Ultrahigh-solid-content nano-grade high-molecular alloy paint

A nano-polymer, ultra-high solid content technology, applied in the field of coatings, can solve the problems of high cost, not durable, short time limit, etc., and achieve the effects of saving energy, solving pollution, energy consumption, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

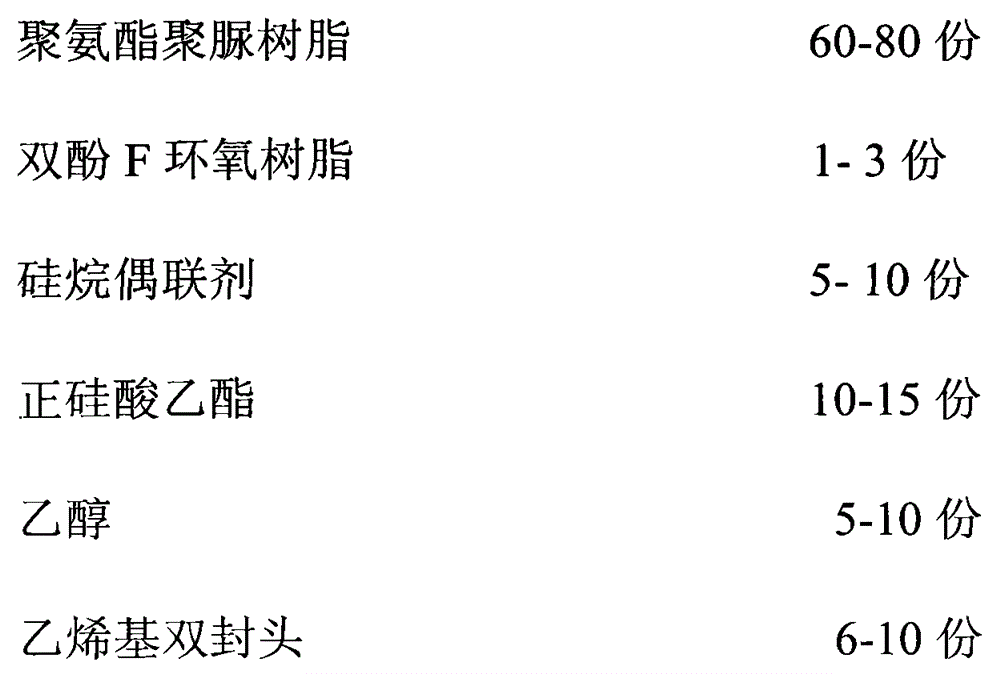

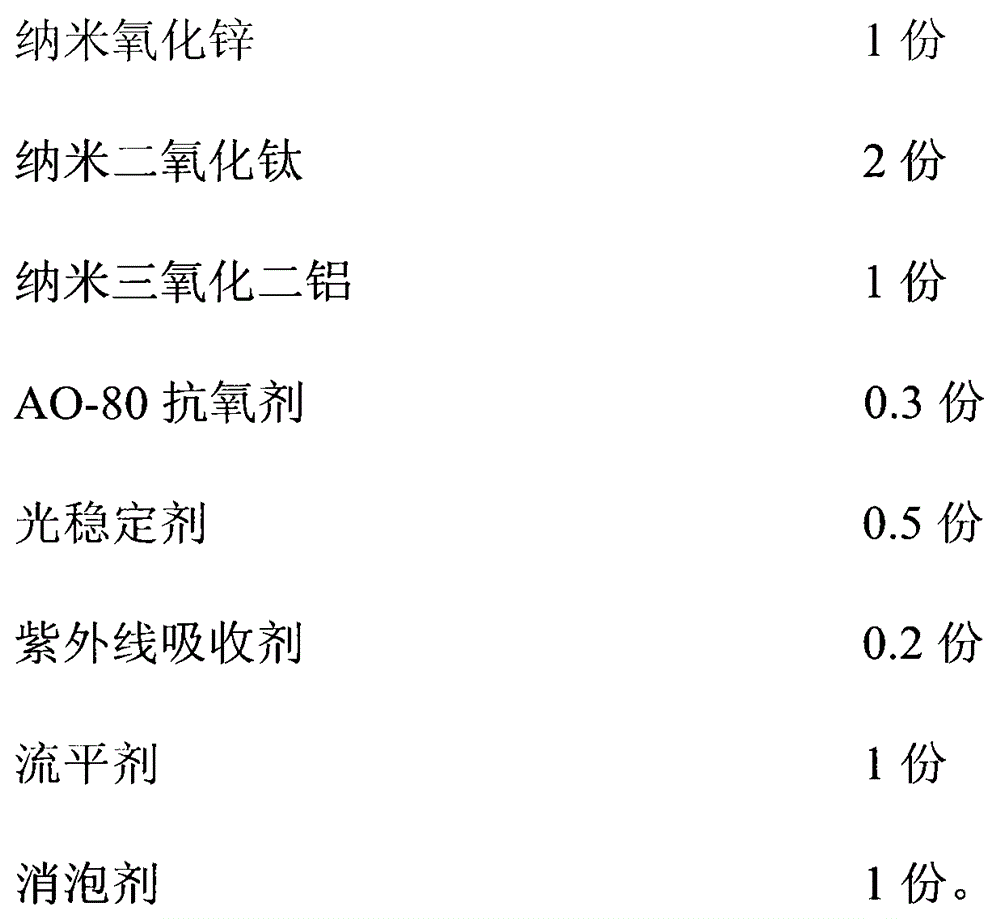

[0061] The ultra-high solid content nano polymer alloy coating comprises the following components by weight:

