Patents

Literature

358 results about "Fibre-reinforced plastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fibre-reinforced plastic (FRP) (also called fiber-reinforced polymer, or fiber-reinforced plastic) is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon fiber reinforced polymer), aramid, or basalt. Rarely, other fibres such as paper, wood, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use.

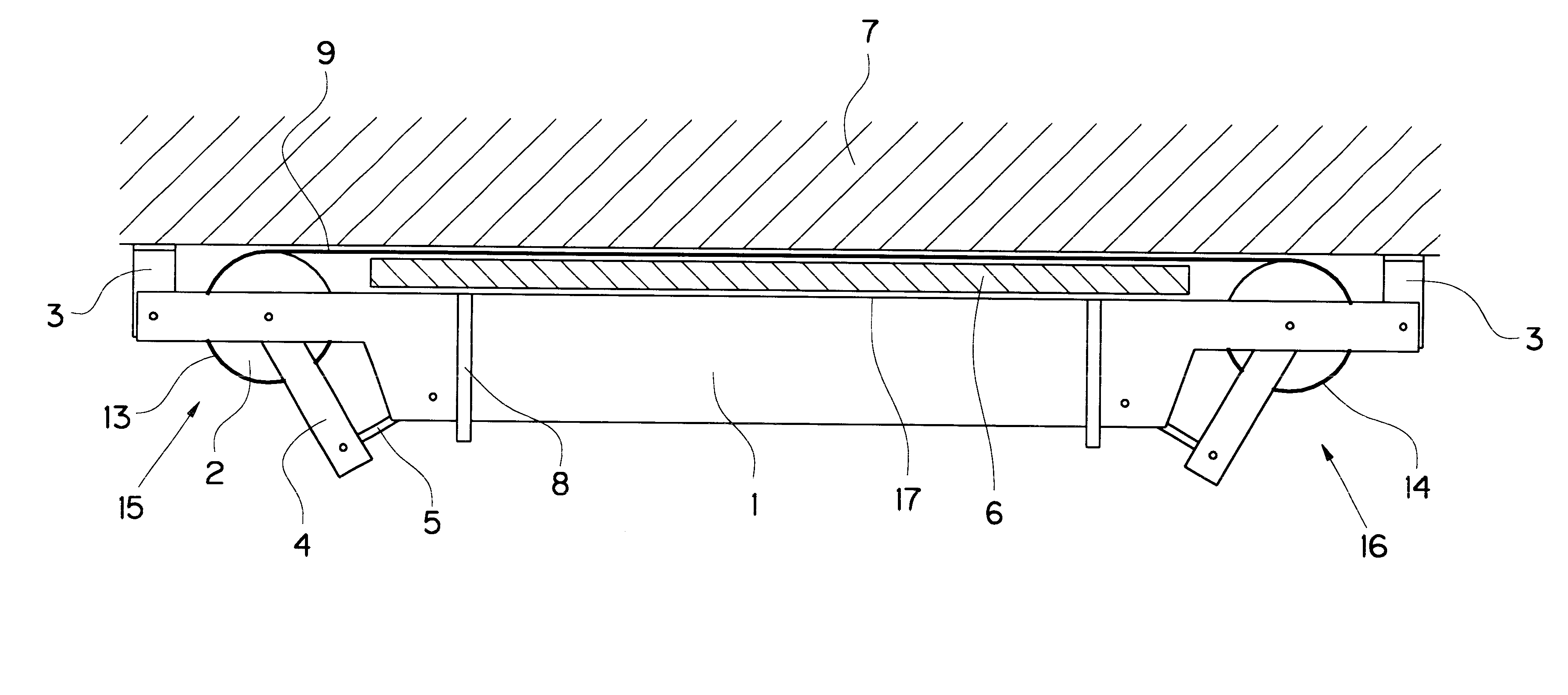

Repair of composite laminates

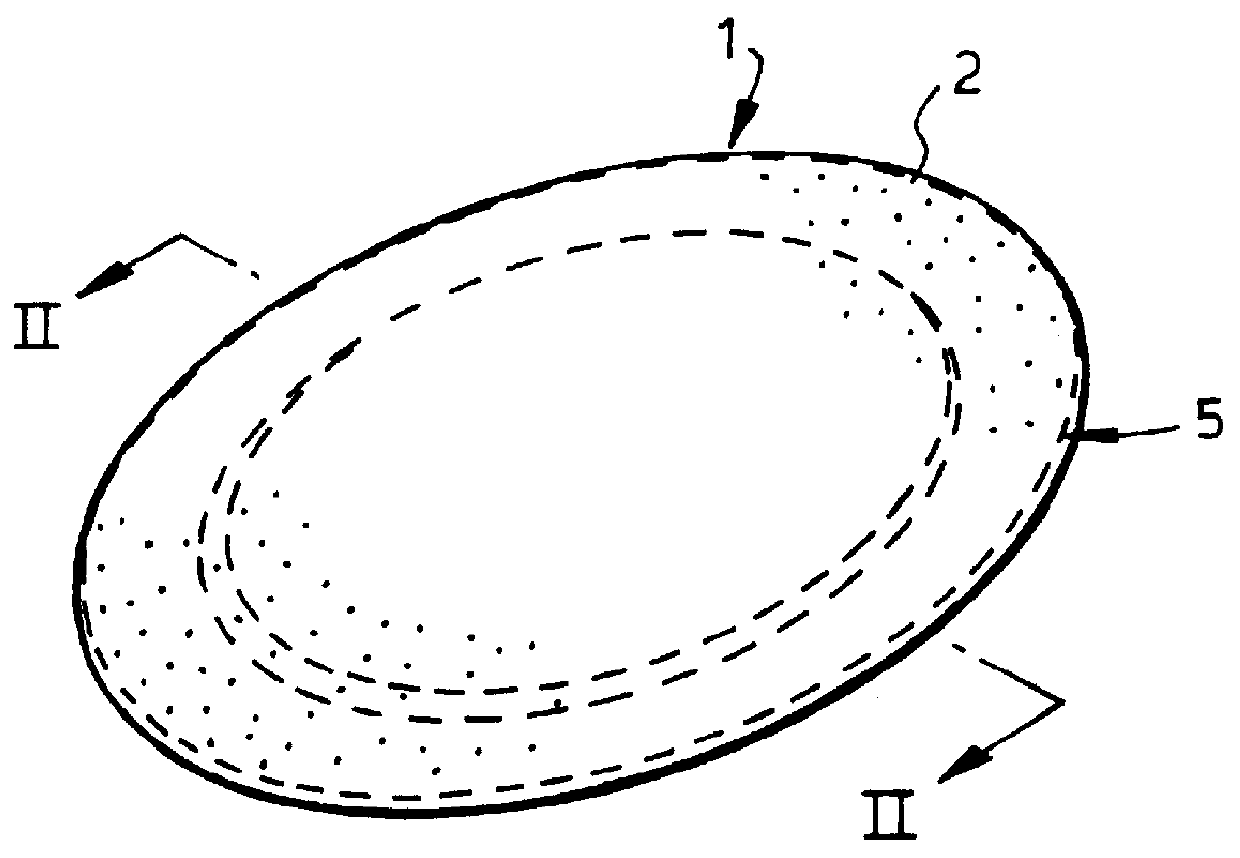

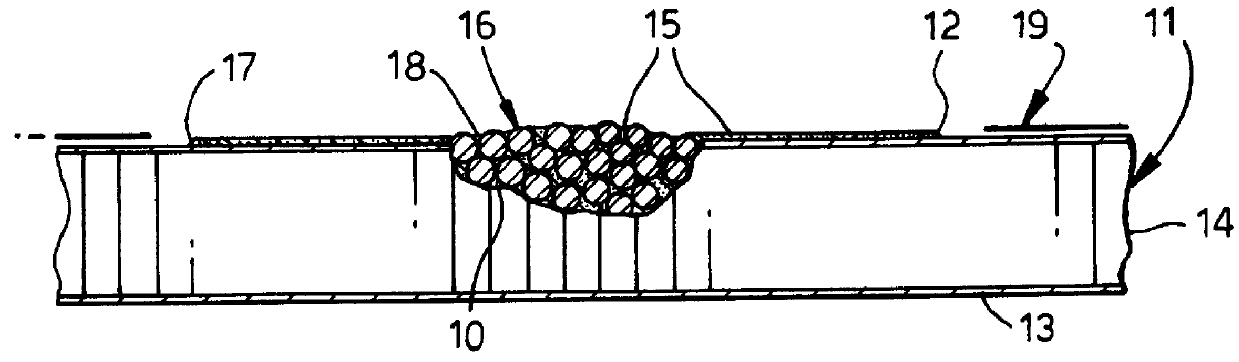

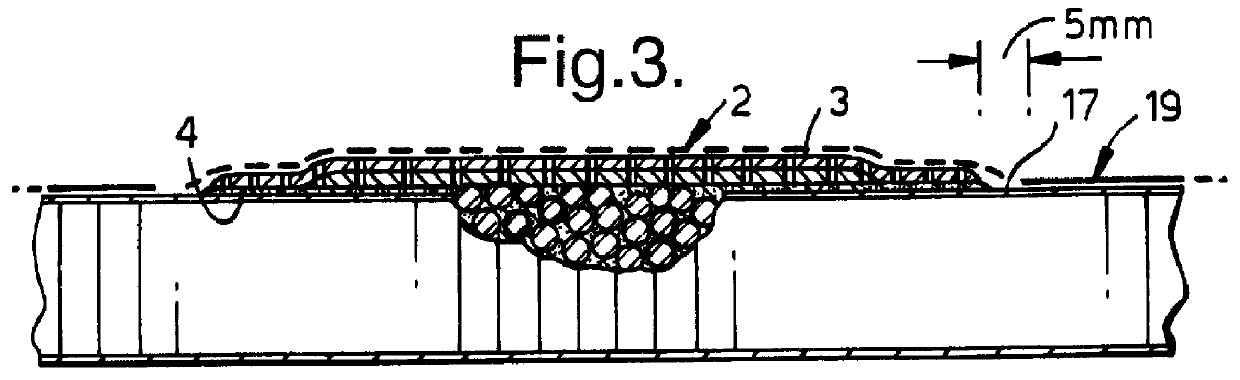

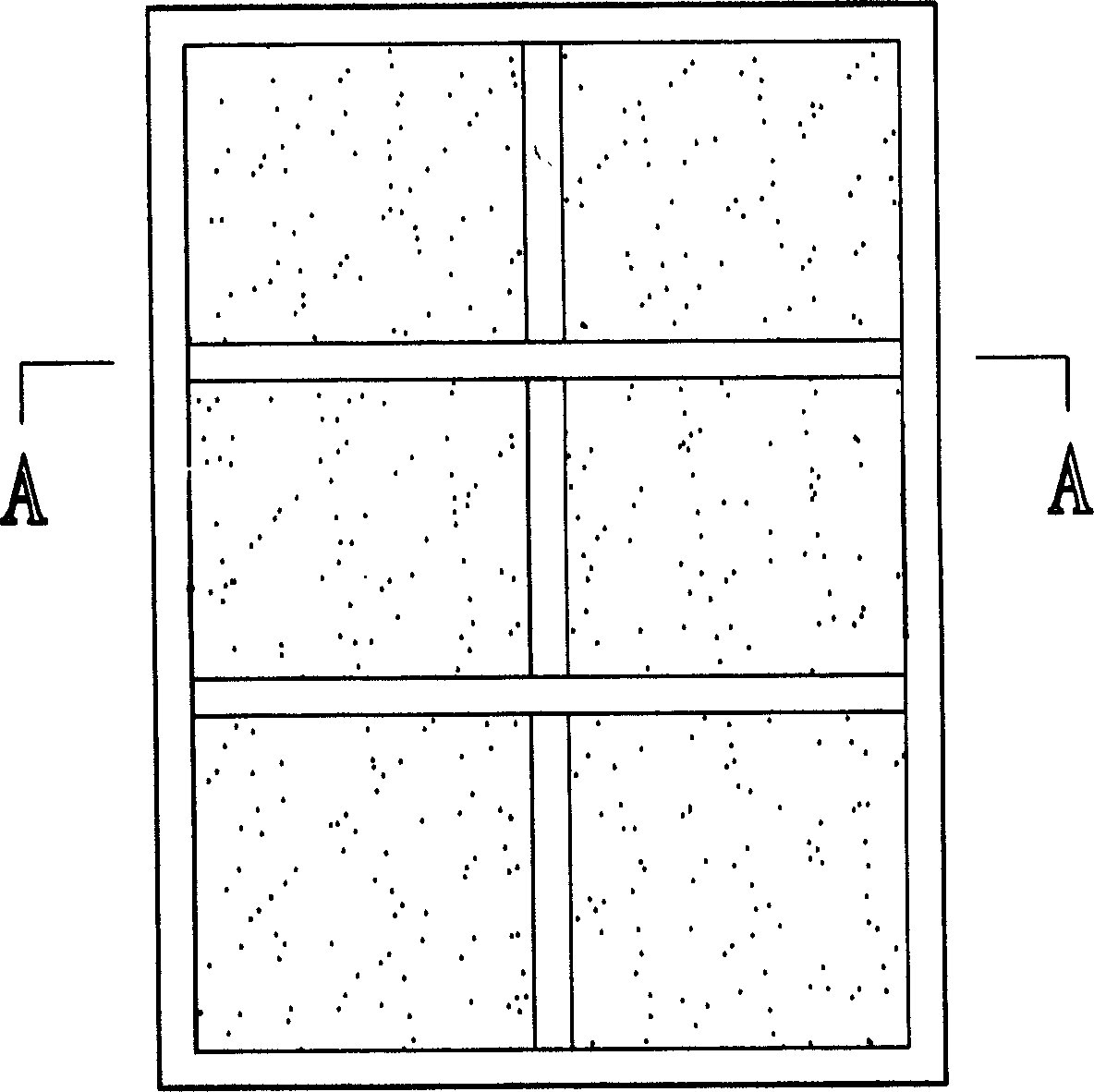

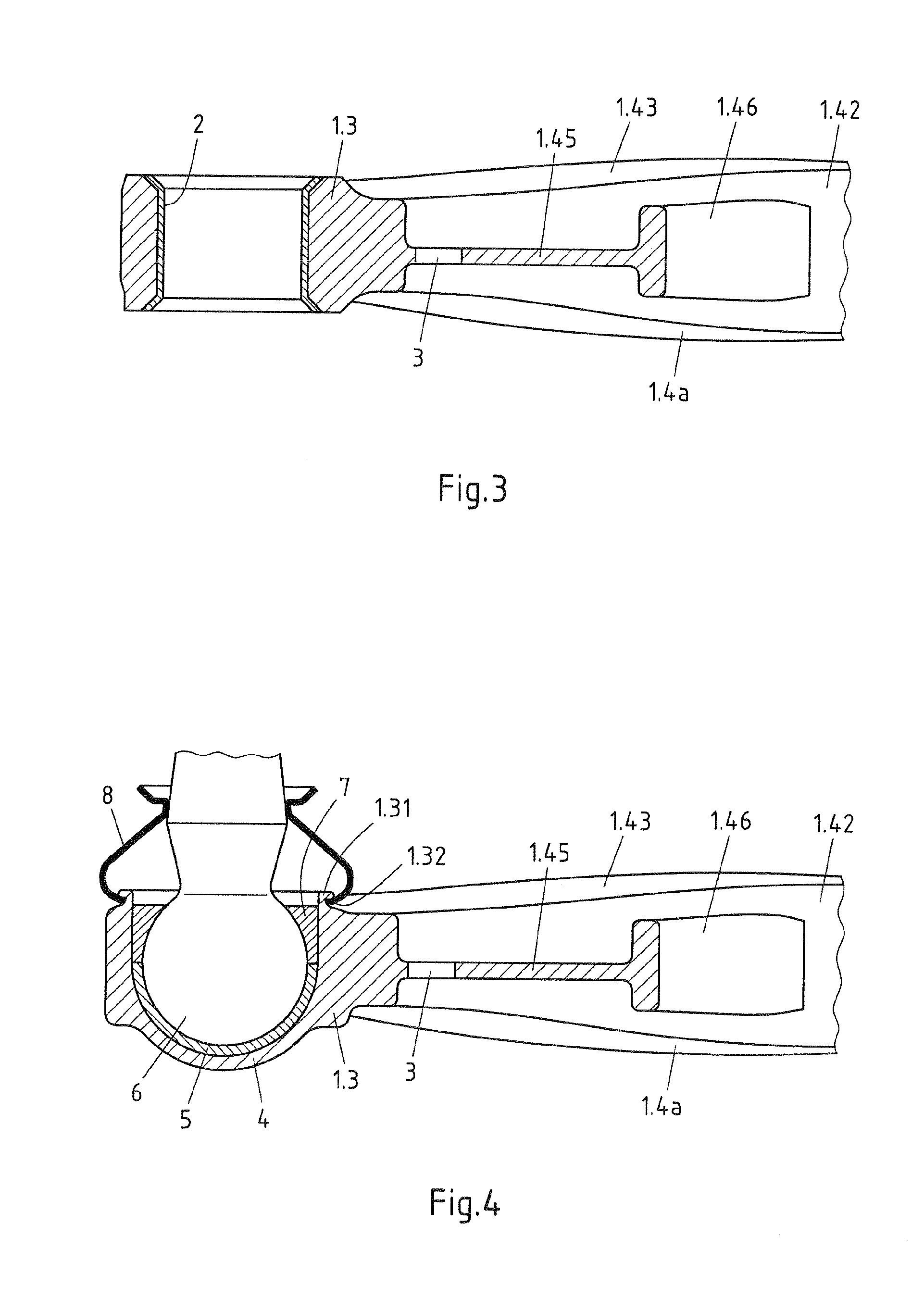

A patch of fibre reinforced plastics composite material, a repair kit including such a patch and a method of using such a patch and repair kit are provided. The patch (1) is for attachment to a surface (17) of a fibre reinforced plastics composite structure (11) over an area of damage (10) to the structure. The patch defines an outer surface (3), a bonding surface (4) opposed thereto and a peripheral edge. The patch includes fibre reinforcement and plastics matrix material with the latter being in a final state of hardness. The patch defines a series of small apertures (6) therethrough to allow the passage of gases and other matter through the patch to prevent entrapped air weakening the repair.

Owner:AIRBUS OPERATIONS LTD

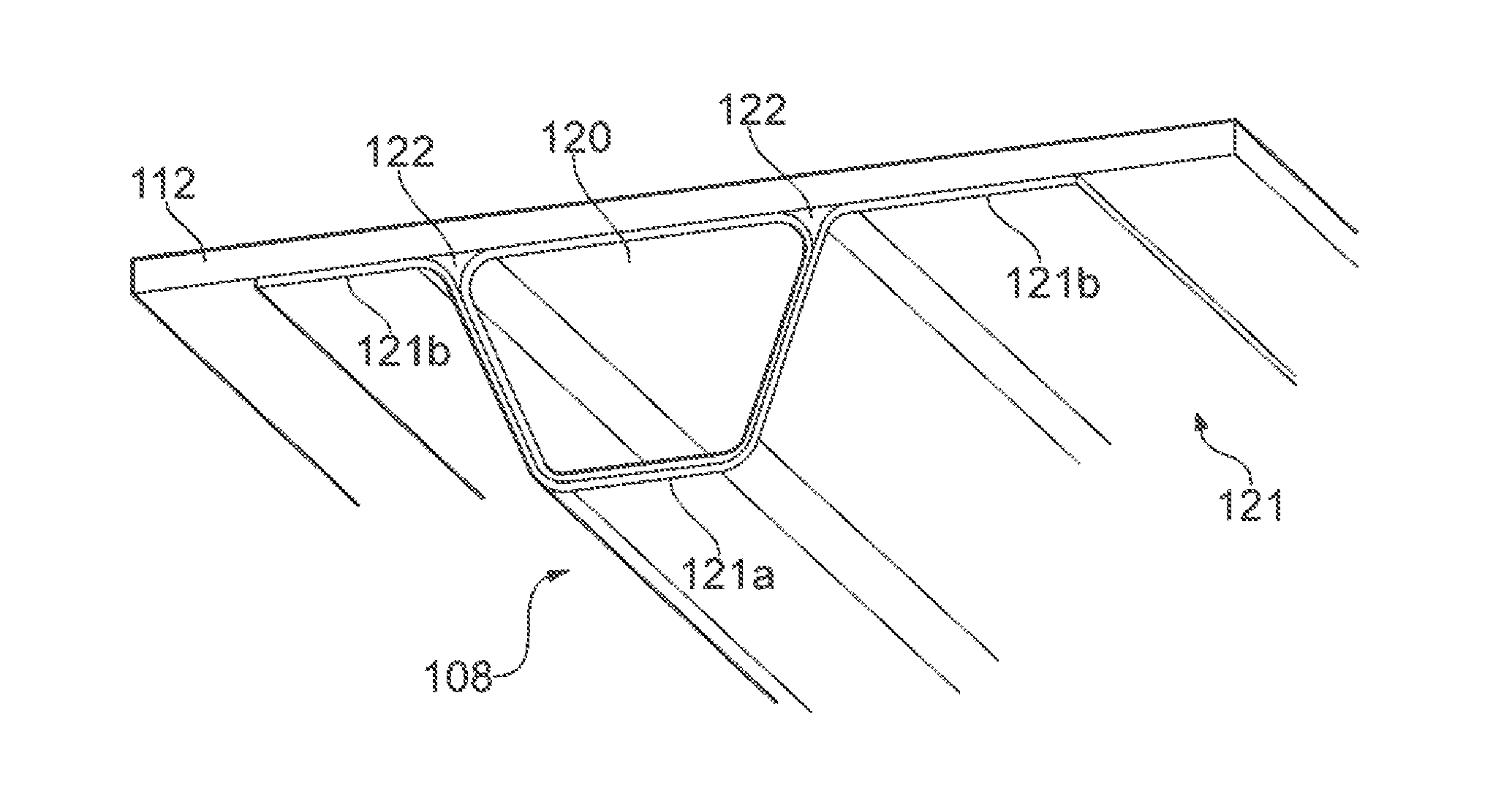

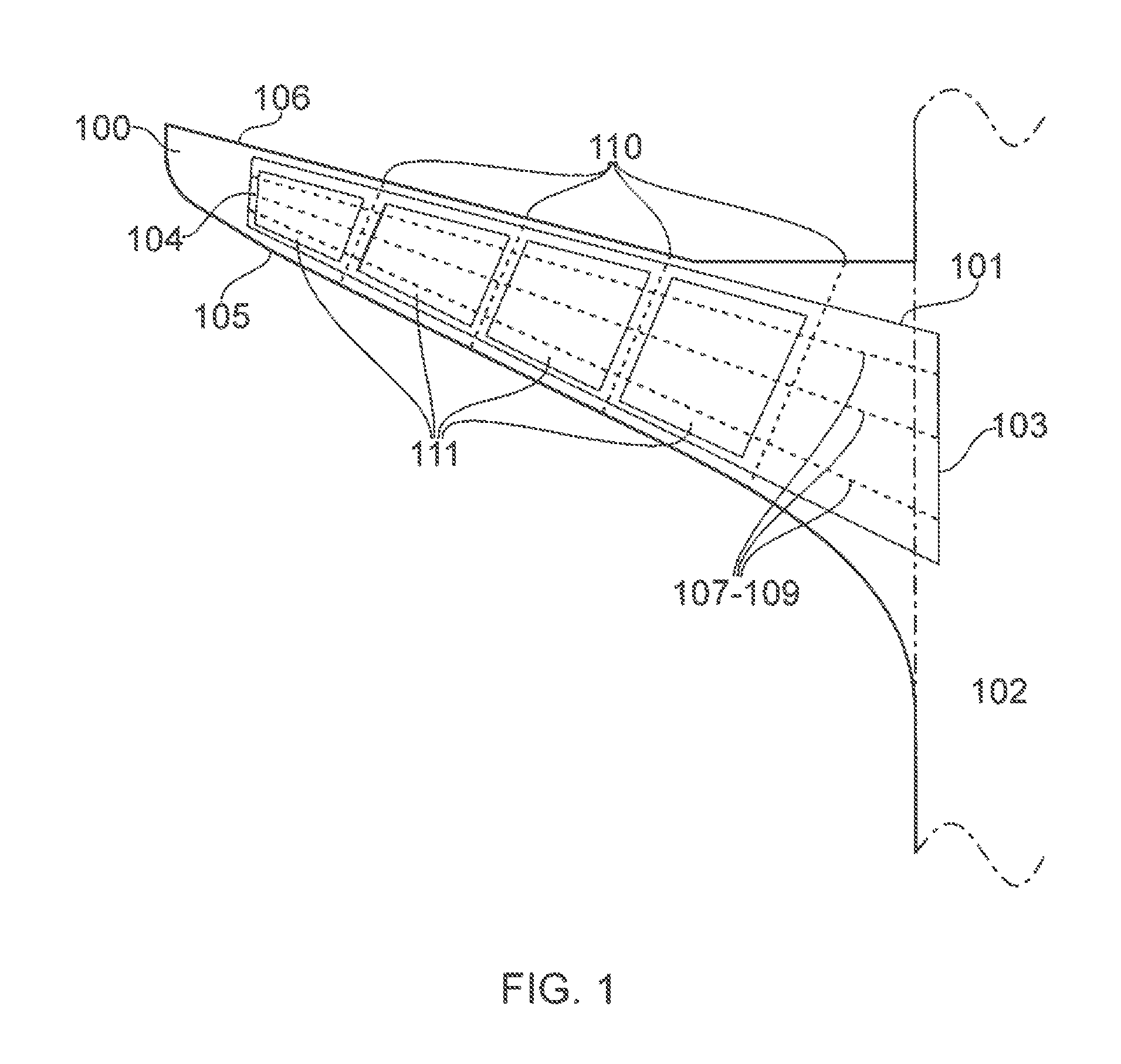

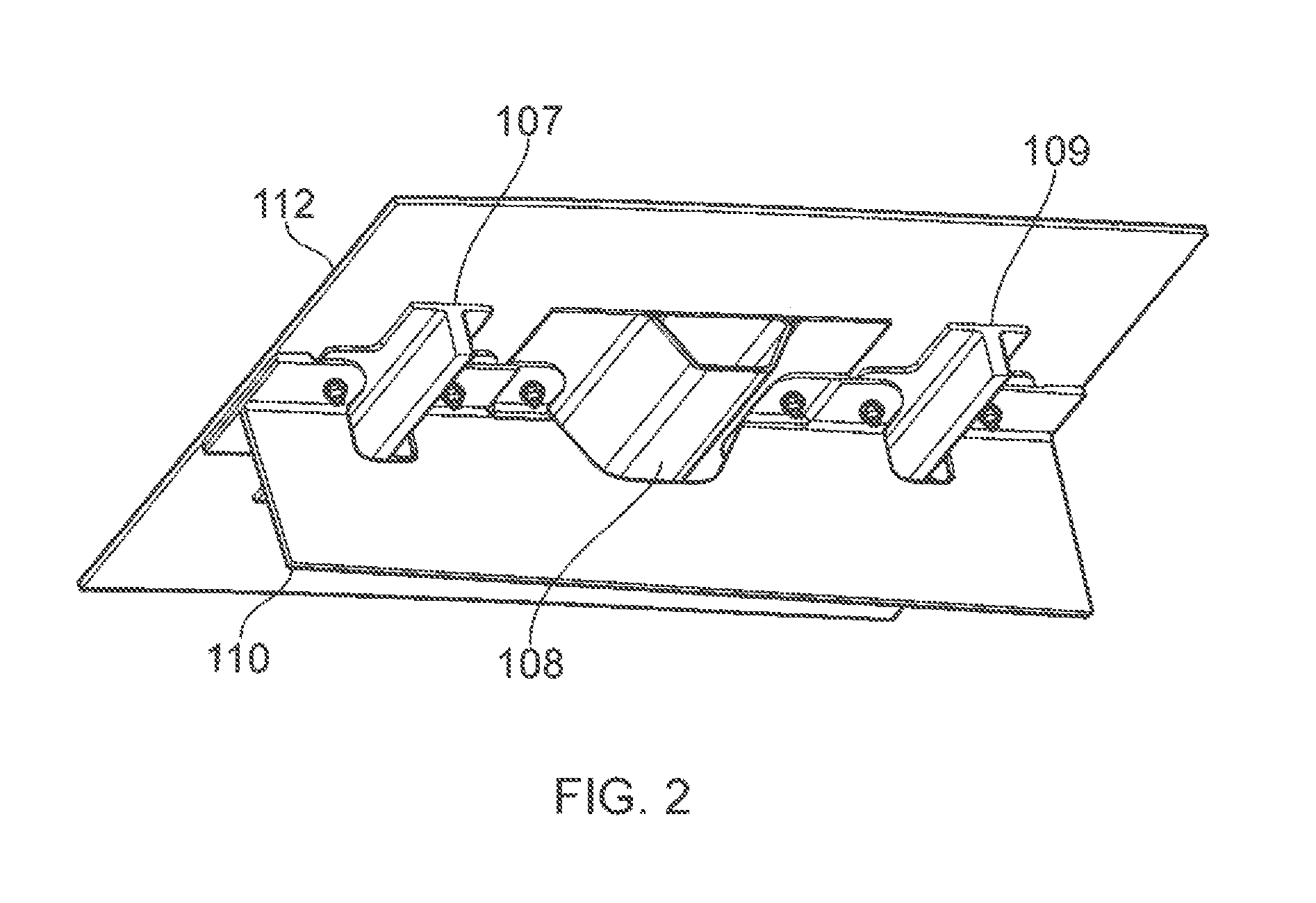

Stringer, aircraft wing panel assembly, and method of forming thereof

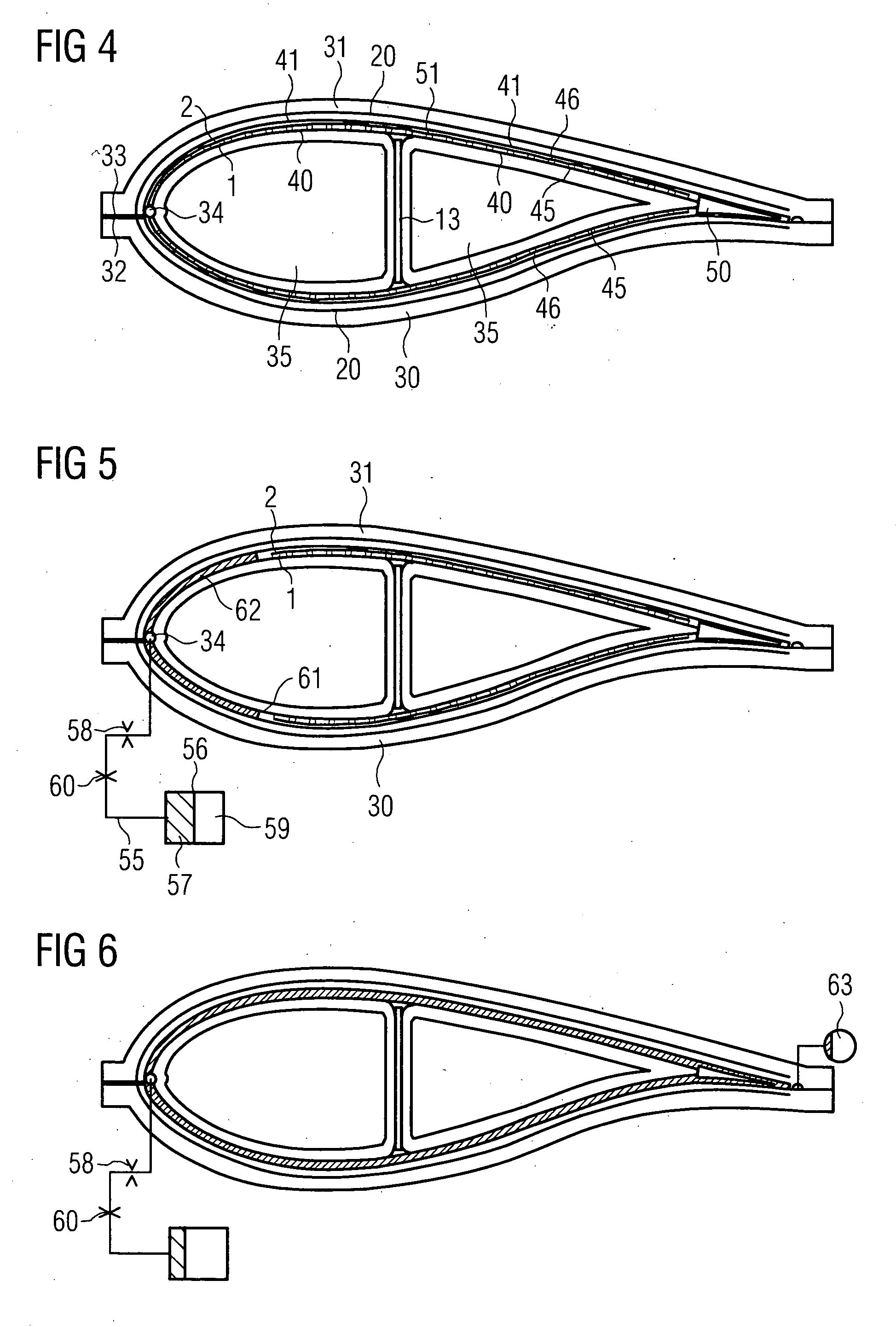

Embodiments of the invention relate to a stringer (108) adapted to transport fluid in an aircraft wing (100). For example, the stringer may be adapted to provide venting to one or more fuel tanks (111) in the aircraft wing, or may be adapted to provide fuel to the one or more fuel tanks. To perform this function, the stringer comprises a duct member (120) providing a duct and a structural member (121) providing an attachment surface for attachment of the stringer to a wing panel (112). Typically, the stringer is formed from a composite material such as carbon fibre reinforced plastic. A method of manufacturing the stringer is also disclosed.

