Bond type anchorage and anchoring method for anchoring fibre reinforced plastic reinforcement or bracing cable

A fiber-reinforced plastic, bonded technology, applied in the direction of structural elements, building reinforcements, building components, etc., can solve the problems of poor thermal stability, excessive creep of bonding medium, long anchorage length, etc., to achieve production and The maintenance is simple, the creep is small, and the effect of reducing the anchorage length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

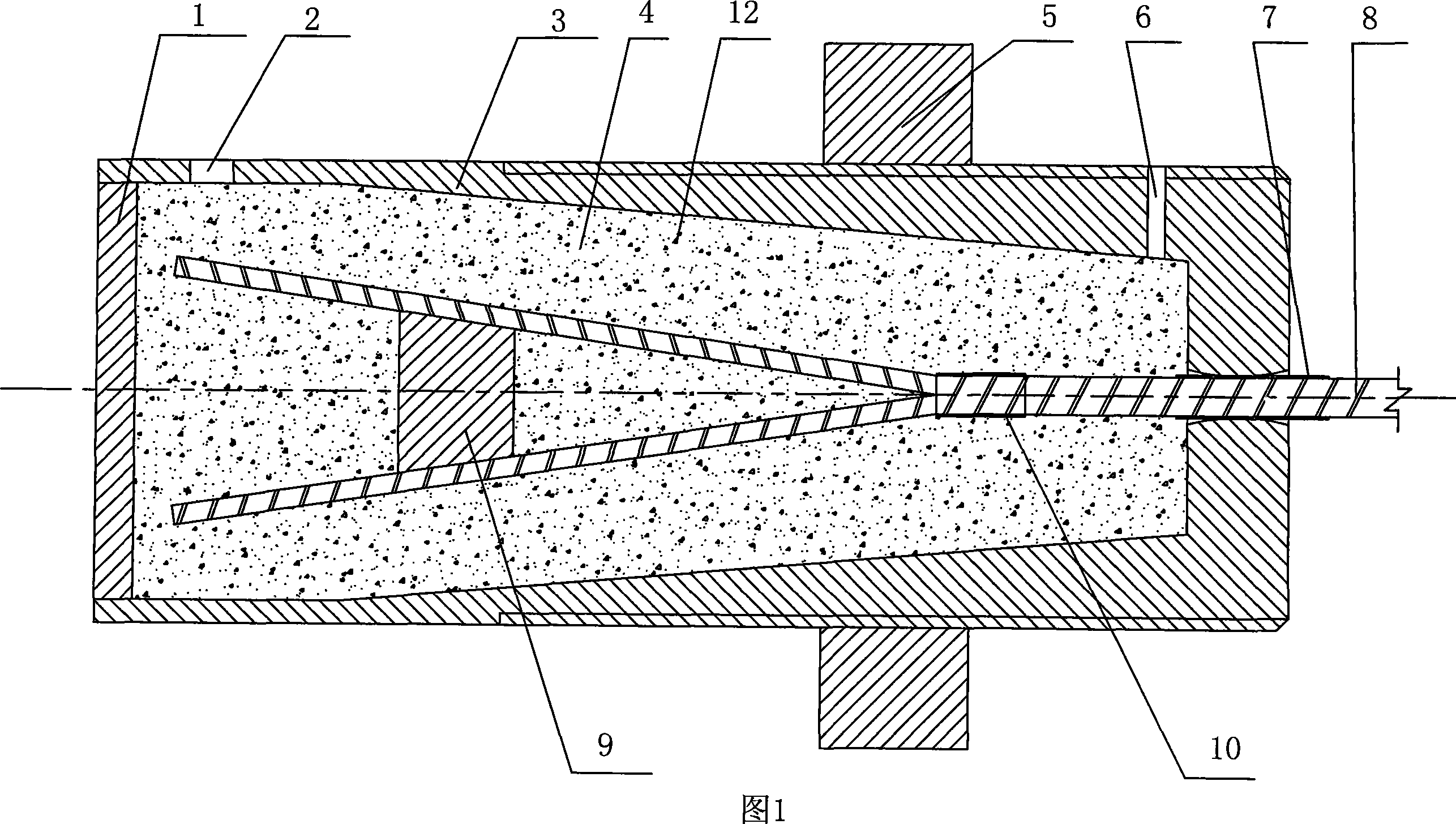

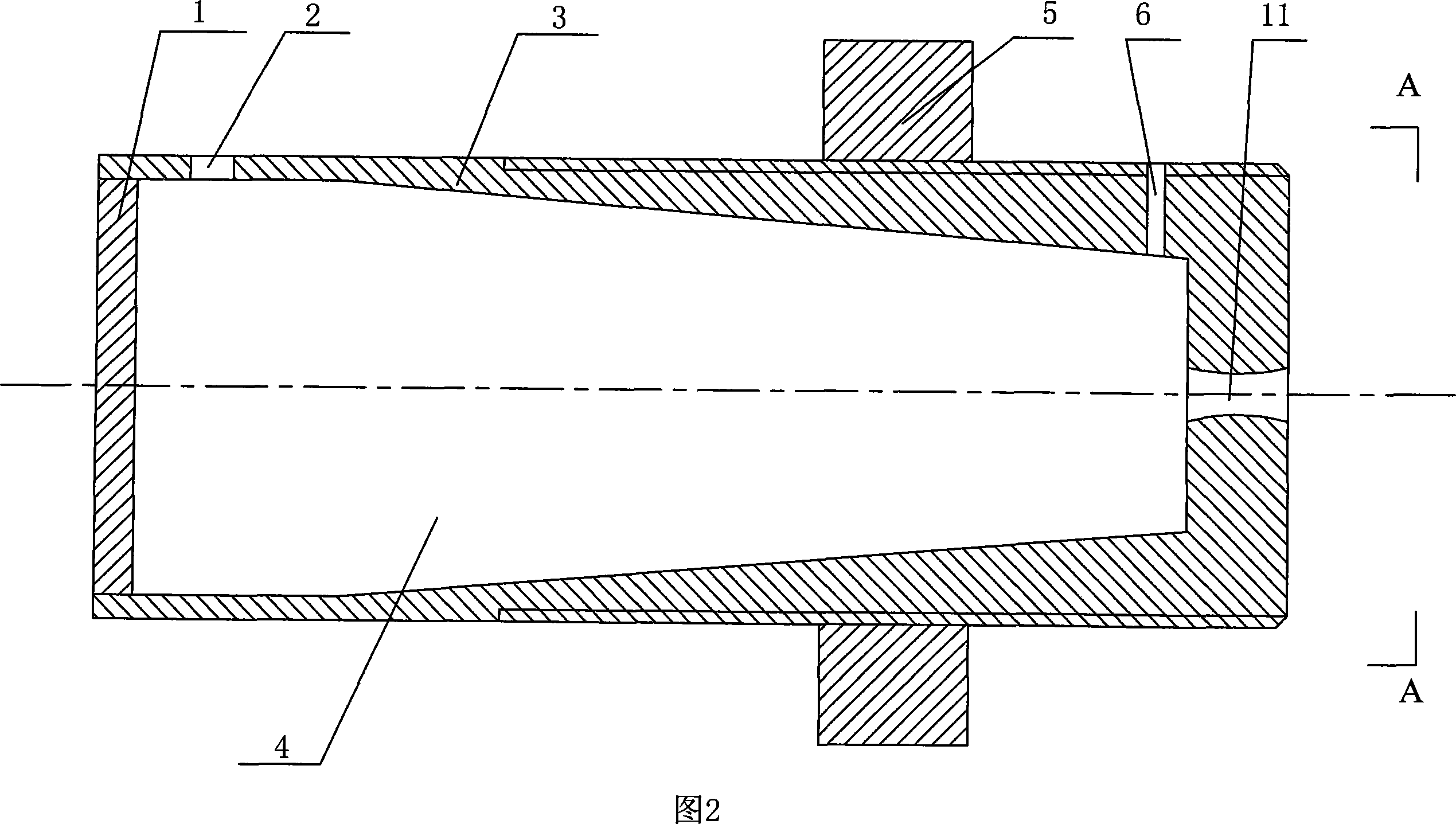

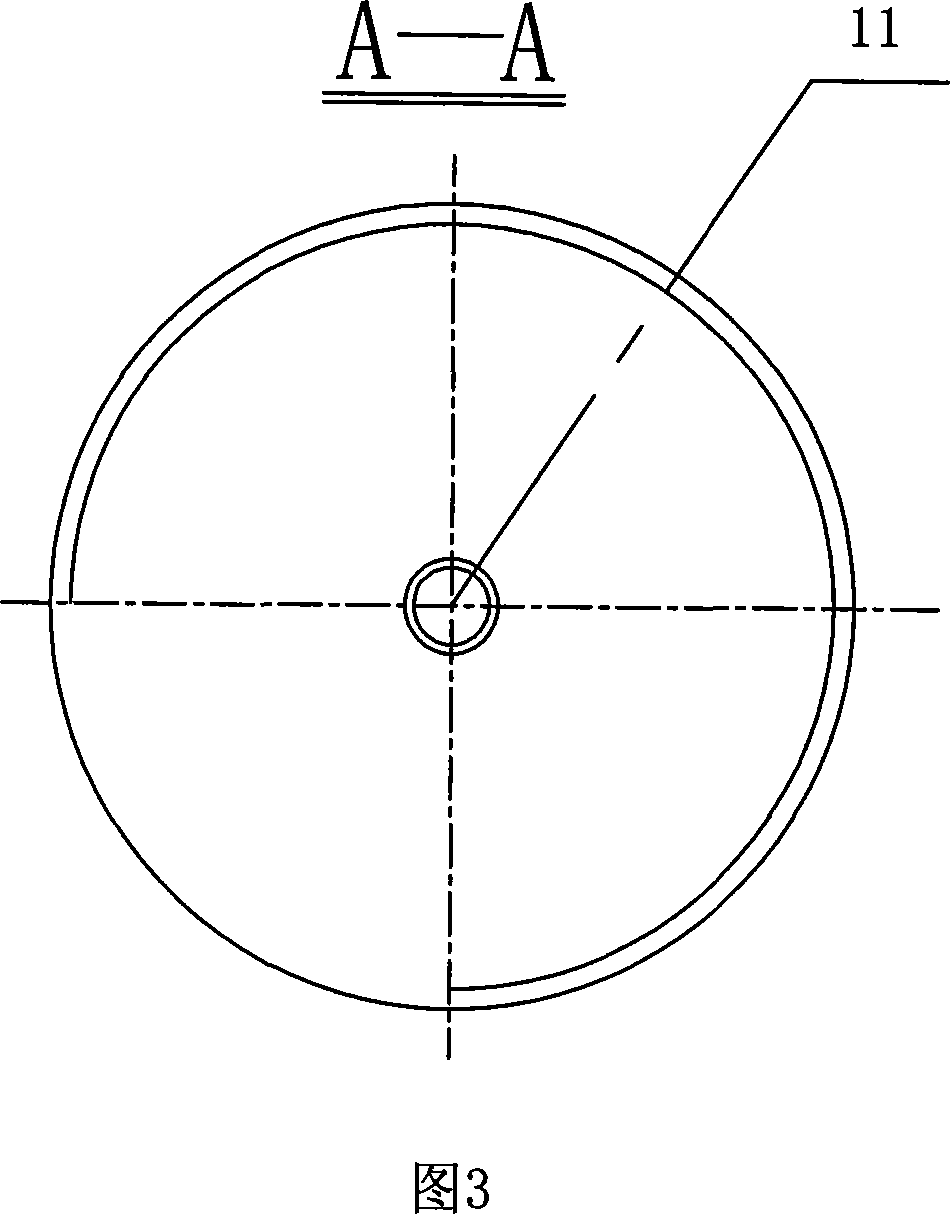

[0024] Embodiment 1: As shown in Figures 1 to 3, the bonded anchor for anchoring fiber-reinforced plastic tendons or cables of the present invention has a cylindrical sleeve with an end cap 1 at one end and a positioning hole 11 at the