Water-rich stratum tunnel bottom drainage structure and construction method thereof

A technology of water-rich strata and drainage structure, applied in the directions of drainage, separation method, water/sewage treatment, etc., can solve the problems of difficult maintenance and management, the inability to effectively drain the accumulated water, and the drainage of water at the bottom of the tunnel. The effect of dredging work, improving the drainage capacity of the tunnel, and increasing the cross-sectional area of the water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

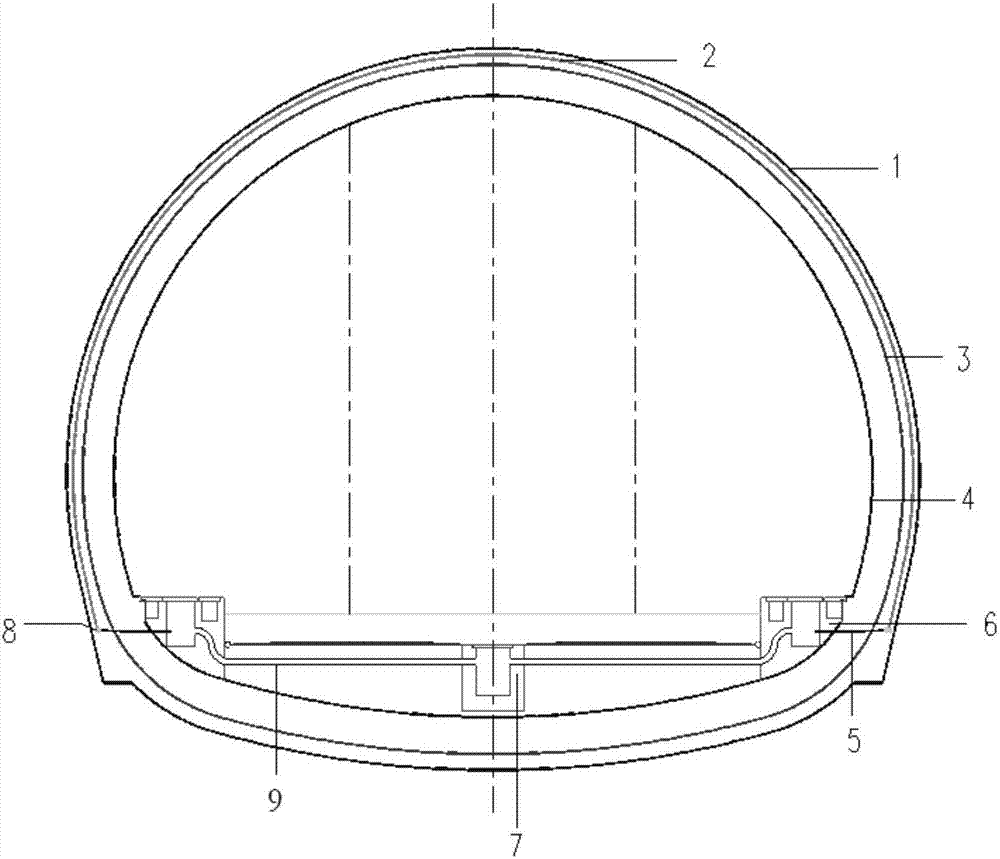

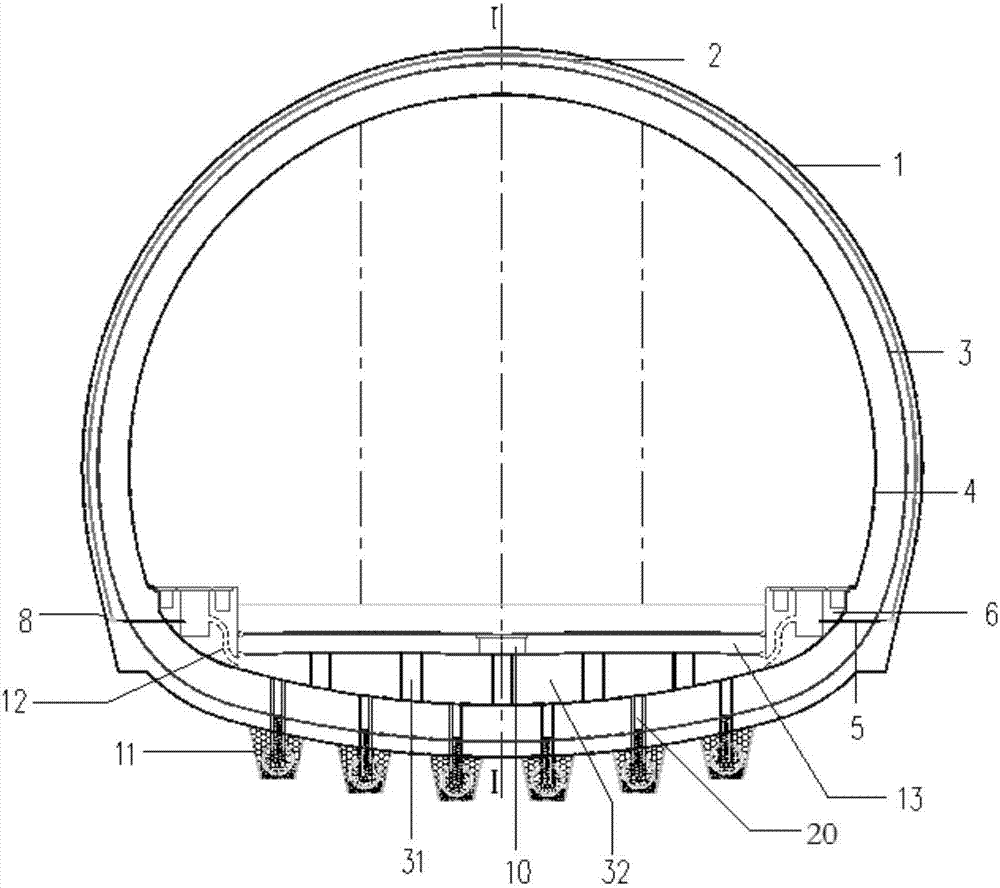

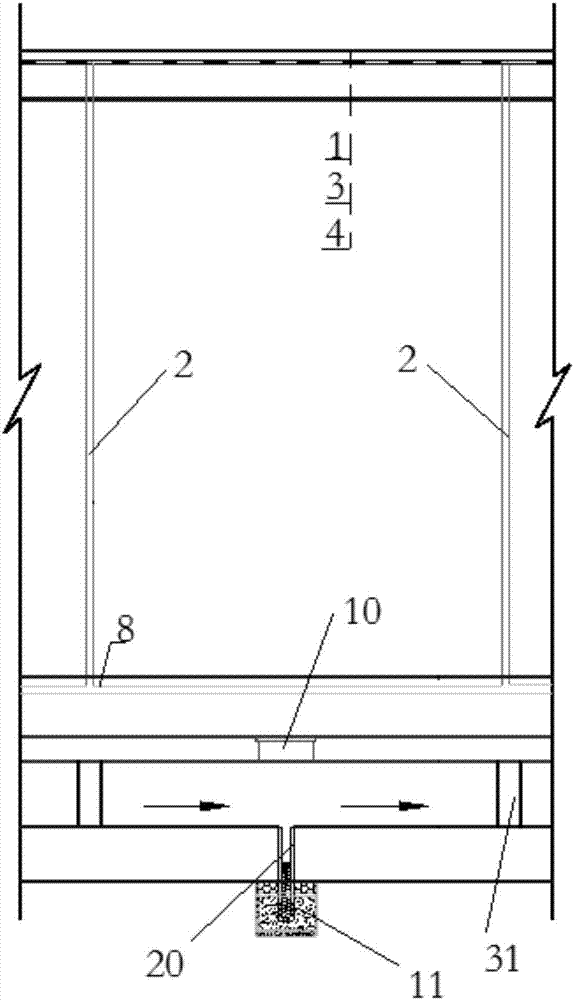

[0043] Such as figure 2 As shown, the drainage structure at the bottom of the tunnel in water-rich strata disclosed by the present invention includes an inverted arch and drainage side ditches 6 on both sides of the tunnel, and a ballast bed floor 13 is arranged above the inverted arch, and a load-carrying structure is arranged between the ballast bed floor 13 and the inverted arch. A culvert 32 at the bottom of the tunnel is formed between the pile 31, the bottom plate of the ballast bed 13 and the invert. The drainage side ditch 6 is connected to the water culvert 32 through the side ditch drain pipe 12, and a plurality of side ditch drain pipes 12 are arranged at intervals.

[0044] In order to facilitate the inspection, maintenance and dredging of the culvert 32 at the bottom of the tunnel, inspection wells 10 are arranged at intervals along the longitudinal direction of the tunnel in the center of the ballast bed floor 13 , and the inspection wells 10 lead to the culvert 32...