Display panel, drive circuit, display device, and electronic equipment

A display panel and drive circuit technology, applied to static indicators, instruments, etc., can solve the problems of residual charges and holding capacitors that cannot be fully discharged, and achieve the effect of preventing charge residues and avoiding deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

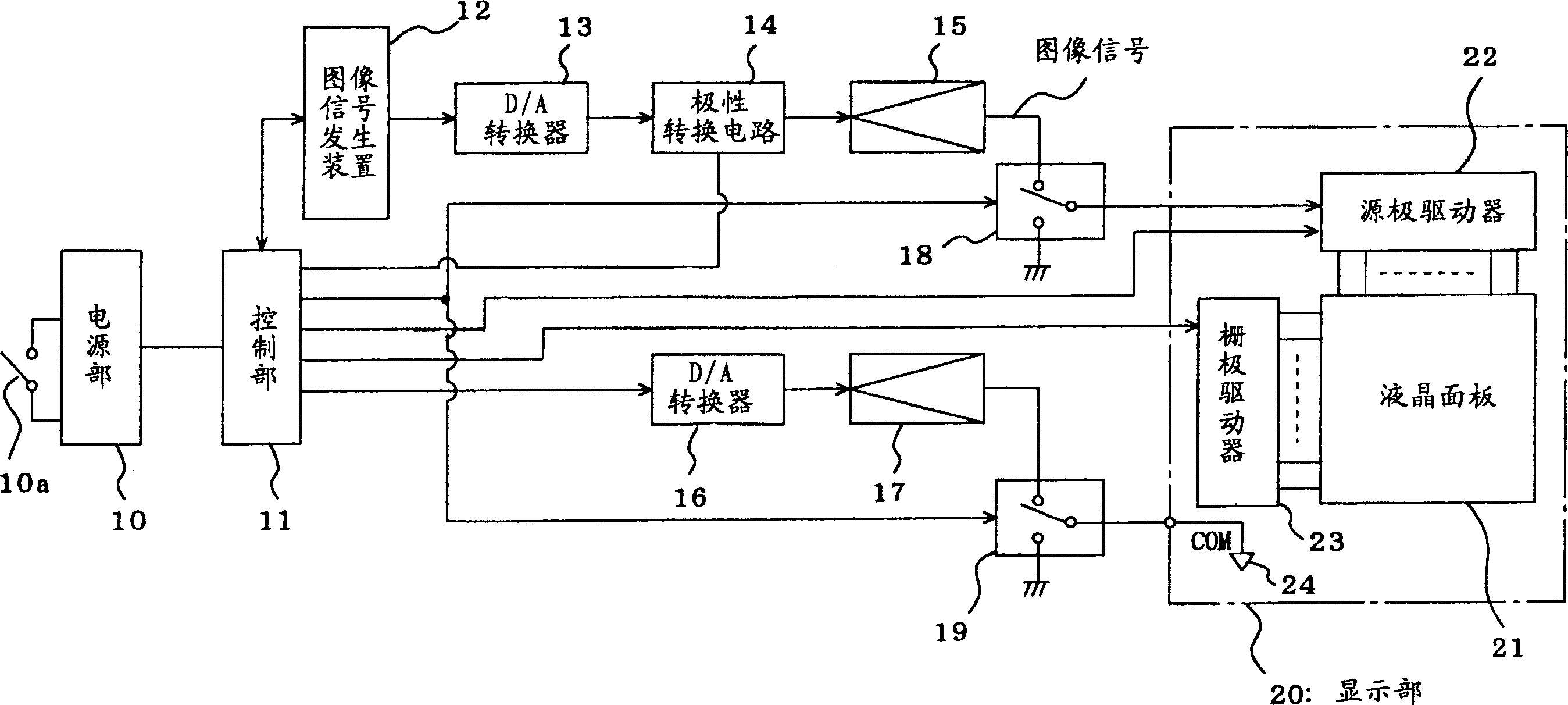

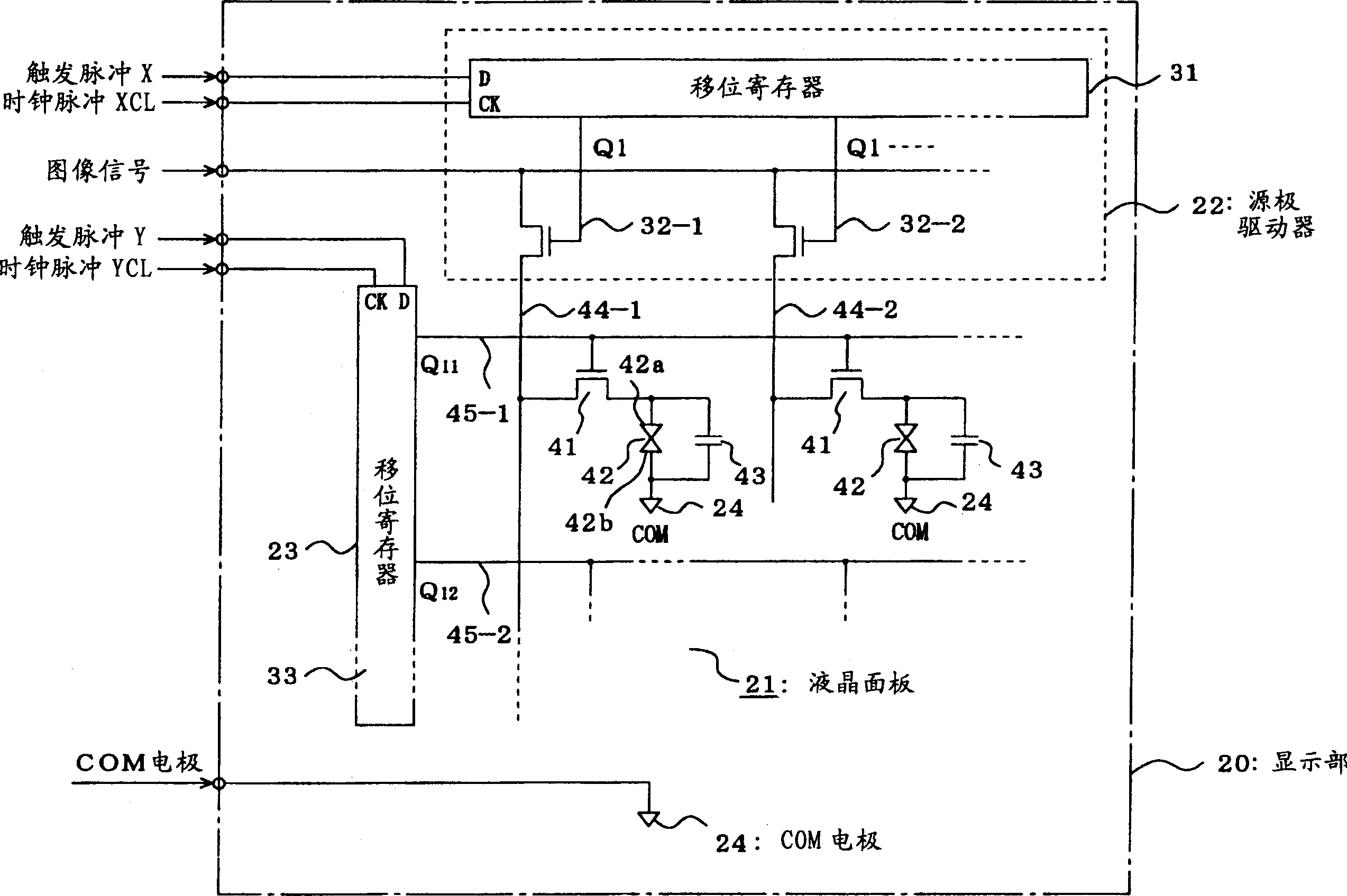

[0024] figure 1 It is a configuration diagram of a display device according to Embodiment 1 of the present invention. This display device is, for example, a device mounted on an electronic device such as a PDA, and has a power supply unit 10, a control unit 11, an image signal generator 12, a D / A converter 13, a polarity conversion circuit 14, an amplifier 15, a D / A A converter 16 , amplifier 17 , switching circuits 18 , 19 and display unit 20 . The display unit 20 has a liquid crystal panel 21 , a source driver 22 and a gate driver 23 . The liquid crystal panel 21 has a structure in which, for example, two transparent substrates such as glass substrates are glued together with a liquid crystal material interposed therebetween, and each pixel is provided with a thin film transistor (TFT) as an active element. In addition, such a liquid crystal panel 21 has, for example, a reflection plate, and displays an image using incident light from the outside.

[0025] The power suppl...

