Metallic corrugated pipe guard cable

A metal corrugated pipe and corrugated pipe technology, applied in the field of protective cables, can solve the problems of reducing the anti-corrosion ability of the cable body, limiting the service life of the cable, hidden dangers of bridge accidents, etc., achieving convenient coiling transportation, reducing maintenance costs, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

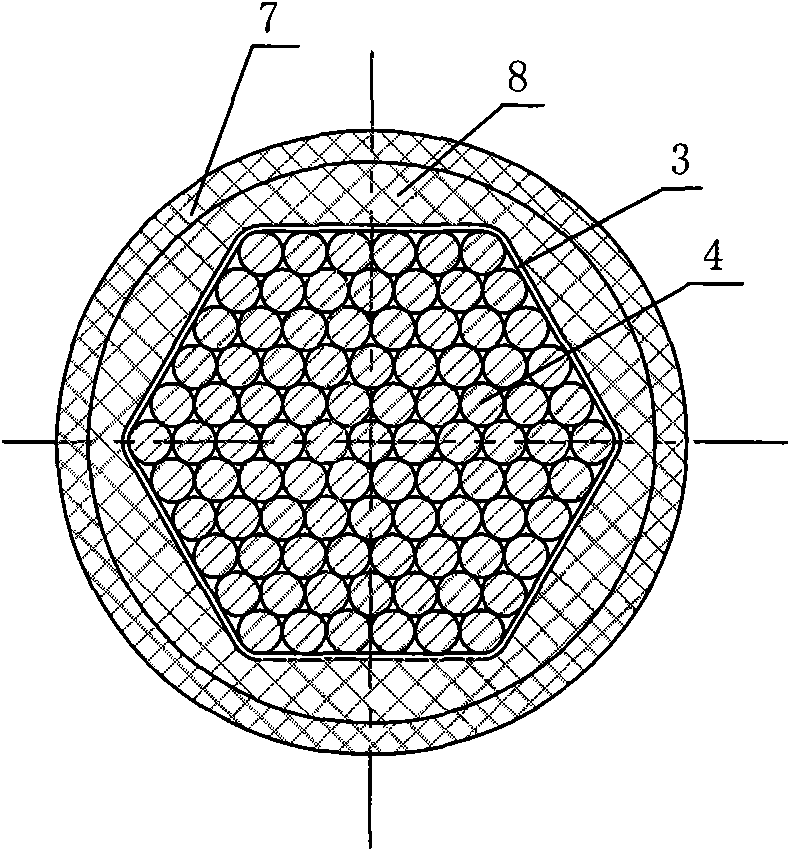

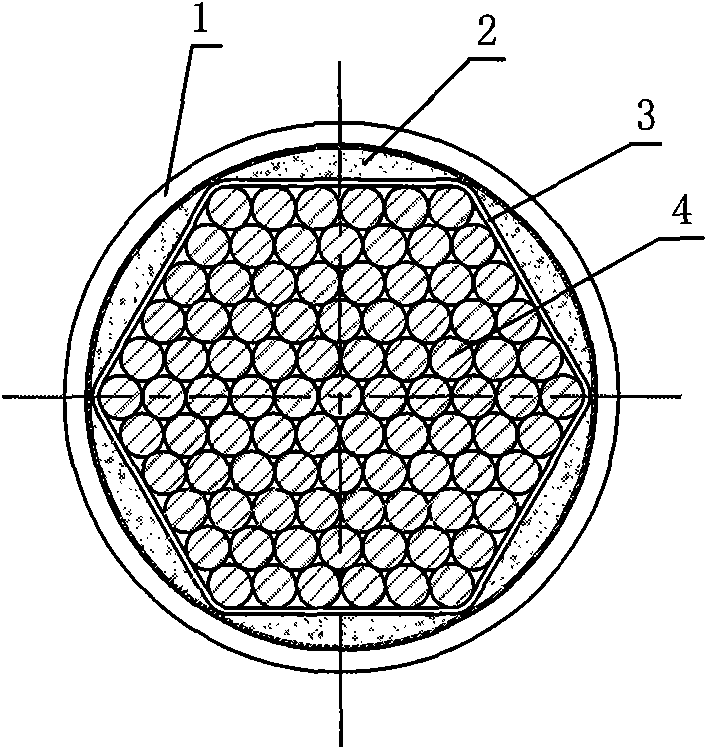

[0025] A bamboo-shaped metal bellows protection cable, including a protective sleeve-metal bellows 1 and a steel wire cable body 4 that is located in the metal bellows 1 and bundled into a bundle with a wrapping belt 3, the steel wire cable body 4 and the metal corrugated Tube 1 is filled with filler 2 (see image 3 );

