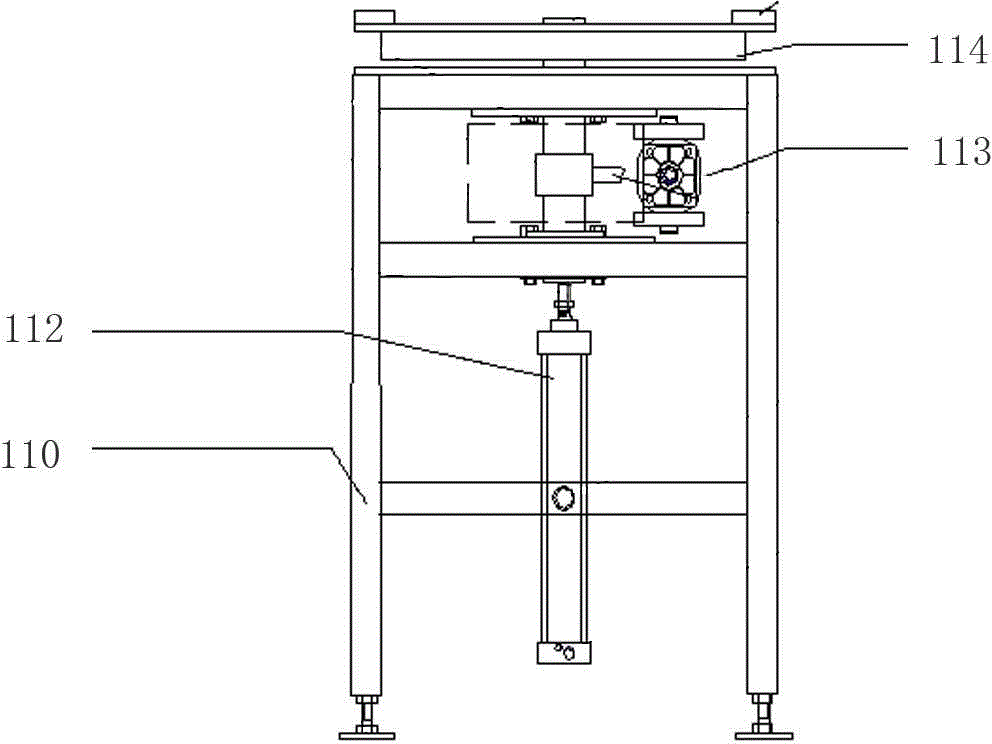

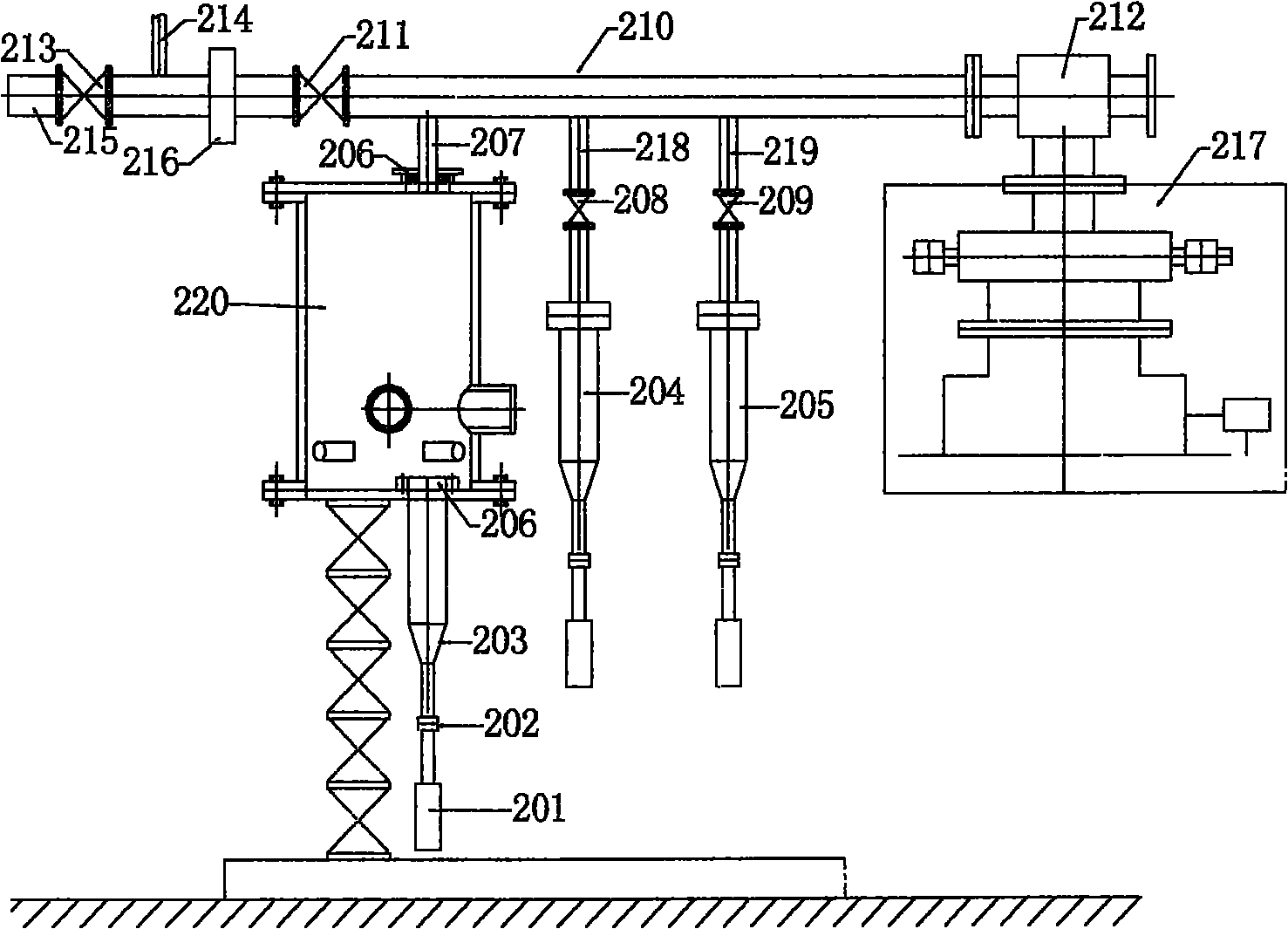

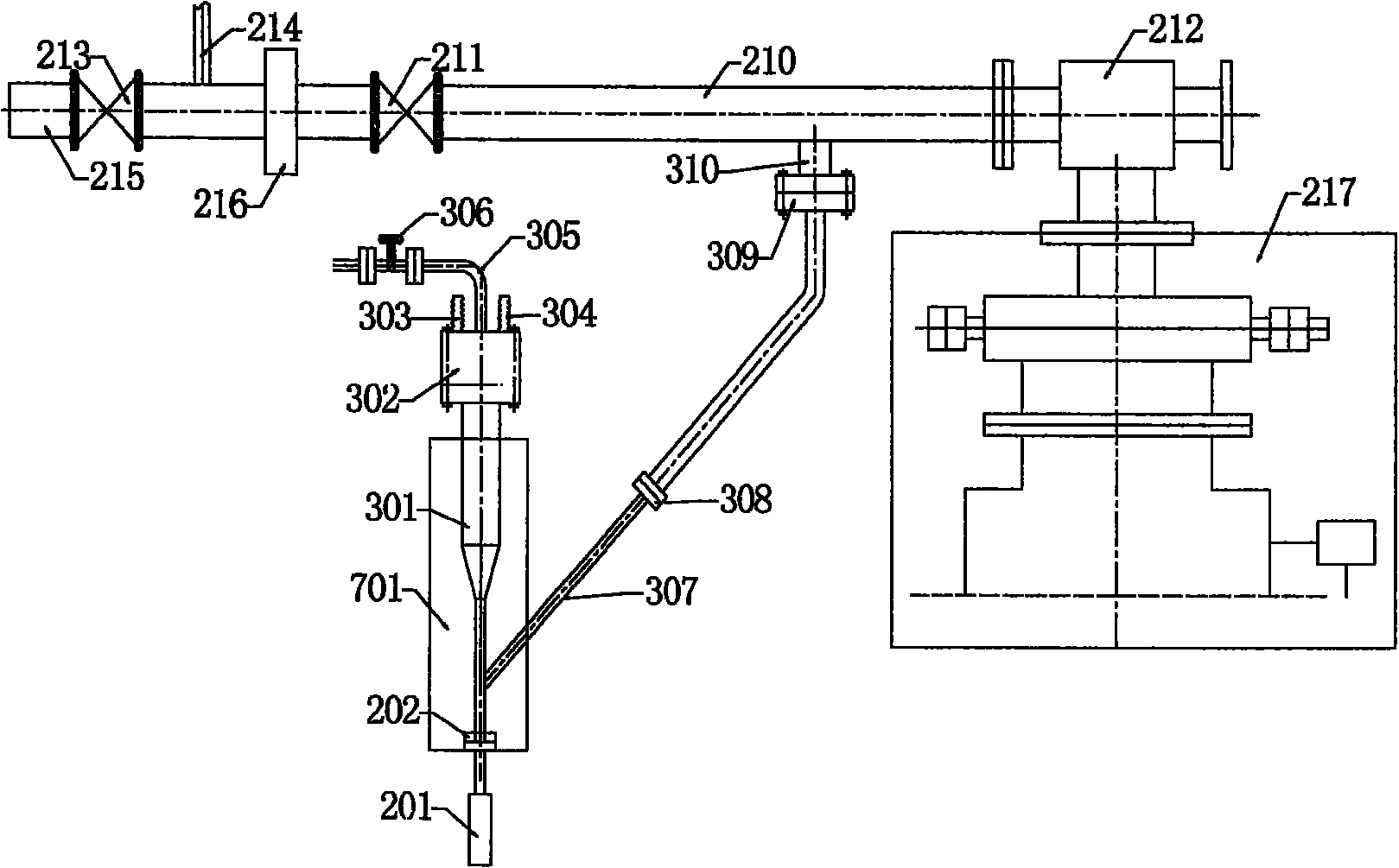

Flexibly packaged lithium battery evacuation apparatus and use method thereof

ActiveCN105552441ADischarge fullyReduce overflowFinal product manufactureElectrolyte accumulators manufactureVacuum pumpingPulp and paper industry

