Joint connection mode for prefabricated spliced bridge pier with flexible layer arranged at bottom of pier and cushion cap and realization method thereof

A technology of prefabricated assembly and node connection, which is applied in the direction of bridges, bridge parts, bridge construction, etc., and can solve the problems of concrete plastic failure and difficult repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

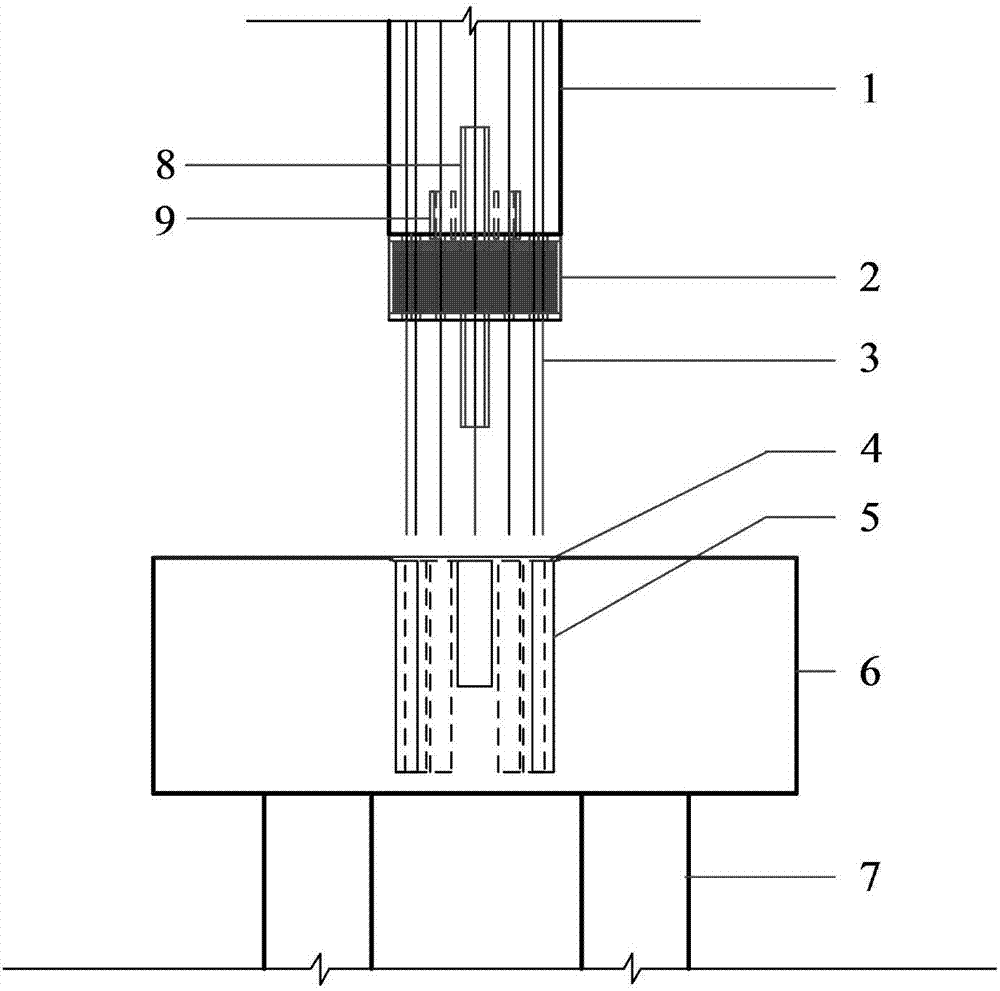

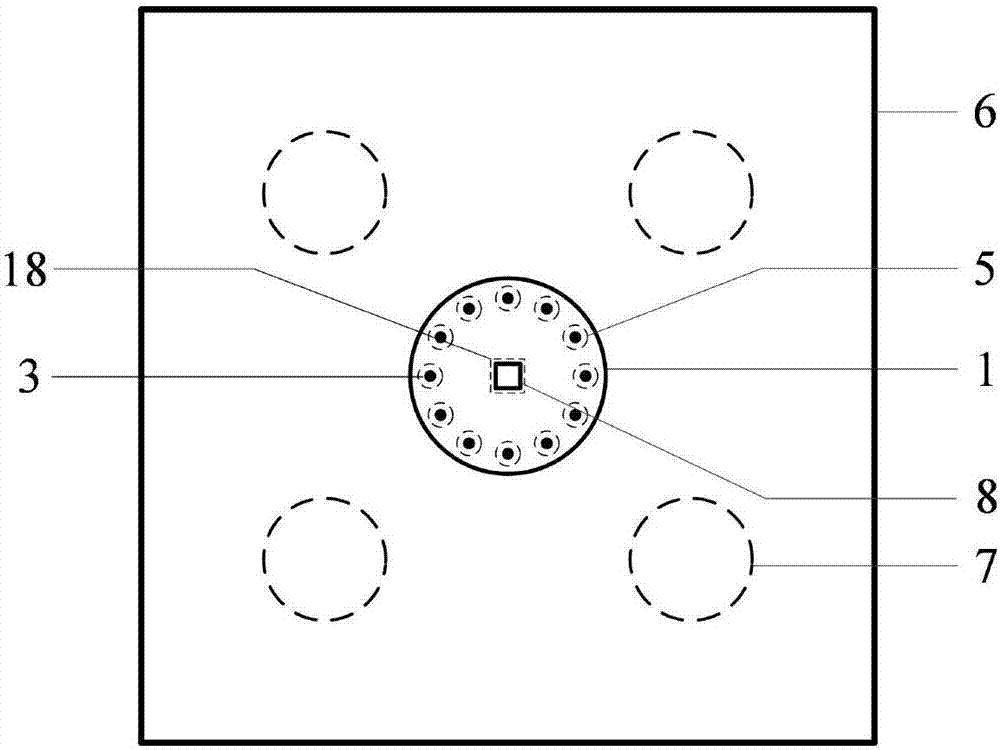

[0023] Such as Figure 1 to Figure 6 , the present invention proposes a prefabricated assembled bridge pier with a flexible layer at the bottom of the pier-cap node connection method and its method, including a flexible layer 2 at the bottom of the prefabricated bridge pier, a