Patents

Literature

33 results about "Erosiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

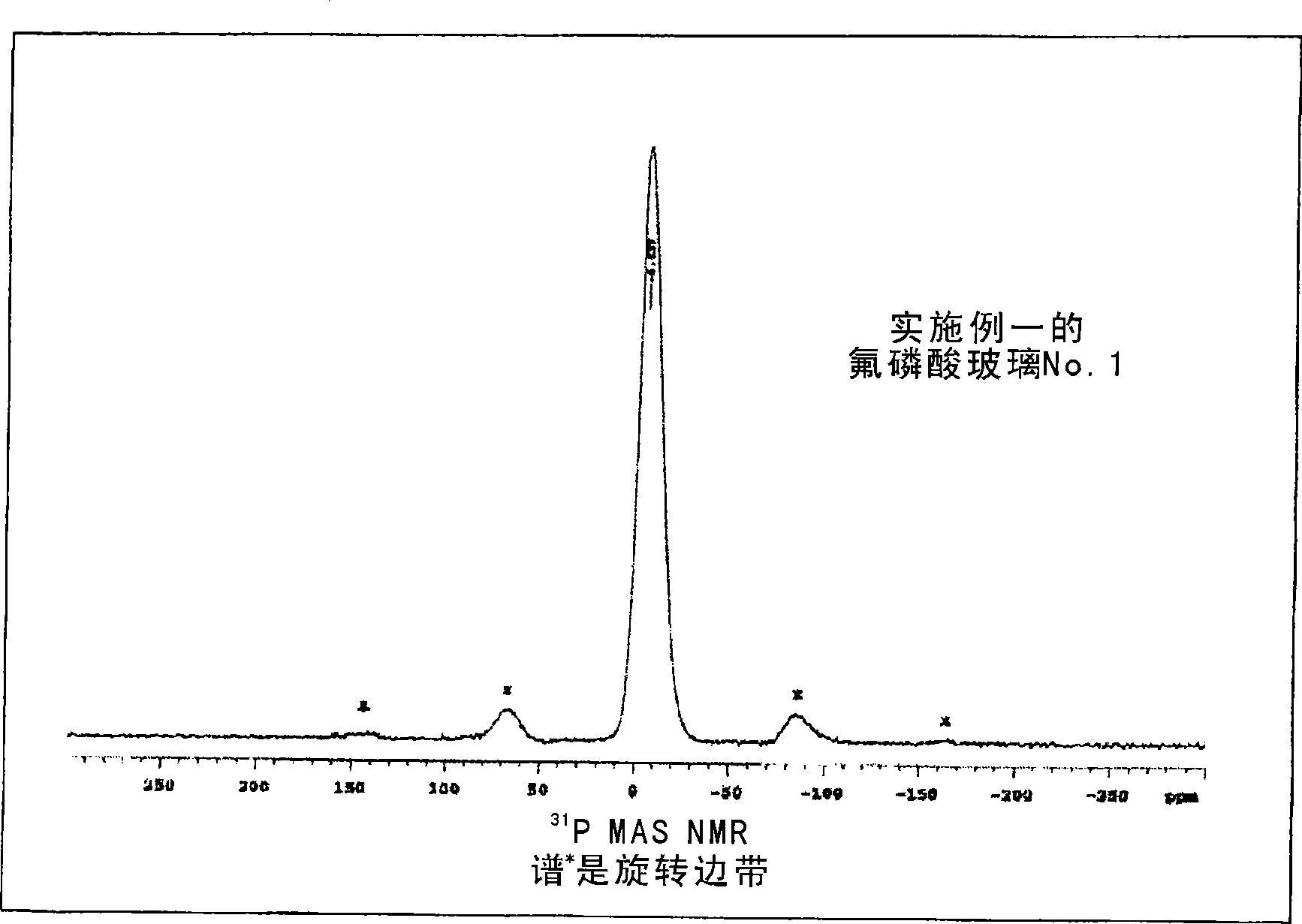

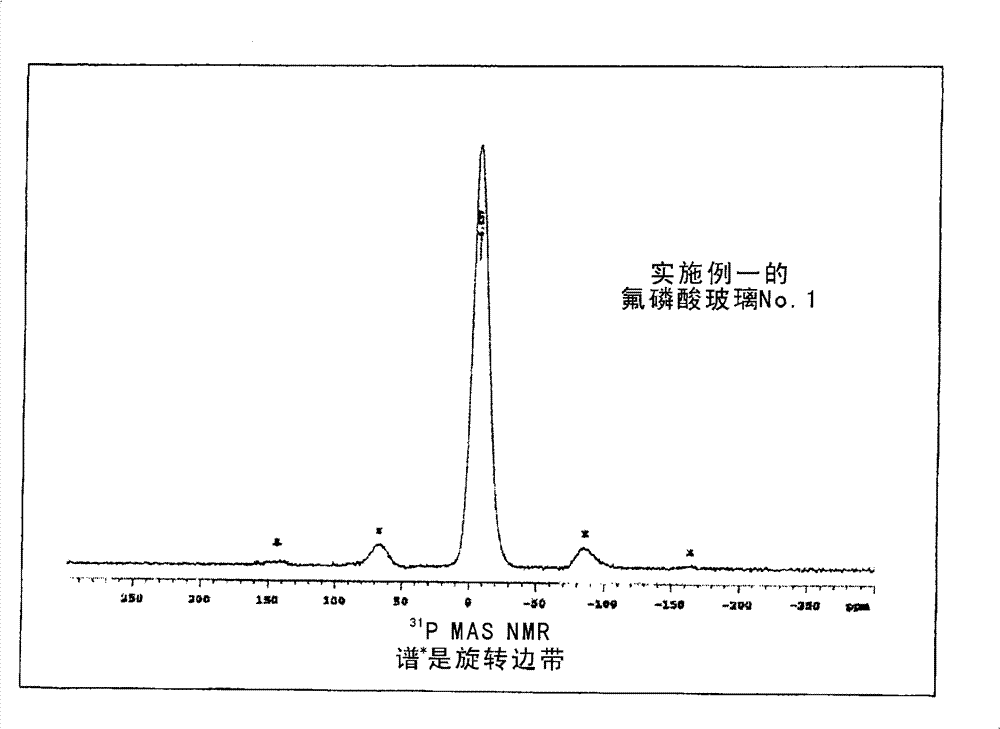

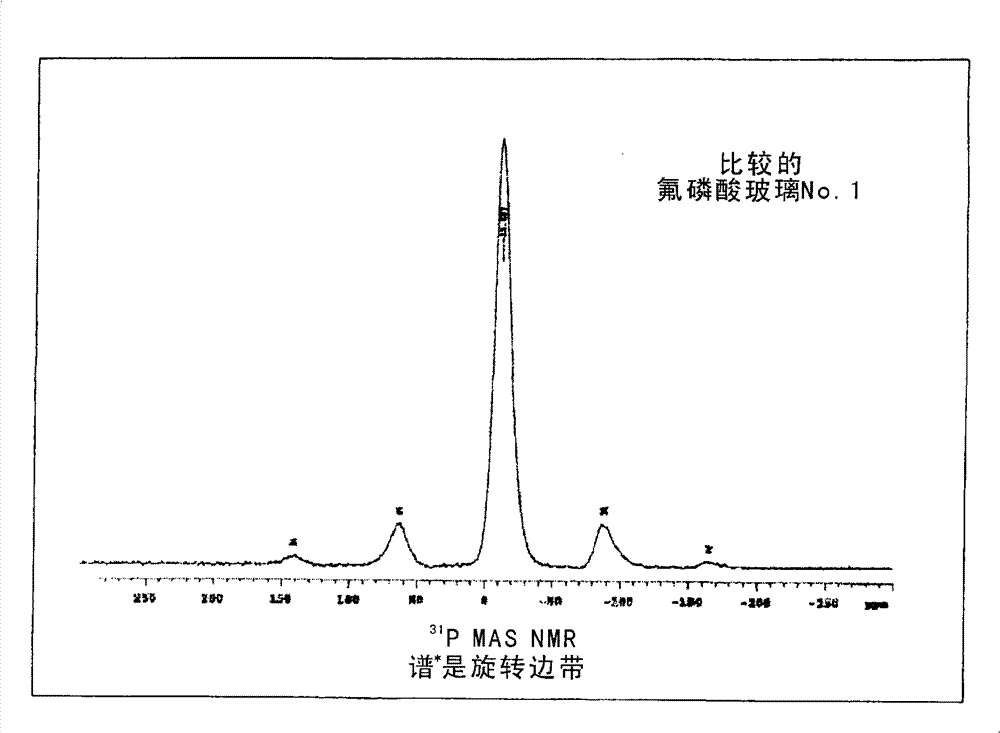

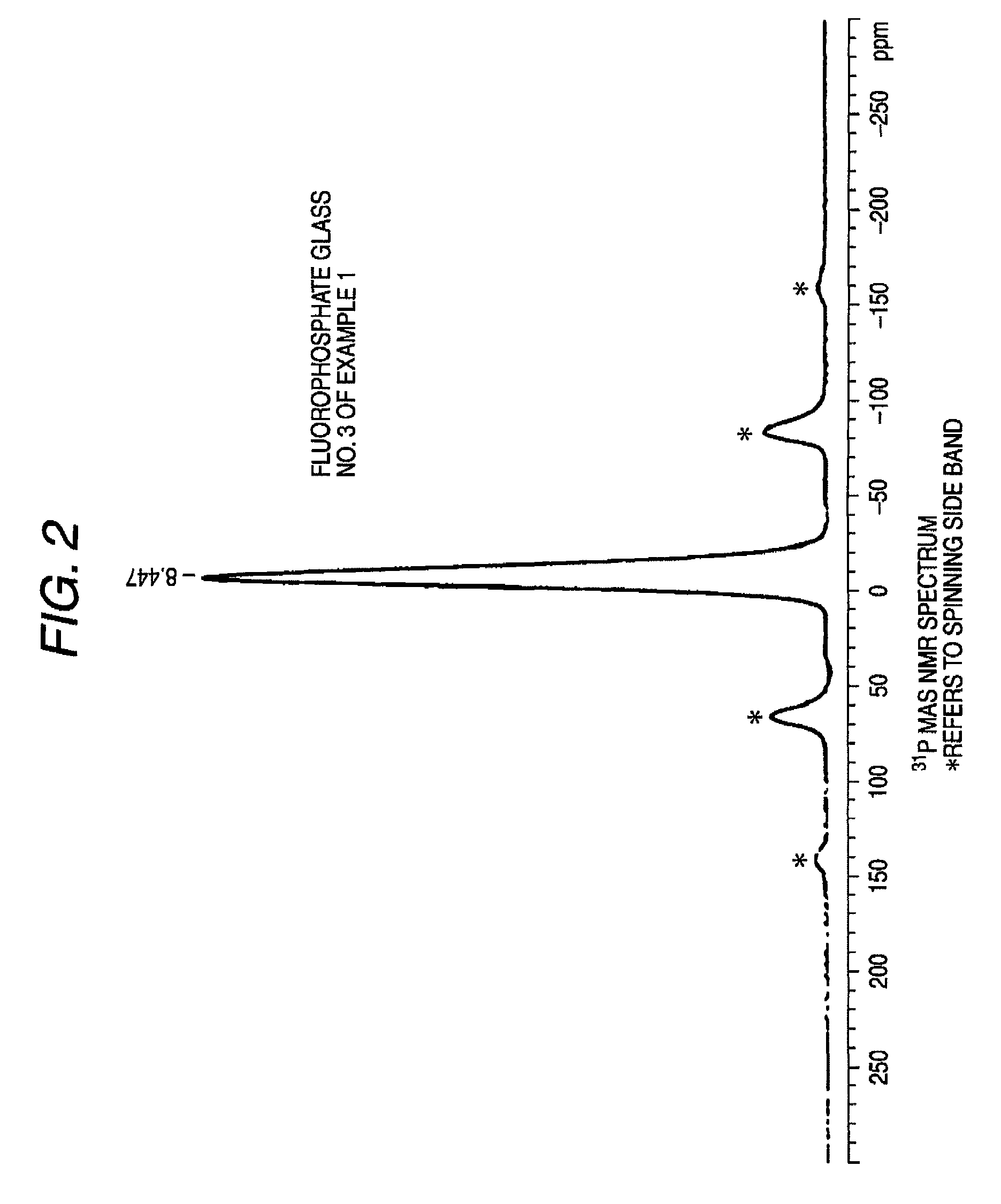

Fluorophosphate glass, precision press molding preform, optical element blank, optical element and methods of manufacturing the same

ActiveUS20090247387A1Quality improvementImprove Optical UniformityOptical articlesOptical elementsNMR - Nuclear magnetic resonanceErosiveness

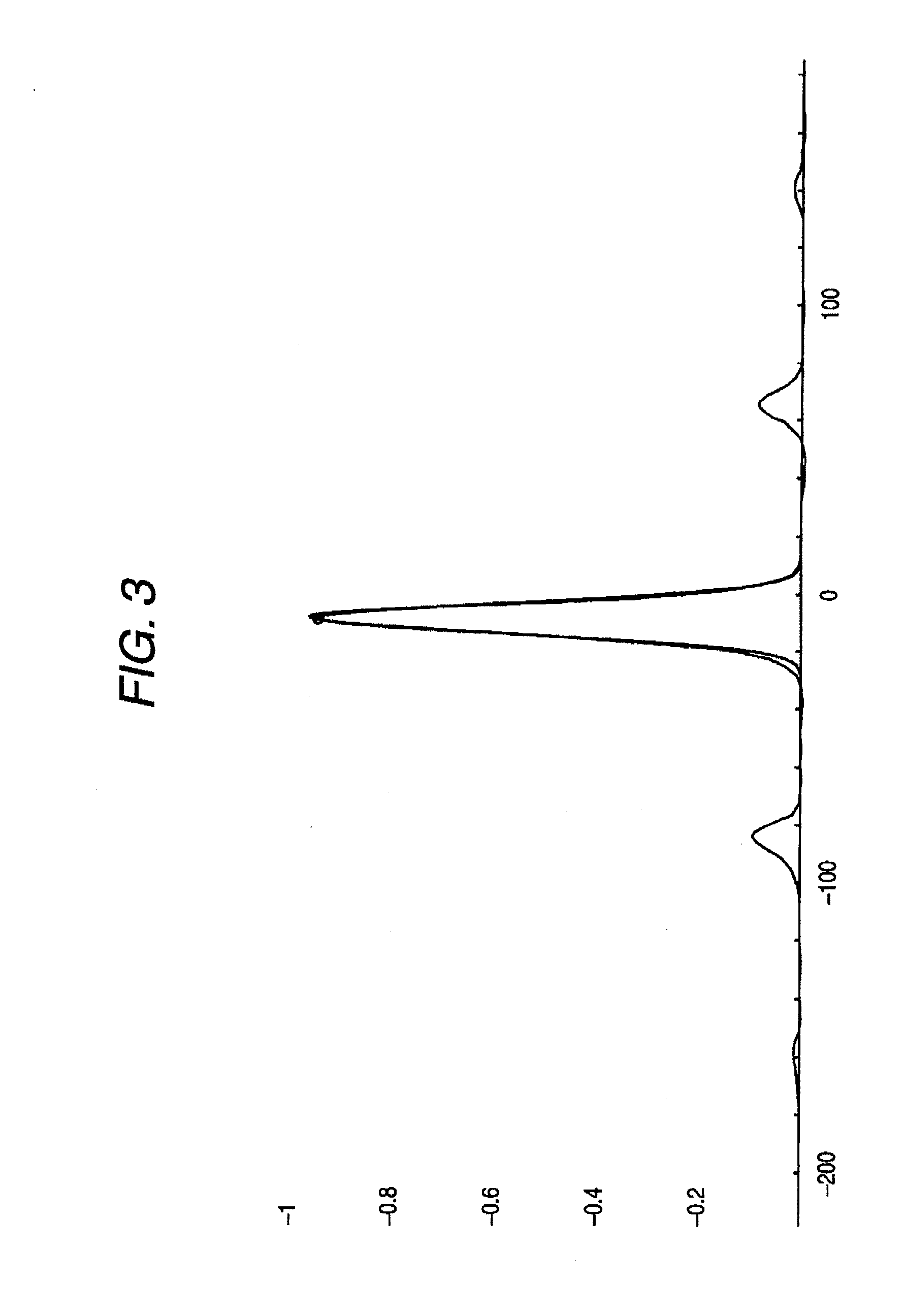

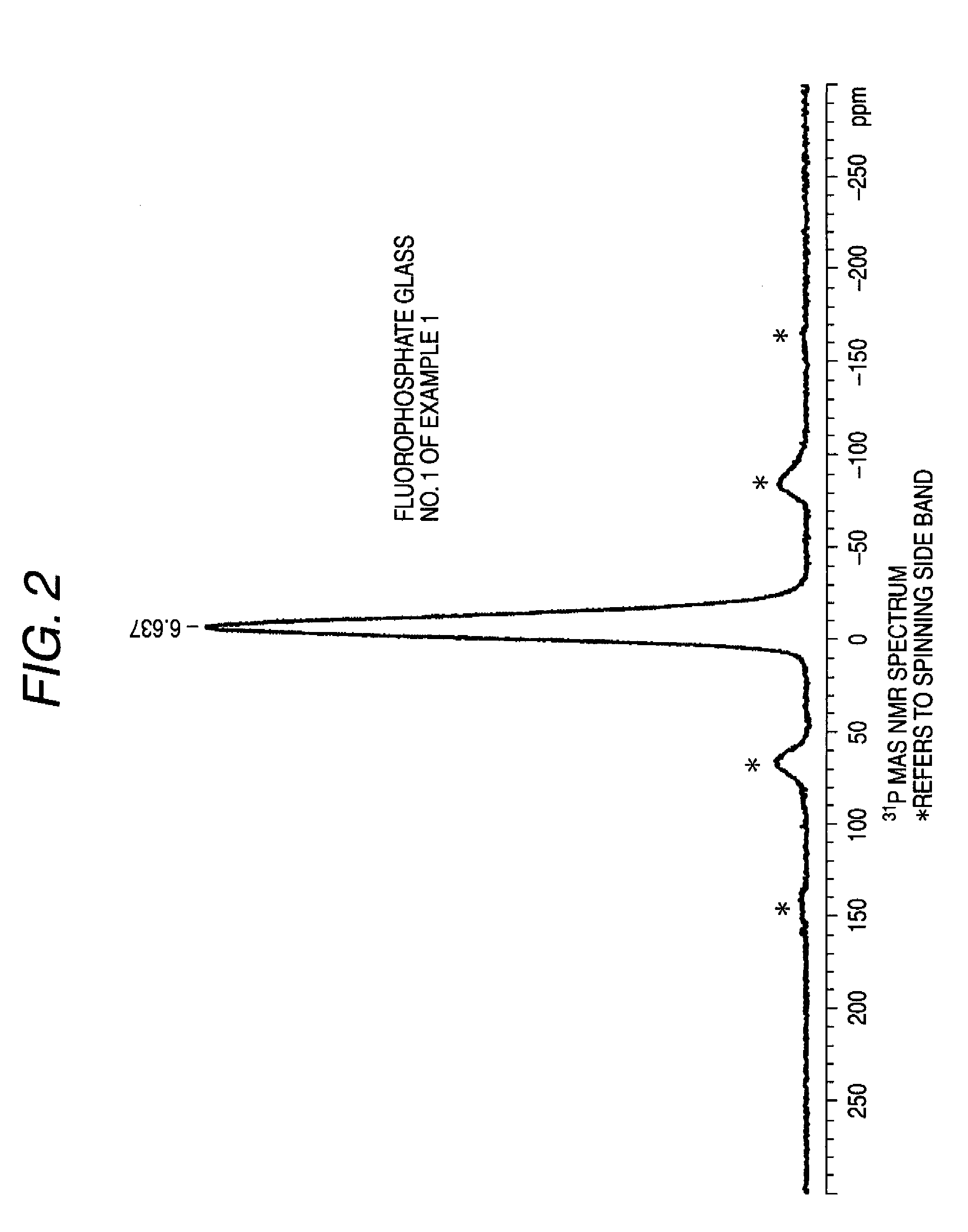

The present invention provides a fluorophosphate glass containing 30 to 50 cationic % of a phosphorus ingredient in terms of P5+, the glass having, in a nuclear magnetic resonance spectrum, a resonance spectrum which is generated near a reference frequency of 31P and has a shape of Gaussian function. The glass of the invention is reduced in volatility and erosiveness.

