Patents

Literature

1035results about How to "Achieve emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

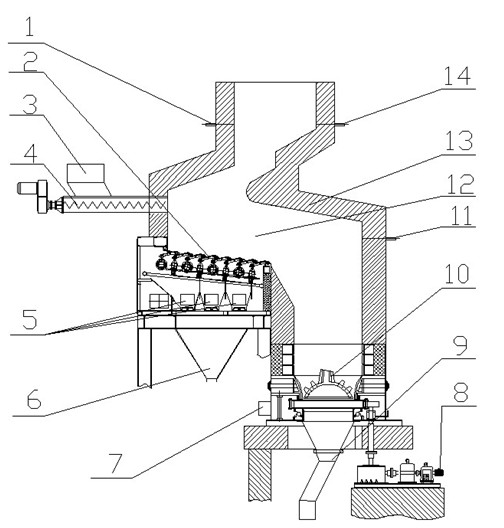

Coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and technology

InactiveCN102350214ARealize reburning and denitrificationFull joint removalDispersed particle separationResource utilizationCoal dust

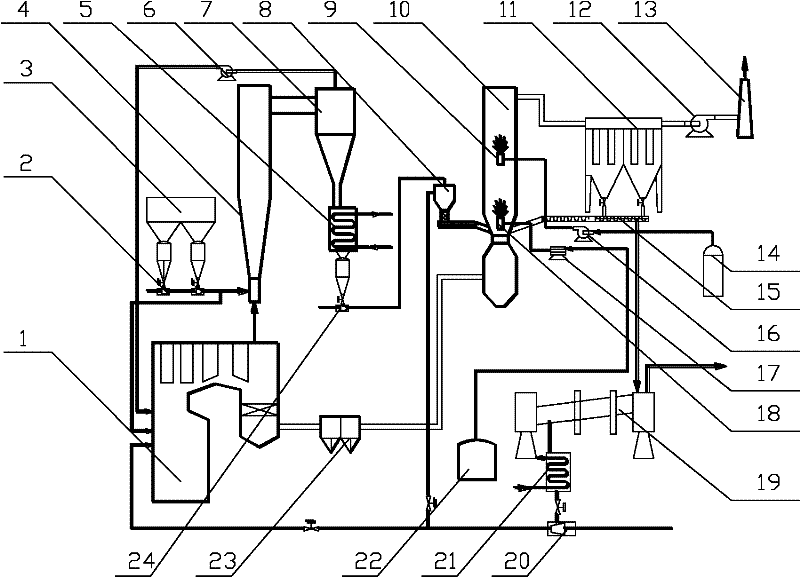

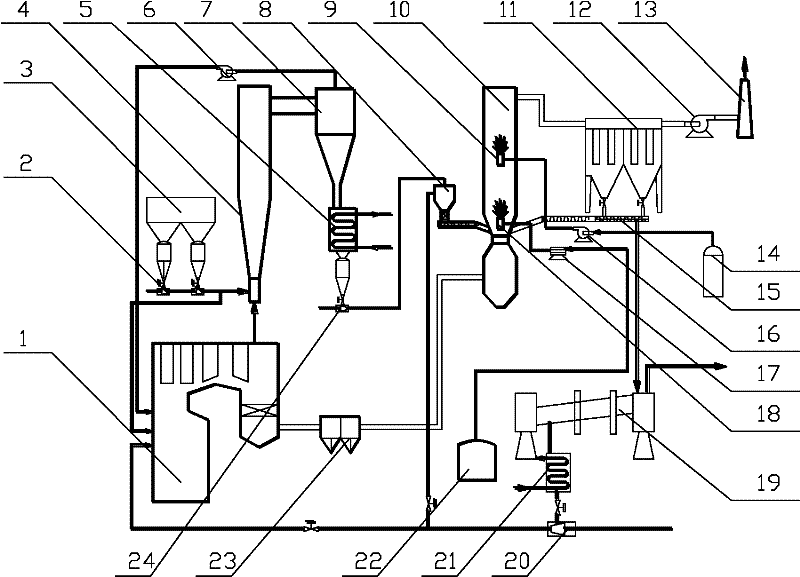

The invention relates to a coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and a technology. The technology provided by the invention comprises the following steps of: using coal dust in a coal-fired power plant as a raw material, simultaneously carrying out carbonization and activation on coal dust in an activated coke preparation reactor to obtain powdered activated coke, using pyrolysis gas obtained during the preparation process as reburning fuel and sending it into a boiler so as to remove part of NOx; sending the powdered activated coke into a flue gas adsorption tower, adsorbing pollutants such as sulfur dioxide, mercury and the like at an appropriate temperature, injecting ammonia gas and nitrogen oxide to perform a catalytic reduction reaction so as to remove nitrogen oxide; reusing the adsorbed activated coke after regeneration; sending the activated coke into the boiler for combustion after multiple adsorption / regeneration; regenerating the activated coke after adsorbing sulfur dioxide to obtain high-density sulfur dioxide gas to realize resource utilization. By the utilization of coal resources in a coal-fired power plant, the comprehensive purification of flue gas and the resource utilization of sulfur dioxide are realized without discharge of waste water, exhaust gas and solid waste.

Owner:SHANDONG UNIV

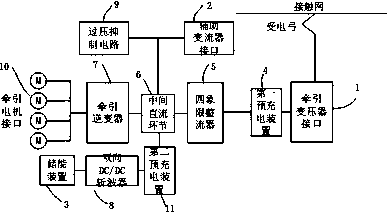

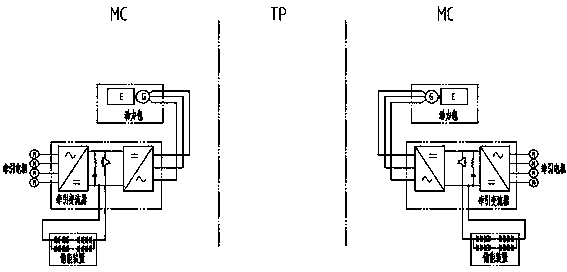

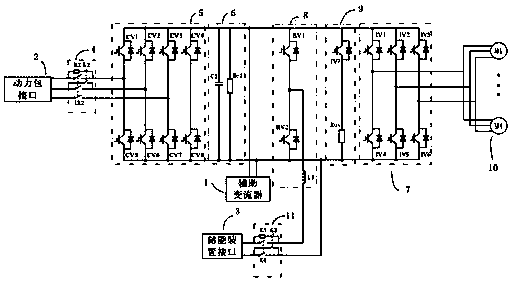

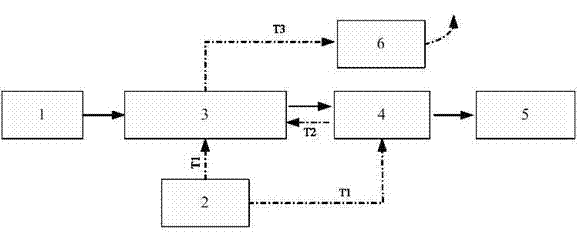

Motor train unit traction system adopting catenary and energy storing devices for hybrid power supply

ActiveCN103350647ARun across the lineAdapt to different transportation needsRailway vehiclesAc-ac conversionTraction systemEmergency rescue

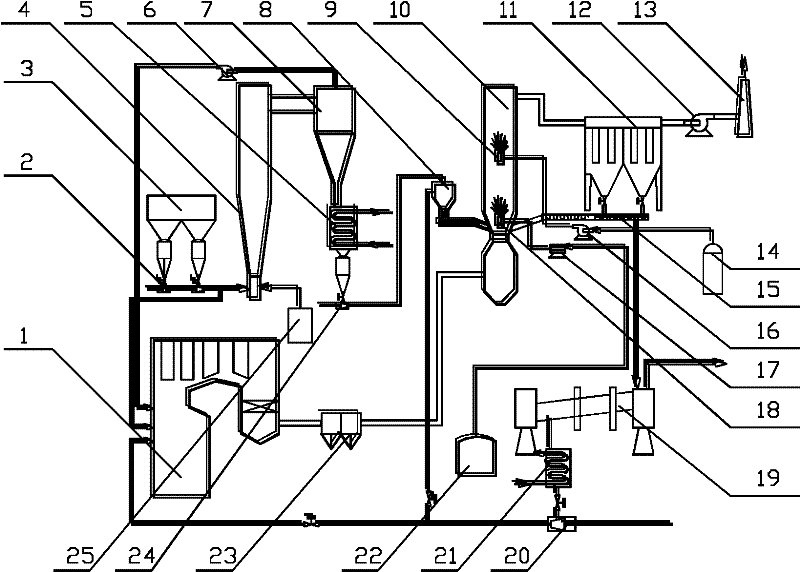

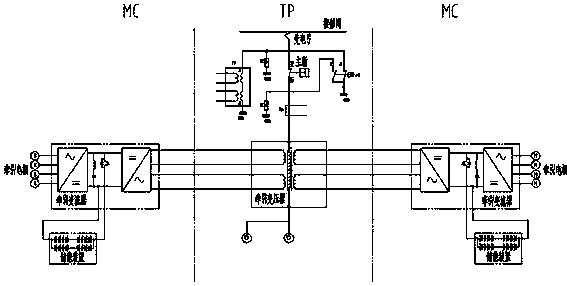

A motor train unit traction system adopting a catenary and energy storing devices for hybrid power supply is characterized by mainly comprising a traction transformer, the energy storing devices, traction converters and traction motors, wherein the catenary is connected with a primary side of the traction transformer through a pantograph, and two secondary side windings of the traction transformer are directly connected with the traction converters which are connected with the traction motors; and the energy storing devices are connected with direct current buses in the middles of the traction converters. The motor train unit traction system can simultaneously operate on an electrification line and a non-electrification line, and the braking energy is absorbed through the energy storing devices under the working condition without the catenary, so that cyclic utilization of the energy is realized, and a green energy saving idea is reflected. Under special rainy or snowy weather or when the catenary is damaged, the motor train unit traction system has emergency rescue and readiness functions, and the energy storing devices can also be used as portable power sources.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

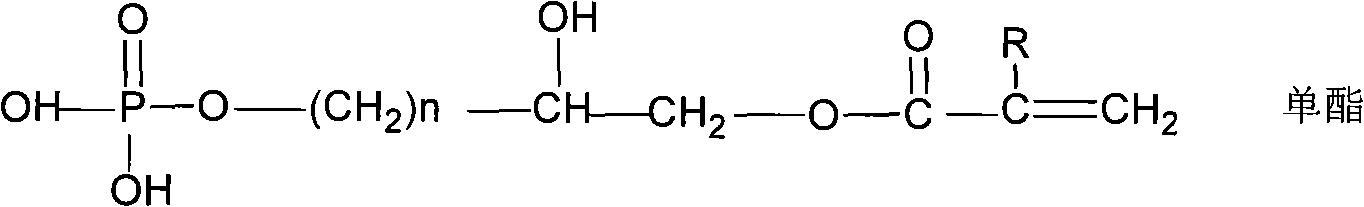

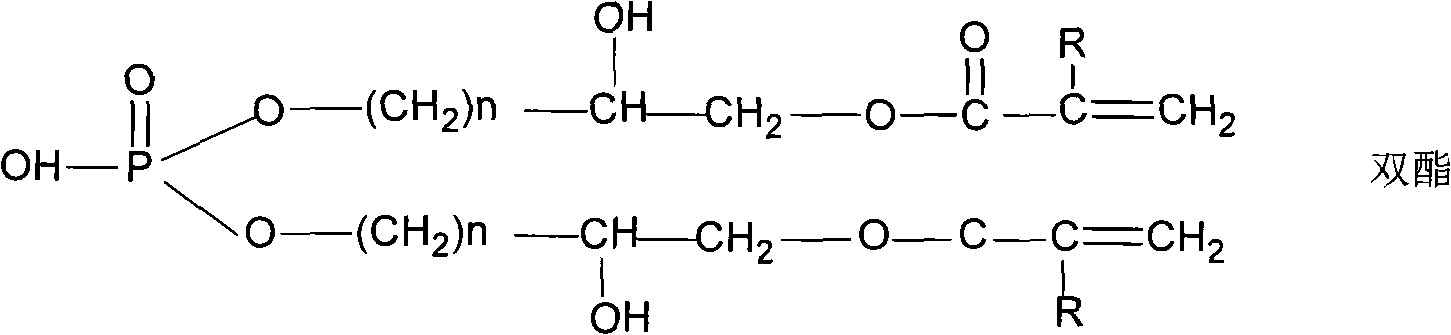

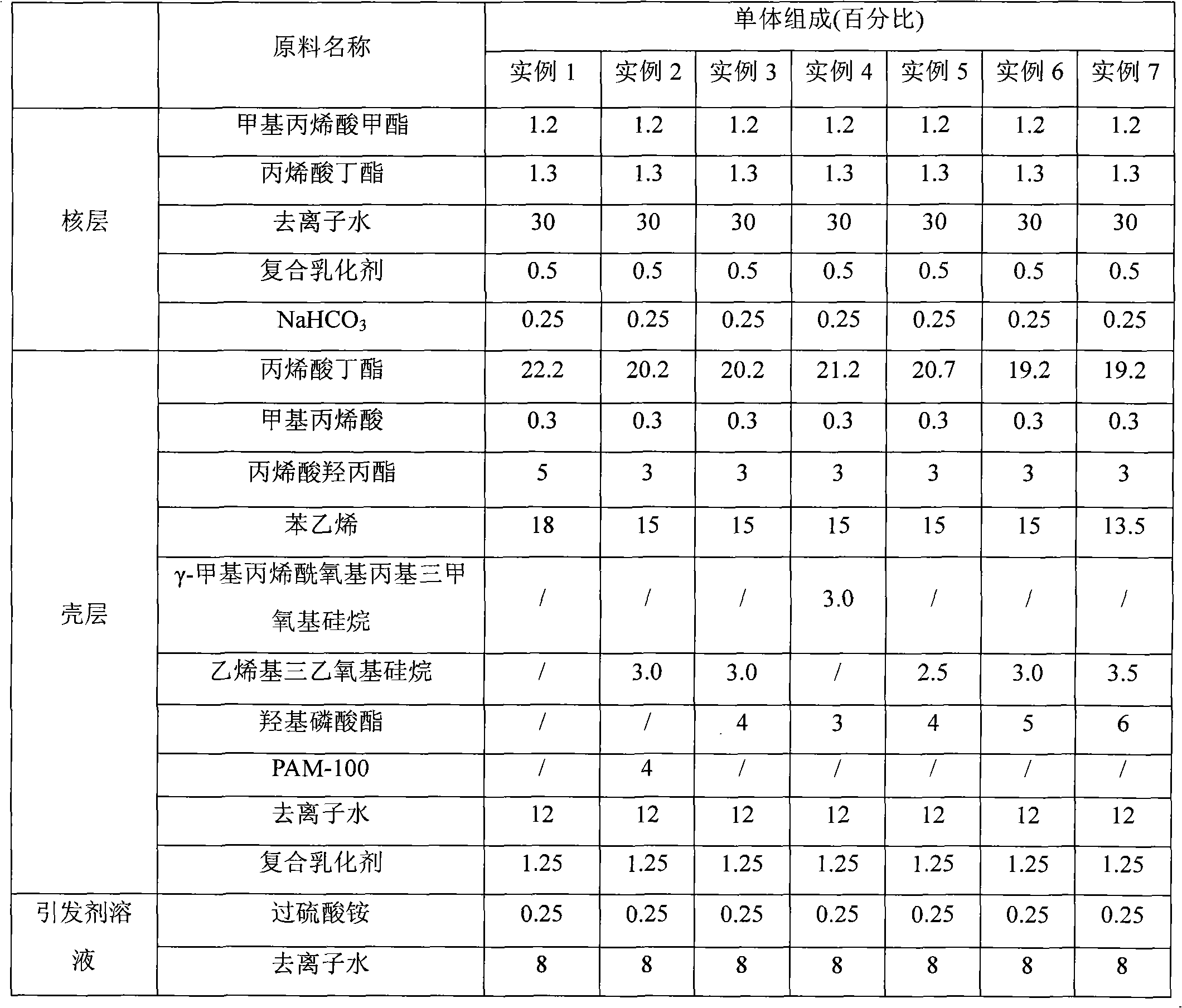

Organic silicon / hydroxyl phosphate composite modified water emulsion acrylic resin and preparation method and application thereof

ActiveCN101775101AIncrease crosslink densityAccelerated corrosionAnti-corrosive paintsWater dispersibleEmulsion

The invention discloses organic silicon / hydroxyl phosphate composite modified water emulsion acrylic resin and a preparation method and application thereof; hydroxy-phosphate and organic siloxane which are synthesized are co-polymerized into modified acrylic resin, wherein the weight percentage of the solid resin is 45 to 55 percent, and the balance is deionized water; the components which form the acrylic resin and the consumption thereof are as follows: 35 to 60 percent of acrylate monomer, 30 to 40 percent of vinyl aromatic monomer, 3 to 10 percent of organic silicon monomer, 5 to 10 percent of hydroxy ester monomer, 1.5 to 4.0 percent of composite emulsifier, 0.5 to 1.0 percent of pH value regulator, and the initiator is 0.5 to 1.5 percent of the consumption of the acrylate monomer; after the resin is prepared into single-component anti-corrosive coating, the anti-corrosive performance of the collating is better than that of the single-component anti-corrosive coating prepared by the traditional water dispersible acrylic resin; and simultaneously, the invention improves the defect that the water dispersible acrylic resin needs to be polymerized through a solution method, facilitates the realization of zero VOC emission, and achieves the purposes of environmental protection and energy saving.