other end 3. The sleeve 3 is a steel sleeve, which has a conical inner cavity 4 and its smaller-diameter end communicates with the positioning hole 11. The surface of the conical inner cavity 4 is preferably made rough; the cylinder body The outer circumference of the sleeve 3 with grouting holes 2 and vent holes 6 respectively has external threads and nuts 5; the grouting holes 2 and vent holes 6 are all connected to the tapered inner cavity 4, and the fiber reinforced plastic A tendon or cable 8 passes through the positioning hole 11 and one end thereof is located in the tapered inner cavity 4, and the one end of the fiber reinforced plastic tendon or cable 8 in the tapered inner cavity 4 is split It is divided into two bifurcated petals, and ...

Embodiment 2

[0026] Embodiment 2: As shown in Figure 4, the anchoring method of the present invention is: a. The anchorage structure (referring to Figure 4) that adopts: this anchorage has the cylinder that one end is provided with end cap 1 and the other end has positioning hole 11 Shaped sleeve 3, the sleeve 3 has a tapered inner cavity 4 and its smaller end communicates with the positioning hole 11, the two ends of the cylinder are respectively provided with the sleeve 3 of the grouting hole 2 and the exhaust hole 6 There are external threads on the outer periphery and nuts 5 are installed, the grouting holes 2 and the exhaust holes 6 are connected with the conical inner cavity 4, and there are through holes 13 on the end cover 1;

[0027] b. Anchoring method: first pass the fiber reinforced plastic tendon or cable 8 through the through hole 13 of the end cover 1 and through the tapered inner cavity 4 of the steel sleeve 3, and then pass through the positioning hole 11, and the fiber rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com