Owner:HOYA CORP

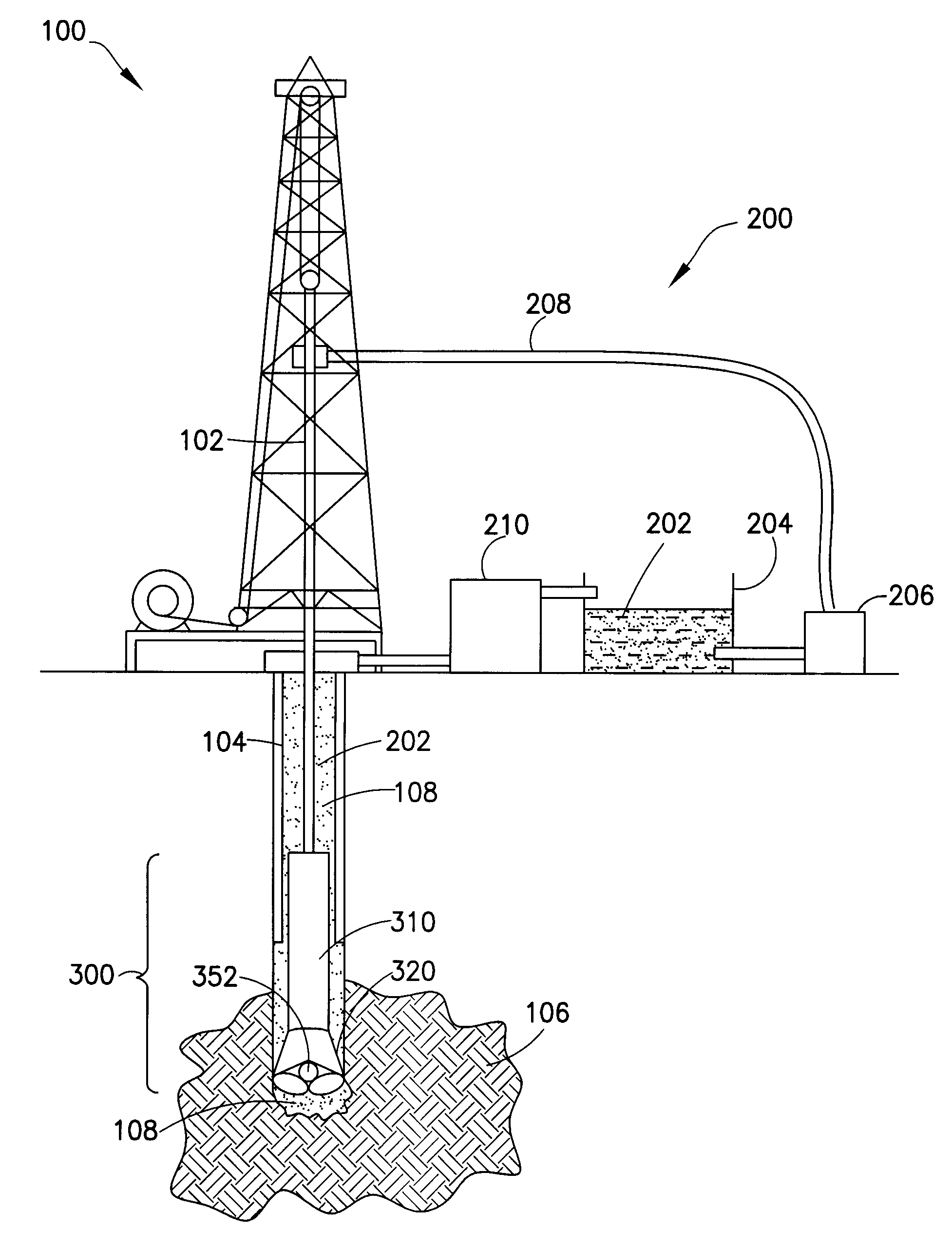

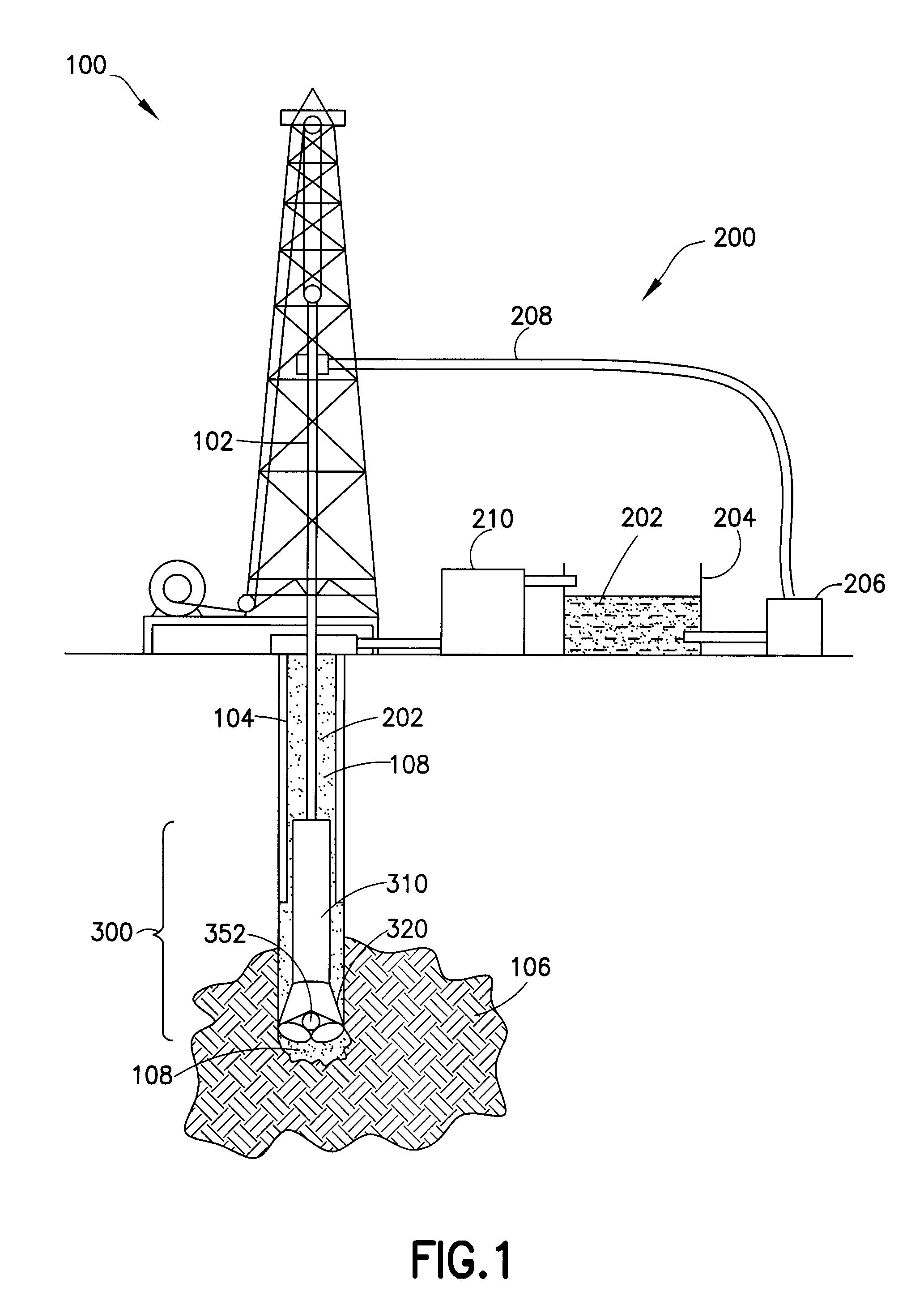

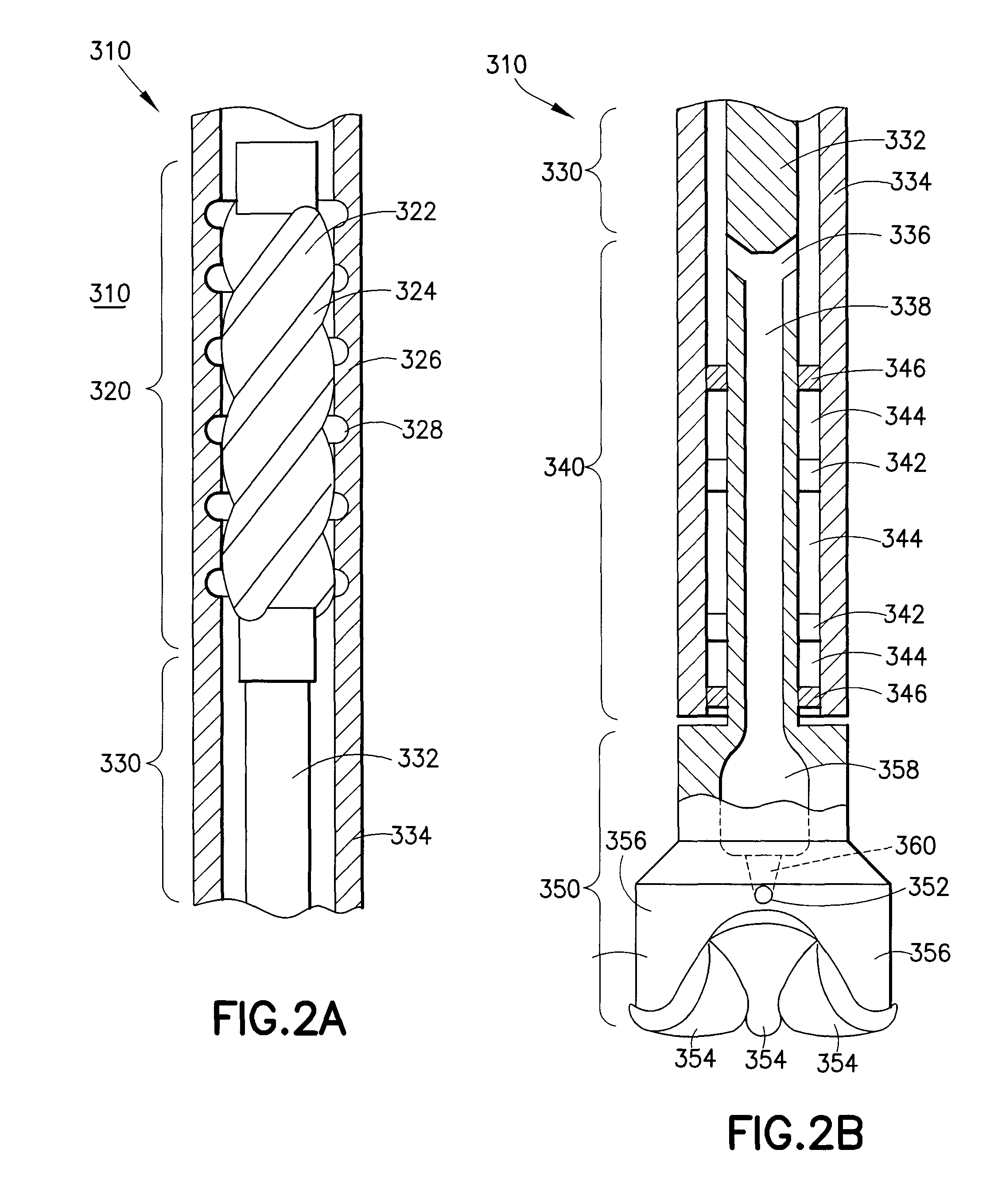

Erosion resistant surface and method of making erosion resistant surfaces

An erosion resistant surface using a dense array of elastic whiskers to slow the velocity of erosive particles before impacting with the surface. A carbon nanotube forest is grown on the surface to provide the erosion resistance. In the alternative, a carbon nanotube forest is grown on a flexible substrate that is bonded to the surface.

Owner:SCHLUMBERGER TECH CORP

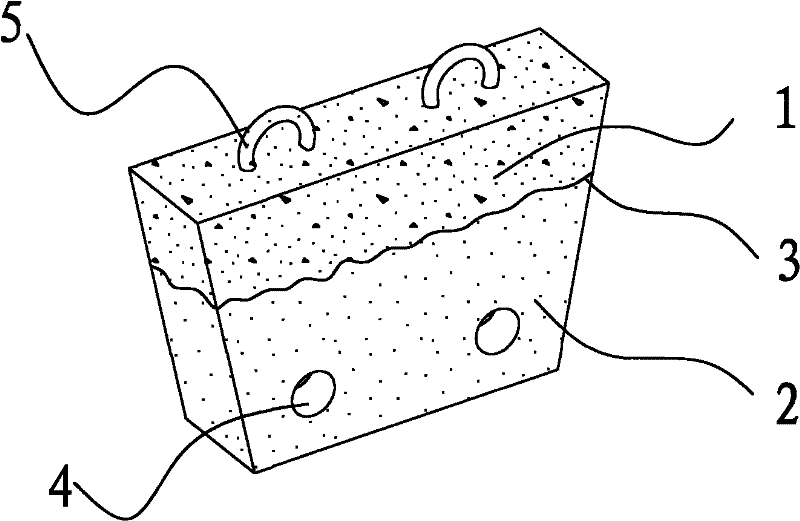

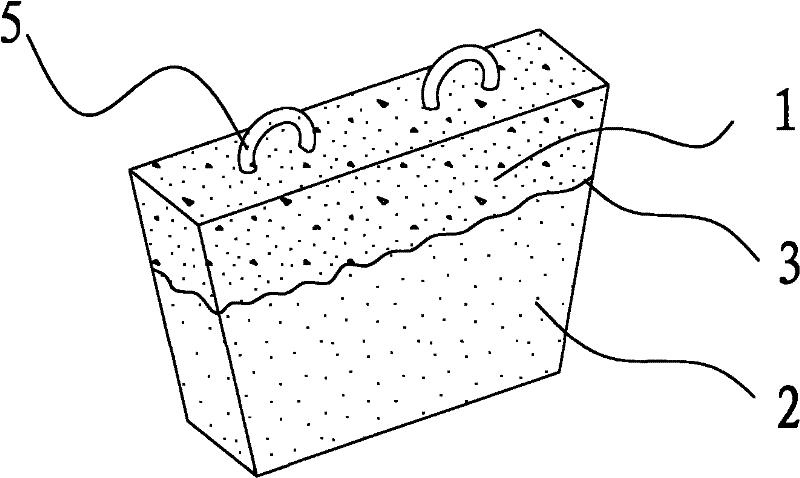

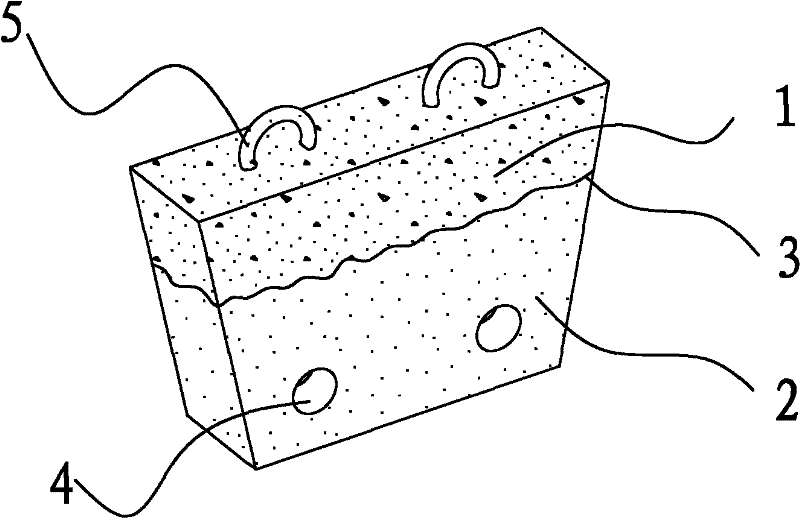

Composite slag weir and preparation method thereof

The invention discloses a composite slag weir and a preparation method thereof; and a body of the slag weir is integrally and tightly connected by an upper slag baffling part and a lower molten steelbaffling part. The upper slag baffling part is manufactured by aluminum and magnesium materials; and the lower molten steel baffling part is manufactured by magnesium materials. Based on the situations that the lower part of the body of the slag weir is mainly contacted with the molten steel with more assuasive erosiveness; while the upper part of the body of the slag weir is mainly contacted withthe slag with stronger erosiveness, the magnesium materials with common corrosion resistance as well as the aluminum and magnesium materials with stronger corrosion resistance are respectively adopted as the manufacturing materials for the upper slag baffling part and the lower molten steel baffling part of the slag weir, and the upper part and the lower part of the body of the slag weir of different materials are organically connected into a whole through a preparation technique. The composite slag weir reasonably uses durable goods resources, which not only guarantees the slag weir not to generate pollution to the molten steel, but also greatly prolongs the service life of the slag weir, simultaneously, the service life of the upper part and the lower part of the slag weir is led to bebasically synchronous, thus most economically using the slag weir and effectively reducing the production cost.

Owner:浙江红鹰集团股份有限公司

Fluorophosphate glass, precision press molding preform, optical element blank, optical element and methods of manufacturing the same

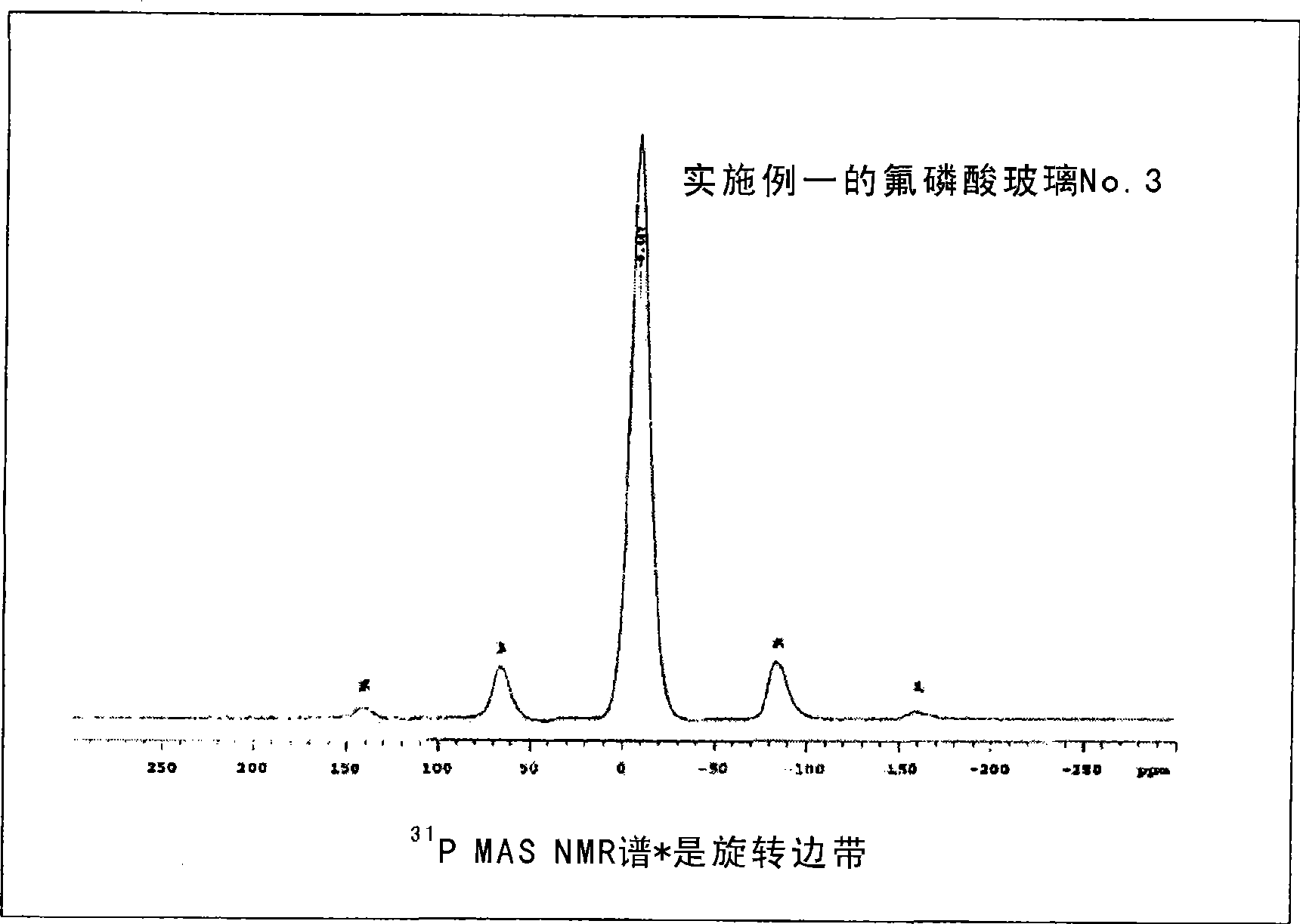

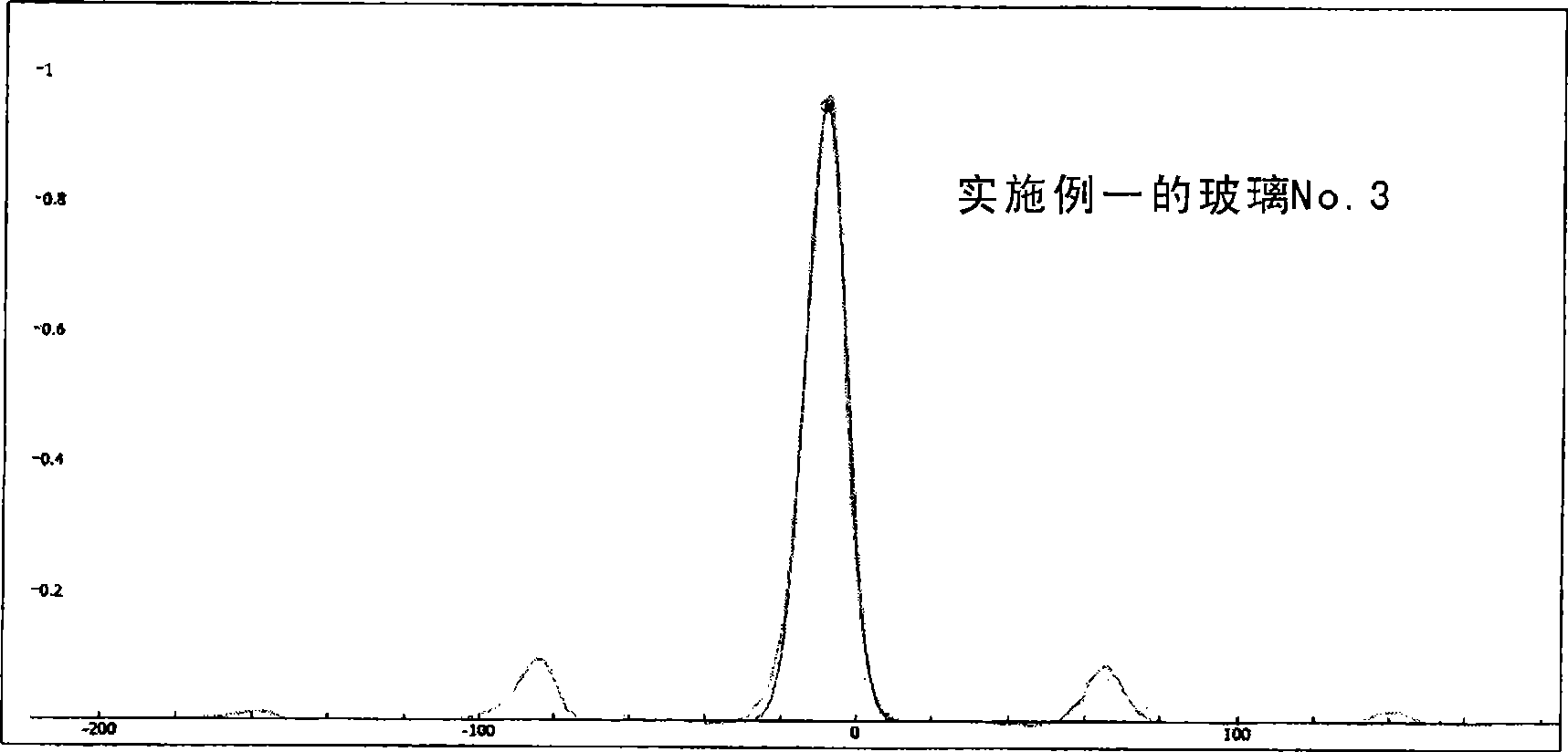

ActiveCN101544469AImprove uniformityGlass pressing apparatusOptical elementsNMR - Nuclear magnetic resonanceErosiveness

The invnetion provides fluoroposphate glass, precision press molding preform, optical element blank, optical element and method of manufacturing the same. A fluorophosphate glass of the invention contains 30 to 50 cationic % of a phosphorus ingredient in terms of P5+, the glass having, in a nuclear magnetic resonance spectrum, a resonance spectrum which is generated near a reference frequency of 31P and has a shape of Gaussian function. The glass of the invention is reduced in volatility and erosiveness.