Owner:广东优贝精细化工有限公司

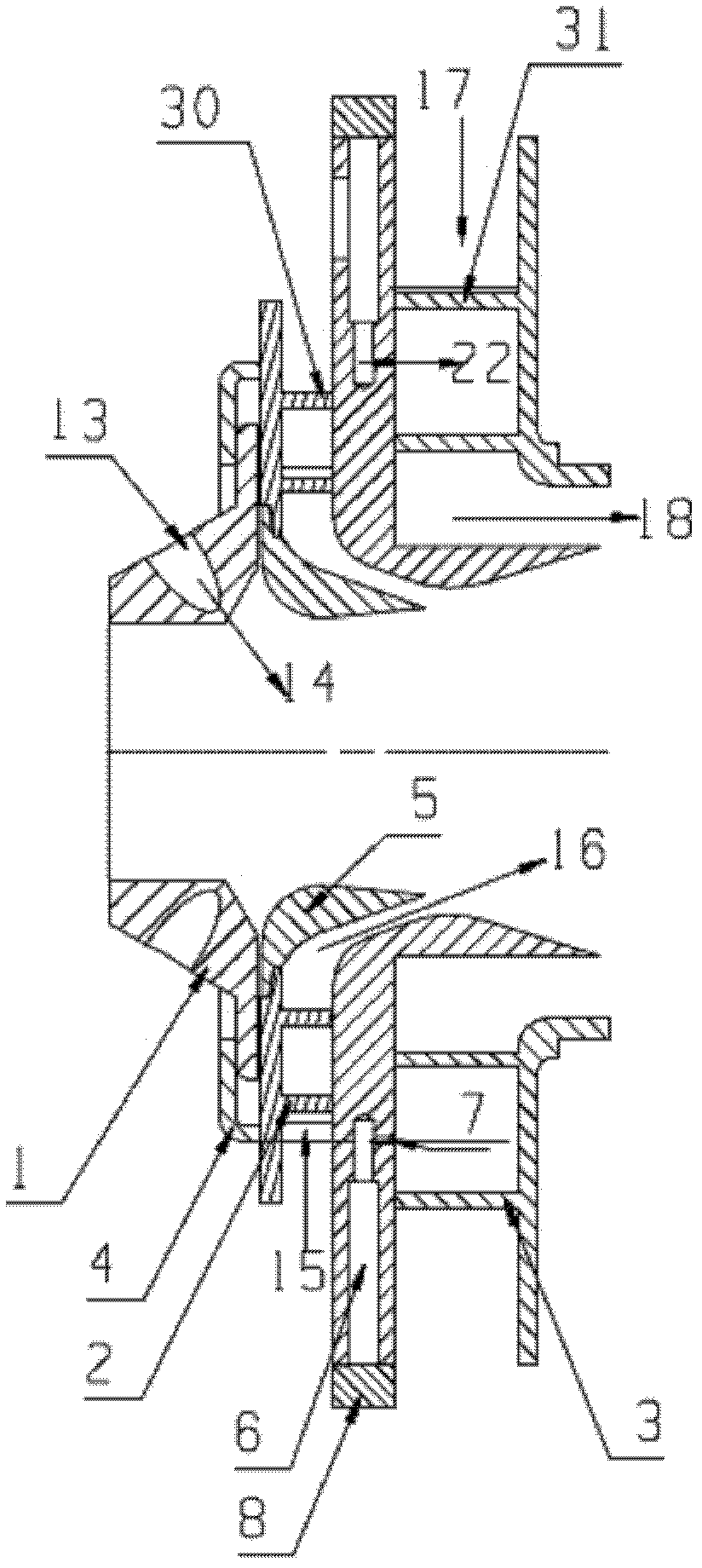

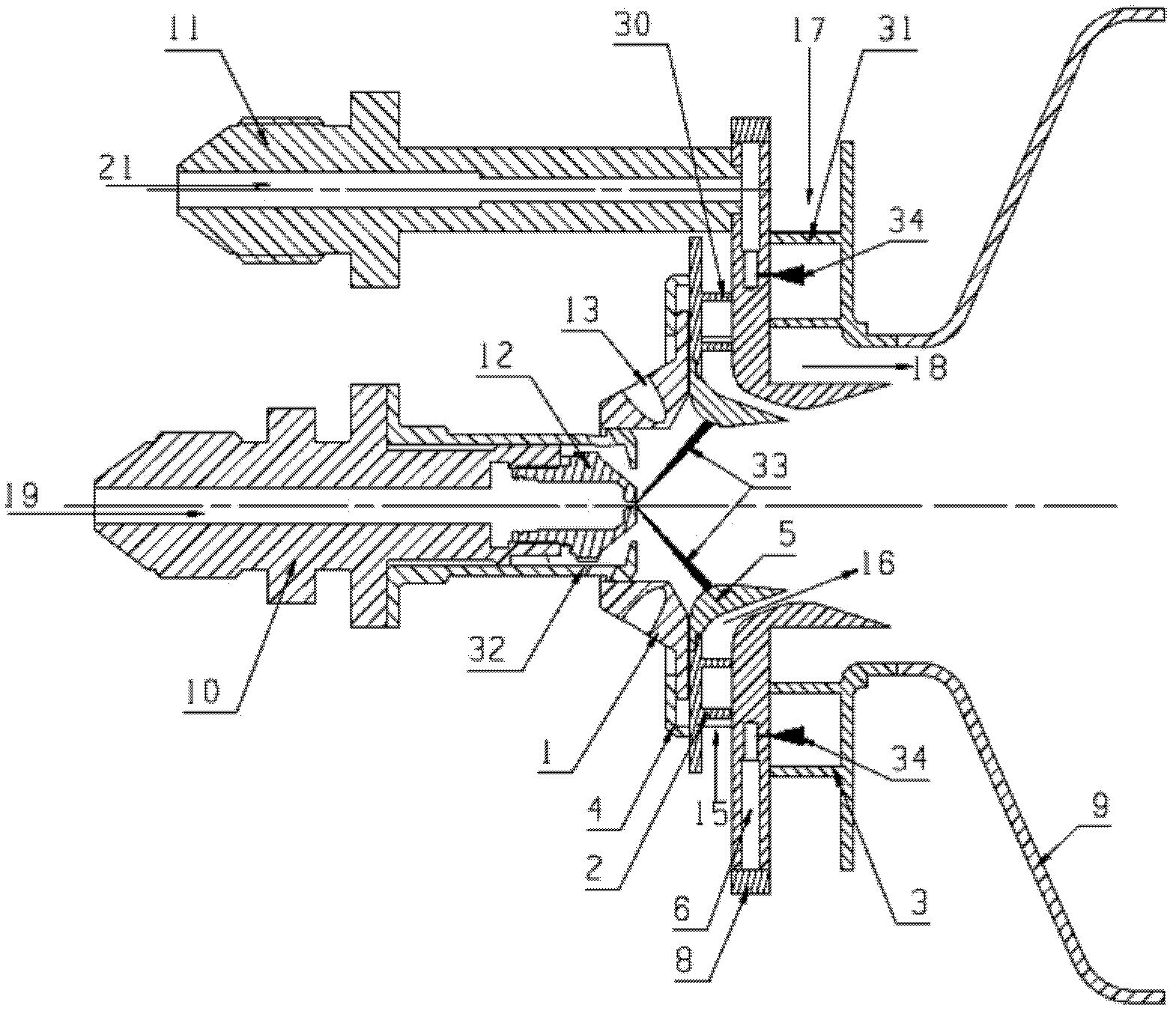

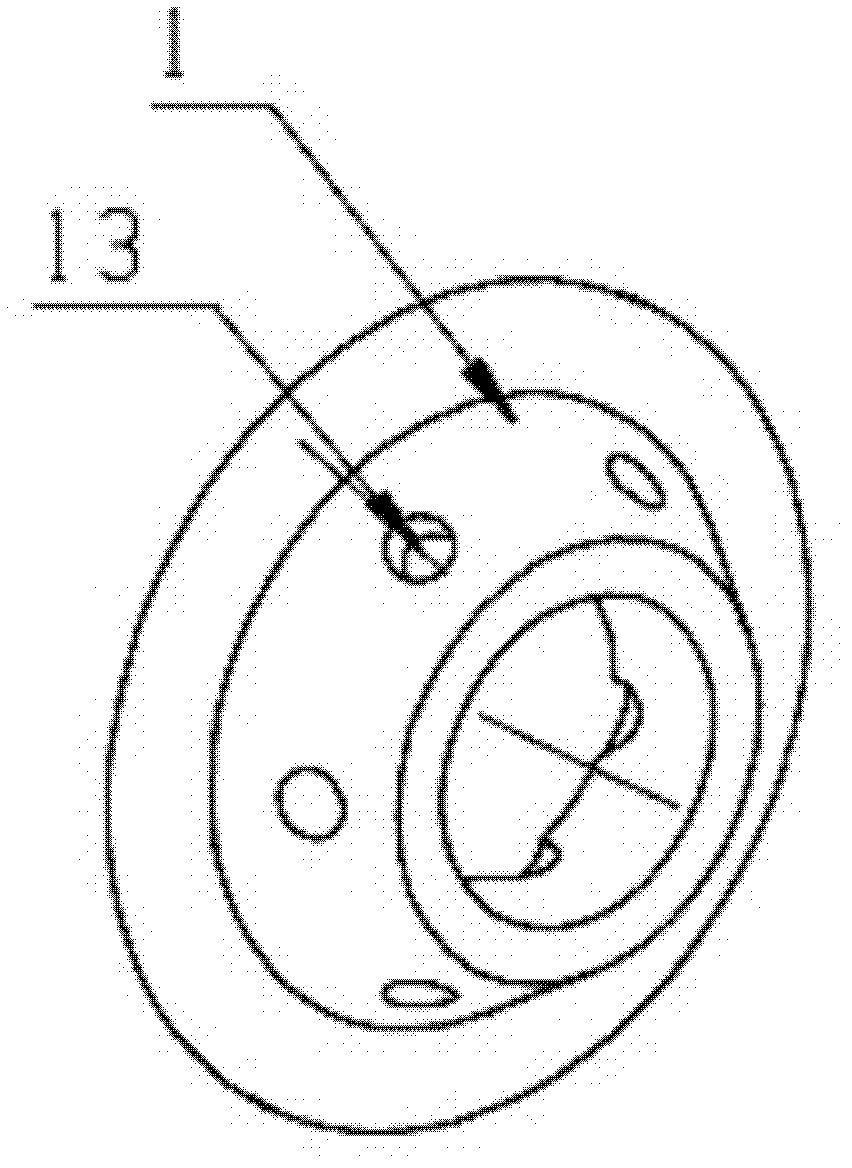

Low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet

ActiveCN103256633AEvenly distributedInhibition formationContinuous combustion chamberCycloneCombustion chamber

The invention discloses a low-pollution combustion chamber adopting fuel-grading and three-stage cyclone air inlet. The low-pollution combustion chamber comprises an on-duty oil supply nozzle, a primary-combustion oil supply nozzle, three-stage cyclones and a flame tube. Fuel is respectively provided for the on-duty oil supply nozzle and the primary-combustion oil supply nozzle in two ways, and the three-stage coaxial cyclones supply air to the head of a combustion chamber. The two stages of cyclones on the inner side of the combustion chamber refer to an oblique-cutting hole cyclone and a radial cyclone, cyclone of the two-stage cyclones are in opposite directions. A centrifugal atomizing nozzle is arranged at the center of the oblique-cutting hole cyclone, and the second-stage cyclone on the inner side are combined and matched with a center on-duty nozzle. The cyclone on the outside of the combustion chamber is a radial cyclone with cyclone direction opposite to that of a second-stage cyclone. Primary combustion fuel enters a cyclone blade channel from small holes of a front wall surface of a third-stage cyclones by way of multipoint direct injection and is accelerated to be crushed and atomized in a cyclone channel to be mixed with the air, and forms premixed or partly premixed fuel-air mixture at an exit of the tertiary swirling influx to enter a primary combustion zone to be combusted. The low-pollution combustion chamber is applicable to aircraft engine combustion chambers or industry fuel turbine combustion chambers.

Owner:中科航空动力(株洲)装备制造研究院有限公司

Membrane-laminated fiberglass filter medium capable of denitration and dust removal

ActiveCN103463871ADoes not affect inherent performanceAchieve emissionsNitrous oxide captureDispersed particle separationGlass fiberFilter media

The invention discloses a membrane-laminated fiberglass filter medium capable of denitration and dust removal. The membrane-laminated fiberglass filter medium capable of denitration and dust removal comprises a fiberglass filter base material, a NOX catalyst removing dip coating layer and an expanding micropore polytetrafluoroethylene filtering film; the membrane-laminated fiberglass filter medium capable of denitration and dust removal is characterized in that firstly, soakage drying post treatment is carried out on the fiberglass filter base material by using a NOX catalyst removing batch mixture, the NOX catalyst removing dip coating layer is formed on the surface of fiberglass, high-temperature hot pressing is carried out on the NOX catalyst removing dip coating layer and a polytetrafluoroethylene surface film, and the functional membrane-laminated filter medium which has a NOX catalyst removing function and can prevent the PM2.5 is prepared. The membrane-laminated fiberglass filter medium capable of denitration and dust removal provided by the invention can not only avoid the detrimental effect on a catalyst caused by flying ash particles, but also effectively reduce tiny dust such as PM2.5, and the discharge of the smoke dust which is below 5mg / Nm<3> is realized; the combination of catalyst powder and the filter medium are firm, the inherent properties of the filter medium are not affected, and the filter medium is particularly suitable for industrialized production.