Owner:AIRBUS OPERATIONS LTD

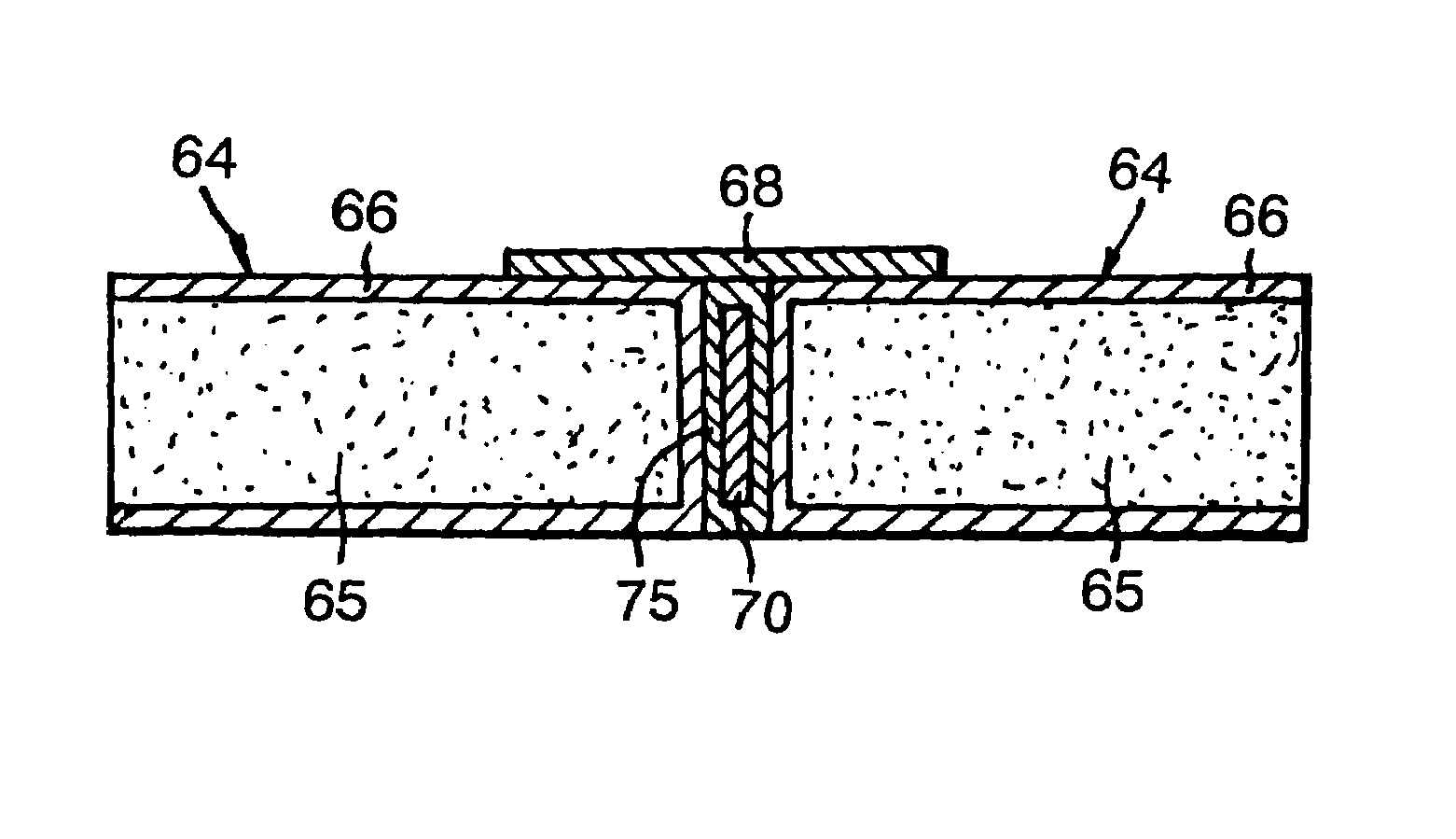

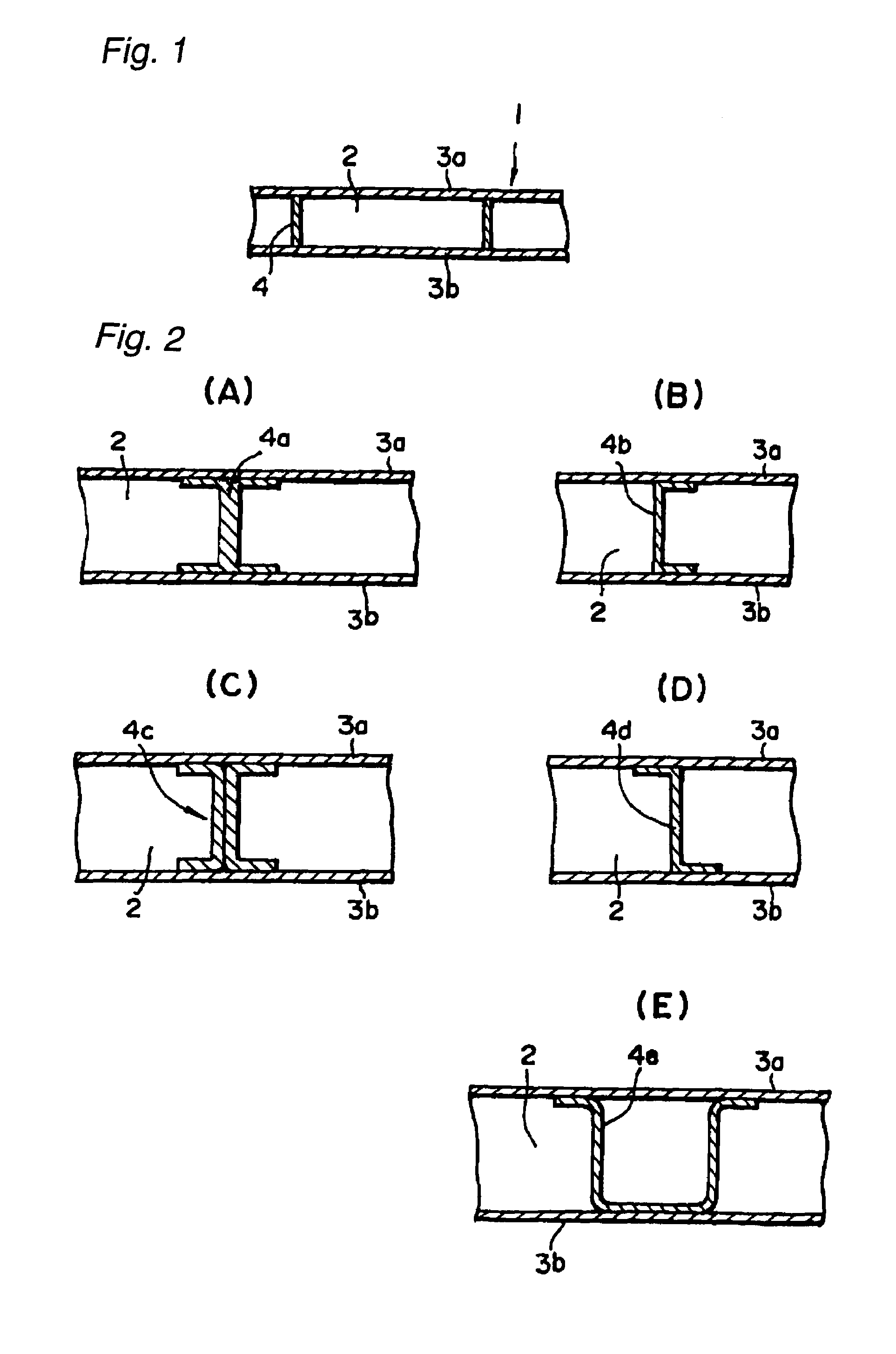

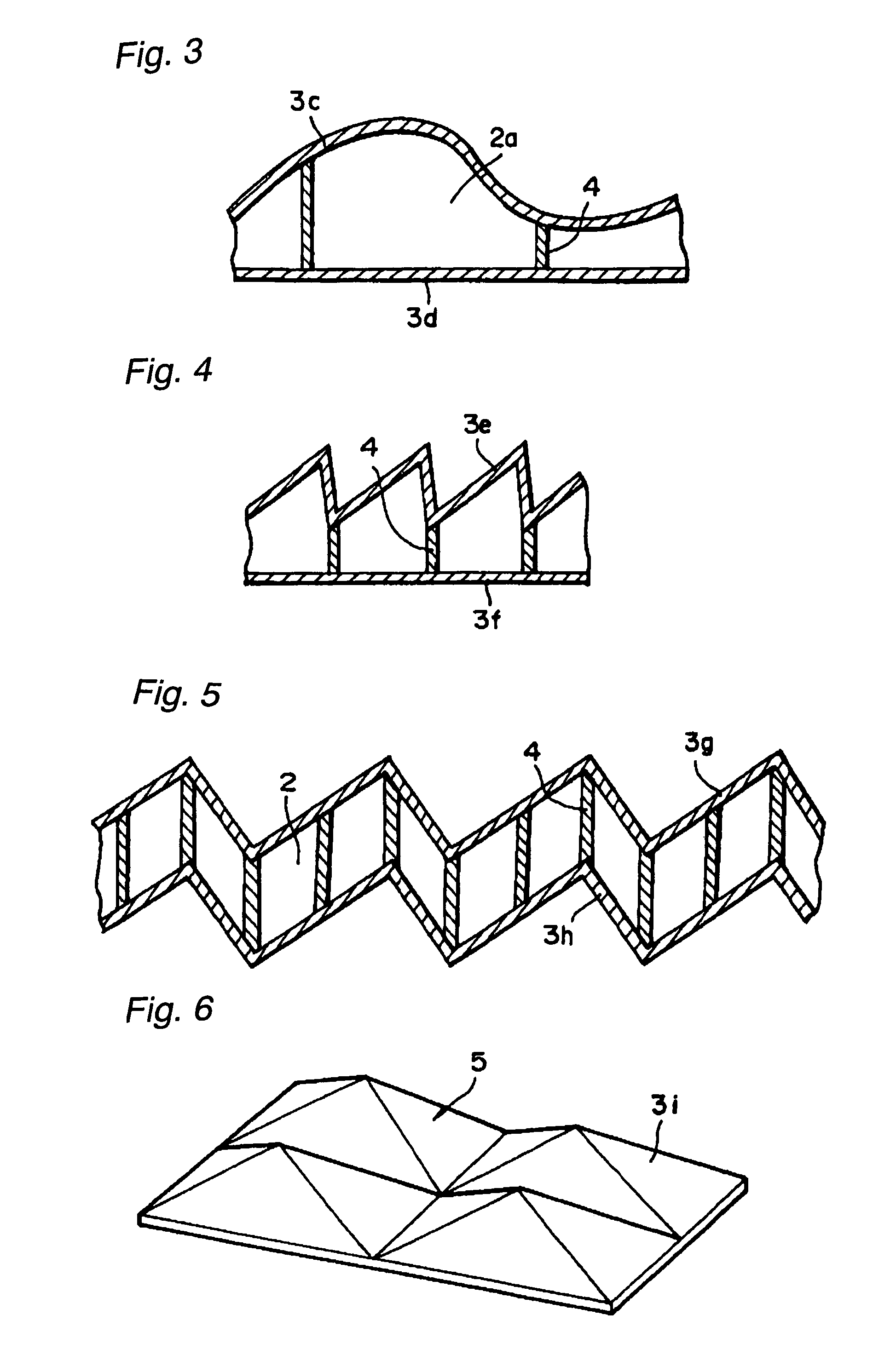

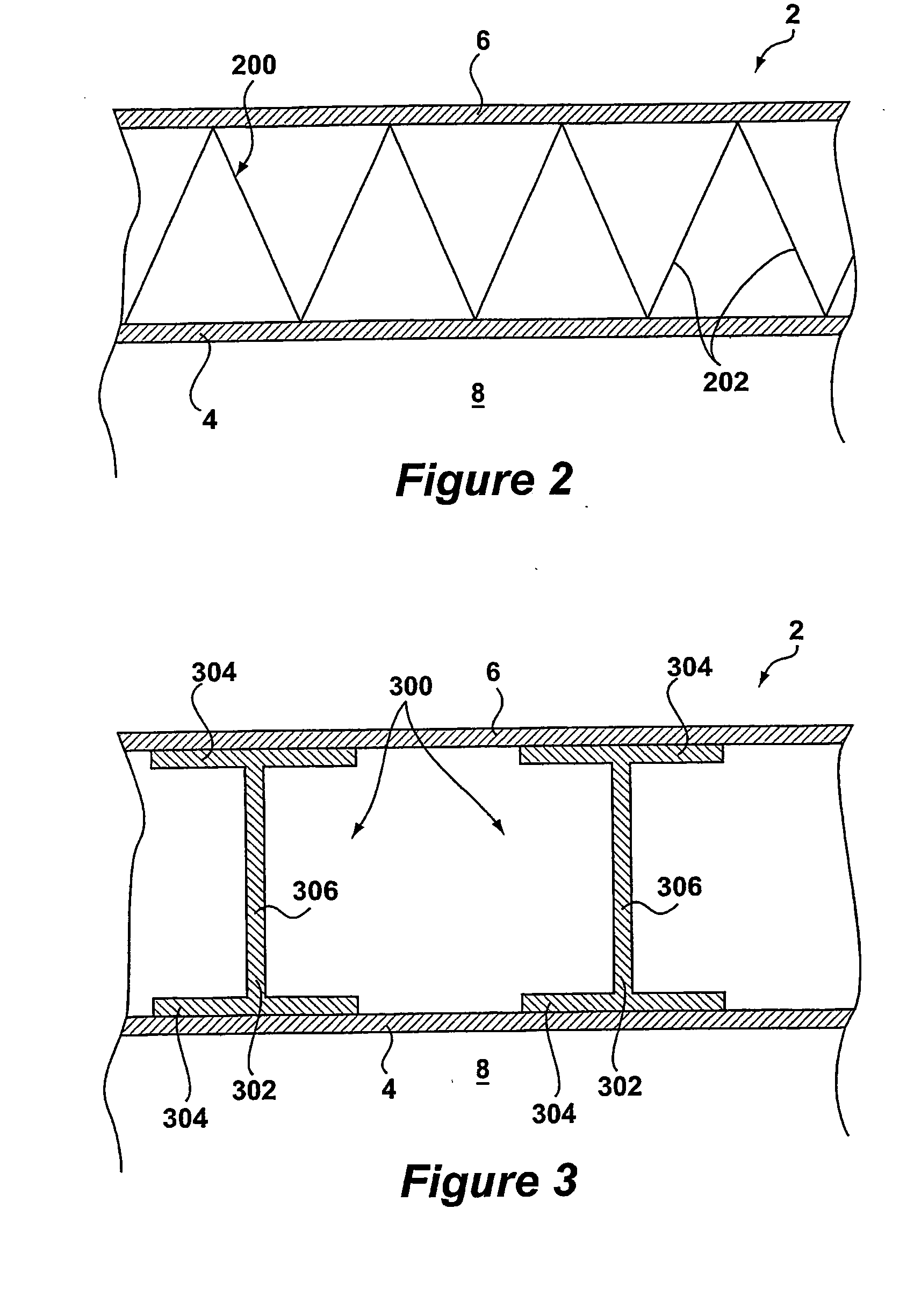

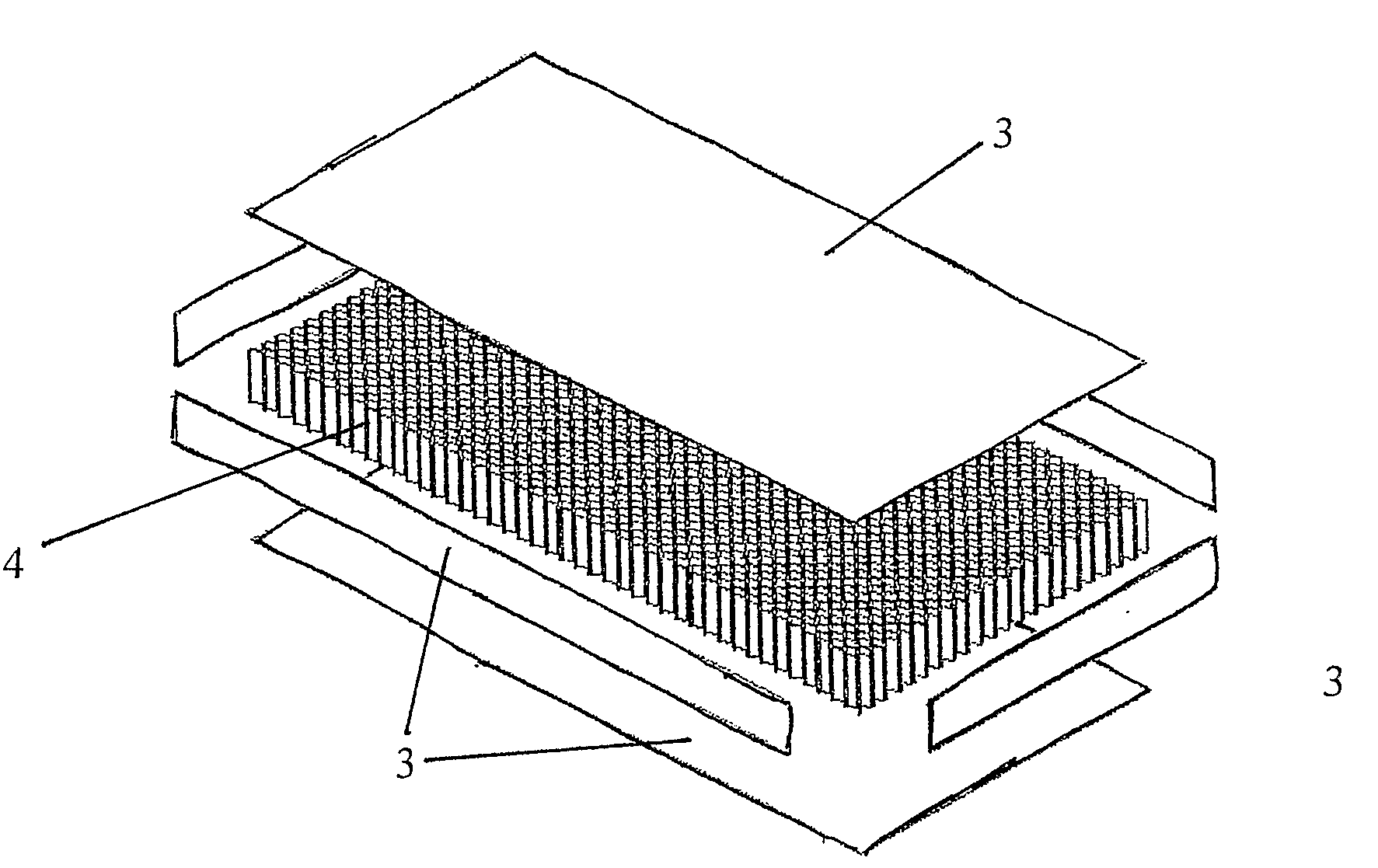

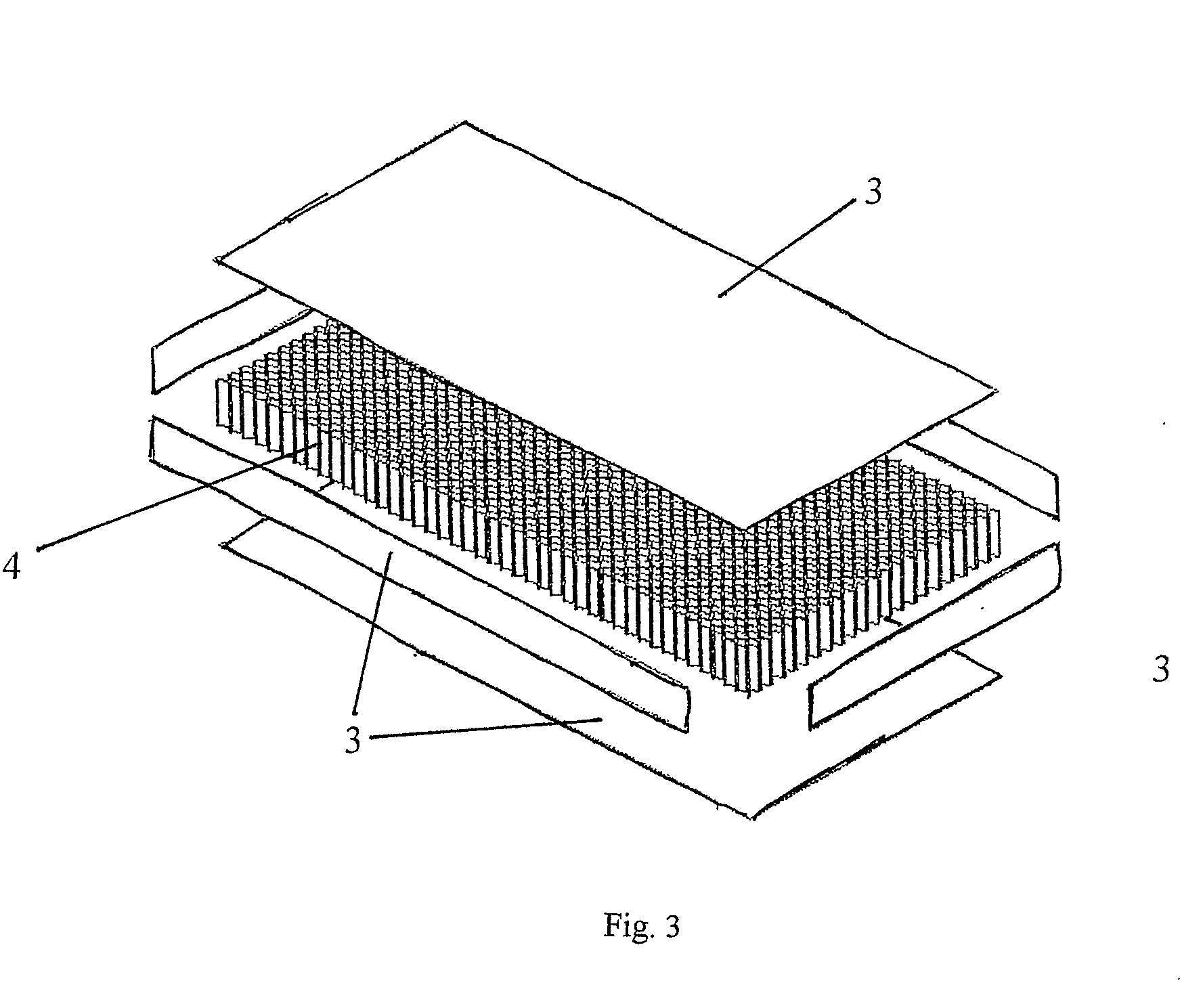

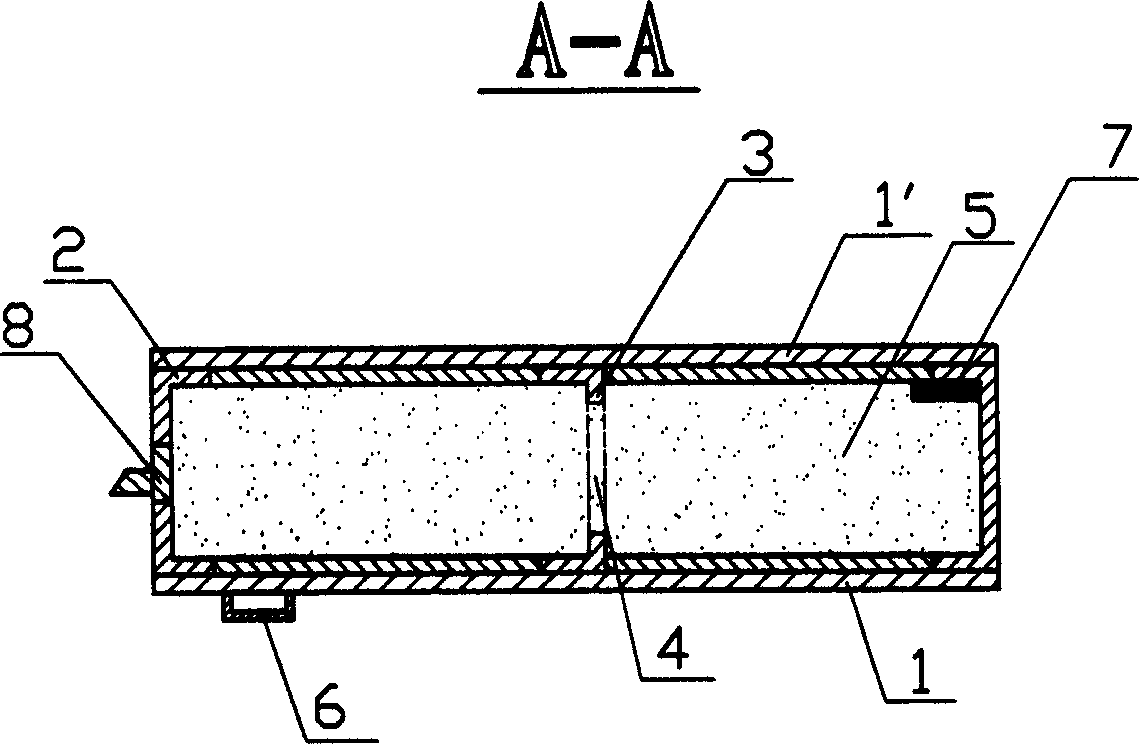

FRP roofing material, manufacturing method, and its connecting structure and connecting method

This invention relates to fibre reinforced plastic (“FPR”) roofing materials with a sandwich structure. A pair of sheets of FRP are arranged with a gap between them, and a rib structure which joins the sheets is interposed. Further, this invention relates to a method for producing FRP roofing material in which channels are provided in the core material and a reinforcing fibre impregnated with a resin is distributed through these channels. A preferred joint structure for the roofing material is to use butt joints and to provide a connecting layer extending across the surfaces of both ends of the sandwich structures. A layer containing a resin distribution medium is provided between the abutting end faces. This invention overcomes various problems of conventional joint structures, permitting the ends of the sandwich structures to be easily, firmly and cheaply joined together, ensuring high joint strength and rigidity, while achieving excellent appearance.

