Patents

Literature

862 results about "Metal bellows" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal bellows are elastic vessels that can be compressed when pressure is applied to the outside of the vessel, or extended under vacuum. When the pressure or vacuum is released, the bellows will return to its original shape, provided the material has not been stressed past its yield strength.

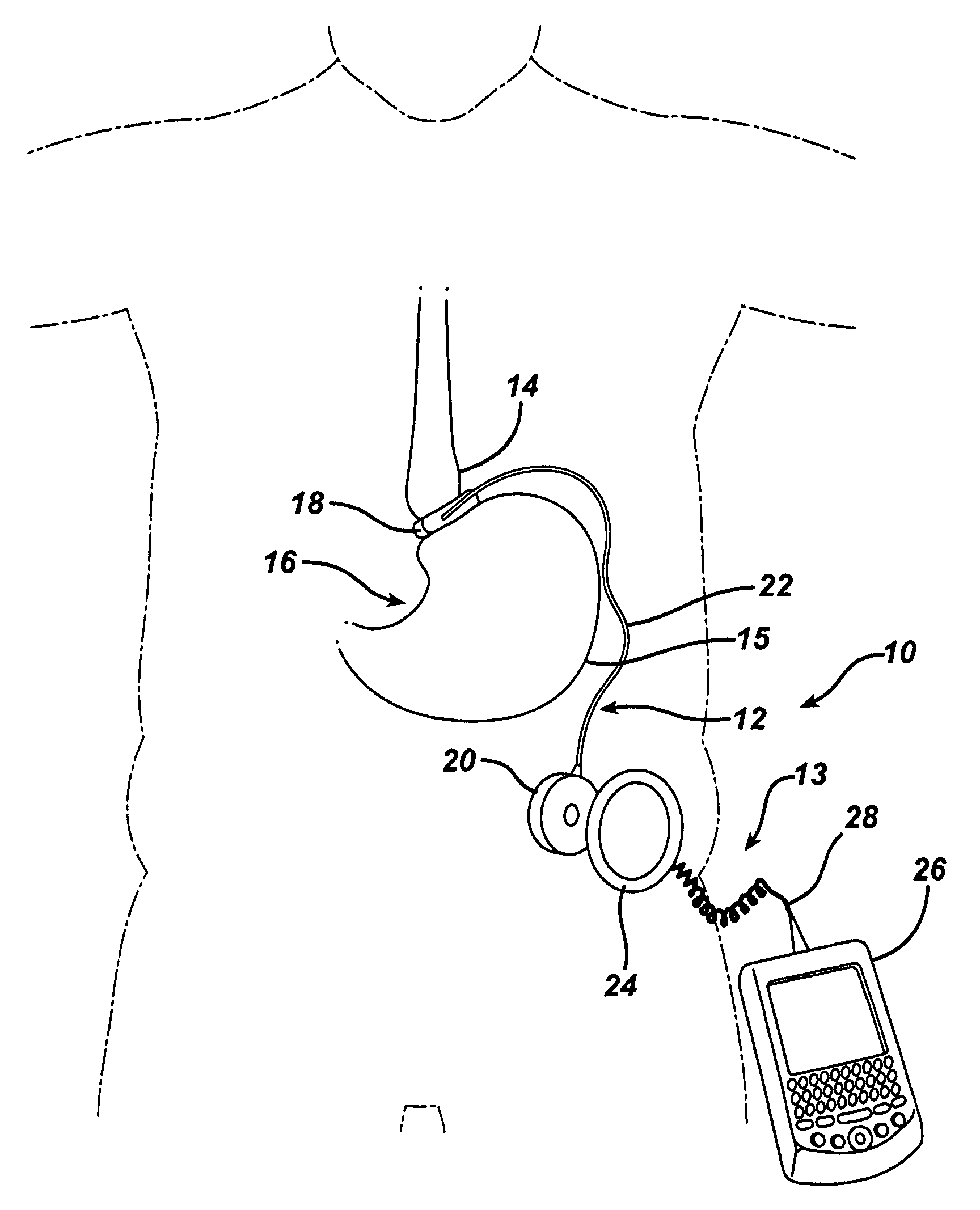

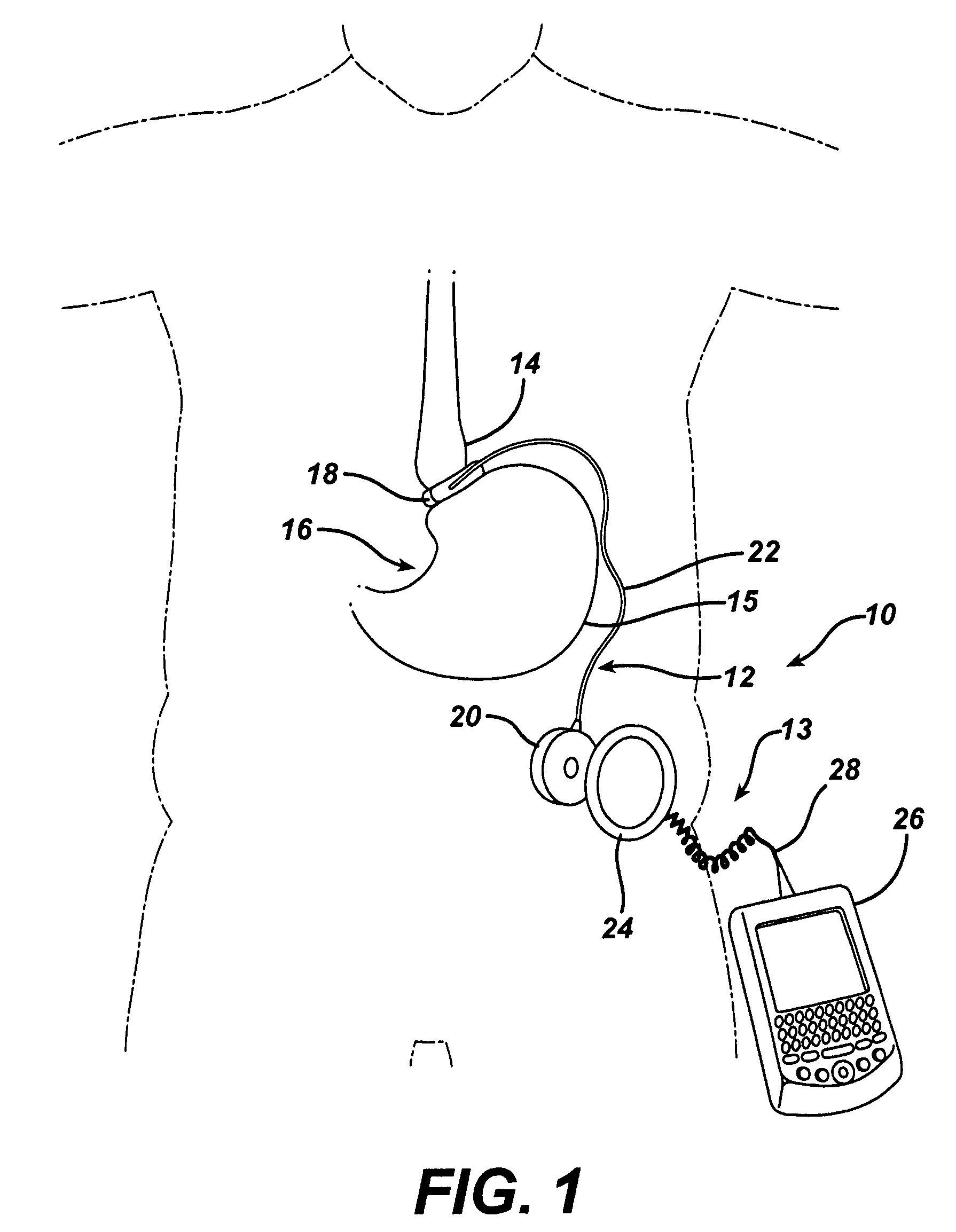

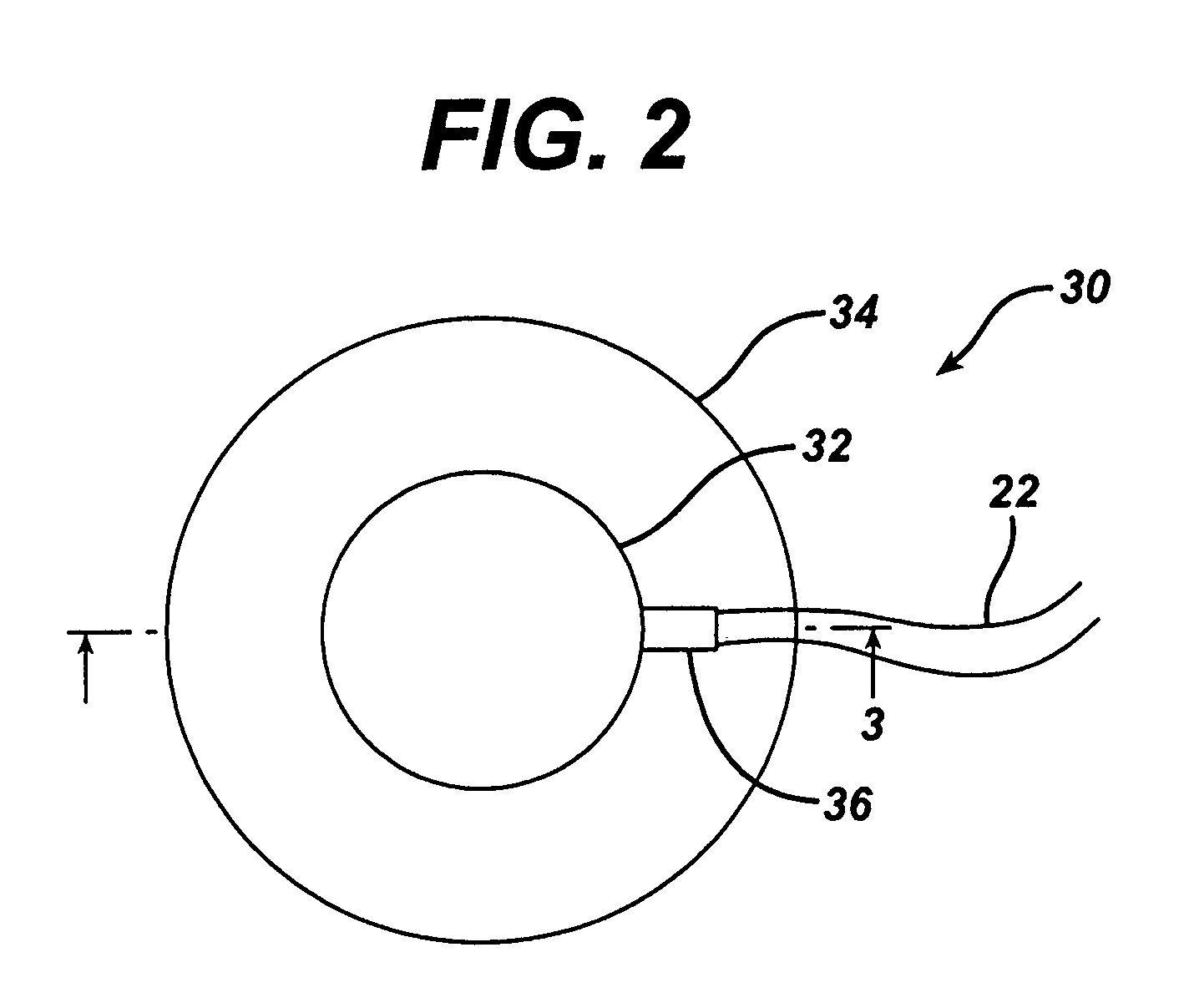

Piezo electrically driven bellows infuser for hydraulically controlling an adjustable gastric band