Owner:ANHUI JINHON GREENISM TECH

Small efficient medicinal rubbish pyrolysis incinerator

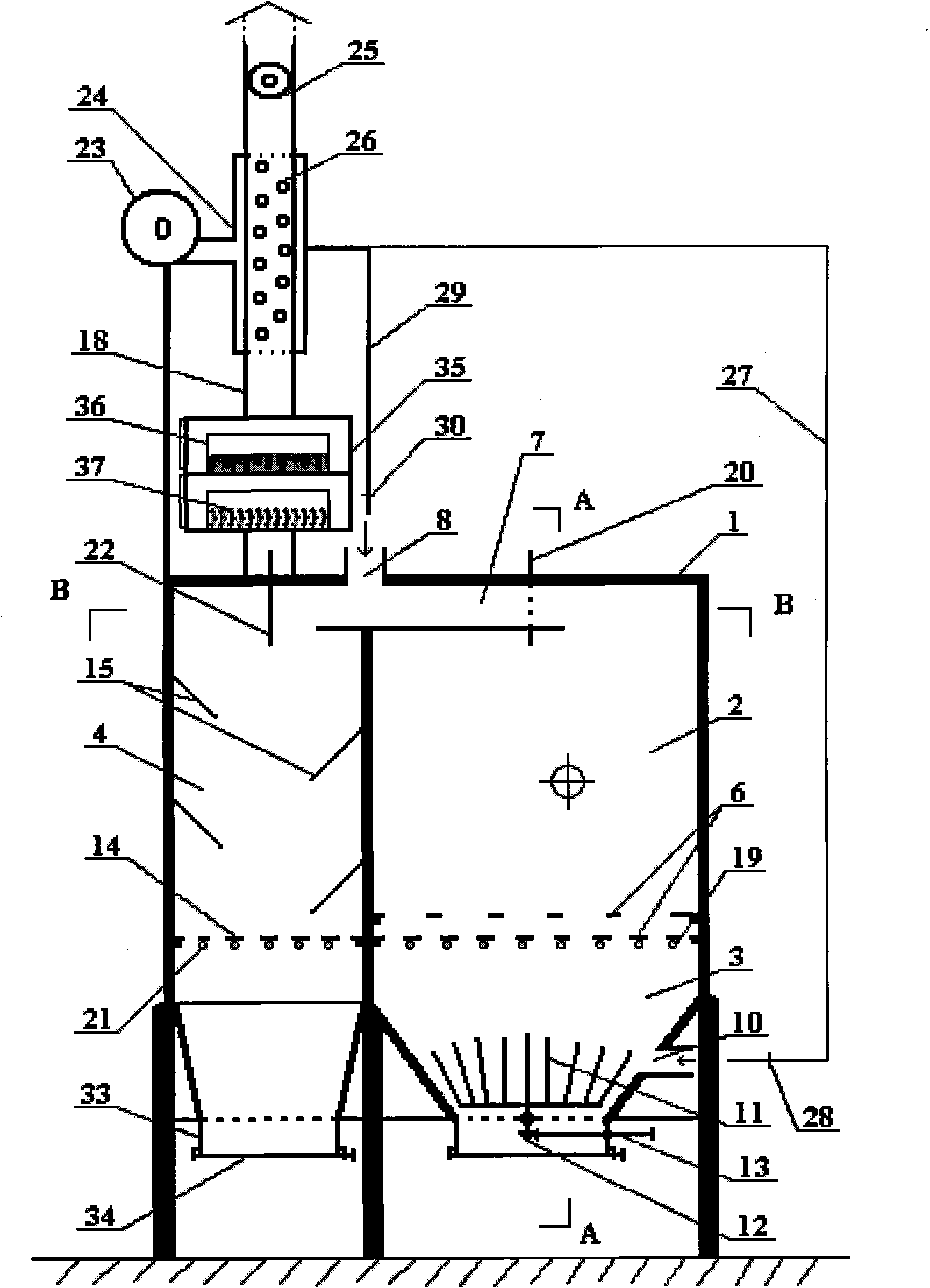

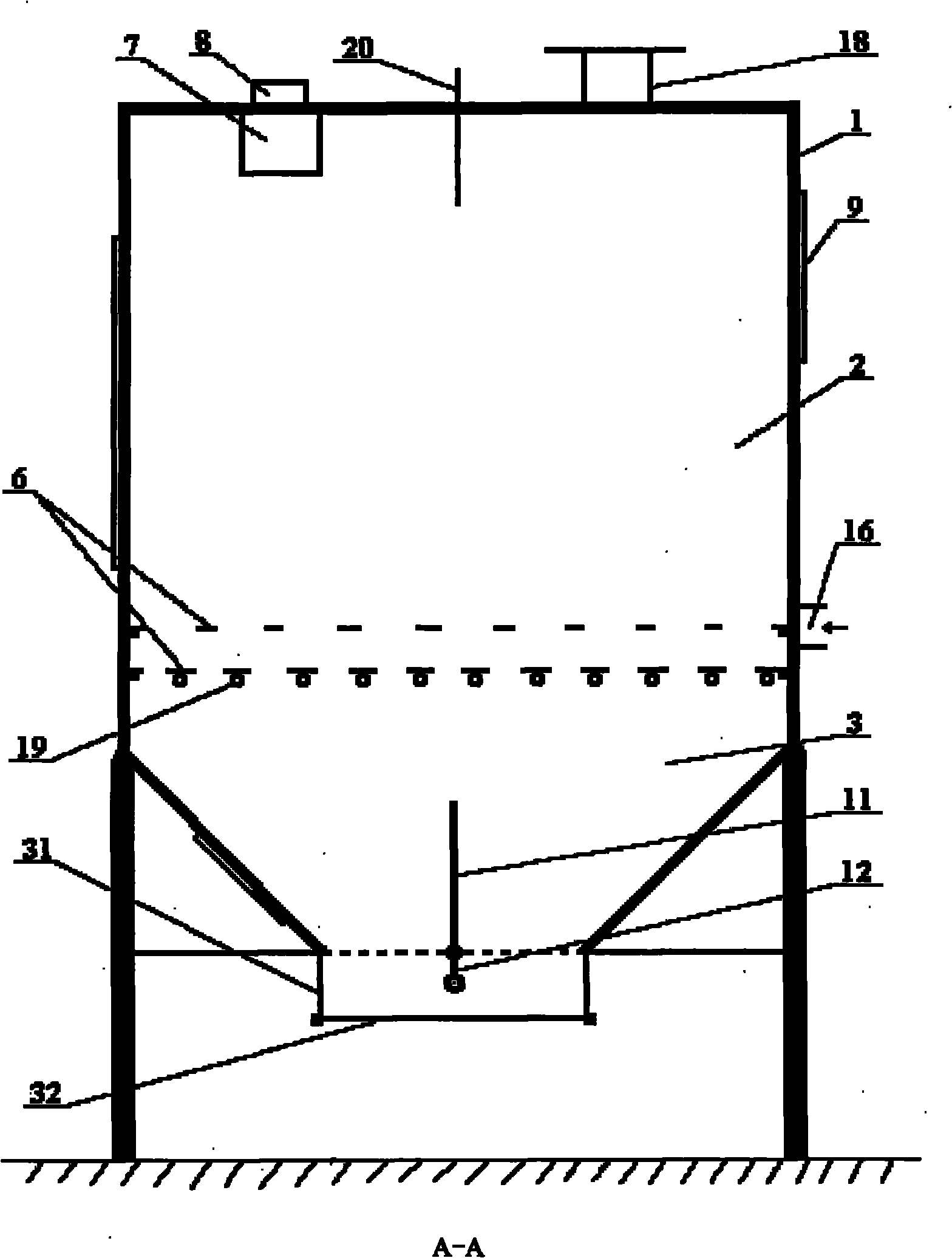

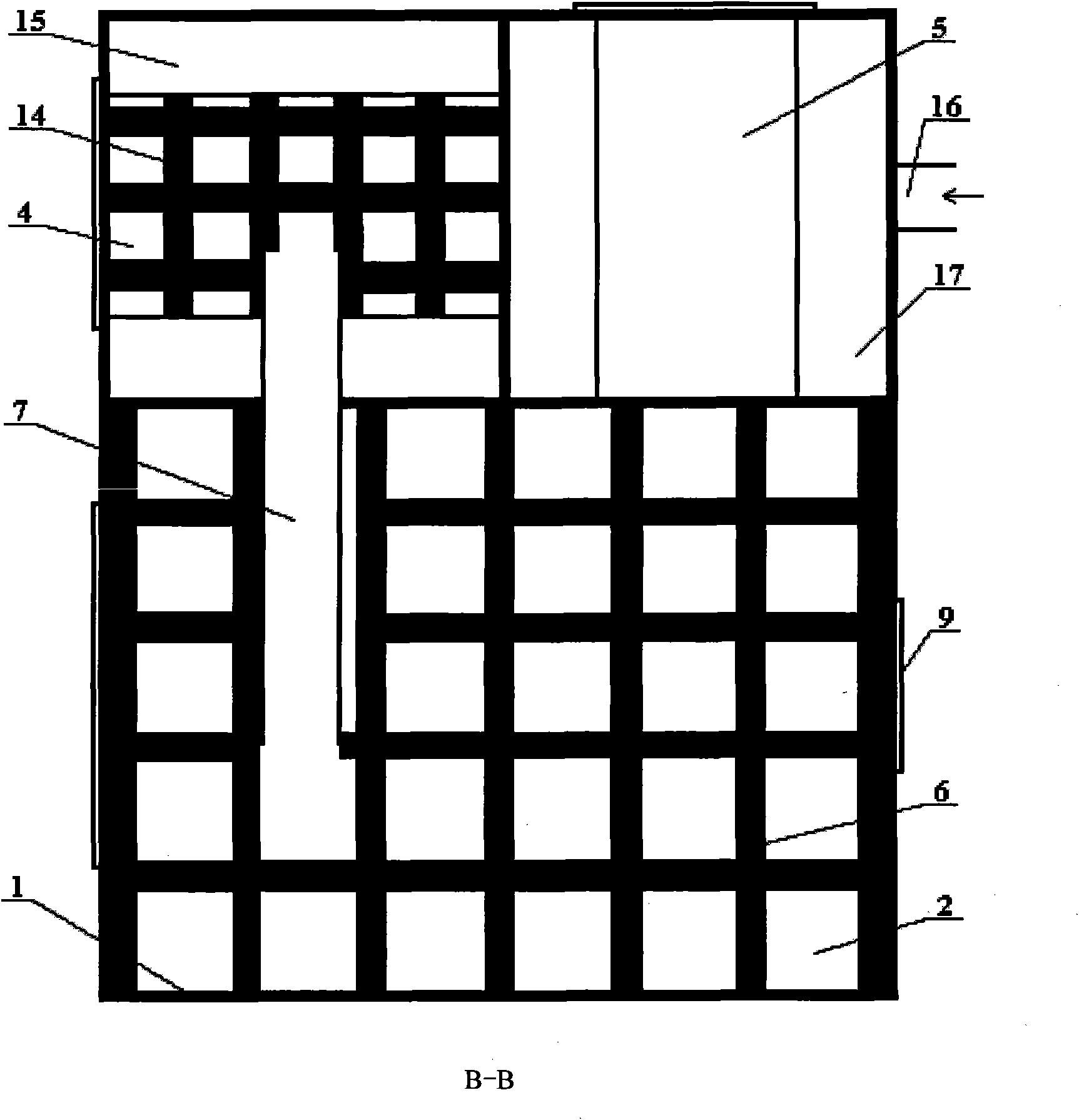

InactiveCN102042601AProblem Solving Using Unitary Furnace StructureLarge capacity reduction ratioIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberGas phase

The invention discloses a small efficient medicinal rubbish pyrolysis incinerator, which belongs to rubbish burning treatment equipment and solves the problems that a gas combustion chamber has simple structure, an auxiliary fuel is needed, the temperature cannot be accurately measured or controlled, and defects are produced in cloth bag dust removal and the like. The hearth of the incinerator consists of a pyrolysis and gasification chamber, a solid-phase burn-out chamber, a gas-phase combustion chamber and a flue gas treatment chamber; the solid-phase burn-out chamber is positioned below the pyrolysis and gasification chamber and communicated through a netlike fire grate; the gas-phase combustion chamber is arranged in parallel to the pyrolysis and gasification chamber, and the top of the gas-phase combustion chamber is communicated with a flue; the flue gas treatment chamber is arranged in parallel to the gas-phase combustion chamber and the pyrolysis and gasification chamber; and the gas-phase combustion chamber is communicated with the lower part of the flue gas treatment chamber, the gas-phase combustion chamber and the flue gas treatment chamber are provided with a fireproof baffle plate respectively, and the lower part of the gas-phase combustion chamber is provided with the netlike fire grate. The temperature in the incinerator is measured and controlled in real time through an electric heating and automatic temperature measurement and control system. A high-temperature granule dust removal and filter device avoids regeneration of dioxin, and the cost is reduced. The incinerator effectively and cleanly burns the medicinal rubbish on the aspects of incinerator shape design, ignition and combustion modes, temperature measurement and control, high-temperature flue gas treatment and the like.

Owner:杨显志

Low-temperature molten salt system for aluminum electrolysis and method for carrying out aluminum electrolysis by same

The invention relates to the field of molten salt electrolysis of nonferrous metal metallurgy and provides a novel molten salt electrolyte system which can be applied to the aluminum electrolysis industry. The molten salt as an electrolyte system of aluminum electrolysis can greatly reduce the electrolysis temperature, and the electrolyte system also presents a favorable dissolving performance onAl2O3 in the process of electrolysis. The novel molten salt electrolyte system comprises ternary or multivariant salt, such as KF, KCl, NaF, NaCl, AlF3, MgF2, CaF2, LiF, BaF2, Al2O3, and the like. Theelectrolyte system has a lower primary crystal temperature and the favorable dissolving performance on the Al2O3. The problems of low Al2O3 solubility and low dissolving speed brought by reducing theelectrolyte primary crystal temperature through reducing the NaF / AlF3 ratio in a sodium cryolite system are solved. In addition, the low-temperature electrolyte system is particularly suitable for adopting an inert anode of metal ceramics or metal alloy.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

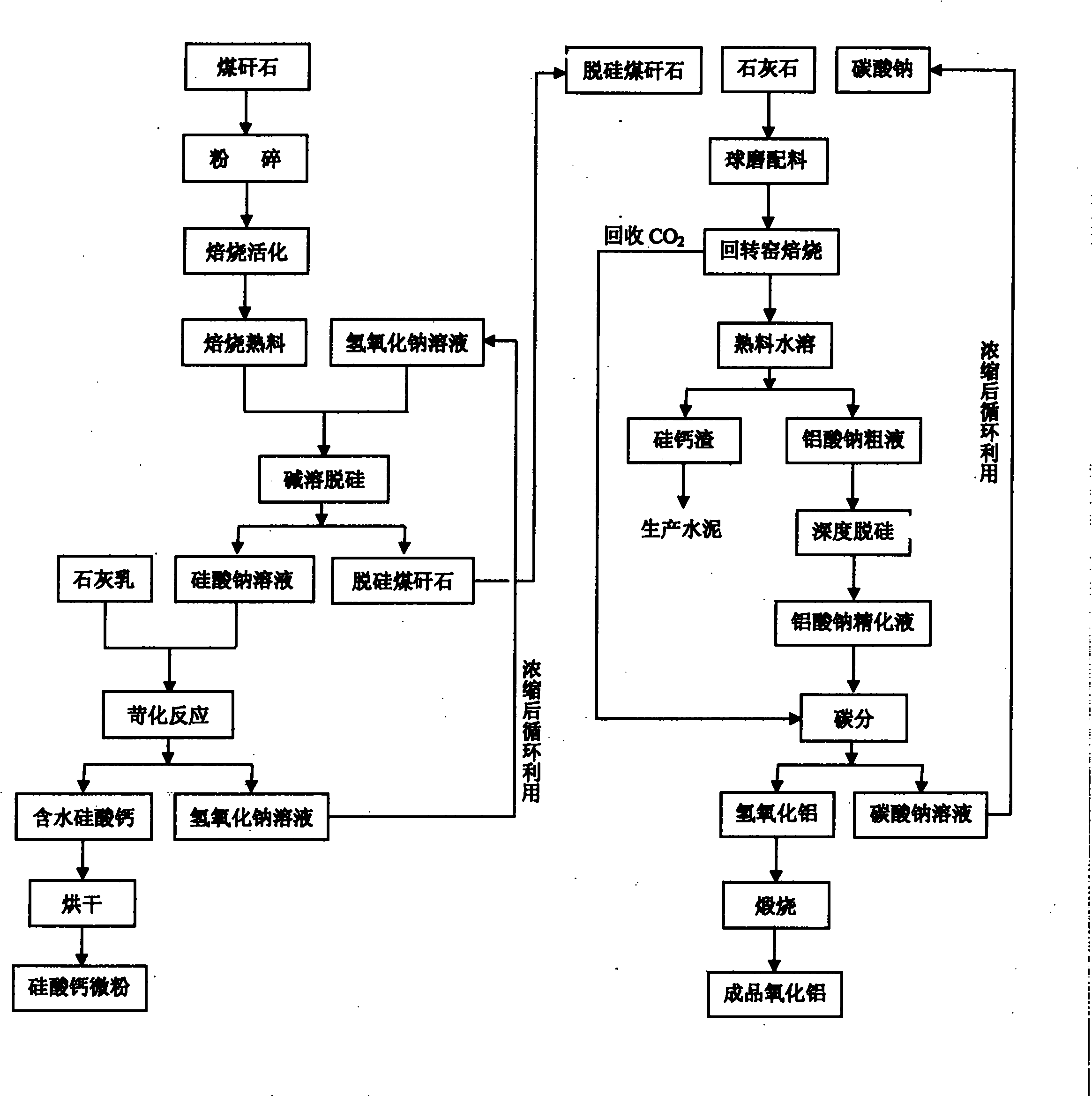

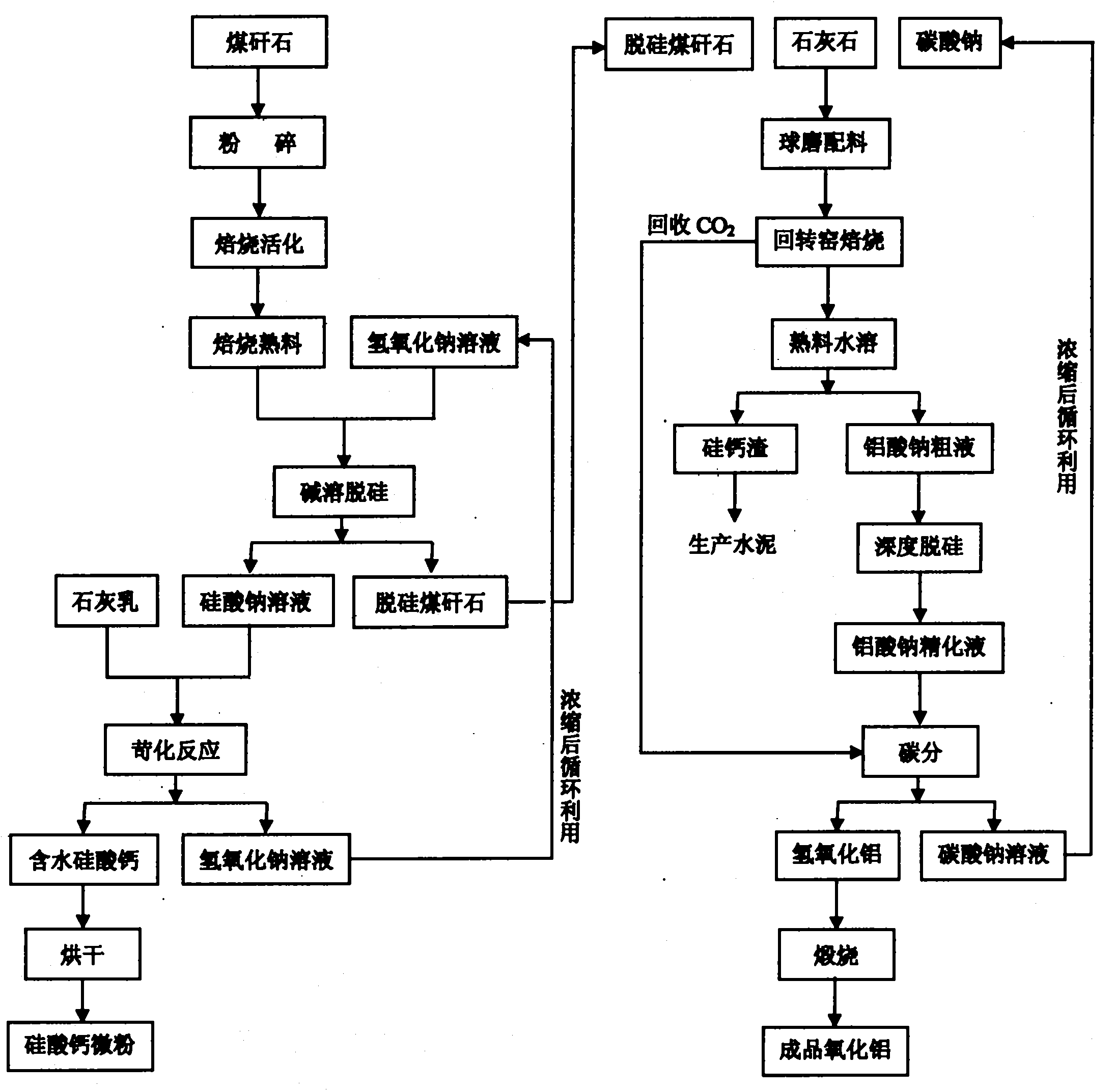

Method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate

ActiveCN101941725ALow firing temperatureHigh activityAlkaline-earth metal silicatesCement productionCoal gangueAluminium oxide

The invention provides a method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate, and relates to the technical field of producing aluminum oxide and the active calcium silicate. The method comprises the following steps of: grinding coal gangue, and roasting and activating the ground coal gangue; performing alkali soluble desilication of coal gangue clinker to obtain desilication coal gangue and solution of sodium silicate; performing causticizing reaction of the solution of sodium silicate to obtain water-containing calcium silicate and solution of sodium hydroxide, and drying the water-containing calcium silicate to obtain micro powder of active calcium silicate; adding limestone and solution of sodium carbonate into the desilication coal gangue, and ball-grinding the mixed solution to obtain raw slurry; dissolving out the clinker which is obtained by roasting the raw slurry with water to obtain crude solution of sodium aluminate and silicon and calcium residues, wherein the silicon and calcium residues can be used as cement raw materials after post-treatment; performing deep desilication of the crude solution of sodium aluminate to obtain the purified solution of sodium aluminate; feeding CO2 into the purified solution of sodium aluminate to obtain aluminum hydroxide and solution of sodium carbonate; and calcining the aluminum hydroxide to obtain the aluminum oxide products. The method has the advantages of simple process, low production cost, low energy consumption and little consumption of raw materials; in addition, by the method, two kinds of silicon-containing byproducts are simultaneously produced, and no waste is generated.