Owner:TORAY IND INC

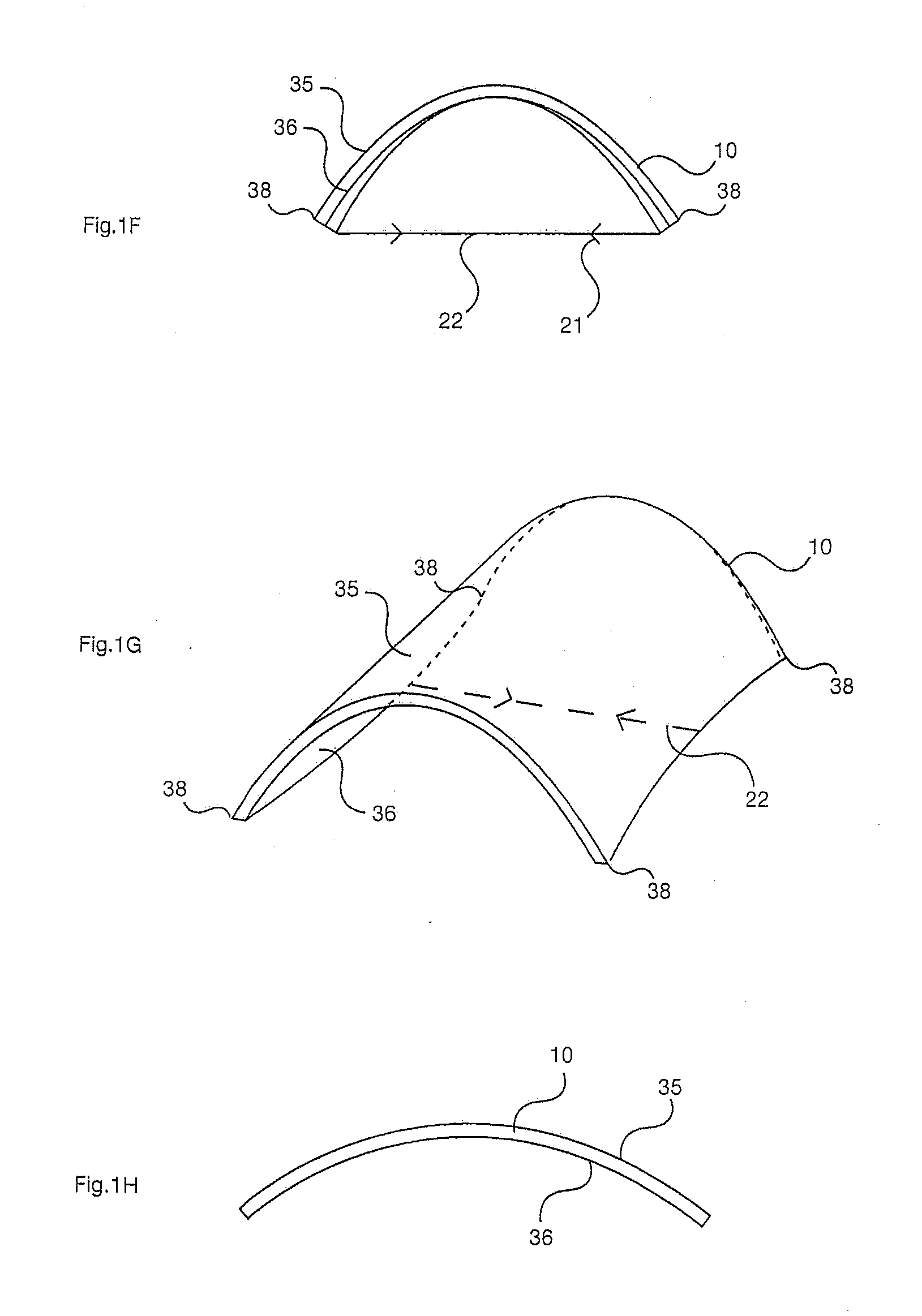

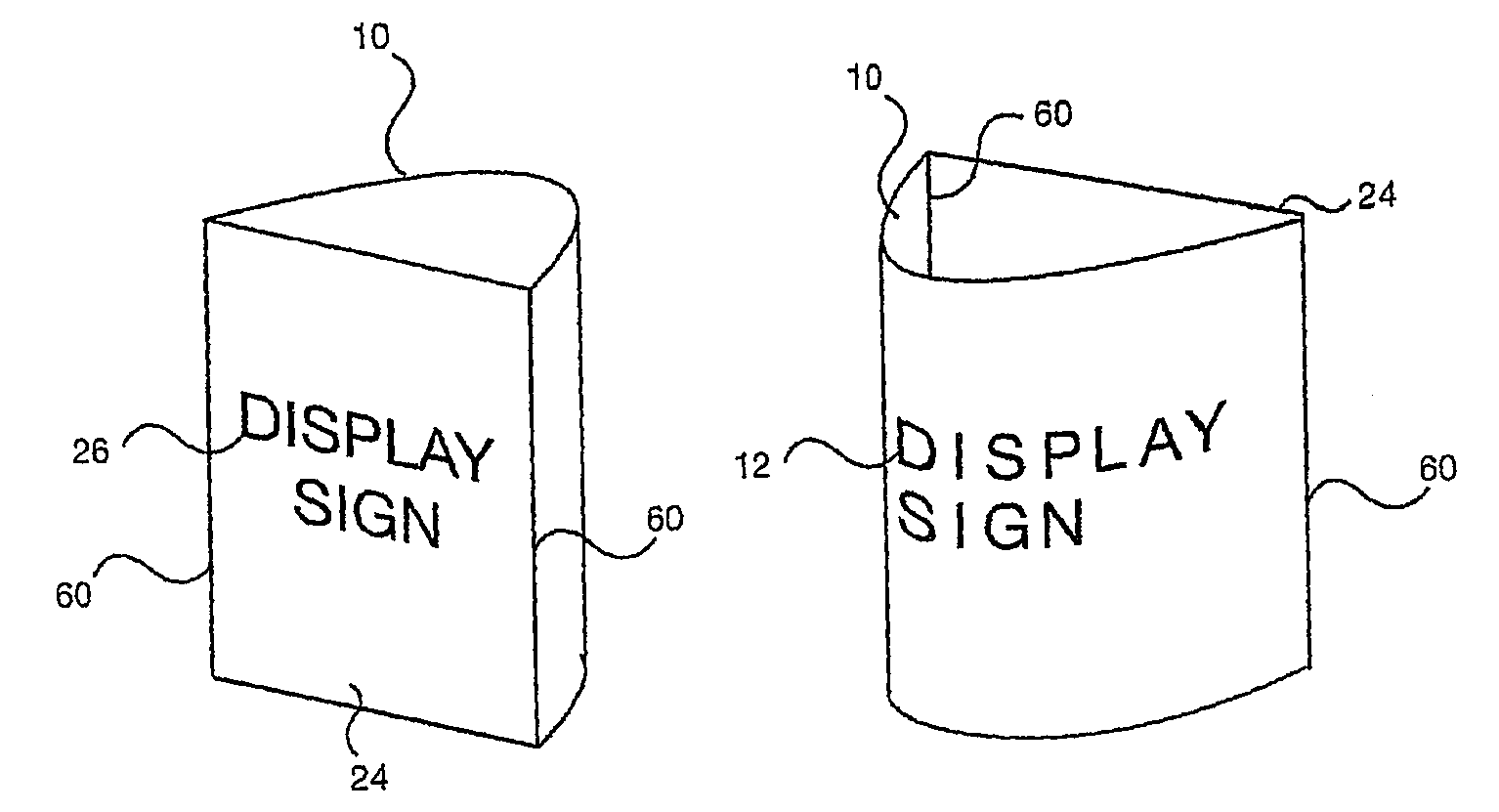

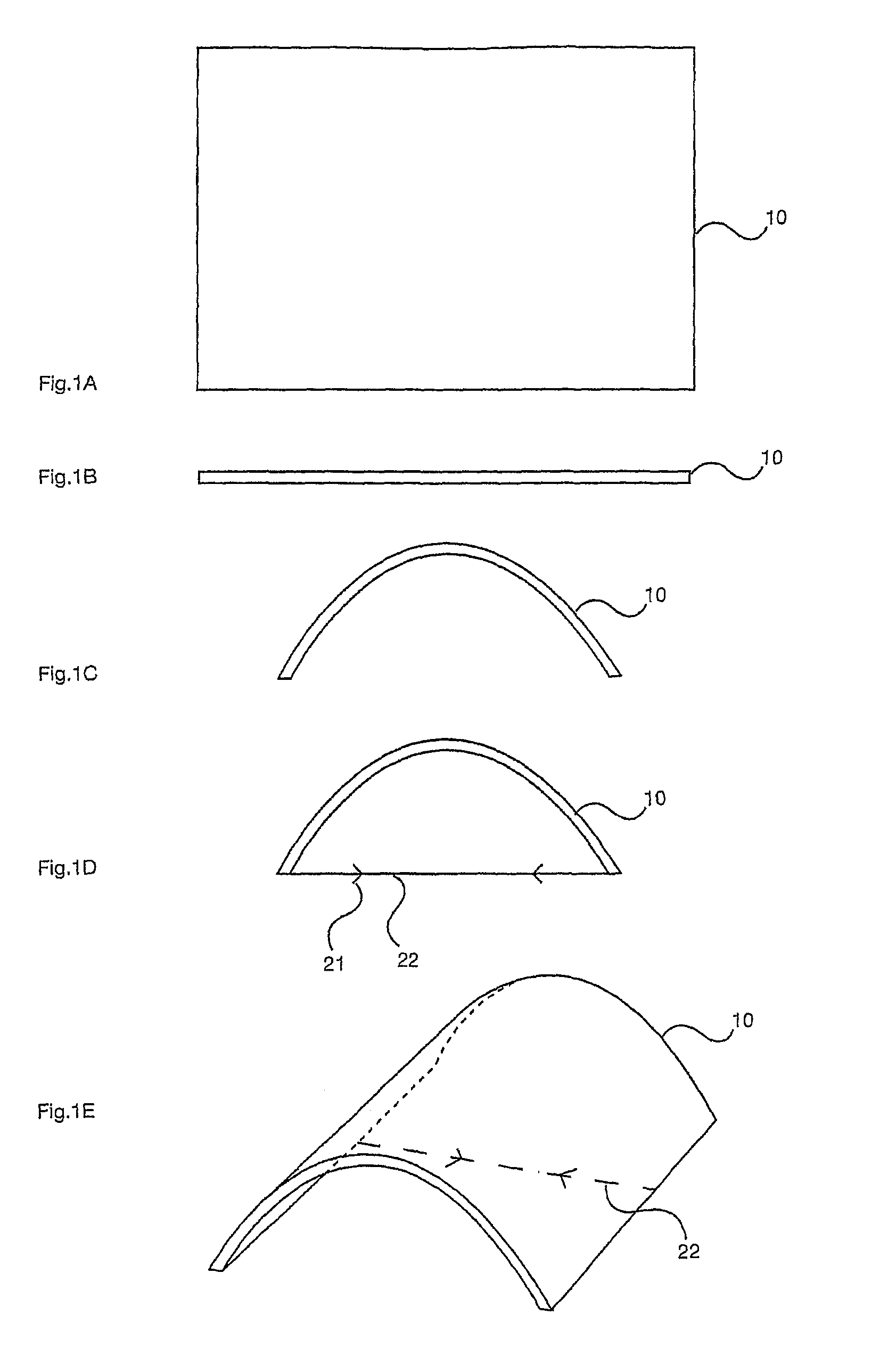

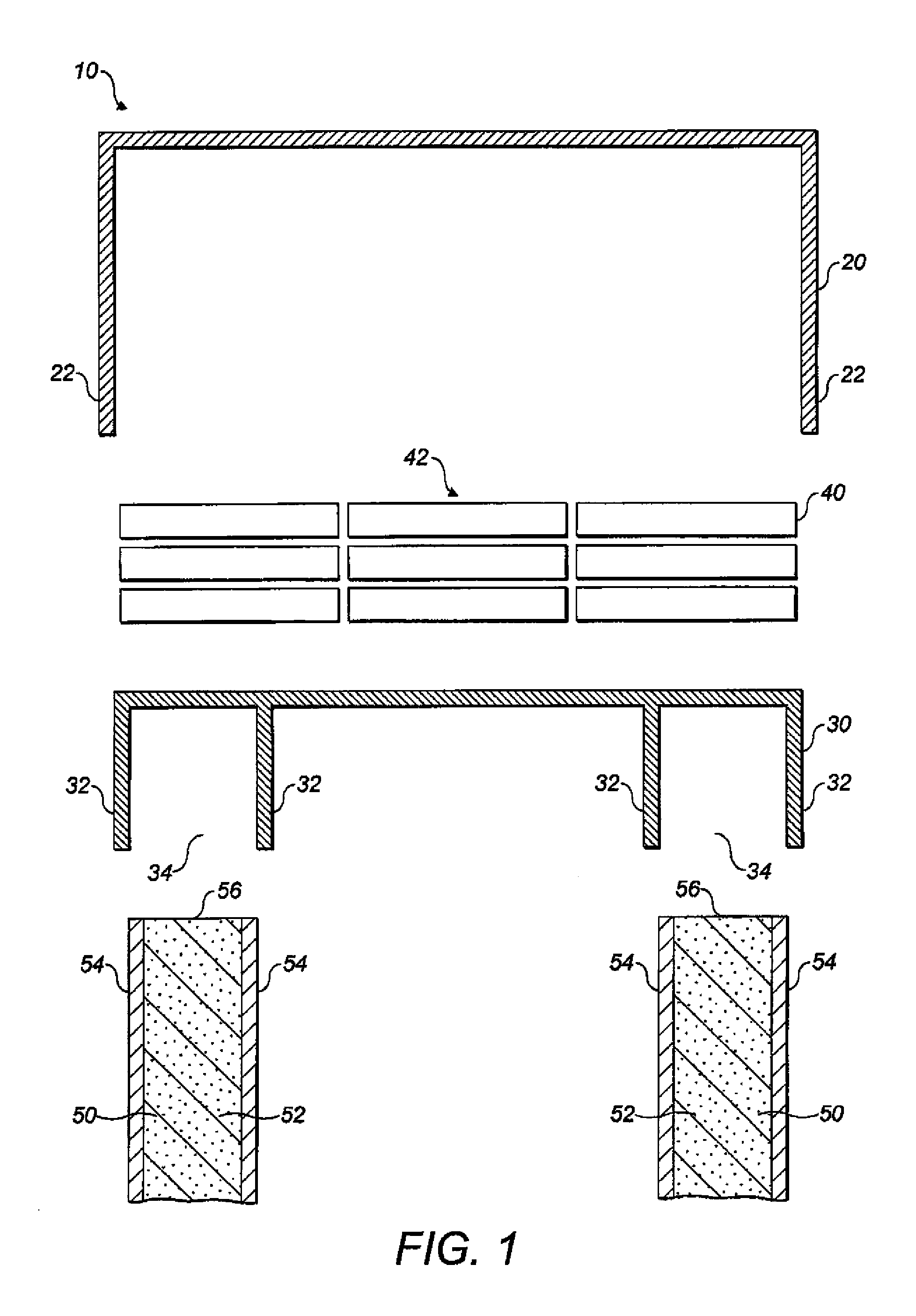

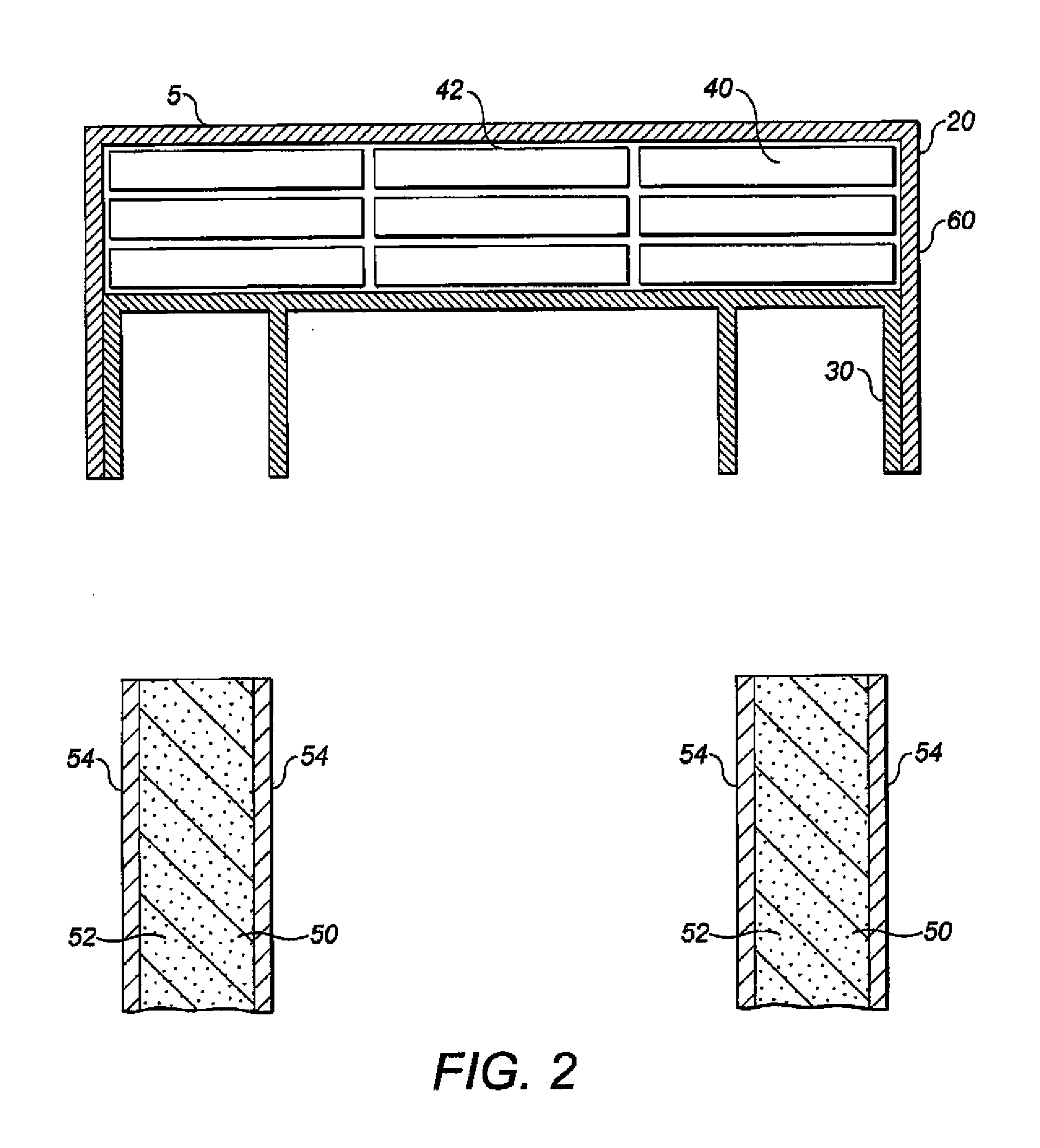

Structural assembly with a flexed, tied panel

InactiveUS20100011641A1Improvement factorBurglar alarm by openingCurtain accessoriesCarbon fibersPre stress

An assembly includes a flexurally deformed panel, which is connected to a membrane tie by a linear connector and is tied by the membrane tie to form a geometrically stable pre-stressed structure. More than one panel may be flexurally deformed and tied together in an assembly and more than one membrane tie may be present within an assembly. Panels are typically semi-rigid sheet materials, for example metal sheets, plastic sheets, or sheets of composite materials, such as glass or carbon fibre reinforced plastics or resins. Membrane tie members are typically flexible, for example plastic films, fabrics or nets or arrays of rods or cables. The assemblies have many different geometric forms and many different practical applications. Assemblies may be relatively large, for example demountable and reusable shelters or flat-pack point-of-purchase display assemblies, or may be relatively small, for example a photograph or postcard display system.

Owner:CONTRA VISION

Fiber wall with strong rib material of plastic

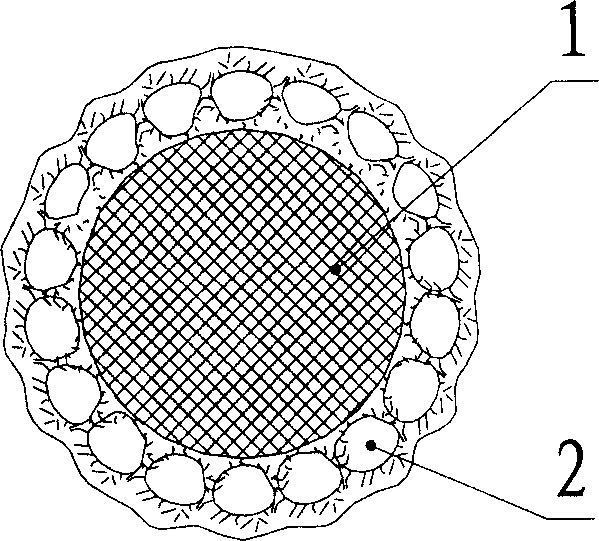

The present invention provides a fibre reinforced plastics rib material. It includes fibre reinforced plastics (FRP) core layer and matrix resin impregnating fibre reinforced plastics (FRP), the peripheral surface of said core layer is axially covered with glass fibre bulk yarn reinforced plastics covering layer. Said glass fibre bulk yarn reinforced plastics covering layer can effectively increase roughness of exterior surface of the fibre reinforced plastics rib material core layer, so that the bond stress of said rib material core layer and concrete also can be raised, and the service lift of concrete member also can be raised.

Owner:SINOMA SCI & TECH

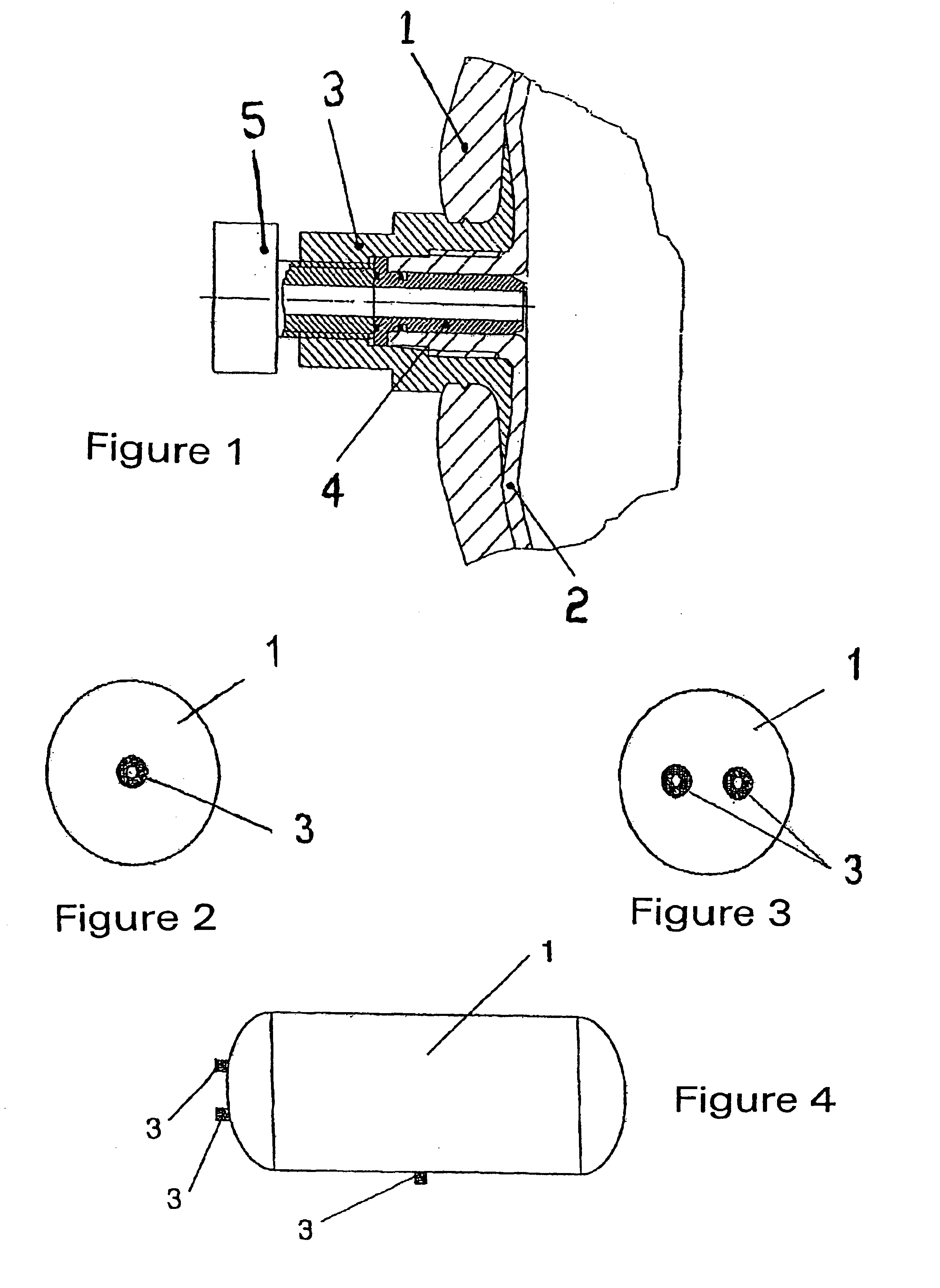

Pressurized container for storing pressurized liquid and/or gaseous media, consisting of a plastic core container which is reinforced with fibre-reinforced plastics and a method for producing the same

InactiveUS7032767B2Reduce weightImprove corrosion resistanceVessel mounting detailsVessel wallsFiberEngineering

