Anchoring structure for end part of steel strand and anchoring method thereof

A technology of end anchoring, anchoring method, applied in the direction of structural elements, building components, building construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

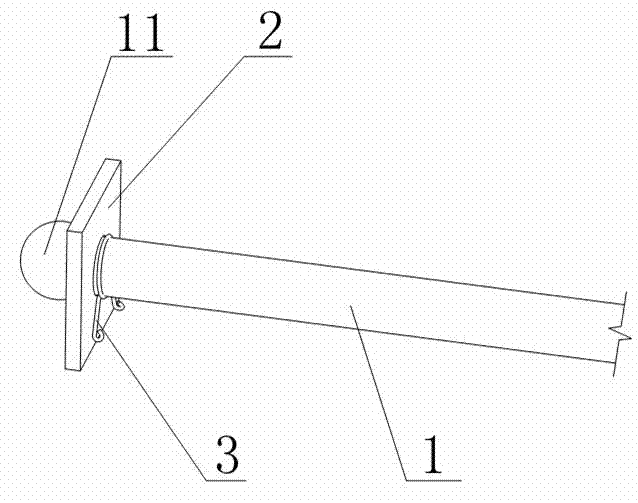

[0018] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is a steel strand end anchorage structure and its anchoring method, which is composed of a steel strand 1, an anchor plate 2, and a clip 3.

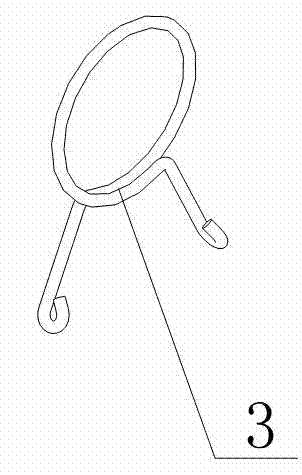

[0019] Wherein, the steel strand 1 is specifically a steel strand 1 whose end portion of a prestressed composite beam 4 is exposed. The clip 3 is clamped on the steel strand 1, and the clip 3 can tighten the steel strand 1 so that the anchor plate 2 will not be displaced.

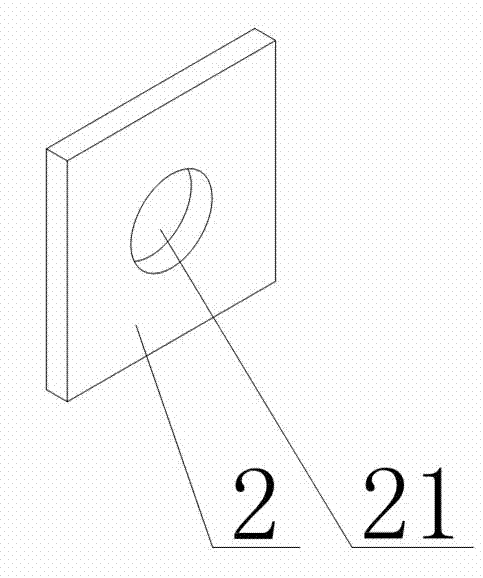

[0020] The anchor plate 2 can be in various shapes such as circular or square, and a circular hole 21 is arranged on it. The diameter of the circular hole 21 is larger than that of the steel strand, so that the steel strand 1 can pass through the circular hole 21 of the anchor plate 2 . The area of the anchor plate 2 is more than four times the cross section of the steel strand 1, thereby enhancing the anchoring strength of the anchoring structure.

[0021] One end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com