Owner:TONGFANG ENVIRONMENT

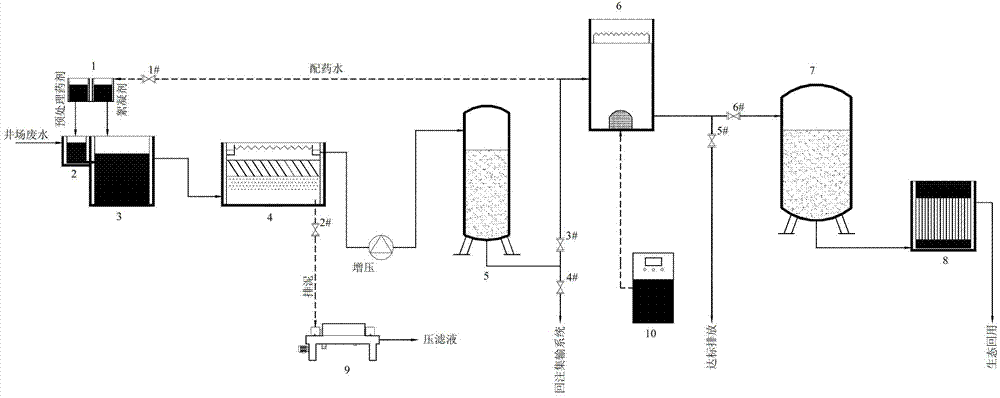

Equipment and process for modular treatment of oil field wastewater

ActiveCN102923878AStrong applicabilityReduce the impactWaste water treatment from quariesMultistage water/sewage treatmentIonActivated carbon

The invention relates to equipment for modular treatment of oil field wastewater. The equipment comprises a wastewater pretreatment unit, a micro interface control unit for performing coagulation, decoloration and oil removing on a micro interface, a sedimentation unit for removing relatively large particle impurities, a sand filter processing unit for retaining fine flocs, an ozone catalytic oxidation unit for removing poisonous and harmful substances, an adsorption processing unit for removing dissolvable organic matters and micro heavy metal ions, a membrane processing unit for further removing the impurities with large particle size and a sludge processing unit for disposing sludge. The specific equipment comprises a chemical feeding system, a micro interface coagulation reaction box, an inclined tube sedimentation box, an intermediate booster pump, a filter, an ozone catalytic oxidation reactor, an activated carbon adsorption device, a membrane processing device, a stacked type sludge water extractor and a matching pipeline and valve control system. By the equipment, corresponding processing unit can be started through the preset pipeline control system according to different destinations of treated wastewater, and modular treatment of different kinds of oil well operation wastewater is realized.

Owner:SHAANXI URSTAR ENVIRONMENTAL SCI & TECH

Non-phosphorus scale and corrosion inhibitor

InactiveCN101565241AAchieve emissionsSolve the emission problemTreatment using complexing/solubilising chemicalsCarbon steelGluconic acid

The invention discloses a non-phosphorus scale and corrosion inhibitor, which is characterized by comprising the following productive raw materials by weight portion: 5 to 80 portion of deionized water, 5 to 60 portions of polyepoxysuccinic acid, 1 to 10 portions of methylbenzotriazole, 3 to 20 portions of sodium gluconate, 1 to 10 portions of imidazoline and 2 to 15 portions of sodium tungstate. The non-phosphorus scale and corrosion inhibitor is a completely non-phosphorus medicament. Experiments show that the non-phosphorus scale and corrosion inhibitor has a scale inhibition rate of above 95 percent, a stainless steel and copper corrosion rate of less than or equal to 0.005mm / a and a carbon steel corrosion rate of less than or equal to 0.075mm / a and realizes phosphor-free discharge, wherein both the scale inhibition rate and the corrosion inhibition rate reach related national and industrial standards. The non-phosphorus scale and corrosion inhibitor has the advantages of radically solving the problem of the discharge of phosphor in circulating water, laying a good foundation for the governance and recycling of discharge water and providing a new environmental protection means.

Owner:李秀宁

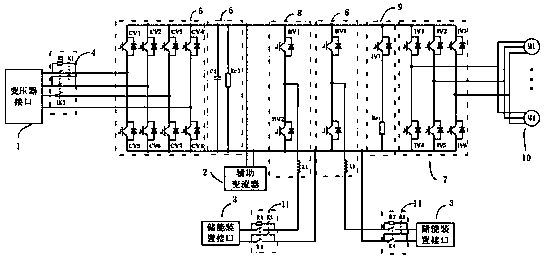

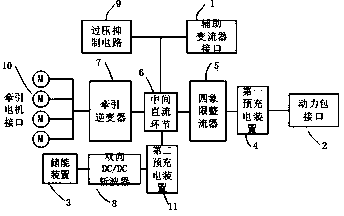

Motor train unit traction system powered by power packs and energy storage devices in mixed mode

ActiveCN103496327AAchieve normal operationAchieve emissionsSpeed controllerElectrodynamic brake systemsEmergency rescueDiesel engine

A motor train unit traction system powered by power packs and energy storage devices in a mixed mode mainly comprises the power packs, the energy storage devices, traction converters and traction motors, wherein the traction converters are connected with the traction motors, a diesel engine and an electric generator form each internal combustion power pack, three-phase output of the electric generators are directly connected with the traction converters, and the energy storage devices are connected with middle direct-current buses of the traction converters. The motor train unit traction system can achieve cross-line running and meet different requirements for transportation in different environments. In a non-electrification road section, the power pack and energy storage device mixed power supply mode is adopted so that normal running under the working condition without a contact system can be achieved. Under the working condition that power is supplied by the power packs and no contact system exists, braking energy is absorbed through the energy storage devices, and therefore recycling of energy is achieved and the green energy saving concept is embodied. Power supplying can be achieved in the acceleration process of a train through the energy storage devices so that the optimum acceleration performance can be achieved. Due to the adoption of the energy storage devices, a power train unit can have the operating capacity in the non-electrification road section and have an emergency rescue function and a war preparedness function in special rainy and snowy days or under the condition that the contact system is damaged, and can also be used as a mobile power supply.

Owner:CHINA RAILWAYS CORPORATION +1

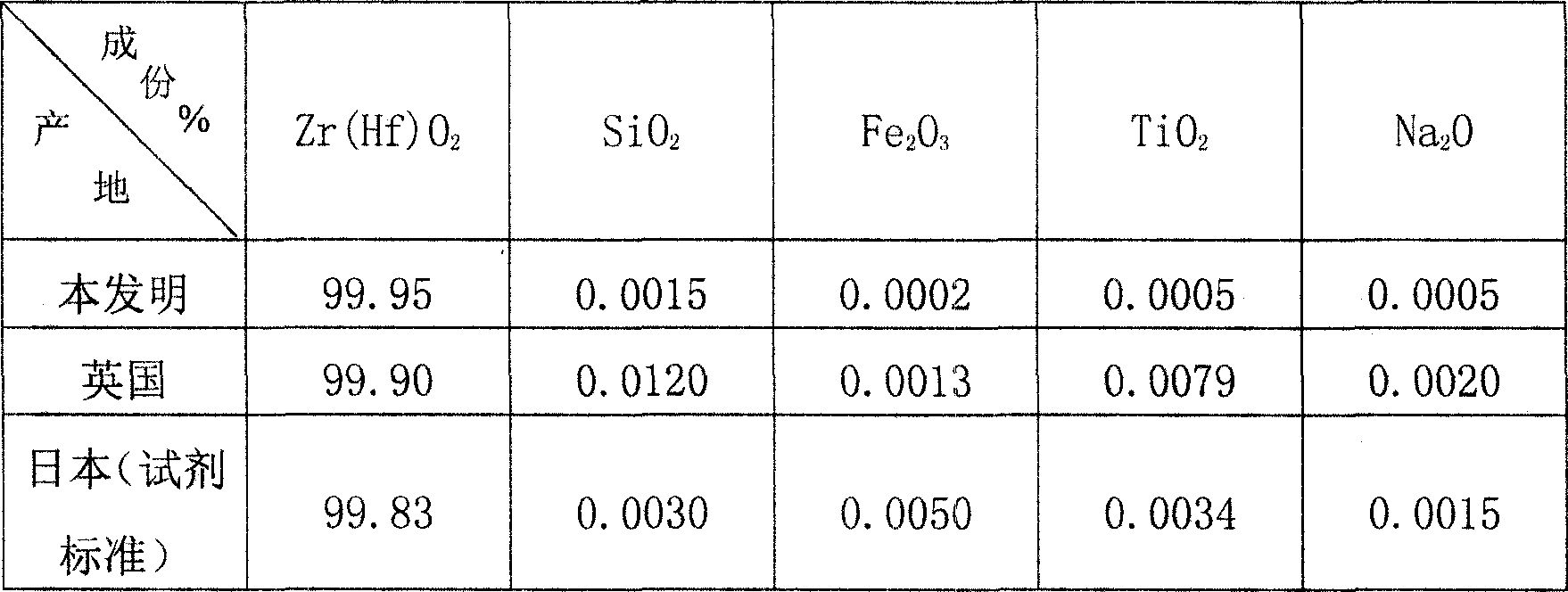

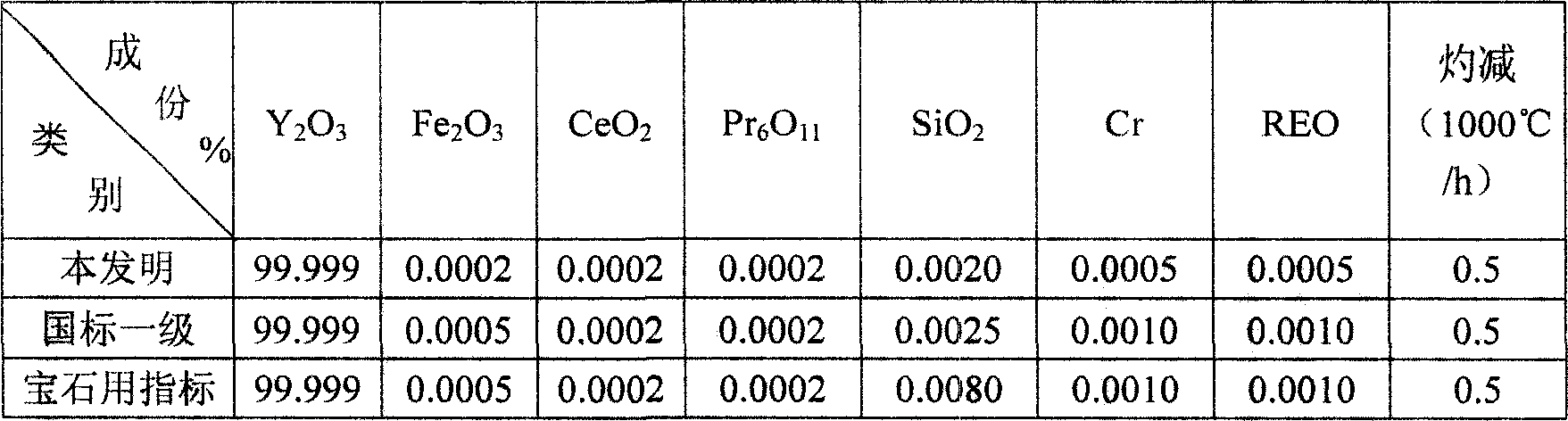

Process of preparing zirconia and yttria with Y-doped cubic zirconia powder

InactiveCN1986423AHigh metal contentLow priceRare earth metal compoundsZirconium oxidesOXALIC ACID DIHYDRATEPhysical chemistry

The process of preparing zirconia and yttria with Y-doped cubic zirconia powder includes the following steps: alkali fusing and sintering Y-doped cubic zirconia powder, water washing to eliminate sodium, acidifying and concentrating to obtain Zr crystal, oxychlorination to re-crystallize and purify, and high temperature calcining to obtain high purity jewel level zirconia; concentrating Y-containing mother liquid to crystallize zirconia, purifying high Y mother liquid, precipitating Y in oxalic acid solution, and high temperature calcining to obtain high purity jewel level yttria. The present invention has relatively low cost.