The invention discloses a flexibly packaged lithium battery evacuation apparatus and a use method thereof. The purpose of the invention is to solve the problems of long vacuum pumping time and electrolyte overflow in the vacuum pumping and dwelling process of present flexibly packaged lithium batteries. The flexibly packaged lithium battery evacuation apparatus comprises a vacuum chamber and a vacuum pipeline, a vacuum adsorption port is arranged in the vacuum chamber, the vacuum pipeline is connected with the vacuum adsorption port, a combined sucker is arranged in the vacuum chamber, the combined sucker comprises a fixed sucker and a telescopic driving sucker, the fixed sucker is fixedly arranged on the inner wall of the vacuum chamber, the driving sucker is arranged facing to the fixed sucker and is connected with the vacuum adsorption port in the vacuum chamber, and a telescopic bayonet is arranged in the driving sucker. Two-stage vacuum pumping of a flexibly packaged lithium battery is carried out through the combined sucker, so the vacuum pumping time is shortened, electrolyte overflow is reduced, and pollution of the electrolyte gasified at a negative pressure to the surface of the battery is avoided.

Owner:WANXIANG 123 CO LTD

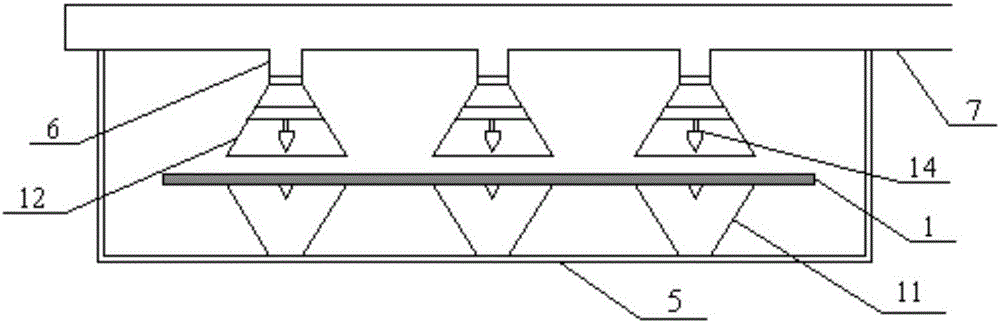

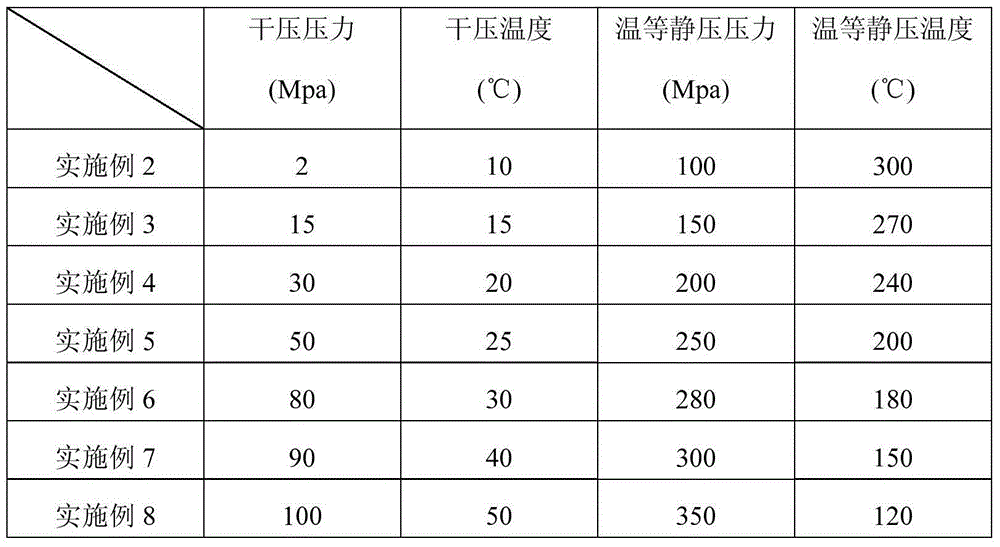

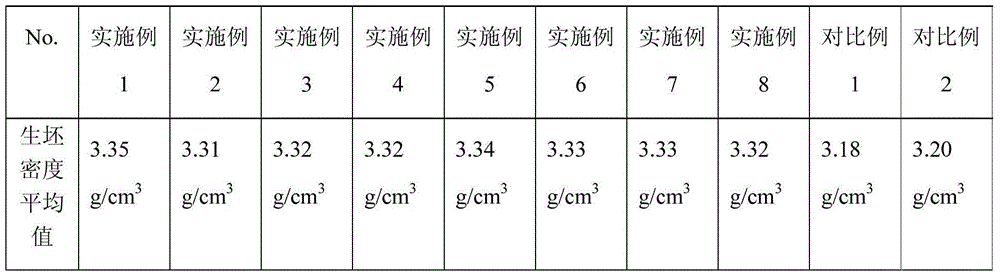

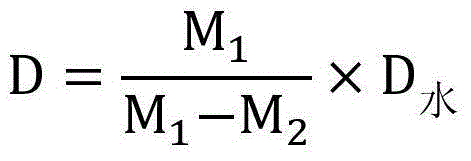

Manufacturing method for zirconium dioxide ceramic green-pressing

InactiveCN105856387ADensified ceramic bodyReduce defectsCeramic shaping apparatusTransmittanceNanometre