Owner:FUNCK RALPH

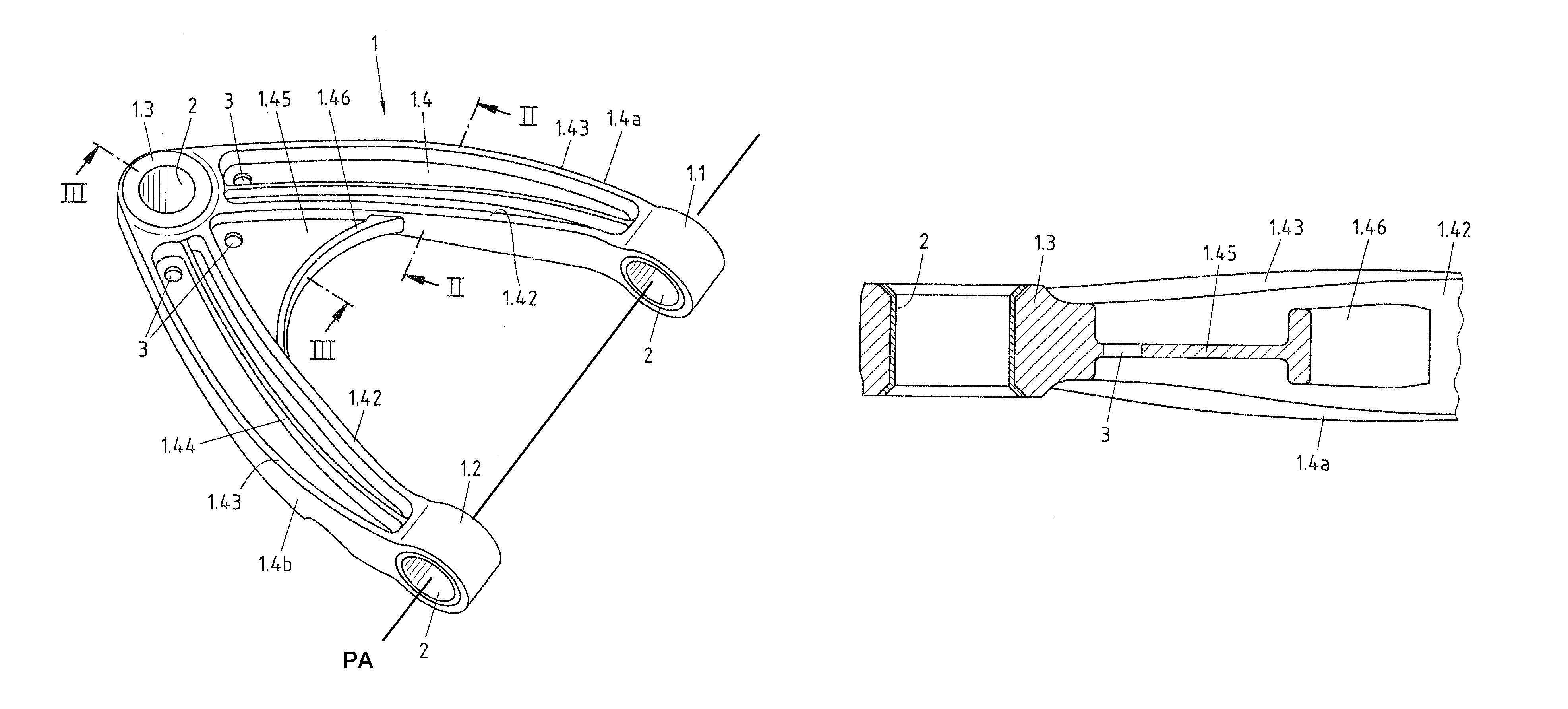

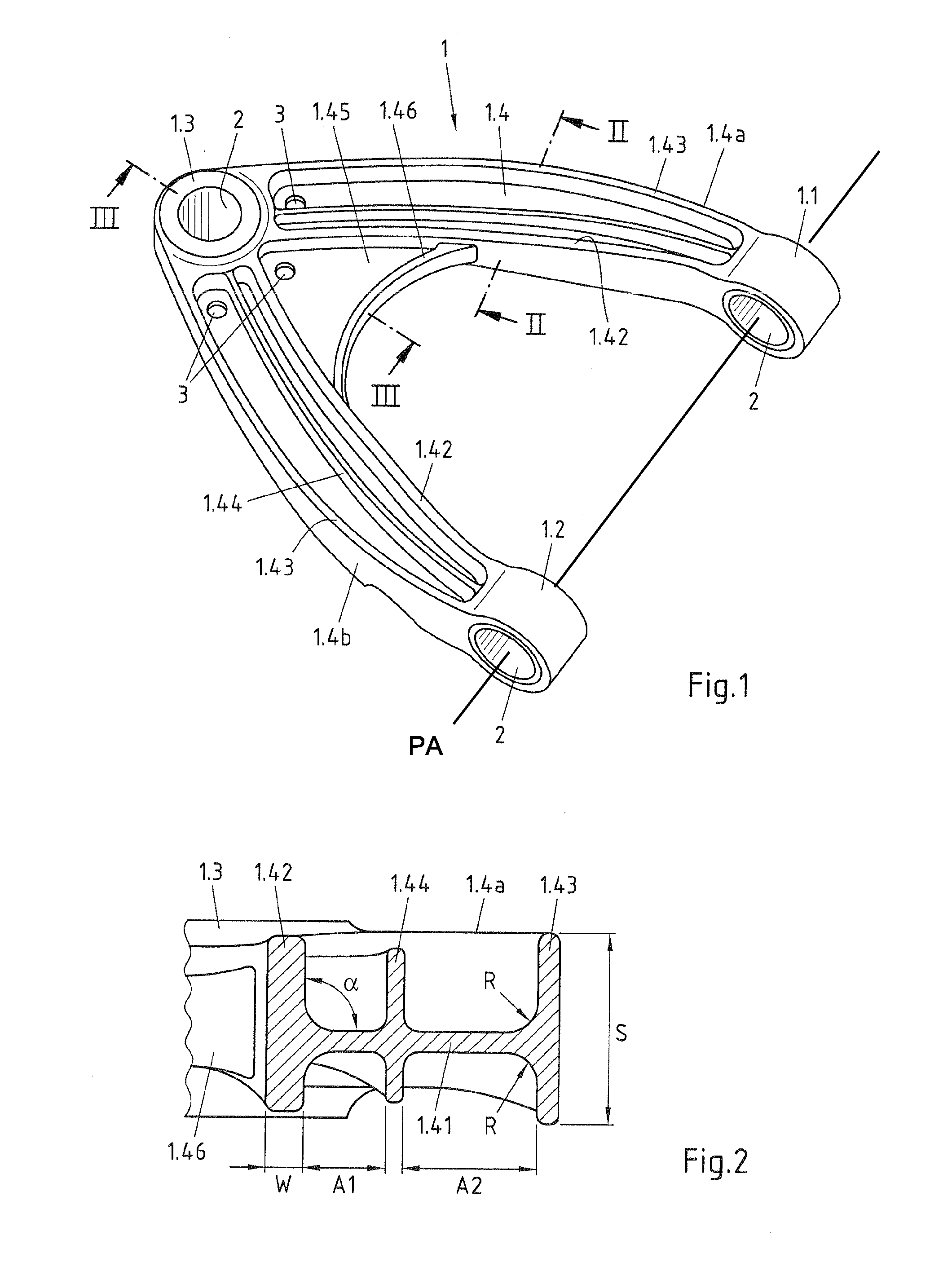

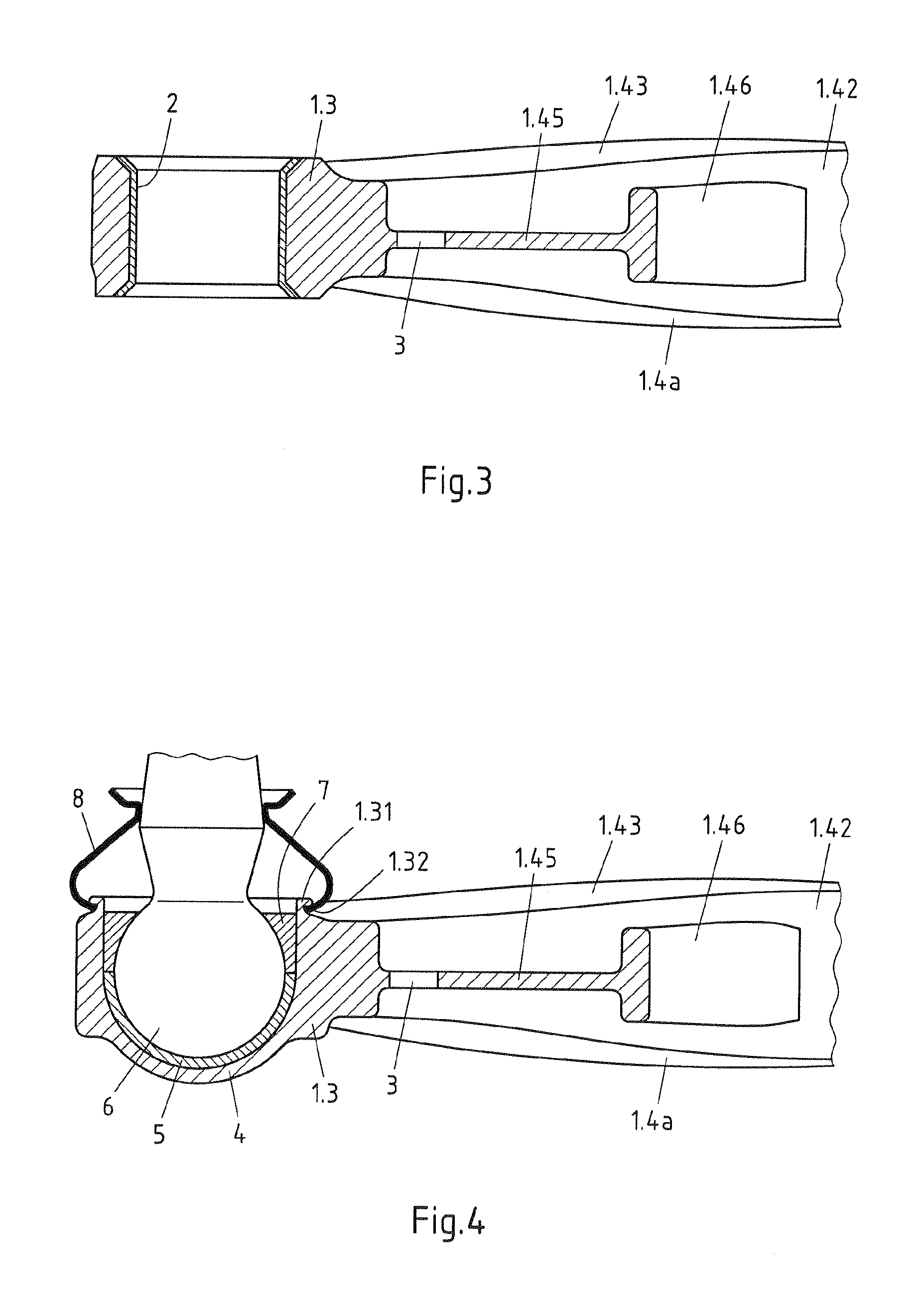

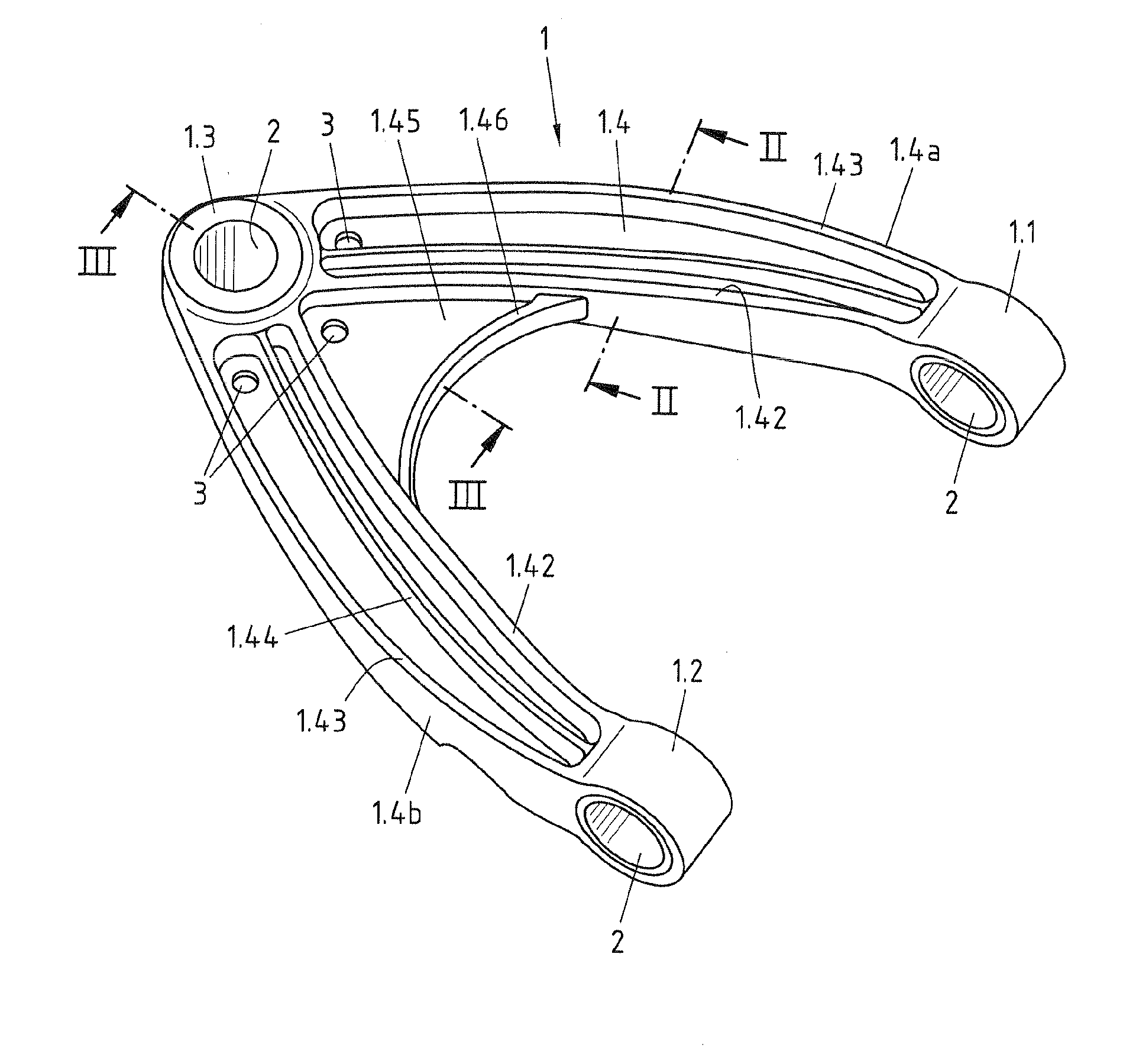

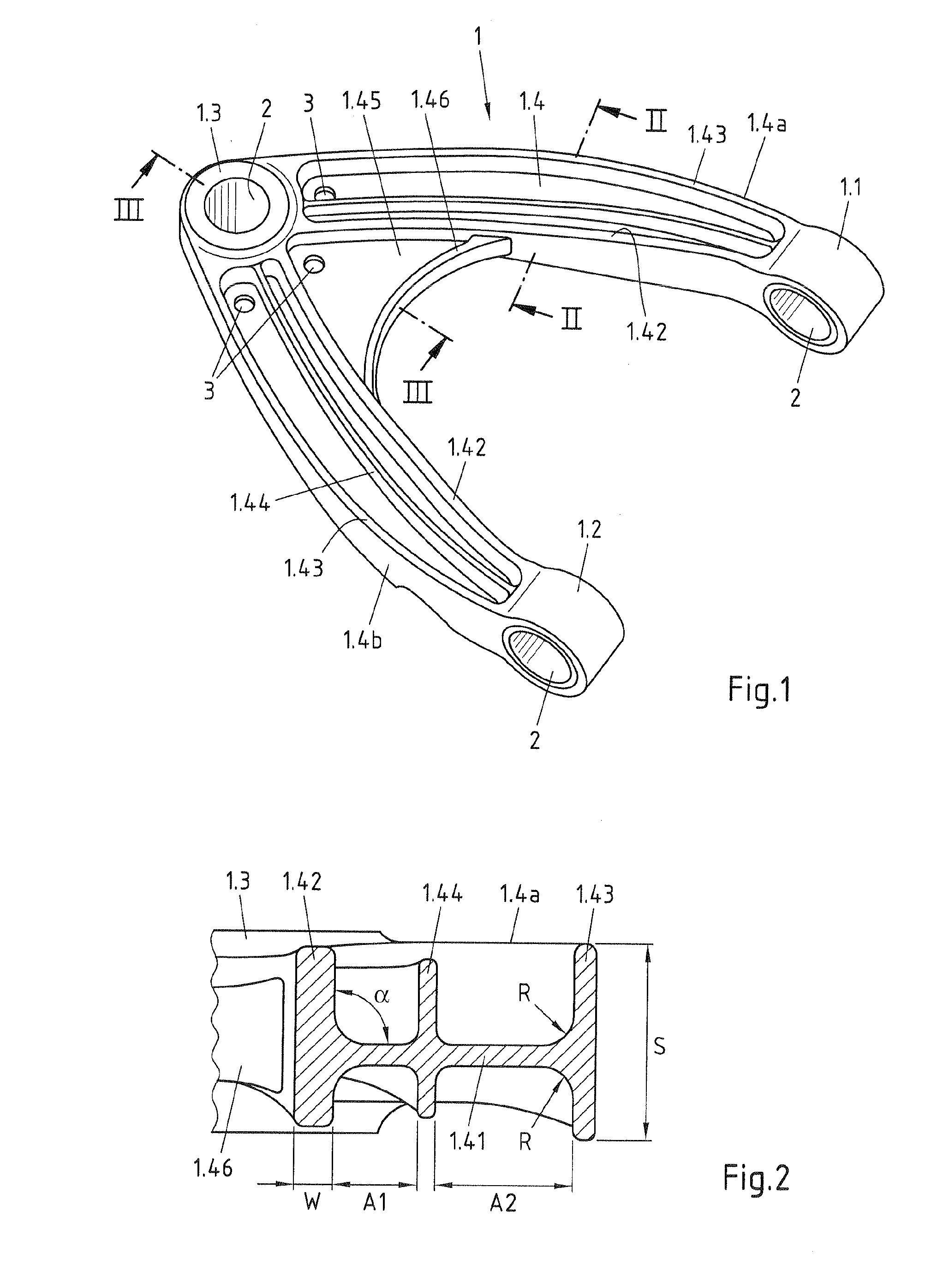

Transverse link made of fibre-reinforced plastics material for a wheel suspension of a vehicle

ActiveUS9168801B2Reduce weightProduced easily and economicallyPivoted suspension armsPlastic materialsFibre-reinforced plastic

Owner:TAMP UMFORMTECHN

Recovering and treating method for glass fibre reinforced plastic waste

InactiveCN1554493ASmall particle sizeFix compatibility issuesSolid waste disposalGlass fiberSheet moulding compound

The recovering and treating method of waste glass fiber reinforced plastic is to treating waste glass fiber reinforced plastic into grains and to utilize the grains as the stuffing for sheet molding compound (SMC). The said method solves the problem of compatibility and adhesion of the waste with resin, reinforcing material and other components and makes SMC possess excellent mechanical performance.

Owner:TONGJI UNIV

High temperature resistant paint for glass fibre reinforced plastic grille

ActiveCN1552784AImprove adhesionExtended protection periodFireproof paintsEpoxy resin coatingsHigh resistanceFiberglass reinforced plastic grating

A refractory paint for the grate made of glass fibre reinforced plastics contains component A and component B, which are proportionally mixed before used. Said component A is prepared from organosilicon resin modified organic resin, high-temp stable pigment and filler, flame retarding-smoke inhibiting agent, coupling agent, solidifying promoter, and UV absorbing or shielding assistant. Said component B is polyurethane solidifying agent containing NCO. Its advantages are high resistance to high temp (900 deg.C) and weatherability and low smoke density at high temp.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

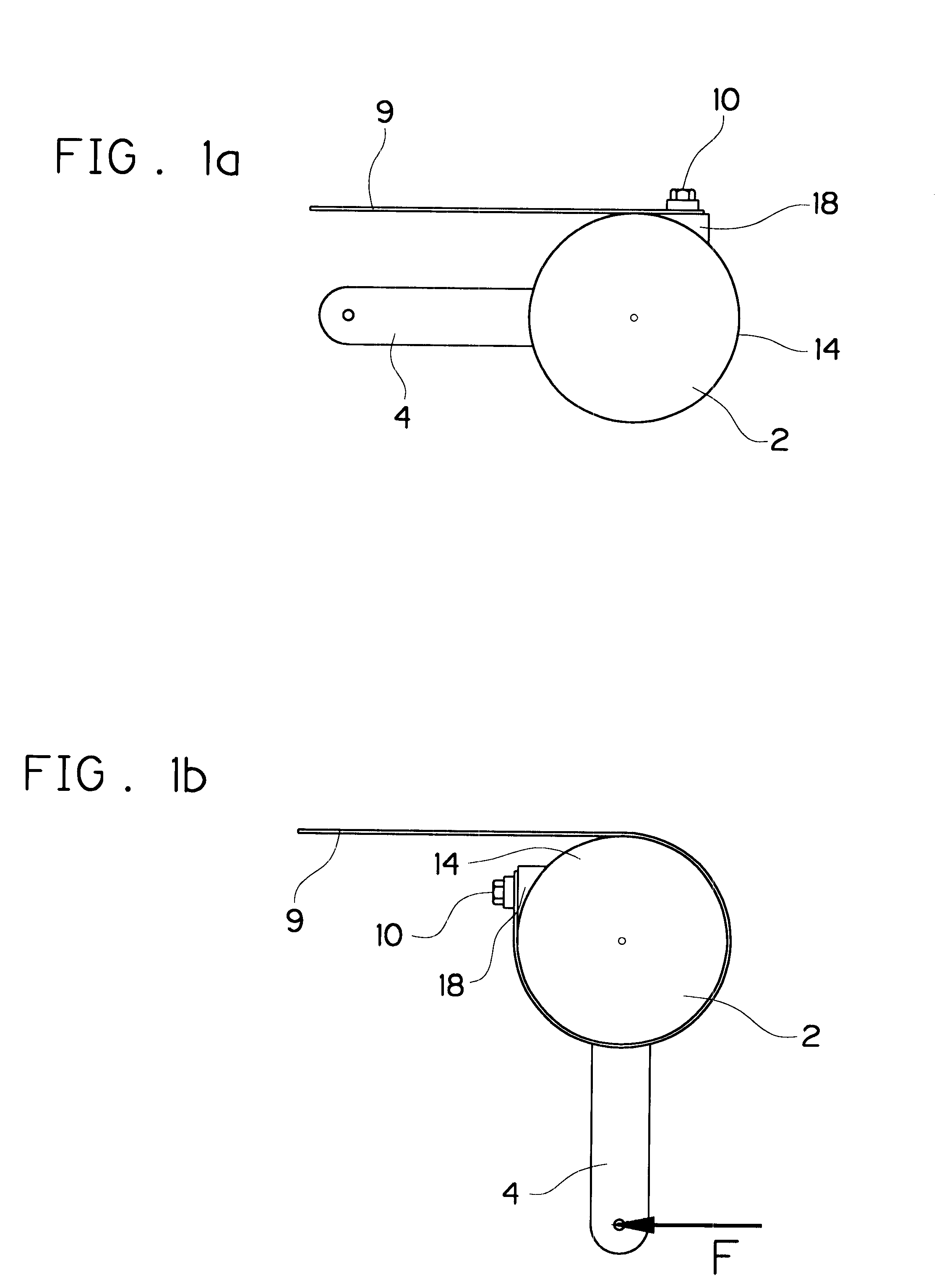

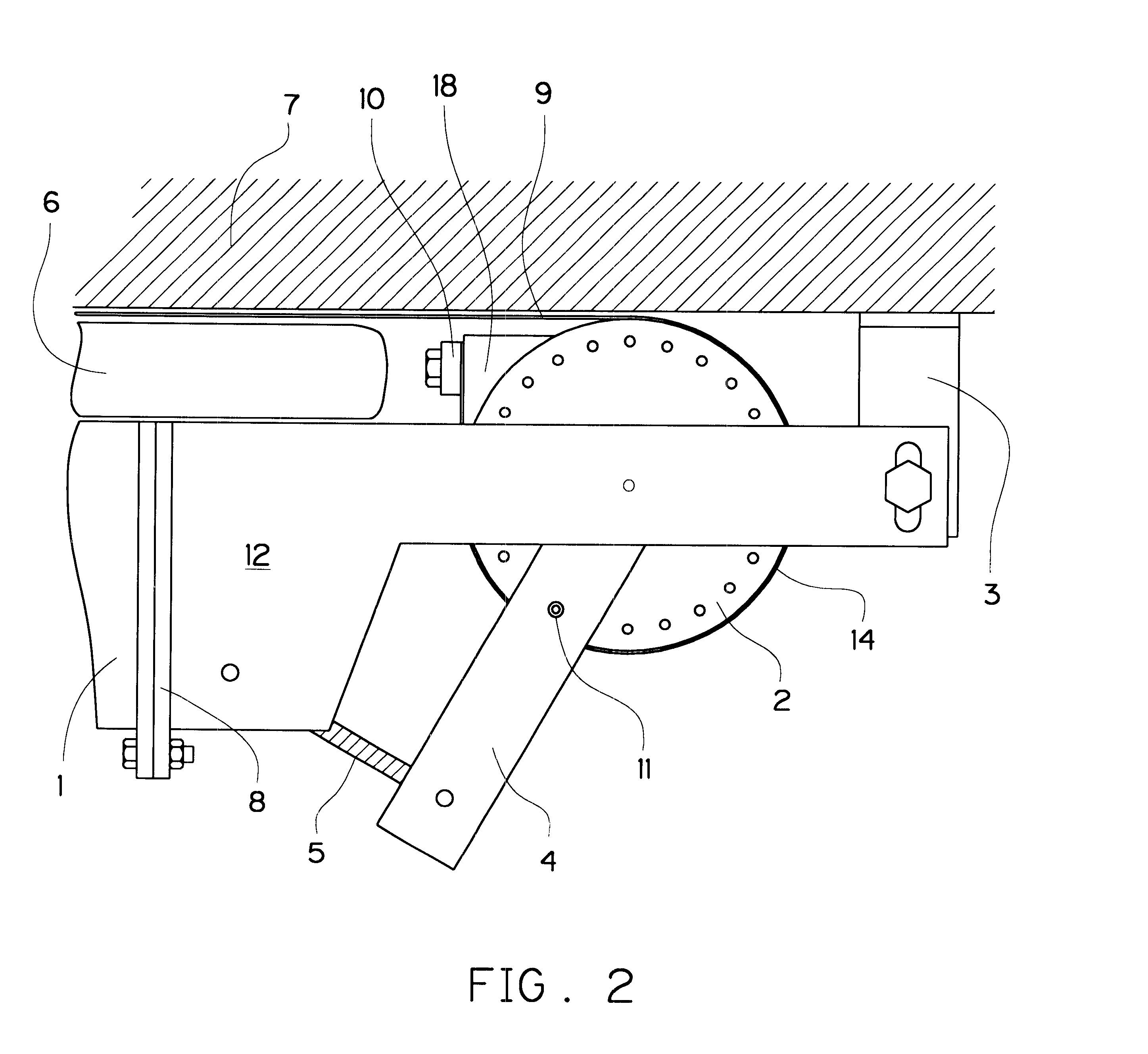

Method and device for applying pretensed tension-proof reinforcing strips to a construction

Lamellar, fibre-reinforced plastic strips can be used to reinforce a linearly expanded or flat construction part having a support function against any bending stress to which it is exposed. The strips are usually applied to the construction from the outside, or from the inside in the case of hollow structures, and fixed by an adhesive. The lamellar strips are pretensed with a tensioning device, treated with adhesive in a pretensed state, and then moved to the area to be treated together with the tension device. The tension device is provisionally fixed to the construction with displaceable fixing devices and pressed against said construction. Thereafter the lamellar strips are pressed against the construction by means of an air bag or air hose until the adhesive has hardened.

Owner:EMPA EIDGENOESSISCHE MATERIALPRFUNGS & FORSCHUNGSANSTALT

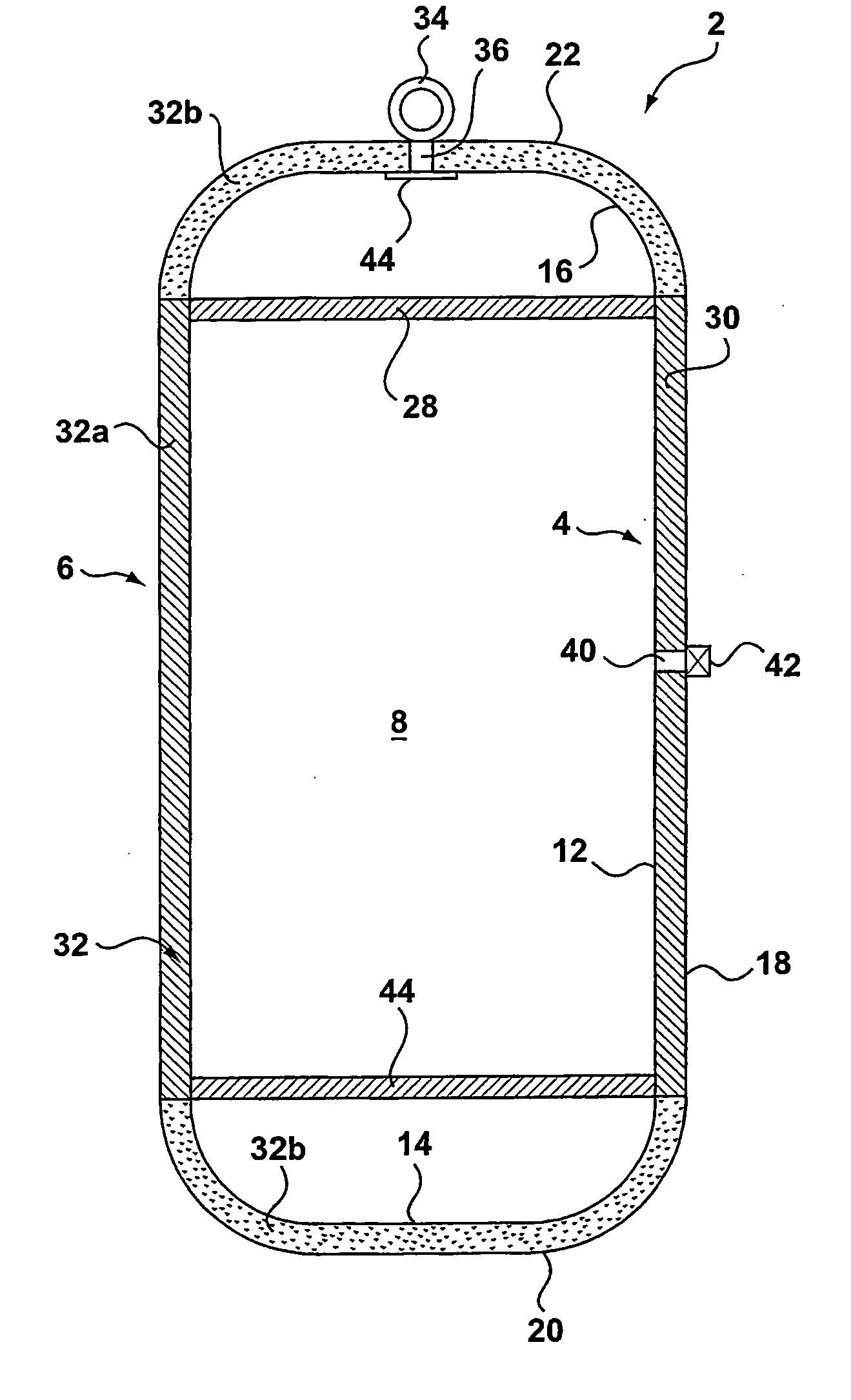

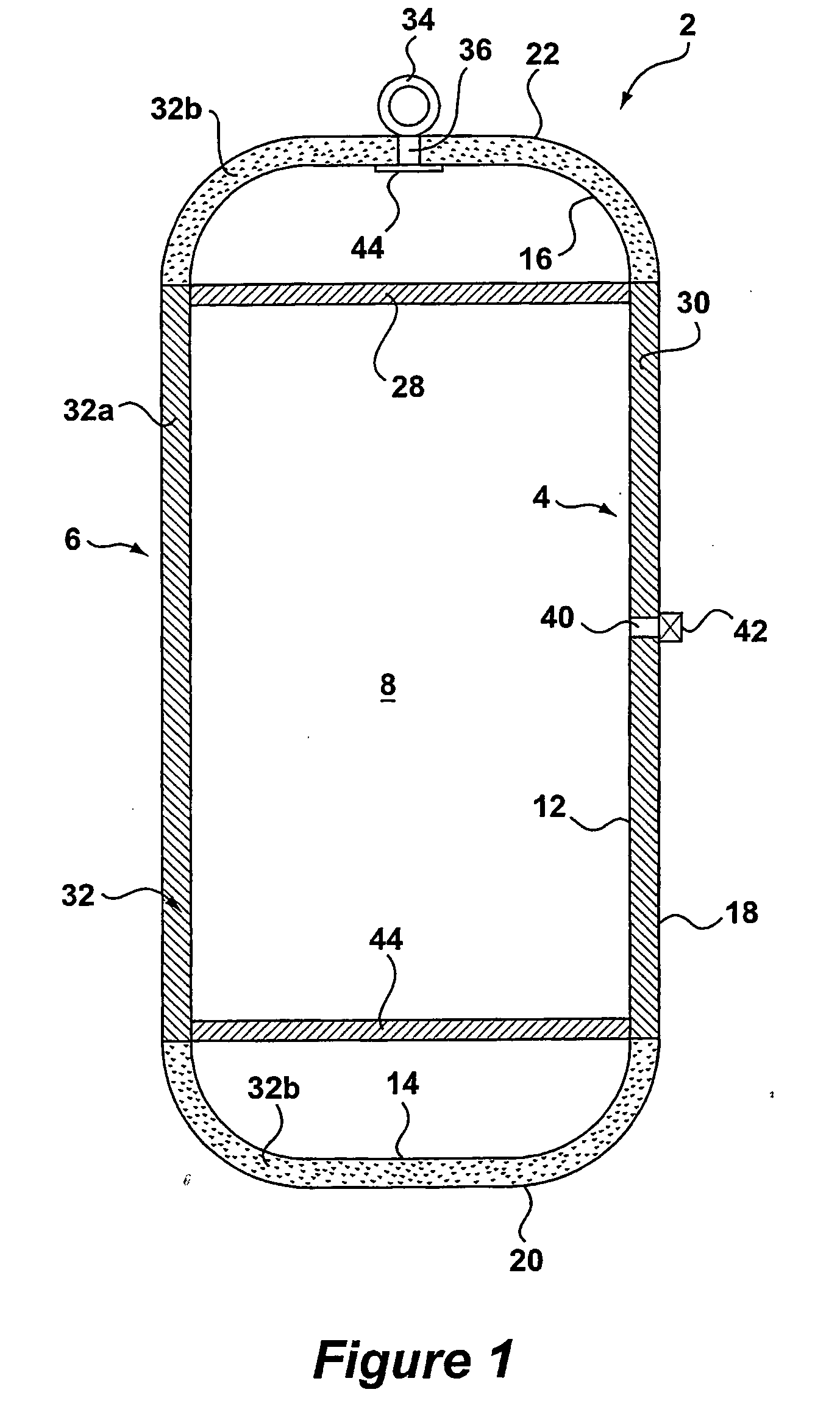

Underwater enclosure apparatus and method for constructing the same

InactiveUS20060159523A1Low curing temperatureMore temperaturePipe laying and repairNon-magnetic metal hullsRadial stressHydrostatic pressure

Apparatus for providing an enclosure, for example as a housing or to provide buoyancy, at underwater locations is disclosed comprising an inner shell and an outer shell, with a structural filler disposed between the two. The shells are prepared from fibre-reinforced plastic, with the fibres being oriented to provide resistance to both longitudinal and radial stresses induced in the apparatus by the hydrostatic pressure. The filler may be a structural filler comprising structural members extending between the inner and outer shells and occupying less than 60% of the volume of the cavity between the two shells. Alternatively, the filler may be a substantially void-free structural filler, such as a polyester resin. Methods of fabricating the apparatus are disclosed. In addition, a method of deballasting a buoyancy module is disclosed, in which the ballast, for example water, is withdrawn from the module by means of reduced pressure. Apparatus for deballasting is also disclosed.