Owner:HOYA CORP

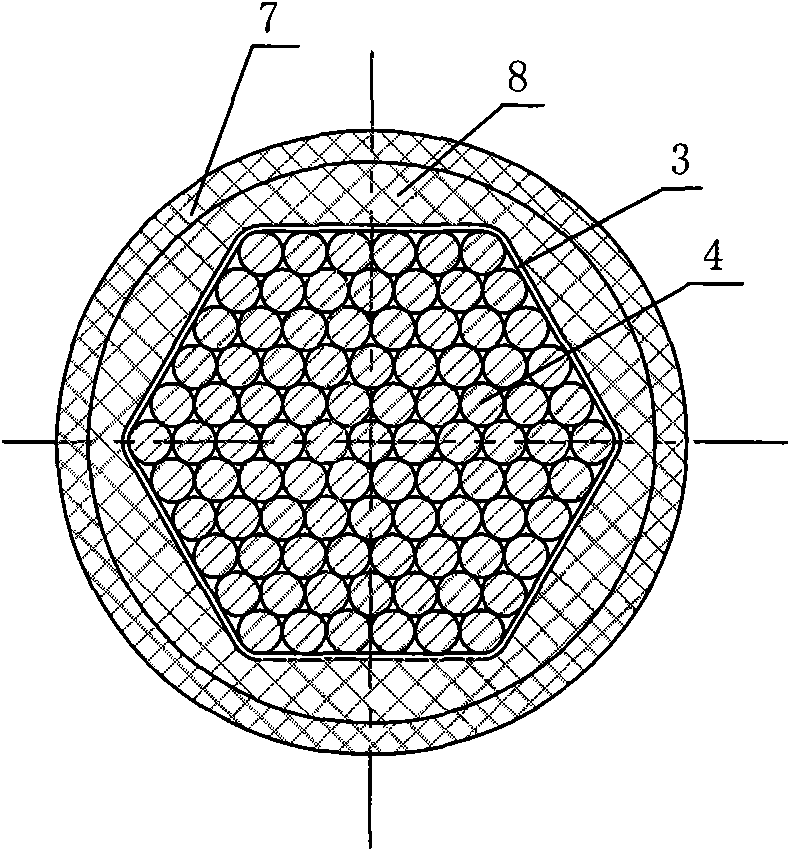

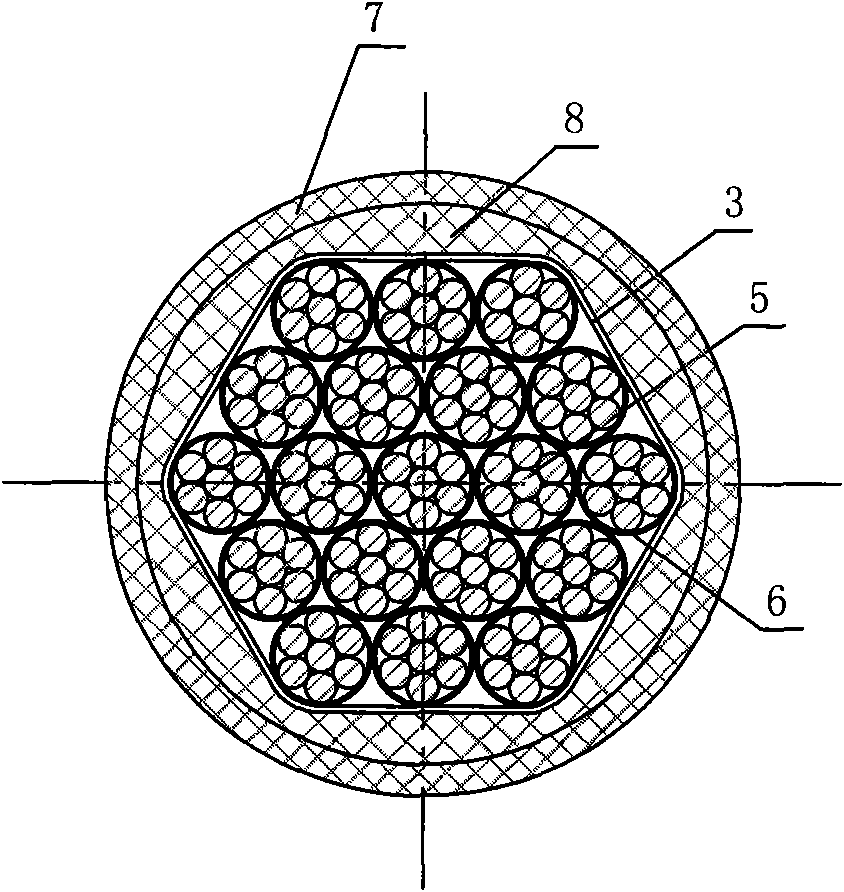

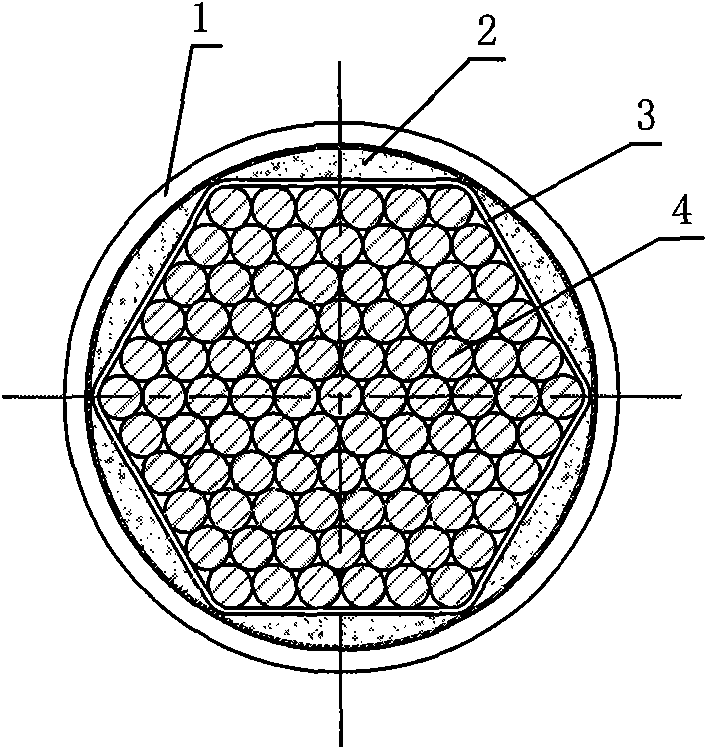

Metallic corrugated pipe guard cable

InactiveCN101581070AImprove corrosion resistanceSolution to short lifeBridge structural detailsBridge materialsErosivenessMetallic materials

The invention relates to a metallic corrugated pipe guard cable which belongs to a bridge guy cable or a suspension cable, comprising: a metallic corrugated pipe and a cable body inside the metallic corrugated pipe, wherein fillers are positioned between the metallic corrugated pipe and the cable body; the metallic corrugated pipe is a corrugated pipe made from stainless steel materials and aluminum or aluminum alloy materials or metallic materials with good corrosion resistance and favorable ocean and erosive industrial atmosphere erosiveness resistance, and the ripple shape of the metallic corrugated pipe is in a bamboo joint shape, a spiral shape or a vertical pivoting shape; the cable body is a steel wire bundle or a steel stranded wire bundle; and the fillers filled between the metallic corrugated pipe and the cable body are one of polyethylene, polyurenthane, asphalt, paraffin or anticorrosive grease materials. The metallic corrugated pipe guard cable has the good anticorrosive property and the long service life of an outer-layer jacket, therefore, the cable body is in an ideal anticorrosive environment for a long time, and the cable body has good corrosion resistance and long service life; in addition, the metallic corrugated pipe guard cable has good flexibility, is convenient to transport in a coiling way, and the outer-layer metallic corrugated pipe has less stress when the cable body stretches out.

Owner:LIUZHOU OVM MASCH CO LTD

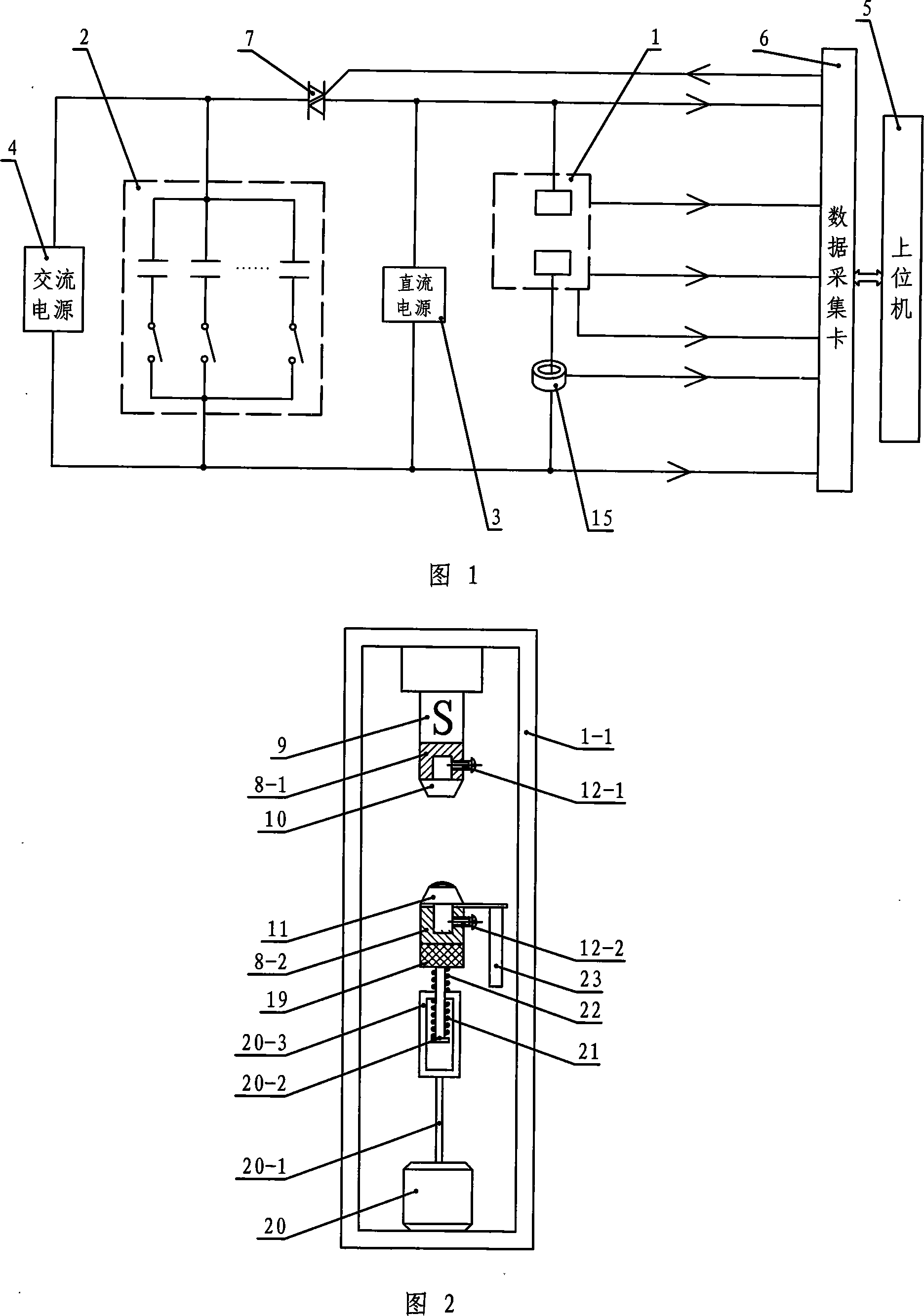

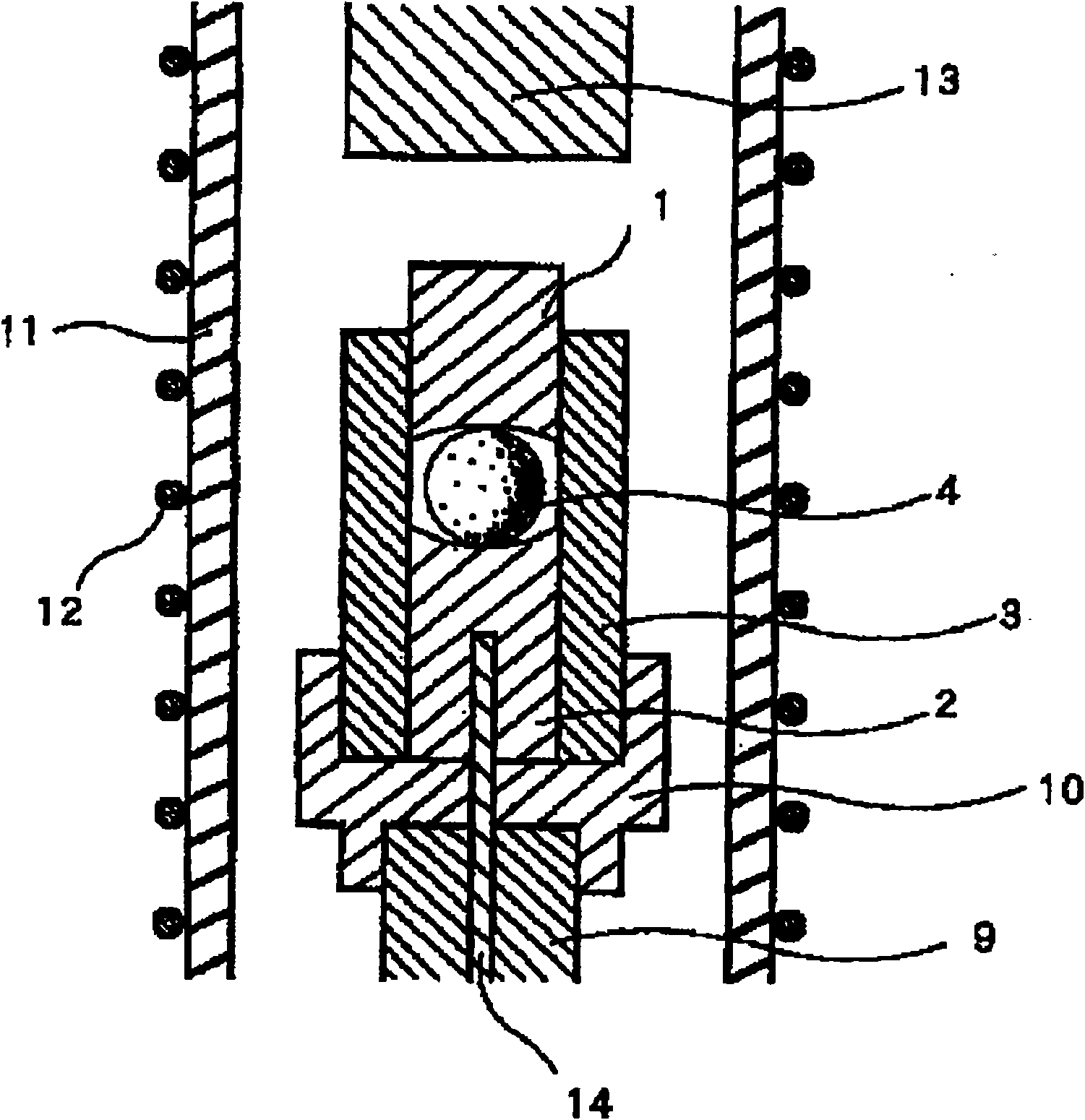

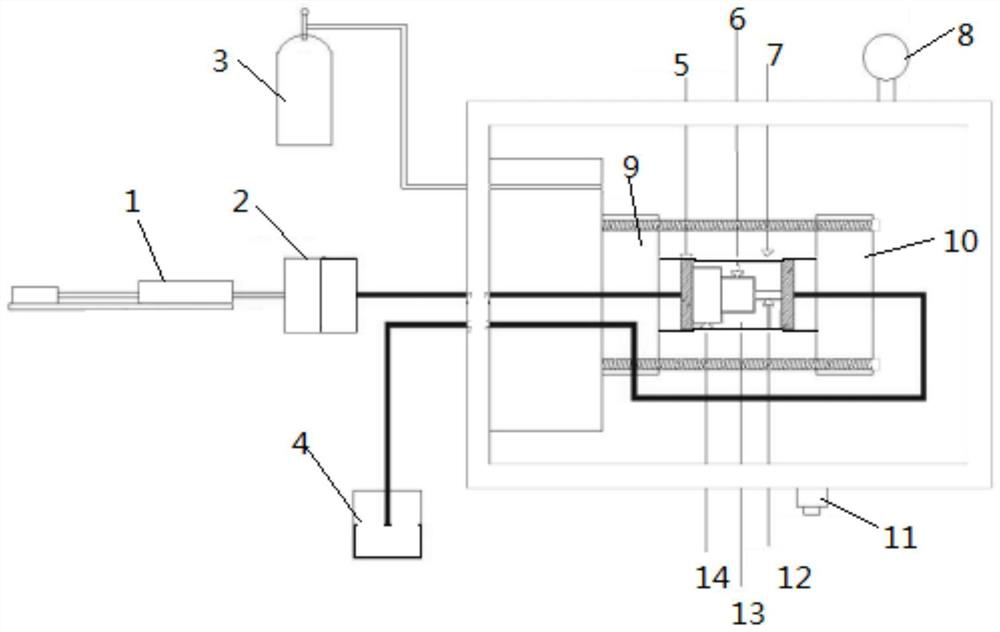

Device for testing electrical erosion property of electrical contact material

InactiveCN101196506AIncrease synchronization controlPrevent discreteMaterial analysisSynchroEngineering

A device for testing the electrical erosiveness of the electrical contact material is provided, which relates to a test equipment for research on the electrical erosiveness of the electrical contact material. The invention comprises an electrical source, an electrical load, a control circuit, an executive body for operation of the electrical contact and the control and measuring system of the arc process. The test equipment can conveniently adjust the electric parameters of the test circuit and the correct operating parameters of the examined electrical contact, which solves the problems in the existing testing device that the current device for testing the electrical erosiveness of the electrical contact material can not detect and control the correct displacement of the electrical contact and can not realize the synchro control to the relationship between the making and breaking operation and the power phase by the electrical contact. Through the accuracy control to the correct displacement process of the electrical contact in the testing process as well as the strict restriction to the phase angle condition corresponding to the making and breaking process of the electrical contact, the device avoids the discreteness of the testing result of the electrical erosiveness of the electrical contact material, which provides equipment means and experimental basis for the research on the mechanism of the electrical erosiveness of the electrical contact material.