Owner:王必庆

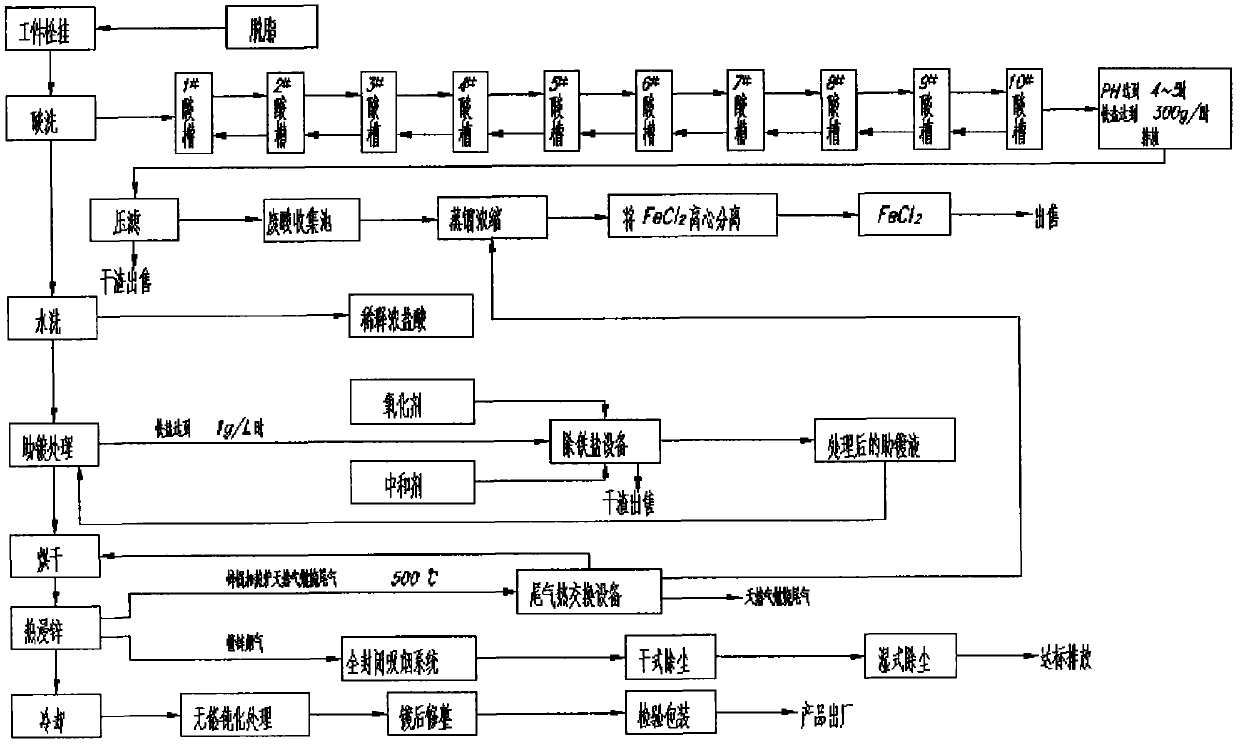

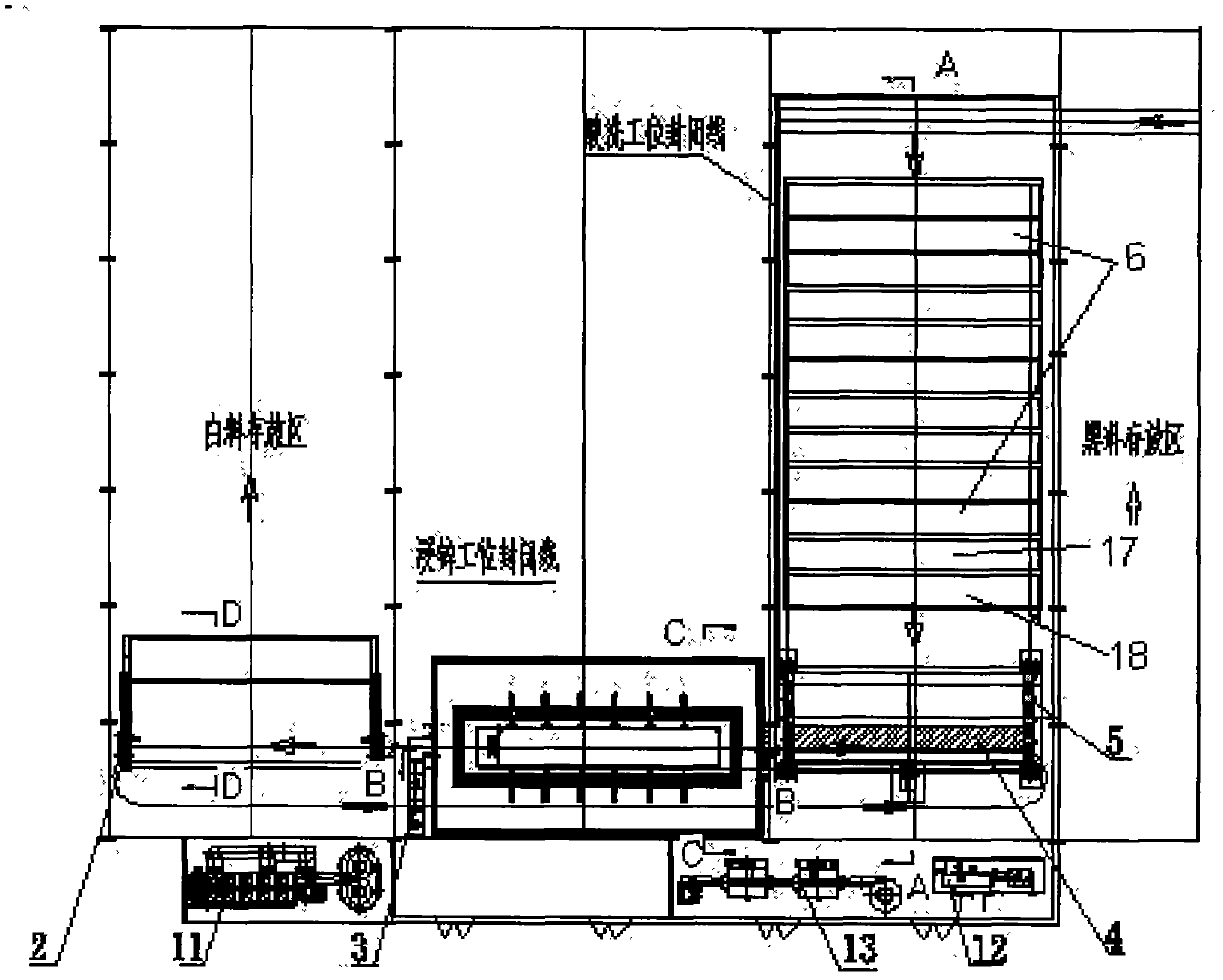

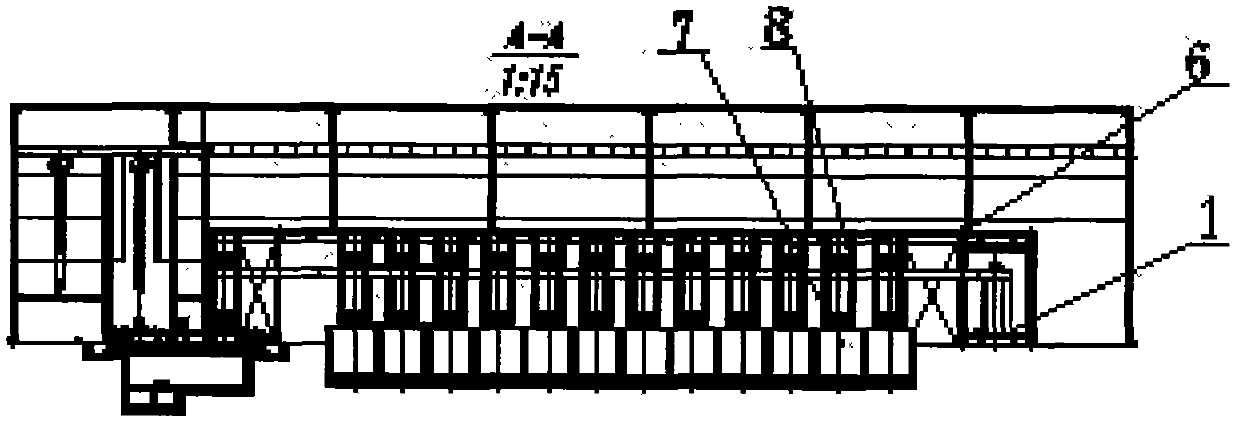

L-shaped full-closed environment-friendly hot galvanizing production equipment and method

InactiveCN102400075ADiffusion space is smallConvenient smokingHot-dipping/immersion processesAcid washingProcess engineering

The invention discloses an L-shaped full-closed environment-friendly hot galvanizing production method. The method is characterized in that: acid washing step-by-step automatic operation is implemented by adopting a mechanical hydraulic transmission manner, namely an acid washing workpiece automatic conveying system horizontally or vertically lifts to automatically convey workpieces to be galvanized to specified anti-collision acid washing tanks for acid washing and dust removing treatment step by step according to the multi-tank acid washing technological requirements, and the whole acid washing process is sequentially, progressively and automatically finished according to the technological requirements. The L-shaped full-closed environment-friendly hot galvanizing production method is pollution-free, environment-friendly, low in energy consumption, mechanical and automatic, and has the characteristics of full closure and integration of reclamation and treatment; and by the method, acid washing automation is realized, the labor intensity is furthest lightened, the production efficiency is improved, and the problem of pollution is solved.

Owner:张志红

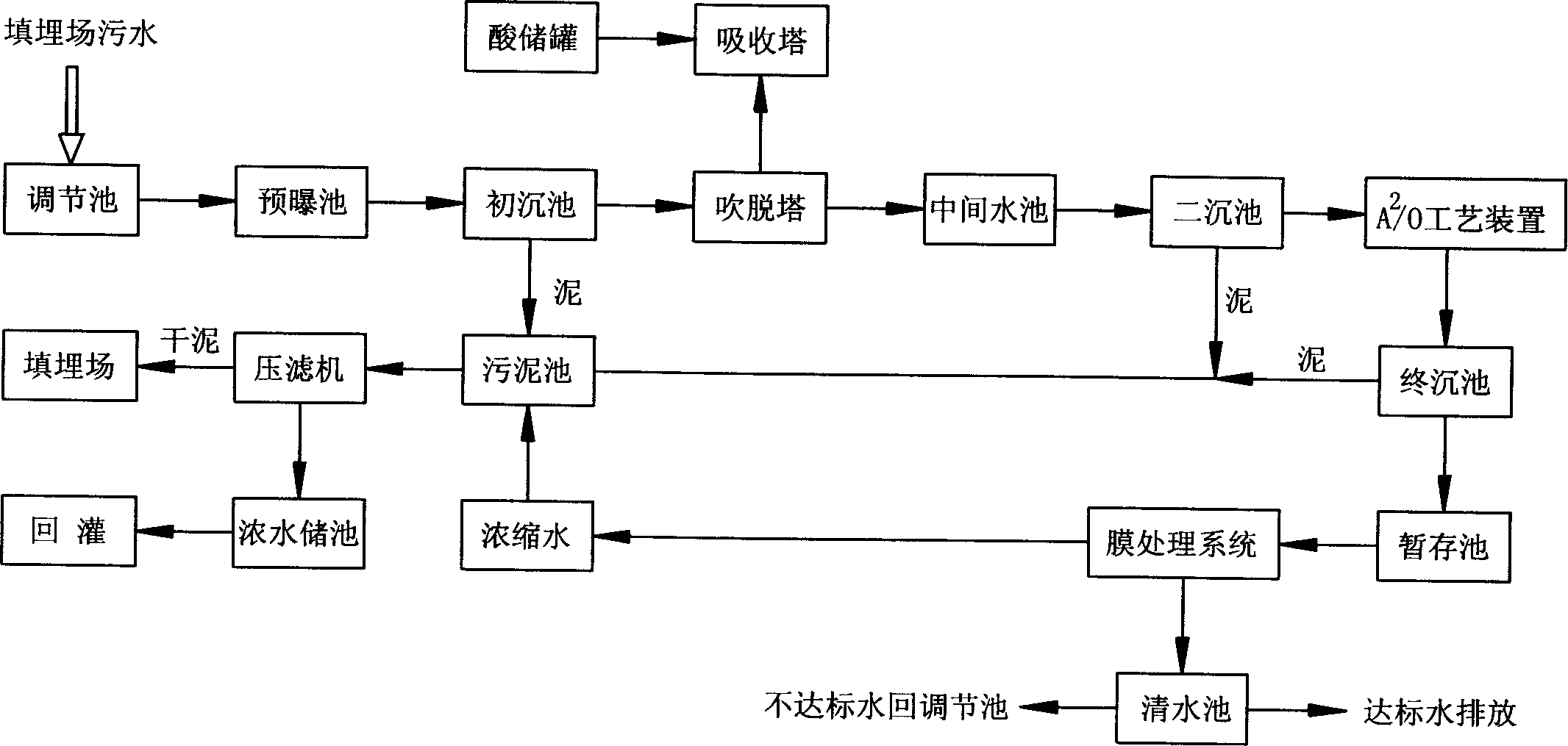

Method and system for harnessing consumer waste landfill percolate

ActiveCN1736908ALess investmentGood effectWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesAmmoniacal nitrogenSewage

The invention discloses a treatment method for percolate in domextic garbage landfill area, which comprises, taking ammonia blow-off to the percolate to degradate the ammonia and nitrogen; taking coagulate and deposite treatment to remove the biochemical property of organic and suspended matter; taking biochemical treatment and following membrane treatment. It also discloses the opposite system, which comprises connected by pipes an adjust pond, a pre-aeration pond, a first deposition pond, an ammonia blow-off tower connected to absorption tower, a middle pool, a second deposition ponds, an A2 / 0 technical device, an end deposition pond, a temporary storage pond, a membrane treatment system and clear-water pond; wherein, three deposition ponds and the membrane treatment system connects to sludege pond linked with pressure filter.

Owner:浙江博世华环保科技有限公司

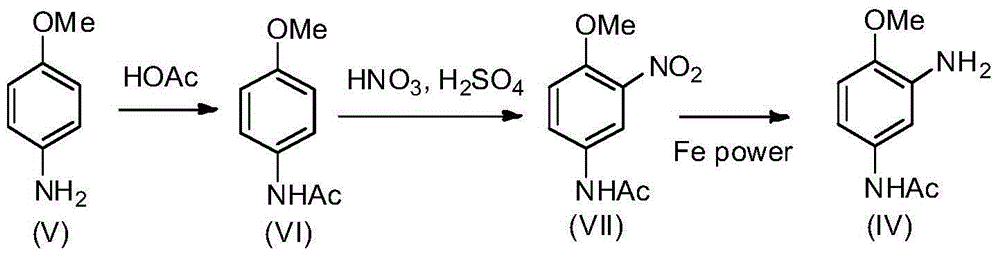

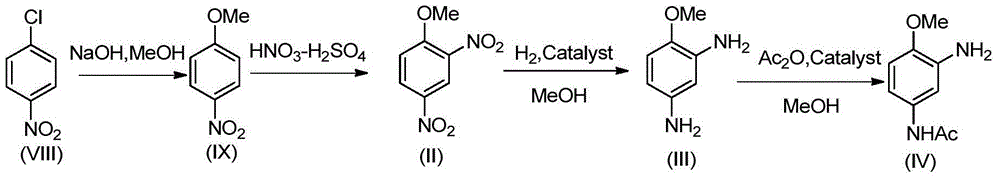

Synthesis process of 2-amino-4-acetamino anisole

InactiveCN104788334AReduce dosageReduce lossOrganic compound preparationCarboxylic acid amides preparationAcetic anhydrideEnergy consumption

The invention discloses a synthesis process of 2-amino-4-acetamino anisole. The synthesis process comprises the following steps: in methanol, under the action of an acid-binding agent, 2,4-diaminoanisole (III) and acetic anhydride are subject to acylation reaction shown in the description to obtain 2-amino-4-acetamino anisole (IV), wherein the molar ratio of the acid-binding agent to 2,4-diaminoanisole is (0.3 : 1)-(0.6 : 1). The synthesis process is low in energy consumption and cost, less in waste solids and waste liquid, environment-friendly, simple in operation, mild in reaction condition and high in industrial safety factor, the yield of the target compound is above 86% (counting according to original reaction raw materials), the HPLC purity is above 99.0%, the target compound is high in yield and good in quality, and the synthesis process is more suitable for industrial production.

Owner:SHANGHAI ZONGXING CHEM TECH CO LTD

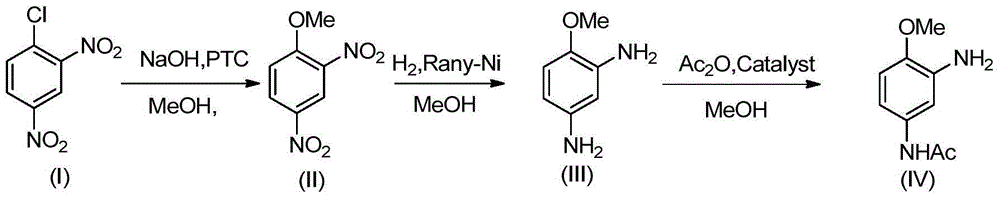

Air injection-assisted super heavy oil underground cracking improvement technology based on shaft heating modes

InactiveCN106499376AEmission reductionAchieve emissionsConstructionsFluid removalReaction rateHeater Rod

The invention provides a technology method for comprehensive oil production and in-situ improvement of super heavy oil, oil shale, kerogen and medium and low-maturity shale oil reservoirs. The technology method is characterized in that a novel shaft electric heating in-situ cracking improvement technology is adopted, and is assisted by an air injection technology; by drilling a production well group into an oil bearing reservoir or adjusting the existing well network, a heating well, an air injection well and a production well are reasonably arranged; air is injected into the reservoir, and a heating cable in a heating well shaft is connected with an electric heating bar to heat the oil bearing reservoir, so as to realize the improvement of underground cracking of crude oil. The technology method has the advantages that by combining the advantages of shaft electric heating and air injection technologies, the problems of single heat transfer type, insufficient driving energy and the like in a single shaft electric heating mode are solved; by utilizing the heat effect of crude oil and oil oxidizing reaction, the stratum temperature is increased, the cracking temperature of the crude oil is decreased, the reaction rate of in-situ cracking is accelerated, the recovery efficient of the crude oil is improved, and the consumption of water resources and carbon emission are decreased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

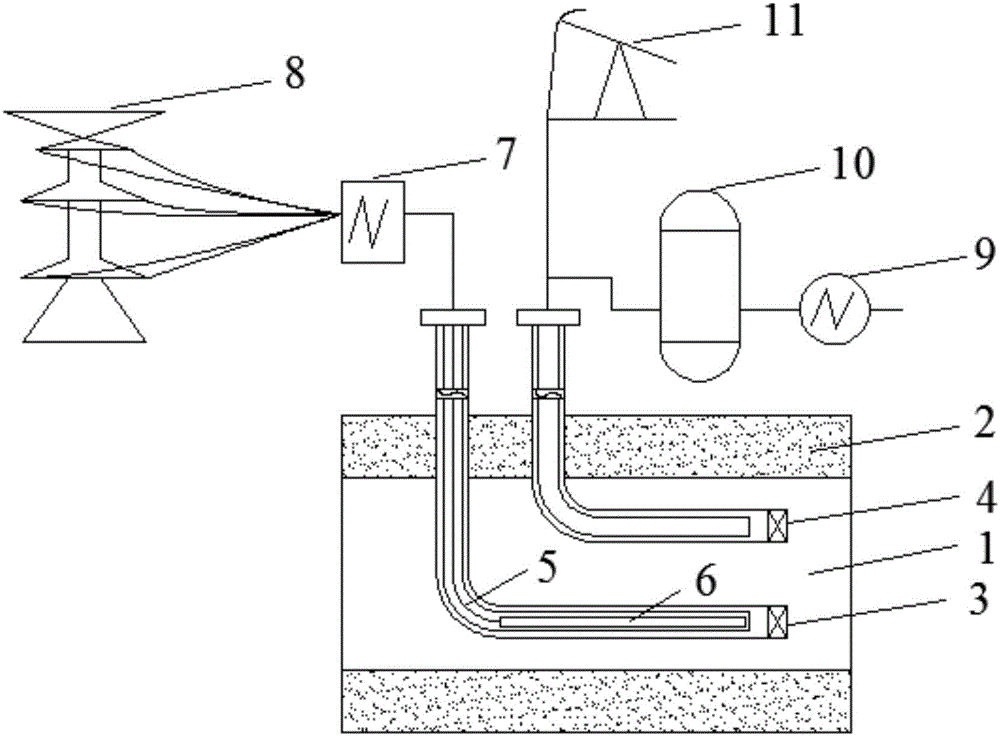

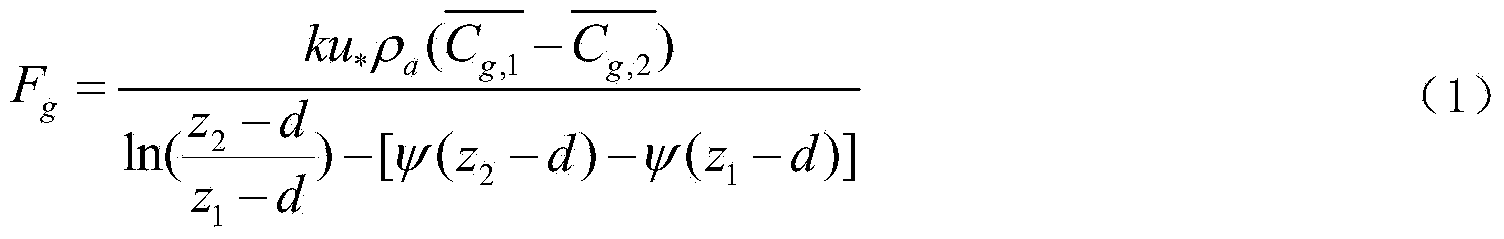

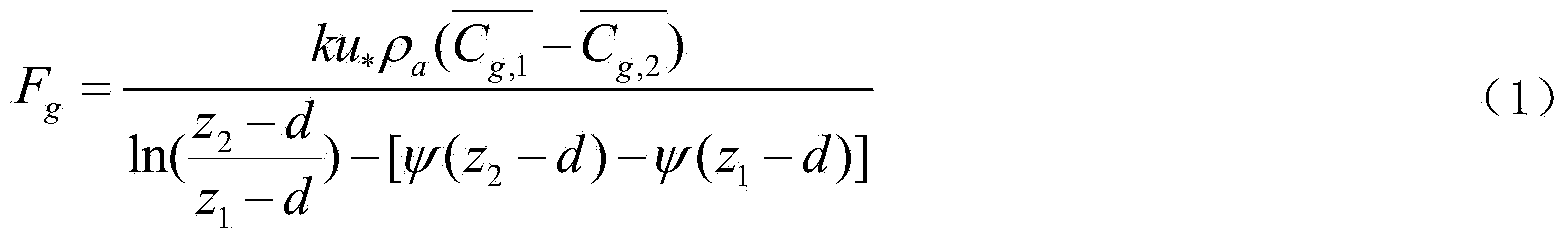

System and method for measuring infrared spectrum in greenhouse gas emission flux

ActiveCN103852437AReal-time emissionAchieve emissionsMaterial analysis by optical meansSurface layerSpectrograph

The invention discloses a system and a method for measuring an infrared spectrum in a greenhouse gas emission flux. The system mainly comprises a two-way-feeding automatic switching gas circuit, a gas sample pool, a Fourier transform infrared (FTIR) spectrograph, a three-dimensional ultrasound anemograph and a computer. According to the system, the emission flux of measured gas is obtained according to the mixing ratio concentration of greenhouse gas measured by the FTIR spectrograph as well as information of a surface layer wind field, close to a concentration measurement height, measured by the three-dimensional ultrasound anemograph.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for recovering lead from lead-containing solid wastes

InactiveCN103290225AHigh puritySimple processProcess efficiency improvementEnvironmental chemistryLead chloride

A method for recovering lead from lead-containing solid wastes comprises the following steps: 1, fragmenting the lead-containing solid wastes, ball-milling, leaching with an alkali chloride-alkaline earth metal chloride solution or an alkaline earth metal chloride solution as a leaching agent, and filtering; 2, adding an NaOH solution or solid NaOH to a filtrate obtained in step 1 for completely converting PbCl2 in the solution at 20-90DEG C for 30-120min to form basic lead chloride, filtering after the reaction completion, and washing to obtain a filtrate and a filter residue which is basic lead chloride; 3, adding basic lead chloride to the NaOH solution for completely converting basic lead chloride into lead hydroxide, filtering after the reaction completion, washing to obtain a filtrate and a filter residue which is lead hydroxide, and carrying out drying dehydration of lead hydroxide to form lead oxide; and 4, recovering or regenerating the leaching agent. The method has the advantages of simple process, simple operation, low processing cost, high lead recovery rate and no pollution to the environment.