Owner:COOPER CAMERON CORP

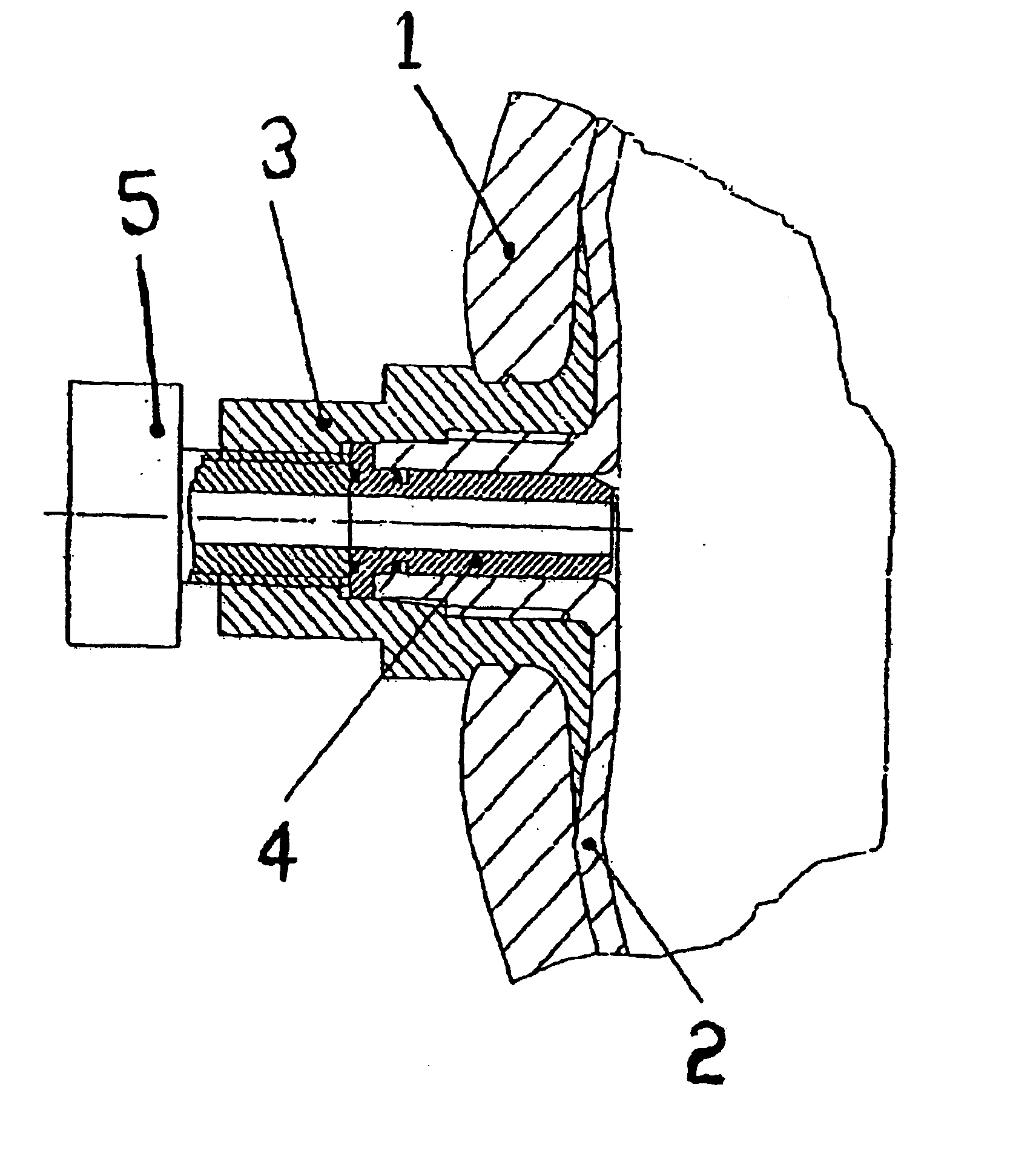

Bond type anchorage and anchoring method for anchoring fibre reinforced plastic reinforcement or bracing cable

ActiveCN101117838AHigh strengthHigh elastic modulusBuilding reinforcementsEngineeringFibre-reinforced plastic

The present invention relates to an adhesive anchoring unit and an anchoring method for anchoring fiber reinforcement plastic bar or cable, an end cover is arranged at one end of the anchoring unit and a sleeve with a locating hole is arranged at the other end of the anchoring unit. An internal cone chamber is arranged in the sleeve, and a nut is arranged surrounding the sleeve provided with a mortar filling hole and a ventilation hole. The fiber reinforcement plastic bar or cable passes through the locating hole and one end in the internal cone chamber was cut into two halves, which are inserted with a wedge to become a wedge form. A starting section of the half of one end of the bar or cable is coated with a retaining ring and the section passing through the locating hole is coated with a thin wall aluminum sleeve tube and active powder concrete is filled in the internal cone chamber of the sleeve. The method is described as follows: after the bar or cable shaft passes through the sleeve of the anchoring unit, a pretension is required on the sleeve, and the active powder concrete is added into the sleeve. The present invention improves anchoring performances of the adhesive media and the FRP bar, therefore, the anchoring length is reduced, the structure is simple, the use is convenient, the present invention is safe and reliable, the cost is low and the PRC manufacturing and maintenance is easy.

Owner:HUNAN UNIV

Sheet entity and an aircraft fuselage with a sheet entity of this type

ActiveUS20130196121A1Optimal stress profileEliminate disadvantagesFuselage framesEfficient propulsion technologiesCarbon fibersEngineering

A sheet entity, in particular for use as a skin panel for an aircraft fuselage, with a carbon fibre-reinforced plastic laminate and an aluminum-based metal laminate in the edge region, which are connected with one another by means of an adhesive bond, and thereby are electrically insulated from one another, and are stepped back by layers. Also disclosed is a fuselage cell of an aircraft with at least one sheet entity of this type.

Owner:AIRBUS OPERATIONS GMBH

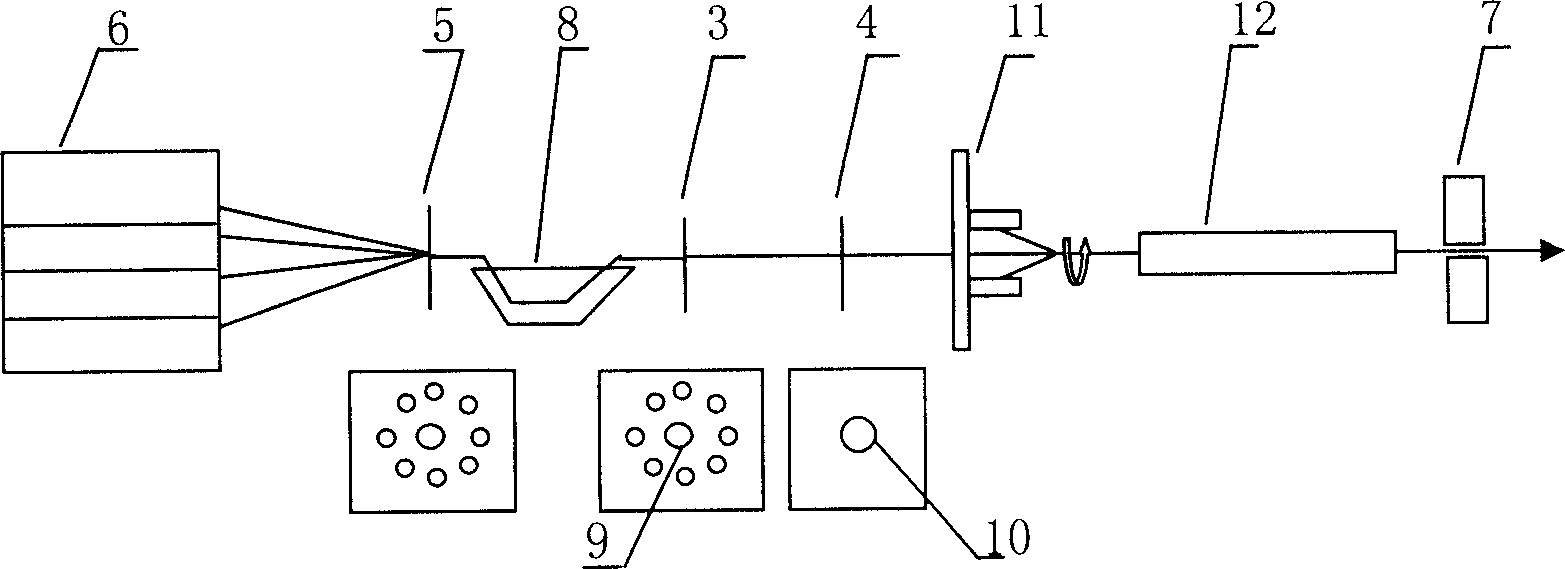

High-strength alkali-free glass fibre direct roving sizing agent for optical cable strengthening core

The invention discloses a size of high-strength alkali-free glass fibre direct yarn used for a reinforced core of an optical cable, comprising coupling agent, lubricant, film forming agent A, film forming agent B, film forming agent C and a pH value regulator; the solid weight of all the materials accounts for 5 to 10 percent, the rest of materials is water, and the content of the water accounts for 90 to 95 percent of the total weight of the size; the coupling agent adopts silane coupling agent and accounts for 3 to 10 percent of the solid weight of the size; the lubricant adopts unsaturated olein lubricant and accounts for 1 to 10 percent of the solid weight of the size; the film forming agent A, the film forming agent B and the film forming agent C respectively adopts one of epoxy emulsion, polyester emulsion and polyvinyl acetate emulsion, wherein, the film forming agent C selects compound with low degree of polymerization, the combination of the film forming agent A and the film forming agent B accounts for 80 to 85 percent of the solid weight of the size, the film forming agent C accounts for 1 to 5 percent of the solid weight of the size, the pH value regulator adopts acid and accounts for 1 to 5 percent of the solid weight of the size and the pH value of the size is 2 to 8. The size has good compatibility with vinyl resin and epoxy resin and can lead the strength of the glass fibre reinforced plastic of the product to be improved.

Owner:JUSHI GRP CO

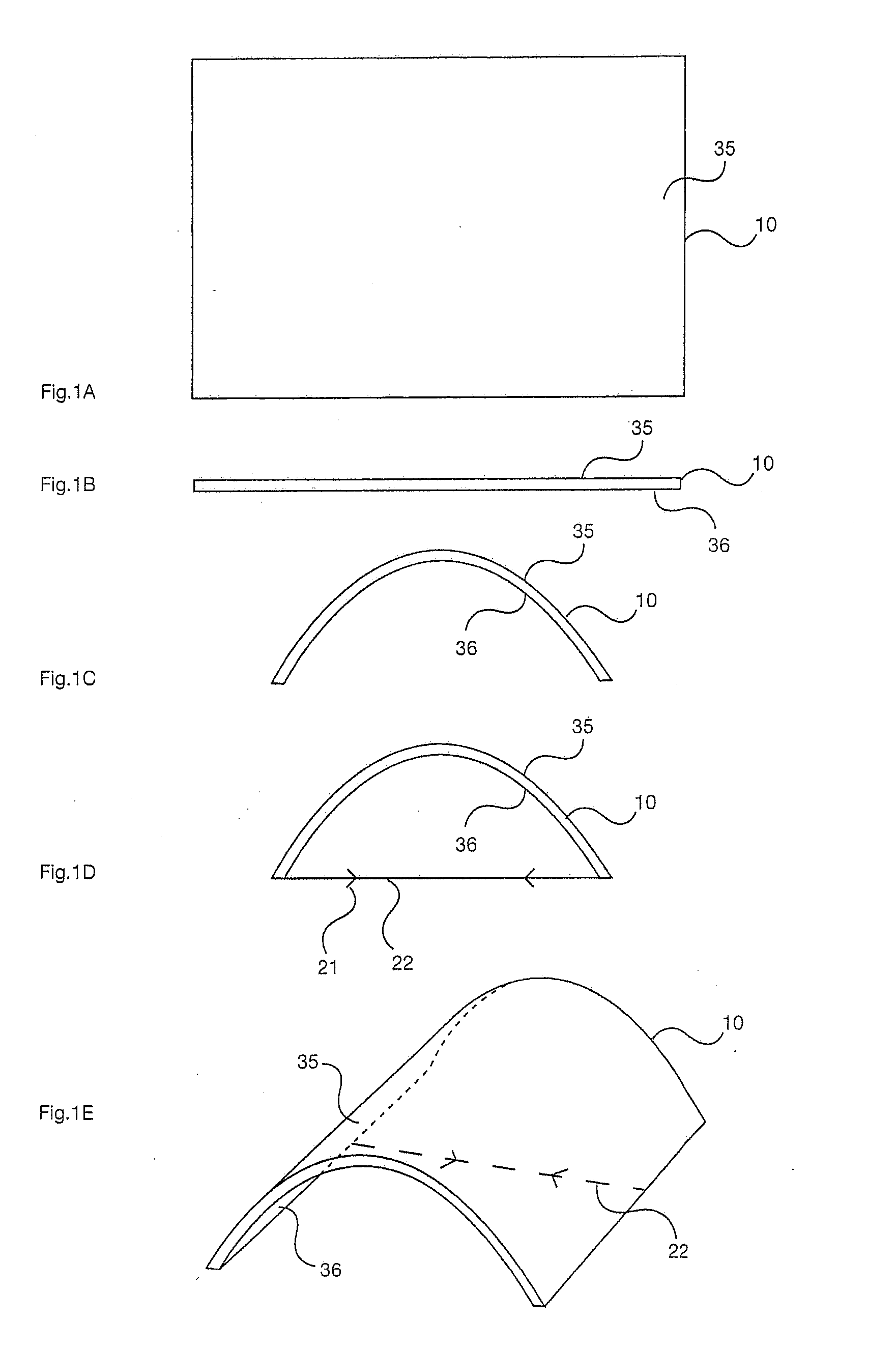

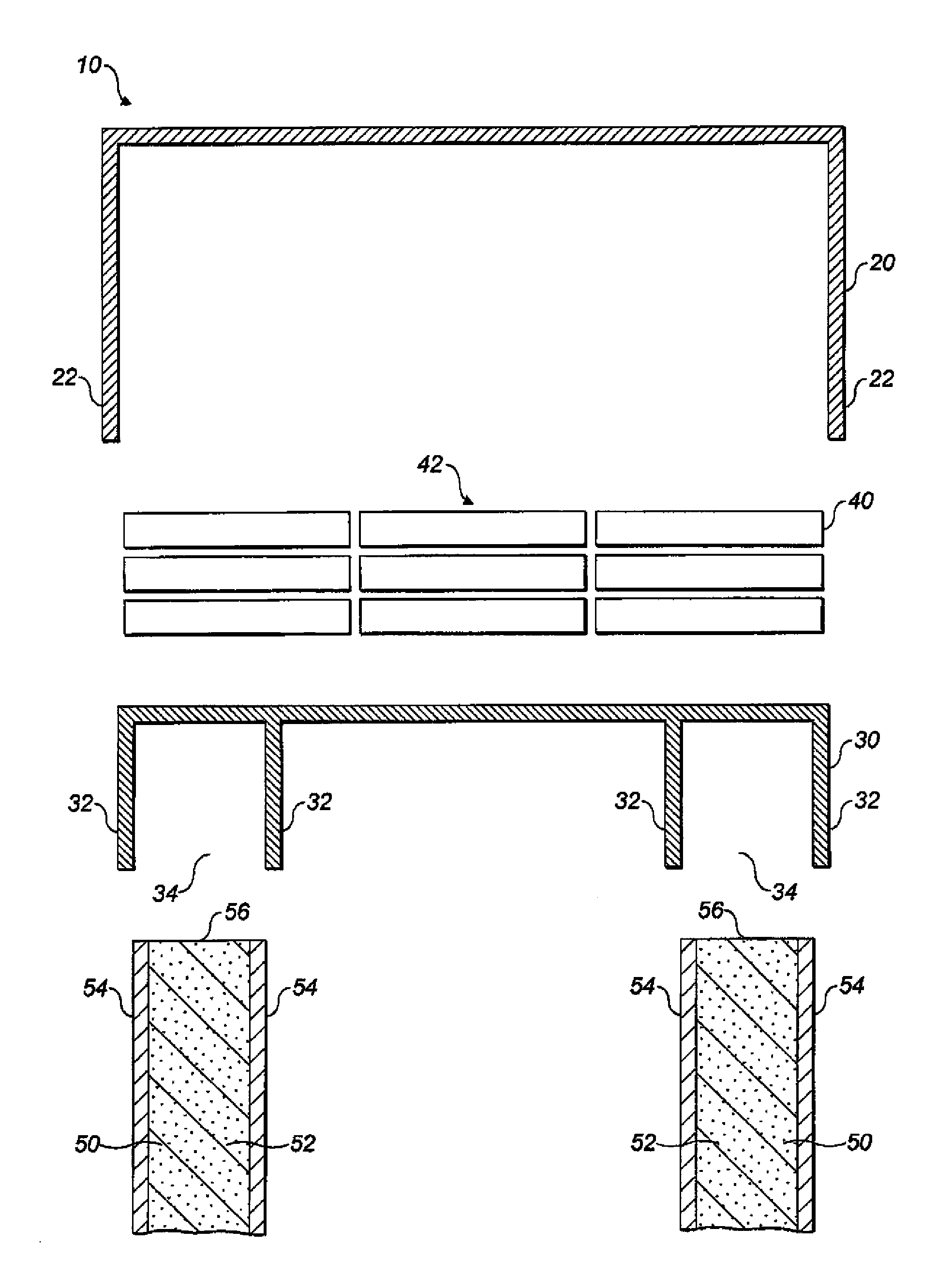

Structural assembly with a tied, flexurally deformed panel

InactiveUS8215041B2Easily manufactured and subsequently processedEasy to dismantlePicture framesSpecial ornamental structuresCarbon fibersPre stress

An assembly includes a flexurally deformed panel, which is connected to a membrane tie by a linear connector and is tied by the membrane tie to form a geometrically stable pre-stressed structure. More than one panel may be flexurally deformed and tied together in an assembly and more than one membrane tie may be present within an assembly. Panels are typically semi-rigid sheet materials, for example metal sheets, plastic sheets, or sheets of composite materials, such as glass or carbon fibre reinforced plastics or resins. Membrane tie members are typically flexible, for example plastic films, fabrics or nets or arrays of rods or cables. The assemblies have many different geometric forms and many different practical applications. Assemblies may be relatively large, for example demountable and reusable shelters or flat-pack point-of-purchase display assemblies, or may be relatively small, for example a photograph or postcard display system.