Owner:HARBIN INST OF TECH

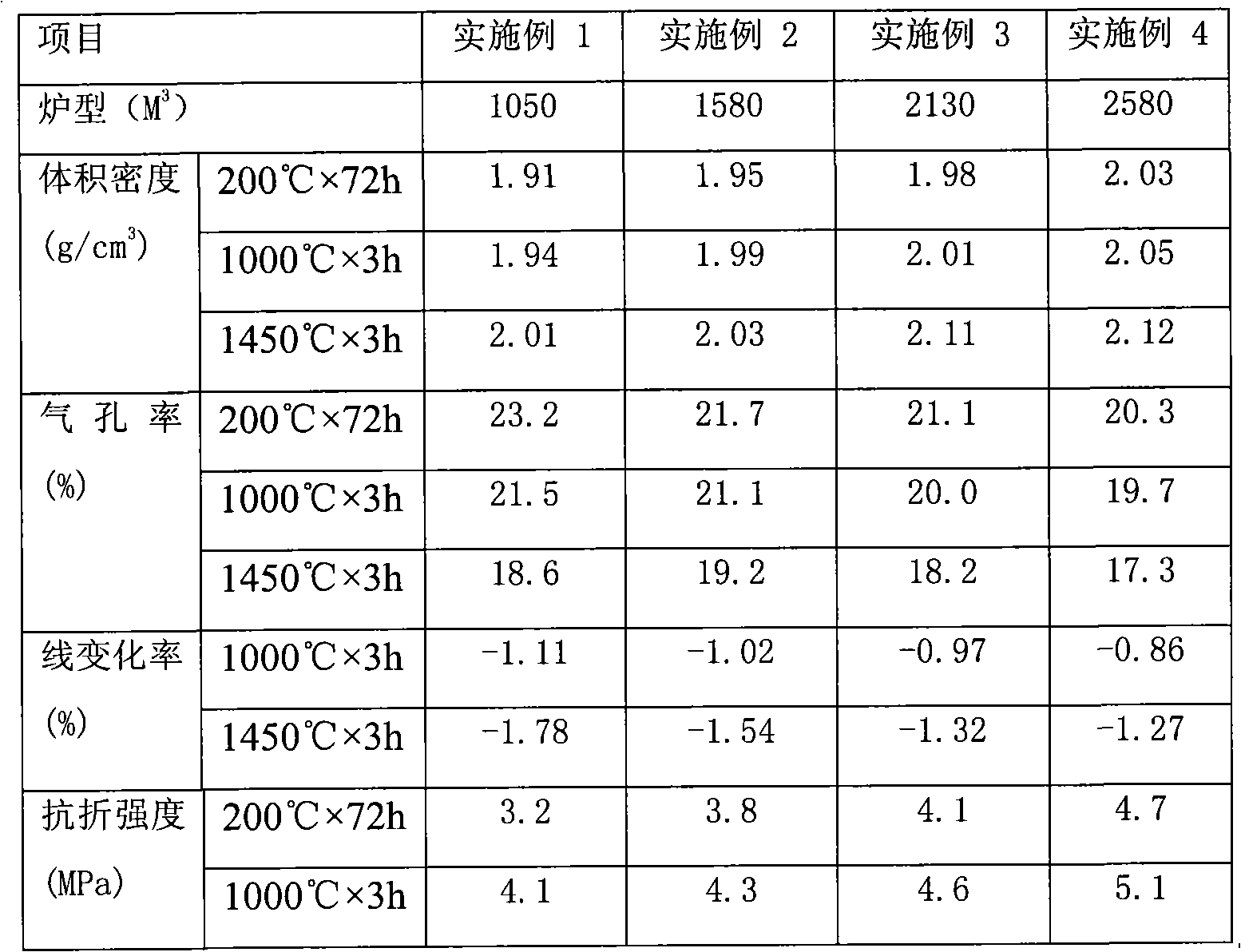

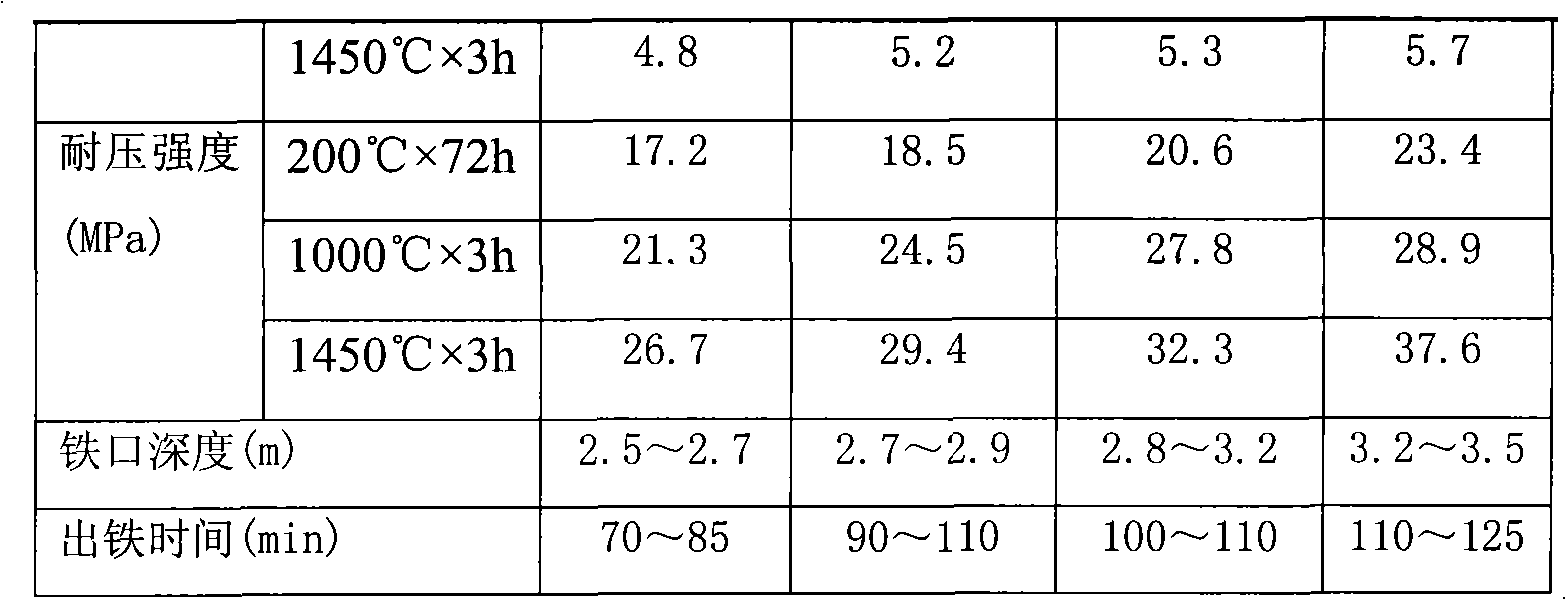

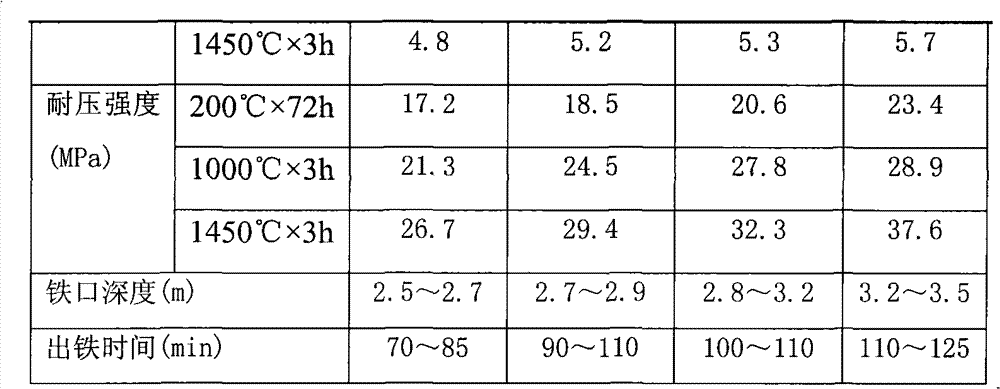

Stemming utilizing waste refractory material and preparation method thereof

InactiveCN102060548AImprove workabilitySmall sintering shrinkageProcess efficiency improvementSlagCorundum

The invention provides a stemming utilizing a waste refractory material and a preparation method thereof. The stemming comprises the following raw materials: silicon carbide particles or fine powder, high-temperature fine asphalt powder, Jilin fine clay powder, coke particles, industrial grade corundum particles or fine powder, wherein recovered aluminum and magnesium material particles or fine powder used for an electric furnace is added; and tar serves as a bonding agent. The preparation method comprises the following steps of: preparing the raw materials according to a proportion; after uniformly stirring particle materials in a stirring machine for 1 to 10 minutes, adding 20 to 30 percent of the tar; stirring for 5 to 10 minutes; adding fine powder materials; stirring for 5 to 15 minutes; adding the remaining tar and stirring for 25 to 40 minutes; and extruding by using a stemming extruder and packaging. The stemming has the following advantages: high operating performance, low stemming sintering shrinkage, rapid sintering property, high scour resistance and slag iron erosiveness. The invention provides a way for regenerating and utilizing the waste refractory material, and contributes to saving resources and protecting environment.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Microporous graphite silicon carbide brick

The invention relates to a microporous graphite silicon carbide brick and belongs to the field of refractory material for iron making blast furnace. The microporous graphite silicon carbide brick is prepared from main raw materials of SiC, Si, Ti and pyrolytic graphite and a binder of modified phenol-formaldehyde resin through steps of pugging, die vibration forming, low temperature baking, immersion and high temperature sintering. The brick has excellent thermal conductivity, alkali resistance, inoxidizability, slag erosiveness, small average aperture and apertures with an aperture larger than 1 mum having a volume no more than 4%, and suits for bosh, belly, middle and lower part of a large blast furnace. Besides, the brick has a long service life and substantial economic benefits.

