Patents

Literature

40results about How to "Reduce anchor length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

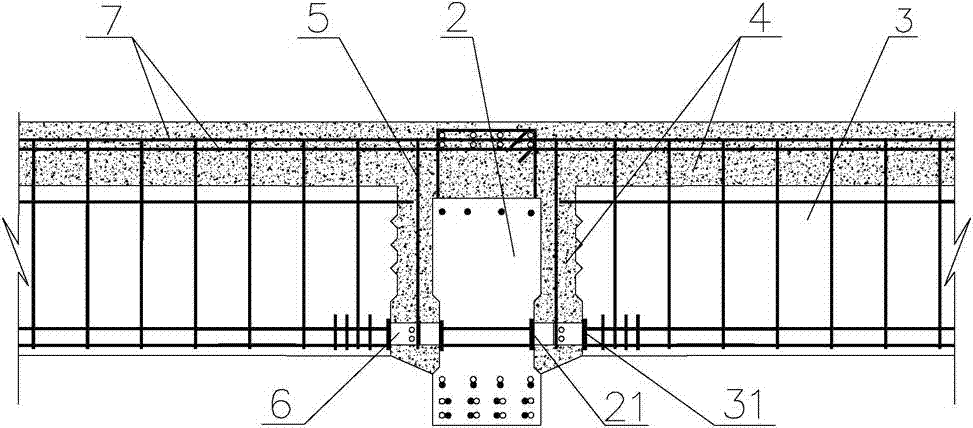

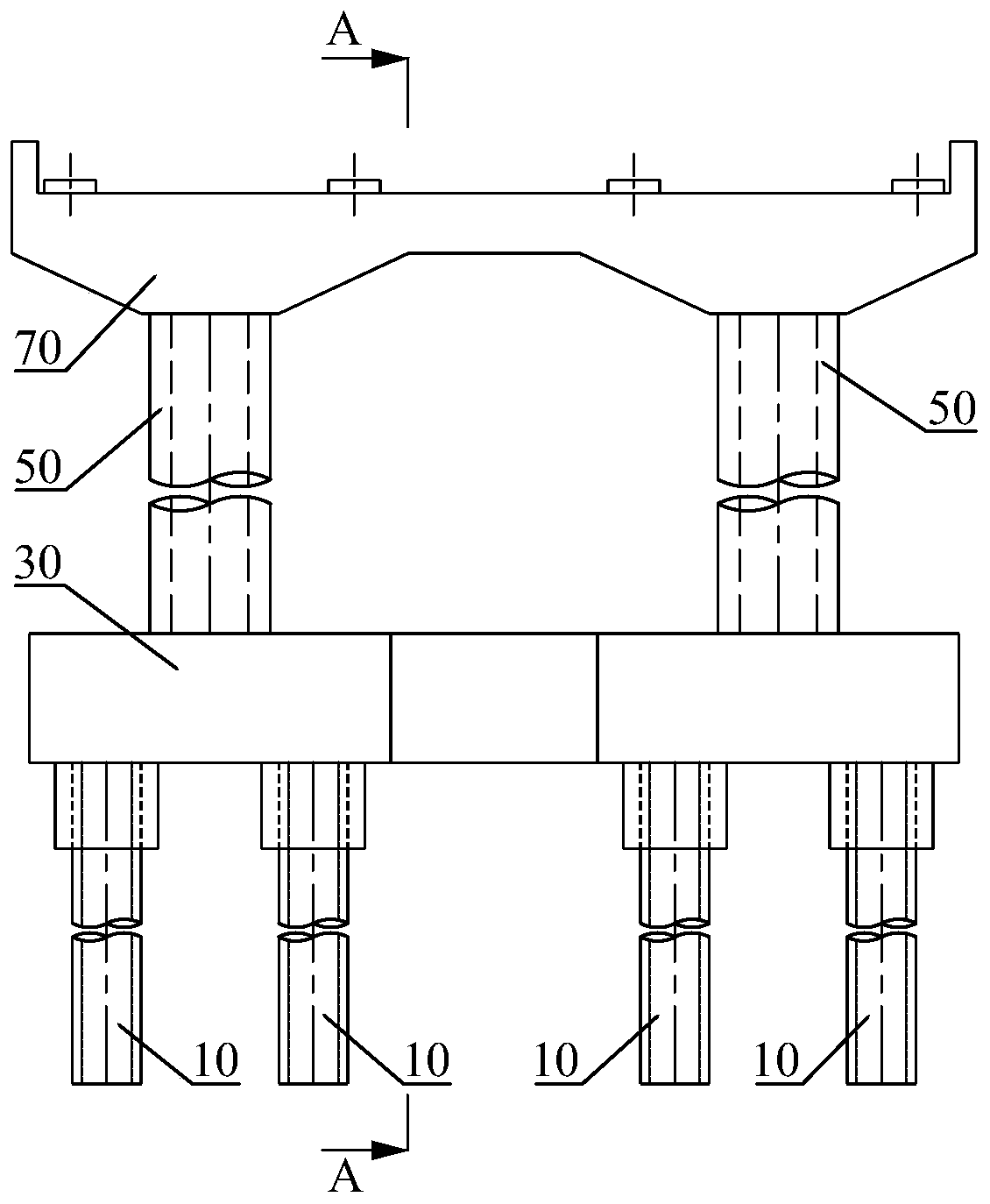

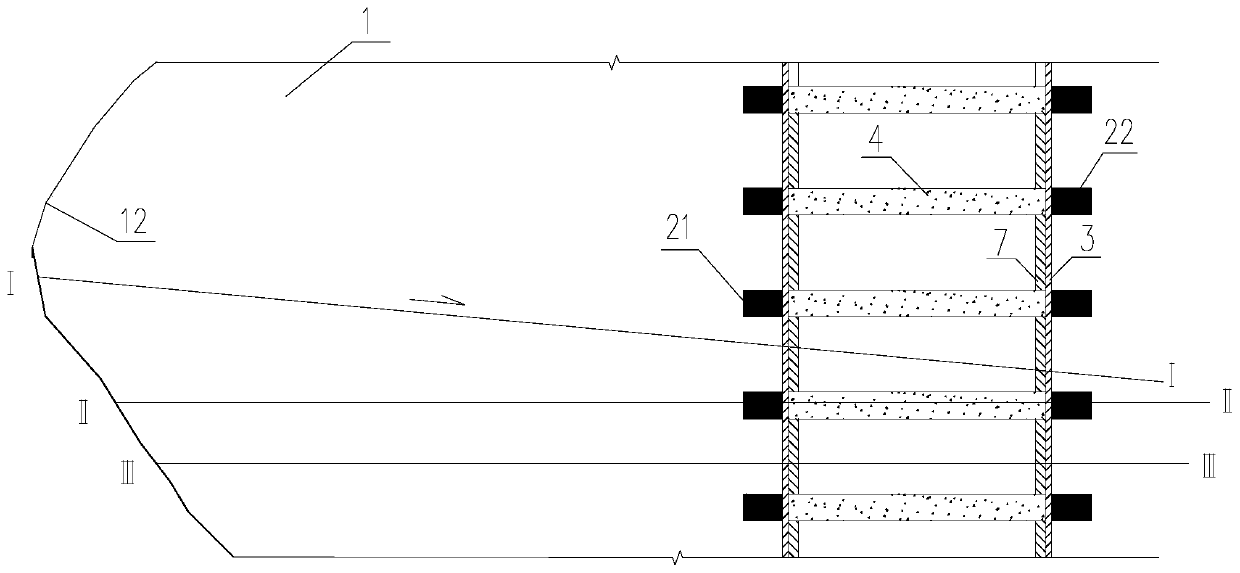

Pre-tensioning prestressed composite beam structural system and construction method thereof

The invention relates to a pre-tensioning prestressed composite beam structural system and a construction method of the pre-tensioning prestressed composite beam structural system. Lower longitudinal reinforcements are bound and lapped on lower longitudinal prestress wires in composite frame beam prefabricated components; the lower longitudinal reinforcements are inserted into frame pillars; second pre-buried steel plates are buried in the lower end portions of the composite frame beam prefabricated components; lower portion longitudinal prestress wires are buried in the composite frame beam prefabricated components; secondary beam longitudinal reinforcements are lapped and bound on the lower portion longitudinal prestress wires; the second pre-buried steel plates are welded with the secondary beam longitudinal reinforcements; first pre-buried steel plates opposite to the second pre-buried steel plates are arranged on the composite frame beam prefabricated components; pitch point steel plates are respectively welded on the first pre-buried steel plates and the second pre-buried steel plates; and the pitch point steel plates are connected through bolts, which enables the composite frame beam prefabricated components to connect with composite secondary beam prefabricated components. Wires and longitudinal reinforcements are lapped to use in the pre-tensioning prestressed composite beam structural system, and therefore the connecting mode of the pre-tensioning prestressed composite beam structural system is scientific and reasonable, and quality is safe and reliable.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

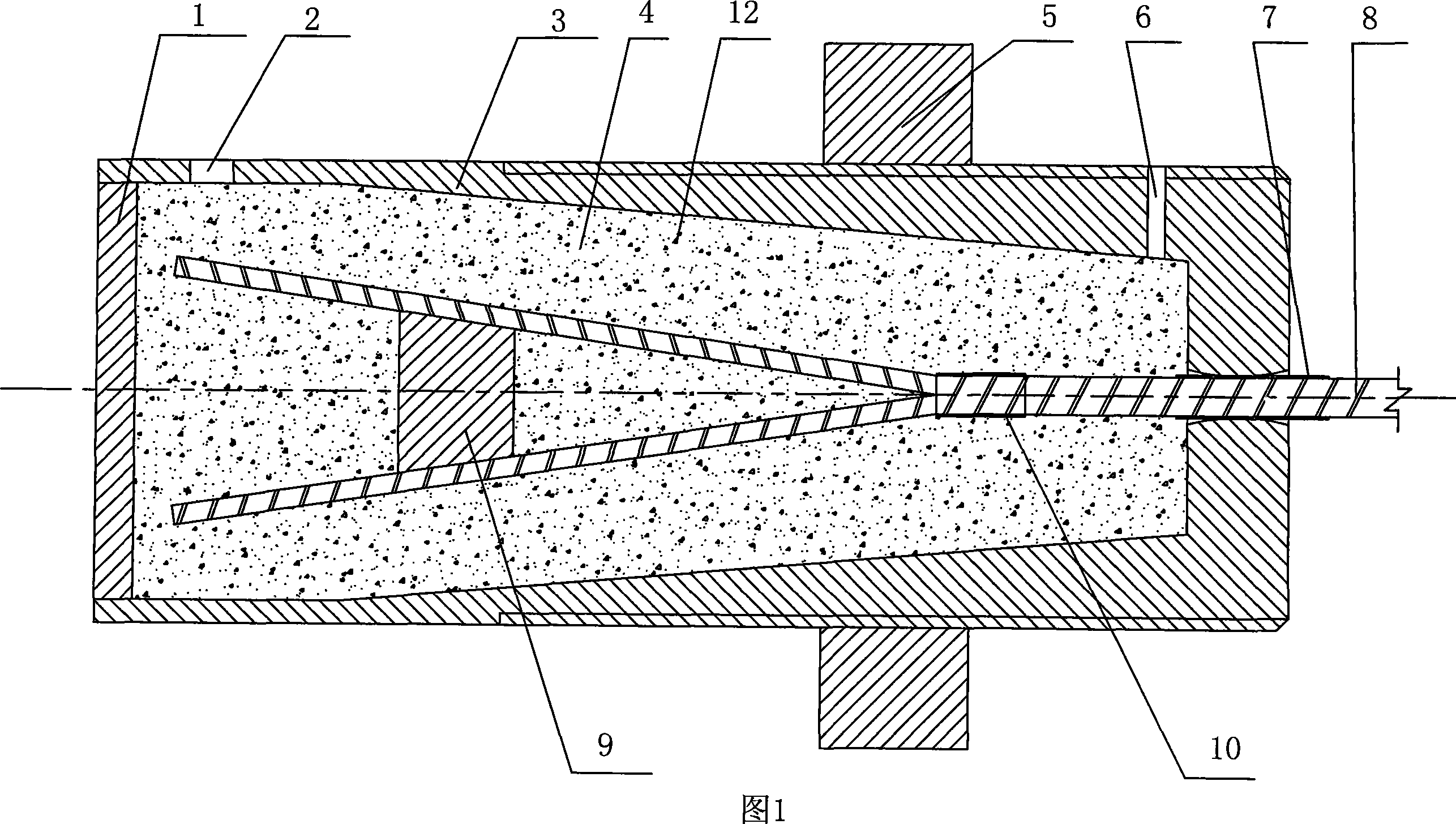

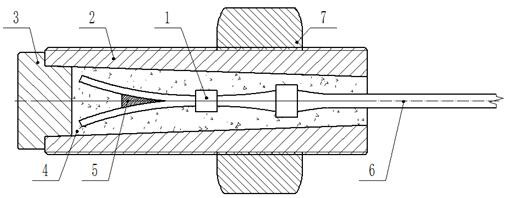

Bond type anchorage and anchoring method for anchoring fibre reinforced plastic reinforcement or bracing cable

ActiveCN101117838AHigh strengthHigh elastic modulusBuilding reinforcementsEngineeringFibre-reinforced plastic

The present invention relates to an adhesive anchoring unit and an anchoring method for anchoring fiber reinforcement plastic bar or cable, an end cover is arranged at one end of the anchoring unit and a sleeve with a locating hole is arranged at the other end of the anchoring unit. An internal cone chamber is arranged in the sleeve, and a nut is arranged surrounding the sleeve provided with a mortar filling hole and a ventilation hole. The fiber reinforcement plastic bar or cable passes through the locating hole and one end in the internal cone chamber was cut into two halves, which are inserted with a wedge to become a wedge form. A starting section of the half of one end of the bar or cable is coated with a retaining ring and the section passing through the locating hole is coated with a thin wall aluminum sleeve tube and active powder concrete is filled in the internal cone chamber of the sleeve. The method is described as follows: after the bar or cable shaft passes through the sleeve of the anchoring unit, a pretension is required on the sleeve, and the active powder concrete is added into the sleeve. The present invention improves anchoring performances of the adhesive media and the FRP bar, therefore, the anchoring length is reduced, the structure is simple, the use is convenient, the present invention is safe and reliable, the cost is low and the PRC manufacturing and maintenance is easy.

Owner:HUNAN UNIV

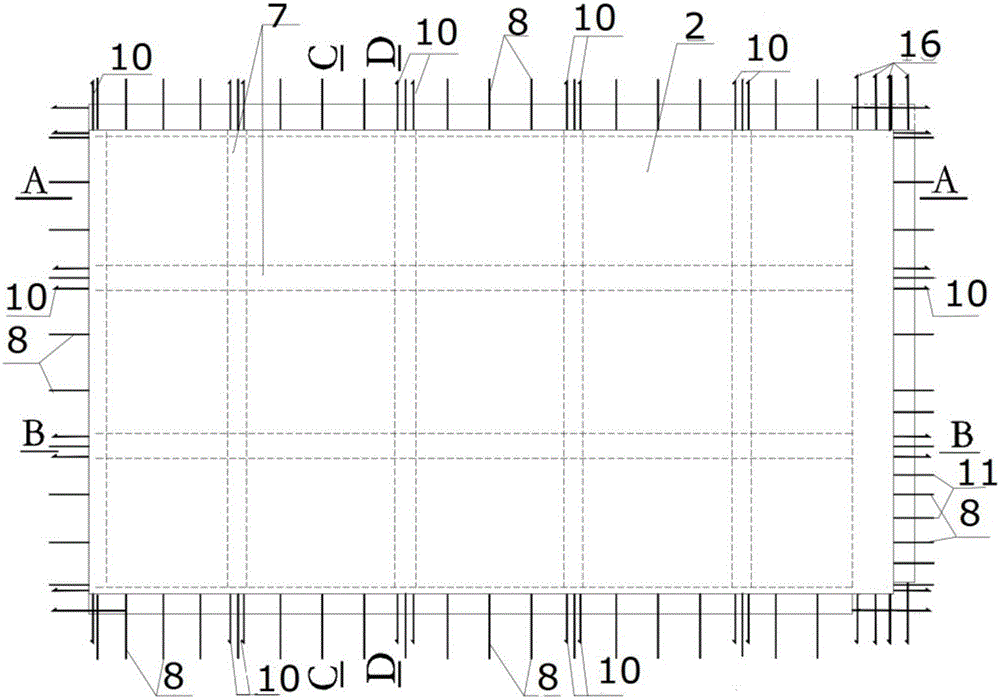

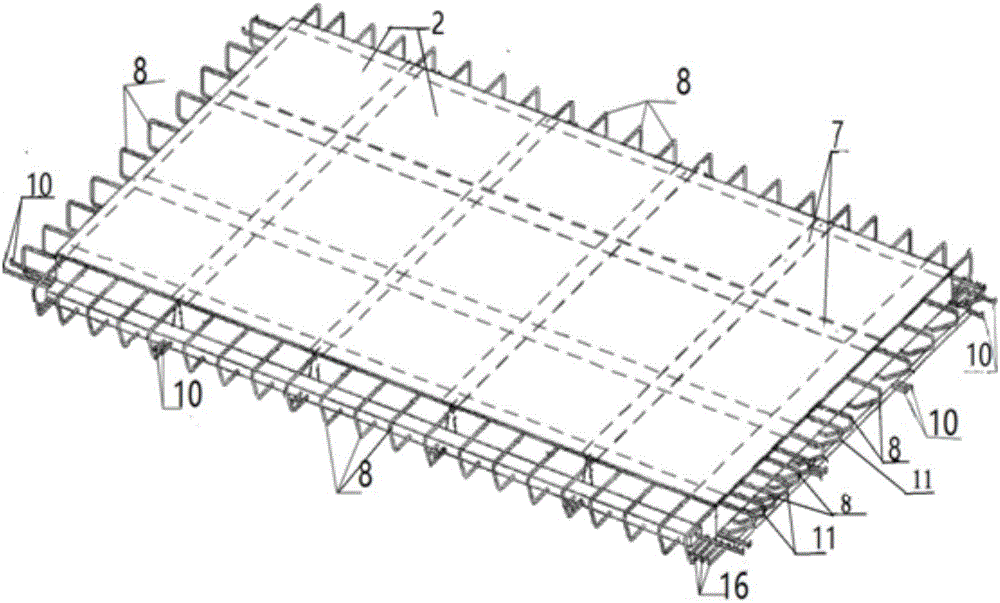

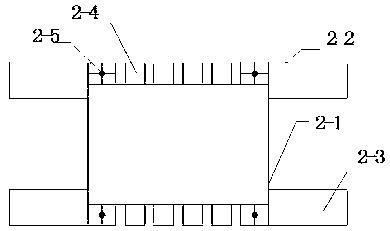

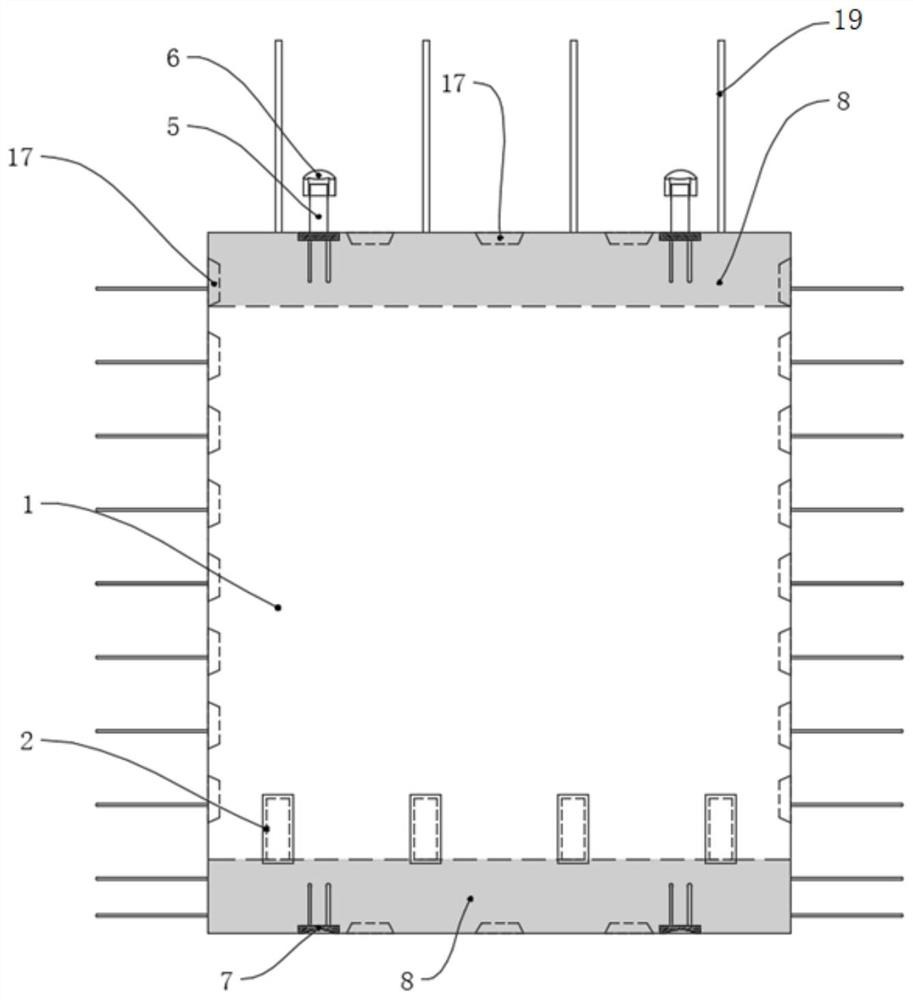

Connecting node of assembled whole thick prefabricated slab unit and slab unit thereof

The invention discloses a connecting node of an assembled whole thick prefabricated slab. Connecting steel bars are reserved on the connecting surface of a prefabricated slab unit in the mode, the exposed parts of the connecting steel bars are ' '-shaped, and the exposed parts and the connecting surface form a closed polygon. In the connecting mode for the prefabricated slab unit and a beam or a wall, the connecting steel bars of the prefabricated slab unit are inserted with steel bars configured for the beam or the wall together at the connecting positions in a penetrating mode. Viewing from the cross section of the whole connecting node, the connecting steel bars and the steel bars configured for the beam or the wall form a single closed stirrup or a composite stirrup, and longitudinal bolt steel bars penetrate into the inner corner position of the single closed stirrup or the composite stirrup. The connecting node of the whole thick prefabricated slab unit can achieve the equivalent performance as a prefabricated slab connecting nodes and a cast-in-place concrete structure while achieving higher prefabrication rate and assembly rate. The invention further provides the whole thick prefabricated slab unit for achieving the connecting mode.