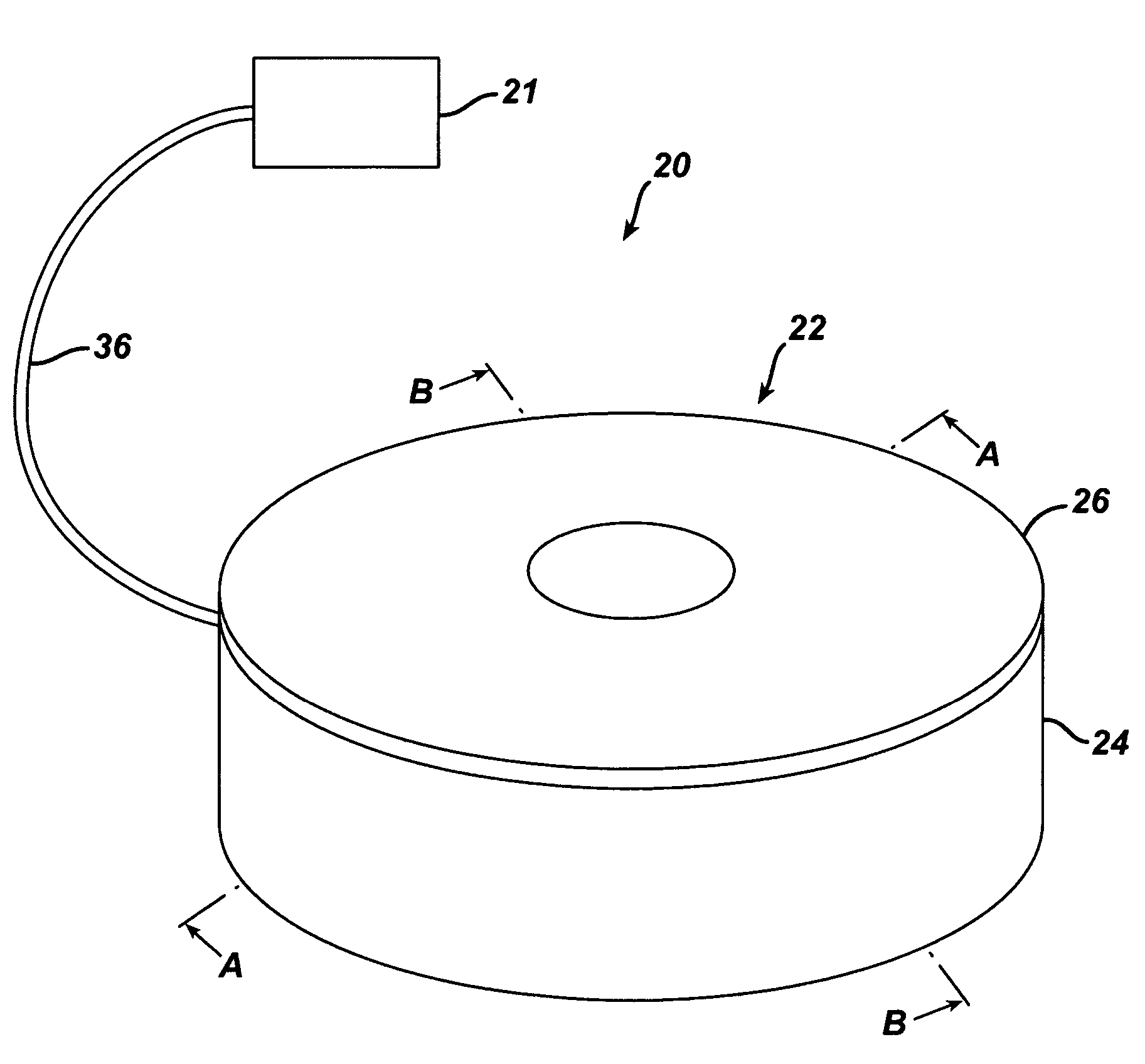

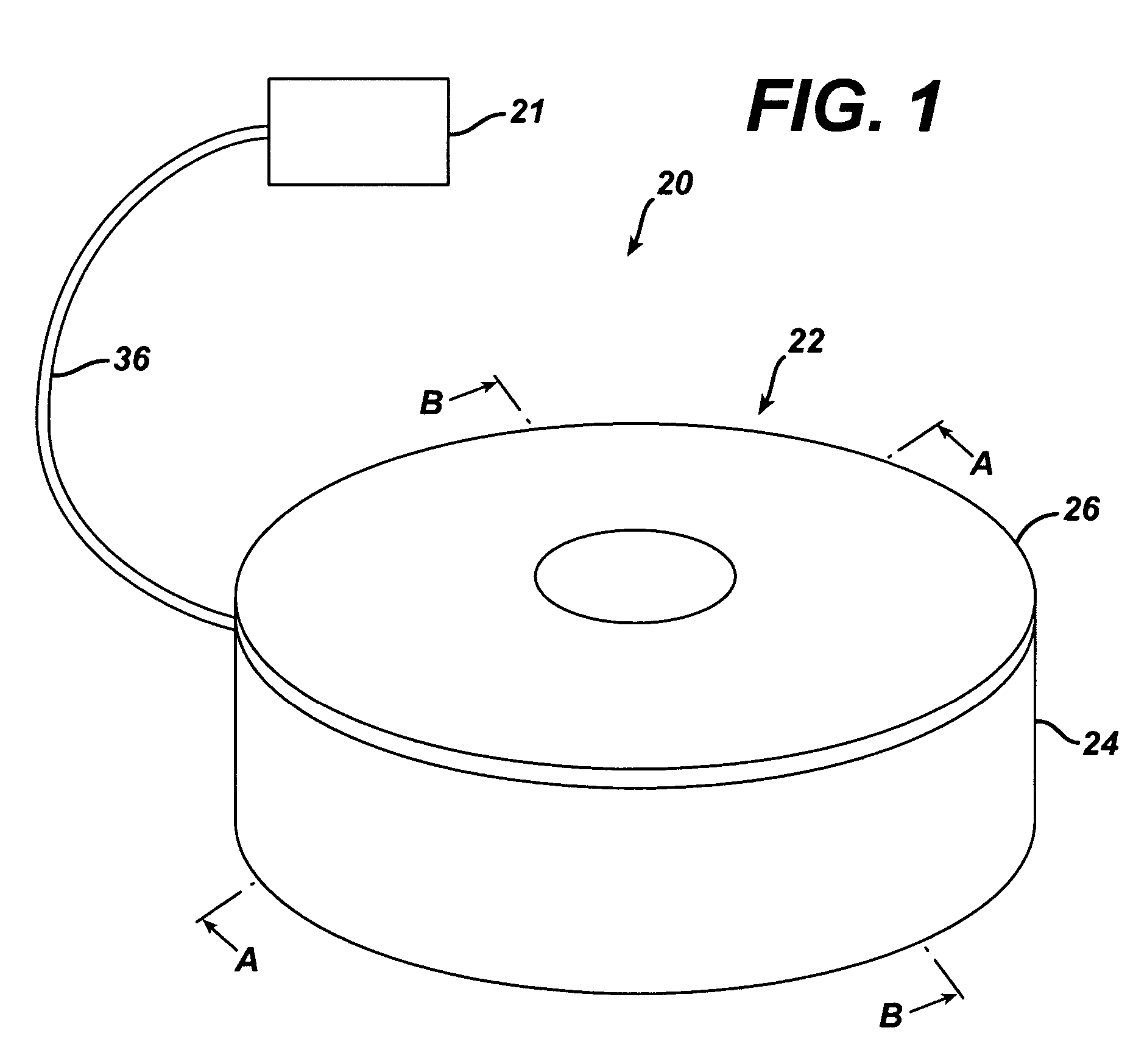

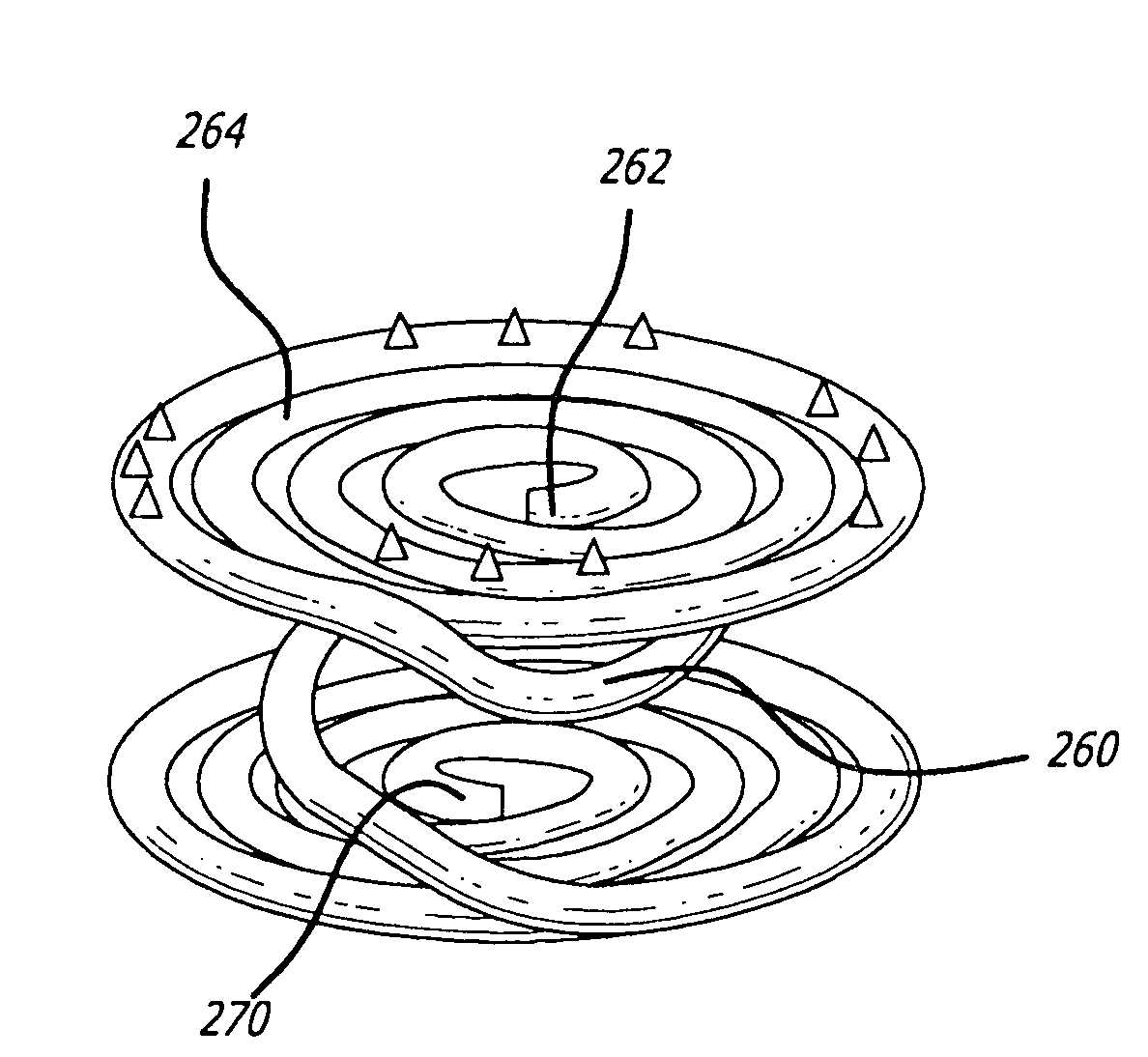

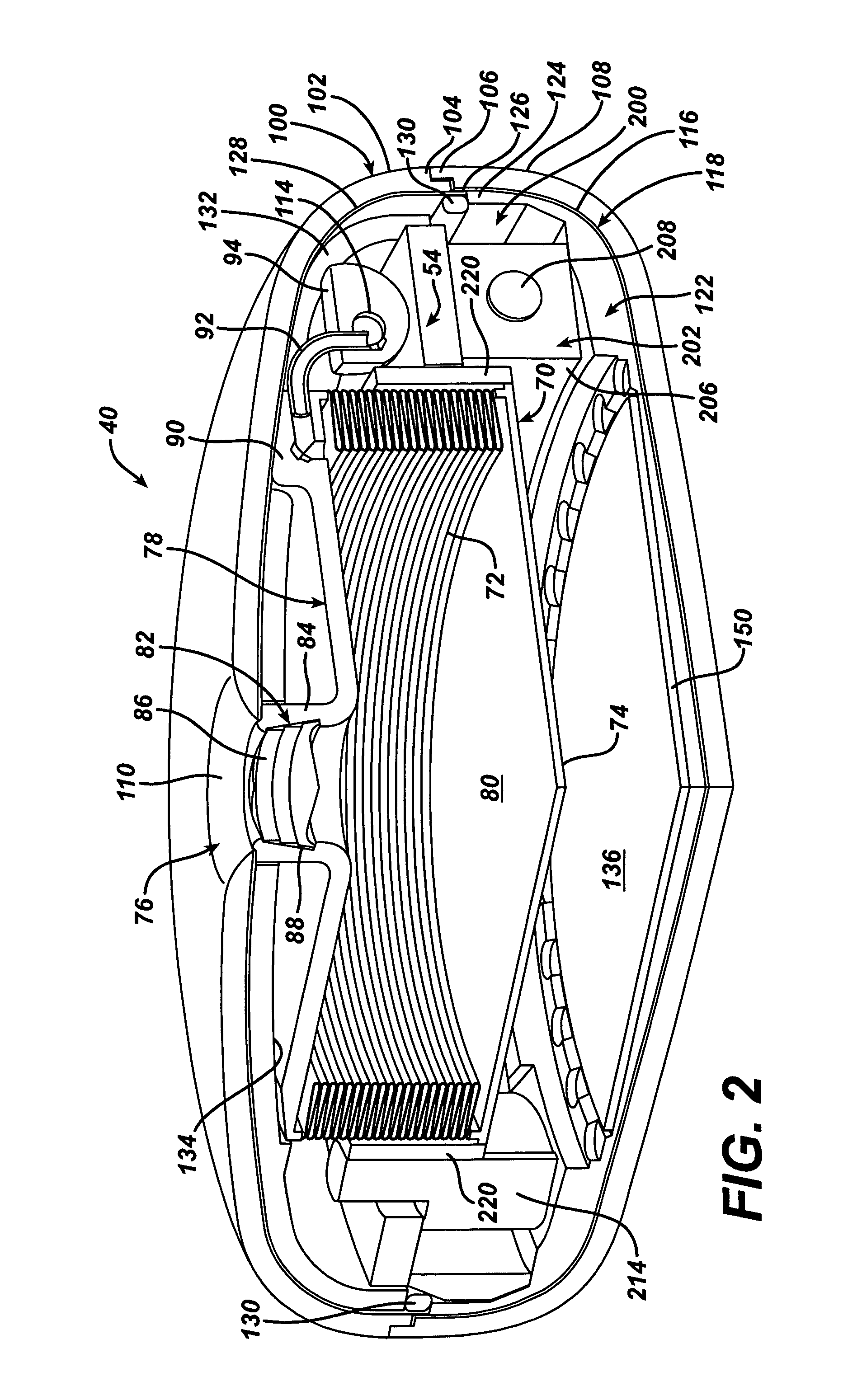

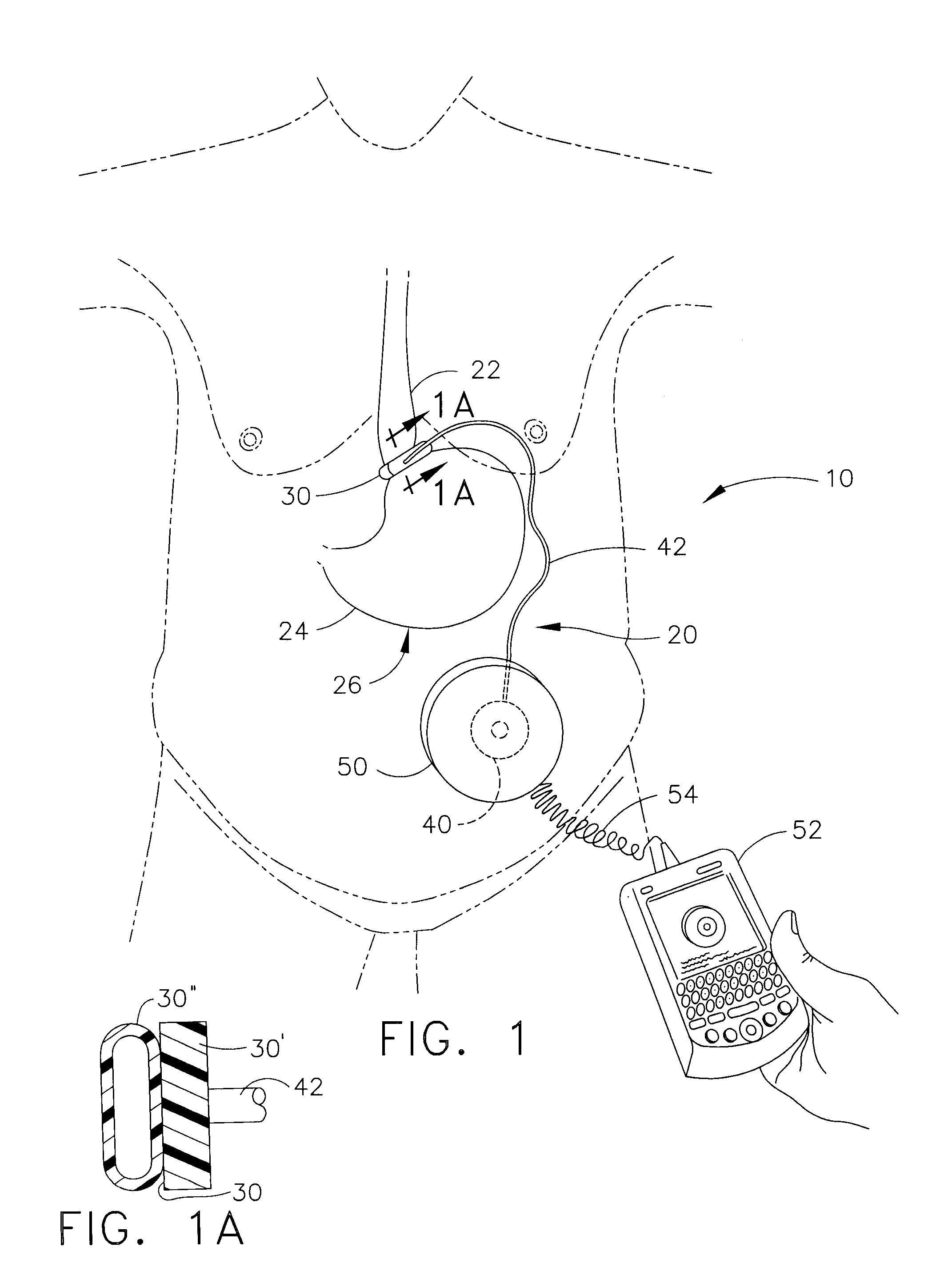

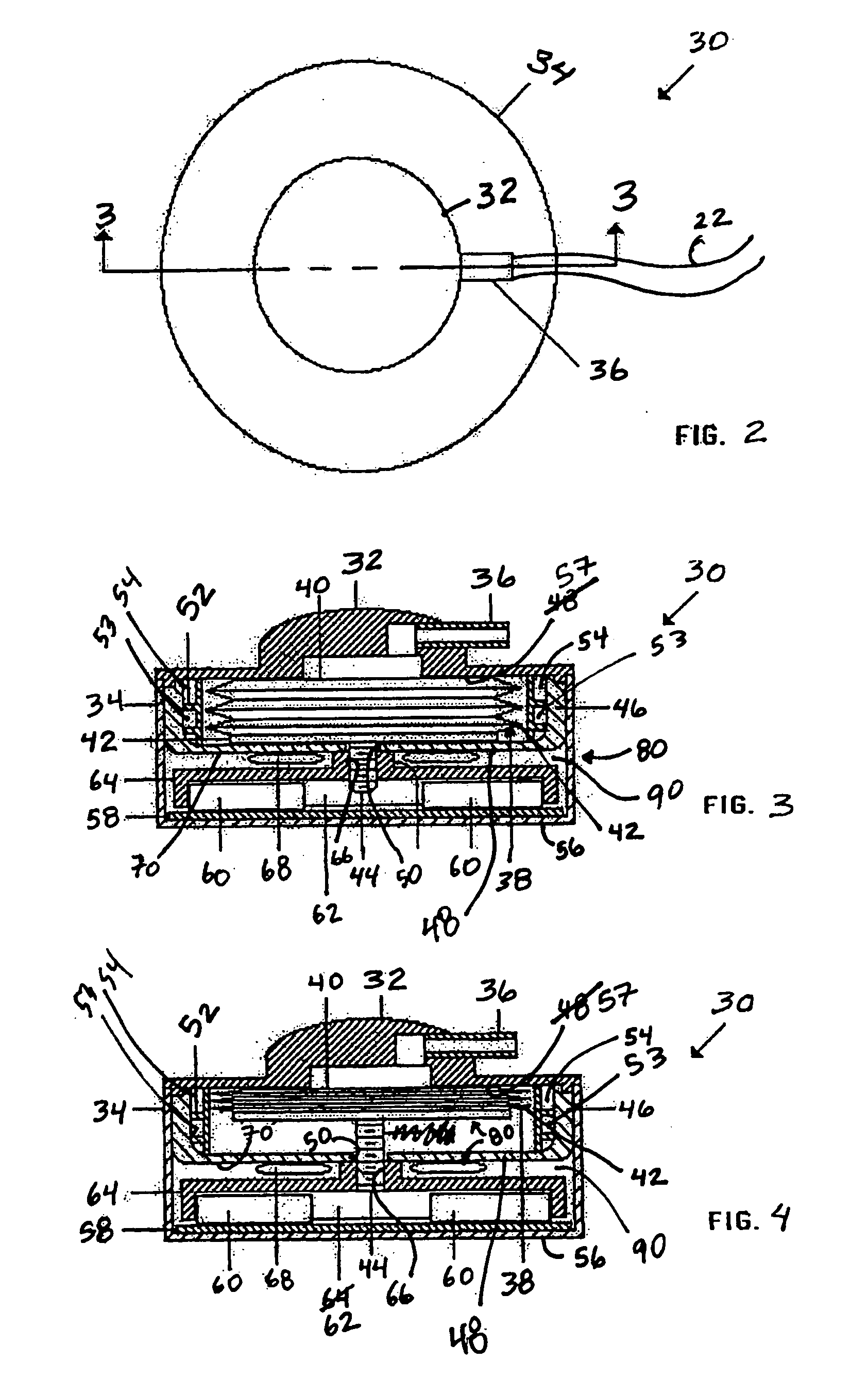

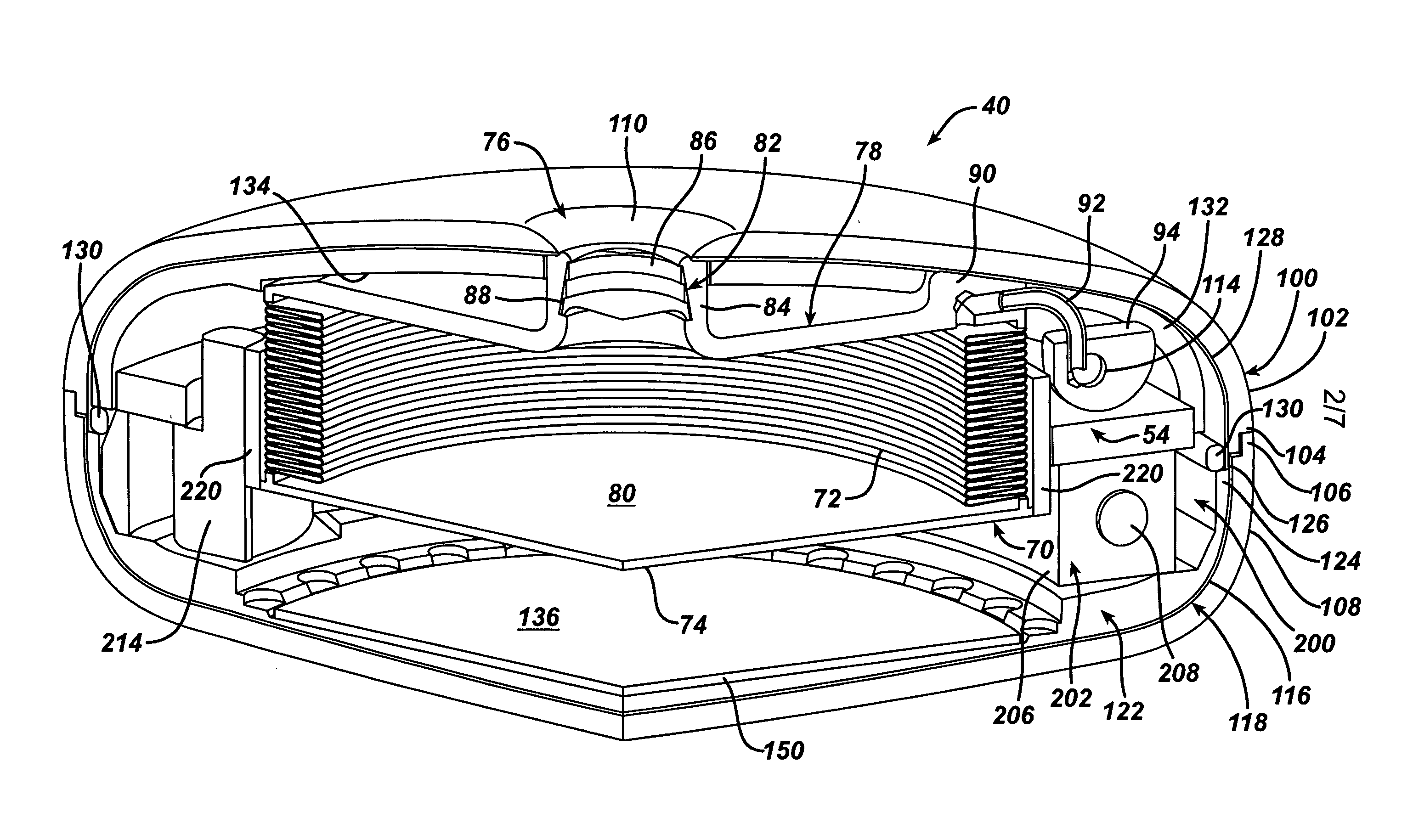

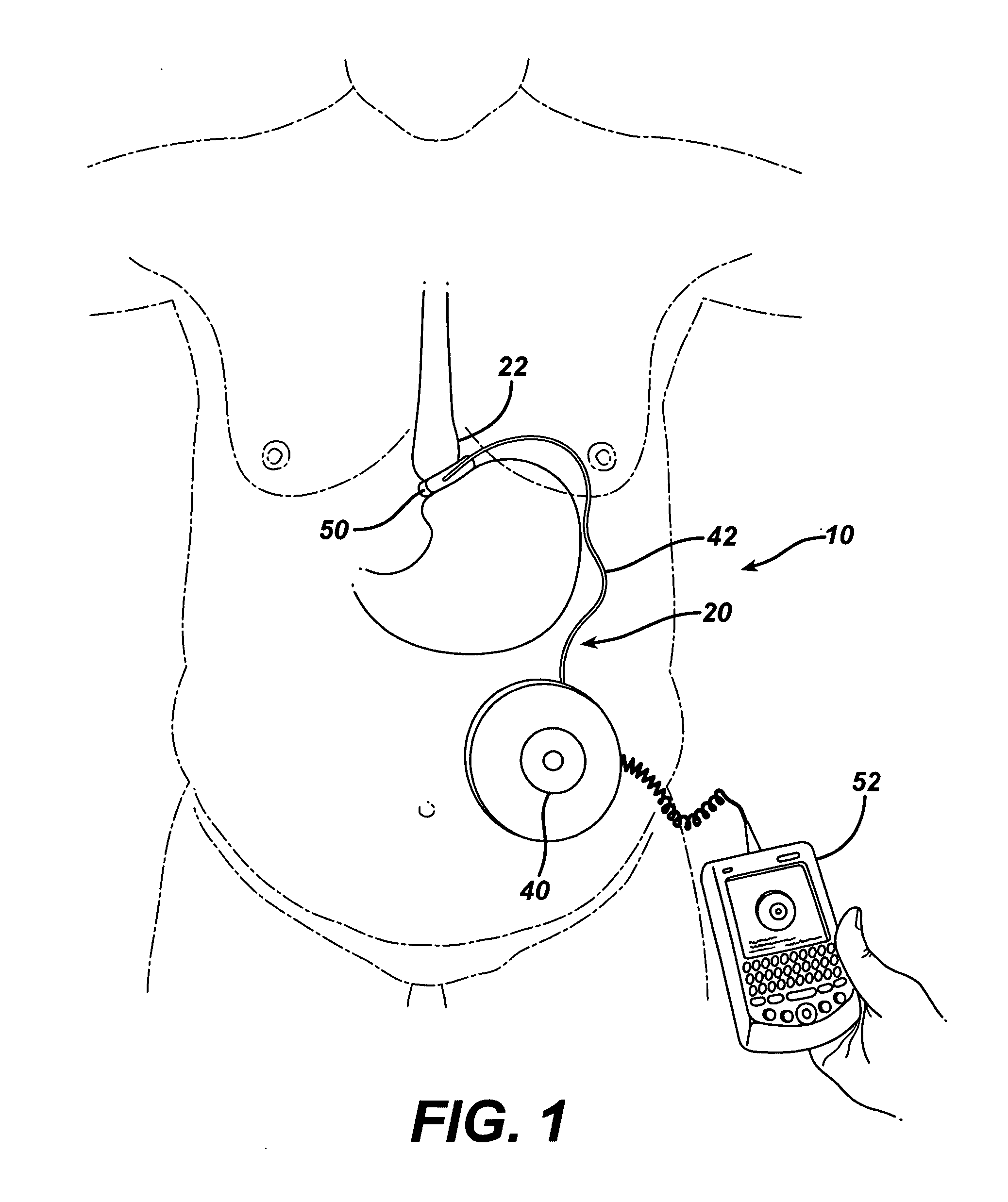

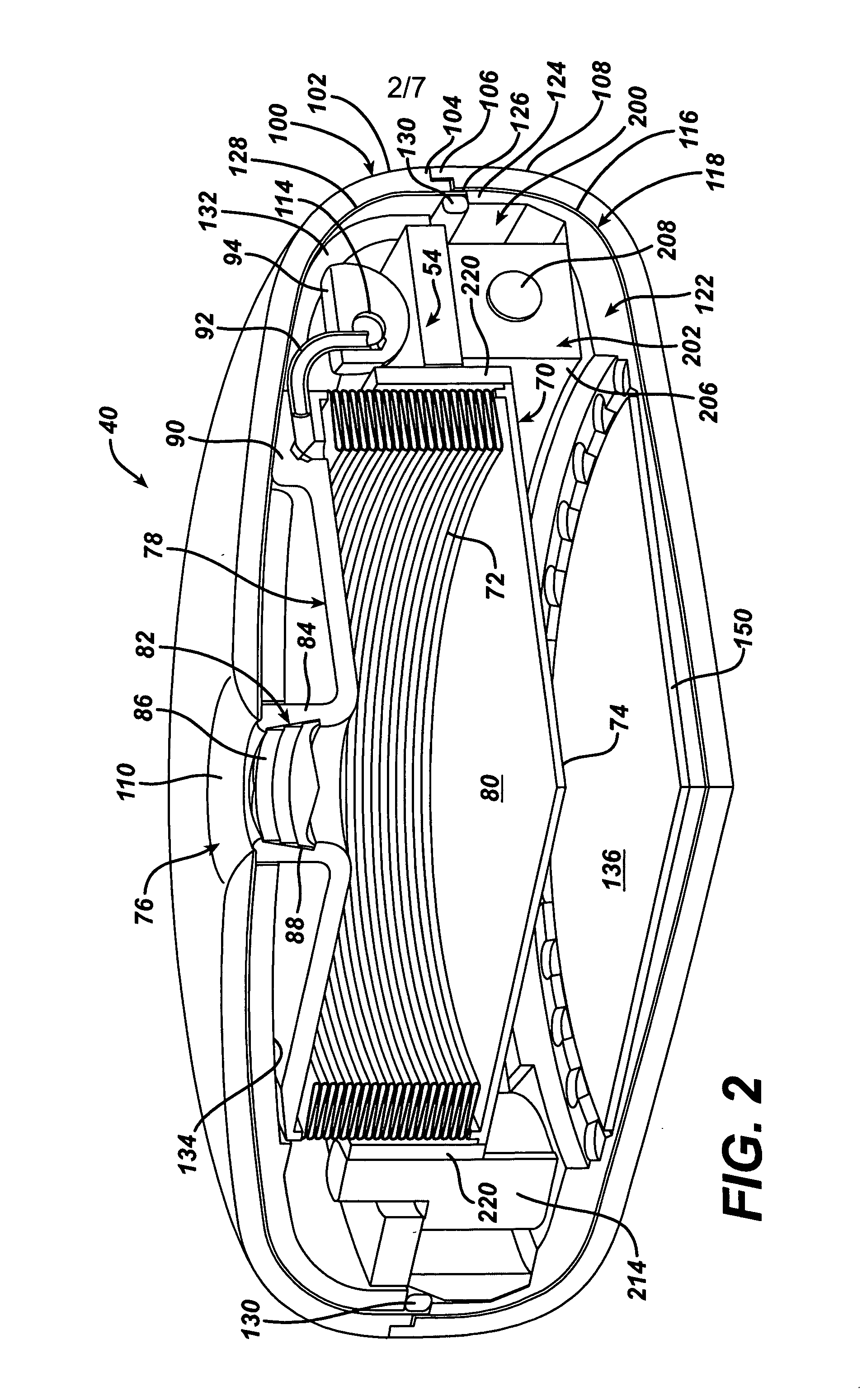

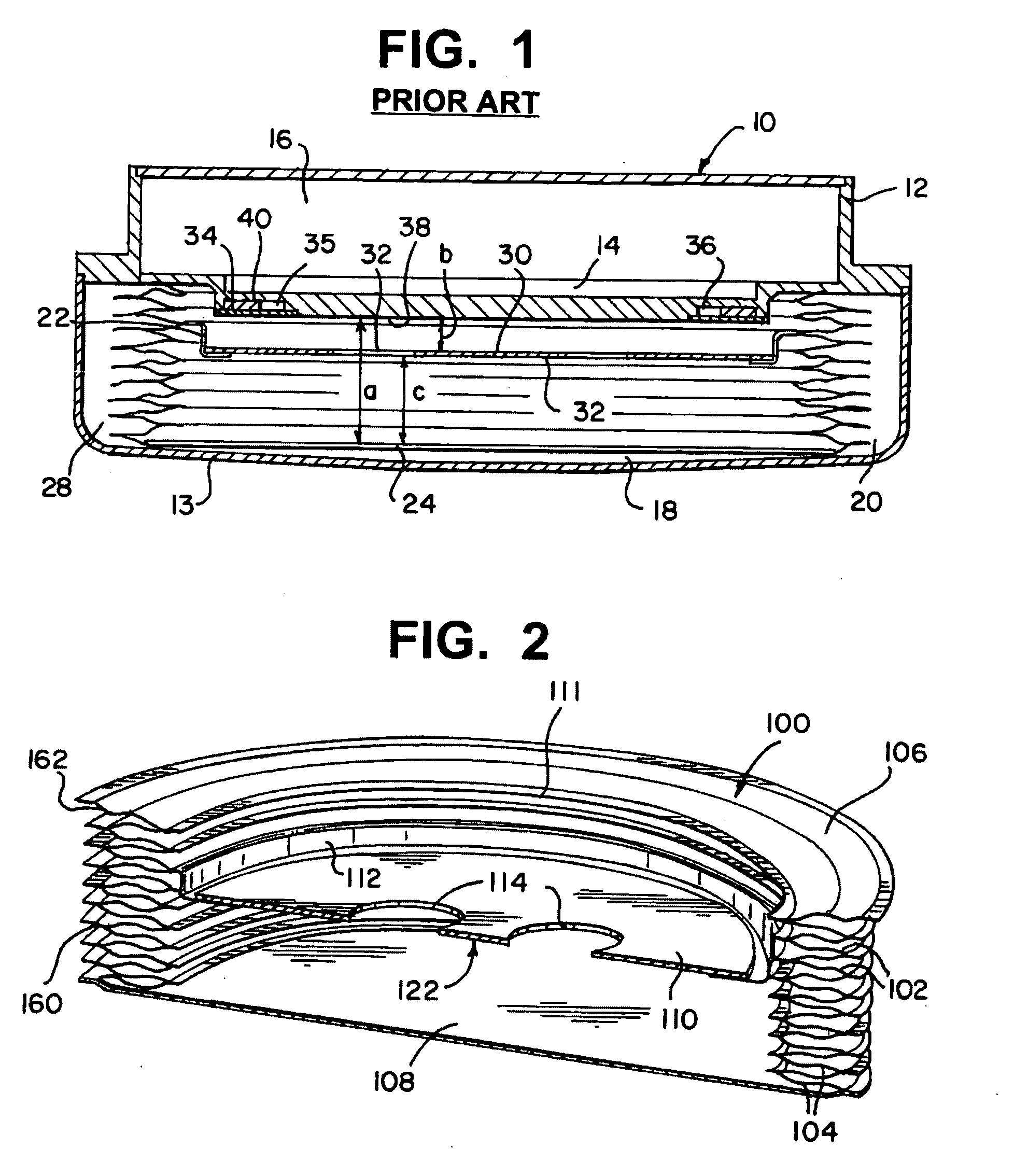

A remotely controlled gastric band system that is practically immune to external magnetic fields, such as from a Magnetic Resonance Imaging (MRI) machine, incorporates a bi-directional pump and fluid reservoir to adjust fluid volume in a gastric band. A piezoelectrically driven (e.g., rotary actuator, linear actuator) selectively compresses and expands a metal bellows hermetically sealed within a biocompatible and nonferromagnetic case such as titanium.

Owner:ETHICON ENDO SURGERY INC

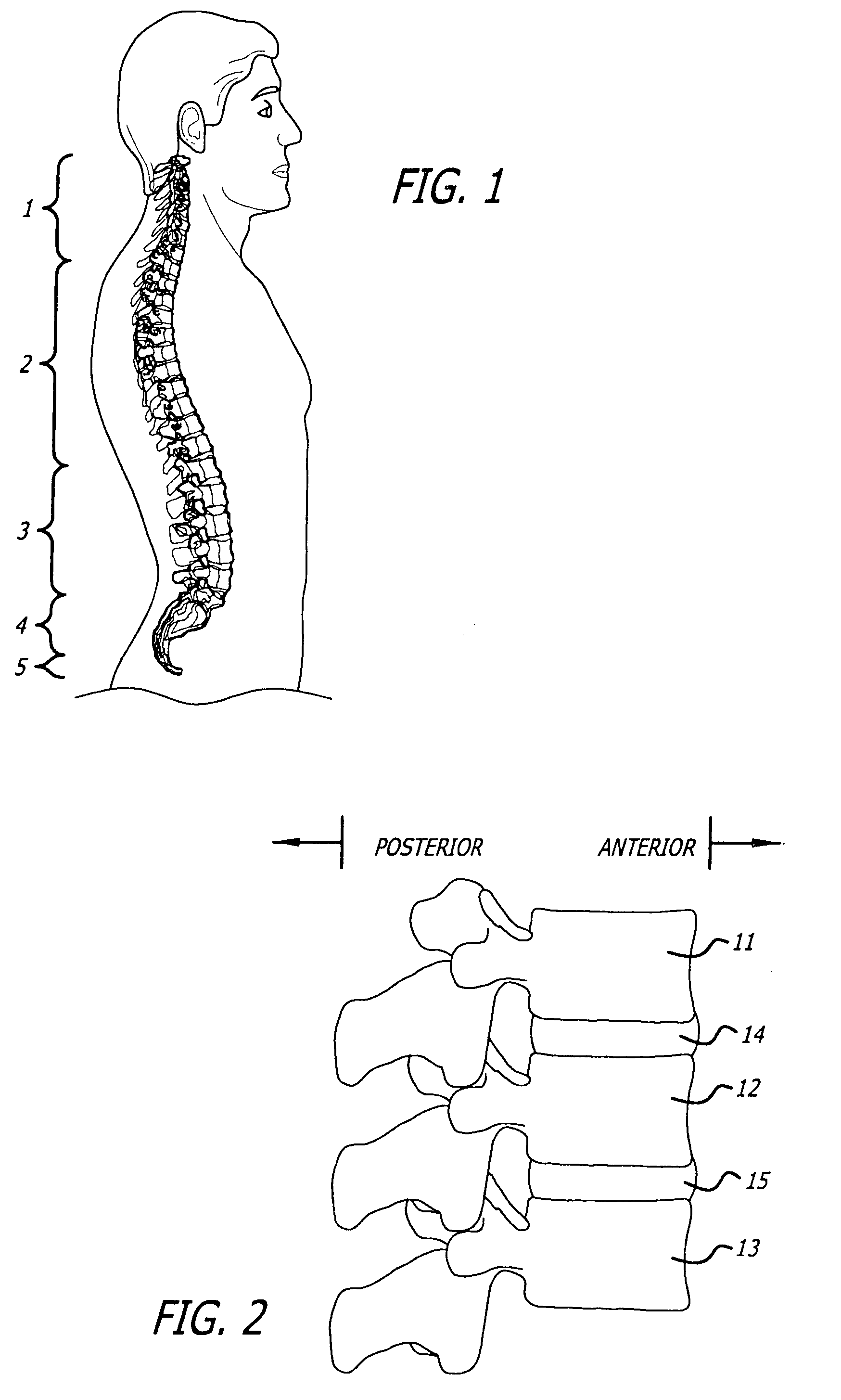

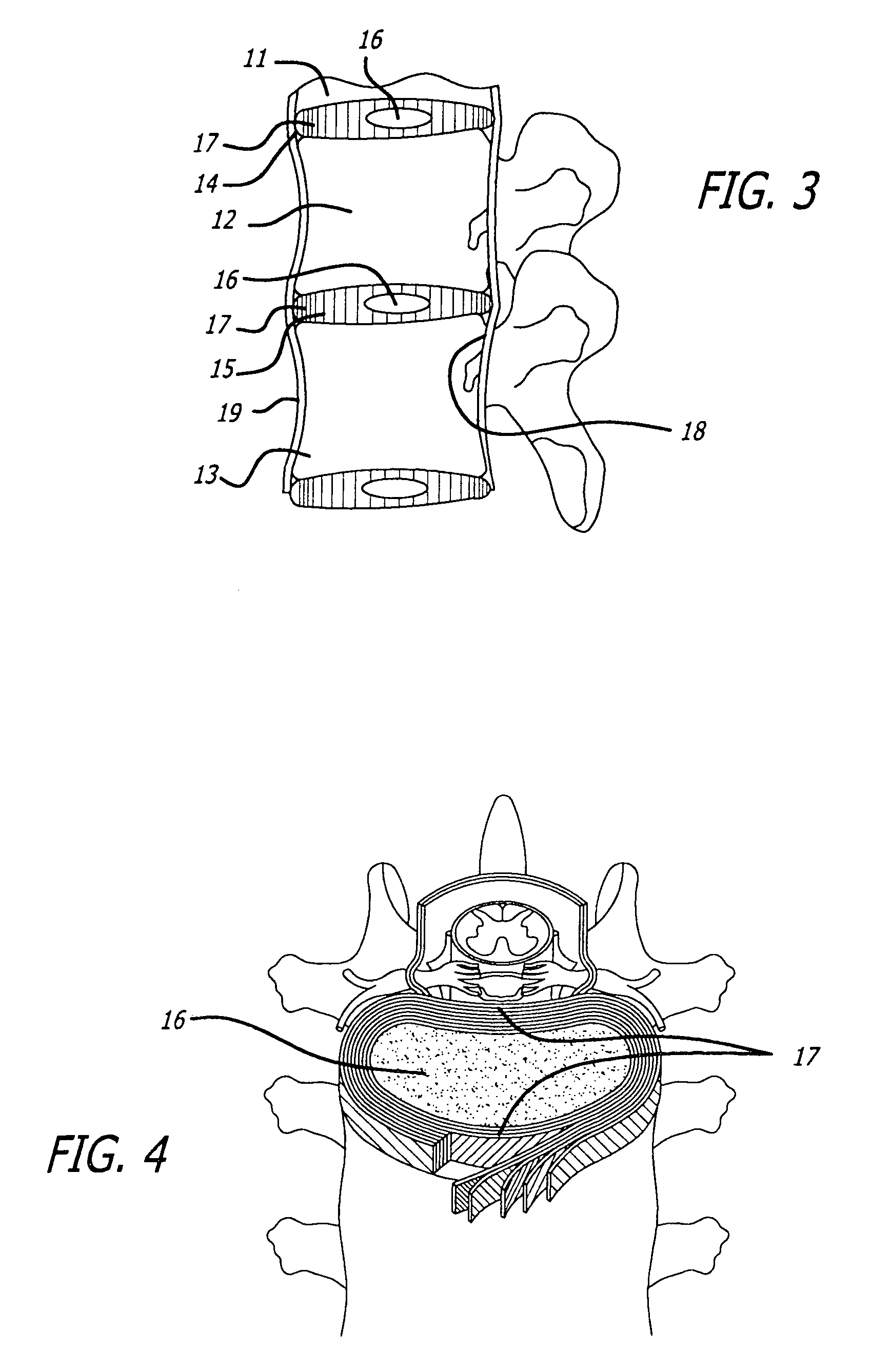

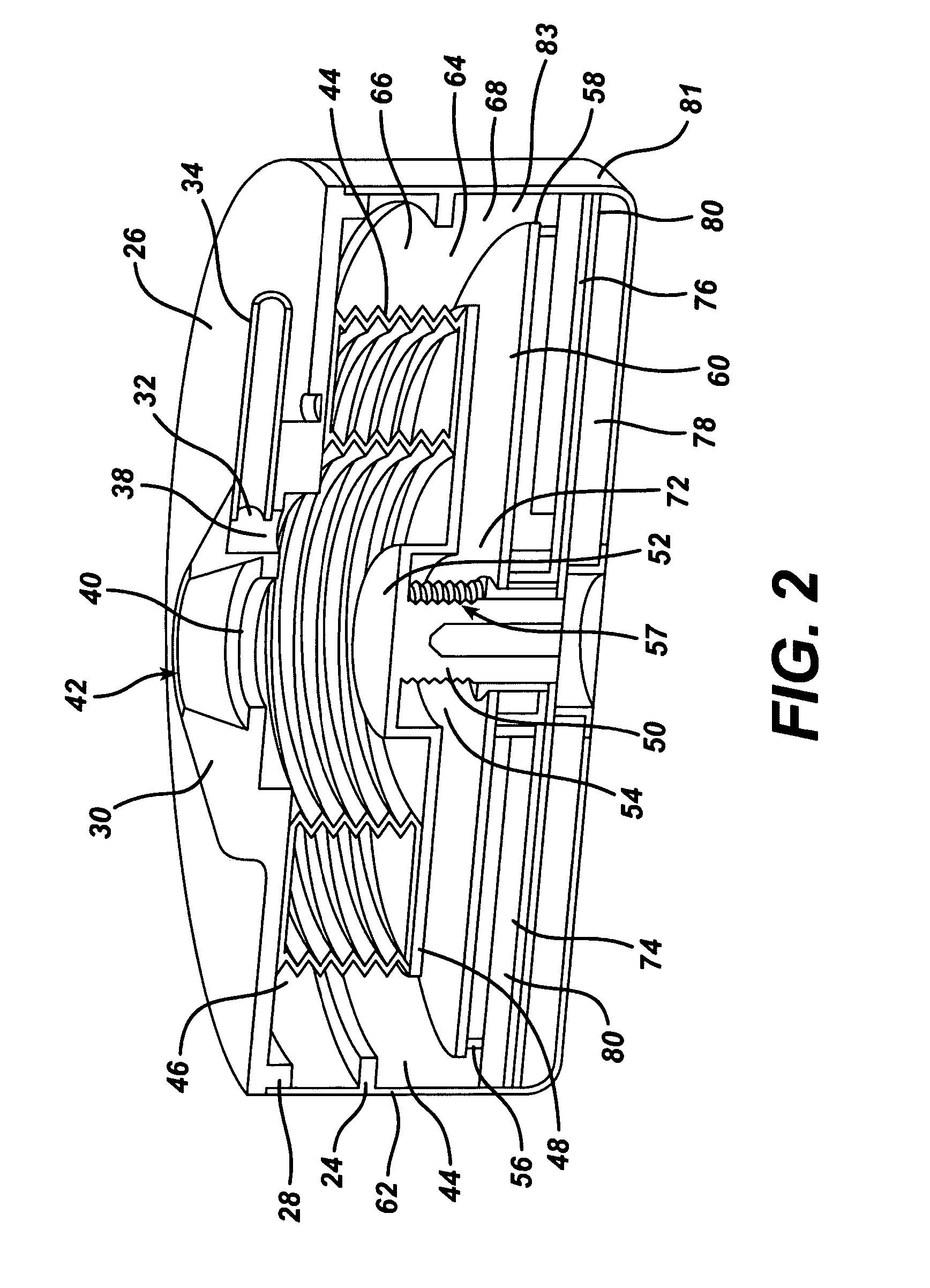

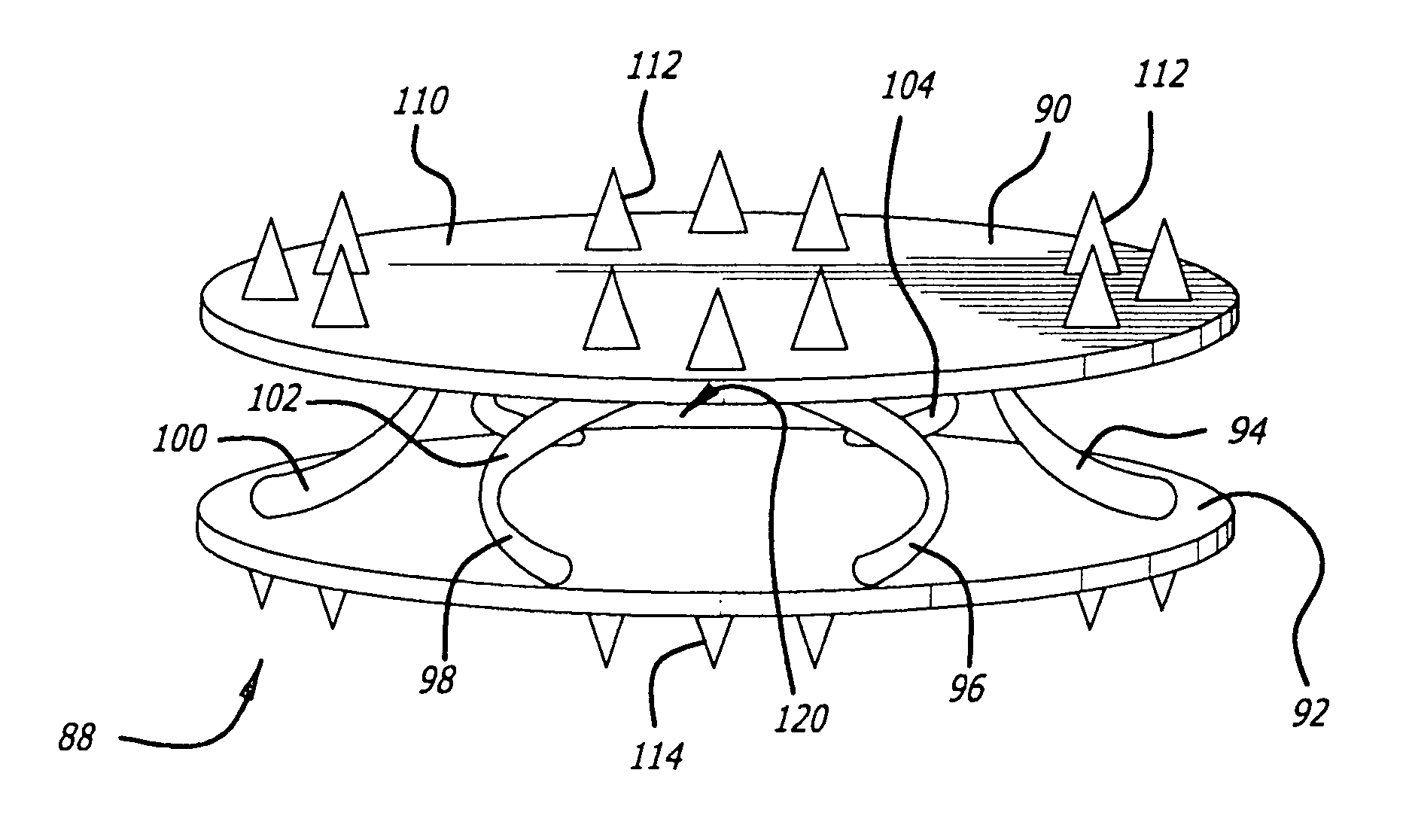

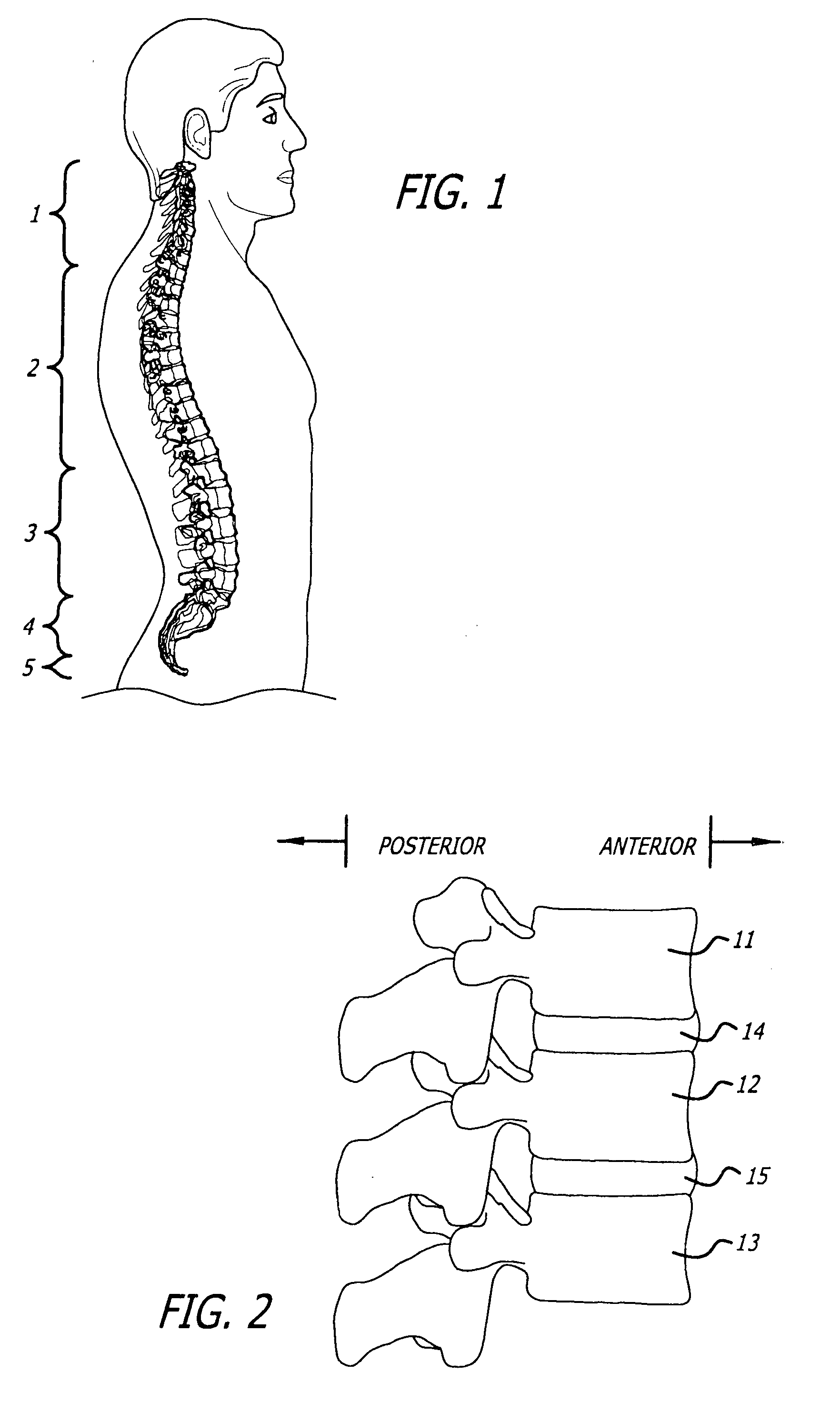

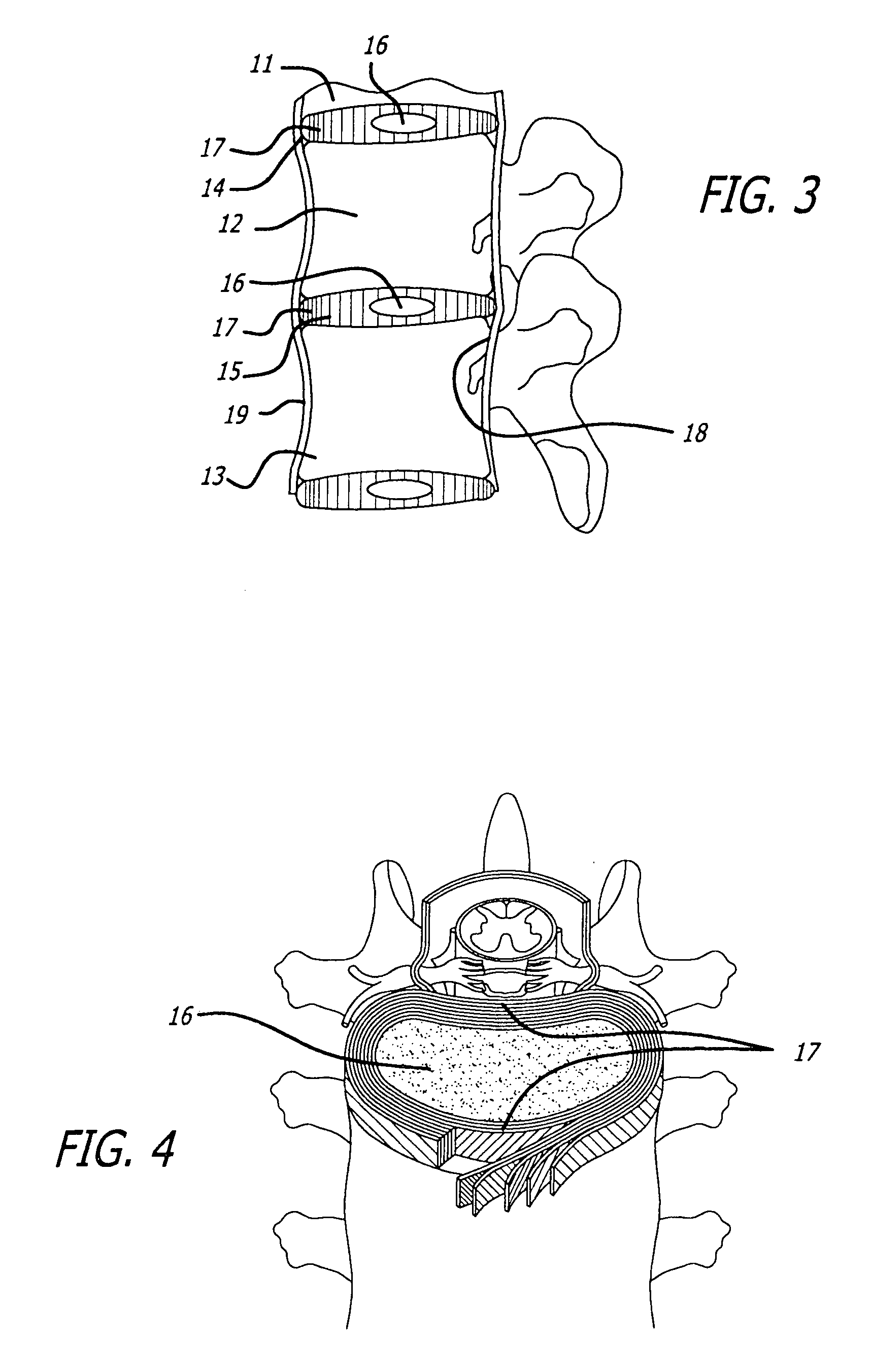

Prosthetic spinal discs

ActiveUS7309357B2Sufficient forceSmooth transitionMultiple spring combinationsSpinal implantsIntervertebral discEngineering