Owner:CONTRA VISION

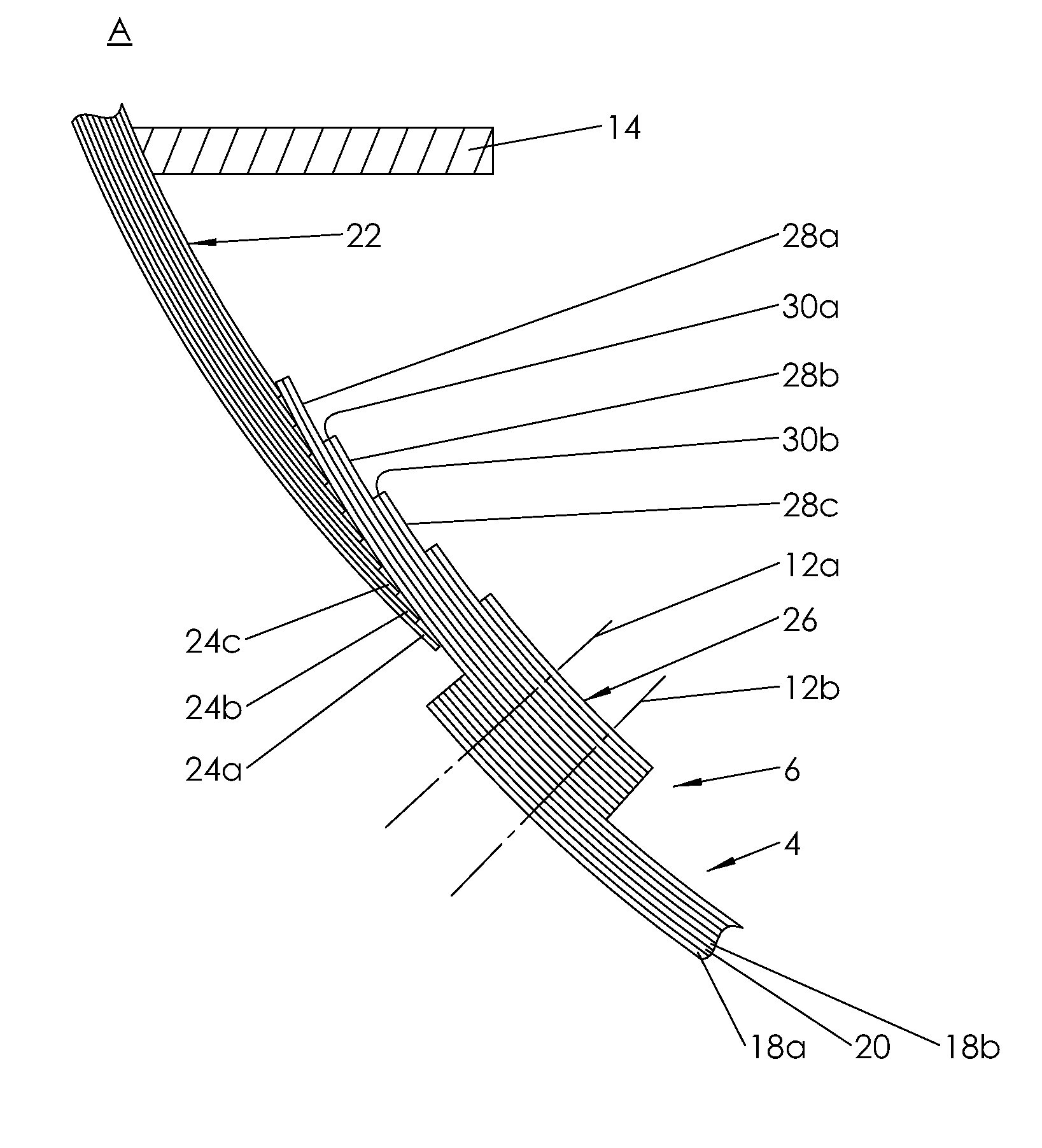

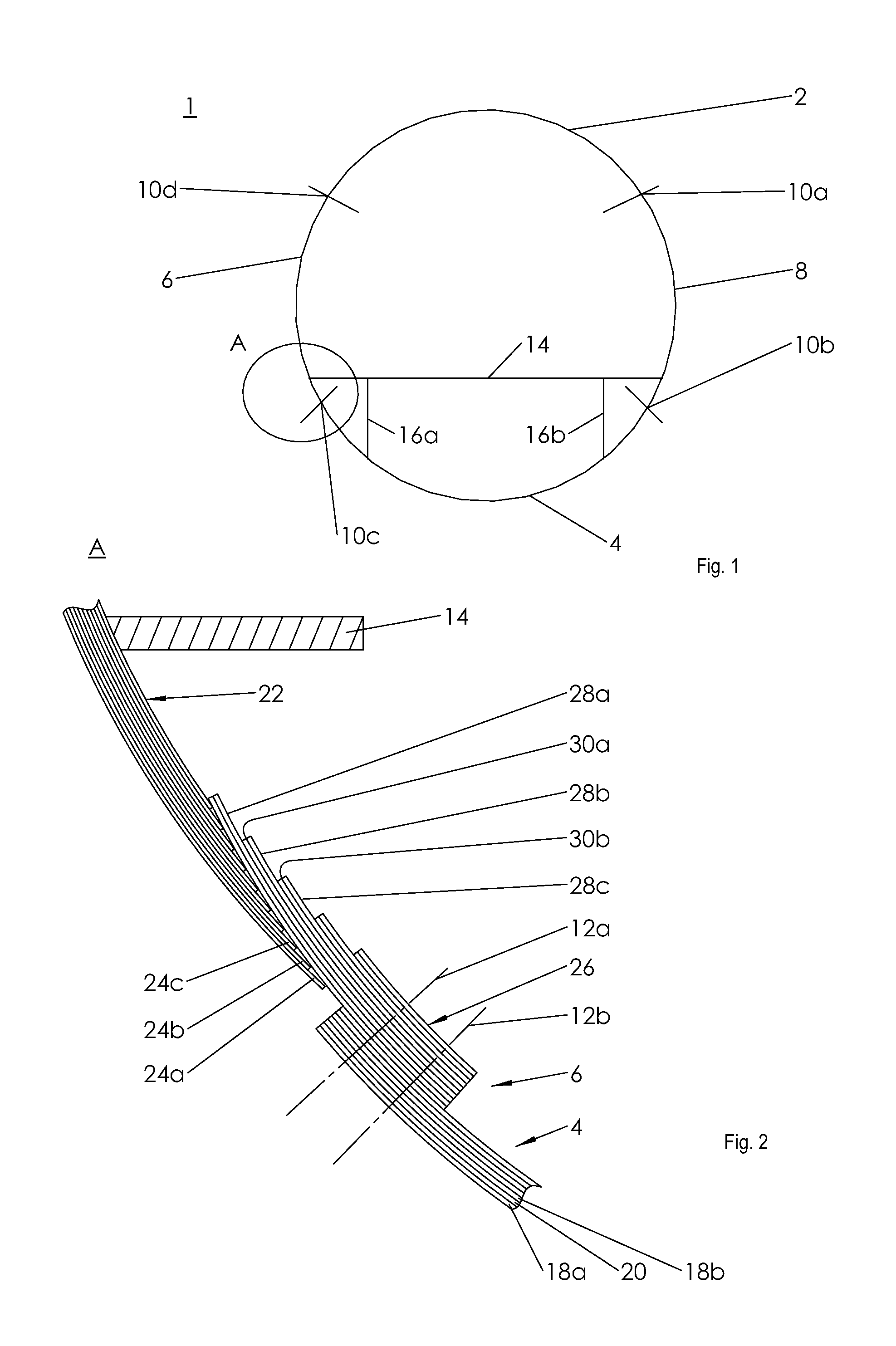

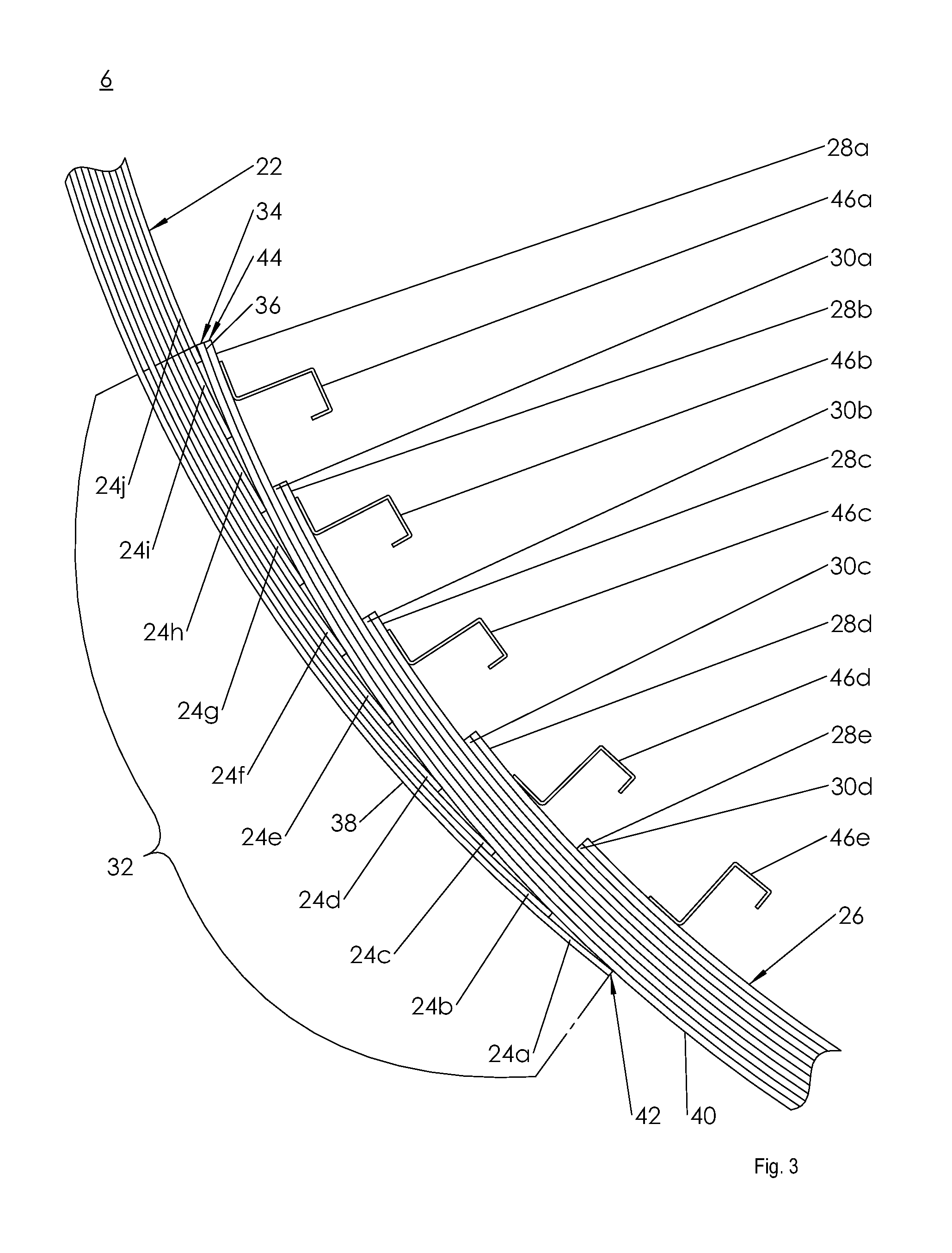

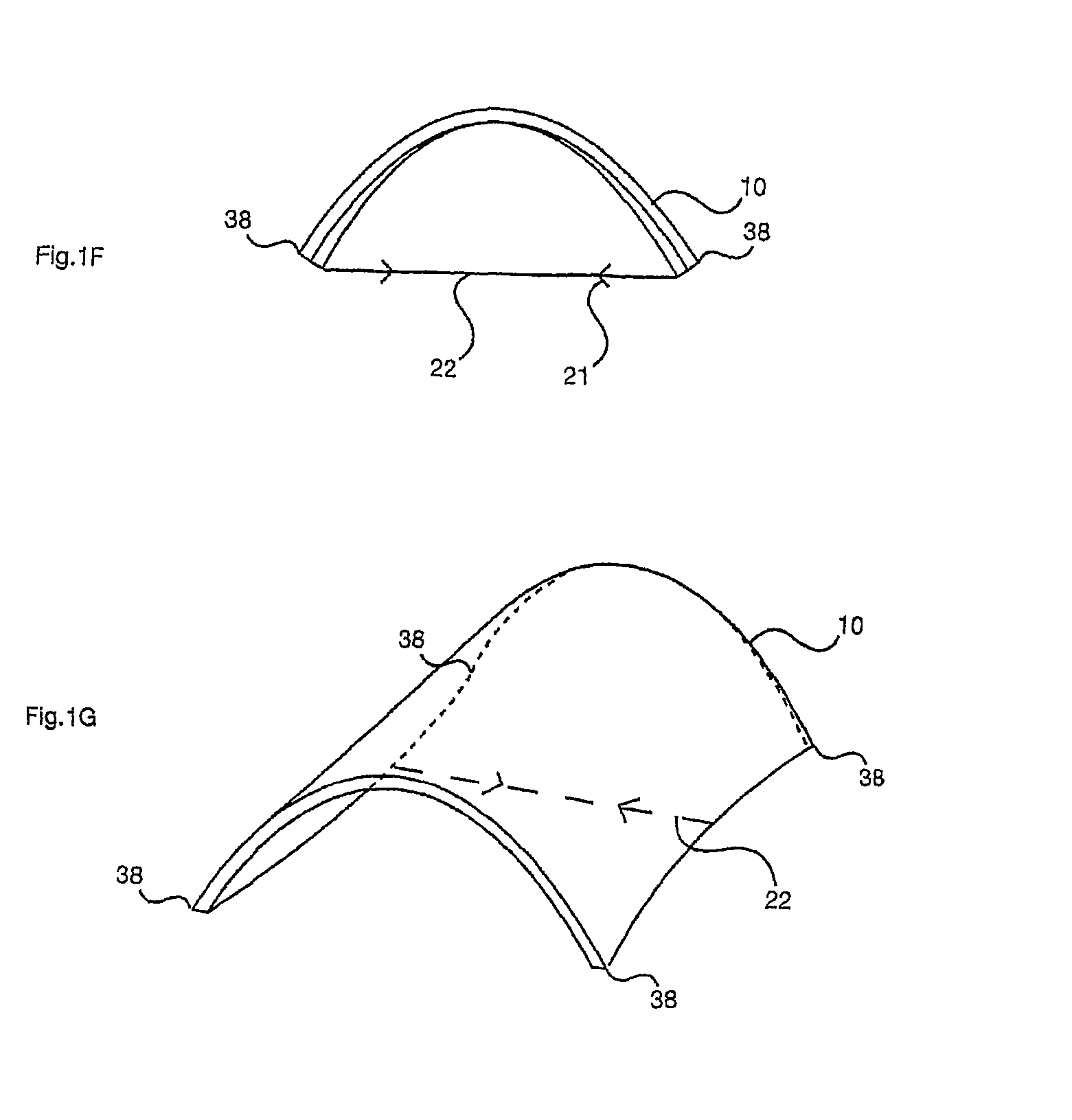

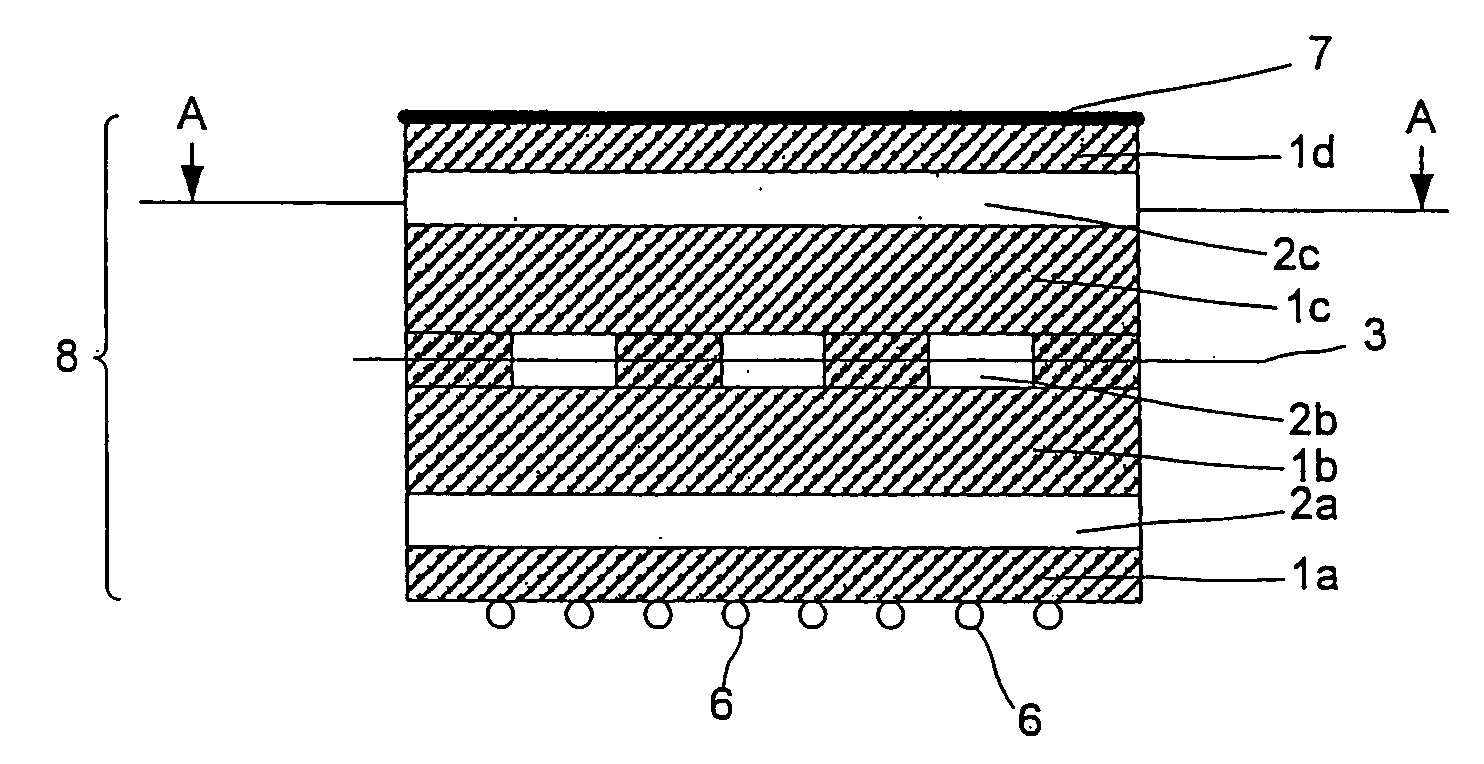

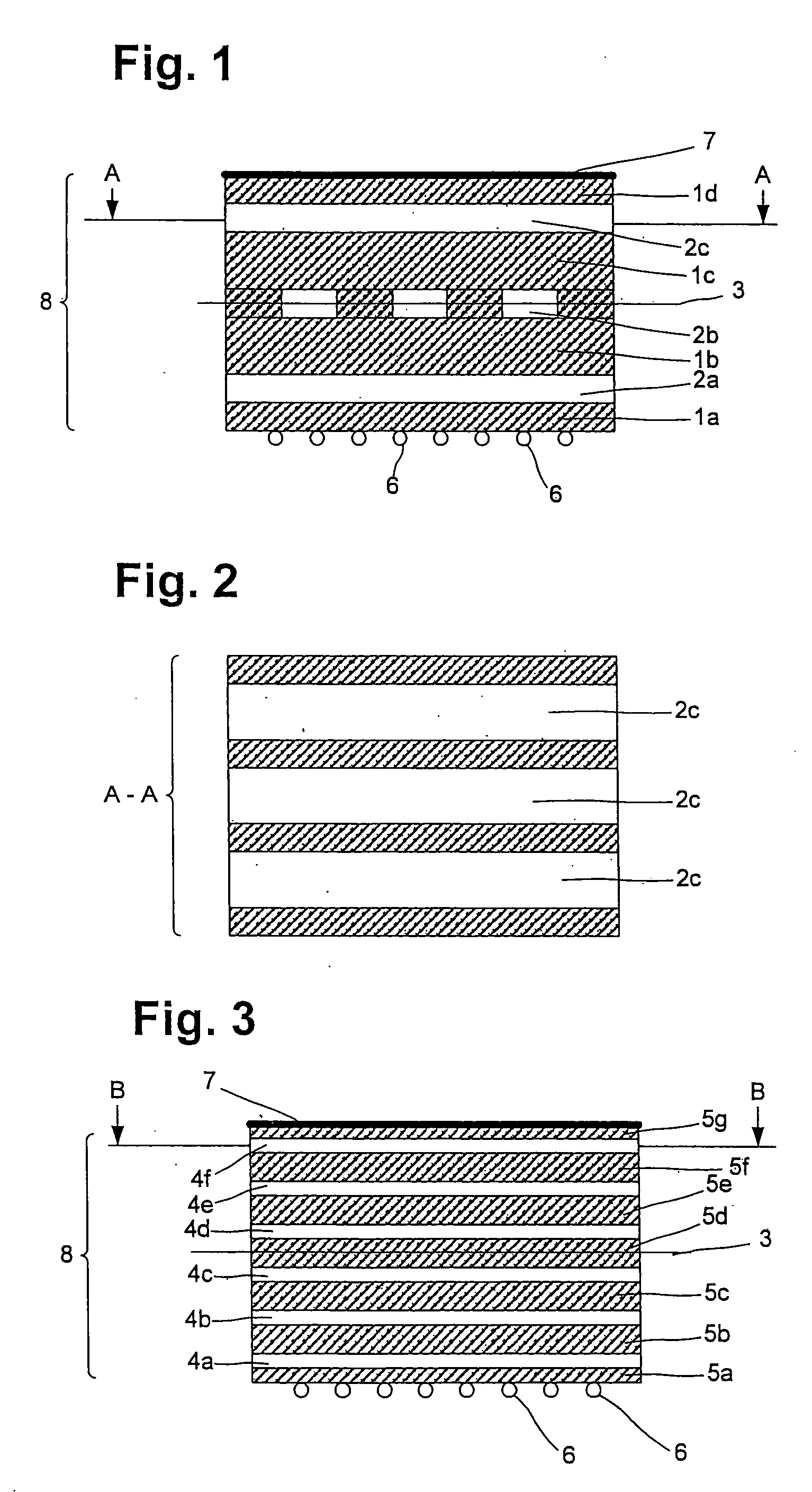

Method for casting a component and a component comprising at least partly of fibre-reinforced plastic laminate

ActiveUS20070274835A1Reduces and eliminates riskReduce inclusionsSynthetic resin layered productsReaction enginesSemipermeable membraneGas passing

There is described a method for casting a component comprising at least partly of fibre-reinforced plastic laminate by which the fibre-reinforcement is arranged in a casting mould, wherein at least one venting duct is placed, wherein said fibre-reinforcement and said venting duct are at least partly wetted by the plastic during the casting process in such a way that venting is achieved through said venting duct, and wherein the surface of the venting duct is at least partially made with a semi-permeable membrane that allows the passage of gases but does not allow or only slowly allows the passage of plastics. Furthermore there is described a component comprising at least partly of fibre-reinforced plastic laminate, wherein the plastic laminate inside comprises of one or more venting ducts, wherein the surface of a venting duct is at least partially made with a semi-permeable membrane that allows the passage of gases but does not allow or only slowly allows the passage of plastics.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

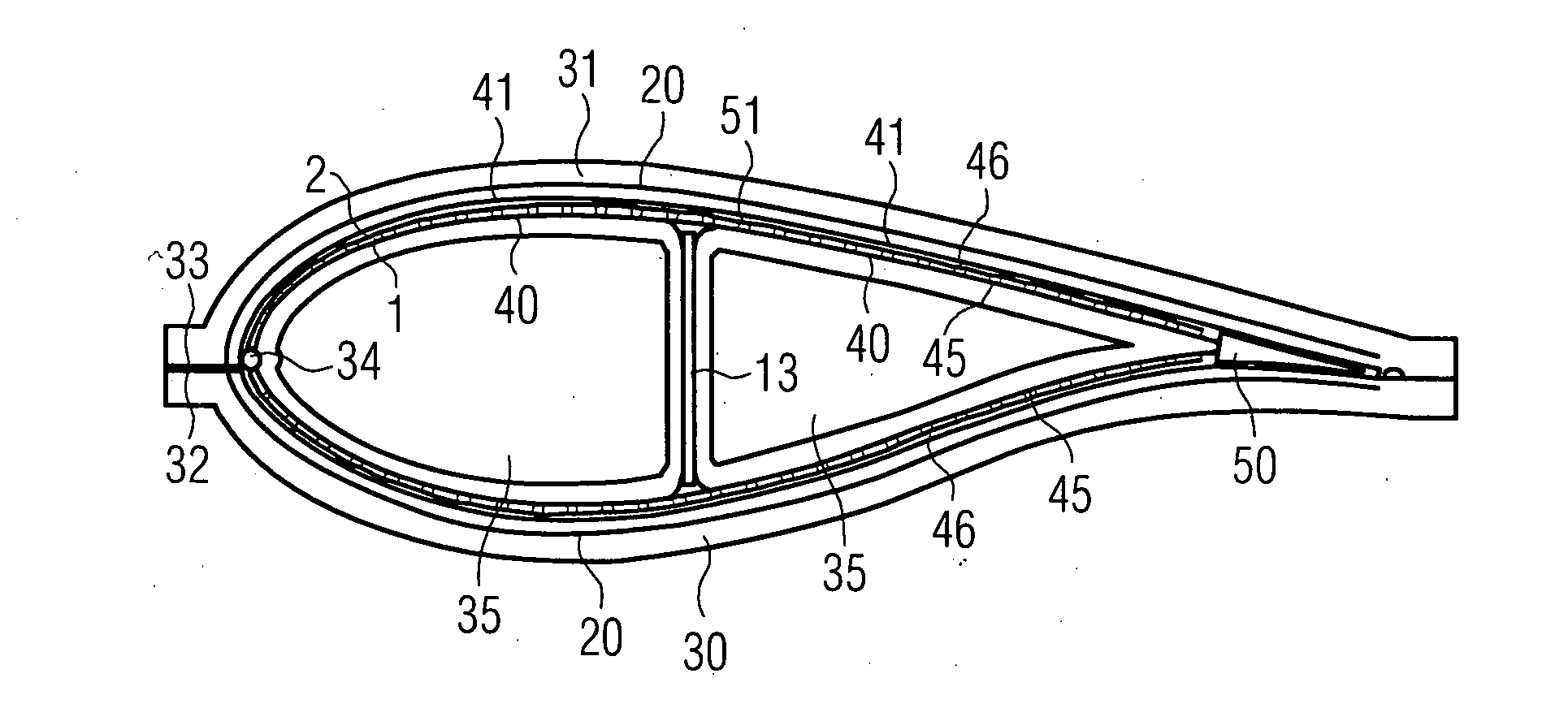

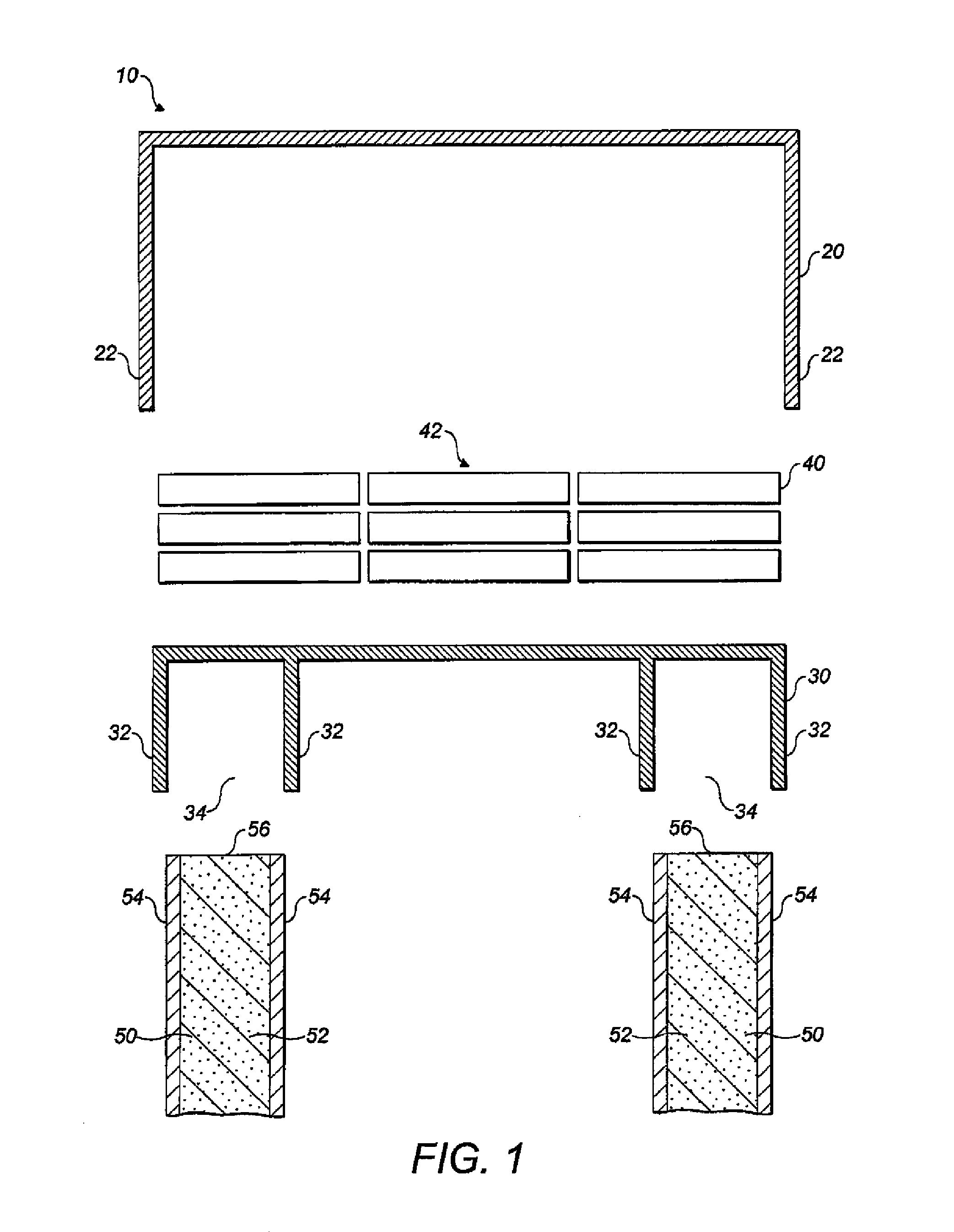

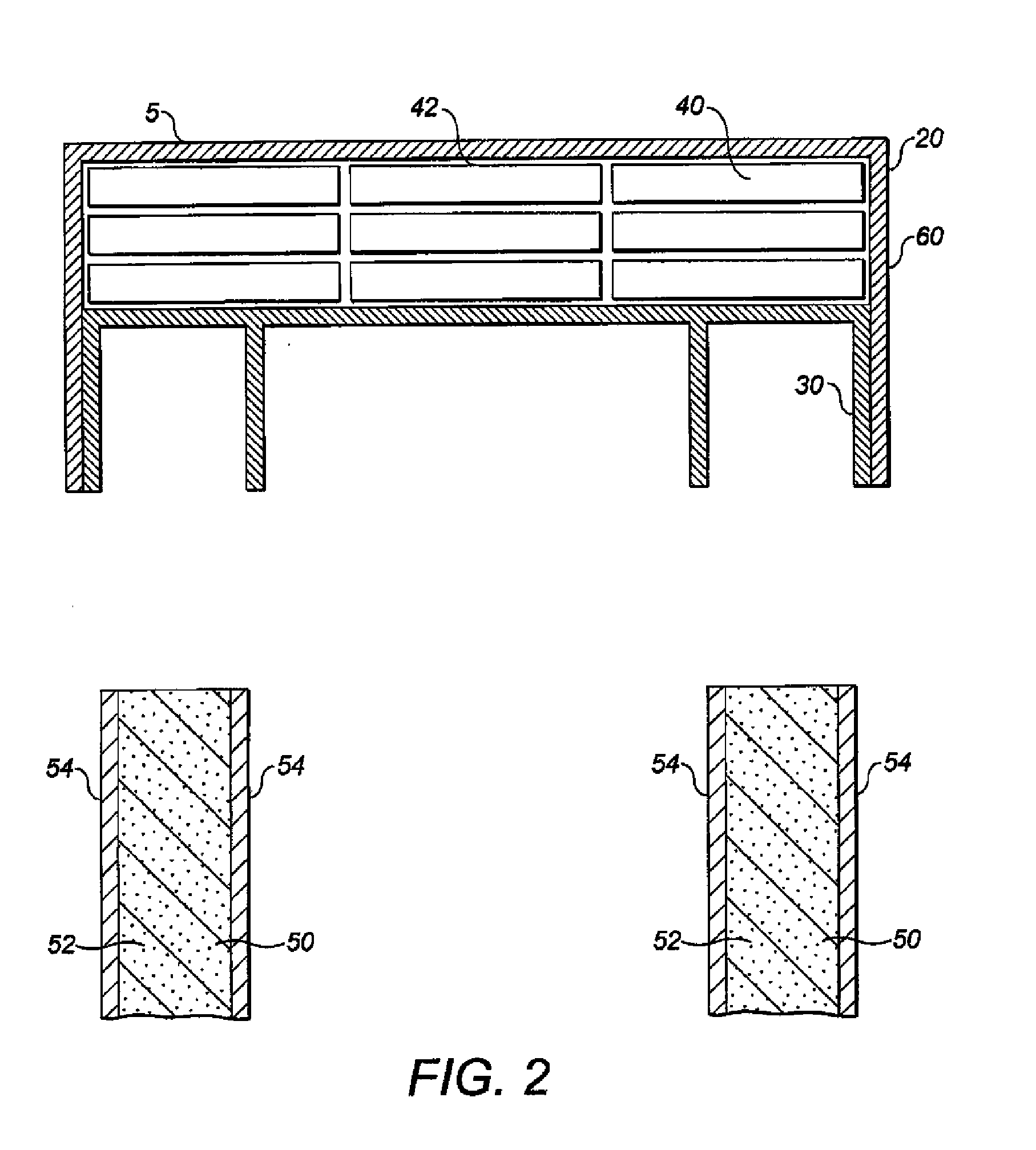

Modular structural composite beam

ActiveUS20130055677A1Improve design flexibilityQuality improvementFinal product manufactureMachines/enginesFiberModularity

Owner:BLADE DYNAMICS LTD

Heat shield

A heat shield having a thermally conductive body. The material of the body is composed of a fibre composite material, preferably carbon fibre, glass fibre, glass-fibre-reinforced plastic and / or aramide, and layers of a heat-conductive metal. Cooling tubes may be applied to an outer surface of the body, incorporated into an outer fibre layer of the body, and / or formed directly within the outer fibre layer.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV +2

Moulded glass fibre reinforced plastic grille and manufacturing method thereof

InactiveCN101131032AGood adhesionHigh strengthCovering/liningsBuilding componentsGlass fiberHigh intensity

The present invention relates to one kind of molded GRP grille and its production process, and features that the molded GRP grille is produced with resin as basic material, and through adding proper amount of promoter and curing agent and glass fiber as reinforcing material, molding and curing. The resin may be one of three kinds of resin, including vinyl resin, etc; the promoter is cobalt isozincate in 0.5-3 wt% of resin; and the curing agent is butanone peroxide in 0.5-3 wt% of resin. The molded GRP grille has high strength and easy edge trimming.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

Lightweight Structural Composite for Load Bearing Application

ActiveUS20090123687A1High strengthLow costSynthetic resin layered productsLaminationAdhesiveEngineering

The present invention relates to a lightweight structural composite, which comprises an inner core of lightweight panel encapsulated by outer layers of polymer material. Specifically, the lightweight panel consists of multiple laminations of corrugated thin metal or fibre reinforced plastic sheets kept in position by polymeric foam and / or adhesive, and enclosed in a casing of the same material. The outer layer is made up of a blend of thermosetting and thermoplastic polymers. The method of forming the composite comprises of stacking the corrugated sheets, filling the interstitial spaces with the foam, constructing the casing, the surface treatment of the panel for good adhesion to the outer polymer layer and the high temperature / pressure encapsulation of the panel with the polymer blend containing curing agents. The composite has application as replacement to wood, concrete or particle board panels used in ship docking, panels for wall, door and windows, blast-proof panels, rail sleepers and shipping pallets.

Owner:DIRECTOR GENERAL DEFENCE RES & DEV ORG

Fire-resisting sound-insulating safety door and its production method

InactiveCN1477286AFireproofWith heat insulationFireproof doorsNoise insulation doors/windowsSheet steelWhole body

The present invention relates to a fire-resisting sound-insulating safety door and its production method. Said door mainly is formed from face layer, steel frame and reinforcing ribs. Two sides of the steel frame are equipped with two face layers, between two face layers several reinforcing ribs are set, and firmly connected together with face layers and made into one whole body. On the reinforcing ribs several holes or spaces through which several foamed cement blocks can be passed, and the interior of the steel frame is filled with foamed cement. The safety door is equipped with door handleand door lock, etc. and the described two face layers are steel plate, also one can be steel plate and another can be wood plate, plastic plate, glass fibre reinforced plastic or cement face layer.