Owner:刘祥锦

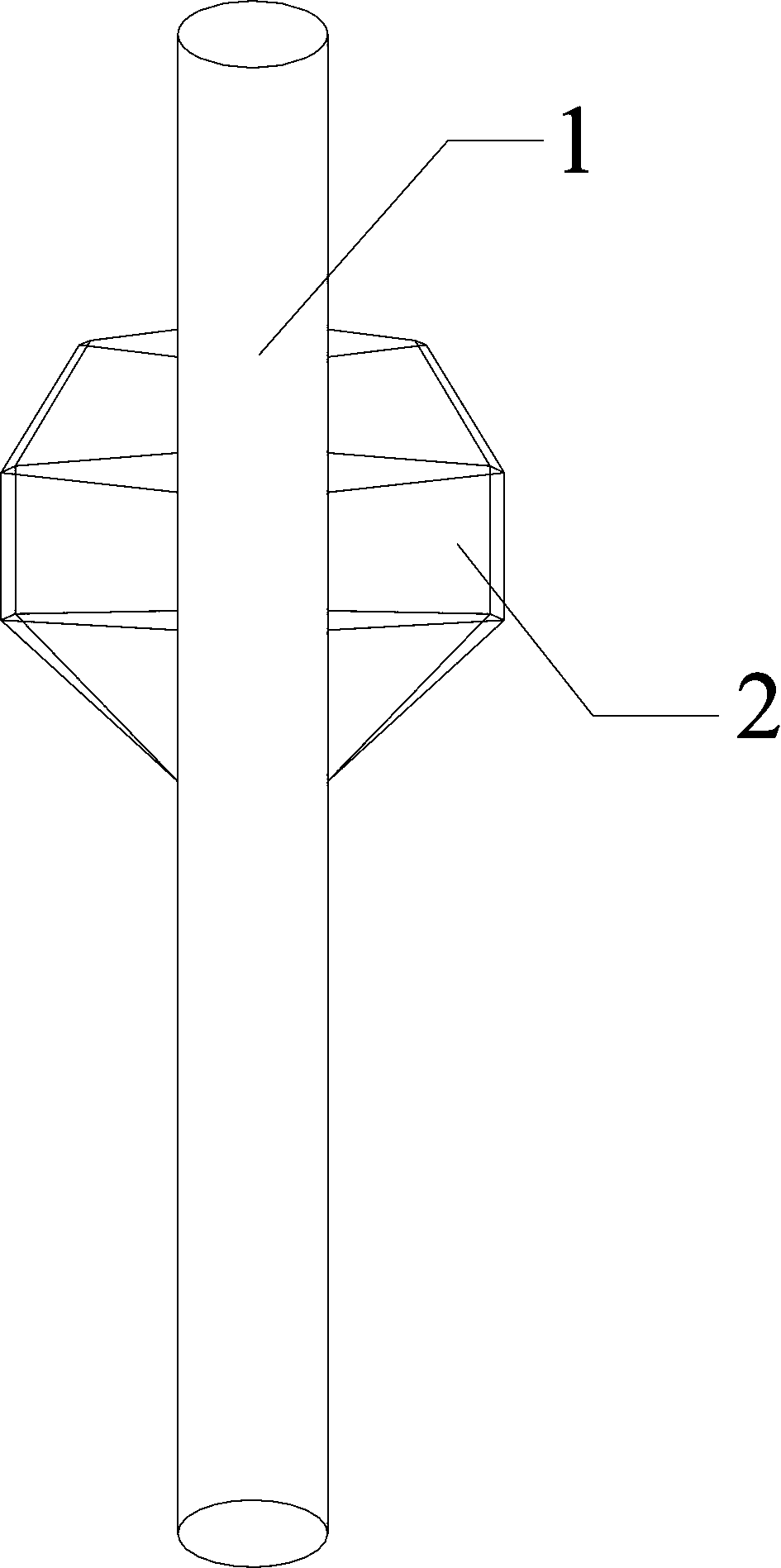

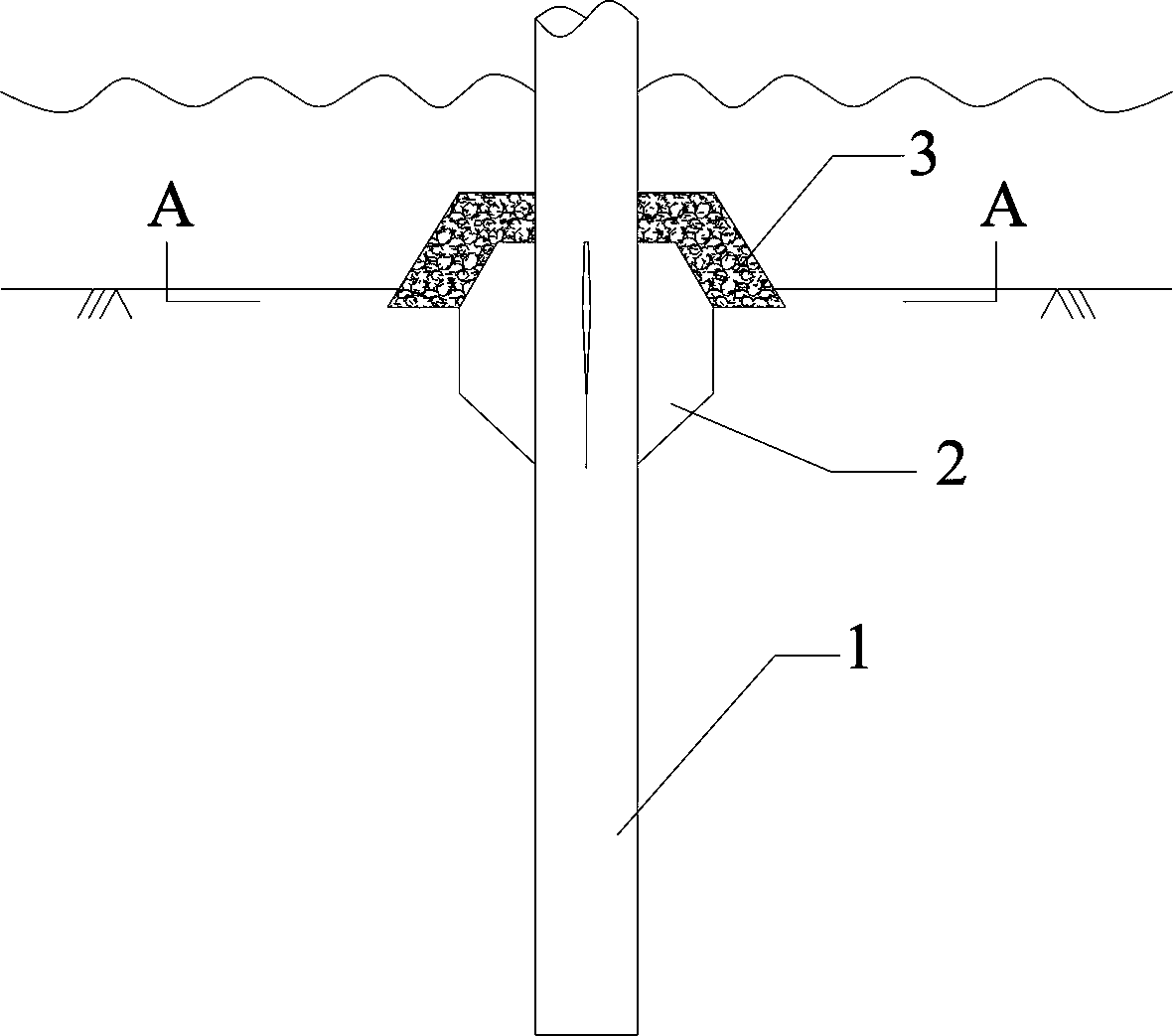

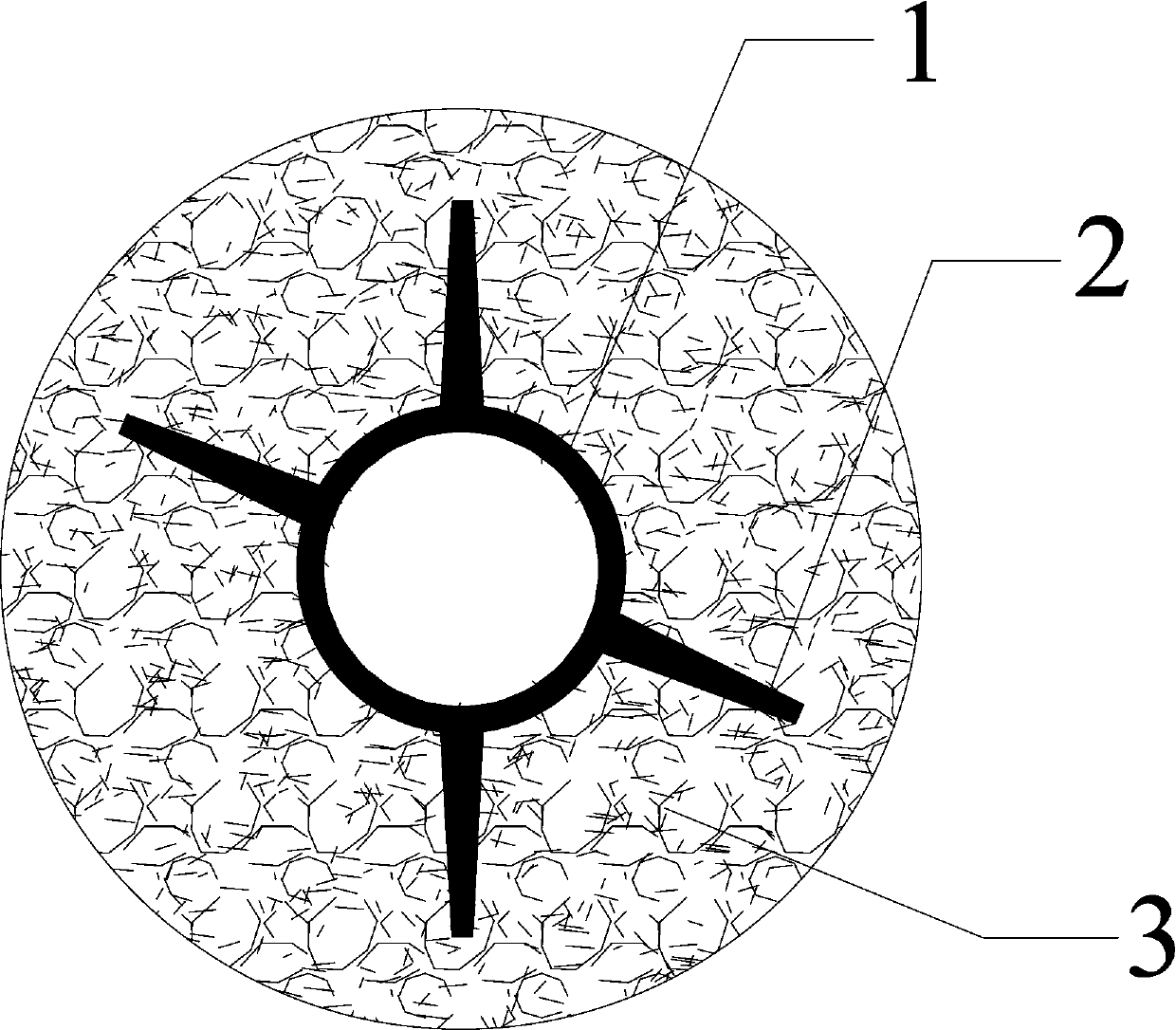

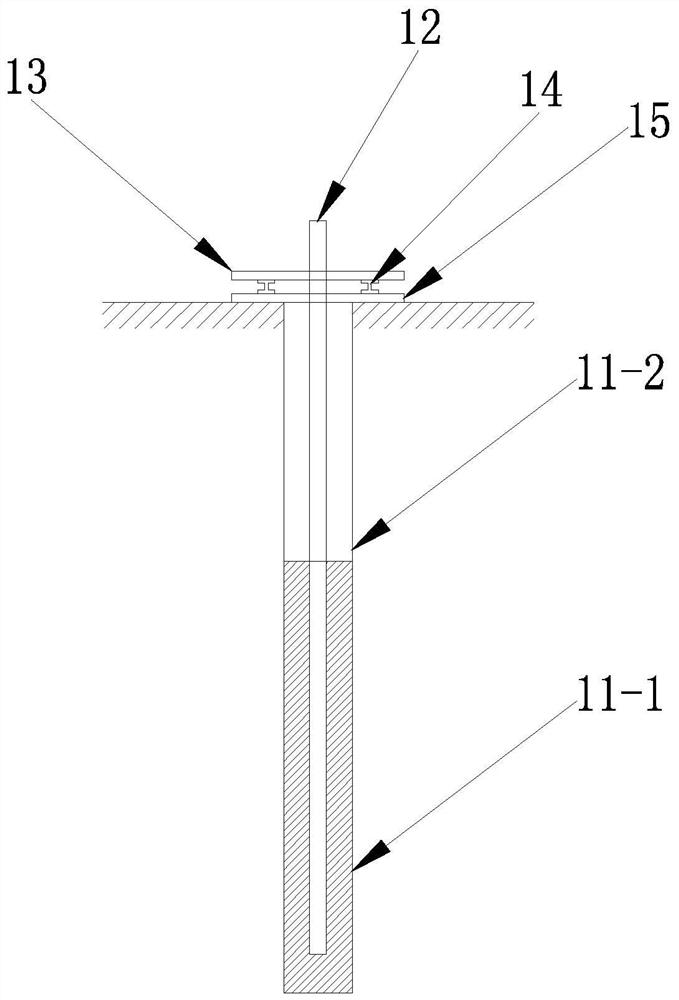

Offshore wind electricity single pile-wing plate-rockfill composite foundation and construction method thereof

PendingCN110984214AImprove carrying capacityFully mobilize resistanceFoundation engineeringRockfill materialStructural engineering

The invention discloses an offshore wind electricity single pile-wing plate-rockfill composite foundation and a construction method thereof. The foundation comprises a single pile, a wing plate and rockfill, the wing plate is of a conical structure, and is welded to the outer wall of a pile body, the rockfill is formed through dense stacking of the rockfill, the upper end of the wing plate is located in the rockfill, and the lower end of a pile wing is located on a seabed supporting layer. The construction method of the offshore wind electricity single pile-wing plate-rockfill composite foundation comprises the following steps of S1, determining the sizes of the single pile, the wing plate and the rockfill; S2, driving the single pile with the wing plate by the designed anchorage depth; and S3, stacking the rockfill on a seabed nearby the single pile. The problems of the low single pile bearing force, the large pile wing of the wing plate pile, serious foundation washing and the like can be solved, the single pile, wing plate and rockfill combination structure uses pile periphery soil resistance and rockfill friction force, the pile foundation bearing force can be improved, the pile foundation horizontal displacement can be reduced, the wing plate size is reduced, a wing plate stress mechanism is changed, washing of waves and ocean currents to seabed soil can be blocked, and safe and stable running of an offshore wind generation set can be ensured.

Owner:CHINA THREE GORGES CORPORATION

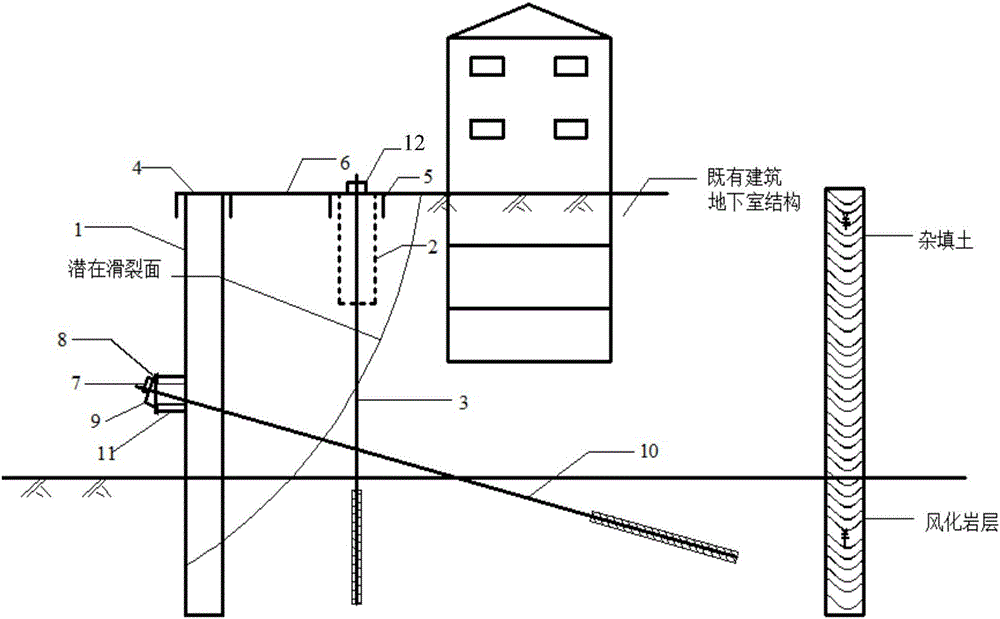

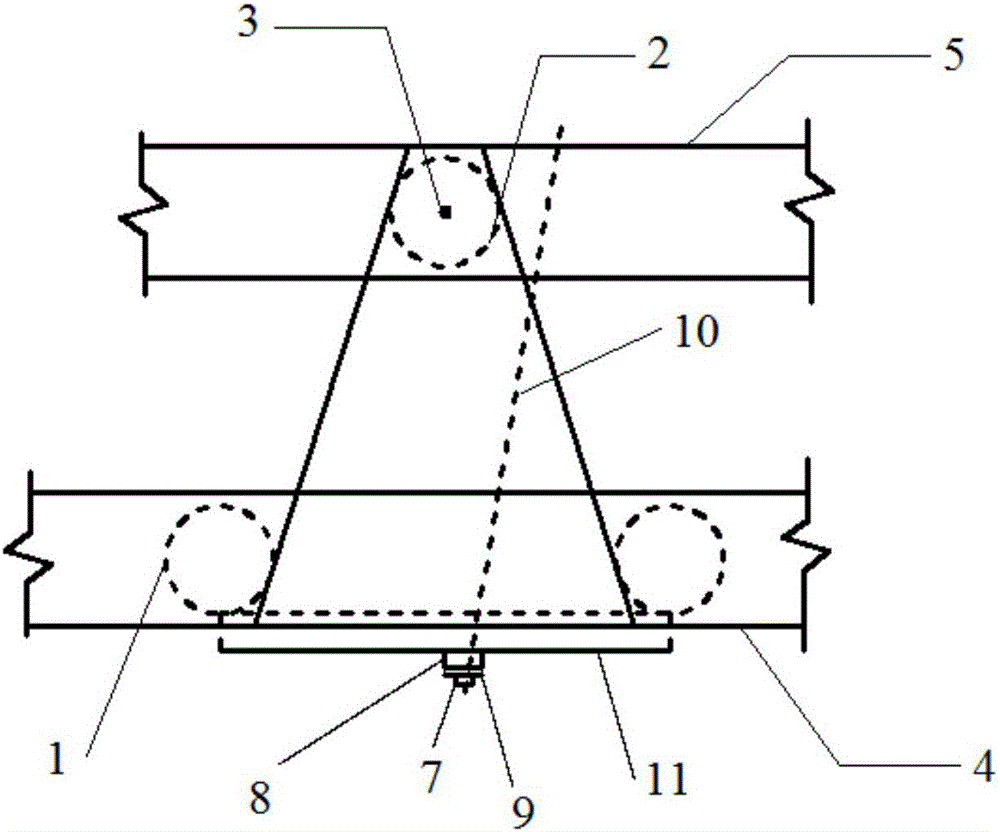

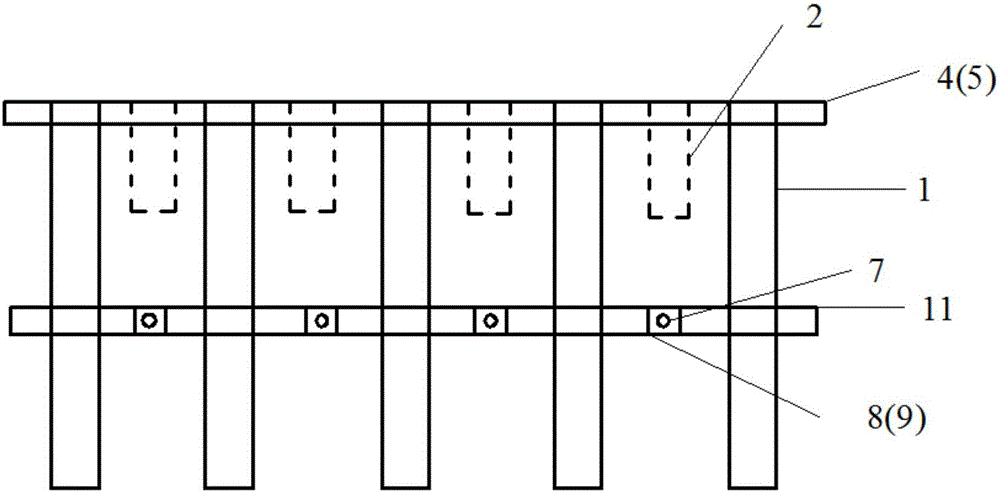

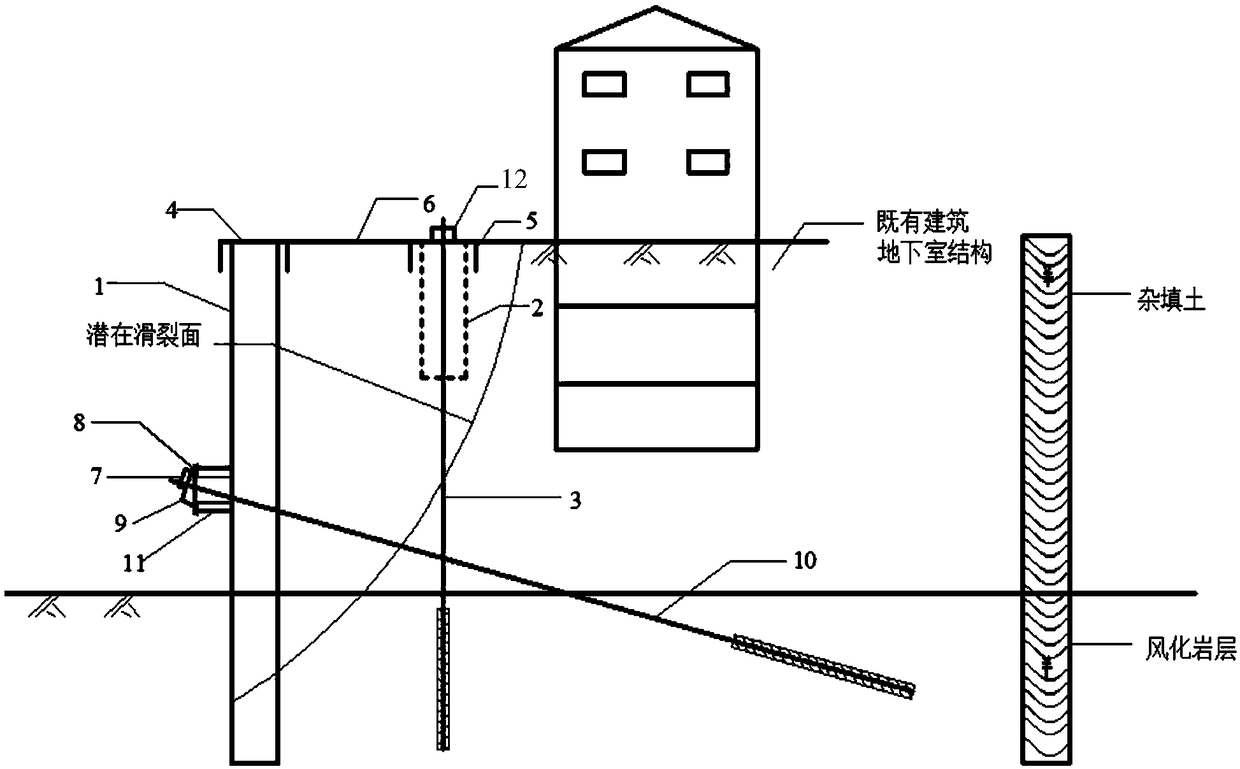

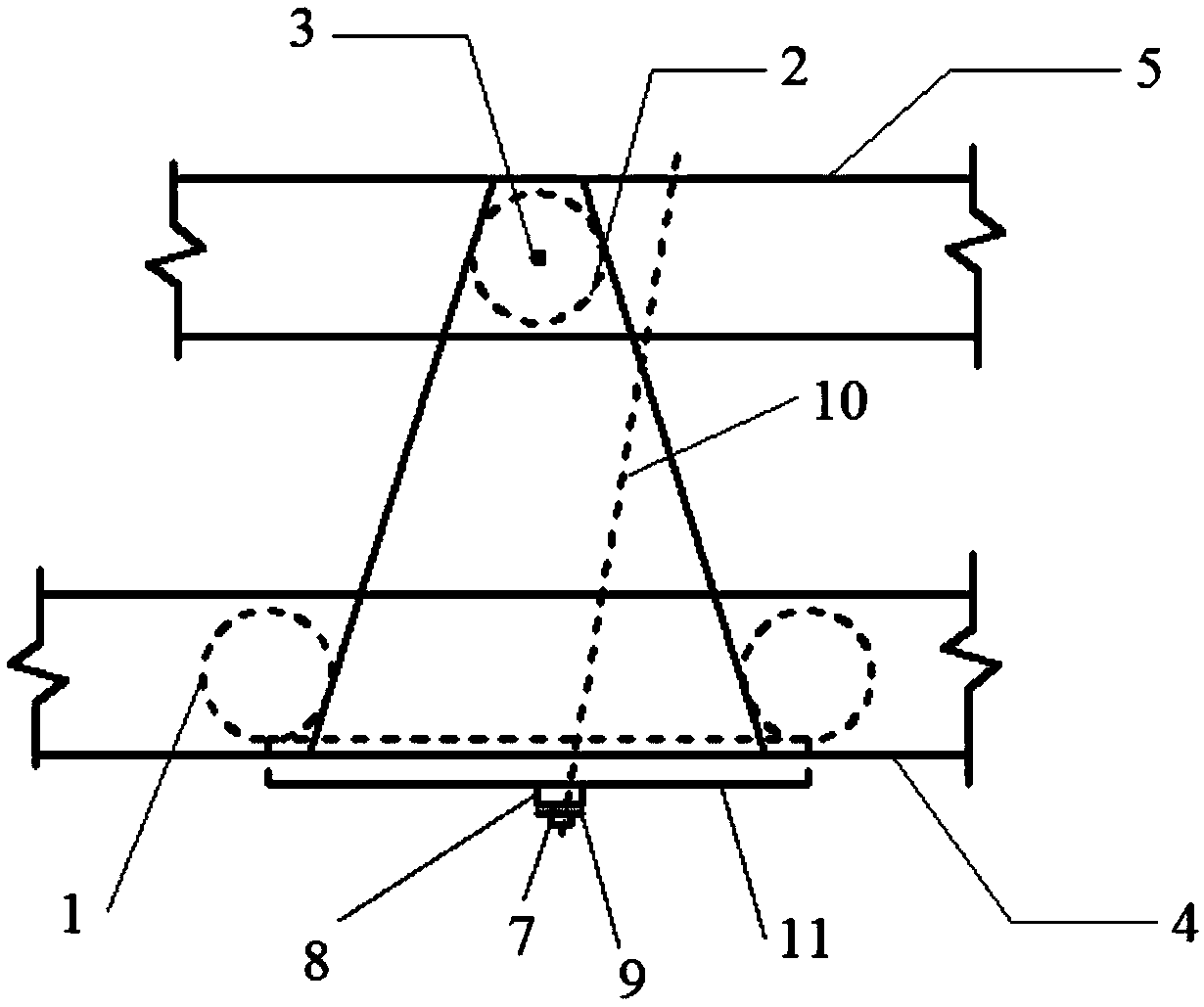

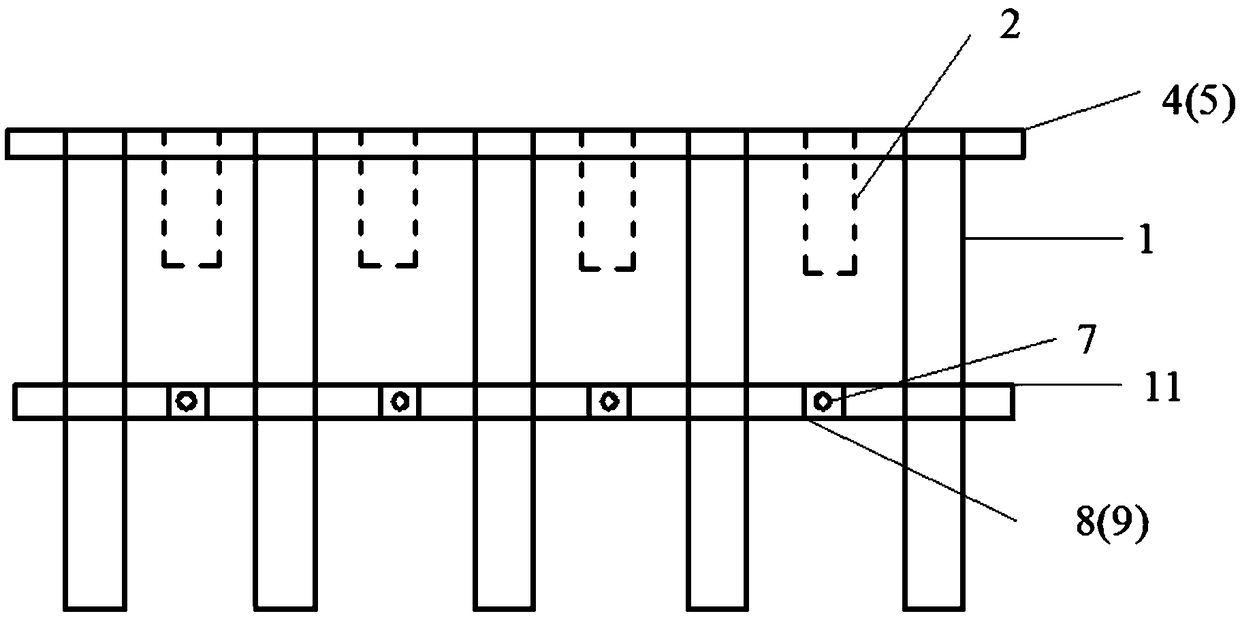

Foundation pile-anchor supporting system for close existing underground structure and construction method of system