Owner:鲁山天诺炉衬材料有限公司

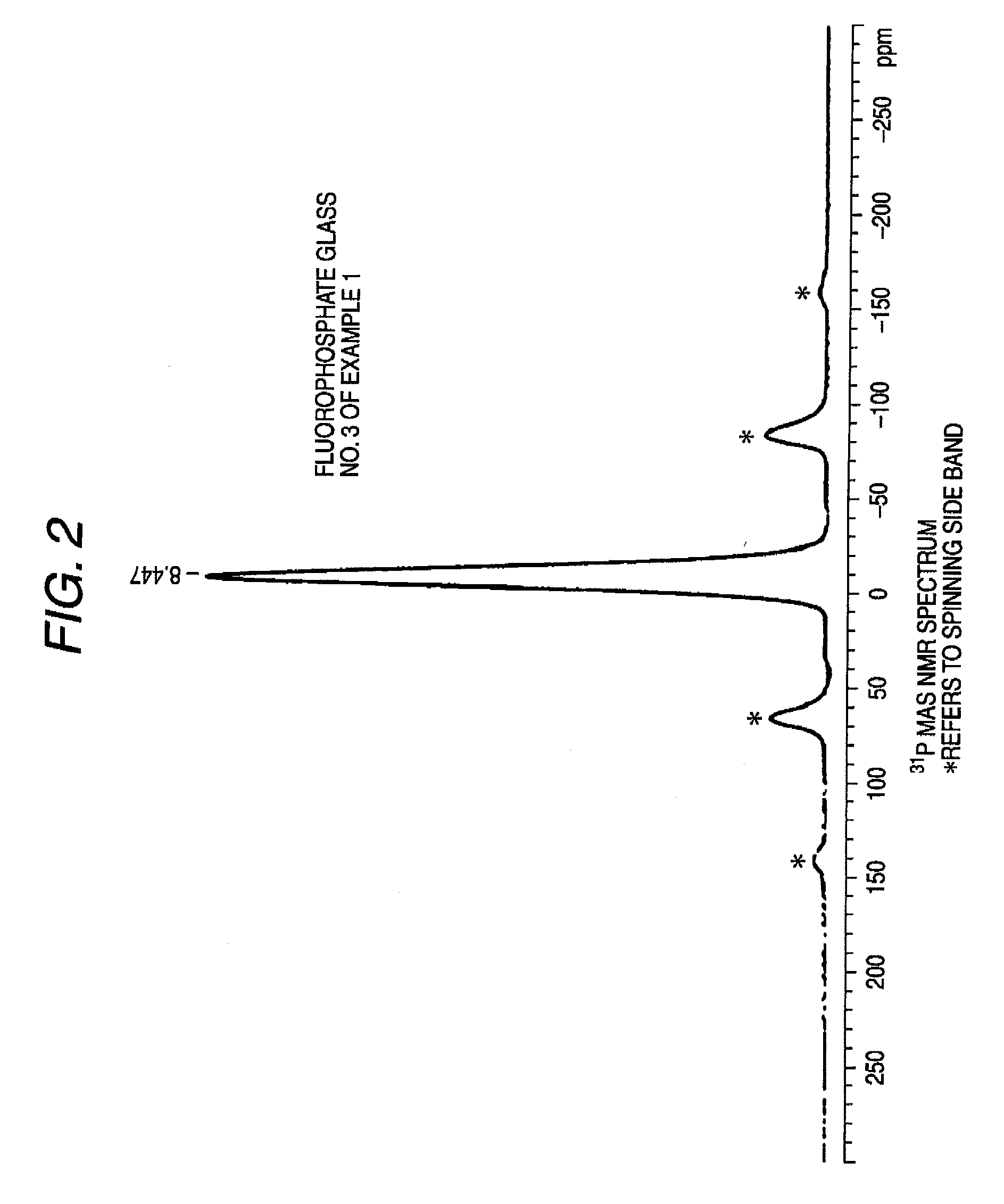

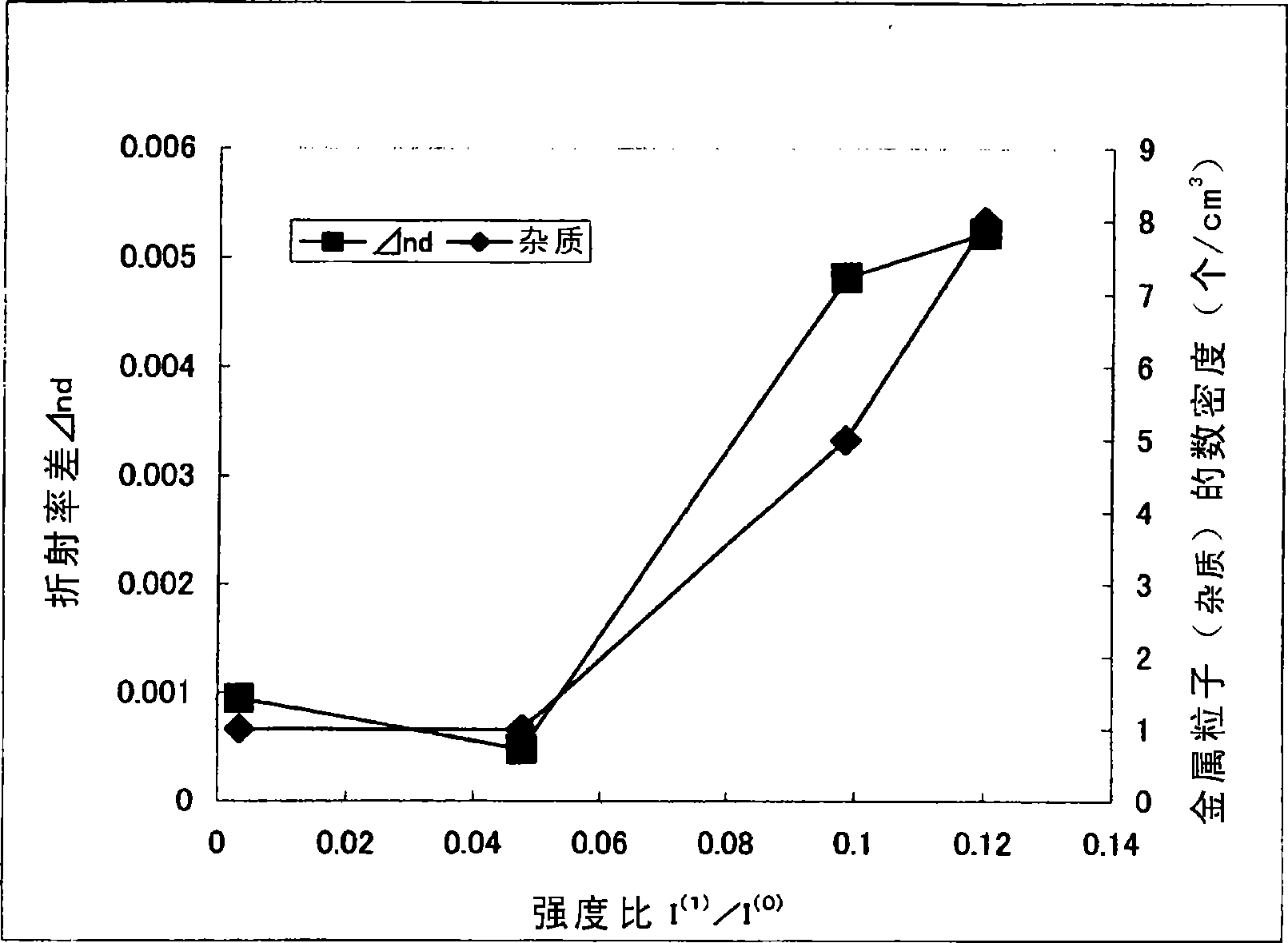

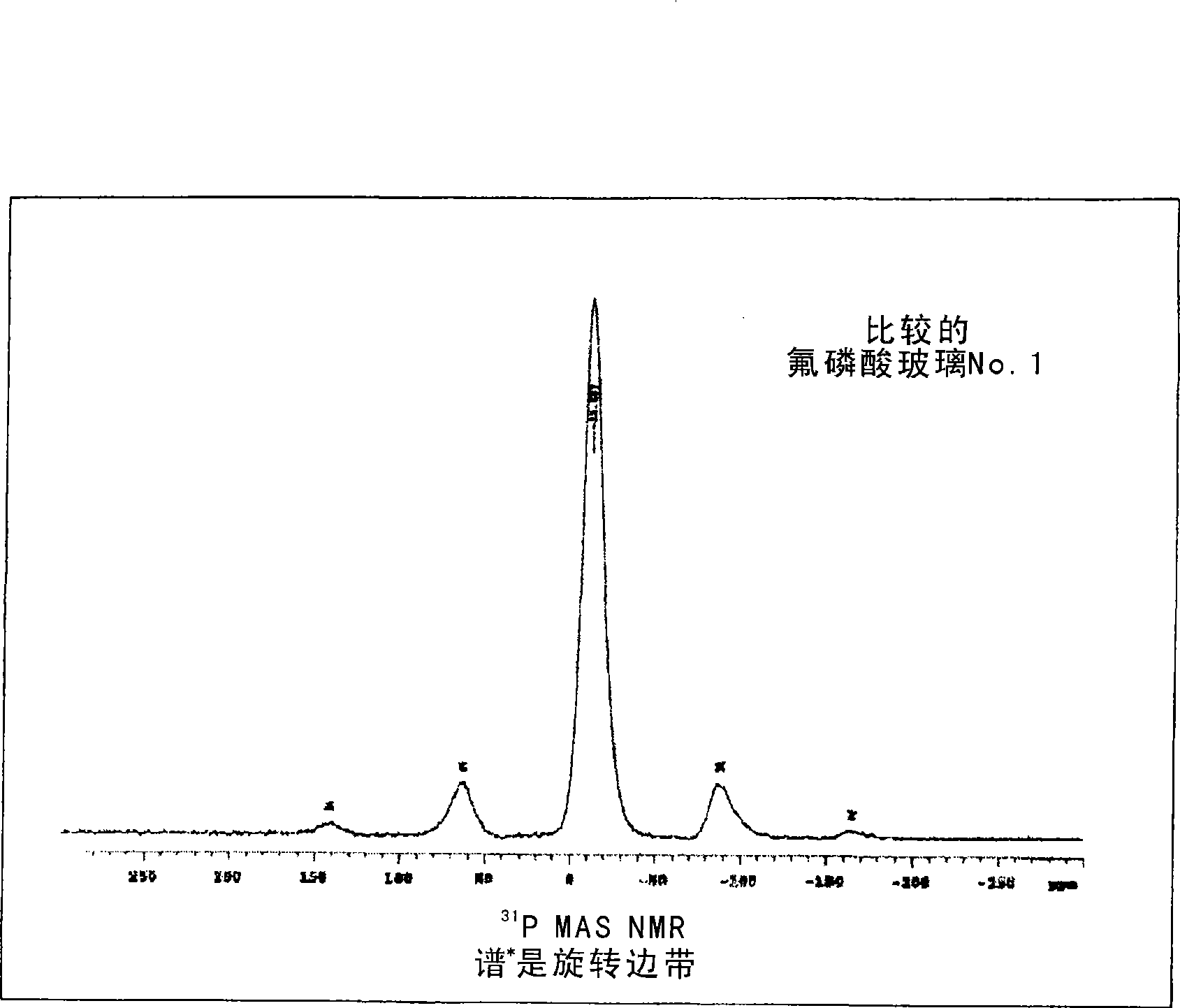

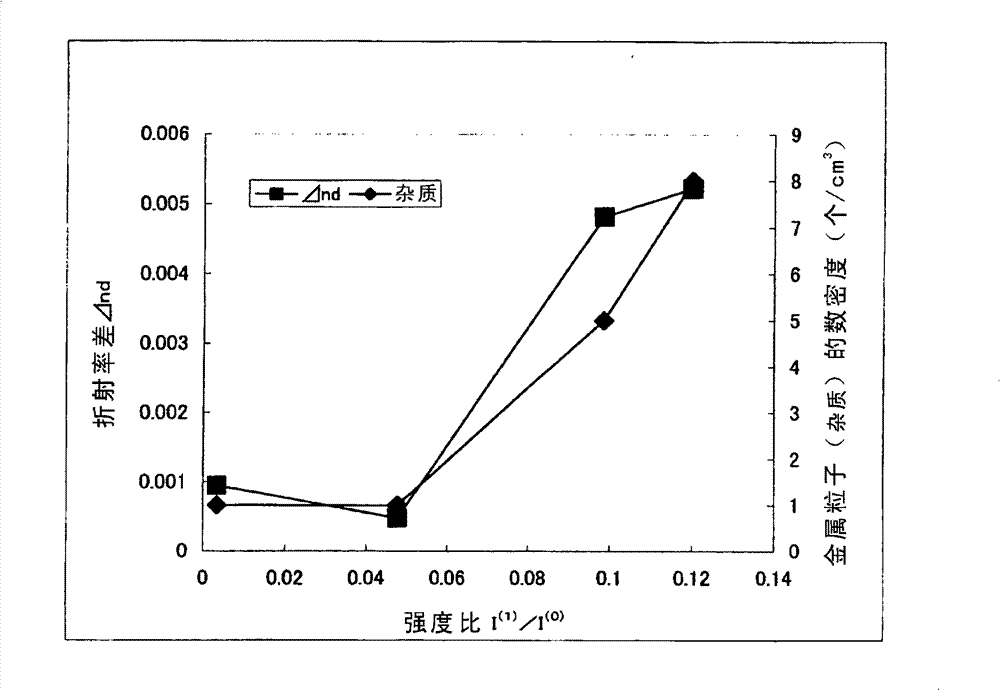

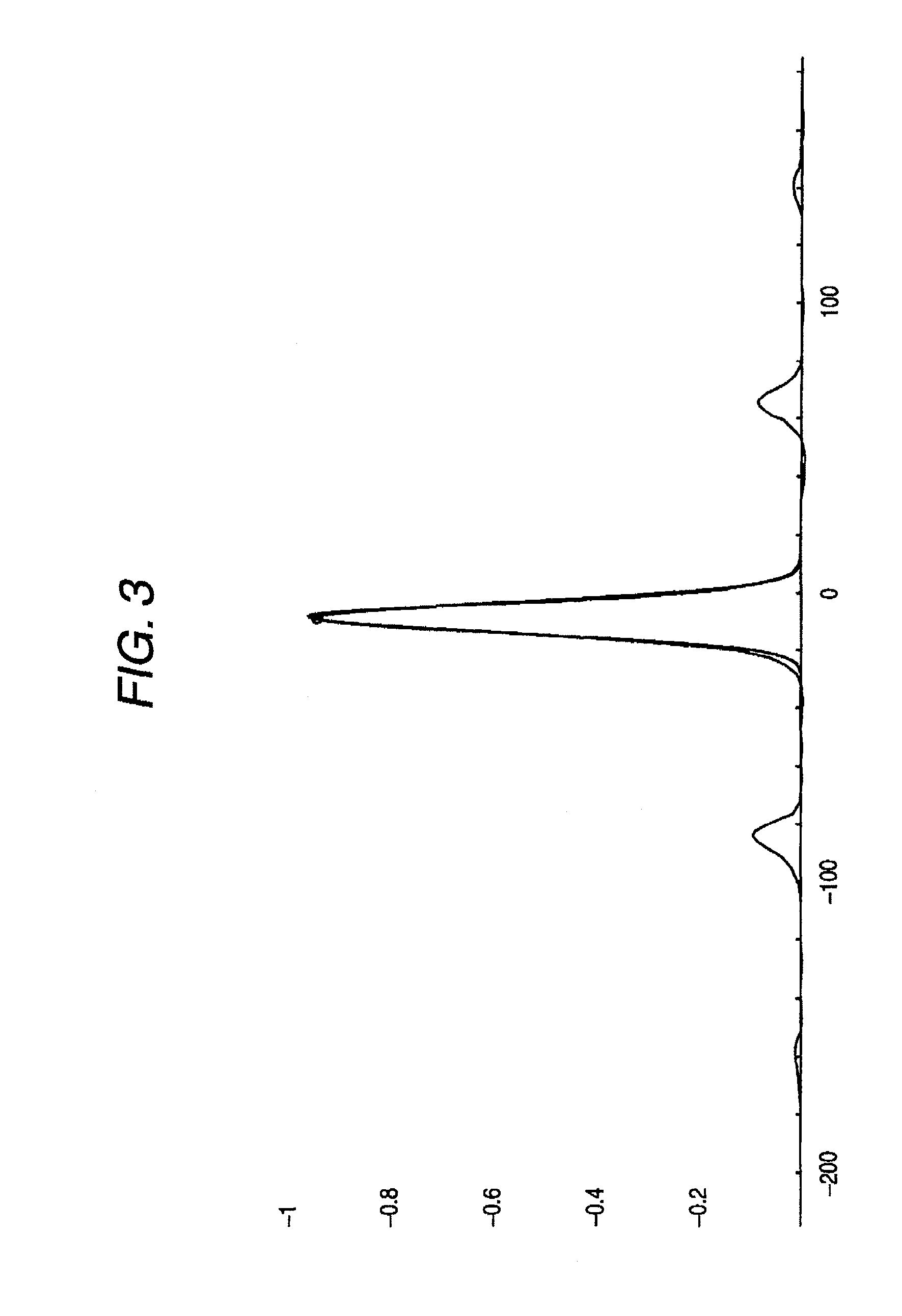

Fluorophosphate glass, precision press molding preform, optical element blank, optical element and method of manufacturing the same

ActiveCN101544468AImprove uniformityGlass pressing apparatusOptical elementsNMR - Nuclear magnetic resonanceErosiveness

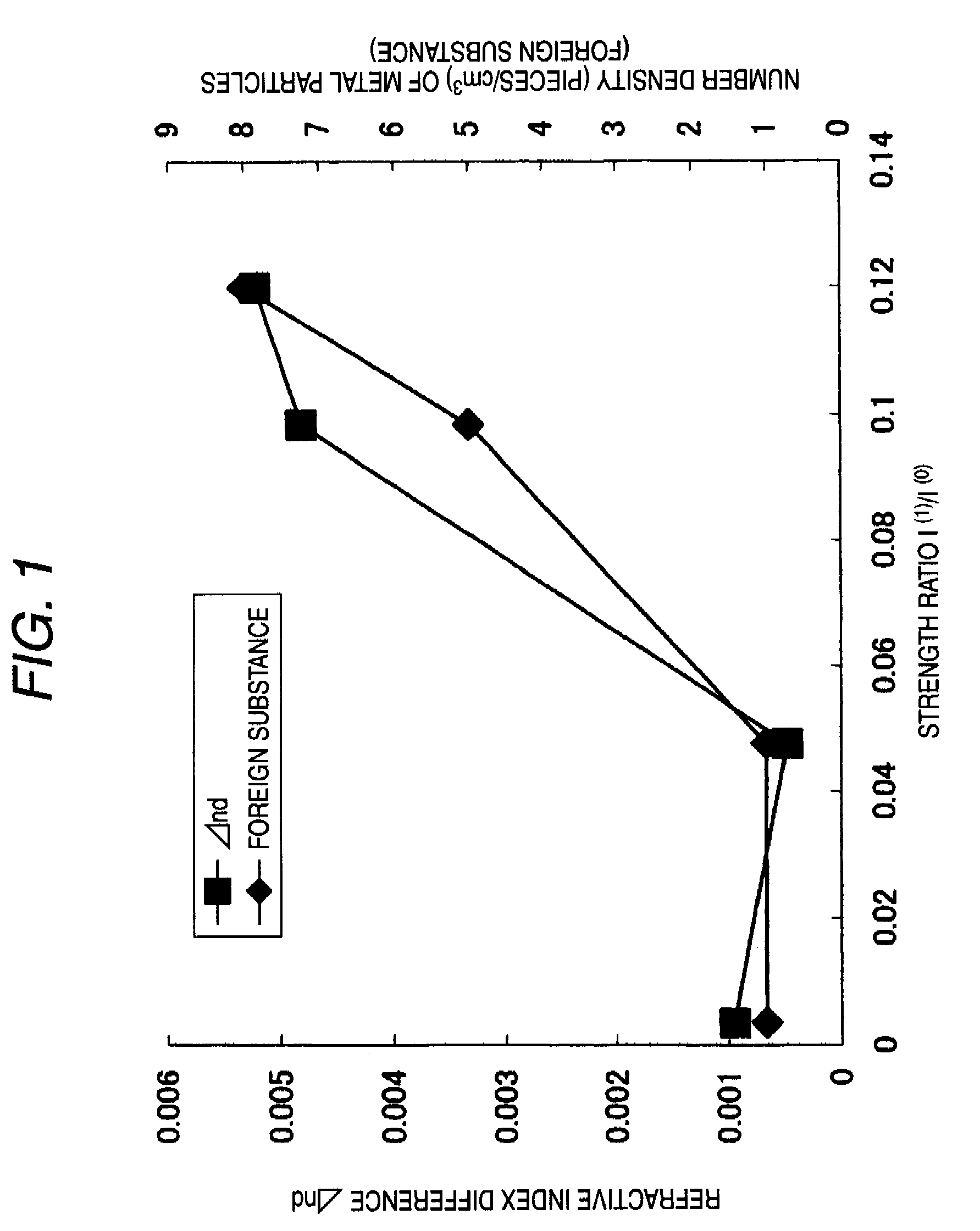

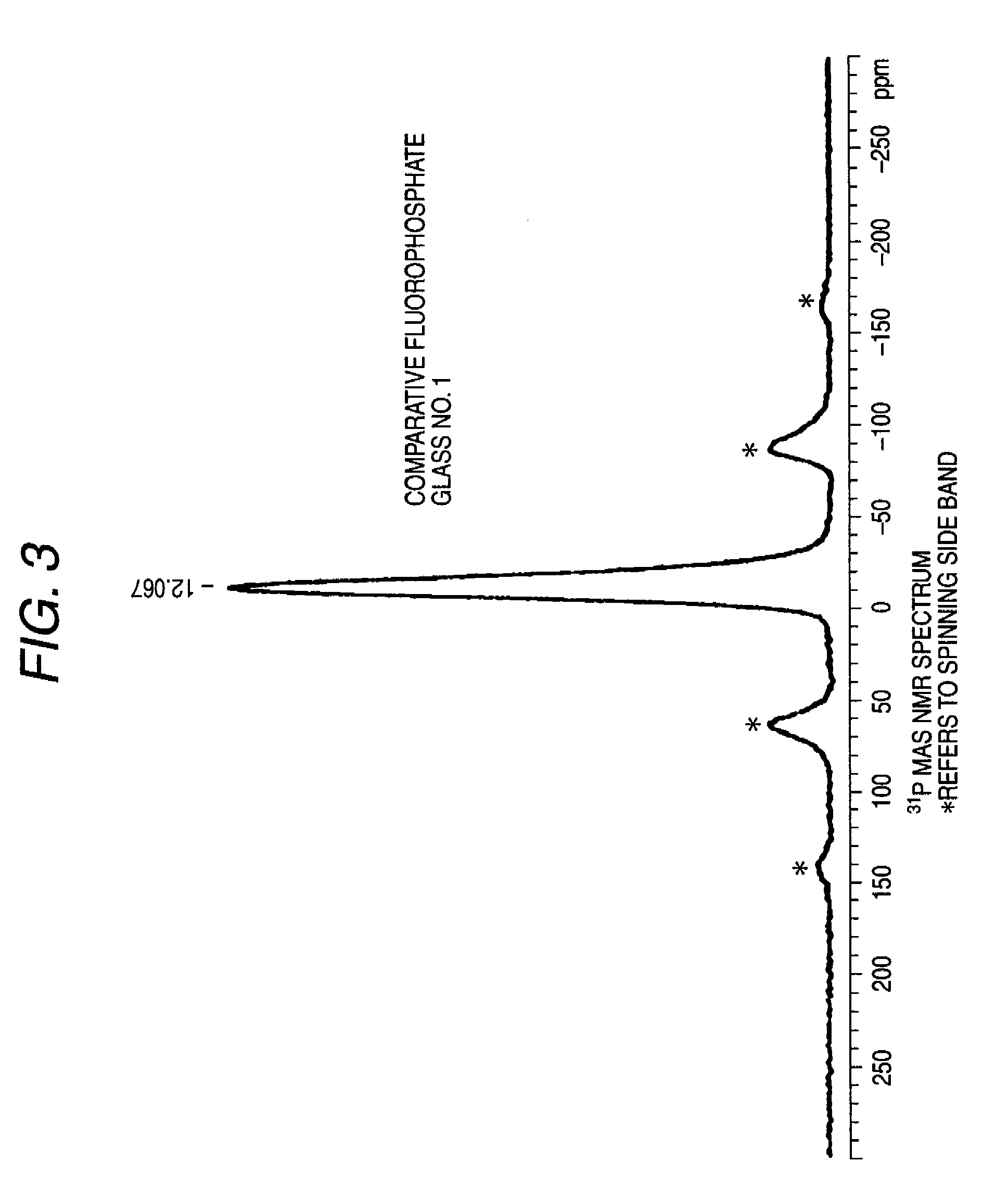

The invnetion provides fluoroposphate glass, precision press molding preform, optical element blank, optical element and method of manufacturing the same. A fluorophosphate glass of the invention contains more than 3 cationic % and 30 cationic % or less of a phosphorus ingredient in terms of P<5+>, the glass having a ratio I(1) / I(0) of equal to or less than 0.08 in which I(0) is a strength of a resonance peak generated near a reference frequency of <31>P in a nuclear magnetic resonance spectrum and I(1) is a strength of a first-order side band peak of the resonance peak. The glass of the invention is reduced in volatility and erosiveness.

Owner:HOYA CORP

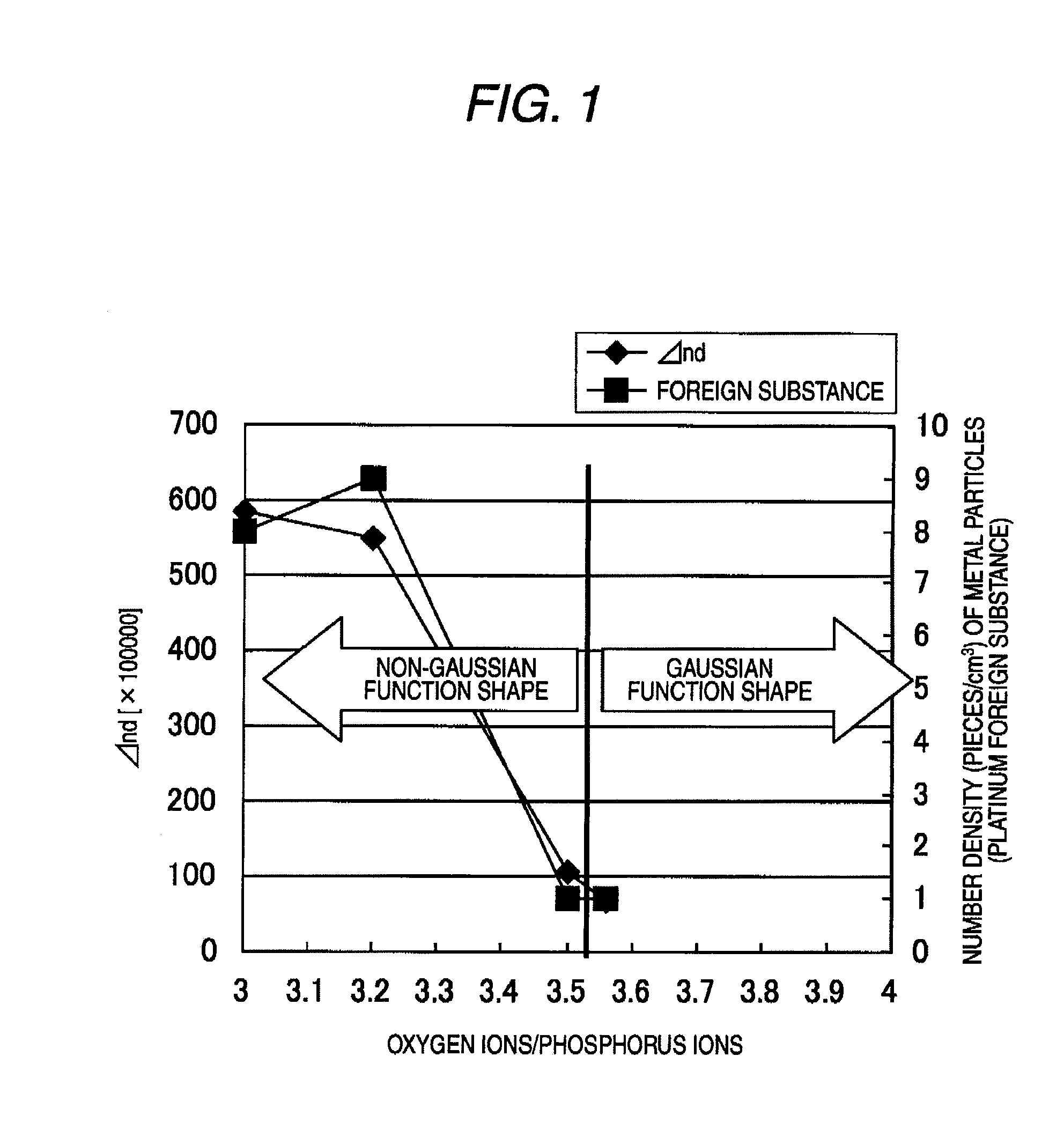

Fluorophoshoric acid glass, die pressing forming glass material, optical element blank, optical element and manufacturing method thereof

ActiveCN101555099AExcellent optical uniformityGlass pressing apparatusOptical elementsVitrificationErosiveness