Owner:CUBIC DIGITAL TECH CO LTD

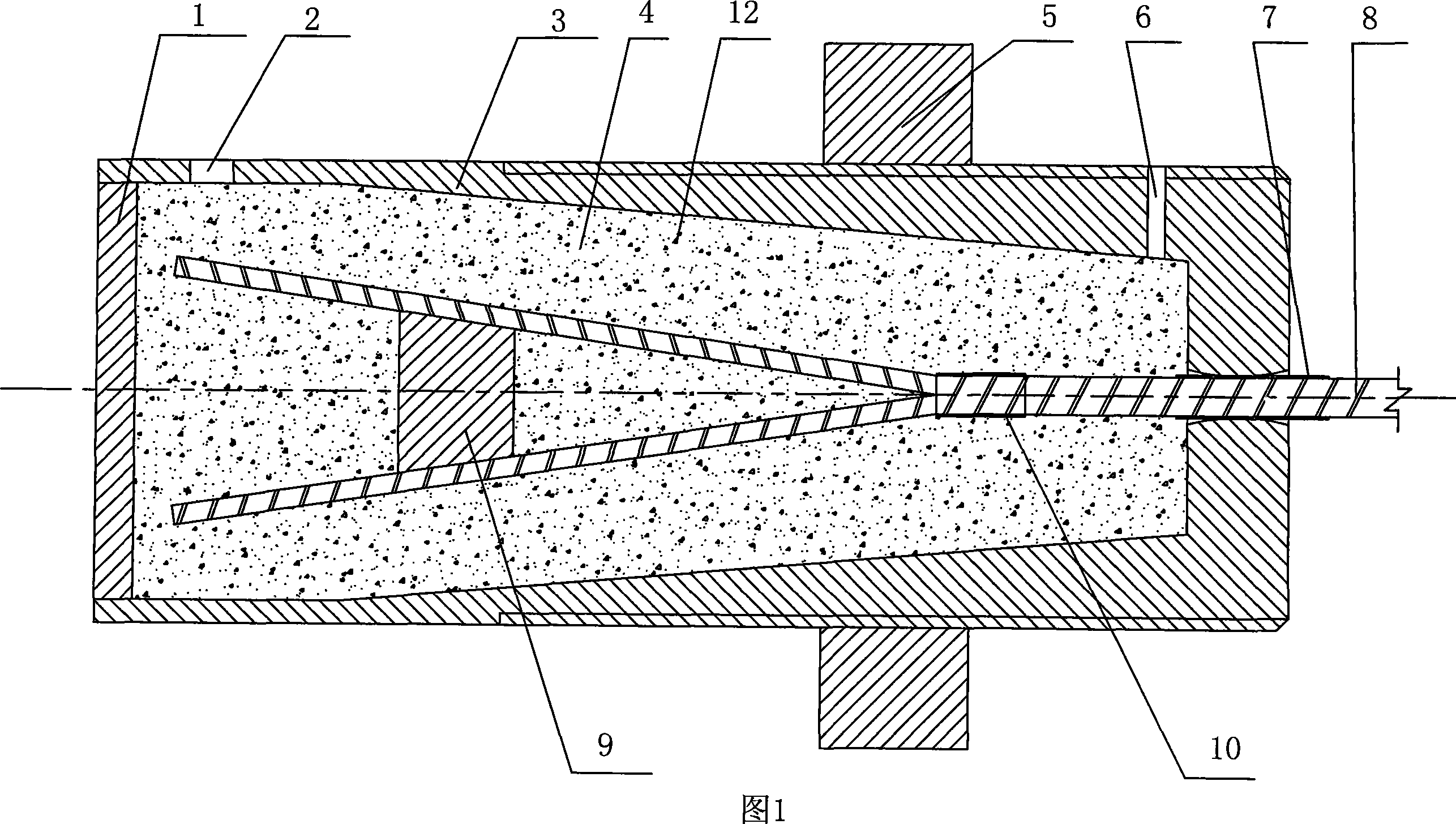

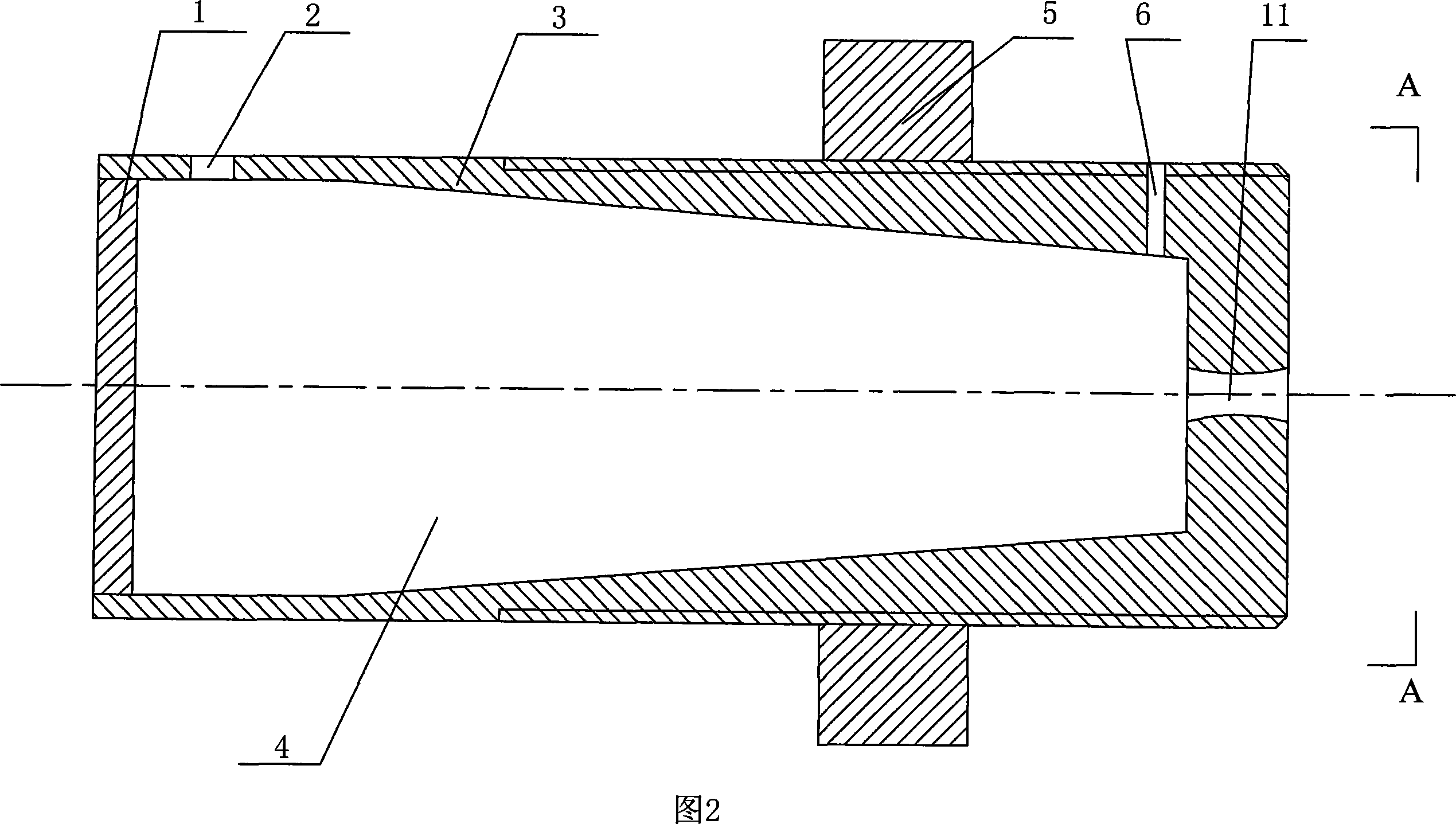

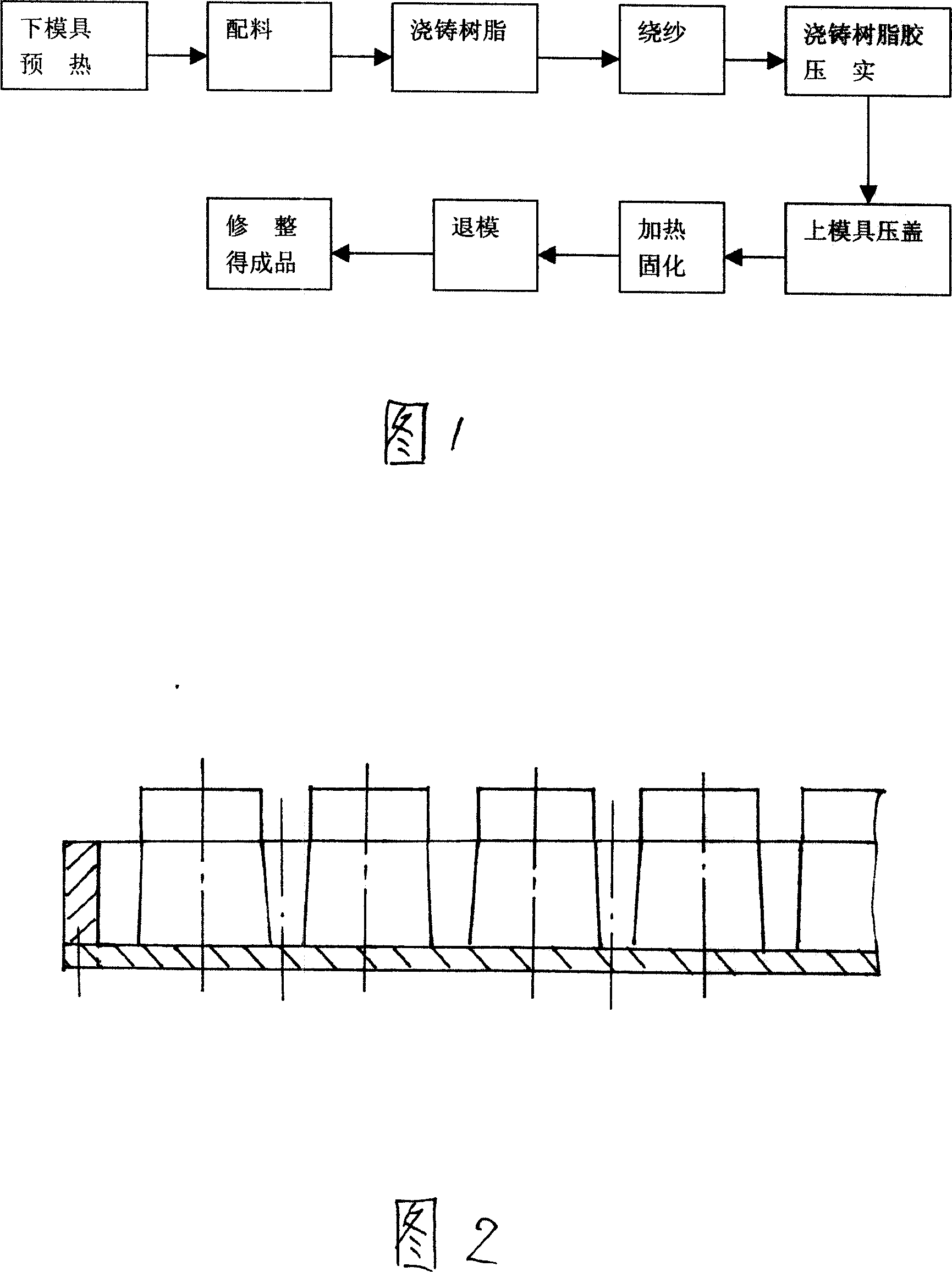

Process for manufacturing septic tank by using glass fibre reinforced plastic

InactiveCN102371685ASatisfy tightnessFulfil requirementsBiological sludge treatmentGlass fiberWater leakage

The invention discloses a process for manufacturing a septic tank by using glass fibre reinforced plastic, relating to a method for manufacturing a composite formed septic tank, belonging to the technical field of glass fibre reinforced plastic pipeline manufacturing. The invention aims to provide a composite formed glass fibre reinforced plastic pipeline, which is low in production cost, free from water leakage, long in service life, light in weight and low in liquid conveying resistance, and a production process thereof. The process has the benefits that: glass fibre taking resin as a basic body is wound on a bushing with a manufactured core mould one by one in three different manners according to process requirements; the glass fibre has corrosion resistance, aging resistance and insulating property; a pipe wall structure is rational and advanced; the action of materials is sufficiently played; the stiffness of a product is increased; the stability and the reliability of the production are ensured; the appearance quality is good; the production cost is reduced; the production process is simplified; the production difficulty is reduced; the production benefit is increased; by using the composite forming process in the invention, the designability of the product is strong; and the comprehensive property of the product is good.

Owner:民勤县威瑞环保有限责任公司

Transverse Link Made of Fibre-Reinforced Plastics Material for a Wheel Suspension of a Vehicle

ActiveUS20140210177A1Reduce weightProduced easily and economicallyResilient suspensionsPivoted suspension armsFiberPlastic materials

A transverse link made of fibre-reinforced plastics material for a wheel suspension, which transverse link is pivotable on its bearing elements about a common pivot axis or axes running substantially coaxially with respect to one another, these bearing elements being connected by a single-shell connecting element having connecting arms to a bearing element having a ball and socket joint bearing. The bearing elements and the connecting element are elements of an integral plastics material. In order to produce a transverse link of this type, disclosed is an integral plastics material moulded part produced by extrusion of plastics, the bearing elements having bearing bushes shells surrounded by extrusion of the plastics material. The ball and socket joint bearing have a bearing bush or a shell-shaped sliding capsule, produced from plastics material and connected to the connecting element, the connecting element comprising a centre or transverse web connecting the bearing elements.

Owner:TAMP UMFORMTECHN

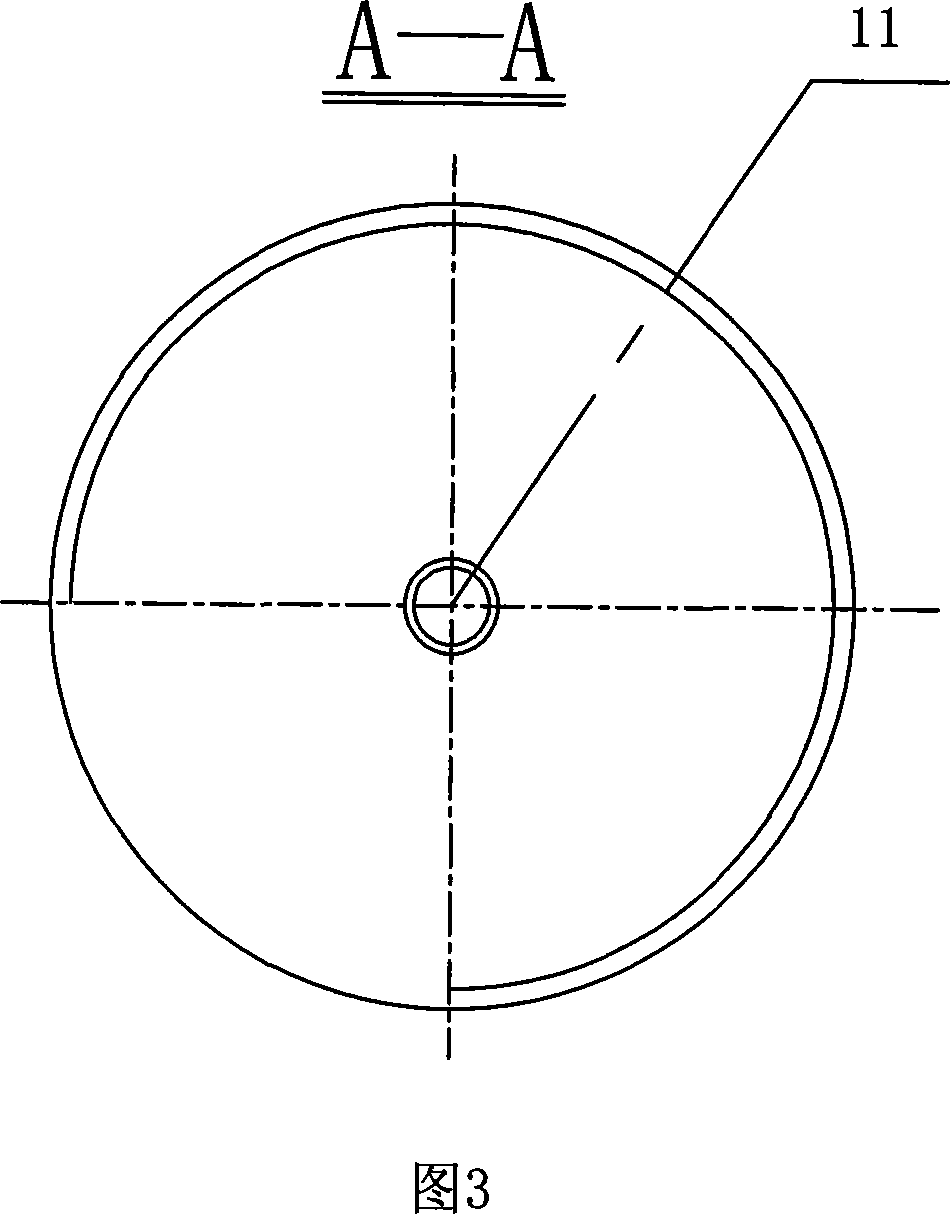

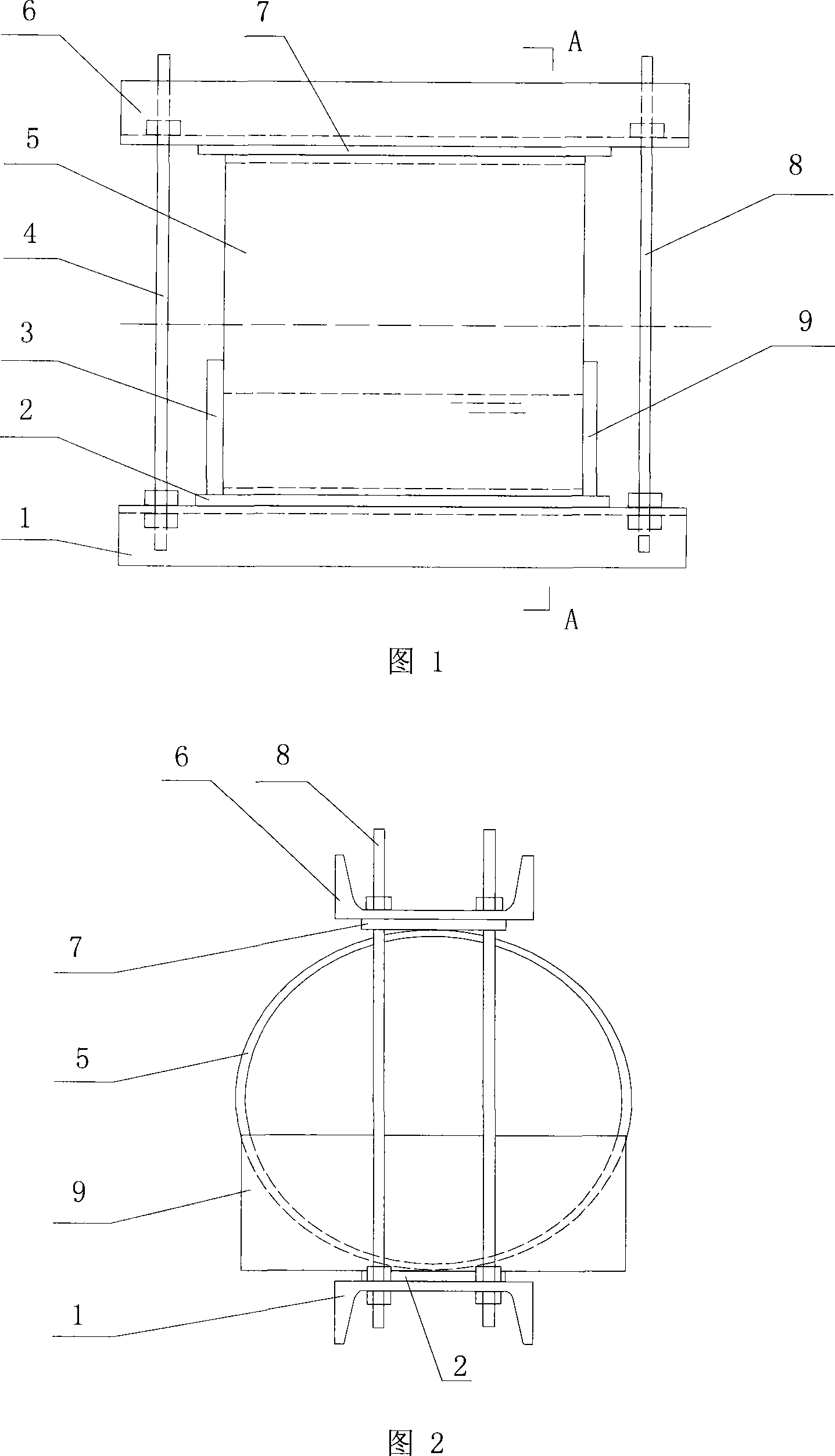

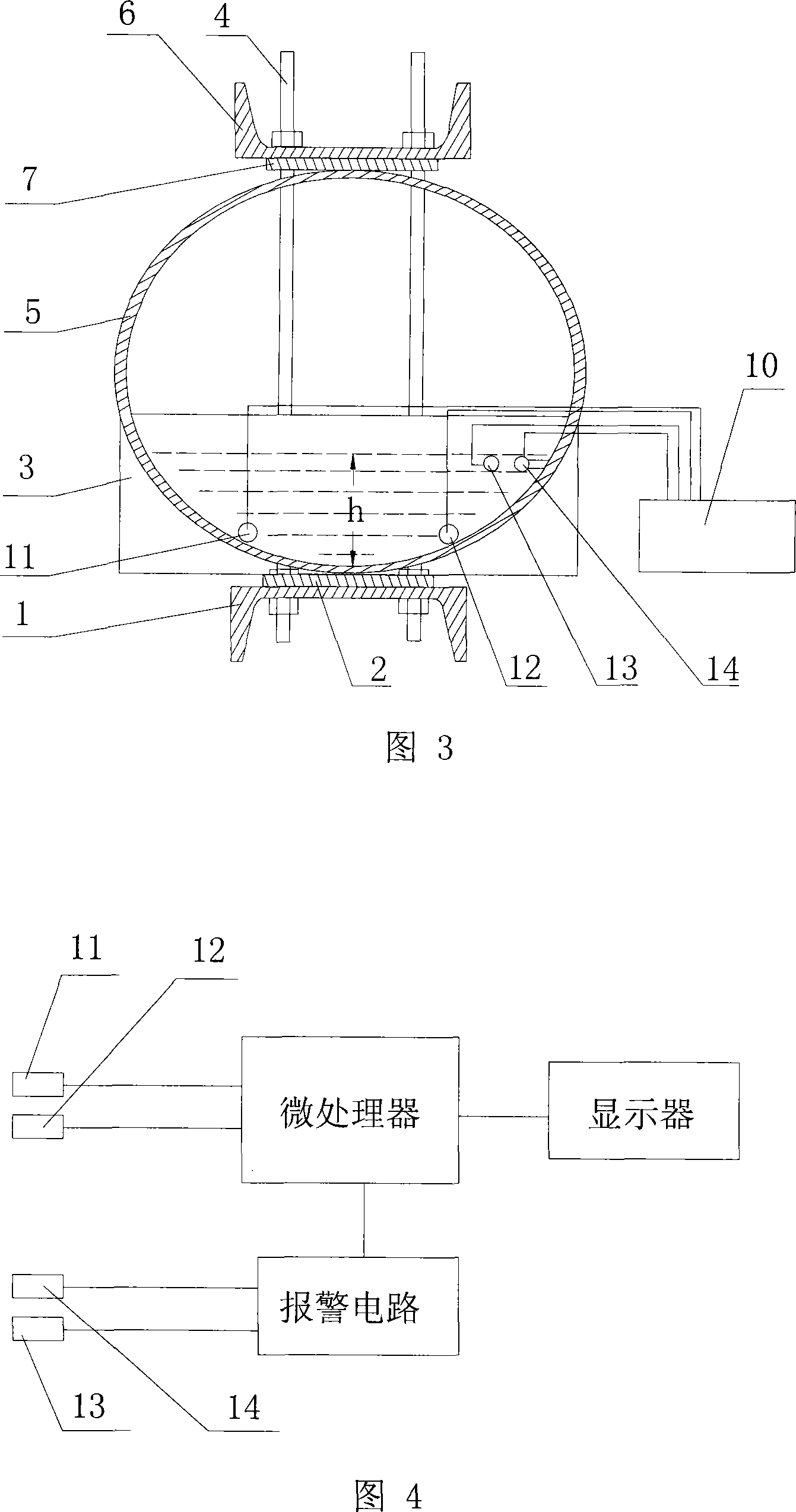

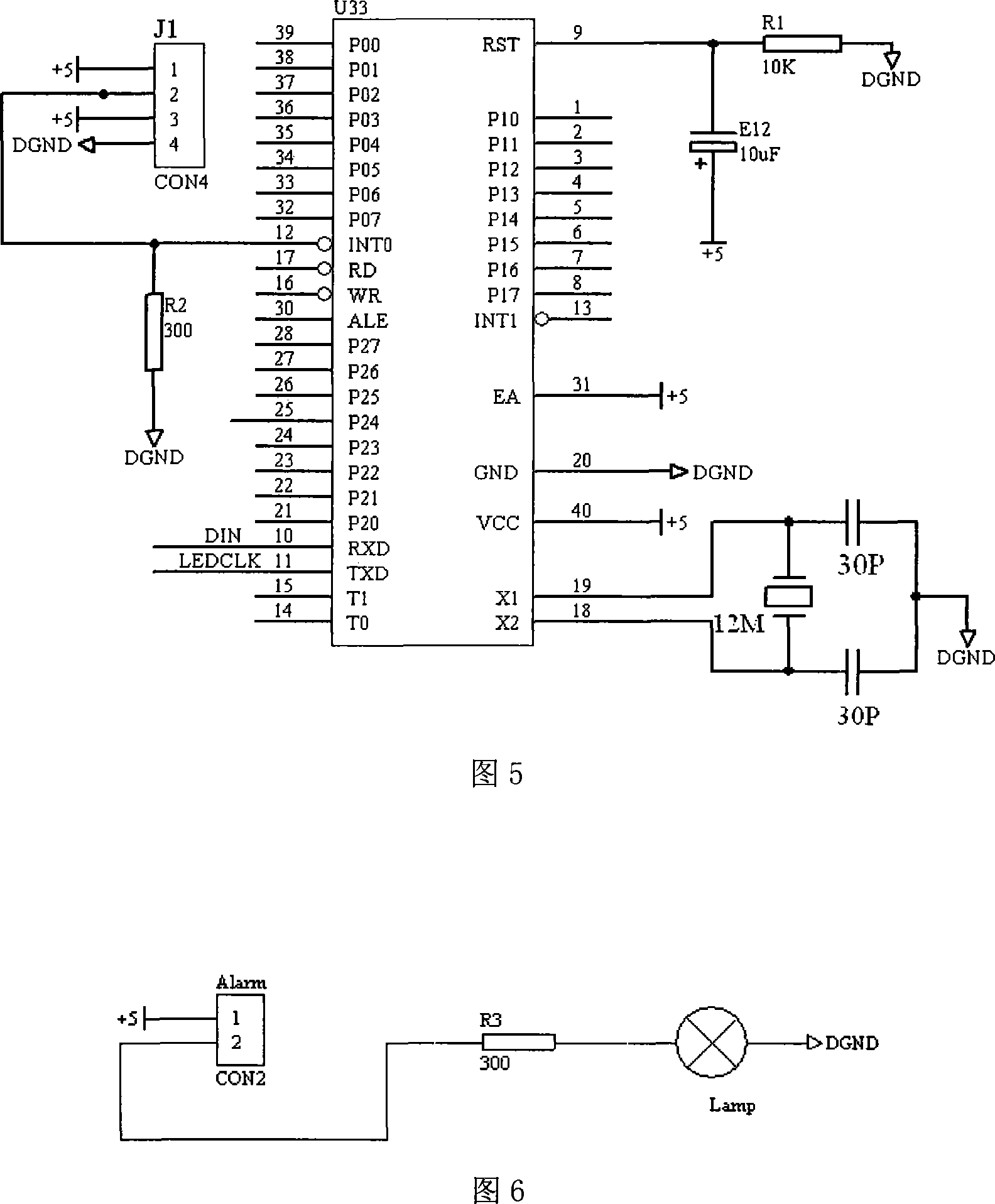

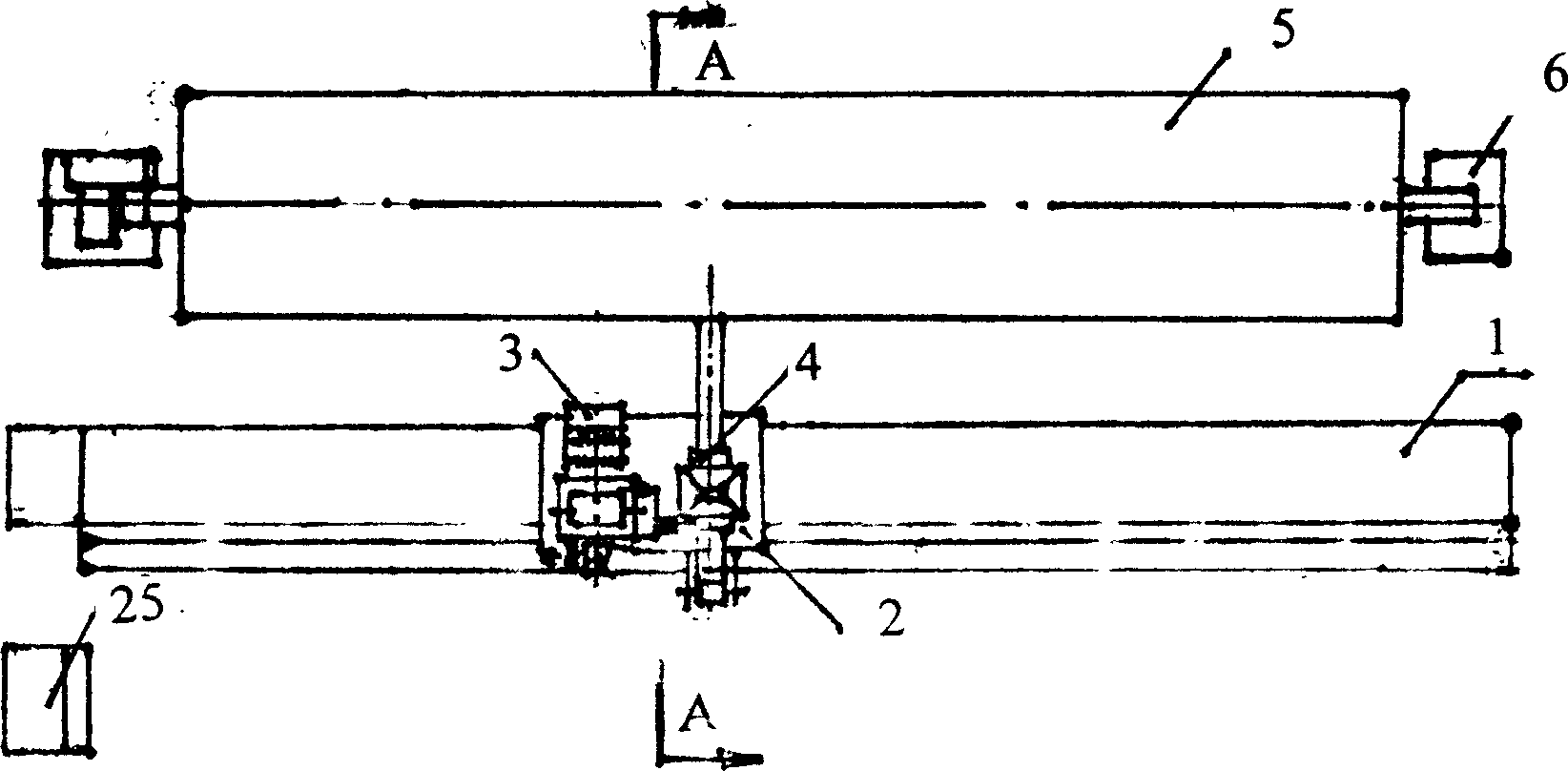

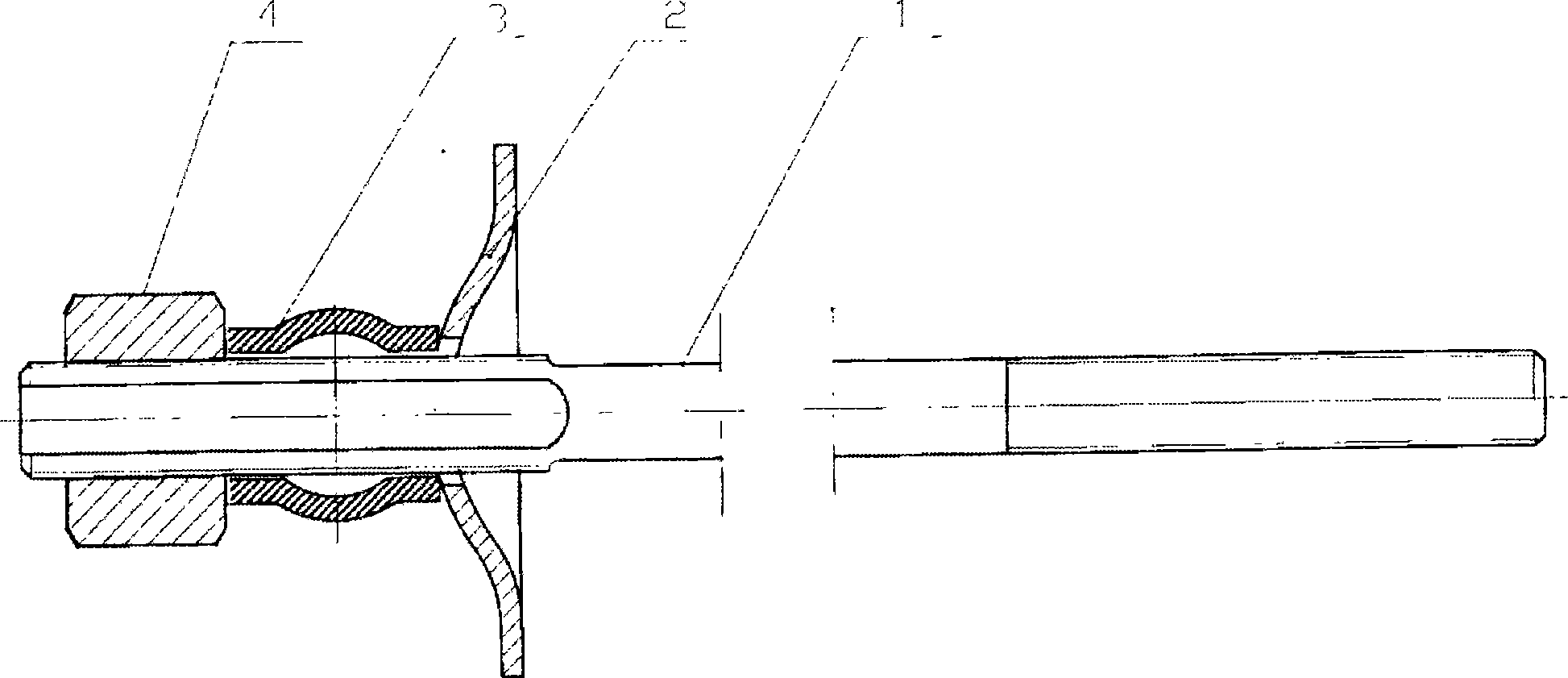

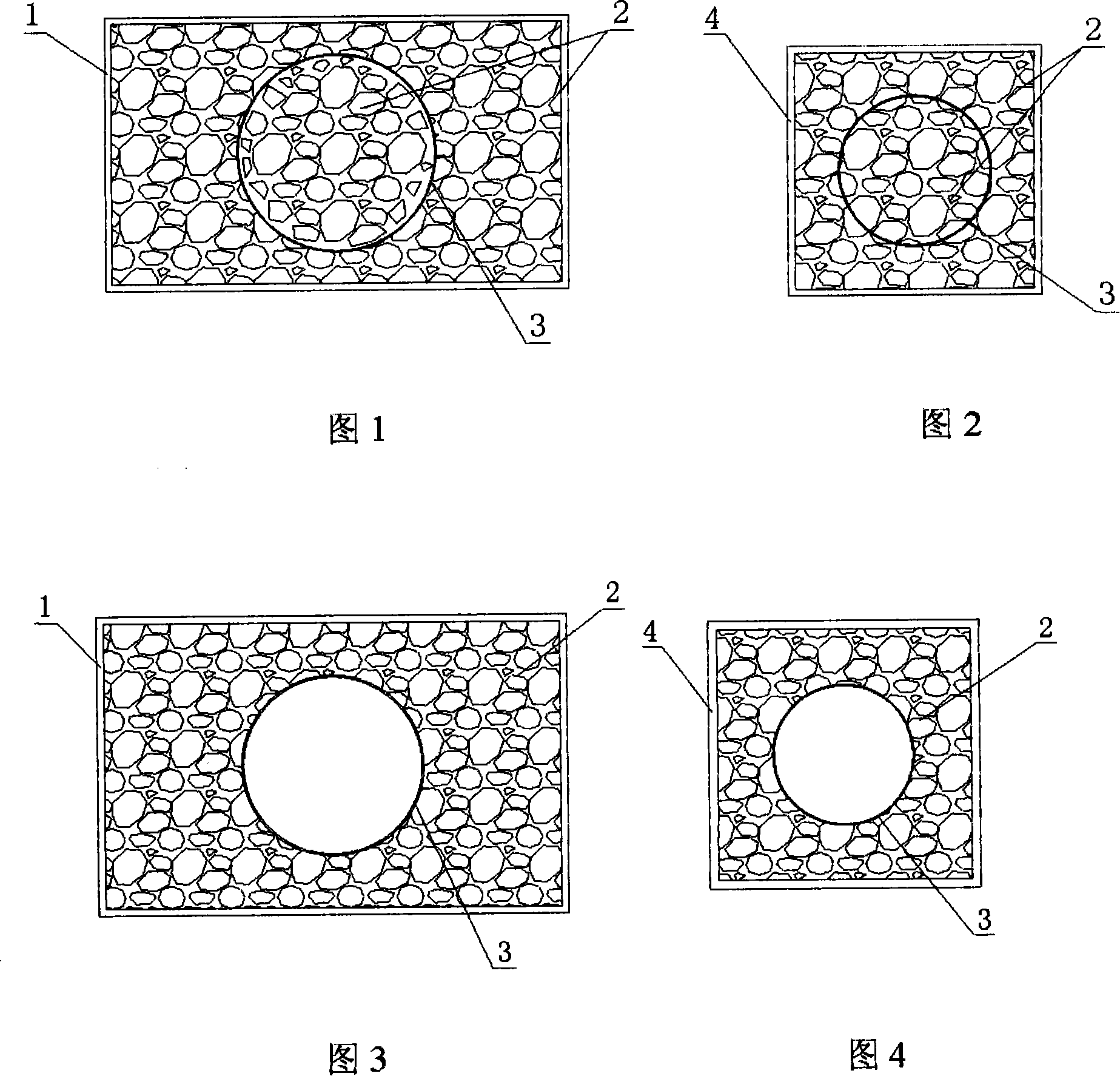

Test method of sample destroy time in tube of glass fibre reinforced plastic long-term performance test