ActiveCN106759376AIncrease the number ofIncrease anchor lengthExcavationsSupporting systemPre stress

The invention discloses a foundation pile-anchor supporting system for a close existing underground structure and a construction method of the system. The supporting system comprises front-row steel pipe piles, rear-row steel pipe piles, rear-row vertical prestressed anchors, a front-row pile top beam, a rear-row pile top beam, transverse connecting reinforcements, front-row anchorages, rear-row anchorages, cushion blocks, tapered iron pieces, front-row prestressed anchors and wales. Through the vertical prestressed anchors arranged in the rear-row steel pipe piles, occupancy in underground space can be reduced greatly, and limited ground surface and space within building lines are fully utilized. The vertical prestressed anchors are anchored to the good ground, usage of the rear-row steel pipe piles can be reduced greatly, good anchorage force is provided, the front-row prestressed anchors are used for anchoring and stabilizing the rock stratum, and overturning resistance of the overall structure is improved. By the aid of the rear-row vertical prestressed anchors and the prestressed anchors arranged in the front-row steel pipe piles, factor of safety against overturning of the supporting system is enhanced effectively, construction cost is lowered, and construction period is shortened.

Owner:DALIAN JIAOTONG UNIVERSITY

A pipe pier and bearing platform connecting structure and a construction method

PendingCN109853363AReduce the thickness of the bottom plateReduce thicknessBridge structural detailsRebarBuilding construction

The invention relates to the technical field of highway bridge construction engineering. The invention discloses a pipe pier and bearing platform connecting structure; socket holes are formed in the upper end of a cast-in-place bearing platform; the lower section of the prefabricated pipe pier is an embedded section which is inserted into the socket hole; a steel end plate fixedly connected with alongitudinal main rib of the prefabricated pipe pier is arranged on the lower end surface of the prefabricated pipe pier; the prefabricated pipe pier is a hollow cylindrical pipe pier, the steel endplate is an annular end plate identical to the end face of the prefabricated pipe pier in shape, pipe pier outer side connecting concrete is poured between the lower end face of the embedded section and the bottom face of the socket holes and between the outer side wall of the embedded section and the inner wall of the socket holes, and a pipe pier inner side core filling concrete is poured into ahollow hole of the embedded section. The invention further discloses a construction method of the pipe pier and bearing platform connecting structure. According to the pipe pier and bearing platformconnecting structure and the construction method, the embedded section of the prefabricated pipe pier is provided with the steel end plate, so that the anchoring length of steel bars in concrete is reduced, the pre-embedded depth and the thickness of the bottom plate of the bearing platform can be reduced, and the overall thickness of the bearing platform is reduced.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD +1

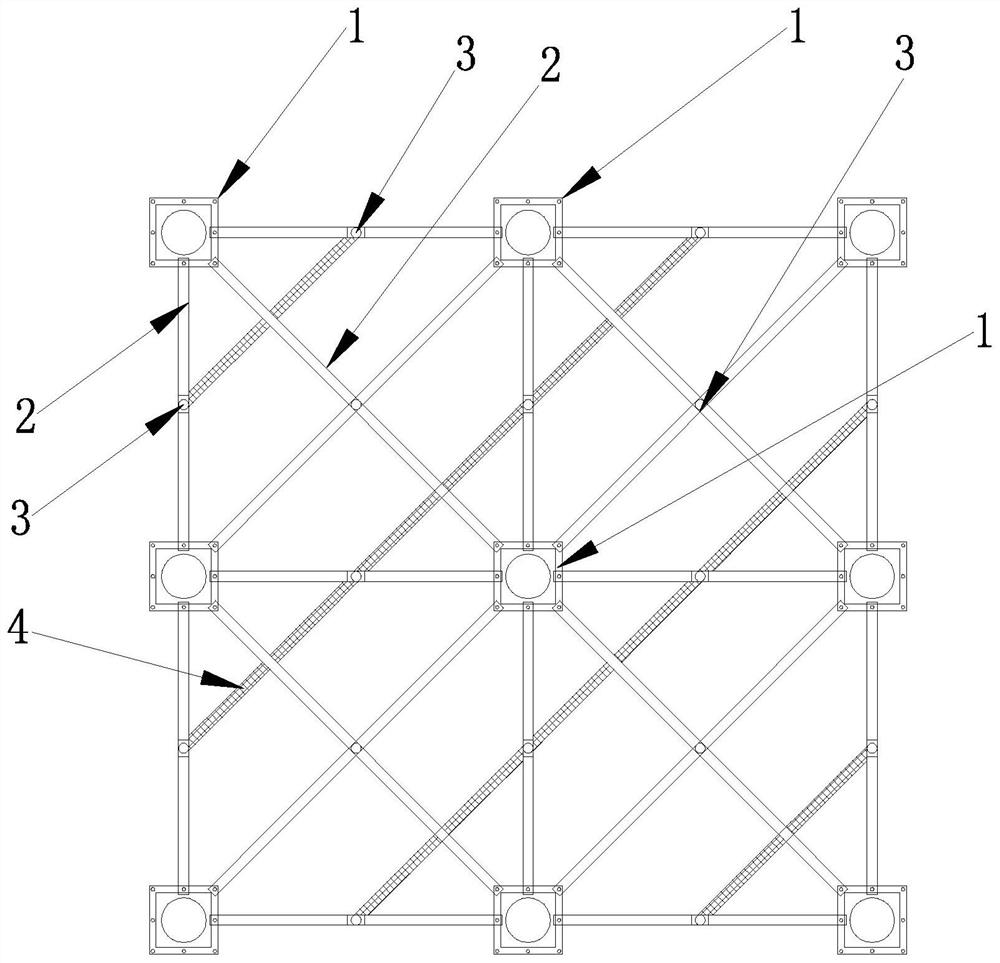

Conical pipe anchor bar connection structure for prefabricated assembly structure

ActiveCN107882051AImprove adhesionImprove binding abilityBridge structural detailsFoundation engineeringReinforced concreteEngineering

The invention discloses a conical pipe anchor bar connection structure for a prefabricated assembly structure, and belongs to the field of prefabricated assembly engineering. The connection structurecomprises a conical pipe, a grouting guide pipe and a fixing circular ring. The conical pipe is of a pre-embedded structure, the conical pipe can achieve a restraint effect on steel bars and groutingmaterials in the conical pipe, and meanwhile the tension capacity of the conical pipe in concrete can be improved. Frame vertical ribs and tie bars in a prefabricated bearing table also achieve a restraint effect on cracking of the bearing table or foundation concrete caused during pulling of the conical pipe. In prefabricated components, a conical pipe group is connected with the surrounding frame vertical ribs and the tie bars, and therefore the anchor performance of the conical pipe group can be improved. The steel bar anchorage length needed by the conical pipe anchor bar connection structure is small, the conical pipe anchor bar connection structure can be used for connection between a reinforced concrete structure prefabricated assembly component and a foundation or the bearing table, and rapid building of the prefabricated assembly reinforced concrete is achieved.

Owner:BEIJING UNIV OF TECH

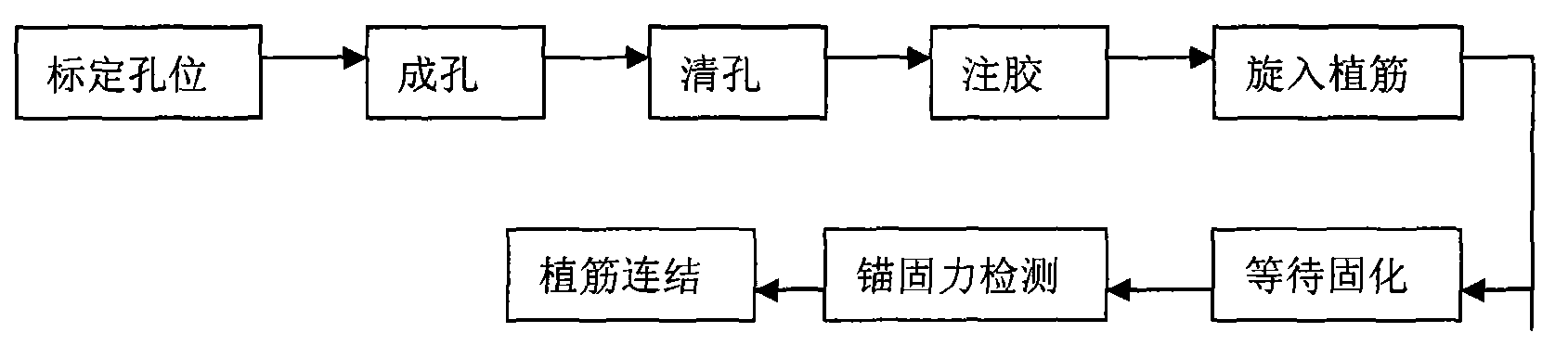

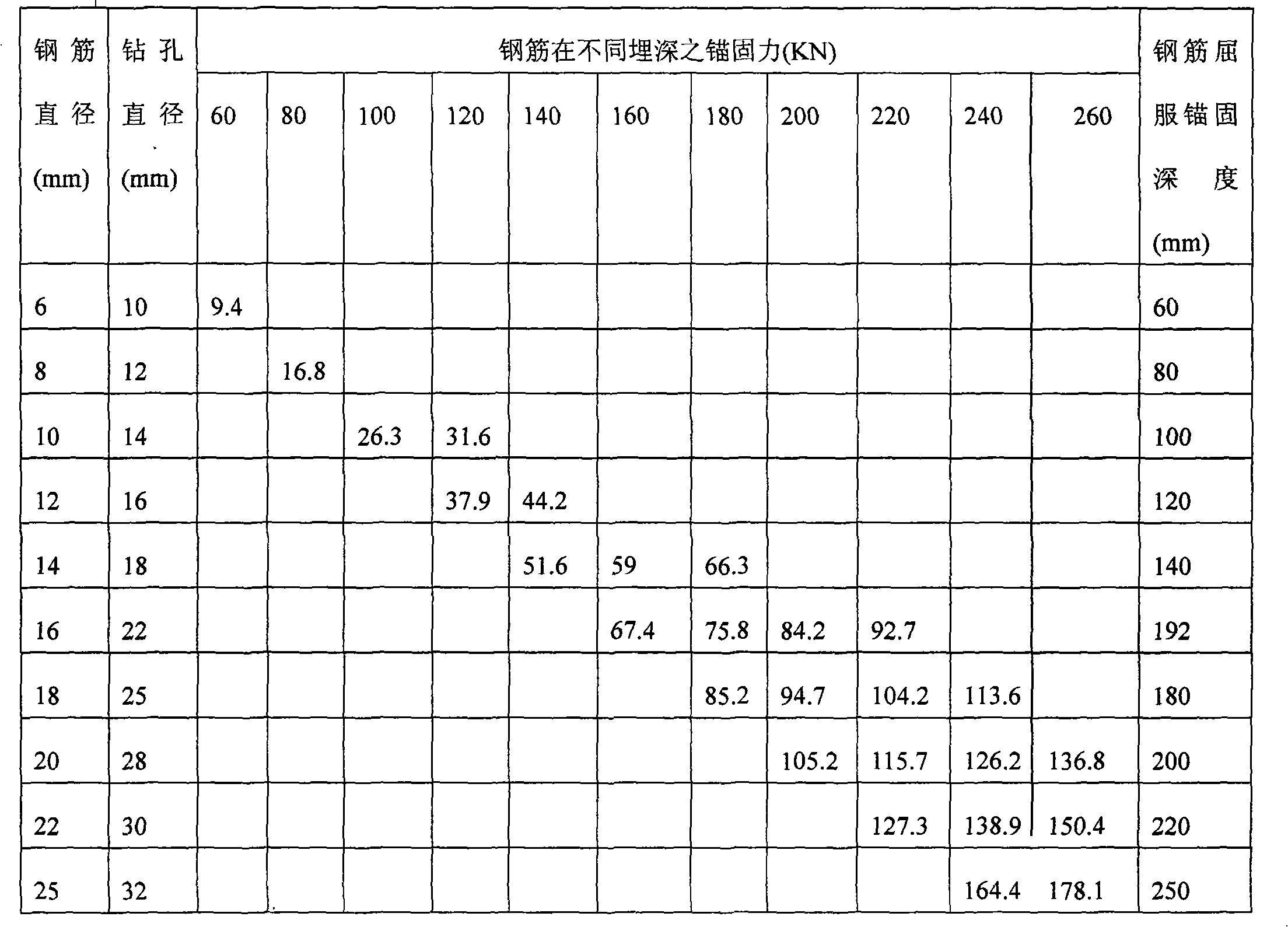

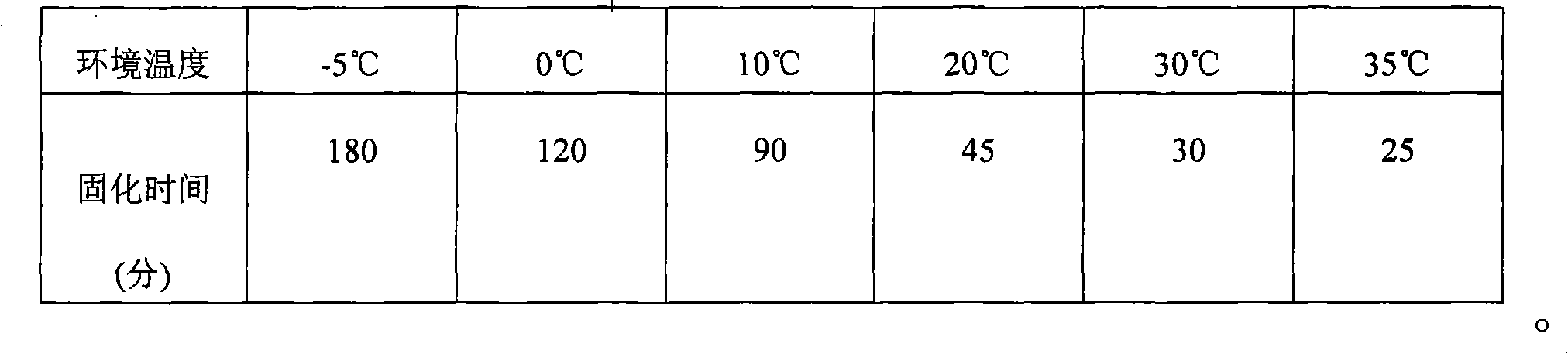

Construction method for rear planted wall steel tie

InactiveCN101899868AReduce retentionImprove the duration effectBuilding constructionsEarthquake resistanceSocial benefits

The invention discloses a construction method for a rear planted wall steel tie. The main technical process is as follows: measuring the specific position of an original rebar on an anchoring position; demarcating a hole site; drilling a hole according to a specified hole diameter; carrying out borehole cleaning and gluing evenly; before glue is solidified, planting the rebar in a mode of rotating while inserting; respectively leading the rebar and glue as well as the glue and a concrete surface to be combined and cured for 24 hours; and after detecting that the anchored force reaches to design requirements, connecting the planted rebar with the connected rebar by binding and welding. The construction method has simple and convenient operation, low construction cost and reliable construction quality, reduces reserved embedded parts and wastes of steel products, improves the whole construction period effect of construction technology and ensures the earthquake resistance of filled wall bodies; and multiple project practical applications prove that economic and social benefits of the method are remarkable.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

