Combing method for lithium ion batteries

A technology of lithium-ion batteries and lithium batteries, which is applied in the field of lithium-ion batteries, can solve problems such as large differences in the voltage range of single batteries and uneven discharge of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

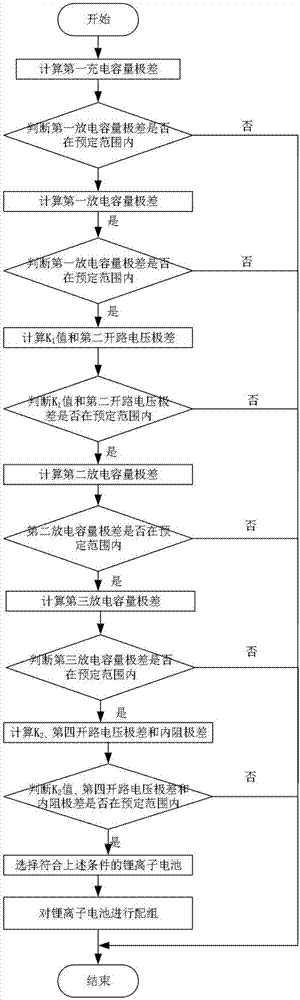

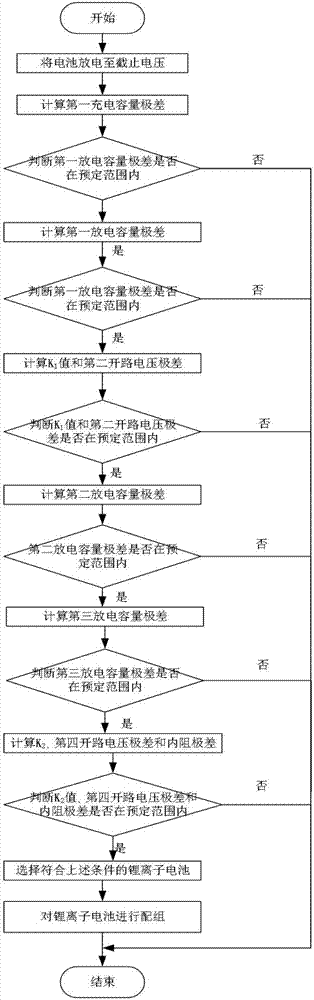

Method used

Image

Examples

Embodiment 1

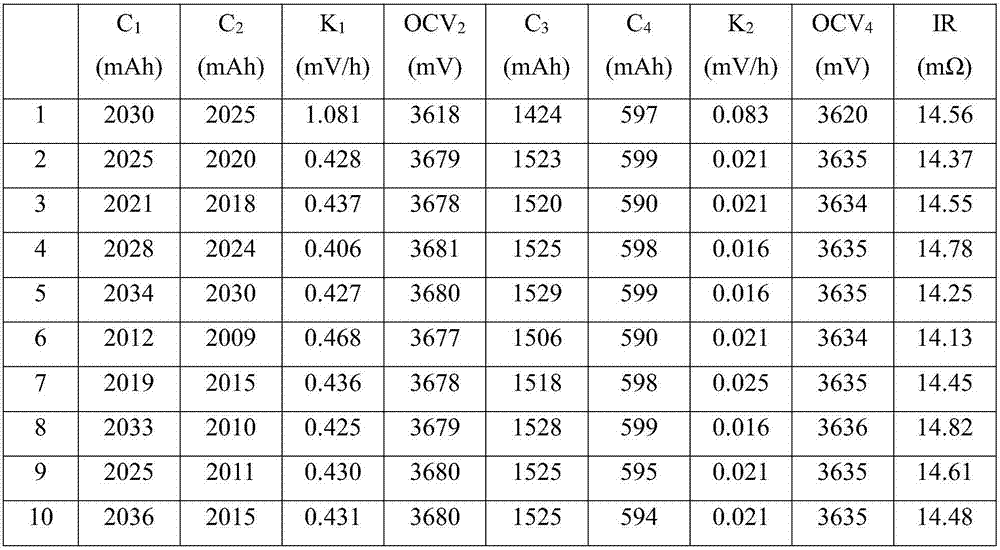

[0081] In this implementation case, a 2000mAh ternary power battery is selected as the lithium-ion single battery, and the module combination uses a combination of 1 parallel and 6 strings. The specific assembly steps are as follows:

[0082] S1: Discharge 10 lithium-ion single cells to 2.75V at a current of 0.8A, and then discharge them at a current of 0.15A to 2.75V after leaving them aside for 10 minutes;

[0083] S2: After completing step S1, put the lithium-ion battery on hold for 30 minutes, charge it to 4.2V with a constant current and constant voltage of 1A, and record the first charging capacity C 1 , calculate the first charging capacity range ΔC of 10 lithium-ion battery cells 1 24mAh;

[0084] S3: The extreme difference of the first charging capacity is within the predetermined range of 30mAh, so lithium-ion battery cells 1 to 10 all enter the next step;

[0085] S4: After completing step S3, put the lithium-ion battery on hold for 10 minutes, discharge it to 2.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com