longitudinal steel bar 3 reserved for protruding from the bottom of the pier, and a pre-embedded bridge in the cap Metal bellows 5. Main structures such as self-compacting high-strength micro-expansion grout that need to be poured into the metal bellows and its prefabricated assembly construction method.

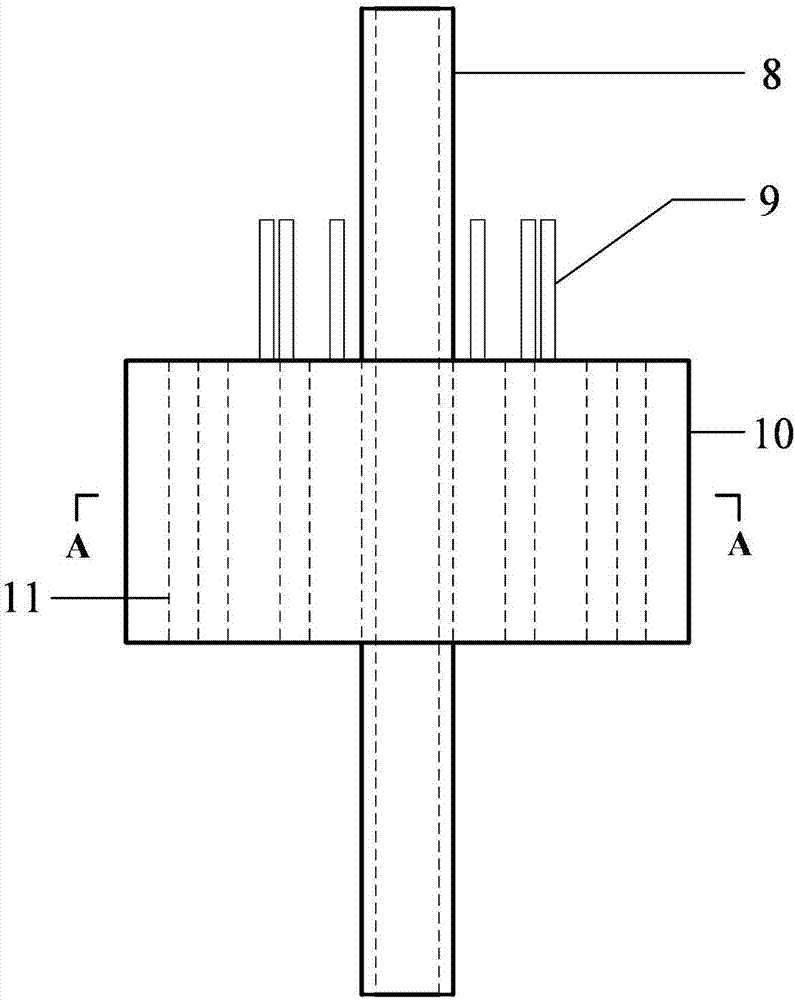

[0024] Specifically, first make the flexible layer 2, tighten the ribbed steel bar screw 9 in the reserved screw hole 17, and at the same time insert the rectangular steel pipe 8 into the reserved steel pipe hole 18 in the laminated steel plate rubber 10, so that the rectangular steel pipe 8 is located in the laminated steel pipe. In the middle of the layer of steel plate rubber 10, apply reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com