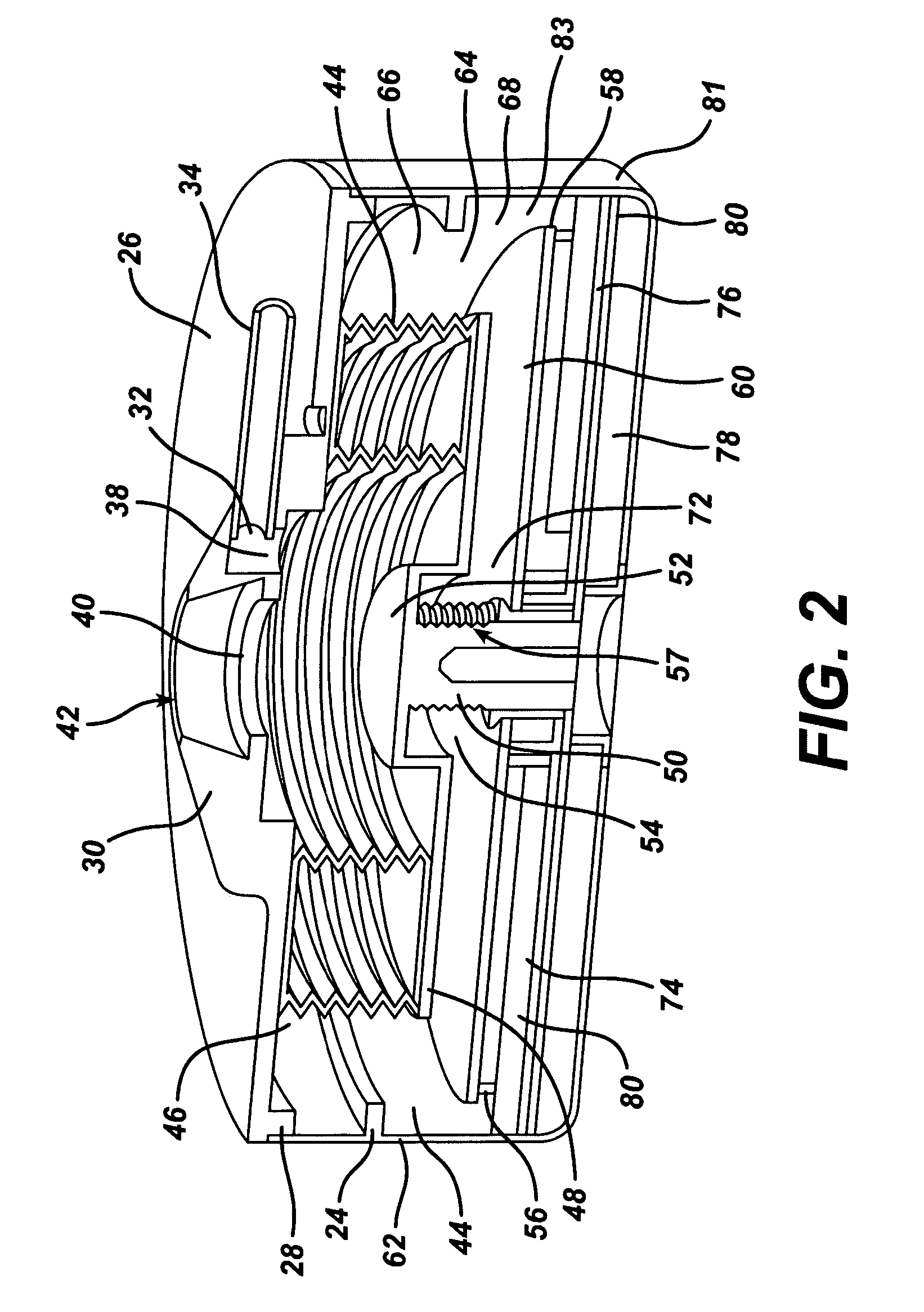

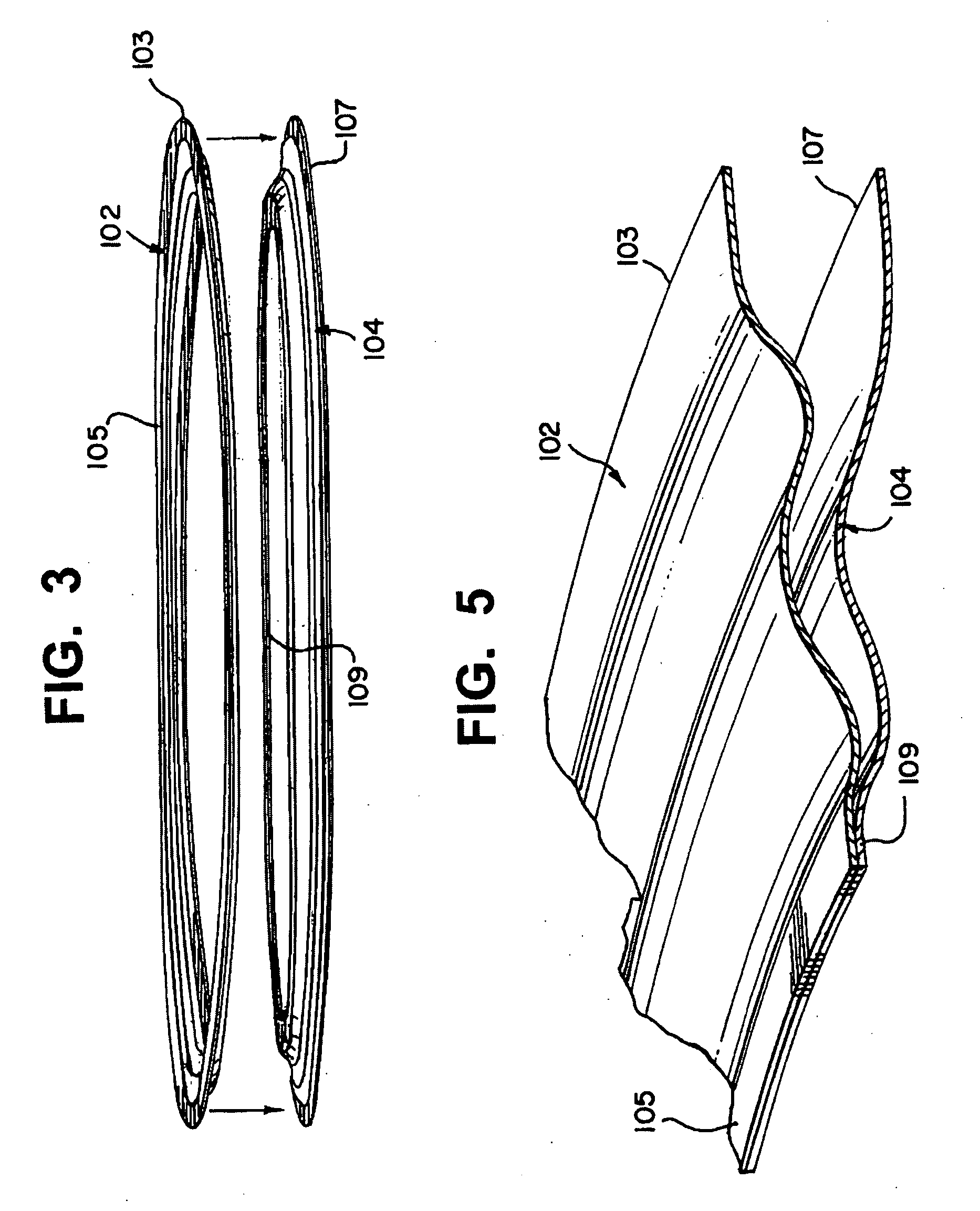

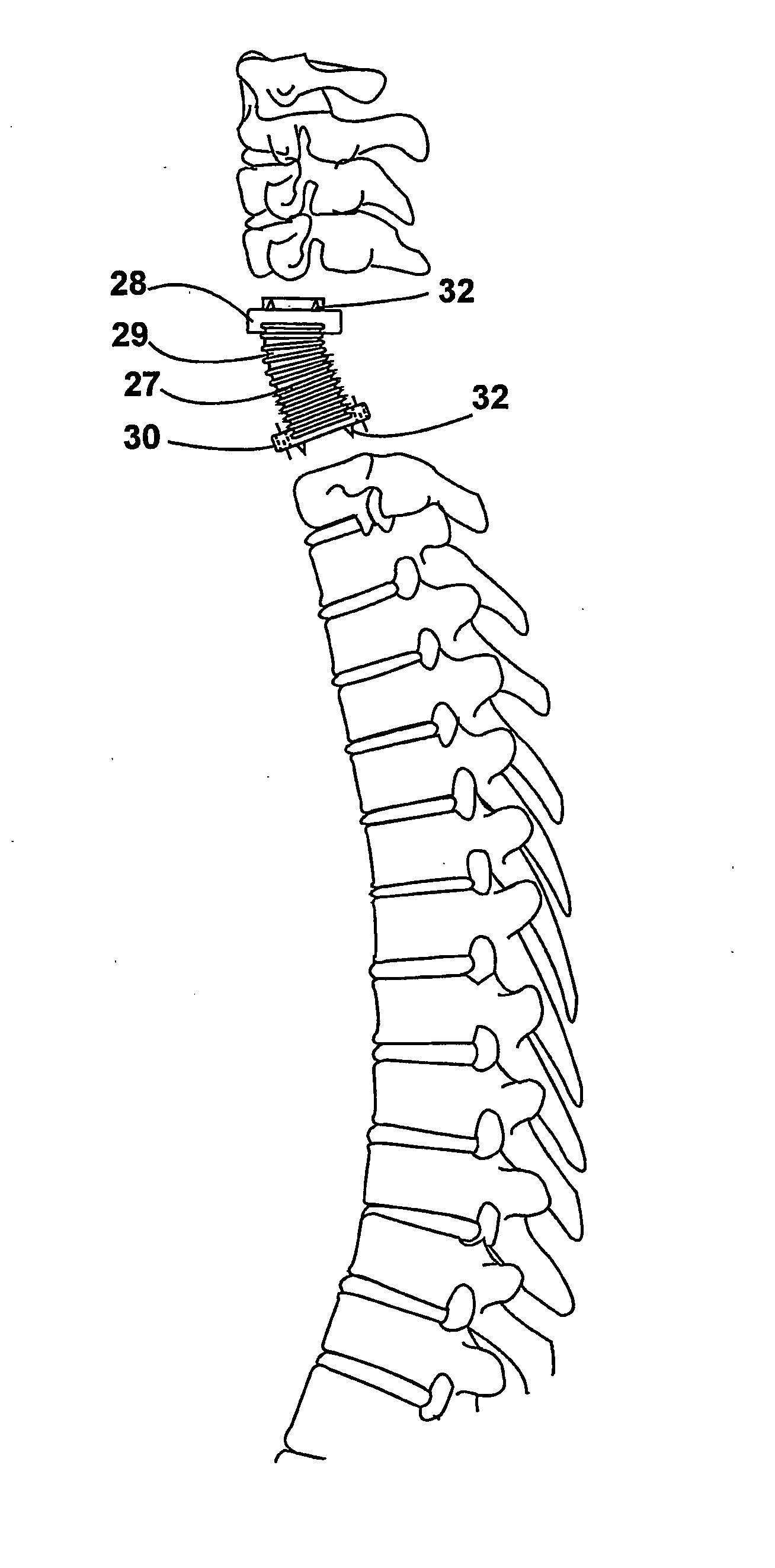

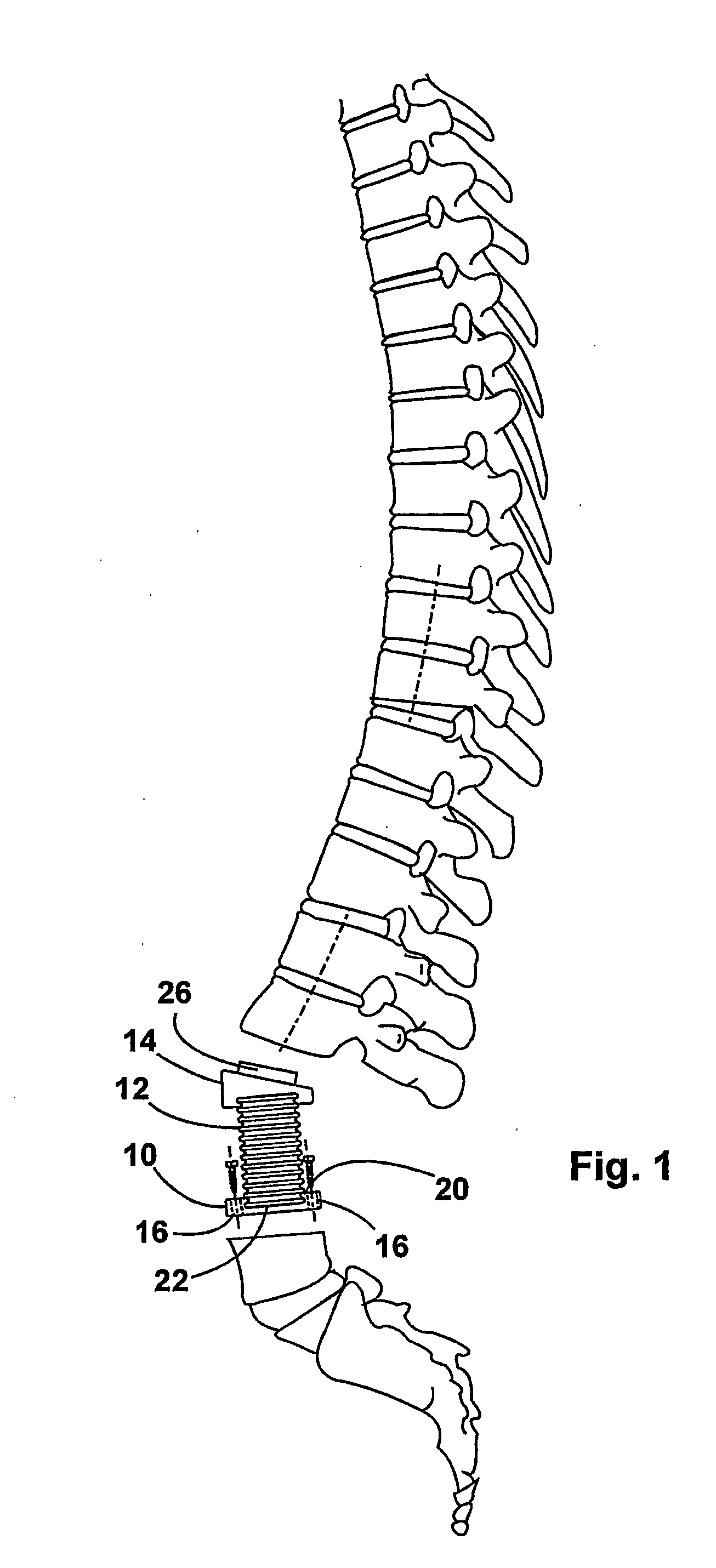

A prosthetic spinal disc uses a stiff spring or springs for resiliency between two plates that attach to adjacent vertebrae. When the disc has multiple springs, they may be adjacent, concentric or nested. Multiple springs may be spaced around the periphery of the plates. A foil metal bellows may surround the plates to prevent material from entering or exiting the space between the plates. Alternatively, the ends of the spring(s) may be machined with spikes to engage the vertebrae directly without plates.

Owner:INFINESSE CORP

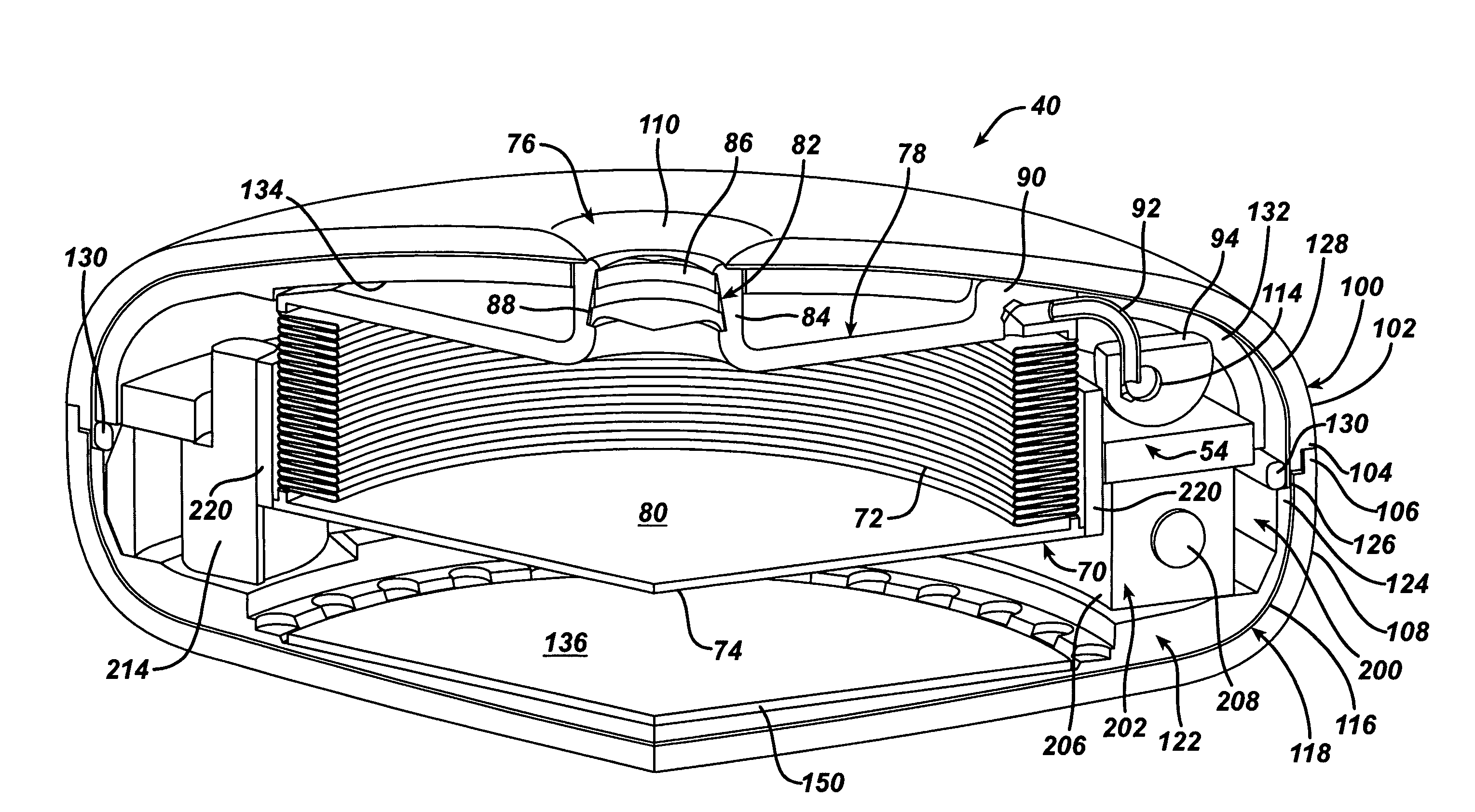

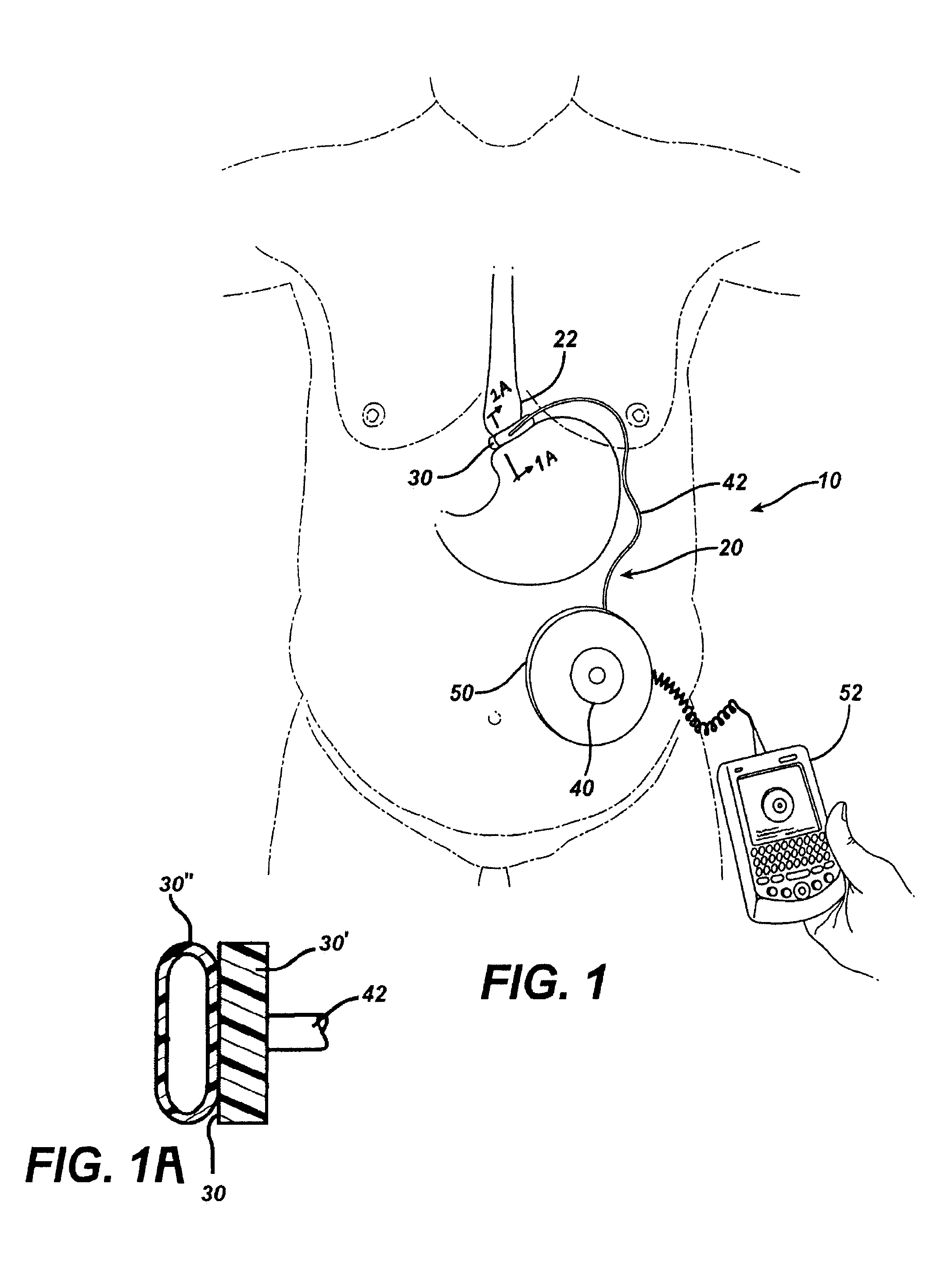

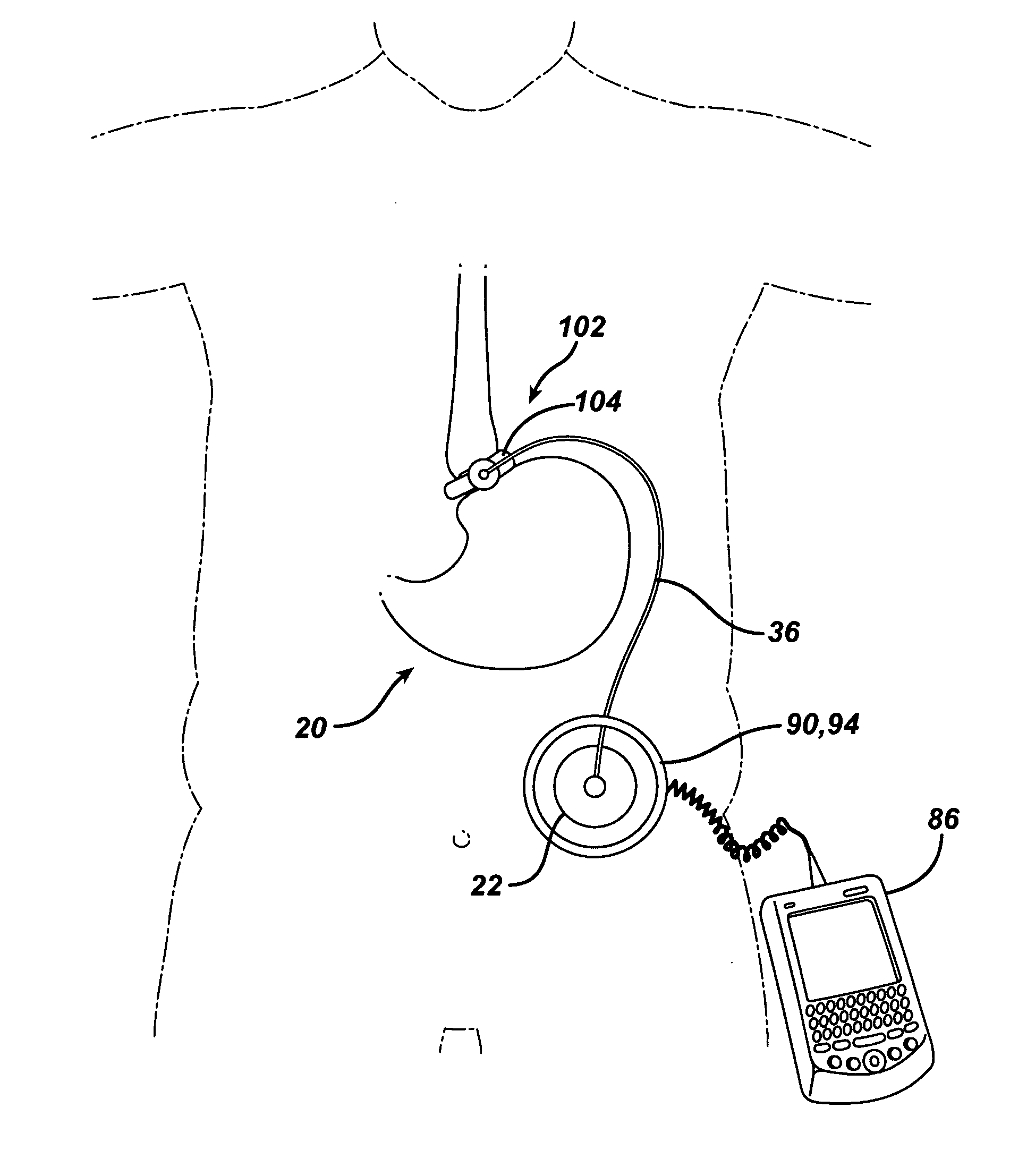

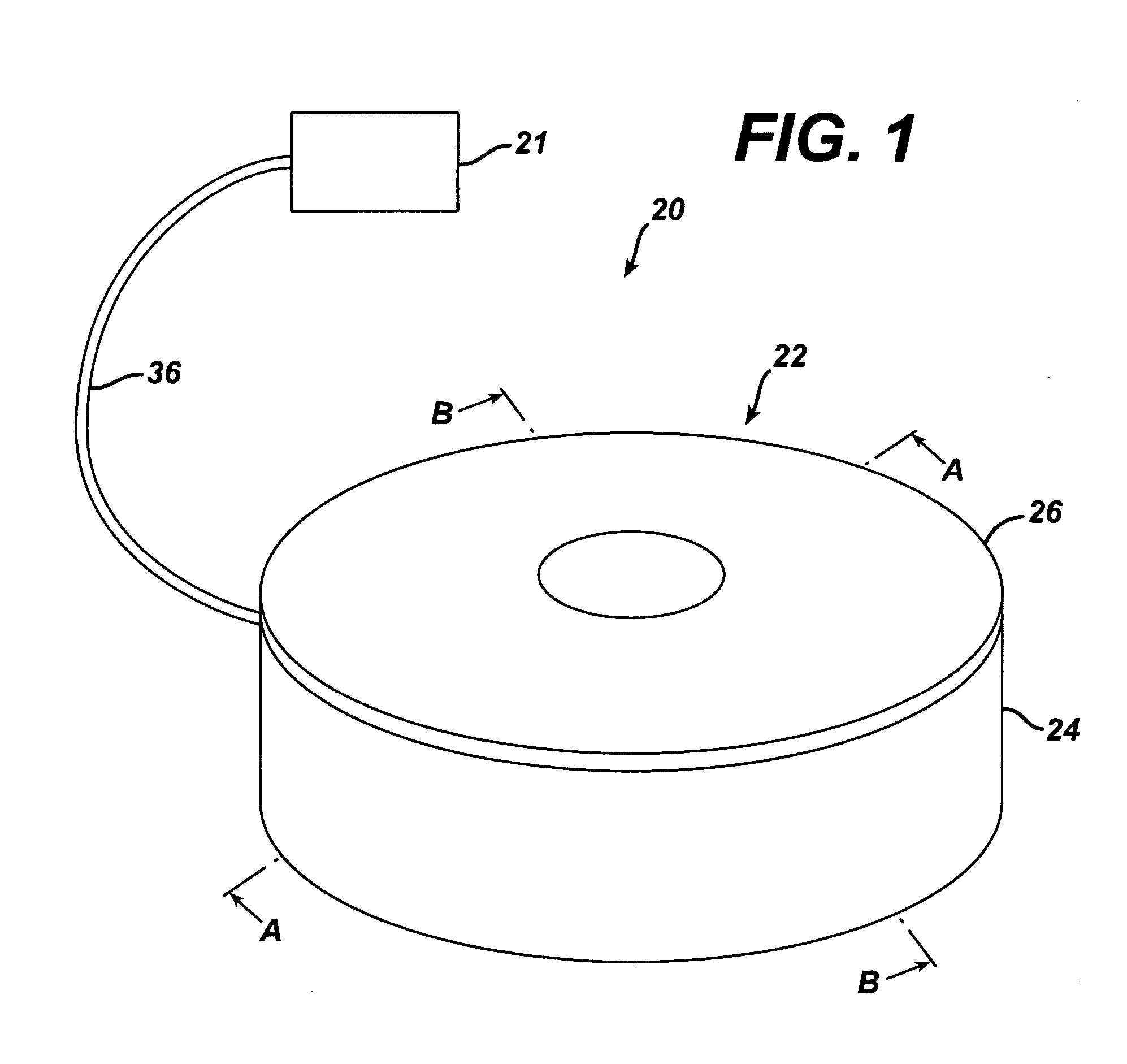

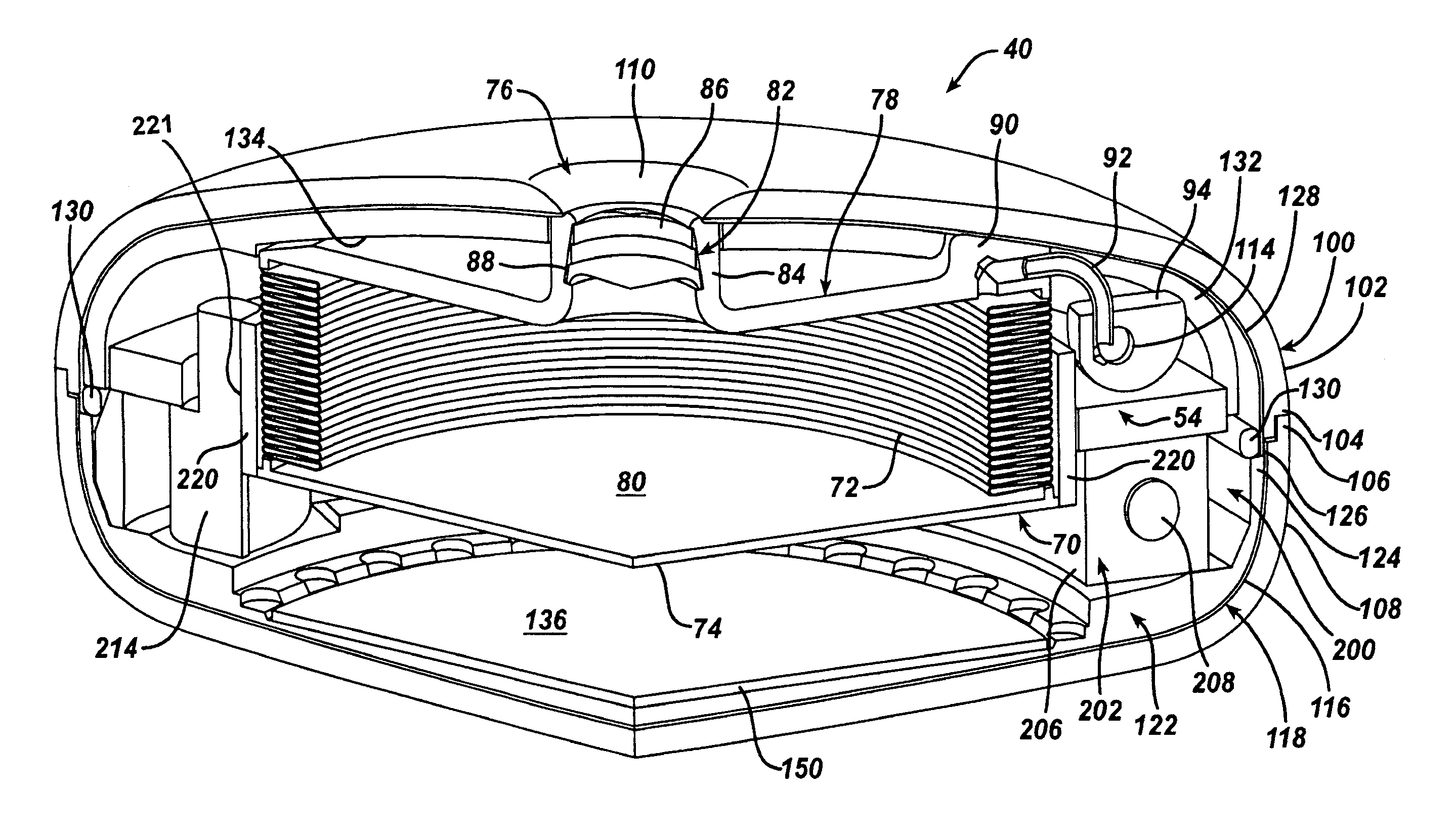

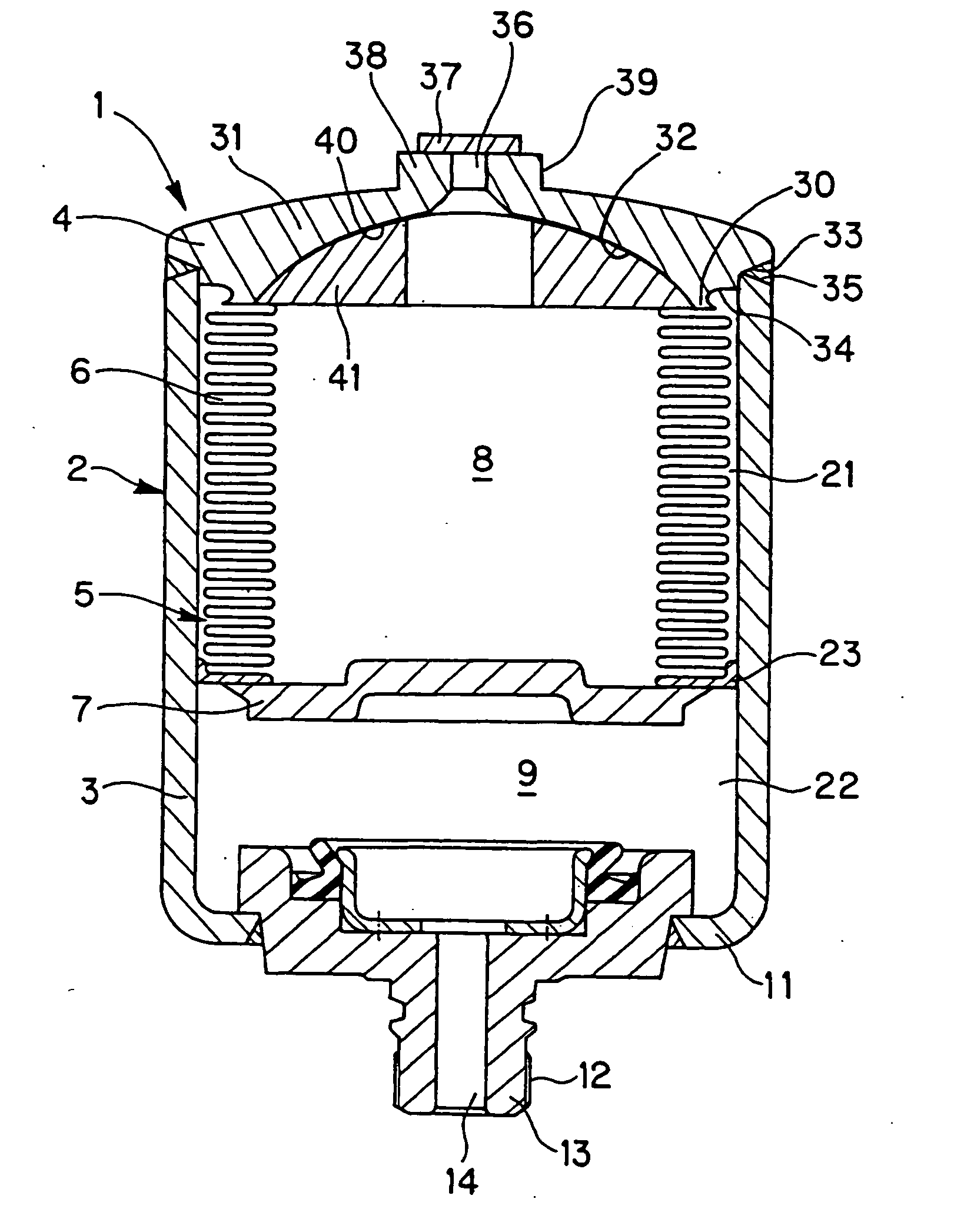

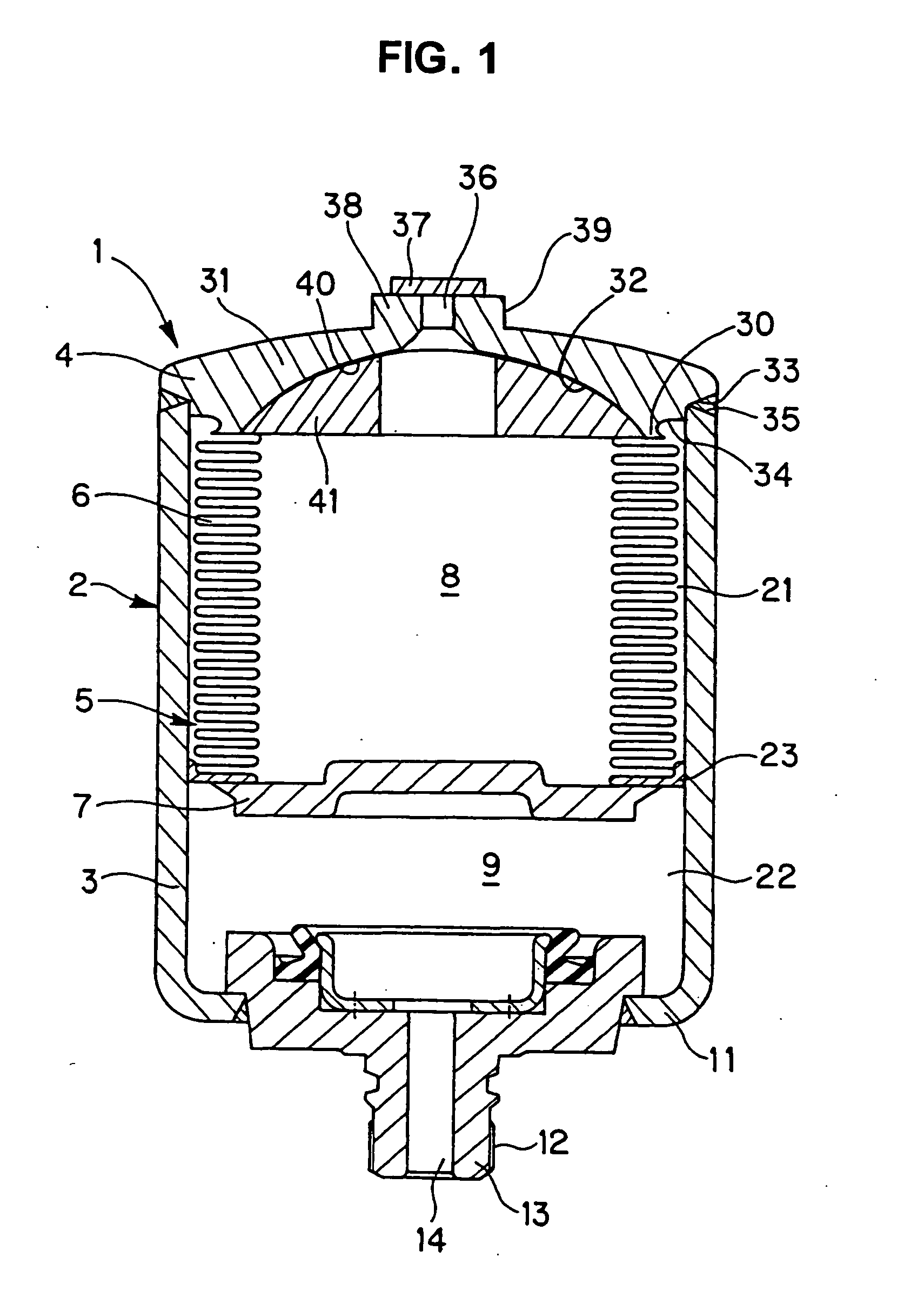

Thermodynamically driven reversible infuser pump for use as a remotely controlled gastric band

InactiveUS7351240B2Small volumeAvoid changeAnti-incontinence devicesFlexible member pumpsEngineeringPiezo electric