Owner:CHANGSHA HUAMING COMPOSITE MATERIAL TECH

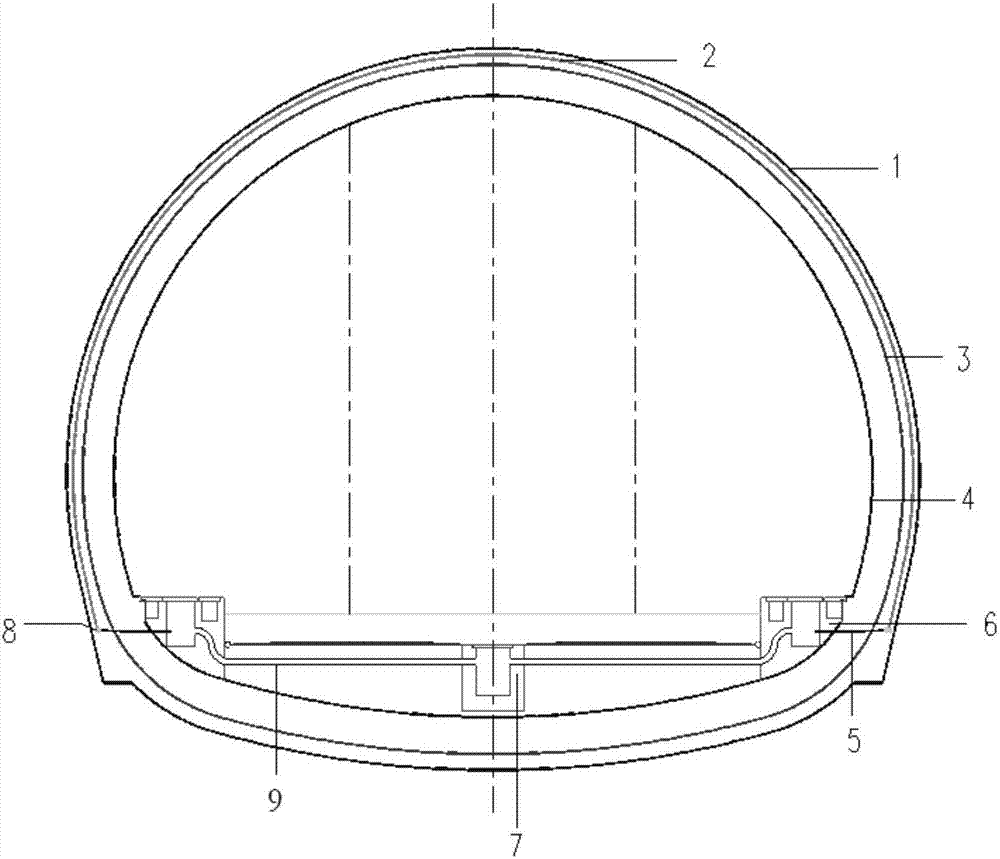

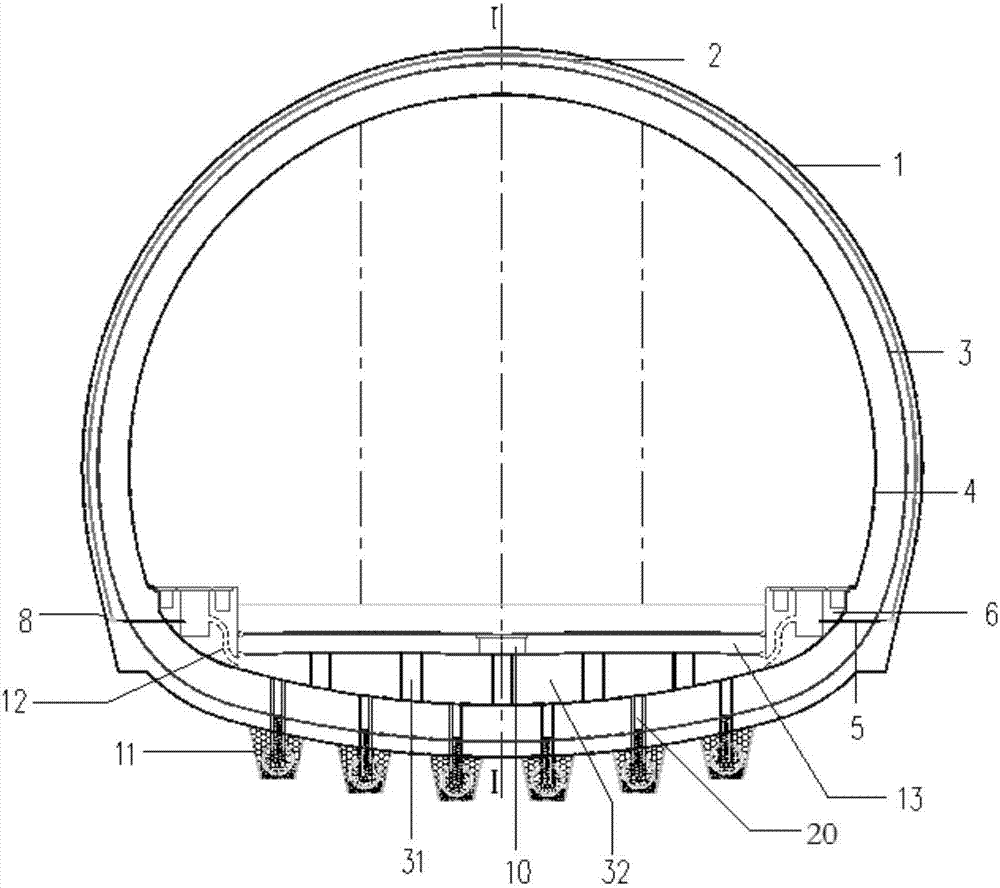

Water-rich stratum tunnel bottom drainage structure and construction method thereof

ActiveCN106968712AReduce water pressureImprove drainage capacityUnderground chambersTreatment involving filtrationDrainage tubesWater well

The invention relates to a water-rich stratum tunnel bottom drainage structure and a construction method thereof. A ballast bed base plate is arranged above an inverted arch in a spaced mode; bearing piles are arranged between the ballast bed base plate and the inverted arch; water passing culverts of the tunnel bottom are formed between the ballast bed base plate and the inverted arch; drainage side ditches communicate with the water passing culverts through side ditch drainage pipes; water collecting wells are arranged on the bottom faces of the water passing culverts; the lower ends of the water collecting wells penetrate through the inverted arch to extend into filtering water collecting devices under the inverted arch; water releasing holes are formed in the bottoms and the side walls of the water collecting wells, and filtering layers are arranged on the outer sides of the water releasing holes; and one-way drainage devices are arranged in the water collecting wells. An inverted arch filling part in the prior art is replaced with the ballast bed base plate and the bearing piles; on the basis of guaranteeing tunnel structure safety, the water passing cross section area of a tunnel drainage system is increased, and the tunnel drainage capacity is improved; and meanwhile, underground water under the water-rich stratum tunnel inverted arch is drained, tunnel bottom water pressure is reduced, and preventing of damage such as upheaval of the tunnel inverted arch and frost boiling and mud pumping of a ballast bed is facilitated.

Owner:SOUTHWEST JIAOTONG UNIV

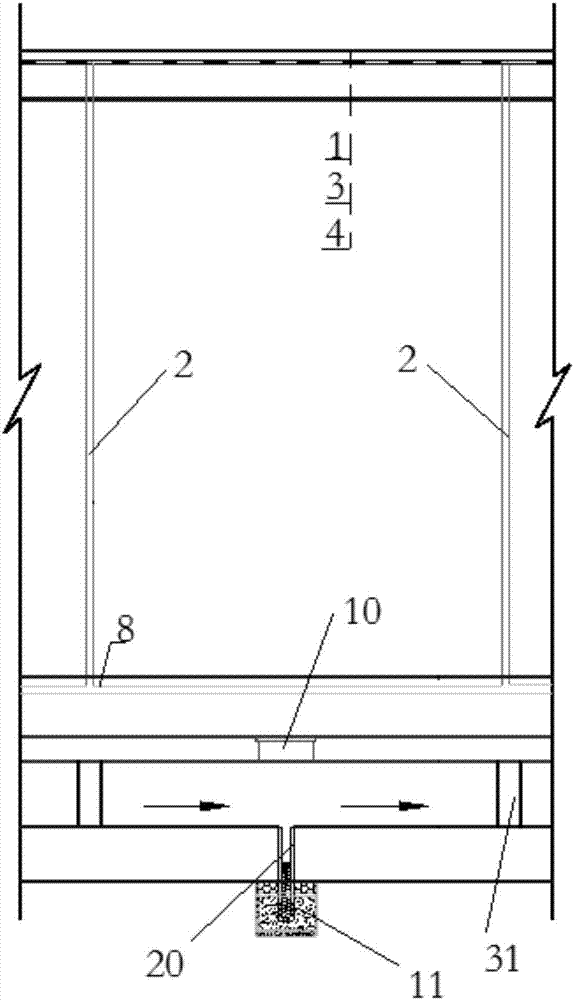

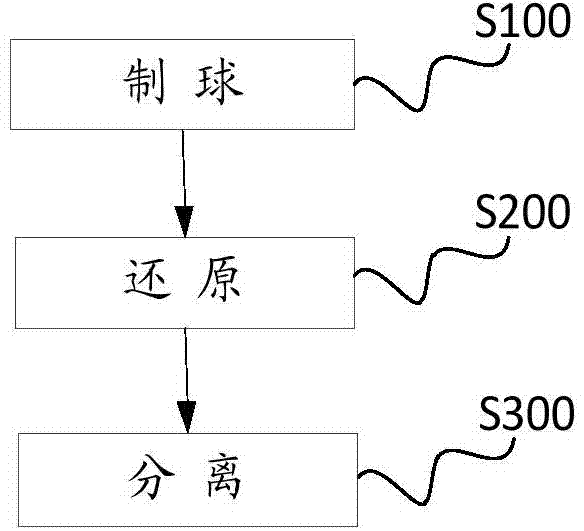

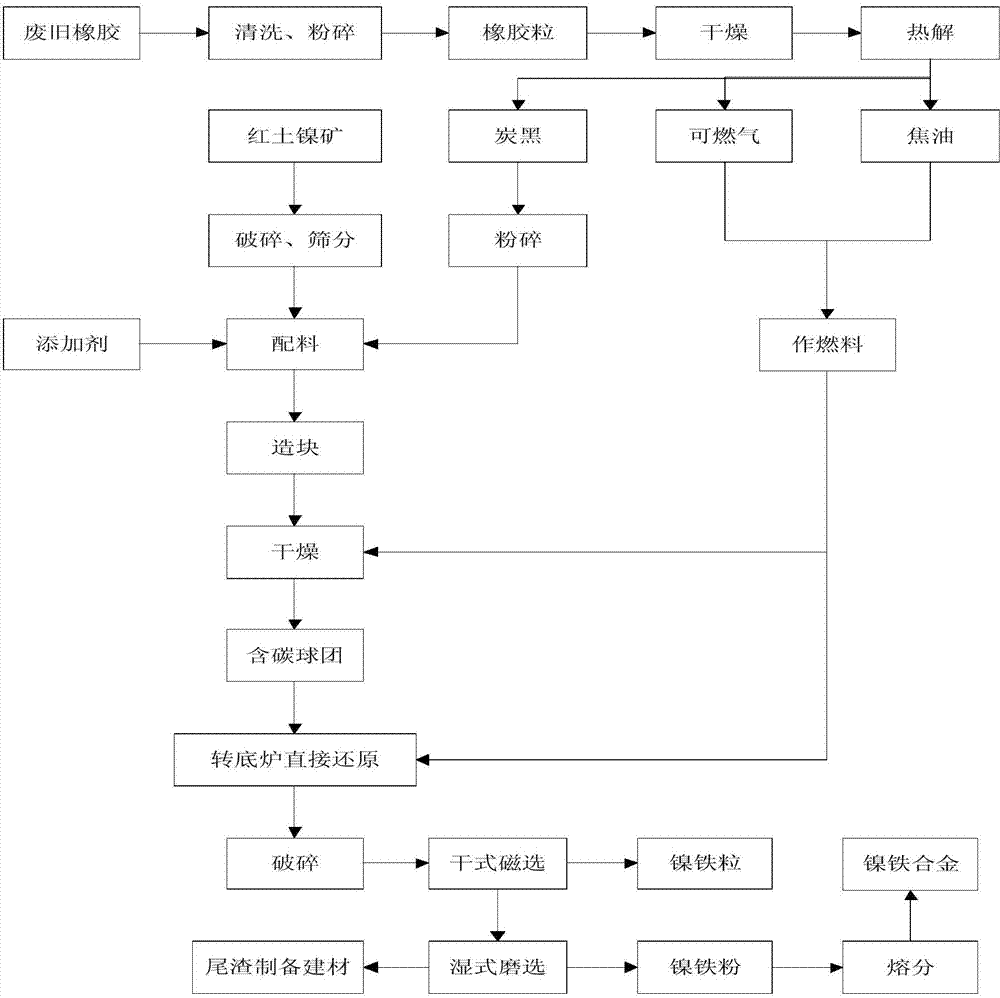

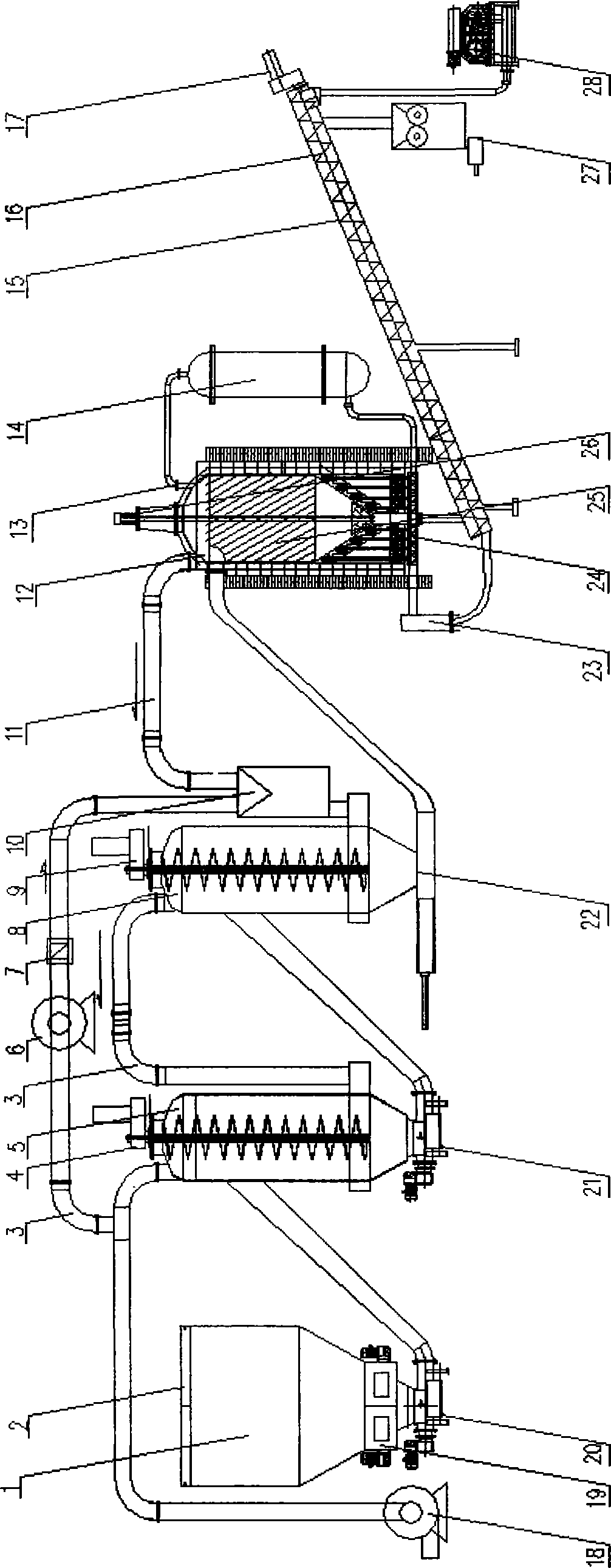

Treatment method of laterite-nickel ore

The invention discloses a treatment method of laterite-nickel ore. The method comprises the following steps: pelleting laterite-nickel ore, a reducer and additives to obtain laterite-nickel ore pellets; carrying out reducing roasting on the laterite-nickel ore pellets in a heat-accumulation rotary hearth furnace to obtain metalized pellets; carrying out crushing and dry magnetic separation on the metalized pellets to obtain nickel iron granules and first tailings; and carrying out wet grinding and wet magnetic separation on the first tailings to obtain nickel iron powder and second tailings, wherein the reducer is carbon black prepared from rubber. The method can be effectively utilized to prepare the nickel iron product.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