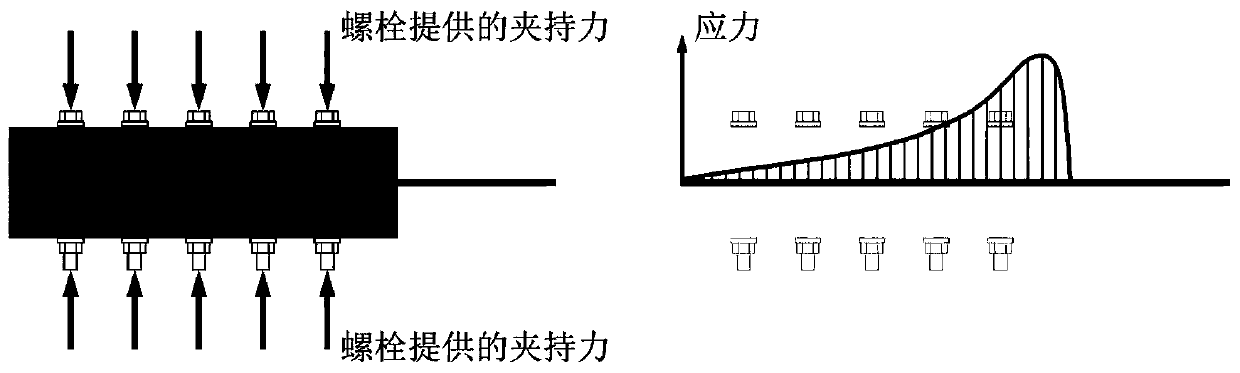

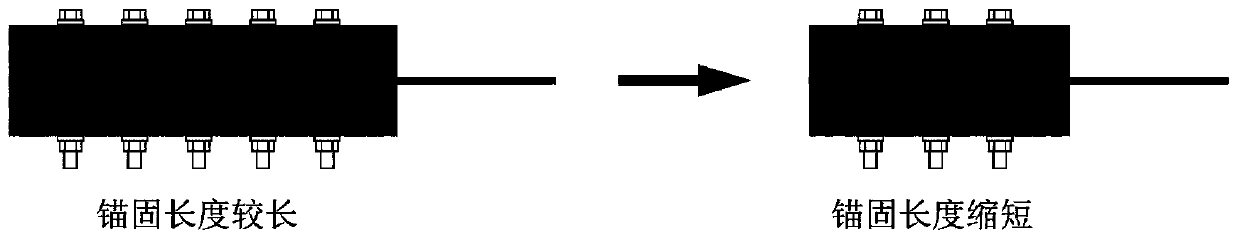

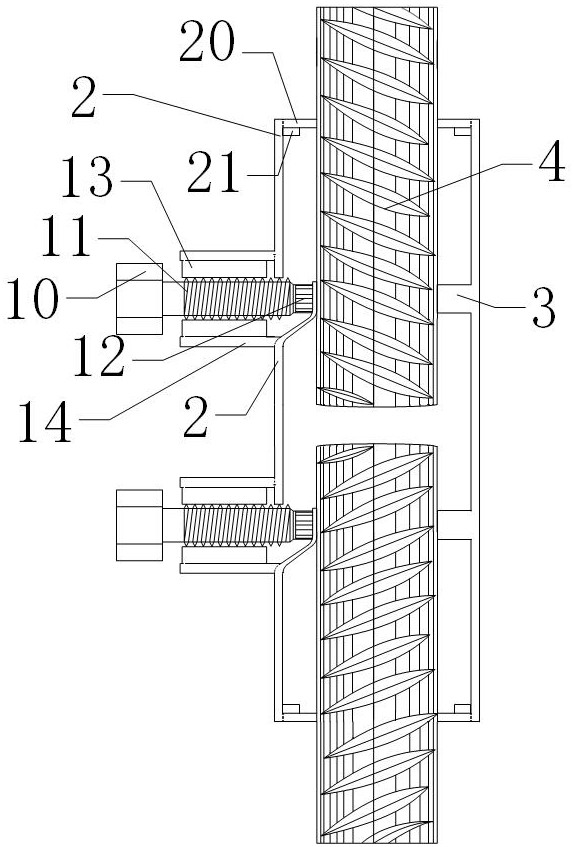

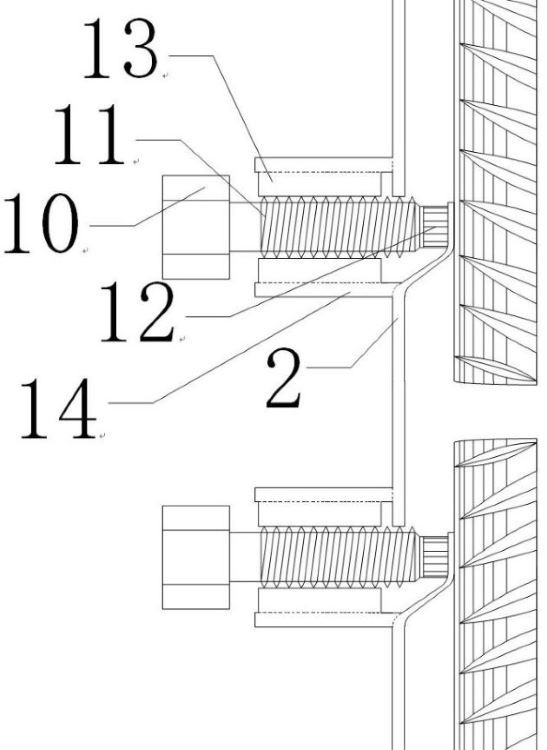

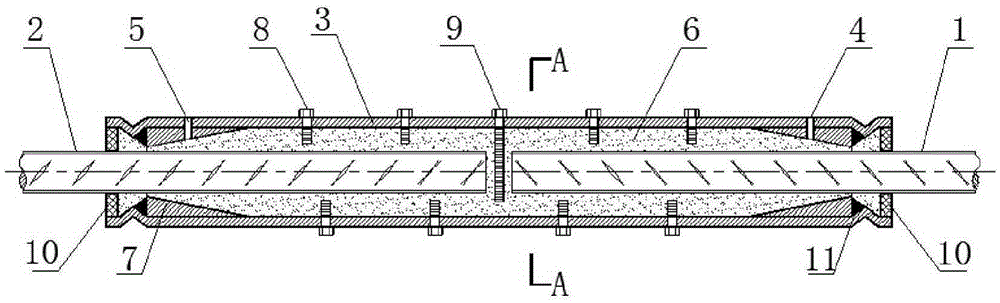

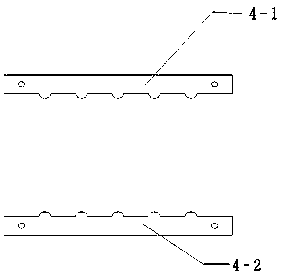

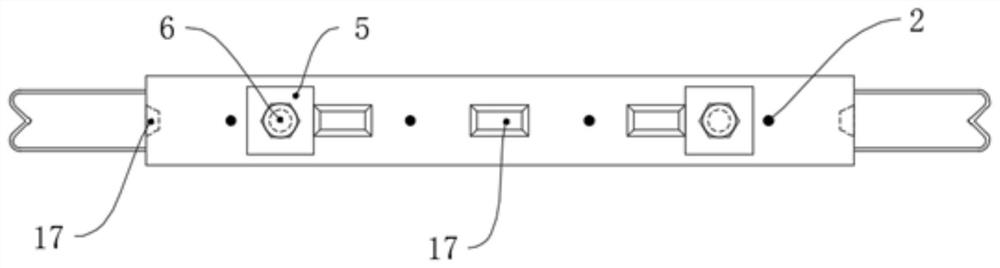

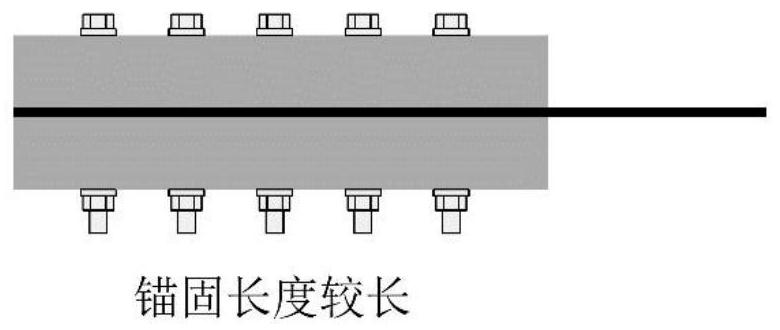

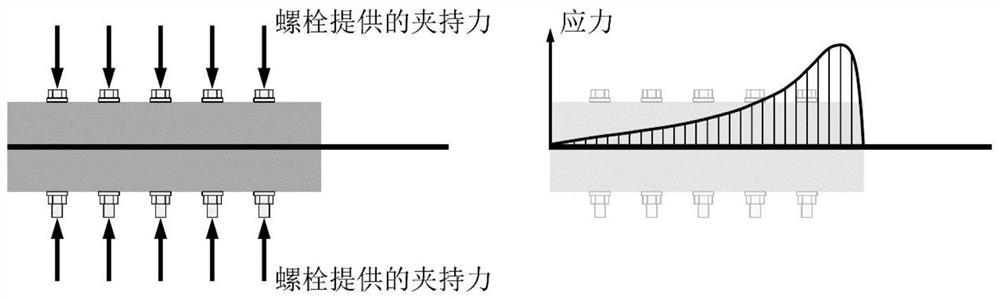

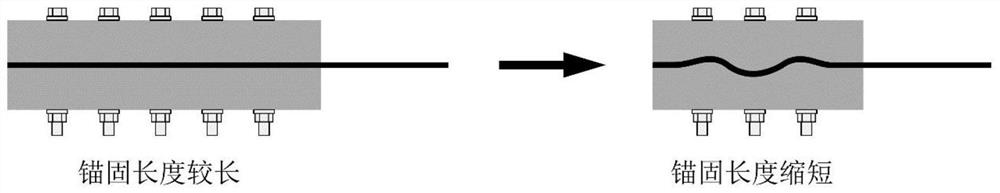

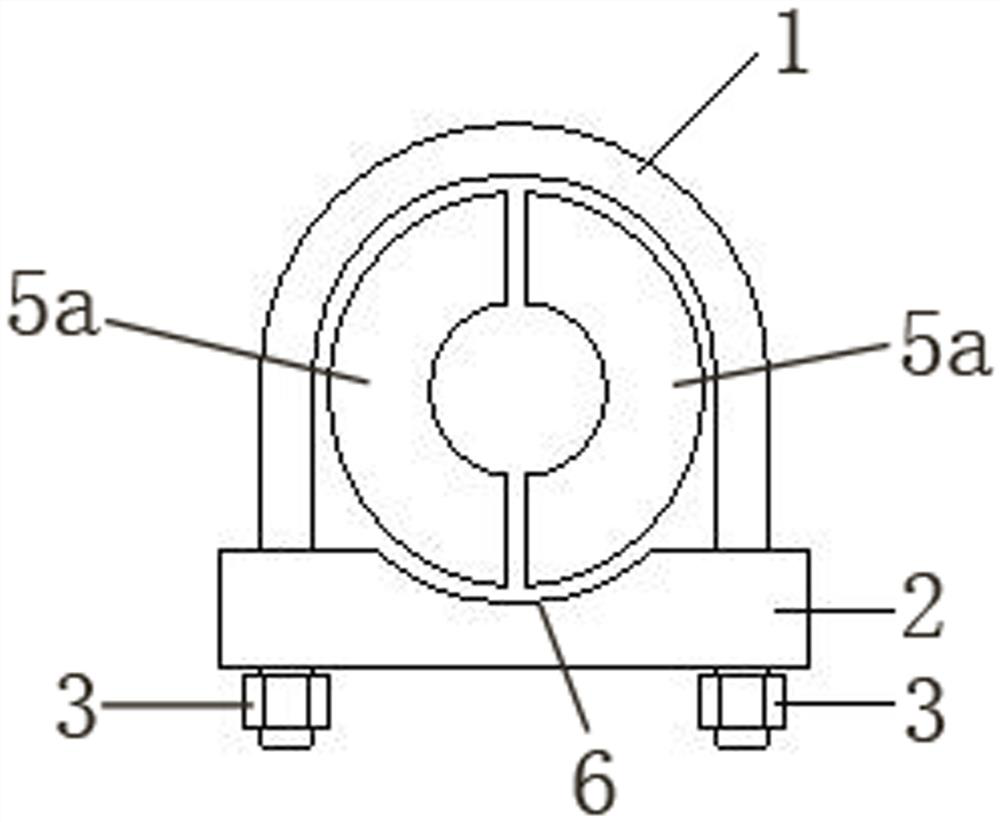

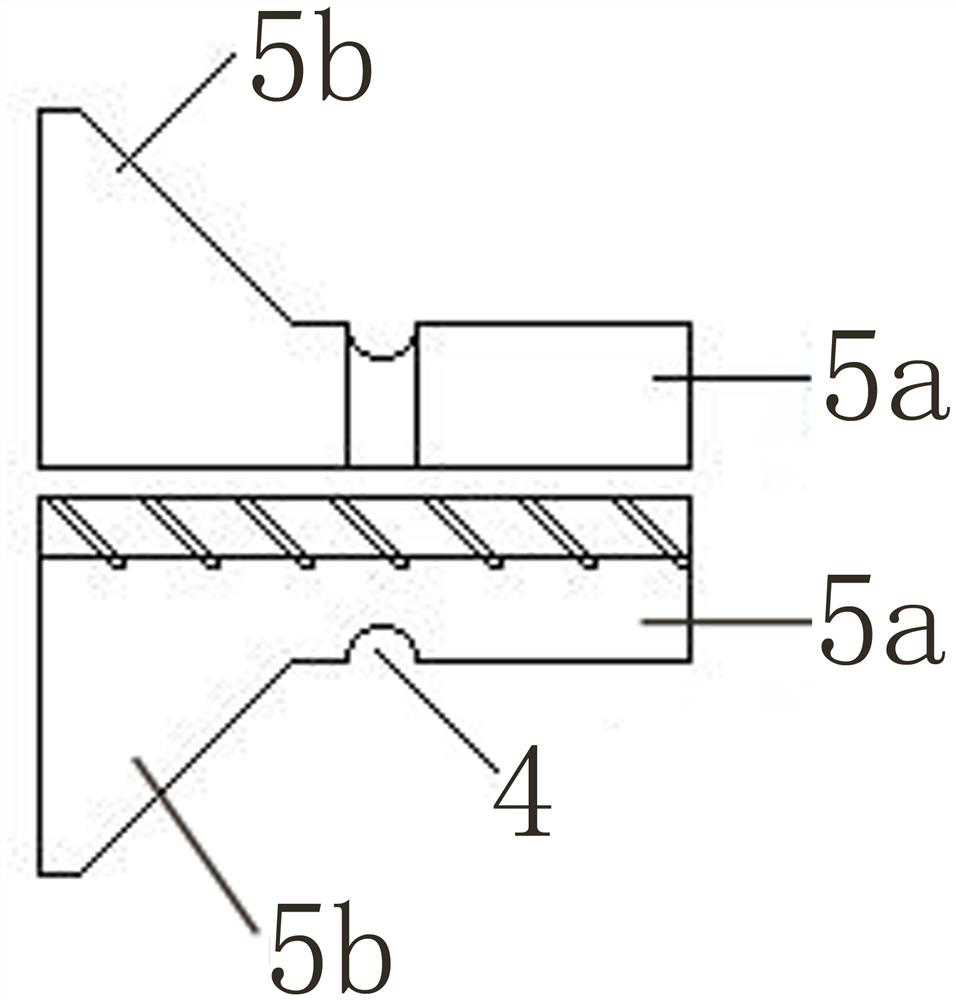

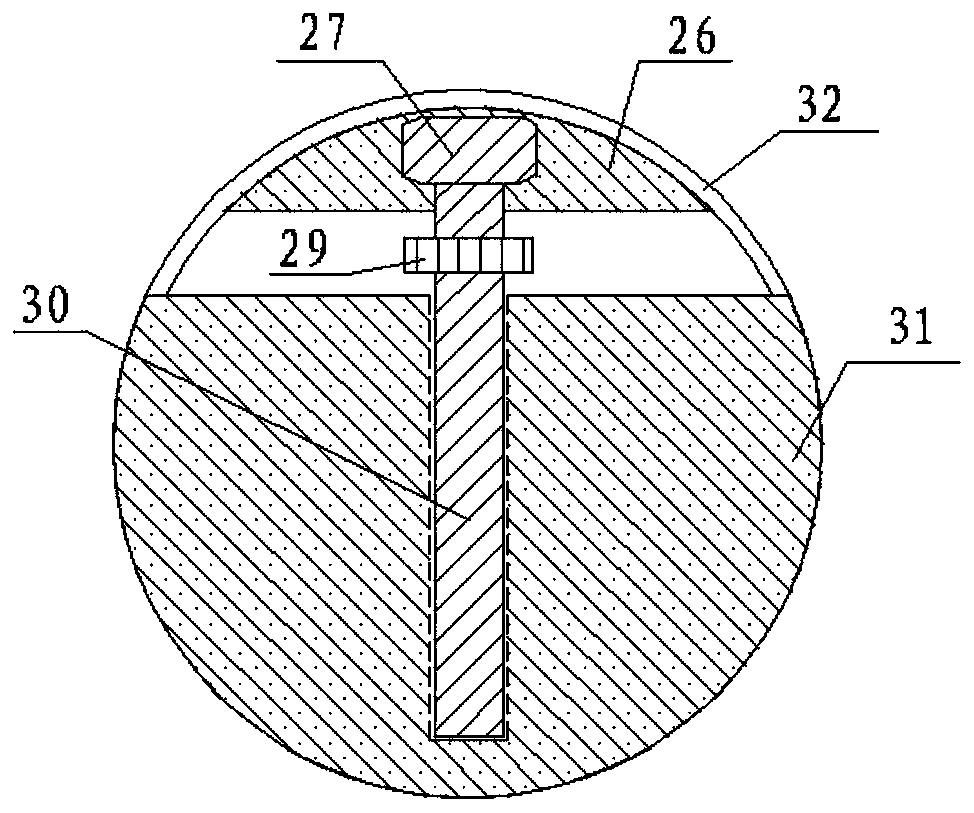

Variable-clamping-force corrugated clamping plate anchor for FRP sheet

ActiveCN109881842AReduce anchor lengthSave materialBridge structural detailsBuilding reinforcementsEngineering structuresAnchor bolt

The invention discloses a variable-clamping-force corrugated clamping plate anchor for an FRP sheet, and relates to an anchor for an engineering structure in the field of high-strength composite materials. The variable-clamping-force corrugated clamping plate anchor for the FRP sheet includes an upper corrugated clamping plate, a lower corrugated clamping plate, bolts, nuts, washers and the FRP sheet. The FRP sheet passes through the upper corrugated clamping and the lower corrugated clamping plate, the upper corrugated clamping plate and the lower corrugated clamping plate clamp the FRP sheettightly, the washers are arranged at bolt holes of the upper corrugated clamping plate and the lower corrugated clamping plate, the nuts penetrate through the upper corrugated clamping plate and thelower corrugated clamping plate, and the FRP sheet is anchored by tightening the nuts. The anchor adopts the corrugated clamping plates to replace flat clamping plates to clamp the FRP sheet, and theanchoring bolt radius gradually increases from an outlet to the end part of the anchor, the clamping force provided by the anchoring bolts further gradually increases from the outlet to the end part of the anchor, the stress peak at the outlet of the anchor can be effectively reduced, the anchoring efficiency is improved, the anchoring length is shortened, materials are saved, and economy is improved.

Owner:重庆卓越强森新材料科技有限公司

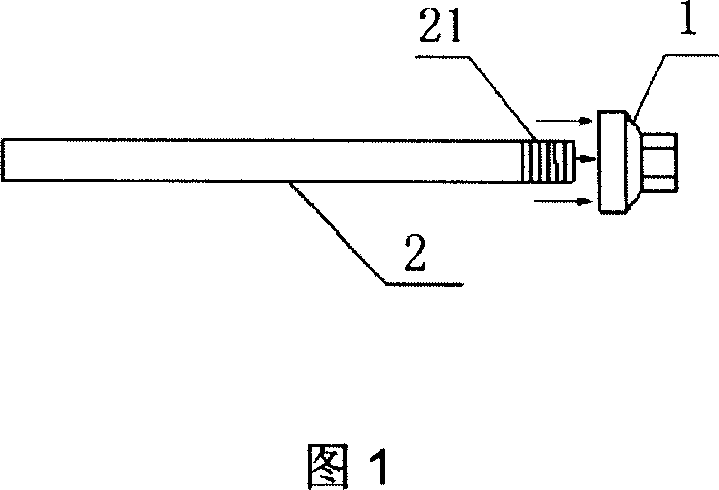

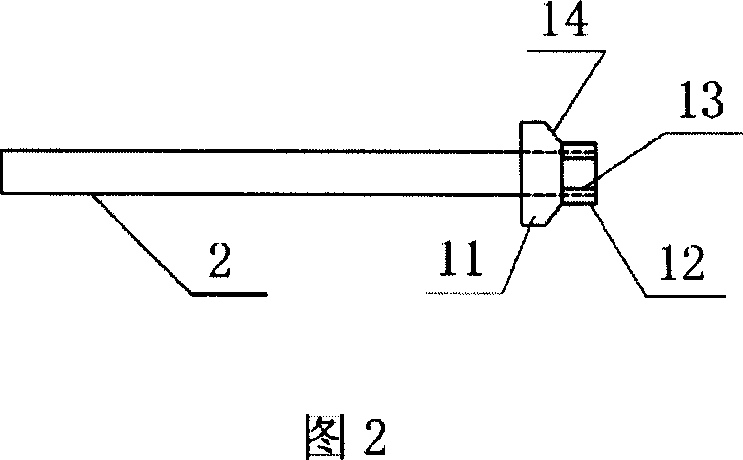

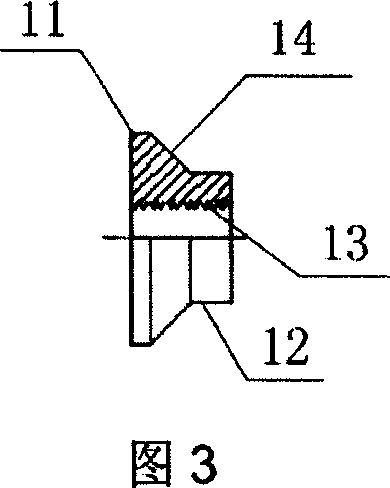

Anchoring structure for end part of steel strand and anchoring method thereof

InactiveCN102373770ALow priceEasy constructionBuilding reinforcementsBuilding material handlingPre stressClassical mechanics

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

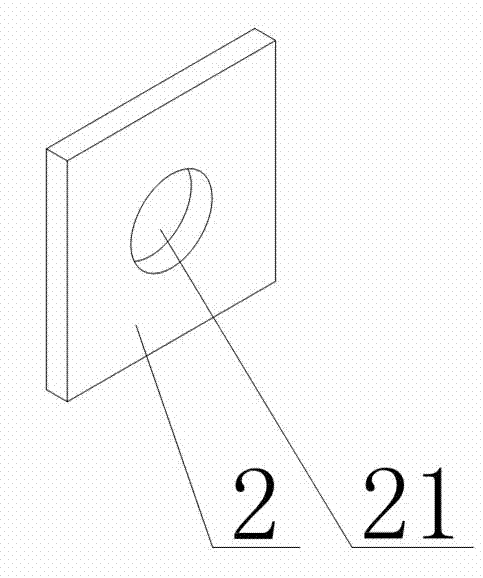

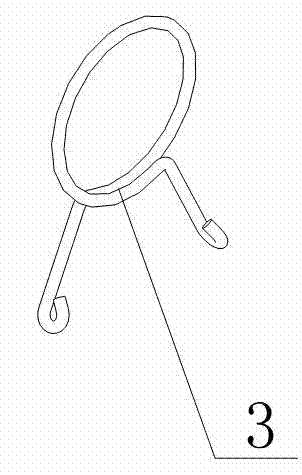

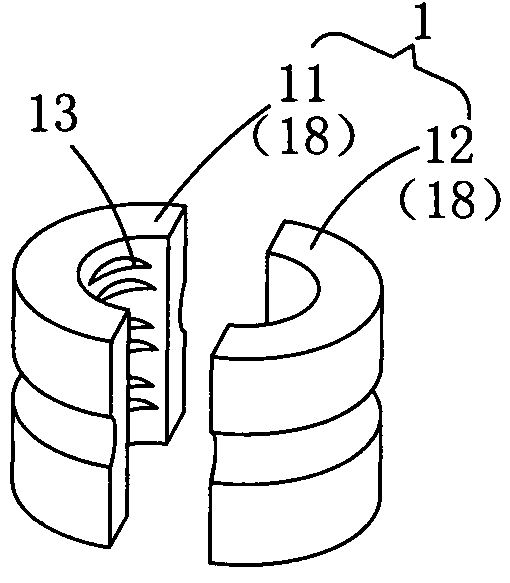

Embedded component and cement consolidation body

The invention relates to the technical field of civil engineering, in particular to an embedded component and a cement consolidation body. A steel bar is embedded in the cement consolidation body and provided with the embedded component, the inner surface of a drum of the embedded component is provided with rib lines snapped with rib lines on the surface of the steel bar, the drum is formed by splicing at least two arc-shaped units arranged in the circumferential direction, and the arc-shaped units are in a split state or a semi-connection state, are fixed on the steel bar in an encircled mode, can be directly fixedly installed at any position of the steel bar, are convenient and rapid to install and do not abrade an anti-corrosion coating on the steel bar. Enough snapping force can be provided only by enabling the rib lines on the inner surface of the drum to be snapped with the rib lines on the steel bar, the embedded component can be applied to zig-zag steel bars, crescent line steel bars and threaded steel bars, and the applied range is expanded.