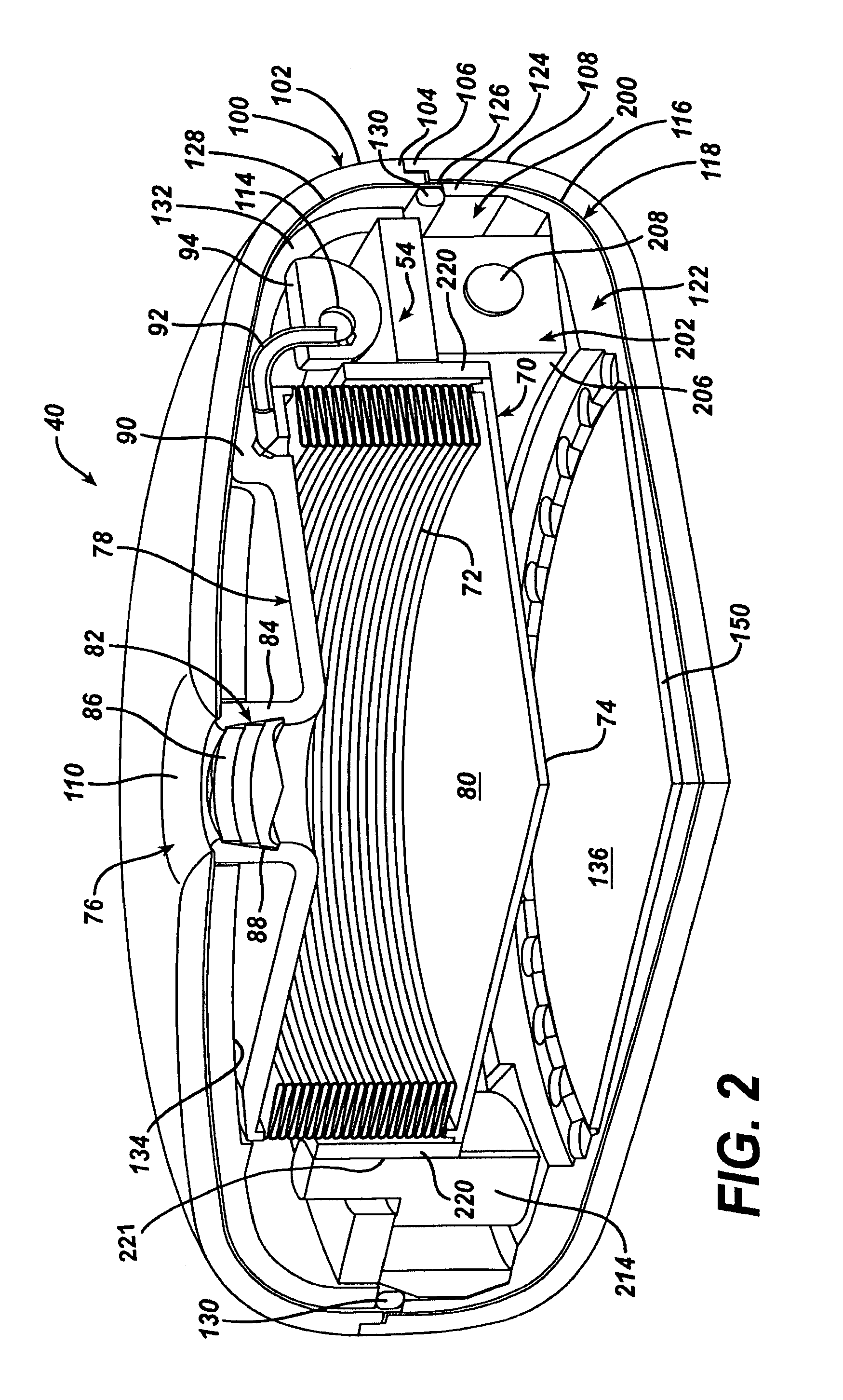

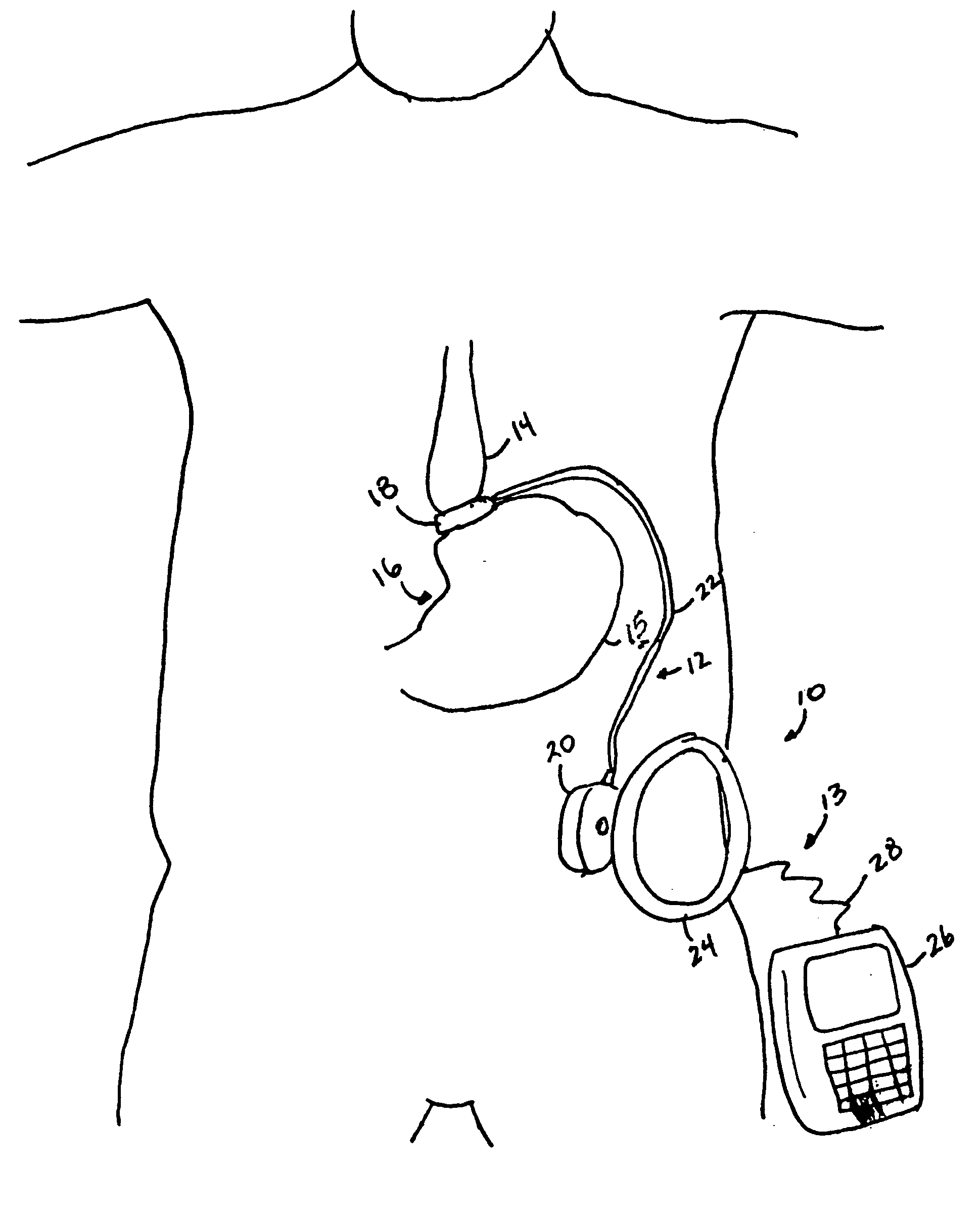

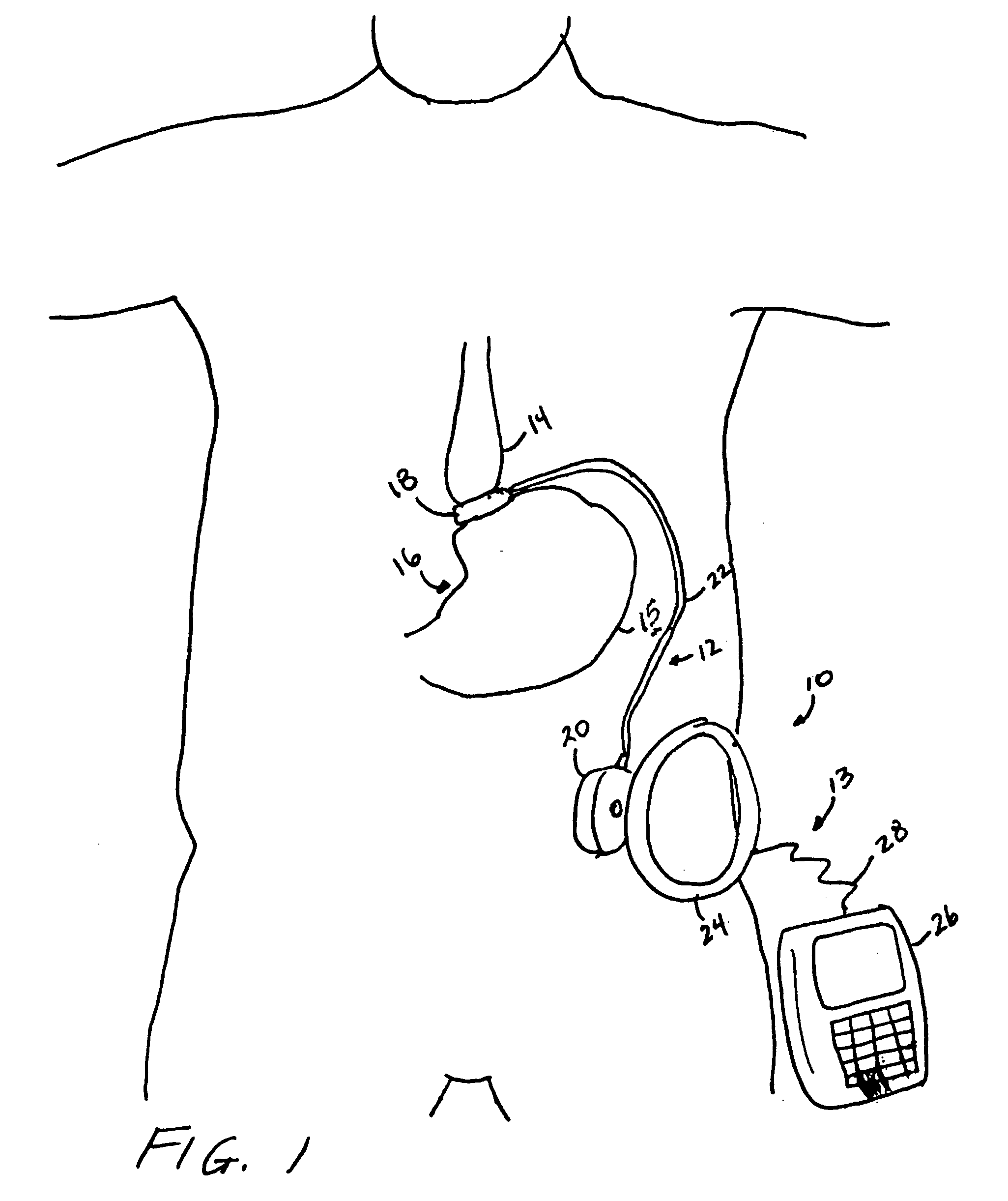

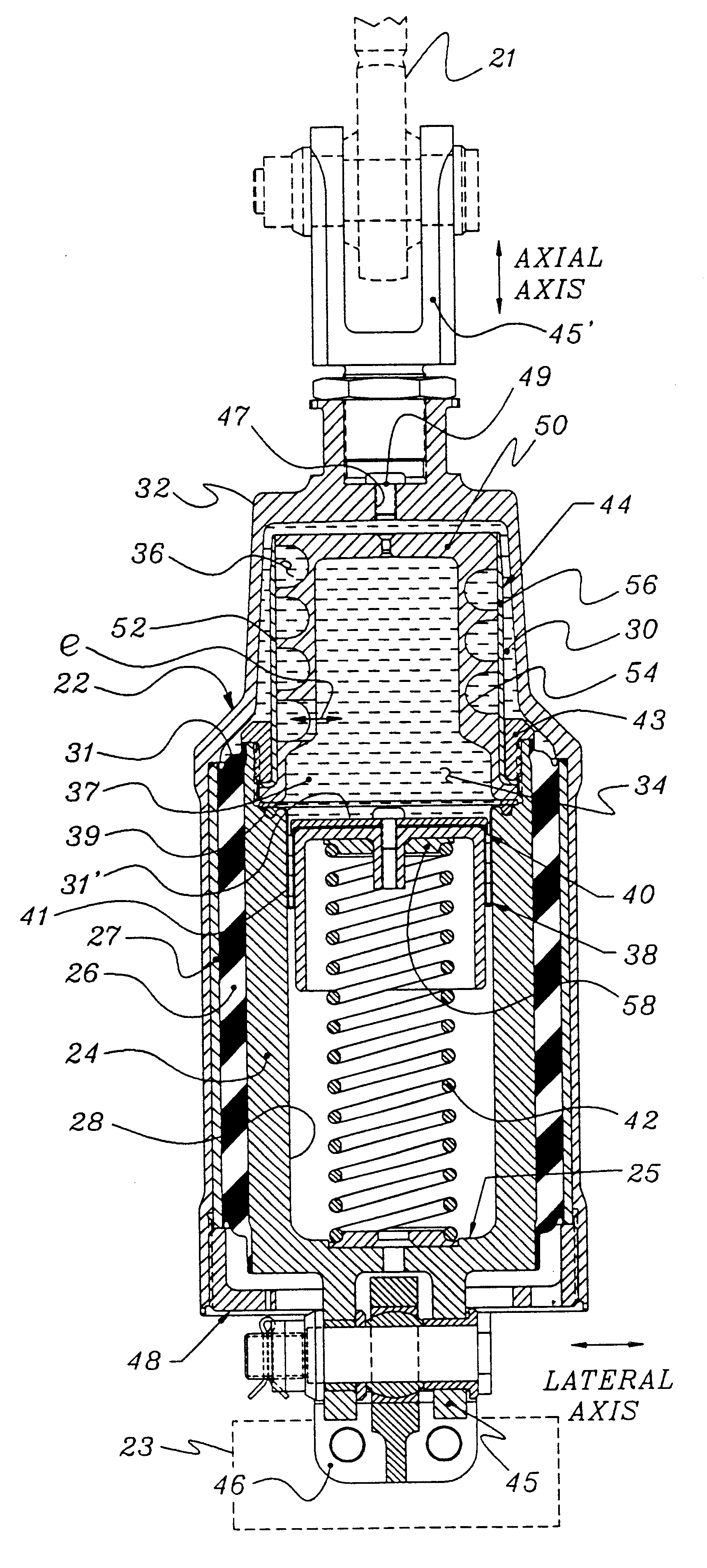

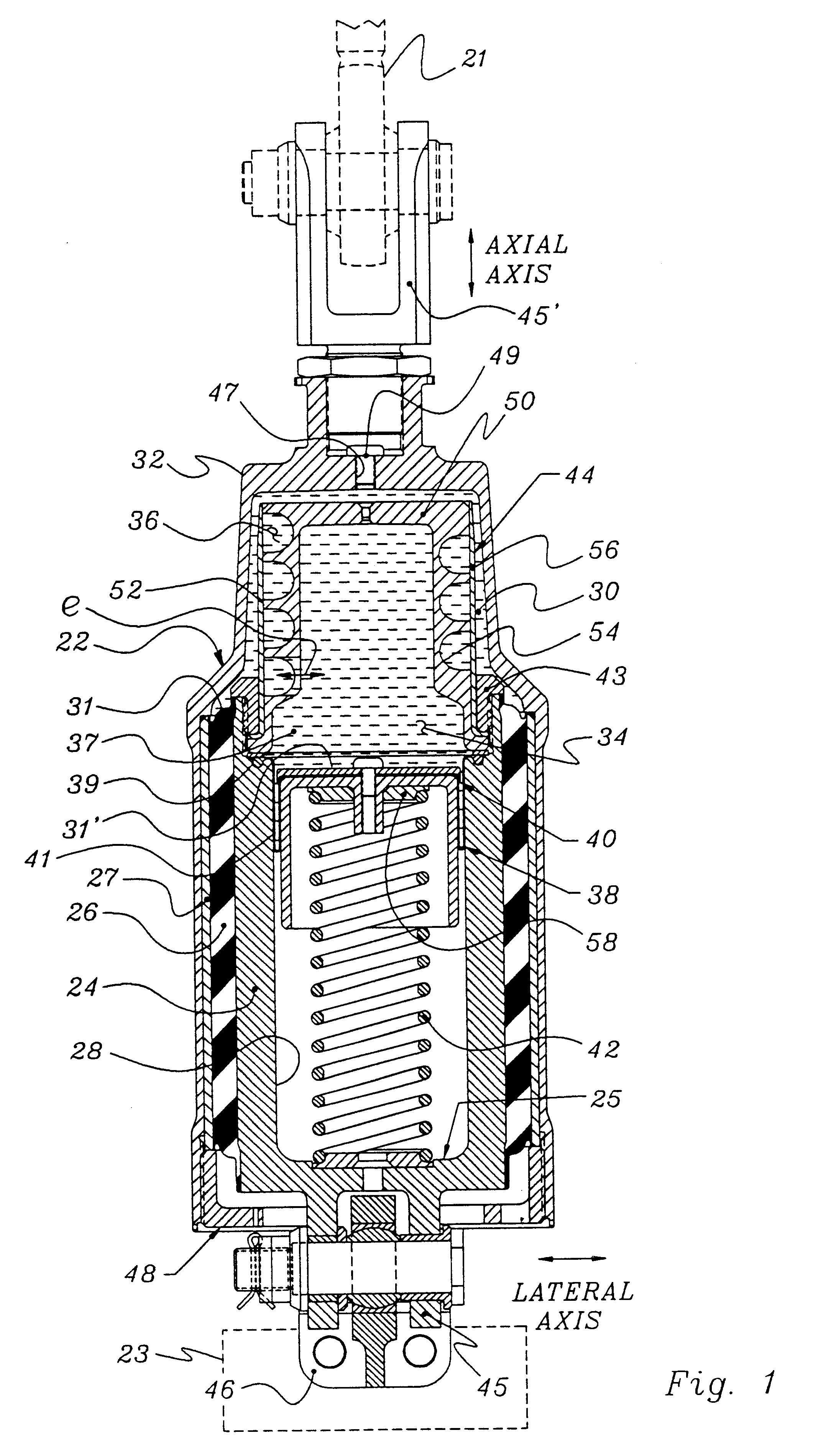

An implantable artificial sphincter system provides long-term adjustment via transcutaneous energy transfer (TET), minimizing invasive adjustment through adding or removing fluid via a syringe. An infuser device provides bi-directional fluid transfer via a flexible conduit to a sphincter band, such as a gastric band, by a combination of thermodynamic actuation and a piezo-electrically disengaged drum brake assembly that thereby achieves a desirable small volume device. A propellant within a propellant cavity surrounds a metal bellows accumulator biased at body temperature to either expand or collapse the bellows accumulator with the opposite direction of movement effected by a thermal element that heats in combination with a negatively-biased propellant or cools in combination with a positively-biased propellant. A drum brake assembly locks the metal bellows accumulator in place between adjustments by thermodynamic actuation by activating piezo-electric stack actuators that disengage calipers from a brake drum attached to the bellows accumulator.

Owner:ETHICON ENDO SURGERY INC

Piezo electrically driven bellows infuser for hydraulically controlling an adjustable gastric band

A remotely controlled gastric band system that is practically immune to external magnetic fields, such as from a Magnetic Resonance Imaging (MRI) machine, incorporates a bi-directional pump and fluid reservoir to adjust fluid volume in a gastric band. A piezoelectrically driven (e.g., rotary actuator, linear actuator) selectively compresses and expands a metal bellows hermetically sealed within a biocompatible and nonferromagnetic case such as titanium.

Owner:ETHICON ENDO SURGERY INC

Metal bellows position feedback for hydraulic control of an adjustable gastric band

InactiveUS7481763B2Avoid the needNon-surgical orthopedic devicesObesity treatmentClosed loopEngineering

A remotely controlled gastric band system that is practically immune to external magnetic fields, such as from a Magnetic Resonance Imaging (MRI) machine, incorporates a bi-directional pump and fluid reservoir to adjust fluid volume for hydraulic control of a gastric band. A piezoelectric driver (e.g., rotary actuator, linear actuator) selectively compresses and expands a metal bellows hermetically sealed within a biocompatible and nonferromagnetic enclosure or case such as titanium. Directly sensing a position of the metal bellows yields an accurate reading of volume contained therein, allowing for closed-loop control of the gastric band.

Owner:ETHICON ENDO SURGERY INC

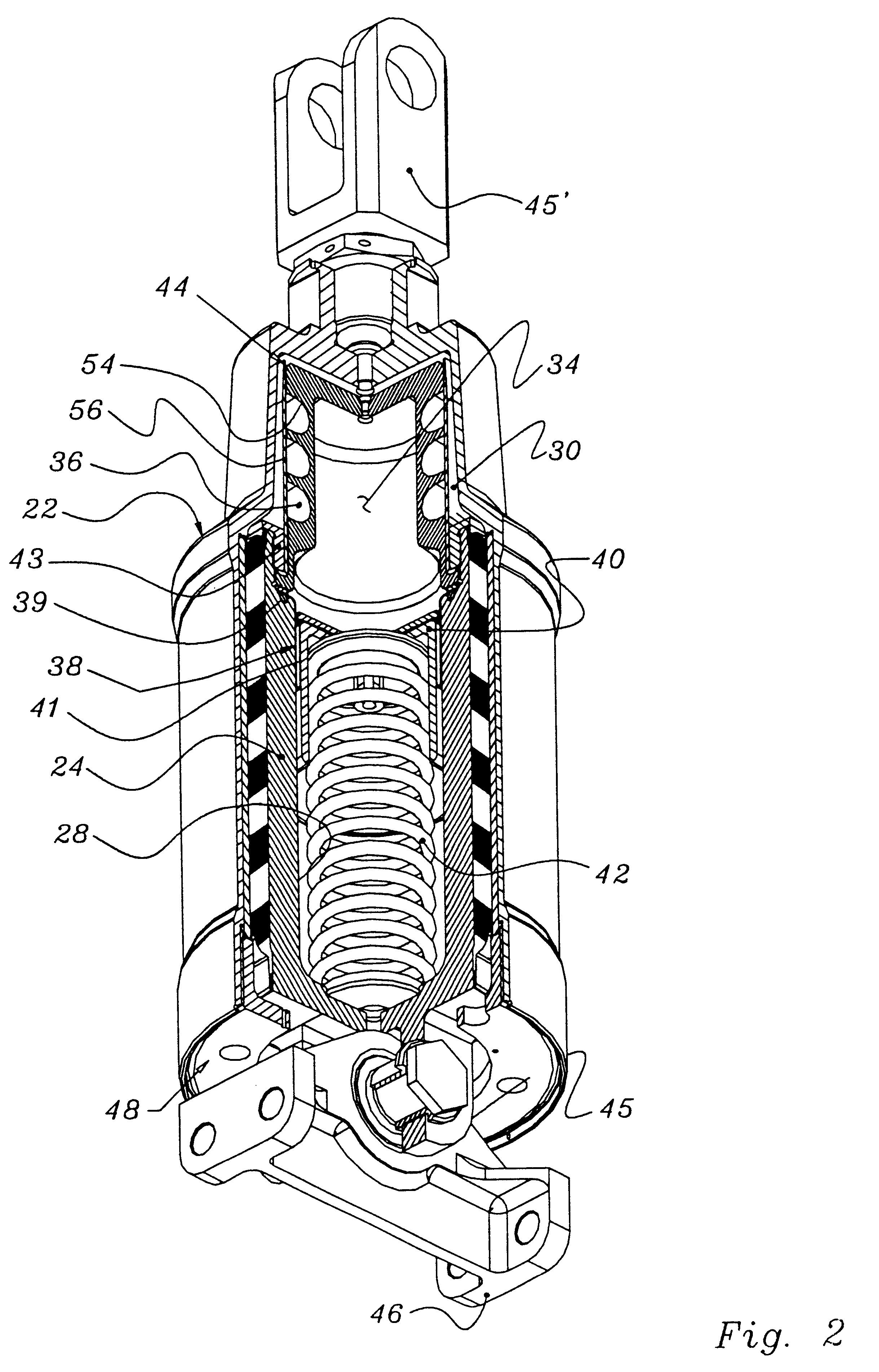

Bi-directional infuser pump with volume braking for hydraulically controlling an adjustable gastric band

InactiveUS7374565B2Increase varietyAvoid changeAnti-incontinence devicesPharmaceutical delivery mechanismPiezo electricEngineering

An implantable artificial sphincter system provides long-term adjustment via transcutaneous energy transfer (TET), minimizing invasive adjustment through adding or removing fluid via a syringe. An infuser device provides bi-directional fluid transfer via a flexible conduit to a sphincter band, such as a gastric band, by a combination of thermodynamic actuation and a piezo-electrically disengaged drum brake assembly that thereby achieves a desirable small volume device. A propellant within a propellant cavity surrounds a metal bellows accumulator biased at body temperature to either expand or collapse the bellows accumulator with the opposite direction of movement effected by a thermal element that heats in combination with a negatively-biased propellant or cools in combination with a positively-biased propellant. A drum brake assembly locks the metal bellows accumulator in place between adjustments by thermodynamic actuation by activating piezo-electric stack actuators that disengage calipers from a brake drum attached to the bellows accumulator.

Owner:ETHICON ENDO SURGERY INC

Metal bellows position feedback for hydraulic control of an adjustable gastric band

InactiveUS20050267500A1Precise motion controlAvoid the needNon-surgical orthopedic devicesObesity treatmentClosed loopEngineering

A remotely controlled gastric band system that is practically immune to external magnetic fields, such as from a Magnetic Resonance Imaging (MRI) machine, incorporates a bi-directional pump and fluid reservoir to adjust fluid volume for hydraulic control of a gastric band. A piezoelectric driver (e.g., rotary actuator, linear actuator) selectively compresses and expands a metal bellows hermetically sealed within a biocompatible and nonferromagnetic enclosure or case such as titanium. Directly sensing a position of the metal bellows yields an accurate reading of volume contained therein, allowing for closed-loop control of the gastric band.

Owner:ETHICON ENDO SURGERY INC

Indwelling heat exchange heat pipe catheter and method of using same

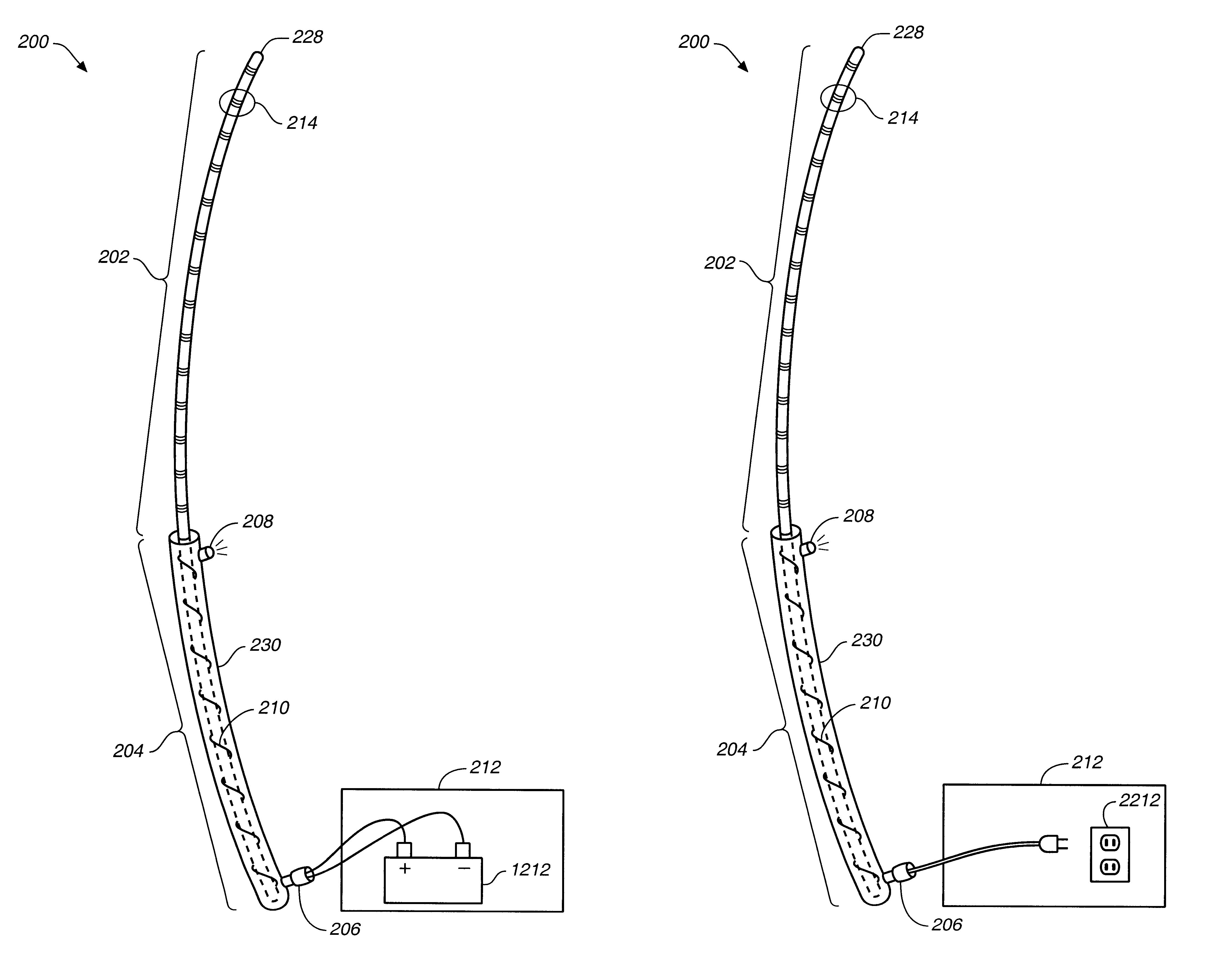

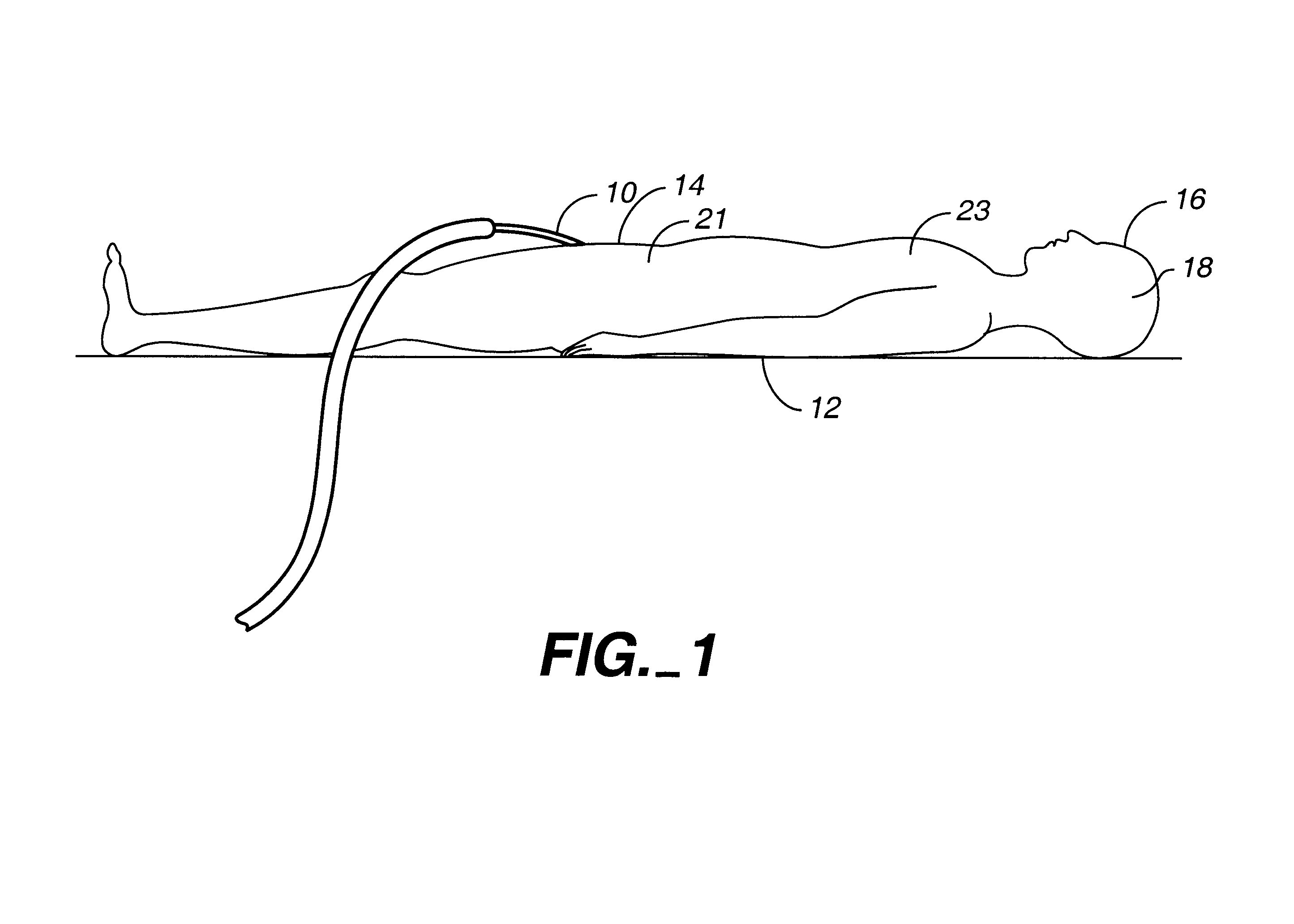

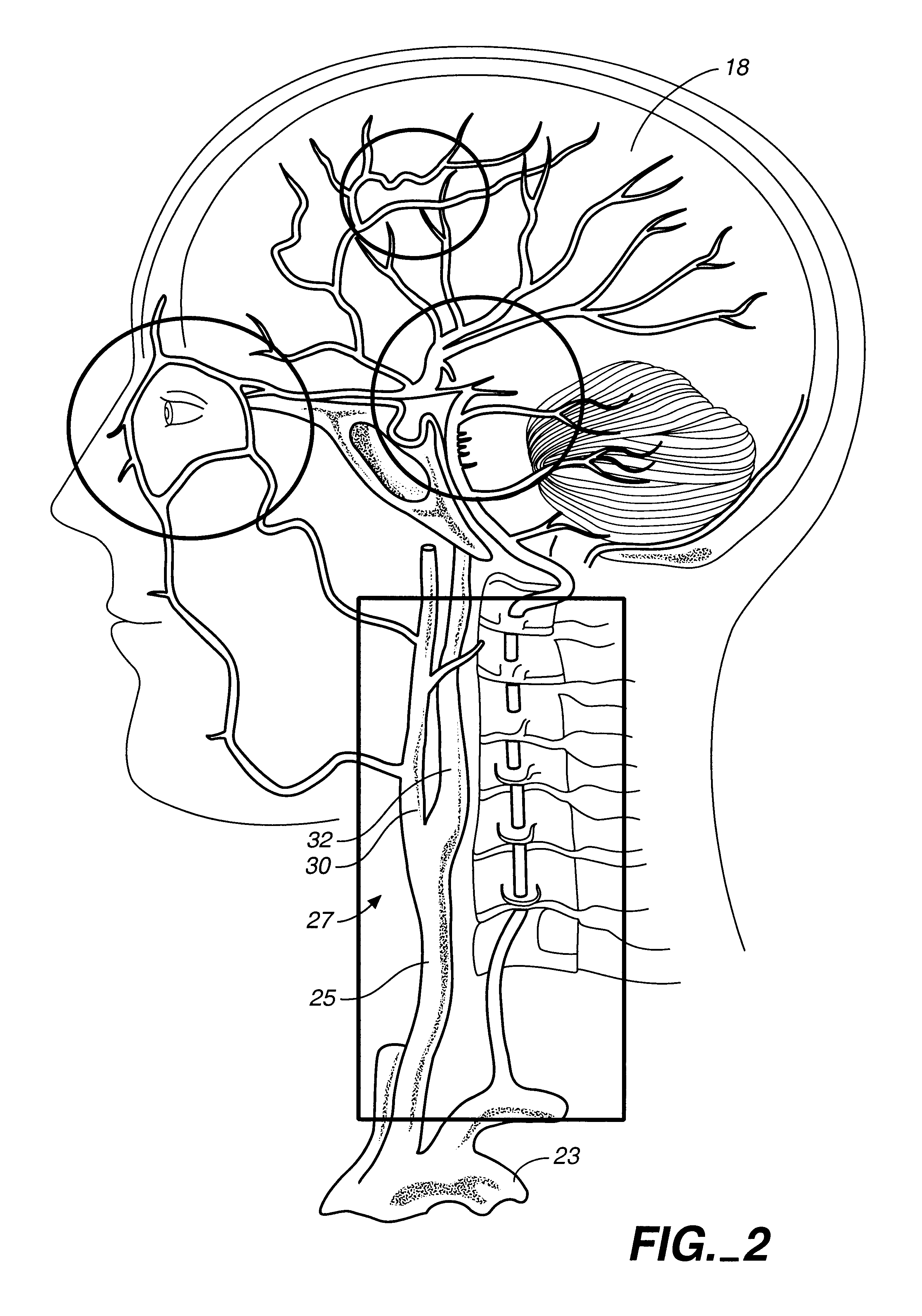

A catheter is adapted to exchange heat with a body fluid, such as blood, flowing in a body conduit, such as a blood vessel. The catheter includes a shaft with a heat exchange region disposed at its distal end. This region may include at least one balloon which is adapted to receive a remotely cooled heat exchange fluid preferably flowing in a direction counter to that of the body fluid. Embodiments including multiple balloons enhance the surface area of contact, and the mixing of both the heat exchange and the body fluid. The catheter can be positioned to produce hypothermia in a selective area of the body without cooling the entire body system. It is of particular advantage in brain surgeries where stroke, trauma or cryogenic tumors can best be addressed under hypothermic conditions. Heat pipe technology can be used to form a heat pipe heat exchange catheter. The heat pipe heat exchange catheter includes metallic bellows which allow for flexibility. The temperature control source can be portable to enable the heat pipe heat exchange catheter to be used in the ambulatory environment.

Owner:ZOLL CIRCULATION

Thermodynamically driven reversible infuser pump for use as a remotely controlled gastric band

InactiveUS20050277974A1Avoid inconvenienceSmallAnti-incontinence devicesFlexible member pumpsEngineeringPiezo electric

An implantable artificial sphincter system provides long-term adjustment via transcutaneous energy transfer (TET), minimizing invasive adjustment through adding or removing fluid via a syringe. An infuser device provides bi-directional fluid transfer via a flexible conduit to a sphincter band, such as a gastric band, by a combination of thermodynamic actuation and a piezo-electrically disengaged drum brake assembly that thereby achieves a desirable small volume device. A propellant within a propellant cavity surrounds a metal bellows accumulator biased at body temperature to either expand or collapse the bellows accumulator with the opposite direction of movement effected by a thermal element that heats in combination with a negatively-biased propellant or cools in combination with a positively-biased propellant. A drum brake assembly locks the metal bellows accumulator in place between adjustments by thermodynamic actuation by activating piezo-electric stack actuators that disengage calipers from a brake drum attached to the bellows accumulator.

Owner:ETHICON ENDO SURGERY INC

Prosthetic spinal discs

ActiveUS20060149381A1Minimizing localized stressIncrease contact areaMultiple spring combinationsSpinal implantsPhysical medicine and rehabilitationIntervertebral disc

A prosthetic spinal disc uses a stiff spring or springs for resiliency between two plates that attach to adjacent vertebrae. When the disc has multiple springs, they may be adjacent, concentric or nested. Multiple springs may be spaced around the periphery of the plates. A foil metal bellows may surround the plates to prevent material from entering or exiting the space between the plates. Alternatively, the ends of the spring(s) may be machined with spikes to engage the vertebrae directly without plates.