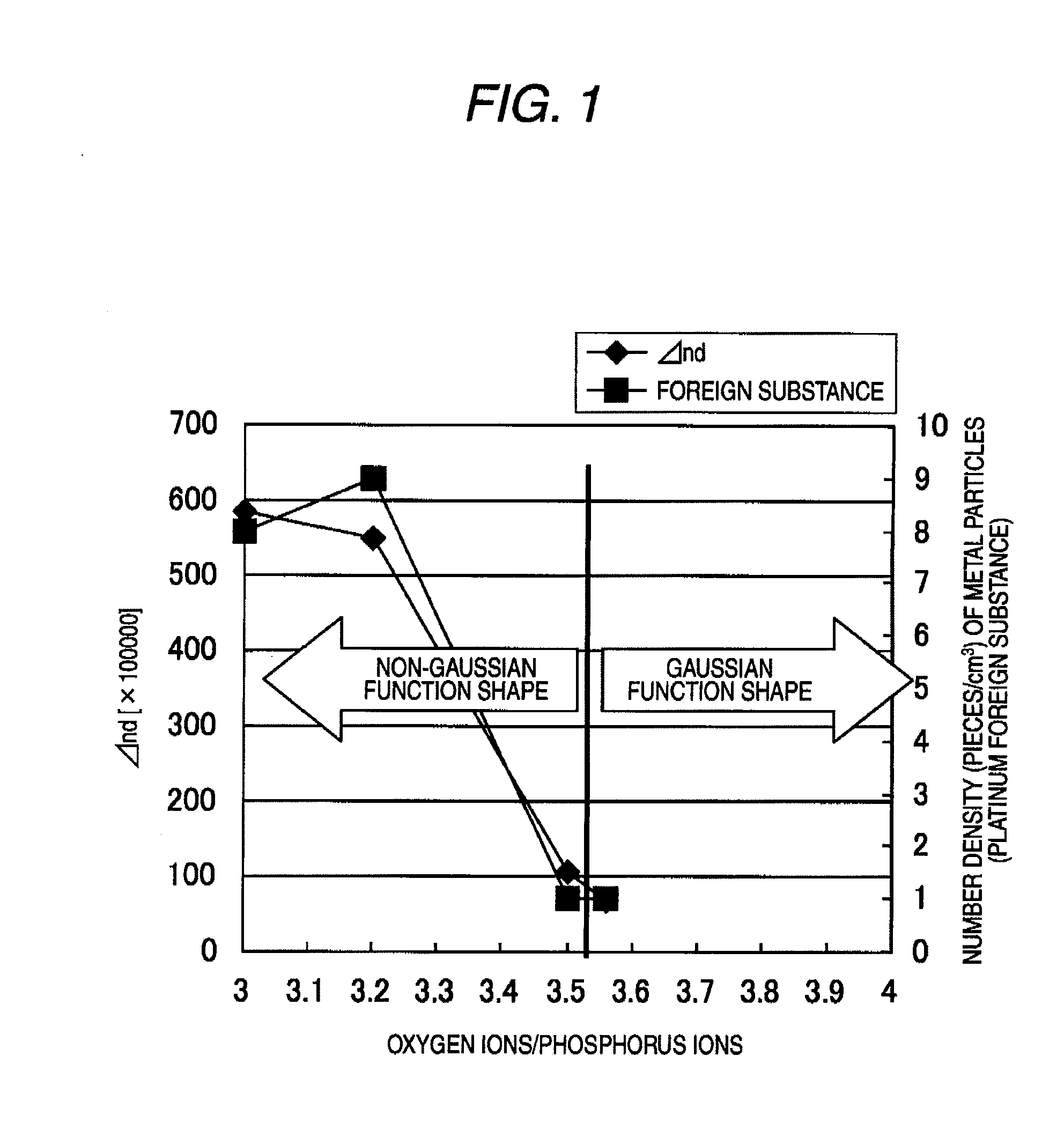

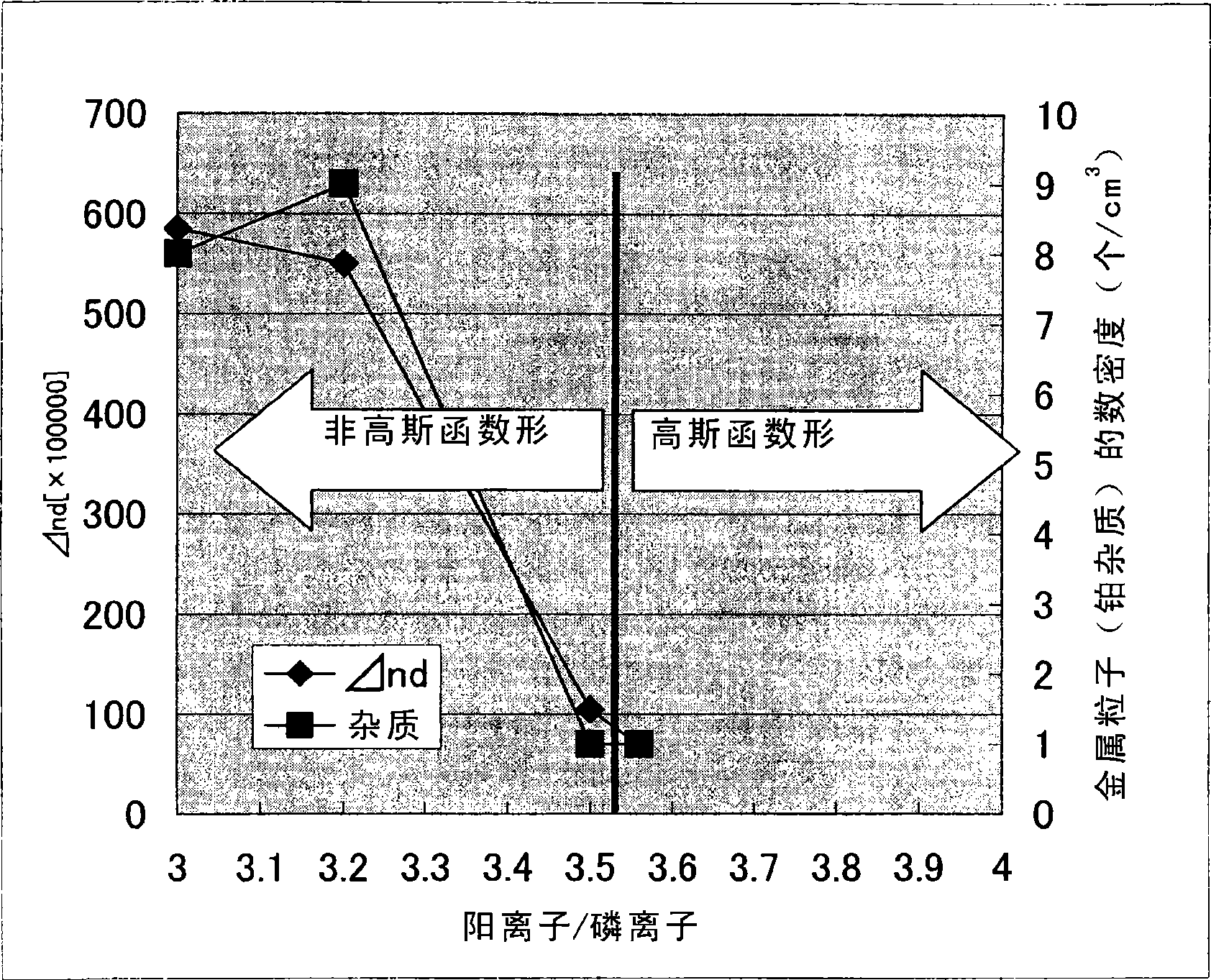

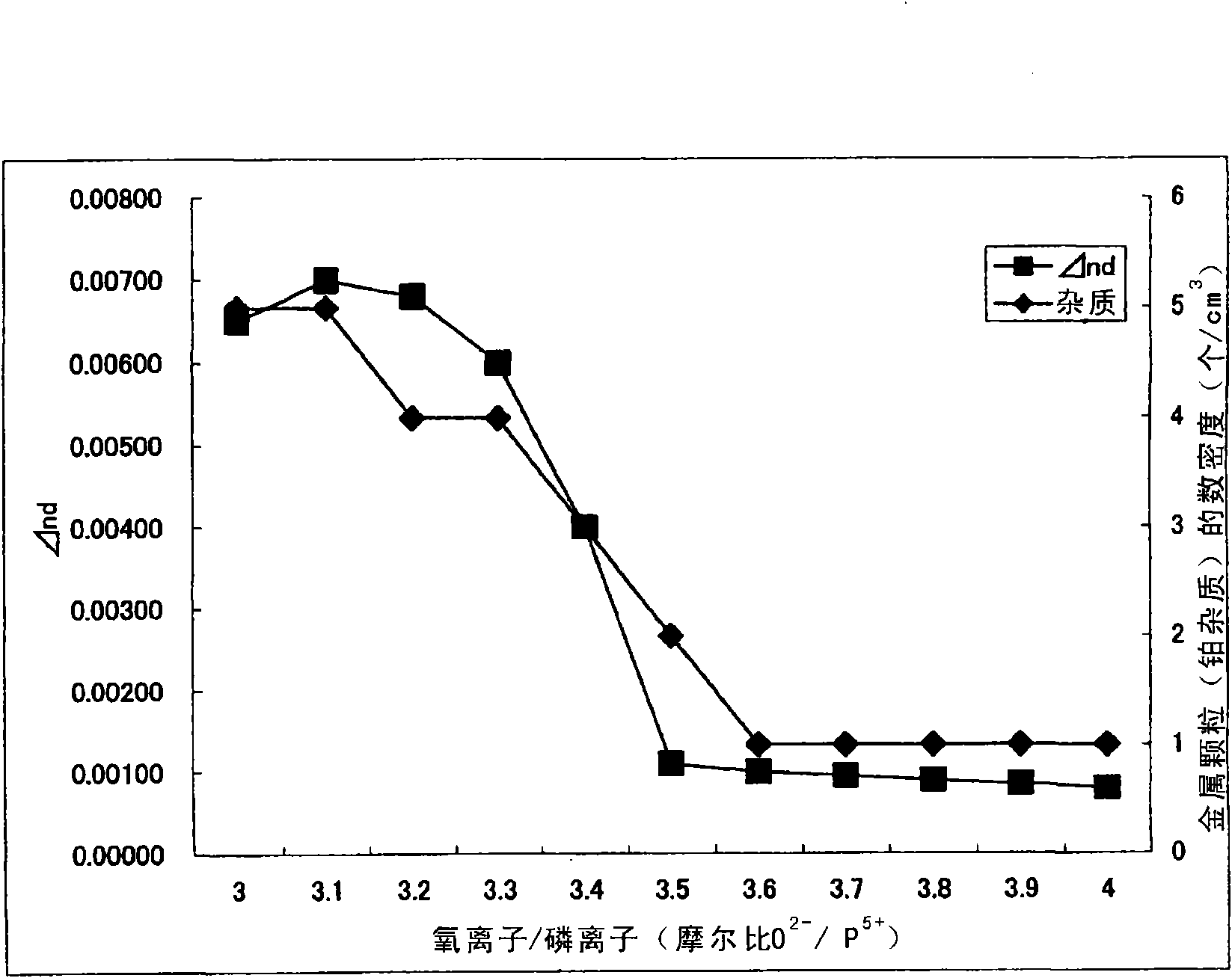

The present invention provides a fluorophosphate glass containing phosphorus, oxygen and fluorine as glass ingredients, in which, provided that a refractive index nd of the glass is nd(1) and a refractive index nd after re-melting the glass at 900 DEG C for 1 hour in a nitrogen atmosphere, cooling the glass to a glass transition temperature and then cooling the glass down to 25 DEG C at a temperature decrease rate of 30 DEG C per hour is nd<(2)>, an absolute value of a difference between nd<(1)> and nd<(2)> (nd<(2)>-nd<(1)>) is equal to or less than 0.00300, and a molar ratio (O<2-> / P<5+>) of a content of O<2-> to a content of P<5+> is equal to or more than 3.5. The glass of the invention is reduced in volatility and erosiveness.

Owner:HOYA CORP

Raw material composition for graphite-silicon carbide riser tube and manufacturing process thereof

The invention discloses a raw material composition for a graphite-silicon carbide riser tube. The raw material composition comprises the following raw materials in percentage by weight: 30% to 50% of flake graphite, 20% to 50% of silicon carbide, 4% to 10% of elemental silicon powder, 1% to 5% of boron carbide powder, and 10% to 14% of a bonding agent. The manufacturing process of the graphite-silicon carbide riser tube comprises the following steps: mixing raw materials evenly, and manufacturing qualified mud materials; loading the qualified mud materials into mould cavities, putting the mould cavities into an isostatic press cylinder, and pressing and shaping; demoulding, and processing blanks into desired sizes; preheating the blanks, and coating anti-oxidation glaze when the blanks are hot; burning the blanks in a naked mode so that the glaze is melted into glass glaze; detecting an air hole rate, and obtaining finished products if burned blanks are qualified. The process disclosed by the invention is simple, the prepared riser tube has high heat stability, the riser tube is ensured not to be burst, in addition, the riser tube has strong resistance to the erosiveness of molten aluminum, the corrosion problem of an iron riser tube is overcome, and the situation that iron is increased in molten aluminum is prevented; compared with the common riser tube which is combined with silicon nitride and silicon carbide, the production cost is low, and the raw material composition is suitable for large-scale industrial promotion.

Owner:QINGDAO BAIDUN CRUCIBLE CO LTD

Durability reinforced material of concrete as well as preparation method and application thereof

InactiveCN102875045AGood resistance to freeze-thaw cyclesMaintain liquidity lossSolid waste managementErosivenessSulfate

The invention relates to a durability reinforced material of concrete as well as a preparation method and application thereof. The reinforced material comprises the following components in parts by weight: 100 parts of original ultra-pulverized fly ash beads, 6-9 parts of water reducing agent, 30-80 parts of ultrafine slag powder, 0.075-0.3 part of air entraining agent, 55-75 parts of excitant and 0.37-1.25 parts of retarding agent. The production method of the durability reinforced material comprises the following steps of: firstly, mixing the original ultra-pulverized fly ash beads with the water reducing agent; and secondly, mechanically mixing the mixture with other components. According to the application of the durability reinforced material, the durability reinforced material of the concrete is doped in cement or cementitious materials, wherein the doping amount of the durability reinforced material of the concrete is 5.0-20.0 percent by weight of the total weight of the cement or cementitious materials. According to the durability reinforced material disclosed by the invention, the capability of the cement of resisting the erosiveness of sulphate can be improved 7-8 times, the capability of the cement of resisting the penetrability of chloride ions can be improved by over 5 times and the service life of a concrete structure is prolonged by 4-5 times.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +2