Owner:曾庆义

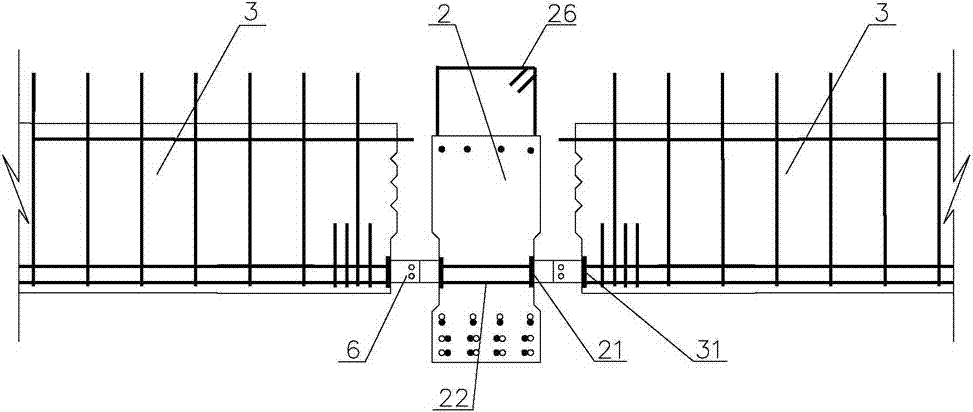

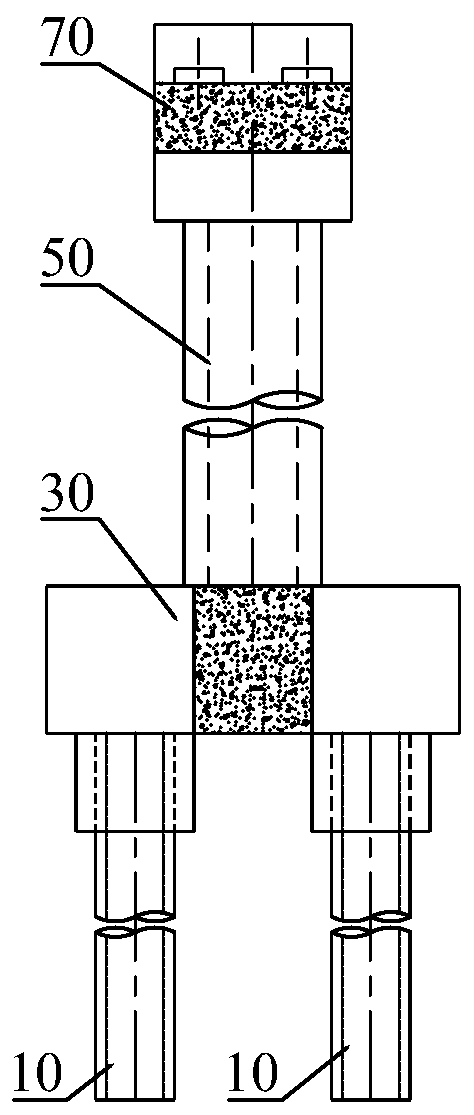

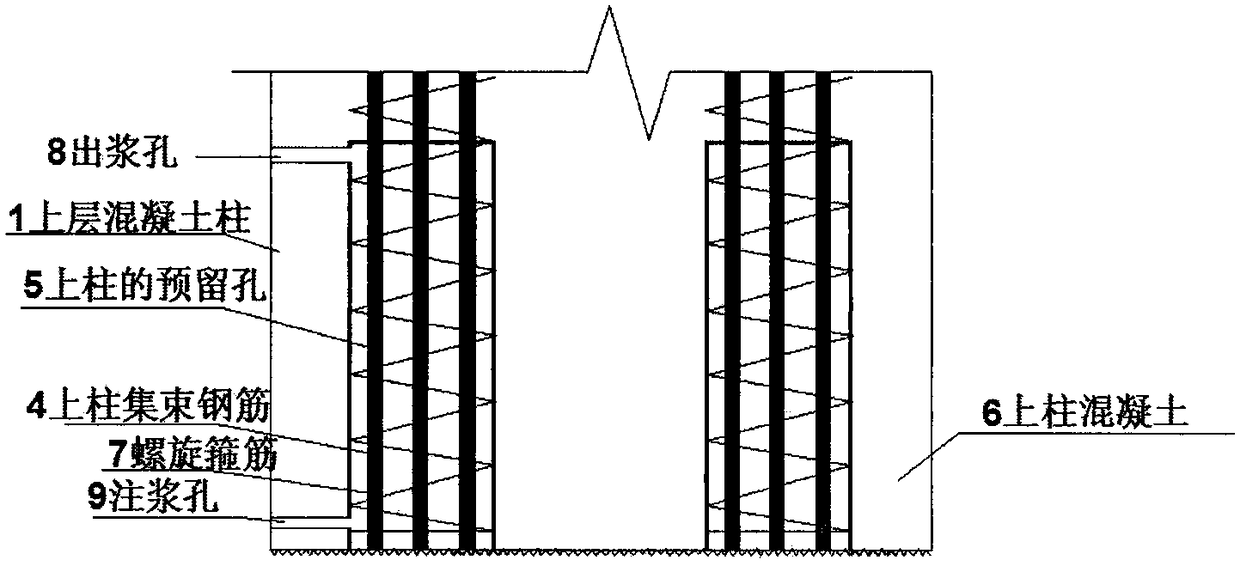

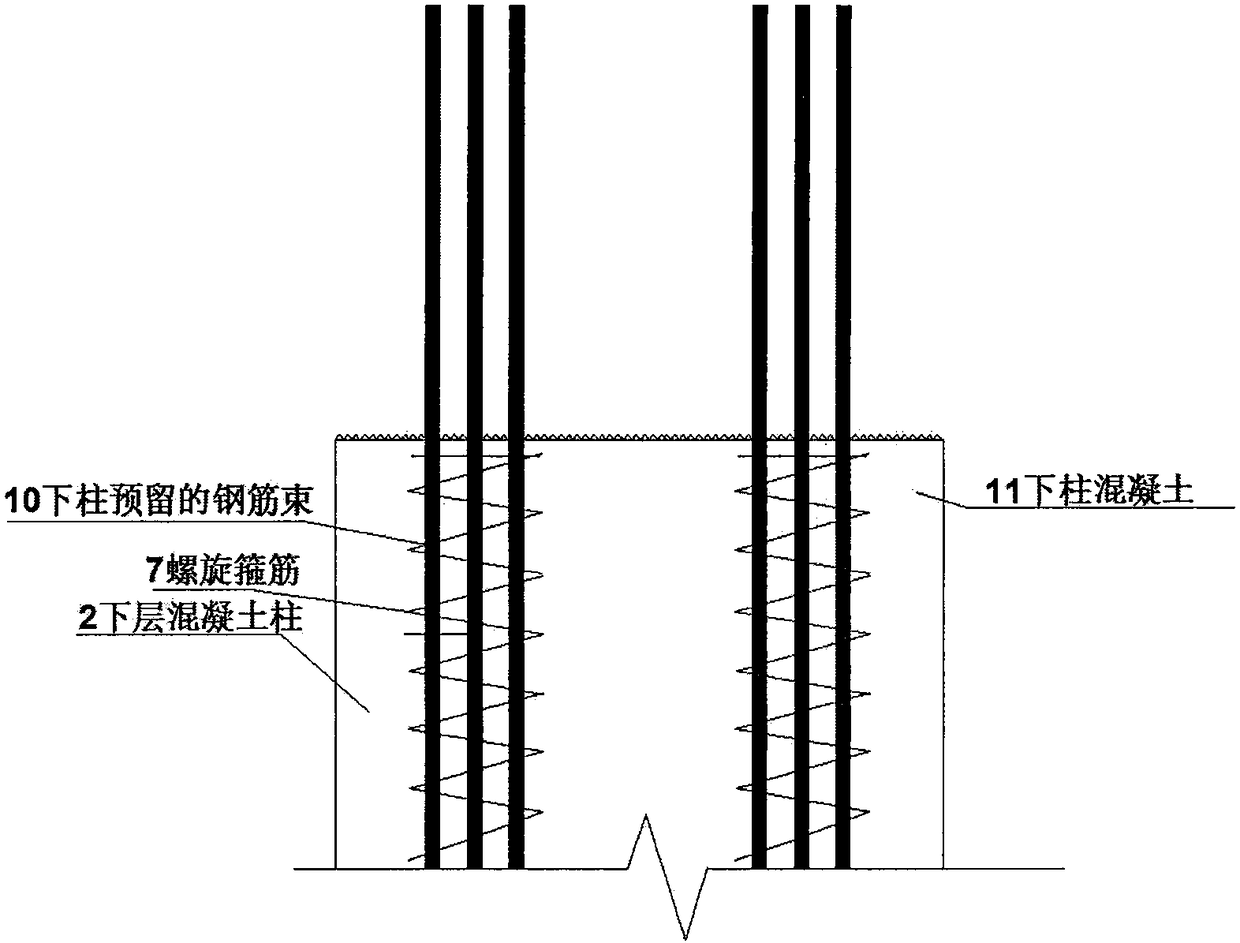

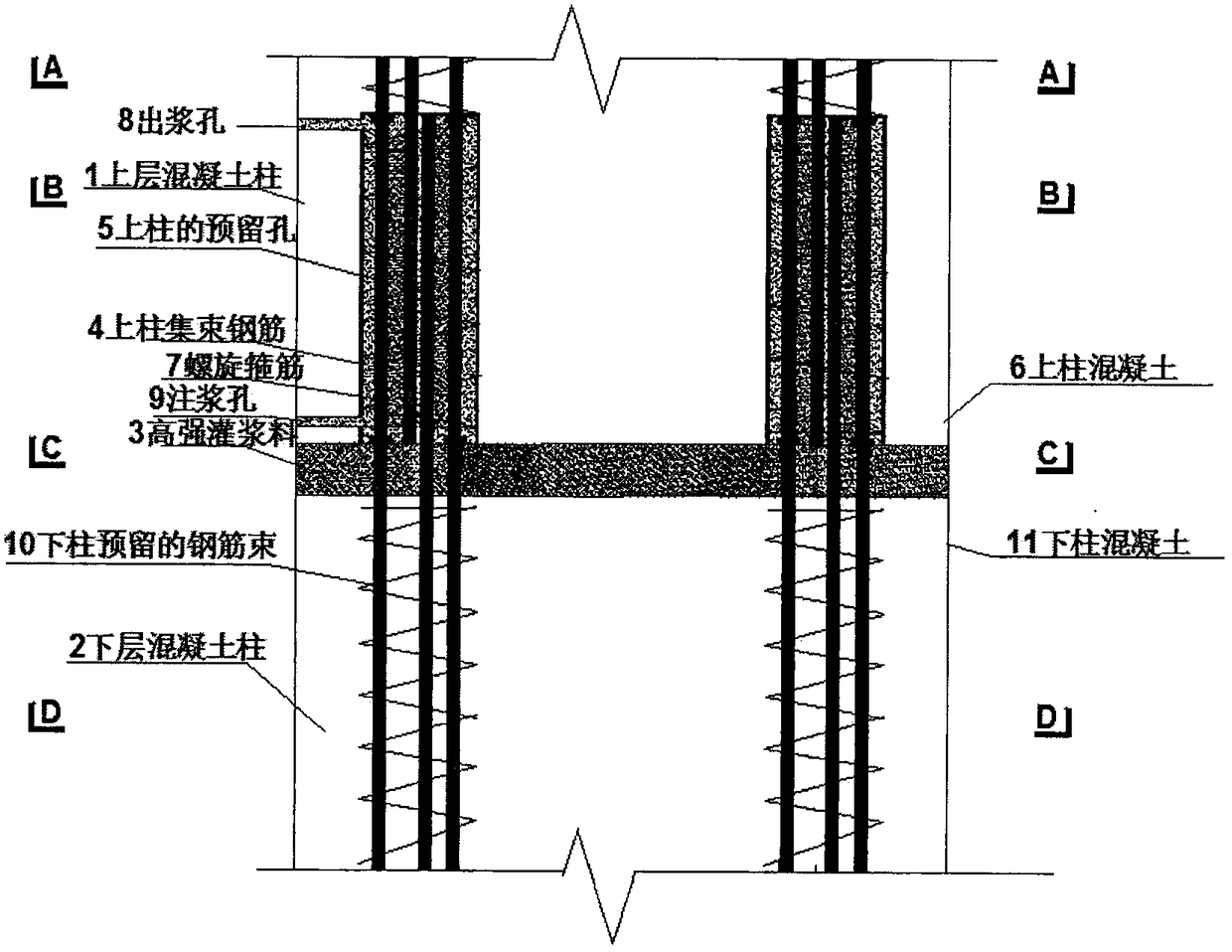

Bundled half-grouting constraint pulp anchor connecting method

InactiveCN109281398AReduce the number of connectionsReduce anchor lengthBuilding constructionsReinforced concrete columnResource utilization

The invention relates to the field of civil engineering and environment and resource utilization. The bundled half-grouting constraint pulp anchor connecting method is suitable for connection of steelbars in fabricated buildings, in particular to steel bar connection in a prefabricated concrete column of bundled reinforcement. According to a bundled reinforcement prefabricated concrete column, bundles of bars are arranged at four corners of the column to replace a plurality of steel bars arranged at the circumference of the column. More than three steel bars are arranged at each edge of the reinforced concrete column, and therefore at least eight steel bars are needed. Pulp anchor connection can not be adopted due to size limitation. Sleeve connection is adopted, and at least eight steelbars are required. According to connection of bundled reinforcement prefabricated concrete upper and lower columns, the bundled half-grouting constraint pulp anchor connecting method is adopted. According to the method, the bundles of bars reserved by the bundled reinforcement prefabricated concrete lower column are inserted into reserved holes of the upper column, a high-strength grouting material is poured, and connection between the bundled reinforcement concrete upper column and lower column is achieved. Through connection, internal forces generated by vertical and horizontal loads on thecolumn can be effectively transferred, and the number of connections and anchoring length of vertical steel bars are reduced.

Owner:SHENYANG JIANZHU UNIVERSITY +3

Anti-skid tunnel structure and construction method thereof

PendingCN111502691AImprove overall stiffnessImprove skid resistanceUnderground chambersTunnel liningRebarRetaining wall

The invention relates to an anti-skid tunnel structure and a construction method thereof. The anti-skid tunnel structure comprises a tunnel structure passing through a slip mass, wherein multiple upper connecting beams and lower connecting beams are respectively arranged on an arch apex and an inverted arch of the tunnel structure; multiple upper-side anti-skid piles and lower-side anti-skid pilesare respectively arranged on two sides of the tunnel structure; and the upper connecting beams and the lower connecting beams are fixedly connected with the upper-side anti-skid piles and the lower-side anti-skid piles. The construction method comprises the steps of (1) excavating a pile well at a pile position of a predetermined anti-skid pile, and constructing an anti-skid pile retaining wall;(2) pouring concrete on the anti-skid pile to the design height; (3) excavating a tunnel and constructing preliminary bracing; (4) implanting first connecting reinforcement steel bars onto the anti-skid piles, binding connecting beam reinforcement steel bars on the first connecting reinforcement steel bars, binding secondary lining inner reinforcement steel bars, arranging second connecting reinforcement steel bars along a trend direction of the tunnel structure, and connecting the connecting beam reinforcement steel bars and the secondary lining inner reinforcement steel bars through the second connecting reinforcement steel bars; and (5) pouring a secondary lining, the upper connecting beams and the lower connecting beams through a vertical formwork.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Steel bar connection grouting-free sleeve device of fabricated concrete structure

InactiveCN113338546AAchieve connectionIncrease positive pressureBuilding reinforcementsArchitectural engineeringRebar

The invention relates to the field of fabricated buildings, and particularly relates to a steel bar connection grouting-free sleeve device of a fabricated concrete structure. The steel bar connection grouting-free sleeve device comprises a boss, a sleeve and a high-strength bolt; the sleeve is provided with a sealing ring and a clamping groove; the high-strength bolt is provided with a nut, a screw, a plum head, a threaded protection arm and a high-strength steel pipe; the boss and the sleeve are made of low-yield-point steel; the high-strength bolt is made of high-strength steel; and the boss is in a crescent shape. The sleeve is extruded and formed through the high-strength bolt, the positive pressure of the contact face is increased by applying pre-tightening force of primary screwing and final screwing to the high-strength bolt, and accordingly steel bars are tightly attached to the boss to be fixed. Filling is not needed in the construction process, and compared with an existing grouting sleeve, the steel bar connection grouting-free sleeve device can avoid the phenomenon of material waste in the grouting process and meanwhile has the beneficial effects that labor force is reduced, the construction efficiency is improved, and the construction difficulty is lowered.

Owner:LIAONING TECHNICAL UNIVERSITY

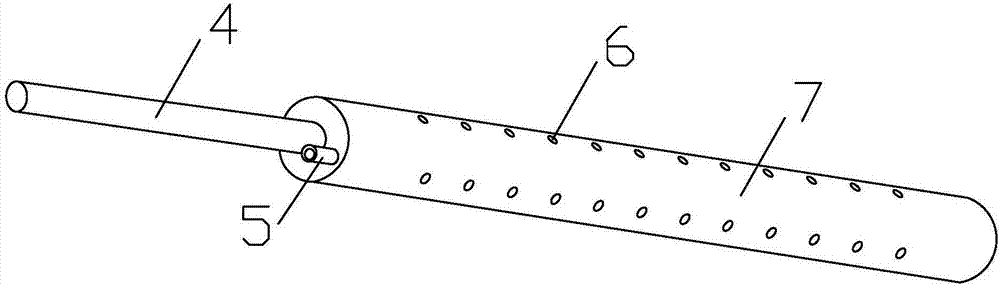

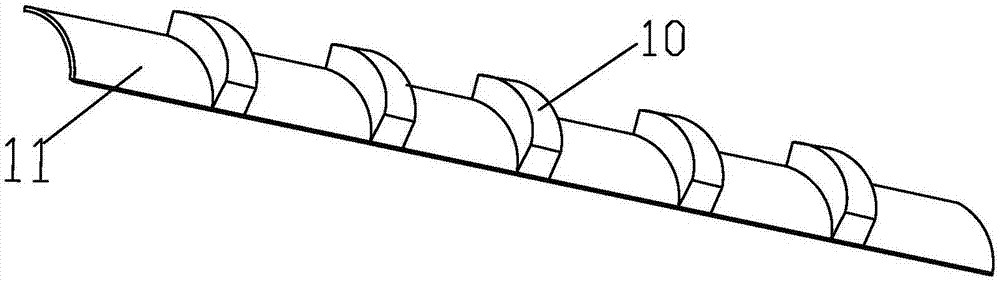

Disc forming tool and multi-disc soil anchor prepared by using same

PendingCN107059861AReduce anchor lengthReduced drilling lengthExcavationsBulkheads/pilesDrill holeEngineering

The invention provides a disc forming tool and a multi-disc soil anchor prepared by using the same. The disc forming tool comprises an inner lining pipe which is arranged on the innermost layer of a disc forming tool body and plays a role in supporting the disc forming tool body; an air bag is arranged on the outer layer of the inner lining pipe in a sleeving mode, has the elasticity and is expandable in the radial direction of the inner lining pipe; and pressing plates are arranged on the outer surface of the air bag, convex blocks are arranged on the pressing plates, and the pressing plates expand in the radial direction of the inner lining pipe along with the air bag to move in the radial direction. The multi-disc soil anchor comprises a cylinder and a plurality of discs, wherein the multiple discs are annularly arranged on the outer surface of the cylinder at intervals. According to the disc forming tool, the air bag is inflated to push the pressing plates to expand in the radial direction, the convex blocks on the surfaces of the pressing plates are pressed into soil of a drilled hole, a plurality of disc cavities are formed through repeated operations such as air inflation and deflation, rotation, stretch and the like, cement paste is poured into the expanded drilled hole, after the cement paste is solidified into disc bodies, the soil facing surface of each disc body is subjected to the pressure effect of the passive soil, and finally the higher anchoring force can be obtained.

Owner:ANHUI UNIV OF SCI & TECH

FRP steel strand composite bar anchorage device and anchoring method

InactiveCN112376803AImprove anchoring performanceSimple structureBuilding reinforcementsBuilding material handlingStructural engineeringPipe

The invention discloses an FRP steel strand composite bar anchorage device and an anchoring method. The anchorage device comprises a soft metal pipe, an opening device, an anchor cup and a grouting material, the anchor cup penetrates into an anchoring area of an FRP steel strand composite bar, the soft metal pipe is fixed to the front end of the anchoring area of the FRP steel strand composite bar, the rear end of the anchoring area is opened through an opening device, the tail end of the anchor cup is filled with the grouting material after being blocked, and anchoring is completed after high-temperature curing. The anchorage device is simple in structure, small in size, high in anchoring efficiency, convenient to construct, capable of effectively improving the anchoring performance of the grouting material and a composite rib material and reducing the anchoring length, clear in stress direction, convenient to use, low in cost and high in reliability.