Owner:INFINESSE CORP

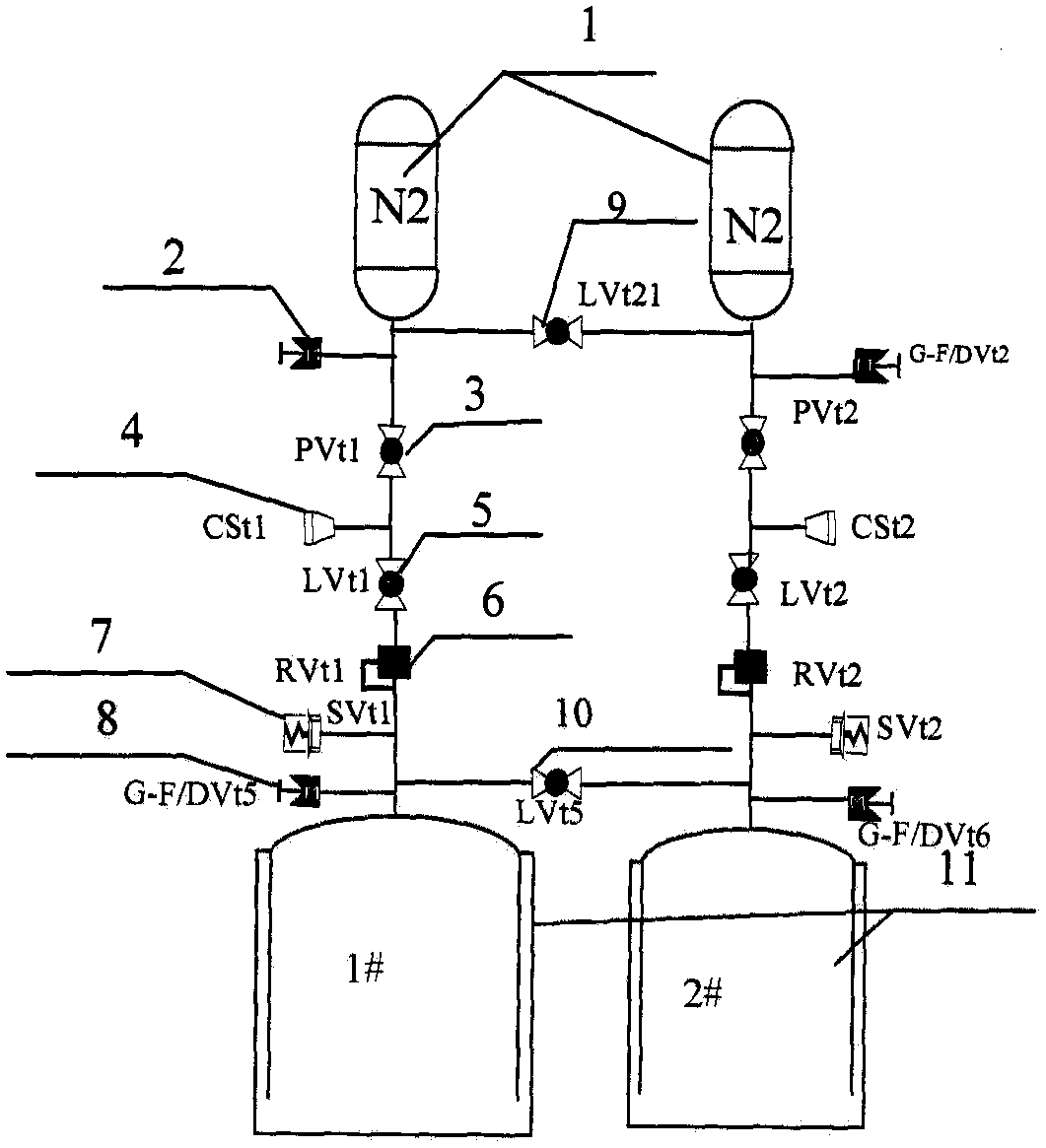

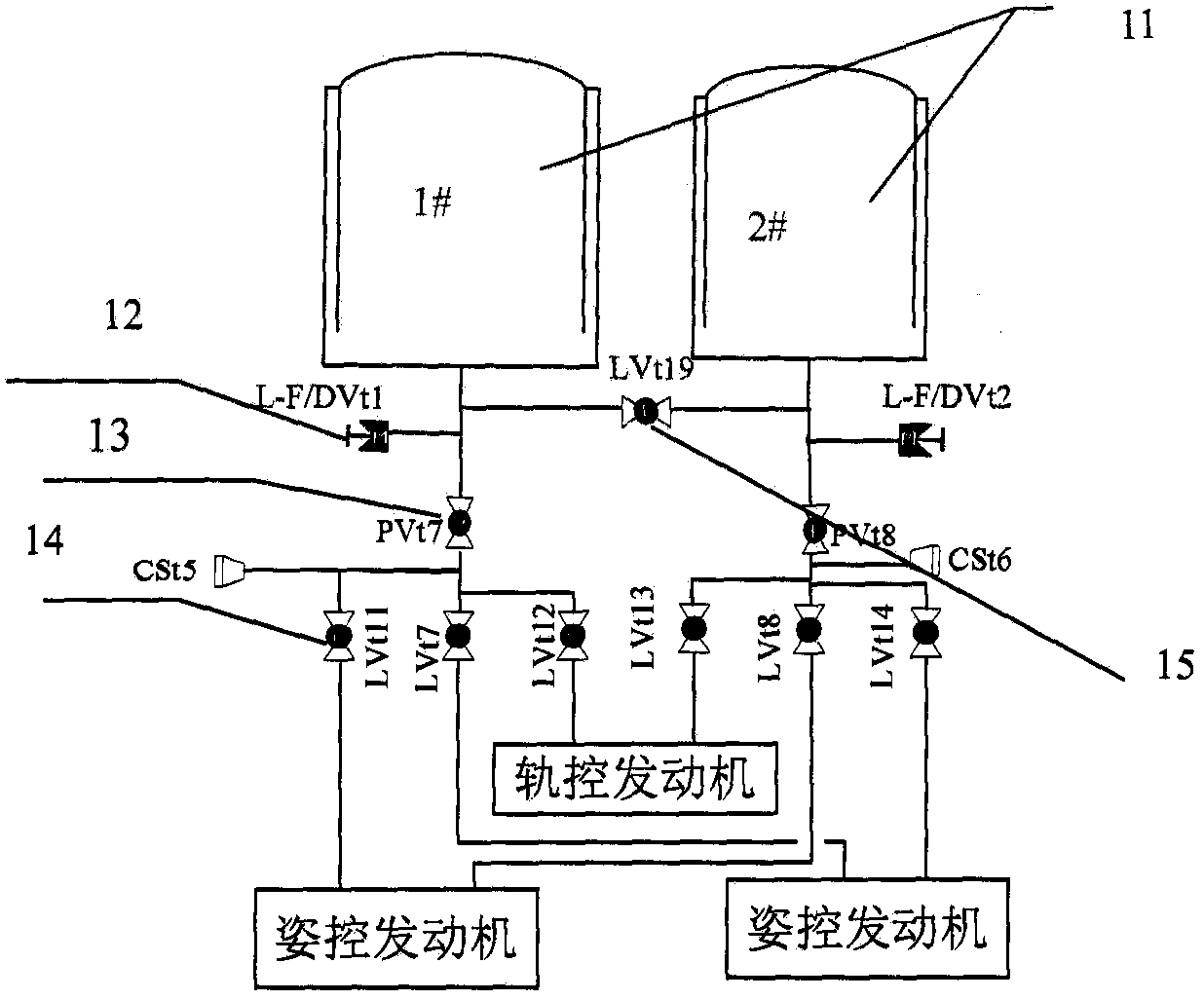

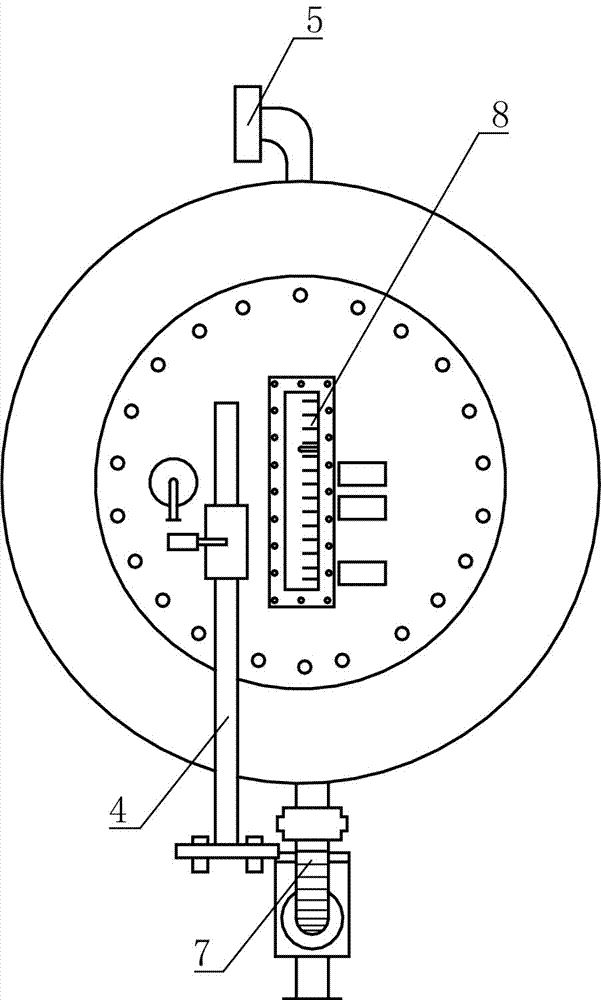

A realization method of space propulsion system

ActiveCN106134390BTroubleshoot fault isolationCosmonautic propulsion system apparatusRocket engine plantsGas chamberOrbit

The invention belongs to the technical field of space propulsion. The technical problem to be solved is to provide a realization method of the space propulsion system, which can effectively overcome the defects of the existing technology, and can adapt to the development requirements of long service life and high safety of space vehicles in orbit. The present invention has designed a "well" structure gas path supply system and a cross-supply propellant supply system, and can realize repeated filling / leaking of the propellant on the ground metal membrane box type storage tank, and the present invention brings the following beneficial effects: 1) The air cavities of the two propellant tanks are physically isolated and not connected to each other; 2) Solve the fault isolation of gas leakage, and the system will not fail to work due to the leakage of a gas cylinder; 3) Meet the long-term on-orbit aircraft to adapt to multiple times Supplemented tank design requirements.

Owner:SHANGHAI INST OF SPACE PROPULSION

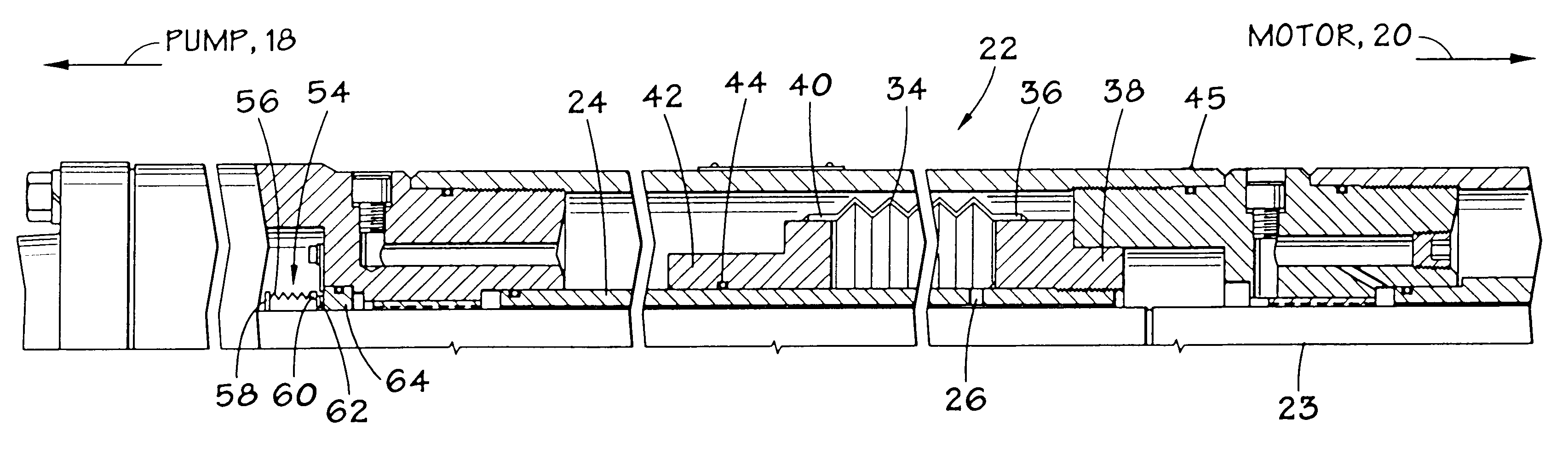

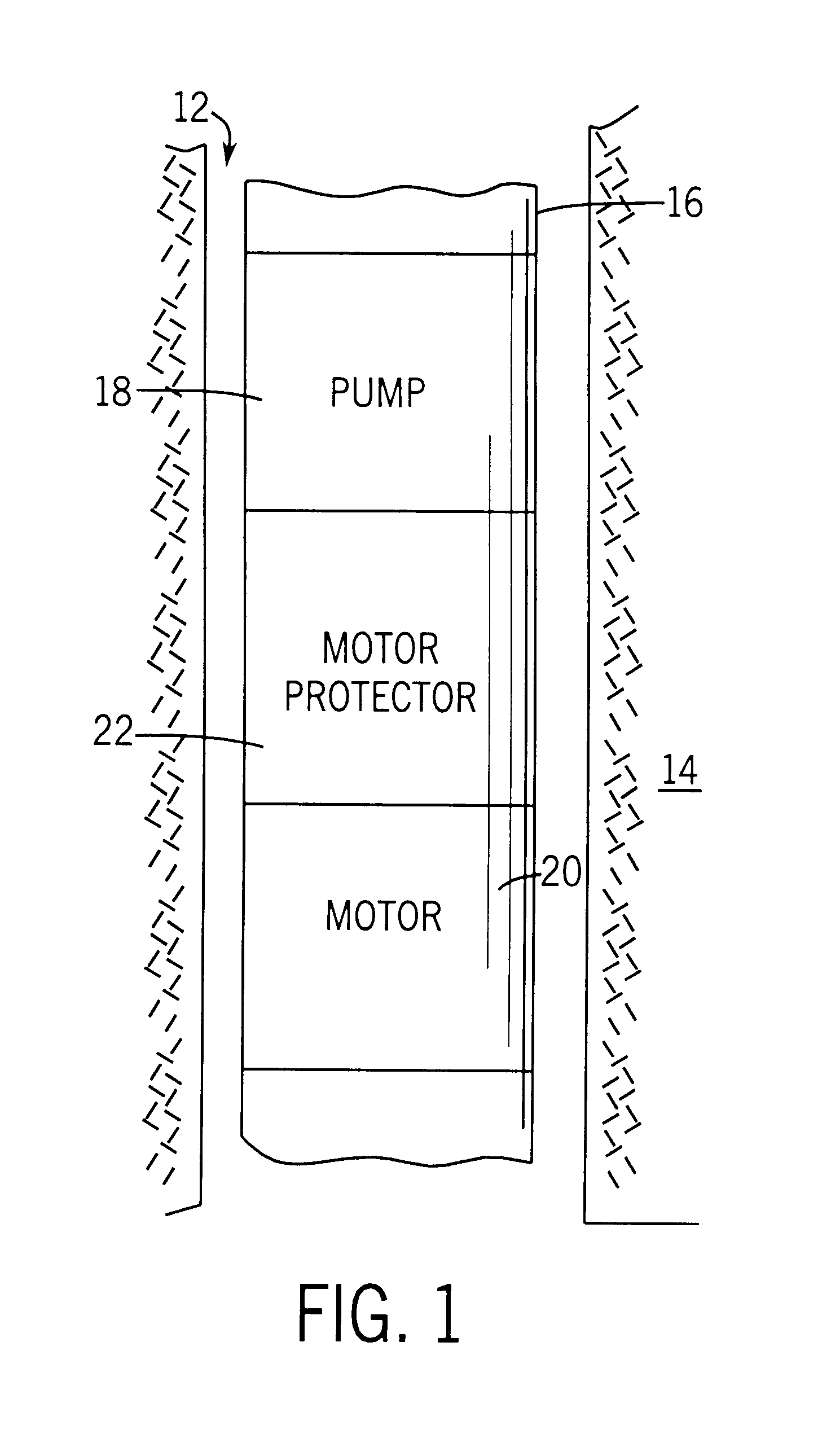

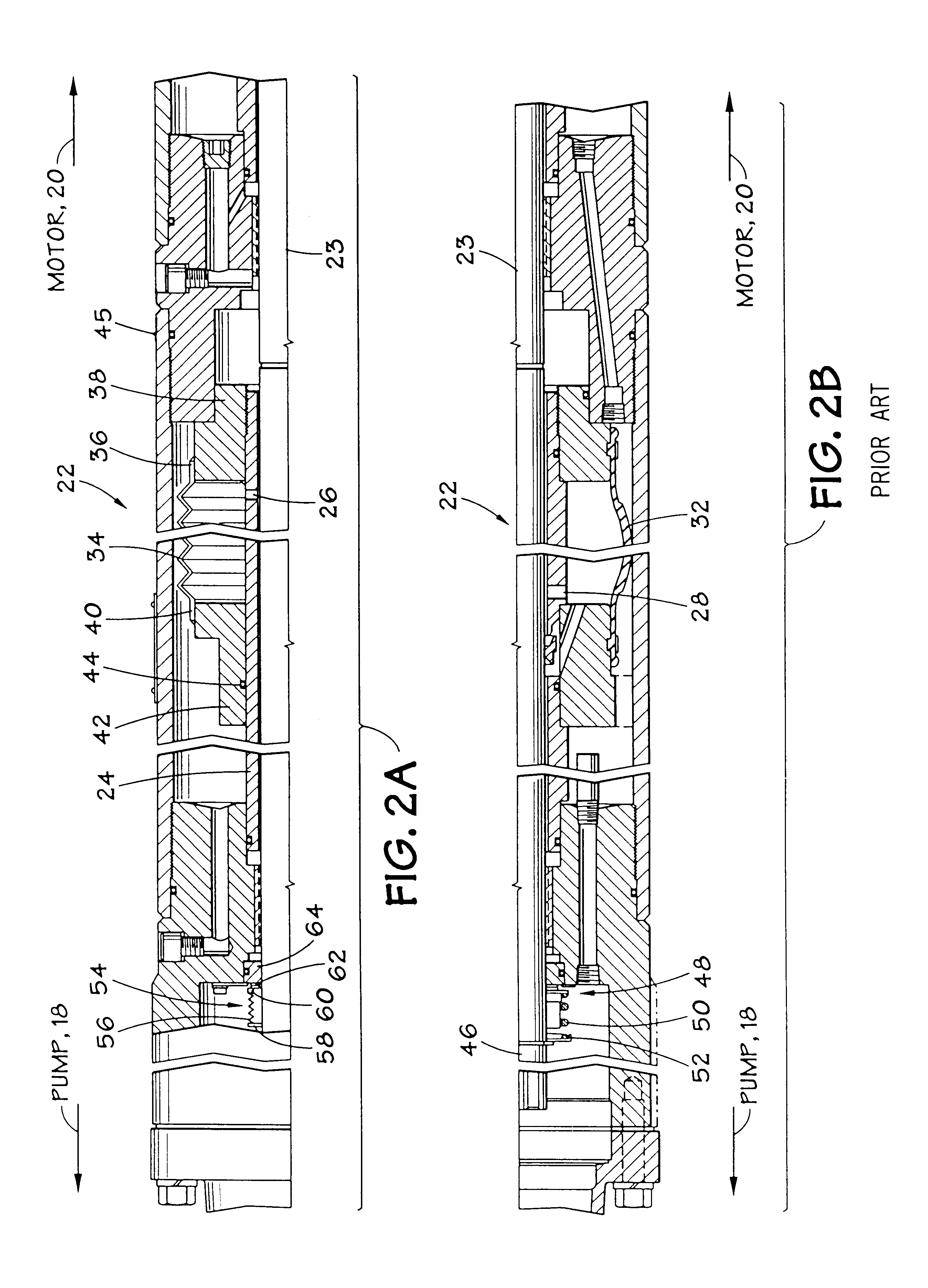

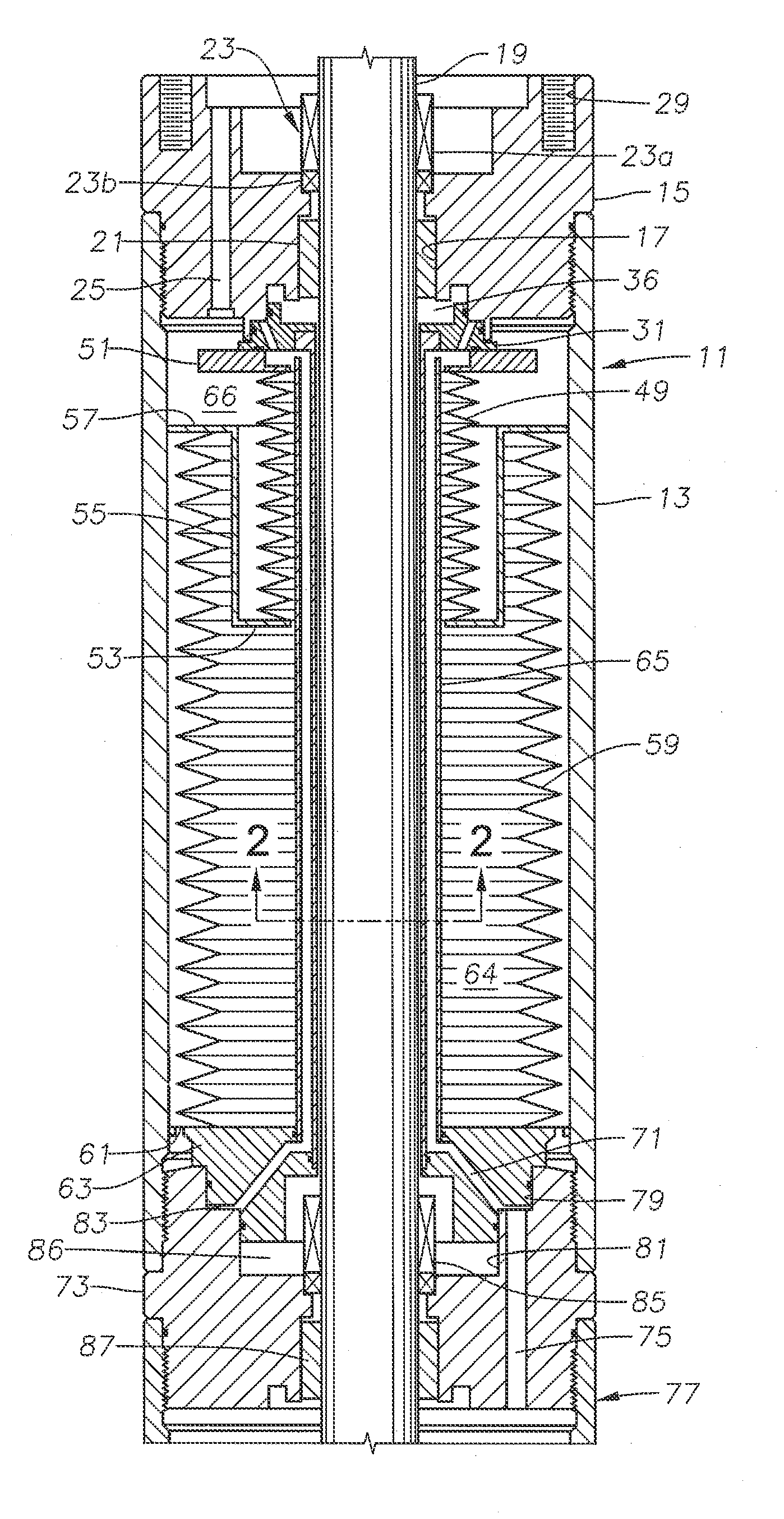

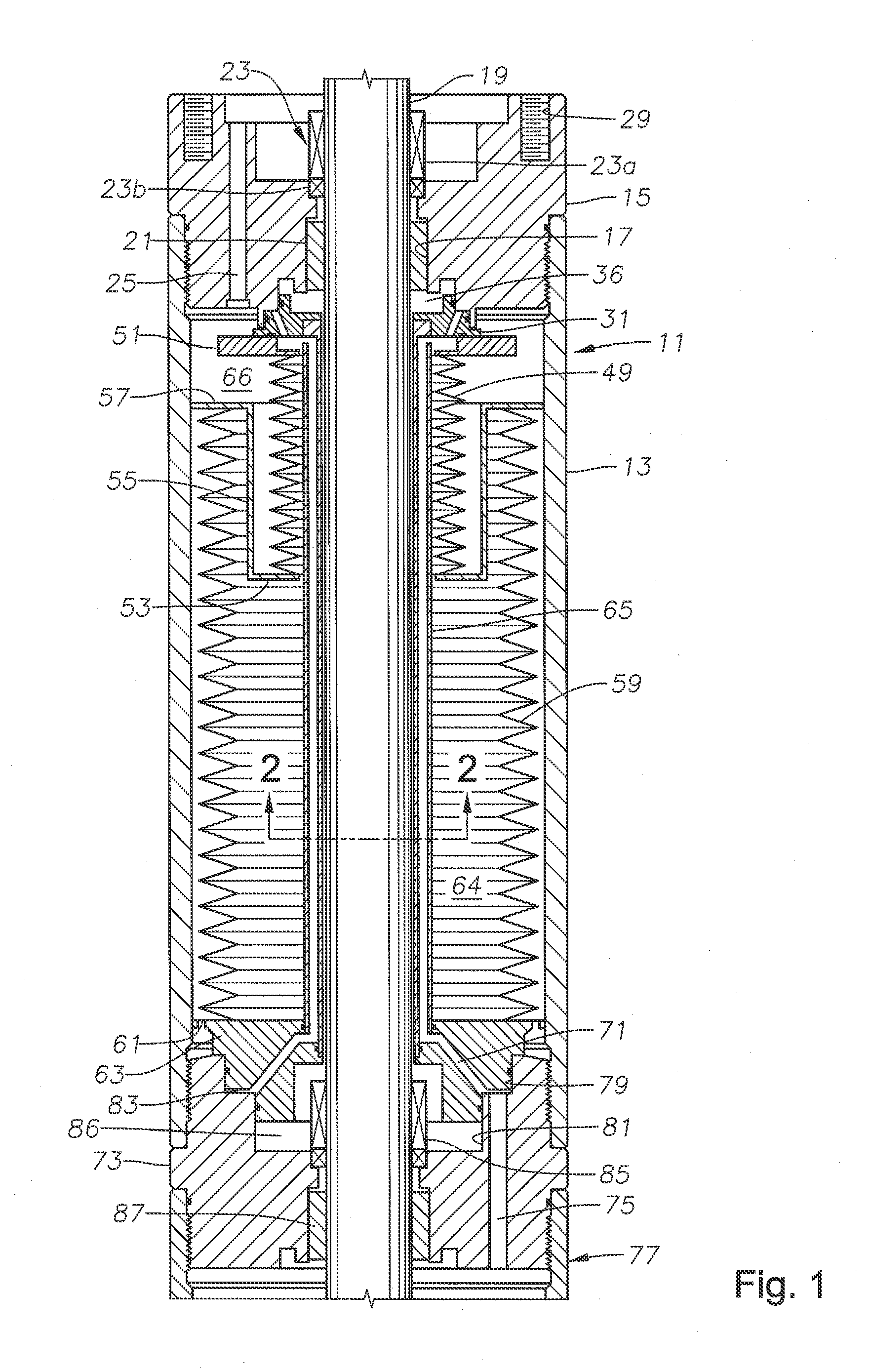

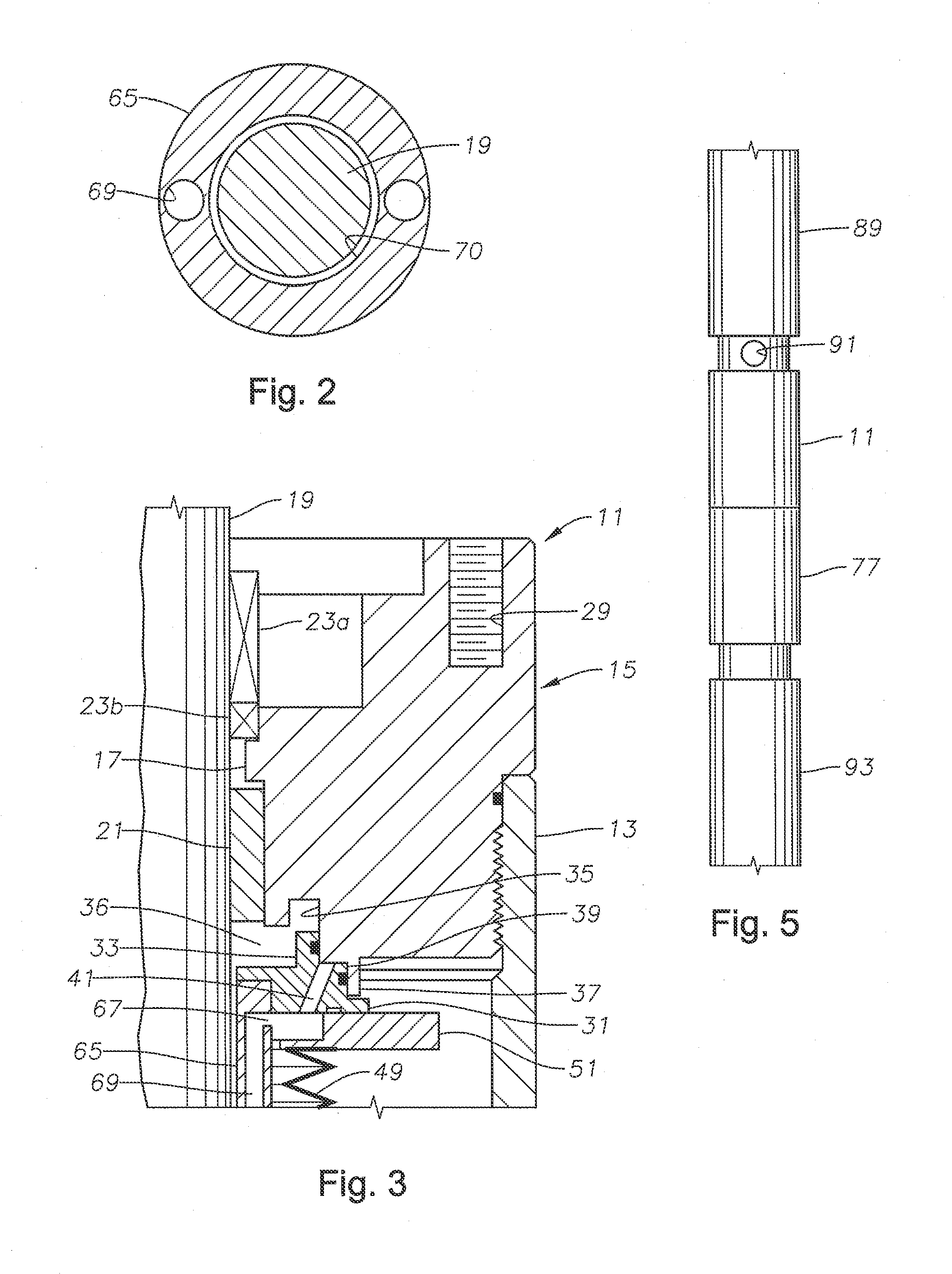

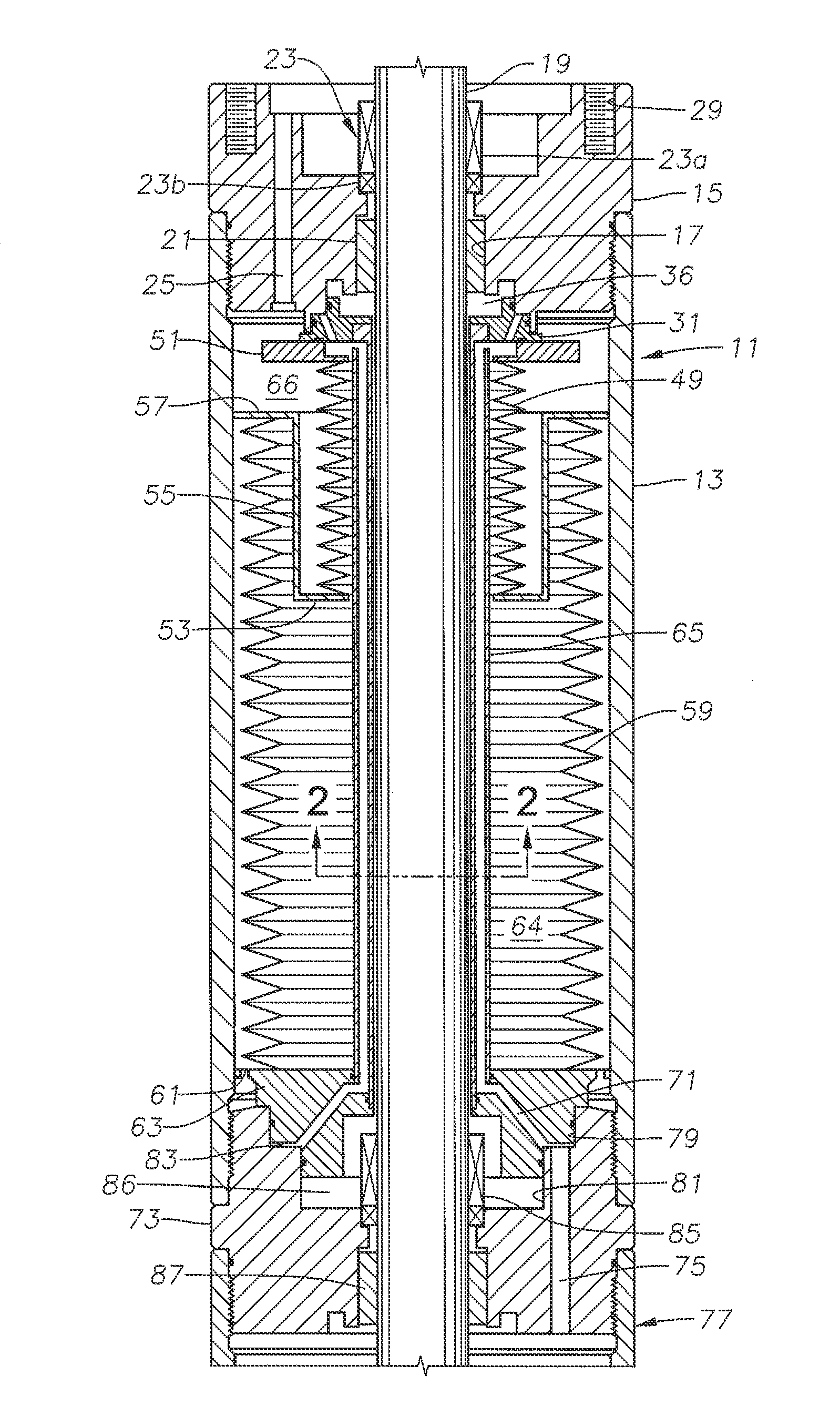

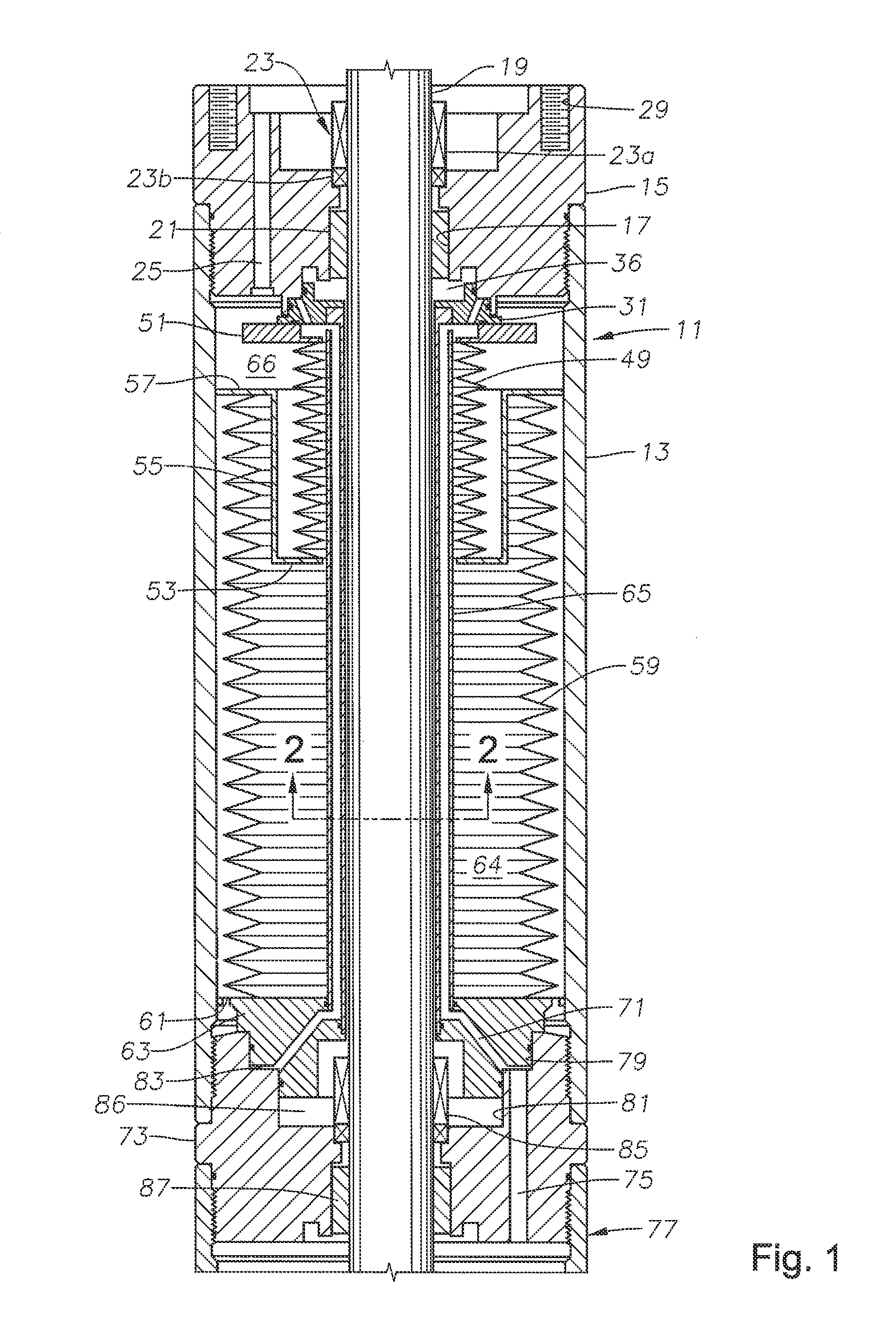

Well Pump with Seal Section Having a Labyrinth Flow Path in a Metal Bellows

A submersible well pump assembly has a rotary pump, a motor, and a seal section coupled between the motor and the pump. The seal section has a cylindrical housing having upper and lower adapter and a shaft extending axially through the housing. A guide tube surrounds the shaft and a bellows surrounds the guide tube. A well fluid passage communicates well fluid to a well fluid chamber between the bellows and the housing. A guide tube passage extends axially within the guide tube between an interior and an exterior of the guide tube from an upper portion to a lower portion of the guide tube for communicating lubricant in the motor with lubricant within the bellows.