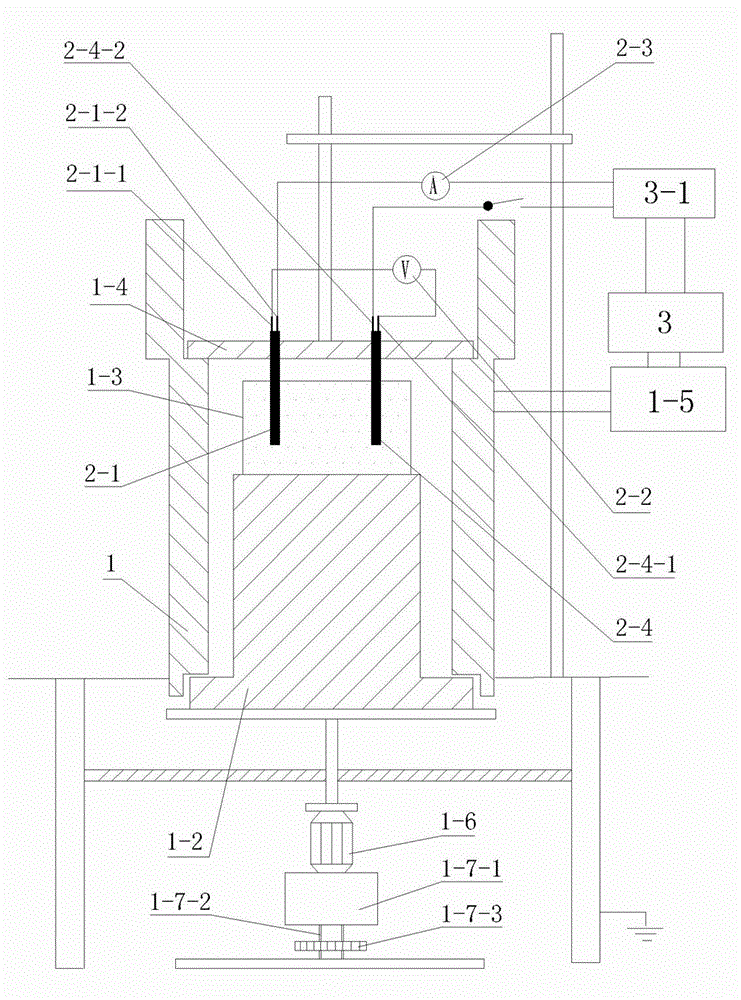

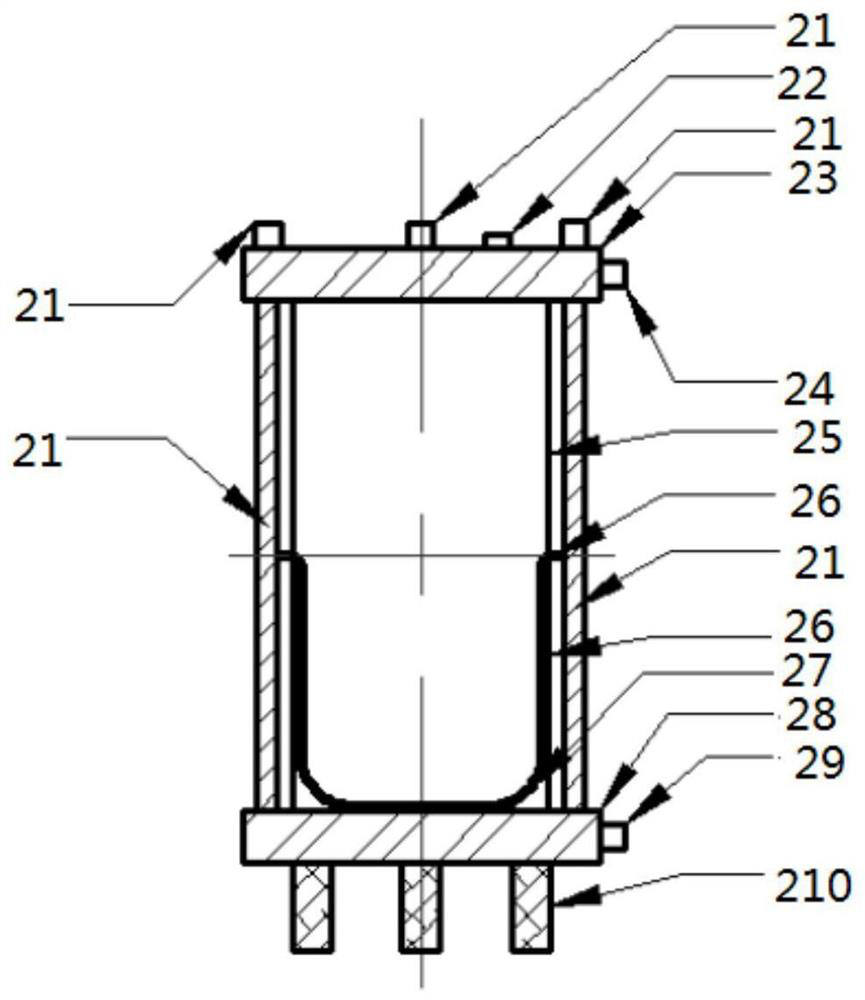

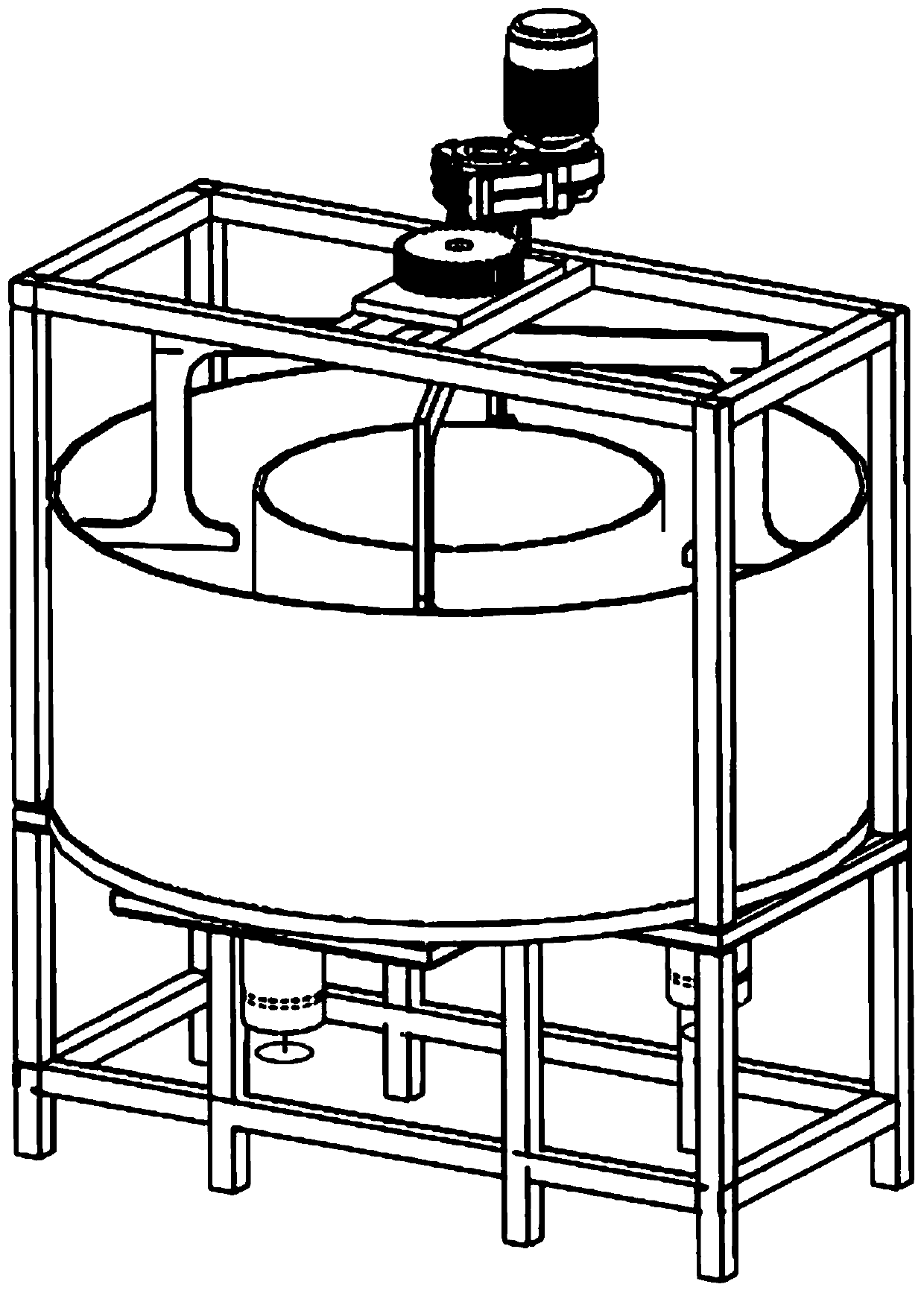

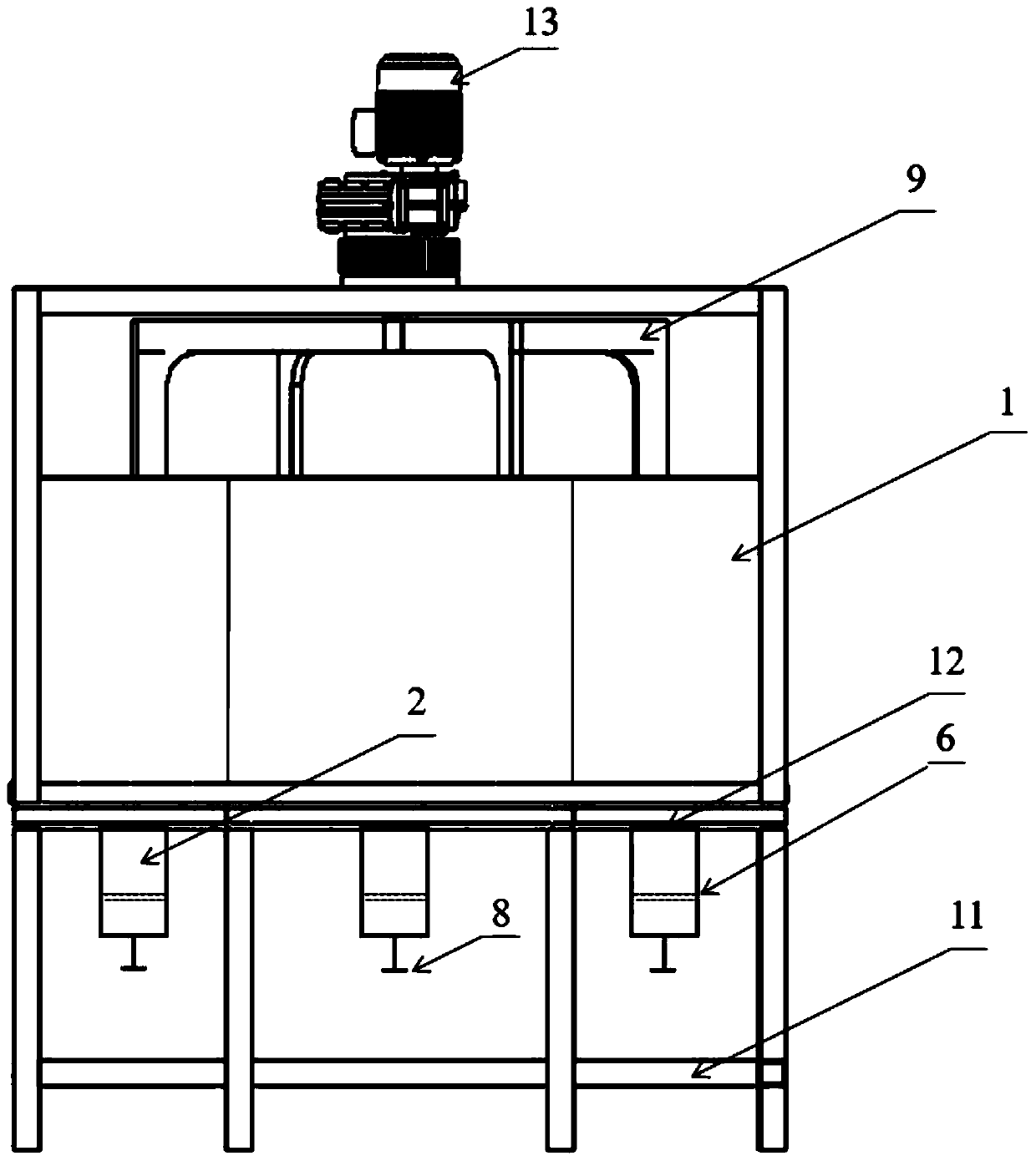

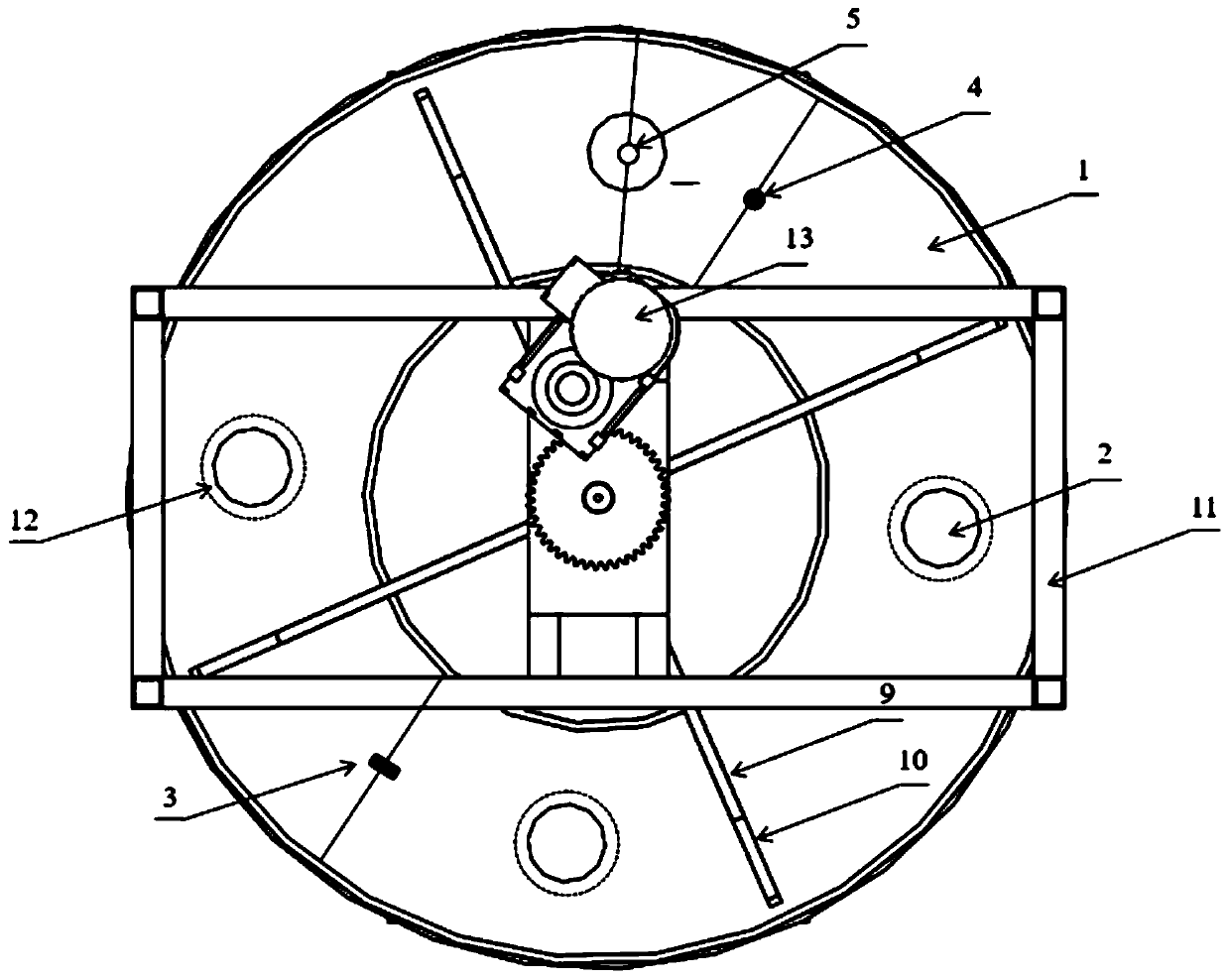

Testing device of high temperature erosiveness of electrodes for glass electric melting furnace and method thereof

ActiveCN104807740AImprove reliabilityImprove stabilityWeather/light/corrosion resistanceVoltmeterGlass manufacture

The invention discloses a testing device of high temperature erosiveness of electrodes for a glass electric melting furnace and a method thereof, and belongs to the field of glassmaking. The testing device comprises electrodes to be tested, a controllable preheating furnace, a rotating base which is arranged at the bottom of the preheating furnace and is driven by means of a motor, a crucible which is disposed on the rotating base and is used for containing erosive molten glass and a furnace lid which is placed on the preheating furnace by means of an adjustment lever. The two electrodes to be tested pass through the furnace lid and are inserted into the erosive molten glass in the crucible. An end of each electrode to be tested above the furnace lid is provided with two connection terminals. A voltmeter is connected in parallel between a connection terminal A1 and a connection terminal B1 of the electrode to be tested A and the electrode to be tested B so as to form a voltage measuring circuit. a connection terminal A2 and a connection terminal B2 are connected in series with an ammeter, a switch and a power supply capable of realizing voltage transformation output to form a current measuring circuit. The testing device provided by the invention has a simple structure, is practical and convenient, has high reliability and stability, and fills up the blank of measuring equipment and measuring methods of this kind.

Owner:CHENGDU TAIYISI SOLAR TECH

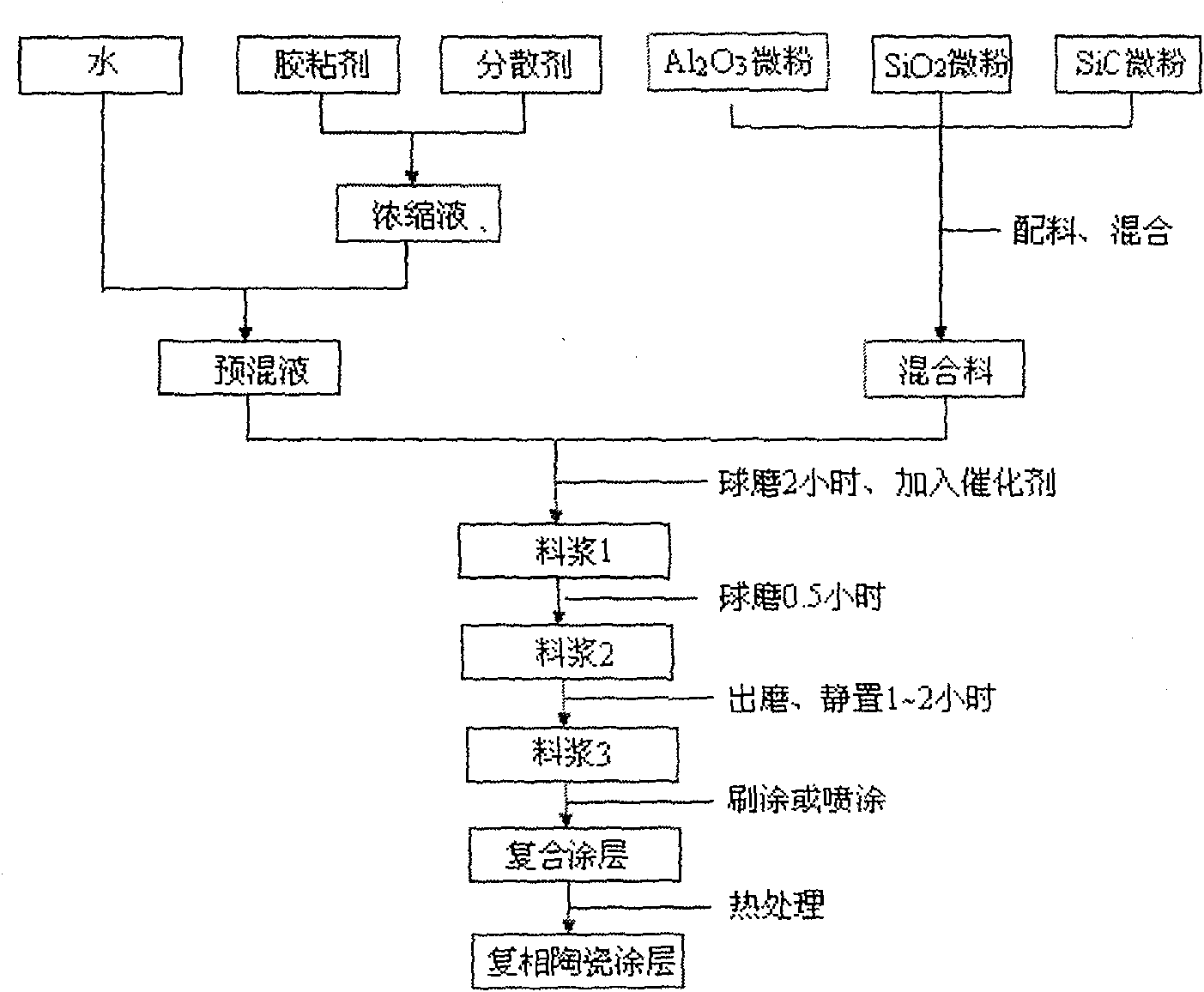

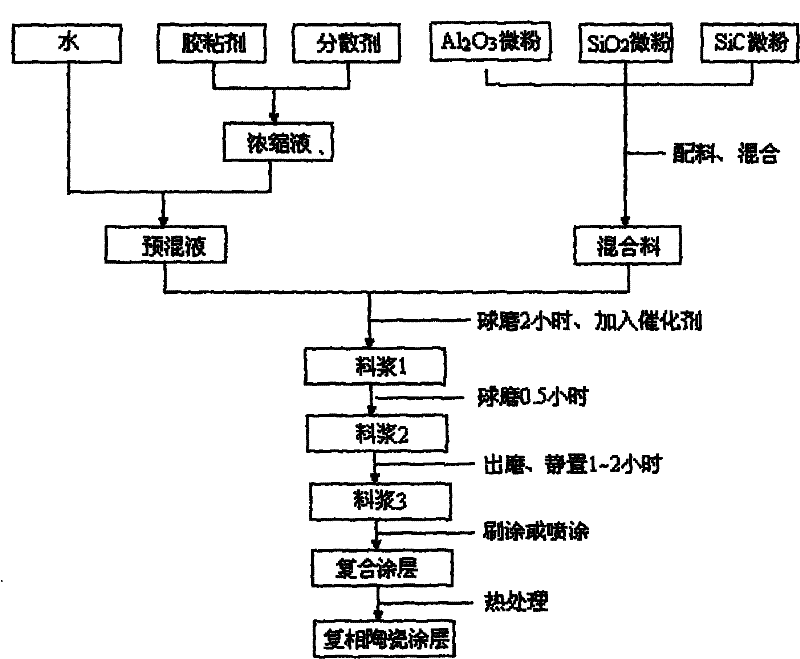

Acid-resisting complex phase ceramic coating and preparation method thereof

The invention belongs to an acid-resisting complex phase ceramic coating and a preparation method thereof. Firstly, 2-5 wt% of adhesive and 2-4 wt% of dispersing agent are prepared into concentrated solution, and then 25-30 wt% of water is added to prepare premixing solution; alumina, silica and silicon carbide micro powder are mixed at ratio and are added into premixing solution and the mixture is carried out ball milling for 2 hours; 0.5-1 wt% of catalyst is added for ball milling for 0.5 hour; after slurry viscosity is suitable, the slurry is brushed or sprayed by a spray gun on the surface of materials, such as cement, concrete and the like to form an even coating; and after heat treatment, Al2O3 / SO2 / SiC series anti-reversion complex phase ceramic coating is obtained. The complex phase ceramic coating not only can be applied on the surface of cement, concrete and the like, but also can be used for the anti-corrosion of metal surface. The coating surface is even and compact, has no cracks and has favorable abrasion performance and favorable acid resistant erosiveness.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Fluorophosphate glass, precision press molding preform, optical element blank, optical element and method of manufacturing the same

InactiveUS8642490B2Quality improvementGlass reforming apparatusGlass severing apparatusNMR - Nuclear magnetic resonanceErosiveness

The present invention provides a fluorophosphate glass containing more than 3 cationic % and 30 cationic % or less of a phosphorus ingredient in terms of P5+, the glass having a ratio I(1) / I(0) of equal to or less than 0.08 in which I(0) is a strength of a resonance peak generated near a reference frequency of 31P in a nuclear magnetic resonance spectrum and I(1) is a strength of a first-order side band peak of the resonance peak. The glass of the invention is reduced in volatility and erosiveness.

Owner:HOYA CORP

Two-step method for preparing high-temperature red ceramic color with nuclear shell structure

The invention discloses a two-step method for preparing high-temperature red ceramic color with a nuclear shell structure. A SiO2 coating layer is coated on a Ce1-xPrxO2 chromogenic unit. The method comprises the following steps: preparing Ce1-xPrxO2 color powder by the conventional method; evenly mixing and stirring TritonX-100, C5H12O, C6H12, and H2O by the mass ratio: (2-3): (1-2):(5-7):(2-3) to obtain a microemulsion system; scattering Ce1-xPrxO2 color powder to the microemulsion system, adding TEOS ethyl orthosilicate, further adding NH3.H2O when stirring, controlling the pH value to be 8 to 10, and generating silica sol solution after the TEOS is completely hydrolyzed; and extracting and filtering silica sol solution, cleaning the filter residue, drying, calcining, grinding, and obtaining Ce1-x PrxO2 or SiO2 high-temperature red ceramic color with the nuclear shell structure. The two-step method for preparing high-temperature red ceramic color with the nuclear shell structure provided by the invention can improve the high-temperature anti-glass melt erosiveness of the red ceramic color.

Owner:SHAANXI UNIV OF SCI & TECH

Method for quantitative measuring erosiveness of antique brick

InactiveCN1544914AQuantitative measurement of corrosionEasy to measureWeather/light/corrosion resistanceBrickErosiveness

The invention discloses a method to quantitatively measure corrosion degree of an ancient brick, firstly defining solid content, reference brick and corrosion degree for the ancient brick, measuring the weights of the water saturated and dried ancient brick and reference brick respectively, calculating solid contents of the ancient brick and reference brick, subtracting the ratio of the solid content of the ancient brick to that of the reference brick from one to obtain the corrosion degree of the ancient brick. This method has the advantages: convenient and easy to operate without complex instruments and devices, by simply measuring and calculating, and it can objectively and quantitatively evaluate the corrosion degree of the ancient brick, and provides scientific basis for protecting, repairing and reasonably using ancient architectures.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

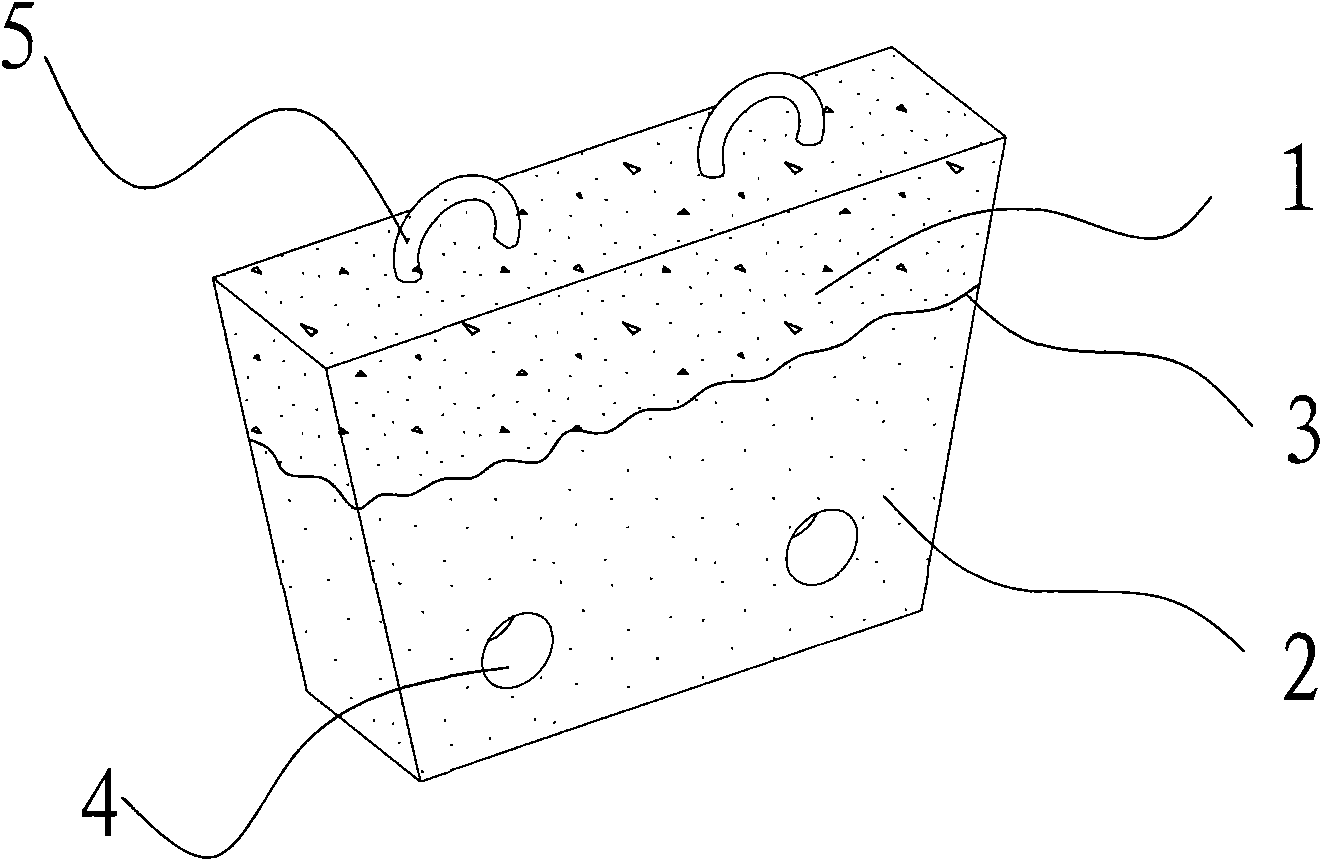

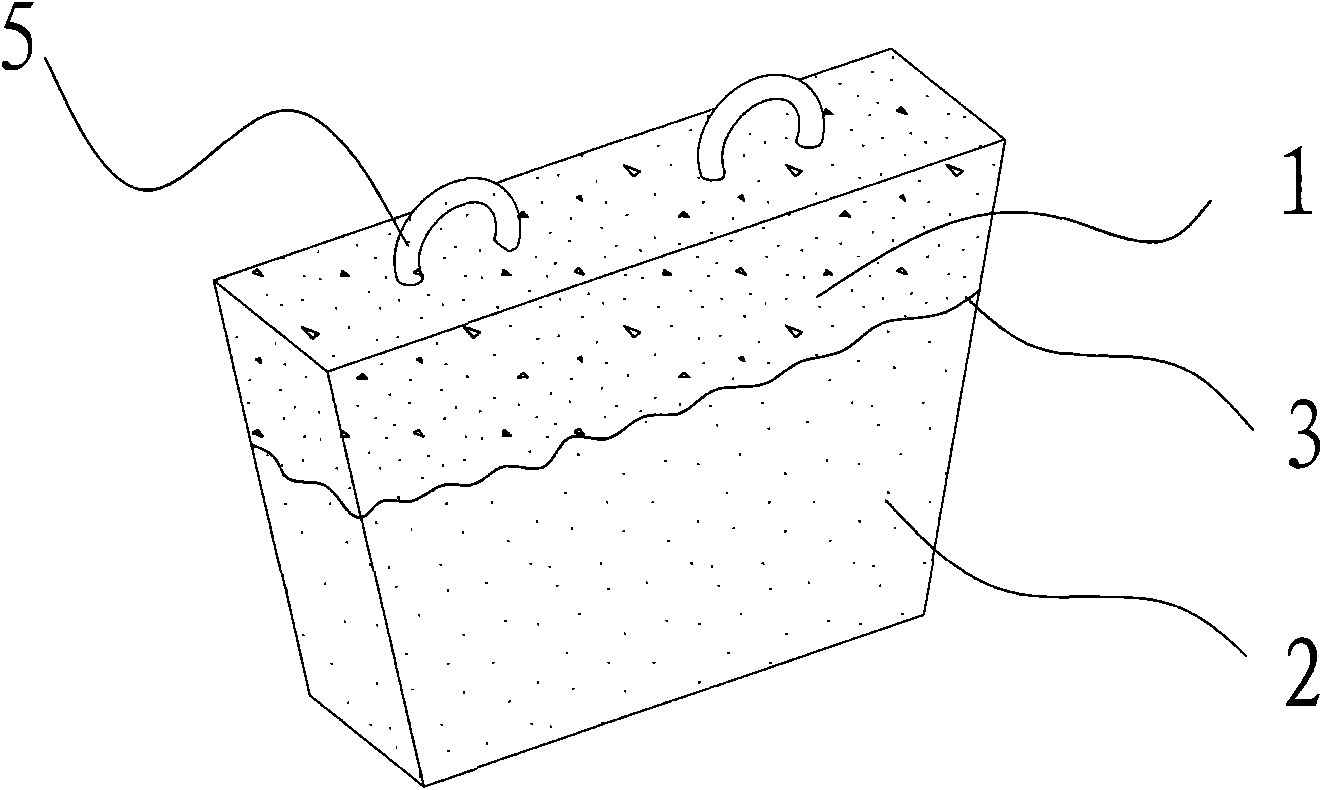

Device and method for researching influence of surrounding rock fracture water on buffer material erosion process

PendingCN112858157AIncrease varietySolve the fundamental problem of not being able to directly study the relationship between these two sets of variablesWeather/light/corrosion resistanceConvertersSodium Bentonite

The invention discloses a device and method for researching influence of surrounding rock fracture water on a buffer material erosion process, and relates to the technical field of surrounding rock fracture research. The device comprises a pressure / volume controller, a pure water / solution converter, a test rock core, a pressurization structure and a recovery structure, wherein a buffer material sample is arranged in the test rock core, the test rock core is arranged in the pressurization structure, one end of the pure water / solution converter is communicated with the pressure / volume controller, the other end of the pure water / solution converter is communicated with one end of the test rock core, and the recovery structure is used for recovering a solution flowing out of the test rock core. According to the invention, a granite core is processed into a hollow cavity, and compacted bentonite is limited to expand in the cavity; artificial fractures can be cut from a complete rock core, or a cavity for accommodating a bentonite sample is processed from a rock core with natural fractures; and underground water or a specific test solution flows in a test system, and the expansion plugging performance and anti-erosion performance of sodium bentonite under the action of granite crack water are studied.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Fluorophosphate glass, precision press molding preform, optical element blank, optical element and method of manufacturing the same

ActiveCN101544468BImprove uniformityGlass pressing apparatusOptical elementsNMR - Nuclear magnetic resonanceResonance

The invnetion provides fluoroposphate glass, precision press molding preform, optical element blank, optical element and method of manufacturing the same. A fluorophosphate glass of the invention contains more than 3 cationic % and 30 cationic % or less of a phosphorus ingredient in terms of P<5+>, the glass having a ratio I(1) / I(0) of equal to or less than 0.08 in which I(0) is a strength of a resonance peak generated near a reference frequency of <31>P in a nuclear magnetic resonance spectrum and I(1) is a strength of a first-order side band peak of the resonance peak. The glass of the invention is reduced in volatility and erosiveness.