Owner:南通装配式建筑与智能结构研究院 +1

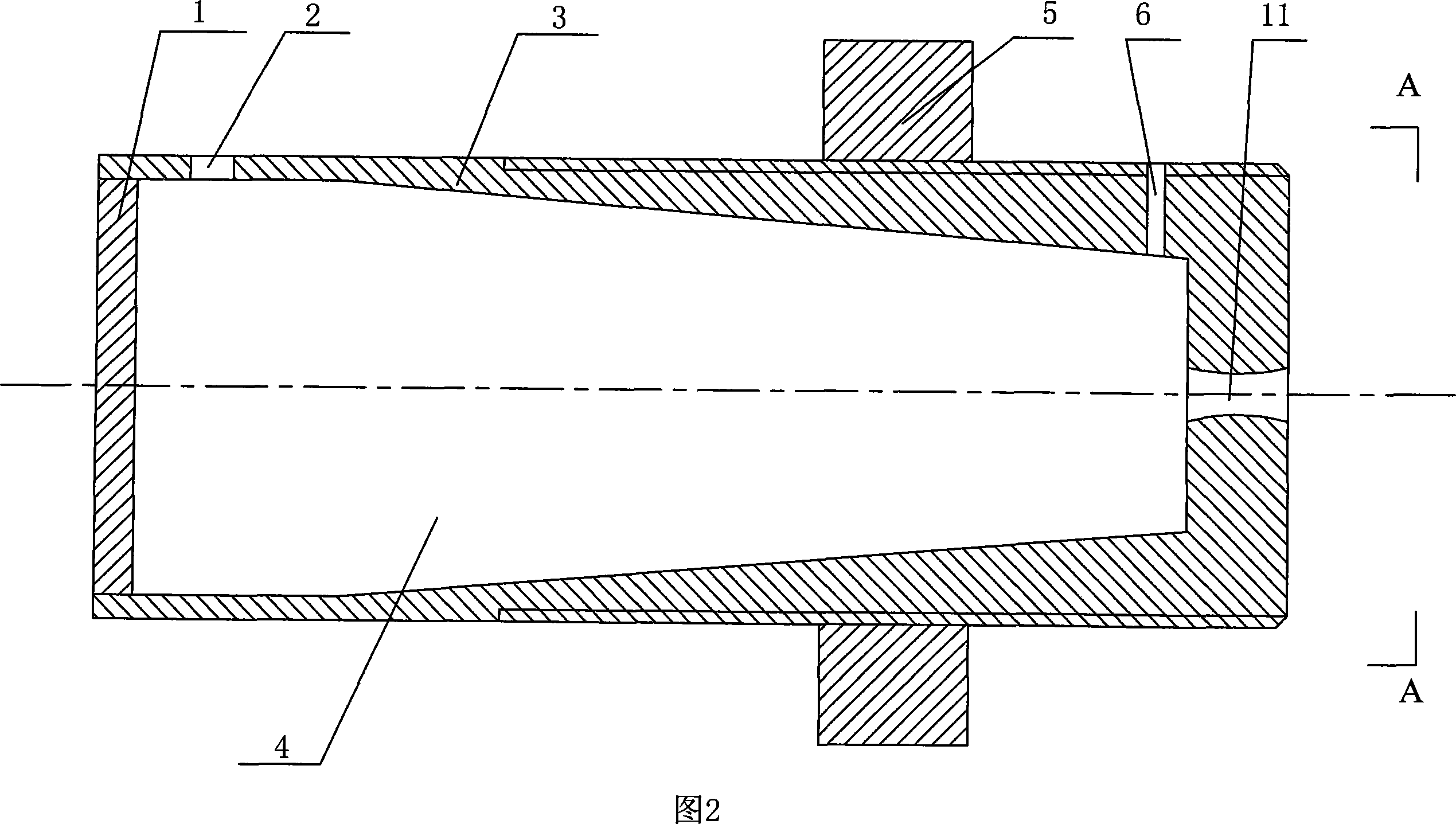

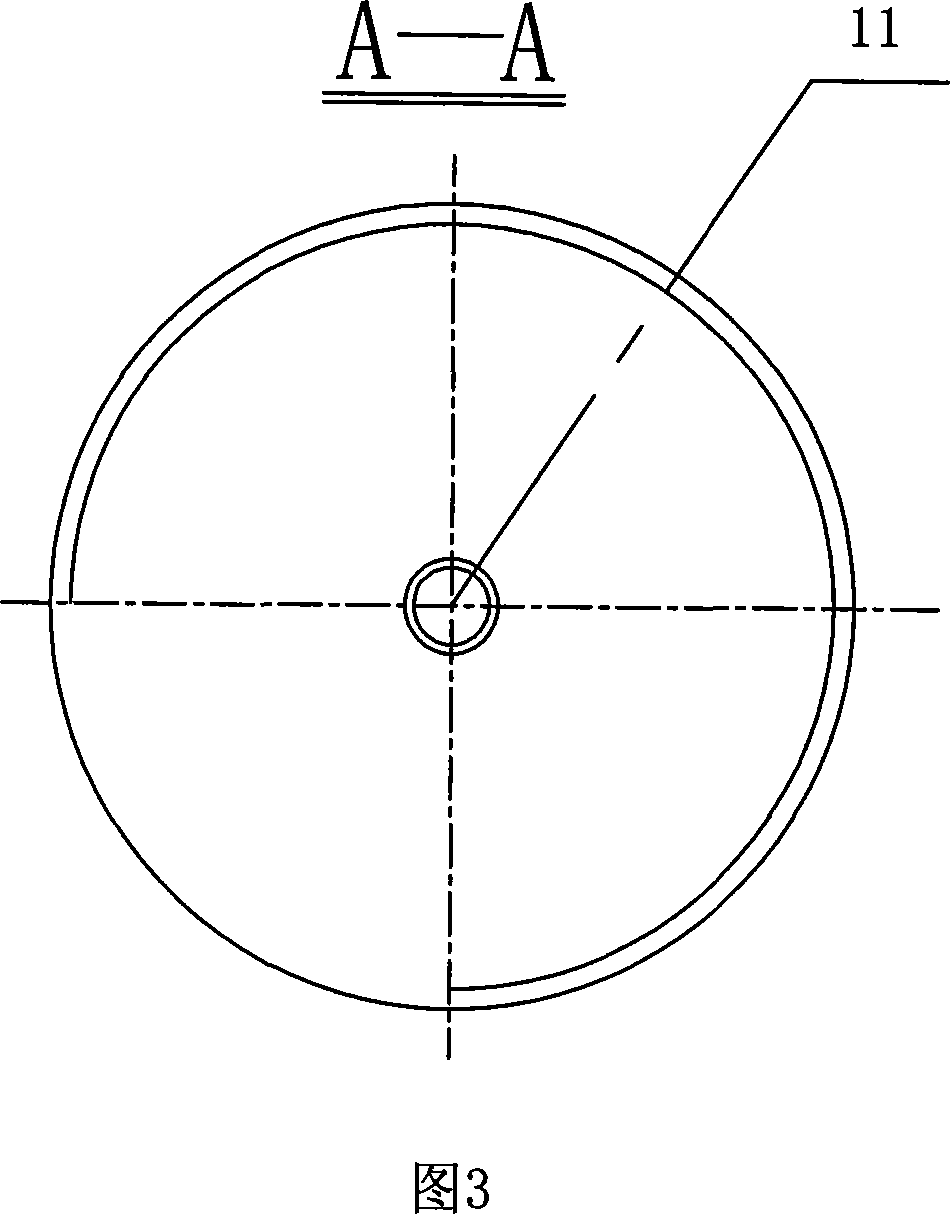

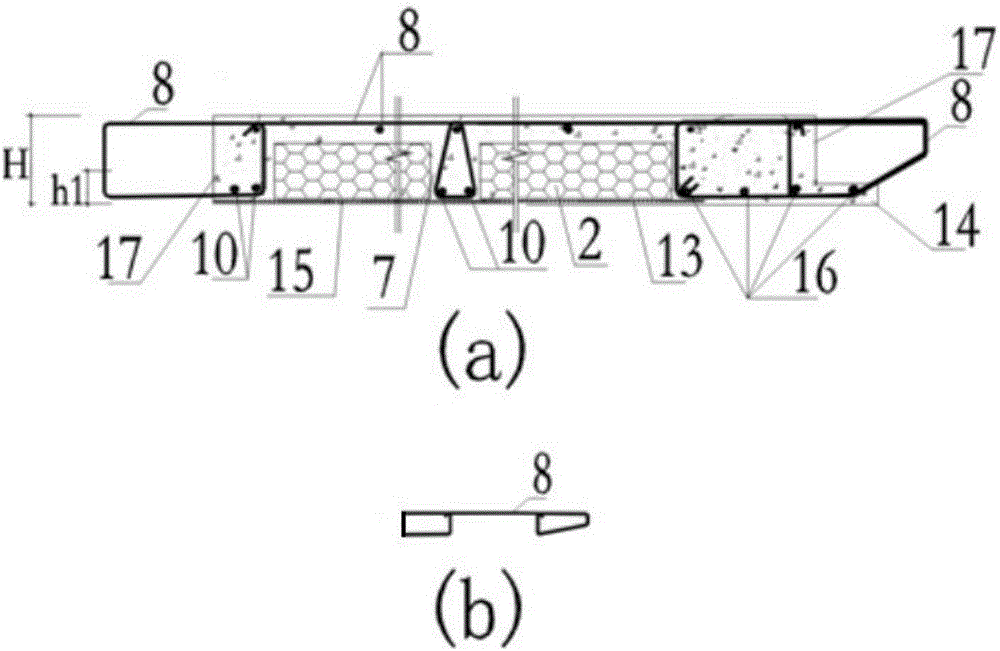

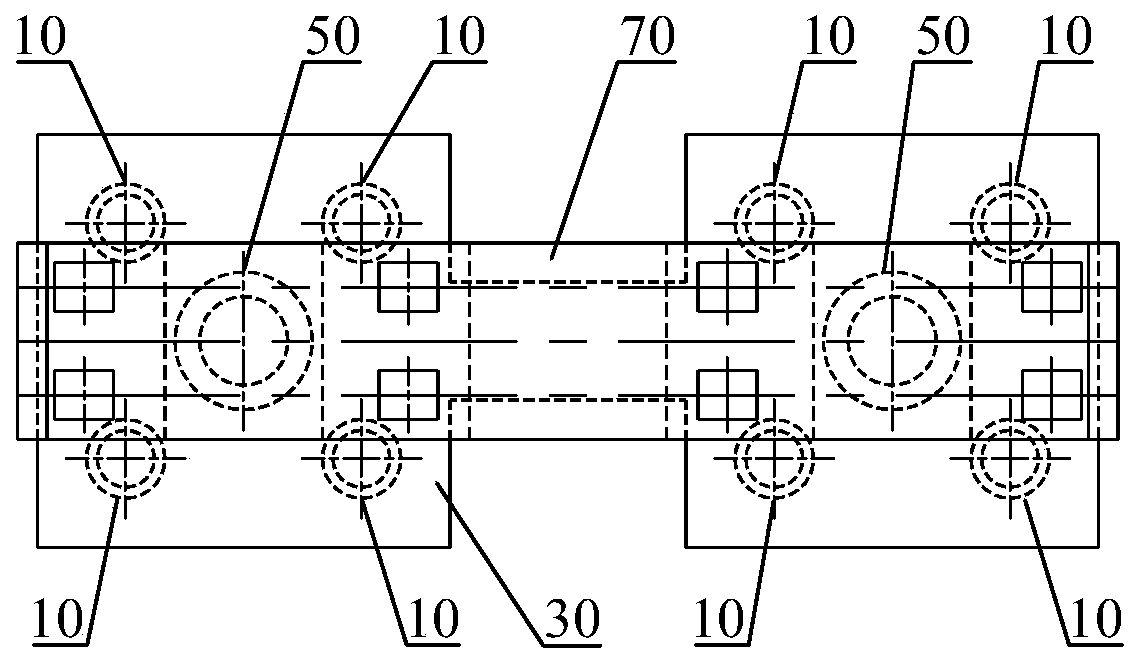

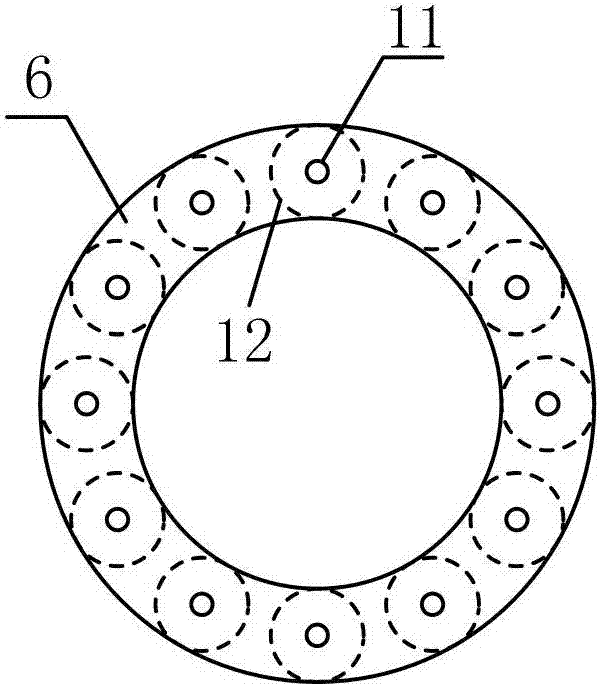

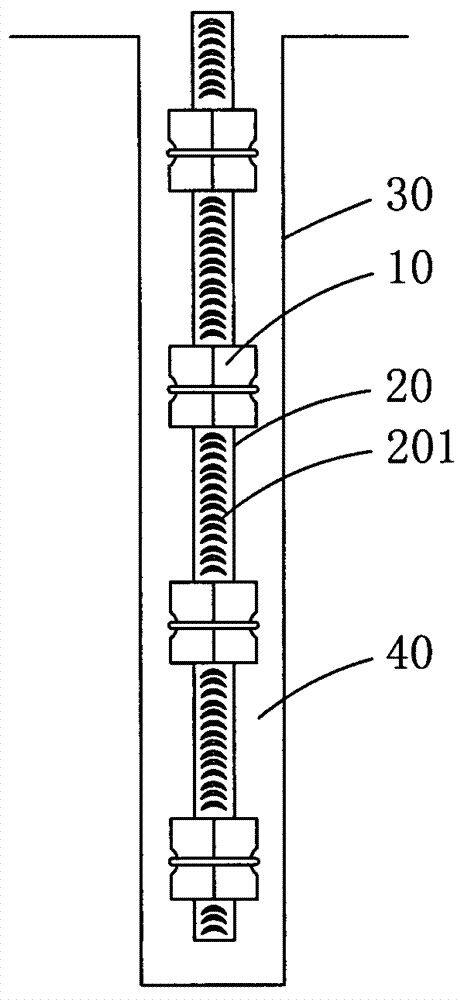

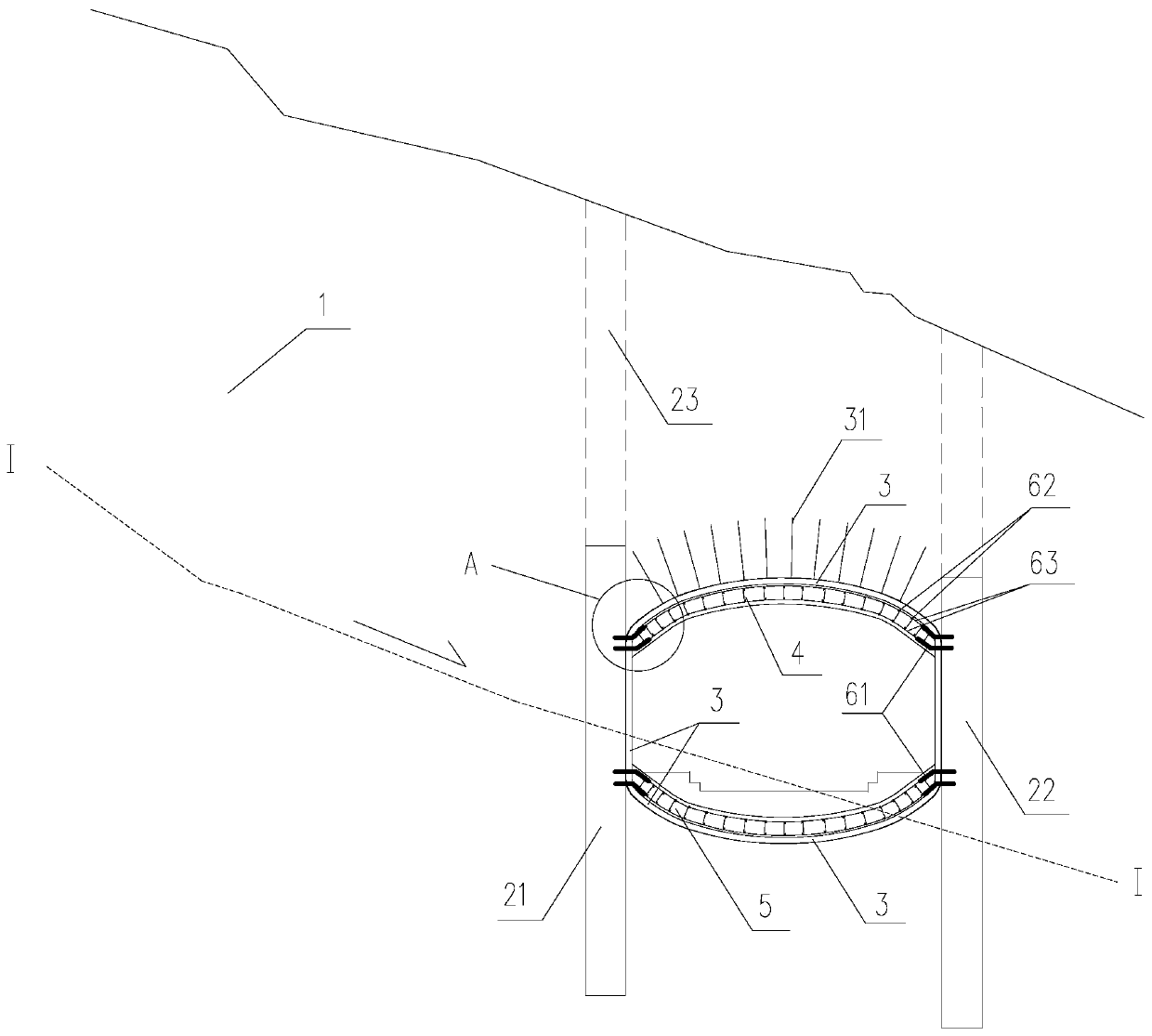

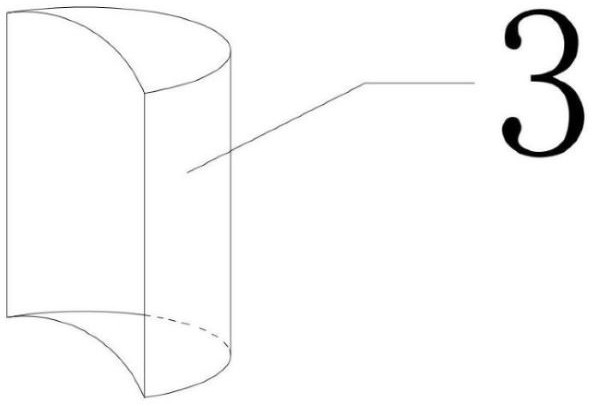

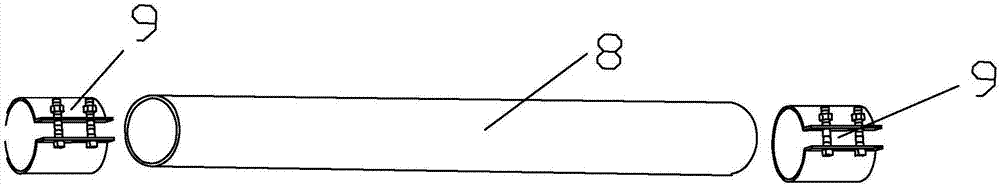

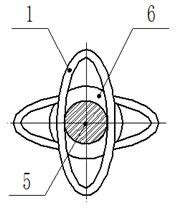

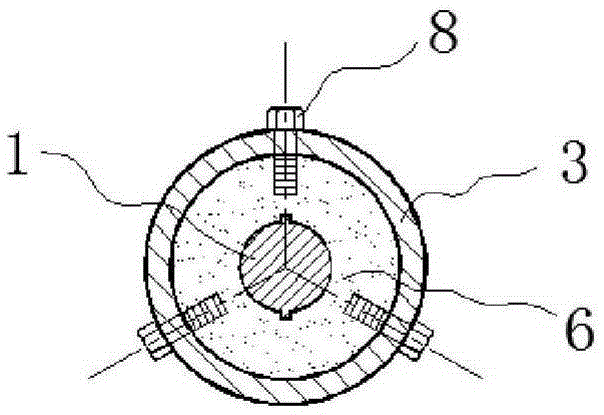

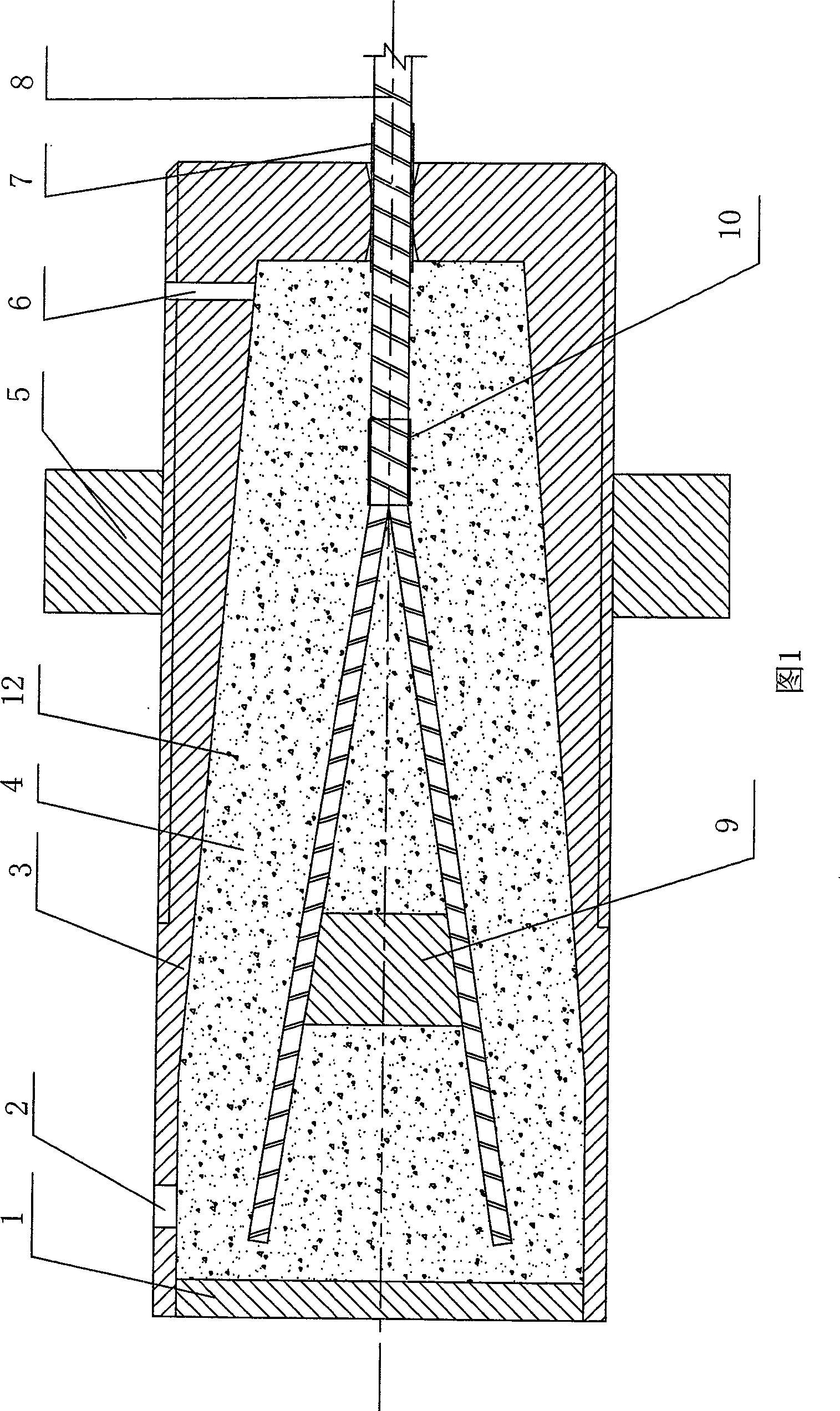

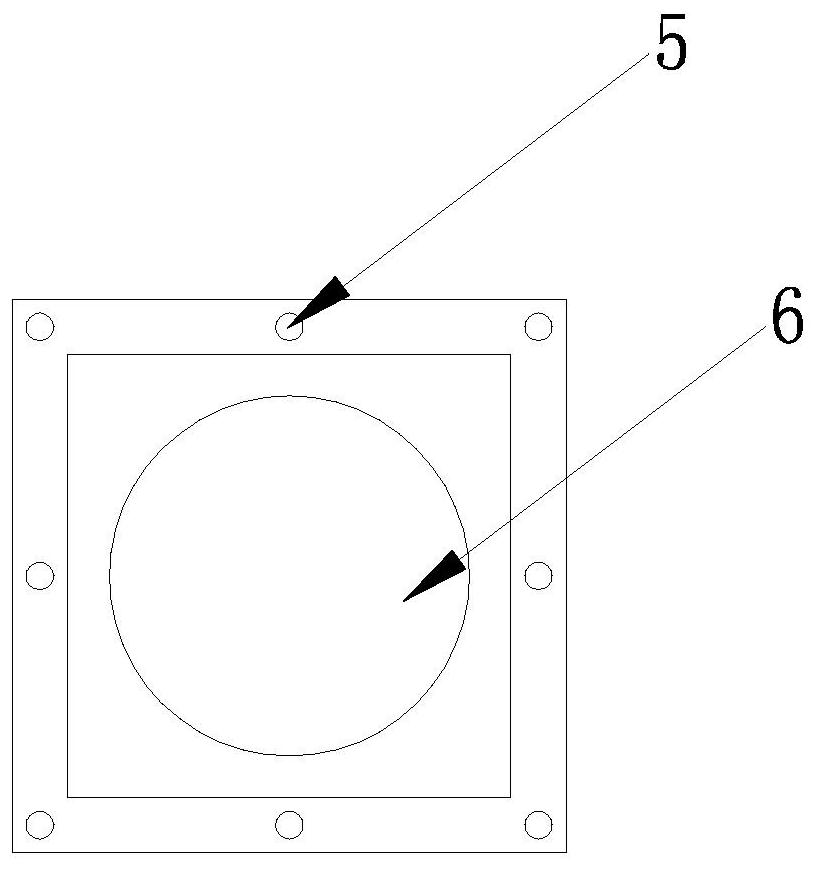

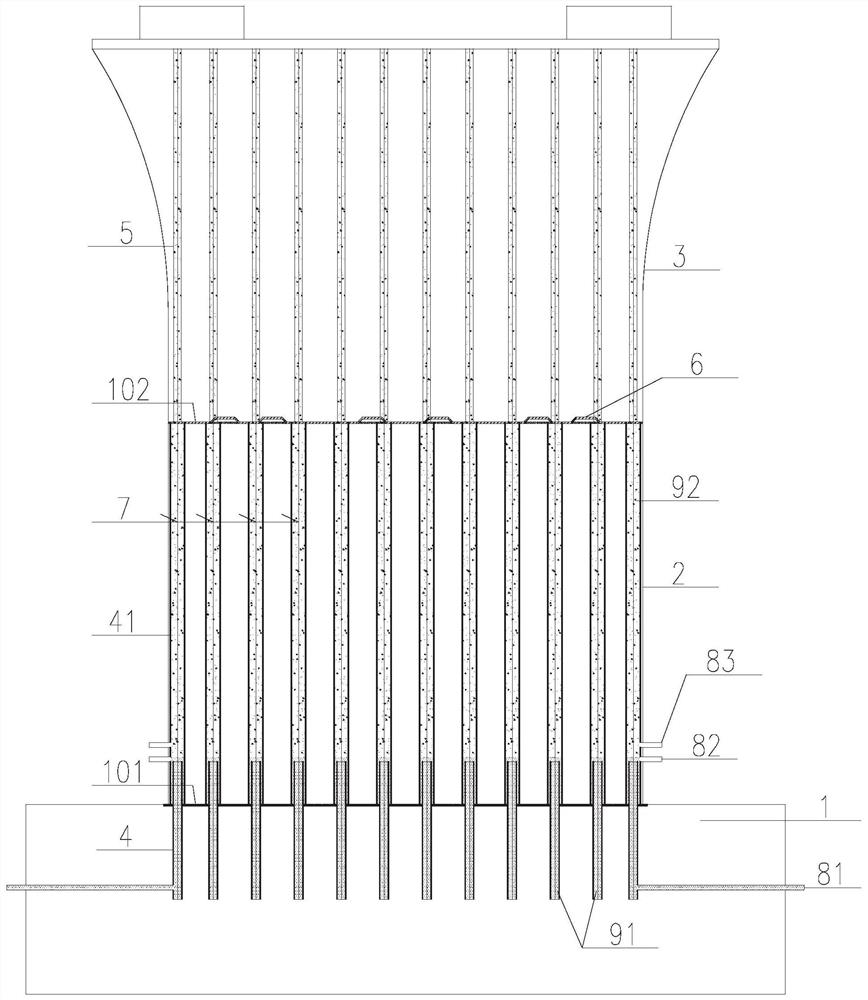

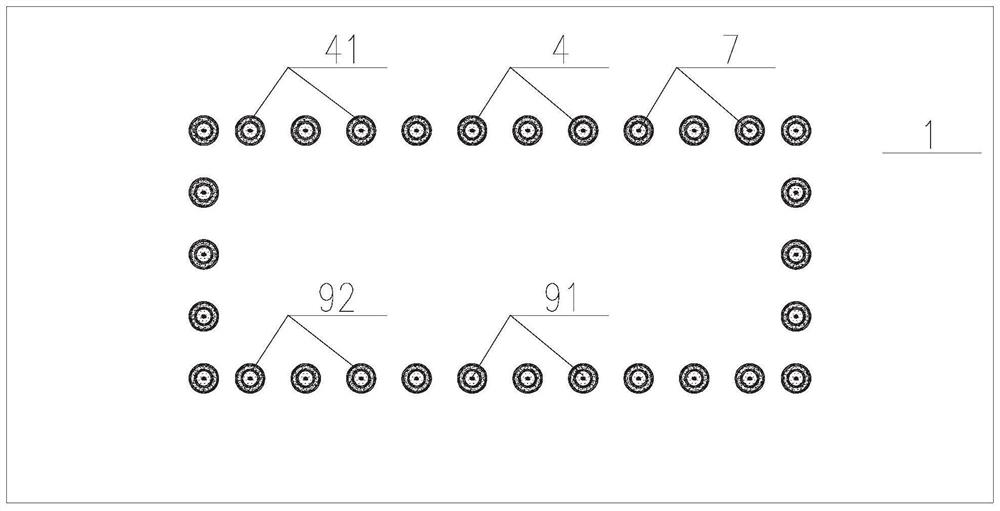

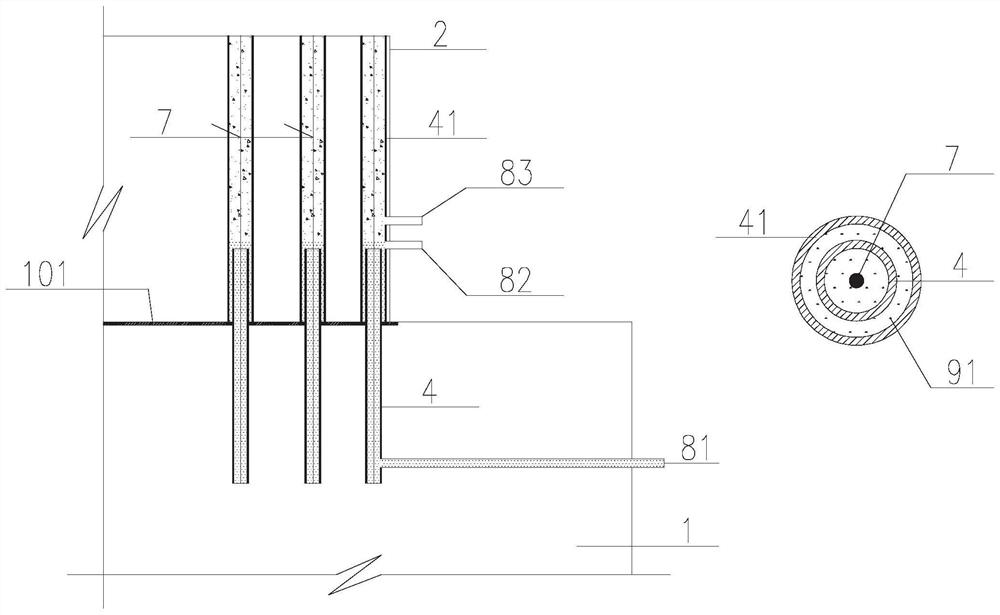

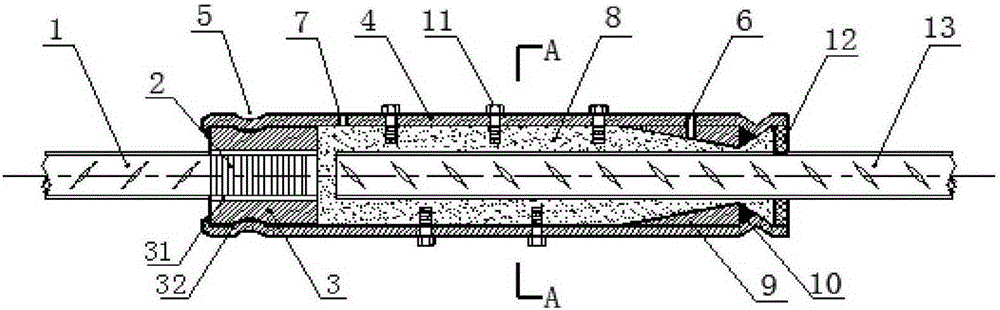

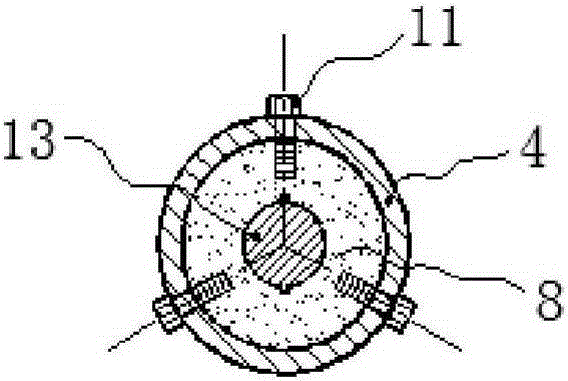

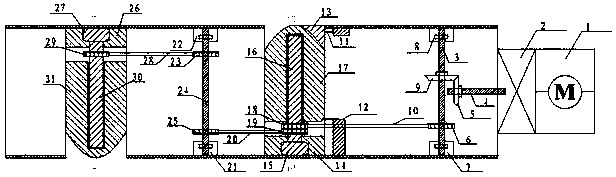

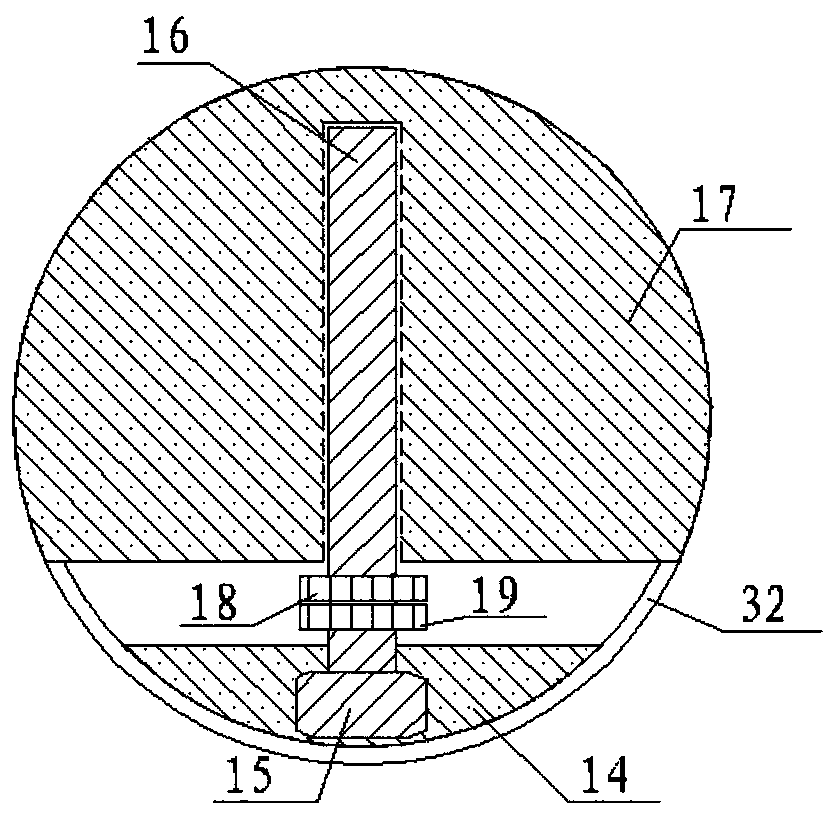

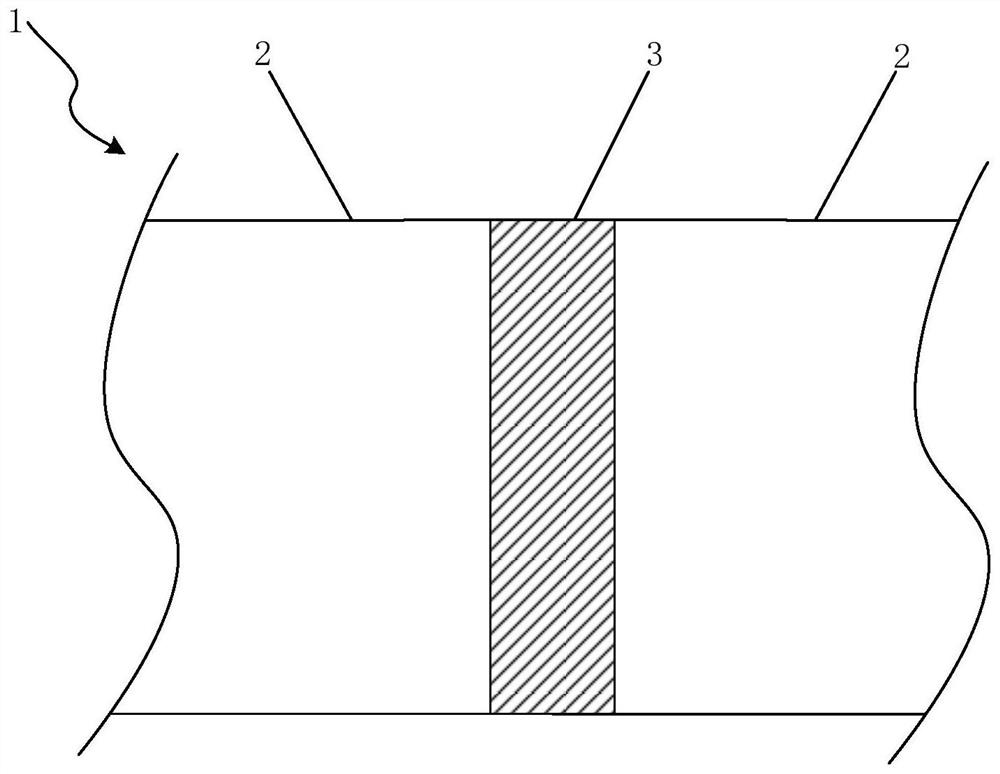

Fully grouted sleeve with built-in cone

ActiveCN103899044BReduce manufacturing costWide variety of sourcesBuilding reinforcementsEngineeringRebar

The invention discloses a full-grouting sleeve embedded with cones. The sleeve comprises a sleeve body (3), cones (7), a grouting port (4), a grout outlet (5), a limiting bolt (9) and rubber sealing rings (10), wherein the rubber sealing rings (10) are arranged at two ends of the sleeve body (3); the cones (7) are respectively and fixedly embedded in two ends of the sleeve body (3); in order to prevent the cones (7) from sliding in the sleeve body, the part of the sleeve body (3) which corresponds to two ends of the cones (7) is subjected to rolling treatment, and the inner diameter of the part of the sleeve body (3) is reduced; the grouting port (4) is formed in an outer wall at one end of the sleeve body (3); the grout outlet (5) is formed in an outer wall at the other end. The full-grouting sleeve has the advantages of simplicity in processing, low cost and the like, is particularly applied to connection of steel bars in member beams, posts and shear wall members, can be widely applied to an assembled concrete structure and has wide engineering application prospects.

Owner:SOUTHEAST UNIV

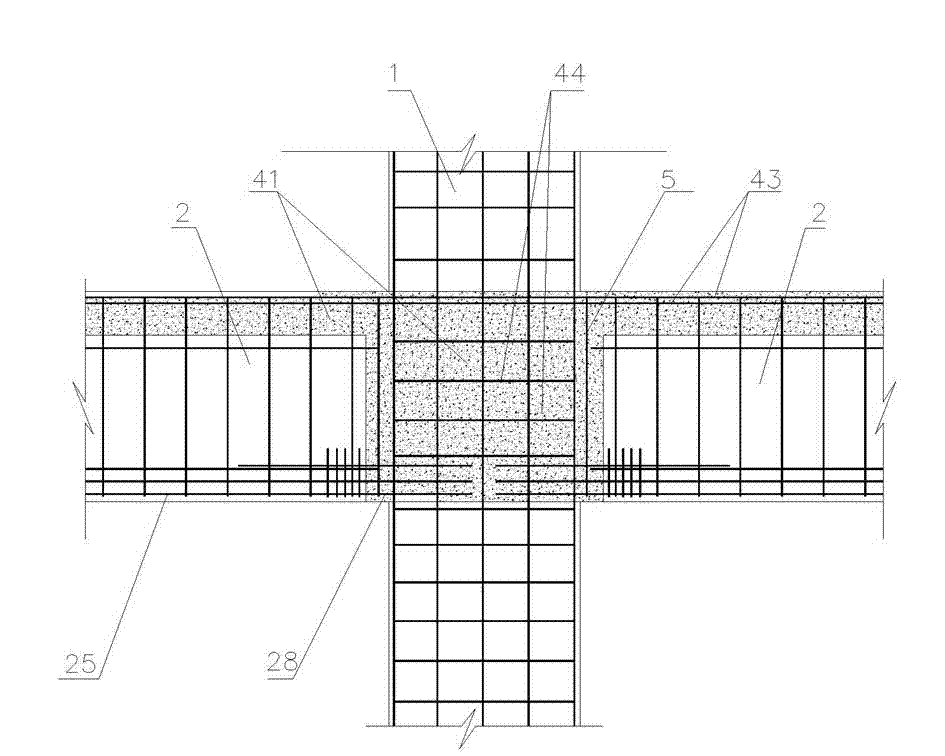

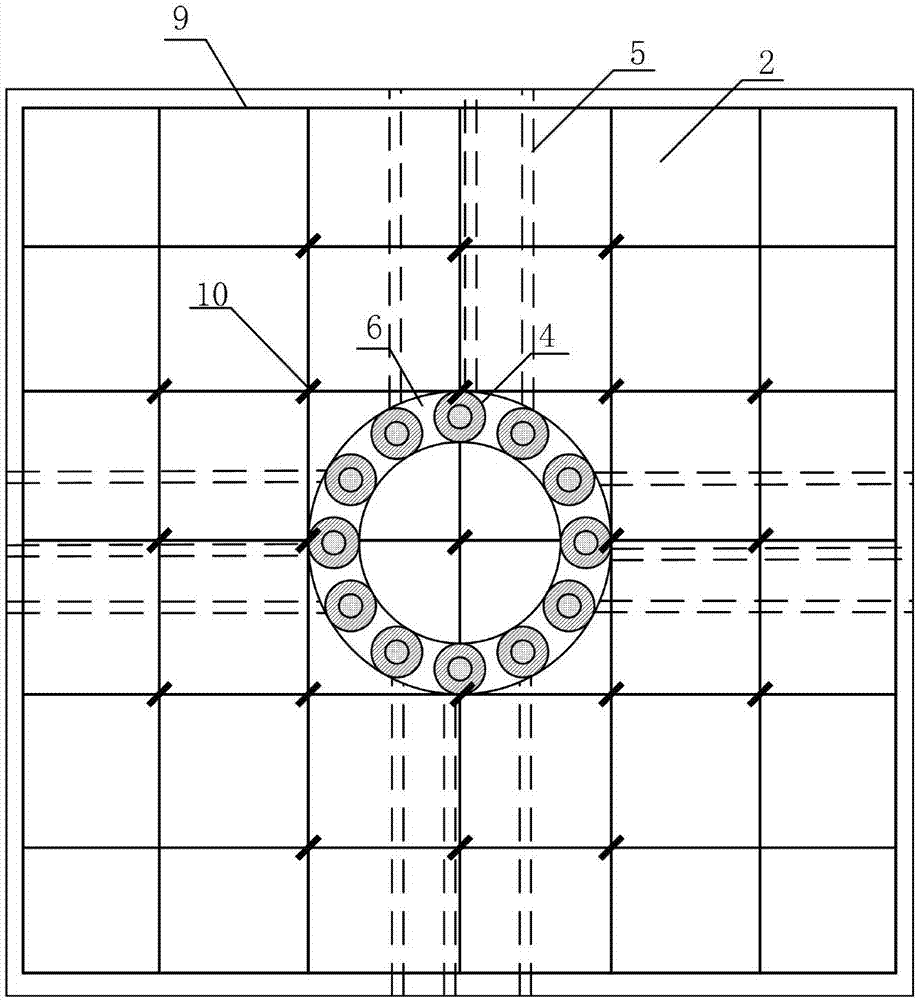

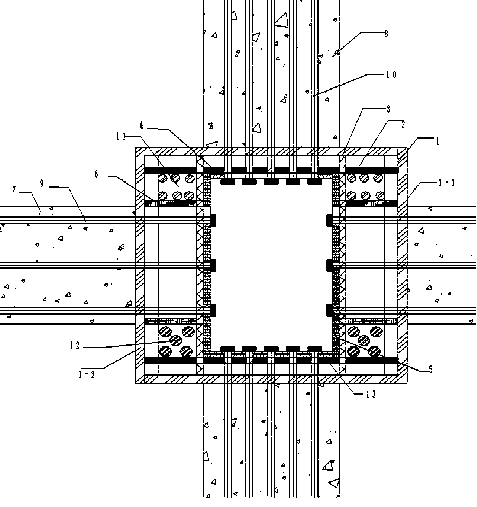

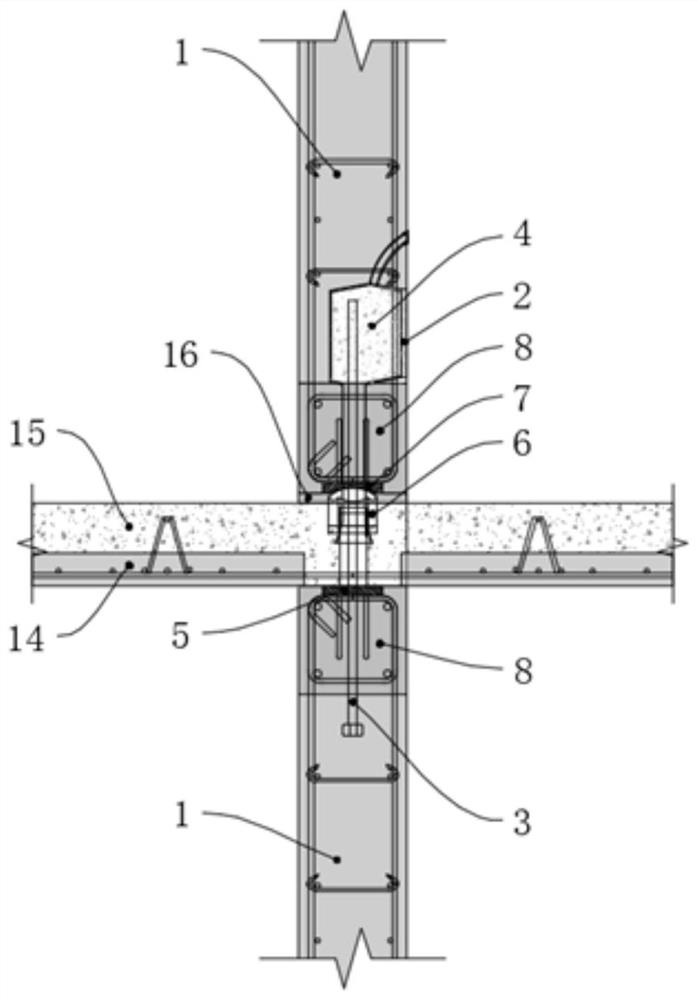

Fabricated concrete structure beam-column dry-wet combination connection structure and implementation method

PendingCN111255066ASave process linksLow construction costBuilding constructionsRebarTransverse beam

The invention discloses a fabricated concrete structure beam-column dry-wet combination connection structure and an implementation method, and belongs to the technical field of fabricated buildings. Acylindrical cavity structure is arranged at the intersection of a transverse beam and a longitudinal beam, the cylindrical cavity structure comprises an outer cylinder and an inner cylinder, and a square ring-shaped cavity is formed by enclosing the outer cylinder and the inner cylinder; column corner part longitudinal reinforcement bars I and column corner part longitudinal reinforcement bars IIare arranged at four corners of the square ring-shaped cavity, transverse beam longitudinal reinforcement bars and longitudinal beam longitudinal reinforcement bars in the transverse beam and the longitudinal beam penetrate through the outer cylinder and the inner cylinder in sequence; and anchoring heads are connected to the inner ends of the transverse beam longitudinal reinforcement bars and the longitudinal beam longitudinal reinforcement bars. According to the fabricated concrete structure beam-column dry-wet combination connection structure and the implementation method, a modular beam-column joint core area connection structure is formed through the construction method of the inner cylinder and outer cylinders, the problems of multi-directional reinforcement bar anchoring connection of a beam body, complex intersection anchoring connection of column body longitudinal reinforcement bars of and stirrups crossing and installation are solved, the process link and construction costof a formwork and a support are saved, and the fabricated concrete structure beam-column dry-wet combination connection structure has the advantages and characteristics of modularization, integration,integration and informatization.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

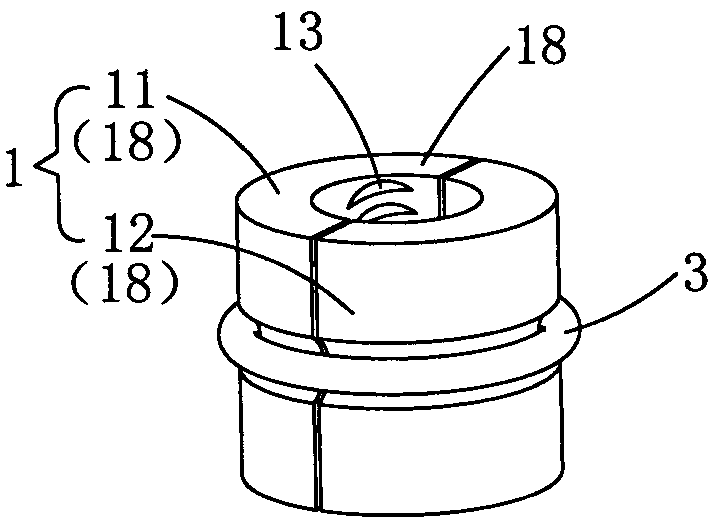

Steel bar anchoring device and construction method thereof

ActiveCN100335728CEasy to installIncrease anchoring forceBuilding reinforcementsBuilding material handlingEngineeringRebar

The invention relates to a steel bar anchor device and relative method, which is formed by connecting anchor plate and the end part with rib steel bar. Wherein, the anchor plate is in head-shoulder integrated shape, while the insert end of shoulder is a plane and the head is in screw cap shape or nut shape. The center of anchor plate has an inner screw matching the external screw of said end part. The anchor plate can be classified into two kinds as full-anchor plate and part-anchor plate, according to the ratio between the area of bearing plate and the section area of steel bar, which can be used in different areas to reduce adhesive anchor length or fully eliminate the length. The invention can reduce 40-50% of anchor steel material, to improve the concrete irrigate quality, the constructing speed, reduce the cost and simplify the process.