Owner:BAKER HUGHES INC

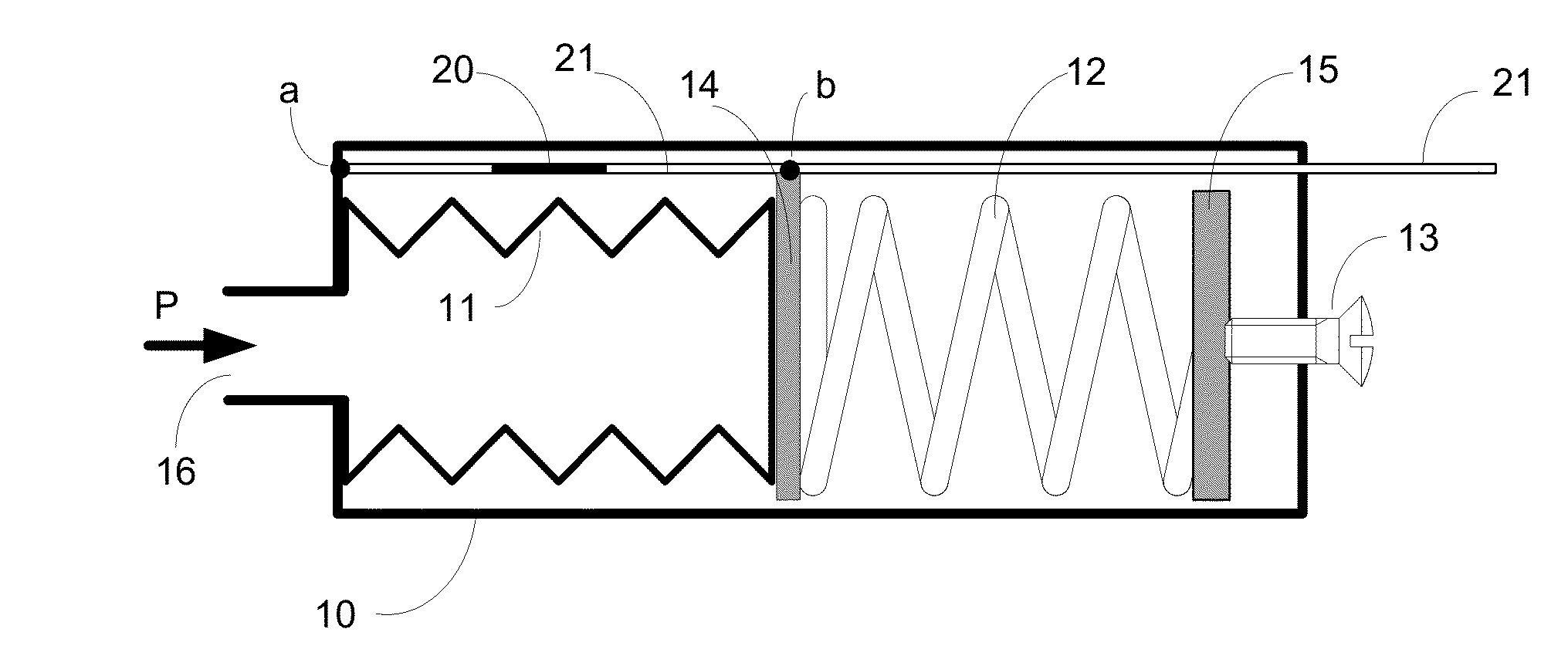

Fiber Bragg Grating Pressure Sensor with Adjustable Sensitivity

PendingUS20140123764A1Direct contact guaranteeFluid pressure measurement by electric/magnetic elementsForce measurementFiberGrating

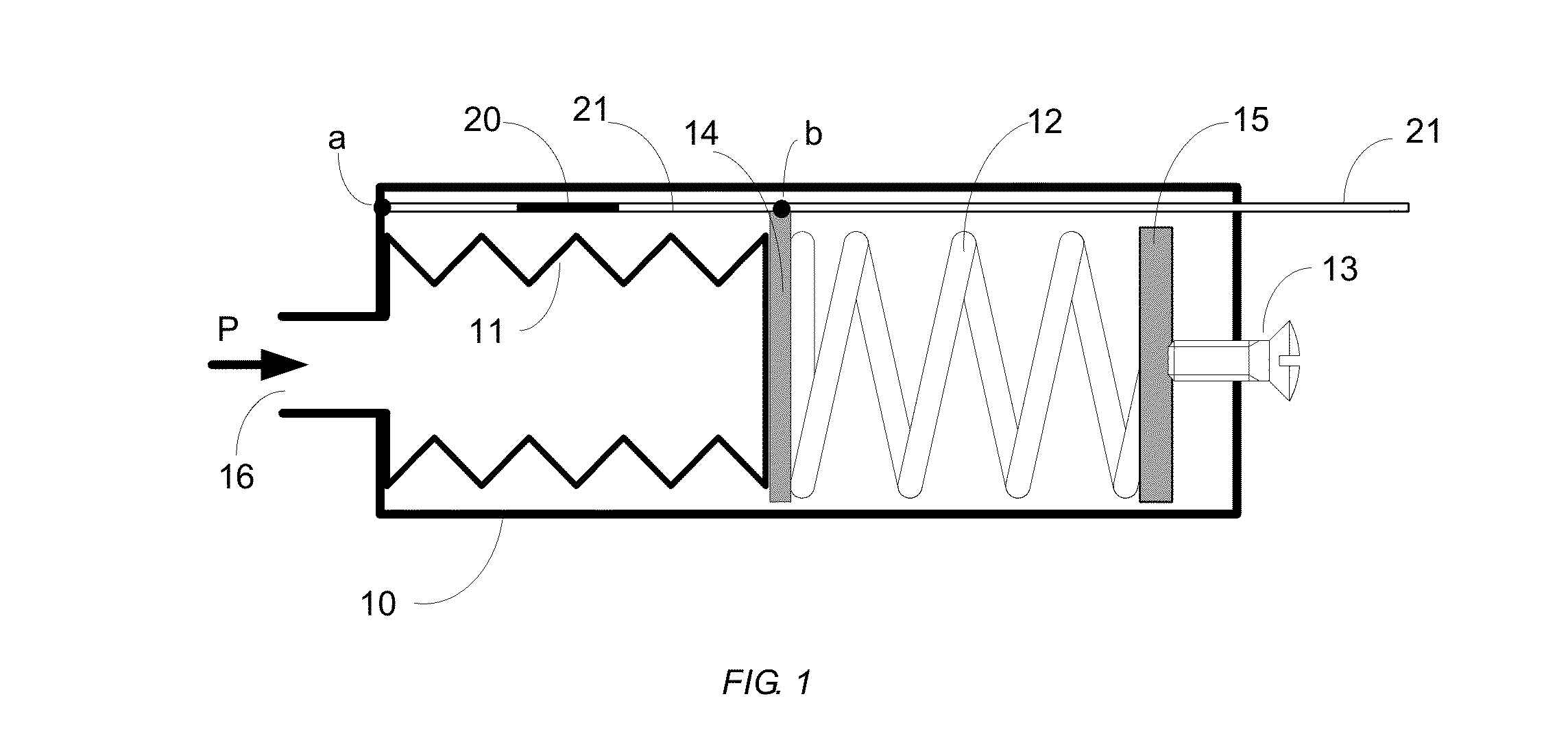

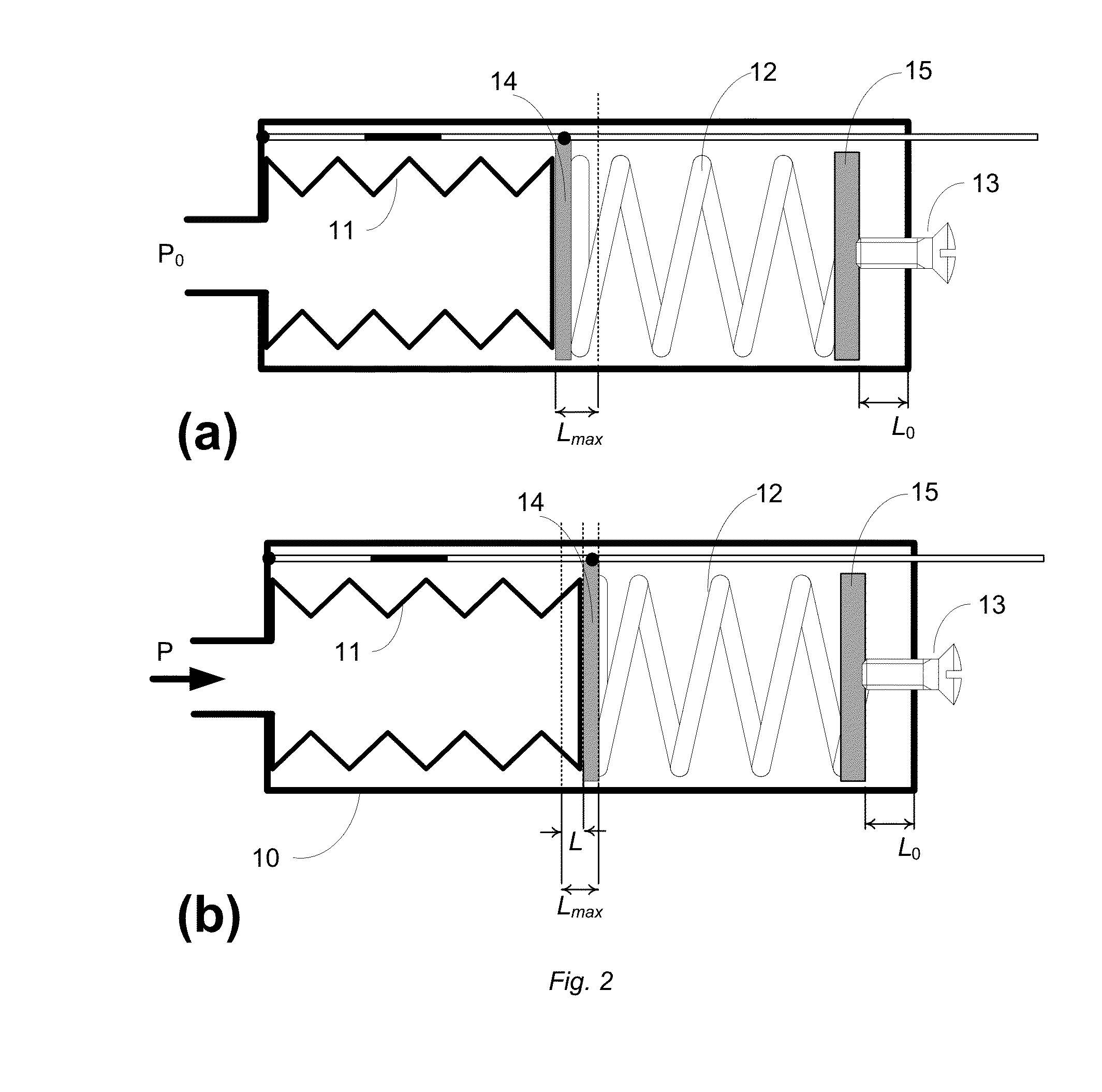

A new type of optical pressure sensor with adjustable sensitivity is proposed based on the fiber Bragg grating (FBG). In this technique, the pressure changes the length of a metal bellows which is placed behind a spring. The fiber grating is fixed over the bellows between a fixed position and the connection point of bellows and spring. The wavelength change of FBG is caused by the change in the bellows length; however, the spring controls the total length expansion of the bellows. It will bring two benefits: first it is easy to change the pressure sensing range by changing the spring rate; and secondly the spring improves the linearity of the wavelength sift due to the pressure. The FBG is installed outside of the bellows and is not in contact with the material in which the pressure should be measured (gas or liquid) in contrast with other pressure sensors where the FBG is inside the bellows. This is an important issue because some materials could damage or change the characteristics of the fiber over the time.The pressure range and the sensitivity of the proposed pressure sensor can be adjusted over a wide range simply and only by tuning two calibration screws, while all components of sensor remain the same.

Owner:ABTAHI MOHAMMAD +2

Fluid and elastomer apparatus

Owner:LORD CORP

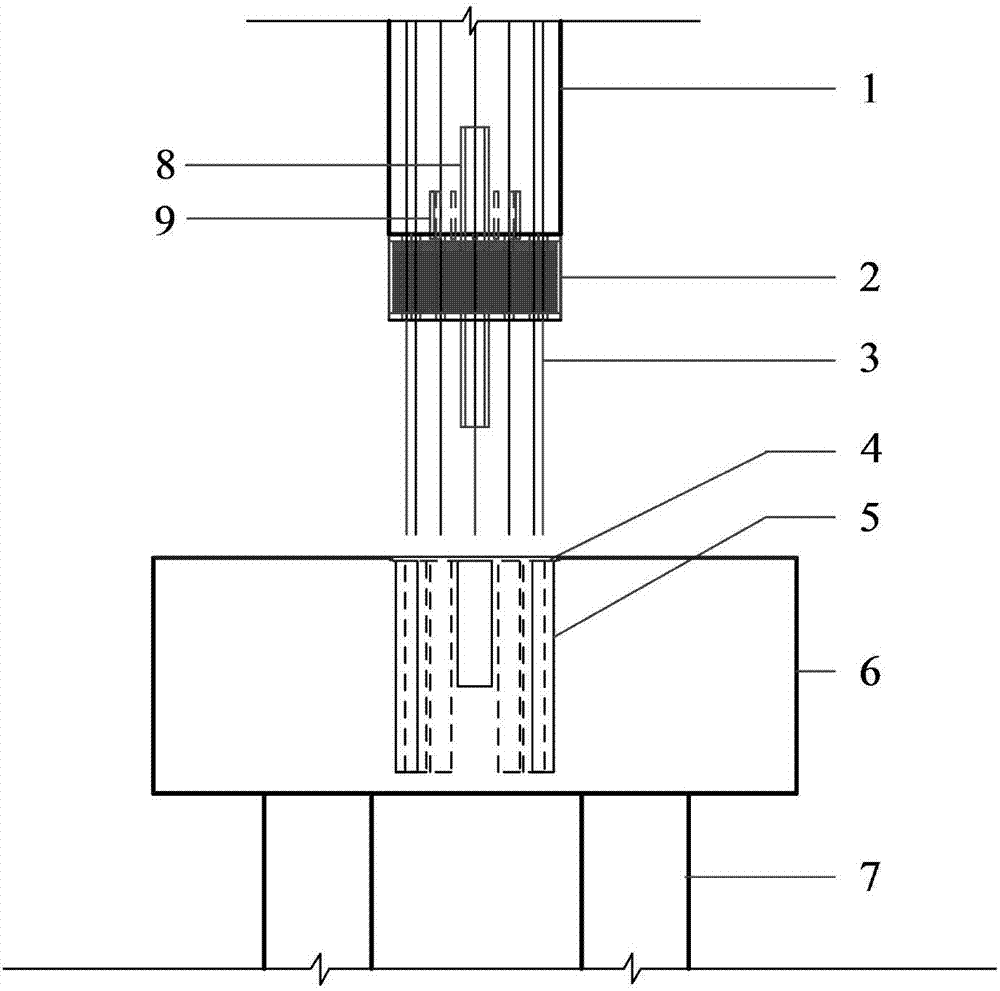

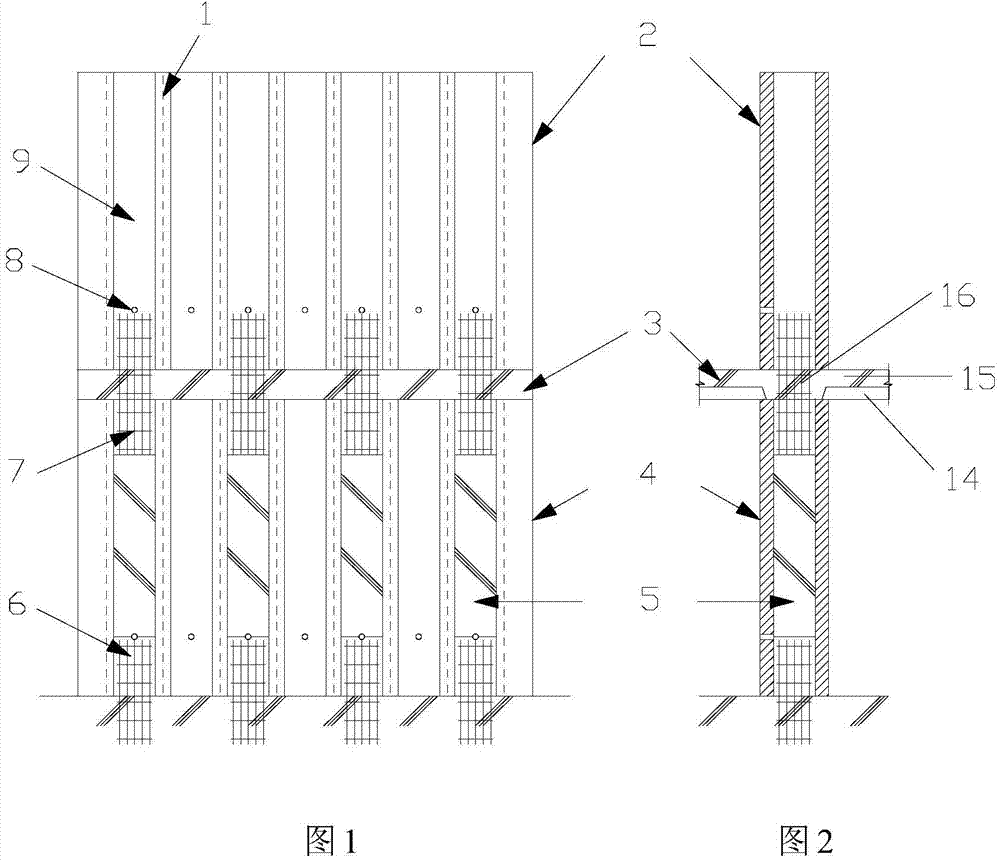

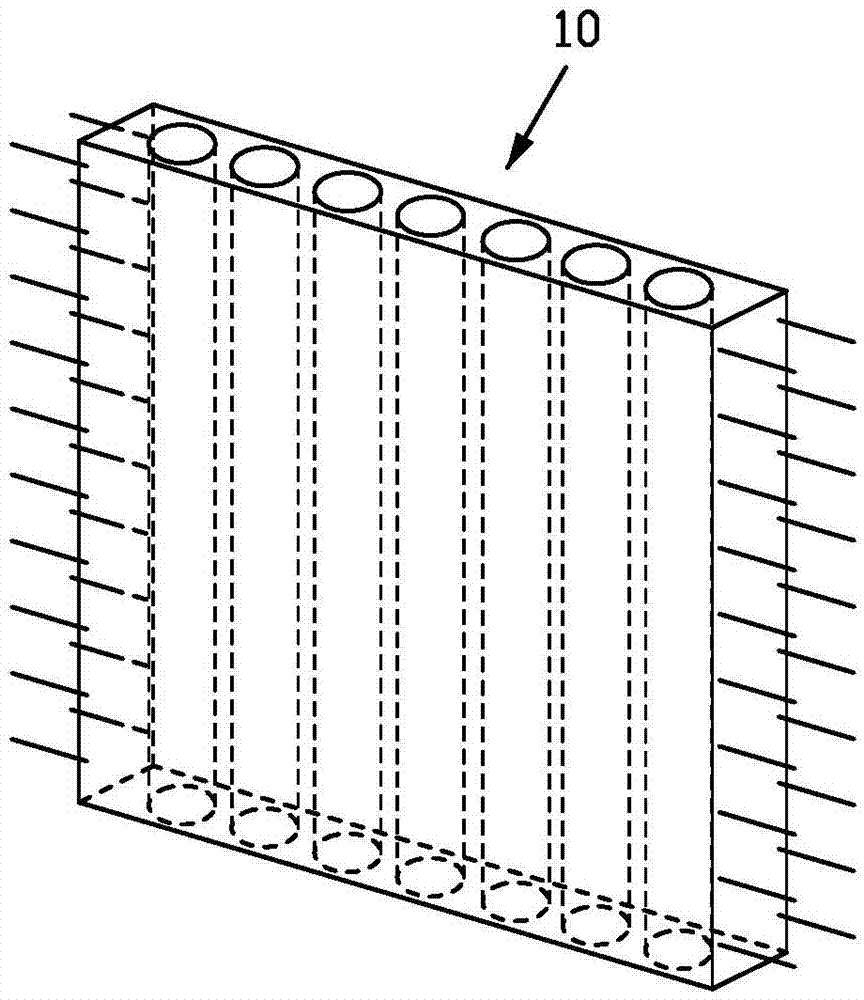

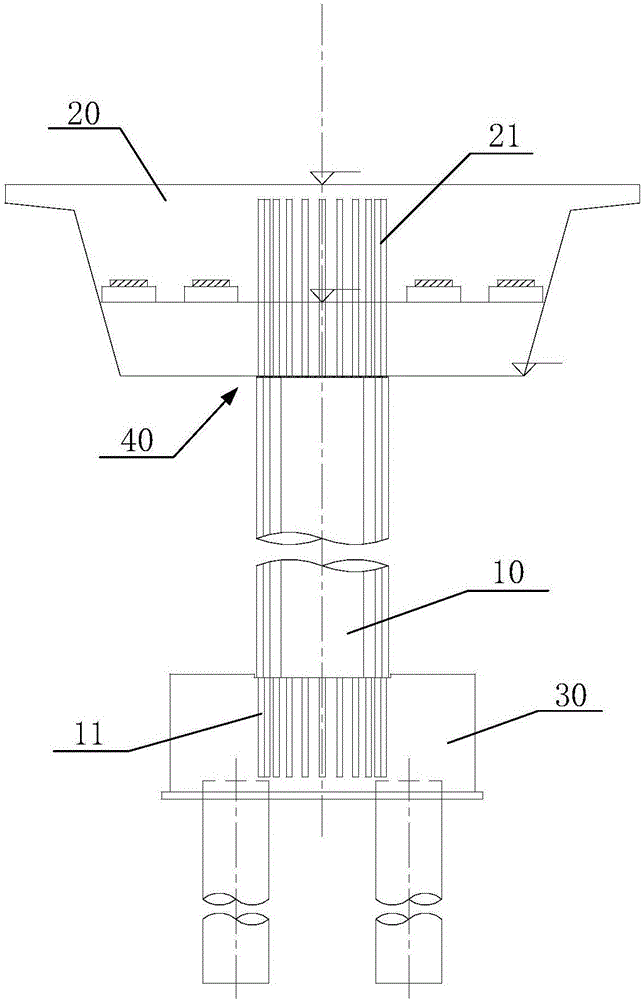

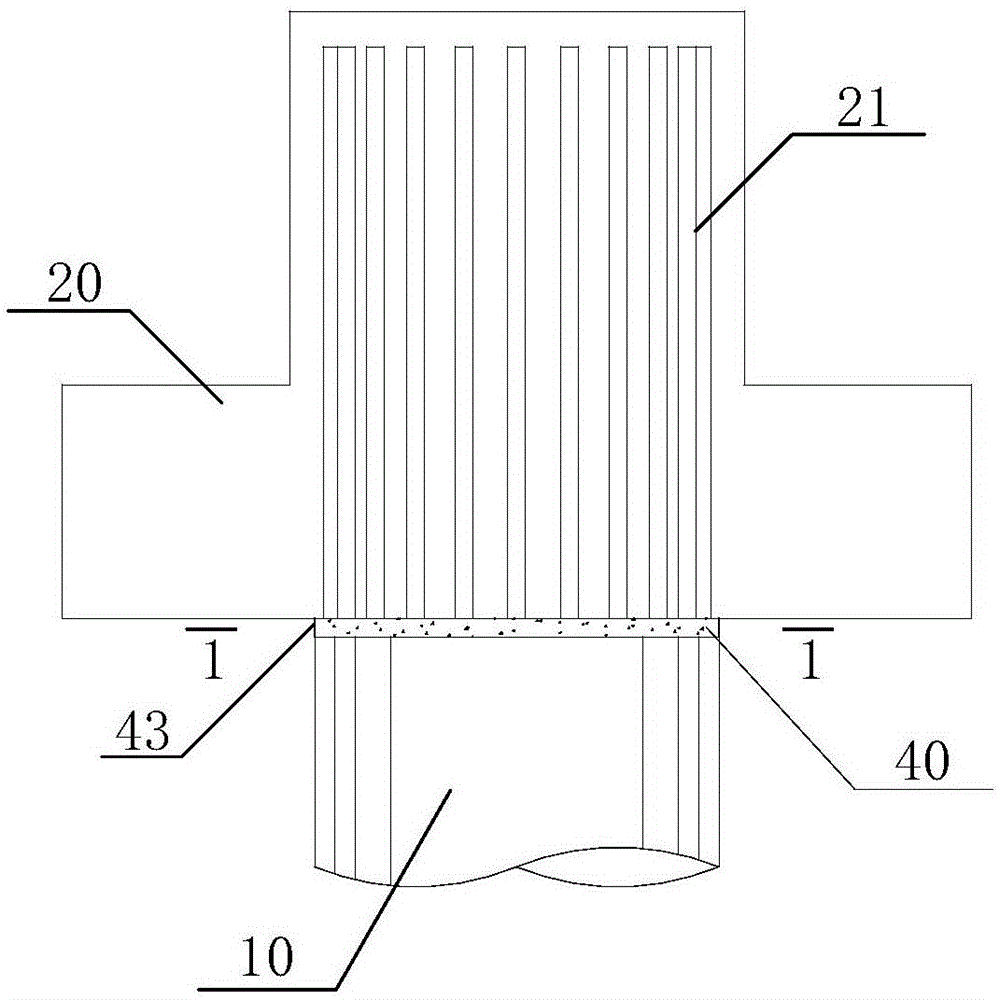

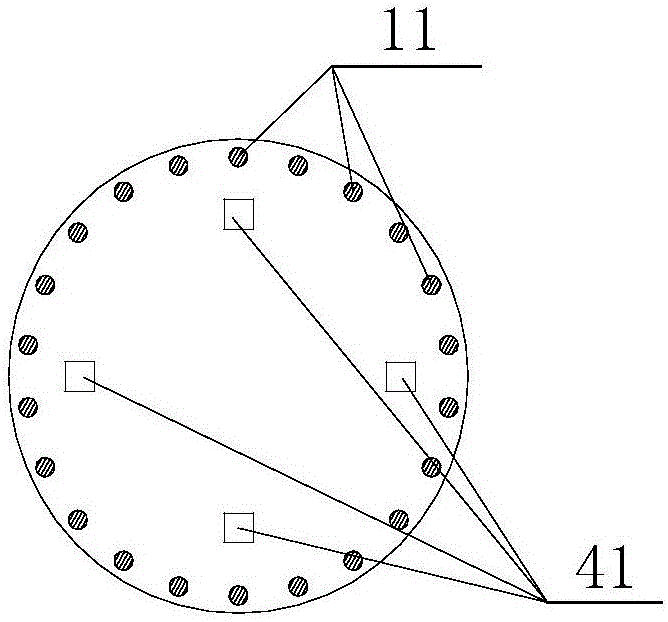

Joint connection mode for prefabricated spliced bridge pier with flexible layer arranged at bottom of pier and cushion cap and realization method thereof

The invention discloses a joint connection mode for a prefabricated spliced bridge pier with a flexible layer arranged at the bottom of the pier and a cushion cap and a realization method thereof. The flexible layer at the bottom of the prefabricated pier, longitudinal reinforcements extending out from the bottom of the prefabricated pier, pre-buried metallic bellows in the cushion cap, preserved grooves in the top face of the cushion cap and self-compaction high-strength micro-expansion grouting materials grouted through the metallic bellows are involved in the joint connection mode. An overlapped steel plate rubber layer is installed at the bottom of the bridge pier and formed with the bridge pier in a cast and prefabricated mode, the self-compaction high-strength micro-expansion grouting materials are grouted into the pre-buried metallic bellows in the cushion cap and overflow so that the grooves can be filled with the grouting materials, and then the longitudinal reinforcements extending out from the bottom of the prefabricated bridge pier are inserted into the pre-buried metallic bellows until the bottom of the prefabricated bridge pier is inserted into the grooves to be compacted. The construction mode is simple; the bridge pier is formed in a prefabricated mode, in this way, the on-site construction speed of projects is increased, and the quality of the projects is improved; due to the overlapped steel plate rubber layer arranged at the bottom of the prefabricated bridge pier, the ductility of the bridge pier can be obviously improved, and the damage degree of the plastic hinge region of a pier stud is reduced.