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is: as figure 2 , 3 As shown, in order to facilitate the discharge of accumulated water below the inverted arch at the same time, a water collection well 20 is arranged on the bottom surface of the water culvert 32. The lower end of the water collection well 20 passes through the inverted arch and extends to below the inverted arch. The bottom and side walls of the water collection well 20 are provided with The drain hole 18 is located below the inverted arch, the outside of the drain hole 18 is provided with a filter layer, and the water collection well 20 is provided with a one-way drainage device.

[0050] Such as Figure 5 As shown, the one-way drainage device includes a movable cover device 21 and a tension spring, and the movable cover device 21 includes a cover plate 28, a cover plate supporting member 29 and a hinge shaft 30, and one side of the cover plate 28 is connected with the hinge shaft 30. The wa...

Embodiment 3

[0056] The difference between this embodiment and embodiment 2 is: as figure 2 , 3 , 4, and 5, the water collection well 20 passes through the filter water collection device 11, the filter water collection device 11 is located below the inverted arch, the filter water collection device 11 includes a water collection pipe 15, and the water collection pipe 15 side walls are provided with water inlets 16 at intervals , The lower end of the water collection well 20 stretches into the water collection pipe 15, and the water discharge hole 18 communicates with the water collection pipe 15 inside. Wherein, the filter layer on the outside of the drain hole 18 includes the second filter layer 26 and the first filter layer 17 arranged from the inside to the outside, as preferably, the first filter layer 17 is a coarse sand filter layer, and the second filter layer 26 is For the fine sand filter layer, preferably, a stainless steel screen layer 27 is also provided between the drain hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com