An embodiment of the invention discloses a manufacturing method for zirconium dioxide ceramic green-pressings. The method comprises the following steps: (1) dry pressing performing: after nanometer zirconium dioxide pelleting powders are put into a dry pressing mold, performing dry pressing performing to obtain a preformed blank, wherein pressure in dry pressing performing is 2-100 MPa; (2) temperature isostatic compaction: after the preformed blank which is preformed by dry pressing is put into a temperature isostatic pressing mold, performing temperature isostatic compaction, to obtain a zirconium dioxide ceramic green-pressing. The method manufactures the zirconium dioxide ceramic green-pressing by firstly performing dry pressing performing and then performing temperature isostatic compaction. Since under the action of pressure and temperature of the temperature isostatic pressing, the preformed blank still has good fluidity, nanometer zirconium dioxide powder particles can be stacked in a compact method, and gas and molten additives among the powders are fully discharged. The method makes a ceramic body more compact and defects less, so that the intensity, density, and light transmittance of sintered nanometer zirconium dioxide ceramic are improved.

Owner:LIAONING UPCERA CO LTD

Semi-automatic eutectic soldering method of GaAs microwave power amplifier chip and product

ActiveCN105965120ASolve surface oxidationImprove solderabilitySolid-state devicesSoldering apparatusTin platingSoldering

The invention discloses a semi-automatic eutectic soldering method of a GaAs microwave power amplifier chip. The method comprises the following steps: (1) a carrier, a solder and a bare chip are cleaned; (2) the power amplifier bare chip is plated with tin; (3) the carrier is plated with tin; and (4) the eutectic soldering is performed, that is, the tin-plated bare chip is preheated; an eutectic heating soldering table provided with the tin-plated carrier is heated; meanwhile, nitrogen is opened for protection; the bare chip is absorbed; an auxiliary heating table is stopped heating; when the eutectic heating soldering table is heated above a certain temperature, the bare chip is eutectically rubbed on the carrier after accurate alignment; and the carrier is cleaned after natural cooling in air. The invention further discloses the GaAs microwave power amplifier chip prepared by the method. The method can prepare the chip with lower voidage, less pseudo soldering and excellent performances through controlling such process details as cleaning, preheating and tin plating in specific process and optimizing process parameters therein, and largely increases the welding success rate.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