Owner:BEIJING UNIV OF TECH

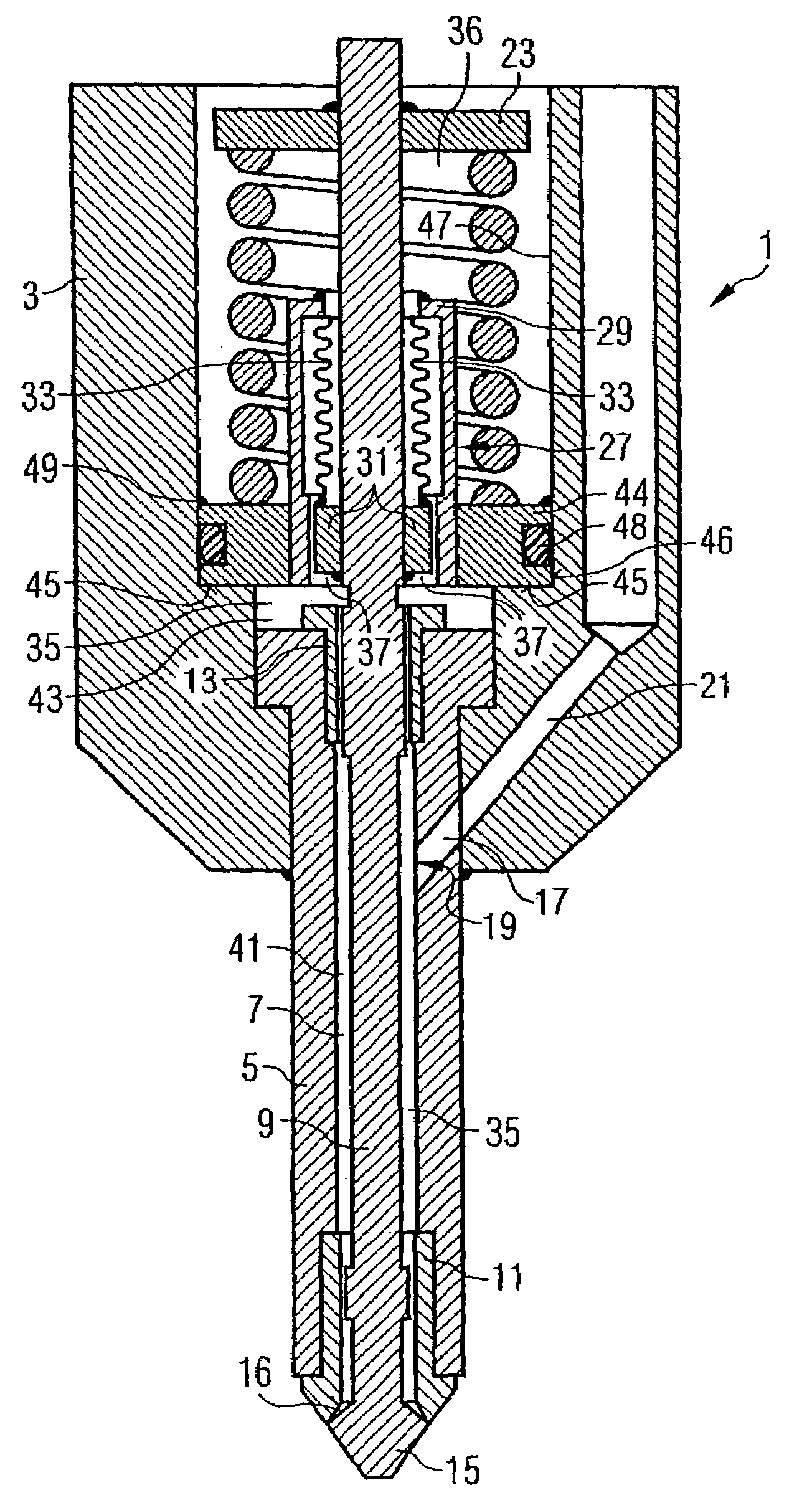

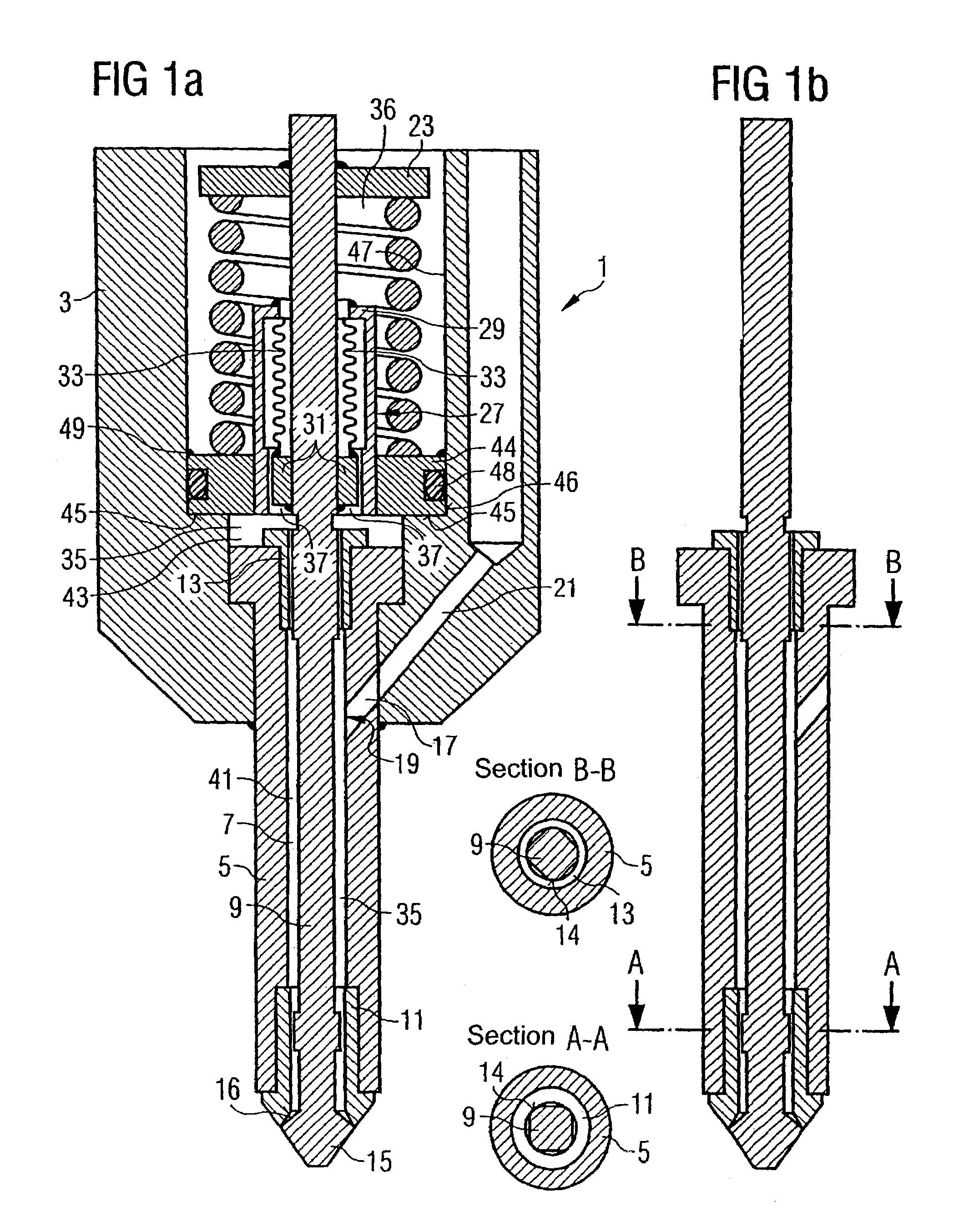

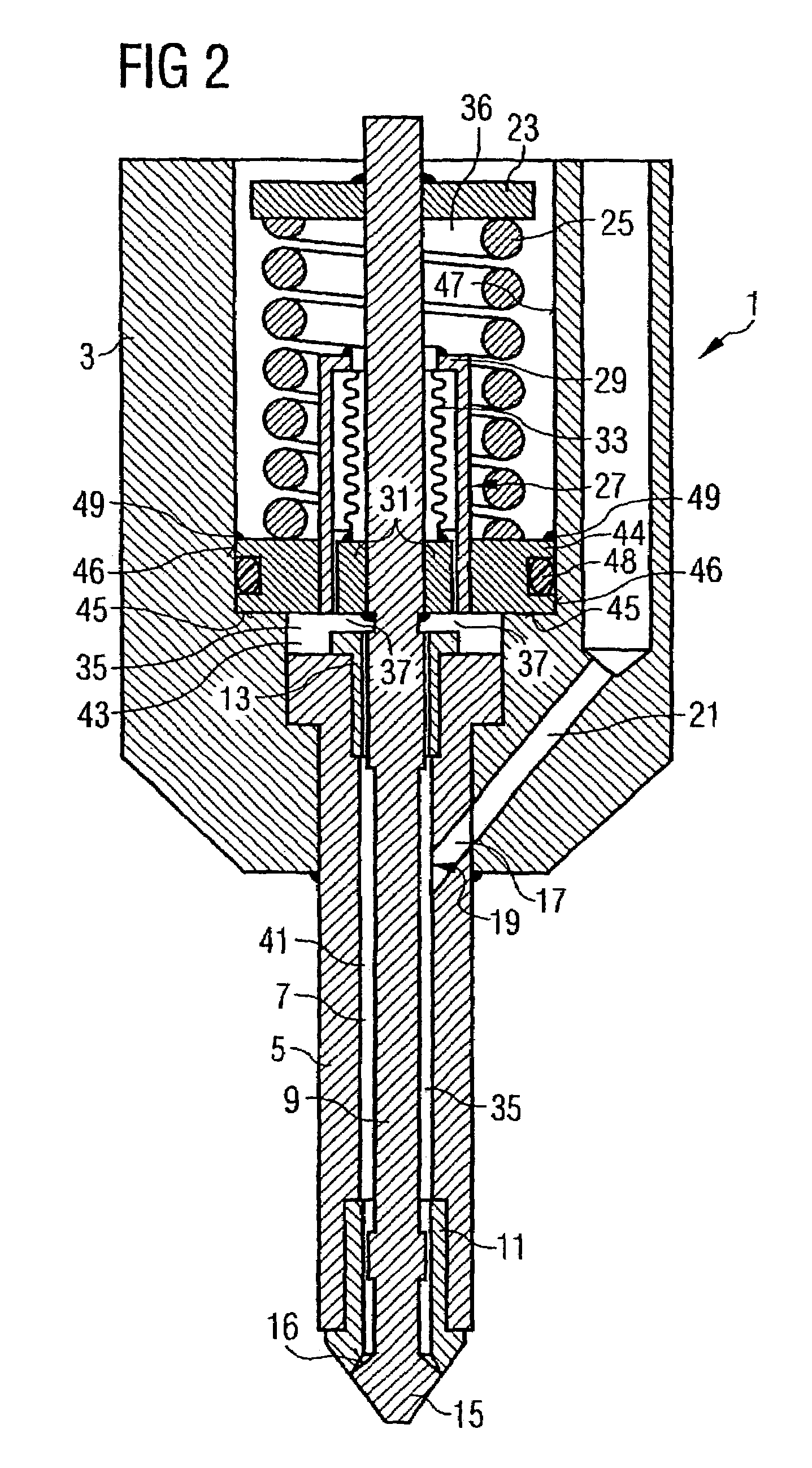

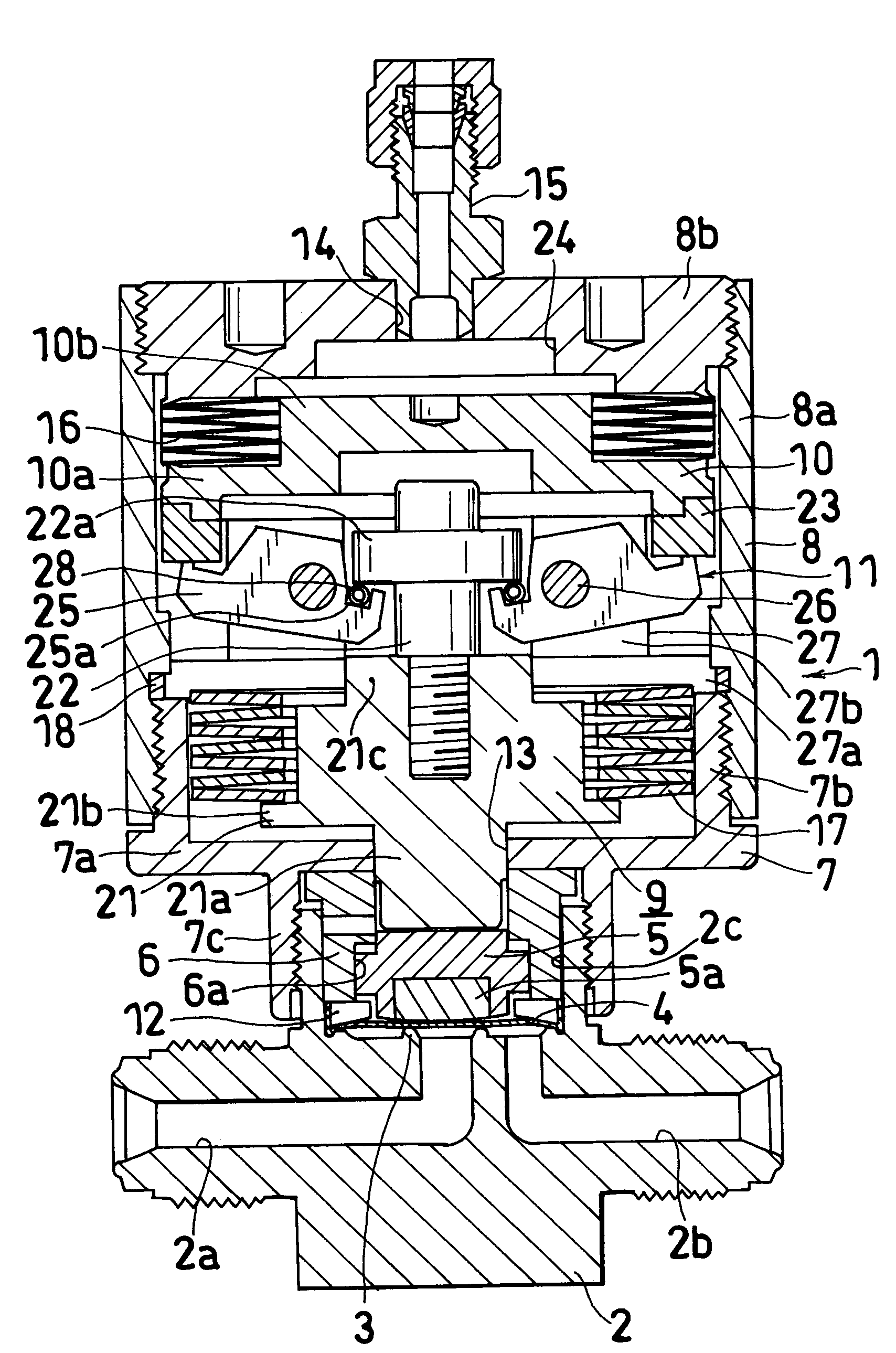

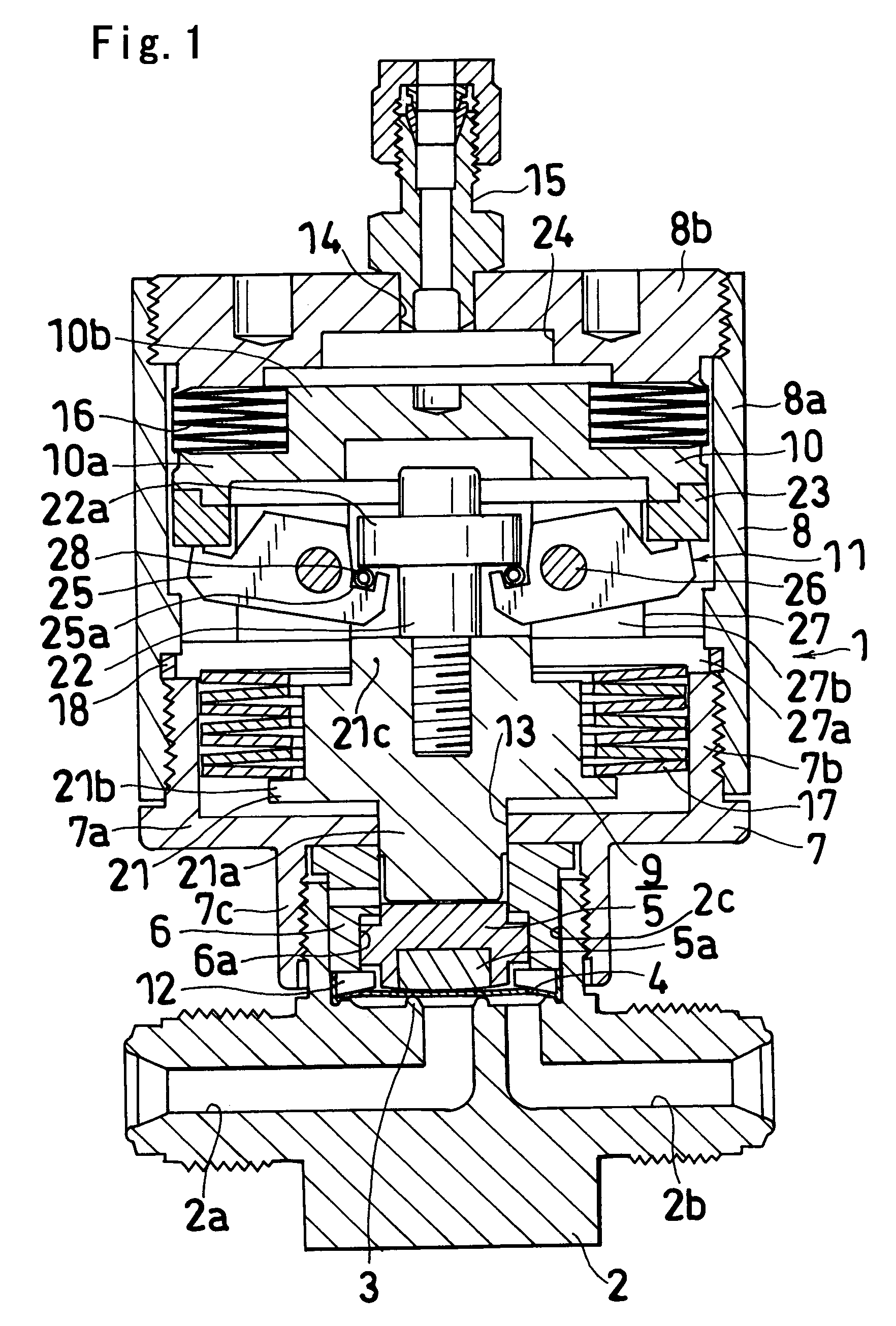

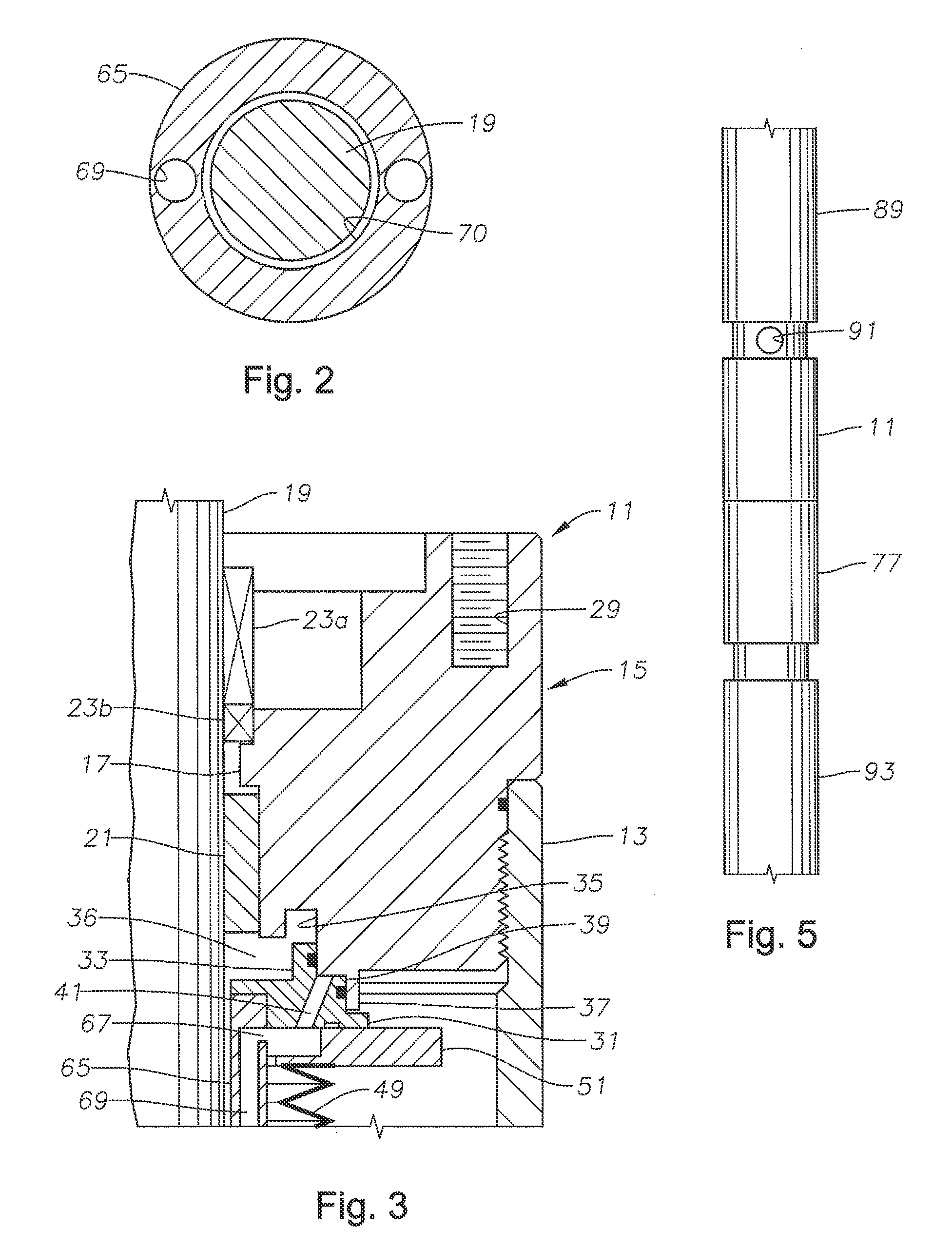

Fluid dosing device with a throttle point

InactiveUS7044407B2Increase resistanceIncrease wall thicknessOperating means/releasing devices for valvesSpray nozzlesBiomedical engineeringThrottle

A fluid dosing device for a pressurized liquid is disclosed, which comprises a chamber (35) which is supplied with pressurized liquid by means of a liquid supply line (17, 19); a valve needle (9) which is guided through the chamber (35), the first end section of said valve needle being able to be lifted and the second end section thereof forming a valve in conjunction with a valve seat disposed on the housing (3). Metal bellows (33) are provided as a leadthrough element for the first end section of the valve needle (9). The metal bellows seal the chamber in said region in a tight manner. A throttle point (37, 39) is provided between the valve needle (9) and the inner wall of the chamber between the metal bellows (33) and the mouth (18) of the liquid supply line (17) leading into the chamber.

Owner:SIEMENS AG

Vertical connection structure for precast concrete shear walls and construction method

ActiveCN104847014ALose weightAvoid crackingConstruction materialWallsHorizontal distributionFloor slab

Owner:吉林长发建筑产业化有限公司

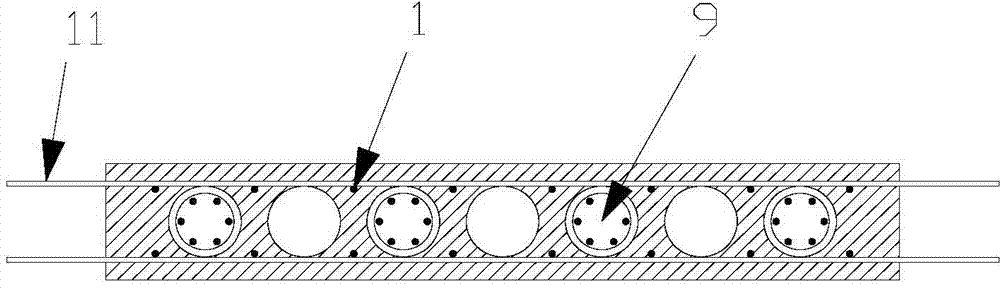

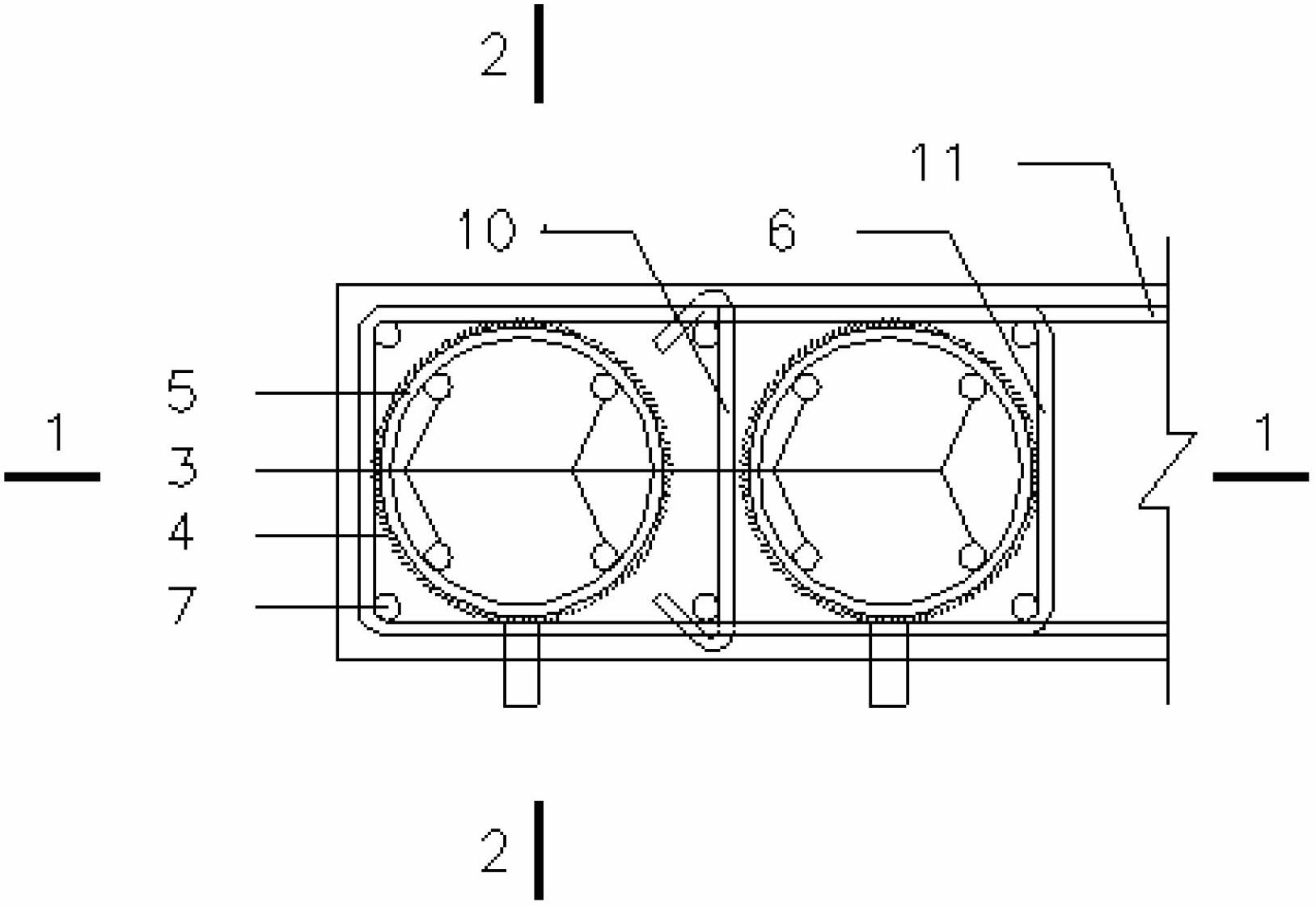

Accumulator

InactiveUS20070102052A1Made smallSolve large capacityAccumulator installationsPipe elementsEngineeringWeld penetration

An accumulator in which a pressure sealed chamber and a pressure flow-in chamber are formed by an operation member including a metallic bellows provided within a housing constituted by a gas end cover and a bottomed tubular shell, wherein a cross sectional inner outline of a peripheral edge portion of the gas end cover is an oval shape which is concave to the pressure sealed chamber side, and a dead space is not formed, so that a capacity of a volume adjusting spacer is reduced by eliminating a dead space, a working step is reduced by simplifying a shape of the gas end cover, and a margin of welding penetration depth is increased by thickening of a backing metal portion.

Owner:NOK CORP

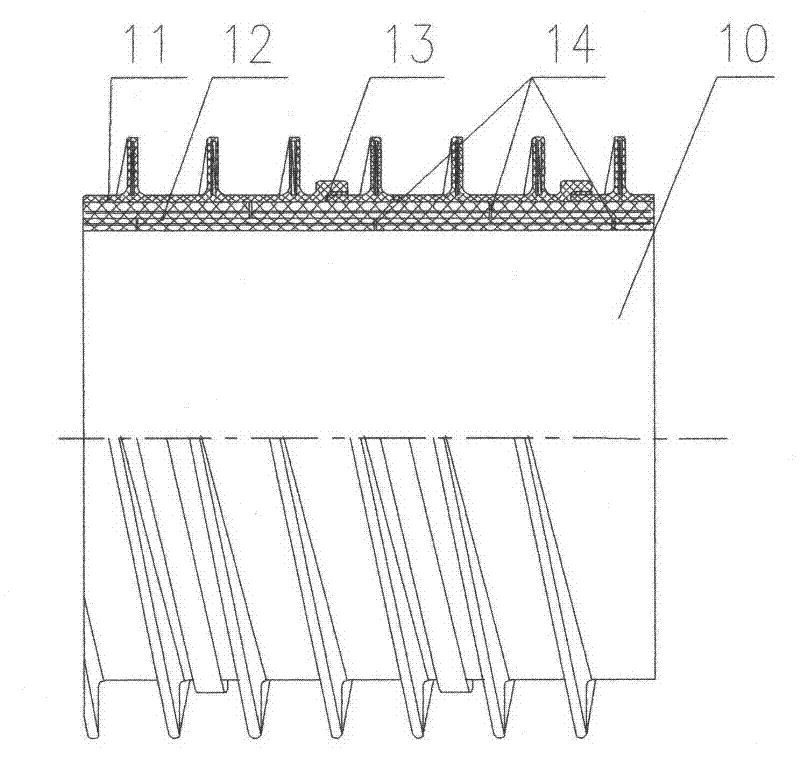

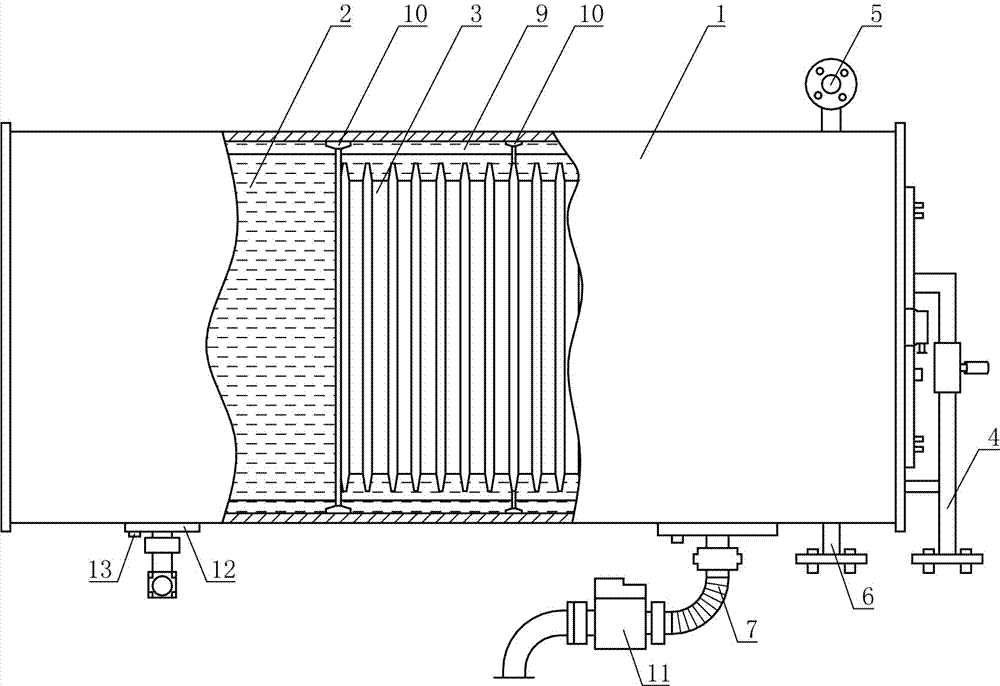

Water pipe, strip material, method and apparatus for manufacturing water pipe

ActiveCN102269298ALess material consumptionLarge caliberSynthetic resin layered productsRigid pipesWater sourceSpiral wound

A water conveying pipe includes a composite reinforced outer pipe formed by spiral winding, and a composite reinforced inner lining pipe formed by spiral winding. The outer tube is a metal-reinforced plastic composite corrugated tube structure or a tube structure with metal-reinforced plastic composite vertical ribs. The inner lining pipe is formed by at least two layers of fiber-reinforced plastic composite strips that are continuously spirally wound along the inner wall of the outer pipe and attached to the inner wall of the outer pipe, and the inner lining pipe covers the helically wound seam of the outer pipe . The present invention also provides strips, methods and devices for manufacturing the above-mentioned water delivery pipe lining pipes. The pipeline can be used as a large and medium-sized water pipeline in the water source transmission of urban water plants.

Owner:ハルビンスターウェイマシーナリーマニュファクチャリングカンパニーリミテッド

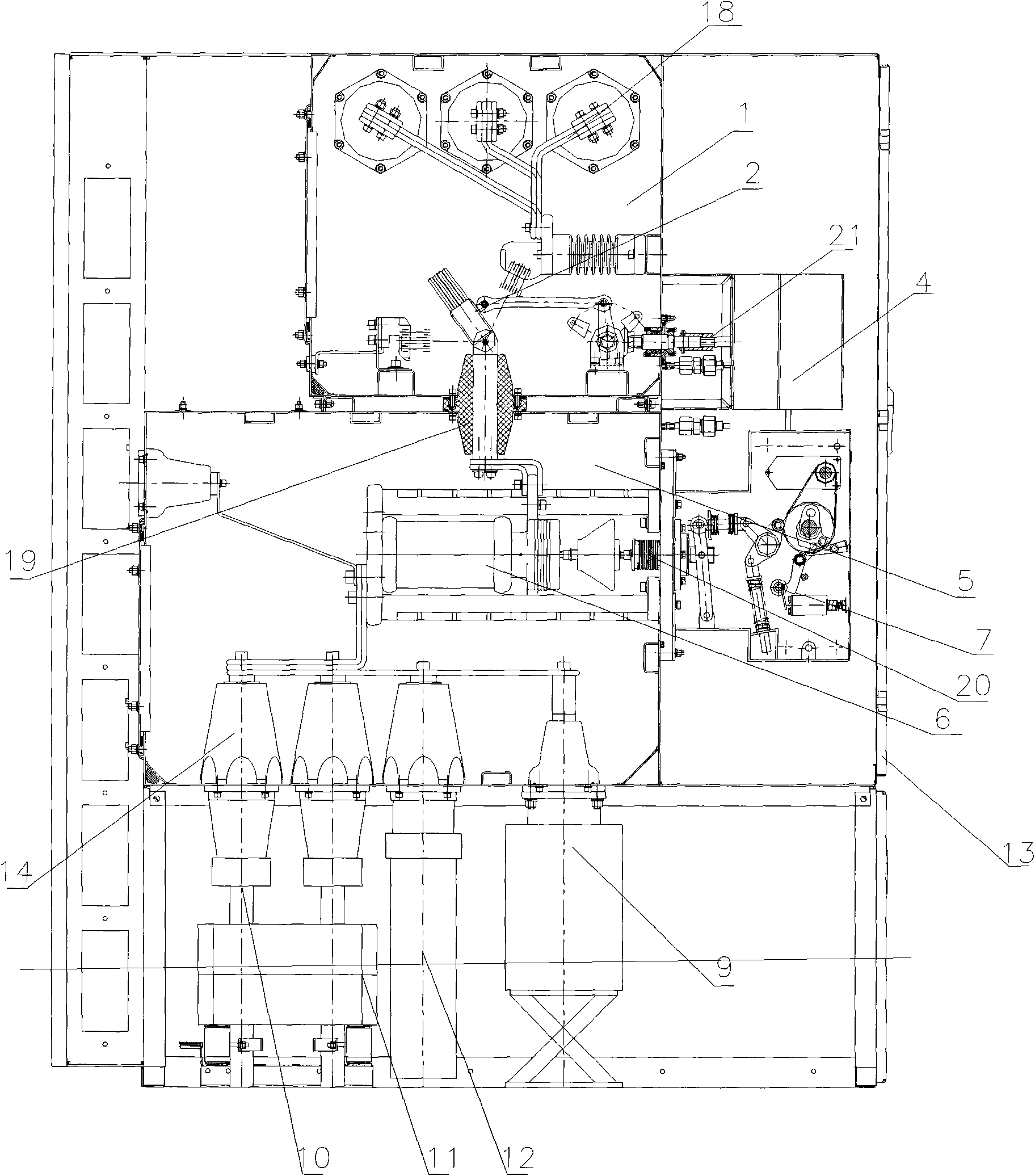

Box-sharing gas-insulated metal enclosed switching device

InactiveCN102044849AReduce volumeReduce areaBus-bar/wiring layoutsSwitchgear arrangementsTransformerPotential transformer

The invention discloses a box-sharing gas-insulated metal enclosed switching device. An upper sealed air box and a lower sealed air box are arranged in a cabinet body; a three-position isolating switch, a main bus casing and a main bus are arranged in the upper air box; an output shaft of a three-position spring operating mechanism extends into the upper air box and is connected with the three-position isolating switch through a rotary sealed connector; the three-position isolating switch is connected with a vacuum circuit breaker in the lower air box through a bus connector; the vacuum circuit breaker is connected with a spring mechanism through a metal corrugated pipe sealing mechanism; the vacuum circuit breaker is connected with an inner conical insulator which is sealed and fixed on the wall of the lower air box through a lead; and the inner conical insulator is inserted into a voltage transformer, a cable joint, a zero sequence transformer and a lightning arrester respectively. The switching device has the characteristics of good sealing effect, long service life, small size and wide application range and is safe and reliable.

Owner:昇辉智能科技股份有限公司

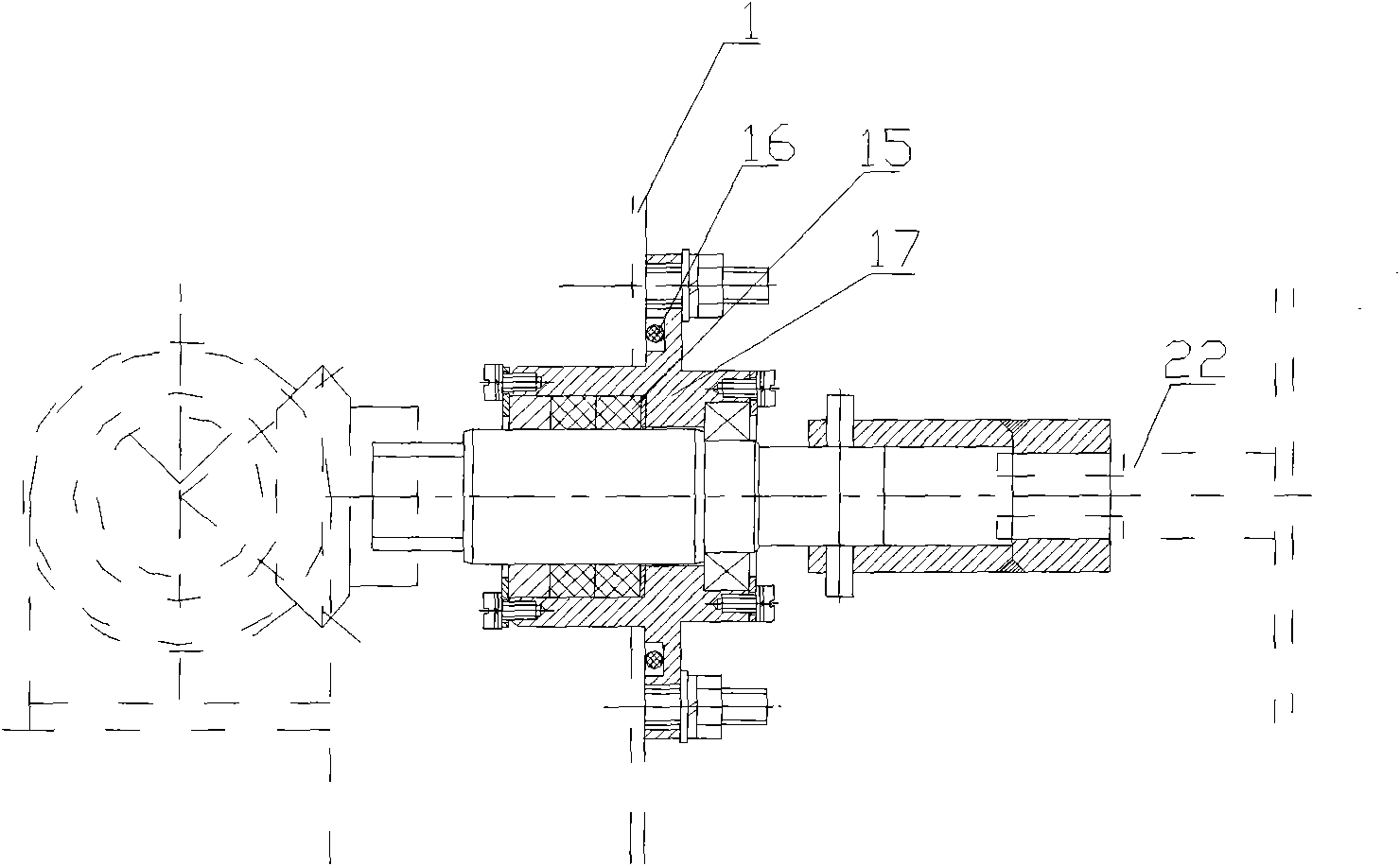

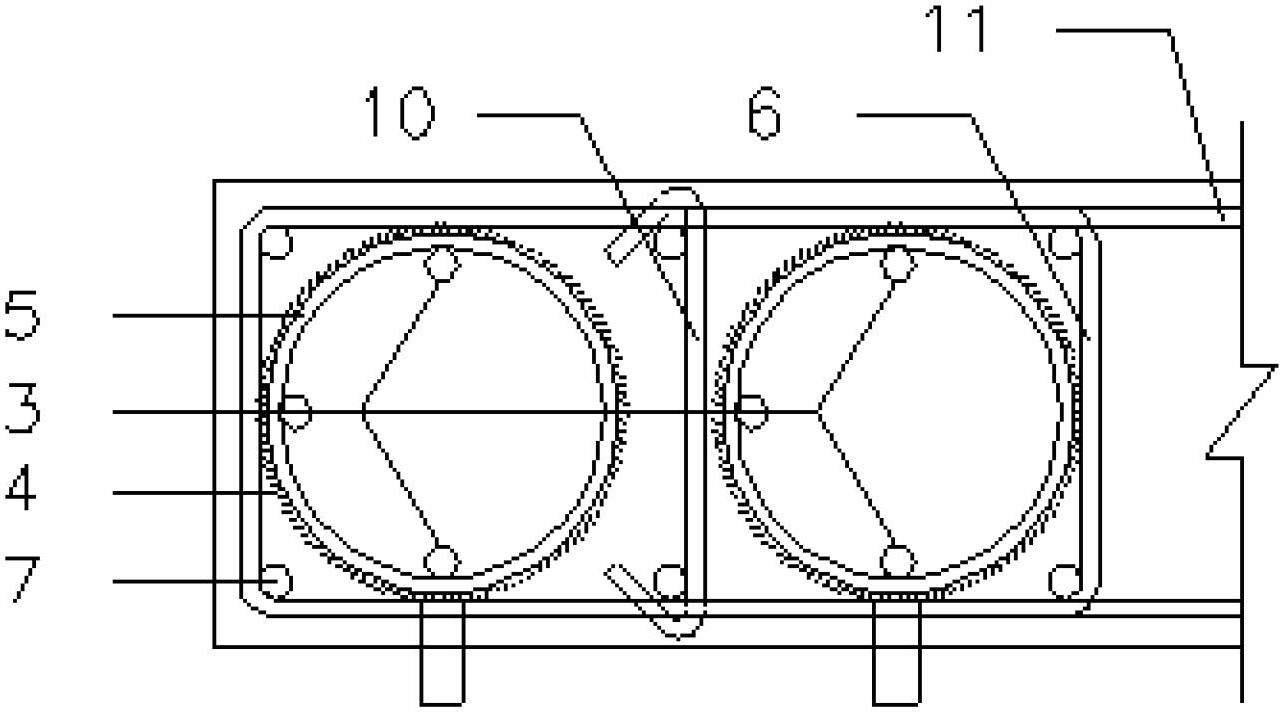

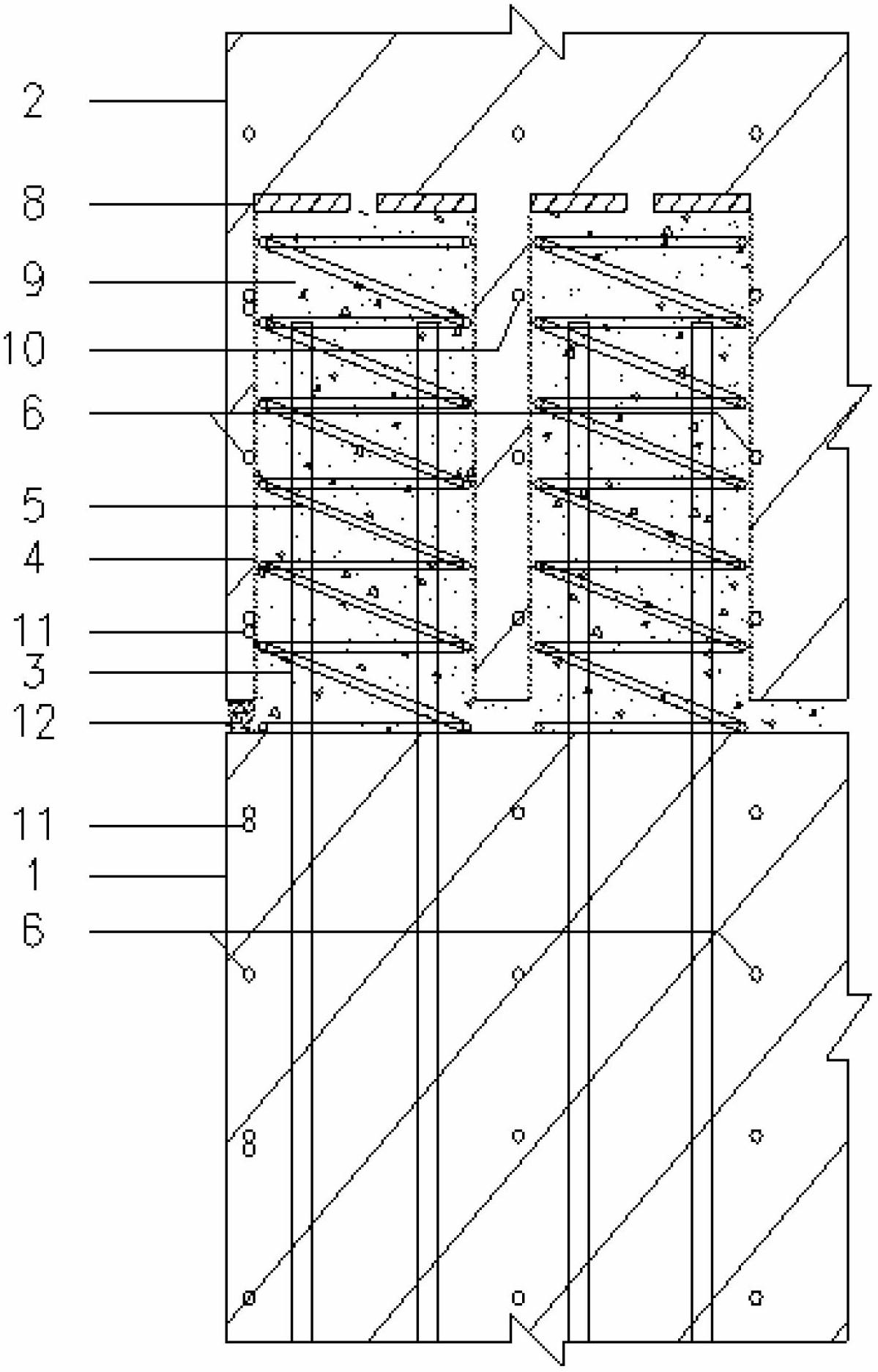

Metal corrugated pipe type oil storage cabinet

InactiveCN102832016AImprove the safe operation factorVolume Compensation RealizedTransformers/inductances coolingInjection portEngineering

The invention relates to a voltage transformation device, in particular to a metal corrugated pipe type oil storage cabinet with good sealing property, long service life, full-vacuum oil injection, visual and reliable indication, less jamming, no maintenance and convenience for installation. The metal corrugated pipe type oil storage cabinet comprises a cabinet body (1), an oil cavity (2), a corrugated pipe assembly (3), a sliding guide mechanism, a breathing port (4), an air exhaust port (5), an oil injection port (6) and a corrugated flexible connecting pipe (7), wherein the corrugated pipe assembly (3) is hermetically arranged at one side inside the cabinet body (1), the sliding guide mechanism is arranged on the side wall inside, the air exhaust port (5) is arranged above the cabinet body (1) outside, and the oil injection port (6) and the corrugated flexible connecting pipe (7) are respectively arranged below the cabinet body (1) outside; the oil cavity (2) is formed inside the cabinet body (1) and outside the corrugated pipe assembly (3); the sliding guide mechanism is in sliding connection with the corrugated pipe assembly (3); and the breathing port (4) is communicated with an inner cavity of the corrugated pipe assembly (3), and the air exhaust pipe (5) is communicated with the oil cavity (2).

Owner:李肃

Control device

InactiveUS7159839B2Increase pressureIncrease resistanceDiaphragm valvesEngine sealsEngineeringValve stem

Booster means 11 for transmitting a force acting on a piston 10 to a valve stem 9 on amplification comprises pivotal members 25 each supported by casings 7, 8 so as to hold an outer end and an inner end thereof in contact with an outer peripheral portion of the piston 10 and a flange portion 22a formed on the valve stem 9 respectively from below and to be pivotally movable about a horizontal rod 26 positioned closer to the inner end. Metal bellows 16 are provided between an outer peripheral portion of the casing top wall 8a and the outer peripheral portion of the piston 10 for sealing off a compressed air admitting space.