Owner:CABR TECH CO LTD

Bond type anchorage and anchoring method for anchoring fibre reinforced plastic reinforcement or bracing cable

ActiveCN100494598CImprove the anchoring effectEasy to makeBuilding reinforcementsEngineeringFibre-reinforced plastic

The present invention relates to an adhesive anchoring unit and an anchoring method for anchoring fiber reinforcement plastic bar or cable, an end cover is arranged at one end of the anchoring unit and a sleeve with a locating hole is arranged at the other end of the anchoring unit. An internal cone chamber is arranged in the sleeve, and a nut is arranged surrounding the sleeve provided with a mortar filling hole and a ventilation hole. The fiber reinforcement plastic bar or cable passes through the locating hole and one end in the internal cone chamber was cut into two halves, which are inserted with a wedge to become a wedge form. A starting section of the half of one end of the bar or cable is coated with a retaining ring and the section passing through the locating hole is coated with a thin wall aluminum sleeve tube and active powder concrete is filled in the internal cone chamber of the sleeve. The method is described as follows: after the bar or cable shaft passes through the sleeve of the anchoring unit, a pretension is required on the sleeve, and the active powder concrete is added into the sleeve. The present invention improves anchoring performances of the adhesive media and the FRP bar, therefore, the anchoring length is reduced, the structure is simple, the use is convenient, the present invention is safe and reliable, the cost is low and the PRC manufacturing and maintenance is easy.

Owner:HUNAN UNIV

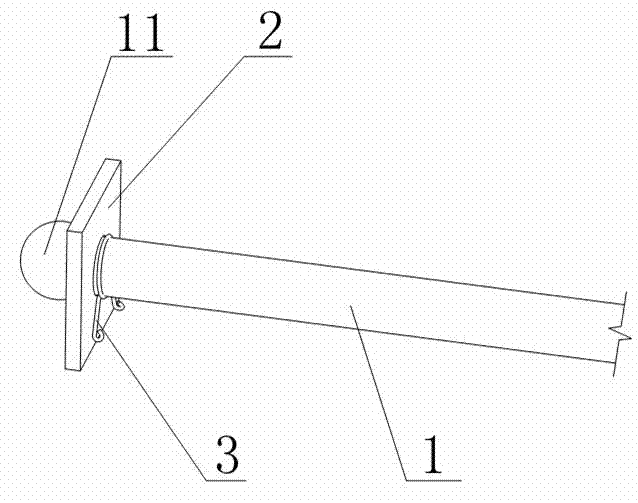

Anchor rod combined anti-floating system

InactiveCN112922044ASimple structureIngenious designProtective foundationBulkheads/pilesStructural reliabilityEngineering

The invention relates to an anchor rod combined anti-floating system. The anchor rod combined anti-floating system comprises a plurality of main anti-floating anchor rod assemblies, and the adjacent main anti-floating anchor rod assemblies are connected through channel steel purlines; and each main anti-floating anchor rod assembly comprises a drill hole, an anchor rod body, a polygonal base plate, a conventional base plate and a plurality of I-shaped cushion blocks, wherein an anchor rod hole is formed in the middle of the polygonal base plate and the middle of the conventional base plate, the anchor rod body is arranged in the anchor rod hole in a penetrating mode, and the I-shaped cushion blocks are assembled between the polygonal base plate and the conventional base plate. The anchor rod combined anti-floating system is simple in structure and ingenious in design, has the characteristics of being low in construction cost, good in structural reliability, high in adaptability and the like, and has good construction convenience.

Owner:ZHEJIANG UNIV OF TECH

Prefabricated wall high-strength concrete connecting joint and construction method

ActiveCN113638486AReduce anchor lengthReduce economic costsWallsFloorsGroutArchitectural engineering

Owner:HUADONG BUILDING CO LTD OF CHINA CONSTR FIFTH ENG BUREAU +3

Construction method for foundation pit pile-anchor support system adjacent to existing underground structures

ActiveCN106759376BIncrease the number ofIncrease anchor lengthExcavationsSupporting systemPre stress

The invention discloses a foundation pile-anchor supporting system for a close existing underground structure and a construction method of the system. The supporting system comprises front-row steel pipe piles, rear-row steel pipe piles, rear-row vertical prestressed anchors, a front-row pile top beam, a rear-row pile top beam, transverse connecting reinforcements, front-row anchorages, rear-row anchorages, cushion blocks, tapered iron pieces, front-row prestressed anchors and wales. Through the vertical prestressed anchors arranged in the rear-row steel pipe piles, occupancy in underground space can be reduced greatly, and limited ground surface and space within building lines are fully utilized. The vertical prestressed anchors are anchored to the good ground, usage of the rear-row steel pipe piles can be reduced greatly, good anchorage force is provided, the front-row prestressed anchors are used for anchoring and stabilizing the rock stratum, and overturning resistance of the overall structure is improved. By the aid of the rear-row vertical prestressed anchors and the prestressed anchors arranged in the front-row steel pipe piles, factor of safety against overturning of the supporting system is enhanced effectively, construction cost is lowered, and construction period is shortened.