[0062]

[0063]

[0064] The preparation method adopted by the ultra-high solid content nano-polymer alloy coating provided by the invention comprises the following steps:

[0065] (1) After adding the Tech-5111 dispersion liquid of 3wt% (in propylene glycol methyl ether acetate) in the solvent propylene glycol methyl ether acetate, fully stir and disperse in the mixer, then the nano-zinc oxide described in the present embodiment, Nano-titanium dioxide and nano-alumina are weighed according to the amount and then poured in. After stirring at a high speed, they are dispersed into a nano-material dispersion with D90≤60nm by a nano-sand mill, and filtered for later use;

[0066] (2) The polyurethane polyurea resin described in this embodiment, bisphenol F epoxy resin, silane coupling agent 6040, tetraethyl orthosilicate, ethanol, vinyl double head, AO-80 antioxidan...

Embodiment 2

[0070] The ultra-high solid content nano polymer alloy coating comprises the following components by weight:

[0071]

[0072]

[0073] The preparation method adopted by the ultra-high solid content nano-polymer alloy coating provided by the invention comprises the following steps:

[0074] (1) After adding the Tech-5111 dispersion liquid of 3wt% (in propylene glycol methyl ether acetate) in the solvent propylene glycol methyl ether acetate, fully stir and disperse in the mixer, then the nano-zinc oxide described in the present embodiment, Nano-titanium dioxide and nano-alumina are weighed according to the amount and then poured in. After stirring at a high speed, they are dispersed into a nano-material dispersion with D90≤60nm by a nano-sand mill, and filtered for later use;

[0075] (2) The polyurethane polyurea resin described in this embodiment, bisphenol F epoxy resin, silane coupling agent 6040, tetraethyl orthosilicate, ethanol, vinyl double head, AO-80 antioxidan...

Embodiment 3

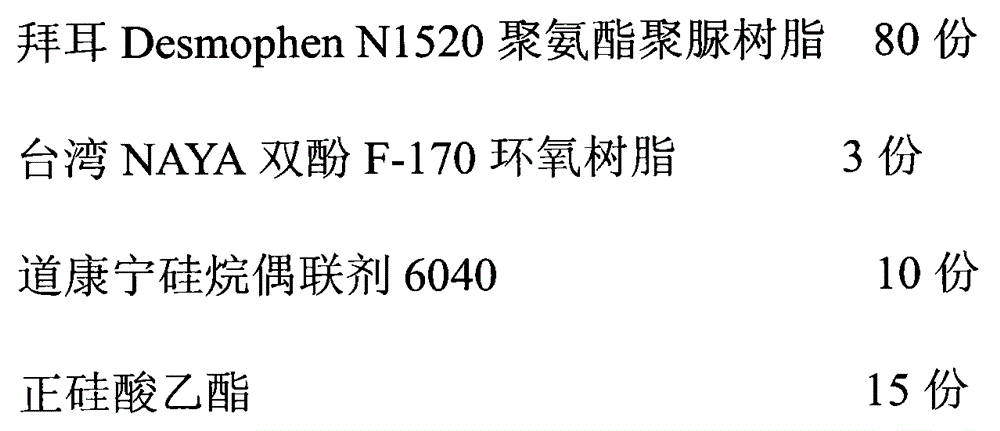

[0079] The ultra-high solid content nano polymer alloy coating comprises the following components by weight:

[0080]

[0081]

[0082] The preparation method adopted by the ultra-high solid content nano-polymer alloy coating provided by the invention comprises the following steps:

[0083] (1) After adding the Tech-5111 dispersion liquid of 3wt% (in propylene glycol methyl ether acetate) in the solvent propylene glycol methyl ether acetate, fully stir and disperse in the mixer, then the nano-zinc oxide described in the present embodiment, Nano-titanium dioxide and nano-alumina are weighed according to the amount and then poured in. After stirring at a high speed, they are dispersed into a nano-material dispersion with D90≤60nm by a nano-sand mill, and filtered for later use;

[0084] (2) The polyurethane polyurea resin described in this embodiment, bisphenol F epoxy resin, silane coupling agent 6040, tetraethyl orthosilicate, ethanol, vinyl double head, AO-80 antioxidan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com