[0026] The metal bellows 1 is a metal bellows 1 made of stainless steel with a bamboo-shaped shape. 1 (see Figure 5 ); The filler 2 filled between the metal bellows and the cable body is polyethylene.

Embodiment 2

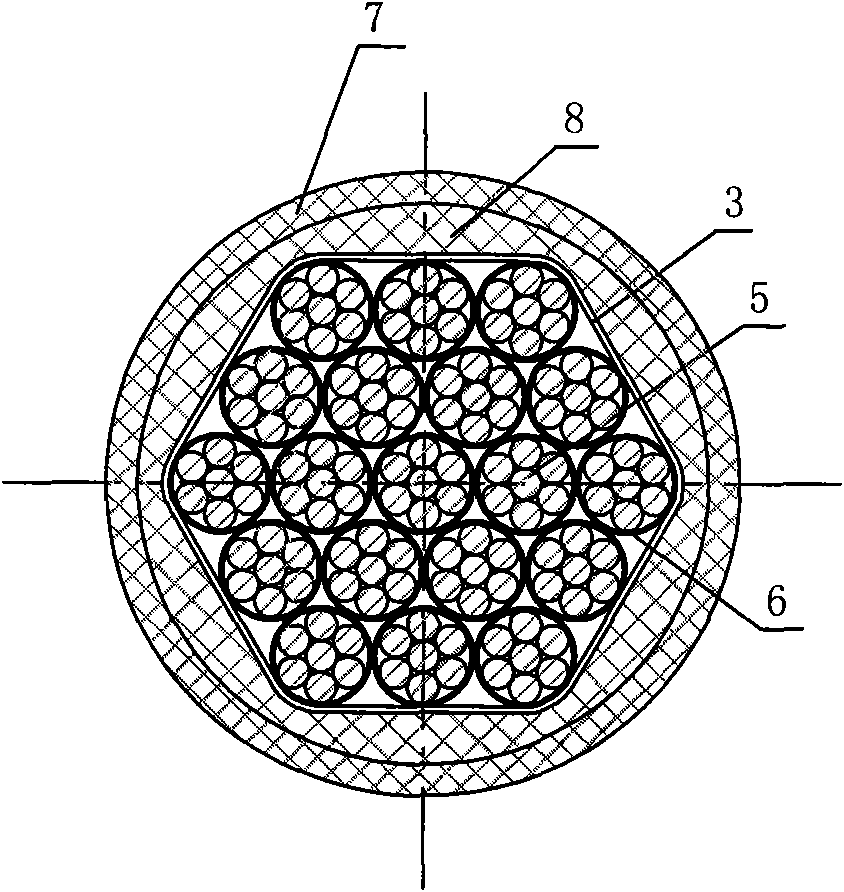

[0028] A spiral metal bellows protection cable, comprising a protective sheath-a metal bellows 1 and a steel strand body 5 that is located in the metal bellows 1 and bundled into a bundle with a wrapping tape 3, the steel strand body 5 and the metal bellows 1 with padding between 2 (see Figure 4 );

[0029] The metal bellows 1 is a metal bellows 1 made of stainless steel with a spiral shape 2 (see Image 6 ); filled in metal bellows 1 2 The filler 2 between the steel strand wire body 5 is polyethylene.

[0030] As a transformation of the various embodiments of the present invention, the shapes of the metal bellows are respectively bamboo-shaped, spiral or straight-spin (see Figure 5 ~ Figure 7 ), the metal bellows are made of stainless steel, aluminum or aluminum alloy metal materials or other metal materials with good corrosion resistance, marine and corrosive industrial atmosphere erosion performance; the metal bellows It can also be a corrugated pipe made of a metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com