Making apparatus and method for wet type sanding and enwinding glass fibre reinforced plastic pipe from underside

A production device and glass fiber reinforced plastic technology are applied in the field of production devices for winding glass fiber reinforced plastic pipes under wet sanding, which can solve the problems of not meeting requirements, affecting product quality, and low work efficiency, saving supporting equipment and investment, and eliminating unsafe hidden dangers. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

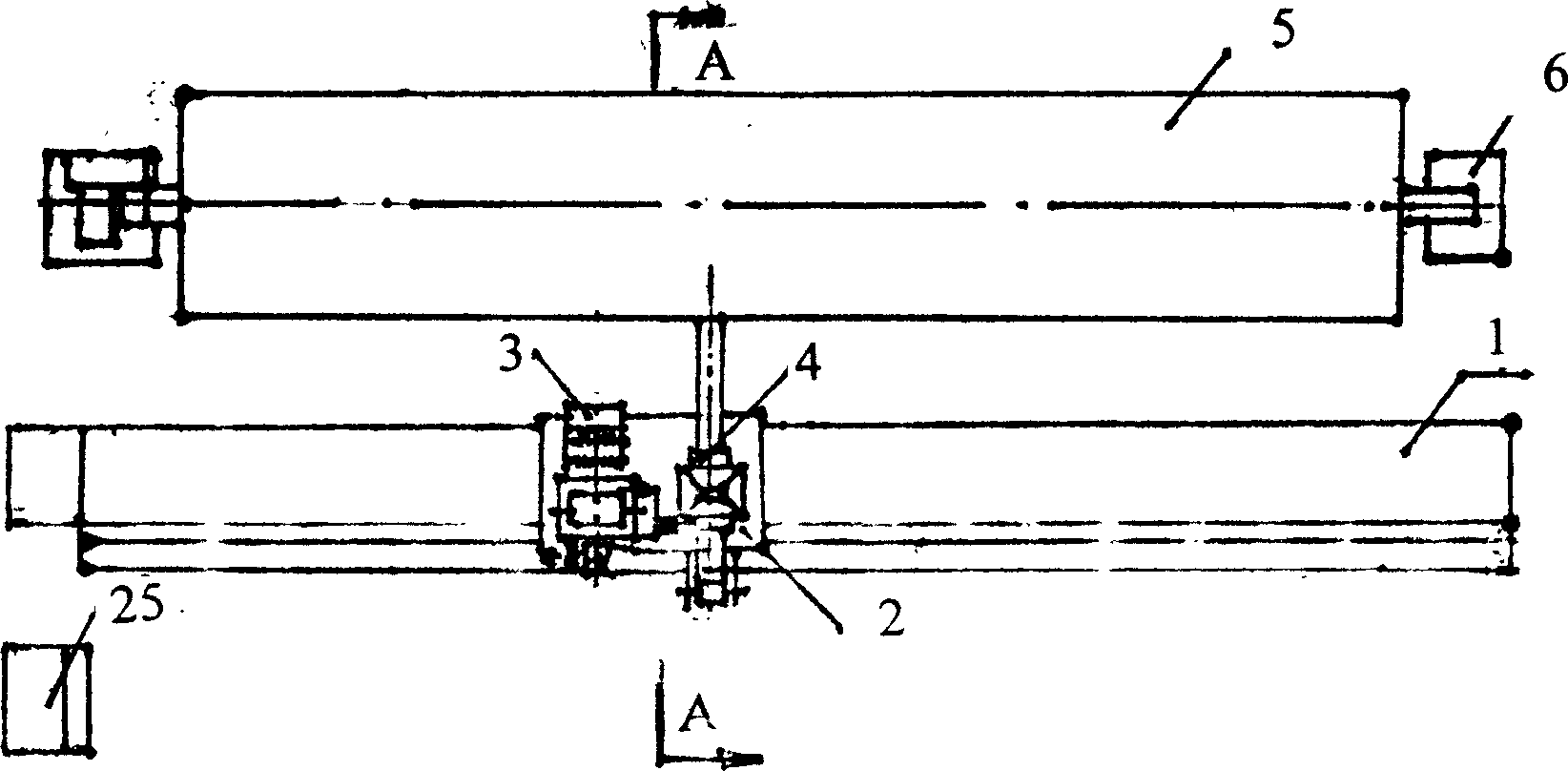

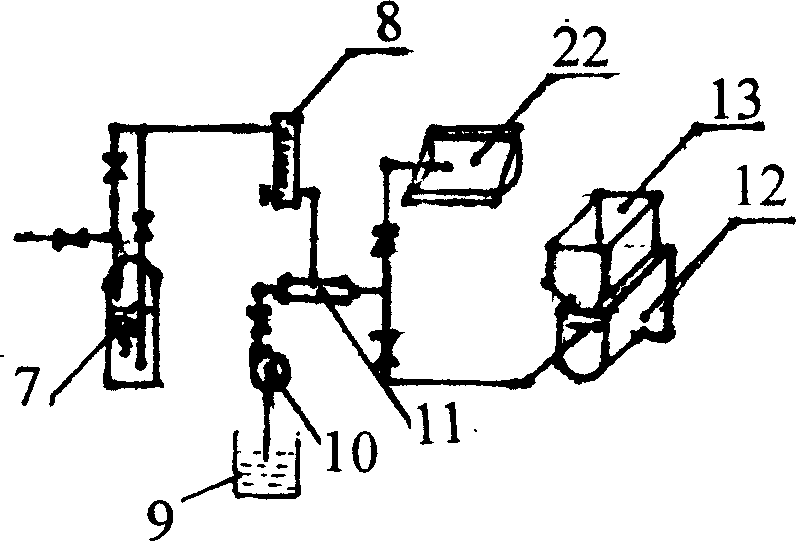

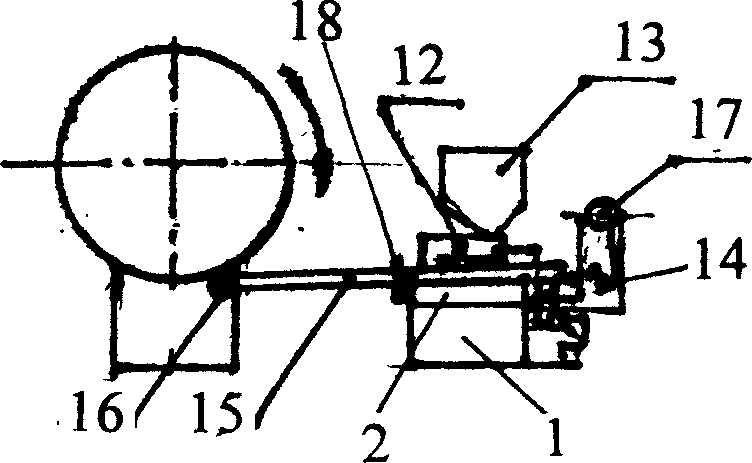

[0022] Such as Figure 1 to Figure 5 As shown, the manufacturing device for winding FRP pipes under wet sanding provided by the present invention is mainly composed of a workbench 1, a walking trolley 2, a winding system 3, a sand adding system 4, a mold 5 and a mold support frame 6; the workbench 1 is fixed on the ground; on the workbench 1, there is a walking trolley 2 that can move along the length direction of the workbench 1 under the drive of a chain located on one side and driven by a motor; some devices of the winding system 3 and the sand adding system 4 Then be fixed on the walking trolley 2; And the mold 5 that both ends are supported by the mold support frame 6 and can rotate under the drive of the motor is set at a certain distance from the workbench 1 and its axial direction is parallel to the length direction of the workbench 1 . The coordination between the speed of the walking dolly 2 and the rotational speed of the mold is accomplished by the computer consol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com