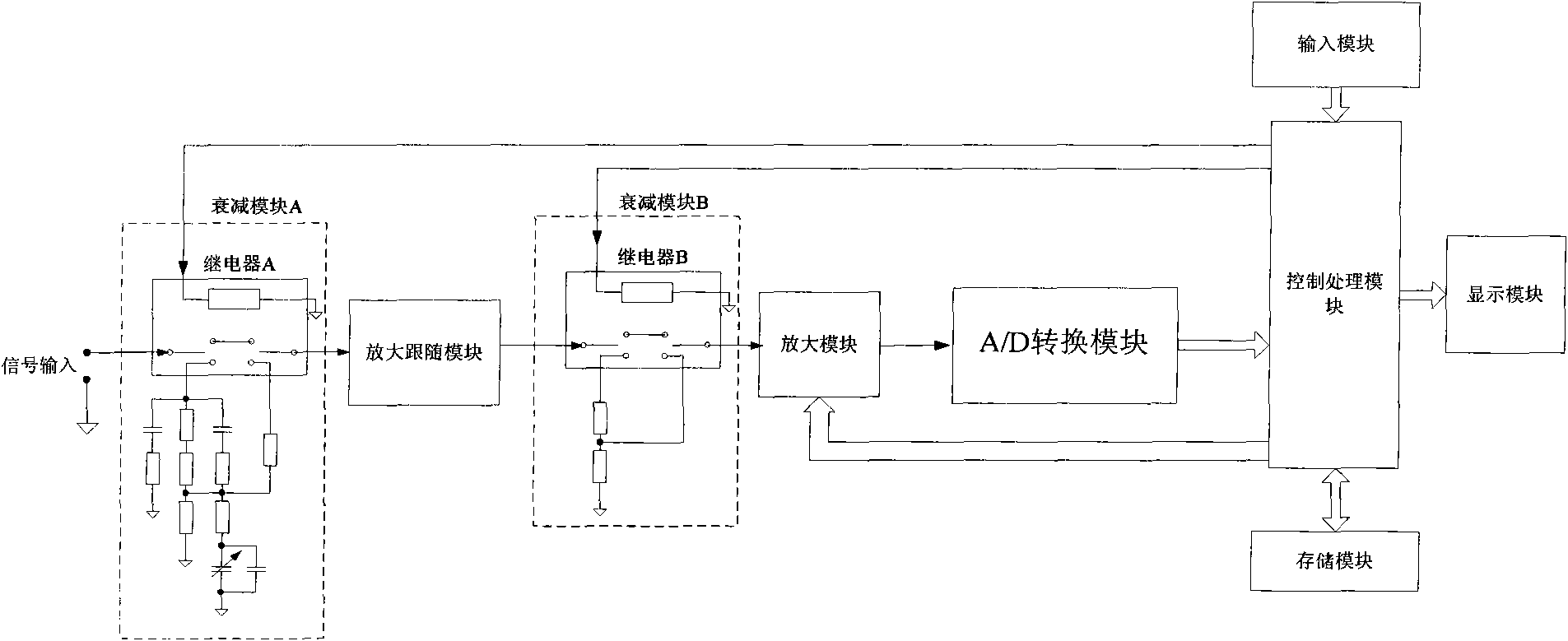

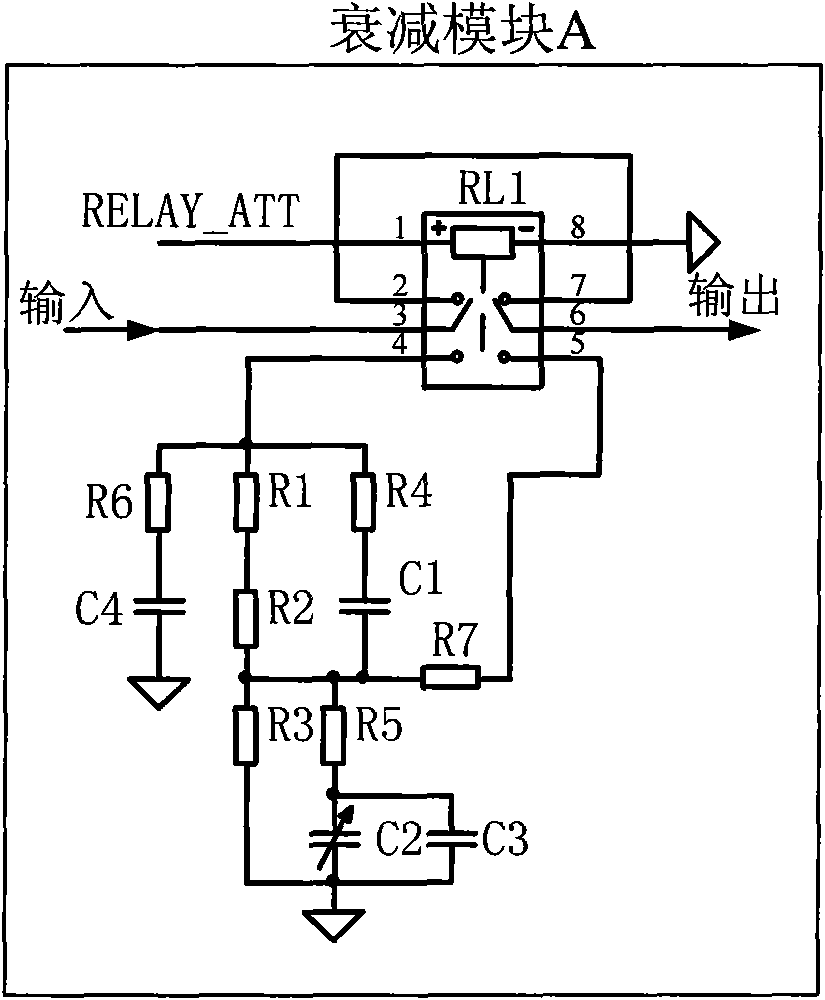

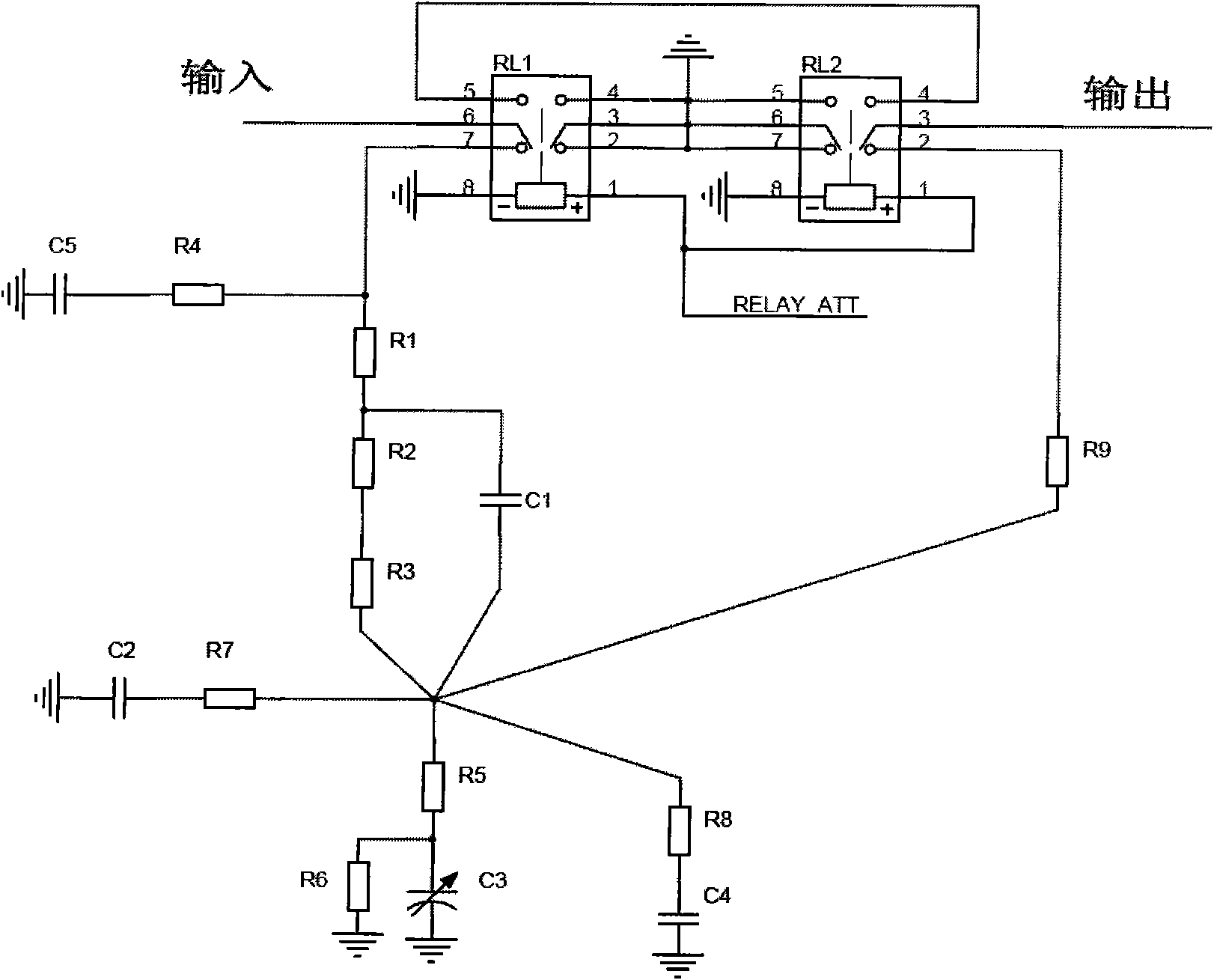

High-resistance broadband attenuation circuit and oscilloscope using same

ActiveCN102053172AReduce crosstalkMany grounding pointsDigital variable displayElectrical measurement instrument detailsHigh resistanceEquivalent series inductance

The invention discloses a high-resistance broadband attenuation circuit and also discloses a digital oscilloscope using the high-resistance broadband attenuation circuit. The high-resistance broadband attenuation circuit comprises a first relay, a second relay, a high-frequency compensation circuit, a first RC (Remote Control) network and a second RC network. The moving contact of the first relay is connected with an input end, the moving contact of the second relay is connected with an output end, and the control ends of the first relay and the second relay are connected together; the second static contact of the first relay is connected with the high-frequency compensation circuit and the first RC network, the other end of the high-frequency compensation circuit is grounded, and the other end of the first RC network is connected with the second RC network; and one end of the second RC network is grounded, and the other end of the second RC network is connected with the second static contact of the second relay through a resistor. The influence of equivalent series inductance at a high frequency on the high-resistance broadband attenuation circuit is quite small; a high-frequency signal component has sufficient release for the ground; and the bandwidth of an output signal is large, the signal overshoot is small, and the frequency response is good.