InactiveCN101118203AReduce labor intensityImprove accuracyWeather/light/corrosion resistanceStrength propertiesEngineeringBending strain

The present invention relates to a test method of a test piece destruction time in a glass-reinforced plastic pipe long-term ring-bending strain test, in particular to a test method of a test piece destruction time in a glass-reinforced plastic pipe long-term performance test. The present invention is characterized in that with the help of the conductive characteristic of corrosive liquor, a corrosion resistant and conductive first interruption electrode 11 and a second interruption electrode 12 are arranged on the two sides of the bottom pipe wall in a glass-reinforced plastic pipe test piece 5; when the glass-reinforced plastic pipe test piece 5 is charged with sulfuric acid corrosive liquor, the first interruption electrode 11 and the second interruption electrode 12 are connected through corrosive liquor, the conductive characteristic of the sulfuric acid corrosive liquor is utilized to make the external interruption pin of a microporocessor in a high level, and the microporocessor starts to record power on time; when the glass-reinforced plastic pipe test piece 5 is broken under the effect of distortion and sulfuric acid corrosion, the sulfuric acid flows out of the glass-reinforced plastic pipe test piece 5 along the fracture, the first interruption electrode 11 and the second interruption electrode 12 are disconnected, the external interruption of the microporocessor is in a low level, and the microporocessor stops timing, thus the test piece destruction time is obtained. The present invention has the advantages of reduced labor intensity, and high accuracy.

Owner:SHENZHEN KANGQIANG CONSTR NEW TECH ENG

Process for producing terephthalic unsaturated polyester resin by using terephthalic acid rinsing residue

InactiveCN1844187AImprove utilization efficiencyOpen up new sourcesOrganic compound preparationCarboxylic compound preparationOrganic solventAlcohol

This invention is preparation of unsaturated polyester resin. The raw material is the terephthalic acid waste containing terephthalic acid 80%-90% and p-aminobenzoic acid 10%-20%. The procedure is as followings: add diatomic alcohol and catalytic composite into the terephthalic acid waste for polycondensation reaction. Add unsaturated diacid for further polycondensation. Add phenylethene for permutoid reaction. This invention's raw material is wasted washing water. The facility is the general ones for unsaturated polyester resin. The product has lower price, high quality, stability and environment-friendness. It could be used in a large scale of tube of glass fibre reinforced plastic, storage tank and instrument backing strip.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

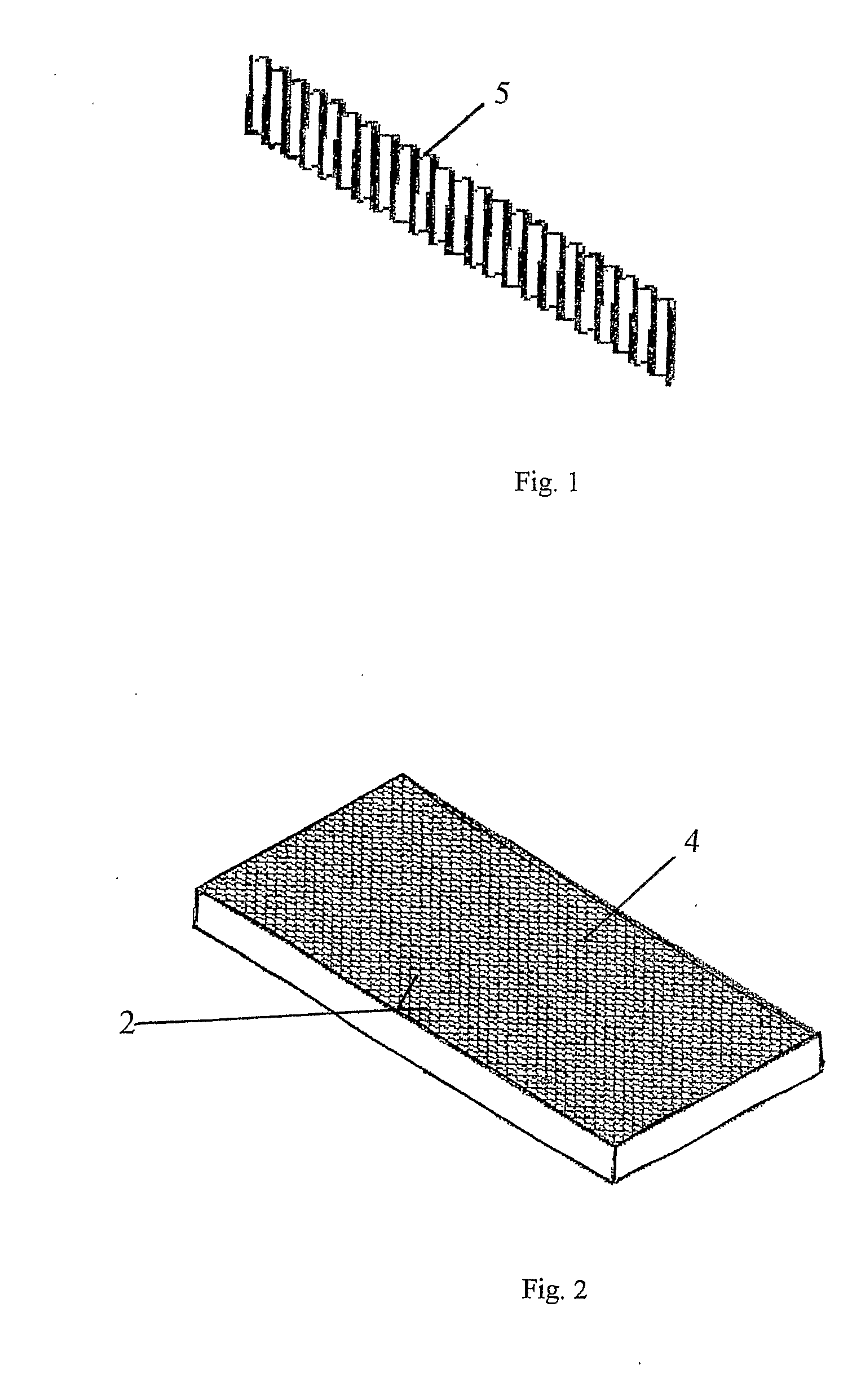

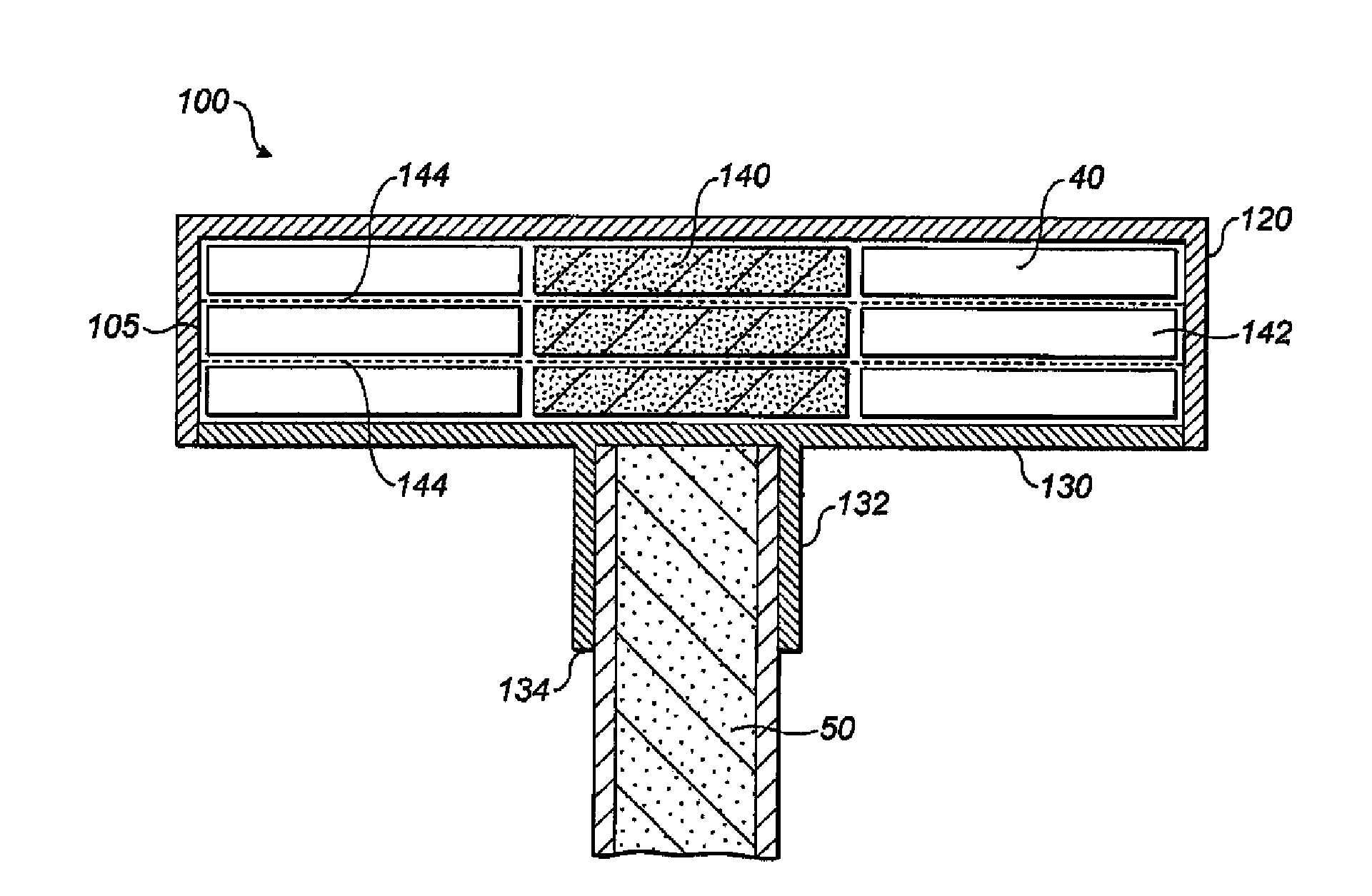

Modular structural composite beam

ActiveUS20130340385A1Increase flexibilityQuality improvementFinal product manufactureMachines/enginesFiberEngineering

A modular fibre reinforced plastic flange for a structural composite beam which comprises a body formed of a plurality of elongate elements arranged in an array, wherein the dimensions of the body are substantially determined by the number and arrangement of the elongate elements in the array, and a skin member at least partially surrounding the array. Also, a structural composite beam comprising the modular fibre reinforced plastic flange and a shear web connected to the skin member of the modular flange. A method of making the modular flange and beams, and a kit of parts for making the modular flange are also disclosed.

Owner:BLADE DYNAMICS LTD

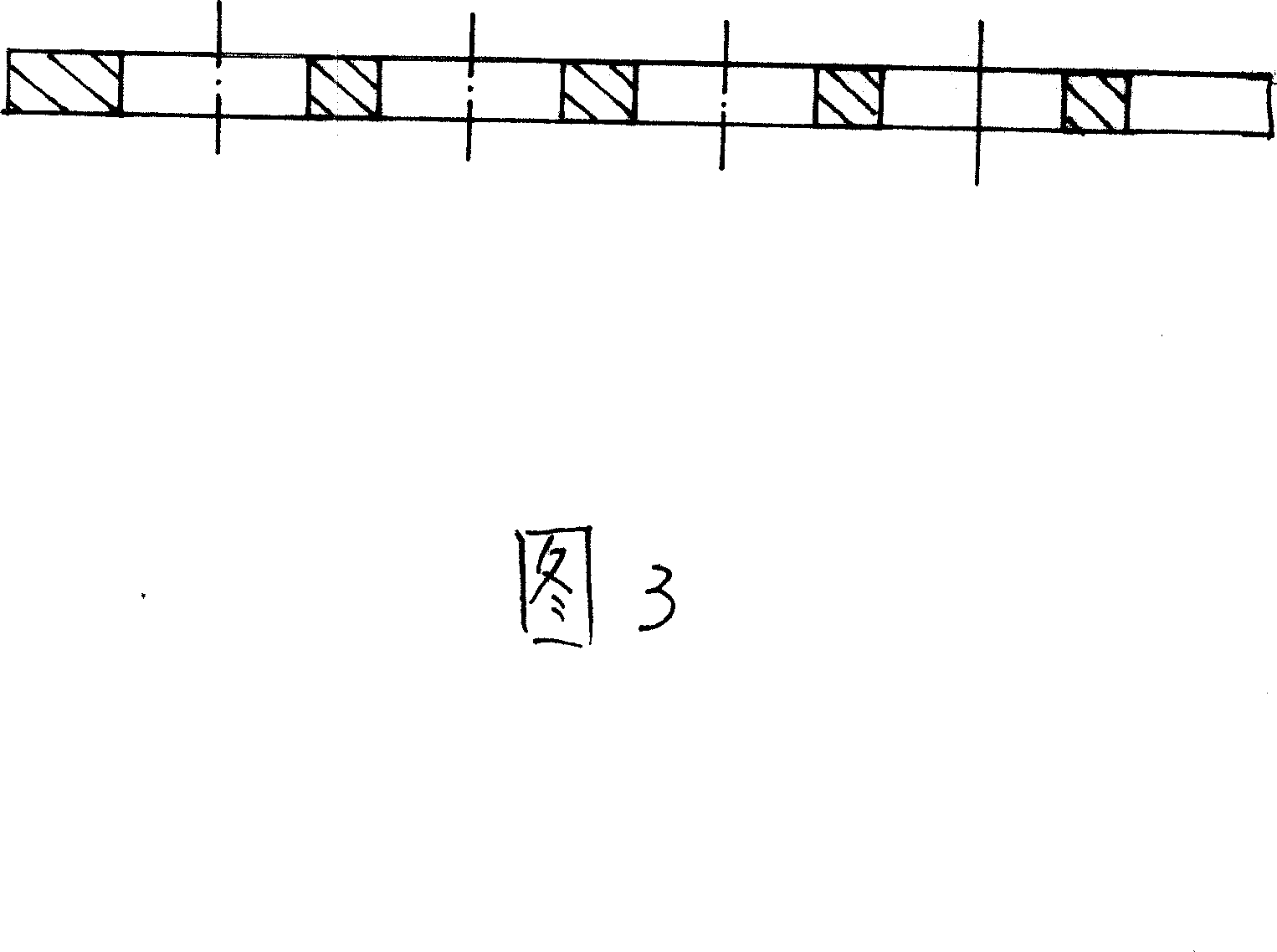

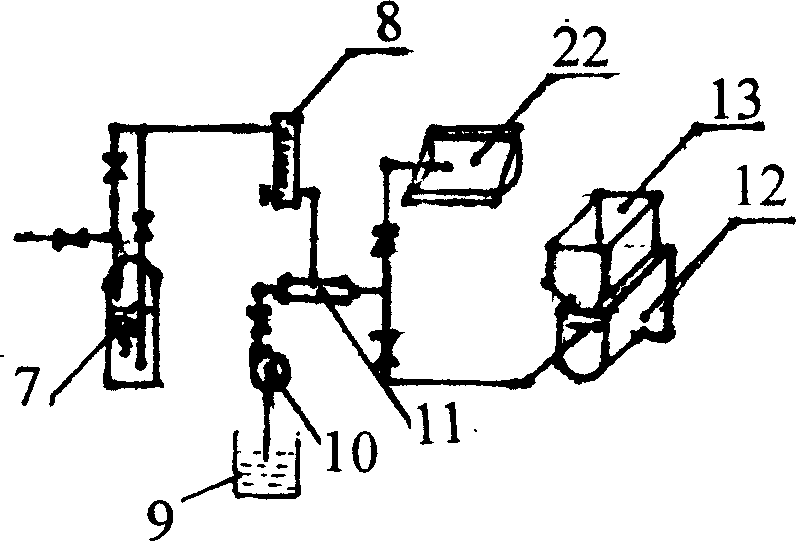

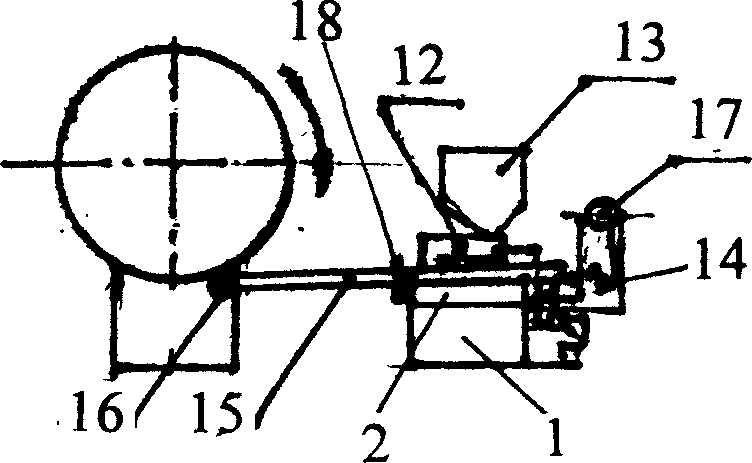

Making apparatus and method for wet type sanding and enwinding glass fibre reinforced plastic pipe from underside

The present invention relates to an equipment for making GFRP pipe by adopting wet sand-adding lower-winding process and method thereof. Said equipment is mainly formed from working table, running carriage, winding system, sand-adding system, mould and mould-supporting frame. Said invention also provides their connection arrangement and working mode. Said invented winding and sand-adding processes can be implemented under the GFRP pipe, and adopts wet sand-adding process so as to reduce dust pollution, and can raise working efficiency.

Owner:天津市天联滨海复合材料有限公司

High-strength pretightening force compressible glass fibre reinforced plastic anchor rod

InactiveCN101498223ASolve the tensile resistanceSolve the problem of poor anchoring effectAnchoring boltsGlass fiberPull force

The invention provides a high-strength pretightening-force yield anchor rod of glass fiber reinforced plastic, which effectively solves the problems of small tensioning force resistance and poor anchoring effect of the original anchor rod. A metal yield ring is arranged between a nut and a tray on an anchor rod assembly. The front end of the anchor rod of glass fiber reinforced plastic is a flat-annular body, and the diameter of the flat-annular body on the front end of the anchor rod is bigger than that of the tail part of the anchor rod. The anchor rod of glass fiber reinforced plastic is effectively prevented from being broken by over-high stress, and the tail part of the rod body is prevented from being broken by applying pretightening force, thereby the torsional resistance of the anchor rod of glass fiber reinforced plastic is improved.

Owner:张延策

Fibre reinforced plastic-steel pipe-concrete column

A fiber reinforced plastic-steel tube-concrete column relates to a construction component. The fiber reinforced plastic-steel tube-concrete column is composed of a steel tube, a round fiber reinforced plastics tube and concrete in the plastic tube, and is characterized in that the steel tube of the concrete column is made by welding of a steel plate, the round fiber reinforced plastics tube is made by winding of fiber reinforced plastic cloth on a winding machine, the round fiber reinforced plastic tube is arranged at the center of the concrete column, the geometric center of the round fiber reinforced plastic tube is overlapped with that of the concrete column, and concrete is poured in the concrete column. The present invention has the advantages of high bearing capacity, large toughness, lightweight, sound plasticity and flexibility, impact and fatigue resistance, sound shockproof, etc.

Owner:SHENYANG JIANZHU UNIVERSITY

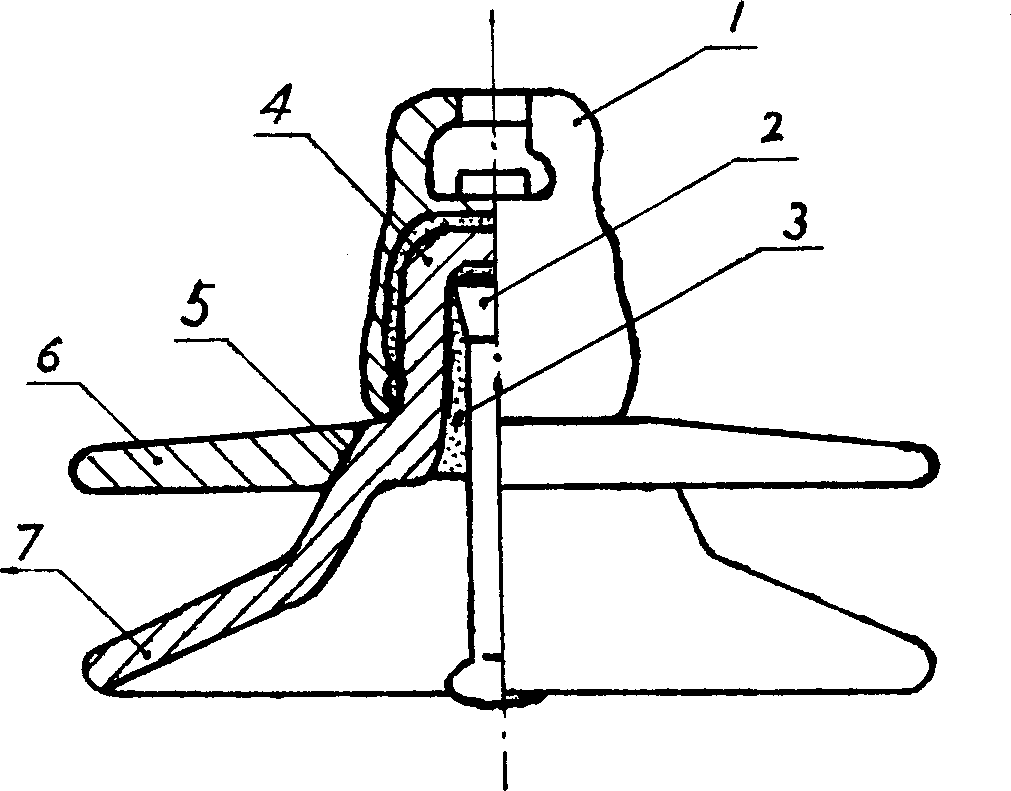

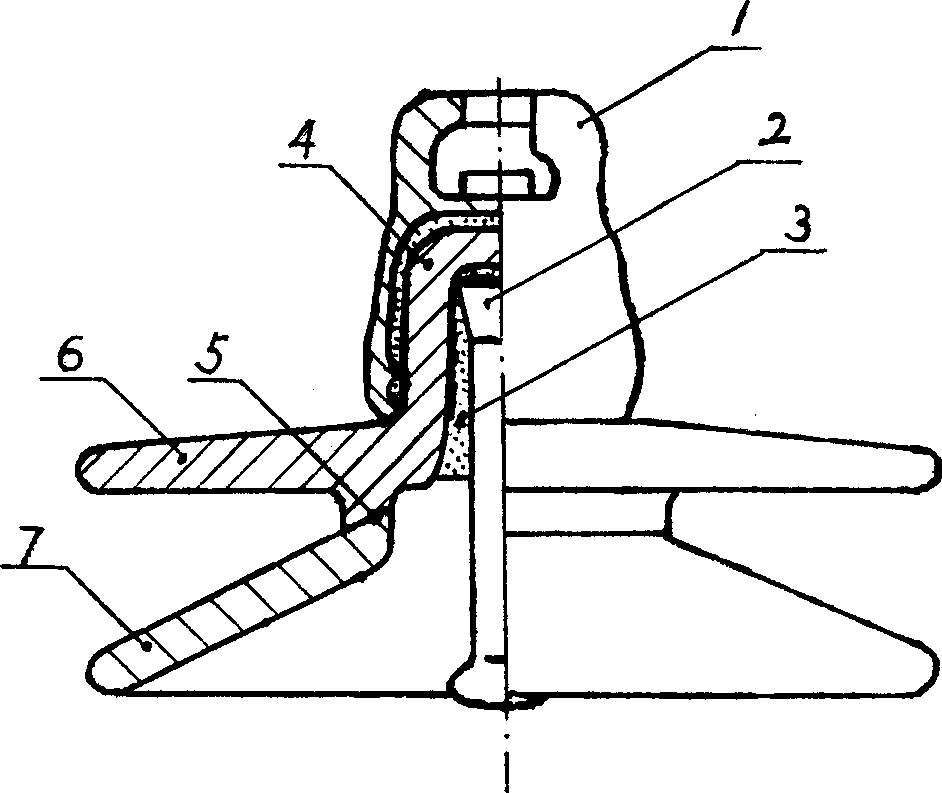

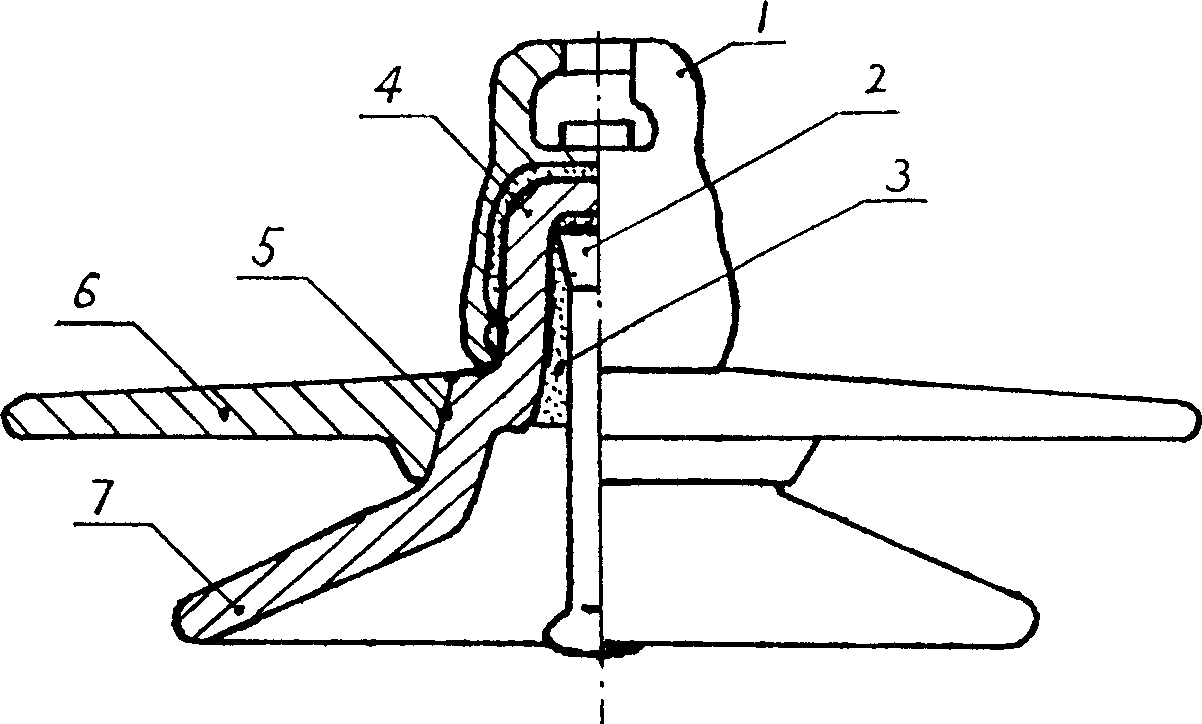

Method for mfg. insulator of multi-layer umbrella suspension glass fibre reinforced plastic insulator

InactiveCN1420503AIncrease creepage distanceSimple structureSuspension/strain insulatorsAdhesiveEngineering

A process for preparing the insulating body of multi-layer umbrella type toughened glass insulator includes preparing the integrated head part and one umbrella disc, preparing each umbrlle disc, and adhering them together with the electrically insulating adhesive.

Owner:王淑兰 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com