Bottom-blowing medium-frequency smelting furnace and in-furnace auxiliary refining method

A melting furnace and bottom blowing technology, applied in the field of induction melting furnaces, can solve the problems of lack of metallurgical reaction conditions and reaction time, affecting the surface quality and internal quality of precision castings, unable to meet the quality requirements of important precision castings, etc. Simple structure, avoid violent boiling and splashing, easy to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

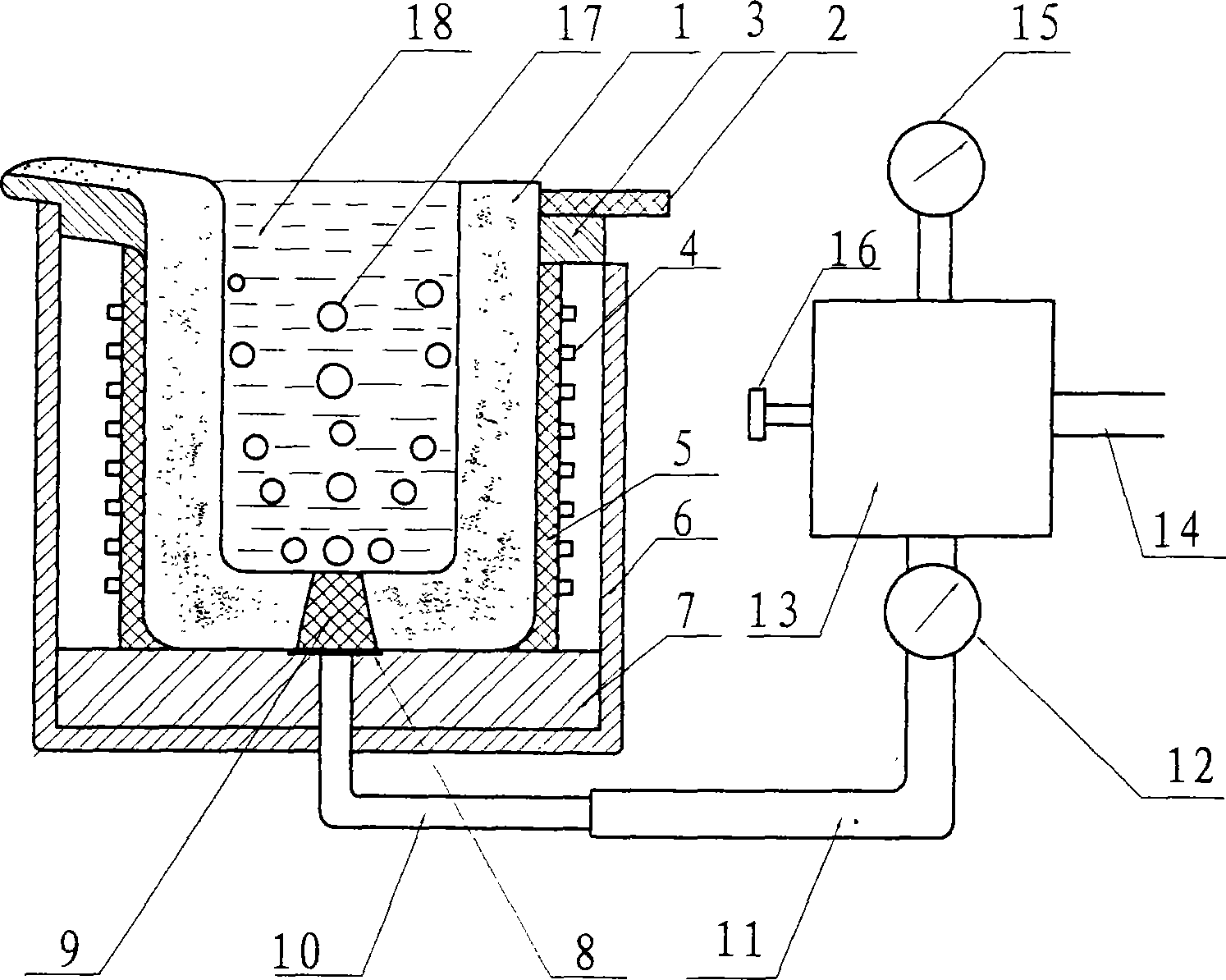

[0018] The bottom-blown intermediate frequency melting furnace shown in the accompanying drawing includes two parts, the furnace body and the gas supply system. The furnace body includes a furnace lining 1 and a cover plate 2 set on the outer periphery of the furnace lining 1, an upper frame brick 3, an induction coil 4, insulating fibers 5, and a shell 6. The bottom plane of the furnace lining 1 is supported on the base 7 plane. The bottom of the furnace lining 1 and the middle part of the base 7 are all through holes, and the through holes on the bottom of the furnace lining 1 are filled with breathable bricks 9, and the gas pipe joint 8 is sealed and connected with the metal bellows 10 to introduce the gas supply system to the furnace body. The gas supply system is composed of a gas source connecting pipe 14 , a gas regulator 13 , a flow meter 12 , a gas delivery hose 11 , a metal bellows 12 and a gas delivery pipe joint 8 which are sequentially connected in series. The gas...

Embodiment 2

[0023] This embodiment is applied to a bottom-blown intermediate frequency smelting furnace with a capacity of 150kg. The structure of the furnace body and the gas supply system are the same as those in Embodiment 1. The metal charge loaded is 304 stainless steel, the charge weighs 150kg, and the bottom of the furnace lining 1 is fitted. The diameter of the small end face of the air-permeable brick 9 is φ100mm, and the thickness is 100mm. First melt the metal charge according to the normal smelting method, and then carry out auxiliary refining in the furnace after the metal charge is completely melted. The specific method is:

[0024] A. The gas source is connected through the gas source connecting pipe 14, and the gas source used in this embodiment is still argon;

[0025] B. Adjust the regulating valve 16 on the gas regulator 13 according to the working conditions. The pressure value of the argon gas delivered to the permeable brick 9 is 0.4-0.6MPa, and the flow rate is betw...

Embodiment 3

[0028] This embodiment is applied to a bottom-blown intermediate frequency smelting furnace with a capacity of 100kg. The structure of the furnace body and the gas supply system are the same as those in Embodiment 1. The metal charge loaded is 304 stainless steel, and the charge weighs 100kg. The diameter of the small end face of the air-permeable brick 9 is φ75mm, and the thickness is 70mm. First melt the metal charge according to the normal smelting method, and then carry out auxiliary refining in the furnace after the metal charge is completely melted. The specific method is:

[0029] A. The gas source is connected through the gas source connecting pipe 14, and the gas source used in this embodiment is still argon;

[0030] B. Adjust the regulating valve 16 on the gas regulator 13 according to the working conditions. The pressure value of the argon gas delivered to the permeable brick 9 is 0.3-0.5MPa, and the flow rate is between 200-300l / s, which can meet the requirements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com