Owner:HOYA CORP

High strength acid resistant refractory brick and preparation method thereof

InactiveCN101555148BImprove corrosion resistanceExcellent resistance to rapid cooling and rapid heatingBrickMetallurgy

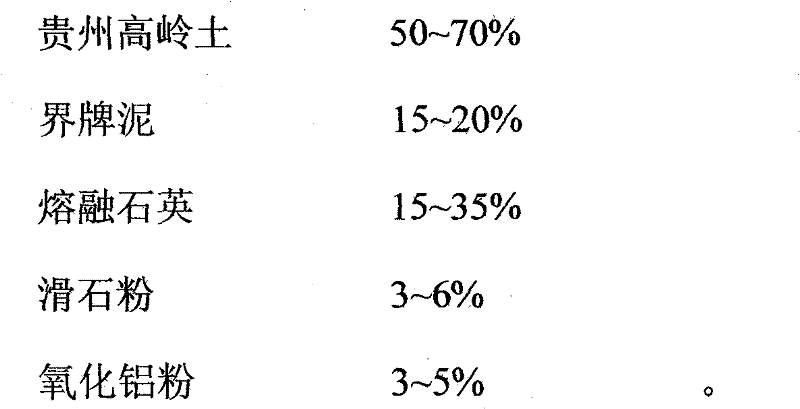

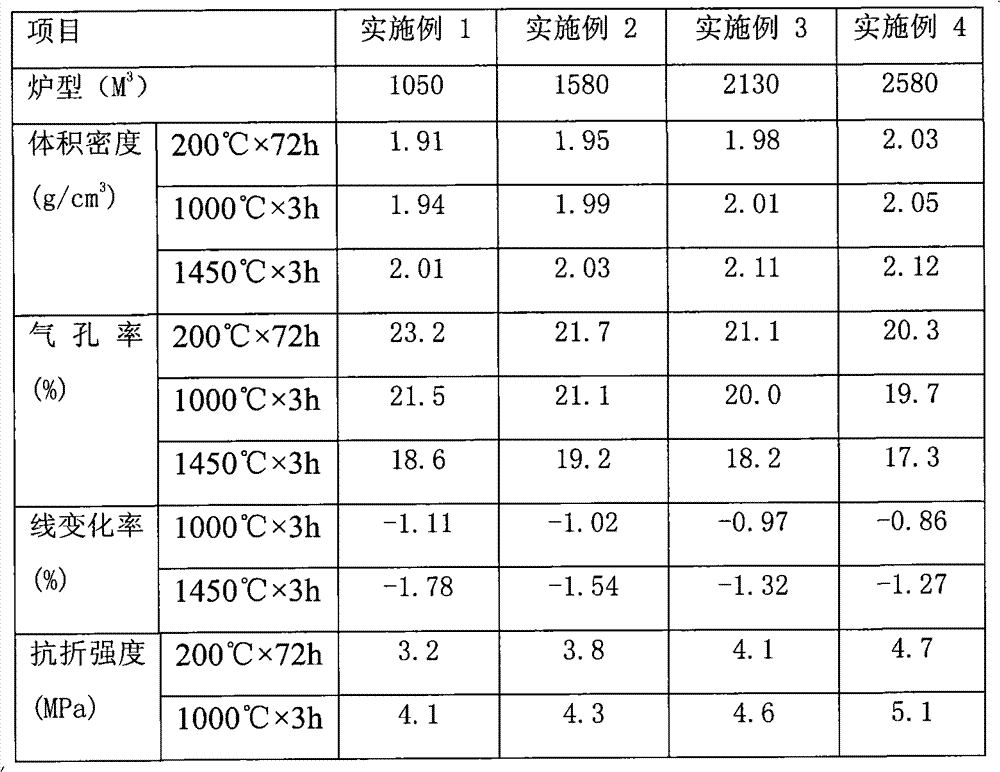

The invention discloses a high strength acid resistant refractory brick which comprises the components with weight percentages as follows: 50-70% of Guizhou kaolin, 15-20% of Jiepai mud, 15-35% of fused quartz, 3-6% of talcum powder and 3-5% of powdered alumina. The invention aims at overcoming the shortcomings in the prior art and providing a high strength acid resistant refractory brick which is high temperature resistant, chilling resistant, good in strong acid erosiveness resistance and environment-friendly. The invention has another aim of providing a method for preparing the high strength acid resistant refractory brick.

Owner:湖南省醴陵市鑫荷化工填料有限公司

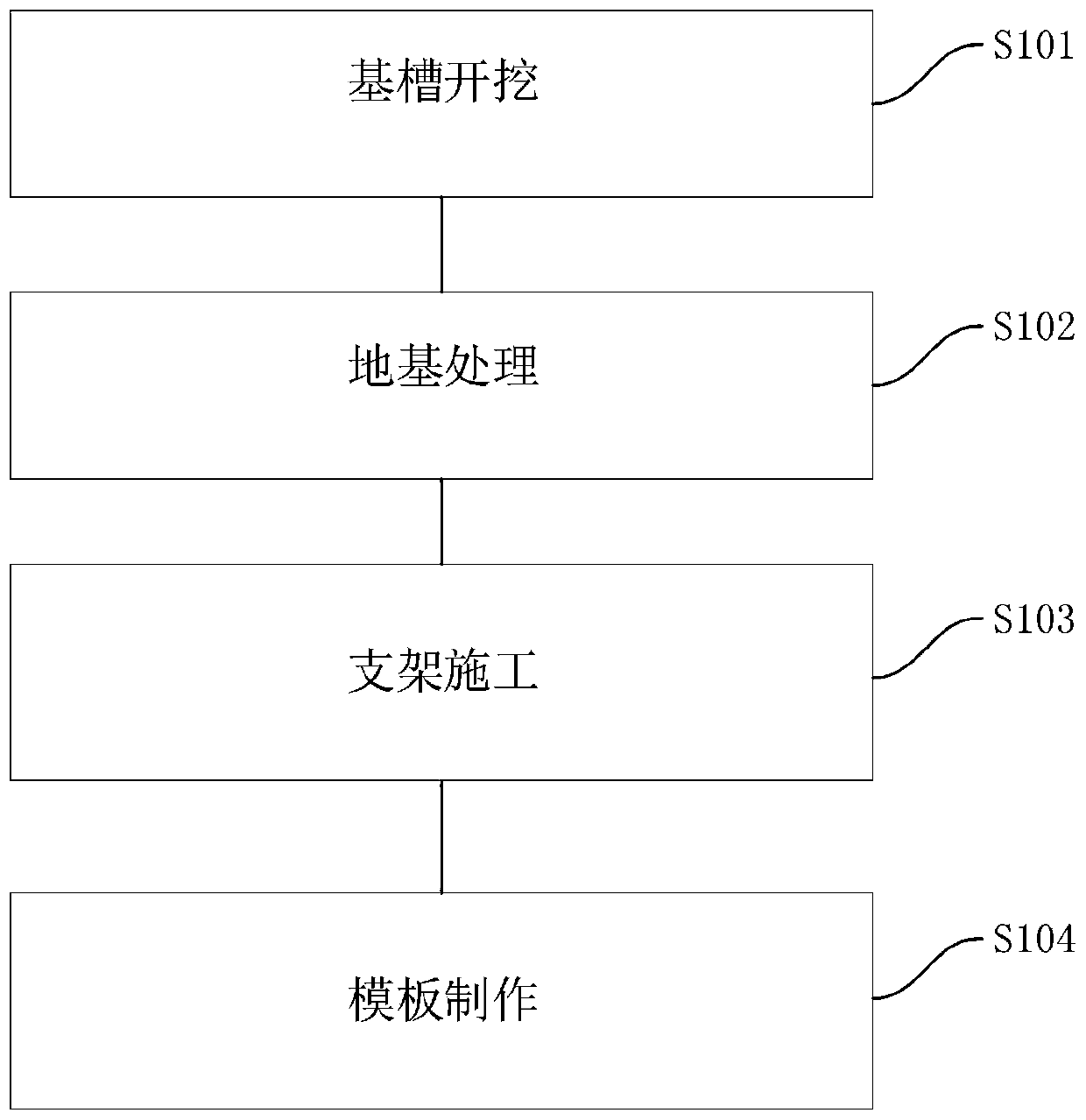

Foundation beam construction method

ActiveCN109778858AShort maintenance periodSave leveling processFoundation engineeringErosivenessEngineering

The invention provides a foundation beam construction method, which comprises the following steps of: foundation trench excavation: increasing the excavation area of a foundation trench so as to facilitate operations of supporting a formwork by short vertical rods, removing the formwork and conveniently leveling the elevation; foundation treatment: compacting the dug foundation trench, digging outa soft soil layer with a preset thickness at a position with non-uniform soil texture in the foundation trench, then using a material with stable performance and no erosiveness as a cushion layer, and filling the dug soft soil layer; support construction: selecting a short rod with the length of 1.2-1.5 m as a vertical rod of a support; and formwork manufacturing: specifically, conducting blanking segmentation on the formwork according to a formwork splicing design drawing, and conducting splicing according to the formwork splicing drawing. According to the construction method, the frame bodyand the formwork are used for well isolating the groove bottom soil layer from poured concrete, the influence of site elevation on construction can be overcome, good effect on construction in rainy seasons is achieved, meanwhile, the cushion layer concrete curing period and the foundation beam groove bottom leveling procedure are omitted, the construction progress is greatly accelerated, and theconstruction efficiency is improved.

Owner:CHINA MCC5 GROUP CORP

Stemming utilizing waste refractory material and preparation method thereof

InactiveCN102060548BImprove workabilitySmall sintering shrinkageBlast furnace componentsBlast furnace detailsSlagErosiveness

The invention provides a stemming utilizing a waste refractory material and a preparation method thereof. The stemming comprises the following raw materials: silicon carbide particles or fine powder, high-temperature fine asphalt powder, Jilin fine clay powder, coke particles, industrial grade corundum particles or fine powder, wherein recovered aluminum and magnesium material particles or fine powder used for an electric furnace is added; and tar serves as a bonding agent. The preparation method comprises the following steps of: preparing the raw materials according to a proportion; after uniformly stirring particle materials in a stirring machine for 1 to 10 minutes, adding 20 to 30 percent of the tar; stirring for 5 to 10 minutes; adding fine powder materials; stirring for 5 to 15 minutes; adding the remaining tar and stirring for 25 to 40 minutes; and extruding by using a stemming extruder and packaging. The stemming has the following advantages: high operating performance, low stemming sintering shrinkage, rapid sintering property, high scour resistance and slag iron erosiveness. The invention provides a way for regenerating and utilizing the waste refractory material, and contributes to saving resources and protecting environment.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Fluorophosphate glass, precision press molding preform, optical element blank, optical element and methods of manufacturing the same

ActiveUS8637415B2Quality improvementImprove Optical UniformityOptical articlesOptical elementsNMR - Nuclear magnetic resonanceErosiveness

The present invention provides a fluorophosphate glass containing 30 to 50 cationic % of a phosphorus ingredient in terms of P5+, the glass having, in a nuclear magnetic resonance spectrum, a resonance spectrum which is generated near a reference frequency of 31P and has a shape of Gaussian function. The glass of the invention is reduced in volatility and erosiveness.

Owner:HOYA CORP

Two-step method for preparing high-temperature red ceramic color with nuclear shell structure

The invention discloses a two-step method for preparing high-temperature red ceramic color with a nuclear shell structure. A SiO2 coating layer is coated on a Ce1-xPrxO2 chromogenic unit. The method comprises the following steps: preparing Ce1-xPrxO2 color powder by the conventional method; evenly mixing and stirring TritonX-100, C5H12O, C6H12, and H2O based on the mass ratio: (2-3): (1-2):(5-7):(2-3) to obtain a microemulsion system; scattering Ce1-xPrxO2 color powder to the microemulsion system, adding TEOS ethyl orthosilicate, further adding NH3.H2O when stirring, controlling the pH value to be 8 to 10, and generating silica sol solution after the TEOS is completely hydrolyzed; and extracting and filtering silica sol solution, cleaning the filter residue, drying, calcining, grinding, and obtaining Ce1-x PrxO2 or SiO2 high-temperature red ceramic color with the nuclear shell structure. The two-step method for preparing high-temperature red ceramic color with the nuclear shell structure provided by the invention can improve the high-temperature anti-glass melt erosiveness of the red ceramic color.

Owner:SHAANXI UNIV OF SCI & TECH

Composite slag weir and preparation method thereof

The invention discloses a composite slag weir and a preparation method thereof; and a body of the slag weir is integrally and tightly connected by an upper slag baffling part and a lower molten steel baffling part. The upper slag baffling part is manufactured by aluminum and magnesium materials; and the lower molten steel baffling part is manufactured by magnesium materials. Based on the situations that the lower part of the body of the slag weir is mainly contacted with the molten steel with more assuasive erosiveness; while the upper part of the body of the slag weir is mainly contacted with the slag with stronger erosiveness, the magnesium materials with common corrosion resistance as well as the aluminum and magnesium materials with stronger corrosion resistance are respectively adopted as the manufacturing materials for the upper slag baffling part and the lower molten steel baffling part of the slag weir, and the upper part and the lower part of the body of the slag weir of different materials are organically connected into a whole through a preparation technique. The composite slag weir reasonably uses durable goods resources, which not only guarantees the slag weir not to generate pollution to the molten steel, but also greatly prolongs the service life of the slag weir, simultaneously, the service life of the upper part and the lower part of the slag weir is led to bebasically synchronous, thus most economically using the slag weir and effectively reducing the production cost.

Owner:浙江红鹰集团股份有限公司

Microporous graphite silicon carbide brick

The invention relates to a microporous graphite silicon carbide brick and belongs to the field of refractory material for iron making blast furnace. The microporous graphite silicon carbide brick is prepared from main raw materials of SiC, Si, Ti and pyrolytic graphite and a binder of modified phenol-formaldehyde resin through steps of pugging, die vibration forming, low temperature baking, immersion and high temperature sintering. The brick has excellent thermal conductivity, alkali resistance, inoxidizability, slag erosiveness, small average aperture and apertures with an aperture larger than 1 mum having a volume no more than 4%, and suits for bosh, belly, middle and lower part of a large blast furnace. Besides, the brick has a long service life and substantial economic benefits.

Owner:鲁山天诺炉衬材料有限公司

An in-situ sediment columnar layered layered erosion resistance measurement device and method

ActiveCN109253968BHierarchical measurement implementationEasy to carryWeather/light/corrosion resistanceMeasurement deviceSoil science

The invention provides an in-situ sediment columnar sample stratified erosion resistance measuring device, and a method thereof. Effective measurement of sediment columnar sample erosion resistance isachieved by reserving a columnar sample placement groove in a small annular water tank in combination with commercial sensors such as turbidity (OBS), three-dimensional flow rate (ADV) and acoustic wave ranging (Altimeter); and further, by designing a lifting tray and a control rotation valve at the bottom of the placement groove, the elevation of the columnar sample can be freely adjusted, thereby realizing the stratified measurement of the columnar sample erosion resistance. At present, the erosion resistance of the columnar sample sediment is mainly measured by a cohesive force instrument(CSM) in the industry, but the cohesive force instrument simulates the undercut stress based on an erupting gas, the cohesive force instrument inevitably has a certain "jet flow" effect, so that the test result is controversial, and the test cost is relatively high. The invention will break through the technical limitation and provide a more realistic, effective, fast and economical measuring device and data analysis method for the stratified measurement of in-situ sediment columnar sample erosion resistance.

Owner:OCEAN UNIV OF CHINA

Acid-resisting complex phase ceramic coating and preparation method thereof

The invention belongs to an acid-resisting complex phase ceramic coating and a preparation method thereof. Firstly, 2-5 wt% of adhesive and 2-4 wt% of dispersing agent are prepared into concentrated solution, and then 25-30 wt% of water is added to prepare premixing solution; alumina, silica and silicon carbide micro powder are mixed at ratio and are added into premixing solution and the mixture is carried out ball milling for 2 hours; 0.5-1 wt% of catalyst is added for ball milling for 0.5 hour; after slurry viscosity is suitable, the slurry is brushed or sprayed by a spray gun on the surface of materials, such as cement, concrete and the like to form an even coating; and after heat treatment, Al2O3 / SO2 / SiC series anti-reversion complex phase ceramic coating is obtained. The complex phase ceramic coating not only can be applied on the surface of cement, concrete and the like, but also can be used for the anti-corrosion of metal surface. The coating surface is even and compact, has nocracks and has favorable abrasion performance and favorable acid resistant erosiveness.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Sliding plate brick for casting high manganese steel

The invention discloses a sliding plate brick for casting high manganese steel. The brick comprises tabular corundum, metal aluminium powder and carbon black; the body of the sliding plate brick further comprises a TiB2 and AlMg alloy composite antioxidant and electric melting spinel, wherein the weight ratio of TiB2 to AlMg in the TiB2 and AlMg alloy composite antioxidant is 1:6; the composite antioxidant accounts for 7-8 parts by weight; the electric melting spinel is added through three modes such as particles, fine powder and micro powder, wherein the particles with the specification of no more than 1 millimeter account for 39-42 parts by weight, the fine powder with the specification of being less than or equal to 28 micrometers accounts for 12-15 parts by weight, and the micro powder with the specification of being less than or equal to 10 micrometers accounts for 4-6 parts by weight; and the tabular corundum accounts for 23-26 parts by weight, the metal aluminium powder accounts for 5-8 parts by weight, and the carbon black accounts for 1-2 parts by weight. Compared with the prior art, the brick has the obvious advantages of good heat impact resistance and slag erosiveness and long service life.

Owner:河南省伯马股份有限公司

Electrofusion-recombined corundum bricks

InactiveCN109534791AExcellent high temperature mechanical propertiesHigh strengthChemical compositionBrick

The invention provides electrofusion-recombined corundum bricks. According to the electrofusion-recombined corundum bricks, AZS fused blocks or electro-fused AZS crushed bricks serve as a raw material, and a small amount of kaolin or alumina is added as a binder. When the temperature of the raw material is heated to a certain temperature, electro-fused AZS aggregates seep a glass phase, the glassphase forms mullite with the binder, brick bodies can be burnt, and the burnt temperature is 1,600 DEG C to 1,700 DEG C. Chemical composition fluctuation ranges of the recombined product provided by the invention are as follows: 50%w / w to 60%w / w of Al2O3, 20%w / w to 30%w / w of ZrO2 and 14%w / w to 20%w / w of SiO2. Compared with electrofusion products, the electrofusion-recombined corundum bricks have the advantages that the seepage of the glass phase is alleviated greatly, the seepage temperature is increased, high-temperature mechanical properties are relatively high, and particularly, the creep resistance and glass erosiveness resistance are good. According to the electrofusion-recombined corundum bricks, a good technical effect is achieved by innovative technological improvement, the cost isrelatively low, the realization is easy, and thus, the electrofusion-recombined corundum bricks have a broad application prospect.

Owner:淄博八陡耐火材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com