Owner:RIGOL

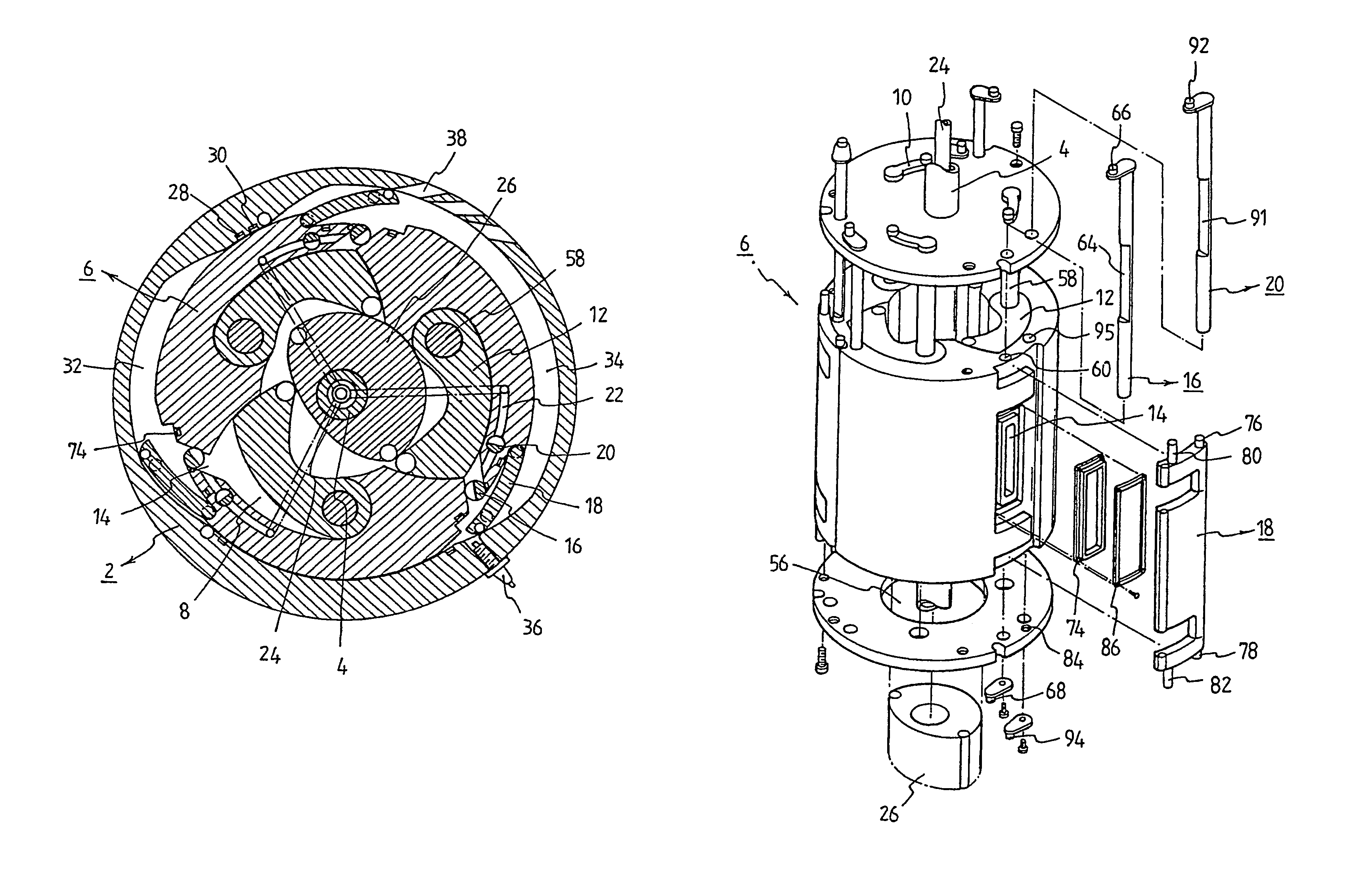

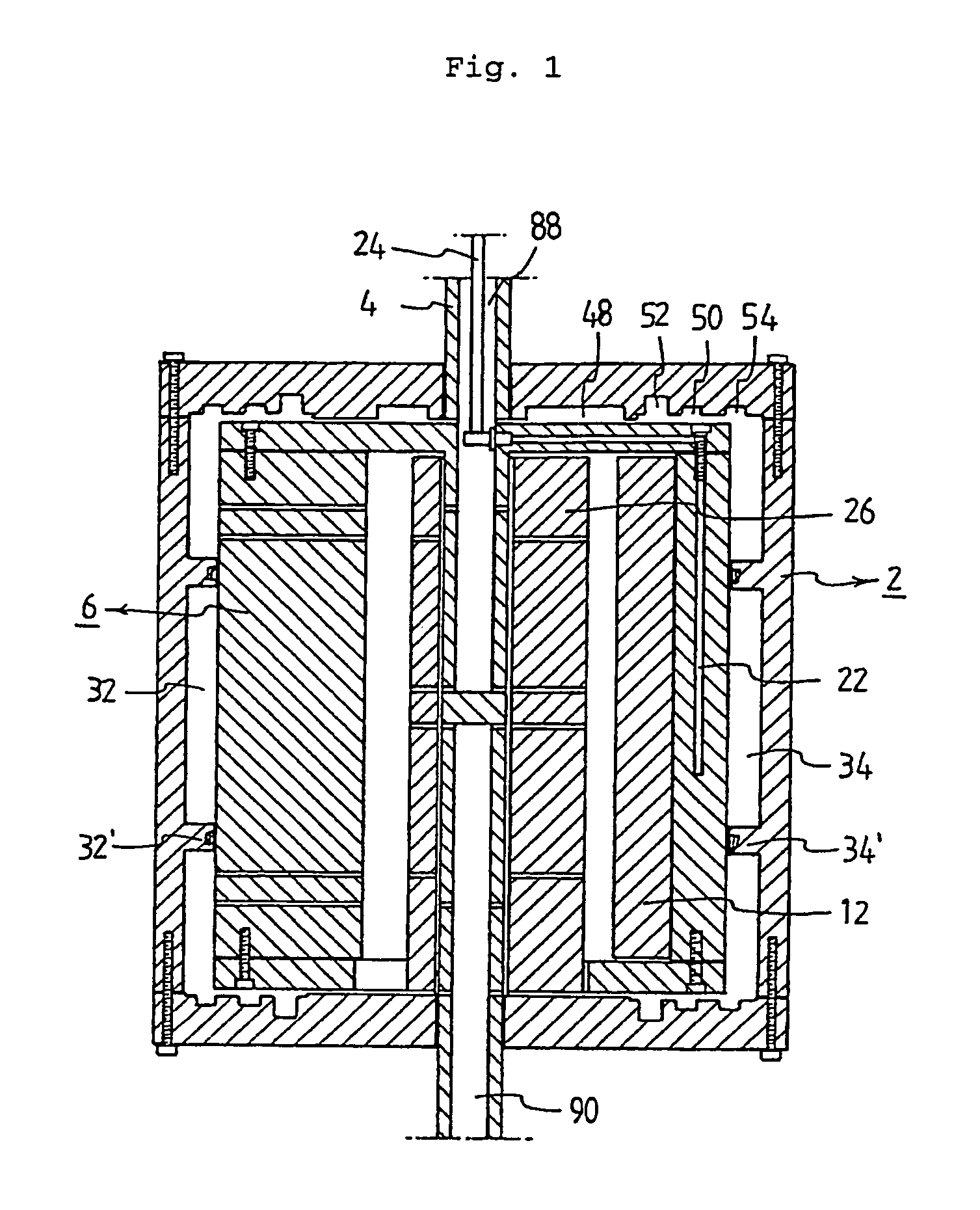

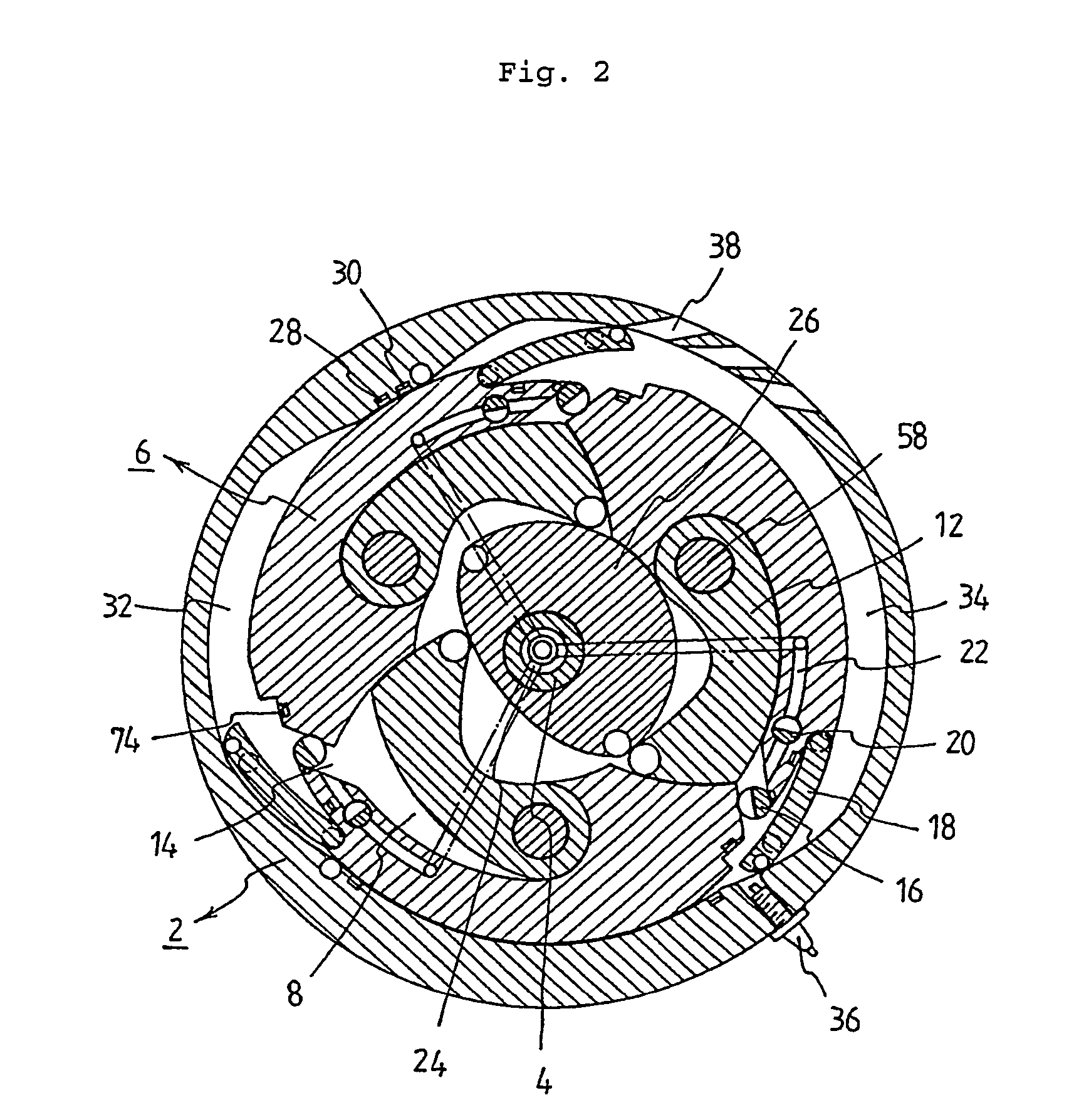

Rotary engine

InactiveUS7143737B2Increase powerPrevent leakageInternal combustion piston enginesOscillating piston enginesRotary enginePiston

A rotary engine includes pistons disposed in operating chambers of a rotary member. The pistons are guided by guiding pieces engaged in a guiding groove formed at a housing so that the operating chambers are expanded. Each of the operating chambers includes an intake / exhaust port, which is opened or closed by a shutoff valve and a shutoff plate guided along guiding grooves formed at the housing. An exhaust chamber is caved in the housing so that an explosion stroke is carried out at the rear part of the exhaust chamber, whereby a rotating force is obtained. Compressed air is supplied into the operating chambers through air-supplying channels, which are opened or closed by shutoff valves, so that gas left in the operating chambers is forcibly discharged. Consequently, introduction of lubricant through the intake / exhaust ports or leakage of pressure is prevented, and large power is obtained.

Owner:KIM DONG HYUN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com