Method for preparing special fracturing propping agent for shale gas by utilizing industrial waste

A technology for fracturing proppant and industrial waste, which is applied in the chemical industry, earthwork drilling, climate sustainability, etc. It can solve the problems that affect the prospect of industrial production and popularization and application, poor mechanical properties of proppant, sintering temperature, and complicated molding methods and other problems, to achieve the effect of high-temperature fluxing, which is beneficial to environmental protection and has high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

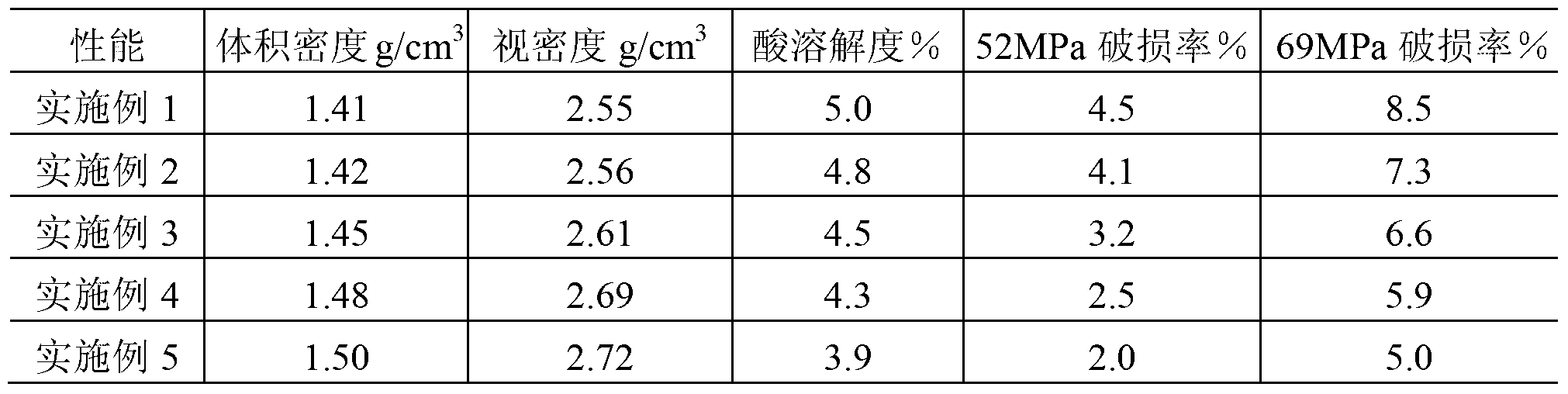

Examples

Embodiment 1

[0029] 1) Calcining the fly ash at a temperature of 830°C and holding it for 40 minutes to obtain a calcined material;

[0030] 2) Put the calcined material into a cyclone airflow mill for crushing to form calcined material fines, which are passed through a 325 mesh sieve to obtain waste residue powder; put kaolin into a cyclone airflow mill for crushing to form kaolin fines, The kaolin fine material is passed through a 325 mesh sieve to obtain kaolin powder;

[0031] 3) Put 93% of waste residue powder, 6% of kaolin powder, and 1% of polysilicon powder into a mixer and mix evenly to obtain a mixture according to the mass percentage;

[0032] 4) The mixture is granulated into balls in a ball forming machine, and the granulated particles pass through a 18-30 mesh sieve, and the sieve residue particles between the two sieves are collected to become granules to be fired;

[0033] 5) Put the particles to be fired into an alumina crucible, and place it in a silicon carbide rod resi...

Embodiment 2

[0035] 1) Calcining coal gangue at a calcination temperature of 840°C and holding for 38 minutes to obtain a calcined material;

[0036] 2) Put the calcined material into a cyclone airflow mill for crushing to form calcined material fines, which are passed through a 325 mesh sieve to obtain waste residue powder; put kaolin into a cyclone airflow mill for crushing to form kaolin fines, The kaolin fine material is passed through a 325 mesh sieve to obtain kaolin powder;

[0037] 3) Put 94.1% waste slag powder, 5% kaolin powder, and 0.9% polysilicon powder into a mixer and mix evenly to obtain a mixture according to the mass percentage;

[0038] 4) The mixture is granulated into balls in a ball forming machine, and the granulated particles pass through a 18-30 mesh sieve, and the sieve residue particles between the two sieves are collected to become granules to be fired;

[0039] 5) Put the particles to be fired into an alumina crucible, and place it in a silicon carbide rod resis...

Embodiment 3

[0041] 1) Calcining the fly ash and coal gangue separately, the calcination temperature is 845°C, and holding for 35min, to obtain the fly ash calcined material and the coal gangue calcined material respectively;

[0042] 2) Put the fly ash calcined material into a cyclone airflow pulverizer and crush it to form a fine fly ash calcined material, which is passed through a 325 mesh sieve to obtain a fly ash waste slag powder; calcinate the coal gangue The raw material is crushed in a cyclone airflow pulverizer to form a fine coal gangue calcined material, which is passed through a 325 mesh sieve to obtain a coal gangue waste slag powder; the kaolin is put into a cyclone airflow pulverizer for crushing to form a kaolin fine Material, kaolin fine material crosses 325 mesh sieves, obtains kaolin powder;

[0043] 3) According to the mass percentage, put 95.3% of the mixture of fly ash waste slag powder and coal gangue powder waste slag powder, 4% of kaolin powder, and 0.7% of polysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com