Owner:FUJIKIN INC

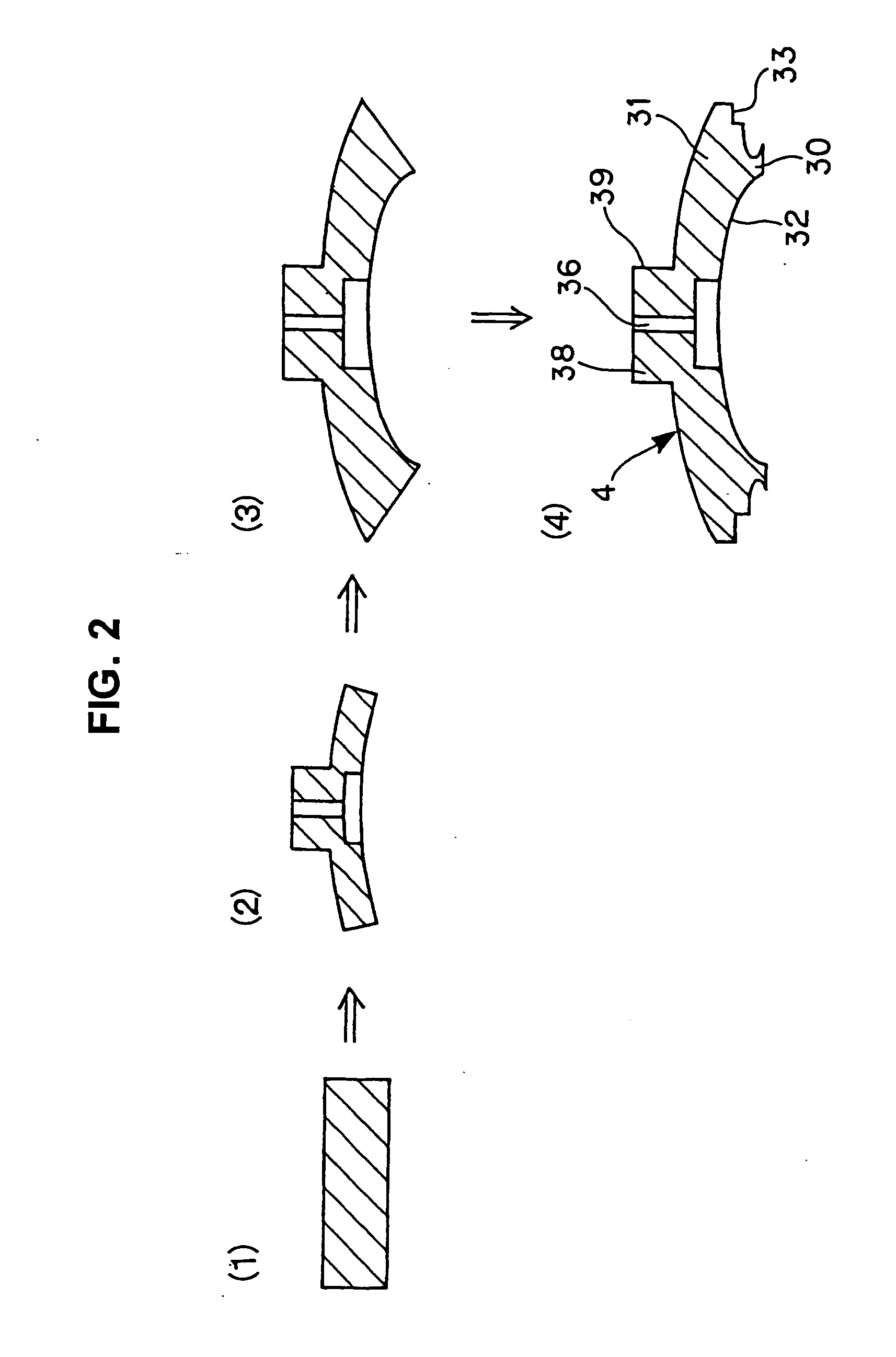

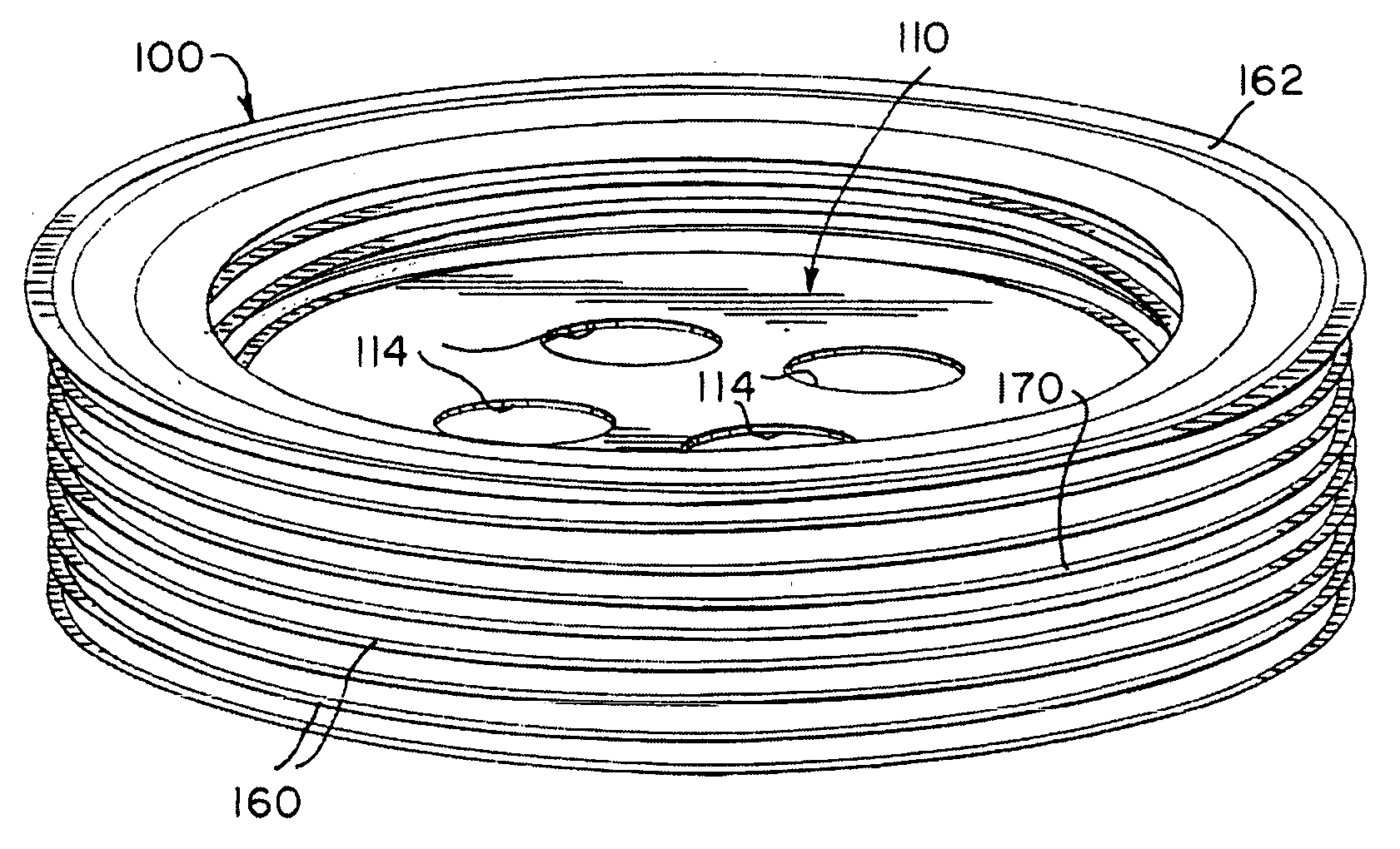

Method of Making a Metal Bellows Assembly Having an Intermediate Plate

InactiveUS20090188897A1Easy to moveIntravenous devicesWelding/cutting media/materialsThin metalSized small

The formation of a bellows made up of a stack of a predetermined number of ring-convolutions and having an intermediate plate supported within said stack is achieved by supplying several thin metal rings, each having inner and outer edges. A pair of these metal rings are positioned in contiguous relationship and their adjacent inside edges are welded together to form a ring-convolution. This process is repeated until a sufficient number of ring-convolutions are made to eventually make the desired bellows. Before these separate ring-convolutions are fused to each other, an intermediate plate and a support ring are made. The intermediate plate is a disc of metal that is sized smaller than the inside diameter of the rings and is secured to the support ring. The support ring is then positioned between two formed ring-convolutions in contiguous relationship and the three abutting outside edges are welded to each other to form a support plate convolution. The already made ring-convolutions and the support plate convolution are then stacked in the desired order and in contiguous relationship. All not-yet welded adjacent outside edges of said ring-convolutions and said support plate convolution are then welded to form the bellows. A bottom plate is formed and welded to the outside edge of the bottommost ring-convolution and a top ring is finally welded to the uppermost convolution to complete the bellows. The top ring is meant to be welded to a base plate of an infusion pump.

Owner:MEDOS INT SARL

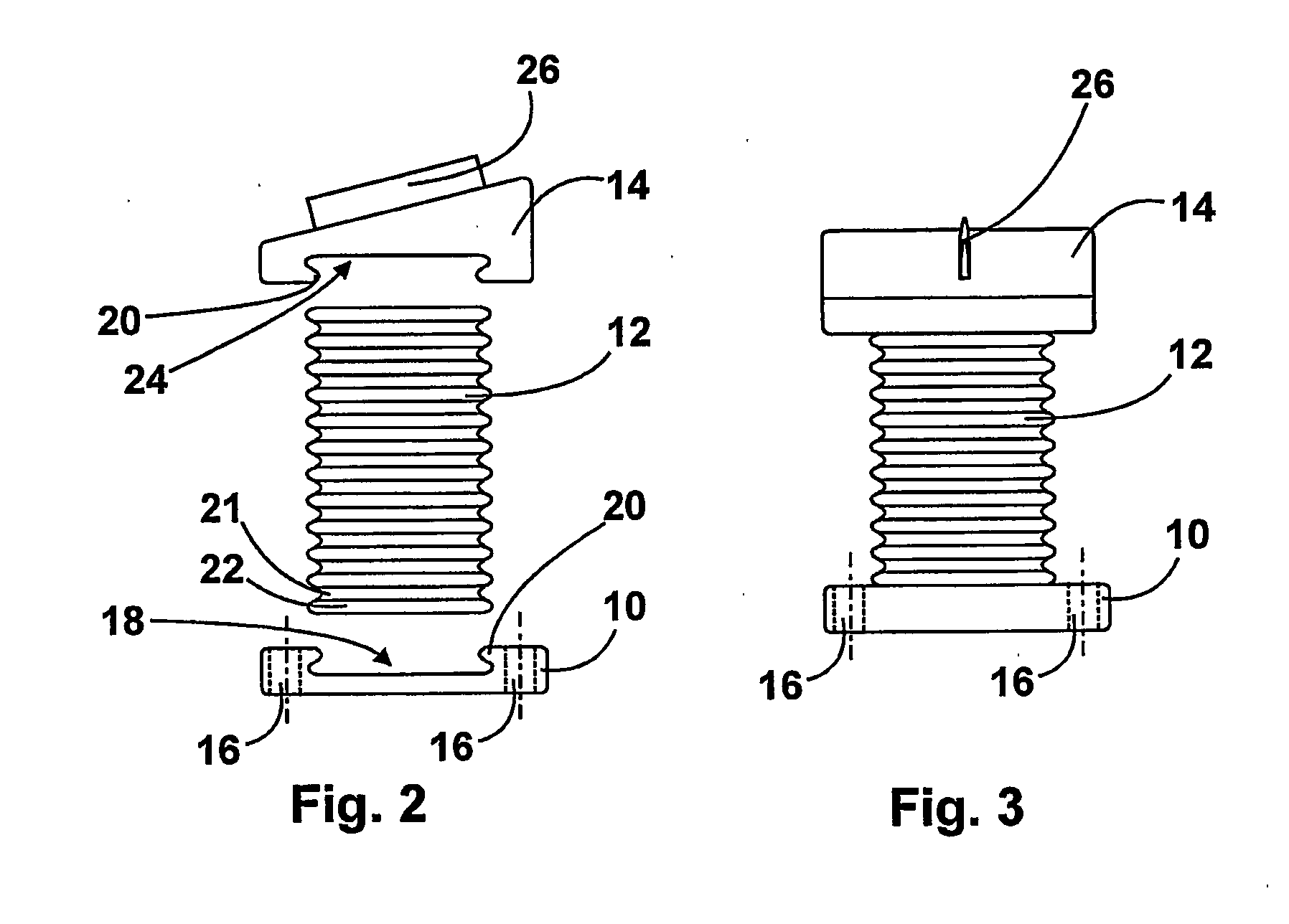

Device for implanting in a human or animal vertebral column

InactiveUS20100292794A1Reduce manufacturing costRigid enoughJoint implantsSpinal implantsBiomedical engineeringLumbar vertebral column

The invention relates to a device for implanting in a human or animal vertebral column, said device comprising a base carrier (10) that can be fixed to a first vertebral body, an upper carrier (14) that can be fixed to a second vertebral body, and a spacer element fixed between the base carrier and the upper carrier. The base carrier (10) and / or the upper carrier (14) are provided with a cavity (18, 24) comprising undercuts, for receiving the spacer element in a positively locked manner. The aim of the invention is to economically create one such device that ensures complete freedom of movement of the vertebral column. To this end, the spacer element is embodied as metallic bellows (12).

Owner:METZ STAVENHAGEN PETER

Well pump with seal section having a labyrinth flow path in a metal bellows

A submersible well pump assembly has a rotary pump, a motor, and a seal section coupled between the motor and the pump. The seal section has a cylindrical housing having upper and lower adapter and a shaft extending axially through the housing. A guide tube surrounds the shaft and a bellows surrounds the guide tube. A well fluid passage communicates well fluid to a well fluid chamber between the bellows and the housing. A guide tube passage extends axially within the guide tube between an interior and an exterior of the guide tube from an upper portion to a lower portion of the guide tube for communicating lubricant in the motor with lubricant within the bellows.

Owner:BAKER HUGHES INC

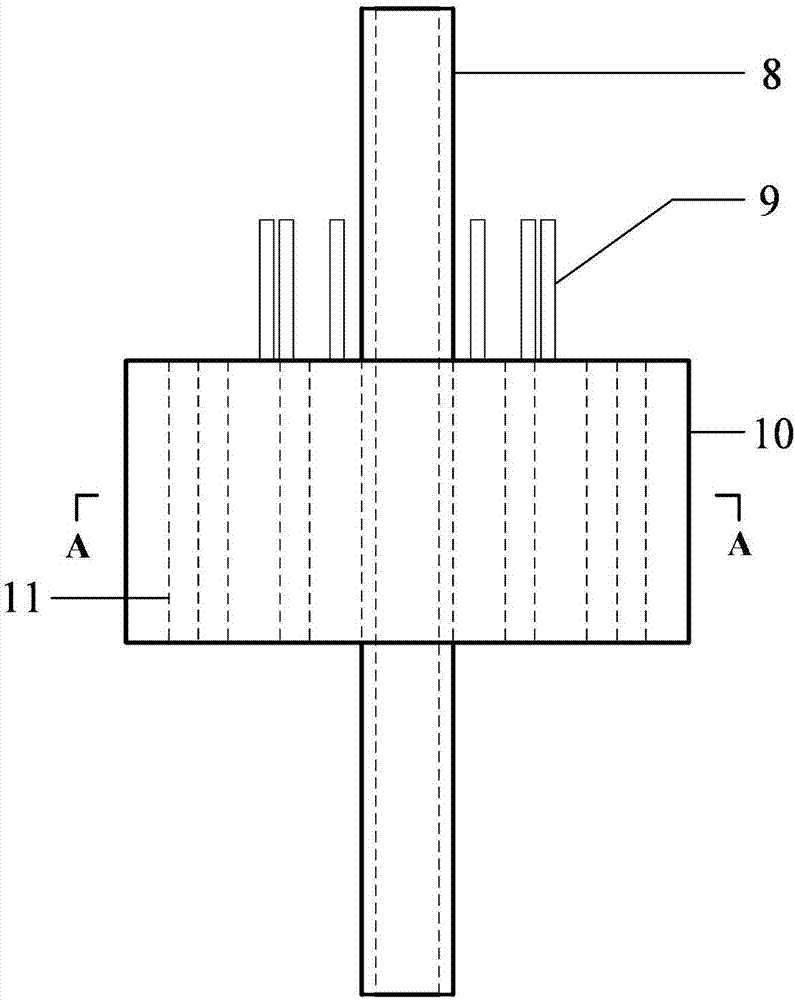

Construction method for stand column and cover beam assembled structure

InactiveCN106400692AAdvantages of construction methodShorten the on-site construction periodBridge structural detailsBridge erection/assemblyEngineeringRebar

The invention relates to a construction method for a stand column and cover beam assembled structure. The construction method includes the following steps that S1, a stand column is prefabricated, rebars are embedded in the stand column in advance; a cover beam is prefabricated, metal bellows are reserved in the cover beam, and a mortar pressing channel is formed in the cover beam; and the spliced face of the stand column and the cover beam is cleaned and measured; S2, pre-assembling is performed, hole channels of the metal bellows are aligned with the rebars to be sleeved in, and after the perpendicularity and the elevation of the cover beam are adjusted, the cover beam is lifted up; and S3, high-strength mortar is laid in a splicing seam between the stand column and the cover beam, then the cover beam drops down, and after the high-strength mortar reaches the strength requirement, the high-strength mortar is pressed in from the mortar pressing channel till mortar pressing ends. According to the construction method, a traditional bridge building manner is changed, no supports and no formworks exist on the construction site, the on-site construction period is shortened, the labor intensity of workers is relieved, and the requirement for the construction site is lowered; the work procedures of on-site support foundation treatment and support formwork erecting are omitted, and the economical efficiency is high; and meanwhile the negative effects on the ambient environment are reduced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

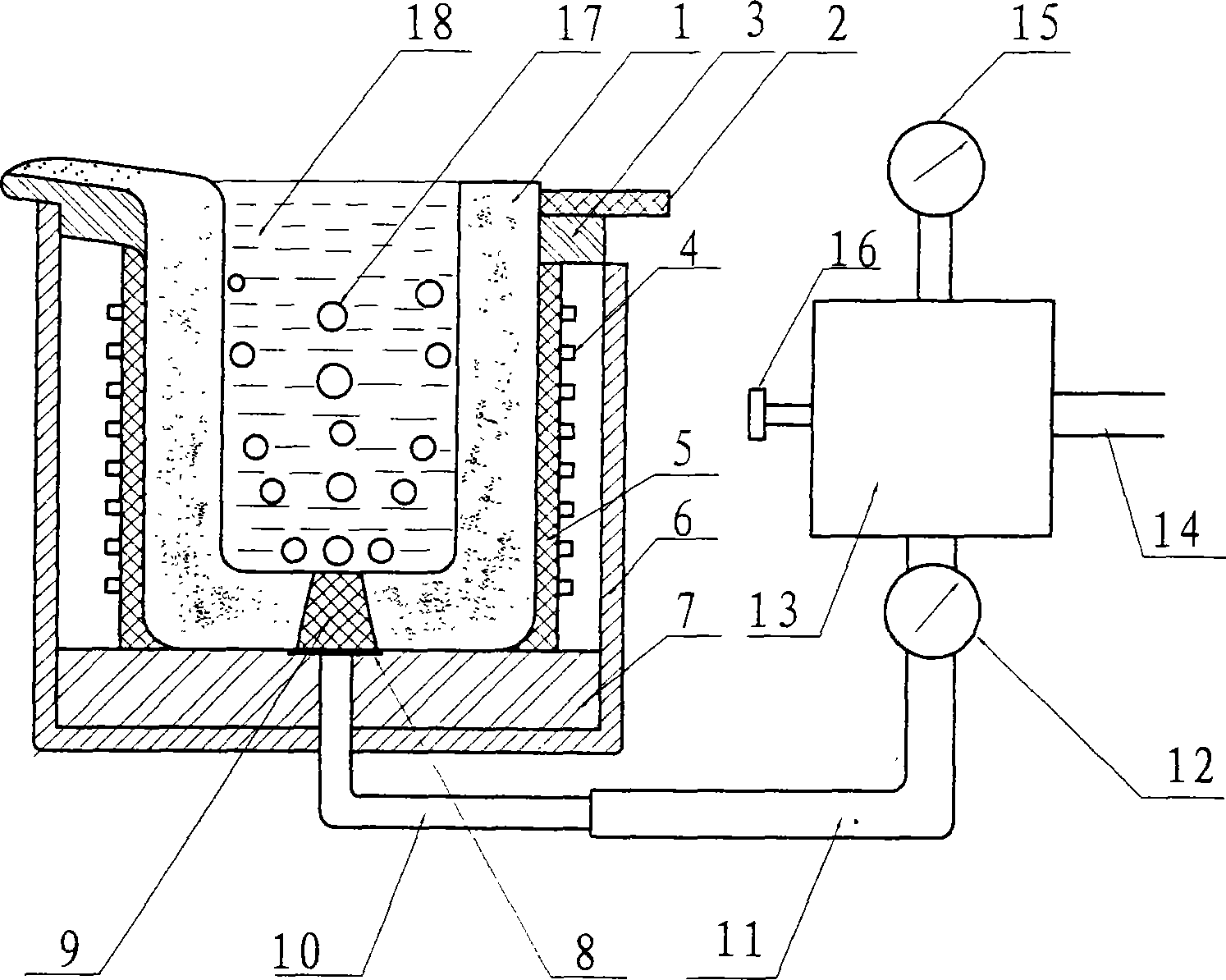

Bottom-blowing medium-frequency smelting furnace and in-furnace auxiliary refining method

The present invention discloses one kind of bottom blown MF smelting furnace, which has a furnace body comprising furnace lining, porous brick, cover plate, induction coil, shell and other parts; and a gas supply system comprising pipe, gas regulator, flowmeter, pressure meter, regulating valve and other parts. The gas supply system is connected to the furnace body through corrugated metal pipe and union. The present invention also discloses the auxiliary refining process in the bottom blown MF smelting furnace, and the process includes introducing inert gas after all the charges inside the furnace are molten to the porous brick in the pressure of 0.1-1.0 MPa and flow rate of 100-700 1 / s, and auxiliary refining for 3-5 min. The present invention is especially suitable for use in MF smelting furnace of capacity less than 250 kg, and has simple furnace structure, good permeating property, good auxiliary refining effect and other advantages.

Owner:TAIZHOU JINDING PRECISION CASTING +1

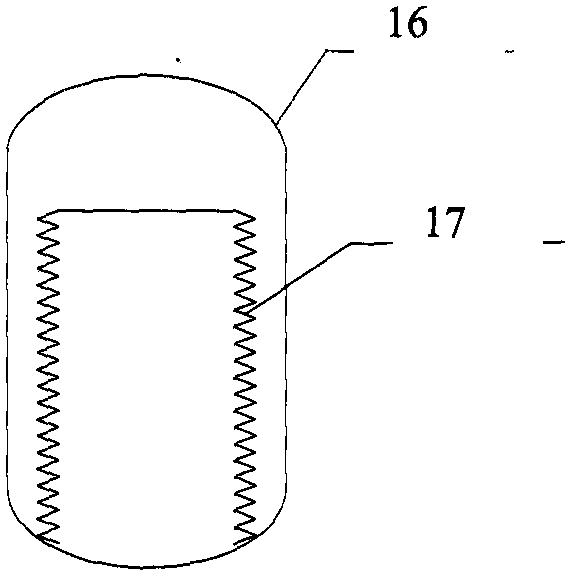

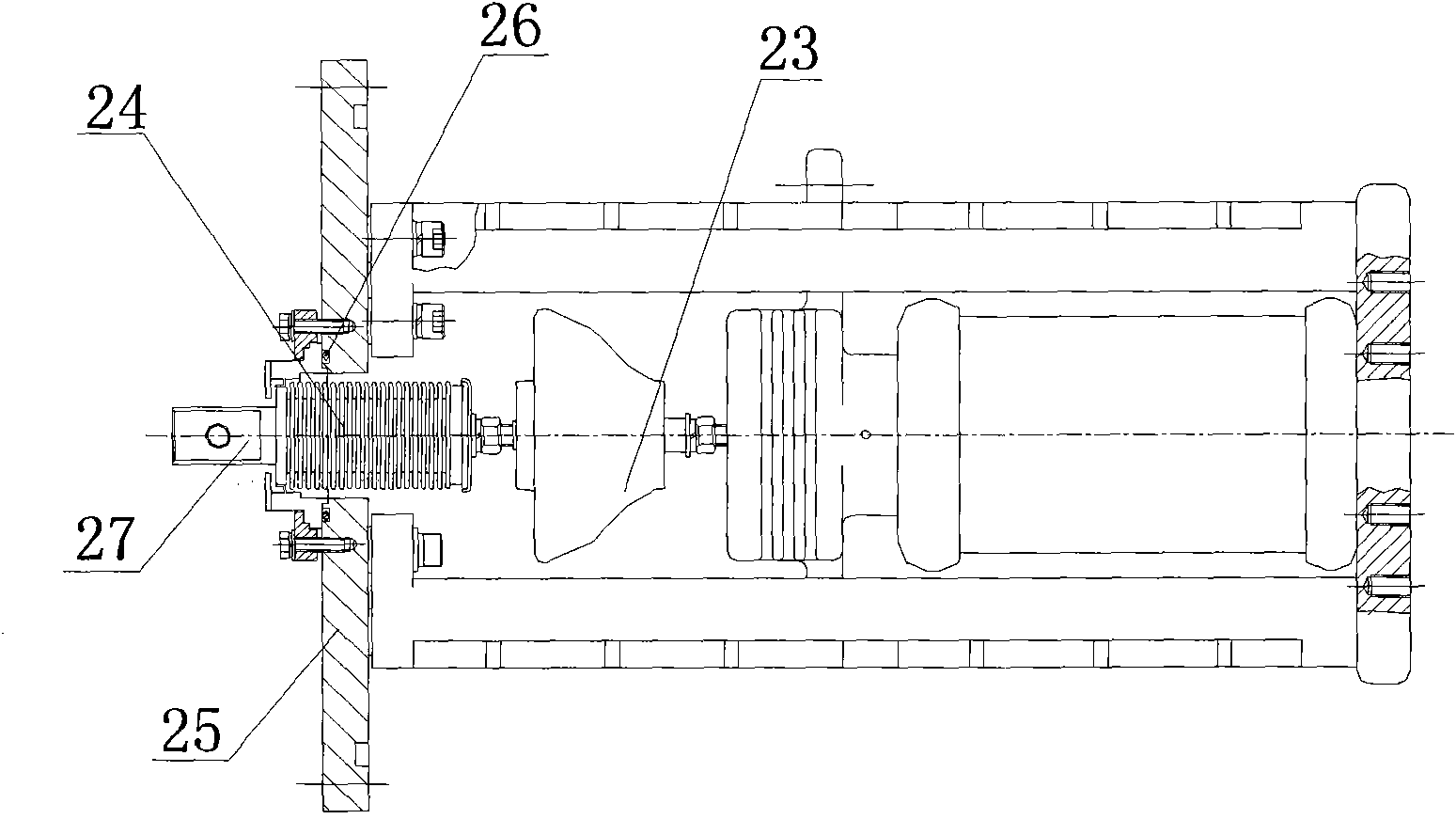

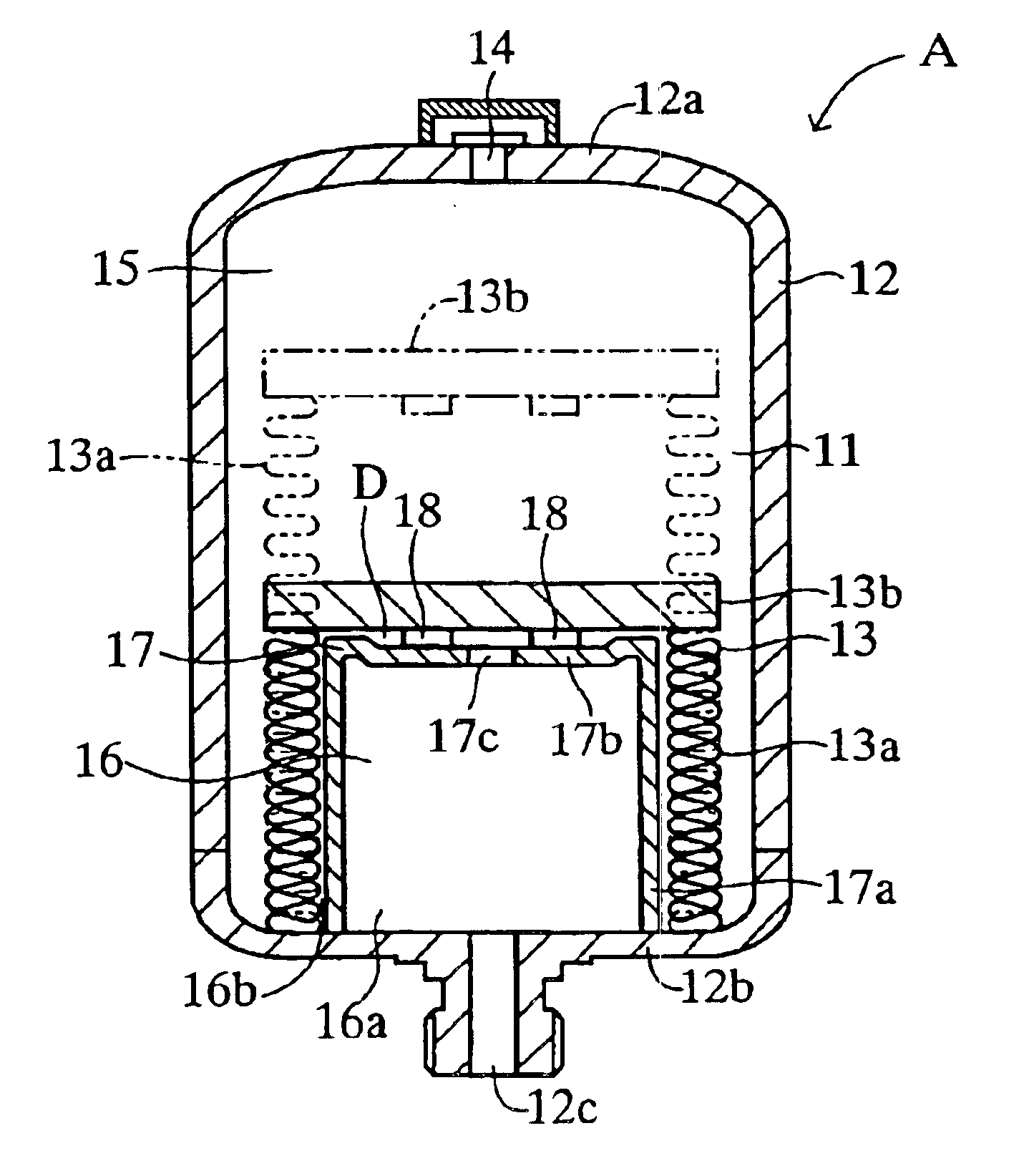

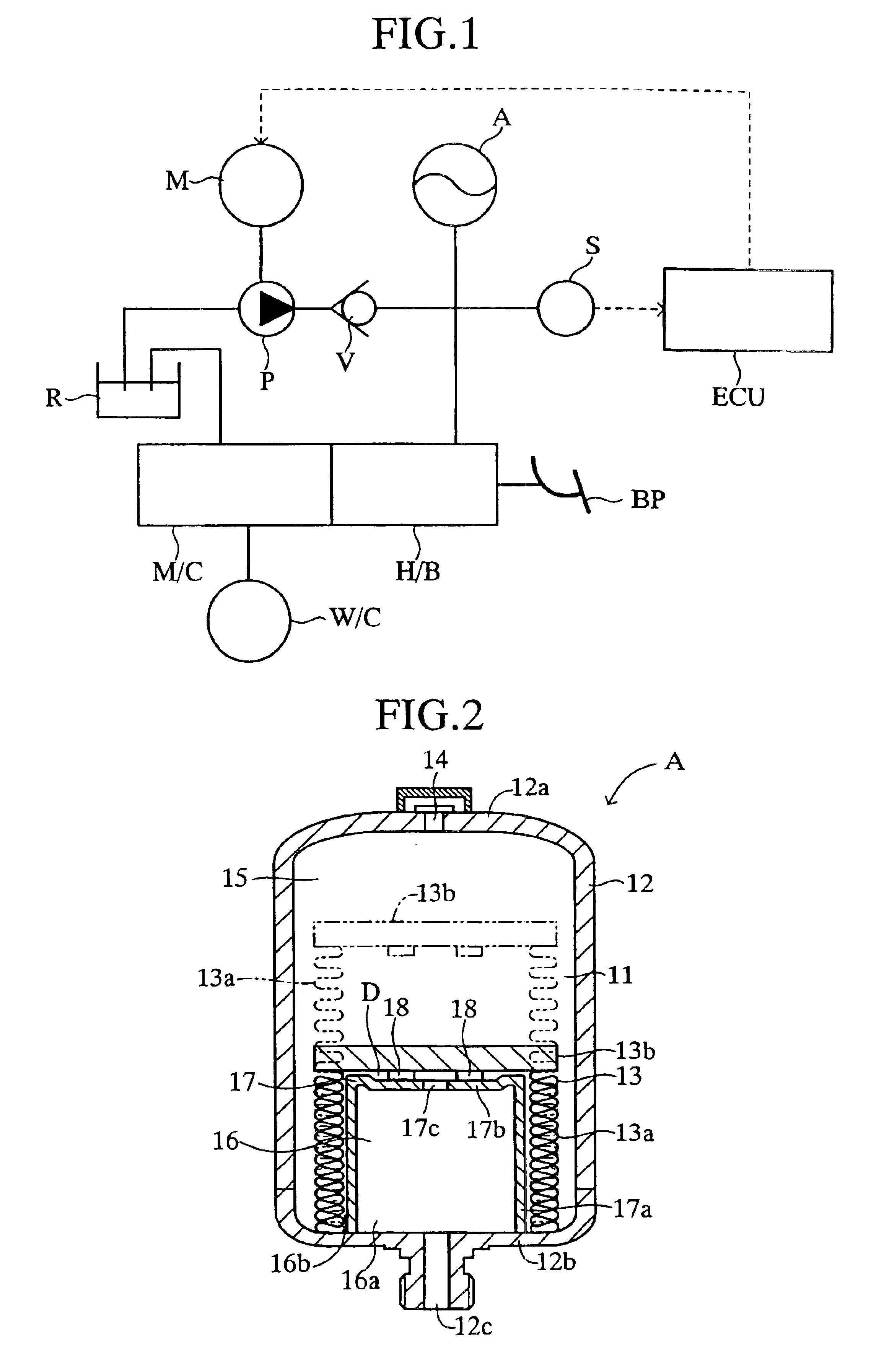

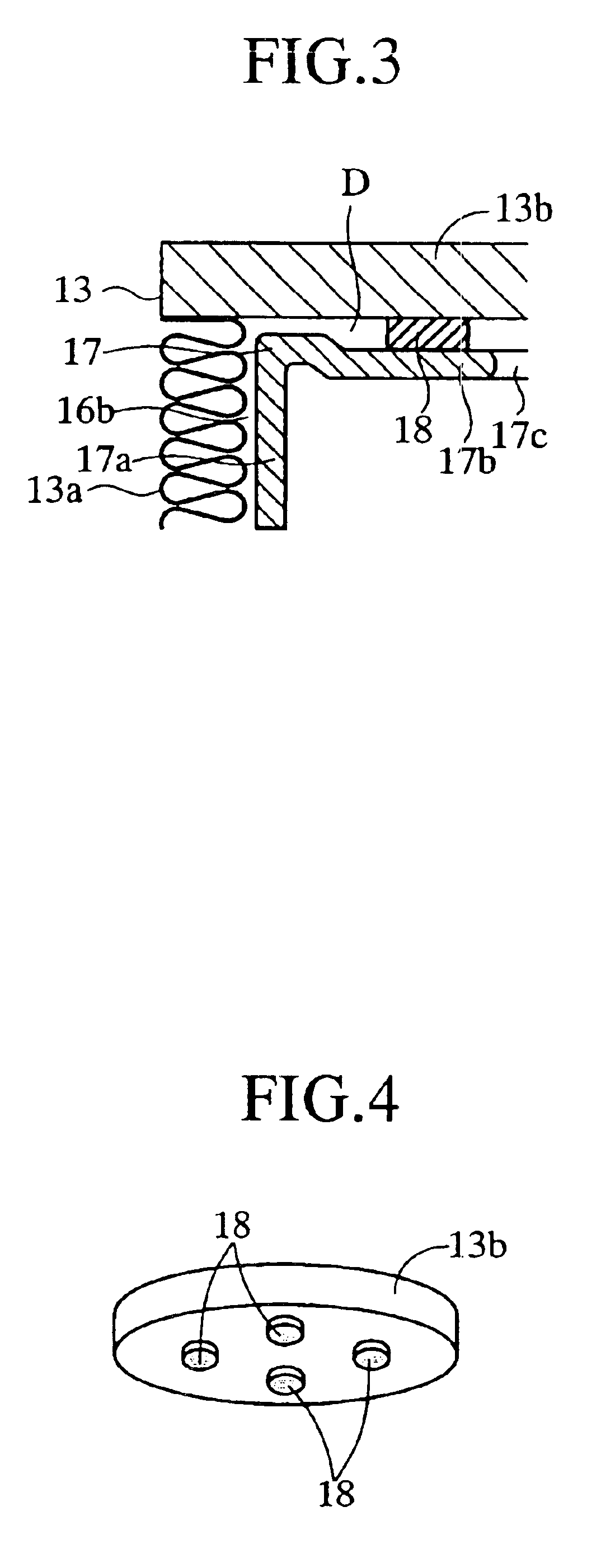

Metal bellows accumulator

InactiveUS6871670B2Compact manufacturingReliably accumulatingAccumulator installationsPipe elementsProduct gasGas chamber

In a metal bellows accumulator, a metallic bellows unit is disposed within a pressure space defined in a main shell, and one end of the metallic bellows unit is fixedly secured to one end wall of the main shell. The metallic bellows unit sections the pressure space into an outer chamber serving as a gas chamber in which a pressurized gas is enclosed, and an inner chamber serving as a liquid chamber communicating with a liquid port formed in the end wall of the main shell. A stopper (auxiliary shell) for limiting collapsing movement of the metallic bellows unit is disposed within the liquid chamber and has a communication passage hole. The liquid port always communicates with a liquid chamber to which an inner circumferential surface of a bellows portion of the metallic bellows unit is exposed via the communication passage hole.

Owner:ADVICS CO LTD

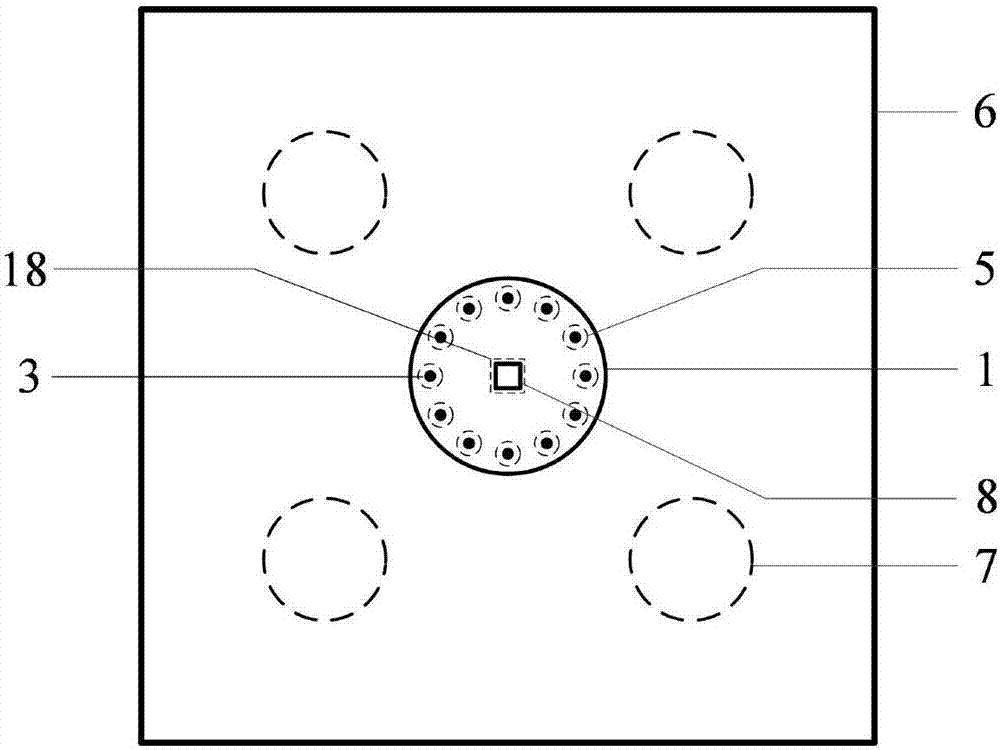

Connecting structure for assembly type concrete shear wall edge member

InactiveCN102691365AImprove the anchoring effectGuaranteed carrying capacityWallsShock resistanceRebar

The invention discloses a connecting structure for an assembly type concrete shear wall edge member. vertical connecting reinforcing steel bar, which can be provided with an upset head, is reserved through a hole reserved in a large-diameter metal bellows, and is sleeved with a continuous spiral stirrup; then the vertical connecting reinforcing steel bar and the continuous spiral stirrup are commonly inserted into the large-diameter metal bellows; and fine aggregate concrete (or a grounding material) is poured into the metal bellows, so that the reliable connection of the edge member is realized. Due to reliable anchoring of the vertical connecting reinforcing steel bar, the optimization of the diameter, the quantity and the plane arrangement of the vertical connecting reinforcing steel bar, and the increase of the wet joint area on a splicing surface, full exertion of the bearing capacity of the shear wall is ensured; and multiple effective restrain for the subsequentlly-poured fine aggregate concrete (or the grouting material) is formed by the shear wall stirrup, a horizontal tie bar, the metal bellows and the continuous circular spiral stirrup, and thus the integral performance of the part is remarkably improved. According to the connecting method for the edge member, which is provided by the invention, the stress continuousness of the vertical steel reinforcing bar is ensured, the deformaility and the ductility performance of the vertical steel reinforcing bar are remarkably improved, and the shock resistance of the assembly type concrete shear wall is improved. Meanwhile, the method is simple in manufacturing process and facilitates the practice and application.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com