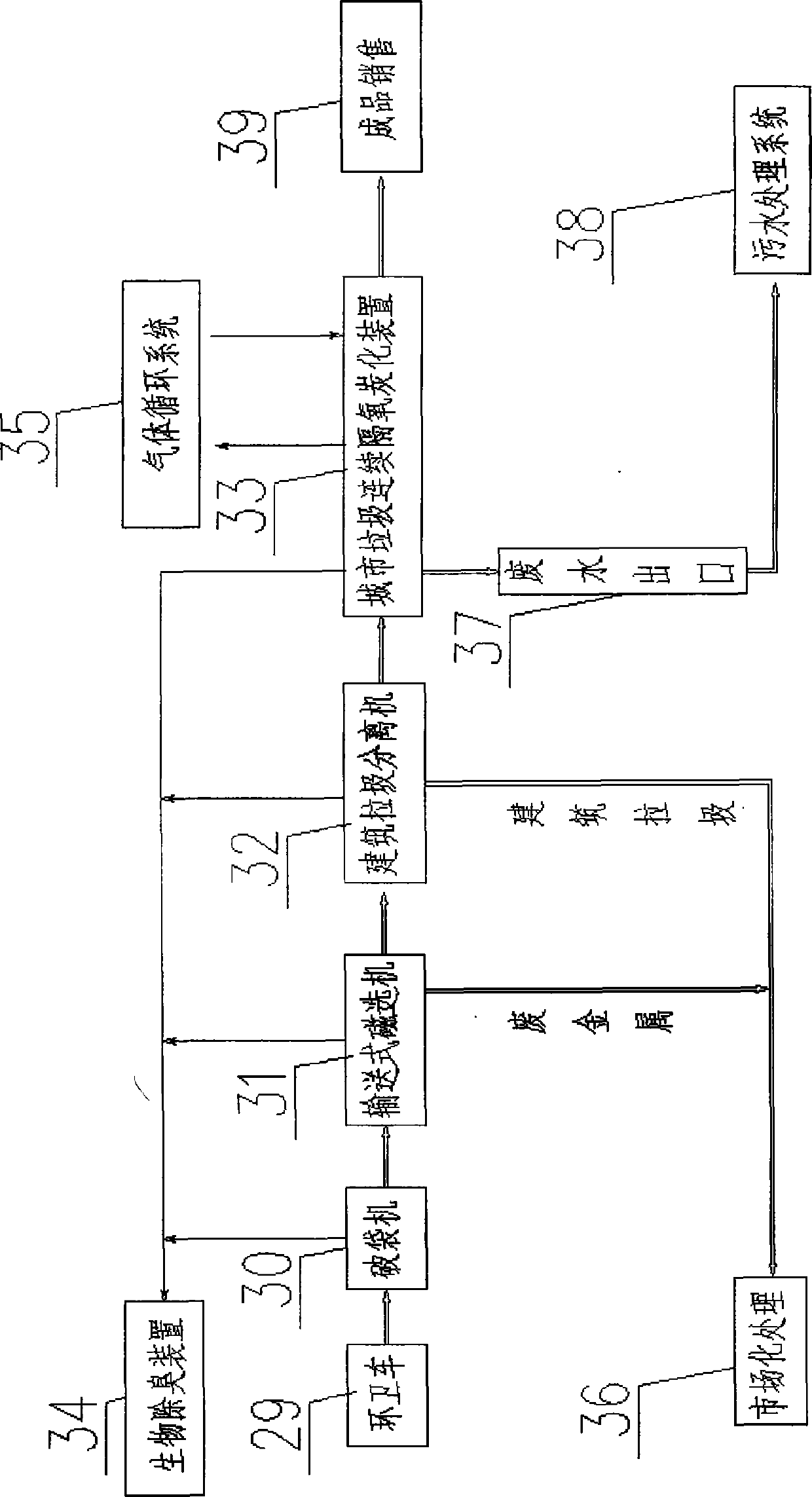

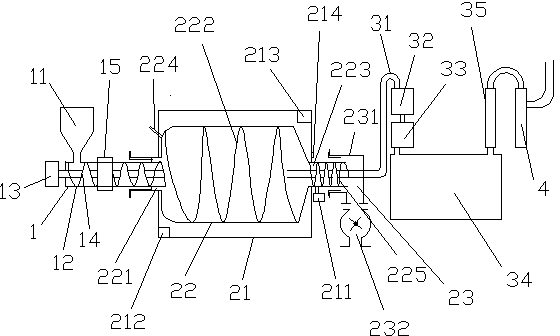

Continuous high-temperature oxygen-isolated carbonization process for treatment of municipal solid waste and apparatus used therein

ActiveCN103624060ASolve tough problemsAvoid it happening againConstruction waste recoverySolid waste disposalLitterCarbonization

The invention is a continuous carbonization process directed at municipal solid waste and an apparatus used therein. The process can mainly overcome problems occurred in treatment of municipal solid waste in the prior art, e.g., generation of oncogenic dioxin in burning of municipal solid waste. The process can realize pollution-free treatment of garbage. The invention has the following advantages: combustible gas produced in cracking and carbonization of municipal solid waste under high temperature and anaerobic conditions is used as an energy source for a system, thereby realizing self-sufficiency of energy; the anaerobic condition can well inhibit generation of dioxin; treating flow of the process is simple and stable, and long-time continuous treatment of municipal solid waste is realized; drying of municipal solid waste, deodorization of gas, circulation of heat and the like are realized.

Owner:宜兴市清泉水质处理设备有限公司

Process for preparing building gypsum powder from phosphogypsum

The invention discloses a process for preparing building gypsum powder from phosphogypsum. The process comprises the technical links of: phosphogypsum drying, fine grinding and powder sorting; suspended dehydration; proper aging and the like. According to the process system disclosed by the invention, the phosphogypsum fine grinding, drying and dehydration process is divided into two relatively independent links, the negative-pressure operation is adopted, and a hot blast stove, a feeding device, a phosphogypsum fine grinding, drying and powder sorting device, a suspended dehydrator, an aging bunker, a dust collecting device, an induced draft fan and the like are provided in the process. The process is stable in production process, capable of saving energy and realizing large-scale production and high in product quality.

Owner:WENGFU (GRP) CO LTD +1

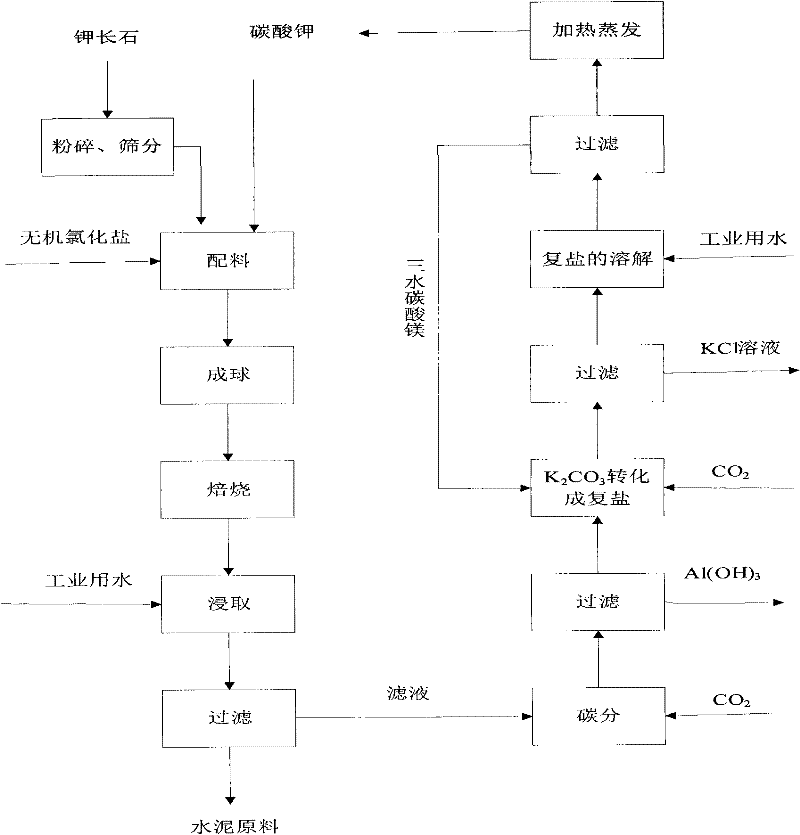

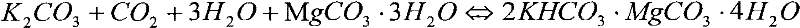

Method for producing potassium fertilizer and aluminum oxide by comprehensively using potassium feldspar

InactiveCN102531710ARealize comprehensive utilizationImprove utilizationAluminium compoundsPotassium fertilisersAluminium hydroxideChloride

The invention relates to a method for producing a potassium fertilizer and aluminum oxide by comprehensively using potassium feldspar. The method comprises the following steps of: (1) smashing potassium feldspar and inorganic chlorate, and burdening potassium feldspar, inorganic chlorate and potassium carbonate in the mass ratio of 1:(1-2):(1-10); (2) pelletizing the prepared material, and sintering at the temperature of 500-1,200 DEG C for 1-5 hours to obtain a sintered material and generate CO2 gas simultaneously; (3) soaking the material obtained in the step (2) into water and filtering; (4) introducing a filtrate obtained in the step (3) into the CO2 gas obtained in the step (2) to obtain an aluminum hydroxide precipitate, and filtering; (5) adding a filtrate obtained in the step (4) into nesquehonite, introducing CO2 gas to obtain a complex salt precipitate, filtering and crystalizing a filtrate to obtain a potassium chloride chemical fertilizer; and (6) adding water for dissolving a complex salt obtained in the step (5) to obtain a solid of nesquehonite, circularly using, heating a potassium bicarbonate solution for decomposing to obtain a potassium carbonate solution for circularly using, and repeating the step (1) to the step (6).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

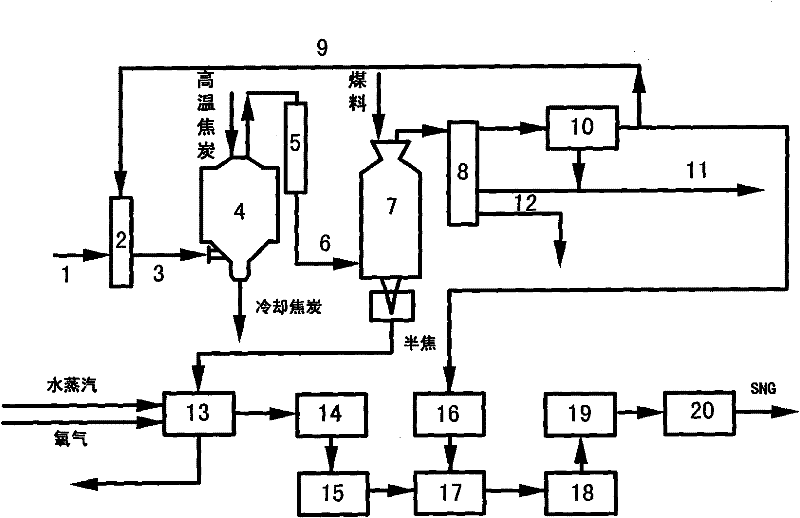

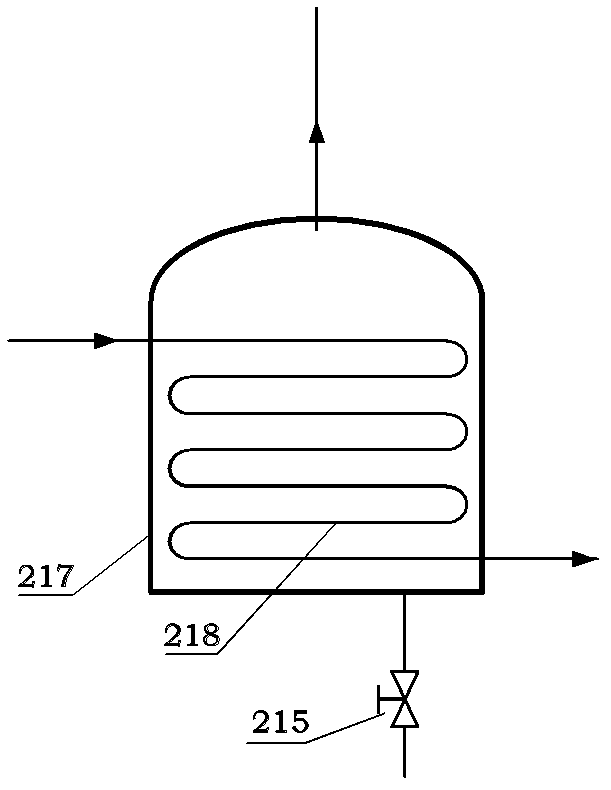

Method for preparing natural gas by dry quenching co-production coal

InactiveCN101747918AAvoid pollutionAchieve emissionsCoke quenchingDirect heating destructive distillationMethanationQuenching

The invention provides a method for preparing natural gas by dry quenching co-production coal. In the method, reducing gas is taken as heat-carrying gas, refrigerant and a pyrolytic process thereof are adopted to recover a great quantity of sensible heat of high-temperature coke so as to couple the dry-method coke quenching process and the coal pyrolytic process of high-temperature metallurgical coke, thus cancelling a gas and air supply system, a combustion control system and a waste gas discharging system in the original pyrolytic process, avoiding pyrolytic combustion process, saving a great quantity of energy, and realizing smoke-free, NOX-free, SOX-free and CO2-free discharging. Meanwhile, gasification gas produced by pyrolytic gas and semi-coke gasification is used for producing andsynthetizing natural gas in a methanation manner so as to realize clean conversion of coal. In addition, the method cancels N2 preparation equipment and waste heat boiler systems in dry quenching, thus simplifying the operation and maintenance process and greatly lowering investment and operation cost.