Owner:DALIAN JIAOTONG UNIVERSITY

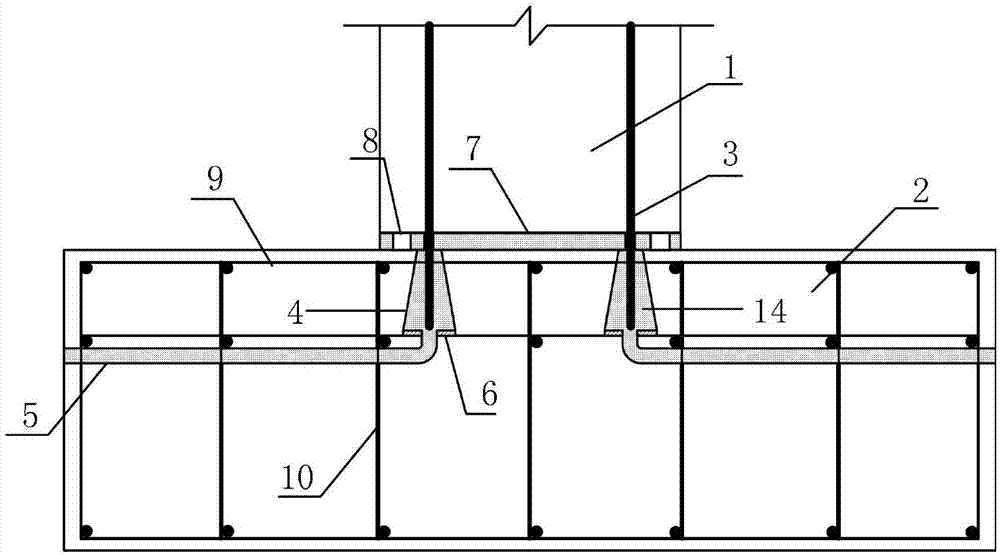

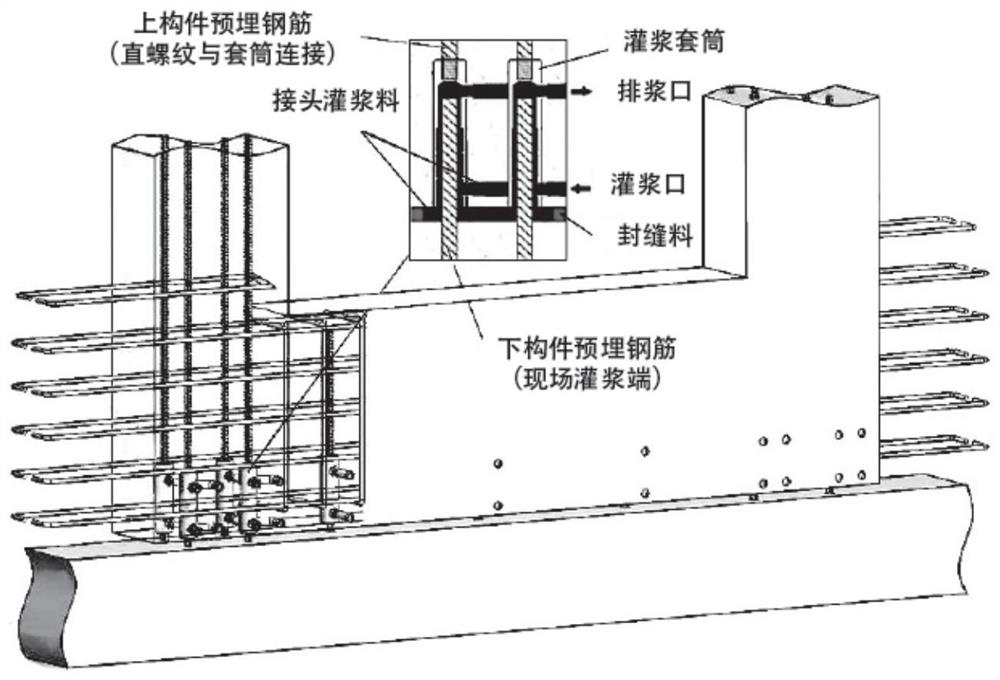

Reinforcing steel bar sleeve connecting structure, segmental prefabricated assembled pier and construction method

PendingCN113106848AImprove shear resistanceLow shear strengthBridge structural detailsFoundation engineeringArchitectural engineeringEngineering

The invention provides a reinforcing steel bar sleeve connecting structure, a segmental prefabricated assembled pier and a construction method. The reinforcing steel bar sleeve connecting structure comprises a foundation, a bottom segment, a bottom joint reinforcing steel bar sleeve, a foundation reserved hole channel, a bottom segment reinforcing steel bar sleeve and the like. When the foundation is constructed, bottom joint steel bar sleeves or reserved hole channels are pre-buried in the positions corresponding to the steel bars, bottom section steel bar sleeves are pre-buried in the positions corresponding to the steel bars when the bottom section is prefabricated, and when the bottom section is spliced with the foundation, the bottom joint steel bar sleeves are sleeved with the bottom section steel bar sleeves one by one, or the bottom section steel bar sleeves penetrate into the reserved hole channels of the foundation one by one. And a reinforcing steel bar penetrates into the bottom section reinforcing steel bar sleeve and the bottom joint reinforcing steel bar sleeve or the reserved hole channel, and a grouting material is injected in a pressing mode to form the reinforcing steel bar sleeve connecting structure. According to the connecting structure, the stress of the bottom joint and the bottom section is remarkably improved, so that the bottom joint and the bottom section are matched with each other in structural arrangement and stress requirements, and the connecting structure can meet the anti-seismic requirements of medium-high seismic areas; and the reinforcing steel bar sleeve connecting structure can adapt to non-matched installation between the prefabricated segment and the foundation, is low in cost and meets the engineering application requirement.

Owner:CHINA RAILWAYS CORPORATION +1

A corrugated plywood anchor with variable clamping force of frp sheet

ActiveCN109881842BReduce anchor lengthSave materialBridge structural detailsBuilding reinforcementsArchitectural engineeringEngineering structures

The invention discloses an FRP sheet variable clamping force waveform splint anchor, which relates to an engineering structure anchor in the field of high-strength composite materials. Including upper corrugated splint, lower corrugated splint, bolts, nuts, washers and FRP sheet. The FRP sheet passes through the upper and lower corrugated splints, and the upper and lower corrugated splints tightly clamp the FRP sheet. Add washers to the bolt holes of the upper and lower corrugated splints. The anchorage adopts a wave splint instead of a flat splint to clamp the FRP sheet, and the radius of the anchor bolt increases gradually from the outlet to the end of the anchor, and the clamping force provided by the anchor bolt also increases from the outlet to the end. Gradually increasing can effectively reduce the stress peak value at the outlet of the anchorage, improve anchorage efficiency, shorten anchorage length, save materials and improve economy.

Owner:重庆卓越强森新材料科技有限公司

Construction method for improving pulling resistance of twisted steel anchor rod

ActiveCN112431199AImprove pullout resistanceIncrease resistance areaExcavationsBulkheads/pilesArchitectural engineeringRebar

The invention particularly relates to a construction method for improving the anti-pulling performance of a twisted steel anchor rod. The problems that when an existing construction method of the twisted steel anchor rod is applied, the length of an anchoring section exceeds the actual requirement by a large amount, resources are wasted, and labor and time are wasted are solved. The construction method for improving the anti-pulling performance of the twisted steel anchor rod comprises the following steps that S1, a plurality of vertical rib column grooves are vertically formed in the wall ofsurrounding rock; S2, a plurality of anchor rod holes are drilled in the bottom wall of each vertical rib column groove; S3, a plurality of anti-pulling resistance blocks are installed on the anchoring section of each twisted steel anchor rod; S4, the twisted steel anchor rods are placed into the anchor rod holes, and cement mortar is poured into the anchor rod holes; S5, steel bars of vertical rib columns and panels are bound, formwork erecting is conducted, and concrete is poured; and S6, the ends of the twisted steel anchor rods are sealed and anchored on the outer sides of the panels. Theconstruction cost is reduced, the construction progress is accelerated, and the method can be suitable for stone excavation high slope stability protection engineering and can be applied and popularized in similar engineering.

Owner:中铁十七局集团第五工程有限公司

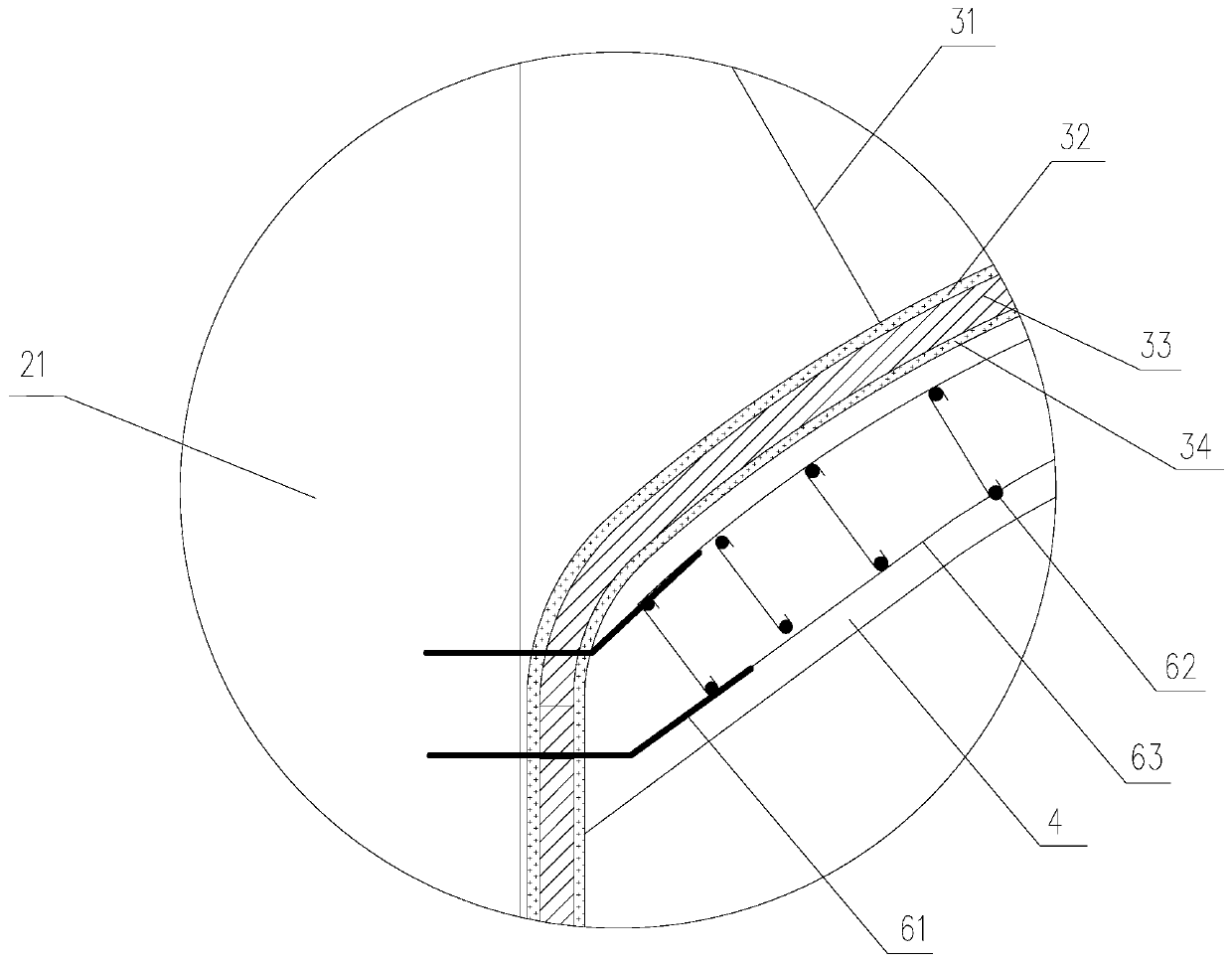

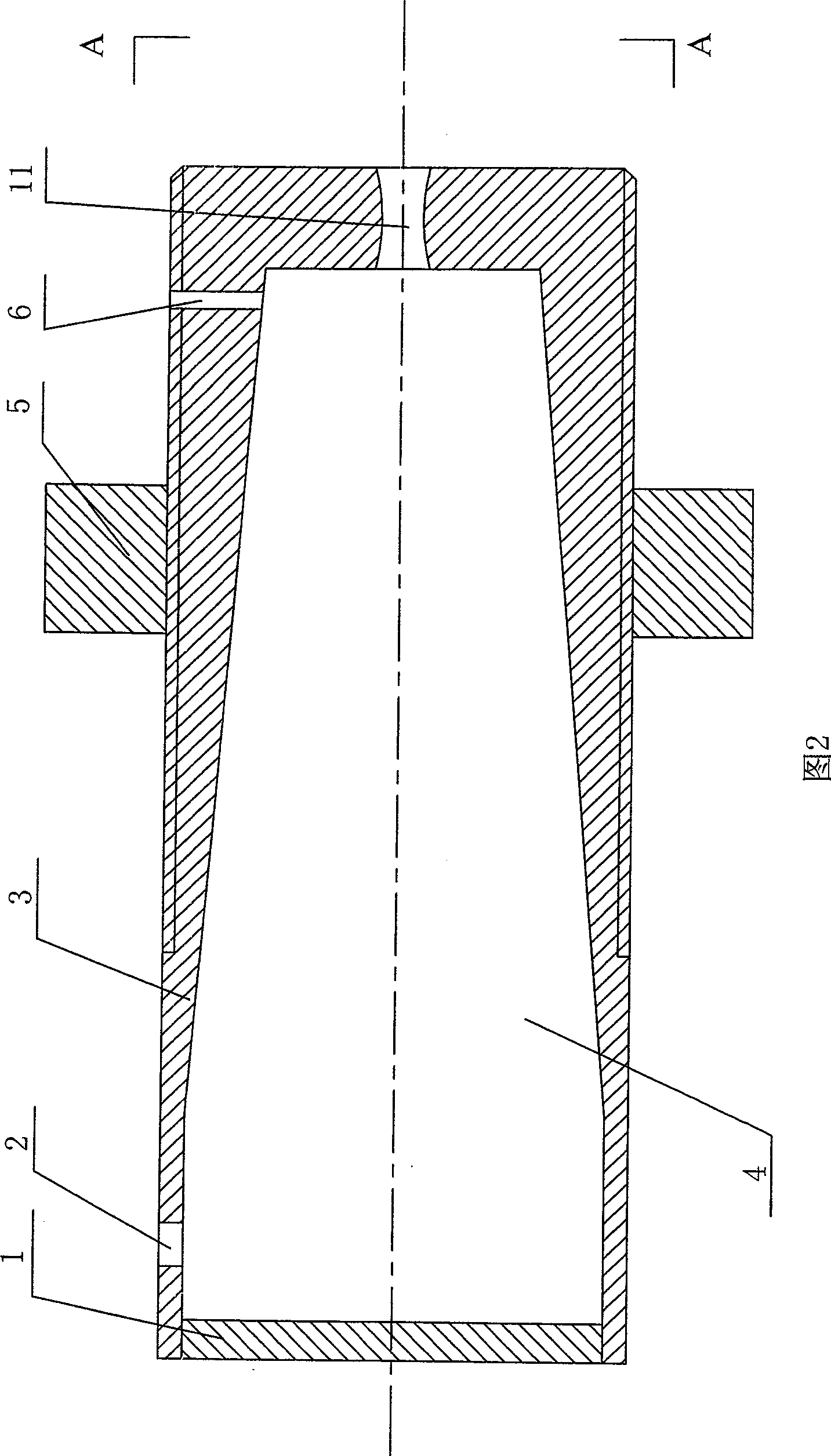

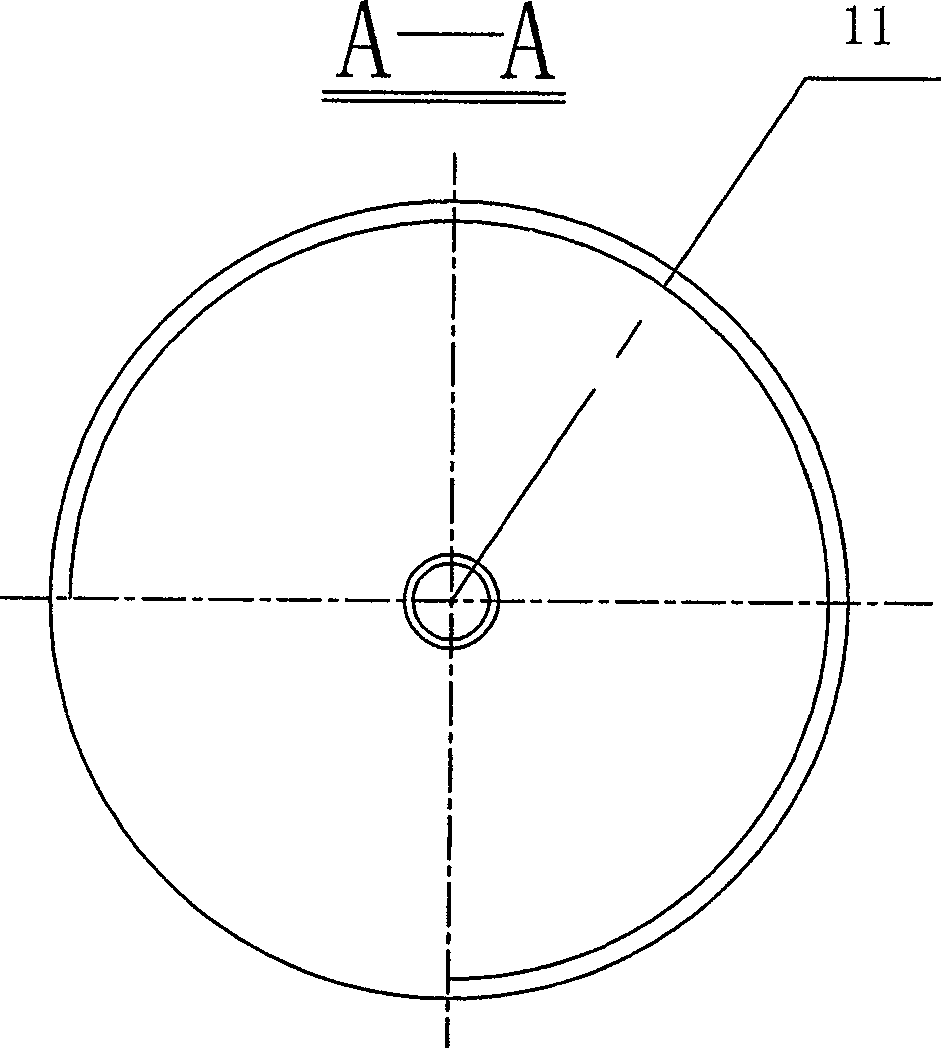

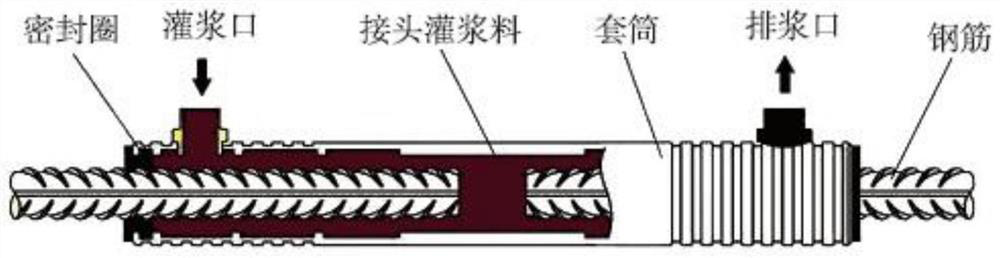

Half-grouted sleeve with built-in cone

ActiveCN103899043BReduce manufacturing costWide variety of sourcesBuilding reinforcementsClassical mechanicsRebar

The invention discloses a semi-grouting sleeve embedded with a cone. The semi-grouting sleeve comprises a connecting piece (3), a sleeve body (4), a grouting port (6), a grouting port (7), a cone body (9), shear bolts (11), elastic rubber sealing ring (12), wherein, one end of the sleeve body (4) is provided with a connector (3), and the other end is equipped with an elastic rubber sealing ring (12 ); the sleeve body (4) is equipped with a cone (9) embedded in one end of the elastic rubber sealing ring (12), and the outer wall of the side of the sleeve body (4) is provided with a grouting port (6) and a grouting port ( 7), there is a shear bolt (11) in the middle; one end of the fixed side threaded steel bar (1) is connected with the connector (3), and one end of the inserted side threaded steel bar (13) passes through the elastic rubber sealing ring (12) , The cone (9) is located in the sleeve body (4). The invention has the advantages of simple manufacture, low cost, etc., and is especially suitable for connecting longitudinal steel bars of beams, columns, and shear wall members, and can be widely used in assembled concrete structures, and has broad engineering application prospects.

Owner:SOUTHEAST UNIV

PC structure grouting sleeve connection construction method

InactiveCN113006378AHigh bonding strengthReduce anchor lengthBuilding reinforcementsBuilding material handlingRebarGrout

The invention belongs to the field of structural connection of fabricated buildings, particularly relates to a PC structure grouting sleeve connection construction method, and aims to solve the technical problems that the field connection quality is difficult to meet the design requirement due to less research on the existing field connection construction process of the fabricated building structure and lack of strict field construction quality control regulations and specifications. According to the scheme, one end of grouting sleeve connection is connected through sleeve grouting, when a component is hoisted, a ribbed steel bar reserved in a base layer needs to be inserted into a reserved sleeve of a PC component, then the position of the steel bar is adjusted through the modes of perpendicularity, elevation, positioning and the like, the component is temporarily fixed, after the strength of a grouting material meets the requirement, grouting material mixtures are injected through grouting holes, grouting is stopped when grout flows out of the grout outlets, and the grouting holes and the grout outlets are blocked. The basic materials of the grouting materials are cement, and the grouting materials also comprise an additive, fine aggregate and other materials, and a proper amount of water is added and stirred.

Owner:浙江宝嵘建设股份有限公司

Bolt forming tool and multiple-transverse-bolt soil anchor prepared with bolt forming tool

PendingCN110397033AReduce anchor lengthReduce anchoring costsBulkheads/pilesHollow cylinderLimit switch

The invention relates to a bolt forming tool and a multiple-transverse-bolt soil anchor prepared with the bolt forming tool. The bolt forming tool which is simple in structure and easy to realize is adopted for forming a plurality of bolt bodies on the surface of the soil anchor. The purpose is that the feature that the multi-transverse bolt earth facing face bears the action of passive earth pressure is adopted, the area of multi-transverse bolt accumulative earth facing faces is larger, and therefore higher anchoring force is obtained; in addition, the cement paste increment is small when bolts are increased, and the bolt forming tool is economic and applicable. In order to achieve the aim, the technical scheme is that the bolt forming tool comprises a hollow cylindrical metal tube, an engine, a speed reducer, a rotating shaft, a bevel gear, a chain wheel, a support base, a rising stroke limit switch, a descending stroke limit switch, a screw with a round nut, a metal block with internal threads and a fixing plate. The multiple-transverse-bolt soil anchor prepared by the bolt forming tool comprises a cylinder formed in the manner that a plurality of bolt cavities and boreholes are solidified by pouring cement slurry or cement mortar, multiple bolt bodies are located on the outer surface of the cylinder, a whole body is formed together with the cylinder, the bolt bodies are semi bolts, and the bolt cross section shape is semicircular.

Owner:ANHUI UNIV OF SCI & TECH

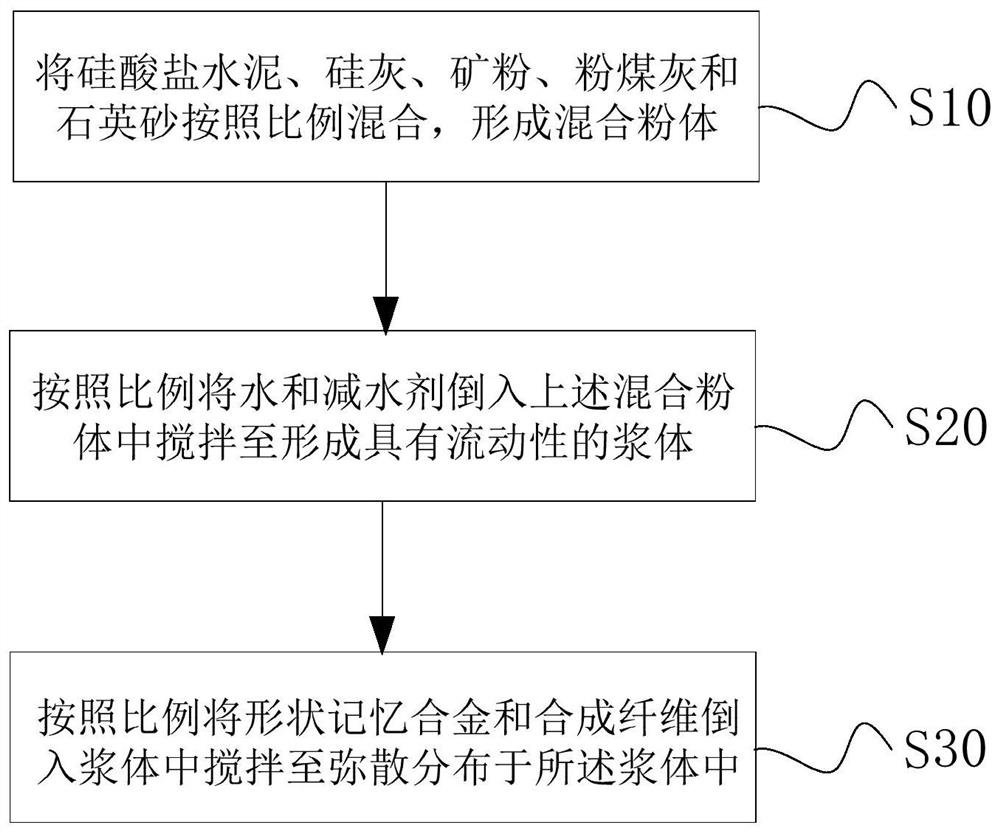

Cement-based composite material, preparation method thereof and floating slab

PendingCN113698147AImprove flexural strengthHigh strengthBallastwayPortland cementShape-memory alloy

The invention discloses a cement-based composite material, a preparation method thereof and a floating slab. The cement-based composite material comprises a base material, wherein the base material comprises Portland cement, silica fume, mineral powder, fly ash, quartz sand, water and a water reducing agent; a shape memory alloy; and a synthetic fiber. The cement-based composite material can improve the strength and toughness of joint areas among a plurality of plates forming the floating slab and greatly reduce the connecting length, so that the long floating slab can be applied to rail traffic engineering, the problems of an existing floating slab rail structure are solved, and the durability and comfort of the floating slab are greatly improved.

Owner:SHANGHAI SHENTONG METRO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com