Embodiment 2

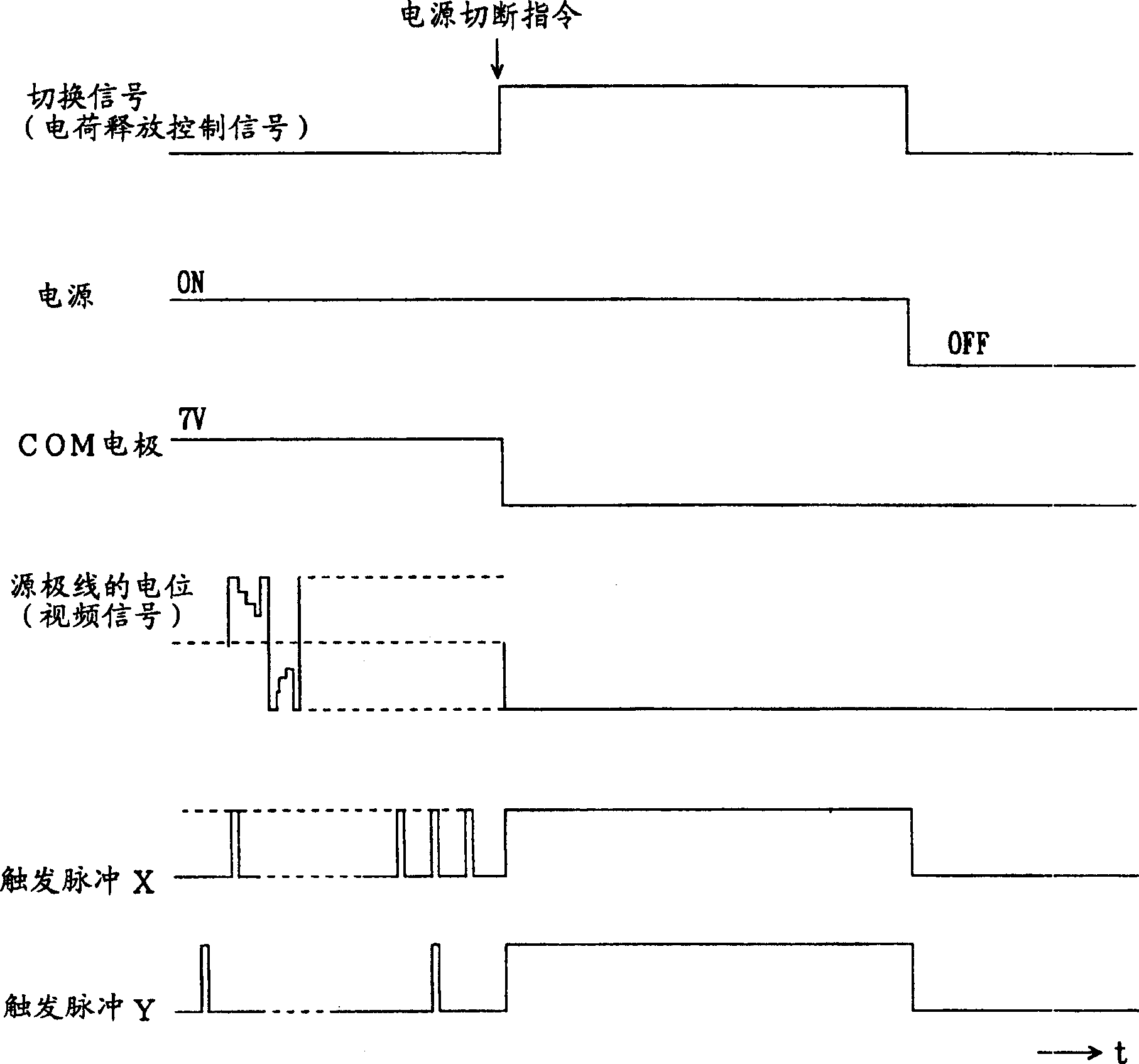

[0034] exist image 3 In the example of , an example in which the power is turned off after the writing process of setting the source lines 44-1, 44-2, ... and the common electrode 24 to the ground potential (0V) is described, but after turning off the power Previously, by turning off all the thin film transistors 41 , it was possible to prevent the pixels from being affected by abnormal image signals accompanying the subsequent power-off. Specifically, by setting the X trigger pulse and the Y trigger pulse at L level for at least one frame, the thin film transistors 41 are gradually turned off, and eventually the thin film transistors 41 of all pixels can be turned off.

Embodiment 3

[0036] In the above-mentioned embodiment, although the example in which the source lines 44-1, 44-2, ... and the common electrode 24 are set to the ground potential (0V) is described, the present invention is not limited to this example. For example, The potential of the source line and the common electrode may be made the same by setting the potential of the common electrode, or the potential of the source line and the potential of the common electrode may be made the same as a DC component of the image signal. In addition, in the above-mentioned embodiments, an example in which all the thin film transistors are turned on in one frame period has been described, but in the present invention, it may be set to be longer than this.

[0037] In addition, as the liquid crystal panel 21, although the example of the reflective type which has a reflector and displays an image using incident light from the outside has been described, the example of a transmissive type which displays an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com