Owner:山西中元煤洁净技术有限公司

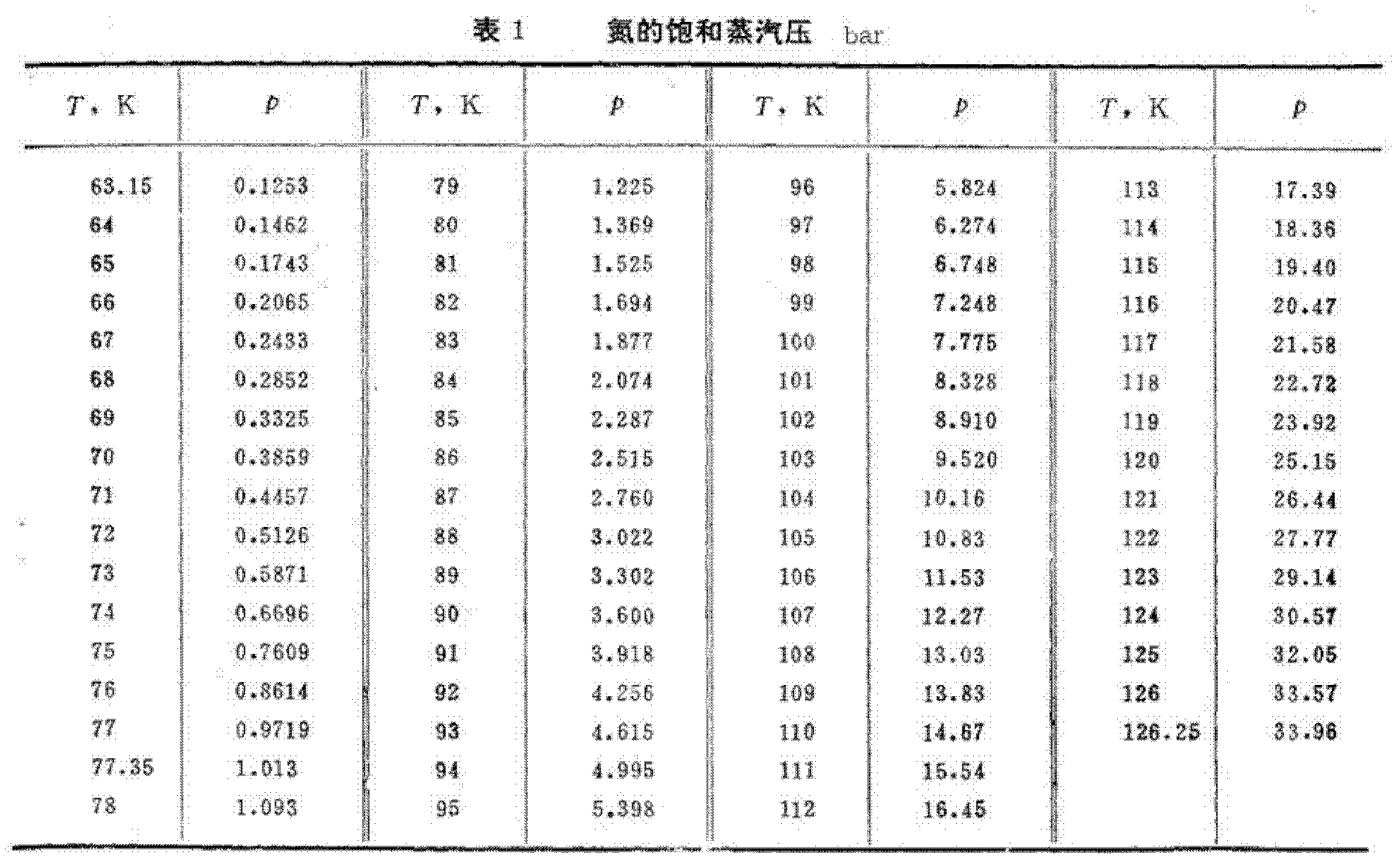

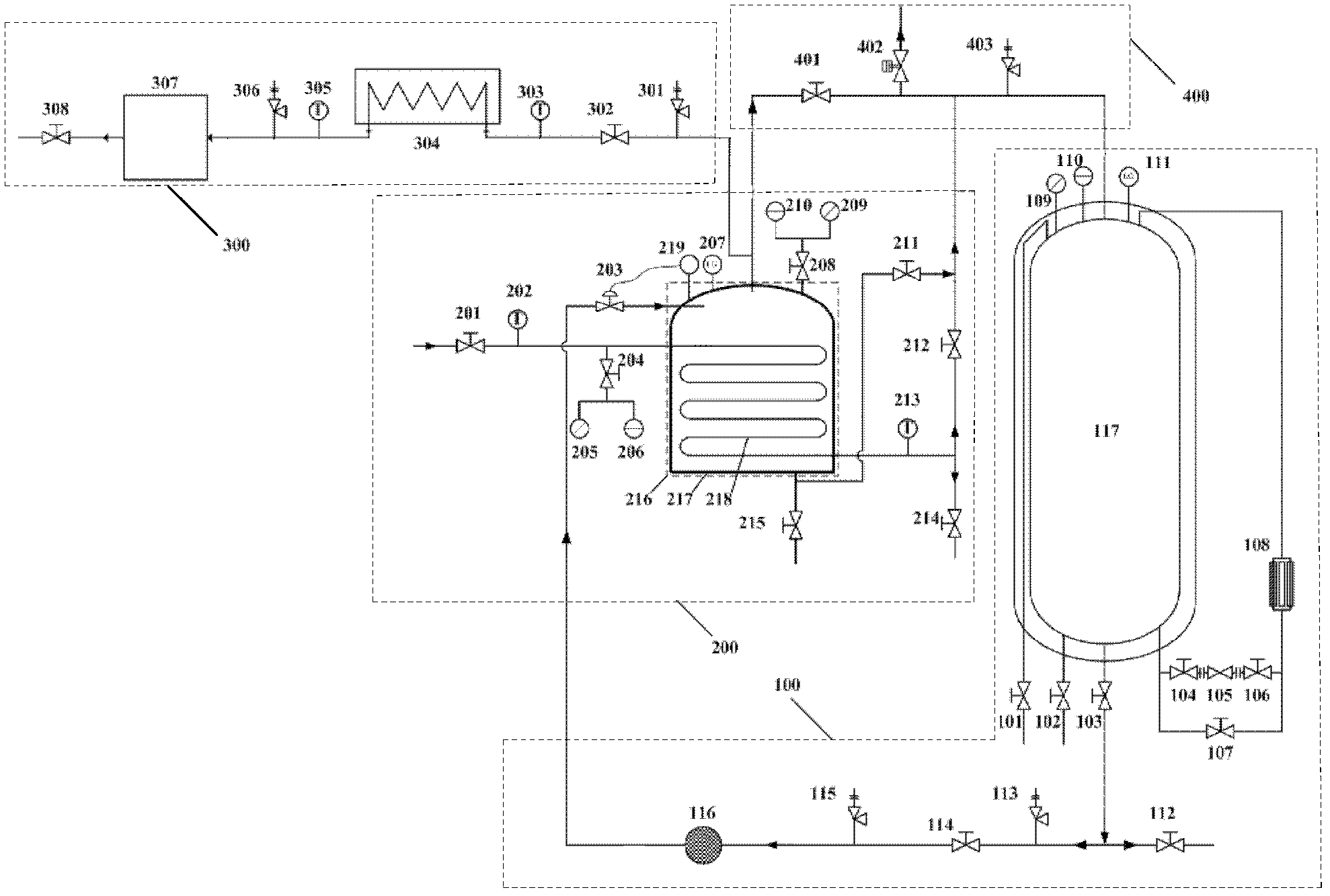

Negative-pressure liquid nitrogen subcooler and method therefore for reducing liquid nitrogen temperature

InactiveCN102374708ALower heat sink temperatureIncreased pumping capacity and efficiencySubcoolersChemistryHeat sink

The invention provides a negative-pressure liquid nitrogen subcooler and a method therefore for reducing liquid nitrogen temperature. The negative-pressure liquid nitrogen subcooler comprises a liquid nitrogen conveying system, a subcooler system, a negative-pressure air exhausting system and a discharging system, wherein the liquid nitrogen conveying system is used for supplying liquid nitrogen to the subcooler system; the negative-pressure air exhausting system is used for reducing pressure for the subcooler; and the discharging system is used for discharging gasified nitrogen. In the negative-pressure liquid nitrogen subcooler, an electric heater is adopted to raise the temperature of gaseous nitrogen to 20-30 DEG C, so that the subcooler is not limited to the weathers; a liquid level sensor is adopted to automatically regulating the opening of a pneumatic regulating valve, so that the height of the liquid level is maintained. The method comprises the steps of: firstly, injecting the liquid nitrogen for a liquid nitrogen container and regulating pressure; then injecting the liquid nitrogen for the subcooler, wherein the height of the liquid level of the liquid nitrogen in the subcooler is kept constant; then starting the negative-pressure air exhausting system, and cooling the liquid nitrogen through a heat exchanger; and finally, recovering the liquid nitrogen and discharging the liquid nitrogen. According to the invention, the temperature of a heat sink can be further reduced, the temperature of the heat sink is regulatable within a range of 70-77k, and the advantagesof simple equipment, good effect and low operating cost are achieved.

Owner:BEIHANG UNIV

Rotary spiral waste organic glass propelling and continuous splitting decomposition method and device

ActiveCN104211984AGood choiceEmission reductionOrganic compound preparationCarboxylic acid esters preparationDecompositionHearth

The invention relates to a rotary spiral waste organic glass propelling and continuous splitting decomposition method and device and belongs to the field of chemical engineering. The raw material splitting decomposition efficiency and product recovery rate can be improved, and energy consumption and pollutant discharge can be reduced. The device comprises a feeding device, a splitting decomposition device, a condensing device and a waste gas treatment device which are sequentially connected, and further comprises a pressure limiting valve, a residue discharging pipe, a star-shaped valve, a feeding port, guide blades and a discharging port, wherein the pressure limiting valve is used for controlling pressure intensity in a splitting decomposition kettle. The feeding port is movably connected with a feeding pipe. The guide blades are fixedly arranged in the splitting decomposition kettle, and materials are spirally propelled from the feeding port to the discharging port. A hearth is provided with a thermometer. The discharging port is movably connected with the residue discharging pipe, and the residue discharging pipe is connected with the star-shaped valve. The condensing device is connected with the splitting decomposition device through a guide pipe, the guide pipe penetrates through the residue discharging pipe to extend into the discharging port, the guide pipe, a water-cooling device, a storage tank and a copious cooling device are connected in sequence, and the storage tank is arranged at the lower end of the water-cooling device and the lower end of the copious cooling device. The waste gas treatment device is connected with the copious cooling device.

Owner:杭州临安清云环保设备有限公司

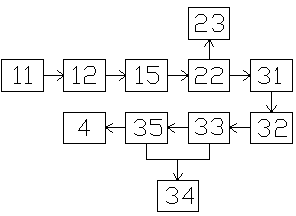

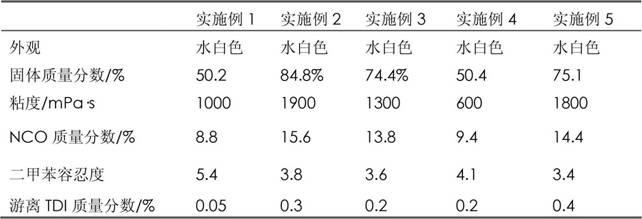

Preparation method of polyurethane prepolymer with low free isocyanate monomer

The invention discloses a preparation method of polyurethane prepolymer with low free isocyanate monomer. The preparation method comprises the following steps of: forming into mixed alcohol by trihydric alcohol and dihydric alcohol under the temperature of 120-150DEG C, and carrying out vacuum dehydration; putting isocyanate monomer and ester solvents into a reactor to keep the temperature at 30-70DEG C, and dropwise adding the mixed alcohol into the reactor; after dropwise adding, continuously reacting for 3-6h under the temperature of 40-70DEG C under stirring, and discharging in a cooling way to obtain polyurethane prepolymer; and separating the obtained polyurethane prepolymer, and adjusting the solid content of polyurethane prepolymer solid and the content of free isocyanate monomer in the separated heavy components by diluted solvent. According to the preparation method, the real continuous production can be realized, all the recovered solvent and isocyanate monomer can be recycled, the zero emission can be realized, and the real clean production can be realized; and the product has the characteristics of being low in viscosity, high and adjustable in NCO value content, low in the content of the free isocyanate monomer, high in solid content, good in compatibility, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

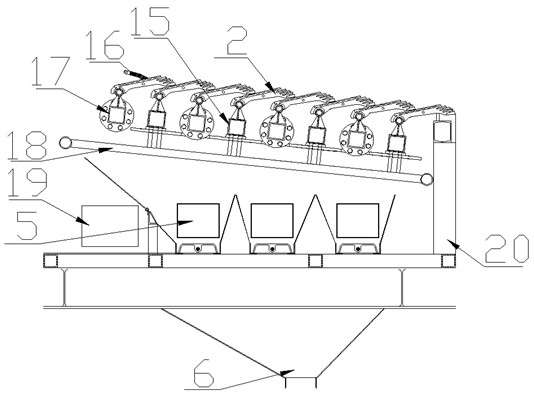

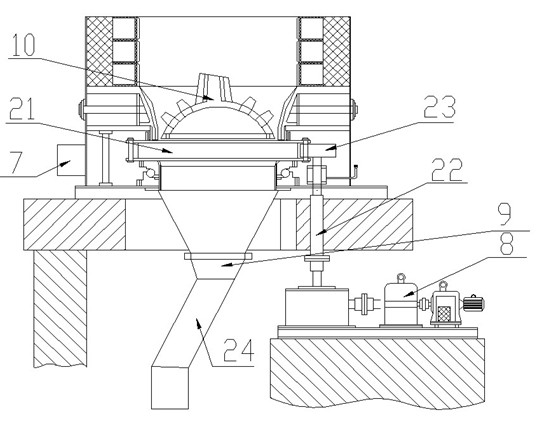

Novel high-efficiency vaporizing combustion compound furnace grate device with slag disintegrating function

ActiveCN102588950APromote precipitationAchieve emissionsChemical industryRevolving grateSlagEngineering

The invention discloses a novel high-efficiency vaporizing combustion compound furnace grate device with a slag disintegrating function. The traditional incinerator has the disadvantages of lower heat efficiency and high repairing and maintenance cost of a furnace grate due to poor fuel mixture and insufficient combustion. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function adopts a two-section compound structure, wherein on the front section of a reciprocating type furnace grate, wastes are dried, vaporized and partially burned; and the unburned parts fall on a back-end rotary furnace grate device to be extruded, crushed and fully mixed to be burned completely. The reciprocating type furnace grate adopts a multi-air-port segmental air distribution way for reasonable air distribution; the heat radiation on the furnace grate is increased due to a long back arch, thereby facilitating the firing of wastes with low heat values. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function is adopted to effectively improve the disadvantages of poor mixing effect and low burn-off rate of the traditional furnace grate incineration device, and meanwhile, the area of a furnace grate bar with high temperature resistance can be reduced, and the investment is reduced.

Owner:ZHEJIANG UNIV

Method for treating molasses alcohol waste water

InactiveCN102537982AAchieve emissionsWater/sewage treatment by heatingIncinerator apparatusAlcohol productionClosed loop

The invention discloses a method for treating molasses alcohol waste water. The method is characterized by comprising the following steps: (1) concentrating molasses alcohol waste water in an evaporator, thereby obtaining the concentrated slurry; (2) discharging waster water in the evaporator in a form of vapor condensed water, wherein the condensed water is recycled for alcohol production; (3) preparing dry powder after the concentrated slurry is incinerated in an incinerator; or (4) combusting the concentrated slurry with combustibility in a boiler to generate vapor; and (5) recycling the vapor for alcohol production and heating in waste water concentration. The method is main used for recycling water and solids and heat in the waster water and is a method for comprehensive treatment and utilization. The molasses alcohol waste water is concentrated in the evaporator, then is prepared into the dry powder, or the concentrated slurry with combustibility is combusted to generate vapor, and then the vapor is recycled for alcohol production and waste water concentration. The waste water in the evaporator is recycled for alcohol production in the form of vapor condensed water, thus an alcohol production closed-loop water system without waste emission is realized.

Owner:广西皎龙能源科技有限公司

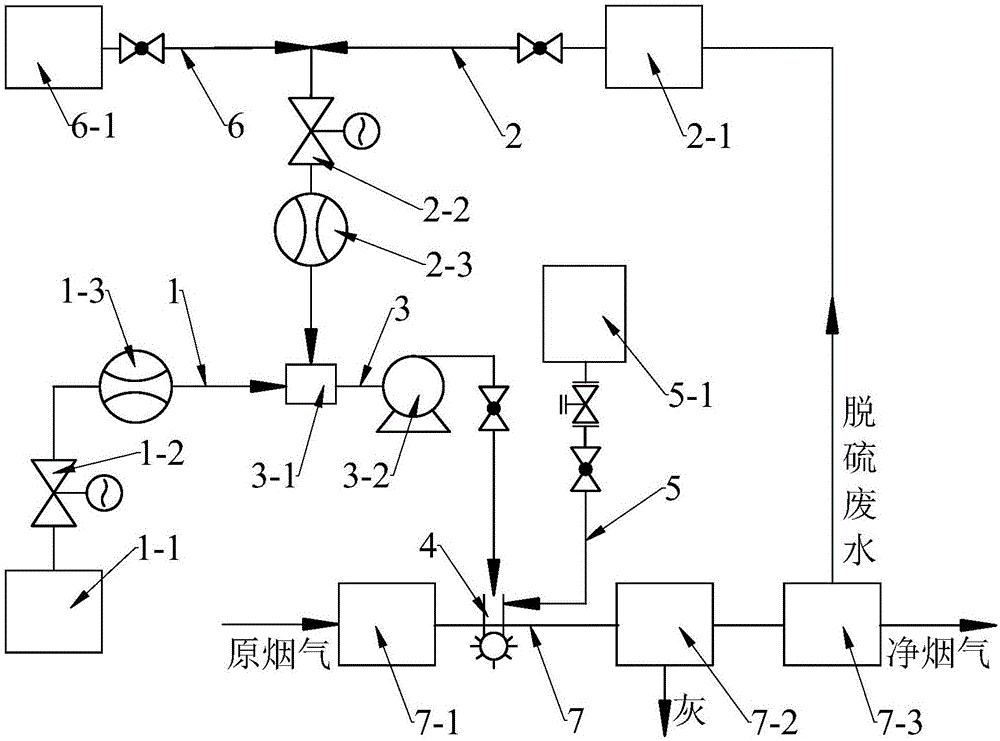

Desulfurization wastewater zero-emission system using coal-fired flue gas semidry method to remove fluorine and chlorine

InactiveCN106076100AEmission reductionAchieve emissionsDispersed particle separationHigh concentrationAir preheater

The invention discloses a desulfurization wastewater zero-emission system using a coal-fired flue gas semidry method to remove fluorine and chlorine. The desulfurization wastewater zero-emission system comprises a high-concentration alkali liquor pipeline, a desulfurization wastewater pipeline, a diluted alkali liquor pipeline, an alkali liquor atomizing device, a compressed air pipeline, a process water pipeline and a flue. The flow of high-concentration alkali liquor is controlled according to unit load and the HCl concentration in flue gas, the high-concentration alkali liquor is mixed with desulfurization wastewater to obtain diluted alkali liquor, the diluted alkali liquor is sprayed into the flue between an air preheater and a dust remover through the alkali liquor atomizing device with multiple nozzles in grid arrangement, the diluted alkali liquor is sufficiently evenly mixed with the flue gas to solidify most of gas such as HCl, HF. SO3 and the like in the flue gas into fly ash, the emission quantity of the desulfurization wastewater is reduced greatly, the desulfurization wastewater can be sprayed into the flue as the base solvent, and zero emission of the desulfurization wastewater is achieved. The desulfurization wastewater zero-emission system has the advantages that the system is low in influence on smoke temperature, the tail flue and equipment, the tendency of fouling corrosion of the tail low-temperature flue and the equipment can be reduced effectively, the desulfurization efficiency is increased, and the system is simple, low in investment and low in operation cost.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com