Vertical connection structure for precast concrete shear walls and construction method

A concrete shear wall and shear wall technology, which is applied to building structures, walls, building components, etc., can solve the problems of easy cracking of the protective layer at the opening, high cost of sleeves and grouting materials, and large amount of grouting materials. problems, achieve the effect of reducing the weight of the wall, making the connection less difficult, and preventing the hole wall from cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

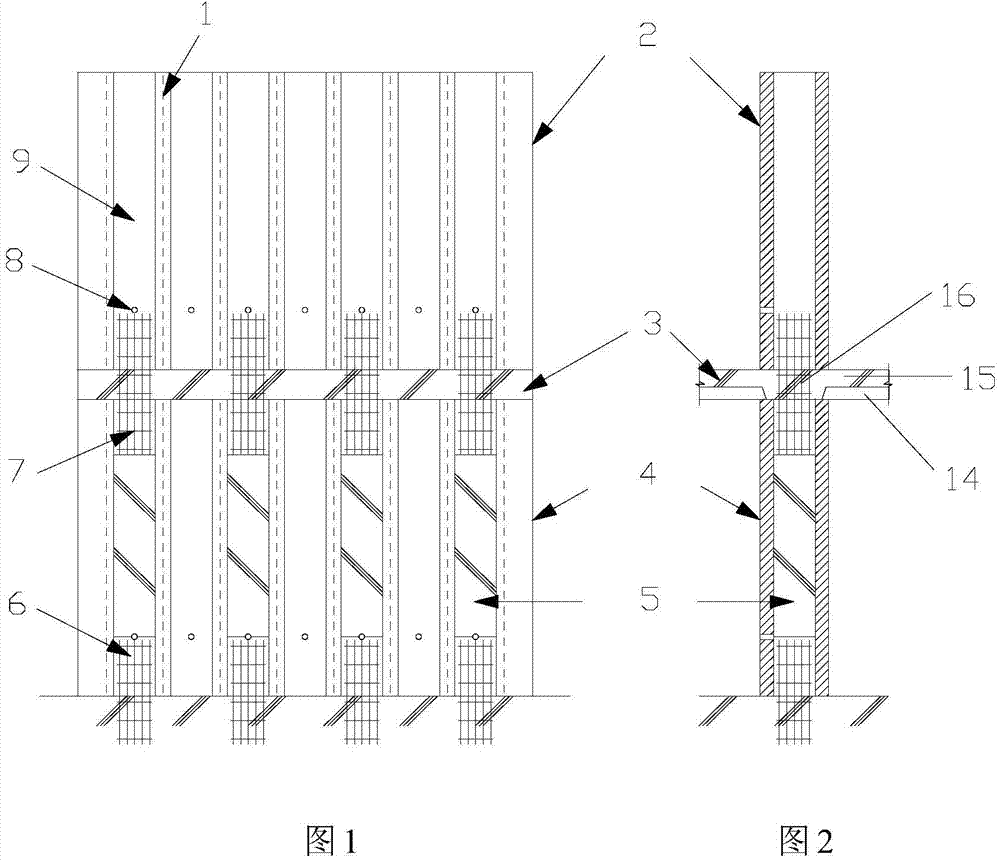

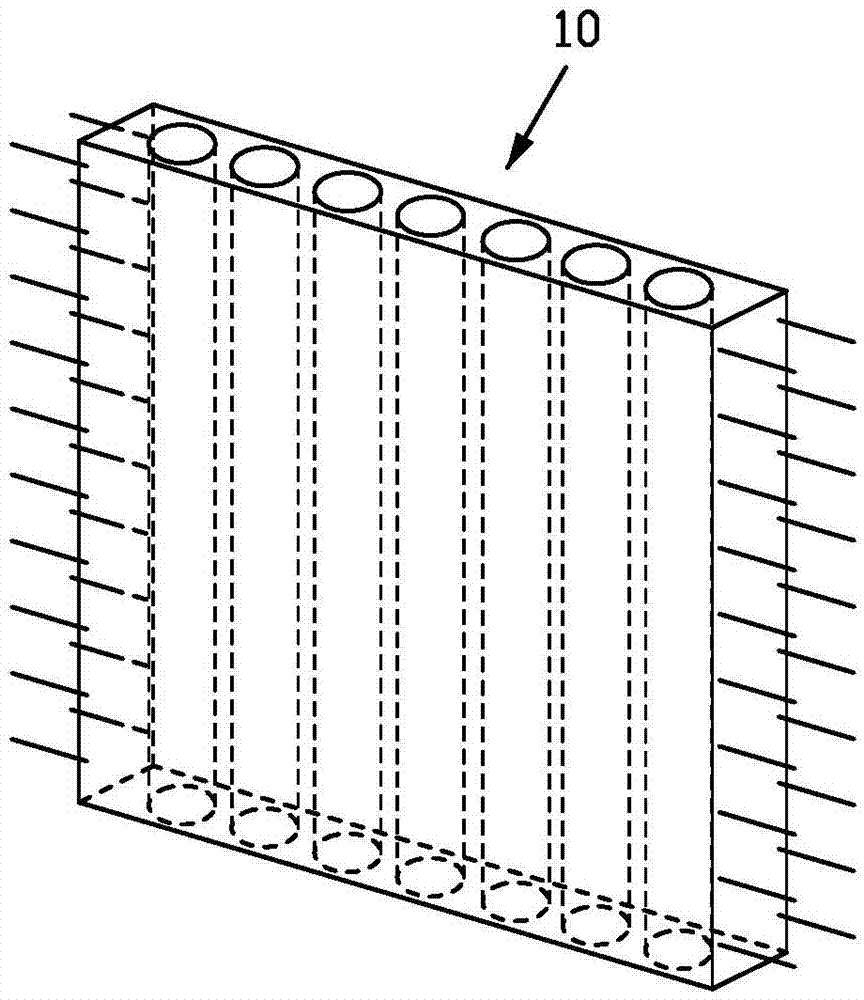

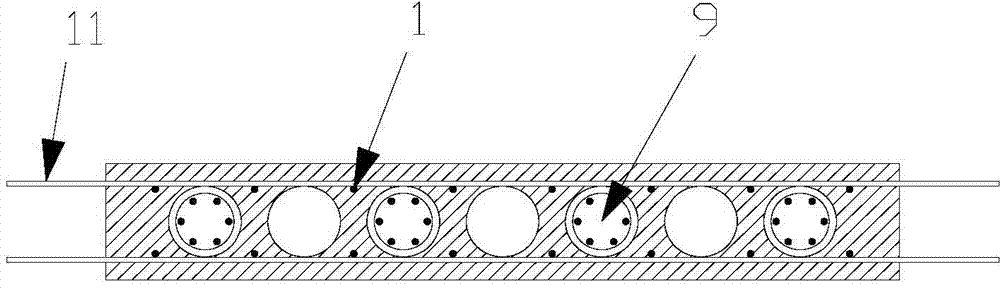

[0031] Such as Figure 1 to Figure 6 As shown, the vertical connection structure of the prefabricated concrete shear wall of the present invention mainly includes: vertically distributed steel bars 1, upper prefabricated porous shear wall 2, floor slab 3, lower prefabricated porous shear wall 4, cast-in-situ concrete or pouring mortar or Other filling materials 5, cast-in-place concrete or pouring mortar 6, connecting reinforcement cage 7, cast-in-place concrete or pouring mortar confirmation hole 8, vertical through hole 9, prefabricated porous shear wall 10, horizontal distribution reinforcement 11, vertical connecting bar 12. Spiral rib or ring rib 13, etc., the specific structure is as follows:

[0032] The prefabricated porous shear wall 10 comprises an upper prefabricated porous shear wall 2 and a lower prefabricated porous shear wall 4, and between the upper prefabricated porous shear wall 2 and the lower prefabricated porous shear wall 4 is a floor 3 (prefabricated flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com